Laser cutting equipment for cutting pipes

A laser cutting and pipe cutting technology, which is applied in laser welding equipment, welding/cutting auxiliary equipment, welding equipment, etc., can solve the problems of large pipe deformation, affecting product quality, and low cutting efficiency, so as to reduce clamping deformation and cut Good quality, good neutral effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be described in detail below with reference to the drawings.

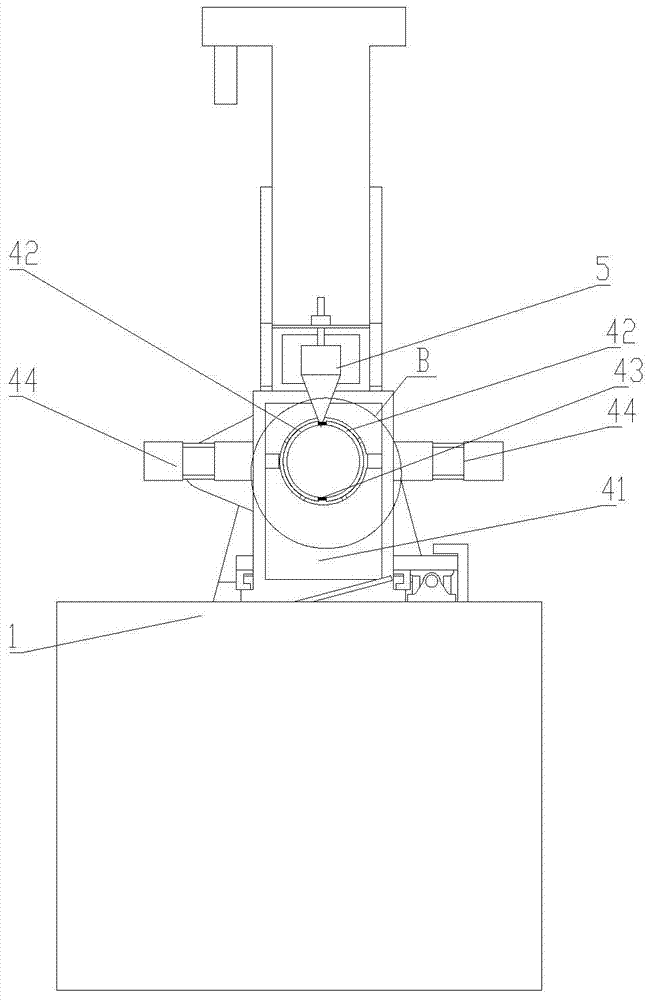

[0025] Such as Figure 1-4 As shown, a laser cutting device for cutting pipes includes a base 1 on which a guide mechanism 2, a main clamping mechanism 3, an auxiliary clamping mechanism 4, and a laser cutting mechanism 5 are sequentially arranged.

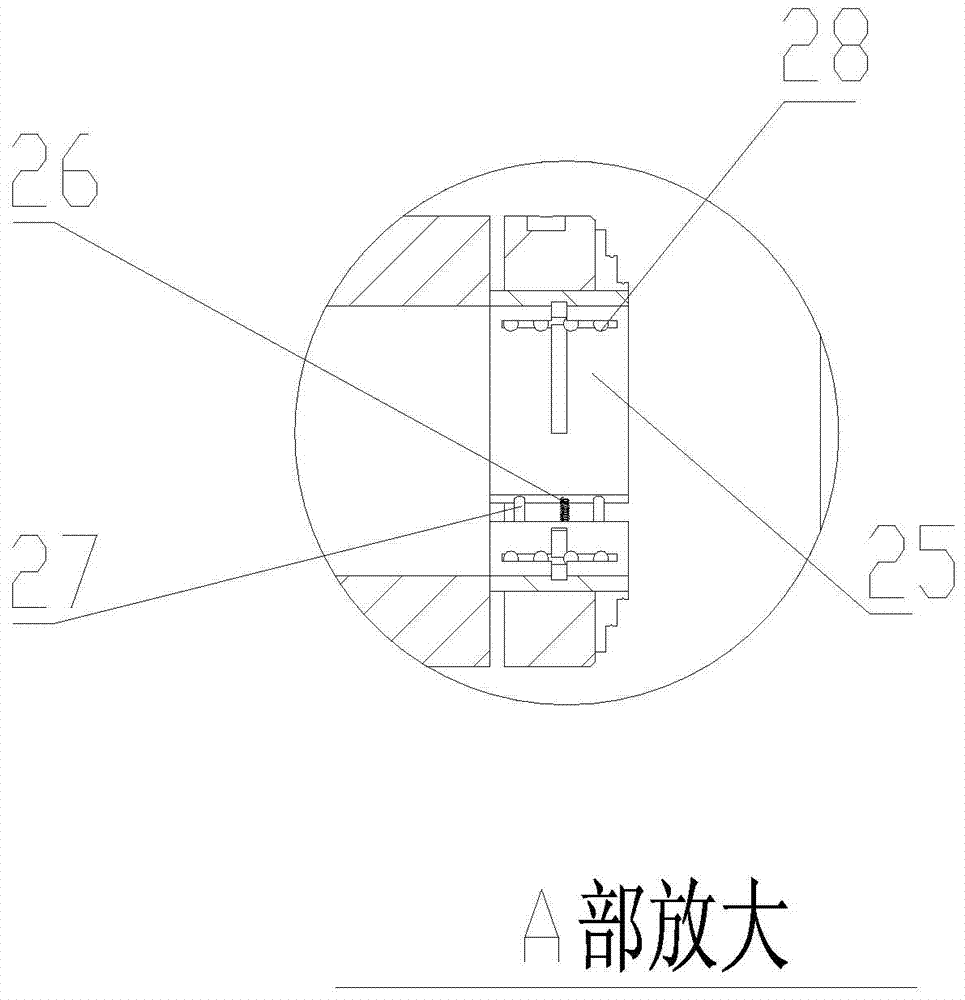

[0026] The guide mechanism 2 includes a mounting seat 21 arranged on the base 1. A circular through hole is provided in the mounting seat 21 along the feeding direction. The circular through hole is detachably provided with an inner diameter matching the diameter of the pipe to be cut. The cylinder sleeve 22 is provided with at least three grooves along the pipe conveying direction in the circumferential direction of the inner surface of the cylinder sleeve 22, and a number of balls 23 are arranged in the grooves.

[0027] The main clamping mechanism 3 includes a lead screw 31 movably arranged on the base 1, a main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com