Ball joint

a ball joint and ball head technology, applied in the direction of shafts, bearings, stents, etc., can solve the problems of affecting the performance of the ball joint, the ball head can be played in the housing, and the play is basically undesirable, so as to achieve the effect of favourable cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

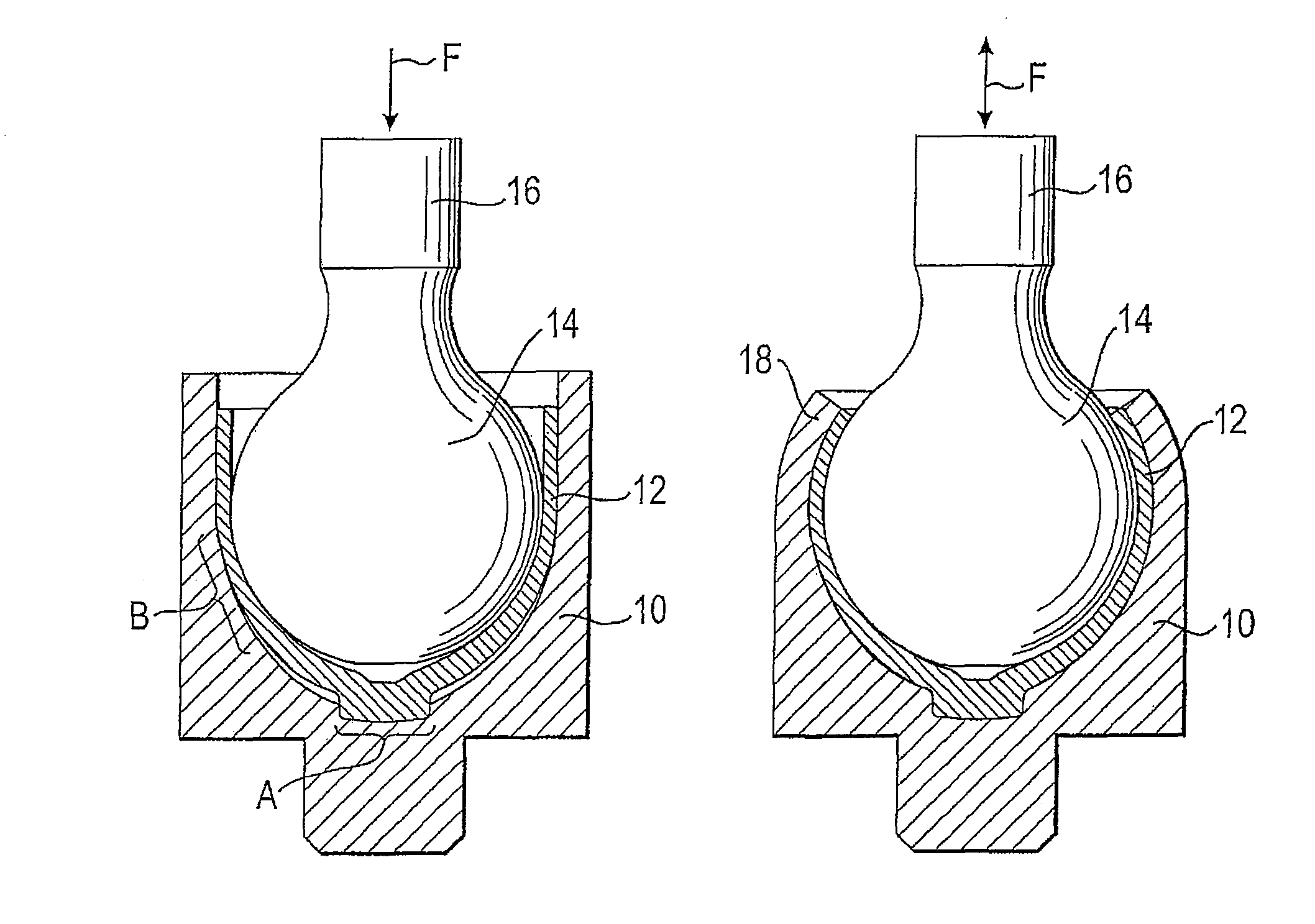

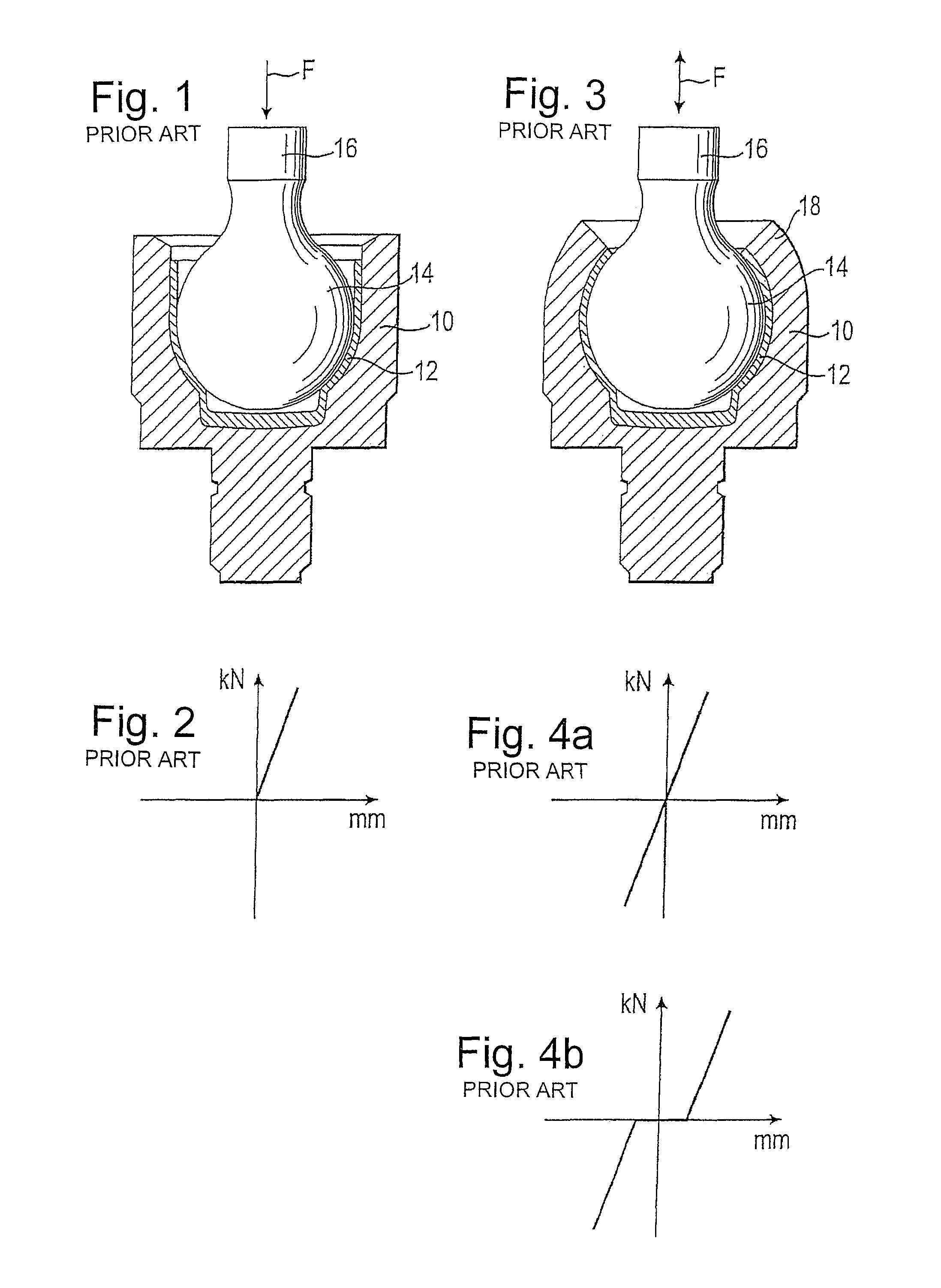

[0022]In FIG. 5 a ball joint can be seen, which in the same manner as the ball joint known from FIG. 1 has a housing 10 in which a bearing shell 12 is arranged, which in turn holds a ball head 14 of a ball pin 16. In contrast to the ball joint of FIG. 1, the bearing shell 12 here is constructed with an internal space the dimensions of which, expressed in general terms, are smaller than the dimensions of the ball head 14. In particular, in an encircling region B which lies slightly below the equator of the ball head 14, the bearing shell has a radius of curvature which is smaller than the radius of the ball head. This leads to the ball head 14 not being able to be fully inserted into the bearing shell 12 and the housing 10. It can be seen that an encircling free space remains both between the ball head and the bearing shell and also between the bearing shell and the housing.

[0023]If the ball head 14 is stressed in this state in the direction of the arrow F, the characteristic of load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com