Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32 results about "Backlash" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

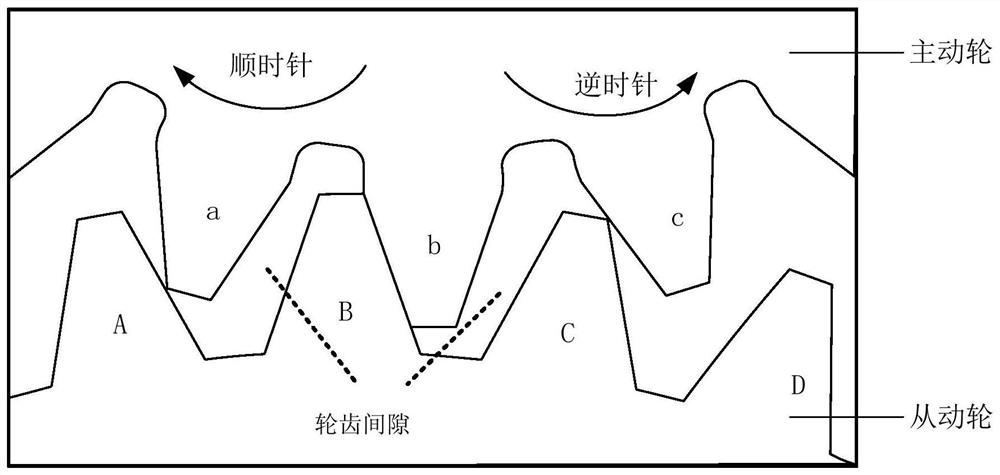

Inventor

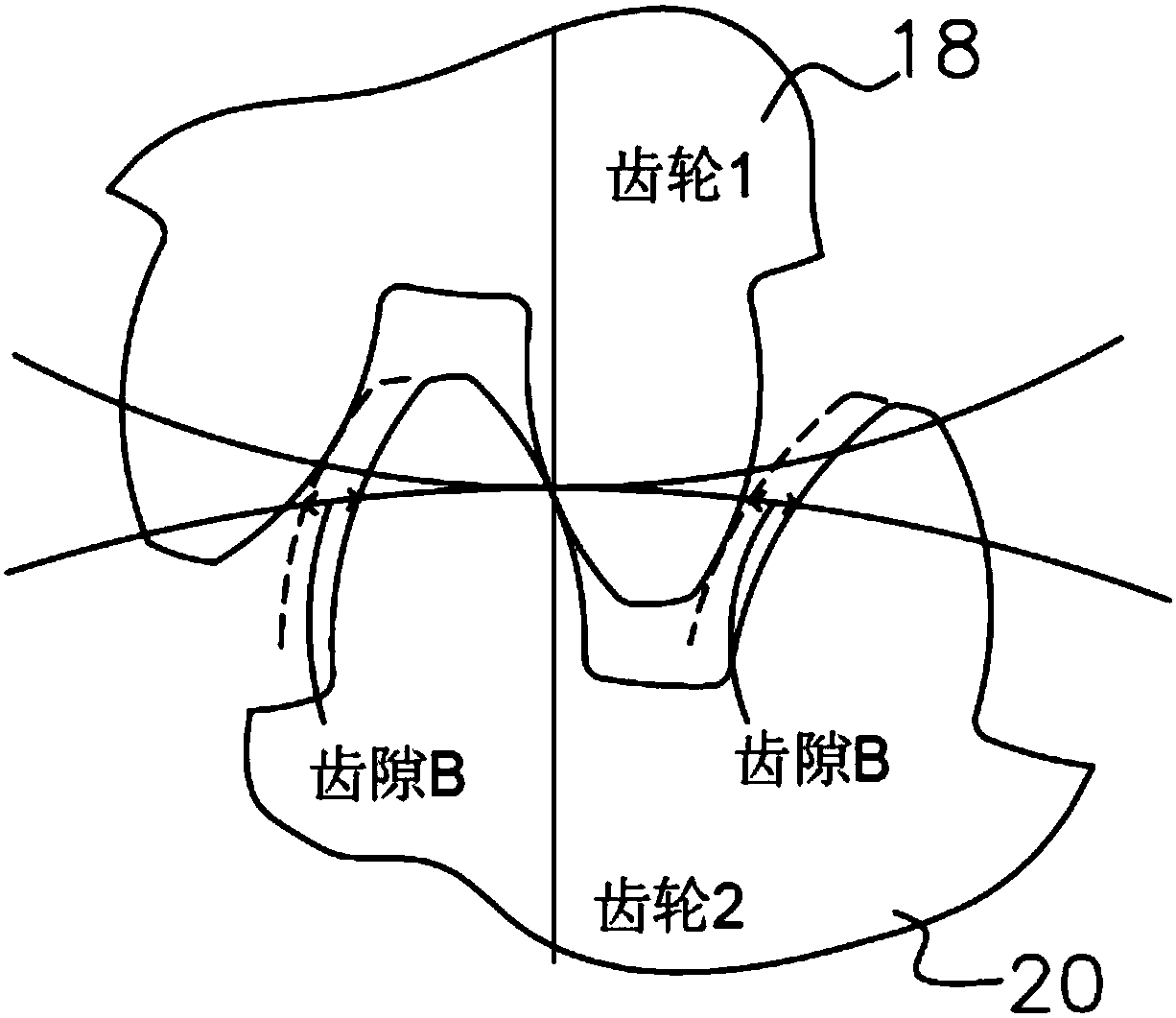

In mechanical engineering, backlash, sometimes called lash or play, is a clearance or lost motion in a mechanism caused by gaps between the parts. It can be defined as "the maximum distance or angle through which any part of a mechanical system may be moved in one direction without applying appreciable force or motion to the next part in mechanical sequence". An example, in the context of gears and gear trains, is the amount of clearance between mated gear teeth. It can be seen when the direction of movement is reversed and the slack or lost motion is taken up before the reversal of motion is complete. It can be heard from the railway couplings when a train reverses direction. Another example is in a valve train with mechanical tappets, where a certain range of lash is necessary for the valves to work properly.

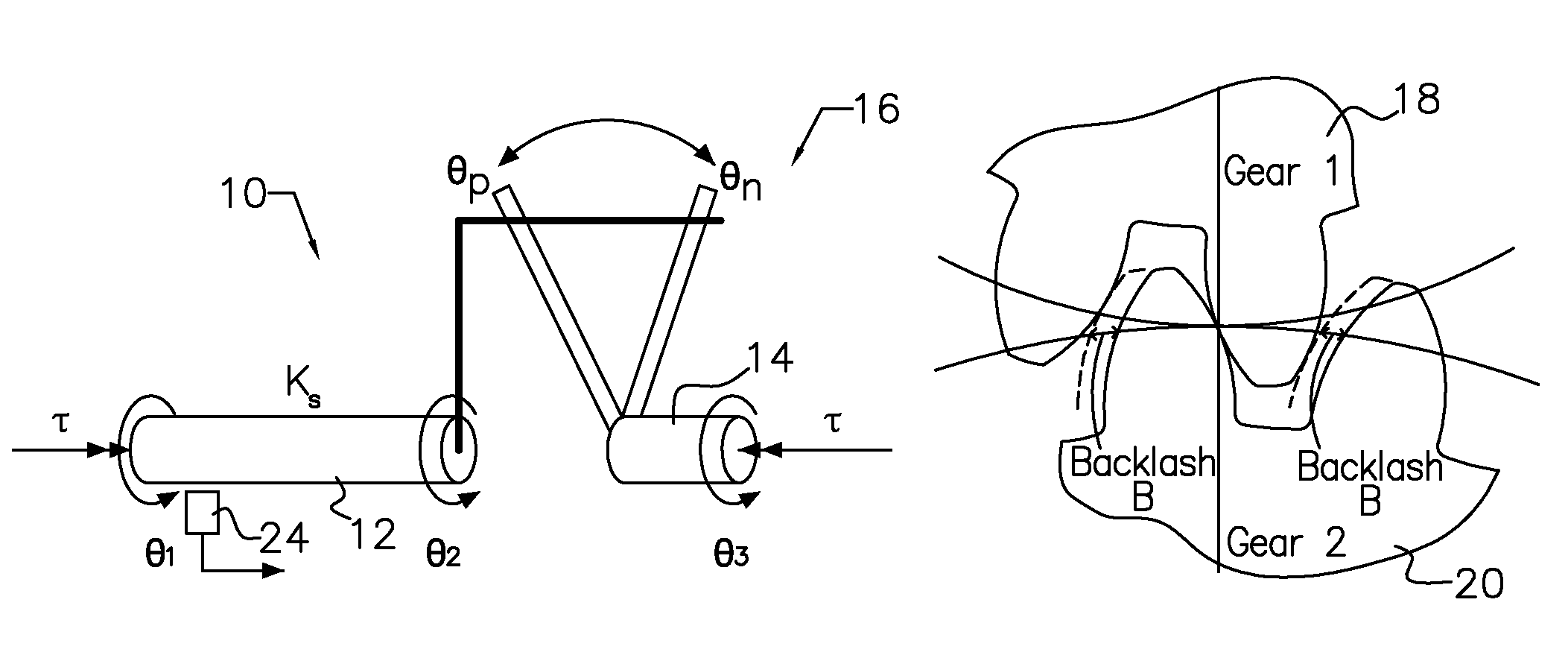

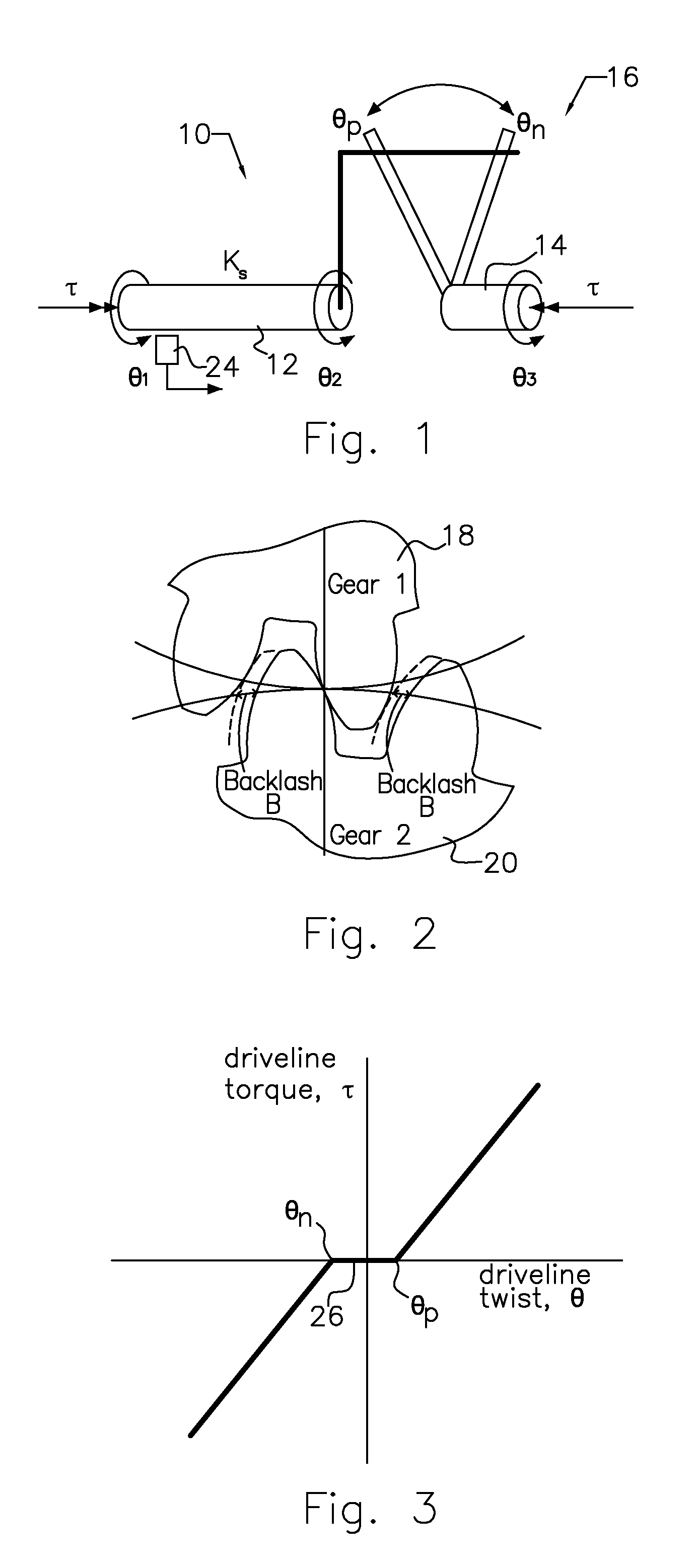

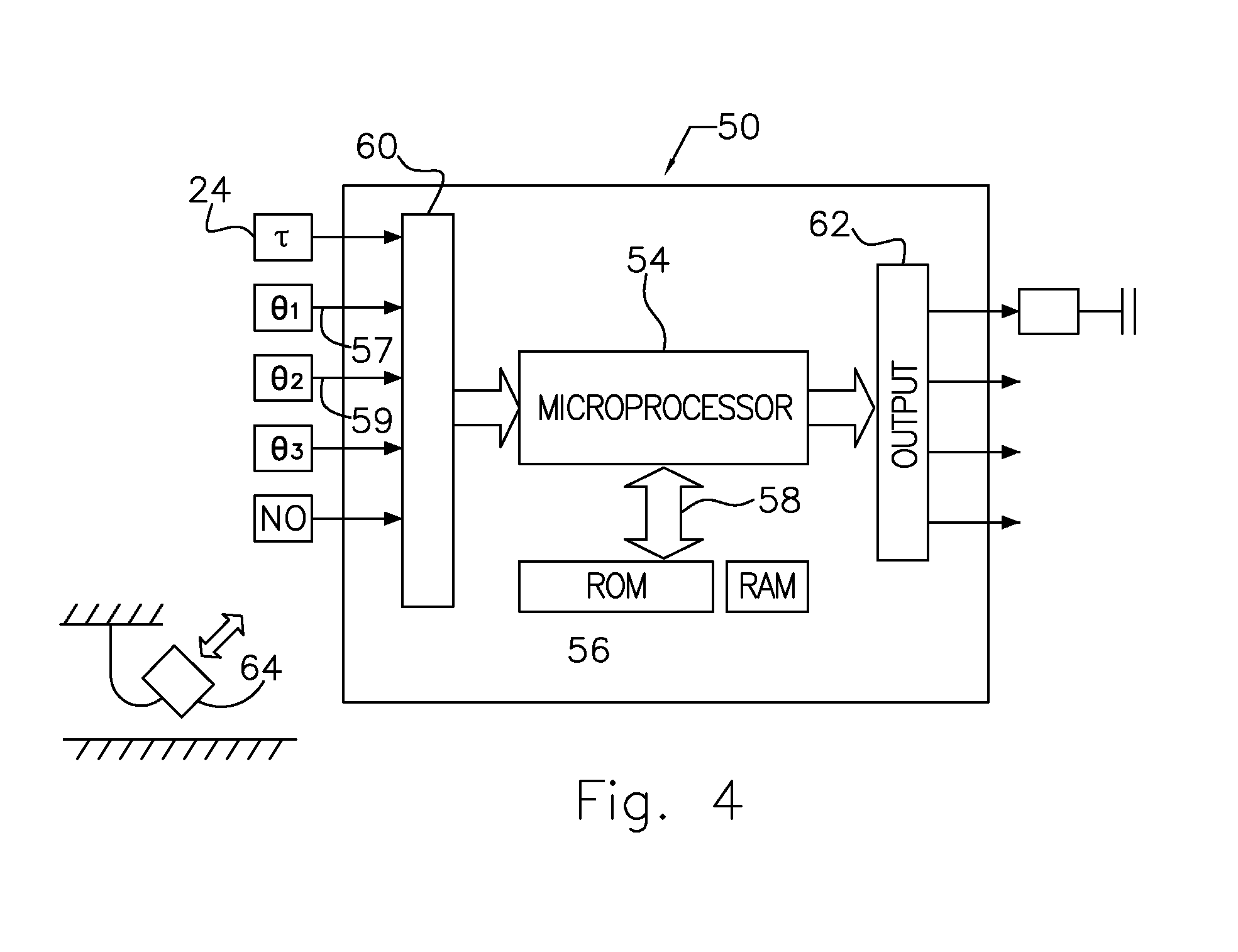

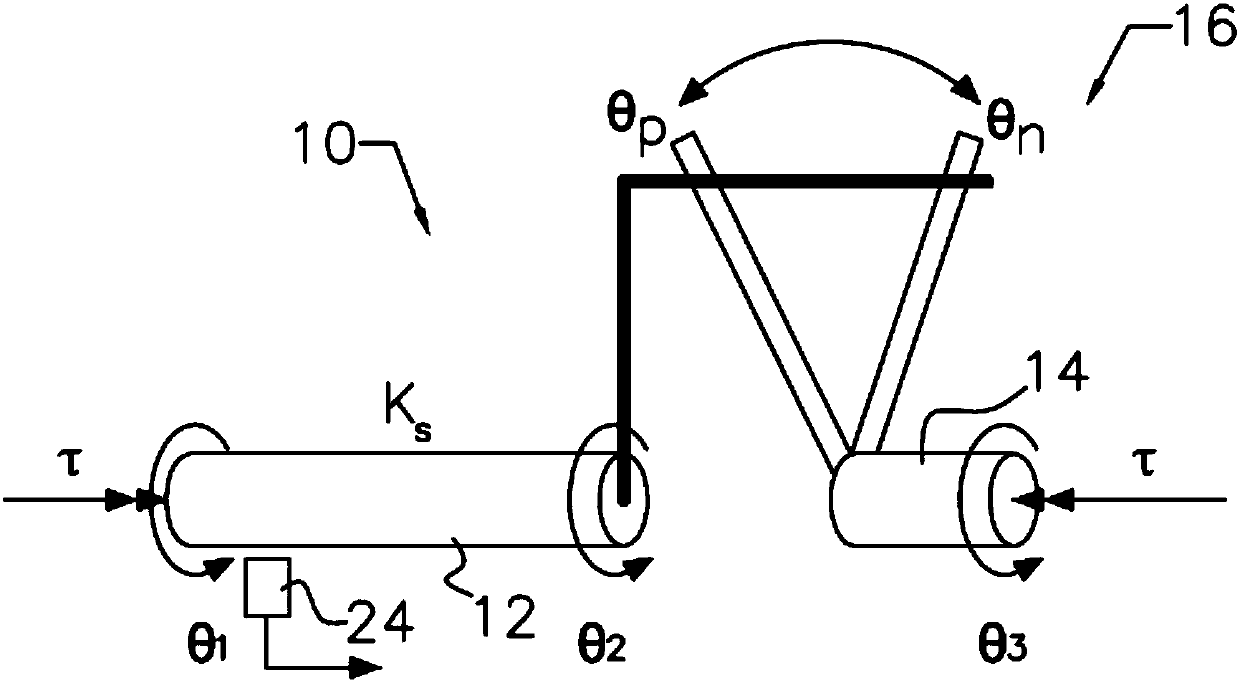

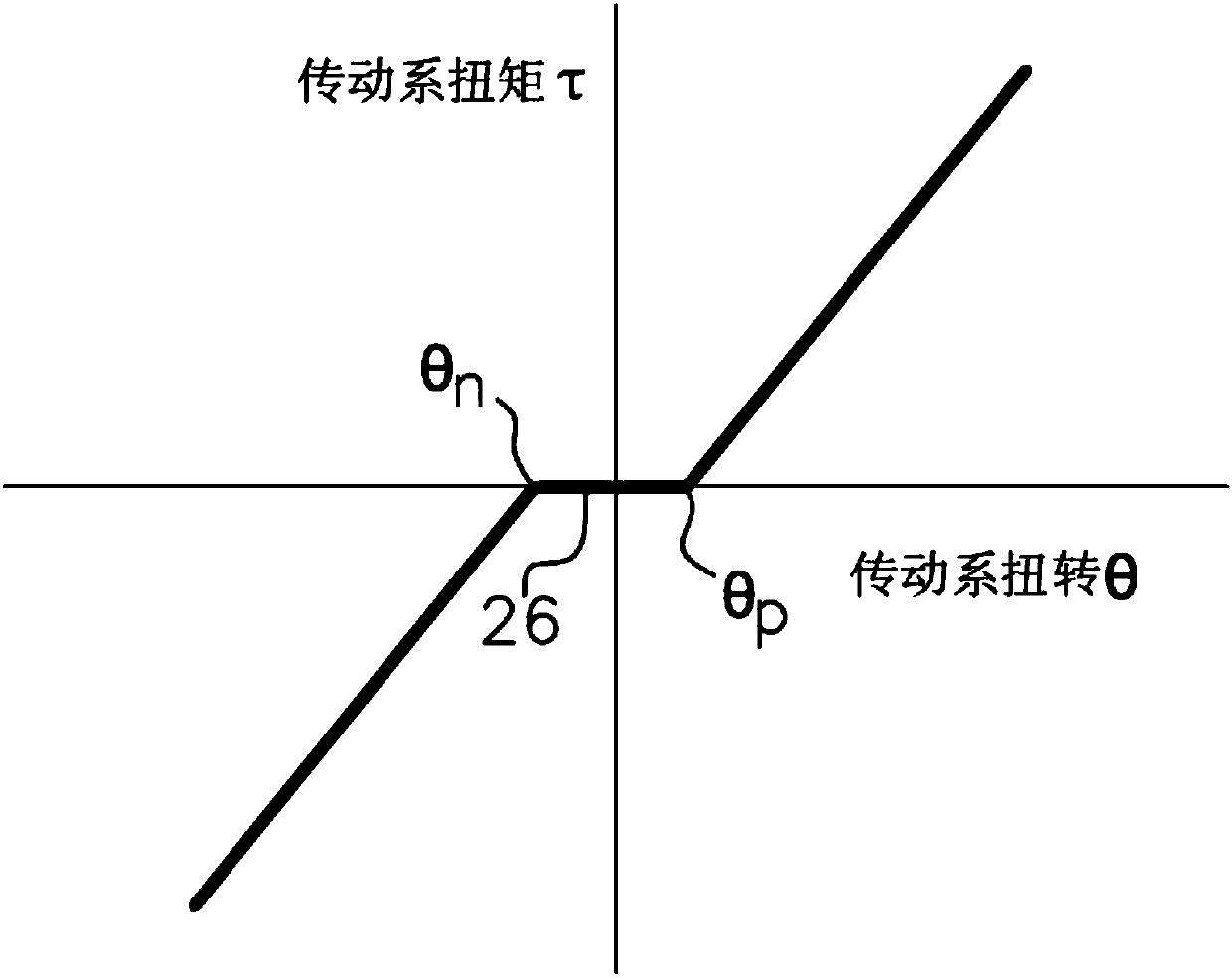

Lash crossing detection using a shaft torque sensor

ActiveUS8733183B1Avoid problemsMachine gearing/transmission testingWork measurementTorque sensorEngineering

Owner:FORD GLOBAL TECH LLC

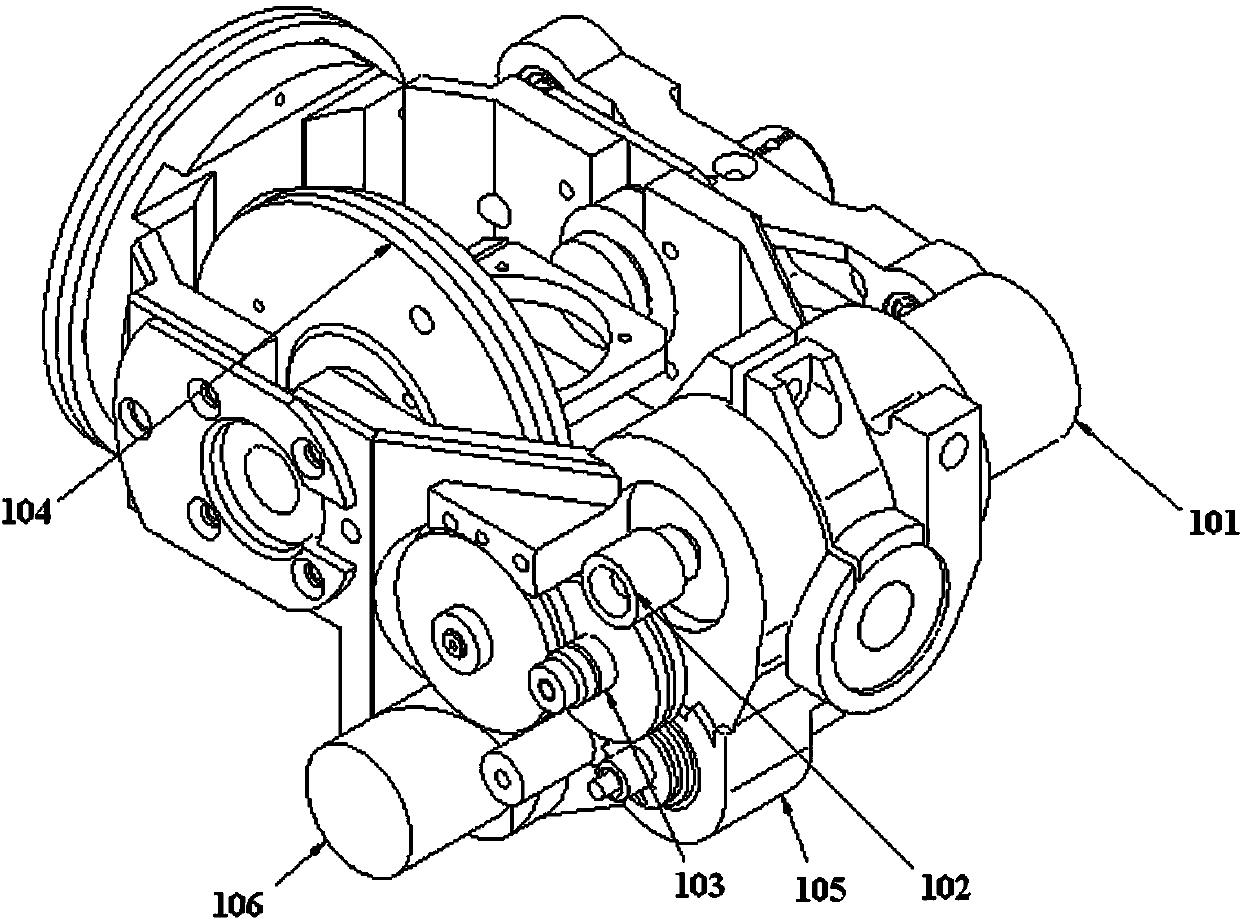

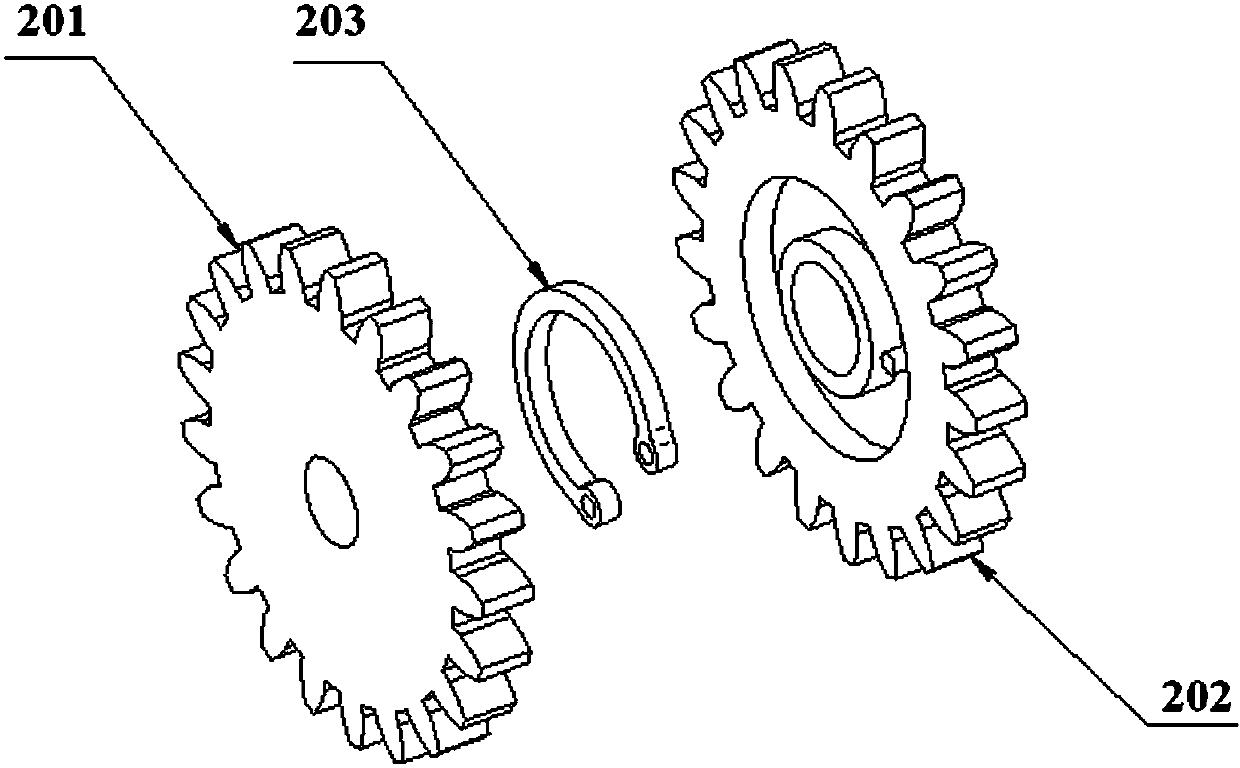

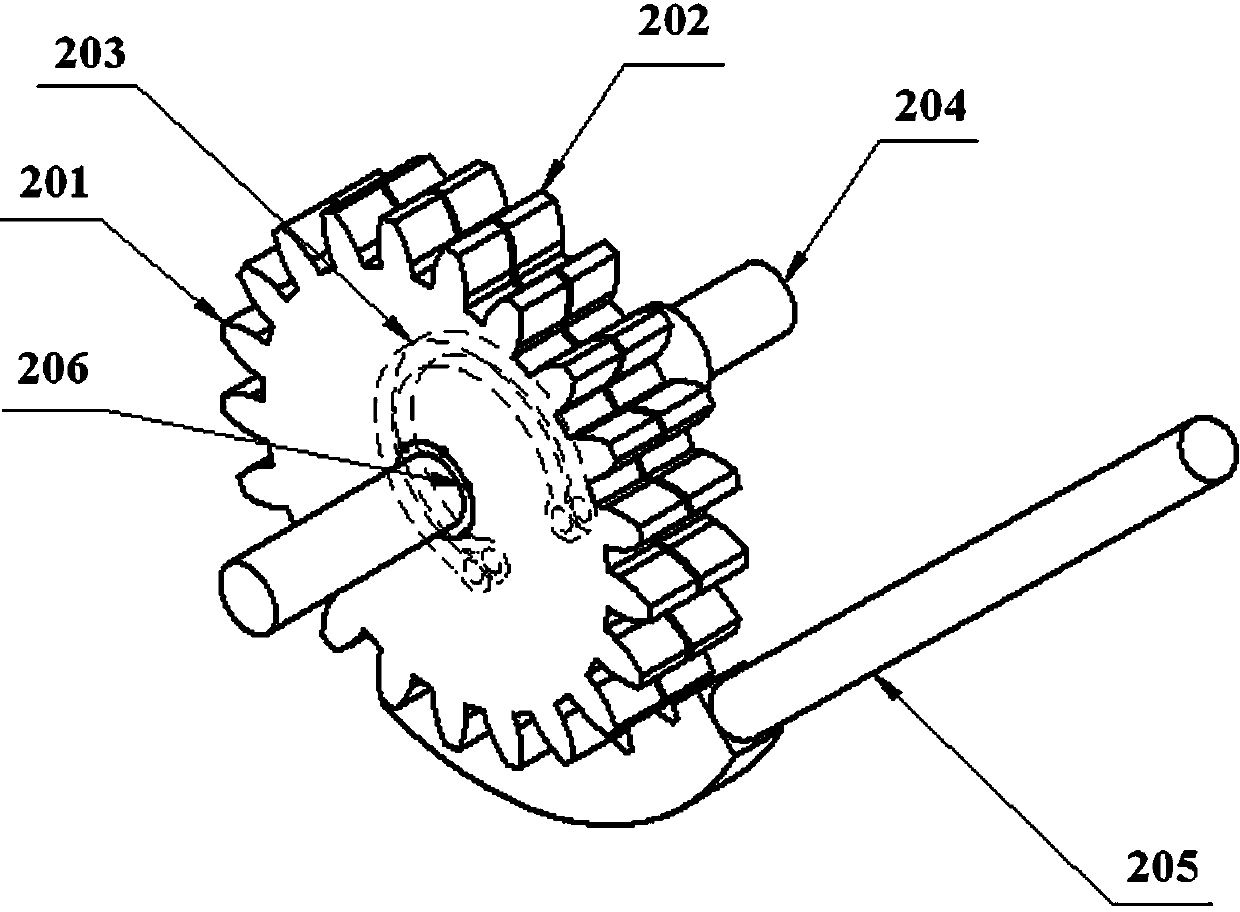

Double-gear assembly provided with backlash spring and mounting method thereof

InactiveCN104179945AEasy to assemblePrecise control statusPortable liftingTransmission elementsBacklashGear wheel

The invention discloses a mounting method of a double-gear assembly provided with a backlash spring. The method comprises the steps as follows: pin holes are performed in a first gear and a second gear respectively and formed in circumferences having equal diameters and taking the centers of the first gear and the second gear as the circle centers; the first gear, the second gear and the backlash spring are arranged on a gear shaft in a sleeving manner, the backlash spring is mounted between the first gear and the second gear, and the double-gear assembly provided with the backlash spring is formed; the pin holes coincide after the first gear and the second gear rotate relatively taking the gear shaft as the center, and pins are mounted in the pin holes; the double-gear assembly provided with the backlash spring is mounted to a transmission chain; and the double-gear assembly provided with the backlash spring is separated from the pins. Through matching of the pin holes in the gears with the pins, the states of the movable gears are controlled accurately, gear profiles coincide all along, and the double-gear assembly provided with the backlash spring can be assembled to the transmission chain; and a tooling for separating the pins is designed, so that the double-gear assembly provided with the backlash spring is conveniently separated from the pins.

Owner:SHANGHAI RADIO EQUIP RES INST

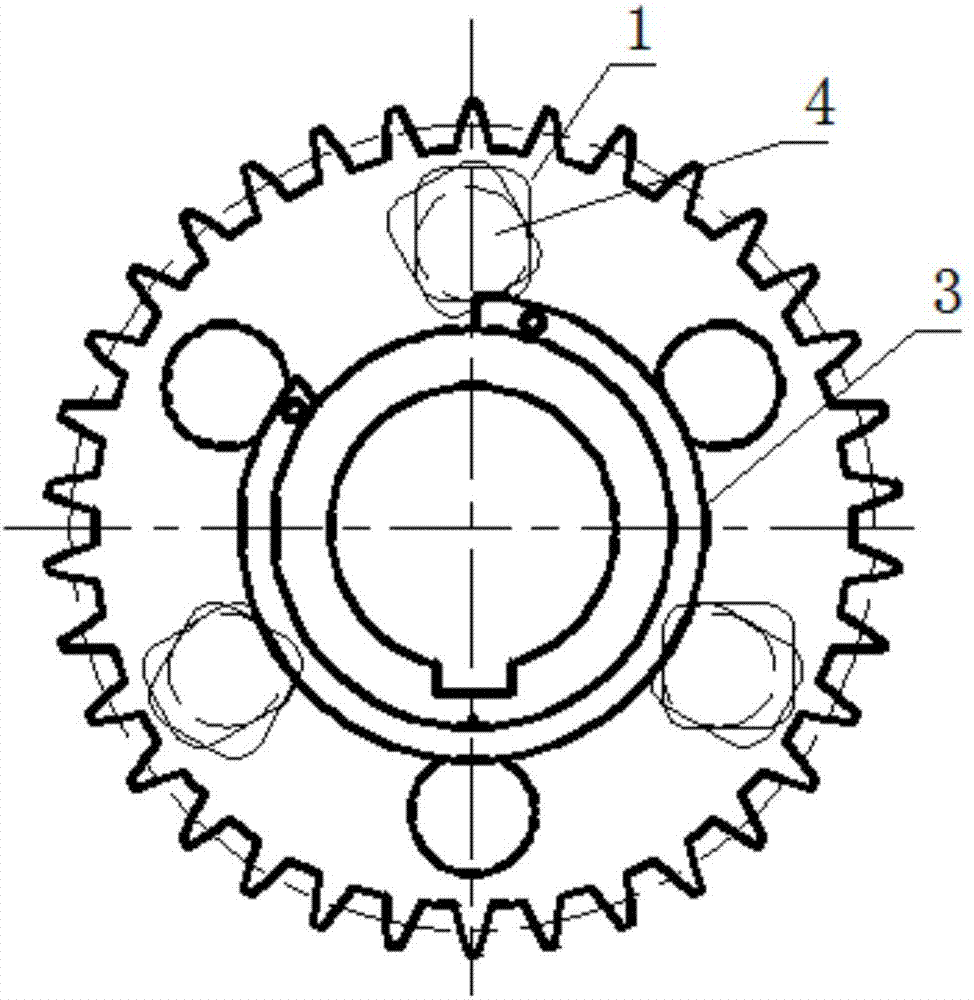

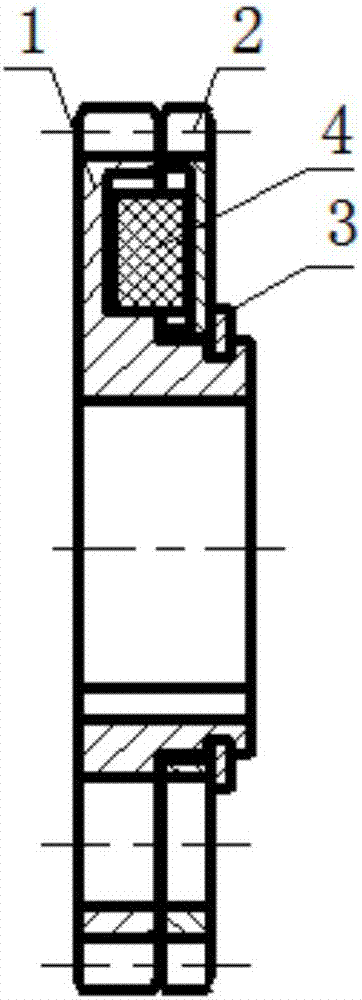

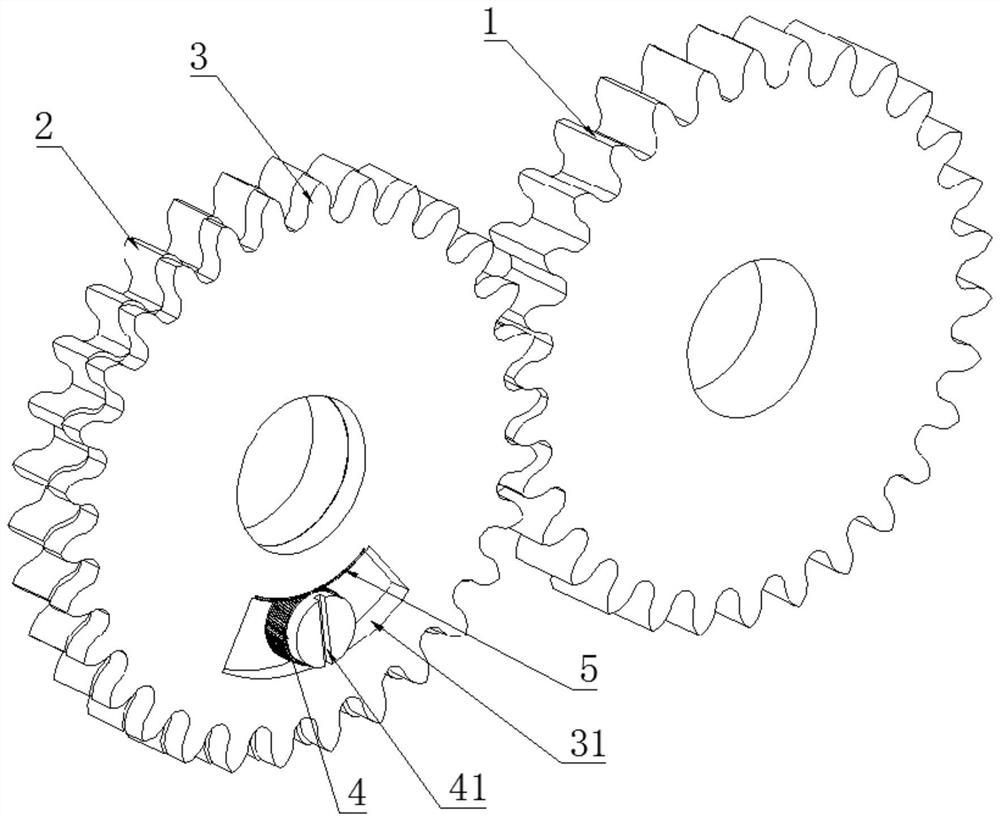

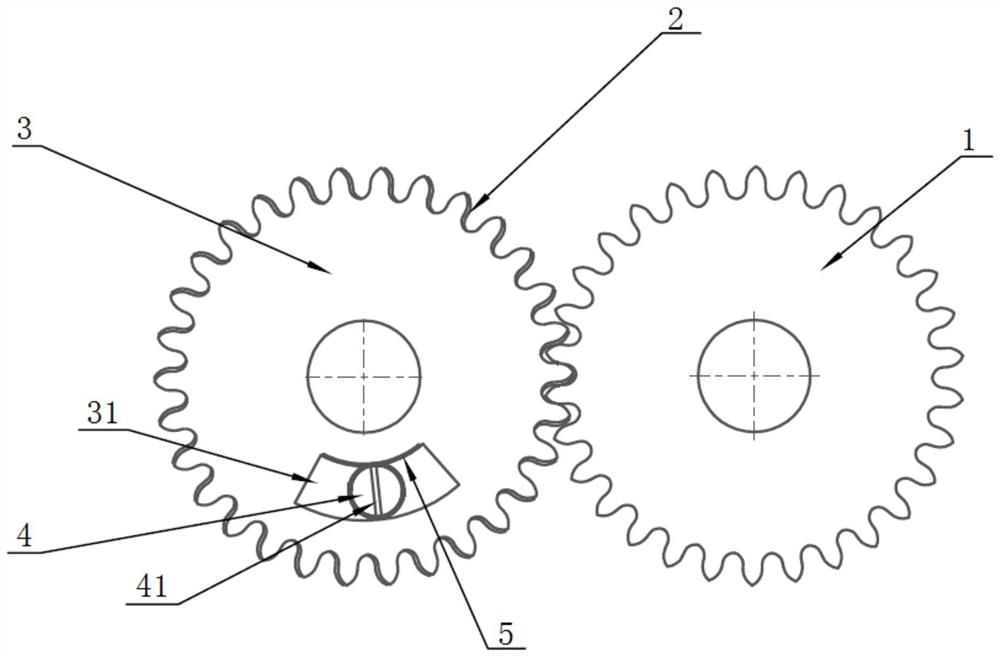

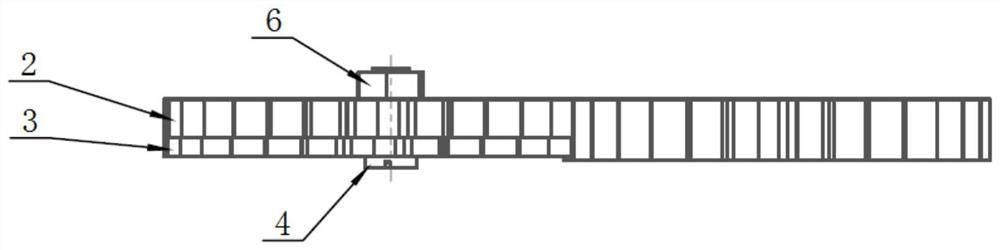

Anti-backlash gear device

PendingCN107166014AEasy to assembleEliminate backlash effectPortable liftingGearing elementsSet screwBacklash

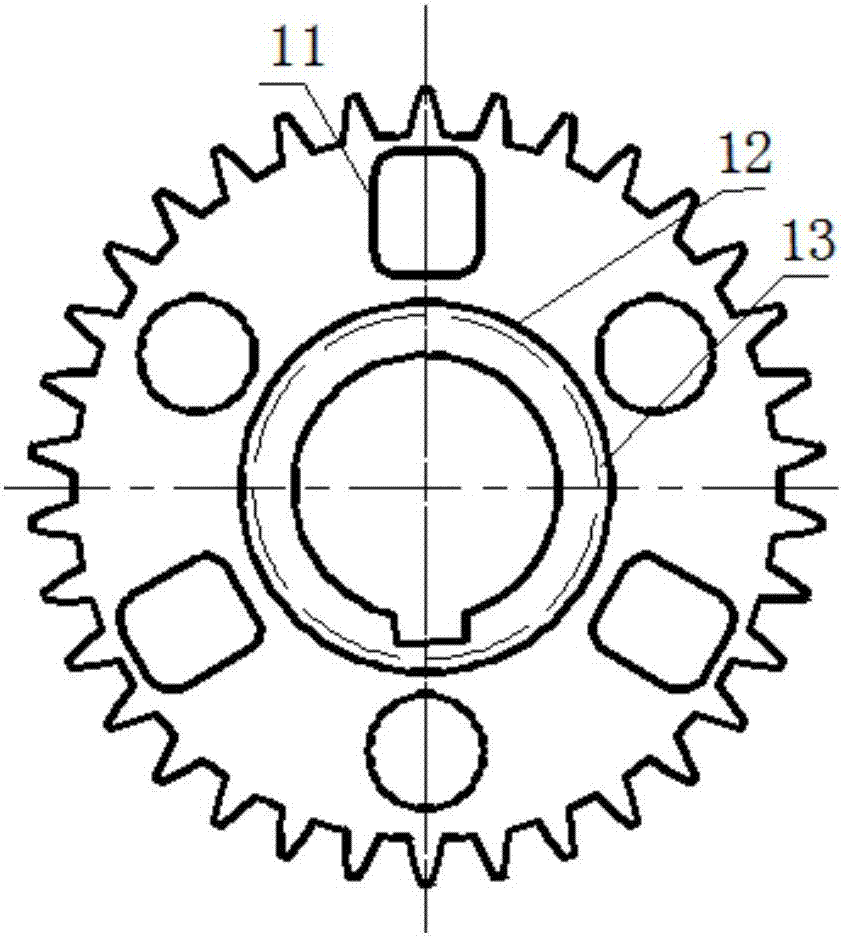

The invention discloses an anti-backlash gear device. The anti-backlash gear device comprises a main gear, an auxiliary gear, snap springs and flay hammers, wherein a plurality of radial sliding grooves are evenly distributed in the periphery of one side of a gear disk of the main gear, the radial sliding grooves are rounded rectangles, a hub extending outwards is arranged in the middle of the main gear, and snap spring grooves are formed in the peripheral side of the hub; a plurality of deflecting sliding grooves are evenly distributed in the periphery of one side of a gear disk of the auxiliary gear, the deflecting sliding grooves are rounded rectangles and are arranged corresponding to the radial sliding grooves of the main gear in a deflecting manner, a center hole is formed in the middle of the auxiliary gear and is arranged to be matched with the hub of the main gear in a sliding manner, and the radial sliding grooves and the deflecting sliding grooves of the auxiliary gear form buckling containing cavities; the snap springs are arranged in the snap spring grooves; and the fly hammers are cylindrical and are arranged in the buckling containing cavities in a sliding matched manner. According to the anti-backlash gear device, dislocation of the main gear and the auxiliary gear is achieved through the centrifugal force of the fly hammers, the gear backlash action is eliminated, a prepositioning screw is relieved, and the gears can be assembled in a complex cavity conveniently.

Owner:GUANGXI YUCHAI MASCH CO LTD

Low-cost angle measurement positioning and locking device based on worm gear and worm

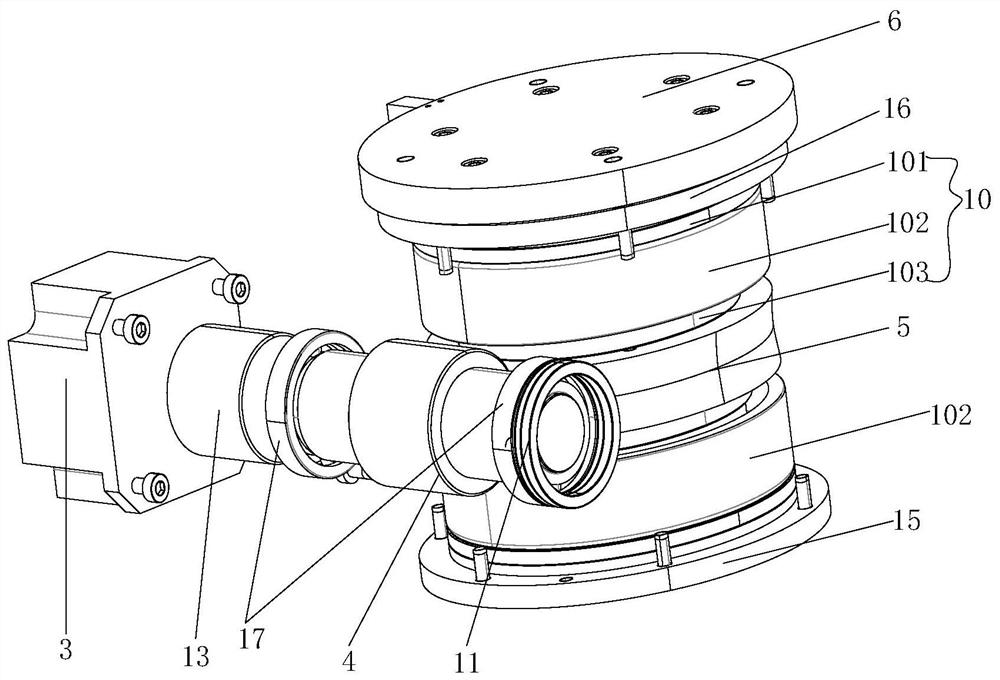

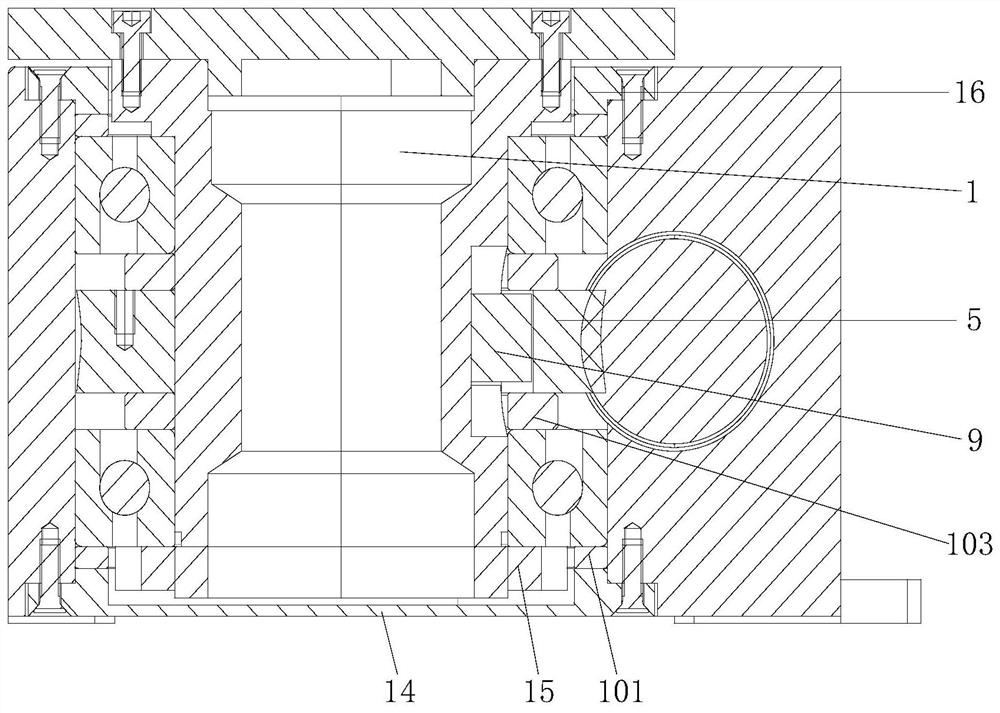

PendingCN112564403APrecise positioningGuaranteed positioning accuracyWork holdersMechanical energy handlingBacklashMotor drive

The invention relates to the technical field of worm and gear transmission, in particular to a low-cost angle measurement positioning and locking device based on a worm gear and a worm. The device comprises a main shaft, a base arranged outside the main shaft, a motor fixed to the base, a worm coaxially connected with an output shaft of the motor and located in the base, a worm gear rotationally connected with the worm and arranged on the main shaft in a sleeving mode, a circular table top fixed to the top end of the main shaft, an anti-dazzling screen fixed on the edge of the table top, and aphotoelectric switch fixed on the base and matched with the anti-dazzling screen. The motor drives the worm gear and the worm to rotate so as to drive the main shaft to rotate freely by 360 degrees,the worm gear and the worm with the variable lead and a stepping motor are used for reliably positioning at corresponding positions according to user requirements, the positioning precision is guaranteed, and the whole device is simple in structure and low in cost. The backlash of the worm gear and the worm is corrected through a backlash adjusting gasket, the idle stroke is eliminated, and the situations that the backlash of the worm gear and the worm becomes large and precision is reduced due to long-time use are avoided.

Owner:JIUJIANG JINGDA MEASUREMENT TECH

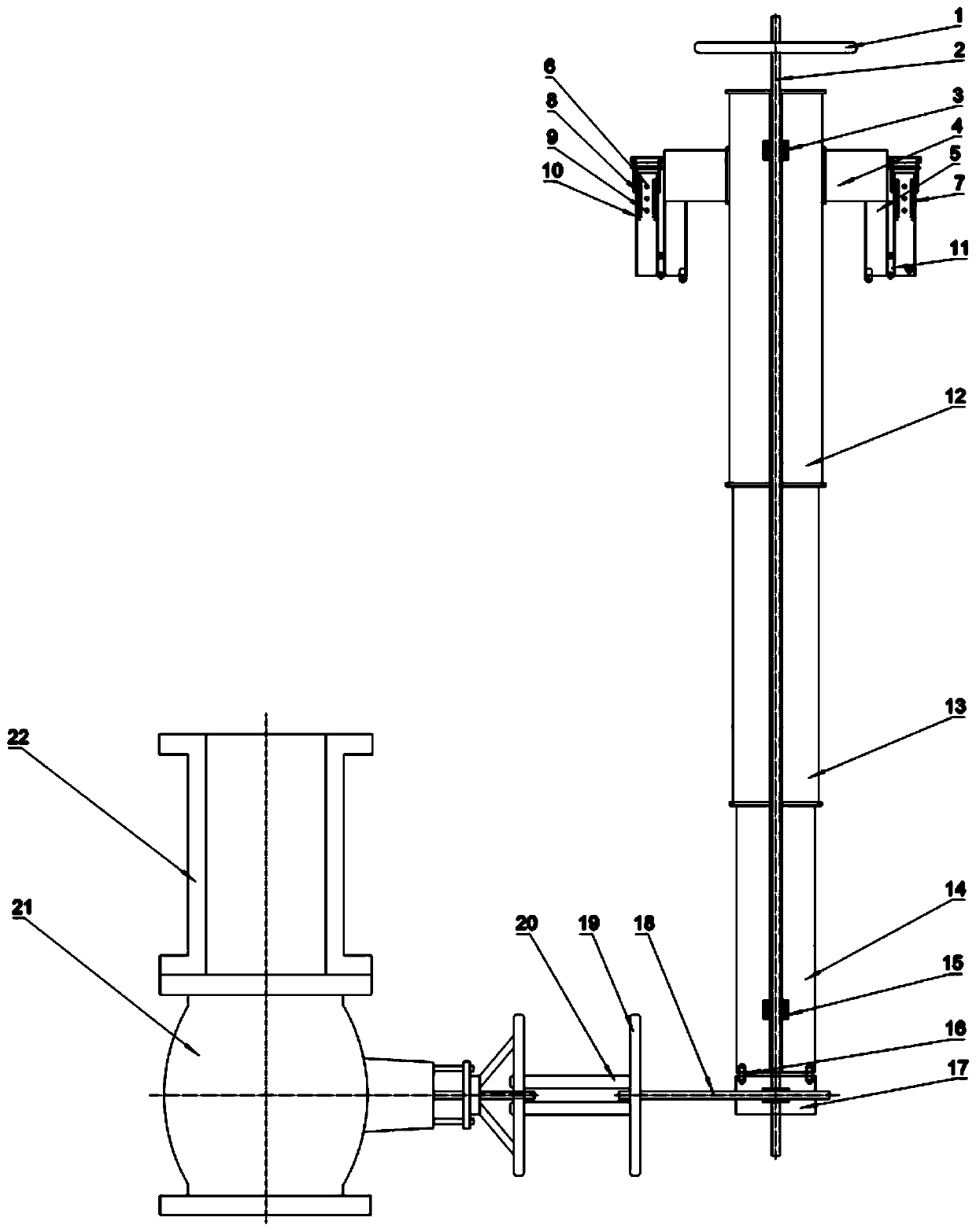

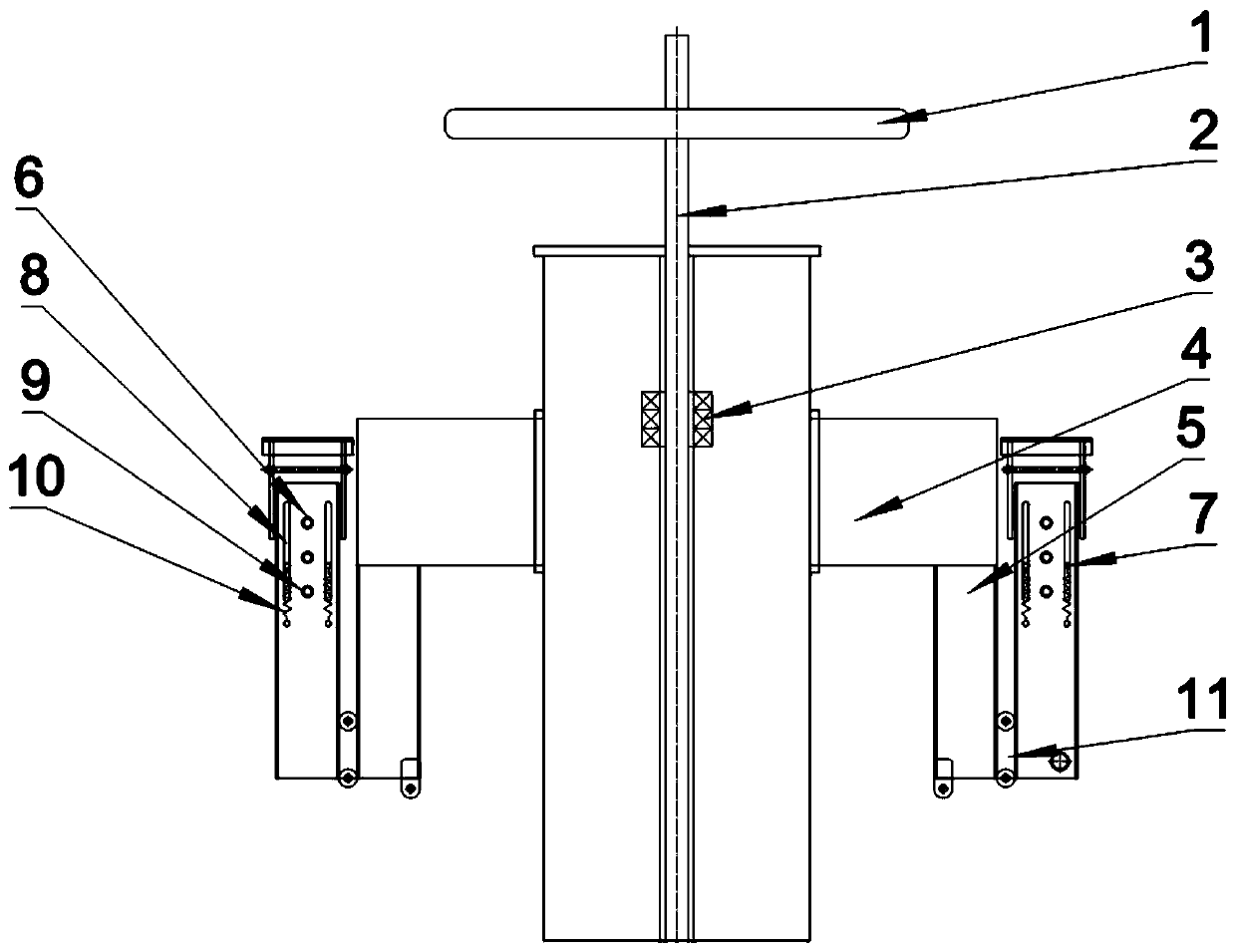

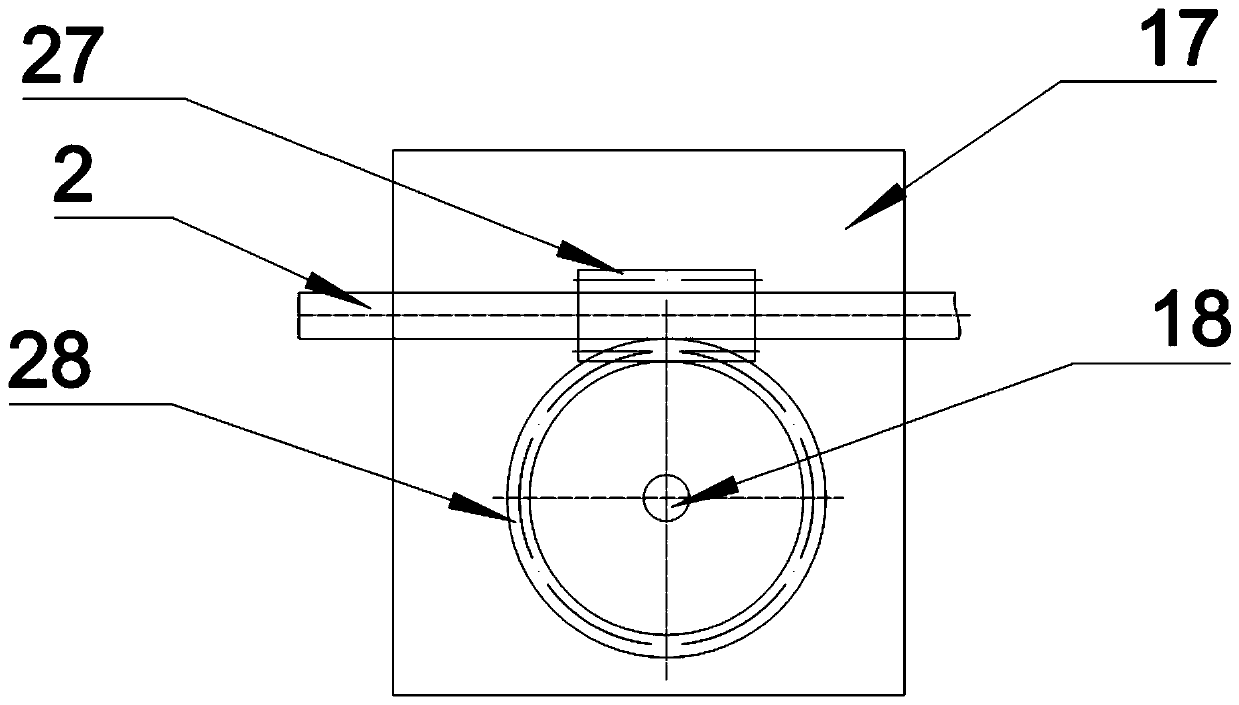

Ball valve auxiliary device capable of being remotely adjusted

InactiveCN110906025ARealize the folding effectAchieve precise adjustmentPlug valvesOperating means/releasing devices for valvesBacklashInvolute gear

The objective of the present invention is to provide a ball valve auxiliary device capable of being remotely adjusted. The opening degree of a valve can be directly adjusted according to the positionof the valve and through remote location. According to a folding type supporting adjusting leg, through ingenious combination of supporting legs, a connecting plate, a spring and other devices, the folding effect of the supporting legs can be achieved. When the folding type supporting adjusting leg does not need to work, the supporting legs are folded, telescopic rods are contracted, and space issaved; during work, the supporting legs are easily straightened to achieve the supporting effect, the telescopic rods are unfolded, remote accurate positioning is achieved according to the position ofthe valve, the opening degree of the valve can be directly adjusted, and operation is convenient and fast. In the opening and closing process, a gear box can adjust the backlash of a transmission pair by axially moving a variable-tooth-thickness involute gear based on the equivalent principle of axial movement and circumferential rotation of a spiral surface, so that the efficiency of the transmission pair is improved, and accurate adjustment of the valve is achieved.

Owner:JIANGSU GUOQUAN PUMP MFG CO LTD

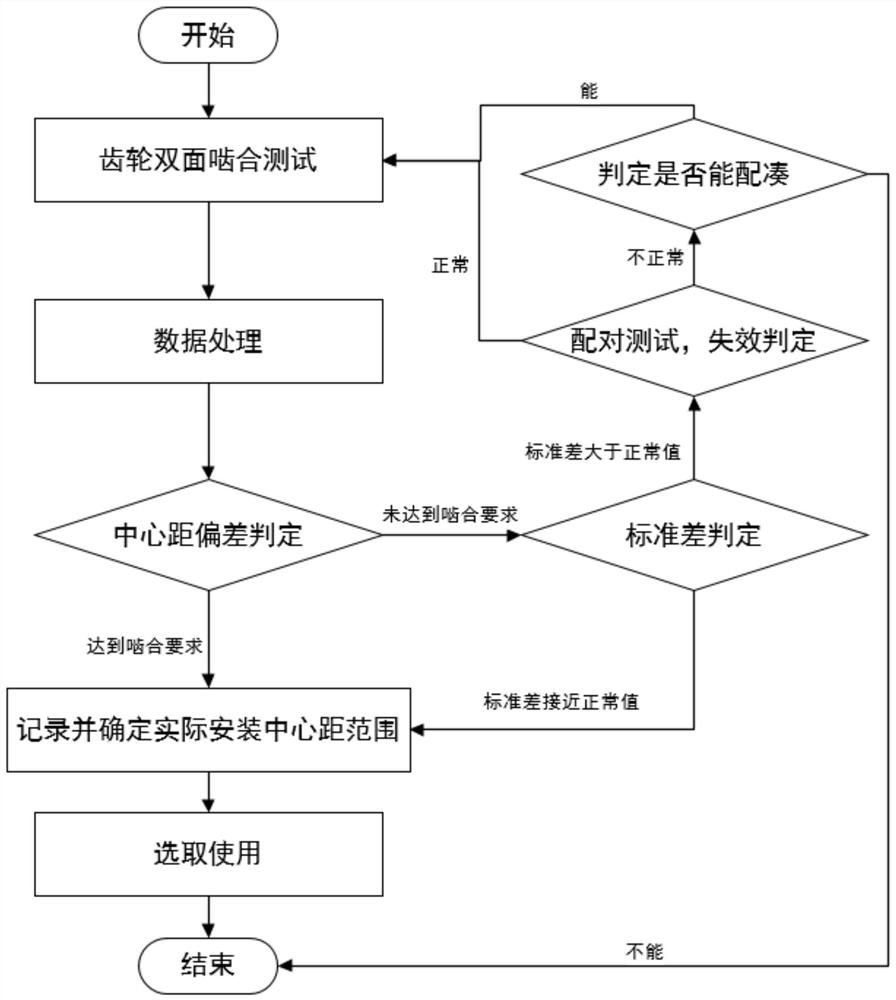

Gear double-sided meshing detection method

The invention relates to a gear double-sided meshing detection method. The gear double-sided meshing detection method comprises the following steps: selecting two tested gears to form a tested gear set to perform gear double-sided meshing test, performing data processing on the obtained tested double-sided meshing center distance, and judging the center distance deviation, recording and calculating the actual installation center distance range of the pair of gears according to the backlash, recording the tested gear set in a standard gear test database, and selecting the gear set with the proper actual installation center distance range from the standard gear test database according to the design. The gear double-sided meshing detection method has the advantages that use of a high-precision gear is avoided, and the rate of defective products is reduced.

Owner:伯朗特机器人股份有限公司

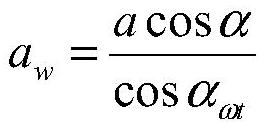

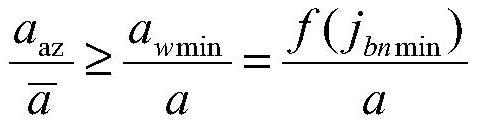

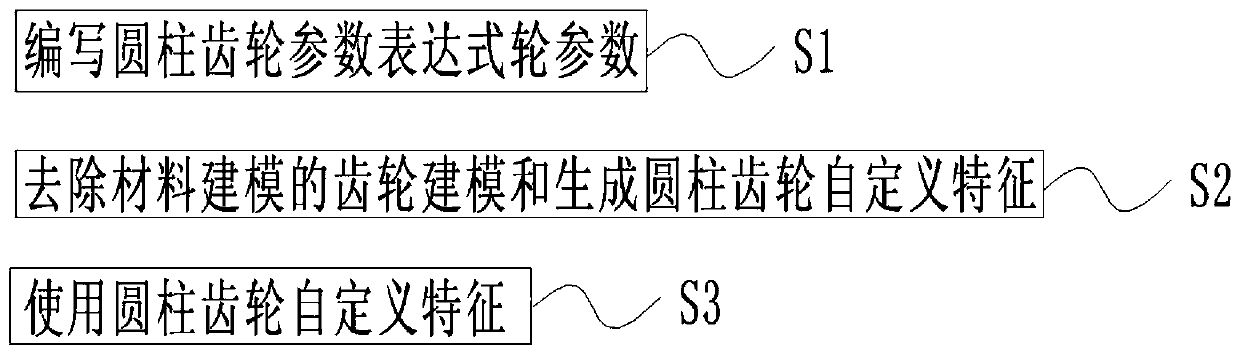

NX involute deflection helical cylindrical gear modeling method

ActiveCN110889194AEfficient modelingImprove accuracyGeometric CADSustainable transportationHobbingBacklash

The invention discloses an NX involute deflection helical cylindrical gear modeling method. The method is a custom feature (hereinafter referred to as UDF) based on NX. The UDF is a hobbing action; custom pairing gear pair parameters can be supported; modified gear can be supported, arbitrary rotation direction switching of helical gear can be supported, switching of driving and driven gear parameters can be supported, deflection or non-deflection straight-tooth gears are compatible, gear pair backlash and gear manufacturing inspection parameters with different parameters and different manufacturing precisions can be output, modleling of cylindrical gears can be realized efficiently and stably, and a tooth model can be generated averagely for 2-4 seconds.

Owner:NANJING HIGH SPEED & ACCURATE GEAR GRP

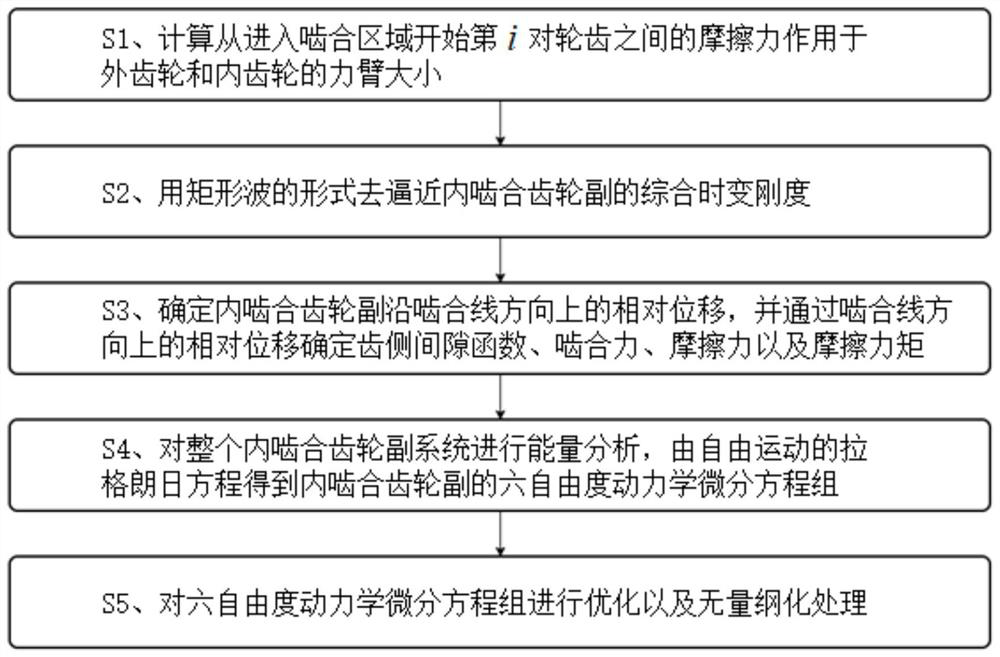

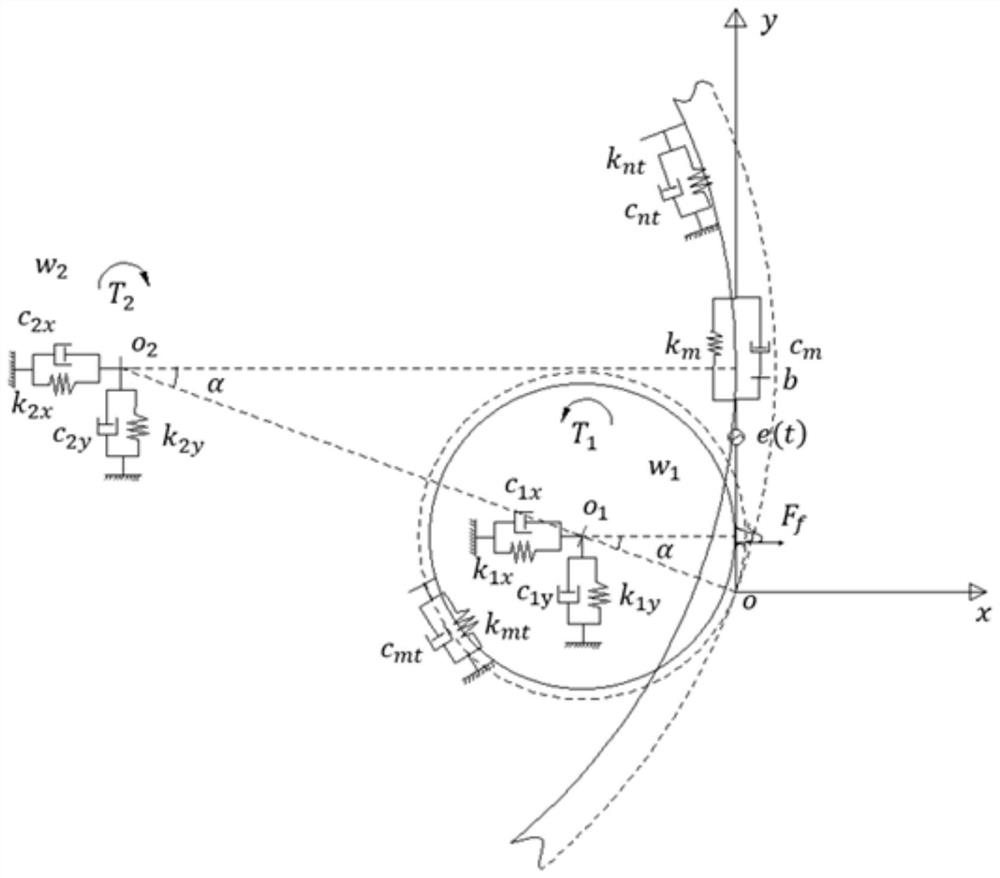

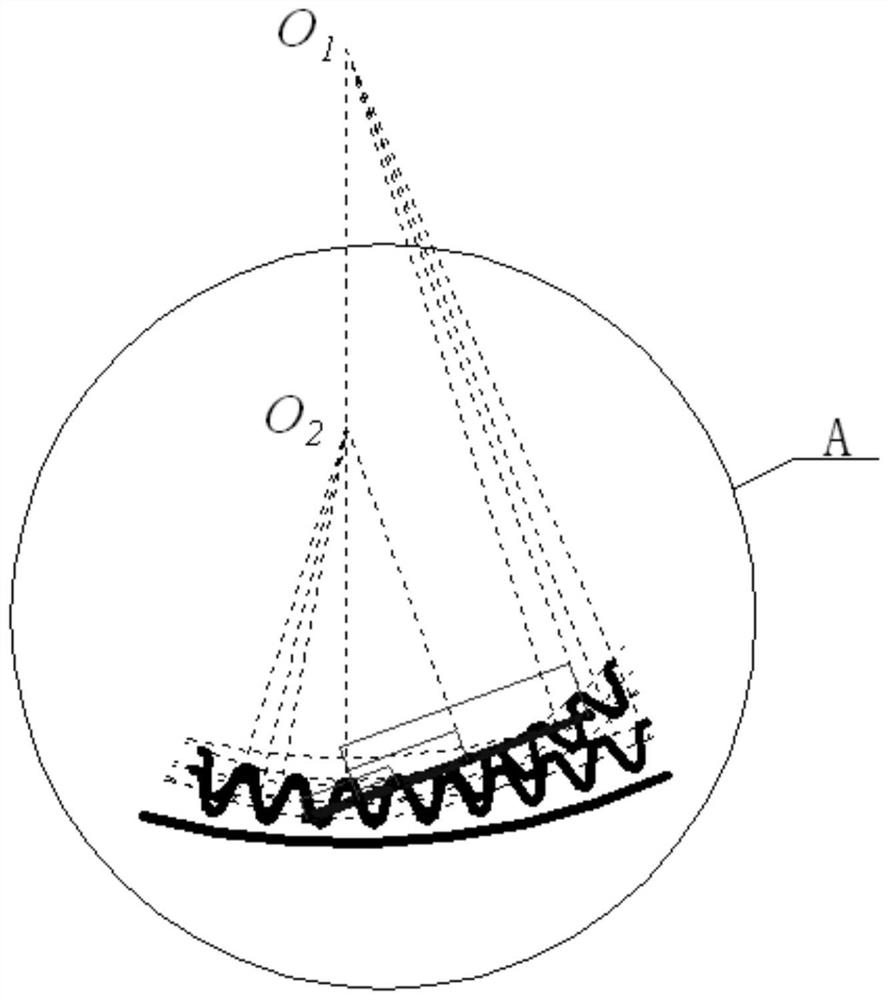

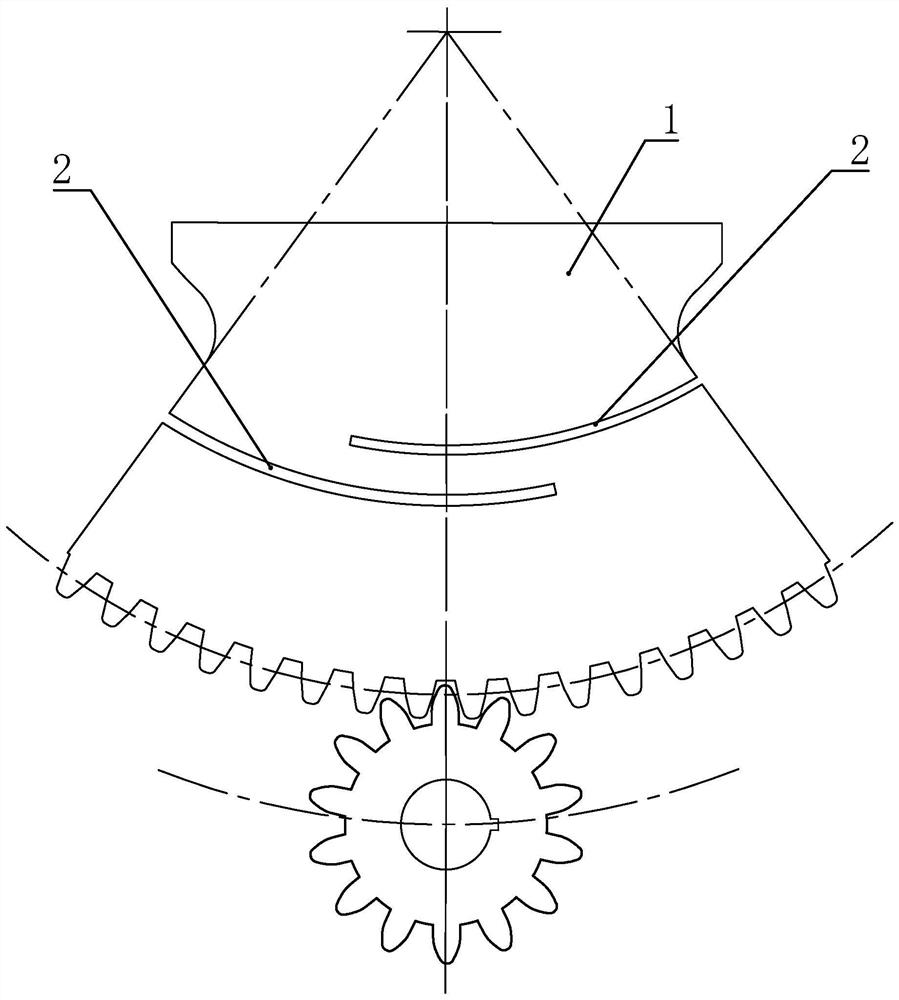

Six-degree-of-freedom kinetic model modeling method for internal meshing gear pair

ActiveCN112395711AReflect the actual working conditionsImprove versatilityGeometric CADSustainable transportationFriction torqueGear wheel

The invention discloses a six-degree-of-freedom kinetic model modeling method for an internal meshing gear pair. The method comprises the following steps: S1, calculating the force arm of the frictionforce between a pair of gear teeth acting on an external gear and an internal gear from entering a meshing area; S2, approximating the comprehensive time-varying stiffness of the internal meshing gear pair in a rectangular wave form; S3, determining the relative displacement of the internal meshing gear pair in the meshing line direction, and determining a gear backlash function, meshing force, friction force and friction torque through the relative displacement in the meshing line direction; S4, performing energy analysis on the whole internal meshing gear pair system, and obtaining a six-degree-of-freedom dynamic differential equation set of the internal meshing gear pair according to the Lagrange equation of free motion; and S5, performing optimization and dimensionless processing on the six-degree-of-freedom kinetic differential equation set. The design is high in accuracy and good in universality.

Owner:WUHAN UNIV OF TECH

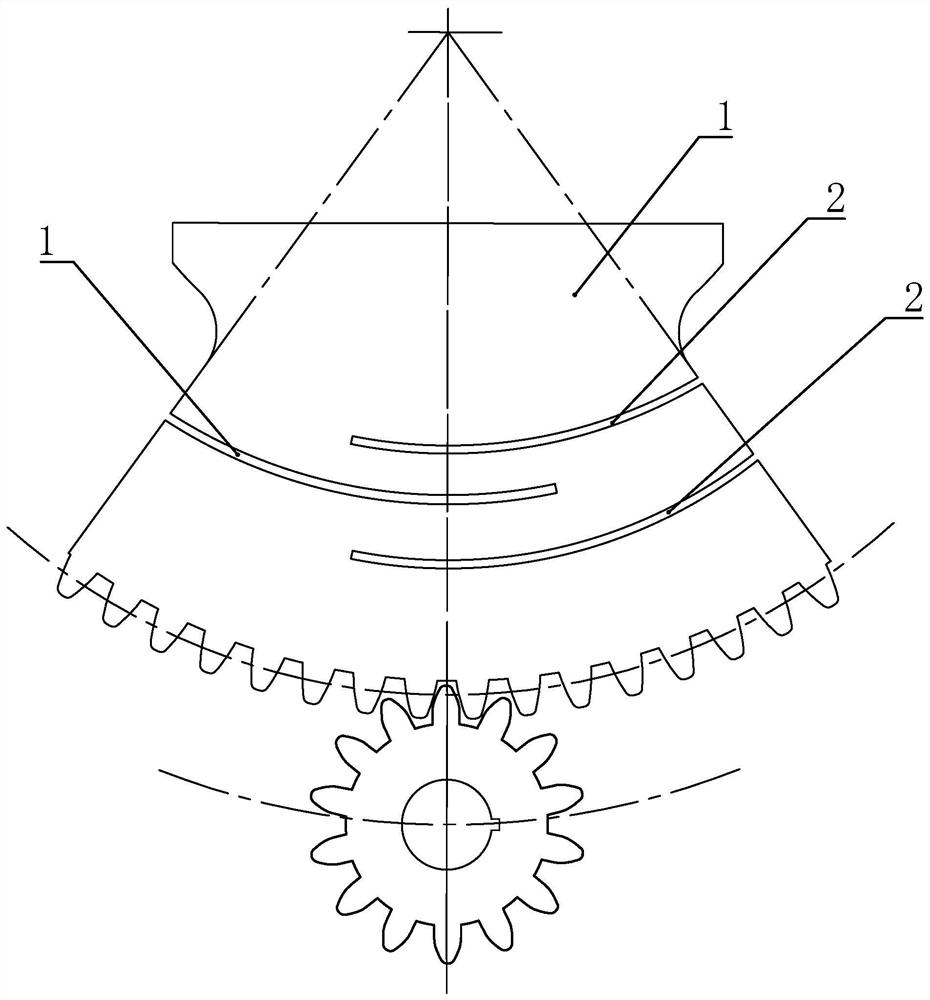

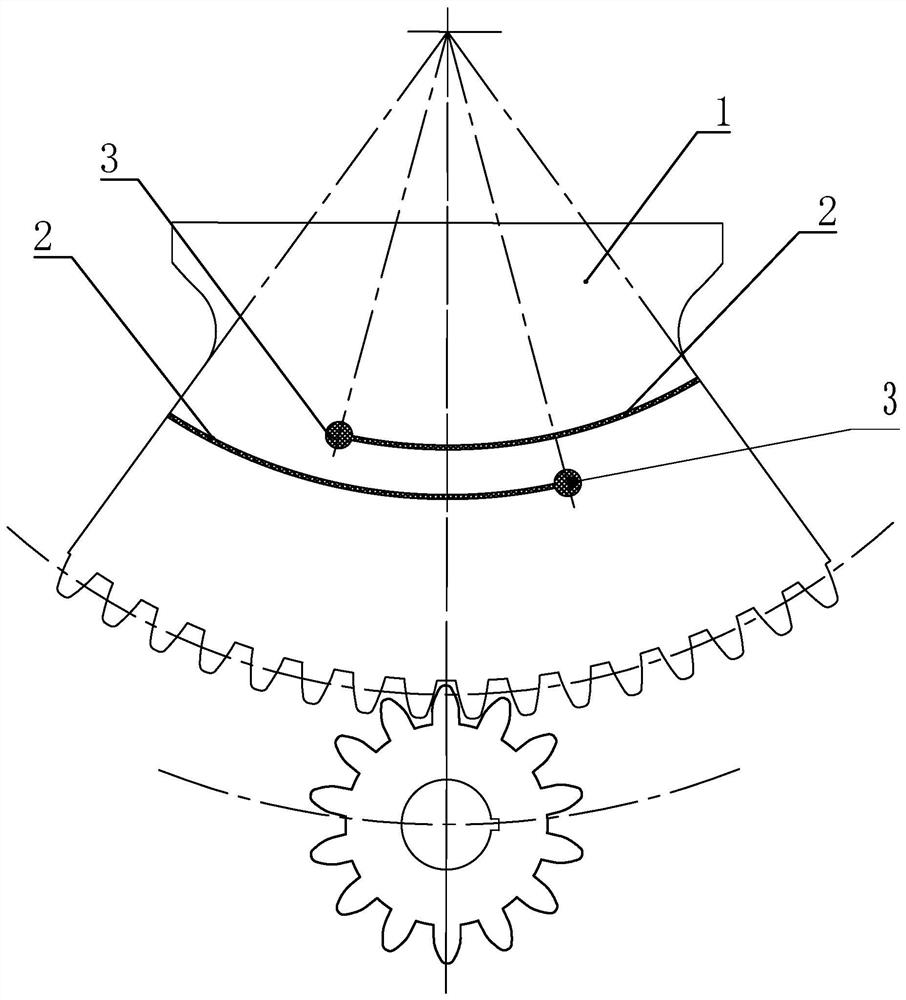

Fan-shaped gear backlash adjusting structure

PendingCN112594351AIncrease dampingSmooth transmissionPortable liftingGearing elementsBacklashGear wheel

The invention discloses a fan-shaped gear backlash adjusting structure. The fan-shaped gear backlash adjusting structure is characterized in that at least one pair of arc-shaped through grooves are formed in the end face of a fan-shaped gear; the arc-shaped through grooves and a reference circle of the fan-shaped gear are concentric and unequal in diameter; one end of each arc-shaped through groove penetrates through the side edge of the fan-shaped gear; at least one pair of arc-shaped through grooves penetrate through the two side edges of the fan-shaped gear in the opposite directions; and the ends, located in the fan-shaped gear, of the arc-shaped through grooves penetrating through the two side edges of the fan-shaped gear are arranged in a staggered mode and extend towards one side, penetrating through the fan-shaped gear, of the arc-shaped through grooves to pass through the center line of the fan-shaped gear but not penetrate through the fan-shaped gear. The arc-shaped through grooves are formed in the end face of the fan-shaped gear, so that the fan-shaped gear can achieve micro elastic deformation in the meshing process; the effect equivalent to a spring is achieved; filling glue is poured into the arc-shaped through grooves, a round through hole and a damping hole to increase damping of the gear; the purposes of automatically adjusting the gear pair backlash, reducingvibration and absorbing energy are achieved; Stable transmission of a light and small servo mechanism is realized; the structure is simple; and the method is suitable for a light-load small servo system.

Owner:SHAANXI AEROSPACE TIMES NAVIGATION EQUIP CO LTD

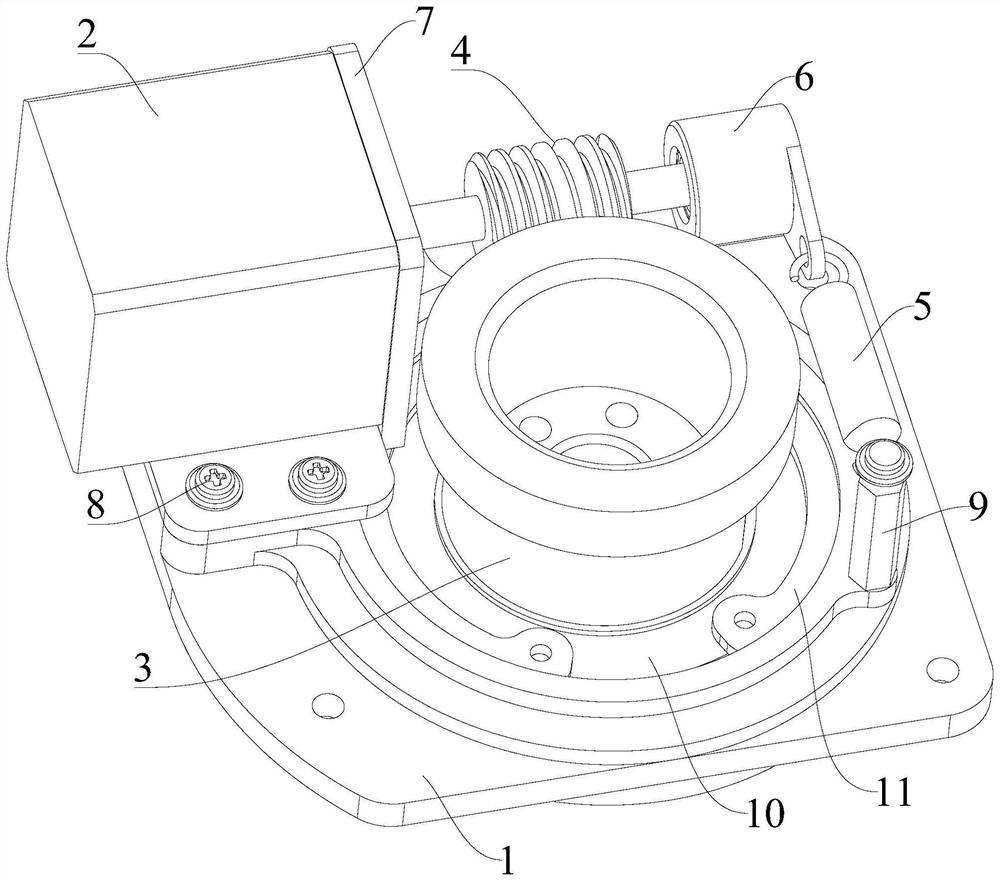

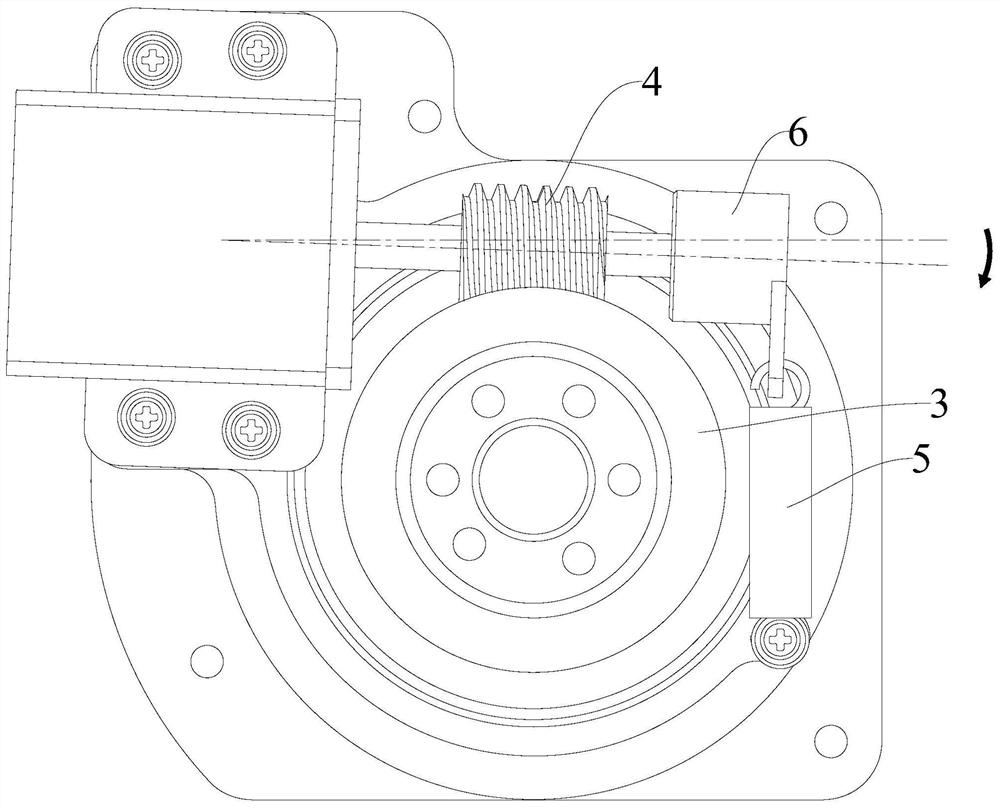

Worm and gear transmission structure

PendingCN112780726AGuaranteed transmission accuracyLow machining accuracy requirementsToothed gearingsGearing detailsBacklashElectric machinery

The invention discloses a worm and gear transmission structure. The worm and gear transmission structure comprises a mounting seat, a motor, a worm and a gear, wherein the worm and the gear are matched with each other, the output end of the motor is connected with one end of the gear, the worm is rotatably arranged on the mounting seat, the motor is movably arranged on the mounting seat, and the worm and gear transmission structure further comprises an elastic part, a first bearing and a bearing seat; and the first bearing sleeves the other end of the gear and fixed to the bearing seat, one end of the elastic part is connected with the mounting seat, and the other end of the elastic part is connected with the bearing seat so as to drive the gear to be close to the worm. Under the action of the elastic part, the worm and the motor can deflect by a certain angle, so that the center distance of the worm and the gear is automatically adjusted, zero-meshing backlash transmission of the worm and the gear is achieved, and the transmission precision of the worm and the gear is effectively guaranteed; and due to the fact that the center distance of the worm and the gear can be automatically adjusted, the machining precision requirement of the worm and the gear can be lowered, and the manufacturing cost of the worm and gear transmission structure is reduced.

Owner:SANLI VIDEO FREQUENCY SCI & TECH SHENZHEN

Method for detecting backlash

ActiveCN103940605BReduce disturbanceReduce measurement errorMachine gearing/transmission testingWork measurementBacklashControl engineering

Owner:FORD GLOBAL TECH LLC

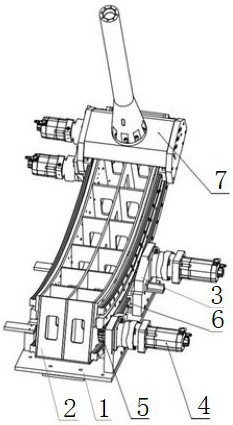

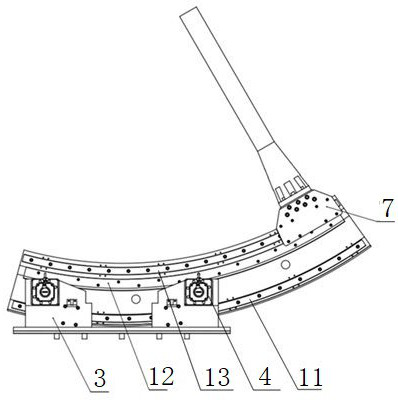

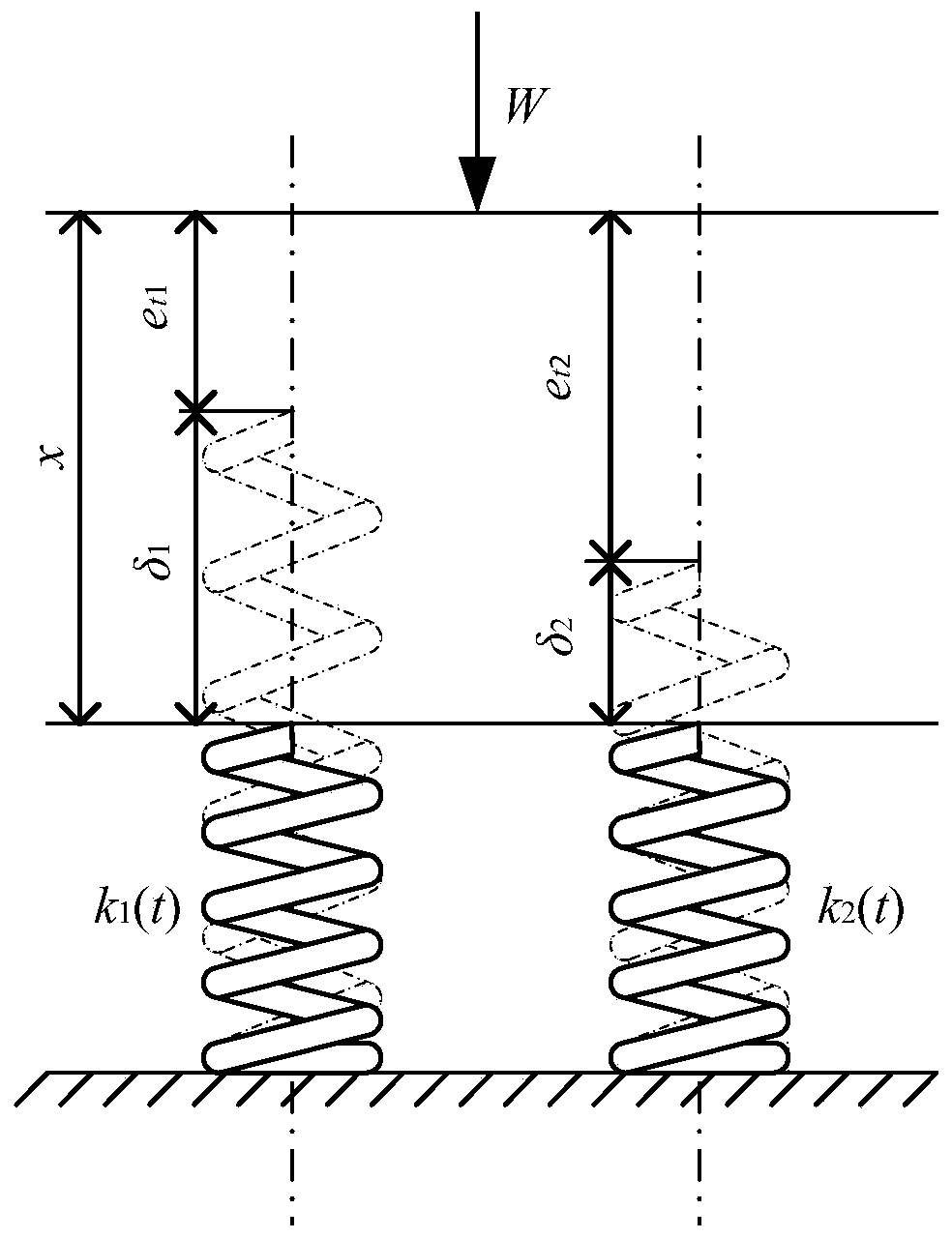

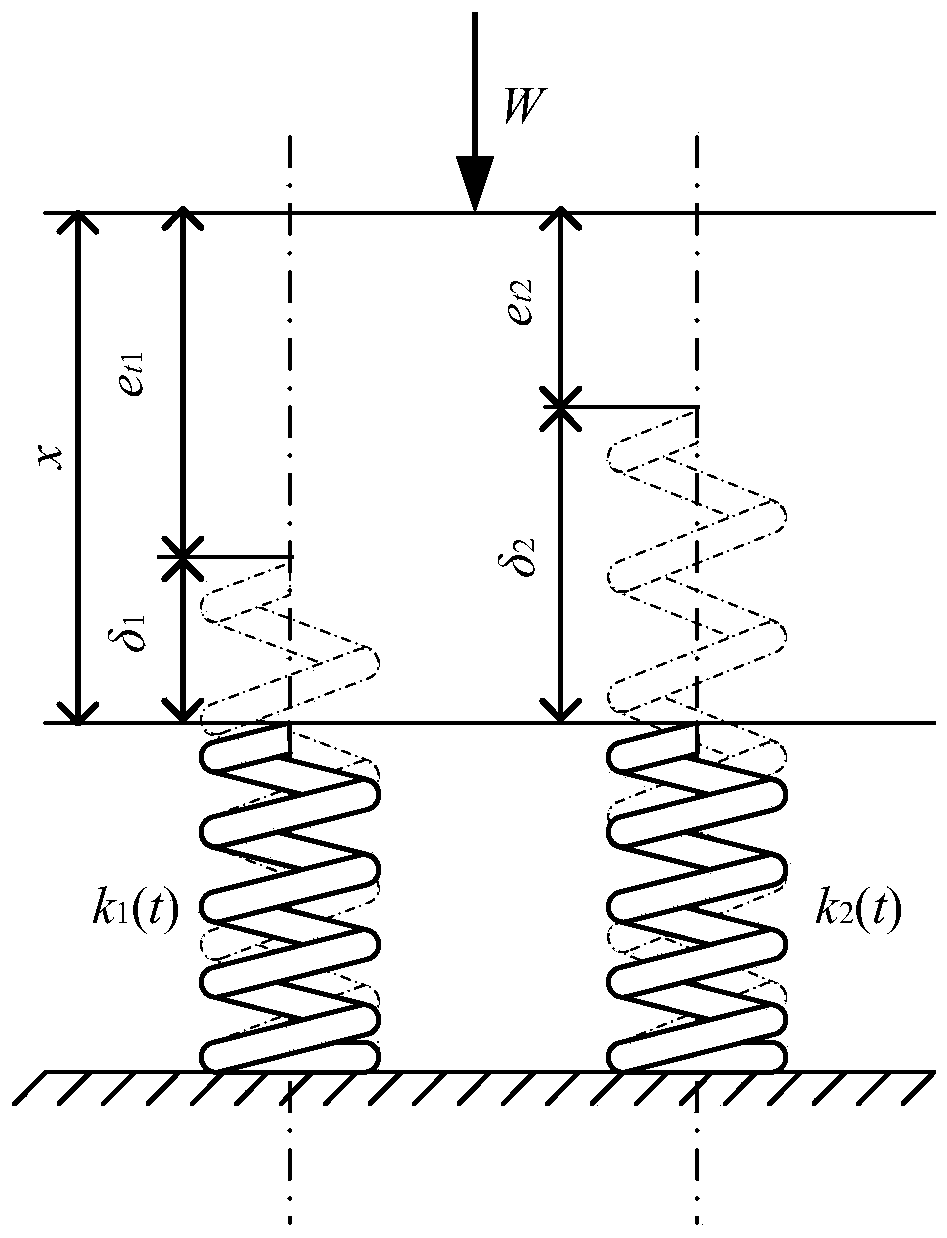

Single-point belly supporting device of two-stage attack angle mechanism and control method

ActiveCN114034463AReduce volumeLong-term maintenance of anti-gap effectAerodynamic testingGearing detailsStructural deformationBacklash

The invention discloses a single-point belly supporting device of a two-stage attack angle mechanism and a control method. The single-point belly supporting device comprises a base, a bent knife and a supporting rod base, wherein a first guide rail, a gear rack and a second guide rail are arranged on the two opposite outer side surfaces of the bent knife respectively, a bent knife supporting seat is arranged on the base, a first sliding block and a first gear are arranged on the bent knife supporting seat, a second sliding block and a second gear are arranged on the supporting rod base, the second sliding block is connected to the second guide rail, the second gear is meshed with the gear rack, the first gear and the second gear are meshed with the gear racks on the different side surfaces of the bent knife respectively, and the first gear and the second gear are independently connected with a driving motor. According to the invention, a two-stage angle-of-attack mechanism is adopted to reach a large angle-of-attack range of -30 degrees to 30 degrees, the size is small, the device is suitable for a narrow installation space, a double-motor-driven anti-backlash structure is adopted, the problems of installation errors, structural deformation, gear abrasion and the like are compensated, and the effect of keeping anti-backlash for a long time is achieved.

Owner:LOW SPEED AERODYNAMIC INST OF CHINESE AERODYNAMIC RES & DEV CENT

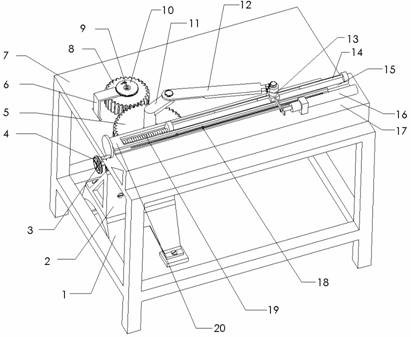

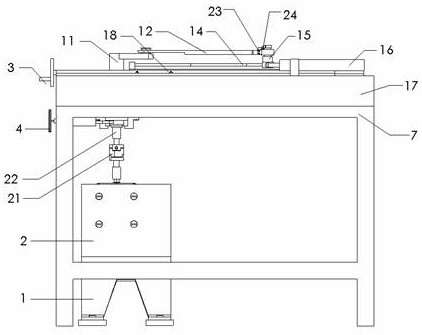

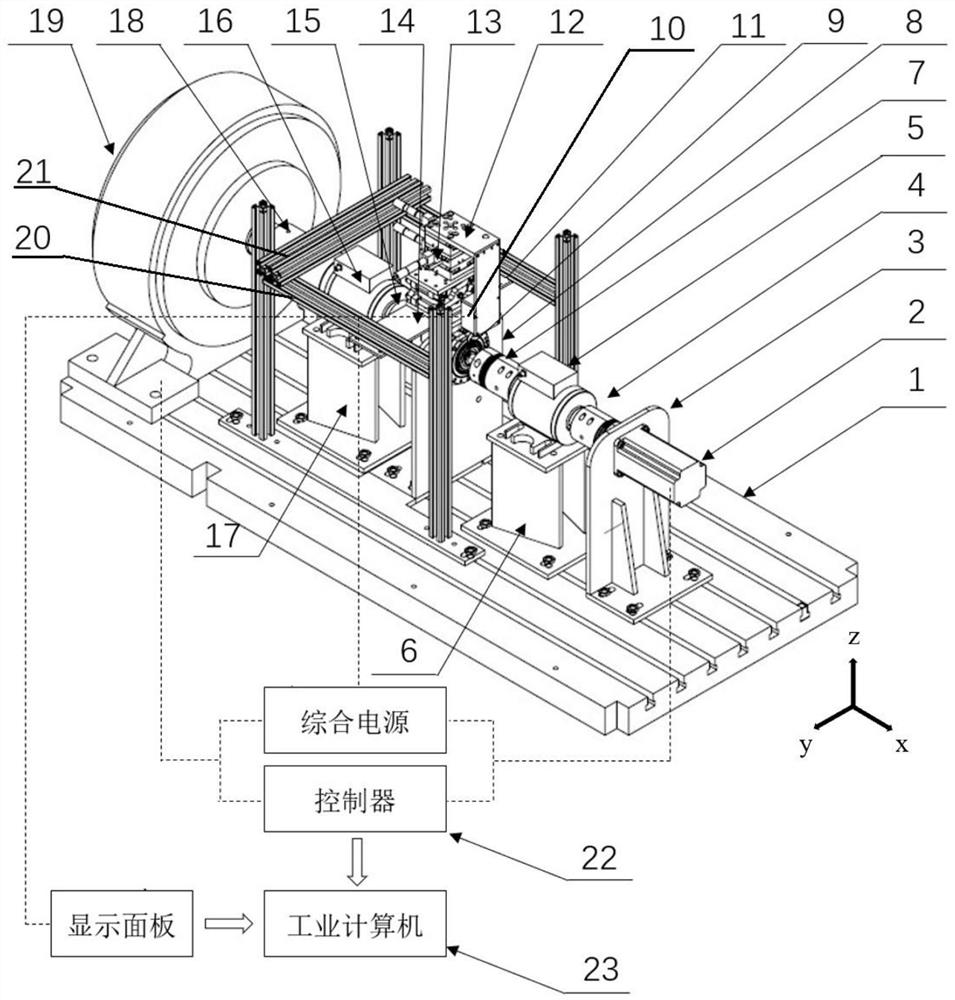

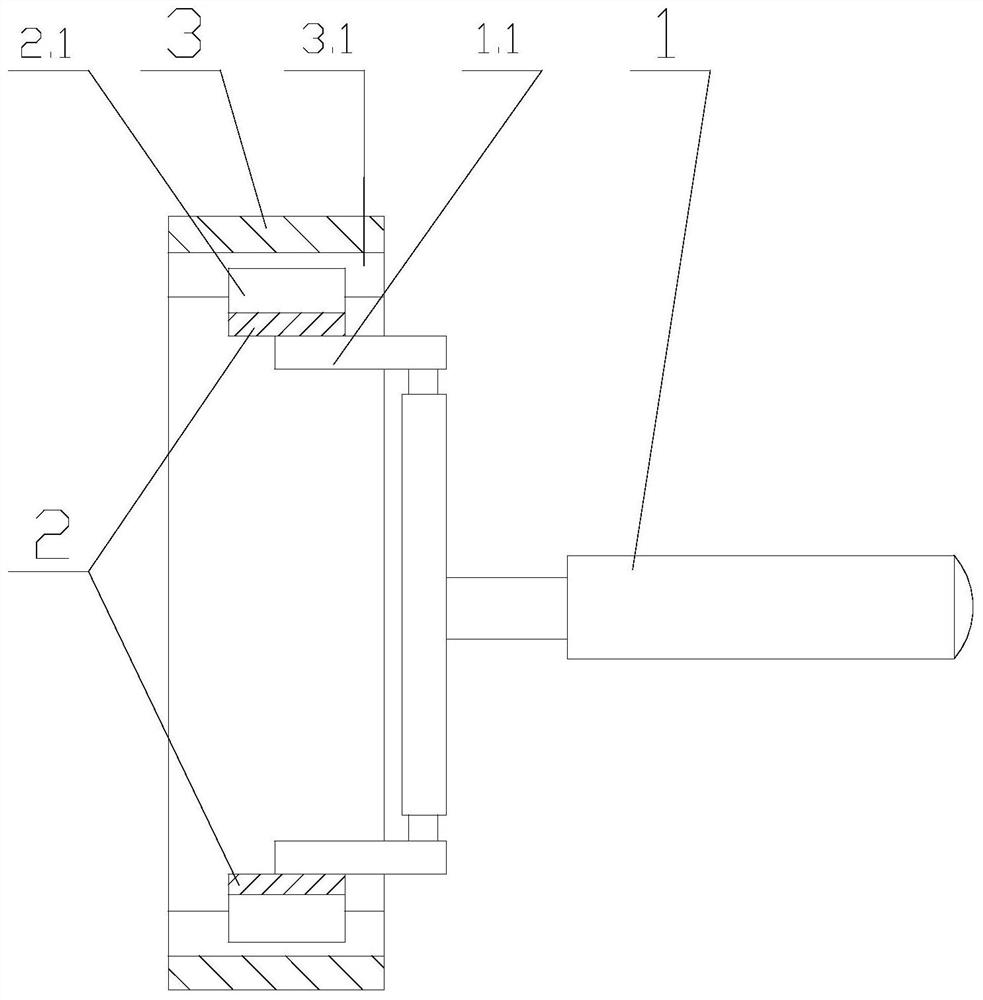

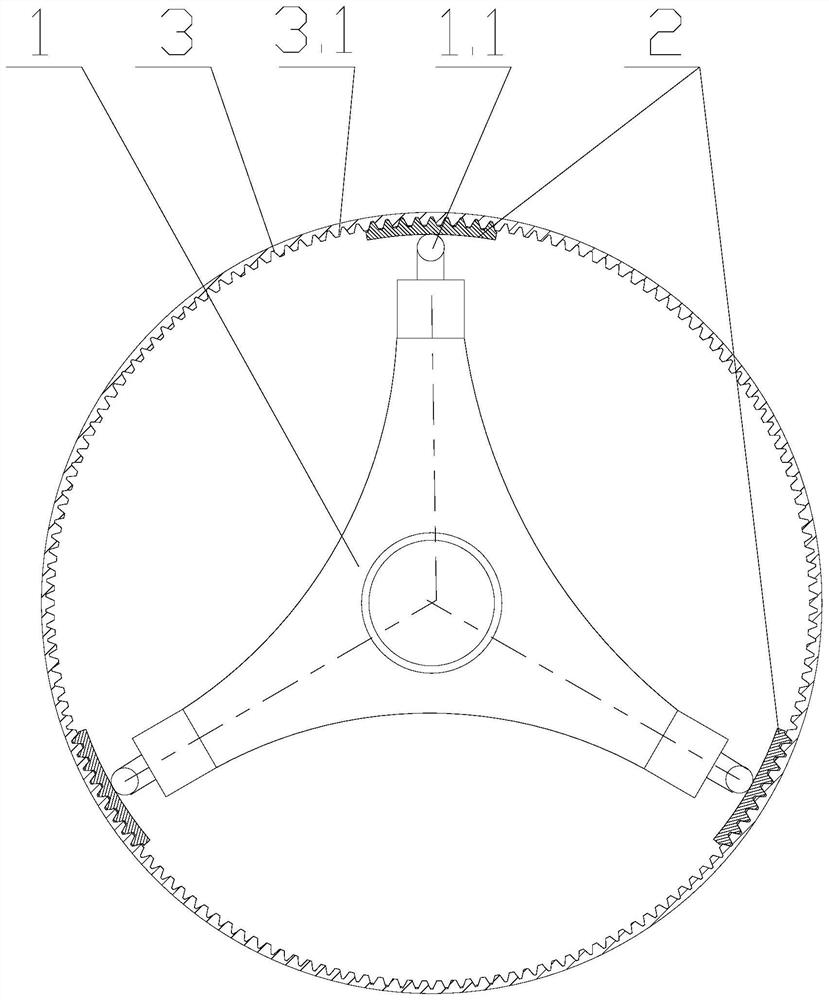

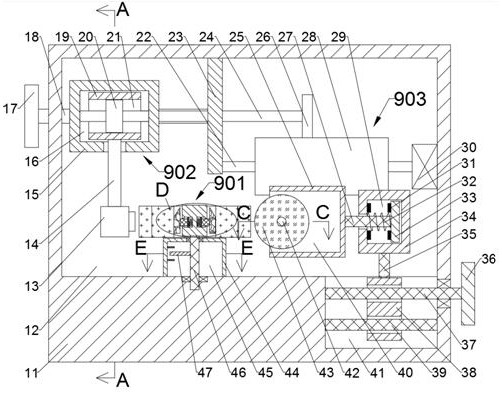

An experimental method for backlash characteristics of an experimental platform

ActiveCN112414696BAdjustable sizeEasy to disassembleMachine part testingBacklashExperimental methods

An experimental method for backlash characteristics of an experimental platform. The experimental method for exploring the influence of backlash on mechanism dynamics is as follows: Step 1: Rotate the backlash pretensioner to fine-tune the position of the pinion; Step 2: Turn the locking The hand wheel fixes the large gear; Step 3: Turn the dial to make the pointer point to zero; Step 4: Turn the small gear and record the swing angle of the pointer, and record the corresponding backlash value at this time ; Step 5: Reversely turn the locking hand wheel to loosen the large gear; Step 6: Drive the motor to move, the output shaft of the motor drives the gear through the coupling, pinion shaft, pinion, bull gear, crank and connecting rod Step 7: Record the data measured by the sensor.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

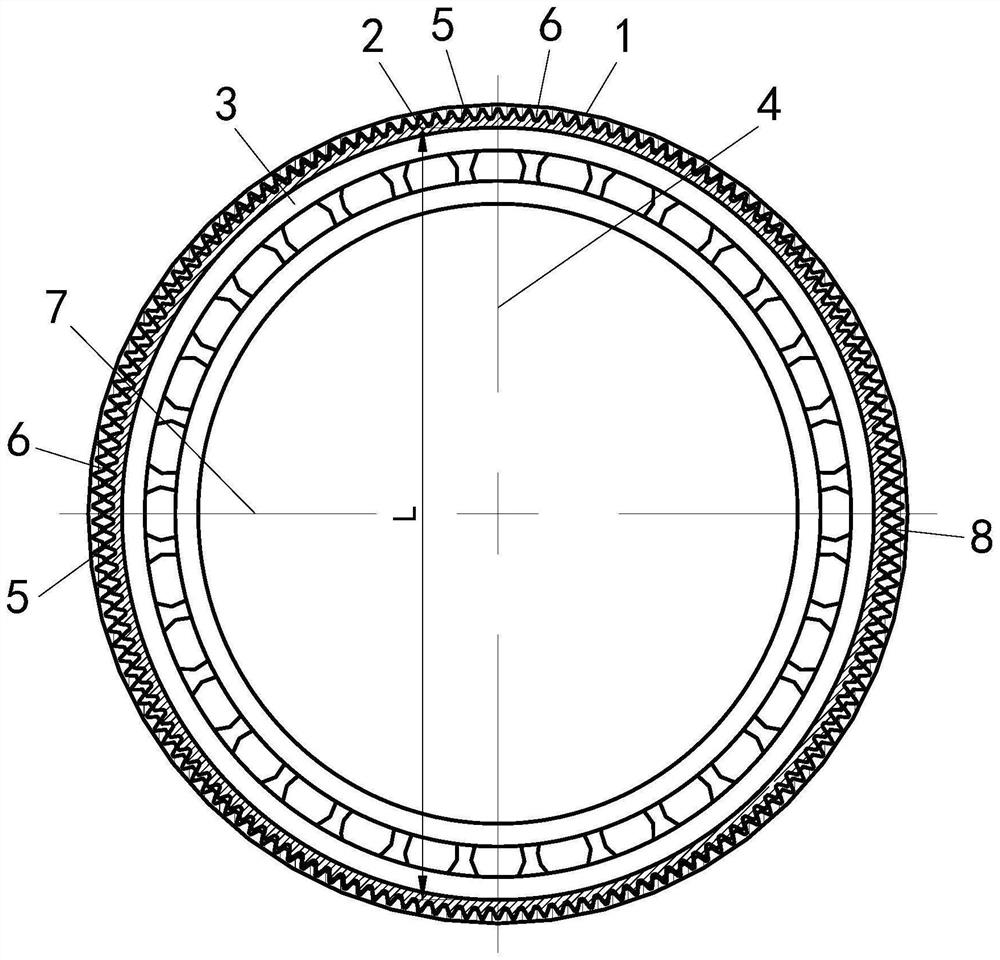

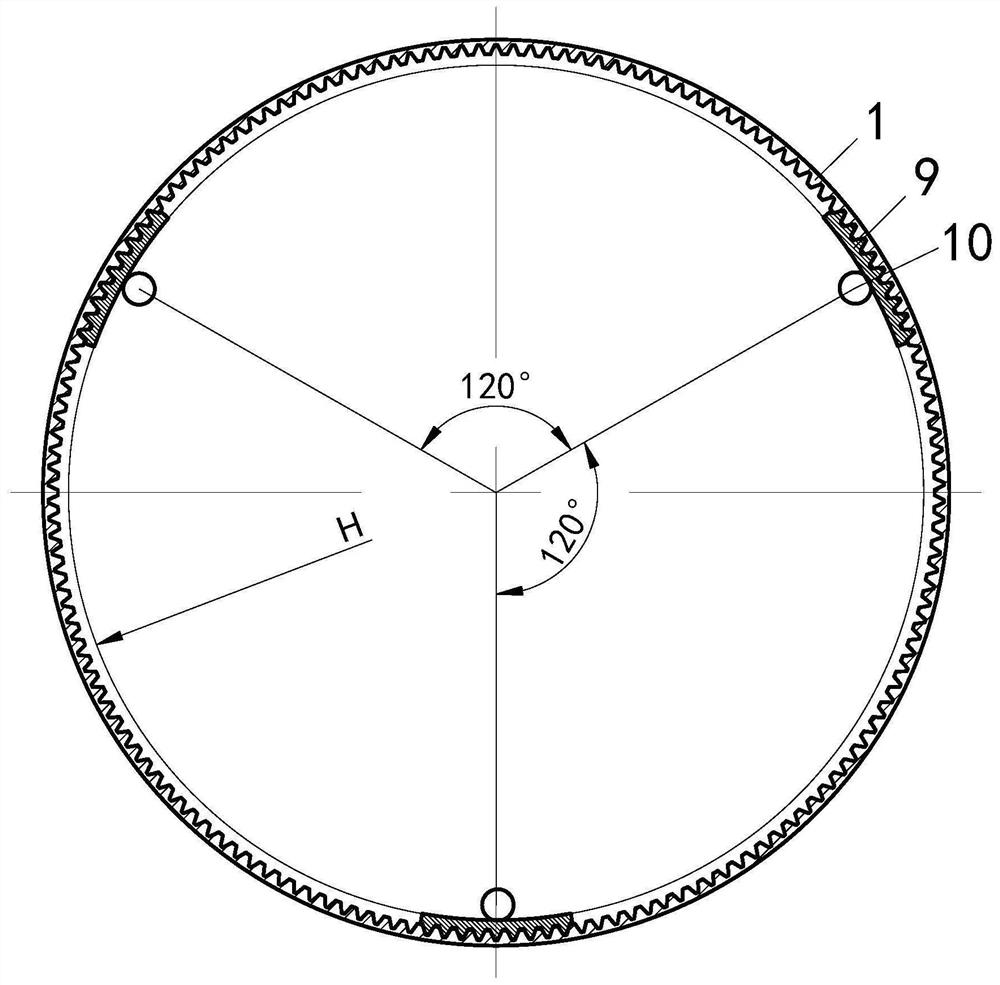

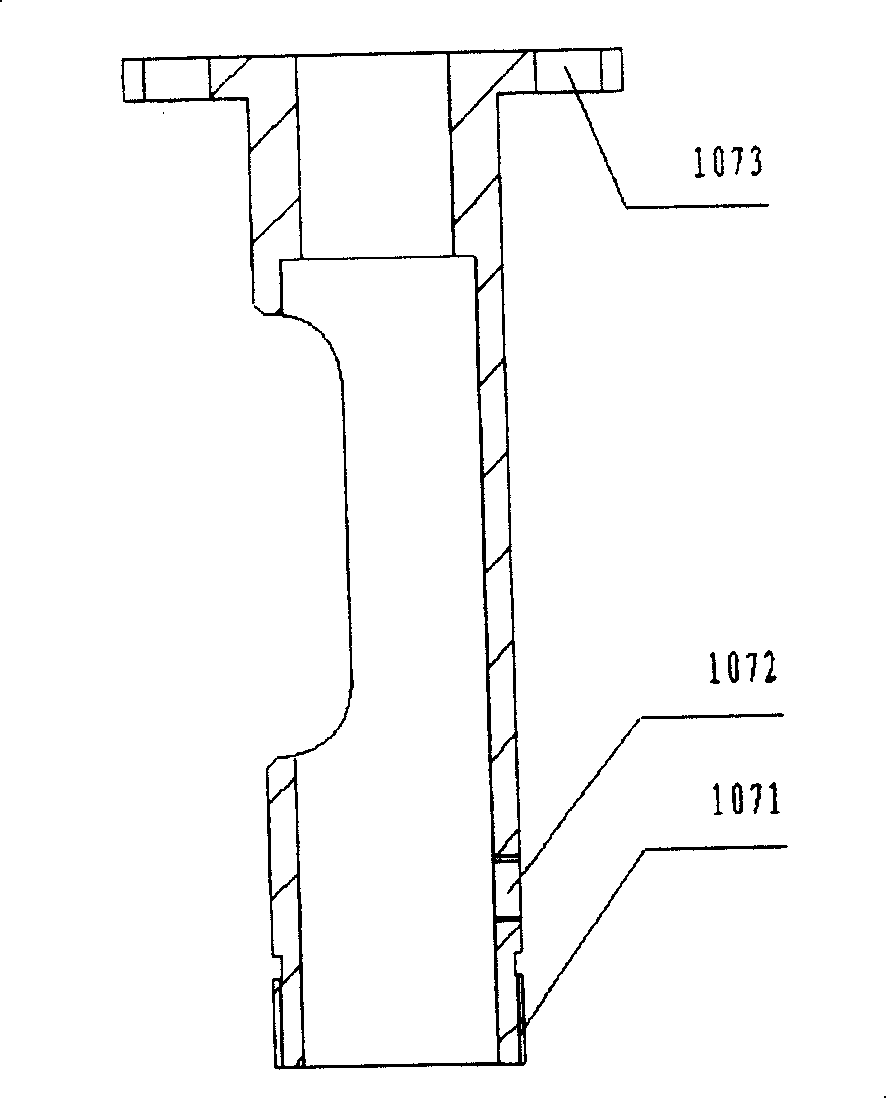

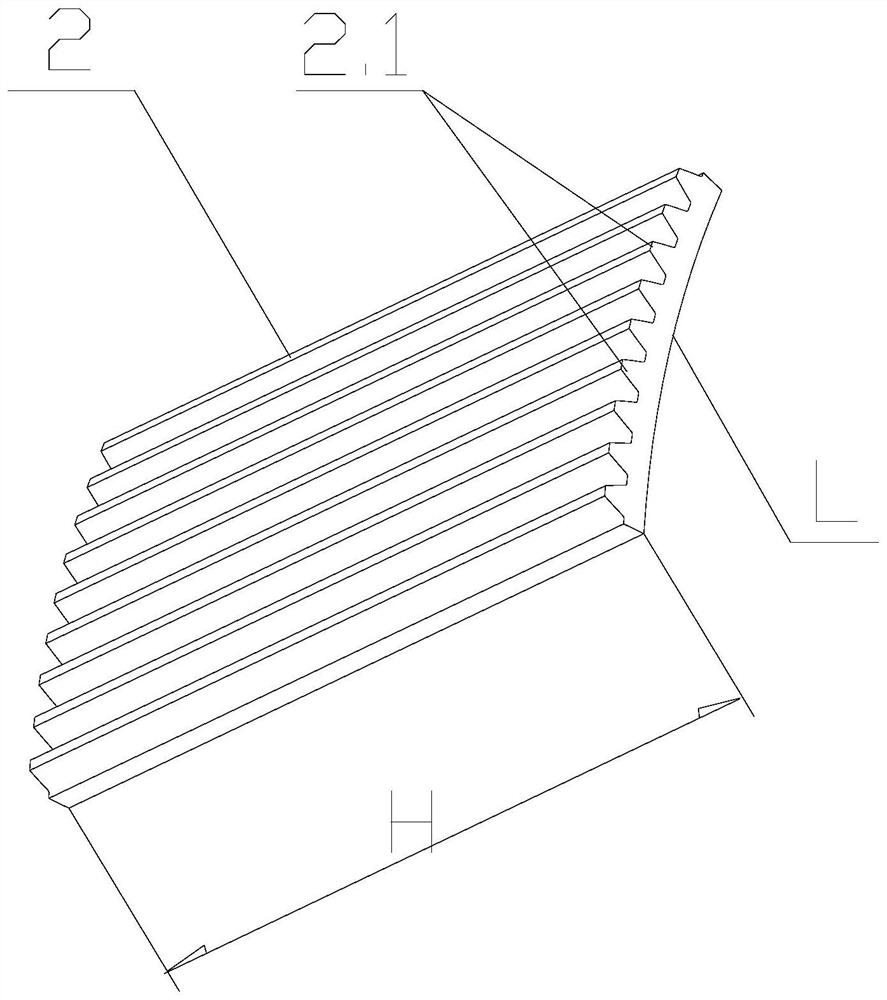

Method for detecting backlash control size of rigid wheel for harmonic drive

PendingCN112304598ARealize detectionAvoid errorsMachine gearing/transmission testingMechanical clearance measurementsBacklashMicrometer

The invention discloses a method for detecting the backlash control size of a rigid wheel for harmonic drive. According to the method, two or three measuring blocks are adopted to be matched with a two-claw or three-claw inside micrometer for detection; and during measurement, a measuring block is adhered to each of the inner teeth of the rigid gear at an interval of 180 degrees or 120 degrees, and then the outer edge of the measuring head of the two-jaw or three-jaw inside micrometer is in contact with the inner wall of the measuring block to measure the control size H of the rigid gear whenthe harmonic gear is reasonably engaged with the backlash. According to the invention, the width of the measuring block is far greater than the tooth pitch of the harmonic gear, so that the measuringblock does not need to be strictly kept at equal intervals of 180 degrees or 120 degrees, and only the measuring contact of the inside micrometer needs to be ensured to be in contact with the inner wall of the measuring block; any position can be measured and is not limited by a rigid gear tooth groove or a tooth crest; comprehensive detection of the tooth surfaces of the rigid gear and the flexible gear can be realized, and errors caused by single-section detection are avoided; and the space position occupied by the flexible gear in actual assembly is simulated, and the control result is moreaccurate and effective.

Owner:GUIZHOU QUNJIAN PRECISION MACHINERY

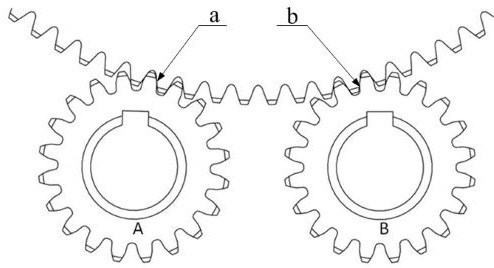

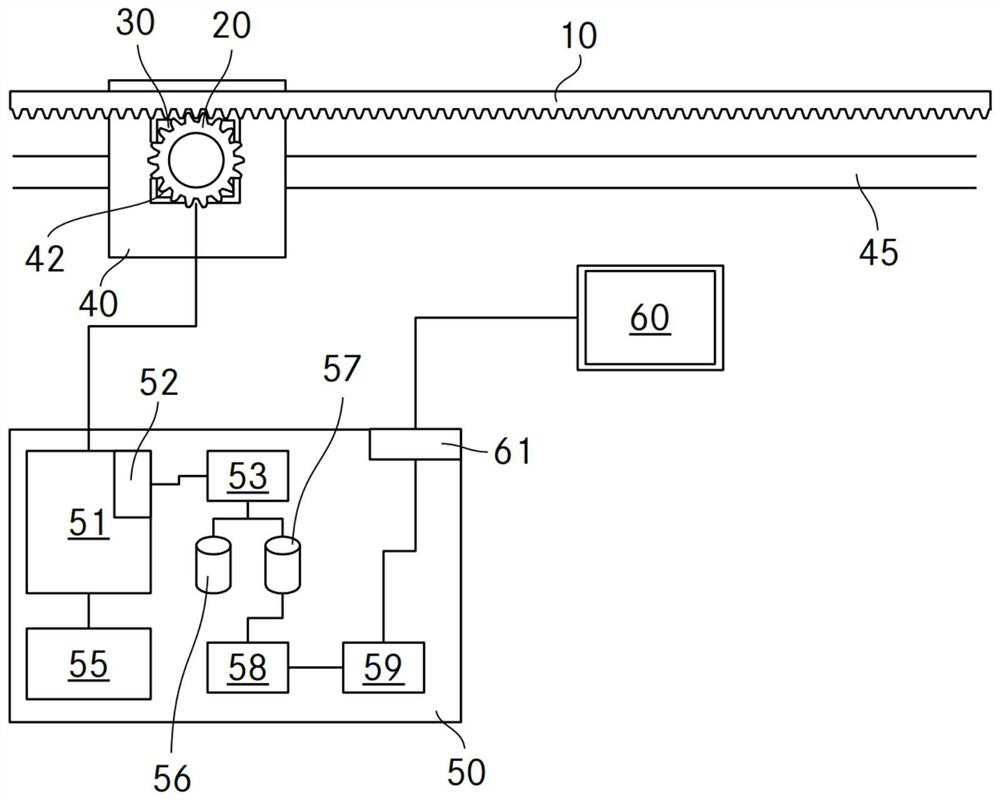

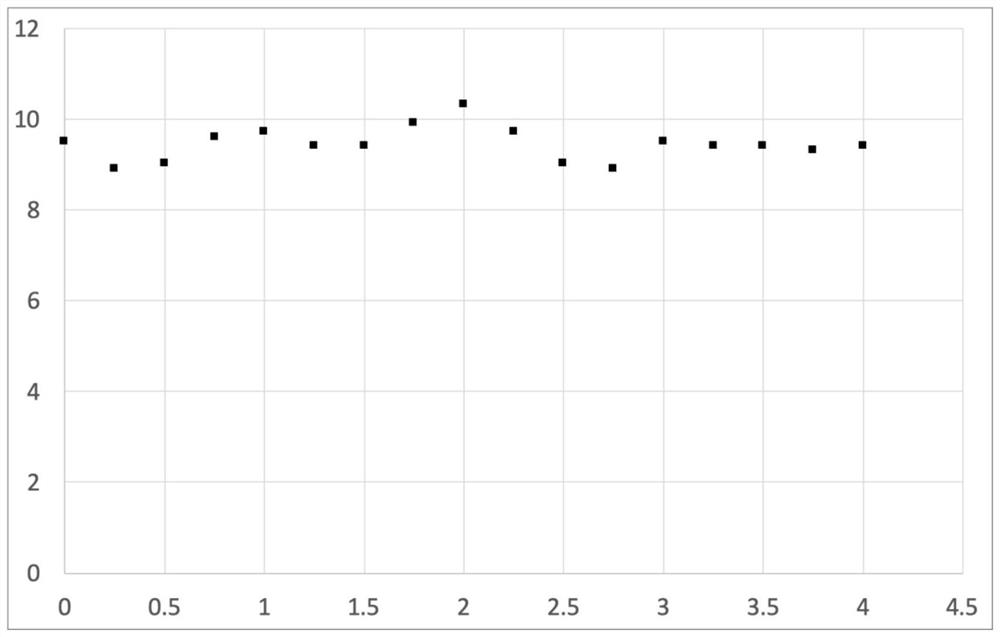

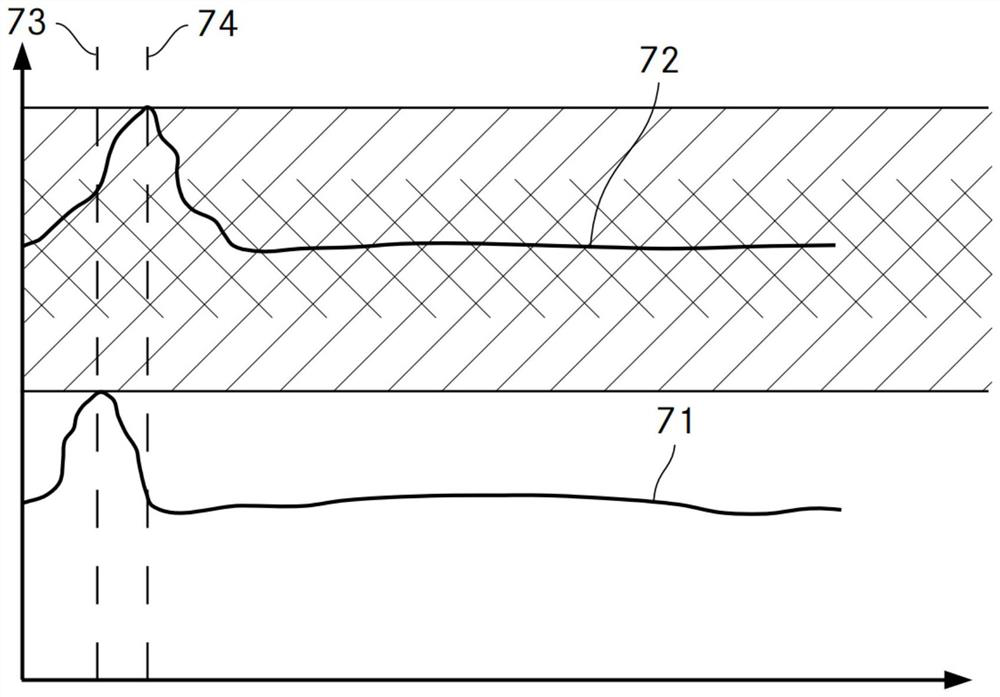

Method for adjusting backlash between pinion and rack in rack-pinion drive

The invention relates to a method for adjusting the backlash between a pinion (20) and a rack (10) in a rack-pinion drive. A motor-gearbox assembly (30) including a motor and a gearbox is supported on the bracket (40) by a positioning mechanism (42) for precisely positioning the assembly (30) in a radial position relative to the rack (10). In the method, the assembly (30) is positioned at a first radial distance from the rack (10) by means of a positioning mechanism (42), and a first circumferential backlash between the pinion (20) and the rack (10) at a first position of the pinion (20) along the rack (10) is determined from measurements taken on the input side of the gearbox. The assembly (30) and / or the rack (10) is then positioned to a second position of the pinion (20) along the rack (10), the second position being different from the first position, and a second circumferential backlash between the pinion (20) and the rack (10) at the second position is determined from measurements taken on the input side of the gearbox. A minimum circumferential backlash is determined as a function of the determined first circumferential backlash and the determined second circumferential backlash (and possibly further measurements), and a radial adjustment distance is determined as a function of the determined minimum circumferential backlash. Finally, the motor-gearbox assembly (30) is repositioned in the radial direction towards the rack (10) by means of a positioning mechanism (42) as a function of the determined radial adjustment distance.

Owner:GUDEL GROUP AG

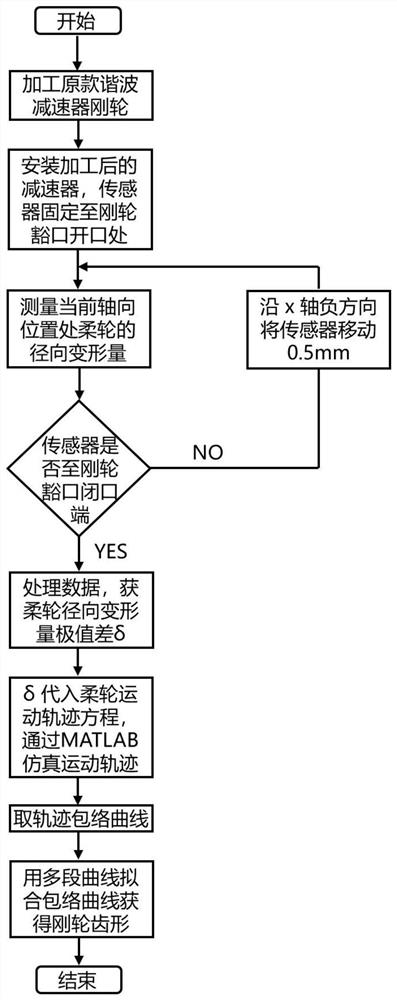

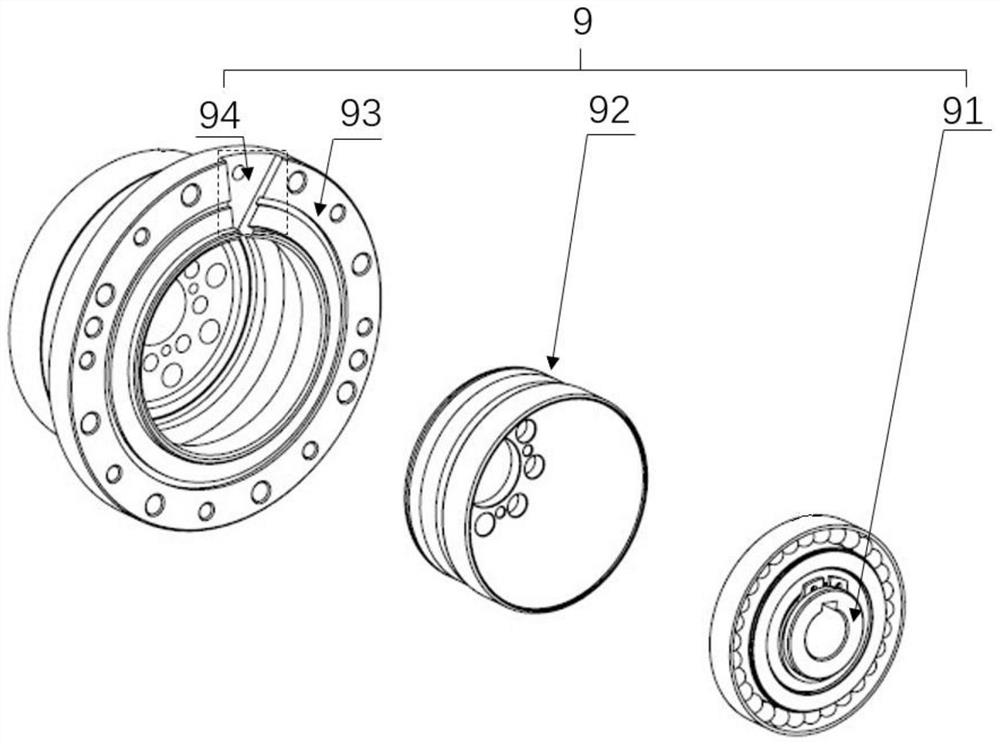

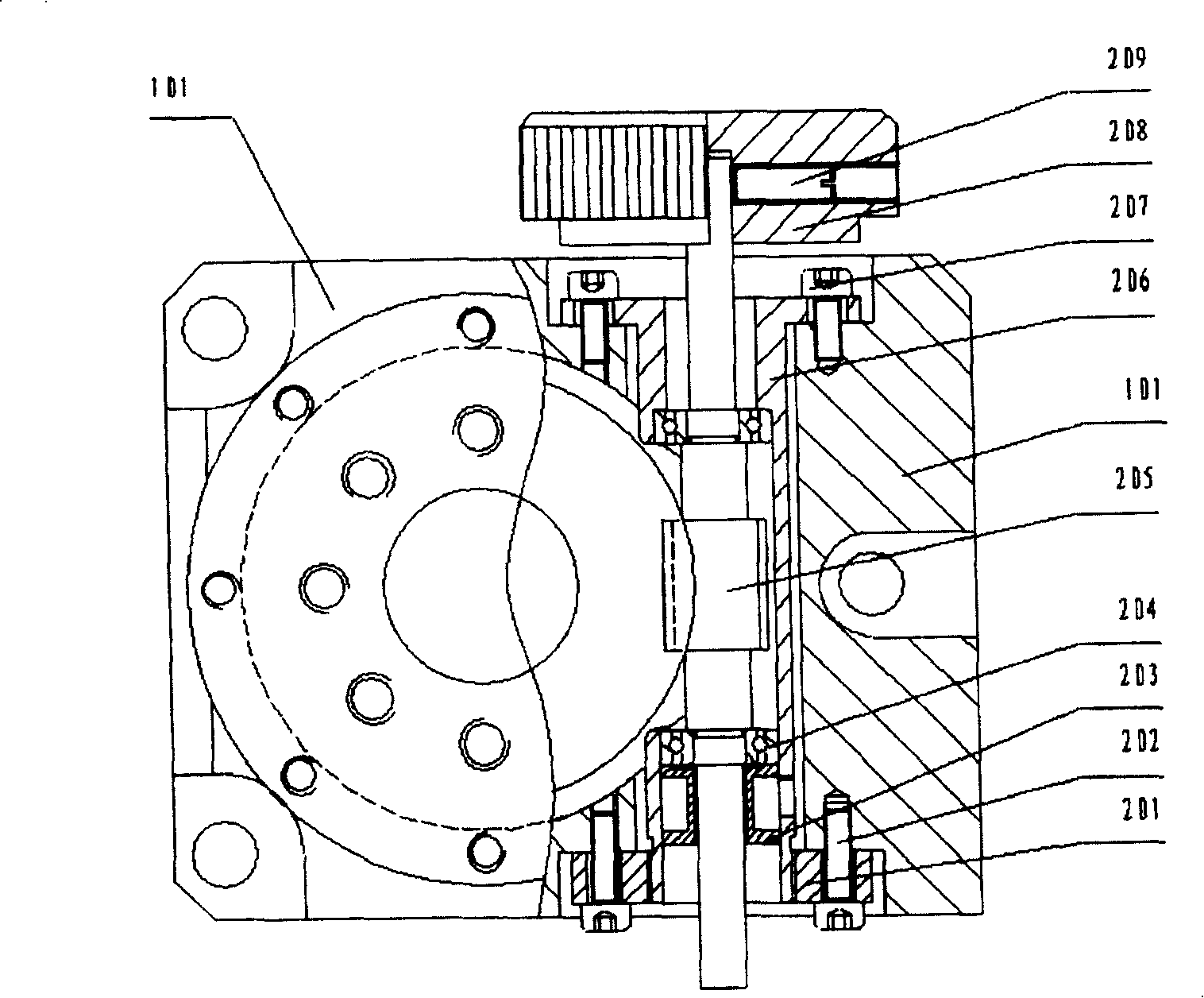

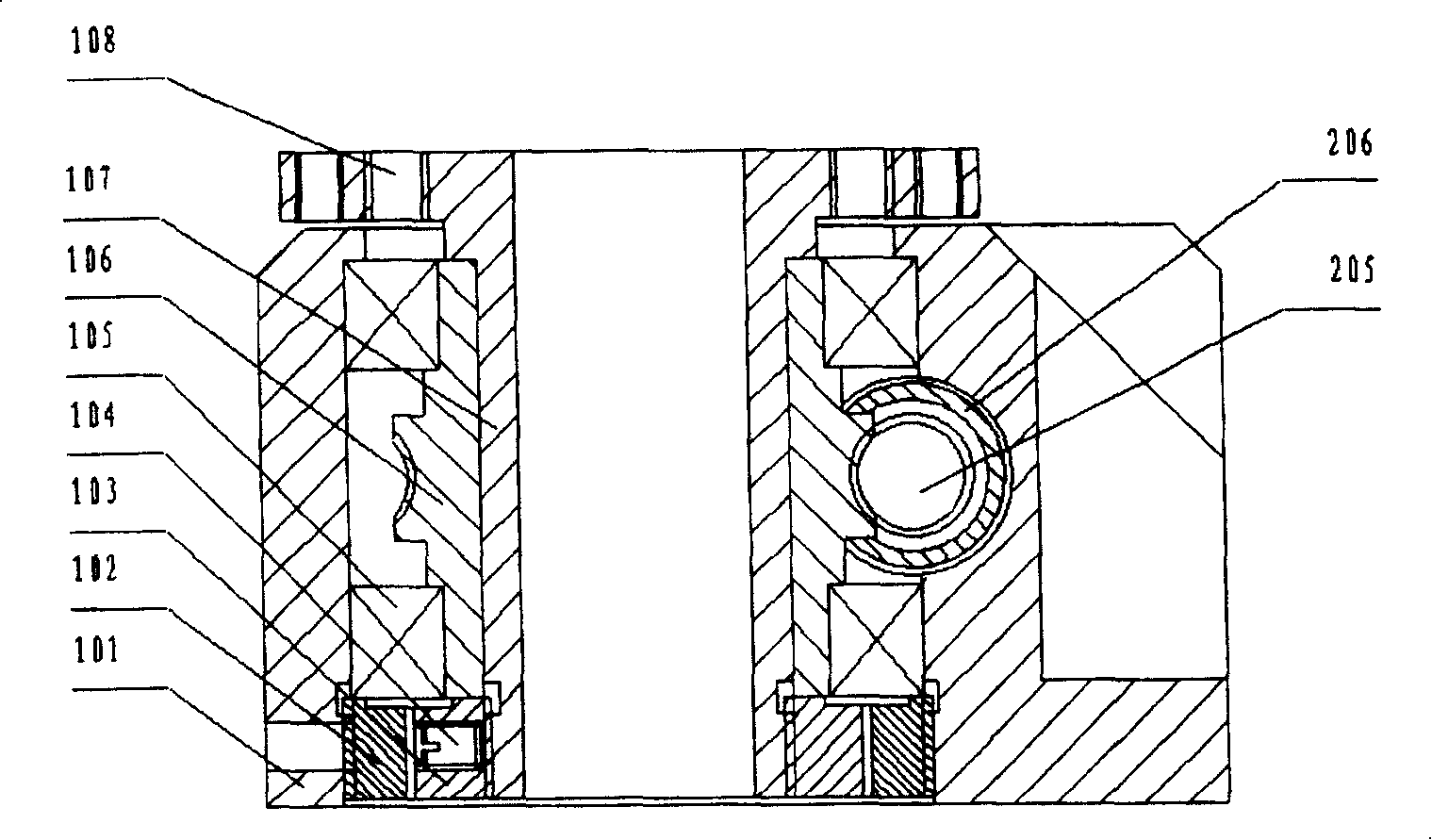

A tooth profile optimization method for a harmonic reducer rigid wheel

ActiveCN113408075BImprove reliabilityExcellent contact stress conditionsGeometric CADDesign optimisation/simulationBacklashReduction drive

The invention discloses a method for optimizing the tooth shape of a rigid wheel of a harmonic reducer. The real parameters of the flexible wheel of the harmonic reducer under the meshing motion state are obtained by using a measuring device for the radial deformation of the tooth of the flexible wheel of the harmonic reducer. , through MATLAB simulation to obtain the motion trajectory that highly fits the real flexspline motion, take the envelope of the flexspline trajectory, and use multiple arcs to fit the envelope based on the envelope to obtain the tooth profile of the optimized rigid spline. The present invention can effectively optimize the tooth profile of the rigid wheel of the harmonic reducer. The side clearance between the rigid wheel and the flexible wheel optimized by the present invention is smaller, the meshing transmission efficiency is higher, the force on the tooth surface is more uniform, and the service life is longer. The flex spline and the rigid spline have better meshing performance, better tooth surface contact stress conditions, and prevent interference with the flex spline due to unreasonable tooth shape design of the rigid spline.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Gap eliminator for worm and wormwheel

InactiveCN100398876CHigh matching precisionManufacturing precision requirements are lowPortable liftingGearing elementsBacklashEngineering

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

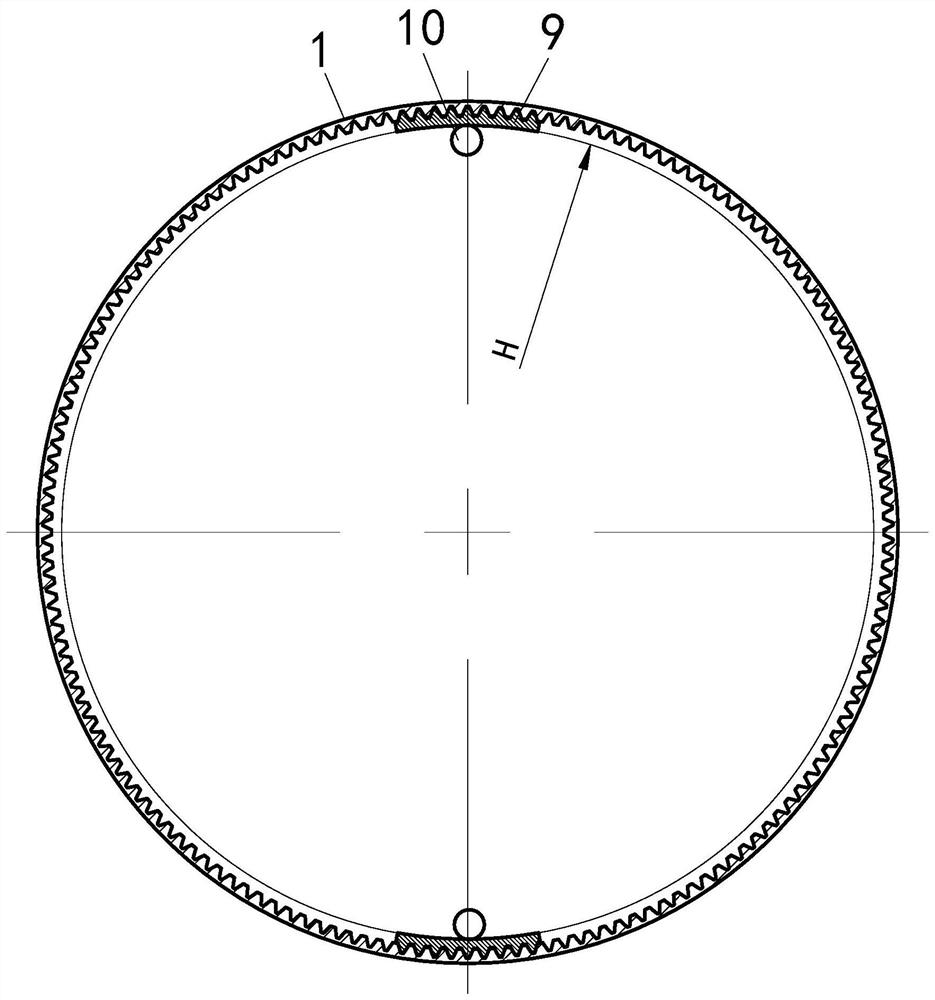

Method and device for detecting backlash-free meshing of rigid gear of harmonic gear

PendingCN112146545AImprove efficiencyEasy to measureMechanical thickness measurementsBacklashMicrometer

The invention discloses a method and a device for detecting backlash-free meshing of a rigid gear of a harmonic gear. The method comprises the following steps of: detecting rigid gear internal teeth of the harmonic gear by adopting a two-claw or three-claw inside micrometer; and when the rigid gear internal teeth of the harmonic gear are detected by adopting the two-claw or three-claw inside micrometer, configuring a fan-shaped measuring block on each measuring head of the two-claw or three-claw inside micrometer, and arranging gear teeth which can be meshed with the rigid gear internal teethon each measuring block to ensure that the gear teeth of the measuring block on each measuring head of the two-claw or three-claw inside micrometer are tightly attached to the rigid gear internal teeth without backlash, so that the tooth thickness control size of the rigid gear internal teeth can be detected through the two-claw or three-claw inside micrometer. By adopting the method and the device, the measurement operation is very convenient, the efficiency of measurement work can be greatly improved, the measurement accuracy is completely determined by the accuracy of the inside micrometer,and the influence of human factors on the measurement accuracy is greatly reduced.

Owner:GUIZHOU QUNJIAN PRECISION MACHINERY

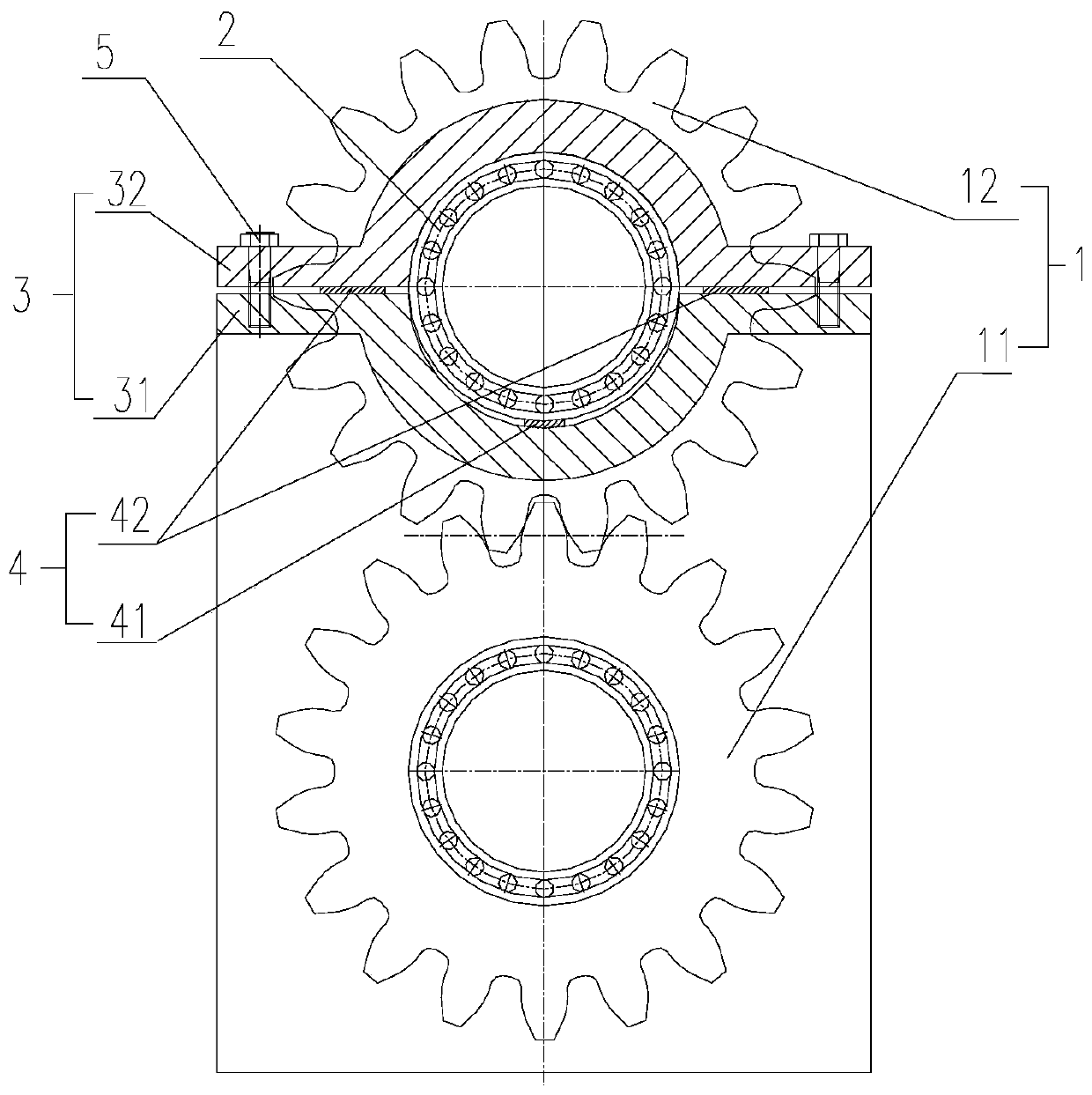

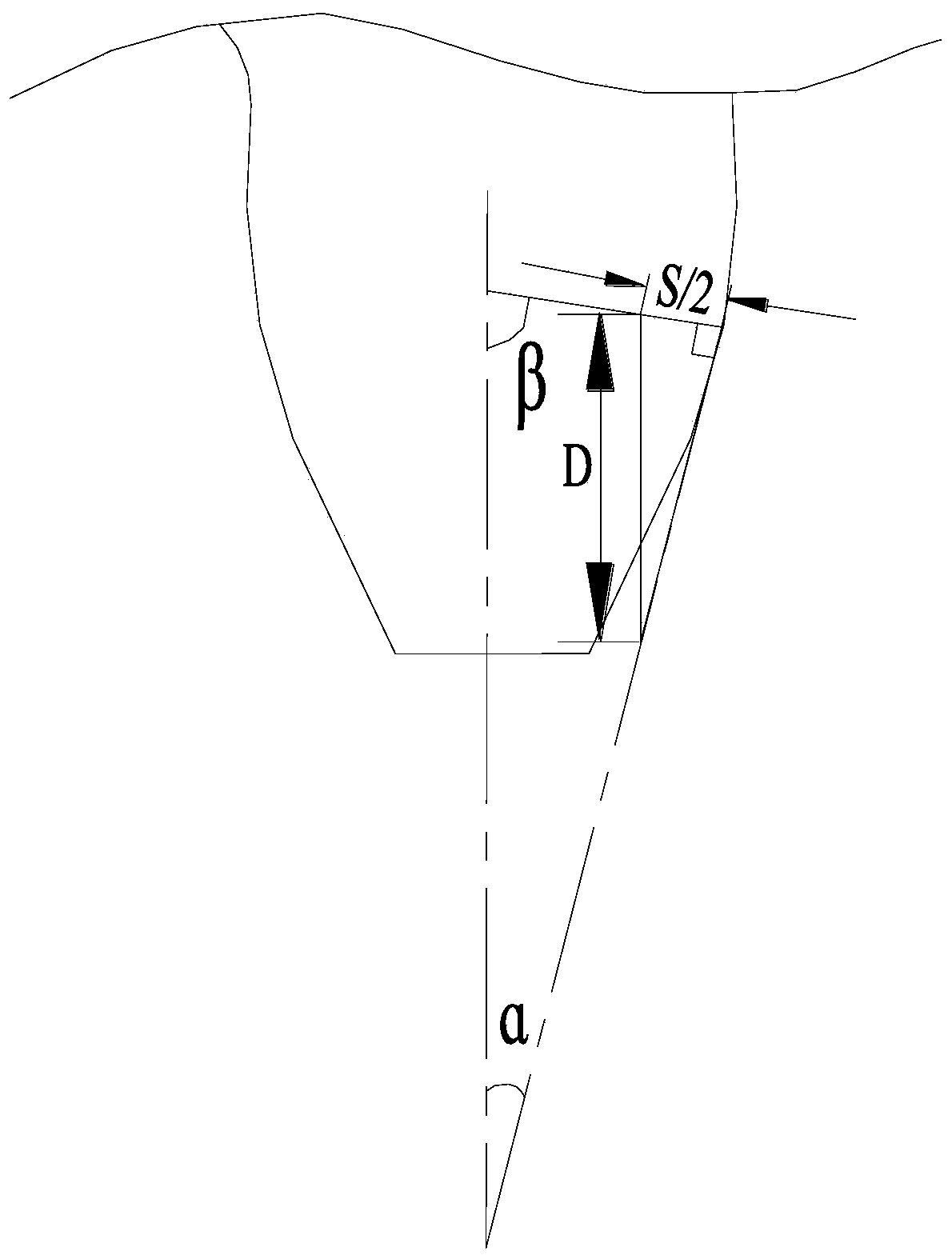

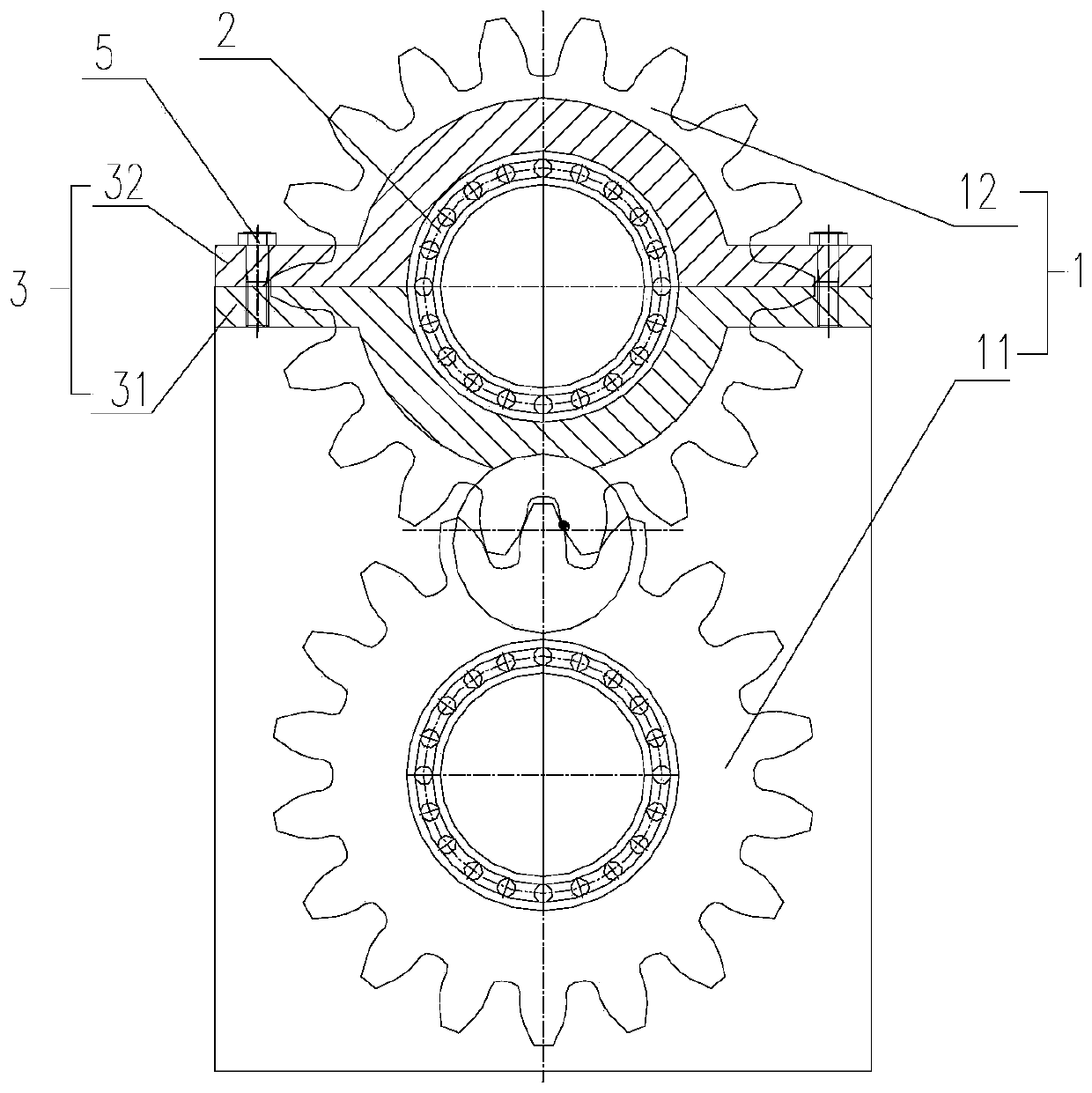

The adjustment method of the backlash of the gear transmission and the calculation method of the grinding amount of the tooth thickness

ActiveCN109578564BThe calculation result is accurateImprove accuracyGearing detailsGear driveBacklash

The invention relates to the field of gear drive, in particular to an adjusting method of a backlash of a gear drive device and a computing method of tooth thickness grinding amount. The adjusting method of the backlash of the gear drive device comprises the following steps of S1, providing a group of mating gears, wherein a grinding allowance is reserved on at least one gear; S2, adjusting assembly clearance between the mating gears to make the assembly clearance between the mating gears meet the backlash requirement, and then, computing the displacement D of the mating gears relative to a standard position; and S3, computing the tooth thickness grinding amount S of the gears according to the displacement D and performing repair grinding on the gears. According to the adjusting method, the displacement is obtained through adjusting the assembly clearance between the mating gears, and then, the grinding amount is computed through the displacement, so that the accuracy of the grinding amount obtained by computing is high; the ground gears are capable of achieving the goal that the backlashes between the mating gears meet the assembly requirement; and the problem that the backlashesbetween the mating gears do not meet the assembly requirement in the prior art is solved.

Owner:CHANGZHOU TIANSHAN HEAVY IND MACHINERY

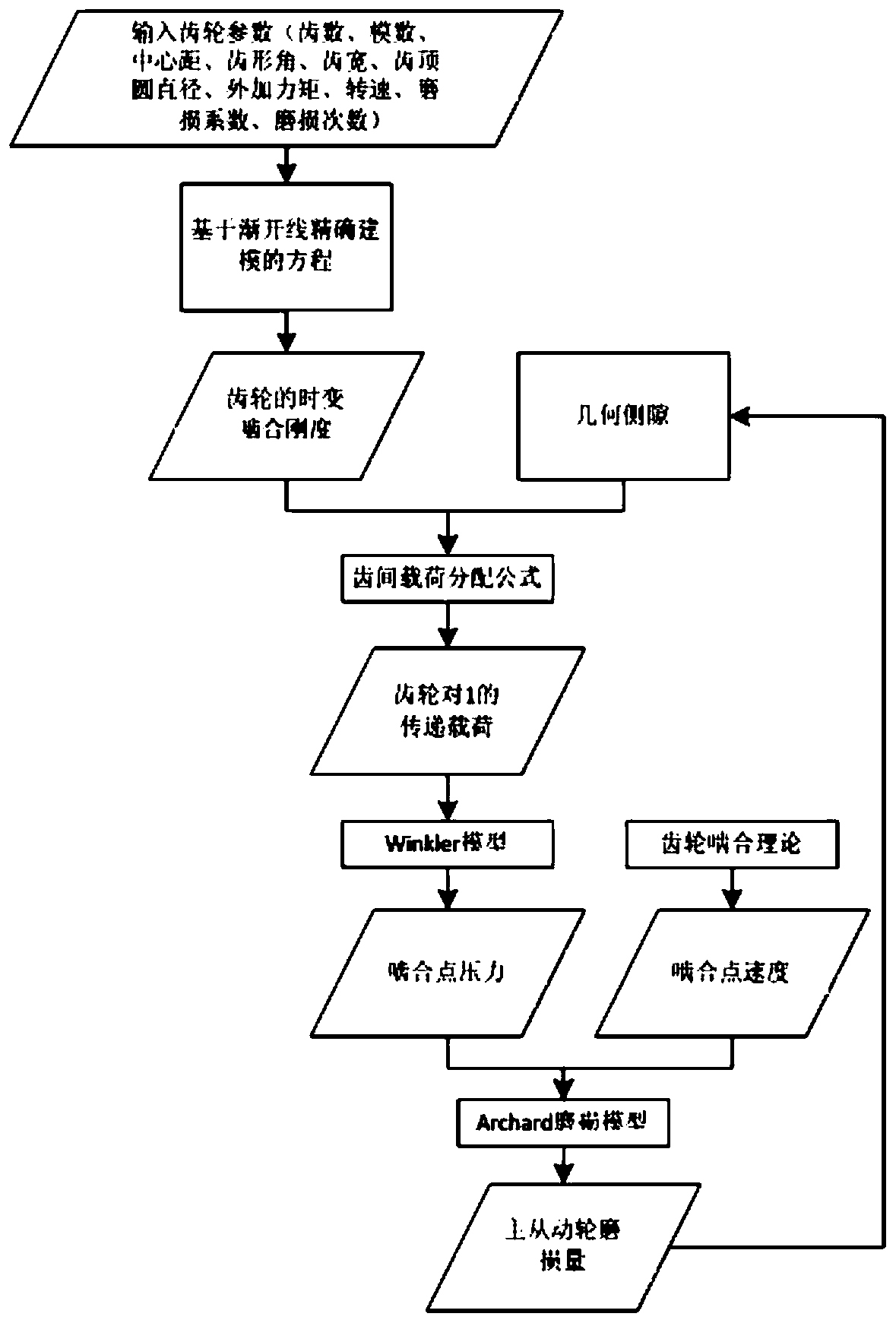

Calculation method of spur gear wear

ActiveCN106845046BReduce vibration shockExtended service lifeDesign optimisation/simulationSpecial data processing applicationsEngineeringSurface pressure

The invention relates to a method for calculating the wear amount of spur gear cylindrical gears. The calculation method of spur gear wear amount includes the following specific process: Step 1: According to the time-varying meshing stiffness of the gear and the geometric backlash of the gear, determine the inter-tooth dynamic load borne by the two pairs of gear tooth meshing pairs, and calculate the meshing point The surface pressure of Calculate the wear depth calculated in step 3. The calculation method of spur gear wear amount takes into account the dynamic load update process under actual geometric backlash, accurately and reasonably determines the wear amount of spur gear teeth at each position, and provides an effective way to reduce gear vibration impact and extend gear service life. .

Owner:NORTHEASTERN UNIV LIAONING

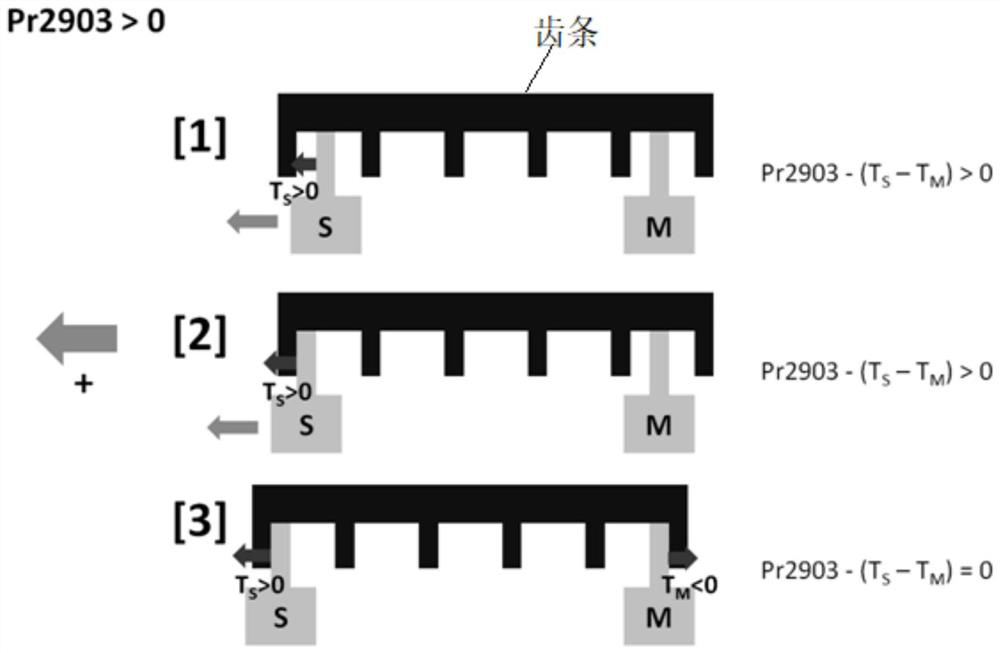

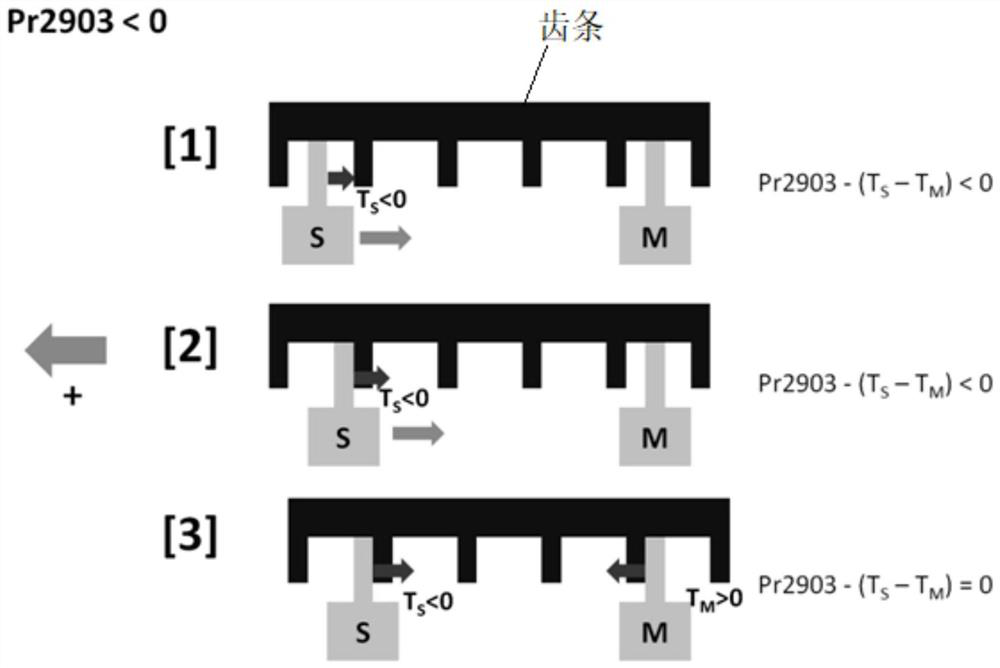

A Method of Eliminating the Backlash of Dual Drive Mechanism by Using Tension Control

ActiveCN111687683BEliminate backlashPrecise motion controlAutomatic control devicesFeeding apparatusBacklashClassical mechanics

The invention discloses a method for eliminating the backlash of a dual-drive mechanism by using tension control, the set tension value is greater than a target tension value and less than twice the target tension value, and the target tension value is any one of the drive The corresponding axial load rate when the part-driven load just starts to move; the controller controls the first drive part to drive the load to move, and monitors the axial load rate of the first drive part and the second drive part in real time; When the difference between the axial load rate of the first drive member and the axial load rate of the second drive member is equal to the set tension value, the first drive member is stopped, that is, the tension control is completed, and the backstage is realized. Gap eliminated. The invention can quickly and completely eliminate the backlash of the movement of the dual-drive mechanism, and realize precise motion control without gaps.

Owner:新代科技(苏州)有限公司

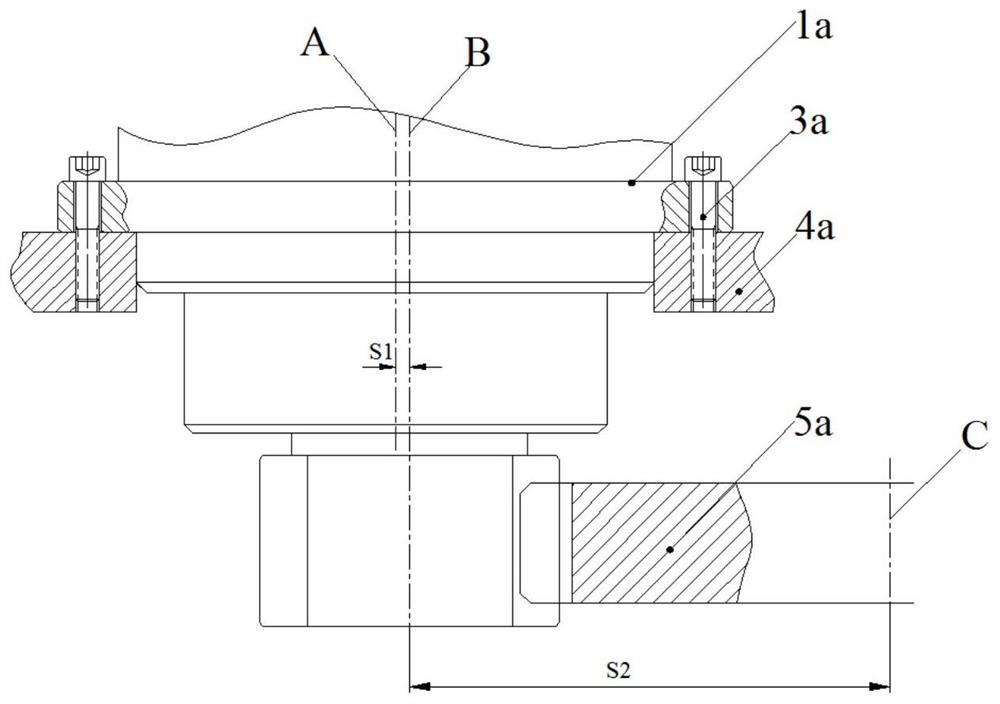

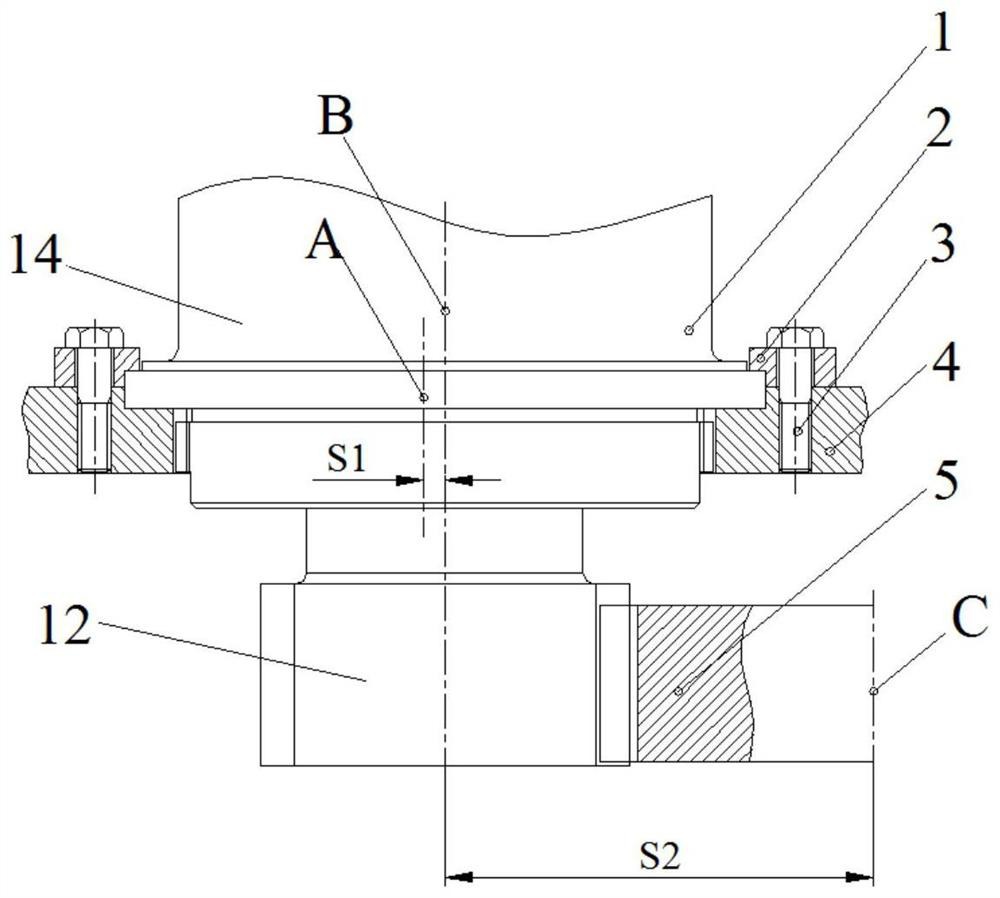

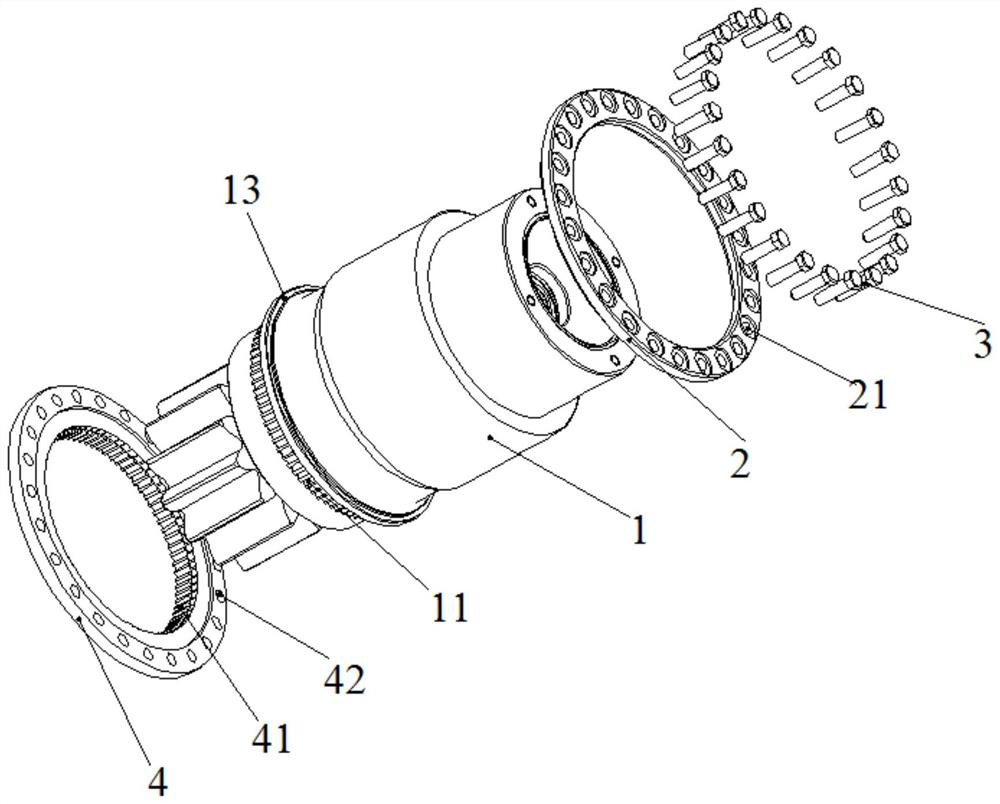

Gear backlash adjusting structure and adjusting method thereof

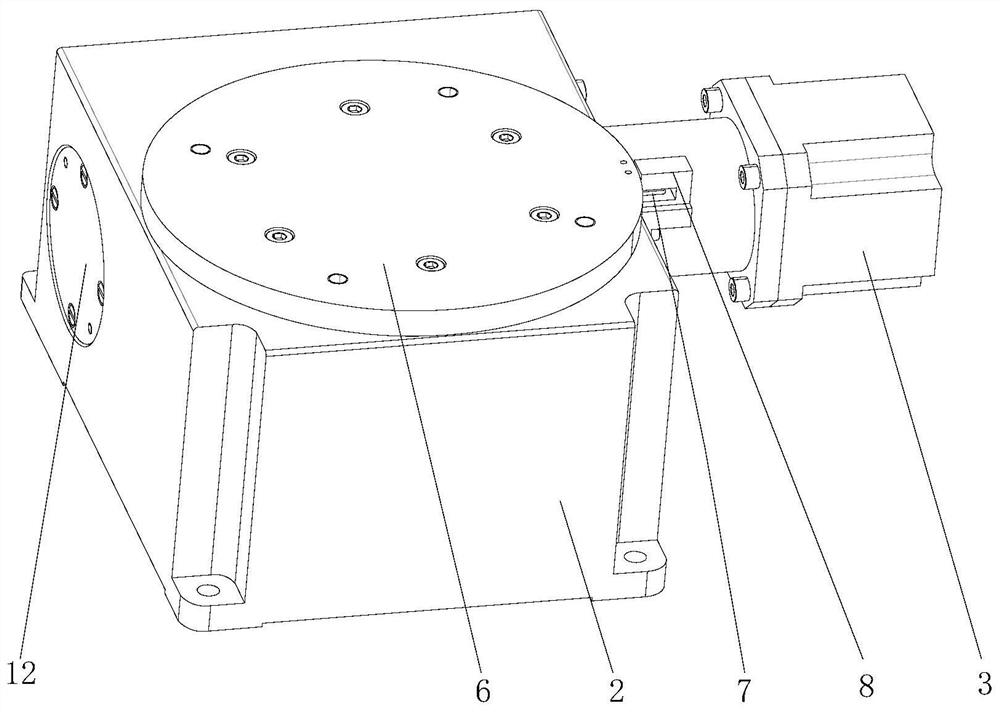

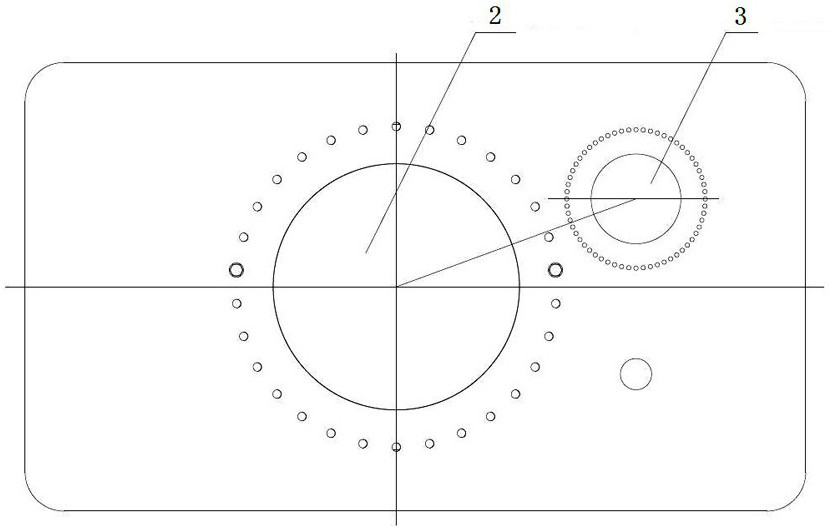

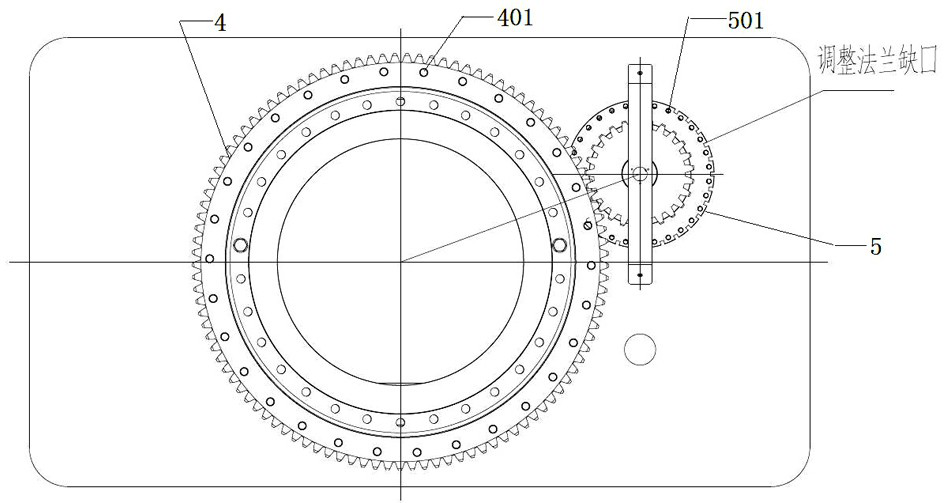

The invention discloses a gear backlash adjusting structure and an adjusting method thereof, and belongs to the technical field of gear backlash adjusting structures and adjusting methods thereof. Thetechnical problem to be solved is to provide the improvement of the gear backlash adjusting structure. According to the technical scheme adopted for solving the technical problem, the gear backlash adjusting structure comprises a platform, a slewing bearing mounting hole and an adjusting flange mounting hole are formed in the platform, a slewing bearing is fixedly connected to the slewing bearingmounting hole, an adjusting flange is fixedly connected to the adjusting flange mounting hole, a transition flange is arranged between the slewing bearing and the platform, a motor and a speed reducer are fixedly connected to the lower portion of the adjusting flange, a pinion is arranged on the adjusting flange, the center of the pinion does not coincide with the center of the adjusting flange,the pinion is engaged with the slewing bearing, a spline of the pinion is fixed to the shaft end of the speed reducer, and a notch is formed in the adjusting flange. The gear backlash adjusting structure and the adjusting method thereof are applied to gear backlash adjustment of engineering vehicles.

Owner:CHANGZHI QINGHUA MACHINERY FACTORY

Slewing mechanism, tooth side clearance adjustment method and crane

The invention discloses a slewing mechanism, a tooth side clearance adjustment method and a crane. The slewing mechanism includes a reducer, a slewing support and a slewing support; the slewing support has a mounting hole for sheathing and installing the reducer; the slewing support and the reducer housing are matched by splines, and the center lines of the splines are opposite It is arranged eccentrically on the center line of the transmission shaft of the reducer; and the slewing bearing is meshed with the gear of the output shaft of the reducer. The slewing mechanism of the present invention uses splines to connect the reducer and the slewing support. During the adjustment process of the tooth side clearance, the adjustment is performed in units of a single spline. Because the number of teeth of the splines is dense and evenly distributed, the tooth side clearance adjustment of the present invention Wider range, better continuity and higher precision.

Owner:XUZHOU HEAVY MASCH CO LTD

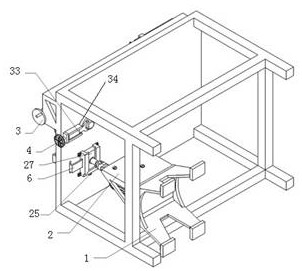

Cleaning and maintaining device for spur gear backlash

The invention discloses a cleaning and maintaining device for a spur gear backlash. The cleaning and maintaining device comprises a box body, a working cavity is formed in the box body, a first bearing plate is fixedly arranged on the inner wall of the upper side of the working cavity, a motor is fixedly arranged on the inner wall of the right side of the working cavity, and a power shaft rotatably connected with the first bearing plate is arranged at the left end of the motor in a power connection mode. A spur gear is stirred tooth by tooth, so that each backlash of the spur gear is cleaned,the cleaning quality is guaranteed, meanwhile, the problems that spur gear backlash cleaning is inconvenient, troublesome and labor-consuming are solved, the automation degree is high, excessive manual operation is not needed, after one-time pre-positioning is conducted, spur gears of the same type can be directly cleaned in batches subsequently, the workload of workers is greatly reduced, meanwhile, the working performance of the spur gears is improved, the service life of the spur gears is prolonged, and a certain maintenance effect on the spur gears is achieved.

Owner:临海科雅智能科技有限公司

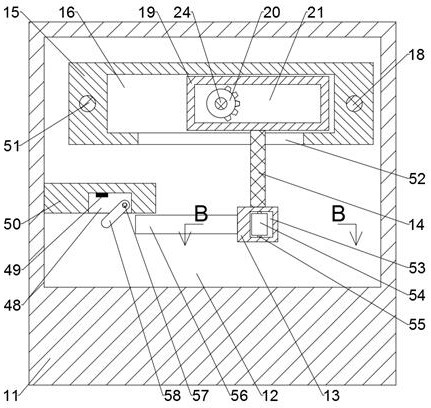

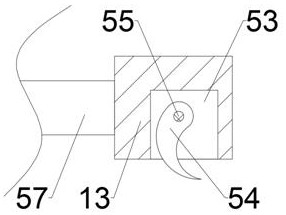

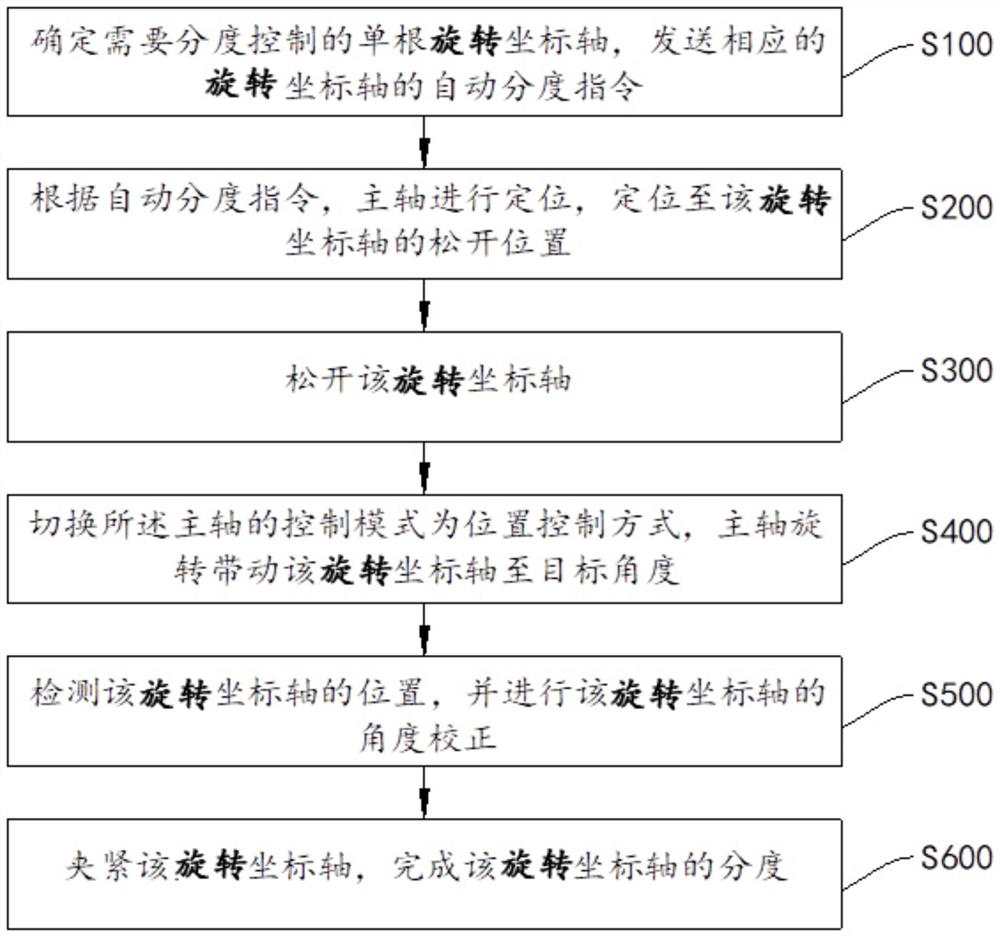

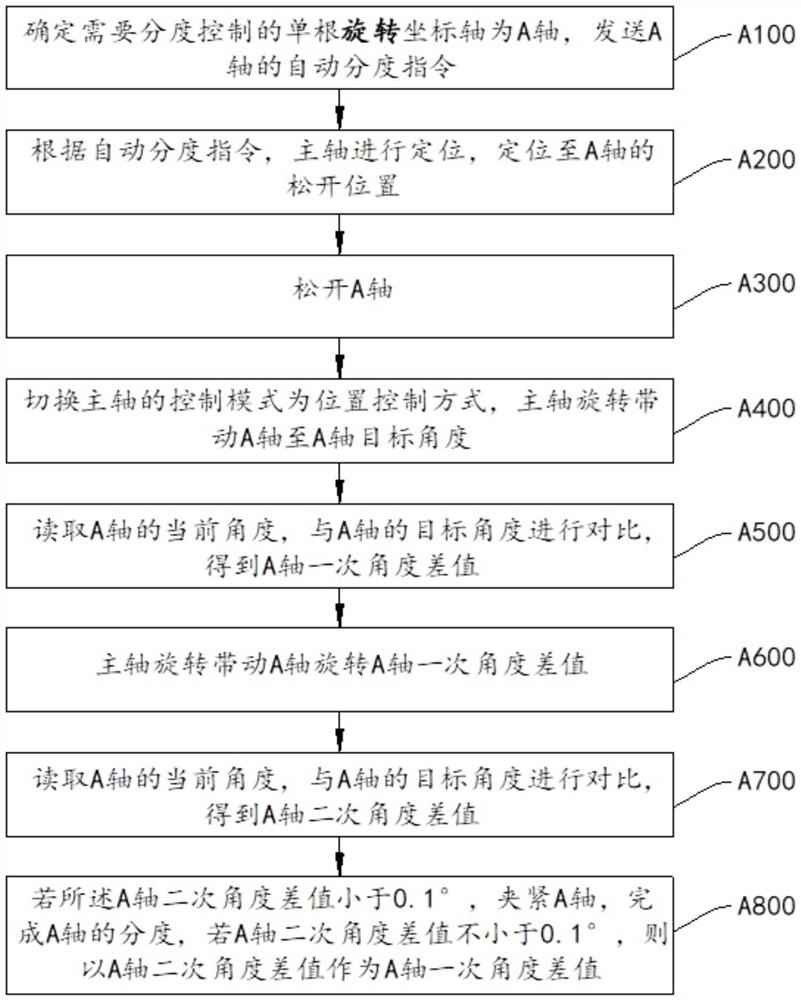

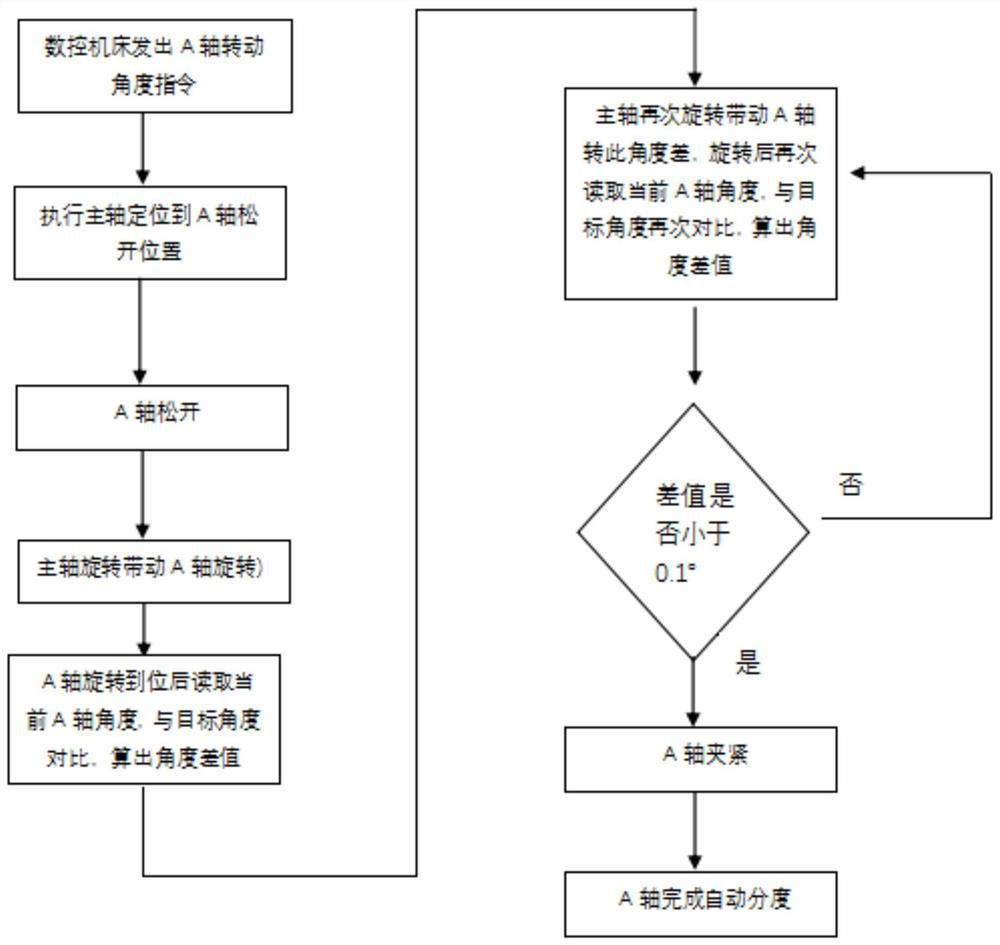

A fully automatic exchange multi-directional swing head automatic indexing control method and device

ActiveCN112846934BResolve Gap DifferencesCompensation value is accurateAutomatic control devicesPrecision positioning equipmentNumerical controlBacklash

The invention relates to the field of numerical control machine tools, in particular to a method and device for automatic indexing control of a fully automatic exchange multi-directional swing head for numerical control machine tools, comprising the following steps: determining a single rotating coordinate axis that requires indexing control, and sending the corresponding The automatic indexing command of the rotating coordinate axis; according to the automatic indexing command, the spindle is positioned to the loose position of the rotating coordinate axis; the rotating coordinate axis is released; the control mode of the spindle is switched to the position control mode, and the spindle rotates to drive The rotating coordinate axis reaches the target angle; the position of the rotating coordinate axis is detected, and the angle correction of the rotating coordinate axis is performed; the rotating coordinate axis is clamped to complete the indexing of the rotating coordinate axis. Gear backlash and C-axis backlash to solve the gap difference between A-axis and C-axis, so that the backlash compensation value is more accurate. By driving the C-axis to swing left and right once until the upper and lower teeth of C are clamped, the problem of the top teeth of the C-axis caused by the change of the tooth gap caused by heat is solved.

Owner:NINGBO SKY MASTER PRECISION MASCH CO LTD

Anti-backlash gear structure

PendingCN112128347AEliminate backlashSimple structureGear vibration/noise dampingPortable liftingBacklashGear wheel

The invention discloses an anti-backlash gear structure. The anti-backlash gear structure comprises a driving gear and a first anti-backlash gear meshing with the driving gear. A second anti-backlashgear capable of coaxially rotating is arranged at one end of the first anti-backlash gear, a turbine structure is arranged on the second anti-backlash gear, a worm structure capable of rotating is arranged on the first anti-backlash gear, spiral teeth matched with vortex teeth of the turbine structure are arranged at one end of the worm structure, and a phase angle adjusting mechanism is arrangedat the other end of the worm structure. The anti-backlash gear structure is insensitive to temperature change, and can well ensure the effect of eliminating gear meshing backlash; and the structure issimple, the size is small, occupied space is small, friction pairs are few, and efficiency is high.

Owner:GUANGXI YUCHAI MASCH CO LTD

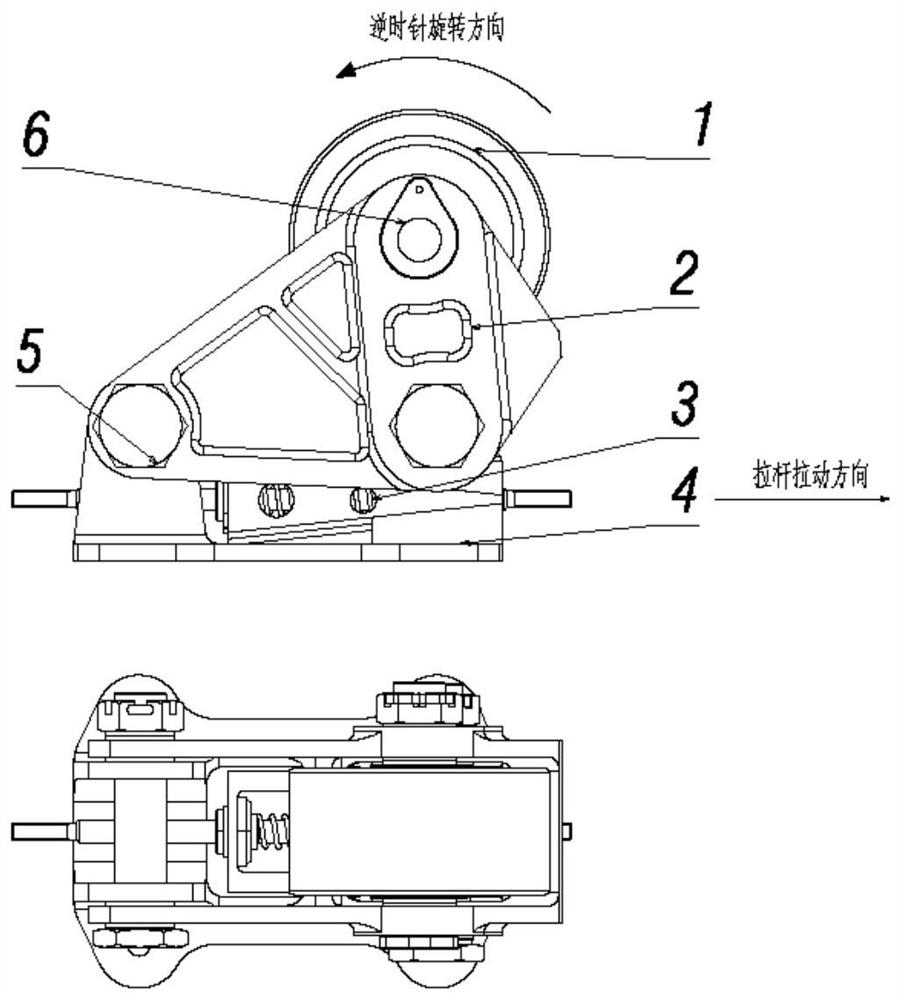

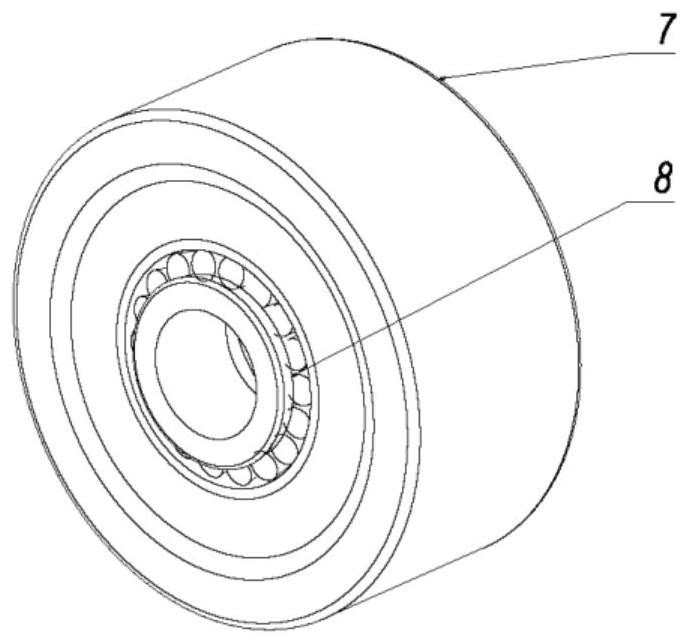

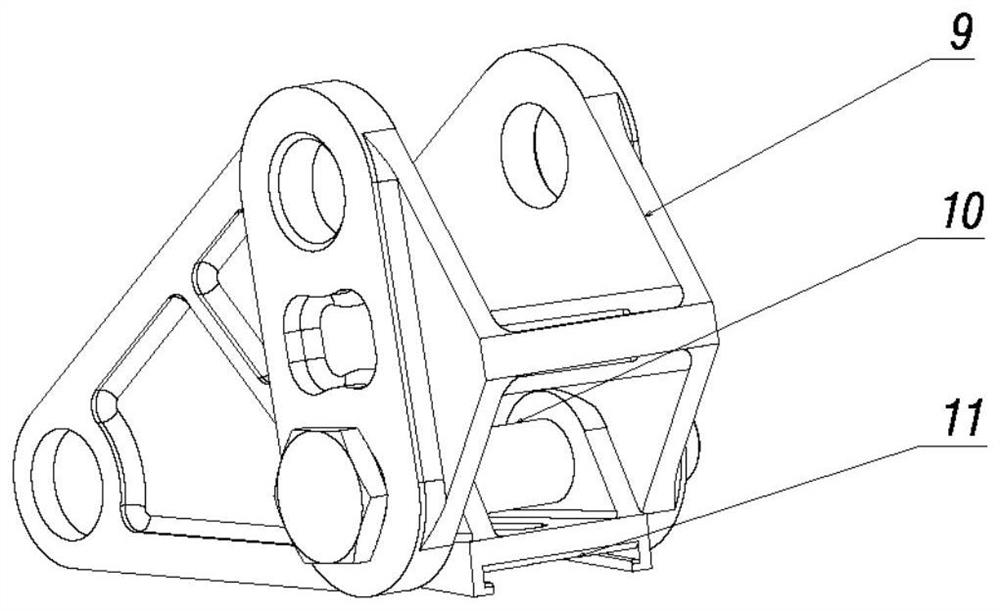

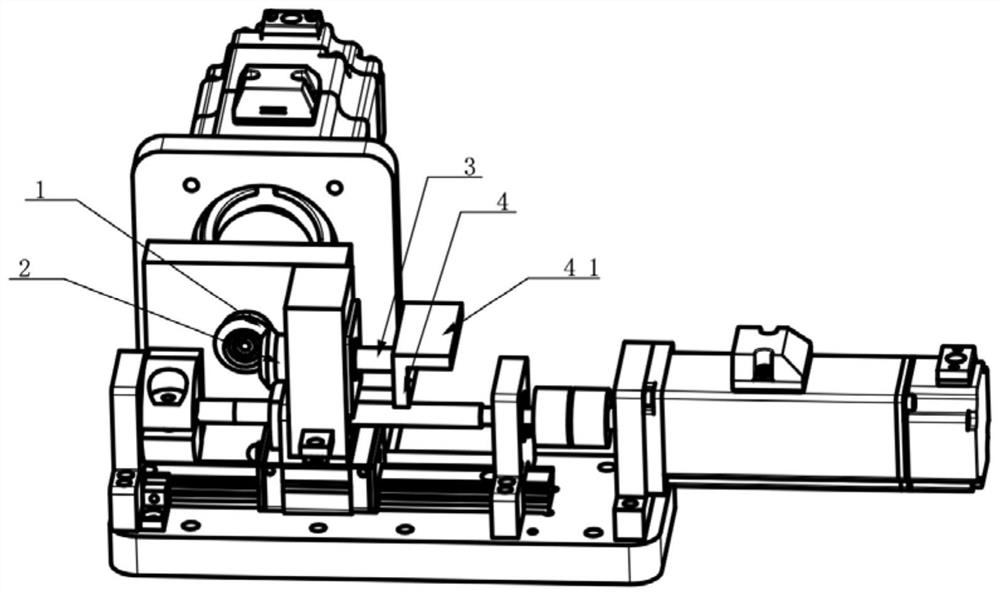

Supporting device and method capable of eliminating backlash

The invention discloses a supporting device and method capable of eliminating backlash, and belongs to the technical field of machinery. Comprising a roller assembly, an upper sliding block assembly, a middle sliding block assembly and a lower sliding block assembly, and the lower sliding block assembly is located at the bottom of the supporting device and serves as a supporting component of other components; the rear end of the upper sliding block assembly is hinged to the rear end of the lower sliding block assembly, the middle sliding block assembly is located between the front middle portion of the upper sliding block assembly and the front middle portion of the lower sliding block assembly, and the upper inclined face and the lower inclined face are installed in a matched mode through sliding grooves and sliding rail structures so that the middle sliding block assembly can slide along sliding rails of the upper sliding block assembly and the lower sliding block assembly. Therefore, the upper sliding block assembly and the rolling wheel assembly are driven to rotate anticlockwise, the rolling wheel assembly moves in the vertical direction to make contact with equipment, and clearance elimination is completed. The whole process is stable in transition, and equipment cannot be shaken; and the pulling force in the pulling process is adjustable, different pulling forces are applied according to different weight equipment, and clearance elimination of various equipment can be met. And self-locking is achieved through a wedge-shaped structure, and the supporting effect on equipment is achieved.

Owner:XIAN QINGAN ELECTRIC CONTROL

A small modulus gear backlash detection method

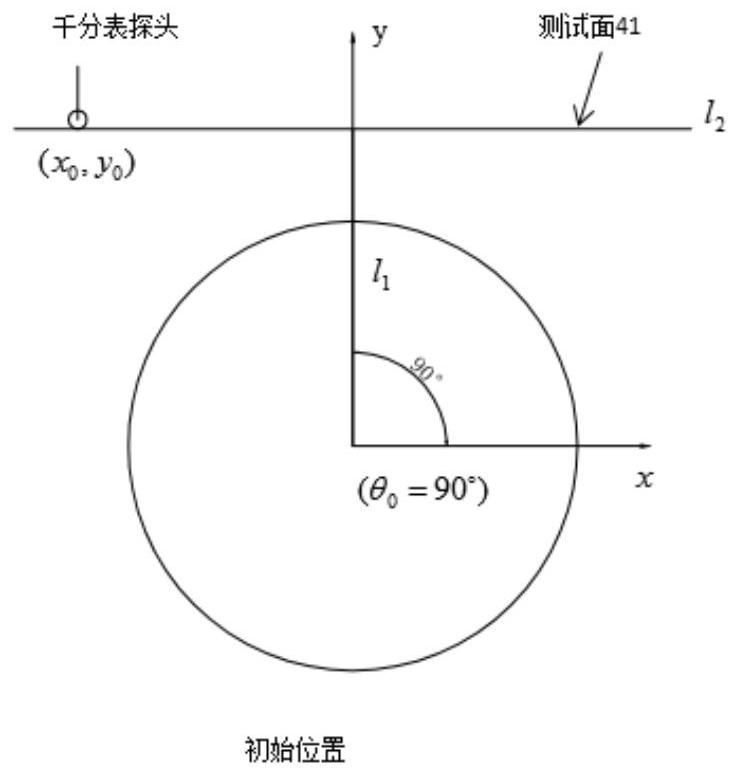

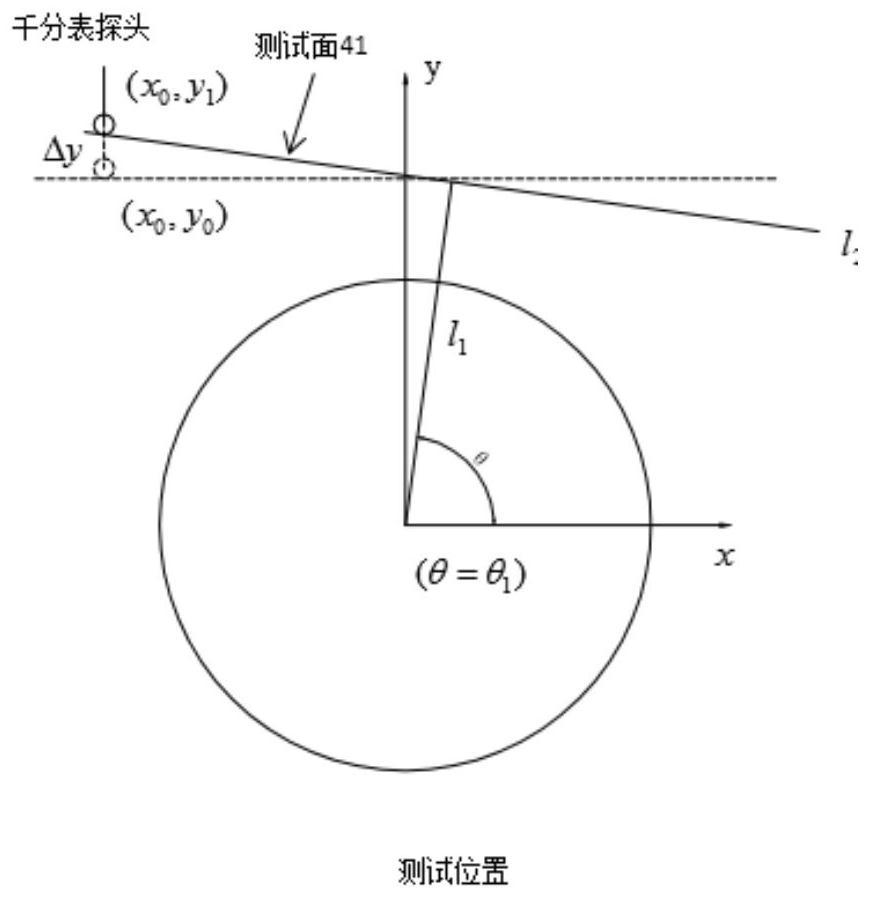

ActiveCN112697022BAccurate measurementThe means of realization are simple and convenientMechanical clearance measurementsBacklashGear wheel

The invention discloses a method for measuring the backlash of small modulus gears. The driven gear is rotated to the state where the test surface is horizontal, and the initial angle θ is determined. 0 is 90 degrees, and the probe of the dial gauge is vertically against the test initial point on the surface of the above-mentioned test surface, and the position data of the test initial point is recorded as (x 0 ,y 0 ), so that the value of the dial gauge returns to zero, at this time y 0 =R, turn the driven gear until one surface of the driven gear meshes with the driving gear, record the current data △y of the dial indicator, and substitute the known parameters R and θ into the formula 0 , Δy, x 0 , get the normal inclination angle θ of the test surface 1 ; Then by knowing the radius of the gear pitch circle as r, measure the gear backlash l: l=r·|θ 1 ‑θ 0 |, the present invention does not need to extend the probe of the dial indicator into the gear gap, and can accurately measure the gear backlash of small modulus, the realization method is simple and convenient, does not require too many auxiliary test tools, and there are few parameters to be tested. The cost is lower.

Owner:伯朗特机器人股份有限公司

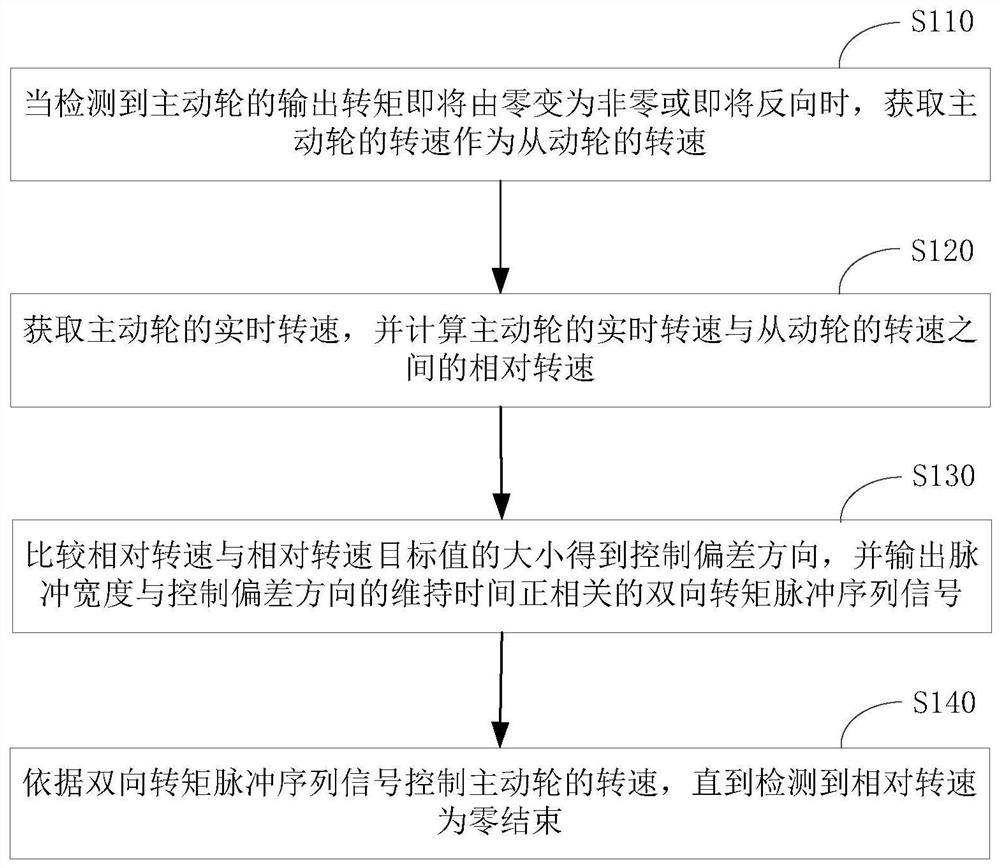

Gear backlash compensation method, system and controller

Owner:合肥阳光电动力科技有限公司

Method for hysteresis compensation in an actuator and a selector fork that is adjustably by this actuator

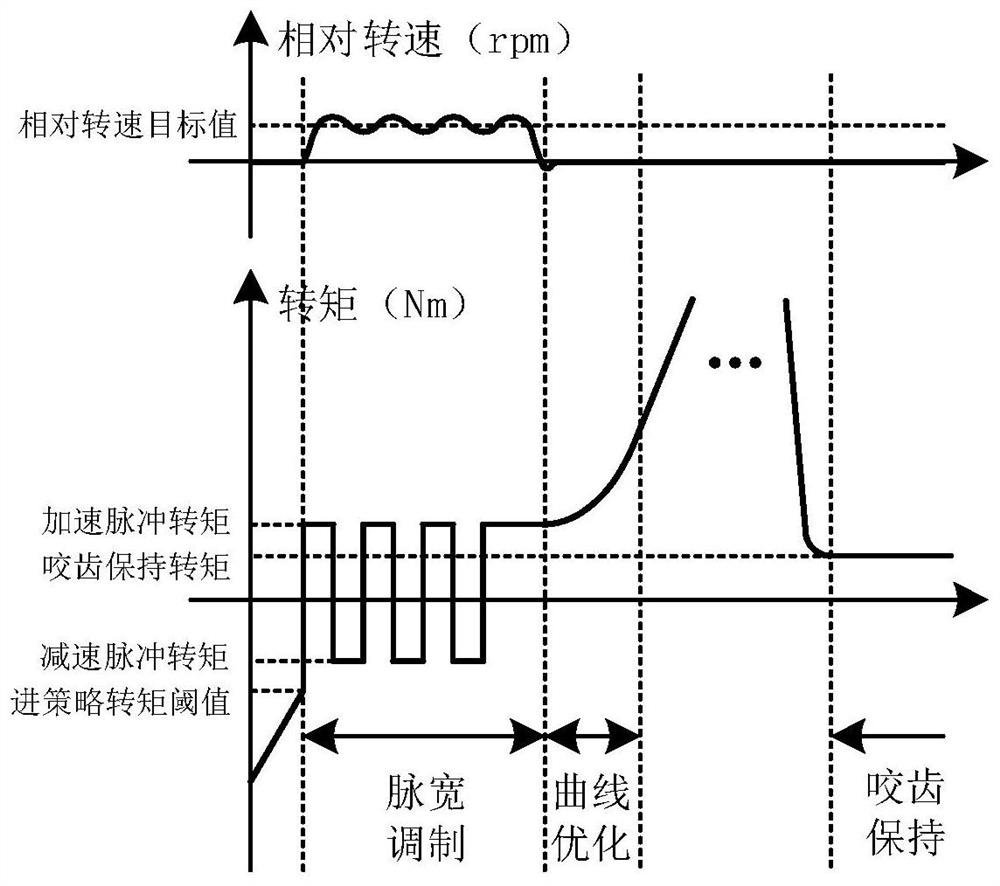

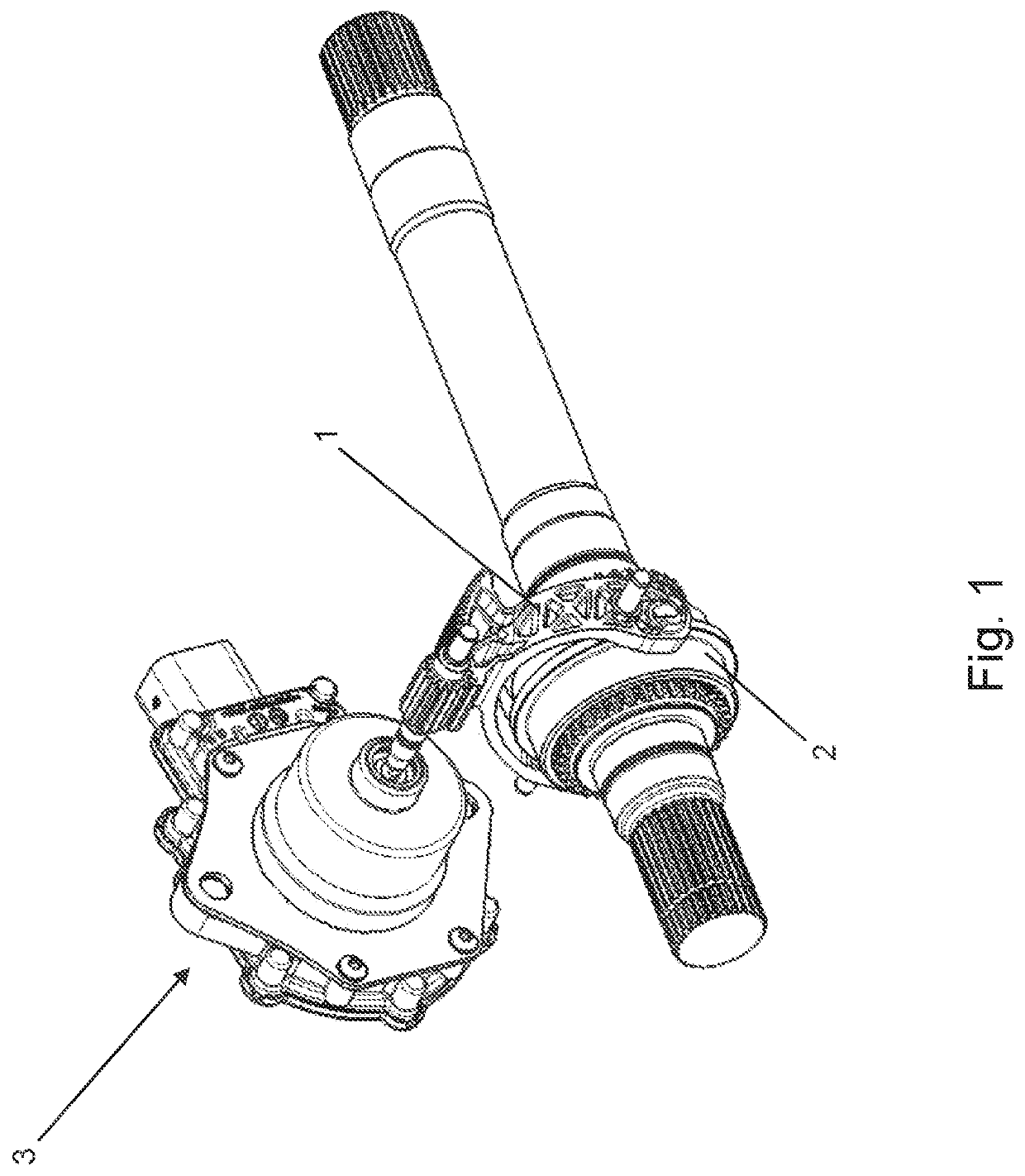

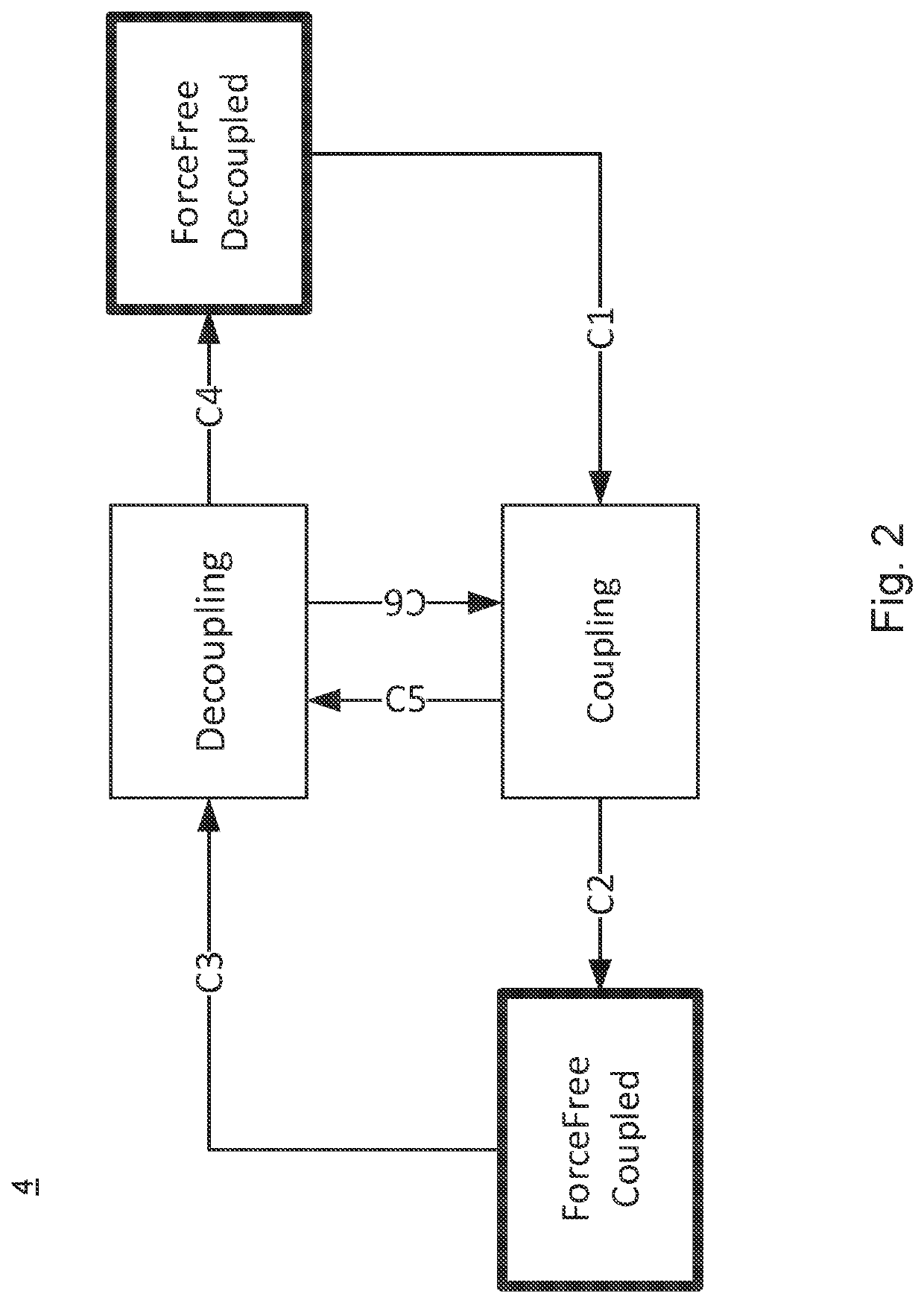

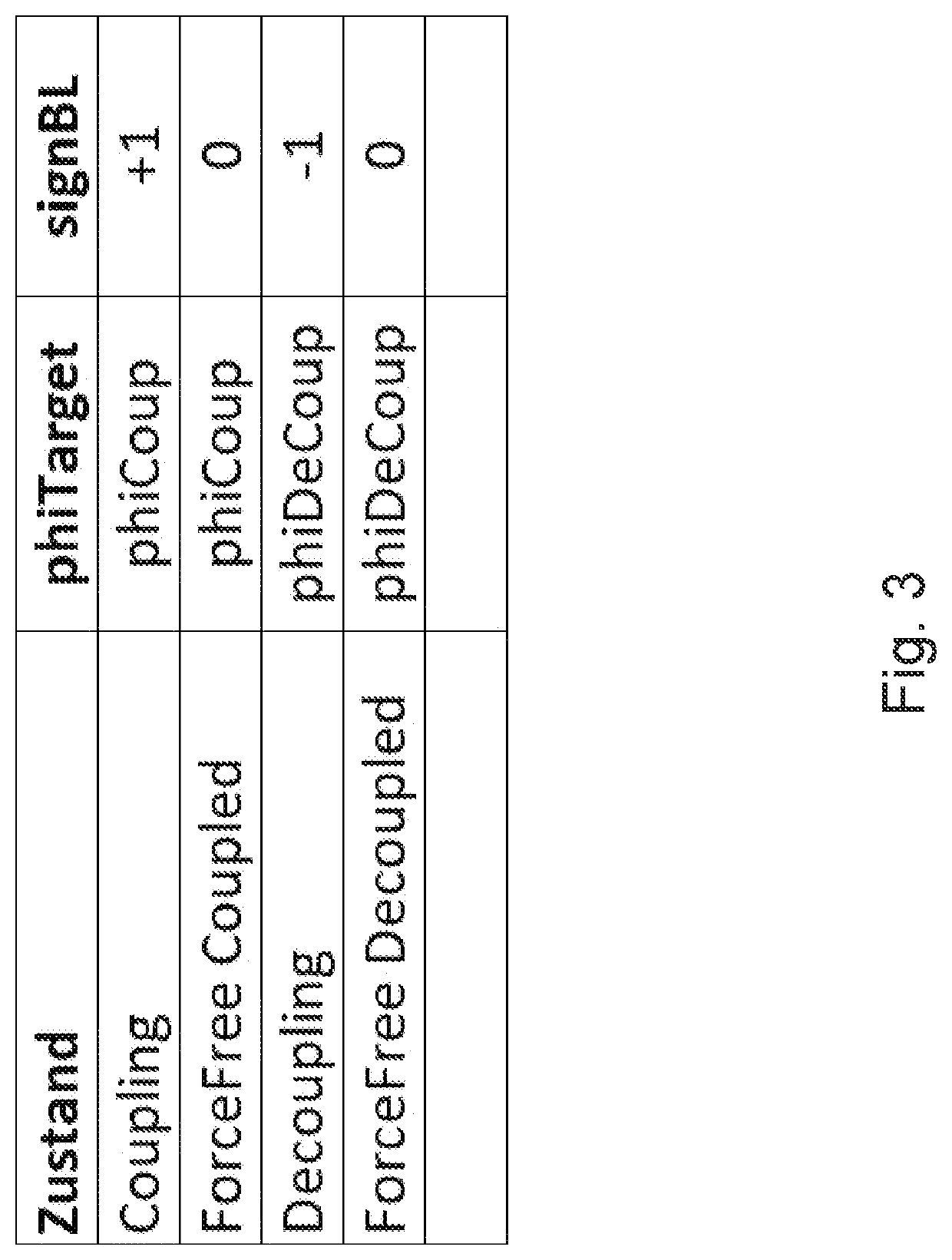

A method for hysteresis compensation in an actuator and a selector fork that is adjustable by this actuator and guides a sliding sleeve, by means of a state machine, wherein the selector fork is moved by means of the actuator from a first shift position (xDecoup), namely a neutral position, into at least one second shift position (xCoup), namely a gear position, and vice versa, wherein the position of the actuator (phiAtr, phiCoup, phiDecoup), in the event of a shift request into the neutral position (xDecoup) or into the gear position (xCoup), is corrected on the basis of stored mechanical backlash (phiBL) between the actuator and the selector fork and of a sign (+1, 0, −1) generated by the state machine and associated with the particular shift request.

Owner:MAGNA POWERTRAIN AG & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com