Red-mud non-fired non-steamed paving brick and preparation method thereof

A technology of pavement bricks and red mud, which is applied to roads, roads, paving surfaces paved with prefabricated blocks, etc. Benefit and economic benefits, improve the comprehensive utilization level, solve the effect of difficult disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

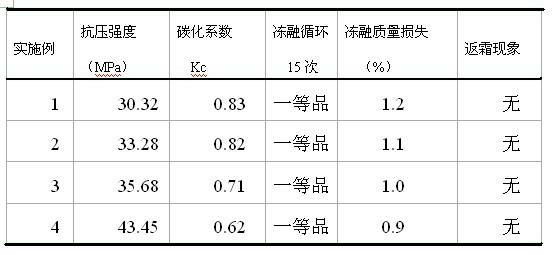

Examples

Embodiment 1

[0016] Example 1 of the present invention: first take 65 parts of red mud, 0 parts of fly ash, 20 parts of cement, 10 parts of aggregate (mountain sand can be used as aggregate), and 5 parts of modifier according to the weight of the dry basis. , wherein: the red mud is made by mixing the existing Bayer process red mud and sintering process red mud at a dry weight ratio of 6:1 (that is, 6 parts by weight of Bayer process red mud and 1 part of sintering process red mud), Fly ash should meet the national Class II ash regulations, and the modifier is a mixture of acidic industrial waste residue and industrial soda ash at a dry basis weight ratio of 8:1 (that is, 8 parts by weight of acidic industrial waste residue and 1 part of industrial soda ash). The acidic industrial waste can use the existing phosphogypsum, sulfuric acid slag or lead-zinc slag; then prepare it according to the following steps: put red mud, modifier and water into a concrete mixer and stir fully to form a past...

Embodiment 2

[0017] Embodiment 2: First take 50 parts of red mud, 10 parts of fly ash, 25 parts of cement, 12 parts of mountain sand, and 3 parts of modifier according to the weight of the dry basis, wherein: the red mud adopts the existing Bayer process red Mud and sintering red mud are mixed at a dry basis weight ratio of 6:1 (that is, 6 parts of Bayer red mud and 1 part of sintering red mud by weight), and the fly ash should meet the national Class II ash regulations. The neutralizing agent is a mixture of acidic industrial waste residue and industrial soda ash at a weight ratio of 8:1 on a dry basis (that is, 8 parts by weight of acidic industrial waste residue and 1 part of industrial soda ash). The acidic industrial waste residue can use existing phosphogypsum and sulfuric acid slag or lead-zinc slag; then prepare according to the following steps: Put the red mud, modifier and water together into a concrete mixer and fully stir to form a paste. The stirring reaction time is 10 to 15 m...

Embodiment 3

[0018] Embodiment 3: First take 40 parts of red mud, 20 parts of fly ash, 20 parts of cement, 18 parts of mountain sand, and 2 parts of modifier according to the weight of the dry basis, wherein: the red mud adopts the existing Bayer process red Mud and sintering red mud are mixed at a dry basis weight ratio of 6:1 (that is, 6 parts of Bayer red mud and 1 part of sintering red mud by weight), and the fly ash should meet the national Class II ash regulations. The neutralizing agent is a mixture of acidic industrial waste residue and industrial soda ash at a weight ratio of 8:1 on a dry basis (that is, 8 parts by weight of acidic industrial waste residue and 1 part of industrial soda ash). The acidic industrial waste residue can use existing phosphogypsum and sulfuric acid slag or lead-zinc slag; then prepare according to the following steps: Put the red mud, modifier and water together into a concrete mixer and fully stir to form a paste. The stirring reaction time is 10 to 15 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com