Porous flared feeder, preparation and its use

A feeder and bell mouth technology is applied in the field of porous bell mouth feeders, which can solve the problems of inability to display the appearance effect of concentrated component fibers, difficulty in spinning, carding, mixing and processing, and low production rate, and achieves low cost, The effect of simple mechanism and convenient processing

Inactive Publication Date: 2005-03-02

DONGHUA UNIV

View PDF1 Cites 23 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] Traditional blended spinning can only provide evenly distributed two-component or multi-component yarns. Not only is the carding and mixing process of the previous spinning difficult and the production rate is low; it is also unable to show the appearance effect of the concentrated component fibers combined.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0026] Second-rate

Embodiment 2

[0028] Second-rate

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

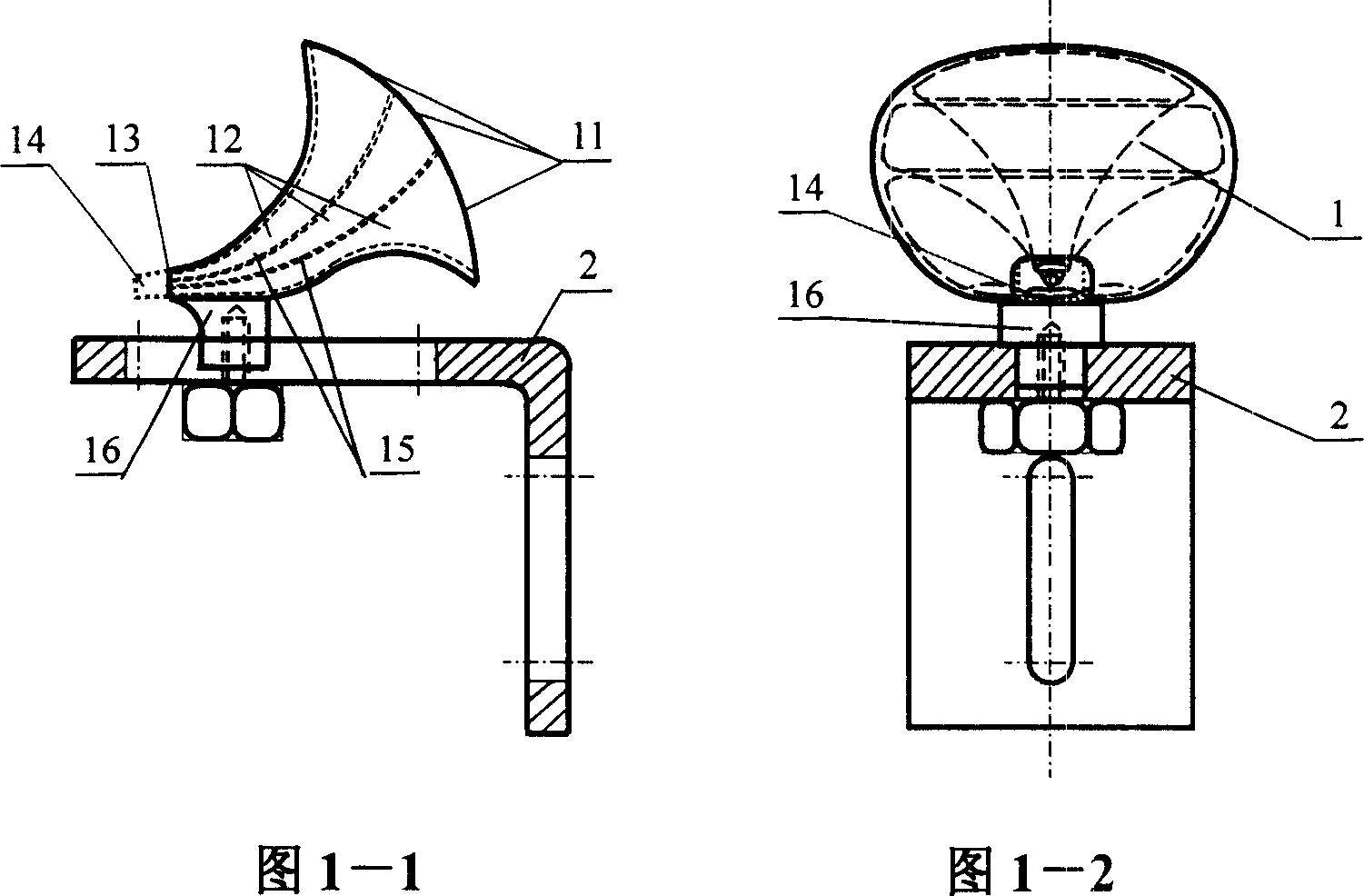

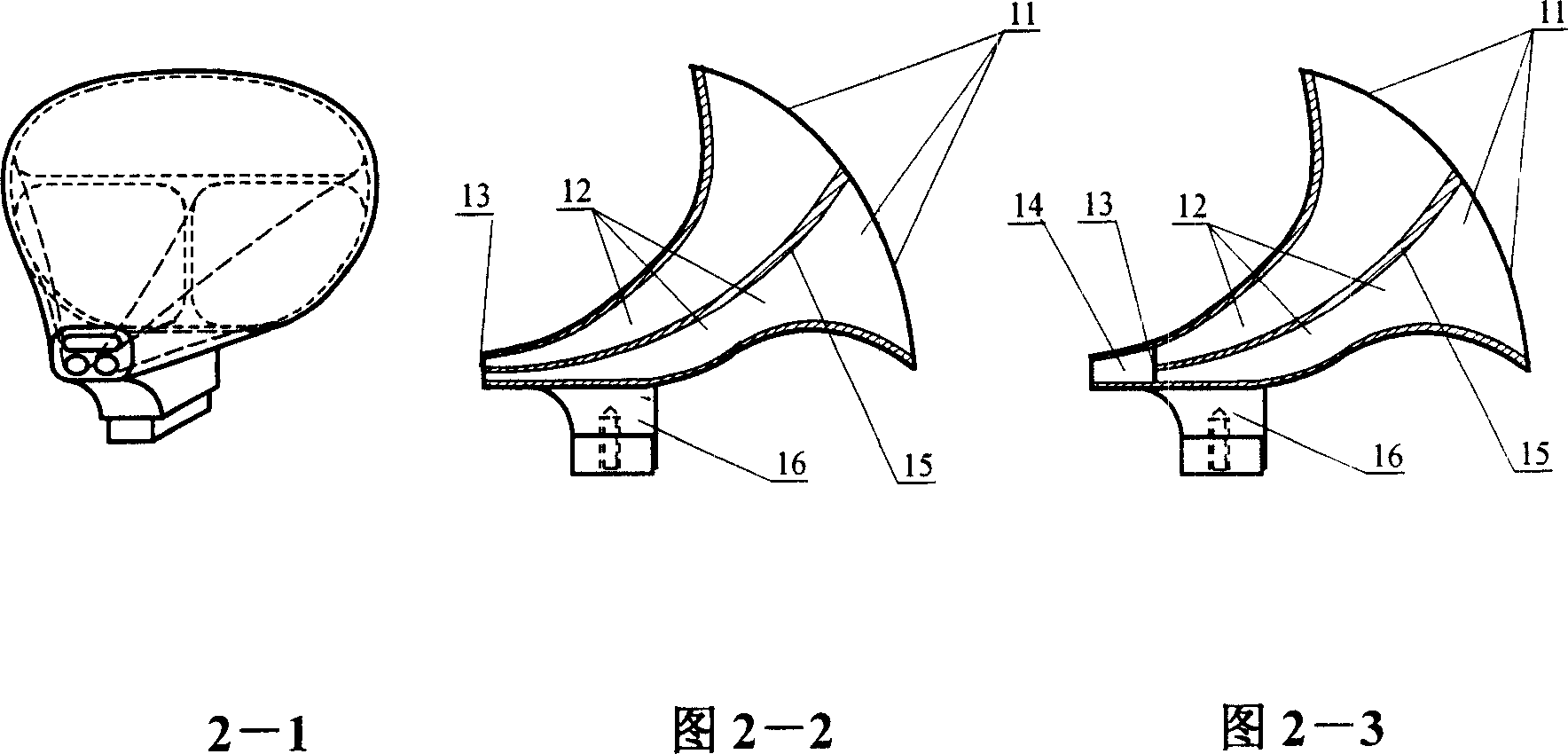

The present invention relates to a kind of porous flared feeder for ring spinning and its making process and use. The porous flared feeder of fiber sliver feeder has 2-7 inlet and outlet hole canals, and has several fiber sliver outlet or single fiber sliver outlet with multiple tow converging unit. The feeder is formed through injection molding or injection molding and heat treatment to bend. It may be sued in converging several kinds of tow for composite spinning in various ring spinning machine. The present invention has simple mechanism, low manufacture cost, convenient installation and use and high applicability in composite spinning.

Description

Technical field: [0001] The invention relates to the compact composite spinning technology in the field of textile fiber composite spinning, in particular to a multi-hole bell mouth feeder used on a ring spinning machine. Background technique: [0002] Composite spinning technology is a matter of more than 20 years. It is mainly researched and industrialized by scientists from the Australian Commonwealth Academy of Sciences (CSIRO) Wool Textile Research Institute (DWT) (Lappage, James, AMethod and Apparatus for Producing a Uniform Yam, C SIRO , AU Patent No.438072, 1971; Plate, D.E.A. and Feehan, JD., Improved Method for the Manufacture of Twisted and Plied Yam, CSIRO, AU Patent No.473153, 1974; Sirospun: Goodbye to Two-Fold?, Textile Horizons, Vol .2, No.2, 1982, pp.34-37; Prins, M.W., Lamb, P.R., Naylor, G.R.S., Tao, X., Yarn spinning from fiber sub-assemblies with variants of their paths of travel, relative positions ortwist levels, US Patent No.6012277,2000), its typica...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B29C45/00B29C57/00D01H1/18D01H13/04

Inventor 于伟东肖远发于昊慧

Owner DONGHUA UNIV

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com