Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Smooth and orderly delivery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

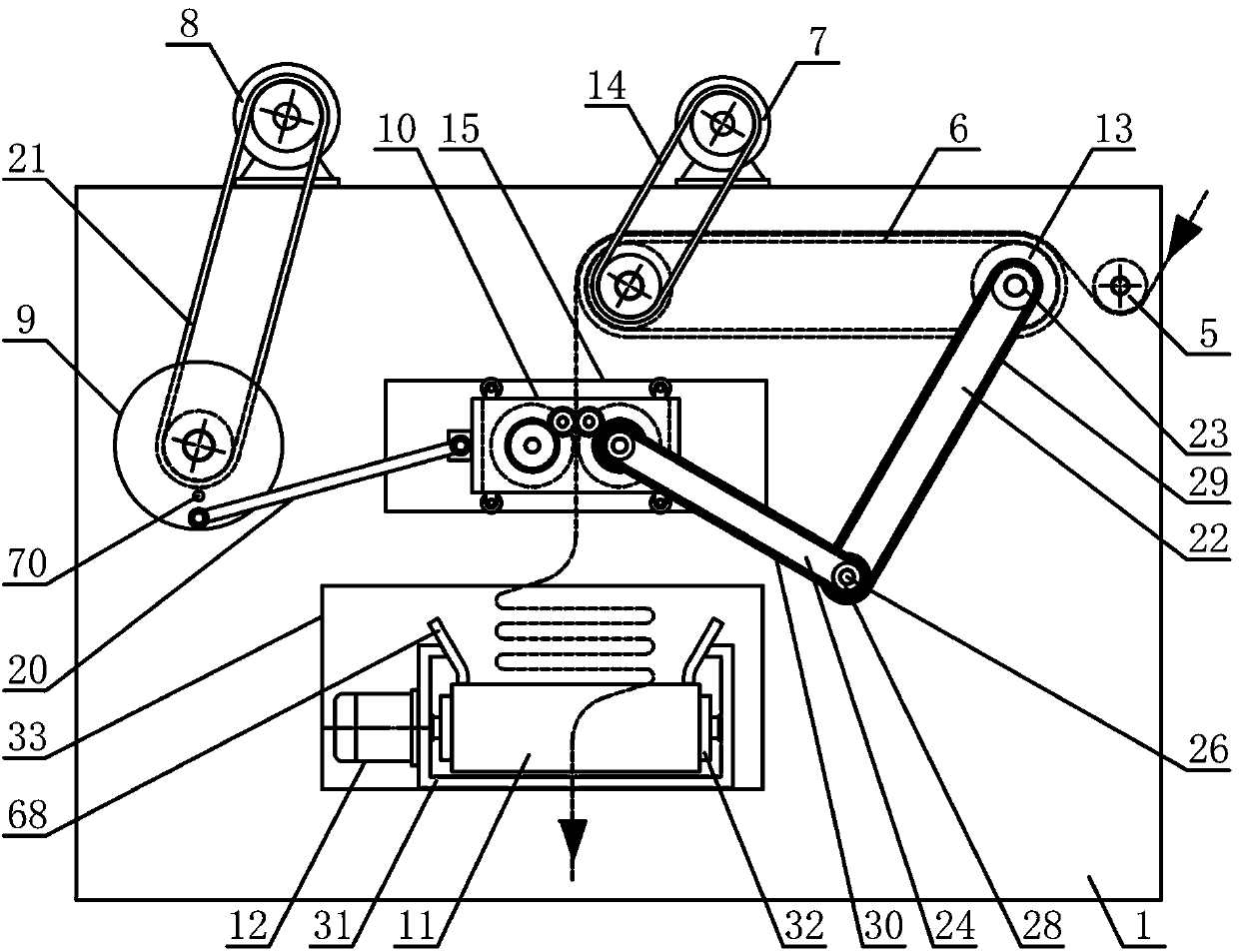

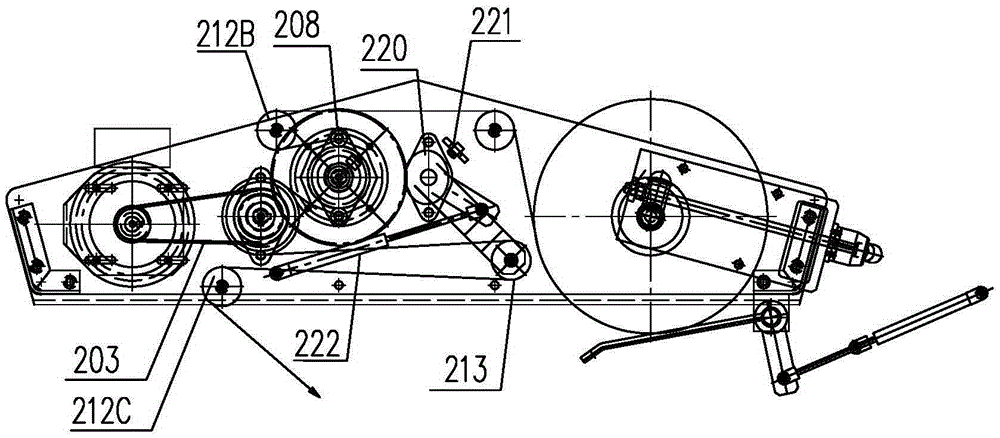

Yarn conveying and pulling mechanism

PendingCN108584532AStable and even stretchingEfficient heatingFilament handlingTextiles and paperYarnHeat conducting

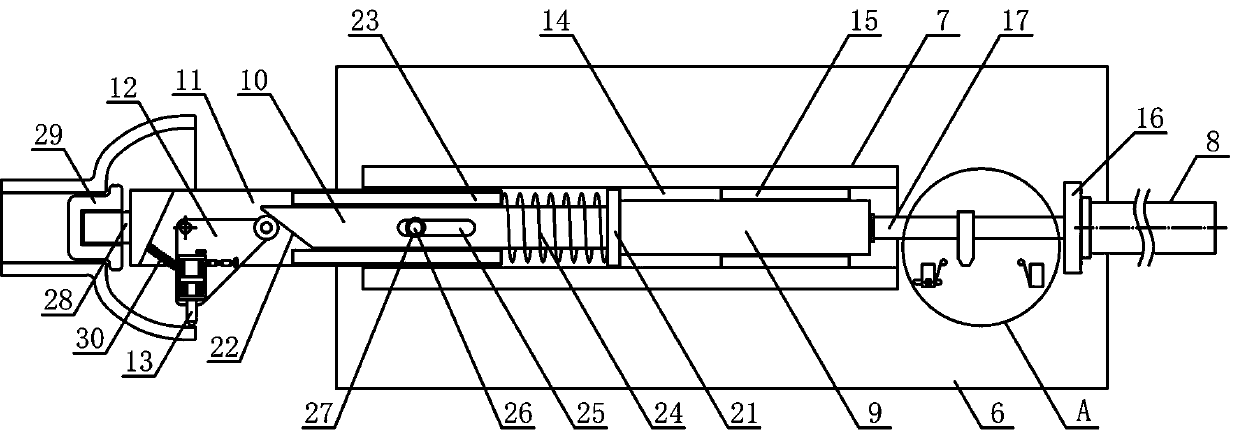

The invention discloses a yarn conveying and pulling mechanism, and belongs to the field of textile processing mechanical equipment. According to the yarn conveying and pulling mechanism, a yarn feeding mechanism, a pulling mechanism and a yarn guide mechanism are arranged on a fixing support in sequence in the horizontal direction. A lower yarn bearing guide roller is connected with the portion,located on the lower side of an upper yarn press guide roller, of the fixing support in a horizontal rotation mode. A shaping rotating drum is connected to the portion, located between a front yarn guide roller and a rear yarn guide roller, of the fixing support in a horizontal rotation mode, and a heat-conducting oil pipe is arranged at the shaft ends of the two sides of the shaping rotating drumin a communicating mode. Pulling guide plates are arranged in pulling guide grooves in a sliding mode in the circular arc direction, and the pulling guide grooves are formed in the two sides of the shaping rotating drum. One end of one pulling rotating roller and the same end of the other pulling rotating roller are connected to the pulling guide plates on the two sides of the fixing support in arotating mode correspondingly. A yarn discharging guide roller is connected to the portion, located on one side of an adjusting support, of the fixing support in a horizontal rotation mode. The yarnconveying and pulling mechanism is reasonable in structural design, can efficiently and accurately convey yarn, and can conduct stable pulling shaping on the yarn section by section in the conveying process, the degree of automation of yarn processing is improved, and the requirements of production and usage are met.

Owner:嘉兴市华益股份有限公司

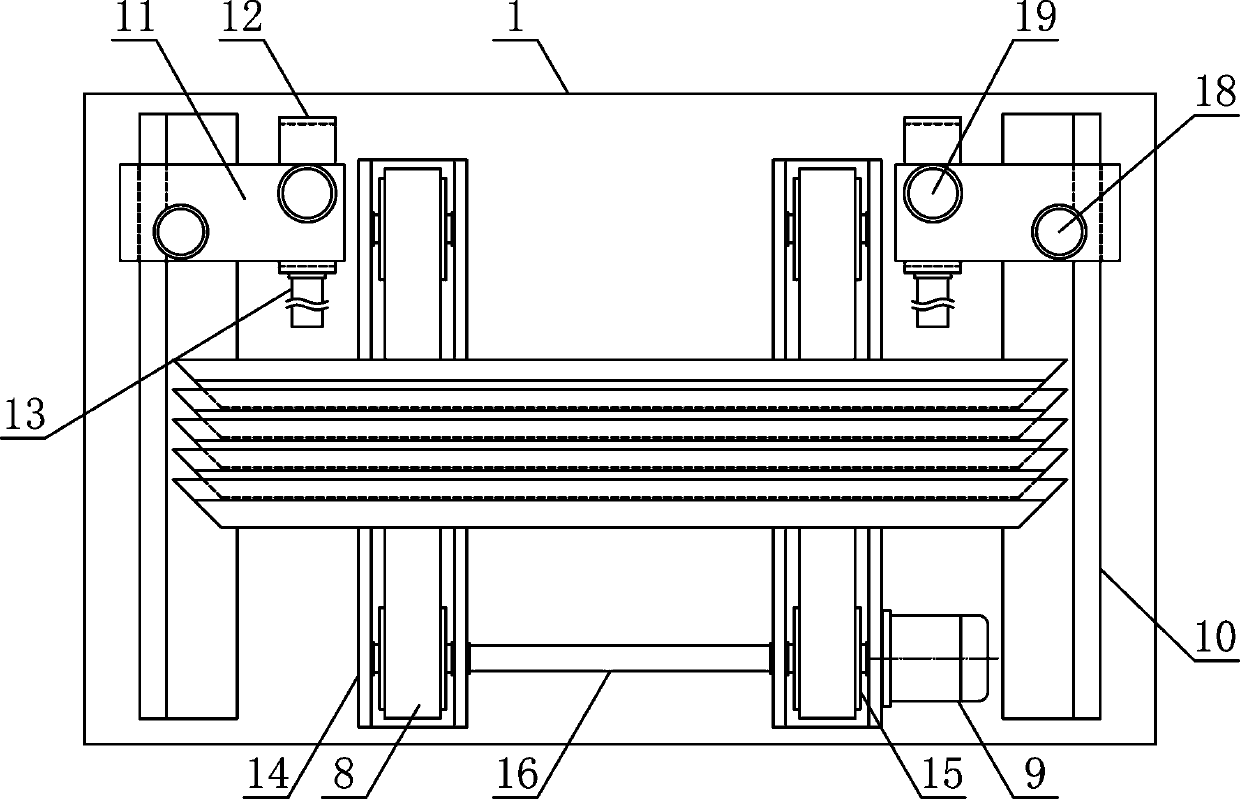

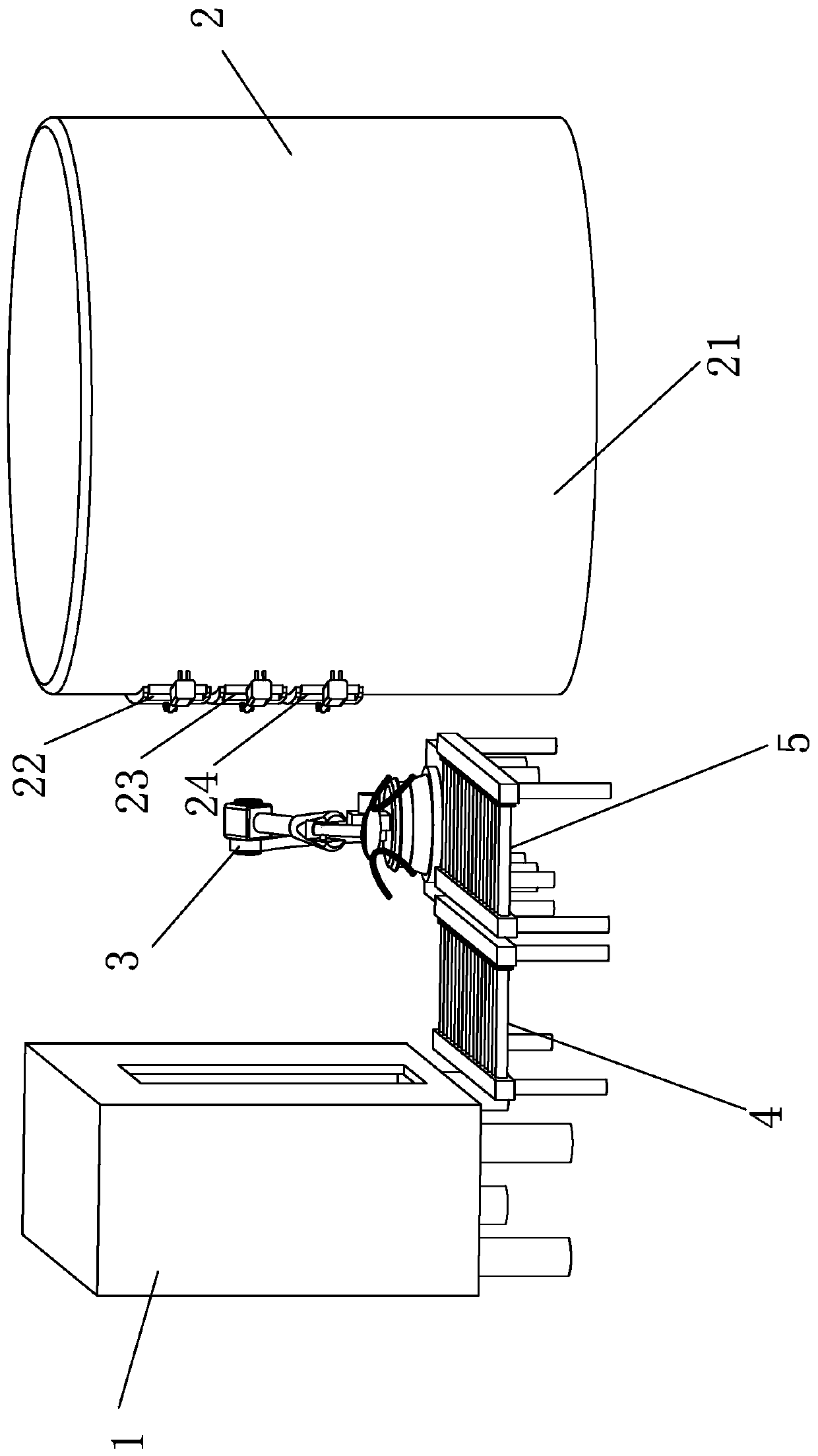

Textile fabric conveying device

ActiveCN111532827ASmooth and orderly unwinding transmissionEfficient and smooth unwinding transmissionWebs handlingMechanical equipmentIndustrial engineering

The invention discloses a textile fabric conveying device, and belongs to the field of textile processing mechanical equipment. According to the textile fabric conveying device, a fabric unwinding mechanism and a fabric conveying mechanism are arranged on the two sides of a fabric conveying support correspondingly, a lifting fabric guide roller is horizontally arranged on the fabric conveying support between the fabric unwinding mechanism and the fabric conveying mechanism, the lifting fabric guide roller is horizontally and rotationally connected to a reciprocating lifting guide block, a fabric unwinding roller is horizontally, coaxially and fixedly arranged in the middle of a fabric unwinding rotary plate, a pressing plate damping swing rod is arranged on a fabric conveying support on the lower side of the fabric unwinding rotary plate, the two sides of a fabric non-return support are horizontally and rotationally connected with a front material guiding rotary roller and a rear material guiding rotary roller correspondingly, and a lifting material pressing rotary roller is arranged on the lower side of a fabric conveying rotary roller. The textile fabric conveying device is reasonable in structural design, textile fabrics can be efficiently, smoothly, sequentially and intermittently conveyed, stable, accurate and continuous sectional conveying of textile fabrics is achieved,the automation degree of textile fabric conveying and processing is improved, and the requirements of production and use are met.

Owner:山东新天合包装制品有限公司

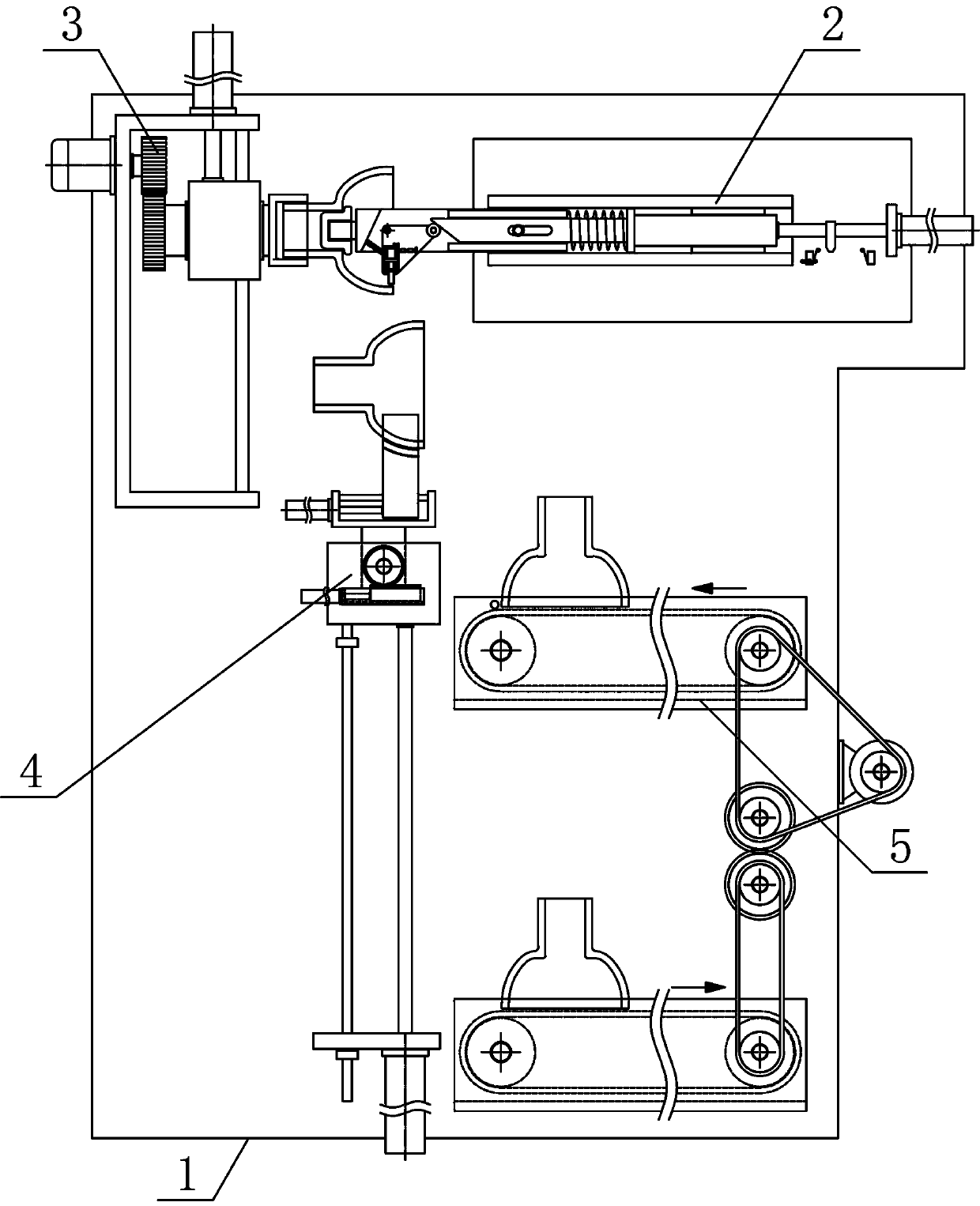

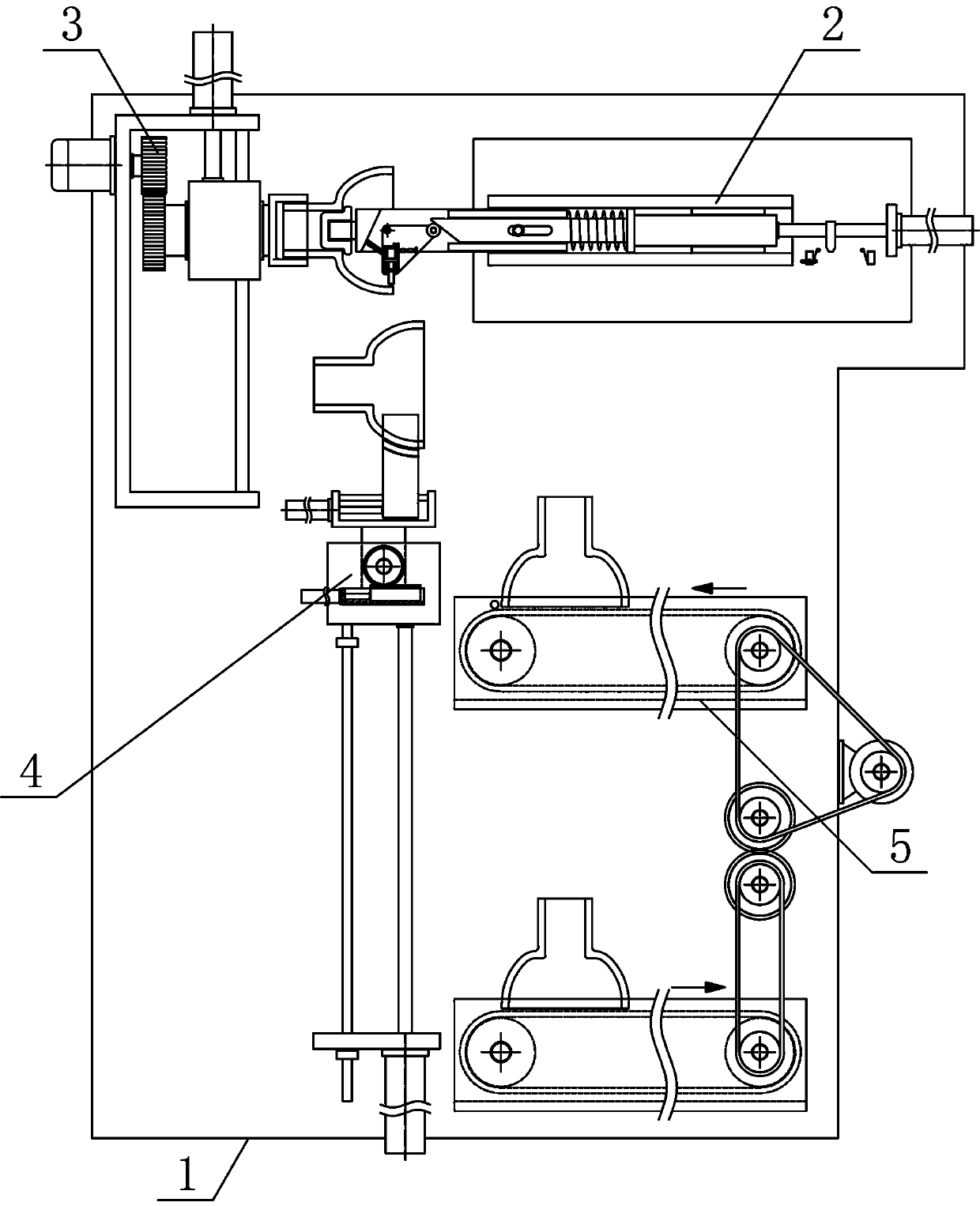

High-pressure water sand-spraying deflashing machine

InactiveCN101143475AStable and orderly deliveryGuaranteed stabilityBlast gunsSedimentation separationAutomatic controlEngineering

The invention relates to a cleaning equipment for a IC molding strip flash, to be more precise, relates to a flash machine with a IC strip high pressure water sand-blast. The invention comprises a charging device, a material pushing and storage device, a transmission part, a spewing system, a baiting device and an automatic control system. The spewing system comprises a sand-collection sand-and-water separation bin, a plurality of sand-and-water spray heads, a plurality of water spray heads, a dried device and a high-pressure pump. The invention is characterized in that the charging device pushes the IC strip into the pushing and storage device through a vacuum grasp manner. The transmission part drives the strips to progress through a drive shaft in an upper and a lower rows. Through a blanking part, the baiting device drives the strip to fall to the location with its own body weight. The invention has the characteristics of easy control of charging and baiting, good processing quality and high efficiency.

Owner:GRAND TECH SHENZHEN

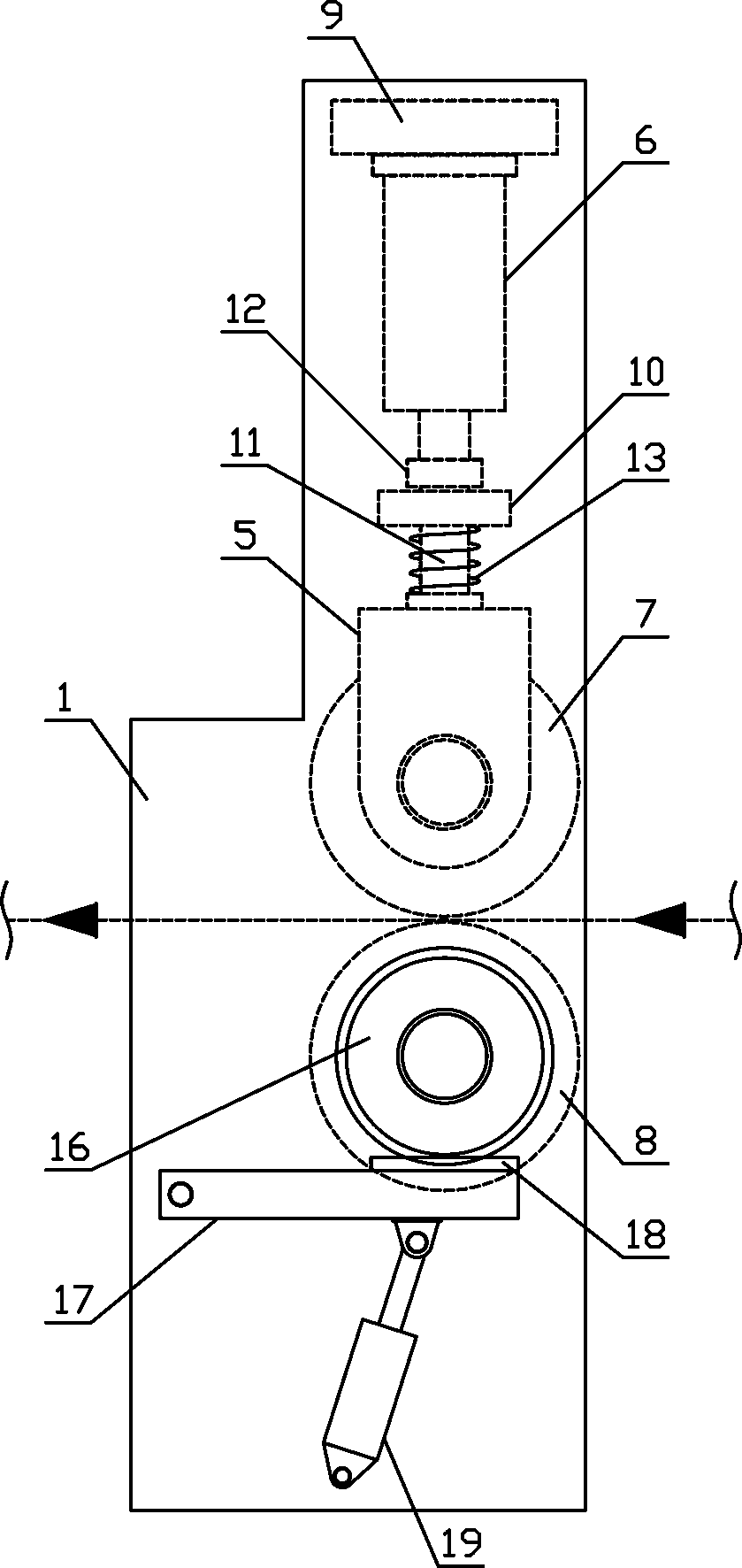

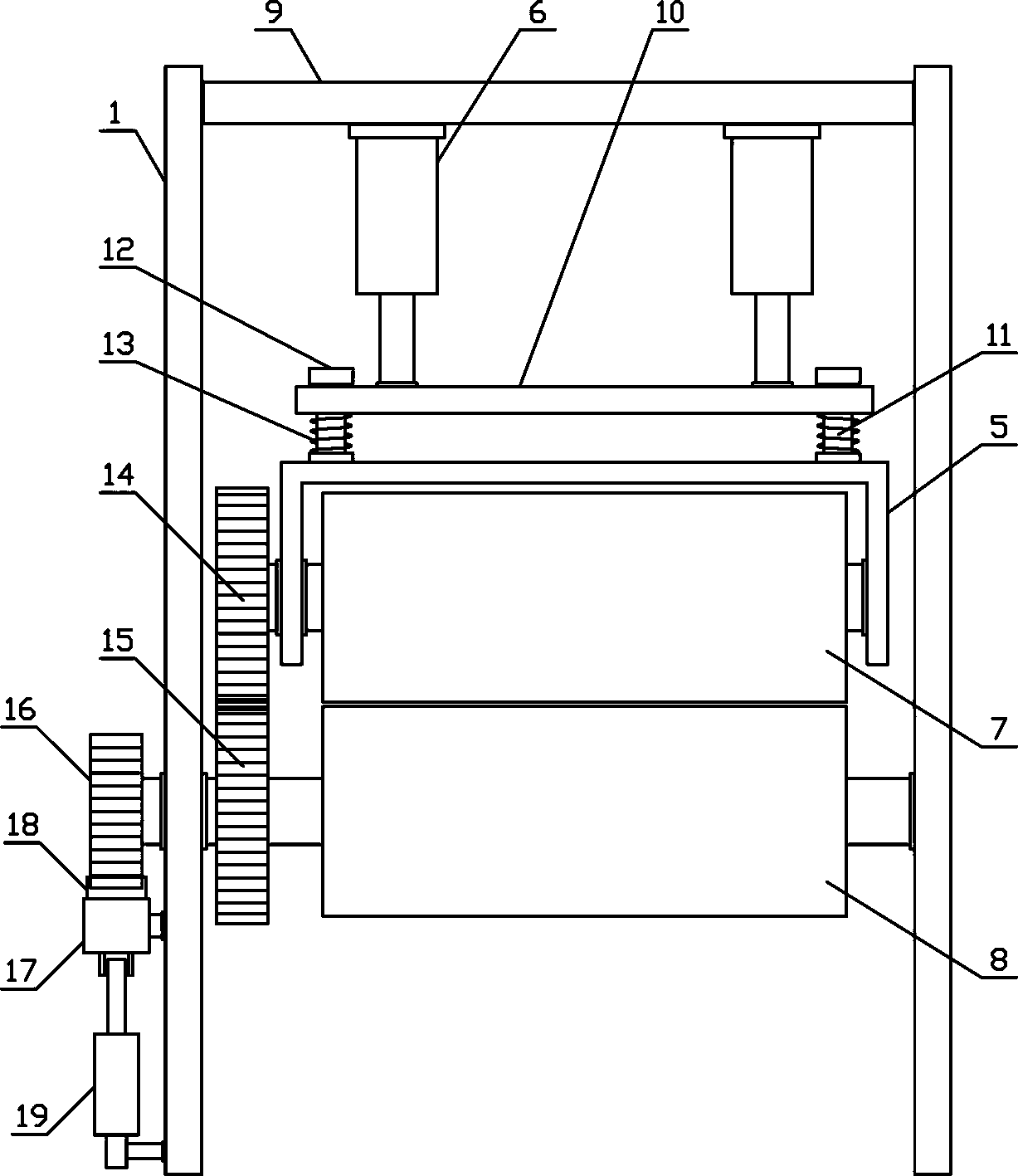

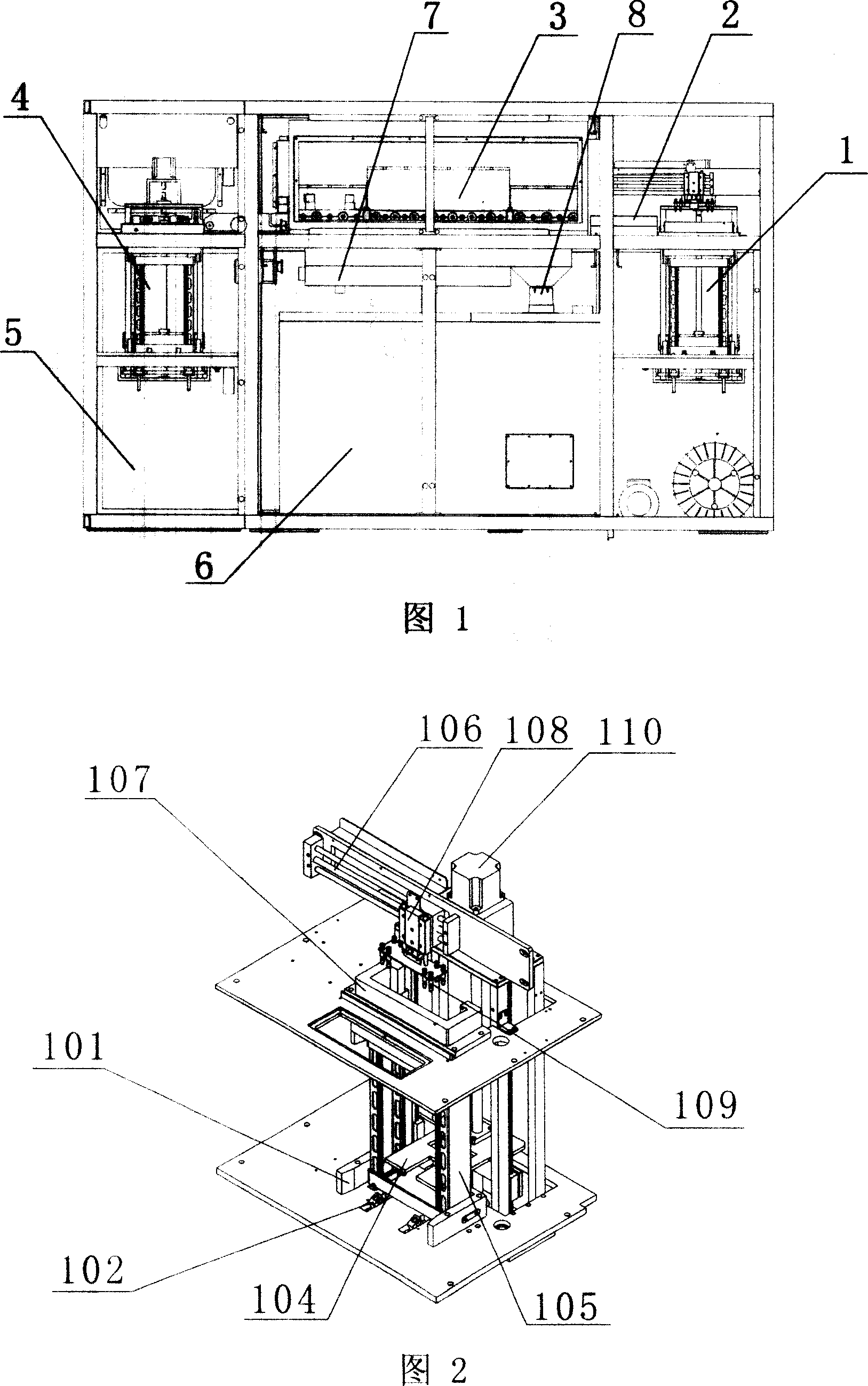

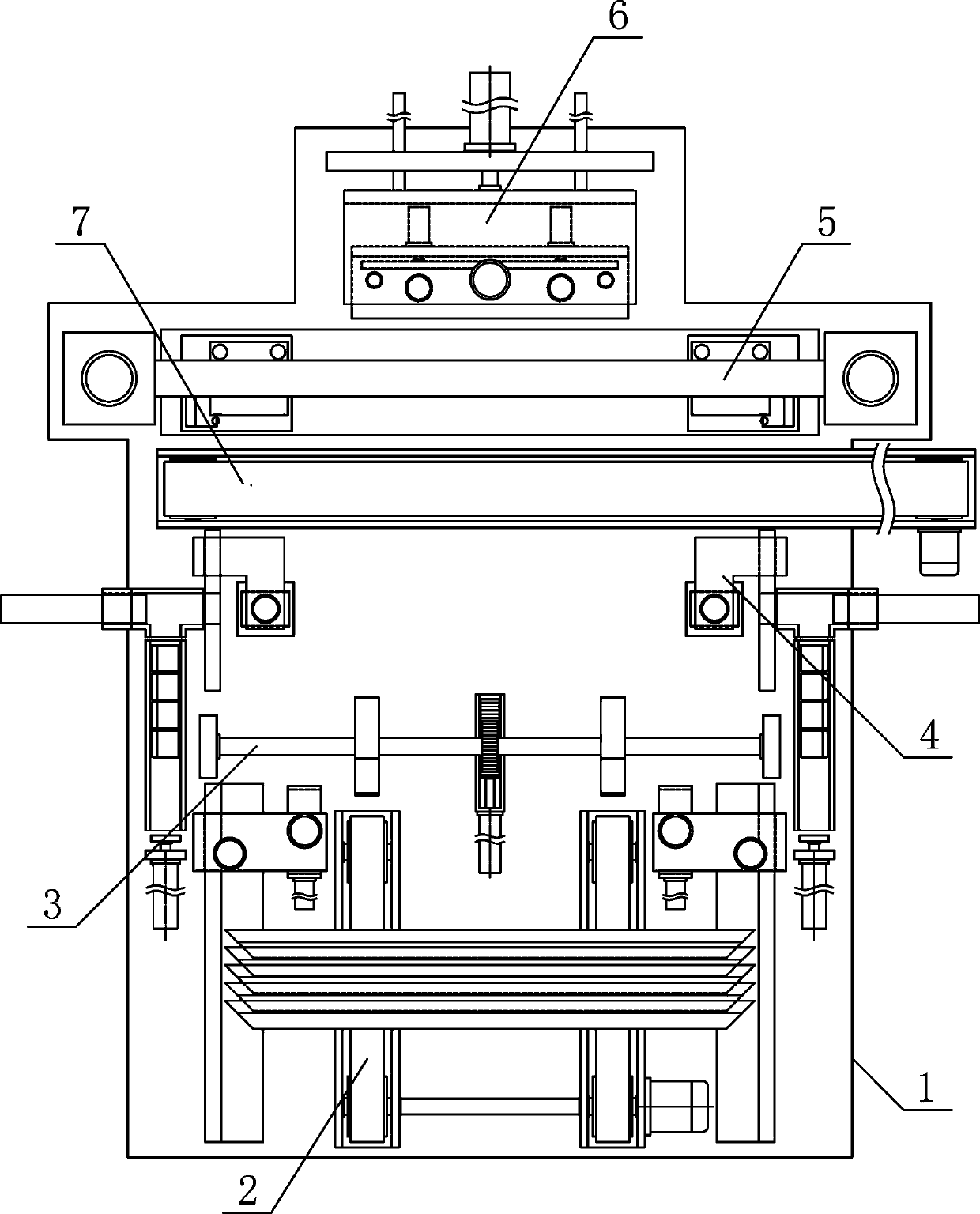

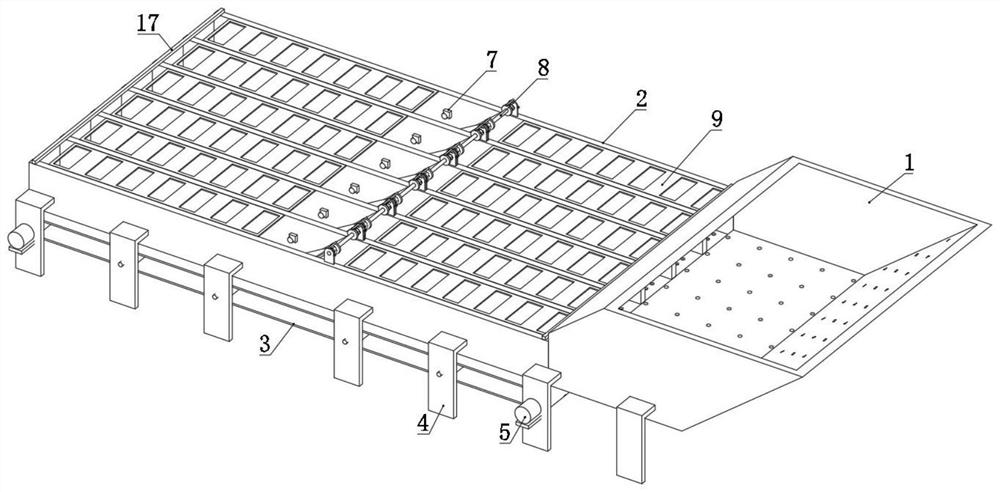

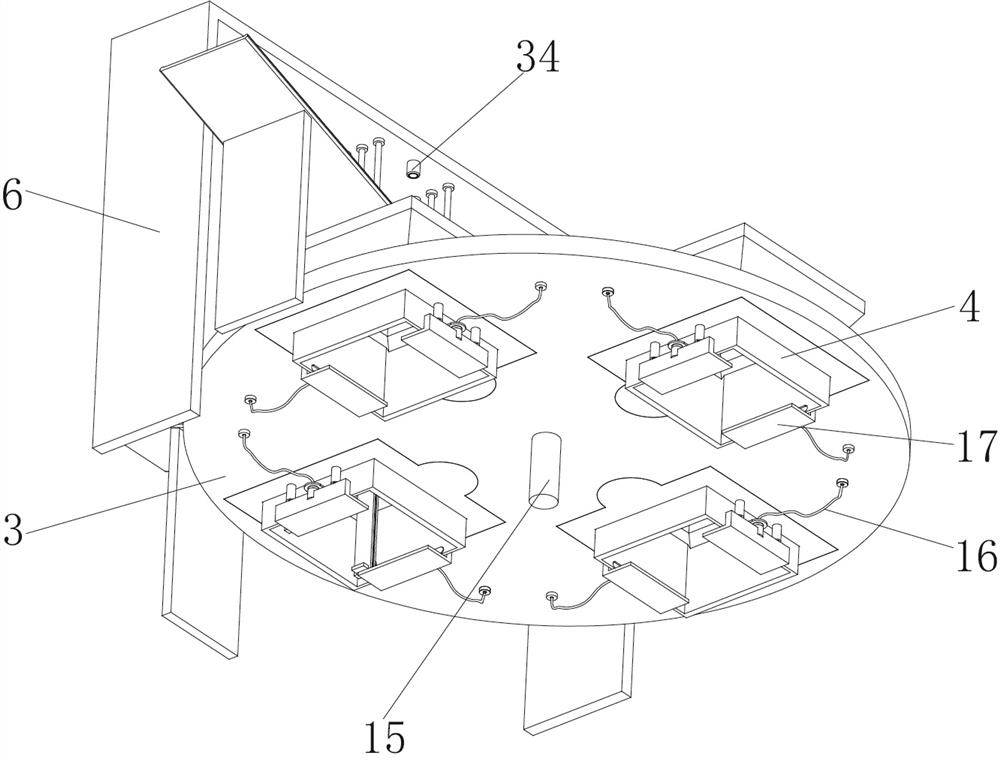

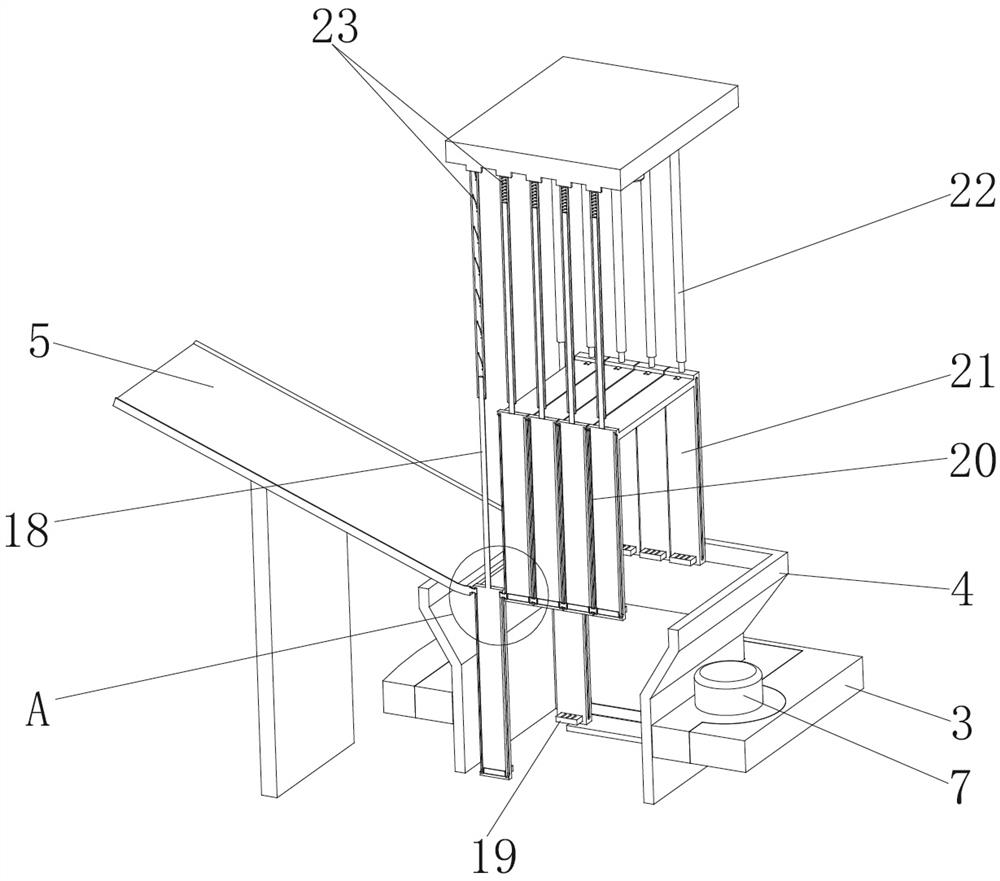

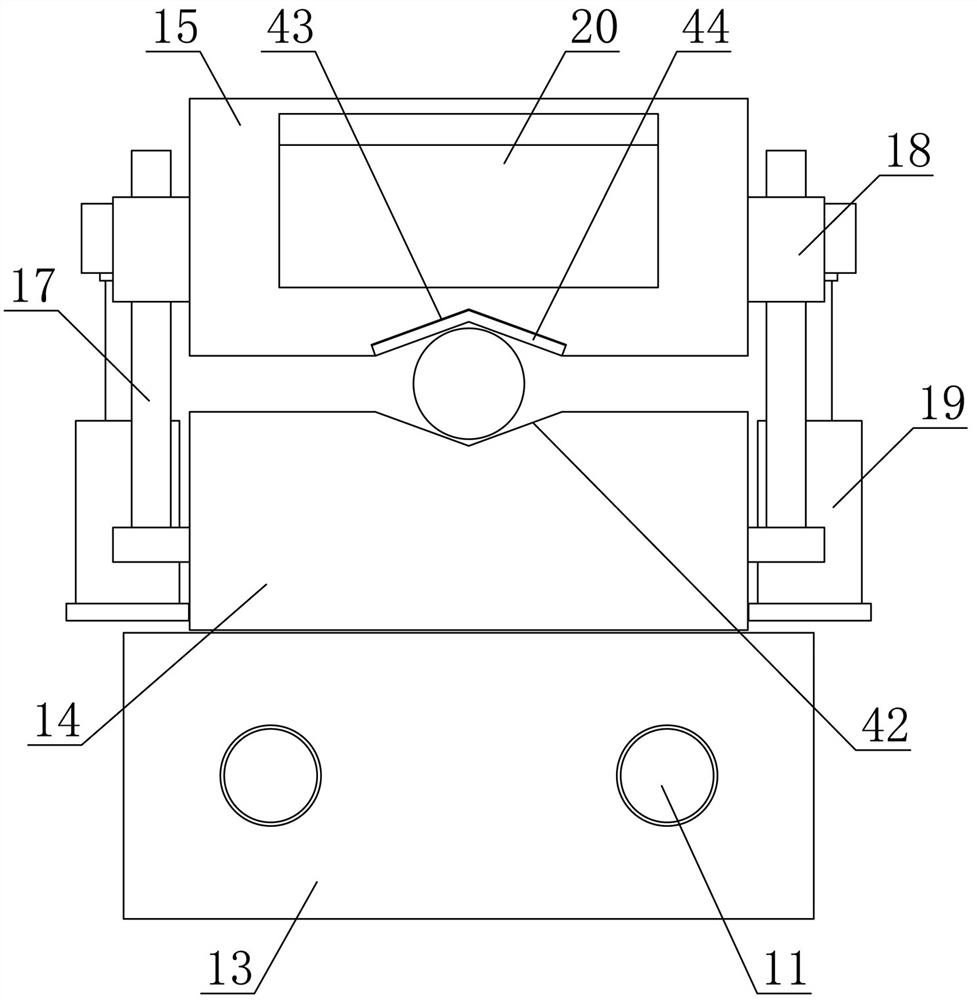

Machining device for solar module frame

ActiveCN111283095ASmooth and precise transmissionGuaranteed normal transmissionMetal-working feeding devicesPhotovoltaicsPunchingEngineering

The invention discloses a machining device for a solar module frame, and belongs to the field of aluminum profile machining mechanical equipment. According to the machining device, a feeding conveyingbelt is horizontally arranged on the upper side of a feeding conveying belt support, and frame bearing supports are horizontally arranged on the two sides of the upper portion of a machining main support correspondingly. Bearing turnover round plates are vertically and fixedly arranged on the two sides of a frame turnover rotary shaft, and the output end of a punching and riveting machining air cylinder is fixedly connected with the upper side of a lifting punching and riveting plate. Multiple punching and riveting pressing nails of conical structures are evenly arranged on the lower side ofa punching and riveting compressing plate. The output end of a frame translation air cylinder is fixedly connected with a frame translation support, and the output end of a lifting adjusting air cylinder is fixedly connected with the middle of the upper side of a frame containing and bearing support. The machining device is reasonable in structural design, corner pressing can be synchronously carried out on the ends of the two sides of the solar module frame fast, accurately, efficiently and stably, continuous and automatic producing and machining of the solar module frame are achieved, and the needs of production use are met.

Owner:ZHEJIANG ZHUOYI ALUMINUM

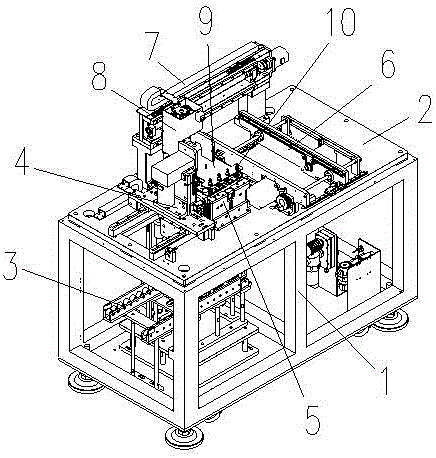

Carrier supply machine

ActiveCN106542309ASmooth and orderly deliveryConveyorsFinal product manufactureEngineeringMechanical engineering

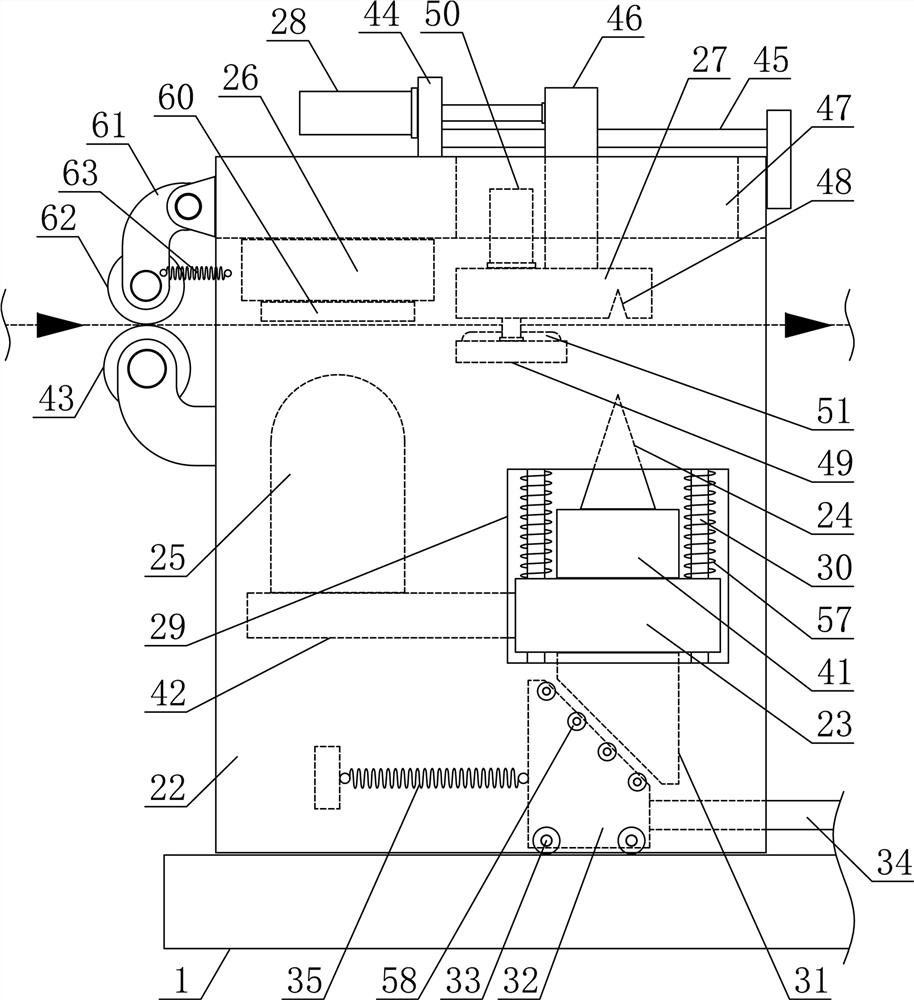

The invention discloses a carrier supply machine. The carrier supply machine comprises a rack, a feeding mechanism, a lifting mechanism, a limiting mechanism, a grabbing mechanism and a belt conveyer line, wherein a rack plate is horizontally fixed to the rack; the feeding mechanism is fixed to the rack under the rack plate; a yielding hole is formed in the position, above the feeding mechanism, on the rack plate; the limiting mechanism is arranged at the yielding hole; the lower end of the limiting mechanism is arranged close to the feeding mechanism; the upper end of the limiting mechanism stretches out of the rack plate; the lifting mechanism is arranged in the position, corresponding to the limiting mechanism, on the rack plate; the belt conveyer line is arranged on the rack plate; and the grabbing mechanism is fixed in the position, between the lifting mechanism and the belt conveyer line, on the rack plate. According to the carrier supply machine, locating and transportation of carriers can be completed, the transportation is steady and ordered, and the carrier supply machine is applicable to carriers of different sizes.

Owner:荣旗工业科技(苏州)股份有限公司

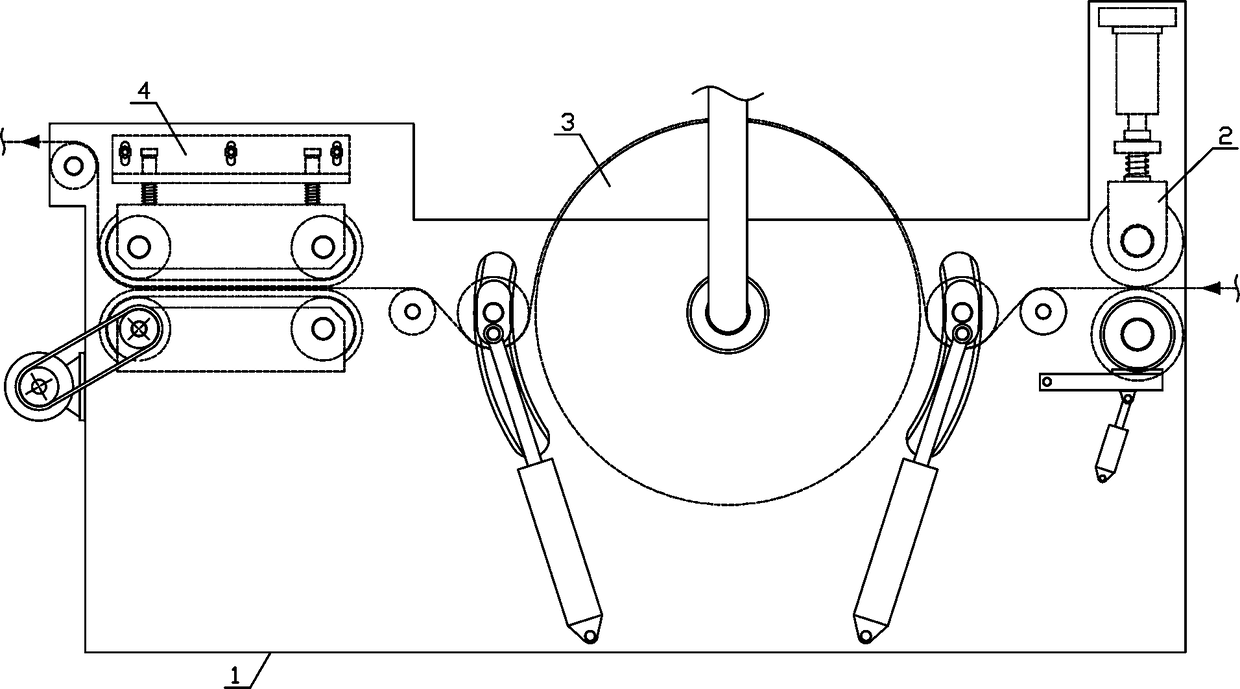

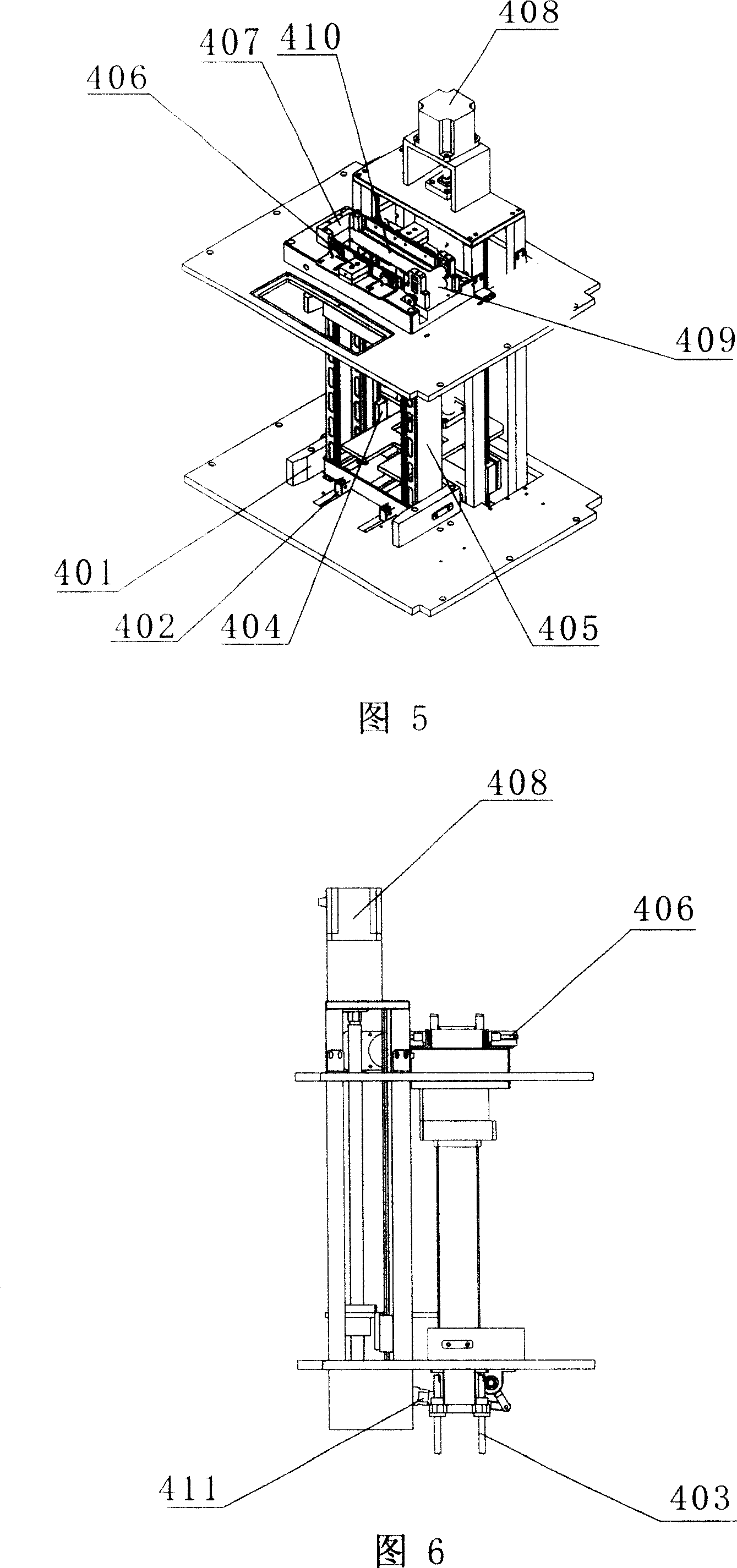

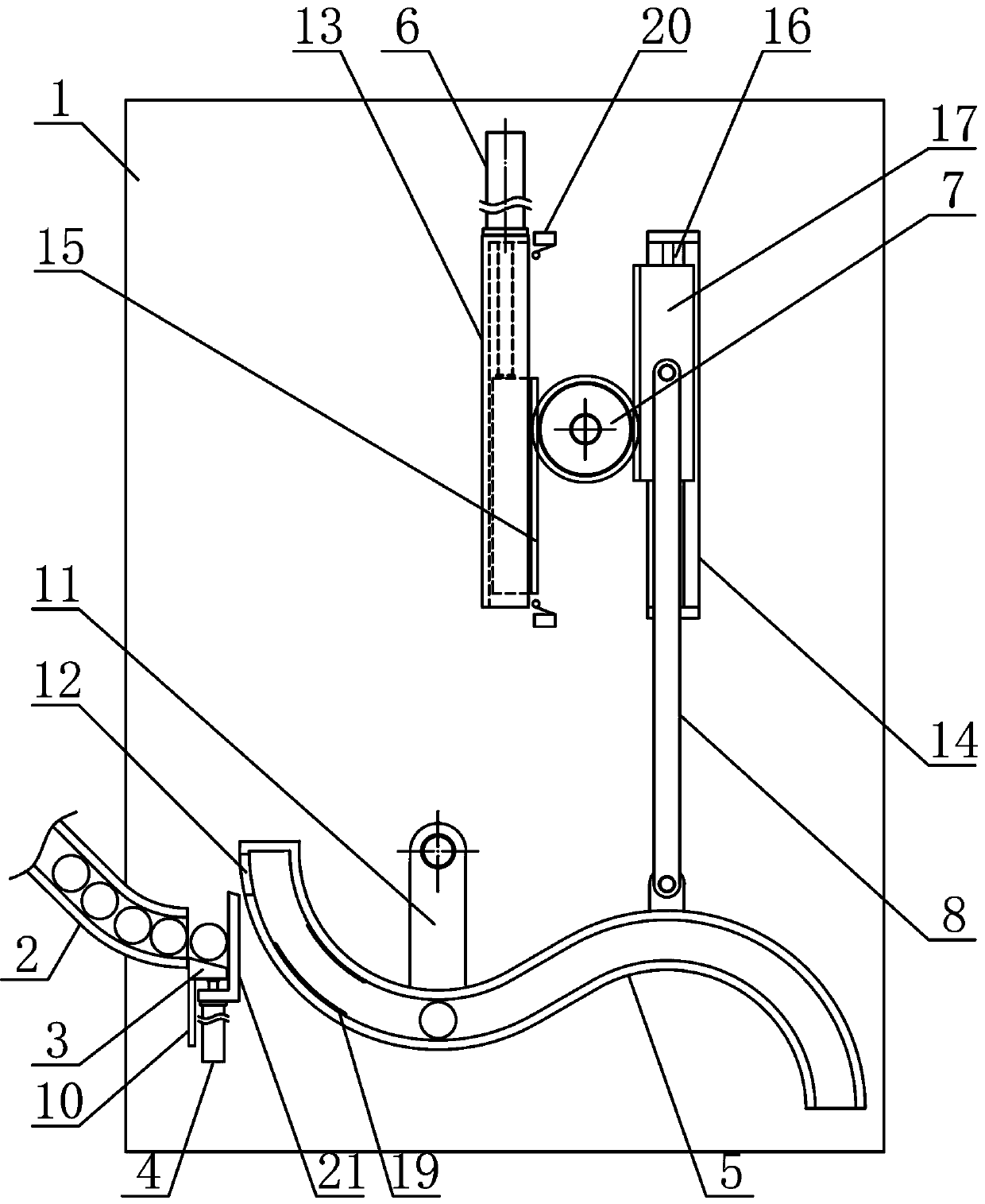

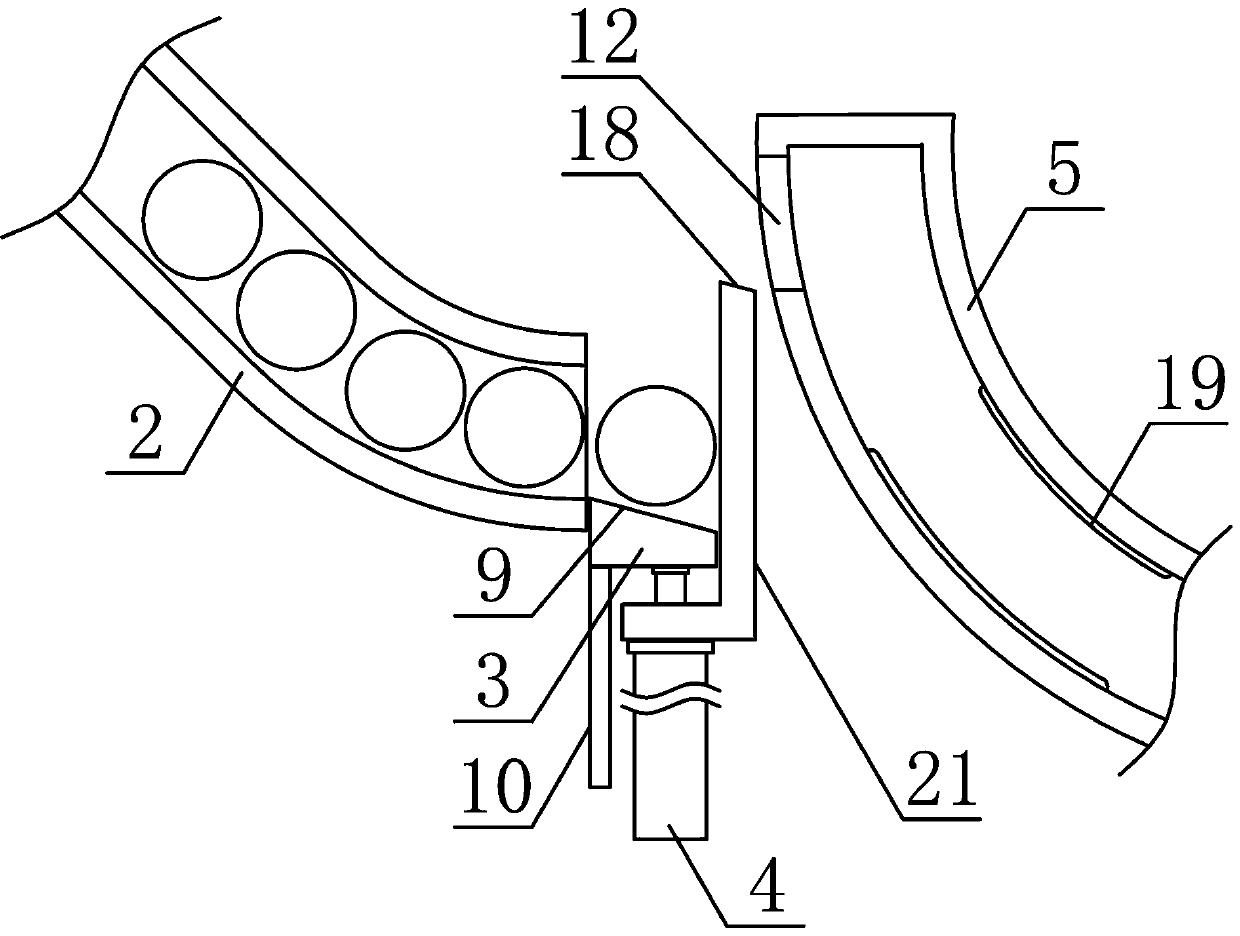

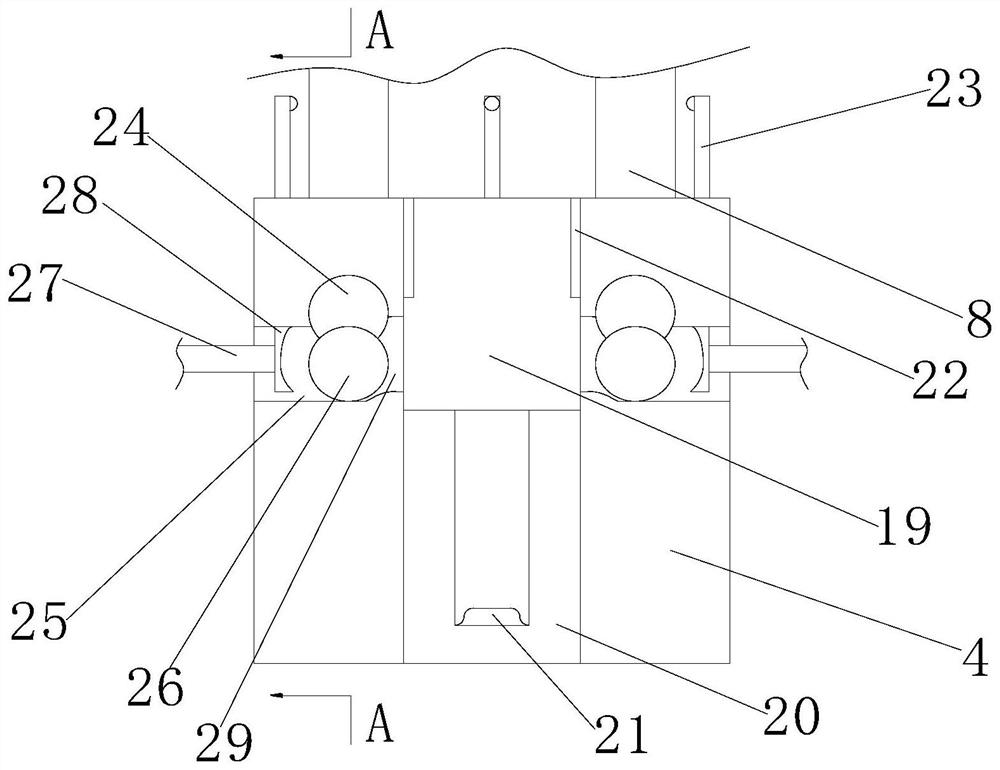

Cutting machining device for spherical-surface workpieces

ActiveCN110586962ARealize automatic transferSmooth rotationAutomatic control devicesFeeding apparatusMechanical equipmentTransfer mechanism

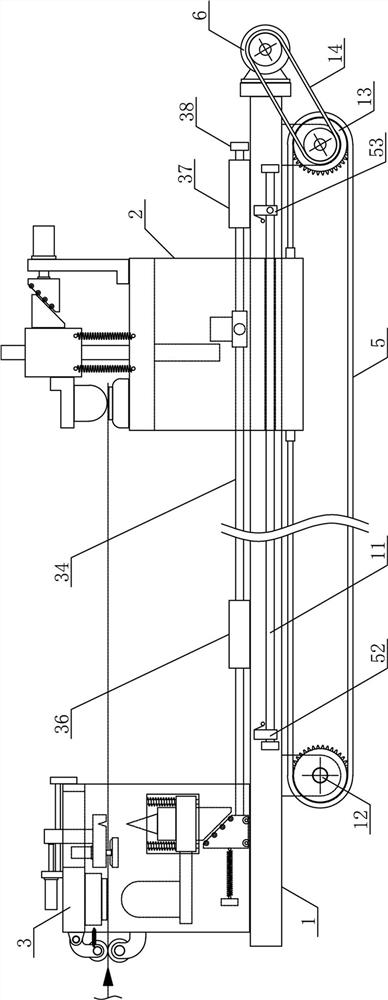

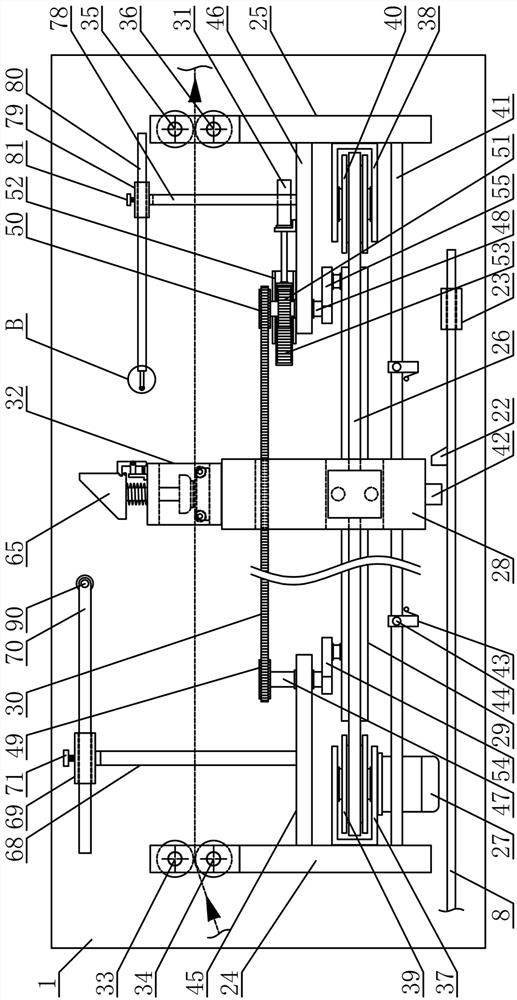

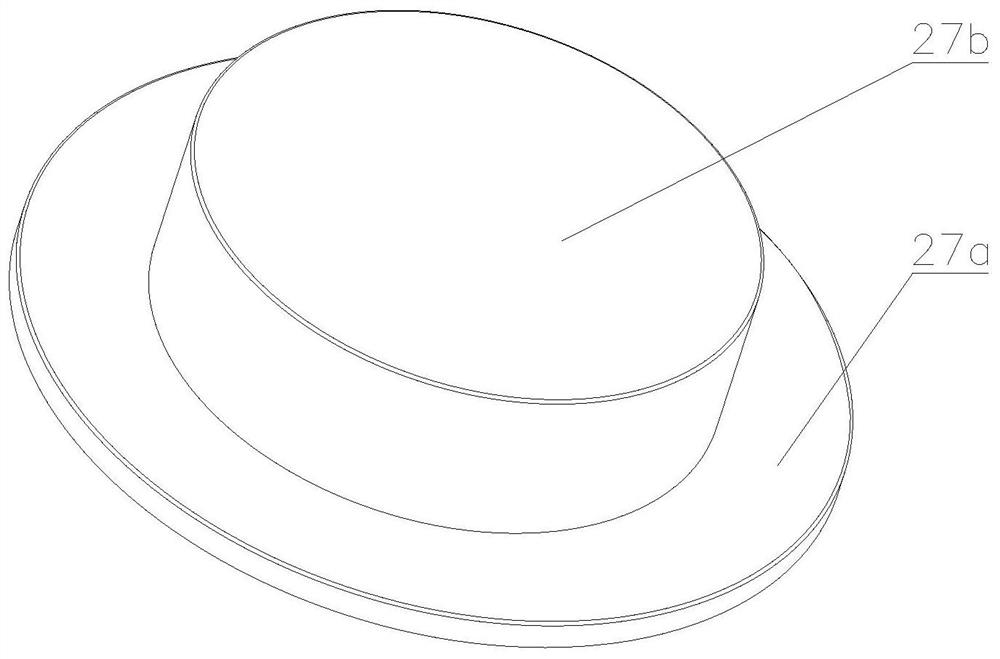

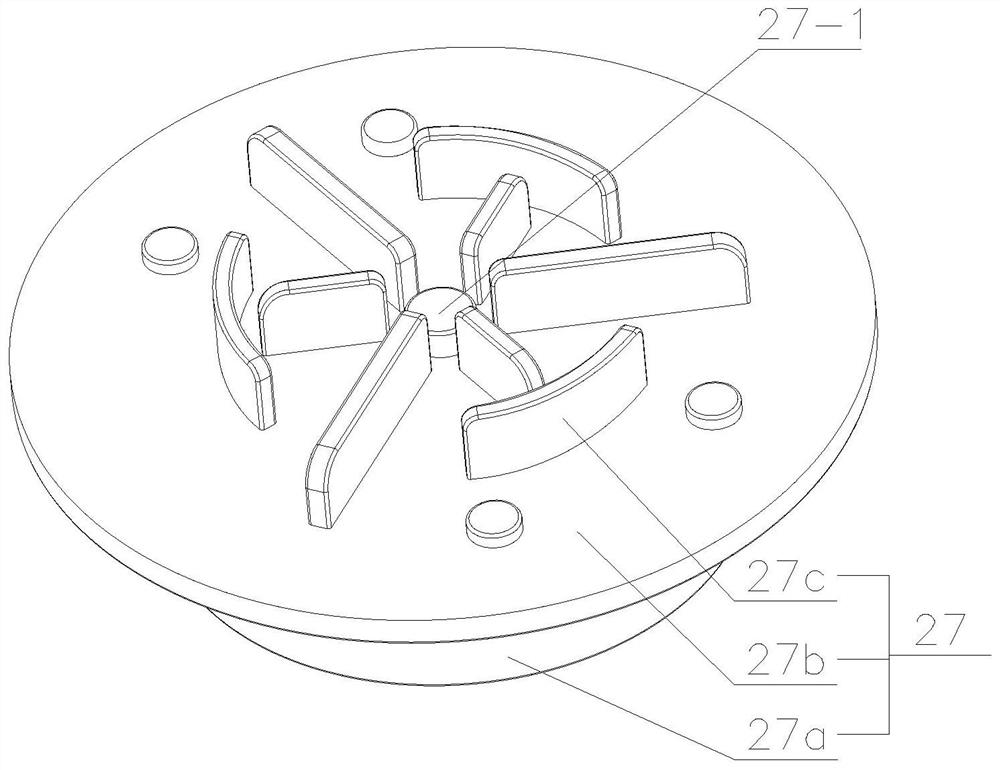

The invention discloses a cutting machining device for spherical-surface workpieces, and belongs to the field of workpiece machining mechanical equipment. The cutting machining device comprises a machining conveying support, a horizontal moving and cutting mechanism, a clamping and lifting mechanism, a turning and transferring mechanism and a workpiece conveying mechanism, wherein the horizontal moving and cutting mechanism is horizontally and fixedly arranged on one side above the machining conveying support, the clamping and lifting mechanism is vertically arranged at the position, on one side of the horizontal moving and cutting mechanism, of the machining conveying support, the turning and transferring mechanism is vertically arranged at the position, on one side below the clamping andlifting mechanism, of the machining conveying support, and the workpiece conveying mechanism is horizontally arranged at the position, on one side of the turning and transferring mechanism, of the machining conveying support in a mode of being adjacent to the turning and transferring mechanism. The cutting machining device has the advantages that the structural design is reasonable, the spherical-surface workpieces can be efficiently and stably cut and machined one by one, moreover, automatic transferring feeding and pushing of the spherical-surface workpieces can be achieved, the machining automation degree is high, and the workpiece machining and use requirements are met.

Owner:昆山勖盟工业科技有限公司

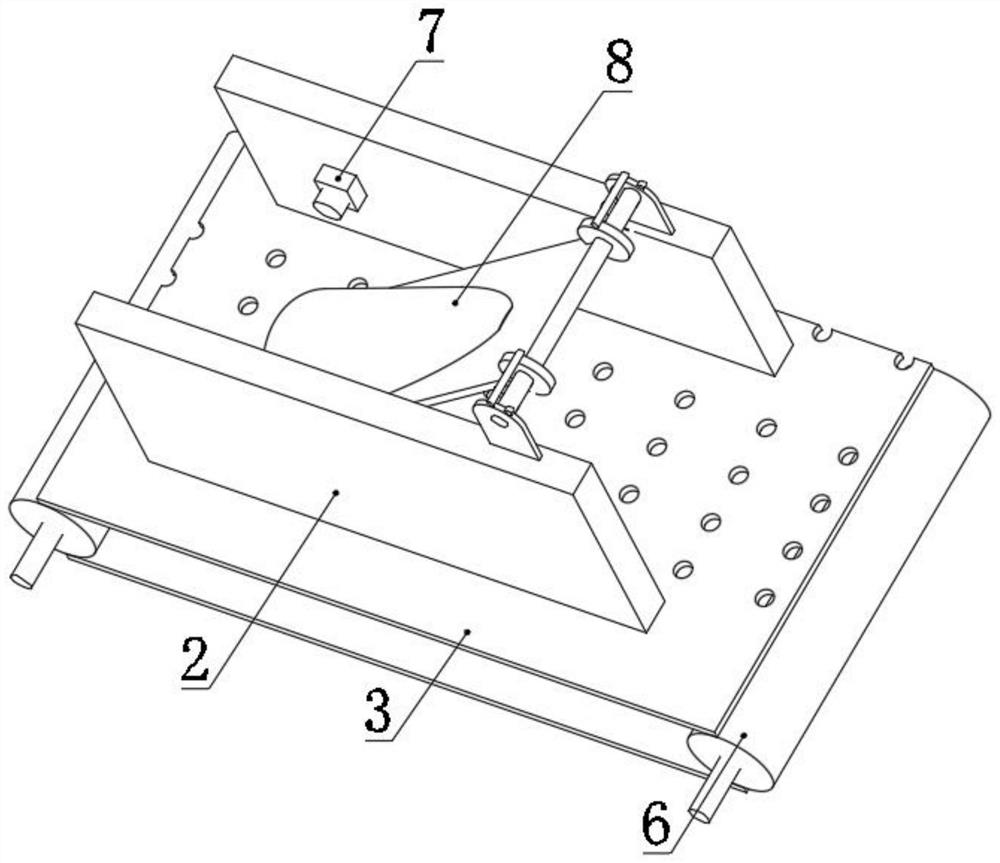

Fabric cutting device for silk quilt production

InactiveCN112850312AStable cutting processEfficient and stable cuttingArticle deliveryStructural engineeringMechanical equipment

The invention discloses a fabric cutting device for silk quilt production, and belongs to the field of home textile processing mechanical equipment. A fabric pressing and cutting mechanism and a fabric pulling and conveying mechanism of the fabric cutting device are arranged on the two sides of a fabric processing support, the two sides of the upper side of a reciprocating pulling chain are fixedly connected with the two sides of the lower side of a fabric pulling and conveying support correspondingly, a pressing plate mounting connecting plate and a lifting fixing wedge plate are horizontally and fixedly arranged on the two sides of the upper side of a lifting reciprocating guide plate correspondingly, a fabric pulling and conveying lower bearing plate is horizontally and fixedly arranged on the fabric pulling and conveying support on the lower side of a fabric pulling and conveying upper pressing plate, a pressing and cutting fixing wedge plate is horizontally and fixedly arranged on the lower side of a pressing and cutting lifting plate, a translation pressing and cutting wedge plate matched with the pressing and cutting fixing wedge plate is horizontally arranged on the fabric processing support on the lower side of the pressing and cutting fixing wedge plate, and a fabric pressing cutter is horizontally and fixedly arranged on the upper side of a cutter mounting base. The fabric cutting device for silk quilt production is reasonable in structural design, silk quilt fabric can be efficiently, stably, continuously and accurately cut in a sectional mode, the processing automation degree is high, and the requirements of production and use are met.

Owner:桐乡市诺创信息科技有限公司

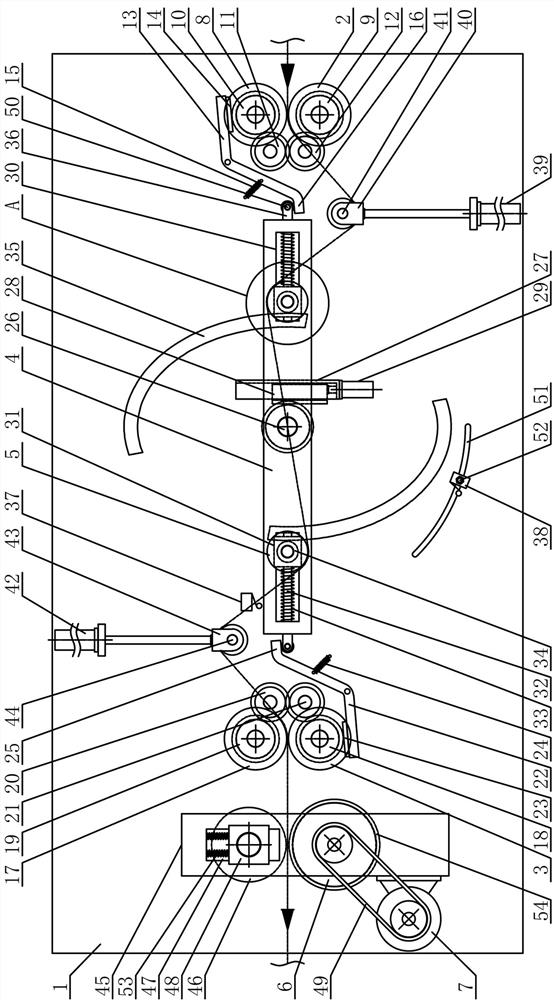

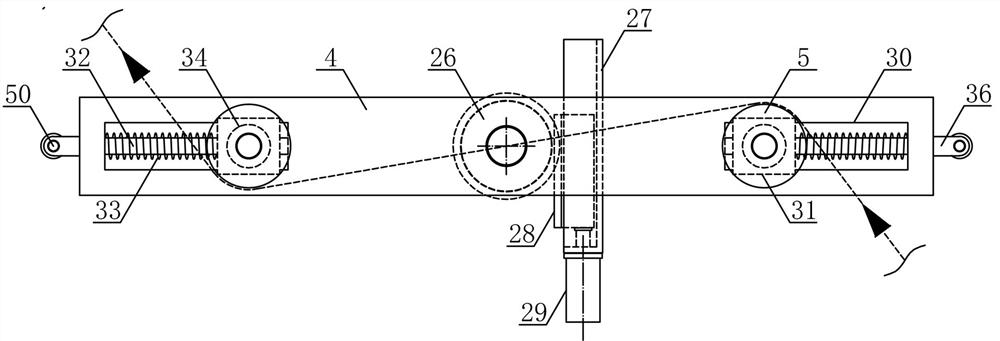

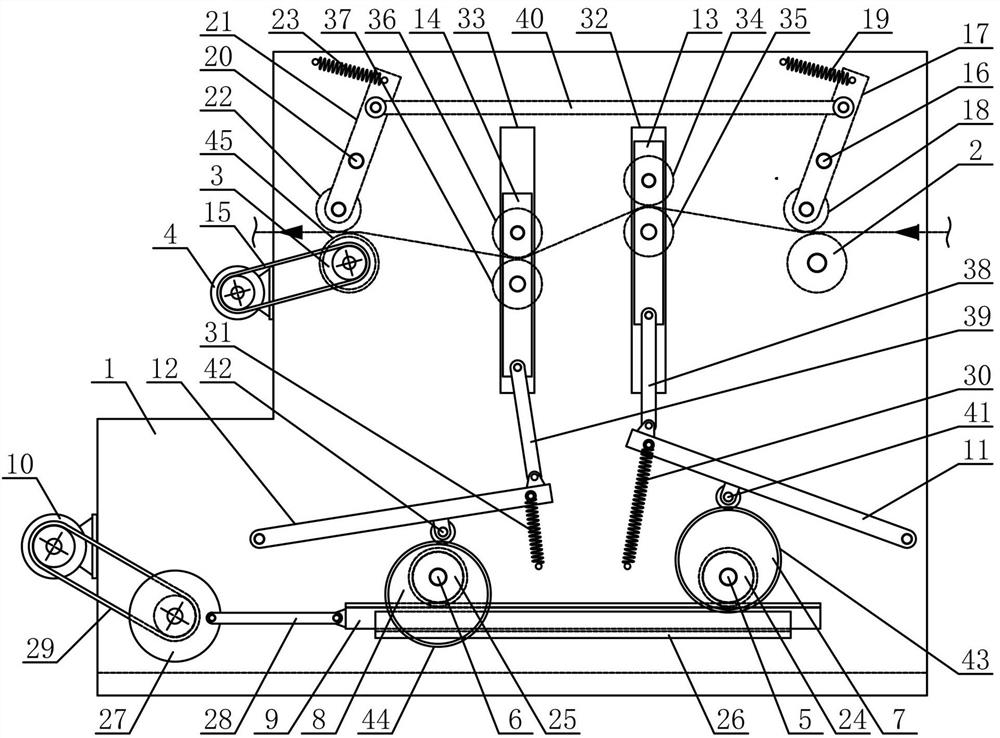

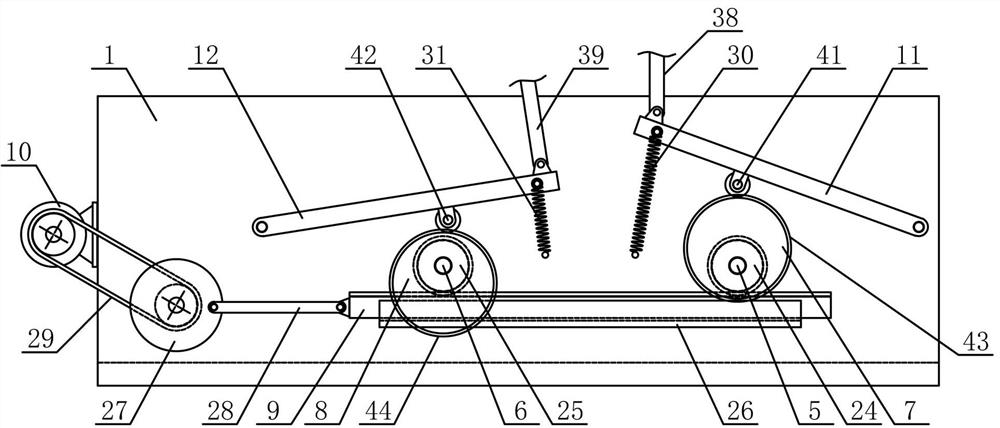

Drafting and setting device for polyester knitted fabric

ActiveCN113529322AReasonable structural designEfficient and smooth at restHeating/cooling textile fabricsStretchingPolyesterElectric machinery

The invention discloses a drafting and setting device for a polyester knitted fabric, and belongs to the field of fabric production and processing mechanical equipment. A fabric feeding guide roller and a fabric discharging guide roller are sequentially, horizontally and rotationally connected to a fabric processing support; a fabric reciprocating rotating plate is arranged on the fabric processing support between the fabric feeding guide roller and the fabric discharging guide roller; a fabric drafting gear is coaxially, vertically and fixedly arranged in the middle of the fabric reciprocating rotating plate along the side of the fabric processing support; a fabric drafting toothed plate at the output end of a fabric drafting air cylinder is in meshed connection with the fabric drafting gear coaxially fixed to the middle of the fabric reciprocating rotating plate; reciprocating drafting rotating rollers are symmetrically arranged on the two sides of the fabric reciprocating rotating plate; and the output end of a fabric pulling and conveying motor is in transmission connection with a fabric pulling and conveying guide roller through a fabric pulling and conveying belt. The device is reasonable in structural design, can efficiently and stably perform sectional drafting and setting processing in the knitted fabric conveying process, improves the production and processing automation degree of the knitted fabric, and meets the processing and using requirements.

Owner:浙江正辉针织科技股份有限公司

Weighing detecting line and application in processing of bottled medicament, milk powder cans and feed cans thereof

PendingCN108341102ARealize online weighing detectionRealize weighing detectionPackaging automatic controlEngineeringFodder

The invention belongs to the technical field of weighing detection, and provides a weighing detecting line. The weighing detecting line comprises a first conveying platform, a weighing detecting platform and a second conveying platform, which are all arranged in sequence. A mounting frame is movably arranged on one side of the first conveying platform. A first regulating mechanism is arranged between the mounting frame and the first conveying platform. The mounting frame is rotatably provided with a conveying roller which is driven by a driving device. The conveying roller is provided with conveying threads with the thread pitch being wider gradually in the conveying direction of processing products. The other side of the first conveying platform is provided with at least two stop levers.A plurality of second regulating mechanisms is uniformly arranged between the stop levers and the first conveying platform. One side of the weighing detecting platform is provided with a weight detector and a supporting plate, and the other side of the weighing detecting platform is provided with a pushing mechanism which is arranged corresponding to the supporting plate. The upper surface of thesupporting plate and a conveying belt of the weighing detecting platform are located at the same level. Smooth and orderly conveying and automatic weighting detection of the processing products are realized, and efficiency of weighing and detecting quality of the processing products are improved.

Owner:青岛创高世纪信息科技有限公司

Zipper puller discharging device

InactiveCN112456039AFirmly connectedSolve the lack of spaceJigging conveyorsStructural engineeringMechanical engineering

The invention provides a zipper puller discharging device, and belongs to the technical field of machinery. The zipper puller discharging device solves the problem that in the prior art, stability ispoor. The zipper puller discharging device comprises a rack and further comprises a discharging plate, a connecting rod, a driving assembly and a spring, the discharging plate is obliquely arranged, the lower end of the discharging plate is hinged to the rack, the upper end of the connecting rod is hinged to the middle of the discharging plate, the driving assembly is connected to the rack, the driving assembly is connected with the lower end of the connecting rod, the two ends of the spring are connected to the discharging plate and the rack correspondingly, the driving assembly can drive theconnecting rod to move up and down, and an inward-concave discharging channel is formed in the discharging plate. The stability of the zipper puller discharging device is high.

Owner:浙江敏杰新材料科技有限公司

Continuous conveying and stacking device for wool spun gauze

PendingCN110129925AAccurate and smooth panning motionEfficient width adjustmentCarding machinesRotating discTextile processing

The invention discloses a continuous conveying and stacking device for a wool spun gauze and belongs to the field of textile processing machinery. A first conveying belt is horizontally arranged on the upper side of a wool spinning guide support, a swing connecting rod is arranged between a rotating disc and a swing support, a second conveying belt is horizontally arranged on the upper side of a bearing conveying support, a front transition guide roll and a rear transition guide roll are symmetrically arranged on a wool spinning guide support on two sides of a third conveying belt, a rotatingsupport is arranged on a reversing conveying support on the lower side of a third reversing rotating roll, a translation guide rod is horizontally arranged on one side of the rotating support, a reciprocating driving mechanism is arranged on the wool spinning guide support on one side of the transition guide rod, and a fourth conveying belt is horizontally arranged below the rotating support. Thedevice is reasonable in structure design, can stably and conveniently perform continuous and smooth stacking processing on the sparse wool spun gauze in the conveying process to form a dense wool spungauze, is high in automation degree and meets the processing use demands.

Owner:浙江秋黎服饰有限公司

Automatic metal ball conveying mechanism

ActiveCN111003481ASmooth and smooth lift transmissionReasonable structural designConveyor partsGear wheelEngineering

The invention discloses an automatic metal ball conveying mechanism, and belongs to the field of processing conveying device. A reciprocating swing material pipe is arranged on a ball conveying bracket on one side of a material conveying pipe. A lifting push plate is fixedly arranged at the output end of a pushing air cylinder on the lower side of a pushing bracket; a material guide rotating seatabove the reciprocating swing material pipe is rotationally connected to the ball conveying bracket; the upper side of the reciprocating swing material pipe is rotationally connected with a reciprocating rotating gear; a main rack bracket and an auxiliary rack bracket are fixedly arranged on the parts, on the two sides of the reciprocating rotating gear, of the ball conveying bracket respectively,a main lifting rack is arranged in the main rack bracket in a sliding mode, an auxiliary lifting rack is arranged on a lifting guide rod in a sliding mode, and a push pipe reciprocating connecting rod is arranged between the auxiliary lifting rack and the reciprocating swing material pipe. The automatic metal ball conveying mechanism is reasonable in structural design, metal balls can be efficiently, stably, accurately and smoothly guided and conveyed one by one, the automation degree is high, and the processing and using requirements are met.

Owner:桐乡市红旗塑料包装袋厂

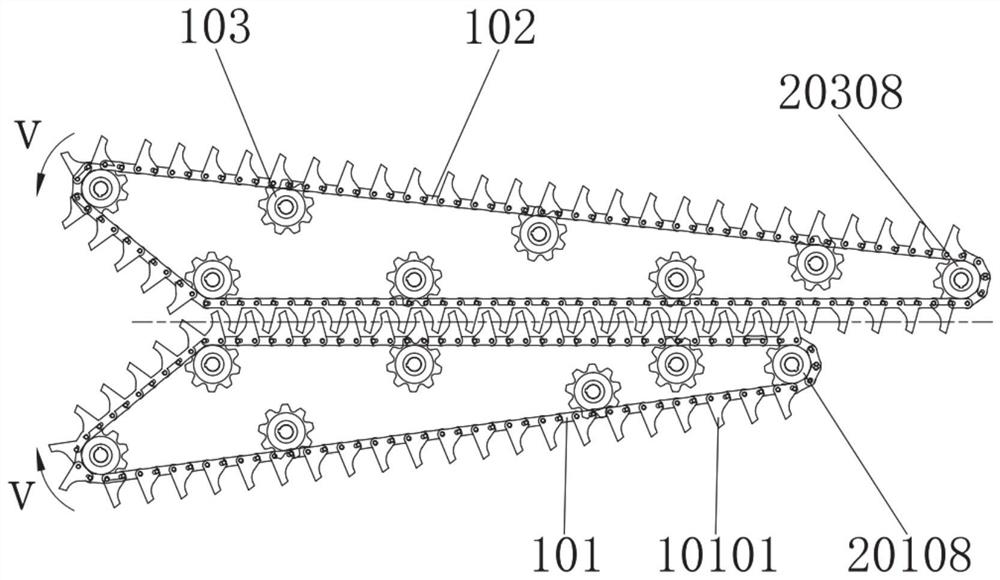

Tuber and seedling clamping and conveying device and equipment for root and tuber crops

PendingCN112930834ASmooth and orderly deliveryNo congestionLiftersTopping machinesAgricultural engineeringMechanical engineering

The invention discloses tuber and seedling clamping and conveying device and equipment for root and tuber crops. According to the technical scheme, the device comprises a clamping chain assembly and a chain cover assembly, wherein the clamping chain assembly comprises a left clamping chain and a right clamping chain which are meshed together; a plurality of shifting teeth are distributed on the outer sides of the left clamping chain and the right clamping chain; the shifting teeth are staggered to form a tuber and seedling conveying channel; the chain cover assembly comprises a left chain cover assembly mounted on the outer side of the left clamping chain and a right chain cover assembly mounted on the outer side of the right clamping chain; the right chain cover assembly is provided with a tuber and seedling guide mechanism; and the left chain cover assembly and the right chain cover assembly are mounted above a rack assembly and form a tuber and seedling guide channel. According to the invention, feeding, clamping, conveying, laying and other operations of tubers and seedlings of the root and tuber crops can be completed at one time, the work is reliable, and the application range is wide.

Owner:SHANDONG ACADEMY OF AGRI MACHINERY SCI

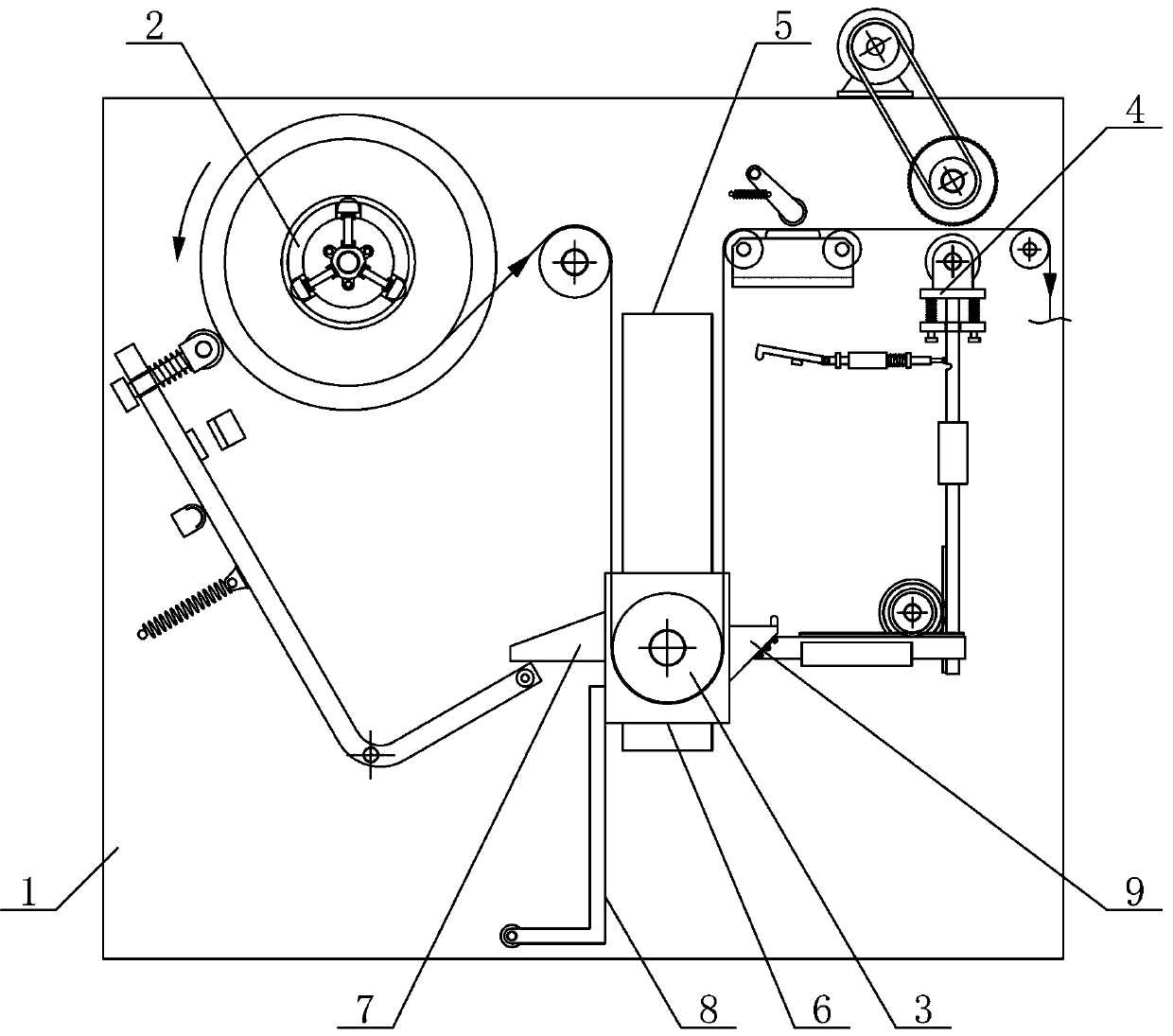

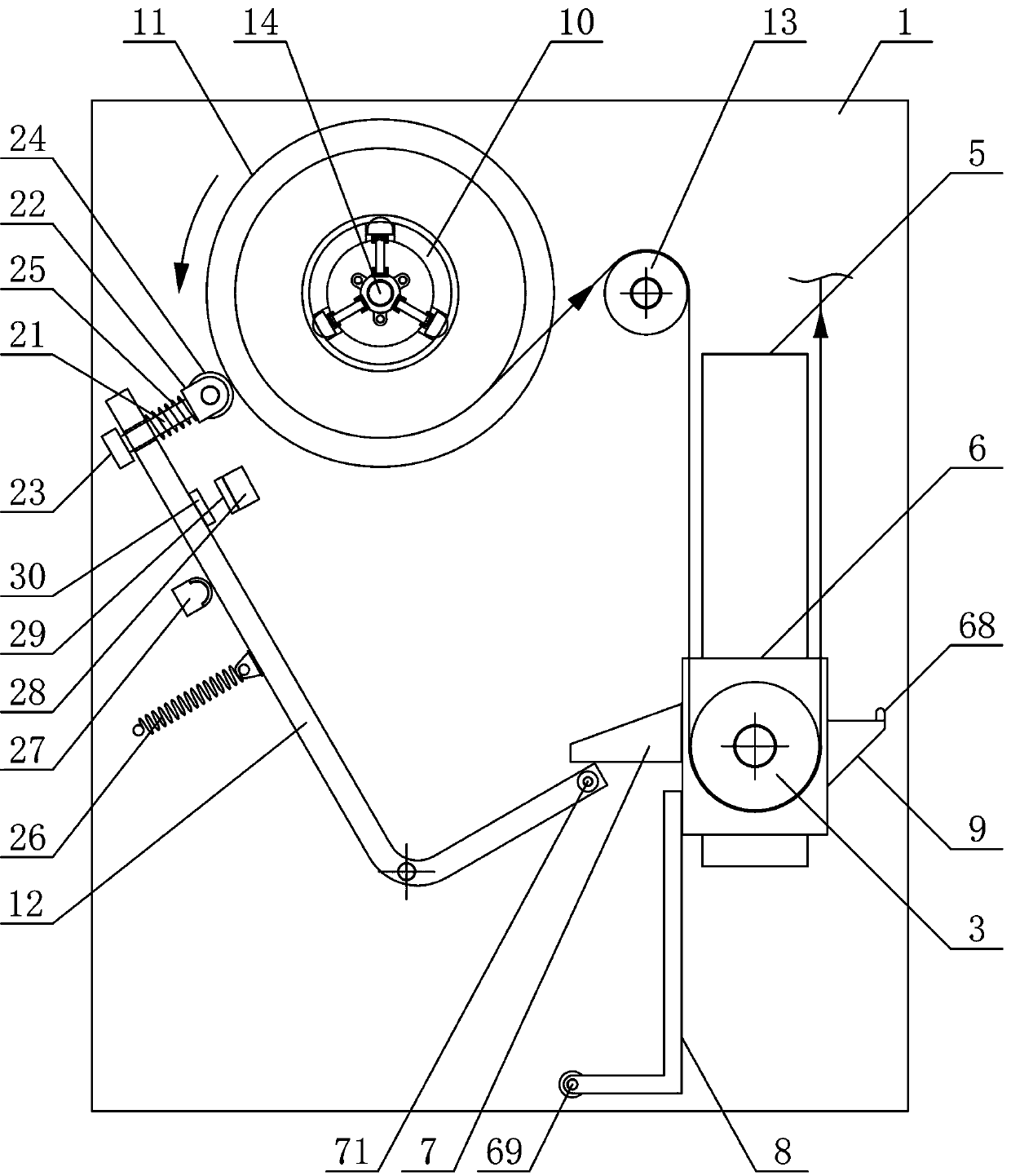

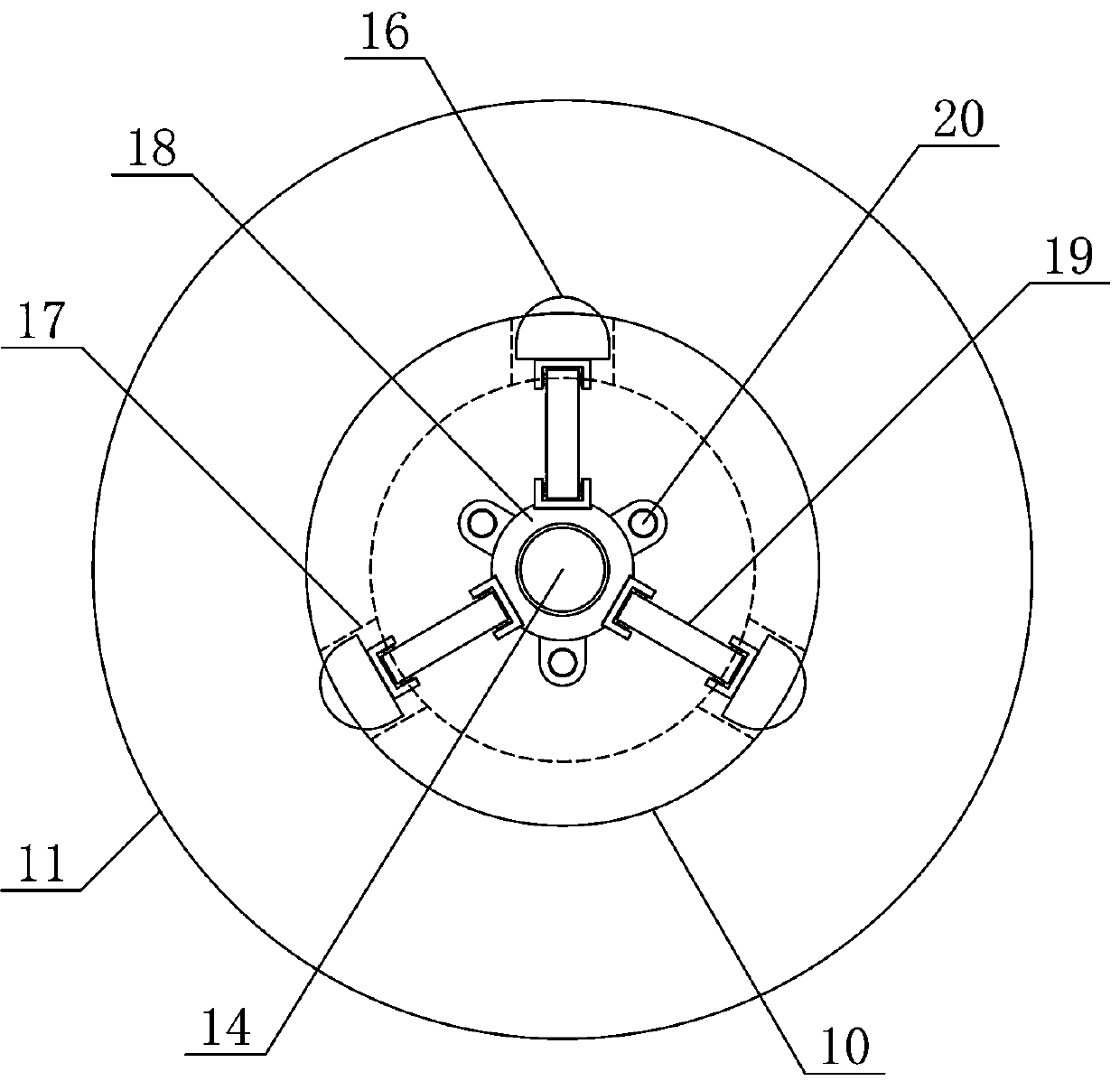

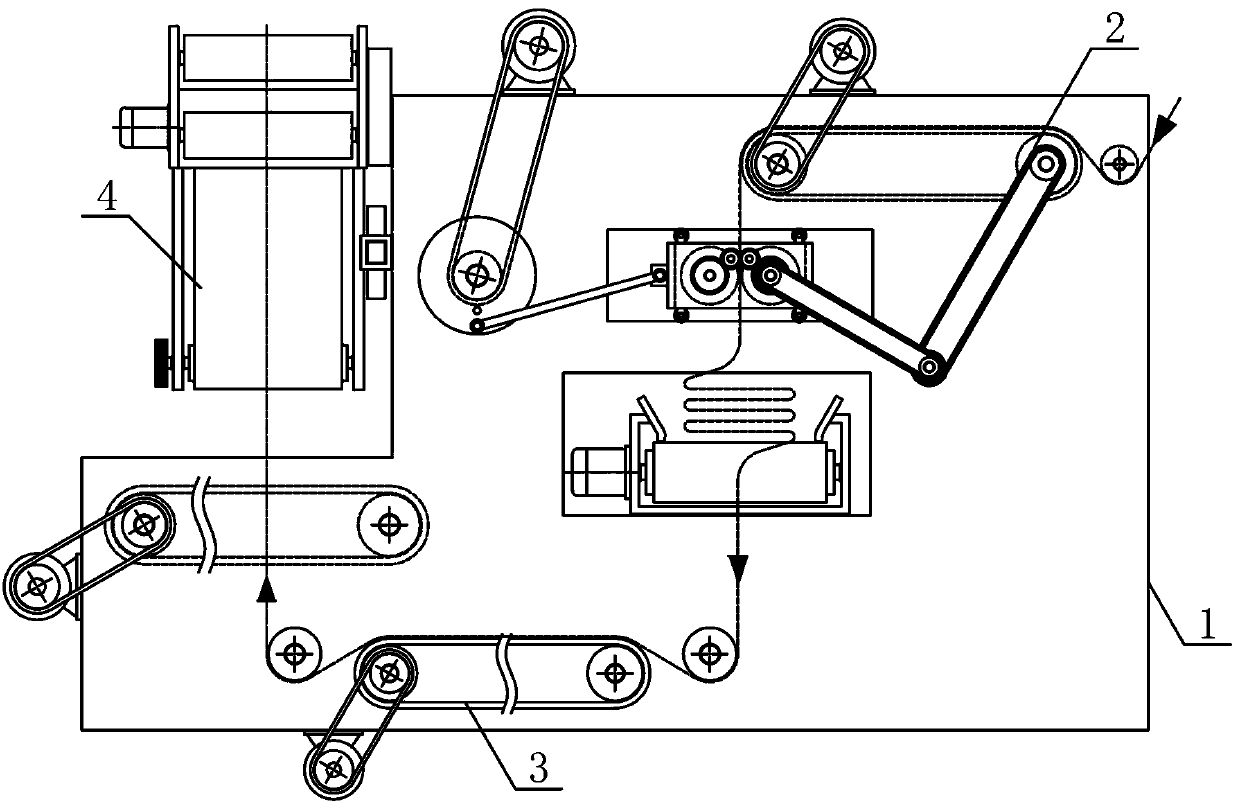

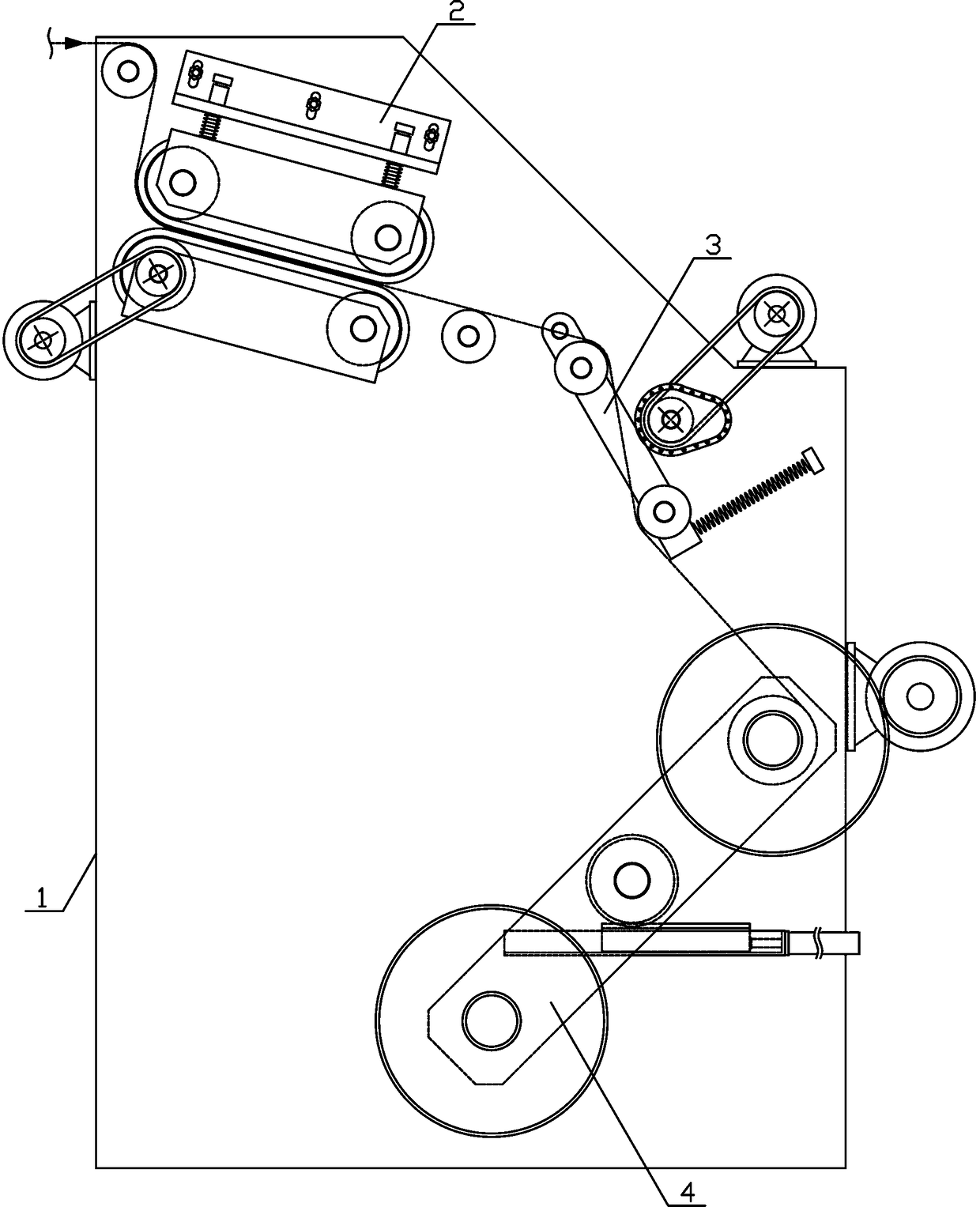

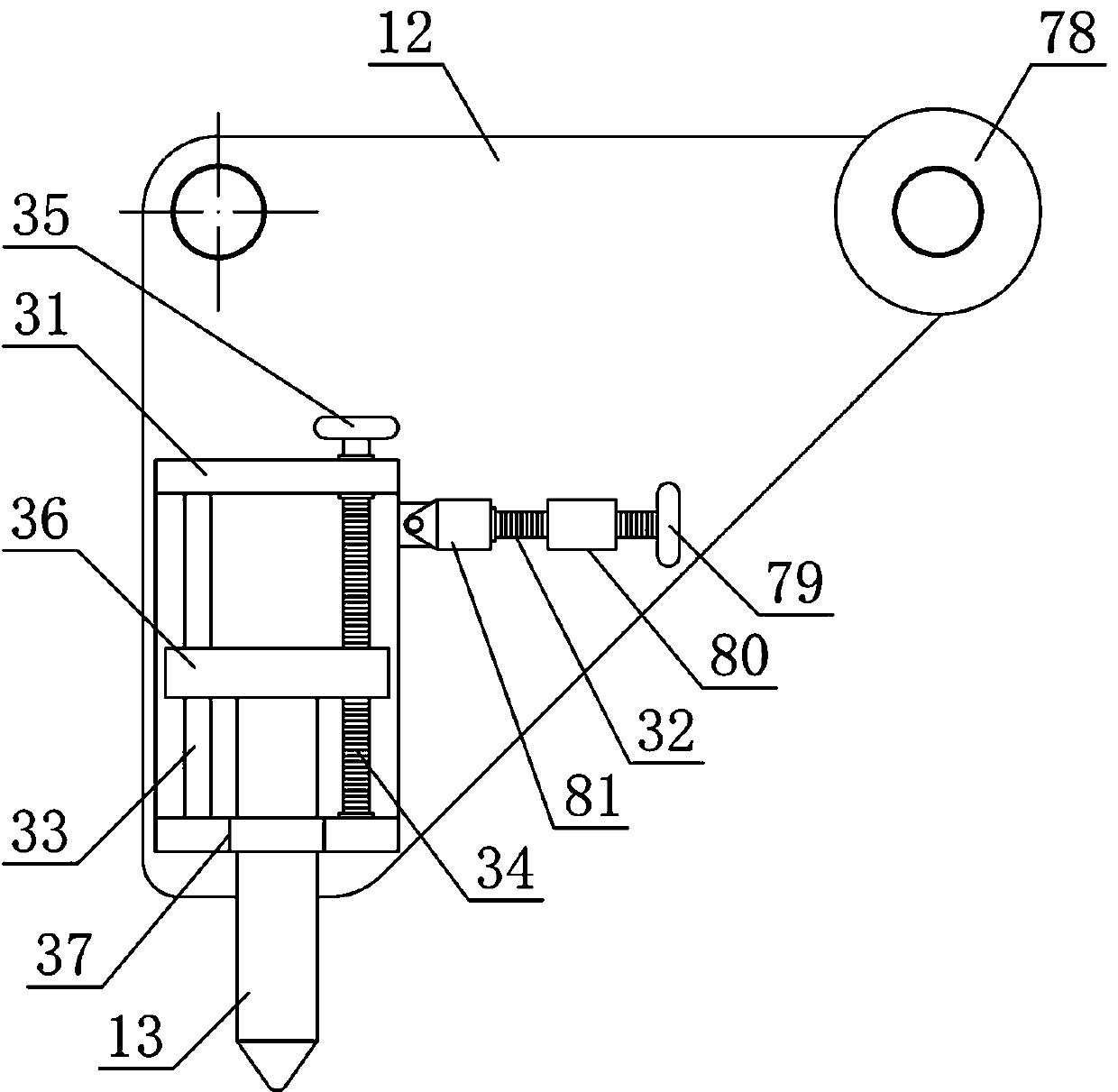

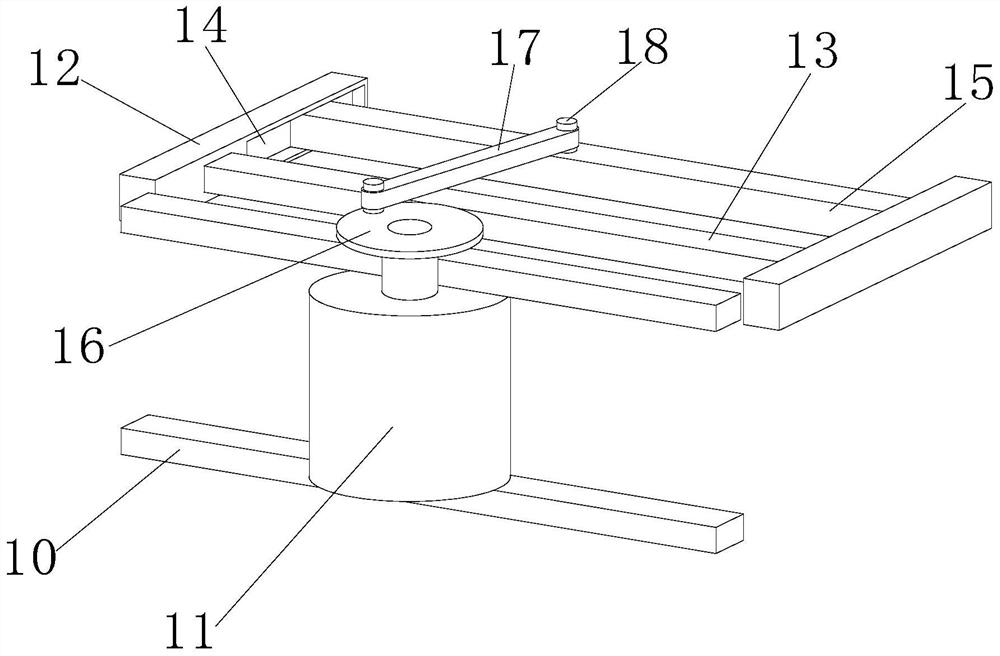

Continuous yarn winding mechanism of blended yarns

PendingCN108584534AContinuous and uniform windingEfficient and compact windingFilament handlingYarnEngineering

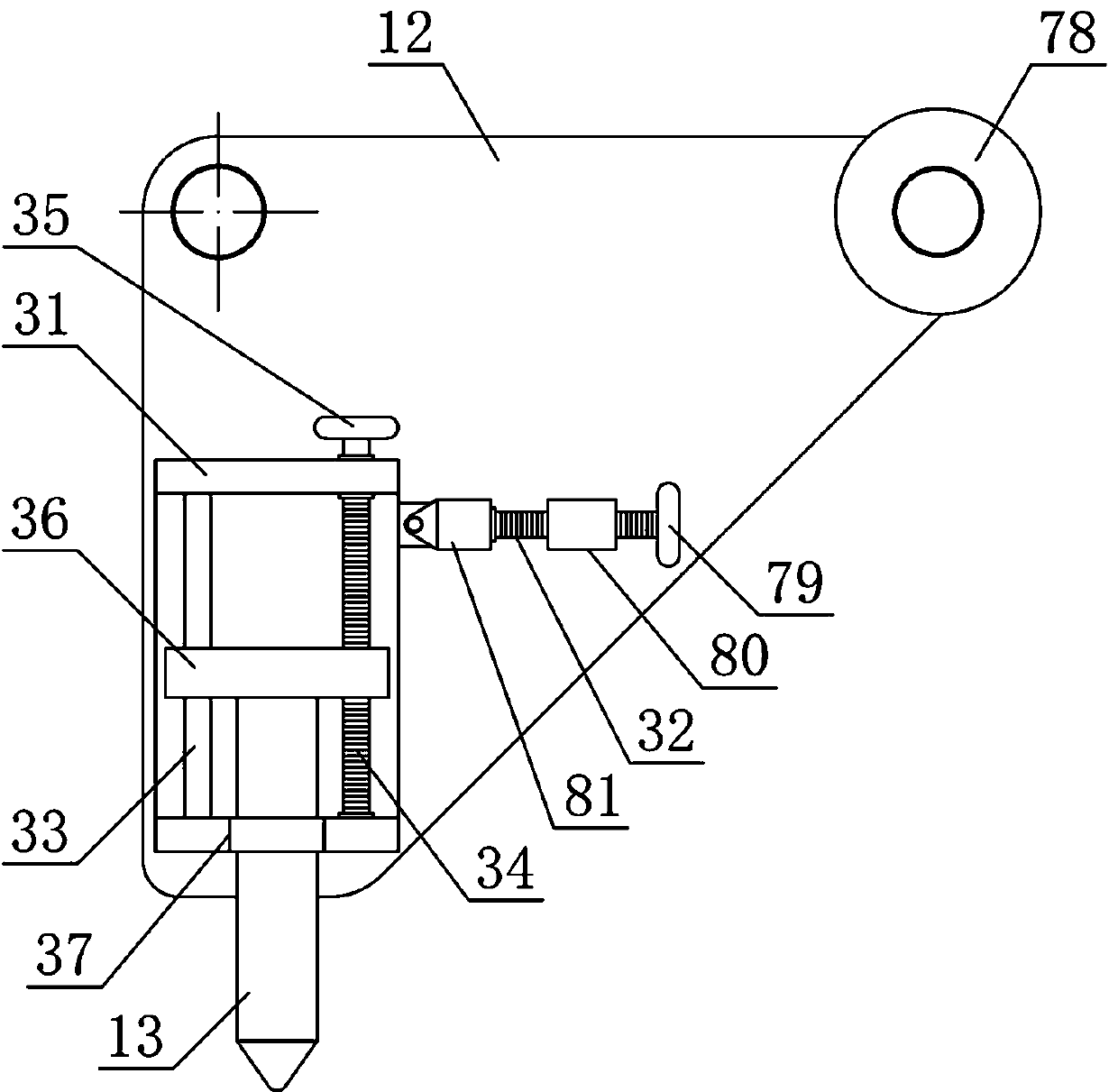

The invention discloses a continuous yarn winding mechanism of blended yarns, and belongs to the field of textile processing machinery equipment. According to the continuous yarn winding mechanism, ayarn drawing mechanism, a yarn guide mechanism and a winding mechanism are sequentially arranged on one side of a fixing support from top to bottom, an adjusting support, a yarn pressing support and ayarn bearing support are obliquely arranged on the fixing support on one side of a yarn inlet guide roller from top to bottom, an upper yarn guide roller and a lower yarn guide roller are horizontally and rotationally connected to a yarn guide rotating plate from top to bottom in sequence, a pull plate spring is obliquely arranged between a spring connecting plate and the lower end of the yarn guide rotating plate, the middle of one side of the winding support is fixedly connected with the outer end of a reciprocating rotating shaft, winding rotating discs are vertically and rotationally connected to the upper end and the lower end of one side of the winding support respectively, and winding and rolling bearing rods are horizontally and fixedly arranged in the middles of one sides of thewinding rotating discs. According to the continuous yarn winding mechanism, the structural design is reasonable, the blended yarns can be efficiently and accurately conveyed and stably and continuously rolled, the rolling automation degree of the blended yarns is improved, and the requirements of production and use are met.

Owner:嘉兴市华益股份有限公司

A high-precision energy-saving fish scanning and counting device

ActiveCN113728960BAvoid counting imprecise problemsHigh precisionPisciculture and aquariaCounting mechanisms/objectsElectric machineryEngineering

The invention discloses a high-precision energy-saving fish scanning and counting device, which belongs to the field of counting devices and includes a fish box. The top wall of the fish box is provided with a fish outlet, and one side of the fish box is provided with a fish outlet. , the outer side of the fish outlet of the fish box is provided with a plurality of fishway partitions arranged in parallel, and the plurality of the fishway partitions are fixed to each other by skeleton rods, and the fish box and the fishway partitions are all connected by brackets The support is fixed, the lower side of the fishway partition is provided with a conveying mechanism, the conveying mechanism includes a conveying belt, a conveying roller and a conveying motor, and the conveying belt is installed on the conveying roller. The invention can realize anti-blocking conveying of fish, and realize continuous and efficient counting during conveying. When counting, multiple fish can be prevented from passing through the counter at the same time, so the equipment counts more accurately, and it is not necessary to measure the size of the fish during counting. Classification, which greatly saves operation time, and the load on the equipment during operation is small, so it is more energy-saving and environmentally friendly.

Owner:易科捷(武汉)生态科技有限公司成都分公司

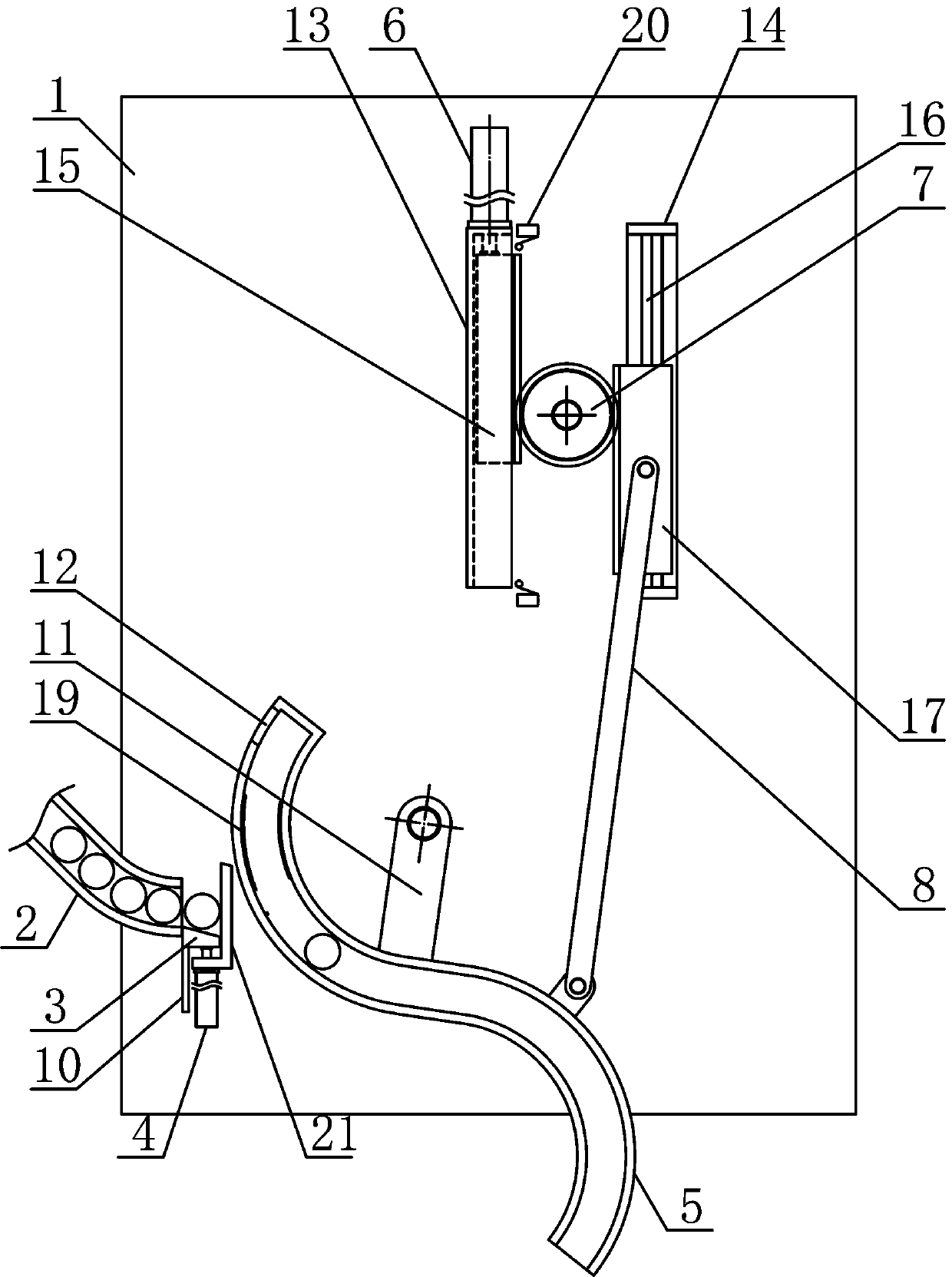

Using method of spherical workpiece cutting machining device

InactiveCN111531227AAccurate and efficient reciprocating translational movementHigh degree of processing automationAutomatic control devicesFeeding apparatusMechanical equipmentMaterial transfer

The invention discloses a using method of a spherical workpiece cutting machining device, and belongs to the field of workpiece machining mechanical equipment. The spherical workpiece cutting machining device comprises a machining material conveying support, a translation cutting mechanism, a material clamping lifting mechanism, a turnover material transferring mechanism and a workpiece conveyingmechanism; the translation cutting mechanism is horizontally and fixedly arranged on one side above the machining material conveying support, the material clamping lifting mechanism is vertically arranged on the machining material conveying support on one side of the translation cutting mechanism, the turnover material transferring mechanism is vertically arranged on the machining material conveying support on one side below the material clamping lifting mechanism, and the workpiece conveying mechanism is horizontally and adjacently arranged on the machining material conveying support on one side of the turnover material transferring mechanism. The spherical workpiece cutting machining device is reasonable in structural design, capable of efficiently and stably cutting spherical workpiecesone by one, capable of achieving automatic transferring, feeding and returning of the spherical workpieces, high in machining automation degree and capable of meeting the requirements for workpiece machining and use.

Owner:黄明珠

Paperboard taking and conveying mechanism

PendingCN113548246AImprove protectionStable deliveryWrapping material feeding apparatusPaperboardElectric machinery

The invention discloses a paperboard taking and conveying mechanism comprising a conveying table. Main installation plates are fixedly installed on the two sides of the conveying table, a pushing motor is fixedly installed on each main installation plate, a first rotating shaft and a second rotating shaft are fixedly installed between the main installation plates on the two sides, and the pushing motors are in transmission connection with the first rotating shaft and the second rotating shaft through transmission belts. Conveying wheels and guide wheels are installed on the first rotating shaft and the second rotating shaft correspondingly. A paperboard suction device is further fixedly installed on each main installation plate, and a conveying chain is arranged on the conveying table. The paperboard taking and conveying mechanism has the beneficial effects that paperboards can be well protected, the stable conveying process is kept, stable and orderly taking and conveying of the paperboards can be achieved through the paperboard suction devices, and the conveying efficiency can be remarkably improved.

Owner:南京恒昌包装机械有限公司

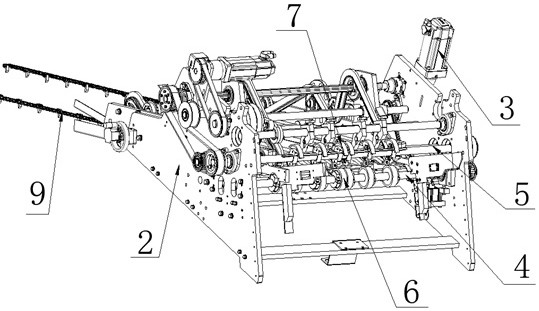

Warp knitting and weft knitting composite weaving equipment

ActiveCN112342683AEasy to adjustSynchronous and smooth unwinding transmissionKnittingIndustrial engineeringTextile processing

The invention discloses warp knitting and weft knitting composite weaving equipment, and belongs to the field of textile processing equipment. A warp yarn guiding and feeding mechanism and a compositeweaving mechanism are sequentially arranged on a fabric weaving support, a weft yarn guiding and feeding mechanism is arranged on the fabric weaving support on the adjacent side of the composite weaving mechanism, a plurality of warp yarn unwinding rotary drums sequentially sleeve the upper edge of a warp yarn guiding and feeding rotary roller, a wool hanging driving mechanism drives a wool hanging moving plate to move up and down and move horizontally, warp guiding and feeding needles are correspondingly arranged in a plurality of yarn guiding needle containing clamping grooves in the upperside of the warp guiding and feeding plate, and fabric production knitting needles are correspondingly arranged in a plurality of knitting needle containing clamping grooves in the upper side of a fabric weaving needle bed. The warp knitting and weft knitting composite weaving equipment is reasonable in structural design, warp knitting and weft knitting can be stably and efficiently combined for production and weaving, continuous and smooth production and weaving of the plaid knitted fabric with plaid patterns and colors are achieved, the plaid patterns and colors of the plaid knitted fabric can be conveniently, rapidly and accurately adjusted and woven according to needs, and the requirements of fabric production are met.

Owner:浙江润龙针织股份有限公司

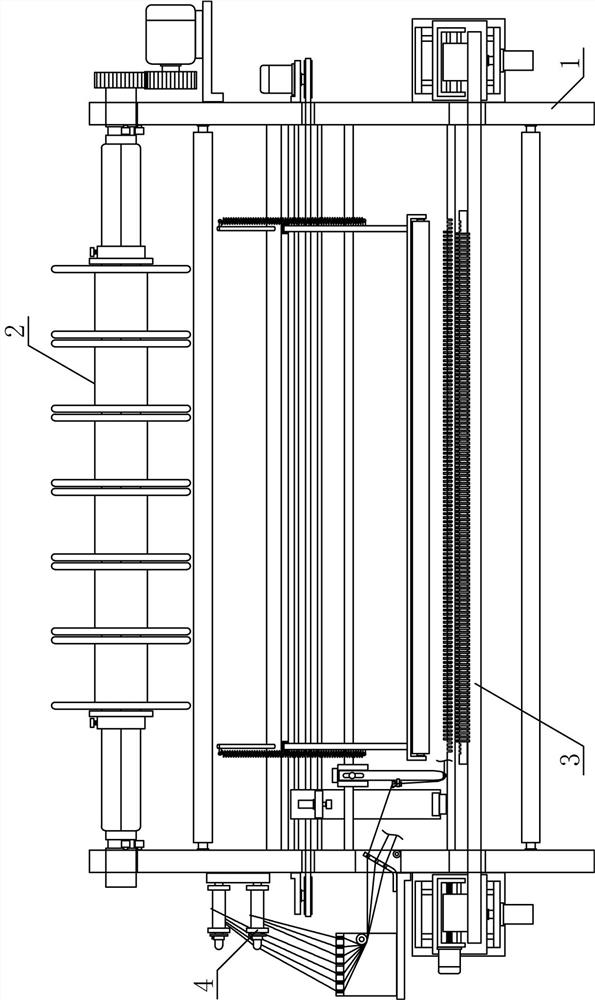

Aluminum roll unwinding and conveying device

ActiveCN112897171ASmooth and orderly deliveryImprove convenience and smoothnessWebs handlingCircular discStructural engineering

The invention discloses an aluminum coil unwinding and conveying device, and belongs to the field of aluminum coil machining mechanical equipment. According to the aluminum coil unwinding and conveying device, an aluminum coil unwinding mechanism and a material pulling conveying mechanism are sequentially arranged on an aluminum coil conveying support in the horizontal direction, a coil blocking rotating disc is coaxially, vertically and fixedly arranged on an aluminum coil unwinding rotating roller along the side end part of the aluminum coil conveying support, reciprocating damping rotating rods are symmetrically arranged on the two sides of the lower portion of the coil blocking rotating disc, the two sides of the lower portion of a reciprocating material pulling support are horizontally arranged on material pulling horizontal moving guide rods on the corresponding sides in a sliding mode respectively, a horizontal moving material pressing support is horizontally and fixedly arranged on the upper side of the reciprocating material pulling support, a material pulling compaction top plate is horizontally arranged on the upper side of a material pulling compaction bottom plate on the inner side of the horizontal moving material pressing support, and a material pressing lifting wedge plate is horizontally arranged on the upper side of the horizontal moving material pressing support. The aluminum coil unwinding and conveying device is reasonable in structural design, aluminum coils can be stably and orderly rotated and unwound, the aluminum coils can be efficiently and accurately pulled, conveyed and guided in a segmented mode, the automation degree of aluminum coil machining is improved, and the requirements of production and use are met.

Owner:肇庆市金达金包装容器有限公司

Valve port conveying and detecting assembly

ActiveCN113800034AImprove production qualitySmooth and orderly deliveryMachine valve testingPackaging by pressurising/gasifyingFilm materialEngineering

The invention discloses a valve port conveying and detecting assembly which comprises a rack. A conveying belt and a driving device for driving the conveying belt to rotate are arranged on the rack, a bearing table is arranged at the output end of the conveying belt, and a through hole which allows the output end of a lifting device to pass through and is located under the conveying path of a film material hot-pressing opening is formed in the bearing table. The output end is further provided with a transferring device, the transferring device is used for transferring the valve port of the output end to the position over the through hole, and the input end of the conveying belt is provided with a feeding device. A first in-place sensor is arranged over the conveying belt, and the detection end of the first in-place sensor faces the conveying belt. According to the valve port conveying and detecting assembly, the first in-place sensor and the feeding device are matched for operation, and it is guaranteed that the conveying belt can stably, orderly and smoothly convey valve ports. And at the conveying end of the conveying belt, the valve ports are transferred to the position over the through hole through the transferring device, so that the lifting device jacks the valve ports to the film material hot-pressing opening, automatic high-precision heat sealing is achieved, and the production quality of vacuum bags is improved.

Owner:WUXI HONGCHANG PRECISION MACHINERY

A ruler body sorting device for level ruler production

ActiveCN112551157BAvoid damageSmooth and orderly deliveryConveyor partsElectric machineryStructural engineering

Owner:JINHUA HAODE TECH CO LTD

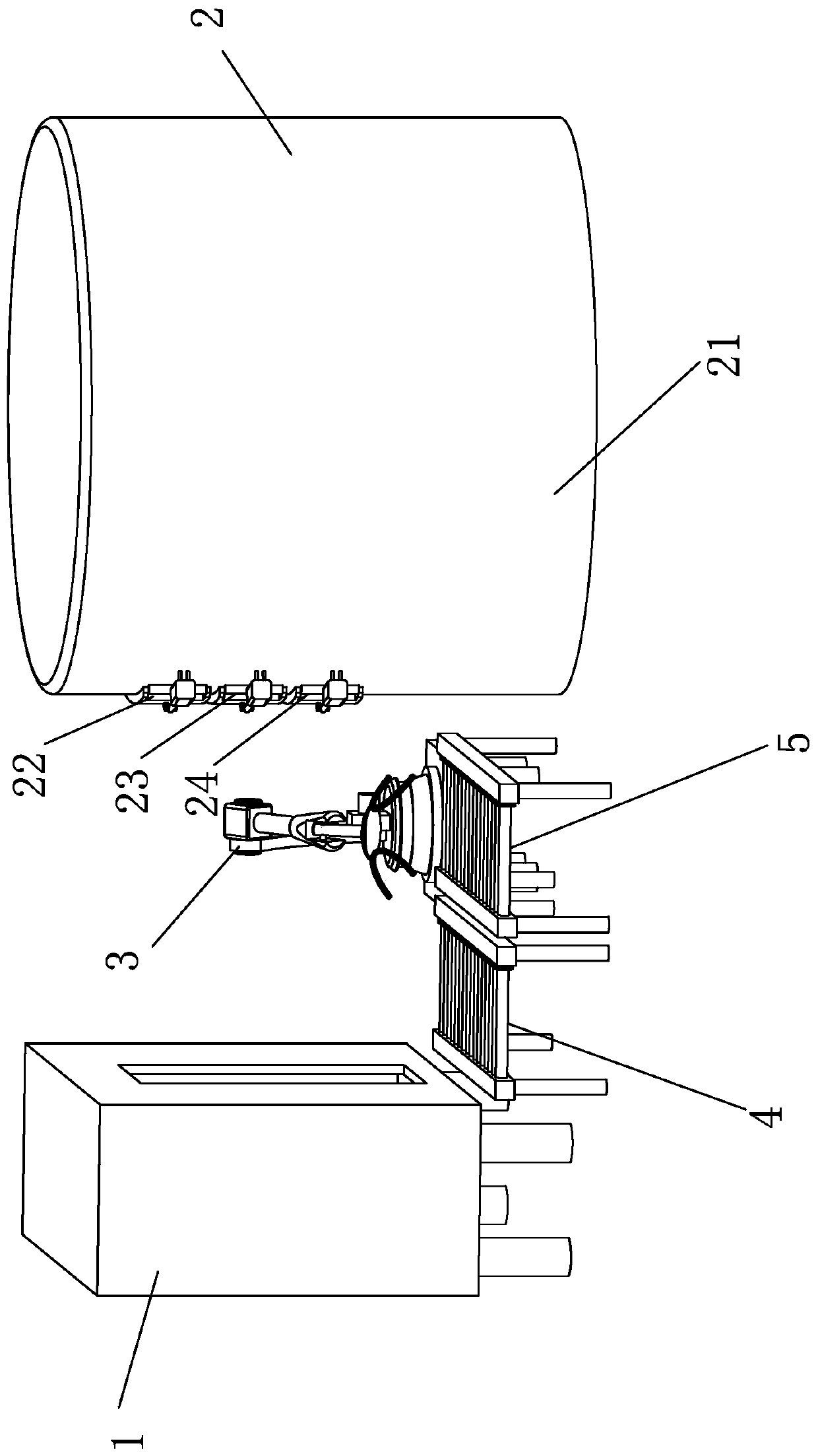

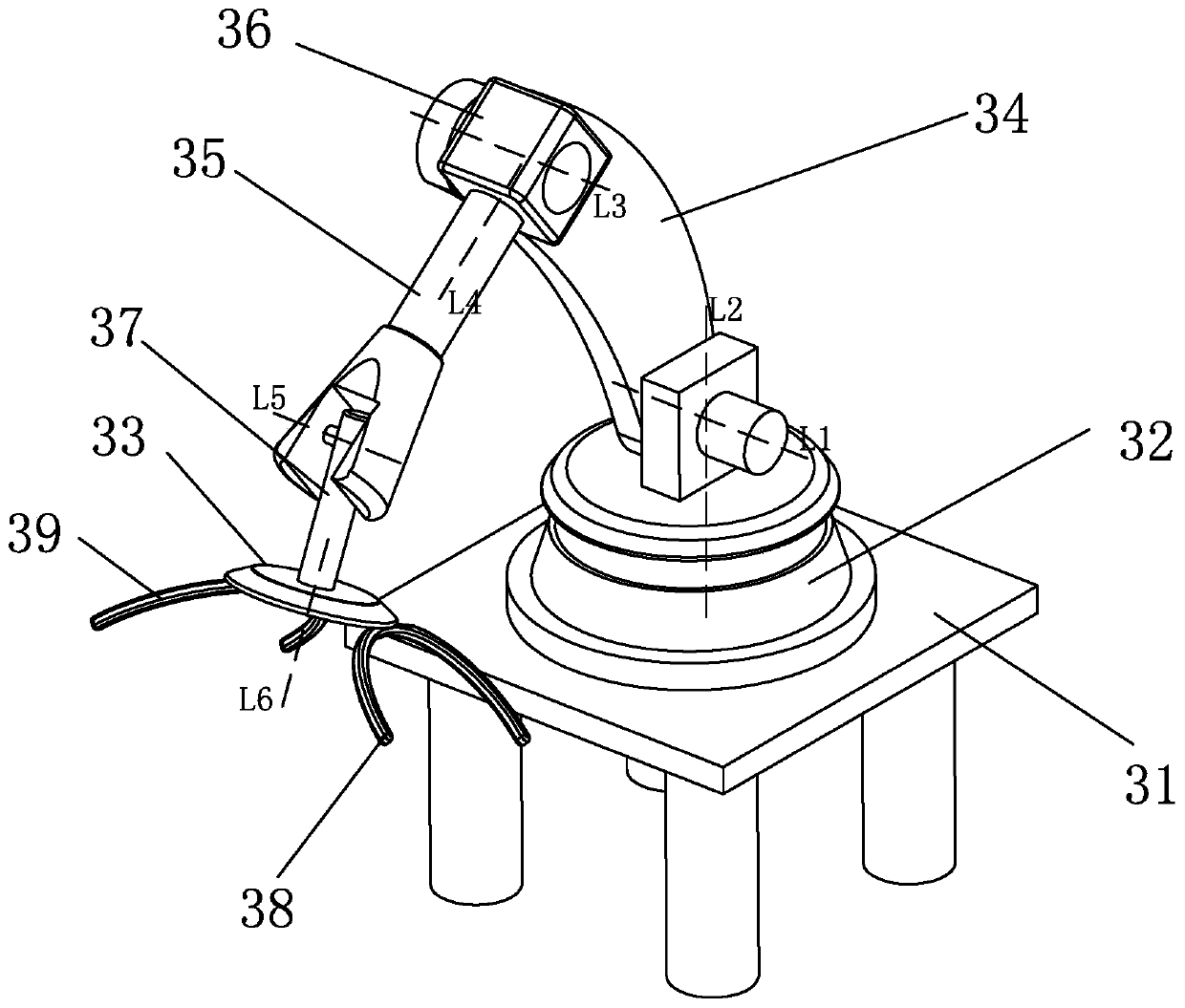

Conveying method of car hub spinning production line

PendingCN110756679ASmooth and orderly deliveryShorten the conveying distanceMetal-working feeding devicesRimsManufacturing engineeringRobot hand

The invention discloses a conveying method of a car hub spinning production line. The conveying method comprises the following steps that 1) a hub blank to be preheated is placed on a second conveyingbelt; 2) a first mechanical arm clamps the hub blank to be preheated from the second conveying belt; 3) a second mechanical arm firstly stretches into a furnace door to clamp the heated hub blank, and then the first mechanical arm stretches into the furnace door to place a hub blank to be preheated on a circular conveying rail; 4) the circular conveying rail conveys the hub blank to be preheatedto be rotationally preheated in a furnace, the hub blank to be preheated becomes a preheated hub blank after preheating is finished, and the preheated hub blank is conveyed to the furnace door; and 5)the first mechanical arm firstly stretches into a spinning machine to clamp a spun semi-finished hub, and then the second mechanical arm stretches into the spinning machine to place the preheated hubblank. The whole conveying method is designed according to the improved layout of the production line, the conveying method is smooth and ordered, the conveying benefit is greatly improved, and therefore the production rate is increased.

Owner:FUJIAN SHENLIKA ALUMINUM IND DEV

Film unreeling control system

ActiveCN105383982AGuaranteed tensionHigh degree of automationFunction indicatorsWebs handlingFrequency changerControl system

The invention discloses a film unreeling control system. The control system comprises a rack and further comprises a film storing mechanism and a film unreeling mechanism which are fixedly arranged on the rack and sequentially connected, and a film is conveyed to a film clamping bar sequentially through the film storing mechanism and the film unreeling mechanism; the film unreeling mechanism comprises a film conveying unit, a tension monitoring unit used for monitoring the film tension of the film conveying unit and a driving unit for driving the film conveying unit to unreel the film; a distance detection sensor in the tension monitoring unit directly controls a film unreeling frequency changer, and a detected distance signal is converted into an output frequency signal of the film unreeling frequency changer; and according to distance parameters reflecting film tension, the rotating speed of a frequency changing motor is controlled, and therefore the film unreeling rate is controlled. The film unreeling control system is simple in structure, high in automation degree and capable of effectively controlling stable film unreeling, so that certain tension of the film can be kept all the time, and the film cannot be tensioned or loosened.

Owner:HEFEI GENERAL MACHINERY RES INST

Automobile hub spinning production line

PendingCN110666065ASmall footprintLow costShaping toolsMetal-working feeding devicesConveyor beltManufacturing line

The invention discloses an automobile hub spinning production line which includes a spinning machine and a preheating furnace, and further comprises a manipulator assembly, a first conveyor belt and asecond conveyor belt which are arranged between the spinning machine and the preheating furnace. The preheating furnace includes a furnace body and an annular conveying track placed in the furnace body. The furnace body is provided with a furnace door. The manipulator assembly includes a first manipulator and a second manipulator which are linked. The automobile hub spinning production line solves the problems of the complex production line structure, the large occupied space, the insufficient production efficiency, unfavorable monitoring operations and the like in the prior art.

Owner:FUJIAN SHENLIKA ALUMINUM IND DEV

Aluminum coil conveying device

PendingCN112897172AQuick and smooth stopStopping rotation is fast and efficientWebs handlingPhysicsEngineering

The invention discloses an aluminum coil conveying device, and belongs to the field of aluminum coil machining mechanical equipment. According to the aluminum coil conveying device, an aluminum coil unwinding mechanism and a material pulling conveying mechanism are sequentially arranged on an aluminum coil conveying support in the horizontal direction, an aluminum coil unwinding rotating roller is horizontally connected to the aluminum coil conveying support in a rotating mode, reciprocating damping rotating rods are symmetrically arranged on the two sides of the lower portion of a coil blocking rotating disc, a pull plate translation connecting rod is horizontally arranged in a connecting rod adjusting sleeve on the lower side of a reciprocating translation wedge plate, a reciprocating material pulling support is horizontally arranged on a material pulling translation guide rod between a front material guiding support and a rear material guiding support in a sliding mode, the end part of a material pulling piston rod at the output end of a reciprocating material pulling air cylinder is fixedly connected to the reciprocating material pulling support, and a translation material pressing support is horizontally and fixedly arranged on the upper side of the reciprocating material pulling support. The aluminum coil conveying device has the advantages that the structural design is reasonable, aluminum coils can be stably and orderly rotated and unwound, in addition, the aluminum coils can be efficiently and accurately pulled, conveyed and guided in a segmented mode, the aluminum coil machining automation degree is improved, and the production and use requirements are met.

Owner:詹塘生

Chemical fiber yarn tension buffer device capable of preventing yarn breakage

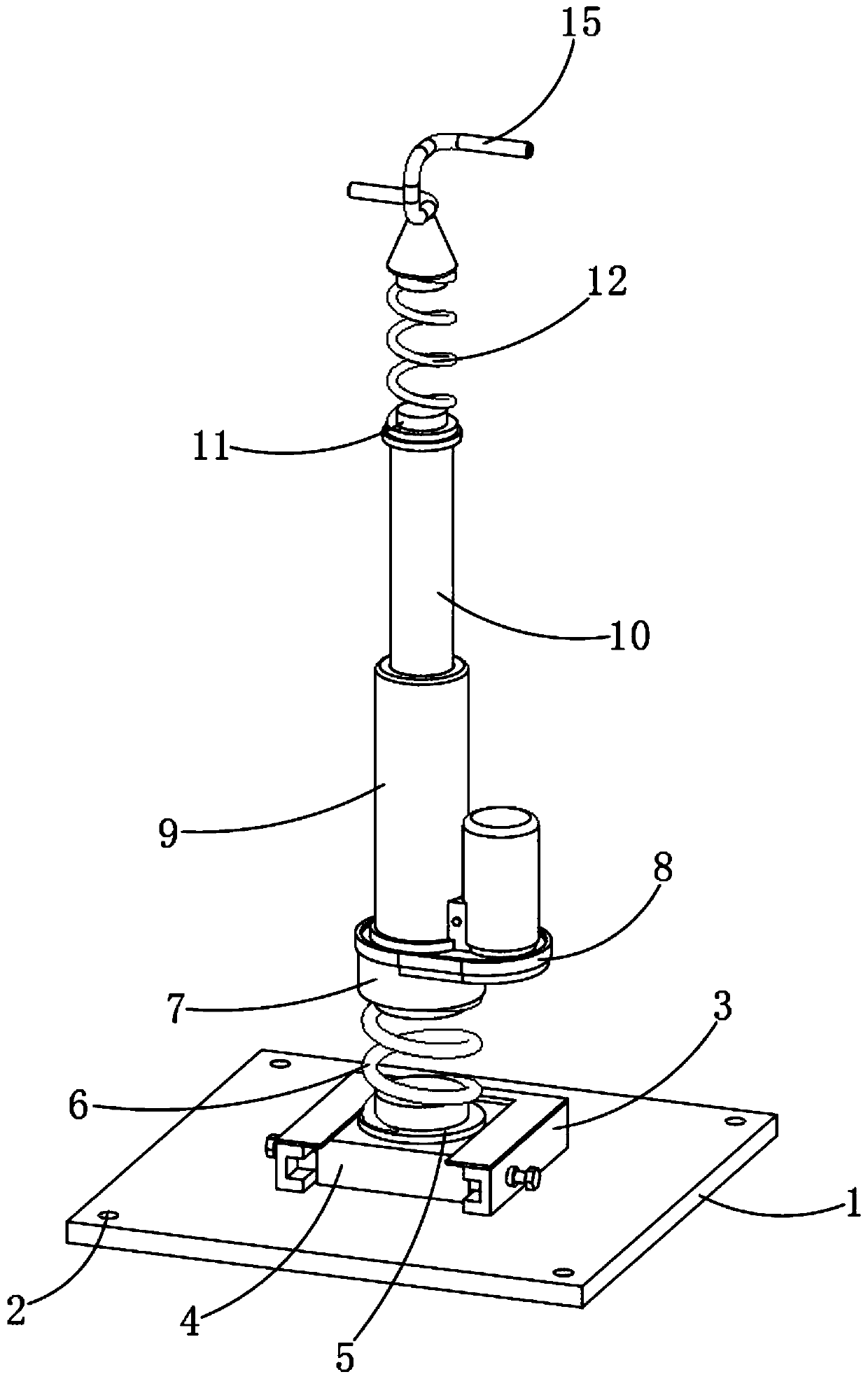

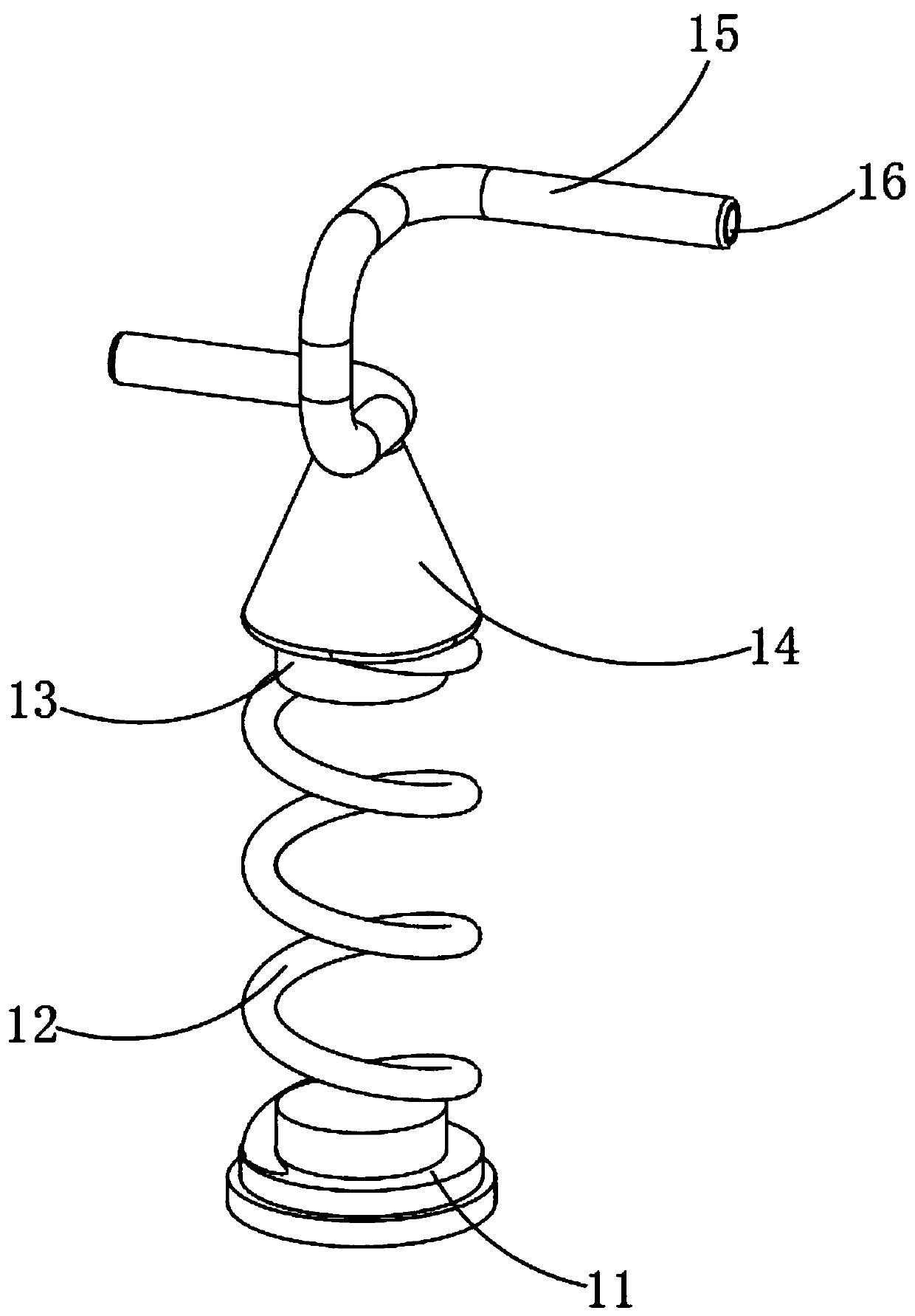

InactiveCN110963363ASmooth and orderly deliveryPrevent the phenomenon of wire breaking and tanglingFilament handlingFiberEngineering

The invention discloses a chemical fiber yarn tension buffer device capable of preventing yarn breakage. The top of a spring seat is fixedly connected with a first buffer spring; a buffer connecting seat is fixedly mounted at the top end of the first buffer spring; a mounting carrying table is mounted at the top of the buffer connecting seat; an electric telescopic rod is fixedly mounted on one side of the interior of the mounting carrying table; a movable rod is movably connected to the inner side of the electric telescopic rod in an embedded mode; a fixed seat is fixedly mounted at the top end of the movable rod; and the top of the fixed seat is fixedly connected with a second buffer spring. By means of the spring seat, the first buffer spring, the buffer connecting seat, the fixed seatand the second buffer spring, tension generated during chemical fiber conveying can be buffered through the first buffer spring and the second buffer spring; by means of the double-buffer mode, stableand orderly conveying of the chemical fibers is guaranteed, and meanwhile the phenomenon that the chemical fibers are broken and wound in the conveying process is avoided.

Owner:长兴国军纺织有限公司

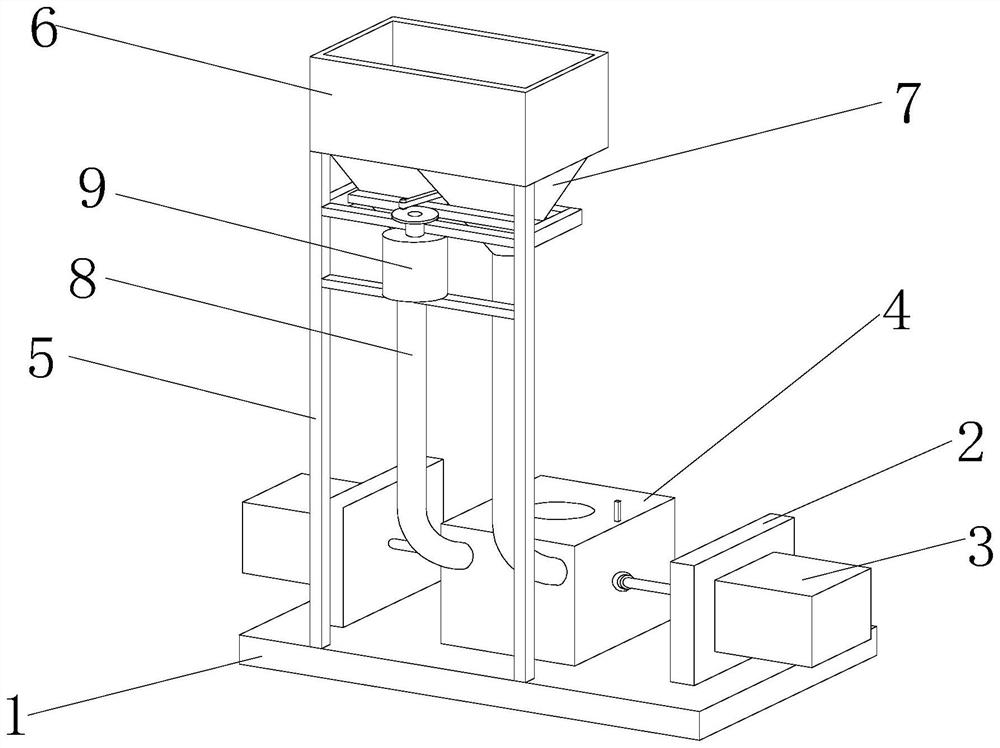

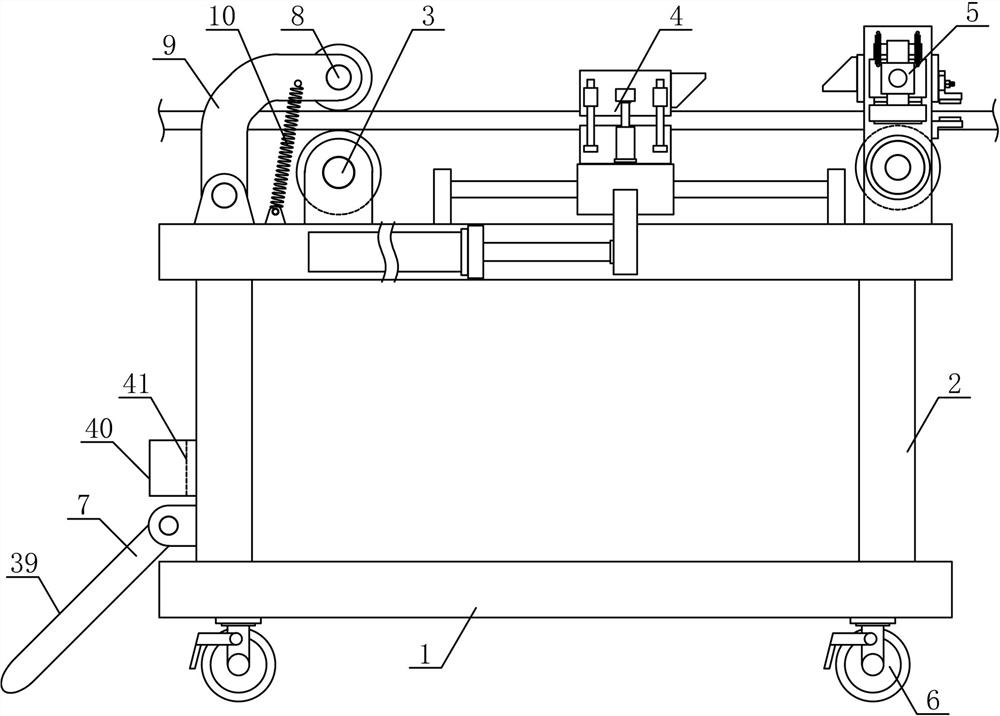

Semi-automatic steel ball mounting equipment and using method thereof

The invention relates to semi-automatic steel ball mounting equipment and a using method thereof. The semi-automatic steel ball mounting equipment comprises a working platform, supporting frames are correspondingly mounted on the two sides of the working platform, air cylinders are mounted on the two supporting frames correspondingly, pushing rods are mounted at the output ends of the air cylinders, and a mounting block is arranged between the two pushing rods; a clamping groove is formed in the middle of the mounting block, a pair of symmetrically-arranged supporting rods are arranged on one side of the mounting block, and a containing box is mounted at the upper ends of the supporting rods; a pair of guide hoppers are mounted on the lower side of the containing box, guide pipes are mounted at the lower ends of the guide hoppers, and a clamping assembly is arranged at the communication position of the guide hoppers and the guide pipes; and when the middle of a wheel shaft is pulled out of the clamping groove, a steel ball moves outwards under the action of a spring and is clamped with a gear, so that the wheel shaft, the steel ball and the gear are clamped, the wheel shaft and the gear are rapidly clamped, consumed time of the whole working procedure is extremely short, and therefore the production efficiency is greatly improved.

Owner:中山市技佳传动科技有限公司

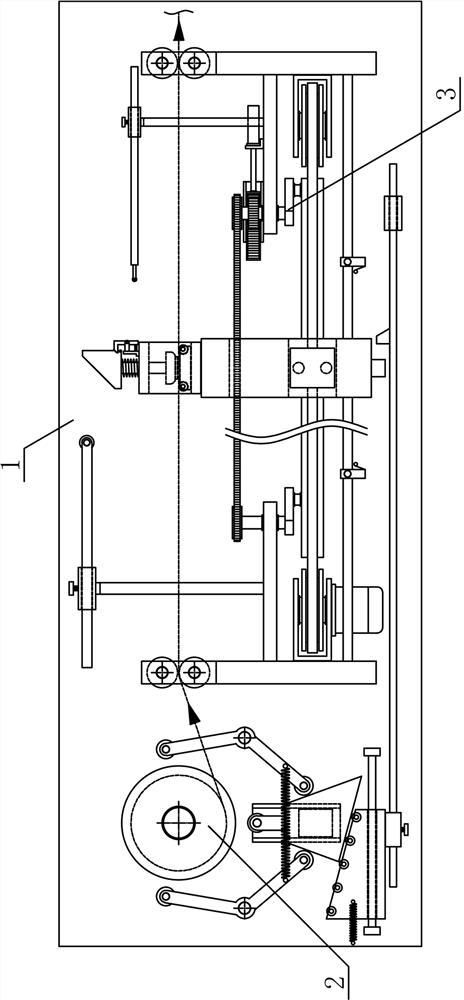

Cable laying device

InactiveCN114188889ARealize intermittent pressing and fixingStable and orderly pulling and laying section by sectionApparatus for laying cablesStructural engineeringPower engineering

The invention discloses a cable laying device, and belongs to the field of electric power engineering equipment. A cable laying support is horizontally and fixedly arranged on the upper side of a cable laying base, a laying positioning mechanism is arranged on the cable laying support along the lower portion of the side of a cable conveying guide roller, the cable conveying guide roller is horizontally and rotationally connected to one side of the upper portion of the cable laying support, and a reciprocating translation guide plate is arranged on a cable pulling and conveying guide rod in a sliding mode in the horizontal direction. The upper pulling and conveying pressing plate is horizontally arranged on the upper side of the lower pulling and conveying bearing plate, a translation pushing wedge plate is horizontally and fixedly arranged on the upper pulling and conveying pressing plate along the cable clamping mechanism side, and the cable clamping pressing plate is horizontally arranged on the upper side of the cable laying guide roller. And the cable clamping pressing plate is horizontally and fixedly provided with a bearing and pushing lifting wedge plate matched with the translation pushing wedge plate along the cable pulling and conveying mechanism side. The cable laying device is reasonable in structural design and stable in operation and use, cables can be efficiently and smoothly pulled and laid section by section, the automation degree of cable laying is improved, and the use requirement is met.

Owner:嘉兴市平安电气工程有限公司

A drafting and setting mechanism for textile yarn processing

ActiveCN110804783BSmooth and orderly deliveryAccurate and efficient transmissionTextiles and paperTextile yarnGear wheel

Owner:TONGXIANG YUESHUN WRAP KNITTING

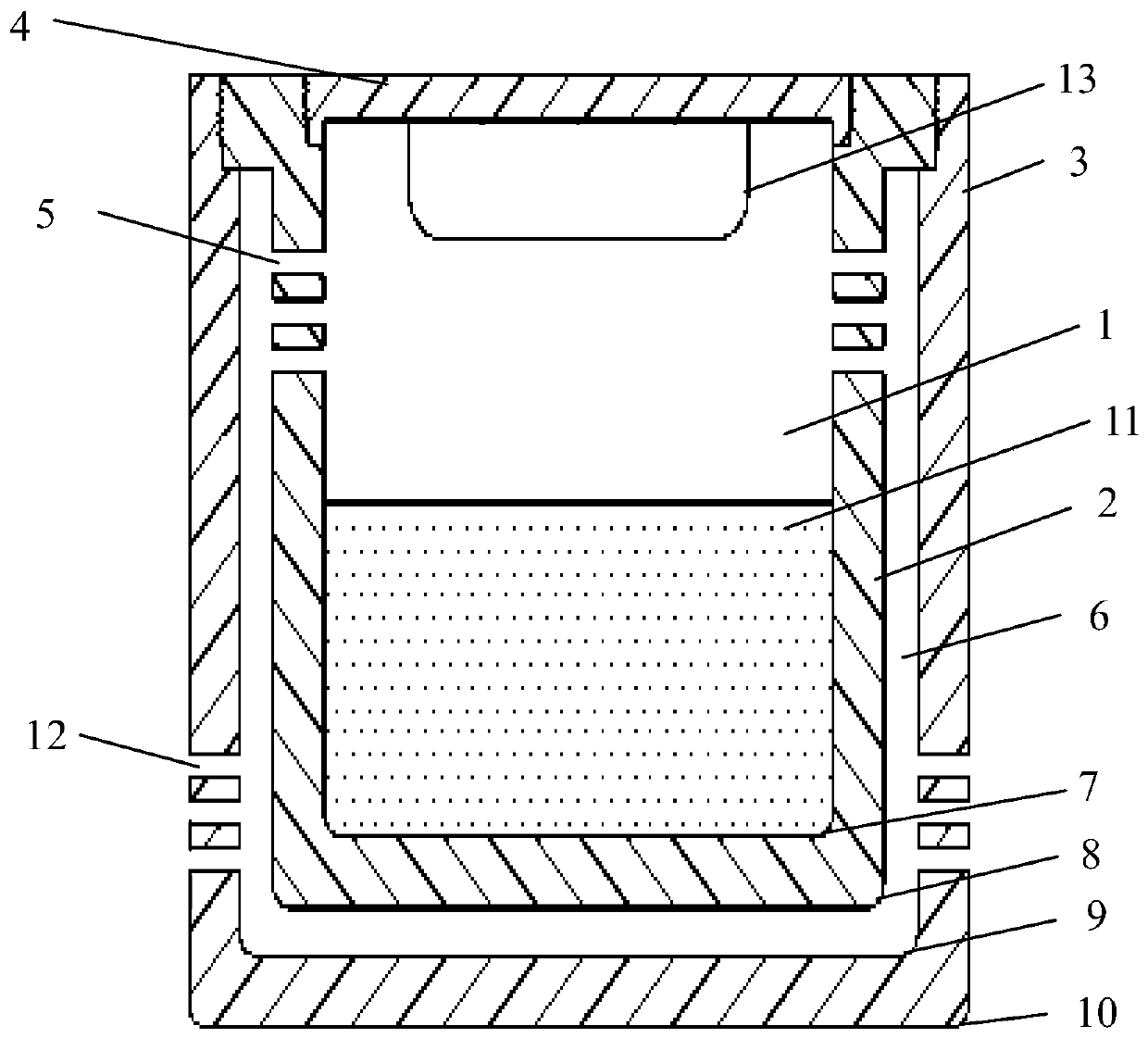

Continuous crystal growth method of silicon carbide single crystal

ActiveCN109234798BAchieve growthSingle crystal defect reductionPolycrystalline material growthFrom condensed vaporsCarbide siliconCrucible

The invention discloses a continuous crystal growing method of silicon carbide single crystals. The method is characterized in that silicon carbide single crystals are produced by using high-purity silicon carbide powder as raw materials by a physical vapor phase transporting method; in the silicon carbide single crystal production process, high-purity silane and carbon particles generating carbonization in high-purity silicon carbide powder react; high-purity silicon carbide powder is formed again to continuously supplement raw materials; the continuous growth of the silicon carbide single crystals is realized. In addition, the method is proceeded by using a crucible with double layer cavity walls, wherein open holes are formed in the side wall of the double layer cavity walls; the bottomcorner part of the cavity wall adopts circular arc design. The method has the important effects in the aspects of ensuring the continuous growth of large-size single crystals, inhibiting the siliconcarbide powder edge carbonization, improving the power quality, reducing the impurity content of the silicon carbide single crystals, improving the quantity of the silicon carbide single crystals andthe like.

Owner:SICC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com