Asphalt stone mixing stirring heating kettle

A technology of mixing, stirring and heating kettles, which is applied in the direction of roads, road repairs, roads, etc., can solve the problems of limited production efficiency, inaccurate mixing ratio, and large labor consumption, and achieve the effect of simple cost, simple mechanism, and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

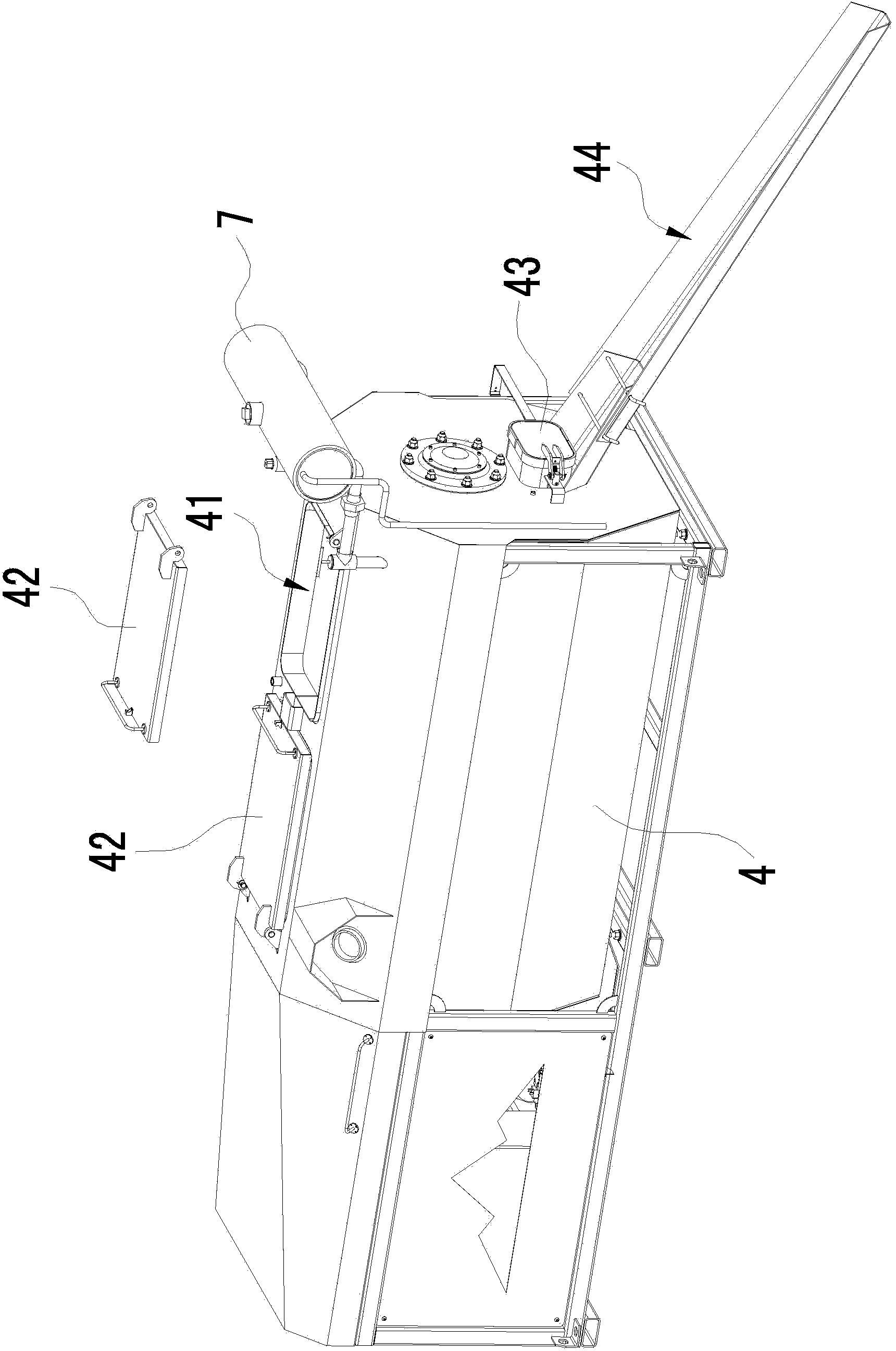

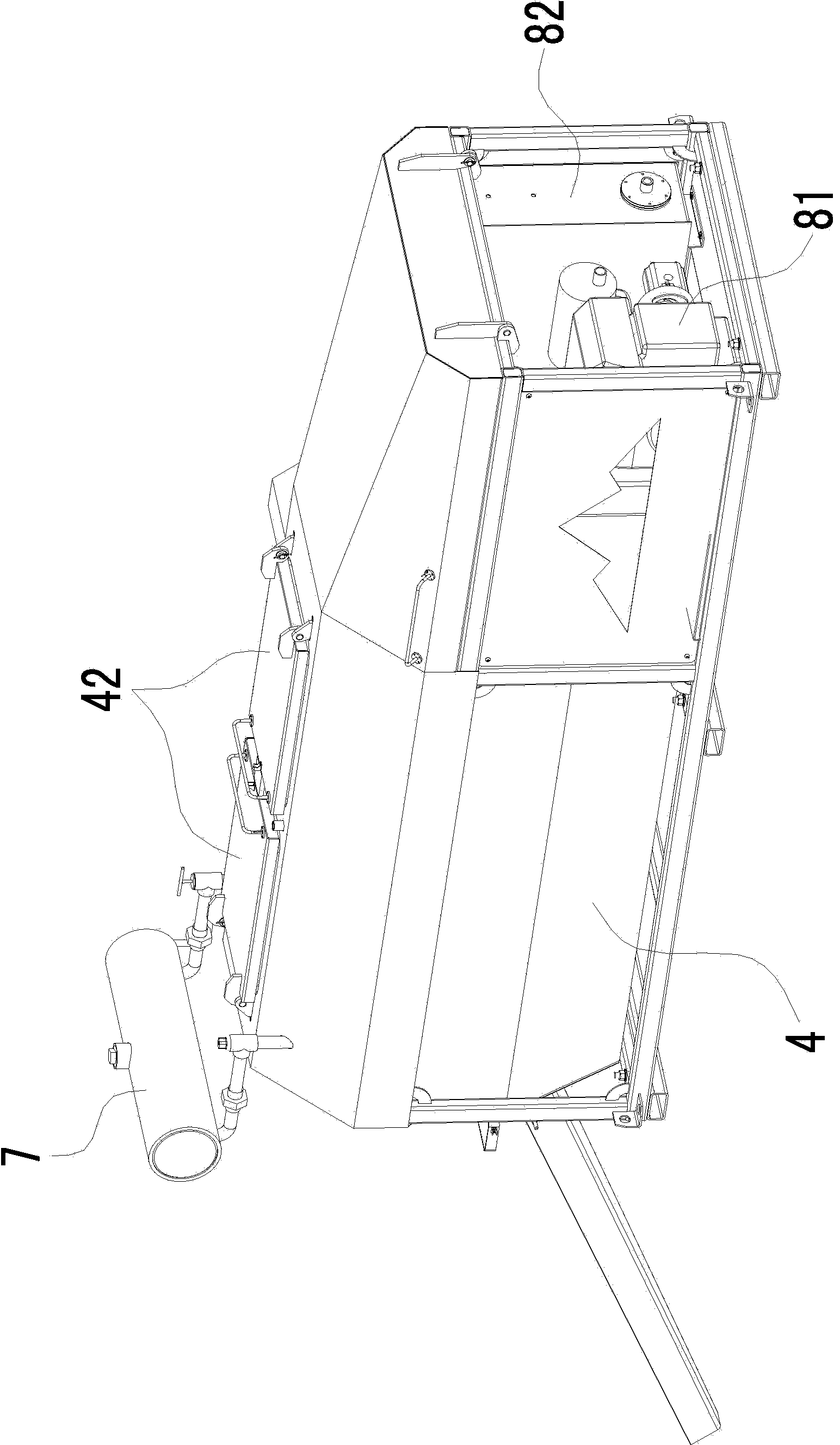

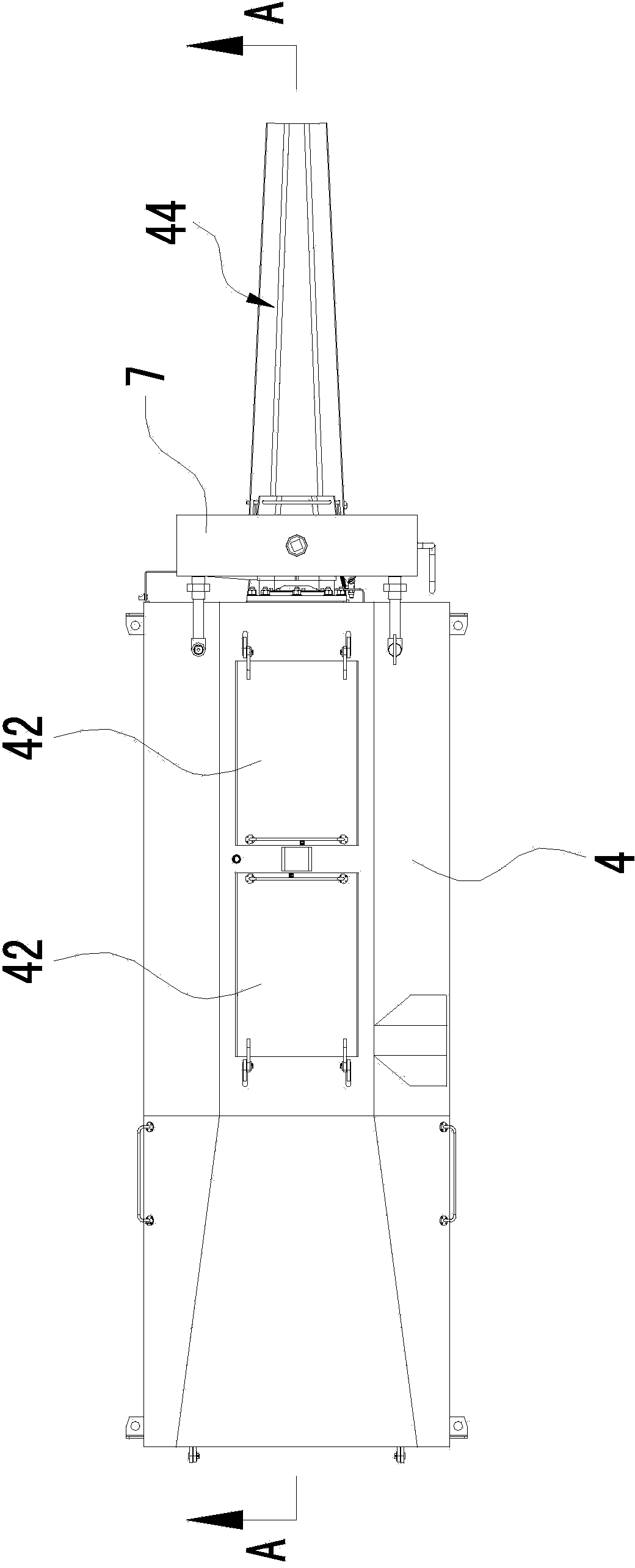

[0046] Such as Figure 1 to Figure 24 As shown, an asphalt stone mixing and stirring heating kettle includes: a shell 4;

[0047] The mixing chamber 1 is arranged in the housing 4, and the top of the housing 4 is provided with a feeding port 41 communicating with the mixing chamber 1; the number of feeding ports 41 can be 2;

[0048] The heating chamber 2 is arranged in the shell 4 and is located on the periphery of the stirring chamber 1;

[0049] The heating chamber 3 is located in the shell 4 and is located on the periphery of the heating chamber 2; as Figure 5 As shown, the stirring chamber 1, the heating chamber 2 and the heat supply chamber 3 are arranged in a sequentially surrounding manner, and a ventilation structure communicating with the heat supply chamber 3 can be provided between the shell 4 and the heat supply chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com