Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "With delivery function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

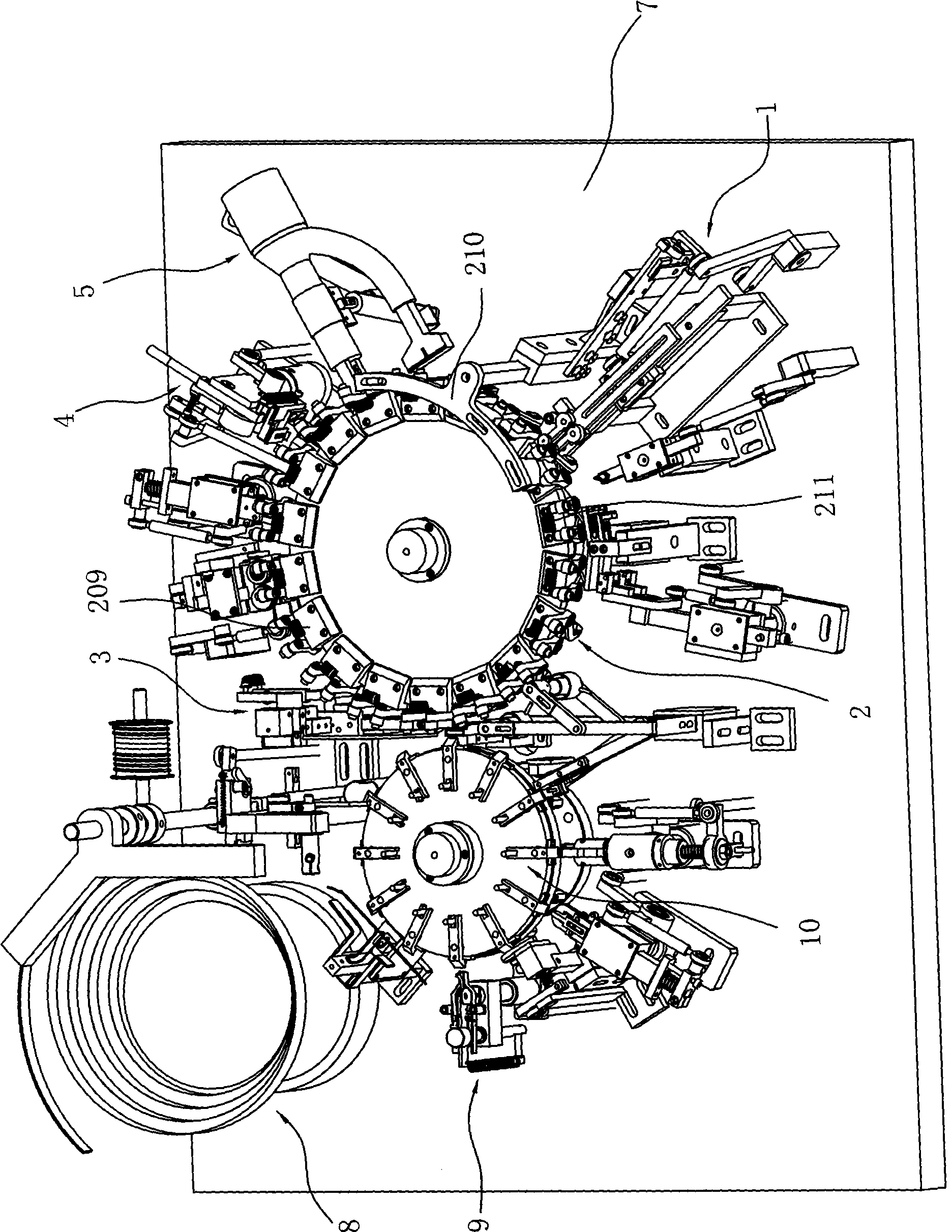

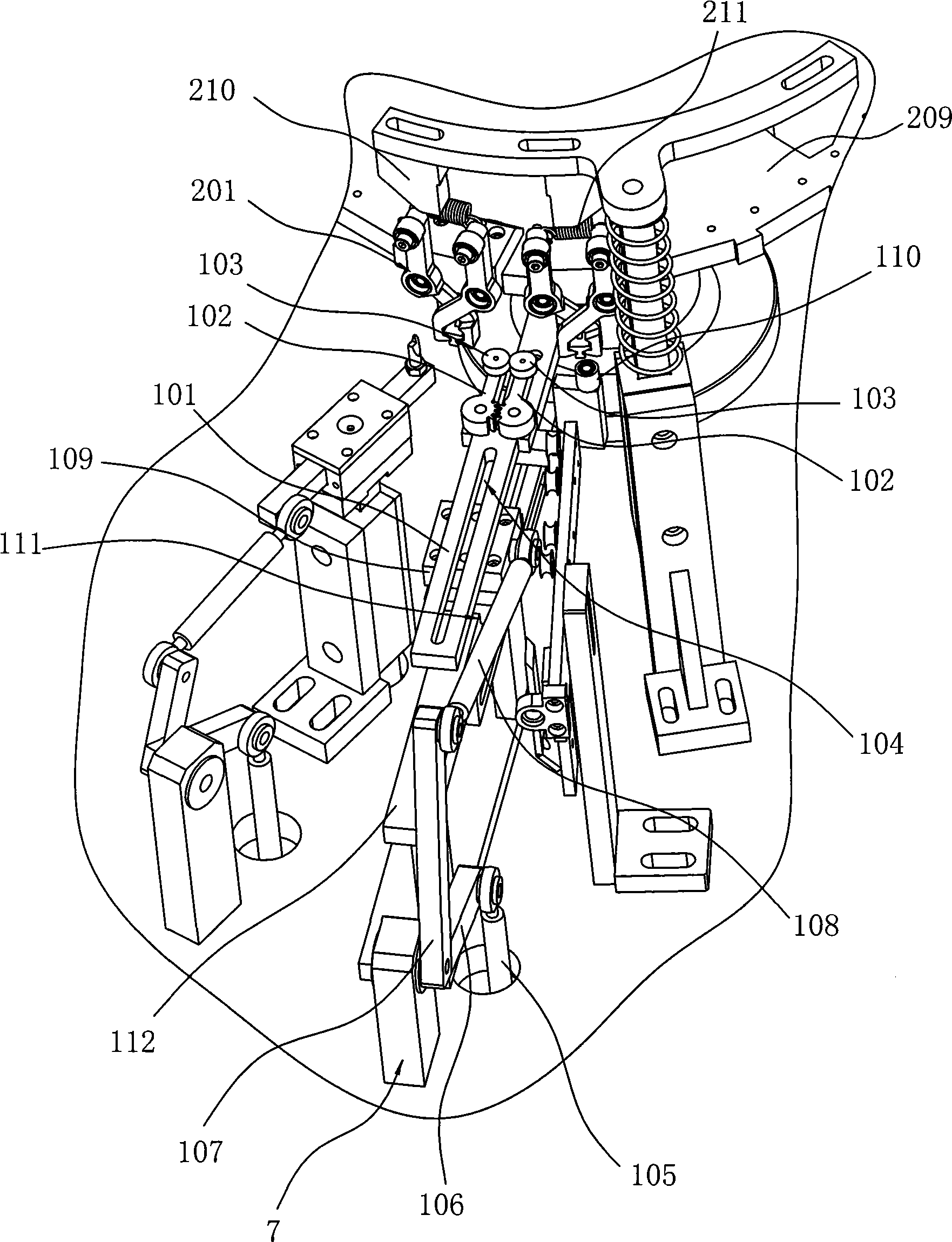

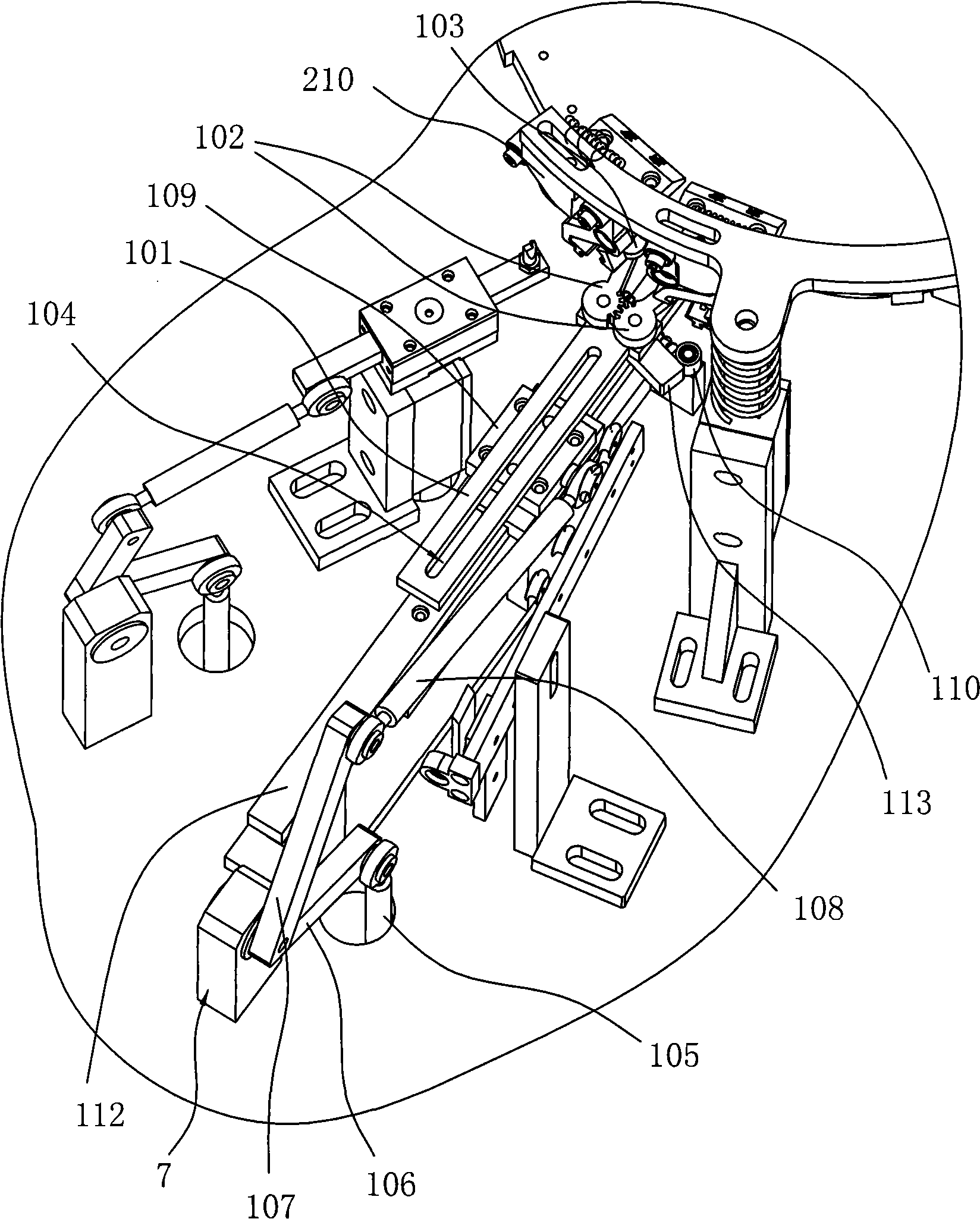

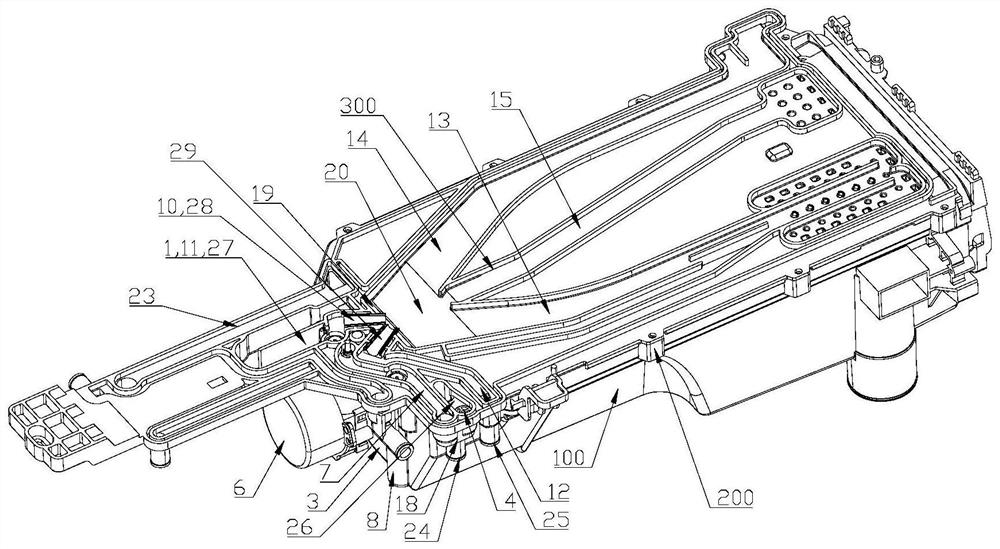

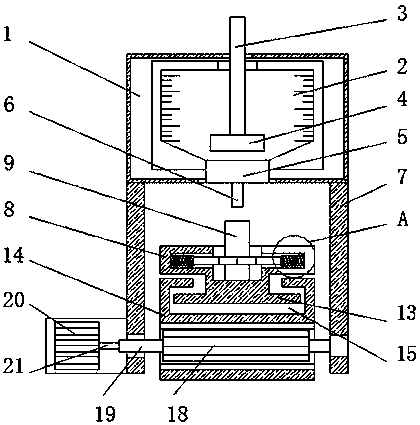

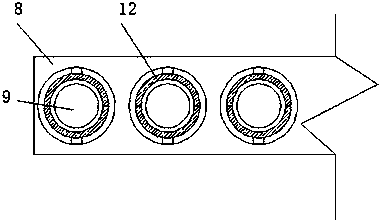

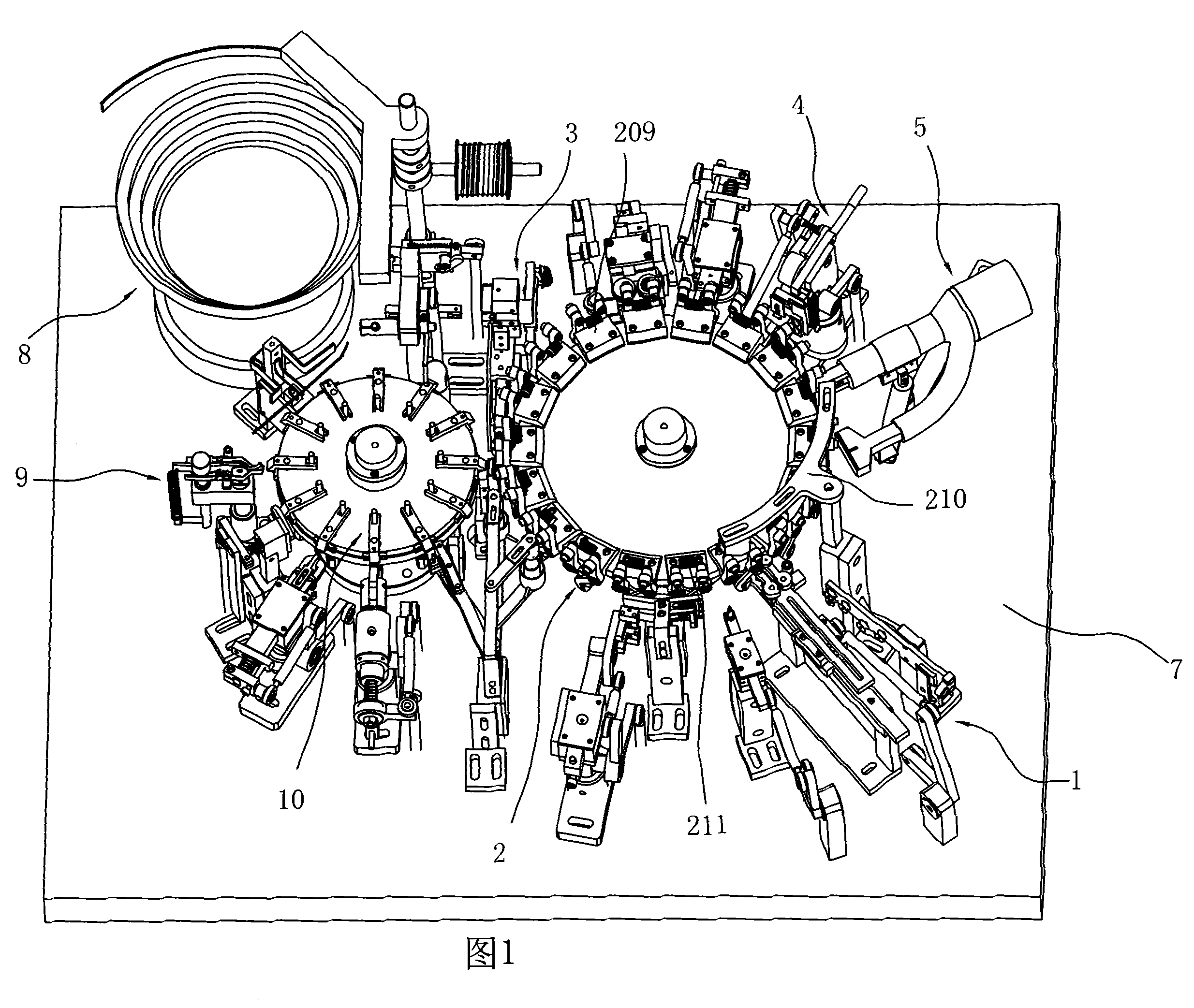

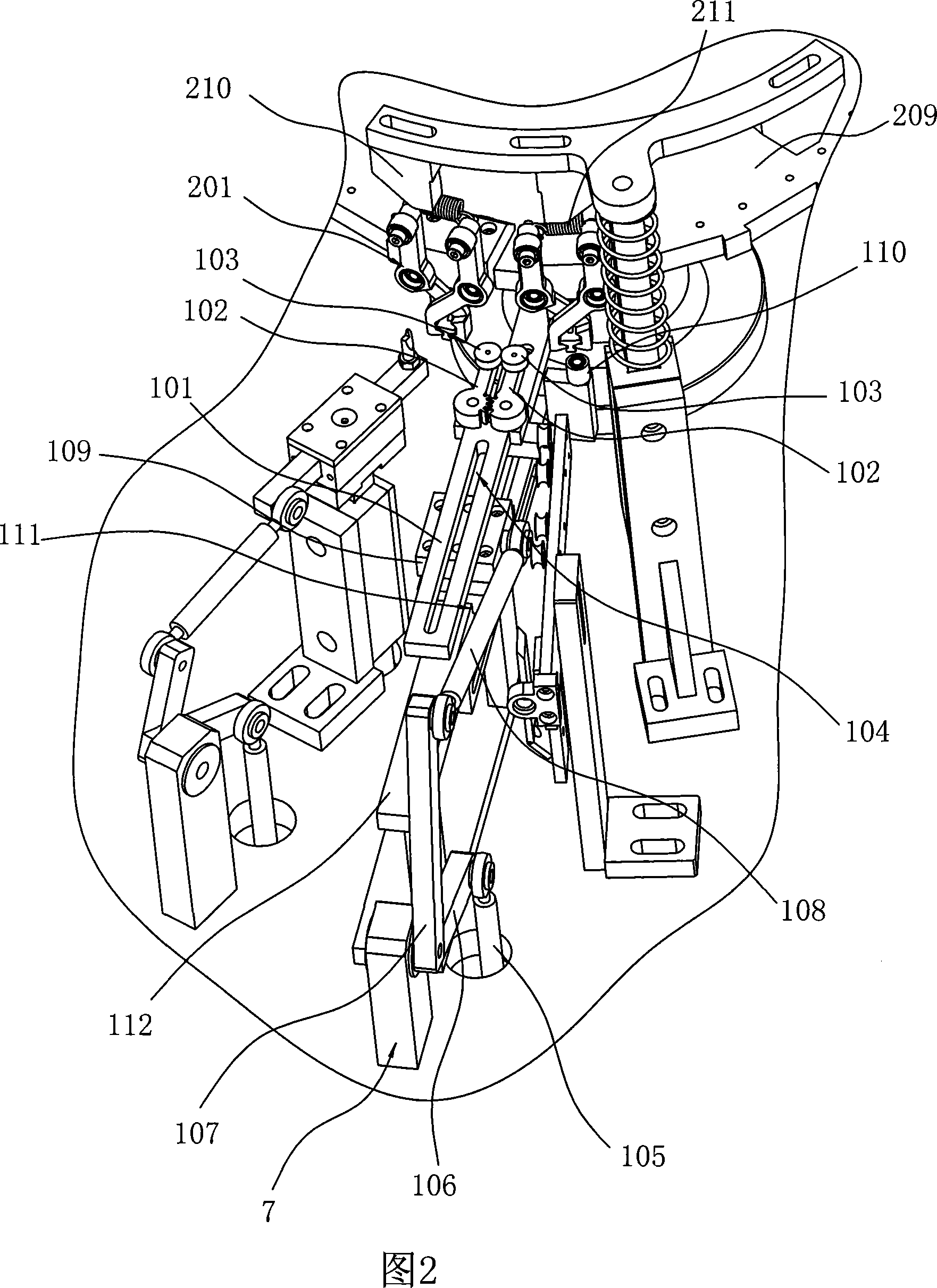

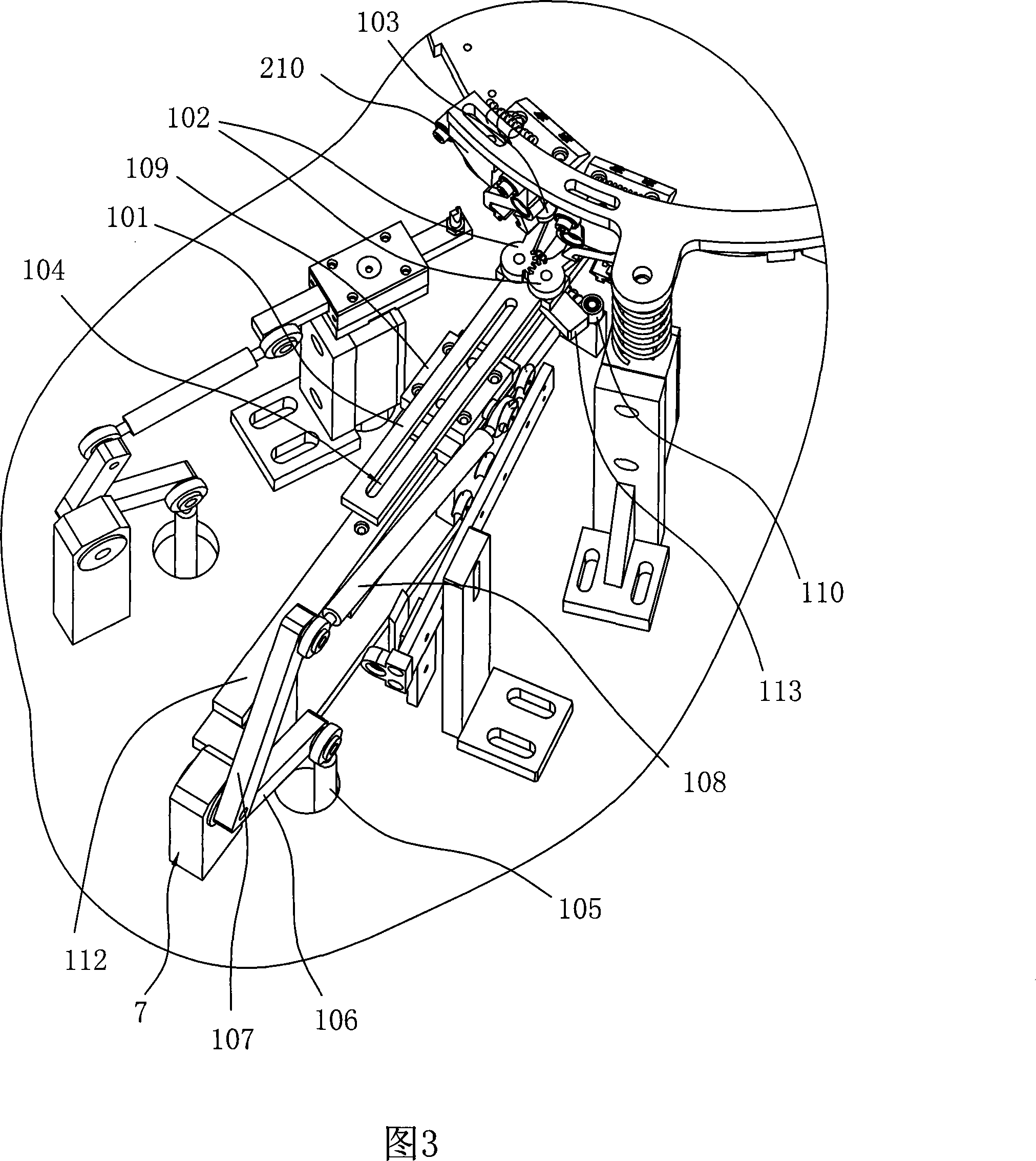

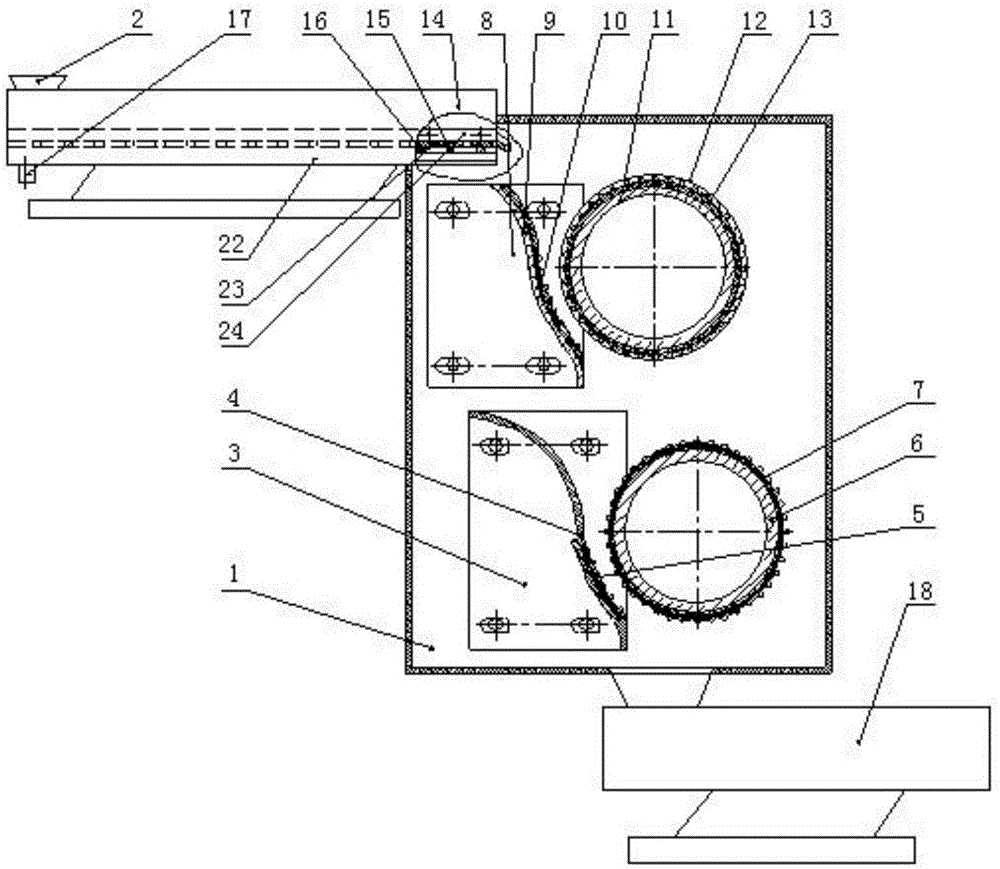

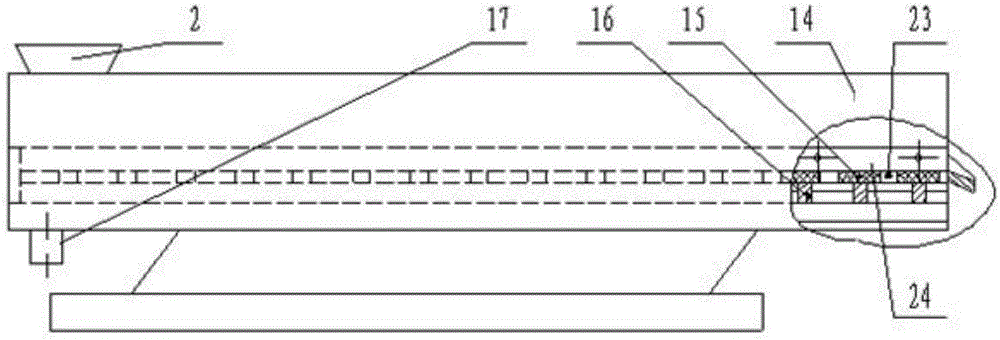

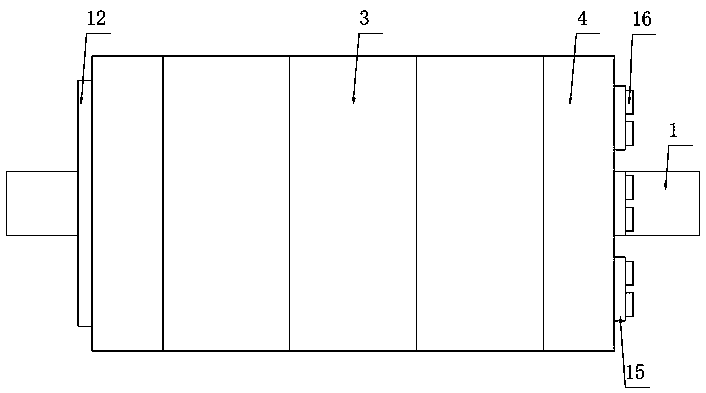

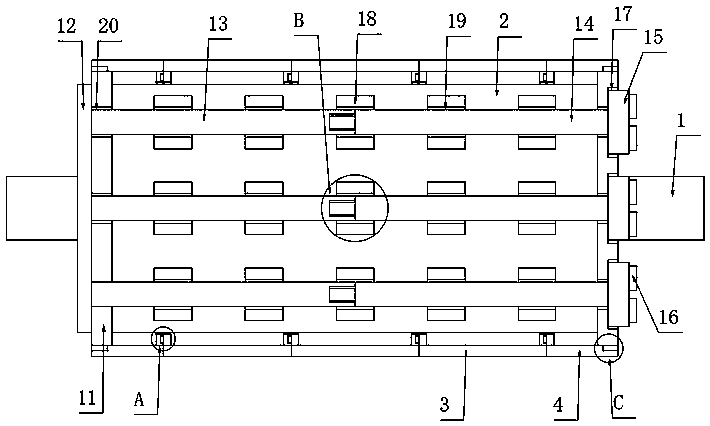

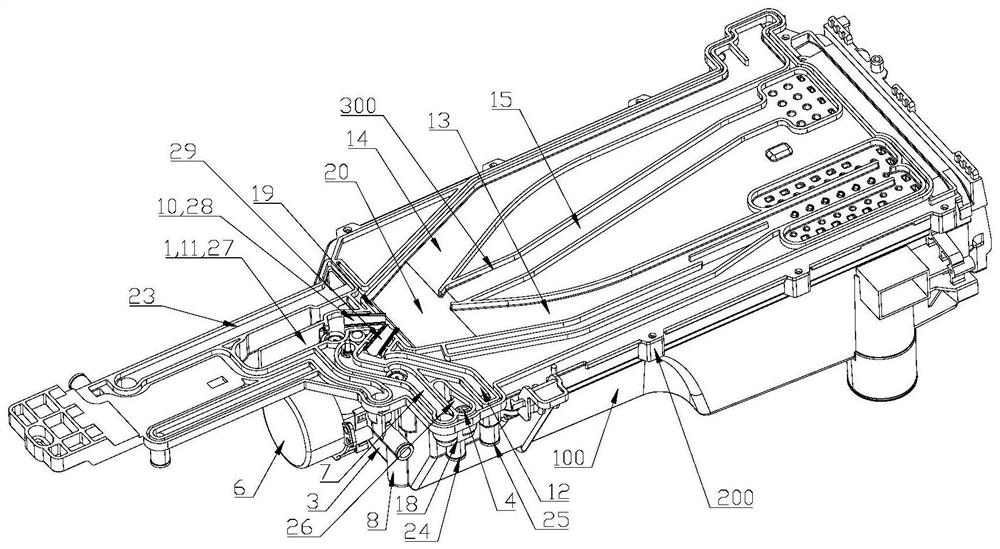

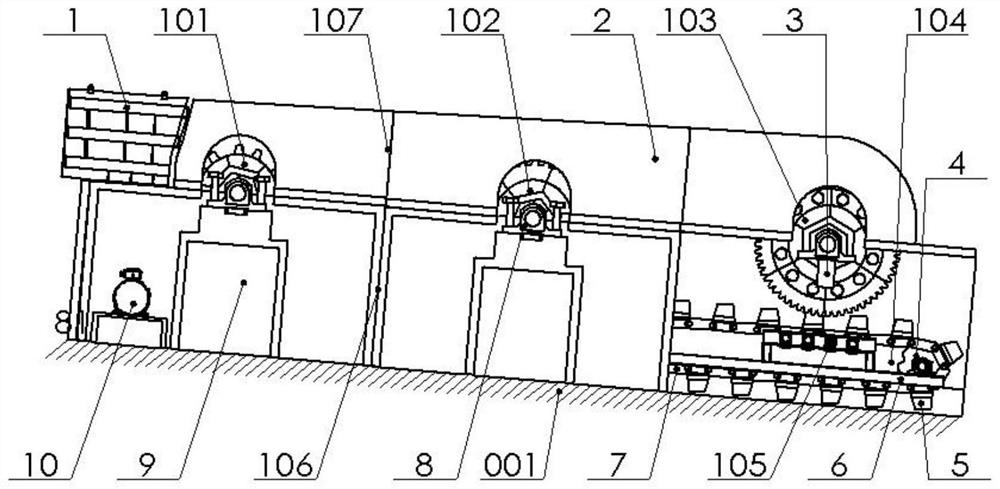

LED bulb welding machine

InactiveCN101499600AGuaranteed stable workPlay a limiting roleLine/current collector detailsWire cuttingSoldering

The invention relates to an LED light bulb soldering machine, which comprises a machine frame, a power transmission device, a bulb-delivering device, a transmission wire device and a bulb wire connecting device; wherein, the power transmission device is arranged on the machine frame; the bulb-delivering device, the transmission wire device and the bulb wire connecting device are driven by the power transmission device, and are arranged in sequence along the welding travel direction of the LED light bulbs; the bulb-delivering device comprises a bulb-delivering mechanism, a bulb pin reshaping mechanism and a bulb inspecting mechanism, which are driven by the power transmission device and are arranged in sequence along the delivering direction of the LED light bulbs; the transmission wire device comprises a delivering wire mechanism, a wire-cutting mechanism and a wire stripping mechanism, which are arranged in sequence along the direction of leads, and are driven by the power transmission device; the bulb wire welding wire comprises a welding mechanism and a complete thermal shrinkage pipe mechanism, which are arranged in sequence along the delivering direction of the LED light bulbs and are driven by a force transmission device. The invention has substantial characteristics and remarkable improvements: the transmission wire operates smoothly and accurately; the clamping wire isreliable; the tinning quantity on the wire is uniform and stable; the efficiency of the transmission pipe is high; the coating effect on the plastic pipes is good; and the cylinder is used for controlling the operation of the clutch.

Owner:吴志浩

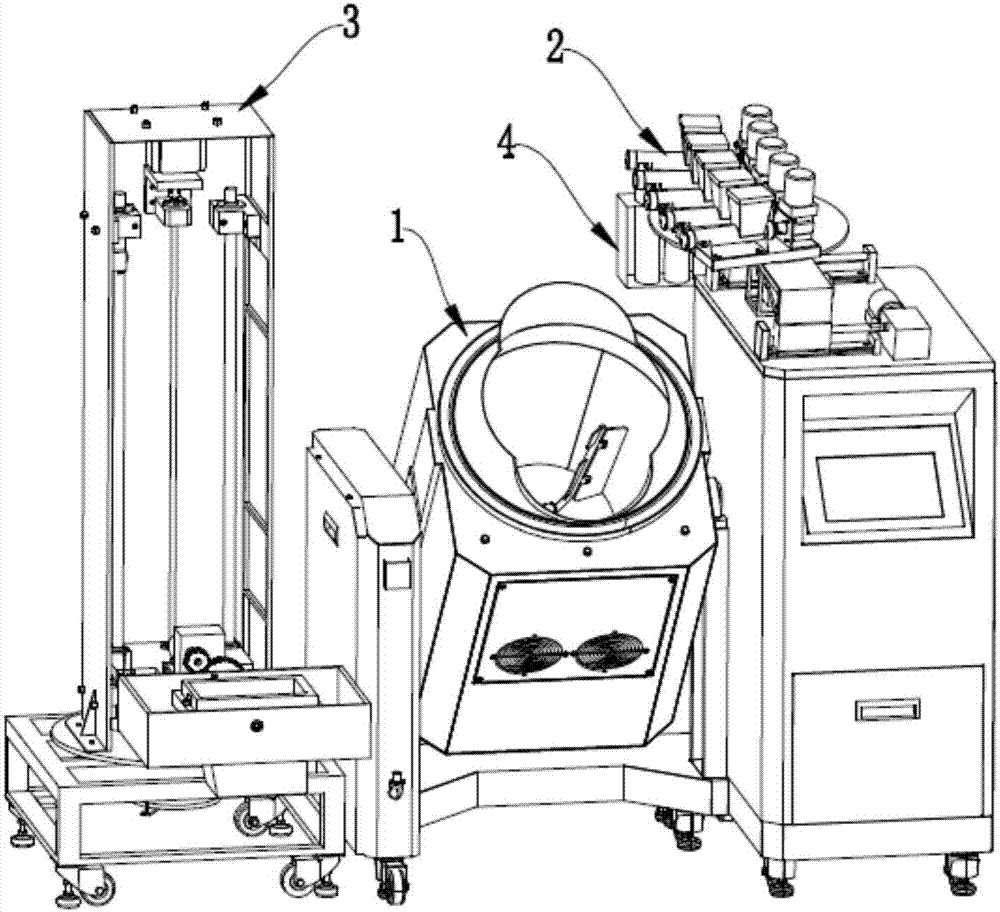

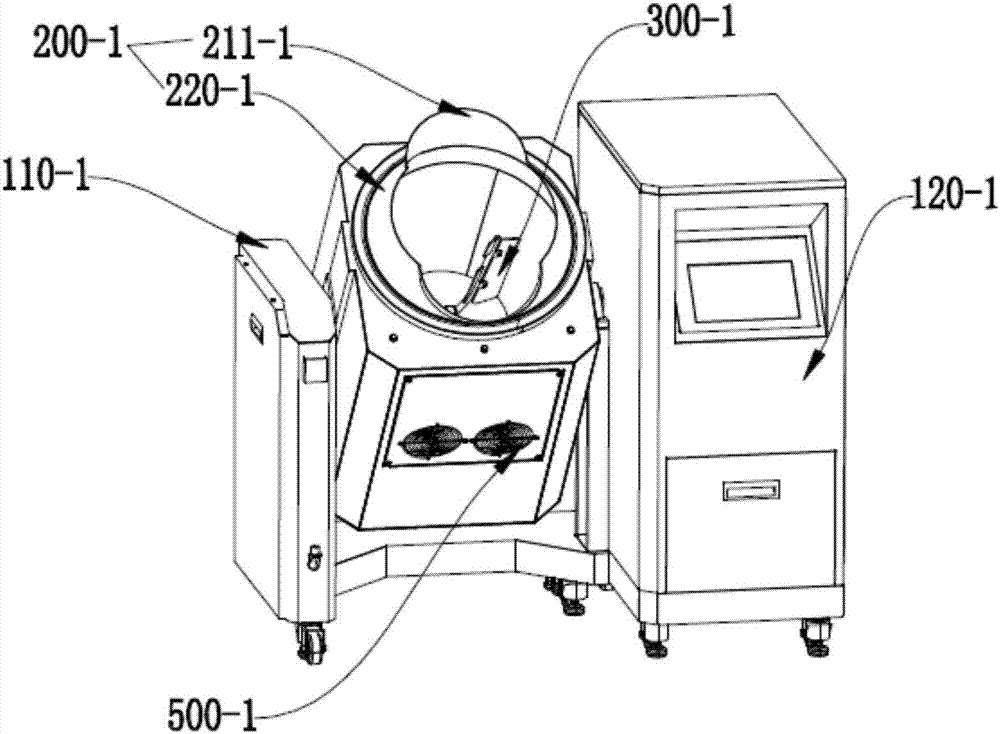

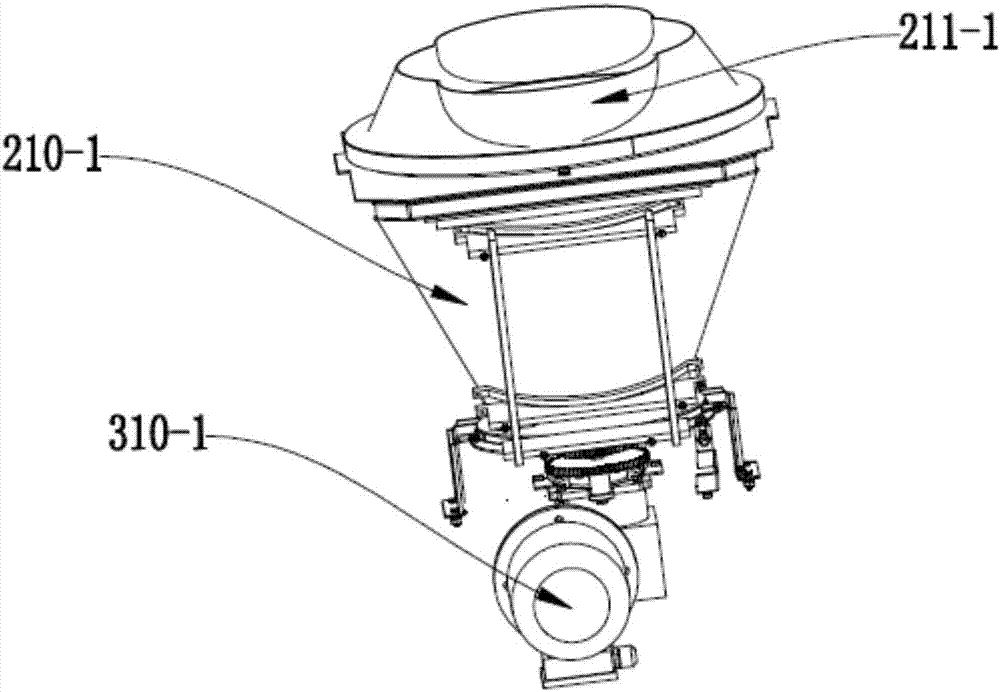

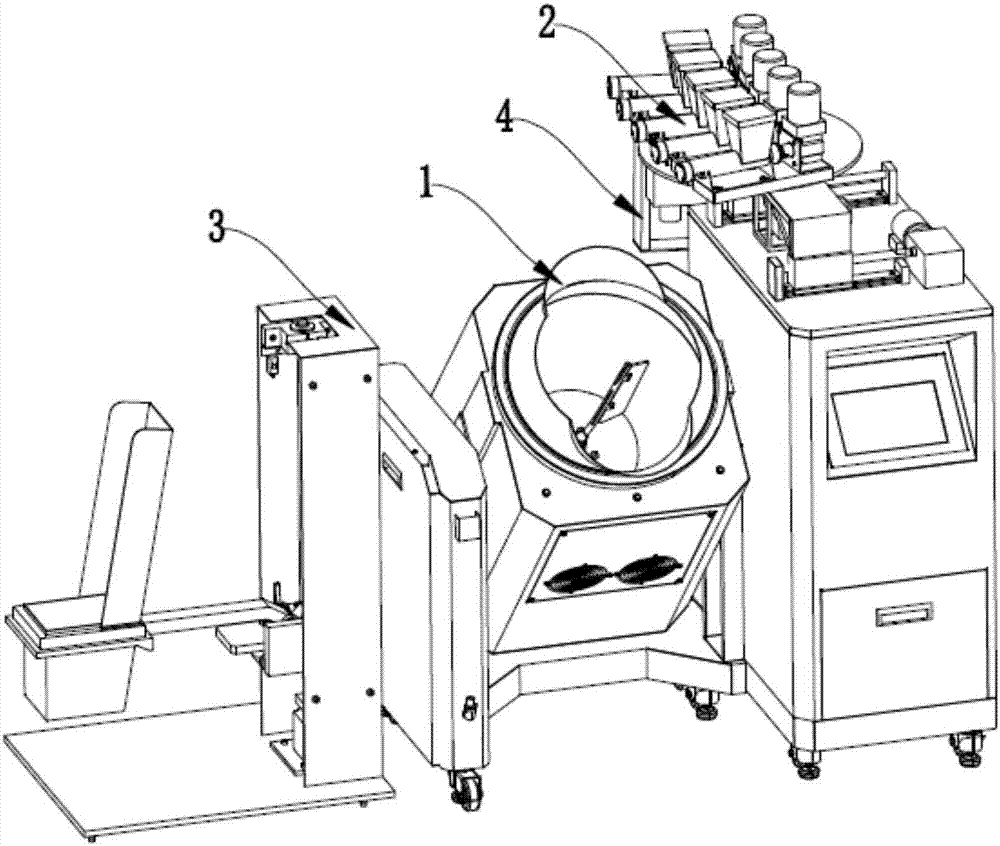

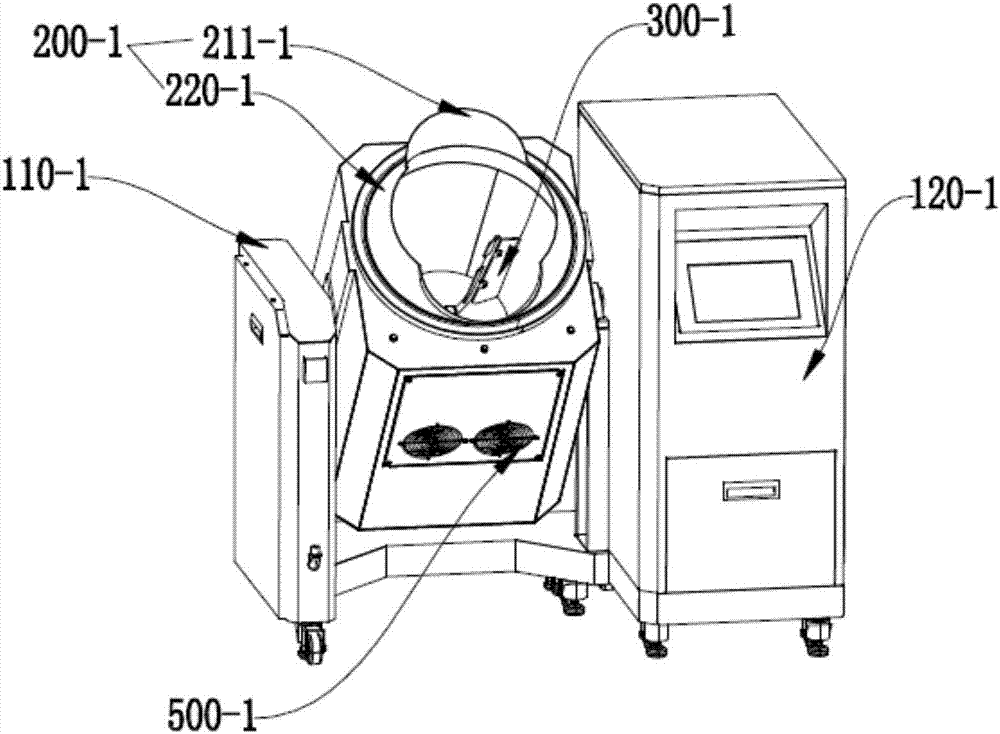

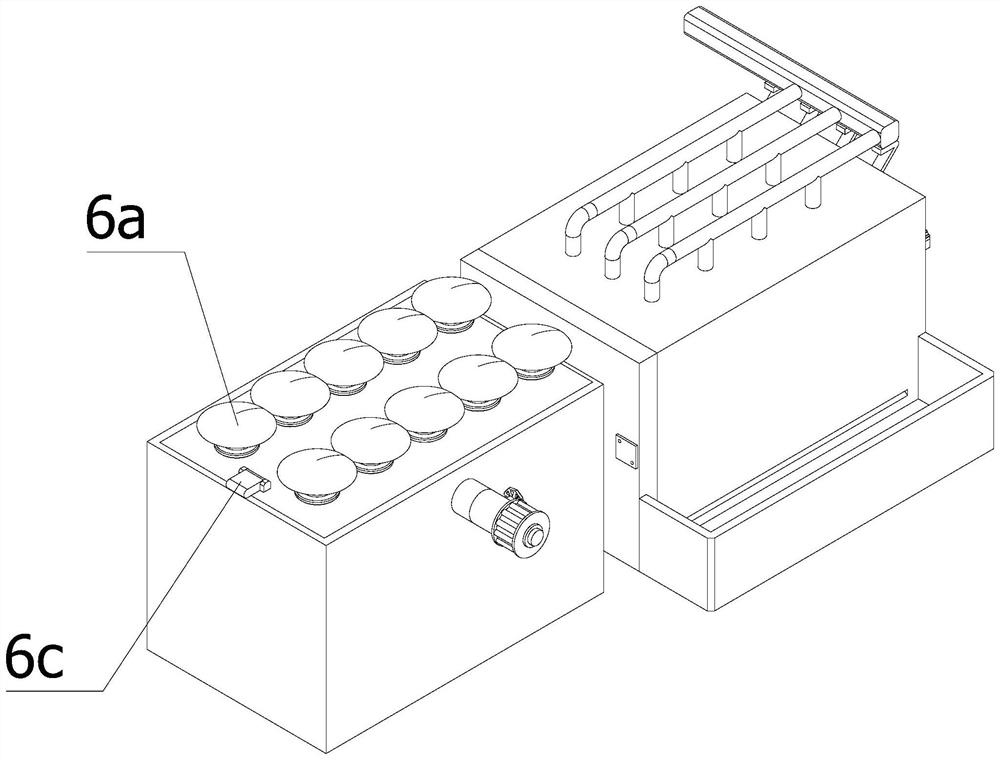

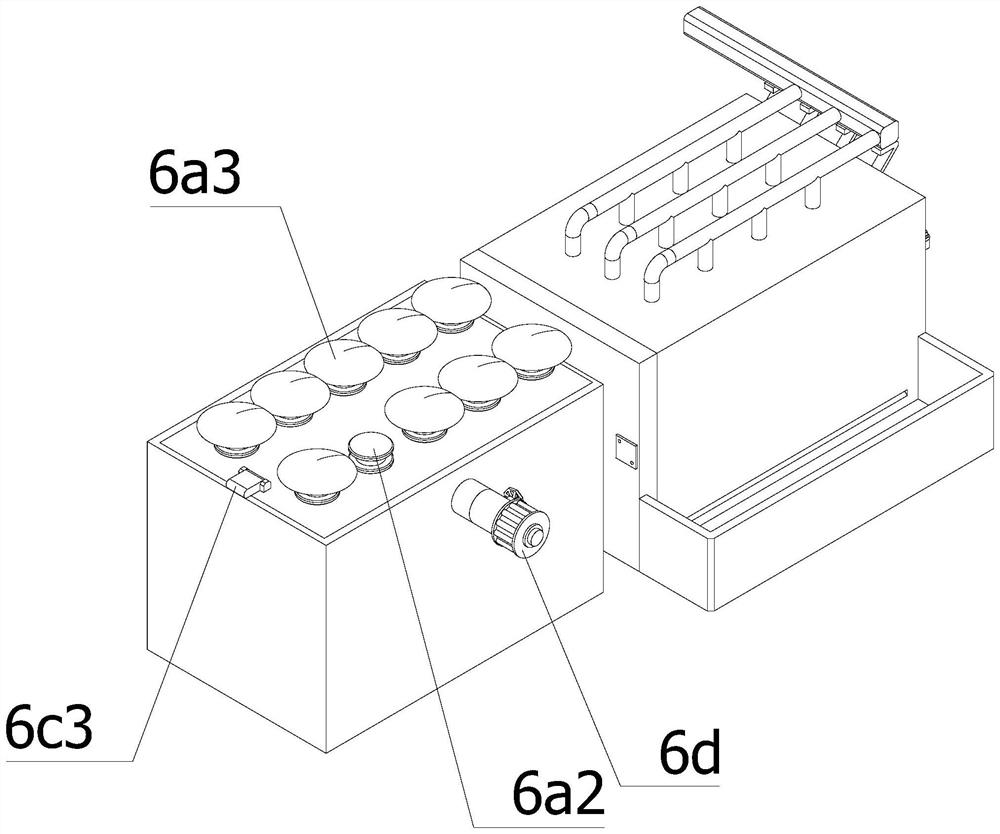

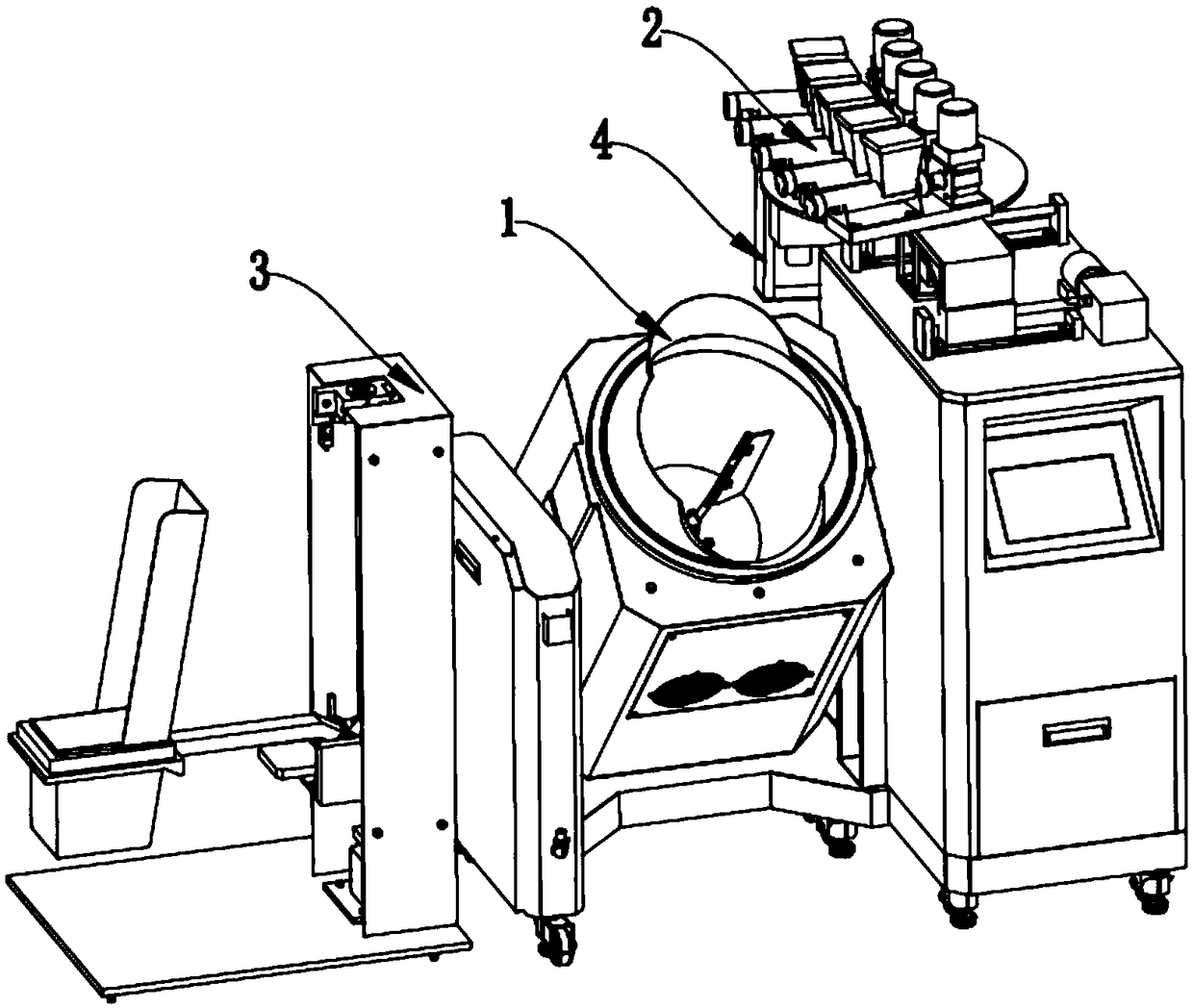

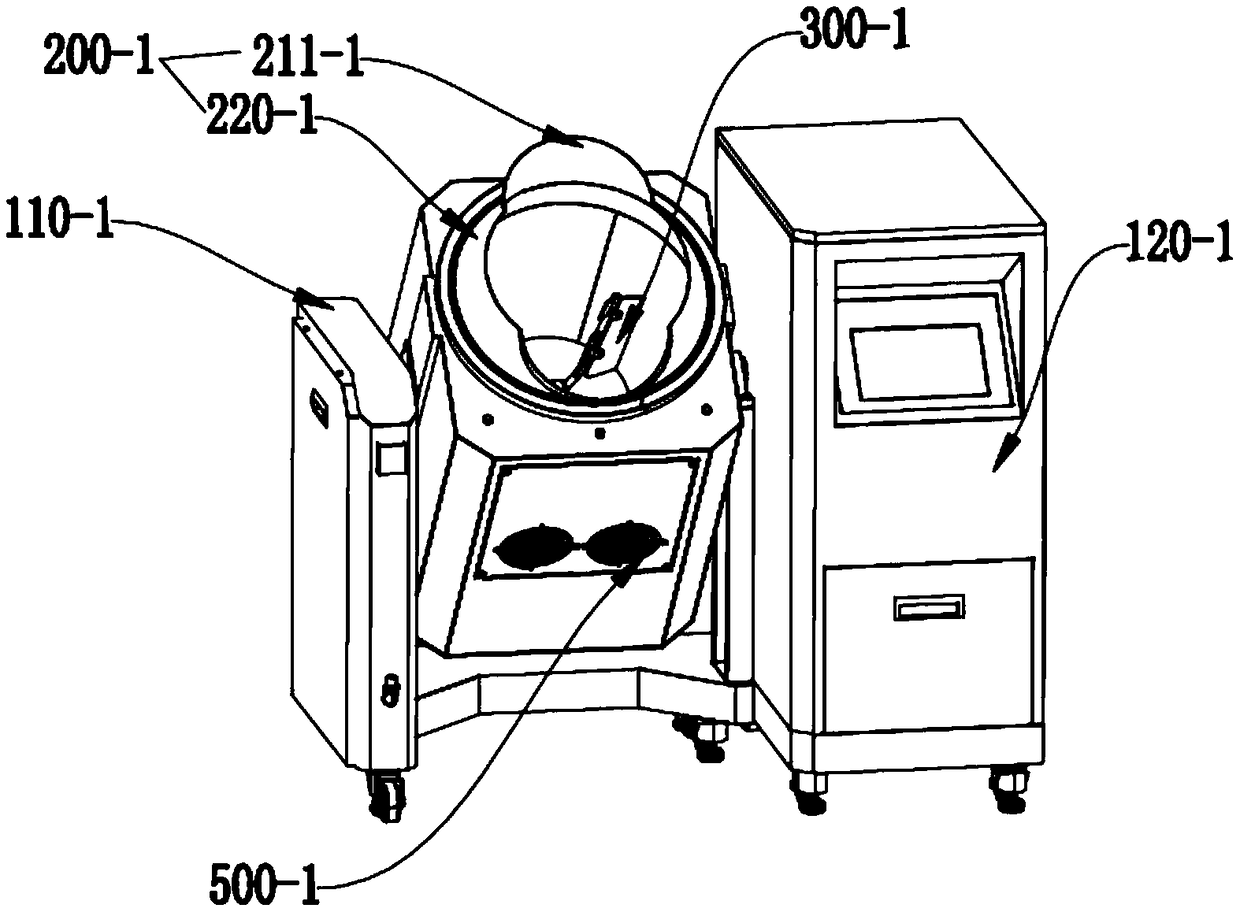

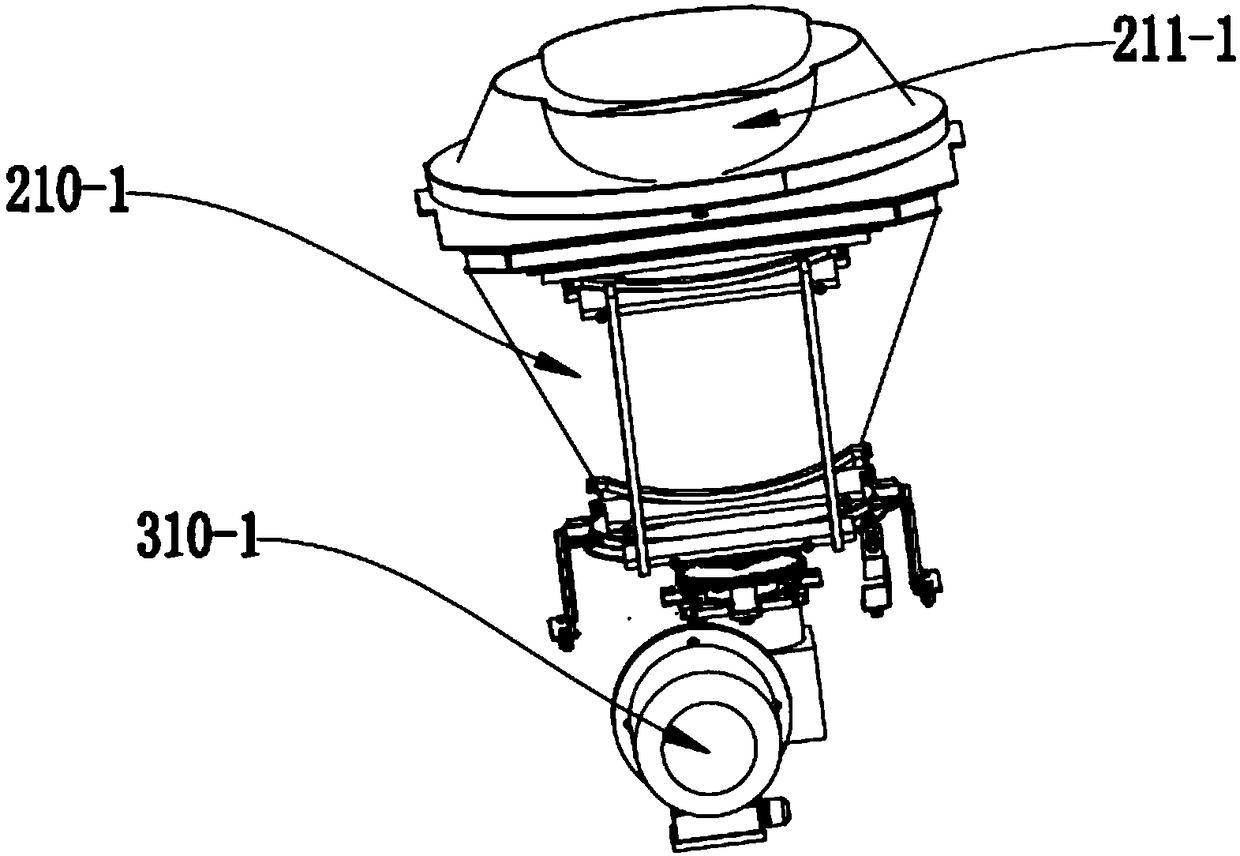

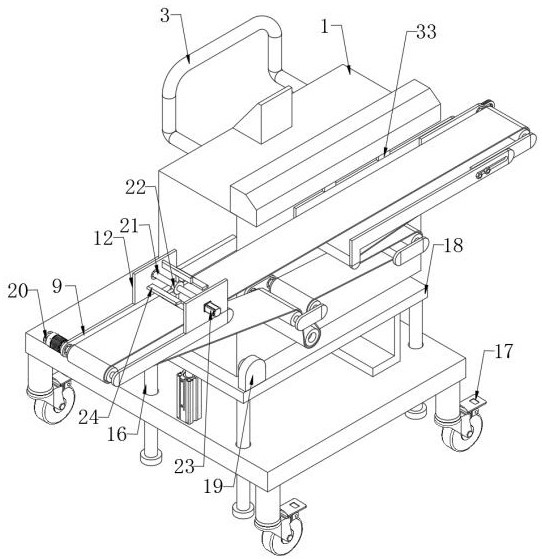

Multifunctional dish cooking device

ActiveCN106889867AImprove efficiencyImprove yieldCooking insertsCooking vessel supportAdditive ingredientEngineering

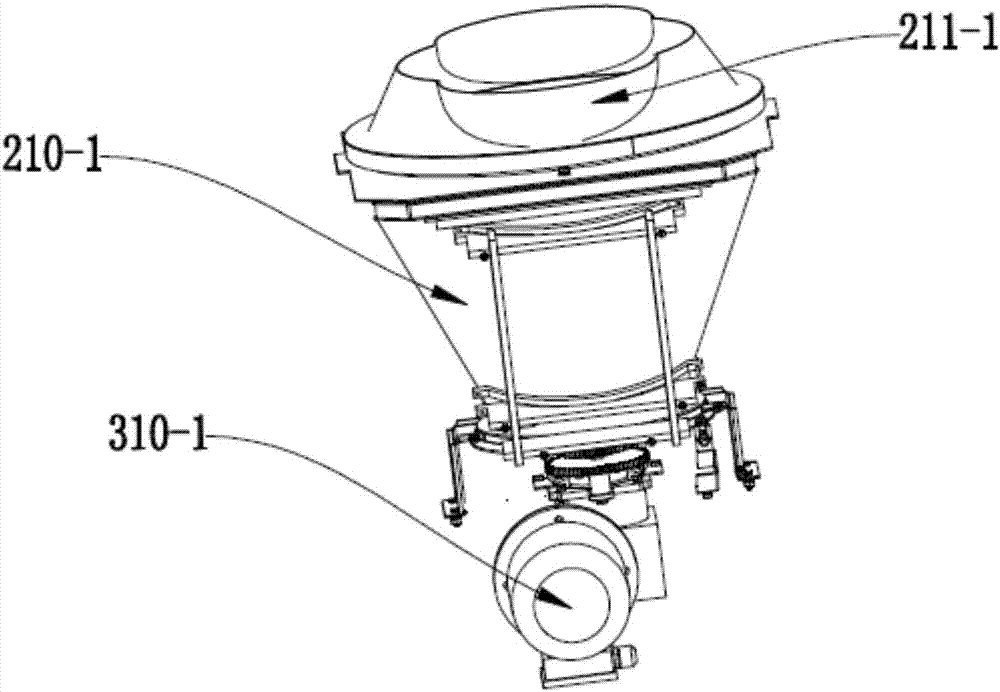

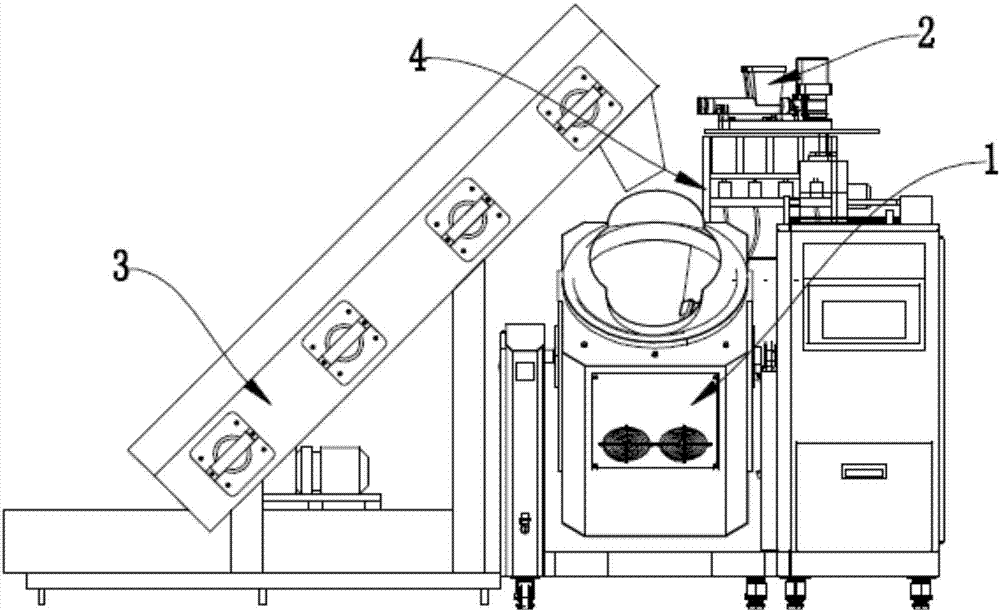

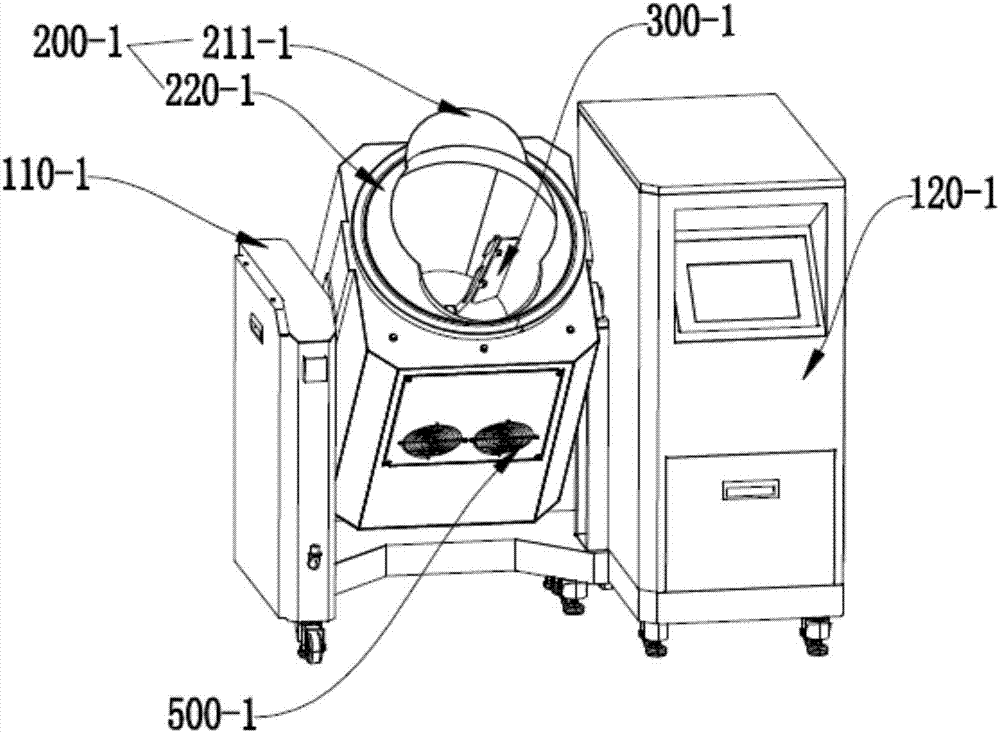

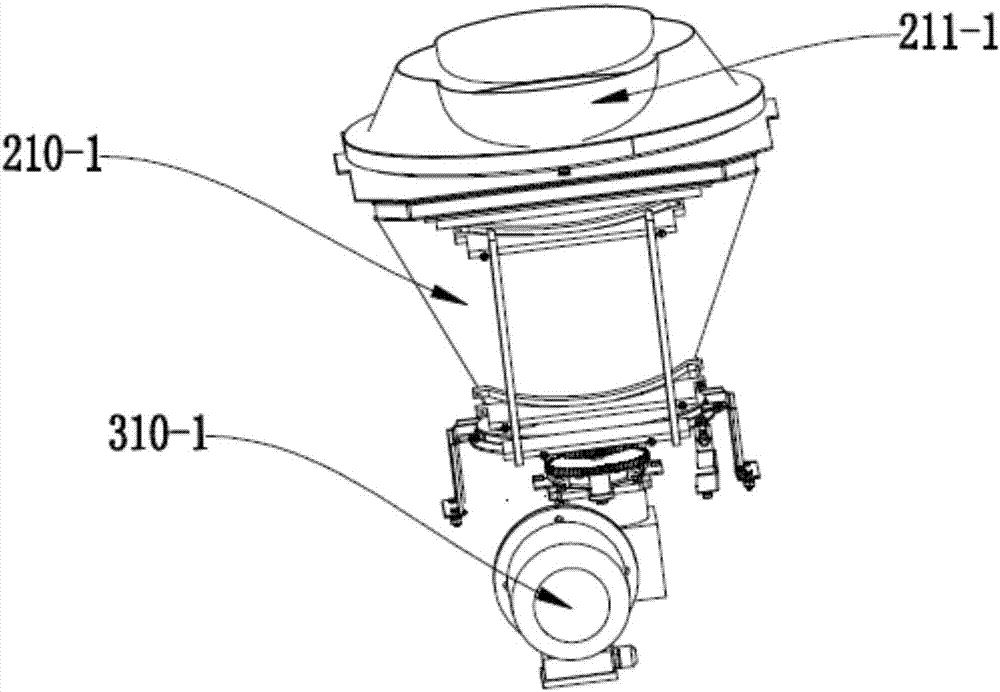

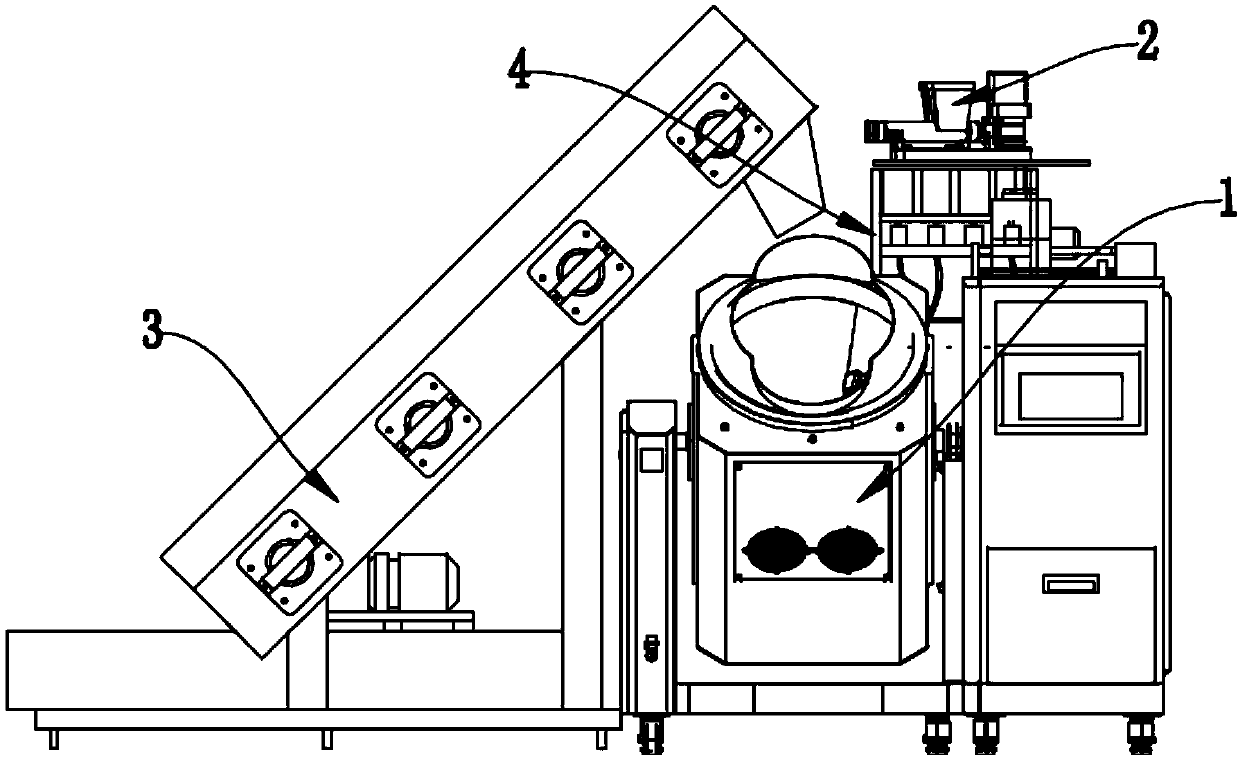

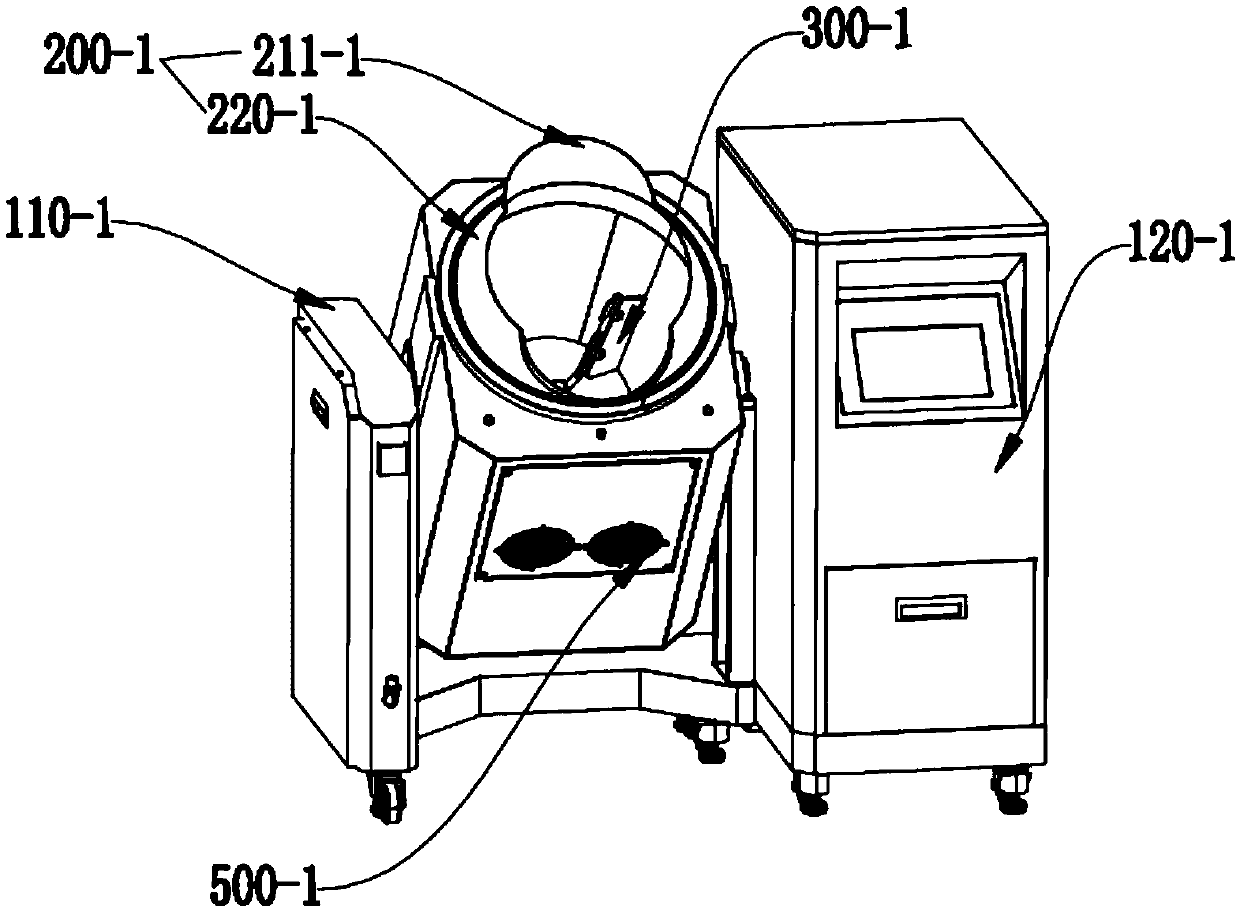

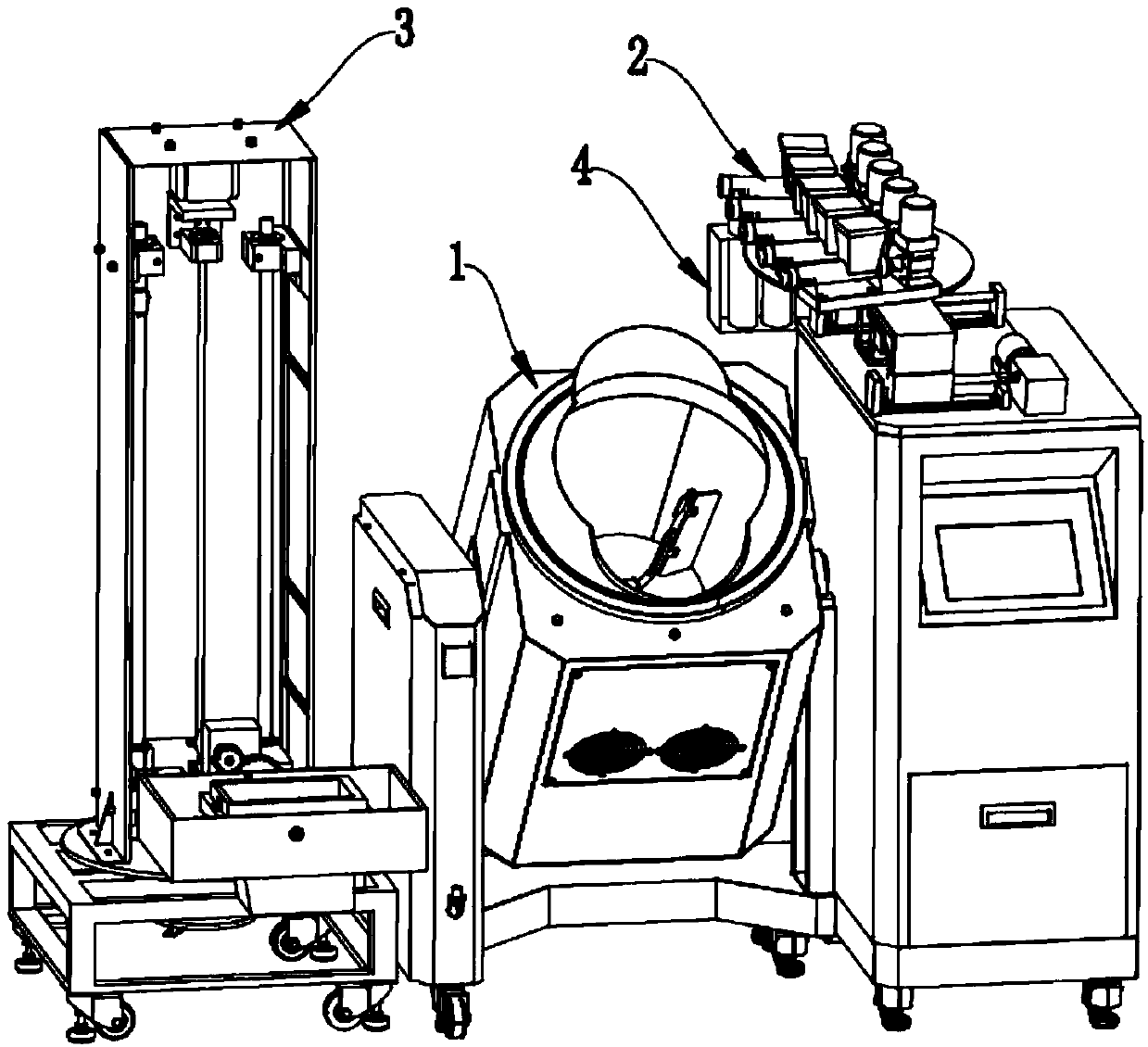

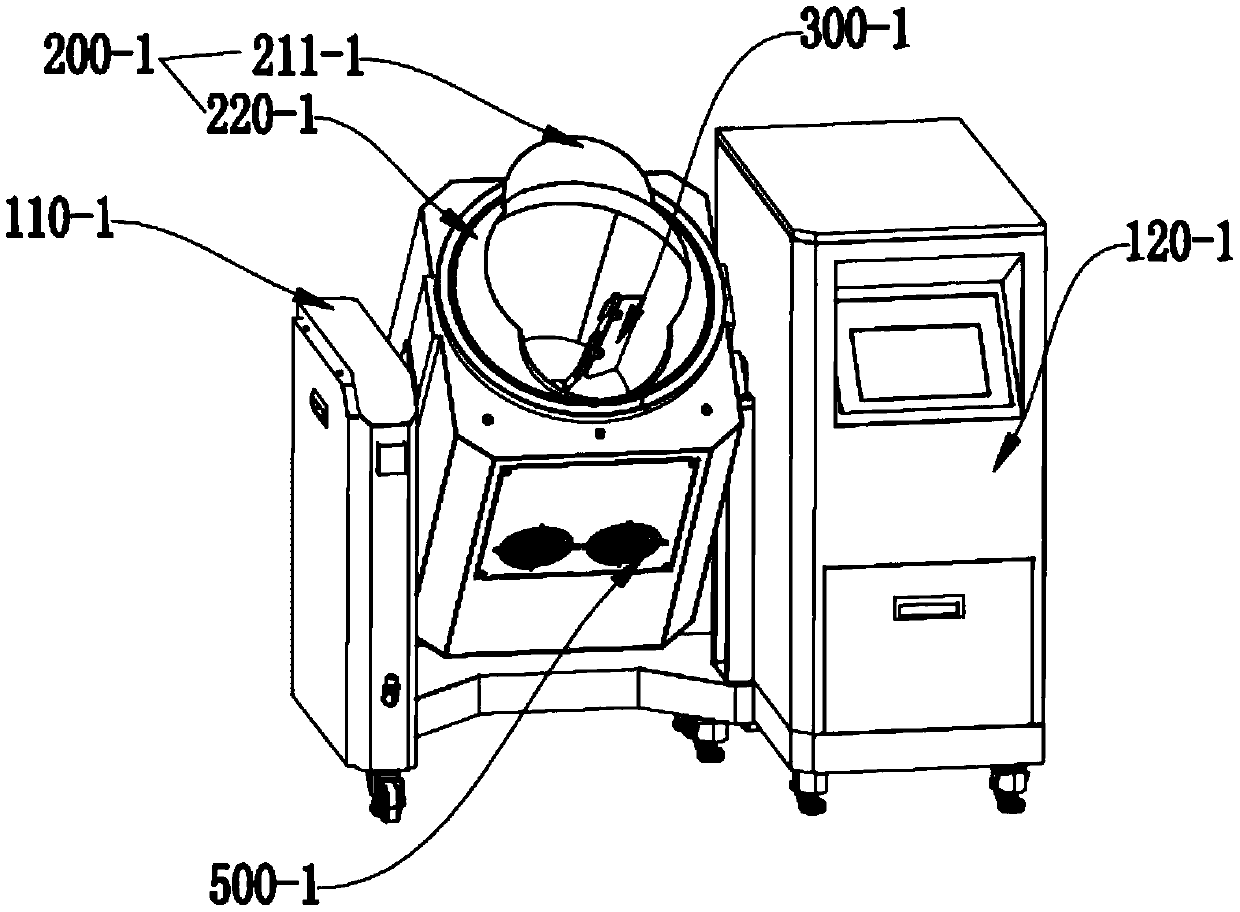

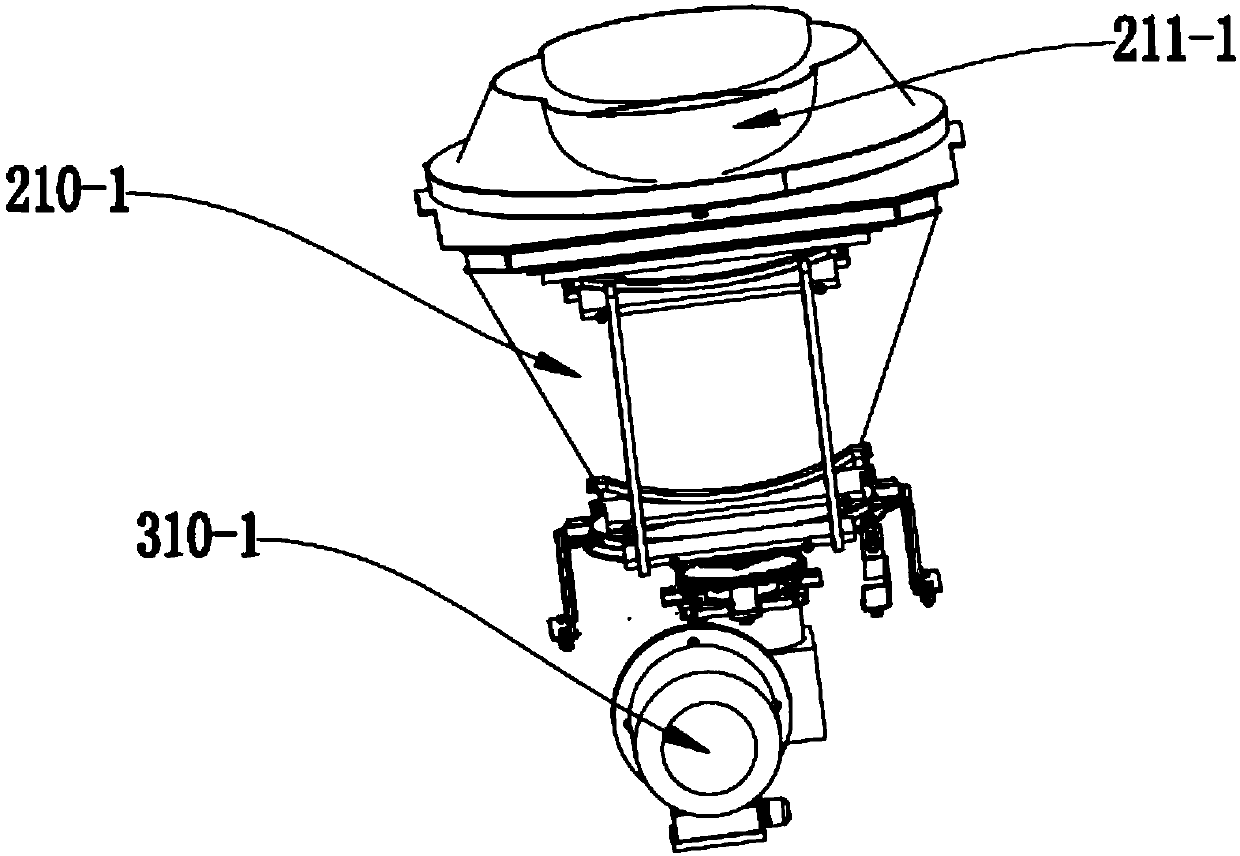

The invention provides a multifunctional dish cooking device. The device comprises a dish cooking machine, a seasoning putting device and a feeding device. The dish cooking machine comprises a machine body and a wok mechanism. The machine body comprises a first machine frame and a second machine frame which are located on the two sides of the wok mechanism respectively, rotary shafts are fixedly arranged on the two sides of the wok mechanism respectively, and the wok mechanism are rotationally installed on the first machine frame and the second machine frame through the rotary shafts. The seasoning putting device is fixedly installed on the second machine frame, and comprises a translation driving device, a guide device, a moving device and a seasoning putting part. The two sides of the moving device are installed on the translation driving device and the moving device respectively, the seasoning putting part is installed on the moving device, and the translation driving device and the guide device are parallelly arranged on the same plane side by side; the seasoning putting part moves above the wok mechanism through the moving device; the feeding device is used for putting dish main ingredients into the wok mechanism.

Owner:FOSHAN POLYTECHNIC

Multifunctional food cooking device

ActiveCN106913196AImprove efficiencyImprove yieldWarming devicesCooking vessel constructionsCookerEngineering

A multifunctional food cooking device comprises an automatic cooker, a seasoning delivery device and a feeding device. The automatic cooker comprises a cooker body and a pan mechanism, wherein the cooker body comprises a first frame and a second frame, the first frame and the second frame are located on the two sides of the pan mechanism respectively, rotary shafts are fixedly installed on the two sides of the pan mechanism, and the pan mechanism is installed on the first frame and the second frame through the rotary shafts in a rotary mode. The seasoning delivery device is fixedly installed on the second frame. The seasoning delivery device comprises a translation driving device, a guiding device, a moving device and a seasoning delivery part, wherein the two sides of the moving device are installed on the translation driving device and the guiding device respectively, the seasoning delivery part is installed on the moving device, the translation driving device and the guiding device are arranged on the same plane in parallel side by side, and the seasoning delivery part can be moved to the space above the pan mechanism through the moving device. The feeding device is used for feeding main materials of a dish into the pan mechanism.

Owner:FOSHAN POLYTECHNIC

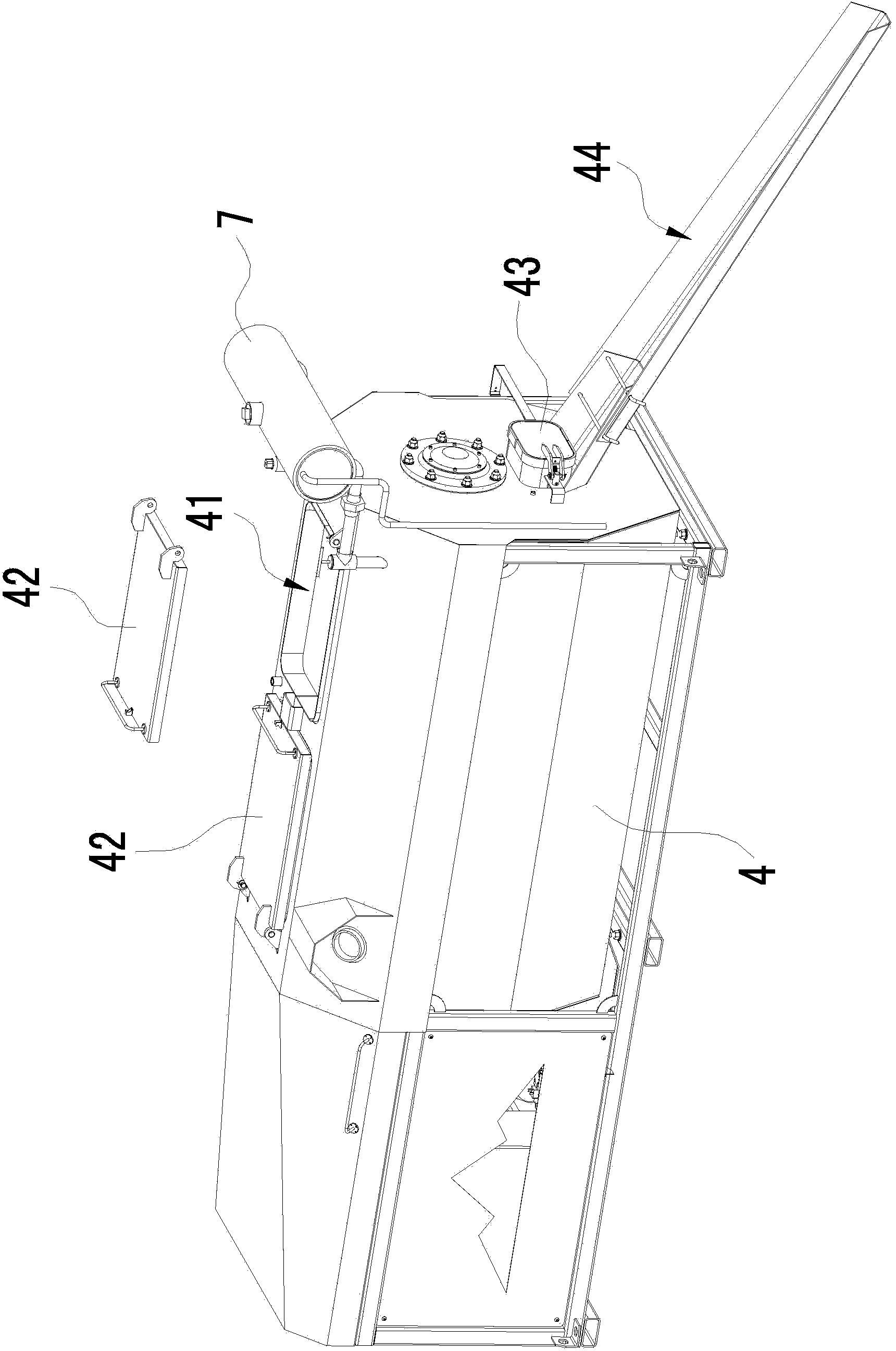

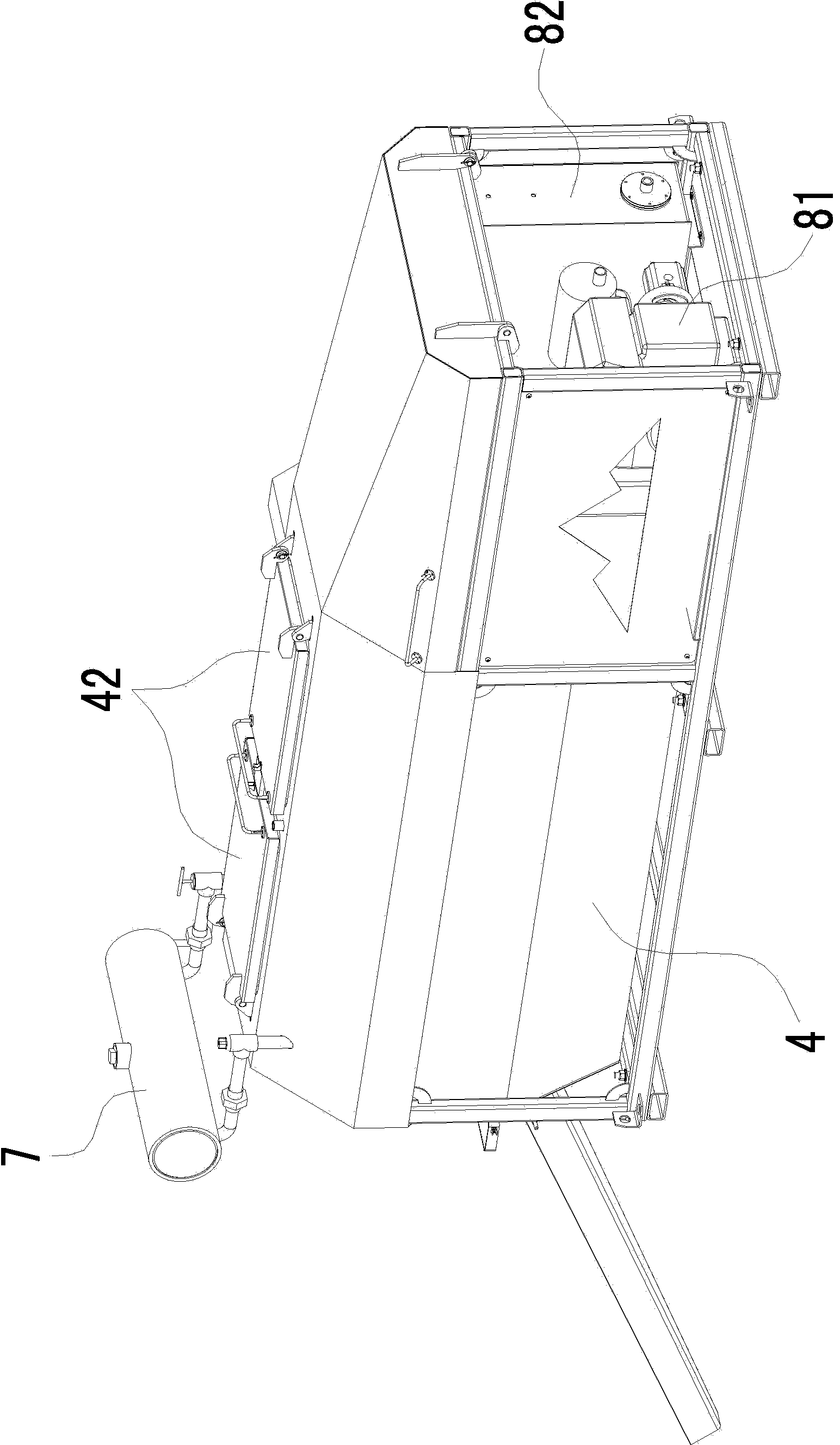

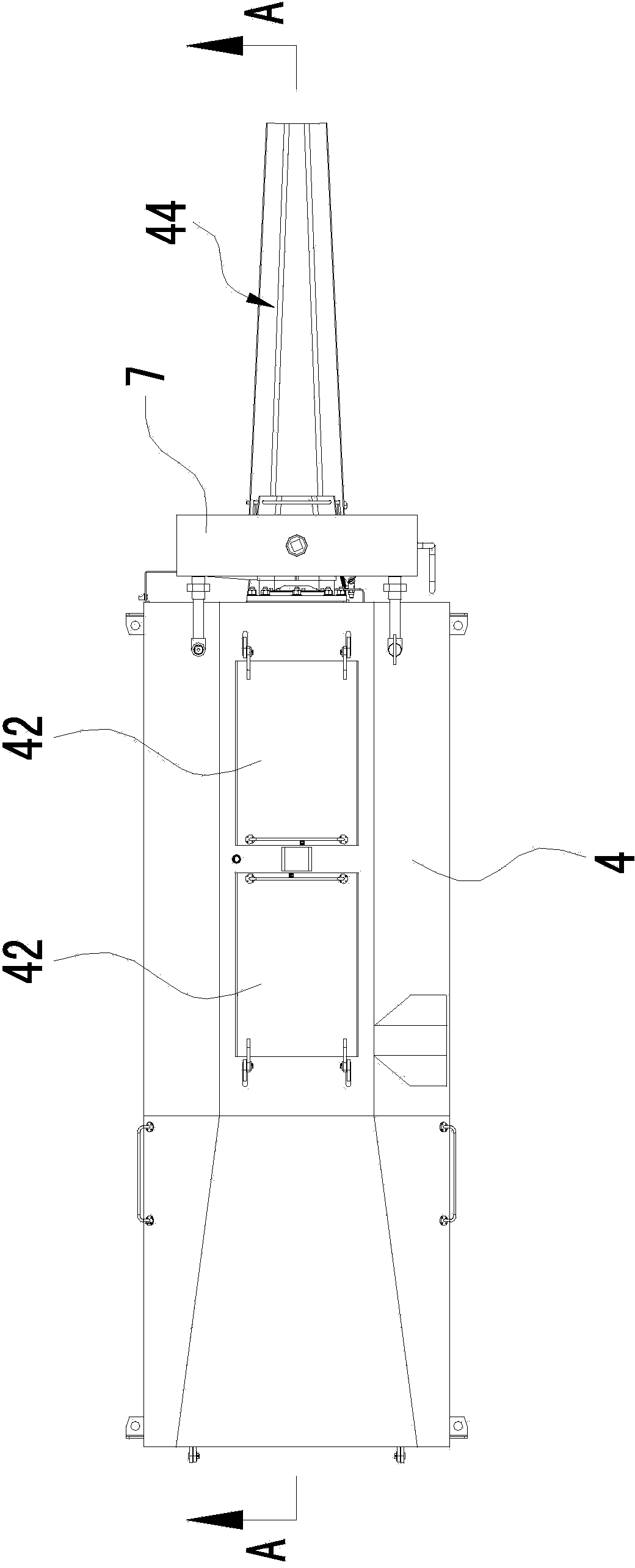

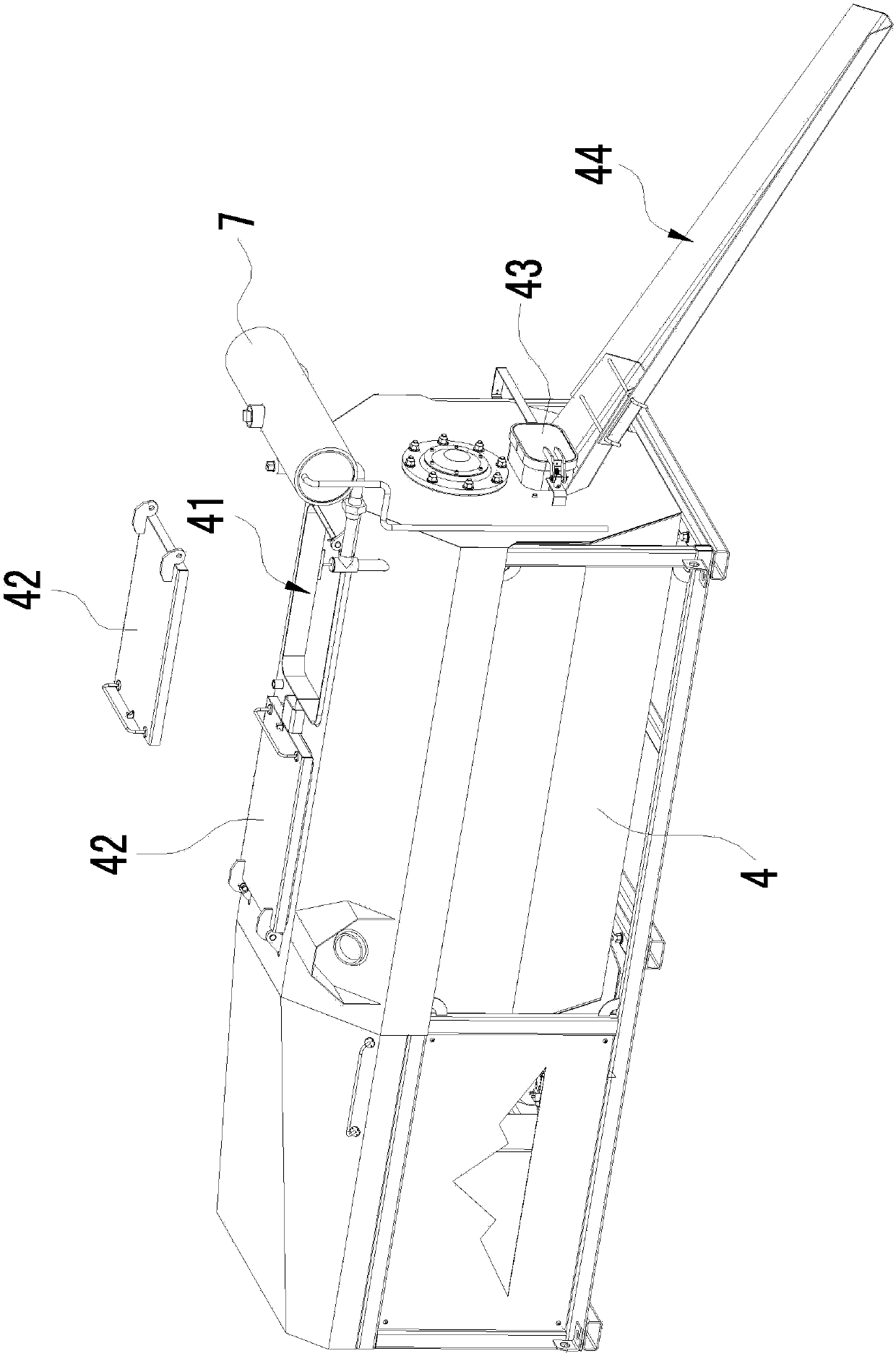

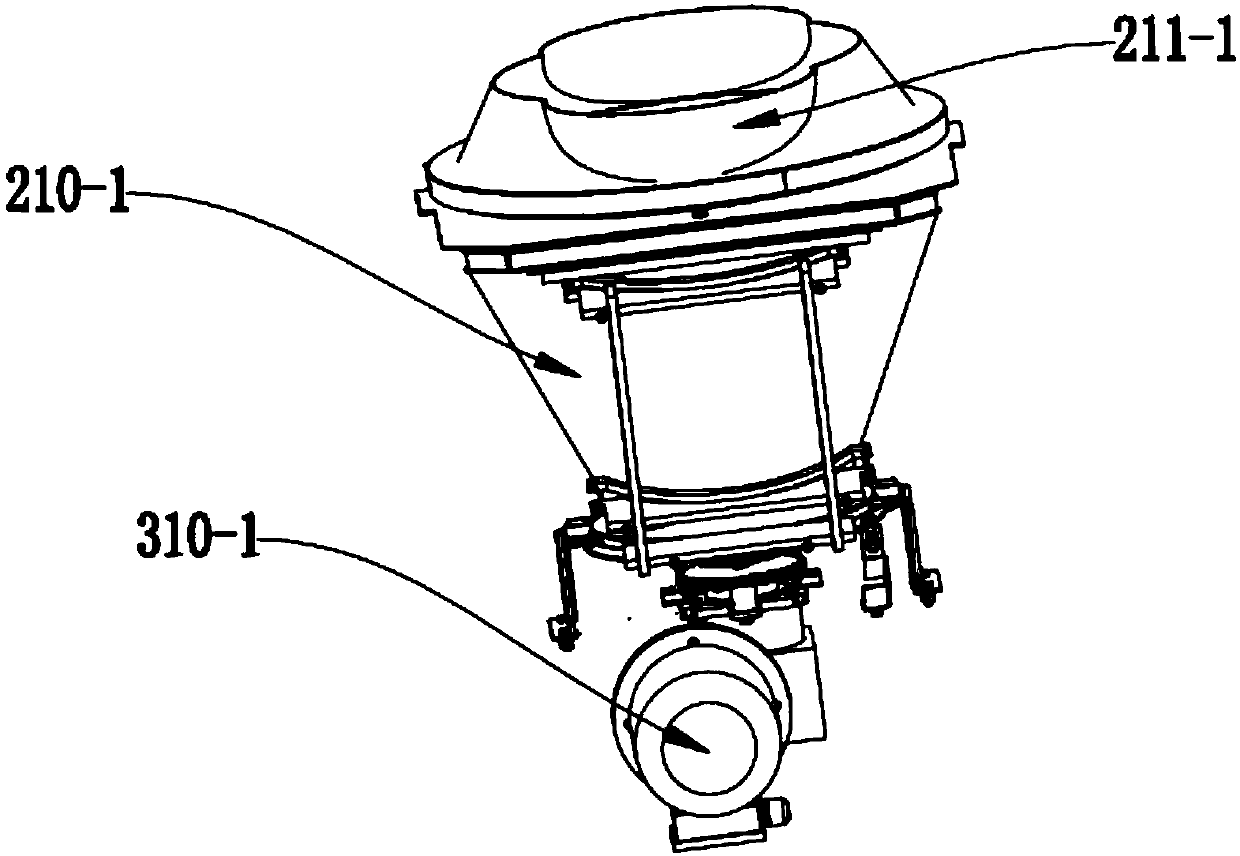

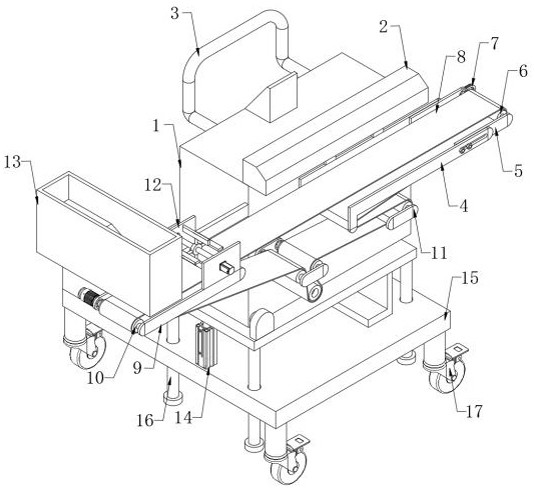

Food cooking device with feeding function

ActiveCN106889869AImprove efficiencyImprove yieldPouring-spoutsCooking insertsAdditive ingredientEngineering

The invention relates to a food cooking device with a feeding function. The food cooking device with the feeding function comprises a cooking machine, a seasoning putting device and a feeding device, wherein the cooking machine comprises a machine body and a pan mechanism, the machine body comprises a first machine frame and a second machine frame, the first machine frame and the second machine frame are located on the two sides of the pan mechanism respectively, rotation shafts are fixedly installed on the two sides of the pan mechanism, and the pan mechanism is installed on the first machine frame and the second machine frame through the rotation shafts; the seasoning putting device is fixedly installed on the second machine frame, and comprises a translation driving device, a guide device, a moving device and a seasoning putting part; the two sides of the moving device are installed on the translation driving device and the moving device respectively, the seasoning putting part is installed on the moving device, and the translation driving device and the guide device are parallelly arranged on the same plane side by side; the seasoning putting part is moved to the portion above the pan mechanism through the moving device; the feeding device is used for putting main ingredients of dishes into the pan mechanism.

Owner:FOSHAN POLYTECHNIC

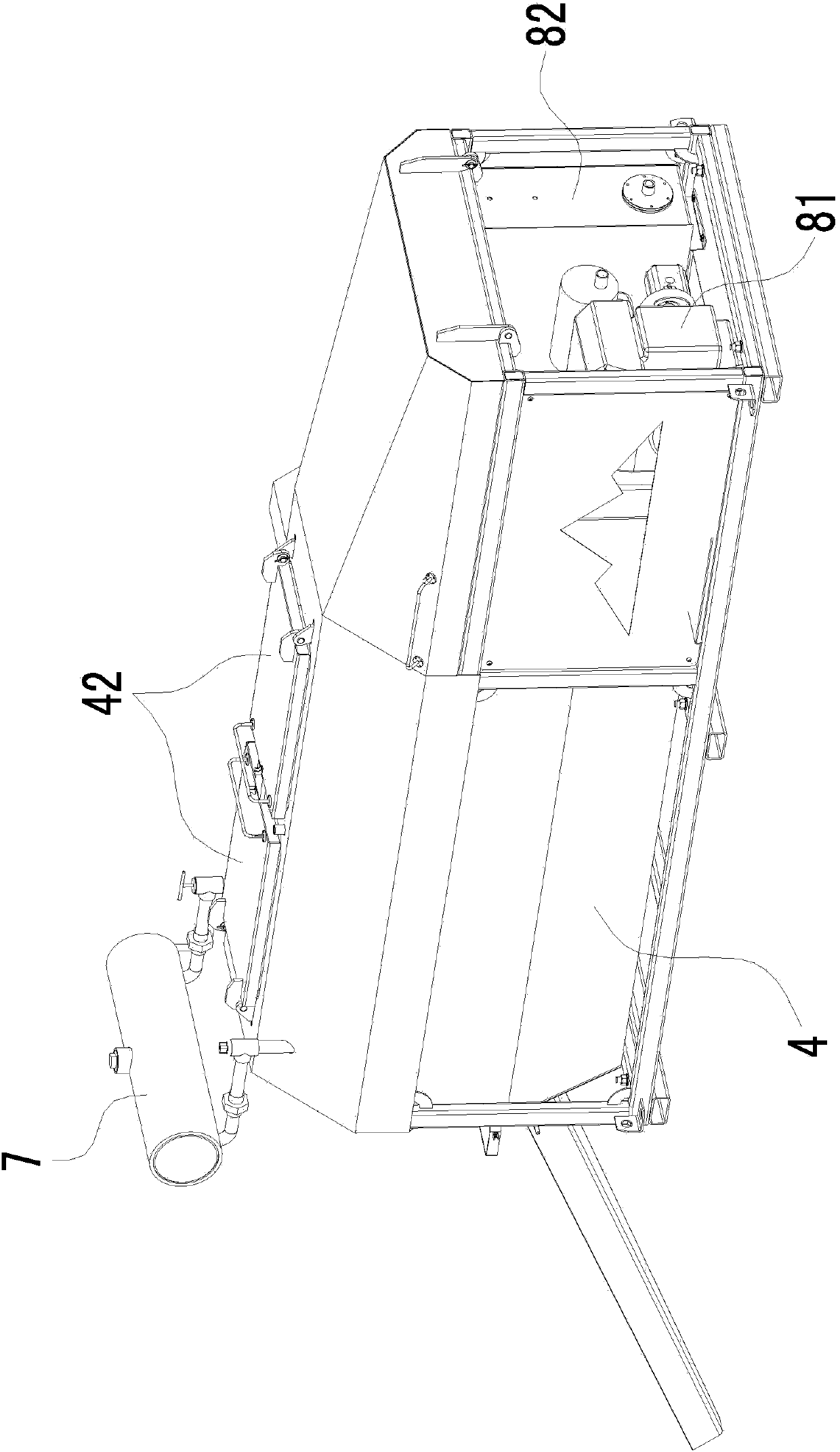

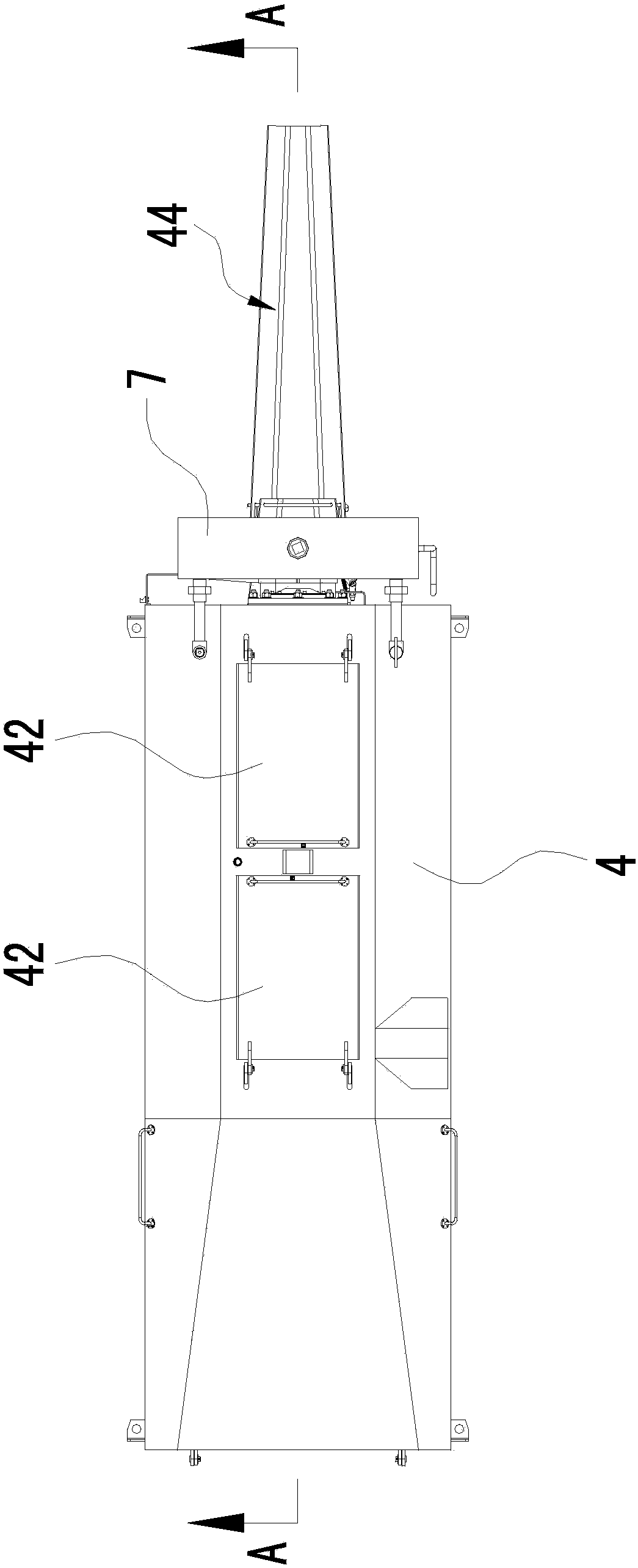

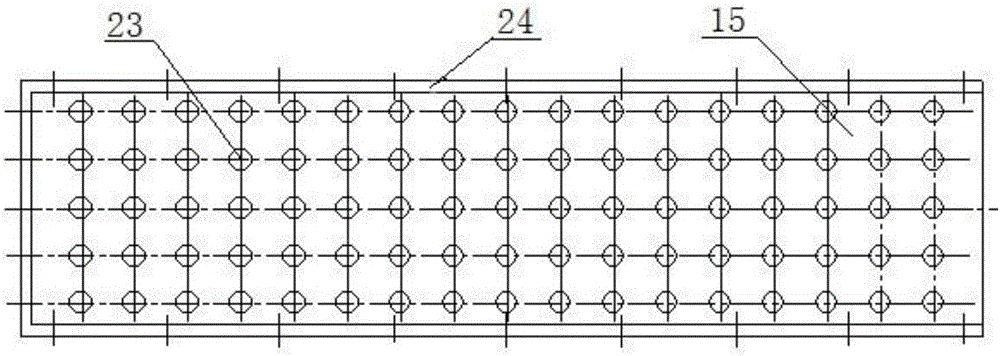

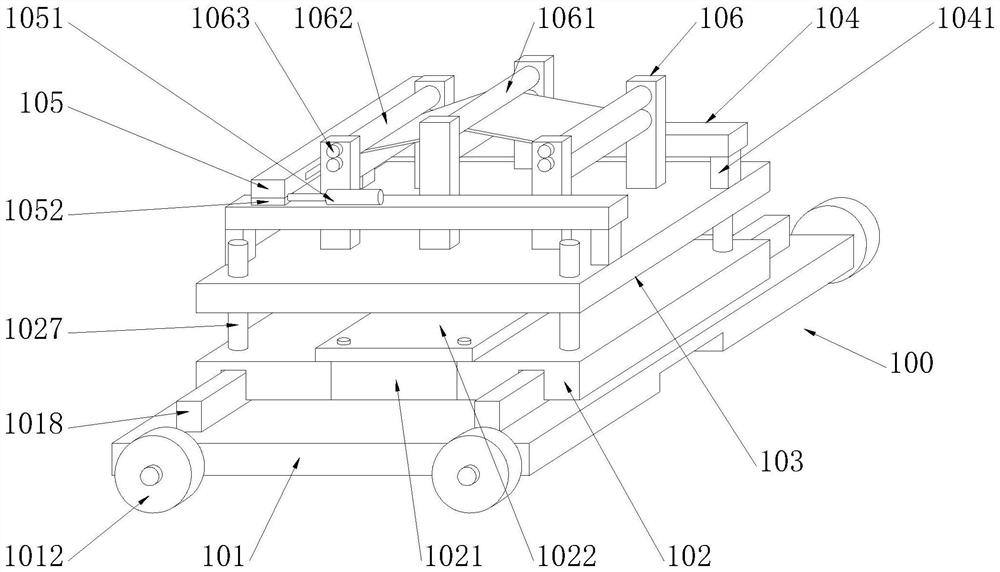

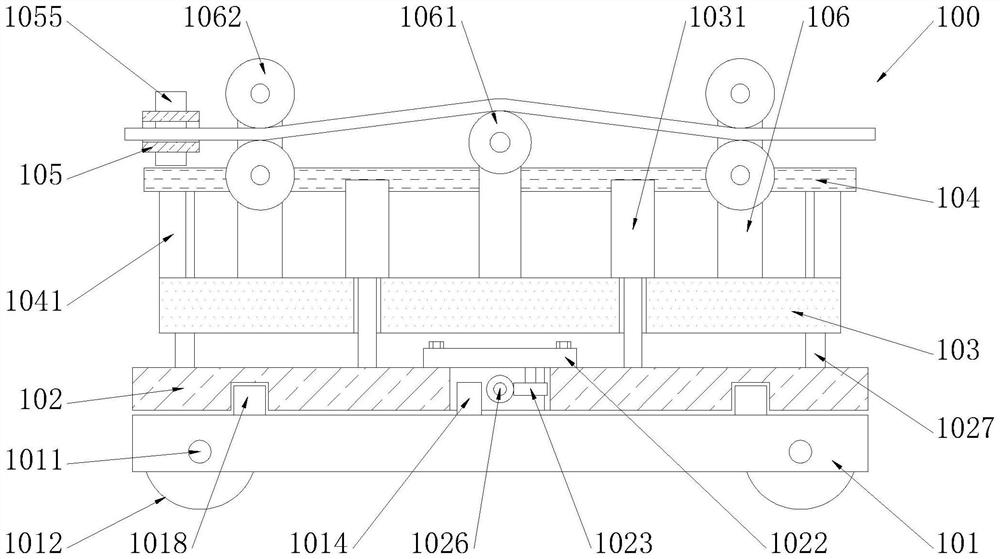

Seedling conveying and sorting system of transplanter

ActiveCN108848816APrevent tippingRealize intermittent deliveryTransplantingAfforestationEngineeringAir compressor

The invention relates to a seedling conveying and sorting system of a transplanter. The system comprises a rack, a row seedling conveying device and an automatic seedling sorting device, wherein a movable baffle plate is arranged at one side of a rear conveyor belt in the row seedling conveying device, and is driven to turn over by means of a first cylinder; the automatic seedling sorting device synchronously drives the translation of a parallel connecting rod frame and the rotation of a shifting fork by means of a second cylinder; an air compressor is installed on the rack; the air compressorsynchronously drives the first cylinder and the second cylinder by means of a reversing valve. The seedling conveying and sorting system of the transplanter can enable the seedlings to be conveyed ina way of standing in rows and divided according to a certain beat, thus realizing accurate seedling taking and planting.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

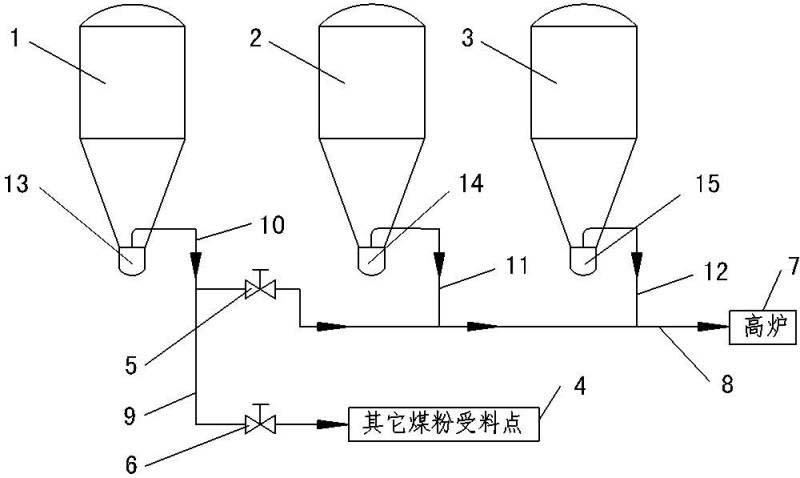

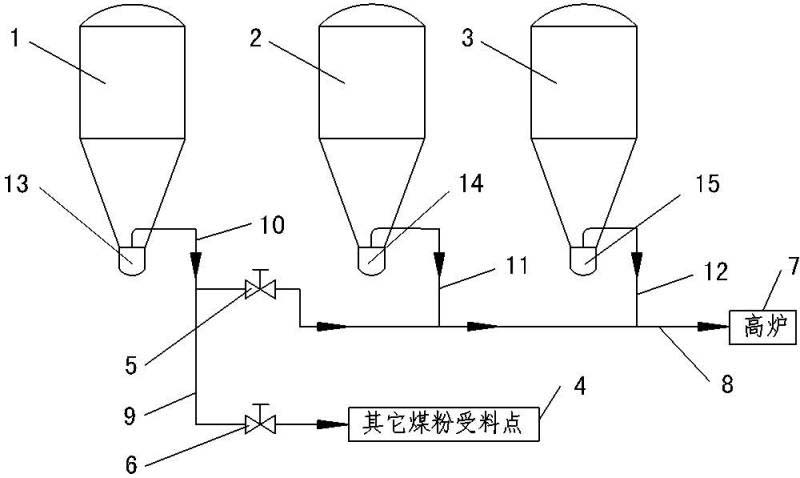

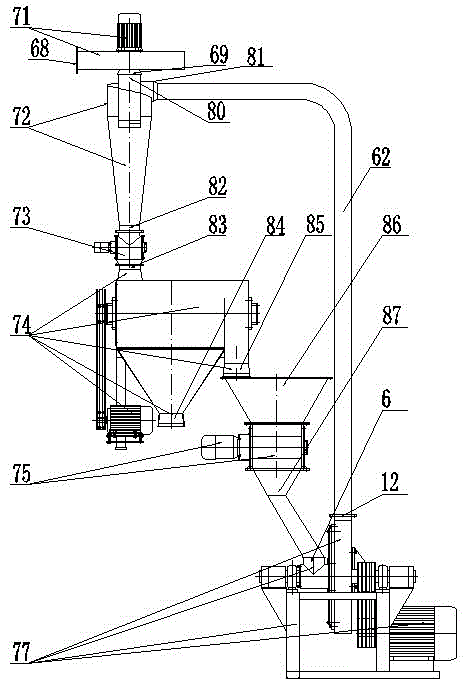

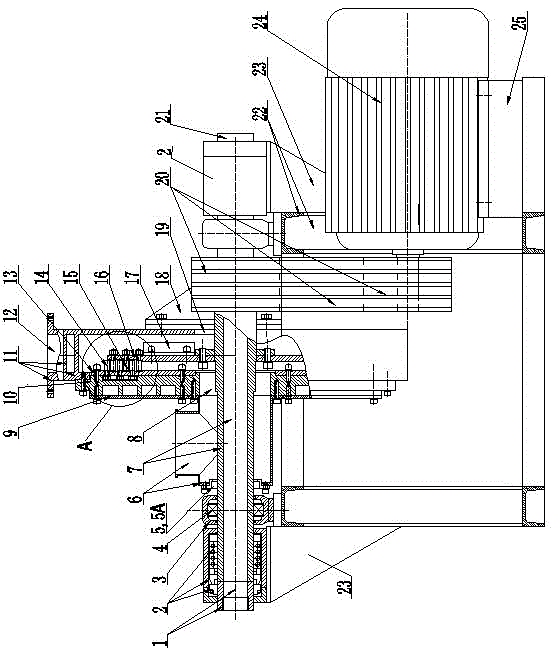

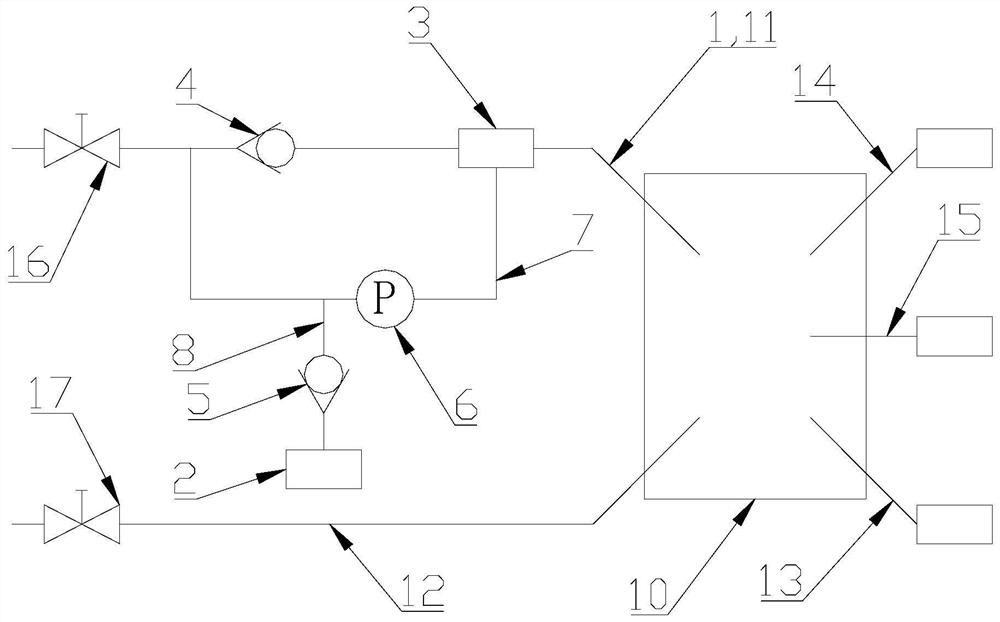

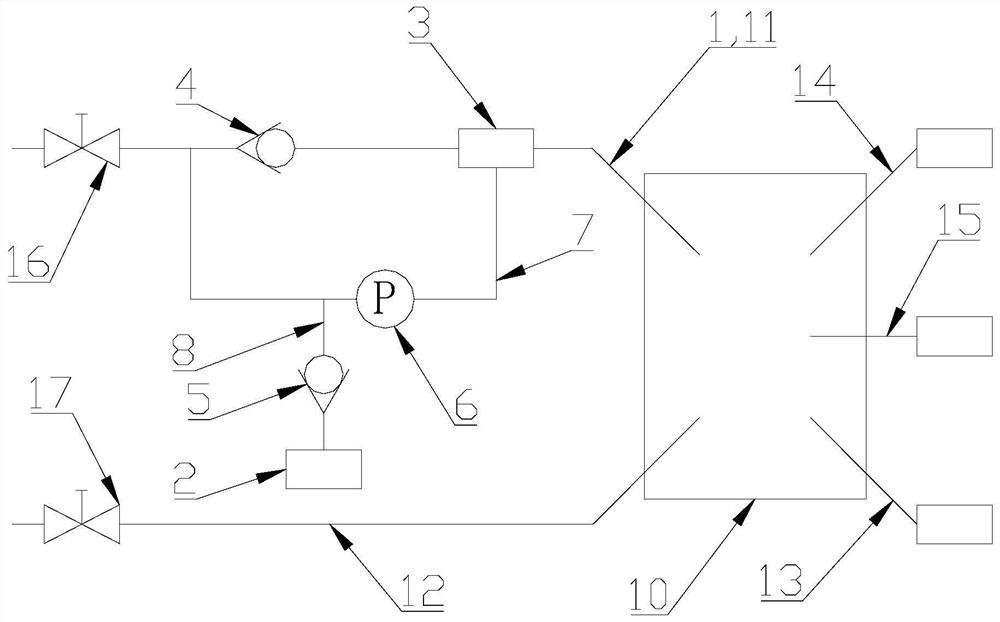

Blast Furnace Direct Coal Injection Device and Process with Coal Pulverized Transport Function

The present invention firstly discloses a device for directly injecting pulverized coal into a blast furnace with the function of conveying pulverized coal. connected, and one of the main pipes is provided with a control valve I, and the main pipe provided with the control valve I is also connected to other pulverized coal receiving points through a branch pipe. The branch pipe is provided with a control valve II, and the control valve I It is located between the connection positions of the main pipe and the branch pipe and the main pipe respectively. The invention also discloses a pulverized coal injection process using the device, the process is that the pulverized coal is injected into the blast furnace communicated with the discharge port of the spray tank, or the pulverized coal can be delivered to other pulverized coal receiving points at the same time. By switching the opening and closing states of control valve I and control valve II, the injection tank can only inject pulverized coal to the blast furnace or one of the injection tanks can deliver pulverized coal to other pulverized coal receiving points, which meets the requirement of redistribution of pulverized coal need.

Owner:CISDI ENG CO LTD

Water-cooling and wind-cooling impact crusher set

InactiveCN102744137AReduce temperature riseExtended service lifeGrain treatmentsAdditive ingredientEngineering

The invention discloses a water-cooling and wind-cooling impact crusher set, which comprises a crusher, a feeding device, a centrifugal separator and a classifying screen. The feeding device comprises a feeding device feeding hopper and a feeding device discharging pipe, a crusher feeding pipe is communicated with the feeding device discharging pipe, and the classifying screen is provided with a classifying screen feed inlet, a finished product exit and a product exit; an air inlet pipe, an air outlet pipe and a discharging pipe are arranged on the centrifugal separator, a crusher discharging port is communicated with the air inlet pipe of the centrifugal separator through a pipe, the discharging pipe of the centrifugal separator is communicated with the classifying screen feed inlet through a wind-preventing device, the discharging pipe of the centrifugal separator is connected with one side of the feeding hoper of the feeding device in the product exit, and the other side of the feeding hopper is used for receiving initial feeding stuff. According to the crusher set, circulated process and continuous production of materials are realized, and the purpose that materials are completely processed into end products by feeding once of the whole crusher set is realized. By the adoption of the crusher set, capacity is increased while energy consumption is reduced, when grains are impacted and crushed, nutritional ingredients and eating quality are not damaged.

Owner:王洪福

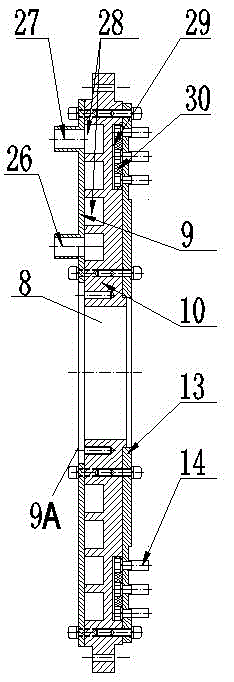

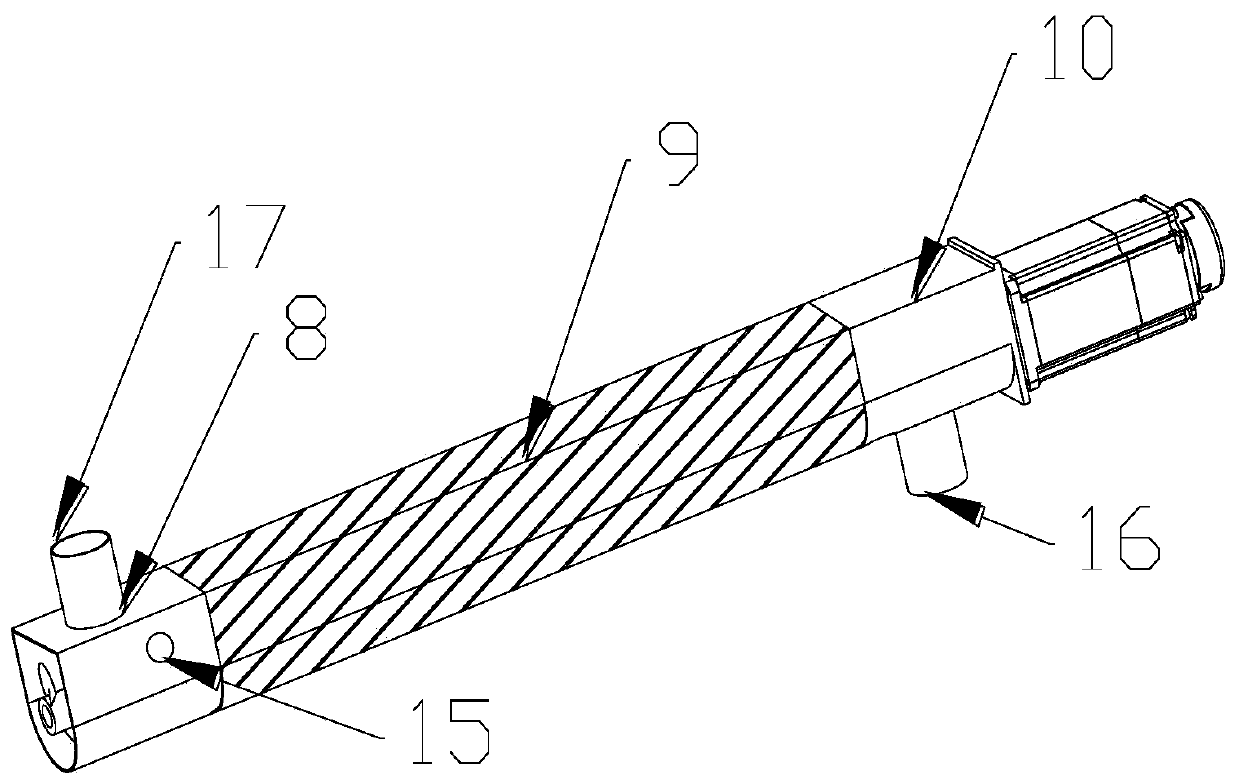

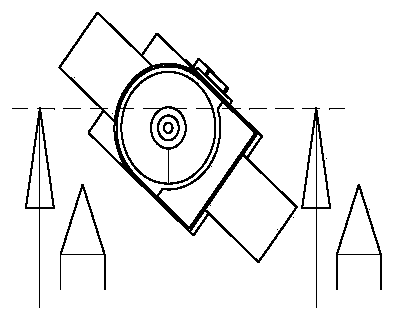

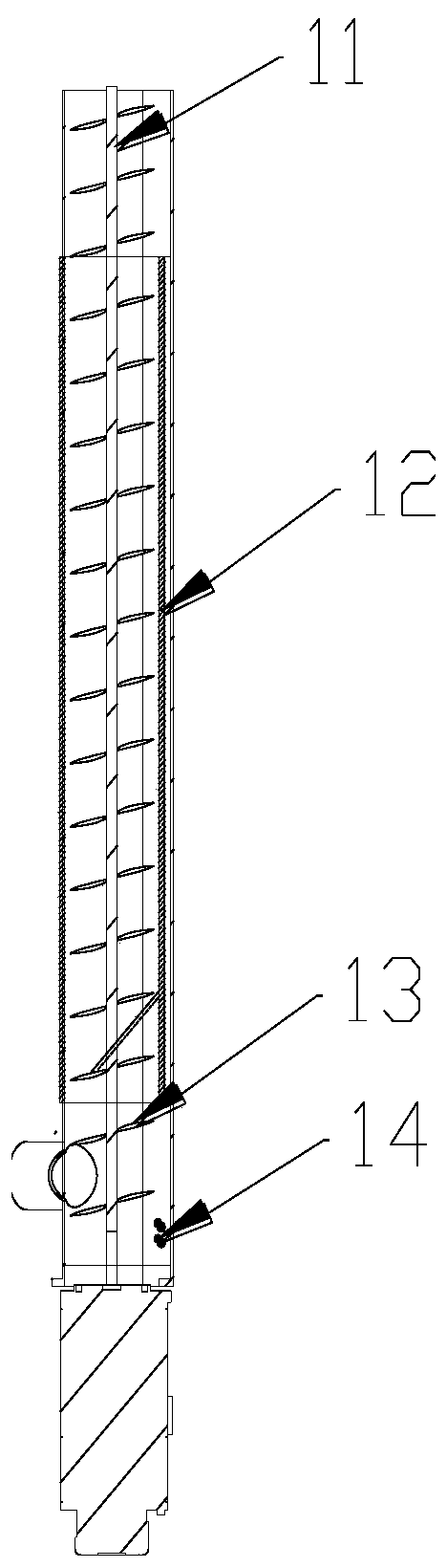

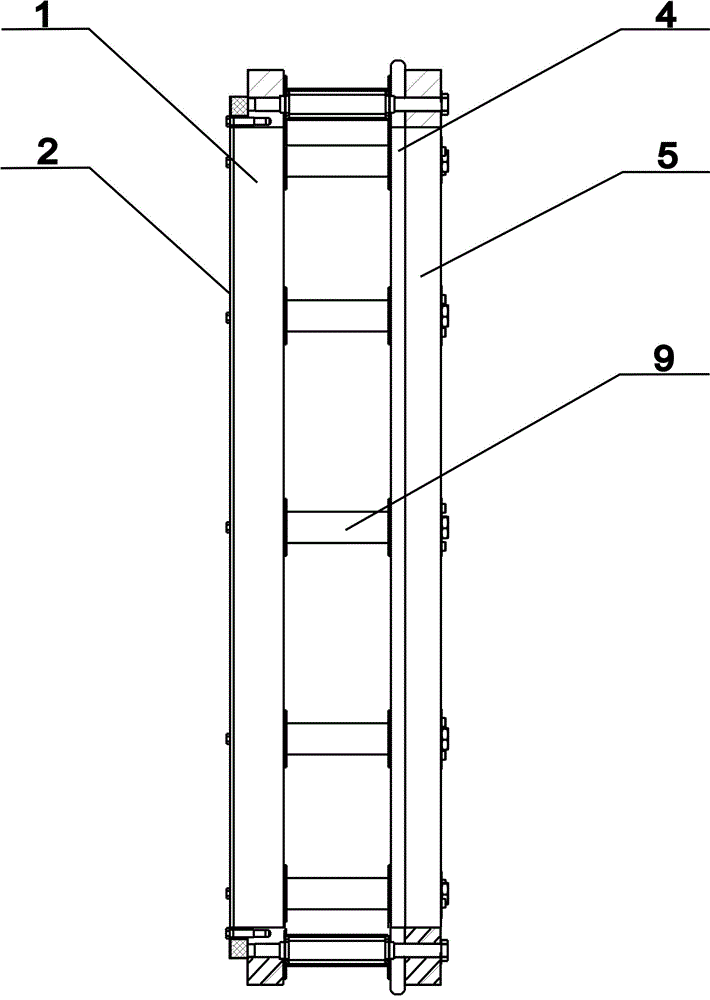

Spiral feeder and screw rod heating conveying type thermochemical energy storage system

PendingCN111532688ASmall footprintImprove overall performanceHeat storage plantsPackagingElectric heatingEngineering

The invention provides a spiral feeder and a screw rod heating conveying type thermochemical energy storage system, and relates to the field of thermochemistry. The spiral feeder comprises a head section, a middle section and a tail section. A spiral conveying rod is arranged in a cavity of the middle section, and an electric heating device is further arranged in the cavity of the middle section;and the tail section is provided with a solid discharge port and an air outlet. The screw rod heating conveying type thermochemical energy storage system comprises the spiral feeder, and further comprises a dry tank, a wet tank, a condenser, a spraying device and a heat exchange pipe; a discharge port at the bottom of the wet tank communicates with a feeding port of the spiral feeder; a solid discharge port of the spiral feeder communicates with a feeding port of the dry tank; an air outlet of the spiral feeder communicates with an air inlet of the condenser, a liquid outlet of the condenser communicates with a liquid inlet of the spraying device, and a spray head of the spraying device extends into the wet tank; a discharge port at the bottom of the dry tank communicates with a feeding port of the wet tank; and the heat exchange portion of the heat exchange pipe is placed in the wet tank. The system is smaller in equipment volume and higher in energy storage density.

Owner:北京华厚能源科技有限公司

Asphalt stone mixing stirring heating kettle

The invention relates to an asphalt stone mixing stirring heating kettle. The asphalt stone mixing stirring heating kettle comprises a housing; a stirring chamber, wherein the top of the housing is provided with a feed inlet communicated with the stirring chamber; a heating chamber; a heat supplying chamber; a conduction oil circulating system comprising an oil storage tank and a conduction oil pipeline, wherein the conduction oil pipeline and the oil storage tank are communicated; a feed outlet which is arranged at the tail end of the housing, is communicated with the stirring chamber, and is provided with a door cover device; a stirring mechanism comprising a rotatable stirring shaft and a plurality of stirring blades arranged on the stirring shaft; a mechanical chamber, wherein a power device used for driving the stirring shaft to rotate is arranged in the mechanical chamber; and a heating device which is arranged between the mechanical chamber and the heat supplying chamber, and is used for providing heat for the heat supplying chamber. The asphalt stone mixing stirring heating kettle is capable of simplifying traditional preparation technology of asphalt concrete, and heating asphalt concrete, frying stone to be hot, and mixing and stirring at the same time so as to mix materials uniformly; mixing proportion is accurate; quality of obtained mixed material is high; labor consumption is reduced; production efficiency is increased, and production cost is reduced.

Owner:GUANGDONG ESUN HEAVY IND CO LTD

A kind of asphalt stone mixing and stirring heating kettle

InactiveCN103669174BQuality improvementReduce consumptionRoads maintainenceProcess engineeringMixed materials

The invention relates to an asphalt stone mixing stirring heating kettle. The asphalt stone mixing stirring heating kettle comprises a housing; a stirring chamber, wherein the top of the housing is provided with a feed inlet communicated with the stirring chamber; a heating chamber; a heat supplying chamber; a conduction oil circulating system comprising an oil storage tank and a conduction oil pipeline, wherein the conduction oil pipeline and the oil storage tank are communicated; a feed outlet which is arranged at the tail end of the housing, is communicated with the stirring chamber, and is provided with a door cover device; a stirring mechanism comprising a rotatable stirring shaft and a plurality of stirring blades arranged on the stirring shaft; a mechanical chamber, wherein a power device used for driving the stirring shaft to rotate is arranged in the mechanical chamber; and a heating device which is arranged between the mechanical chamber and the heat supplying chamber, and is used for providing heat for the heat supplying chamber. The asphalt stone mixing stirring heating kettle is capable of simplifying traditional preparation technology of asphalt concrete, and heating asphalt concrete, frying stone to be hot, and mixing and stirring at the same time so as to mix materials uniformly; mixing proportion is accurate; quality of obtained mixed material is high; labor consumption is reduced; production efficiency is increased, and production cost is reduced.

Owner:GUANGDONG ESUN HEAVY IND CO LTD

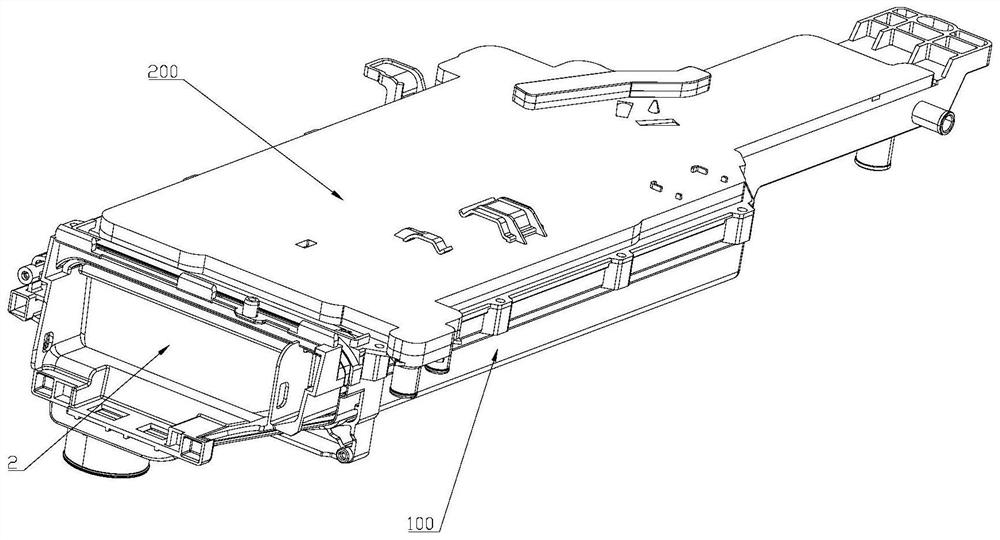

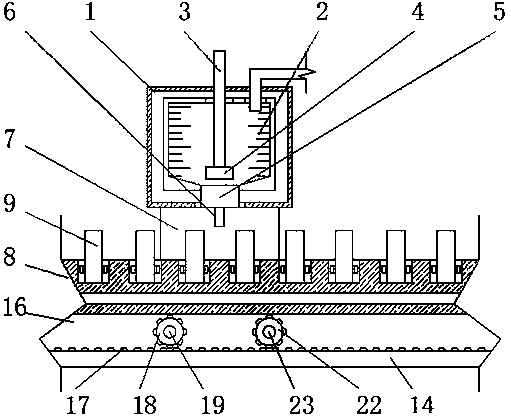

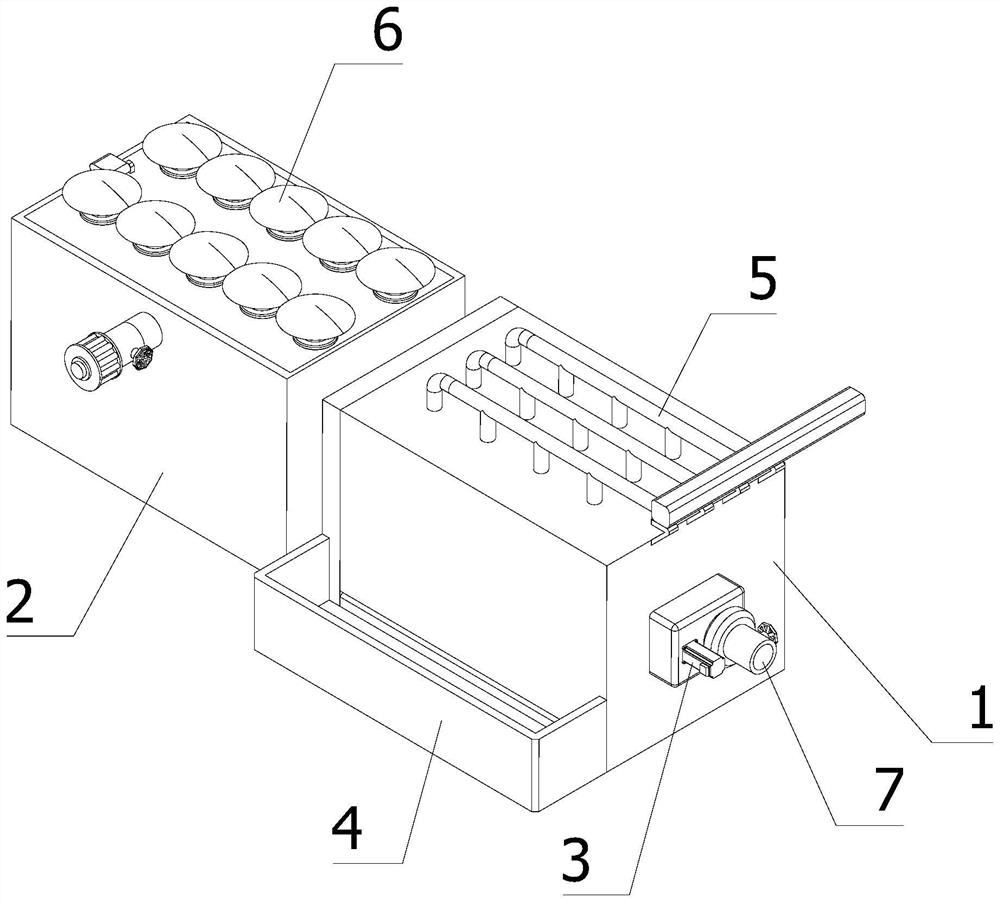

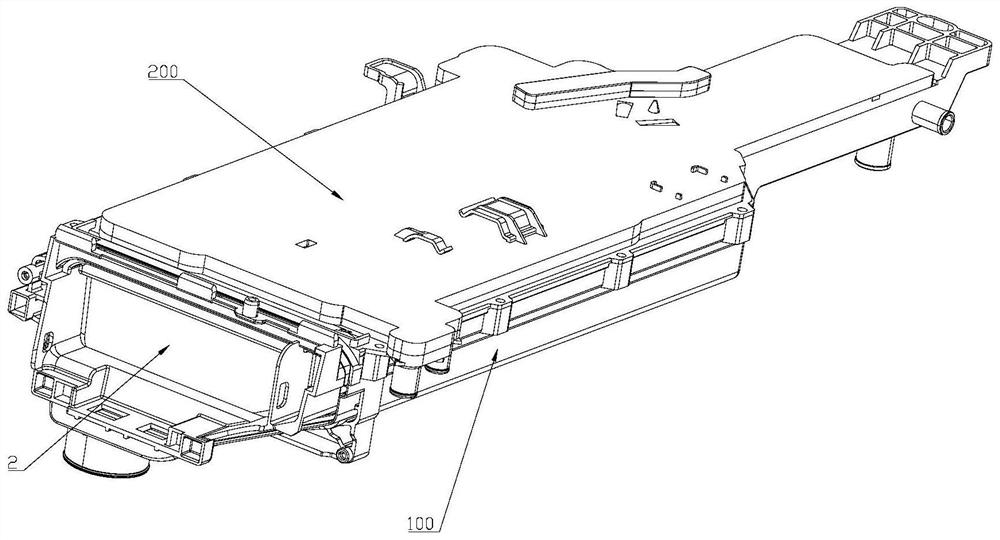

Additive feeding device and washing machine

ActiveCN112301667ARich flow formSimple structureOther washing machinesTextiles and paperLaundry washing machineWater flow

The invention discloses an additive feeding device which comprises a liquid storage box for accommodating an additive and a water path for feeding water, wherein the water path comprises a first watersupply pipeline and a second water supply pipeline which are connected with a hedging mechanism and are used for respectively or simultaneously feeding water to form multiple paths of feeding water flow; the first water supply pipeline is connected with the liquid storage box through a pumping structure, a liquid storage cavity is formed in the first water supply pipeline, and the pumping structure is used for pumping the additive in the liquid storage box into the liquid storage cavity and then flushing the additive to the hedging mechanism along with fed water of the first water supply pipeline for feeding correspondingly . Through the above-mentioned arrangement, the water supply pipeline with an additive feeding function forms one path of feeding water flow of the hedging mechanism, and an automatic feeding device can use the hedging mechanism to correspondingly feed the liquid additive. Meanwhile, the invention further comprises a washing machine which is provided with the additive feeding device.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

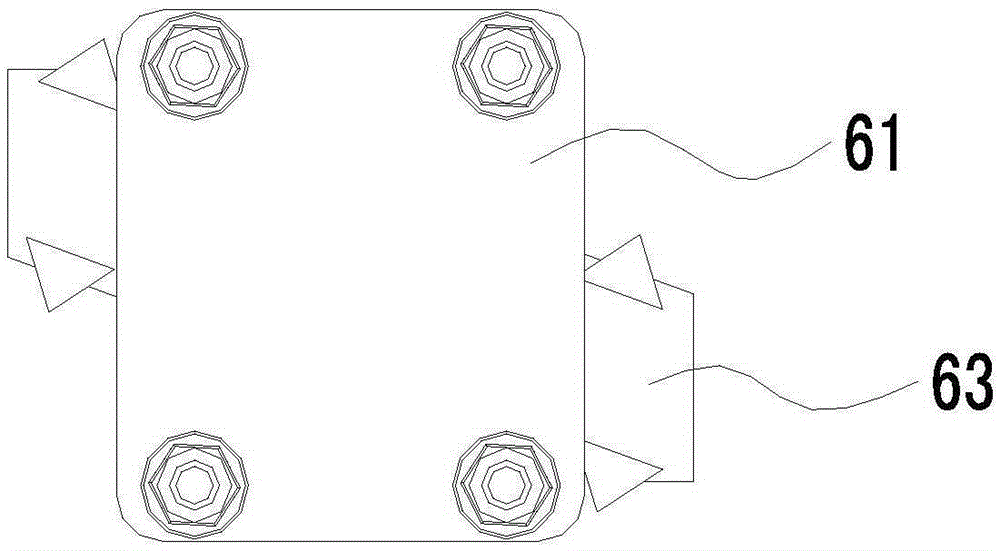

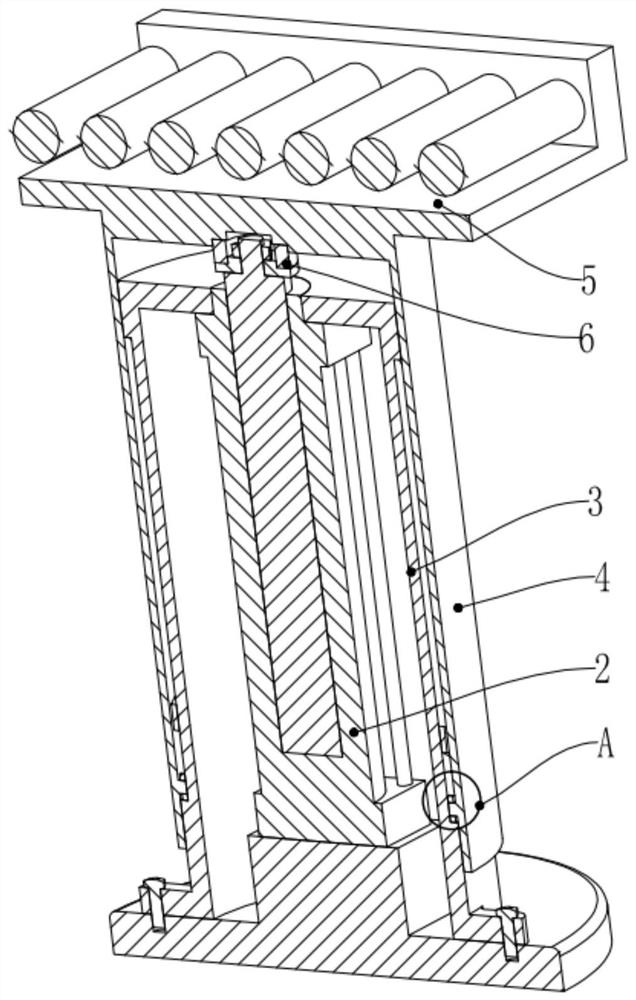

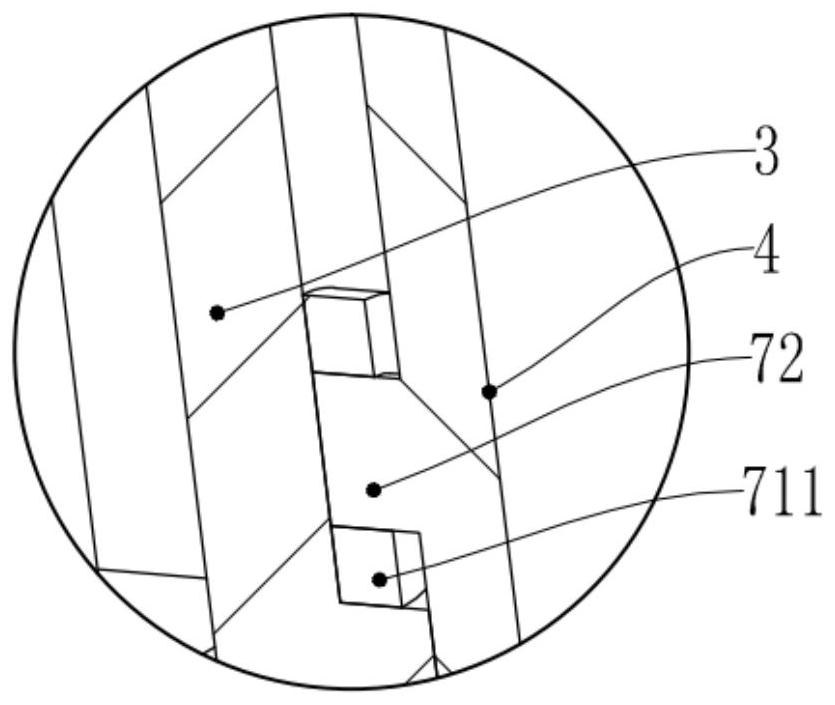

Winding reel with electric power transmission and heating functions

InactiveCN106185399AWith delivery functionWith heating functionWebs handlingWinding machineElectric power transmission

The invention discloses a winding reel with electric power transmission and heating functions. The winding reel comprises a gear, a gear side plate, a mounting bottom plate, an electric brush side plate and an electric brush ring. The gear is arranged on the right side of the gear side plate and fixedly connected with the gear side plate. The electric brush side plate is arranged on the right side of the gear, the electric brush ring is arranged on the right side of the electric brush side plate, a spindle is arranged in the middle position between the gear and the electric brush side plate, and the gear, the electric brush side plate and the electric brush ring are fixedly connected through the spindle. By means of the winding reel with the electric power transmission and heating functions, the problem that an automatic winding machine cannot automatically heat anticorrosion heat-shrinkable tape can be solved effectively, the winding quality of the automatic winding machine for winding the anticorrosion heat-shrinkable tape is greatly improved, the service life of a steel pipe or pipeline is prolonged, and meanwhile the labor intensity for winding operation of the anticorrosion heat-shrinkable tape is relieved.

Owner:HENAN XINKAIYUAN PETROCHEM PIPELINE

Filling machine having conveying function and used for cosmetic products

The invention discloses a filling machine having conveying function and used for cosmetic products. The filling machine comprises a fixing box, a fixing plate, a sliding block, a motor and a second gear, wherein the inner side of the fixing box is provided with a storage box, an active plug is arranged inside the storage box, the fixing plate is fixed on both ends of the bottom side of the fixingbox, the upper side of a placing box is provided with cosmetic bottles, a concave groove is connected to a snapping block through a reset spring, the sliding block is placed below the placing box, thebottom portion of a second sliding groove is provided with snapping teeth, a first gear is arranged inside the second sliding groove, the motor is arranged on the left side of the fixing plate, the second gear is arranged inside the second sliding groove, and the inner side of the second gear is provided with a second rotation shaft. According to the present invention, the concave groove forms the stretching structure through the reset spring and the snapping block, and the snapping block is snapped with the cosmetic bottle, such that the cosmetic bottle is stable, and the condition that thecosmetic bottle falls due to the imbalance caused by the loading of the cosmetic product in the bottle cannot be generated.

Owner:安徽润仕佳化妆品有限公司

A food cooking device with feeding function

ActiveCN106889869BImprove efficiencyImprove yieldPouring-spoutsCooking insertsAdditive ingredientEngineering

The invention relates to a food cooking device with a feeding function. The food cooking device with the feeding function comprises a cooking machine, a seasoning putting device and a feeding device, wherein the cooking machine comprises a machine body and a pan mechanism, the machine body comprises a first machine frame and a second machine frame, the first machine frame and the second machine frame are located on the two sides of the pan mechanism respectively, rotation shafts are fixedly installed on the two sides of the pan mechanism, and the pan mechanism is installed on the first machine frame and the second machine frame through the rotation shafts; the seasoning putting device is fixedly installed on the second machine frame, and comprises a translation driving device, a guide device, a moving device and a seasoning putting part; the two sides of the moving device are installed on the translation driving device and the moving device respectively, the seasoning putting part is installed on the moving device, and the translation driving device and the guide device are parallelly arranged on the same plane side by side; the seasoning putting part is moved to the portion above the pan mechanism through the moving device; the feeding device is used for putting main ingredients of dishes into the pan mechanism.

Owner:FOSHAN POLYTECHNIC

LED bulb welding machine

InactiveCN101499600BGuaranteed stable workPlay a limiting roleLine/current collector detailsWire cuttingSoldering

The invention relates to an LED light bulb soldering machine, which comprises a machine frame, a power transmission device, a bulb-delivering device, a transmission wire device and a bulb wire connecting device; wherein, the power transmission device is arranged on the machine frame; the bulb-delivering device, the transmission wire device and the bulb wire connecting device are driven by the power transmission device, and are arranged in sequence along the welding travel direction of the LED light bulbs; the bulb-delivering device comprises a bulb-delivering mechanism, a bulb pin reshaping mechanism and a bulb inspecting mechanism, which are driven by the power transmission device and are arranged in sequence along the delivering direction of the LED light bulbs; the transmission wire device comprises a delivering wire mechanism, a wire-cutting mechanism and a wire stripping mechanism, which are arranged in sequence along the direction of leads, and are driven by the power transmission device; the bulb wire welding wire comprises a welding mechanism and a complete thermal shrinkage pipe mechanism, which are arranged in sequence along the delivering direction of the LED light bulbs and are driven by a force transmission device. The invention has substantial characteristics and remarkable improvements: the transmission wire operates smoothly and accurately; the clamping wire isreliable; the tinning quantity on the wire is uniform and stable; the efficiency of the transmission pipe is high; the coating effect on the plastic pipes is good; and the cylinder is used for controlling the operation of the clutch.

Owner:吴志浩

A multifunctional cooking device

ActiveCN106889867BImprove efficiencyImprove yieldCooking insertsCooking vessel supportEngineeringMechanical engineering

The invention provides a multifunctional dish cooking device. The device comprises a dish cooking machine, a seasoning putting device and a feeding device. The dish cooking machine comprises a machine body and a wok mechanism. The machine body comprises a first machine frame and a second machine frame which are located on the two sides of the wok mechanism respectively, rotary shafts are fixedly arranged on the two sides of the wok mechanism respectively, and the wok mechanism are rotationally installed on the first machine frame and the second machine frame through the rotary shafts. The seasoning putting device is fixedly installed on the second machine frame, and comprises a translation driving device, a guide device, a moving device and a seasoning putting part. The two sides of the moving device are installed on the translation driving device and the moving device respectively, the seasoning putting part is installed on the moving device, and the translation driving device and the guide device are parallelly arranged on the same plane side by side; the seasoning putting part moves above the wok mechanism through the moving device; the feeding device is used for putting dish main ingredients into the wok mechanism.

Owner:FOSHAN POLYTECHNIC

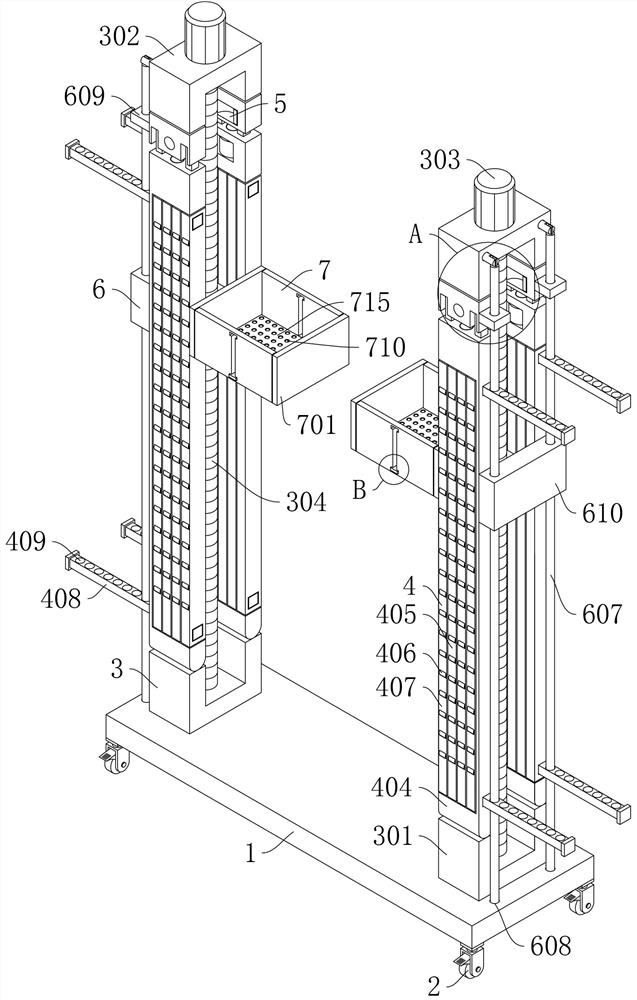

Unloading device used for logistics and provided with lifting mechanism and using method of unloading device

InactiveCN113581885AWith delivery functionReduce labor intensityLoading/unloadingLogistics managementEngineering

The invention relates to an unloading device used for logistics and provided with a lifting mechanism and a using method of the unloading device, and belongs to the field of transportation or storage devices. A connecting limiting mechanism and a conveying protection mechanism are arranged, people can operate a rotating cylinder to enable a lead screw to move under the limitation of a square block and a square groove, and after the top end of the lead screw is inserted into a first inserting hole, and the overturning of a supporting frame can be limited; when the lead screw is separated from the first inserting hole, the supporting frame can turn over, the supporting frame and a second unloading frame can be lapped on a truck, goods can be conveniently moved into a conveying and bearing mechanism through the second unloading frame and a roller to be unloaded, the unloading device has a conveying function, and the labor intensity of people is reduced. The working efficiency is improved, and the functionality is high.

Owner:湖南兴运物流有限公司

Vegetable transplanting machine

ActiveCN108770423APrevent tippingRealize intermittent deliveryTransplantingAgriculture gas emission reductionEngineeringSeedling

The invention relates to a vegetable transplanting machine. The vegetable transplanting machine comprises a rowed seedling conveying device, an automatic seedling separating device and a planting device, wherein the rowed seedling conveying device comprises a rear conveying belt, a left baffle and a right baffle, the left baffle comprise a fixed baffle and a movable baffle, and the right baffle and the fixed baffle are fixedly mounted on a base; the movable baffle is driven by a first air cylinder and can be overturned; the automatic seedling separating device comprises a front conveying beltand a parallel connecting rod frame, and a fixed side conveying belt and a movable side conveying belt are arranged on two sides of the front conveying belt; a stirring fork is arranged on a movable block of a parallel connecting rod frame, and the stirring fork and the movable side conveying belt are driven by a second air cylinder; and the first air cylinder and the second air cylinder are synchronously driven by a two-position five-way switch valve, and the planting device is used for driving a bow-shaped rod to drive the switch valve to execute an elastic contact action. The vegetable transplanting machine which can be used for finishing the procedures of ridge surface leveling, seedling conveying, seedling separation, seedling planting and the like once is low in seedling growing requirement, simple in structure and good in stability.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Soybean seed screening device

PendingCN109731784AIncrease contact rateWith delivery functionGas current separationAir volumePrimary screening

The invention relates to a soybean seed screening device, and belongs to the field of agricultural equipment. The soybean seed screening device comprises a machine frame, a primary screening mechanism, a secondary screening mechanism and a tertiary screening mechanism; the primary screening mechanism comprises a conveying screen, a spiral conveyor and an electric component I; a feeding port I is formed in one end of the conveying screen, and a discharging port I is formed in the other end of the conveying screen; through holes are uniformly distributed in the bottom of the conveying screen; the secondary screening mechanism is an air duct for conveying the air volume; the tertiary screening mechanism comprises a roller screen which is obliquely arranged and an electric assembly II; screenholes are uniformly distributed in the cylinder body of the roller screen; one end, close to the discharging port I, of the roller screen is provided with a feeding port II, and one end, away from thefeeding port II, of the roller screen is provided with an impurity outlet; and a material collecting tank is arranged below the roller screen. The soybean seed screening device is used for screeningthe impurities with smaller diameters in the lifting operation through the conveying screen, then air separation is carried out on the materials to remove the light impurities, the screening of the soybean seeds is completed by using the roller screen to remove the large impurities, the soybean seed screening device is convenient and fast, and the screening efficiency is high.

Owner:HENAN UNIV OF SCI & TECH

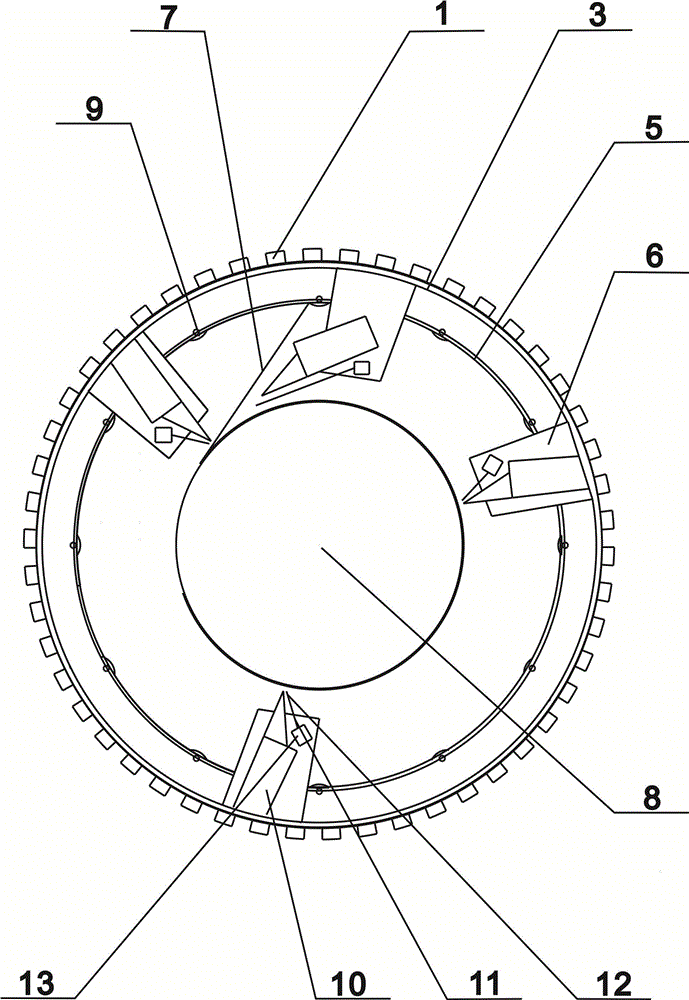

Industrial wastewater treatment equipment with good safety

PendingCN114735889ADoes not affect normal workImprove securitySpecific water treatment objectivesWater contaminantsIndustrial waste waterEngineering

The invention relates to the technical field of wastewater treatment, in particular to industrial wastewater treatment equipment with good safety, which comprises a first box body, a rotating cavity is formed in the first box body, and the center shaft is rotatably arranged on the first box body along the axis of the rotating cavity; the gear rings are rotatably arranged on the side walls of the two ends of the rotating cavity along the axis of the central shaft; a transmission assembly is arranged between the gear ring and the central shaft; the driving assembly is arranged on the central shaft; the first hinge seat is fixedly arranged on the gear ring around the axis of the gear ring; the baffle is fixedly arranged on the side wall of the gear ring; one end of the scraper is hinged to the first hinge seat; the recycling mechanism is arranged on the side wall of the first box body; the first material blocking part is fixedly arranged on the side wall of the rotating cavity below the recycling mechanism; and the second material blocking part is fixedly arranged on the side wall of the rotating cavity above the recycling mechanism. By arranging the recycling mechanism and the scraping mechanism, automatic cleaning of the equipment is achieved, and therefore the technical requirement for safety of the equipment is improved.

Owner:RI MING COMPUTER ACCESSORY (SHANGHAI) CO LTD

Walnut peeling system

InactiveCN103610218BReduce moisture contentWith delivery functionHuskingHullingBreakage rateEngineering

The invention discloses a walnut green seedcase stripping system. The walnut green seedcase stripping system comprises a box body, a vibrating conveyer and a vibrating screen, wherein the vibrating conveyer is arranged on the box body, and the vibrating screen is arranged below the box body. A green seedcase incising device and a green seedcase stripping device are arranged in the box body, and the green seedcase stripping device is arranged below the green seedcase incising device. According to the walnut green seedcase stripping system, walnut fruits are vibrated and conveyed, and hot air defrosting and drying are conducted on the walnut fruits at the same time, so that the water content of green seedcases of walnuts is reduced, in the follow-up green seedcase stripping process, liquid and adhesion due to the fact that the water content of the green seedcases is high are avoided, a processing site is clean and environmentally friendly, and food pollution is avoided. In the green seedcase incising process, a plurality of incisions are cut on the circumferences of the walnut fruits, and therefore rubbing force and shearing force are greatly reduced when the green seedcases of the walnut fruits are removed, the breakage rate is greatly reduced, and even breakage of the walnuts is avoided.

Owner:SHAANXI UNIV OF SCI & TECH

Conveying roller for water-free textile cotton

ActiveCN110127273AIncrease manufacturing costReduce use costRollersRoller-waysTextileMechanical engineering

The invention discloses a conveying roller for water-free textile cotton. The conveying roller comprises a conveying shaft and a roller, wherein first round covers and second round covers are placed on the roller, and the first round covers and the second round covers are clamped and fixed to each other; a fixed disc is installed on each second round cover, a first mounting block is arranged on the fixed disc on the left side, and a plurality of first fixing rods are fixedly installed on the first mounting block; and a plurality of second fixing blocks are fixedly arranged on the fixed disc onthe right side through bolts, and one second fixed rod is fixedly arranged on each second fixing block. The conveying roller has the advantages that a plurality of the first round covers and the second round covers which can rotate along with the roller are arranged outside the roller, so that the conveying roller still has an original conveying function, and meanwhile the use cost is reduced; and when parts of the round covers are worn, and the normal conveying function is affected, only the severe friction parts needs to be replaced, the integral replacement is not needed, and the method ismore advantageous for long-term development of enterprises.

Owner:绍兴柯桥广多纺织品有限公司

A multifunctional food cooking device

ActiveCN106913196BImprove efficiencyImprove yieldWarming devicesCooking vessel constructionsCookerMultiple function

A multifunctional food cooking device comprises an automatic cooker, a seasoning delivery device and a feeding device. The automatic cooker comprises a cooker body and a pan mechanism, wherein the cooker body comprises a first frame and a second frame, the first frame and the second frame are located on the two sides of the pan mechanism respectively, rotary shafts are fixedly installed on the two sides of the pan mechanism, and the pan mechanism is installed on the first frame and the second frame through the rotary shafts in a rotary mode. The seasoning delivery device is fixedly installed on the second frame. The seasoning delivery device comprises a translation driving device, a guiding device, a moving device and a seasoning delivery part, wherein the two sides of the moving device are installed on the translation driving device and the guiding device respectively, the seasoning delivery part is installed on the moving device, the translation driving device and the guiding device are arranged on the same plane in parallel side by side, and the seasoning delivery part can be moved to the space above the pan mechanism through the moving device. The feeding device is used for feeding main materials of a dish into the pan mechanism.

Owner:FOSHAN POLYTECHNIC

Additive injection device and washing machine

ActiveCN112301667BWith delivery functionTo achieve the purpose of deliveryOther washing machinesTextiles and paperLaundry washing machineWater flow

The invention discloses an additive feeding device, which comprises a liquid storage box containing the additive and a water channel for water intake; the water channel includes a first water supply pipeline and a second water supply pipeline connected with a hedging mechanism, which are used for respectively At the same time, the water enters to form multiple water inlet flows; the first water supply pipeline is connected to the liquid storage box through the suction structure, and the first water supply pipeline is provided with a liquid storage cavity, and the suction structure is used to suck the additives in the liquid storage box into the liquid storage box. In the liquid storage chamber, the water is flushed to the hedging mechanism along with the first water supply pipeline for corresponding delivery. Through the above arrangement, the water supply pipeline with the additive injection function constitutes one water inlet flow of the hedging mechanism, and the automatic injection device can use the hedging mechanism to perform corresponding injection of liquid additives. At the same time, the present invention also includes a washing machine, which is equipped with the above-mentioned additive feeding device.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Stirring mechanism of asphalt stone mixing and stirring heating tank

InactiveCN103726431BStir wellImprove the mixing effectRoads maintainenceBituminous materialsEngineering

The invention relates to a stirring mechanism for mixing, stirring and heating kettle of bituminous materials and aggregates. The stirring mechanism includes a stirring shaft and a plurality of stirring blades mounted on the stirring shaft, wherein the rotary stirring shaft drives the stirring blades to rotate; the stirring blades are arrayed at intervals in the axial direction of the stirring shaft; each stirring blade includes a base, a stirring arm and a blade part; one end of the stirring arm is connected with the base, the other end of the stirring arm is connected with the blade part, and the base is mounted on the stirring shaft; the projection of the two adjacent stirring blades on the plane vertical to the axis of the stirring shaft is V-shaped; the blade parts of all the stirring blades are arrayed to be spiral in space. The stirring mechanism is uniform in stirring operation and better in stirring effect and improves the stirring efficiency, through the arrangement manner of all the blade parts, the mixture of mixed bituminous materials and aggregates can be conveyed during the rotation of the blade parts, so as to give assistance to discharge, as a result, the stirring mechanism can be used for conveying the mixture, and when the mixture is stirred, the stirring blades can be used for pushing and squeezing the mixture, and all the stirring blades can be used for cutting and smashing the mixture.

Owner:GUANGDONG ESUN HEAVY IND CO LTD

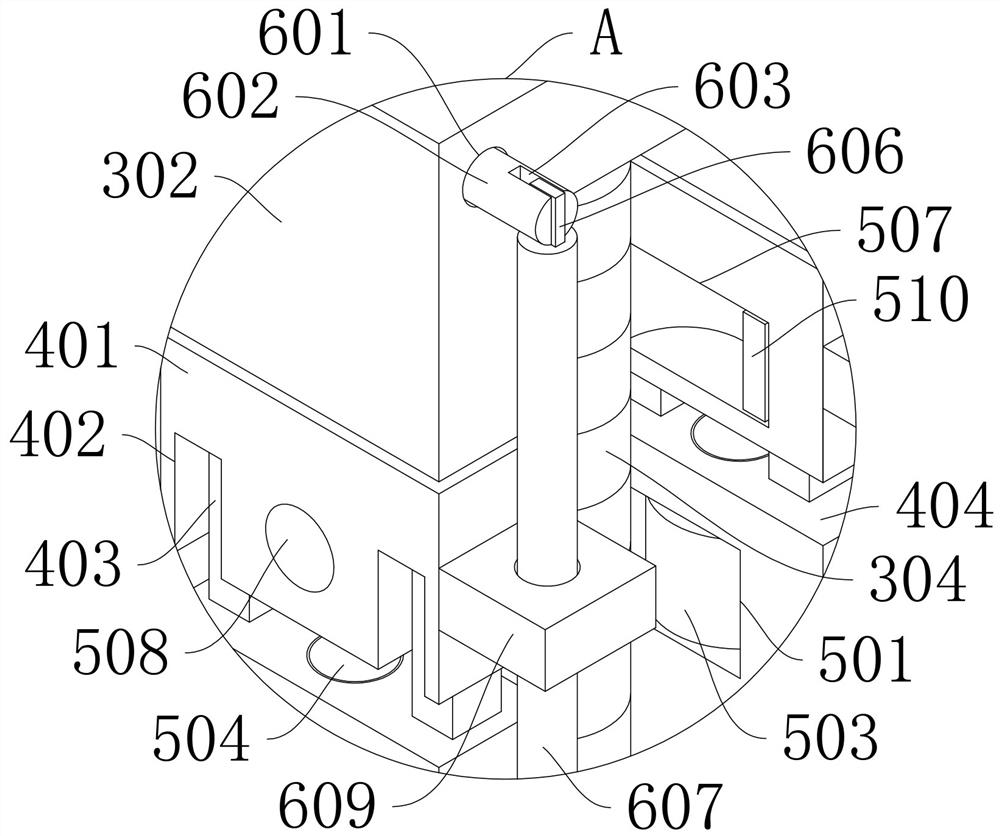

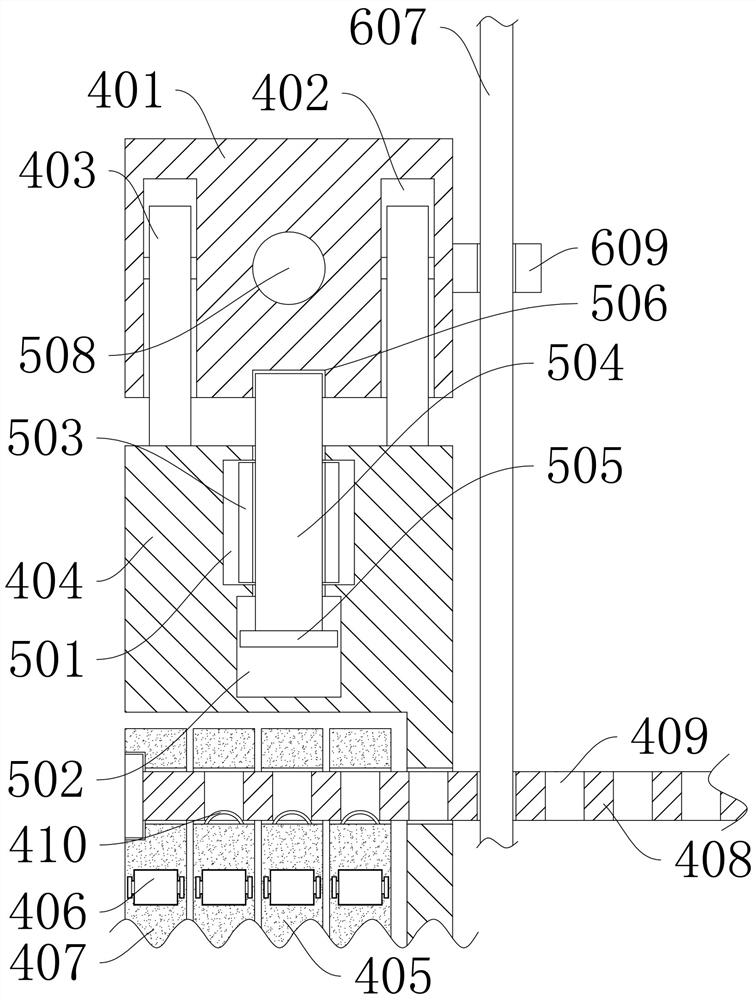

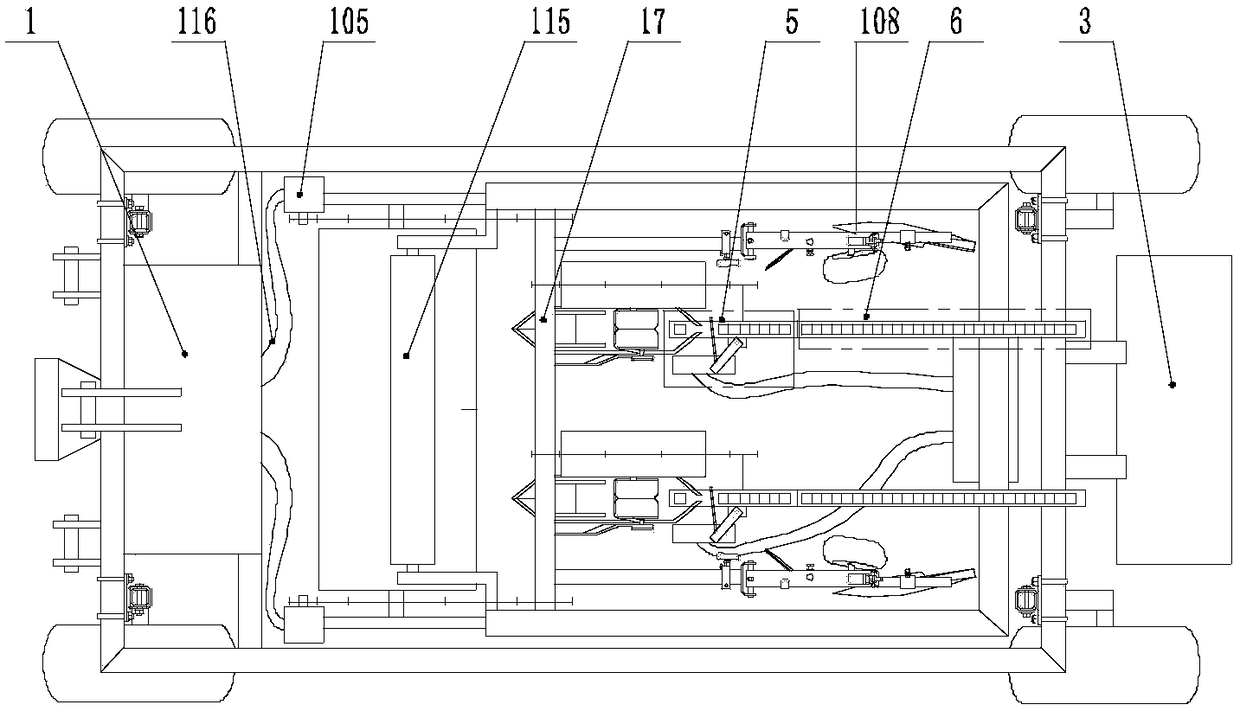

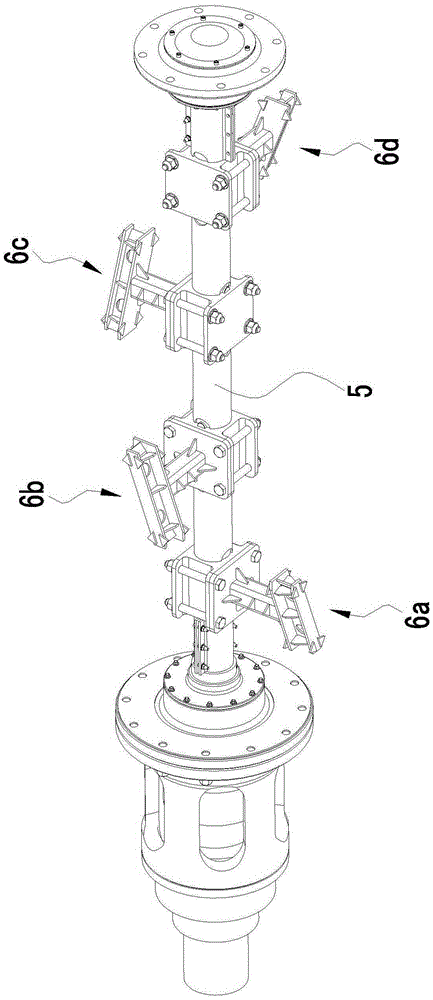

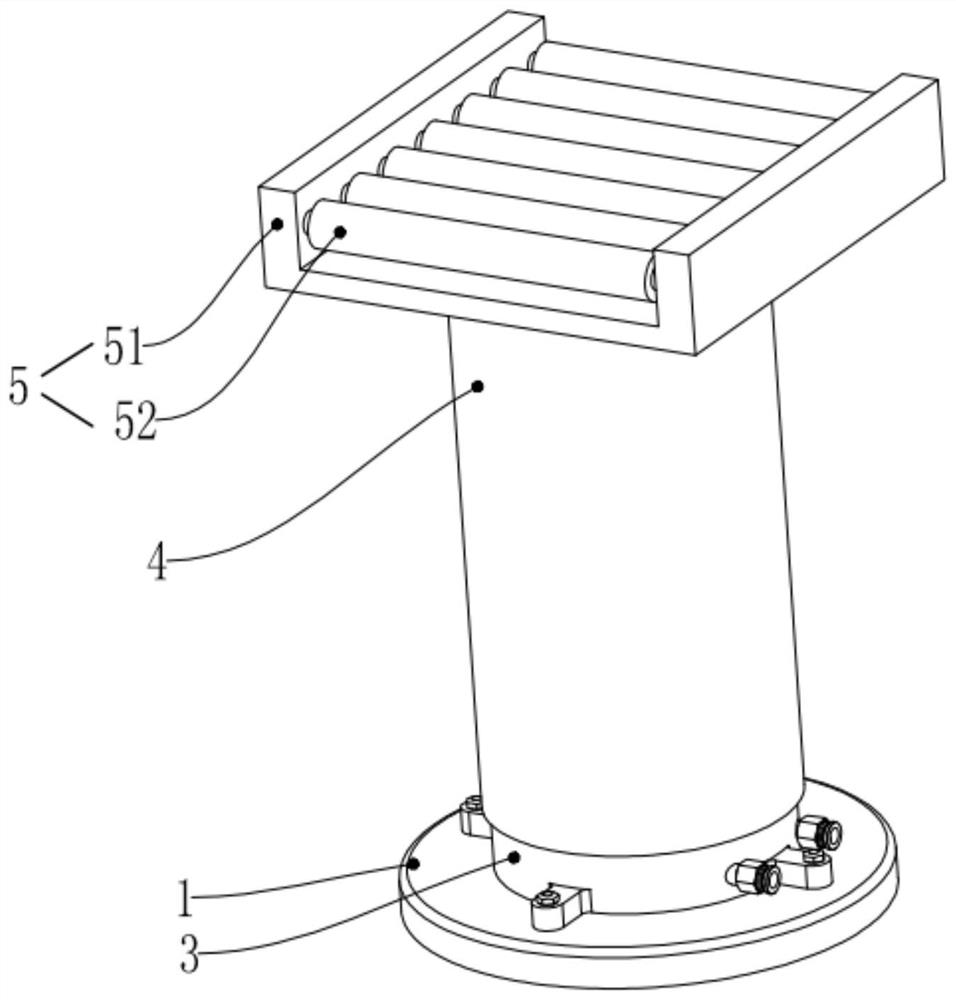

A single power source lifting rotating device and production line conveyor belt for production line

ActiveCN111532656BWith delivery functionImprove work efficiencyLifting framesConveyor partsProduction lineRotational axis

The invention discloses a single-power-source lifting rotating device for a production line and a production line conveyor belt. The single-power-source lifting rotating device comprises a fixing base, a vertical driver, a fixed cylinder, a movable cylinder, a conveying device and a rotating bearing. A movable part is movably matched with the interior of an annular lifting groove and a vertical lifting groove. The vertical driver drives the movable cylinder to ascend and descend, so that the movable part relatively moves in the annular lifting groove and the vertical lifting groove, the movable cylinder is rotated and lifted, and the conveying device is driven to rotate, ascend and descend. The production line conveyor belt comprises a conveyor belt base and a plurality of single-power-source lifting rotating devices. The single-power-source lifting rotating devices are installed on the conveyor belt base. According to the single-power-source lifting rotating device, the lifting rotating device with a single power source can be formed, a workpiece is rotated by different angles, meanwhile, the conveying function between high and low conveyor belts can be achieved, the structure issimple, the working efficiency is high, and the production efficiency and economic benefits can be greatly improved.

Owner:GUANGDONG UNIV OF TECH

Automatic leaf adding machine for silkworm breeding

PendingCN113875708AWith delivery functionFast transferAnimal husbandryAgricultural engineeringStructural engineering

The invention discloses an automatic leaf adding machine for silkworm breeding. The automatic leaf adding machine comprises a workbench, a guide rod is fixedly arranged on one side of the top end of the workbench, a limiting sliding groove is formed in the middle of the bottom end of the guide rod, and the two sides of the inner wall of the limiting sliding groove are slidably connected with the tops of the outer walls of two limiting sliding blocks correspondingly; the bottom ends of the two limiting sliding blocks are fixedly connected with the two sides of the top end of a first supporting frame correspondingly, a connecting block is fixedly arranged on one side of the first supporting frame, and one end of the connecting block is fixedly connected with the output end of an electric telescopic rod. According to the automatic leaf adding machine for silkworm breeding, the electric telescopic rod connected by the workbench is connected with the connecting block on the first supporting frame, a limiting sliding block on the first supporting frame is in sliding connection with a limiting sliding groove formed in the guide rod, a first parallel roller and a second parallel roller are in transmission connection through a conveying belt, the automatic leaf adding machine can have a delivery function, the first supporting frame is driven to move front and back through stretching and retracting of the electric telescopic rod, and it is guaranteed that the automatic leaf adding machine for silkworm breeding delivers mulberry leaves more quickly; the mulberry leaves can be uniformly delivered, and the use of personnel is facilitated.

Owner:SERICULTURAL RES INST ANHUI ACADEMY OF AGRI SCI

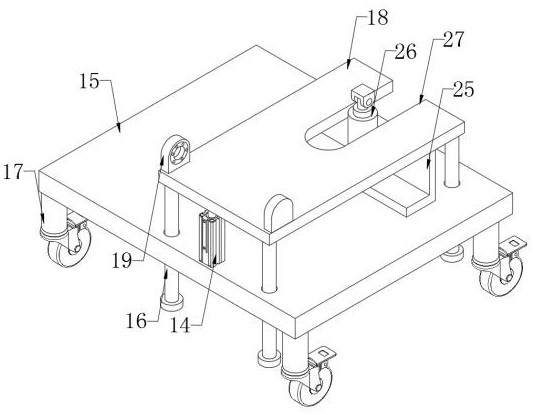

Membrane processing and positioning bracket for laminator

PendingCN113696501AReasonable and reliable structureWith adjustment functionHydraulic cylinderGear wheel

The invention discloses a membrane processing and positioning bracket for a laminator. The bracket comprises a bottom plate, a rotating shaft, rolling wheels, a limiting gear, a driving motor, a driving gear, a rack, a limiting plate, a guide rail, a groove, a sliding plate, a connecting plate, a cover plate, a transmission gear, a fixing base, an adjusting motor, a worm, a guide rod, a tooth groove, a cavity, a supporting plate, a hydraulic cylinder, a cross beam, a supporting rod, a moving plate, an air cylinder, a fixing plate, a positioning motor, a lead screw, an adjusting plate, a control switch, a sliding groove, an electric push rod, a pressing plate, a side plate, a guide roller, a press roller and a steering gear. The membrane processing and positioning bracket has the beneficial effects that the positioning bracket is adopted for conveying membranes, the positioning bracket has the functions of moving and height adjusting, the membranes can be rapidly conveyed, the membranes can be conveniently conveyed to the position of the laminator for processing and production of the membranes, the moving plate further has a limiting function and can conduct limiting treatment while the membranes are conveyed, the problem of movement deviation of the membranes during conveying is avoided, and accurate membrane positioning is guaranteed.

Owner:绍兴市上虞龙马机电有限公司

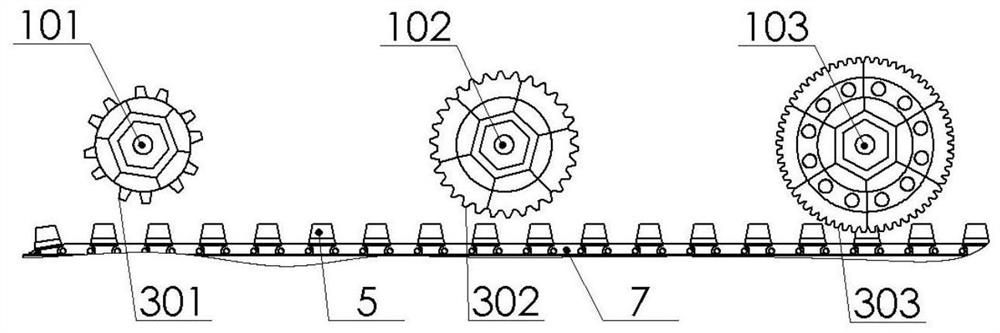

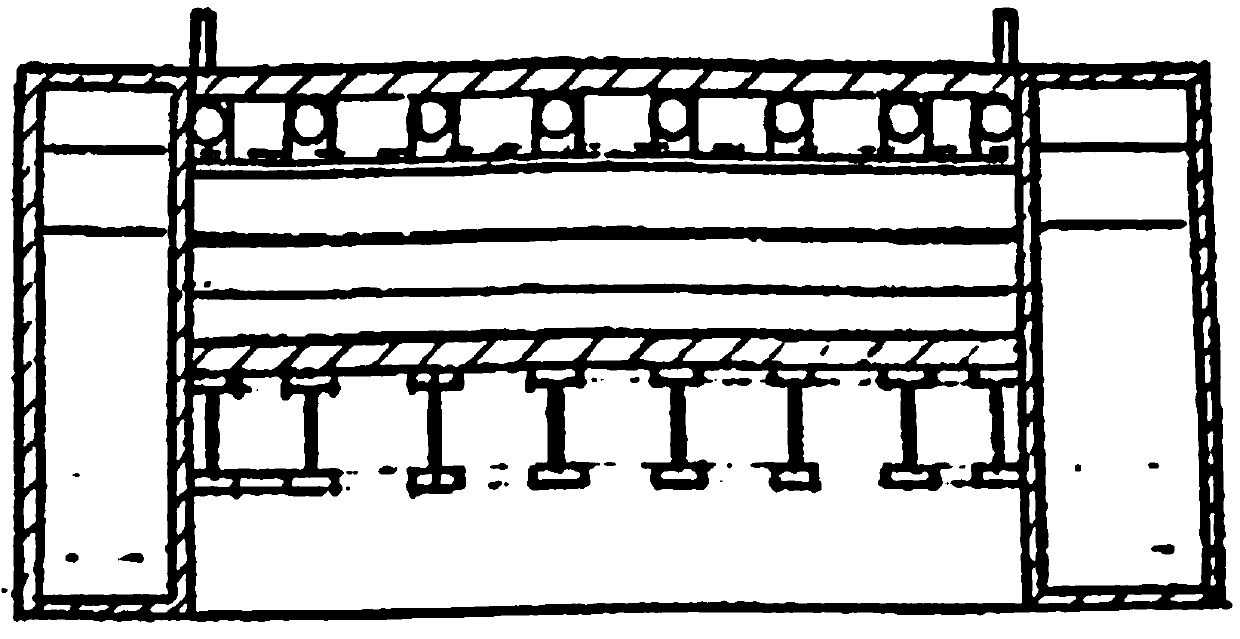

Plate chain composite crusher with adjustable crushing ratio

PendingCN114713331AThe crushing ratio can be adjustedLarge adjustment rangePlastic recyclingGrain treatmentsDrive wheelStructural engineering

The invention discloses a plate chain combined type crusher with an adjustable crushing ratio. The plate chain combined type crusher comprises a lower machine body, a movable tooth roller and a chain wheel assembly. The movable tooth roller is arranged on the lower machine body, a chain wheel assembly is arranged on the lower portion of the inner side of the lower machine body and comprises a plate chain, a driving wheel and check blocks, the plate chain is meshed with the driving wheel, the check blocks are distributed on the upper surface of the plate chain, and the movable tooth roller and the check blocks on the plate chain form a crushing combination for extruding and crushing materials. A plurality of movable tooth rollers are arranged, and a crushing cavity is formed between each movable tooth roller and the plate chain. The multifunctional crusher has the advantages of being diversified in function, simple in structure, small in occupied space, high in crushing efficiency, low in cost and the like, meanwhile, the crushing ratio can be changed within a large range, and then the adaptability to various operation scenes is improved.

Owner:南昌矿机集团股份有限公司

Slag scraping and slag breaking system for high-grade direct-method zinc oxide grate furnace

PendingCN110592394AClean slag and no residueEasy to transportCharge manipulationIncrustation removal devicesSlagSprocket

The invention discloses a slag scraping and slag breaking system for a high-grade direct-method zinc oxide grate furnace. The system involves a slag scraping mechanism and a slag breaking mechanism; the slag scraping mechanism comprises eight slag scraping pieces on a grate, the two groups of slag scraping pieces are positioned on the two sides of the two ends of the grate and in the middle of thegrate correspondingly, the side slag scraping pieces located on the two sides are tightly attached to the furnace wall of the grate furnace, and the two groups of middle slag scraping pieces locatedin the middle and the side slag scraping pieces are installed on the same straight line in the transverse direction of the grate; and the slag breaking mechanism is located on the side, close to a driven roller, of the grate and is composed of a hollow shaft, hook hammers and a driving device, wherein a slag breaking driving reducer of the driving device is connected with a rotating shaft througha chain wheel, the middle of the rotating shaft is fixedly provided with a breaking hollow shaft in a sleeve mode, and the plurality of groups of hook hammers are arranged on the breaking hollow shaft. According to the system, the slag scraping pieces clear slag and wall-hanged matter on the wall of a furnace body so that the furnace body can maintain the normal effective smelting area, meanwhile,the slag scraping pieces break the slag, with the combination of a slag breaking device, the slag can be discharged from the furnace smoothly, and the production interruption caused by slagging and slag discharging problems of the furnace body is avoided.

Owner:赫章领轩环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com