Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39 results about "Axial joints" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

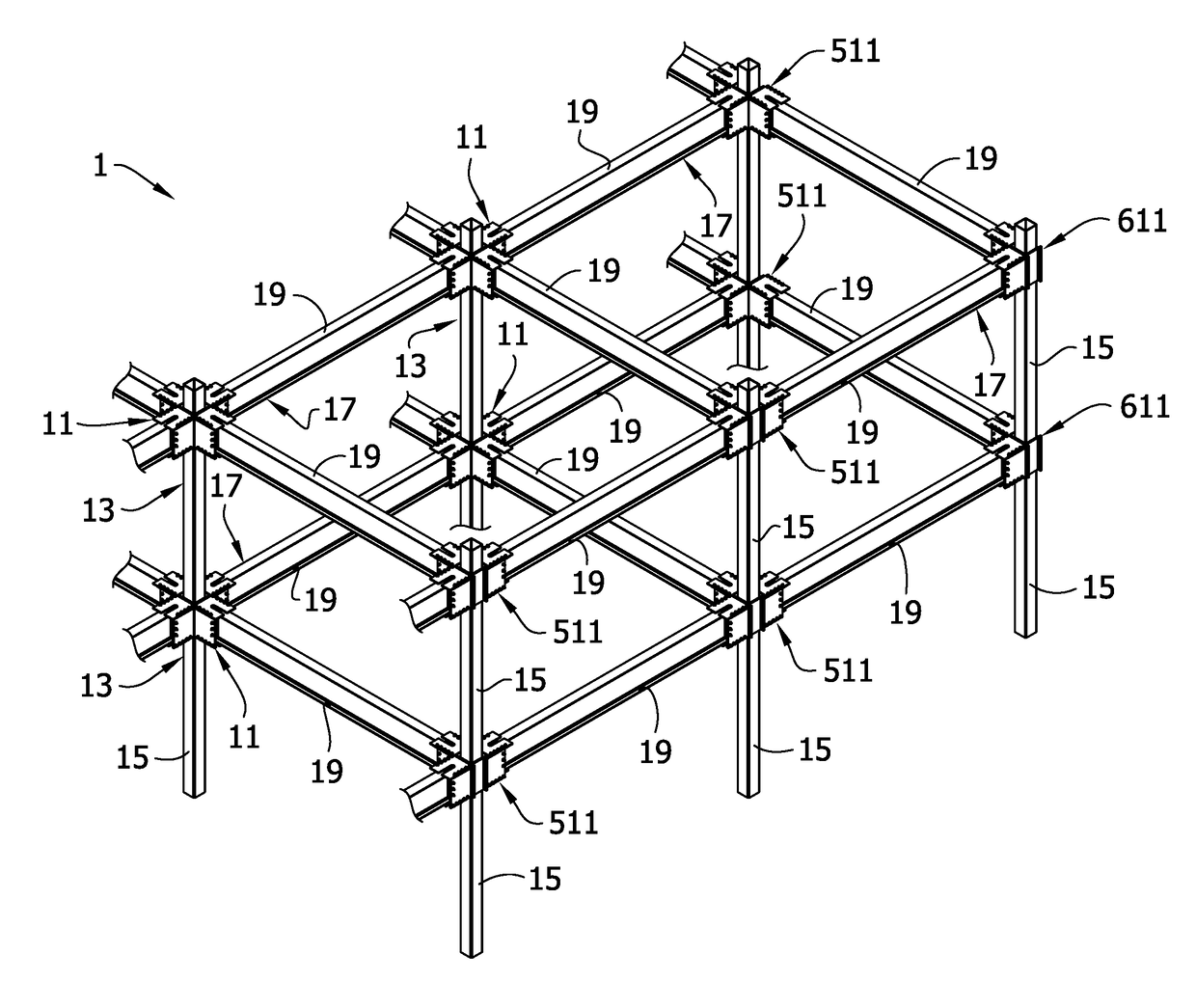

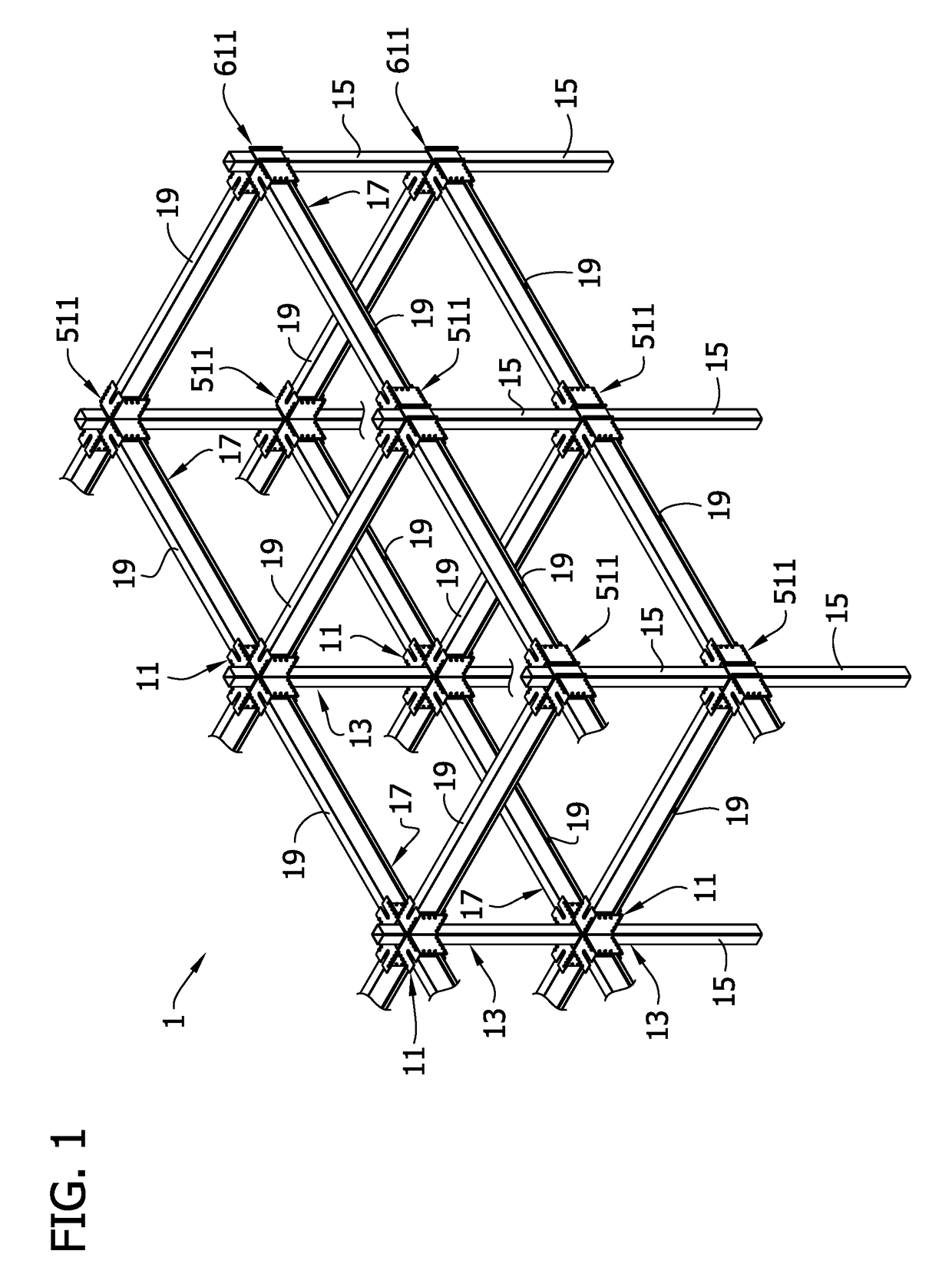

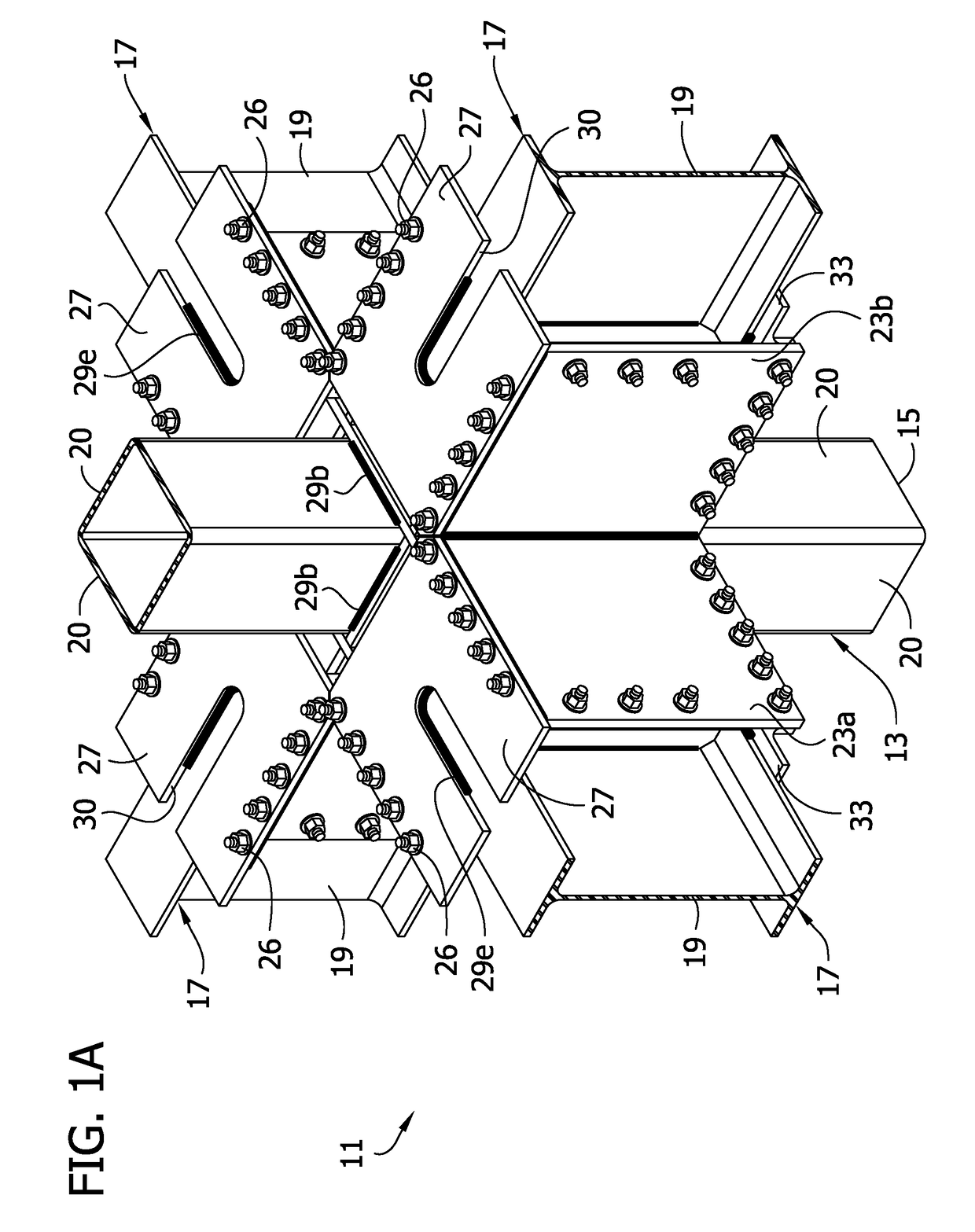

Moment resisting bi-axial beam-to-column joint connection

InactiveUS20170314254A1Building constructionsWelding/soldering/cutting articlesGusset plateAxial joints

A prefabricated column assembly includes a hollow tubular column having a longitudinal axis. A gusset plate assembly includes a plurality of gusset plates connected to the column and extending laterally outward from the column in planes generally parallel to the longitudinal axis of the column. A first pair of the gusset plates extends laterally outward from the column along a first axis and defines a space for receiving an end portion of a first beam for mounting the first beam on the first pair of gusset plates. A second pair of the gusset plates extends laterally outward from the column along a second axis that is nonparallel and non-coincident with the first axis. The second pair of gusset plates defines a space for receiving an end portion of a second beam for mounting the second beam on the second pair of gusset plates to provide a bi-axial joint connection.

Owner:MITEK HLDG INC

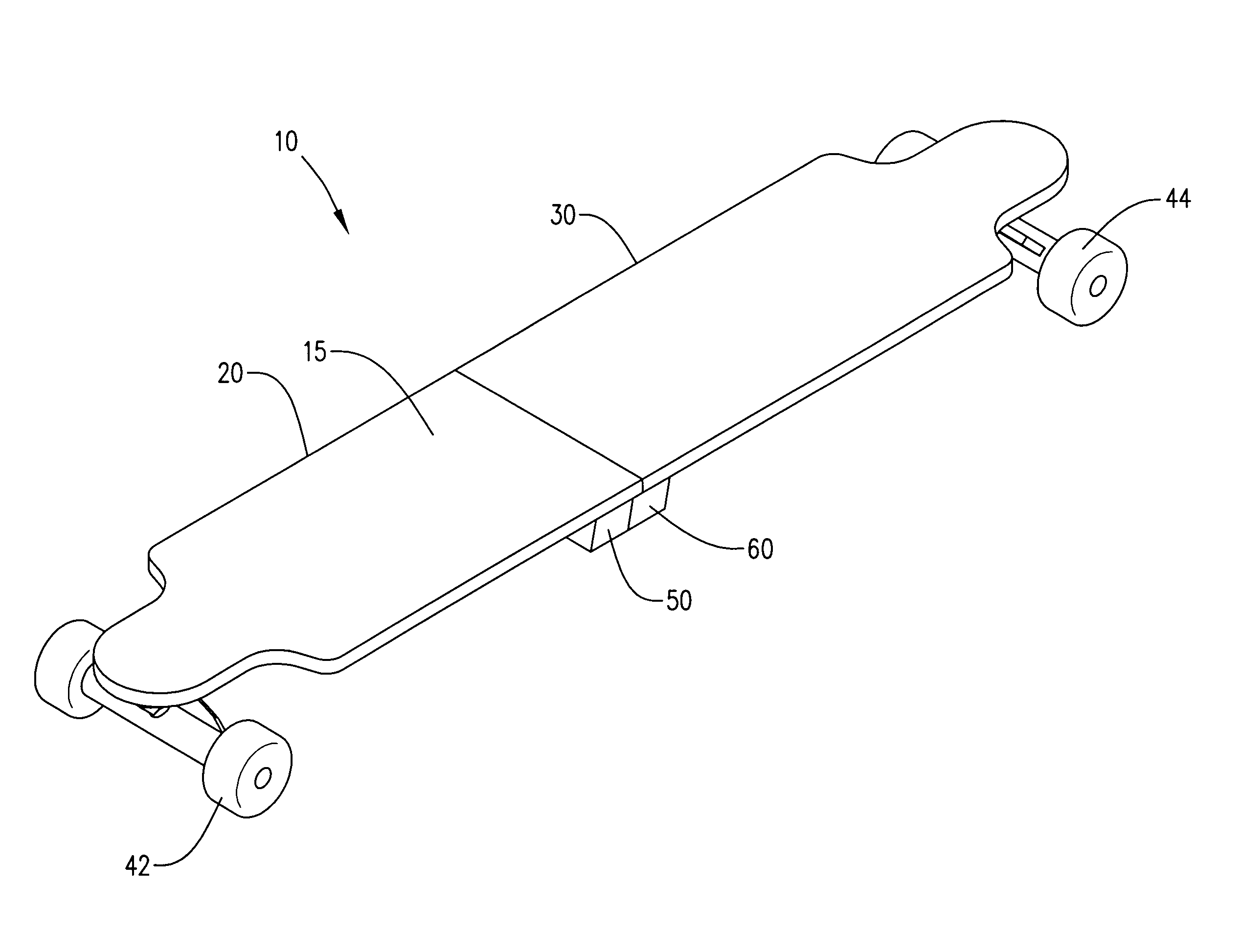

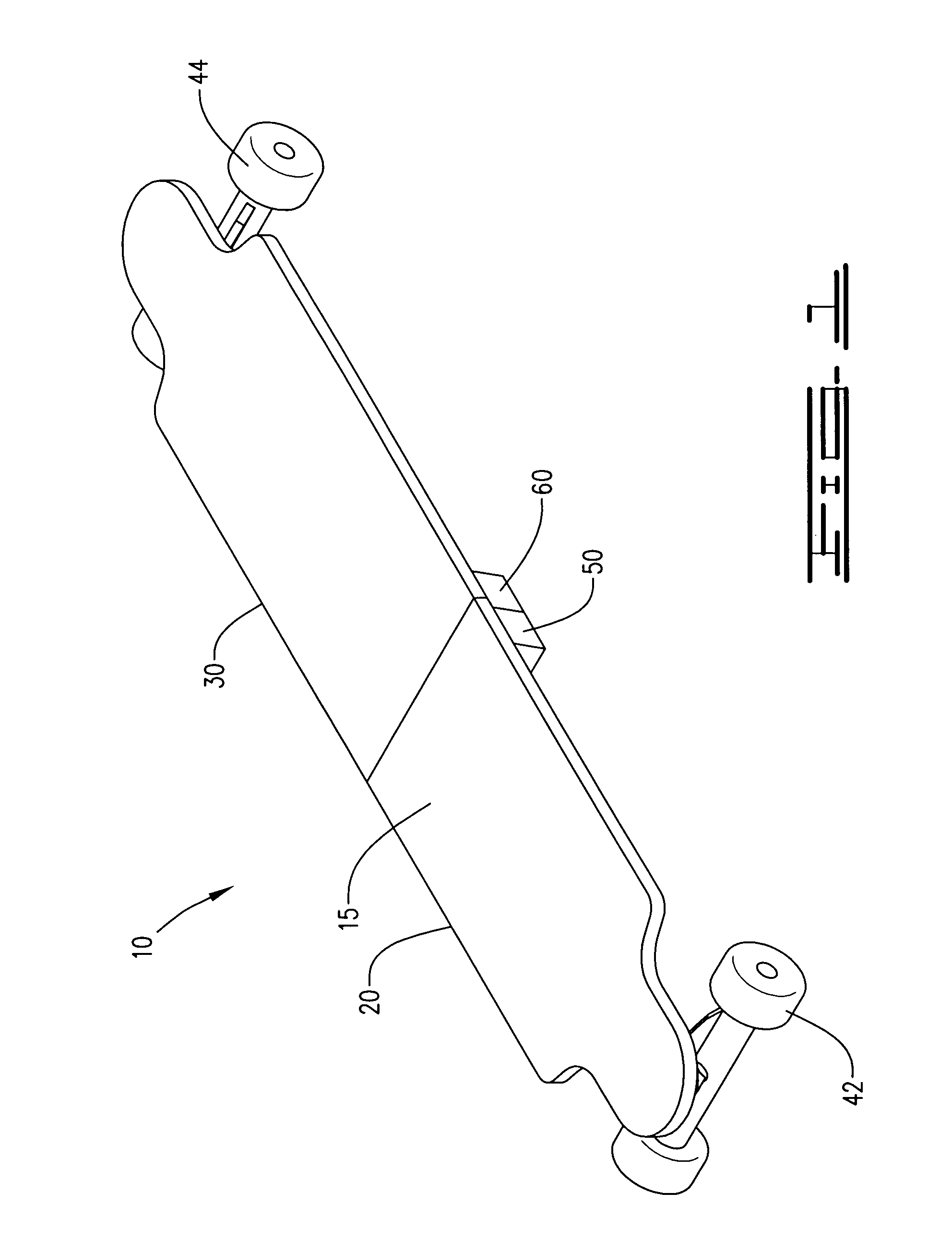

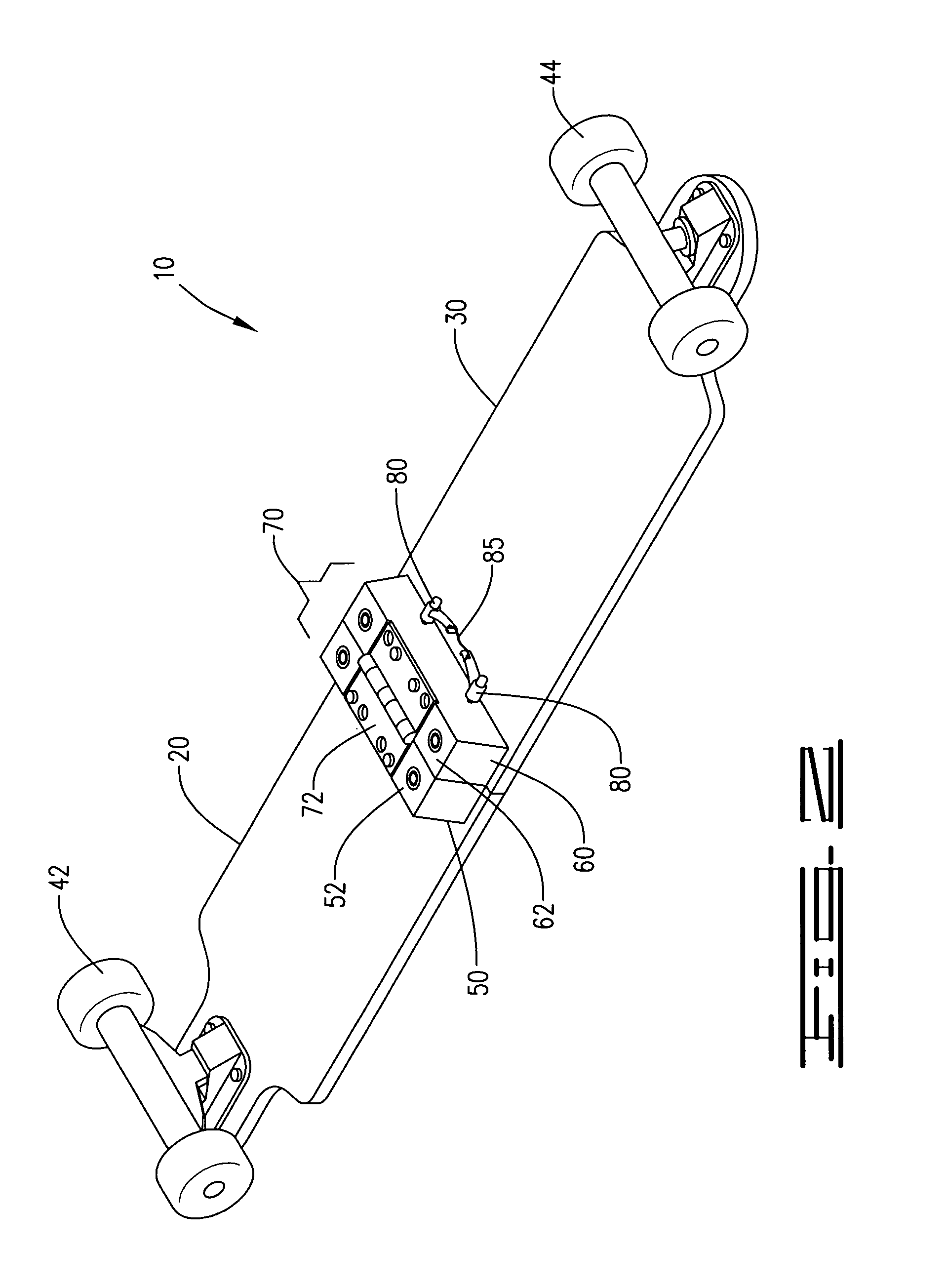

Compact folding long board

InactiveUS8459670B1More compact carryingLean structureRider propulsionSkate-boardsOn boardAxial joints

Owner:TIZZONE VINCENZO

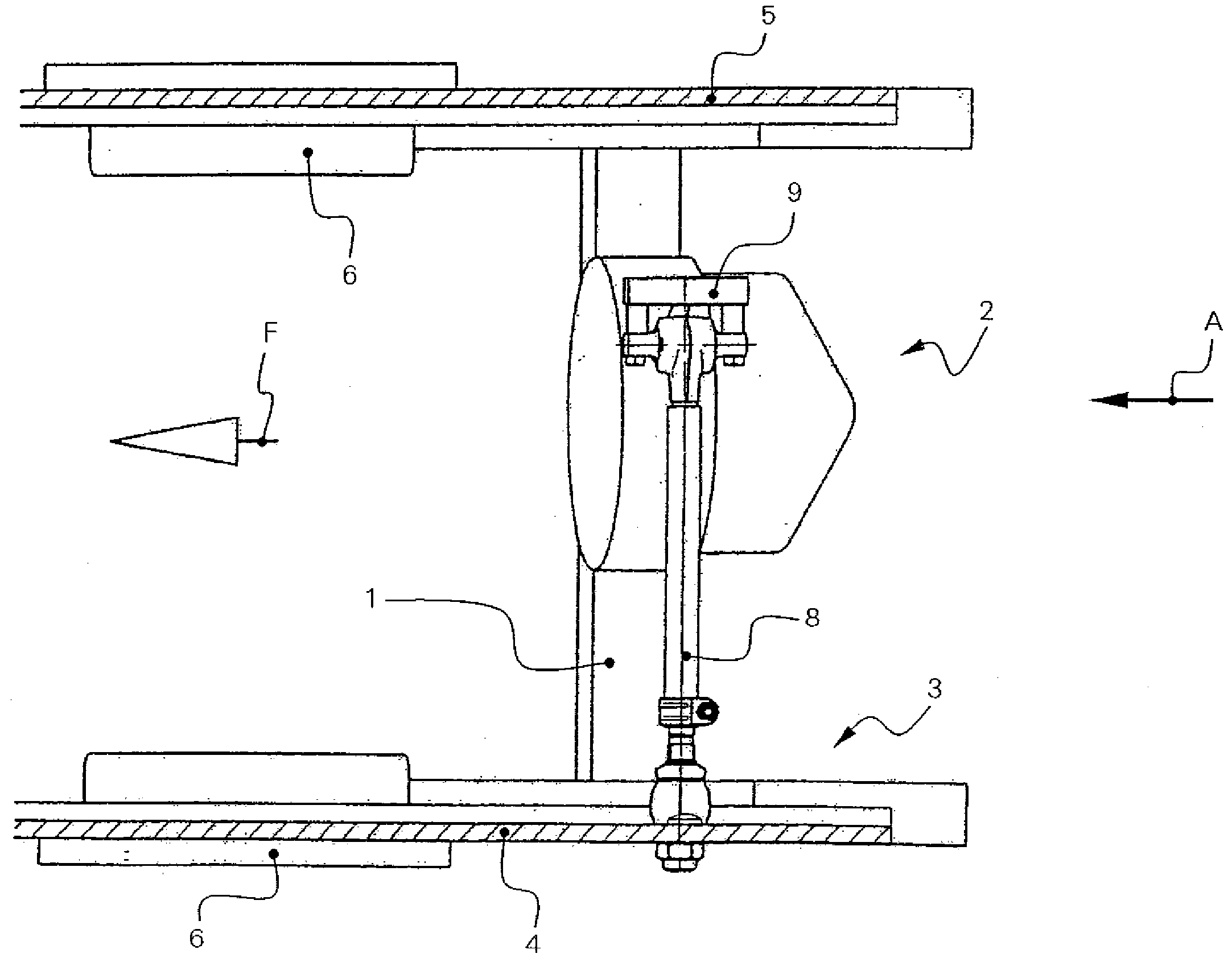

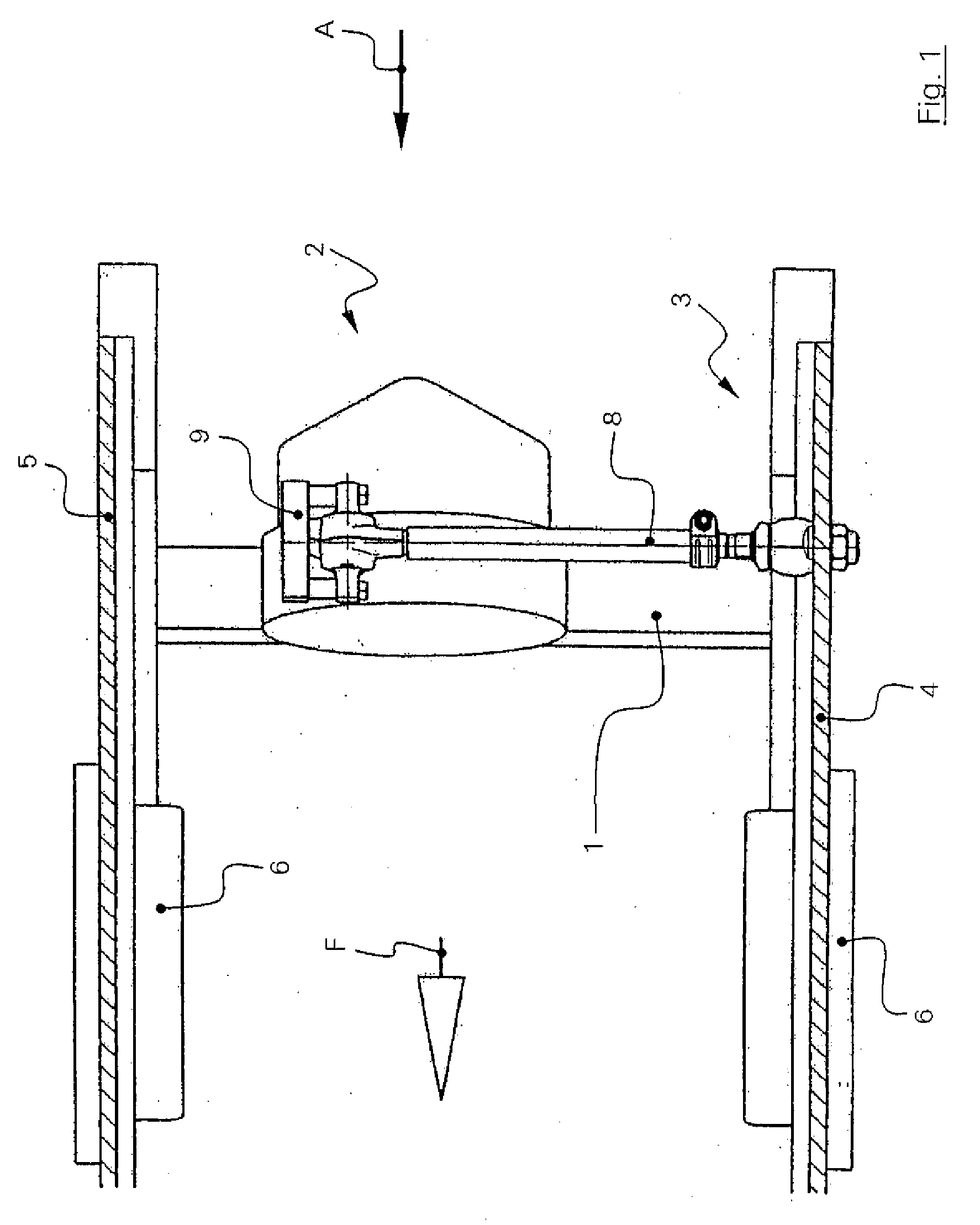

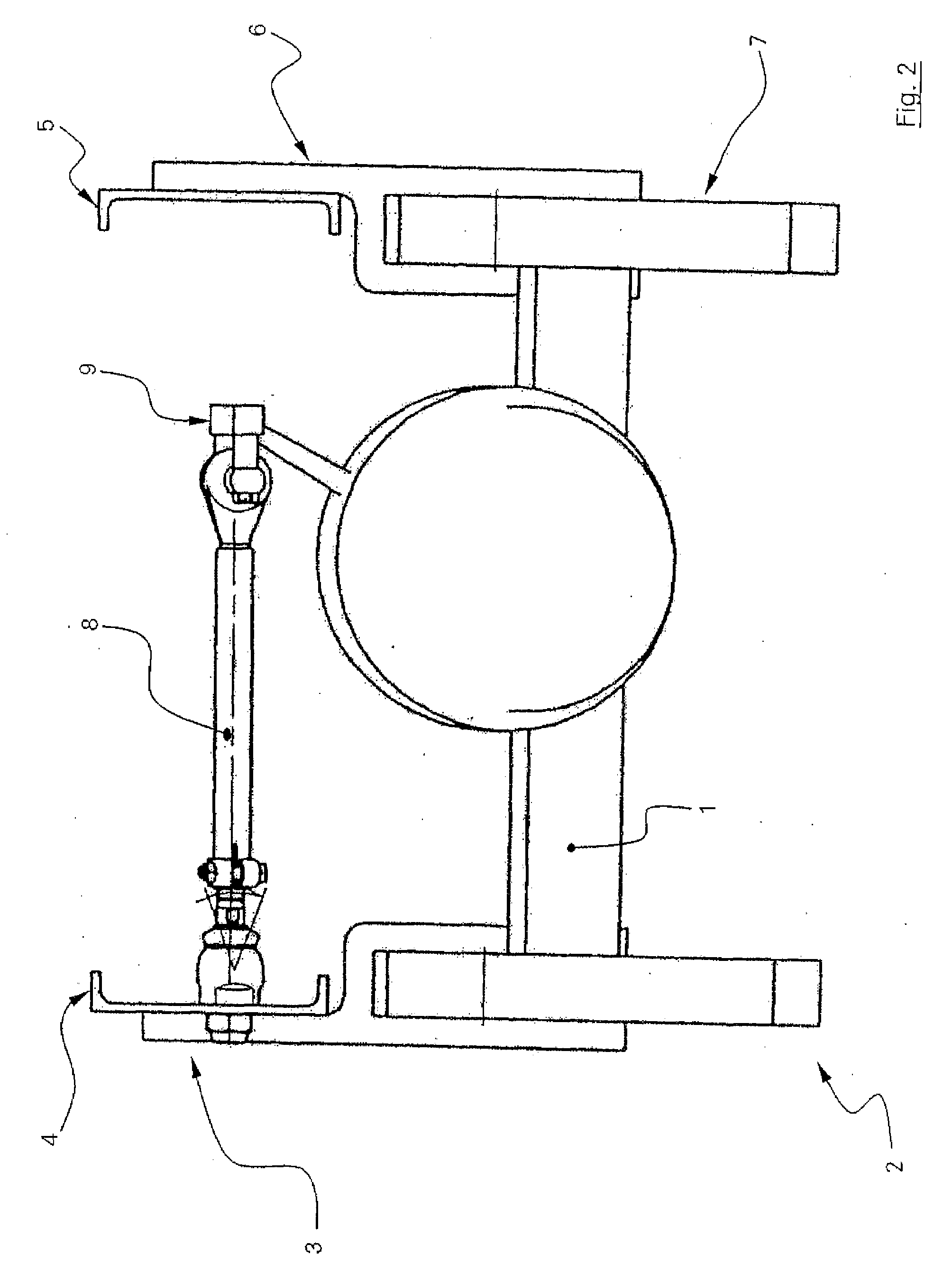

Motor Vehicle

InactiveUS20090001680A1Simple designReduces weight and number of componentResilient suspensionsPivoted suspension armsMobile vehicleAxial joints

A motor vehicle, especially a utility vehicle, with a vehicle chassis (3) as well as with a rear axle arrangement (2) having a rigid axle (1). A Panhard rod (8) for supporting lateral forces or a control arm for supporting longitudinal forces is arranged between the vehicle chassis (3) and the rigid axle (1). The motor vehicle has the Panhard rod (8), which is directly articulated to the vehicle chassis (3) with an axial joint (11) in a pivotingly movable manner or by a control arm. The Panhard rod (8) is articulated to the rigid axle directly with an axial joint (11) in a pivotingly movable manner.

Owner:ZF FRIEDRICHSHAFEN AG

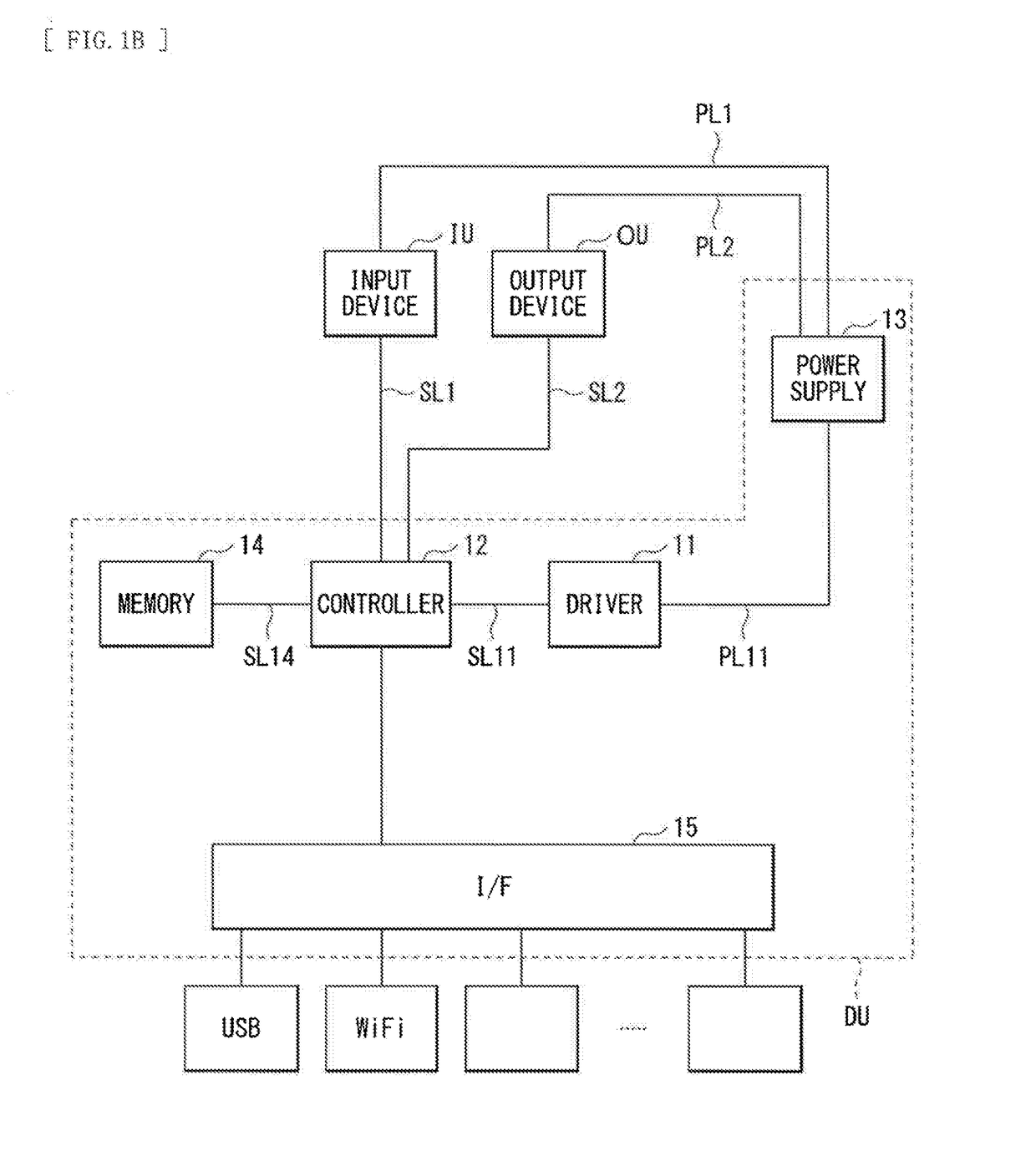

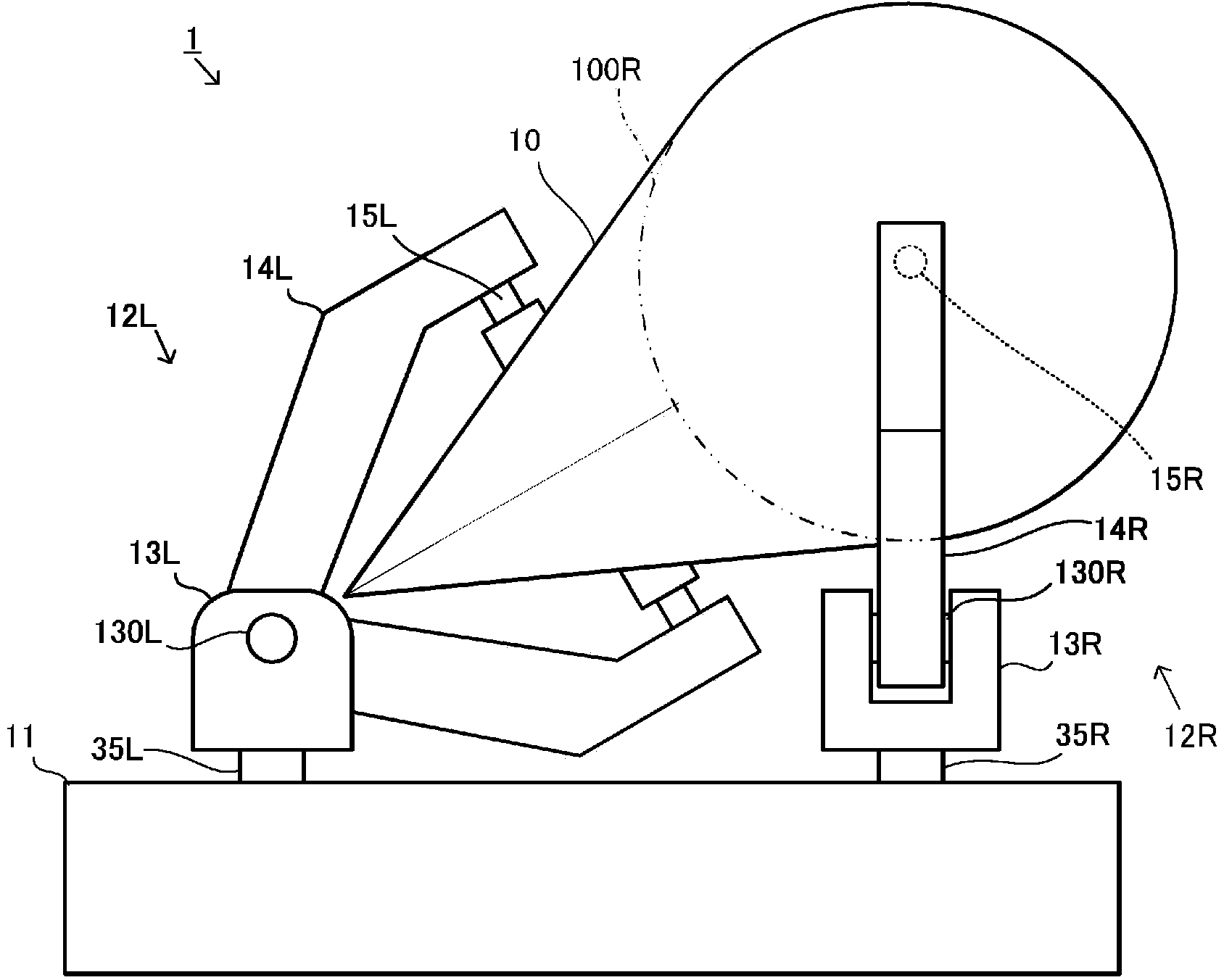

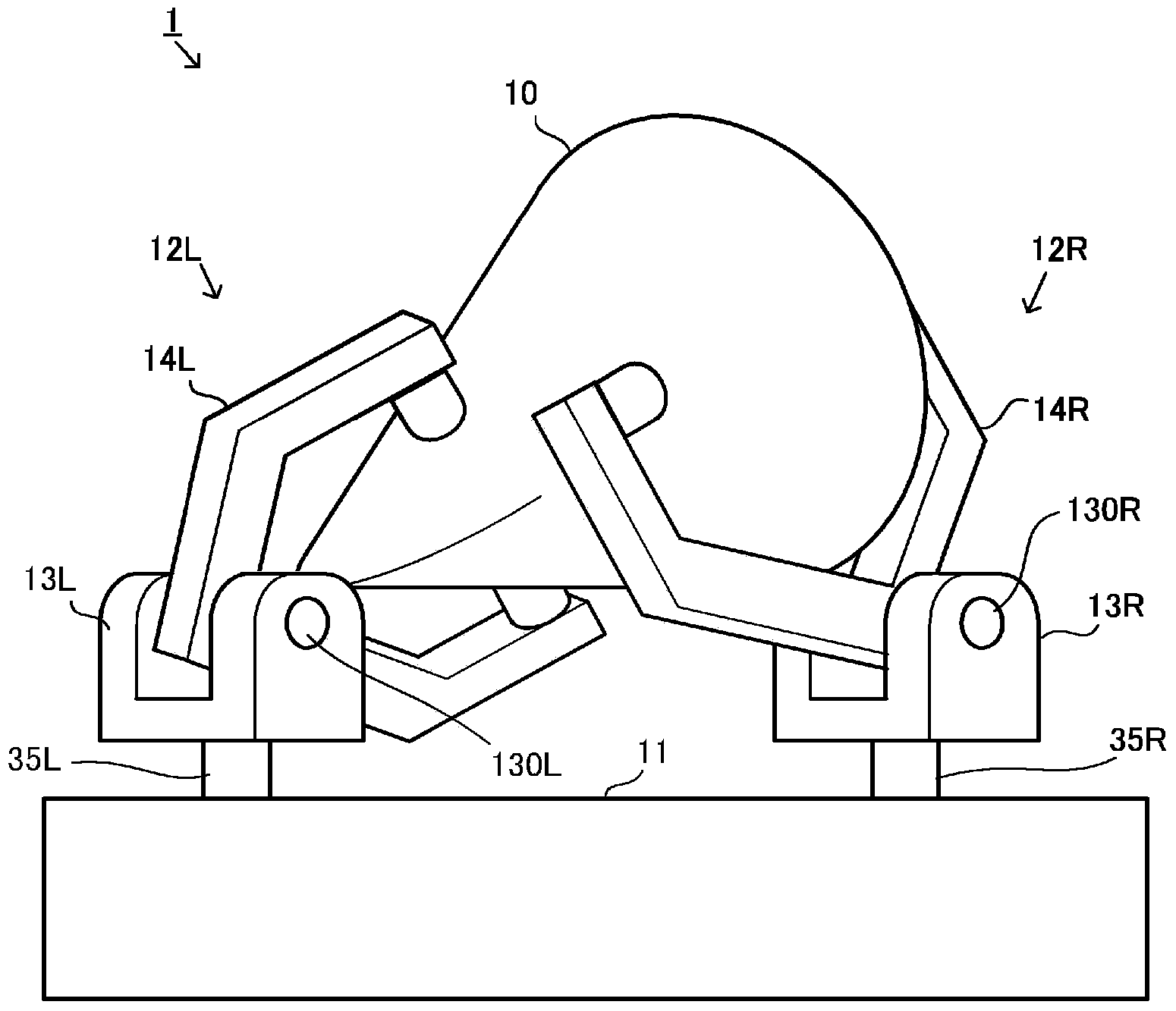

Figure, base, and figure system

ActiveUS20170162088A1Easy to solveEasy to implementDollsSelf-moving toy figuresDrive shaftAxial joints

A figure system includes a drive unit and a figure. The drive unit includes a plurality of first actuators. The figure includes a plurality of joints. The joints have one or more axial joint mechanisms. Drive force derived from at least one of the first actuators is transmitted to corresponding at least one of the axial joint mechanisms through a wire. The drive unit includes, as the plurality of first actuators, a plurality of servomotors having respective drive shafts. The figure includes coupler members having respective bearing holes. The bearing holes are detachably coupled to the respective drive shafts of the servomotors, or configured to be detachably coupled to the respective drive shafts of the servomotors. The wire has a first end coupled to corresponding one of the axial joint mechanisms, and a second end coupled to corresponding one of the coupler members.

Owner:SPEECYS

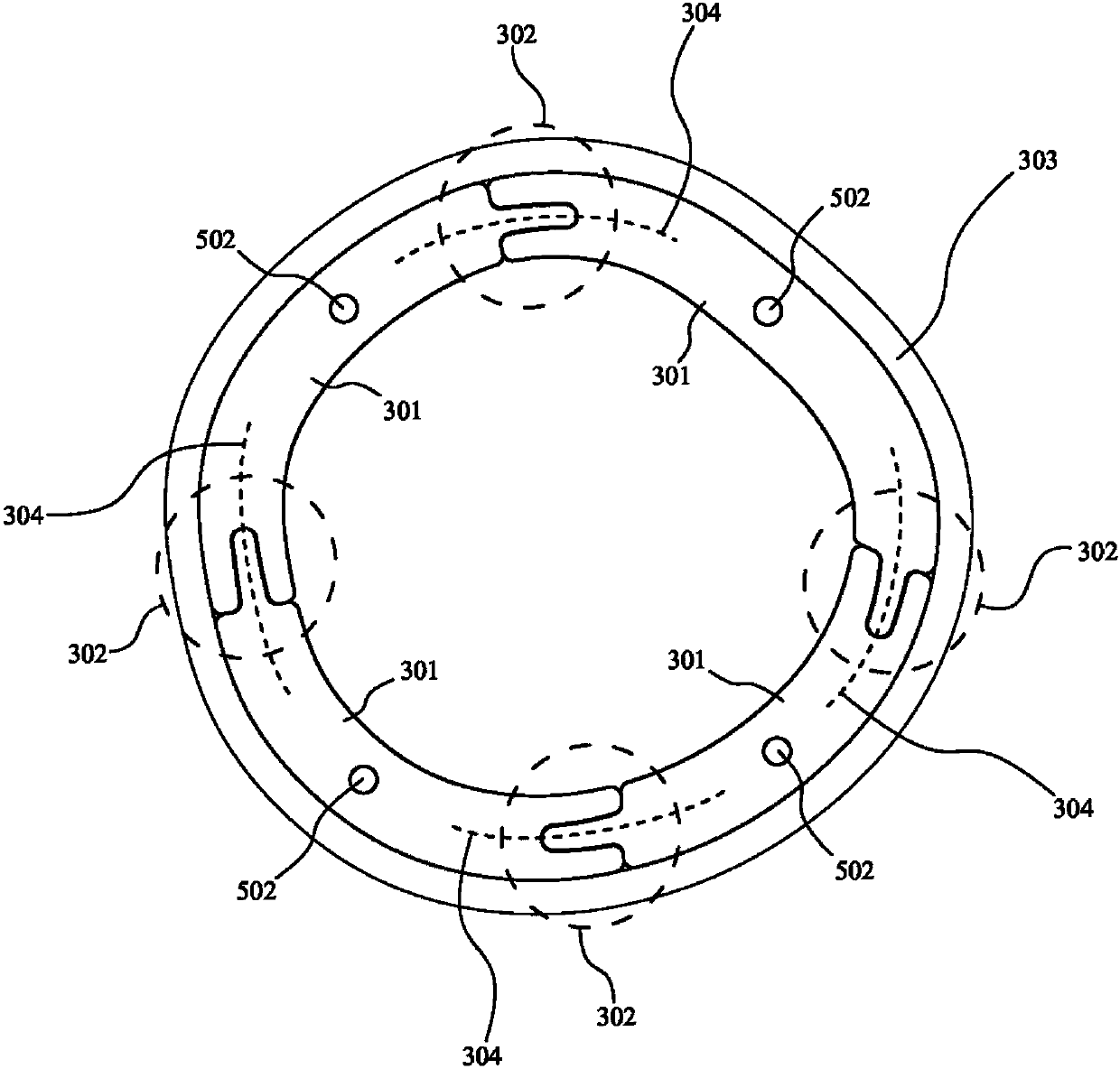

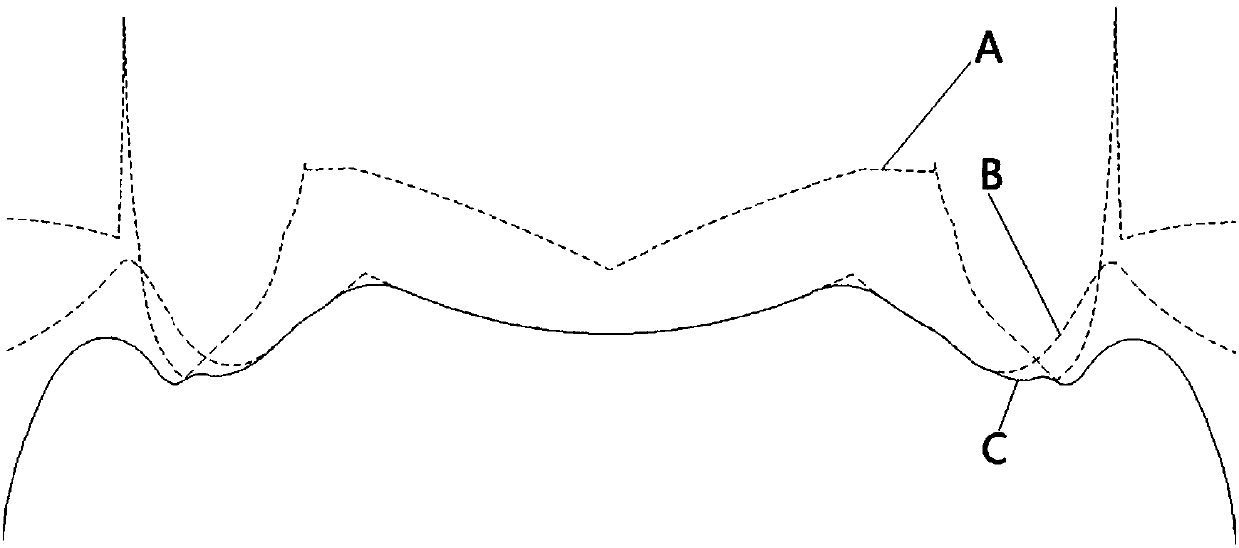

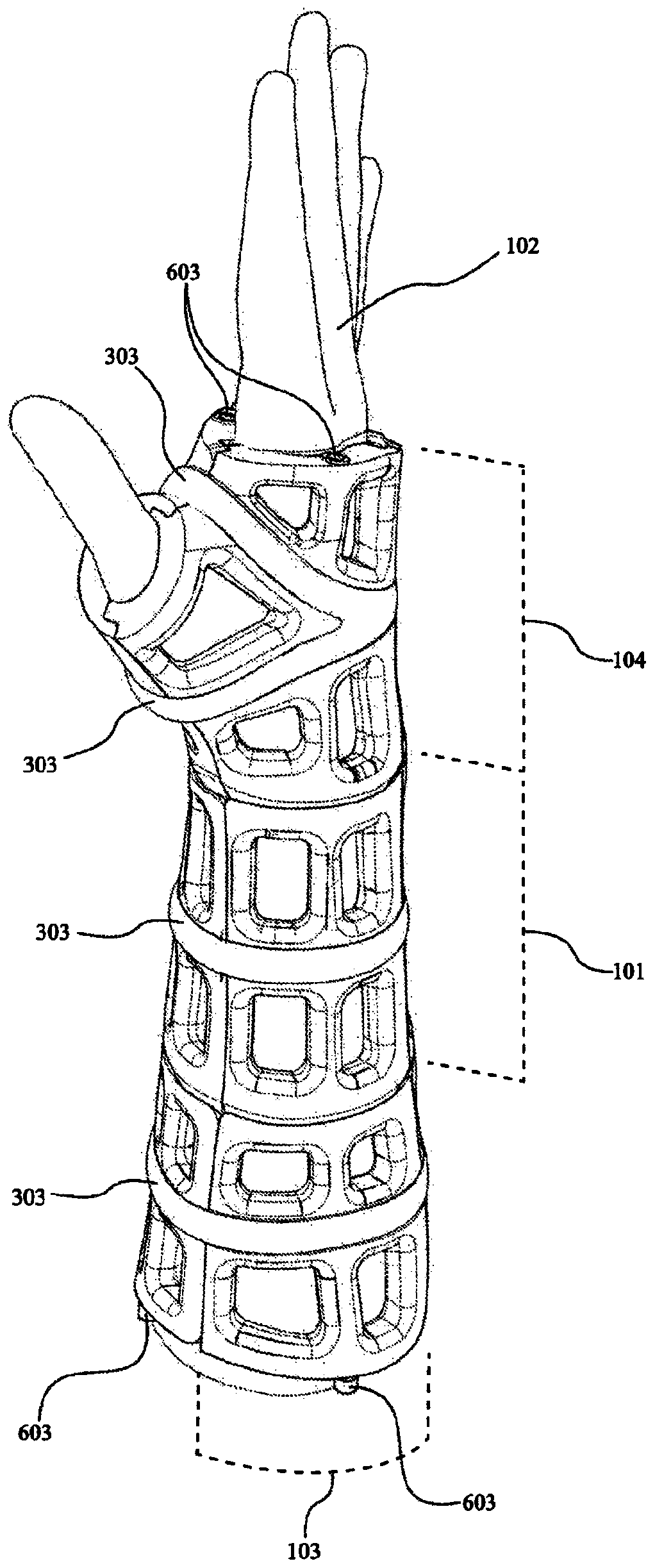

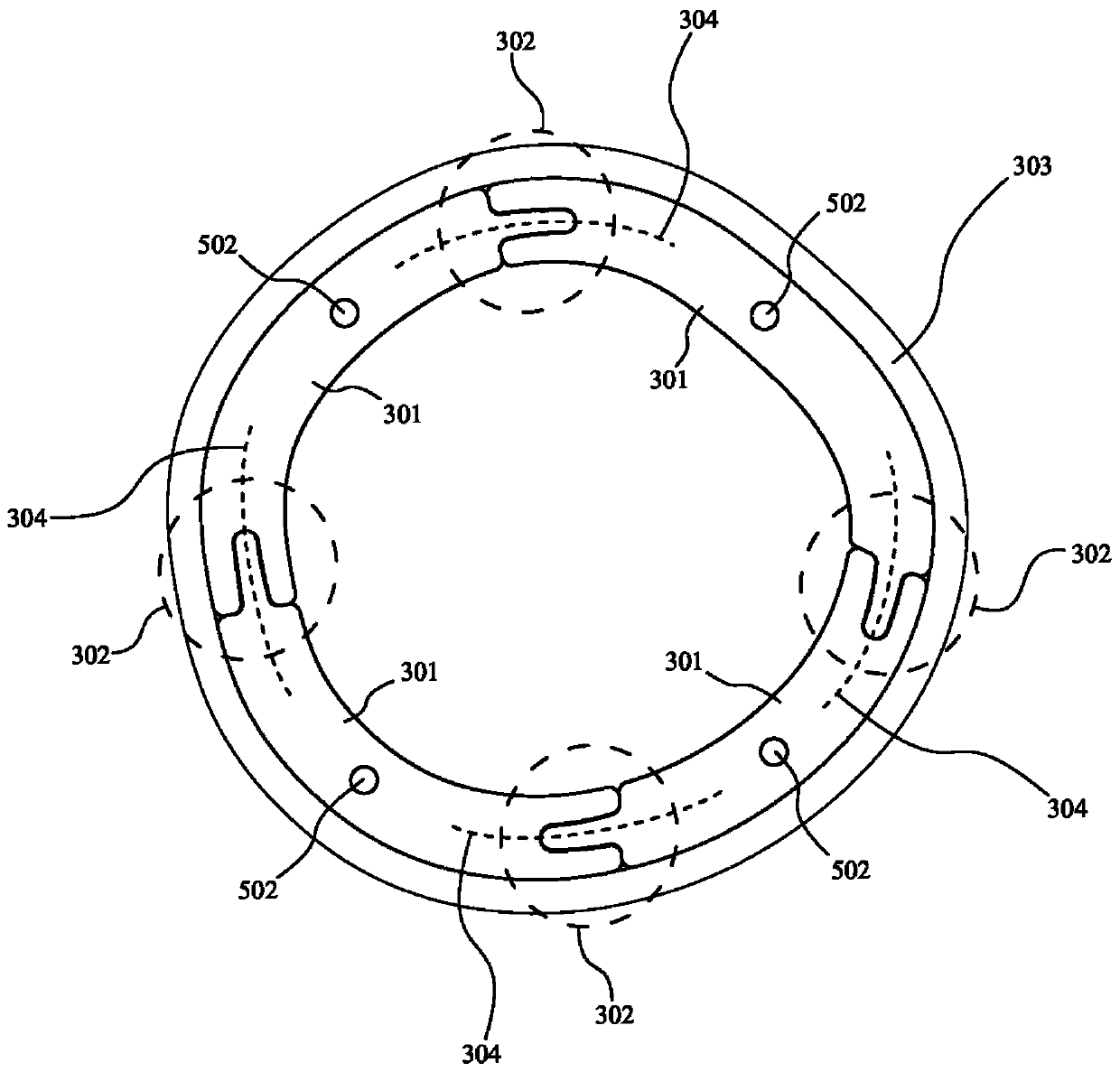

Adaptive three-dimensional orthoses and methods for their manufacture and use

ActiveCN107771069AConstrained radial expansionConstrained bendingMedical simulationFractureAxial jointsOrthotic device

A conformable body interface is fabricated using a data set representing a three- dimensional, soft tissue body surface. The conformable body interface includes a body scaffold that is divided into two or more longitudinal segments separated by axial joints. Optionally, the body scaffold is further divided into two or more circumferentially split segments separated by circumferential joints. The axial joints are circumferentially constrained by elastic bands, tabs, or similar structures and the circumferential joints are longitudinally constrained by elastic axial tethers or similar structures. In this way, the body interfaces can accommodate swelling and bending of the body surface.

Owner:OSTEOID SAGLIK TEKNOLOJILERI AS

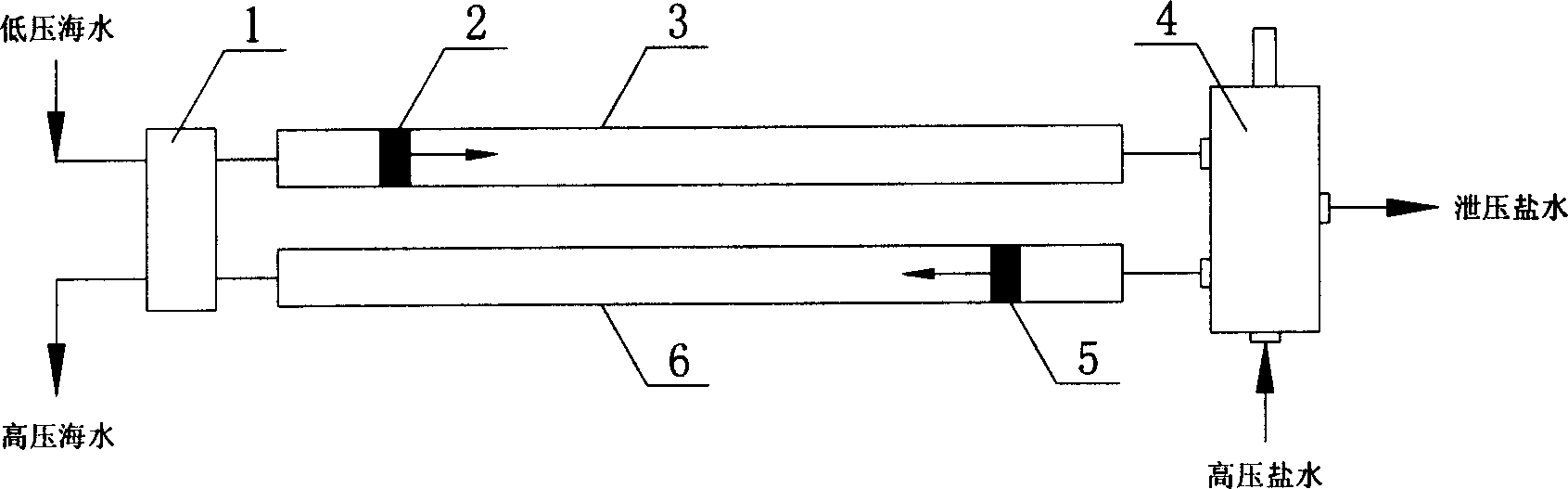

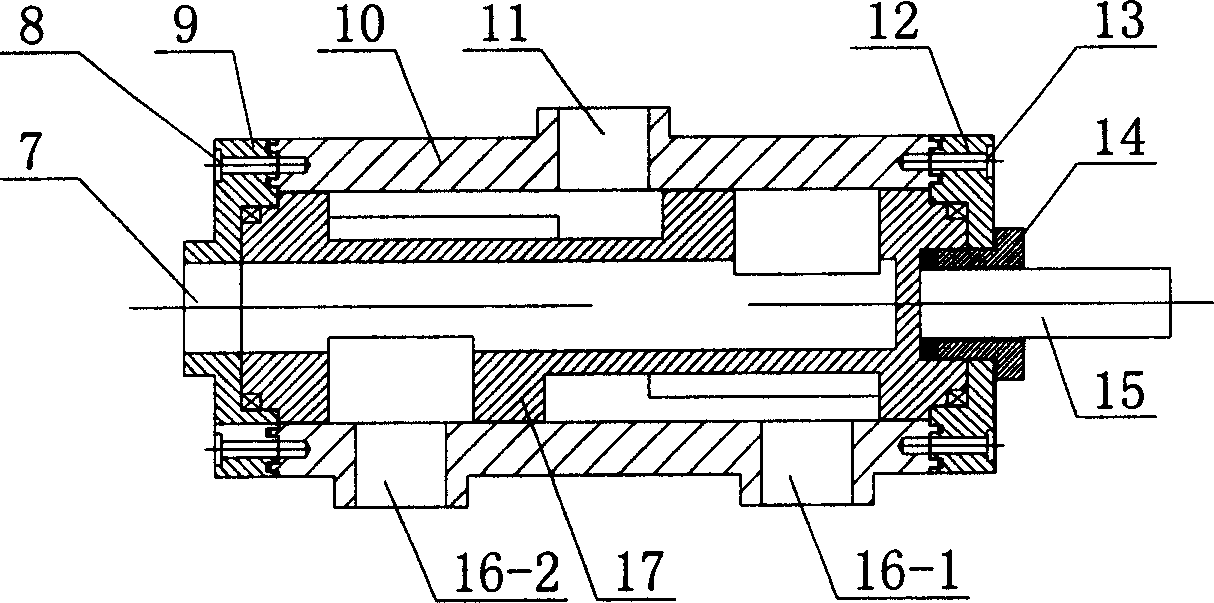

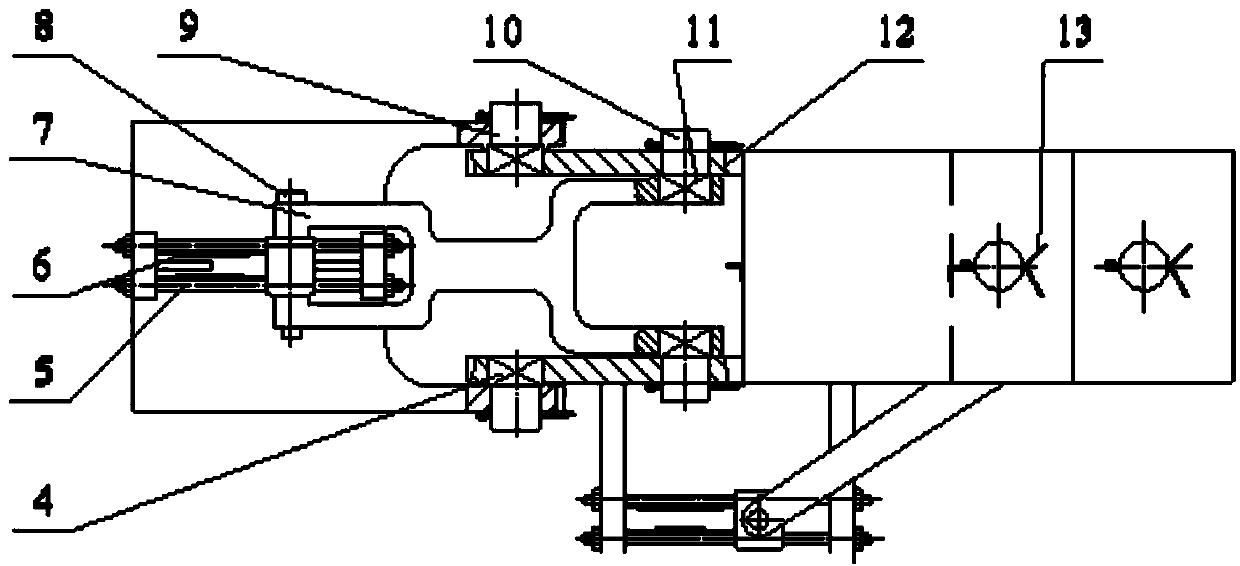

Multi-path pressure switcher for reverse osmosis sea water desalting energy recovery device

InactiveCN1821107ANon-fluctuating flowNo fluctuating pressureGeneral water supply conservationSeawater treatmentSaline waterCentral pressure

The present invention discloses one multipath pressure switcher for reverse osmosis sea water desalting energy recovering apparatus, and belongs to the field of liquid after-pressure recovering technology. The switcher is a casing, a rotating core and end caps assembled to ends. The casing is provided one axial joint and two other joints distributed symmetrically about the axial joint. The rotating core is one hollow cylinder and has sealed joints on two ends, and each of the joints has two radial fan-shaped slots, two fan-shaped holes communicated to the central hole of the rotating core and one central pressure releasing slot communicated to the two fan-shaped slots. The present invention has the advantages of no fluctuation in flow rate and pressure of inflow and outflow salty water and sea water, low rotation speed of the rotating core without noise, good sealing performance, and less leakage and back mixing of salty water and sea water.

Owner:TIANJIN UNIV

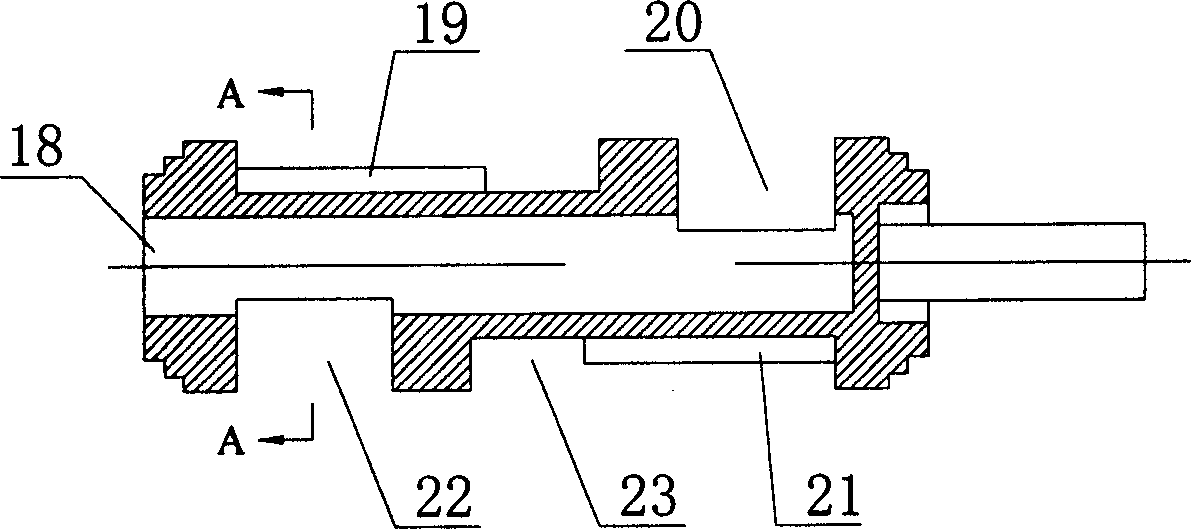

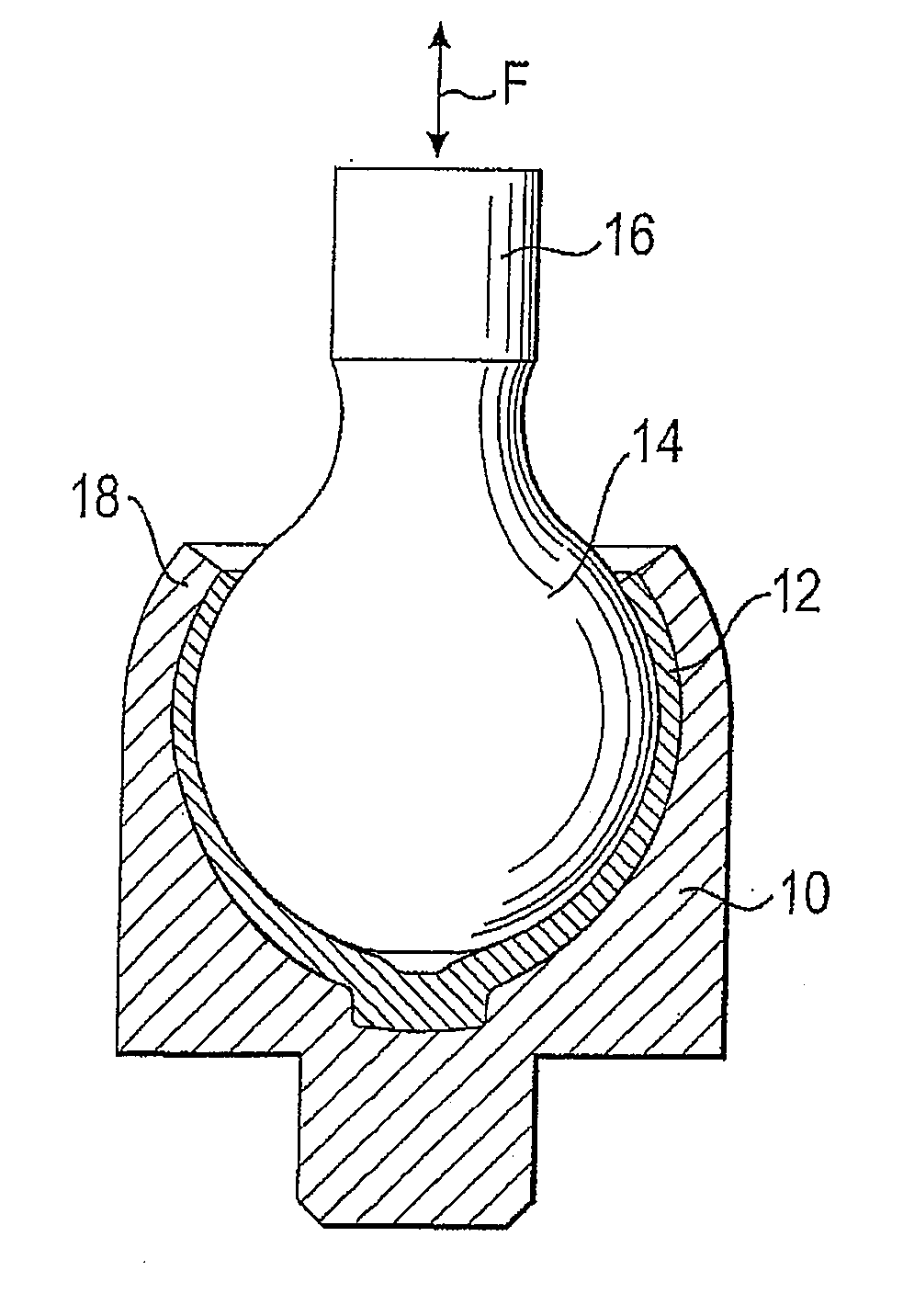

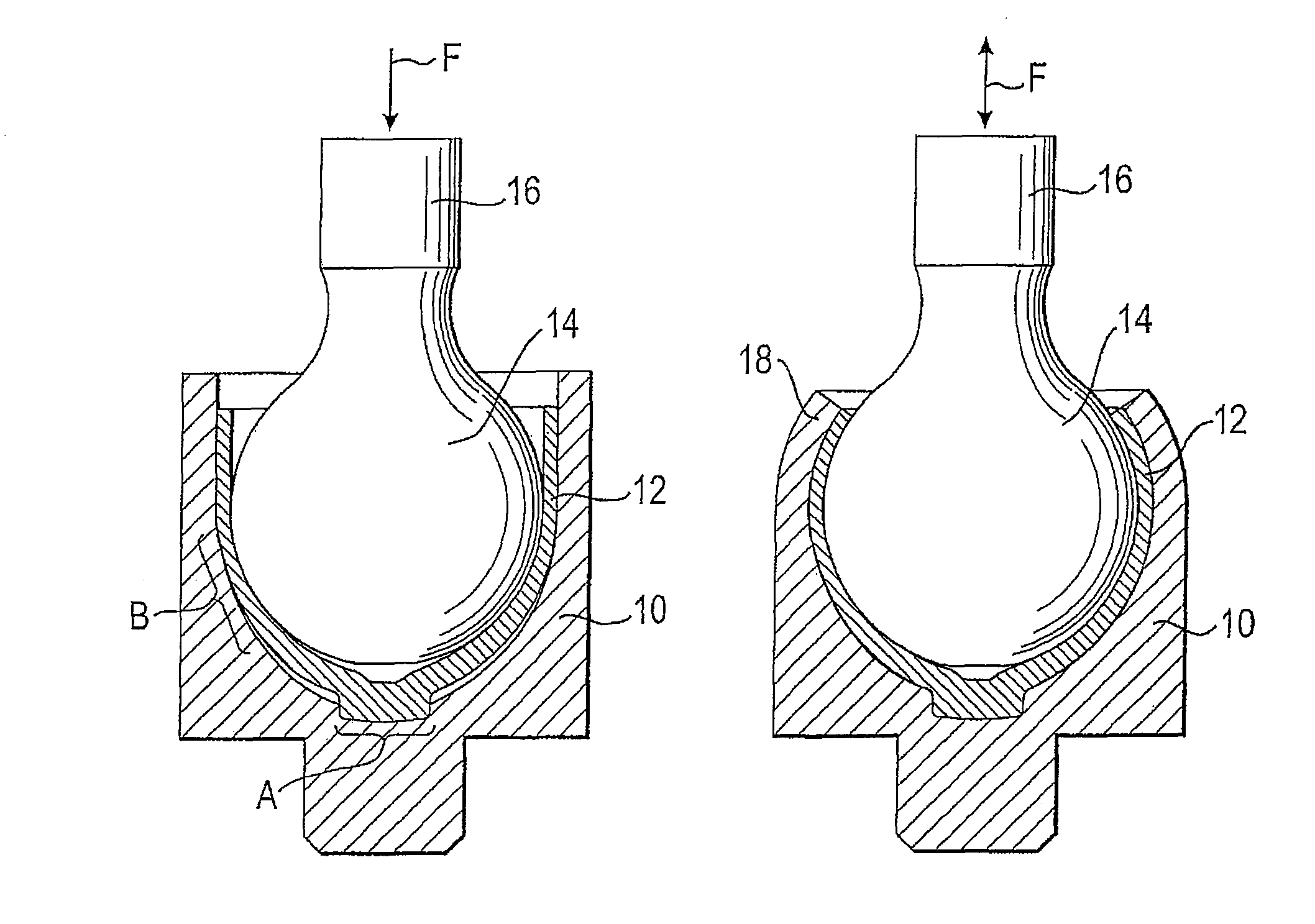

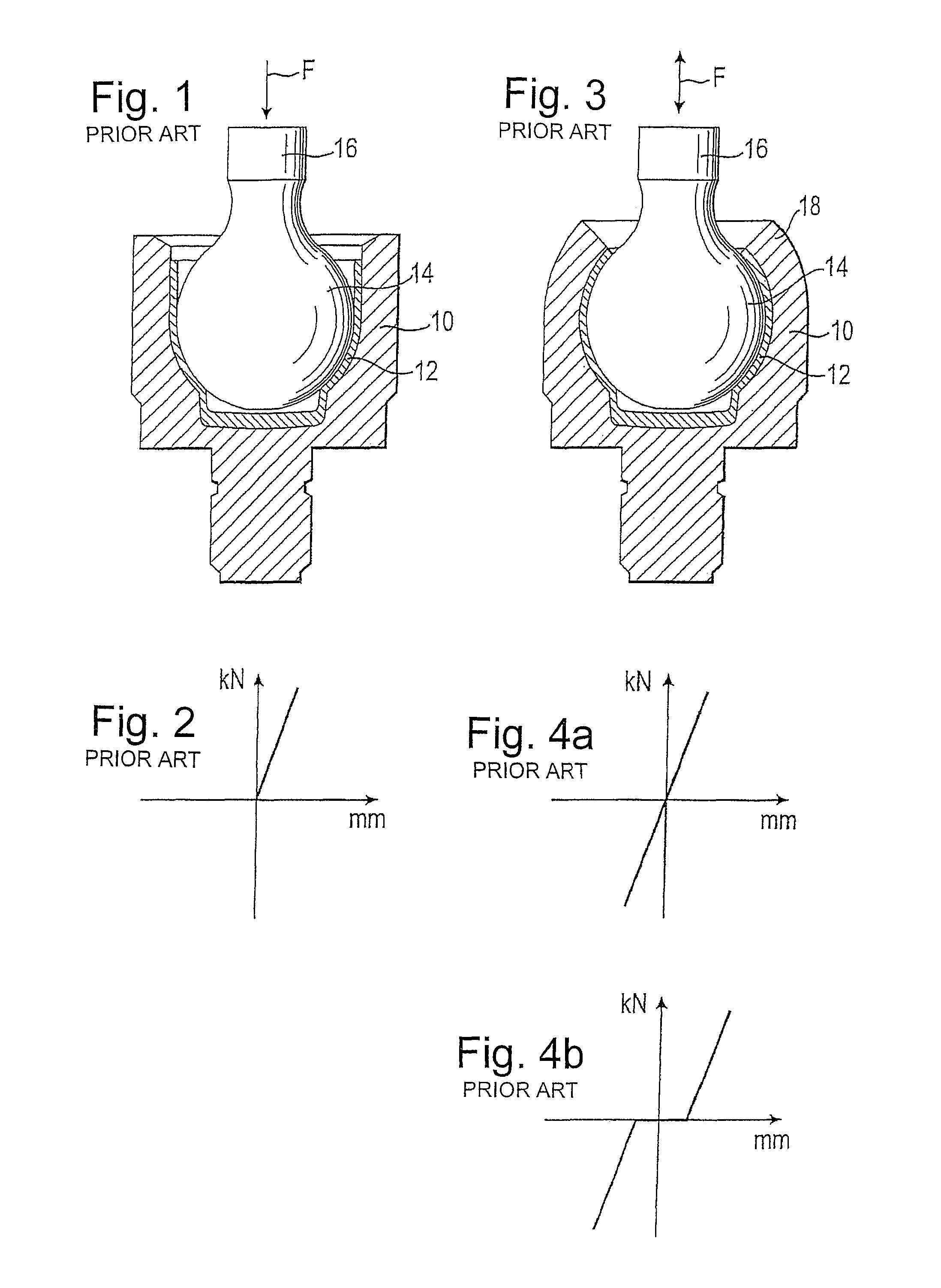

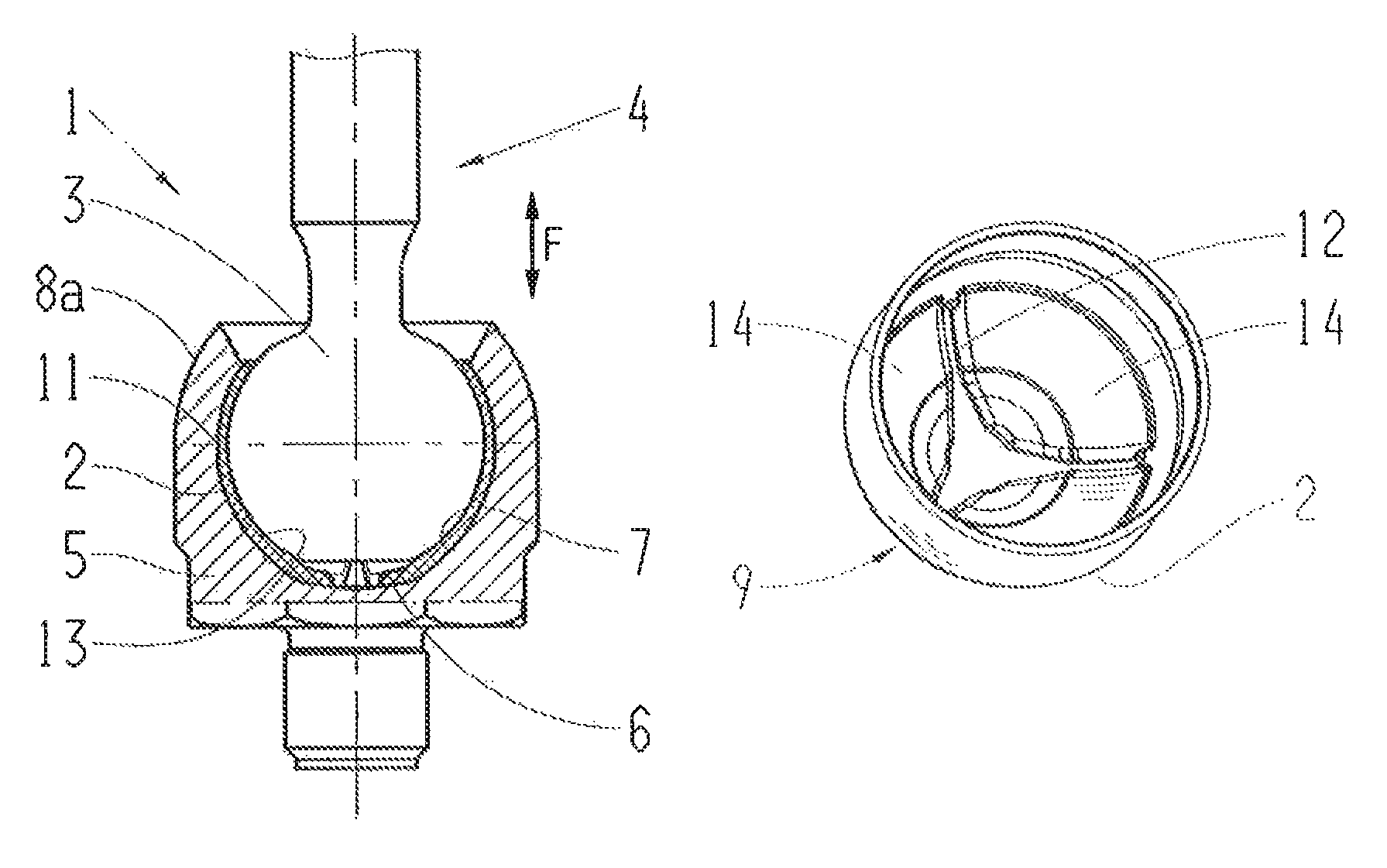

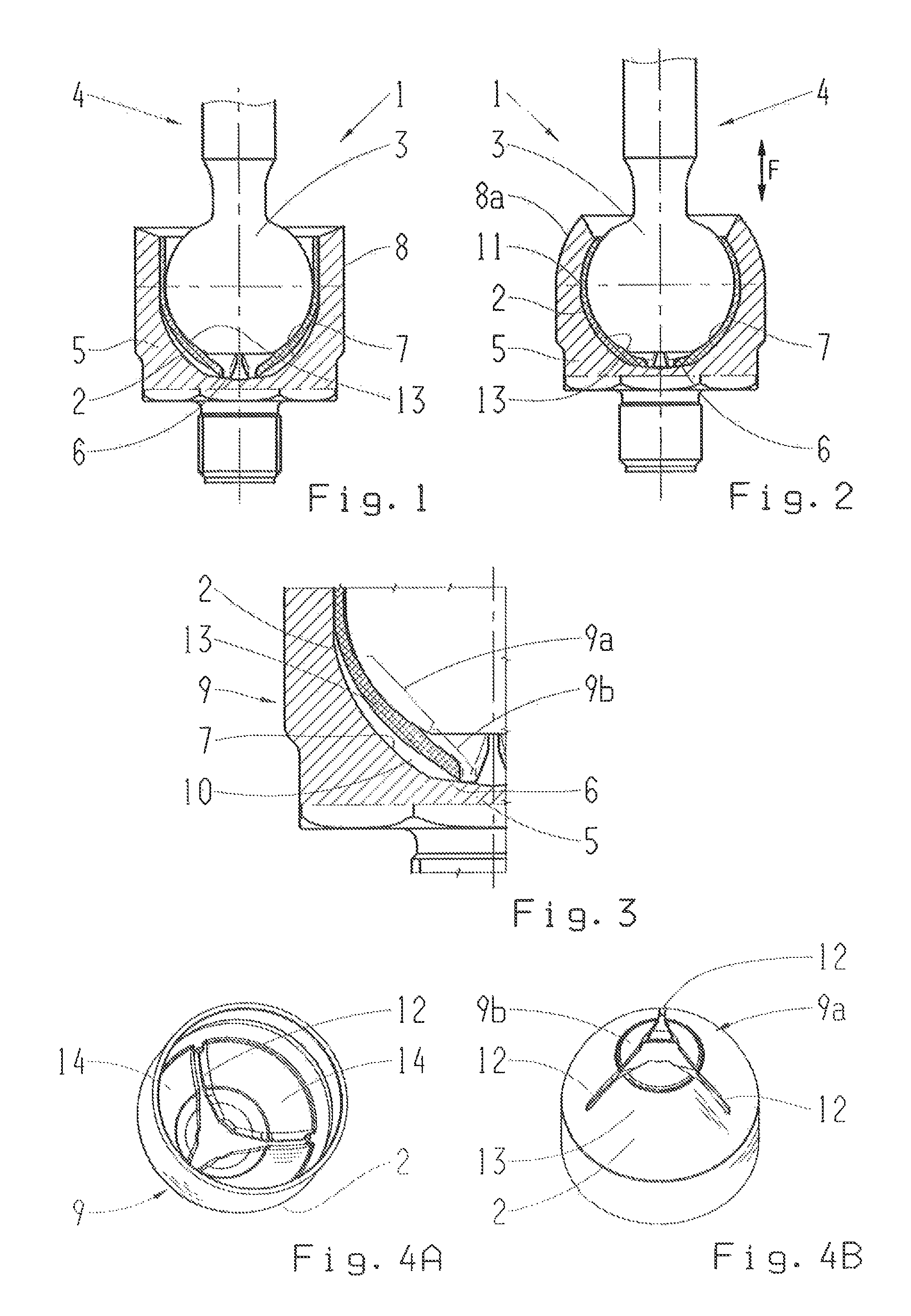

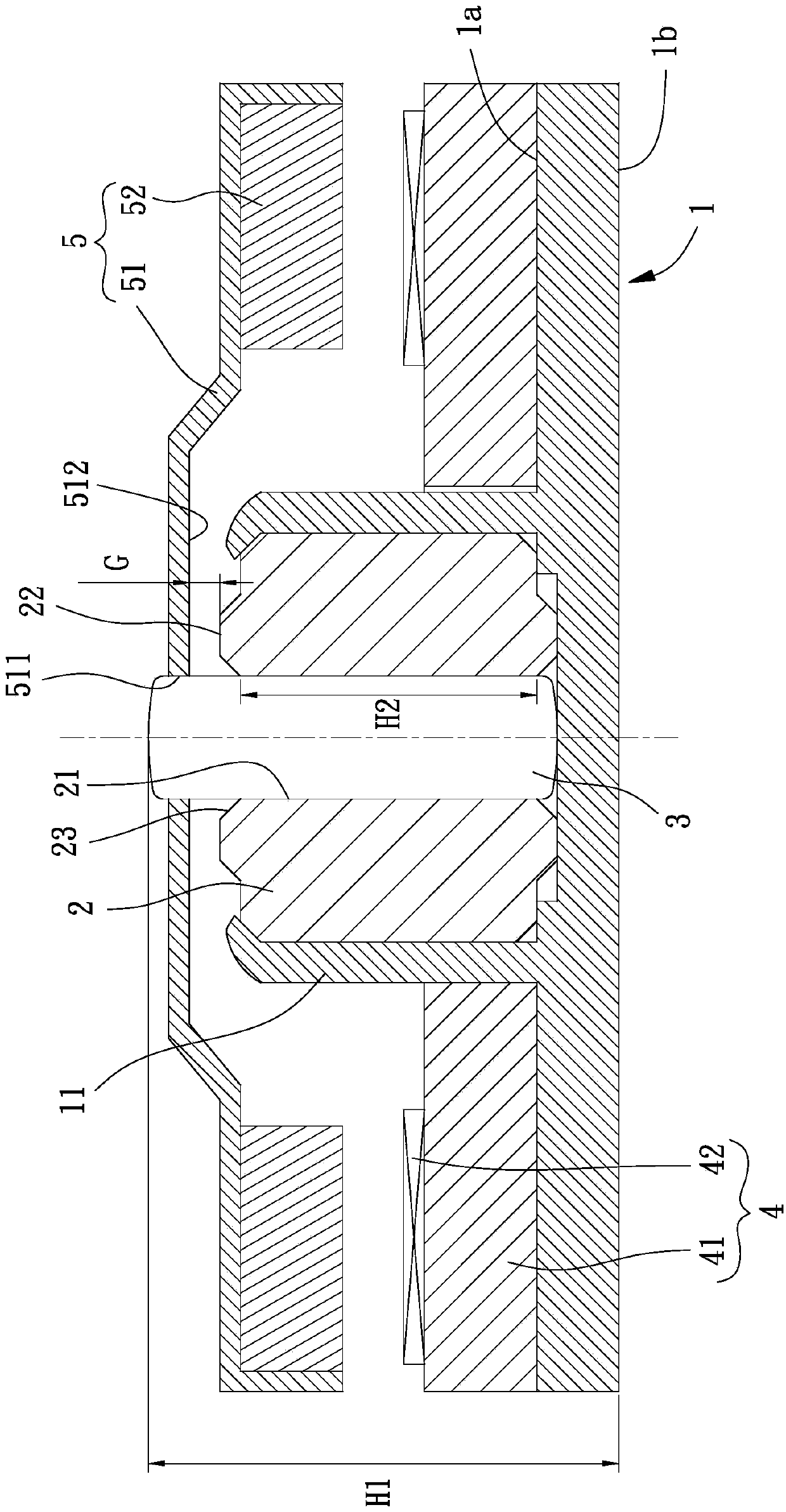

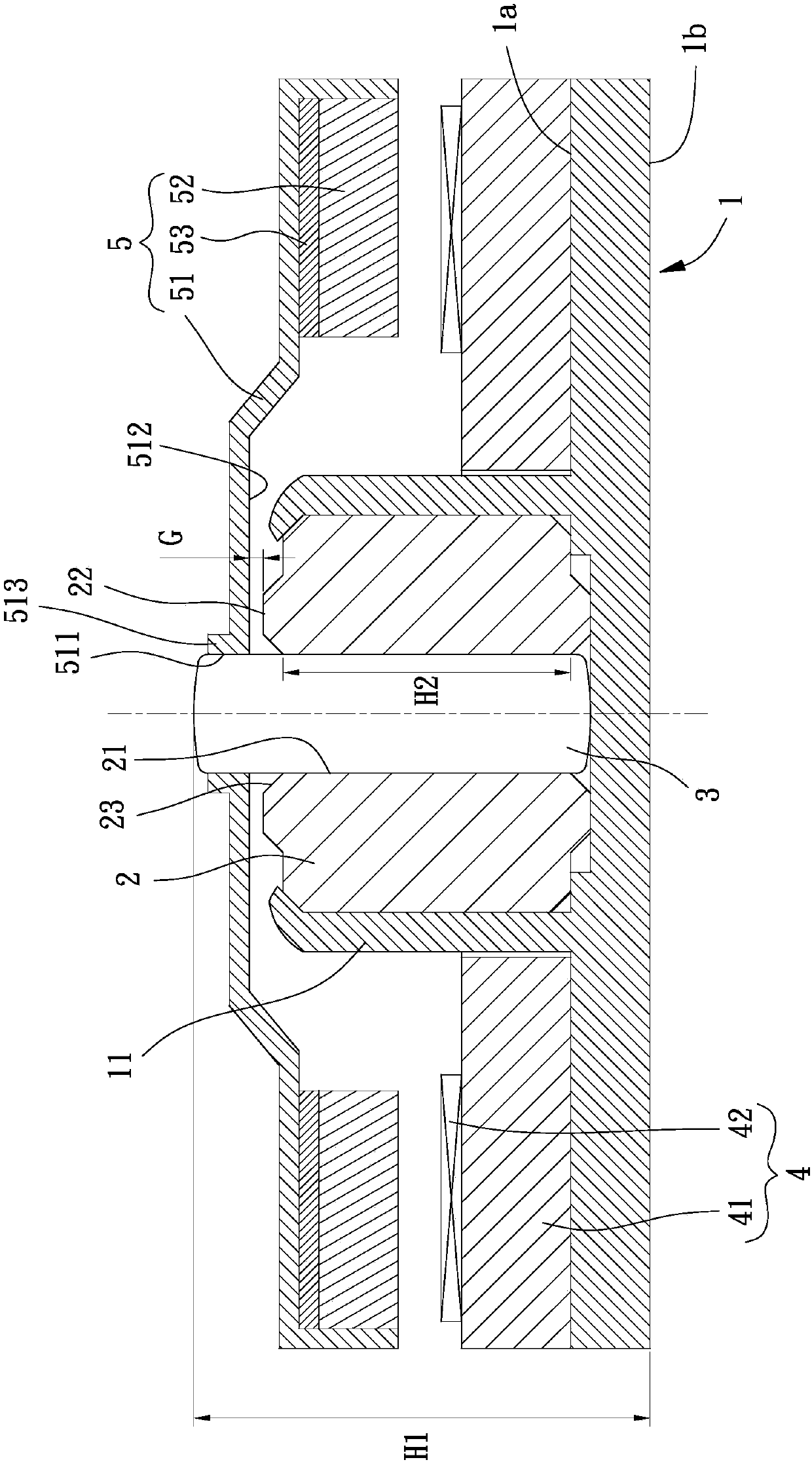

Ball joint

ActiveUS20150337892A1Increase capacityProduced cost-effectivelyCouplings for rigid shaftsPivotal connectionsAxial jointsBall joint

A ball joint, in particular, an axial joint, having a ball stud, which is enclosed in a ball socket. The ball socket is enclosed in a joint housing and is integrally formed having at least one spring element in a region of the ball socket that faces away from the opening of the joint housing. The spring element has discontinuities, in particular in the form of slots, so that wear compensation is created by the spring element within the ball joint.

Owner:ZF FRIEDRICHSHAFEN AG

Ball Joint

A ball joint, particularly an axial joint, having a housing, a bearing shell which is arranged in the housing, and a ball pin with a ball head which is arranged in the bearing shell, is characterized in that the bearing shell is bent open elastically by the ball head so that the restoring force resulting from its deformation applies a prestress onto the ball head which attempts to press the latter out of the housing.

Owner:THK RHYTHM AUTOMOTIVE GMBH

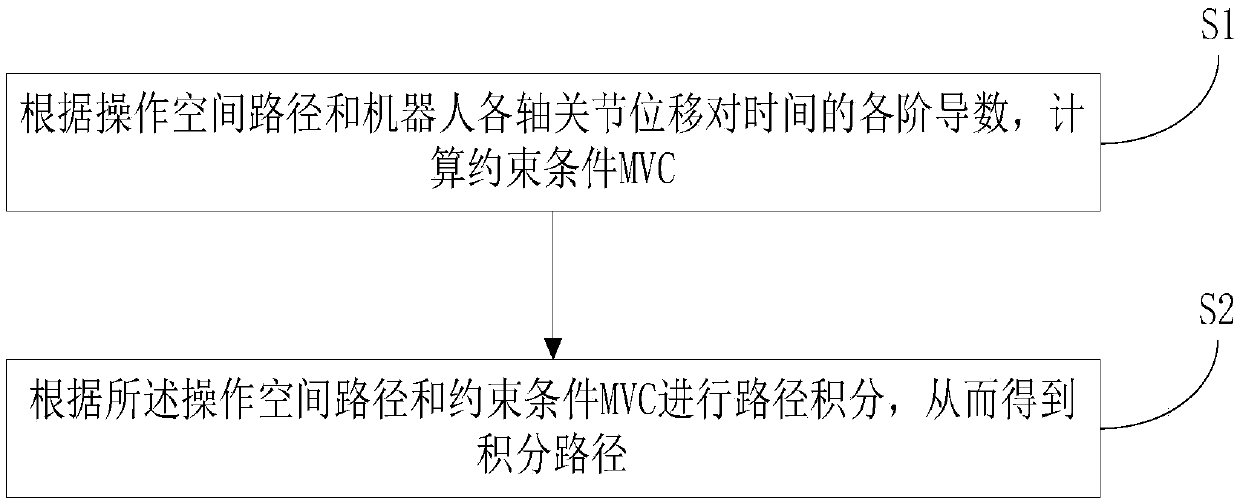

Time-optimal trajectory planning method and device aiming at robot operation space

ActiveCN108544493AImprove operational efficiencyReduce jitterProgramme-controlled manipulatorAxial jointsEngineering

The invention discloses a time-optimal trajectory planning method and a time-optimal trajectory planning device aiming at a robot operation space. The method comprises the steps of calculating a constrained curve MVC according to a path of the operation space and all-order derivatives of various axial joint displacement of a robot on the time; carrying out path integration in the operation space according to the path of the operation space and the constrained curve MVC; obtaining an integrated path; and the like. The device comprises a memorizer and a processor. According to the time-optimal trajectory planning method and the time-optimal trajectory planning device aiming at the robot operation space provided by the invention, the limitation of the all-order derivatives of the various axial joint displacement of the robot on the time is converted into the limitation of all-order derivatives of arc length parameters, so that a multi-dimension constraint condition is converted into a single-dimension constraint condition, and the whole trajectory planning process is simple and high efficient; various axial joints are always at a saturation condition of constraint, so that the runningefficiency of the robot is improved; and after introducing higher-order derivatives of displacement such as accelerated speed and acceleration jerk of the various axial joints, the shaking of the tail end of the robot can be effectively reduced through an obtained trajectory planning result, and the stability of the robot is improved.

Owner:中正数据技术有限公司

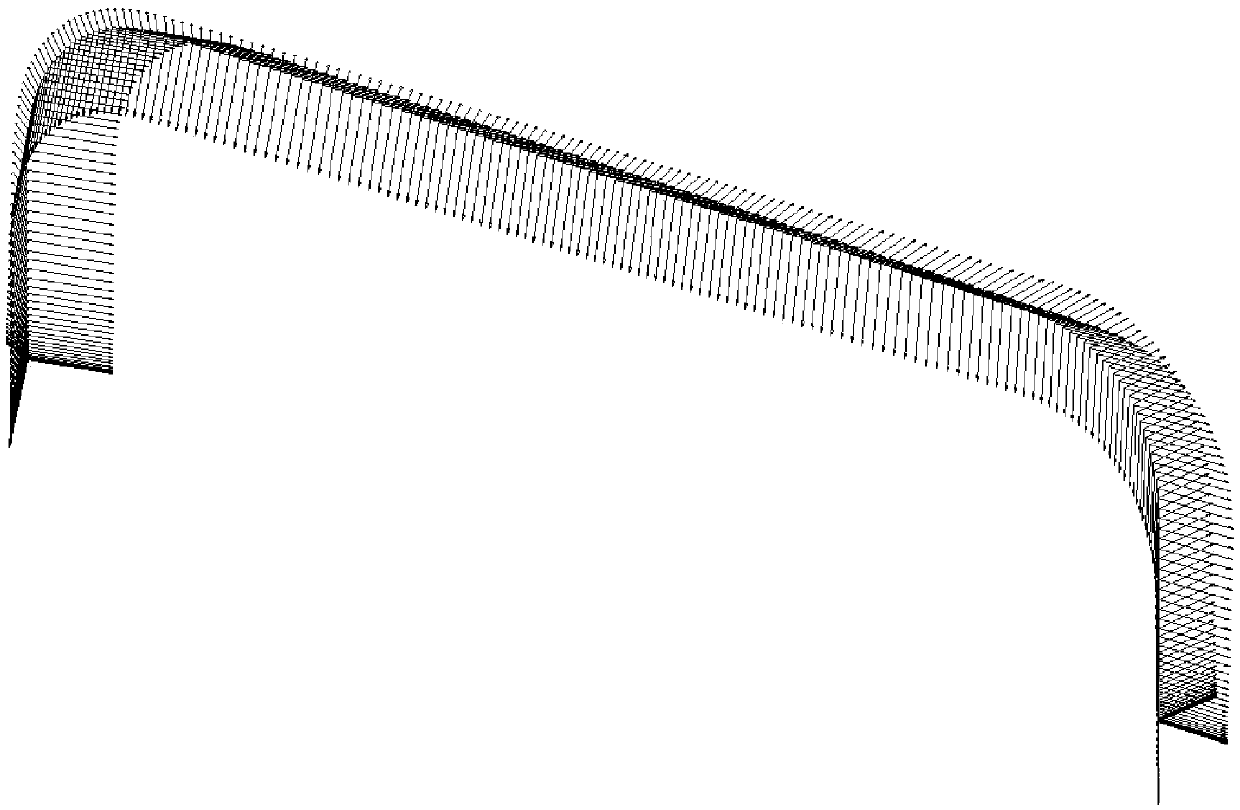

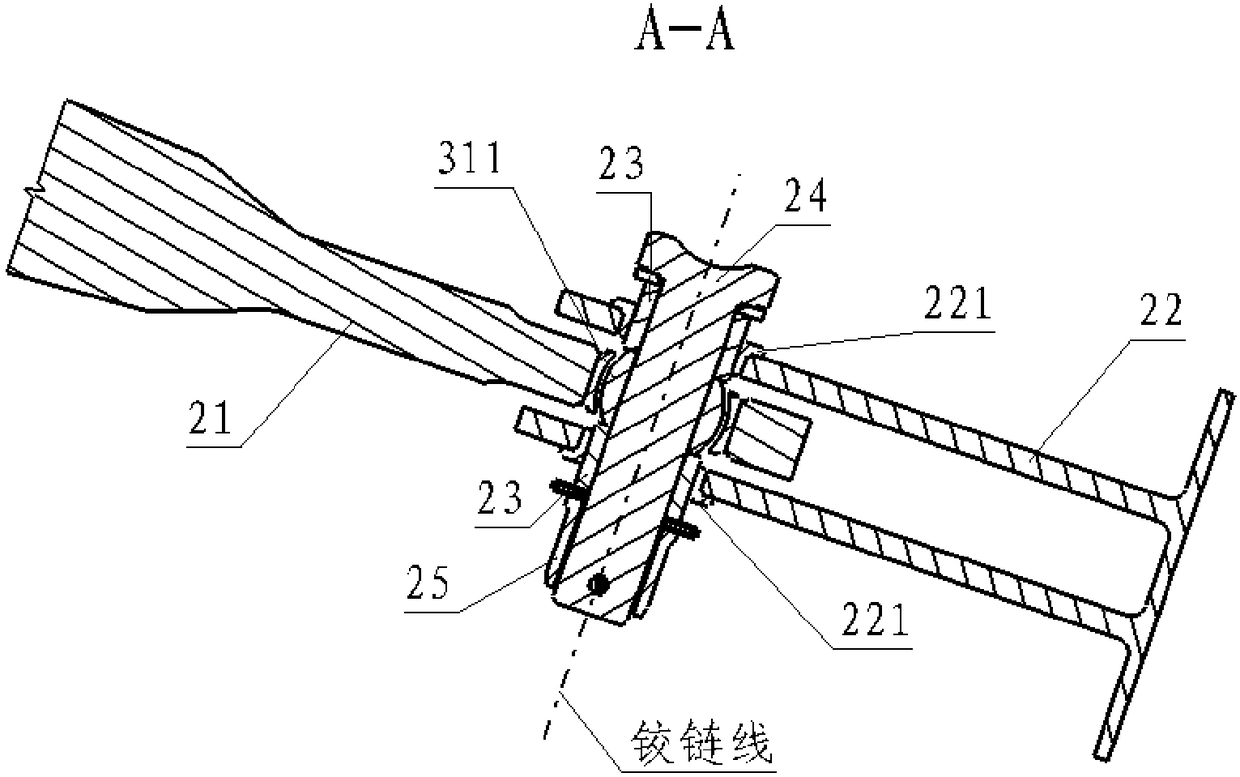

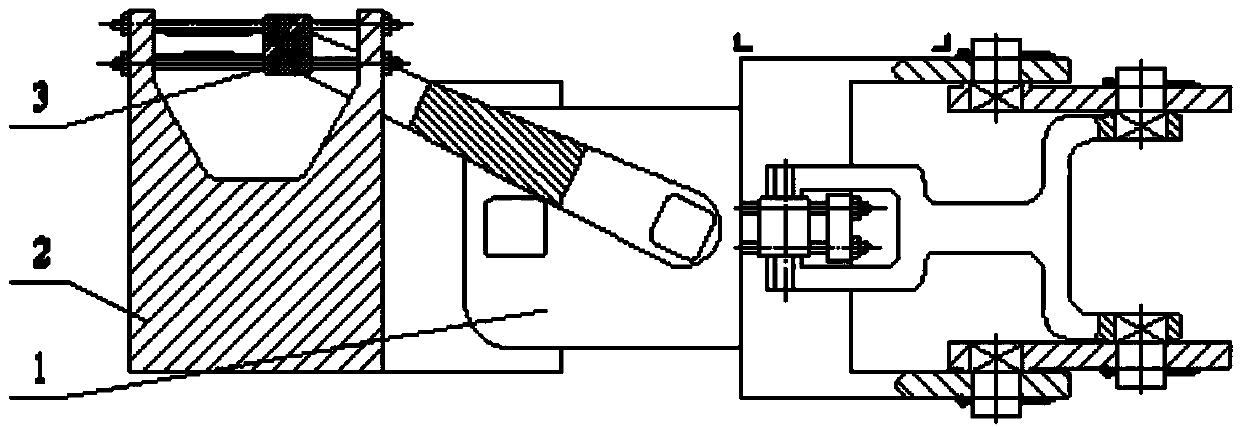

Suspension structure of control surface of large aircraft

ActiveCN108082449AReduced aerodynamic efficiencyPower transmission is simple and directAircraft controlShaped beamAerodynamic drag

The invention provides a suspension structure of a control surface of a large aircraft. The suspension structure of the control surface of the large aircraft is comprised of a hinged line load bearingstructure (1) and an aerodynamic load bearing structure (2). Hinged line load is independently borne by the hinged line load bearing structure (1), wherein the hinged line load bearing structure (1)is comprised of box-shaped beams (11), bolt shafts (13), and an axial joint (12). The box-shaped beams (11) are arranged in a stabilizing plane (4), the bolt shafts (13) are arranged in the box-shapedbeams (11), and the axial joint (12) is arranged in the control surface (3). Aerodynamic load is independently borne by the aerodynamic load bearing structure (2), wherein the aerodynamic load bearing structure (2) is comprised of a suspension support arm (21) and a suspension joint (22). The suspension support arm (21) is arranged in the stabilizing plane (4), and the suspension joint (22) is arranged in the control surface (3). The hinged line load bearing structure (1) is arranged on the root portion of the control surface and the lower portion of the stabilizing plane, so that a large opening in the front of the control surface is avoided, and the aerodynamic efficiency of the control surface is enhanced; the box-shaped beams (11) are directly connected with butt joints on a tail wing, the force transmission is simple and direct, and the weight is light; and through the combination of a bushing and a bearing and a clearance which is arranged reasonably, different degrees of freedom are released, and the work of each structure is non-interference and reliable.

Owner:中航通飞华南飞机工业有限公司

Ball joint

A ball joint, particularly an axial joint, having a housing, a bearing shell which is arranged in the housing, and a ball pin with a ball head which is arranged in the bearing shell, is characterized in that the bearing shell is bent open elastically by the ball head so that the restoring force resulting from its deformation applies a prestress onto the ball head which attempts to press the latter out of the housing.

Owner:THK RHYTHM AUTOMOTIVE GMBH

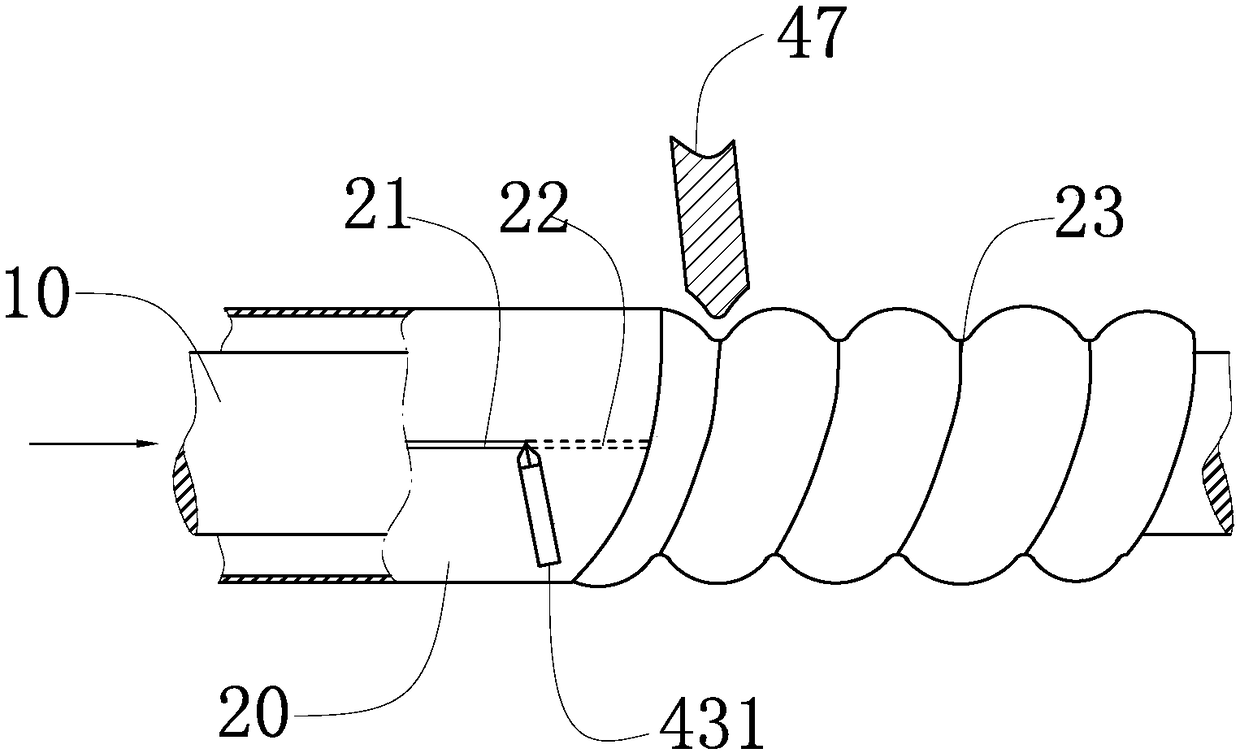

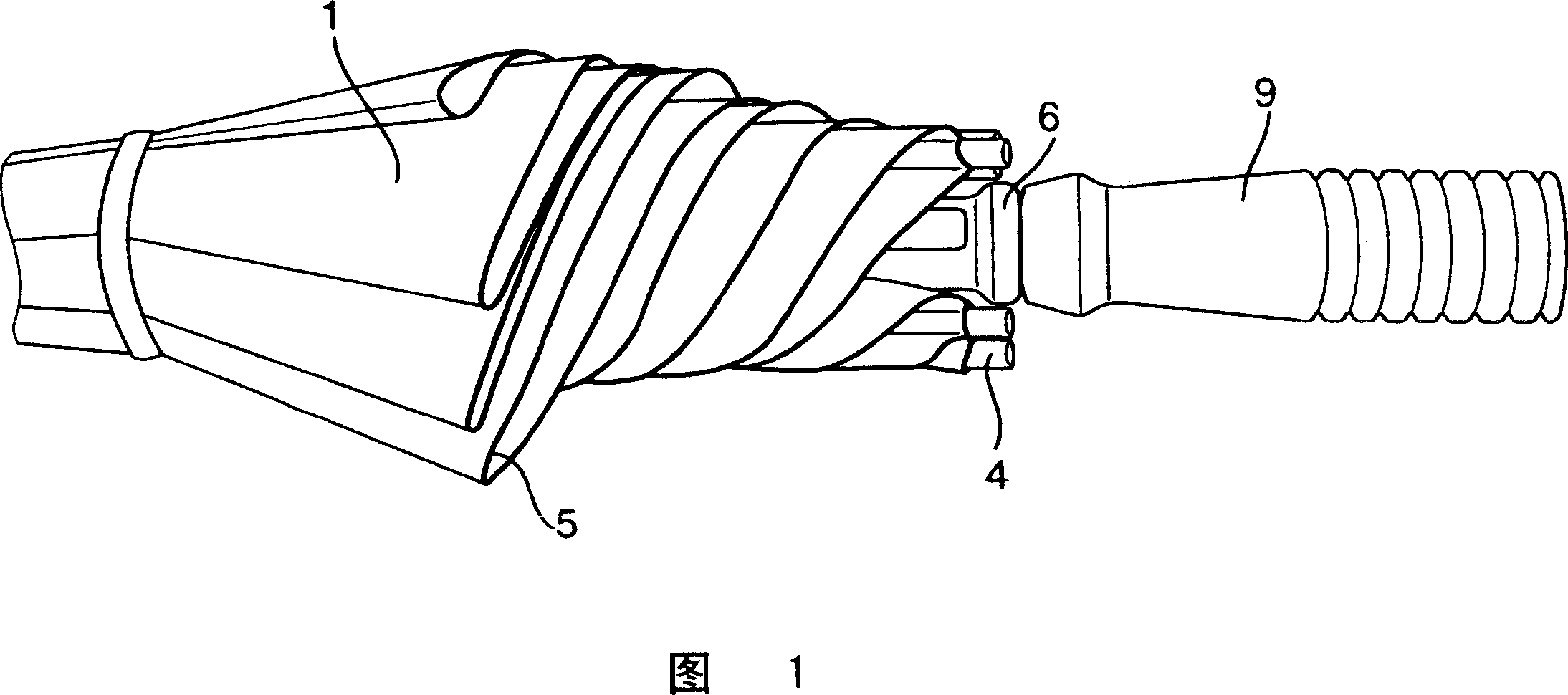

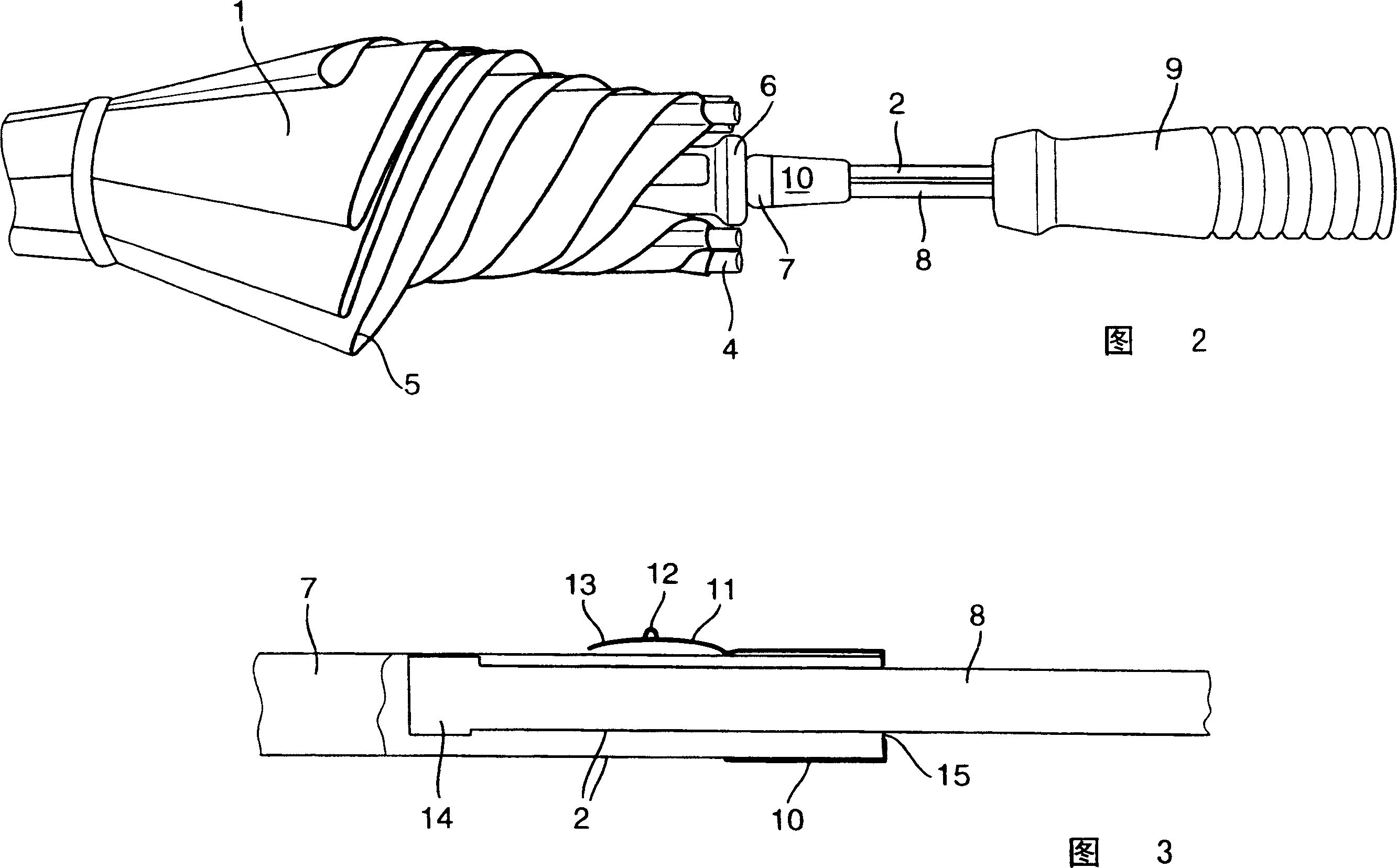

Stirring device

ActiveCN104394973AShaking/oscillating/vibrating mixersTransportation and packagingDrive shaftAxial joints

Provided is a stirring device that can drive a stirring body with a simple structure and without applying excessive force. The stirring device is provided with: the stirring body, which is a two-circle roller having an axis of rotation and two stirring fins; first and second drive shafts with axial centers not matching the axis of rotation; a first axial joint, which connects the first drive shaft on a first stirring fin side of the axis of rotation; a second axial joint, which connects the second drive shaft on a second stirring fin side of the axis of rotation; and a drive unit that exclusively carries out rotary drive of only either one of the first and second drive shafts. The drive unit is provided with a regulating member that makes a tooth part of a first gear face a drive side gear without play at a rotary position where the boundary between the tooth part and a toothless part of the first gear faces the drive side gear and makes a tooth part of a second gear face the drive side gear without play at a rotary position where the boundary between the tooth part and a toothless part of the second gear faces the drive side gear.

Owner:MITUYATEC +1

Ball joint

ActiveUS9541124B2Increase capacityProduced cost-effectivelyPivotal connectionsPivotsAxial jointsEngineering

A ball joint, in particular, an axial joint, having a ball stud, which is enclosed in a ball socket. The ball socket is enclosed in a joint housing and is integrally formed having at least one spring element in a region of the ball socket that faces away from the opening of the joint housing. The spring element has discontinuities, in particular in the form of slots, so that wear compensation is created by the spring element within the ball joint.

Owner:ZF FRIEDRICHSHAFEN AG

Multifunctional surface aerator

The invention relates to a multifunctional surface aerator. The multifunctional surface aerator comprises a motor, a coupler, a lifting device and a reduction gearbox, the motor drives the reduction gearbox through the coupler, the output end of the reduction gearbox is sequentially connected with an inverted umbrella seat and an impeller shaft, an inverted umbrella impeller and an inverted umbrella conical surface body are installed on the impeller shaft, the portions, corresponding to the conical surface and the horizontal plane of the inverted umbrella conical surface body, of the inverted umbrella impeller are each provided with blades, and the blades all extend outwards; the blades arranged on the portions, corresponding to the horizontal plane of the inverted umbrella conical surface body, of the inverted umbrella impeller are unequal in height, and blades are further arranged on the portions, corresponding to the axial joint of the impeller shaft, of the inverted umbrella impeller. By means of the multifunctional surface aerator, the technical problems that for an existing aerator, the oxygenation efficiency is not high, and the flow-pushing and stirring capacity is poor are solved, and the vast application prospect is achieved.

Owner:JIANGSU UNIV

Stabilization and manipulation of a delivery system for a percutaneous procedure

Disclose herein are embodiments related to a delivery system for performing a minimally invasive procedure, the system including one or more station legs configured to attach to an operating surface and a cross-beam connected to the one or more station legs and running from 0 degree to 45 degrees relative to a top of the operating surface, wherein a distance between the operating surface and the cross-beam is adjustable. Additionally, an embodiment may have a first arm connected to the cross-beam, a second arm connected to the first arm, and an axial member connected to the second arm, the axial member comprising an axial joint. The delivery system may then be configured to advance to an internal target site using the axial joint while maintaining a stationary trajectory in relation to theinternal target site with the delivery system trajectory is modifiable at the target site.

Owner:沃卡尔有限公司

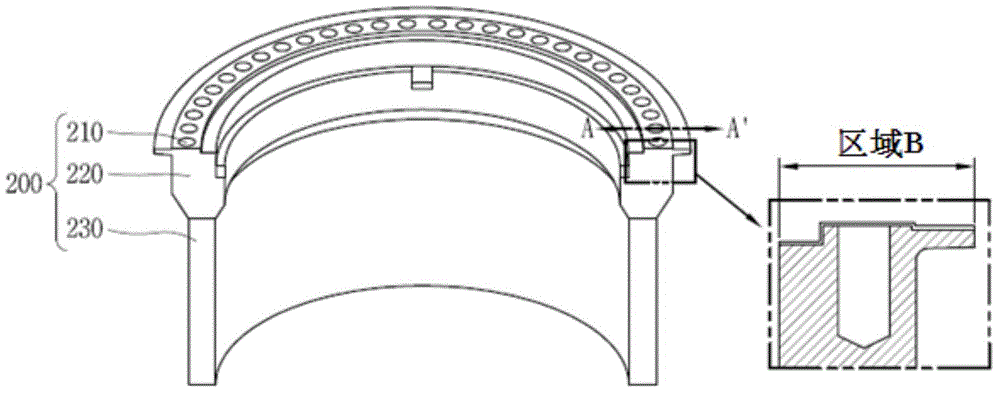

Pipe gallery joint waterproofness test method

ActiveCN109000862AImprove test efficiencyShorten test timeDetection of fluid at leakage pointMeasurement of fluid loss/gain rateTest efficiencyButt joint

The invention discloses a pipe gallery joint waterproofness test method, which is used for carrying out a waterproofness test on a jack type pipe gallery. Water is injected into an axial joint in a labyrinth type butt joint by utilizing a water injection pipe. Compared with a method for injecting the water from the outer side to the inner side, the method for injecting the water from the middle and extending the water to two outer ends has the advantage that equivalently two groups of waterproofness tests are carried out at the same time, so that the test efficiency is greatly improved, the test time is shortened, and the problem that the test effect is influenced because the water injection time is not accurate, the water pressure cannot be increased and the like due to transverse diffusion of water flow during water injection is also avoided. The pipe gallery joint waterproofness test method has the advantages of being convenient, rapid and efficient in operation, accurate in test result and the like.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Feeder duct assembly with flexible end fittings

A feeder duct assembly for a gas turbine engine, which negates the need for a ball or axial joint in the duct for required for flexibility under thermal loading. The feeder duct assembly of the present innovation comprises an end fitting designed to meet flexibility requirements without compromising dynamic performance of the system with added weight from ball or axial joints in the ducts.

Owner:UNISON INDUSTRIES

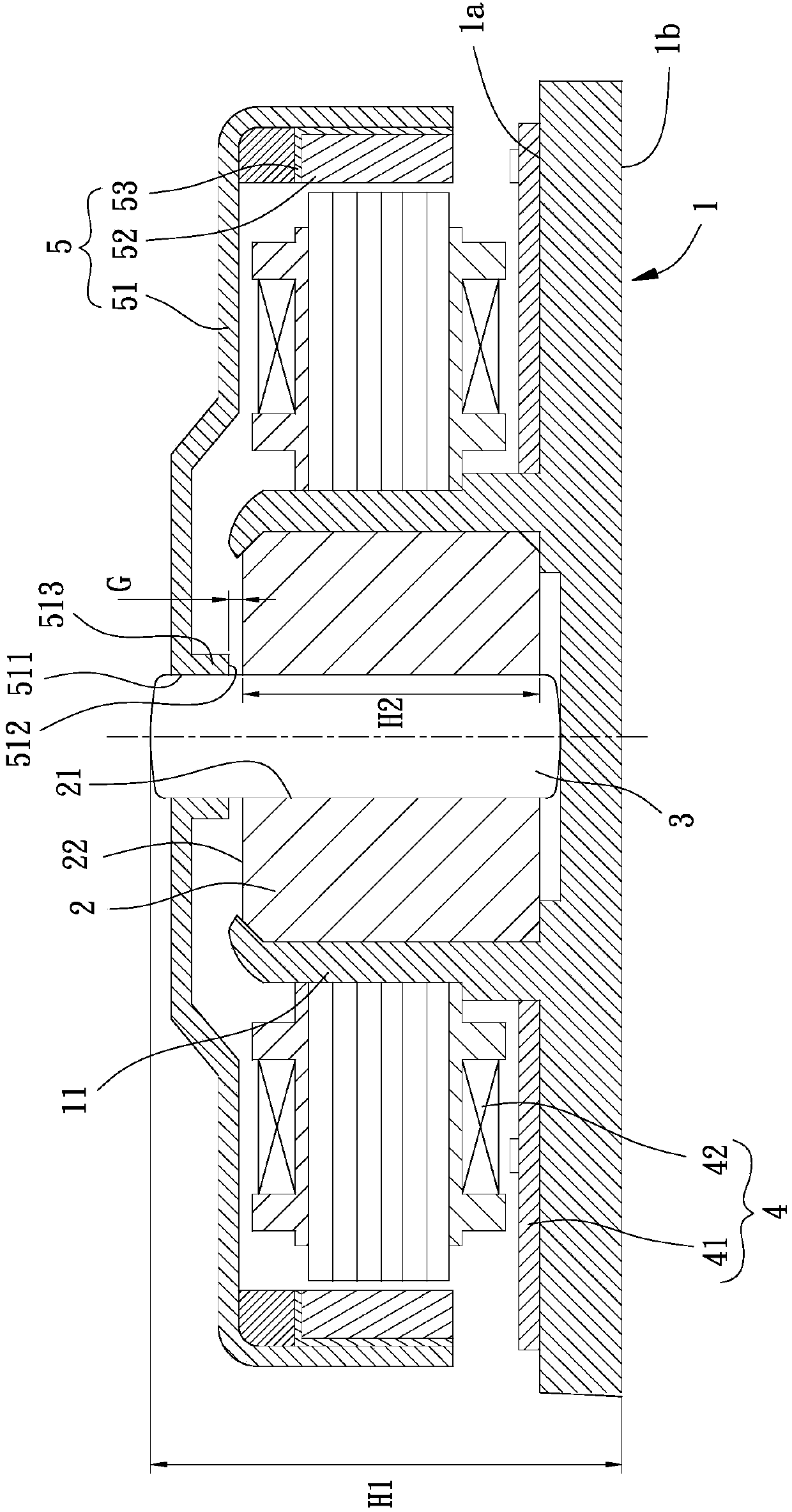

Non-standard four-point-contact mounted insert bearing

PendingCN109268386AIncrease loading capacityHigh overturning momentBall bearingsEngine lubricationBall bearingRadial plane

An embodiment of the invention discloses a non-standard four-point-contact mounted insert bearing, comprising a bearing block and a four-point-contact ball bearing. The bearing block is provided witha bearing mounting hole; the inner surface of the bearing mounting hole is an internal spherical surface. The four-point-contact ball bearing that is a non-standard four-point-contact insert bearing at least includes an outer ring, an inner ring, and a steel ball arranged between the outer ring and the inner ring; a line of contacts of the steel ball with circular grooves of the inner and outer rings forms first contact angle a1 and second contact angle a2 with a radial plane of the bearing; the outer surface of the outer ring is an external spherical surface; the external spherical surface ofthe outer ring fits the internal spherical surface of the bearing mounting hole of the bearing block. The non-standard four-point-contact mounted insert bearing can bear radial load or axial load orbear radial and axial joint load, has higher load-bearing capacity, can bear higher tilting torque, can be automatically aligned and corrected through the external spherical surface of the outer ringand the internal spherical surface of the bearing mounting hole even when bearing tilting torque.

Owner:中山市盈科轴承制造有限公司

Rapid mounting structure of steel bar group

PendingCN110005136ASolve the problem of not being able to weldAvoid welding qualityBuilding reinforcementsAxial jointsSteel bar

The invention discloses a rapid mounting structure of a steel bar group. The rapid mounting structure of the steel bar group comprises steel columns composed of a group of steel bars connected axially, and the upper section of the steel bars and the lower section of the steel bars realize axial rapid connection through a cross-shaped key; the steel columns are distributed in a queue mode to form the steel bar group; spline rings are welded to the axial joint of the steel bars; the steel columns in the steel bar group are connected through horizontal connecting pieces; inserting pieces are welded to the two ends of the horizontal connecting pieces; and the inserting pieces at the two ends of the horizontal connecting pieces are connected with key grooves of the spline rings in an insertingmode, and rapid connection between the steel columns is realized. According to the rapid mounting structure of the steel bar group, the problem that the inner sides of the steel bars cannot be weldedis solved, and the connection requirement is met while the requirements of permanent connection and temporary fixing are met; the construction difficulty is reduced, the factory welding construction time is shortened, and the welding quality of the steel bars is ensured; and the mounting time of the steel bars can be shortened, the construction speed is accelerated and the cost is reduced, the perpendicularity of the steel bar group is better guaranteed, and the construction error is reduced.

Owner:CHINA CONSTR 4TH ENG BUREAU 6TH

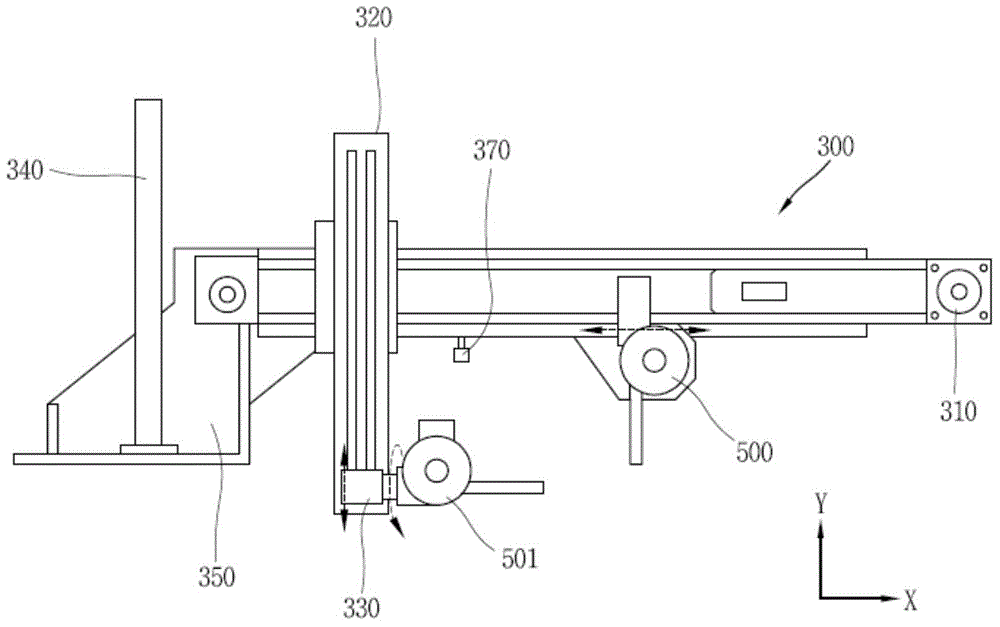

Automatic coating apparatus

ActiveCN104025202APrevent penetrationLiquid surface applicatorsNuclear energy generationComputer moduleAxial joints

The present invention relates to an automatic coating apparatus which coats a cylindrical flange to prevent corrosion. The automatic coating apparatus includes: a rail mounted on a flange; a first body configured to rotate along the rail, and having at least one axial joint configured to rotate or to move in a straight line; a coating module disposed on one end of the axial joint, and including a coating gun configured to coat the flange; and a control part controlling the rotation of the first body, the movement of the axial joint, and the operation of the coating gun.

Owner:DOOSAN HEAVY IND & CONSTR CO LTD

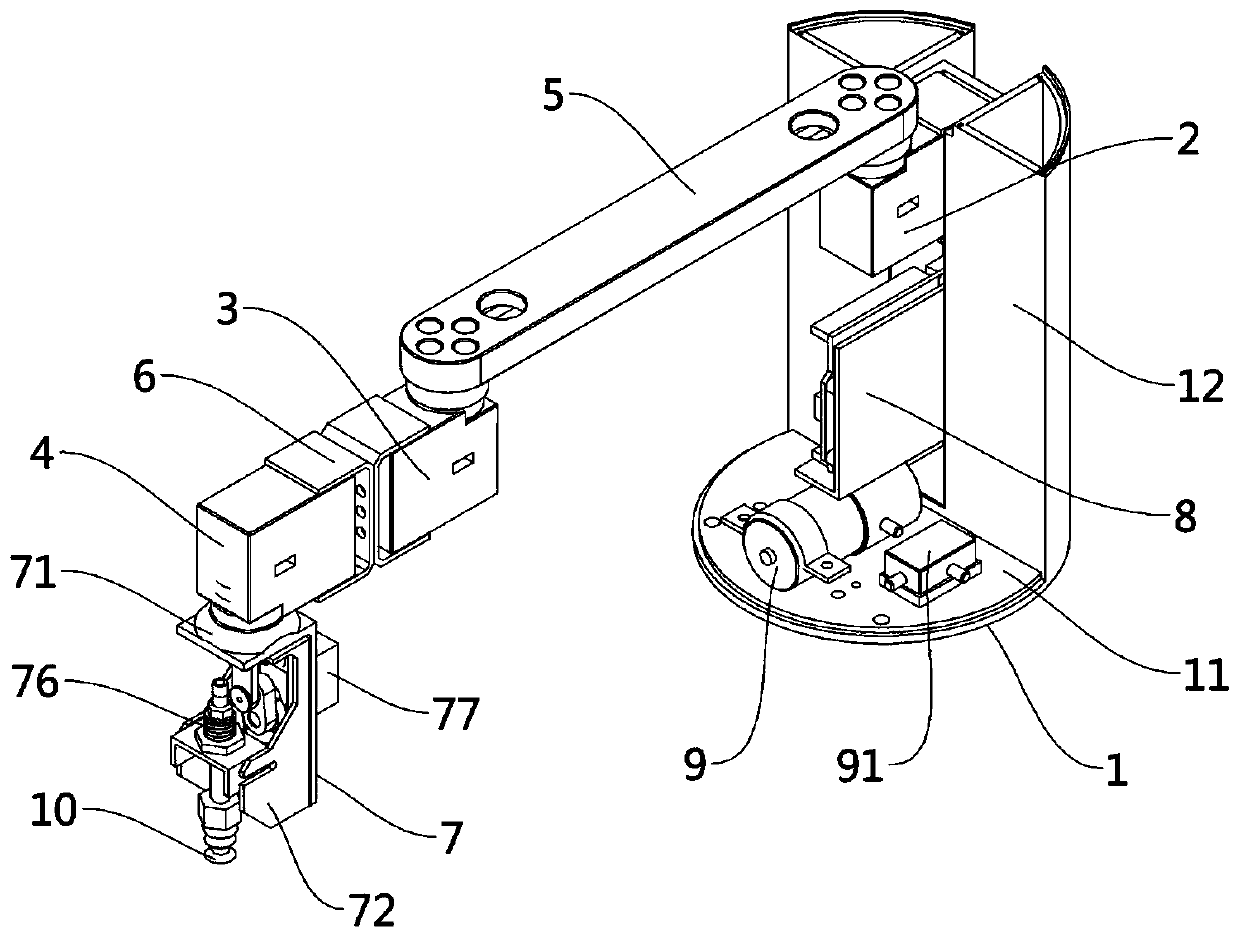

Mosaic image paving robot

PendingCN110549324ASmall footprintConvenient and convenientProgramme-controlled manipulatorGripping headsControl systemAxial joints

The invention relates to the technical field of mosaic paving equipment, in particular to a mosaic image paving robot. The mosaic image paving robot comprises a stand and a first mechanical arm horizontally assembled onto the stand rotatably; the first mechanical arm is horizontally equipped with a second mechanical arm rotatably; the second mechanical arm is further horizontally equipped with a printing device rotatably; the printing device includes a fixed seat and a lifting seat, wherein the fixed seat is horizontally assembled onto the second mechanical arm rotatably, and the lifting seatis movably assembled onto the fixed seat in the vertical direction; and the lifting seat is equipped with a printing head. The mechanical arms rotate to determine the horizontal position of the printing device, the lifting seat moves so as to determine the vertical position of the printing head, and mosaic grains are grabbed and released by utilizing the printing head, so that a linear guideway isomitted, and the occupied space is saved; and meanwhile, the mechanical arms are reduced to two in number, and the whole robot only has three axial joint degrees of freedom, so that the action of therobot is flexible and convenient, a control system of a controller is simplified, the cost of the robot is reduced.

Owner:刘邵宏

Spiral armored cable and production method thereof

ActiveCN106205830APrevent oxidationExtend your lifeClimate change adaptationInsulated cablesExtensibilityAxial joints

The invention discloses a spiral armored cable and a production method thereof. The spiral armored cable comprises a cable body and a metal armor layer wrapping the periphery of the cable body, wherein the metal armor layer is provided with an axial joint; the axial joint is a welding part; spiral impressions which extend along the axial direction of the cable body are arranged on the periphery of the metal armor layer; and an inflatable layer for being filled with an inert gas is arranged between the cable body and the metal armor layer. Compared with the prior art, a metal band directly wraps the periphery of the cable body, the axial joint of two sides of the metal band is welded to form a metal round tube, and then the spiral impressions are pressed, so that the spiral armored cable has the advantages that the material is saved, the production technology is simple, the cost is low and the like. The metal armor layer with the spiral impressions has the advantages of good extensibility, high compressive strength, good stability, good flexibility and the like. The inflatable layer between the metal armor layer and the cable body is filled with the inert gas, so that oxidation of the cable is prevented and the lifetime of the cable is prolonged.

Owner:深圳市金环宇电线电缆有限公司

Linear-driven multi-freedom-degree mechanical arm joint based on smart material

The invention provides a linear-driven multi-freedom-degree mechanical arm joint based on a smart material. Under the excitation of signals, a moving sliding block is pulled by an SMA driving wire to drive a split fork to move so as to pull a joint connecting frame to rotate, and the joint connecting frame is made to swing around the perpendicular plane with a shoulder end brace as a center. At a fore joint driving position, a moving sliding block is pulled by an SMA driving wire to pull a split fork to rotate, and a joint connecting frame is driven to swing around the horizontal plane with a shaft hole of the perpendicular plate side of the joint connecting frame as a center. At two fore joint driving positions, an SAM driving wire on a joint connecting frame drives a moving sliding block to drive the split fork to rotate around an outer side shaft hole of the joint connecting frame so as to drive an axial joint connecting frame to rotate in the axis direction, and the multi-freedom-degree movement of the mechanical arm joint is achieved finally. According to the linear-driven multi-freedom-degree mechanical arm joint based on the smart material, due to the fact that the SMA wires are adopted, the linear output of power driving can be achieved directly, and the defects of energy consumption and noise caused by using a middle mechanism in the axial driving of a traditional motor are overcome.

Owner:HARBIN ENG UNIV

Adaptive three-dimensional orthosis and manufacturing method thereof

ActiveCN107771069BConstrained radial expansionConstrained bendingMedical simulationFractureData setAxial joints

Owner:OSTEOID SAGLIK TEKNOLOJILERI AS

Floating panel for a gas powered turbine

A foil assembly for a gas powered turbine includes a plurality of floating wall sectors arranged circumferentially about an axis defined by a flowpath. Each of the floating wall sectors includes a first flowpath strut component, a second flowpath strut component, a floating wall panel connected to the first flowpath strut component by a first clamp seal at a first axial joint and connected to the second flowpath strut component by a second clamp seal at a second axial joint, and a plurality of leading edge structures fore of the plurality of floating wall sectors. Each of the leading edge structures is configured to define a foil profile in conjunction with a first flowpath strut component of a first floating wall sector and an adjacent flowpath strut component of a second floating wall sector.

Owner:RTX CORP

A kind of production method of spiral armored cable

ActiveCN106205830BPrevent oxidationExtend your lifeClimate change adaptationInsulated cablesExtensibilityAxial joints

The invention discloses a spiral armored cable and a production method thereof. The spiral armored cable comprises a cable body and a metal armor layer wrapping the periphery of the cable body, wherein the metal armor layer is provided with an axial joint; the axial joint is a welding part; spiral impressions which extend along the axial direction of the cable body are arranged on the periphery of the metal armor layer; and an inflatable layer for being filled with an inert gas is arranged between the cable body and the metal armor layer. Compared with the prior art, a metal band directly wraps the periphery of the cable body, the axial joint of two sides of the metal band is welded to form a metal round tube, and then the spiral impressions are pressed, so that the spiral armored cable has the advantages that the material is saved, the production technology is simple, the cost is low and the like. The metal armor layer with the spiral impressions has the advantages of good extensibility, high compressive strength, good stability, good flexibility and the like. The inflatable layer between the metal armor layer and the cable body is filled with the inert gas, so that oxidation of the cable is prevented and the lifetime of the cable is prolonged.

Owner:深圳市金环宇电线电缆有限公司

A multifunctional surface aerator

The invention relates to a multifunctional surface aerator. The multifunctional surface aerator comprises a motor, a coupler, a lifting device and a reduction gearbox, the motor drives the reduction gearbox through the coupler, the output end of the reduction gearbox is sequentially connected with an inverted umbrella seat and an impeller shaft, an inverted umbrella impeller and an inverted umbrella conical surface body are installed on the impeller shaft, the portions, corresponding to the conical surface and the horizontal plane of the inverted umbrella conical surface body, of the inverted umbrella impeller are each provided with blades, and the blades all extend outwards; the blades arranged on the portions, corresponding to the horizontal plane of the inverted umbrella conical surface body, of the inverted umbrella impeller are unequal in height, and blades are further arranged on the portions, corresponding to the axial joint of the impeller shaft, of the inverted umbrella impeller. By means of the multifunctional surface aerator, the technical problems that for an existing aerator, the oxygenation efficiency is not high, and the flow-pushing and stirring capacity is poor are solved, and the vast application prospect is achieved.

Owner:JIANGSU UNIV

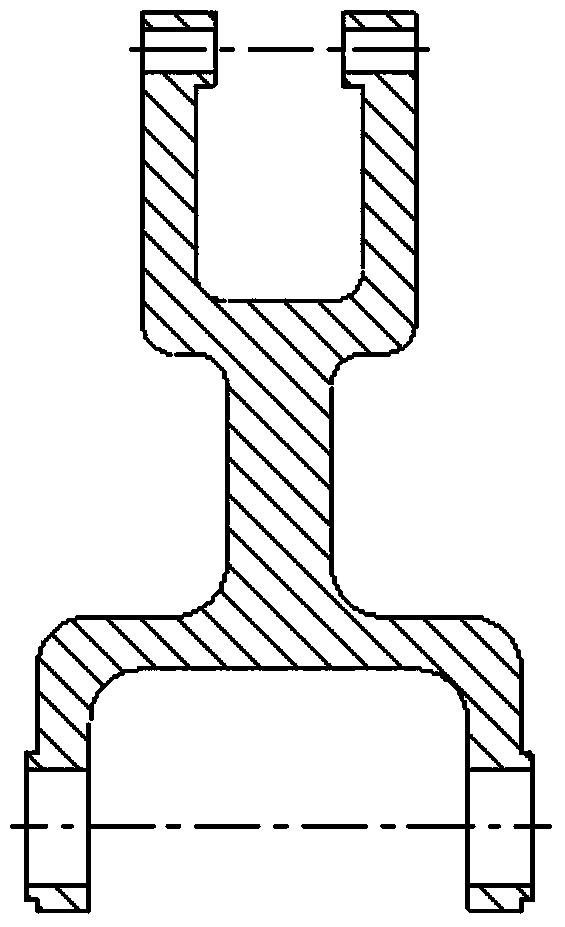

Rack and method for producing a rack for a steering gear of a motor vehicle

ActiveCN109415082AHigh hardnessMechanical steering gearsEngine componentsFriction weldingAxial joints

The invention relates to a method for producing a rack (2) for a steering gear of a motor vehicle, having at least one toothed section (21) with a toothing (22) and at least one shaft section (24) comprising at least one functional section. Separate segments, comprising at least one toothed segment (61) and a shaft segment (62), are provided, the segments are oriented on a common longitudinal axis(L), and the axial joint surfaces (28) of the segment, said joint surfaces being oriented towards one another, are connected together at a welding point by means of friction welding. For the purposesof the friction welding process, the joint surfaces (28) are brought into frictional contact, the segments (61, 62) are rotated relative to each other about the longitudinal axis (L) in order to rubtogether, the joint surfaces (28) are pressed against each other with a pressing force, - the segments (61, 62) are moved towards each other in the axial direction (A) by a specified joining distance(X), and the segments (61, 62) are held in position without rubbing. The aim of the invention is to improve the joining process of segments of a constructed rack. This is achieved according to the invention in that the method has the following steps: rubbing with a pressing force amounting to a rubbing force, rubbing so as to introduce heat with a heat-introducing force which equals 5 to 12 timesthe rubbing force, and pressing the joint surfaces together until the specified joining distance (X) is reached with a welding force which approximately equals 10 to 20 times the rubbing force.

Owner:THYSSENKRUPP PRESTA AG +1

A micro-motor and a fan including the same

InactiveCN110022026ASmooth and stable operationExtended service lifePump installationsSupports/enclosures/casingsAxial jointsHigh surface

A micro-motor is used to solve the problem of insufficient axial joint height between existing bearings and shafts. The micro-motor comprises a base; a bearing arranged on the base and having a shafthole and a highest surface in the axial direction; an axial center rotatably coupled to the shaft hole; a stator assembly coupled to the base; and a rotor assembly coupled to the axial center. The rotor assembly comprises a motor housing having a lowest bottom edge in the axial direction corresponding to the bearing. The lowest bottom edge has a minimum spacing from the highest surface of the bearing, the minimum spacing being between 0.05 mm and 0.16 mm. The invention also provides a fan for the micro-motor.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

Umbrella

InactiveCN1961773AAvoid radial expansionFavorable axial movementWalking sticksUmbrellasAxial jointsEngineering

The present invention relates to an umbrella, especially to a bumbershoot, having an umbrella bar (2) and an umbrella stand (3) disposed on the umbrella bar (2). The umbrella stand includes an umbrella net and a strutting spoke, wherein the umbrella net is composed of an umbrella spoke (4) and supporting an umbrella fabric (5), while the strutting spoke can be hinged with the slider (6) longitudinally moving to be supported on the umbrella bar (2) and the umbrella spoke (4), wherein the umbrella stand (3) has the width larger than 0.9 m in the opening state, characterized in that, the umbrella bar (2) includes a hollow standpipe (7) made of fiberous glass reinforced plastic (GFK) and a sliding tube (8) made of GFK, wherein the wall thickness of the standpipe (7) is less than / equal to 2 mm, preferably 1 mm. The sliding tube (8) can make longitudinal shift in the standpipe (7) and be fixed in any axial joint relative to the standpipe (7).

Owner:EBERHARD GOBEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com