Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

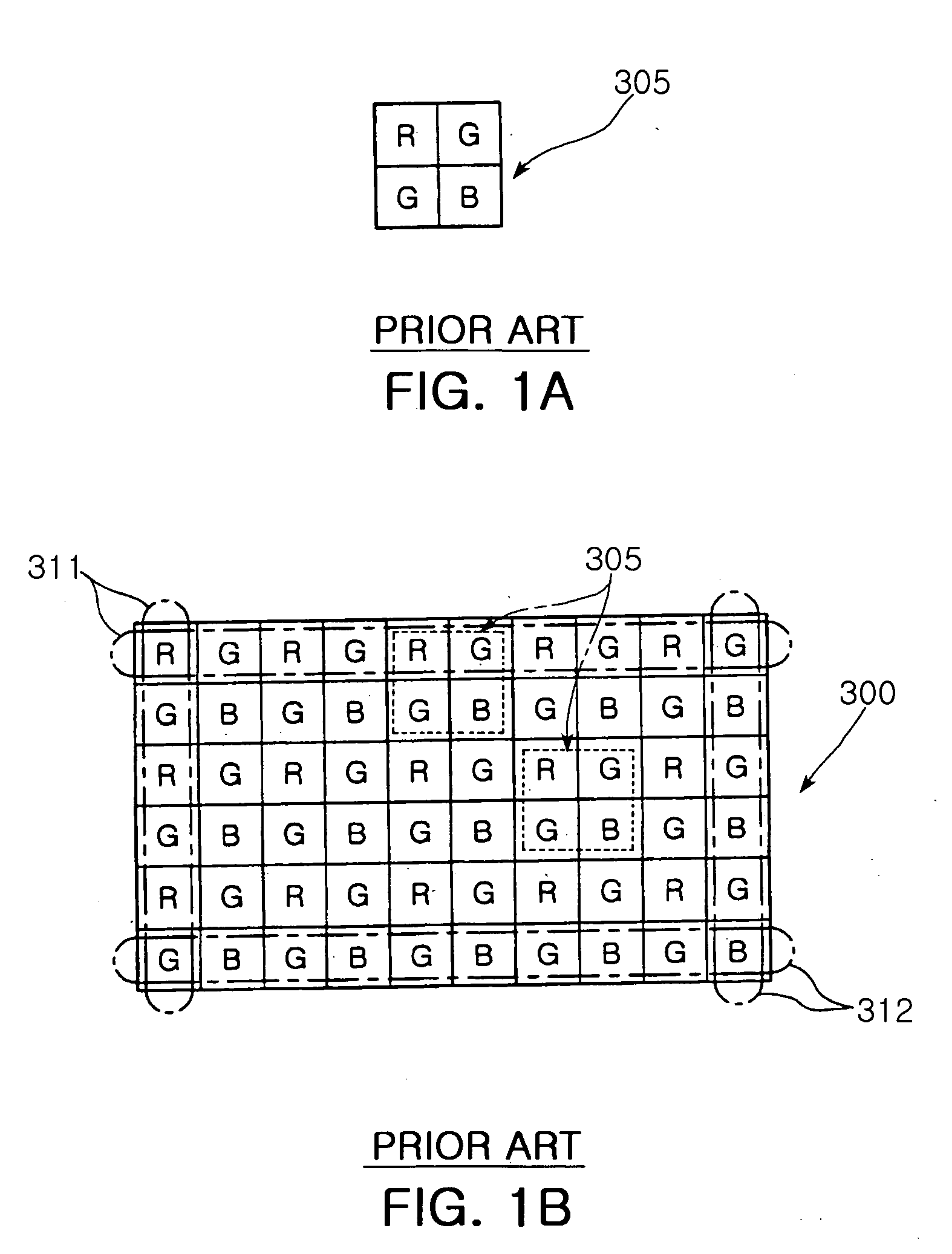

36results about How to "Uniform white light" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

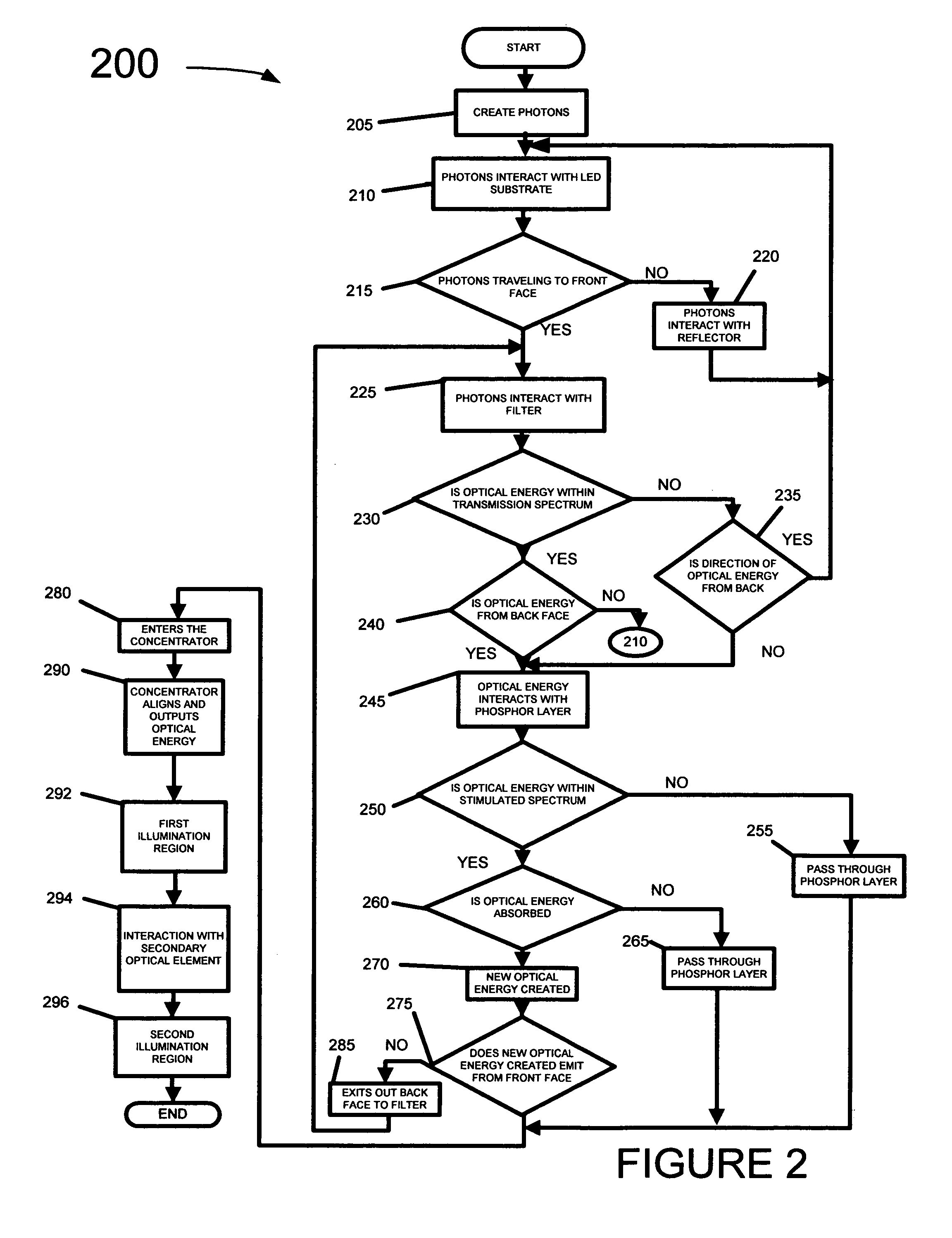

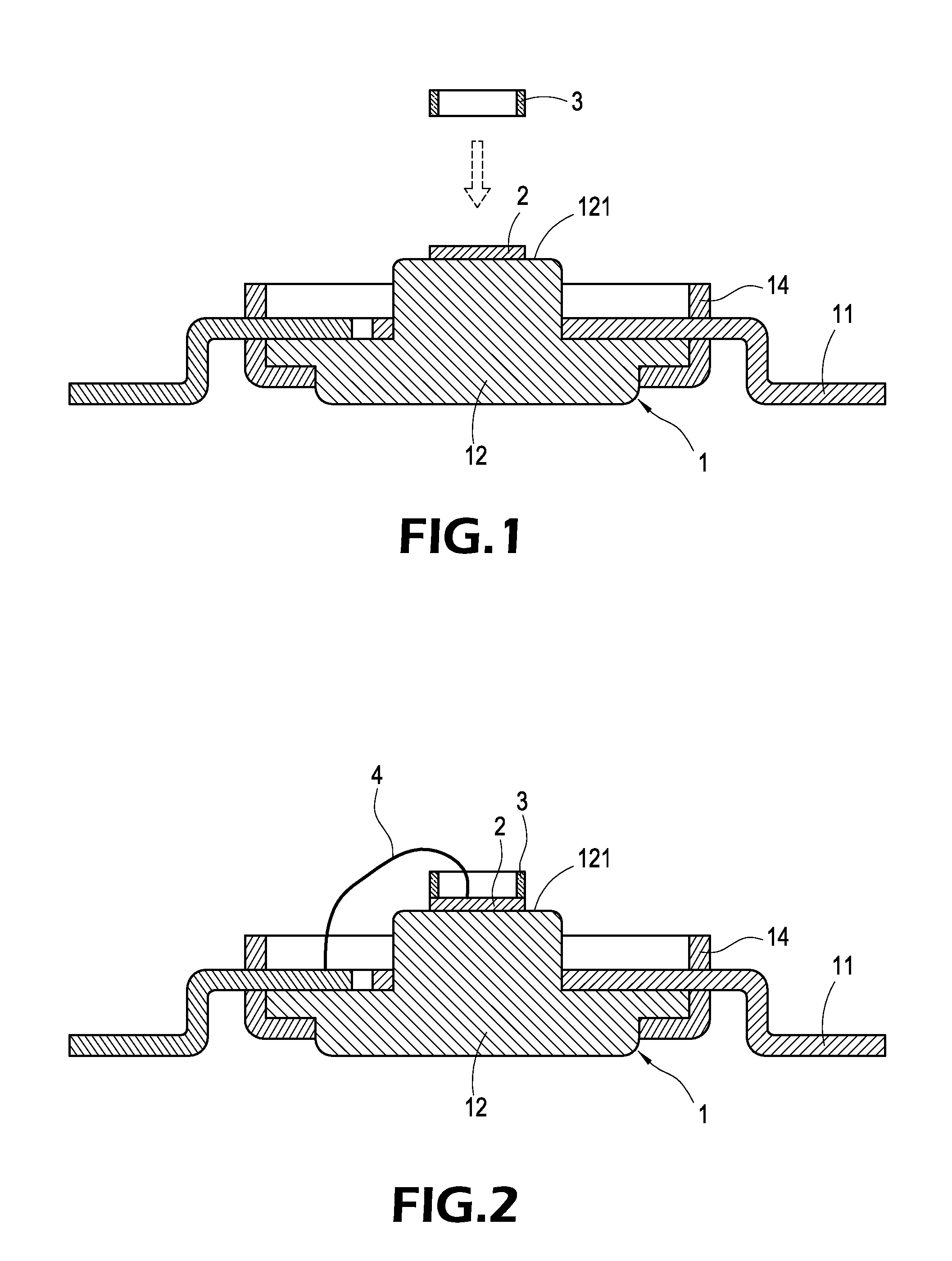

Led white light optical system

ActiveUS7153015B2Reduce package sizeHigh strengthLight therapyIlluminated signsEffect lightHigh intensity

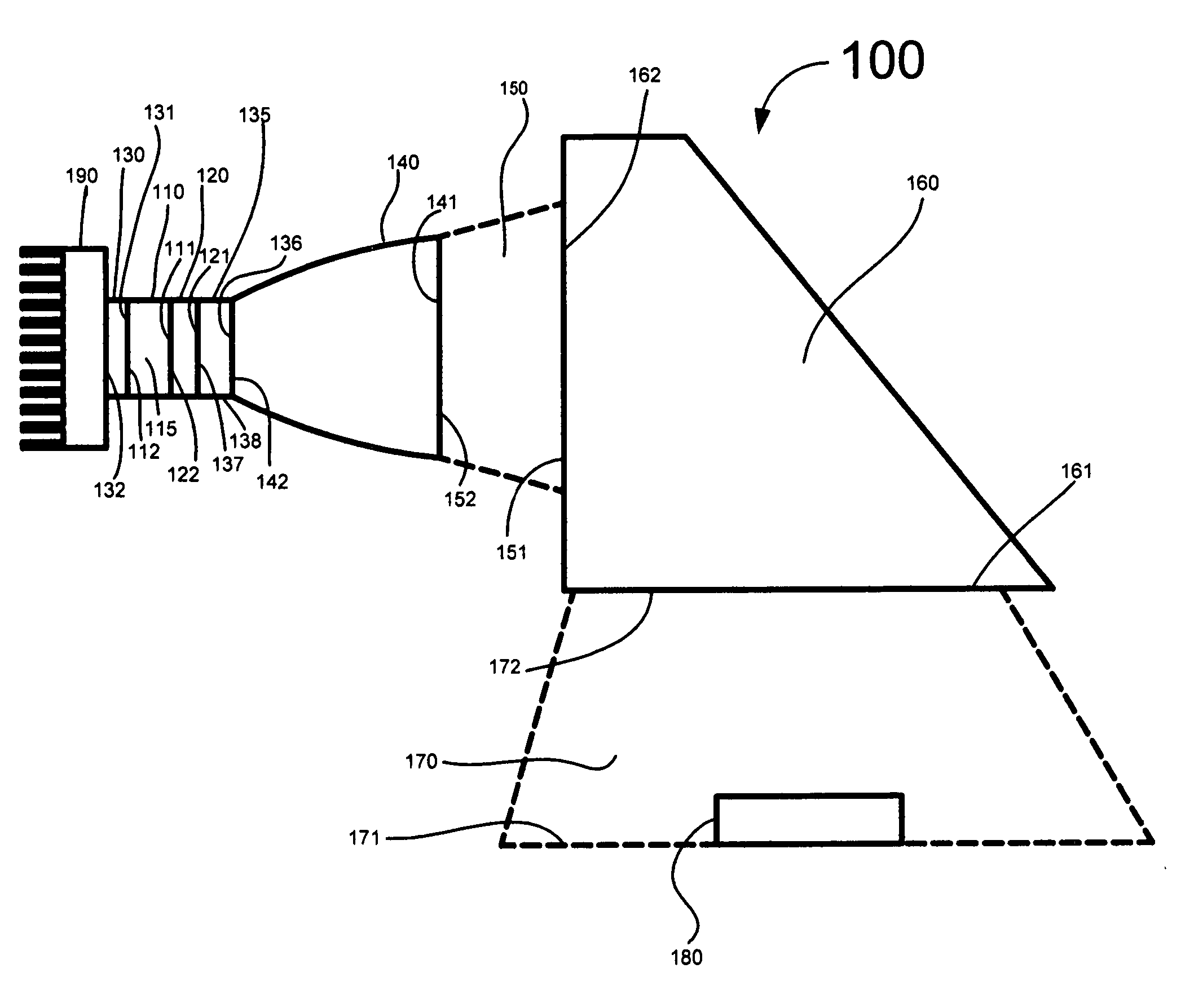

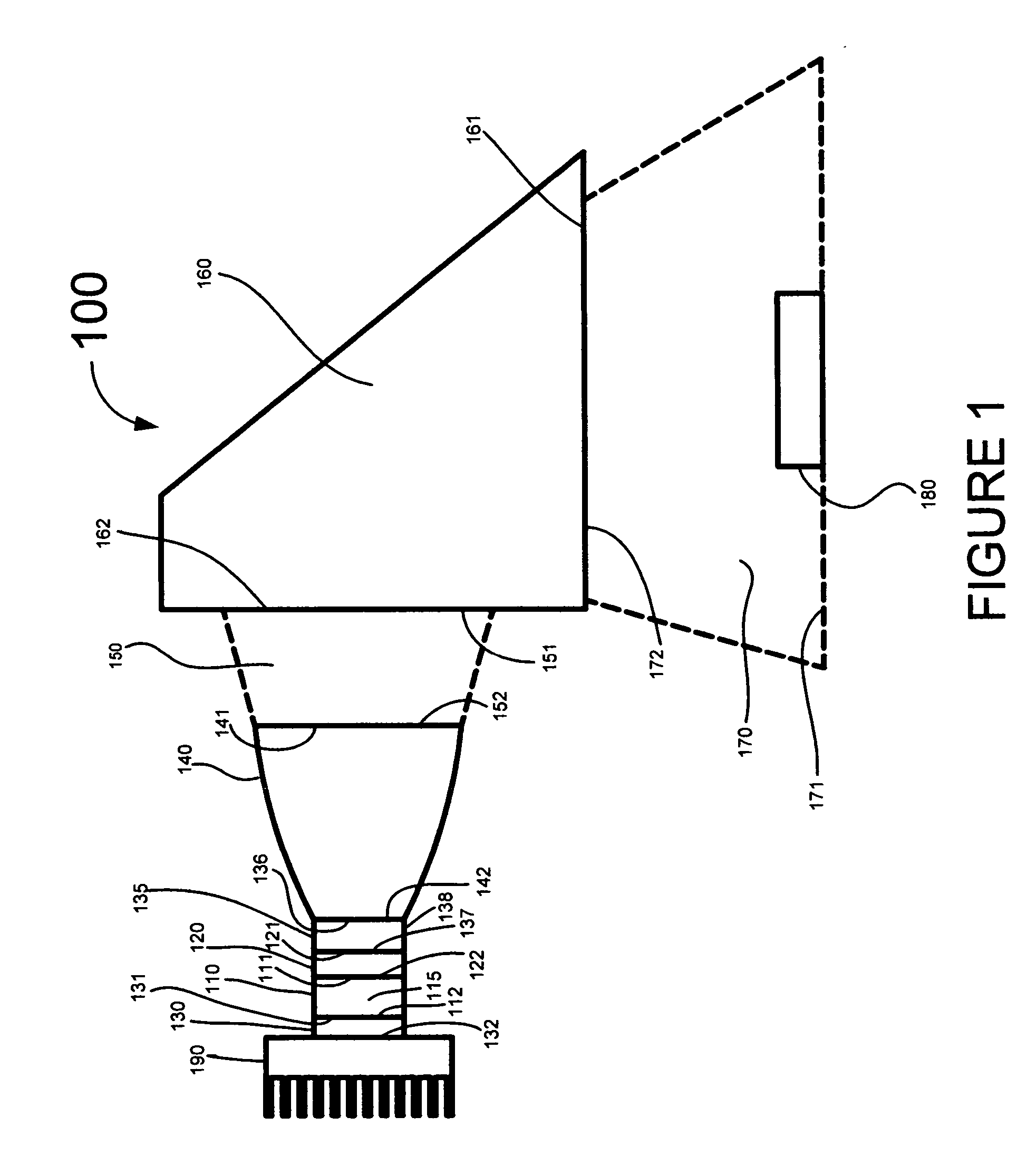

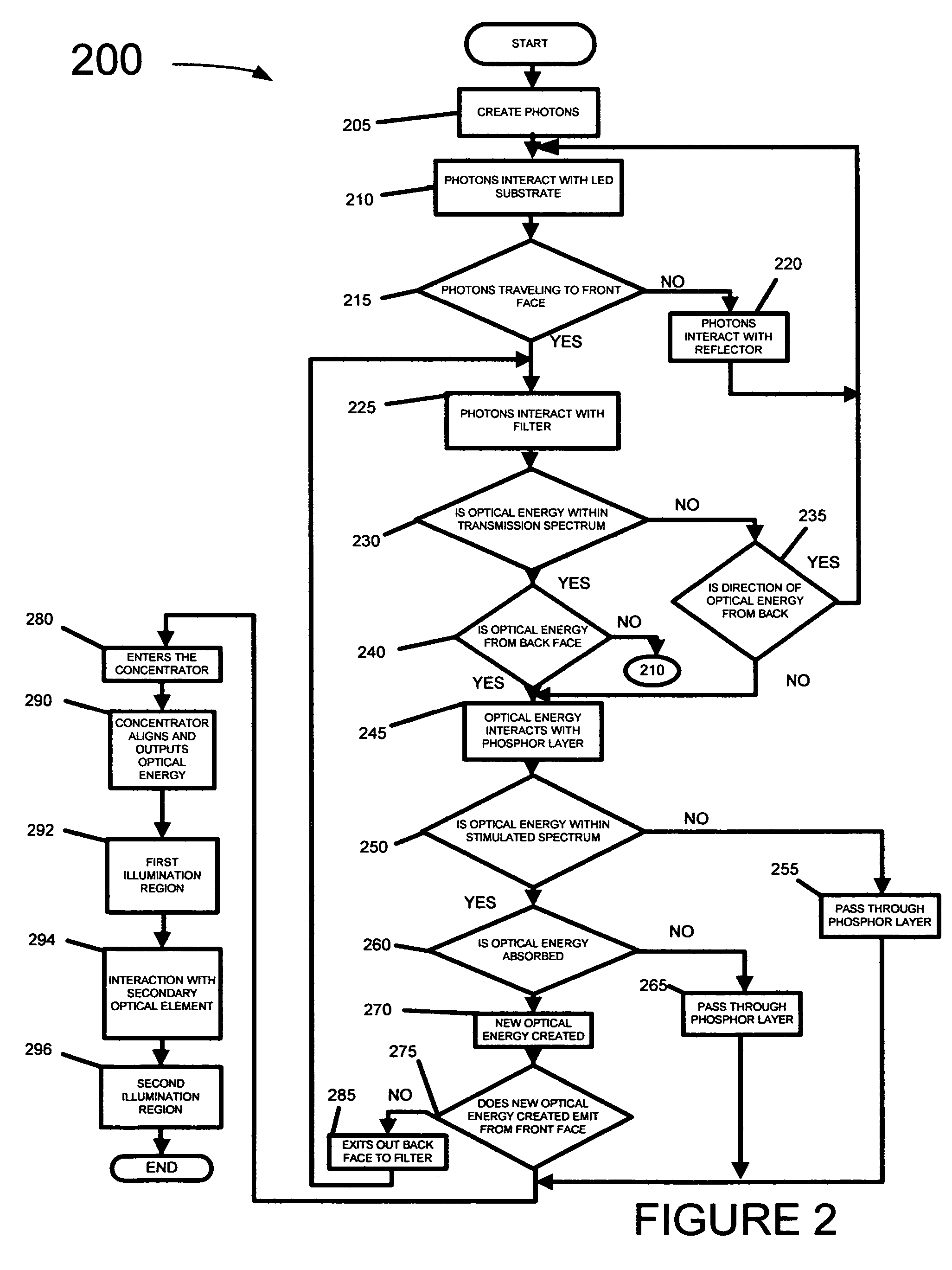

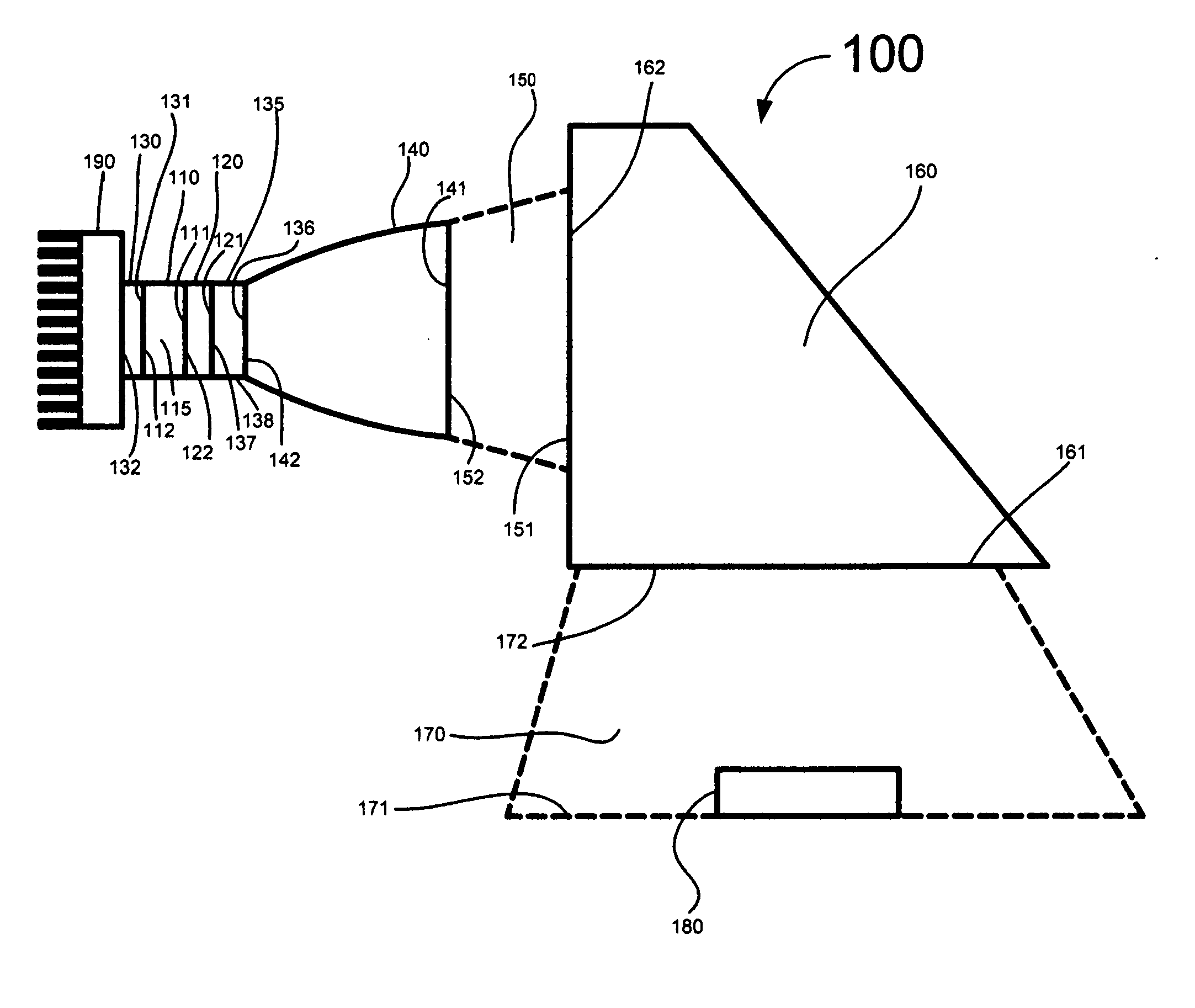

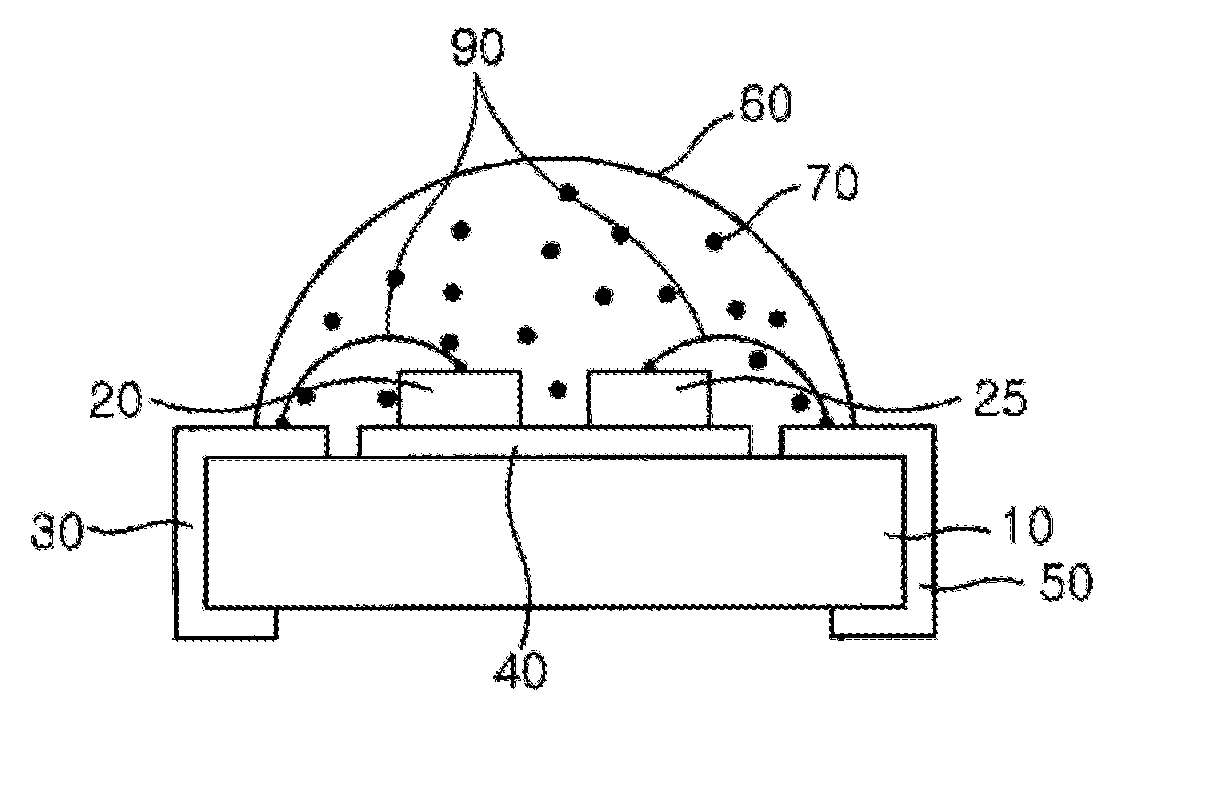

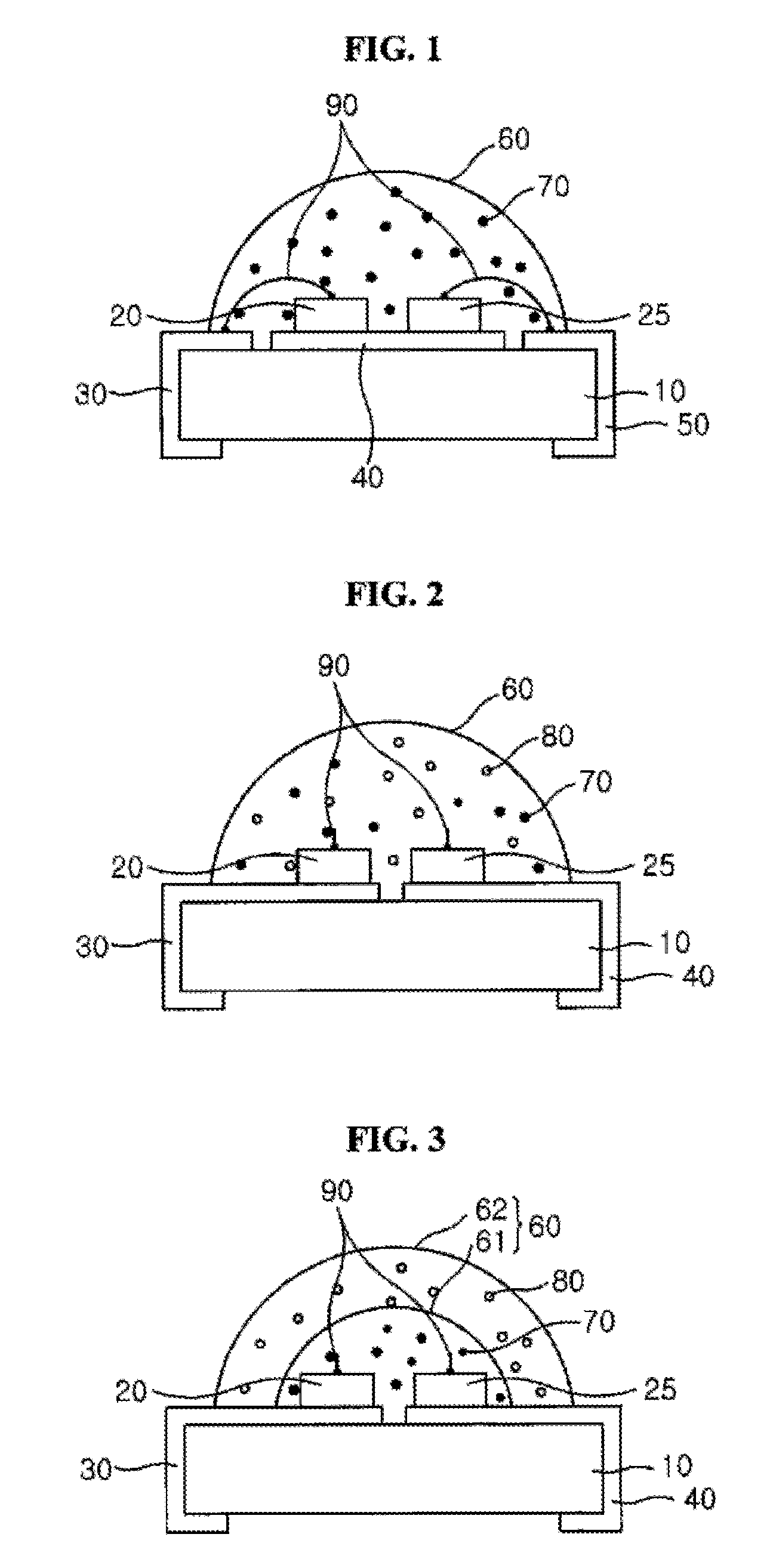

The invention provides an LED lighting device and method that produces high intensity, spatially uniform, white light in the near and far fields in a reduced package size that does not significantly heat the surrounding environment, wherein the white light is produced by using a phosphor layer in conjunction with a single LED.

Owner:INNOVATIONS & OPTICS

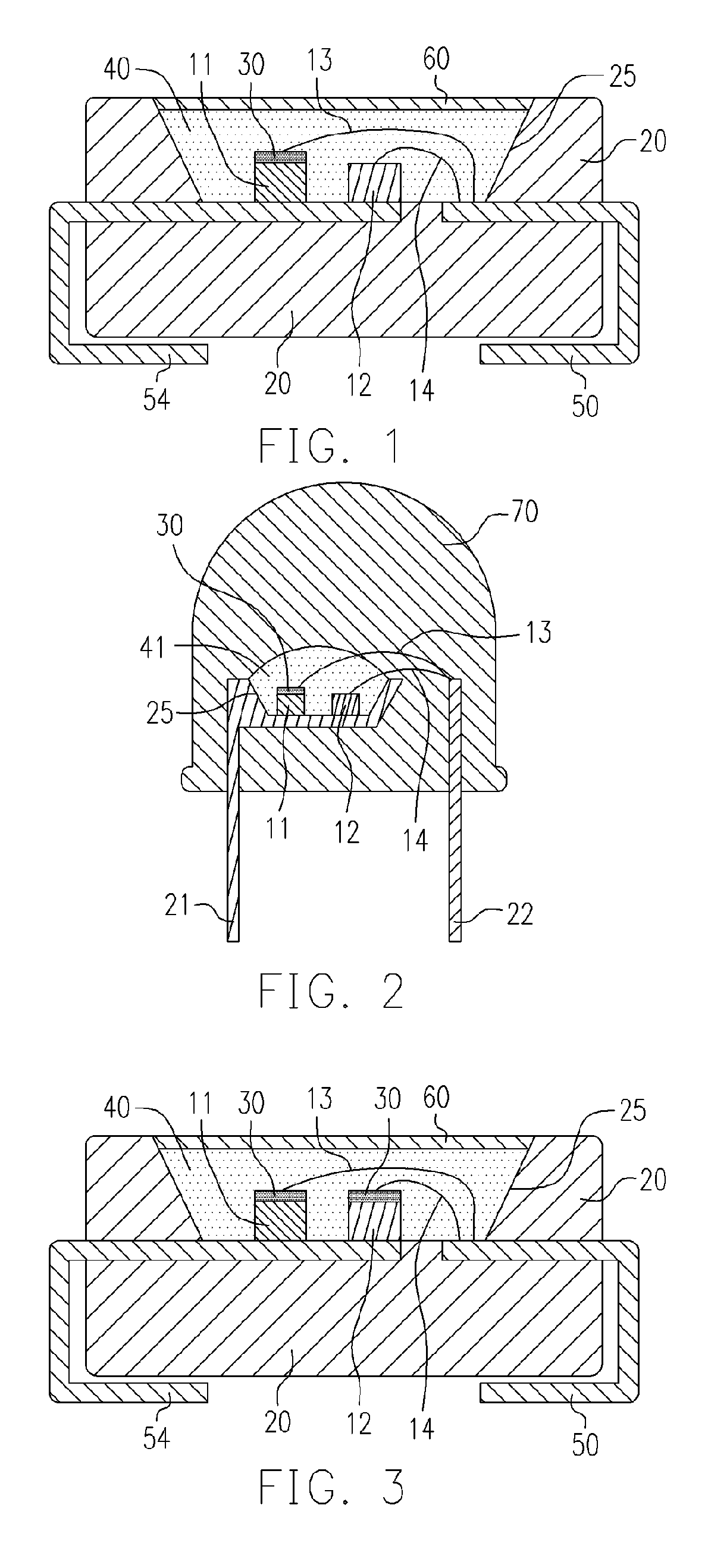

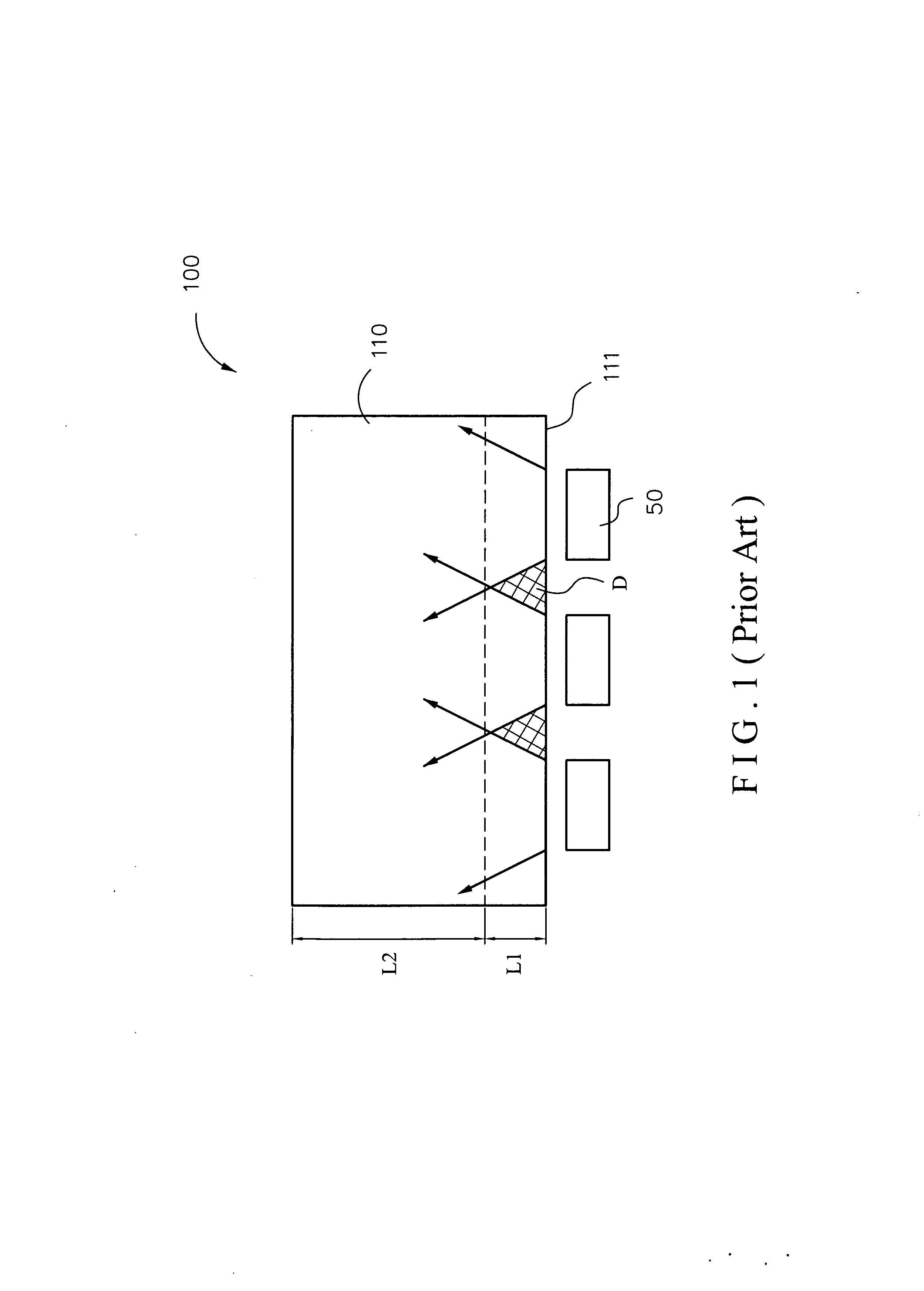

White LED device

InactiveUS20060067073A1Increase production costUniform white lightNon-electric lightingPoint-like light sourcePhosphorFluorescence

A white LED device is described, including two LED dies capable of emitting a first color light and a second color light, respectively, and a phosphor layer coated on at least one of the two LED dies. The phosphor layer is capable of emitting a third color light when stimulated by the first or second color light, and a light mixing structure is also disposed to mix the first to third color lights into uniform white light without chromatic deviation.

Owner:CHUNGHWA PICTURE TUBES LTD

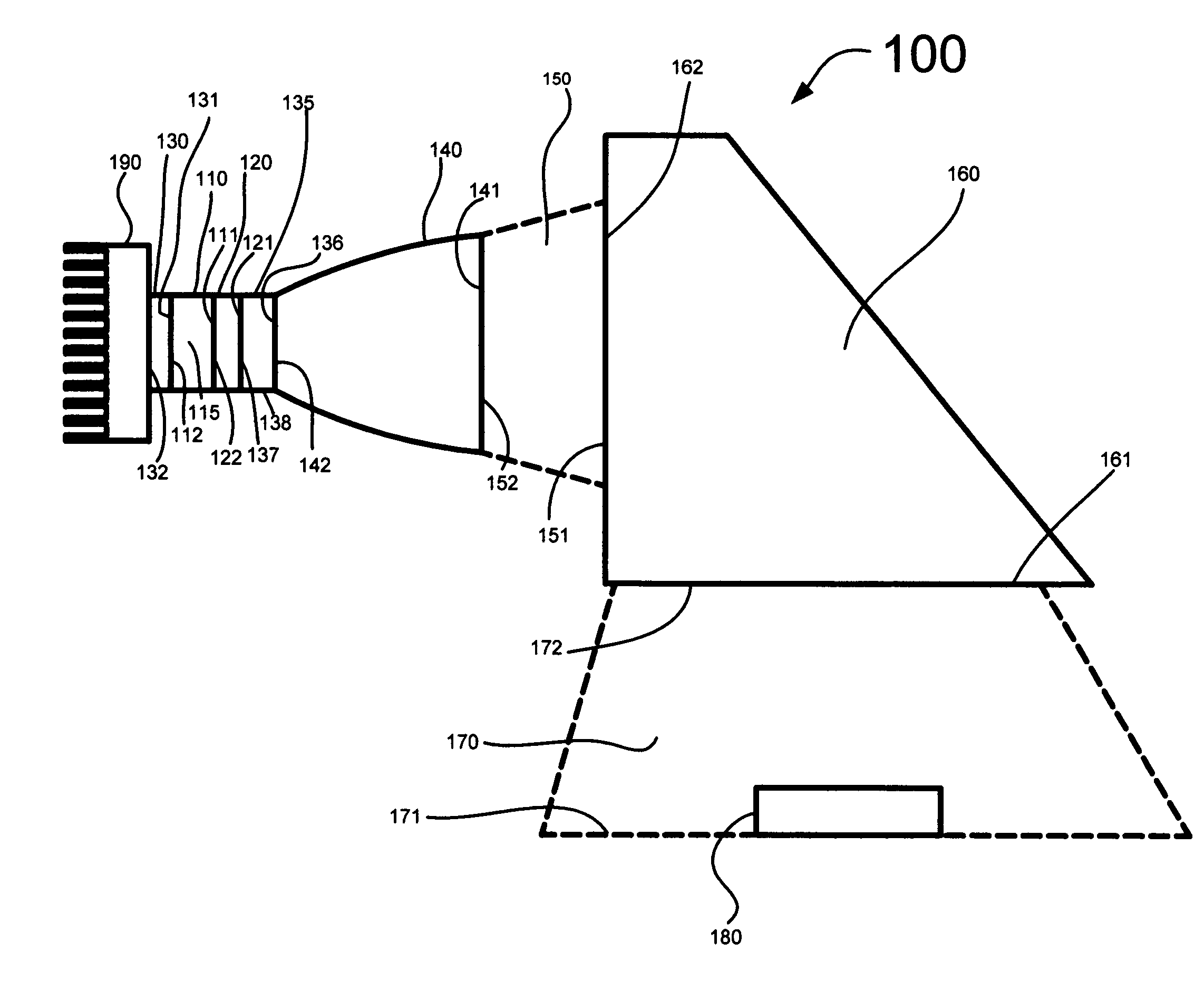

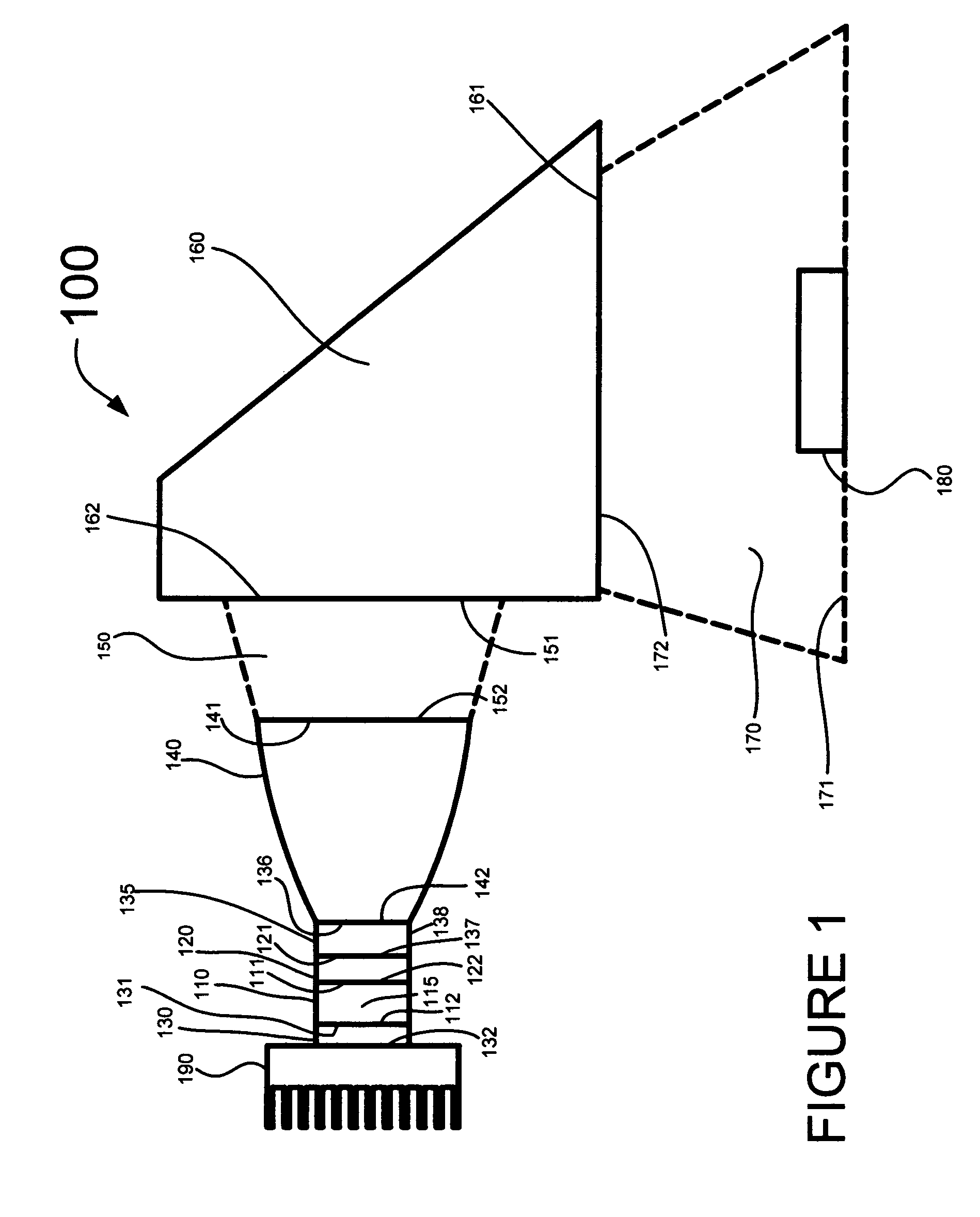

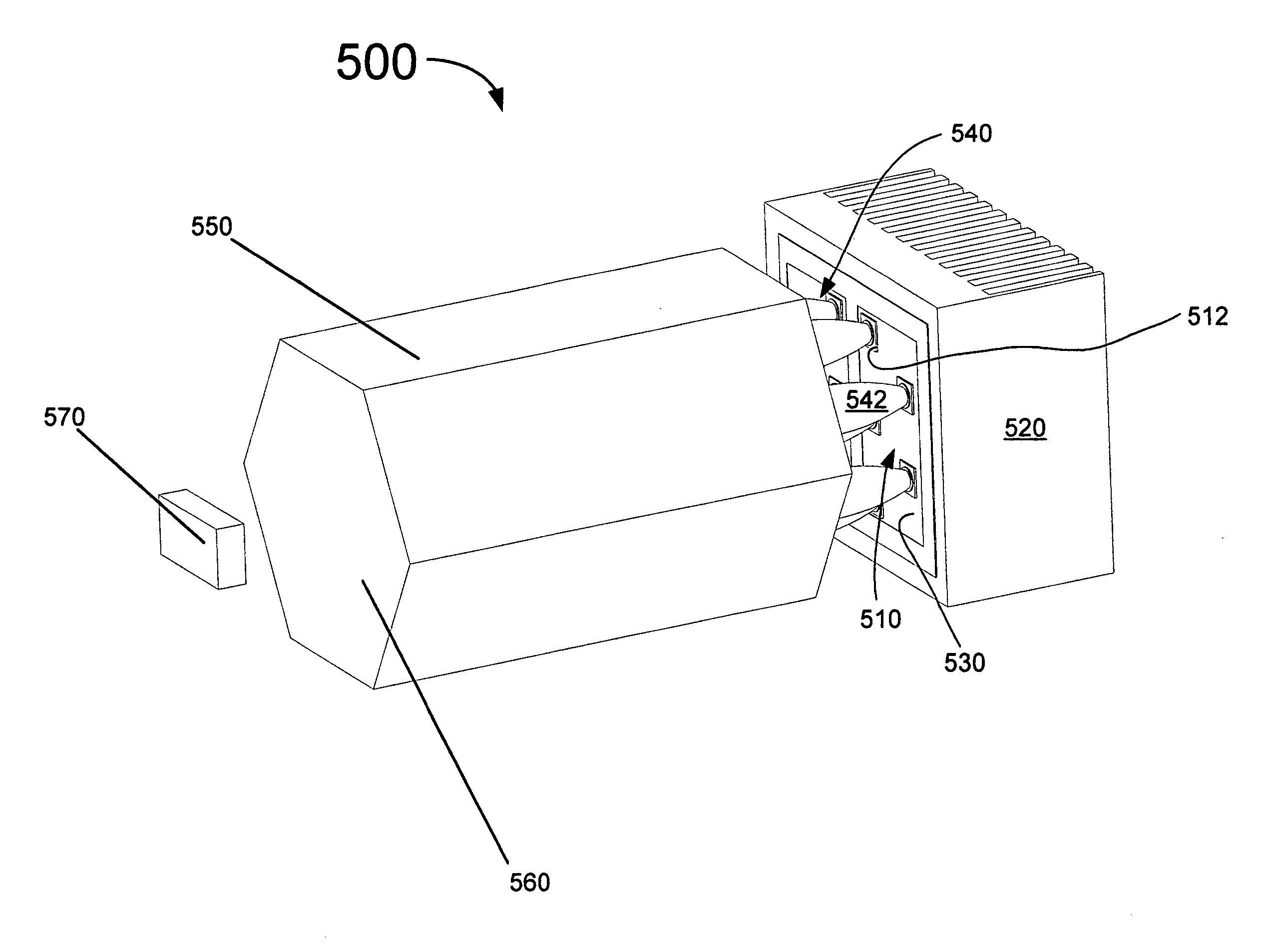

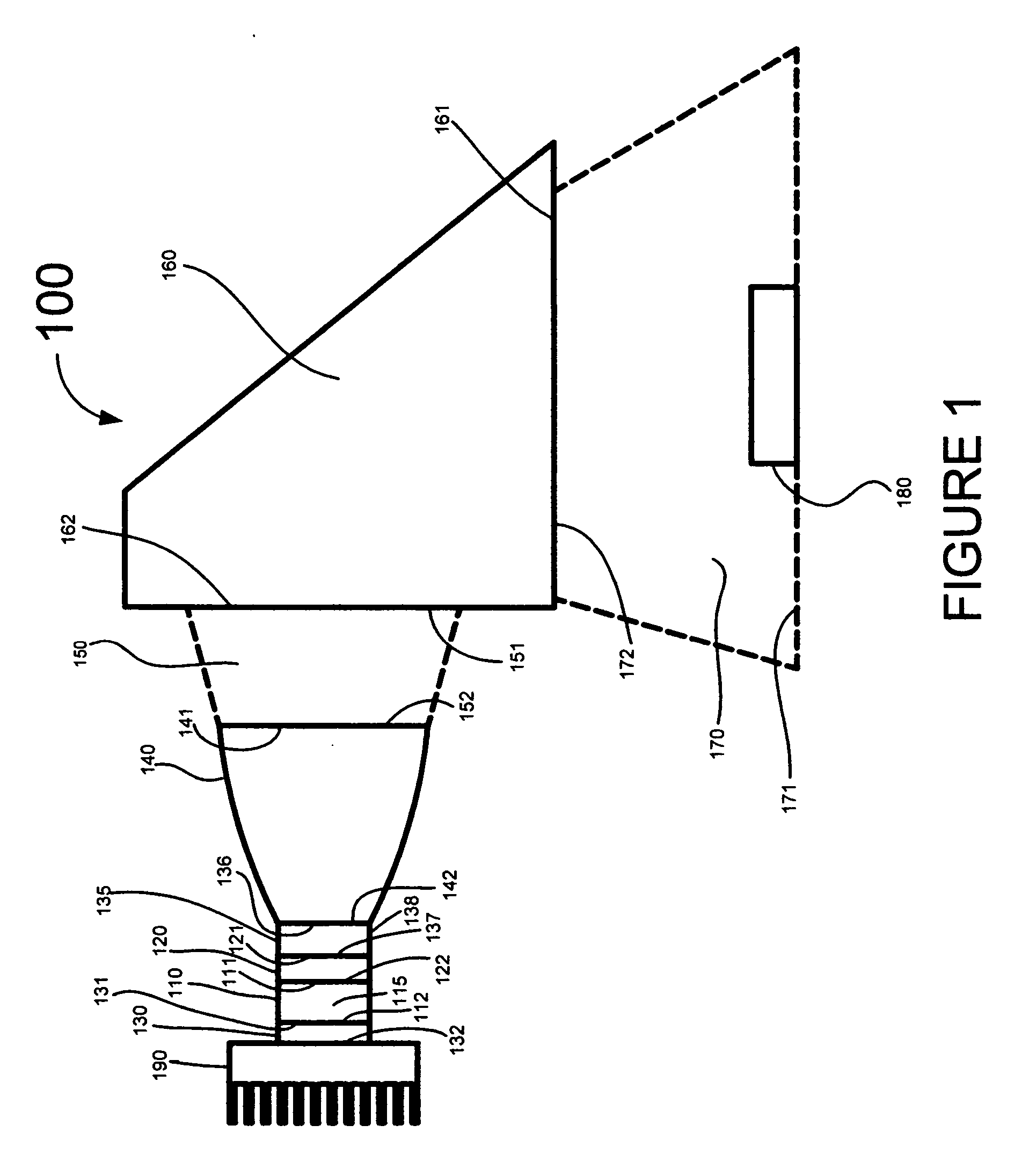

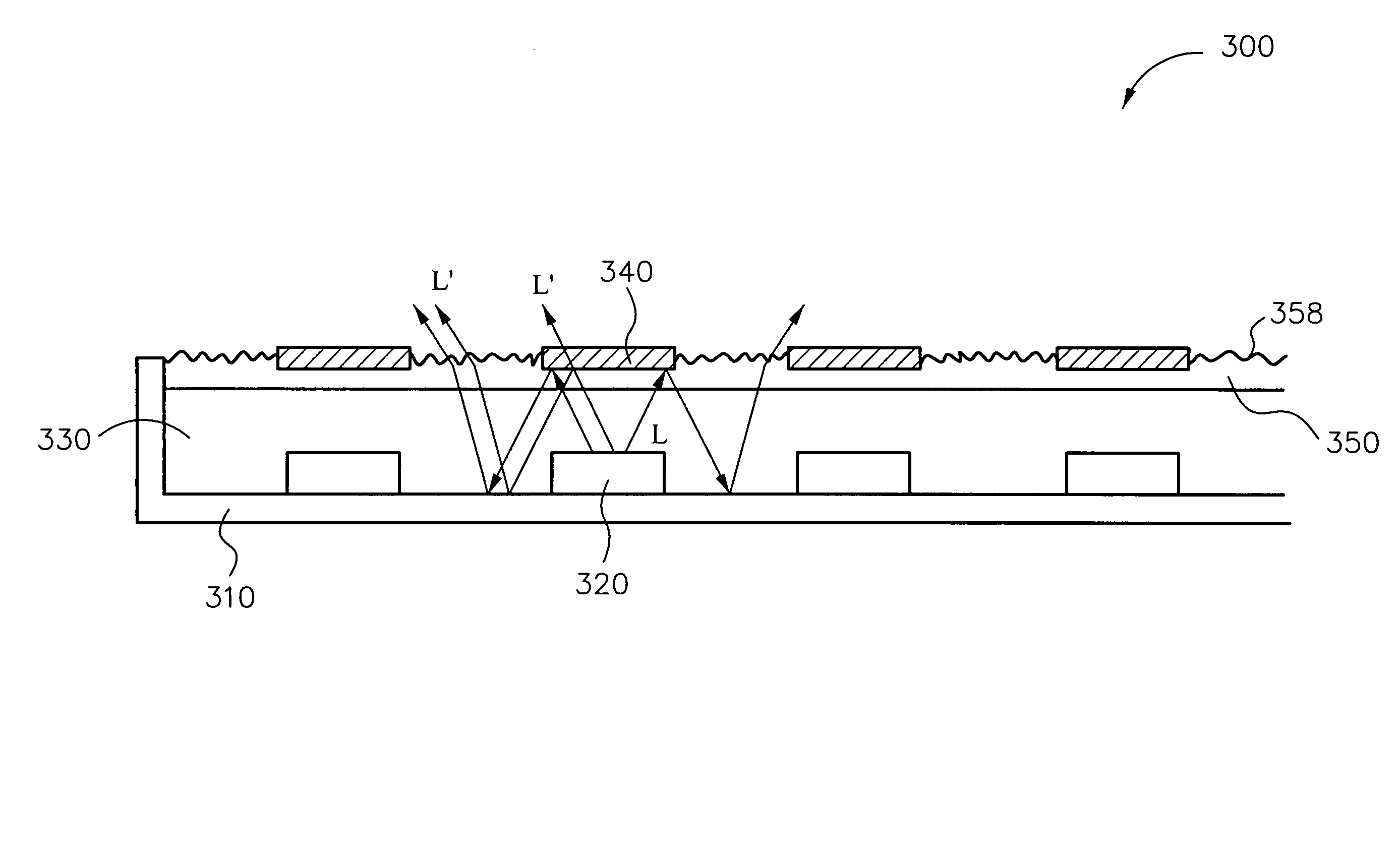

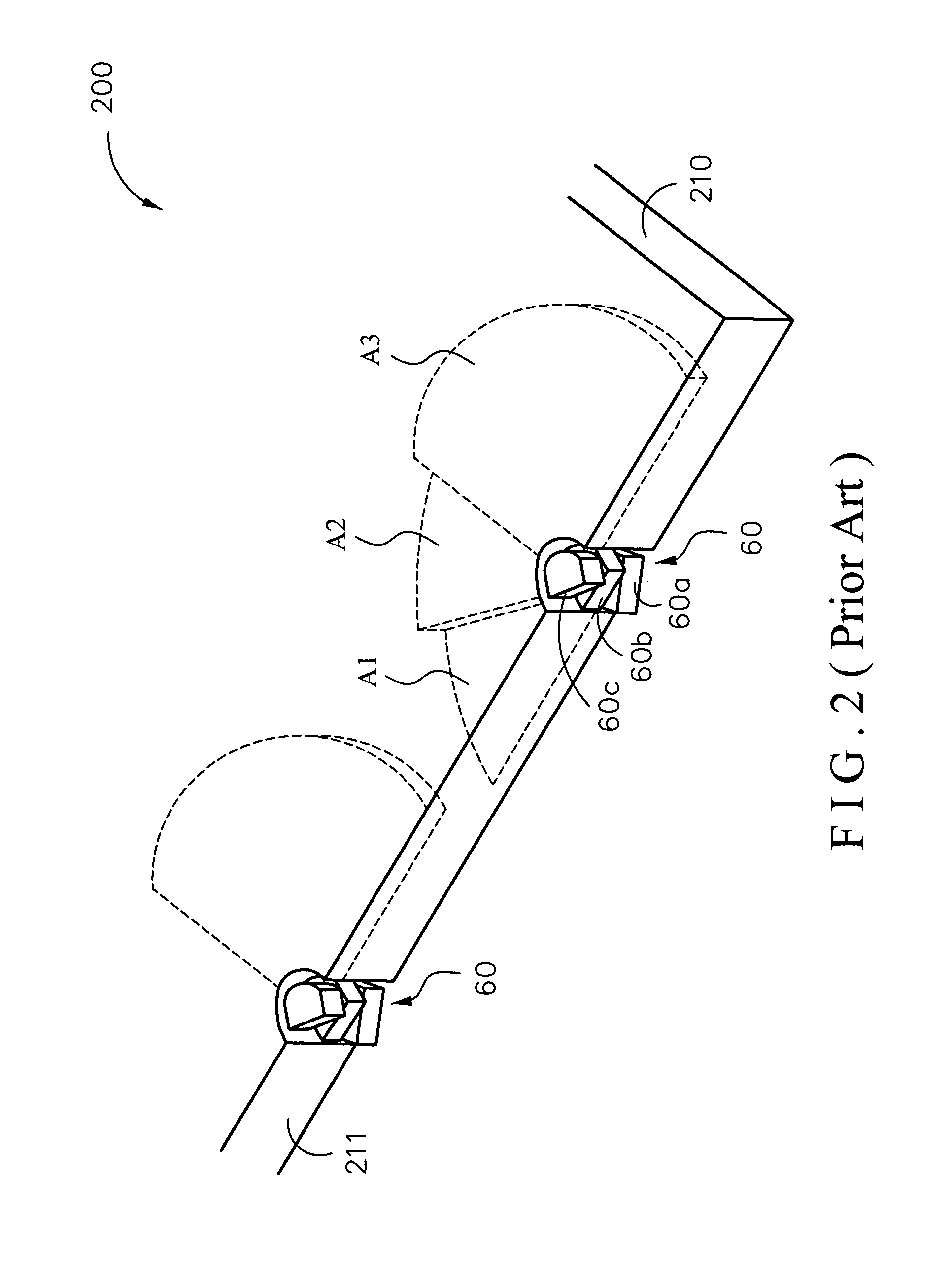

High intensity LED array illuminator

InactiveUS20070053200A1High strengthReduce package sizeLighting heating/cooling arrangementsLight therapyIntegratorLed array

A high intensity mutli-wavelength illumination apparatus comprising an array of LEDs each of which has a predetermined spectral output that is emitted over a predetermined solid angle, an array of non-imaging concentrators the individual non-imaging concentrators of which are optically coupled in one-to-one correspondence with the LEDs, each non-imaging concentrator in the array of non-imaging concentrators operating to collect radiation emitted by each of the LEDs and to re-emit substantially all the collected radiation as a beam having a diverging solid angle smaller than said predetermined solid angle over which radiation is emitted by each of the LEDs, the non-imaging concentrators each having an entrance aperture for receiving radiation emitted by a corresponding one of the LEDs and an exit aperture from which the LEDs output emerges spatially and spectrally uniform in the near field of the exit aperture, and a light integrator having an entrance facet optically coupled to each of the exit apertures of the non-imaging concentrators for receiving radiation there through and conducting it to an exit facet thereof from which radiation is emitted for a downstream application, the light integrator being structured and arranged to substantially uniformly mix the individual beams emitted by each concentrator so that radiation emitted from its exit facet is uniformly colored.

Owner:INNOVATIONS & OPTICS

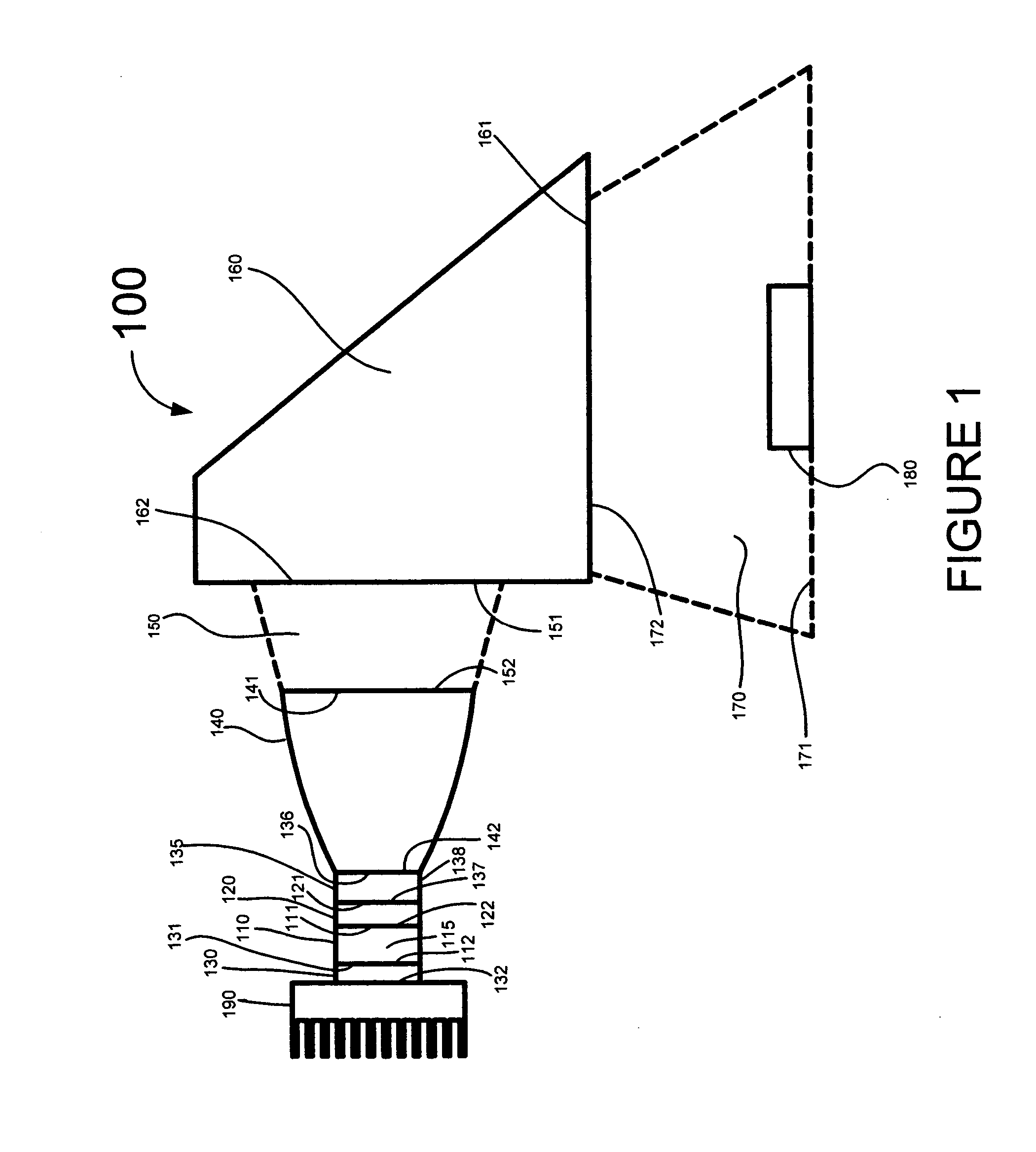

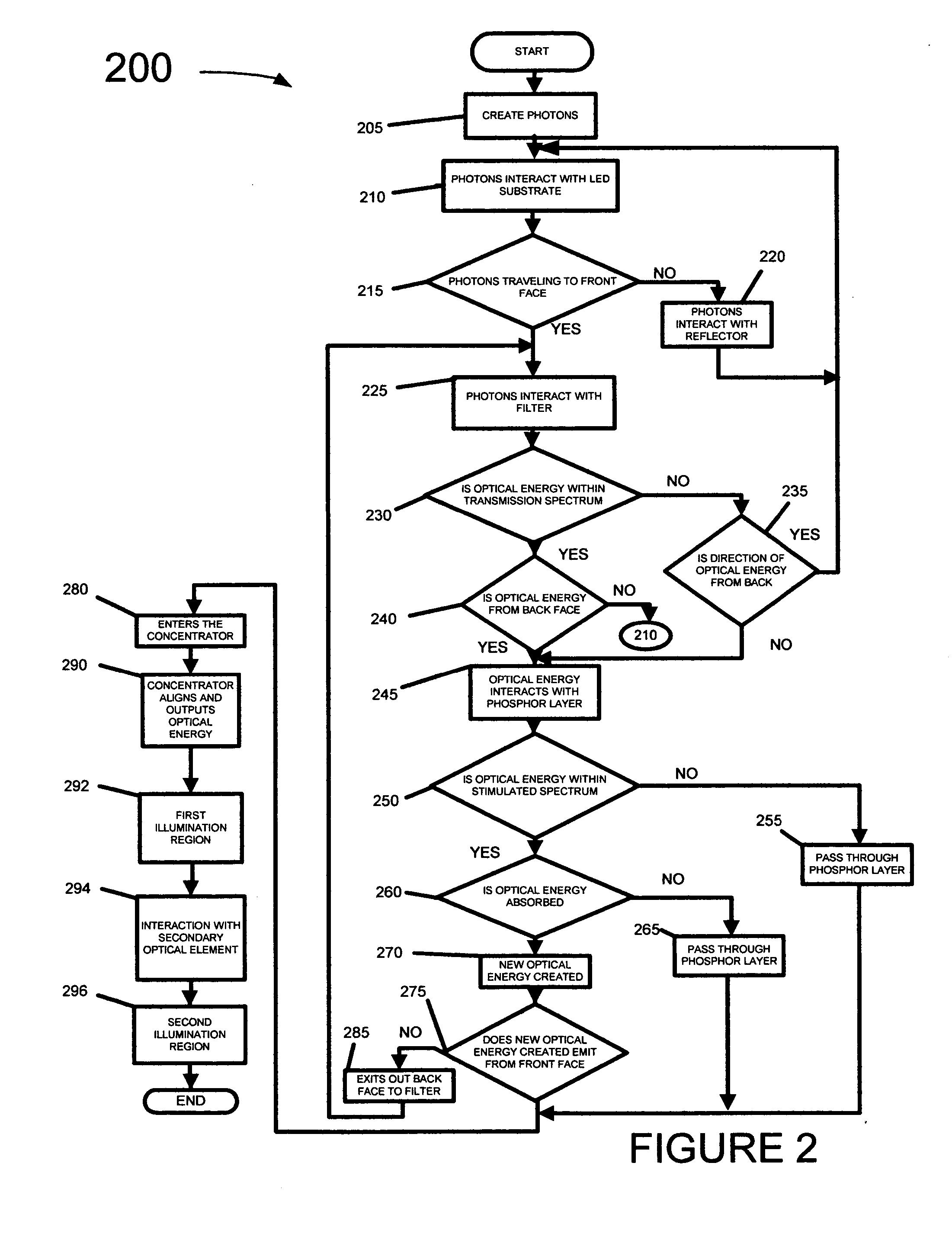

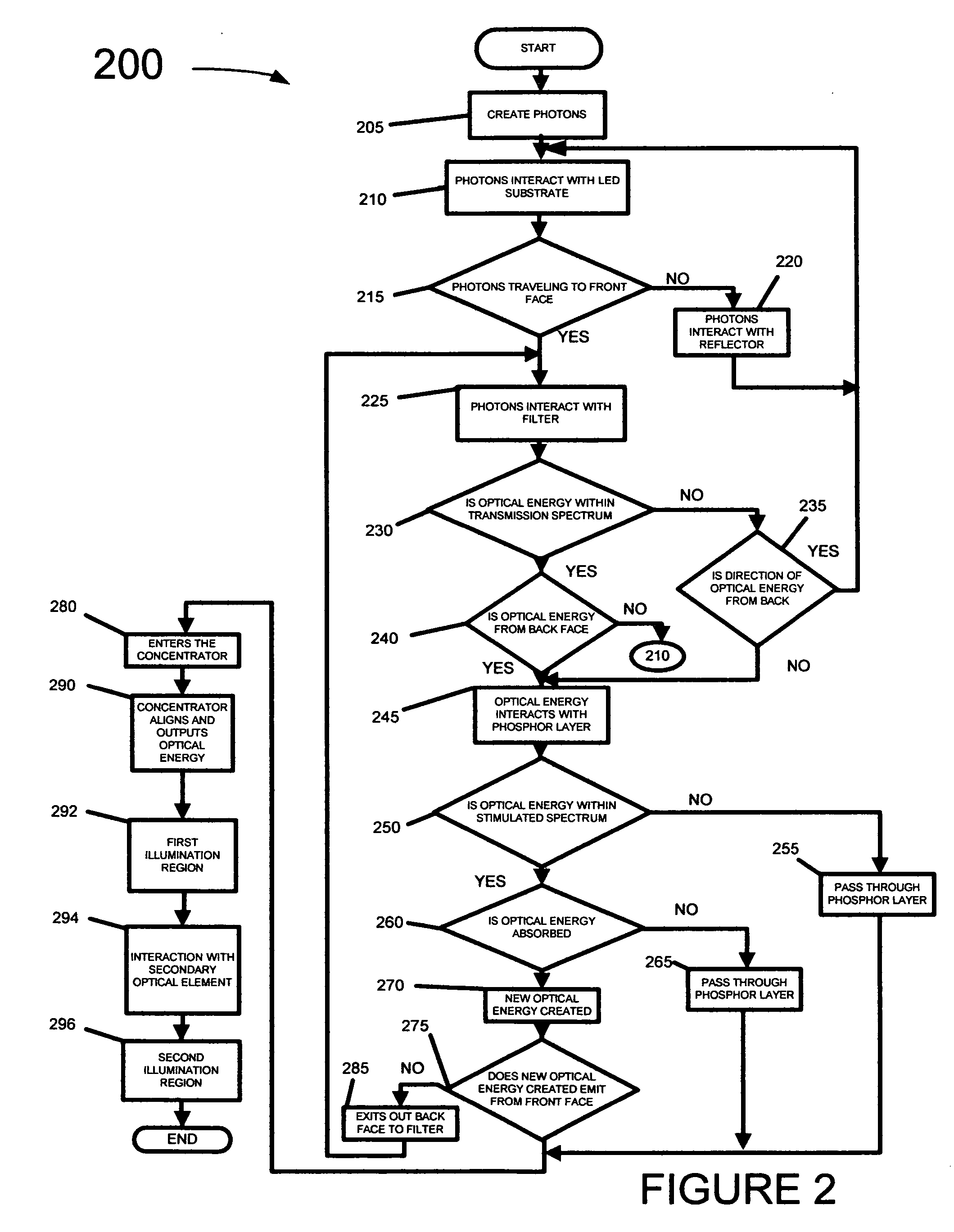

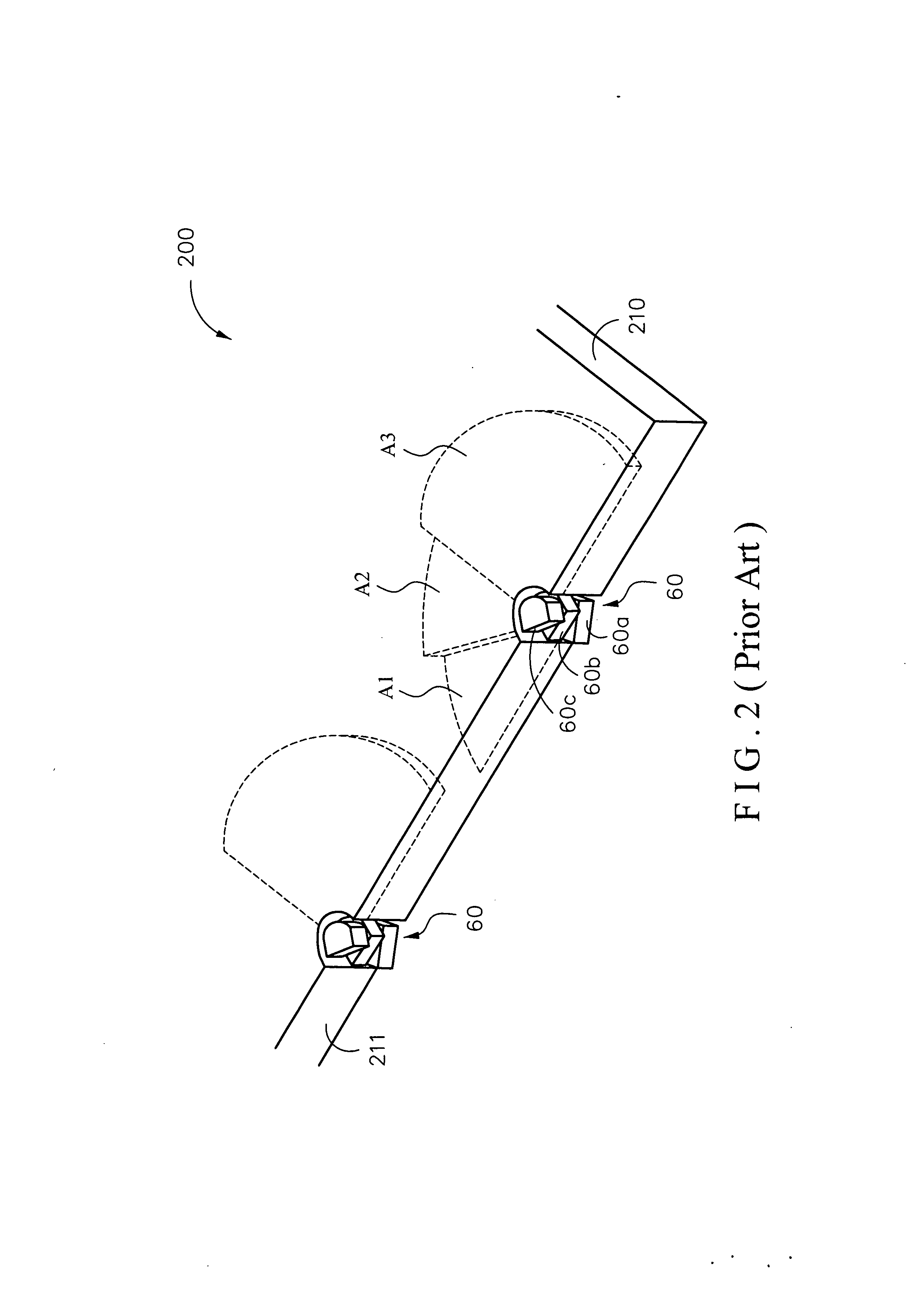

LED illuminator with retro reflector

InactiveUS20070053184A1High strengthReduce package sizeLight therapyOptical light guidesPhosphorLight beam

An illuminator with blue and red LEDs, a reflector upstream of the LEDs for capturing upstream light emitted out of the back surfaces of the LEDs and redirecting downstream as useful illumination, a band pass filter for conditioning the downstream light, a phosphor layer for changing the spectral properties of light from the LEDs, and a non-imaging concentrator for creating a beam of illumination over a predetermined solid angle, uniformity, and spectral content.

Owner:INNOVATIONS & OPTICS

Led white light illuminator

InactiveUS20070058389A1High strengthReduce package sizeLighting heating/cooling arrangementsLight therapyEffect lightHigh intensity

Owner:INNOVATIONS & OPTICS

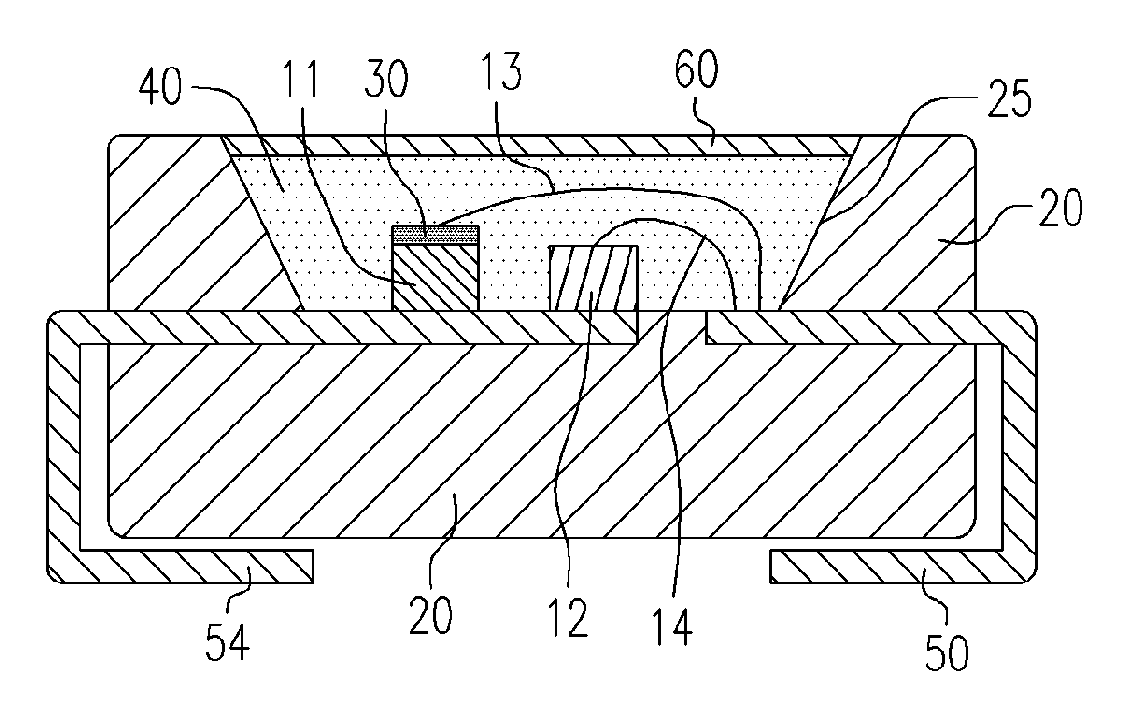

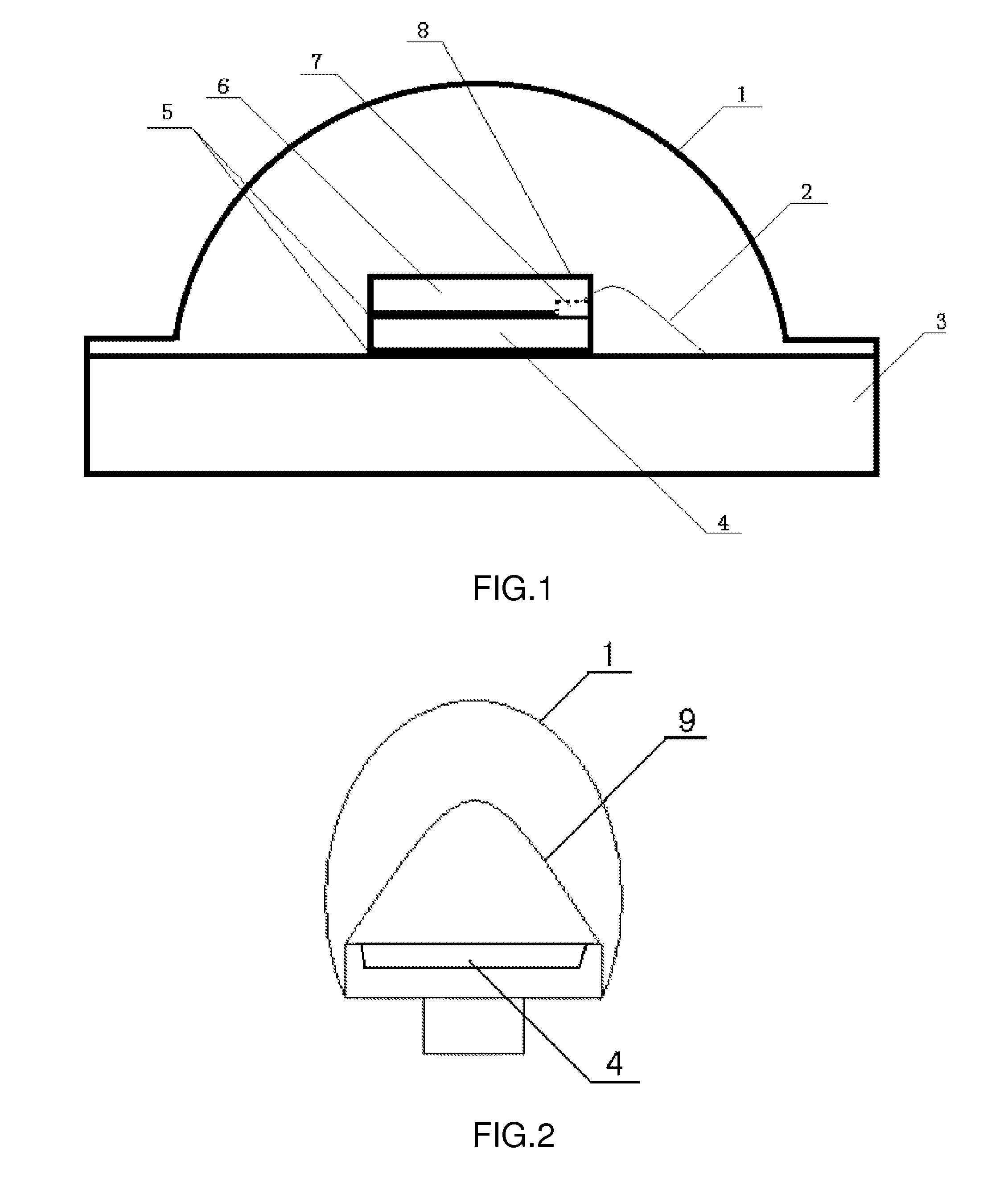

Light emitting diode package

ActiveUS20100244058A1Improve uniformityImprove directivityNon-linear opticsSemiconductor devicesFluorescenceLight-emitting diode

A light emitting diode package includes a substrate, a plurality of light emitting diode chips, a fluorescence layer, and a plurality of reflecting layers. The light emitting diode chips, the fluorescence layer, and the reflecting layers are disposed on the substrate. The fluorescence layer covers the light emitting diode chips, and the reflecting layers are disposed right above the light emitting diode chips, respectively.

Owner:CORETRONIC

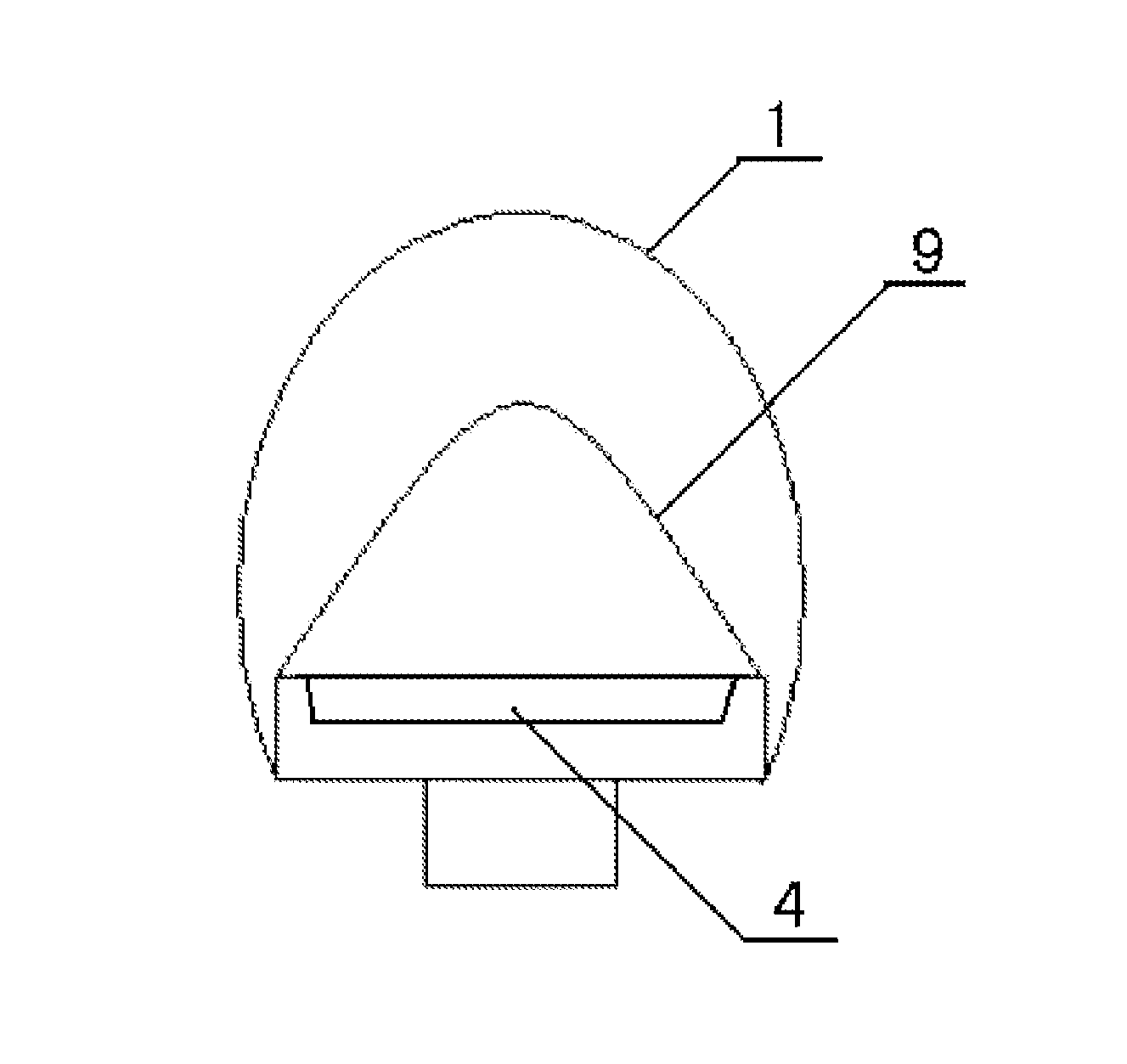

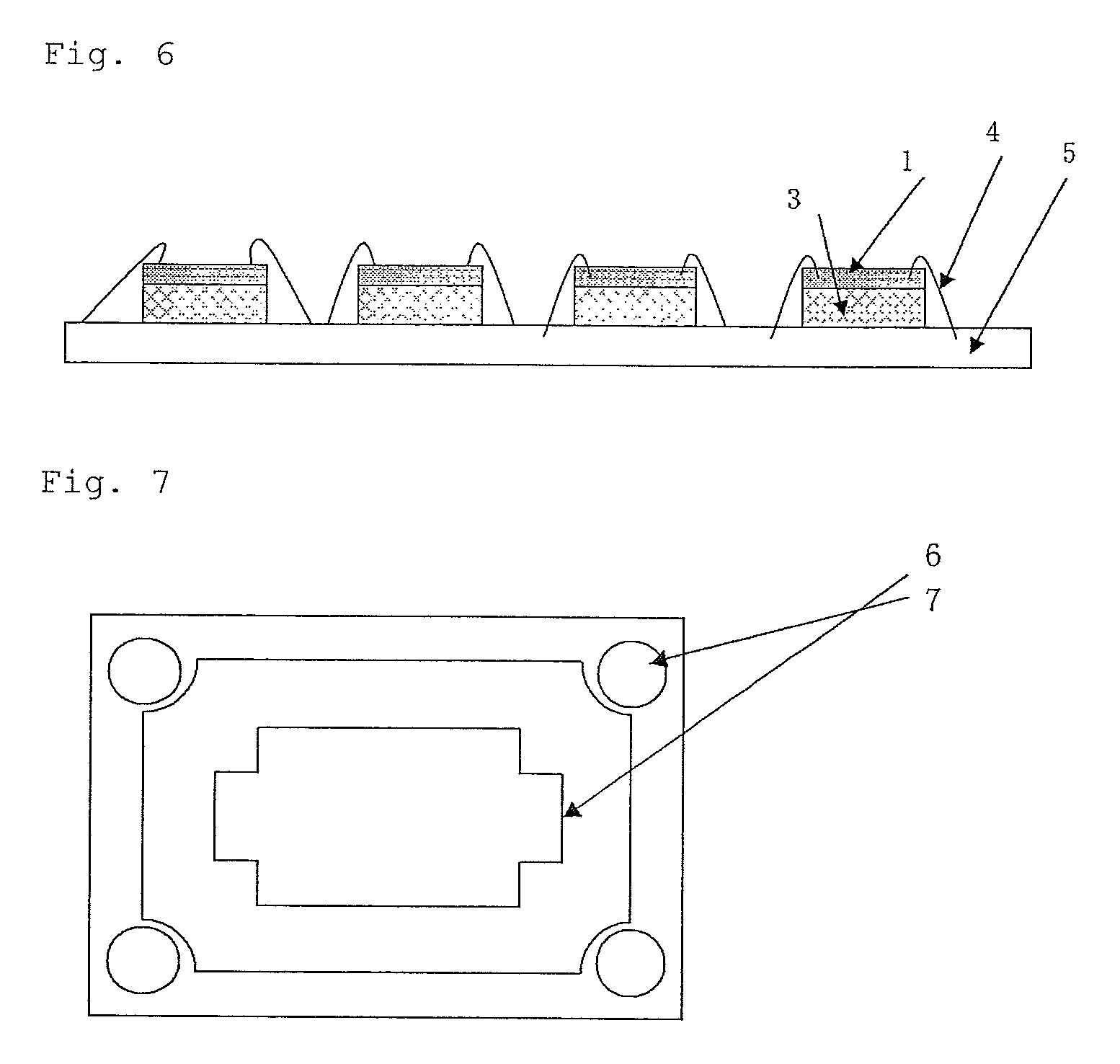

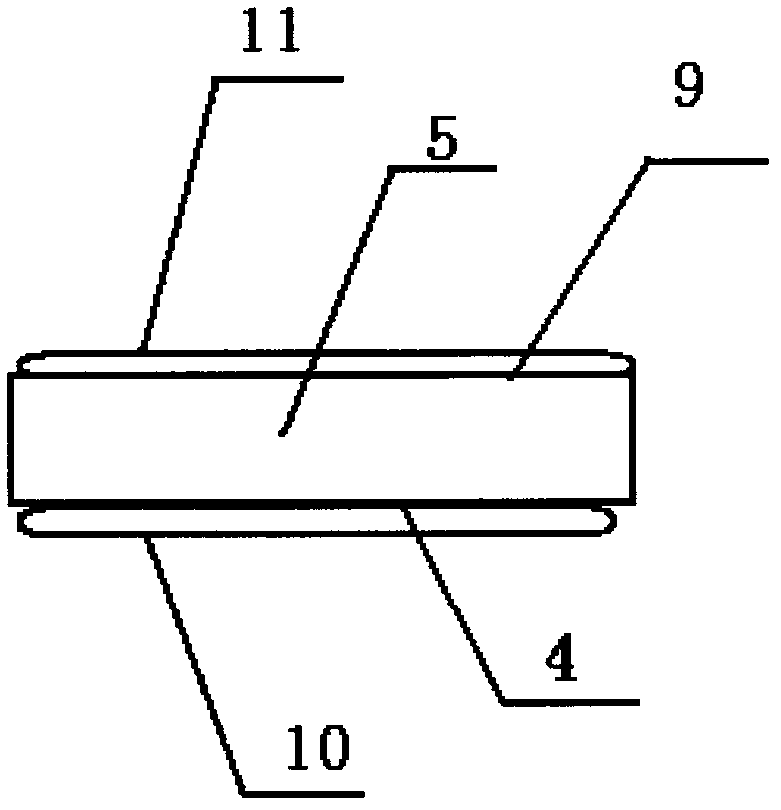

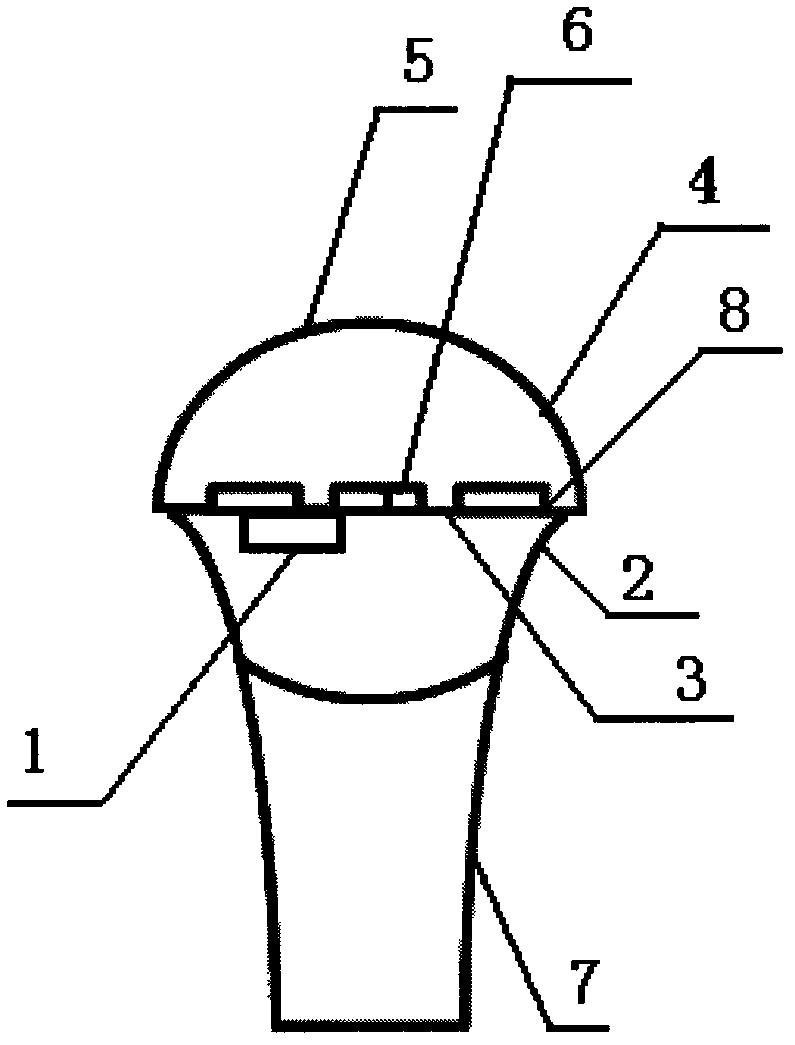

White LED Lamp Secondary Encapsulation Structure Capable of Reducing Blue-light Hazards

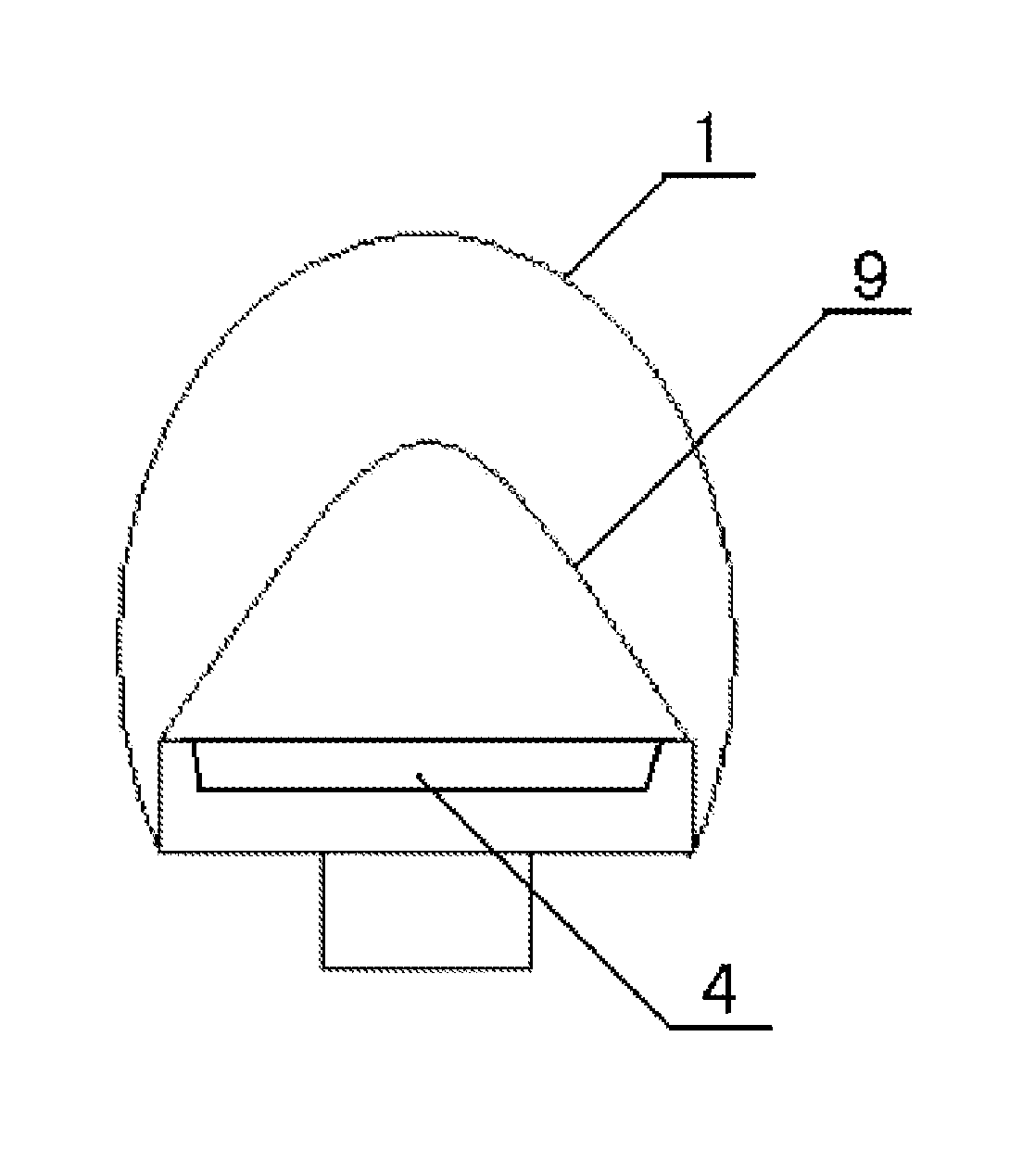

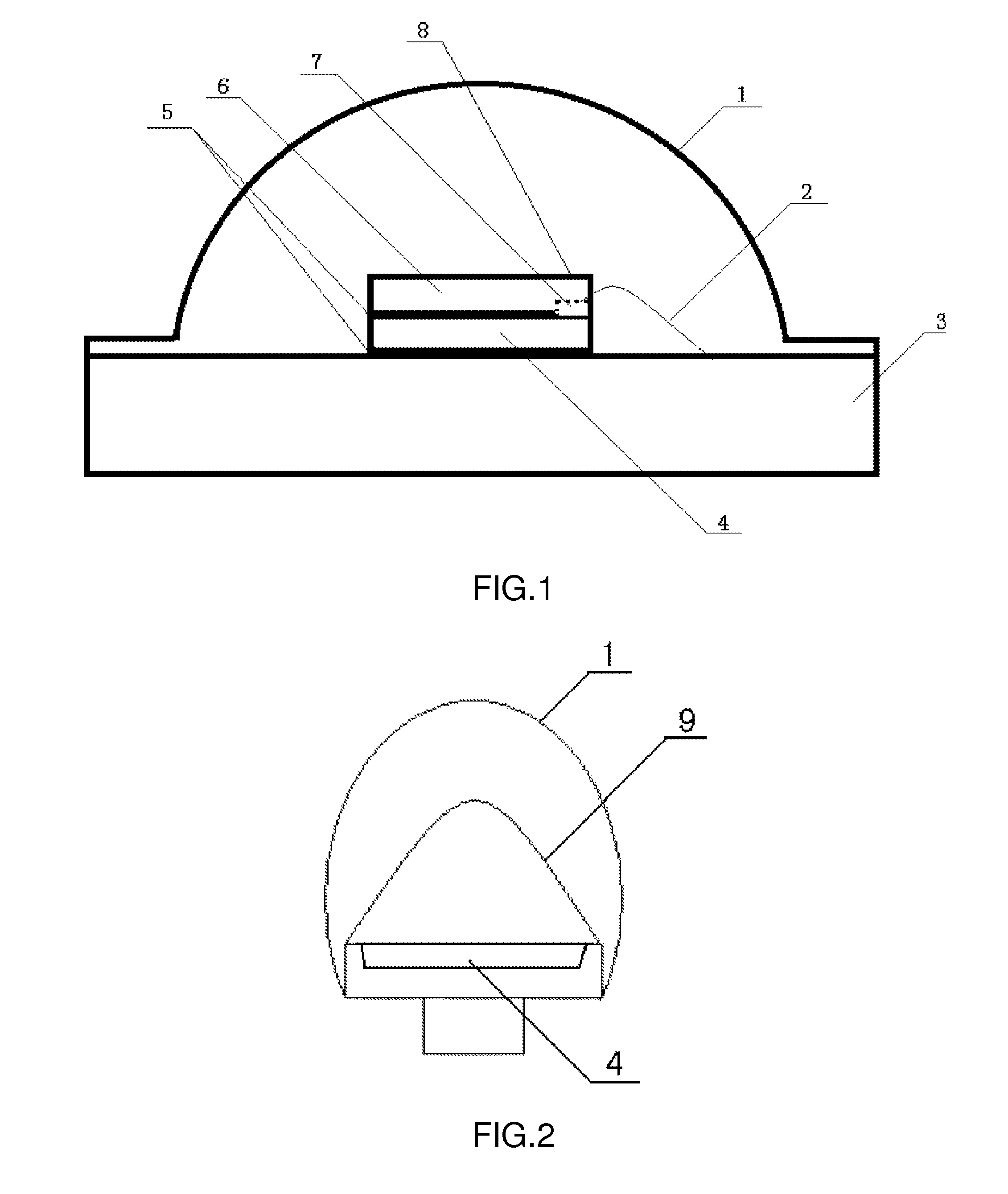

InactiveUS20160003424A1Reduce blue light hazardsReduce the impactDischarge tube luminescnet screensPoint-like light sourceBiological bodyFluorescence

A white LED lamp secondary encapsulation structure capable of reducing blue-light hazards has a substrate (3), a blue light LED chip (4) fixed on the substrate (3), and a YAG yellow fluorescent powder layer (6) overlaid on the blue light LED chip (4). A fluorescent outer lampshade (1) covering the blue light LED chip (4) and the YAG yellow fluorescent powder layer (6) is further fixed on the substrate (3). YAG yellow fluorescent powder is provided on the fluorescent outer lampshade (1). The structure allows emission of more uniform, soft and harmonious colors of white light, and reduces the influence of heat dissipated by the blue light chip on the performance of the fluorescent powder, thus preventing color temperature drift due to the heat of the chip, prolonging the lifespan of the fluorescent powder, reducing blue-light radiation dosage, scattering blue-light radiation, and reducing potential hazards to human and organisms.

Owner:WU ZHENGMING

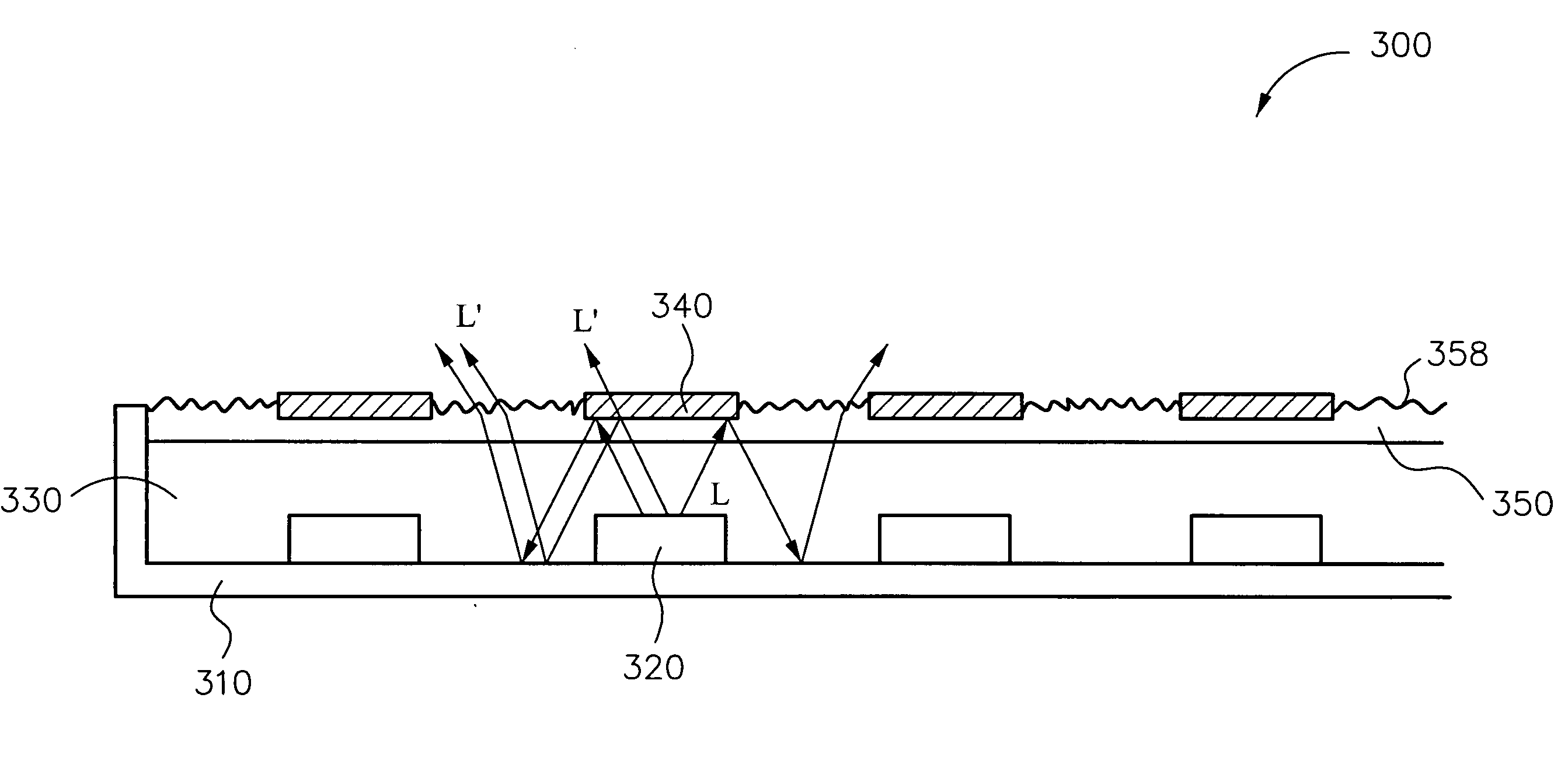

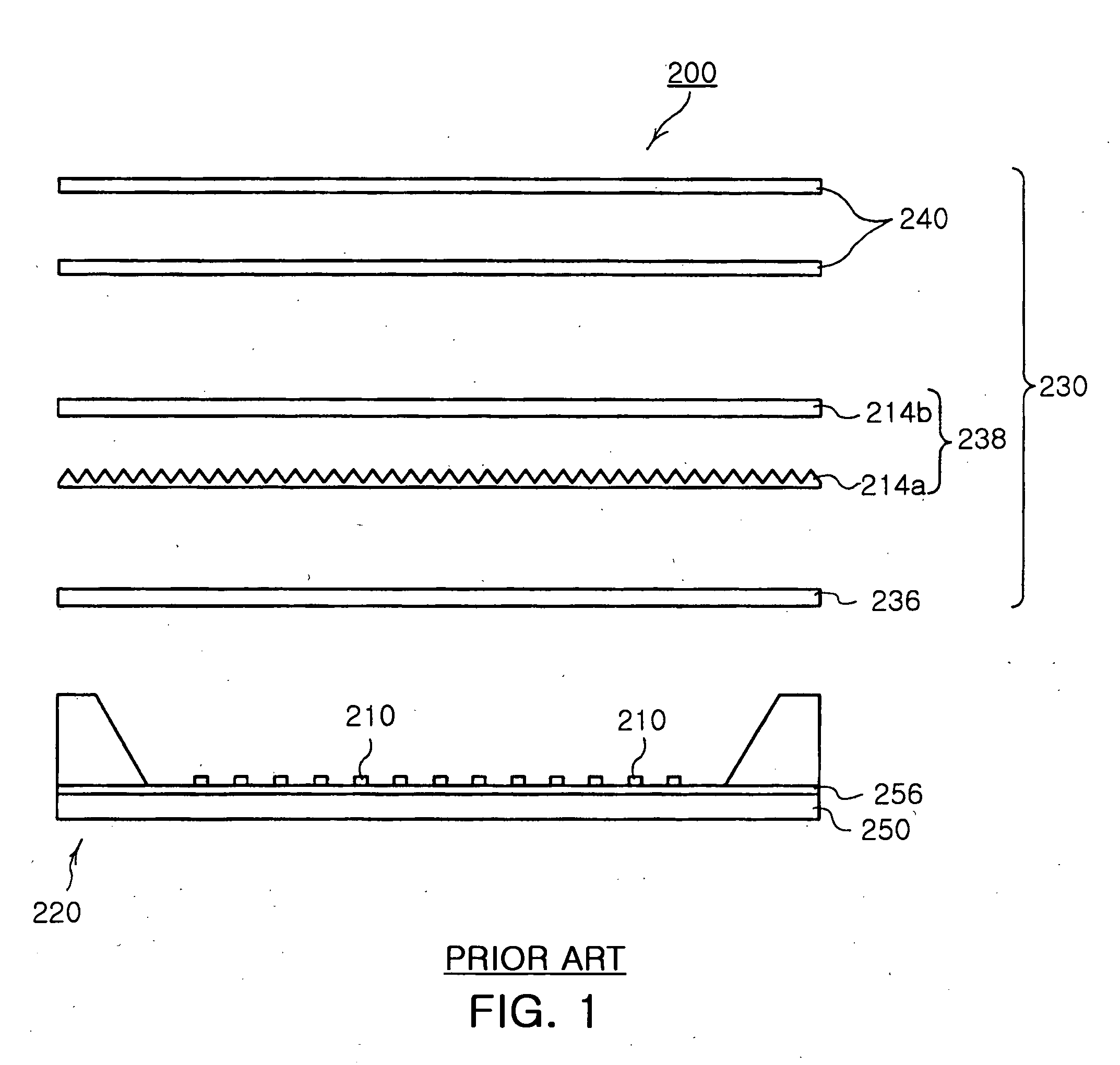

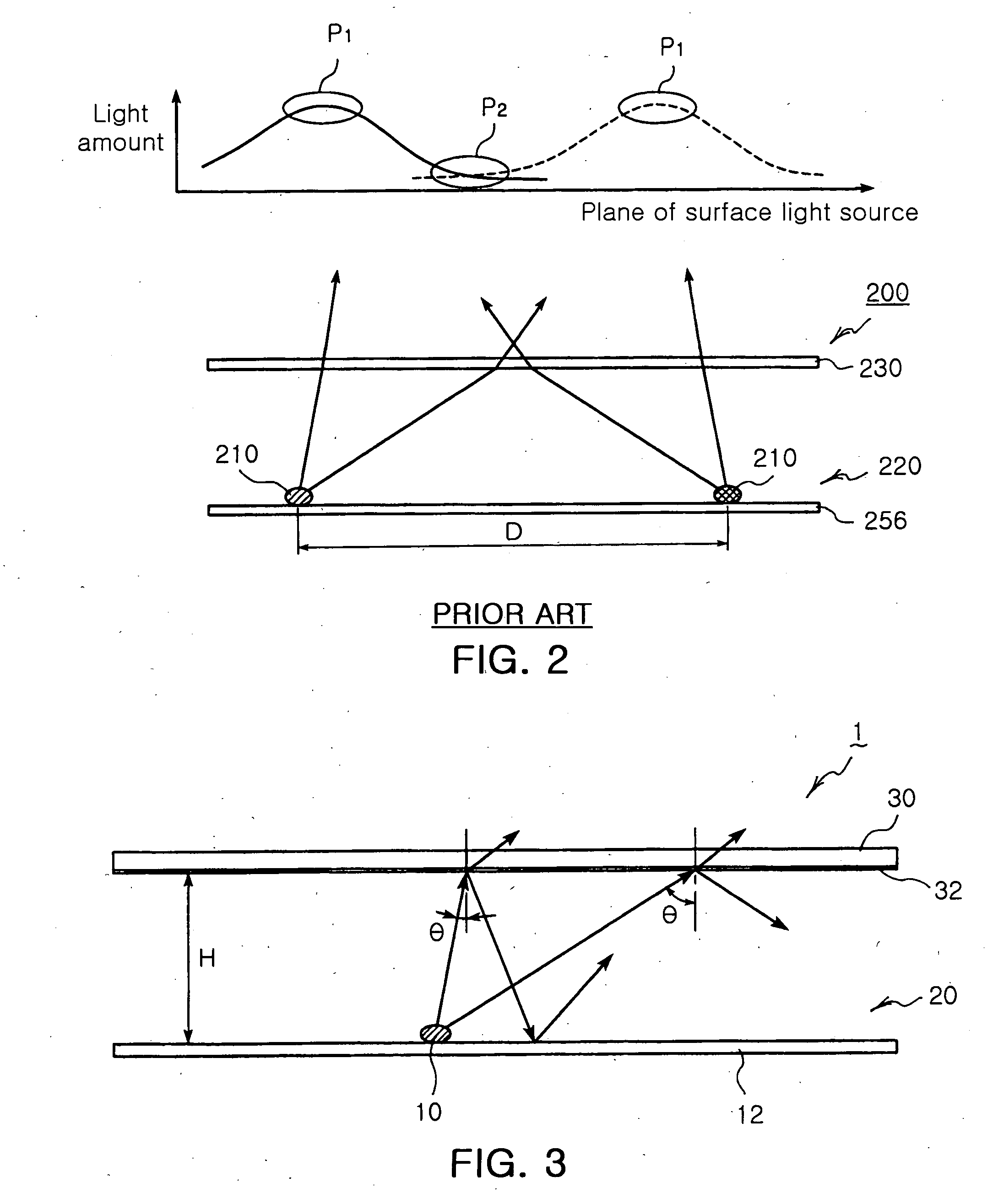

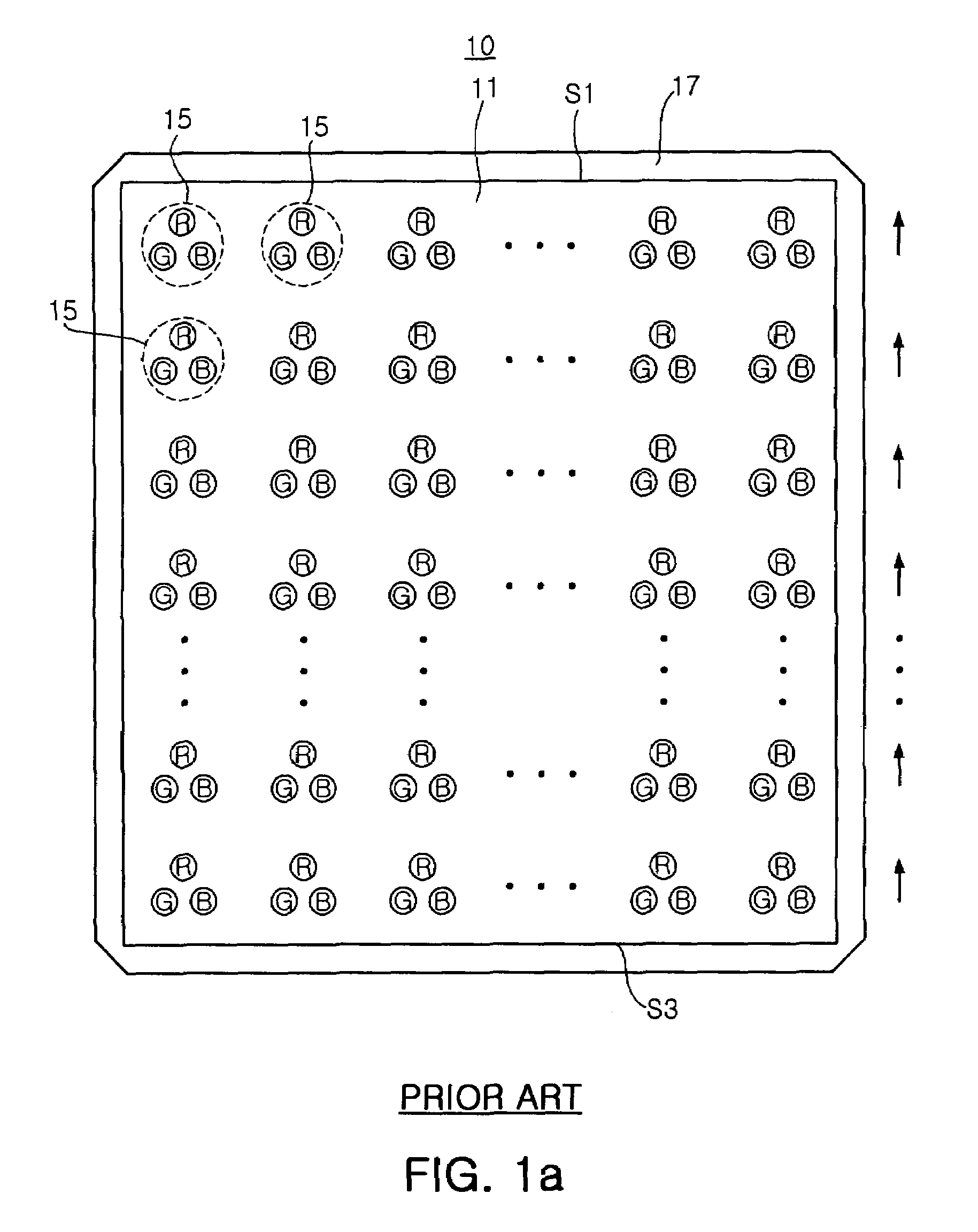

Surface light source and backlight unit having the same

InactiveUS20070008740A1Less color stainUniform white lightLighting support devicesPoint-like light sourceLiquid-crystal displayLight source

Owner:SAMSUNG ELECTRONICS CO LTD

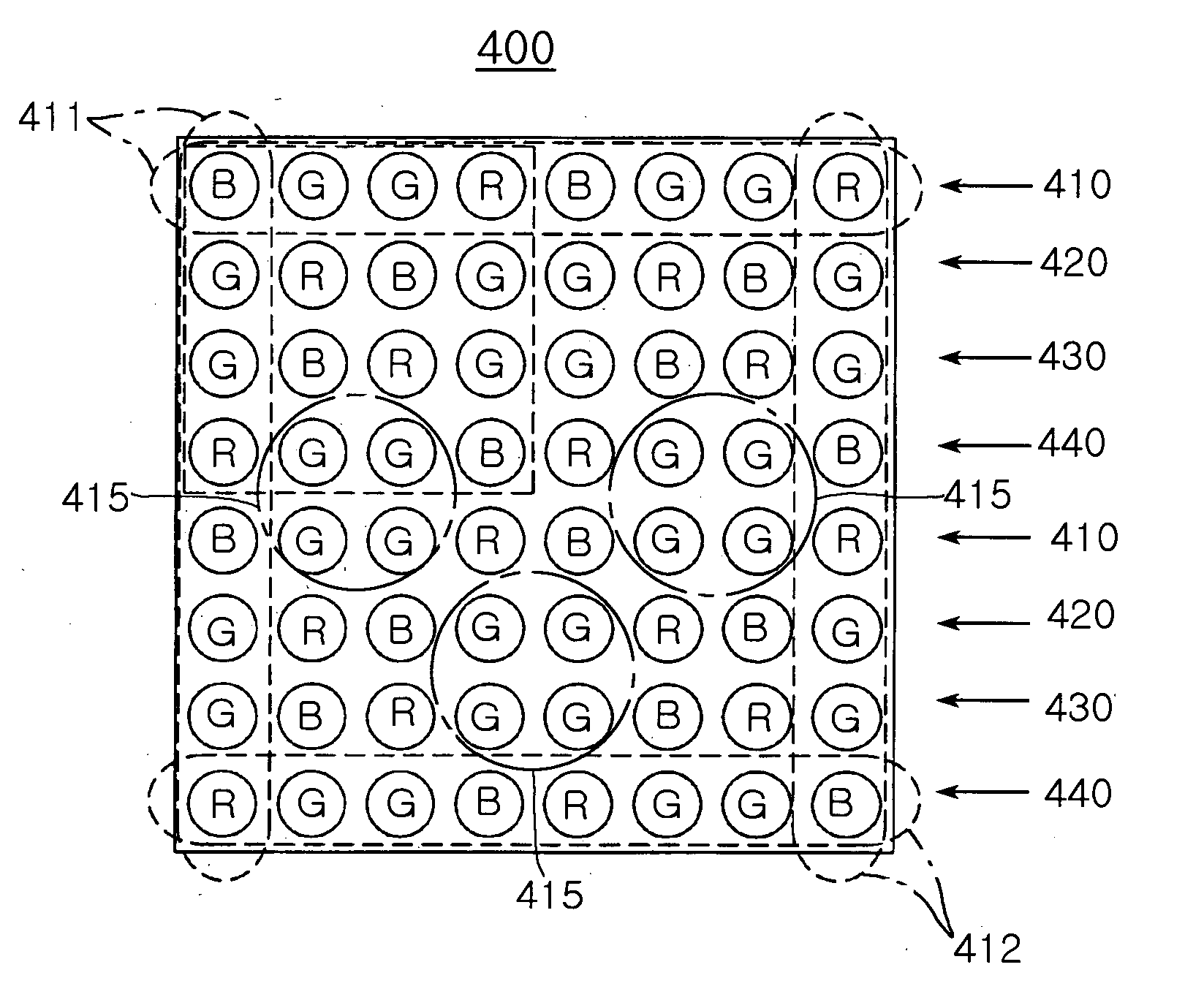

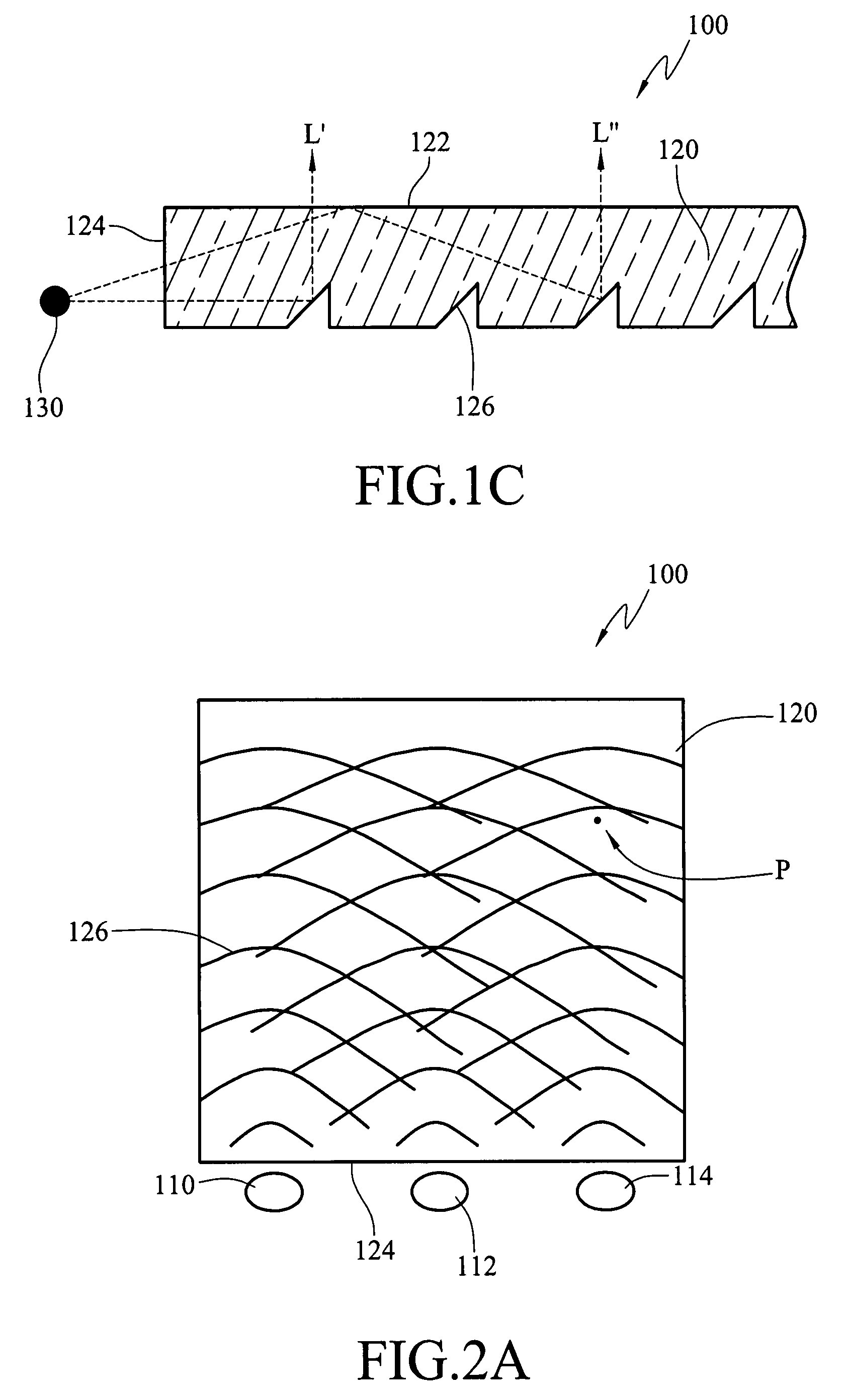

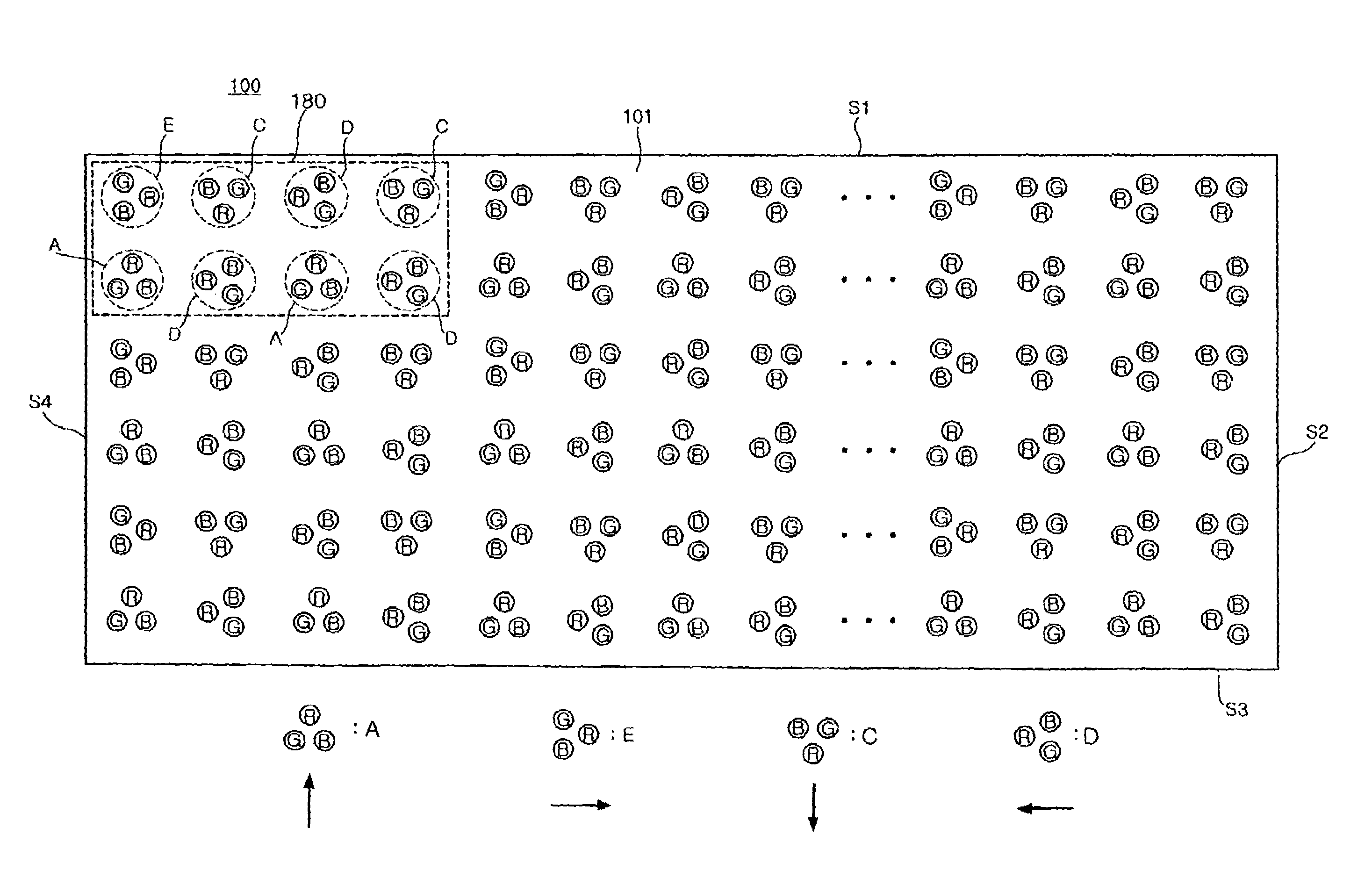

Surface light source device and backlight unit having the same

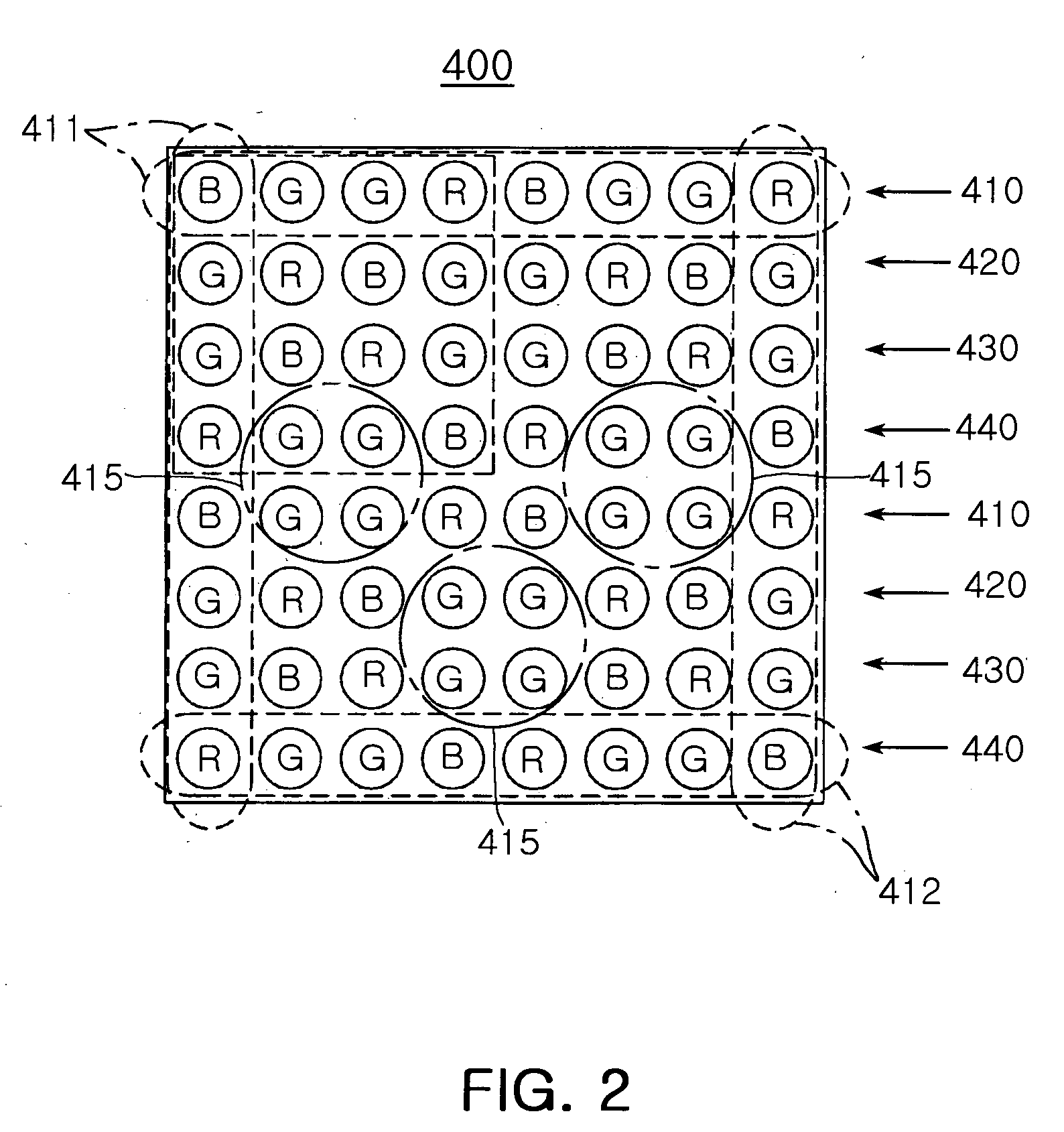

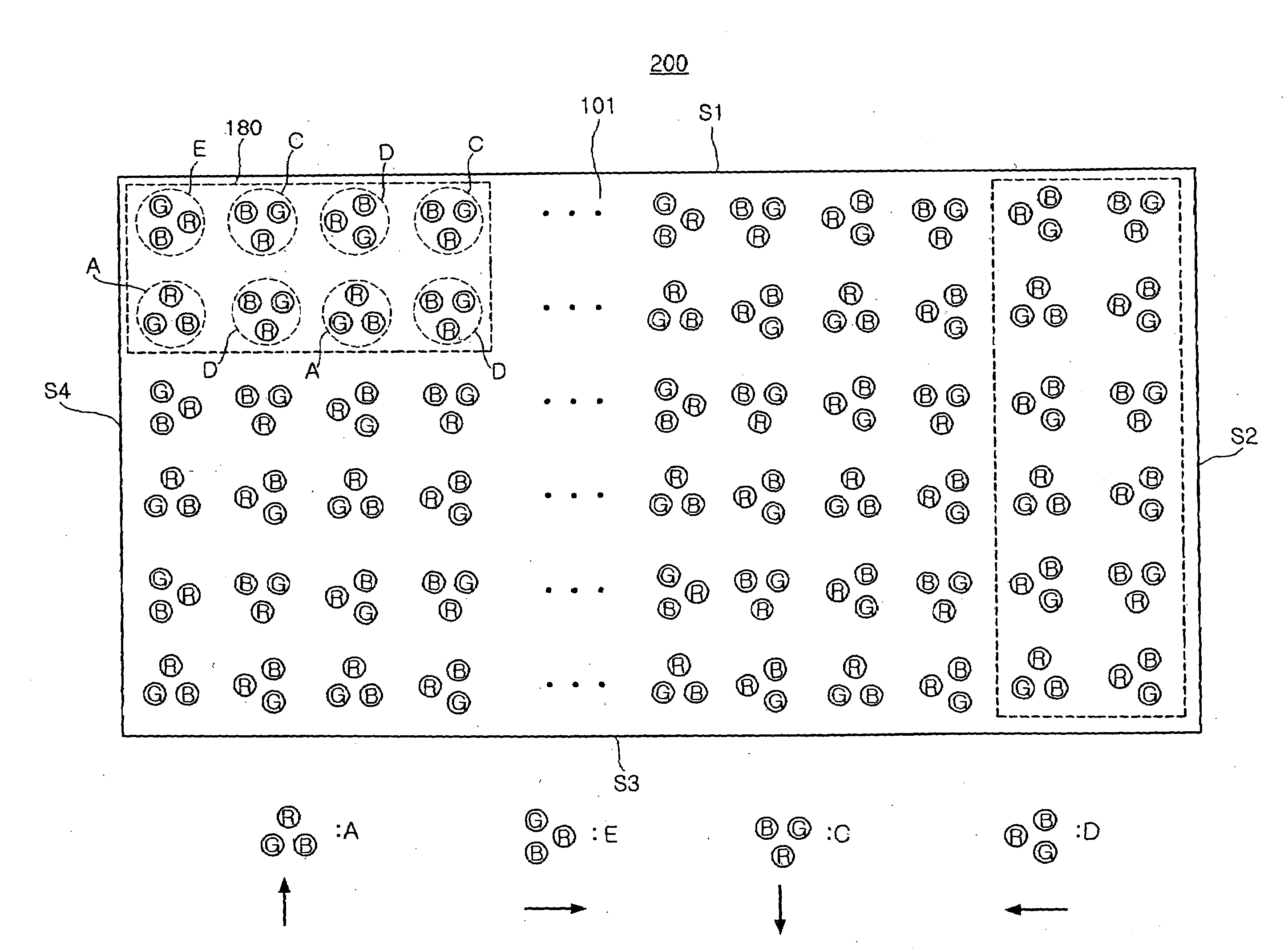

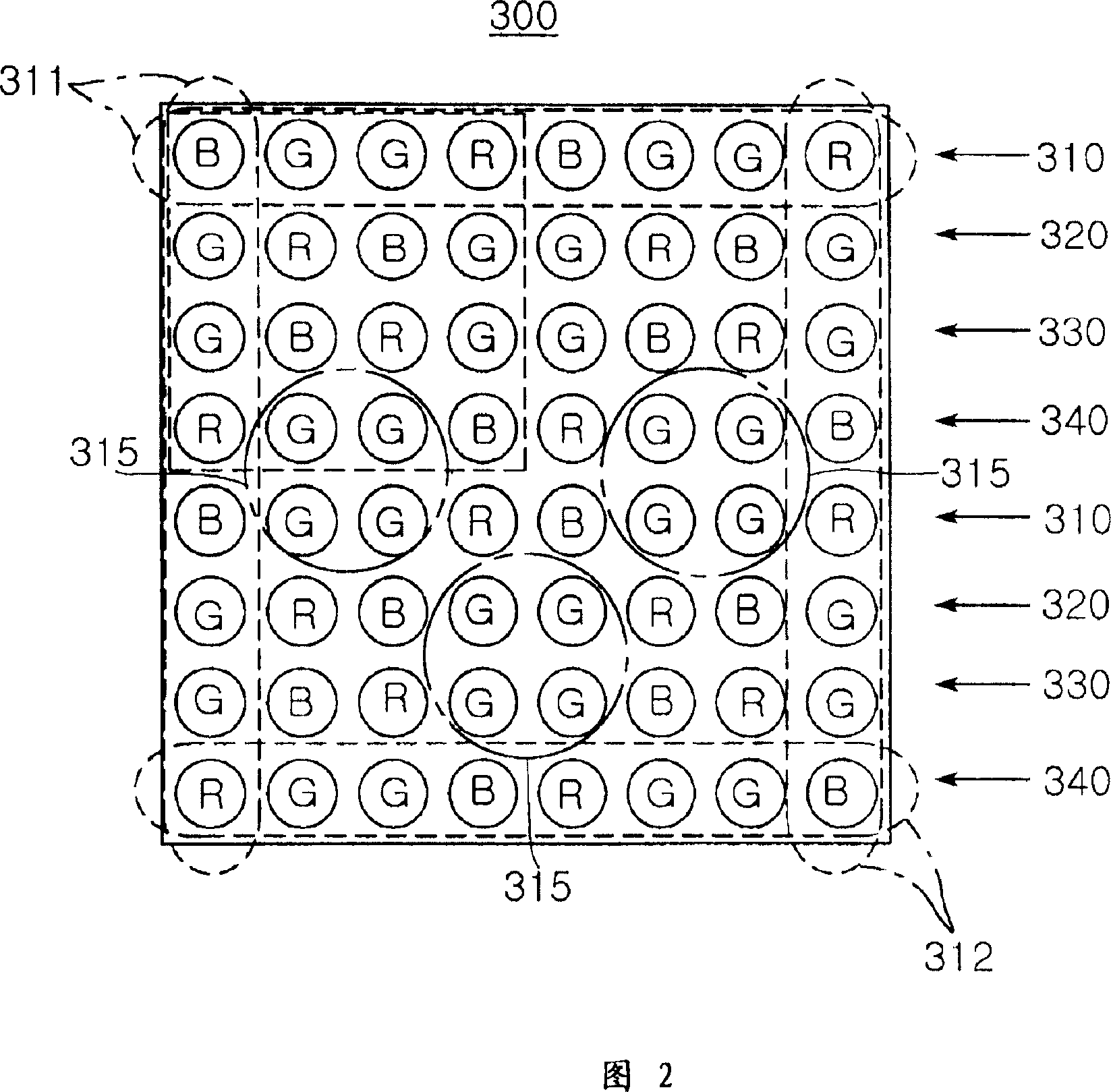

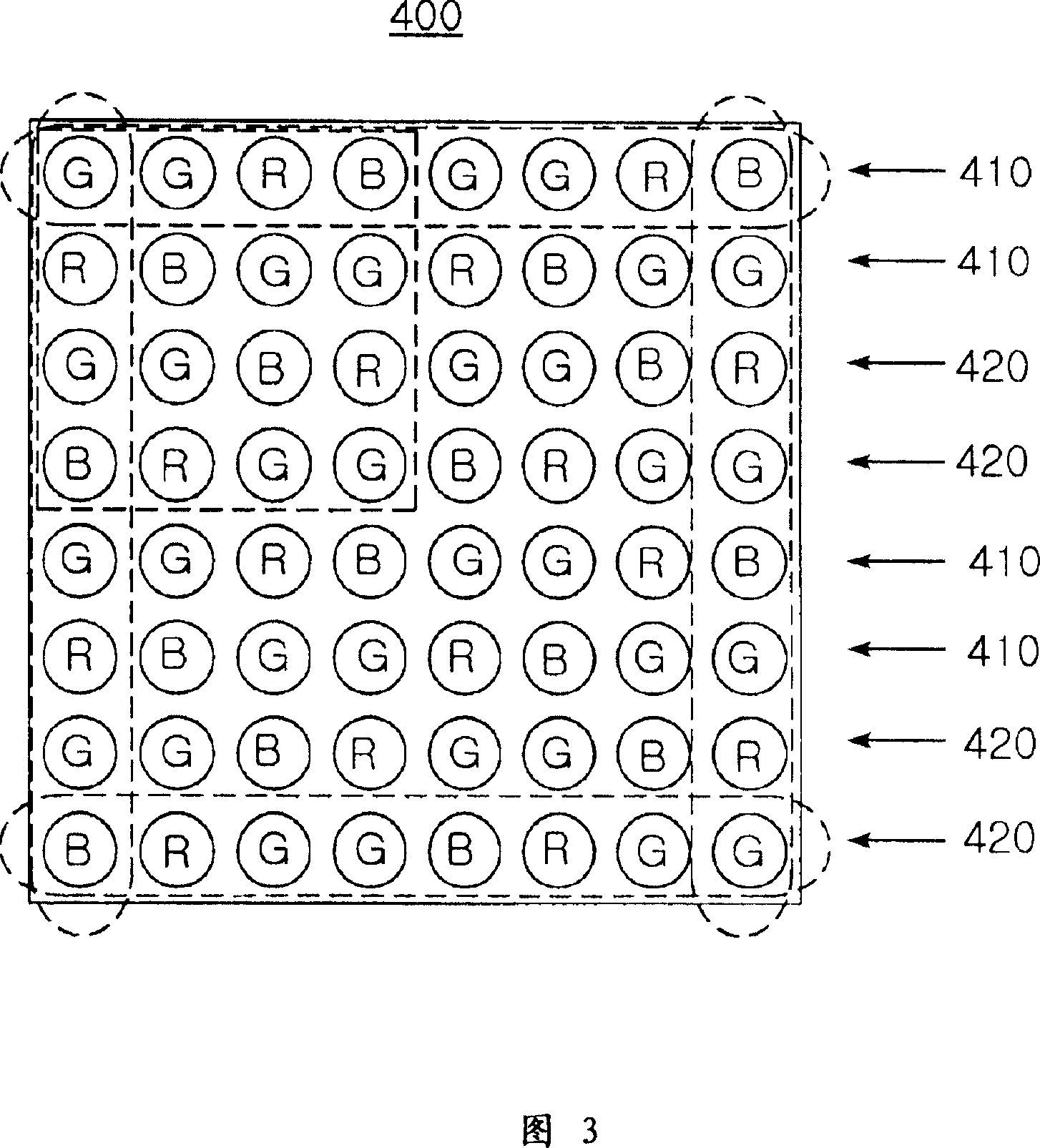

InactiveUS20080025019A1Suppressing colorUniformNon-electric lightingPoint-like light sourceOptoelectronicsTriangle center

A surface light source device having LED clusters arranged in a matrix of rows and columns on a board. Each of the LED clusters includes red, green and blue LEDs arranged in a triangle. The LED clusters are grouped into A, E, C and D, which have the red LEDs located top, right, bottom and left, respectively, from a center of the triangle. The matrix of the LED clusters includes alternating first and second type rows arranged repeatedly from top to bottom of the matrix, terminating with the second type row. The first type rows each have first type cluster arrays of the LED clusters arranged in a repeating order of E, C, D and C from left to right. The second type rows each have second type cluster arrays of the LED clusters arranged in a repeating order of A, D, A and D from left to right.

Owner:SAMSUNG ELECTRONICS CO LTD

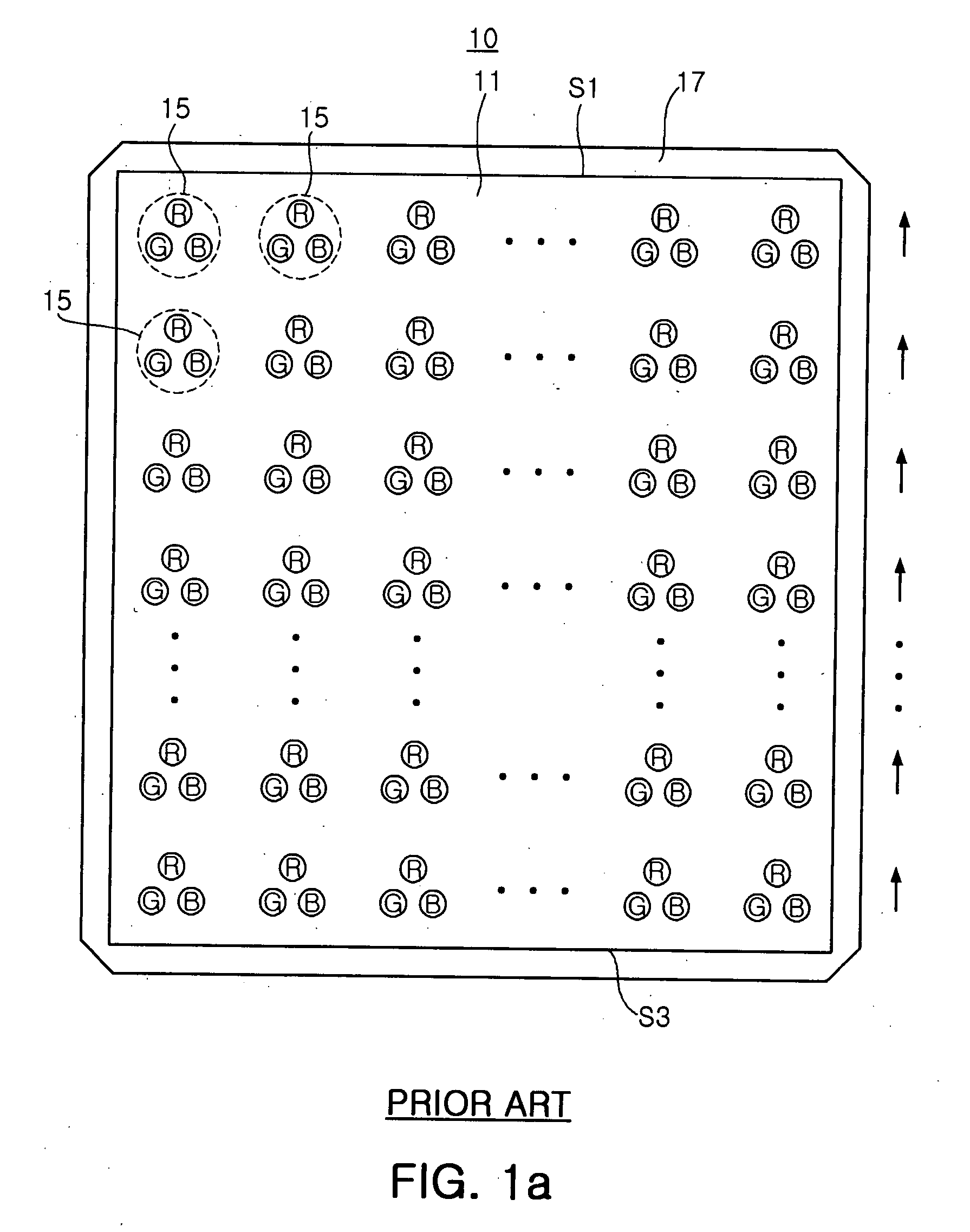

Surface light source using light emitting diode and liquid crystal display backlight unit employing the same

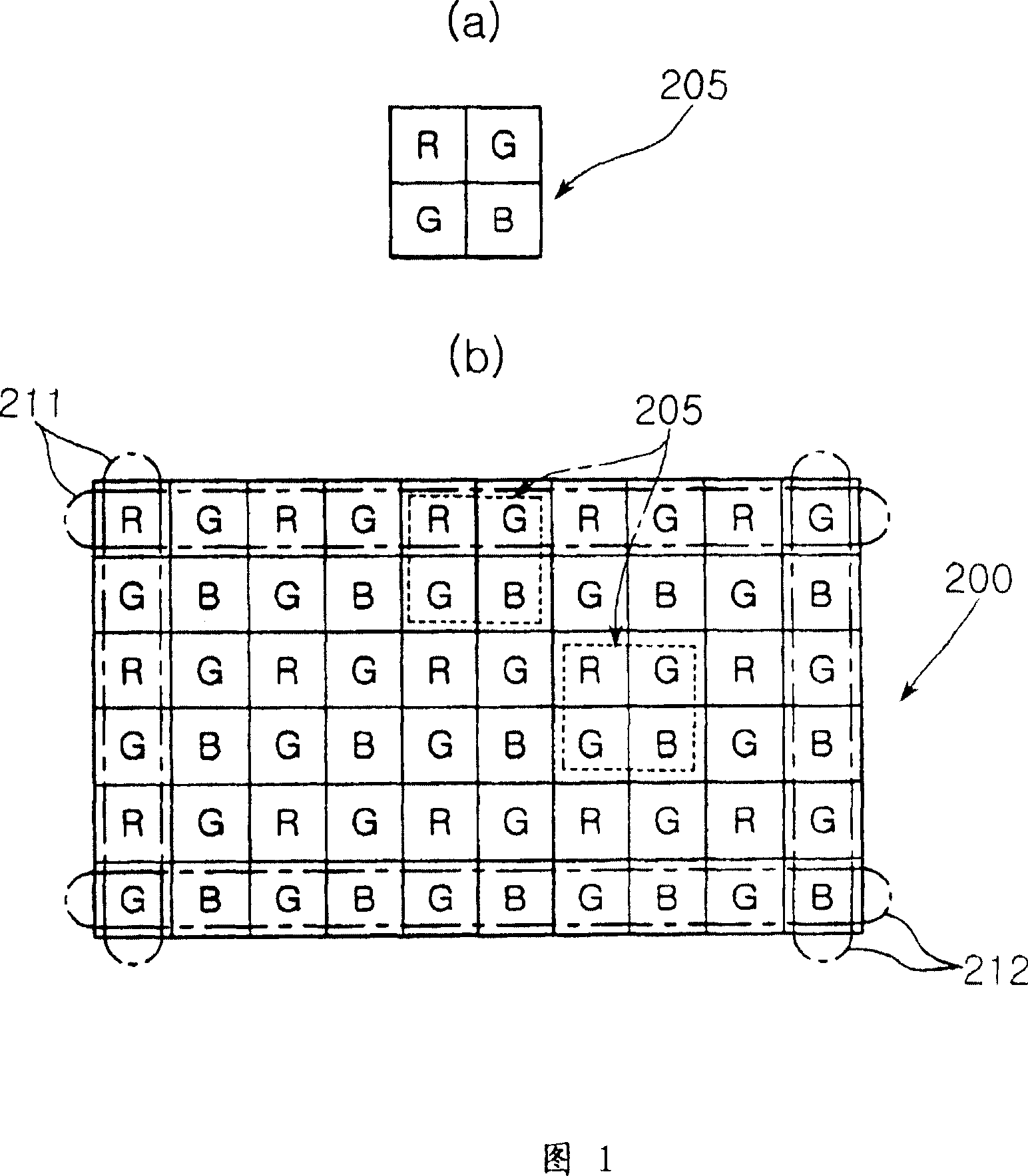

InactiveCN101000125AReduce dark spotsUniform white lightPlanar light sourcesPoint-like light sourceManufacturing cost reductionLiquid-crystal display

A surface light source capable of reducing color stains with reduced number of light emitting diodes and manufactured at low costs, and a liquid crystal display backlight unit employing the same. The surface light source includes a plurality of light source clusters arrayed along first and second directions, each of the clusters including three light emitting diodes disposed in a triangular arrangement, the three light emitting diodes including green, red and blue light emitting diodes. The surface light source also includes a first array of the clusters lined along and inverted alternately about the first direction; and a second array of the clusters lined along and inverted alternately about the second direction, where the first array is perpendicular to the second array. The invention reduces color stains to achieve uniform white light and reduces the number of light emitting diodes to manufacture a product at low costs.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Method for preparing fluorescent powder colloid

InactiveCN101704988AEvenly dispersedUniform lightLuminescent compositionsSemiconductor devicesEpoxyColloid

The invention discloses a method for preparing fluorescent powder colloid. The method comprises the following processing steps: 1) preheating an epoxy resin A agent for 1 to 1.5 hours at the temperature of between 55 and 65 DEG C; 2) putting fluorescent powder, the preheated epoxy resin A agent and a curing agent B into a mixer in a mass ratio of 6-15: 100: 100, and evenly mixing the materials for 10 to 15 minutes at the stirring rate of 30 to 40rpm; and 3) vacuumizing the mixture for 5 to 10 minutes at the temperature of between 75 and 85 DEG C to remove bubbles in the mixture so as to obtain a finished product. The fluorescent powder, the epoxy resin A agent and the curing agent B are evenly mixed to prepare the fluorescent powder colloid so that the fluorescent powder is evenly dispersed in the fluorescent powder colloid; the fluorescent powder colloid applied to a product can remarkably improve the luminous quality, has even rays, good consistency and high excitation efficiency, enables a whole light-emitting diode to emit light in 360 degrees, and has no ray loss.

Owner:东莞市永兴电子科技有限公司

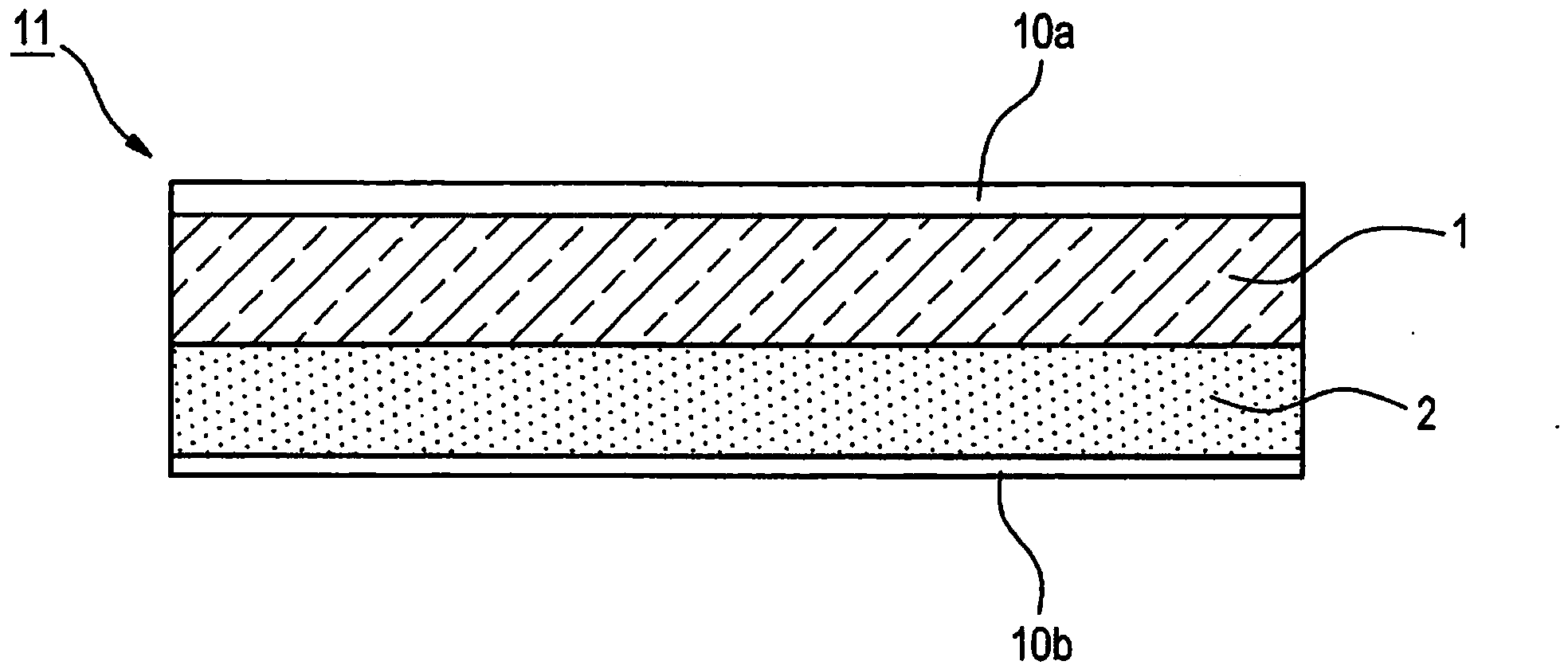

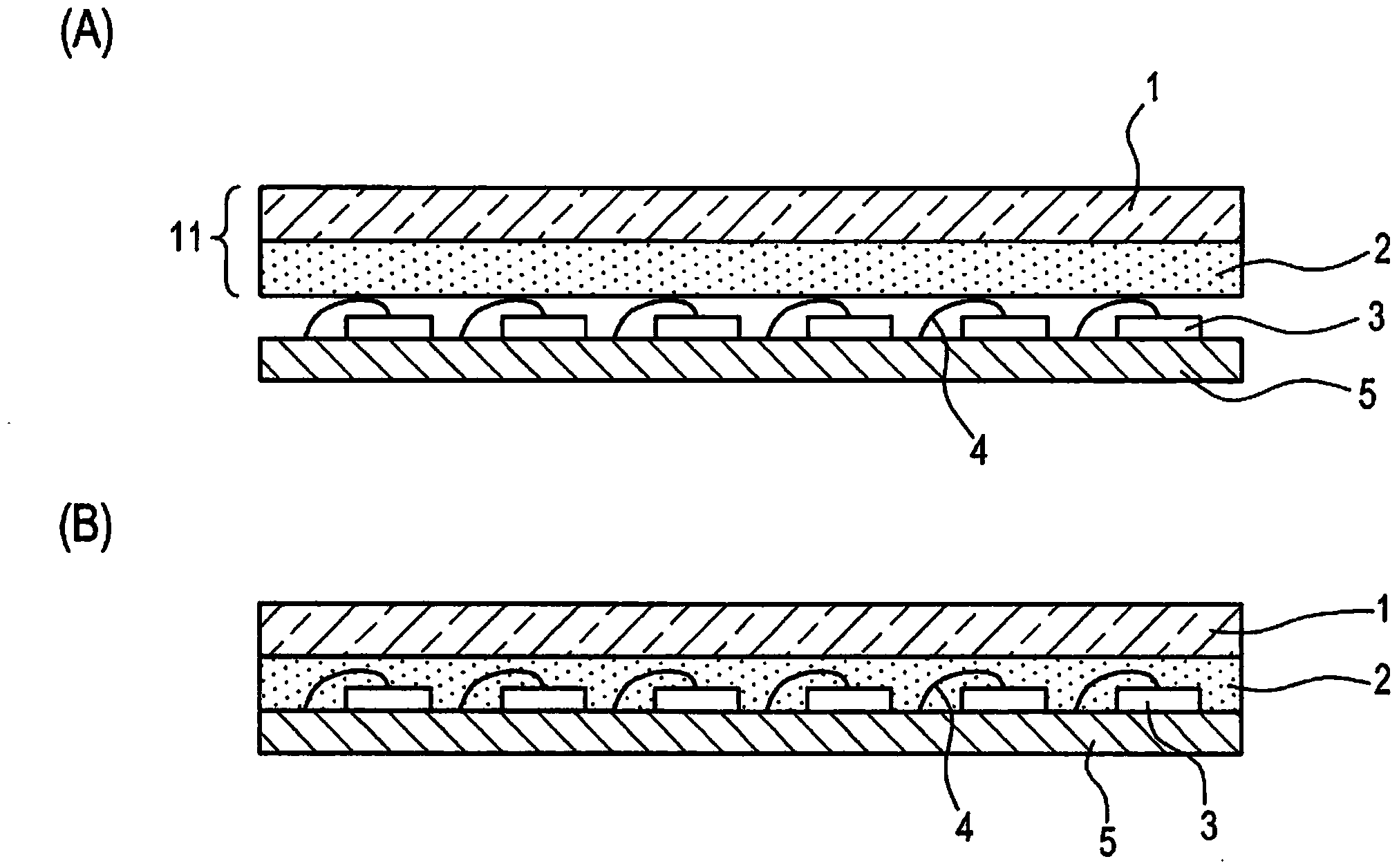

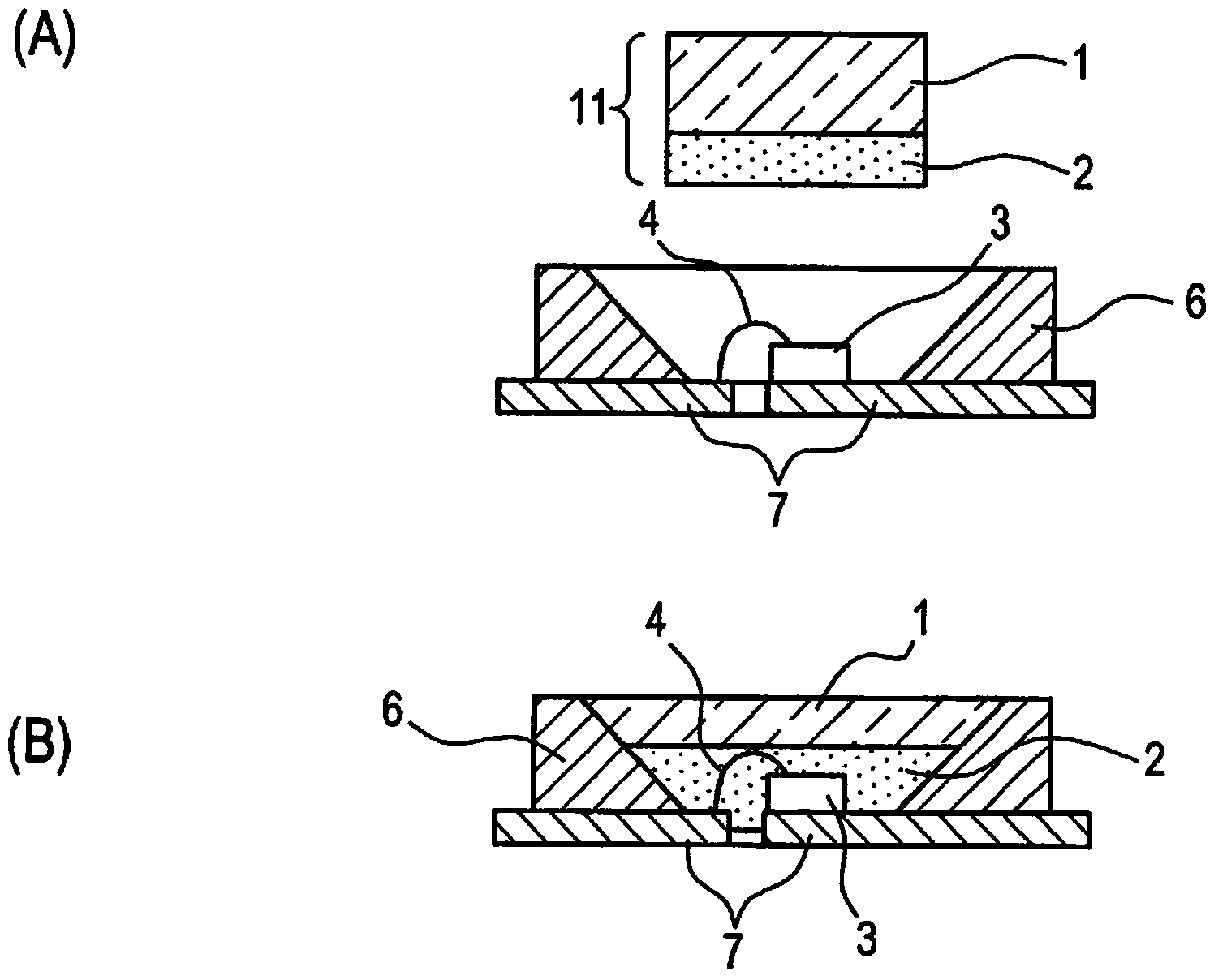

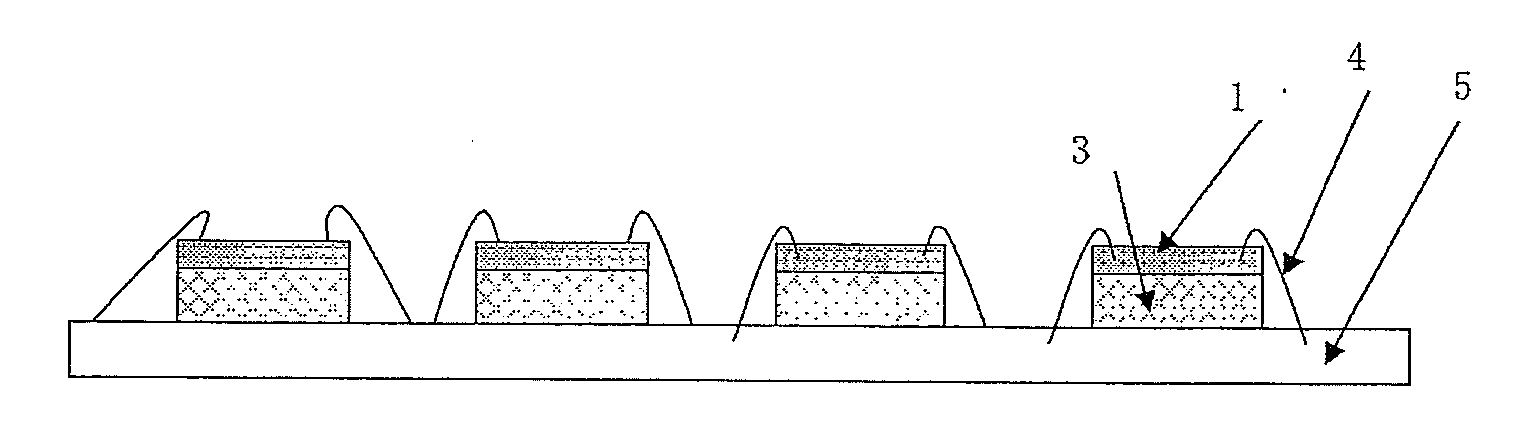

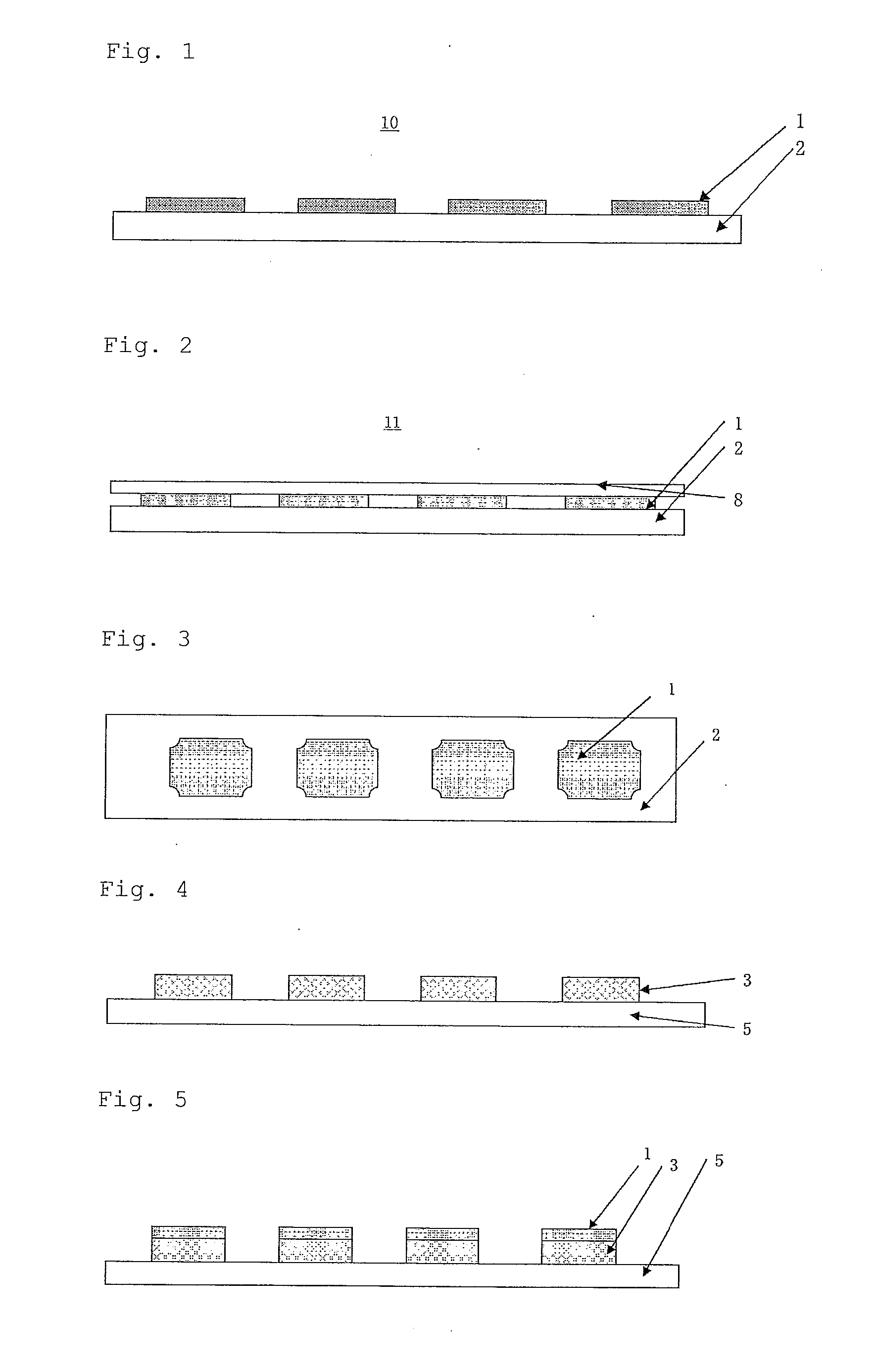

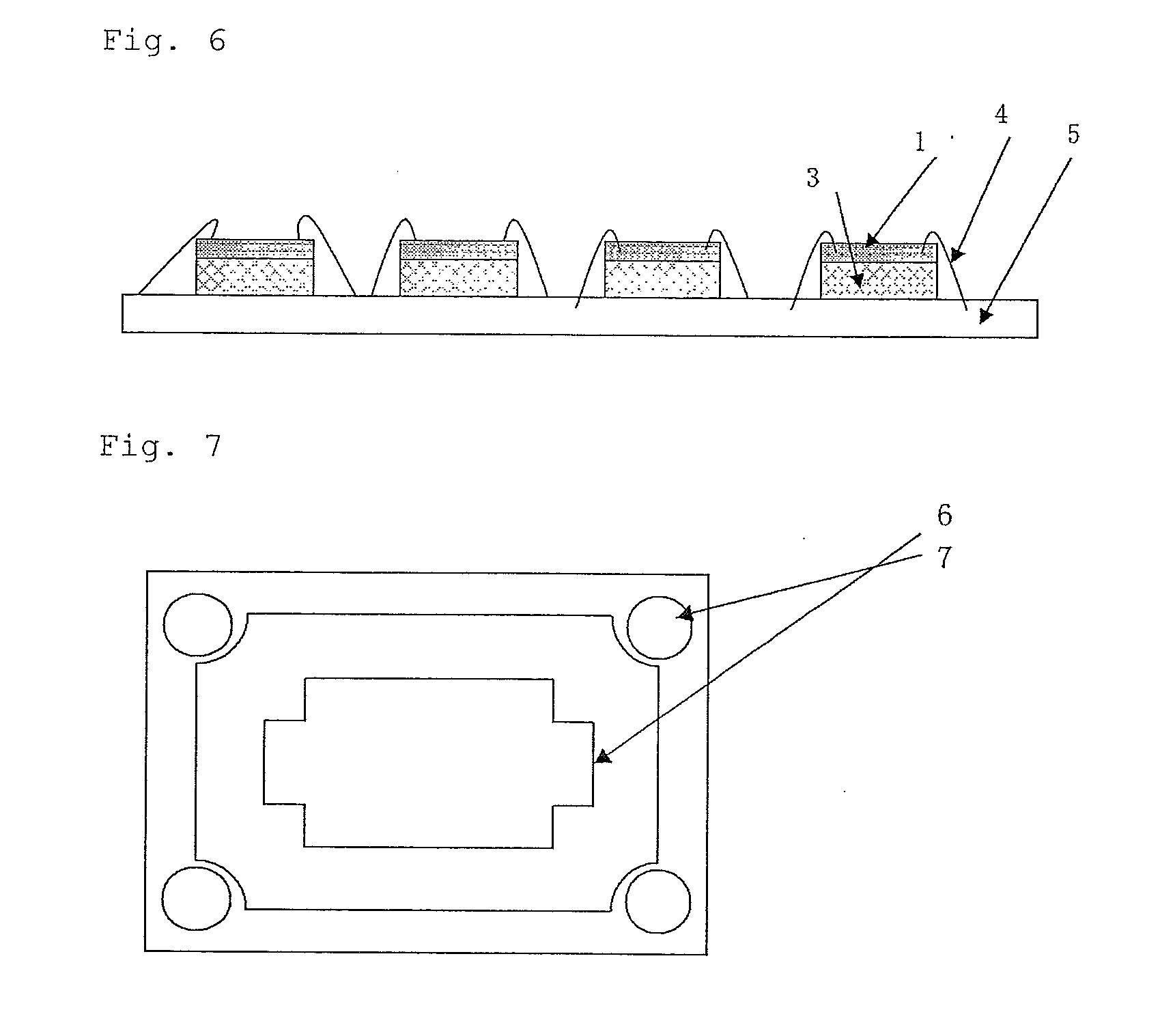

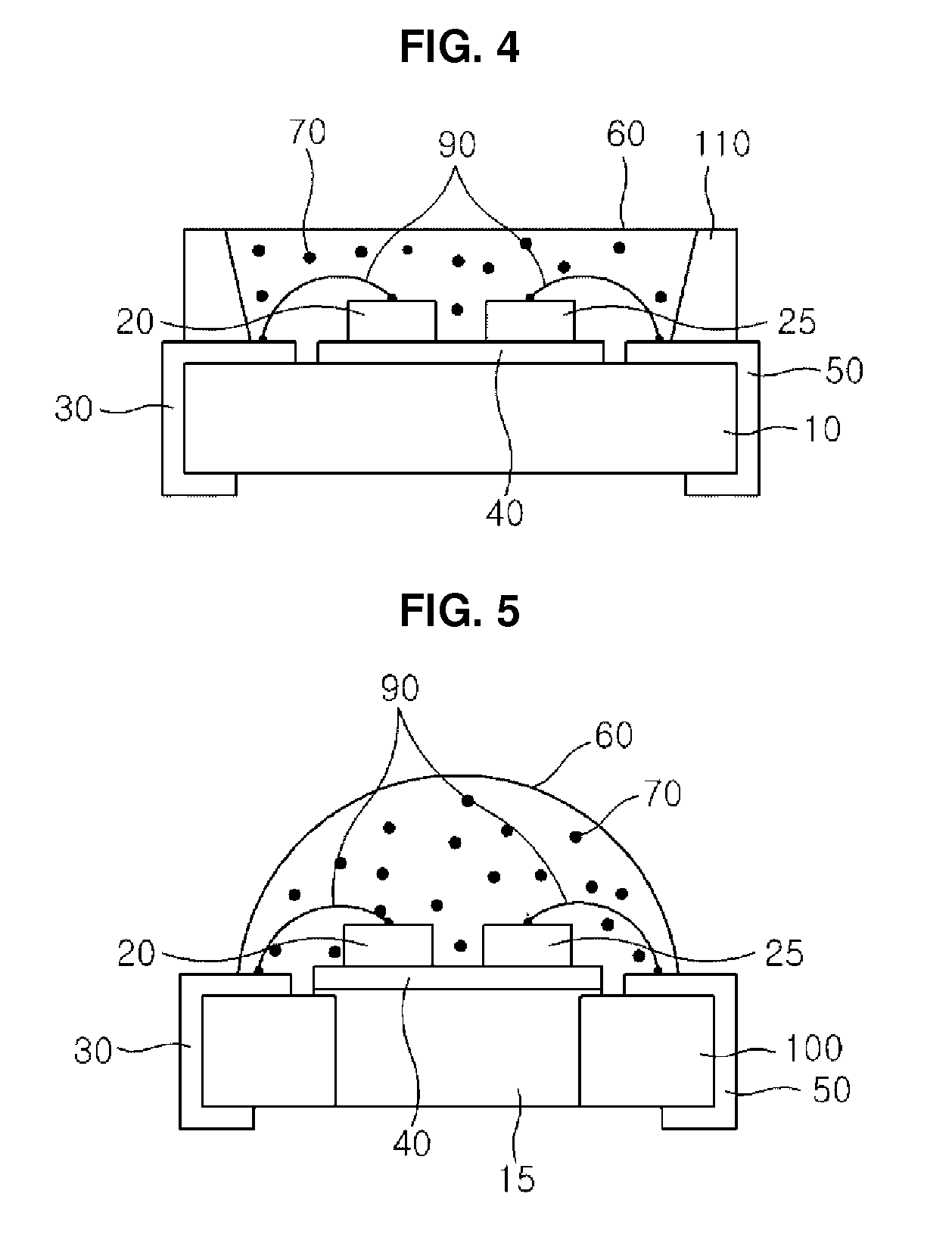

Heat-curable silicone resin sheet having phosphor-containing layer and white pigment-containing layer, method of producing light emitting device using same and encapsulated light emitting semiconductor device produced thereby

ActiveCN103879099AGood dispersionDispersion is stable and maintained evenlySynthetic resin layered productsSolid-state devicesPhosphorSemi solid

The invention provides a heat-curable silicone resin sheet, a method of producing a light emitting device using the heat-curable silicone resin sheet and an encapsulated light emitting semiconductor device produced thereby. The heat-curable silicone resin sheet is capable of easily and uniformly dispersing phosphors on an LED element surface and reducing a brightness through a light-diffusing effect. The heat-curable silicone resin sheet includes at least two layers that are: a phosphor-containing layer (2) consisting essentially of a phosphor-containing heat-curable silicone resin composition that is in a plastic solid or plastic semi-solid state at room temperature; and a white-pigment-containing layer (1) consisting essentially of a white pigment-containing heat-cured silicone resin composition.

Owner:SHIN ETSU CHEM IND CO LTD

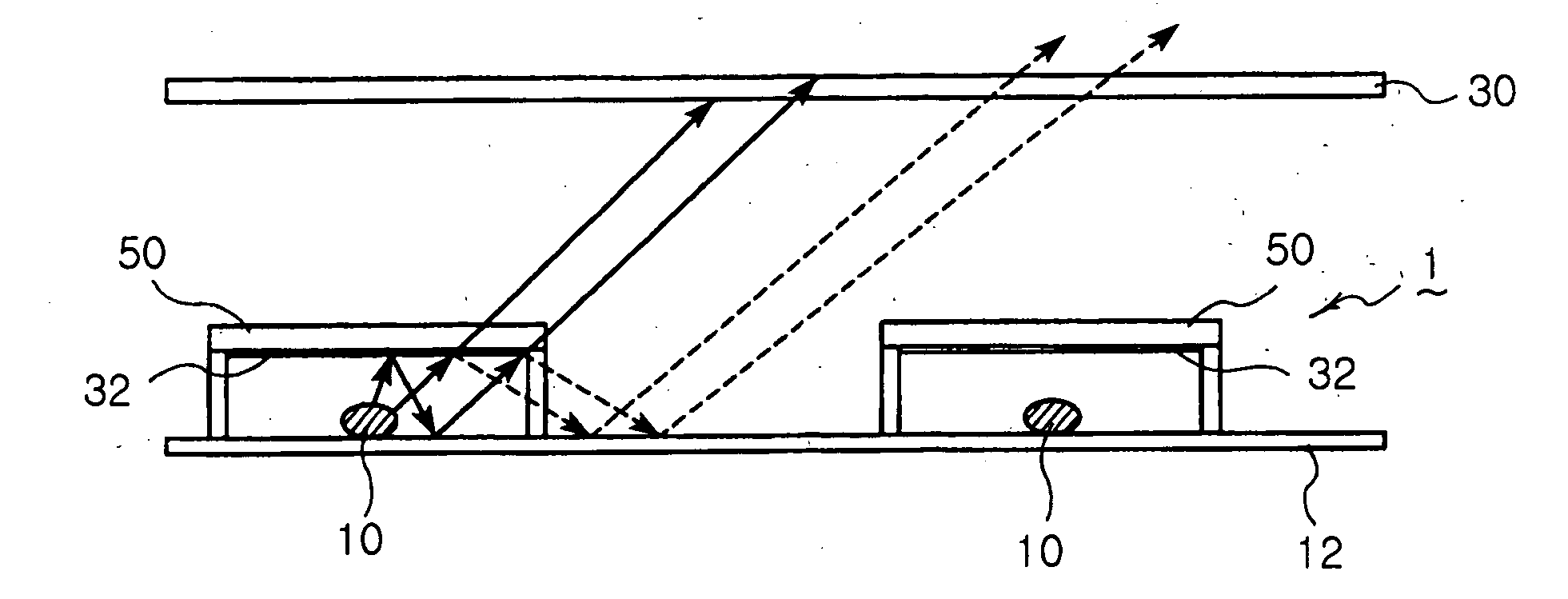

Backlight unit improved in light mixing feature

ActiveUS20070159573A1Uniform white lightImprove featureRoad vehicles traffic controlNon-linear opticsReflectivityLight source

Light beams are outputted from optical devices and mixed together to obtain uniform white light free from color stains, thereby achieving a backlight unit improved in light mixing feature. In the backlight unit, a surface light source has a reflecting surface with a plurality of optical devices mounted thereon. An optical sheet is disposed in front of the surface light source. A reflecting layer is disposed between the surface light source and the optical sheet and has reflectivity varied by an incident angle of light beams from the optical devices. The backlight unit enables the light beams from the optical devices to be mixed together. The light beams outputted from the optical devices are effectively mixed together by a reflecting layer having reflectively varied by an incident angle of the light beams from the optical devices, thereby achieving uniform white light without color stains.

Owner:SAMSUNG ELECTRONICS CO LTD

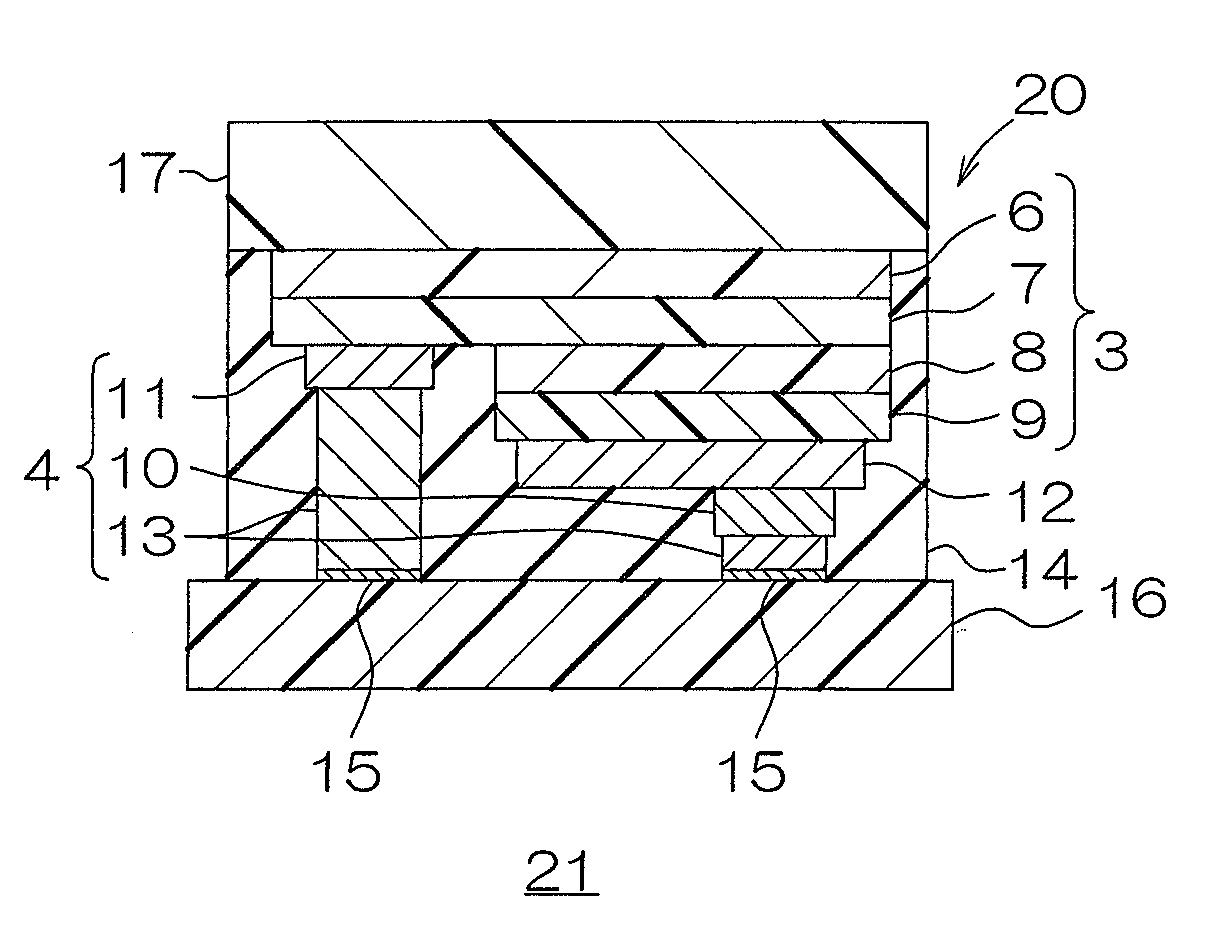

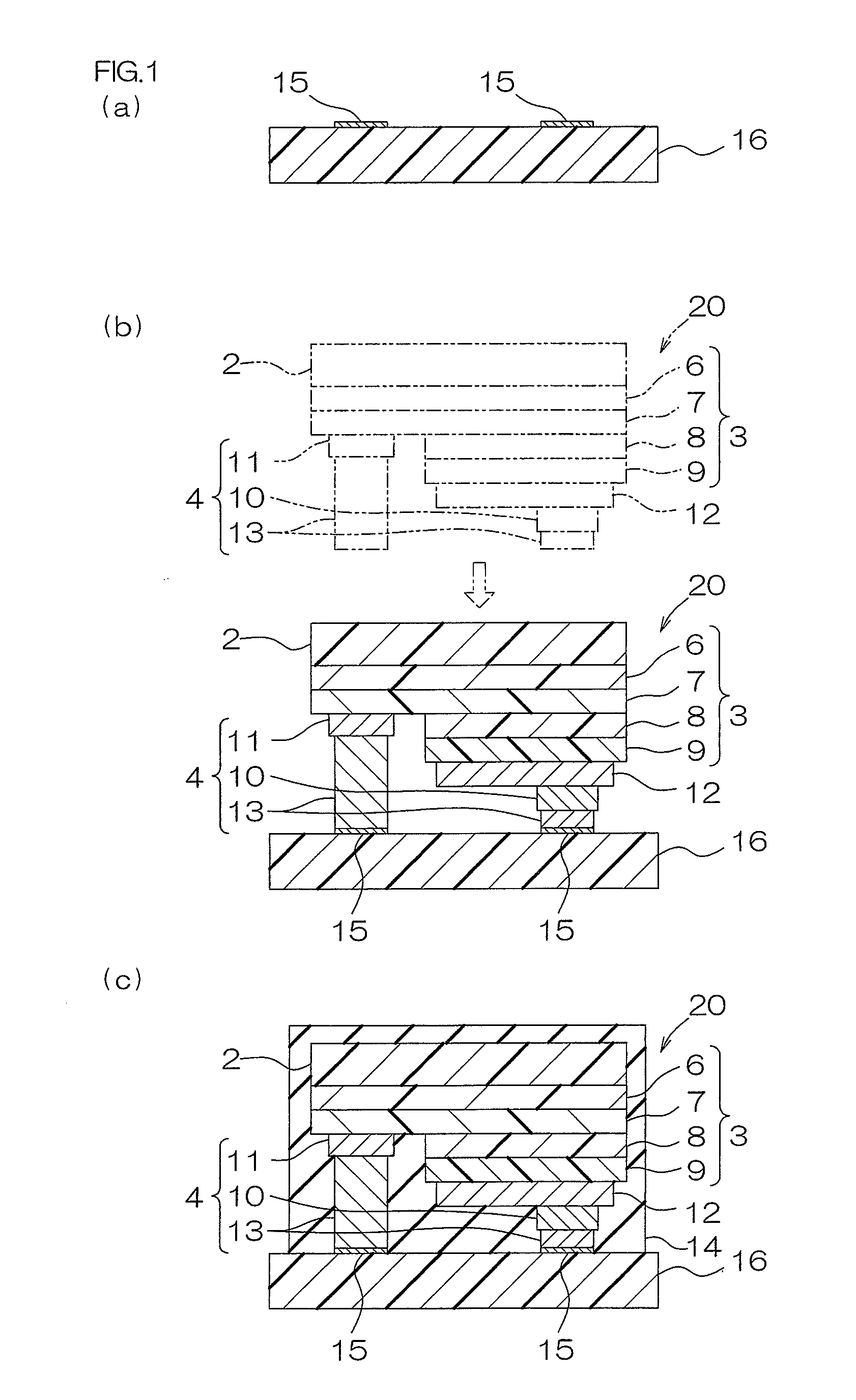

Light emitting diode device and producing method thereof

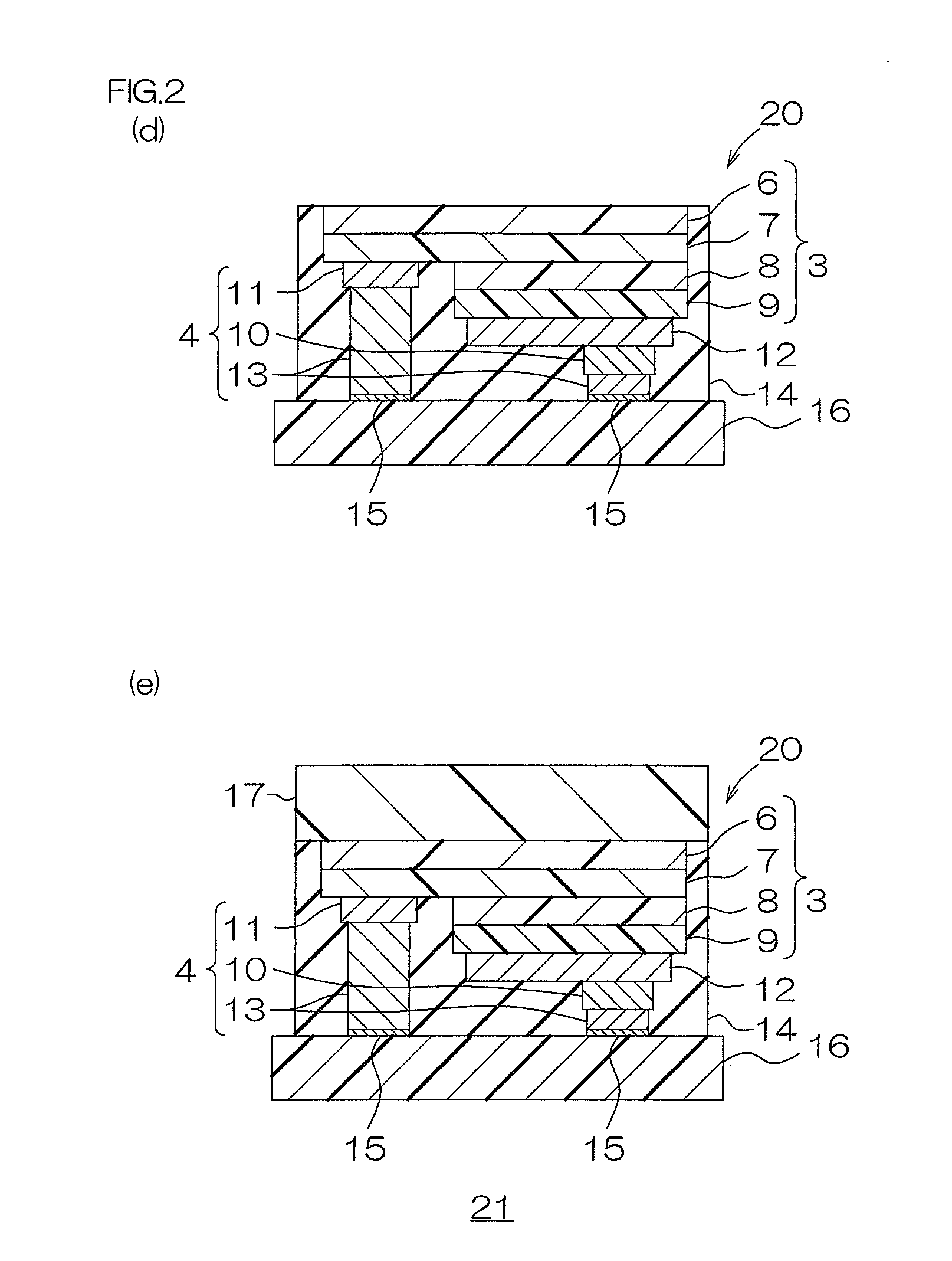

ActiveUS20120248484A1Reliable formingUniform white lightSolid-state devicesSemiconductor/solid-state device manufacturingPhosphorLight reflection

A method for producing a light emitting diode device includes the steps of preparing a base board; allowing a light semiconductor layer where an electrode portion is provided at one side in a thickness direction to be disposed in opposed relation to the base board, and the electrode portion to be electrically connected to a terminal, so that the light semiconductor layer is flip-chip mounted on the base board; forming an encapsulating resin layer containing a light reflecting component at the other side of the base board so as to cover the light semiconductor layer and the electrode portion; removing the other side portion of the encapsulating resin layer so as to expose the light semiconductor layer; and forming a phosphor layer formed in a sheet state so as to be in contact with the other surface of the light semiconductor layer.

Owner:EPISTAR CORP

Backlight module

InactiveUS7740391B2Improve color saturationEnhancing front-side illuminanceShow cabinetsMechanical apparatusLight guideLength wave

Owner:WINTEK CORP

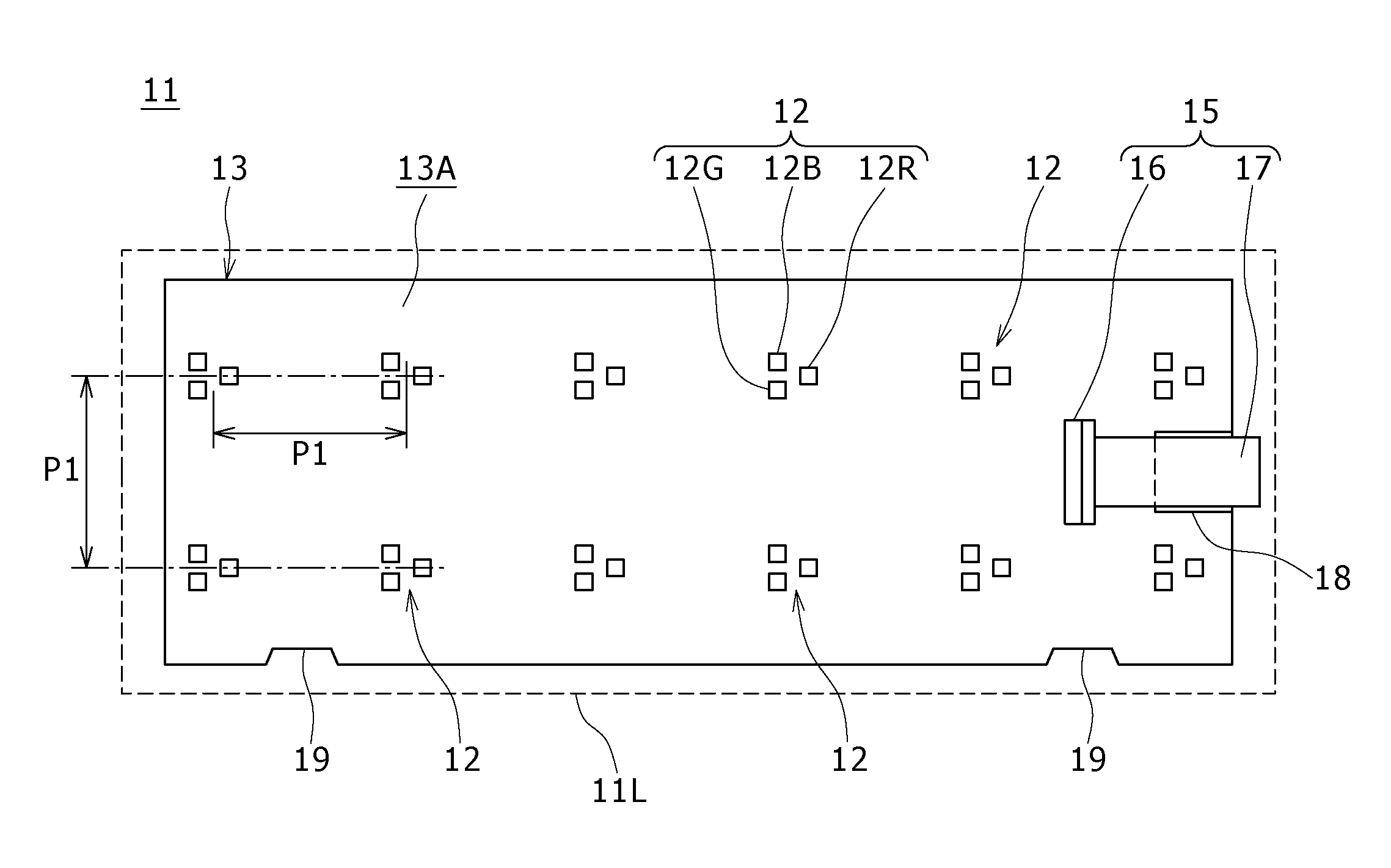

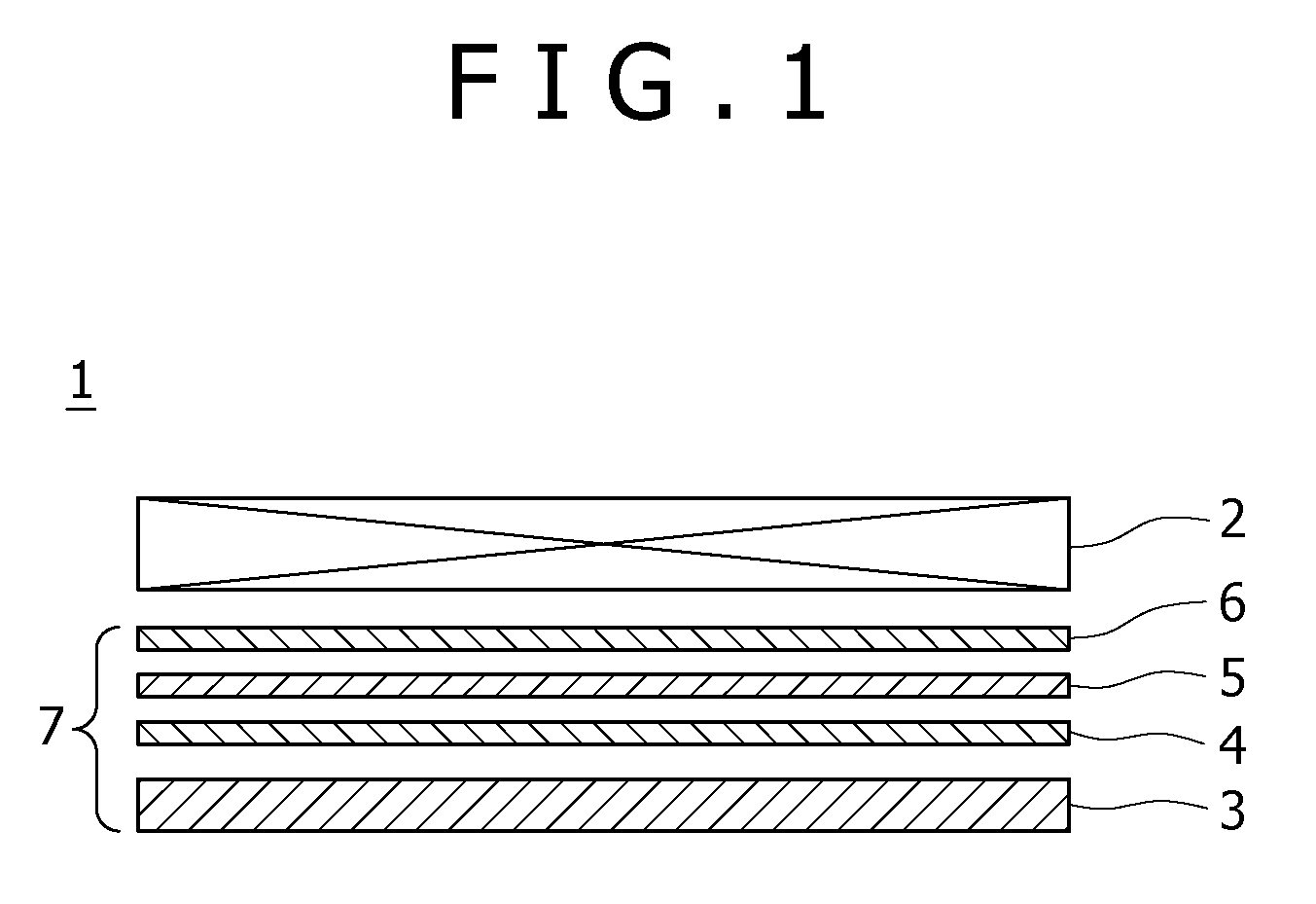

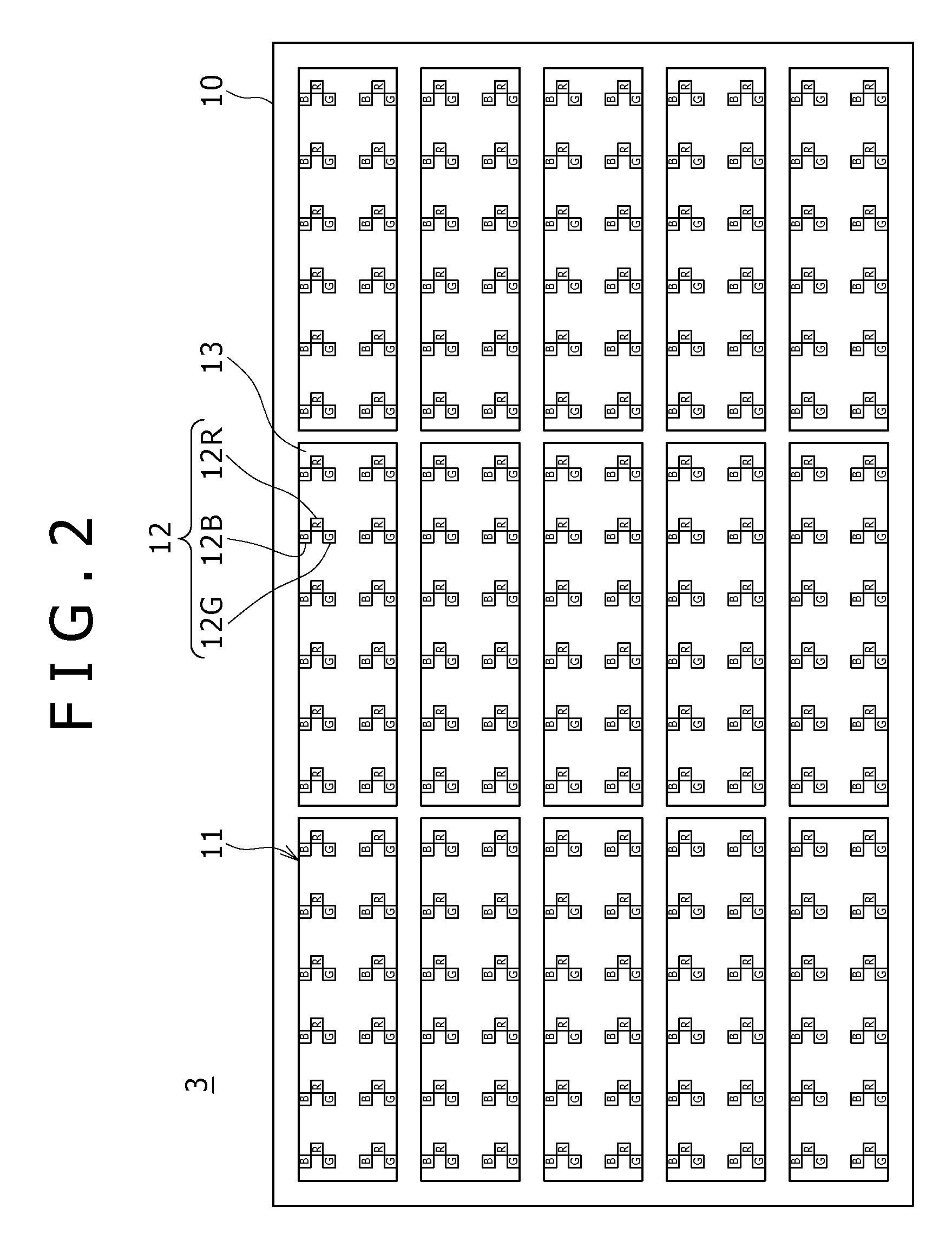

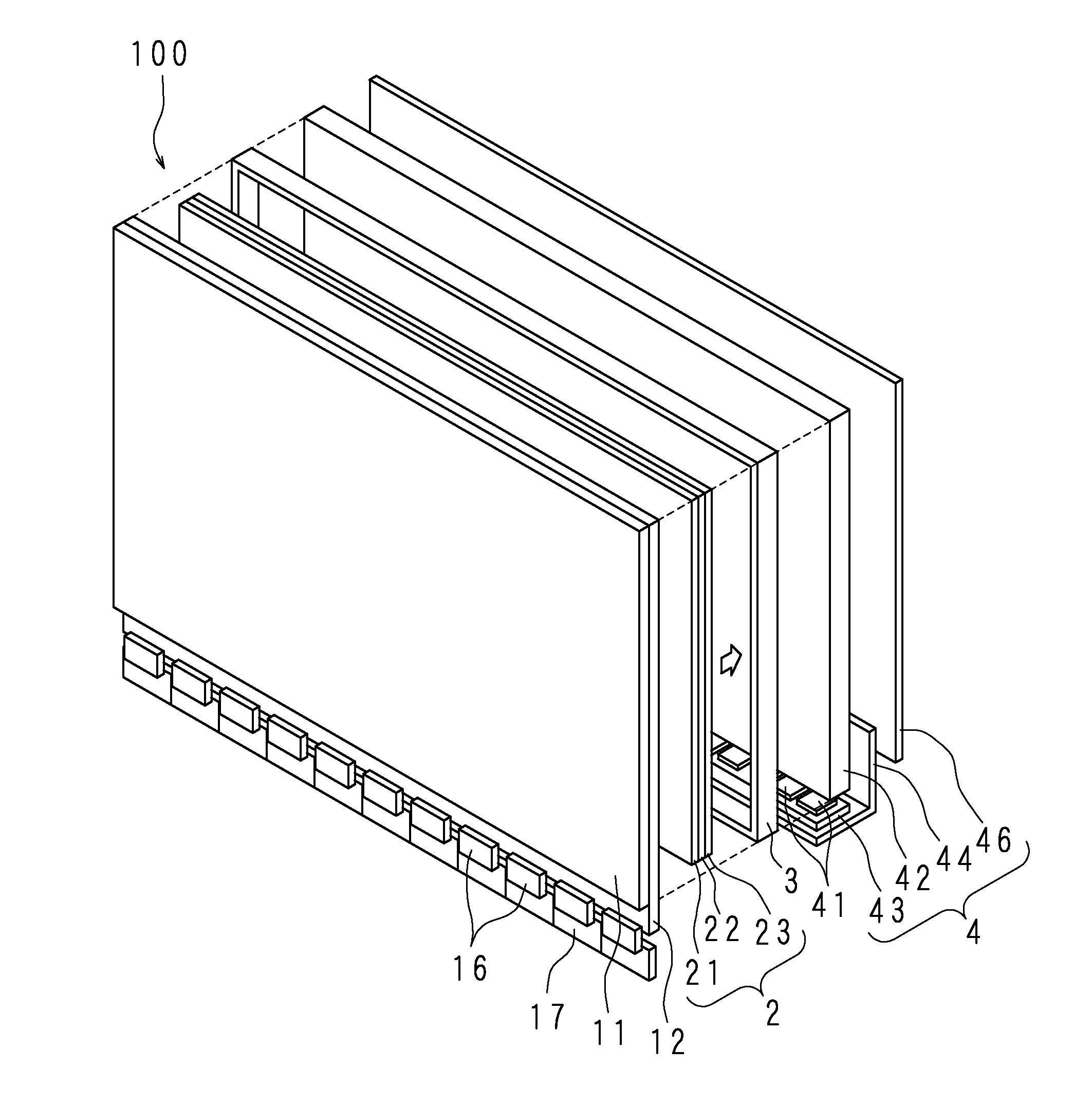

Light source module, light source apparatus and liquid crystal display

InactiveUS7878680B2Improve propertiesUniform brightnessLighting support devicesLighting heating/cooling arrangementsLiquid-crystal displayDevice form

A light source module includes a light emitting diode and a wiring board. The light emitting diode (LED) chip group includes LED chips for red, green and blue colors. A plurality of the LED chip groups are mounted on the wiring board. A surface on one side of the wiring board is a device forming surface including the plurality of the LED chip groups, an external connecting terminal for leading out electrodes, and a wiring pattern for electrical connection between the LED chip groups and the external connecting terminal. A surface on the other side of the wiring board is a heat radiating surface which is thermally connected to the device forming surface and operative to radiate heat generated at the device forming surface to the exterior.

Owner:SONY CORP

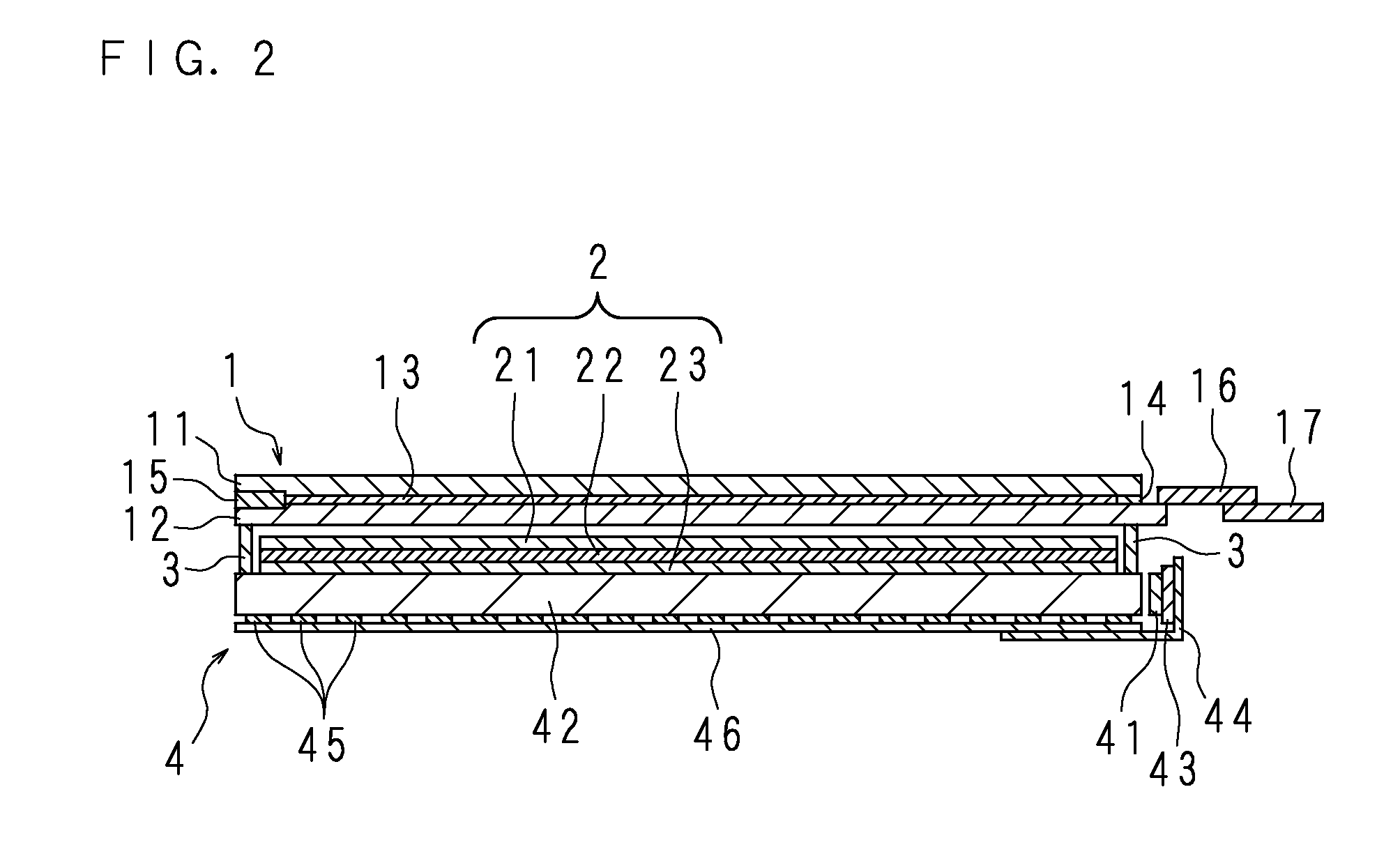

Display Apparatus

ActiveUS20160259122A1Uniform white lightAvoid expansionMechanical apparatusStatic indicating devicesEngineeringGlass sheet

Provided is a display apparatus having a structure capable of realizing reduction in thickness and border width.A display apparatus having a liquid-crystal panel prepared by enclosing a liquid-crystal material between a pair of glass substrates opposing to each other, a transparent plate opposed to the liquid-crystal panel, and an optical sheet arranged between the liquid-crystal panel and the transparent plate, and having a face smaller than the liquid-crystal panel, wherein the transparent plate is a glass plate having a wide surface of substantially a same shape as a wide surface of each of the glass substrate, and the display apparatus further comprises a frame body arranged between the liquid-crystal panel and the transparent plate, the frame body surrounding an outer periphery of the optical sheet, the frame body being thicker than the optical sheet.

Owner:SAKAI DISPLAY PROD

Surface light source device and backlight unit having the same

InactiveUS7476003B2Suppressing color stains at side portions of the boardUniform white lightNon-electric lightingPoint-like light sourceOptoelectronicsTriangle center

A surface light source device having LED clusters arranged in a matrix of rows and columns on a board. Each of the LED clusters includes red, green and blue LEDs arranged in a triangle. The LED clusters are grouped into A, E, C and D, which have the red LEDs located top, right, bottom and left, respectively, from a center of the triangle. The matrix of the LED clusters includes alternating first and second type rows arranged repeatedly from top to bottom of the matrix, terminating with the second type row. The first type rows each have first type cluster arrays of the LED clusters arranged in a repeating order of E, C, D and C from left to right. The second type rows each have second type cluster arrays of the LED clusters arranged in a repeating order of A, D, A and D from left to right.

Owner:SAMSUNG ELECTRONICS CO LTD

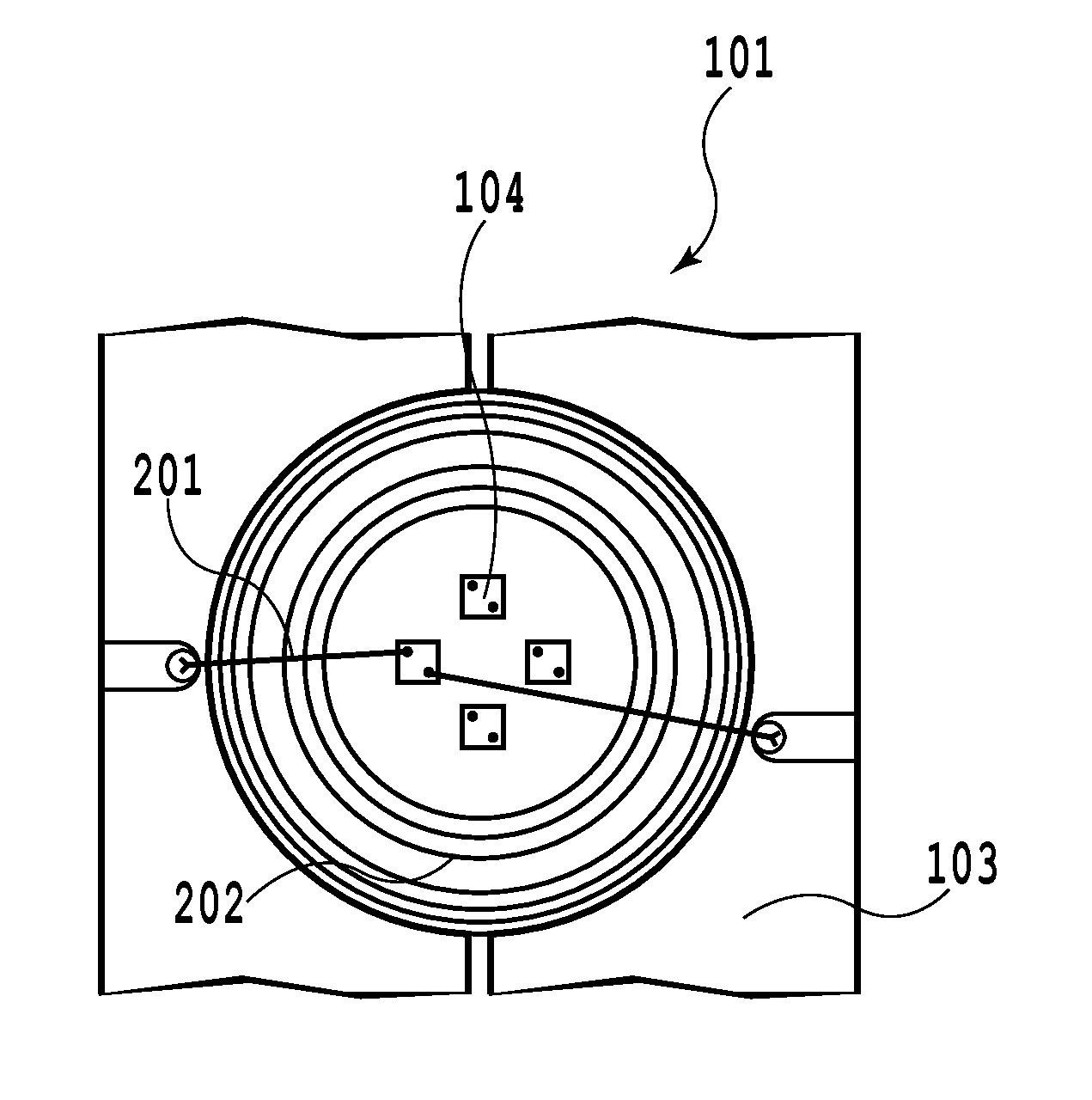

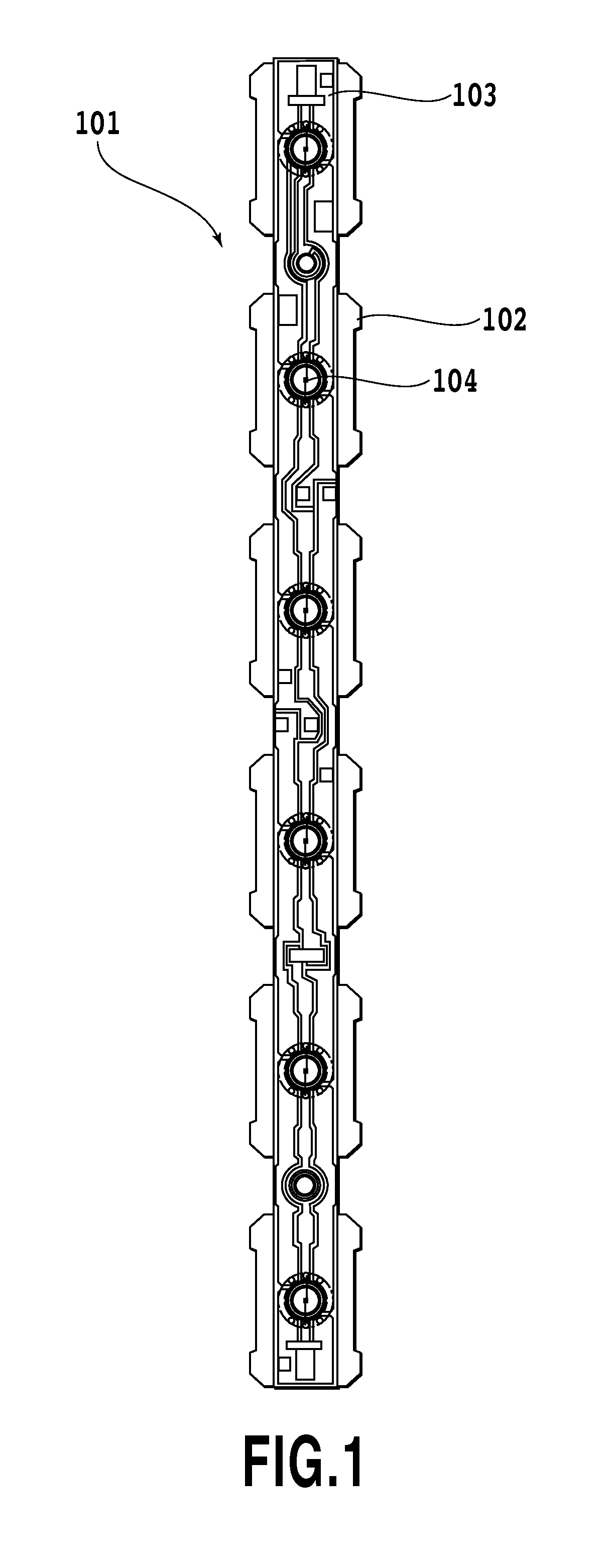

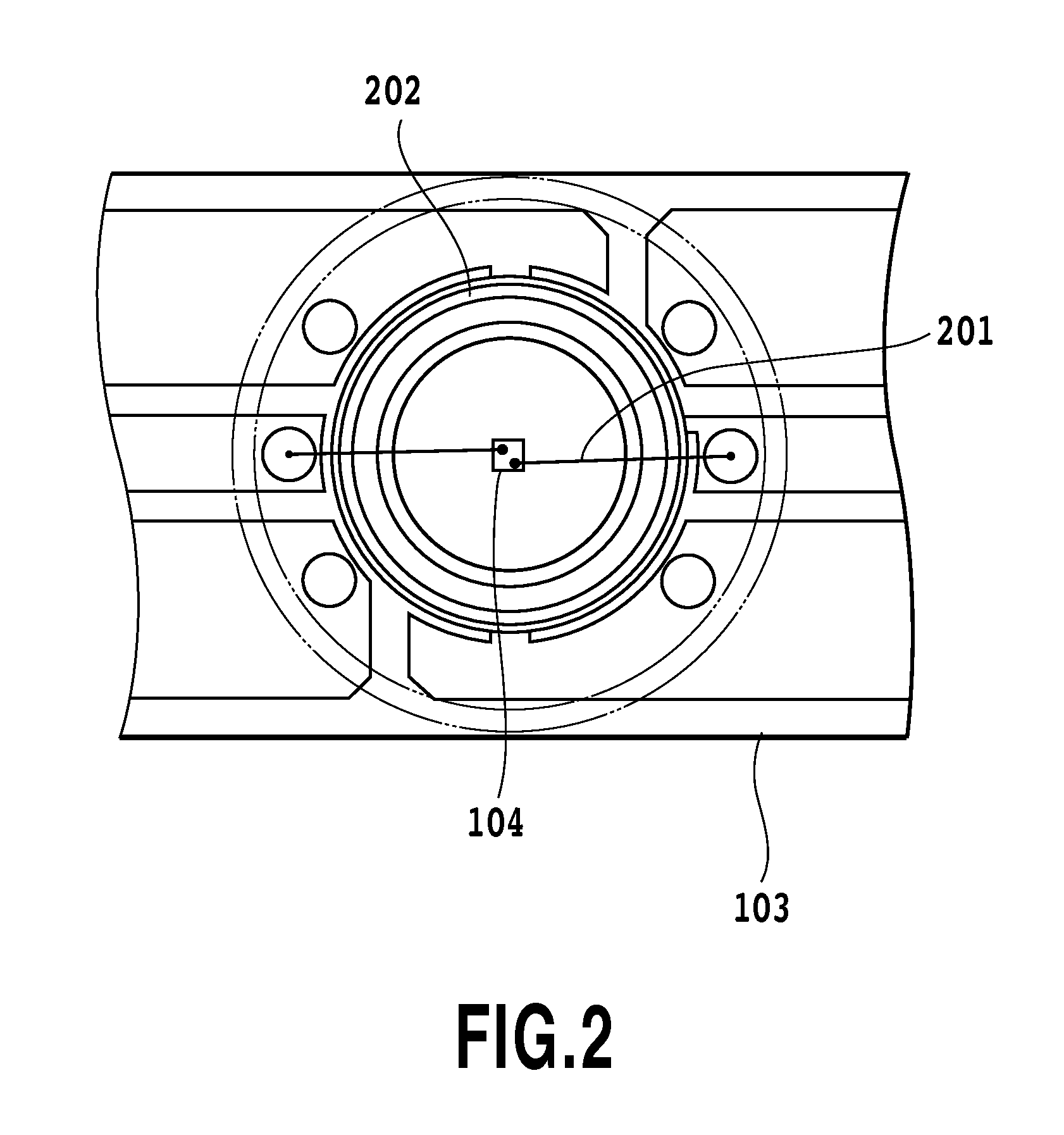

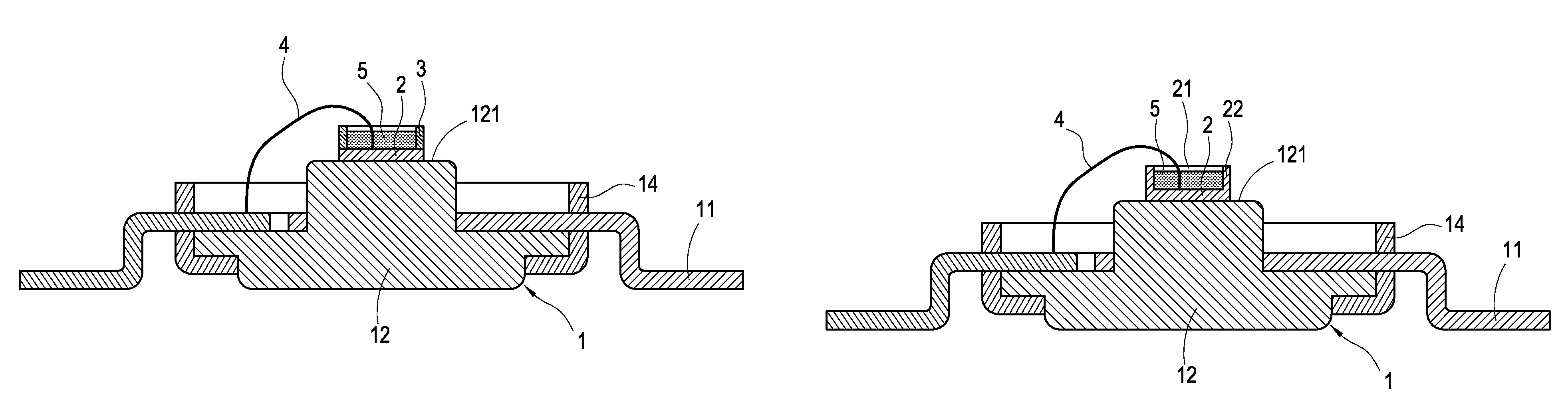

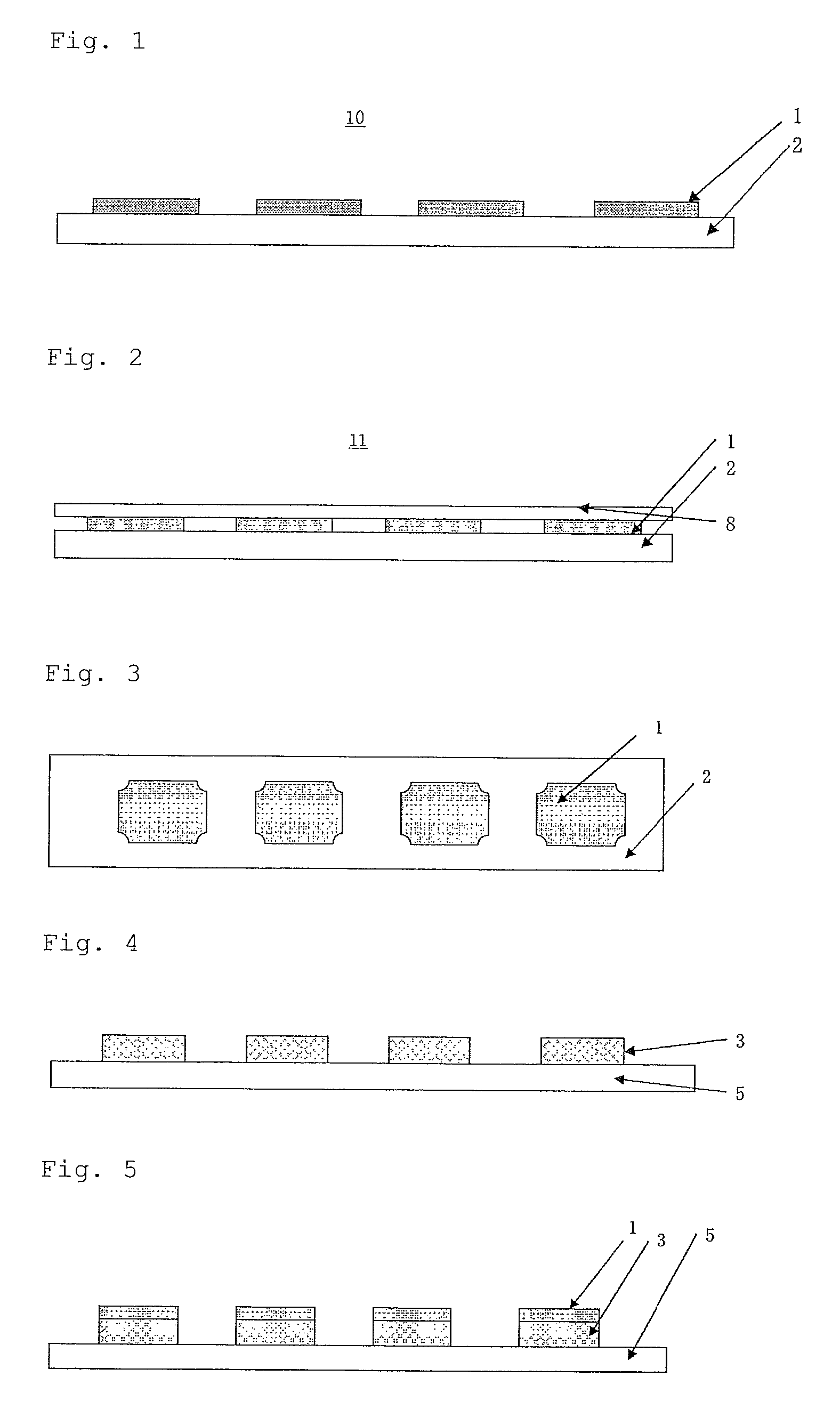

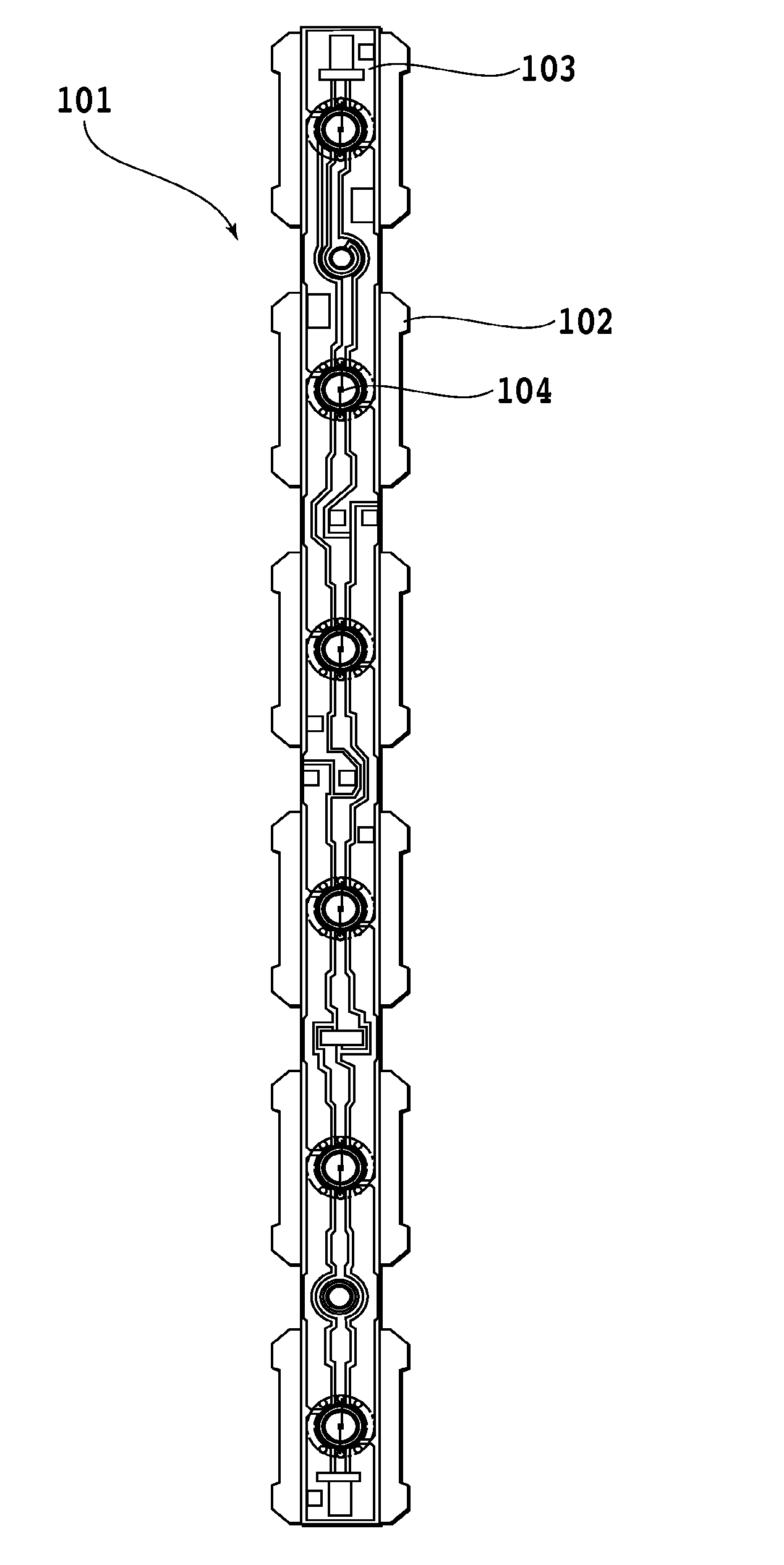

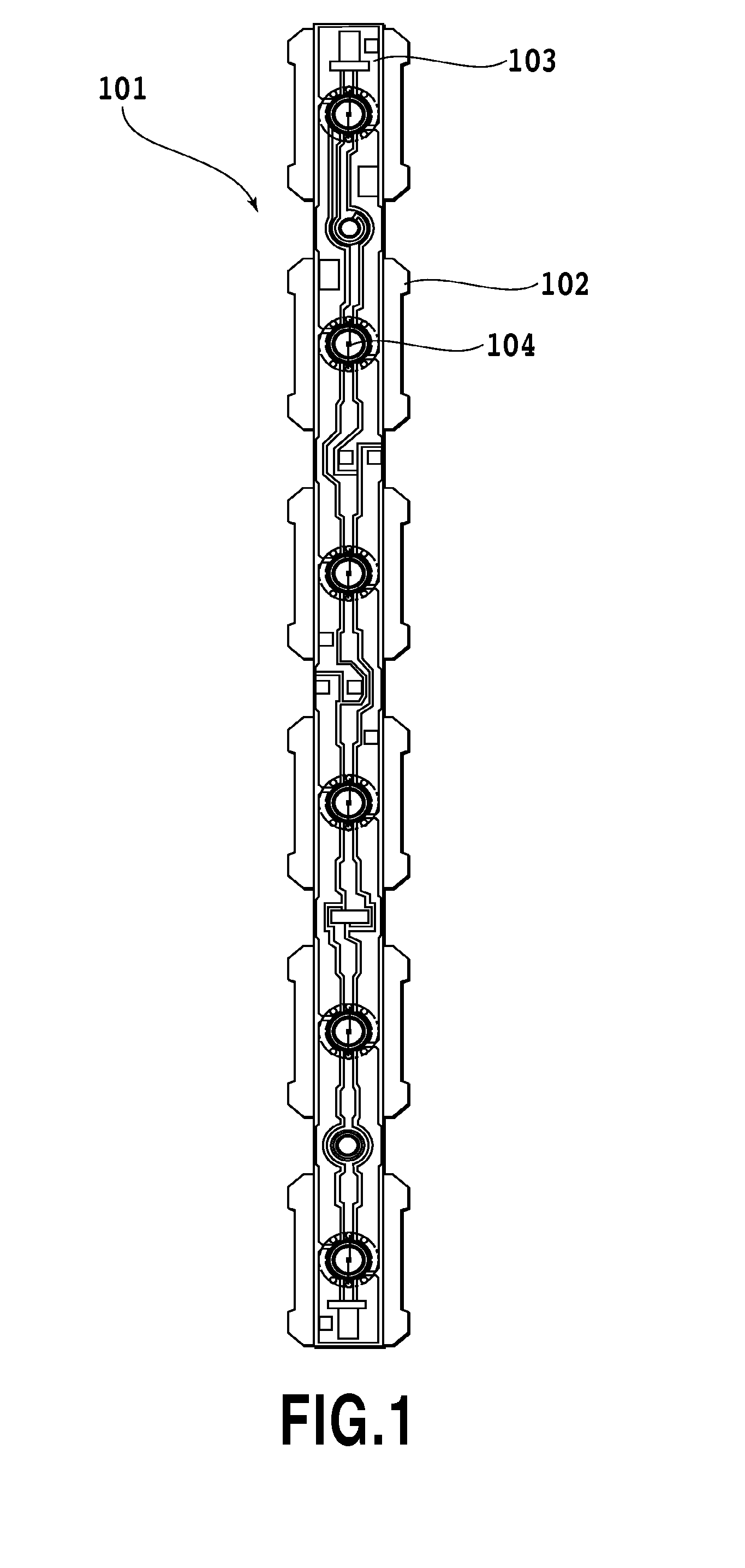

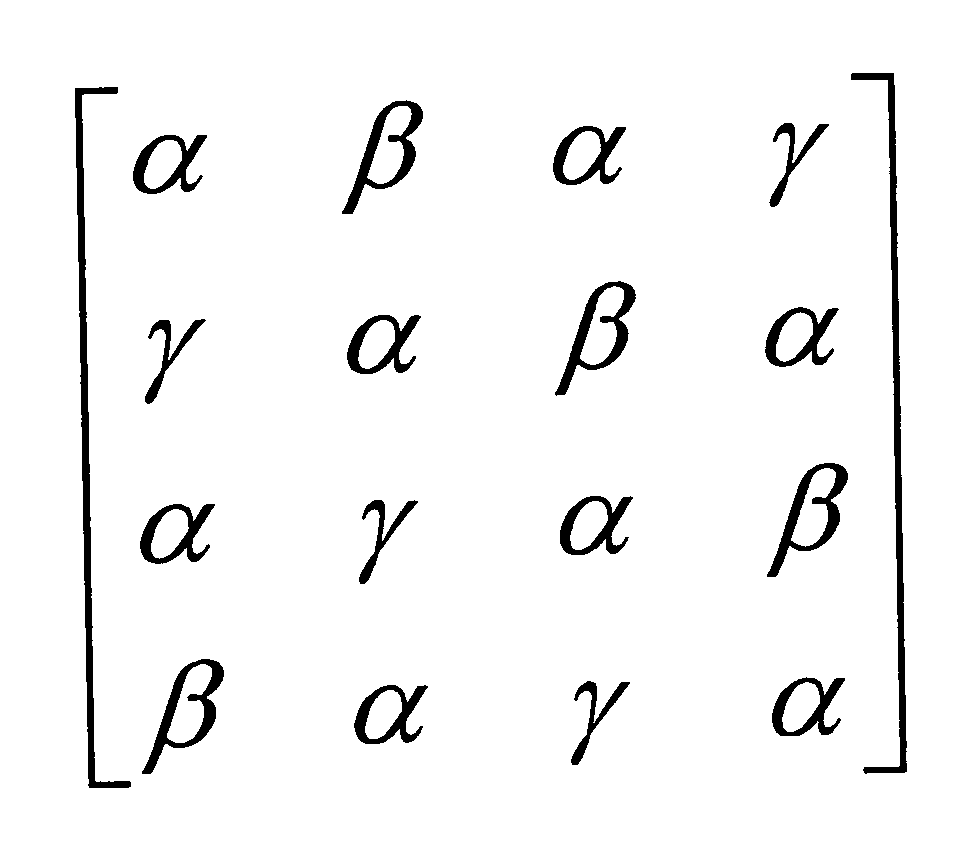

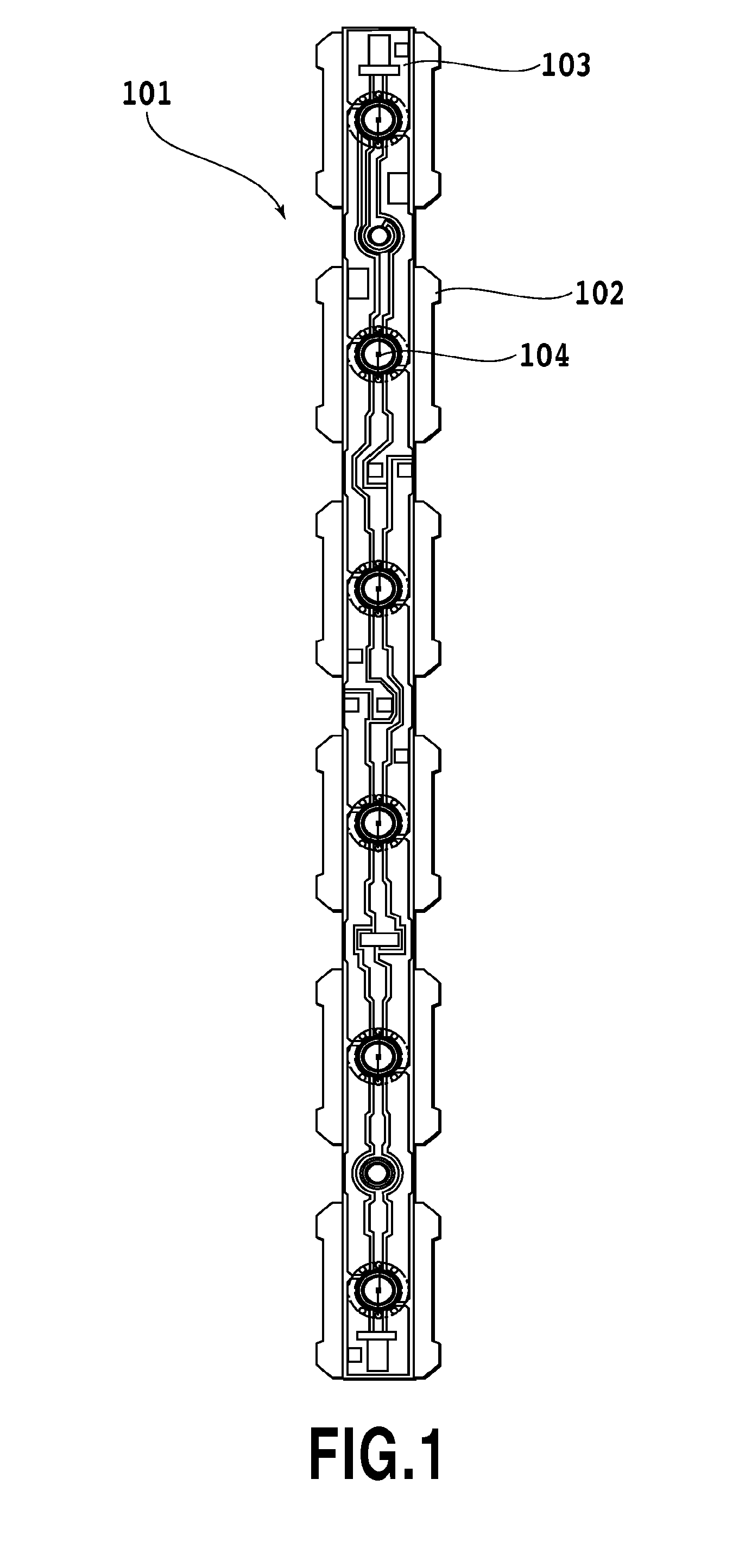

Semiconductor light emitting module and method of manufacturing the same

InactiveUS20110095310A1High reflection coatingImprove reflectivityPlanar light sourcesPoint-like light sourceHigh luminanceLight emission

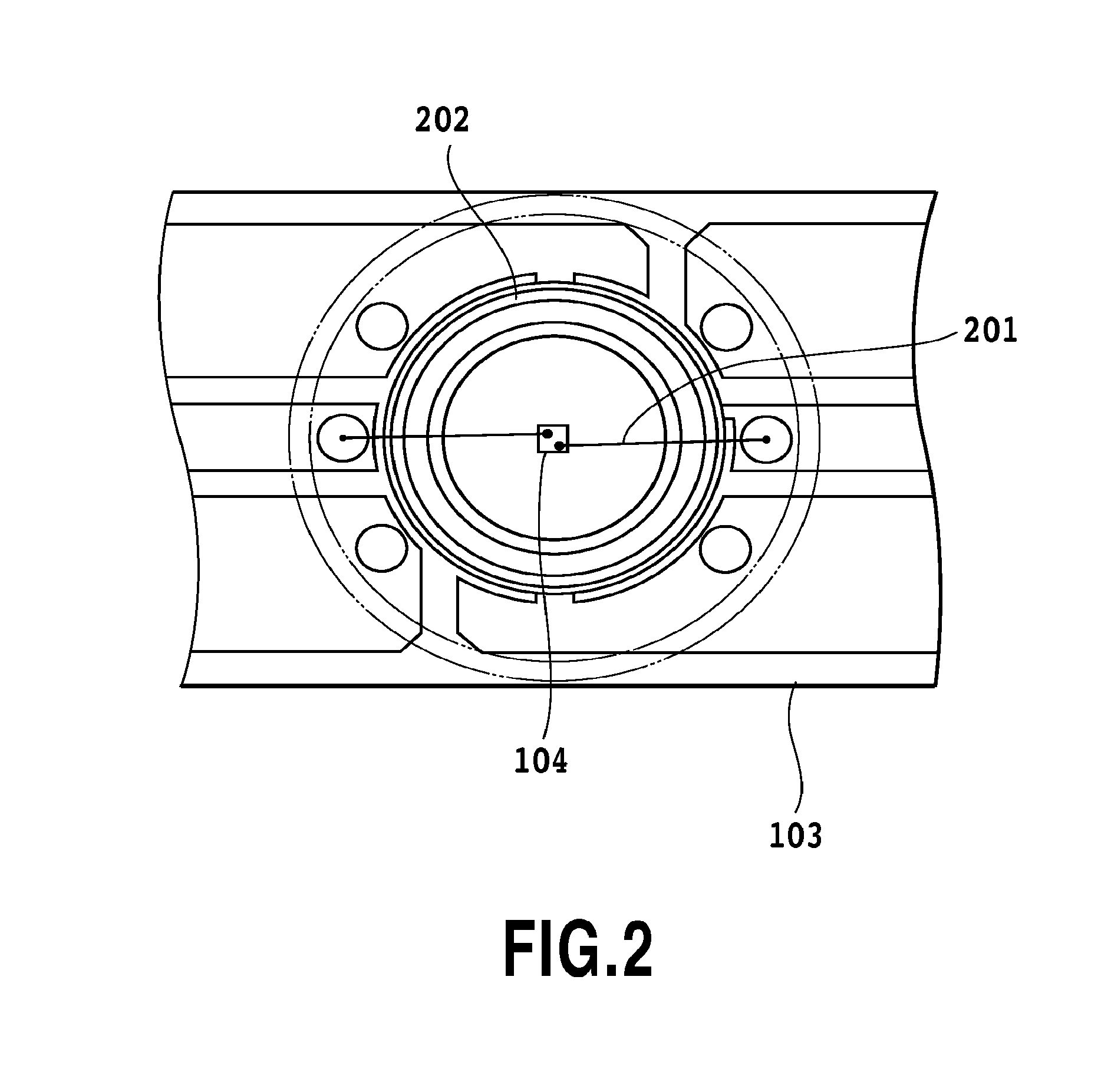

Provided are a semiconductor light emitting module and a method of manufacturing the same, which allow achieving high luminance light emission as well as lightweight and compact features. In a semiconductor light emitting module (101), a projecting portion (202) serving as a reflecting member is formed on a metal thin plate (102) to surround a semiconductor light emitting element (104). The semiconductor light emitting element (104) is connected to a printed board (103) by using a wire (201), for example. The projecting portion (202) is formed by pressing and bending the metal thin plate (102) from a back surface, for example, to surround the element and to be higher than the semiconductor light emitting element (104).

Owner:SHIMANE ELECTRONICS IMAFUKU WORKS +1

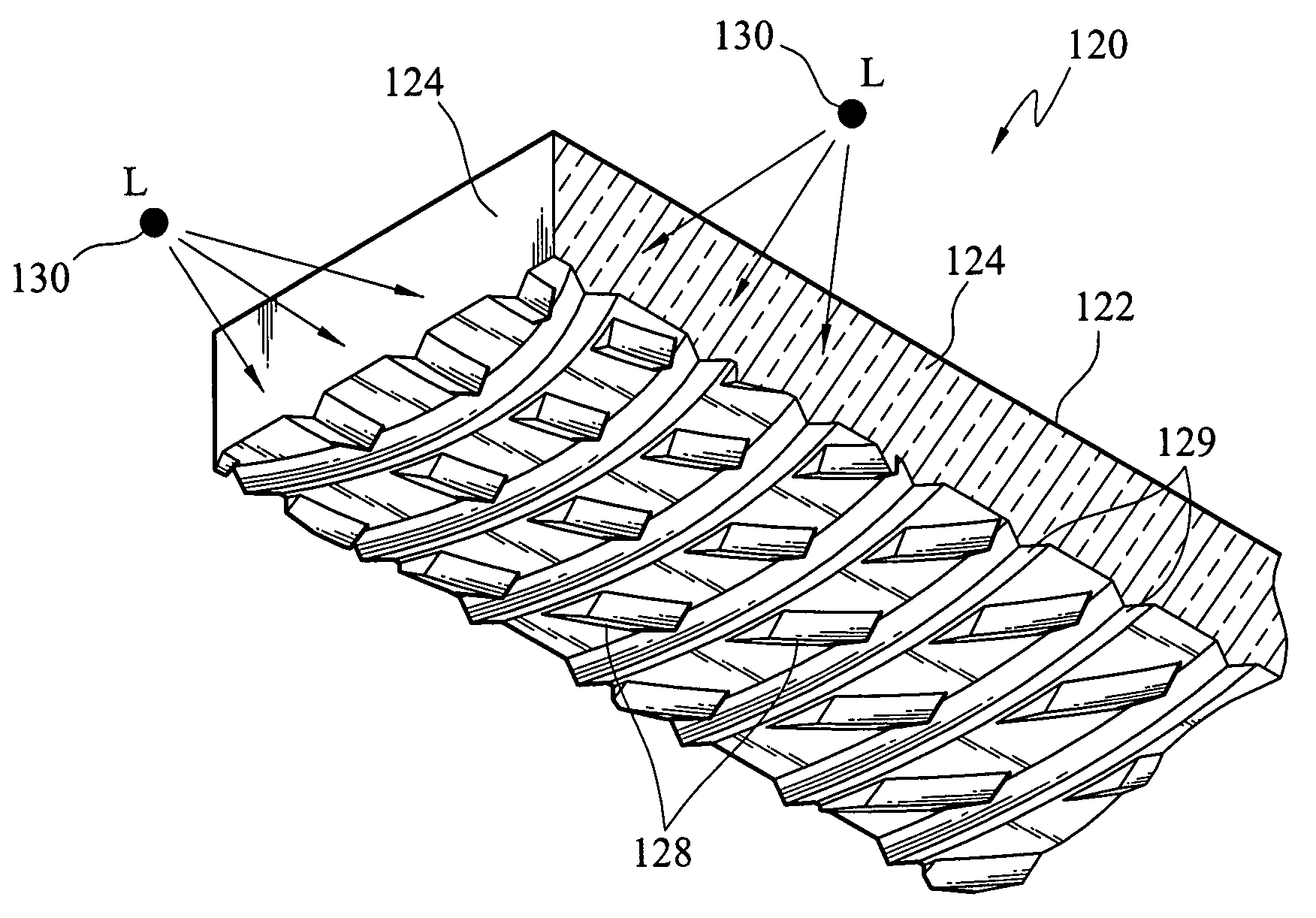

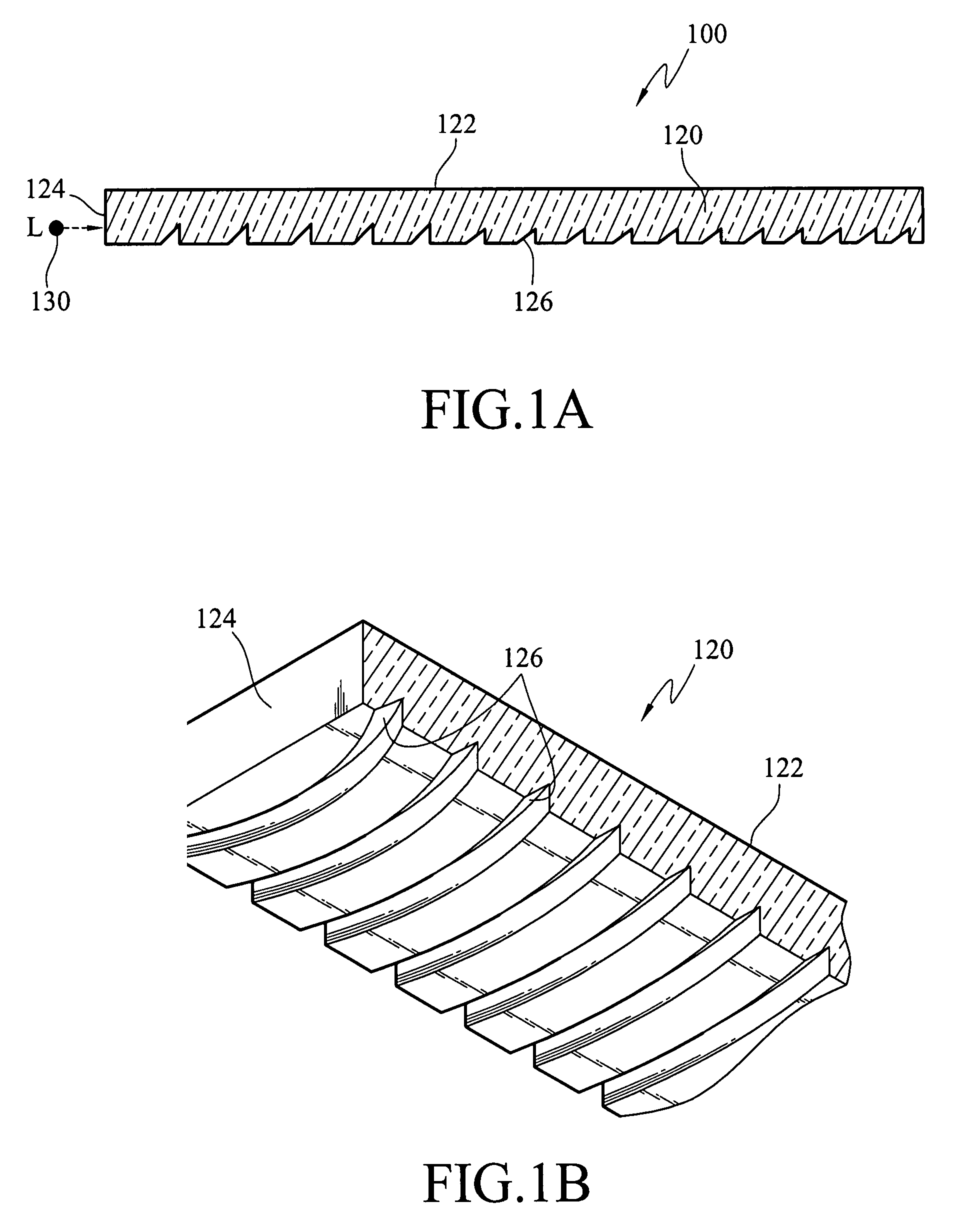

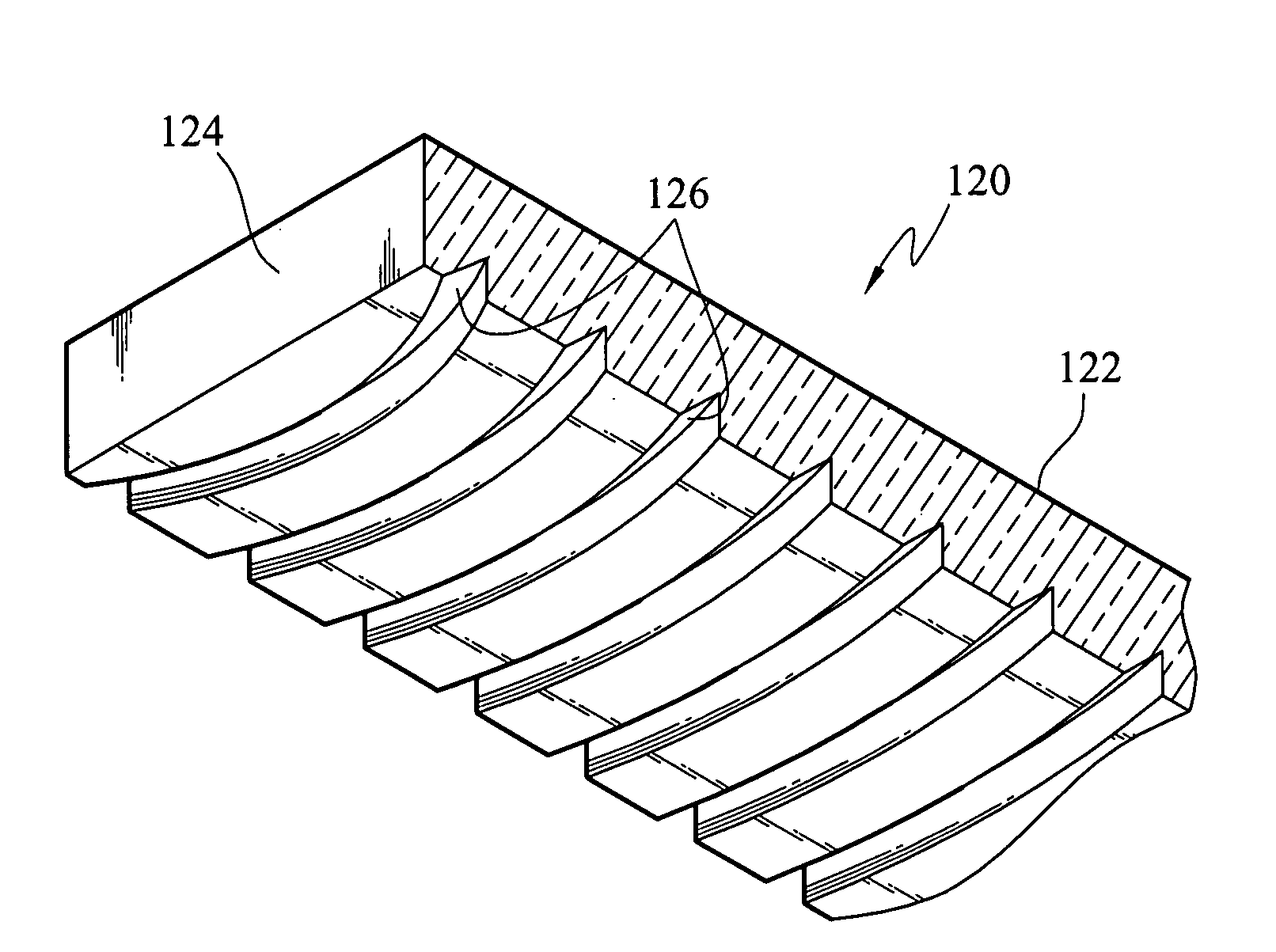

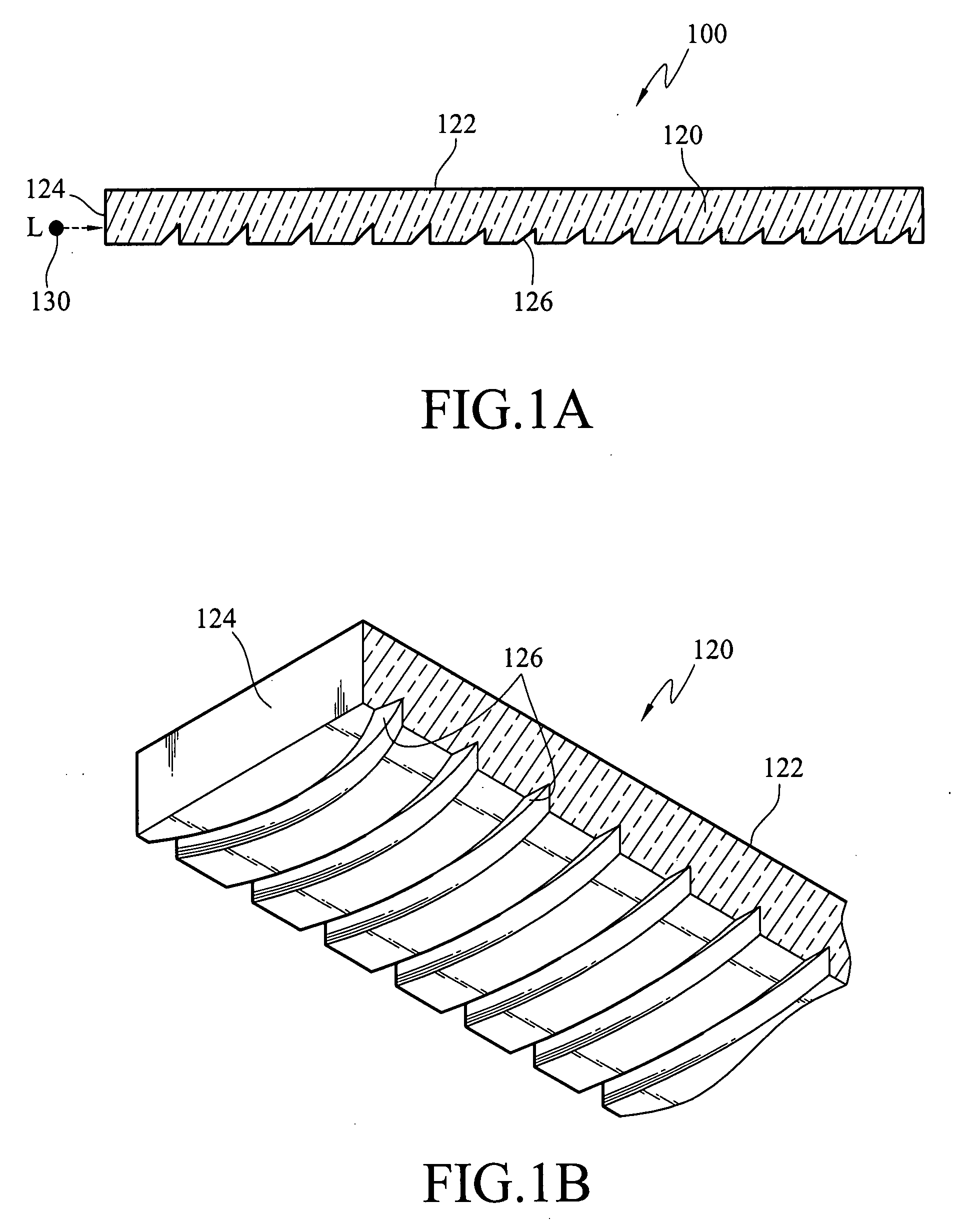

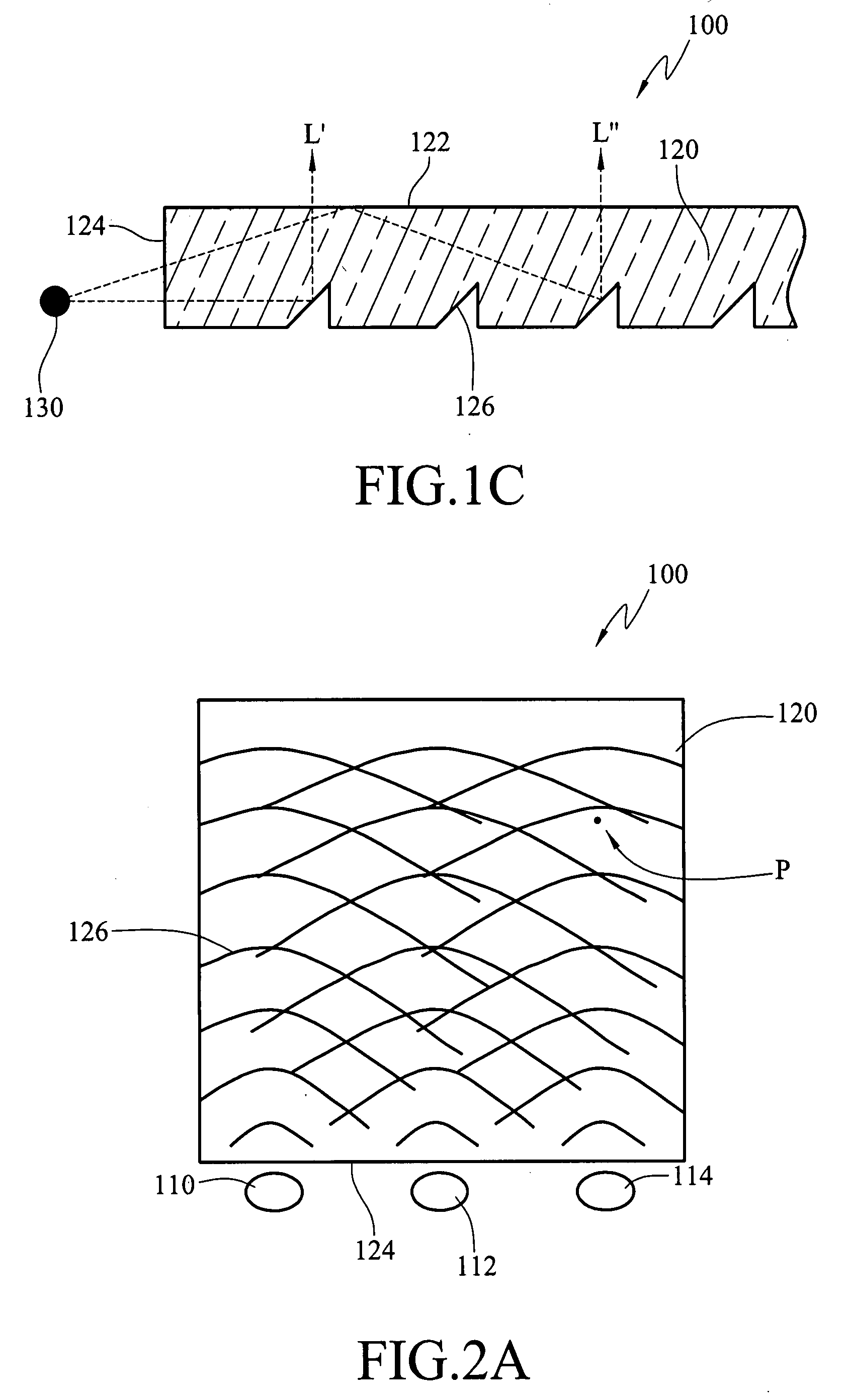

Backlight module

InactiveUS20080198626A1Improve color saturationEnhancing front-side illuminanceShow cabinetsMechanical apparatusLight guideLength wave

A backlight module has a light guide plate and a plurality of light sources. The light guide plate includes a light exit surface, a plurality of light entrance surfaces round the light exit surface, and a plurality of light guide portions disposed on the bottom surface opposite to the light exit surface. The light guide portions corresponding to the same imaginary circle center constitute a concentric arc-shaped light guide portion set. The imaginary circle center of each light guide portion set is located at the outer side of the light entrance surfaces. Light rays projected to one of the light entrance surfaces from the imaginary circle center of each light guide portion set are guided to a light exit surface by the light guide portion set. The wavelength of the light ray projected by each light source is not equal to that of the light projected by another light source.

Owner:WINTEK CORP

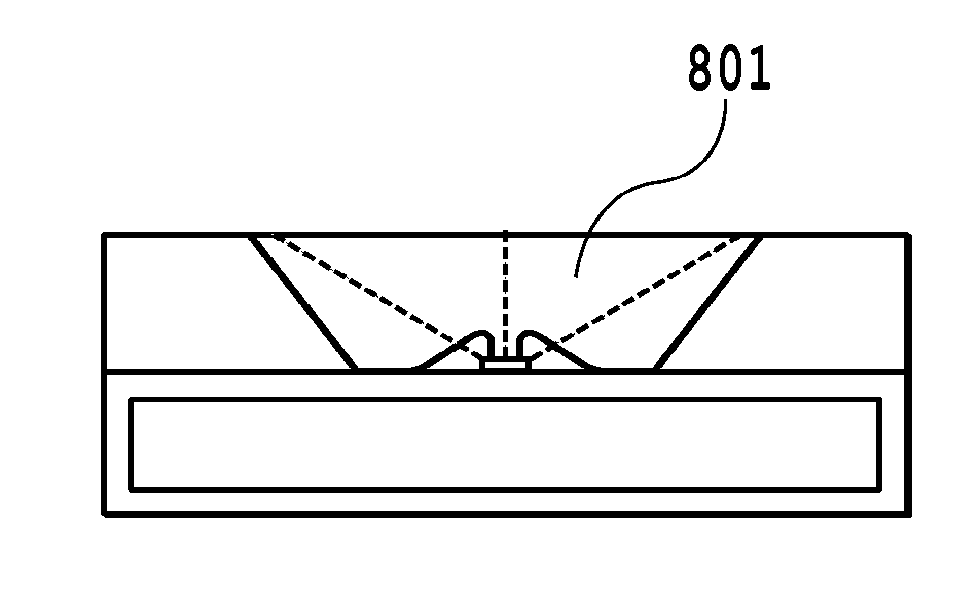

Light emitting diode package

ActiveUS8507926B2Well mixedImprove reflectivitySemiconductor/solid-state device manufacturingNon-linear opticsFluorescenceLight-emitting diode

A light emitting diode package includes a substrate, a plurality of light emitting diode chips, a fluorescence layer, and a plurality of reflecting layers. The light emitting diode chips, the fluorescence layer, and the reflecting layers are disposed on the substrate. The fluorescence layer covers the light emitting diode chips, and the reflecting layers are disposed right above the light emitting diode chips, respectively.

Owner:CORETRONIC

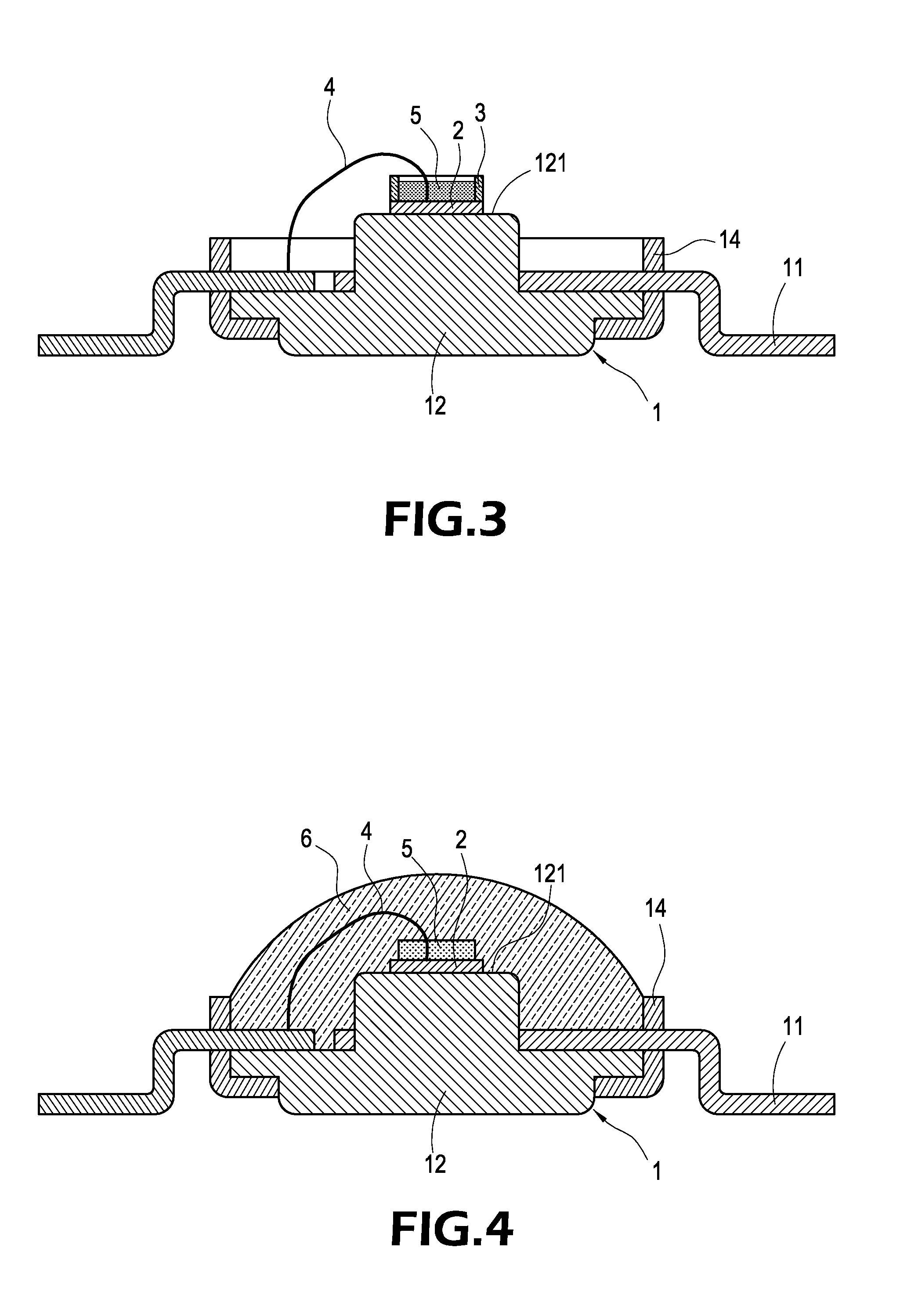

Thermosetting silicone resin sheet and method for producing the same, and light-emitting apparatus using the thermosetting silicone resin sheet and method for producing the same

ActiveUS20140124809A1Easy laminationEasy adhesionLayered productsSolid-state devicesPhosphorRoom temperature

The present invention provides a thermosetting silicone resin sheet having a phosphor-containing thermosetting silicone resin layer formed in the form of an LED device and a method for producing the same, and a light-emitting apparatus using the thermosetting silicone resin sheet and a method for producing the same. The present invention was accomplished by the phosphor-containing thermosetting silicone resin sheet comprising a substrate film and a phosphor-containing thermosetting silicone resin layer that is a plastic solid or a semi-solid at room temperature composed of a single layer having no adhesive layer, formed by printing and molding a phosphor-containing thermosetting silicone resin composition on the substrate film in the form of an LED device.

Owner:SHIN ETSU CHEM IND CO LTD

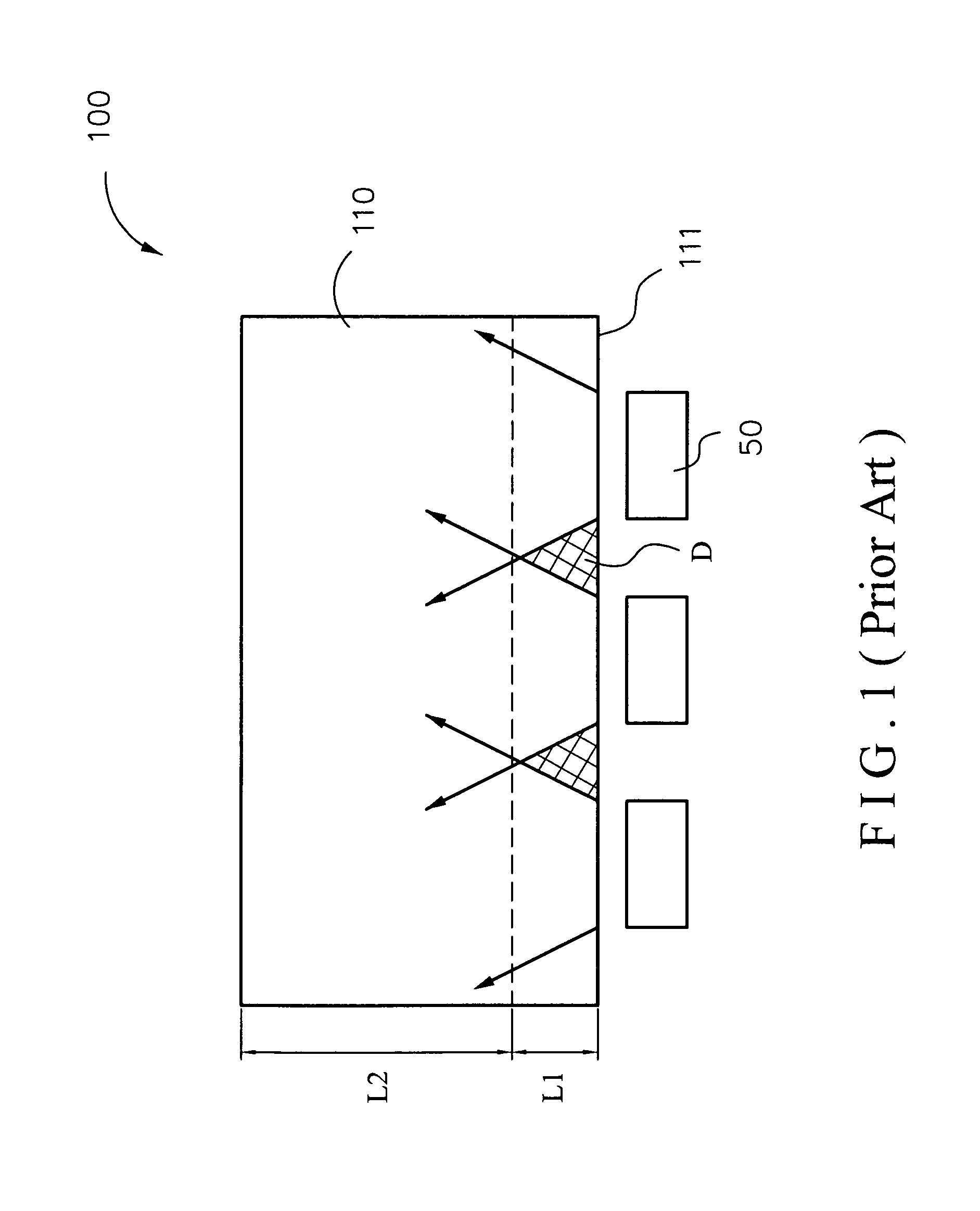

Light emitting device and LCD backlight using the same

InactiveUS20130039032A1Increase brightnessUniform white lightSolid-state devicesSpectral modifiersPhosphorGreen-light

Owner:SEOUL SEMICONDUCTOR

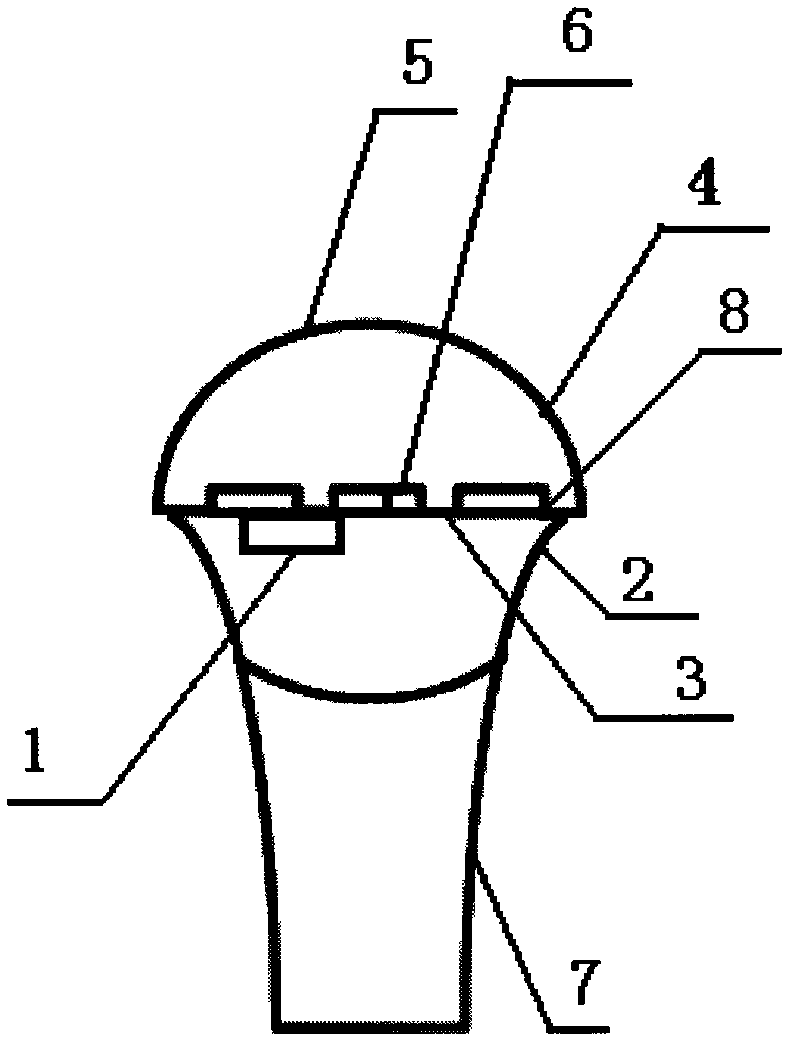

LED structure and fabricating method for the same

InactiveUS7755282B2Uniform white lightImprove light uniformityDischarge tube luminescnet screensElectroluminescent light sourcesFluorescencePhosphor

A method is performed for the fabrication of LED and its structure. The LED is capable of emitting uniform white light and includes a substrate, an LED die, a holding frame and fluorescent substance where the holding frame is of hollow shape. The LED contains a die emitting blue light, and the fluorescent substance is a yellow phosphor. As the LED die is mounted on the substrate, the holding frame is seated on the die, and a bond wiring is performed. The holding frame is filled with the fluorescent substance in a uniform distribution on the die to form a layer of fluorescence. Finally the structure of the LED is accomplished as the packaging is completed.

Owner:EDISON-OPTO

Thermosetting silicone resin sheet and method for producing the same, and light-emitting apparatus using the thermosetting silicone resin sheet and method for producing the same

ActiveUS9117978B2Readily be laminatedMaintain stabilityLayered productsSolid-state devicesPhosphorSemi solid

The present invention provides a thermosetting silicone resin sheet having a phosphor-containing thermosetting silicone resin layer formed in the form of an LED device and a method for producing the same, and a light-emitting apparatus using the thermosetting silicone resin sheet and a method for producing the same. The present invention was accomplished by the phosphor-containing thermosetting silicone resin sheet comprising a substrate film and a phosphor-containing thermosetting silicone resin layer that is a plastic solid or a semi-solid at room temperature composed of a single layer having no adhesive layer, formed by printing and molding a phosphor-containing thermosetting silicone resin composition on the substrate film in the form of an LED device.

Owner:SHIN ETSU CHEM CO LTD

Semiconductor light emitting module and method of manufacturing the same

InactiveUS20140319552A1Improve reflectivityEnhanced glowPlanar light sourcesPrinted circuit aspectsLight emissionHigh luminance

Provided are a semiconductor light emitting module and a method of manufacturing the same, which allow achieving high luminance light emission as well as lightweight and compact features. In a semiconductor light emitting module (101), a projecting portion (202) serving as a reflecting member is formed on a metal thin plate (102) to surround a semiconductor light emitting element (104). The semiconductor light emitting element (104) is connected to a printed board (103) by using a wire (201), for example. The projecting portion (202) is formed by pressing and bending the metal thin plate (102) from a back surface, for example, to surround the element and to be higher than the semiconductor light emitting element (104).

Owner:SHIMANE PREFECTURAL GOVERNMENT MATSUE +1

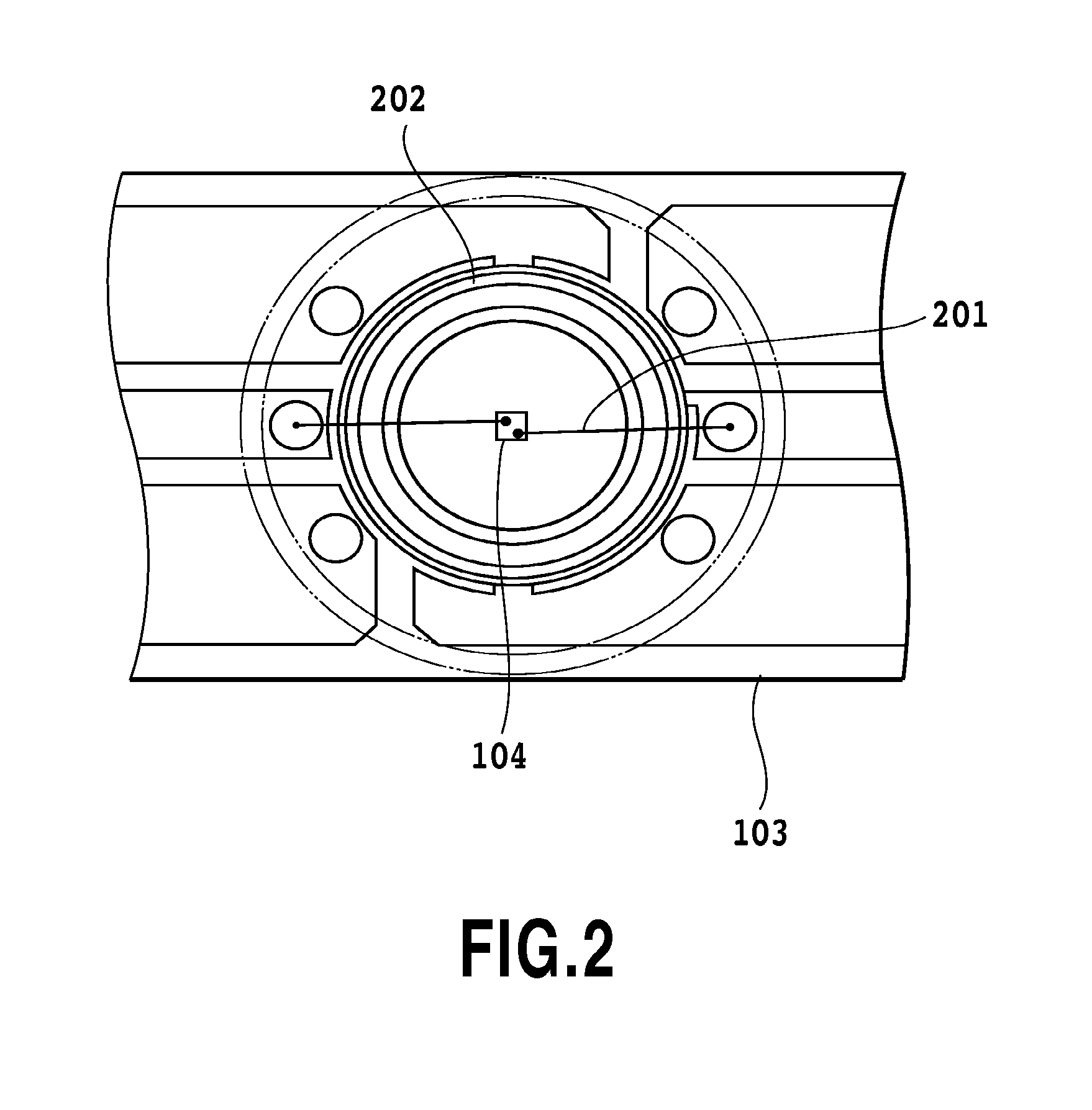

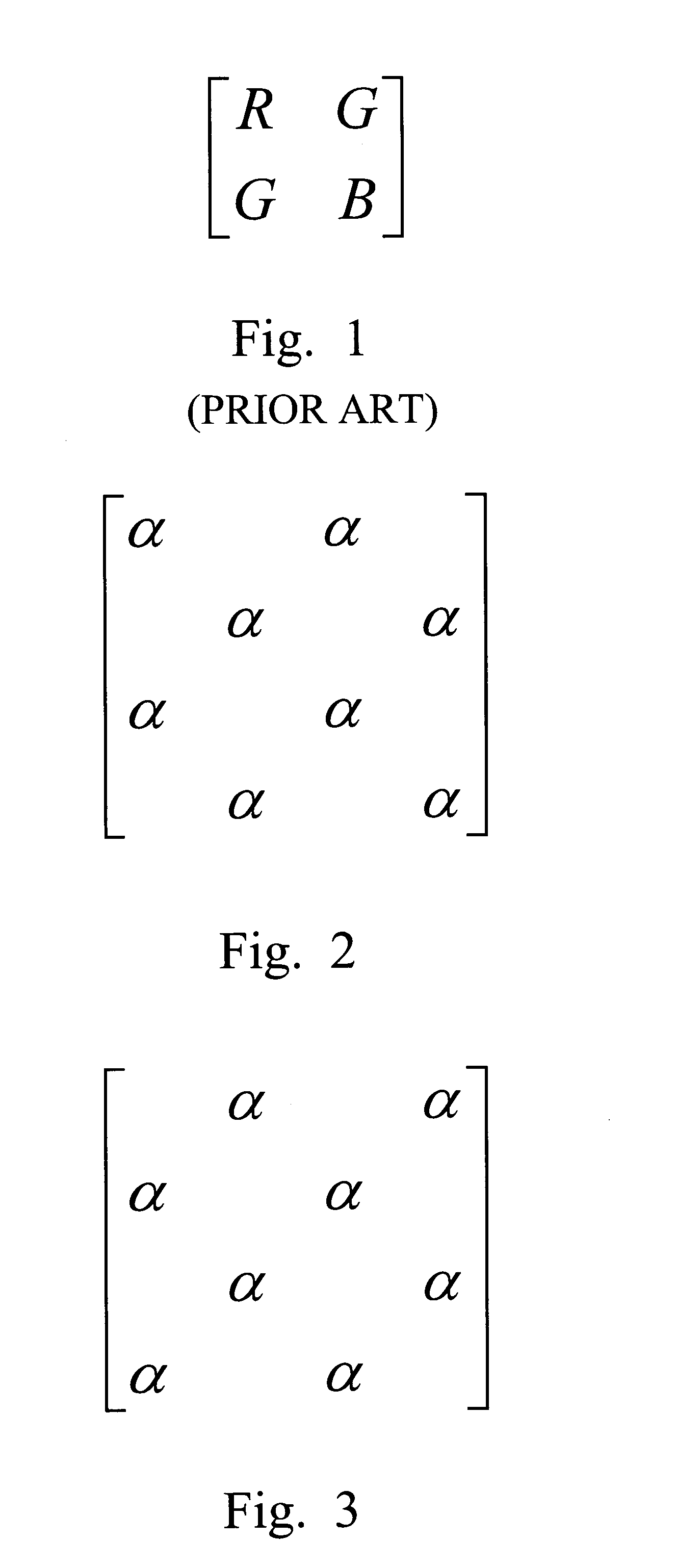

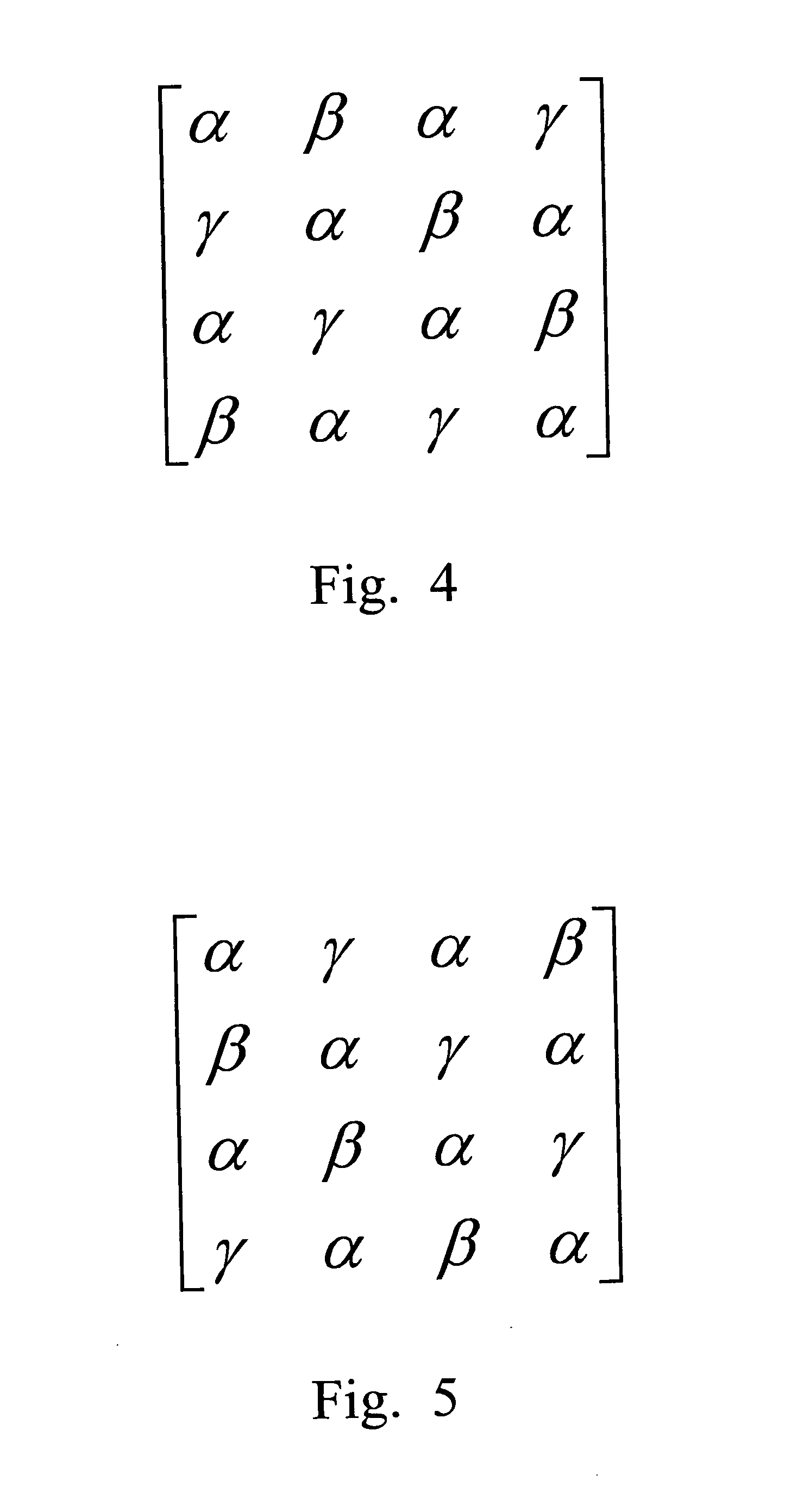

Arrangement matrix of primary color LEDs

InactiveUS20080001908A1Reduce chromatic polarizationGenerate uniformPoint-like light sourceStatic indicating devicesEngineeringPrimary color

An arrangement matrix of primary color LEDs is provided. The arrangement matrix includes a first LED, a second LED and a third LED. The first LED, the second LED and the third LED are arranged to form a 4×4 lowest matrix unit. The ratio of the numbers of the first LEDs, the second LEDs and the third LEDs is 2:1:1. The first LED, the second LED and the third LED are presented as α,β, and γ. The arrangement of the lowest repeat matrix unit is shown below:[αβαγγαβααγαββαγα].

Owner:EVERLIGHT ELECTRONICS

Semiconductor light emitting module and method of manufacturing the same

InactiveUS20130105849A1Improve reflectivityEnhanced glowPlanar light sourcesPoint-like light sourceHigh luminanceLight emission

Provided are a semiconductor light emitting module and a method of manufacturing the same, which allow achieving high luminance light emission as well as lightweight and compact features. In a semiconductor light emitting module (101), a projecting portion (202) serving as a reflecting member is formed on a metal thin plate (102) to surround a semiconductor light emitting element (104). The semiconductor light emitting element (104) is connected to a printed board (103) by using a wire (201), for example. The projecting portion (202) is formed by pressing and bending the metal thin plate (102) from a back surface, for example, to surround the element and to be higher than the semiconductor light emitting element (104).

Owner:S E I INC +1

White LED lamp secondary encapsulation structure capable of reducing blue-light hazards

InactiveUS9353919B2Reduce blue light radiation doseUniform white lightPoint-like light sourceElectroluminescent light sourcesBiological bodyFluorescence

A white LED lamp secondary encapsulation structure capable of reducing blue-light hazards has a substrate (3), a blue light LED chip (4) fixed on the substrate (3), and a YAG yellow fluorescent powder layer (6) overlaid on the blue light LED chip (4). A fluorescent outer lampshade (1) covering the blue light LED chip (4) and the YAG yellow fluorescent powder layer (6) is further fixed on the substrate (3). YAG yellow fluorescent powder is provided on the fluorescent outer lampshade (1). The structure allows emission of more uniform, soft and harmonious colors of white light, and reduces the influence of heat dissipated by the blue light chip on the performance of the fluorescent powder, thus preventing color temperature drift due to the heat of the chip, prolonging the lifespan of the fluorescent powder, reducing blue-light radiation dosage, scattering blue-light radiation, and reducing potential hazards to human and organisms.

Owner:WU ZHENGMING

Novel LED (light emitting diode) white light lamp and white light generation method thereof

InactiveCN102606918AUniform white lightSolve the uneven lighting anglePoint-like light sourceElectric circuit arrangementsWhite lightBlue light

The invention discloses a novel LED (light emitting diode) white light lamp and a white light generation method of the lamp. The LED white light lamp comprises a substrate arranged in a lamp body, a blue light device or a white light device arranged on the substrate, at least one blue LED chip arranged in the blue light device or the white light device, and a lamp shade arranged in front of the lamp body, wherein yellow fluorescent powder is sprayed on the inner surface or outer surface of the lamp shade. The white light generation method of the novel LED white light lamp comprises the following steps: the blue LED chip in the blue light device generates a blue light to excite the yellow fluorescent powder on the inner wall of the lamp shade to generate white light on the surface of the lamp shade; and the blue LED chip in the white light device generates a blue light to excite the yellow fluorescent powder on the inner wall of the lamp shade to generate white light on the surface of the lamp shade. The LED lamp produced by a new method can effectively lower the temperature of the light emitting device because the white light is not excited on the light emitting device, thereby prolonging the service life of the lamp.

Owner:SHENZHEN MARY PHOTOELECTRICITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com