Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Wall thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

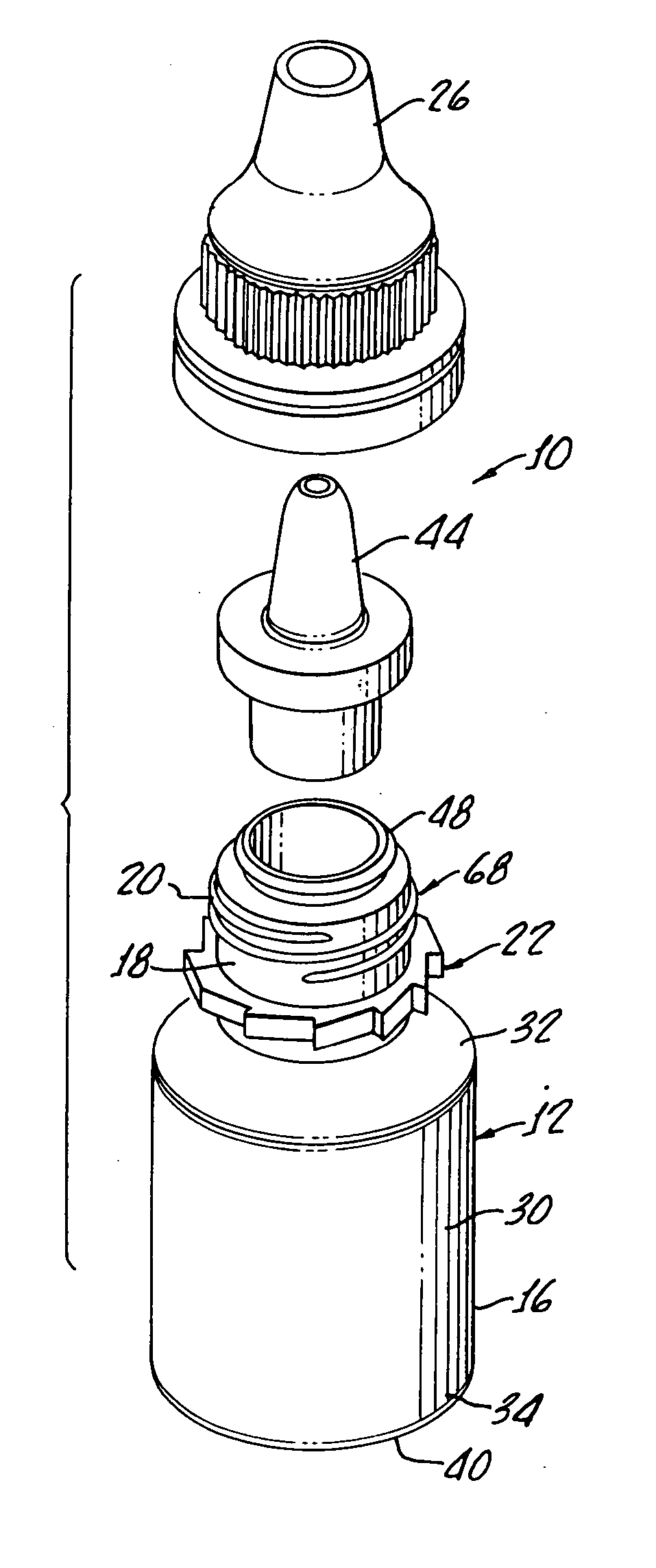

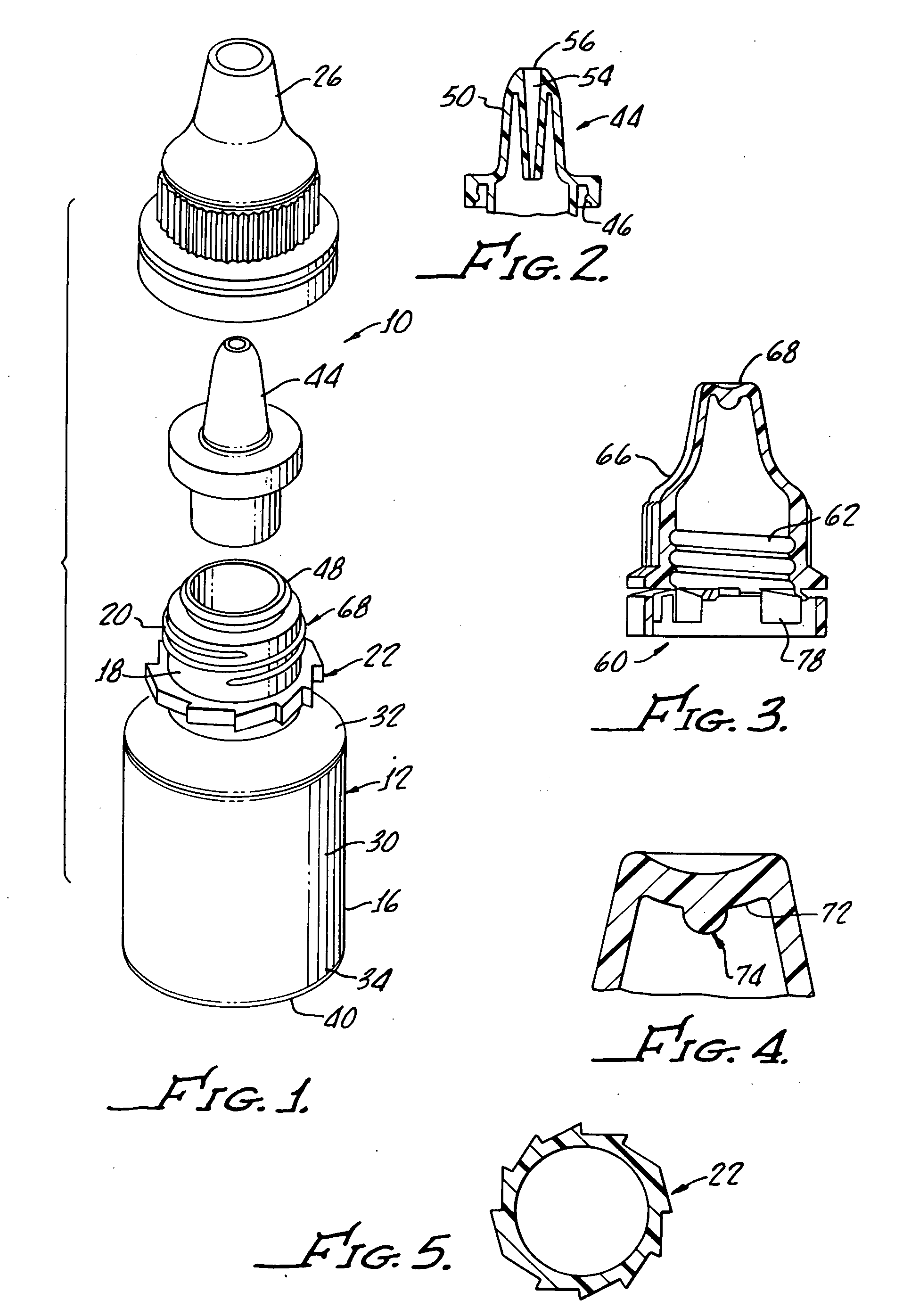

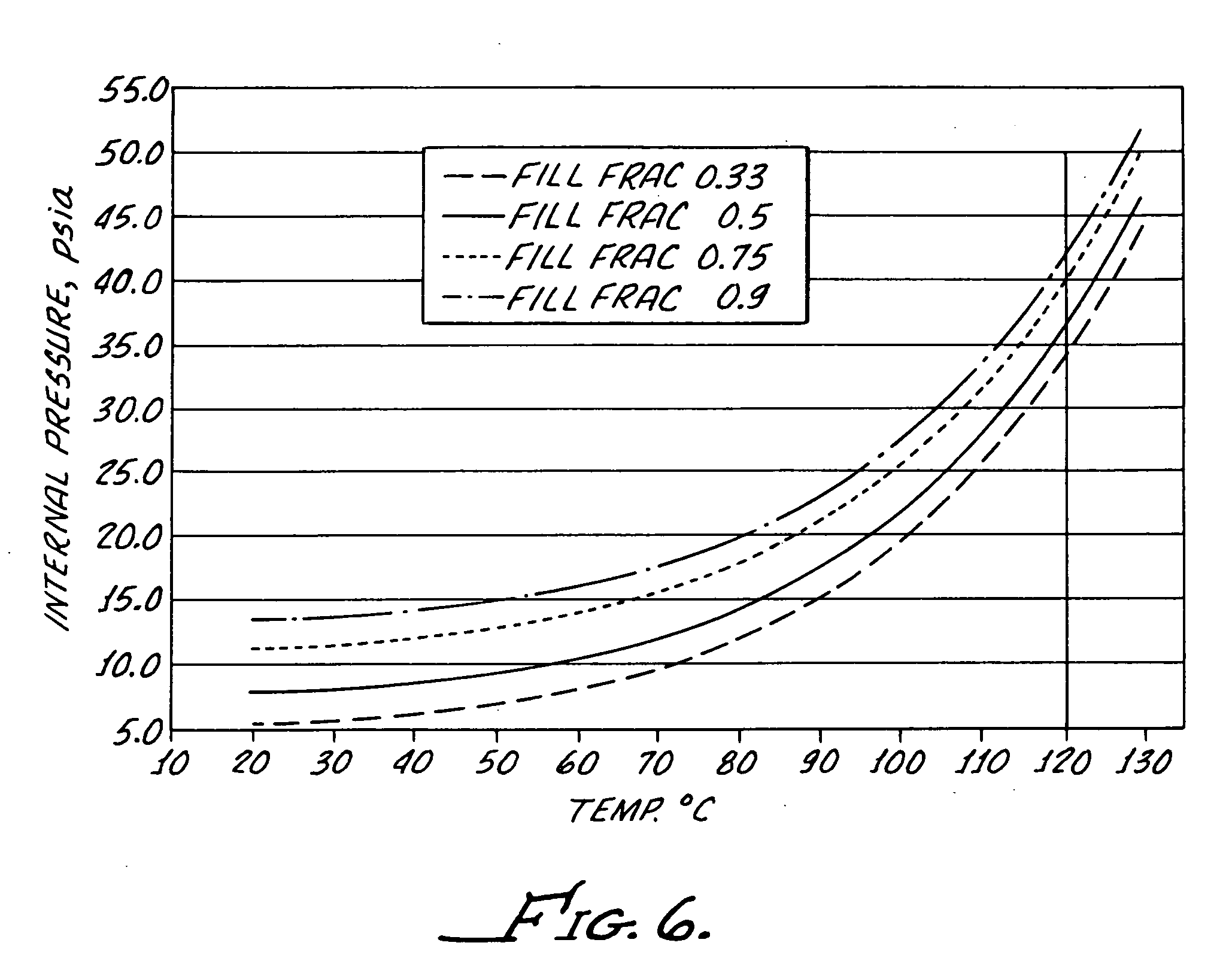

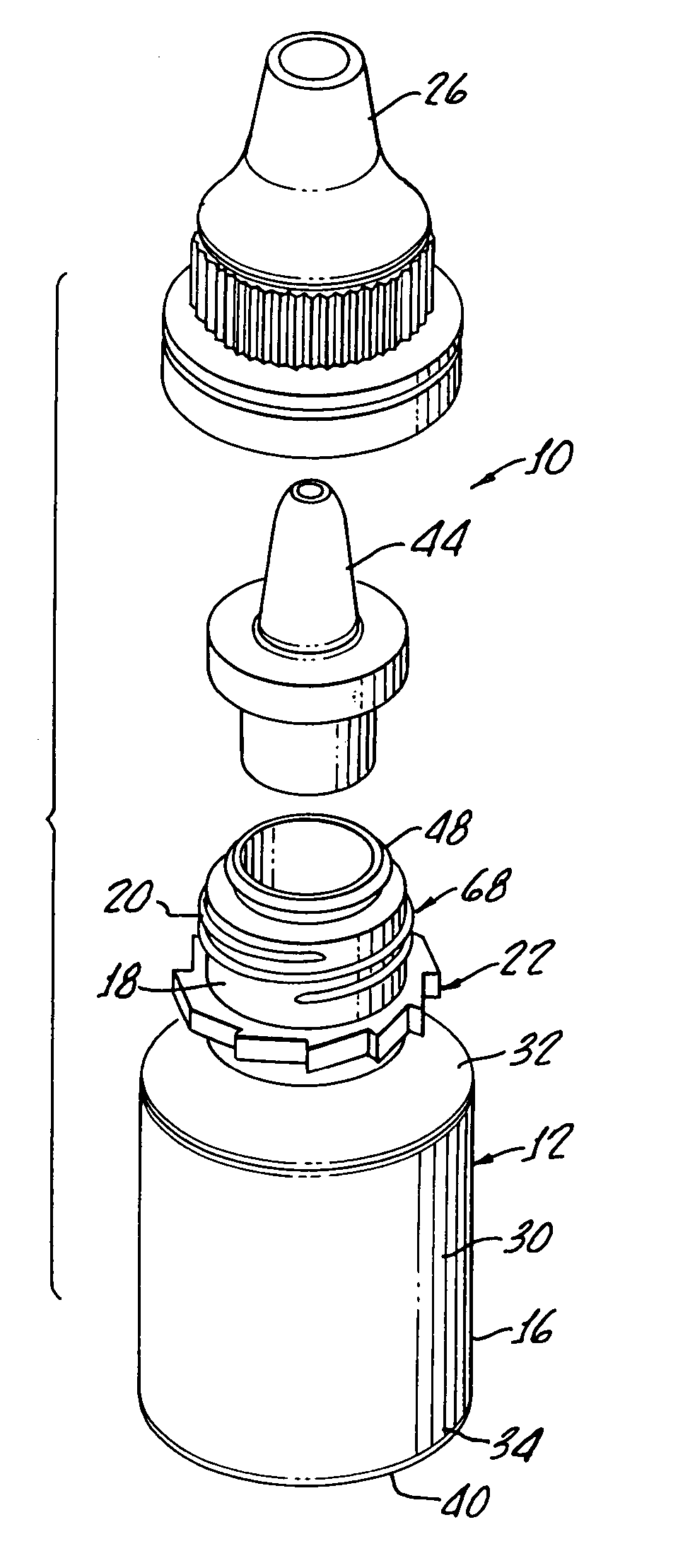

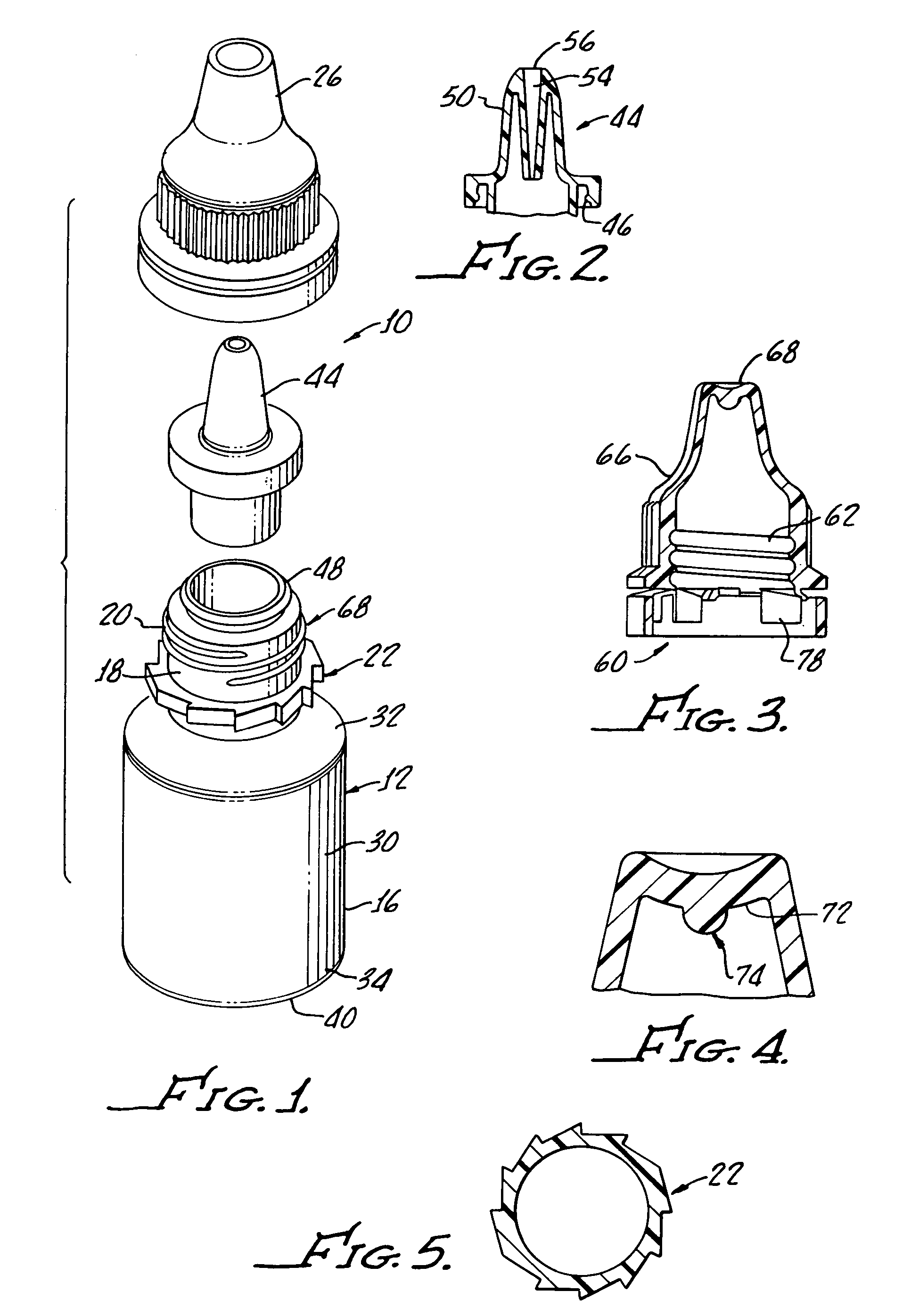

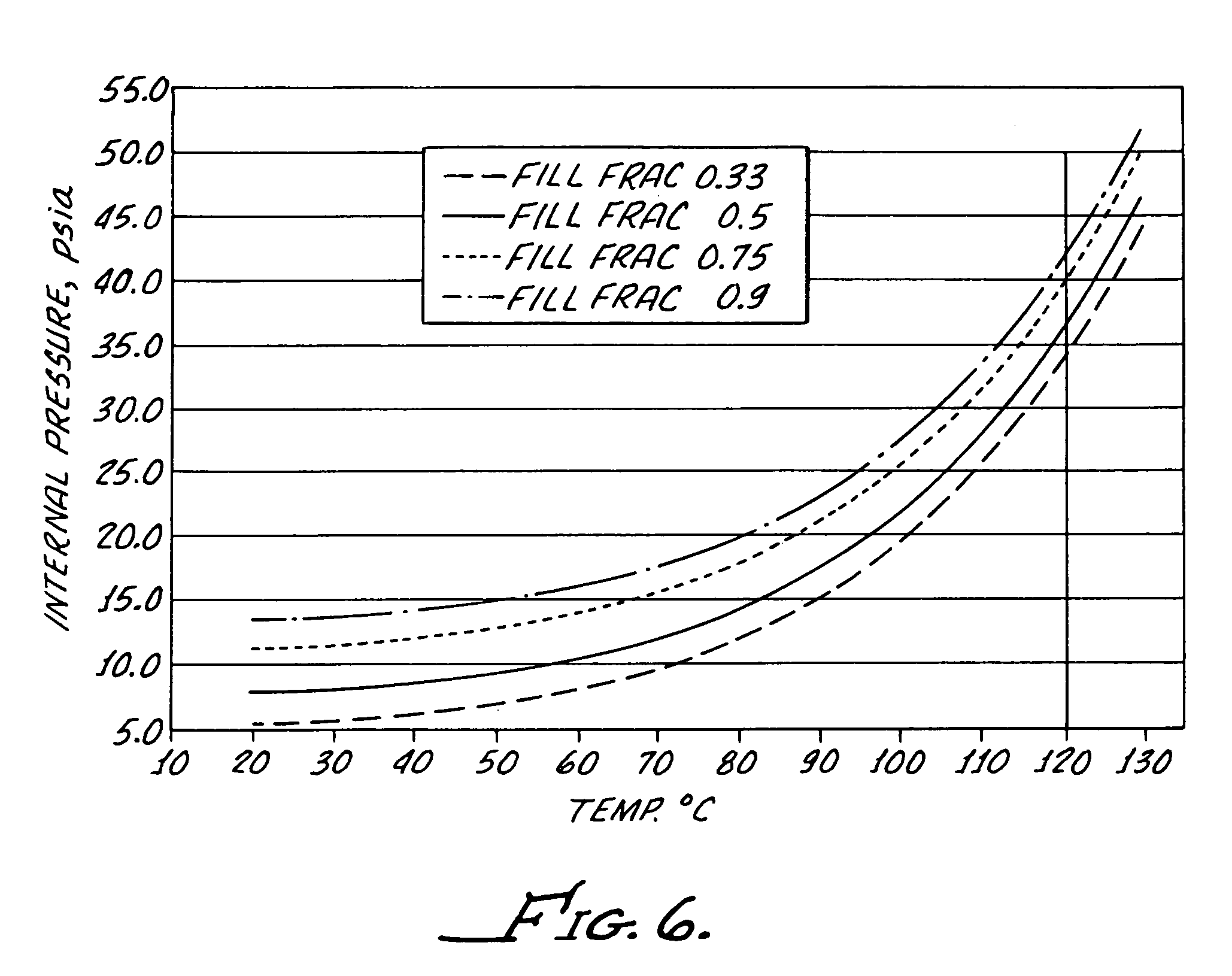

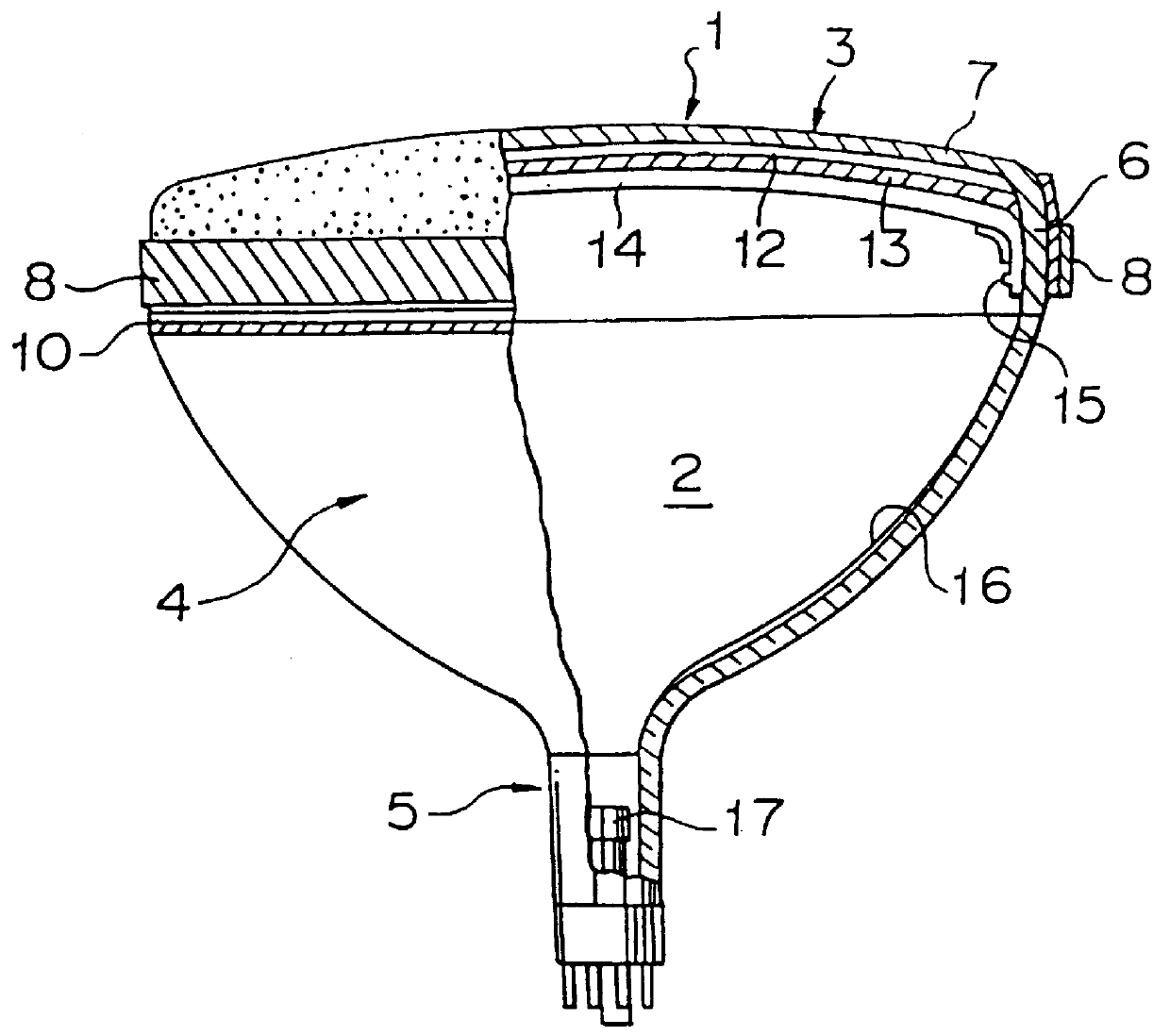

Autoclaveable small-volume dropper bottle

ActiveUS20060111680A1Short lifeLow acceptabilityClosuresLiquid flow controllersEngineeringHigh pressure

A terminally sterilizable container includes a polypropylene bottle having a body with a manually squeezable sidewall and a thickness preventing water loss. The bottle body includes shoulders for providing autoclave produced pressure distribution and deformation resistance along with an elongated tips outfitted to a neck of the body and having a lumen therethrough with a drop dispensing orifice. A cap enclosed the elongated tip and includes enclosed with a nub for sealing the orifice to prevent autoclave produced pressure leaks.

Owner:ALLERGAN INC

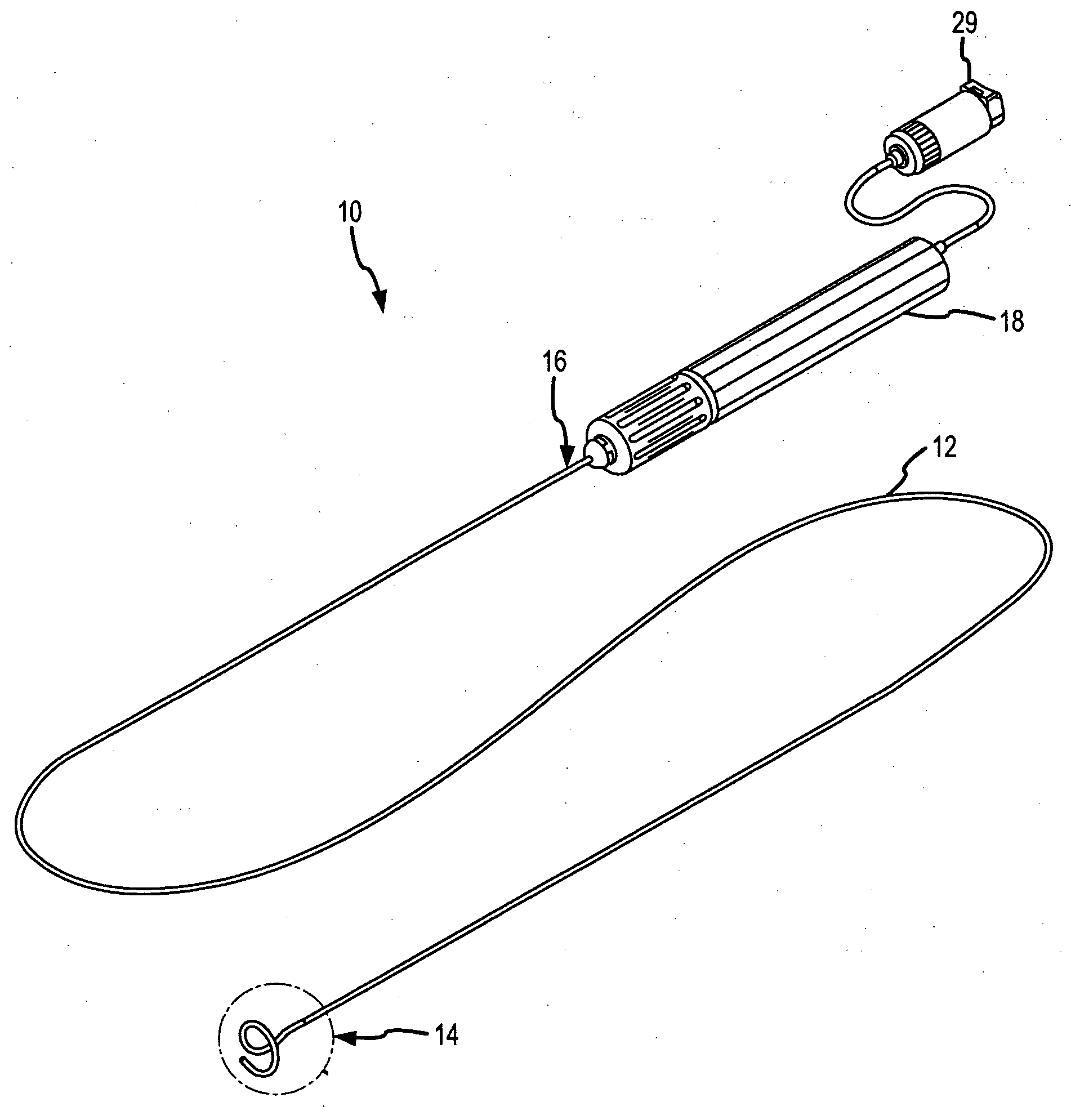

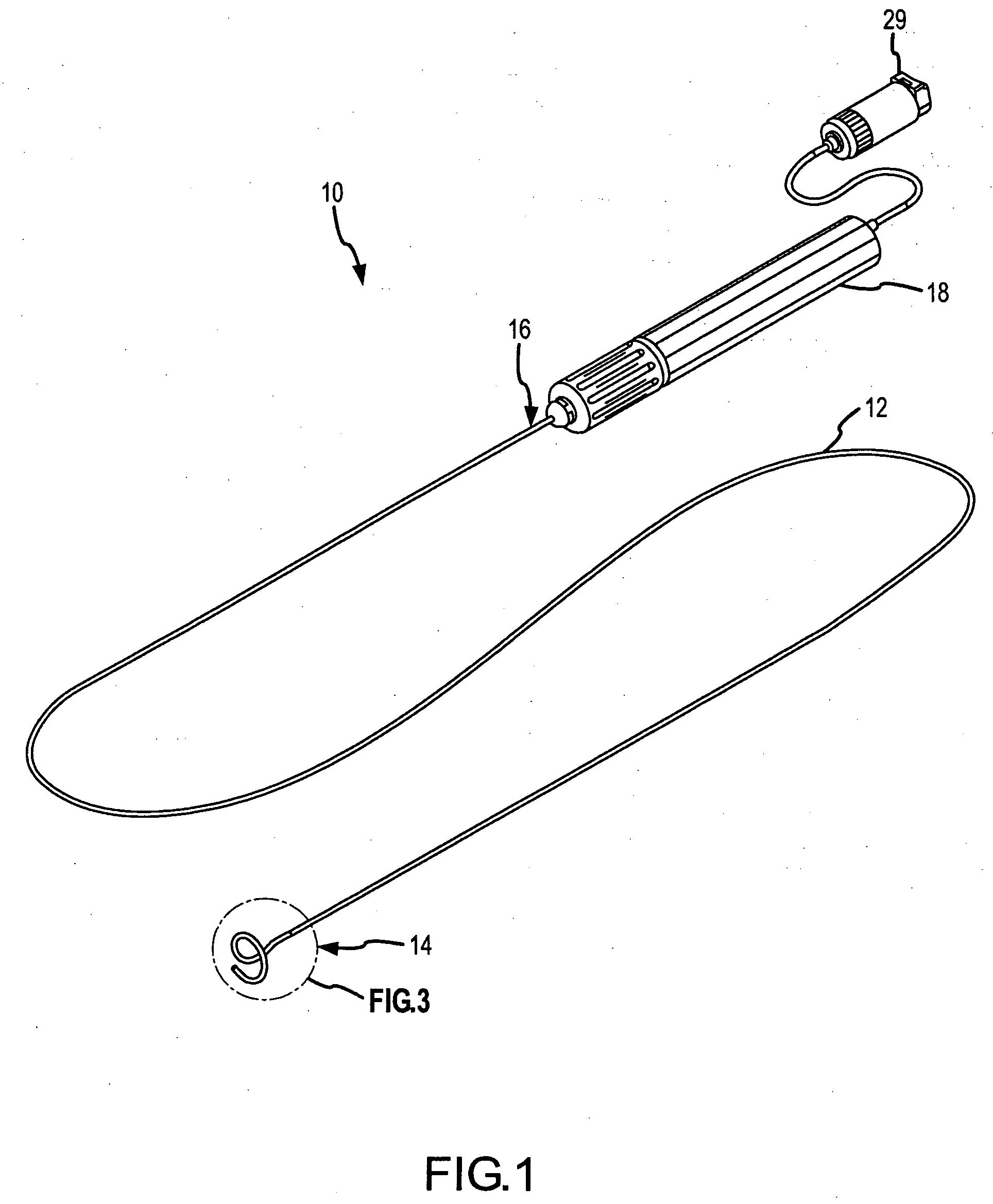

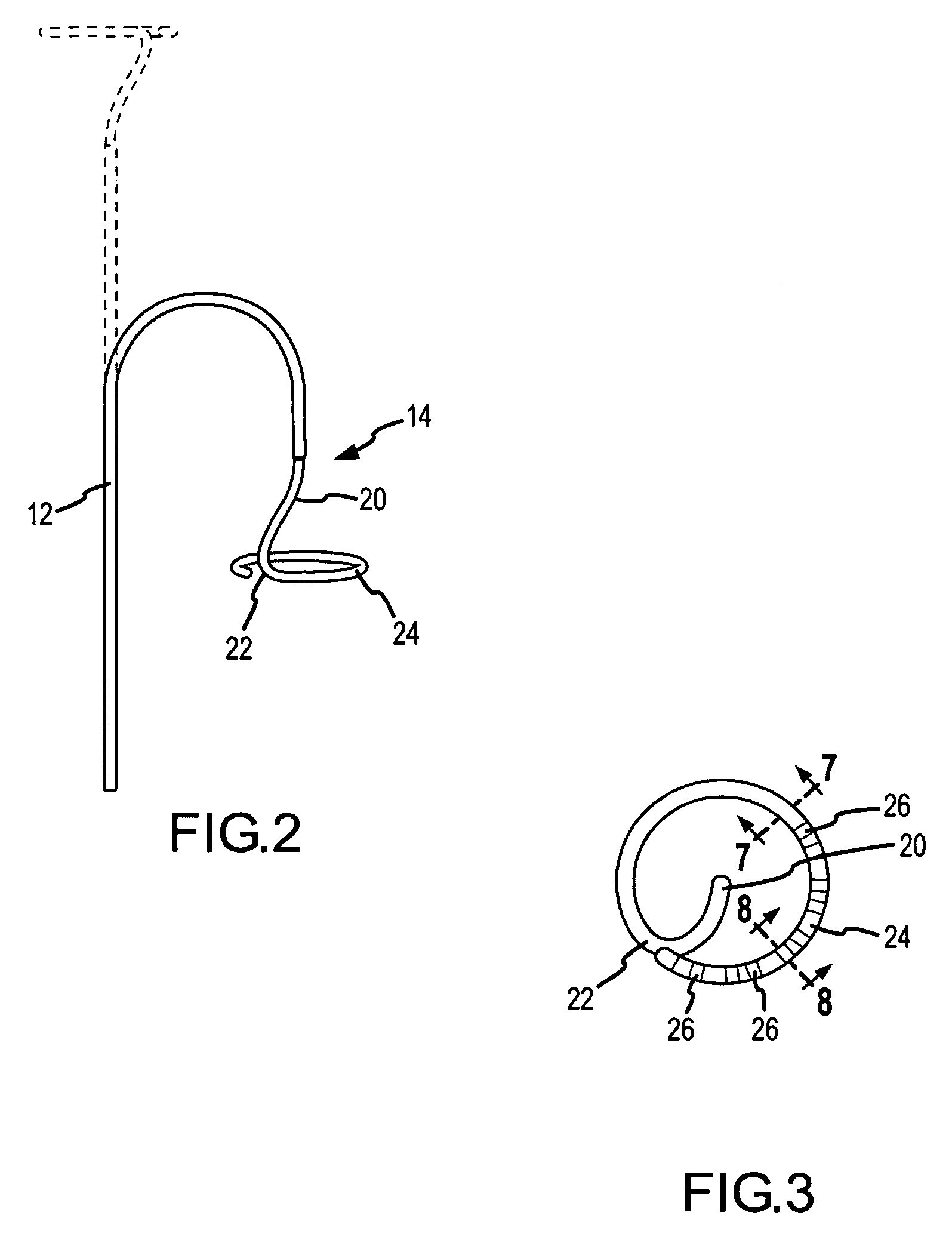

Catheter with embedded components and method of its manufacture

InactiveUS20080161774A1Wall thicknessIncrease hoop stiffnessElectrocardiographyLamination ancillary operationsCatheter device

A method of manufacturing a catheter includes providing an outer shaft having a lumen therethrough and at least one catheter component disposed at least partially within the lumen, placing an inner shaft within the lumen such that the at least one catheter component is located between the shafts, thereby forming a catheter assembly having an outer surface, and applying energy to the catheter assembly to melt at least the outer shaft to bond the outer shaft to the inner shaft. A unitary catheter shaft having the at least one catheter component substantially embedded therein results. The durometer of the outer shaft may differ from the durometer of the inner shaft, such that the catheter shaft varies radially in durometer. The durometer of the catheter shaft may also vary longitudinally. A shaping wire may be provided to form the distal end of the catheter shaft into a desired shape.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

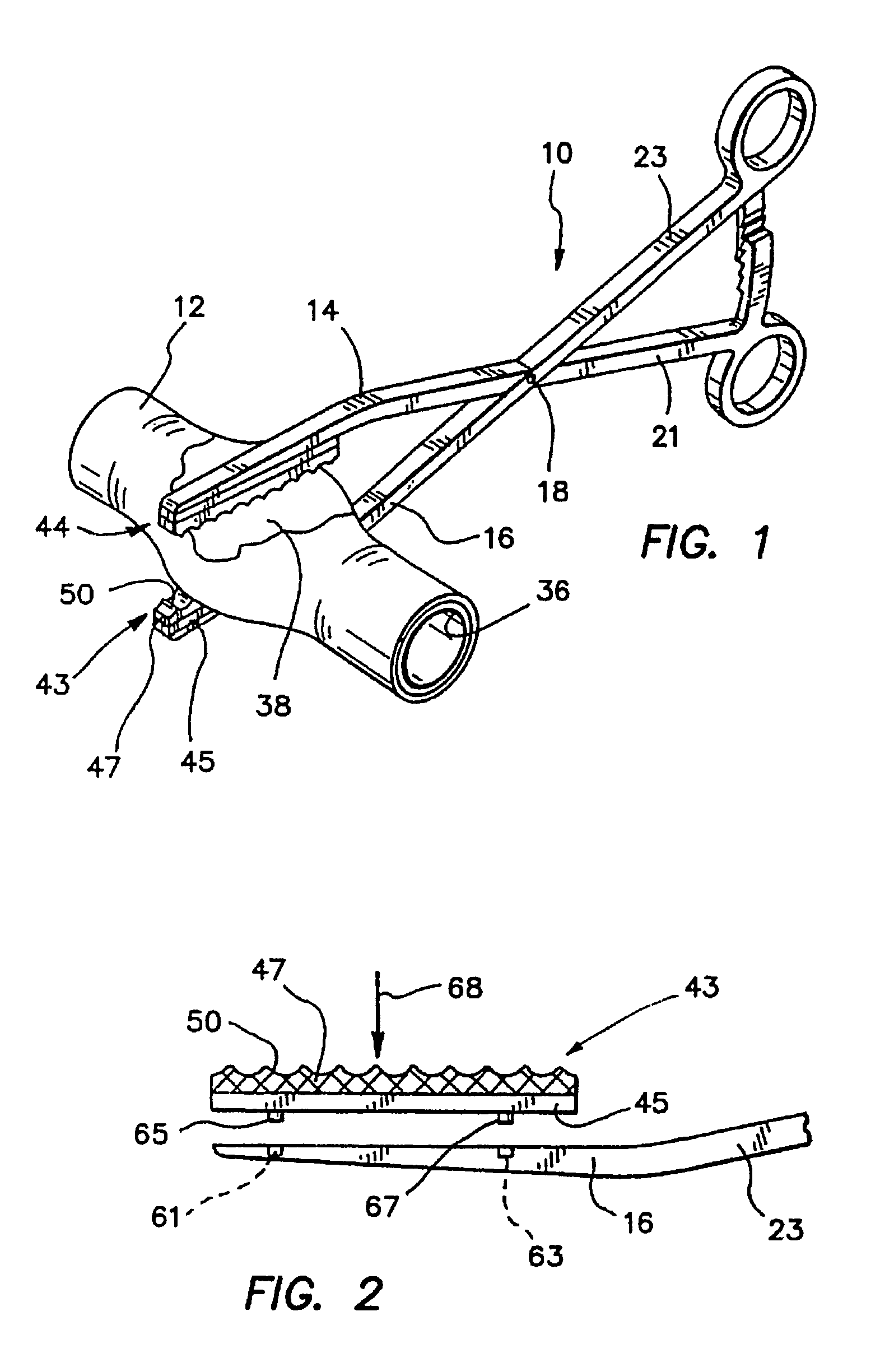

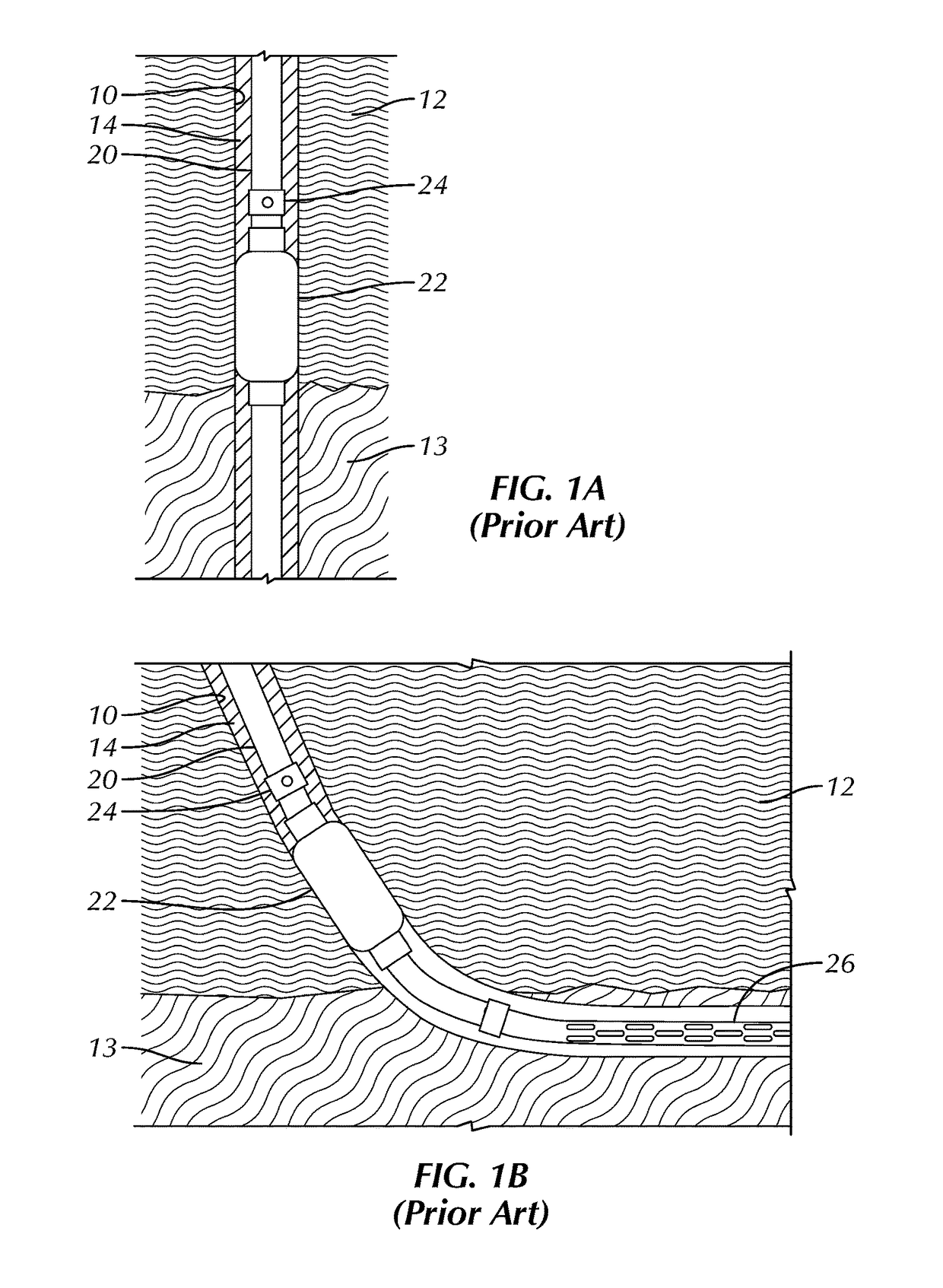

Peripheral vascular occlusion devices

InactiveUS20050240219A1Minimize trauma during surgeryInstallationSurgical forcepsWound clampsSurgery procedureBlood vessel

The invention relates to a surgical instrument for at least partially occluding a body conduit comprising a first jaw, a second jaw opposing the first jaw and moveable relative to the first jaw to occlude the conduit, and an insert being mounted by at least one of the first and second jaws with a length of the insert extending along at least one of the first and second jaws. One of the first and second jaws may further comprise a retention barb to provide a friction fit with the insert. The insert is flexible, disposable and may be formed by injection molding. The retention barb may be a three-sided or multiple-sided barb that is formed at the proximal end of at least one of the first and second jaws. The first and / or second jaws may be bent and / or curved. In another aspect, the insert comprises an outer wall and an inner wall for fitting over the jaw, and the inner wall further comprises a molded, rectangular raised ring formed at the proximal end to aid the retention of the insert over the retention barb of the jaw. The insert may be removed from the jaw by pulling the insert in a distal direction to overcome the friction fit of the retention barb. The insert may further include a soft tip covering the distal end of one of the jaws to minimize trauma during surgery. The distal ends of the jaw and the insert may be tapered to allow ease of installation and removal. In another aspect, the insert and jaws may be removably attached to one another in a snap-fit relationship where the jaws may include one or more holes and the insert may include one or more projections. It is appreciated that the holes and projections may vary in width, depth and height depending on application.

Owner:APPL MEDICAL RESOURCES CORP

Autoclaveable small-volume dropper bottle

A terminally sterilizable container includes a polypropylene bottle having a body with a manually squeezable sidewall and a thickness preventing water loss. The bottle body includes shoulders for providing autoclave produced pressure distribution and deformation resistance along with an elongated tips outfitted to a neck of the body and having a lumen therethrough with a drop dispensing orifice. A cap enclosed the elongated tip and includes enclosed with a nub for sealing the orifice to prevent autoclave produced pressure leaks.

Owner:ALLERGAN INC

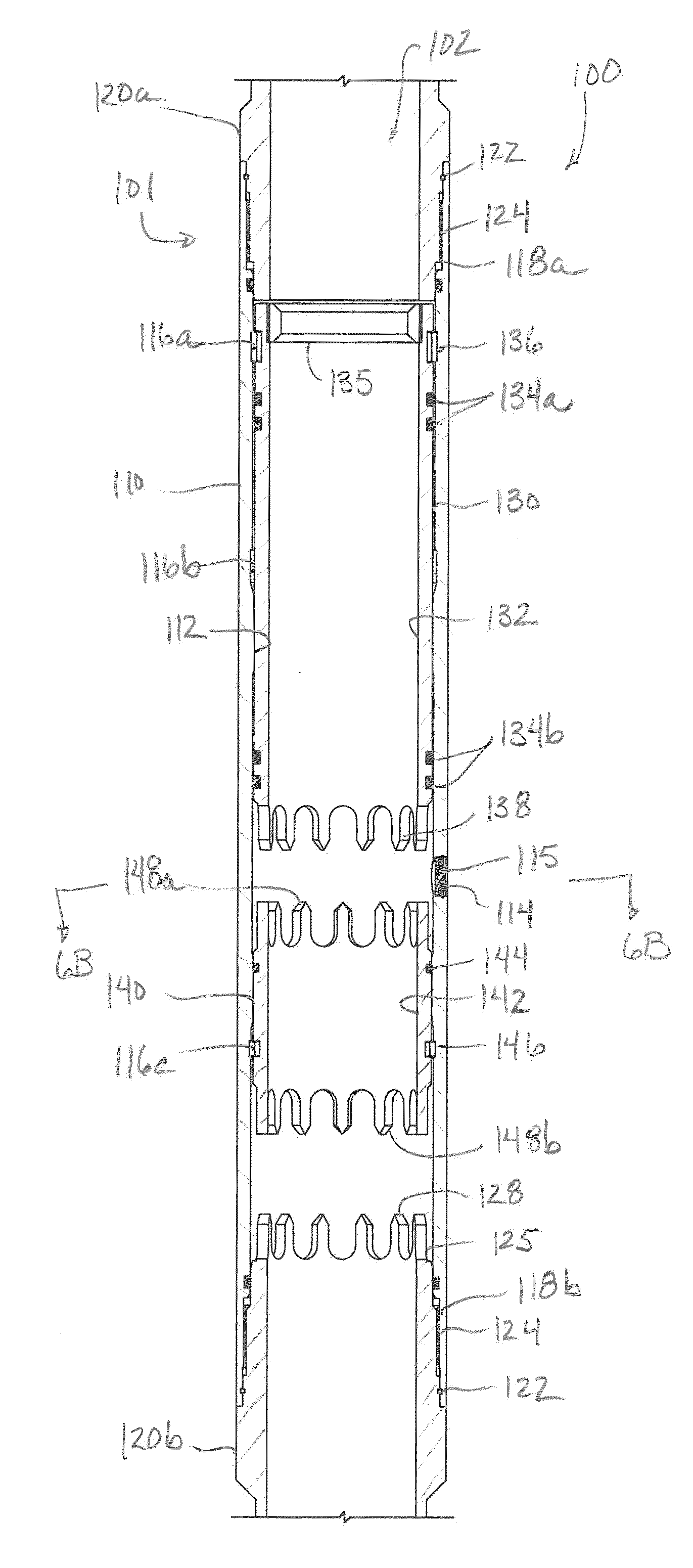

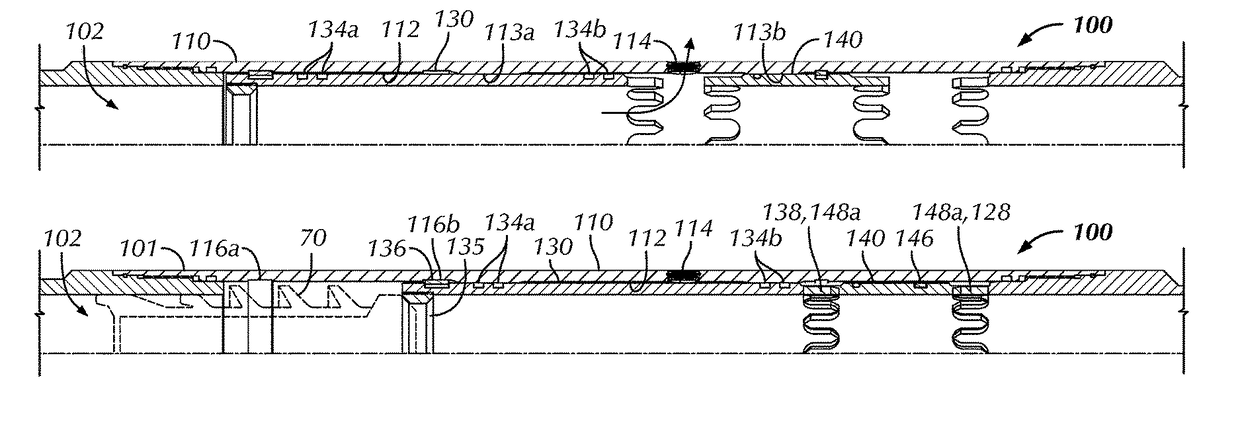

Zone Select Stage Tool System

A stage tool operable with a plug is used for cementing a tubing string in a wellbore annulus. The tool can have a housing with a closure sleeve movably disposed in the internal bore of the housing. When pressure is applied downhole to the tool, a breachable obstruction on an exit port of the tool's bore opens and allows fluid such as cement slurry to communicate to the wellbore annulus. When cementing through the open tool finished, a plug deployed downhole lands on a seat in the closure sleeve, and applied fluid pressure in the tool's bore against the seated plug closes the closure sleeve relative to the housing's exit port. Rotational catches between the housing's bore and the closure sleeve prevent the closure sleeve from rotating. Preferably, an intermediate sleeve is used in the housing's bore and has rotational catches on each end. When the closure sleeve moves closed, the intermediate sleeve is also moved to engage between the catches on the end of the closure sleeve and the catches on a shoulder of the housing's bore. In further arrangements, a hydraulic mechanism on the tool can facilitate movement of the closure sleeve in response to a fluid pressure component.

Owner:WEATHERFORD TECH HLDG LLC

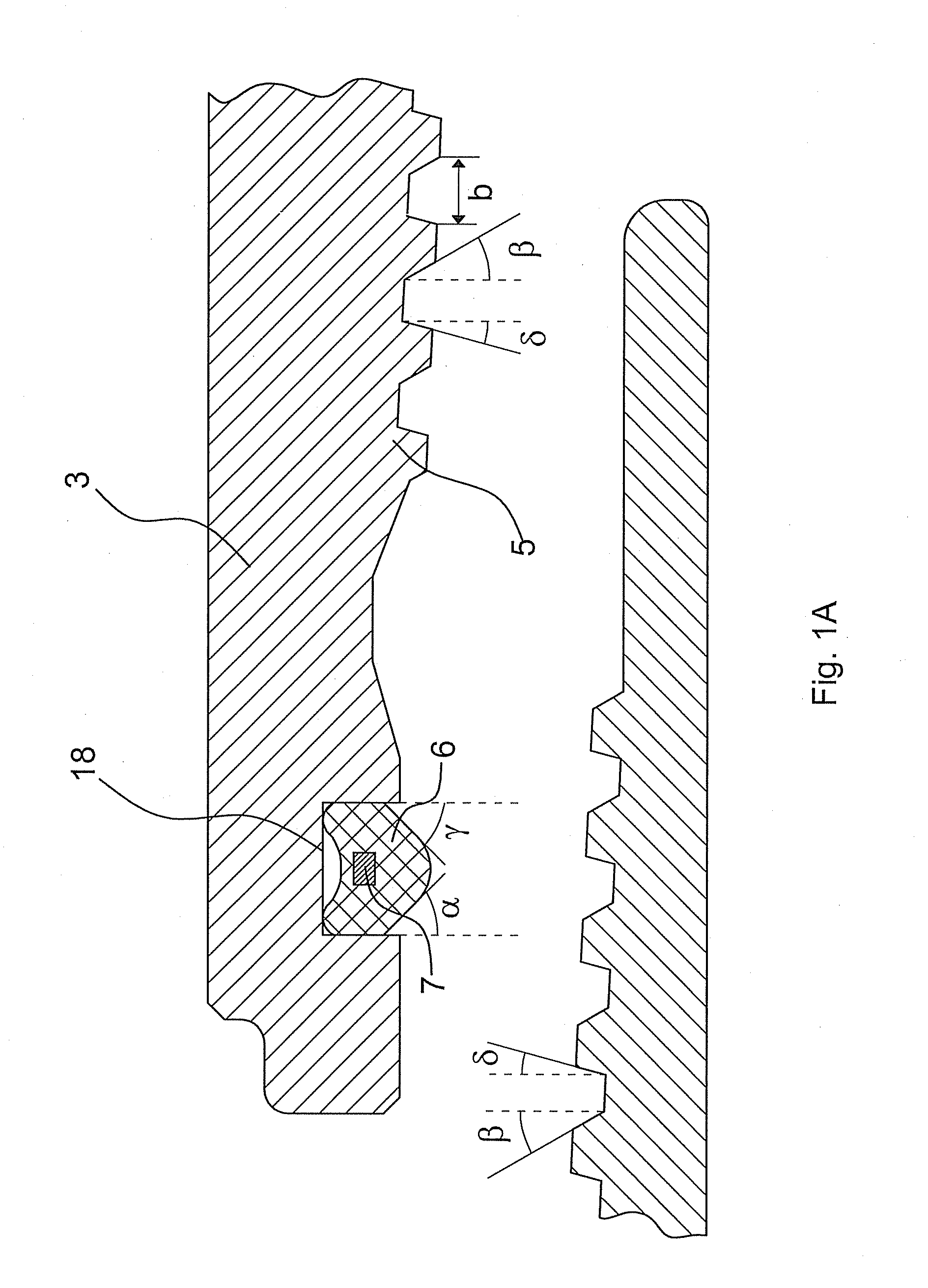

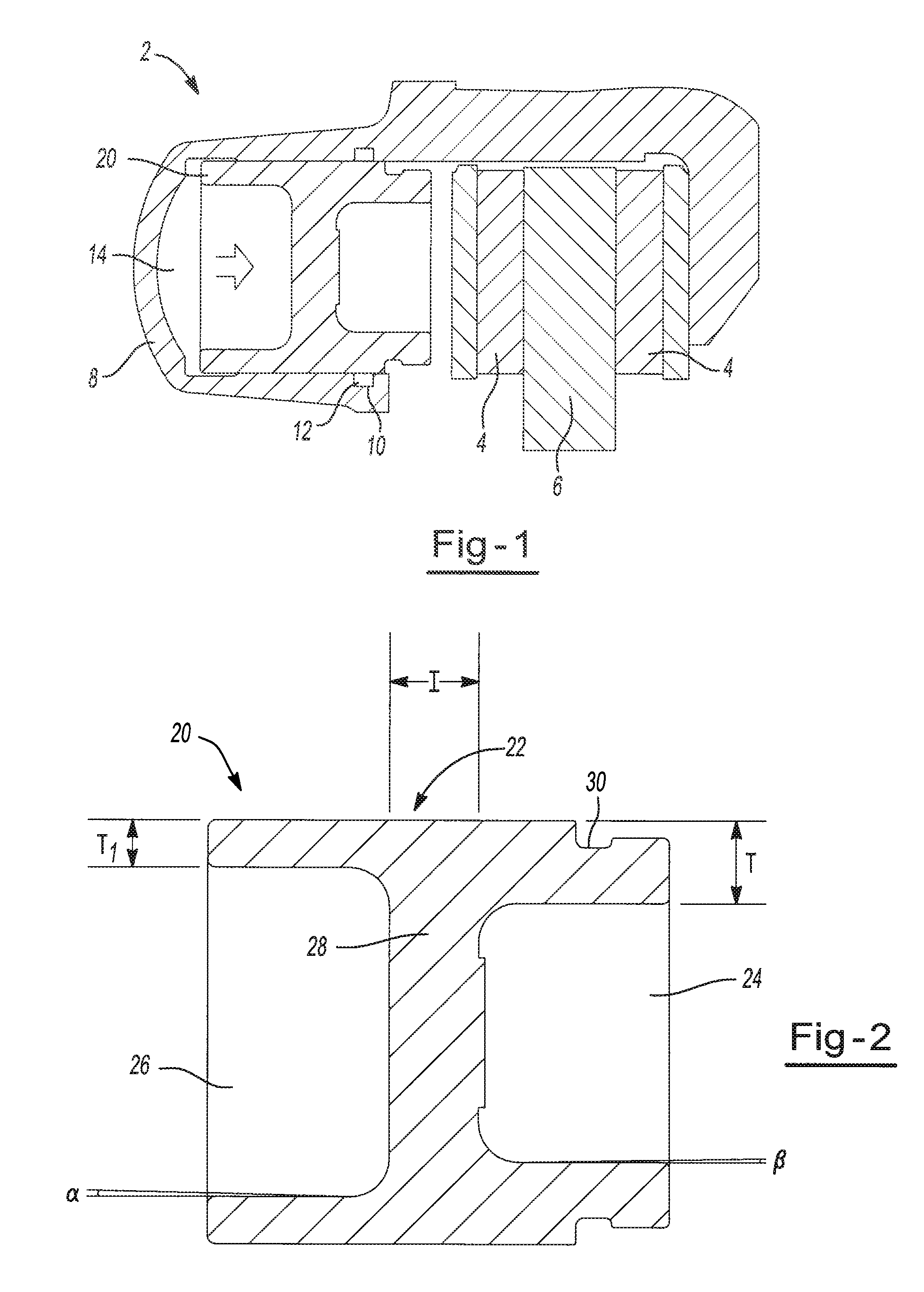

Threaded joint with resilient seal ring

ActiveUS20100181761A1Reduce operating costsIncrease costDrilling rodsHose connectionsEngineeringScrew thread

A threaded joint comprises a seal ring positioned between a pin and a box, and located in a groove between the end of a threaded section and the nose of the box. The seal ring has a first base, a second base axially opposite to the first base, at least two protruding annular ribs on the external surface, and an internal surface comprising, in an unloaded position, two frustoconical annular surfaces tapering towards the center of the seal ring and joined by a fillet.

Owner:TENARIS CONNECTIONS

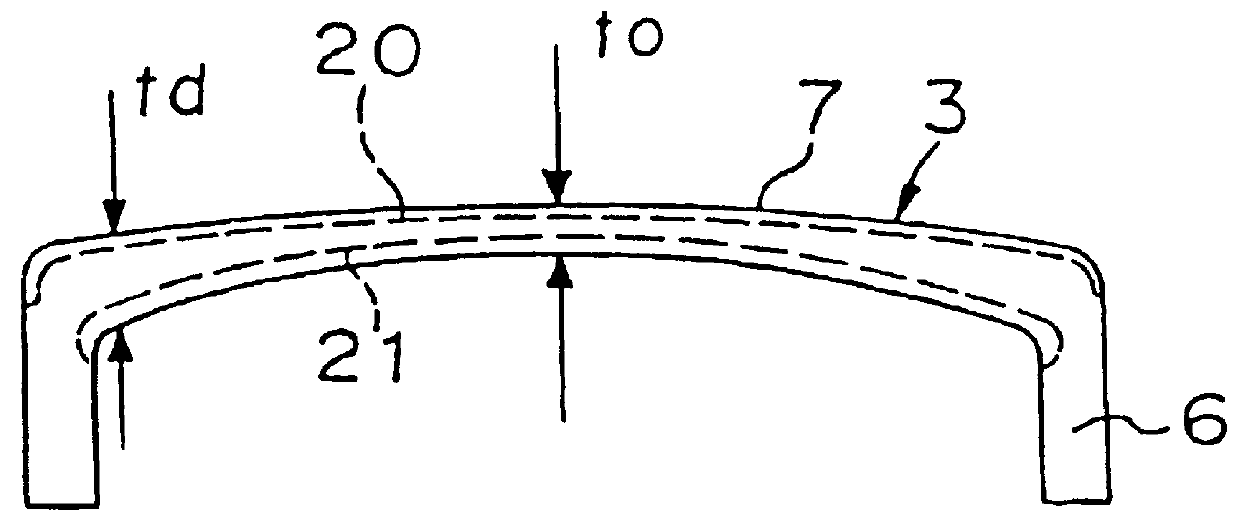

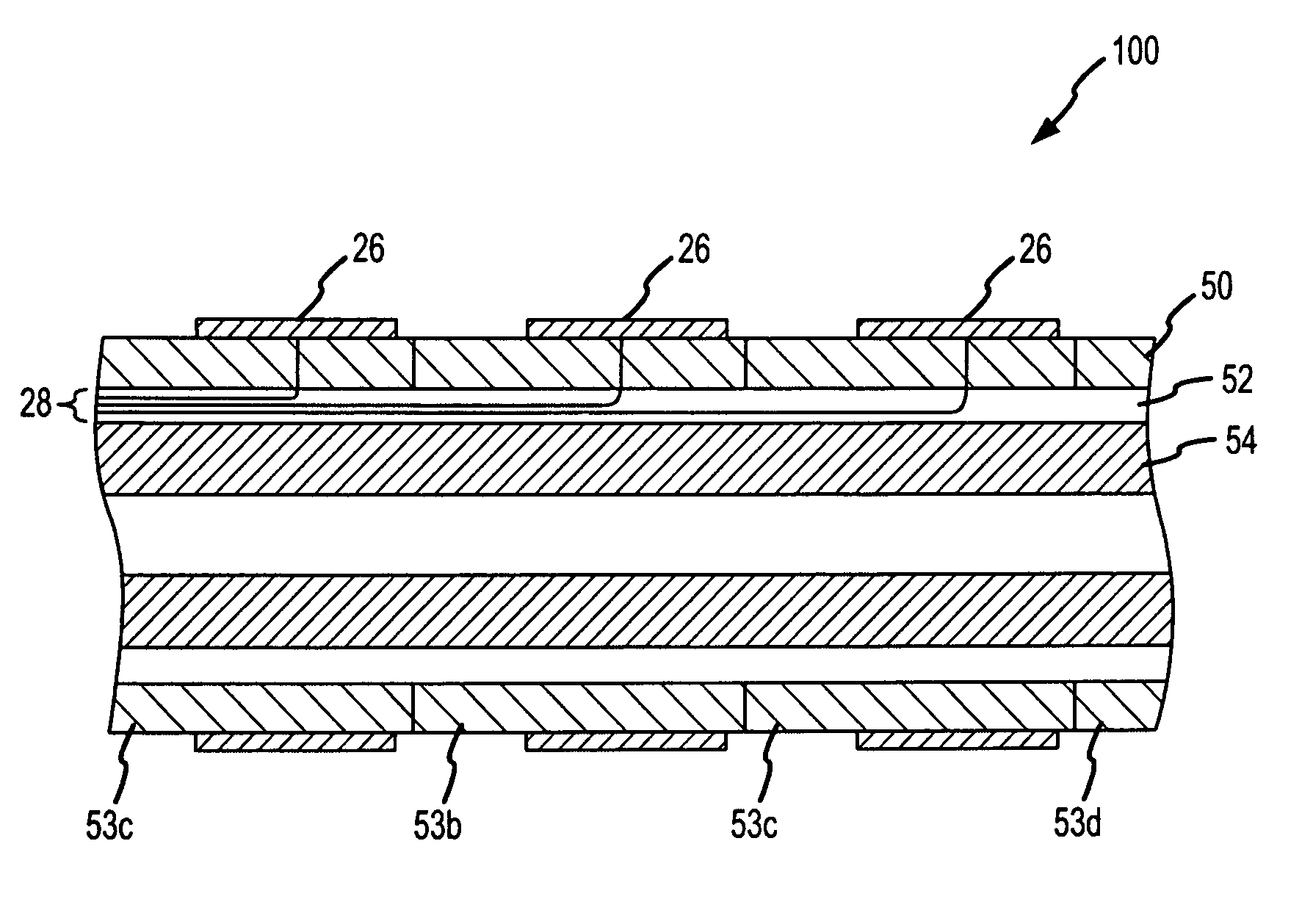

Glass bulb for a cathode ray and a method of producing the same

InactiveUSRE36838E1Inhibit the development of cracksUniform wall thicknessCathode-ray/electron-beam tube electrical connectionCathode-ray/electron-beam tube vessels/containersDiagonalEngineering

A glass panel 3 for a glass tube for a cathode ray tube has a flat panel face portion 7 and a reduced thickness while maintaining a sufficient strength without increasing a difference of brightness, and with less shrinking deformation due to the cooling and solidification of the glass panel. Compressive stress layers 20, 21 having a thickness of to / 10 or more are formed in outer and inner surfaces of the face portion 7 of the glass panel 3 respectively. The relation to the wall thickness td of the central portion of the face portion to the wall thickness to of a portion near an edge portion on a diagonal line is 1.0< / =td / to< / =1.2. Compressive stress layers 22, 23 are formed in outer and inner surfaces of a skirt portion 6 wherein the compressive stress value of the face portion 7 is larger than the compressive stress value of the skirt portion, and the compressive stress value of the outer surface 20 of the face portion is larger than that of the inner surface 21.

Owner:ASAHI GLASS CO LTD

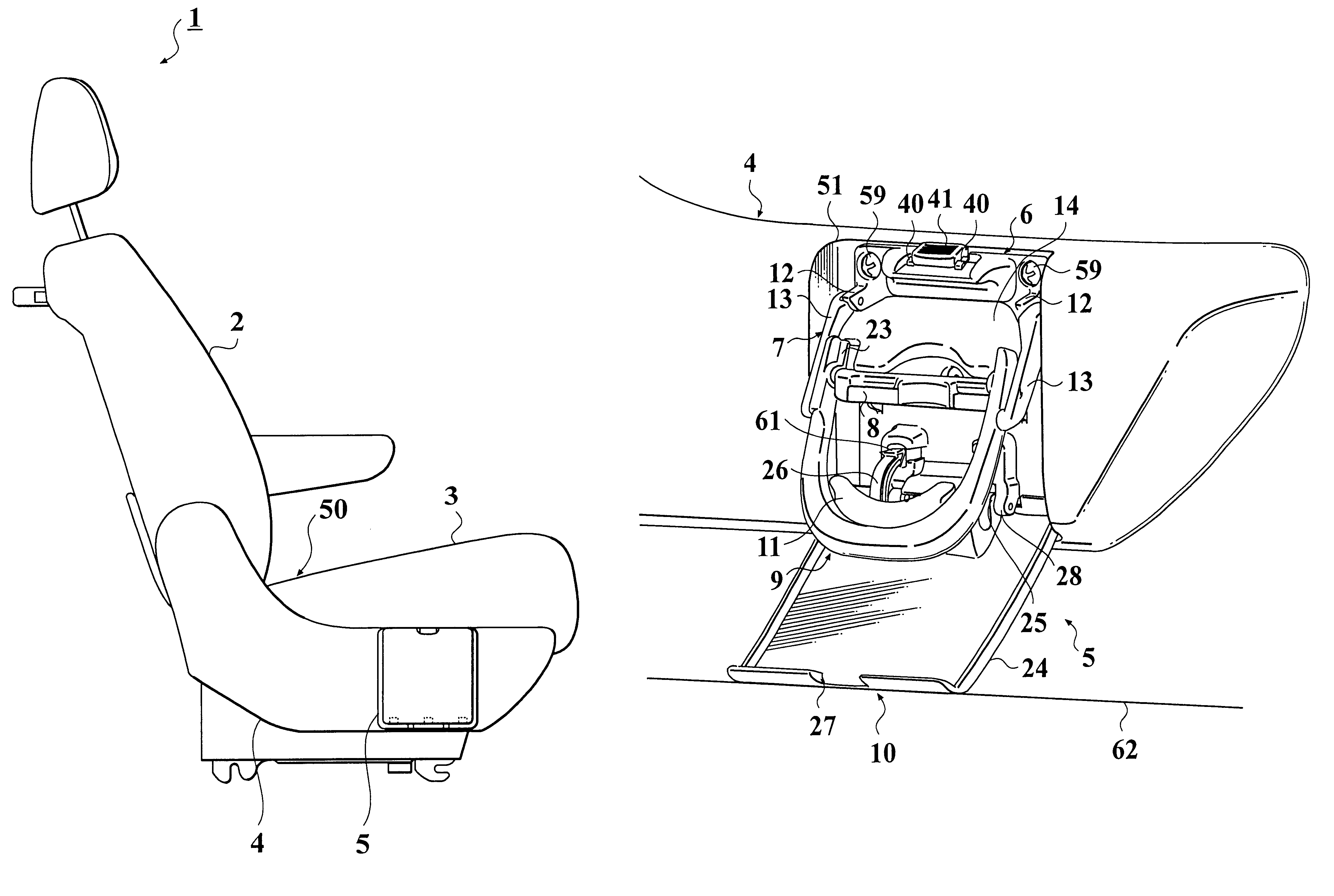

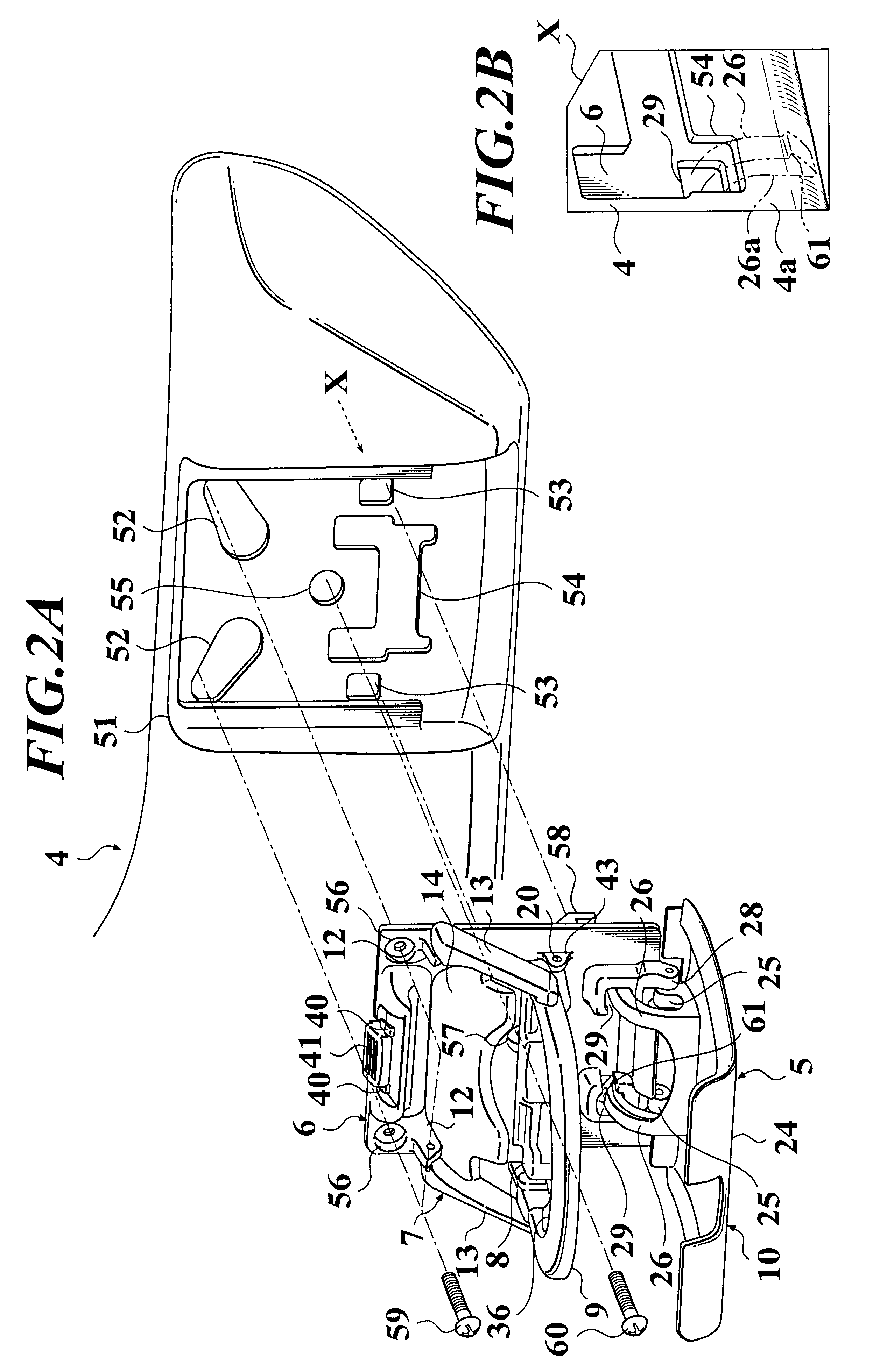

Vehicle seat having container holder and container holder

A vehicle seat having a container holder which is stably attached to the vehicle seat even if a base member is not fixed to the vehicle seat in the whole area of the base member is provided. The vehicle seat comprises a seat body, a side cover attached to a side portion of the seat body, and a cup holder. A penetrating opening is formed in the side cover. The cup holder comprises a base member of which an upper portion is fixed to the side cover, and a saucer member turnably supported up and down to the base member. Penetrating openings are formed in the base member. The saucer member is provided with curved bars curving and projecting toward the base member. When the saucer member stands vertically, the curved bars penetrate the penetrating openings and are hooked on the side cover.

Owner:TS TECH CO LTD

Catheter with embedded components and method of its manufacture

InactiveUS7993481B2Wall thicknessIncrease hoop stiffnessElectrocardiographyLamination ancillary operationsCatheter

A method of manufacturing a catheter includes providing an outer shaft having a lumen therethrough and at least one catheter component disposed at least partially within the lumen, placing an inner shaft within the lumen such that the at least one catheter component is located between the shafts, thereby forming a catheter assembly having an outer surface, and applying energy to the catheter assembly to melt at least the outer shaft to bond the outer shaft to the inner shaft. A unitary catheter shaft having the at least one catheter component substantially embedded therein results. The durometer of the outer shaft may differ from the durometer of the inner shaft, such that the catheter shaft varies radially in durometer. The durometer of the catheter shaft may also vary longitudinally. A shaping wire may be provided to form the distal end of the catheter shaft into a desired shape.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

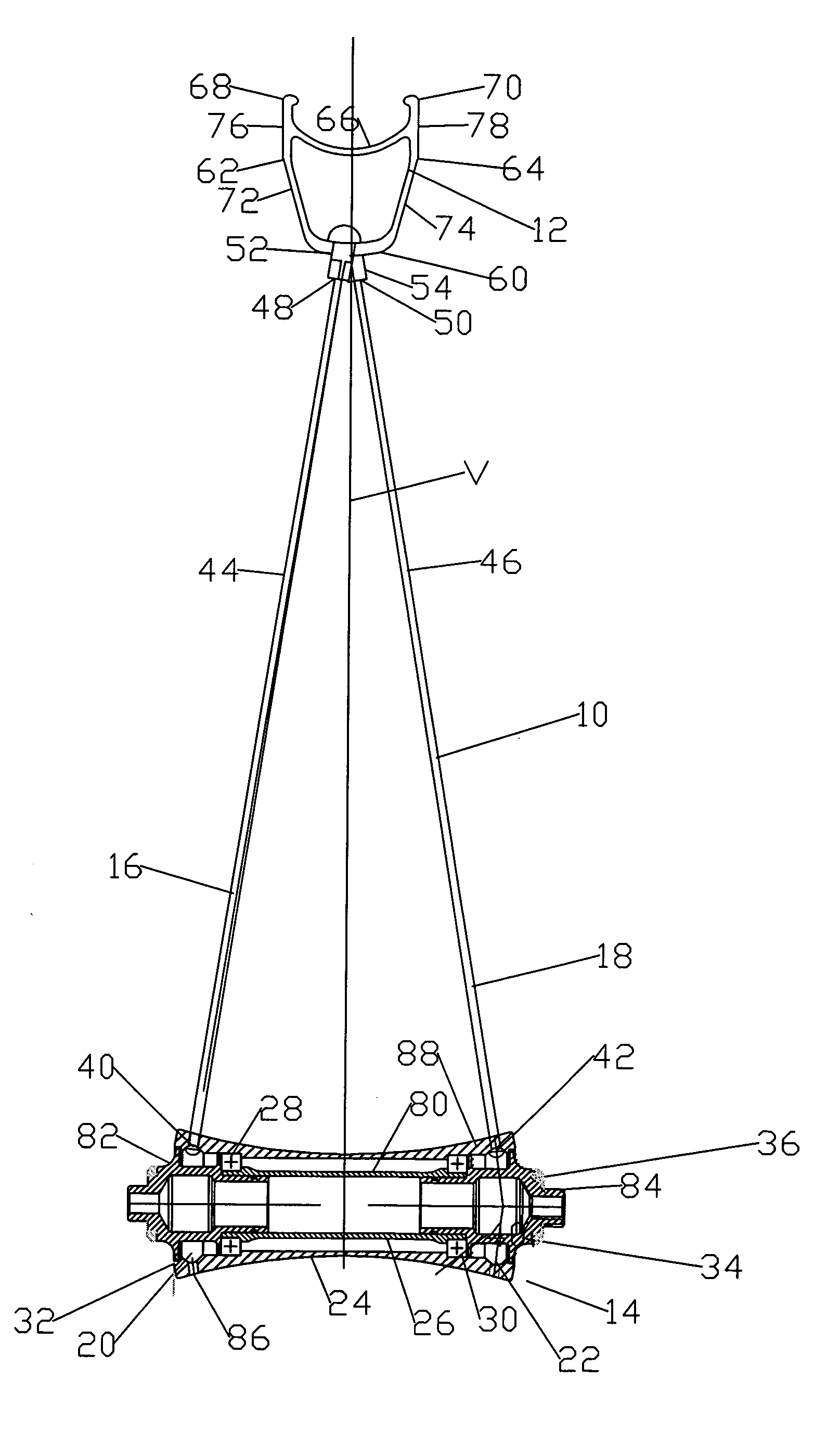

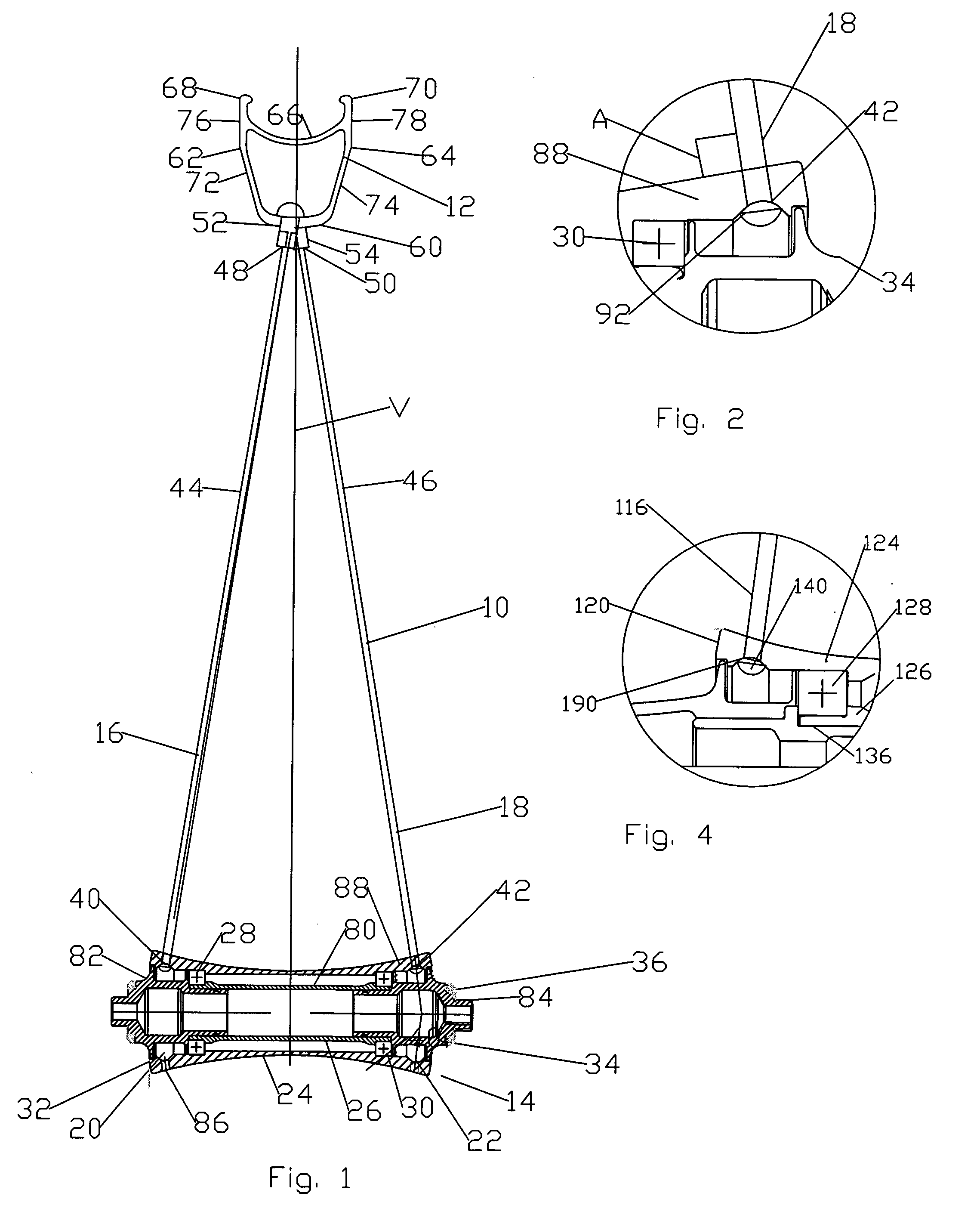

Flangeless and straight spoked bicycle wheel set

A high performance bicycle wheel set uses a flangeless front hub with straight spokes perpendicular to a tangent at the biconcave ends of the hub body, with a single flanged rear hub having straight spokes on the nondrive side and “J-bent” spokes in a flange on the drive side.

Owner:TREK BICYCLE CORPORATION

Chemiluminescent materials and method of making same

ActiveUS10040993B1Improve stabilityHigh energyAnthracene dyesMicroballoon preparationOxalatePhotosensitizer

Chemiluminescent materials are provided that include an encapsulated oxalate-containing composition that includes a core portion and a polymeric coating, a peroxide source, and a fluorescent dye. The core portion includes an oxalate; a polymerizable component composition that polymerizes upon exposure to ultraviolet radiation; a photosensitizer; and an ultraviolet screening agent. The polymeric coating layer surrounding the core portion comprises a polymer derived from the polymerizable component composition. A fluorescent dye may be intermixed in the oxalate-containing composition, intermixed with the peroxide source, present in the chemiluminescent material as a separate dye layer or particle, or present within another component of the chemiluminescent material. A method for making the chemiluminescent material is also provided.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

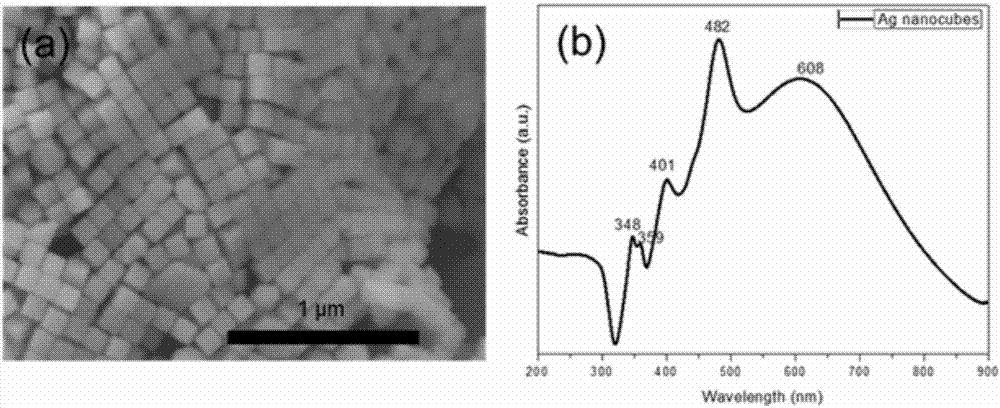

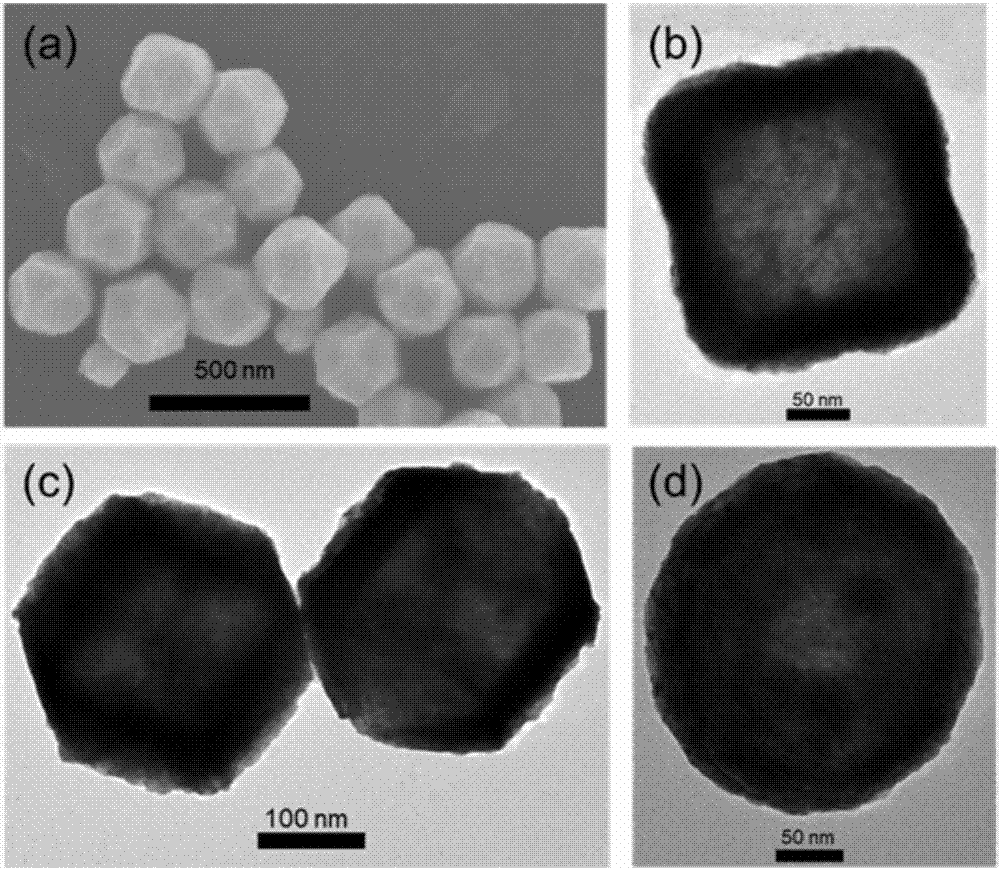

Preparing method for gold-silver alloy hollow polyhedron

InactiveCN107999782AEvenly distributedUnbreakableTransportation and packagingMetal-working apparatusAlcoholActive agent

The invention discloses a preparing method for a gold-silver alloy hollow polyhedron. The preparing method comprises the steps that silver nano cubes are prepared in an oil bath at the temperature ranging from 150 DEG C to 195 DEG C through the polyhydric alcohols reducing method; the silver nano cubes are scattered into a surface active agent solution, and accordingly, the silver nano cubes in which a surface active agent is scattered are obtained; a reducing agent and chloroauric acid in which the surface active agent is scattered are sequentially added in the silver nano cubes in which thesurface active agent is scattered, centrifuging separation is conducted after the reaction is conducted for 10 min-2 h, particles obtained after centrifuging separation are washed, and accordingly thegold-silver alloy hollow polyhedron is prepared. The silver nano cubes can serve as a template for preparing of the hollow polyhedron in which gold and silver elements are evenly distributed, and thetemplate feature is not copied; and the wall of the hollow polyhedron is thick, and the hollow polyhedron is firm and not prone to breakage.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Objective lens holder, objective lens driving device including same and optical disk read/write device

InactiveUS7391582B2Reduce intensityWall thicknessScattering properties measurementsRecord information storageBeam diameterLight beam

An objective lens holder of the present invention includes: (i) a cavity, having an entrance and an exit, which guides, to an objective lens, an incident light beam entering the entrance, the exit being provided on a side of the cavity where the objective lens is housed; and (ii) an aperture having an opening for limiting, to an effective diameter of the objective lens, a beam diameter of the incident light beam passing through the cavity. The cavity is surrounded with internal wall surfaces facing each other so that space between the internal wall surfaces gradually increases from the opening of the aperture toward the entrance or the exit. This makes it possible to provide a highly rigid objective lens holder that allows high speed read / write operations.

Owner:SHARP KK

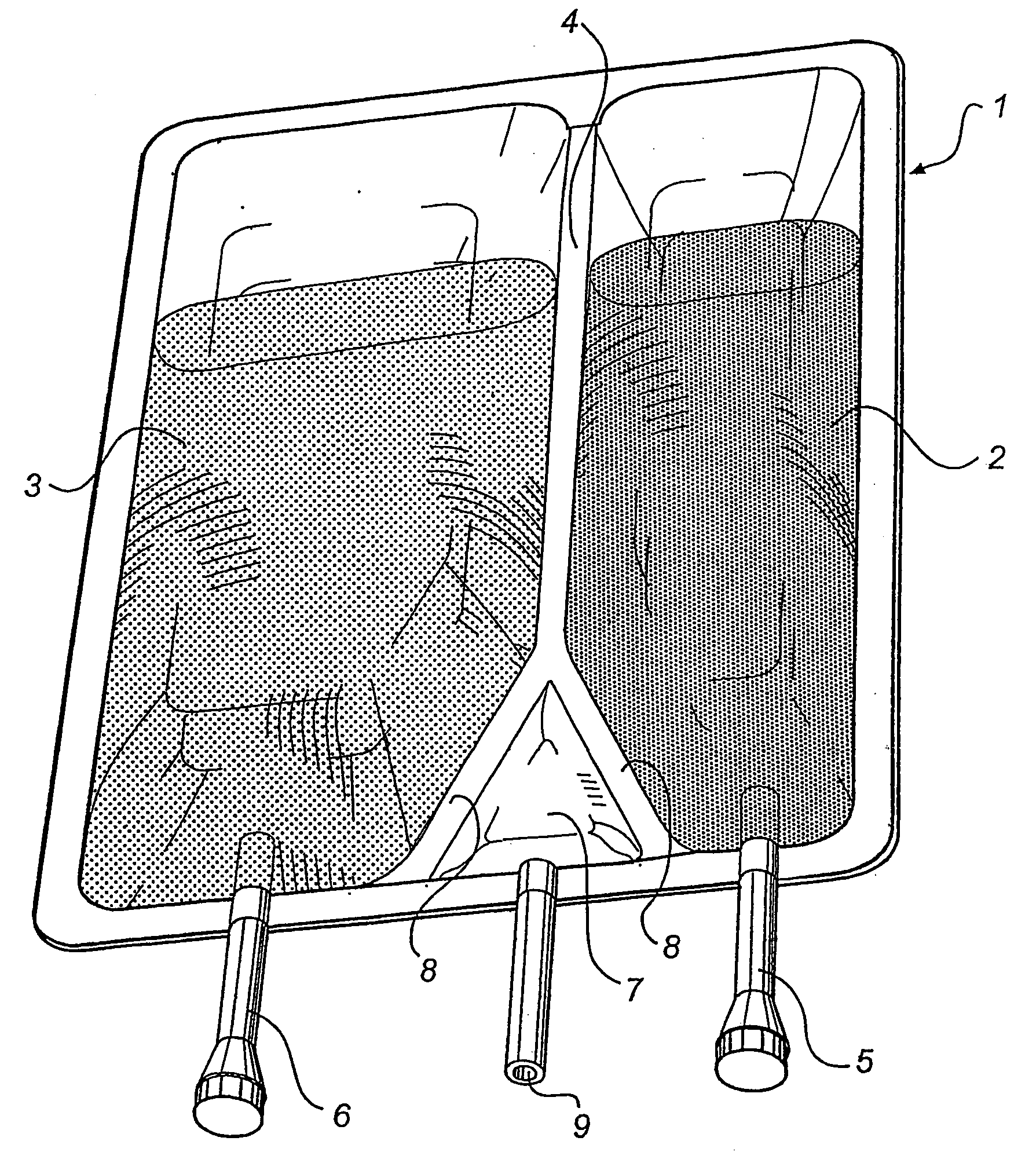

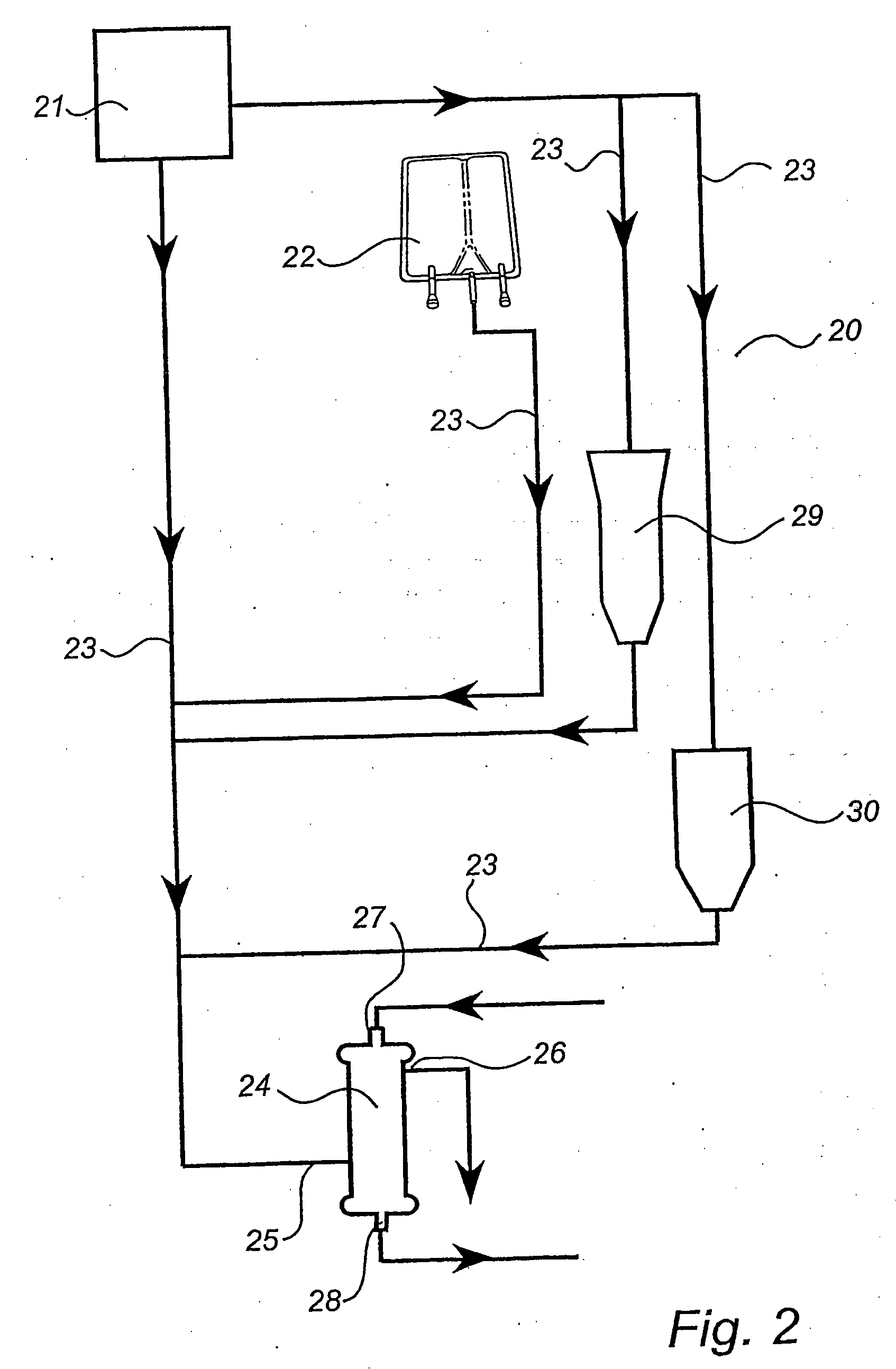

Container with acid diffusion barrier and use thereof

InactiveUS20060210739A1Flexible and convenientSmall wall thicknessSynthetic resin layered productsDialysis systemsDiffusion barrierPolymer chemistry

The invention relates to a container having a wall structure comprising a polymer material including an acid diffusion barrier. The invention also relates to a use of a cycloolefin polymer, COP, and / or a cycloolefin copolymer, COC, as an acid diffusion barrier polymer in a container for an acid. The invention further relates to a use of such a container and to a system for providing a medical solution comprising at least one container according to the invention. Finally the invention relates to a method for treatment by means of a container according to the invention.

Owner:GAMBRO DIALYSATOREN

Zone select stage tool system

ActiveUS9856714B2Wall thicknessConstructionsWell/borehole valve arrangementsRegion selectionEngineering

A stage tool operable with a plug is used for cementing a tubing string in a wellbore annulus. The tool can have a housing with a closure sleeve movably disposed in the internal bore of the housing. When pressure is applied downhole to the tool, a breachable obstruction on an exit port of the tool's bore opens and allows fluid such as cement slurry to communicate to the wellbore annulus. When cementing through the open tool is finished, a plug can be deployed downhole lands on a seat in the closure sleeve, and applied fluid pressure in the tool's bore against the seated plug closes the closure sleeve relative to the housing's exit port. Rotational catches between the housing's bore and the closure sleeve prevent the closure sleeve from rotating. A hydraulic mechanism on the tool can facilitate movement of the closure sleeve in response to a fluid pressure component.

Owner:WEATHERFORD TECH HLDG LLC

VE (Vitamin E) coenzyme Q10 composition for assisting to reduce blood fat and boosting immunity and preparation method thereof

The invention discloses a VE (Vitamin E) coenzyme Q10 composition for assisting to reduce blood fat and boosting immunity and a preparation method of the composition. The VE coenzyme Q10 composition comprises the following components in parts by weight: 0.5-5 part(s) of coenzyme Q10, 0.7-21 part(s) of vitamin E and 25-300 parts of granulesten. The preparation method for the composition comprises the following steps of: adding the materials to matrix which is mixed and dissolved with soybean oil and beewax; stirring and dissolving the materials in the matrix at about 50 DEG C; putting the mixture to a colloid mill for grinding and circulating until the mixture is uniform; and obtaining soft capsule preparation by carrying out the processes such as pelleting, shaping, pill-washing, drying in the air, drying, picking and the like. According to the VE coenzyme Q10 composition provided by the invention, the bioavailability and stability of the coenzyme Q10 are greatly increased; and the dual effects of assisting to reduce blood fat and boosting immunity are achieved.

Owner:CSPC ZHONGQI PHARM TECH (SHIJIAZHUANG) CO LTD

Turbine airfoil

InactiveUS9267383B2Avoiding and minimizingImprove the level ofPropellersEngine manufactureCoated surfaceLeading edge

A turbine airfoil includes an airfoil body with a leading edge, trailing edge, and an exterior surface including a suction side and a pressure side located opposite to the suction side. The exterior surface shows away from the interior of the airfoil body. A thermal barrier coating system is present on the exterior surface of the airfoil body in a coated surface region. The airfoil also includes an uncoated surface region where a thermal barrier coating system is not present. The uncoated region extends on the suction side of the exterior surface from the trailing edge towards the leading edge to a boundary line between the coated surface region and the uncoated surface region, wherein the boundary line is located on the suction side between the leading edge and the trailing edge. The airfoil body also includes a step in the exterior surface extending along the boundary line.

Owner:SIEMENS AG

Piston with improved displacement properties

InactiveUS8348030B2Failure be reduced and eliminatedPerformed easily and quicklyFluid actuated brakesBraking element arrangementsEngineeringMechanical engineering

A brake pad actuating device comprising: a piston including: a first pocket; an opposing second pocket; and an internal wall located in the piston separating the first pocket and the second pocket, wherein the volume of the first pocket to the volume of the second pocket form a ratio of less than about 20:1; and wherein the piston is adapted to be used as a brake piston.

Owner:AKEBONO BRAKE

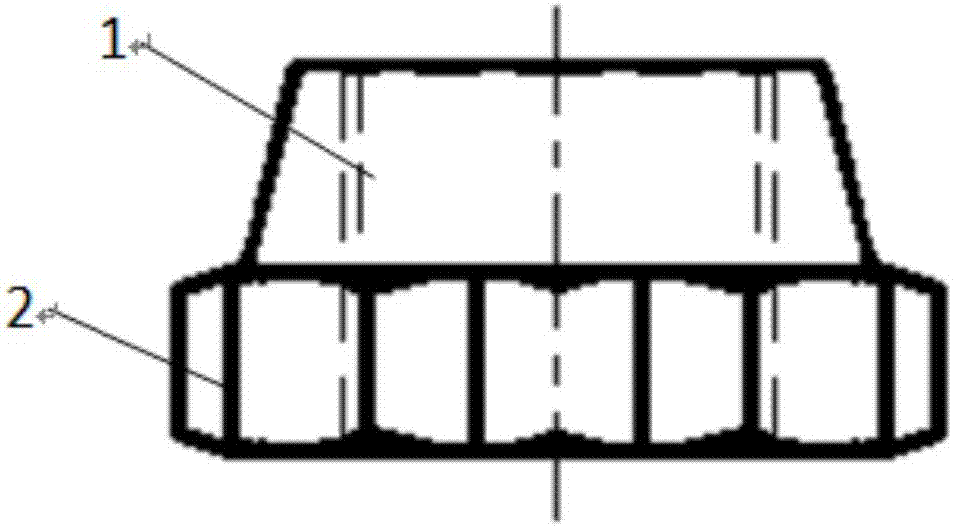

Shear-resistant type dodecagonal self-locking nut for space navigation structure and processing process for shear-resistant type dodecagonal self-locking nut

The invention provides a shear-resistant type dodecagonal self-locking nut for a space navigation structure and a processing process for the shear-resistant type dodecagonal self-locking nut. The shear-resistant type dodecagonal self-locking nut comprises a close-up table, a dodecagonal supporting table and an inner threaded hole, wherein the close-up table is a close-up table with taper; a wide-mouth end of the close-up table is connected with the dodecagonal supporting table; the close-up table is coaxial with the dodecagonal supporting table; the inner threaded hole is formed in the close-up table which takes the axis as an axle center; and the inner threaded hole penetrates through the dodecagonal supporting table. The shear-resistant type dodecagonal self-locking nut provided by the invention has the advantages such as great wrenching torque, a small structural size, light weight, looseness prevention and reliability, high strength, good heat and corrosion resistance and excellent anti-fatigue performance, and can be popularized and applied to important supporting-shearing structures in the field of weapons and equipment such as aerospace, engines, ships and nuclear energy.

Owner:AEROSPACE PRECISION PROD INC LTD

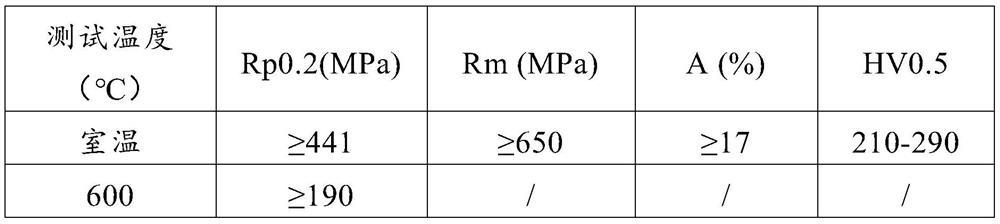

Extrusion casting aluminum alloy material and preparation method thereof

The invention provides an extrusion casting aluminum alloy material and a preparation method thereof. The extrusion casting aluminum alloy material comprises, by weight, 8%-12% of Si, less than 0.9% of Fe, 1%-4% of Cu, 0.2%-0.8% of Mn, 0.3%-0.8% of Mg, less than 0.35% of Zn, less than or equal to 0.01% of Sn, less than or equal to 0.01% of Cd, and the balance Al, and the total amount of other impurities is not more than 0.3%. The extrusion casting aluminum alloy material has good tensile strength, yield strength and hardness, and thick-wall and thin-wall molding can be simultaneously satisfied.

Owner:GUANGZHOU ZHIYUAN ALLOY PROD CO LTD

Forming machining method for blind hole hollow motor shaft

InactiveCN113084467AReduce difficultySuitable for mass productionElectric machineryStructural engineering

The invention relates to a forming machining method for a blind hole hollow motor shaft, and belongs to the technical field of precision transmission part machining. The forming machining method comprises the following steps that S100, a sub-part A is machined; S200, a sub-part B is machined; and S300, the sub-part A and the sub-part B are machined to form the blind hole hollow motor shaft, wherein the step (S200) of machining the sub-part B comprises the following substeps of (S210) obtaining a bar material which meets the requirements of the part; S220, the bar is made into a pipe blank; S230, the pipe blank is subjected to heat treatment, and a pipe material with the length needed by the manufactured sub-part B is obtained; S240, the outer circle of the pipe material is subjected to preprocessing treatment; S250, the pipe material is subjected to rotary swaging, and a variable-diameter multi-step sub-part B is obtained; and S260, the sub-part B is machined. By the adoption of the process method, the blind hole hollow motor shaft meeting the requirement can be machined and manufactured, the machining procedure of parts is shortened, the machining efficiency is improved, and the utilization rate of related materials and the product competitiveness are improved.

Owner:JIANGSU PACIFIC PRECISION FORGING +1

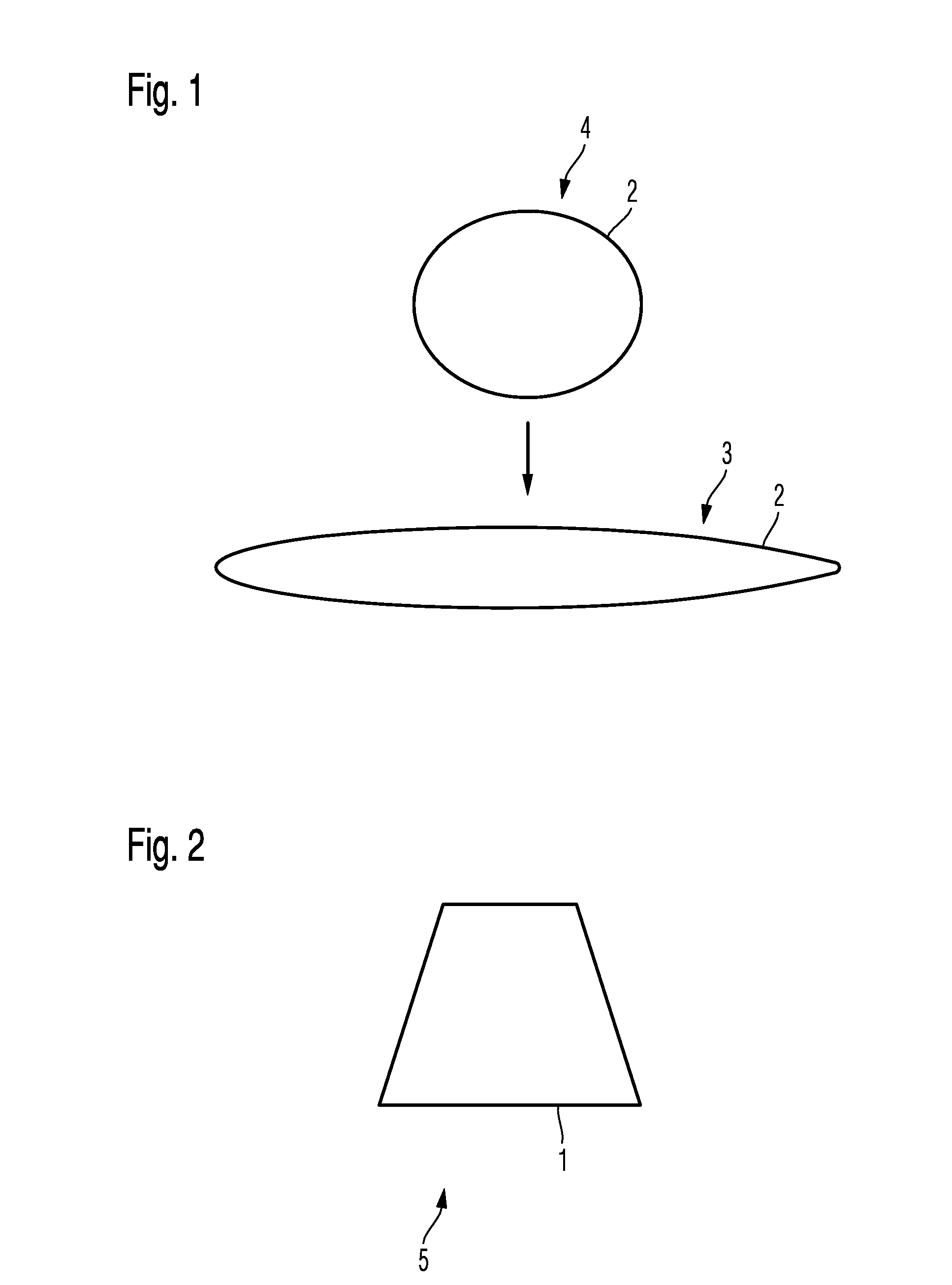

Method for producing a plastic foil tube and a related plastic foil tube

InactiveUS20100151169A1Relieve pressureHigh geometric accuracyLaminationLamination apparatusAviationFiber

The invention relates to a method for producing a plastic foil tube with an intended cross-section that derives from a circular cross-section as a means for the production of fiber compound components for aviation or aerospace. It comprises the following method steps: mounting a semi-finished tube on a core tool; charging the mounted semi-finished tube with a predetermined force to press the semi-finished tube on a core cross section of the core tool, wherein while charging the mounted semi-finished tube with the force crinkles are formed in longitudinal direction of the semi-finished tube; heating the semi-finished tube to a predetermined forming temperature for a predetermined time period for the production of the plastic foil tube with the intended cross-section and stripping the plastic foil tube which is formed in such a manner and cooled down off the core tool.

Owner:AIRBUS OPERATIONS GMBH

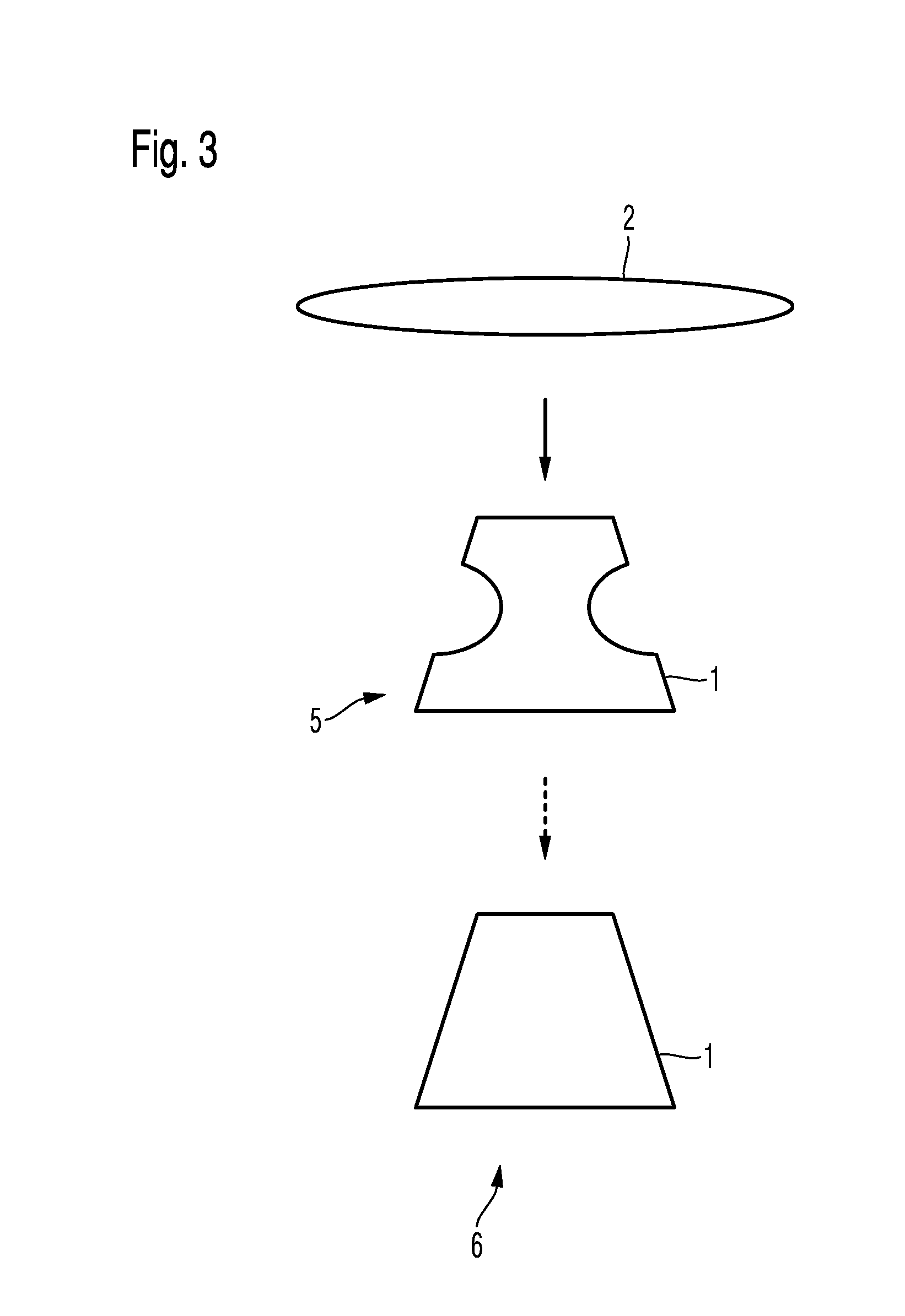

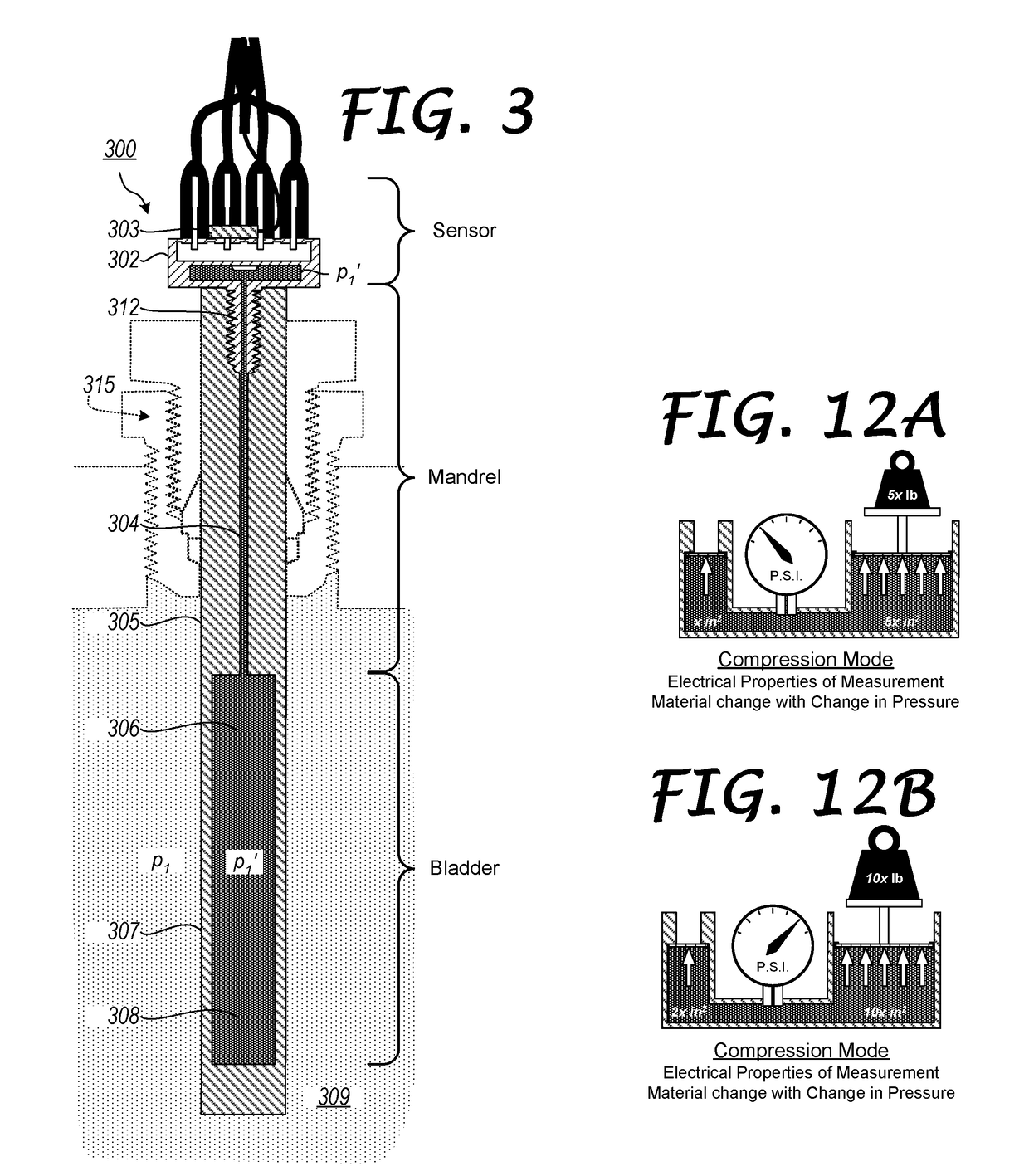

Pressure Sensor System

InactiveUS20190003871A1Accurate measurementGood transmitterLevel controlFluid speed measurement using pressure differenceElectricityElectrical conductor

A pressure bladder comprising a substantially cylindrically shaped interior chamber is formed from a pliable, yet chemically resistant material, for example a fluoropolymer, such as FEP (fluorinated ethylene propylene). The interior chamber of the pressure bladder is hydraulically sealed at a distal end and is hydraulically coupled to a pressure sensor at a proximate end. Both the pressure bladder and pressure sensor are filled with an inert, non-reactive, stable measurement fluid. Optionally, a support mandrel with a second, smaller substantially cylindrically shaped interior chamber is hydraulically coupled between the pressure bladder and the pressure sensor and also filled with the measurement fluid. The pressure sensor is electrically coupled to electrical conductors, as is an optional thermistor. The conductors are received within a conductor protective tubing. The pressure sensor is disposed within a protective isolation tubing which is hydraulically coupled to the conductor protective tubing and to either the pressure bladder or support mandrel.

Owner:WESTMORELAND III AUBREY DARE

Manufacturing method for controlling deformation of ferrite/martensitic steel hexagonal pipe

The invention belongs to the technical field of metallurgical materials, and relates to a manufacturing method for controlling deformation of a ferrite / martensitic steel hexagonal pipe. The manufacturing method sequentially comprises the following steps of (1), carrying out hot extrusion; (2), rolling and annealing intermediate cold; (3), rolling a circular tube into a hexagonal tube; (4), normalizing and tempering an intermediate pipe; (5), carrying out cold rolling on finished product; (6), carrying out final heat treatment. By means of the manufacturing method for controlling deformation of the ferrite / martensitic steel hexagonal pipe, the obtained hexagonal pipe can meet the strict requirements of a fast reactor core assembly on the straightness, the wall thickness, the inner opposite side distance, the torsion resistance and the like of the ferrite / martensitic steel hexagonal pipe.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

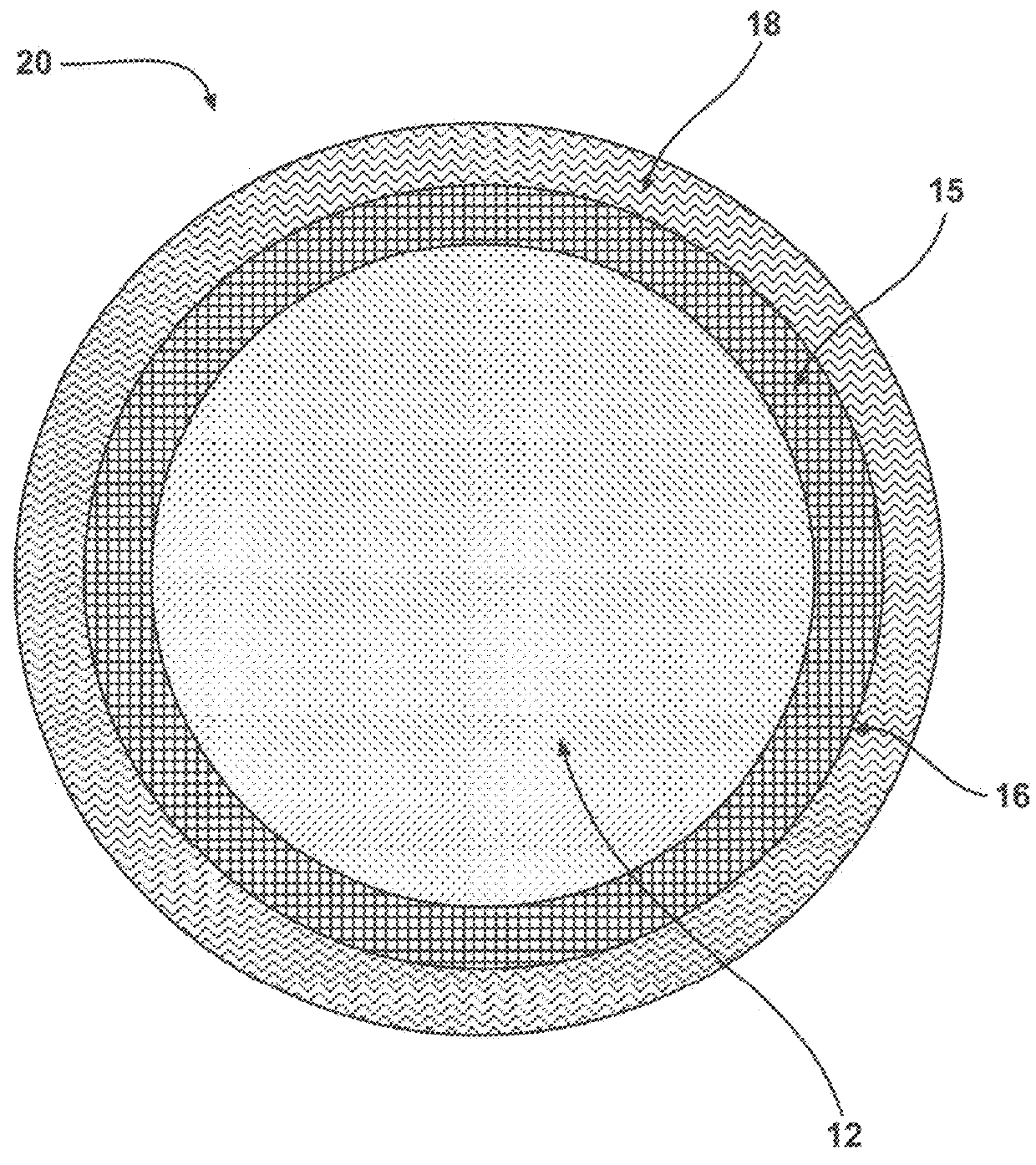

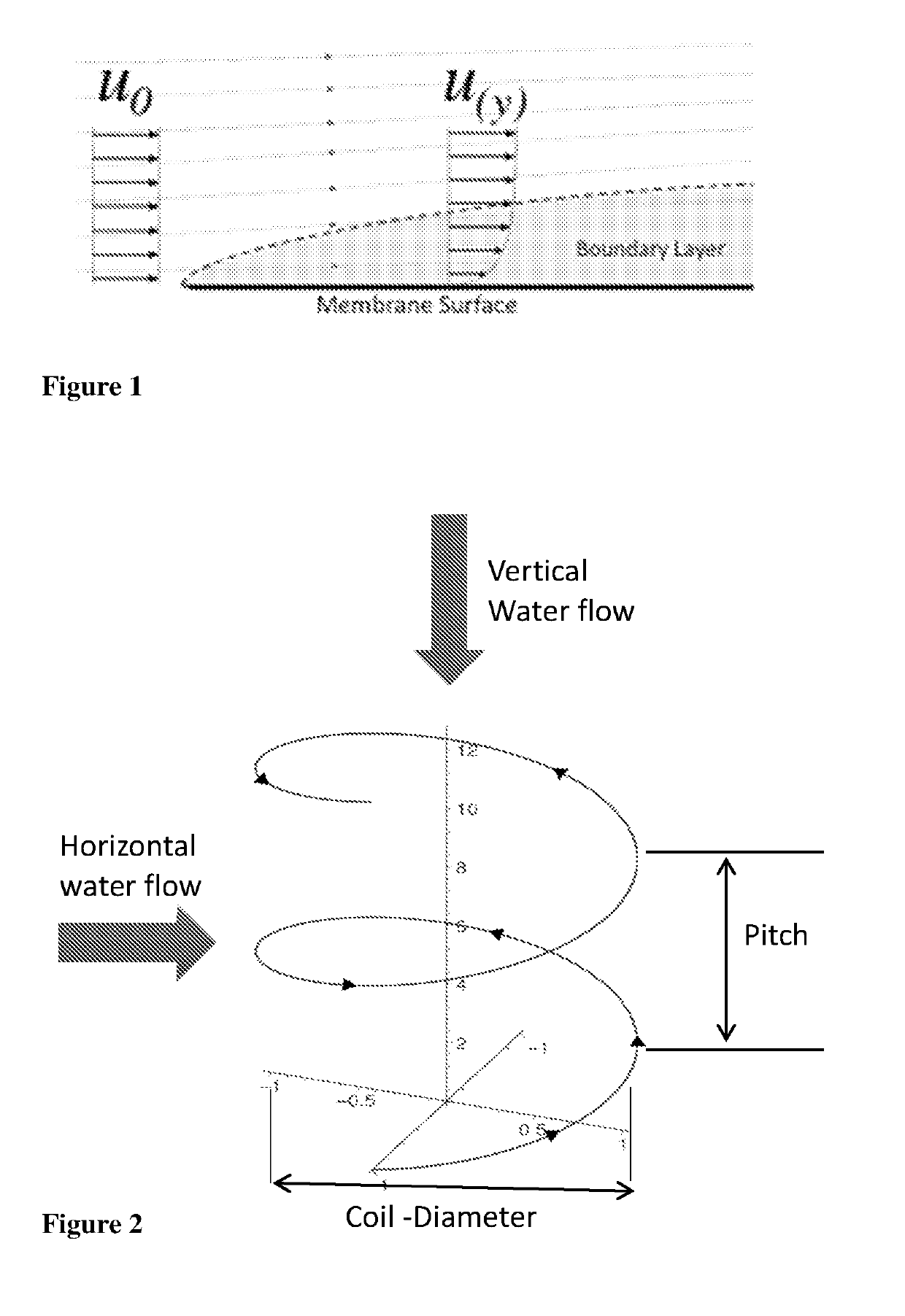

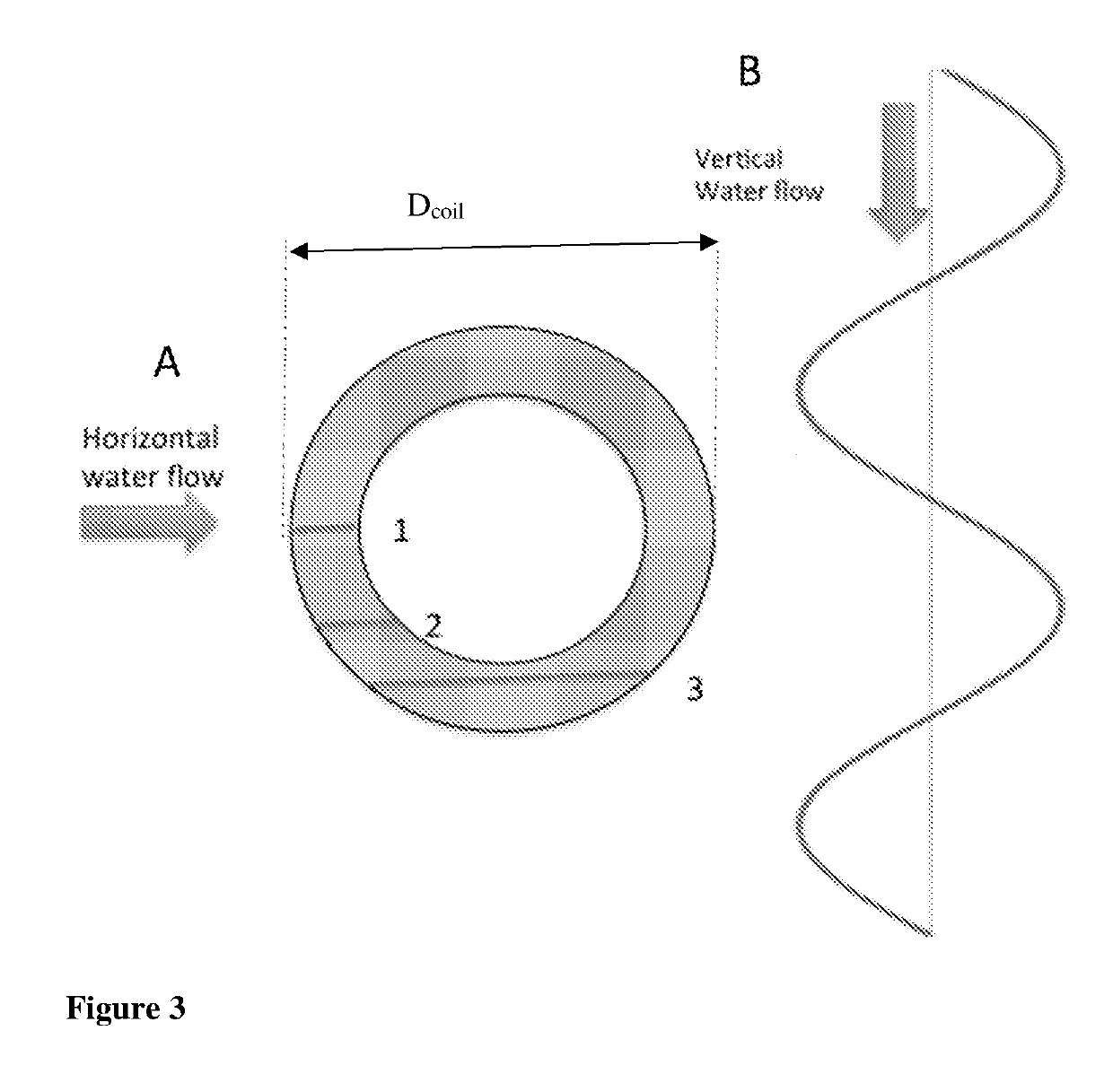

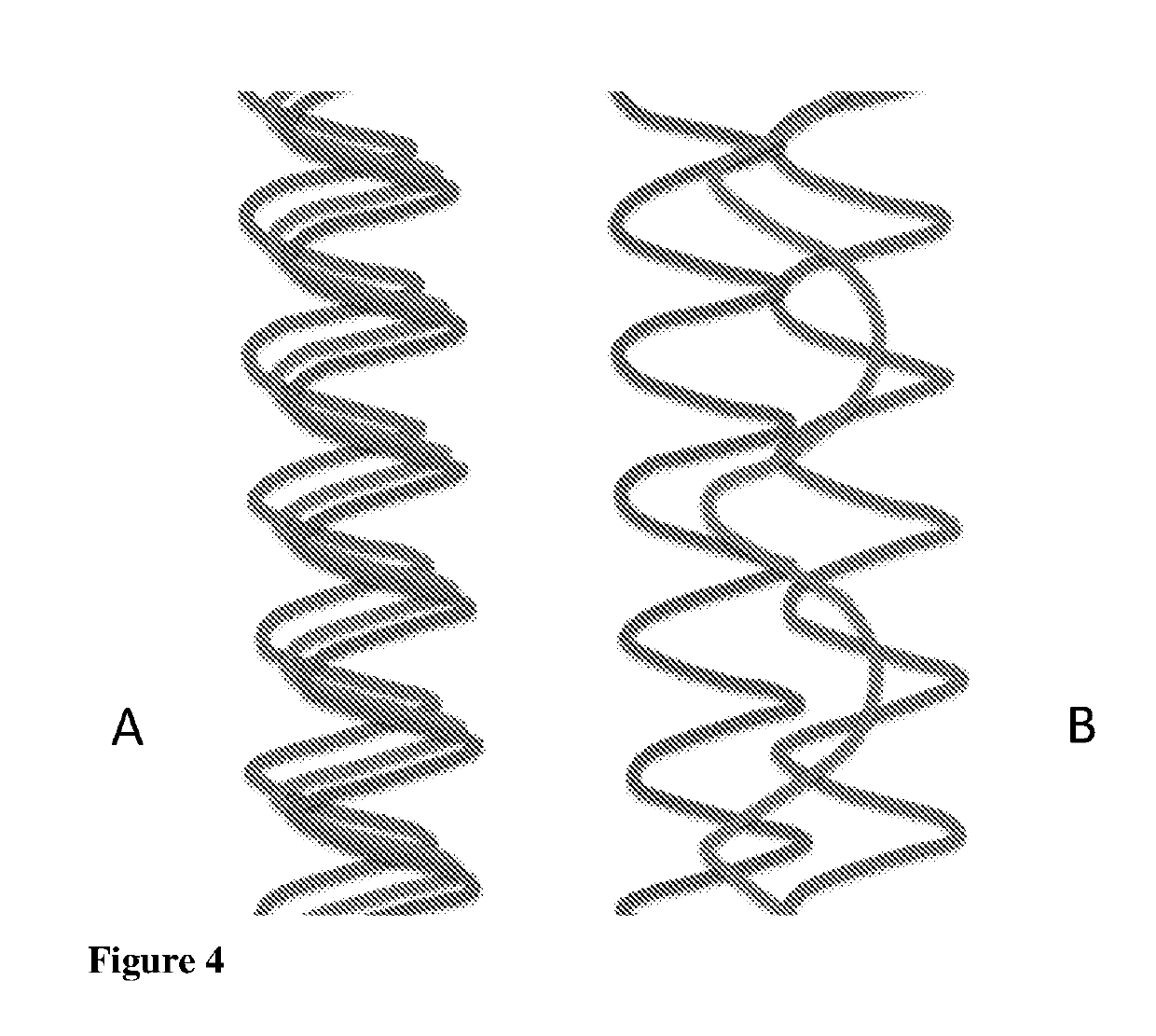

Self-coiling hollow fibre membrane

ActiveUS20190217253A1Reduce tensionMinimizing associated energy penaltyMembranesSemi-permeable membranesFiberHollow fibre membrane

A hollow fibre membrane having a coiled, a hemihelix, a helical or an undulated native form, in which the membrane can be stretched by up to 4-times its original length with no plastic deformation, and wherein the native form of the membrane is produced by the asymmetric flow of liquid polymer through an opening of a die or nozzle.

Owner:OXYMEM

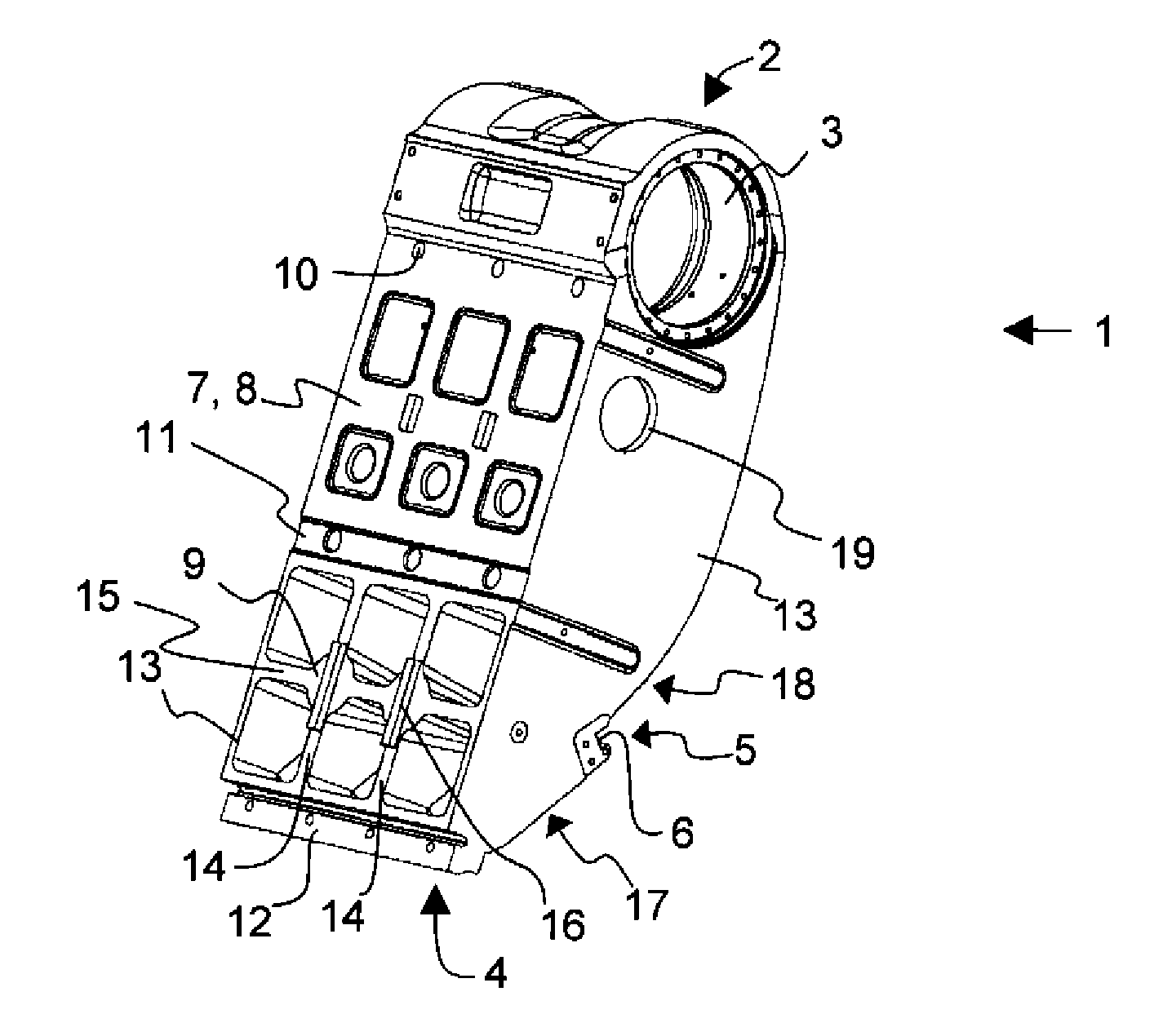

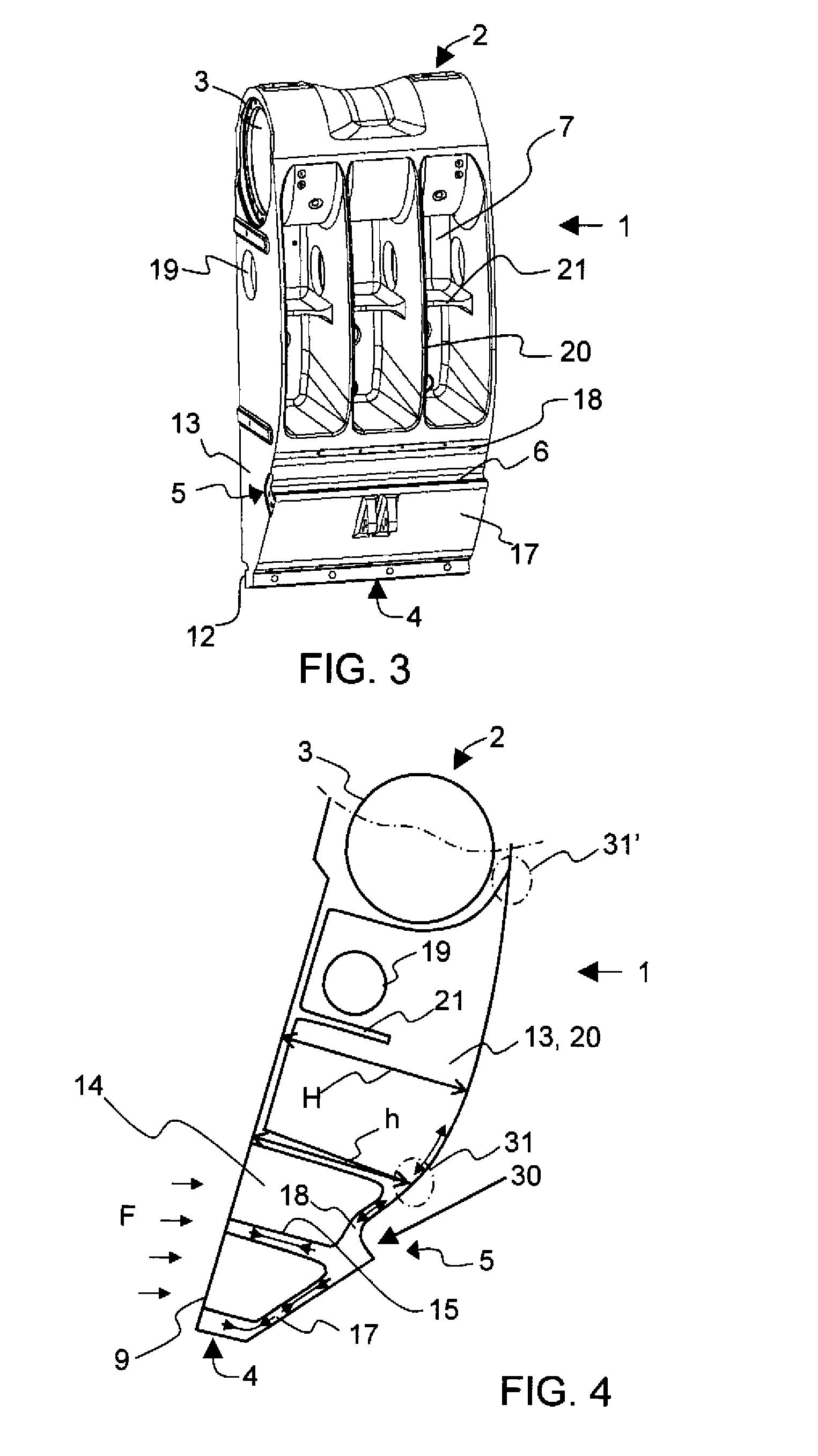

Pitman of a jaw crusher, jaw crusher, crushing plant and crushing method

A pitman of a jaw crusher comprising an upper part, which comprises an upper supporting point for supporting the pitman in the body of the jaw crusher, and a lower part comprising a lower supporting point for supporting the pitman in the body of the jaw crusher through a toggle plate. The lower part of the pitman comprises sidewalls and honeycomb structure open to the crushing direction, which structure comprises one or more cross-sectional supports reaching from the first sidewall of the pitman to the second sidewall. A jaw crusher, a crushing plant and a method for increasing crushing capacity of mineral material.

Owner:METSO OUTOTEC (FINLAND) OY

Turbine airfoil

InactiveUS20130058787A1Avoiding and minimizingImprove the level ofPropellersEngine manufactureTrailing edgeLeading-edge slats

A turbine airfoil includes an airfoil body with a leading edge, trailing edge, and an exterior surface including a suction side and a pressure side located opposite to the suction side. The exterior surface shows away from the interior of the airfoil body. A thermal barrier coating system is present on the exterior surface of the airfoil body in a coated surface region. The airfoil also includes an uncoated surface region where a thermal barrier coating system is not present. The uncoated region extends on the suction side of the exterior surface from the trailing edge towards the leading edge to a boundary line between the coated surface region and the uncoated surface region, wherein the boundary line is located on the suction side between the leading edge and the trailing edge. The airfoil body also includes a step in the exterior surface extending along the boundary line.

Owner:SIEMENS AG

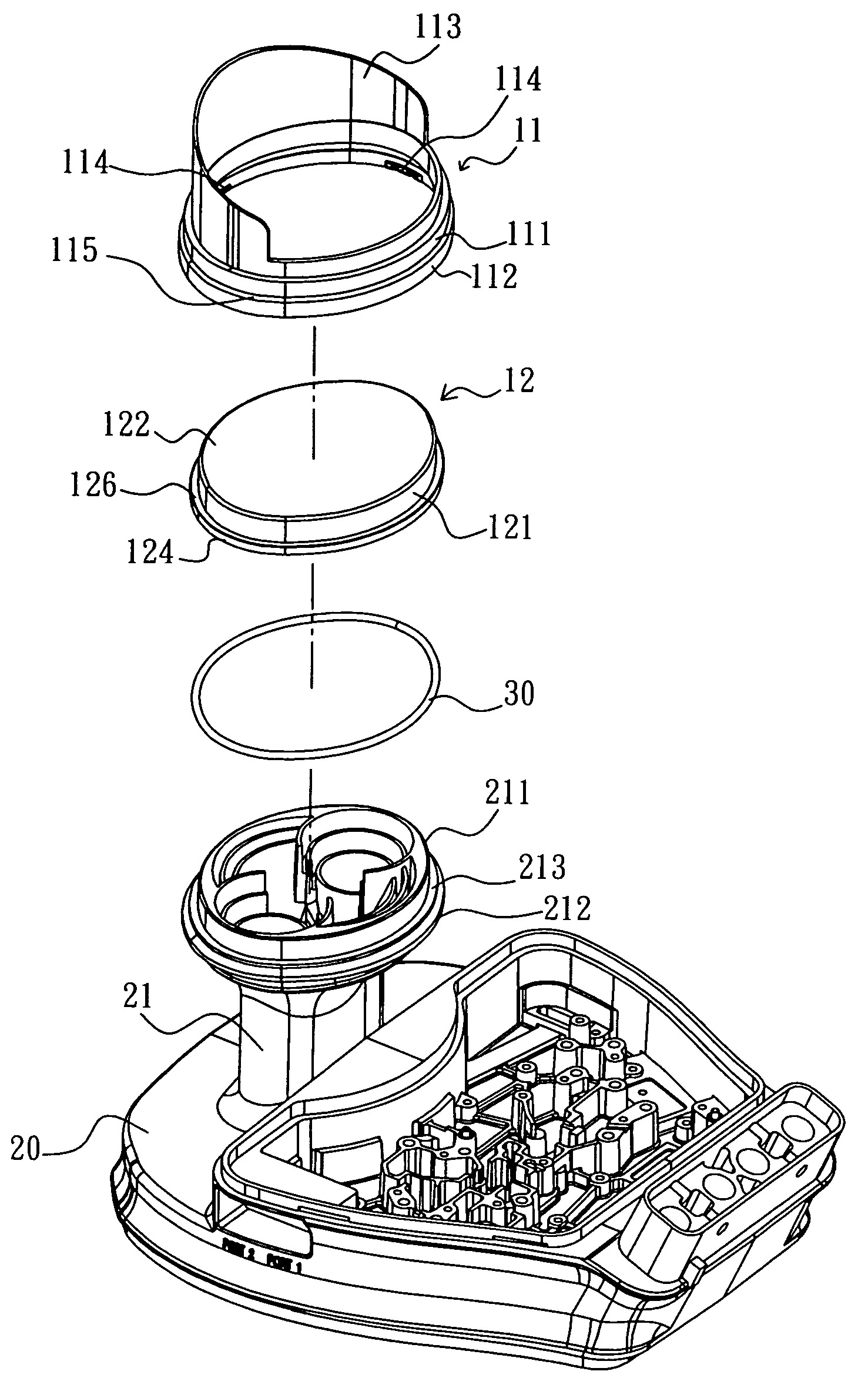

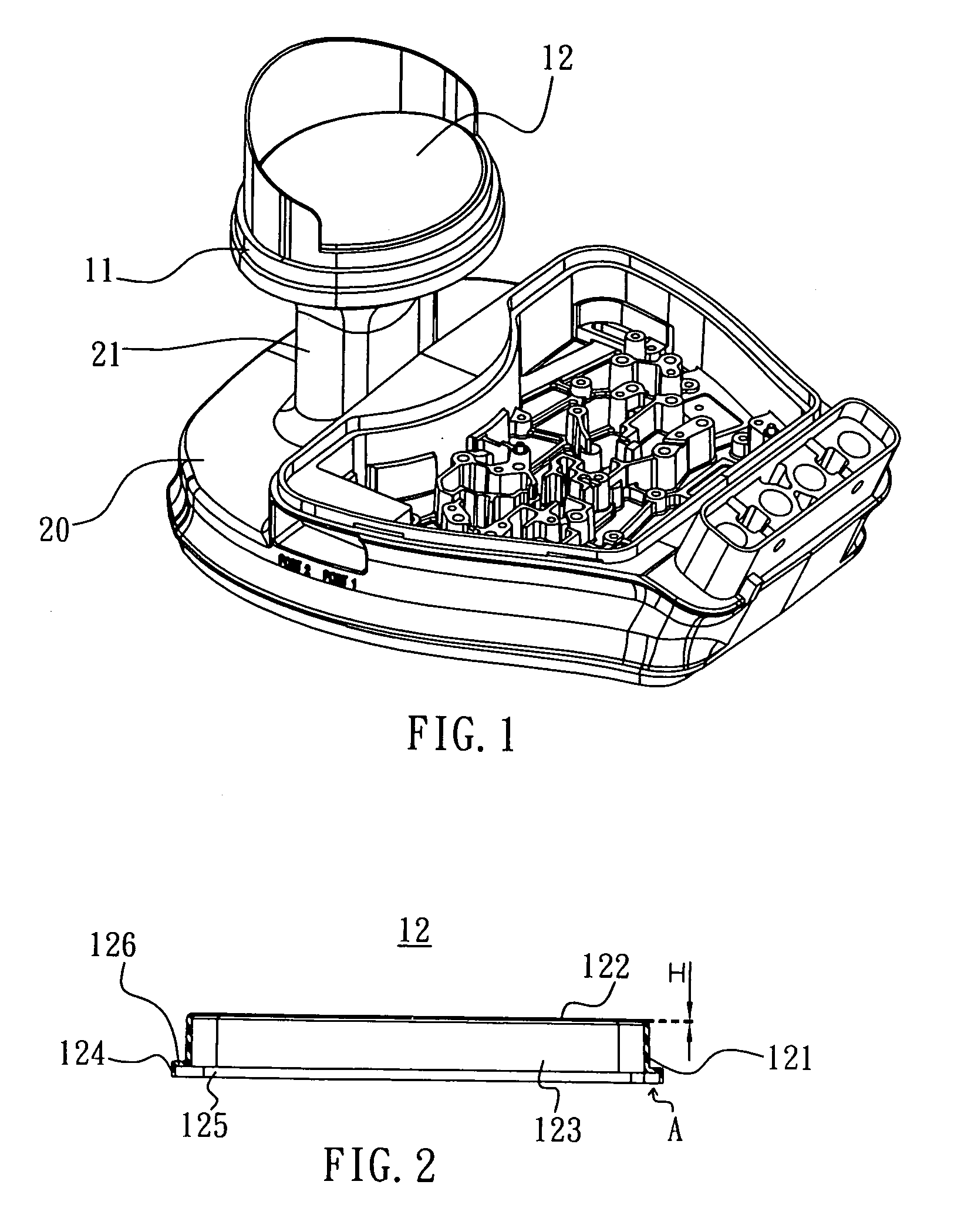

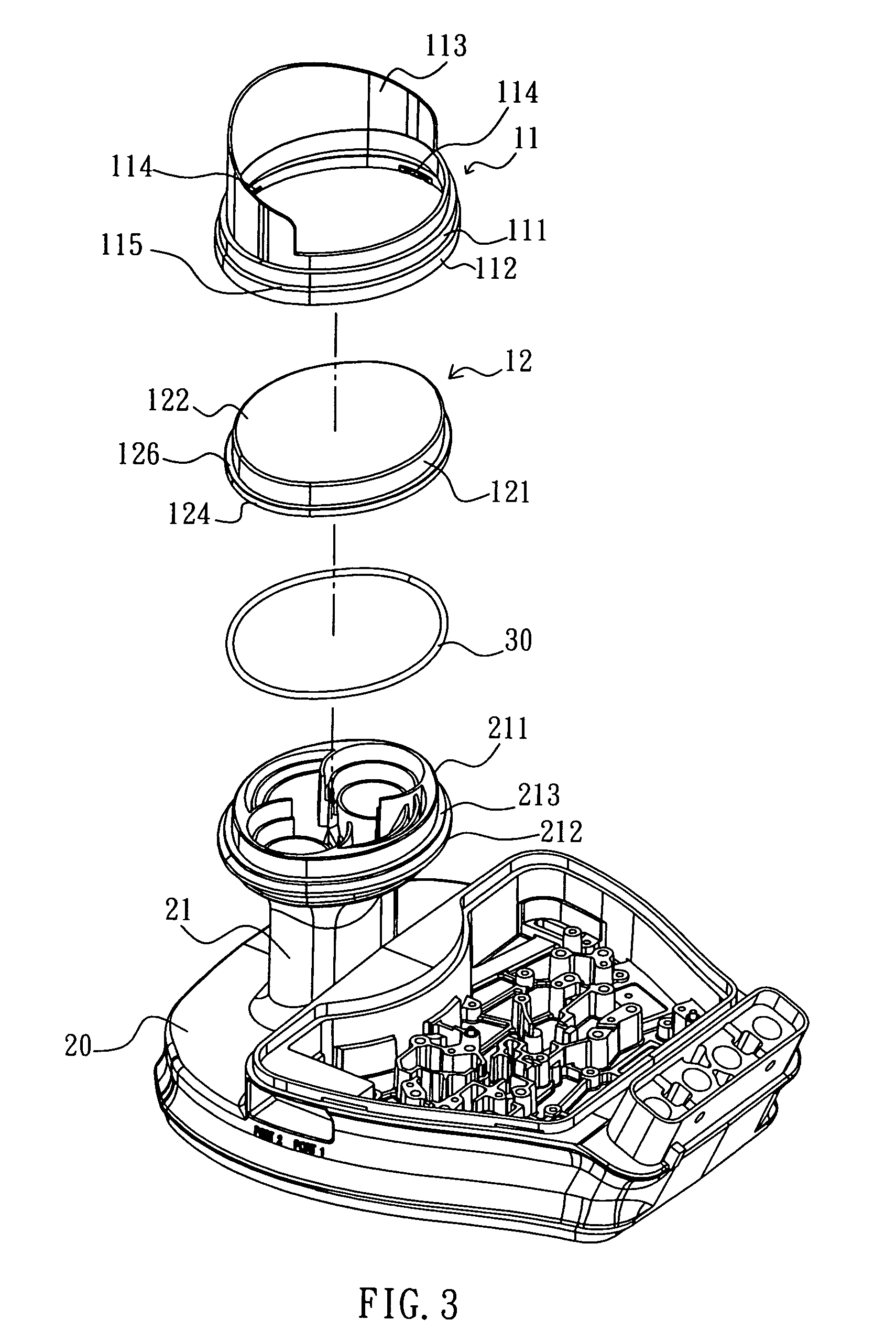

Waterproof mechanism for satellite antenna

A waterproof mechanism for a satellite antenna is to separate a waterproof cover of the known technology into two components of a fixing cover and a thin wall cap used for compressing an O-ring, cause the thin wall cap and the O-ring to be combined closely and stably on the upper end of a wave-guide tube, and enable the stability and the strength of the entirety to be increased. But, the thin wall cap is unnecessary to have a same thickness as the fixing cover. Therefore, the thickness of the thin wall cap can approximately be reduced to 3 mm. This can increase broadly the passing rate of satellite signal and allow a low noise block with integrated feed (LNBF) to have a better satellite signal receiving effect.

Owner:WISTRON NEWEB

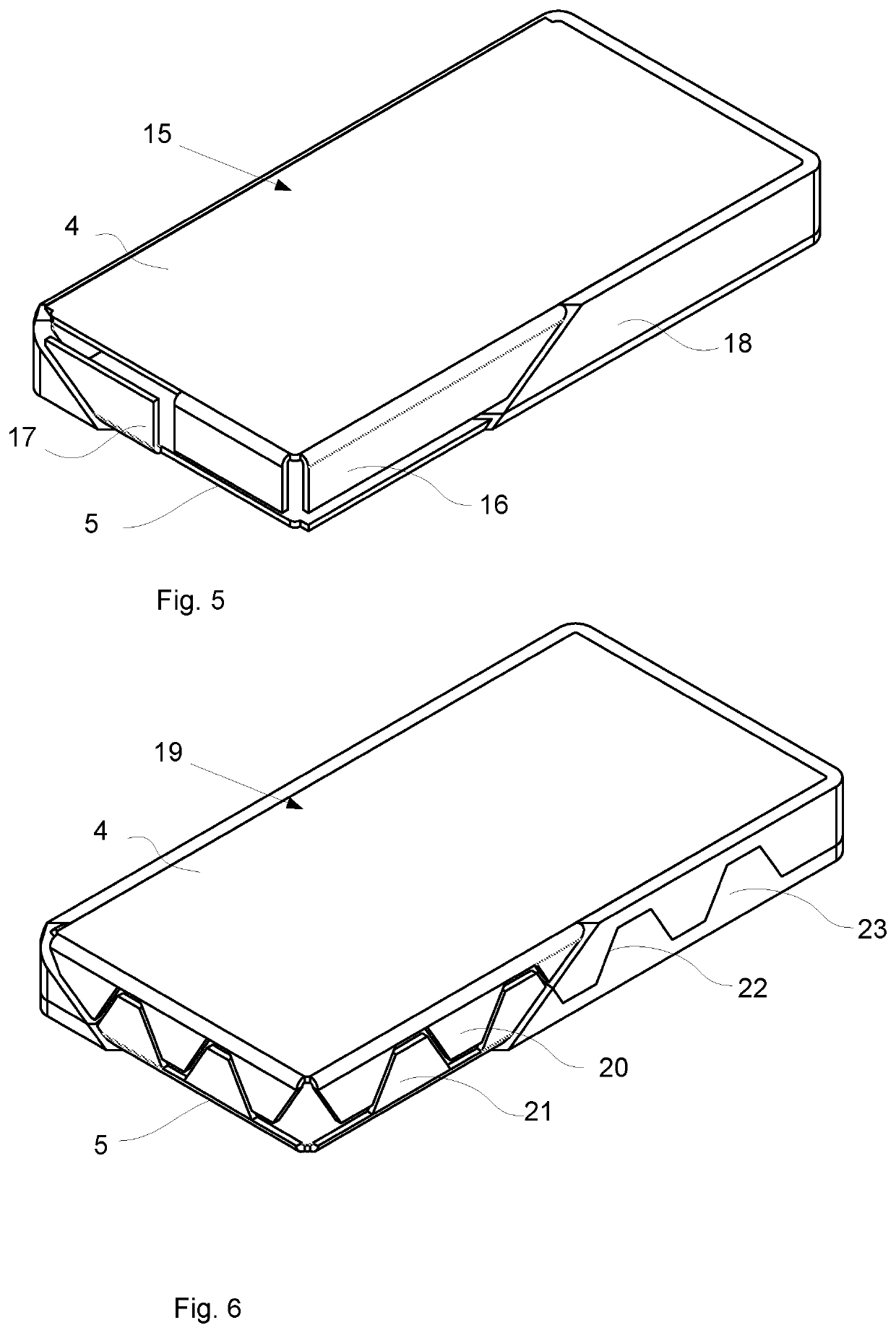

A battery module casing, a battery module and a battery

InactiveUS20200243809A1High mechanical strengthFast heat conductionSmall-sized cells cases/jacketsCell temperature controlEngineeringStructural engineering

A battery module casing (2) configured to house at least one battery cell, said battery module casing (2) comprising: a first metal plate (4), configured to form a positive terminal of a battery module and to be positioned on a first side of said at least one battery cell, a second metal plate (5), configured to form a negative terminal of a battery module (1) and to be positioned on an opposite second side of said at least one battery cell, a lateral wall element (6) configured to extend around a lateral periphery of said at least one battery cell, wherein the lateral wall element (6) is located between said first metal plate (4) and said second metal plate (5), and wherein said lateral wall element (6) comprises an electrically isolating material and is sealingly attached to the first metal plate (4) and to the second metal plate (5) respectively. At least one of said first and second metal plates (4, 5) comprises at least one lateral extension (7, 8) that, along at least a part of a periphery of the plate to which it is associated, forms a lateral wall together with said lateral wall element (6).

Owner:NILAR INT AB

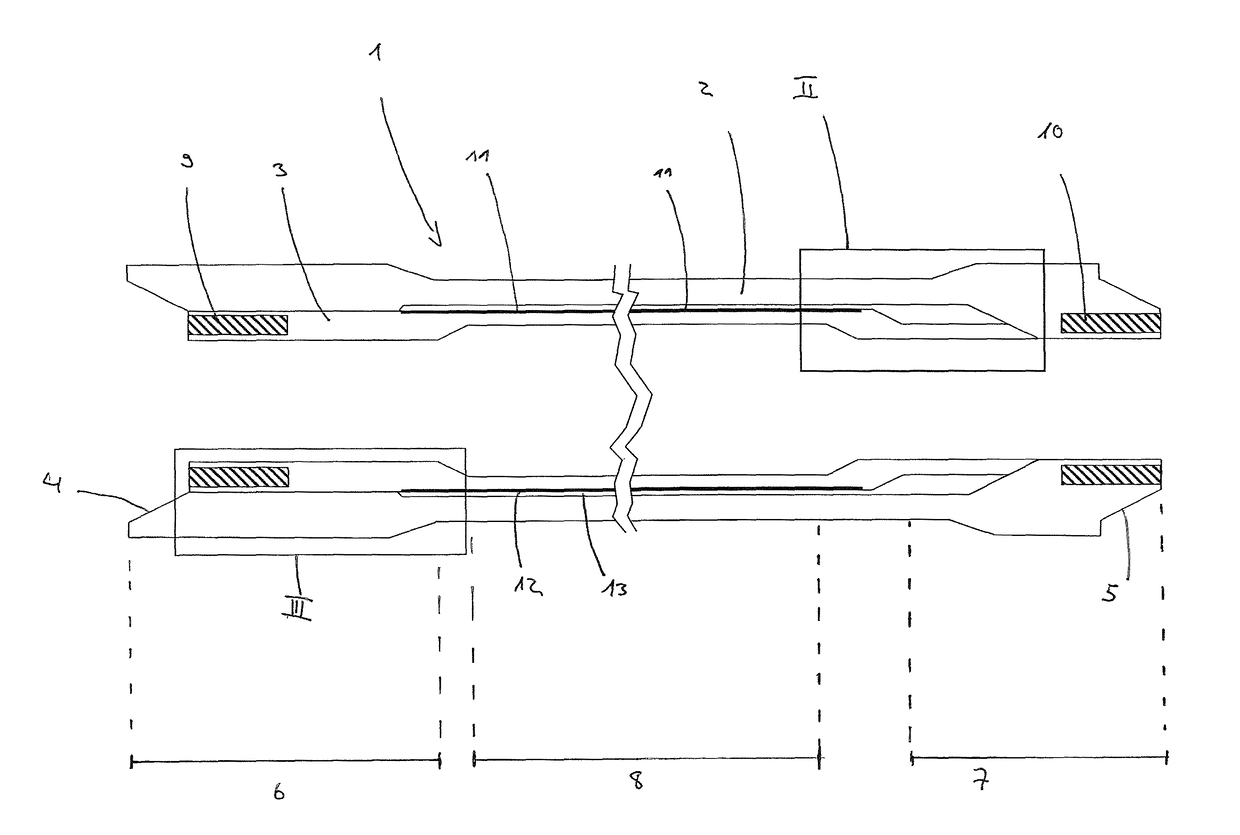

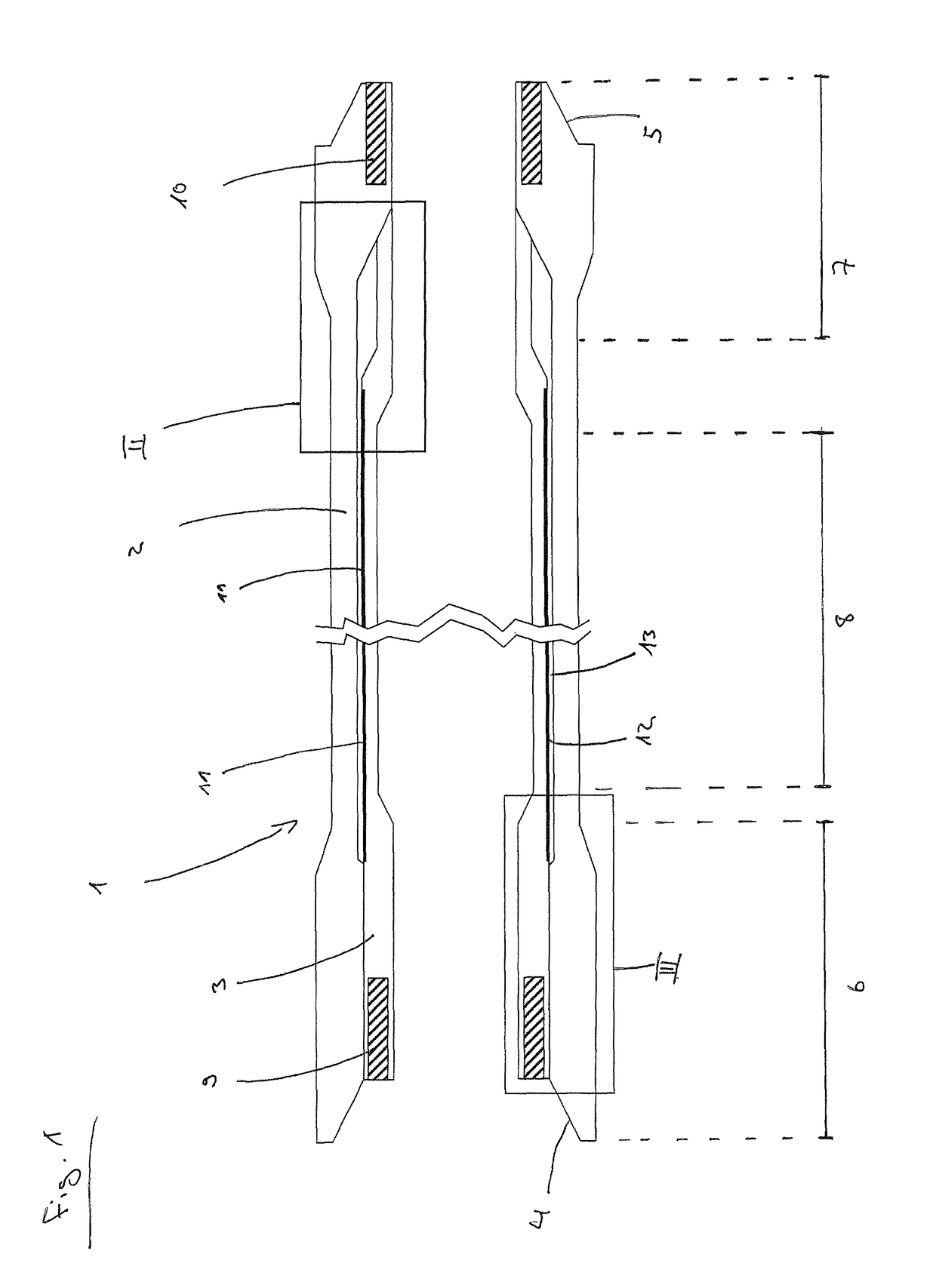

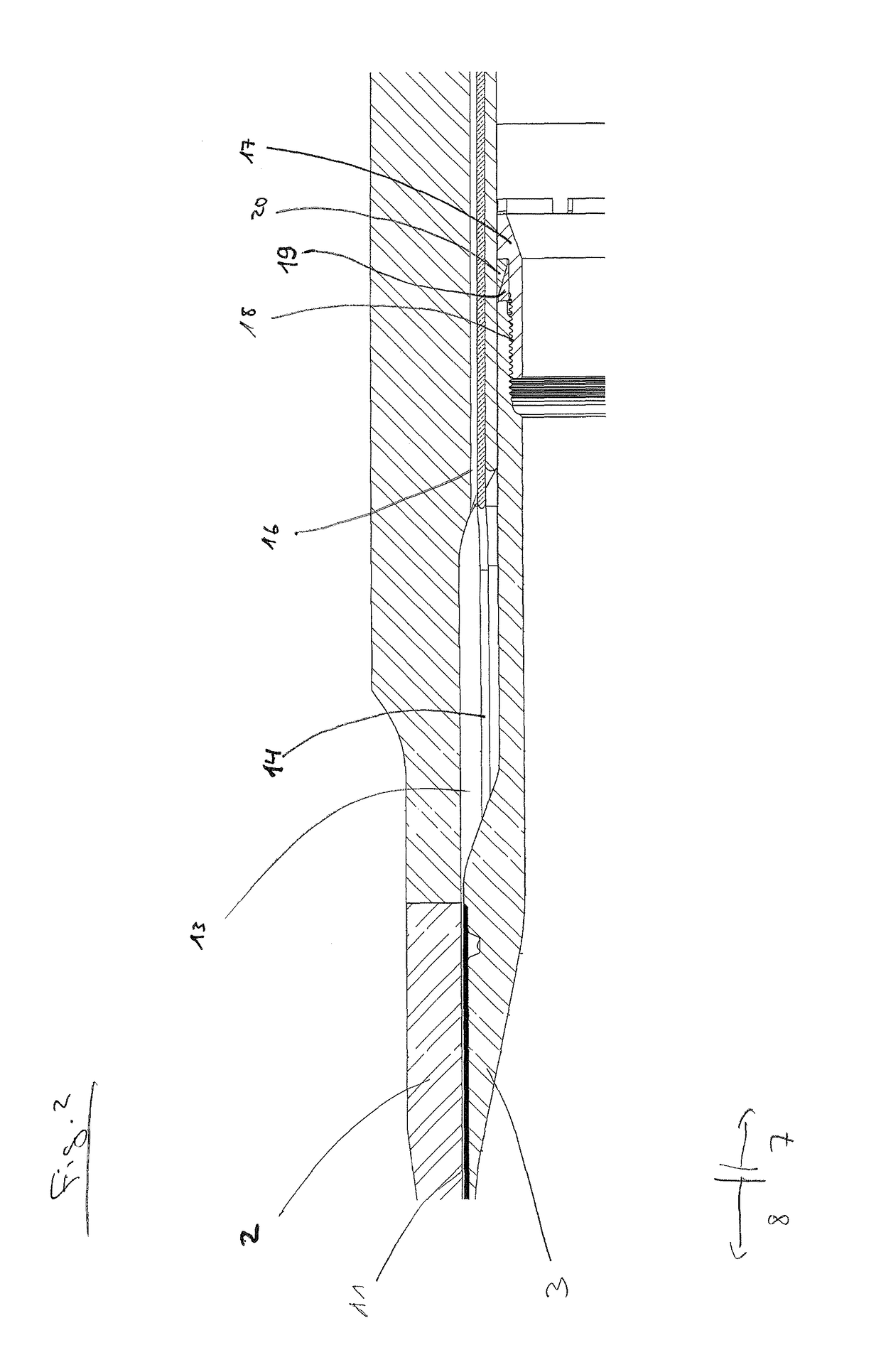

Drill pipe

ActiveUS10107049B2Minimized pressure lossNo lossDrilling rodsGeothermal energy generationPetroleum engineeringDrill pipe

A drill pipe, particularly for a drill string, having an outer and an inner pipe (3), a female connector (4) with an internal thread at one end of the drill pipe (1), and a male connector (5) with an external thread at the end opposite from the female connector (4), wherein the inner pipe (3) is arranged substantially concentrically in the outer pipe (2) and the drill pipe (1) has a center region (8) with an internal diameter. The outer pipe (2) has an inwardly thickened wall portion at an end region (7) on the male connector side, having a smaller internal diameter than the internal diameter of the center region (8), and the internal diameter of the outer pipe (2) remains substantially the same at an end region (6) on the female connector side in relation to the internal diameter of the center region (8).

Owner:THINK & VISION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com