Novel tunnel anchor cable/rod support method

A new method, technology of roadway, applied in the installation of bolts, earth-moving drilling, mining equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

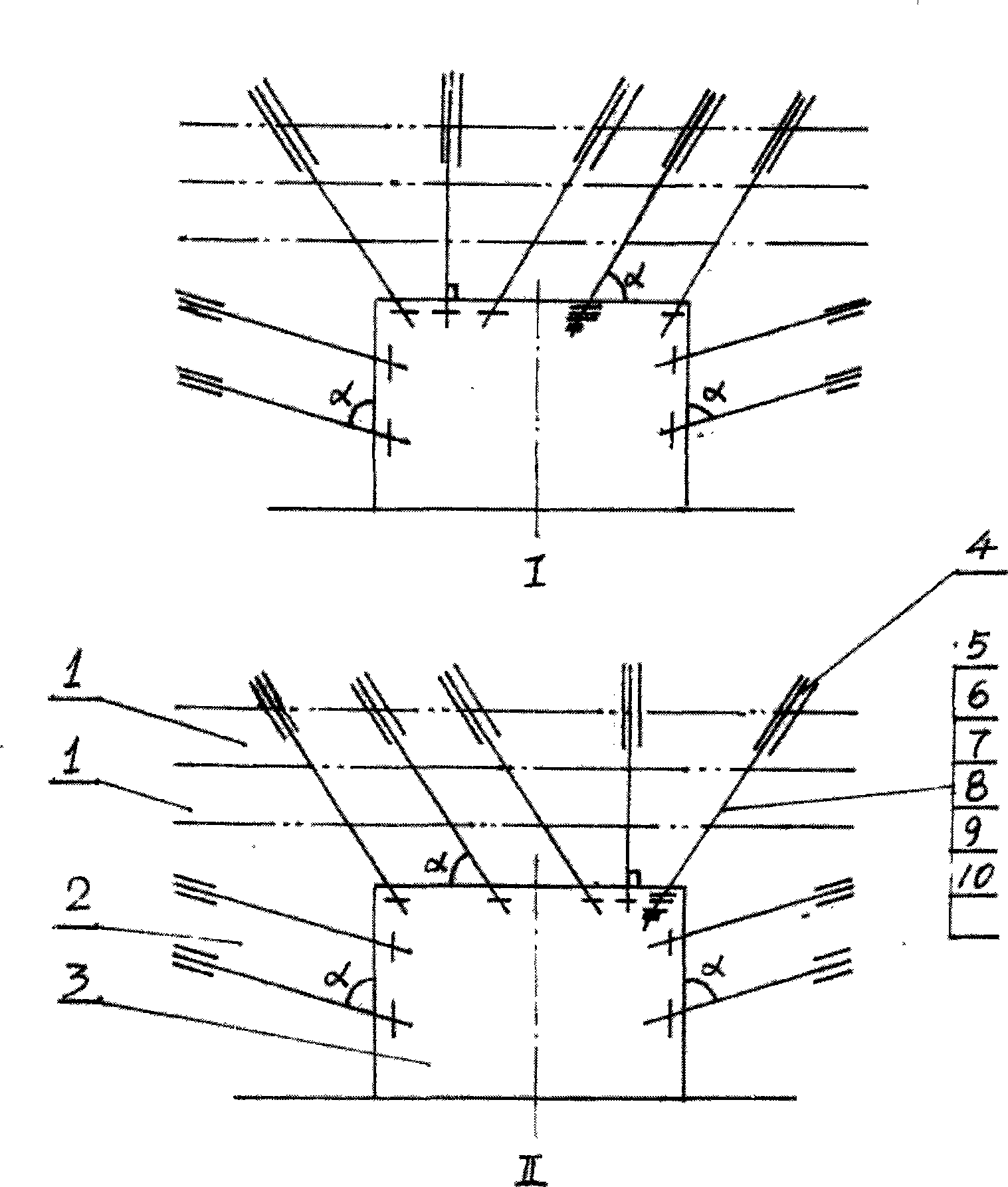

[0006] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings, as shown in the accompanying drawings: the anchor cable (rod) 5 supporting the roof 1 of the rock mass in the roadway 3 and the two walls 2 of the coal seam is characterized by the new method of supporting The matrix-shaped hole drilling method of the rock mass roof surface 1 perpendicular or in the same direction to the roadway section I and II is changed to the plum blossom-shaped hole drilling method inclined to the two walls 2 of the roadway section. The inclination angle of the drilling holes in face 1 is staggered with each row, that is, the inclination angle of the drilling holes in this row is opposite to the direction of the adjacent two rows; the original drilling method perpendicular to the coal seam wall 2 is changed to the upward inclined drilling method . Use the top of the anchor cable (rod) 5 to push the resin charge 4 to the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com