Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Unlimited concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

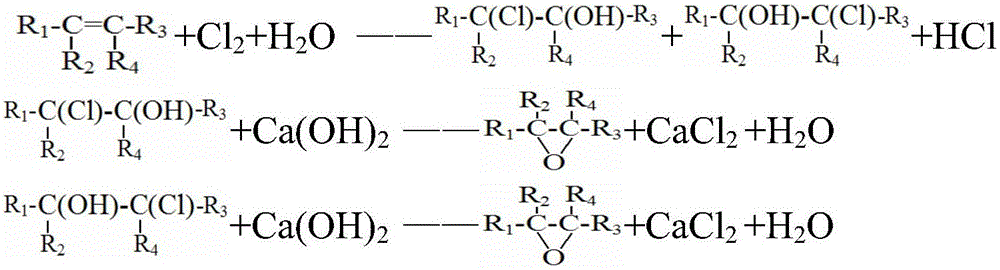

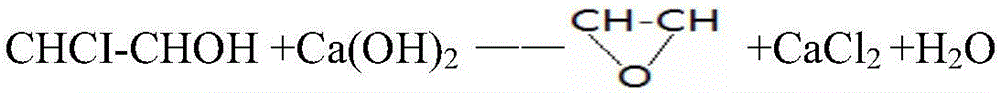

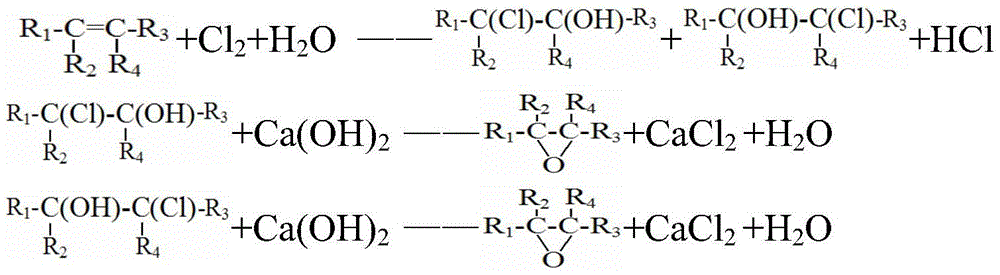

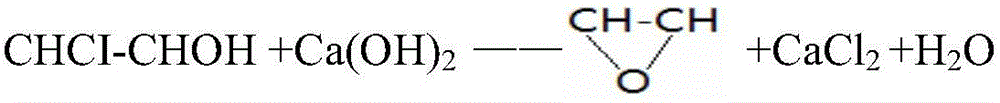

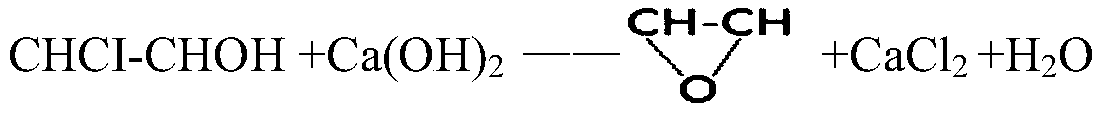

Method for preparing halogenohydrin and epoxide

ActiveCN106518624AEasily damagedSolve intractableWater contaminantsDispersed particle separationHalogenWastewater

Owner:JIANGXI SUKEER NEW MATERIAL

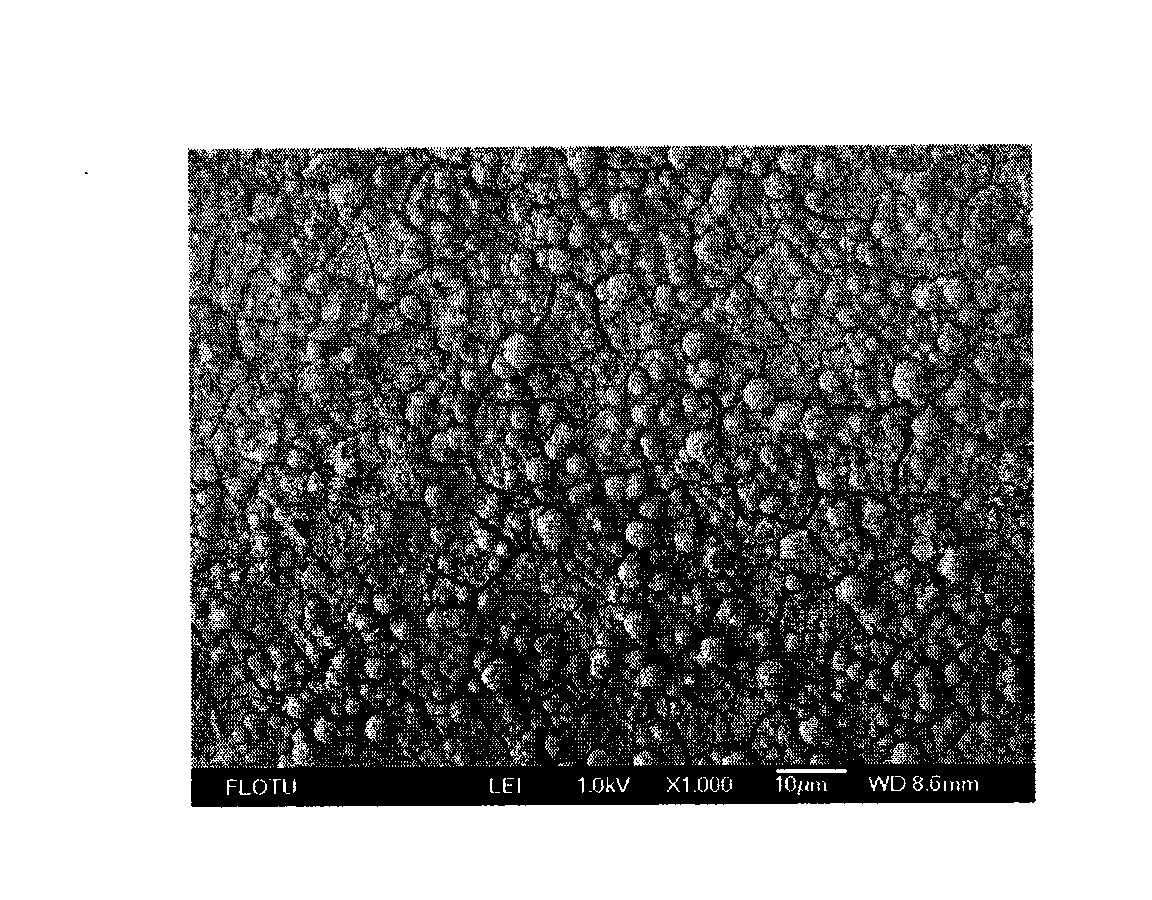

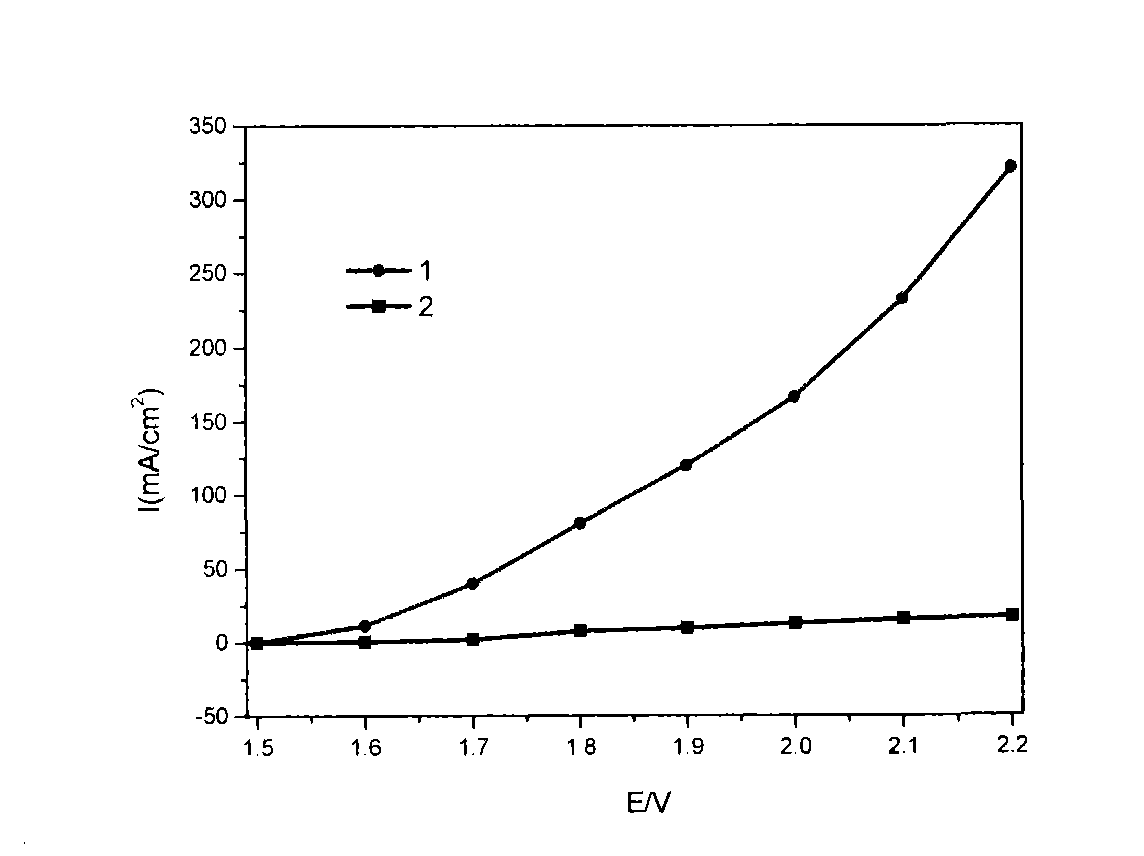

Preparation method of anode catalyst for water electrolysis reaction

ActiveCN101638796AFast productionLarge specific surface areaElectrodesBiological activationBuffer solution

The invention provides a preparation method of an anode catalyst for water electrolysis reaction, comprising the following steps: a. adding solution containing catalyst precursors into an alkaline buffer solution to obtain precipitate powder by chemical precipitation; and b. performing electrolytic activation to the precipitate powder to obtain the catalyst. By adopting the method, high productionefficiency of the catalyst is ensured, and the obtained catalyst has high catalysis activity and is easy to transfer.

Owner:ENN SCI & TECH DEV

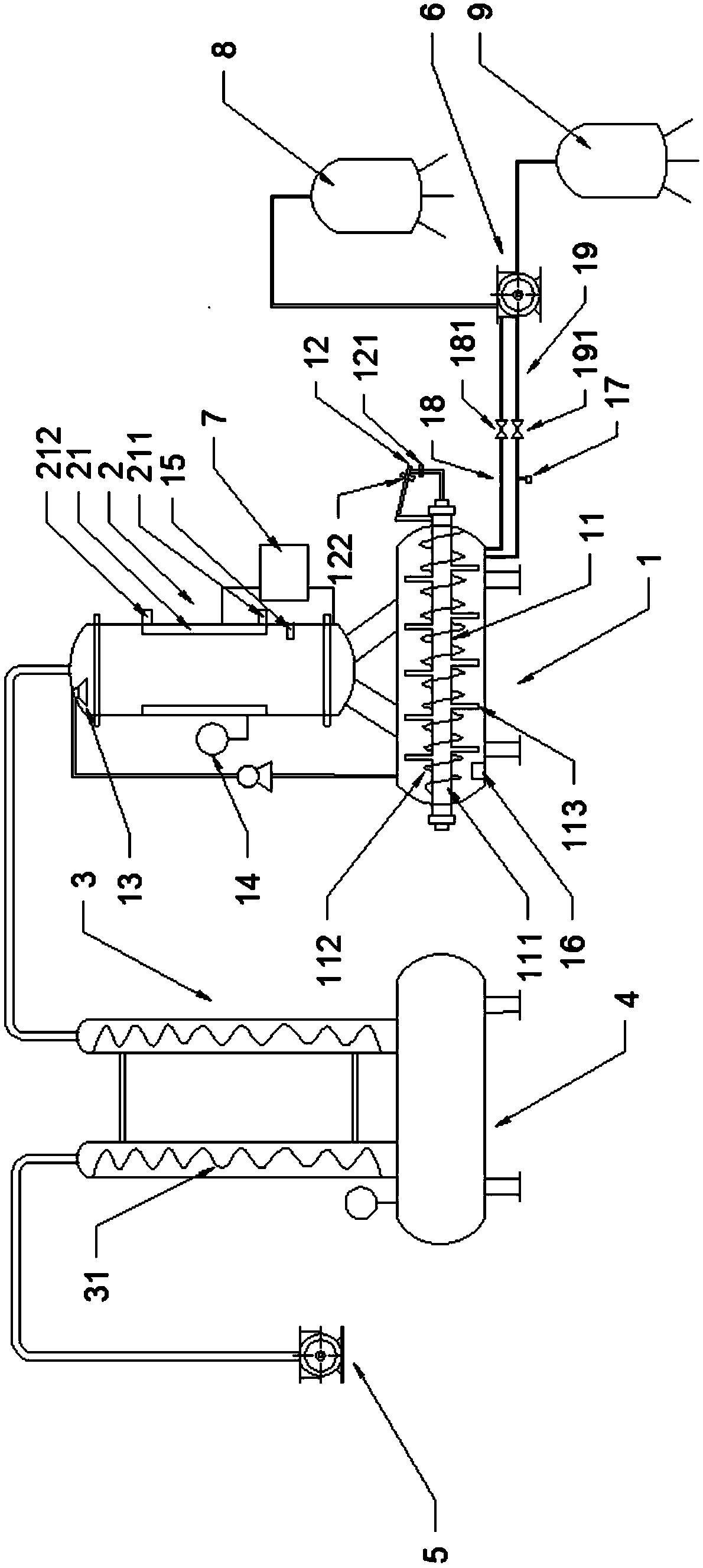

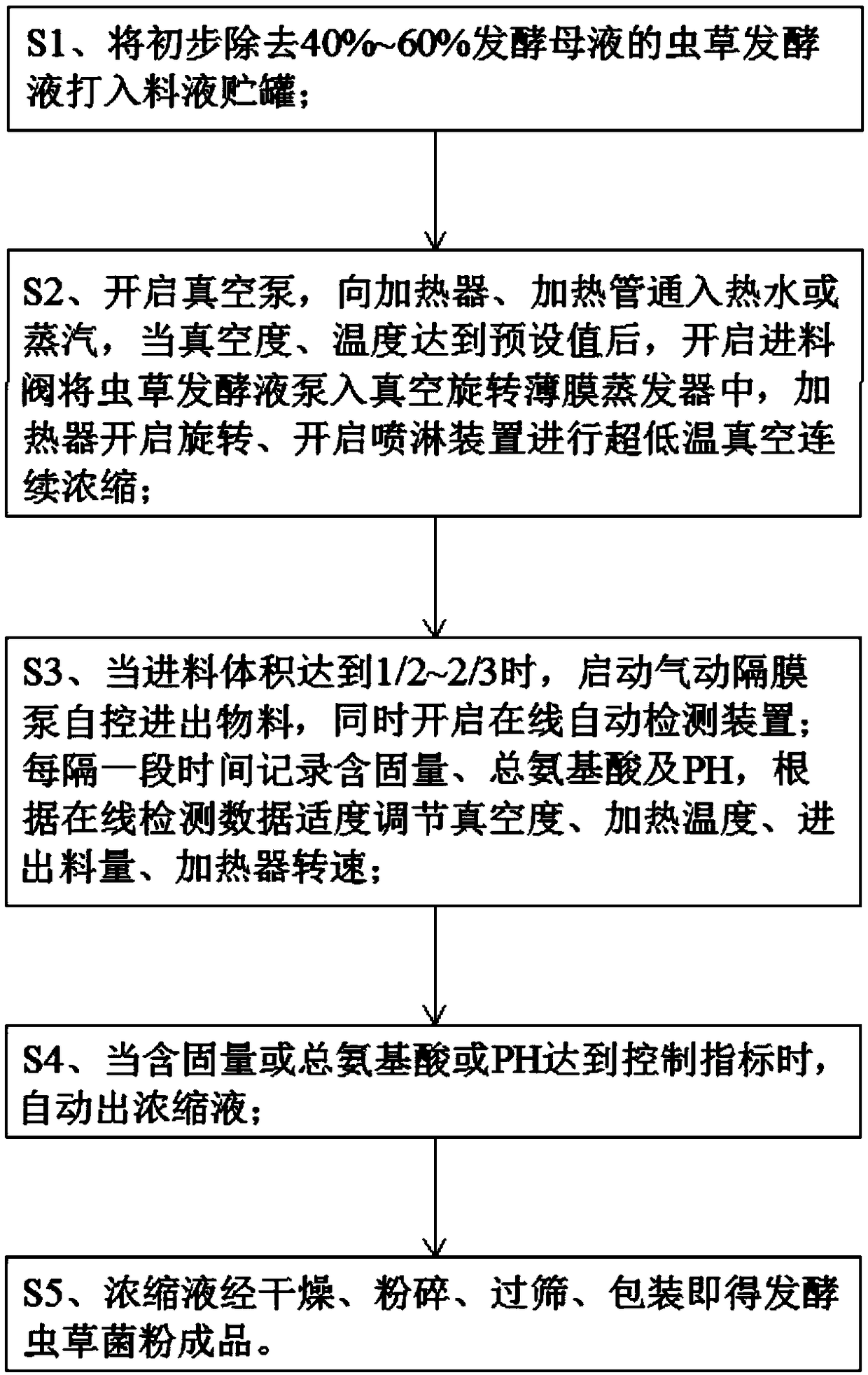

Concentration method in production process of ferment cordyceps sinensis fungus powder

ActiveCN108905240ALow boiling pointPipeliningEvaporator accessoriesEvaporator regulation/controlDiaphragm pumpEnrichment methods

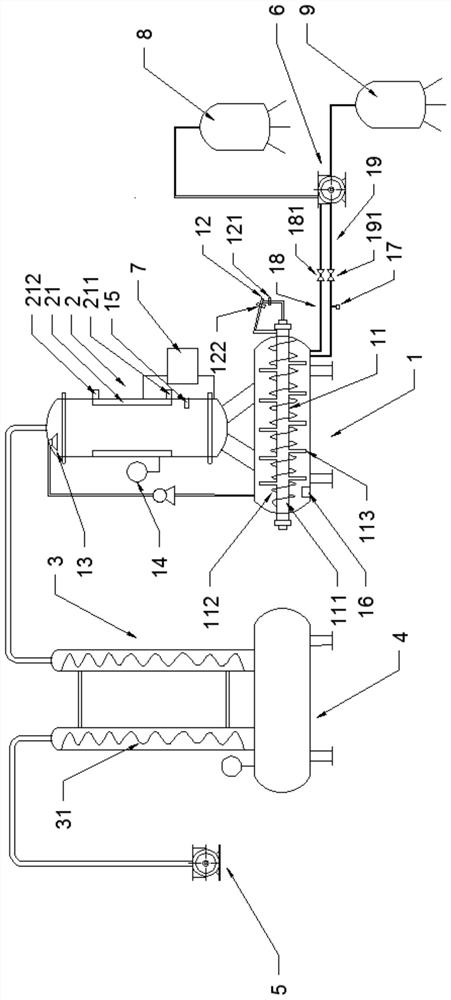

The invention provides a concentration method in the production process of ferment cordyceps sinensis fungus powder. The method comprises the following steps: S1, injecting a cordyceps sinensis fermenting liquid which is subjected to the removal of 40%-60% of a fermenting mother liquid into a liquid storage tank; S2, turning on a vacuum pump, introducing hot water or water vapor into a heater anda heating pipe, pumping the cordyceps sinensis fermenting liquid into a vacuum rotary film evaporator when the vacuum degree and the temperature reach preset values, starting the rotation of the heater, and turning on a spraying device to carry out ultralow-temperature vacuum continuous concentration; S3, turning on a pneumatic diaphragm pump to automatically control the material feeding and discharging when the volume of the fed material reaches 1 / 2-2 / 3, simultaneously turning on an online automatic detecting device, recording the solid content, the total amino acids and the pH value at regular intervals, and moderately adjusting various concentration technical parameters according to the online detected data; S4, when the solid content or the total amino acids or the pH values reach thecontrol indexes, automatically discharging a concentrated liquid; and S5, drying the concentrated liquid, carrying out crushing, sieving and packaging to obtain a finished product of the ferment cordyceps sinensis fungus powder. The product provided by the invention has high quality and effective components of the product are preserved greatly.

Owner:JIANGXI GUOYAO PHARMA LLC

Electrolyte solution used for preventing positive pole from scaling and producing electrolytic copper foil and preparing method thereof

ActiveCN105862089APrevent scalingAvoid premature failureElectroforming processesElectrolysisCarboxylic acid

The invention discloses an electrolyte solution used for preventing the positive pole from scaling and producing electrolytic copper foil. An electrolyte solution body is a water solution dissolving copper sulfate, sulfuric acid and carboxylic acid, the content, calculated based on cupric ions, of copper sulfate in the electrolyte solution body is 60-90 g / L, the content of sulfate ions in the electrolyte solution body is 150-270 g / L, and a preparing method of the electrolyte solution for producing electrolytic copper foil mainly includes the steps of dissolving copper, filtering, purifying, adding carboxylic acid, mixing carboxylic acid uniformly and the like. According to the electrolyte solution used for preventing the positive pole from scaling and producing electrolytic copper foil, the surface of the electrolysis positive pole is effectively prevented from scaling in the copper foil production process, and the problems that due to positive pole scaling, a ti-based metal oxide positive pole loses efficacy in advance, and quality of electrolyzed copper foil descends seriously are solved.

Owner:JIUJIANG TELFORD ELECTRONICS MATERIAL CO LTD

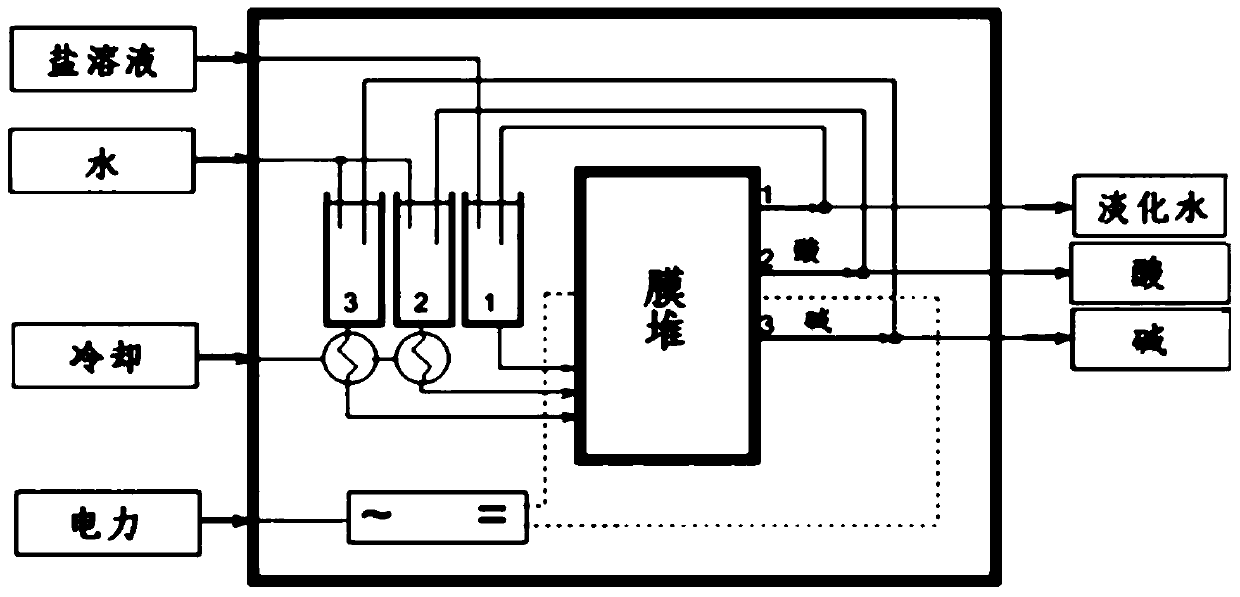

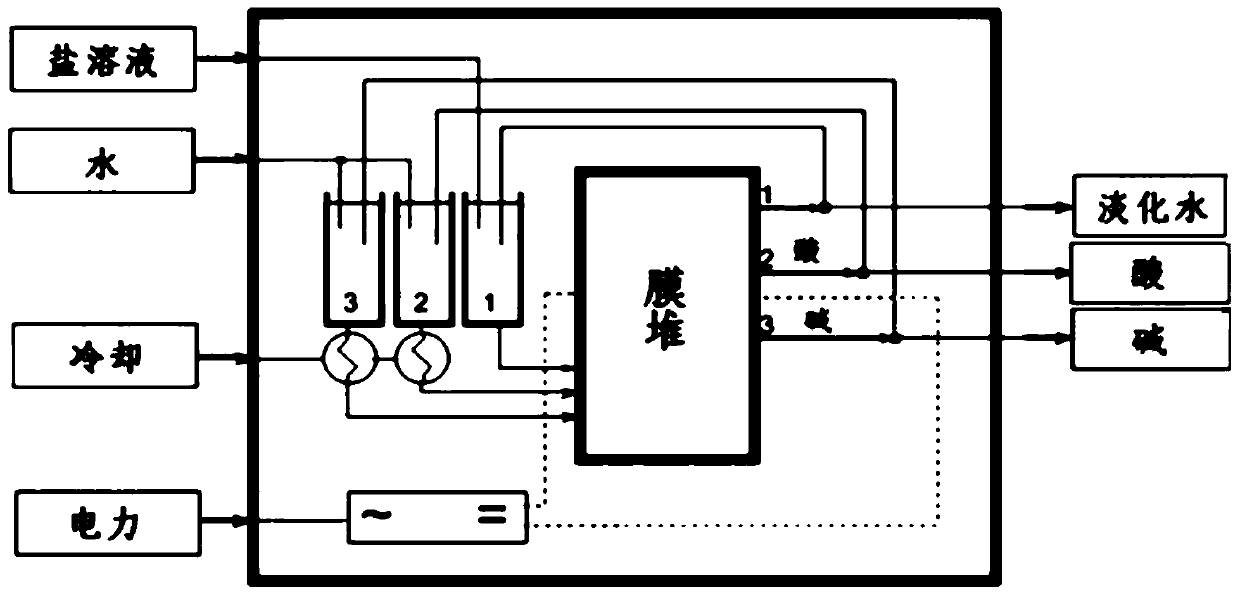

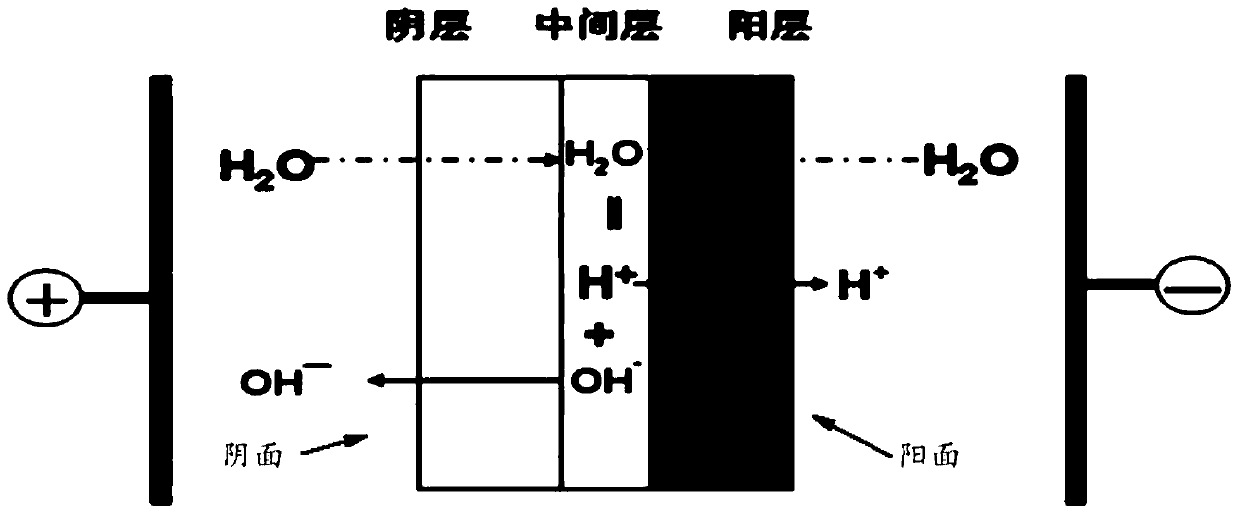

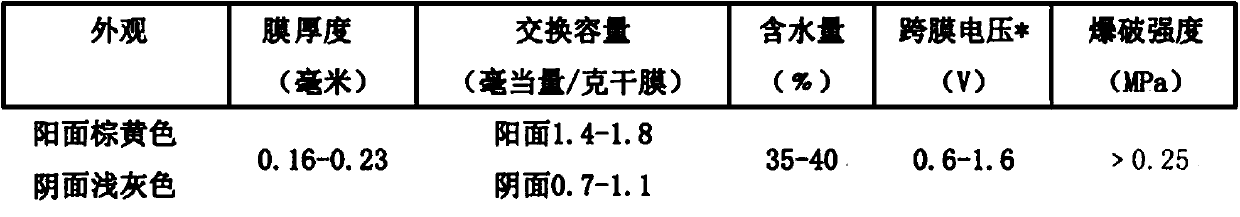

Method for preparing halopropyl alcohol and propylene oxide

ActiveCN106560466ASolve intractableDifficult problems to overcomeDispersed particle separationPreparation by OH and halogen introductionHydrogen halideAlcohol

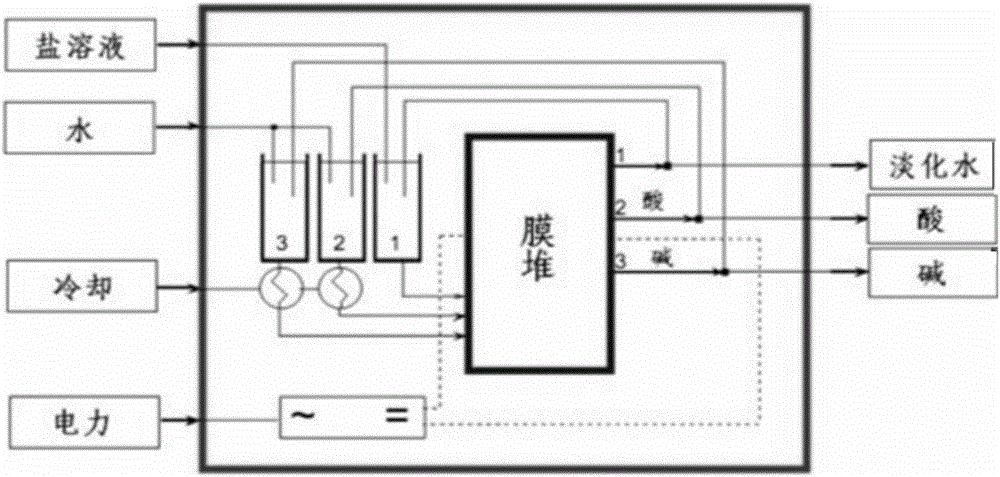

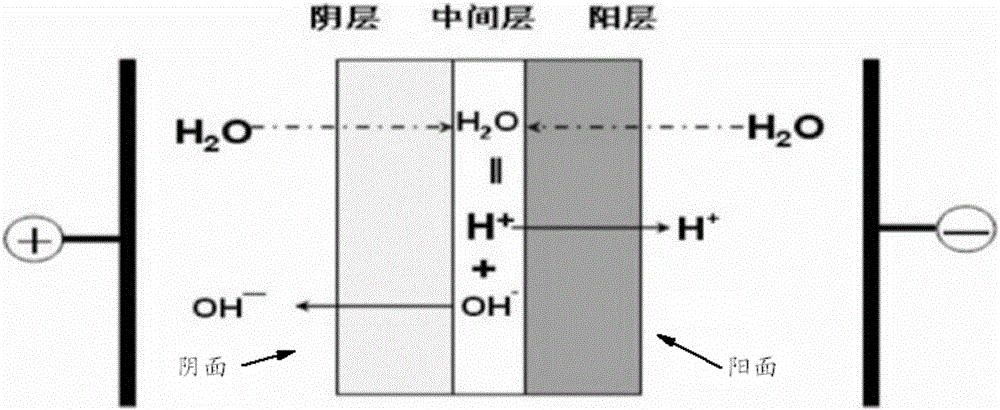

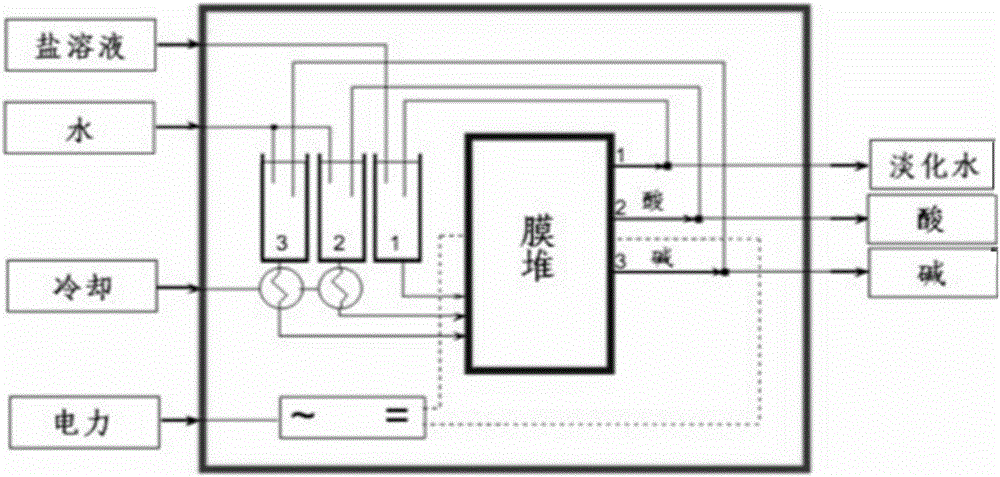

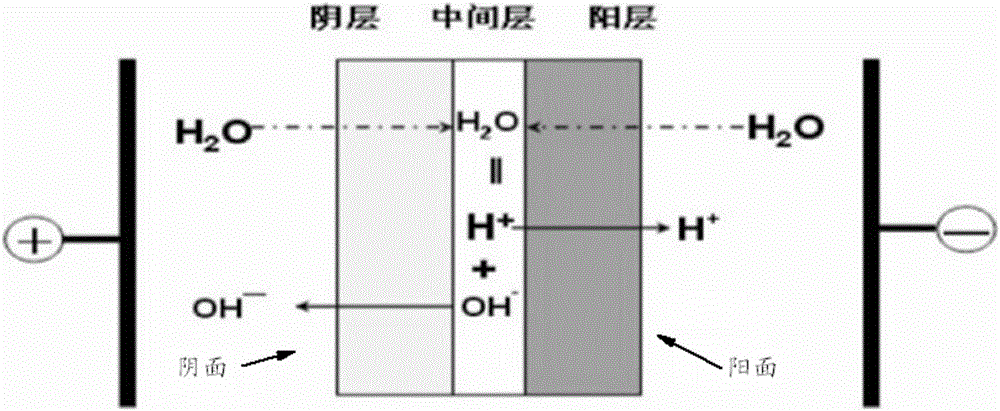

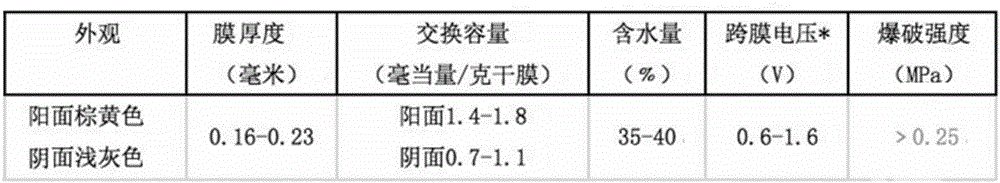

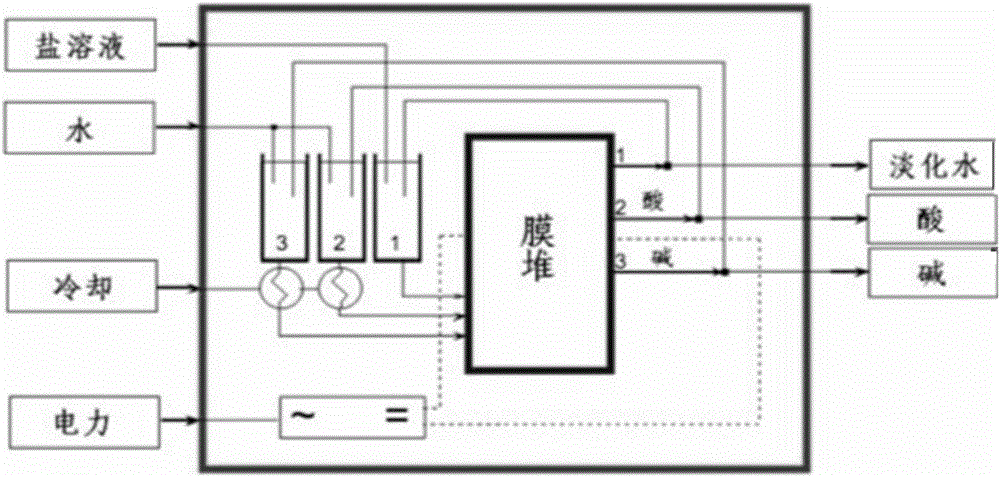

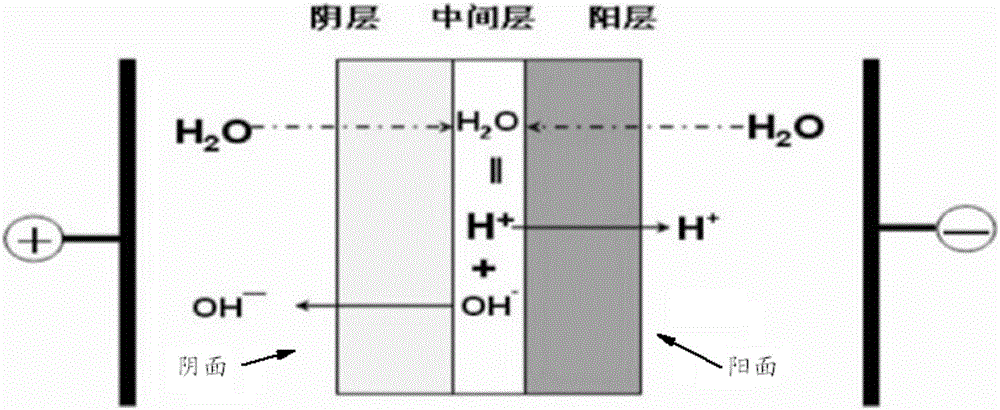

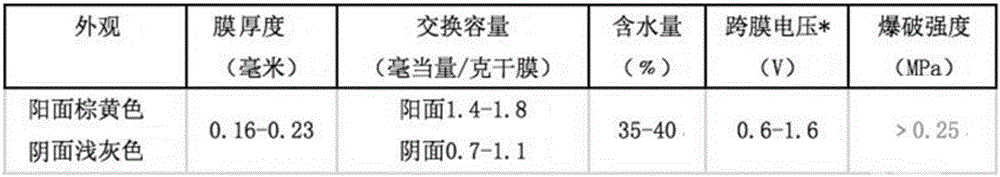

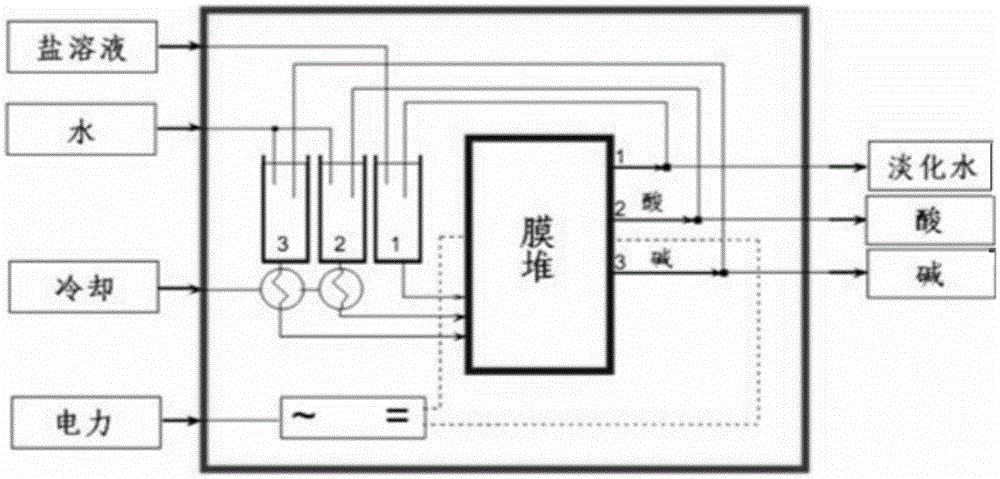

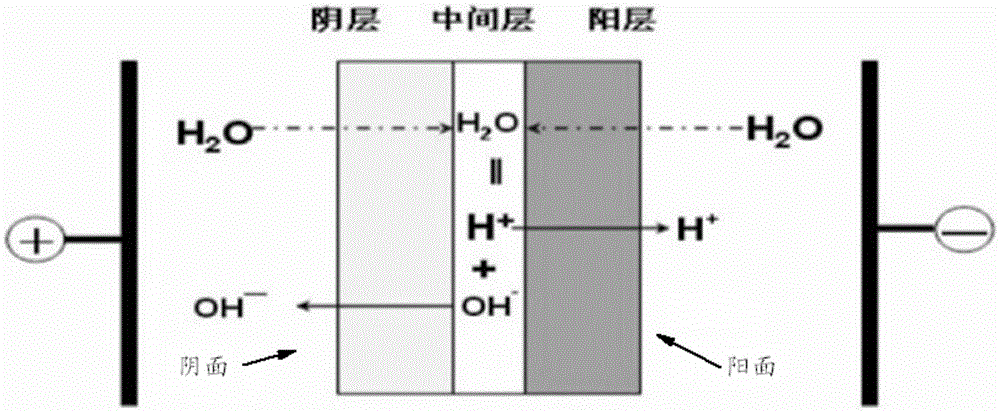

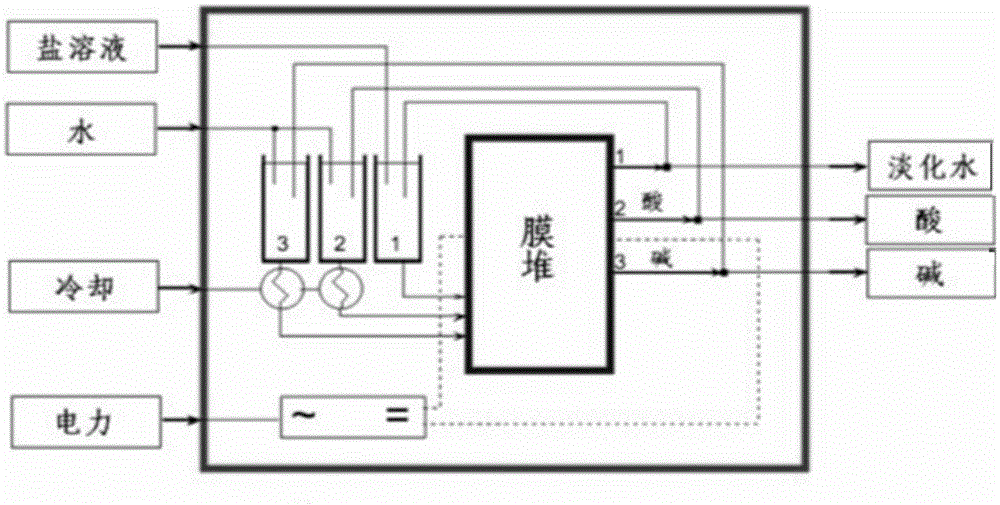

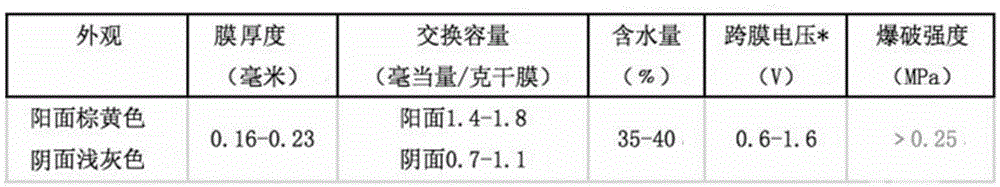

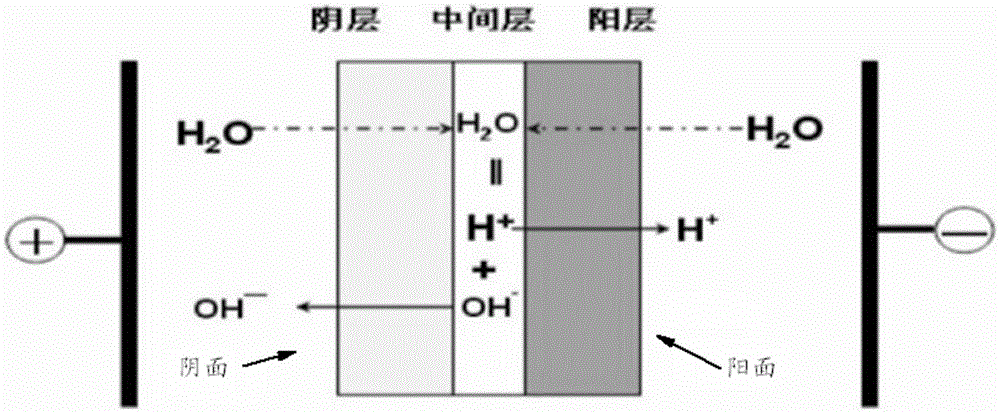

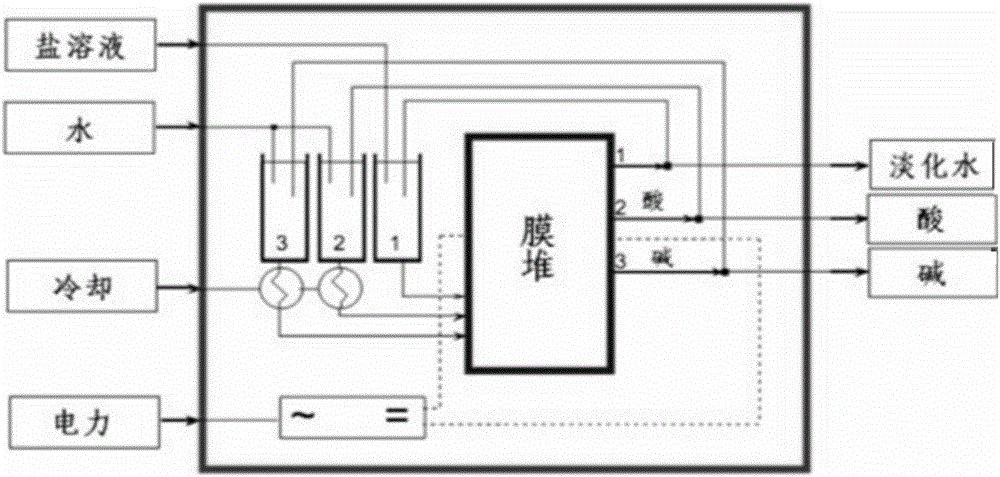

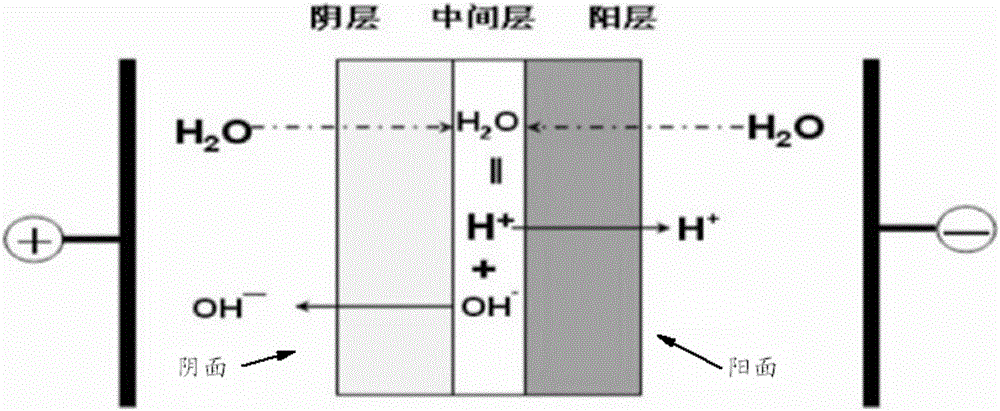

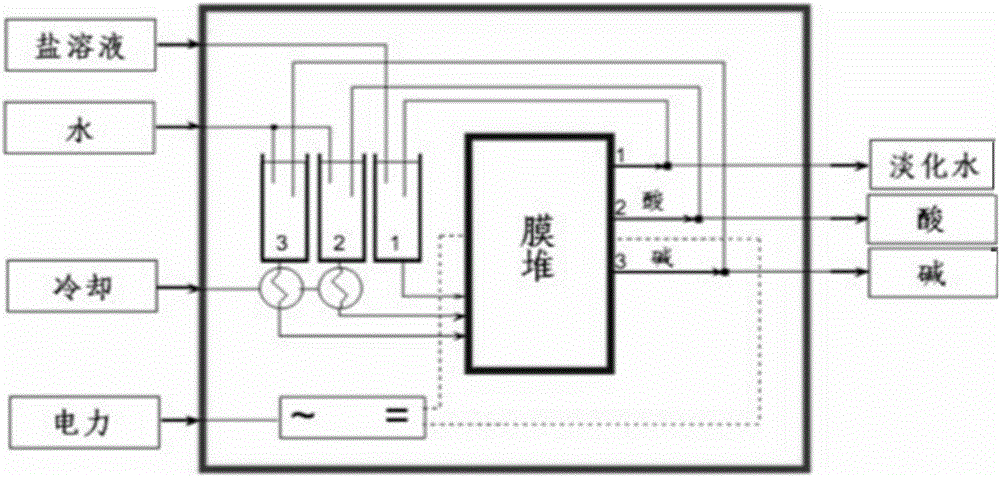

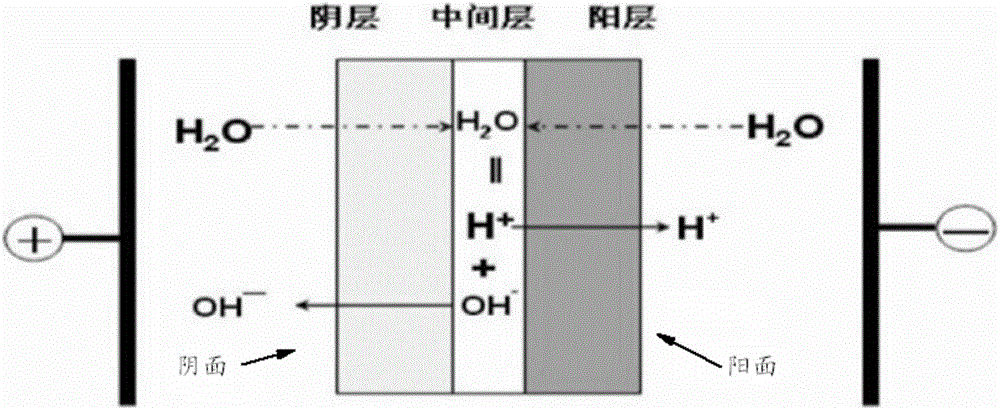

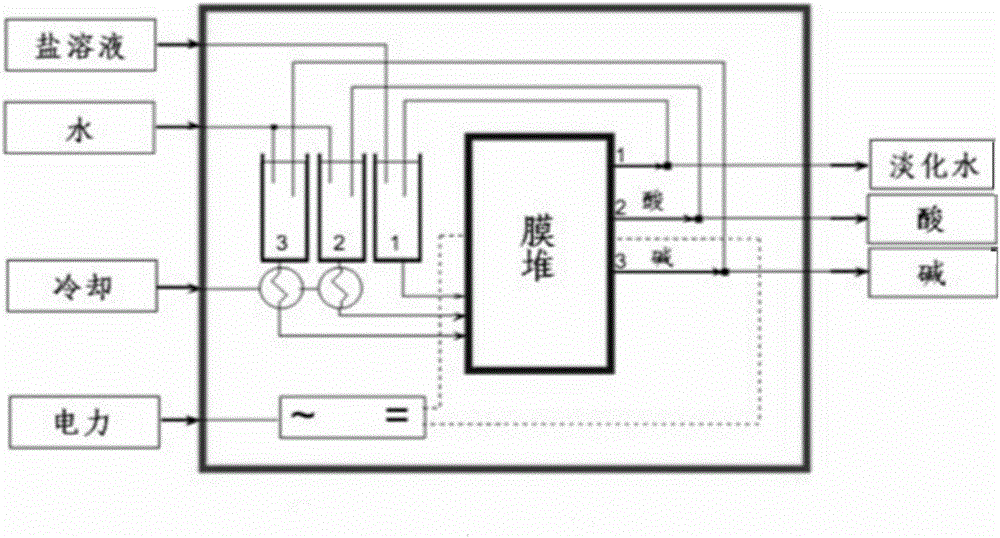

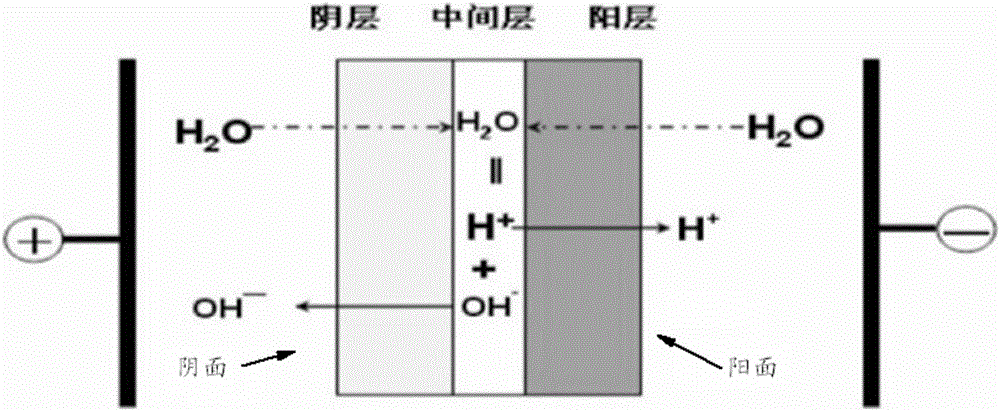

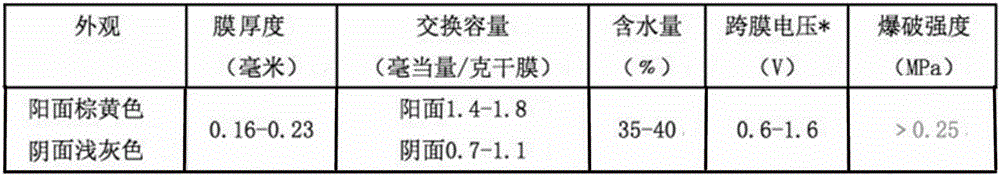

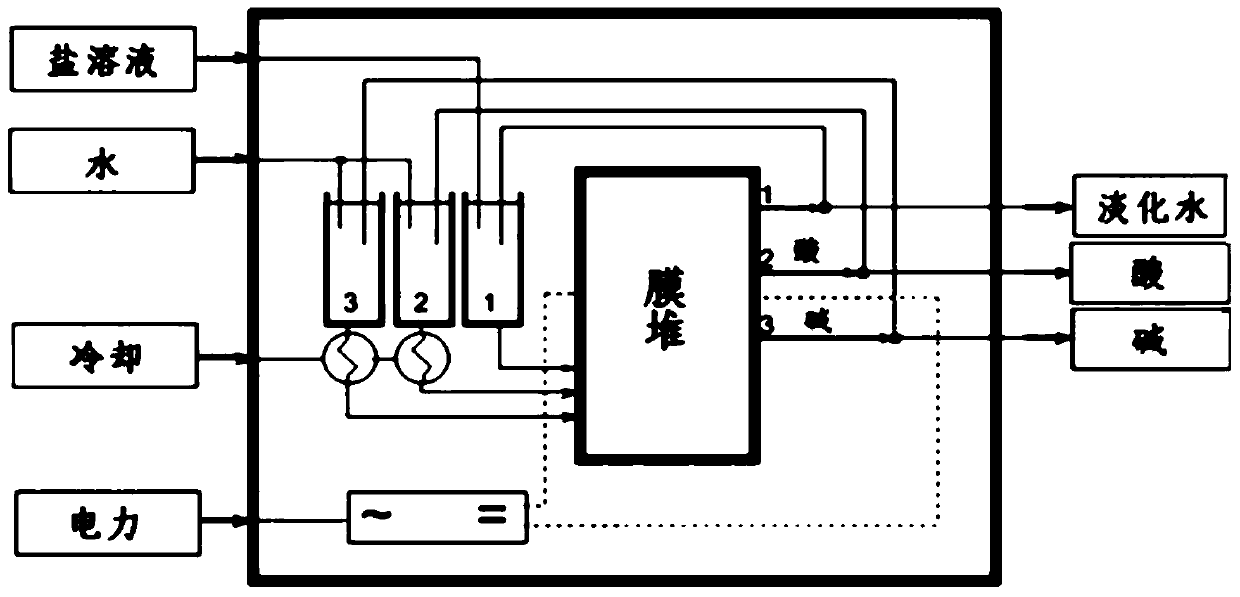

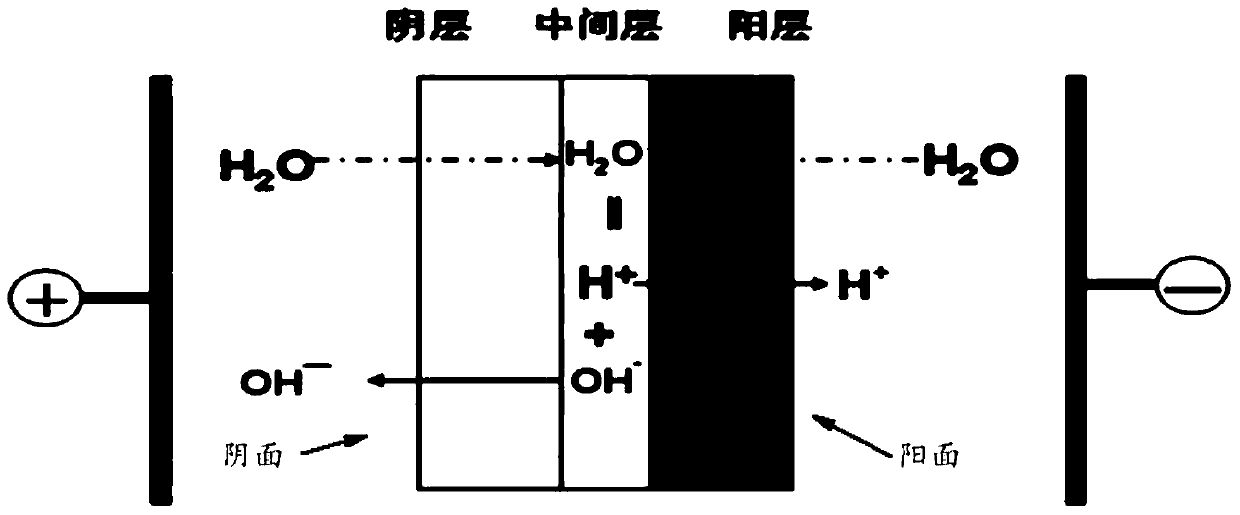

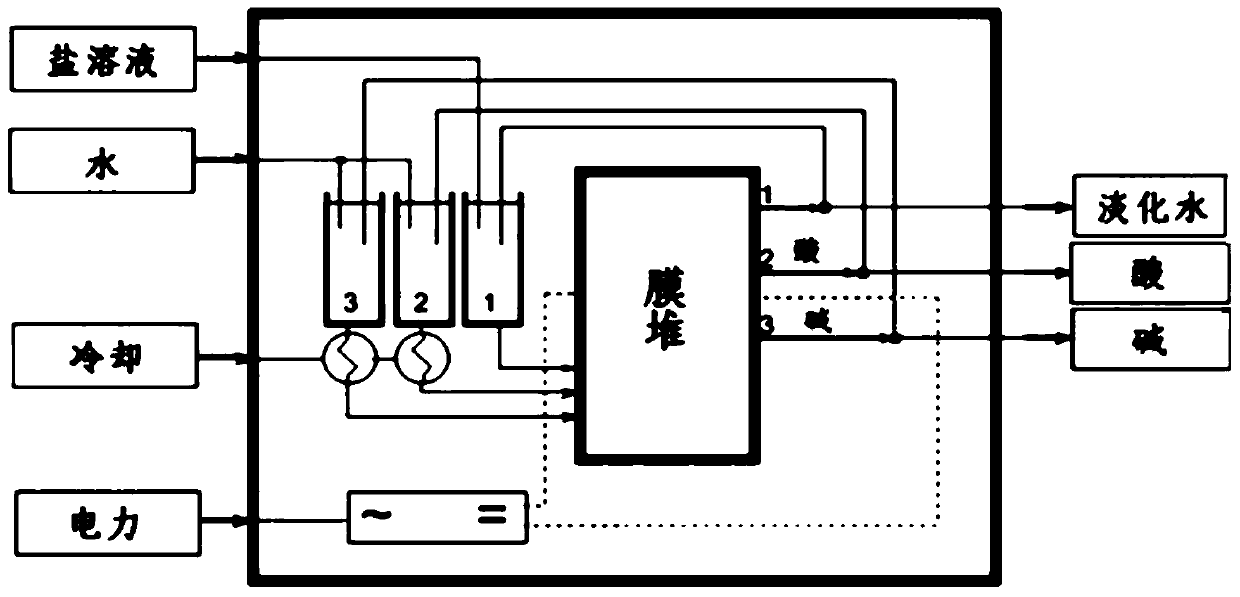

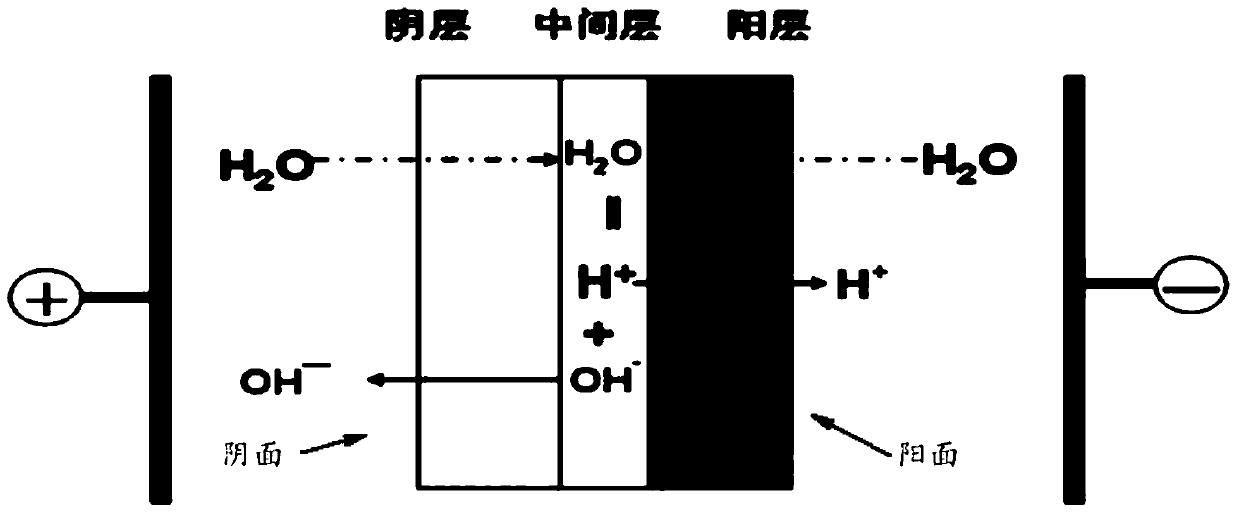

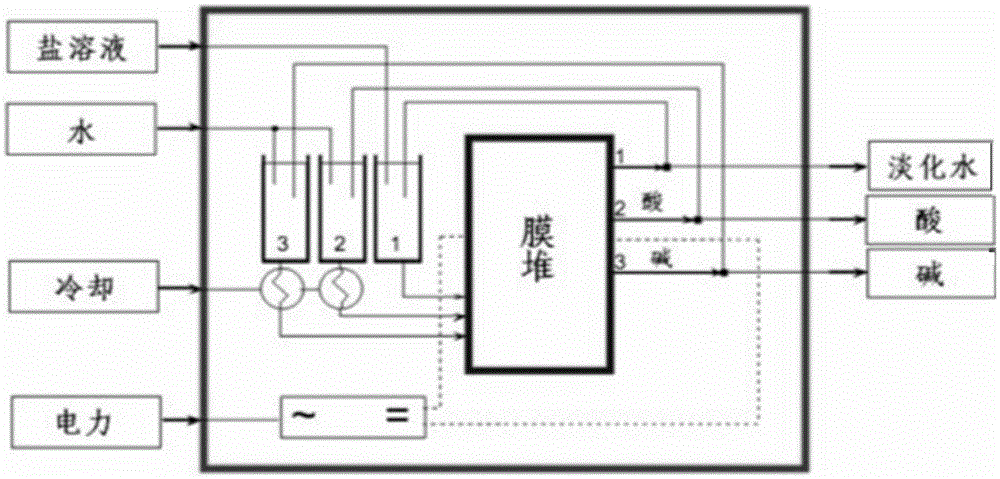

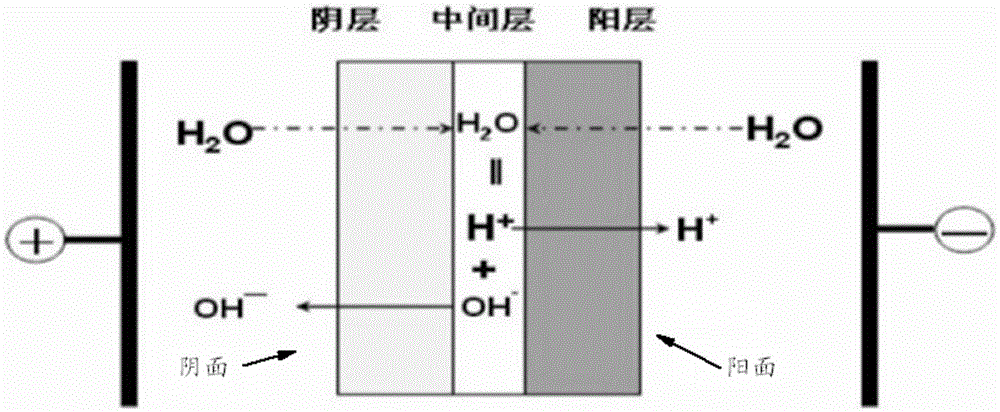

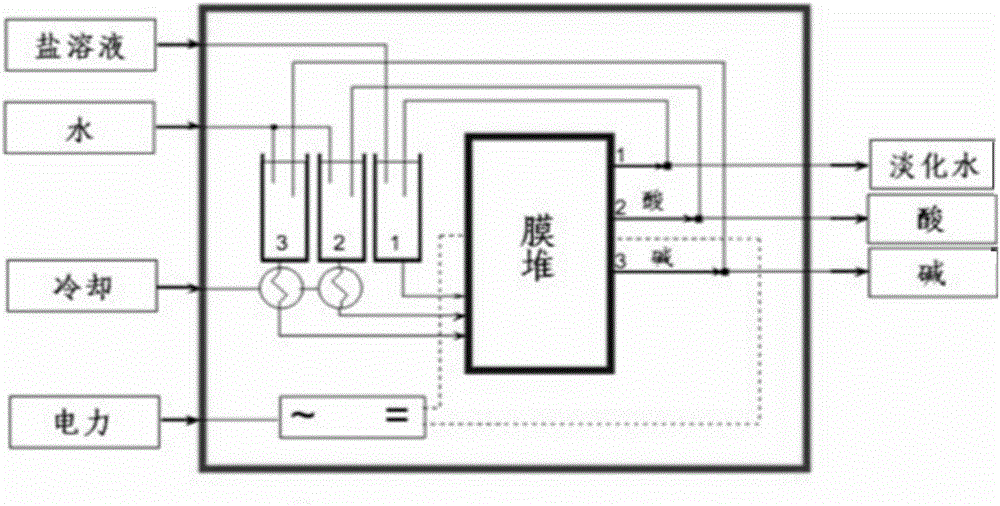

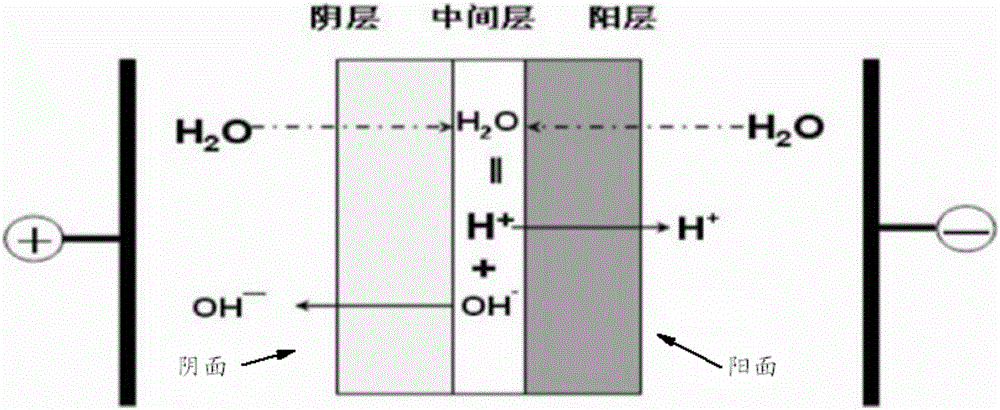

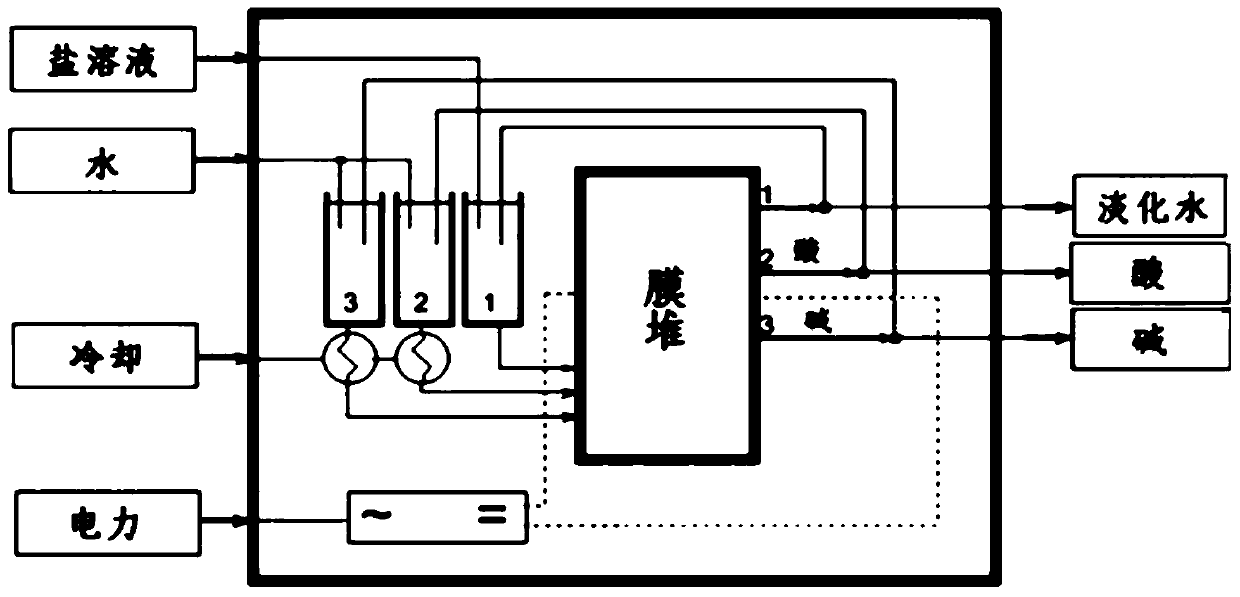

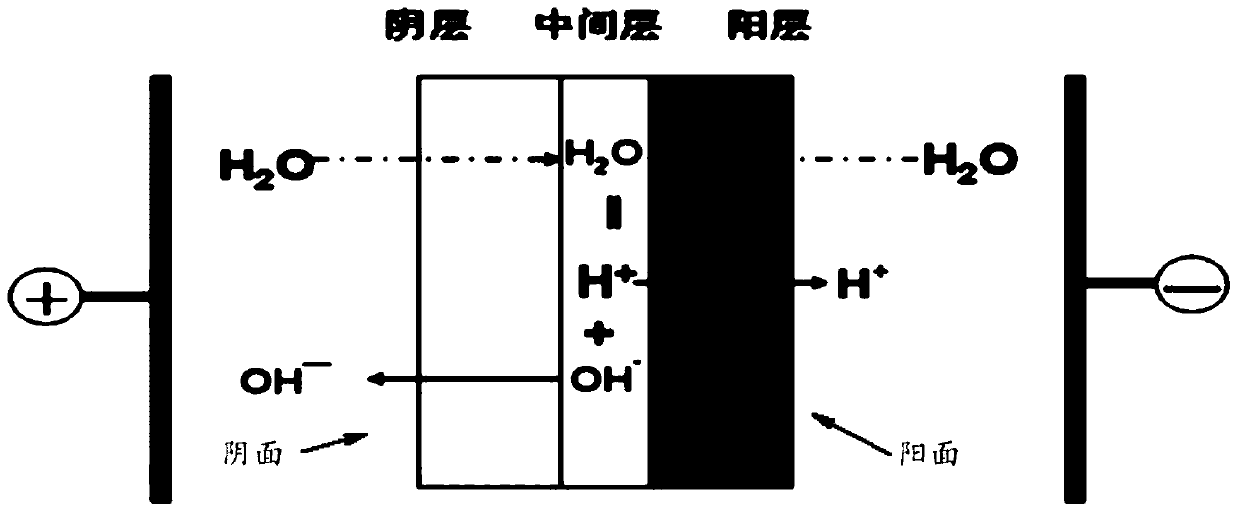

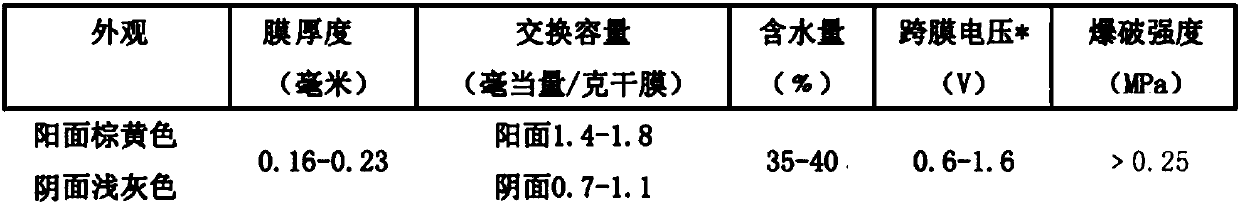

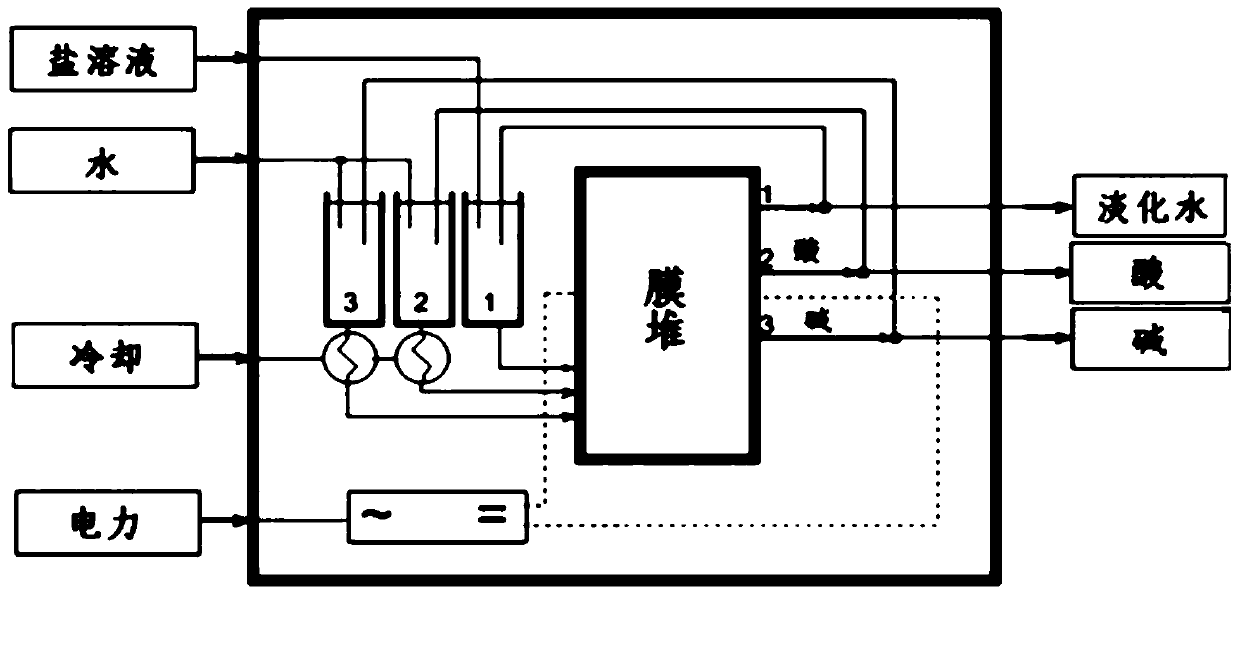

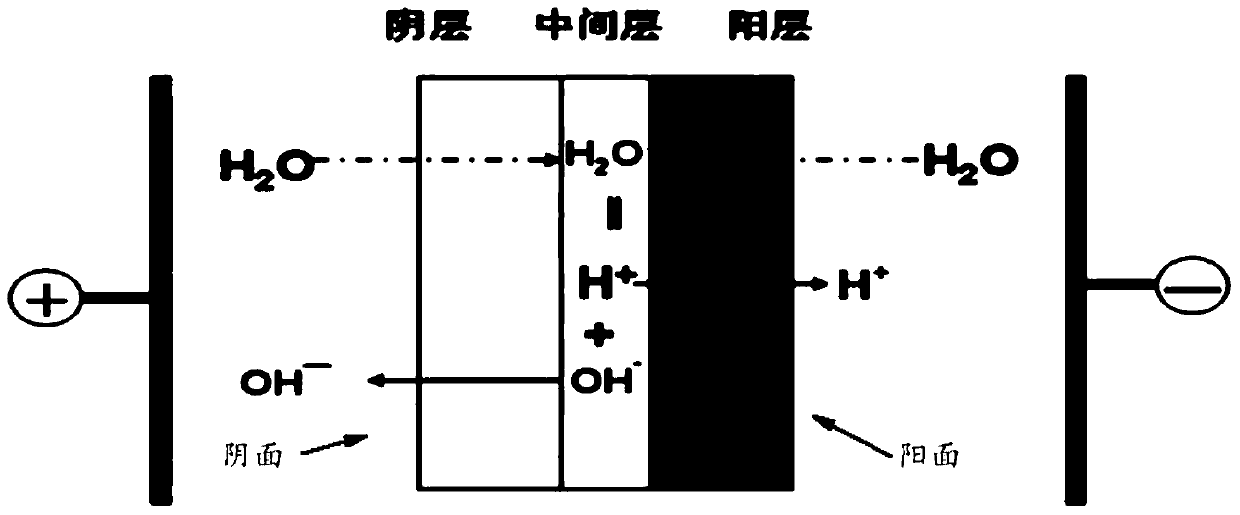

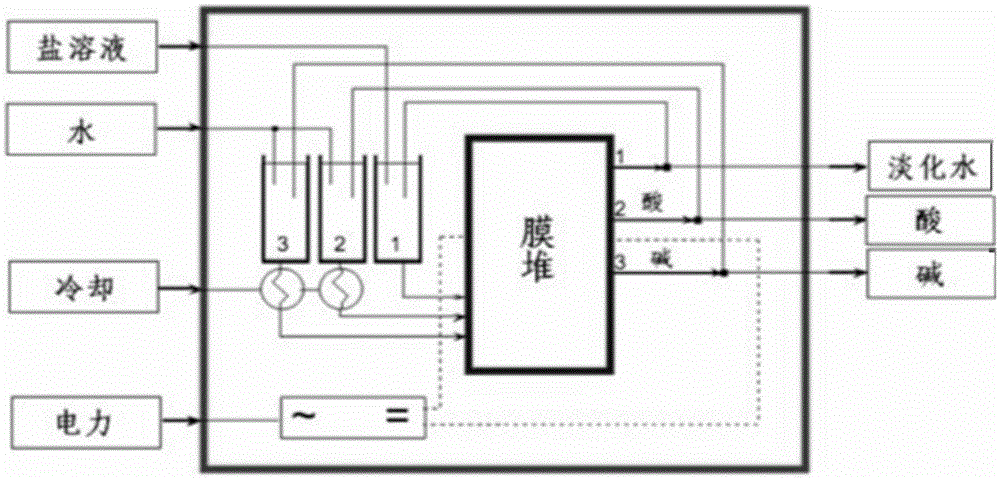

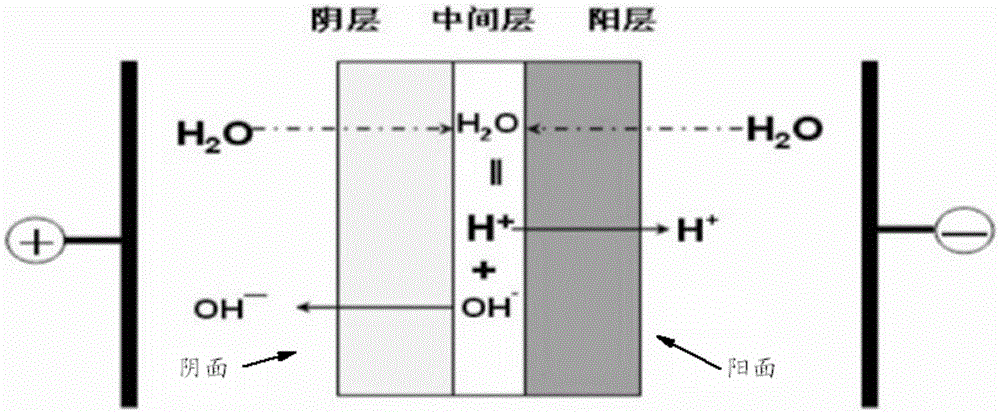

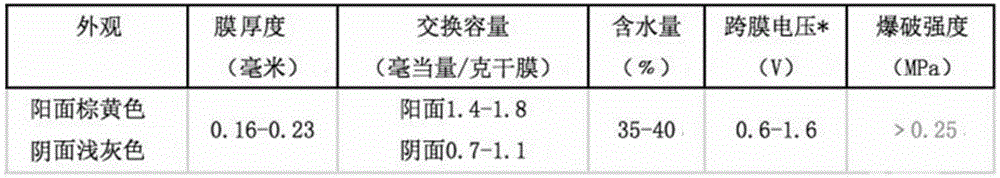

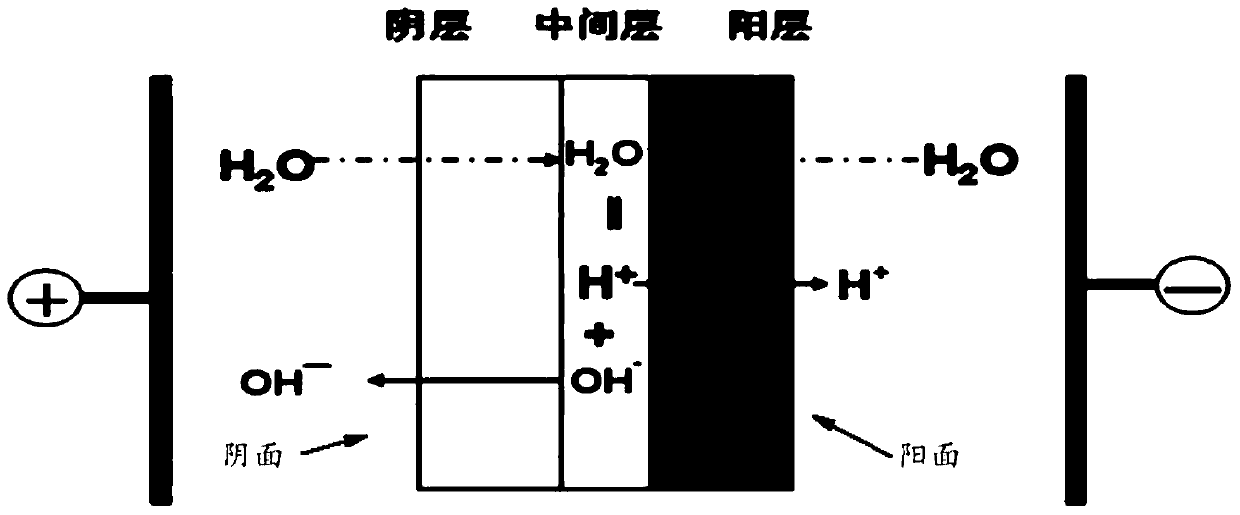

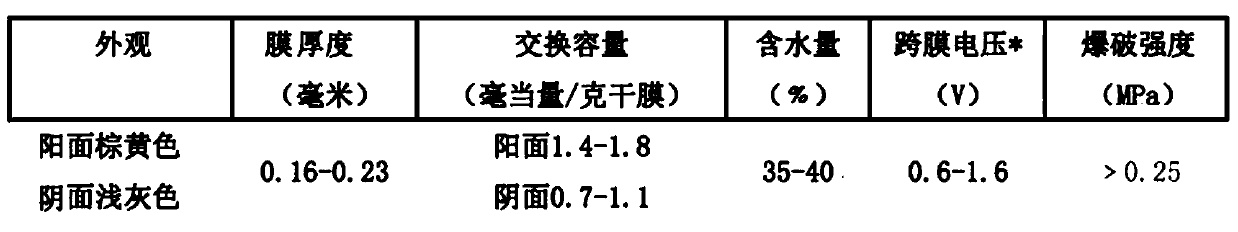

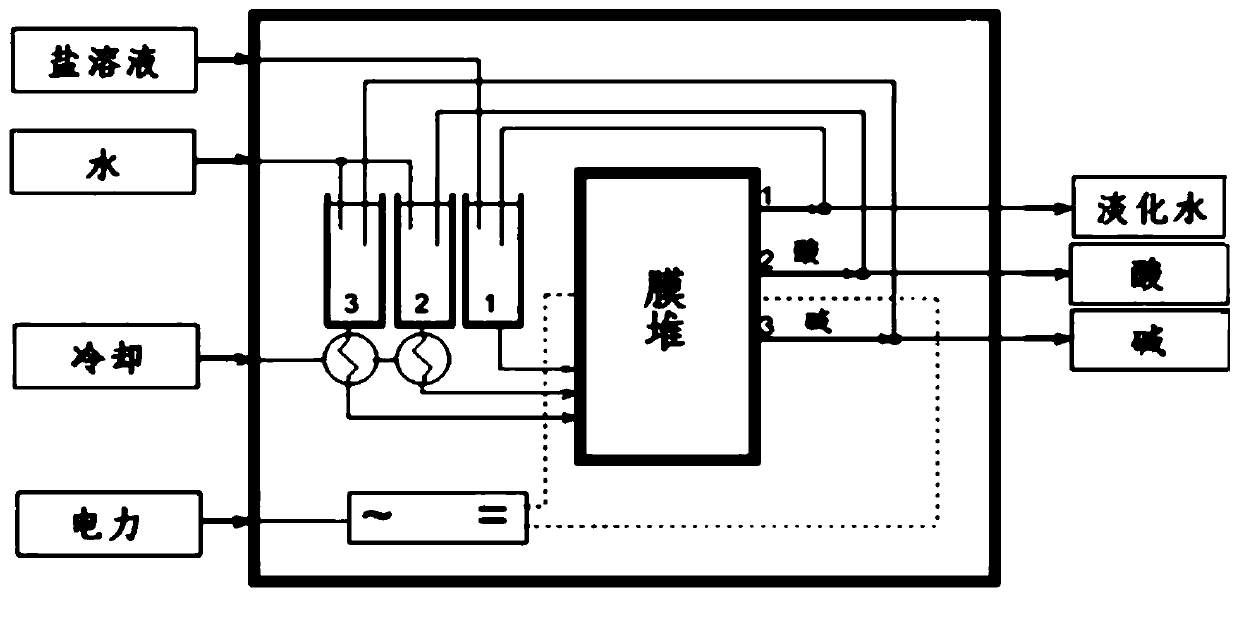

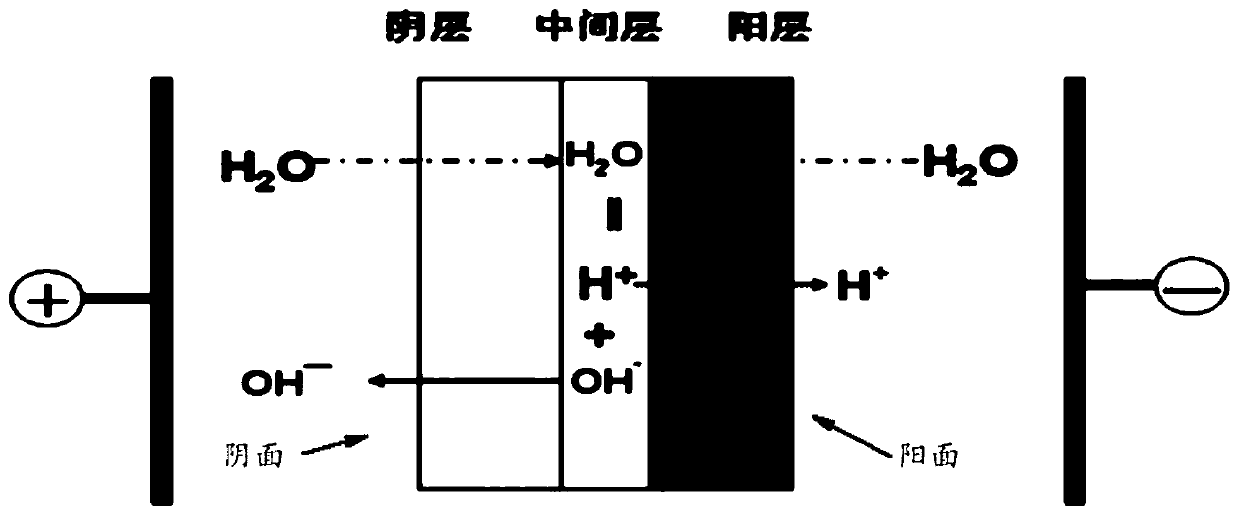

The invention provides a halopropyl alcohol preparation method, which comprises: (1) a catalyst acid treatment: soaking a catalyst in an acid, washing the catalyst, and drying the catalyst; (2) halo alcoholization: adding hydrogen halide, H2O2, propylene and the catalyst treated in the step (1) to a reaction device, and carrying out a halo alcoholization reaction to obtain halopropyl alcohol; optionally, (3) saponification: carrying out a saponification reaction on the halopropyl alcohol obtained in the step (2) and an alkali metal hydroxide, and separating to obtain propylene oxide and a halogenated alkali metal salt; and optionally, (4) electrodialysis: carrying out bipolar membrane electrodialysis on the halogenated alkali metal salt obtained in the step (3) to obtain the hydroxide of the alkali metal and the hydrogen halide. With the method of the present invention, the halopropyl alcohol can be produced in the extremely high selectivity and extremely high yield manner, and the emissions of wastewater and waste residue are substantially reduced.

Owner:JIANGXI SUKEER NEW MATERIAL

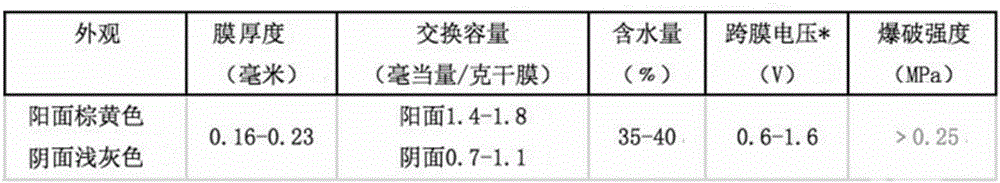

Method for preparing epoxide by halogen-alcohol method

A method for preparing epoxide by a halogen-alcohol method comprises the following steps: (1) halogenation-alcoholization: adding H2O, halogen elementary substance (optimally selecting chlorine, bromine or iodine) and an olefinic unsaturated compound or olefin compound which contains one or multiple C=C double bonds into a reaction device, and carrying out halogenation-alcoholization reaction to obtain halogenohydrin; (2) saponification: carrying out saponification reaction on the halogenohydrin obtained in the step (1) and hydroxide of an alkali metal, and separating to obtain the epoxide and halogenated alkali metal salt; (3) electrodialysis: carrying out bipolar membrane electrodialysis on the halogenated alkali metal salt obtained in the step (2), thus obtaining the hydroxide of the alkali metal and halogen hydride. The method provided by the invention has the characteristics that the method can be used for preparing the epoxide with extremely high selectivity and yield, and the discharge of wastewater and waste residues is reduced greatly.

Owner:JIANGXI SUKEER NEW MATERIAL

Method for preparing halohydrin and ethylene oxide

ActiveCN106518623AReduce loadReduce dosageDispersed particle separationPreparation by OH and halogen introductionHalohydrinSaponification

The invention provides a method for preparing halohydrin. The method comprises the following steps: 1) halogen alcoholization: halogen hydride, H2O2, and a catalyst are added in a reaction apparatus, and ethylene is added for a halogen alcoholization reaction to obtain halohydrin. The invention also provides a method for preparing ethylene oxide by a halogen alcoholization method, which comprises the step 1) in right claim 1, the method also comprises a step of 2) saponification: halohydrin in the step 1) and hydroxide of alkali metal are subjected to a saponification reaction, then separated to obtain ethylene oxide and alkali halide metal salt; and an optional step of 3) electrodialysis: the obtained alkali halide metal salt is subjected to bipolar membrane electrodialysis to obtain the hydroxide of alkali metal and the halogen hydride. The method is used for preparing halohydrin or ethylene oxide with high selectivity and yield, and greatly reduces the discharge of waste water and waste residue.

Owner:JIANGXI SUKEER NEW MATERIAL

Methods for preparing halogen ethanol and ethylene oxide

ActiveCN106518611ASolve intractableDifficult problems to overcomeDispersed particle separationPreparation by OH and halogen introductionHydrogen halideSaponification

The invention provides a method for preparing halogen ethanol, wherein the method comprises: (1) acid treatment of a catalyst, wherein a catalyst is soaked in an acid, the soaked catalyst is washed, and the washed catalyst is dried; (2) halogen alcoholization, wherein hydrogen halide, H2O2, ethylene and the catalyst treated in the step (1) are added to a reaction device, and a halogen alcoholization reaction is performed to obtain the halogen ethanol; optionally (3) saponification, wherein the halogen ethanol obtained in the step (2) and the hydroxide of an alkali metal are subjected to a saponifying reaction, and separation is performed to obtain ethylene oxide and a halogenated alkali metal salt; and optionally, (4) electrodialysis, wherein the halogenated alkali metal salt obtained in the step (3) is subjected to bipolar membrane electrodialysis to obtain the hydroxide of the alkali metal and the hydrogen halide. According to the present invention, the halogen ethanol is prepared in the forms of the extremely high yield and the extremely high selectivity, and the emission of wastewater and waste residue is substantially reduced.

Owner:JIANGXI SUKEER NEW MATERIAL

Method for preparing halogen ethyl alcohol and ethylene oxide

ActiveCN106518622AReduce loadReduce dosagePreparation by OH and halogen introductionSaponificationHigh selectivity

The invention provides a method for preparing halogen ethyl alcohol. The method comprises the following step: (1) halogen alcoholization: adding halogen hydride, H2O2, ethylene and a Ti heteroatom-containing molecular sieve into a reaction device, and carrying out halogen alcoholization reaction to obtain the halogen ethyl alcohol. The invention also provides a method for preparing ethylene oxide with a halogenohydrin method. The method comprises the following steps: (1) halogen alcoholization: adding halogen hydride, H2O2, ethylene and a Ti heteroatom-containing molecular sieve into the reaction device, and carrying out the halogen alcoholization reaction to obtain the halogen ethyl alcohol; (2) saponification: carrying out saponification reaction on the halogen ethyl alcohol in the step (1) and a hydroxide of alkali metal, and separating to obtain the ethylene oxide and alkali halide metal salt; optionally (3) electroosmosis: carrying out bipolar membrane electroosmosis on alkali halide metal salt obtained in step (2) to obtain the hydroxide of alkali metal and the halogen hydride. According to the methods, the halogen ethyl alcohol or the ethylene oxide can be prepared at extremely high selectivity and yield, and the discharging of waste water and waste residues can be drastically lowered.

Owner:JIANGXI SUKEER NEW MATERIAL

Method for preparing halogenated propanol and propylene oxide

ActiveCN106518626AReduce loadReduce dosageDispersed particle separationPreparation by OH and halogen introductionHydrogen halideWastewater

The invention provides a method for preparing halogenated propanol. The method comprises the following step: (1) halogenohydrination: a step of adding hydrogen halide, H2O2 and a catalyst into a reactor, after a period of time, adding propylene, and carrying out a halogenohydrination reaction so as to obtain halogenated propanol. The invention also provides a method for preparing propylene oxide through a halogenohydrination method. The method for preparing propylene oxide is characterized by comprising the step (1) as described in claim 1 of the patent, and also comprising the following steps: (2) saponification: a step of subjecting halogenated propanol in the step (1) and alkali metal hydroxide to a saponification reaction, and carrying out separation so as to obtain propylene oxide and halogenated alkali metal salt; and optionally, (3) electrodialysis: a step of subjecting the halogenated alkali metal salt obtained in the step (2) to bipolar membrane electrodialysis so as to obtain alkali metal hydroxide and hydrogen halide. With the methods provided by the invention, halogenated propanol or propylene oxide can be prepared with high selectivity and yield; meanwhile, the discharge of wastewater and waste residues is greatly reduced.

Owner:JIANGXI SUKEER NEW MATERIAL

Methods for preparing halogen ethanol and ethylene oxide

ActiveCN106518613AReduce loadReduce dosageDispersed particle separationPreparation by OH and halogen introductionHydrogen halideSaponification

The invention provides a method for preparing halogen ethanol, wherein the method comprises: (1) halogen alcoholization, wherein hydrogen halide, H2O2, ethylene and a HTS molecular sieve are added to a reaction device, and a halogen alcoholization reaction is performed to obtain the halogen ethanol. The invention further provides a method for preparing ethylene oxide through a halogen alcoholization method, wherein the method comprises: (1) halogen alcoholization, wherein hydrogen halide, H2O2, ethylene and a HTS molecular sieve are added to a reaction device, and a halogen alcoholization reaction is performed to obtain halogen ethanol; (2) saponification, wherein the halogen ethanol obtained in the step (1) and the hydroxide of an alkali metal are subjected to a saponifying reaction, and separation is performed to obtain ethylene oxide and a halogenated alkali metal salt; and optionally, (3) electrodialysis, wherein the halogenated alkali metal salt obtained in the step (2) is subjected to bipolar membrane electrodialysis to obtain the hydroxide of the alkali metal and the hydrogen halide. According to the present invention, the halogen ethanol or the ethylene oxide is prepared in the forms of the extremely high yield and the extremely high selectivity, and the emission of wastewater and waste residue is substantially reduced.

Owner:JIANGXI SUKEER NEW MATERIAL

Methods for preparing halogenated ethanol and ethylene oxide by dry gas

ActiveCN106518614AEasily damagedSolve intractablePreparation by OH and halogen introductionBulk chemical productionHydrogen halideLithium hydroxide

A method for preparing halogenated ethanol by a dry gas is disclosed, and the method comprises the following steps: (1) halohydrination, to be more specific, adding hydrogen halide, H2O2 and the dry gas in a reactor for halohydrination to obtain the halogenated ethanol. A method of producing ethylene oxide by the dry gas is also disclosed, and the method comprises the following steps: (1) halohydrination, to be more specific, adding the hydrogen halide, the H2O2 and the dry gas in the reactor for halohydrination to obtain the halogenated ethanol; and (2) saponification, to be more specific, taking the halogenated ethanol obtained by the step (1) and an alkali metal hydroxide (preferably, sodium hydroxide, potassium hydroxide or lithium hydroxide) for saponification, and separating to obtain the ethylene oxide and a halogenated alkali metal salt. By preparation of the halogenated ethanol from the hydrogen halide, the H2O2 and the dry gas and then saponification, the ethylene oxide can be prepared by extremely-high-selectivity and high-yield use of an ethylene component in the dry gas, and waste water and waste residue discharge is greatly reduced.

Owner:JIANGXI SUKEER NEW MATERIAL

Molybdenum-tungsten separating process for molybdenum-tungsten mixed ammonium salt solution in tungsten hydrometallurgy

InactiveCN102140578BIncrease the precipitation rateEasy to produceProcess efficiency improvementHigh concentrationTungstate

The invention discloses a molybdenum-tungsten separating process for a molybdenum-tungsten mixed ammonium salt solution in tungsten hydrometallurgy and relates to the molybdenum-tungsten separating process for cooling and crystallizing an ammonium tungstate solution from high-concentration molybdenum to separate out tetrathio ammonium molybdate. The ammonium tungstate solution is subjected to sulfo-treatment, so that the molybdenum in the solution preferably generates the tetrathio ammonium molybdate. Under the condition of no addition of any chemical agent, the temperature of the solution isproperly reduced; and by standing or mechanical stirring, majority of molybdenum is separated out in a (NH4)2MoS4 crystal form without separating out the tungsten, thereby achieving the effects of effectively separating and recycling the molybdenum from the ammonium tungstate solution.

Owner:CENT SOUTH UNIV

Preparation methods for halopropanol and epoxypropane

ActiveCN106560465AReduce loadReduce dosageDispersed particle separationPreparation by OH and halogen introductionMolecular sieveHalogen

The invention provides a preparation method for halopropanol. The preparation method comprises the following step: (1) halogenohydrination: adding halogen hydride, H2O2, propylene and a molecular sieve containing Ti heteroatoms into a reaction apparatus and carrying out halogenohydrination so as to obtain halopropanol. The invention also provides a halogenohydrin preparation method for epoxypropane. The halogenohydrin preparation method comprises the following step: (1) halogenohydrination: adding halogen hydride, H2O2, propylene and the molecular sieve containing Ti heteroatoms into the reaction apparatus and carrying out halogenohydrination so as to obtain halopropanol; (2) saponification: subjecting halogenohydrin prepared in the step (1) and a hydroxide of an alkali metal to saponification and carrying out separation so as to obtain epoxypropane and a halogenated alkali metal salt; and optionally, (3) electrodialysis: subjecting the halogenated alkali metal salt obtained in the step (2) to bipolar membrane electrodialysis so as to obtain the hydroxide of the alkali metal and halogen hydride. The methods provided by the invention realize high selectivity and yield in preparation of halopropanol or epoxypropane, and greatly reduce discharge of waste water and waste residues.

Owner:JIANGXI SUKEER NEW MATERIAL

A method for preparing haloethanol and ethylene oxide

ActiveCN106518625BSolve intractableDifficult problems to overcomeDispersed particle separationPreparation by OH and halogen introductionHalohydrinSaponification

Owner:JIANGXI SUKEER NEW MATERIAL

Methods for preparing halogen propanol and ethylene oxide

ActiveCN106518612AAchieve recyclingReduce loadPreparation by OH and halogen introductionHydrogen halideSaponification

The invention provides a method for preparing halogen propanol, wherein the method comprises: (1) halogen alcoholization, wherein hydrogen halide, H2O2, ethylene and a Zr heteroatom-containing molecular sieve having an MFI structure are added to a reaction device, and a halogen alcoholization reaction is performed to obtain the halogen propanol. The invention further provides a method for preparing ethylene oxide through a halogen alcoholization method, wherein the method comprises: (1) halogen alcoholization, wherein hydrogen halide, H2O2, ethylene and a Zr heteroatom-containing molecular sieve having an MFI structure are added to a reaction device, and a halogen alcoholization reaction is performed to obtain halogen propanol; (2) saponification, wherein the halogen propanol obtained in the step (1) and the hydroxide of an alkali metal are subjected to a saponifying reaction, and separation is performed to obtain ethylene oxide and a halogenated alkali metal salt; and optionally, (3) electrodialysis, wherein the halogenated alkali metal salt obtained in the step (2) is subjected to bipolar membrane electrodialysis to obtain the hydroxide of the alkali metal and the hydrogen halide. According to the present invention, the halogen propanol or the ethylene oxide is prepared in the forms of the extremely high yield and the extremely high selectivity, and the emission of wastewater and waste residue is substantially reduced.

Owner:JIANGXI SUKEER NEW MATERIAL

A kind of method for preparing halopropanol and propylene oxide

ActiveCN106518626BSolve intractableDifficult problems to overcomeDispersed particle separationPreparation by OH and halogen introductionHydrogen halideWastewater

The invention provides a method for preparing halogenated propanol. The method comprises the following step: (1) halogenohydrination: a step of adding hydrogen halide, H2O2 and a catalyst into a reactor, after a period of time, adding propylene, and carrying out a halogenohydrination reaction so as to obtain halogenated propanol. The invention also provides a method for preparing propylene oxide through a halogenohydrination method. The method for preparing propylene oxide is characterized by comprising the step (1) as described in claim 1 of the patent, and also comprising the following steps: (2) saponification: a step of subjecting halogenated propanol in the step (1) and alkali metal hydroxide to a saponification reaction, and carrying out separation so as to obtain propylene oxide and halogenated alkali metal salt; and optionally, (3) electrodialysis: a step of subjecting the halogenated alkali metal salt obtained in the step (2) to bipolar membrane electrodialysis so as to obtain alkali metal hydroxide and hydrogen halide. With the methods provided by the invention, halogenated propanol or propylene oxide can be prepared with high selectivity and yield; meanwhile, the discharge of wastewater and waste residues is greatly reduced.

Owner:JIANGXI SUKEER NEW MATERIAL

A kind of method for preparing halopropanol and propylene oxide

ActiveCN106560465BSolve intractableDifficult problems to overcomeDispersed particle separationPreparation by OH and halogen introductionMolecular sieveHalogen

The invention provides a preparation method for halopropanol. The preparation method comprises the following step: (1) halogenohydrination: adding halogen hydride, H2O2, propylene and a molecular sieve containing Ti heteroatoms into a reaction apparatus and carrying out halogenohydrination so as to obtain halopropanol. The invention also provides a halogenohydrin preparation method for epoxypropane. The halogenohydrin preparation method comprises the following step: (1) halogenohydrination: adding halogen hydride, H2O2, propylene and the molecular sieve containing Ti heteroatoms into the reaction apparatus and carrying out halogenohydrination so as to obtain halopropanol; (2) saponification: subjecting halogenohydrin prepared in the step (1) and a hydroxide of an alkali metal to saponification and carrying out separation so as to obtain epoxypropane and a halogenated alkali metal salt; and optionally, (3) electrodialysis: subjecting the halogenated alkali metal salt obtained in the step (2) to bipolar membrane electrodialysis so as to obtain the hydroxide of the alkali metal and halogen hydride. The methods provided by the invention realize high selectivity and yield in preparation of halopropanol or epoxypropane, and greatly reduce discharge of waste water and waste residues.

Owner:JIANGXI SUKEER NEW MATERIAL

Preparation method for halogenohydrin and epoxide

ActiveCN106518589ASolve intractableSolve processing problemsDispersed particle separationHydroxy group formation/introductionHalogenEpoxide

The invention provides a preparation method for halogenohydrin and an epoxide. The method comprises the following steps: (1) halogenohydrination: adding H2O2 (or hydrogen peroxide), elemental halogen and an olefinic unsaturated compound with one or more C=C double bonds into a reaction apparatus for halogenohydrination so as to prepare halogenohydrin; (2) saponification: subjecting halogenohydrin prepared in the step (1) and a hydroxide of an alkali metal to saponification and carrying out separation so as to obtain the epoxides and a halogenated alkali metal salt; and (3) electrodialysis: subjecting the halogenated alkali metal salt obtained in the step (2) to bipolar membrane electrodialysis so as to obtain the hydroxide of the alkali metal and halogen hydride. The method has realizes high selectivity and yield in preparation of halogenohydrin or the epoxide, and greatly reduces discharge of waste water and waste residues.

Owner:JIANGXI SUKEER NEW MATERIAL

Method for preparing halohydrin and ethylene oxide through dry gas

ActiveCN106518615ASolve intractableOvercome the problemPreparation by OH and halogen introductionHalohydrinSaponification

The invention discloses a method for preparing halohydrin. The method comprises the steps of 1, haloid alcoholization, wherein H2O2, halogen simple substance and the dry gas are added into a reaction device, and carrying out a haloid alcoholization reaction to obtain halohydrin. The invention discloses a method for preparing ethylene oxide. The method comprises the steps of 1, haloid alcoholization, wherein H2O2, the halogen simple substance and the dry gas are added in the reaction device, and carrying out the haloid alcoholization reaction to obtain halohydrin; 2, saponification, wherein a saponification reaction are carried out on halohydrin obtained in the step 1 and hydroxide of alkali metal, and carrying out separation to obtain the ethylene oxide and alkali halide metal salt. The dry gas, the halogen simple substance and H2O2 are adopted to prepare halohydrin and then carrying out saponification, therefore, an ethylene ingredient in the dry gas and be utilized with an extremely high selectivity and yield to prepare ethylene oxide, and discharge of wastewater and residues is reduced by a large margin.

Owner:JIANGXI SUKEER NEW MATERIAL

A method for preparing haloethanol and ethylene oxide

ActiveCN106518611BSolve intractableDifficult problems to overcomeDispersed particle separationPreparation by OH and halogen introductionHydrogen halideSaponification

The invention provides a method for preparing halogen ethanol, wherein the method comprises: (1) acid treatment of a catalyst, wherein a catalyst is soaked in an acid, the soaked catalyst is washed, and the washed catalyst is dried; (2) halogen alcoholization, wherein hydrogen halide, H2O2, ethylene and the catalyst treated in the step (1) are added to a reaction device, and a halogen alcoholization reaction is performed to obtain the halogen ethanol; optionally (3) saponification, wherein the halogen ethanol obtained in the step (2) and the hydroxide of an alkali metal are subjected to a saponifying reaction, and separation is performed to obtain ethylene oxide and a halogenated alkali metal salt; and optionally, (4) electrodialysis, wherein the halogenated alkali metal salt obtained in the step (3) is subjected to bipolar membrane electrodialysis to obtain the hydroxide of the alkali metal and the hydrogen halide. According to the present invention, the halogen ethanol is prepared in the forms of the extremely high yield and the extremely high selectivity, and the emission of wastewater and waste residue is substantially reduced.

Owner:JIANGXI SUKEER NEW MATERIAL

A kind of electrolytic solution for producing electrolytic copper foil and preparation method thereof for preventing anode fouling

ActiveCN105862089BPrevent scalingAvoid premature failureElectroforming processesElectrolytic agentSulfate radicals

Owner:JIUJIANG TELFORD ELECTRONICS MATERIAL CO LTD

A kind of method for preparing halopropanol and propylene oxide

ActiveCN106518612BSolve intractableDifficult problems to overcomePreparation by OH and halogen introductionHydrogen halideSaponification

The invention provides a method for preparing halogen propanol, wherein the method comprises: (1) halogen alcoholization, wherein hydrogen halide, H2O2, ethylene and a Zr heteroatom-containing molecular sieve having an MFI structure are added to a reaction device, and a halogen alcoholization reaction is performed to obtain the halogen propanol. The invention further provides a method for preparing ethylene oxide through a halogen alcoholization method, wherein the method comprises: (1) halogen alcoholization, wherein hydrogen halide, H2O2, ethylene and a Zr heteroatom-containing molecular sieve having an MFI structure are added to a reaction device, and a halogen alcoholization reaction is performed to obtain halogen propanol; (2) saponification, wherein the halogen propanol obtained in the step (1) and the hydroxide of an alkali metal are subjected to a saponifying reaction, and separation is performed to obtain ethylene oxide and a halogenated alkali metal salt; and optionally, (3) electrodialysis, wherein the halogenated alkali metal salt obtained in the step (2) is subjected to bipolar membrane electrodialysis to obtain the hydroxide of the alkali metal and the hydrogen halide. According to the present invention, the halogen propanol or the ethylene oxide is prepared in the forms of the extremely high yield and the extremely high selectivity, and the emission of wastewater and waste residue is substantially reduced.

Owner:JIANGXI SUKEER NEW MATERIAL

A method for preparing haloethanol and ethylene oxide

ActiveCN106518622BSolve intractableDifficult problems to overcomePreparation by OH and halogen introductionSaponificationHigh selectivity

Owner:JIANGXI SUKEER NEW MATERIAL

Method for preparing halohydrin and ethylene oxide

ActiveCN106518625ASolve intractableDifficult problems to overcomeDispersed particle separationPreparation by OH and halogen introductionHalohydrinSaponification

The invention provides a method for preparing halohydrin. The method comprises the following steps: 1) halogen alcoholization: halogen hydride, H2O2, ethylene and Zr-containing hetero atoms having a MFI structural molecular sieve are added in a reaction apparatus, and then are subjected to a halogen alcoholization reaction to obtain halohydrin. The invention also provides a method for preparing ethylene oxide by a halogen alcoholization method, which comprises the following steps: 1) halogen alcoholization: halogen hydride, H2O2, ethylene and Zr-containing hetero atoms having the MFI structural molecular sieve are added in the reaction apparatus, and then are subjected to the halogen alcoholization reaction to obtain halohydrin; 2) saponification: halohydrin and hydroxide of alkali metal are subjected to a saponification reaction, then separated to obtain ethylene oxide and alkali halide metal salt; and optionally, 3) electrodialysis: the obtained alkali halide metal salt is subjected to bipolar membrane electrodialysis to obtain the hydroxide of alkali metal and the halogen hydride. The method is used for preparing halohydrin or ethylene oxide with high selectivity and yield, and greatly reduces the discharge of waste water and waste residue.

Owner:JIANGXI SUKEER NEW MATERIAL

A kind of concentration method in the production process of fermented Cordyceps powder

ActiveCN108905240BLow boiling pointPipeliningEvaporator accessoriesEvaporator regulation/controlBiotechnologyDiaphragm pump

The invention provides a concentration method in the production process of ferment cordyceps sinensis fungus powder. The method comprises the following steps: S1, injecting a cordyceps sinensis fermenting liquid which is subjected to the removal of 40%-60% of a fermenting mother liquid into a liquid storage tank; S2, turning on a vacuum pump, introducing hot water or water vapor into a heater anda heating pipe, pumping the cordyceps sinensis fermenting liquid into a vacuum rotary film evaporator when the vacuum degree and the temperature reach preset values, starting the rotation of the heater, and turning on a spraying device to carry out ultralow-temperature vacuum continuous concentration; S3, turning on a pneumatic diaphragm pump to automatically control the material feeding and discharging when the volume of the fed material reaches 1 / 2-2 / 3, simultaneously turning on an online automatic detecting device, recording the solid content, the total amino acids and the pH value at regular intervals, and moderately adjusting various concentration technical parameters according to the online detected data; S4, when the solid content or the total amino acids or the pH values reach thecontrol indexes, automatically discharging a concentrated liquid; and S5, drying the concentrated liquid, carrying out crushing, sieving and packaging to obtain a finished product of the ferment cordyceps sinensis fungus powder. The product provided by the invention has high quality and effective components of the product are preserved greatly.

Owner:JIANGXI GUOYAO PHARMA LLC

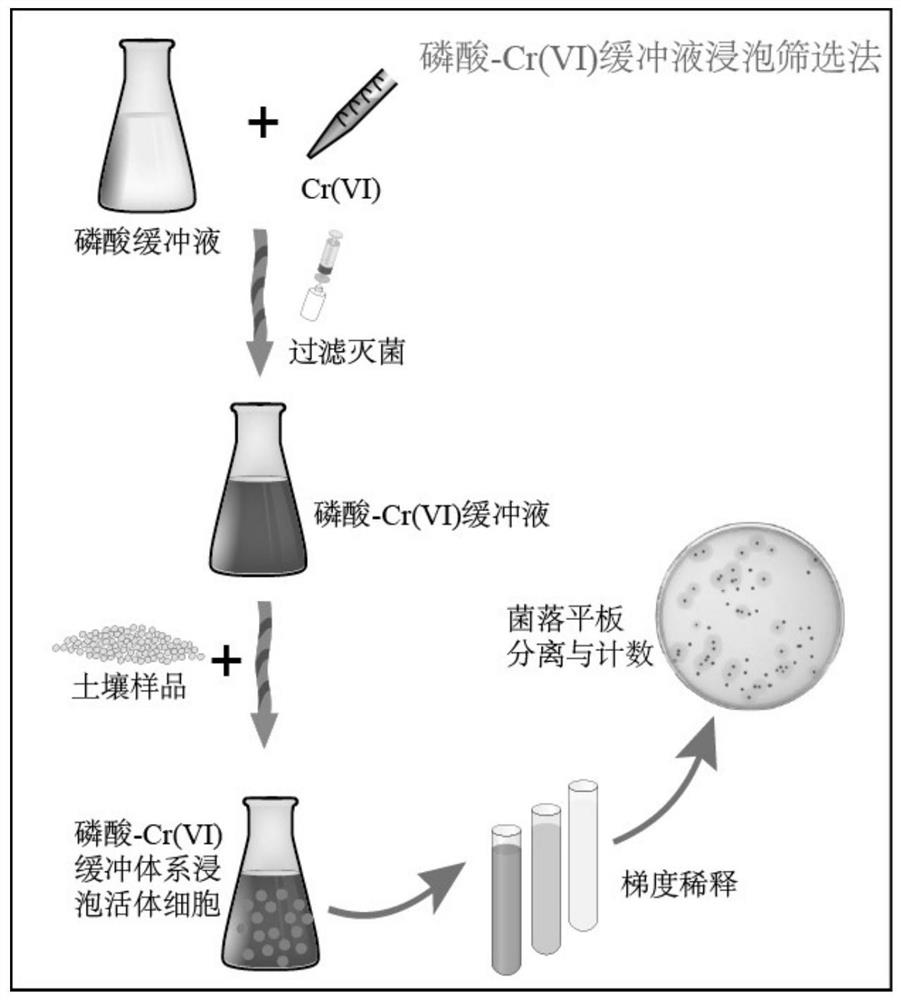

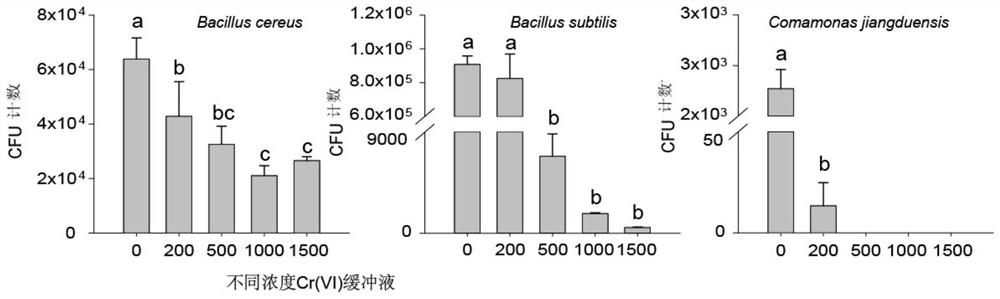

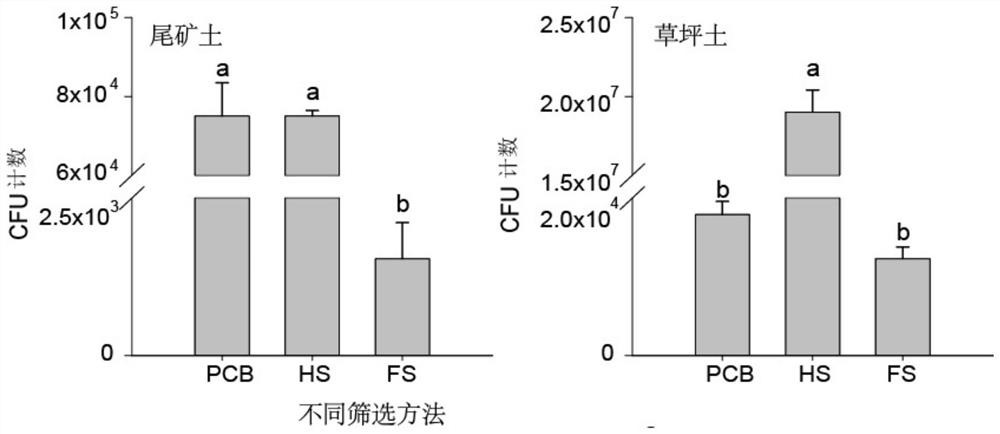

A screening method for heavy metal-resistant microorganisms

ActiveCN109321498BTrue concentration is accurateTrue Concentration ReliableBacteriaMicroorganism based processesInorganic saltsMicroorganism

A screening method for heavy metal-resistant microorganisms, characterized in that: sequentially comprising the following steps: preparing a buffer solution, adding a heavy metal salt solution to the buffer solution, and then preparing buffer solutions containing heavy metal ions with different concentration gradients, and filtering to sterilize For later use, the buffer solution is a neutral inorganic salt buffer solution; the buffer solution containing heavy metal ions is mixed with the environmental sample to prepare an environmental sample suspension, and after mixing, incubate at a constant temperature of 20-40°C for 0.5-5 Hours, let the microorganisms in the environmental samples accept heavy metal ion immersion screening; after the immersion, carry out gradient dilution to the environmental sample suspension to obtain a dilution, transfer the dilution to a medium without heavy metal ions, and then cultivate to obtain a stable Resistant to heavy metal microorganisms. The method of the invention has the characteristics of quickness, simplicity, no interference to the culture medium, no selectivity, high recognition rate for heavy metal-resistant microorganisms, and sensitivity to non-heavy metal-resistant microorganisms.

Owner:SUZHOU ACADEMY OF AGRI SCI

A method for preparing haloethanol and ethylene oxide

ActiveCN106518623BSolve intractableDifficult problems to overcomeDispersed particle separationPreparation by OH and halogen introductionHalohydrinSaponification

The invention provides a method for preparing halohydrin. The method comprises the following steps: 1) halogen alcoholization: halogen hydride, H2O2, and a catalyst are added in a reaction apparatus, and ethylene is added for a halogen alcoholization reaction to obtain halohydrin. The invention also provides a method for preparing ethylene oxide by a halogen alcoholization method, which comprises the step 1) in right claim 1, the method also comprises a step of 2) saponification: halohydrin in the step 1) and hydroxide of alkali metal are subjected to a saponification reaction, then separated to obtain ethylene oxide and alkali halide metal salt; and an optional step of 3) electrodialysis: the obtained alkali halide metal salt is subjected to bipolar membrane electrodialysis to obtain the hydroxide of alkali metal and the halogen hydride. The method is used for preparing halohydrin or ethylene oxide with high selectivity and yield, and greatly reduces the discharge of waste water and waste residue.

Owner:JIANGXI SUKEER NEW MATERIAL

A method for preparing haloethanol and ethylene oxide from dry gas

ActiveCN106518615BSolve intractableOvercome the problemPreparation by OH and halogen introductionHalohydrinSaponification

The invention discloses a method for preparing halohydrin. The method comprises the steps of 1, haloid alcoholization, wherein H2O2, halogen simple substance and the dry gas are added into a reaction device, and carrying out a haloid alcoholization reaction to obtain halohydrin. The invention discloses a method for preparing ethylene oxide. The method comprises the steps of 1, haloid alcoholization, wherein H2O2, the halogen simple substance and the dry gas are added in the reaction device, and carrying out the haloid alcoholization reaction to obtain halohydrin; 2, saponification, wherein a saponification reaction are carried out on halohydrin obtained in the step 1 and hydroxide of alkali metal, and carrying out separation to obtain the ethylene oxide and alkali halide metal salt. The dry gas, the halogen simple substance and H2O2 are adopted to prepare halohydrin and then carrying out saponification, therefore, an ethylene ingredient in the dry gas and be utilized with an extremely high selectivity and yield to prepare ethylene oxide, and discharge of wastewater and residues is reduced by a large margin.

Owner:JIANGXI SUKEER NEW MATERIAL

A method for preparing haloethanol and ethylene oxide

ActiveCN106518613BSolve intractableDifficult problems to overcomeDispersed particle separationPreparation by OH and halogen introductionHydrogen halideSaponification

The invention provides a method for preparing halogen ethanol, wherein the method comprises: (1) halogen alcoholization, wherein hydrogen halide, H2O2, ethylene and a HTS molecular sieve are added to a reaction device, and a halogen alcoholization reaction is performed to obtain the halogen ethanol. The invention further provides a method for preparing ethylene oxide through a halogen alcoholization method, wherein the method comprises: (1) halogen alcoholization, wherein hydrogen halide, H2O2, ethylene and a HTS molecular sieve are added to a reaction device, and a halogen alcoholization reaction is performed to obtain halogen ethanol; (2) saponification, wherein the halogen ethanol obtained in the step (1) and the hydroxide of an alkali metal are subjected to a saponifying reaction, and separation is performed to obtain ethylene oxide and a halogenated alkali metal salt; and optionally, (3) electrodialysis, wherein the halogenated alkali metal salt obtained in the step (2) is subjected to bipolar membrane electrodialysis to obtain the hydroxide of the alkali metal and the hydrogen halide. According to the present invention, the halogen ethanol or the ethylene oxide is prepared in the forms of the extremely high yield and the extremely high selectivity, and the emission of wastewater and waste residue is substantially reduced.

Owner:JIANGXI SUKEER NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com