Semiconductor diode lead-wire sealing system

A diode and semiconductor technology, which is applied in the field of semiconductor diode lead sealing system, can solve the problems of unsuitable sealing, low versatility, and low drying efficiency, so as to avoid uneven drying, avoid overvoltage deformation, reduce The effect of clamping deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

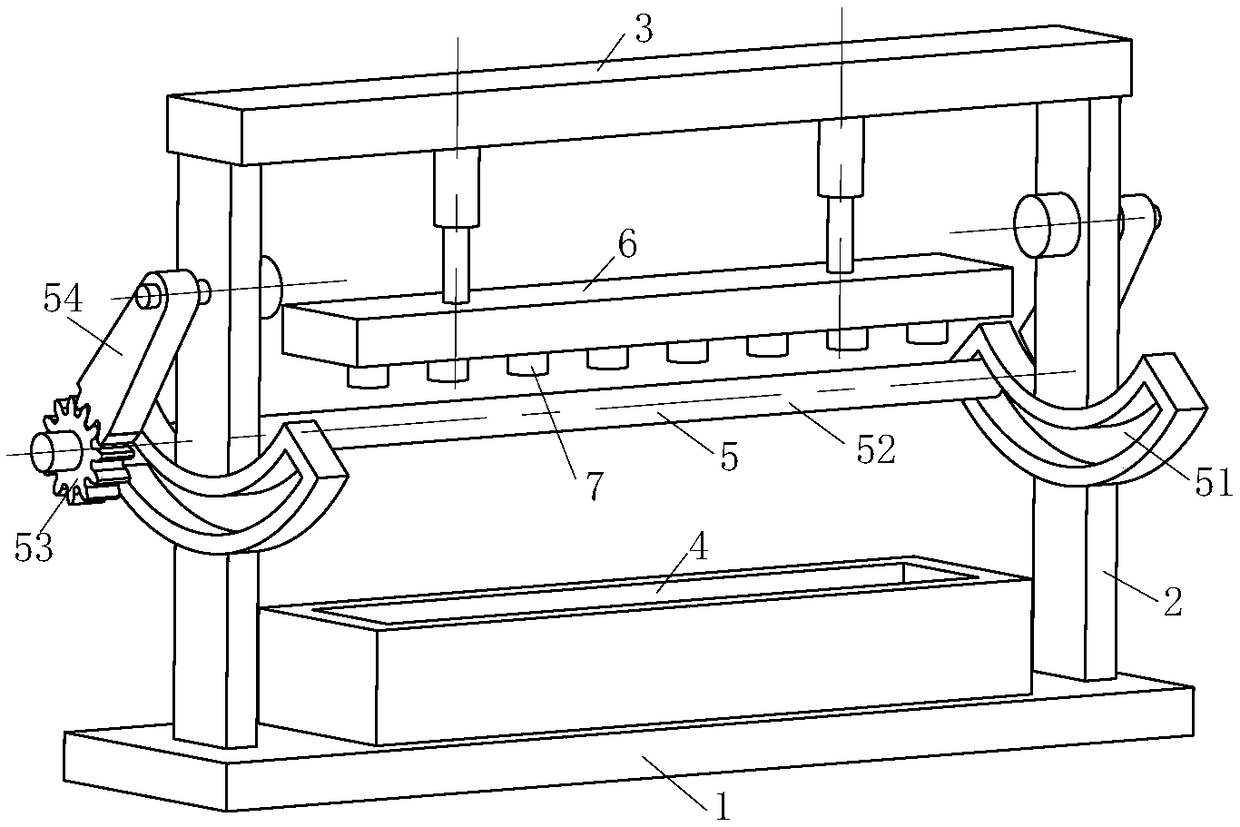

[0024] As an embodiment of the present invention, the outer ring of the placement hole 7 is provided with a clamping device 8; the clamping device 8 includes a slider 81, a swivel 82 and an electric push rod 83; the inner wall of the placement hole 7 slides A group of sliders 81 are installed; the swivel 82 is screwed on the outer ring of a group of sliders 81 through a tapered thread; the swivel 82 is rotatably installed inside the placement block 6; One side of the ring 82; the electric push rod 83 is tangent to the swivel 82, and the electric push rod 83 stretches and is used to drive the swivel 82 to rotate, and the rotation of the swivel 82 is used to clamp or loosen the lead. When working, the electric push rod 83 telescopically pushes the swivel 82 to rotate, and the rotation of the swivel 82 makes the distance between the sliders 81 smaller or larger, correspondingly clamping lead wires of different thicknesses.

[0025] As an embodiment of the present invention, a set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com