Method for recovering valuable metals from copper-cadmium slag of zinc hydrometallurgy

A valuable metal, hydrometallurgical zinc smelting technology, applied in the improvement of process efficiency, instruments, optics, etc., can solve problems such as pollution, waste of resources and the environment, and achieve the effects of short process flow, high current efficiency, and efficient recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

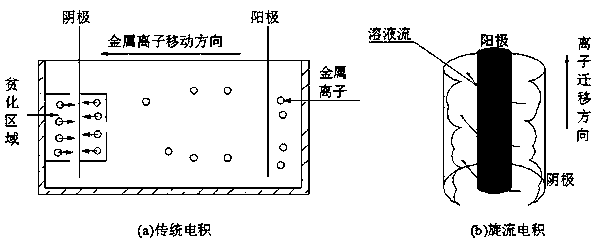

[0025] Such as figure 1 Shown, the method for reclaiming valuable metals from the zinc-copper-cadmium slag of hydrometallurgy, its concrete steps are as follows:

[0026] (1) First, the copper cadmium slag (the copper cadmium slag produced during the zinc smelting process of a wet zinc smelting plant in Yunnan, whose composition contains Cu26.52wt%, Fe2.53wt%, Cd4.55wt%, Zn3.54wt% ) drying and dehydration, after drying, finely grind to a particle size of 100 mesh to obtain copper cadmium slag, add it to sulfuric acid solution, and perform one leaching to obtain cadmium-rich liquid and primary leaching residue; the specific process is: the solid-liquid ratio of copper cadmium slag and sulfuric acid solution 1:7g / mL, leached for 3 hours at a temperature of 60°C, and the concentration of the sulfuric acid solution was 60g / L;

[0027] (2) Dilute the primary leaching slag obtained in step (1) with zinc electrowinning waste liquid (the zinc electrowinning waste liquid includes the...

Embodiment 2

[0034] Such as figure 1 Shown, the method for reclaiming valuable metals from the zinc-copper-cadmium slag of hydrometallurgy, its concrete steps are as follows:

[0035] (1) First, the copper cadmium slag (the copper cadmium slag produced during the zinc smelting process of a wet zinc smelting plant in Yunnan, whose composition contains Cu34.52wt%, Fe1.03wt%, Cd5.94wt%, Zn3.87wt% ) drying and dehydration, and after drying, finely grind to a particle size of 200 mesh to obtain copper cadmium slag, add it to sulfuric acid solution, and perform one leaching to obtain cadmium-rich liquid and primary leaching slag; the specific process is: the solid-liquid ratio of copper cadmium slag and sulfuric acid solution 1:5g / mL, leached at 70°C for 2h, the concentration of sulfuric acid solution is 40g / L;

[0036] (2) Dilute the primary leaching slag obtained in step (1) with zinc electrowinning waste liquid (the zinc electrowinning waste liquid includes the following components: Zn: 45-...

Embodiment 3

[0043] Such as figure 1 Shown, the method for reclaiming valuable metals from the zinc-copper-cadmium slag of hydrometallurgy, its concrete steps are as follows:

[0044] (1) First, the copper cadmium slag (the copper cadmium slag produced during the zinc smelting process of a wet zinc smelting plant in Yunnan, whose composition contains Cu51.36wt%, Fe0.97wt%, Cd3.69wt%, Zn6.97wt% ) drying and dehydration, and after drying, finely grind to a particle size of 200 mesh to obtain copper cadmium slag, add it to sulfuric acid solution, and perform one leaching to obtain cadmium-rich liquid and primary leaching slag; the specific process is: the solid-liquid ratio of copper cadmium slag and sulfuric acid solution 1:6g / mL, leaching at 65°C for 2.5h, the concentration of sulfuric acid solution is 50g / L;

[0045] (2) Dilute the primary leaching slag obtained in step (1) with zinc electrowinning waste liquid (zinc electrowinning waste liquid includes components: Zn: 40-65g / L, H 2 SO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com