Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Suppress afterimage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

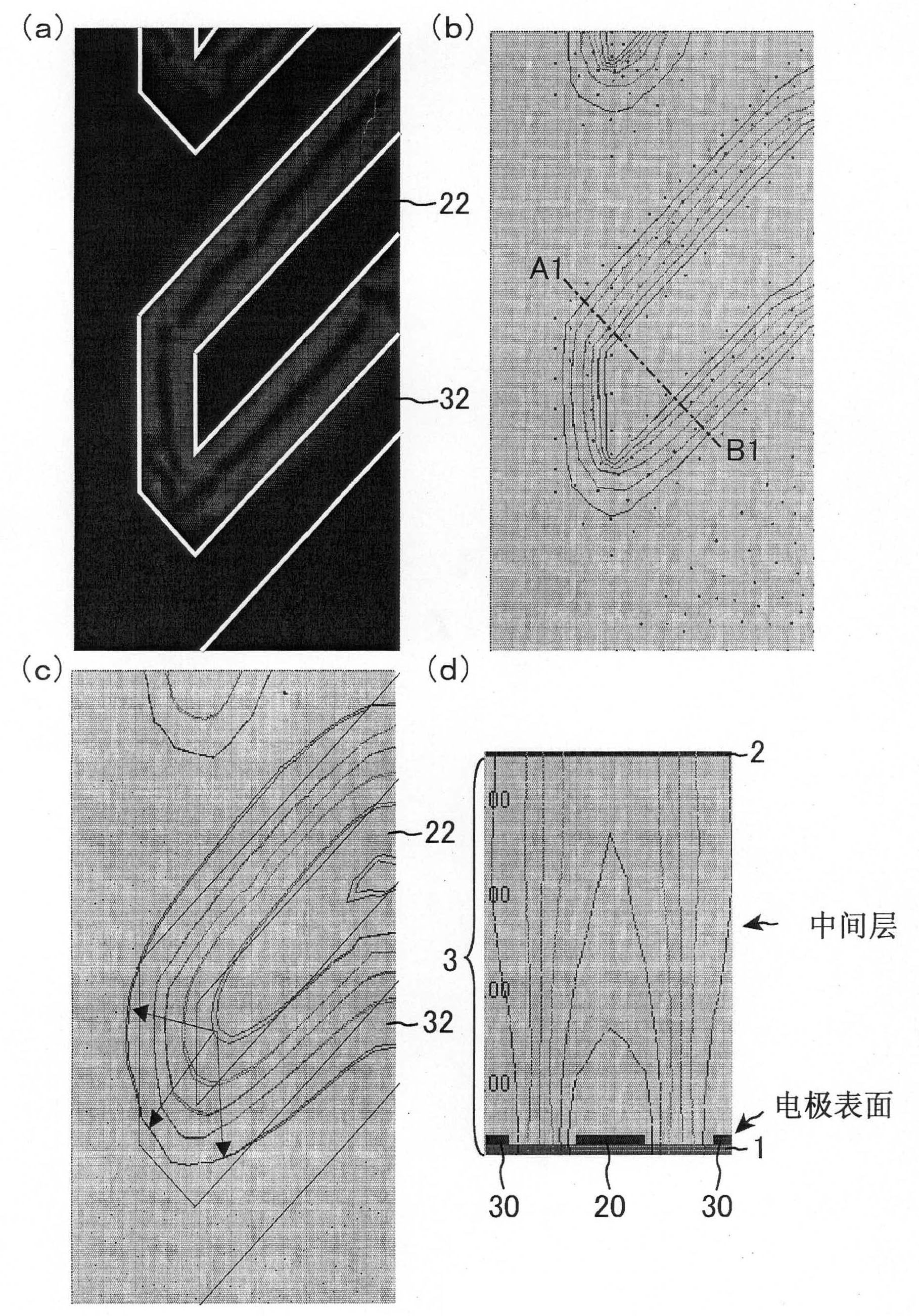

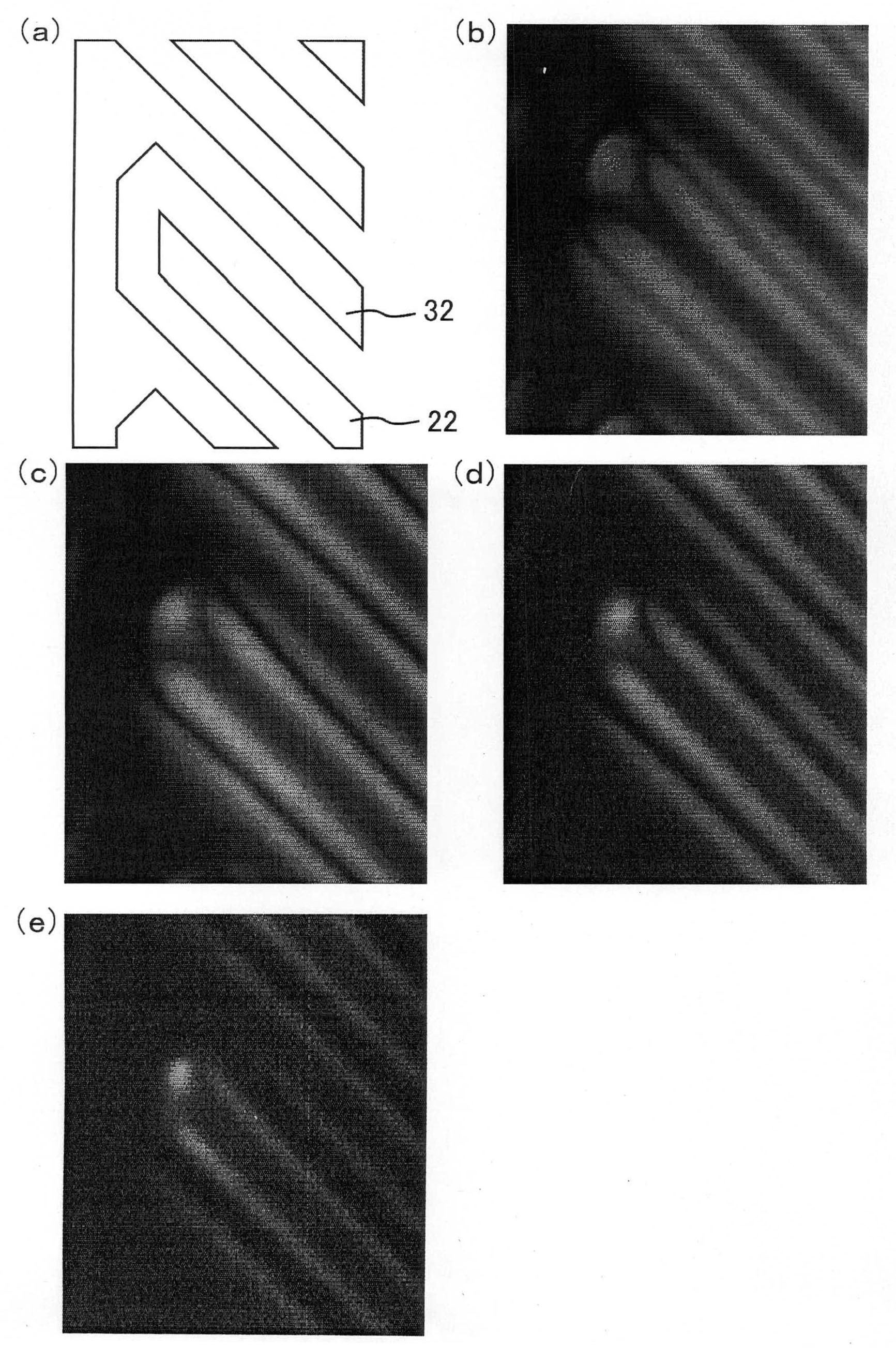

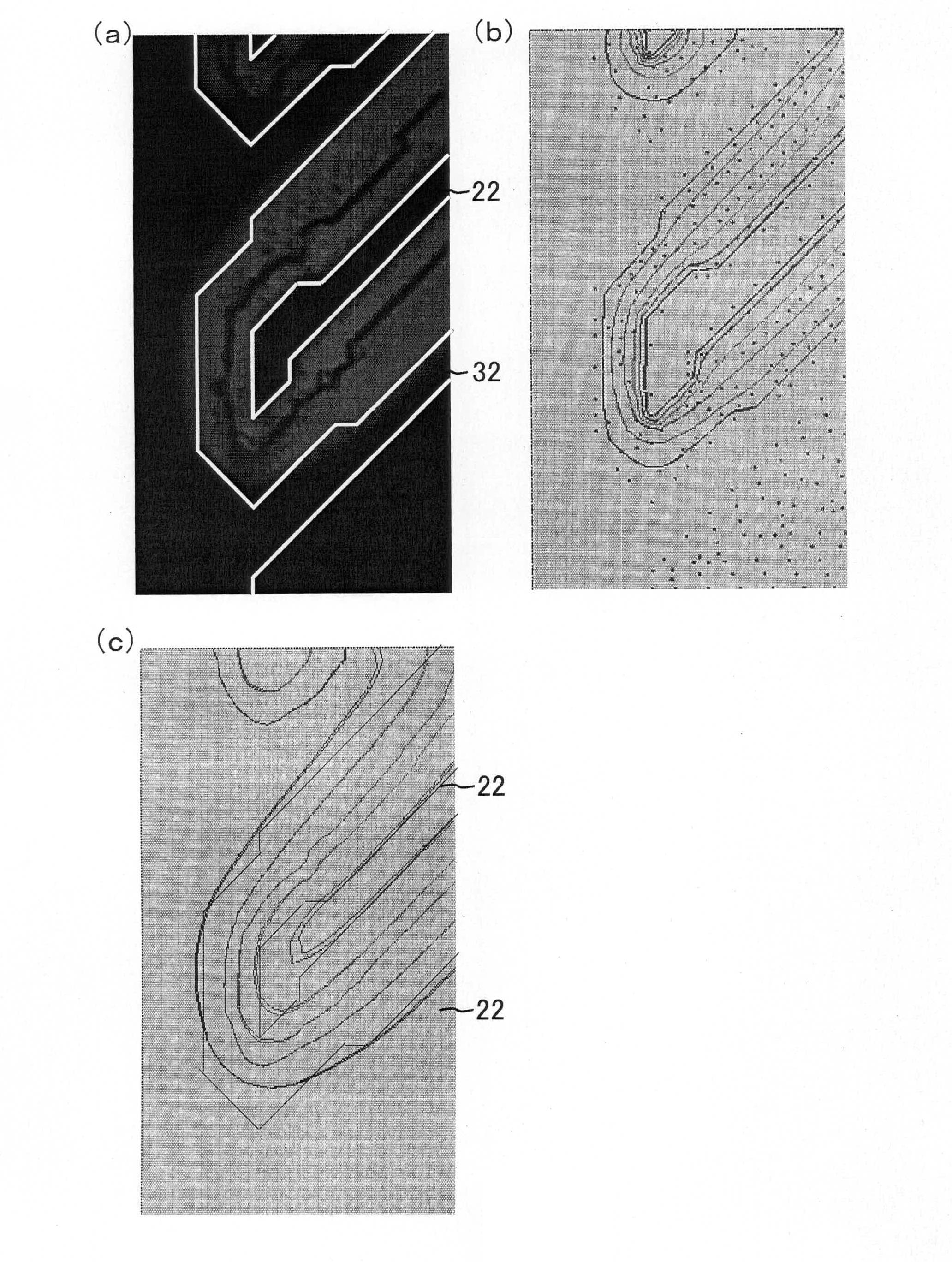

Liquid crystal display device

Provided is a liquid crystal display device capable of preventing the occurrence of a residual image. The liquid crystal display device is provided with a first substrate and a second substrate which are disposed to face each other, and a liquid crystal layer sandwiched between the first substrate and the second substrate. The first substrate comprises a comb-shaped first electrode including first branch portions and a comb-shaped second electrode including second branch portions, and the first electrode and the second electrode are disposed to planarly face each other in a pixel. The liquid crystal layer includes p-type nematic liquid crystal and is driven by an electric field generated between the first electrode and the second electrode. The p-type nematic liquid crystal is aligned perpendicularly to the first substrate and the second substrate when no voltage is applied. The first branch portions and the second branch portions extend diagonally to boundaries between adjacent pixels, and the intervals between the first electrode and the second electrode in a region surrounding the tip of the first branch portion are substantially equal.

Owner:SHARP KK

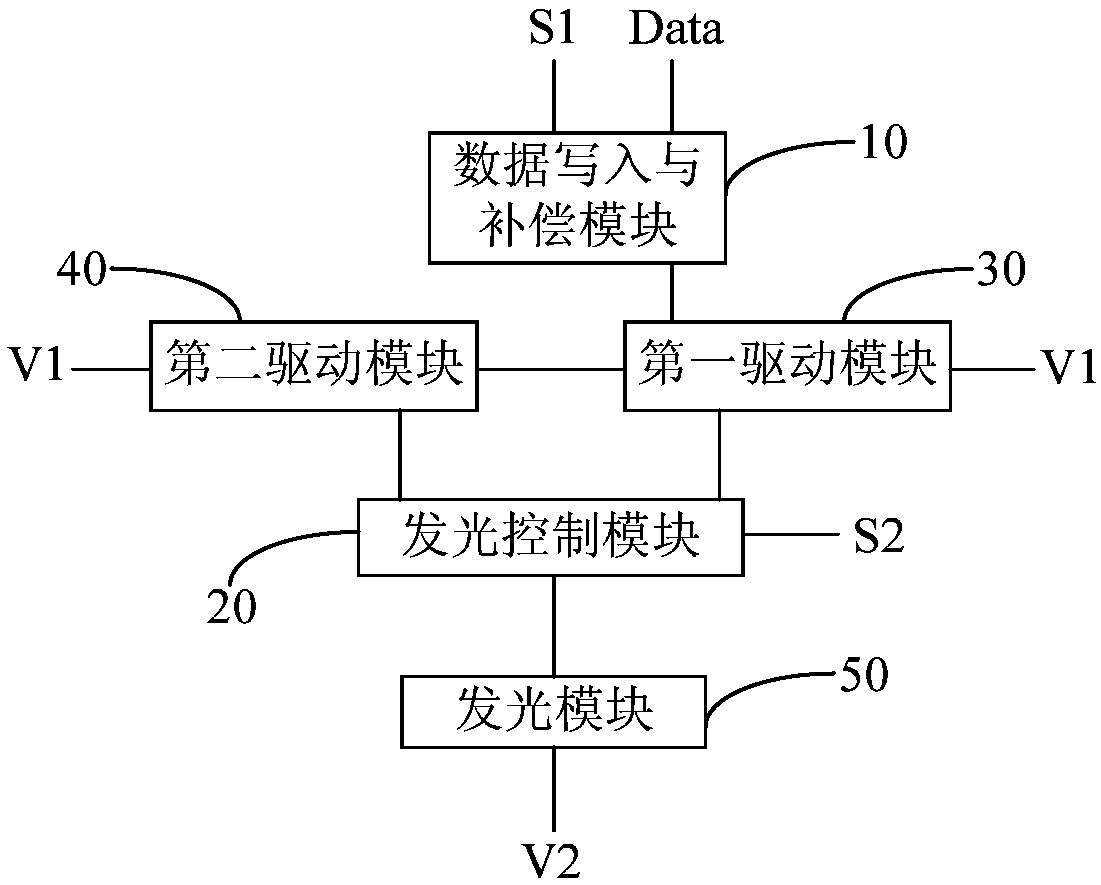

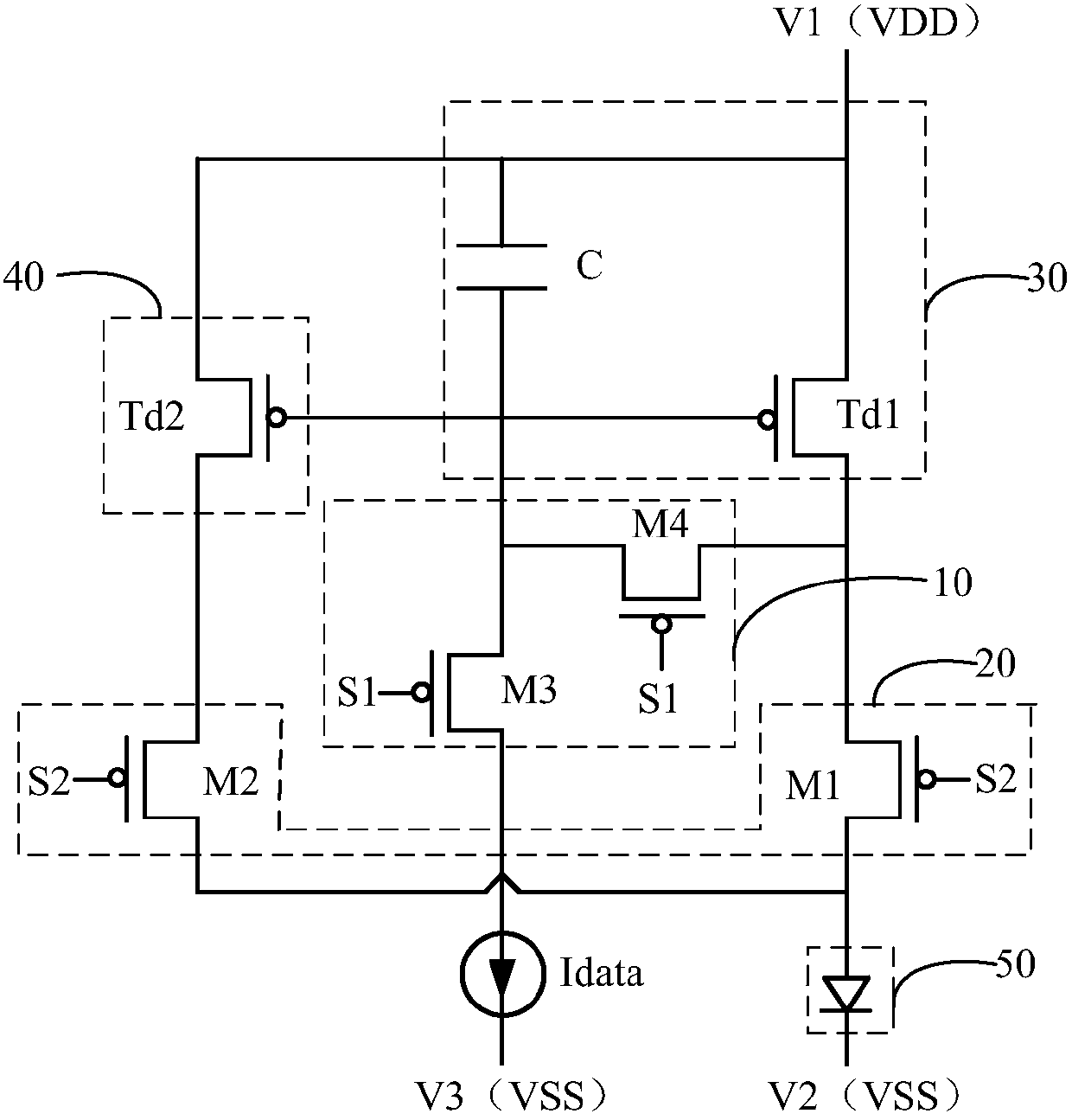

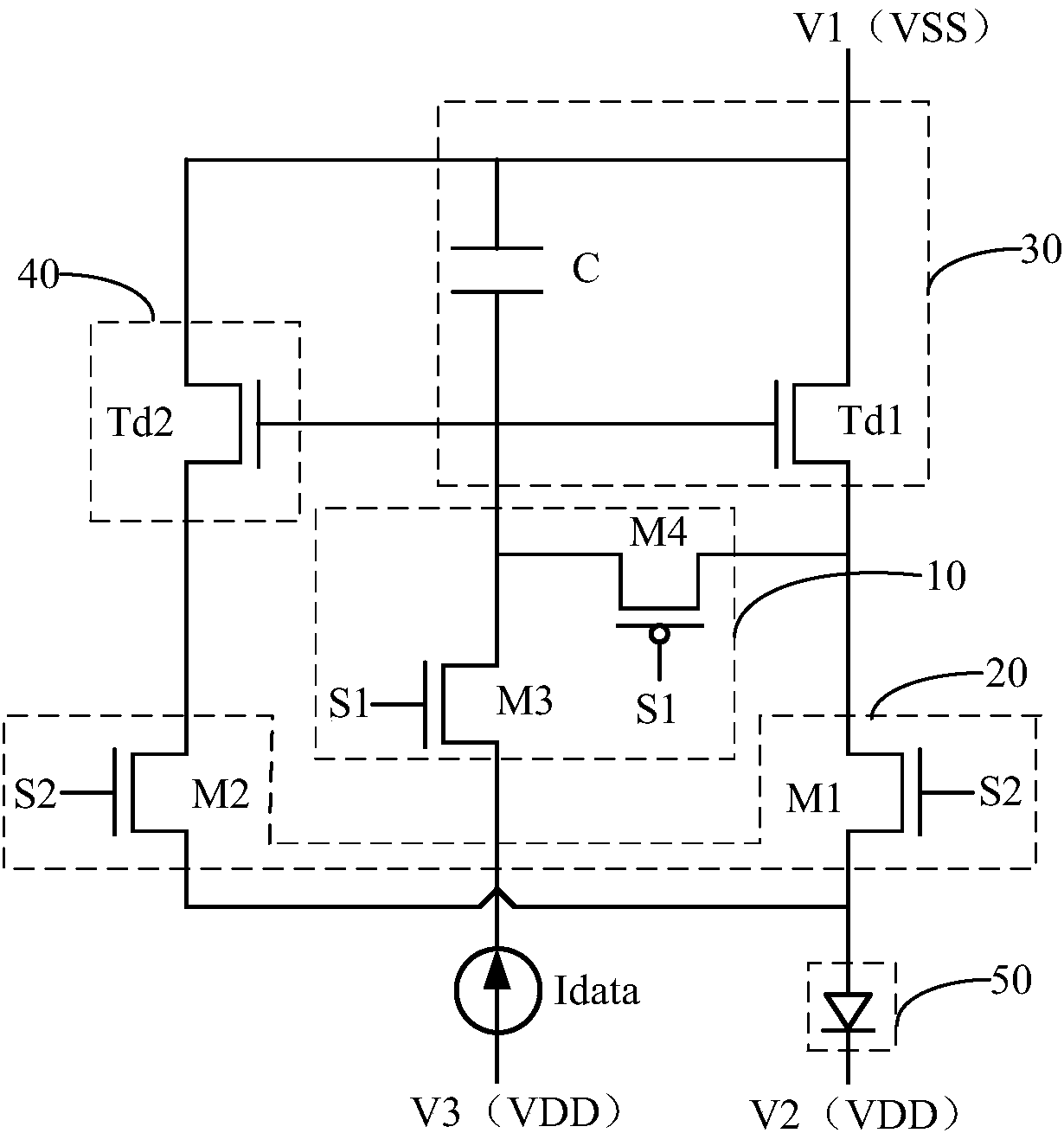

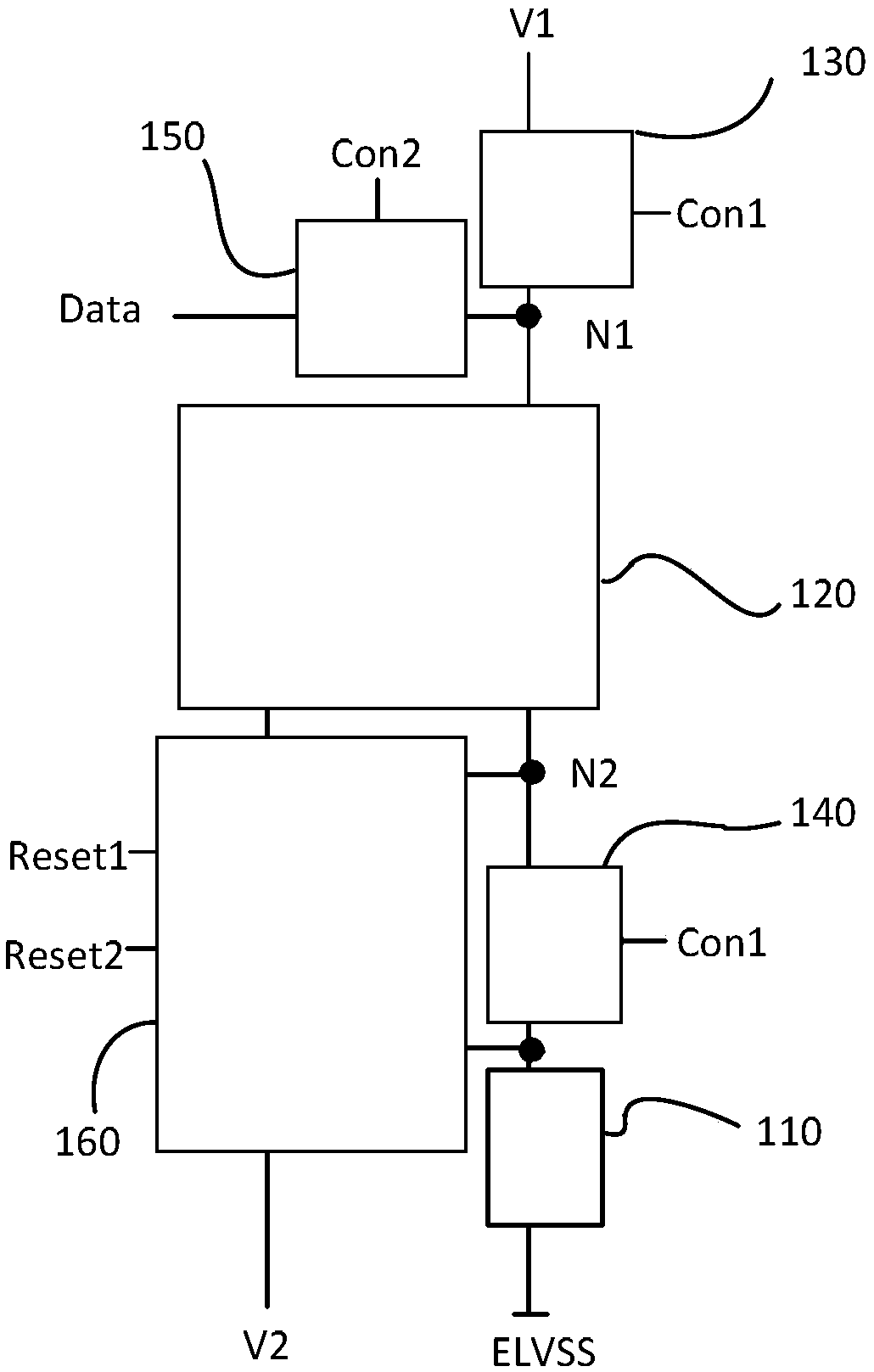

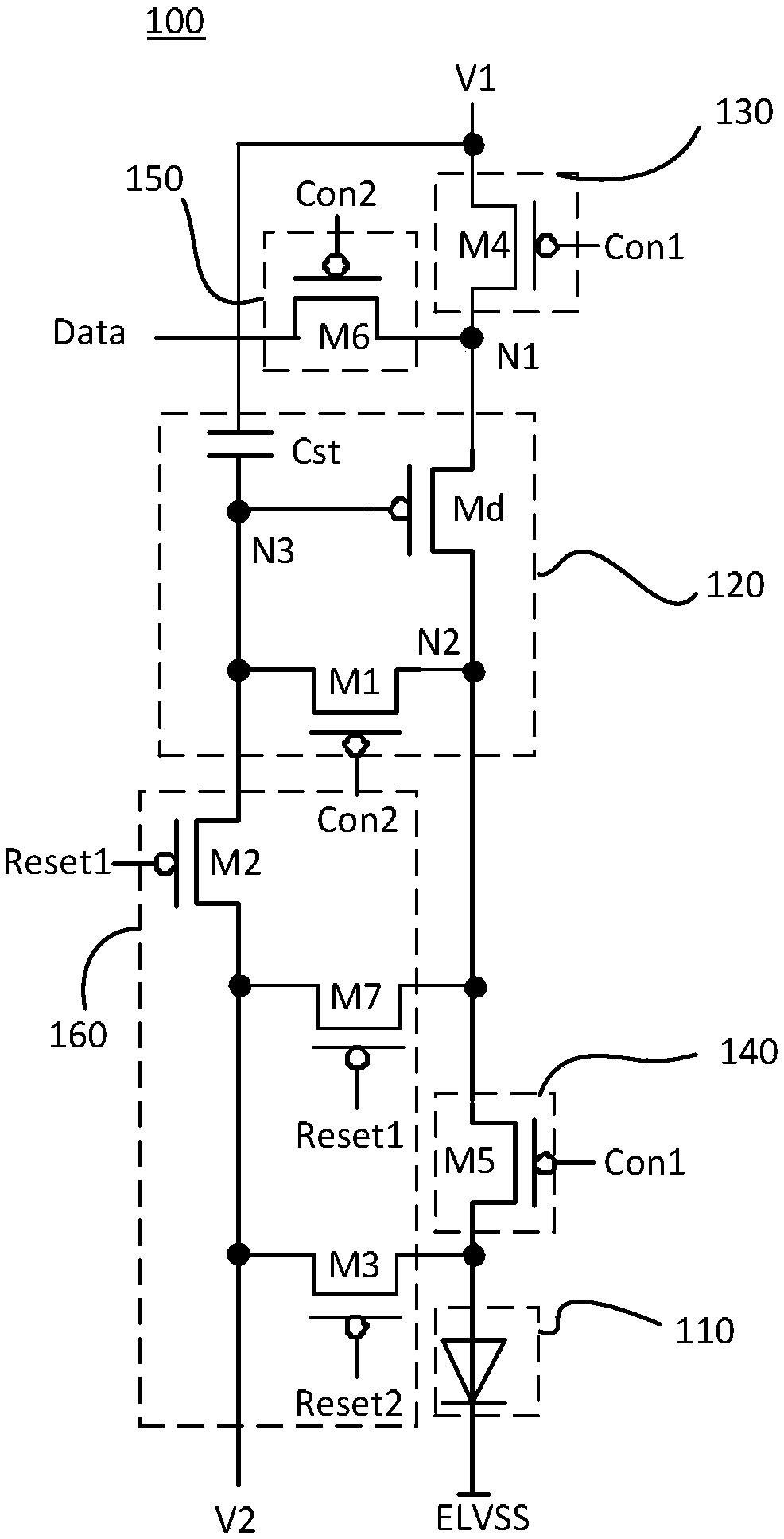

OLED (Organic Light Emitting Diode) pixel circuit, driving method thereof and display device

ActiveCN108039149AFast chargingIncrease pixel densityStatic indicating devicesSemiconductor devicesData signalDisplay device

The invention provides an OLED (Organic Light Emitting Diode) pixel circuit, a driving method thereof and a display device and belongs to the display technological field. With the OLED (Organic LightEmitting Diode) pixel circuit, the driving method thereof and the display device adopted, the problem of afterimages appearing on an OLED display caused by the increase of the formation time and cut-off time of the channel of a driving transistor. The OLED pixel circuit of the invention includes a data write-in and compensation module, a first driving module, a second driving module, a light emitting control module, and a light emitting module; the data write-in and compensation module is connected with the first driving module, a first signal end, and a data signal end and is used for compensating the threshold voltage of the first driving module; the first driving module is connected with the light emitting control module and a first voltage end and is used used for driving the light emitting module after the compensation of the threshold voltage is realized; the second driving module is connected with the first driving module, the light emitting control module and the first voltageend and is used for driving the light emitting module; the light emitting control module is further connected with the light emitting module and a second signal end and is used for making the first driving module and the second driving module connected with the light emitting module; and the light emitting module is used for emitting light under the common driving of the first driving module and the second driving module.

Owner:BOE TECH GRP CO LTD +1

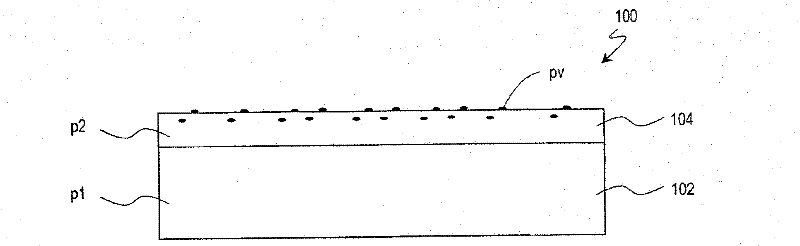

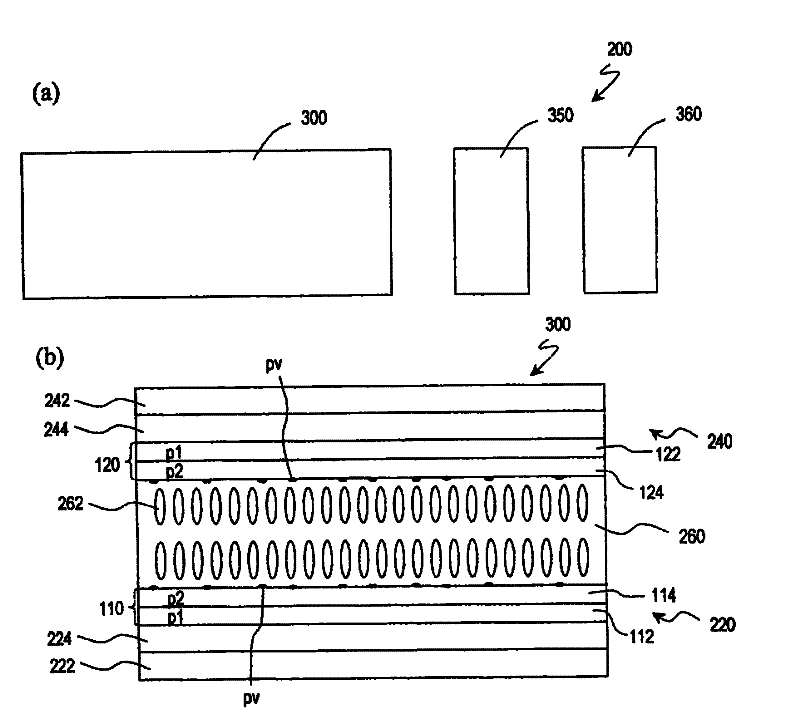

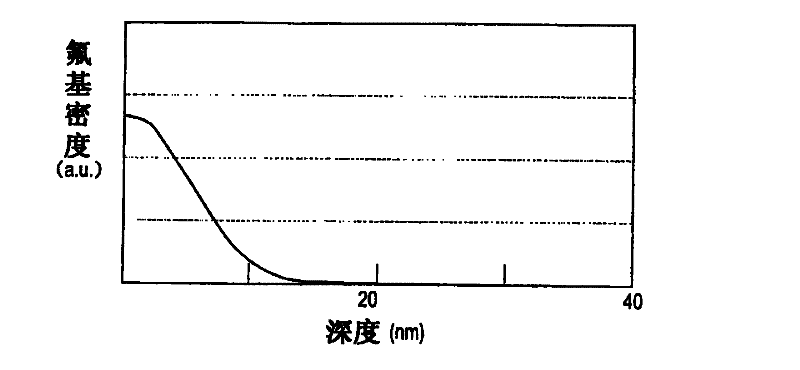

Orientation film, orientation film material, liquid crystal display having orientation film, and method for forming the same

ActiveCN102197333ASuppress afterimageThin material handlingNon-linear opticsMethacrylateFilm material

The present invention provides an orientation film, an orientation film material, a liquid crystal display having the orientation film, and a method for forming the same. The orientation film material comprises a first polyimide (p1) precursor, a second polyimide (p2) and precursor thereof, and a vinyl monomer. The vinyl monomer is represented by general formula (1). P1-A1-(Z1-A2)n-P2 (1) (In general formula (1), P1 and P2 are independently acrylate, methacrylate, acrylamide, or methacrylamide; A1 and A2 are independently 1,4-phenylene, 1,4-cyclohexane, or 2,5-thiophene, or napthalene-2,6-diyl or anthracene-2,7-diyl; A1 and / or A2 are substituted by at least one fluorine group; Z1 is a -COO-, -OCO-, -O-, or -CONH- group or a single bond; and n is 0 or 1.).

Owner:MERCK PATENT GMBH

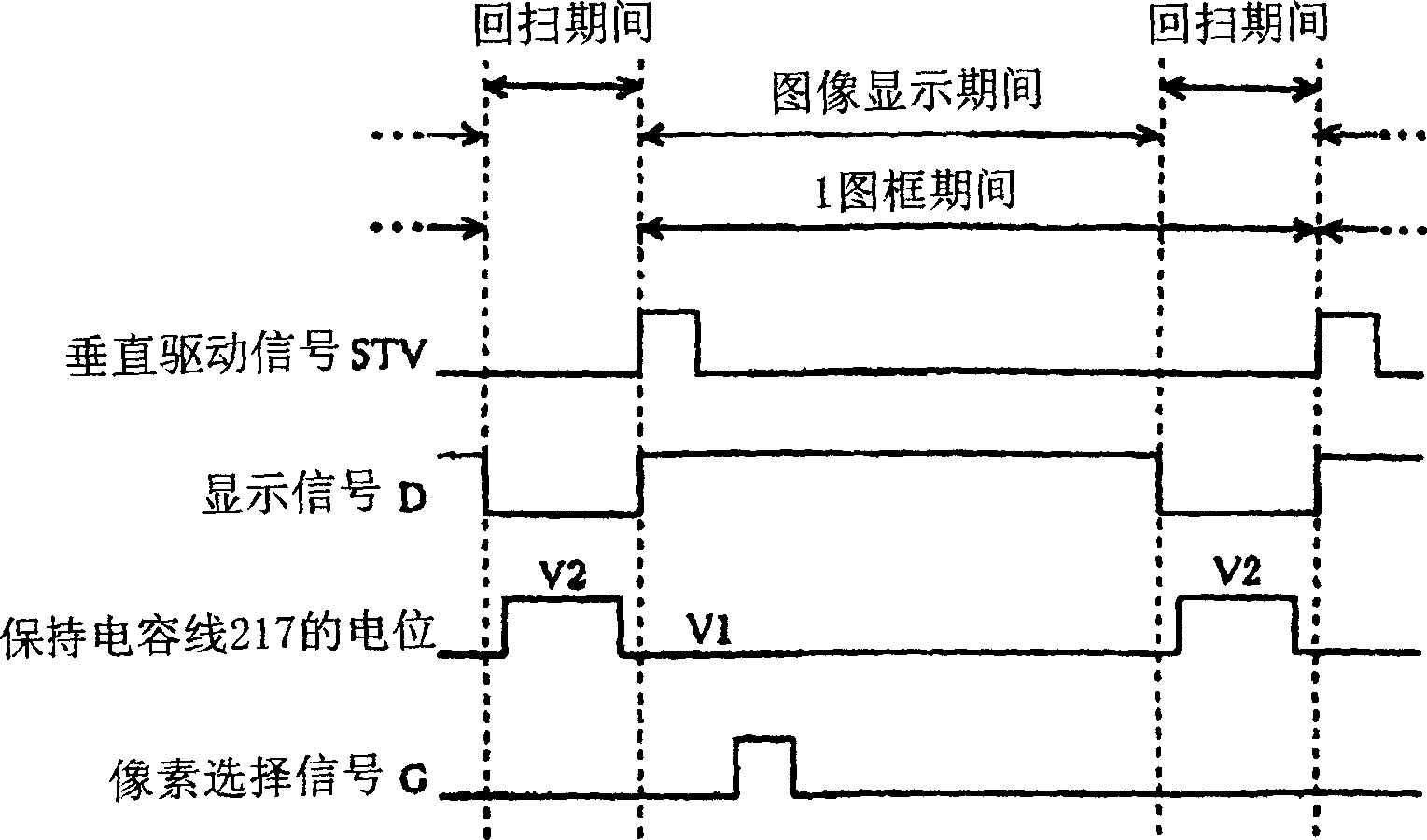

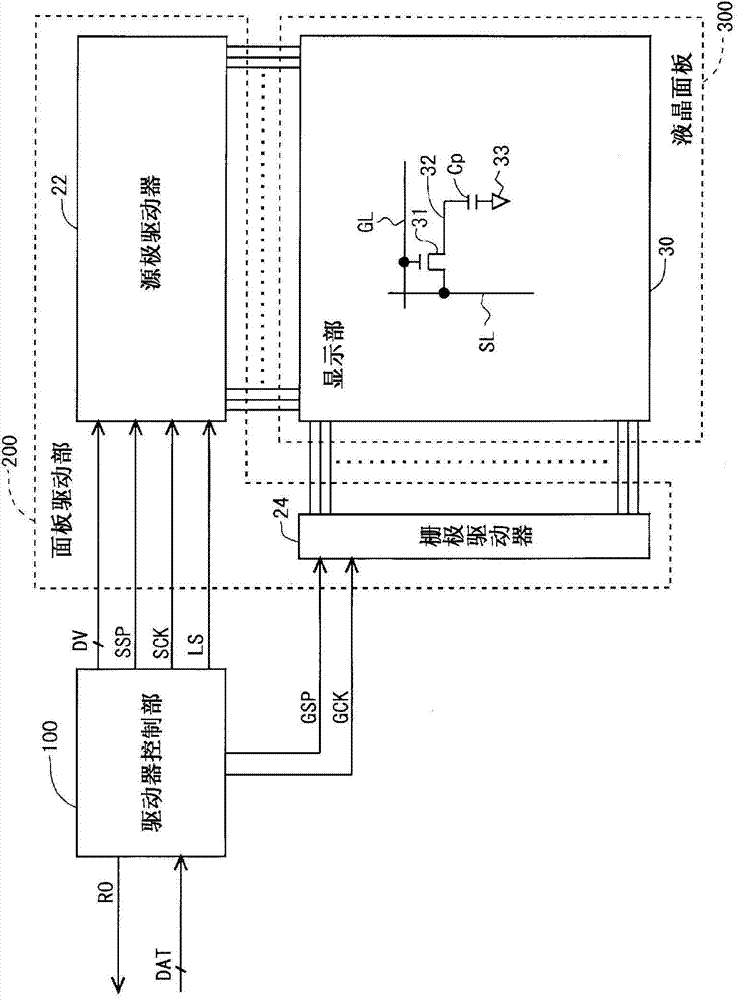

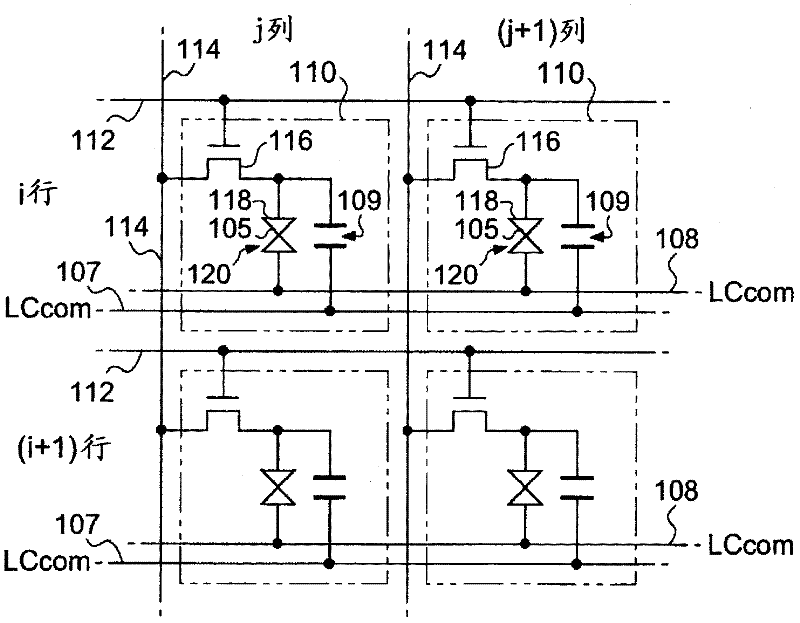

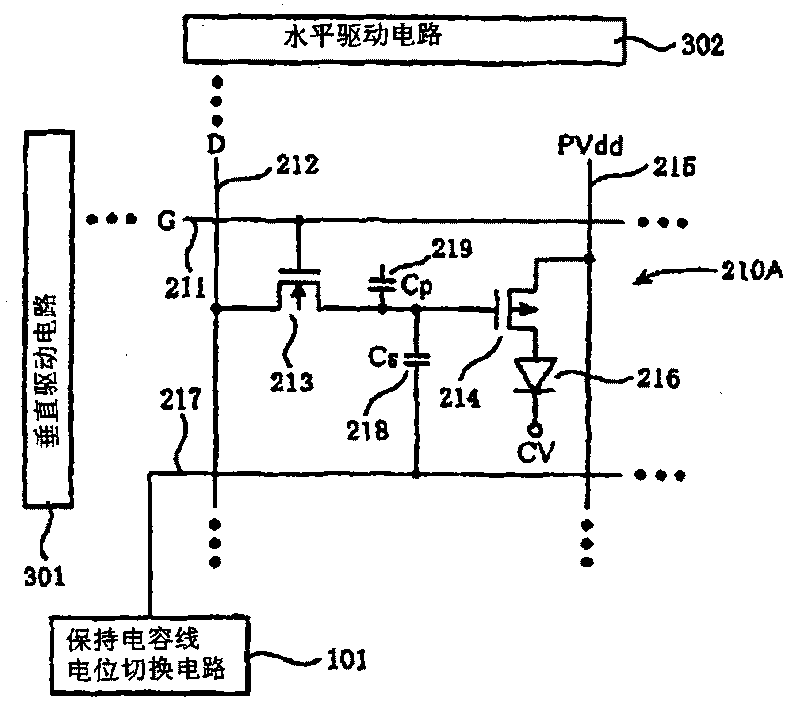

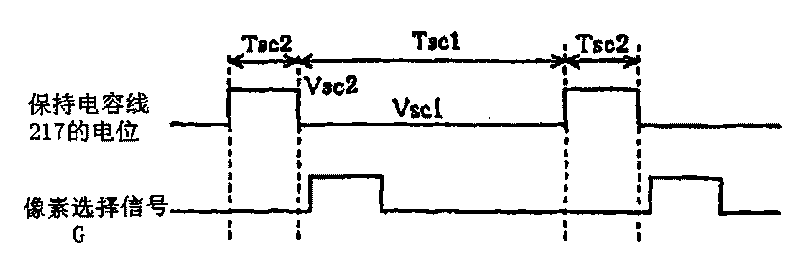

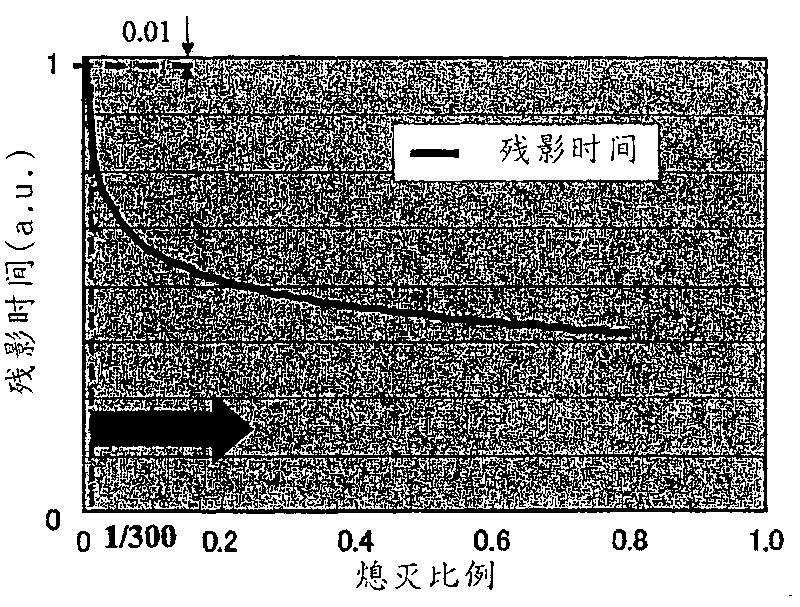

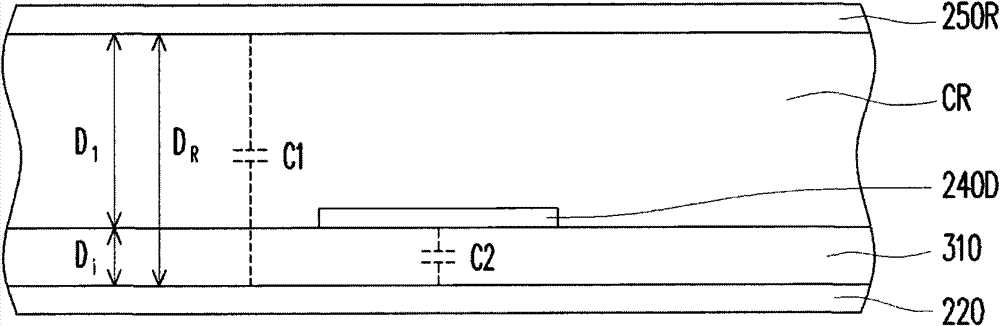

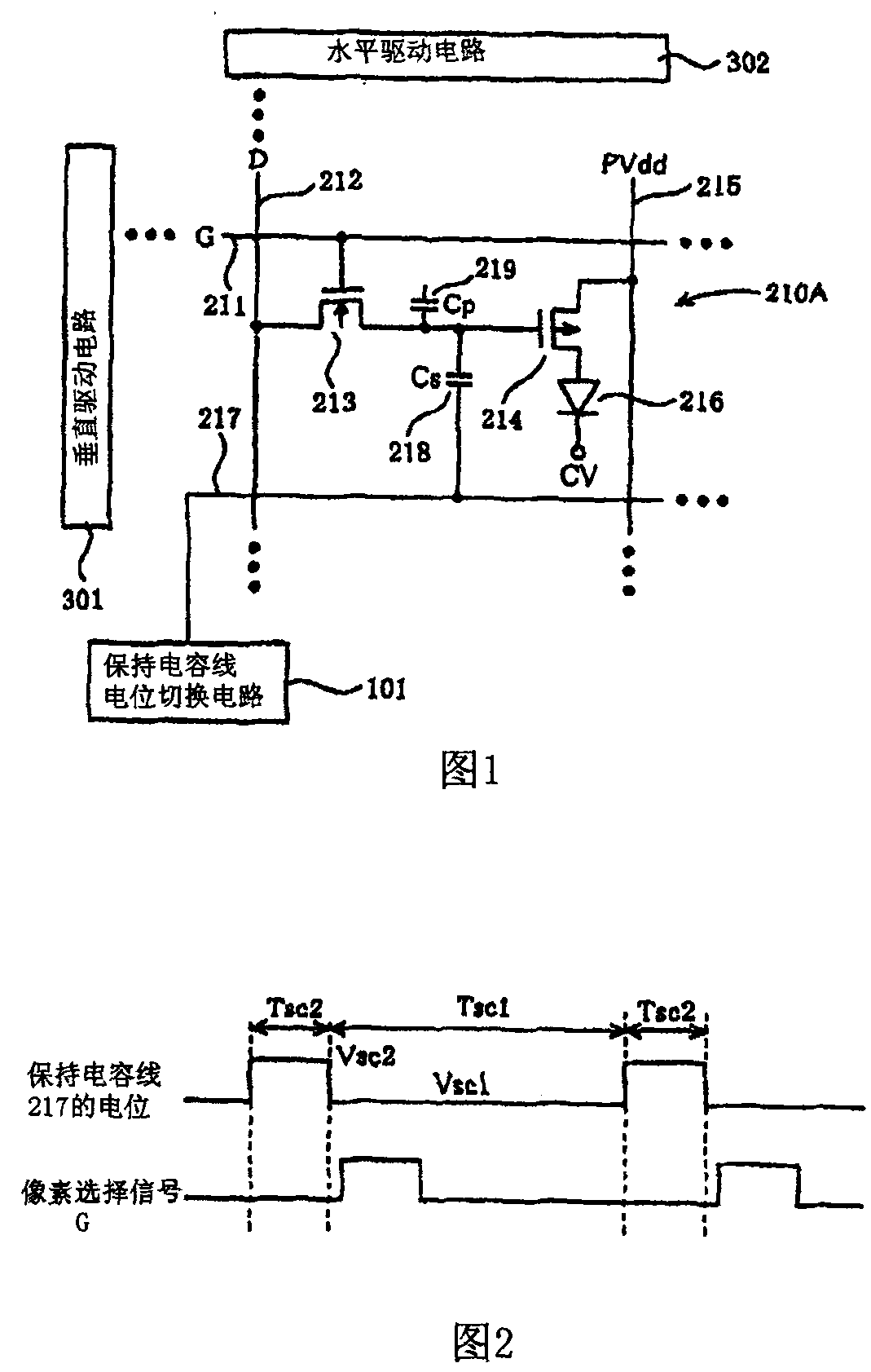

Active matrix type display device and driving method thereof

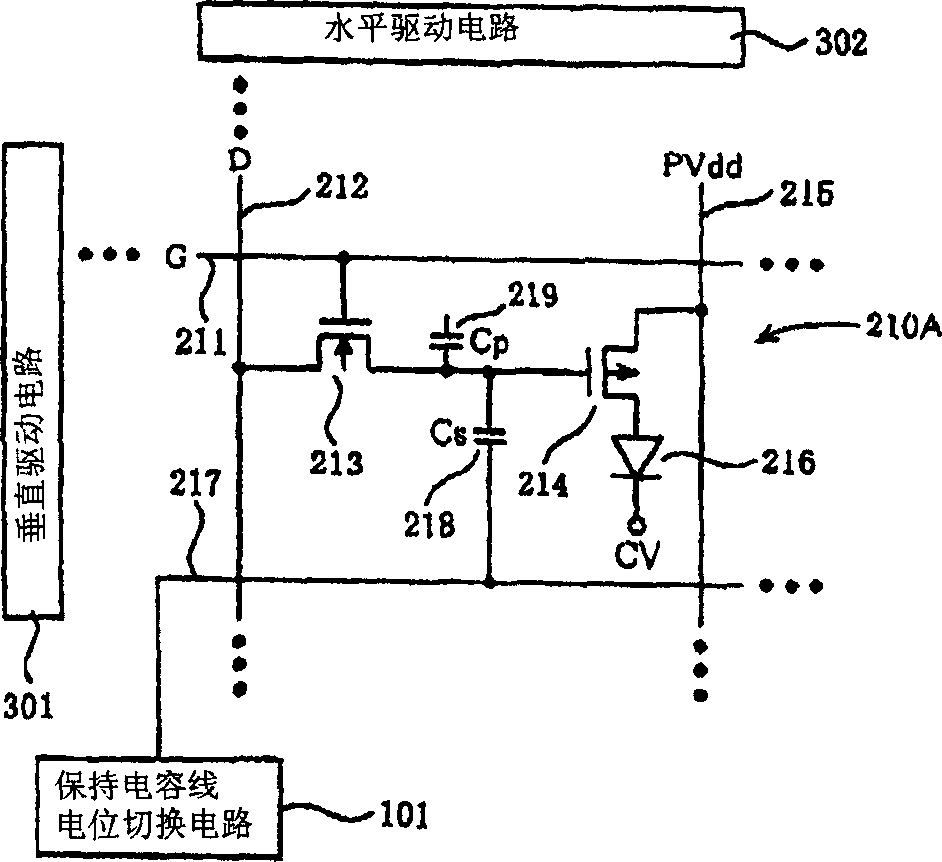

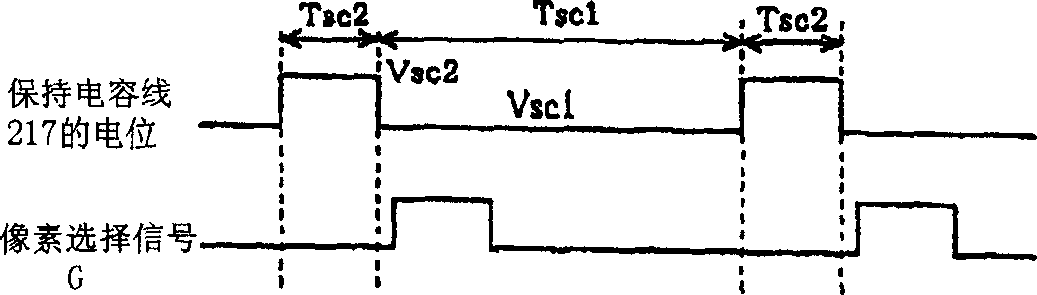

ActiveCN1831918ASuppress afterimageImprove display qualityElectrical apparatusStatic indicating devicesCapacitanceCapacitive coupling

A residual image effect is suppressed to improve quality of display of an active matrix type display device. An electric potential switching circuit switches an electric potential on a capacitor line from a first capacitor electric potential (ground electric potential, for example) to a second capacitor electric potential (power supply electric potential, for example) during a blanking period. At that time, an electric potential at a gate of a driver transistor is raised by capacitive coupling through a storage capacitor. As a result, the electric potential at the gate of the driver transistor becomes higher than an electric potential at a source of the driver transistor. Assuming that holes are trapped in a gate insulation film of the driver transistor due to writing-in of a display signal during a preceding frame period, the holes are extracted from the gate insulation film to the source or a drain of the driver transistor. With this, electric characteristics of the driver TFT are initialized. And the electric potential switching circuit switches the electric potential on the capacitor line back to the first capacitor electric potential from the second capacitor electric potential before an end of the blanking period.

Owner:SANYO ELECTRIC CO LTD

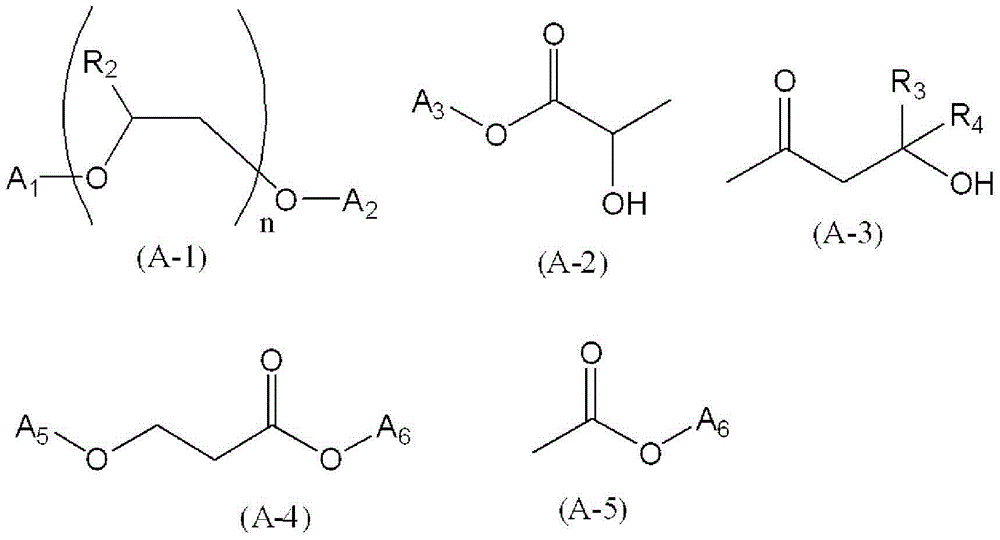

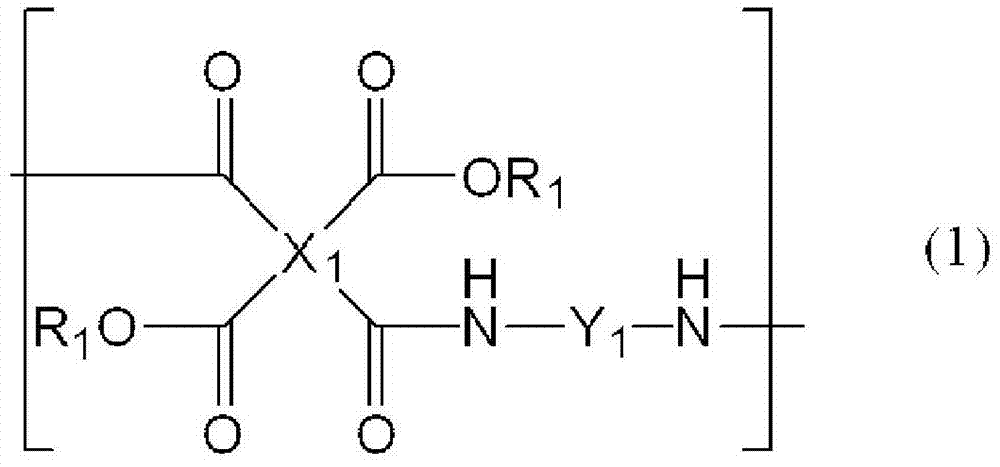

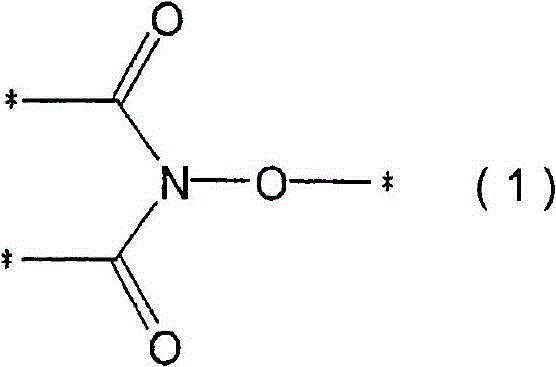

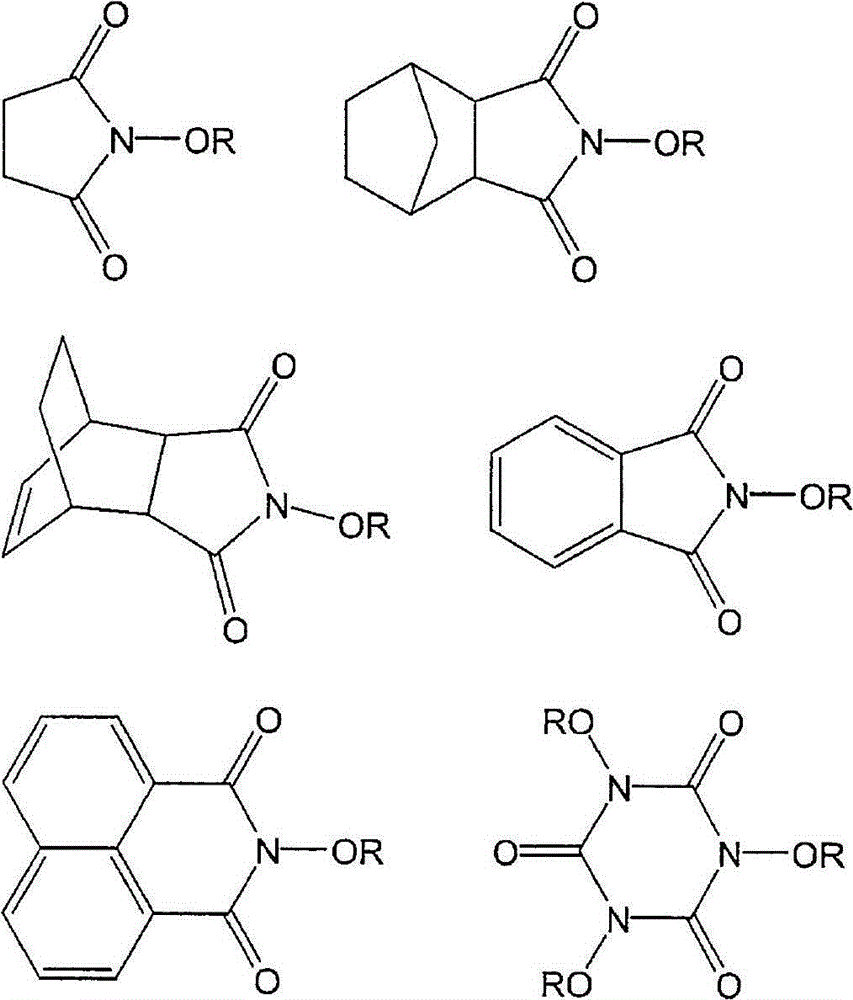

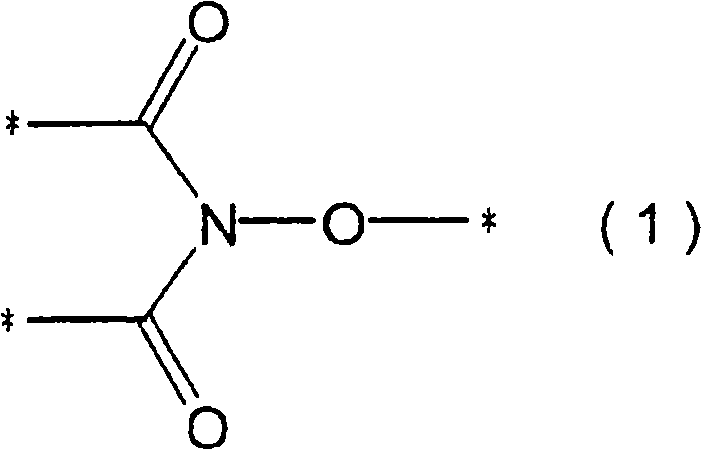

Liquid crystal orientation liquid for light orientation processing technique, and liquid crystal orientation film employing same

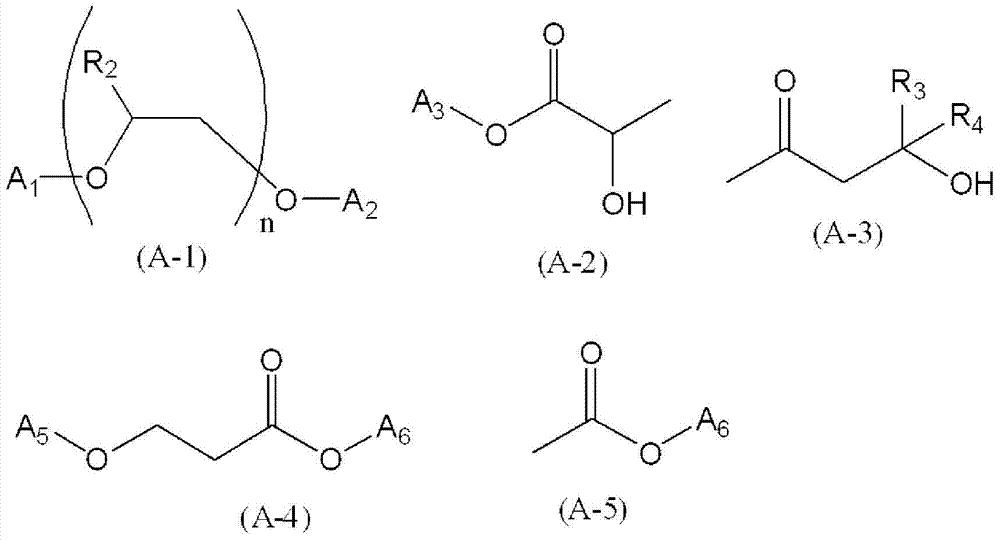

Provided are a liquid crystal orientation film with which it is possible to alleviate an afterimage resulting from AC driving which occurs with an IPS drive format or an FFS drive format liquid-crystal display element, and a liquid crystal orientation liquid for a light orientation processing technique for said film. A liquid crystal orientation liquid for a light orientation processing technique includes a constituent (A), a constituent (B), and an organic solvent, wherein the degree of inclusion of the constituent (B) is 0.1-15 parts to 100 parts of the constituent (A). Constituent (A): one or more polymers, wherein by illuminating with polarized light, one of the following reactions progresses: photolysis, photodimerization, or photoisomerization, and wherein an anisotropy is applied in either the same direction as the polarized light direction or the perpendicular direction to the polarized light direction. Constituent (B): a polymer having a structure which is represented with formula (1), following: (Chemical Formula 1) (Wherein W1 and W2 are independent bivalent organic groups including an aromatic group with 6-30 carbons, and A is a bivalent organic group including an alkylene group with 2-20 carbons.

Owner:NISSAN CHEM IND LTD

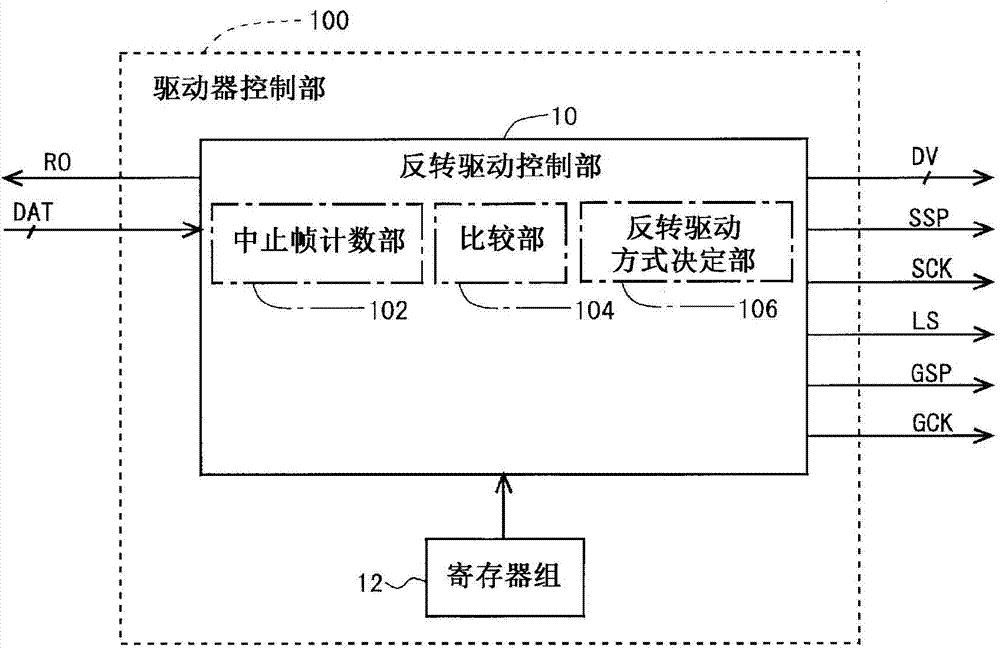

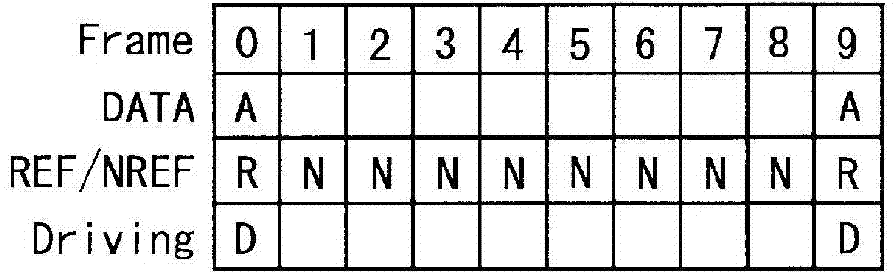

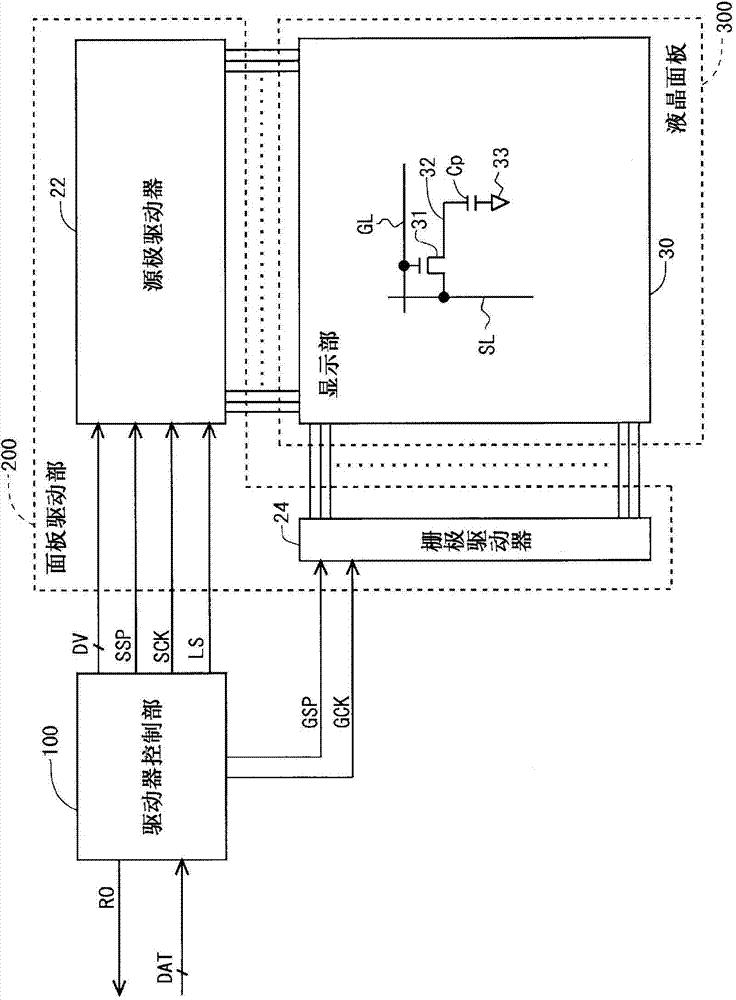

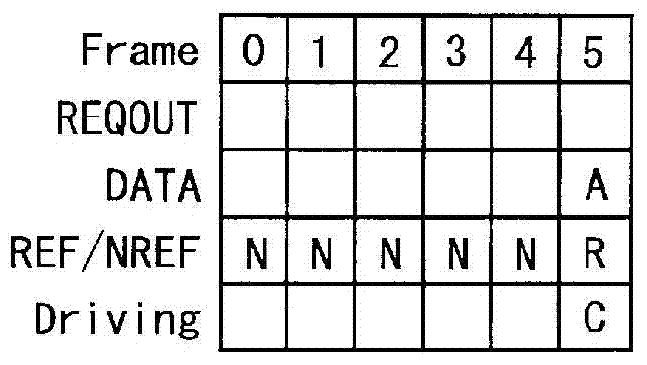

Liquid crystal display device and method for driving same

InactiveCN104781872APrevent display quality degradationSuppress afterimageStatic indicating devicesLiquid-crystal displayImage signal

A liquid crystal display device which implements a pause-drive technique, wherein flickering is effectively suppressed while also suppressing increases in power consumption. A frame (a first input frame) to which an image signal (DAT) is inputted without making a request to the outside for the input of an image signal (DAT) is specified as a refresh frame by an inversion driving technique determination unit (106). A pause frame counting unit (102) counts the number of pause frames since the previous refresh frame as a count value. A comparison unit (104) compares the count value and a pre-set threshold value. If the count value is equal to or greater than the threshold value, the inversion drive technique determination unit (106) sets the inversion drive technique of the first input frame to the dot inversion drive technique. If the count value is less than the threshold value, the inversion drive system determination unit (106) sets the inversion drive technique of the first input frame to the column inversion drive technique.

Owner:SHARP KK

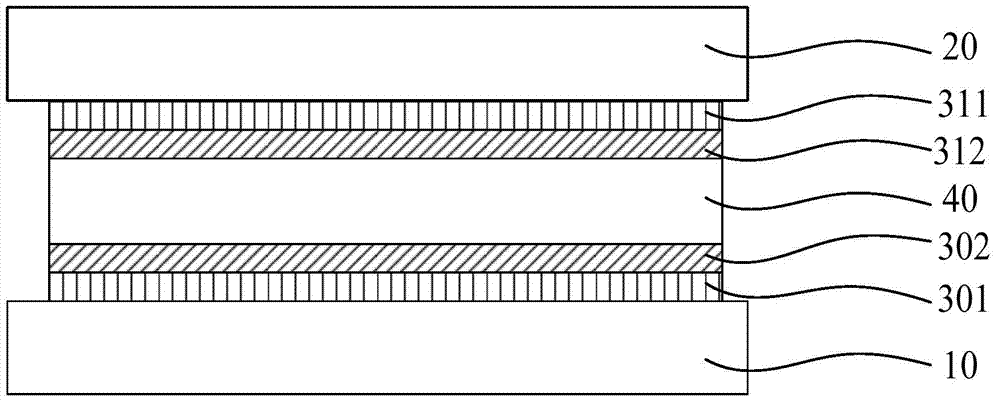

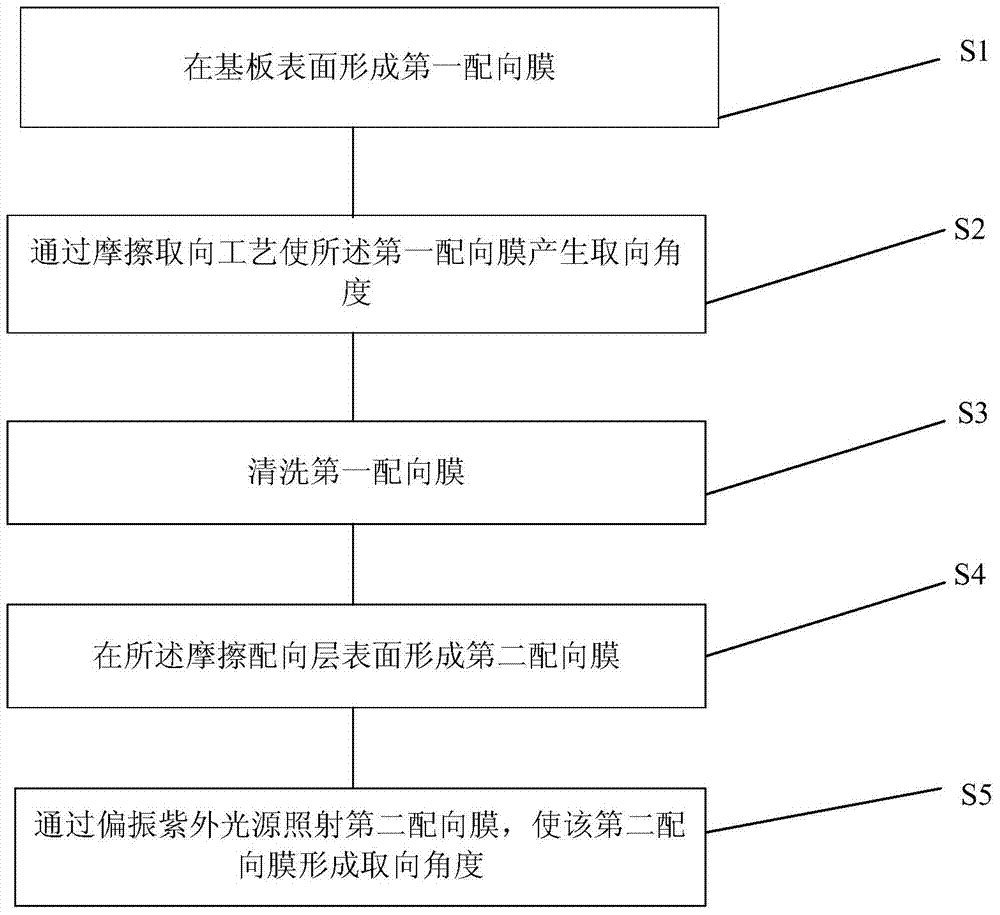

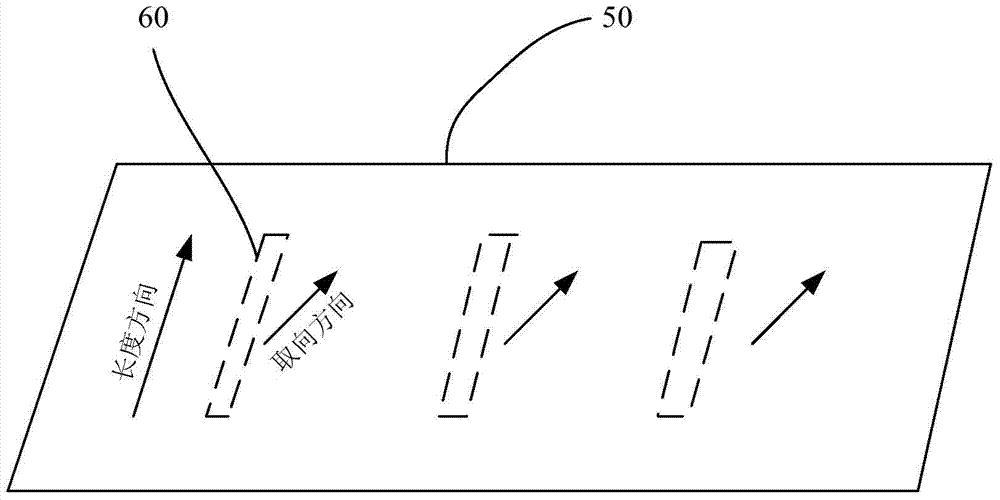

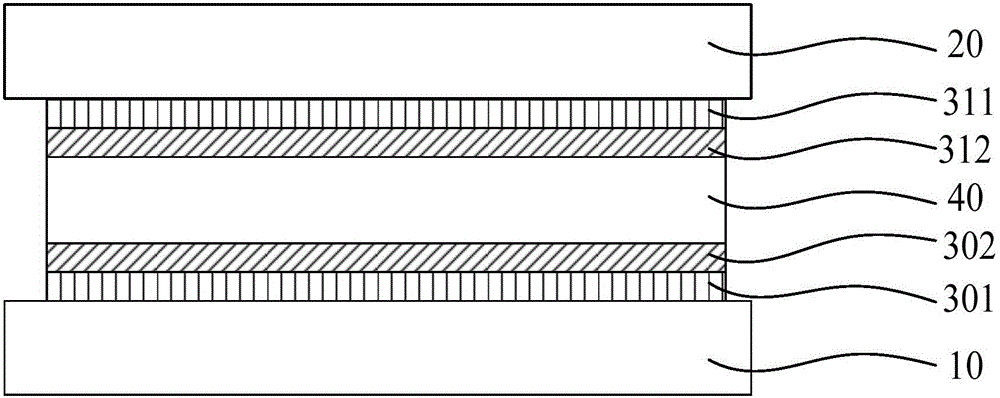

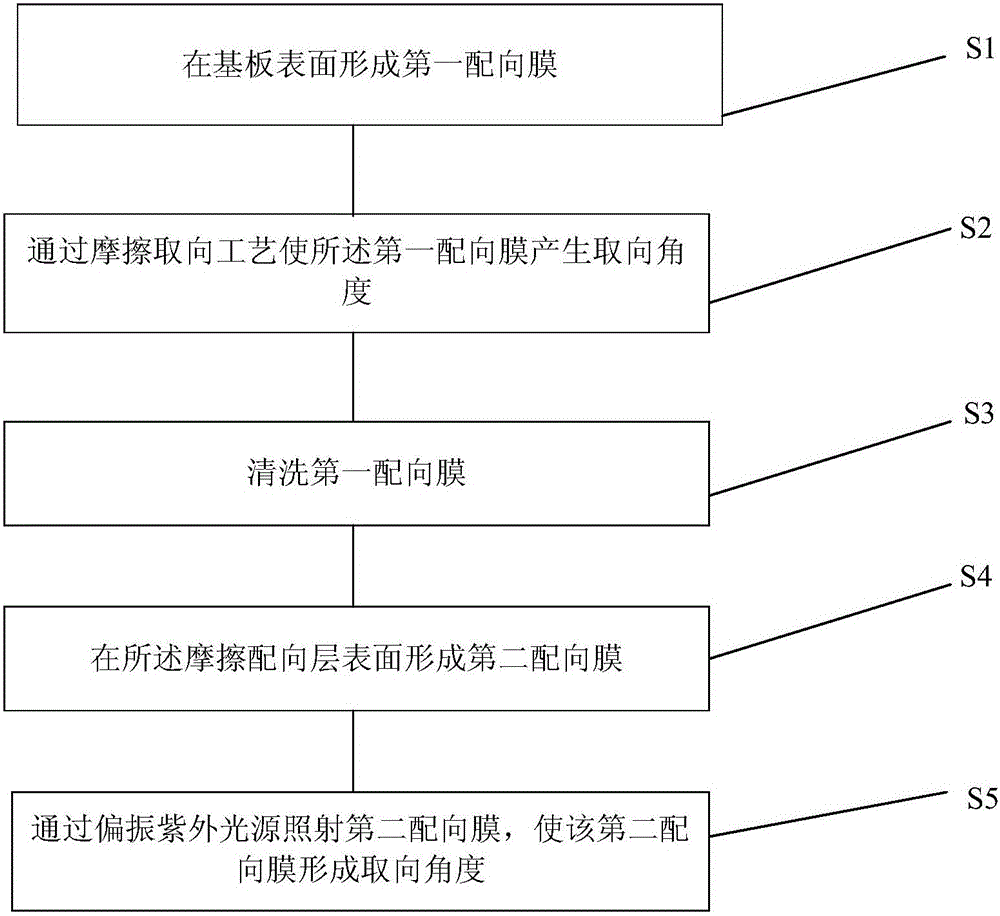

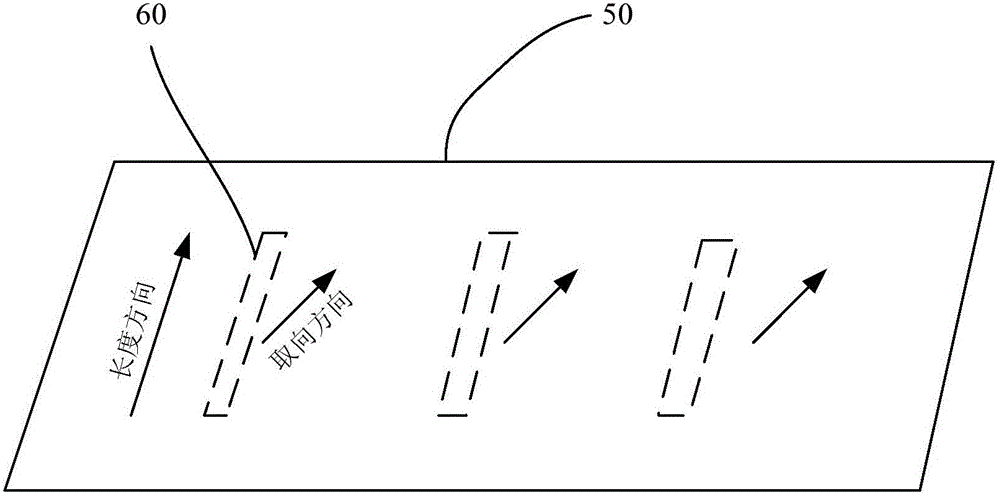

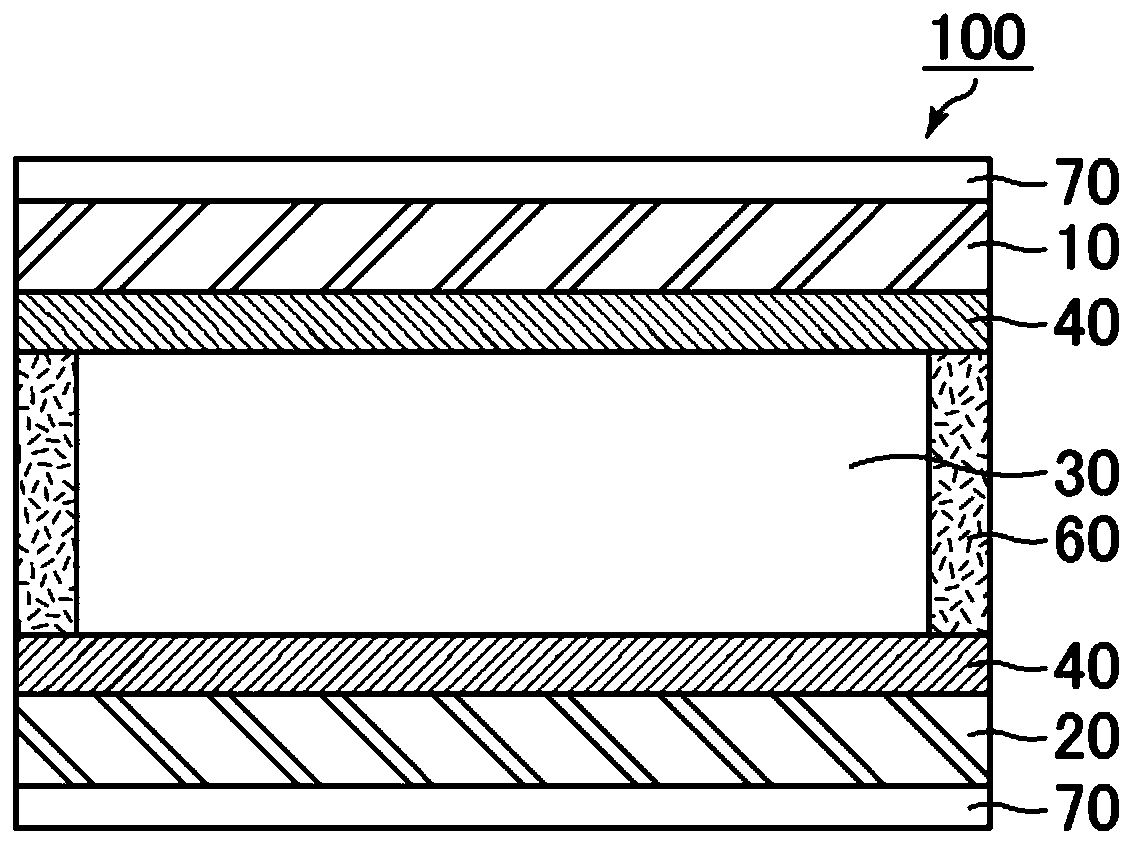

Alignment layer set, manufacturing method thereof, substrate and display device

InactiveCN103576389AIncrease contrastSuppress afterimageNon-linear opticsLiquid-crystal displayLiquid crystal

The invention relates to the technical field of liquid crystal display, in particular to an alignment layer set, a manufacturing method thereof, a substrate and a display device. The alignment layer set comprises friction alignment layers and smooth alignment layers, wherein the friction alignment layers and the smooth alignment layers are arranged on the upper surface of the substrate in the direction far away from the upper surface of the substrate, and the orientation of the friction alignment layers is identical with that of the smooth alignment layers. According to the alignment layer set, the manufacturing method thereof, the substrate and the display device, a structure of combining the smooth alignment layers and the friction alignment layers is adopted, and the purposes of improving the contrast ratio of liquid crystal panels and simultaneously restraining the generation of residual images to improve the display quality of the liquid crystal panels are achieved by covering detects generated in the friction alignment layers through the smooth alignment layers and by using the anchoring energy of the friction alignment layers for compensating the defect that the smooth alignment layers are poor in anchoring engine.

Owner:BOE TECH GRP CO LTD

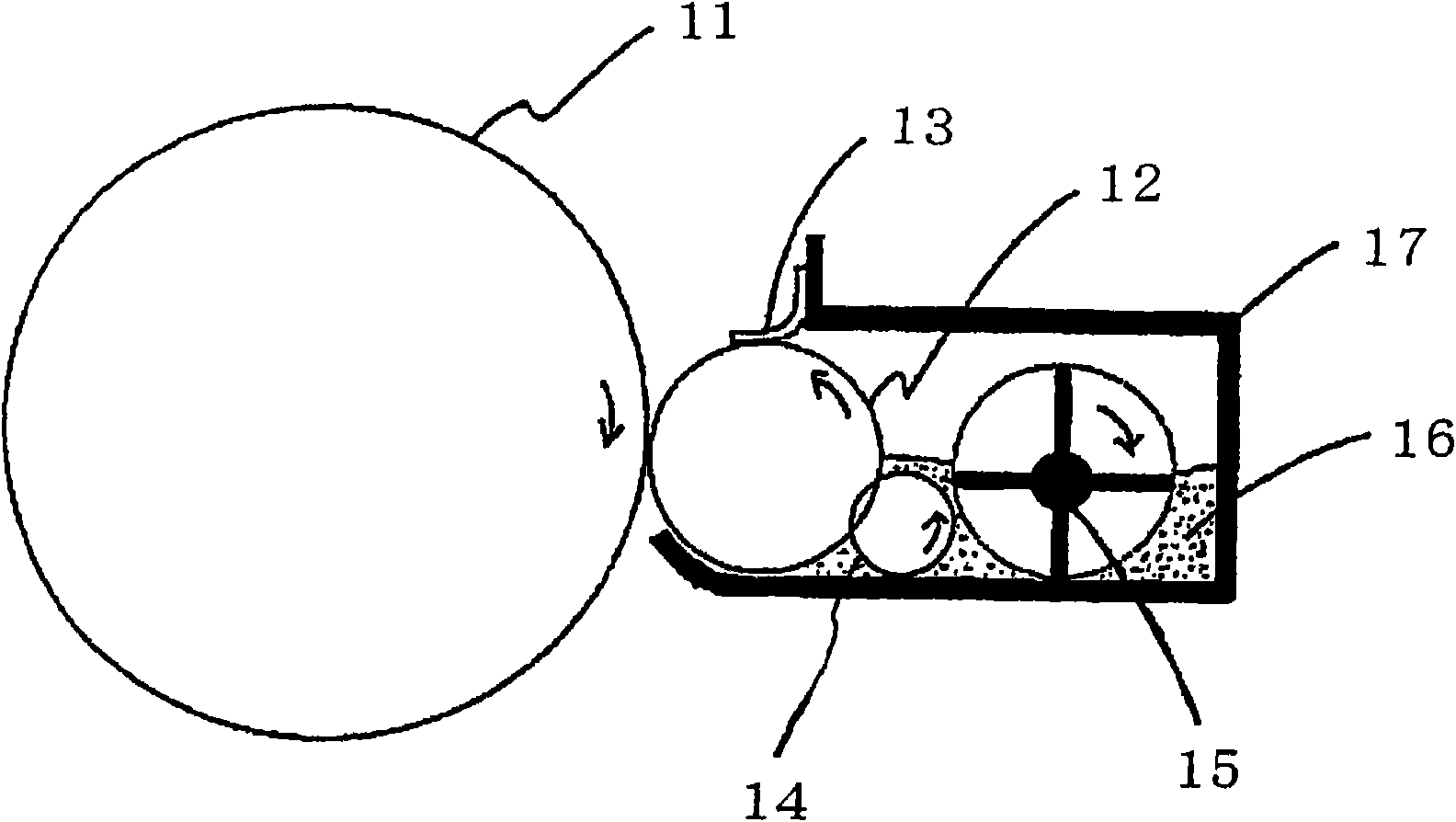

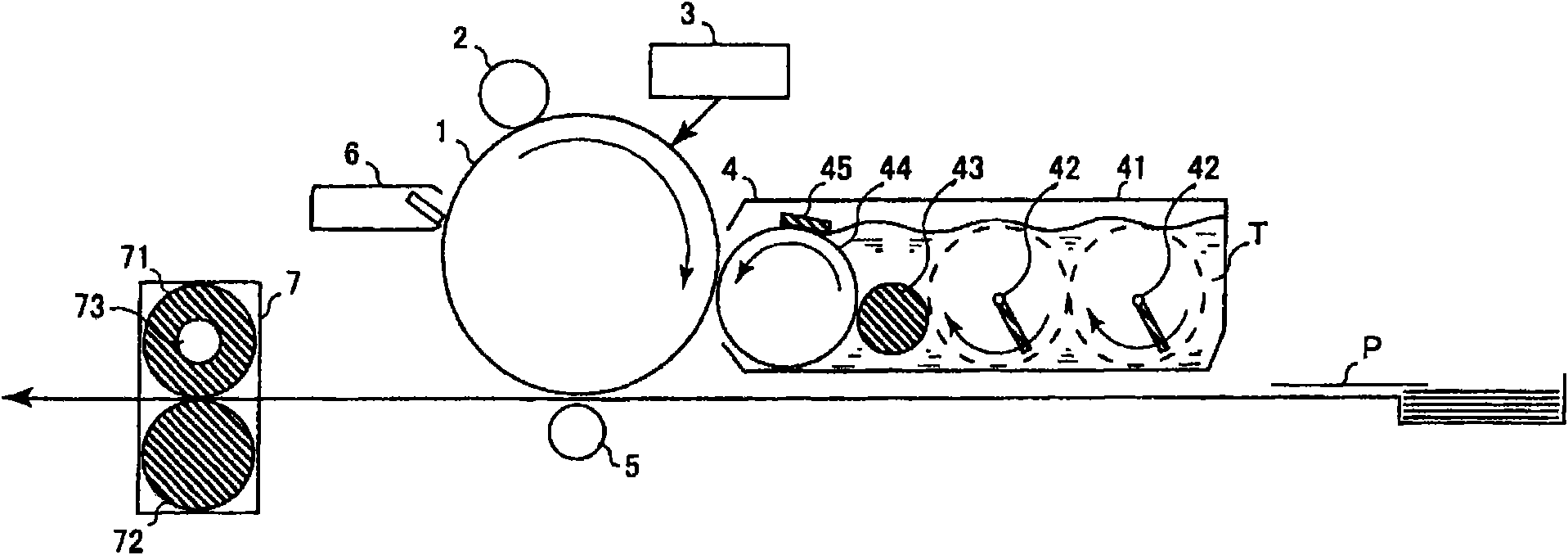

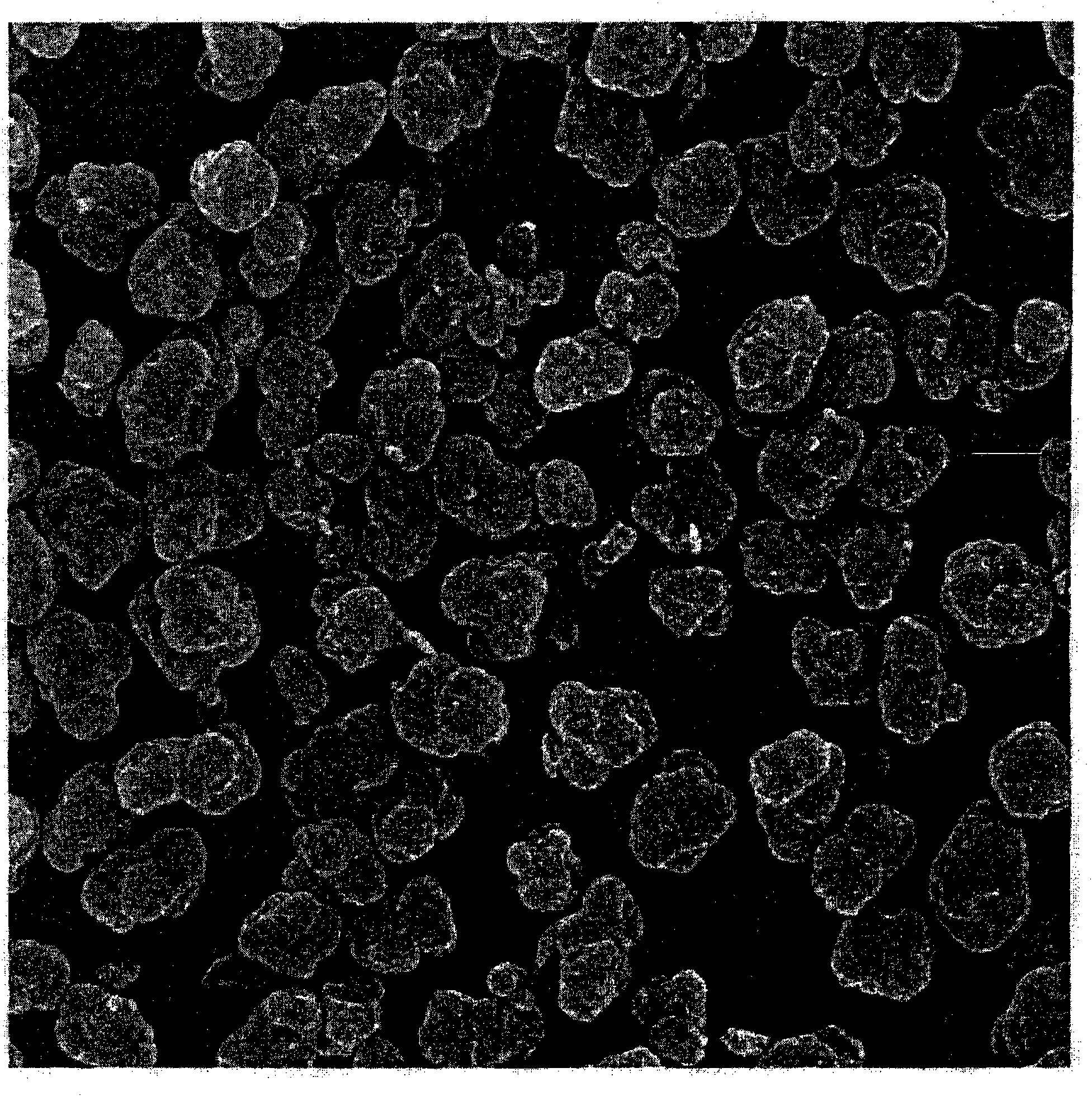

Image-forming apparatus and cartridge

ActiveCN101681135AExcellent image stabilityExcellent thin line reproducibilityElectrographic process apparatusDevelopersImaging qualityImage formation

The invention provides an image-forming apparatus and a cartridge which inhibit troubles attributable to toner particle size distribution or toner / photoreceptor matching, such as a white-background fouling, afterimage, scattering, streaks, blurring, and blind spots, and are satisfactory with respect to image quality, thin-line reproducibility, and cleanability. Even when applied to a high-speed printer, the apparatus and cartridge can prevent fouling and selective development in long-term use and can stably form high-resolution images. The image-forming apparatus has an electrophotographic photoreceptor which includes a photosensitive layer containing an oxytitanium phthalocyanine which has major diffraction peaks for a CuK alpha line at Bragg angles (2 theta) of 9.0 DEG and 27.2 DEG andhas at least one major diffraction peak for the line in the range of from 9.3 DEG to 9.8 DEG . It employs a toner satisfying all of the following requirements: (1) the volume median diameter (Dv50)is 4.0-7.0 mu m; (2) the average roundness is 0.93 or higher; and (3) the volume median diameter (Dv50) and the percentage by number of toner particles having a size of 2.00-3.56 mu m (Dns) satisfy the relationship Dns<=0.233EXP(17.3 / Dv50).

Owner:MITSUBISHI RAYON CO LTD

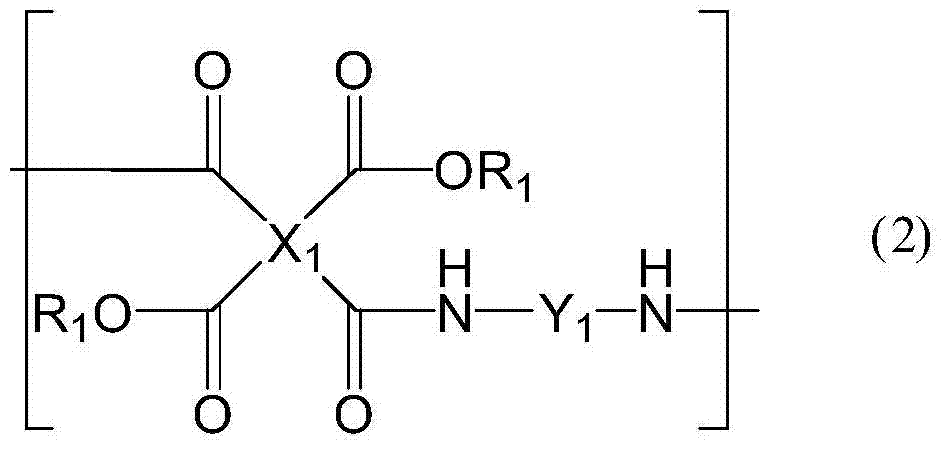

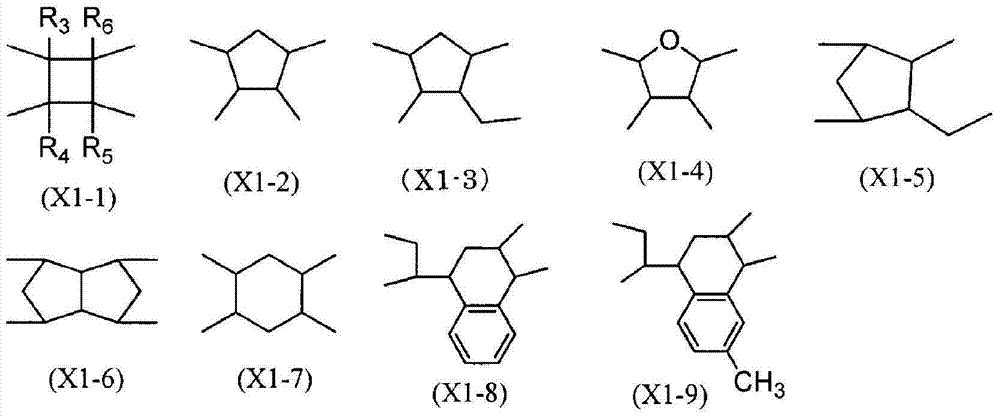

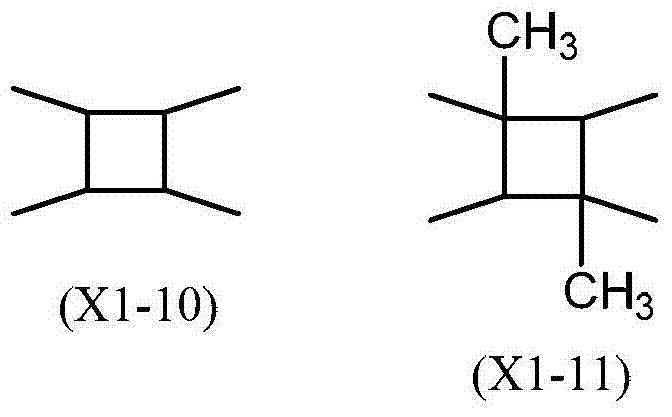

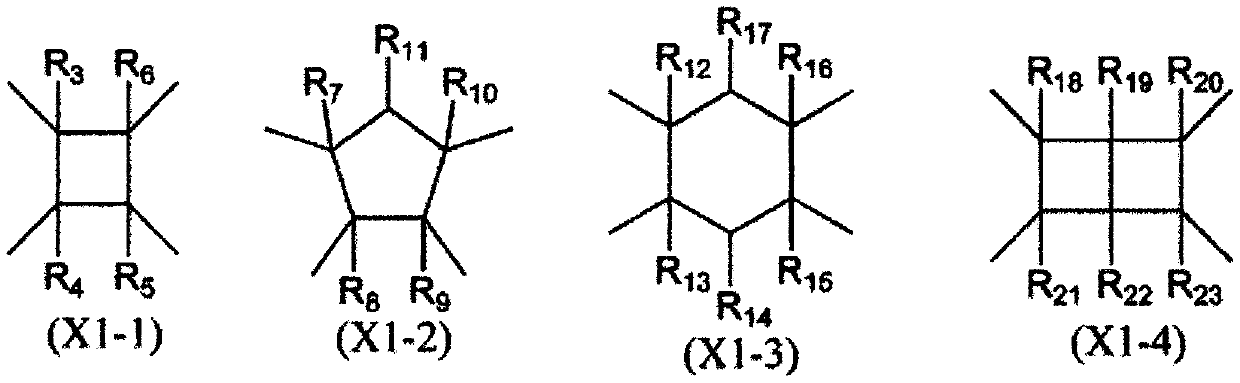

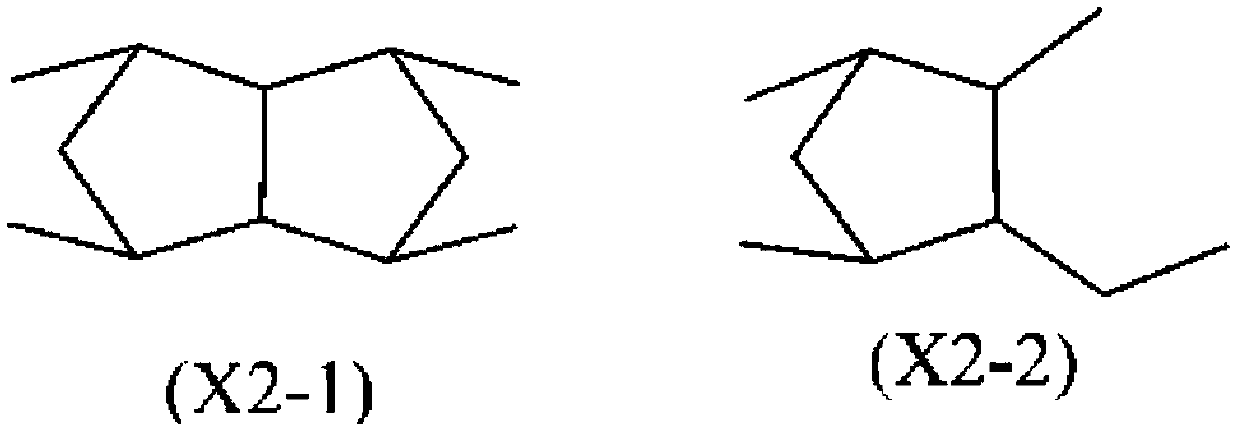

Method for producing liquid crystal alignment film, liquid crystal alignment film, and liquid crystal display element

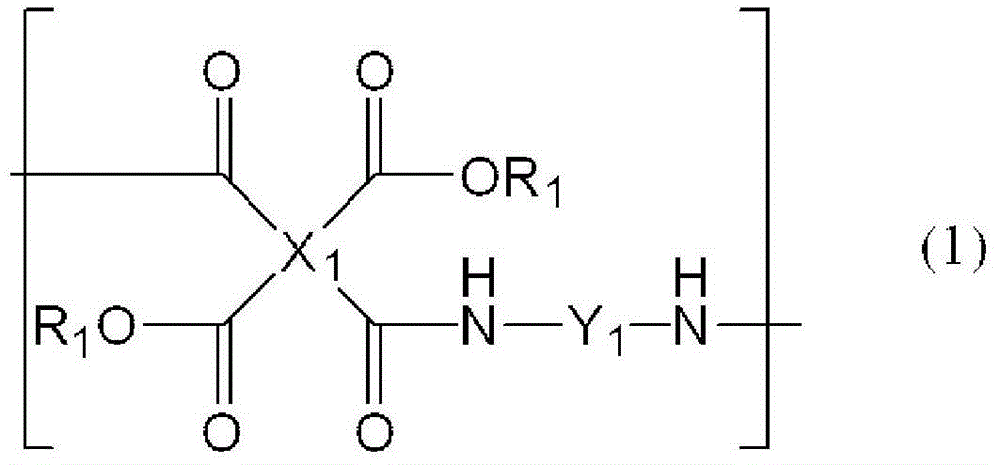

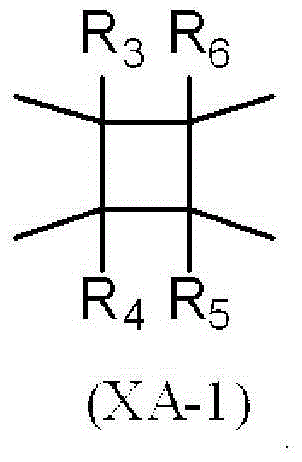

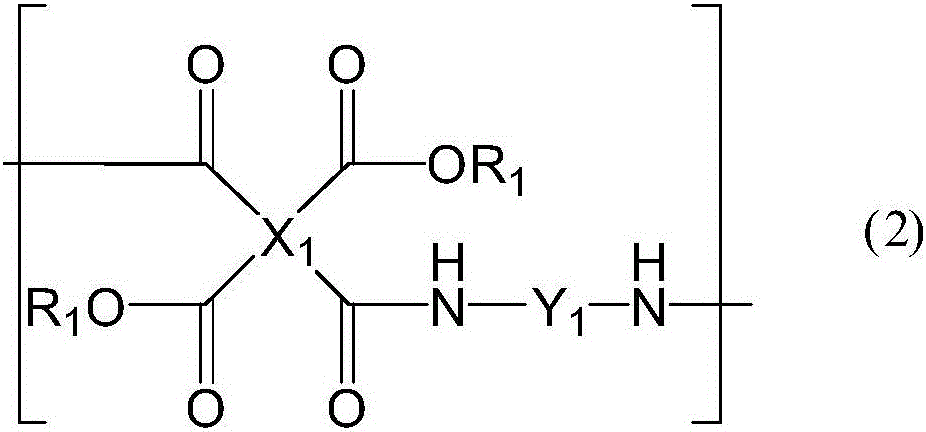

ActiveCN104838311AReduce afterimageIncreased anisotropyCoatingsNon-linear opticsOrganic solventLiquid-crystal display

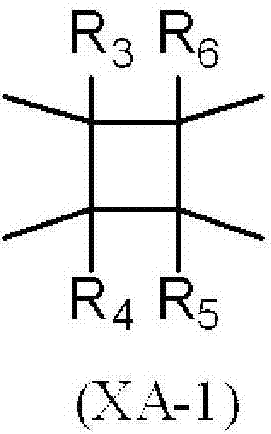

Provided is a method for producing a photoalignment liquid crystal alignment film which is capable of minimizing afterimages resulting from AC driving. Polarized radiation is applied to a film obtained by applying and sintering a liquid crystal alignment agent, which contains at least one type of polymer selected from a group comprising polyimide precursors represented by formula (1) and imidized polymers of said polyimide precursors, on a substrate. After the film has been brought into contact with an organic solvent having a boiling point of 110 to 180°C, the film is then brought into contact with water or a water-soluble organic solvent having a boiling point of 50 to 105°C before being treated with heat at 150°C or above. (X1 represents the formula (XA-1); Y1 represents a divalent organic group; R1 represents H or the like; and R3 to R6 represent H or the like.)

Owner:NISSAN CHEM IND LTD

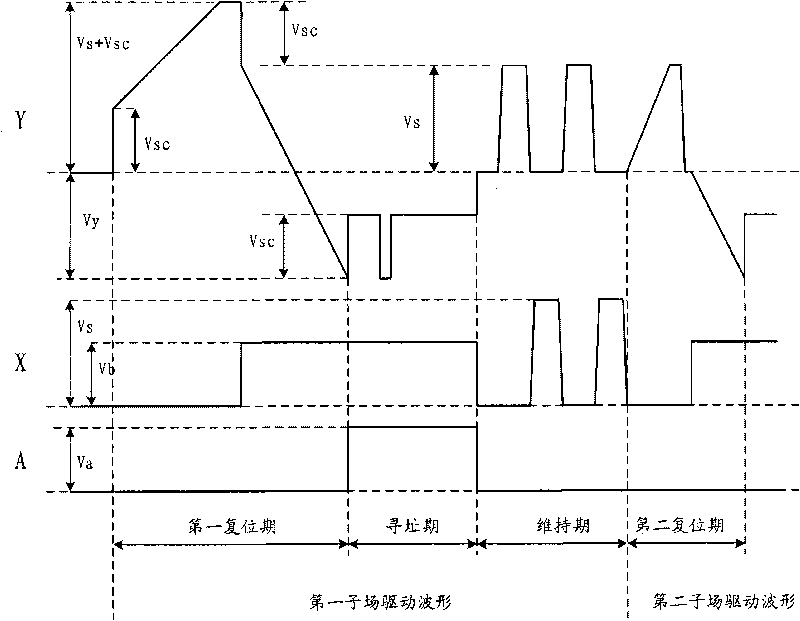

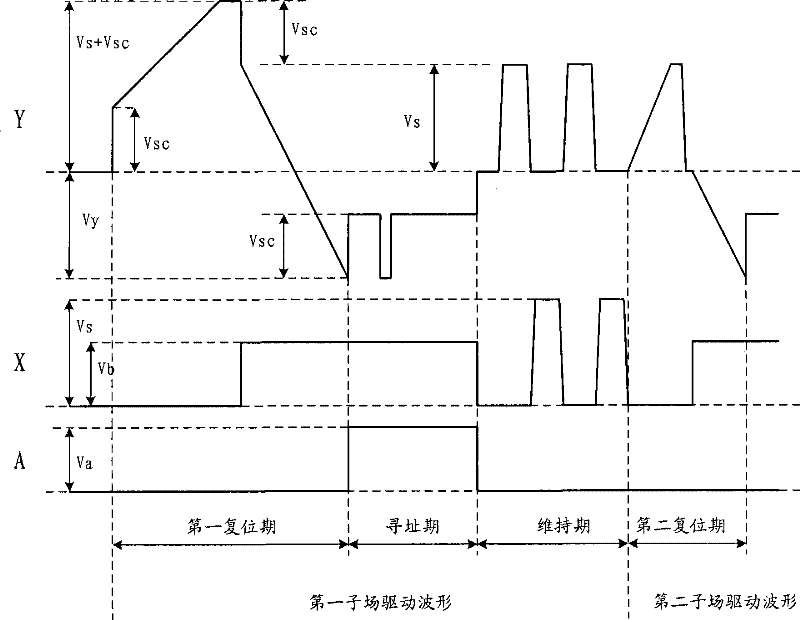

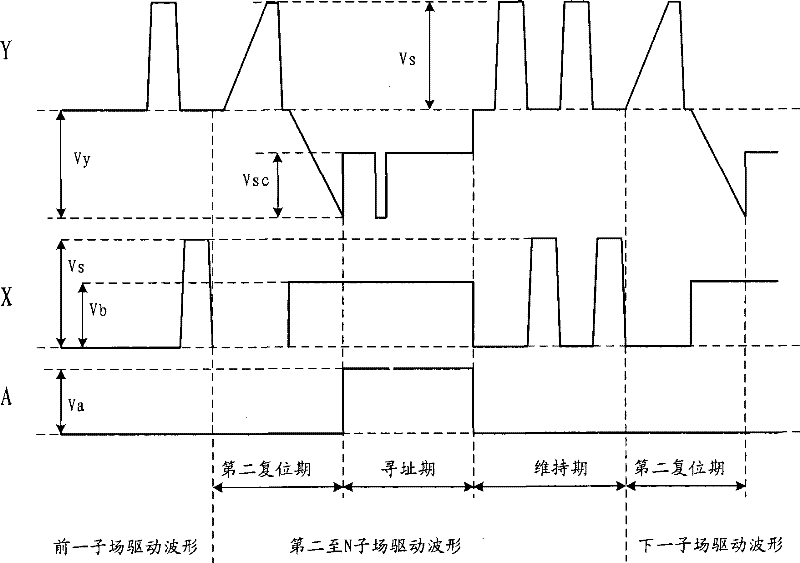

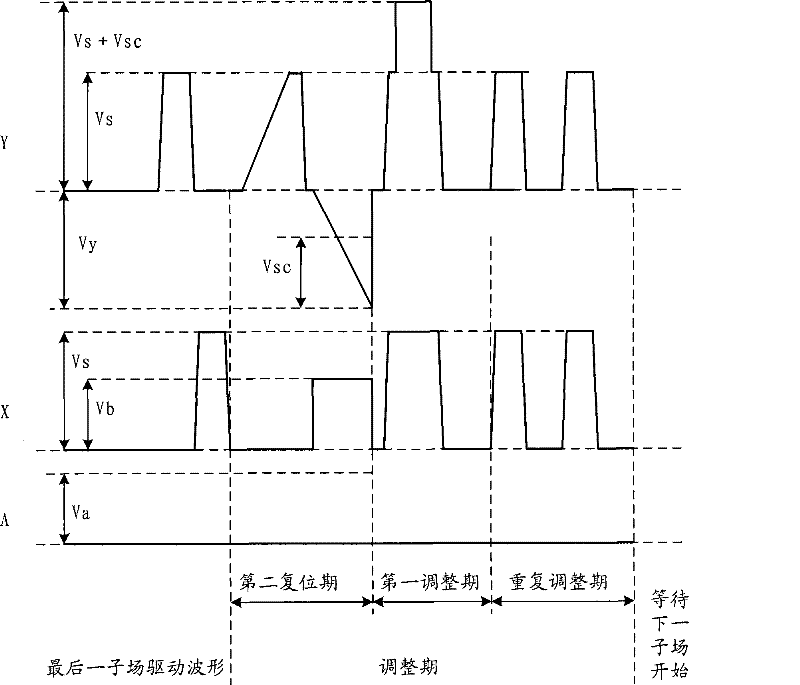

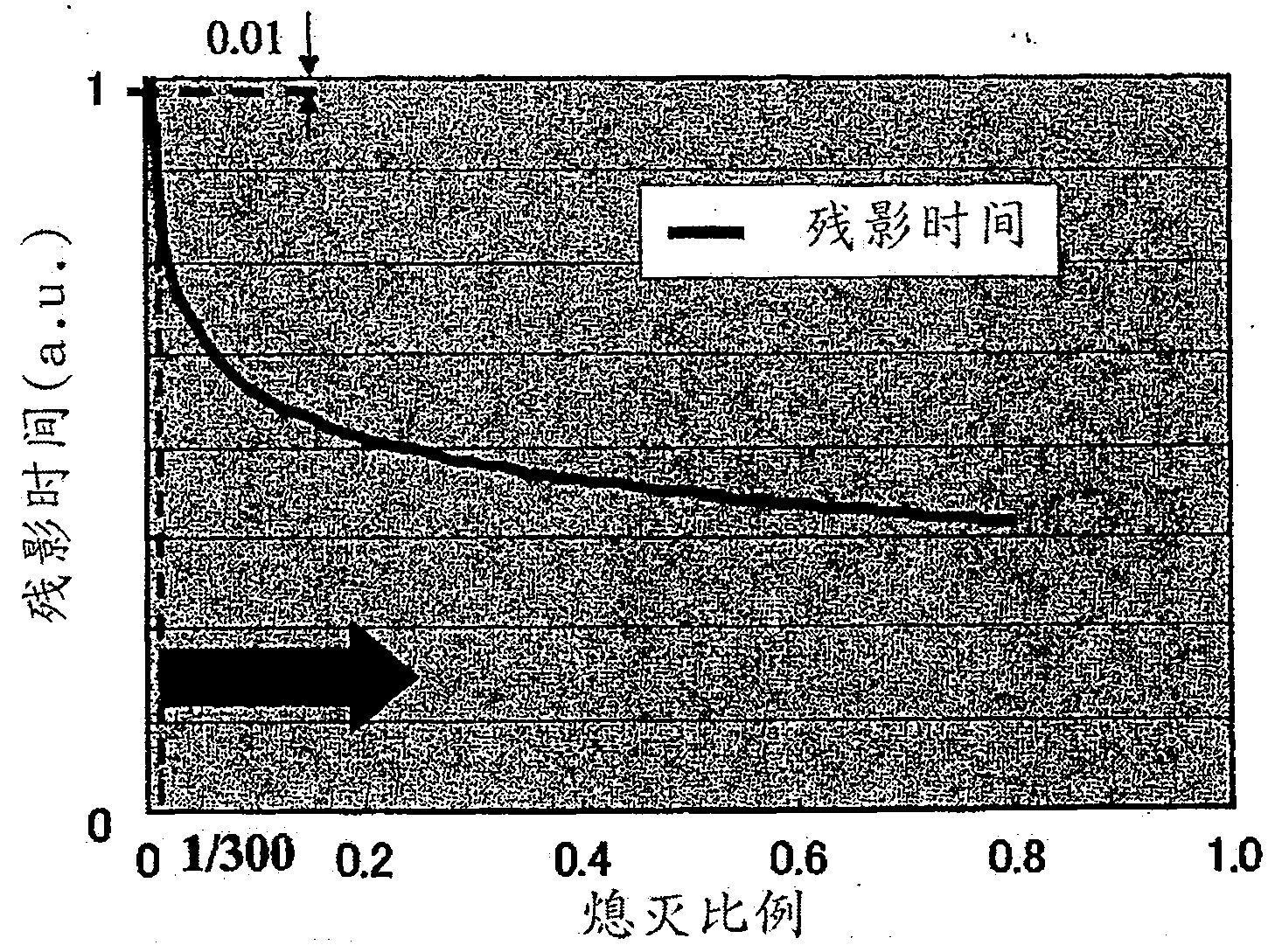

Actuating device for plasma display and method

InactiveCN101727818AImprove adaptabilitySuppress afterimageStatic indicating devicesImage detectionDisplay device

The invention provides an actuating device for a plasma display, which is characterized in that: the actuating device comprises an image detection module which is used for judging whether the imaged displayed by the display is in one of a long-term static mode, a dynamic mode, and a mode from the static mode to the dynamic mode and outputting a judgment result; and a driving control module which is used for setting the actuating mode according to the judgment result output from the image detection module; by adopting the invention, the purpose of inhibiting residual images is achieved, and the adaptability of PDP display devices in various occasions can be improved.

Owner:SICHUAN COC DISPLAY DEVICES

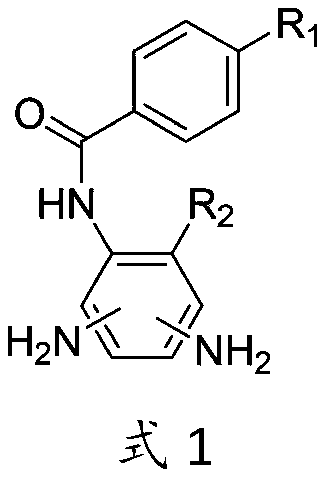

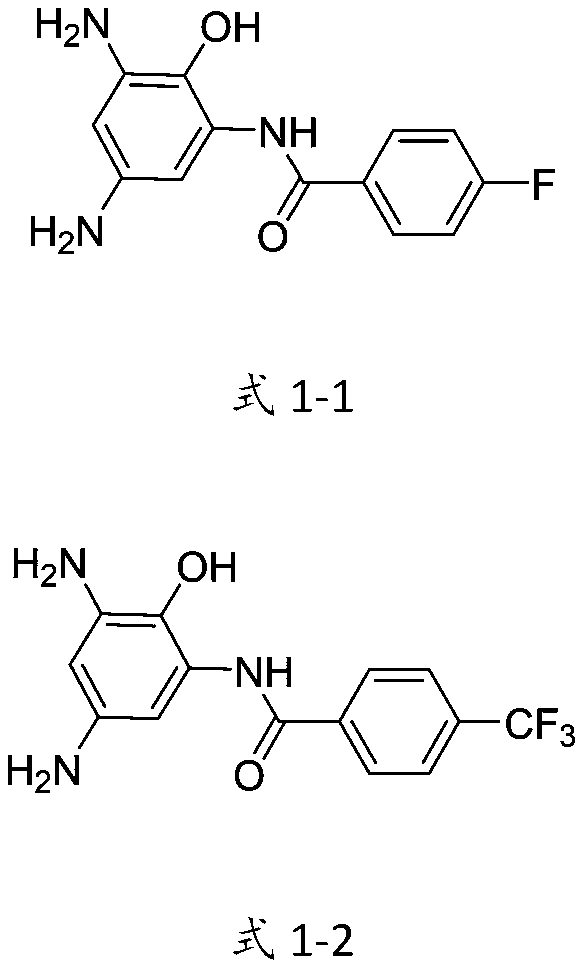

Liquid crystal aligning agent, liquid crystal alignment film, and liquid crystal display element

ActiveCN110734771AIncrease anchoring forceStable in natureLiquid crystal compositionsNon-linear opticsCrystallographyLiquid-crystal display

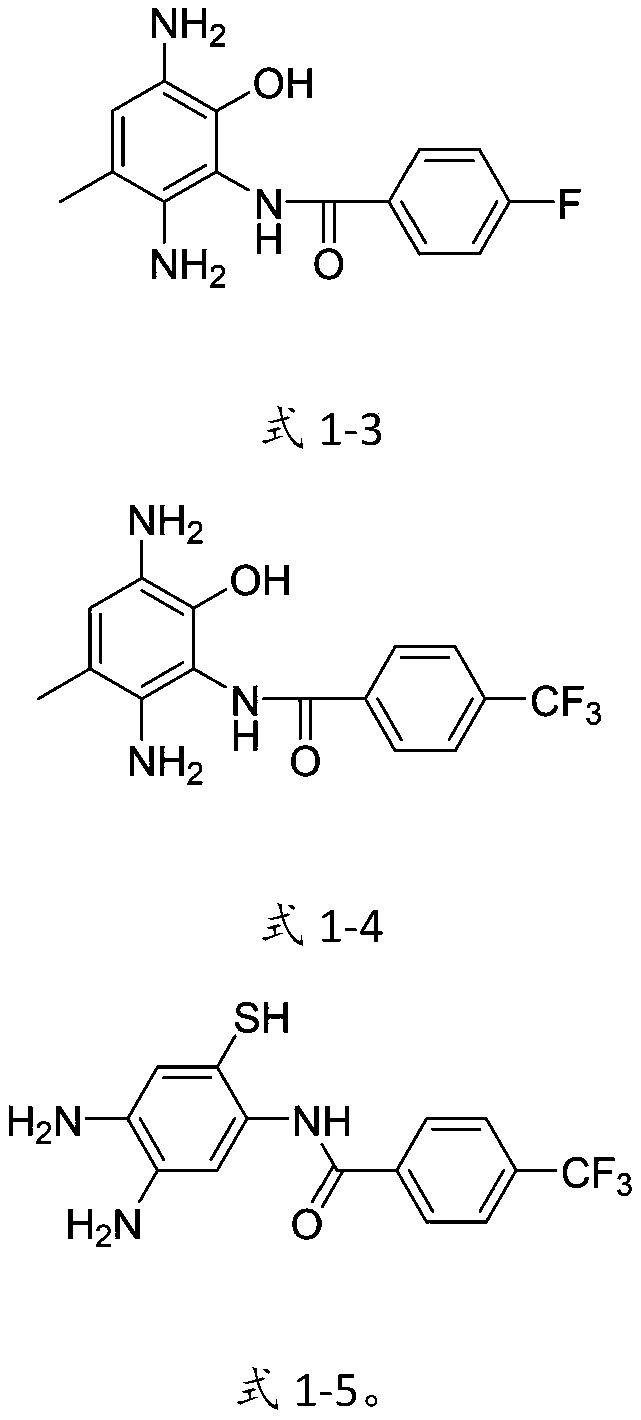

The invention provides a liquid crystal aligning agent, a liquid crystal alignment film and a liquid crystal display element. The liquid crystal aligning agent at least comprises one of a polyamide acid solution and a polyimide solution, wherein the polyamide acid solution is obtained by carrying out polymerization reaction of a diamine compound component A and a dianhydride compound component B in a solvent; the polyimide solution is obtained by carrying out dehydration imidization treatment on the polyamide acid solution; the diamine compound component A at least comprises one of diamine compounds as shown in formula 1. The liquid crystal aligning agent disclosed by the invention has relatively good liquid crystal aligning capability, an excellent ghost effect and an effect of easily removing decomposition products after photo-alignment.

Owner:JIANGSU SUNERA TECH CO LTD

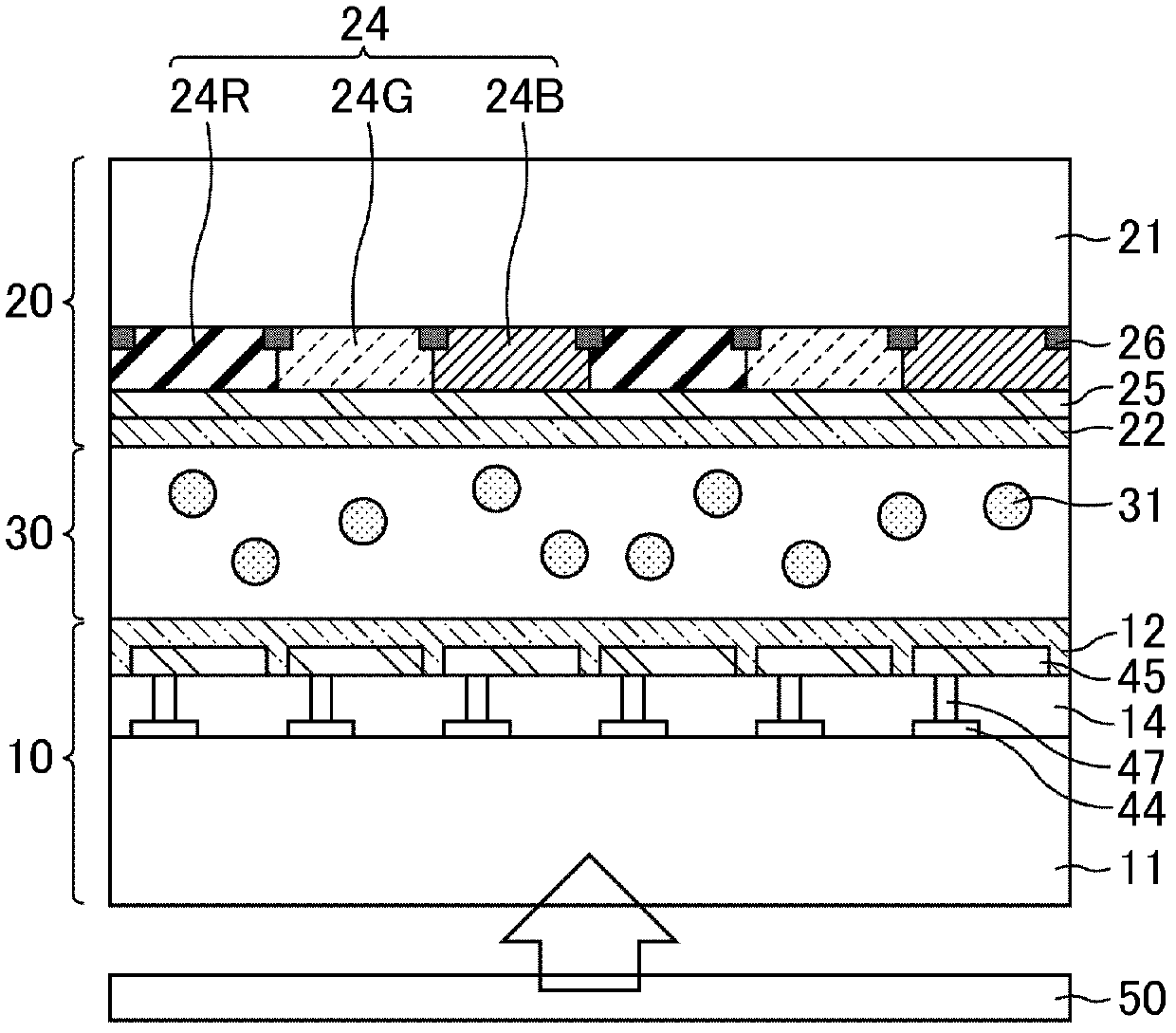

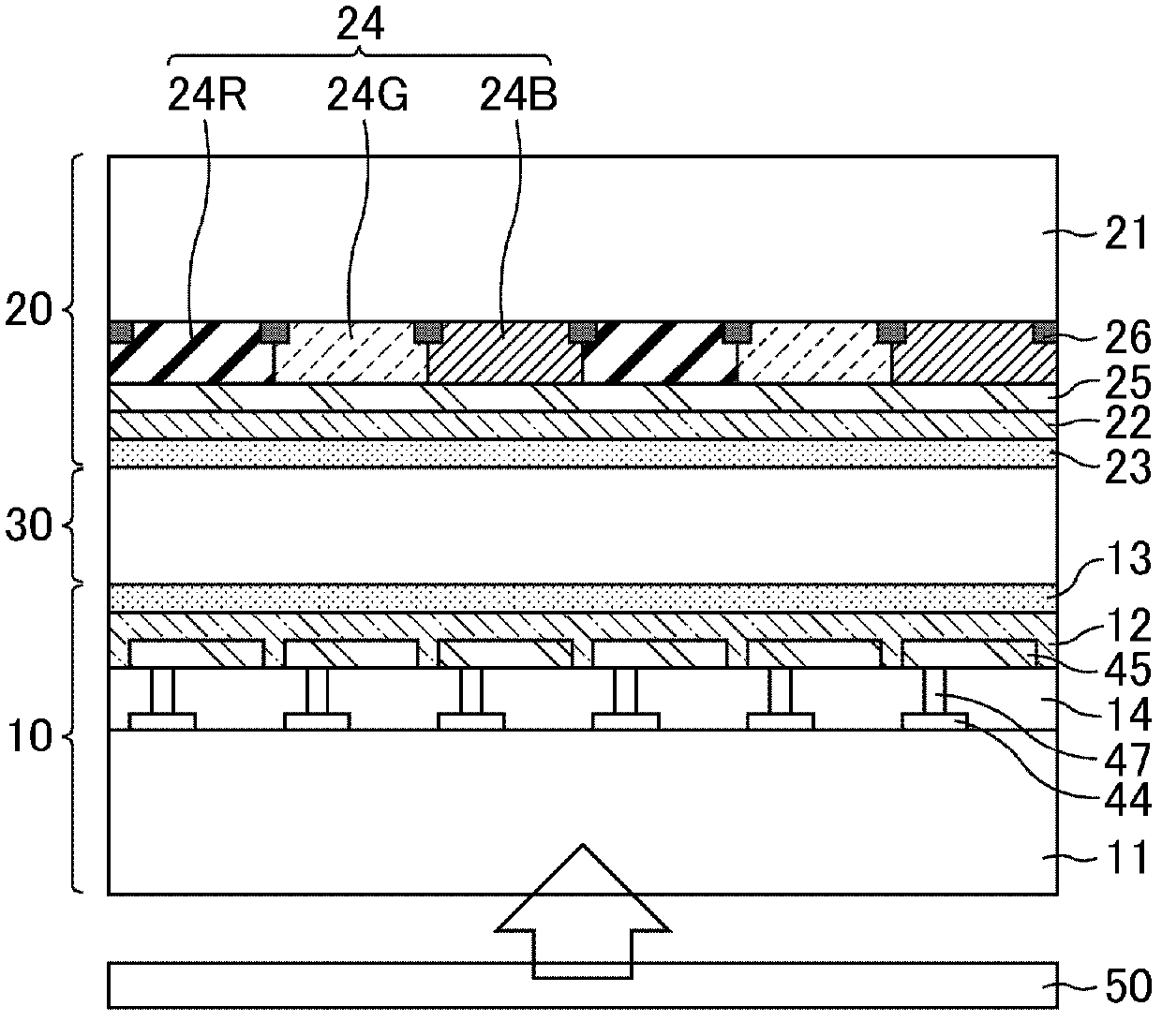

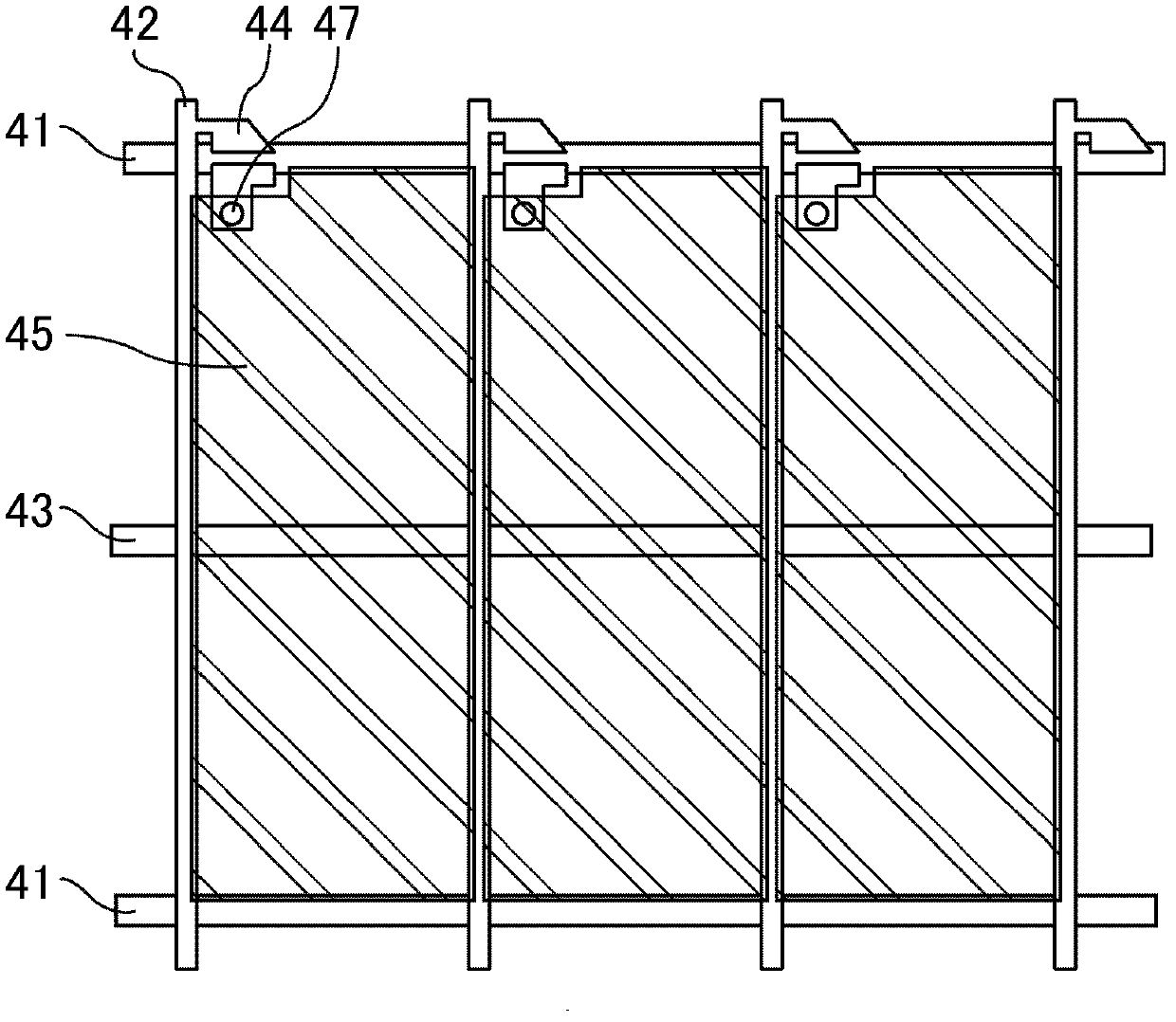

Liquid crystal display device

The present invention relates to a liquid crystal display device which has a polymer layer that is formed on an alignment film and controls the alignment of liquid crystal molecules adjacent thereto. The polymer layer is formed by polymerizing monomers that are added into a liquid crystal layer, and the monomers are compounds represented by general formula (I). P1-A1-(Z1-A2)n-P2 (I) (In the formula, P1 and P2 may be the same as or different from each other and each represents an acrylate group or a methacrylate group; in cases where there are a plurality of Z1 moieties, the Z1 moieties may be the same as or different from each other and each represents COO, OCO or O, or alternatively represents that A1 and A2 or A2 and A2 are directly bonded with each other; a hydrogen atom may be substituted by a halogen atom, a methyl group, an ethyl group or a propyl group; and A1 and A2 may be the same as or different from each other and each represents a specific phenanthrene group.) The light source of a backlight is composed of at least one light emitting diode, and each light emitting diode substantially emits only such light that has a wavelength of 400 nm or more.

Owner:MERCK PATENT GMBH

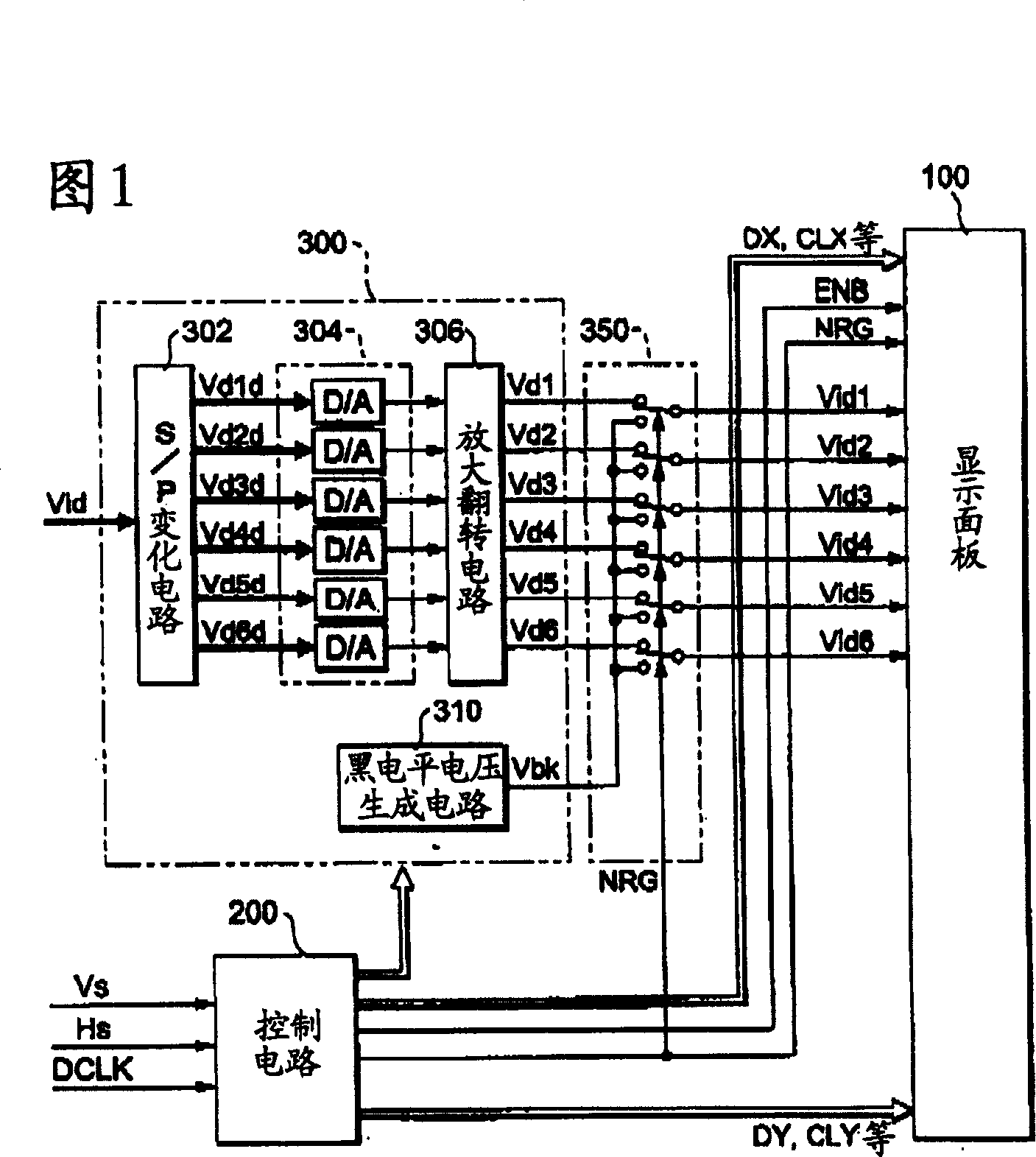

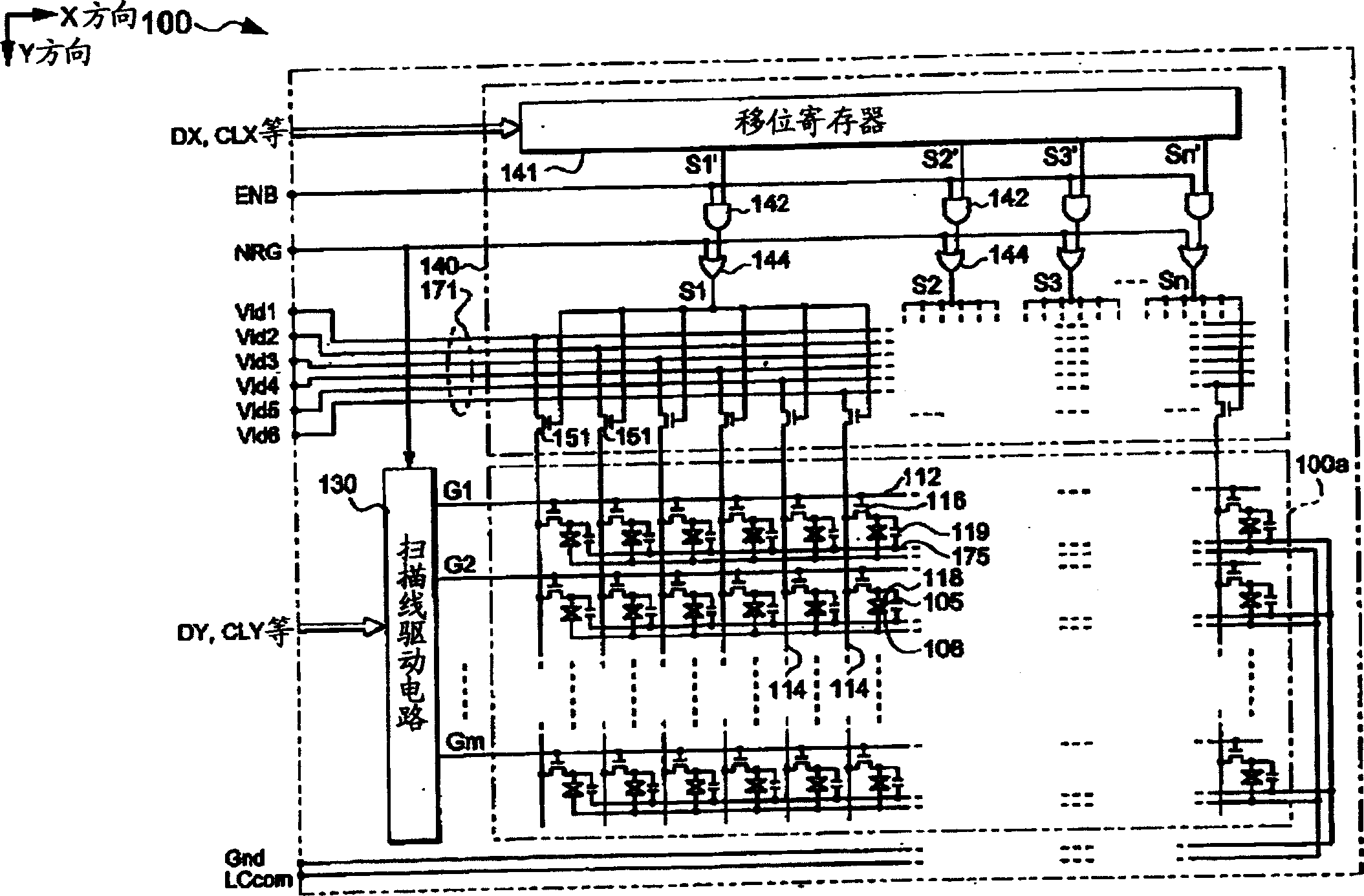

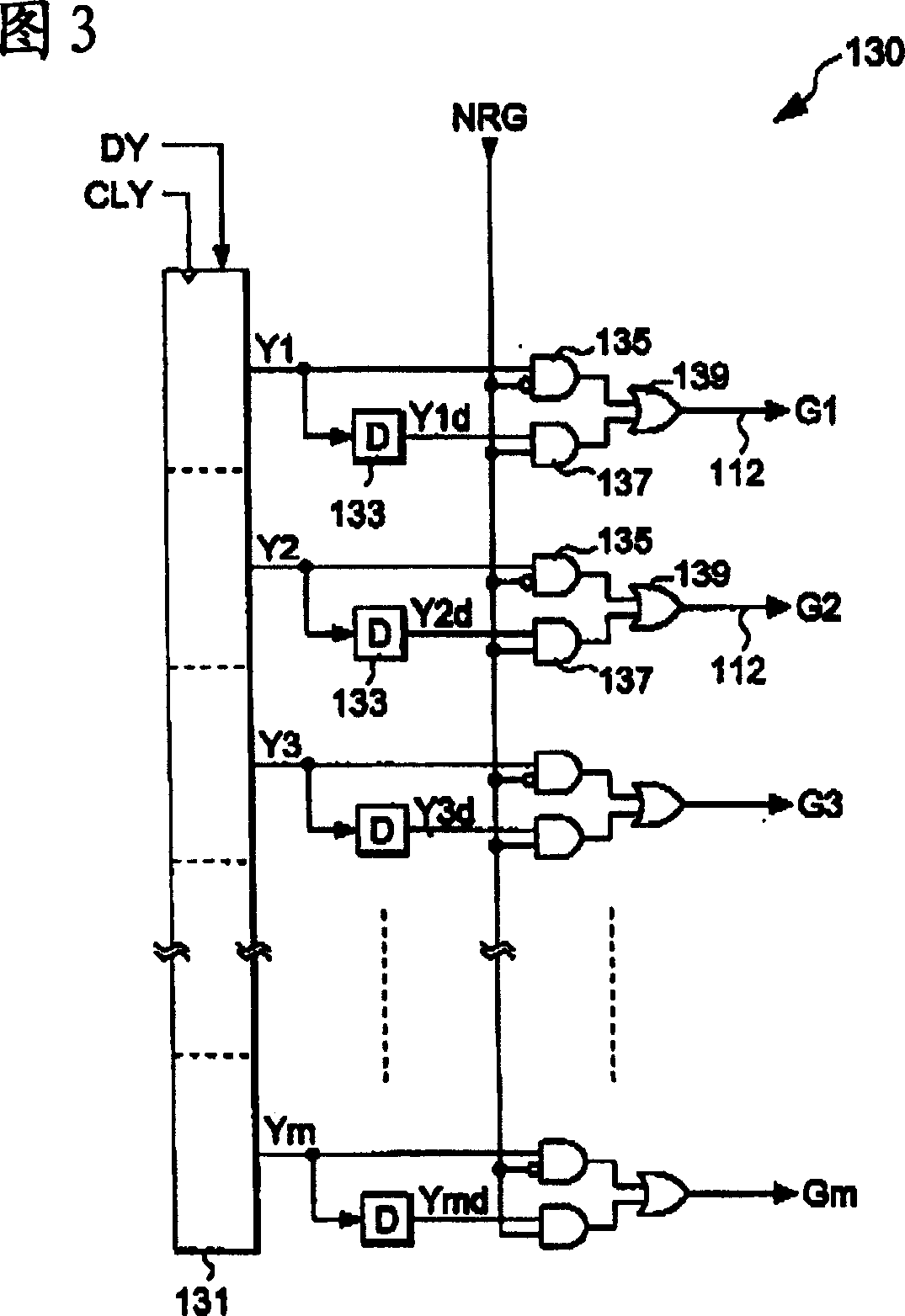

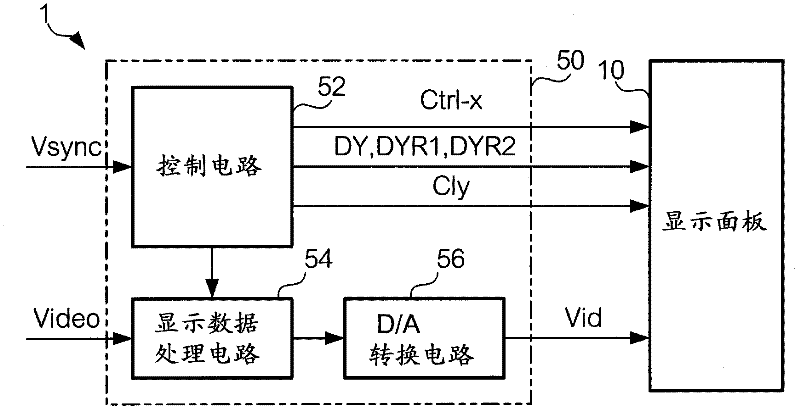

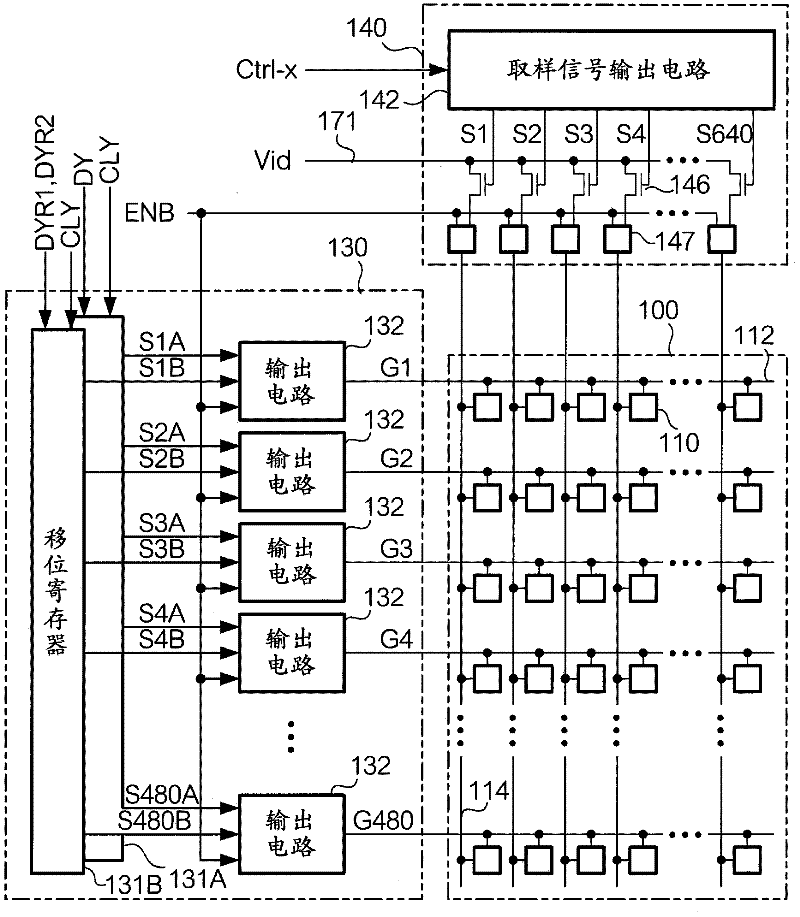

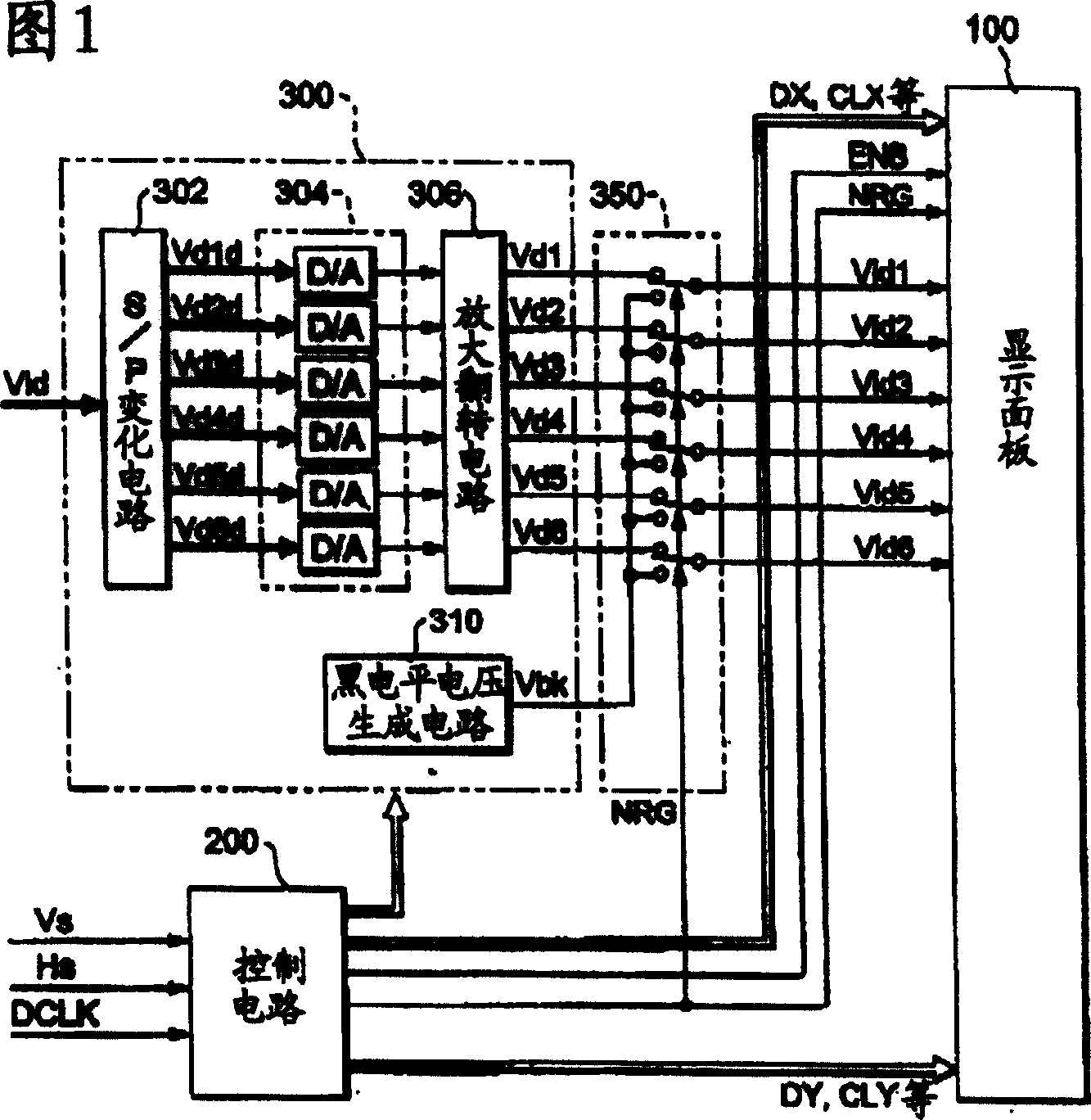

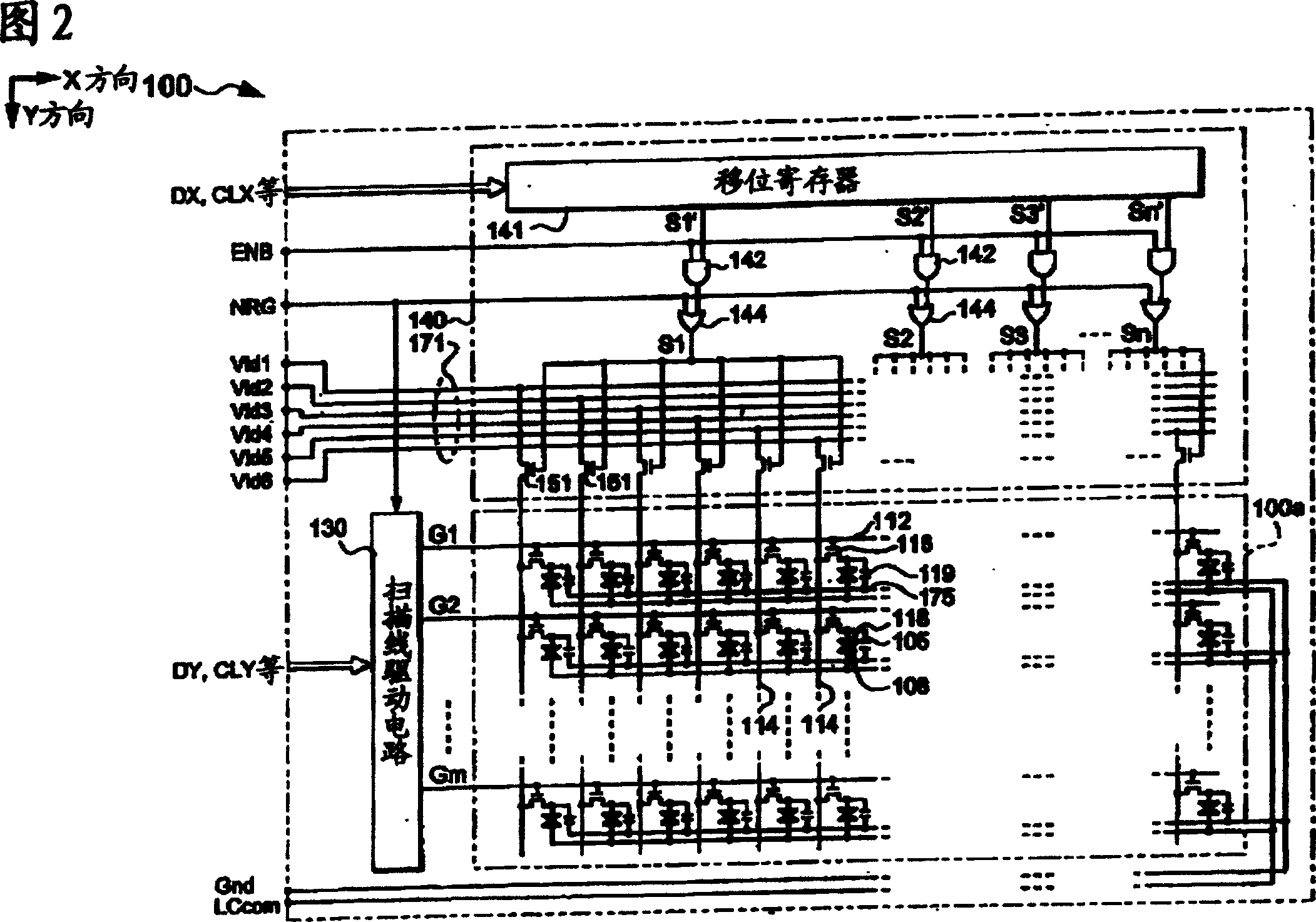

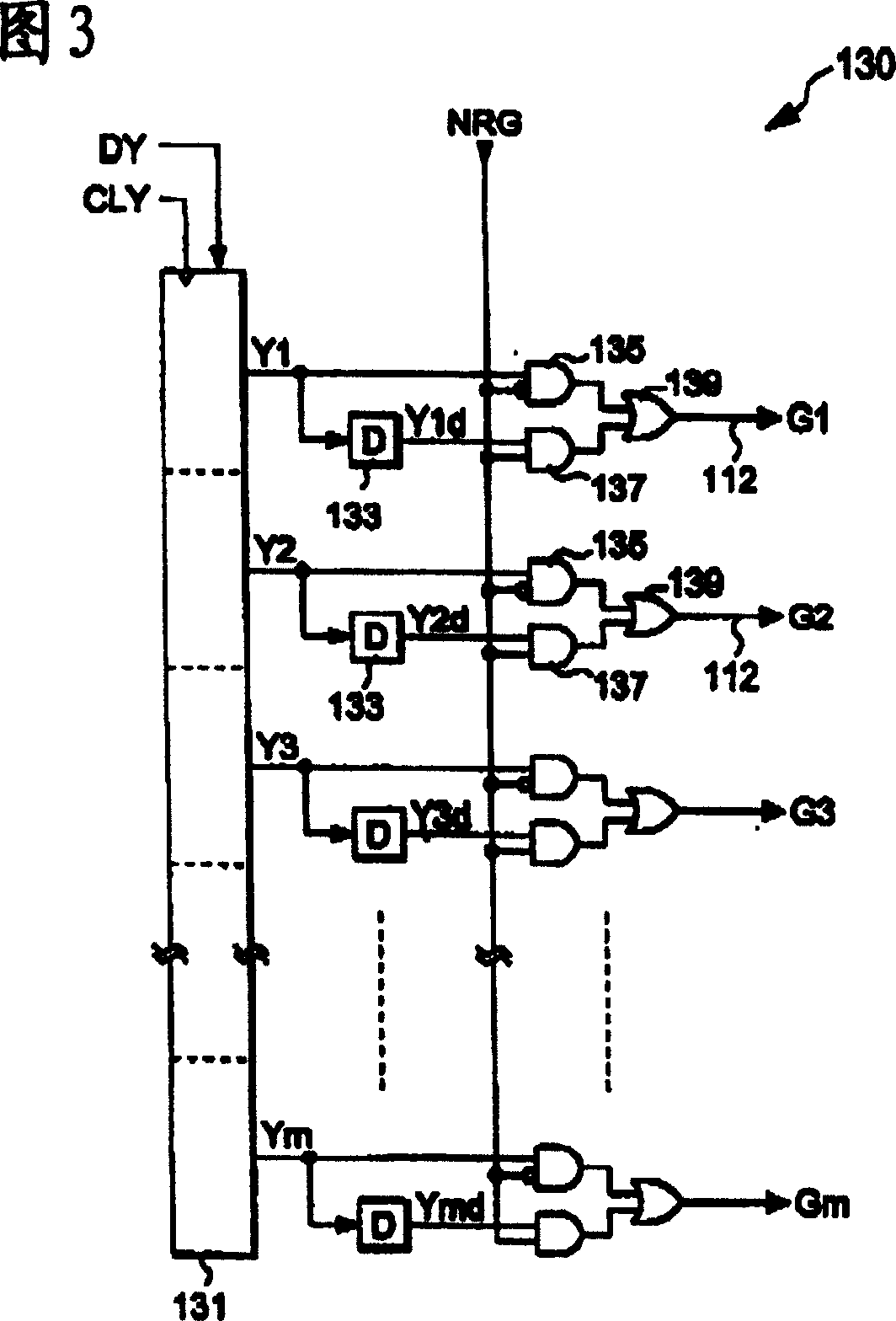

Electro-optical device, its driving circuit, driving method and electronic apparatus

InactiveCN1648983ASuppress afterimageChiropractic devicesCathode-ray tube indicatorsLiquid crystalData lines

To improve the display quality of a moving picture by performing a hold-type display of a liquid crystal, etc. using an impulse-type response. A selection voltage is applied to a selected scanning line during an effective horizontal scan period, and a voltage corresponding to the brightness of a pixel corresponding to an intersection with the selected scanning line is applied to one data line. During a horizontal flyback period when another scanning line is selected, a selection voltage is applied to the selected scanning line and a voltage allowing the pixel to display black as the least brightness is applied to the data line. As a result, the display of the pixel is erased and the data lines are precharged with the voltage erasing the display, for preparation of the subsequent writing operation.

Owner:SEIKO EPSON CORP

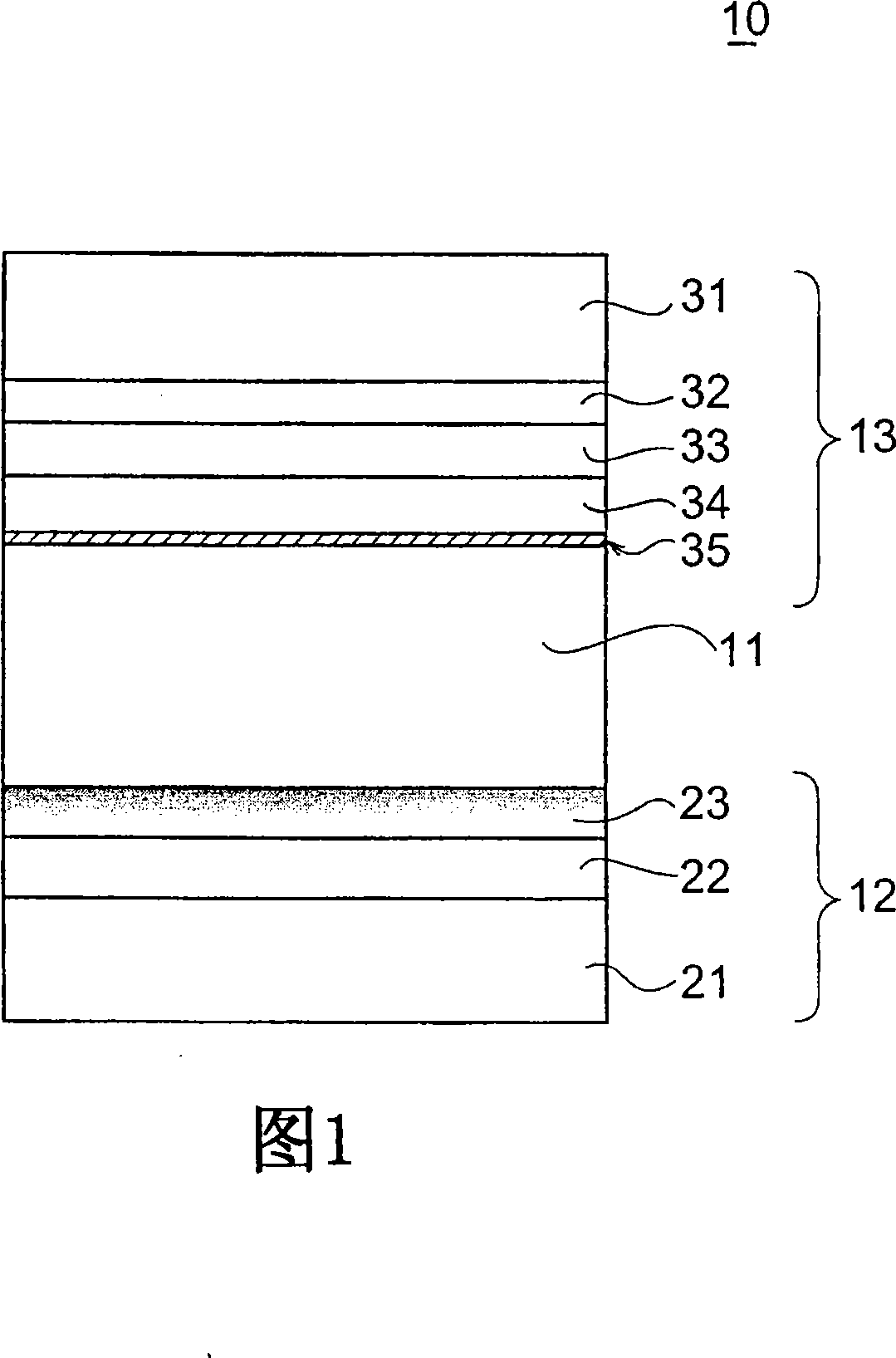

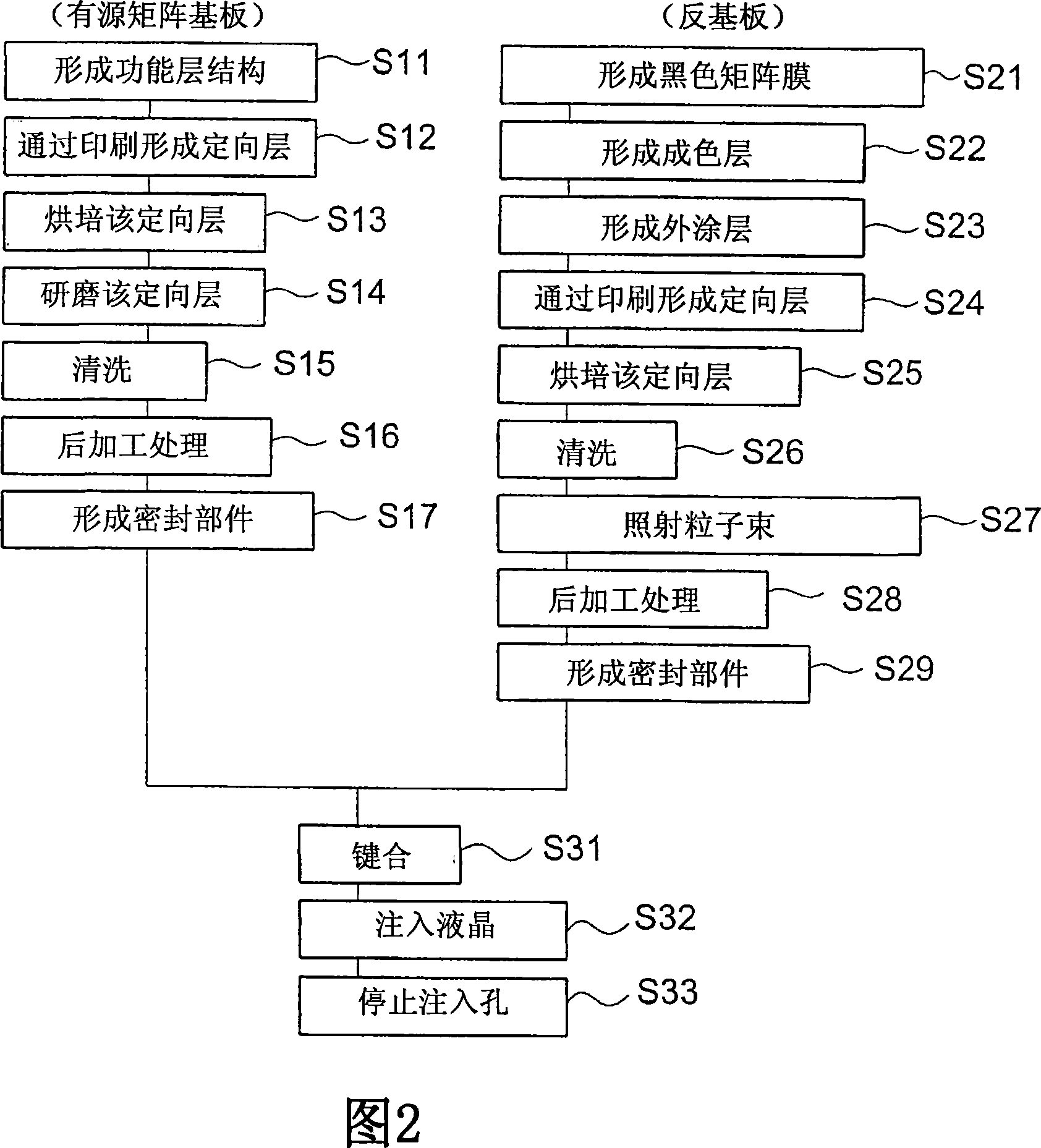

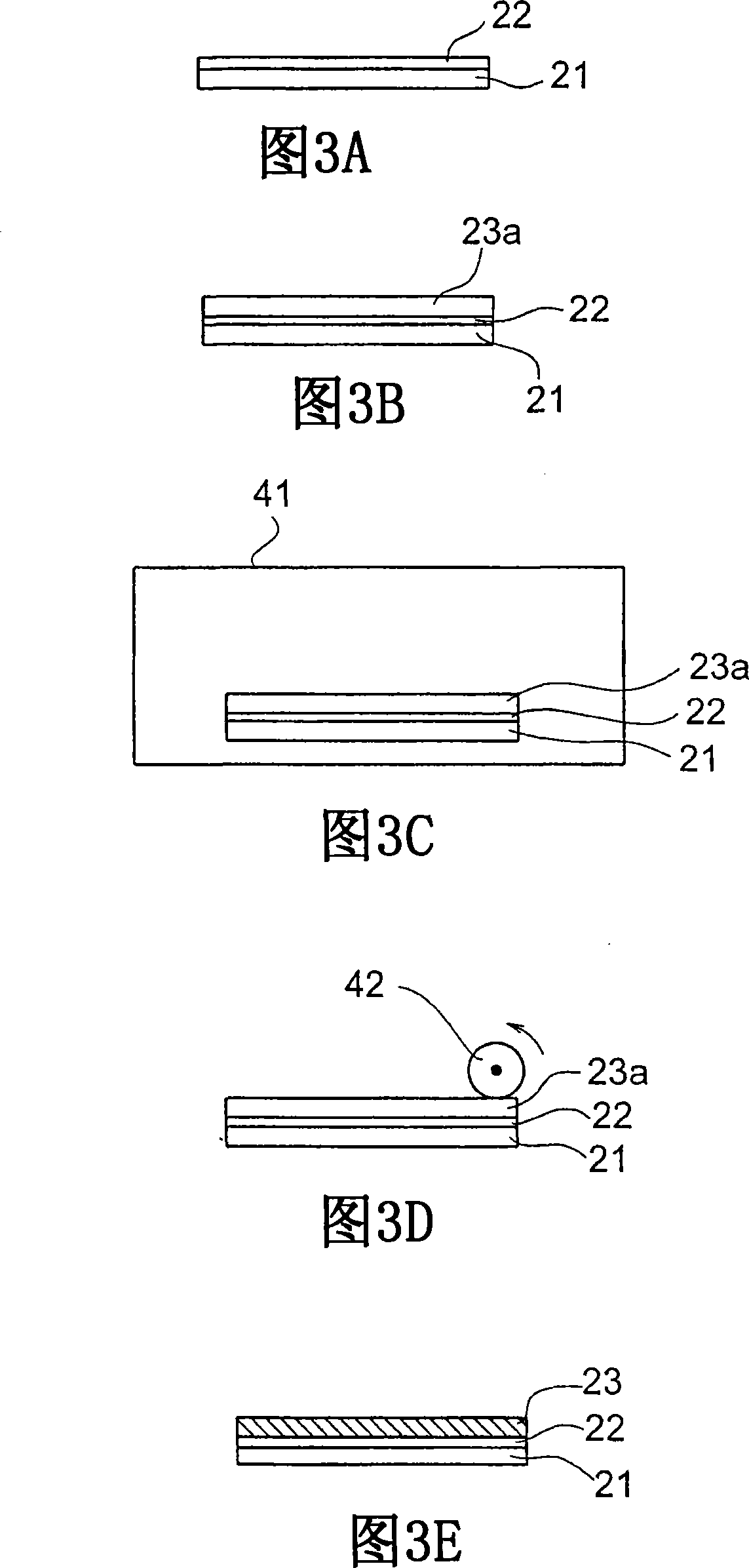

Ips-mode LCD device having an improved image quality

InactiveCN101126878AImprove image qualitySuppress afterimageNon-linear opticsLiquid-crystal displayImaging quality

A LCD panel includes a LC layer, an active-matrix substrate including an electrode layer for applying a lateral electric field to the LC layer, and a counter substrate opposing the active-matrix substrate with an intervention of the LC layer 11. The active-matrix substrate includes a first alignment film formed in the surface which touches the LC layer 11 by the rubbing technique is formed, and second alignment film 35 formed in the surface which touches the LC layer 11 by the particle beam glaring technique is formed on the counter substrate 13.

Owner:NEC LCD TECH CORP

Electrooptic device, method for controlling electrooptic device, and electronic apparatus

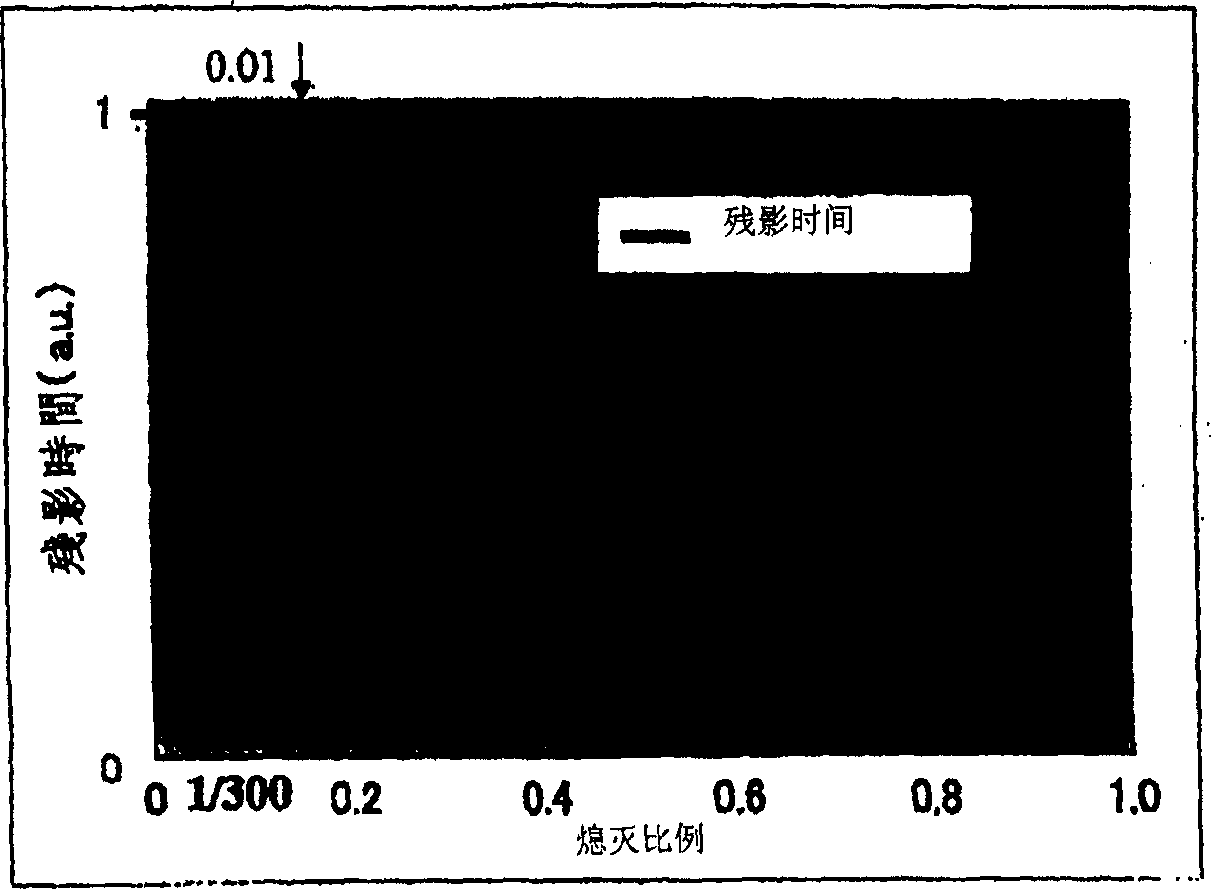

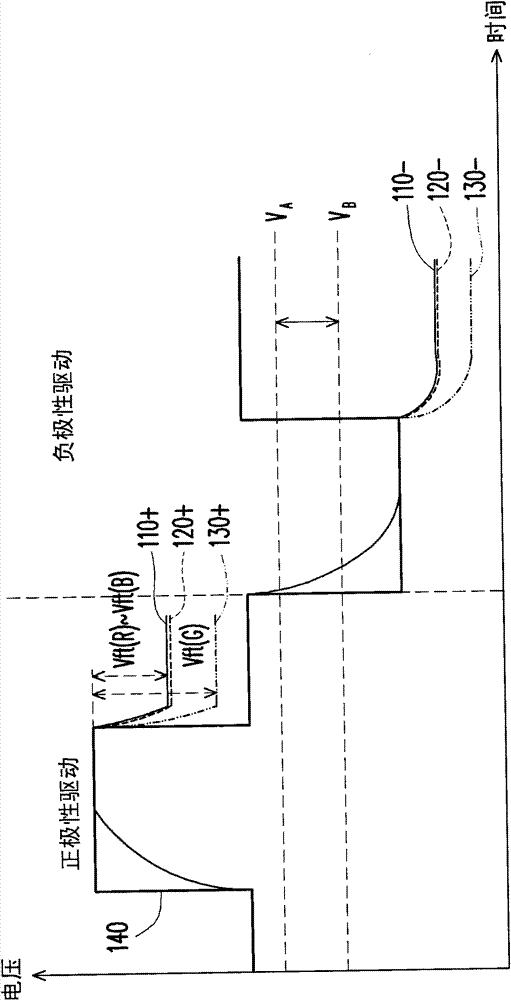

In writing performed at a start pulse DY1, the writing is performed with a positive-polarity voltage, and, in writing performed at a start pulse DY2, the writing is performed with a negative-polarity voltage. In writing performed at start pulses DYR1 and DYR2, the writing is performed with a voltage that turns pixels into black of minimum gradation. Since a period in which the positive-polarity voltage is retained is different from a period in which the negative-polarity voltage is retained, a direct-current component which is applied to a liquid crystal capacitor is cancelled, whereby the occurrence of burn-in is prevented.

Owner:SEIKO EPSON CORP

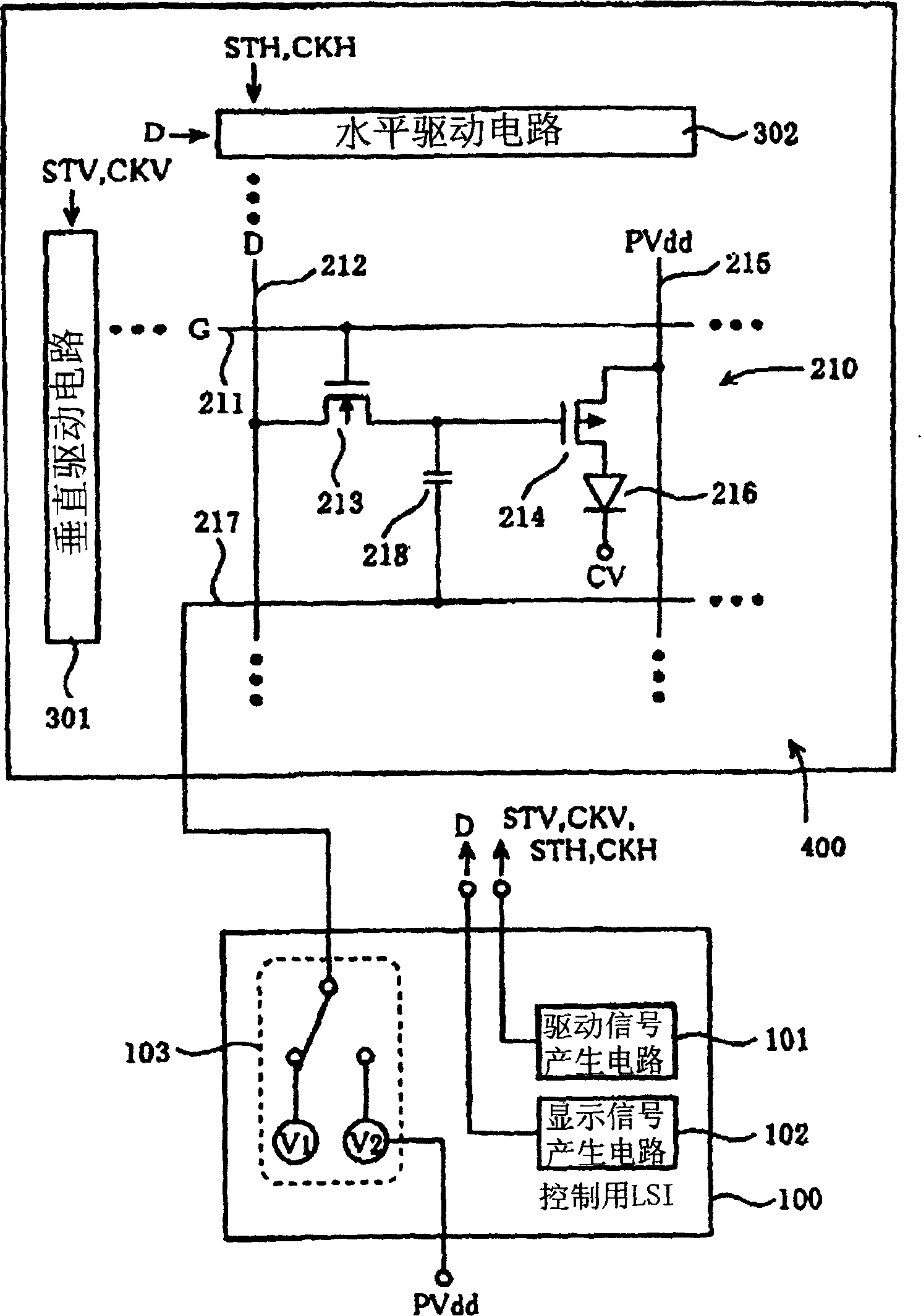

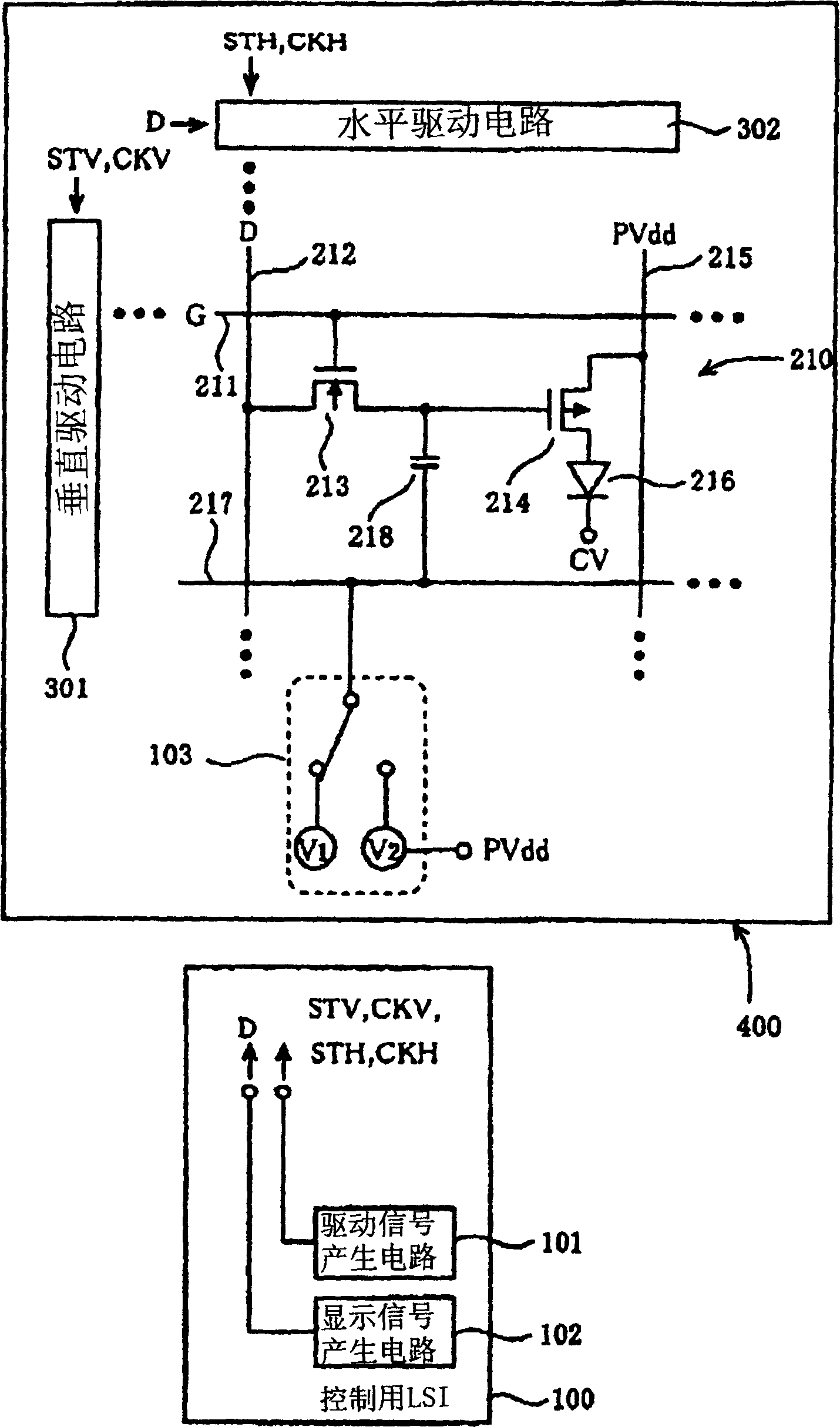

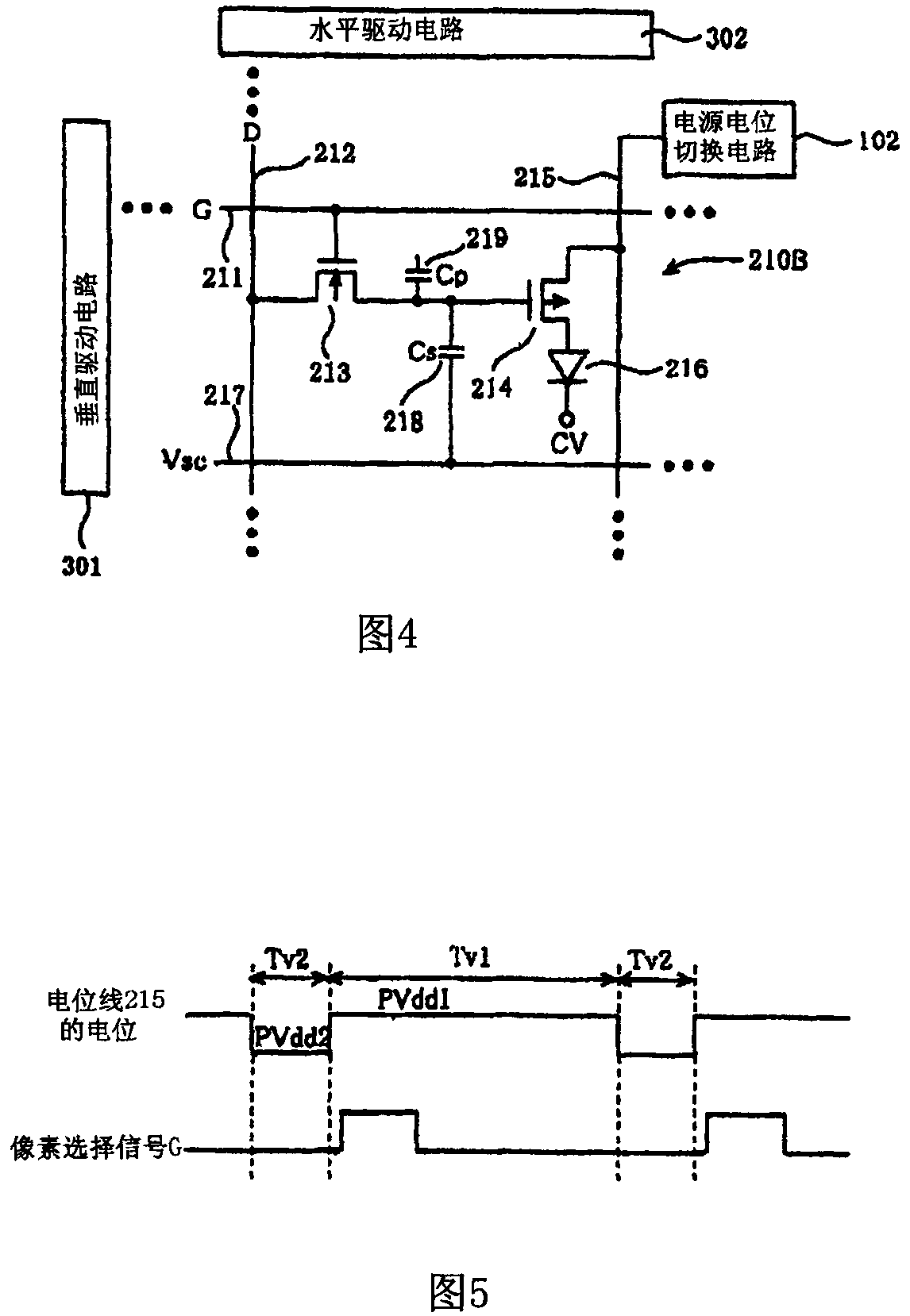

Active matrix type display device and driving method thereof

ActiveCN101763823ASuppress afterimageSuppress bright spot defectsStatic indicating devicesActive matrixDisplay device

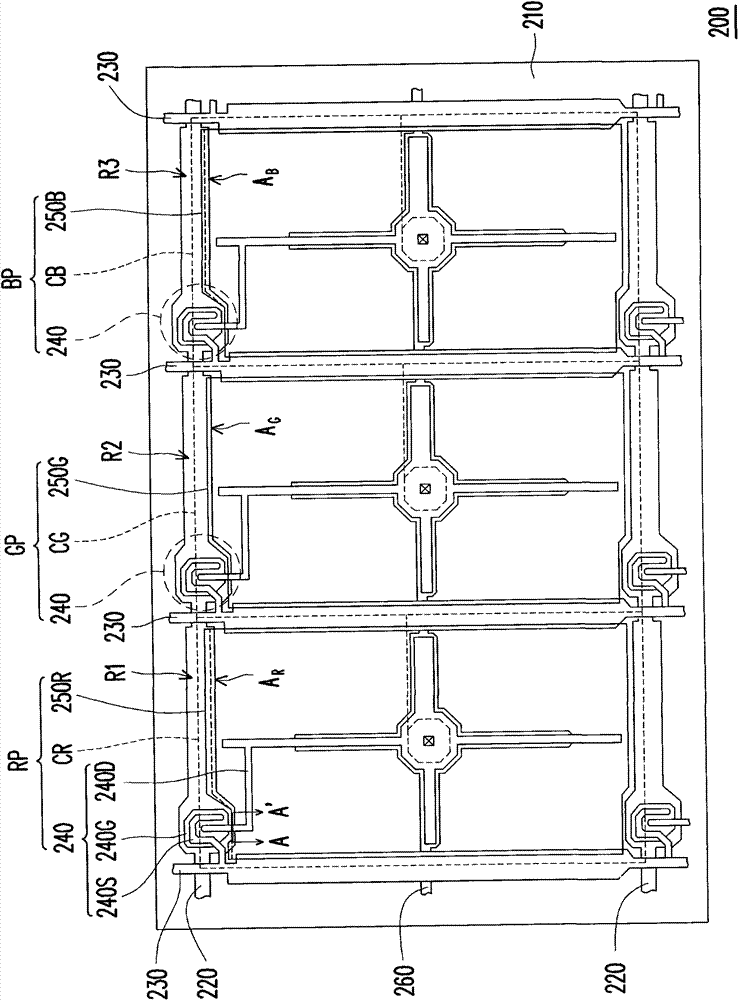

A storage capacitor line potential switching circuit 101 switches potential of a storage capacitor line 217 from first potential Vsc1 to second potential Vsc2 higher than the first potential Vsc1, and at the same time, a power source potential switching circuit 102 switches potential of a power source line 215 from first power source potential PVdd1 to second power source potential PVdd2 lower than the first power source potential PVdd1. By a synergistic effect of them, gate potential Vg of a TFT 214 for drive becomes higher than threshold Vtp to its source potential. If a positive hole is trapped to a gate insulating film of the TFT 214 for drive by writing of a display signal D in the previous time, the positive hole is extracted from the gate insulating film to a source or a drain. Thus, electronic characteristics of the TFT 214 for drive are initialized.

Owner:SANYO ELECTRIC CO LTD

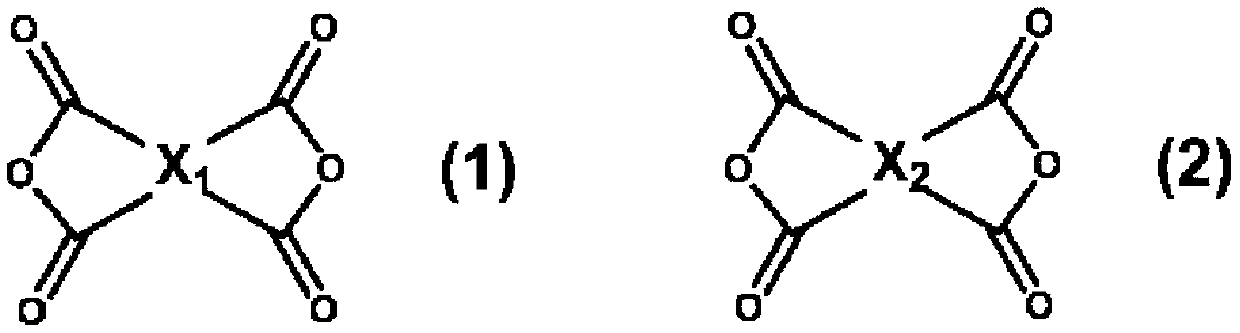

Liquid crystal alignment agent, liquid crystal alignment film, and liquid crystal display element

ActiveCN110325902AGood orientationExcellent electrical propertiesLiquid crystal compositionsNon-linear opticsImidePolymer science

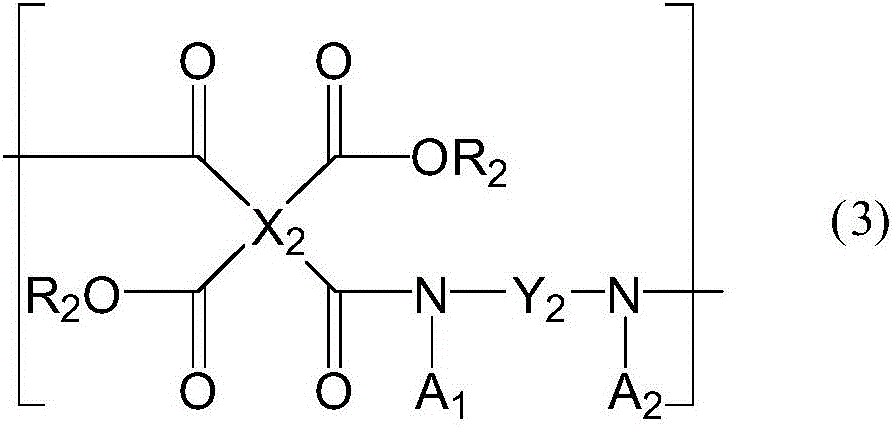

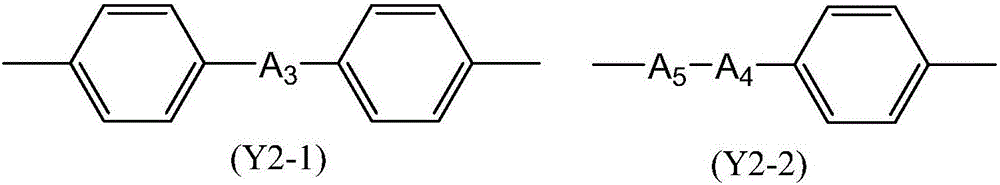

Provided is a liquid crystal alignment agent containing at least one polymer selected from among polyimide precursors and polyimides that are imidized products thereof obtained from: a tetracarboxylicacid derivative component containing at least one substance selected from among a tetracarboxylic acid dianhydride represented by formula (1) and derivatives thereof and at least one substance selected from among a tetracarboxylic acid dianhydride represented by formula (2) and derivatives thereof; and a diamine component containing at least one diamine selected from between formulas (3) and (4).

Owner:NISSAN CHEM IND LTD

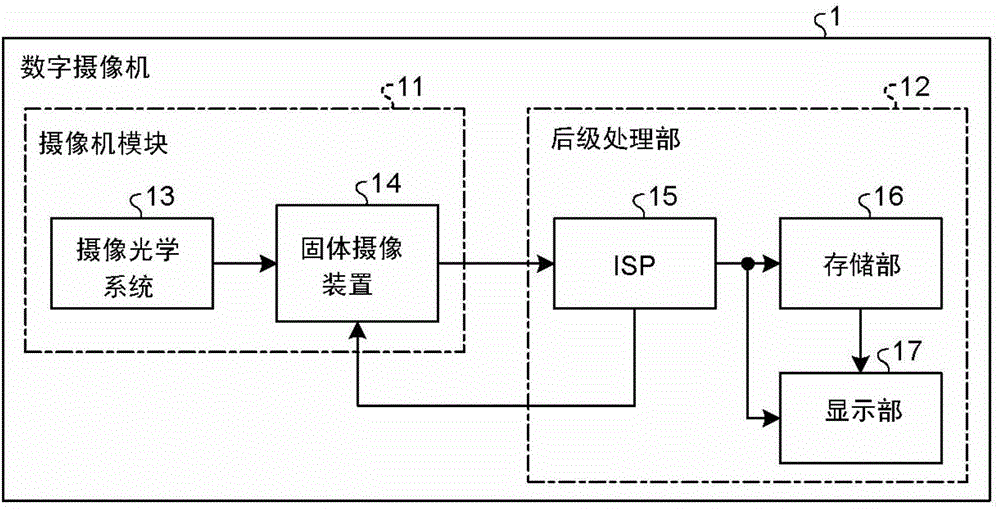

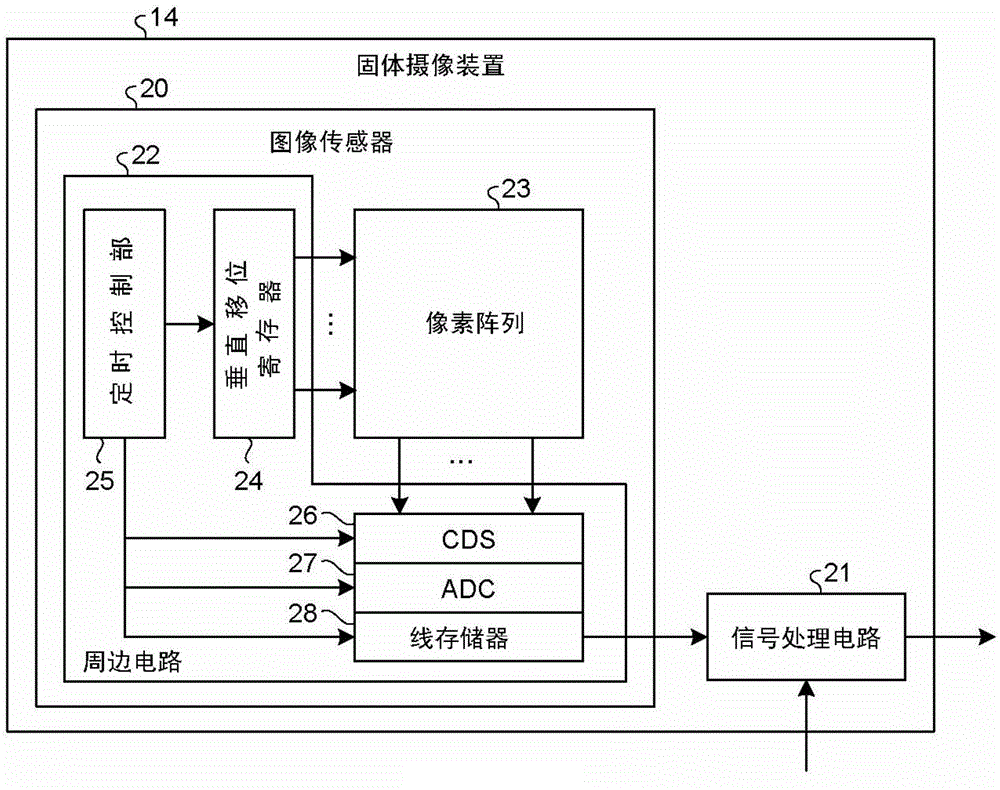

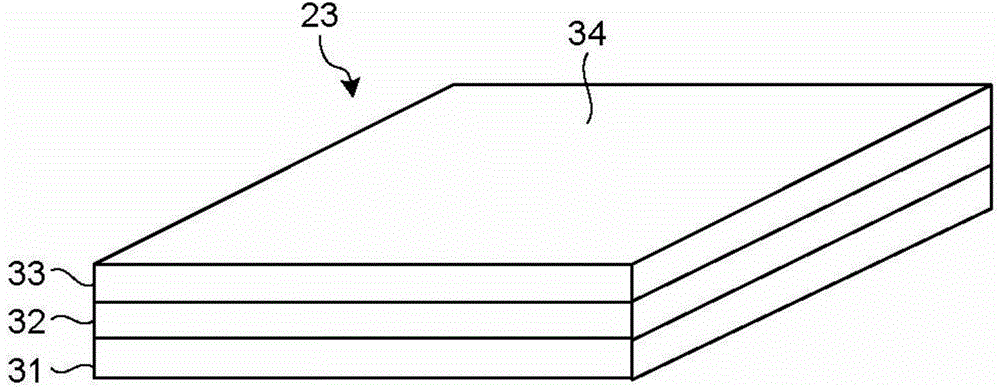

Solid-state imaging device and method for manufacturing solid-state imaging device

InactiveCN105304657ASuppress afterimageTransistorSolid-state devicesEngineeringPhotoelectric conversion

The invention relates to a solid-state imaging device and a method for manufacturing a solid-state imaging device. The solid-state imaging device includes a semiconductor layer, a charge transfer region, a floating diffusion (FD), and a reading gate. The semiconductor layer is provided with a photoelectric conversion element. The charge transfer region is formed on a surface of the semiconductor layer over a charge accumulation region in the photoelectric conversion element. The FD is provided on the charge transfer region to hold a charge transferred from the charge accumulation region. The reading gate is provided on a side surface of the FD and a side surface of the charge transfer region via an insulating film.

Owner:KK TOSHIBA

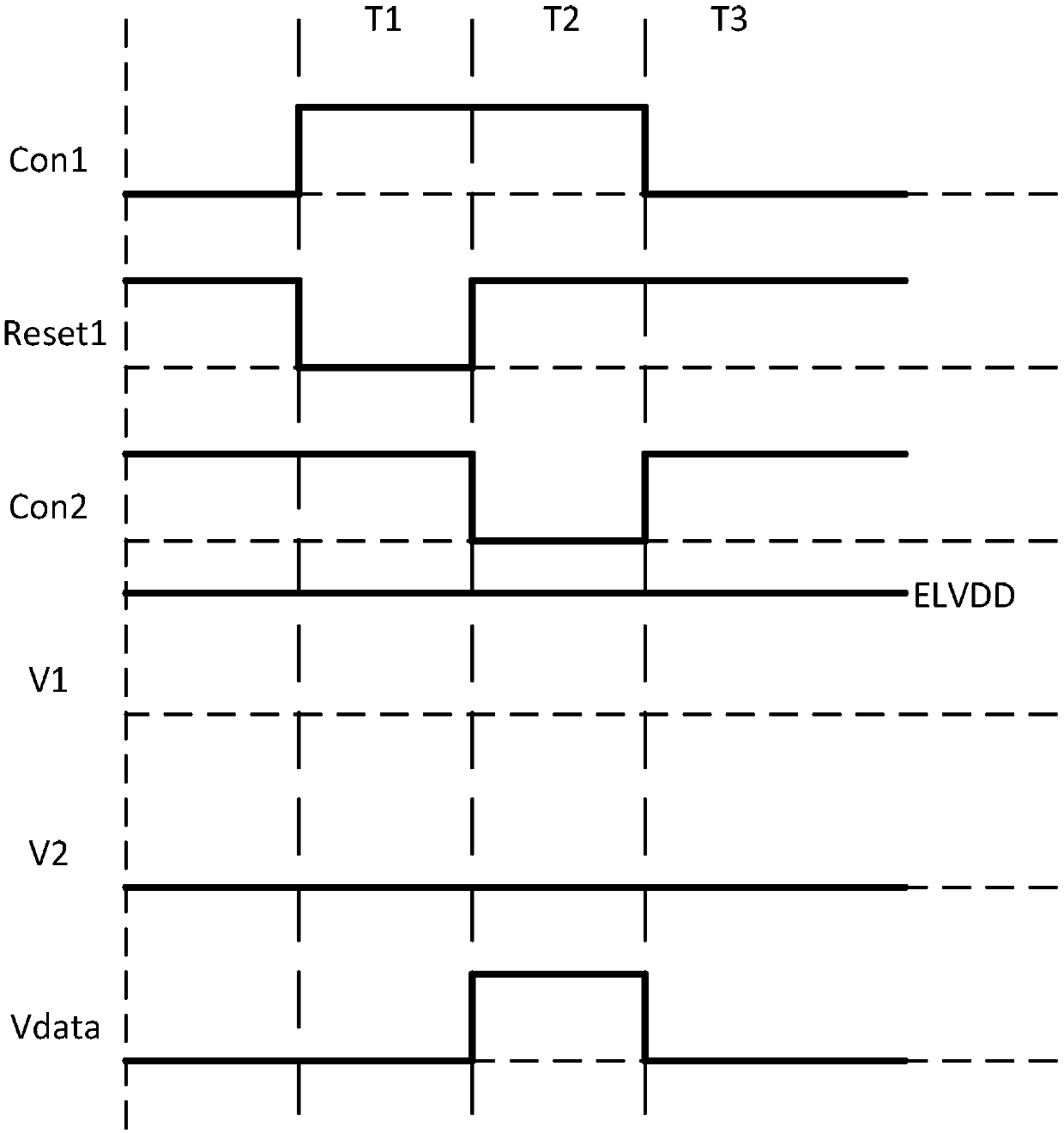

Pixel circuit, driving method thereof and display panel

The invention provides a pixel circuit, a driving method thereof and a display panel. The pixel circuit includes: a light emitting element; a driving sub-circuit configured to generate a current for causing the light emitting element to emit light; a first light-emitting control sub-circuit and the second light-emitting control sub-circuit, respectively configured to supply current for enabling the light-emitting element to emit light to the first end of the light-emitting element under the control of a first control signal; a driving control sub-circuit, configured to provide the data voltagesignal to the driving sub-circuit under the control of the second control signal; and a reset sub-circuit, configured to use the second voltage to reset the driving sub-circuit, the first end of thelight-emitting element and the second node under the control of the first reset signal and the second reset signal.

Owner:BOE TECH GRP CO LTD +1

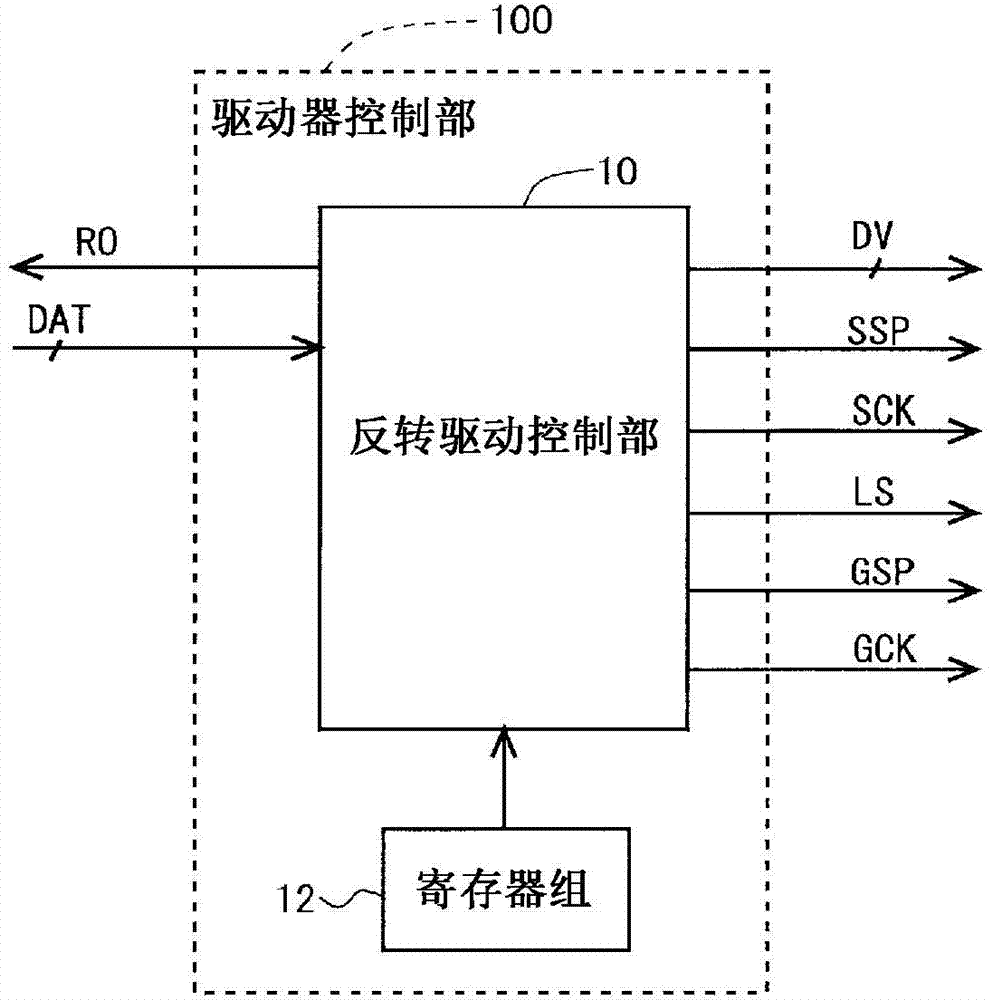

Liquid crystal device and method for driving same

InactiveCN104781871APrevent pixel voltage dropReduce power consumptionStatic indicating devicesLiquid-crystal displayComputer science

A liquid crystal display device which implements a pause-drive technique, wherein flickering is effectively suppressed while also suppressing increases in power consumption. When a frame, to which an image signal (DAT) is inputted from the outside without outputting a request signal (RO) that makes a request to the outside for the input of the image signal (DAT), is defined as a first input frame, an inversion drive control unit (10) specifies that the first input frame is a refresh frame defined as a first refresh frame, also specifies that the inversion drive technique of the first input frame is the column inversion drive technique, specifies that the three frames following the first refresh frame are pause frames, specifies that the frame following the final pause frame is a refresh frame defined as a second refresh frame, and specifies that the inversion drive technique of the second refresh frame is the dot inversion drive technique.

Owner:SHARP KK

Alignment layer group and its manufacturing method, substrate and display device

InactiveCN103576389BImprove display qualityIncrease contrastNon-linear opticsLiquid-crystal displayDisplay device

The invention relates to the technical field of liquid crystal display, in particular to an alignment layer set, a manufacturing method thereof, a substrate and a display device. The alignment layer set comprises friction alignment layers and smooth alignment layers, wherein the friction alignment layers and the smooth alignment layers are arranged on the upper surface of the substrate in the direction far away from the upper surface of the substrate, and the orientation of the friction alignment layers is identical with that of the smooth alignment layers. According to the alignment layer set, the manufacturing method thereof, the substrate and the display device, a structure of combining the smooth alignment layers and the friction alignment layers is adopted, and the purposes of improving the contrast ratio of liquid crystal panels and simultaneously restraining the generation of residual images to improve the display quality of the liquid crystal panels are achieved by covering detects generated in the friction alignment layers through the smooth alignment layers and by using the anchoring energy of the friction alignment layers for compensating the defect that the smooth alignment layers are poor in anchoring engine.

Owner:BOE TECH GRP CO LTD

Method for producing liquid crystal alignment film, liquid crystal alignment film, and liquid crystal display element

ActiveCN104838311BReduce afterimageIncreased anisotropyCoatingsNon-linear opticsLiquid-crystal displayOrganic solvent

Provided is a method for producing a photoalignment liquid crystal alignment film which is capable of minimizing afterimages resulting from AC driving. Polarized radiation is applied to a film obtained by applying and sintering a liquid crystal alignment agent, which contains at least one type of polymer selected from a group comprising polyimide precursors represented by formula (1) and imidized polymers of said polyimide precursors, on a substrate. After the film has been brought into contact with an organic solvent having a boiling point of 110 to 180°C, the film is then brought into contact with water or a water-soluble organic solvent having a boiling point of 50 to 105°C before being treated with heat at 150°C or above. (X1 represents the formula (XA-1); Y1 represents a divalent organic group; R1 represents H or the like; and R3 to R6 represent H or the like.)

Owner:NISSAN CHEM CORP

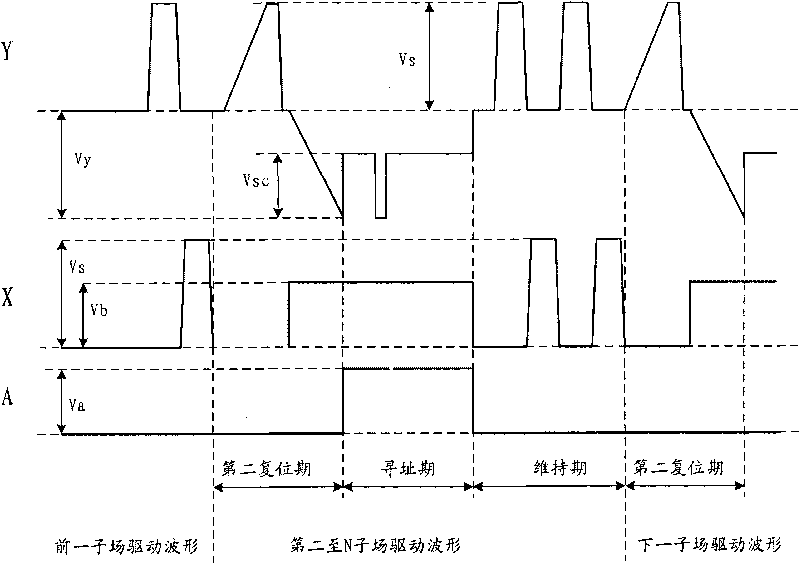

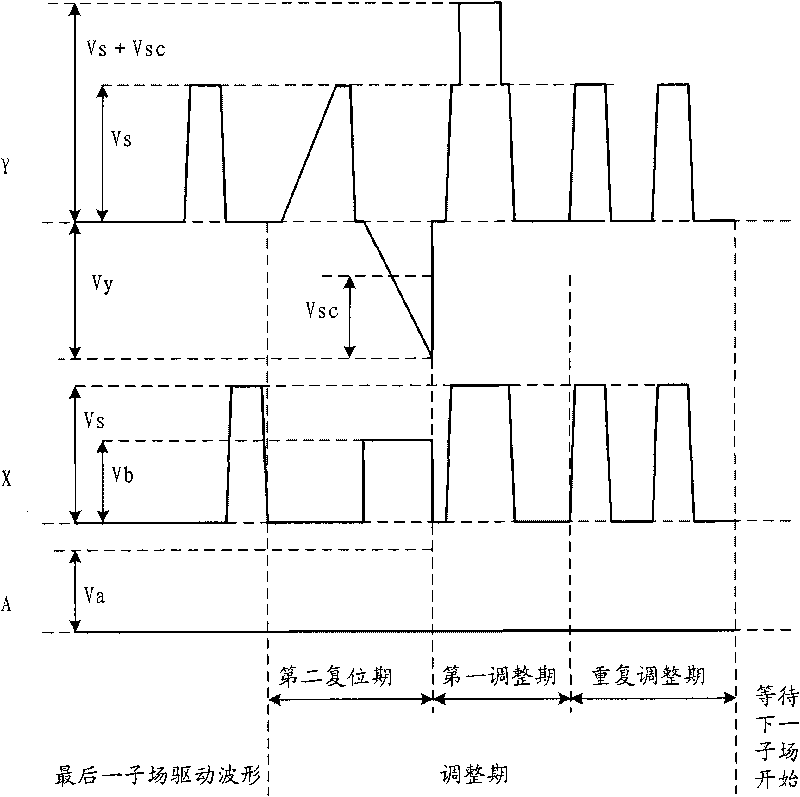

Active matrix type display device and driving method thereof

ActiveCN1838218ASuppress afterimageSuppress bright spot defectsElectrical apparatusStatic indicating devicesCapacitanceActive matrix

A residual image effect is suppressed to improve quality of display of an active matrix type display device. A capacitor line electric potential switching circuit switches an electric potential of a capacitor line from a first capacitor electric potential Vsc 1 to a second capacitor electric potential Vsc 2 that is higher that the first capacitor electric potential Vsc 1 , while a power supply electric potential switching circuit switches an electric potential of a power supply line from a first power supply electric potential PVdd 1 to a second power supply electric potential PVdd 2 that is lower than the first power supply electric potential PVdd 1 . As a result of synergistic effect, an electric potential Vg at a gate of a driver TFT becomes higher than an electric potential at its source by more than a threshold voltage Vtp of the driver TFT. Assuming carriers are trapped in a gate insulation film of the driver TFT due to writing-in of a display signal in a preceding frame period, the carriers are extracted from the gate insulation film to the source or a drain of the driver TFT. With this, electric characteristics of the driver TFT are initialized.

Owner:SANYO ELECTRIC CO LTD

Electro-optical device, its driving circuit, driving method and electronic apparatus

InactiveCN100365696CSuppress afterimageChiropractic devicesCathode-ray tube indicatorsDriver circuitEngineering

To improve the display quality of a moving picture by performing a hold-type display of a liquid crystal, etc. using an impulse-type response. A selection voltage is applied to a selected scanning line during an effective horizontal scan period, and a voltage corresponding to the brightness of a pixel corresponding to an intersection with the selected scanning line is applied to one data line. During a horizontal flyback period when another scanning line is selected, a selection voltage is applied to the selected scanning line and a voltage allowing the pixel to display black as the least brightness is applied to the data line. As a result, the display of the pixel is erased and the data lines are precharged with the voltage erasing the display, for preparation of the subsequent writing operation.

Owner:SEIKO EPSON CORP

Driving device and method for plasma display

InactiveCN101727818BImprove adaptabilitySuppress afterimageStatic indicating devicesImage detectionDisplay device

The invention provides an actuating device for a plasma display, which is characterized in that: the actuating device comprises an image detection module which is used for judging whether the imaged displayed by the display is in one of a long-term static mode, a dynamic mode, and a mode from the static mode to the dynamic mode and outputting a judgment result; and a driving control module which is used for setting the actuating mode according to the judgment result output from the image detection module; by adopting the invention, the purpose of inhibiting residual images is achieved, and the adaptability of PDP display devices in various occasions can be improved.

Owner:SICHUAN COC DISPLAY DEVICES

Liquid crystal alignment agent and liquid crystal panel

ActiveCN110832393AImprove thermal stabilityImprove solubilityLiquid crystal compositionsNon-linear opticsCrystallographyVertical alignment

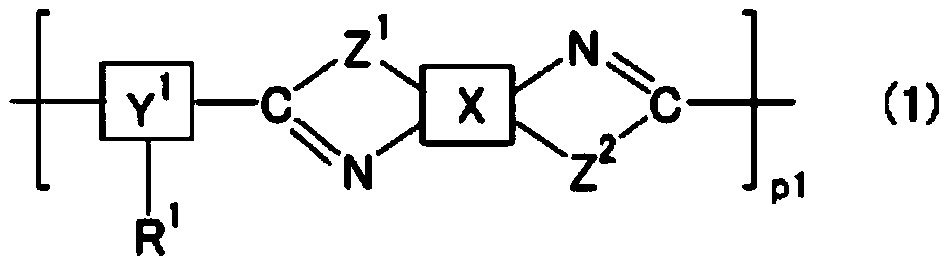

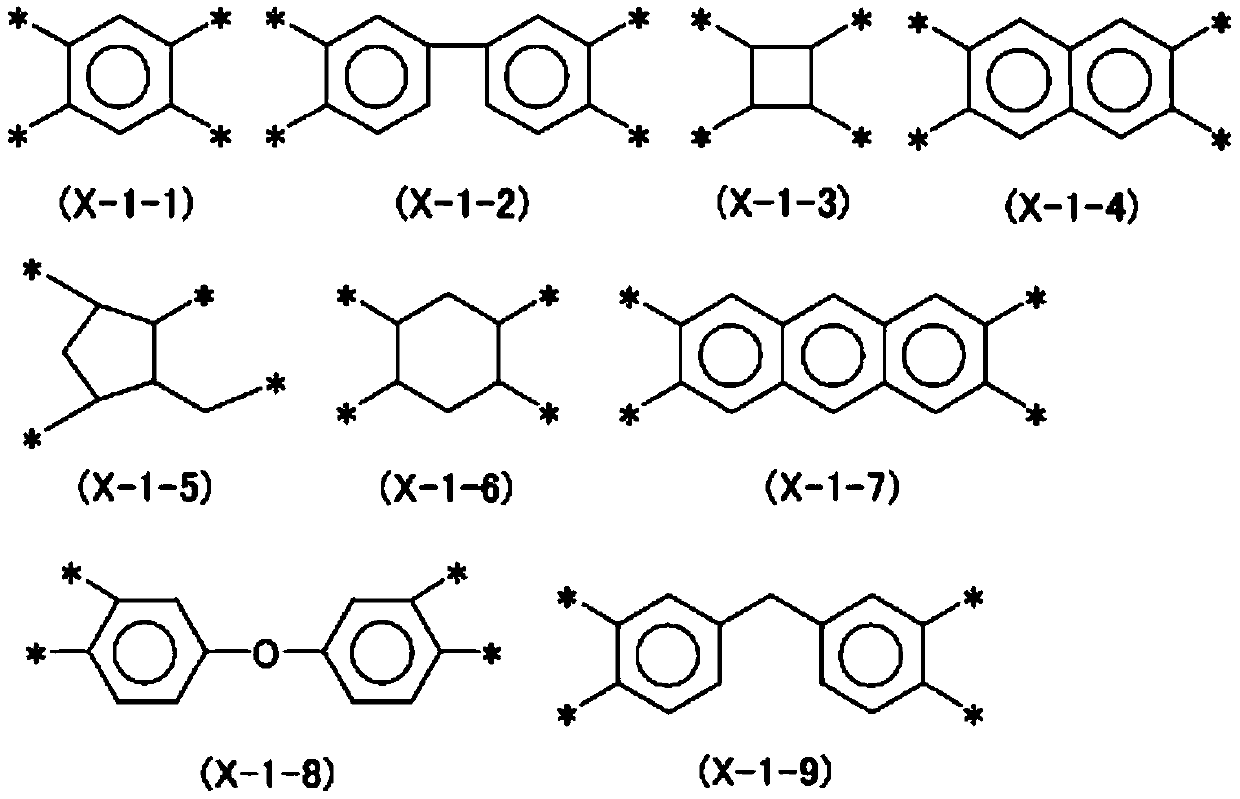

The present invention provides: a liquid crystal alignment agent that has excellent thermal stability and solvent solubility; and a liquid crystal panel that allows inhibition of generation of ghosting and stains and inhibition of decrease of contrast even in high-temperature environments over a long time period. The present invention is a liquid crystal alignment agent that includes: a solvent; and a copolymer including a structure represented by chemical formula (1). In the formula, X represents a specific structure that includes a cyclic hydrocarbon group, Y1 represents a specific structurethat includes a cyclic hydrocarbon group, R1 represents a horizontal alignment group, a vertical alignment group, or a photoreactive functional group, and Z1 and Z2 are the same or different from each other and each represent a -NH-group, an -O-group, or an -S-group.

Owner:SHARP KK

Active component array substrate

InactiveCN101901802BSuppress color castSuppress afterimageSolid-state devicesNon-linear opticsCapacitanceActive component

The invention discloses an active component array substrate, which comprises a substrate, a plurality of scanning lines, a plurality of data lines and a plurality of pixels. The scanning lines and the data lines are configured on the substrate; each pixel comprises a plurality of sub-pixels; and each sub-pixel comprises at least one transistor, a pixel electrode and a color filter film. The transistor is configured on the substrate and is electrically connected with a corresponding scanning line and a corresponding data line; partial color filter film is positioned between the pixel electrodeand the scanning line; and the pixel electrode and a corresponding scanning line are coupled into a first capacitor, and the drain of the transistor and a corresponding scanning line are coupled intoa second capacitor. In a single pixel, the coupled areas of pixel electrodes and the scanning lines corresponding to different color filter films are different, so that the first capacitors are essentially same.

Owner:AU OPTRONICS CORP

X-ray sensitive resin composition, barrier body and protection film of liquid crystal display member and their forming methods

ActiveCN101458452BWon't fall offHigh strengthPhotomechanical apparatusNon-linear opticsPolymer scienceLiquid-crystal display

Owner:JSR CORPORATIOON

Liquid crystal aligning agent for photo-alignment treatment method, and liquid crystal aligning film using the liquid crystal aligning agent

Owner:NISSAN CHEM CORP

Active matrix type display device and driving method thereof

ActiveCN1838218BSuppress afterimageSuppress bright spot defectsElectrical apparatusStatic indicating devicesCapacitanceActive matrix

A residual image effect is suppressed to improve quality of display of an active matrix type display device. A capacitor line electric potential switching circuit switches an electric potential of a capacitor line from a first capacitor electric potential Vsc 1 to a second capacitor electric potential Vsc 2 that is higher that the first capacitor electric potential Vsc 1 , while a power supply electric potential switching circuit switches an electric potential of a power supply line from a first power supply electric potential PVdd 1 to a second power supply electric potential PVdd 2 that is lower than the first power supply electric potential PVdd 1 . As a result of synergistic effect, an electric potential Vg at a gate of a driver TFT becomes higher than an electric potential at its source by more than a threshold voltage Vtp of the driver TFT. Assuming carriers are trapped in a gate insulation film of the driver TFT due to writing-in of a display signal in a preceding frame period,the carriers are extracted from the gate insulation film to the source or a drain of the driver TFT. With this, electric characteristics of the driver TFT are initialized.

Owner:SANYO ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com