Manufacturing method for controlling deformation of ferrite/martensitic steel hexagonal pipe

A manufacturing method, martensitic steel technology, applied in the field of metallurgical materials, can solve the problems of different deformation forms, different heat treatment systems, and large differences in manufacturing processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Embodiment 1: Manufacture of controlled deformation of ferrite / martensitic steel hexagonal tube (1)

[0063] The size of the ferritic / martensitic steel hexagonal tube prepared in this embodiment is: 115mm (outer side distance)×3mm (wall thickness), including the following steps.

[0064] 1) Hot extrusion

[0065] After the forged bar is heated, it is hot-extruded, and the extrusion ratio is controlled at 5-15%. After water-cooling, the extruded pipe is obtained after roller straightening, pipe cutting, and surface grinding.

[0066] 2) Intermediate cold rolling and annealing

[0067] The extruded tube is cold-rolled in the middle of one pass, and the rolling speed is controlled not to exceed 200mm / min, and then degreased and cleaned. The intermediate heat treatment adopts black annealing, the annealing temperature is controlled at 820-880°C, and the holding time is 60-90min. After the intermediate heat treatment, the internal and external surfaces are ground and stra...

Embodiment 2

[0077] Embodiment 2: Manufacture of controlled deformation of ferrite / martensitic steel hexagonal tube (two)

[0078] The size of the ferritic / martensitic steel hexagonal tube prepared in this embodiment is: 59mm (outer side distance)×3mm (wall thickness). The preparation steps are basically the same as in Example 1, except that the middle cold rolling pass is 2 passes, and the ultrasonic flaw detection standard flaw is 0.15mm×0.3mm×3.0mm (depth×width×length).

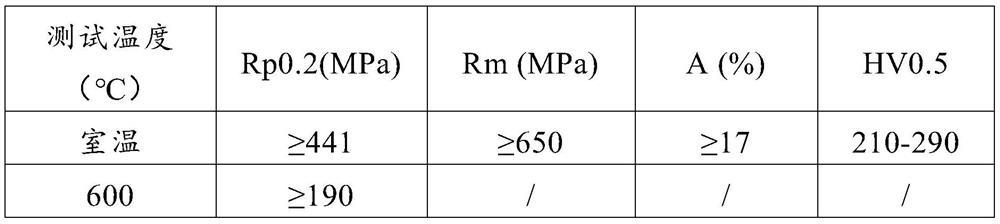

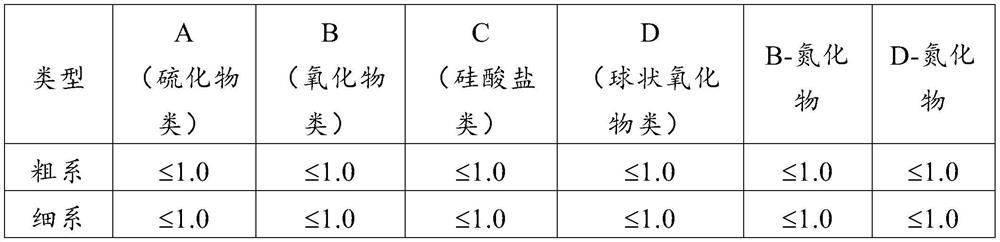

[0079] The prepared hexagonal tube has a total length of 1449mm ± 0.5mm, a wall thickness within the range of (3 ± 0.1mm), and an inner distance between sides of 53 -0.1 +0.3 Within mm range, inner corner radius R=3.0mm, ridge line straightness<0.7mm / m, full-length straightness≤1.0mm / m, twist ≤40′ / full length, finished pipe inner and outer surface smoothness Ra≤1.6um. The grain size is grade 9, the mechanical properties meet the requirements in Table 1, and the metallographic structure and non-metallic inclusions all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com