Processing aid of polyolefine for food flexible packing, preparation method and application thereof, and modified polyolefine adopting processing aid

A processing aid and polyolefin technology, which is applied in the field of polyolefin processing aids for food flexible packaging, its preparation and use, and polyolefins modified by using the processing aids, which can solve the problems of poor heat resistance, large stretching ratio, and thin films. Improve the anchoring ability, improve the seepage problem, and reduce the coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Adding 120 grams of EVA emulsion with a solid content of 50% in a 500-milliliter four-necked bottle equipped with an electric stirrer, a thermometer, and a dropping funnel, the temperature of the system is controlled at 40° C. Add 55 grams of water glass (40 ° Be) dropwise from the dropping funnel to the above system within 30 minutes, and mix for 1 hour. Add 10% (v%) sulfuric acid dropwise from the dropping funnel into the system until the system pH=4, and continue stirring for 1 hour. Pour the precipitate into 1 liter of distilled water, wash the precipitate, then let it stand still, pour off the supernatant; then add distilled water, stir for 10 minutes, let it stand, pour off the supernatant again, until it is washed without sulfate radicals ion. The slurry obtained is ground with a colloid mill, then spray-dried and pulverized to obtain EVA-modified nano-silica (abbreviated EVA-SiO 2 ).

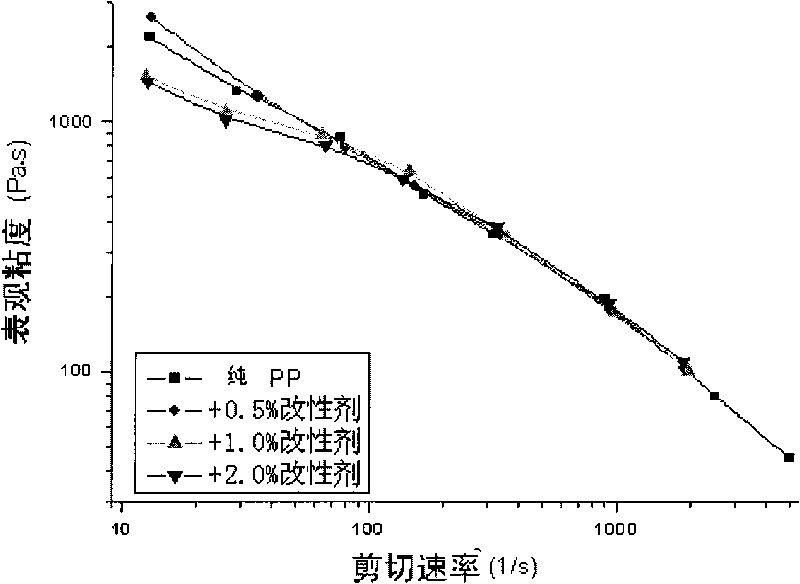

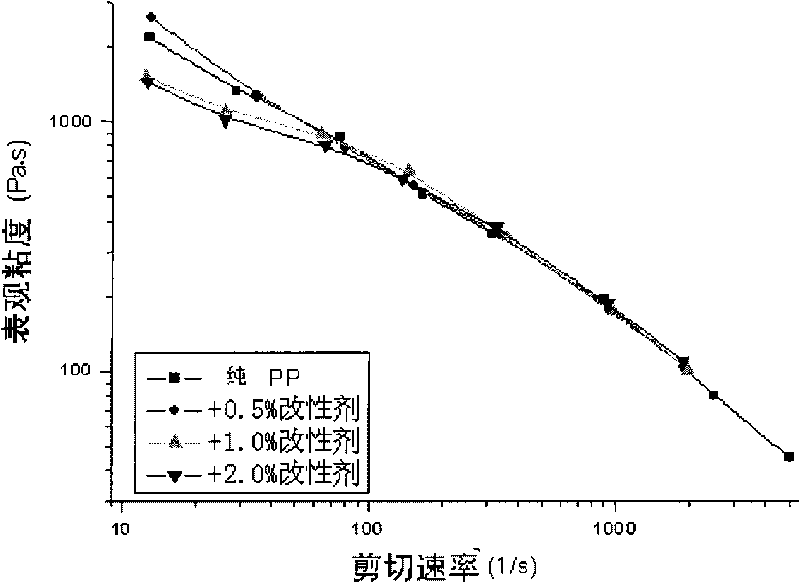

[0037] EVA-SiO 2 Modified polypropylene (PP)

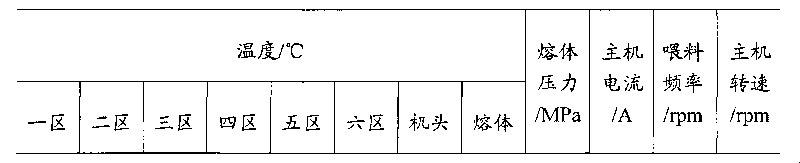

[0038] Weigh a certain ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com