Pipeline remote monitoring valve

A remote monitoring and pipeline technology, applied in valve details, safety valves, balance valves, etc., can solve the problems of reducing the service life and reliability of pipelines, wasting fluid resources, and high installation and maintenance costs. The effect of pipe bursting and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

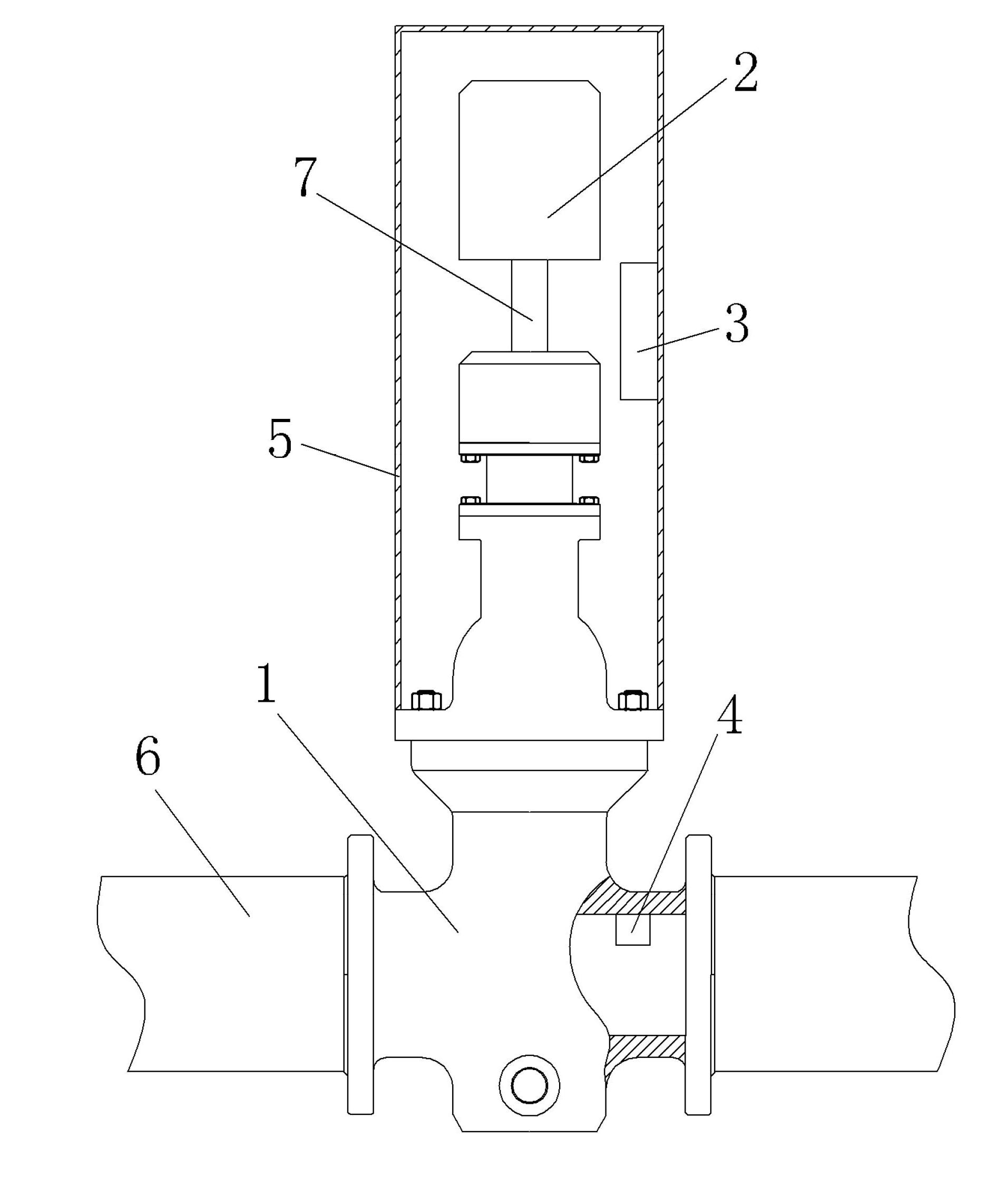

[0020] like figure 1 As shown, a specific embodiment of the present invention is: a pipeline remote monitoring valve, including a valve body 1 installed on the pipeline 6 and a valve stem 7 on the valve body 1, characterized in that: the valve stem 7 Connected with the driving mechanism 2, the valve body 1 is equipped with a sensor 4, and both the sensor 4 and the driving mechanism 2 are electrically connected with the GPRS wireless data transmission unit 3.

[0021] The valve stem 7 , the driving mechanism 2 and the GPRS wireless data transmission unit 3 of this example are packaged in the sealed case 5 , and the GPRS wireless data transmission unit 3 is installed on the inner wall of the sealed case 5 . During actual implementation, the GPRS wireless data transmission unit 3 can also be installed on the casing of the driving mechanism 2 or any part that can be fixed in the sealed casing 5 .

[0022] The driving mechanism 2 of this example is a motor, and the output shaft of...

Embodiment 2

[0025] The composition of this example is basically the same as that of the first embodiment, the only difference is that the driving mechanism is a rotary pneumatic device, and the output shaft of the rotary pneumatic device is connected to the valve stem.

[0026] The GPRS wireless data transmission unit 3 adopted by the present invention is an existing technology, and can be various wireless terminal equipments that can convert the signals output by sensors into IP data and transmit them through GPRS wireless communication.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com