Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66 results about "Diode bridge rectifier" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

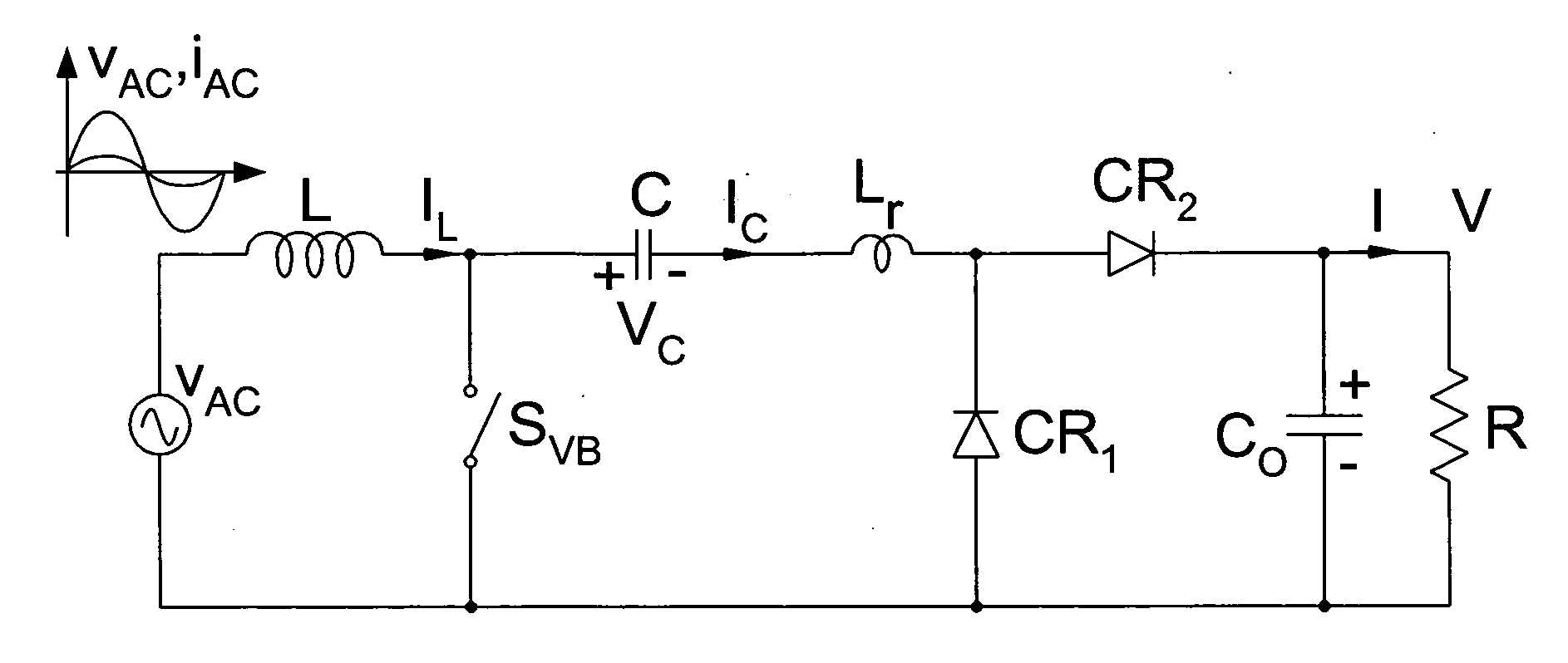

Bridgeless PFC converter

InactiveUS20100259240A1Efficient power electronics conversionConversion using Cuk convertorsDiode bridge rectifierEngineering

A truly Bridgeless PFC converter is provided which eliminates the four-diode bridge rectifier and operates directly from the AC line to result in high-efficiency, small size and low cost solution for Power Factor Correction applications.

Owner:CUKS

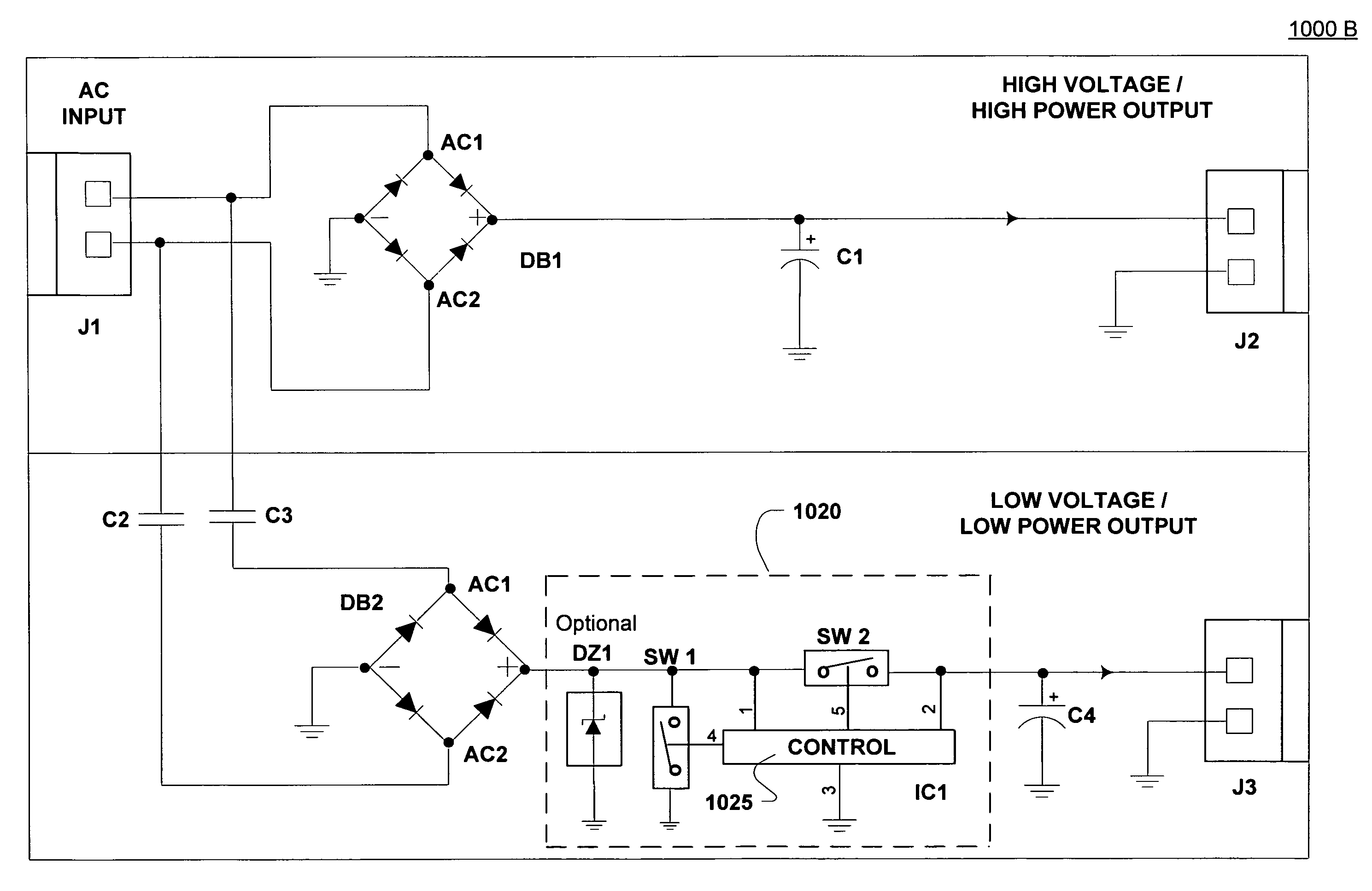

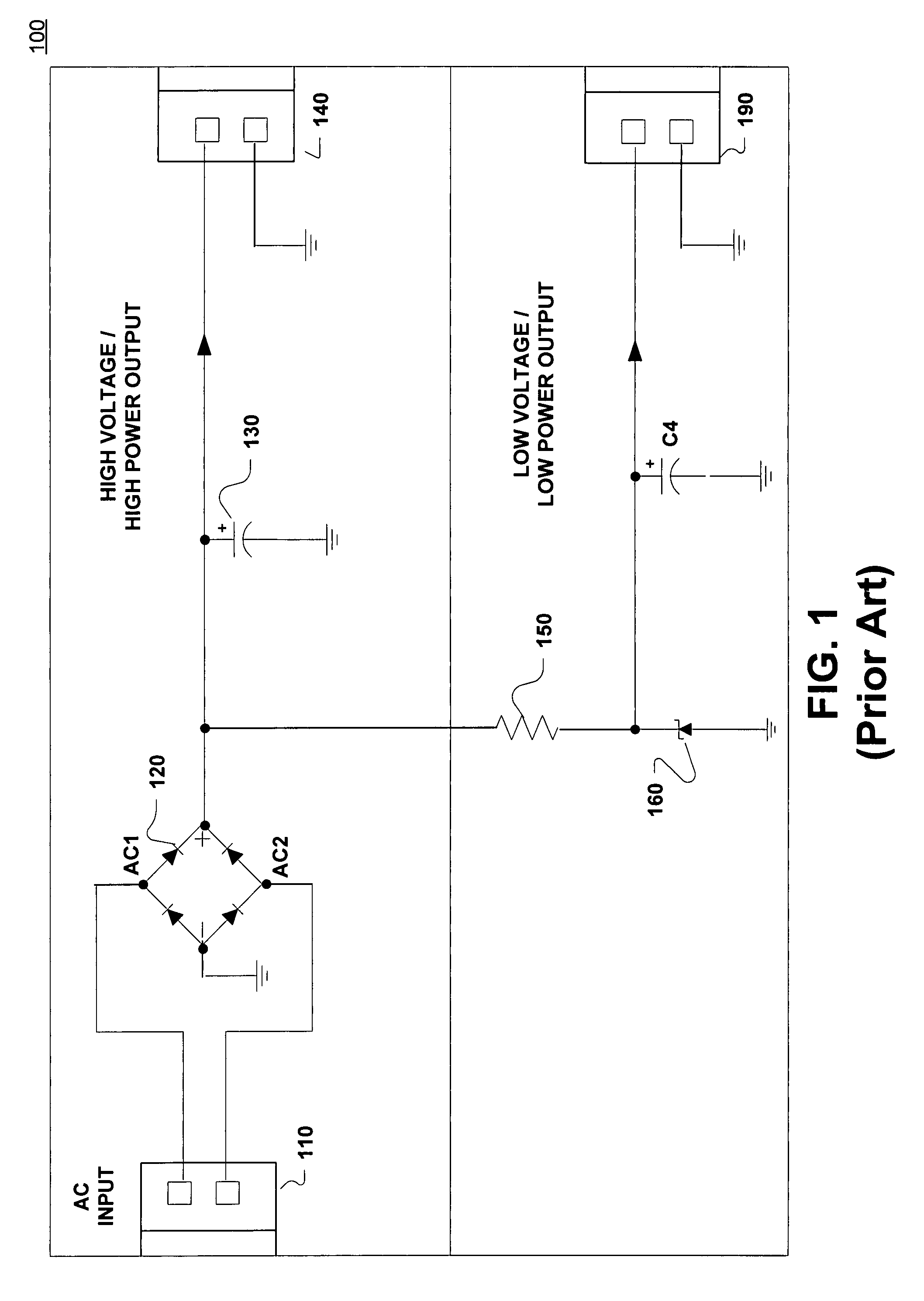

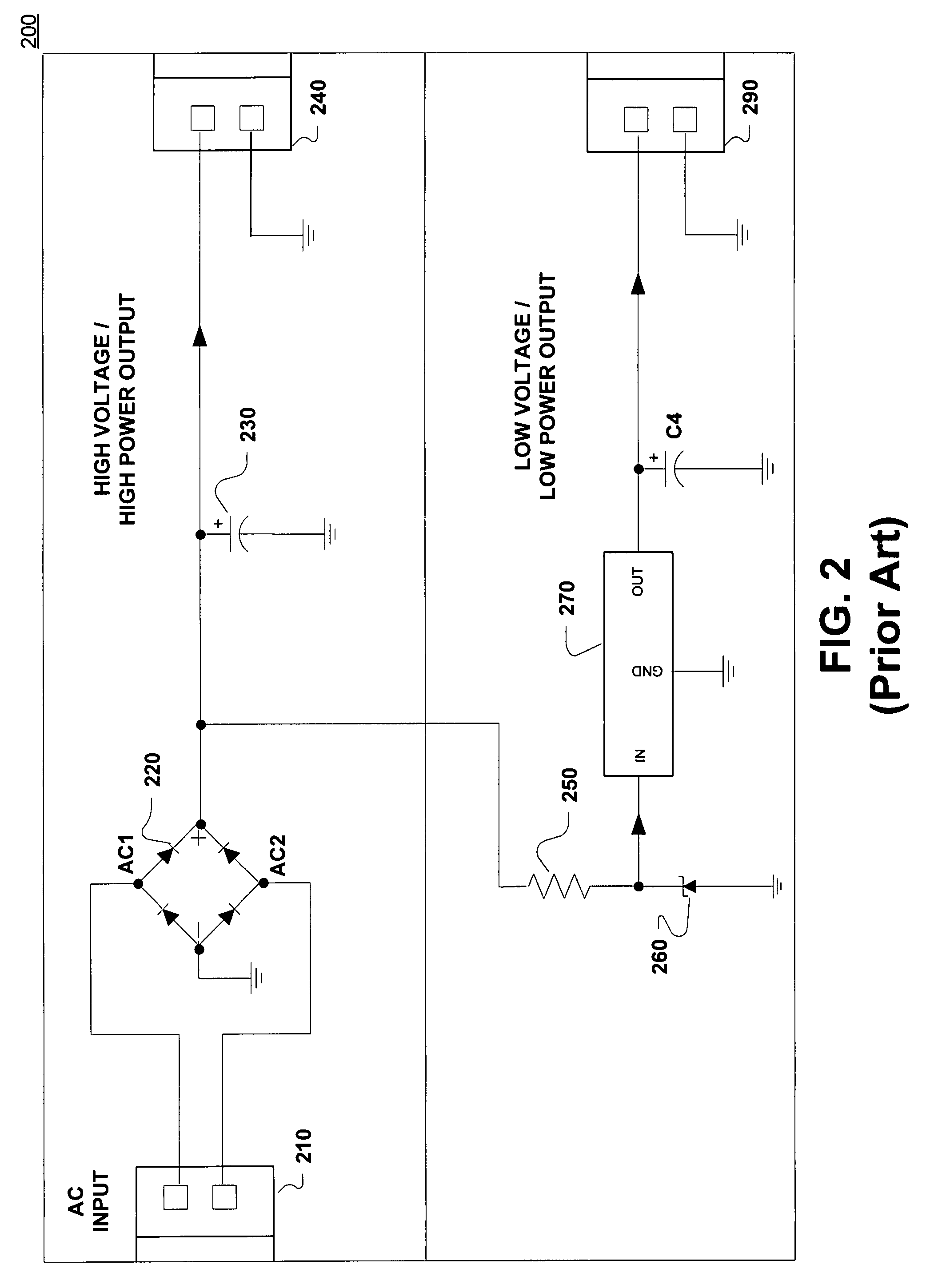

Power circuit for generating non-isolated low voltage power in a standby condition

ActiveUS7602158B1Reduce voltageAc-dc conversion without reversalEfficient power electronics conversionDiode bridge rectifierMicrocontroller

A power circuit generating a non-isolating low voltage power supply using a capacitive AC voltage drop in standby. Specifically, the power circuit includes an AC connector that generates a first AC input and a second AC input that are opposite in phase. The power circuit also includes first and second diode bridge rectifier circuits that are coupled to the first AC input, the second AC input, and a ground. A first capacitor drops a voltage of the first AC input, and a second capacitor drops a voltage of the second AC input. The first diode bridge rectifier circuit provides a high voltage power signal to a load. The second diode bridge rectifier circuit provides a low voltage power signal to a microcontroller.

Owner:NAT SEMICON CORP

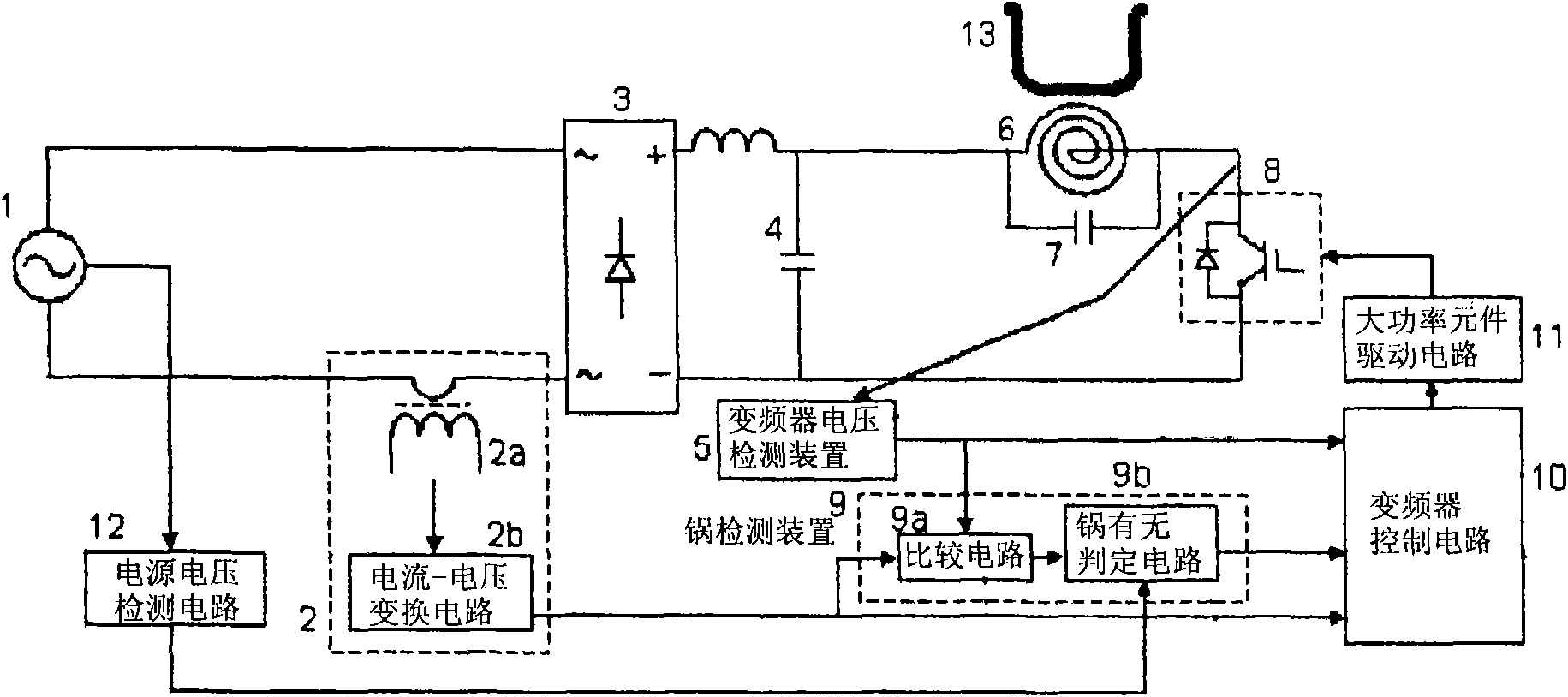

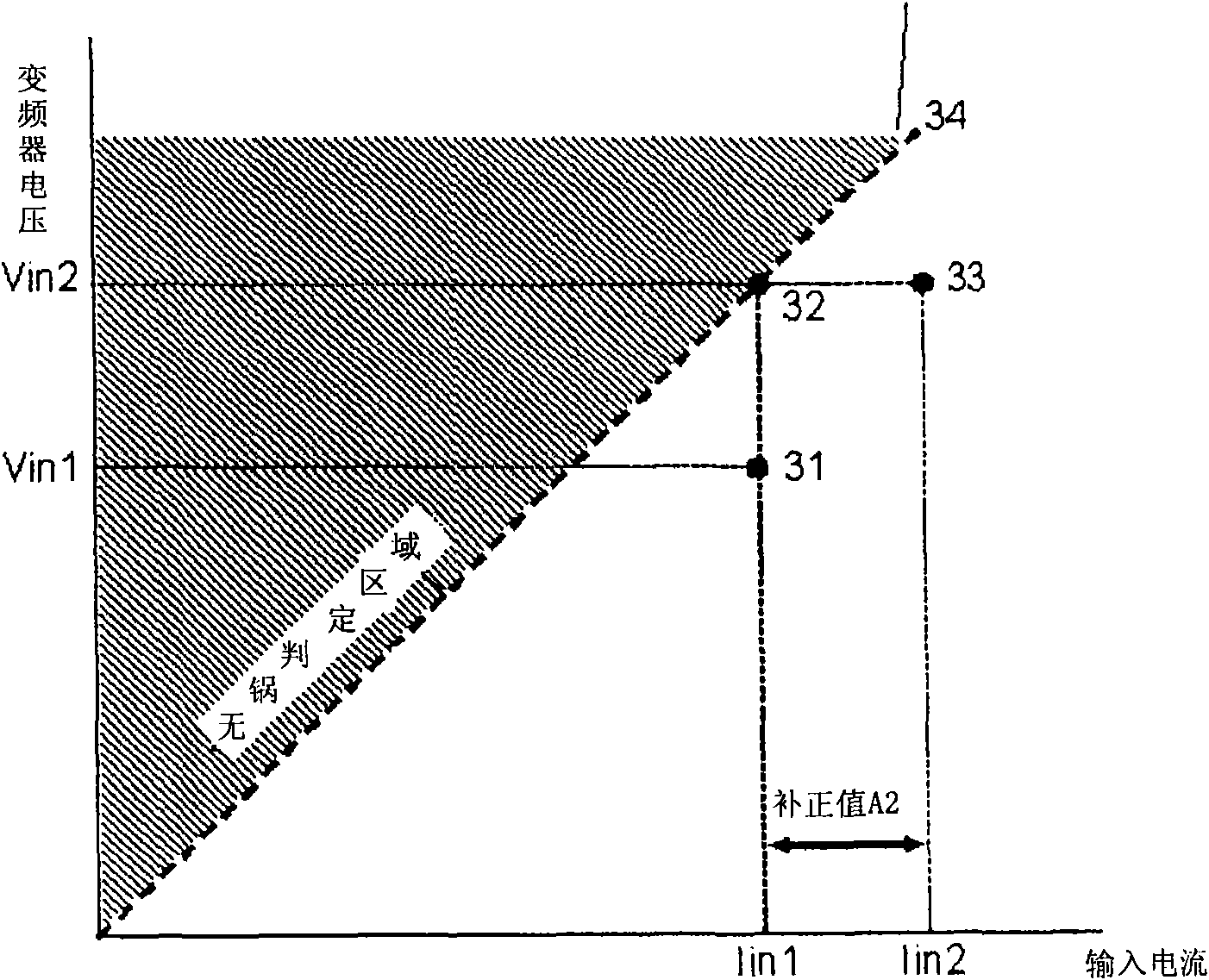

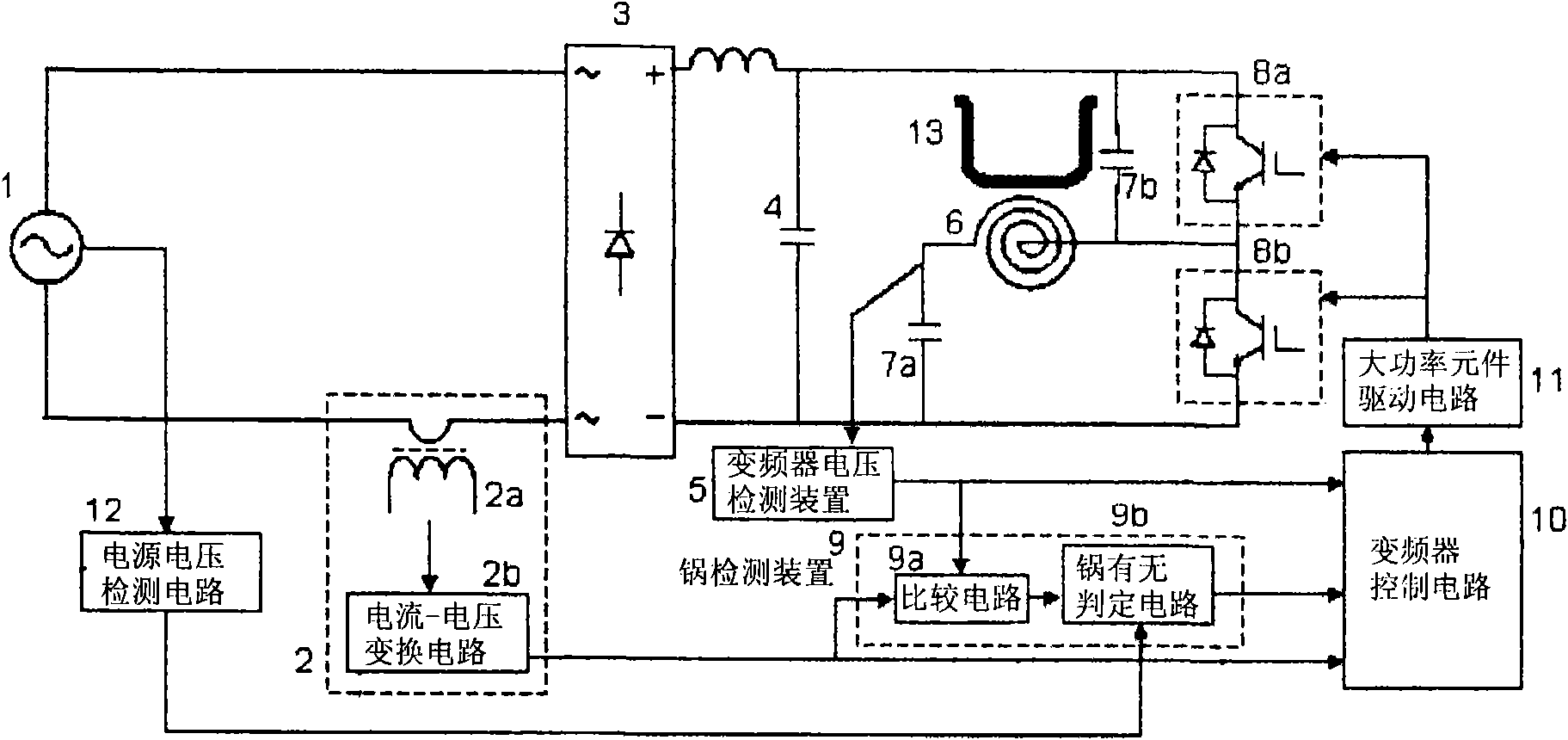

Rice cooker

ActiveCN101953626AExpand the allowable range of variationThe allowed range of variation is expandedCooking vesselsElectricityDiode bridge rectifier

The invention provides a rice cooker which can enlarge permitted changing range of the supply voltage, and can reliably determined whether the cooker is existed or not in an area with unstable supply voltage. The rice cooker comprises a converter circuit consisting of heating coils, a resonant capacitor and a large power element; a current detecting device which is used for detecting the AC current flowing into a diode bridge rectifier circuit and outputting the voltage which is directly proportional to the detected current; a converter voltage detecting device which is used for detecting the voltage in a converter circuit and outputting the voltage which is directly proportional to the detected voltage; a supply voltage detecting circuit which is used for detecting the mains supply voltage; and a cooker detecting device which is used for judging whether the cooker is installed on the regulated position when the output voltage of the converter voltage detecting device is higher than the output voltage of the current detecting device in a regulated threshold voltage. Under the condition that the detecting voltage of the supply voltage detecting circuit is higher than the standard voltage, the threshold voltage is set to be higher than the preset threshold voltage.

Owner:PANASONIC CORP

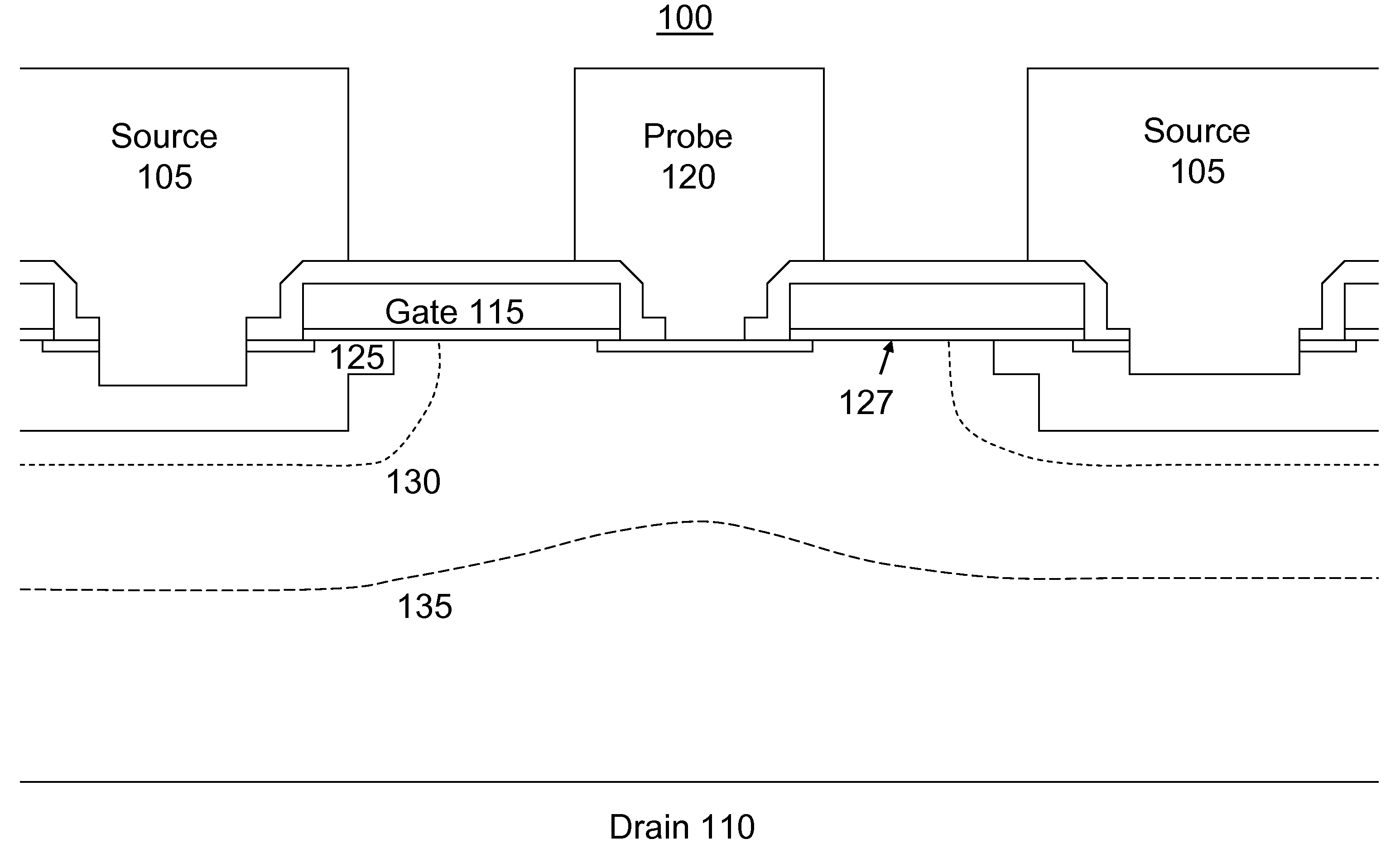

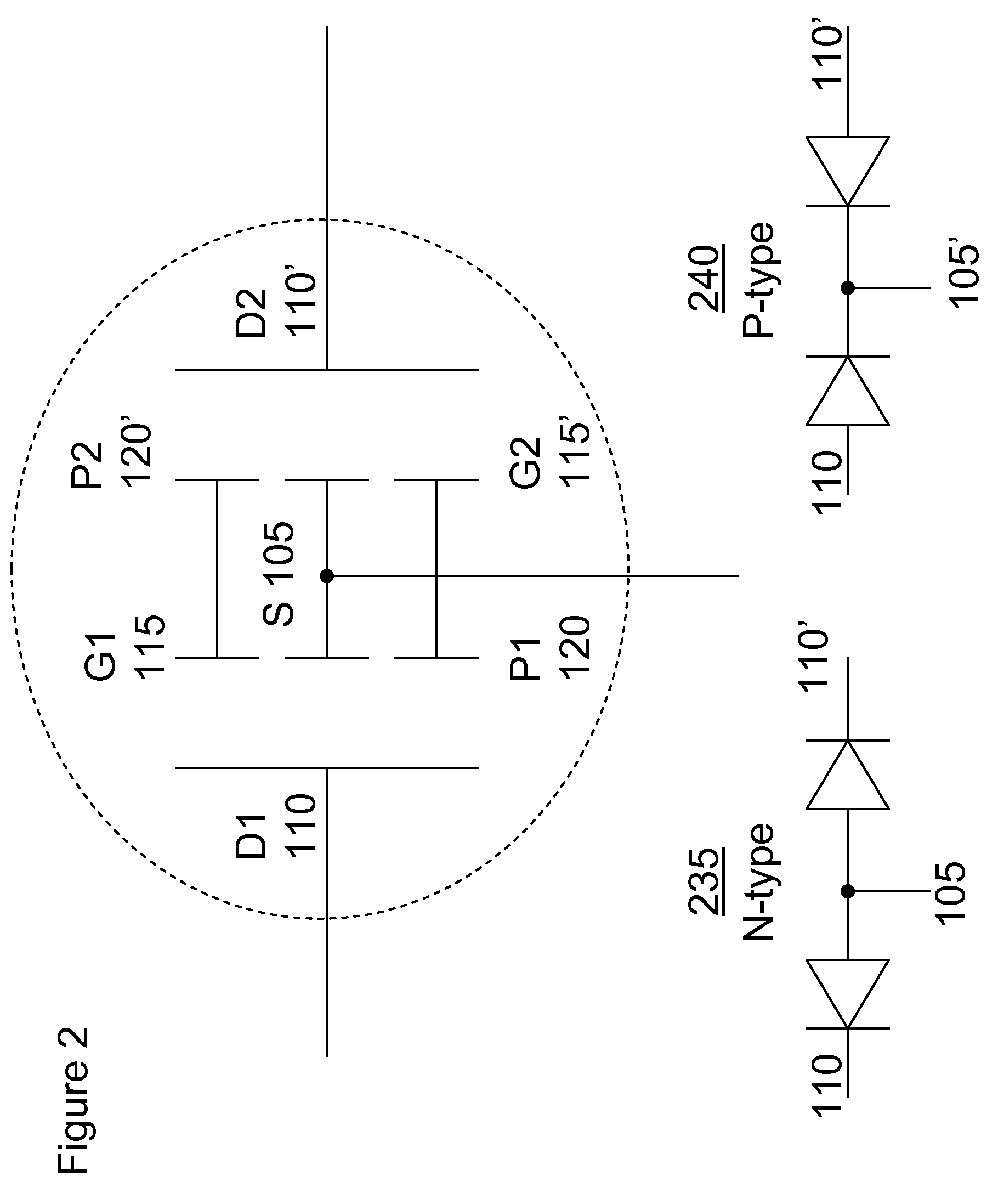

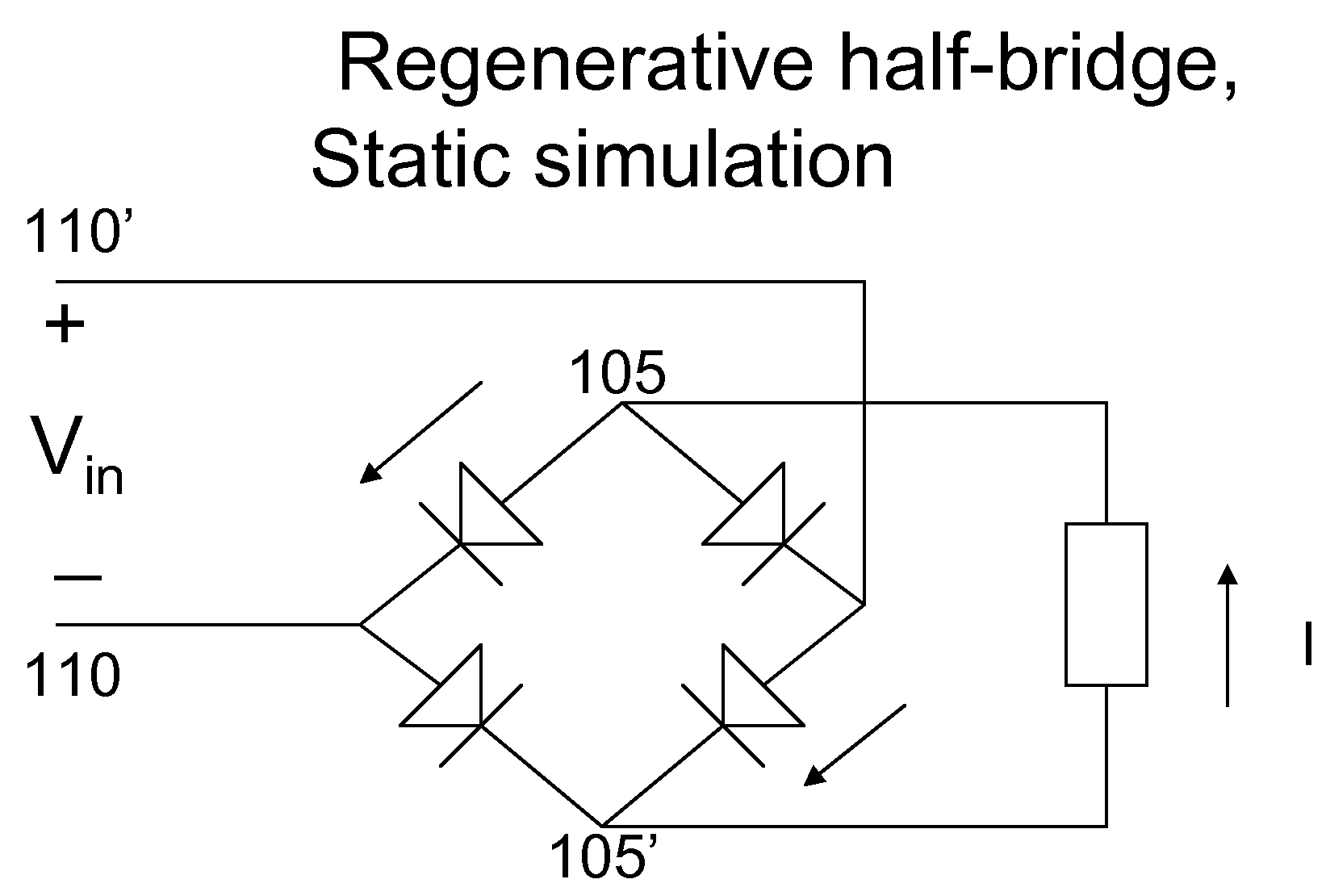

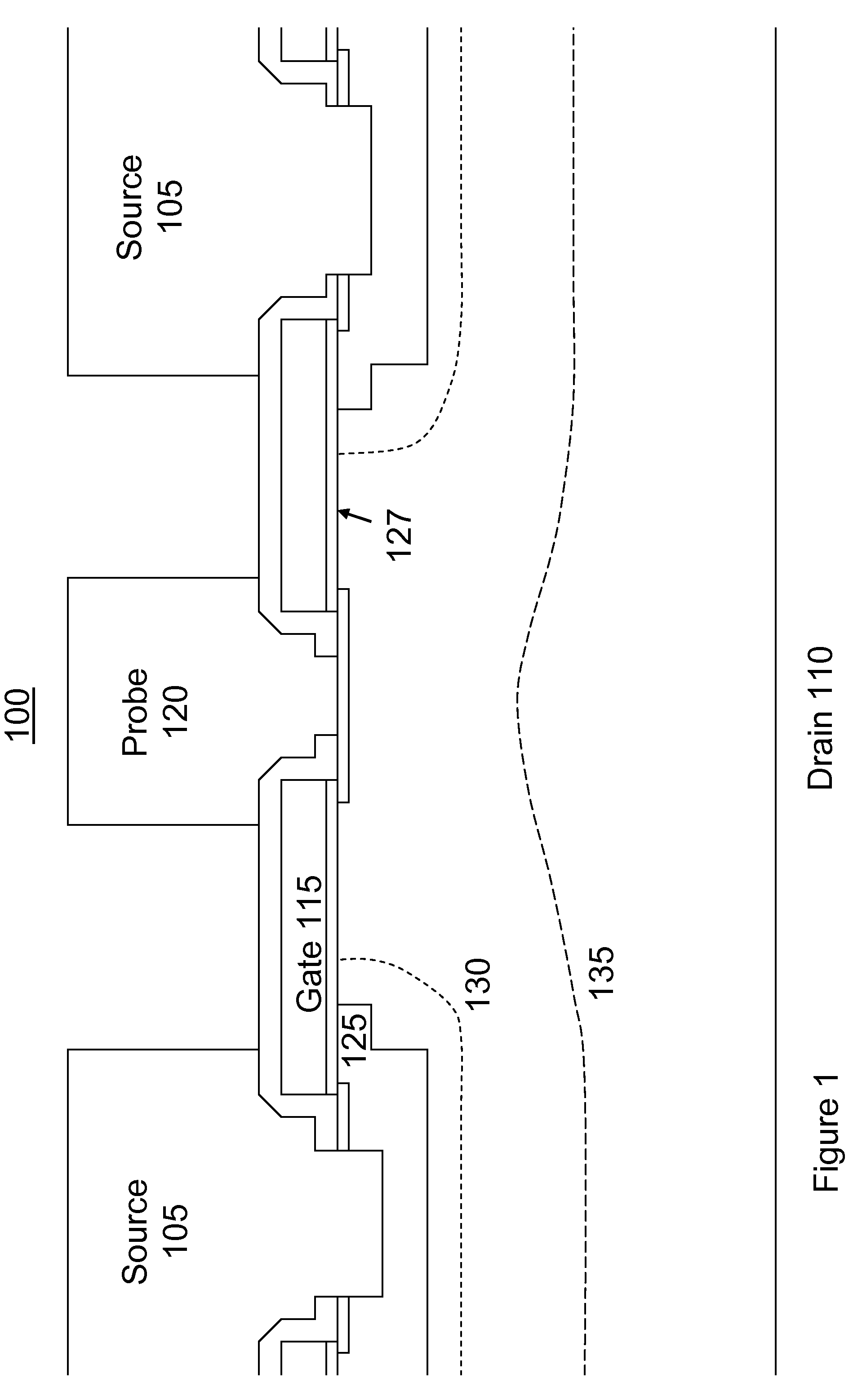

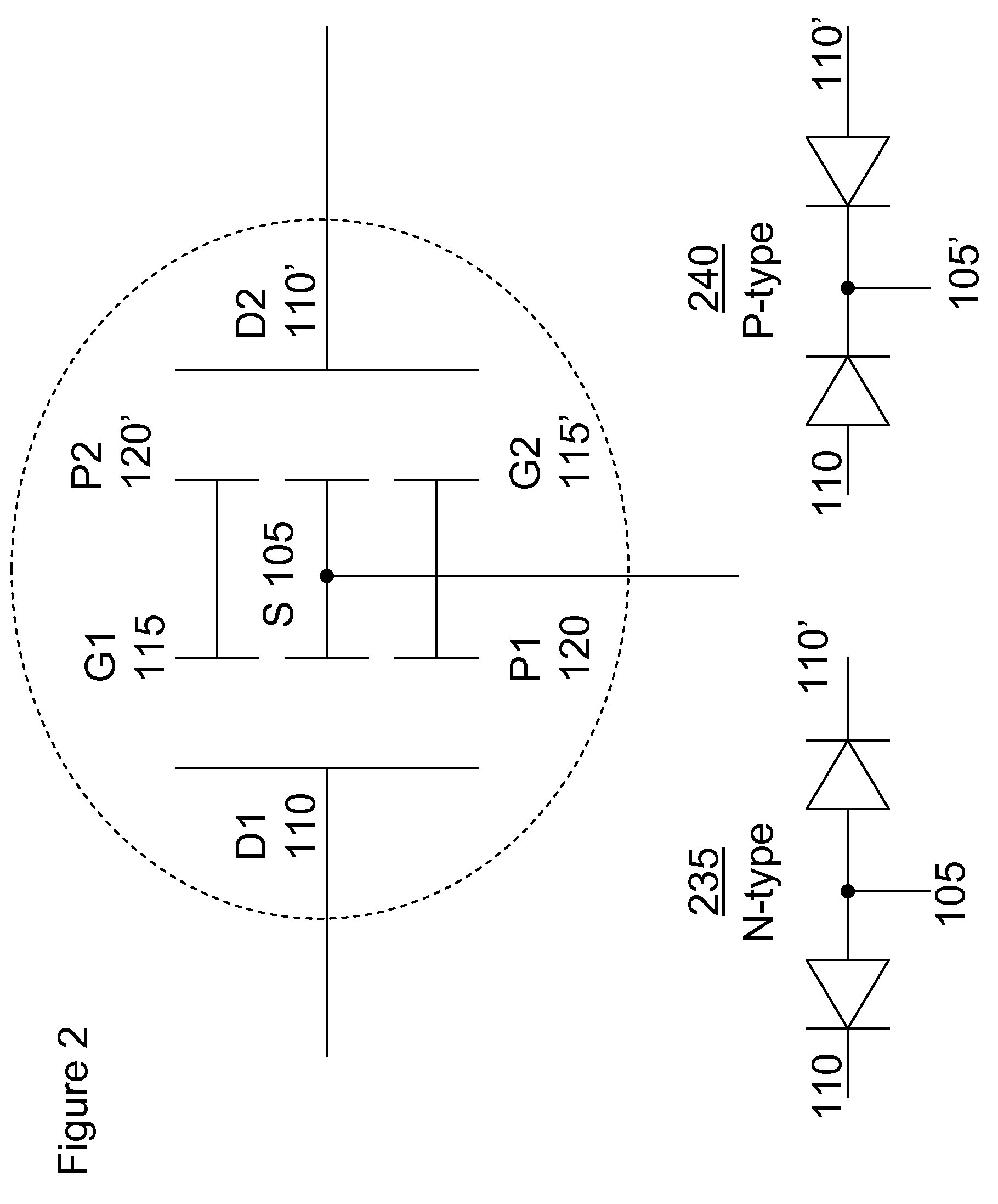

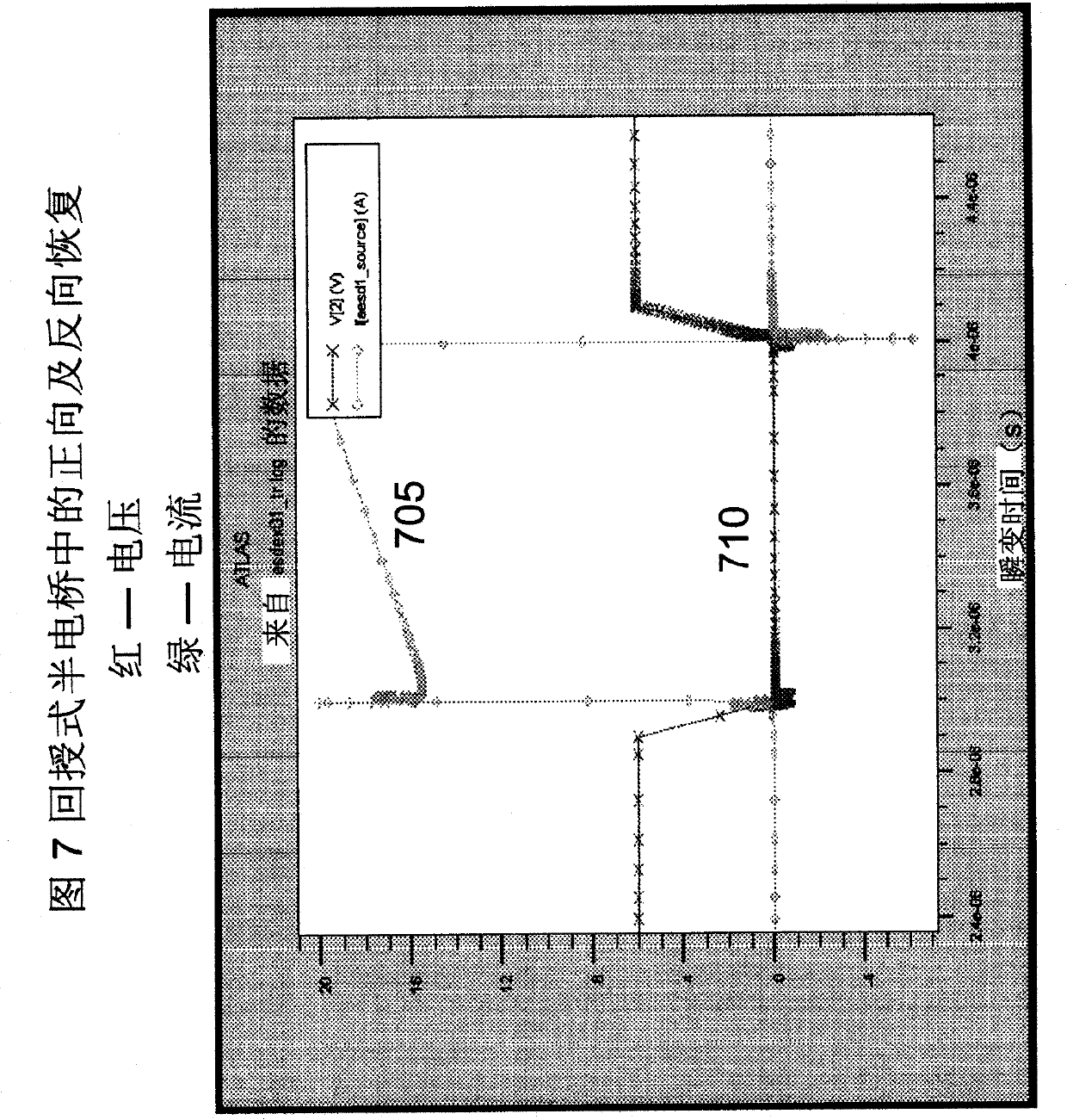

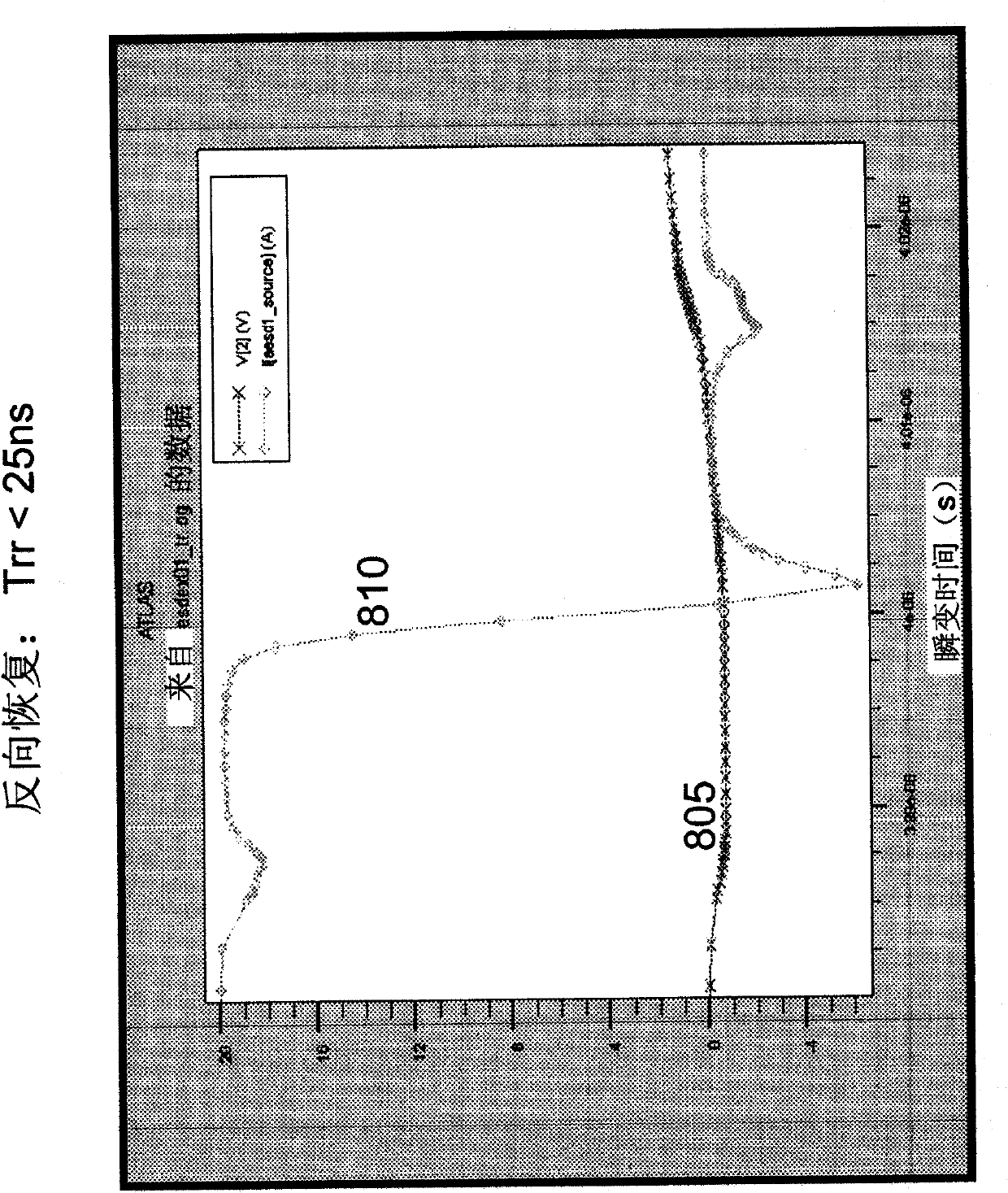

Regenerative building block and diode bridge rectifier and methods

ActiveUS8421118B2Low voltage without unacceptable lossIdeal overall performanceAc-dc conversion without reversalThyristorDiode bridge rectifierPower flow

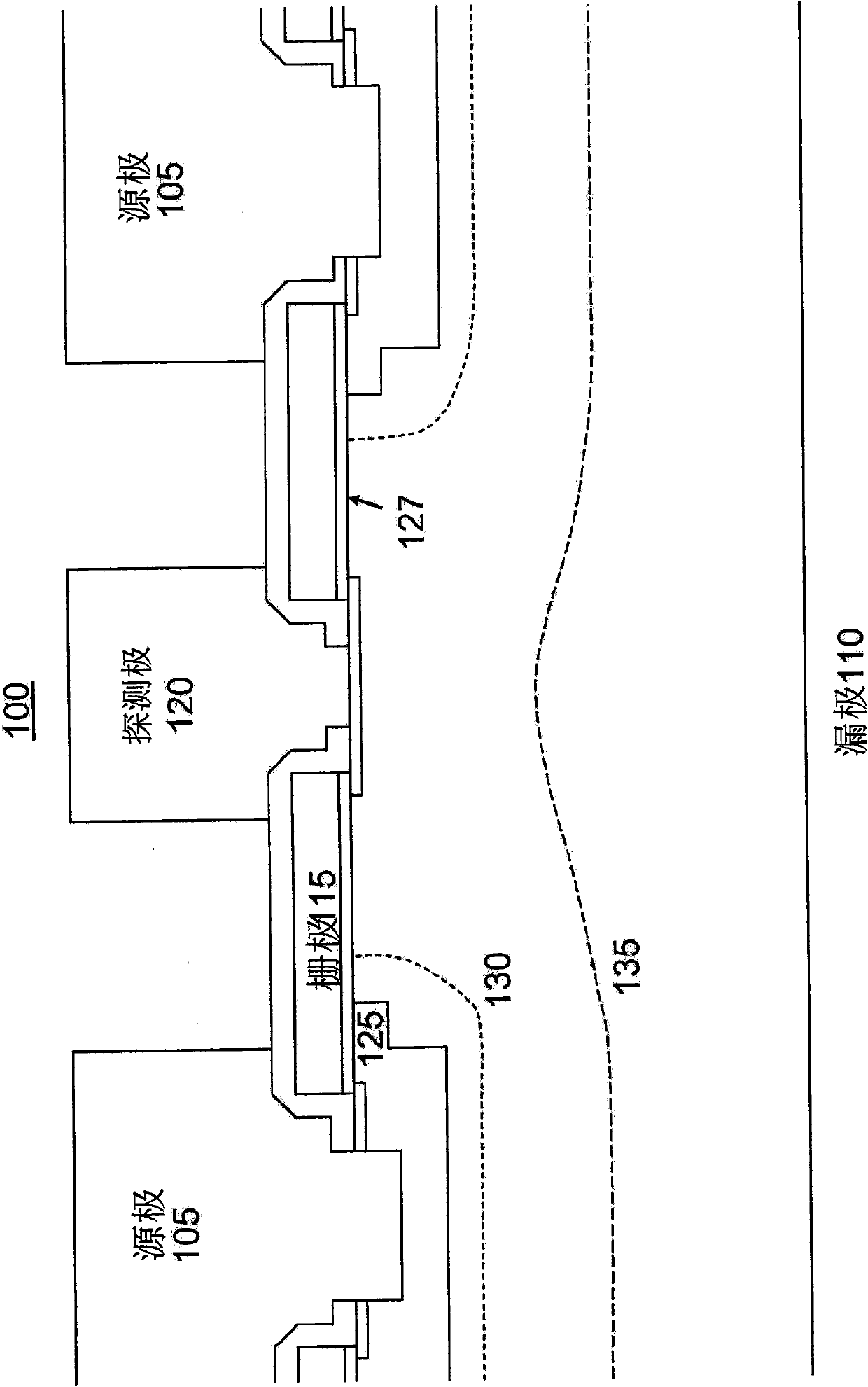

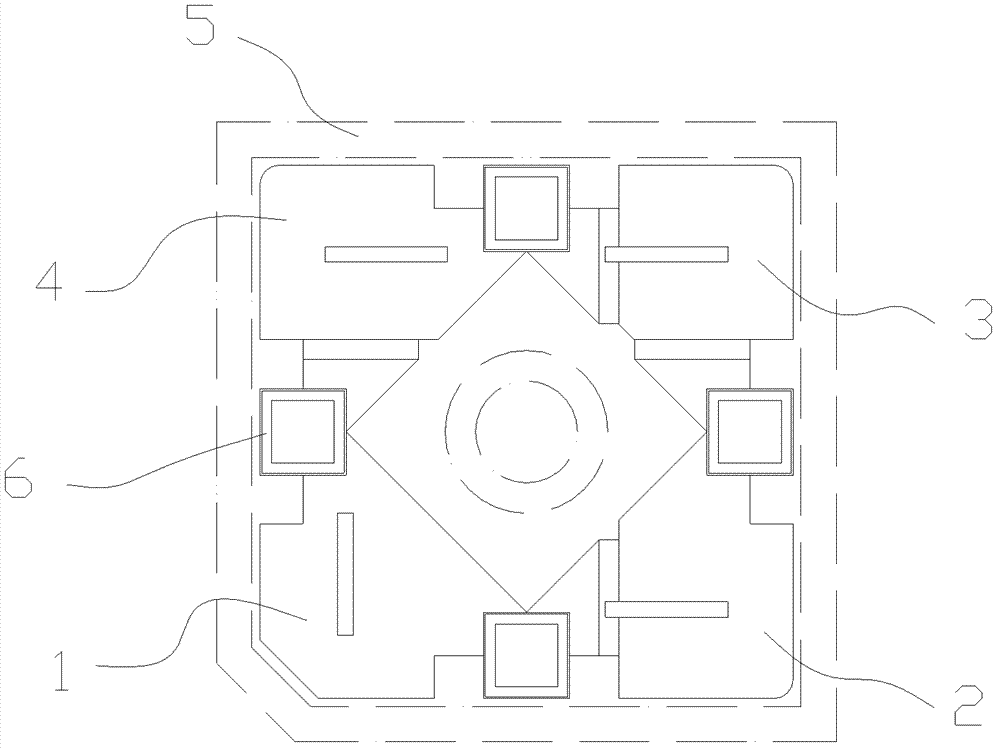

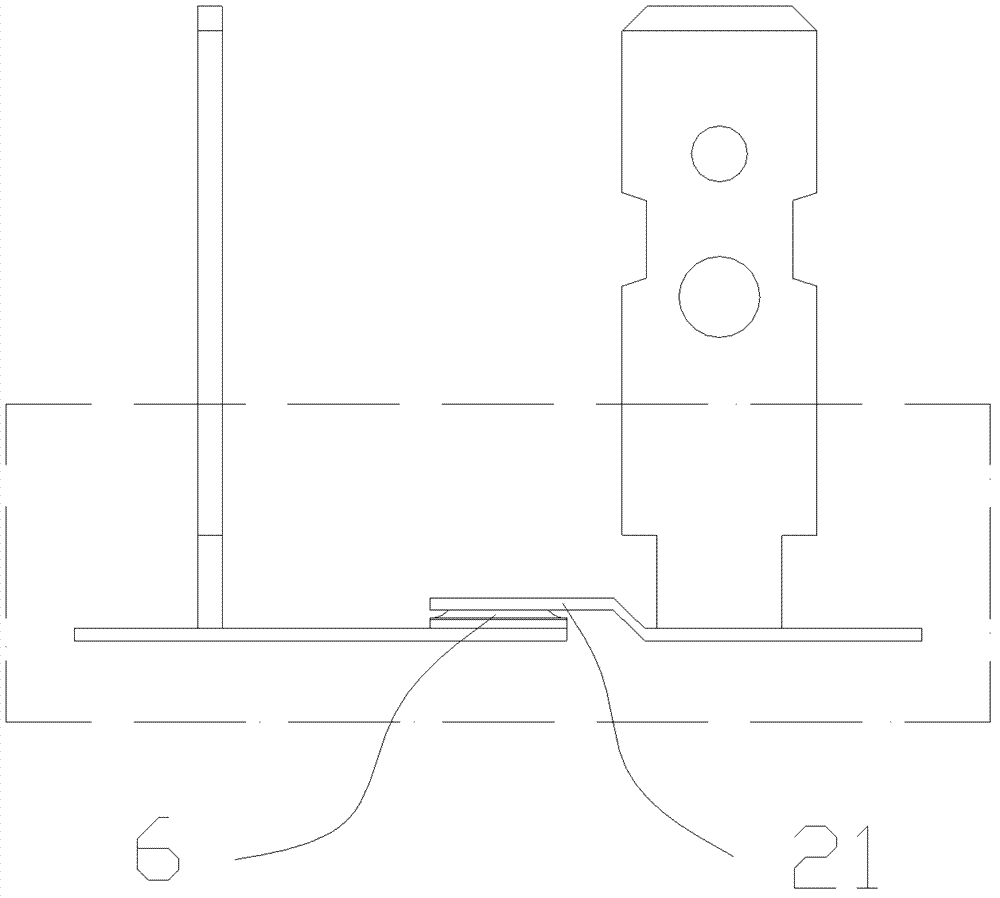

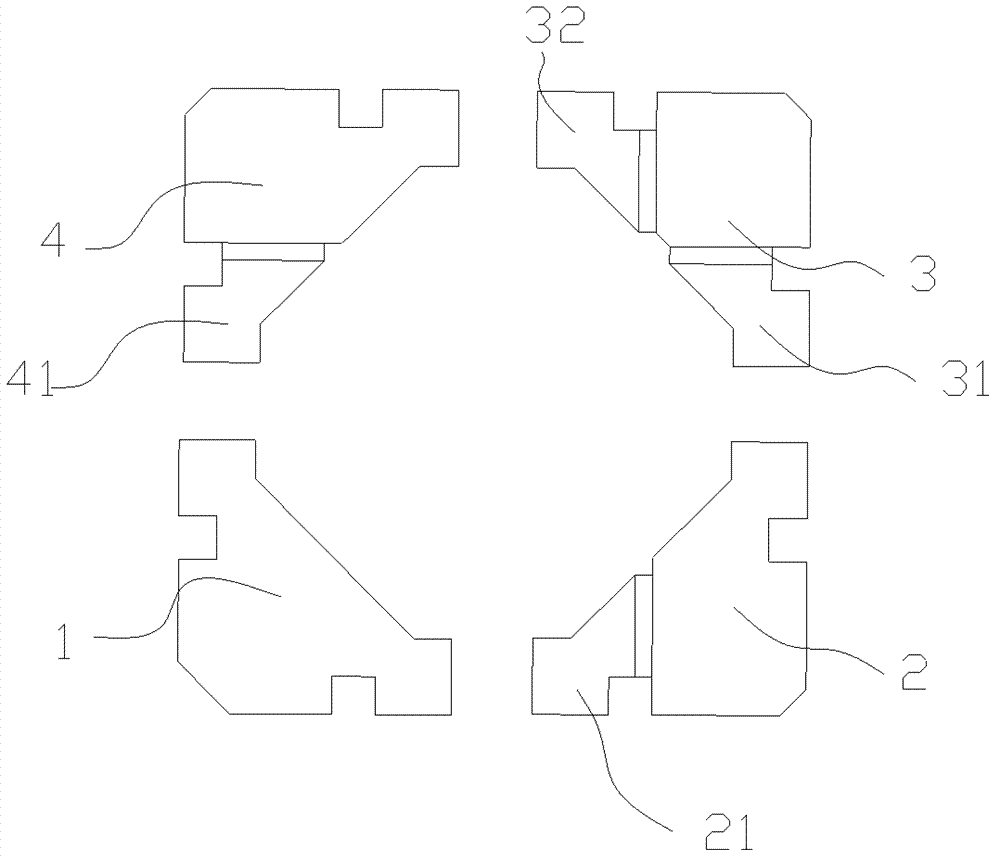

A rectifier building block has four electrodes: source, drain, gate and probe. The main current flows between the source and drain electrodes. The gate voltage controls the conductivity of a narrow channel under a MOS gate and can switch the RBB between OFF and ON states. Used in pairs, the RBB can be configured as a three terminal half-bridge rectifier which exhibits better than ideal diode performance, similar to synchronous rectifiers but without the need for control circuits. N-type and P-type pairs can be configured as a full bridge rectifier. Other combinations are possible to create a variety of devices.

Owner:STMICROELECTRONICS INT NV

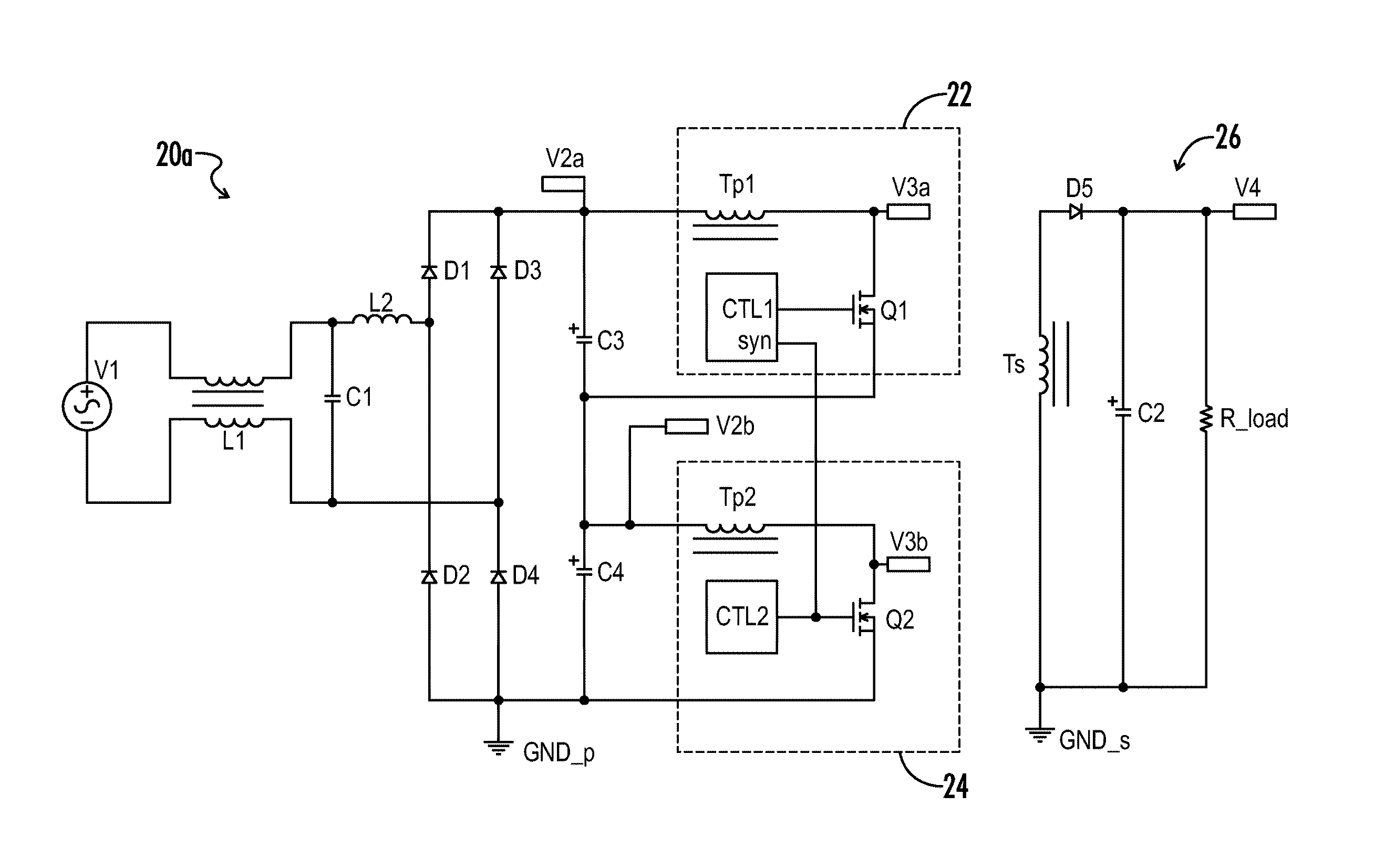

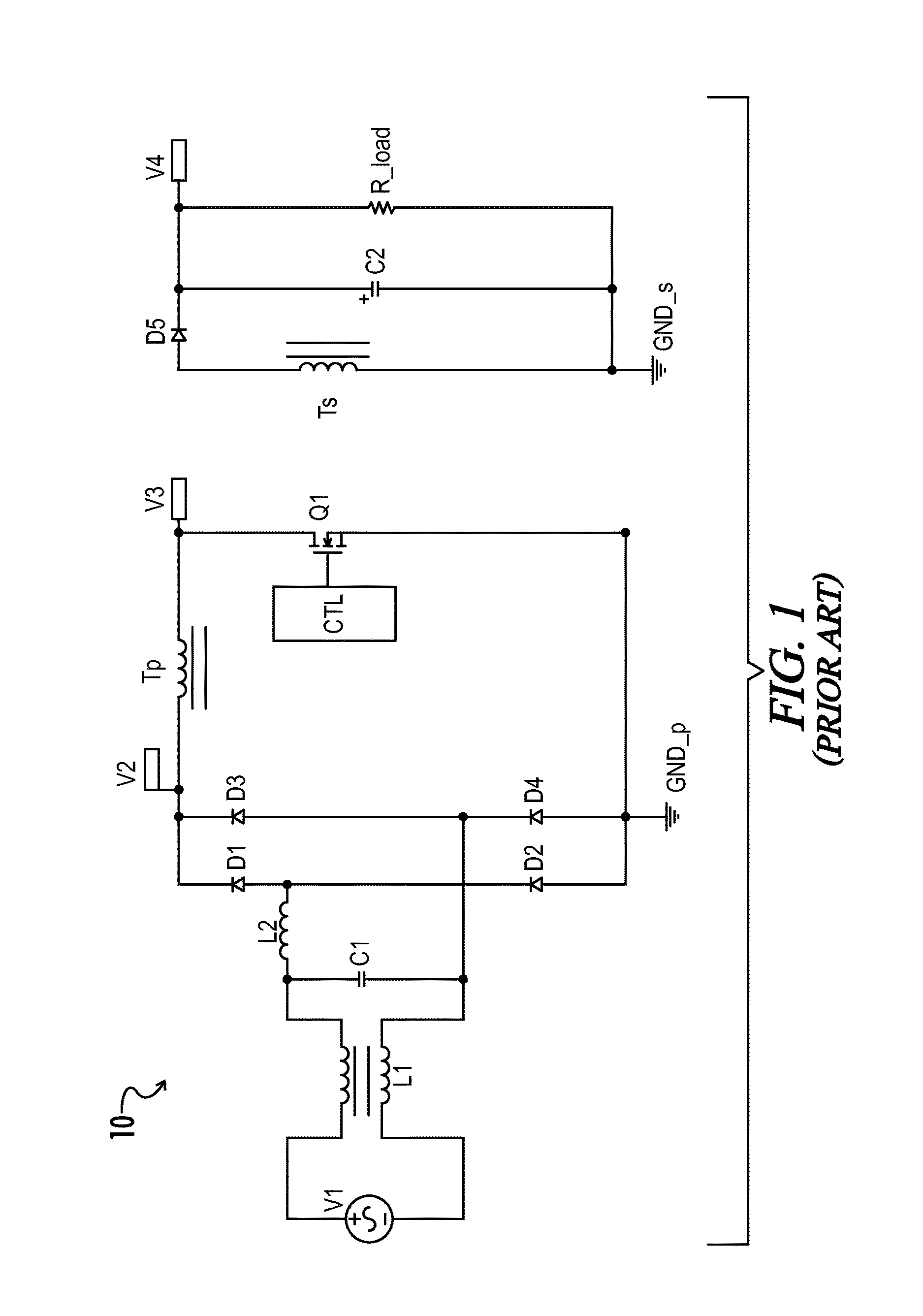

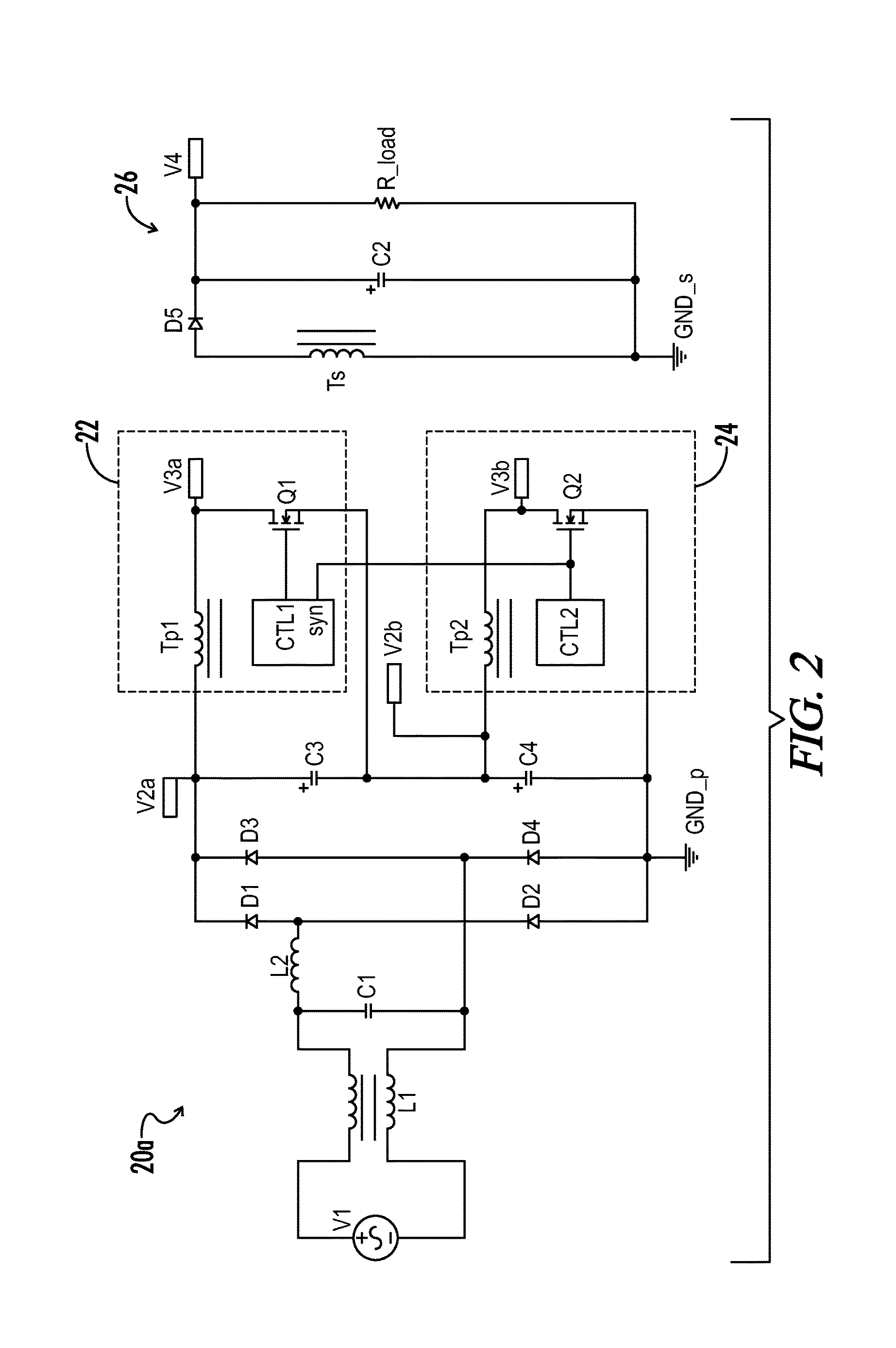

Multi-stage flyback converter for wide input voltage range applications

InactiveUS9577540B1Efficient solutionHigh stressDc-dc conversionElectric variable regulationDiode bridge rectifierVoltage range

A multi-stage flyback circuit is provided for a wide range of DC input voltage applications. An intermediate circuit is coupled across a DC source which may be for example an output from a diode bridge rectifier. A first flyback stage includes a primary winding of a flyback transformer and a first switch coupled in series between a midpoint of the intermediate circuit and a negative DC terminal. A second flyback stage includes a second primary winding and a second switch coupled in series between the midpoint of the intermediate circuit and a positive DC terminal. A secondary winding of the flyback transformer is coupled to a DC load. The first and second switches are operated synchronously, wherein the voltage stress on each of the first and second switches is substantially reduced.

Owner:UNIVERSAL LIGHTING TECHNOLOGIES

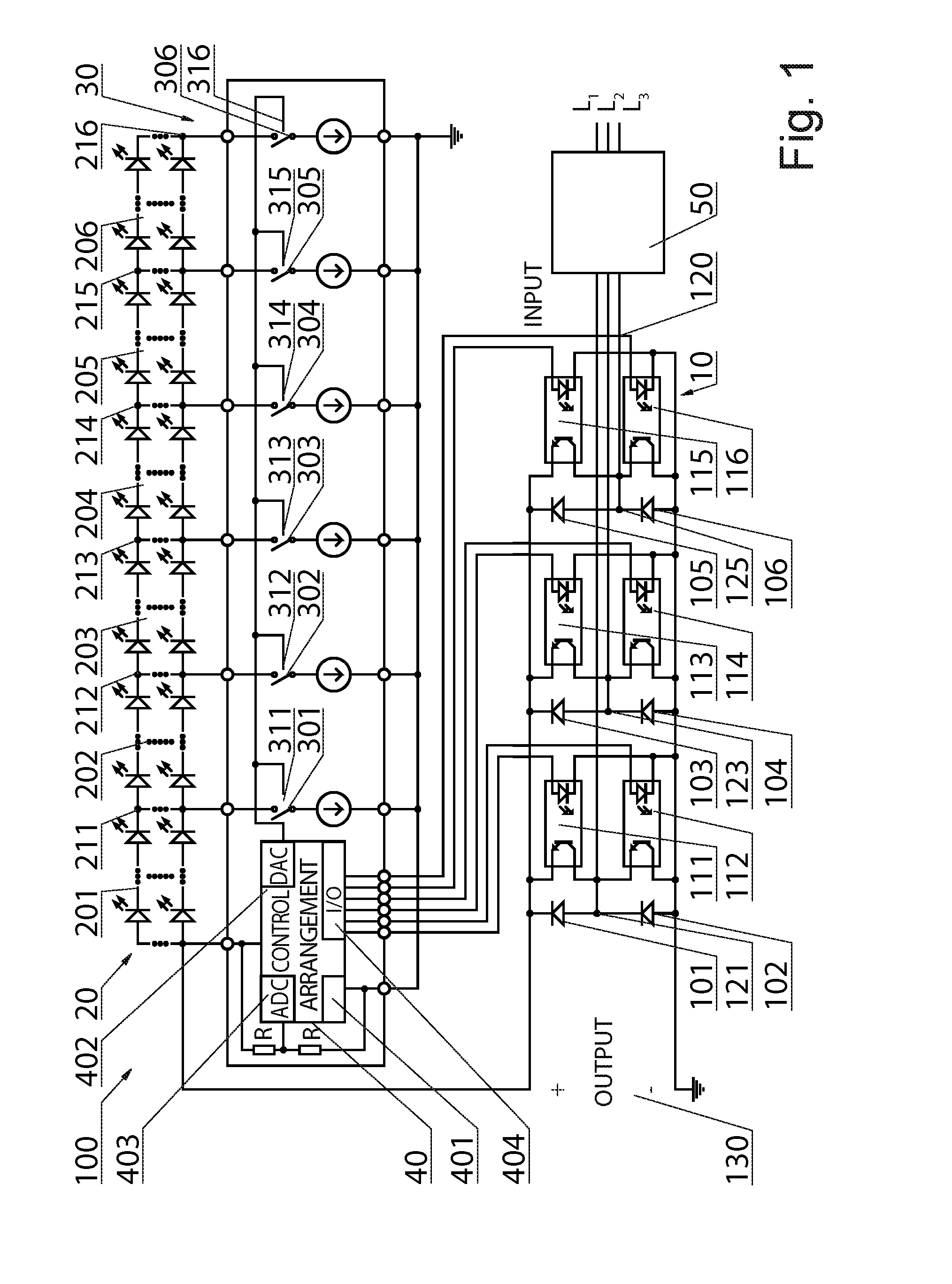

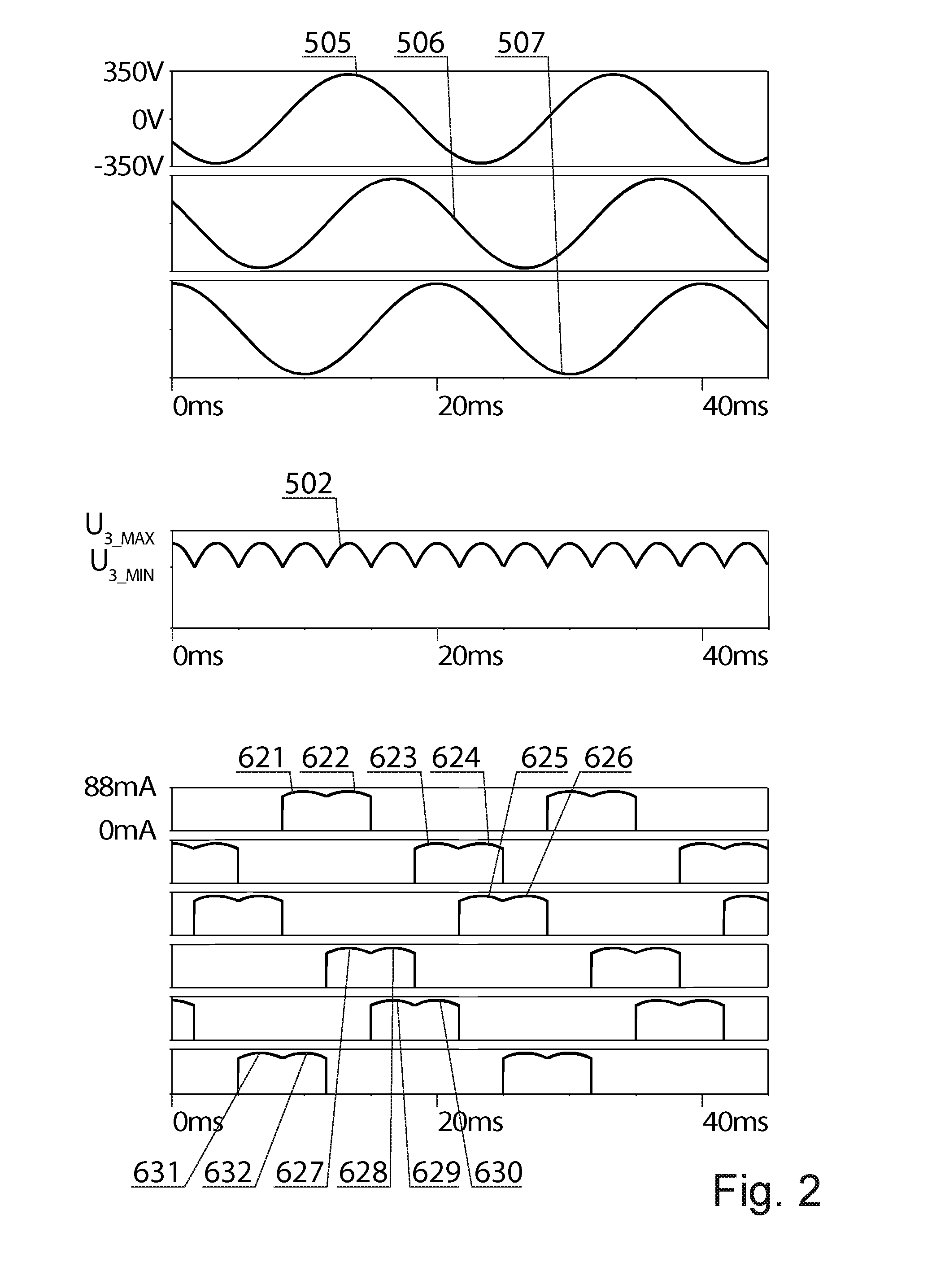

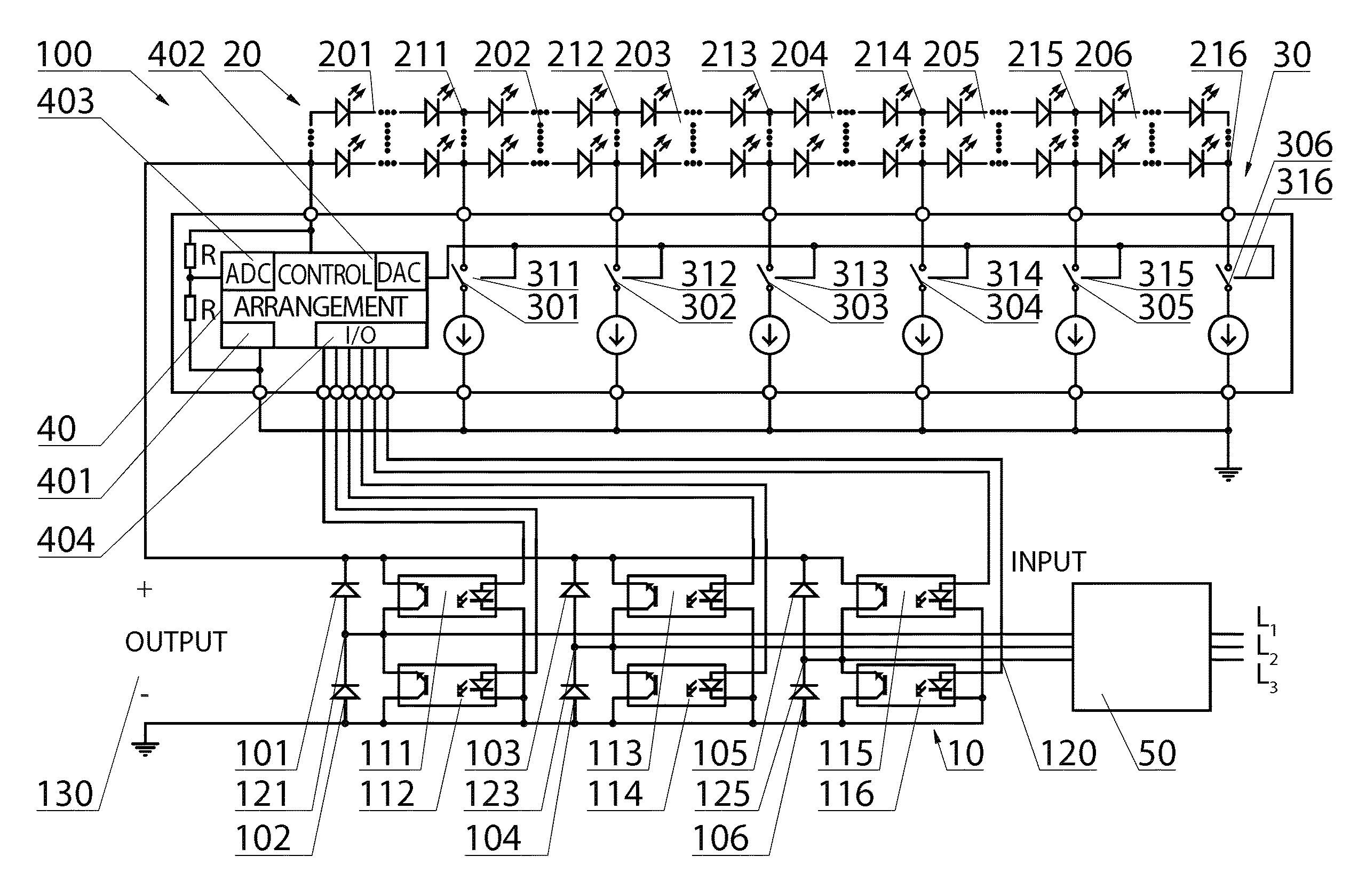

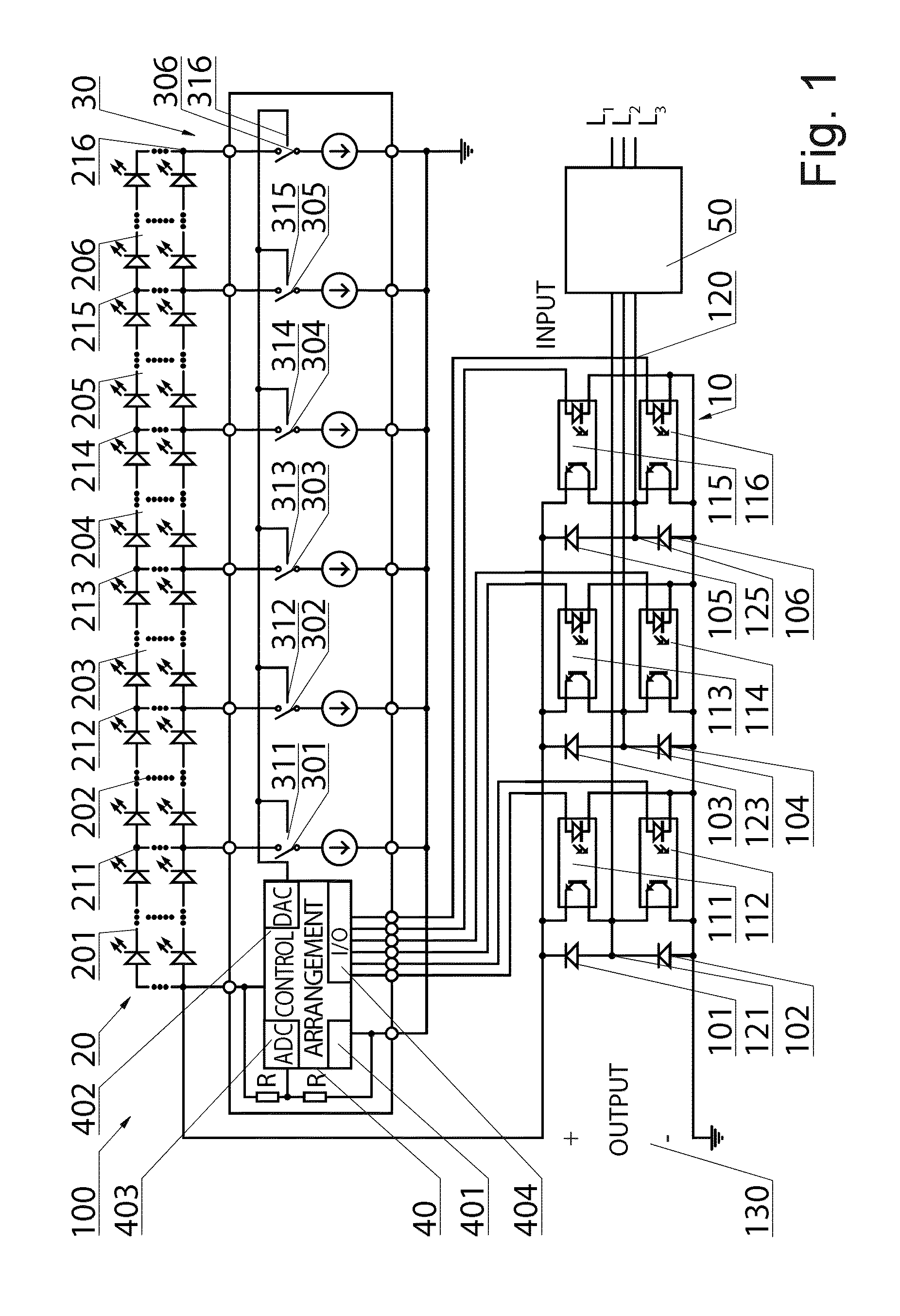

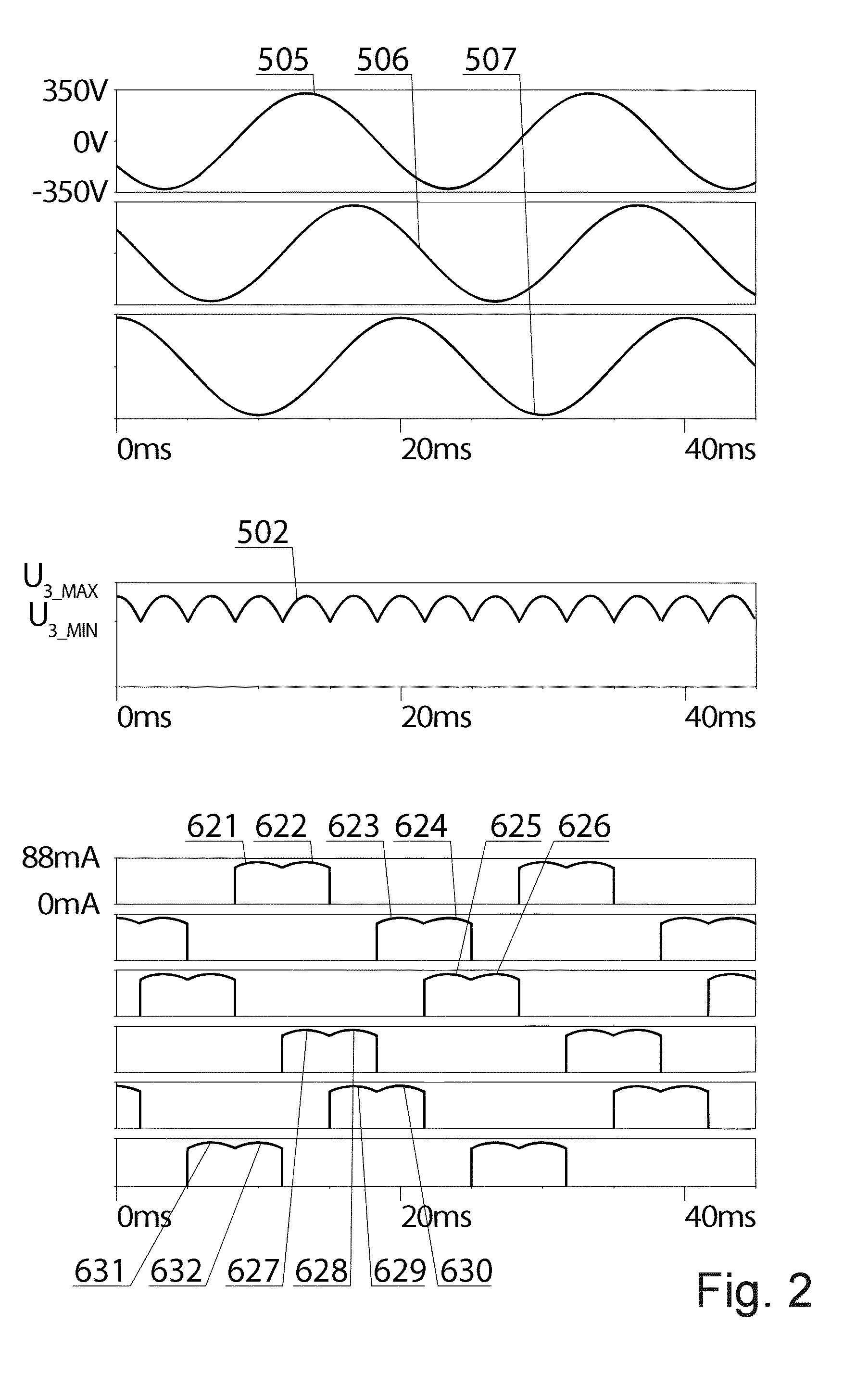

Three-phase power supply and system of leds with three-phase power supply

ActiveUS20150054408A1Reduce power consumptionReduce lossesEfficient power electronics conversionElectroluminescent light sourcesMicrocontrollerDiode bridge rectifier

A three-phase power supply (10), intended especially to supply LEDs system (20), has a system of a diode bridge rectifier which comprises rectifying diodes (101, 102, 103, 104, 105, 106). The three-phase power supply (10) is additionally equipped with FETs and each of the rectifying diodes is bypassed by an FET of a rectifying unit (111, 112, 113, 114, 115, 116), respectively, which is controlled by a control system (40), comprising en anglogue-to-digital converter ADC 403, a digital-to-analogue converter (402), a microcontroller (401), which provides a control signal to a gate of the appropriate FET through the input / output (404). Once the control system (40), in particular the microcontroller (401), detects stable power supply conditions and starts operation of elements of an LED sequencer (30), it starts at the same time to control over the FETs in the active rectifier.

Owner:MILOO ELECTRONICS

Regenerative Building Block and Diode Bridge Rectifier and Methods

ActiveUS20090185404A1Ideal overall performanceComplexity in control signalAc-dc conversion without reversalThyristorDiode bridge rectifierFull bridge

A rectifier building block has four electrodes: source, drain, gate and probe. The main current flows between the source and drain electrodes. The gate voltage controls the conductivity of a narrow channel under a MOS gate and can switch the RBB between OFF and ON states. Used in pairs, the RBB can be configured as a three terminal half-bridge rectifier which exhibits better than ideal diode performance, similar to synchronous rectifiers but without the need for control circuits. N-type and P-type pairs can be configured as a full bridge rectifier. Other combinations are possible to create a variety of devices.

Owner:STMICROELECTRONICS INT NV

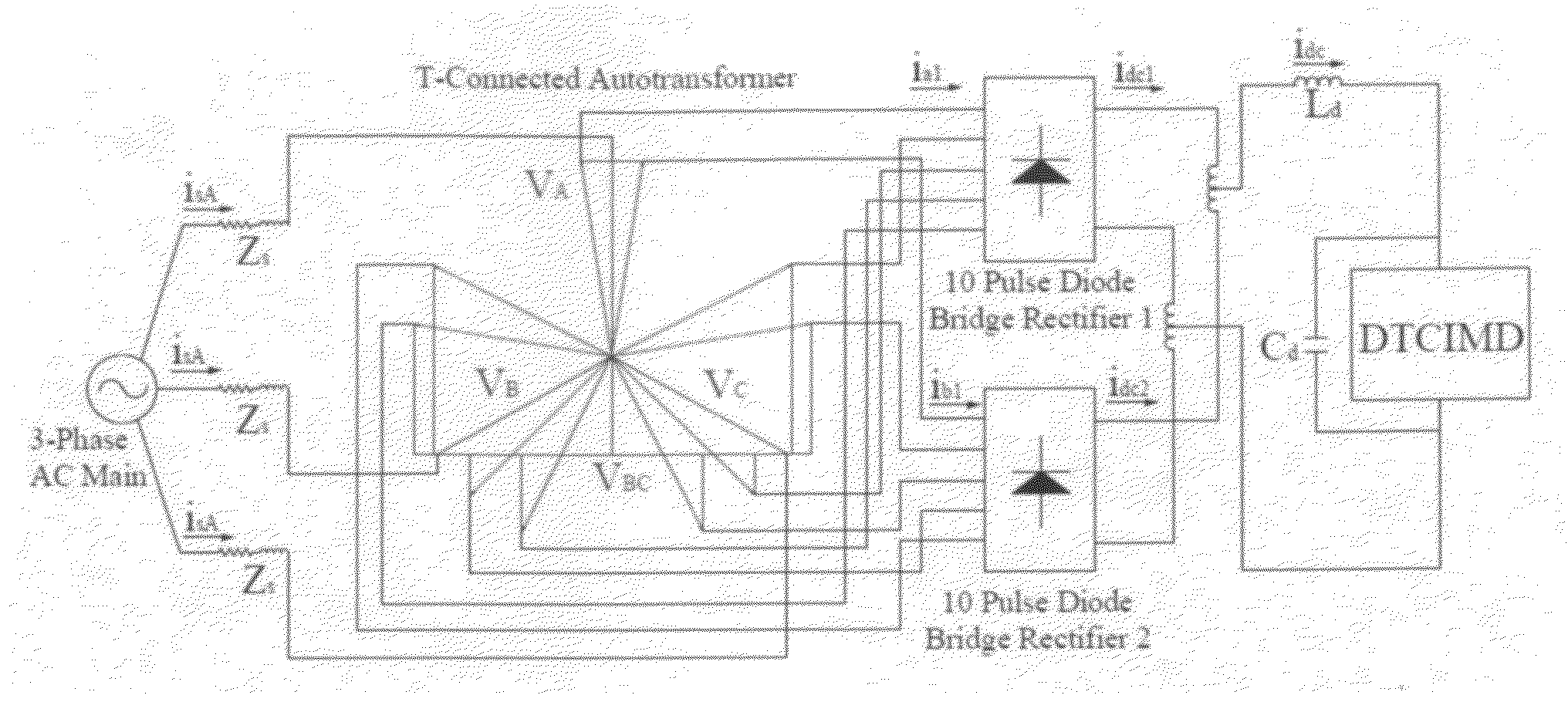

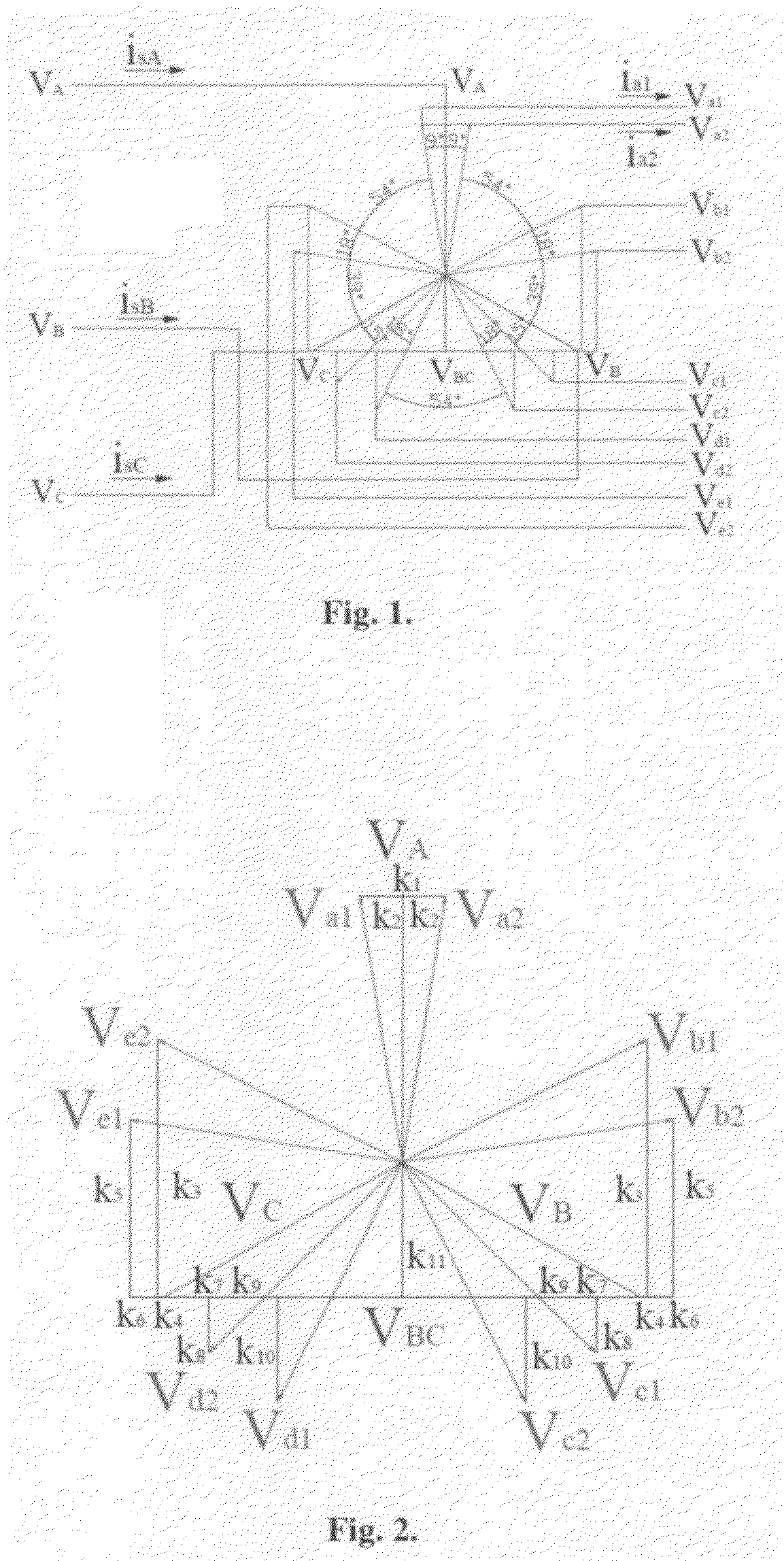

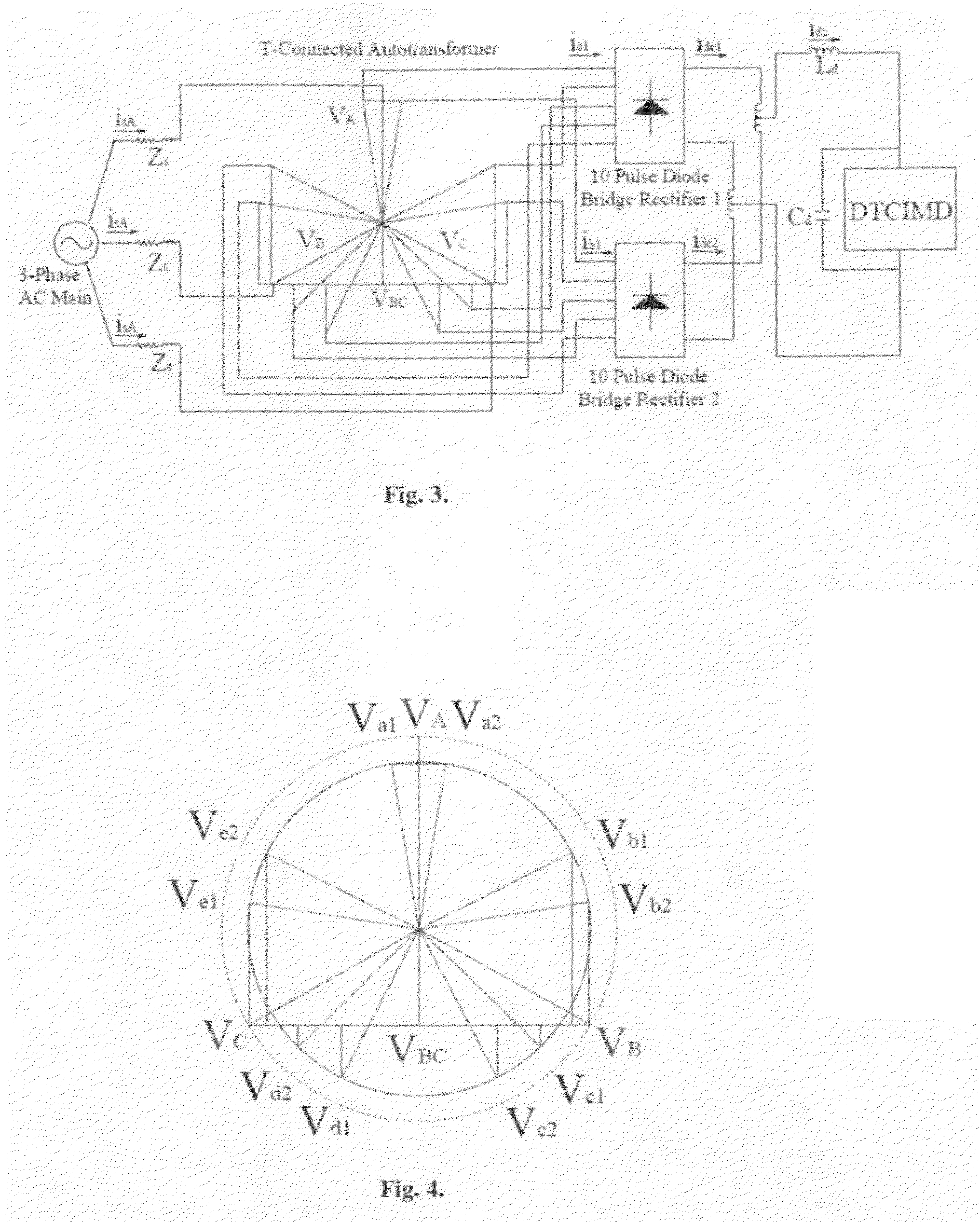

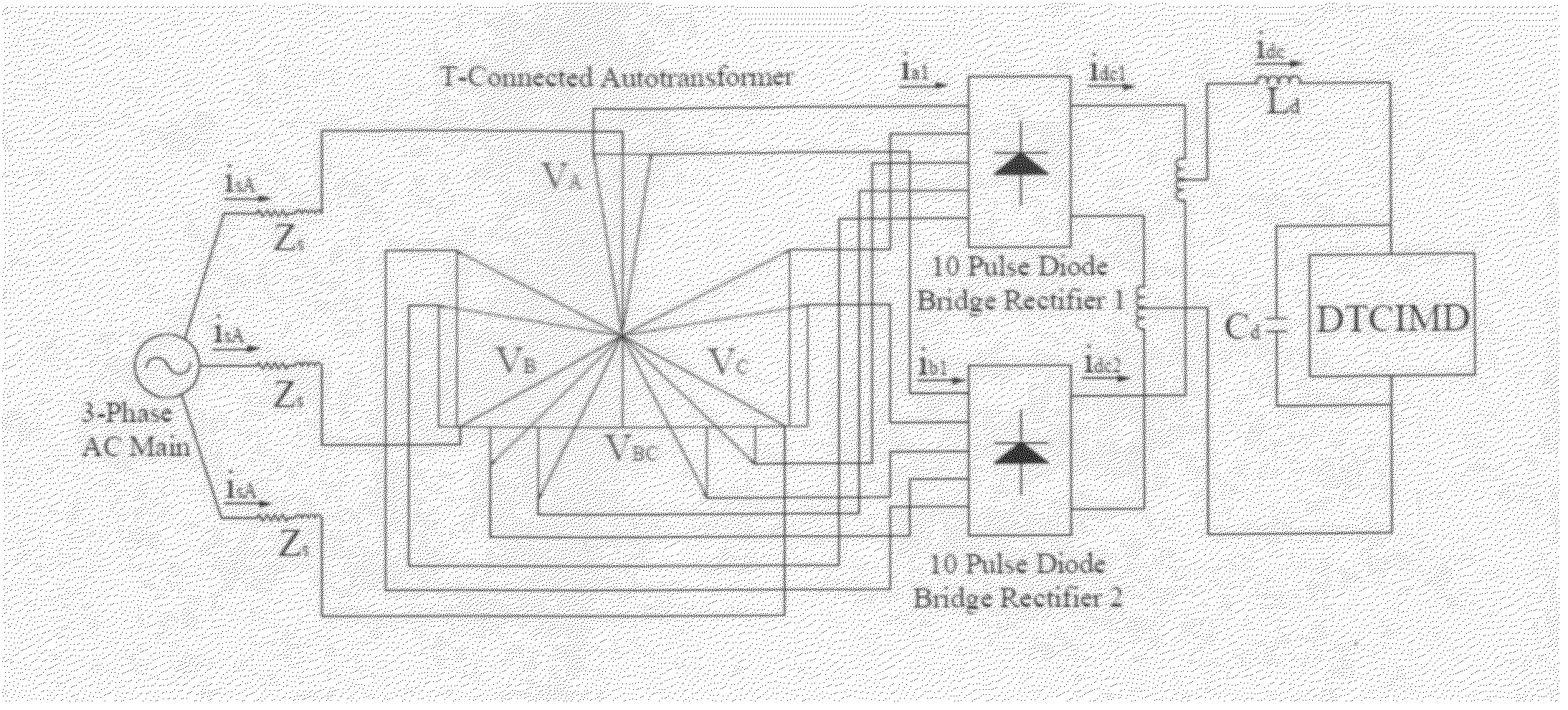

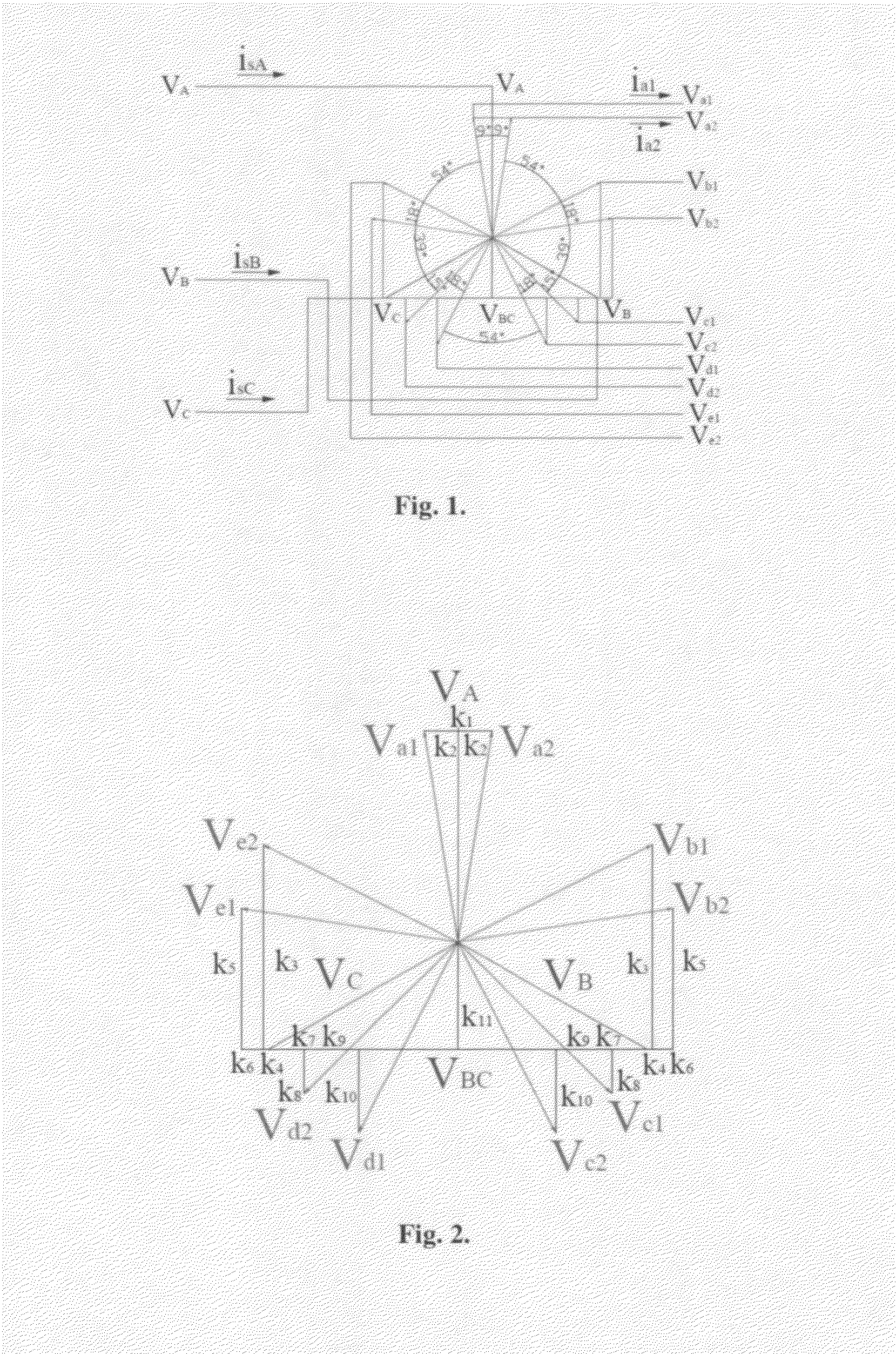

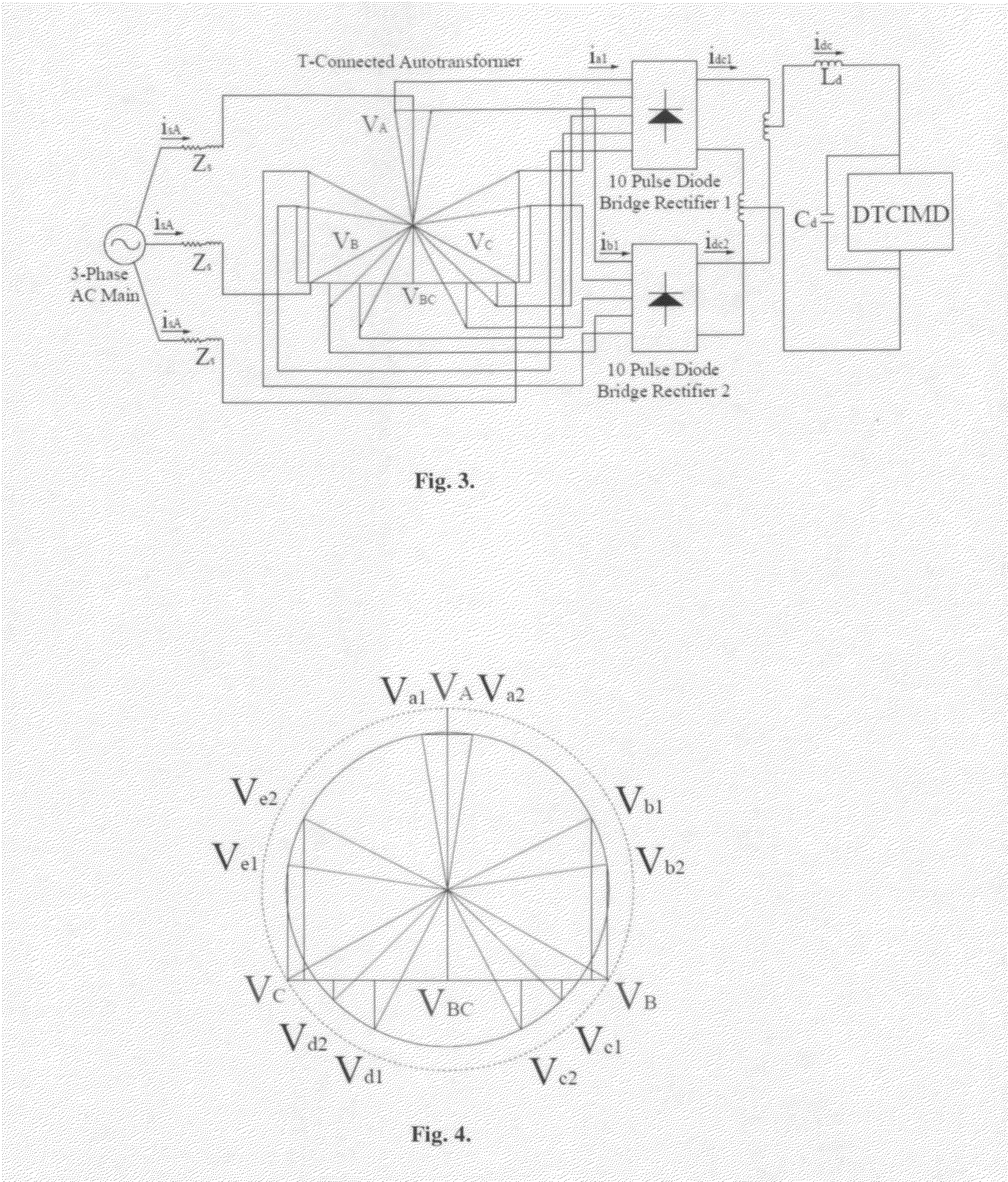

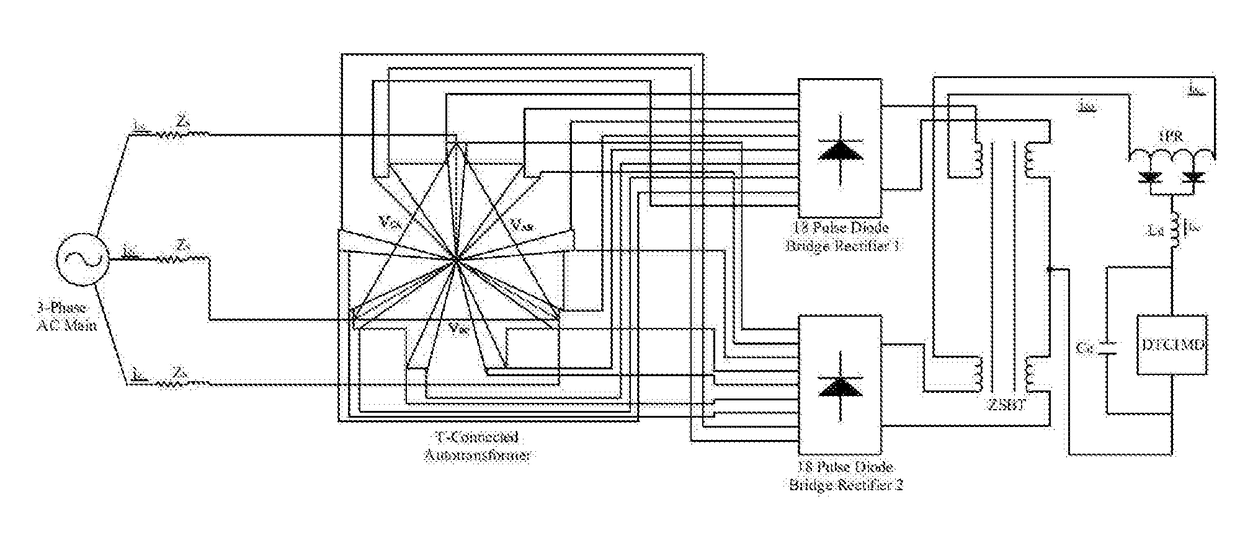

T-connected autotransformer-based 40-pulse AC-DC converter for power quality improvement

InactiveUS8982595B2Electronic commutation motor controlMotor/generator/converter stoppersPower qualityAutotransformer

Design of a T-connected autotransformer based 20-pulse ac-dc converter is presented in this invention. The 20-pulse topology is obtained via two paralleled ten-pulse ac-dc converters each of them consisting of a five-phase (five-leg) diode bridge rectifier. For independent operation of paralleled diode-bridge rectifiers, a zero sequence blocking transformer (ZSBT) is designed and implemented. Connection of a tapped inter-phase transformer (IPT) at the output of ZSBT results in doubling the number of output voltage pulses to 40. Experimental results are obtained using the designed and constructed laboratory prototype of the proposed converter to validate the design procedure and the simulation results under varying loads. The VA rating of the magnetic in the proposed topology are calculated to confirm the savings in space, volume, weight, and cost of the proposed configuration.

Owner:ABDOLLAHI ROHOLLAH

T-Connected Autotransformer-Based 40-Pulse AC-DC Converter for Power Quality Improvement

InactiveUS20140218982A1High impedanceAc-dc conversion without reversalEfficient power electronics conversionPower qualityAutotransformer

Design of a T-connected autotransformer based 20-pulse ac-dc converter is presented in this invention. The 20-pulse topology is obtained via two paralleled ten-pulse ac-dc converters each of them consisting of a five-phase (five-leg) diode bridge rectifier. For independent operation of paralleled diode-bridge rectifiers, a zero sequence blocking transformer (ZSBT) is designed and implemented. Connection of a tapped inter-phase transformer (IPT) at the output of ZSBT results in doubling the number of output voltage pulses to 40. Experimental results are obtained using the designed and constructed laboratory prototype of the proposed converter to validate the design procedure and the simulation results under varying loads. The VA rating of the magnetic in the proposed topology are calculated to confirm the savings in space, volume, weight, and cost of the proposed configuration.

Owner:ABDOLLAHI ROHOLLAH

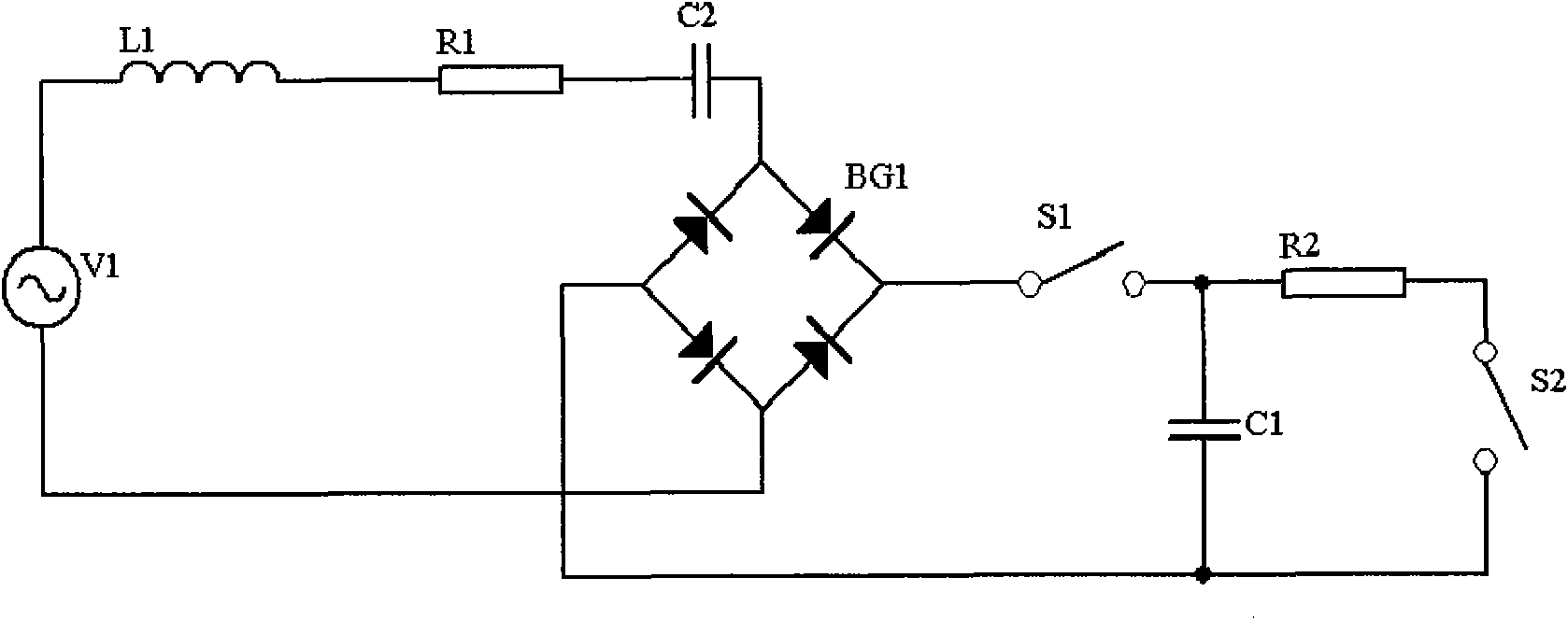

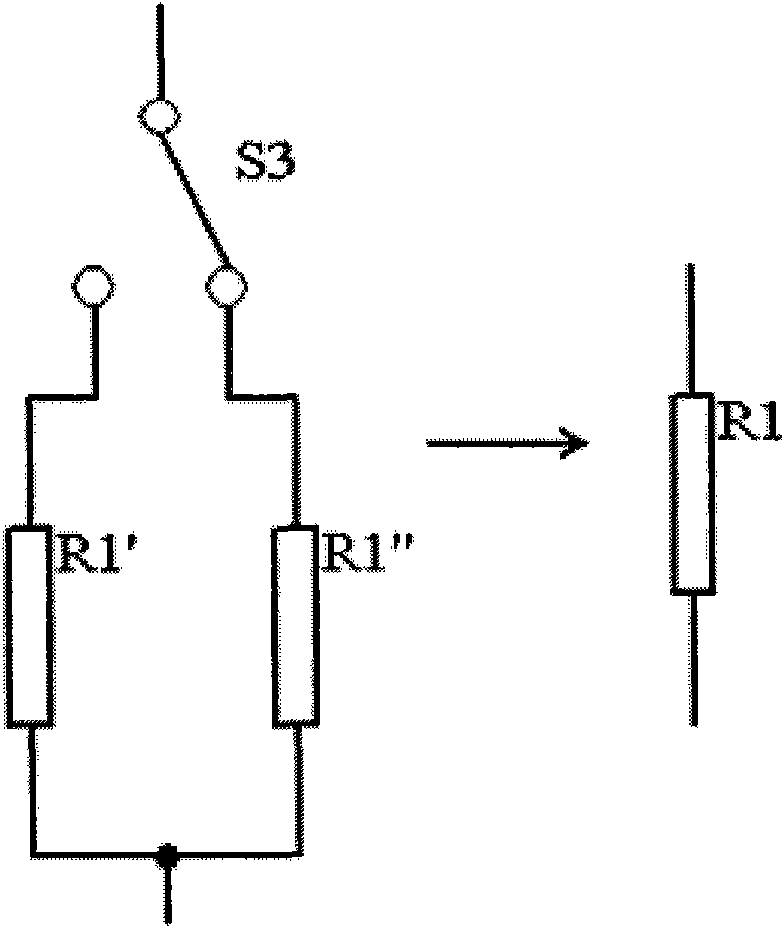

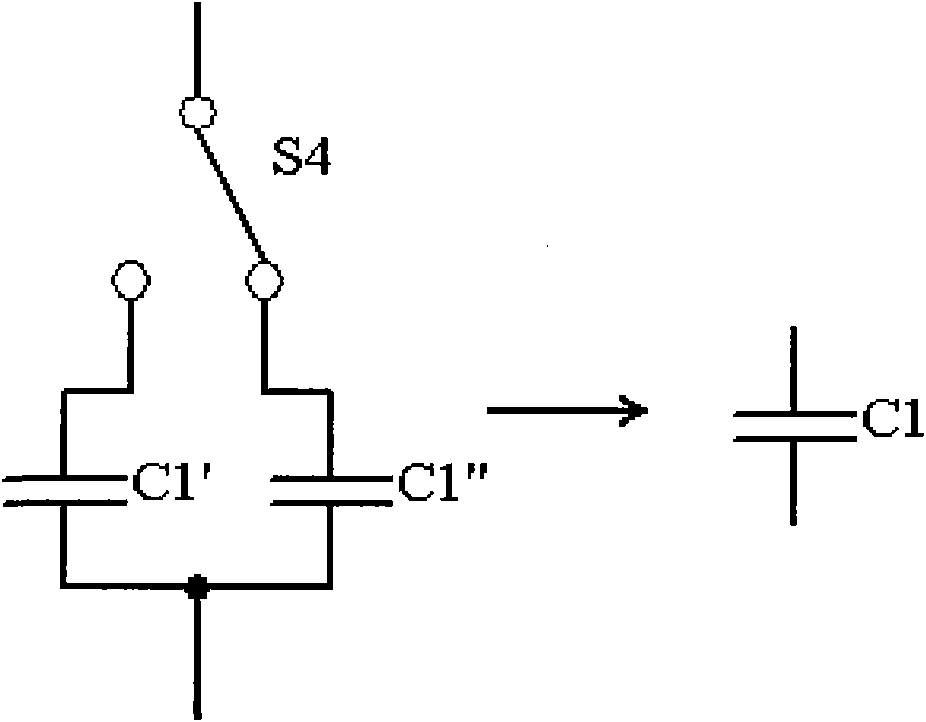

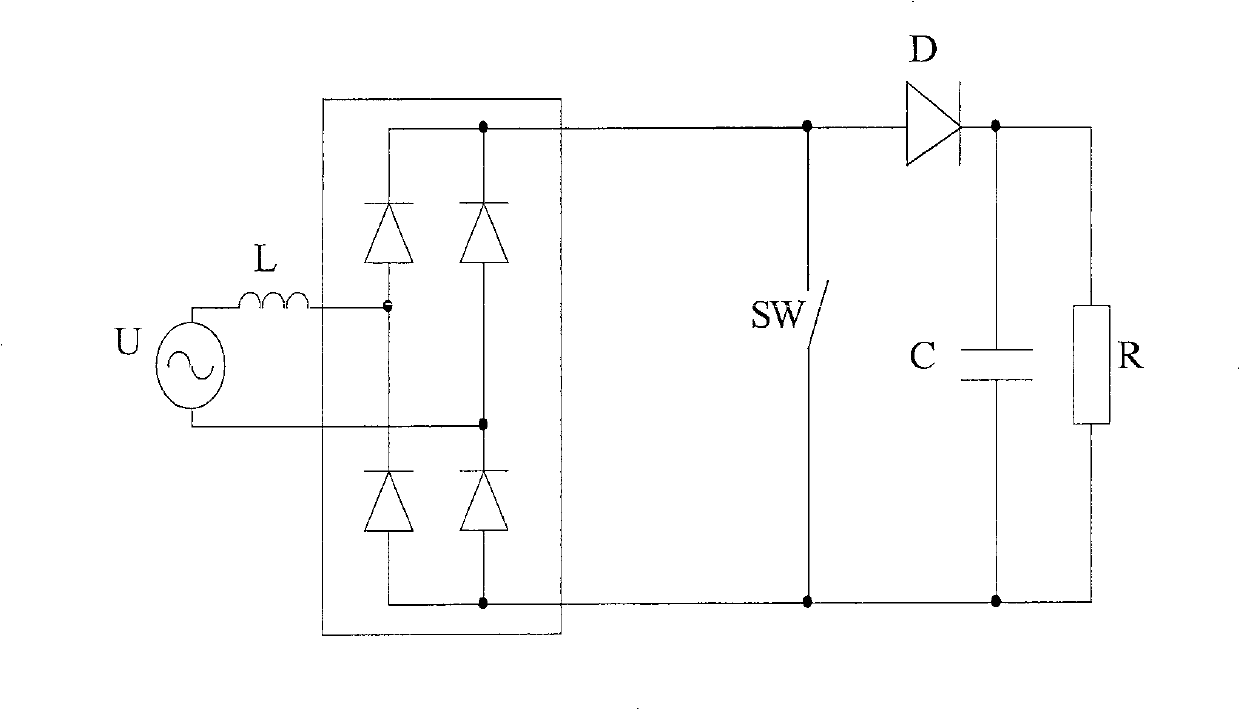

Demagnetization method and demagnetization circuit

InactiveCN101819850AIngenious structureThe principle is simpleMagnetic bodiesDiode bridge rectifierCapacitance

The invention discloses a demagnetization method and a demagnetization circuit. The change rule that charge current slowly decreases along with time and finally decreases to zero when a rectifying circuit charges a capacitor is used as the current change rule required for demagnetization in a magnetic field coil to achieve the purpose of demagnetizing magnetic materials. The demagnetization circuit comprises an AC main loop, a DC charge loop and a discharge loop, wherein the AC main loop is formed by connecting an AC power source, a magnetic field coil, a current limiting resistor, a resonant capacitor and an AC terminal of a diode bridge rectifier stack in series; the DC charge loop is formed by connecting a DC terminal of the diode bridge rectifier stack, two switches, a capacitor and a resistor; and one switch is used for controlling the DC charge loop, and the other switch is used for controlling the discharge loop. The invention has the advantages of novel method, skillful circuit structure, simple realization and good demagnetization effect, can achieve the purpose of repeated demagnetization, and can freely and flexibly regulate the demagnetization degree and the demagnetization time.

Owner:湖南省联众科技有限公司

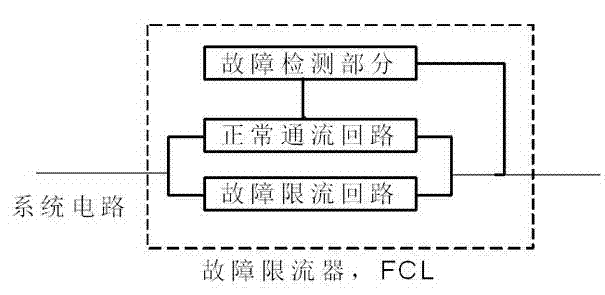

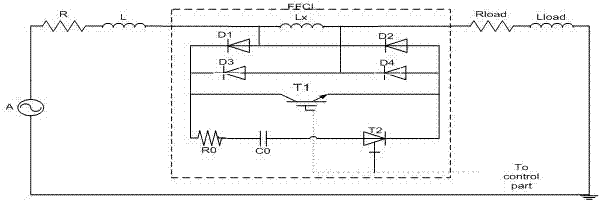

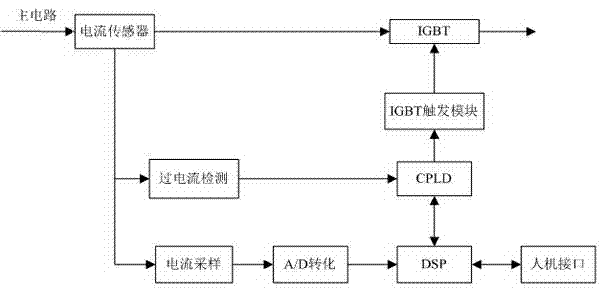

SSCB-based coal mine power grid fast fault current limiter

InactiveCN104852348AReduce short circuit current levelsGuaranteed normal opening and closingArrangements responsive to excess currentCapacitanceDiode bridge rectifier

Owner:HENAN POLYTECHNIC UNIV

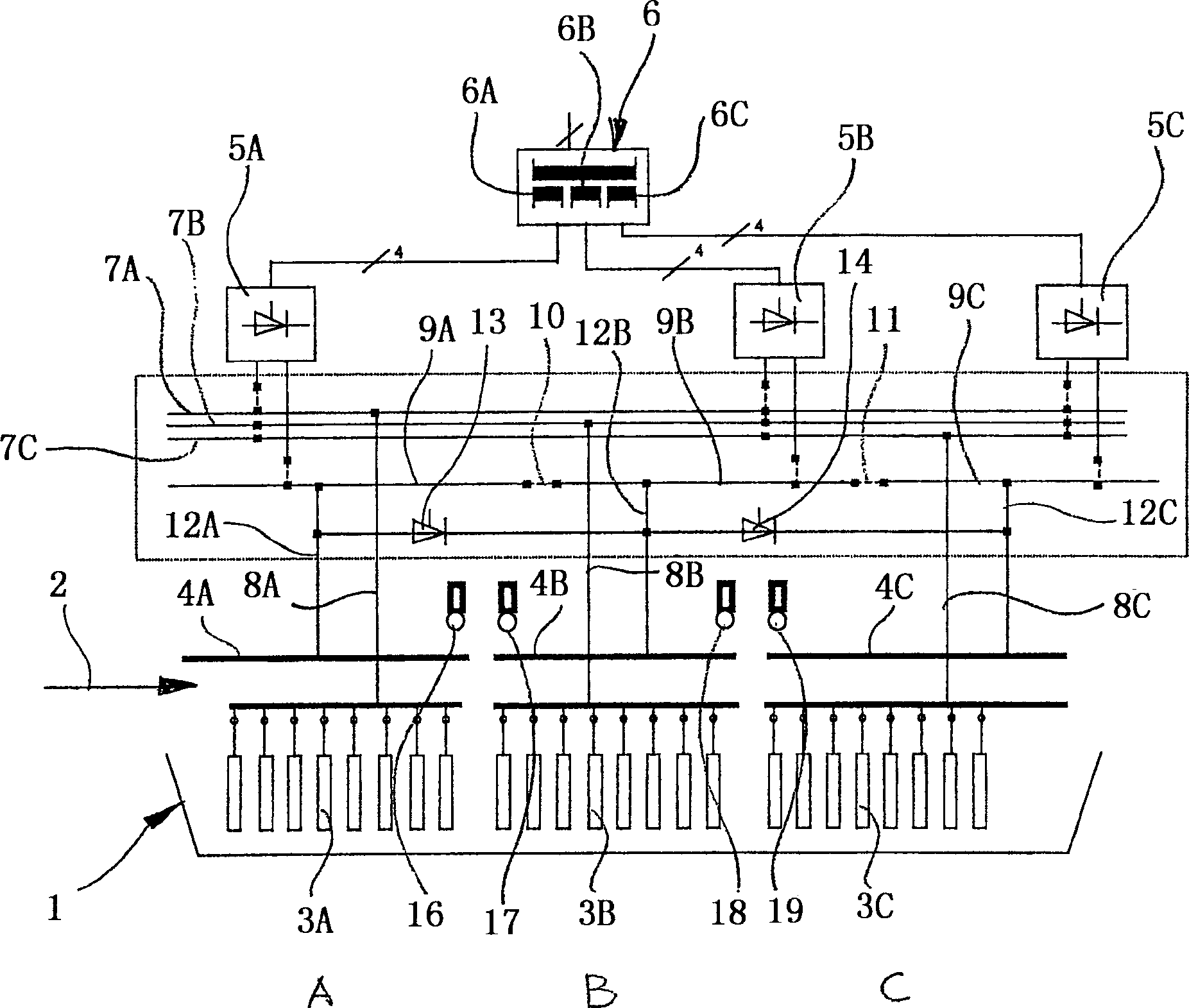

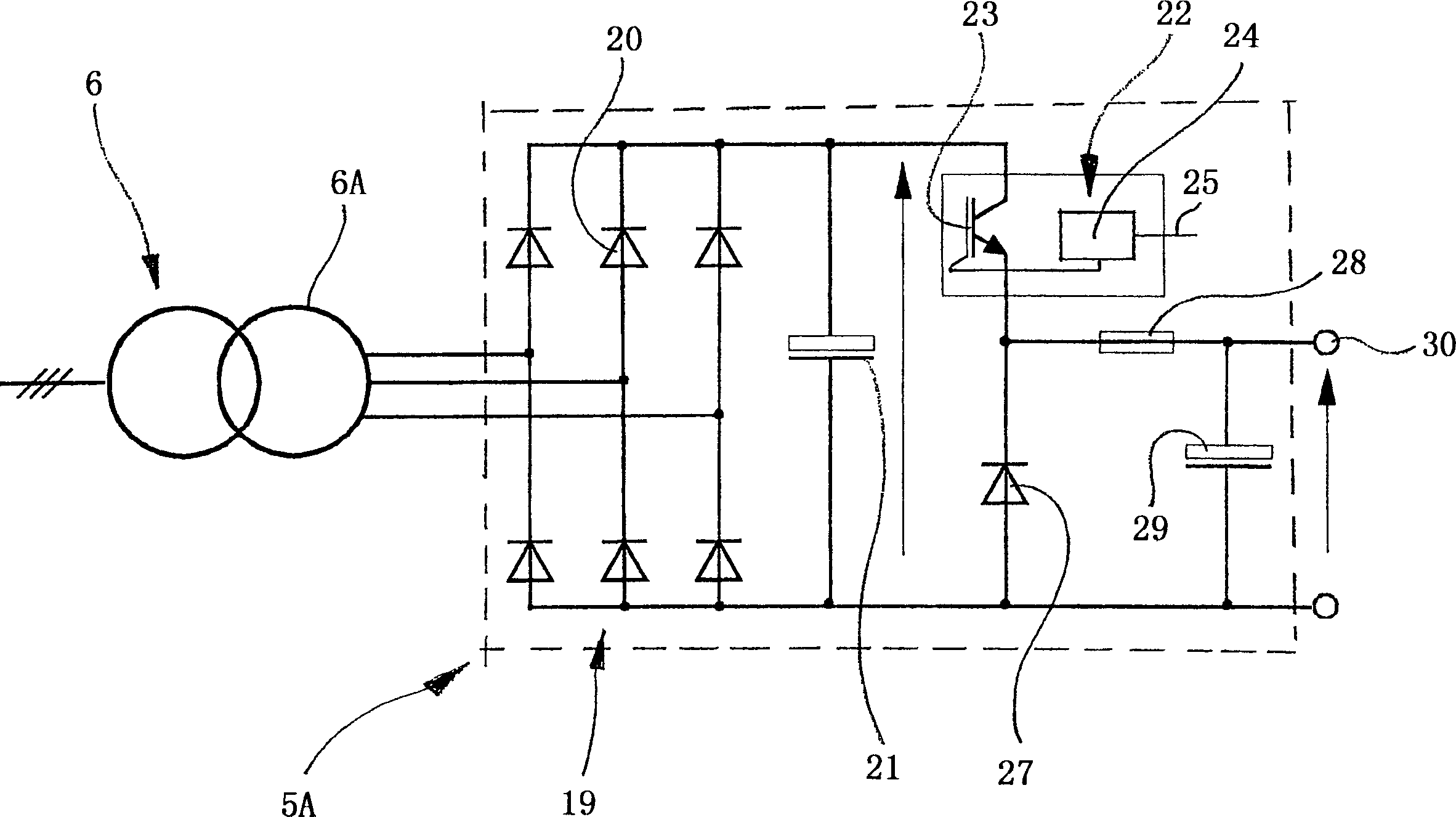

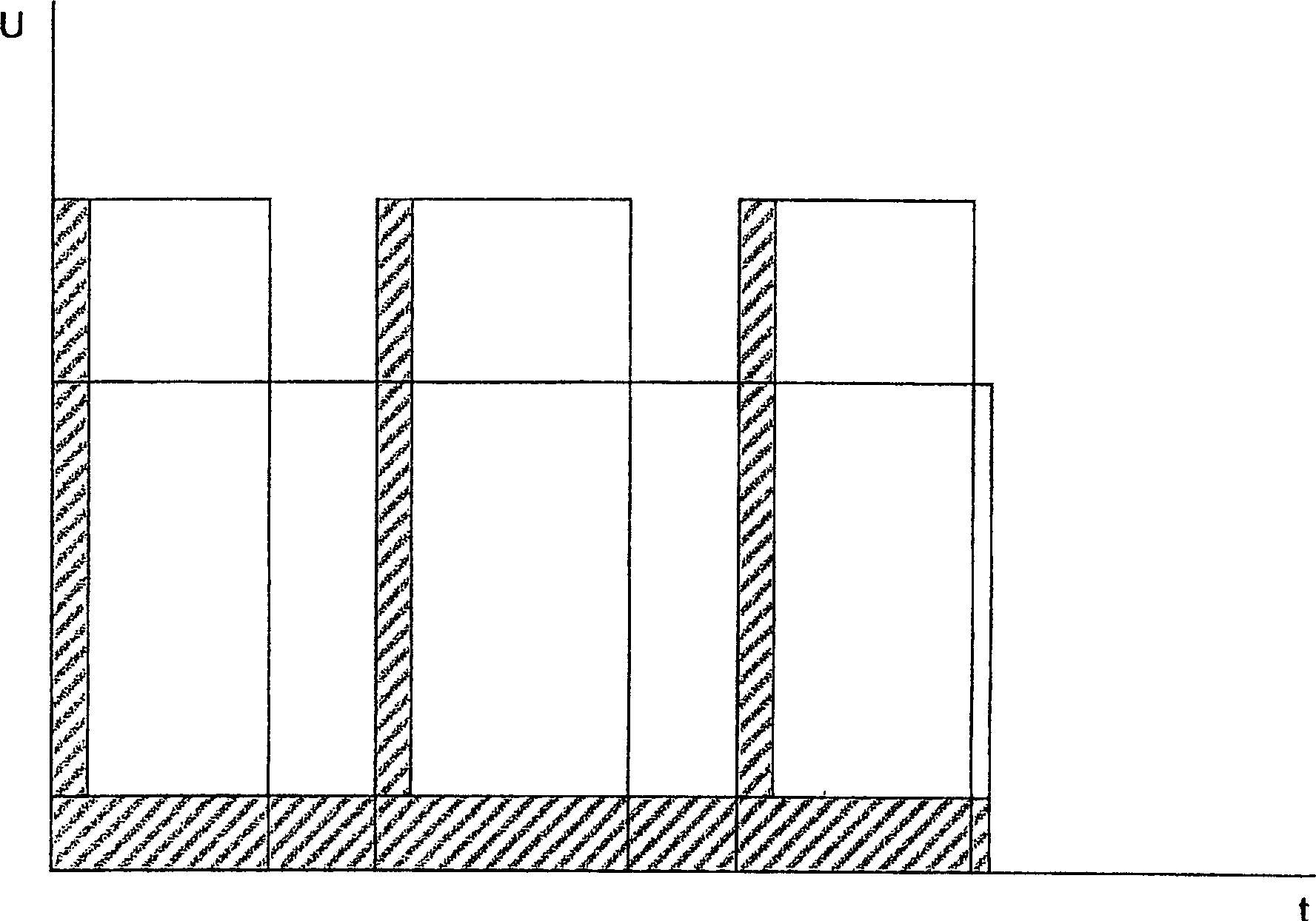

Electrophoretic dipping system

InactiveCN1802457ASmall sizeAc-dc conversionElectrophoretic coatingsDiode bridge rectifierVoltage pulse

The invention relates to an electrophoretic dipping system comprising at least one dipping bowl (1) which can be filled with a liquid and an object which is to be coated and which can be dipped therein. At least one power supply unit (5A, 5B, 5C) produces DC voltage with definite residual ripple from AC voltage. The one pole thereof can be connected to at least one electrode of a first polarity (3A, 3B, 3C), said electrode being arranged in the dipping bowl (1) and the other pole thereof can be connected to the object which is to be coated. The power supply unit (5A, 5B, 5C) comprises one uncontrolled diode rectifier bridge (19) and an IGBT switch (22) which comprises a controllable oscillator (24) and a power transistor (23). The controllable oscillator (24) generates pulses having a repetition frequency ranging from between 5 and 30 kHz with variable pulse widths. The power transistor (23) is controlled by said pulses. The voltage pulses produced therefrom can be smoothed out with the aid of relatively small smoothing elements until a highly reduced residual ripple which benefits the quality, especially the smoothness and the roughness of the applied protective coating is obtained. Said power supply unit (5A, 5B, 5C) also has a highly improved cos Phi compared to currently known thyristor bridge switches used for the same purpose.

Owner:EISENMANN MASCHINENBAU GMBH & CO KG

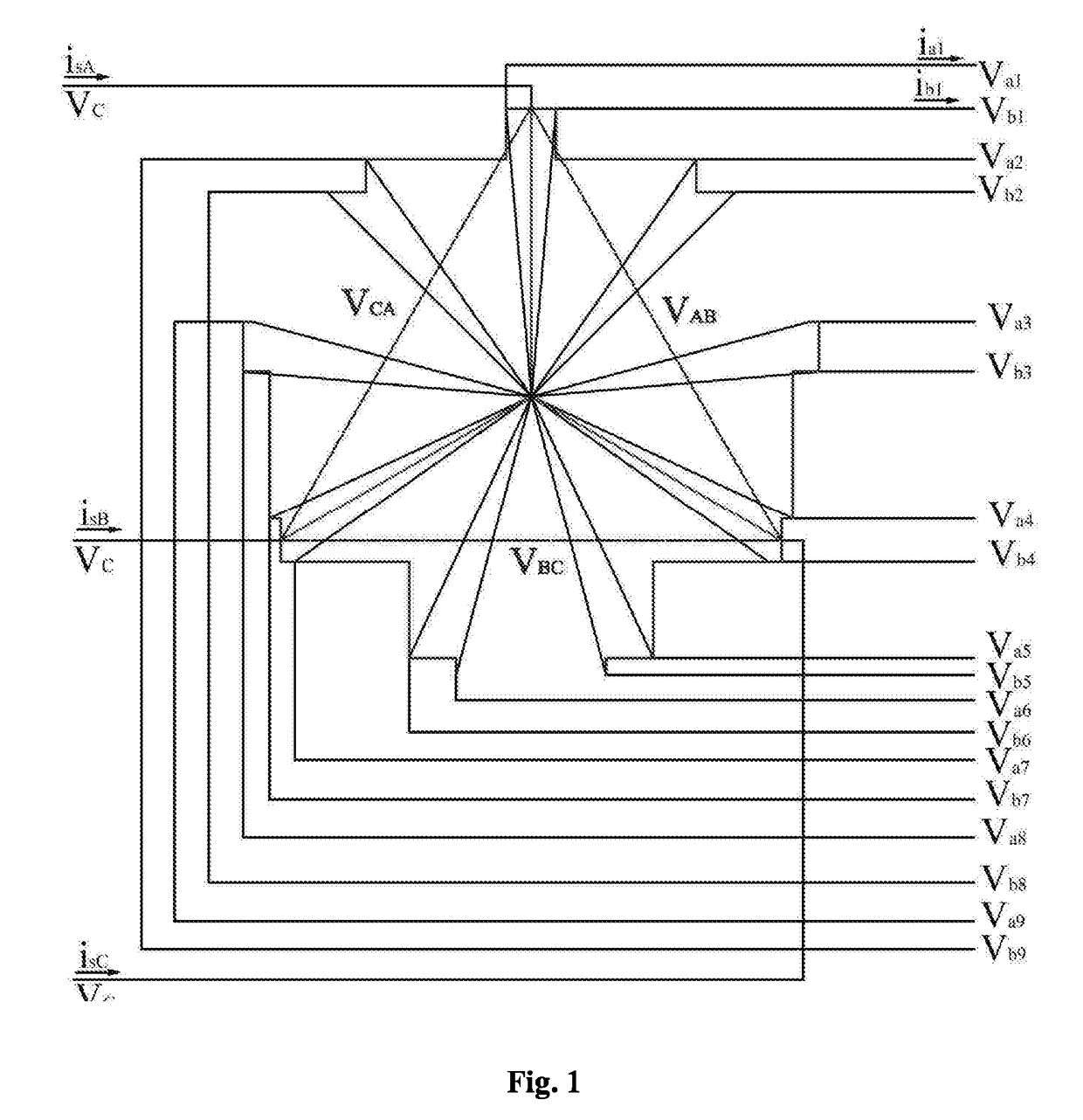

T-connected autotransformer based converter providing reduced rating for retrofit applications

InactiveUS20170141696A1Ac-dc conversion without reversalFixed transformersAutotransformerDiode bridge rectifier

A 72-pulse clean power AC-DC converter, based on a T autotransformer configuration with reduced kilovolt ampere rating and a THD of lower than 3% is presented. The T-Connected autotransformer based 36-pulse converter is obtained via two paralleled 18-pulse AC-DC converters each of them consisting of a 9-phase (9-leg) diode bridge rectifier. To achieve a 72 pulse output, a pulse doubling circuit is applied which, in one embodiment, is a tapped inter-phase transformer. A T-connected autotransformer is utilized to supply the rectifiers.

Owner:ABDOLLAHI ROHOLLAH

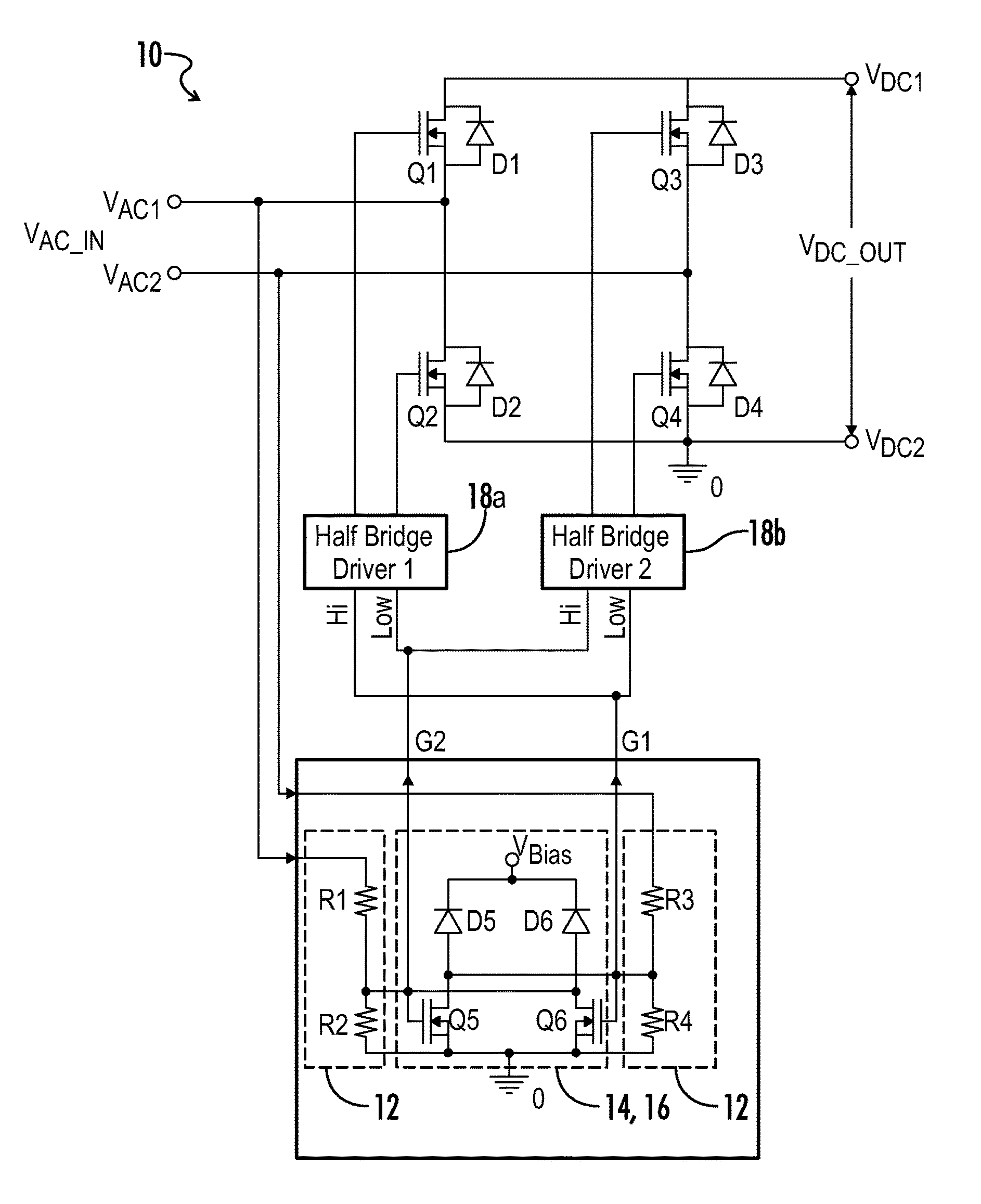

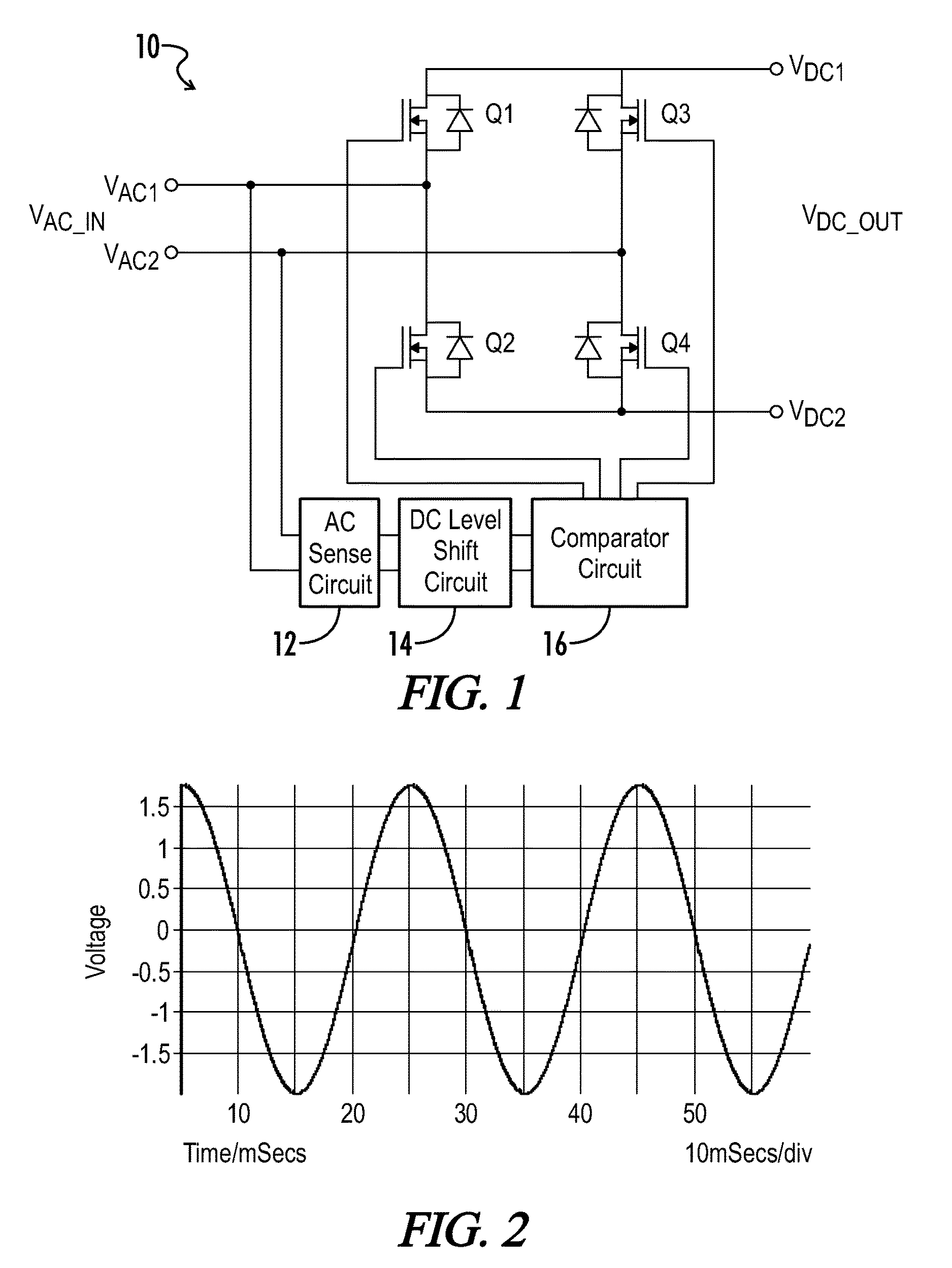

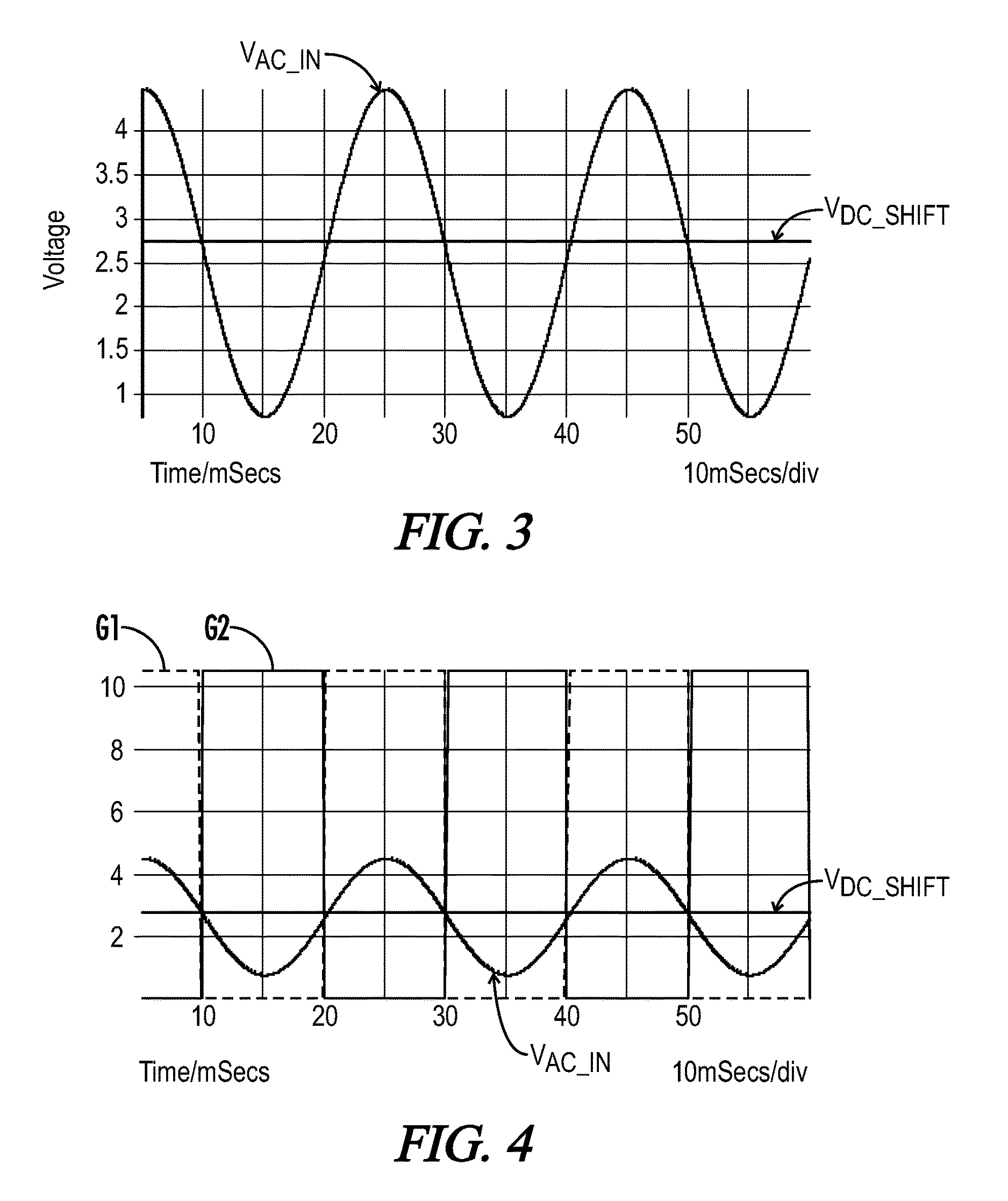

Power converter with self-driven synchronous rectifier control circuitry

ActiveUS9577546B2Reduce pressure drop lossImprove efficiencyEfficient power electronics conversionAc-dc conversionLevel shiftingDiode bridge rectifier

An AC-DC power converter is provided with two pairs of self-driven synchronous rectifier switches in addition to, or in place of, diode bridge rectifiers for boosting efficiency and reducing cost. An AC sensing circuit is coupled to AC input terminals, and a DC level shifting circuit applies a DC offset to an AC input signal received via the sensing circuit. A comparator circuit determines positive and negative half waves of the AC input signal relative to the DC offset value. Gate drive signals are provided for driving a first set of parallel rectifier switches during a positive half cycle of the AC input signal, and for driving a second and opposing pair of parallel rectifier switches during a negative half cycle of the AC input signal. In an embodiment, high side gate drive signals may be electrically isolated from the active rectifier control circuitry.

Owner:BEL POWER SOLUTIONS INC

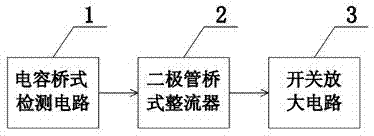

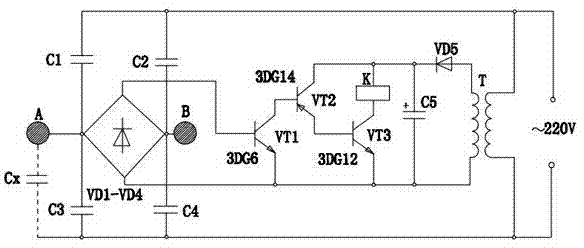

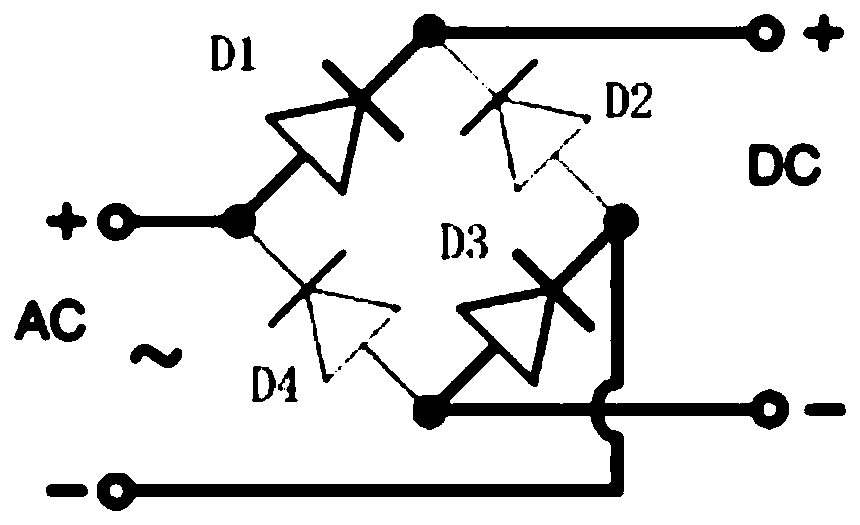

Proximity switch

The invention relates to a switch, in particular to a proximity switch. The proximity switch is characterized by consisting of a capacitance bridge detection circuit, a diode bridge rectifier and a switch amplifying circuit which are connected in a matching way, wherein the capacitance bridge detection circuit consists of capacitors C1-C4; the diode bridge rectifier consists of diodes VD1-VD4; the switch amplifying circuit consists of transistors VT1-VT3, a voltage stabilizing diode VD5, a capacitor C5 and a relay K; the input end of the capacitance bridge detection circuit is connected with 220V commercial power, and the output end of the capacitance bridge detection circuit is connected with the input end of the diode bridge rectifier; the output end of the diode bridge rectifier is connected with the switch amplifying circuit; and the two ends of the input end of the diode bridge rectifier are connected with a metal sheet A and a metal sheet B respectively. The proximity switch can be used be applied to burglary prevention alarm, automatic notification, automatic protection and the like, runs stably, is prevented from being interfered easily and performing error actions, and has low production cost.

Owner:浙江正泰机床电气制造有限公司

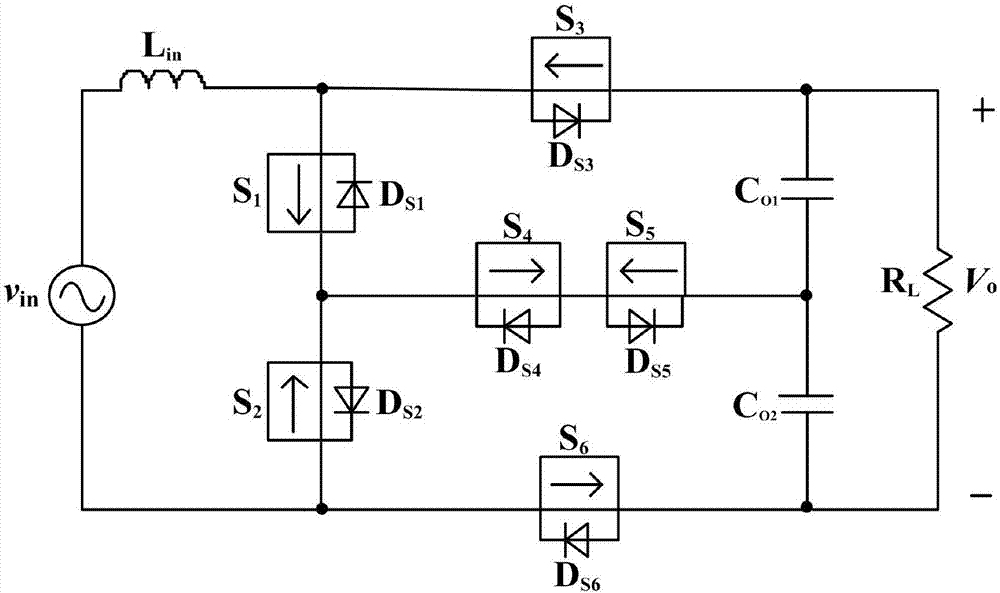

Boost power factor correction converter

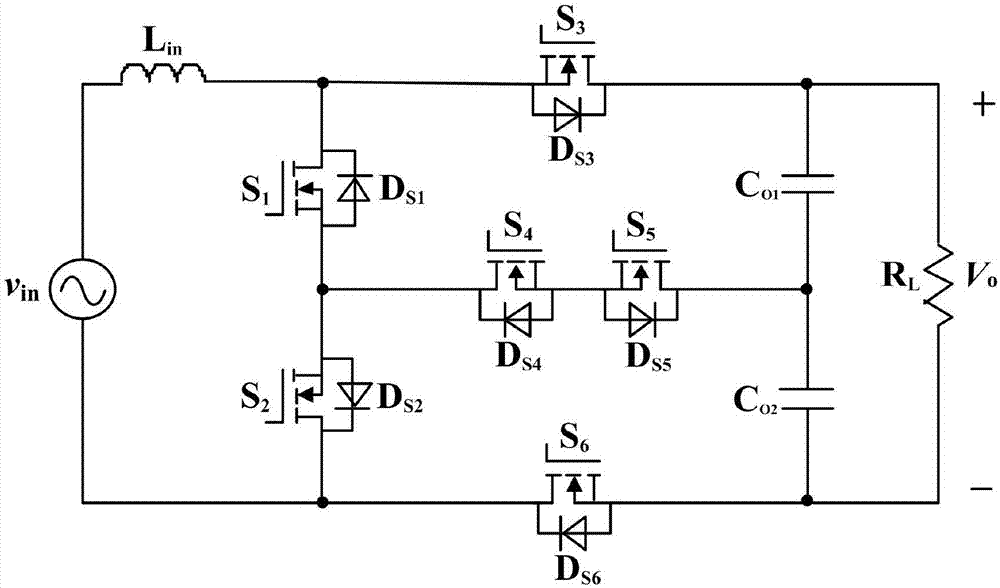

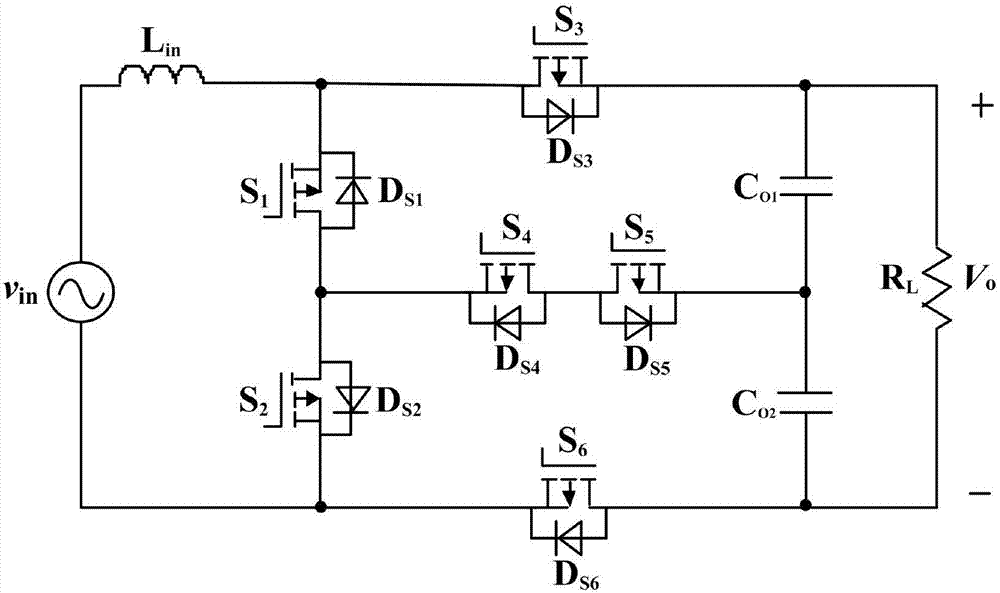

ActiveCN107425709AEasy selectionReduce voltage stressEfficient power electronics conversionDc-dc conversionDiode bridge rectifierThree level

The invention relates to the technical field of electric energy conversion, and particularly, relates to a Boost power factor correction converter. The Boost power factor correction converter provided by the invention can achieve a power factor correction function under positive and negative input voltage conditions without a diode-bridge rectifier by controlling on-off states of a first power switch tube, a second power switch tube, a third power switch tube, a fourth power switch tube, a fifth power switch tube and a sixth power switch tube, has a small volume, reduces conduction loss and improves a device utilization rate. Moreover, the Boost power factor correction converter provided by the embodiment of the invention adopts a three-level topological structure, thereby effectively reducing voltage stresses of the first power switch tube, the second power switch tube, the third power switch tube, the fourth power switch tube, the fifth power switch tube and the sixth power switch tube, facilitating selection of the power switch tubes and reduction of switching loss and conduction loss, improving an output voltage level and the like.

Owner:南京凌鸥创芯电子有限公司

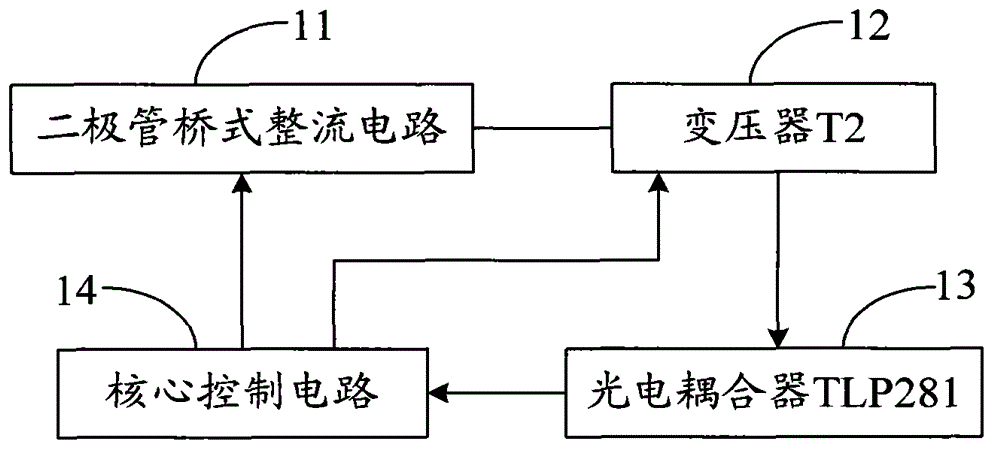

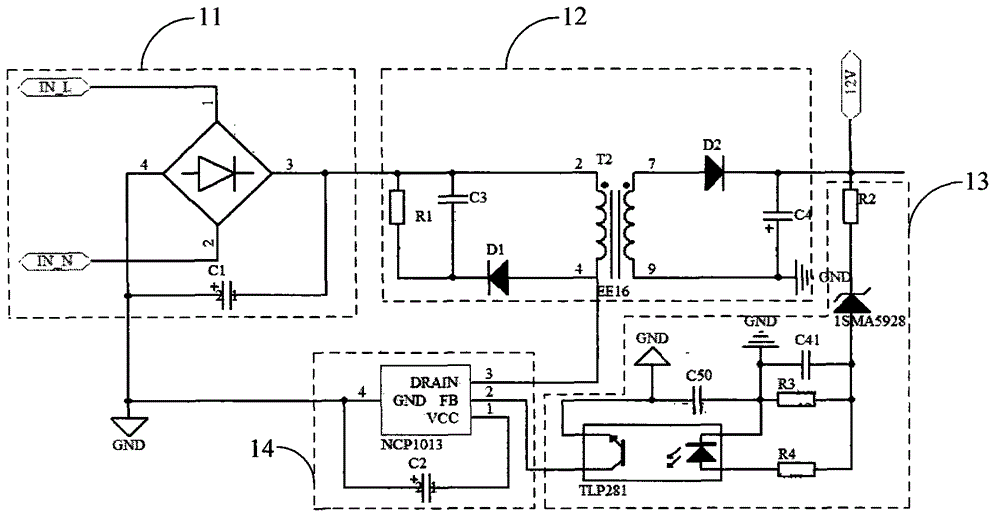

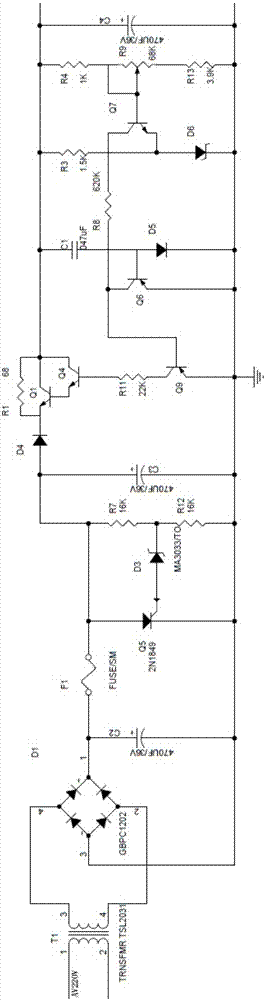

Power module circuit for electric vehicle charger controller

InactiveCN103337971AExtended service lifeImprove job stabilityAc-dc conversion without reversalDc-dc conversionDiode bridge rectifierComputer module

The invention discloses a power module circuit for an electric vehicle charger controller. A diode bridge rectifier circuit is used for receiving an input alternating current, converting the alternating current into a direct current and outputting the direct current; a transformer T2 is used for receiving the direct current output by the diode bridge rectifier circuit and transforming a direct-current voltage; a photoelectric coupler TLP281 is connected with the primary and secondary sides of the transformer T2 and used for feeding a voltage output by the secondary side of the transformer T2; and a core control circuit is connected with the diode bridge rectifier circuit, the transformer T2 and the photoelectric coupler TLP281 and used for controlling the transformer T2 to work at a frequency of 66 kHz and adjusting the duty ratio of a switch frequency according to the feedback of the photoelectric coupler TLP281 to guarantee that the fixed voltage is output from the secondary side of the transformer T2. The power module circuit is higher in working stability and reliability, effectively prolongs the service life of a power module of the electric vehicle charger controller, and is simple in structure, strong in practicality, higher in promotion and application values, small in occupied space and high in drive power.

Owner:JIANGSU XINTONGDA ELECTRONICS SCI & TECHCO

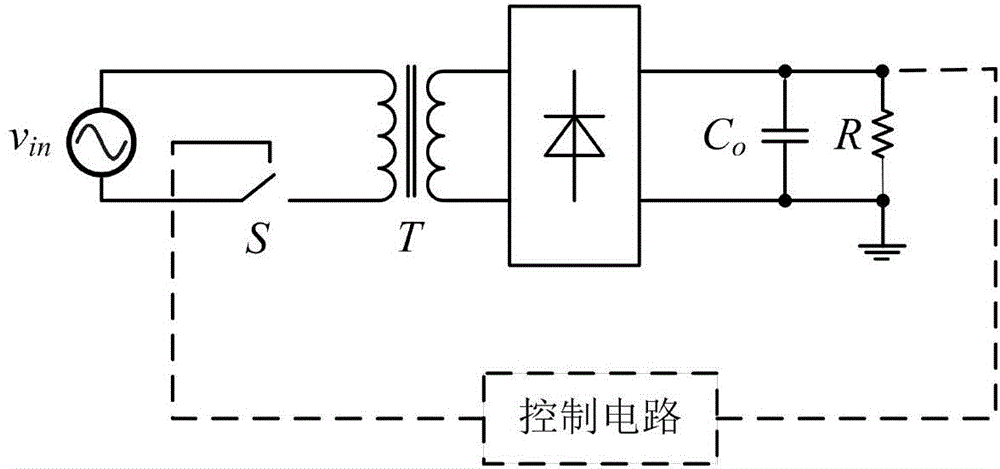

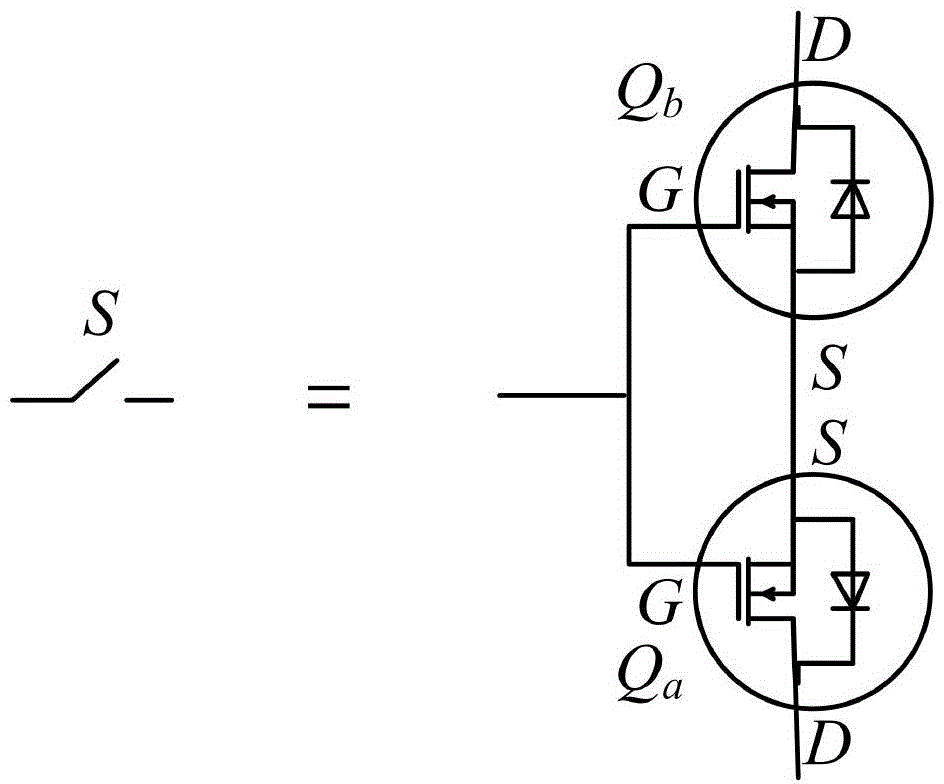

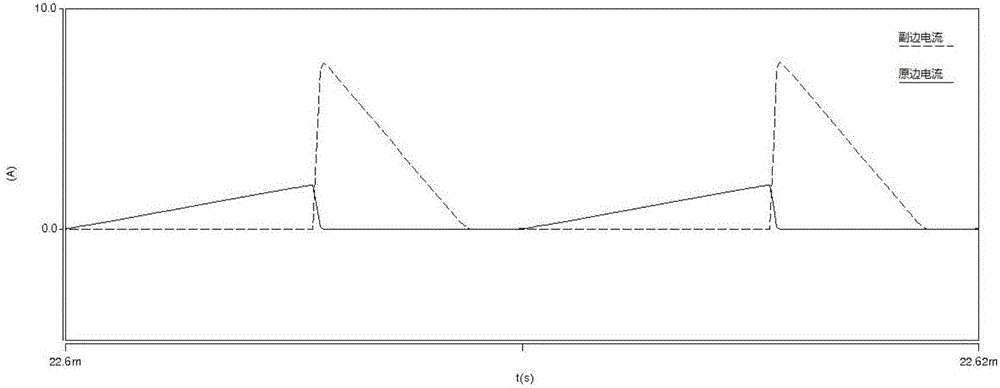

Flyback power factor correction (PFC) converter with bridge-free structure

InactiveCN106160522AEliminate the defect of zero-crossing distortionReduce lossEfficient power electronics conversionAc-dc conversionCapacitanceDiode bridge rectifier

The invention provides a flyback power factor correction (PFC) converter without a bridge-free structure. The flyback PFC converter comprises an isolation transformer, a bidirectional switch, a secondary-side diode bridge rectifier circuit, an output capacitor and a load. The bidirectional switch is composed of two switch tubes which are connected in series. The two switch tubes share the same source electrode and the same gate electrode. One end of a voltage source in a main power circuit is connected with any end of the primary side of the isolation transformer. The other end of the primary side of the isolation transformer is connected with any end of the bidirectional switch. The other end of the bidirectional switch is connected with the other end of the voltage source. The secondary side of the isolation transformer is connected with the diode rectifier circuit. The diode rectifier circuit is connected with an energy storage capacitor and the load in parallel. According to the technical scheme of the invention, the flyback PFC converter eliminates the defect of current zero-zero distortion and reduces the conduction loss at the same time. On the premise that the power factor is not changed, the overall efficiency is improved.

Owner:NANJING UNIV OF SCI & TECH

Three-phase power supply and system of LEDs with three-phase power supply

ActiveUS9247593B2Reduce power consumptionReduce lossesEfficient power electronics conversionElectroluminescent light sourcesMicrocontrollerDiode bridge rectifier

A three-phase power supply (10), intended especially to supply LEDs system (20), has a system of a diode bridge rectifier which comprises rectifying diodes (101, 102, 103, 104, 105, 106). The three-phase power supply (10) is additionally equipped with FETs and each of the rectifying diodes is bypassed by an FET of a rectifying unit (111, 112, 113, 114, 115, 116), respectively, which is controlled by a control system (40), comprising an analog-to-digital converter ADC 403, a digital-to-analog converter (402), a microcontroller (401), which provides a control signal to a gate of the appropriate FET through the input / output (404). Once the control system (40), in particular the microcontroller (401), detects stable power supply conditions and starts operation of elements of an LED sequencer (30), it starts at the same time to control over the FETs in the active rectifier.

Owner:MILOO ELECTRONICS

Regenerative building block and diode bridge rectifier and methods

ActiveCN102027594AAvoid complexityImprove performanceAc-dc conversion without reversalSemiconductor/solid-state device detailsDiode bridge rectifierFull bridge

A rectifier building block has four electrodes: source, drain, gate and probe. The main current flows between the source and drain electrodes. The gate voltage controls the conductivity of a narrow channel under a MOS gate and can switch the RBB between OFF and ON states. Used in pairs, the RBB can be configured as a three terminal half-bridge rectifier which exhibits better than ideal diode performance, similar to synchronous rectifiers but without the need for control circuits. N-type and P-type pairs can be configured as a full bridge rectifier. Other combinations are possible to create a variety of devices.

Owner:STMICROELECTRONICS SRL

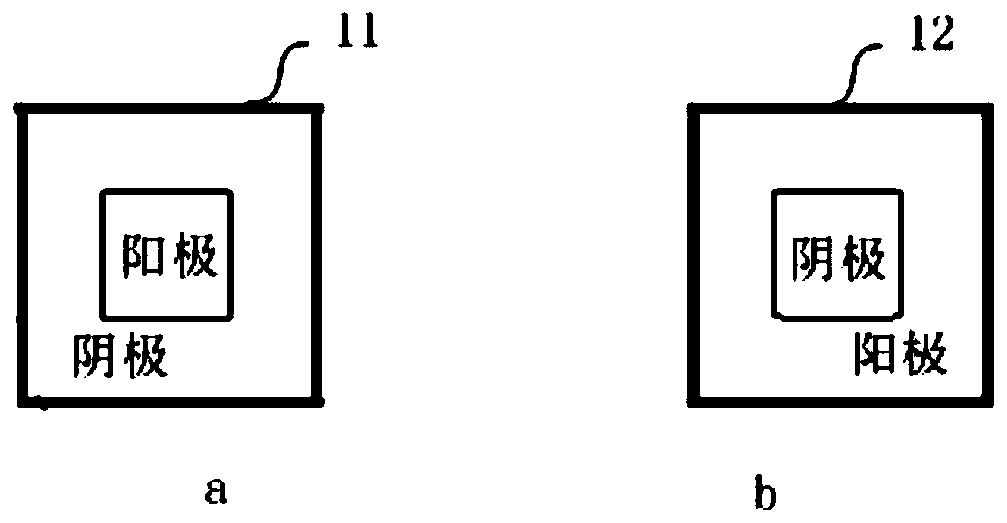

Single-phase bridge rectifier

InactiveCN103117274AReduce labor intensityImprove cooling effectSemiconductor/solid-state device detailsAc-dc conversionDiode bridge rectifierSurface mode

The invention discloses a single-phase bridge rectifier, relates to the improvement for a single-phase diode bridge rectifier structure, and provides the single-phase bridge rectifier which can improve a heat dissipation effect and relieve labor intensity. The single-phase bridge rectifier comprises a packaging body, a first frame, a second frame, a third frame, a fourth frame and four chips, an acute-angle corner, facing towards the first frame, of the second frame, two acute-angle corners of the third frame and an acute-angle corner, facing towards the first frame, of the fourth frame are respectively bent towards the direction where leads are arranged to form a section difference face which is parallel to each frame body, and N faces of the four chips are respectively welded on the plane of two acute-angle corners of the first frame, the plane of the acute-angle corner, facing toward the third frame, of the second frame, and the plane of the acute-angle corner, facing towards the third frame, of the fourth frame. All the chips are enabled to be arranged in a product in a consistent orientation mode to form a rectification return circuit. Due to the fact that all the large faces (N faces) face a heat dissipation face at the top, the heat dissipation effect of the product is improved. In addition, the single-phase bridge rectifier is placed in a single-surface mode, for an operator, careful discrimination is not needed, and labor intensity of the operator can be greatly relieved.

Owner:YANGZHOU YANGJIE ELECTRONIC TECH CO LTD

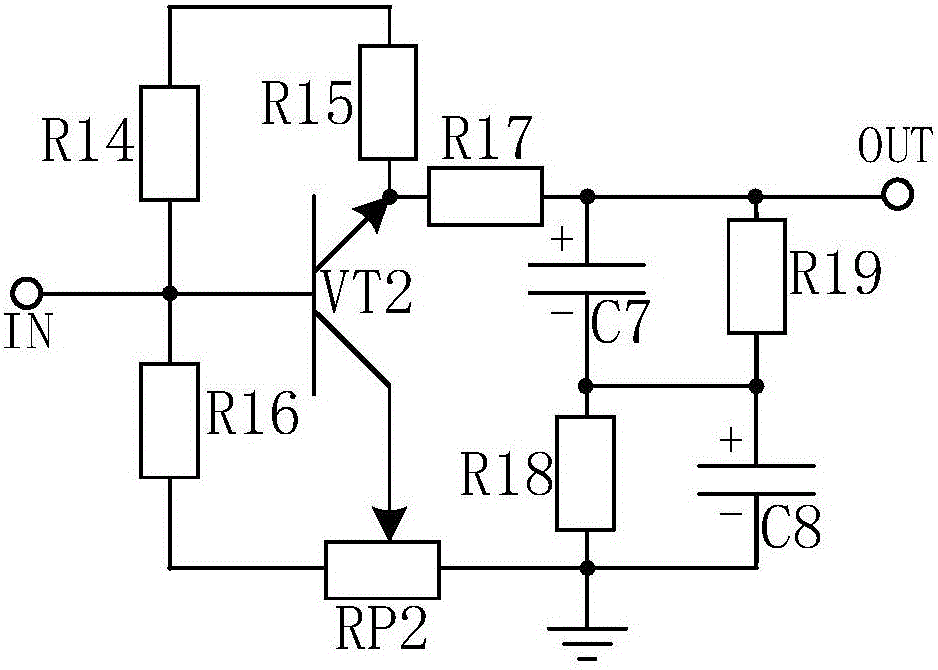

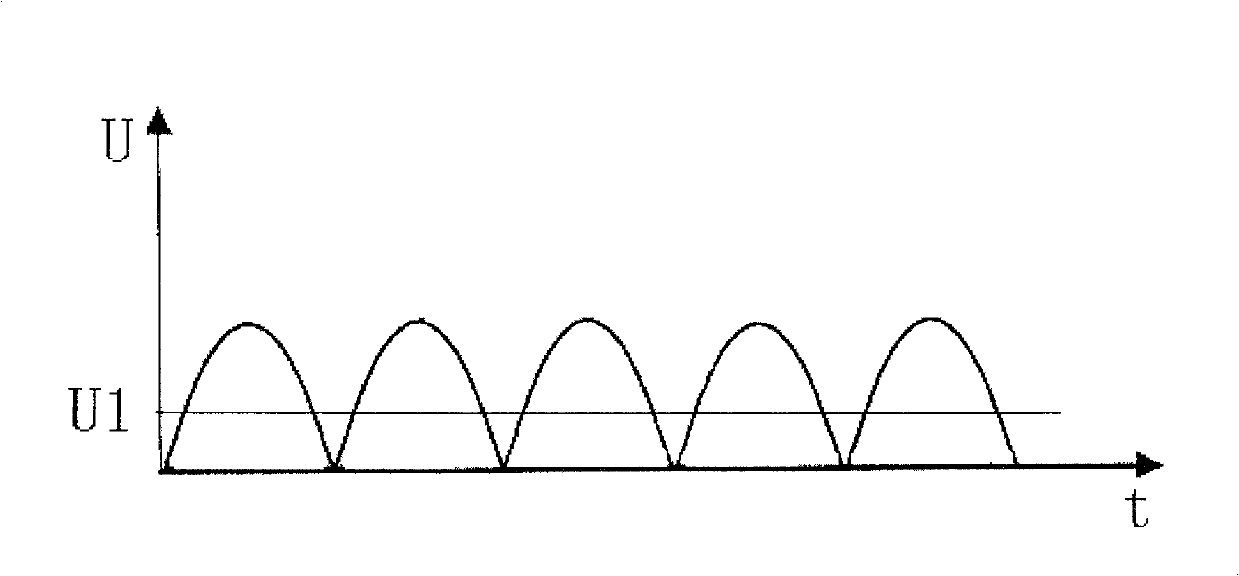

Soft start protective power circuit

InactiveCN107994540AImprove securityImprove stabilityArrangements responsive to excess voltagePower conversion systemsDiode bridge rectifierTransformer

The invention discloses a soft start protective power circuit which comprises a transformer T1 with the input end connected to 220V alternating current, a diode bridge rectifier D1 with the input endconnected with the output end of the transformer T1, an over-voltage protective circuit connected with the diode bridge rectifier D1, and a soft start circuit connected with the over-voltage protective circuit. According to the soft start protective power circuit, during power supply, the power supply electric quantity for electric appliances can be increased step by step, the impact of a power source on power supply of the electric appliances during starting is lowered, the impact on components and parts inside the circuit is lowered, and the effect of protecting the circuit and the electricappliances is well achieved.

Owner:四川新驱科为科技有限公司

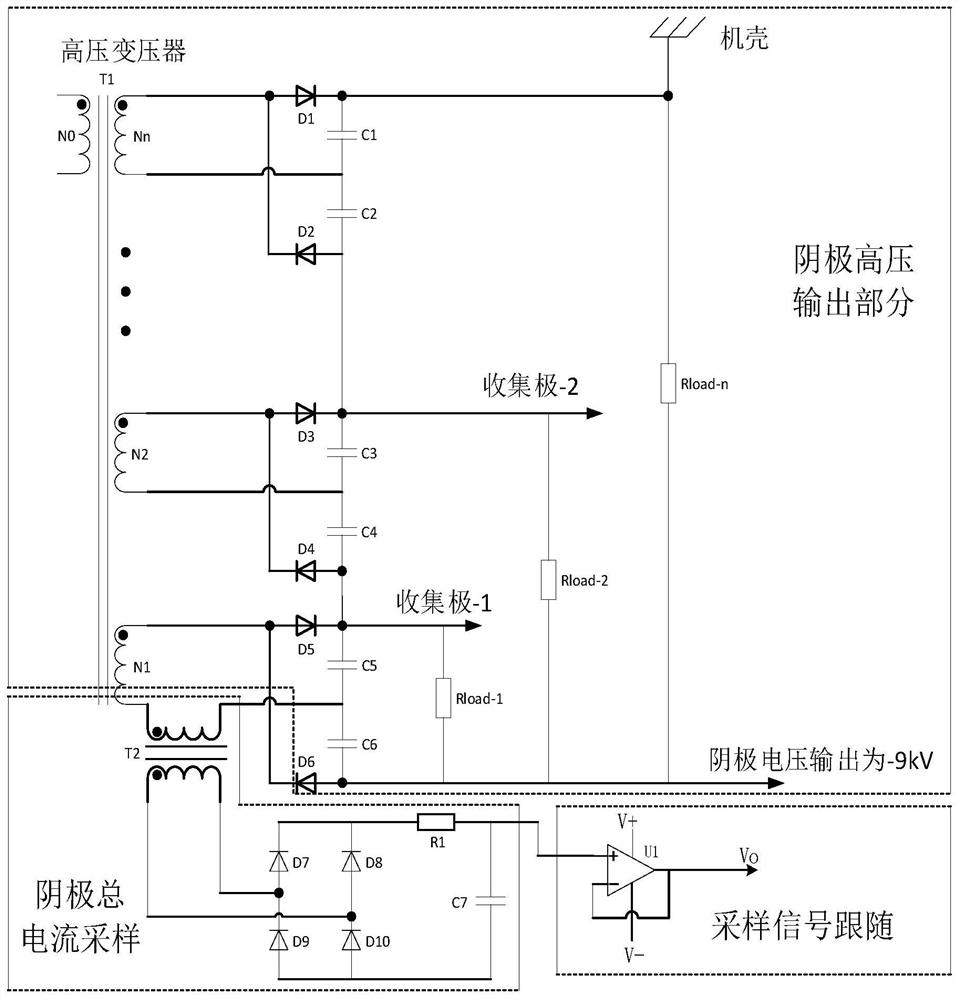

Detection circuit and method for total current of high-voltage cathode

PendingCN112816761AAchieve outputImprove reliabilityCurrent measurements onlyDiode bridge rectifierHemt circuits

The invention discloses a detection circuit and method for a total current of a high-voltage cathode. The detection circuit comprises a cathode high-voltage output unit, a cathode total current sampling unit and a sampling signal following unit which are connected in sequence. The detection method comprises the steps that a cathode voltage is input through a primary side of a high-voltage transformer, multiple windings of a secondary side of the high-voltage transformer achieve multi-path high-voltage output in a cascade connection mode, the output load common end of each winding is connected to a cathode, and the current of the primary winding is equal to the total current of the whole cathode; the primary side of the high-voltage current transformer is connected in series with the primary winding of the secondary side of the high-voltage transformer; the primary side current of the high-voltage current transformer is equal to the total current of the whole cathode; the secondary side of the high-voltage current transformer is rectified through a diode bridge rectifier, and then the average value of the cathode total current is collected through an RC filter circuit; and an operational amplifier of a sampling signal following unit changes the low impedance characteristic of the sampling output signal into the high impedance characteristic of the output current signal.

Owner:重庆两江卫星移动通信有限公司

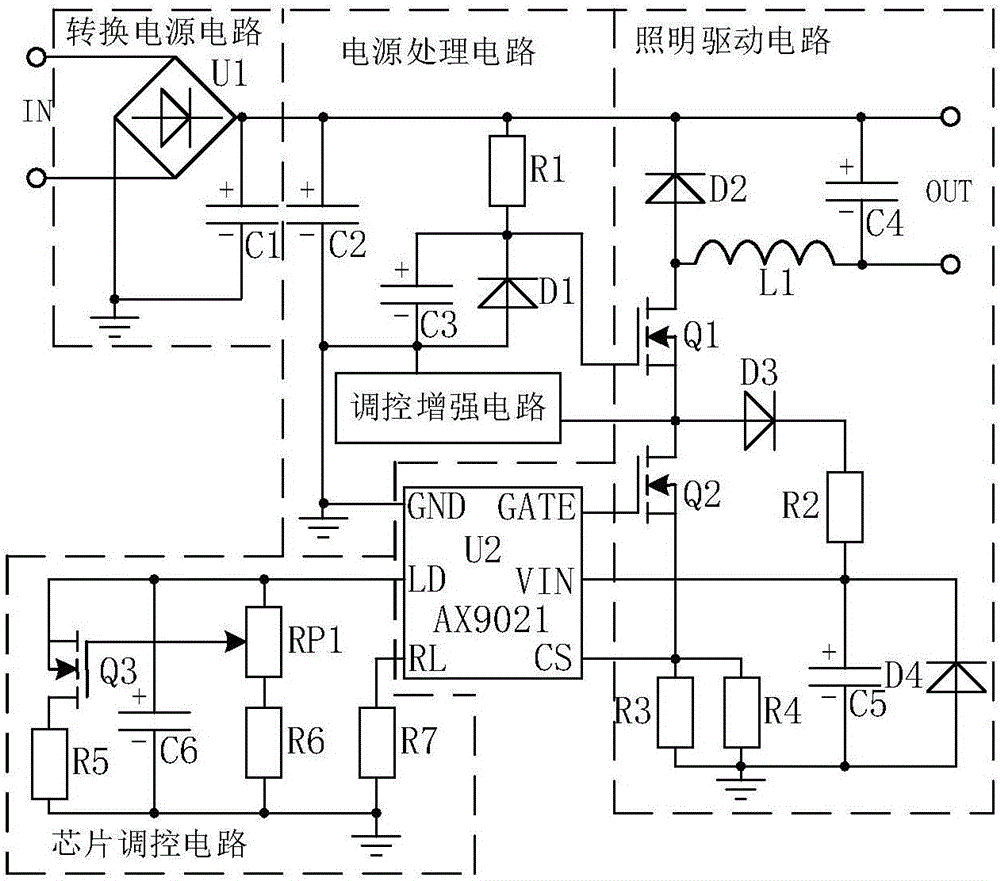

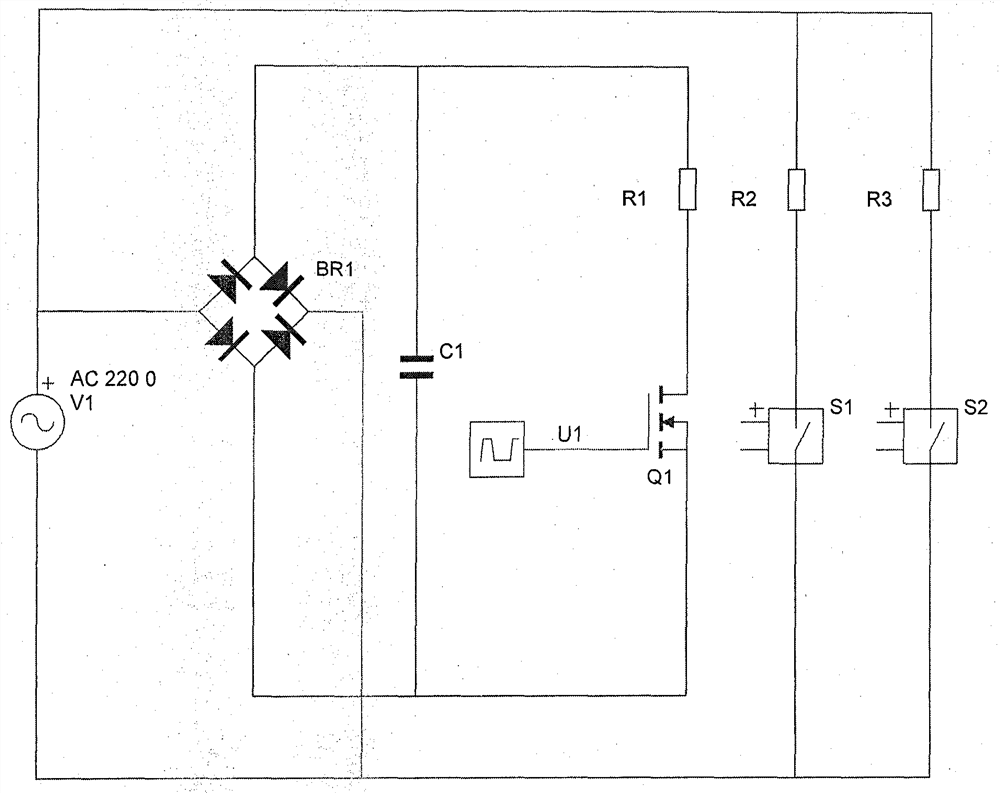

Machine tool LED illumination driving system provided with regulation and enhancement circuit

InactiveCN105934033AIncrease relative volatilitySafe to useElectrical apparatusElectroluminescent light sourcesCapacitanceDiode bridge rectifier

The invention discloses a machine tool LED illumination driving system provided with a regulation and enhancement circuit. The machine tool LED illumination driving system comprises a chip U2 with the type of AX9021, and a switching power supply circuit composed of a diode bridge rectifier U1 and a capacitor C1, wherein the anode of the capacitor C1 is connected with the positive output end of the diode bridge rectifier U1 while the cathode of the same is connected with the negative output end of the diode bridge rectifier U1, the cathode of the capacitor C1 is grounded, and two input ends of the diode bridge rectifier U1 constitute the input end of the switching power supply circuit; the machine tool LED illumination driving system also comprises a power supply processing circuit, a chip regulation circuit, an illumination driving circuit and a regulation and enhancement circuit respectively connected with the chip U2. According to the machine tool LED illumination driving system provided with the regulation and enhancement circuit provided by the invention, the LED lamp can be selected for illumination on the machine tool, the service life of the illumination lamp is improved, and the heating value during the illumination process is reduced, and the better working environment is provided for related operation staffs.

Owner:CHENGDU YUEXIANGXIANG TECH CO LTD

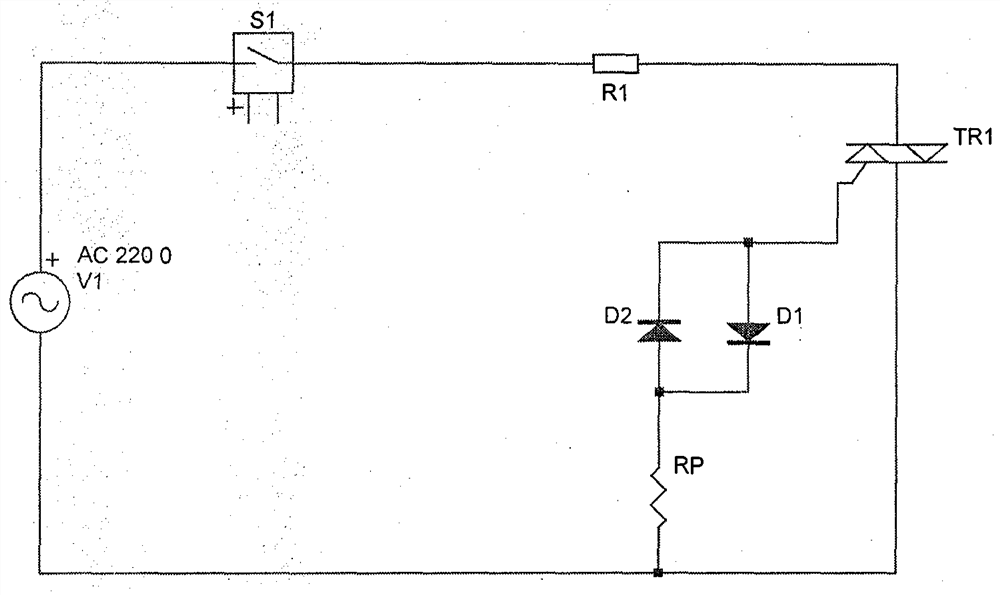

New temperature control method

PendingCN113805621AReduce pollutionImprove efficiencyTemperature control using electric meansDiode bridge rectifierMOSFET

The invention discloses a temperature control method, which adopts a mode of combining step control and continuous control for temperature control, so as to realize a function of continuously adjusting temperature in a full power range. The continuous control part comprises a diode bridge rectifier, a filter capacitor, a heating wire and an MOSFET; and the step control comprises a series of heating wires and corresponding control switches (such as relays), wherein the heating wires and the corresponding control switches are connected in series and then are directly connected to an alternating current input power supply. According to the continuous control part, high-frequency pulse width modulation control is adopted for driving signals of the MOSFET, and switching modulation is carried out by adjusting the duty ratio of pulses so as to achieve the purpose of continuously adjusting the power. When the required power exceeds the continuously adjustable part, the step cascade part is synchronously connected in a grid to participate in the adjustment process in a larger power range, and the continuous part and the grading part are matched to work to realize high-power constant temperature control.

Owner:刘浪 +1

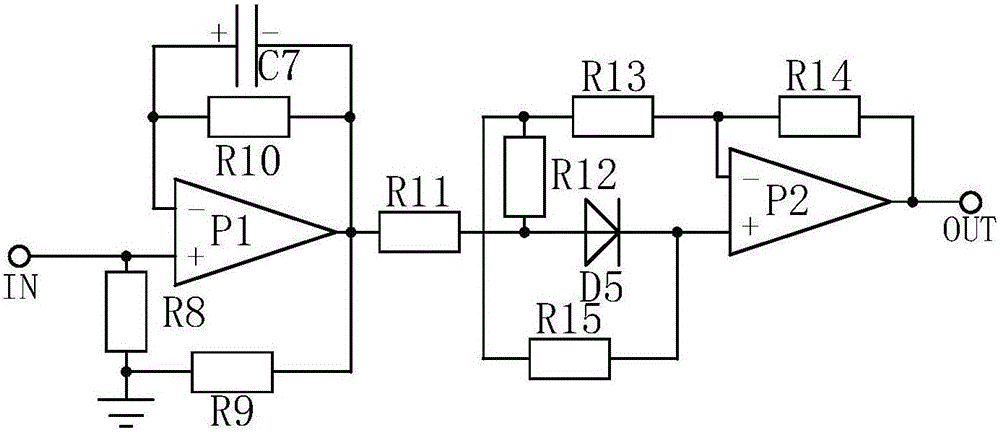

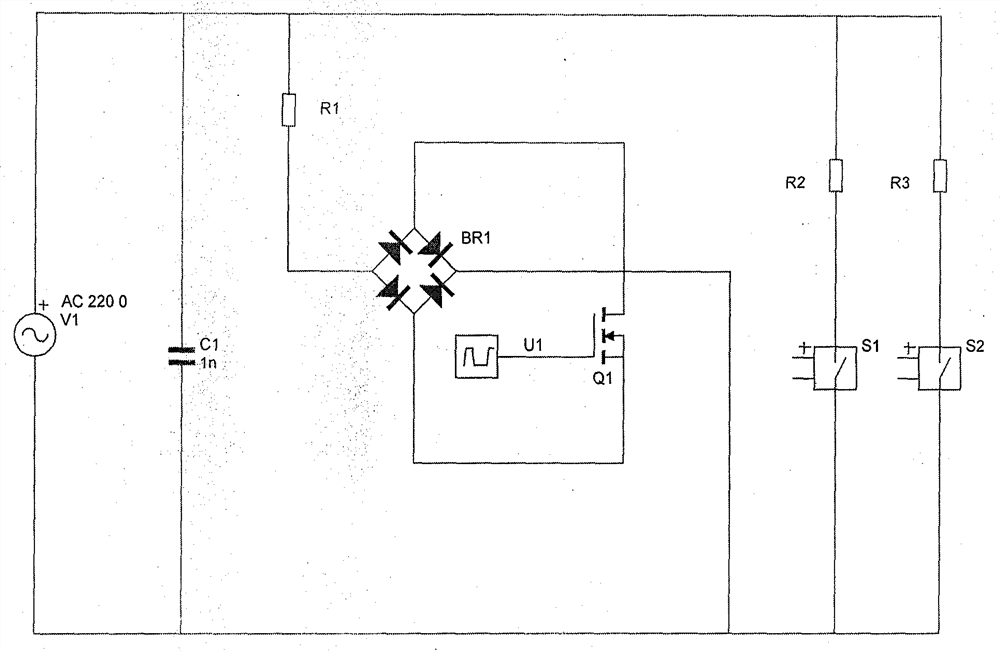

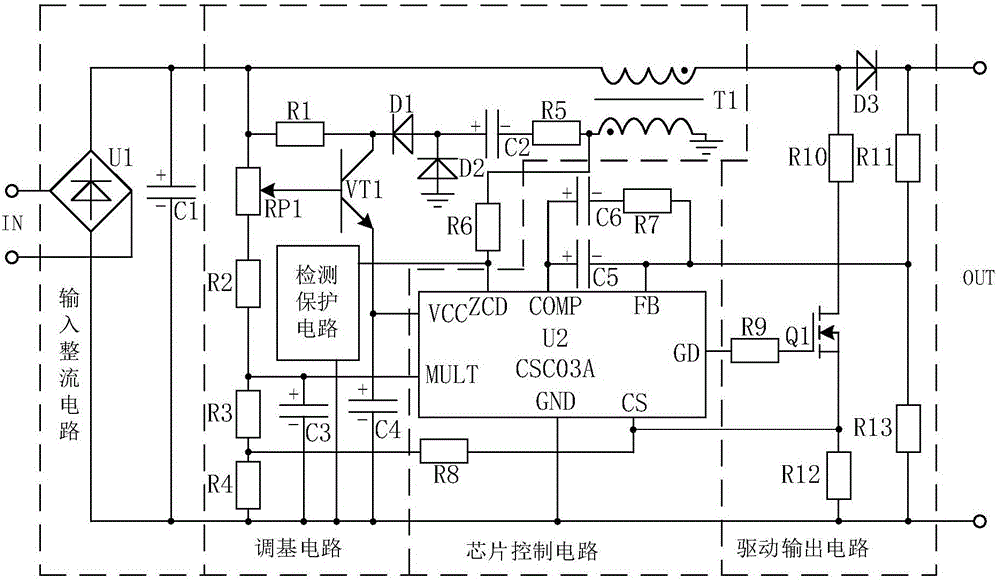

Normally-on LED illumination power supply system equipped with detection protection circuit

InactiveCN105934032AGuaranteed uptimeAvoid volatilityElectrical apparatusElectroluminescent light sourcesDiode bridge rectifierCapacitance

The invention discloses a normally-on LED illumination power supply system equipped with a detection protection circuit. The normally-on LED illumination power supply system comprises an input rectifier circuit consisting of a diode bridge type rectifier U1 and a capacitor C1, wherein the positive electrode of the capacitor C1 is connected with the positive output end of the diode bridge type rectifier U1 while the negative electrode of the capacitor C1 is connected with the negative output end of the diode bridge type rectifier U1; the two input ends of the diode bridge type rectifier U1 form the power supply input end of the input rectifier circuit; and the normally-on LED illumination power supply system also comprises a base regulation circuit, a chip control circuit, a driving output circuit and the detection protection circuit which are mutually connected and then are connected with the input rectifier circuit. By adoption of the normally-on LED illumination power supply system equipped with the detection protection circuit provided by the invention, the power supply stability of the LED lamp is improved; current surge on the LED lamp in the operation can be well avoided; and the service life of the LED lamp is greatly prolonged.

Owner:CHENGDU YUEXIANGXIANG TECH CO LTD

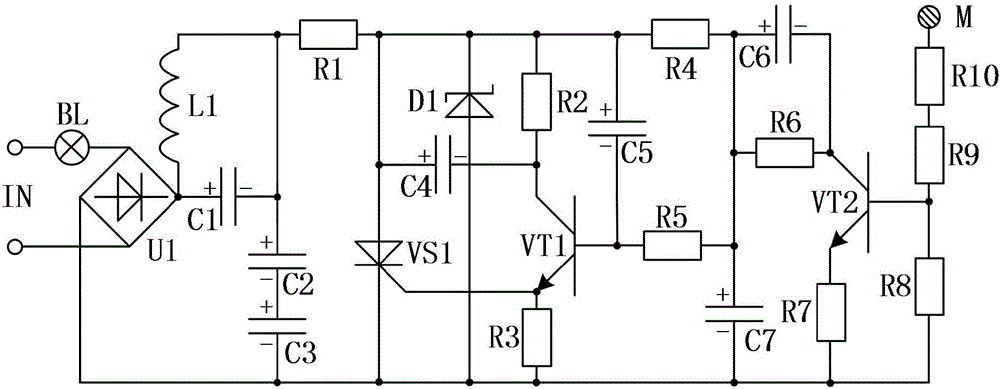

Lighting starting stable light circuit used for wardrobe

InactiveCN106413227ASimple structureEasy maintenanceElectrical apparatusElectric light circuit arrangementDiode bridge rectifierEffect light

The invention discloses a lighting strong signal starting circuit which is composed of a diode bridge rectifier U1, a unidirectional thyristor VS1, a triode VT1, a triode VT2, a touch sheet M, a lighting lamp BL and other electronic components. The invention provides the lighting strong signal starting circuit used for a wardrobe. The lighting lamp can be automatically started for lighting when the user opens the wardrobe, and the circuit has a delay turn-off function so that the situation that electric energy is wasted by long time of lighting and use cost of the user is enhanced can be avoided, and the service life of the lighting lamp can also be greatly prolonged and the use effect of the product can be enhanced.

Owner:成都烨辰新材料科技有限公司

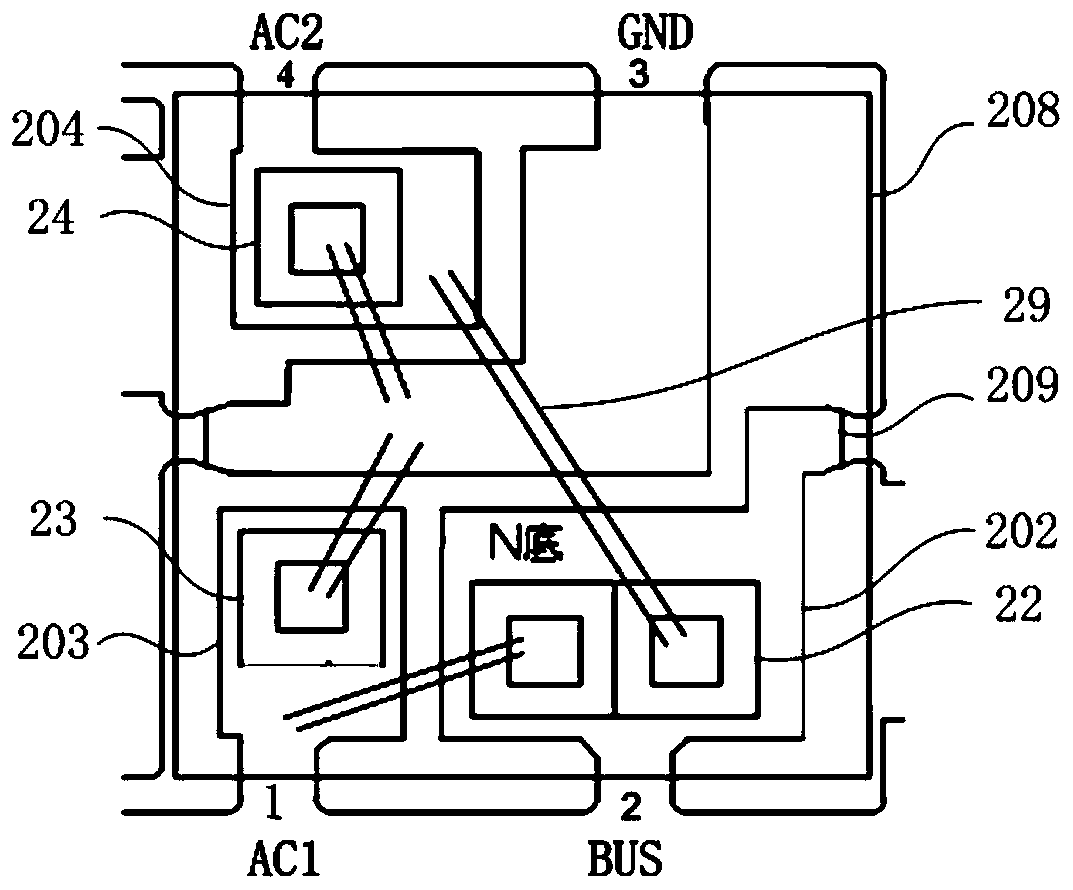

Chip packaging structure adopting multi-base island lead frame

InactiveCN111180437ALow costHighly integratedSemiconductor/solid-state device detailsSolid-state devicesDiode bridge rectifierLead frame

The invention discloses a chip packaging structure adopting a multi-base island lead frame. A double-N-substrate diode and two N-substrate diodes are placed on three different base islands to forma diode bridge rectifier. Compared with a traditional four-independent-diode bridge rectifier, the scheme is simpler to implement, easier to operate and lower in cost.

Owner:SHANGHAI BRIGHT POWER SEMICONDUCTOR CO LTD

Partial active electrical source power factor correction circuit

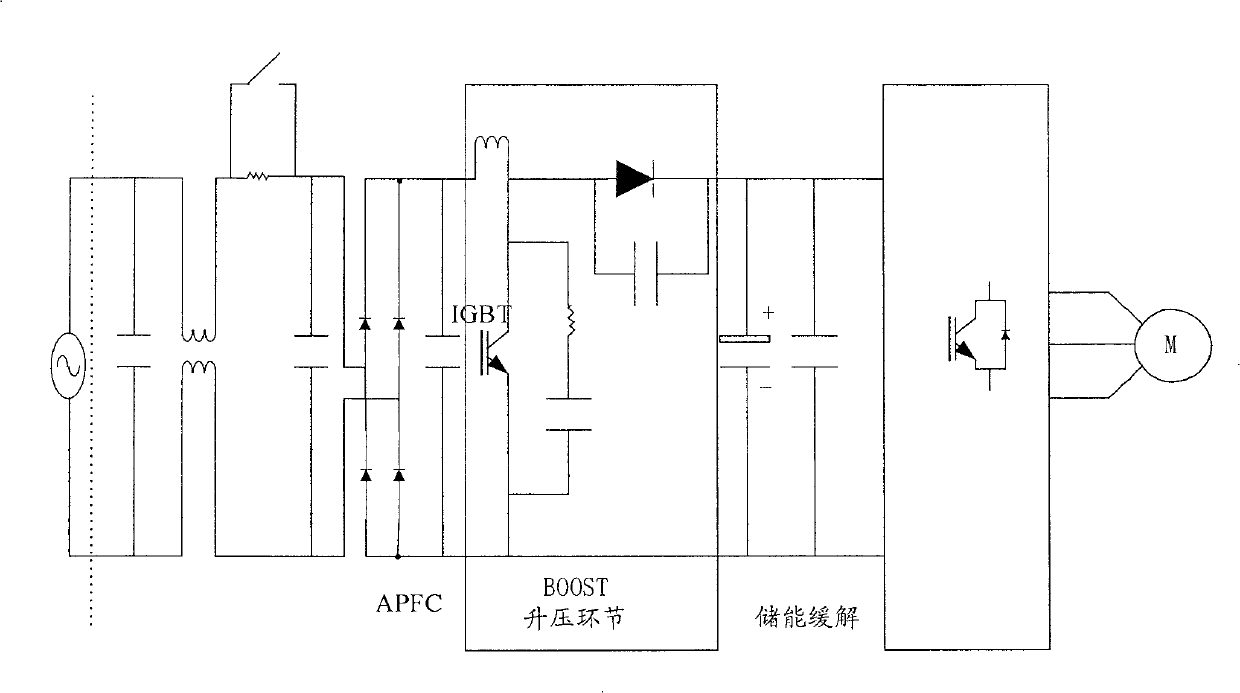

ActiveCN100517926CReduce electromagnetic interferenceTake advantage ofPower conversion systemsCapacitanceDiode bridge rectifier

The present invention provides a partial active power supply power factor correction circuit. On the basis of the prior art, the partial active power supply power factor correction circuit is provided with a branch between the anode of the isolation diode and the negative pole of the bridge rectifier circuit, including one end and The anode of the isolation diode is connected to the second capacitor, the other end of the second capacitor is connected to the cathode of the second diode, the anode of the second diode is connected to the cathode of the third diode, and the anode of the third diode is connected to the third capacitor One end, the other end of the third capacitor is connected to the negative pole of the DC output terminal of the bridge rectifier circuit; the common end connected to the second diode anode and the third diode cathode is connected to the AC input end of the bridge rectifier circuit not connected to The other end of the inductance is connected; a controlled switch is connected between the cathode of the second diode and the anode of the third diode; the controlled switch is controlled to close when the DC side voltage of the bridge rectifier circuit is lower than the critical voltage, When the DC side voltage of the bridge rectifier circuit is higher than the critical voltage, it is controlled to shut down.

Owner:HAIER GRP CORP +1

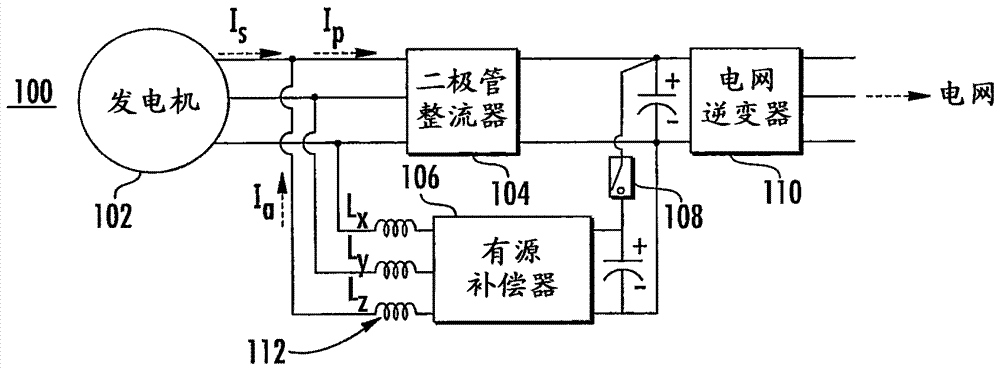

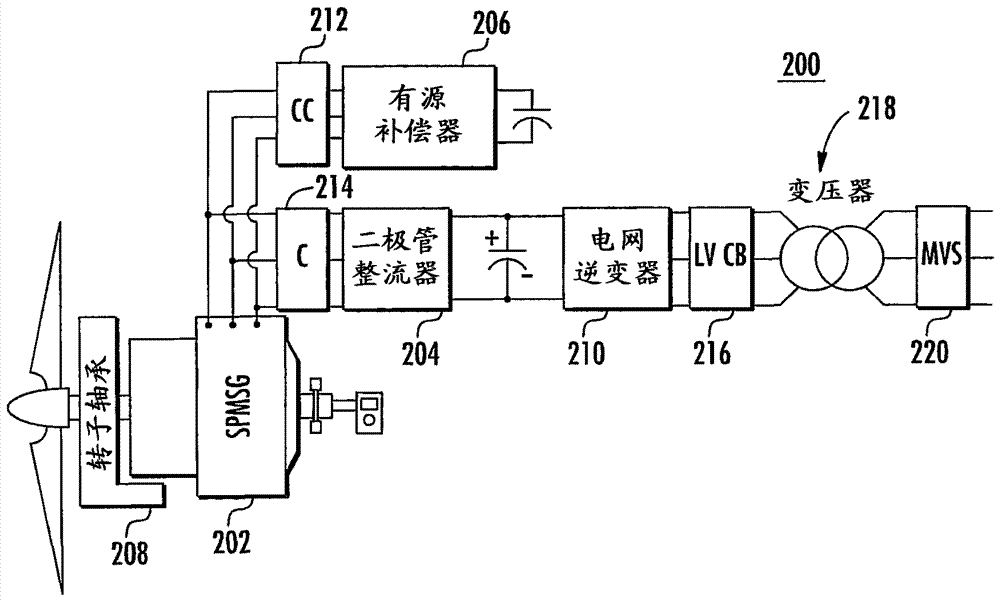

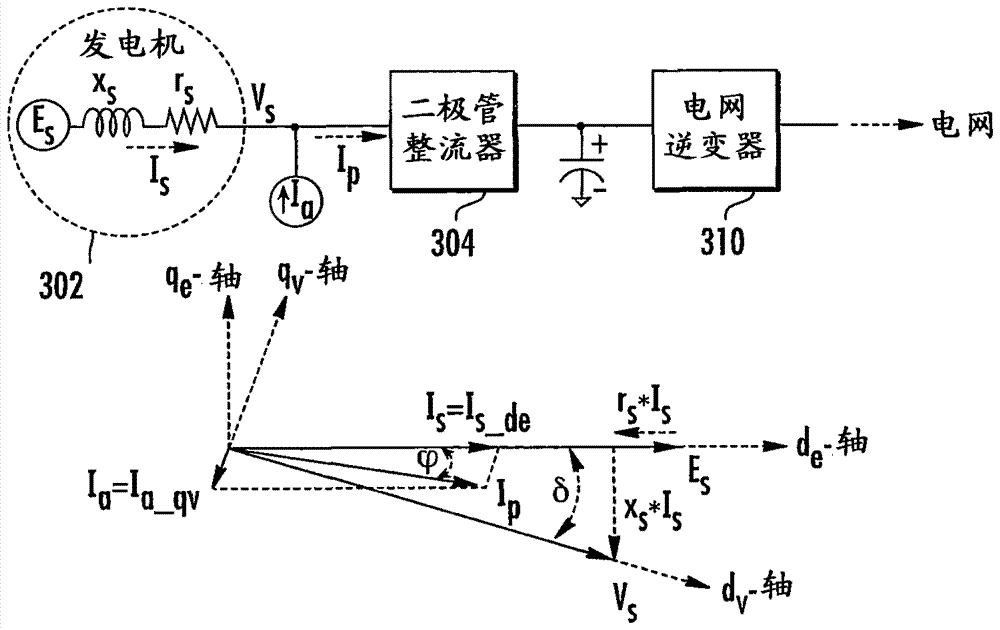

Systems and methods for augmenting diode rectifiers with active compensators

ActiveCN103956765BGenerator control circuitsActive power filteringDiode bridge rectifierSubject matter

The subject matter described herein includes an actively compensated augmented diode bridge rectifier system. According to one aspect, the system includes: a generator unit configured to generate a current flow consisting entirely of real current; and a diode rectifier configured to receive the real current from the generator unit to direct the real current to the connected power grid and receives reactive current. The system also includes an active compensator configured to optimize the generator unit to generate real current and generate reactive power to facilitate operation of the diode rectifier.

Owner:ABB (SCHWEIZ) AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com