Liquid crystal aligning agent, liquid crystal alignment film, and liquid crystal display element

A technology of liquid crystal aligning agent and solvent, which is applied in the direction of liquid crystal materials, instruments, chemical instruments and methods, etc., can solve problems such as insufficient removal of decomposition products, display of broken bright spots in the display area, and poor regional orientation, so as to suppress broken bright spots and increase Effect of force, resistance to hydrolysis or degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The preparation method of the above polyimide can adopt but not limited to the following two imidization methods, the two imidization methods refer to thermal imidization method or chemical imidization method.

[0053] The thermal imidization method refers to directly heating the polyimide solid to dehydrate and form a ring, and the heating temperature is preferably 150-300°C.

[0054] The chemical imidization method comprises the following steps: in the presence of a dehydrating agent and a catalyst, the polyamic acid is dehydrated and ring-closed at a lower temperature to prepare polyimide.

[0055] The solvent for the imidization reaction may be the same as the solvent for the polyamic acid reaction, so details will not be repeated here.

[0056] Wherein, the weight ratio of the polyamic acid and the imidization reaction solvent is 1:(2~50); the temperature of the imidization reaction is 0~100°C, more preferably 30~70°C; the reaction time is 1 to 50 hours, more pref...

Synthetic example 1

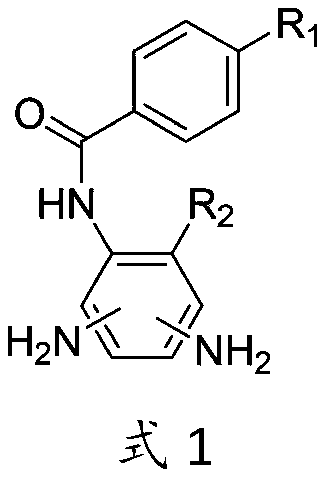

[0082] The preparation of the diamine compound represented by structural formula 1-1 is shown in Synthetic Route 1:

[0083]

[0084] The specific operation process is:

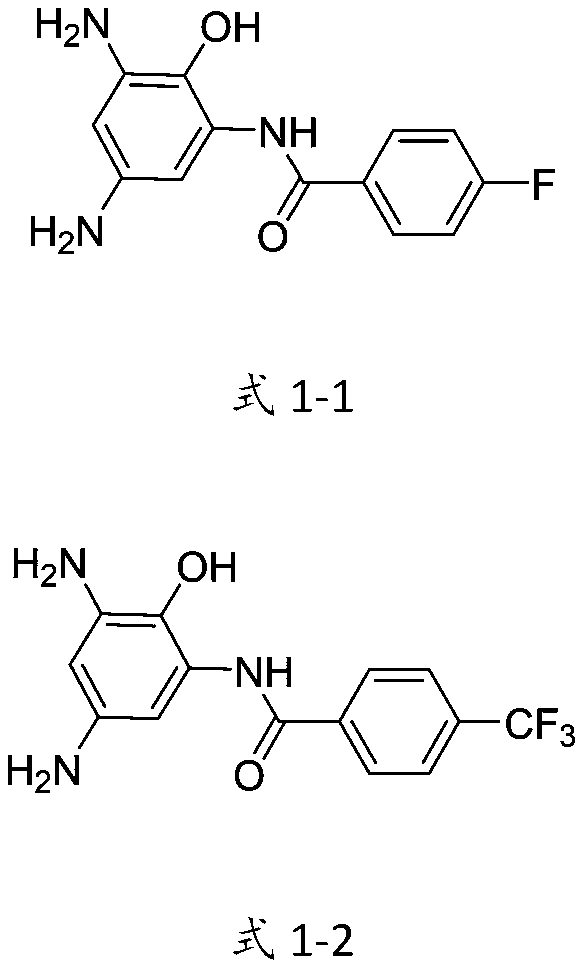

[0085] (1) Synthesis of compound 1-1-a

[0086] In a 500mL three-neck round bottom flask, drop into p-2-hydroxyl-3-amino-1,5-dinitrobenzene (19.91g, 100mmol), triethylamine (11.13g, 110mmol) and 200ml of DMAC solvent , drop the temperature to 0-10°C and start to drop the mixed solution of p-fluorobenzoyl chloride (17.44g, 110 mmoles) and 100ml solvent DMAC in the system, after 2 hours, the dropwise addition was completed, and the temperature was raised to 30°C for 5 hours of insulation reaction, and then The reaction solution was poured into ice water, the precipitate was filtered out, washed with water, and the filter cake was crystallized from a mixture of tetrahydrofuran / methanol (2:3) to obtain 26 g of a light yellow solid with a product yield of 81%. The product was tested by high-resolution mass spe...

Synthetic example 2~5

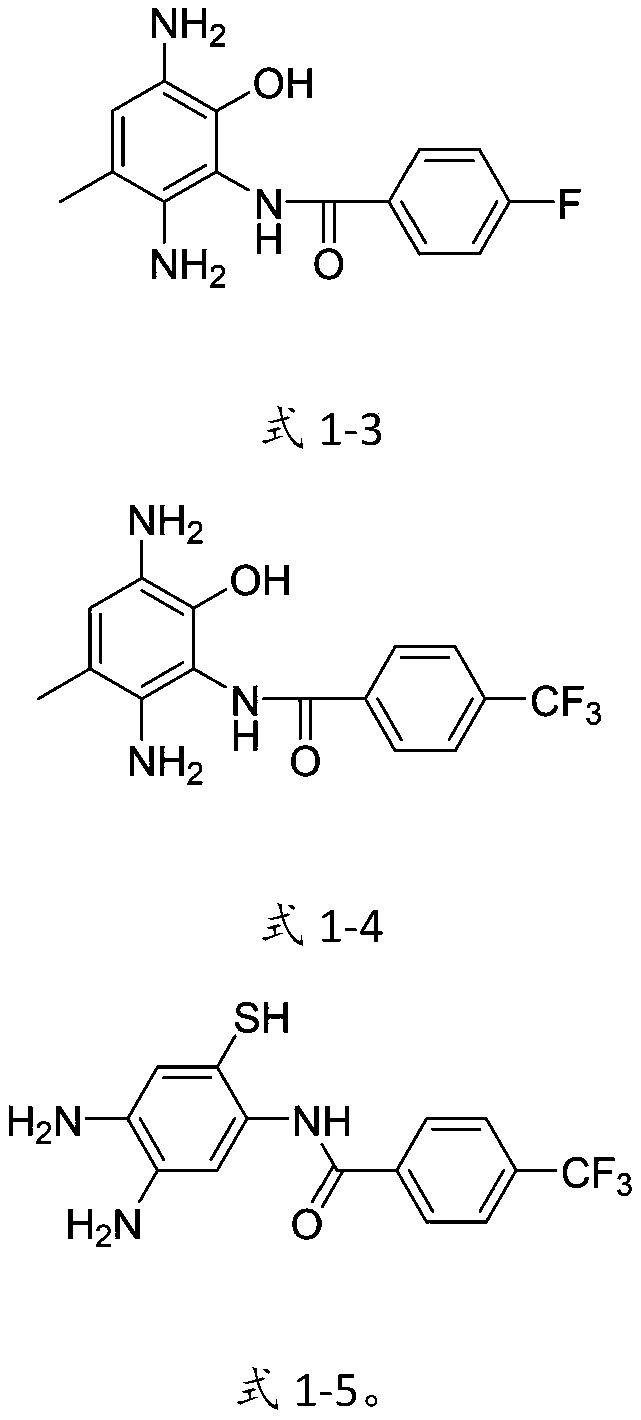

[0092] The compounds represented by the structural formulas (1-2)-(1-5) can use the corresponding dinitro compound and p-fluorobenzoyl chloride or p-trifluoromethylbenzoyl chloride respectively, according to the synthetic route 1 Carry out synthesis, carry out the synthesis of amide first, then hydrogenation reduction is target product, the high-resolution mass spectrometry result of corresponding target compound, elemental analysis result, synthetic yield and the structural formula of the dinitro compound used for synthesis are shown in Table 1 below.

[0093] Mass spectrum, elemental analysis, yield and raw material structure data of each compound in Table 1 Synthesis Examples 2-5

[0094]

[0095]

[0096] Examples are given below to illustrate the present invention in more detail, but the present invention is not limited by them. The compound abbreviation used in the present embodiment and comparative example and the measuring method of each characteristic are as foll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com