A kind of concentration method in the production process of fermented Cordyceps powder

A fermented cordyceps fungus powder and production process technology, applied in separation methods, chemical instruments and methods, evaporation, etc., can solve the problem of large fluctuations in the overall level of adenosine and ergosterol content in the product, and low adenosine and ergosterol content in the cortex , local heat transfer effect decline and other problems, to achieve the effect of improving concentration efficiency and product quality, realizing solvent recovery and shortening concentration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

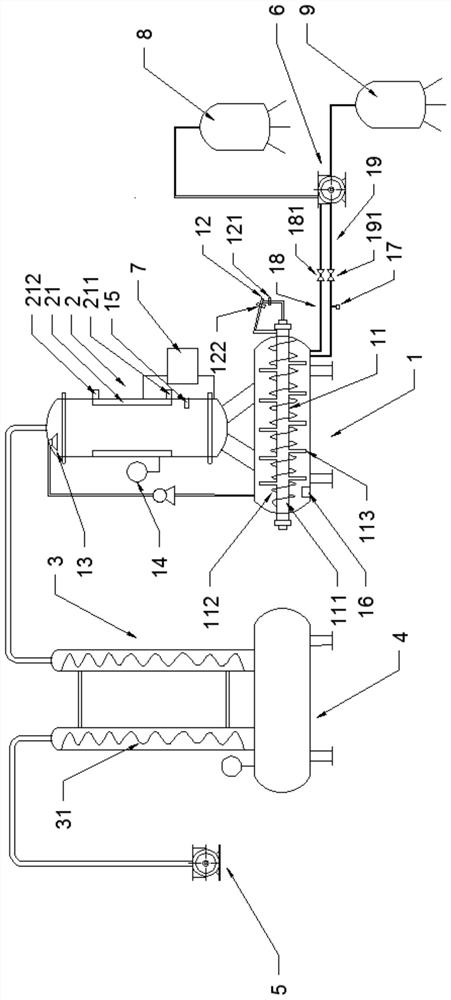

[0045] figure 1 , 2 Shown, the method for concentrating in the production process of fermented Cordyceps powder of the present invention comprises the following steps:

[0046] 1) Put 50 kg of cordyceps fermented liquid to be concentrated, which is initially filtered with a plate frame to remove 50% of the fermented yeast liquid, into the feed liquid storage tank 8 of the ultra-low temperature vacuum continuous concentration device, the storage temperature is ≤ 20 ° C, and the storage time is ≤ 3h.

[0047] 2) Turn on the power, start the industrial computer 7 control system, and control the operation of the whole device. Initially set the vacuum degree in the vacuum rotary thin film evaporator 1 to -0.09MPa, the heater speed to 80r / min, and the temperature to 50°C, turn on the vacuum pump 5, turn on the water inlet valve 121, pass the hot water / steam inlet and outlet 12, turn on the heating The pipe water inlet valve 211 feeds hot water into the heater 11 and the heating pi...

Embodiment 2

[0053] figure 1 , 2 Shown, the method for concentrating in the production process of fermented Cordyceps powder of the present invention comprises the following steps:

[0054] 1) Put 60 kg of Cordyceps fermented liquid to be concentrated, which is initially filtered with a ceramic membrane to remove 55% yeast liquid, into the feed liquid storage tank 8 of the ultra-low temperature vacuum continuous concentration device, the storage temperature is 20°C, and the storage time is 2h.

[0055] 2) Turn on the power, start the industrial computer 7 control system, and control the operation of the whole device. Initially set the vacuum degree in the vacuum rotary thin film evaporator 1 to -0.10MPa, the heater speed to 100r / min, and the temperature to 30°C, turn on the vacuum pump 5, turn on the water inlet valve 121, pass the hot water / steam inlet and outlet 12, turn on the heating The pipe water inlet valve 211 feeds hot water into the heater 11 and the heating pipe 21 respectivel...

Embodiment 3

[0061] figure 1 , 2 Shown, the concentration method of the present embodiment, similar to embodiment 1, 2, comprises the following steps:

[0062] 1) Put 55 kg of Cordyceps fermented liquid to be concentrated, which is preliminarily filtered with a ceramic membrane to remove 50% of the fermented yeast liquid, into the feed liquid storage tank 8 of the ultra-low temperature vacuum continuous concentration device, the storage temperature is 15°C, and the storage time is 3h.

[0063] 2) Turn on the power, start the industrial computer 7 control system, and control the operation of the whole device. Initially set the vacuum degree in the vacuum rotary thin film evaporator 1 to -0.10MPa, the heater speed to 90r / min, and the temperature to 35°C, turn on the vacuum pump 5, turn on the water inlet valve 121, pass the hot water / steam inlet and outlet 12, turn on the heating The pipe water inlet valve 211 feeds steam into the heater 11 and the heating pipe 21 respectively, and when th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com