Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Small clamping deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

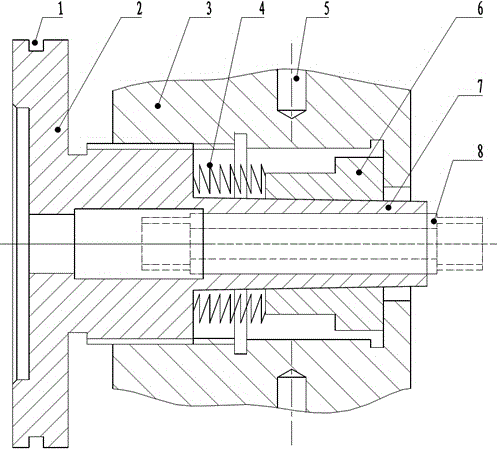

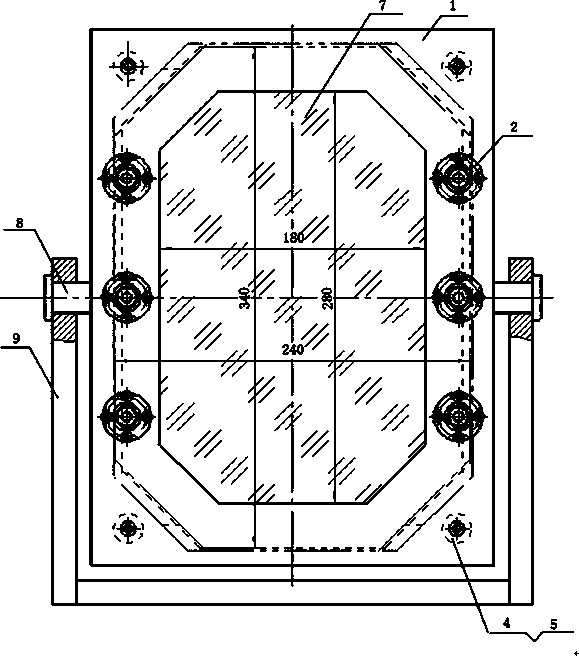

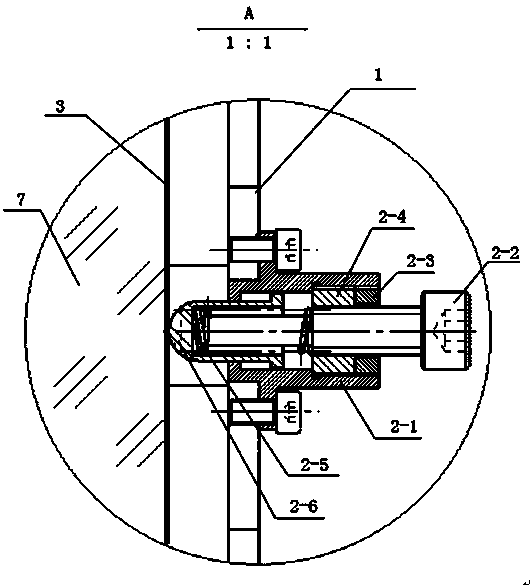

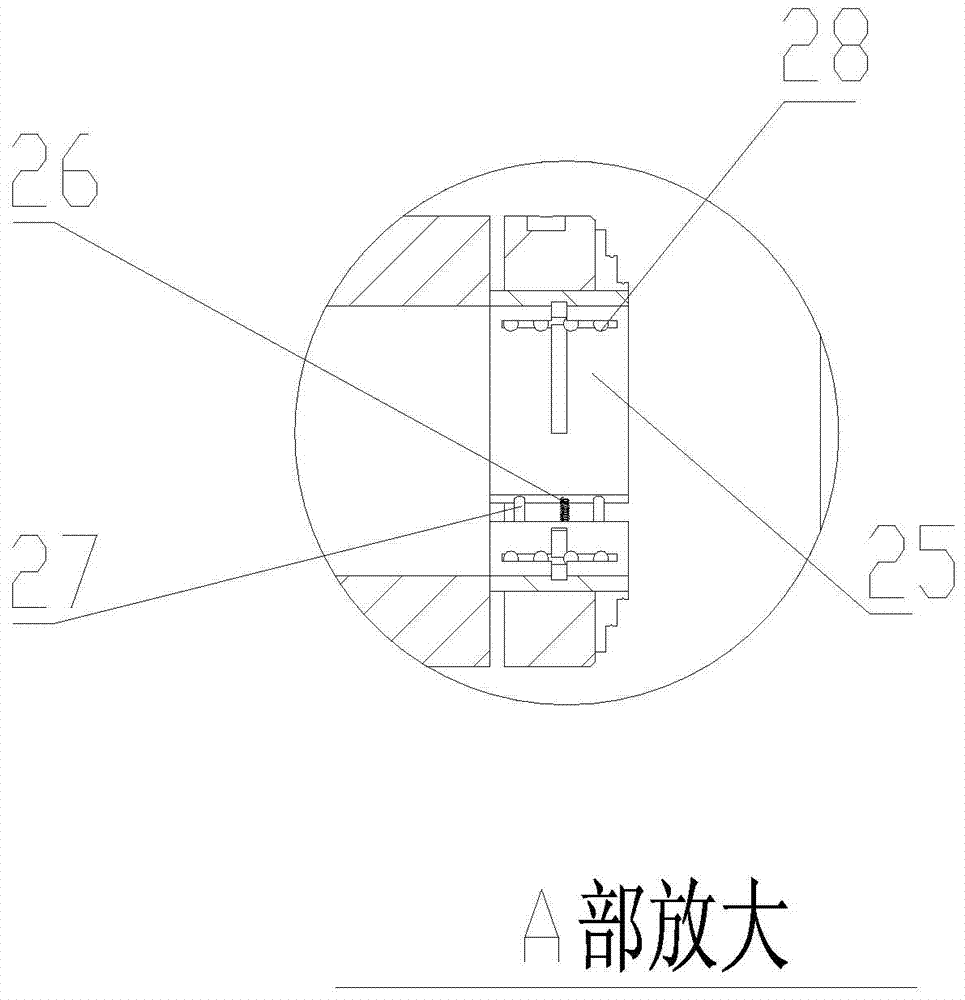

Clamp and clamping method for large-diameter plane optical element

ActiveCN102615567AReduced precision requirementsSmall clamping deformationOptical surface grinding machinesOptical engineeringEngineering

Provided are a clamp and a clamping method for a large-diameter plane optical element. The clamp comprises a large-diameter plane optical element press plate, an elastic pivot, a transformation thin plate frame, an inner hexagonal cylindrical head screw, a boss, a lens frame, a rotational shaft and a support. The clamp and the clamping method utilize a metal structure to directly clamp the large-diameter optical element, can produce no optical element clamping stress under the condition that surface processing accuracy of a metal clamping frame is reduced and the optical element is in any inclination angle. Simultaneously, the metal structure is utilized to conduct direct clamping, thereby well avoiding organic pollution caused by stress-free clamping of tradition organics. The clamp the clamping method can be widely applied to clamping of the large-diameter plane optical element in optical engineering and optical experiment devices and has strong practicability.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

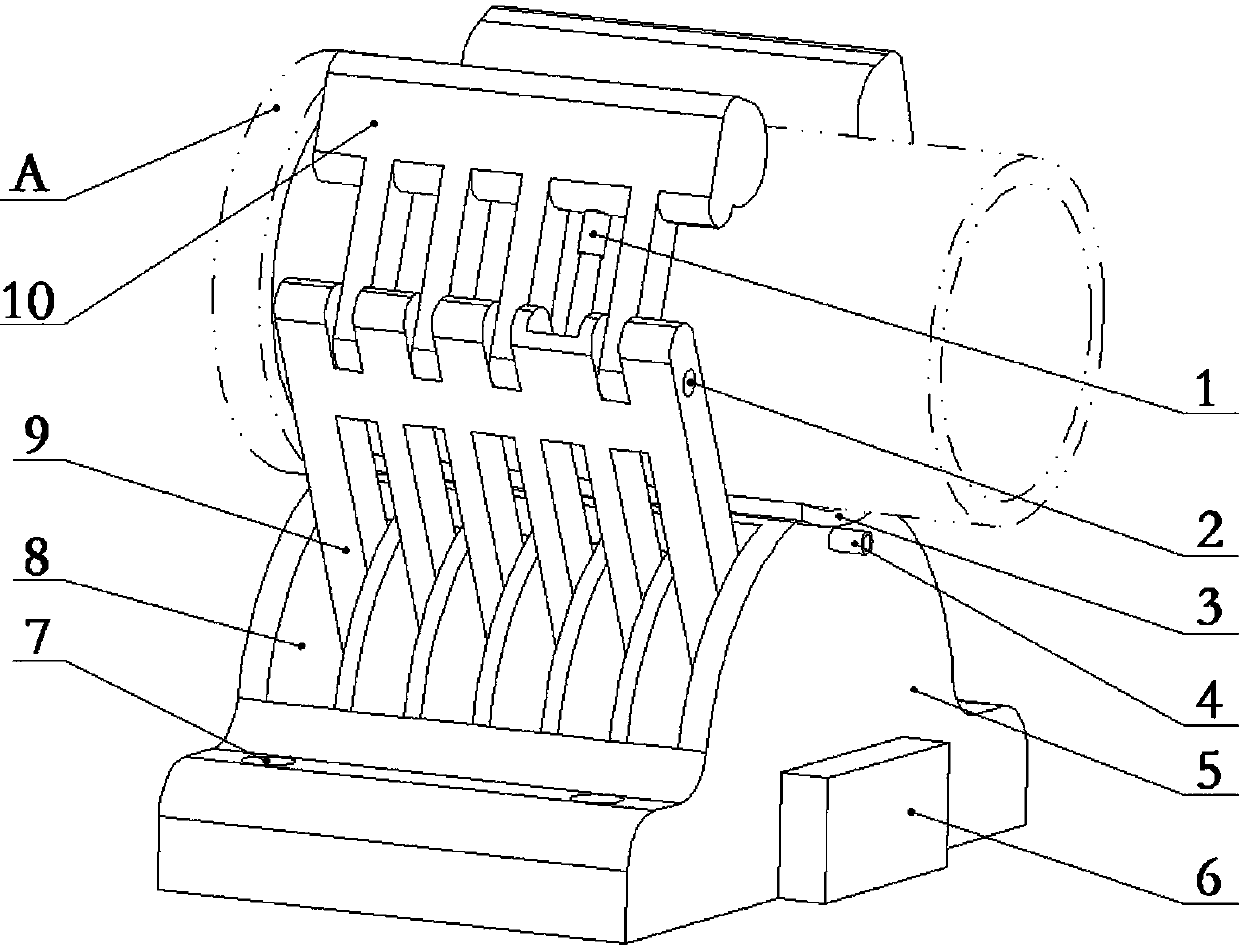

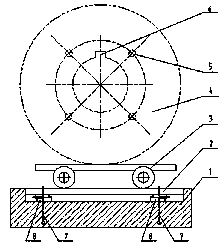

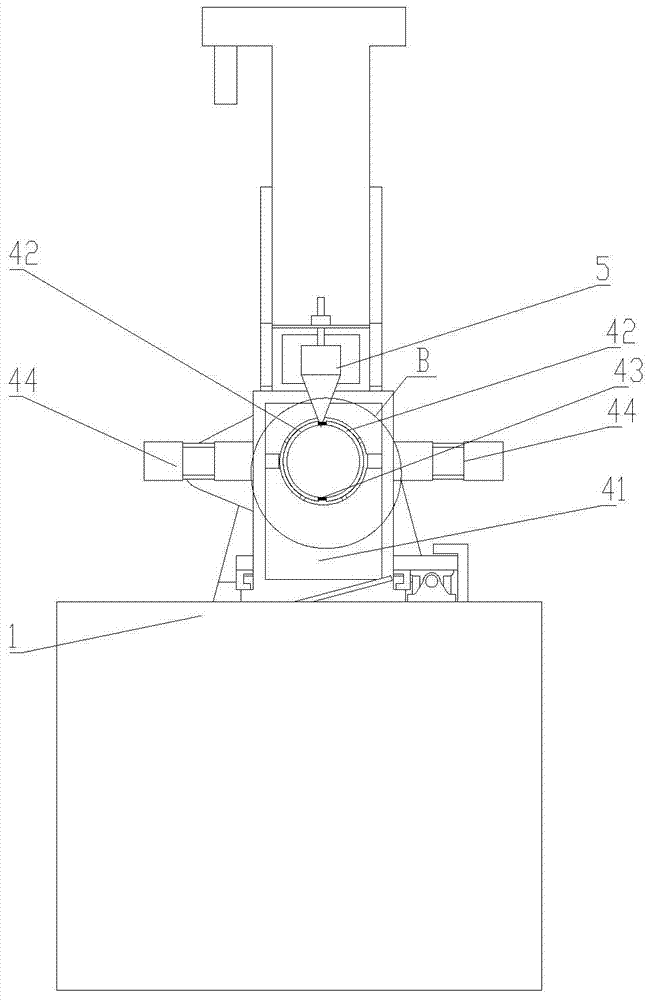

Fixture for processing and detecting blade of aircraft engine

InactiveCN102357813AReduce clamping stressReduce residual stressPositioning apparatusMetal-working holdersAviationEngineering

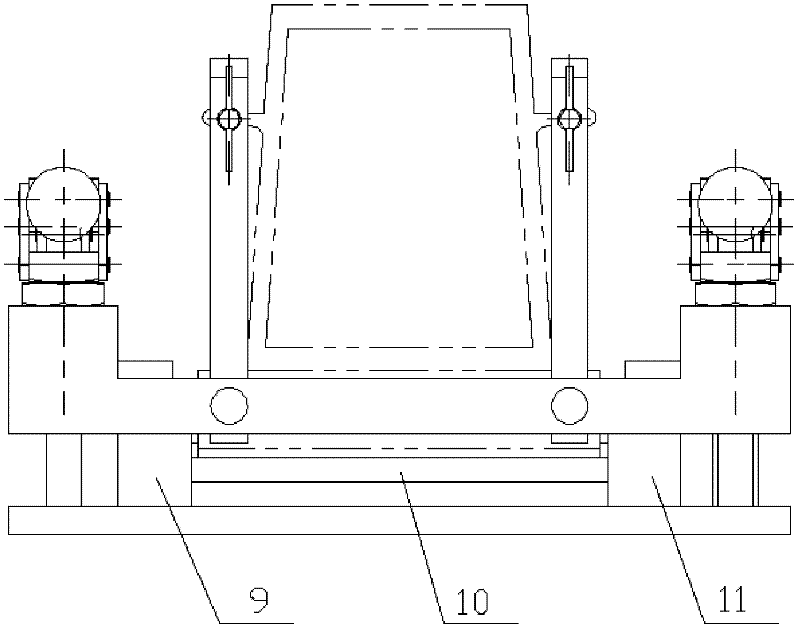

The invention discloses a fixture for processing and detecting a blade of an aircraft engine. The fixture comprises a mounting base, a clamping framework, rotating frameworks and clamping devices, wherein a guide pillar is arranged on the mounting base; the clamping framework is mounted on the mounting base through the guide pillar; the clamping framework can move along the guide pillar; the clamping framework has a frame structure, in which a cavity is arranged; a set of clamping device is respectively arranged on each side of the clamping framework; two sets of clamping devices are both fixedly connected to the mounting base; two rotating frameworks are arranged between the two sets of clamping devices on the clamping framework; the two rotating frameworks are respectively mounted on the clamping framework through pin shafts; the rotating frameworks can swing round the pin shafts; spring plungers are arranged on the rotating frameworks; and a positioning element is mounted on the mounting base. The fixture provided by the invention can reduce a clamping stress generated during a process of clamping the blade, reduce clamping deformation of the blade and promote the processing precision of the blade. The fixture can simultaneously realized the process and on-line detection of the blade.

Owner:SHANDONG UNIV

Turning method for winding heat-proof layer on metal shell cabin section and device thereof

ActiveCN102658467AImprove resection rateImprove the clamping methodEngineeringUltimate tensile strength

The invention relates to the technical field of nonmetal material cutting processing, and discloses a turning method for winding a heat-proof layer on a metal shell cabin section and a winding core mould. In the invention, the parameters of the turning method are controlled, and the phenomena of splitting, cracking, scrap falling, block drop and fracture easily caused by the existing machining turning of the heat-proof layer are effectively improved, thus the qualified rate of finished products is improved; by changing the clamping mode, the clamping deformation of parts in processing is reduced, and the alignment difficulty is reduced; and through the improvement of the manufacturing method of the heat-proof layer, the heat-proof layer can be directly wound on the metal shell cabin section, the manufacturing and assembling processes of the heat-proof layer are simplified, the labor intensity is lowered, and the connection between the heat-proof layer and the metal shell cabin section is tighter. The processing method disclosed by the invention is universal, realizes low rejection rate of the parts, and is safe and reliable to use; and the provided winding core mould has a simple structure and is easy to manufacture and convenient to use.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

Thin-wall sleeve part processing method

The invention discloses a thin-wall sleeve part processing method which comprises the steps of firstly roughly turning an excircle and drilling and boring an inner hole; after roughly turning the excircle and roughly boring the inner hole to the reserved processing allowance, semi-extractive turning an excircle of a thin-wall sleeve part, obtaining a semi-finished product of the thin-wall sleeve part, and cutting off from a bar material; loading the semi-finished product on a digital controlled lathe, precisely turning an incircle and an excircle of the semi-finished product to the set processing allowance, half cutting-off, reserving the set thickness during half cutting-off after chamfering an excircle of a part at the cut-off end, and semi-extractive turning the excircle to the design dimension again; and thoroughly cutting off the processed thin-wall sleeve part from the semi-finished product. The process method provided by the invention is simple and feasible, no working procedureis increased, the deformation in the part processing process is greatly reduced, the excircle dimension tolerance can be ensured to meet the technical requirement of the process design, the product qualification rate is remarkably improved, the method can be completed by adopting a cutting manner, the production period is short, and no auxiliary fixture with high cost is required to be configured.

Owner:AECC AVIATION POWER CO LTD

Air cylinder sleeve clamp

ActiveCN107900746AAvoid damageSmall clamping deformationWork holdersPositioning apparatusEngineeringMechanical engineering

Owner:UNIV OF JINAN

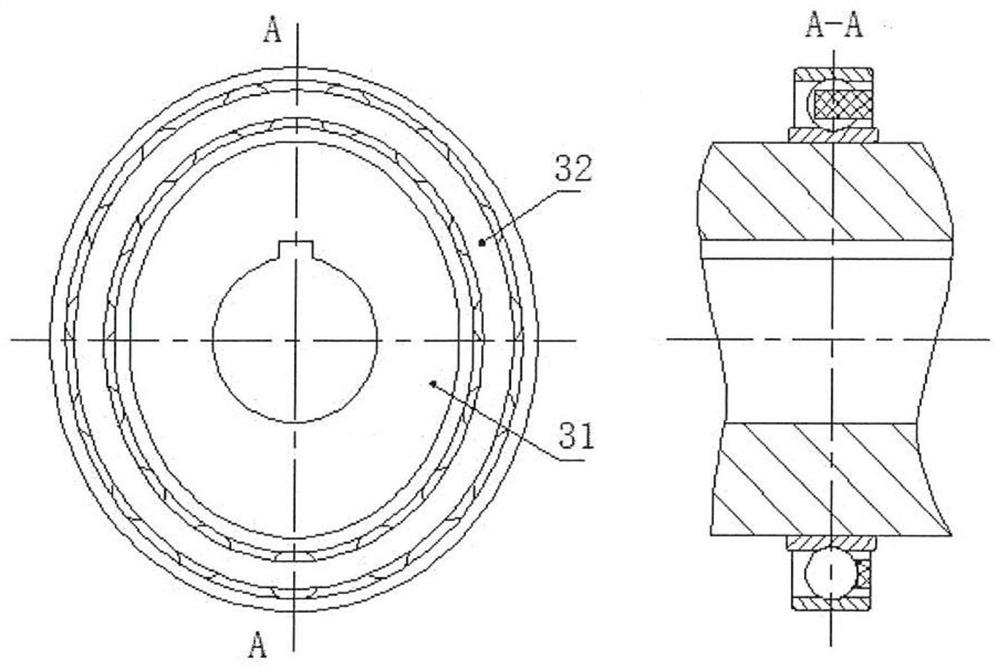

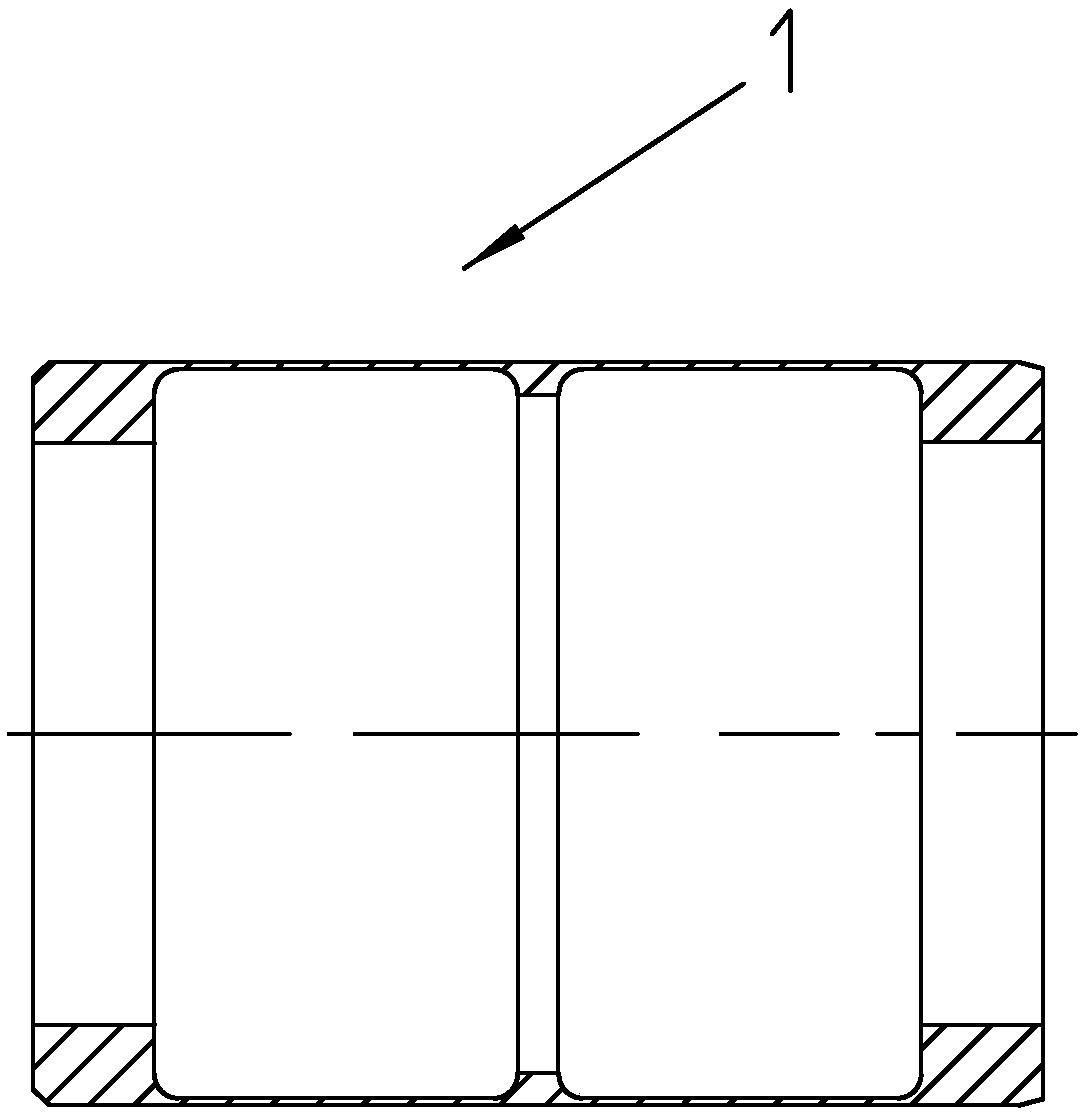

Annular part grinding fixture

InactiveCN104842268ASimple structureEasy to useGrinding work supportsEngineeringMechanical engineering

An annular part grinding fixture comprises a taper handle shaft of hollow structure, an outer taper shaft, an inner taper shaft and a pushing disc. An outer taper face is arranged at one end of the outer taper sleeve, and an inner taper face is arranged at one end of the inner taper sleeve; the outer surface of the outer taper sleeve is sleeved with the inner taper sleeve, and the outer taper face of the outer taper sleeve is matched with the inner taper face of the inner taper sleeve; the outer taper sleeve is fixedly connected with the taper handle shaft, and the inner taper sleeve is fixedly connected with the pushing disc; and the pushing disc is arranged in the outer taper sleeve, and a plurality of axial opening gaps are formed in the outer taper sleeve in the circumferential direction. The annular part grinding fixture is simple in structure, convenient to use, capable of achieving automatic centering, and high in centering precision; and clamping force is controlled, so that clamping deformation can be reduced, and the machining precision is ensured.

Owner:CHENGDU YUNLI MACHINERY

Tooling random support part

InactiveCN102975033ASmall clamping deformationImprove flatnessPositioning apparatusMetal-working holdersArchitectural engineering

Owner:JIANGSU WANSHENG FOUNDRY

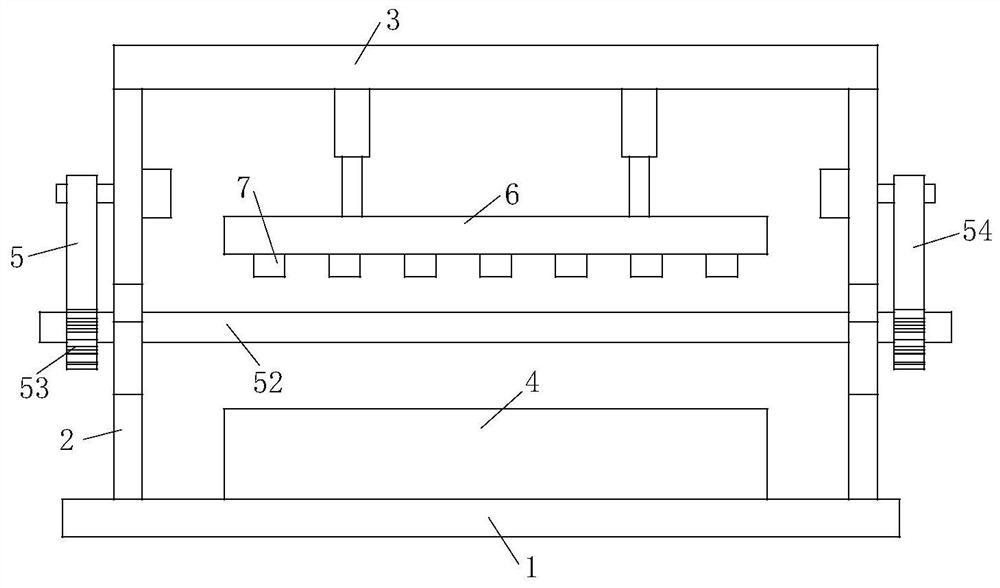

Semiconductor diode lead-wire sealing system

ActiveCN108461430ADry evenlySmall clamping deformationSemiconductor/solid-state device manufacturingTorsion springElectric heating

The invention belongs to the technical field of semiconductor diode production, and particularly relates to a semiconductor diode lead-wire sealing system. The semiconductor diode lead-wire sealing system comprises a bottom plate, a vertical column, a top plate, a sealing groove, a drying module, a storing block and storing holes; a set of telescopic rods are arranged at the bottom of the top plate; the storing block is fixedly connected with the ends of the telescopic rods, and the set of storing holes are formed in the bottom of the storing block; the drying module comprises an arc-shaped sliding groove, an electric heating pipe, swinging gears and a swinging plate; the arc-shaped sliding groove is mounted in the middle of the vertical column; the electric heating pipe is slidably mounted in the arc-shaped sliding groove; a spring connected with the electric heating pipe is arranged at one end of the arc-shaped sliding groove; the swinging gears are rotatably mounted at the two endsof the electric heating pipe through torsion springs; the swinging plate rotatably mounted on the vertical column is arranged above the arc-shaped sliding groove; gear sockets meshed with the swinginggears are arranged at the ends of the swinging plate; and the swinging plate is controlled to rotate through a motor. The semiconductor diode lead-wire sealing system can conduct uniform drying on the sealed lead-wire; and by arranging a clamping device, the system can adapt to sealing of lead-wires with different thickness.

Owner:苏州因知成新能源有限公司

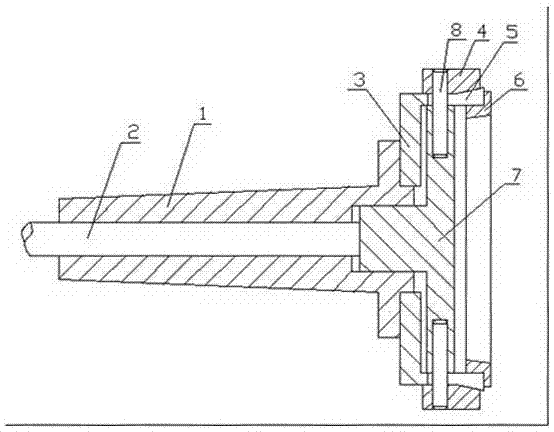

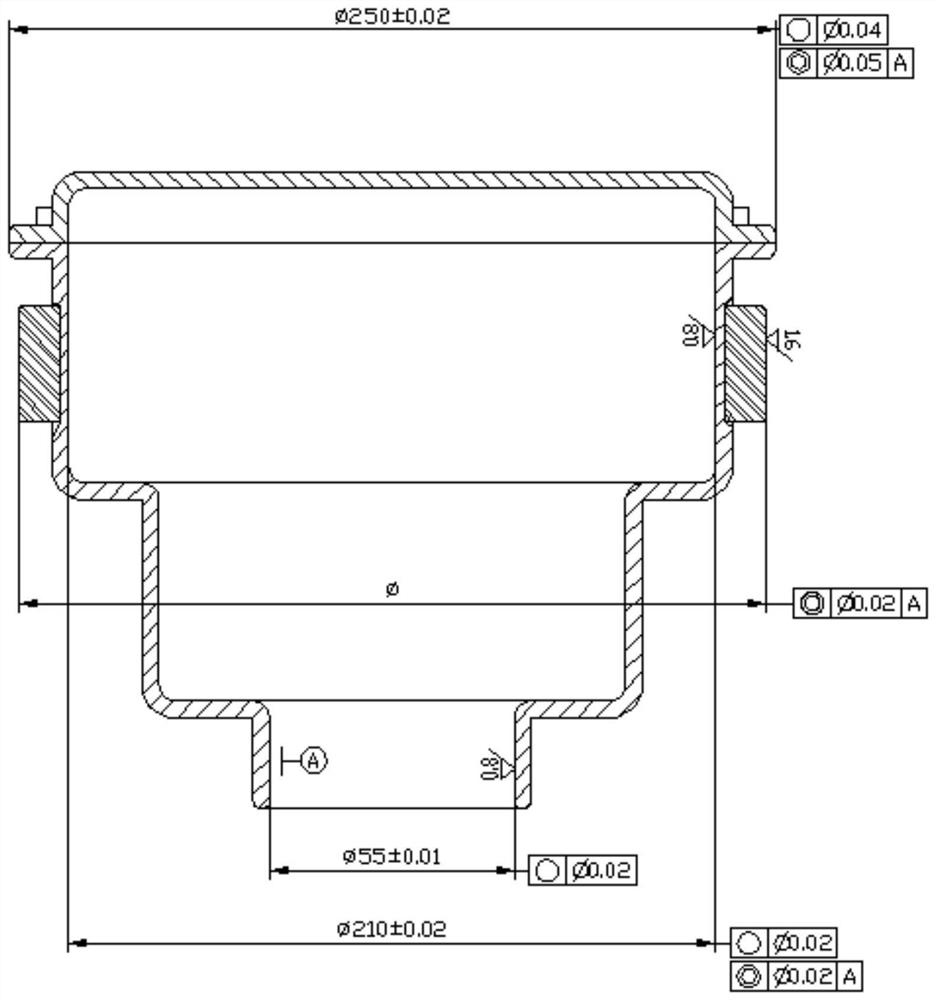

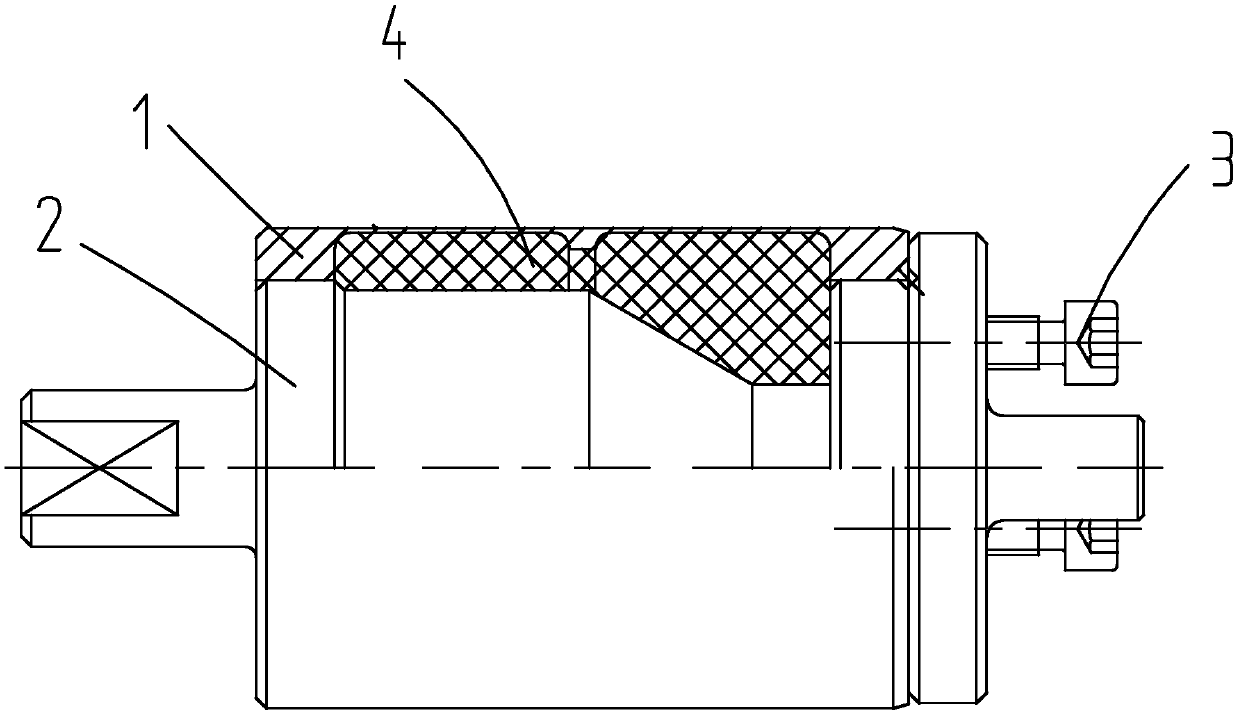

Screw sleeve part inner hole processing lathe clamp

ActiveCN104647101AGuaranteed reliabilityGuarantee processing qualityPositioning apparatusMetal-working holdersBarrel ShapedBody positions

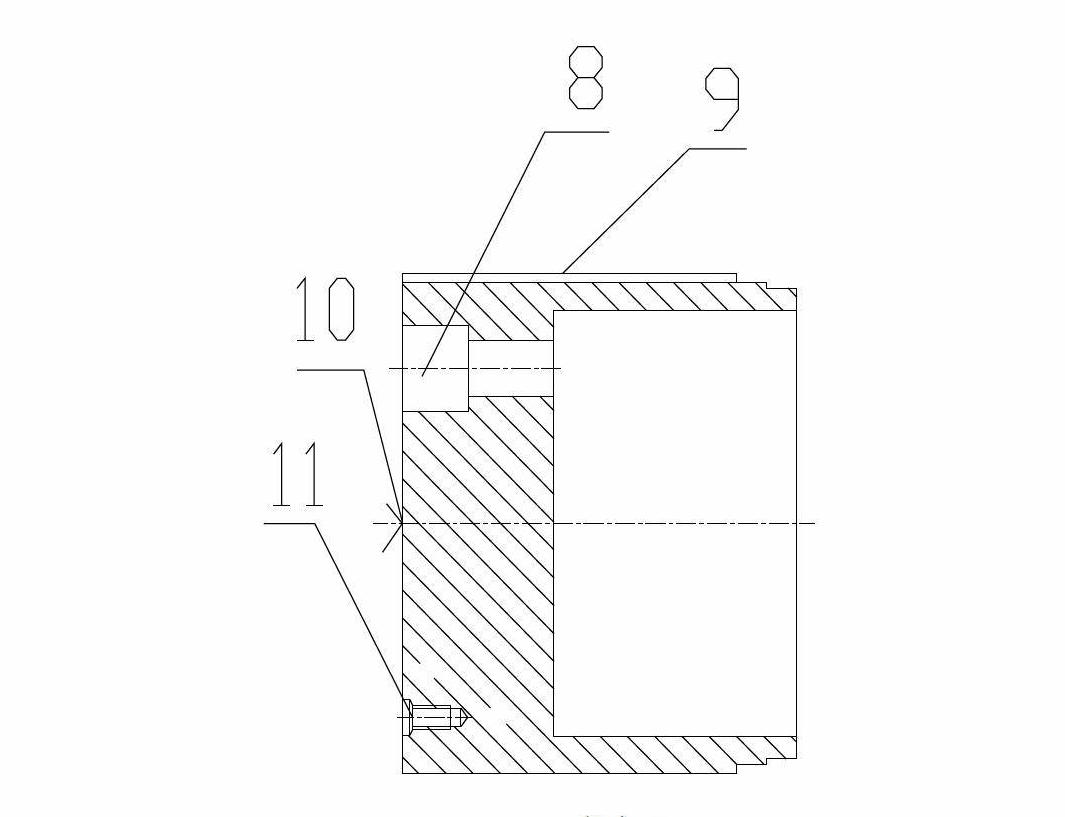

The invention discloses a screw sleeve part inner hole processing lathe clamp, which comprises a clamp body, a screw nut, a cone sleeve and a reset spring, wherein a clamp body positioned by a notch is arranged on a lathe main shaft through a transition disc, the front end of the clamp body is a barrel-shaped thin wall with the external taper, in addition, the outer diameter of the back end of the thin wall is greater than the outer diameter of the front end, the inner diameter of the thin wall is matched with the outer diameter of a screw sleeve to be processed, the cone sleeve with the internal taper matched with the external taper of the thin wall is arranged on the outer side of the thin wall in a sleeving way, the reset spring is arranged at the thin wall part in a sleeving way and is positioned between a cone sleeve and a threaded step positioned at the back part of the clamp body, and the screw nut passes through the thin wall and the cone sleeve and is connected with the clamp body through screw threads. The screw sleeve part inner hole processing lathe clamp has the advantages that the structure is compact, the operation is simple, convenient and reliable, the positioning precision is very high, the processing quality can be easily ensured, and higher practicability is realized.

Owner:南京力全科技有限公司

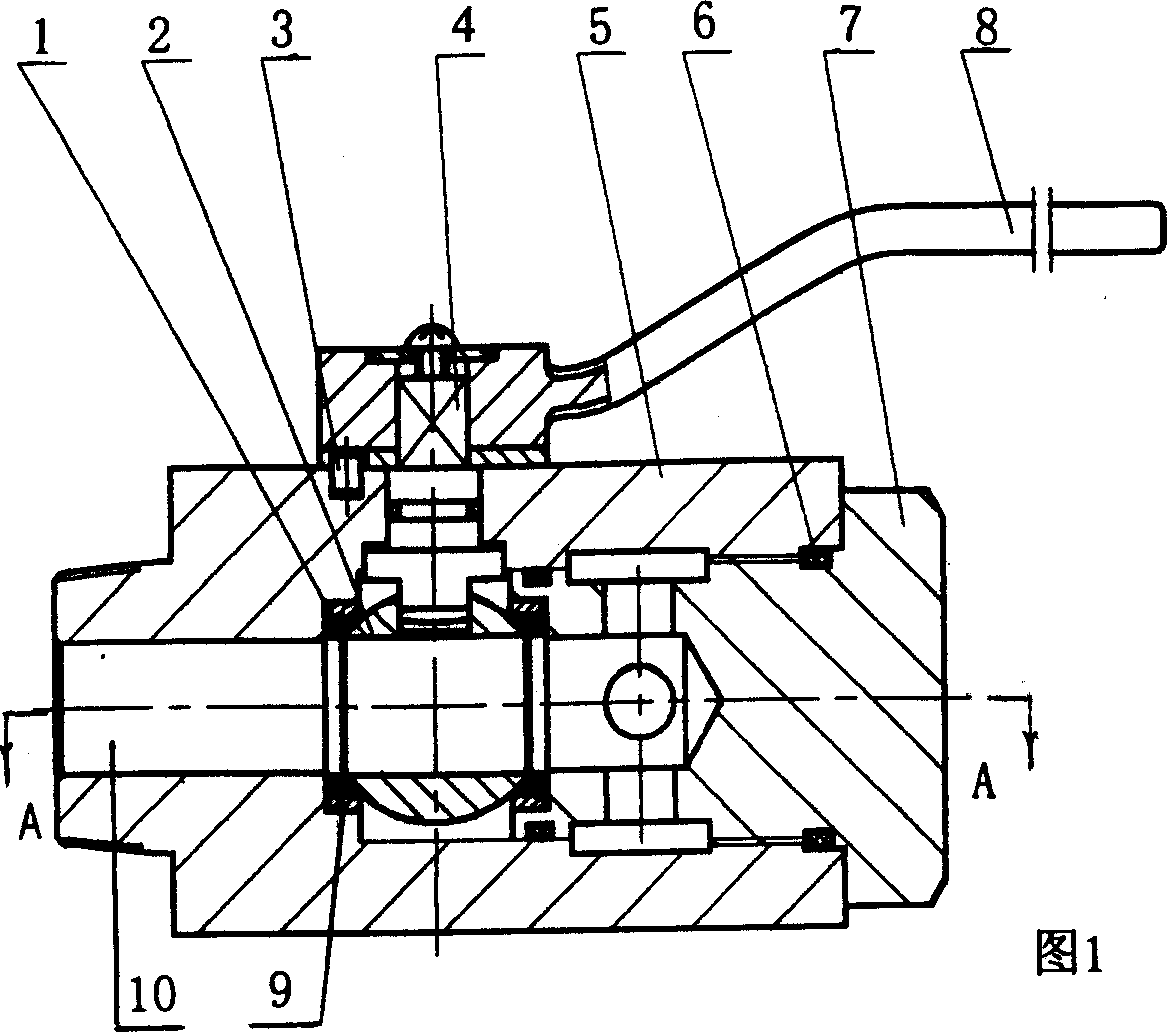

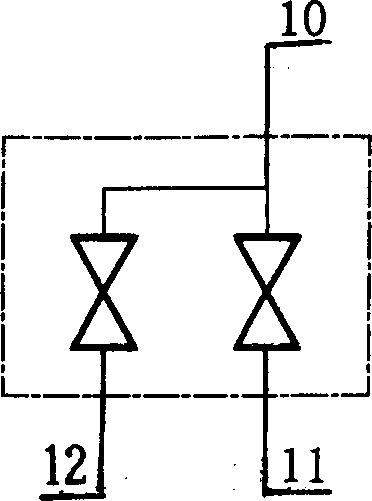

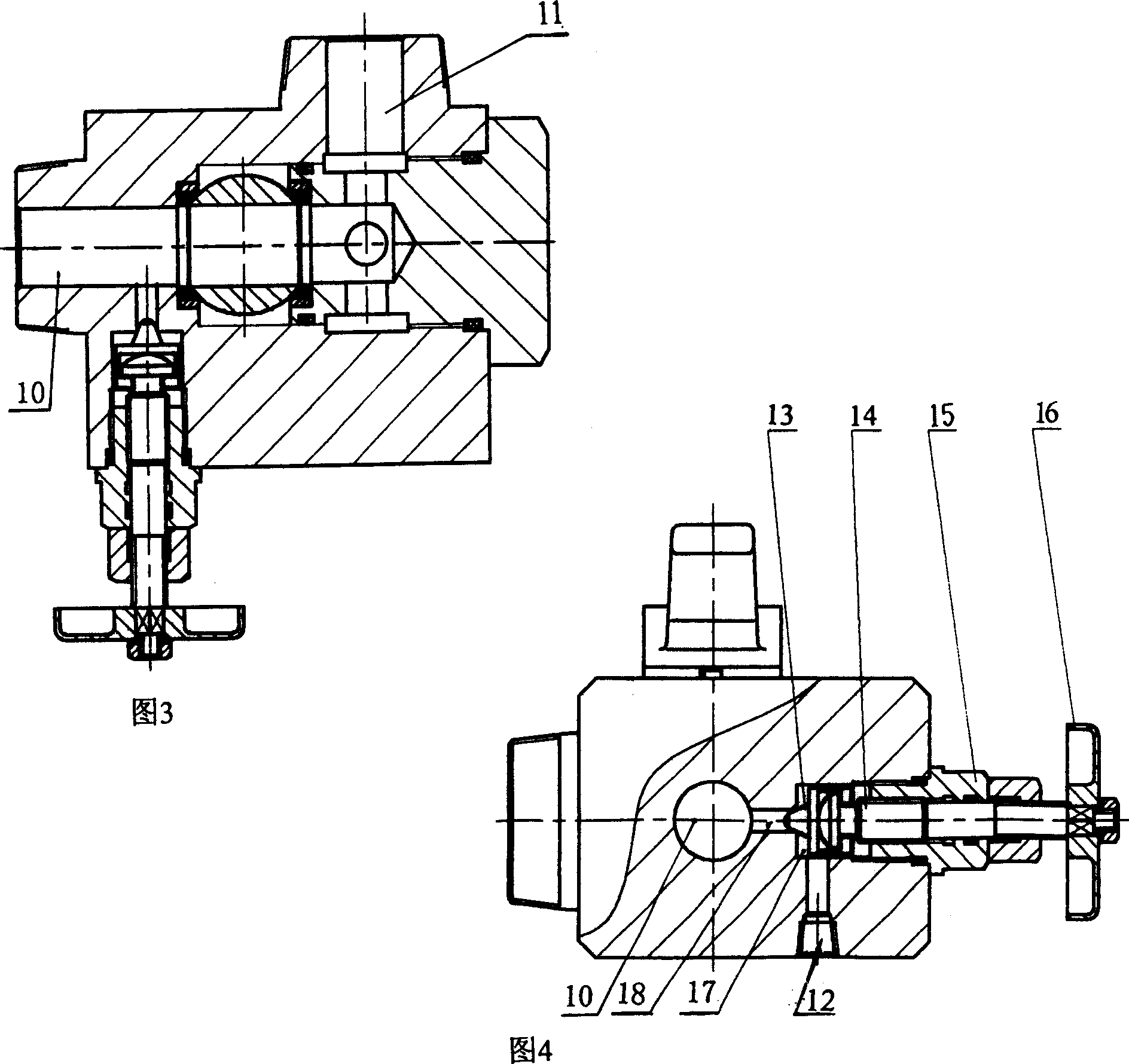

Safety valve assembly

InactiveCN1570404AReduce the numberBlock out hidden dangersPlug valvesServomotor componentsCircular coneEngineering

One kind of safety valve group, and the spatial control valve and the discharge valve function to a body, specially is suitable in the petroleum guards against in the jet hydraulic system, took and gathers can its product necessary use special-purpose valve, partially is composed by the control valve part and the discharge valve, states the valve body is an end aperture, middle has the cavity the overall construction, and with stops up connects the whole the valve group body, states on the valve body has mutually has the right angle two circular cones external screw thread raised, between raised Taichung has in a post plane two oils mouths, states ball valve core in vitro as a result of its coordination, Seals the constitution by the outside package of skeleton ball the packing assembly, installs in valve group in vivo. Because directly processes on the valve body protrudes the valve body to have the mouth raised, and the oil mouth directly with the system oil source, the accumulator connection, reduced outside the valve body components machine to divulge the link, caused its structure compact, volume small, matched the tube conveniently, reasonable, seal effect good, the use was safer, reliable.

Owner:竺浩君

Clamp and clamping method for large-diameter plane optical element

ActiveCN102615567BReduced precision requirementsSmall clamping deformationOptical surface grinding machinesEngineeringOptical engineering

Provided are a clamp and a clamping method for a large-diameter plane optical element. The clamp comprises a large-diameter plane optical element press plate, an elastic pivot, a transformation thin plate frame, an inner hexagonal cylindrical head screw, a boss, a lens frame, a rotational shaft and a support. The clamp and the clamping method utilize a metal structure to directly clamp the large-diameter optical element, can produce no optical element clamping stress under the condition that surface processing accuracy of a metal clamping frame is reduced and the optical element is in any inclination angle. Simultaneously, the metal structure is utilized to conduct direct clamping, thereby well avoiding organic pollution caused by stress-free clamping of tradition organics. The clamp the clamping method can be widely applied to clamping of the large-diameter plane optical element in optical engineering and optical experiment devices and has strong practicability.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

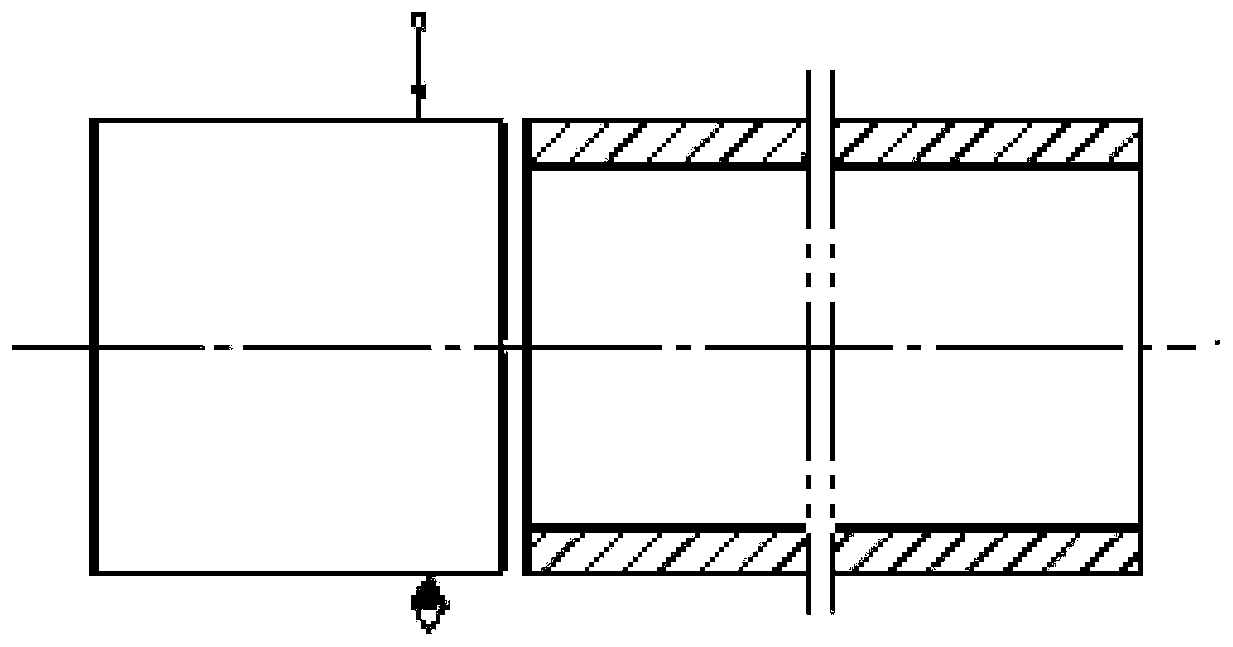

Inner hole processing fixed fixture of ring-like parts

The invention discloses an inner hole processing fixed fixture of ring-like parts. The fixture comprises a taper handle shaft, an outer taper sleeve and an inner taper sleeve, wherein an outer conical surface is arranged at one end of the outer taper sleeve; an inner conical surface is arranged at one end of the inner taper sleeve; the inner taper sleeve coats the outer surface of the outer taper sleeve; the outer conical surface of the outer taper sleeve fits the inner conical surface of the inner taper sleeve; fit threads are arranged on left end planes of the outer taper sleeve and the inner taper sleeve; the outer taper sleeve and the inner taper sleeve are connected through the threads; the outer taper sleeve and the taper handle shaft are fixedly connected; and multiple axial opening gaps are formed in the outer taper sleeve in a peripheral direction. The fixture is simple in structure and convenient to use, can realize automatic centering to achieve high centering precision, and can reduce the clamping deformation to guarantee the processing precision through controlling the clamping force.

Owner:CHENGDU YUNLI MACHINERY

Method of shaping machine for shaping key groove of large disc workpiece body

InactiveCN104162709ASmall clamping deformationHigh positioning accuracyPlaning/slotting machinesSizingAnchor bolt

A method of a shaping machine for shaping a key groove of a large disc workpiece body comprises the steps that a concrete foundation pit is dug right ahead of a workbench of the shaping machine; a flat plate is supported on the foundation pit via foundation bolts embedded in concrete and adjustment sizing blocks placed on the concrete and the height and the levelness of the flat plate are adjusted according to the demand; a trolley capable of moving horizontally is placed on the flat plate; and the large workpiece body is fastened on the workbench of the shaping machine by T bolts via technology holes in the large workpiece body. Horizontal feeding motion of machining the key groove in the large workpiece body is achieved via the support of the trolley and a labor-saving rolling principle of the trolley, and vertical feeding of the key groove of the workpiece body is still achieved by vertical adjustment of a screw rod transmission mechanism on a ram of the shaping machine. The clamping deformation is small and the positioning accuracy is high by using the method to shape the key groove in the large workpiece body with the common shaping machine.

Owner:湖南奇力工具有限公司

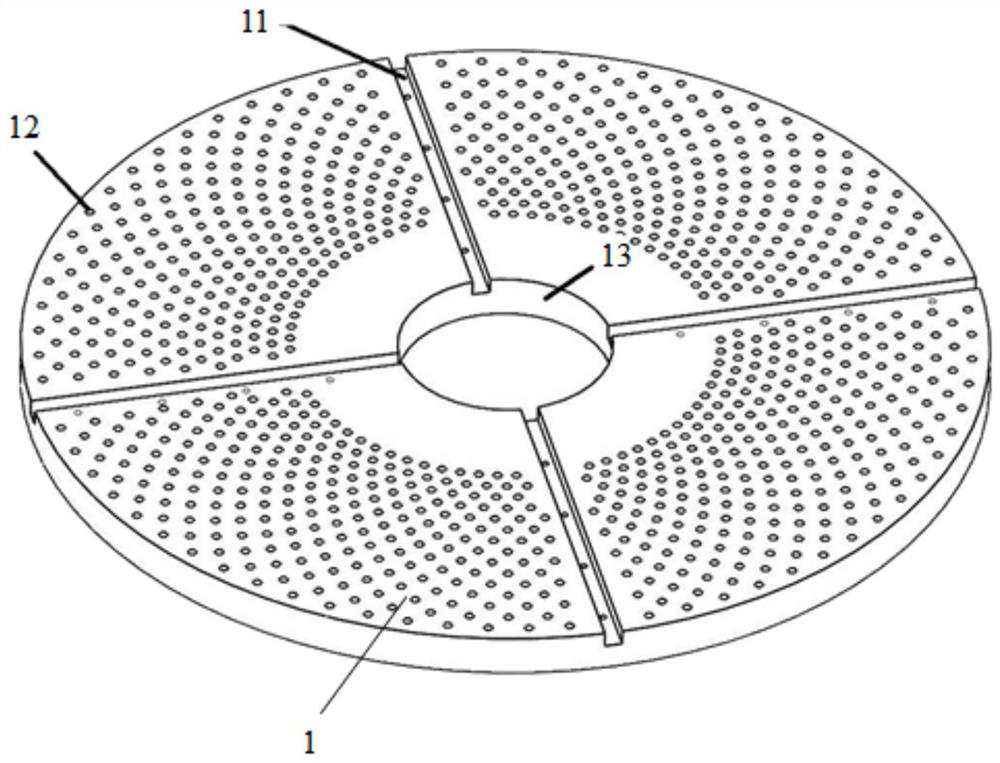

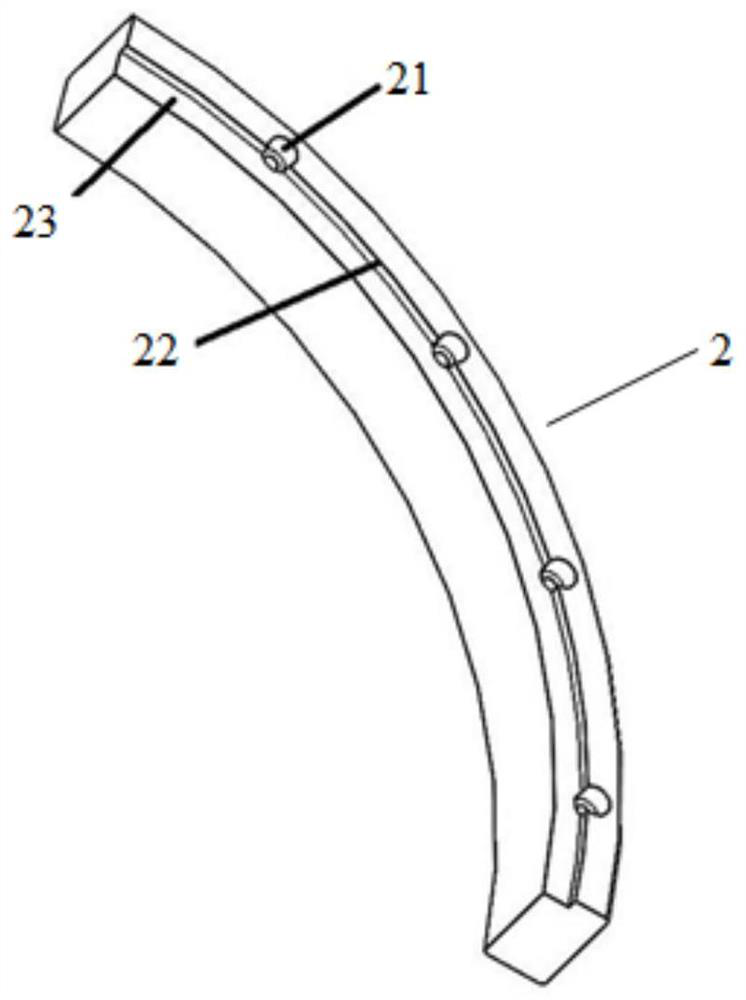

Tool for machining large-size thin-wall disc ring parts

PendingCN113070704AQuick positioning clampingSmall clamping deformationPositioning apparatusMetal-working holdersEngineeringPoint contact

The invention provides a tool for machining large-size thin-wall disc ring parts. The tool comprises a bottom plate, a plurality of cushion blocks and a plurality of clamping pieces, wherein the bottom plate is circular, a through hole is formed in the circle center of the bottom plate, and a plurality of screw holes which are uniformly distributed along the radial direction are formed in the bottom plate; the cushion blocks are detachably connected with the bottom plate through the screw holes, and all the cushion blocks form an annular supporting part used for placing a workpiece; and each clamping piece comprises a pressing plate, and the pressing plates are used for pressing the workpiece on the supporting part. The tool has the beneficial effects that through the arrangement of the bottom plate on which the screw holes are uniformly distributed, an operator can mount the cushion blocks of different specifications on the bottom plate according to the appearances of different workpieces, so that the time consumed for designing and building the tool is shortened, and rapid positioning and clamping of the workpieces are realized. Meanwhile, the pressing plate is adopted to replace an existing clamping jaw, point contact is changed into surface contact, and therefore clamping deformation of the workpiece is effectively reduced, the percent of pass of parts is improved, and the manufacturing cost of an enterprise is reduced.

Owner:SHANGHAI TOBACCO MACHINERY

Laser cutting equipment for cutting pipes

ActiveCN103817443BAvoid deformationImprove deformationWelding/cutting auxillary devicesAuxillary welding devicesLaser cuttingEngineering

The invention discloses laser cutting equipment used for cutting pipes, which has the advantages that automatic feeding is realized, the clamping is steady and the cutting quality is good. The laser cutting equipment comprises a base, wherein a guide mechanism, a main clamping mechanism, an auxiliary clamping mechanism and a laser cutting mechanism are arranged on the base in sequence; the main clamping mechanism comprises a screw rod which is movably arranged on the base; a main motor which is used for driving the screw rod is arranged on the base; a sliding seat is sleeved on the screw rod; a sliding rail is arranged on the base; the bottom of the sliding seat is movably clamped on the sliding rail; a feeding hole is formed in the sliding seat; a barrel-shaped clamping component is embedded in the feeding hole; a plurality of flexible grooves are arranged in the periphery of the discharge end of the clamping component; a plurality of grooves are arranged in the periphery of the external surface of the part, stretching out of the sliding seat, of the discharge side of the clamping component; the depths of the grooves are gradually reduced in the feeding direction; a movable sleeve is sleeved on one section, provided with the grooves, of the clamping component; a plurality of grooves which are matched with the grooves of the external surface of the clamping component and are formed in the feeding direction are formed in the periphery of the inner surface of the movable sleeve; balls are arranged between the grooves of the movable sleeve and the grooves of the clamping component; a main air cylinder used for driving the movable sleeve to move is arranged on the sliding seat.

Owner:JIANGSU HEFENG MECHANICAL MAKING

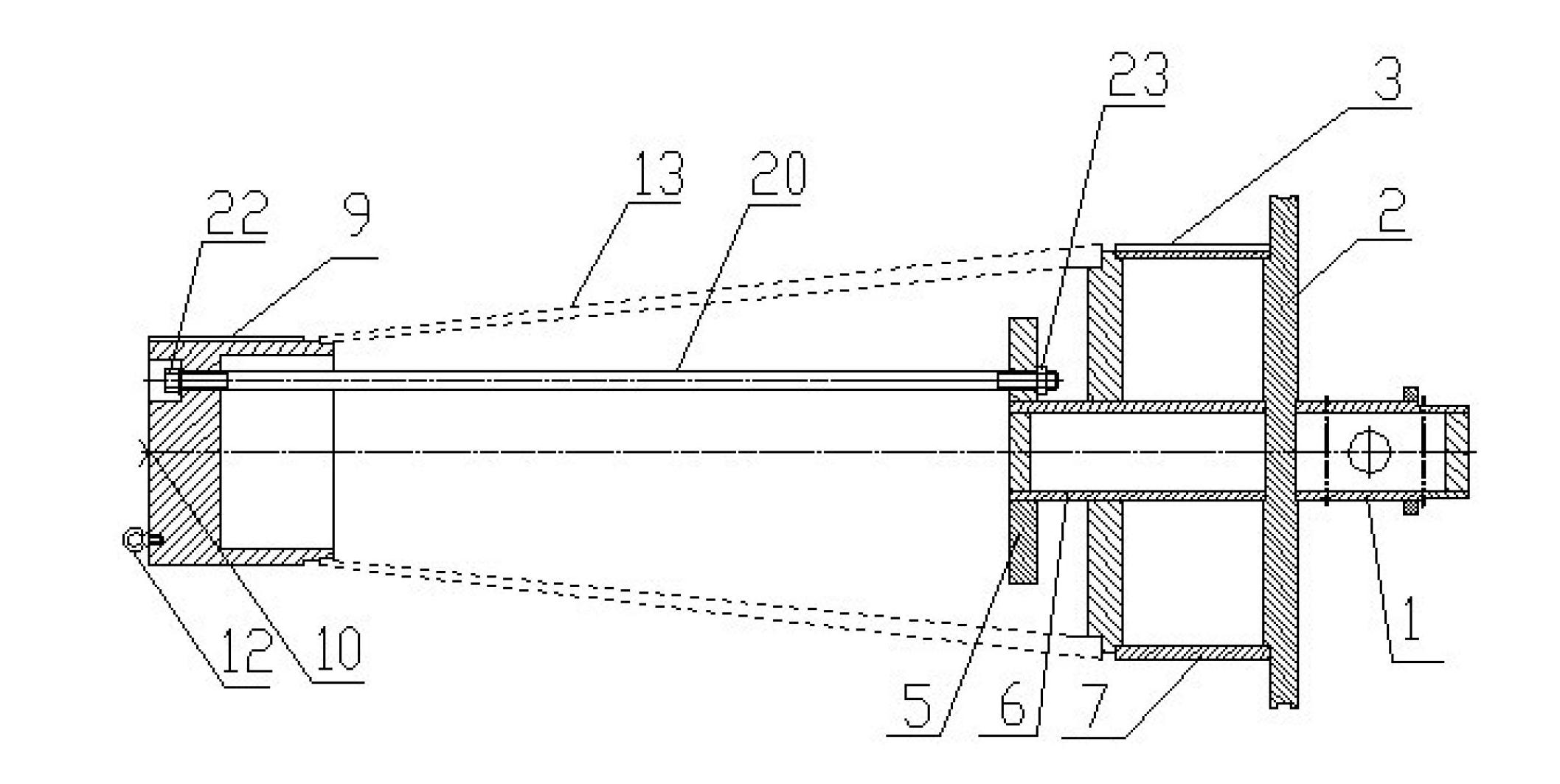

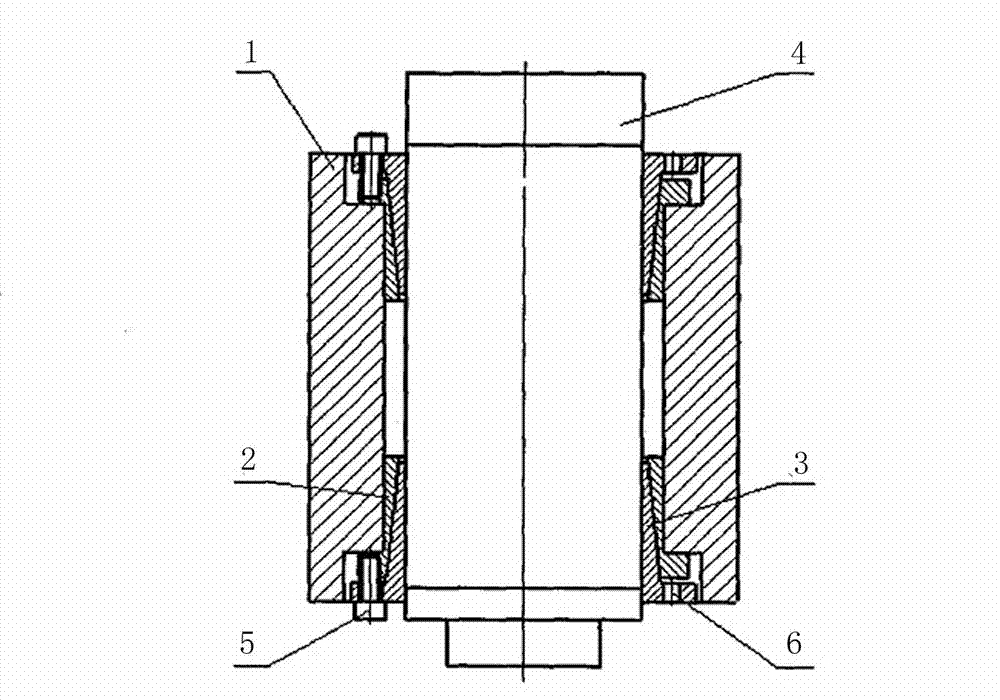

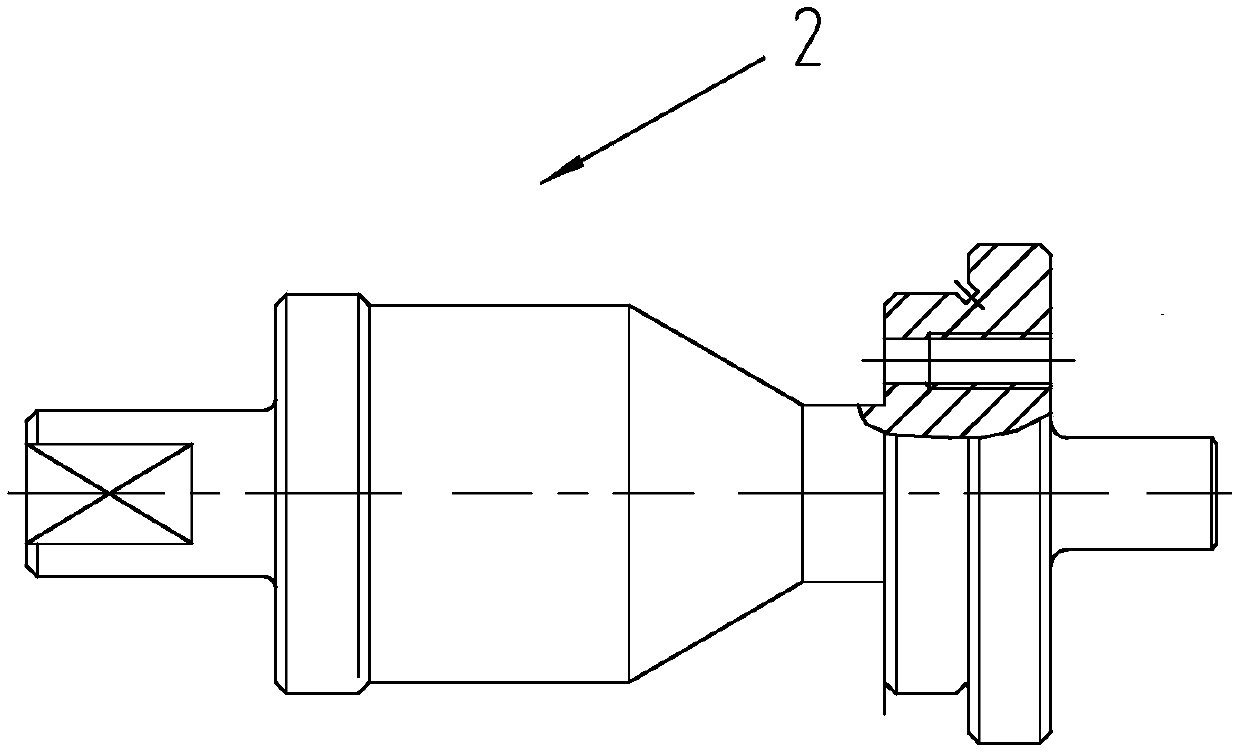

Machining method and device for ultra-long and ultra-thin sleeve parts

PendingCN114700505ASimple processing methodIncrease productivityTurning machinesTotal factory controlNumerical controlForce direction

The invention relates to the technical field of machining and clamps, in particular to a machining method and device for ultra-long and ultra-thin sleeve parts. According to the technical scheme, a turning machining mode is adopted, inner hole final machining is completed on a vertical numerical control lathe, outer circle final machining is completed on a horizontal numerical control lathe, the machining sequence is that the hole is machined first and then the outer circle is machined, a slotted sleeve is adopted for clamping in inner hole machining, and a thin-wall sleeve special device capable of changing the clamping force direction is adopted for outer circle machining. The machining of the ultra-long and ultra-thin sleeve type part is specifically completed through the three procedures of rough turning of an outer circle, turning of an inner hole and finish turning of the outer circle. The special device for the thin-wall sleeve is composed of an installation mandrel, a positioning sleeve, a pressing plate, a gasket and a pressing nut, and the clamping force direction is changed from the radial direction to the axial direction. The special device for the slotted sleeve and the thin-wall sleeve is adopted, so that the requirements for the size, the shape, the position precision and the surface roughness of the inner hole and the outer circle of the ultra-long and ultra-thin sleeve part are met. The method has the beneficial effects that the process method is simple and can be completed in one processing mode, and the production efficiency and the processing quality are high.

Owner:CHINA COAL ZHANGJIAKOU COAL MINING MACHINERY

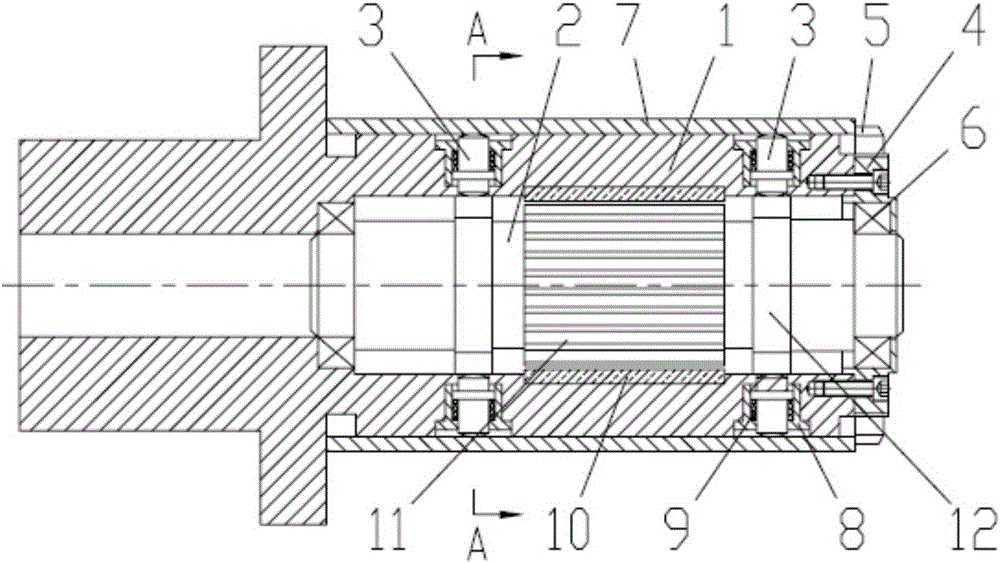

Tool structure of electric spindle

InactiveCN102764901ASmall clamping stabilityEasy and uniform deformationMetal-working apparatusEngineeringSelf locking

The invention discloses a tool structure of an electric spindle. The tool structure comprises a base, an outer taper sleeve and an inner taper sleeve, the outer taper sleeve and the inner taper sleeve are matched with each other to form a taper ring, the inner taper sleeve is sleeved on the outer side of the electric spindle, the base is sleeved on the outer side of the outer taper sleeve, a locking screw is arranged on the base, and the taper ring is axially locked by the locking screw. The outer taper sleeve and the inner taper sleeve have small taper angles, a taper surface of the taper ring and a threaded surface of the screw are used for double force increase, the force increasing ratio is high, self-locking can be realized, clamping is reliable, a taper ring group with an opening is easy and uniform in deformation, can keep good surface contact with (the electric spindle) internally and externally matched cylindrical surfaces and is low in clamping deformation and high in positioning precision and clamping rigidity, and the taper ring with two grouped ends has double support and fine clamping stability.

Owner:CHANGZHOU TPD PRECISION MACHINERY

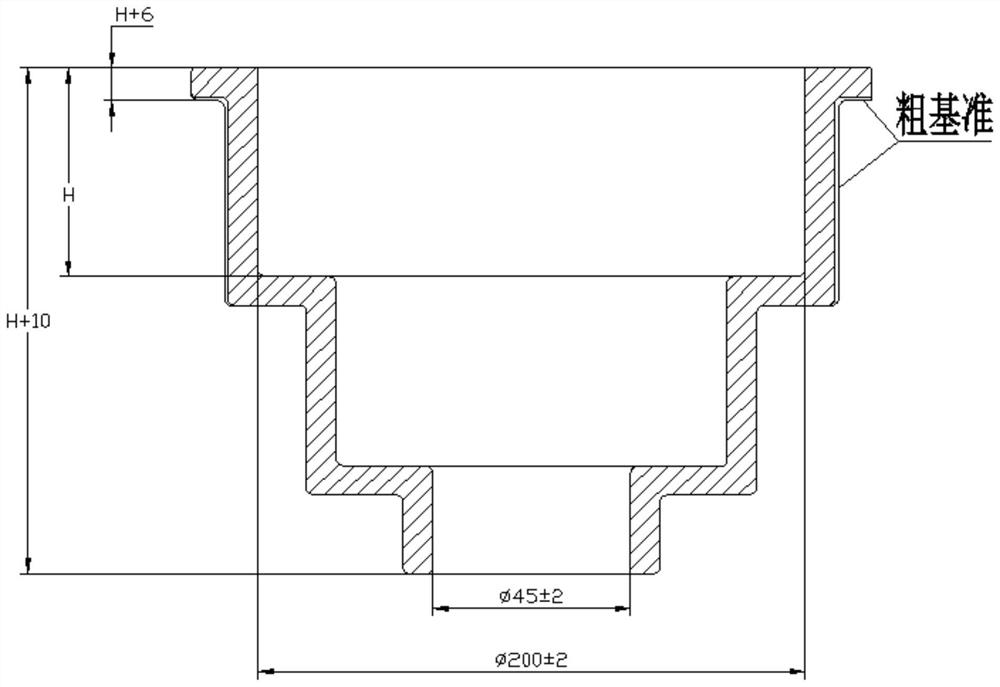

Manufacturing method of supporting base for separation of effective compositions of plant herbs

The invention relates to a manufacturing method of a supporting base for separation of effective compositions of plant herbs. The manufacturing method comprises the following steps of casting, whereinaccording to the size of a supporting base finished product, 10-12 mm of machining allowances are reserved in both sides, a casting head is reserved at the small end, and a supporting base blank is completed through one-time casting; detection, wherein dye checking or X-ray crack detection is conducted; pellet blasting; benching, wherein a height machining line and a circumference machining lineare drawn with the large-end stepped end face of the supporting base and the external circle at the root of the step as the reference plane; rough machining; low-temperature aging treatment; detection; dye checking; semifinishing; low-temperature aging treatment; finish machining; finish turning, wherein the external circle plane of a slider is machined to the size; right boring, wherein the two stepped holes must be clamped one time; benching, wherein a supporting base cover is arranged, and benching is conducted for storage. By means of the manufacturing method, deformation caused by clamping during machining and deformation caused by machining stress can be obviously reduced, a high size precision and a high position precision are kept, and the machining quality is improved.

Owner:TIBET UNIV

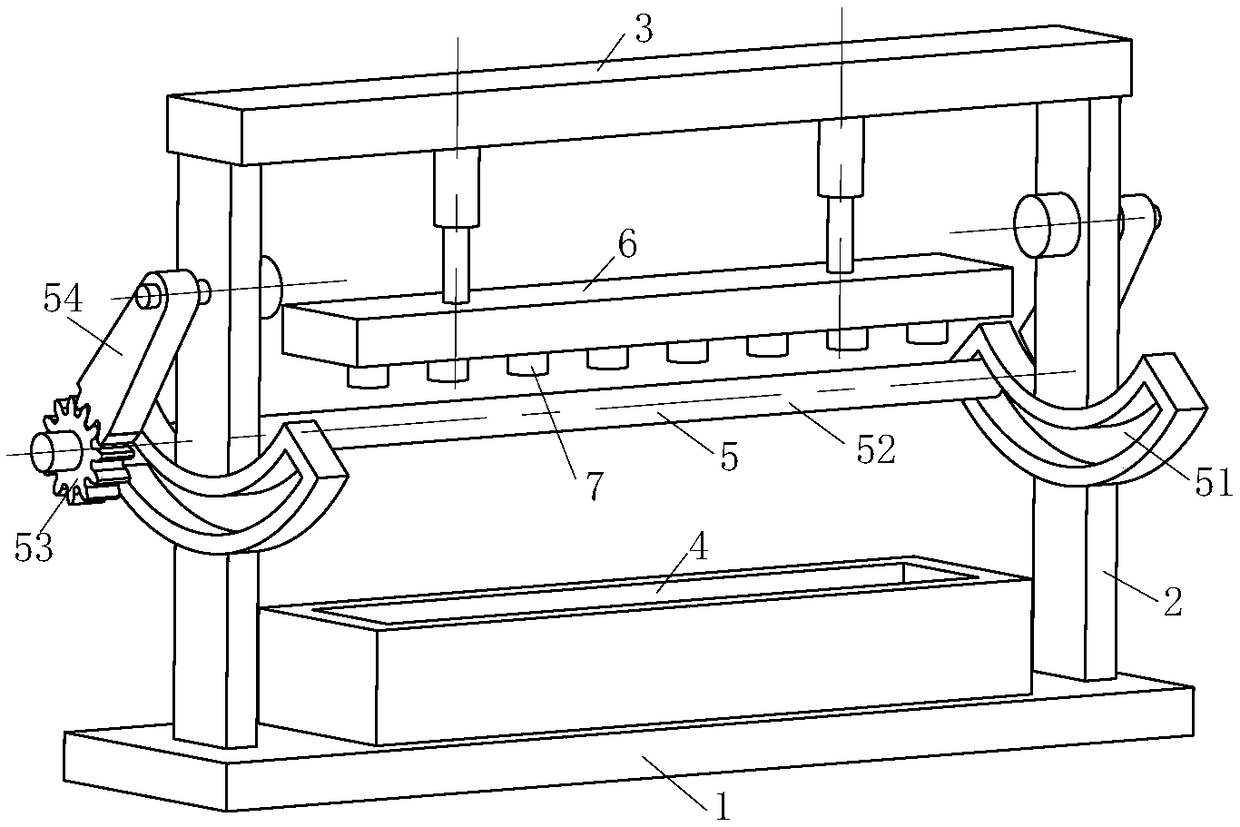

Adaptive clamping device and clamping method for irregular objects

ActiveCN109623890BAchieve clampingSmall clamping deformationMetal working apparatusEngineeringApparatus instruments

The invention belongs to the field of medical apparatus, and discloses an self-adaptive clamping device for an irregular object. The self-adaptive clamping device includes a positioning platform, anda flexible clamping mechanism, the flexible clamping mechanism comprises a flexible fixture bracket and a plurality of flexible fixtures connected in parallel, each flexible fixture comprises a springmounting rod, a spring and a pressing disc, and one end of each spring mounting rod is movably mounted in the flexible fixture bracket; and the other end of each spring mounting rod is hinged to thecorresponding disc so that the corresponding pressing disc can swing around the hinge center, and the springs are externally arranged on the spring mounting rods in a sleeving mode and placed betweenthe flexible fixture bracket and the pressing discs so that the springs generate the self-adaptive pressure to the flexible fixture bracket and a hinging rotating shaft when the spring mounting rods move in the flexible fixture bracket. The self-adaptive clamping device further includes a position adjusting mechanism and a cutting mechanism except the flexible clamping mechanism and aims to solvethe technical problems that large elastic deformation or even yield deformation and invalid clamping are easily produced during clamping of the irregular object, especially, the elastic textures.

Owner:HUAZHONG UNIV OF SCI & TECH

Lathe fixture for inner hole processing of screw sleeve parts

ActiveCN104647101BProcessing quality is easy to guaranteeSmall clamping deformationPositioning apparatusMetal-working holdersBarrel ShapedEngineering

The invention discloses a screw sleeve part inner hole processing lathe clamp, which comprises a clamp body, a screw nut, a cone sleeve and a reset spring, wherein a clamp body positioned by a notch is arranged on a lathe main shaft through a transition disc, the front end of the clamp body is a barrel-shaped thin wall with the external taper, in addition, the outer diameter of the back end of the thin wall is greater than the outer diameter of the front end, the inner diameter of the thin wall is matched with the outer diameter of a screw sleeve to be processed, the cone sleeve with the internal taper matched with the external taper of the thin wall is arranged on the outer side of the thin wall in a sleeving way, the reset spring is arranged at the thin wall part in a sleeving way and is positioned between a cone sleeve and a threaded step positioned at the back part of the clamp body, and the screw nut passes through the thin wall and the cone sleeve and is connected with the clamp body through screw threads. The screw sleeve part inner hole processing lathe clamp has the advantages that the structure is compact, the operation is simple, convenient and reliable, the positioning precision is very high, the processing quality can be easily ensured, and higher practicability is realized.

Owner:南京力全科技有限公司

Clamping device and clamping method thereof

InactiveCN111618630AUniform forceSolve the deformationPositioning apparatusMetal-working holdersEngineeringMachining

The invention relates to the field of machining, and discloses a clamping device. The clamping device comprises an upper sucker, a lower sucker and a sucker valve body, wherein the upper sucker is opposite to the lower sucker, the sucker valve body is arranged on the end face of one side of the lower sucker, the upper sucker is provided with a positioning structure used for positioning a workpiece, and the positioning structure is deformable. The invention also discloses a clamping method. According to the clamping device, the problem that a thin-wall piece is easy to deform due to clamping iseffectively solved.

Owner:绵阳市正阳科技有限公司

A positioning tool for thin-walled cylindrical parts

The invention relates to a positioning tool for thin-walled cylindrical parts, which belongs to the field of mechanical processing. The positioning tooling of the present invention comprises an expansion sleeve, an expansion inner sleeve, a locking ring, an expansion body and an elastic ring; the expansion sleeve is a split cylindrical structure; the expansion inner sleeve is a circle with a tapered inner cavity. Cylindrical structure; the inner hole of the locking ring is a threaded hole; the front section of the expansion body is a cylindrical section, the rear section is a tapered section, and the rear end of the cylindrical section is processed with external threads; the expansion sleeve is bonded to the elastic ring on the inner wall Closed into a cylindrical assembly, the locking ring and the inner sleeve of the expansion sleeve are put into the inner cavity of the expansion sleeve in turn; the front end of the expansion body passes through the inner sleeve and the locking ring, and passes through the rear end of the cylindrical section of the expansion body The external thread of the outer wall is threadedly connected with the internal hole of the expansion sleeve. The positioning tool of the present invention has simple structure, convenient processing and simple operation, can quickly and reliably clamp thin-walled cylindrical parts, has small clamping deformation, ensures the processing accuracy of products, and improves processing efficiency.

Owner:XIANGYANG WU ER WU PUMP IND

Clamping tool for thin-wall cylindrical parts

The invention relates to a clamping tool for thin-wall cylindrical parts. The clamping tool comprises an expansion outer sleeve, an expansion inner sleeve, a locking ring, an expansion body and an elastic sleeve; the expansion outer sleeve is a split cylindrical closing piece; the expansion inner sleeve is a split annular closing piece; an inner cavity of the expansion inner sleeve is a conical surface; guide pins are arranged on the front end surfaces of all components of the expansion inner sleeve; an inner hole of the locking ring is a threaded hole; guide grooves are formed in the back endsurface of the locking ring; the front section of the expansion body is a cylindrical section, and the back section of the expansion body is a conical section; the guide pins of all the components ofthe expansion inner sleeve are inserted in all guide grooves of the locking ring respectively; the front end of the expansion body penetrates through the expansion inner sleeve and the locking ring,and is in threaded connection with a connecting ring of the expansion inner sleeve through an external thread on the back end outer wall of the cylindrical section of the expansion body; the elastic sleeve is fixedly bonded on the inner walls of all the components of the expansion outer sleeve to form the cylindrical closing piece; and the expansion outer sleeve sleeves the expansion inner sleeve.The clamping tool can quickly realize reliable clamping of the thin-wall cylindrical parts.

Owner:XIANGYANG WU ER WU PUMP IND

Clamp for automobile front beam upper plate assembly

InactiveCN103624444AClamp evenlyClamping mechanism provides even clampingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMotive power

The invention provides a clamp for an automobile front beam upper plate assembly. The clamp comprises a platform, positioning elements, positioning frames and at least three clamping mechanisms. The positioning frames are fixed on the platform and connected with the clamping mechanisms, and the clamping mechanisms are lever type clamping mechanisms. Each clamping mechanism comprises a power source, a power transmission rod, a clamping element and a supporting frame. One end of each power transmission rod is connected with each power source, and the other end of each power transmission rod is connected with each clamping element. The middle portions of the power transmission rods are movably connected with the supporting frames, the power sources are connected with the supporting frames, the supporting frames are connected with the positioning frames, and the positioning elements are arranged on the supporting frames. The clamp for the automobile front beam upper plate assembly is reasonable in structural design and facilitates reasonable arrangement of flow line production in the process of welding, station time balancing is convenient, non-production consumed time is reduced, and convenience is provided for production management.

Owner:JIANGSU KAWEI SPECIAL PURPOSE VEHICLE MFG

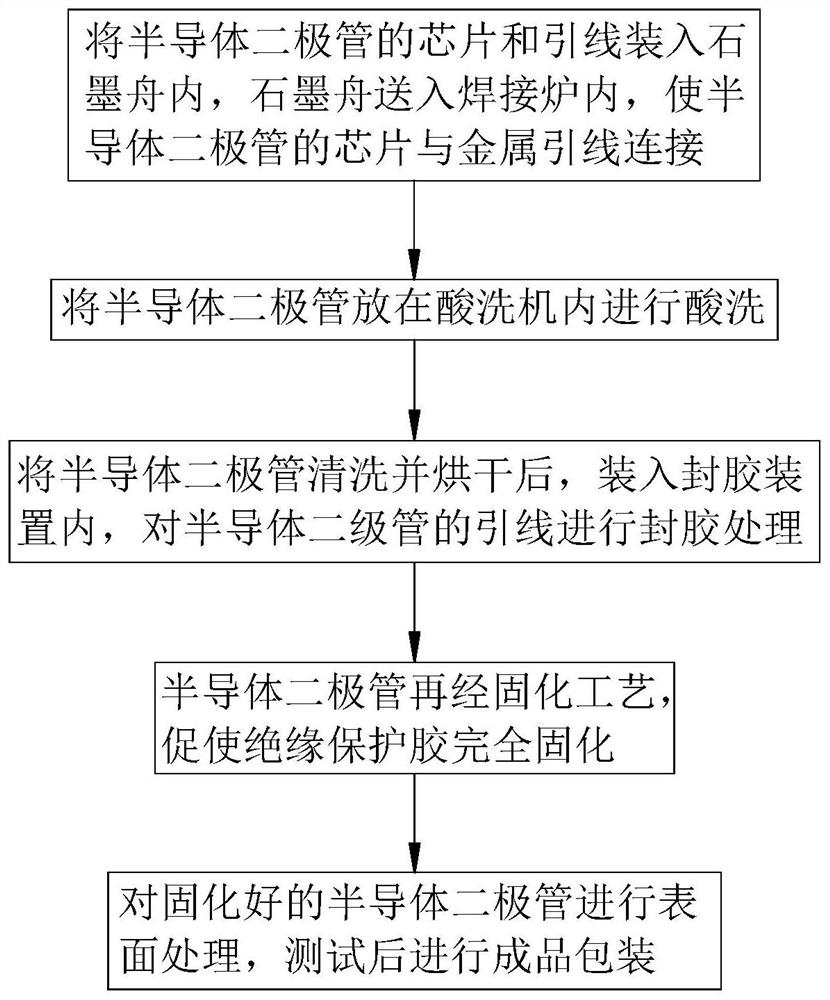

A kind of semiconductor diode production process

ActiveCN108745801BDry evenlySmall clamping deformationPretreated surfacesSemiconductor/solid-state device manufacturingEngineeringSemiconductor

The invention belongs to the technical field of production of semiconductor diodes, and particularly relates to a semiconductor diode production technology. The semiconductor diode production technology adopts a glue sealing device. The glue sealing device comprises a bottom plate, vertical columns, a top plate, a glue sealing groove, drying modules, a storing block and storing holes. A set of telescopic rods is arranged at the bottom of the top plate. The storing block is arranged at the ends of the telescopic rods. The set of storing holes is formed in the bottom of the storing block. Each drying module comprises an arc-shaped sliding groove, an electric heating pipe, a swinging gear and a swinging plate. Each arc-shaped sliding groove is formed in the middle of the corresponding vertical column. Each electric heating pipe is slidably mounted in the corresponding arc-shaped sliding groove. A spring connected with the corresponding electric heating pipe is arranged at one end of eacharc-shaped sliding groove. Each swinging gear is rotationally mounted at the two ends of the corresponding electric heating pipe through torsional springs. A swinging plate rotationally mounted on thecorresponding vertical column is arranged on each arc-shaped sliding groove. A tooth groove meshing with the corresponding swinging gear is formed in the end of each swinging plate. The swinging plates are controlled to rotate through a motor. According to the semiconductor diode production technology, leads subjected to glue sealing can be dried uniformly, and by arranging a clamping device, thesemiconductor diode production technology can adapt to glue sealing of the leads of different thicknesses.

Owner:深圳市信展通电子股份有限公司

A Clamping Device for Thin-walled Cylindrical Parts

The invention relates to a clamping device for thin-walled cylindrical parts, which belongs to the field of mechanical processing. The clamping tooling of the present invention comprises an expansion sleeve, an expansion inner sleeve, a locking ring, an expansion body and an elastic ring; the expansion sleeve is a split cylindrical structure; the expansion inner sleeve is a tapered inner cavity Cylindrical structure; the inner hole of the locking ring is a threaded hole; the front section of the expansion body is a cylindrical section, the rear section is a tapered section, and the rear end of the cylindrical section is processed with external threads; the expansion sleeve is bonded to the elastic ring inside Closed into a cylindrical assembly, the locking ring and the inner sleeve of the expansion sleeve are put into the inner cavity of the expansion sleeve in turn; the front end of the expansion body passes through the inner sleeve and the locking ring, and passes through the rear end of the cylindrical section of the expansion body The external thread of the outer wall is threadedly connected with the internal hole of the expansion sleeve. The clamping tooling of the present invention has simple structure, convenient processing and simple operation, can quickly realize reliable clamping of thin-walled cylindrical parts, has small clamping deformation, ensures the processing accuracy of products, and improves processing efficiency.

Owner:XIANGYANG WU ER WU PUMP IND

A new flexible spline and wave generator assembly for harmonic gear transmission

ActiveCN106640958BImprove machining accuracySmall clamping deformationValve arrangementsRolling contact bearingsGear driveGear wheel

A new type of flexible spline and wave generator assembly for harmonic gear transmission, the assembly can overcome the following technical and quality problems existing in the existing flexible spline and wave generator assembly due to the use of special-shaped ferrule flexible bearings: (1) The outer ring of the flexible bearing slips relative to the flexible wheel, causing the speeds of the two to be incompletely synchronized; (2) The outer ring of the flexible bearing made of bearing steel breaks and fails under the repeated action of alternating bending stress; (3) The precision after processing When the higher flexible bearing is installed on the cam with interference, the groove shape will be distorted, the geometrical and shape accuracy will be greatly reduced, and the compressive stress formed on the working surface will become tensile stress during processing; (4) the ball of the flexible bearing is the same The raceway of the outer ring is a single-point contact, which causes the flexspline teeth to undergo predetermined radial deformation, and at the same time, there is additional warping along the tooth width direction and additional twisting deformation along the circumferential direction, all of which make the assembly have higher transmission accuracy , operational reliability and longer service life.

Owner:SHANGHAI F&S BEARING TECH +1

Automatic Self-Centering Fixtures

InactiveCN103753323BEasy loading and unloadingSmall clamping deformationExpansion mandrelsPositioning apparatusMechanical engineeringStator

Owner:庄景惠

A semiconductor diode lead wire sealing system

ActiveCN108461430BDry evenlySmall clamping deformationSemiconductor/solid-state device manufacturingElectric machineTorsion spring

The invention belongs to the technical field of semiconductor diode production, and particularly relates to a semiconductor diode lead-wire sealing system. The semiconductor diode lead-wire sealing system comprises a bottom plate, a vertical column, a top plate, a sealing groove, a drying module, a storing block and storing holes; a set of telescopic rods are arranged at the bottom of the top plate; the storing block is fixedly connected with the ends of the telescopic rods, and the set of storing holes are formed in the bottom of the storing block; the drying module comprises an arc-shaped sliding groove, an electric heating pipe, swinging gears and a swinging plate; the arc-shaped sliding groove is mounted in the middle of the vertical column; the electric heating pipe is slidably mounted in the arc-shaped sliding groove; a spring connected with the electric heating pipe is arranged at one end of the arc-shaped sliding groove; the swinging gears are rotatably mounted at the two endsof the electric heating pipe through torsion springs; the swinging plate rotatably mounted on the vertical column is arranged above the arc-shaped sliding groove; gear sockets meshed with the swinginggears are arranged at the ends of the swinging plate; and the swinging plate is controlled to rotate through a motor. The semiconductor diode lead-wire sealing system can conduct uniform drying on the sealed lead-wire; and by arranging a clamping device, the system can adapt to sealing of lead-wires with different thickness.

Owner:苏州因知成新能源有限公司

Manufacturing method of precision positioning mandrel

ActiveCN107891250BHigh centering accuracyAchieve clampingMetal working apparatusSynthetic materialsEngineering

The invention discloses a machining and manufacturing method of a precision positioning central spindle. The precision positioning central spindle is formed by assembling an elastic sleeve, a centralspindle body and pressurization inner hexagon screws. According to the working condition of the precision positioning central spindle, when a workpiece is installed on the elastic sleeve, the pressurization inner hexagon screws are screwed into the elastic sleeve, and a liquid synthetic material is pressurized through an end head; when a liquid synthetic material cavity is sealed, the pressure borne by the liquid synthetic material is uniformly acted on the elastic sleeve according to the incompressibility of liquid and the principle that the liquid can transfer pressure uniformly in all the directions, the elastic sleeve generates radial elastic deformation and makes cylindrical contact with the workpiece to enable the workpiece to be accurately positioned and reliably clamped. When a screw plunger is screwed out, the elastic sleeve returns to the original position under the action of elasticity, and the workpiece is loosened. Through the improvement on the machining method of the elastic sleeve, the central spindle body and the pressurization inner hexagon screws, the precision of the positioning central spindle is improved remarkably, and the workpiece can be prevented from being pinched in the using process.

Owner:CHONGQING YUEJIN MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com