Method for preparing halohydrin and ethylene oxide through dry gas

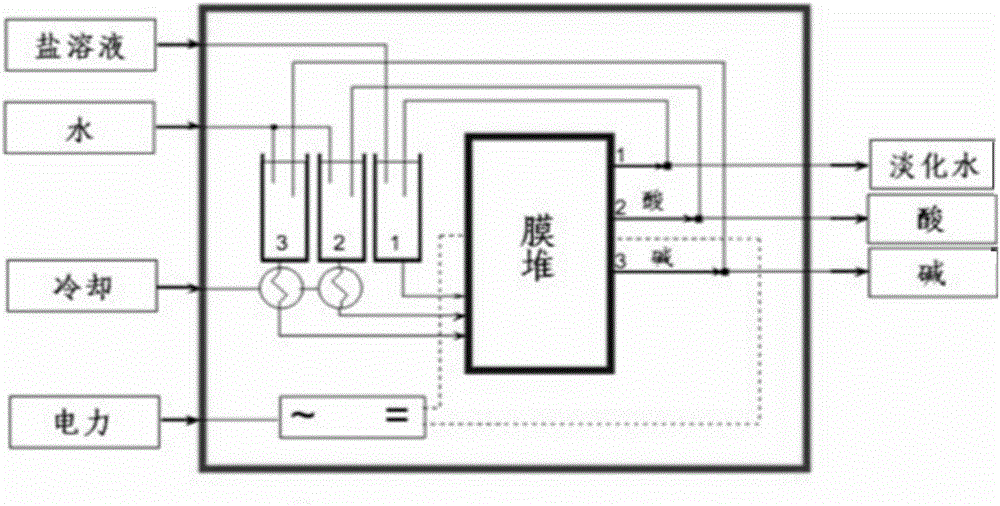

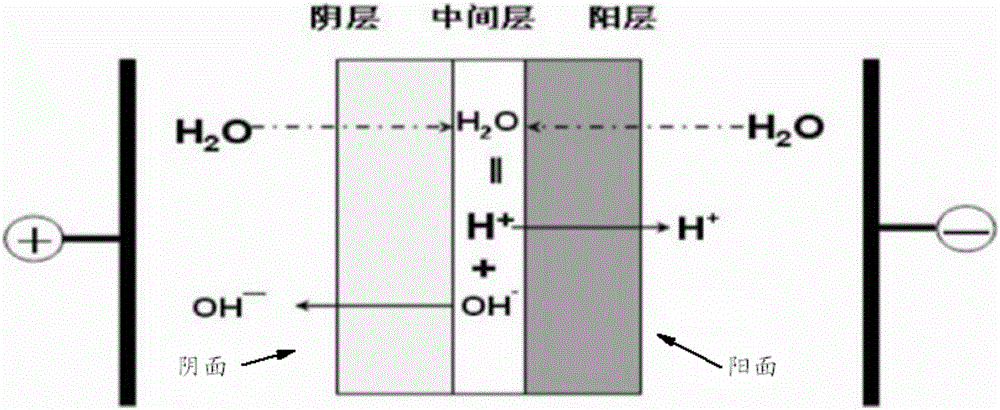

A technology of ethylene oxide and haloethanol, which is applied in the field of preparation of haloethanol and the preparation of ethylene oxide by the new alcohol method, which can solve the problems of large consumption of water resources, high COD of wastewater, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0099] A method for preparing haloethanol from dry gas, the method may further comprise the steps:

[0100] (1) Haloalcoholization: Add 70wt% concentration of hydrogen peroxide H 2 o 2 , chlorine and dry gas (the volume content of ethylene is 33.7vol%), carry out chlorohydrinization reaction at the temperature of 45 ℃, wherein the hydrogen peroxide H of 70wt% concentration 2 o 2 The flow rates of , chlorine and dry gas should make H 2 o 2 The volume ratio of chlorine to dry gas is about 1.1:0.5:1. Chlorohydrin is obtained.

Embodiment 2

[0105] A method for preparing haloethanol from dry gas, the method may further comprise the steps:

[0106] 1) Haloalcoholization: add tungstic acid catalyst, 35wt% concentration of hydrogen peroxide H in the tower reactor 2 o 2 , chlorine gas and dry gas, carry out chloroalcoholization reaction at the temperature of 35 ℃, wherein the mass ratio of tungstic acid catalyst and dry gas is 0.05:1, the hydrogen peroxide H of 35wt% concentration 2 o 2 , chlorine and dry gas should be added in such a way that H 2 o 2The volume ratio of chlorine to dry gas is about 2:1:1. Chlorohydrin is obtained.

Embodiment 3

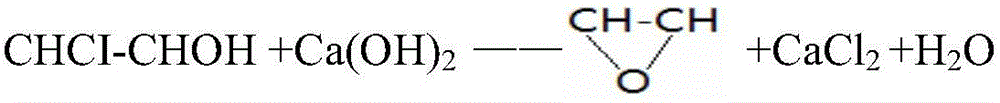

[0114] A method for preparing ethylene oxide from dry gas, the method may further comprise the steps:

[0115] (1) Haloalcoholization: add tungstic acid catalyst, 70wt% concentration of hydrogen peroxide H in the tower reactor 2 o 2 , chlorine and dry gas, carry out chloroalcoholization reaction at a temperature of 35°C, wherein 70wt% concentration of hydrogen peroxide H 2 o 2 , chlorine gas and dry gas alkene flow should make H 2 o 2 The volume ratio of chlorine to dry gas is about 1.1:0.5:1. Chlorohydrin is obtained.

[0116] (2) Saponification: carry out saponification reaction with the chloroethanol obtained in step (1) and sodium hydroxide, obtain ethylene oxide organic phase and sodium chloride solution. The saponification reaction is carried out in a steel tower reactor, and the upper part is designed as a sieve tray tower. Steam enters from the bottom of the tower to blow out the crude ethylene oxide generated from the top of the tower. The saponification tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com