Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38 results about "Carbon dioxide scrubber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A carbon dioxide scrubber is a piece of equipment that absorbs carbon dioxide (CO₂). It is used to treat exhaust gases from industrial plants or from exhaled air in life support systems such as rebreathers or in spacecraft, submersible craft or airtight chambers. Carbon dioxide scrubbers are also used in controlled atmosphere (CA) storage. They have also been researched for carbon capture in process of direct air capture as a means of combating global warming.

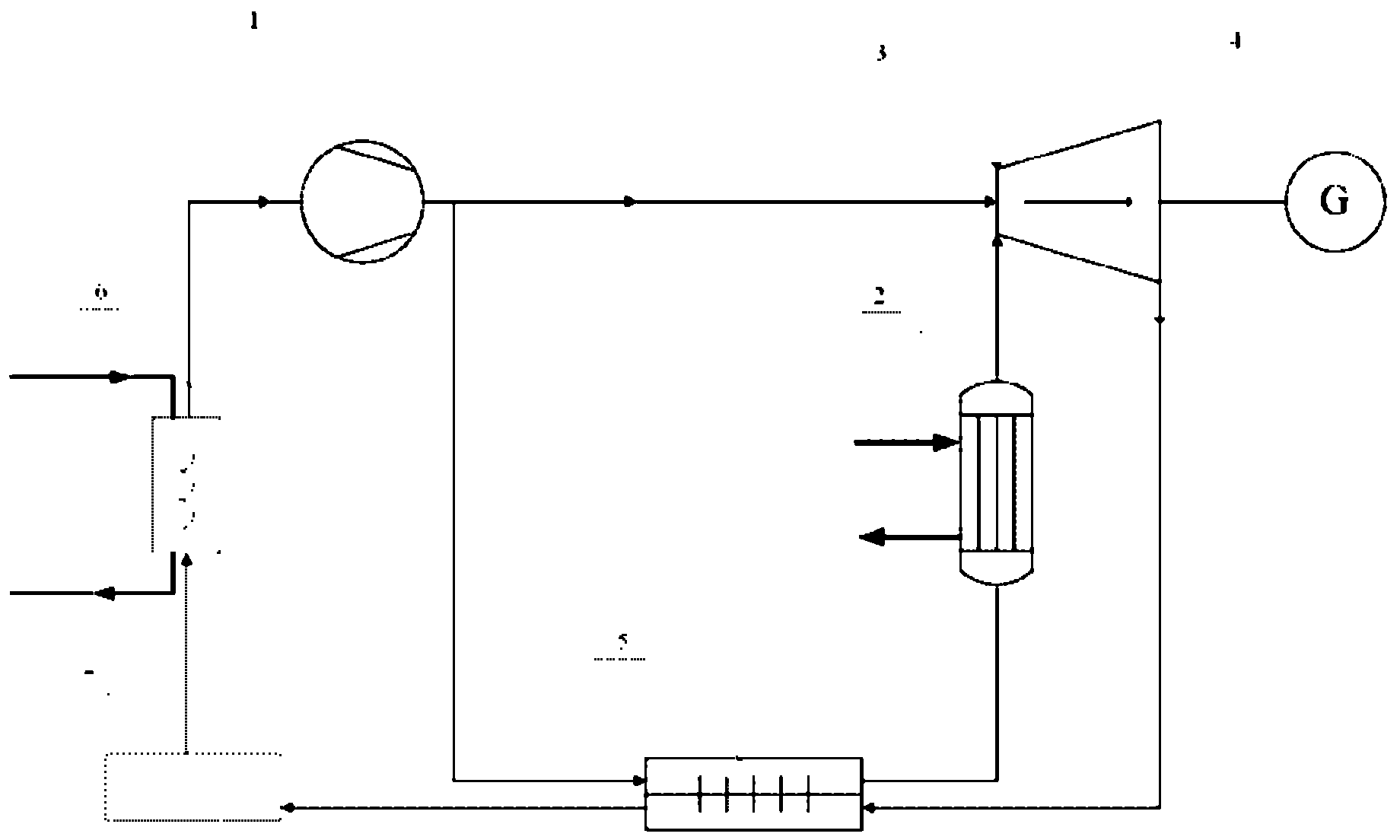

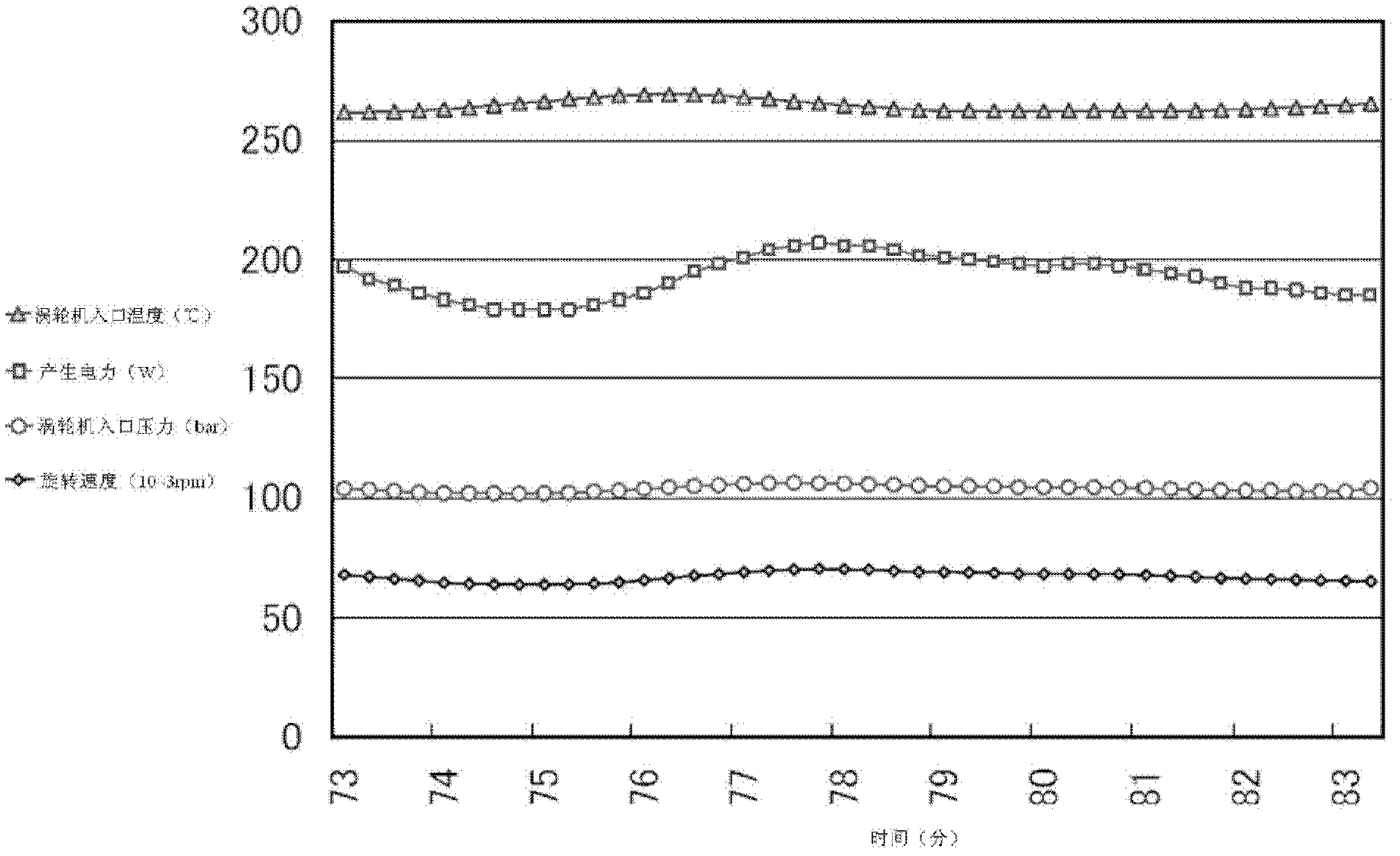

Power generating system based on supercritical carbon dioxide

InactiveCN102606241ANo pollution in the processImprove power generation efficiencySteam engine plantsWater vaporClosed loop

The invention relates to the technical field of power generating systems and methods, in particular to a power generating system based on supercritical carbon dioxide, which comprises a compressor, a heat collector, a carbon dioxide turbine, a generator and a cooling device. An outlet of the compressor is connected with an inlet of the heat collector, an outlet of the heat collector is connected with an inlet of the carbon dioxide turbine, an output end of the carbon dioxide turbine is connected with an input end of the generator, an outlet of the carbon dioxide turbine is connected with an inlet of the cooling device, an outlet of the cooling device is connected with an inlet of the compressor, and accordingly a loop is formed. Heat is absorbed from the outside by the supercritical carbon dioxide in the closed loop to carry out heat circulation, and accordingly the power generating system not only can be used for generating power, but also can provide air conditioning refrigeration and hot water for users. Compared with a traditional power generation mode by the aid of steam, the power generating system has the advantages that power generation efficiency is higher than that of the traditional power generation mode by the aid of steam by 10% to 20%, the system is exquisite and is compact in structure and free of environmental pollution, and equipment cost is low.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Method for Removing CO2 from Coal-Fired Power Plant Flue Gas Using Ammonia as the Scrubbing Solution, with a Chemical Additive for Reducing NH3 Losses, Coupled with a Membrane for Concentrating the CO2 Stream to the Gas Stripper

ActiveUS20110311429A1Improve concentrationCombination devicesMembranesAmmoniaCarbon dioxide scrubber

A method for removing and capturing carbon dioxide from a fluid stream includes the steps of exposing the fluid stream to an aqueous scrubbing solution that removes and holds carbon dioxide from the fluid stream, passing the aqueous scrubbing solution through a membrane in order to separate excess water from the scrubbing solution and increase the concentration of carbon dioxide in the scrubbing solution, heating the scrubbing solution having an increased concentration of carbon dioxide so as to release carbon dioxide gas and recycling the scrubbing solution. A carbon dioxide capture apparatus includes a carbon dioxide scrubber, a membrane downstream from the scrubber for separating water and concentrating carbon dioxide in a scrubbing solution and a stripper vessel.

Owner:UNIV OF KENTUCKY RES FOUND

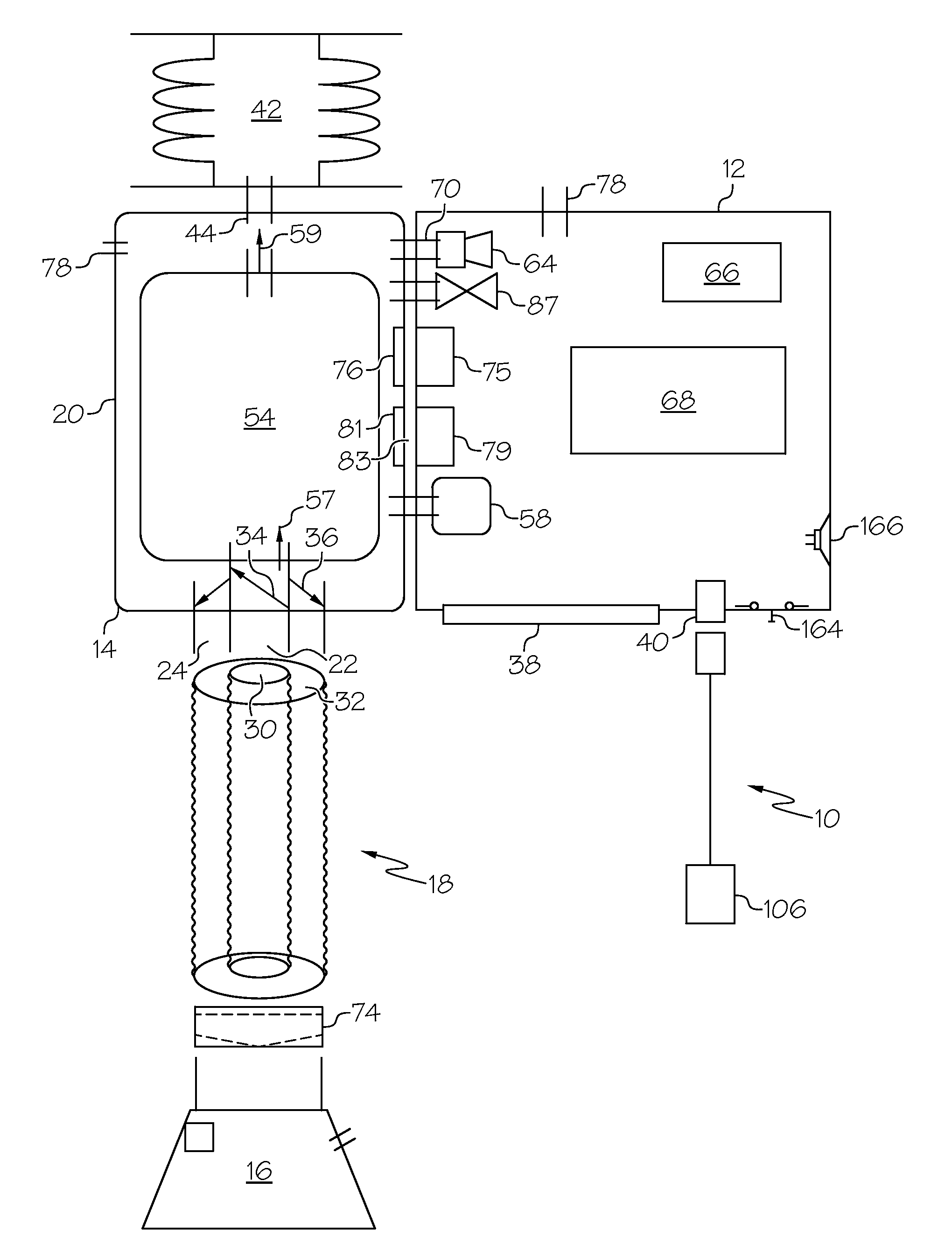

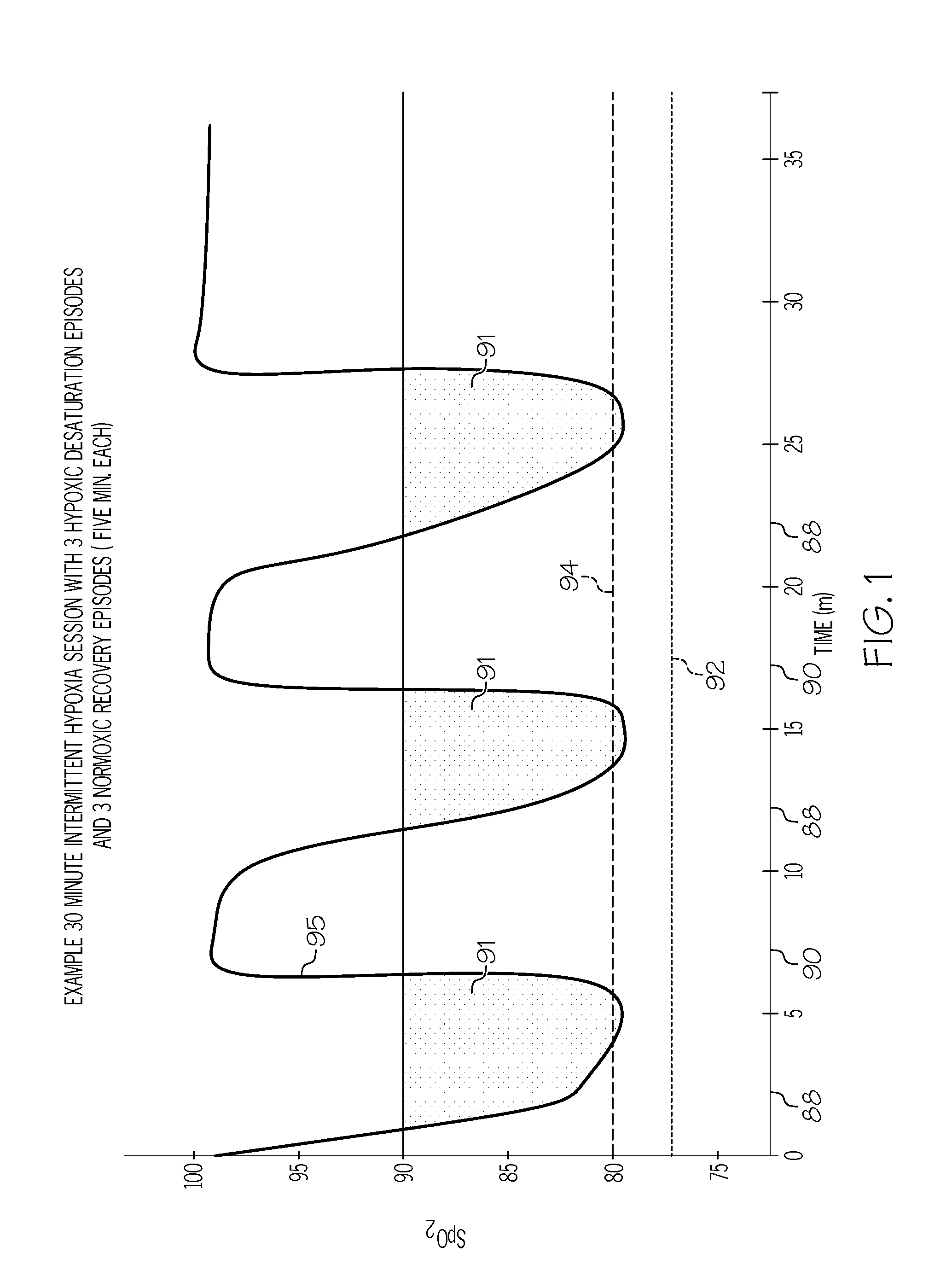

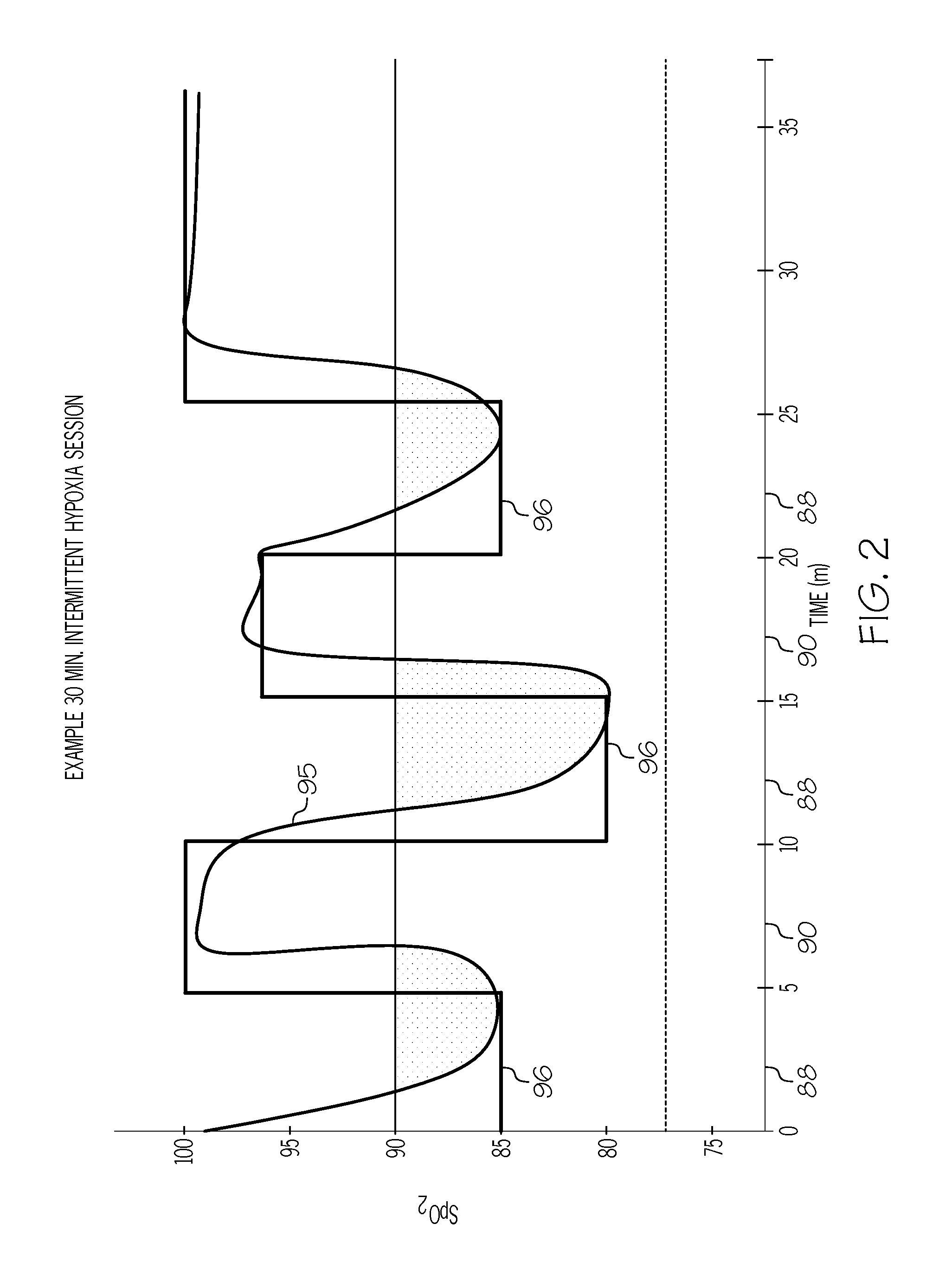

Hypoxic Breathing Apparatus and Method

InactiveUS20160095994A1Gas treatmentOperating means/releasing devices for valvesIntensive care medicineCarbon dioxide scrubber

A breathing apparatus includes a breathing mask, hose, and first housing in fluid communication with the hose and breathing mask. The first housing has first and second chambers which are separated by a barrier comprising a carbon dioxide scrubber. The breathing apparatus is configured to conduct hypoxic therapy and tailor the therapeutic session to the patient while collecting data about patient response.

Owner:THIRD WIND LLC

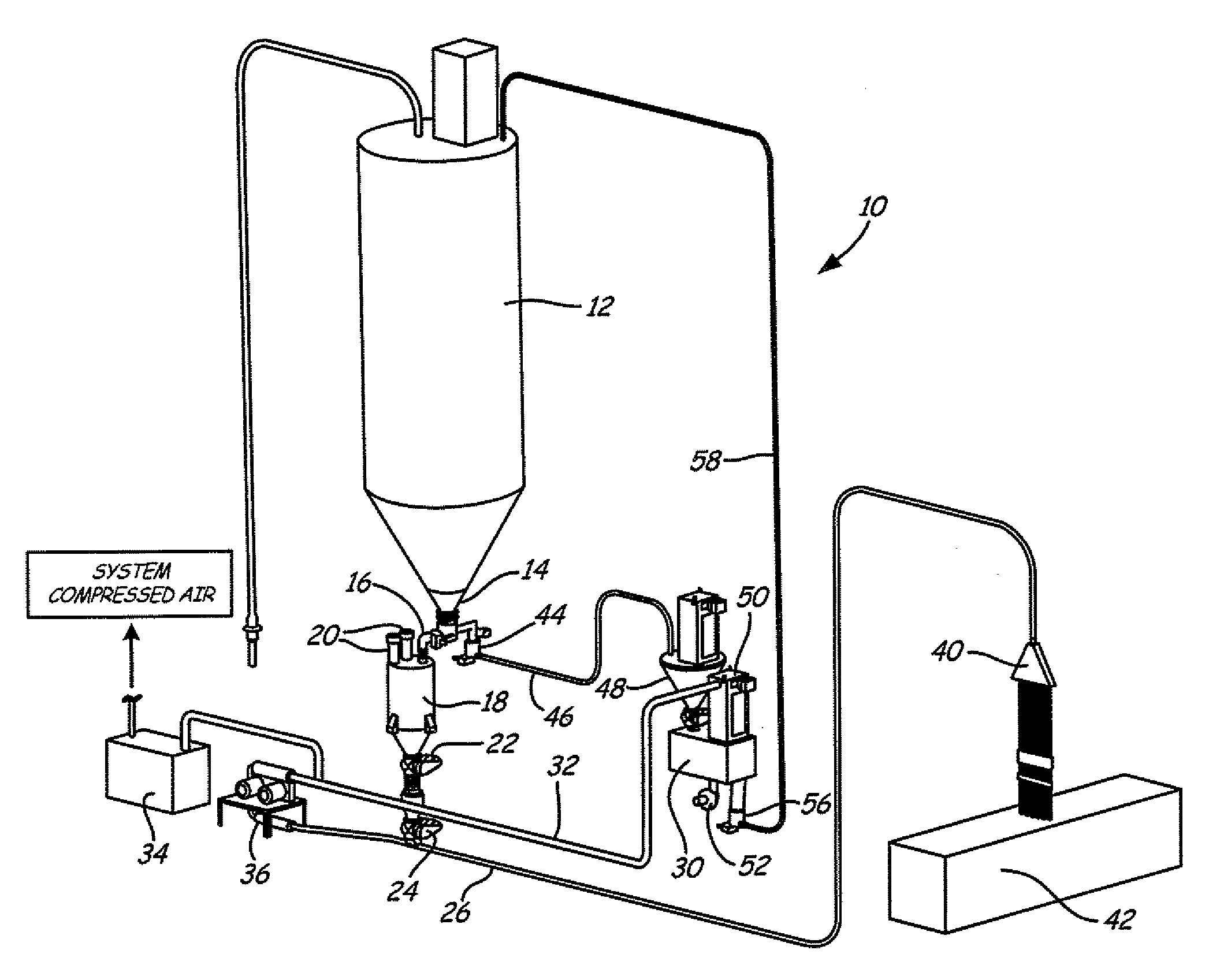

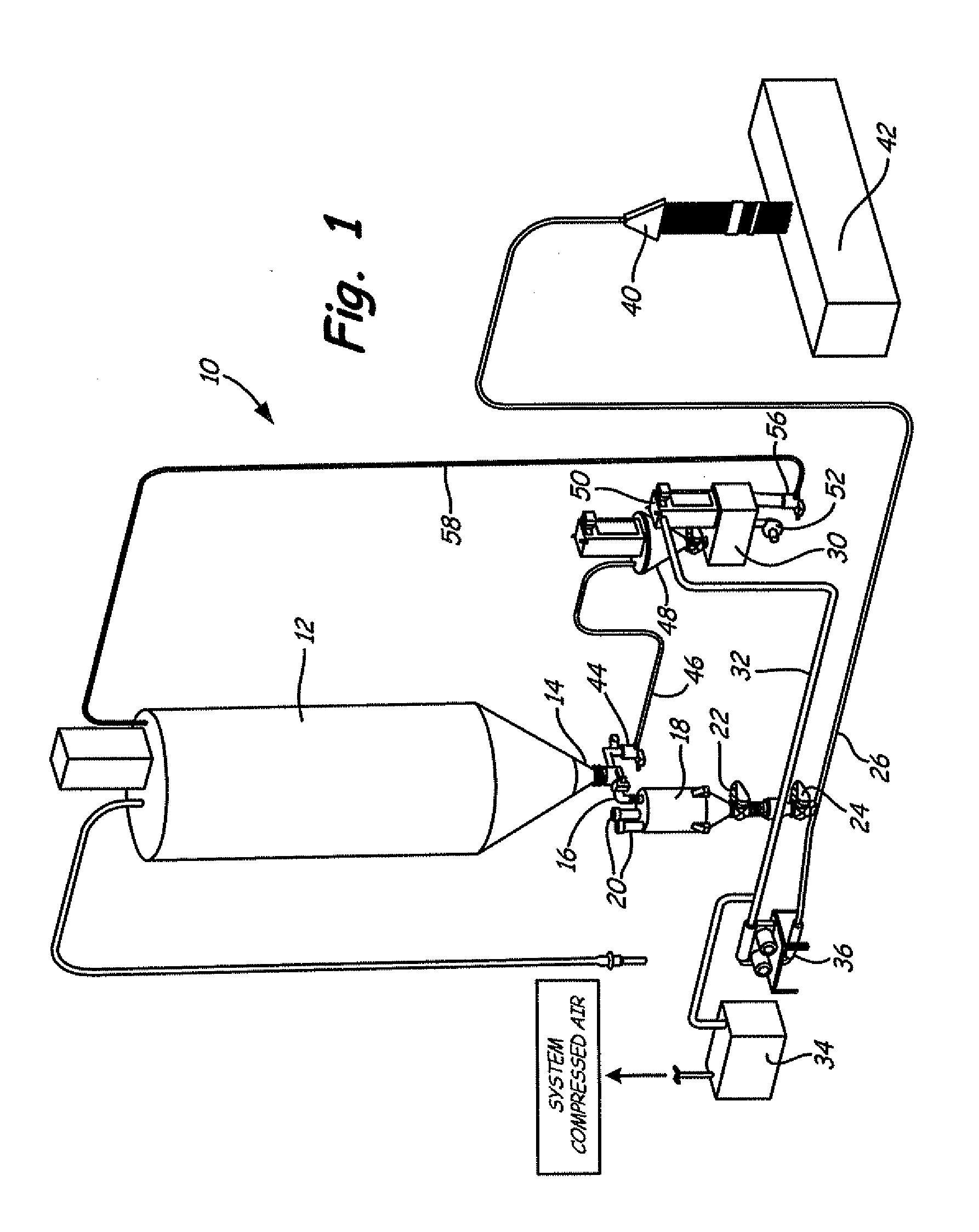

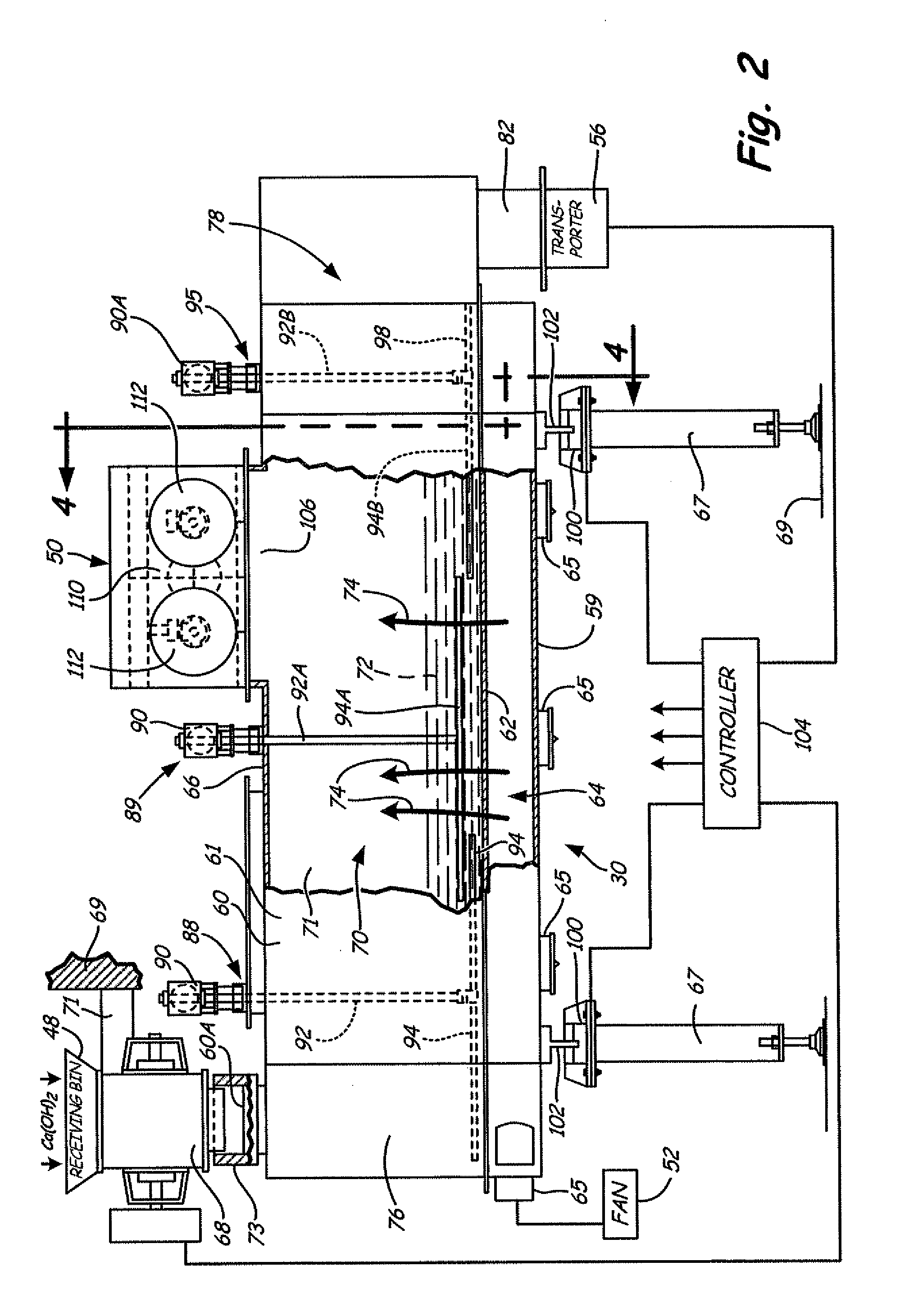

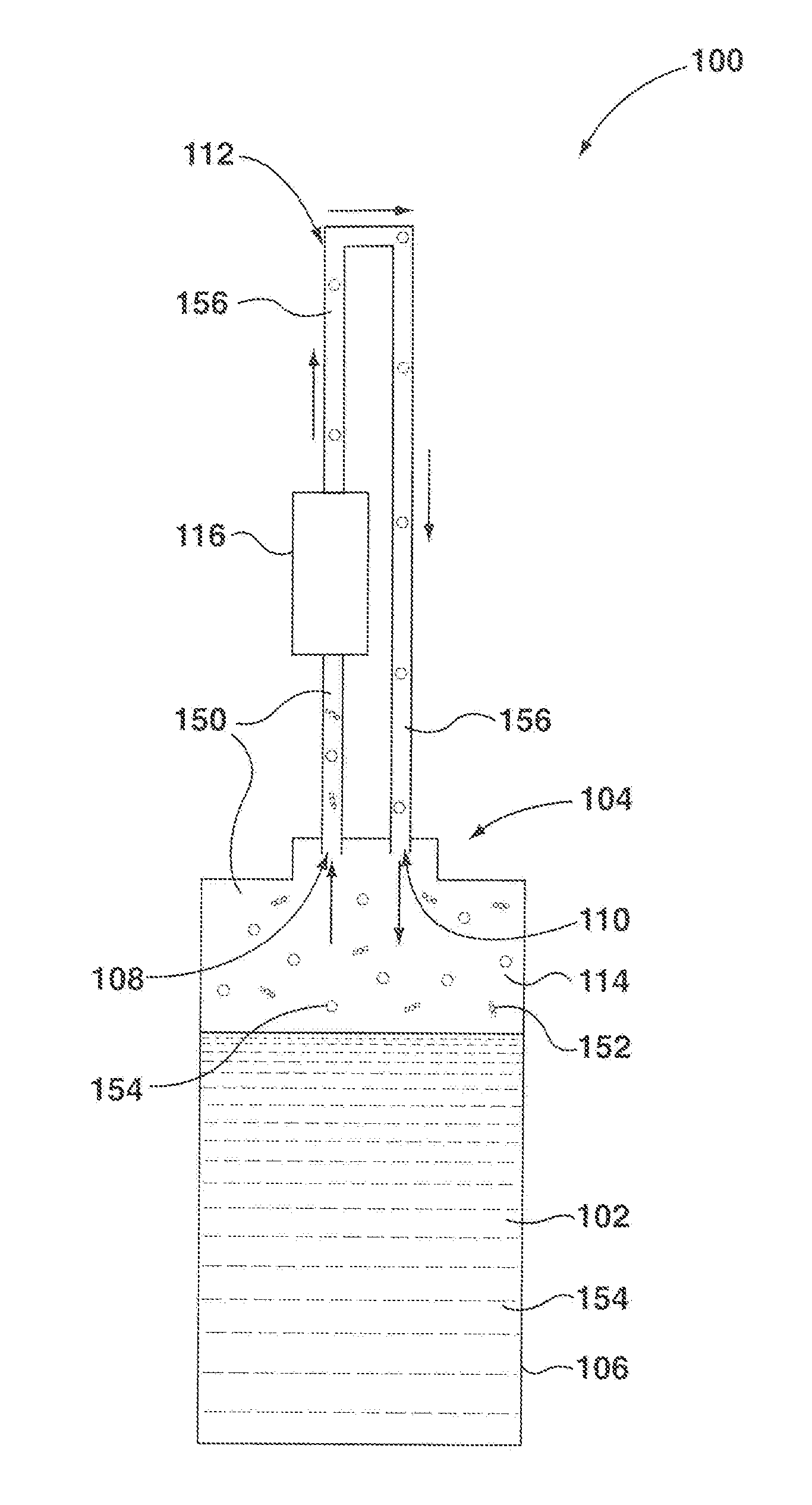

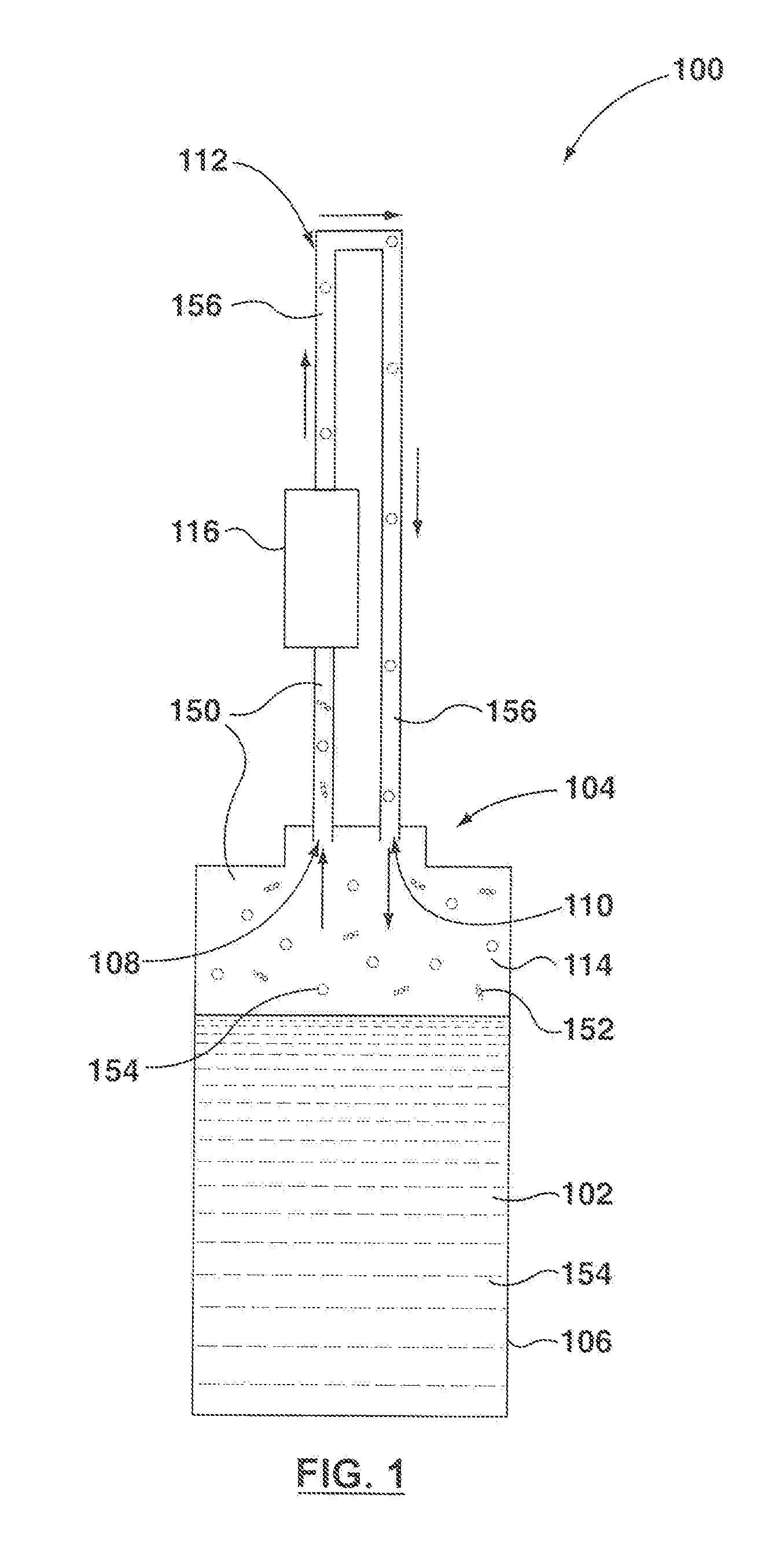

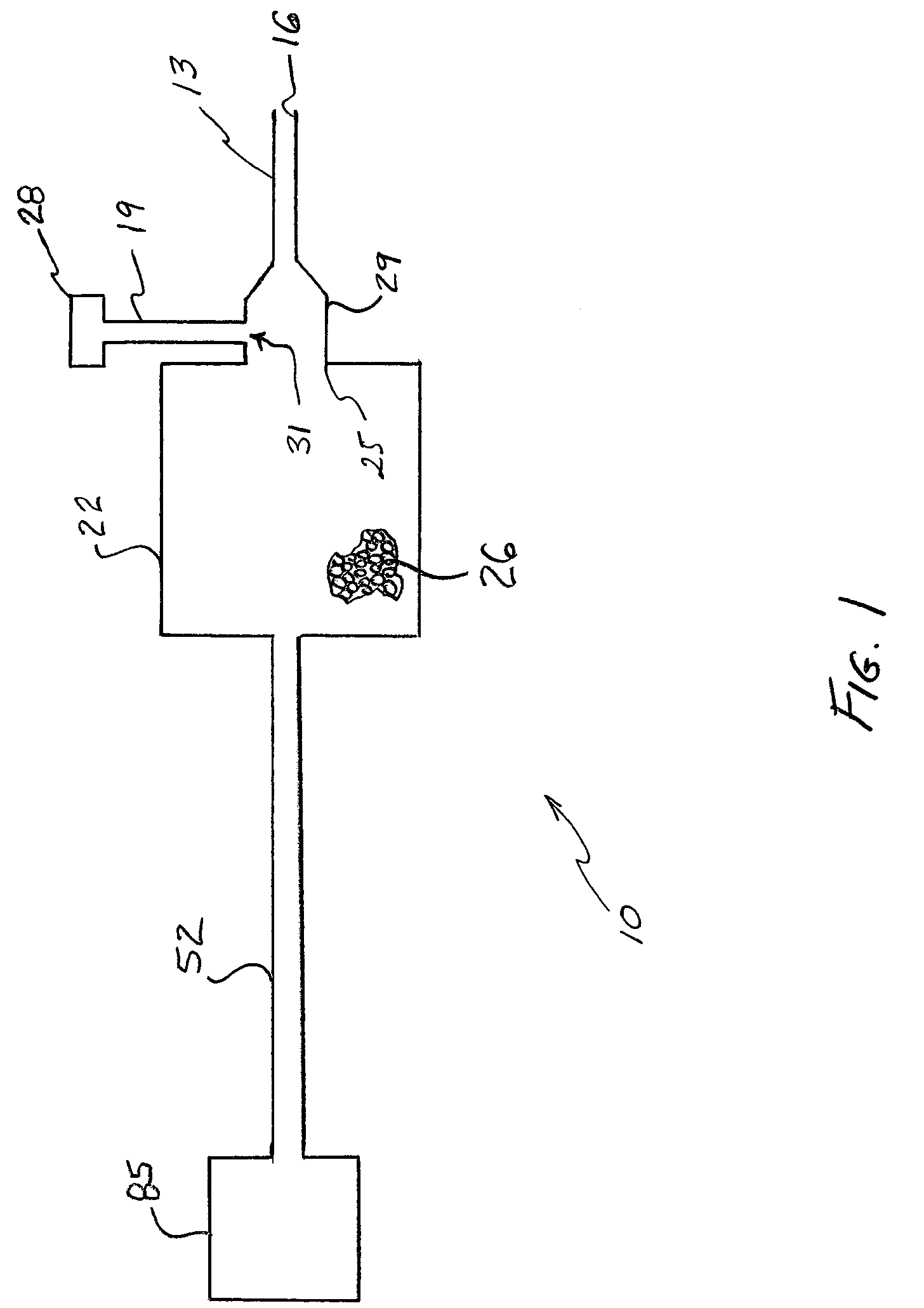

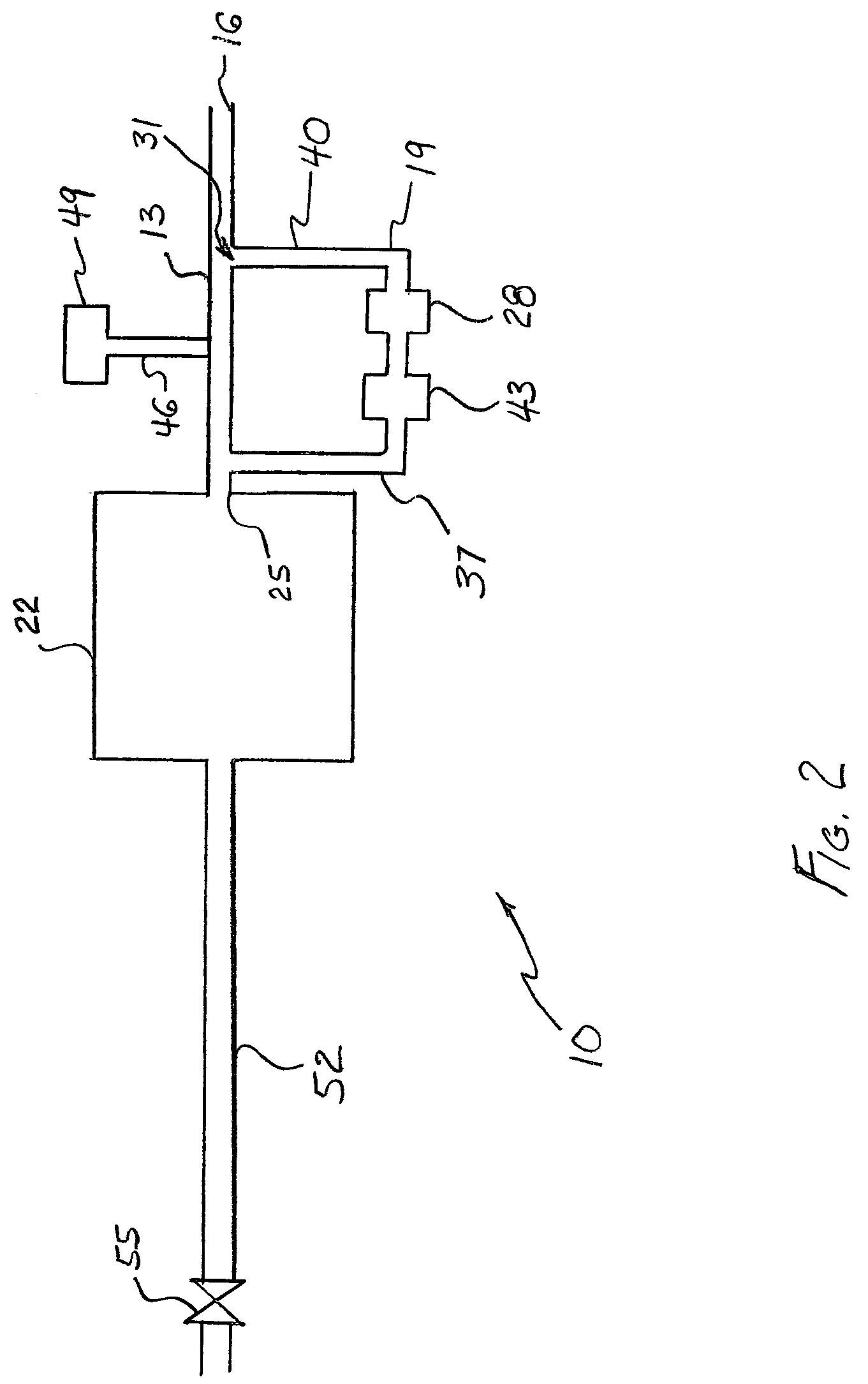

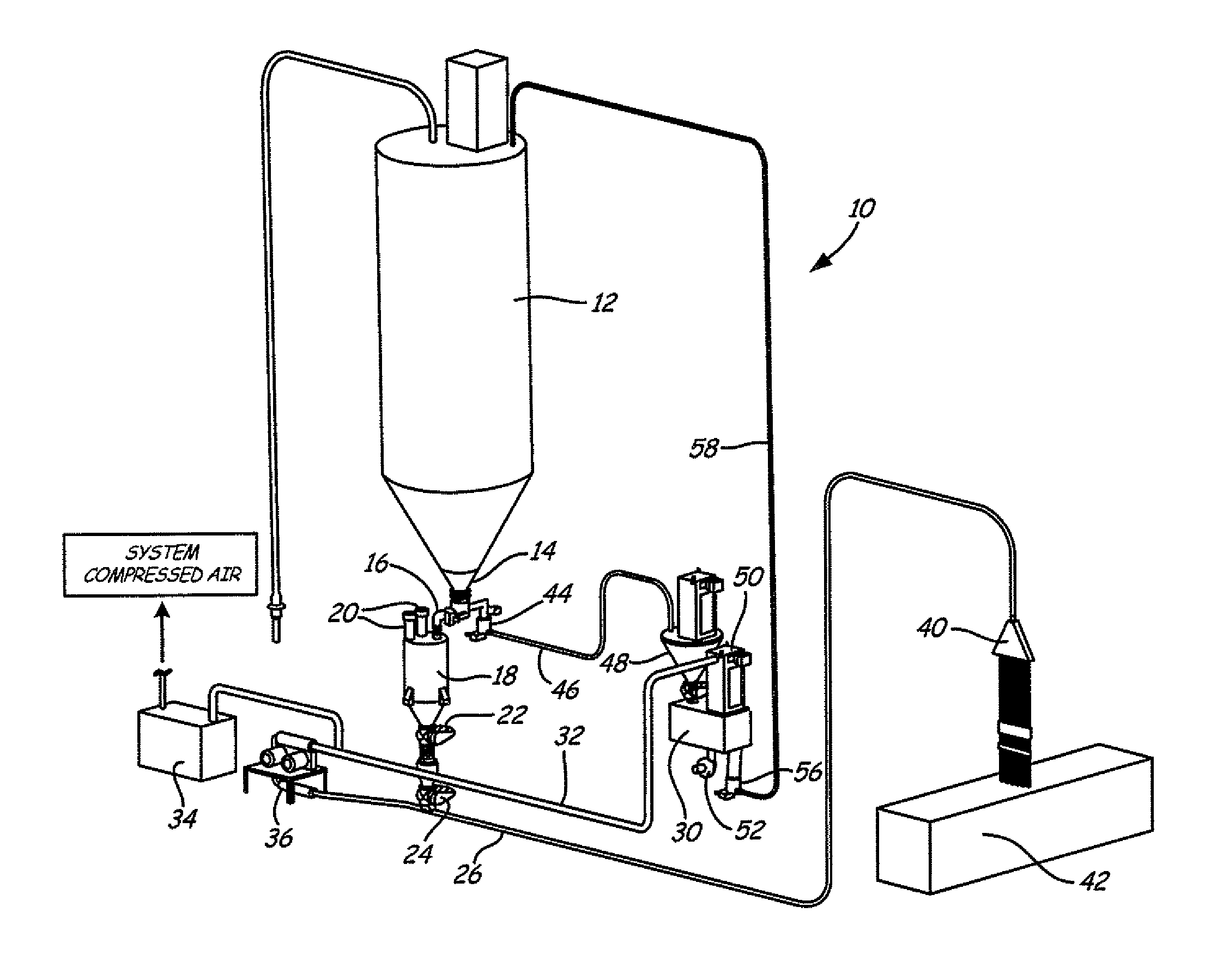

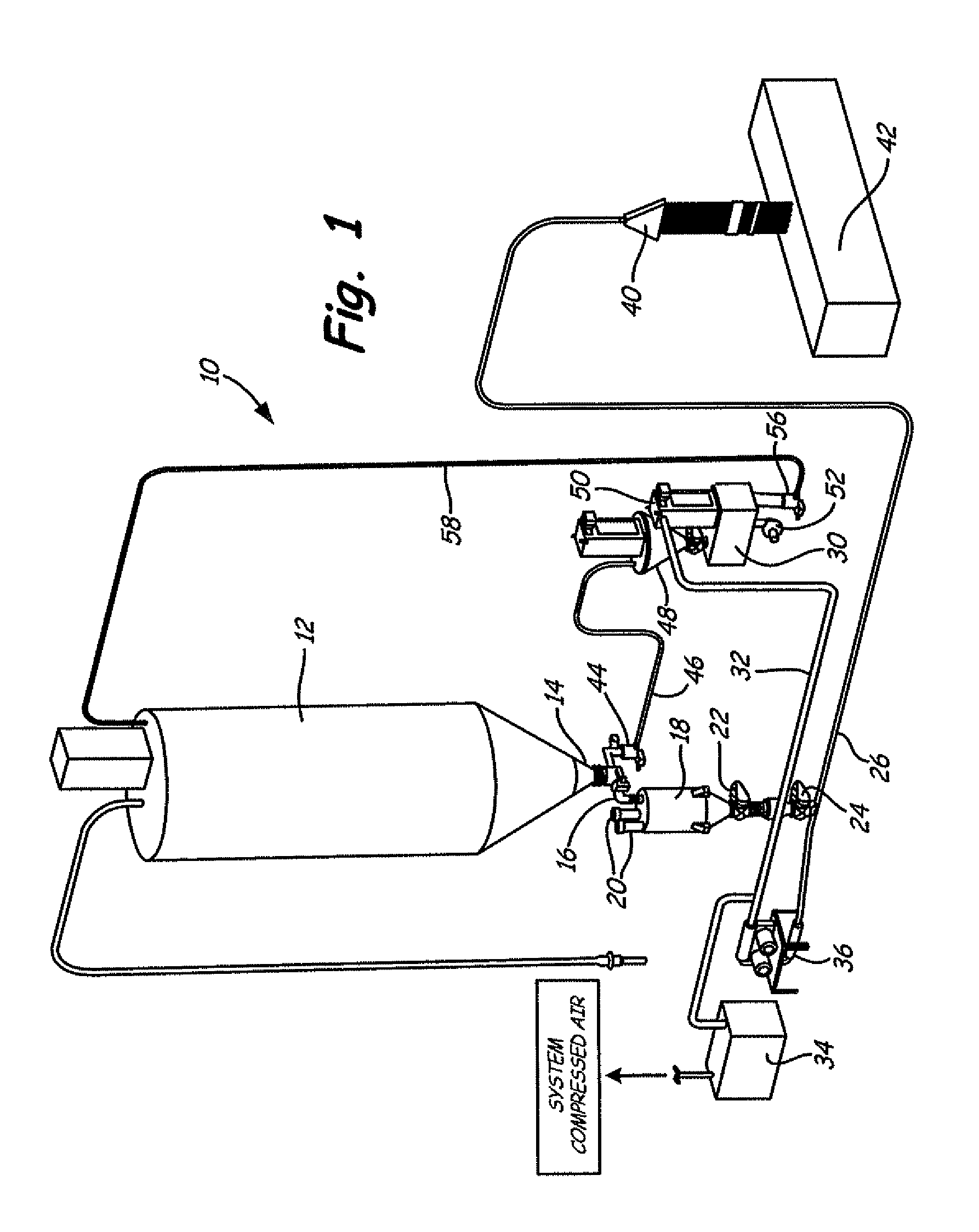

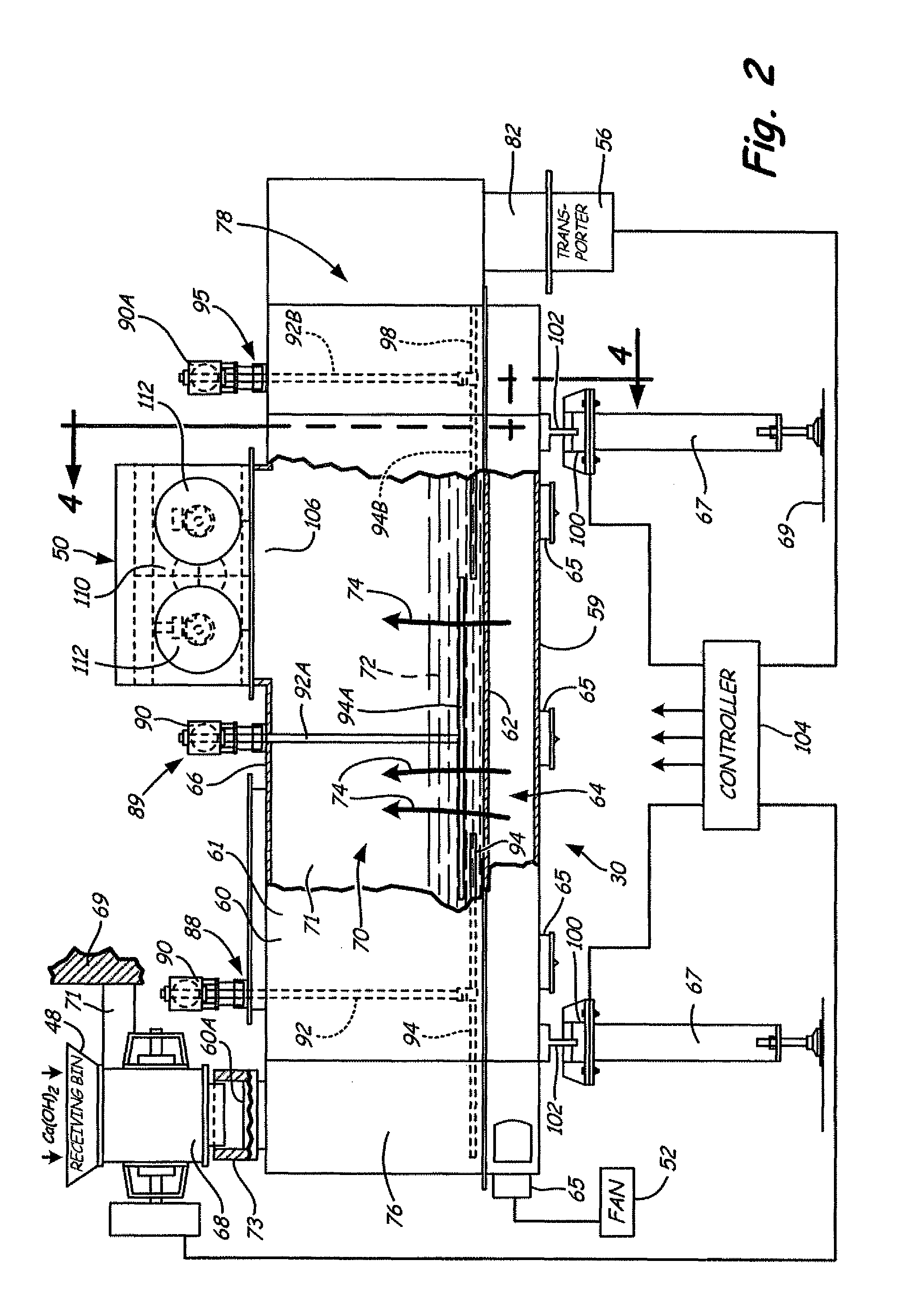

Fluidized Bed Carbon Dioxide Scrubber For Pneumatic Conveying System

InactiveUS20110206586A1Avoid problemsGas treatmentHydrogen sulfidesFluidized bedEnvironmental engineering

A pneumatic conveying system for conveying hydrated lime is provided with ambient air for the pneumatic conveying system from a scrubber that removes carbon dioxide from the ambient air used in the conveying system. The scrubber includes a bed of hydrated lime through which ambient air is passed, to react carbon dioxide in the air with the hydrated lime in a reaction that forms limestone and water. The air that has passed through the fluidized bed, which is essentially carbon dioxide free, is also passed through a filter to remove particles suspended in the carbon dioxide free air. The carbon dioxide free air from the filter is provided to the pneumatic conveying system. The use of carbon dioxide free air ensures that the hydrated lime being transported in the conveying system will not react in the various conduits and ducts of the pneumatic conveying system to cause problems.

Owner:NOL TEC SYST

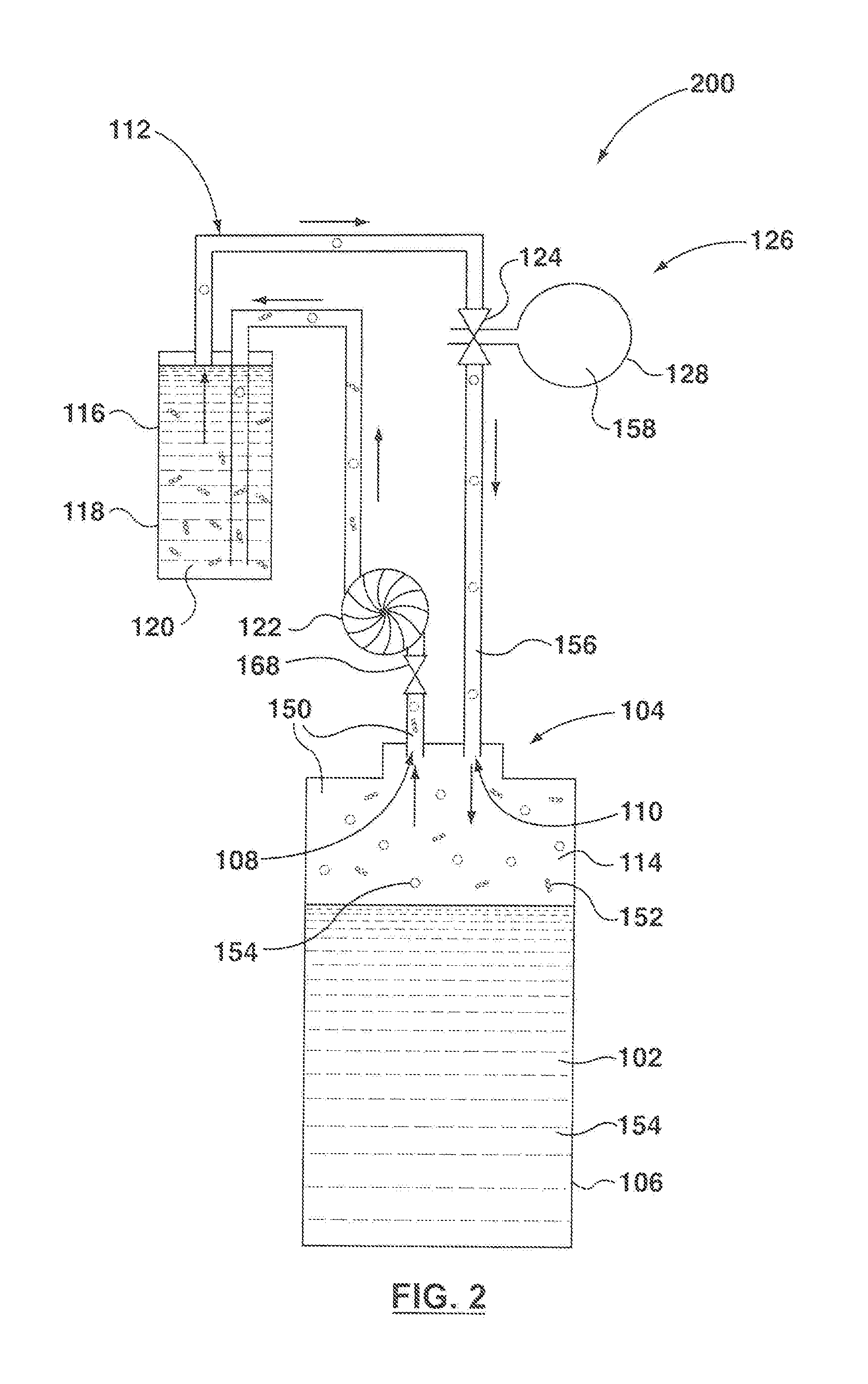

Apparatus and method for preserving the aroma of a fermentable beverage

ActiveUS20150322390A1Removal rateEasy accessBy-product recoveryLiquid degasification with auxillary substancesGas concentrationFermentation

A fermentation apparatus for preserving the aroma of a fermentable beverage is provided. The fermentation apparatus comprises a flow passage fluidly connectable to the headspace located above a fermentable beverage in a fermentation container. A carbon dioxide scrubber in the flow passage receives a headspace fluid mixture comprising at least carbon dioxide gas and an aromatic fluid originating from the fermenting beverage. When the headspace fluid mixture contacts the carbon dioxide scrubber, the carbon dioxide scrubber retains a modified fluid in the flow passage. The modified fluid has a lower carbon dioxide gas concentration and a higher aromatic fluid concentration than the headspace fluid mixture. The flow passage directs the modified fluid back to the headspace to at least partially retain the aromatic fluid in the fermentable beverage in the fermentation container. A method for preserving the aroma of a fermentable beverage is also provided.

Owner:AROMALOC INC

Method for removing CO2 from coal-fired power plant flue gas using ammonia as the scrubbing solution, with a chemical additive for reducing NH3 losses, coupled with a membrane for concentrating the CO2 stream to the gas stripper

A method for removing and capturing carbon dioxide from a fluid stream includes the steps of exposing the fluid stream to an aqueous scrubbing solution that removes and holds carbon dioxide from the fluid stream, passing the aqueous scrubbing solution through a membrane in order to separate excess water from the scrubbing solution and increase the concentration of carbon dioxide in the scrubbing solution, heating the scrubbing solution having an increased concentration of carbon dioxide so as to release carbon dioxide gas and recycling the scrubbing solution. A carbon dioxide capture apparatus includes a carbon dioxide scrubber, a membrane downstream from the scrubber for separating water and concentrating carbon dioxide in a scrubbing solution and a stripper vessel.

Owner:UNIV OF KENTUCKY RES FOUND

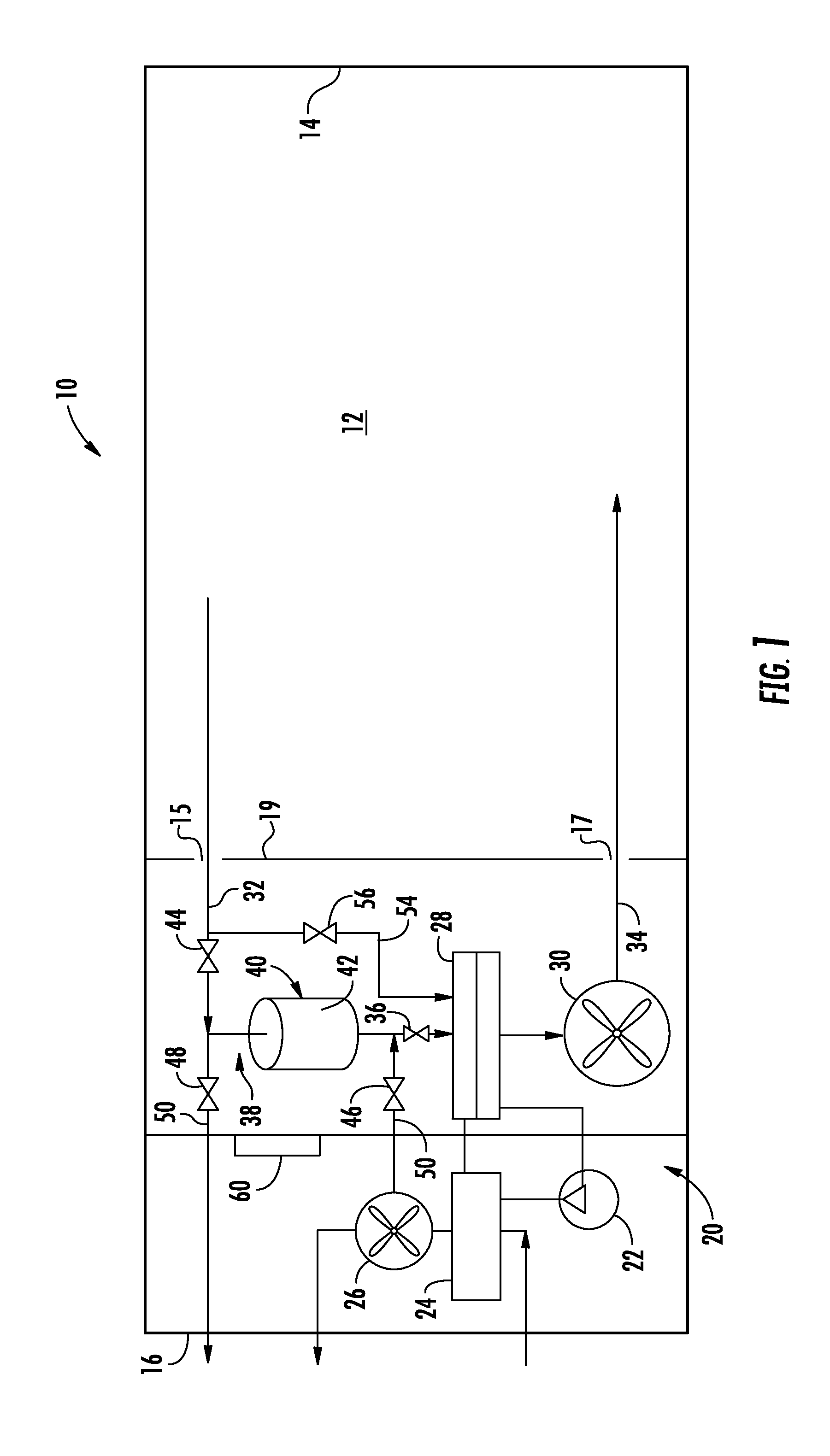

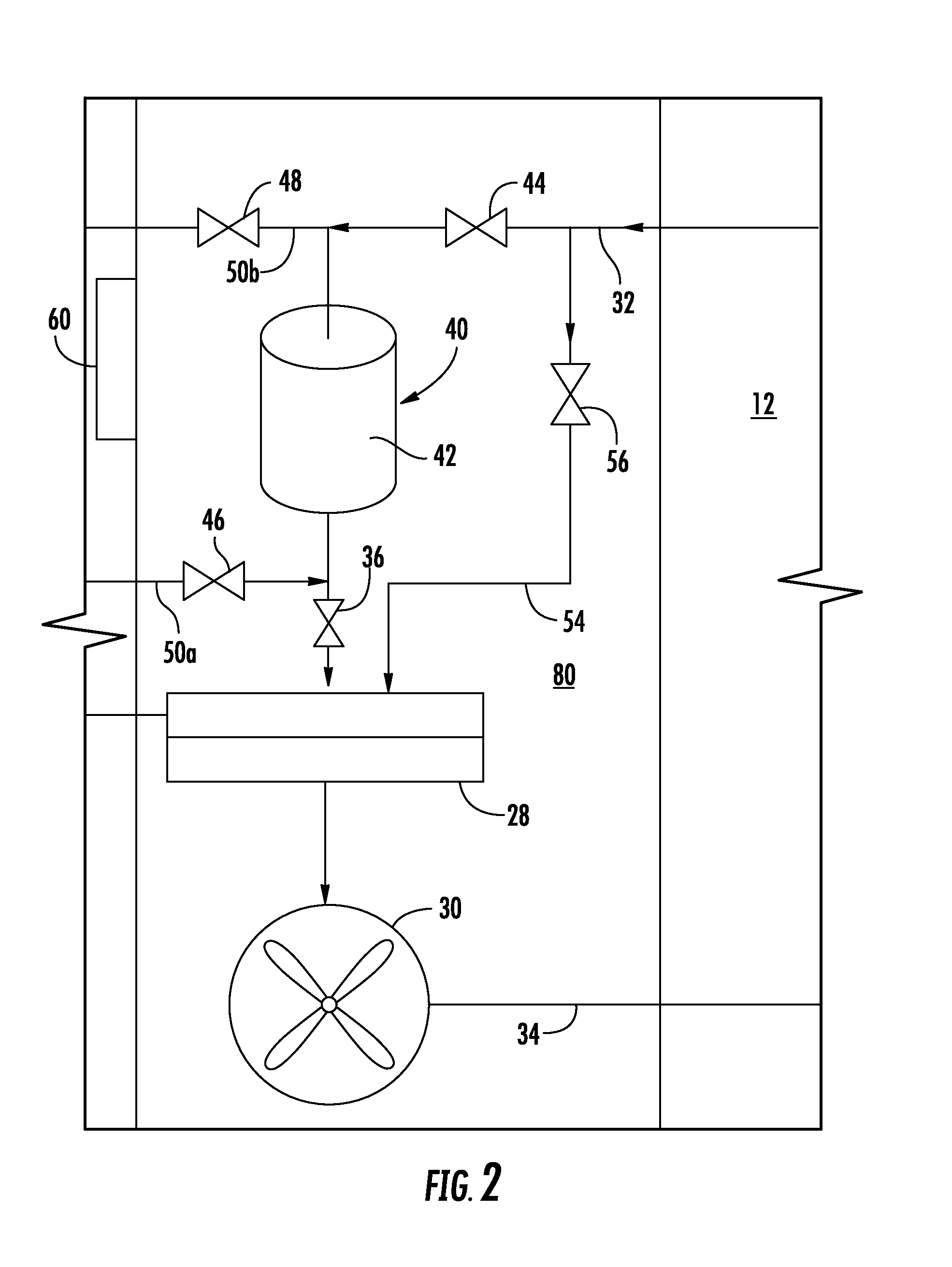

Control of atmosphere within a closed environment

ActiveCN103687494AFruit and vegetables preservationDispersed particle separationRipeningGaseous atmosphere

A method and apparatus are disclosed for controlling a concentration of carbon dioxide in a gaseous atmosphere within a closed environment of a refrigerated transport container to maintain the concentration of carbon dioxide therein at a desired level. A carbon dioxide scrubber apparatus operates alternately in an adsorption mode and a regeneration mode. When a perishable produce is stowed in the closed environment, for example in a cargo box of a refrigerated transport container, the concentration of carbon dioxide may be maintain at a desired level to retard ripening of the perishable produce.

Owner:CARRIER CORP

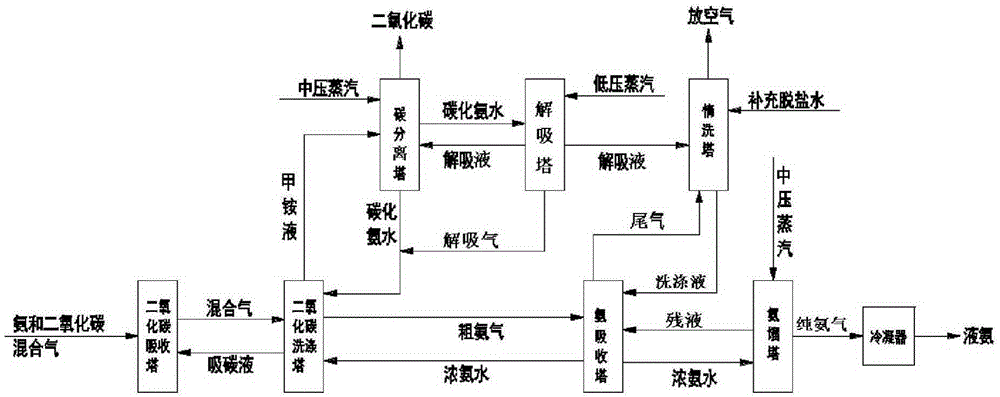

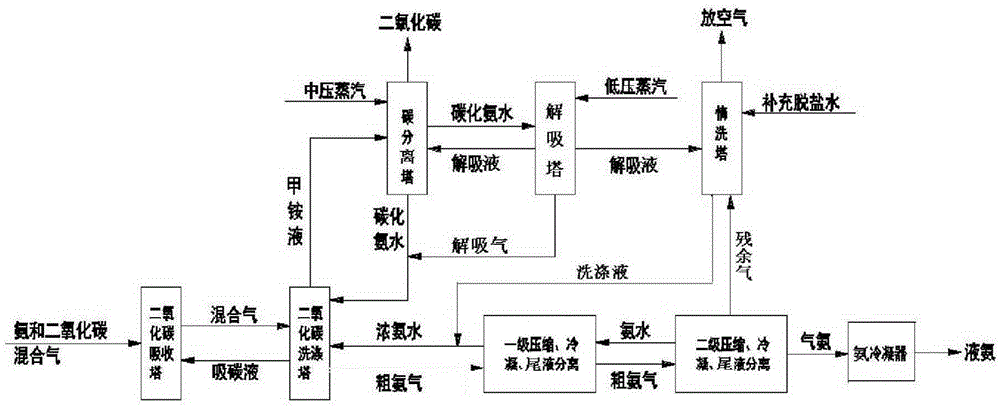

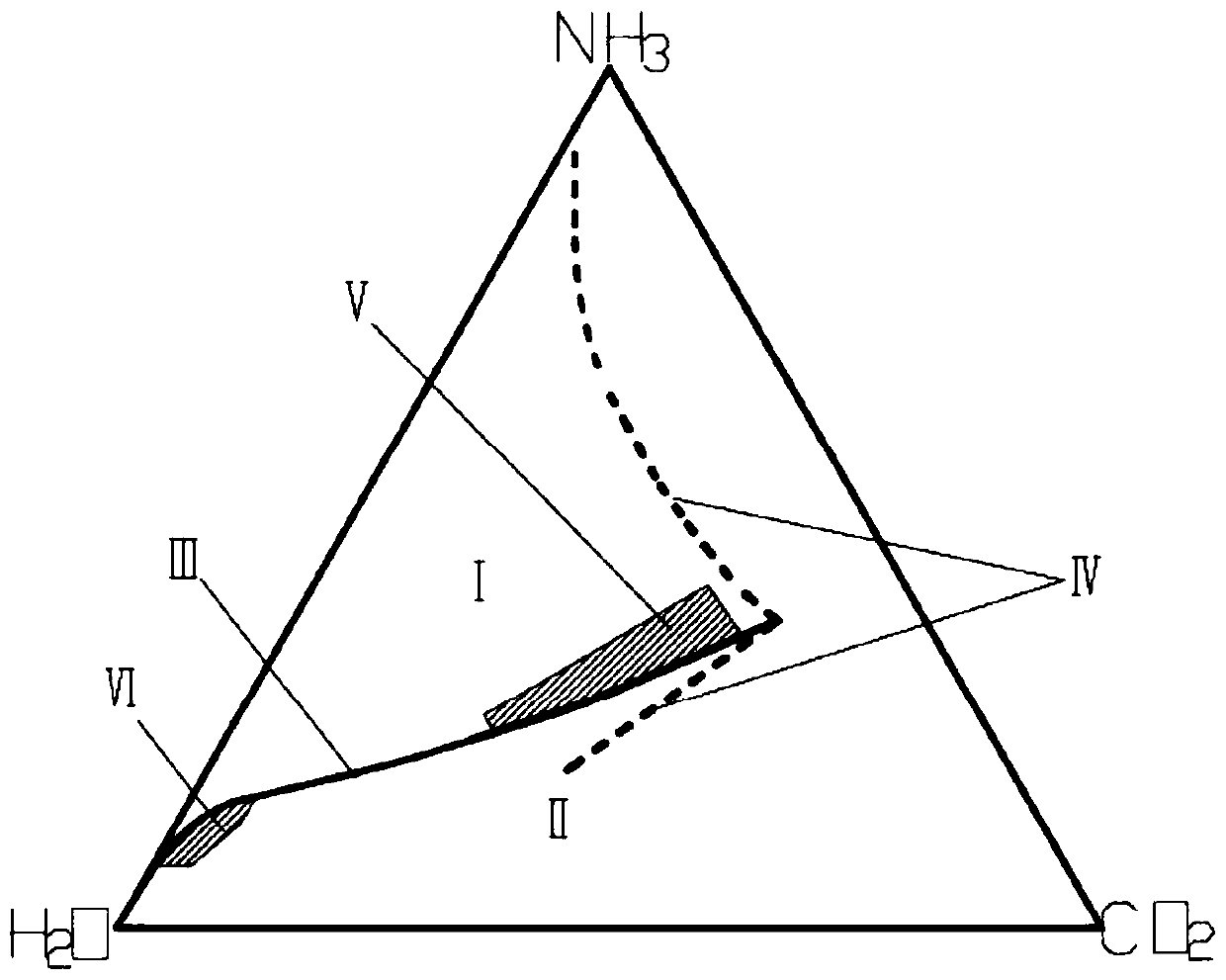

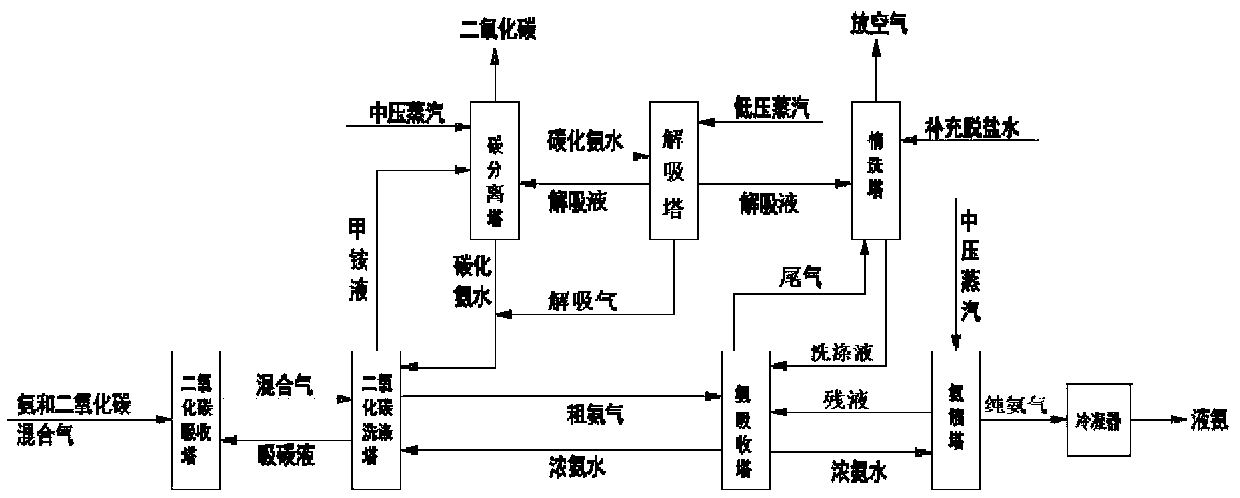

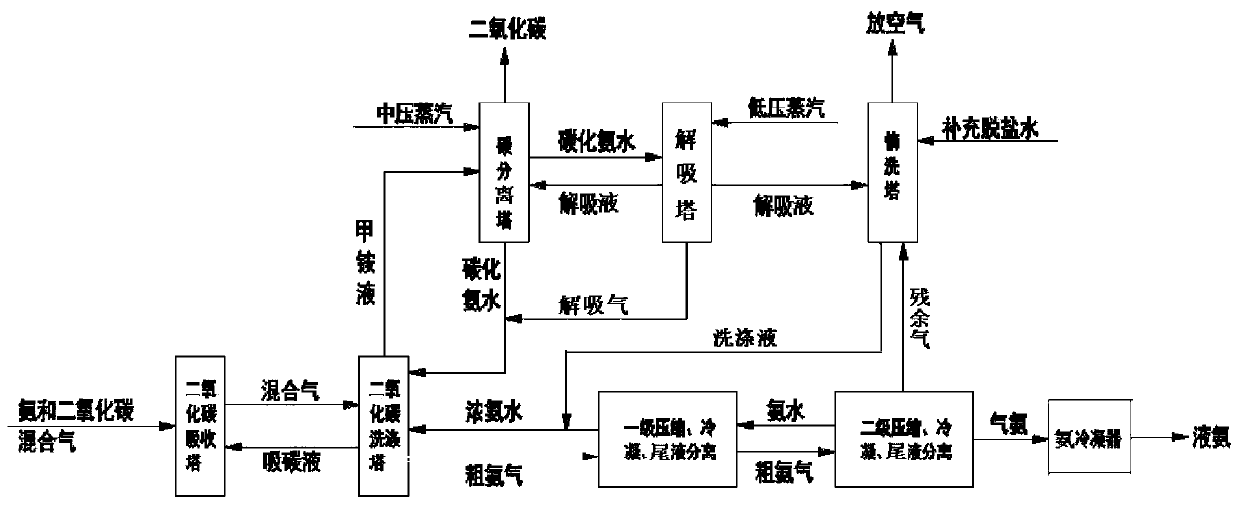

Ammonia-carbon separation process

ActiveCN105289210AEasy to separateReduce circulationProductsCarbon compoundsCo2 absorptionEconomic benefits

The invention provides an ammonia-carbon separation process. The process comprises the step of carbon dioxide absorption, wherein a gas mixture sequentially makes contact with carbonized ammonia water and strong ammonia water in a carbon dioxide washing tower, carbon absorbing liquid is formed, the carbon absorbing liquid makes contact with a gas mixture in a carbon dioxide absorption tower, and ammonium carbamate liquid is obtained. According to the process, synergism of the carbon dioxide absorption tower and the carbon dioxide washing tower is initiatively utilized, carbon dioxide is separated from the gas mixture to the greatest extent, to be specific, the carbon dioxide absorption tower adopts the carbon absorbing liquid for absorbing carbon dioxide in the gas mixture, while carbon dioxide washing tower adopts carbonized ammonia water as the main medium and strong ammonia water as the auxiliary medium for precisely absorbing carbon dioxide, therefore the content of carbon dioxide in obtained coarse ammonia gas can be controlled below 50 ppm, then ammonia is separated from the coarse ammonia gas, and finally pure ammonia containing no carbon dioxide or water is obtained. By means of the ammonia-carbon separation process, thorough separation of ammonia and carbon dioxide is achieved in real sense, the ammonia-carbon separation effect is improved, and it is helpful to increase economic benefits.

Owner:BEIJING EDGEIN TECH +1

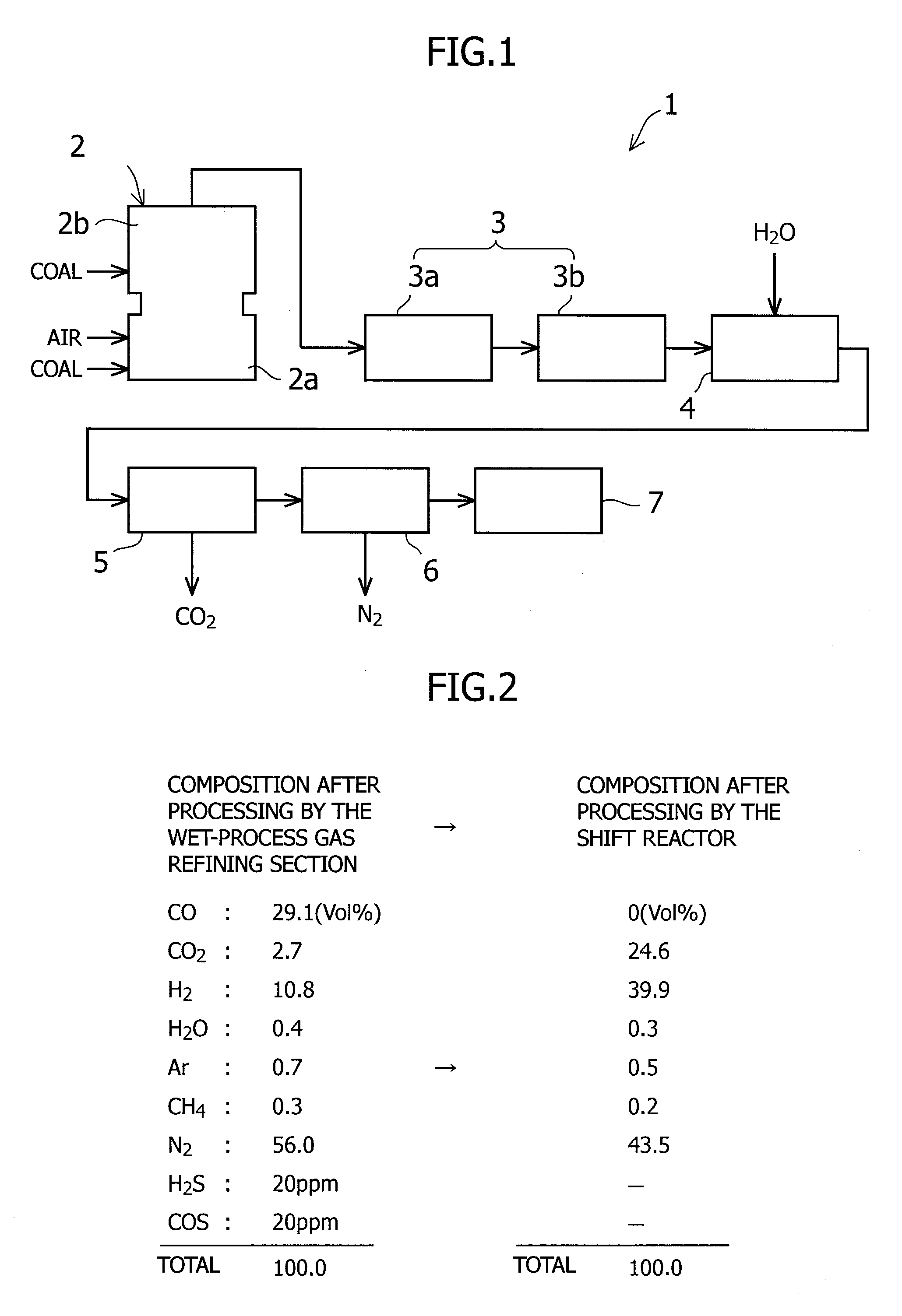

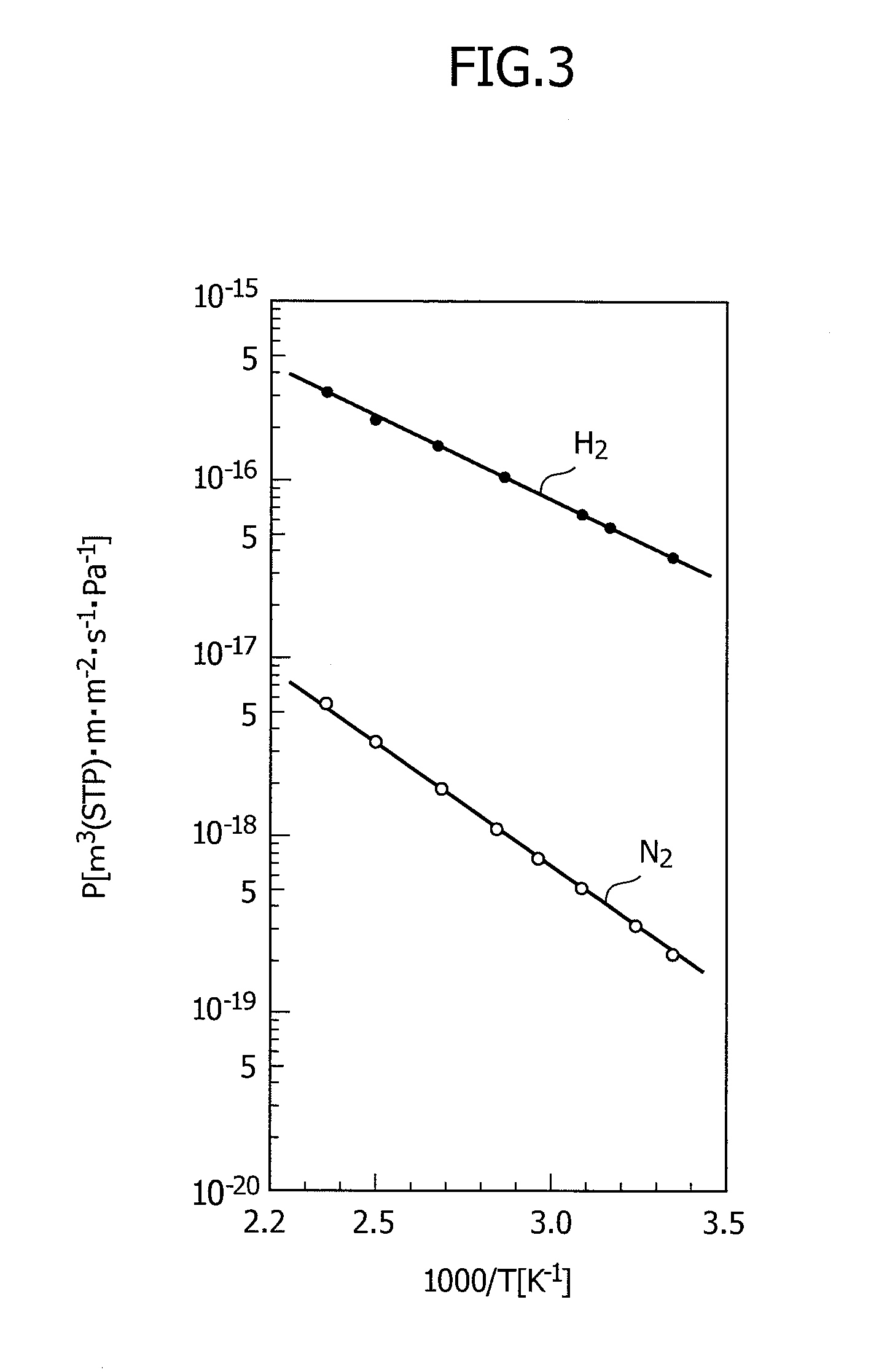

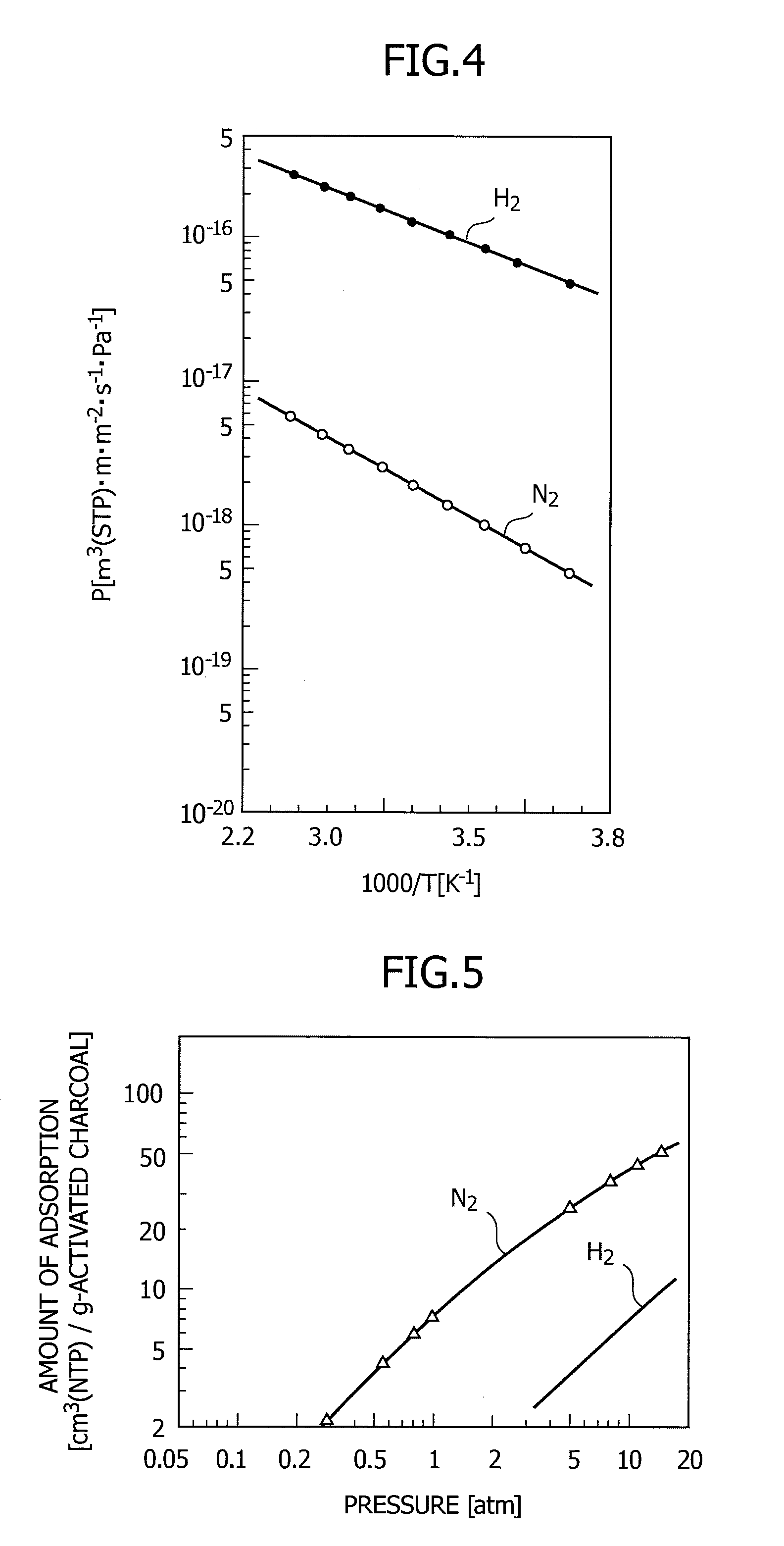

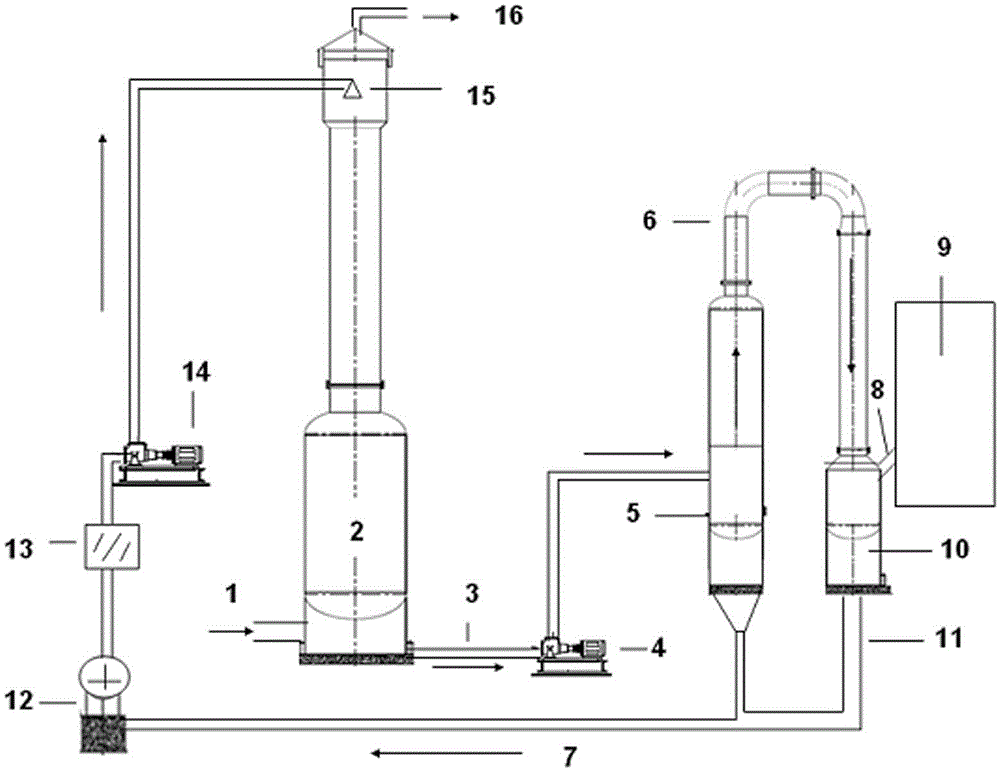

Ammonia generating method and apparatus therefor

InactiveUS20110064641A1Prolong lifeReduce stepsCombustible gas catalytic treatmentHydrogen/synthetic gas productionPartial oxidationHydrogen

An object of the present invention is to provide an ammonia generating method and apparatus that can be operated continuously for a long period of time, and that reduces the cost.The present invention has a gasification furnace 2 into which coal and air are introduced, constituted to perform partial oxidation to gasify the coal; a desulfurizing apparatus 3 constituted to desulfurize the gas generated by the gasification furnace 2; a shift reactor 4 constituted to convert carbon monoxide present in the gas exhausted from the desulfurizing apparatus 3 to carbon dioxide; a carbon dioxide scrubber 5 constituted to remove carbon dioxide present in the gas exhausted from the shift reactor 4; a denitrification apparatus 6 constituted so that, by removing nitrogen present in the gas exhausted from the carbon dioxide scrubber 5, the molar ratio between nitrogen and hydrogen present in the gas is adjusted to approximately 1:3; and an ammonia generator 7 that generates ammonia by causing a reaction between the nitrogen and hydrogen present in the gas exhausted from the denitrification apparatus 6.

Owner:MITSUBISHI HEAVY IND LTD

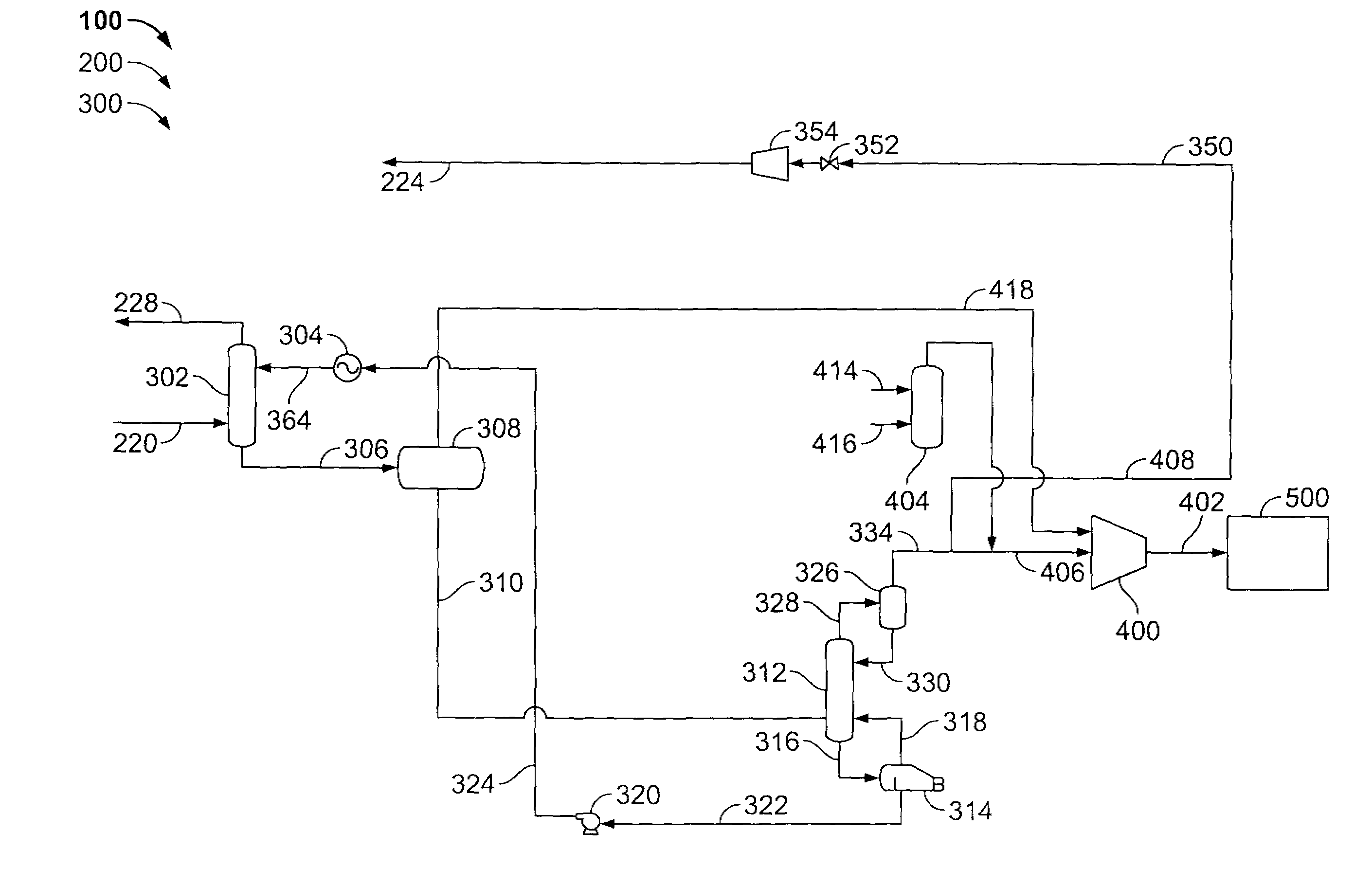

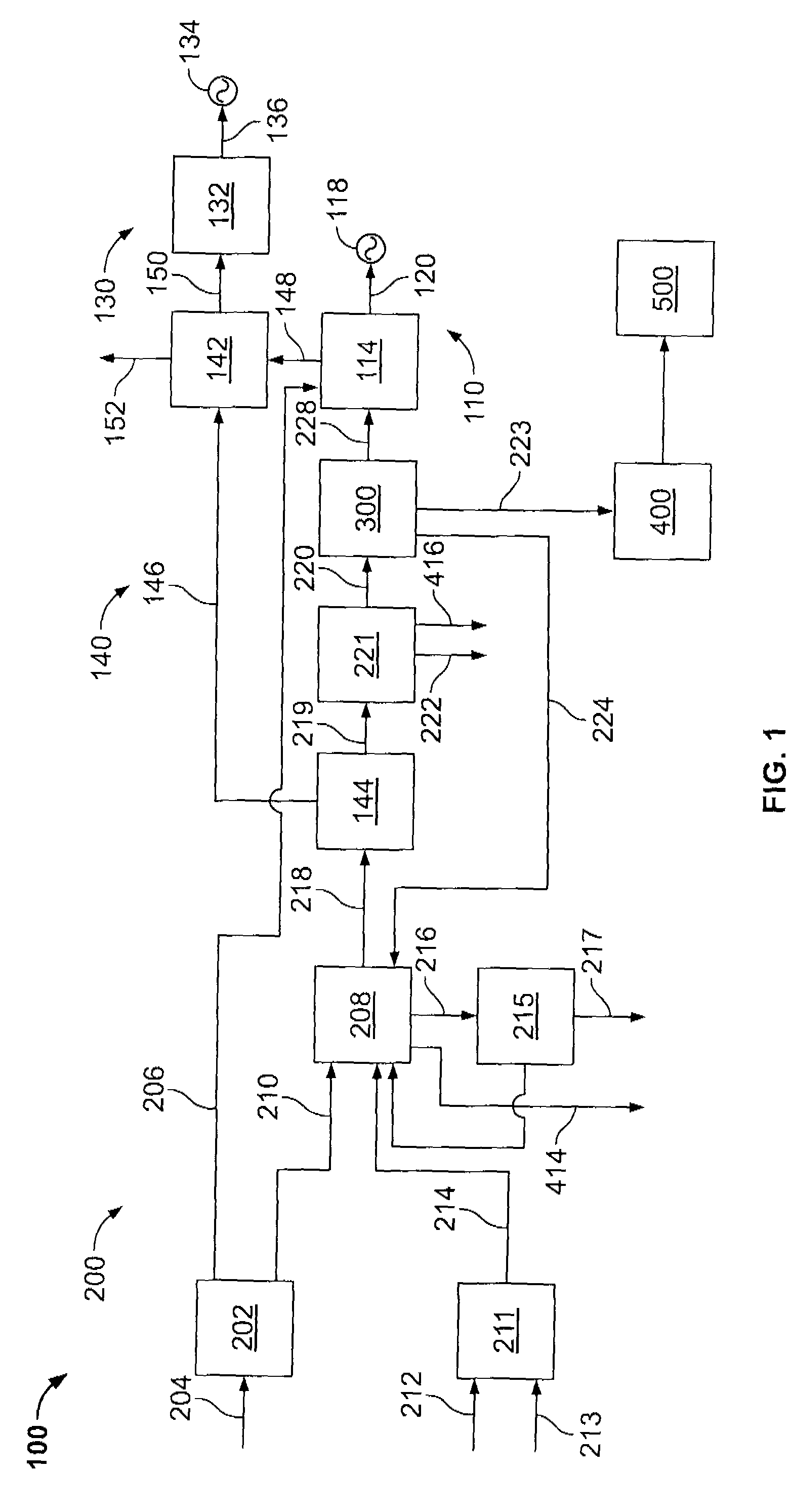

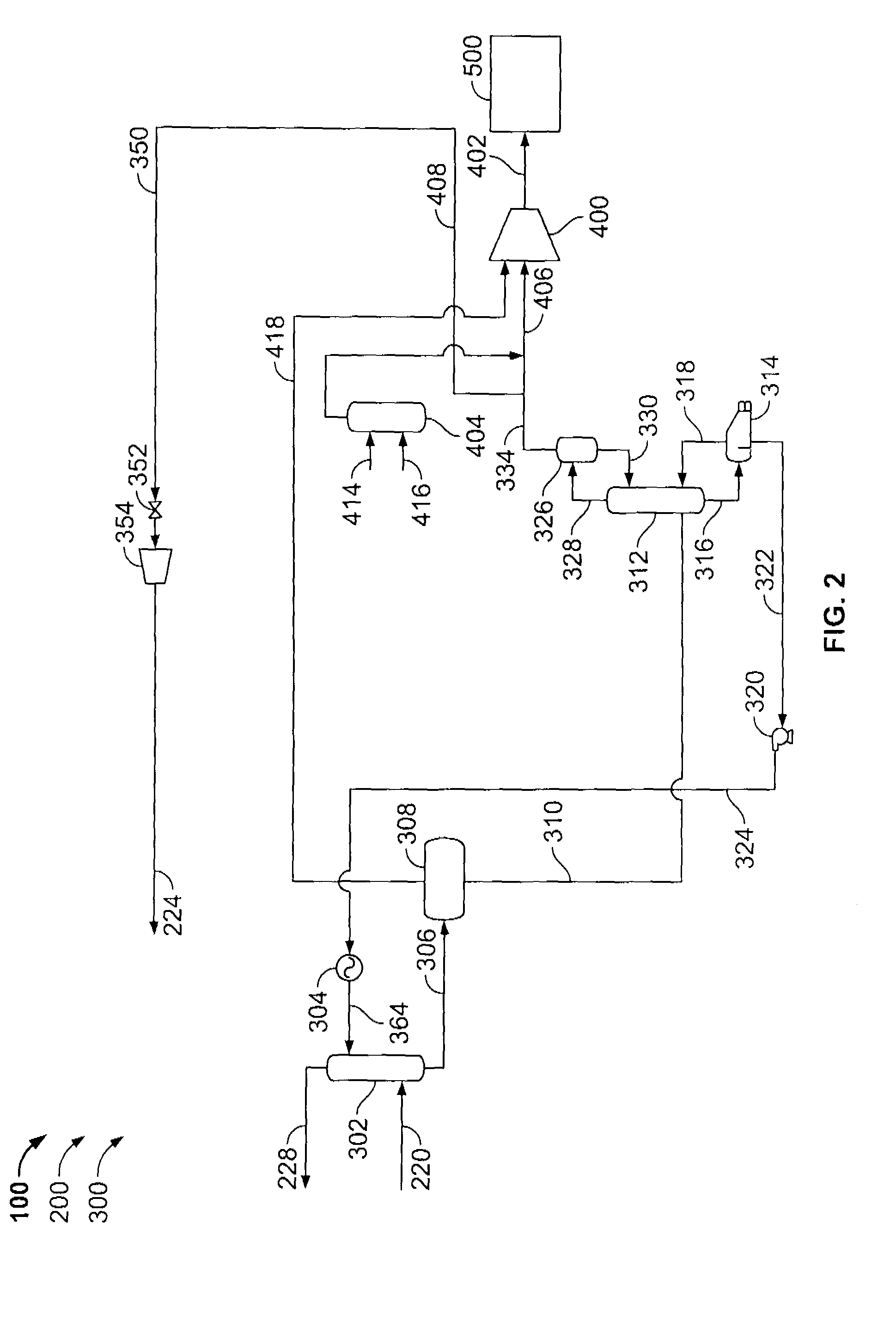

Systems and methods for carbon dioxide capture

Methods and systems for handling sour carbon dioxide (CO2) streams are provided. In one aspect, a method for sequestering an emissions-heavy gas includes removing at least a portion of an acid gas from a rich solvent in an acid gas stripper to create the emissions-heavy gas, and channeling the emissions-heavy gas to a storage system.

Owner:AIR PROD & CHEM INC

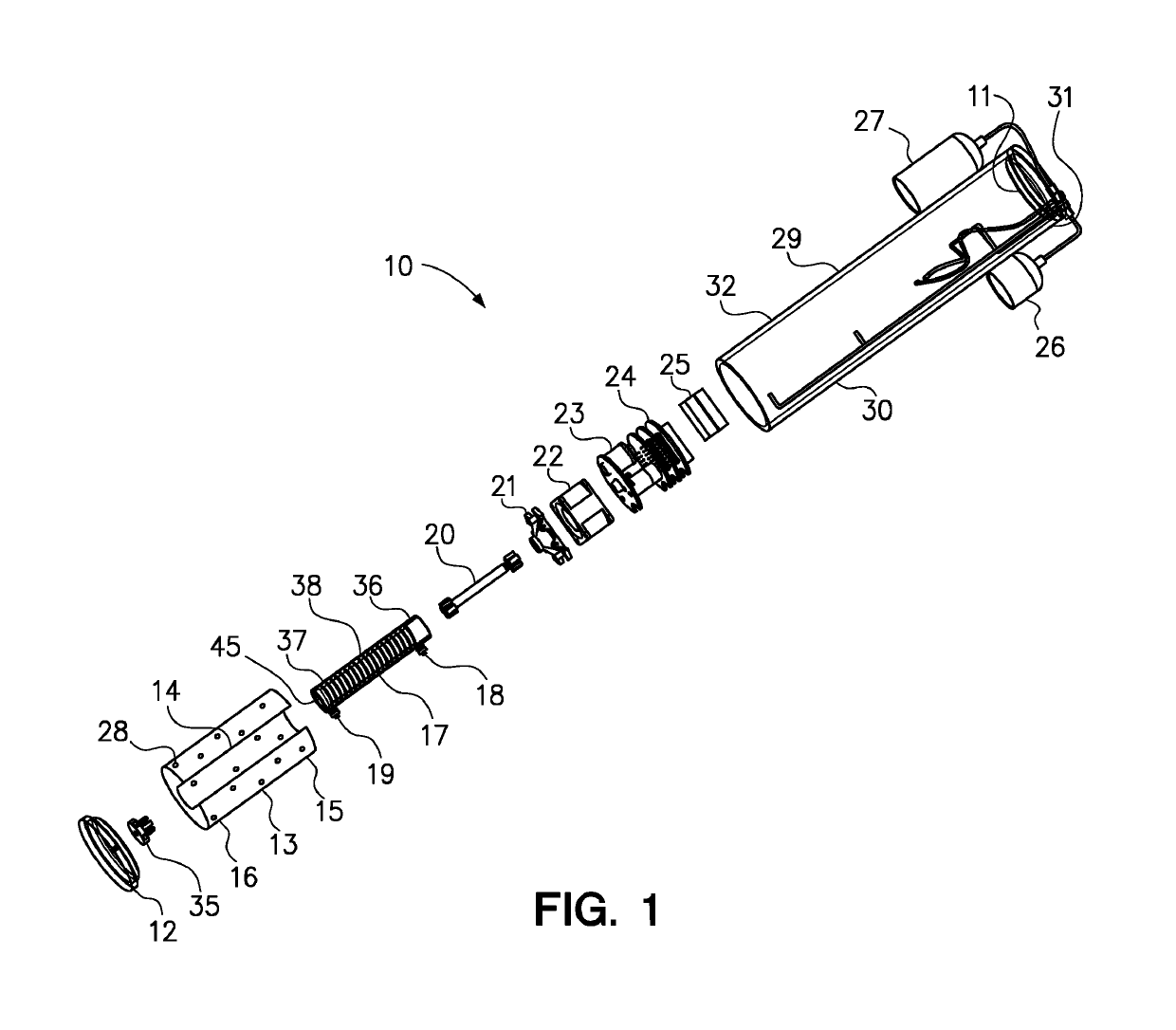

Therapeutic agent delivery device and method

A method of delivering a particulate therapeutic agent is disclosed. Such a method may include providing a carbon dioxide scrubber in pneumatic communication with the respiratory system of a patient. Gas and particulate therapeutic agent expired by the patient are passed through the scrubber to provide treated gas, and the treated gas and particulate therapeutic agent are provided back to the respiratory system.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

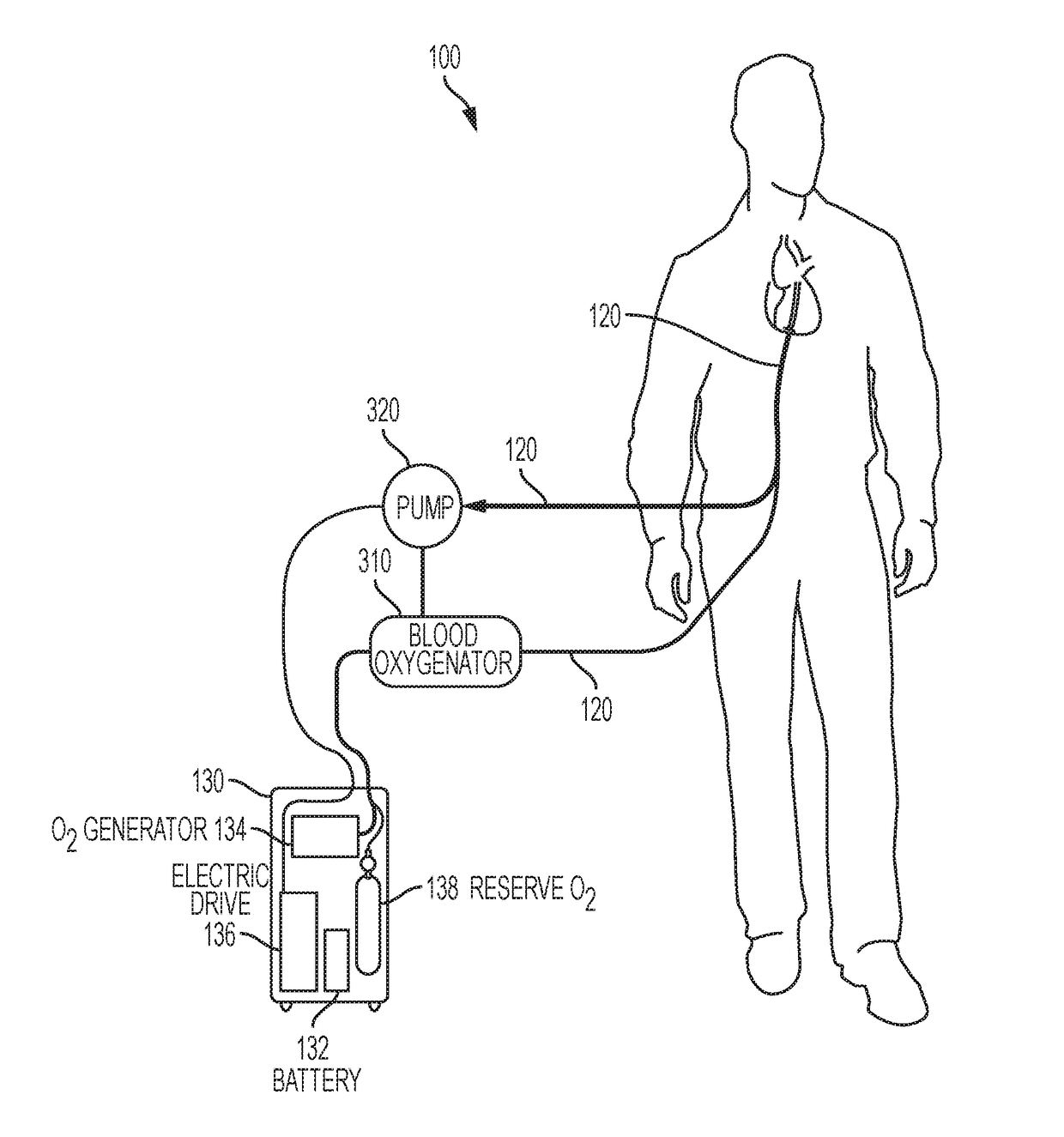

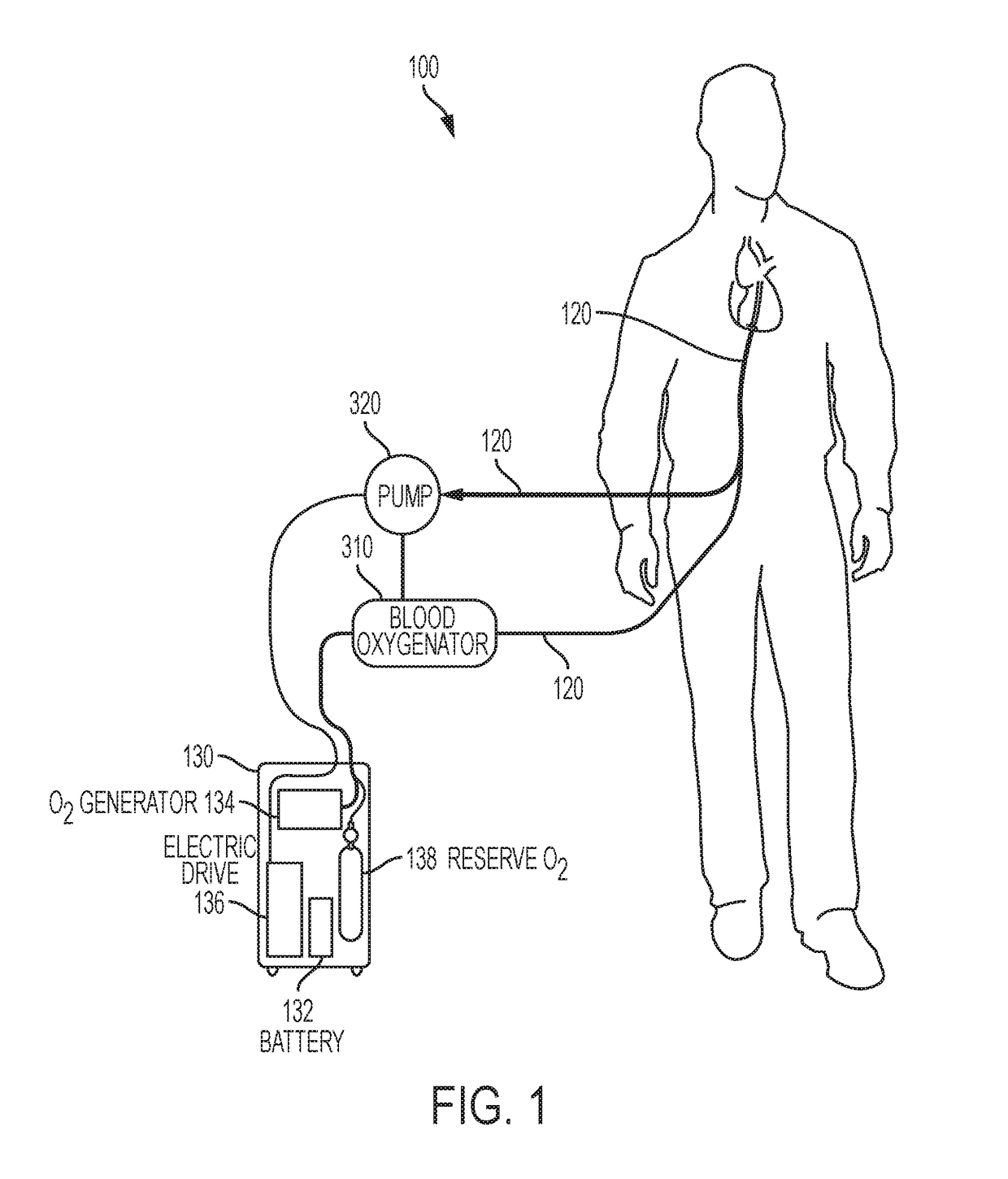

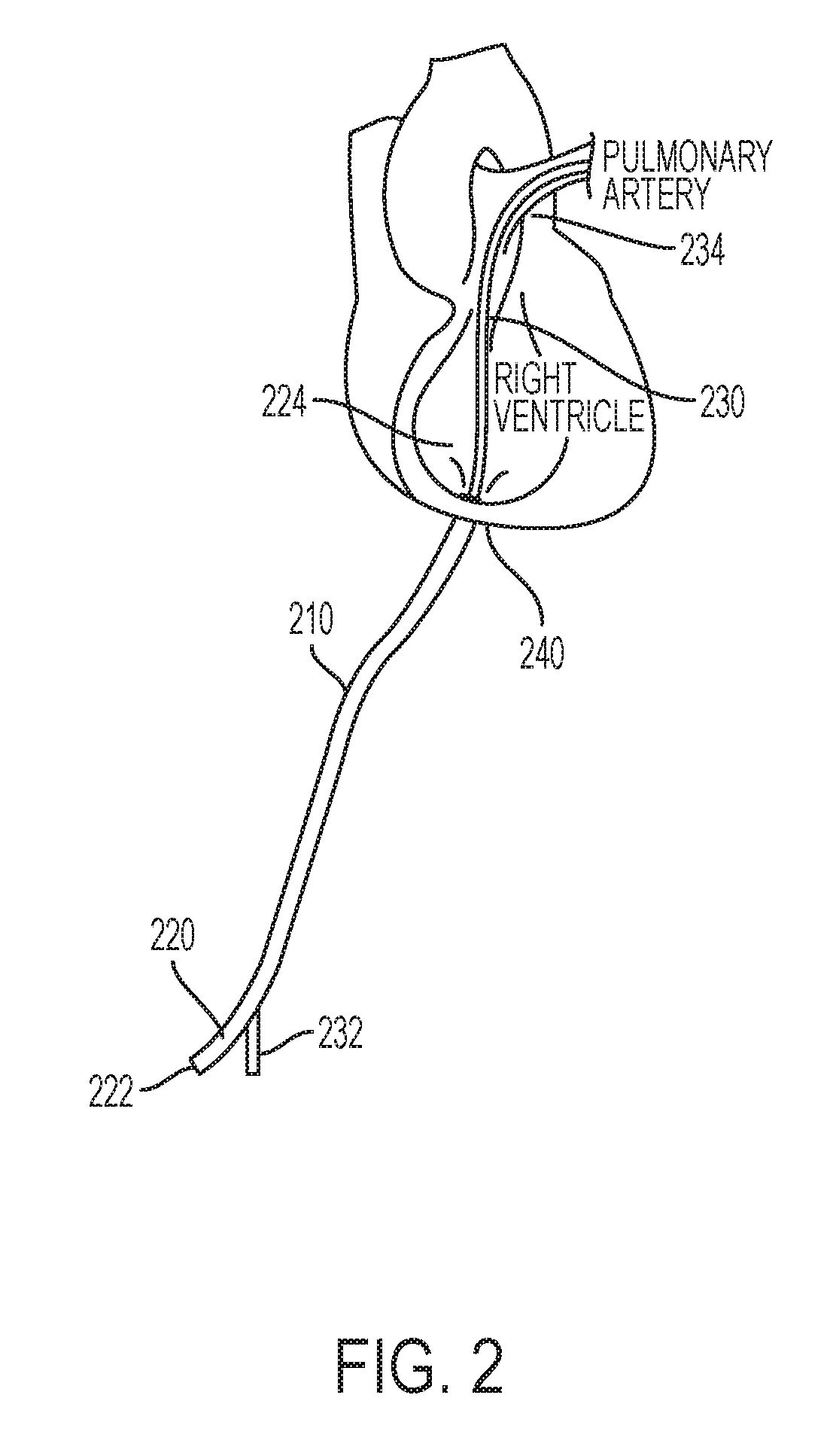

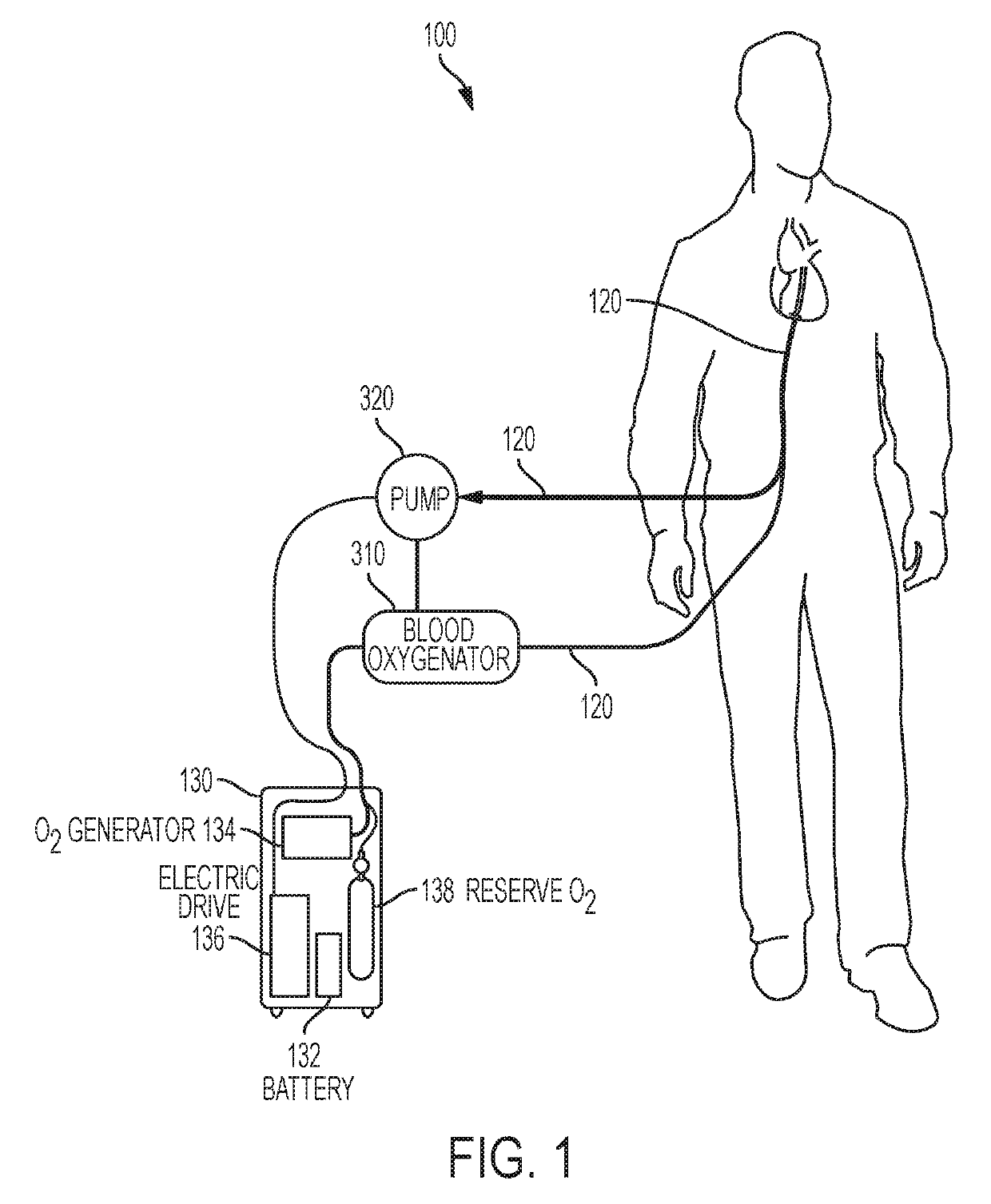

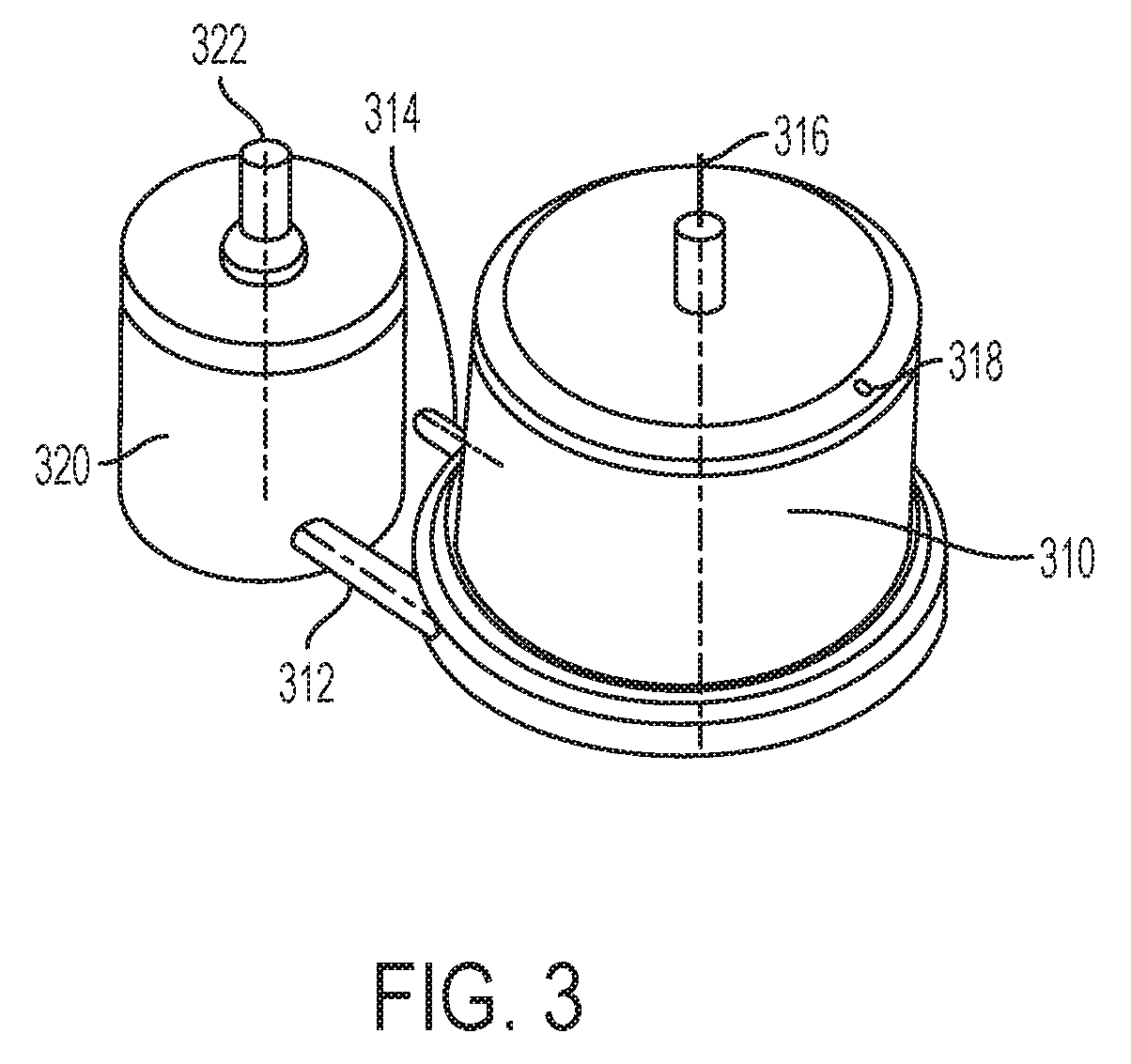

Artificial lung system and its methods of use

ActiveUS20170252505A1Extend battery lifeProlong lifeOther blood circulation devicesMedical devicesEngineeringLung

An oxygen supply unit for use with a blood oxygenator comprises an oxygen concentrator and a carbon dioxide scrubber. In an on-line operational mode, oxygen-rich gas from the oxygen concentrator is predominantly supplied to the blood oxygenator with a reduced flow of recycled gas from the concentrator. In an off-line operational mode where the oxygen supply unit is being powered by battery only, a larger flow of recycled gas from the blood oxygenator is passed through the carbon dioxide scrubber and combined with a lesser amount of oxygen-rich gas from the oxygen concentrator. The oxygen supply unit may be used in combination with a blood pump and oxygenator to provide ambulatory blood oxygenation to patients with compromised lung function.

Owner:BREETHE +1

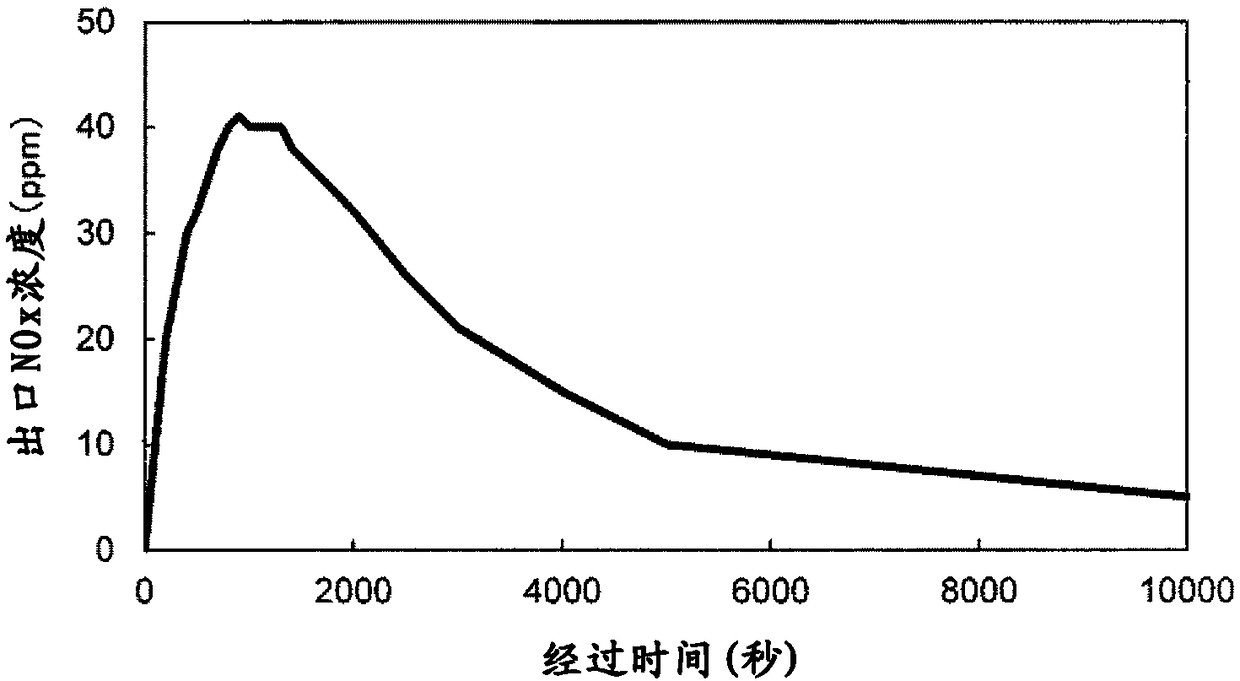

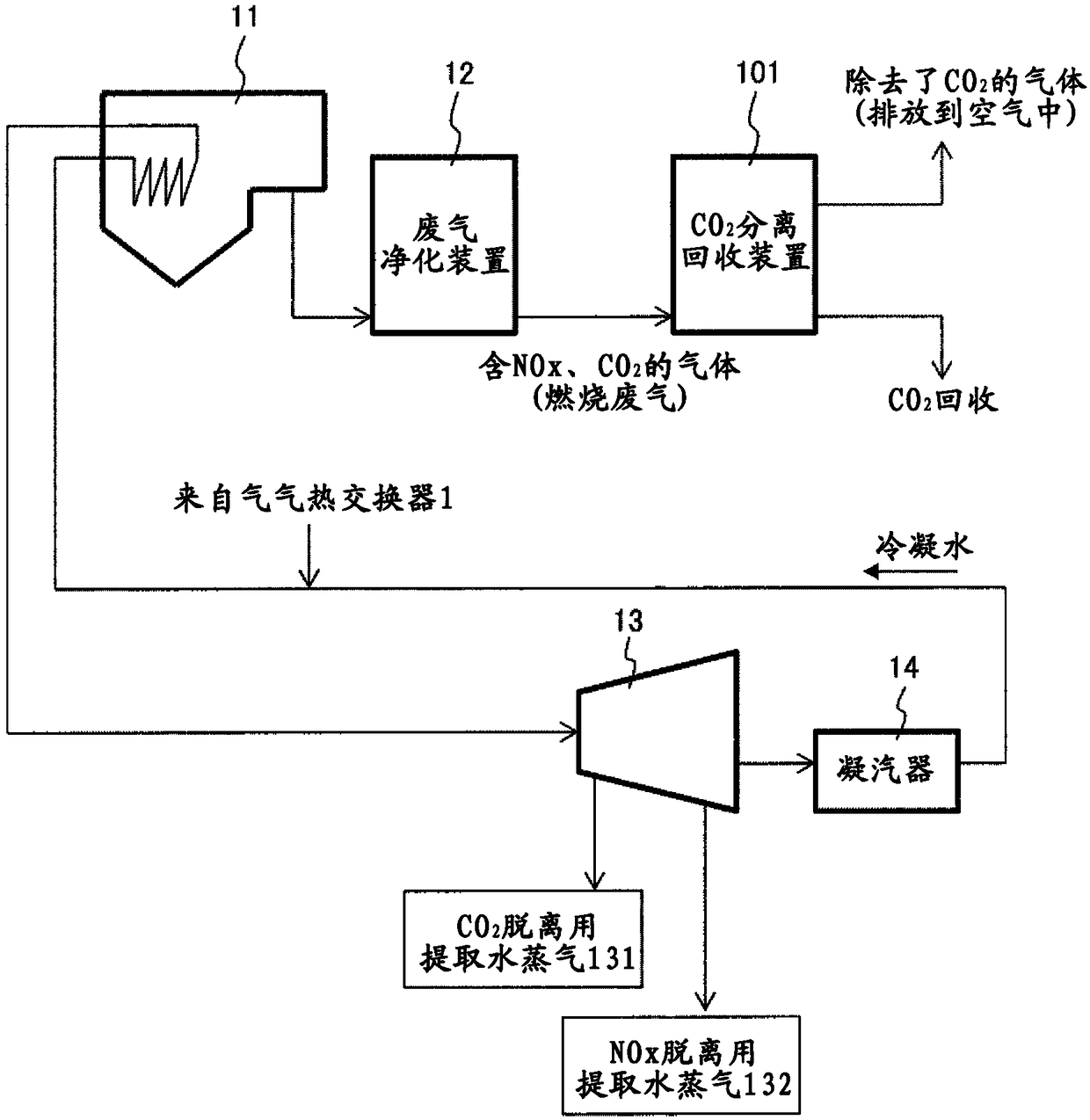

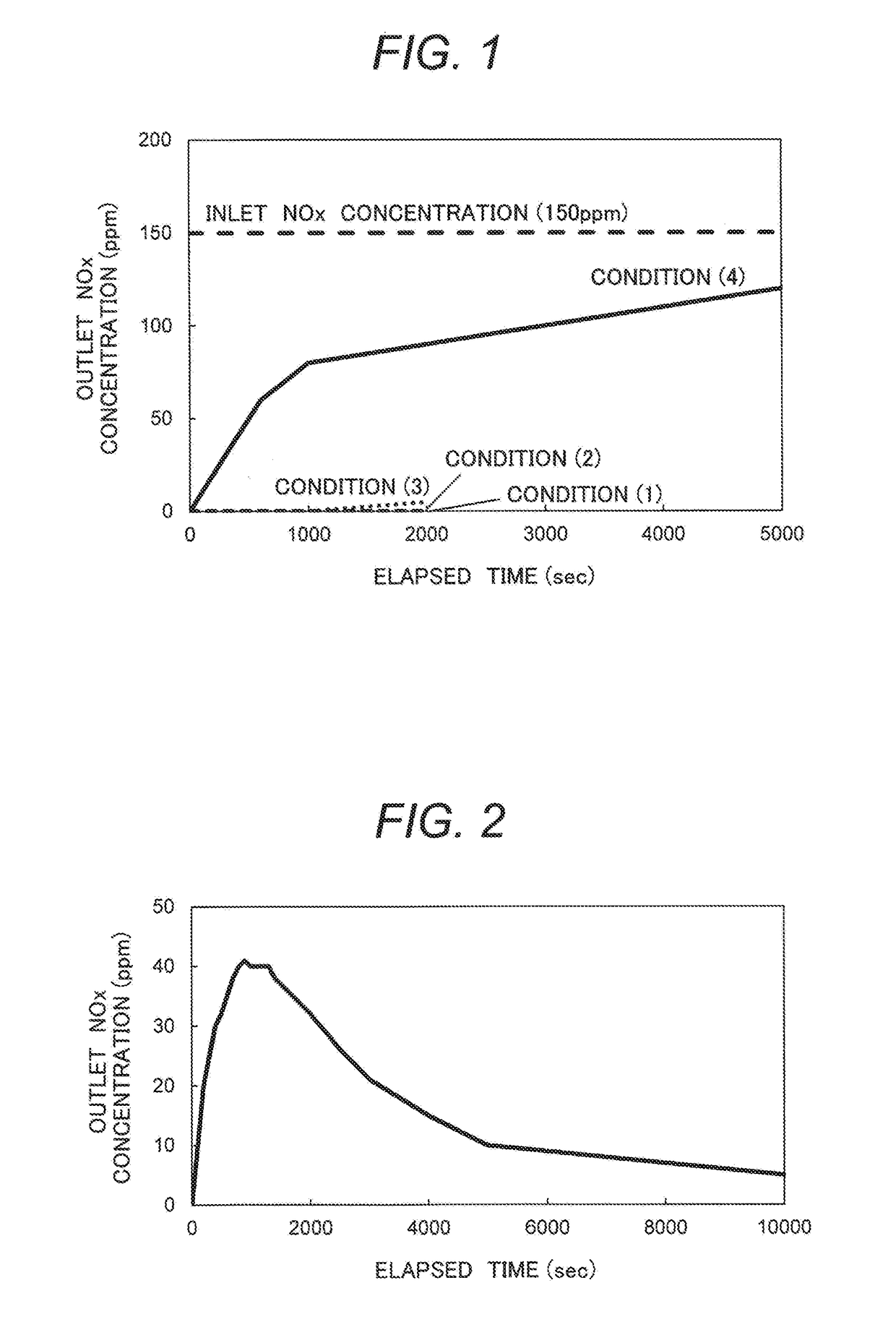

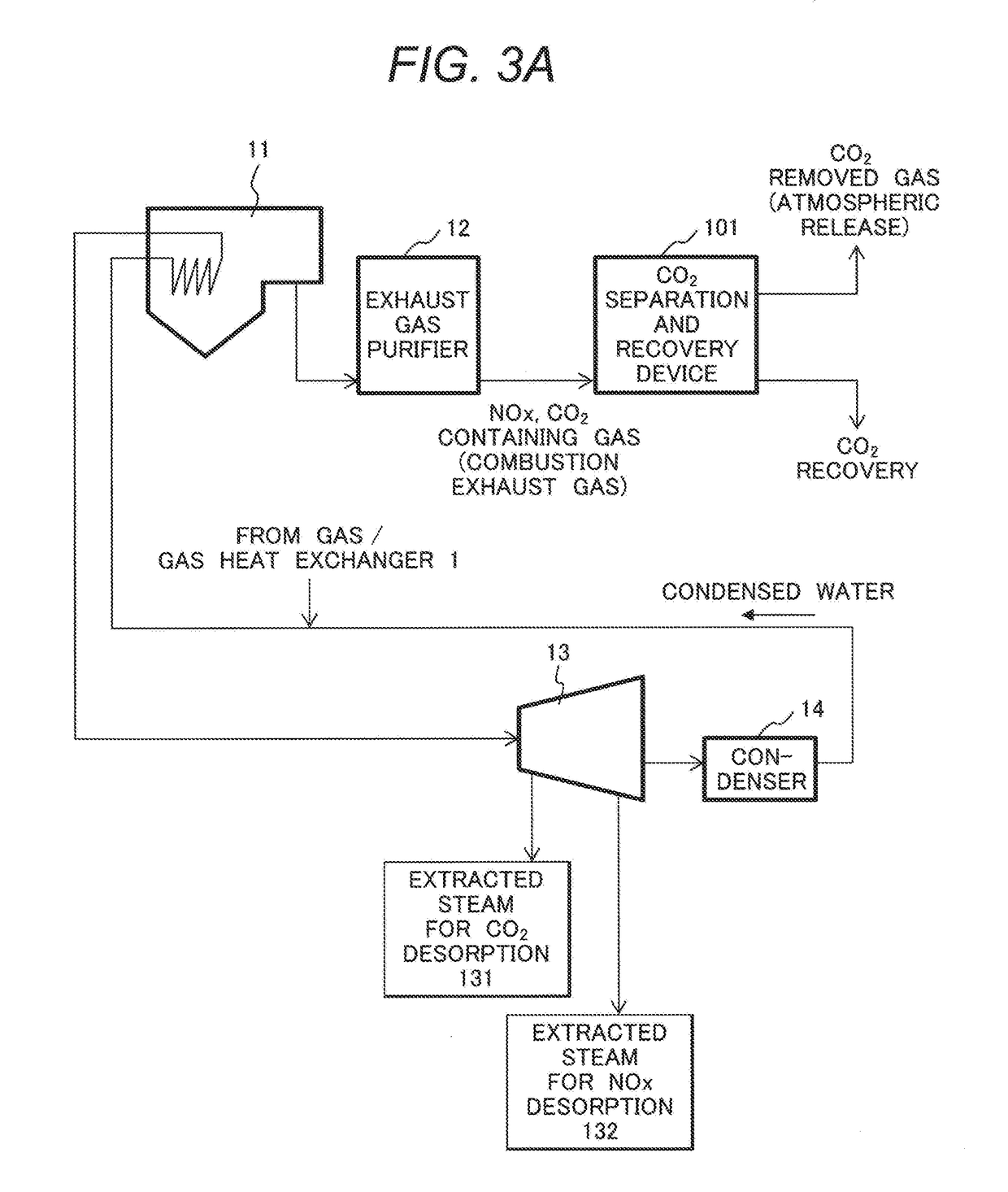

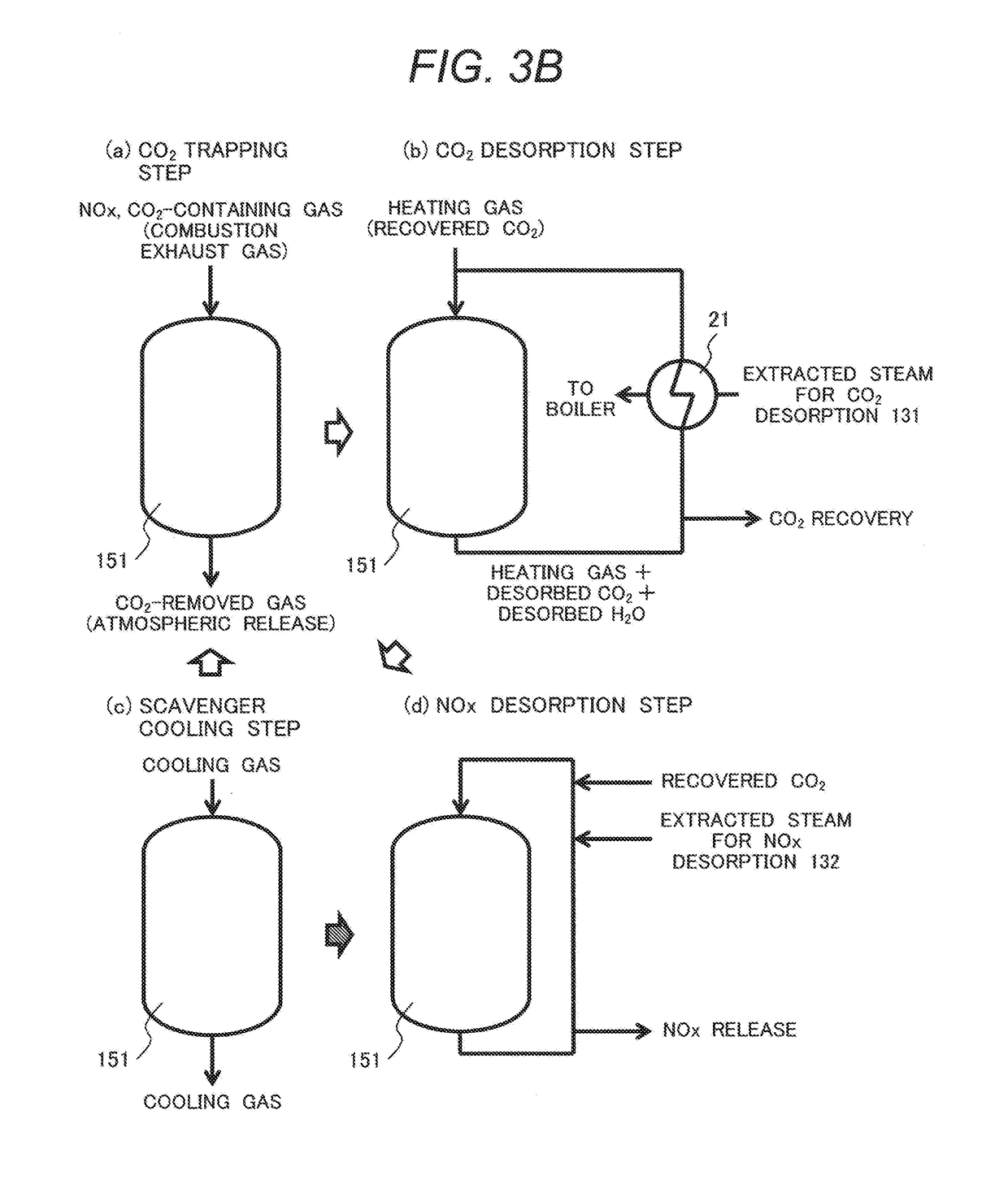

Carbon dioxide separation/recovery device, combustion system using same, thermal power generation system using same, and method for separating and recovering carbon dioxide

InactiveCN108472571AReduce performanceInhibition to reduce operating costsProductsReagentsCombustion systemScavenger

This carbon dioxide separation / recovery device for separating and recovering carbon dioxide from a gas to be processed, which contains nitrogen oxides and carbon dioxide, with use of a carbon dioxidescavenger is provided with a carbon dioxide trapping unit that comprises a carbon dioxide scavenger. The carbon dioxide trapping unit comprises: a gas inlet for introducing the gas to be processed; aheating unit for heating a scavenger heating gas to a predetermined temperature, said scavenger heating gas being used when carbon dioxide trapped by the carbon dioxide scavenger is separated therefrom; a cooling gas feed port for introducing a scavenger cooling gas that is used when the carbon dioxide scavenger is cooled; and a moisture mixing part for adding moisture to a nitrogen oxide separation gas that is used when nitrogen oxides are separated from the carbon dioxide scavenger. Consequently, NOx accumulated in the carbon dioxide scavenger is separated, thereby suppressing decrease in the performance of the carbon dioxide scavenger and reducing the running cost.

Owner:HITACHI CHEM CO LTD

Artificial lung system and its methods of use

ActiveUS10413655B2Extend battery lifeProlong lifeOther blood circulation devicesDialysis systemsScrubberChemistry

An oxygen supply unit for use with a blood oxygenator comprises an oxygen concentrator and a carbon dioxide scrubber. In an on-line operational mode, oxygen-rich gas from the oxygen concentrator is predominantly supplied to the blood oxygenator with a reduced flow of recycled gas from the concentrator. In an off-line operational mode where the oxygen supply unit is being powered by battery only, a larger flow of recycled gas from the blood oxygenator is passed through the carbon dioxide scrubber and combined with a lesser amount of oxygen-rich gas from the oxygen concentrator. The oxygen supply unit may be used in combination with a blood pump and oxygenator to provide ambulatory blood oxygenation to patients with compromised lung function.

Owner:BREETHE +1

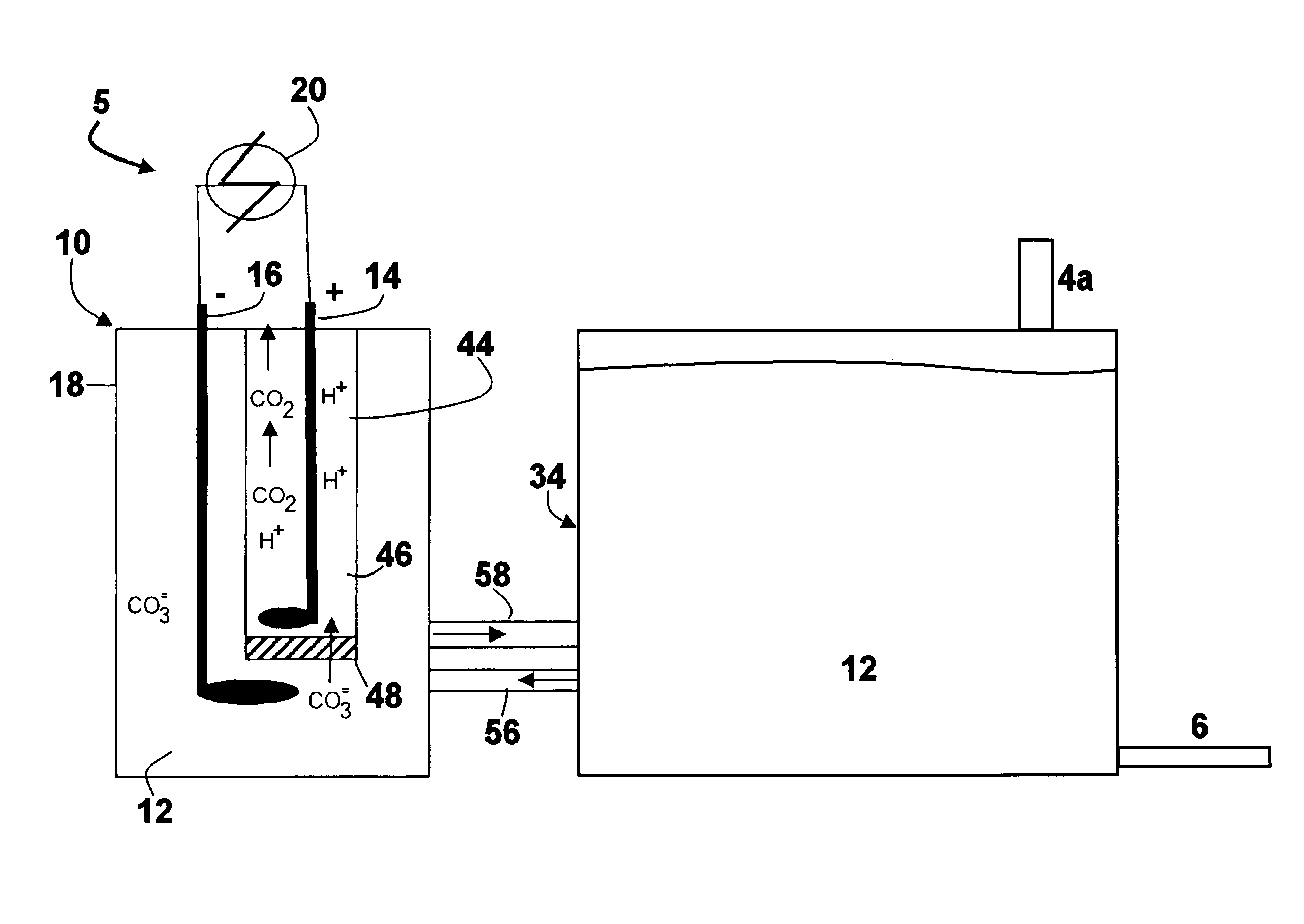

Remote emergency power unit having electrochemically regenerated carbon dioxide scrubber

An emergency power system is provided in accordance with an exemplary embodiment of the present invention. The emergency power system includes a fuel cell and an electrochemically regenerated air scrubber which removes carbon dioxide from air.

Owner:ENERGY CONVERSION DEVICES INC

A kind of ammonia carbon separation process

ActiveCN105289210BEasy to separateReduce circulationProductsCarbon compoundsCo2 absorptionEconomic benefits

The invention provides an ammonia-carbon separation process. The process comprises the step of carbon dioxide absorption, wherein a gas mixture sequentially makes contact with carbonized ammonia water and strong ammonia water in a carbon dioxide washing tower, carbon absorbing liquid is formed, the carbon absorbing liquid makes contact with a gas mixture in a carbon dioxide absorption tower, and ammonium carbamate liquid is obtained. According to the process, synergism of the carbon dioxide absorption tower and the carbon dioxide washing tower is initiatively utilized, carbon dioxide is separated from the gas mixture to the greatest extent, to be specific, the carbon dioxide absorption tower adopts the carbon absorbing liquid for absorbing carbon dioxide in the gas mixture, while carbon dioxide washing tower adopts carbonized ammonia water as the main medium and strong ammonia water as the auxiliary medium for precisely absorbing carbon dioxide, therefore the content of carbon dioxide in obtained coarse ammonia gas can be controlled below 50 ppm, then ammonia is separated from the coarse ammonia gas, and finally pure ammonia containing no carbon dioxide or water is obtained. By means of the ammonia-carbon separation process, thorough separation of ammonia and carbon dioxide is achieved in real sense, the ammonia-carbon separation effect is improved, and it is helpful to increase economic benefits.

Owner:BEIJING EDGEIN TECH +1

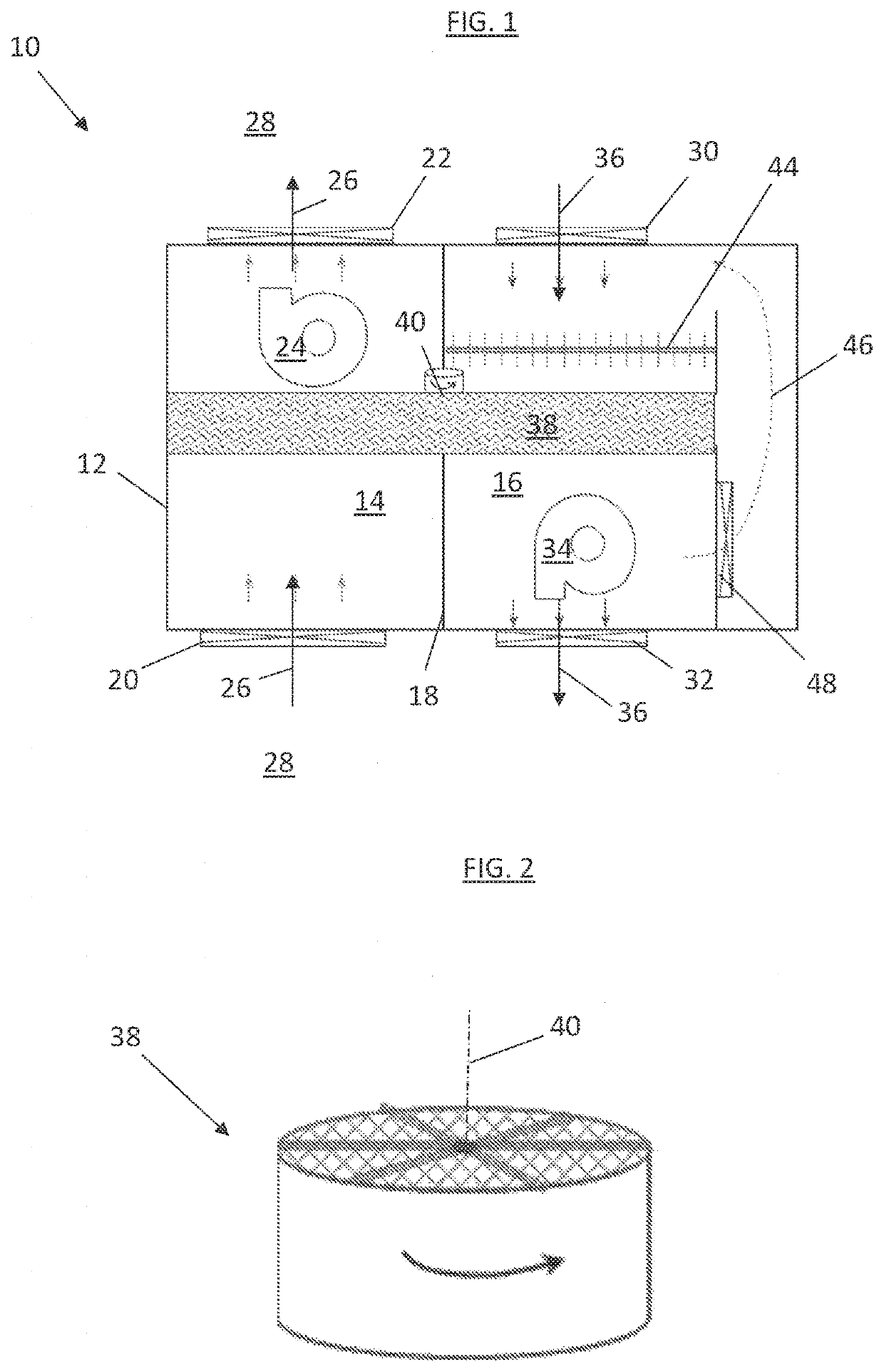

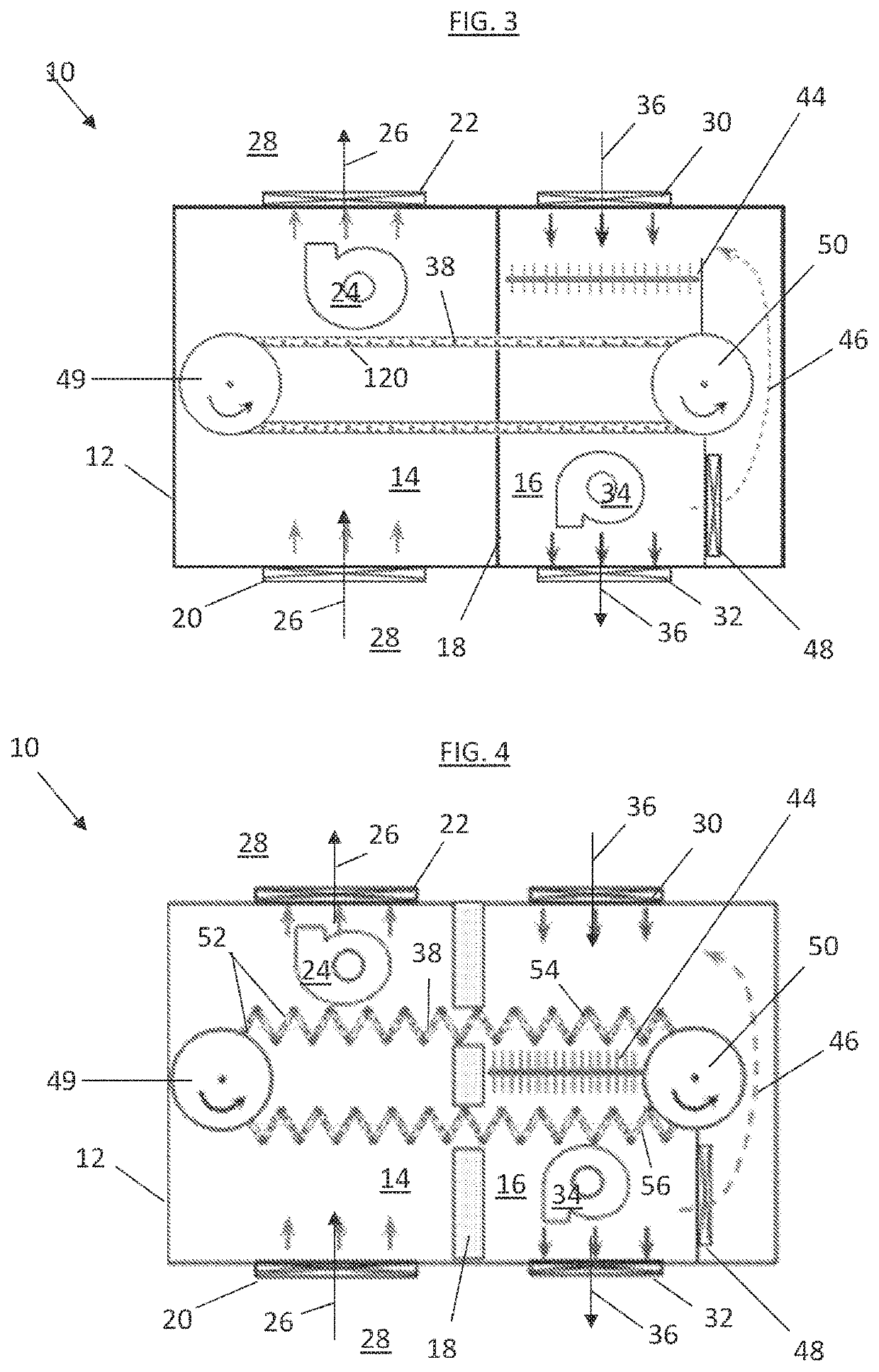

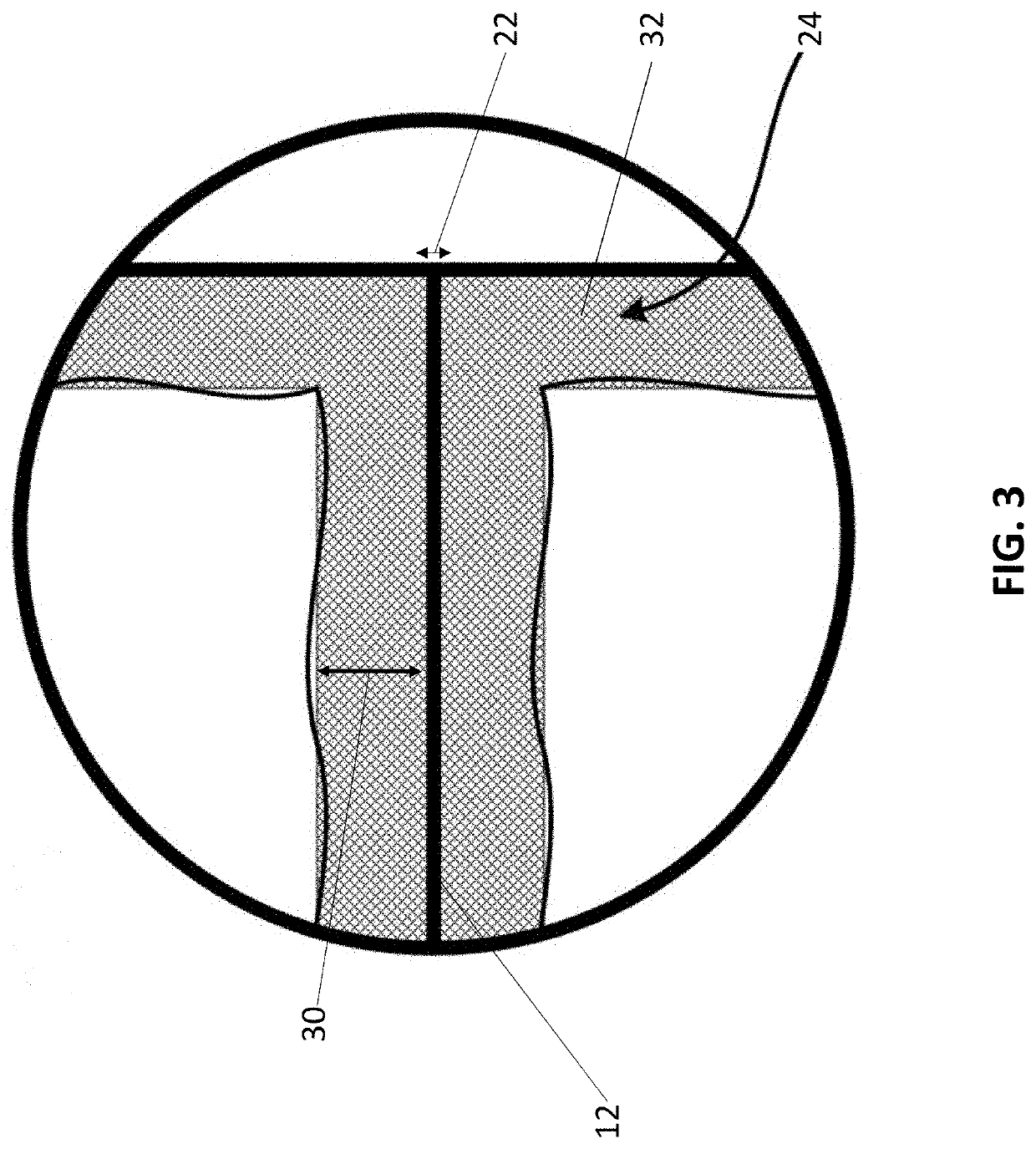

Co2 scrubber with moving bed structure

A carbon dioxide scrubber includes an adsorption chamber through which an adsorption airflow is directed, a regeneration chamber through which a regeneration airflow is directed, and a divider wall separating the adsorption chamber from the regeneration chamber. A carbon dioxide sorbent bed extends across the adsorption chamber and the regeneration chamber. The carbon dioxide sorbent bed is configured to adsorb carbon dioxide from the adsorption airflow into the sorbent bed and exhaust carbon dioxide from the carbon dioxide sorbent bed into the regeneration airflow. The carbon dioxide sorbent bed is continuously movable through the adsorption chamber and the regeneration chamber.

Owner:CARRIER CORP

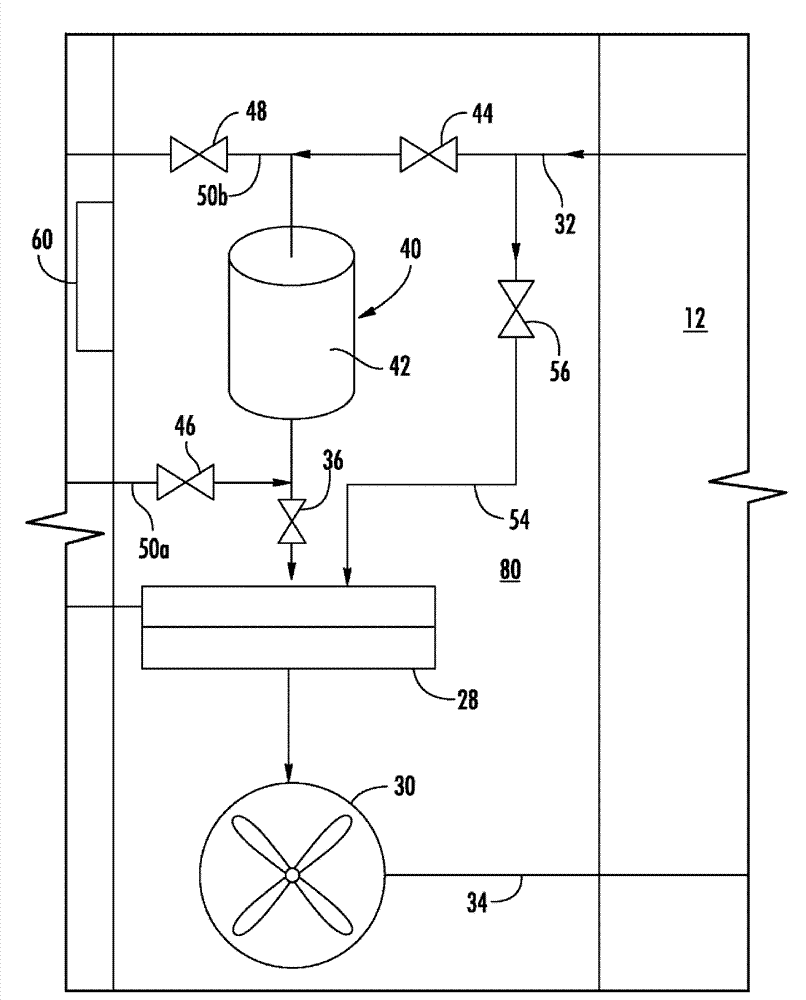

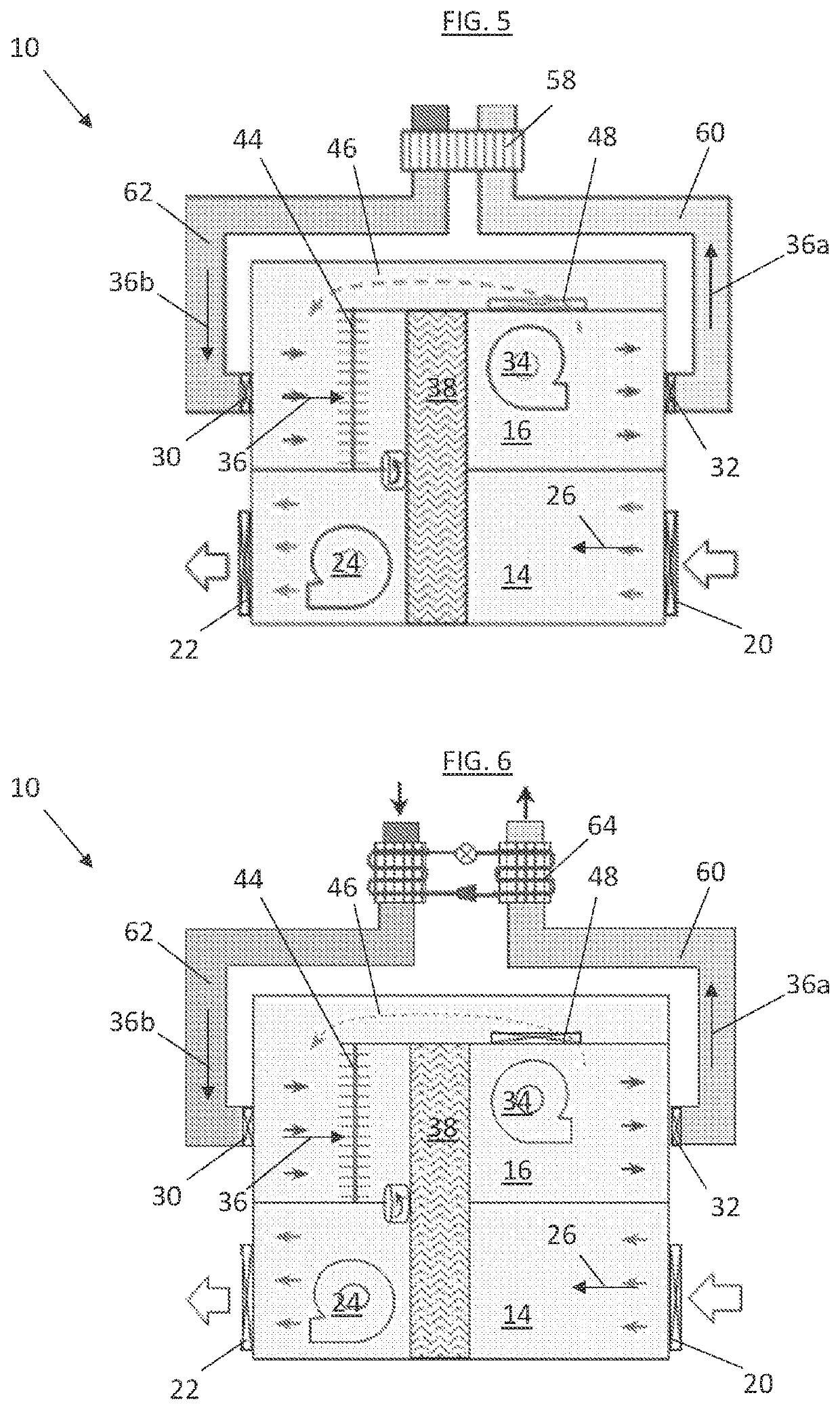

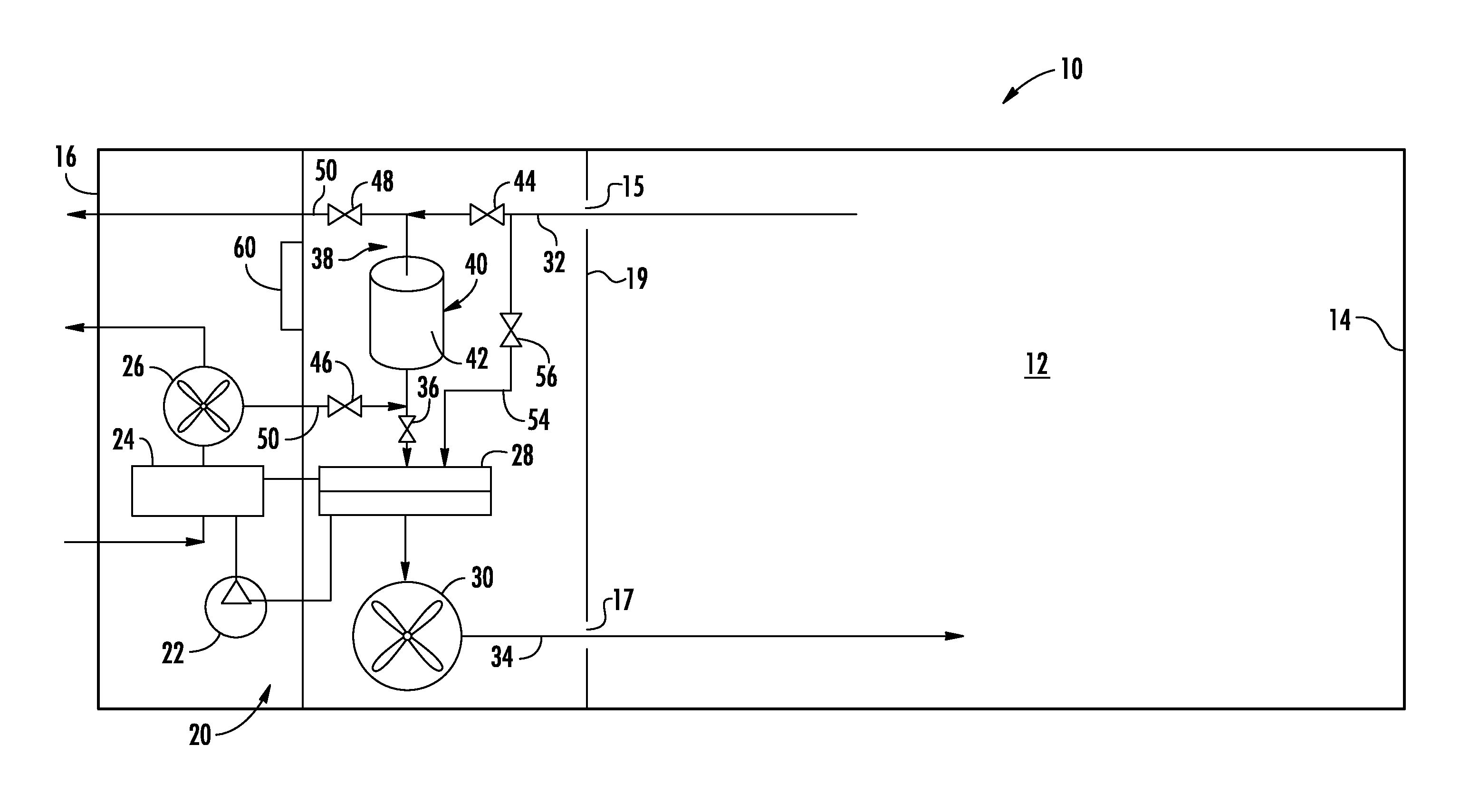

Control of atmosphere within a closed environment

ActiveUS9339045B2Improve thermal conductivityFruit and vegetables preservationDispersed particle separationEnvironmental engineeringGaseous atmosphere

A method and apparatus are disclosed for controlling a concentration of carbon dioxide in a gaseous atmosphere within a closed environment of a refrigerated transport container to maintain the concentration of carbon dioxide therein at a desired level. A carbon dioxide scrubber apparatus operates alternately in an adsorption mode and a regeneration mode. When a perishable produce is stowed in the closed environment, for example in a cargo box of a refrigerated transport container, the concentration of carbon dioxide may be maintain at a desired level to retard ripening of the perishable produce.

Owner:CARRIER CORP

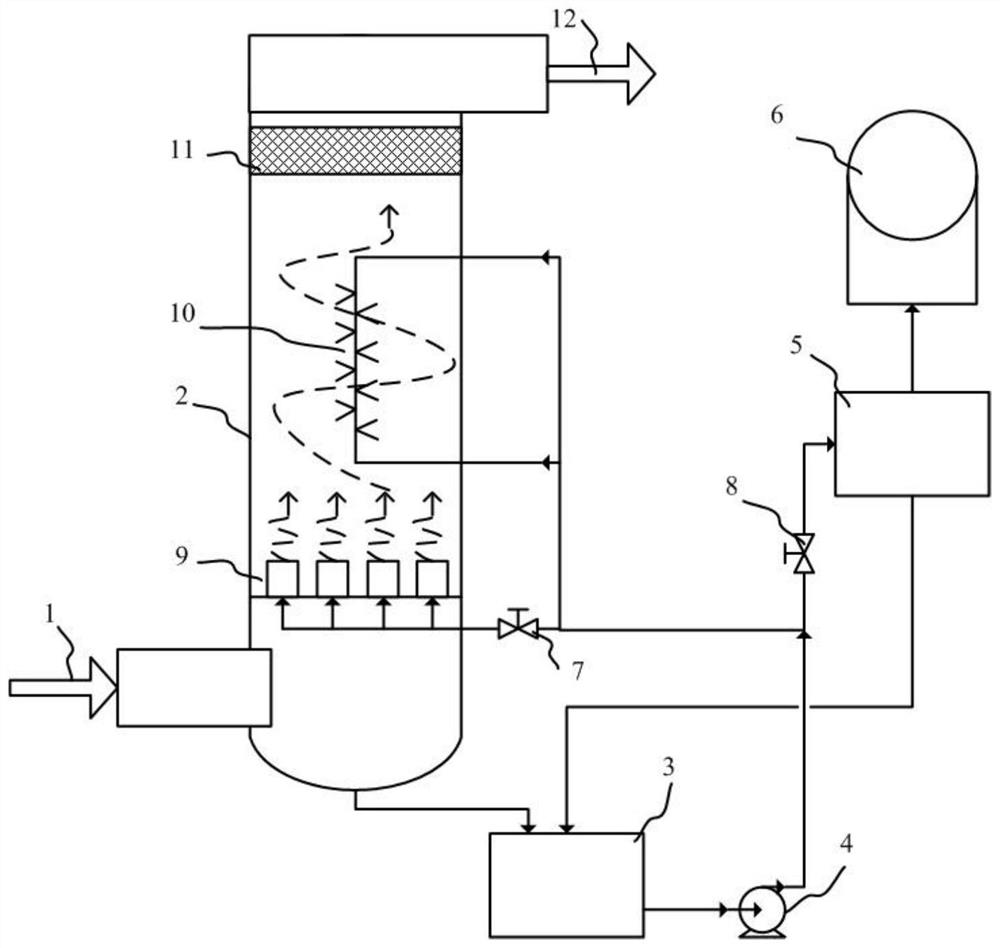

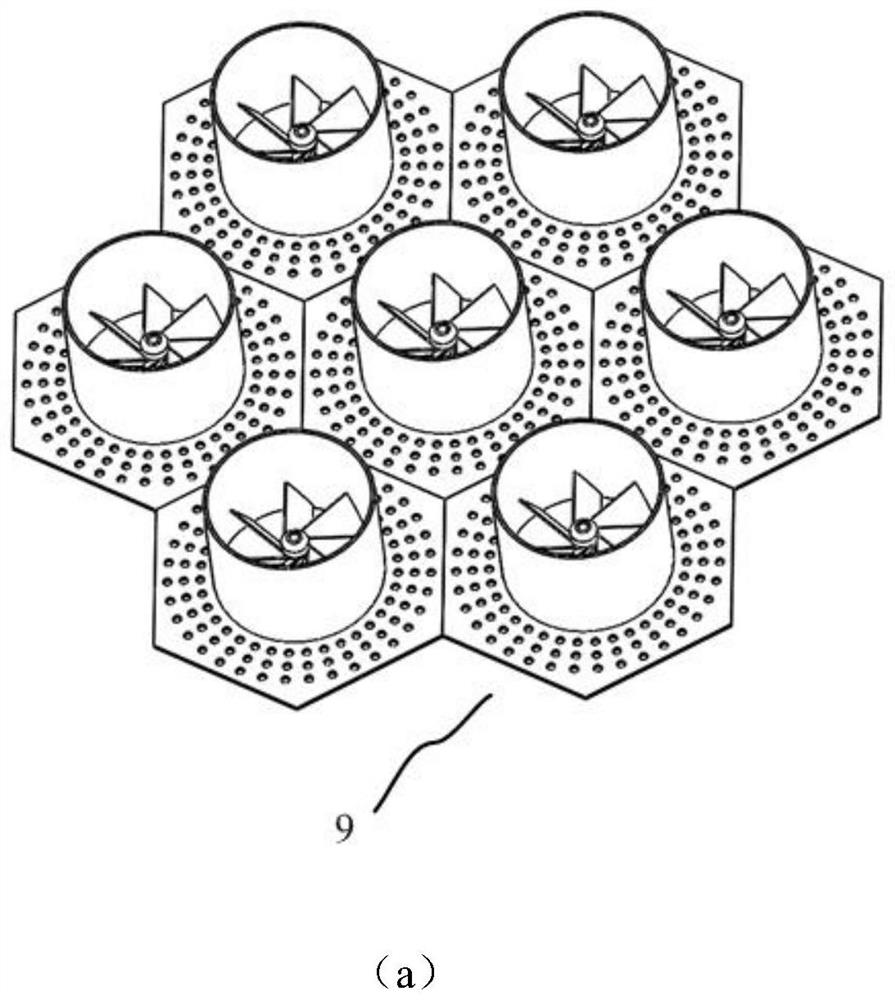

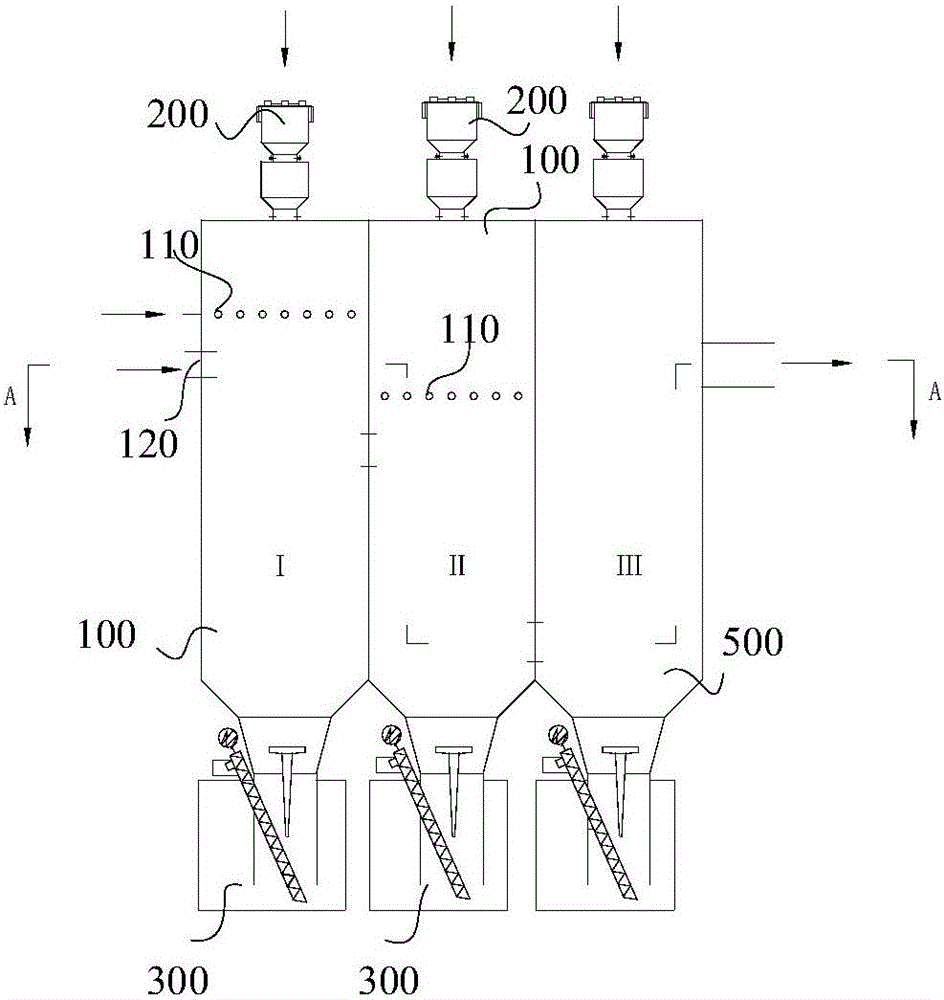

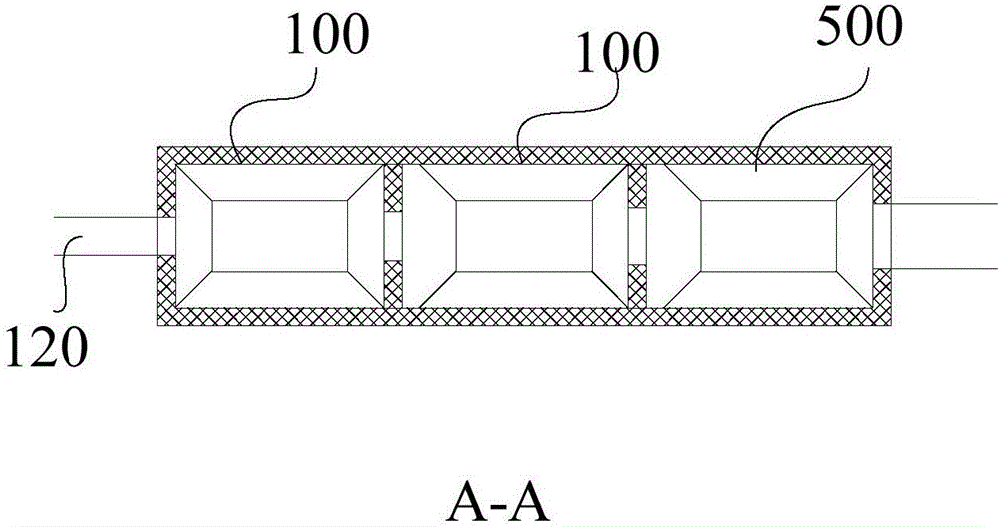

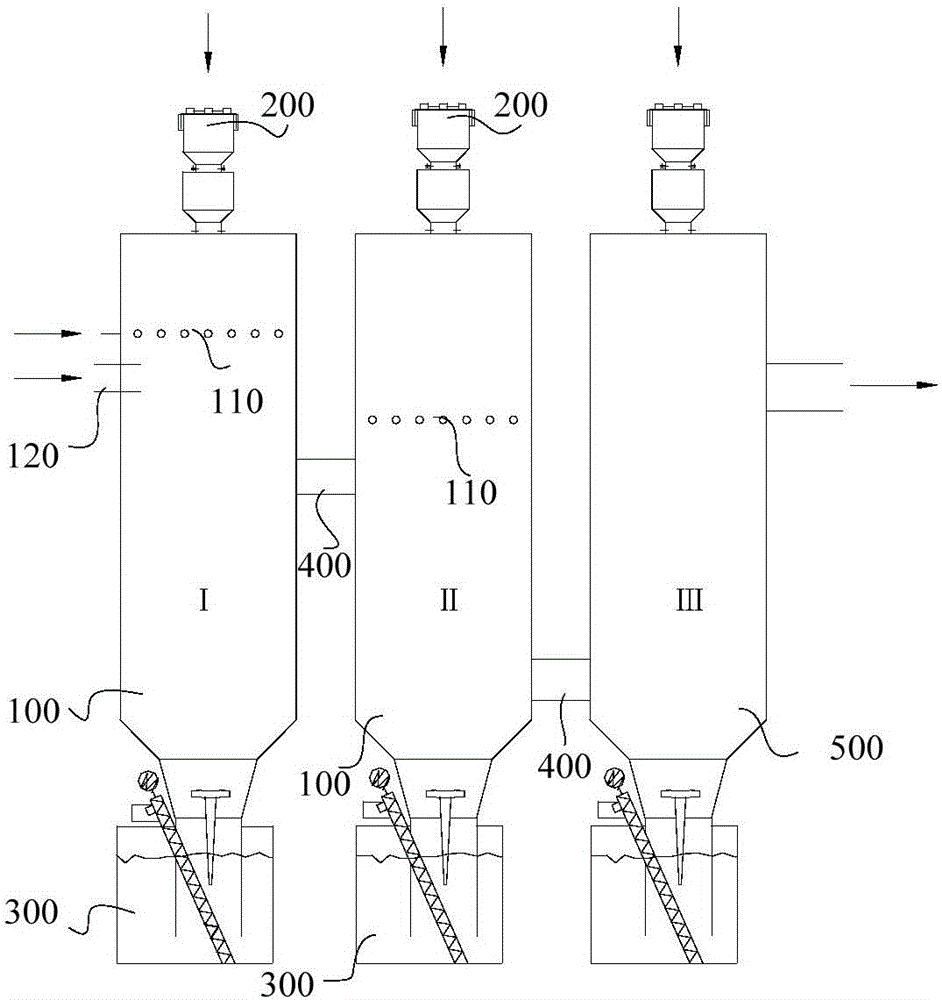

Marine carbon dioxide washing tower and spray washing absorption system and method

ActiveCN113731171ASimultaneous drag reduction and enhanced mixingProlong contact reaction timeGas treatmentDispersed particle separationMixed flowEnvironmental engineering

The invention discloses a marine carbon dioxide washing tower, a spray washing absorption system and a spray washing absorption method, which are used for high-efficiency low-resistance capture of carbon dioxide in marine exhaust gas. The system comprises a washing tower, a circulating pool and an absorption liquid regeneration device, the washing tower is internally provided with a swirl-confluence coupling area, a swirl-flow spraying area and a demister from bottom to top, the swirl-confluence coupling area is formed by splicing a plurality of flow guide units, each flow guide unit is provided with a center nozzle used for spraying absorption liquid, the swirl-flow spraying area is distributed in a transverse, longitudinal and circumferential mode, and the spraying direction of the nozzles is the horizontal direction. Waste gas forms a plurality of small spiral rising gas-liquid mixed flows through the swirl-confluence coupling area, and then forms a large and small spiral mixed turbulent flow field through the swirl-flow spraying area, so that the contact reaction time is prolonged, the reaction efficiency is improved, and the resistance loss of the waste gas is reduced. The problems that a ship exhaust gas carbon dioxide washing tower is large in resistance, easy to block and low in efficiency are effectively solved.

Owner:DALIAN MARITIME UNIVERSITY

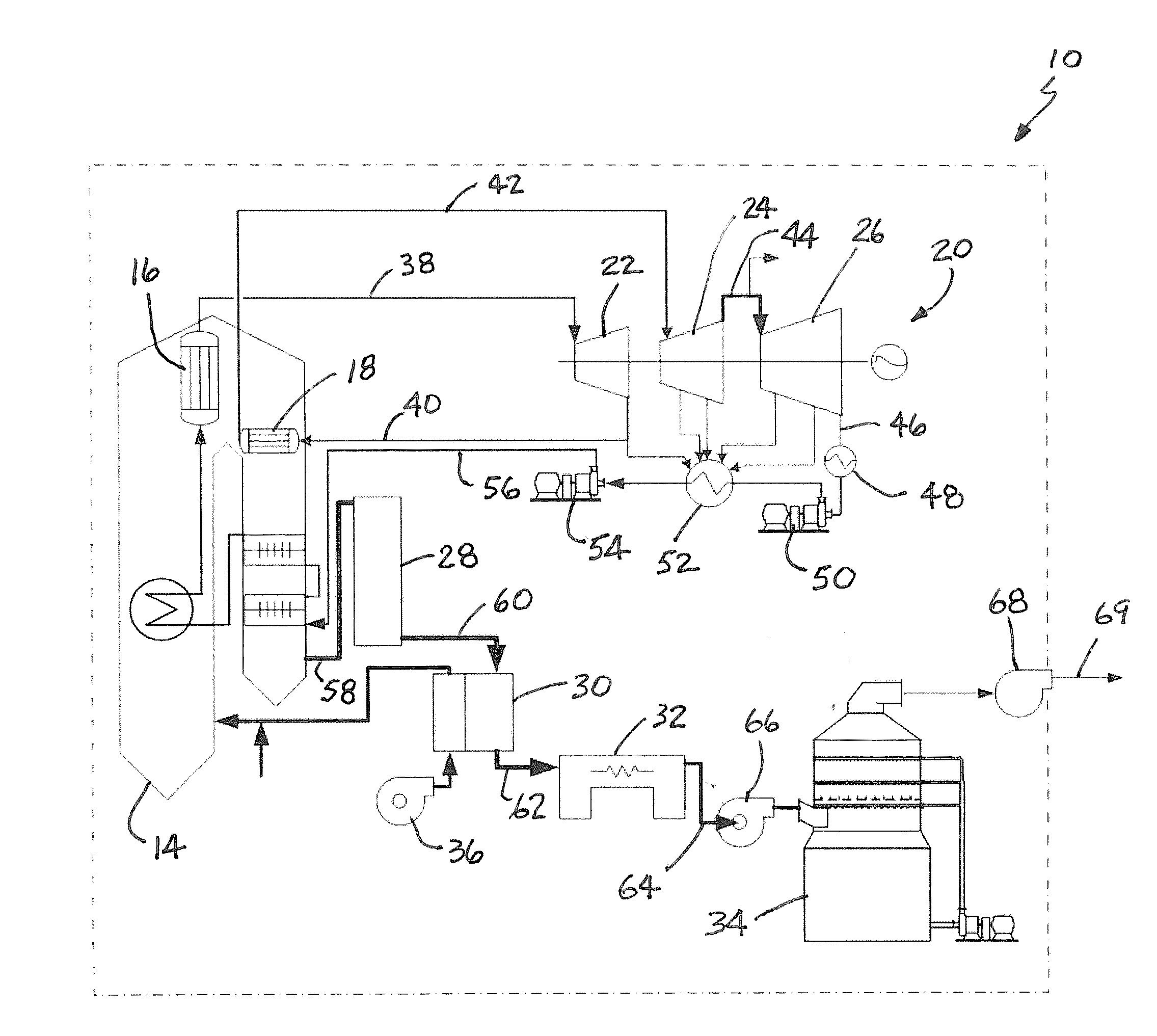

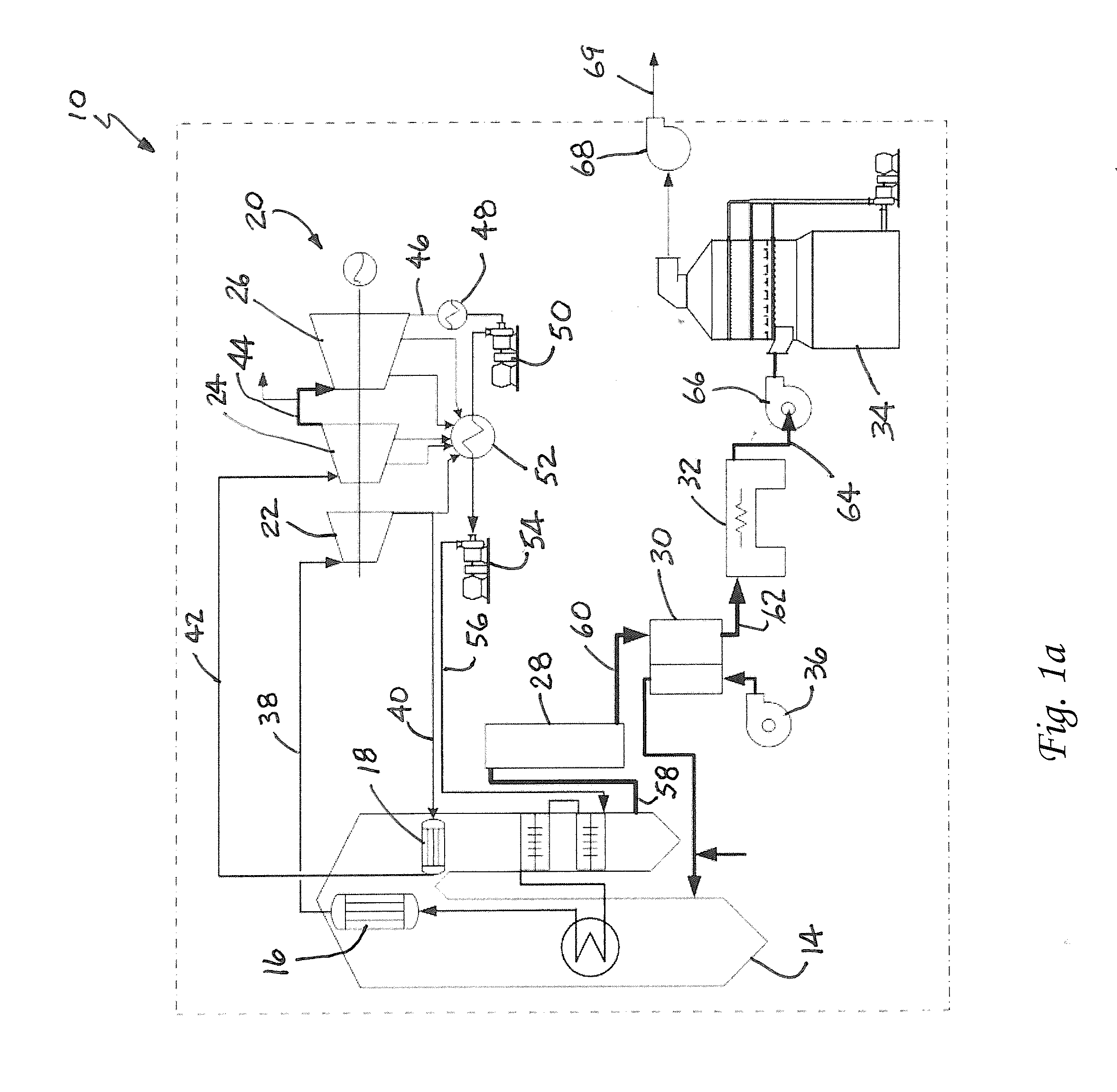

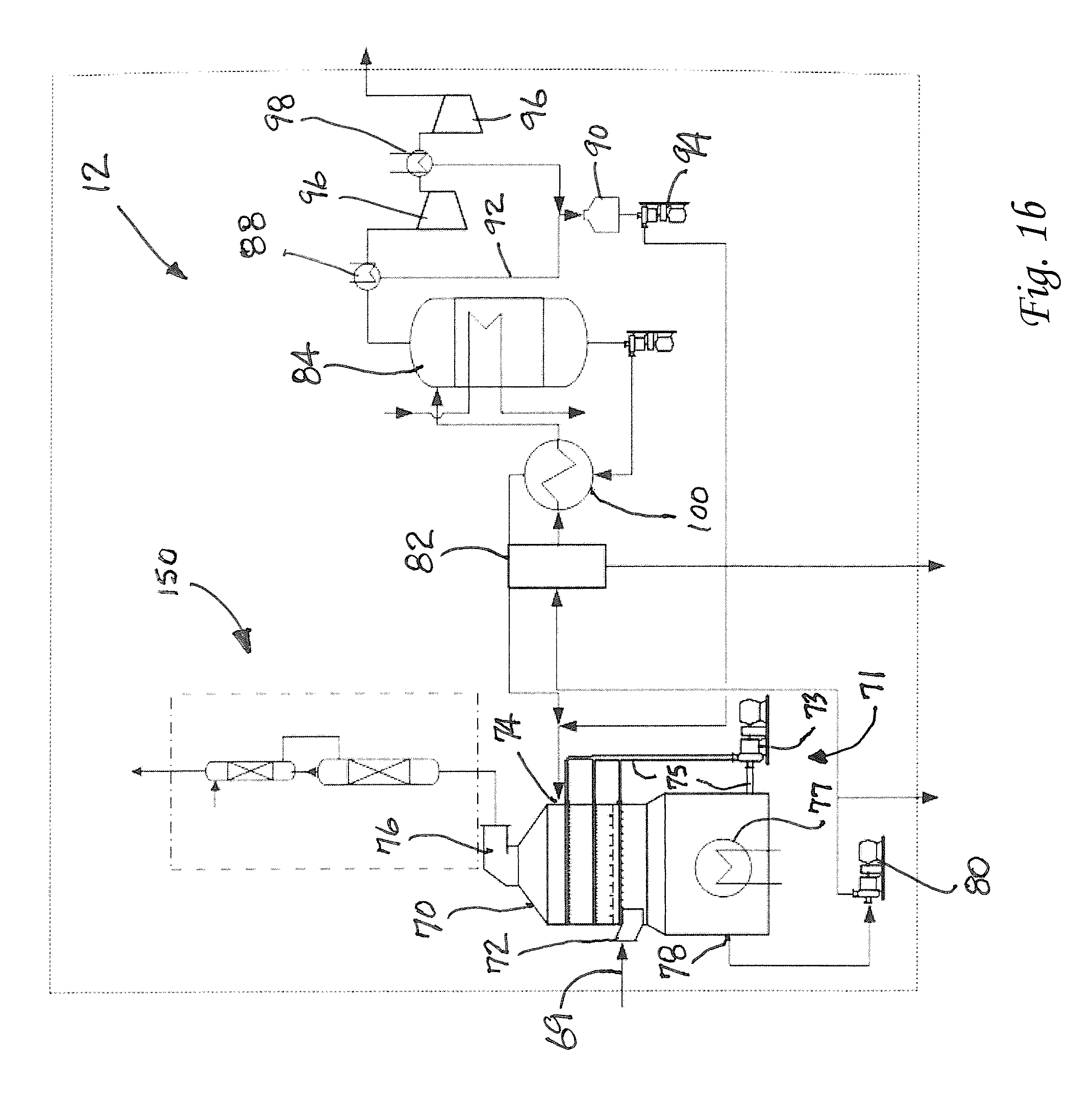

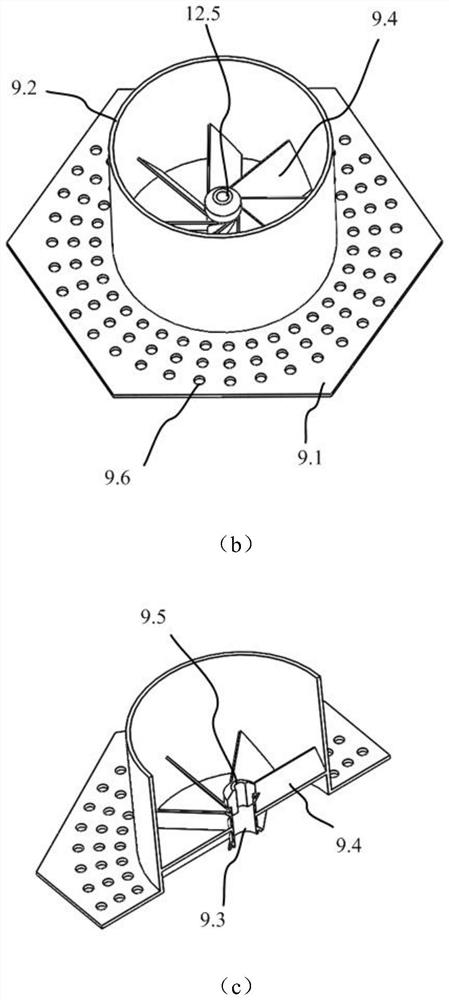

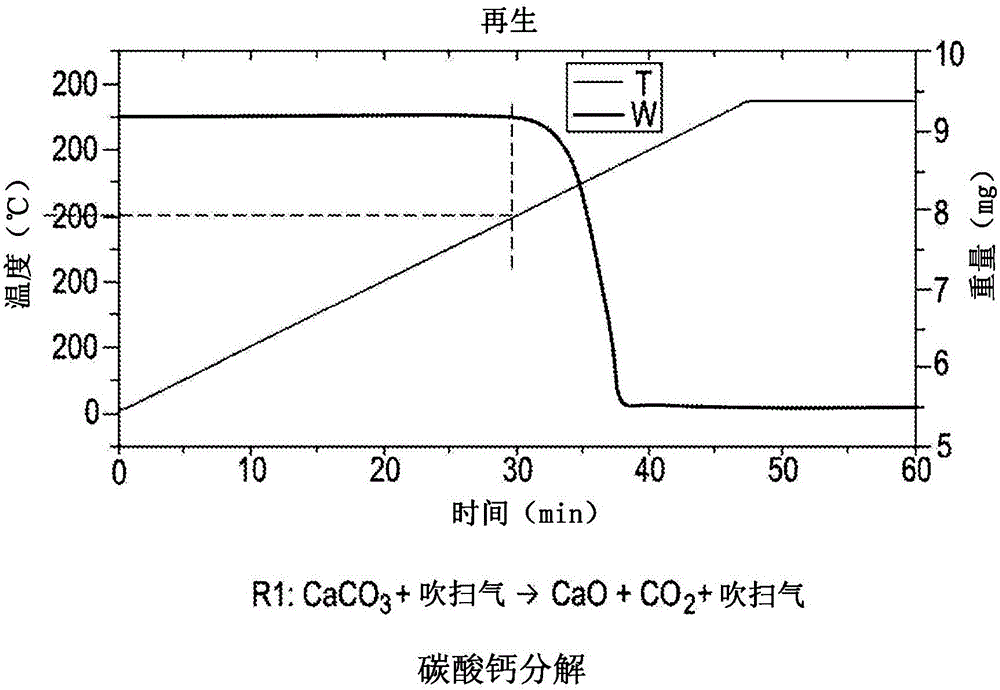

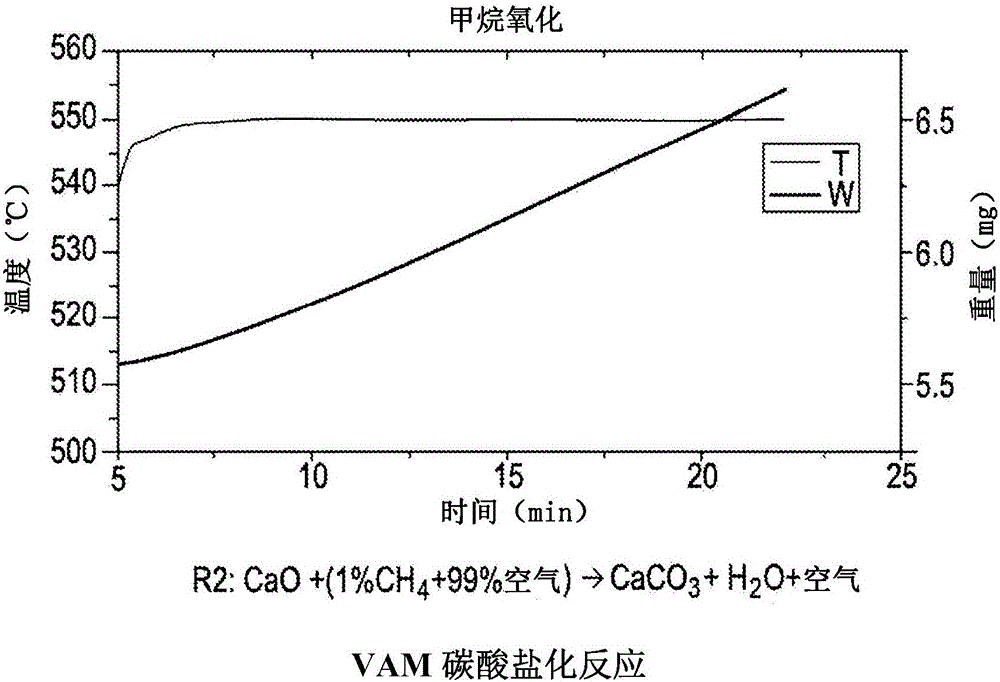

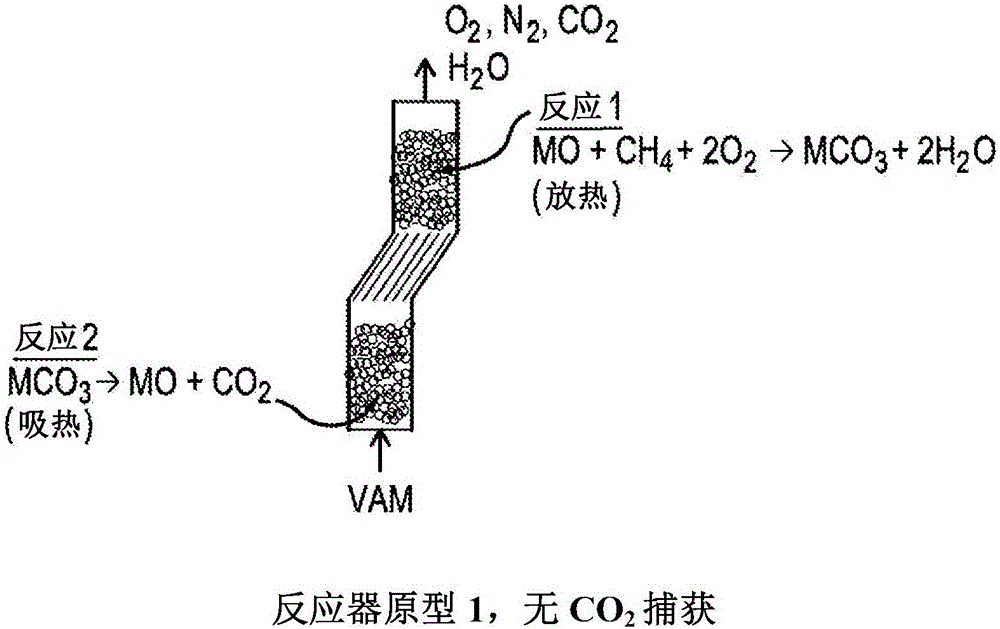

Mineral carbonate looping reactor for ventilation air methane mitigation

A method and apparatus for removing methane from ventilation air in a mining situation is provided by a carbonation reactor CAR (1) which reacts a ventilation air methane stream VAR with a carbon dioxide scavenger to form a mineral carbonate which is passed to a calcination reactor CAL (2) in which a regeneration reaction decomposes the mineral carbonate back to a mineral or mineral oxide. Additional heat may be added to the CAL (2) by steam (7), solar energy (6) or by burning drainage gas, natural gas, or coal. Steam or supercritical fluid given off by the CAR (1) can be utilized for heating, cooling, or energy generation. The carbon dioxide scavenger can be any metal, metal oxide, mineral or mineral waste having a carbonation tendency, used in the process referred to as "Mineral Carbonate Looping Reactor" (MCLR), or can be stone dust from the mining site used in the process referred to as "Stone Dust Looping Reactor" (SDLR).

Owner:NEWCASTLE UNIV

Fluidized bed carbon dioxide scrubber for pneumatic conveying system

A pneumatic conveying system for conveying hydrated lime is provided with ambient air for the pneumatic conveying system from a scrubber that removes carbon dioxide from the ambient air used in the conveying system. The scrubber includes a bed of hydrated lime through which ambient air is passed, to react carbon dioxide in the air with the hydrated lime in a reaction that forms limestone and water. The air that has passed through the fluidized bed, which is essentially carbon dioxide free, is also passed through a filter to remove particles suspended in the carbon dioxide free air. The carbon dioxide free air from the filter is provided to the pneumatic conveying system. The use of carbon dioxide free air ensures that the hydrated lime being transported in the conveying system will not react in the various conduits and ducts of the pneumatic conveying system to cause problems.

Owner:NOL TEC SYST

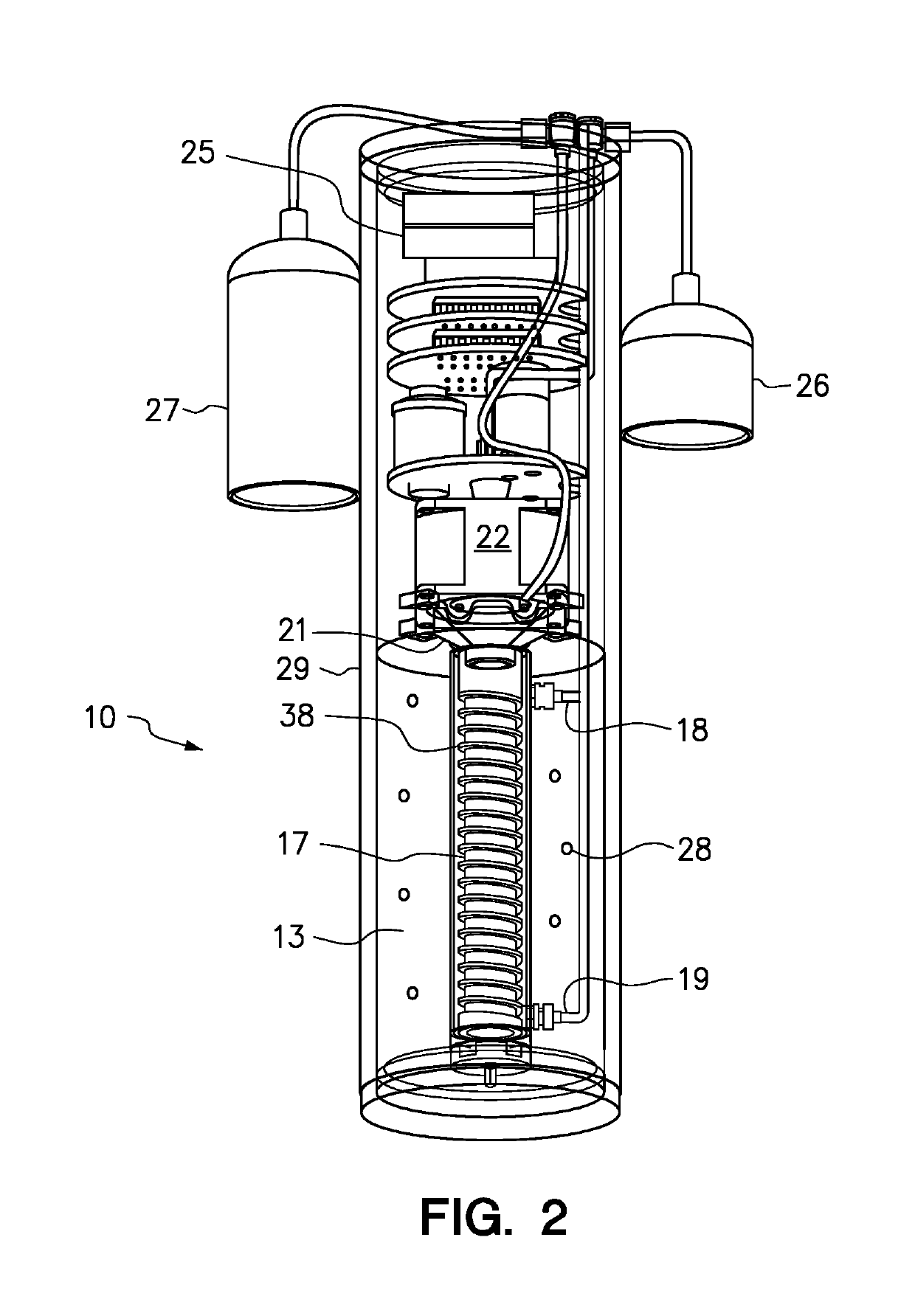

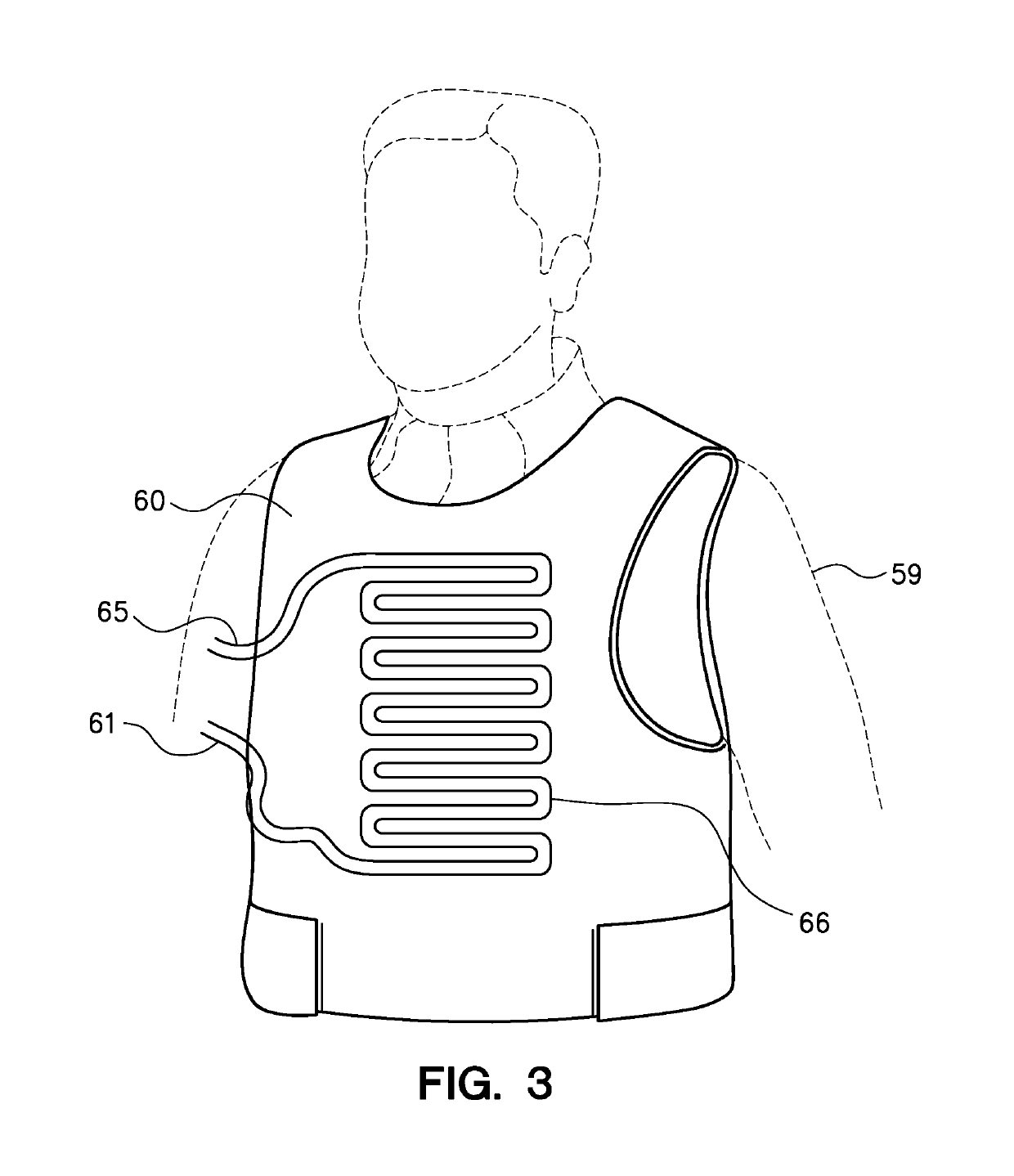

Submersible warming device

ActiveUS10308333B2Lighting and heating apparatusExothermal chemical reactions for heatingWater storageCombustion

An embodiment of a submersible warming garment comprises a closed fluid loop including a warming conduit disposed in thermal communication with a chamber containing a catalyst and a cooling conduit disposed within a wearable garment. A pump moves the fluid through the warming conduit, where heat is gained, to the cooling conduit, where heat is surrendered to a human wearing the garment, and back to the pump. An actuated valve on a container of fuel and an actuated valve on a container of oxygen are controlled using a controller to provide a combustible mixture into the chamber where the mixture reacts in the presence of a catalytic member to generate heat and combustion by-products. The combustion by-products, including carbon dioxide and water, are one of adsorbed and absorbed by a carbon dioxide scrubber and a reusable water storage medium. A fan moves the by-products into the scrubber and water storage medium.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

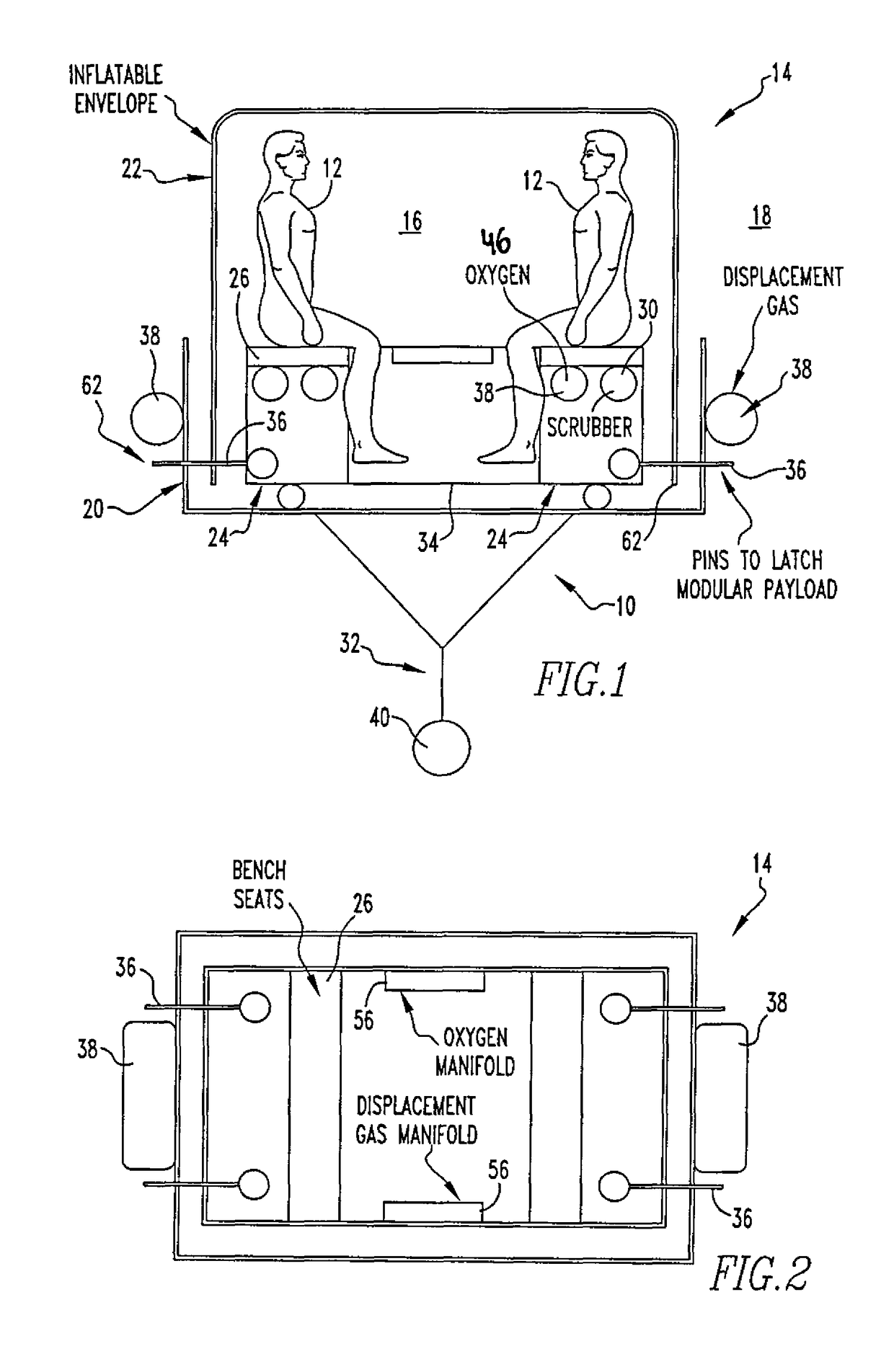

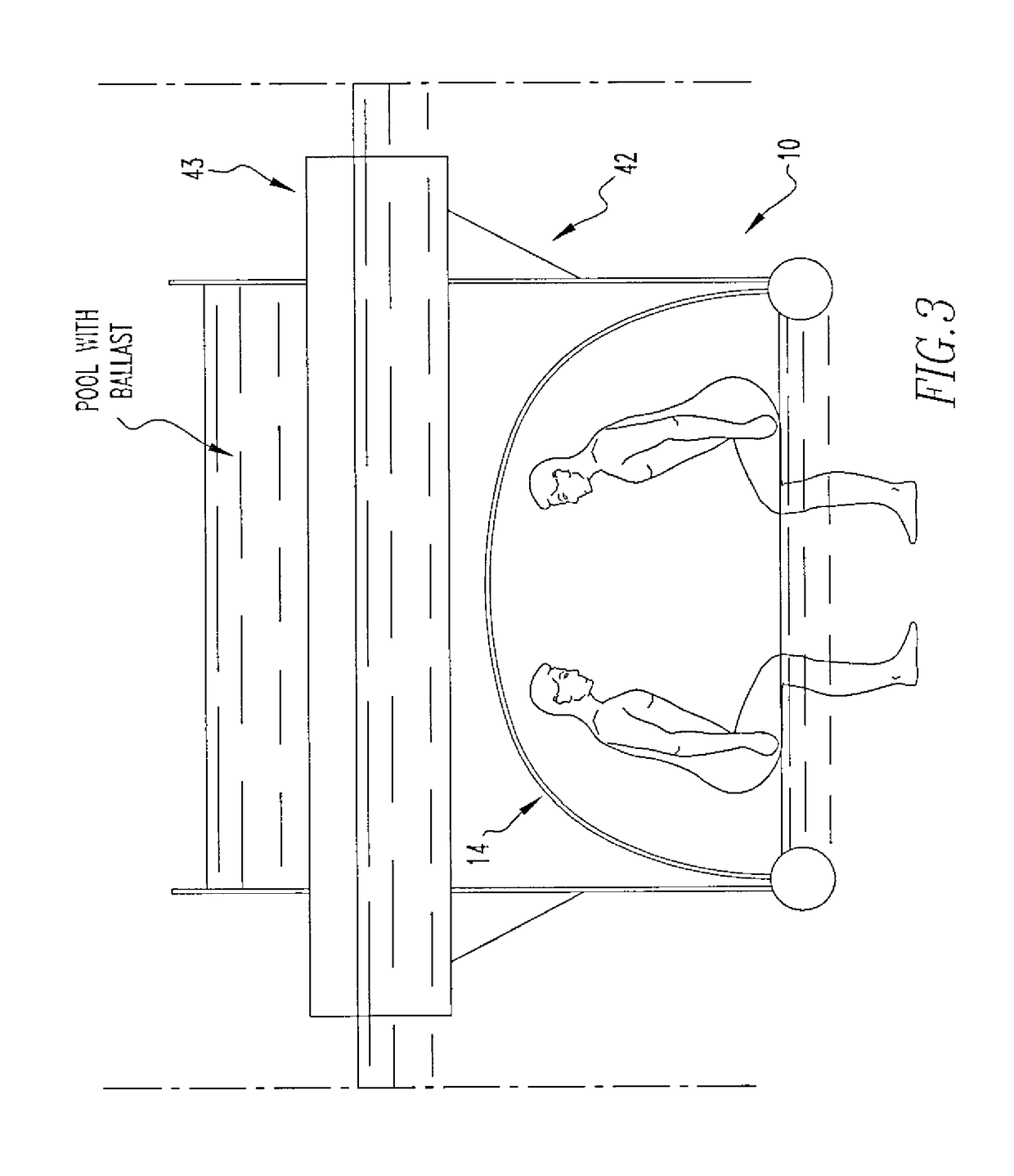

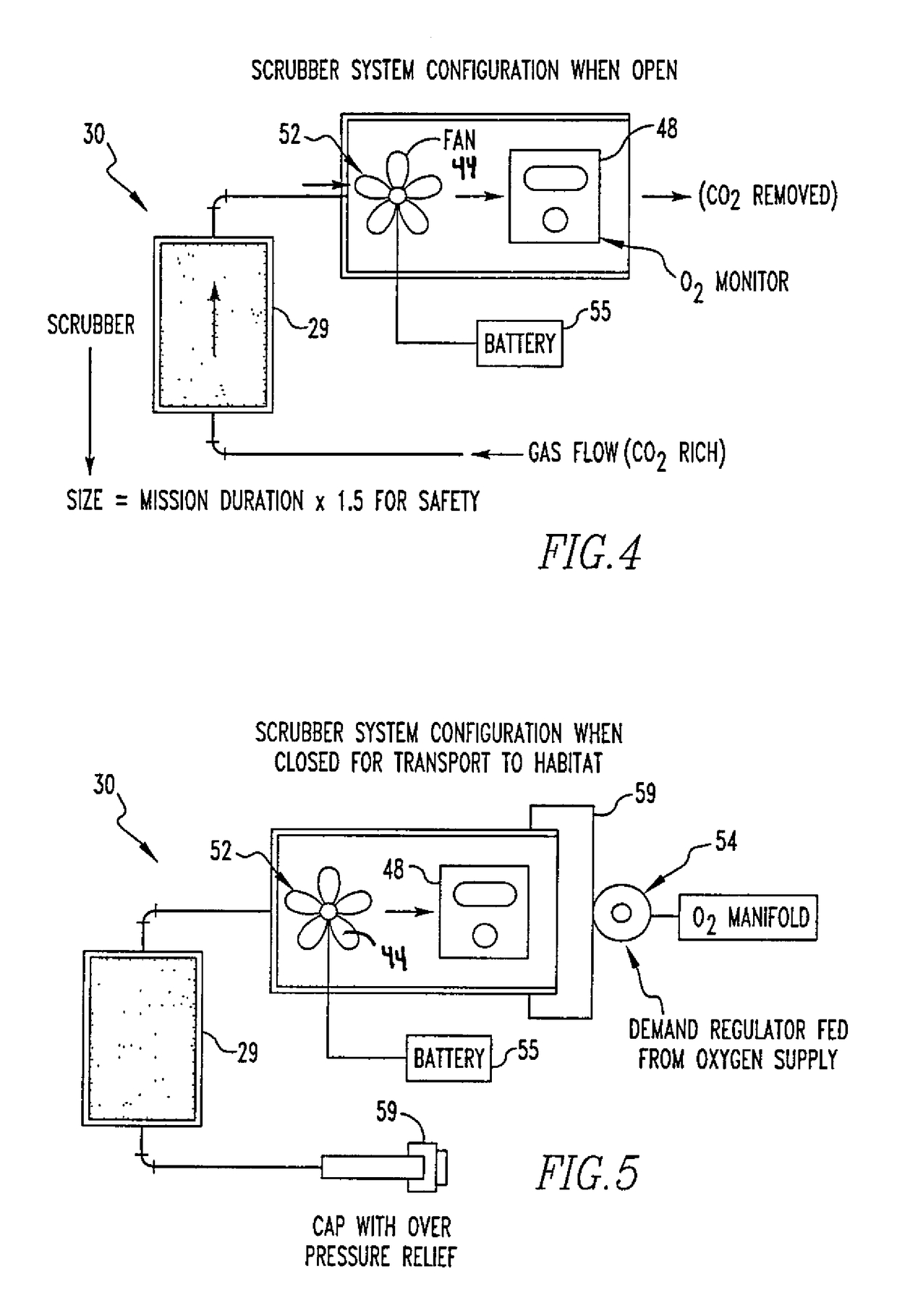

Portable inflatable habitat with modular payload, system and method

ActiveUS10155573B2Easy to deployEasy to useGas treatmentDispersed particle separationUnderwaterModularity

A diving apparatus for a diver underwater includes a portable habitat in which a breathable environment is maintained underwater. The habitat has a collapsible envelope. The collapsible envelope takes shape through inflation to an expanded state underwater. The habitat has a modular payload which removably attaches to the envelope underwater. The habitat has a seat on which a diver can sit while the habitat is underwater. The modular payload has a breathable gas source to provide breathable gas for the diver to breathe in the habitat and a carbon dioxide scrubber which removes carbon dioxide from the environment when the habitat is underwater. The apparatus has an anchor mechanism attached to the habitat to maintain the habitat at a desired depth underwater. A method for a diver to dive underwater. A system for supporting a diver underwater. A diving apparatus having a propulsion unit. An apparatus for a user in outer space or on another planet.

Owner:NEW YORK UNIV

Carbon Dioxide Separation/Recovery Device, Combustion System Using Same, Thermal Power Generation System Using Same, and Method for Separating and Recovering Carbon Dioxide

InactiveUS20190022572A1Suppressing lowering in performanceLow running costProductsOther chemical processesCombustion systemScavenger

A carbon dioxide separation / recovery device for separating and recovering carbon dioxide from a gas to be processed and containing nitrogen oxides and carbon dioxide by using a carbon dioxide scavenger, including a carbon dioxide trapping unit having the carbon dioxide scavenger, in which the carbon dioxide trapping unit includes: a gas flow inlet which introduces the gas to be processed; a heating unit of heating a scavenger heating gas used upon desorption of carbon dioxide trapped by the carbon dioxide scavenger to a predetermined temperature; a cooling gas introduction port which introduces a scavenger cooling gas used when cooling the carbon dioxide scavenger; and a moisture mixing part which adds moisture to a gas for nitrogen oxide desorption used in desorption of nitrogen oxides from the carbon dioxide scavenger. Consequently, NOx accumulated to the carbon dioxide scavenger is desorbed, thereby capable of suppressing lowering in the performance of the carbon dioxide scavenger and reducing the running cost.

Owner:HITACHI CHEM CO LTD

Portable rebreathing system with pressurized oxygen enrichment

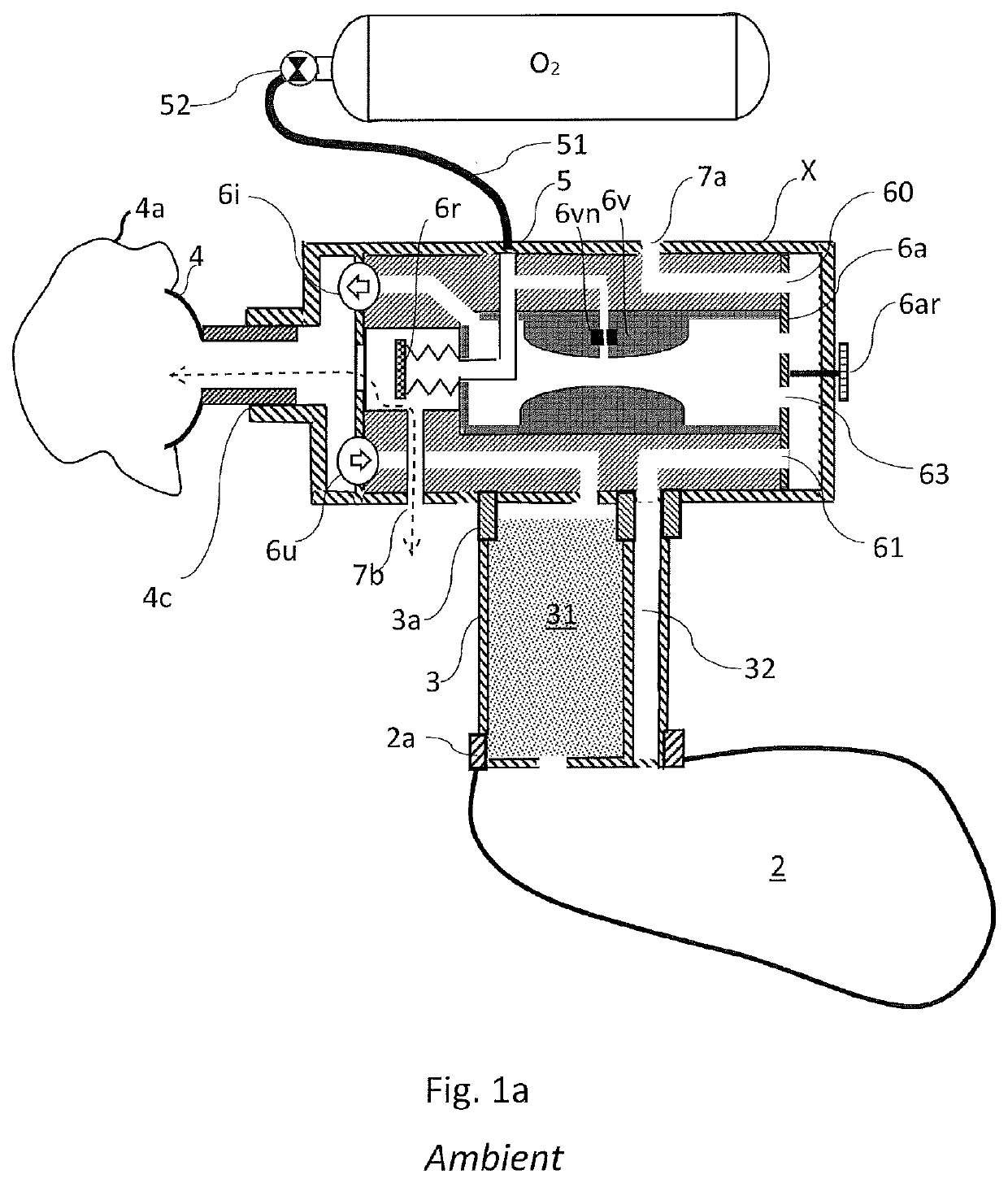

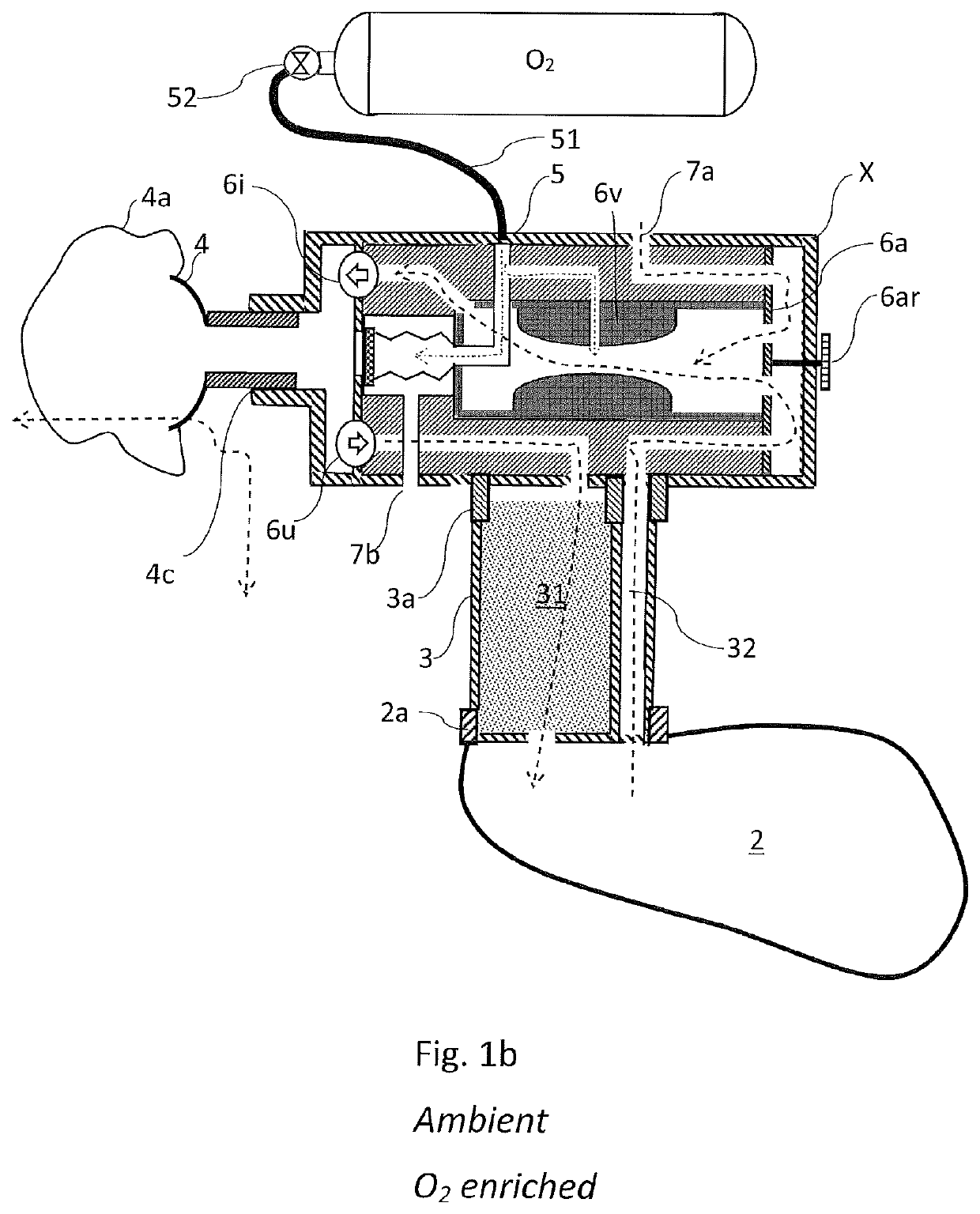

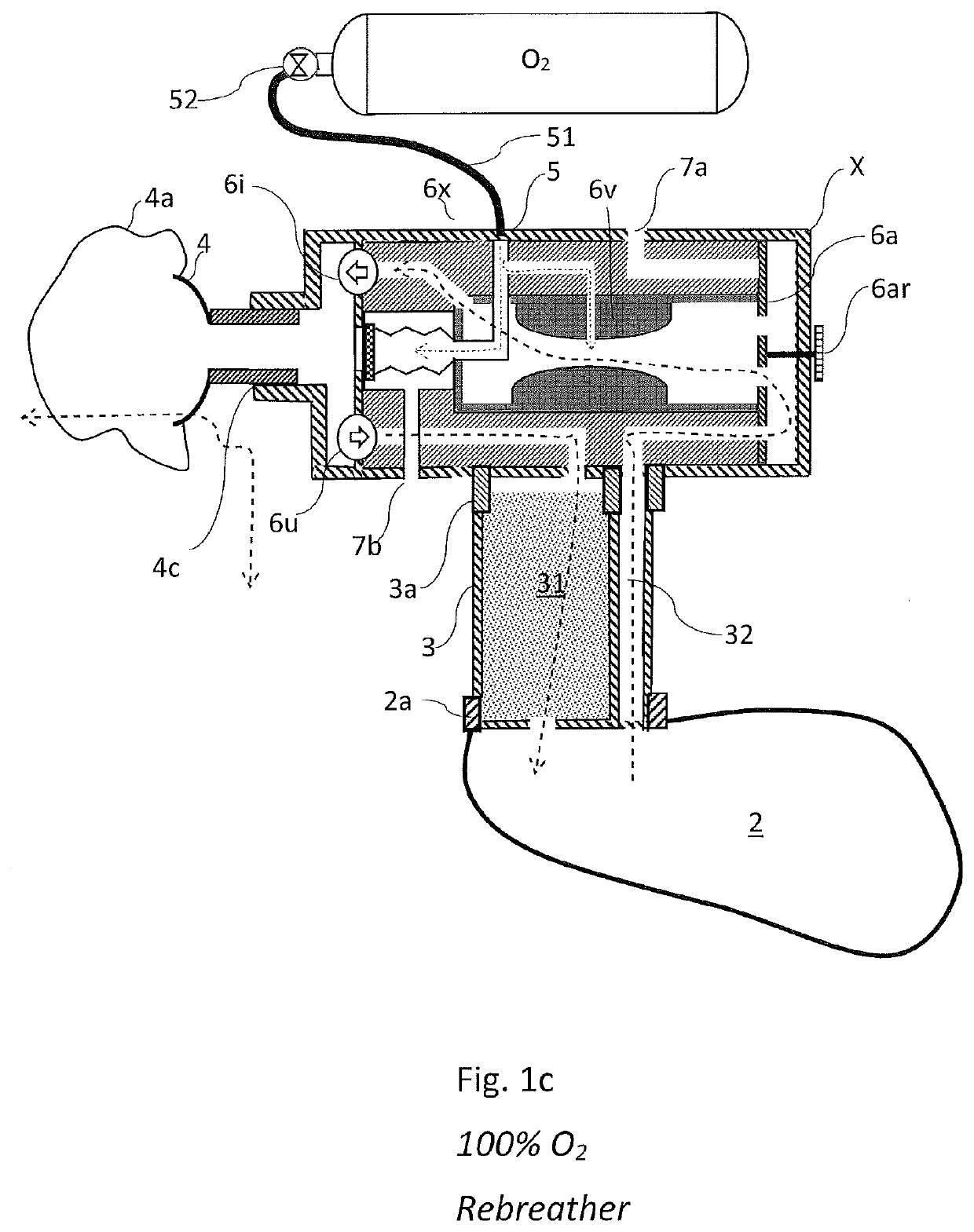

InactiveUS20200023149A1Minimizing dead volumeIncrease oxygen concentrationRespiratory masksMedical devicesBreathing systemCheck valve

This invention relates to a portable rebreathing system, said portable rebreathing system comprising a breathing mask (4), a carbon dioxide scrubber (3), a counter lung (2), ambient air ports and an oxygen supply port (5), with the breathing mask (4) connectable with a mask connector to a common valve housing (X) containing said carbon dioxide scrubber (3), ambient air port and oxygen supply port, and with the counter lung (2) connectable with a counter lung connector to the common housing.The main features of the invention are two one way check valves close to breathing mask connects to an exhale passage and an inhale passage respectively in a rebreathing mode. A small common valve housing (X) with control valves open a rebreathing circuit to the counter lung when pressure from an oxygen supply source is applied on the control valves, and when pressure drops open a breathing circuit to ambient air. Supply of fresh oxygen is added into the rebreathing circuit directly upstream of or at the inhale check valve.This design utilizes the oxygen supply efficiently with minimum oxygen losses.

Owner:GLOBAL RESCUE INNOVATION AB

A method of carbon dioxide capture and pyrolysis

The invention relates to the field of emission reduction and conversion of carbon dioxide, in particular to a trapping and pyrolysis method for carbon dioxide. The carbon dioxide in smoke is converted into a sodium bicarbonate solution by a sodium carbonate solution in a carbonizer, and a pyrolyzer resolves high-purity carbon dioxide quickly. The pollution due to excessive carbon dioxide generated when fossil fuel is burnt is avoided, and energy conservation, environmental protection, energy crisis reduction and greenhouse effect reduction are realized. The method has the benefits that (1) the trapping rate of the carbon dioxide is significantly increased by the synergistic action of sodium carbonate, a catalyst and an activating agent; (2) the solution decomposes the carbon dioxide quickly, and the dissociation cost is lowered; and (3) the equipment investment is low, a large amount of carbon dioxide can be trapped and pyrolyzed, near zero release of the carbon dioxide can be realized, and the method is suitable for key coal-consumption industries of coal power, coal chemistry, steel, cement, papermaking, metallurgy, printing and dyeing, chemical engineering and the like to trap, recover and apply carbon dioxide resources on a large scale, and reduces the greenhouse effect.

Owner:浙江森井生物技术股份有限公司

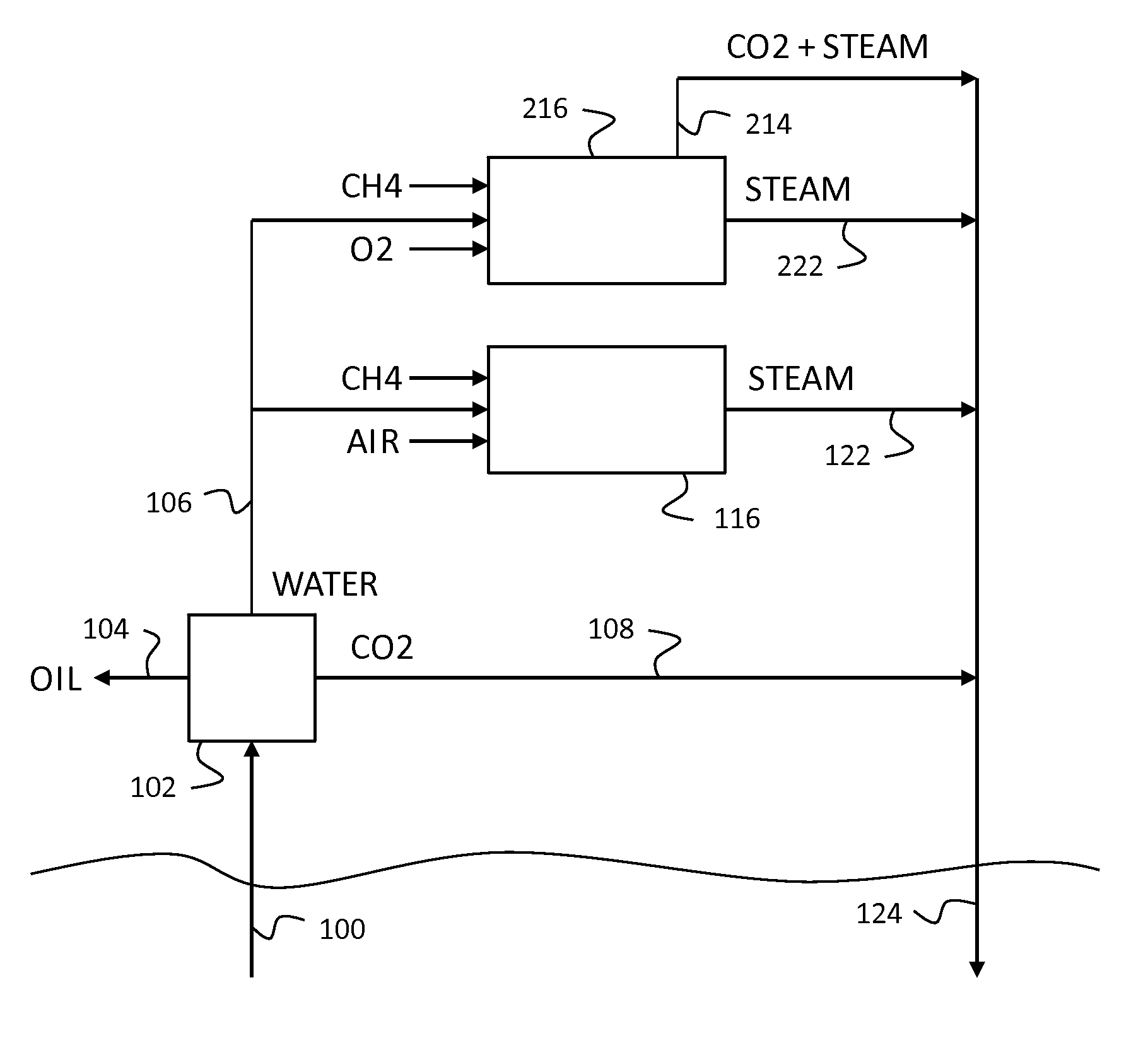

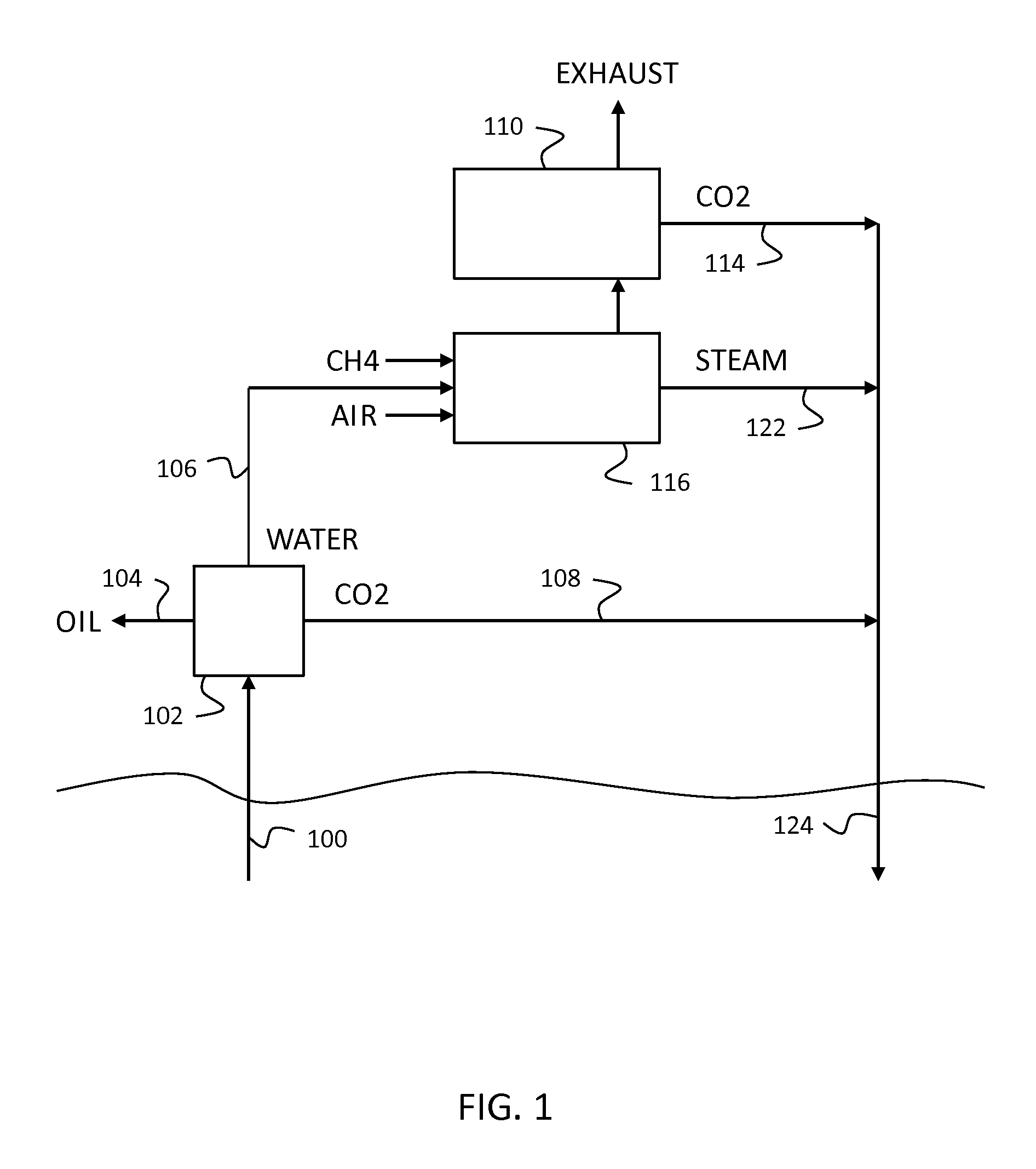

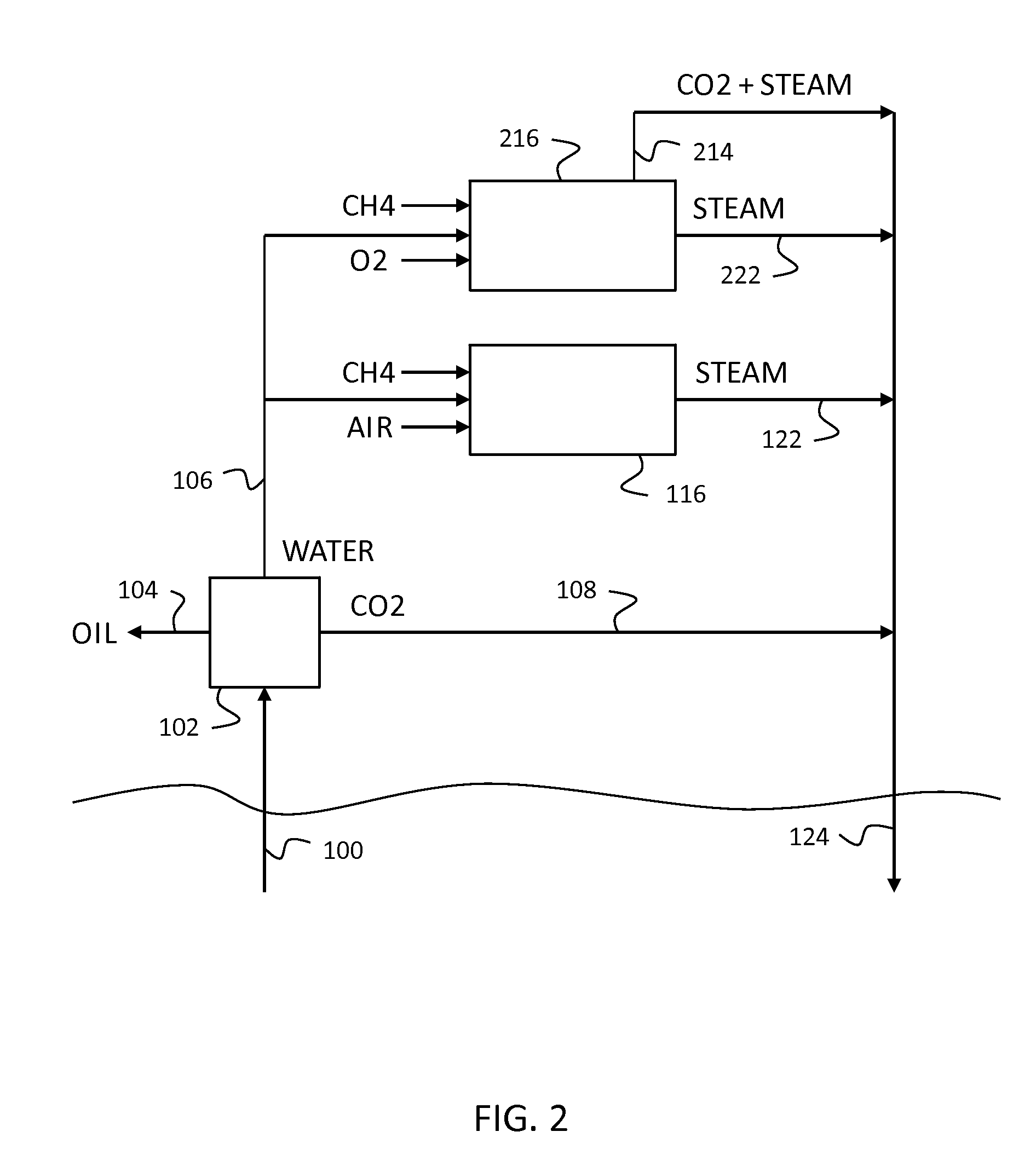

Steam generation with carbon dioxide recycle

Systems and methods relate to recovering hydrocarbons by injecting into a reservoir steam along with carbon dioxide recovered from flue gases produced while generating the steam and from separation of produced fluids. Due to benefits from the carbon dioxide injection, carbon dioxide capture rates from the flue gases selected below fifty percent in such combined recovery of the carbon dioxide enables lower fuel consumption even given that additional fuel is needed for the carbon dioxide capture versus steam only operations. As the capture rates from the flue gases increase above fifty percent like when employed for sequestration purposes, such approaches use more fuel than the steam only operations and may not be cost efficient. A carbon dioxide recovery unit coupled to an air-fired boiler or an auxiliary oxy-fired boiler may supply the carbon dioxide recovered from the flue gases.

Owner:CONOCOPHILLIPS CO

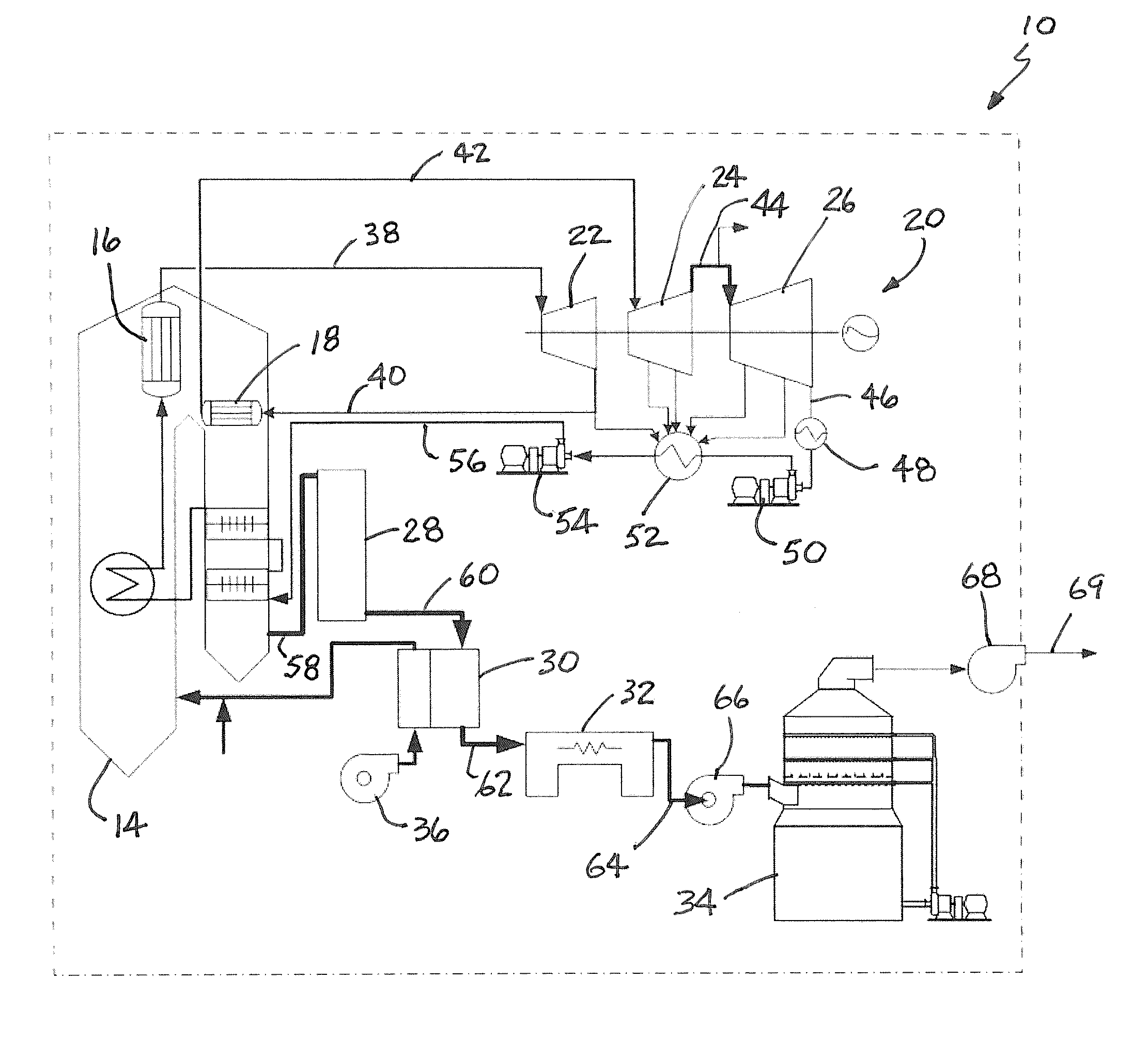

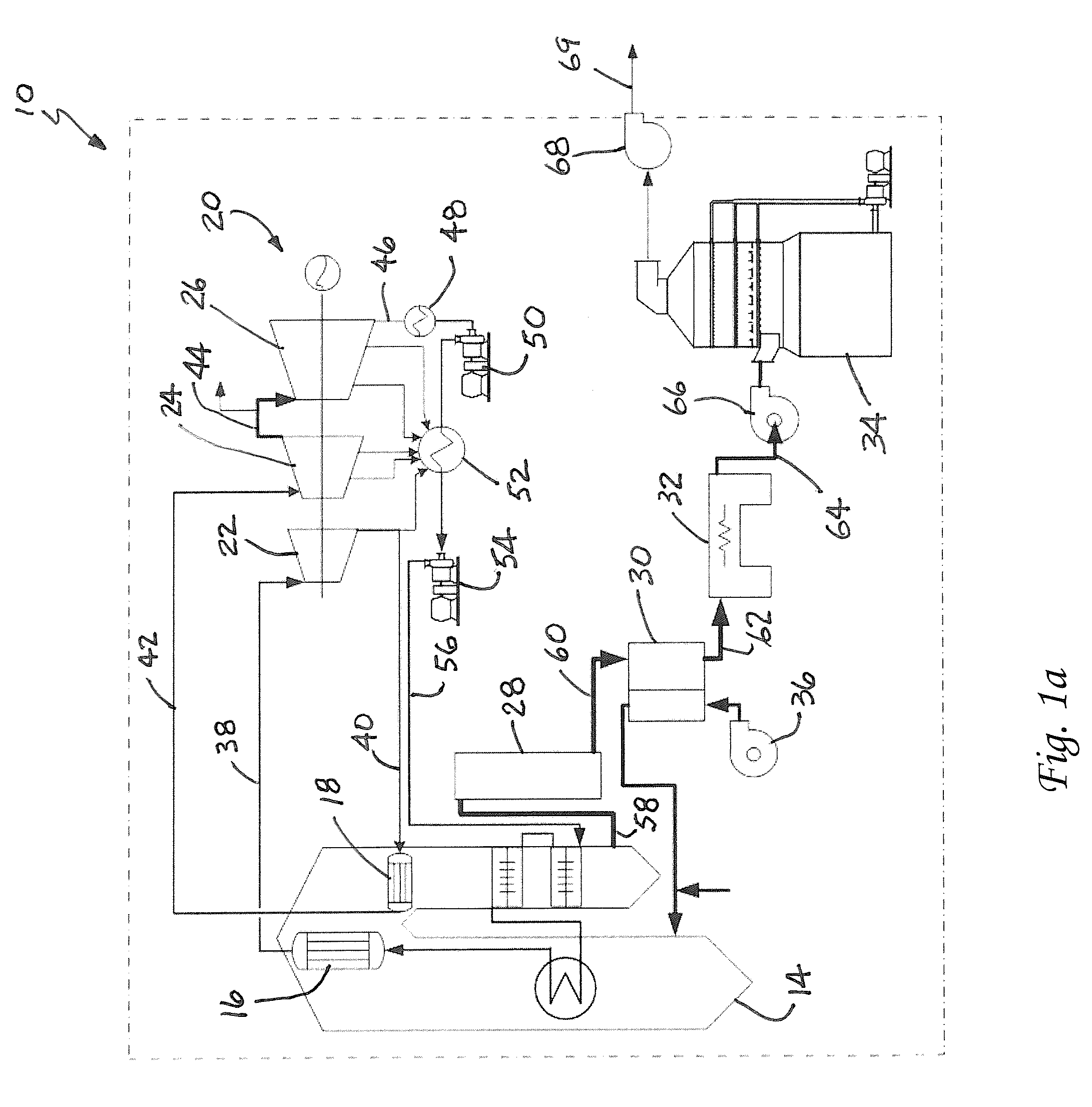

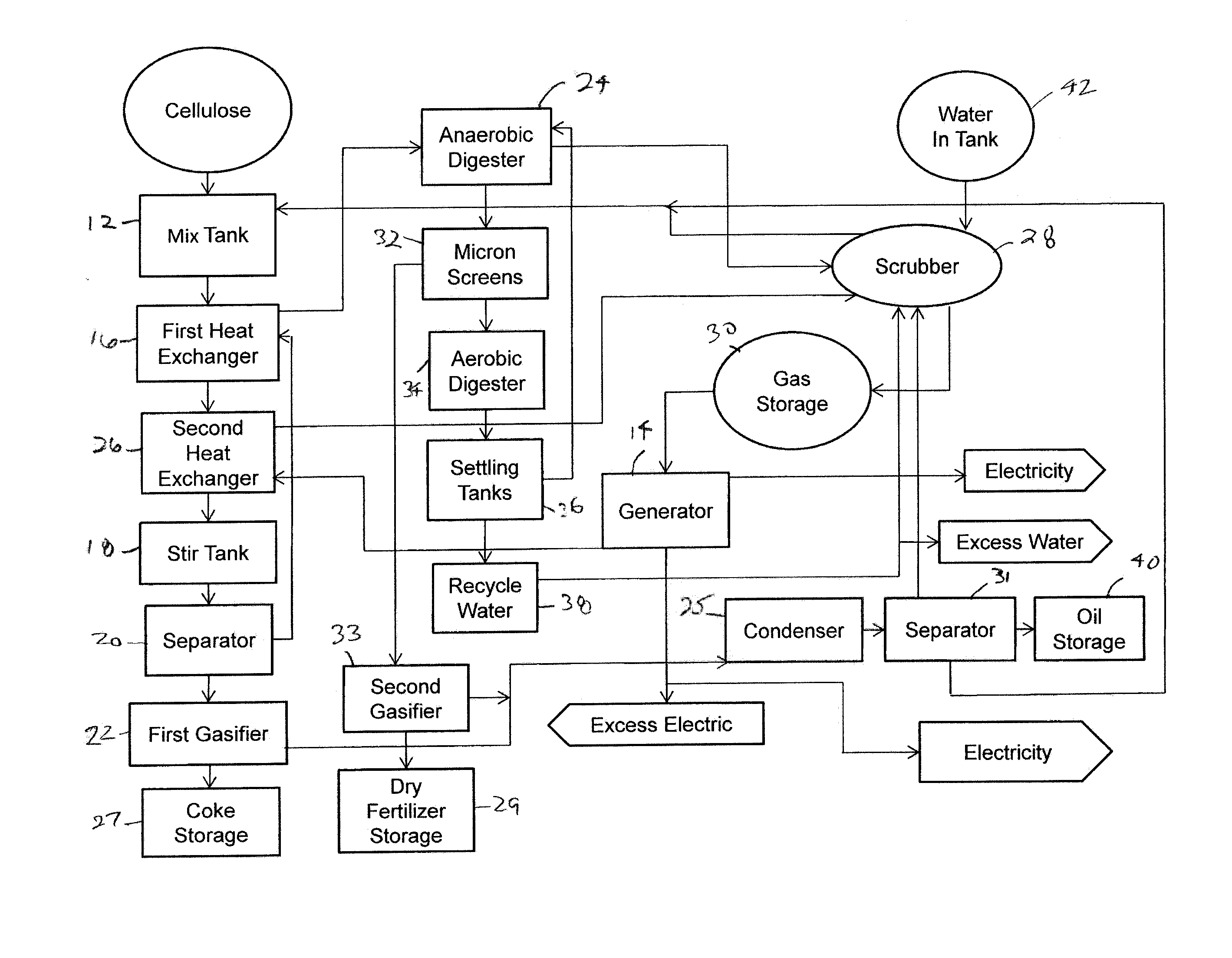

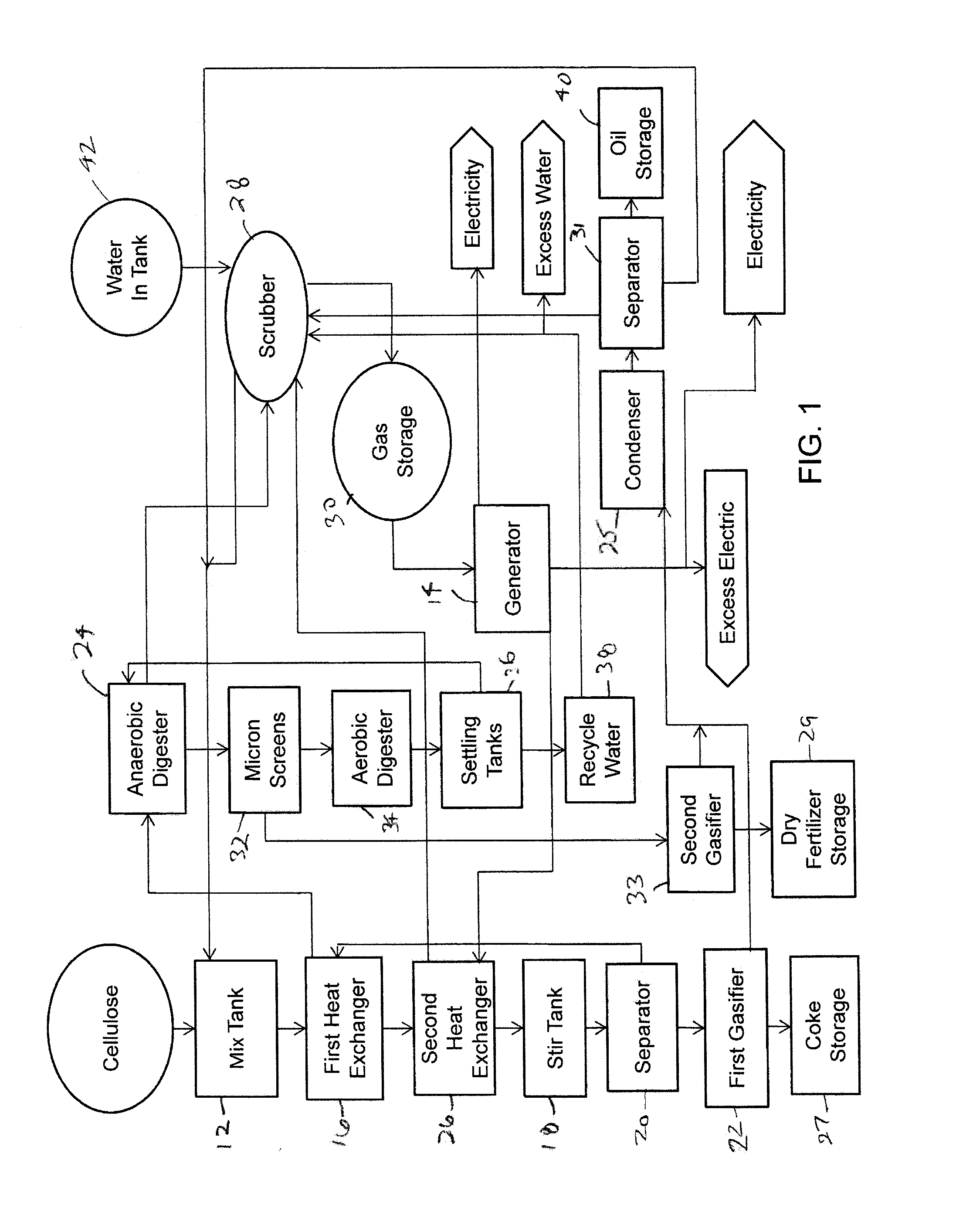

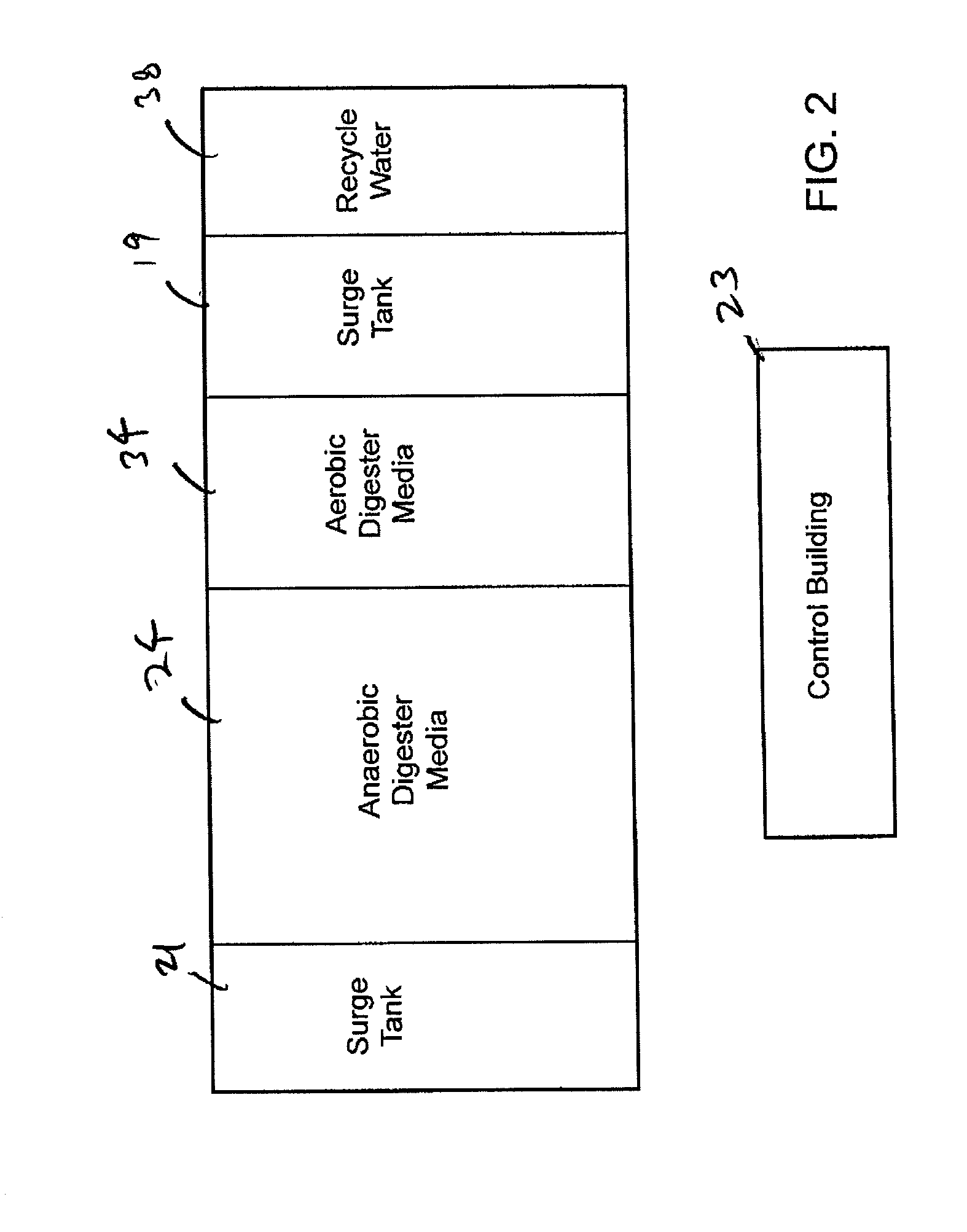

Method and Apparatus for Producing Engineered Fuel from High Cellulose Feedstock

InactiveUS20130183715A1Bioreactor/fermenter combinationsBio-organic fraction processingCelluloseSlurry

An apparatus and method for producing methane gas, synthetic hydrocarbon gas, and fertilizer is provided. The apparatus includes a mix tank for mixing cellulosic material with a solvent into a slurry and a generator having an exhaust. The apparatus further includes a stir tank reactor for converting the slurry to a solution containing lignin-like carbon and liquid, and a separator for separating the lignin-like carbon and liquid. An anaerobic digester decomposes the received liquid received from the stir tank into methane and liquid components. A carbon dioxide scrubber scrubs the methane component of carbon dioxide.The method includes mixing cellulosic material with a solvent into a slurry, and converting the slurry to a solution containing lignin-like carbon and liquid. It also includes separating the lignin-like carbon and liquid and decomposing the liquid into methane and liquid components, and scrubbing the methane component of carbon dioxide.

Owner:BASKIS PAUL T

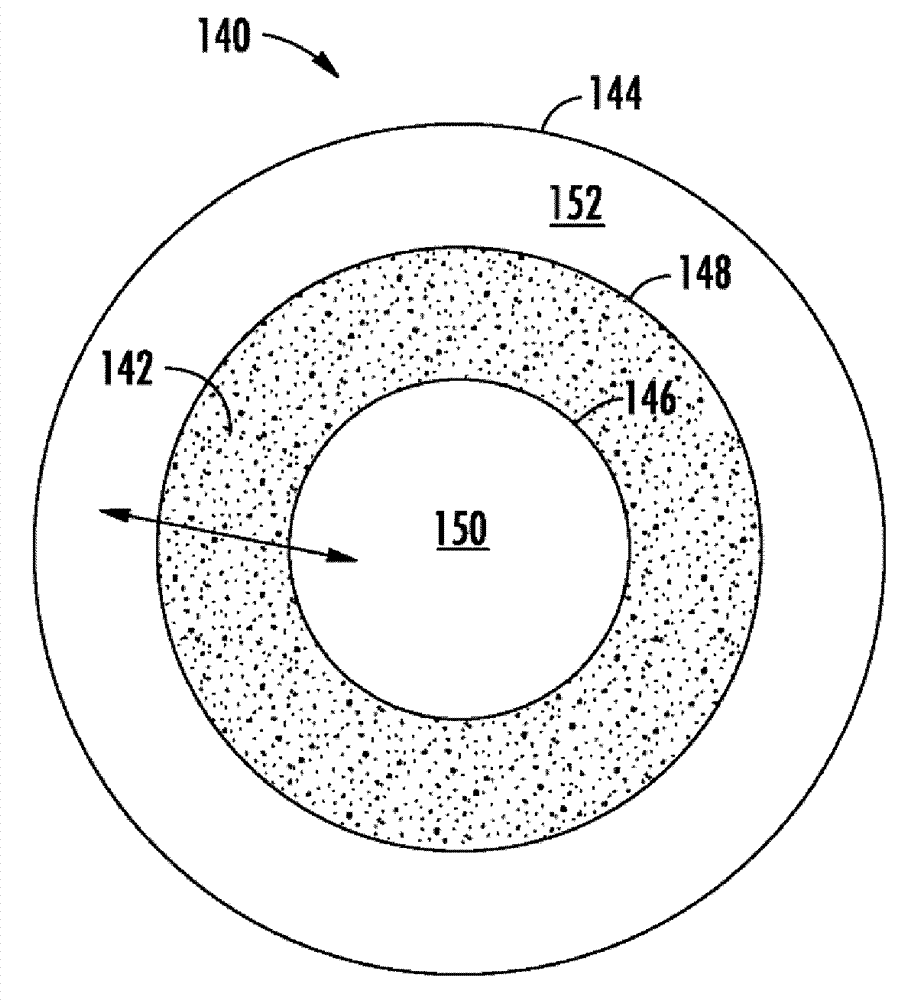

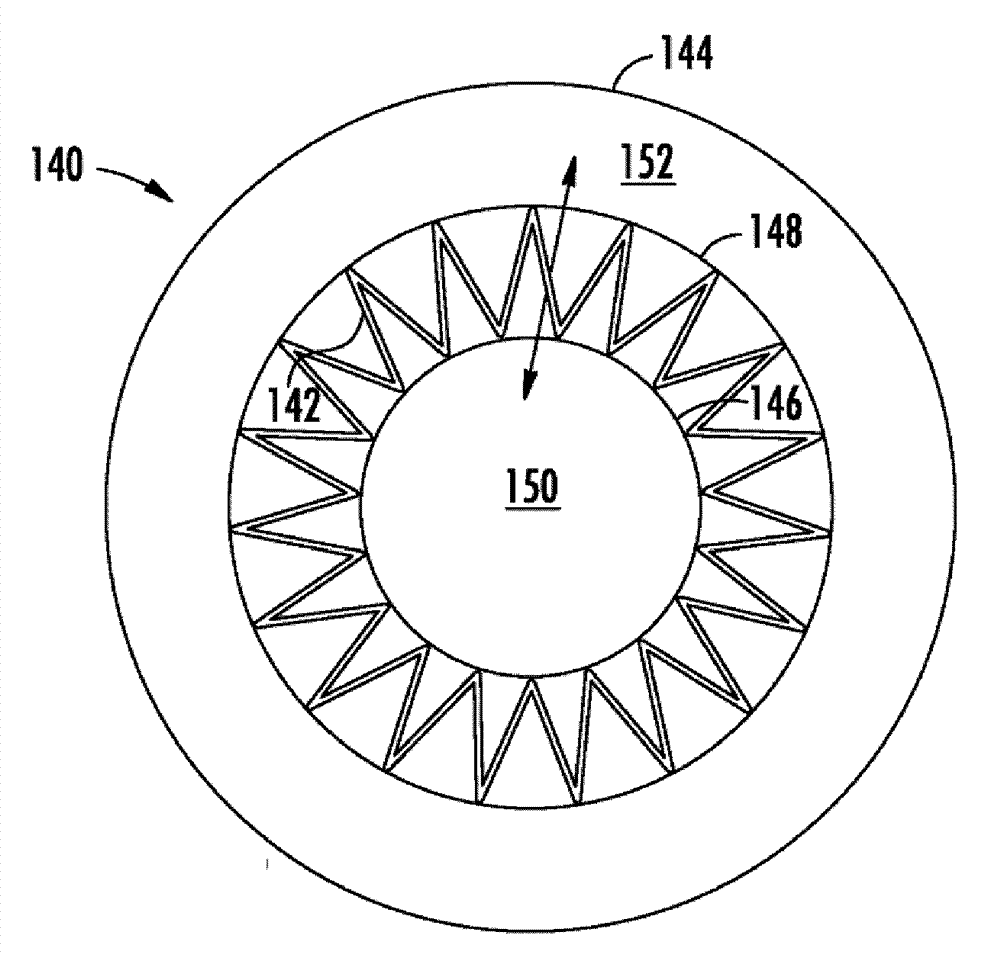

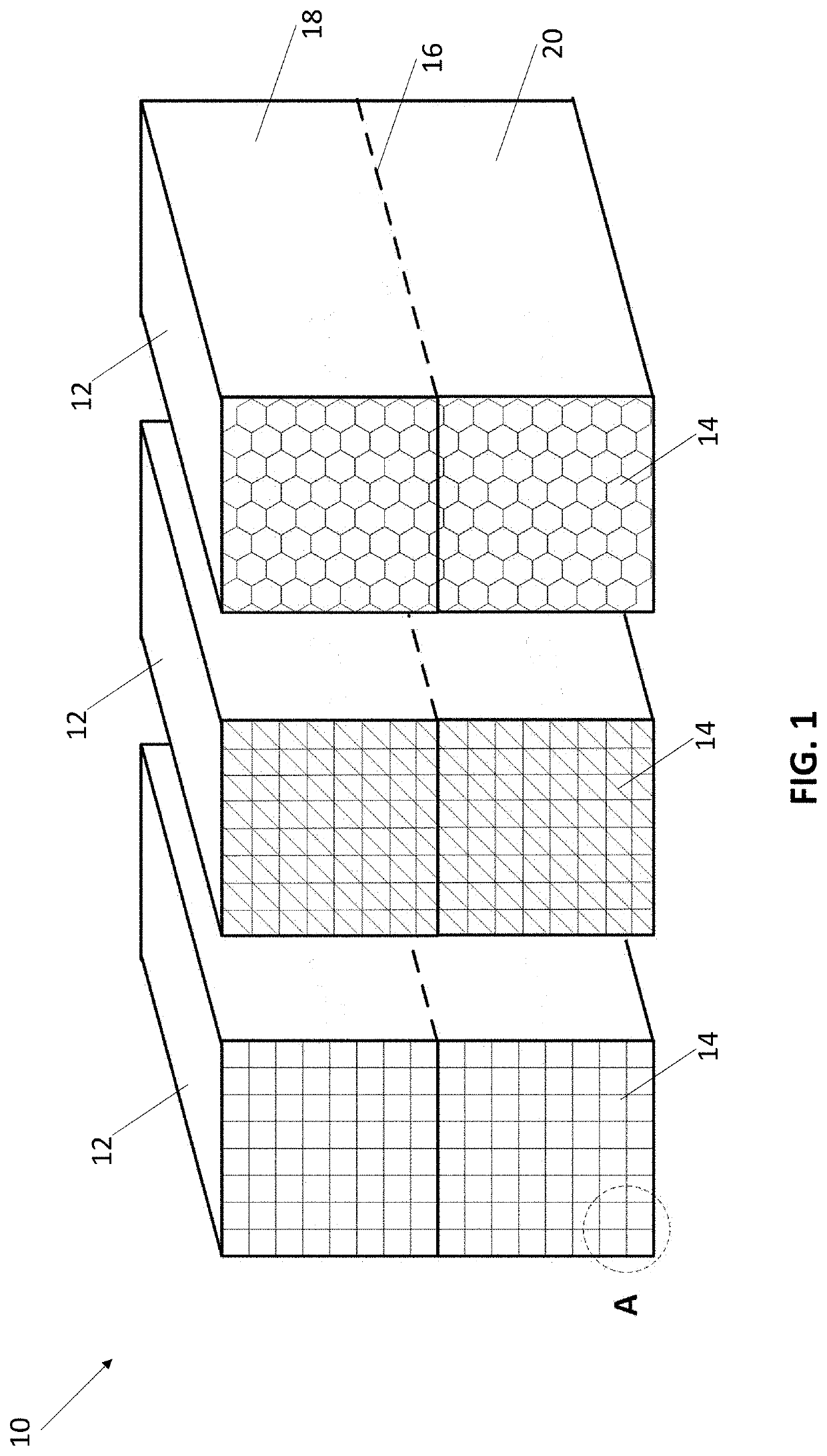

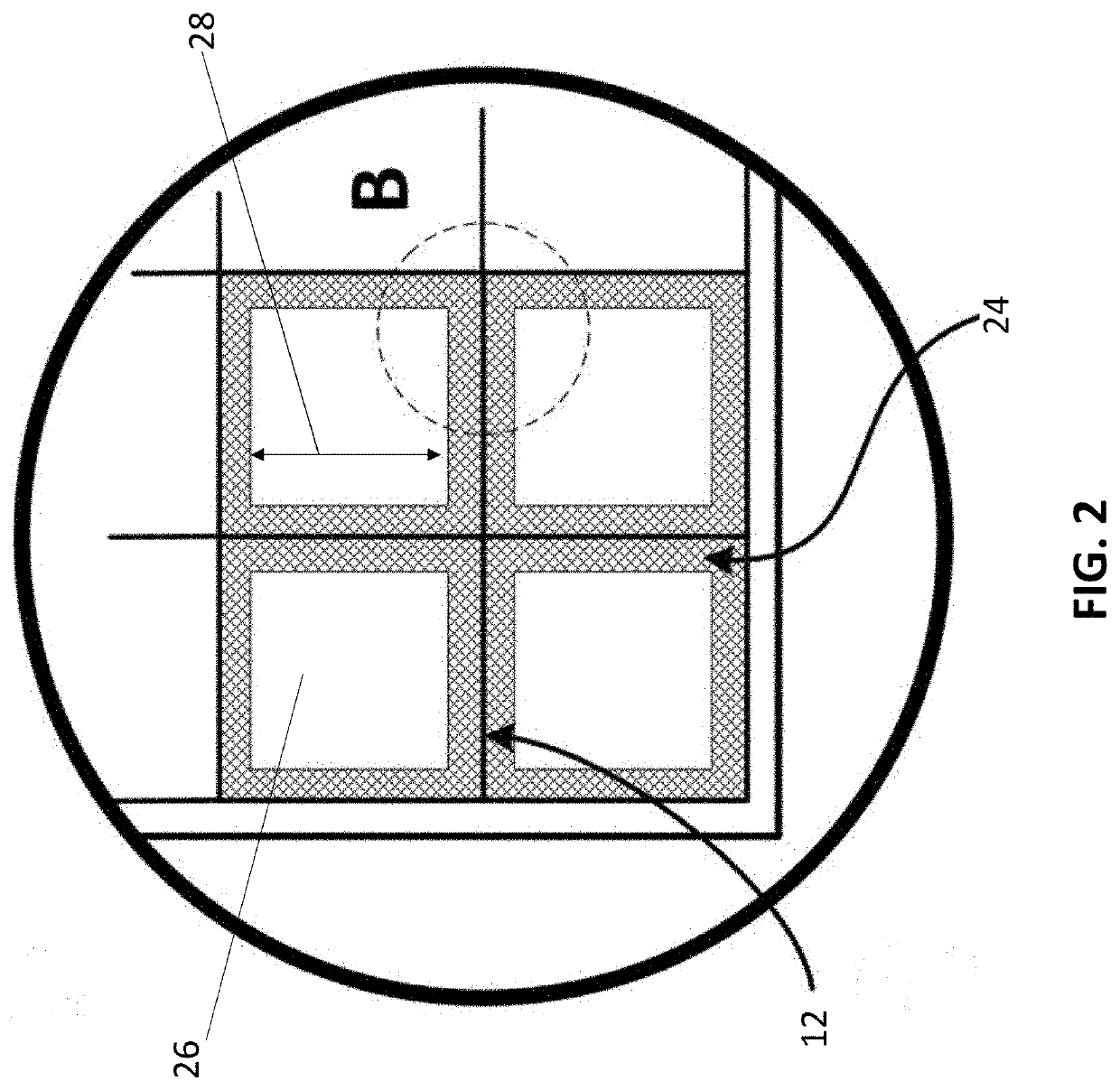

Filtration structure for carbon dioxide scrubber

Disclosed is a filtration structure, comprising: a substrate, wherein the substrate is a three-dimensional lattice formed from repeating geometric shapes; a layer of porous material bonded over the substrate; and a liquid amine retained within the pores of the porous material. Also disclosed is a carbon dioxide scrubber comprising the filtration structure.

Owner:HAMILTON SUNDSTRAND CORP

Device for reducing carbon dioxide into carbon monoxide

The invention provides a device for reducing carbon dioxide into carbon monoxide, and relates to the technical field of carbon dioxide reduction. The device comprises at least one reactor, closed feeding systems, closed slag removal systems and oxygen branch pipes, wherein each reactor is provided with an air inlet and an air outlet, and the air inlet of the first reactor is the carbon dioxide inlet in the gas flowing direction, and the closed feeding systems correspond to the reactors one to one; according to each pair of corresponding reactor and closed feeding system, the closed feeding system is located on the top of the reactor and communicated with the reactor, and the closed slag removal systems correspond to the reactors one to one; according to each pair of corresponding reactor and closed slag removal system, the closed slag removal system is located at the bottom of a processor and communicated with the reactor; the oxygen branch pipes correspond to the reactors one to one, and the air inlets and the air outlets are arranged in a staggered mode in the extending direction of the closed feeding systems and the closed slag removal systems. The device aims at solving the problem that the carbon dioxide rate is low in the prior art.

Owner:王立臣

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com