Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Simplify calibration work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Non-contact high-precision calibration method and application of base reference coordinate system of robot

ActiveCN104165584AEliminate manual cumbersome operationsEfficient calibration workUsing optical meansContact highRobotic systems

The invention discloses a non-contact high-precision calibration method and application of the base reference coordinate system of a robot. The non-contact high-precision calibration method comprises the following steps: step 1: installing calibration index tool; step2. calibrating and getting points; step 3. obtaining calibration matrix of the base reference coordinate system of the robot through a coordinate transformation algorithm. By means of the advantages of high precision and non-contact measurement of a laser measuring instrument provided by the invention, through a position encoder and the calibration index tool of internal joint of the robot, the coordinate transformation algorithm is applied, and the non-contact high-precision calibration of the base reference coordinate system of the robot is realized. The non-contact high-precision calibration method of the base reference coordinate system of the robot, the non-contact high-precision calibration method of the workpiece coordinate system of the single robot and the non-contact high-precision calibration method of the tool coordinate system of the single robot are cooperated and applied, hence the non-contact high-precision calibration of the integral robot system is realized. The invention also discloses a non-contact high-precision calibration method of poses between a plurality of robots.

Owner:SHANGHAI MITSUBISHI ELEVATOR CO LTD

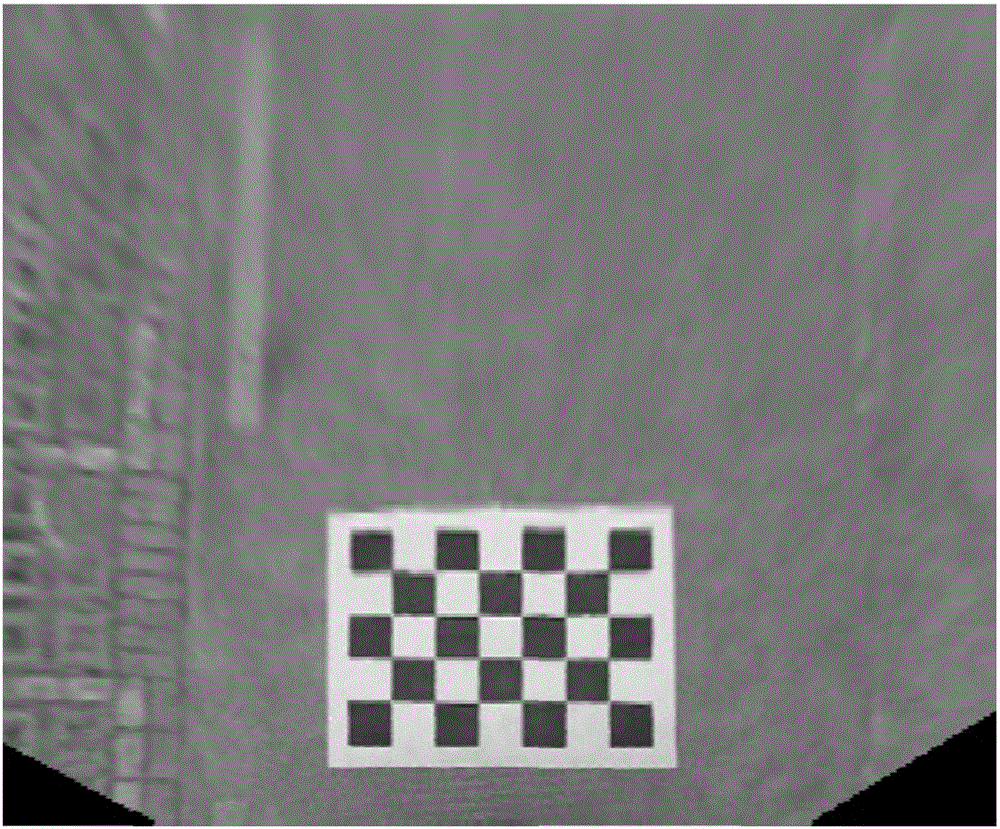

Camera calibration device and method, and vehicle

InactiveCN101836451ASimplify calibration workImage enhancementImage analysisCamera imageComputer graphics (images)

Owner:SANYO ELECTRIC CO LTD

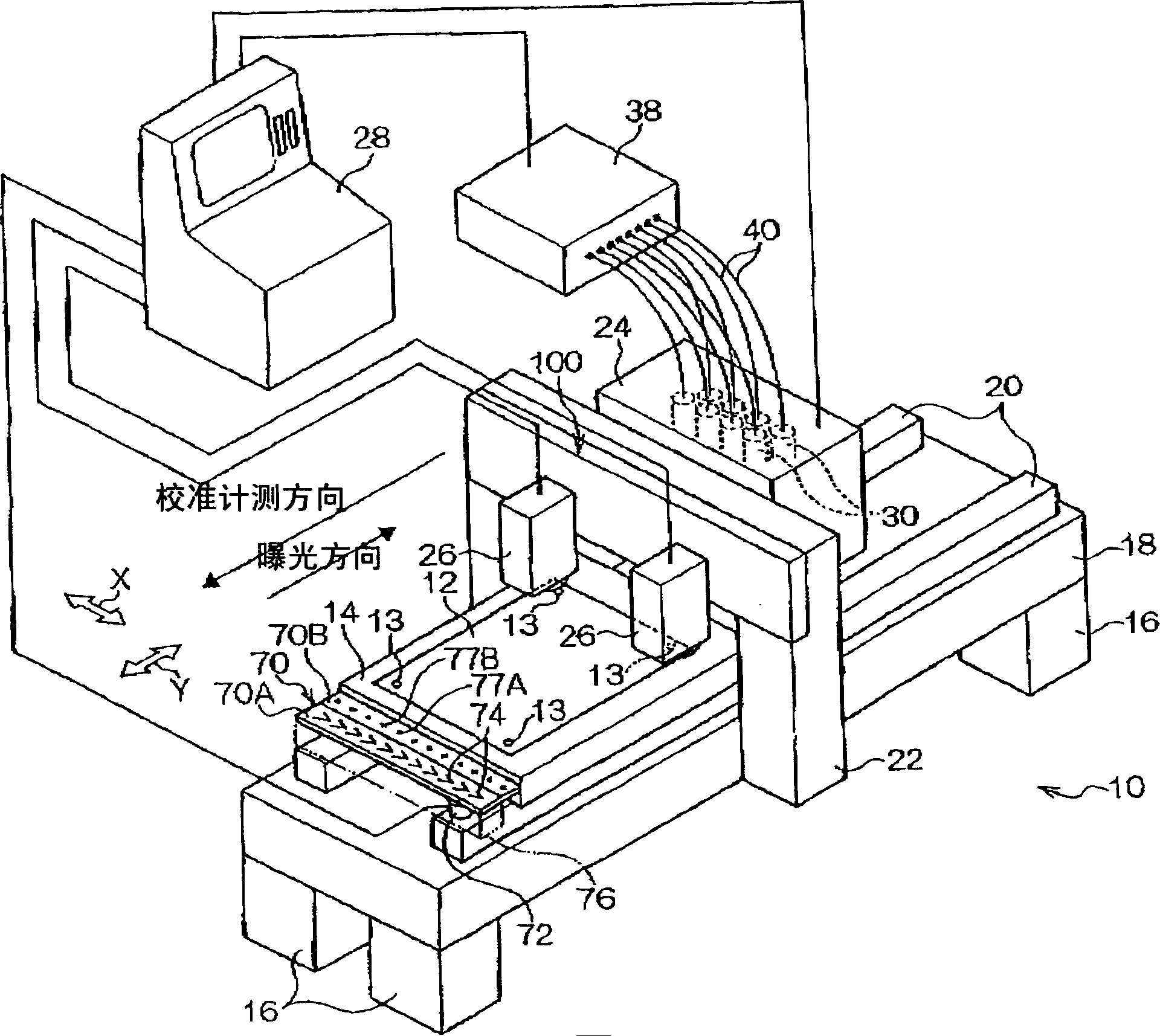

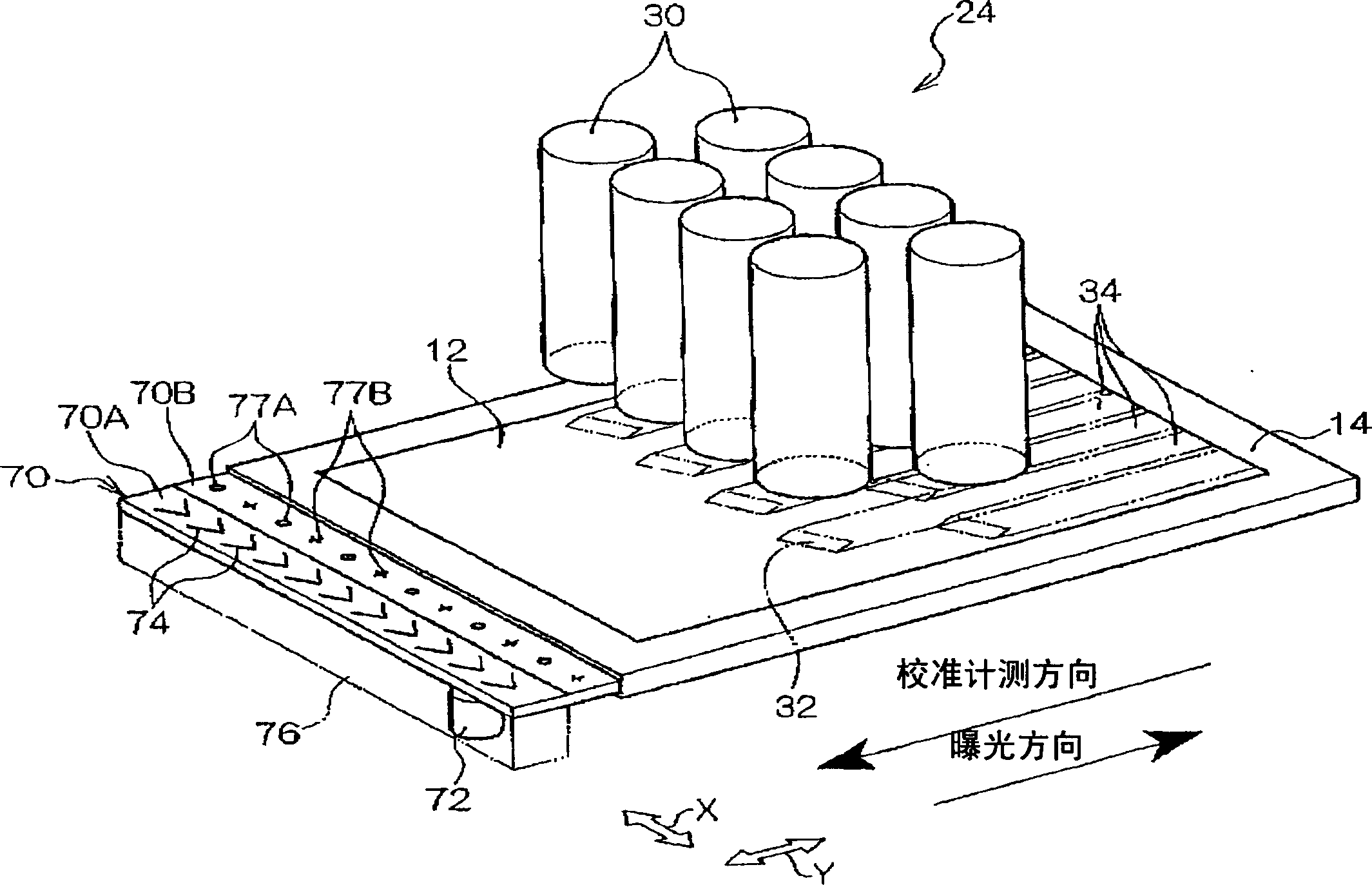

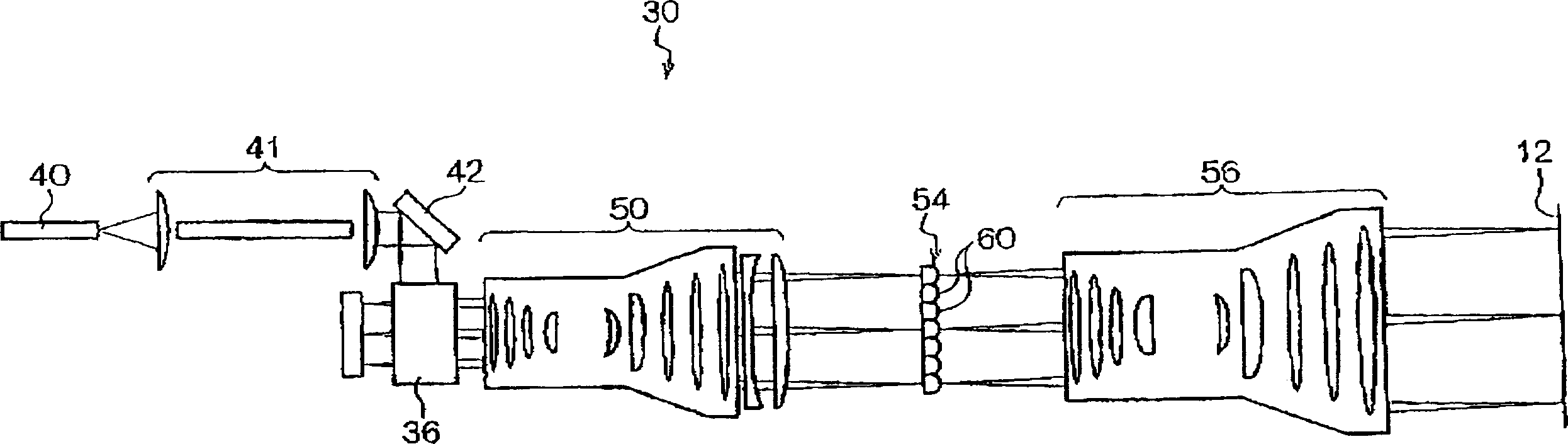

Exposure apparatus and exposure method and correction method

InactiveCN1677244ASimplify calibration workImprove correction accuracyElectrographic process apparatusPhotomechanical exposure apparatusCcd cameraExposure Location

Owner:FUJIFILM CORP

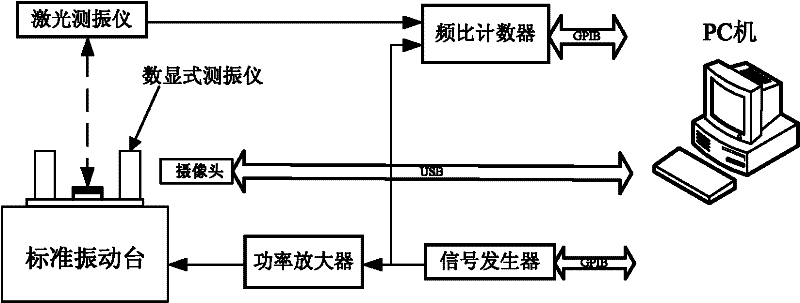

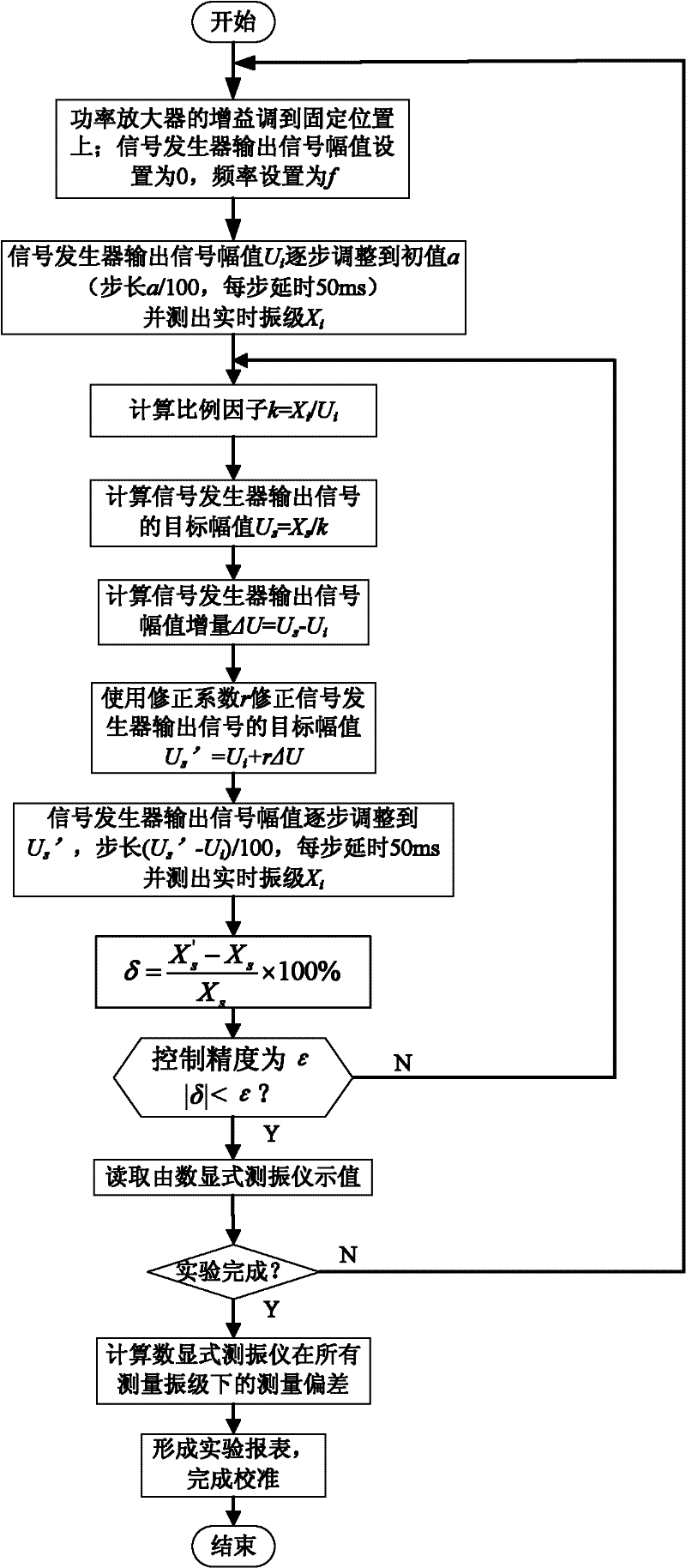

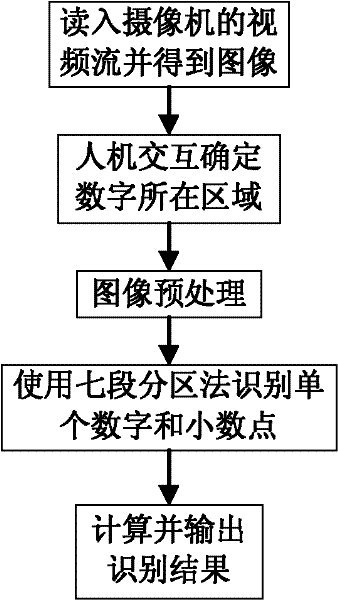

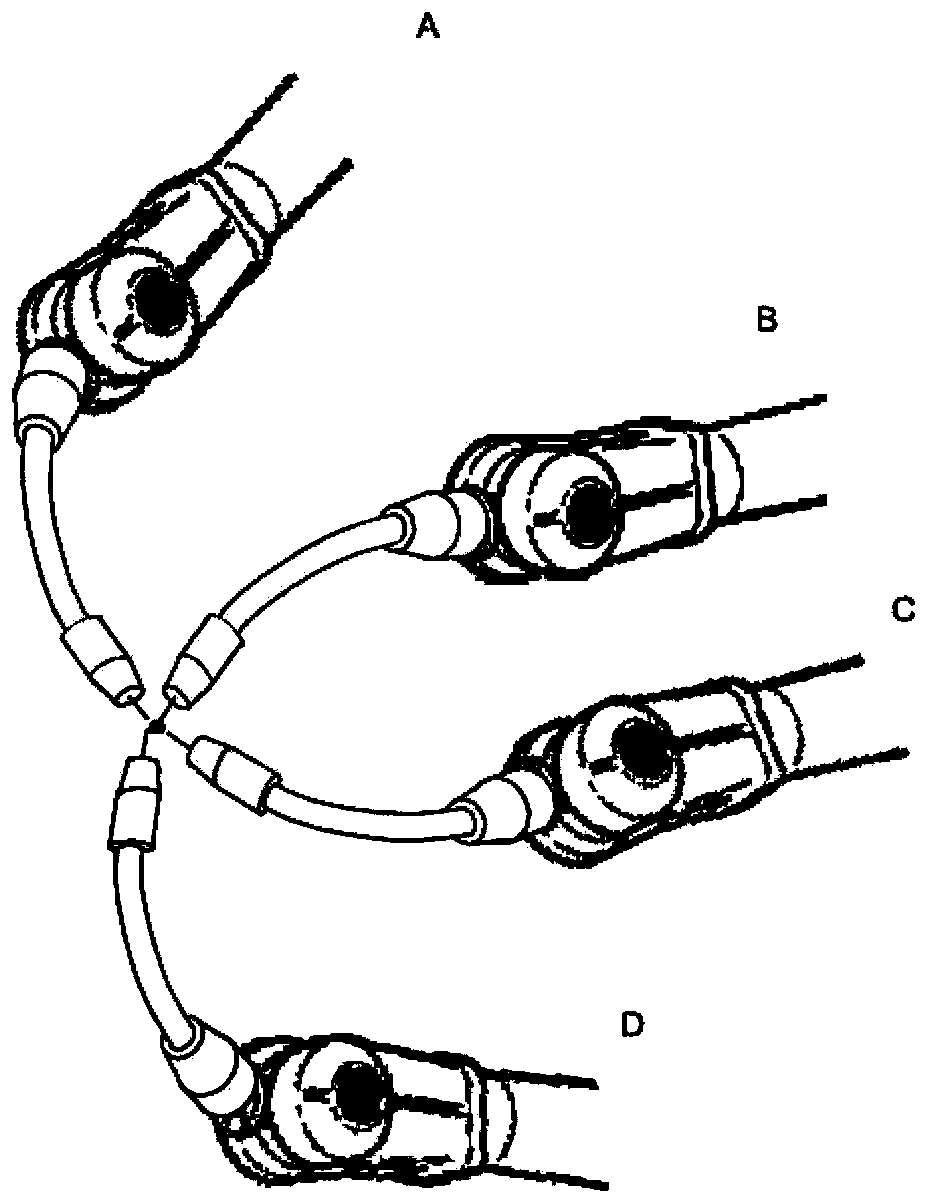

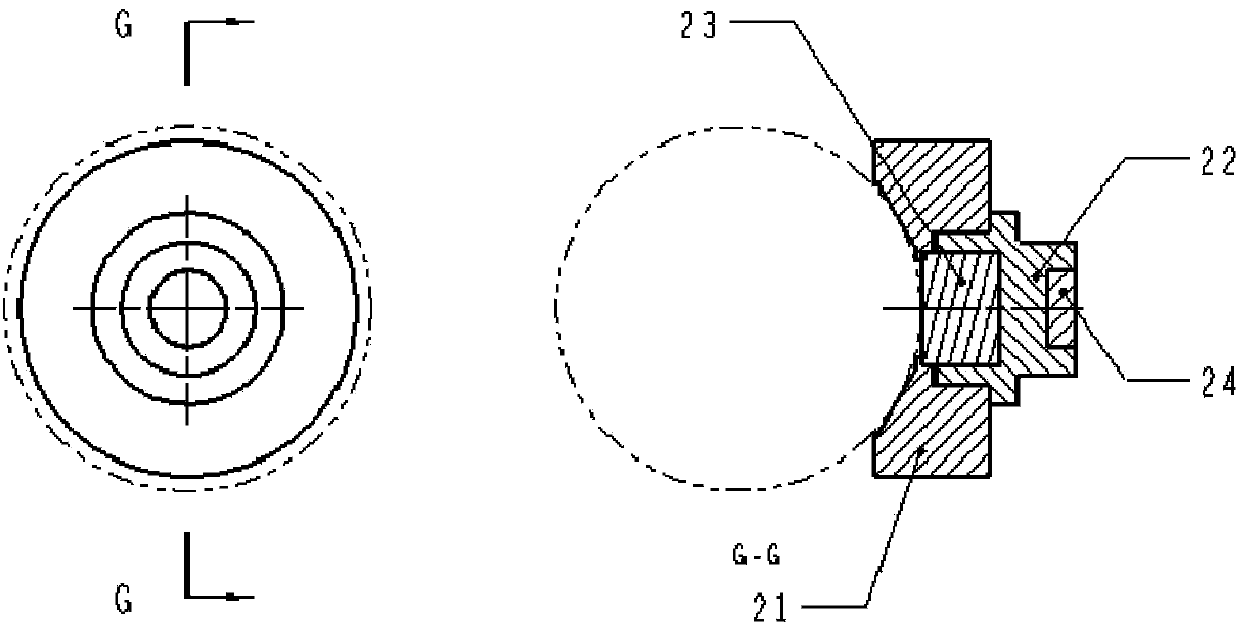

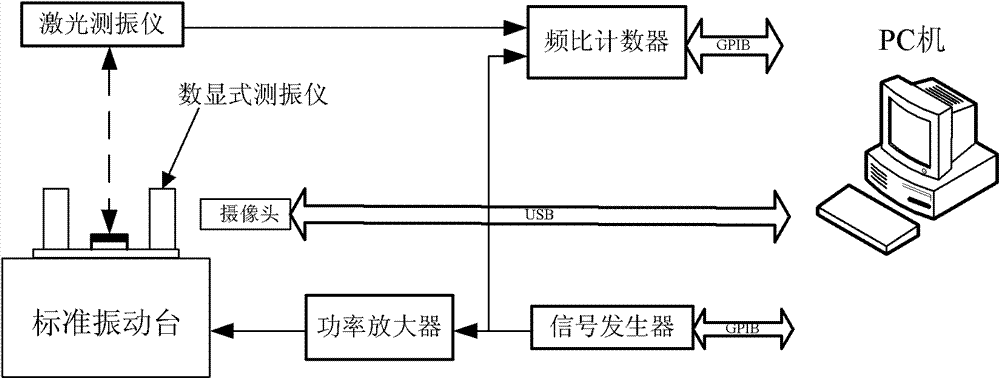

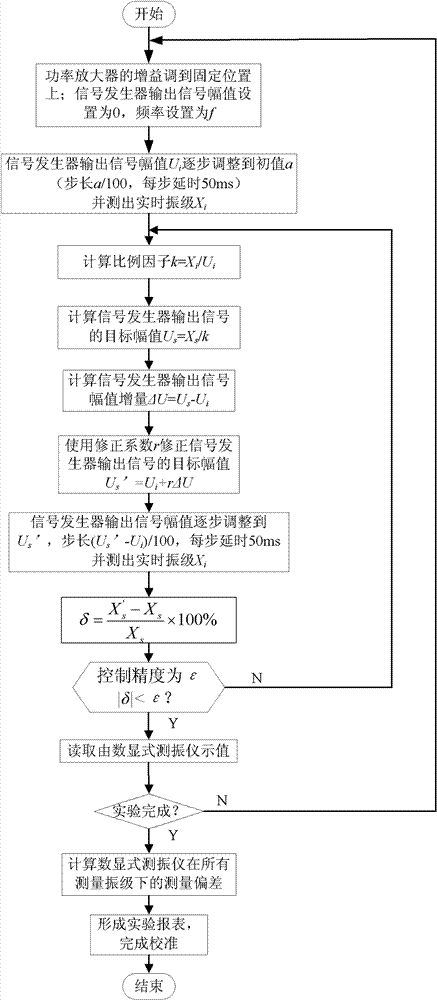

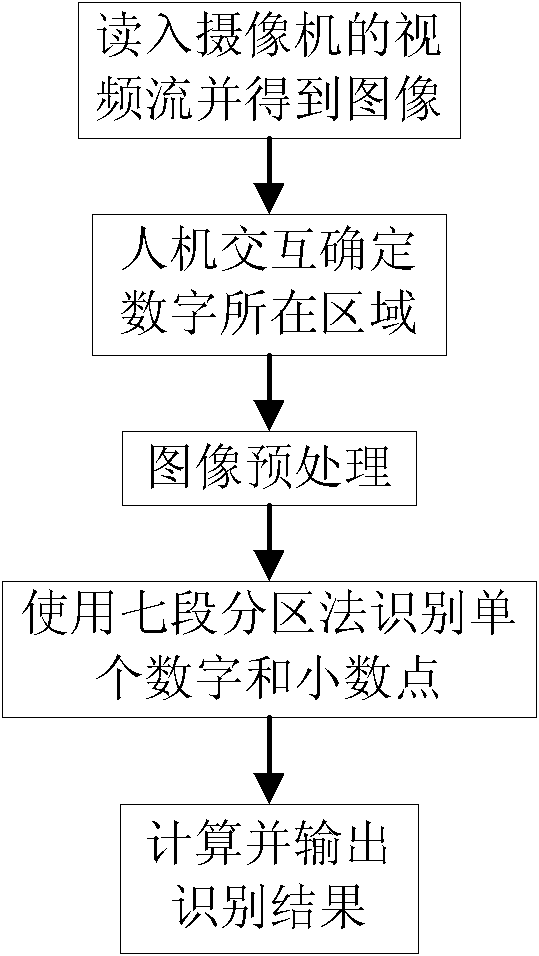

Automatic Calibration Device and Calibration Method for Digital Vibration Meter

ActiveCN102288278ASimplify calibration workCalibration Work IntelligenceSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansFrequency ratioSignal generator

The invention discloses an automatic calibrating device of a digital display type vibration measurer, which comprises a signal generator, a power amplifier, a standard vibration table, a camera, a laser vibration measurer, a frequency ratio counter and a processor. A digital display type vibration measurer to be calibrated is mounted on the standard vibration table. The automatic calibrating method comprises the following steps of: adjusting the gain of the power amplifier to a predetermined position; increasing the amplitude Ui of an output signal of the signal generator to an initial value to measure the real-time vibration level of the standard variation table; measuring the real-time vibration level of the vibration table; adjusting the deviation of the vibration level to be smaller than the control precision of the vibration level; reading the vibration level of the standard vibration table measured by the digital display type vibration measurer by adopting an image recognizing method; judging whether a test is completed or not; and generating a test report form. The calibrating device and the calibrating method have the advantages that the calibration work of the digital display type vibration measure becomes simple and intelligent; the calibration time is shortened greatly; and the labor intensity is also lightened greatly.

Owner:ZHEJIANG UNIV

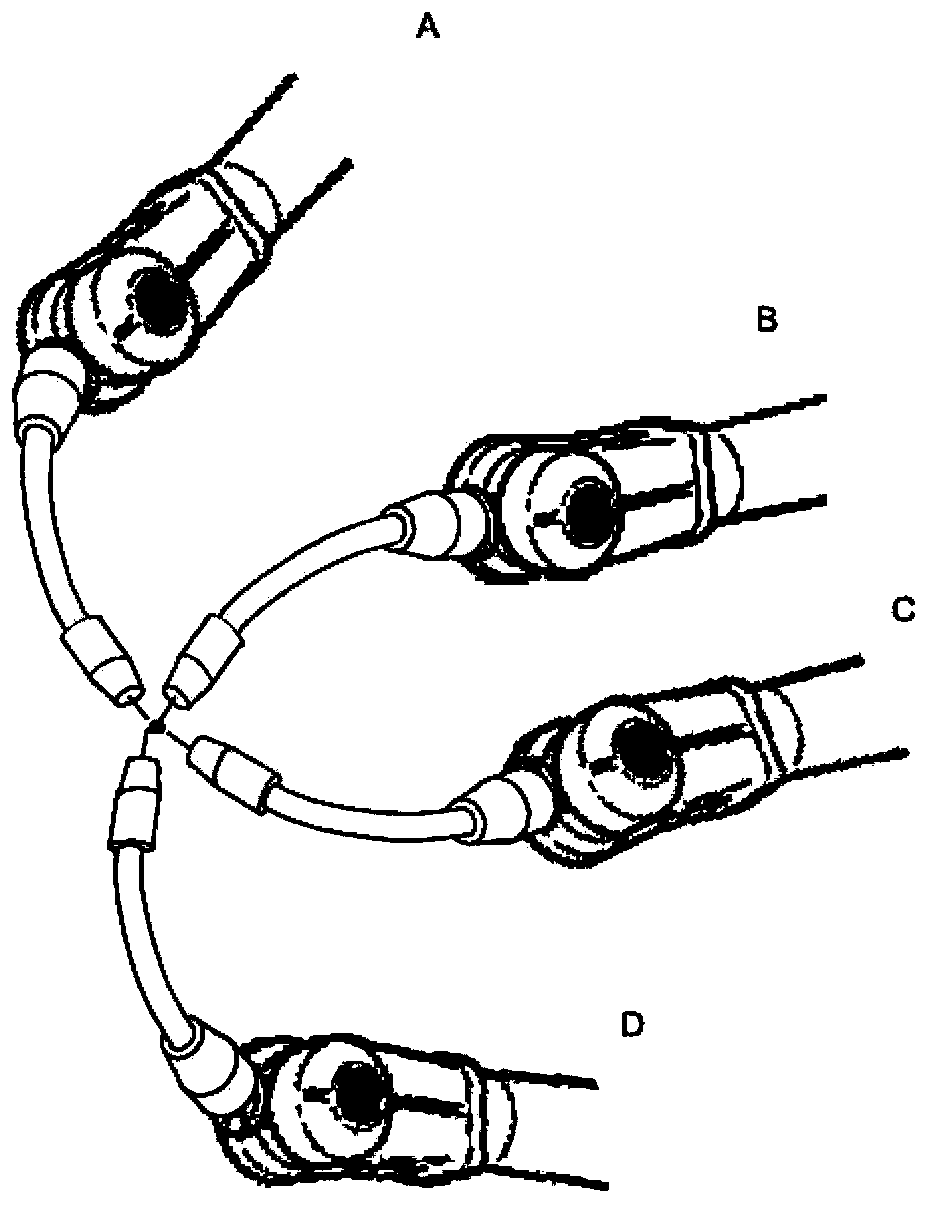

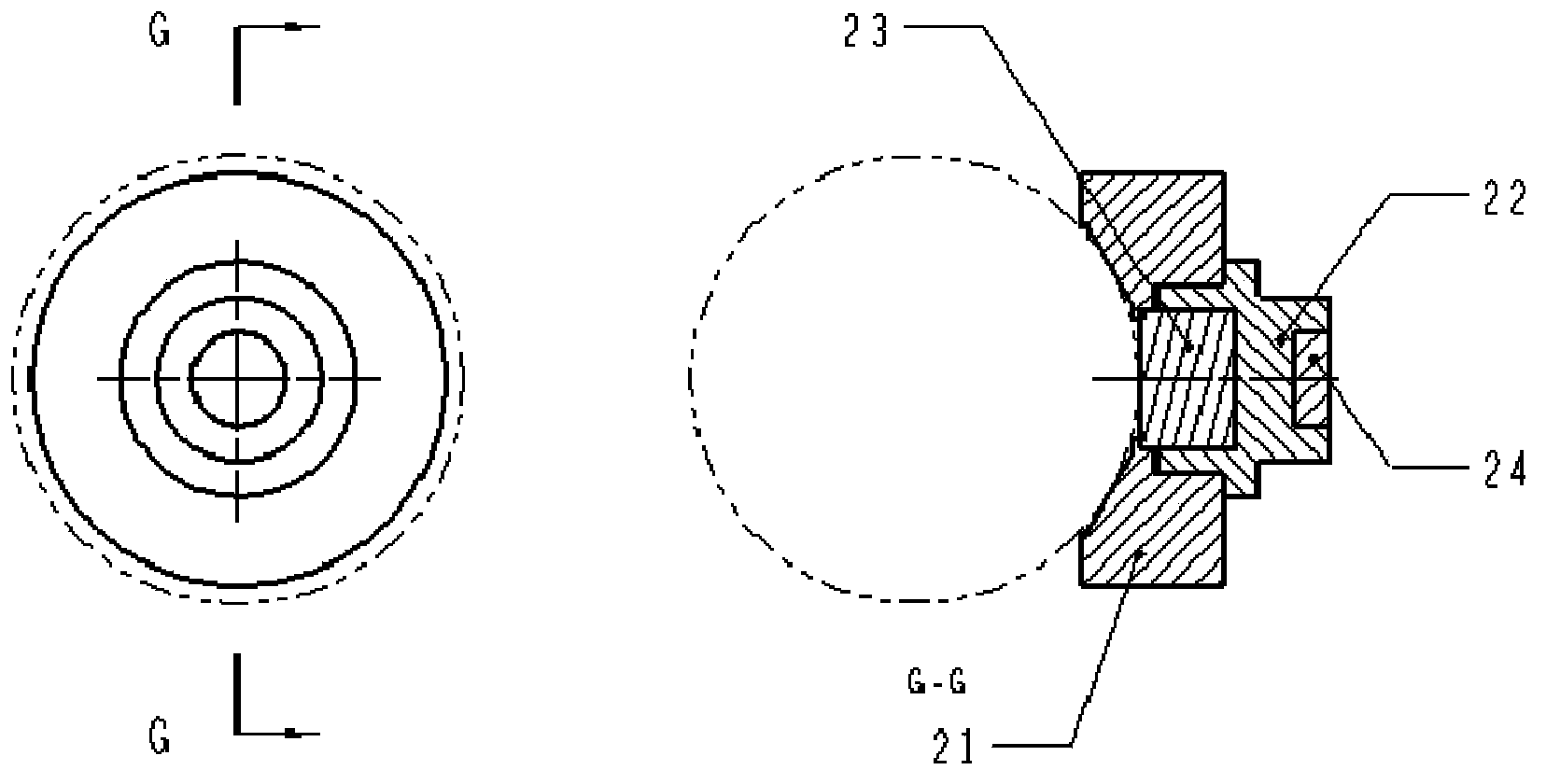

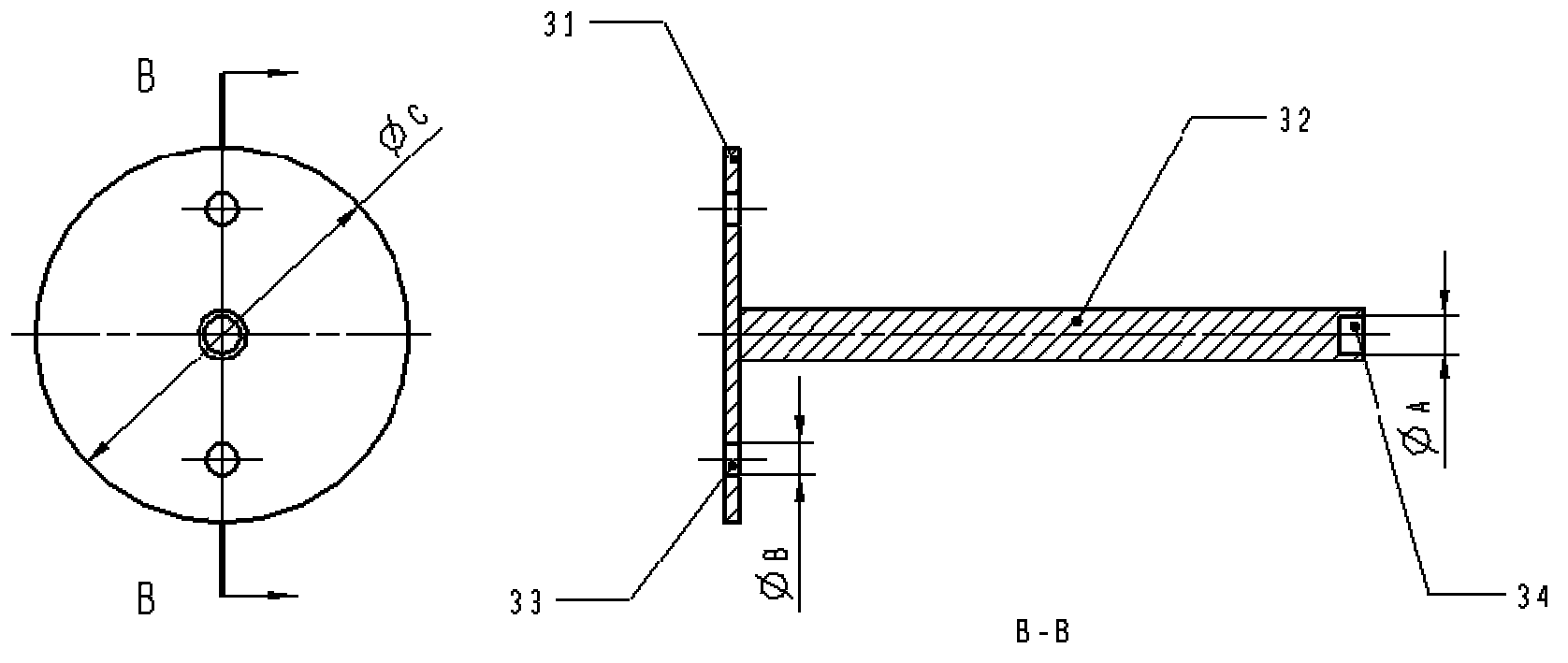

Non-contact high-precision calibration method of tool coordinate system of single robot

ActiveCN104165585AGuaranteed repeatabilityReduce mistakesUsing optical meansRobotic systemsContact high

The invention discloses a non-contact high-precision calibration method of a tool coordinate system of a single robot, comprising the following steps: first, calibrating a fundamental coordinate system of a robot; second, calibrating a workpiece coordinate system of the robot. The calibration employed by the invention is that a tool sleeve can perform a significantly complete calibration on the tool coordinate system of the robot. The calibration is that the tool sleeve can ensure repeatability of each operation, so as to furthest reduce errors generated by man-made calibration. The method provided by the invention, the non-contact high-precision calibration method of the fundamental coordinate system of the robot, and the non-contact high-precision calibration method of a tool coordinate system of the single robot are cooperated for application, so that basic technical basis is provided to realize accurate transformation of the robot pose, parameterization programming of the robot, high-precision coordination work of a robot group and pose transformation of the robot, resettlement of the robot system, multi-station program share of the robot and locus program of the robot and the like.

Owner:SHANGHAI MITSUBISHI ELEVATOR CO LTD

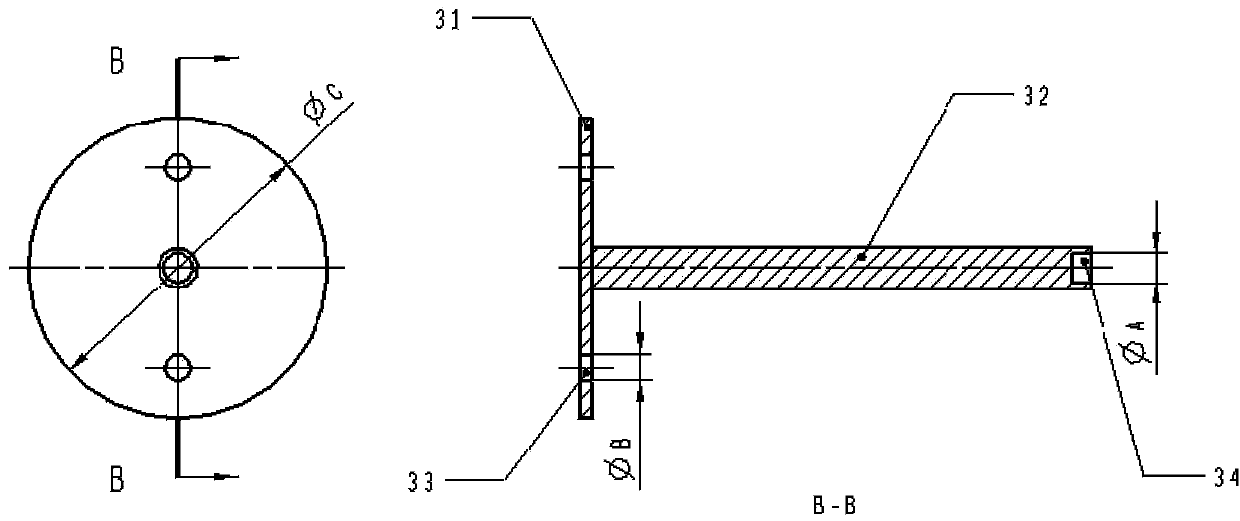

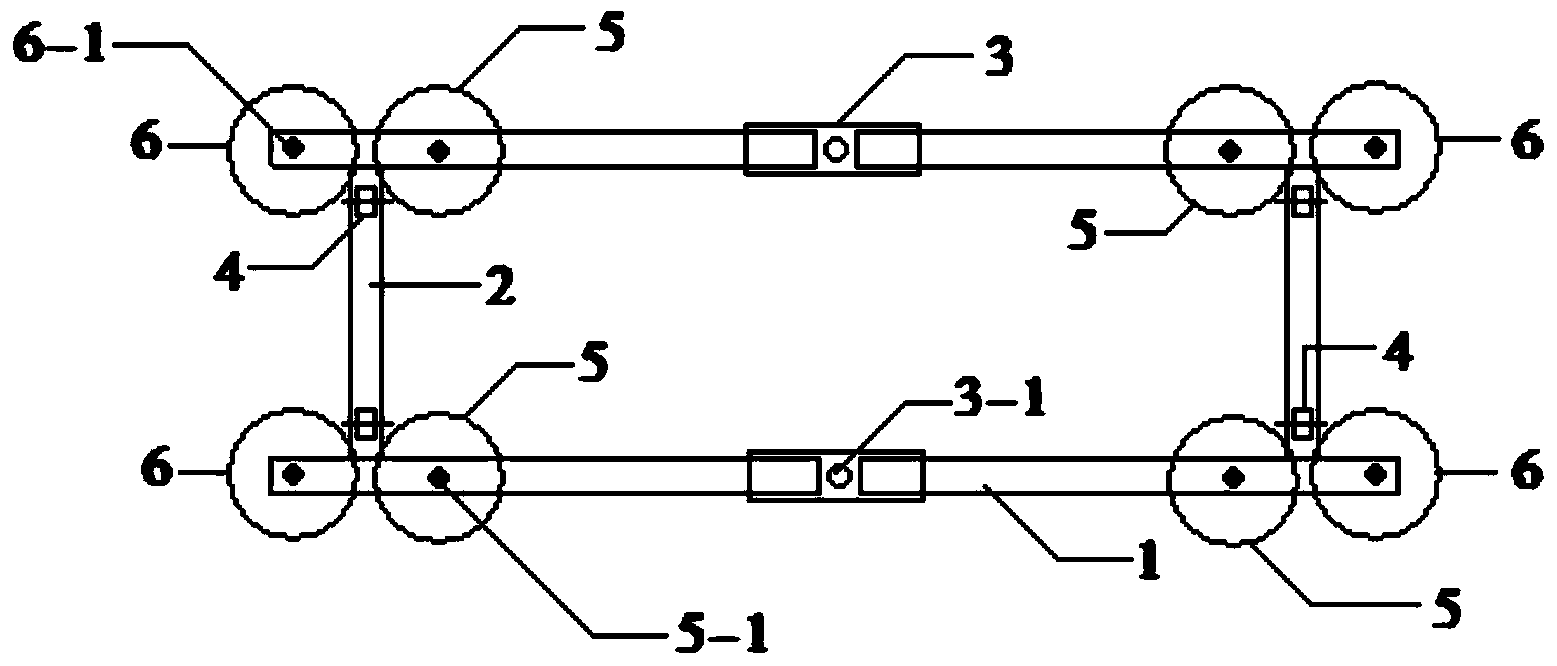

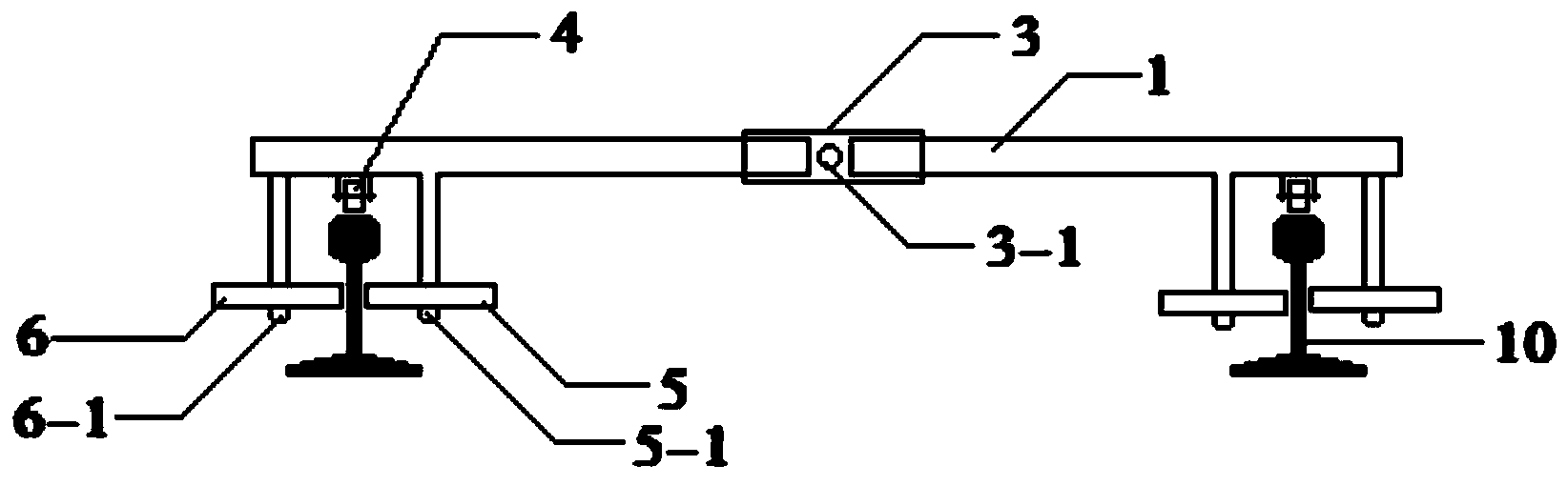

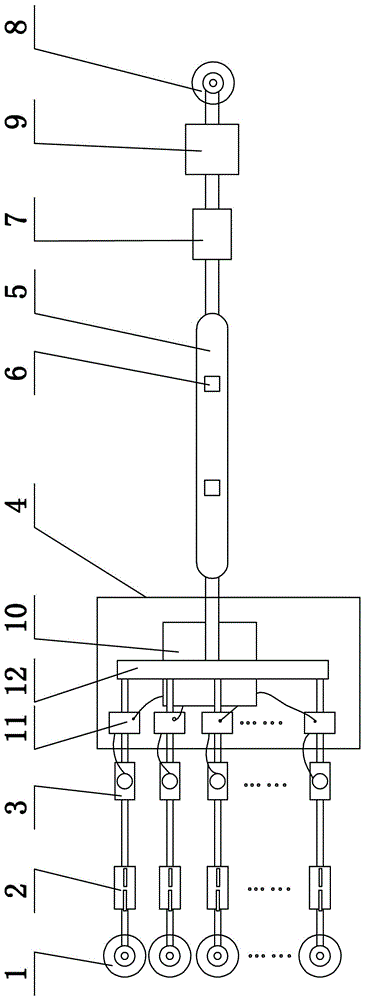

Track gauge correction method for double-block type ballastless track construction

ActiveCN103452018ACorrect installation errorsEasy to operateMeasuring apparatusControl theoryCorrection method

The invention discloses a track gauge correction method for double-block type ballastless track construction. The method comprises the following steps of: (1) manufacturing a track gauge correction device; (2) adjusting the track gauge accuracy of the track gauge correction device by using a tool track of a group of track panels; (3) correcting a track gauge in construction, properly loosening fastener screw spikes before the track panels are raised, inserting the track gauge correction device from the start end of the tool track to press four pairs of track gauge correction wheels against two sides of the track wrist of the tool track, arranging supporting traveling wheels on the track surface of the tool track, longitudinally moving the device along the tool track, arranging a sleeper between front and back track gauge correction wheels to enable the track gauge correction wheels to apply force to the tool track so as to realize track gauge correction, manually screwing the fastener screw spikes, and fixing a track gauge relationship between the tool track and the sleeper to complete the track gauge correction operation of the sleeper; (4) sequentially performing the track gauge correction operation, in the step (3), on all sleepers.

Owner:THE 2ND ENG CO LTD OF CHINA RAILWAY 17 BUREAU GRP

Non-contact high-precision calibration method and application of workpiece coordinate system of robot

ActiveCN104165586AGuaranteed repeatabilityReduce mistakesUsing optical meansContact highRobotic systems

The invention discloses a non-contact high-precision calibration method of a workpiece coordinate system of a single robot, comprising: first, calibrating a fundamental coordinate system of a robot; second, calibrating a workpiece coordinate system of the robot. The method provided by the invention, the non-contact high-precision calibration method of the fundamental coordinate system of the robot, and the non-contact high-precision calibration method of a tool coordinate system of the single robot employ a unified non-contact high-precision way, so that the precision of the whole system reaches a height that the calibration method in the prior art cannot touch. The calibration employed by the invention is that a tool sleeve can calibrate the workpiece coordinate system of the robot on an inclined surface. The calibration is that the tool sleeve can ensure repeatability of each operation, so as to furthest reduce errors generated by man-made calibration. The invention also discloses a method of making a robot system adapt a method of the change of the robot and the environment pose.

Owner:SHANGHAI MITSUBISHI ELEVATOR CO LTD

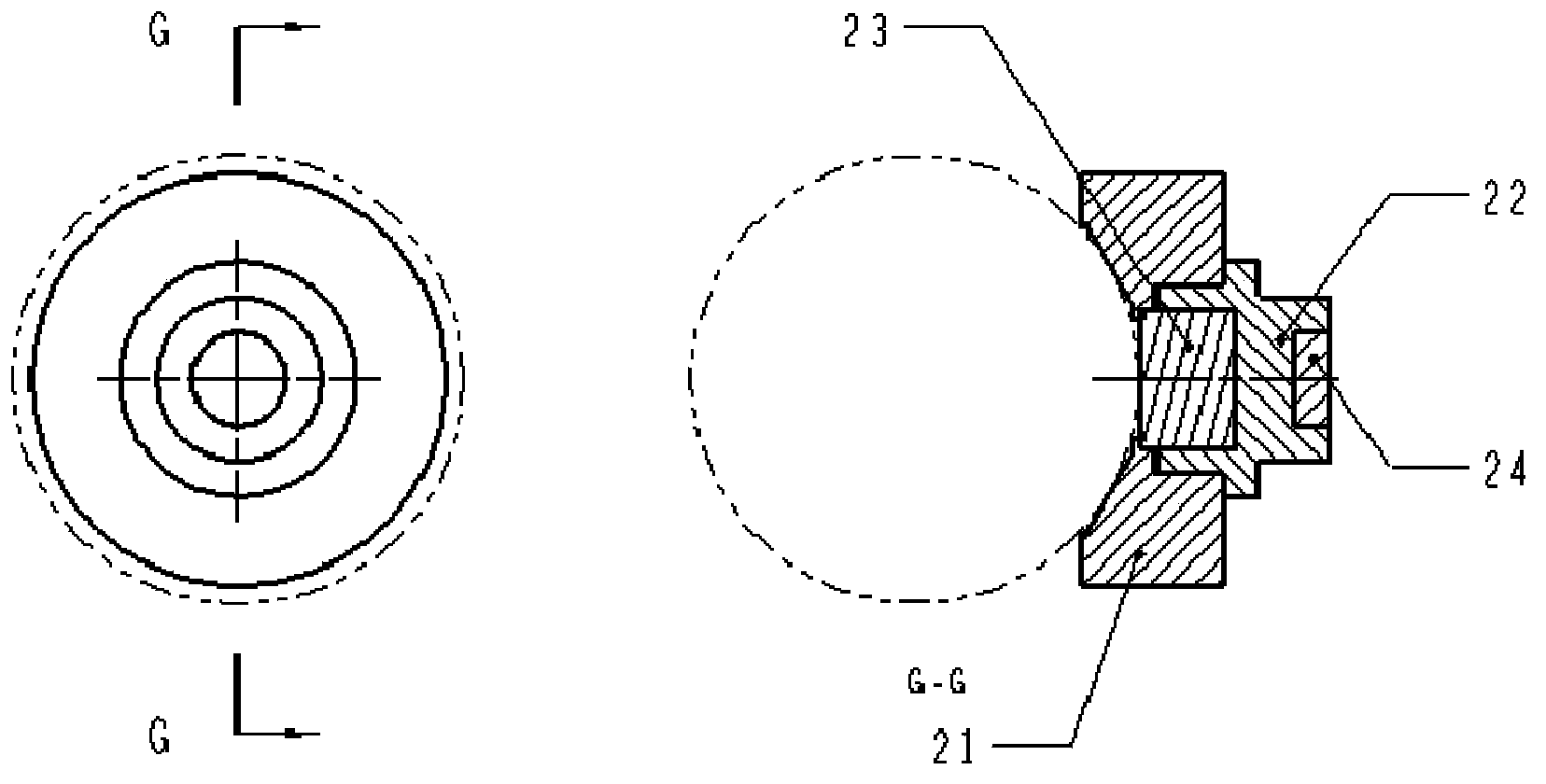

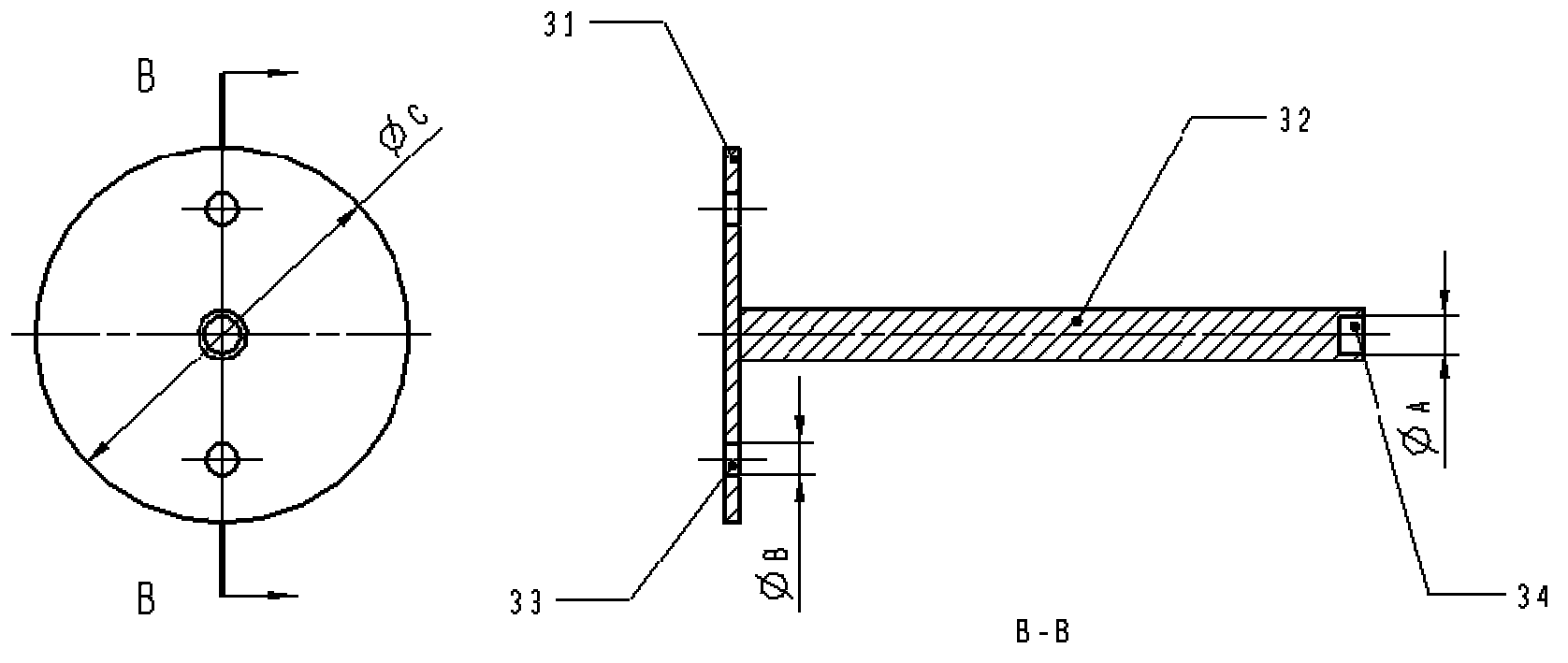

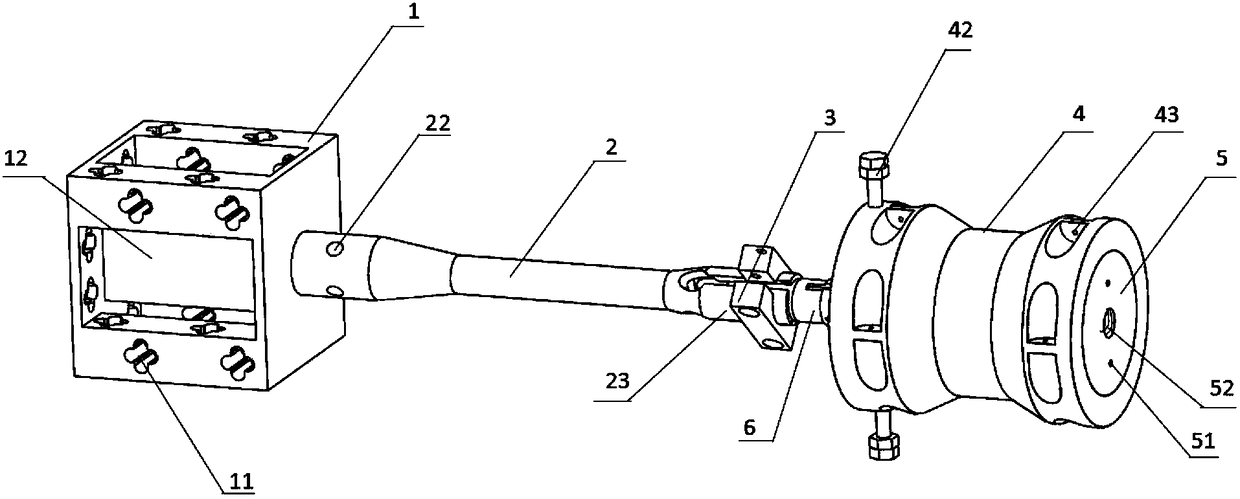

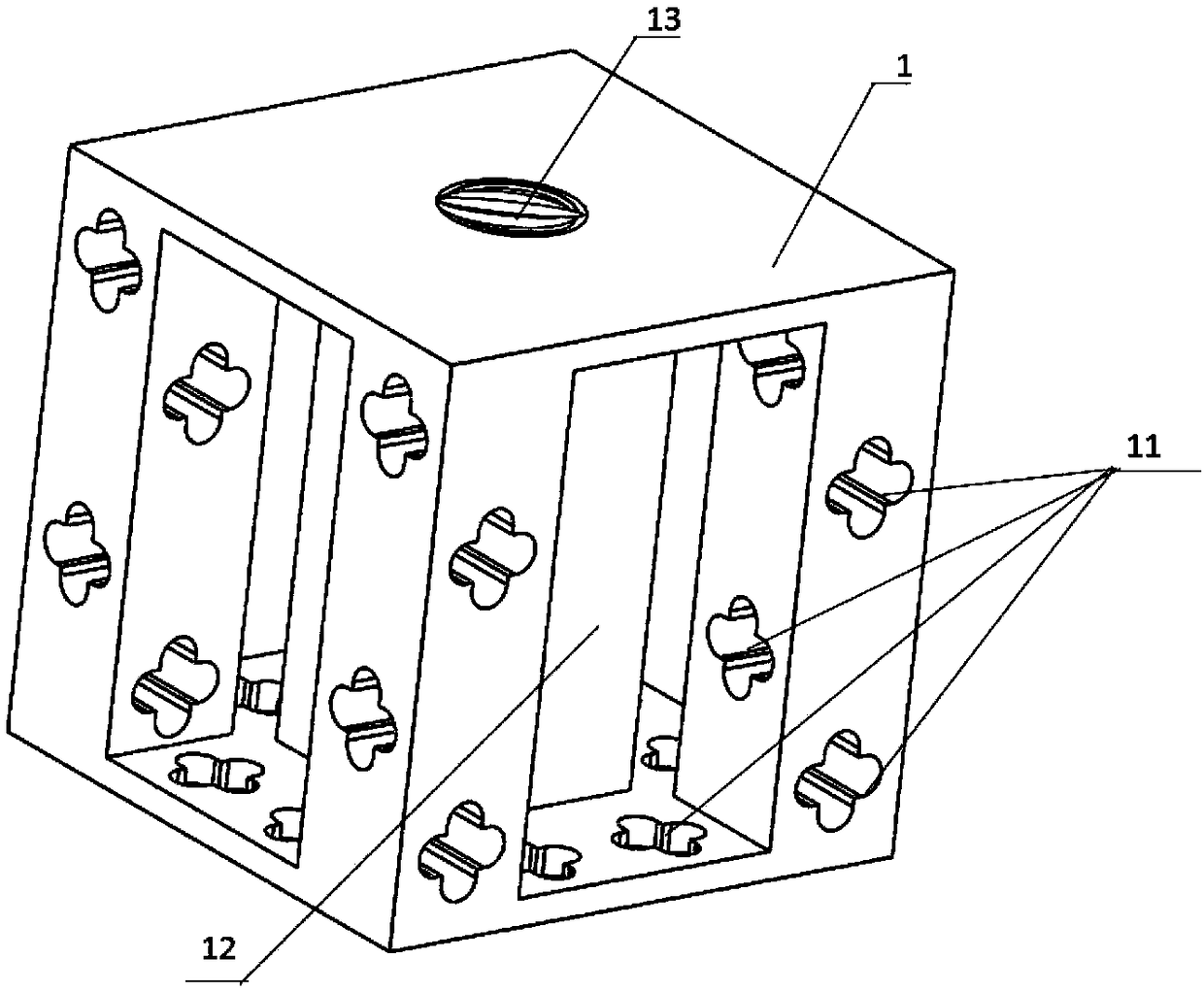

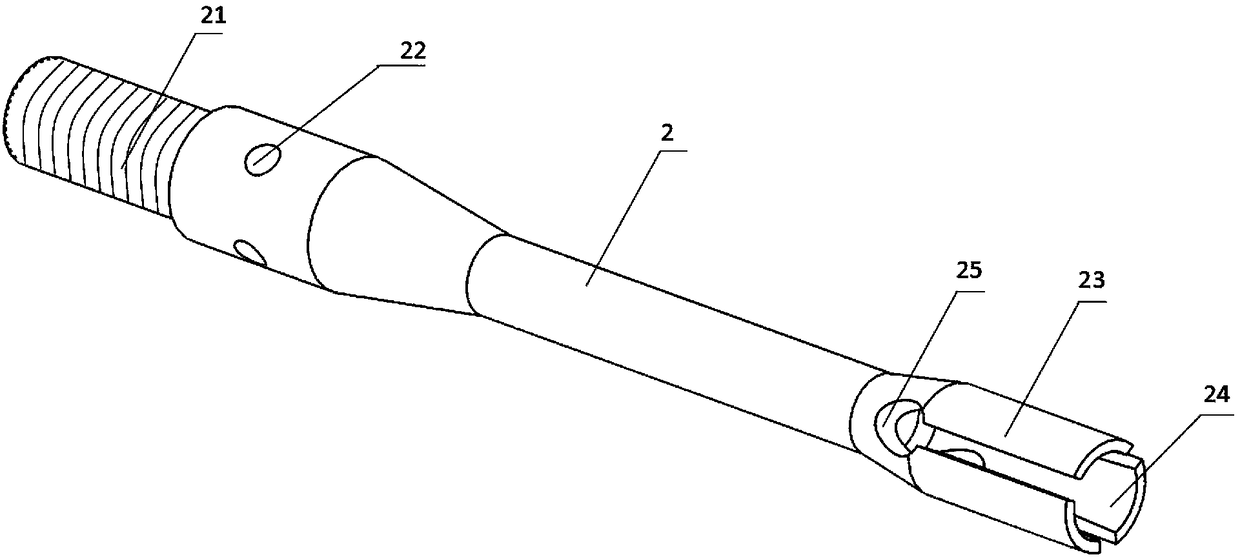

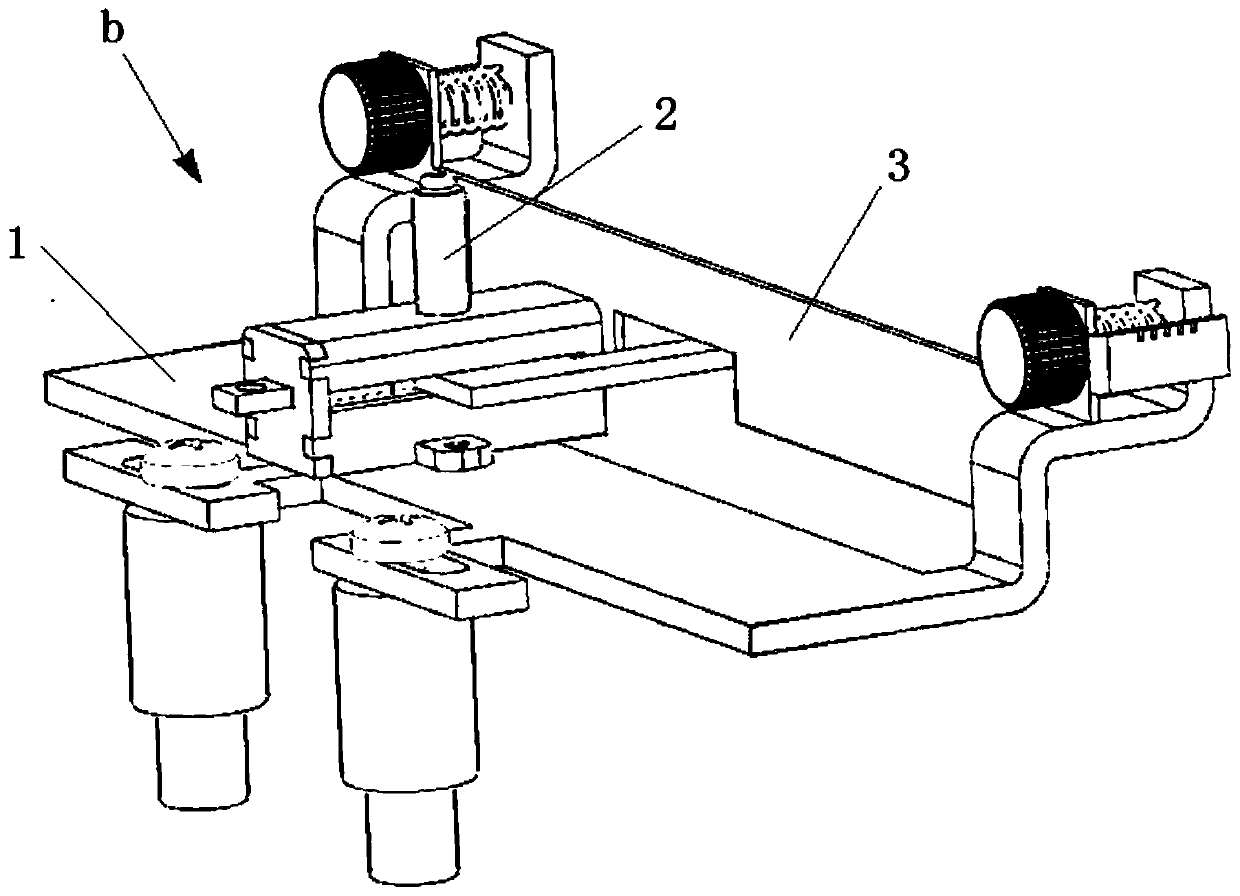

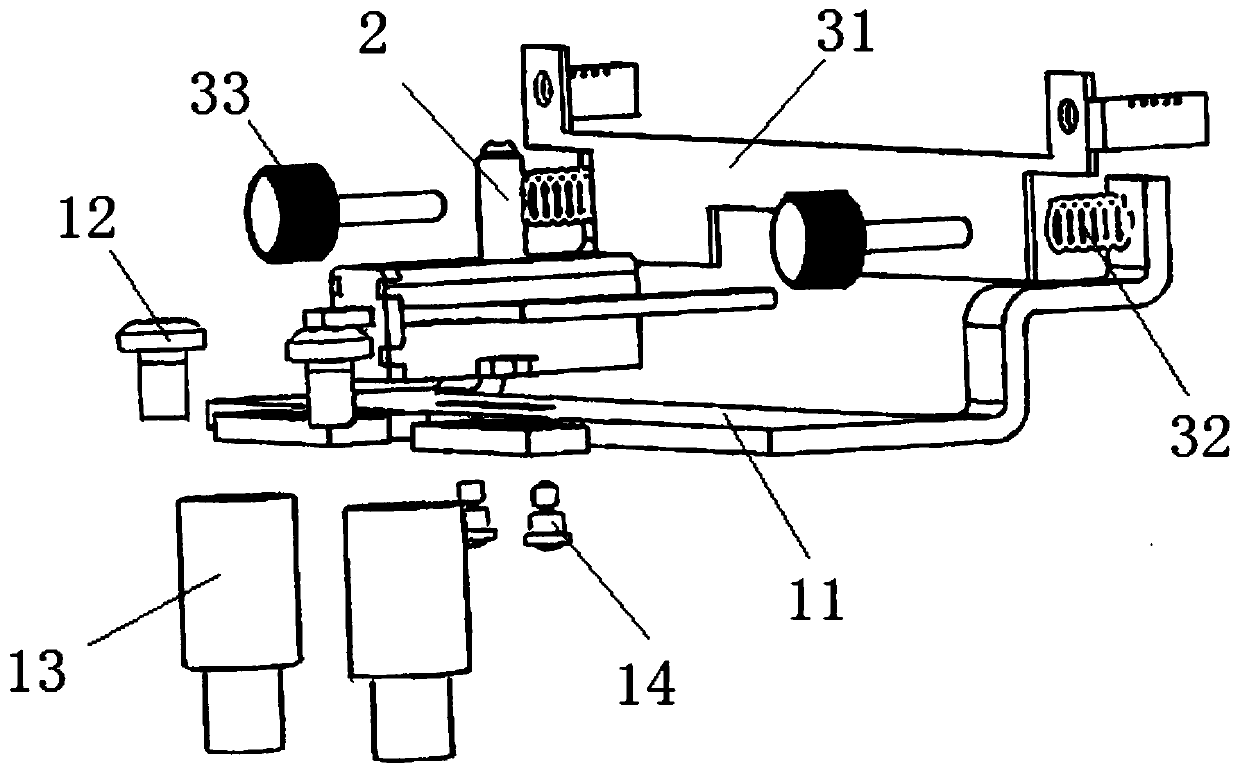

Simple loading calibration device for aerodynamic force measurement balance

PendingCN108254126ASimplify calibration workImprove placement efficiencyAerodynamic testingFluid pressure measurementRoll momentEngineering

The invention discloses a simple loading calibration device for an aerodynamic force measurement balance. The device comprises a base, a support rod, a clamping block, a loading sleeve and a core holder; after the whole device is assembled, different faces of the base are fixed to an optical table through screws, weights are loaded on corresponding mount points on the loading sleeve, and the function of conducting quantitative loading of axial force, normal force, yawing force, rolling moment and yawing moment on the balance is achieved. Accordingly, by designing the simple rod type strain balance loading calibration device, simple calibration work of the balance in the patching link is achieved, all strain bridge forms of the balance can be loaded effectively to inspect the patching quality, the balance patching efficiency is greatly improved, and then support is provided for carrying out an wind tunnel experiment as planned.

Owner:中国空气动力研究与发展中心超高速空气动力研究所

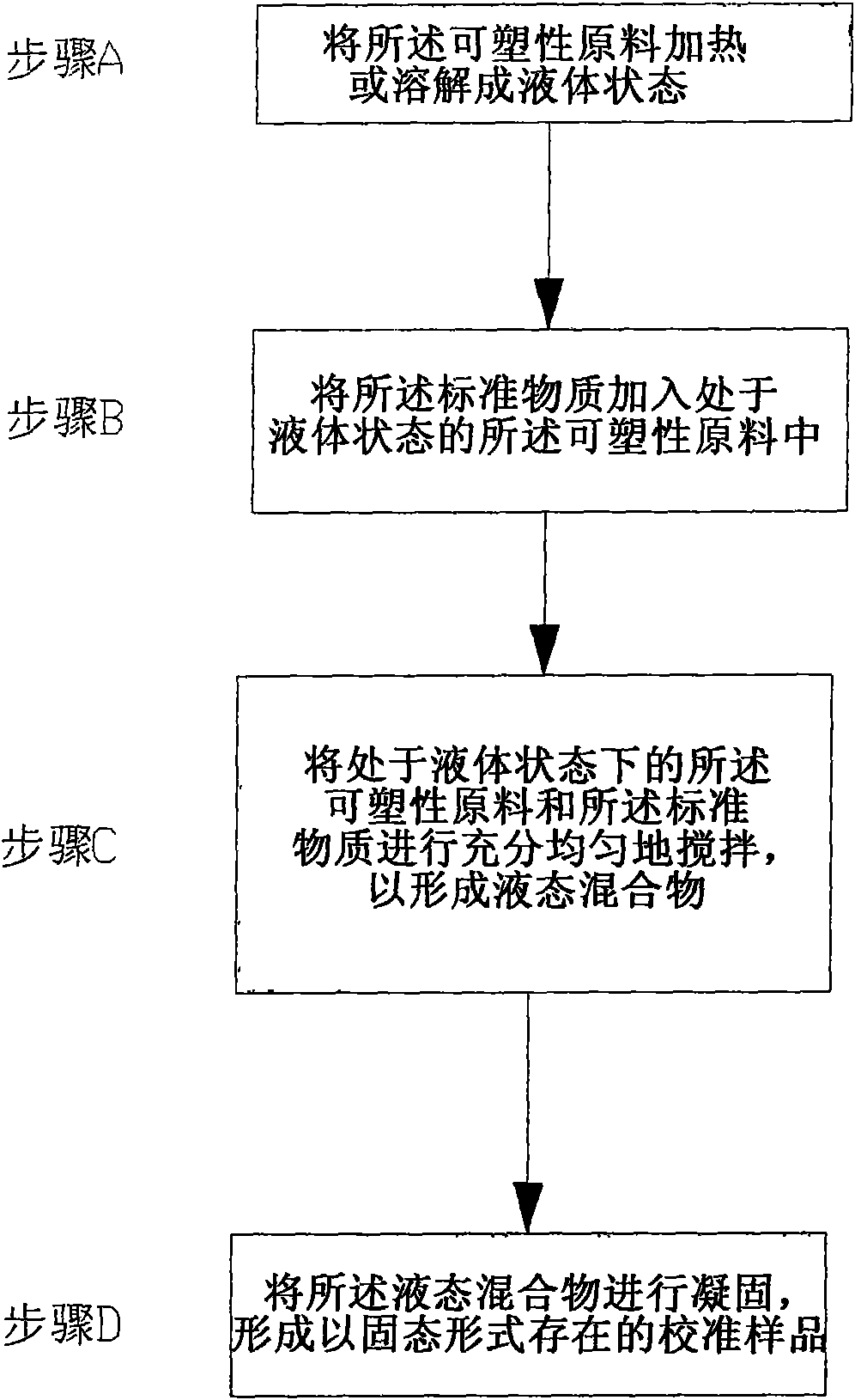

Calibration sample of ion mobility spectrometer as well as preparation method and use method thereof

ActiveCN101936947ASimplify calibration workAchieve preparationPreparing sample for investigationMaterial analysis by electric/magnetic meansLiquid stateIon-mobility spectrometry

The invention provides a calibration sample of an ion mobility spectrometer as well as a preparation method and a use method thereof. The preparation method comprises the following steps of: heating or dissolving a plastic raw material into a liquid state; then, adding a standard substance to the plastic raw material in the liquid state; fully and evenly stirring the plastic raw material in the liquid state and the standard substance to form a liquid mixture; and finally, solidifying the liquid mixture to form the calibration sample existing in a solid form. By adopting the technical scheme, the invention solves the technical problems of high preparation and use requirements, inconvenient storage and carrying, unsafety, environmental pollution, and the like due to the organic solution mode of the calibration sample used in the prior art, also simplifies the calibration work of the ion mobility spectrometer and saves time and labor.

Owner:NUCTECH CO LTD

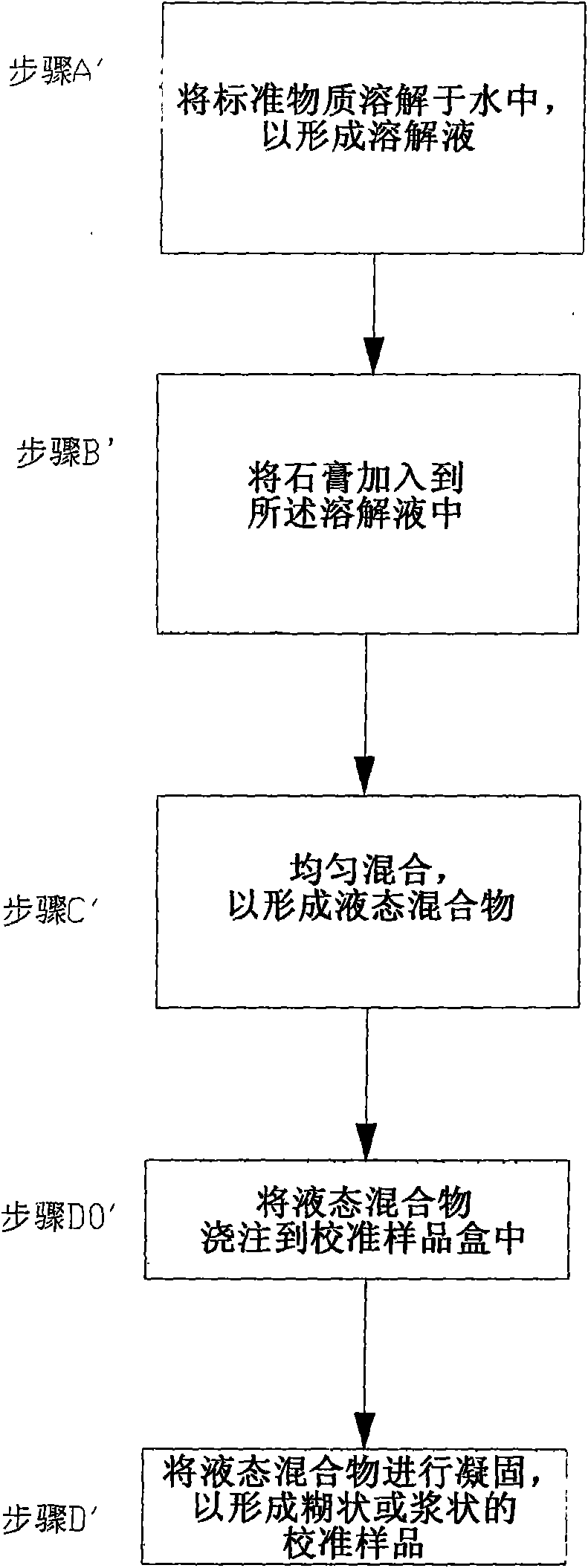

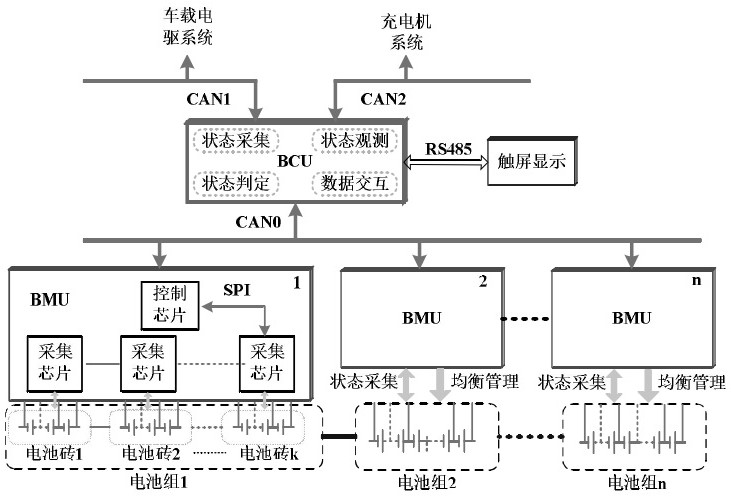

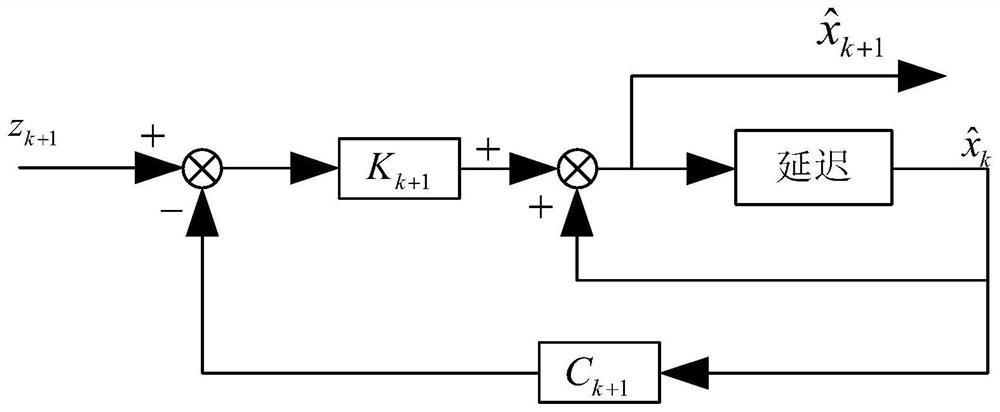

New energy automobile battery management system

ActiveCN109606200AAccurate SOC stateSimplify calibration workElectric powerSecondary cells servicing/maintenanceManagement unitEstimation methods

The invention relates to the technical field of a battery management system, in particular to a new energy automobile battery management system. The new energy automobile battery management system comprises a battery management unit and a battery control unit; the battery management unit is used for acquiring battery brick information and uploading the information to the battery control unit whichis communicated with the battery management unit; and the battery control unit receives the battery brick information uploaded by the battery management unit which is in communicating connection withthe battery control unit, and performs SOC estimation and balanced control operation. Equivalent parameters of the battery are estimated by a real-time on-line estimation method, so that the SOC state of a battery pack is estimated accurately. The calibration work of the battery is simplified through real-time on-line estimation. Accurate control on the battery pack state with low consistency isrealized. Through real-time on-line estimation, both the new battery and the aged battery can maintain high precision and high error correction capability.

Owner:江苏科达车业有限公司

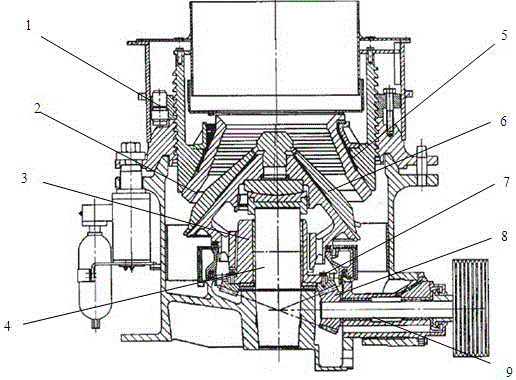

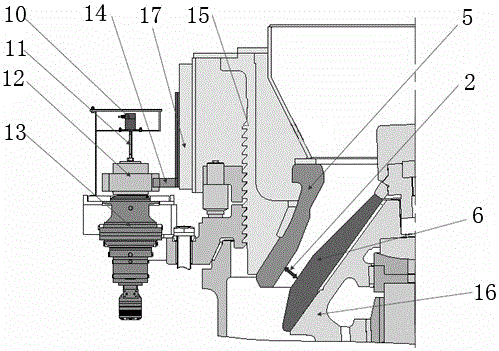

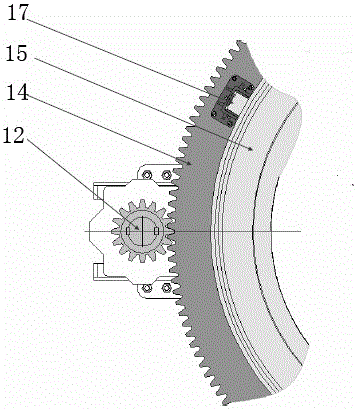

Control method used for discharge opening of cone crusher with multiple hydraulic cylinders

ActiveCN106216078ASimplify calibration workSimplifies adjustment workGrain treatmentsHydraulic cylinderCrusher

The invention discloses a control method used for a discharge opening of a cone crusher with multiple hydraulic cylinders. The method includes the steps of initial value setting, new lining plate calibration, discharge opening calibration and lining plate replacement. The discharge opening of the cone crusher with the multiple hydraulic cylinders can be accurately measured through an absolute value encoder, and the problems existing in a proximity switch pulse counting method are solved.

Owner:CITIC HEAVY INDUSTRIES CO LTD

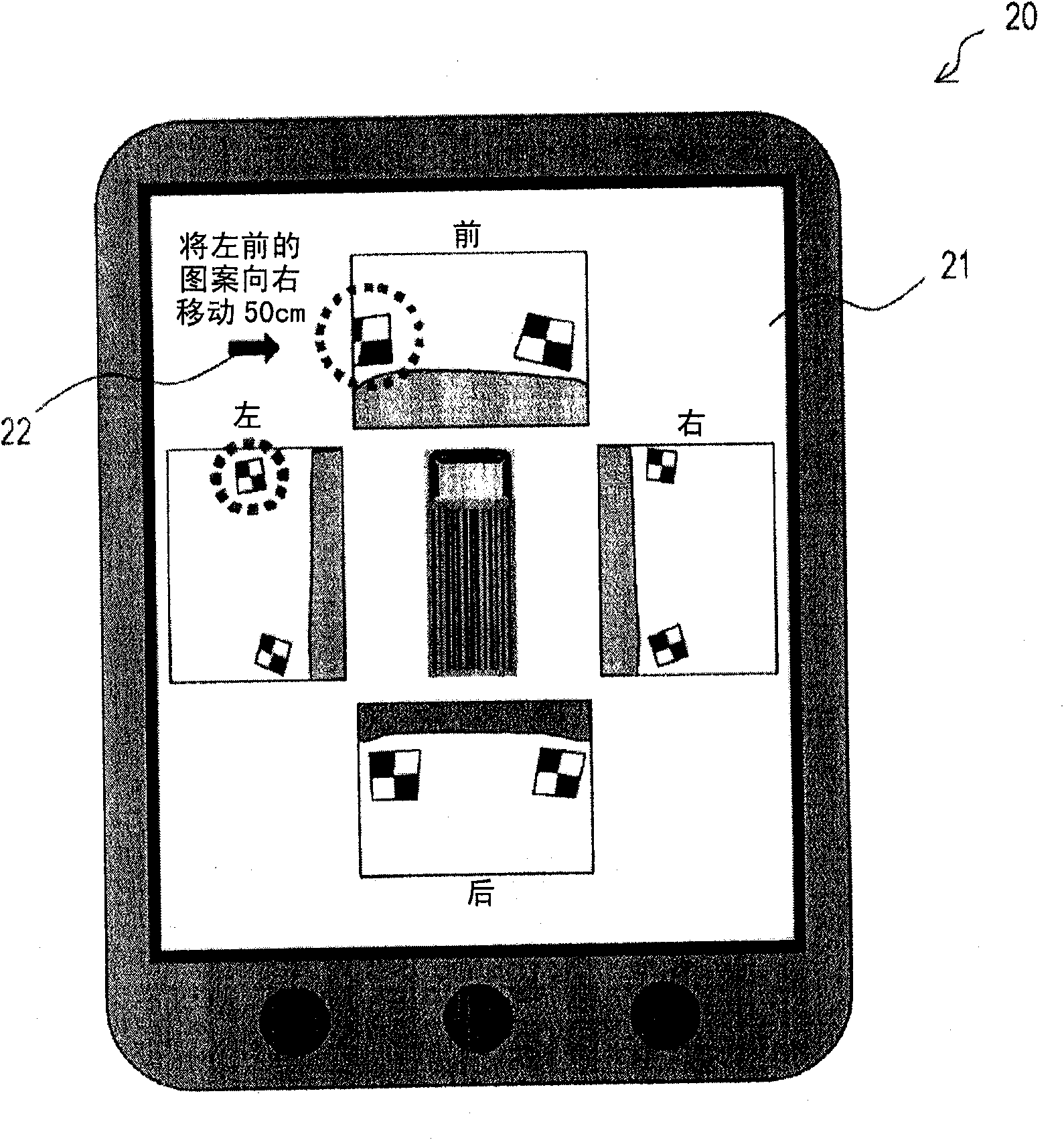

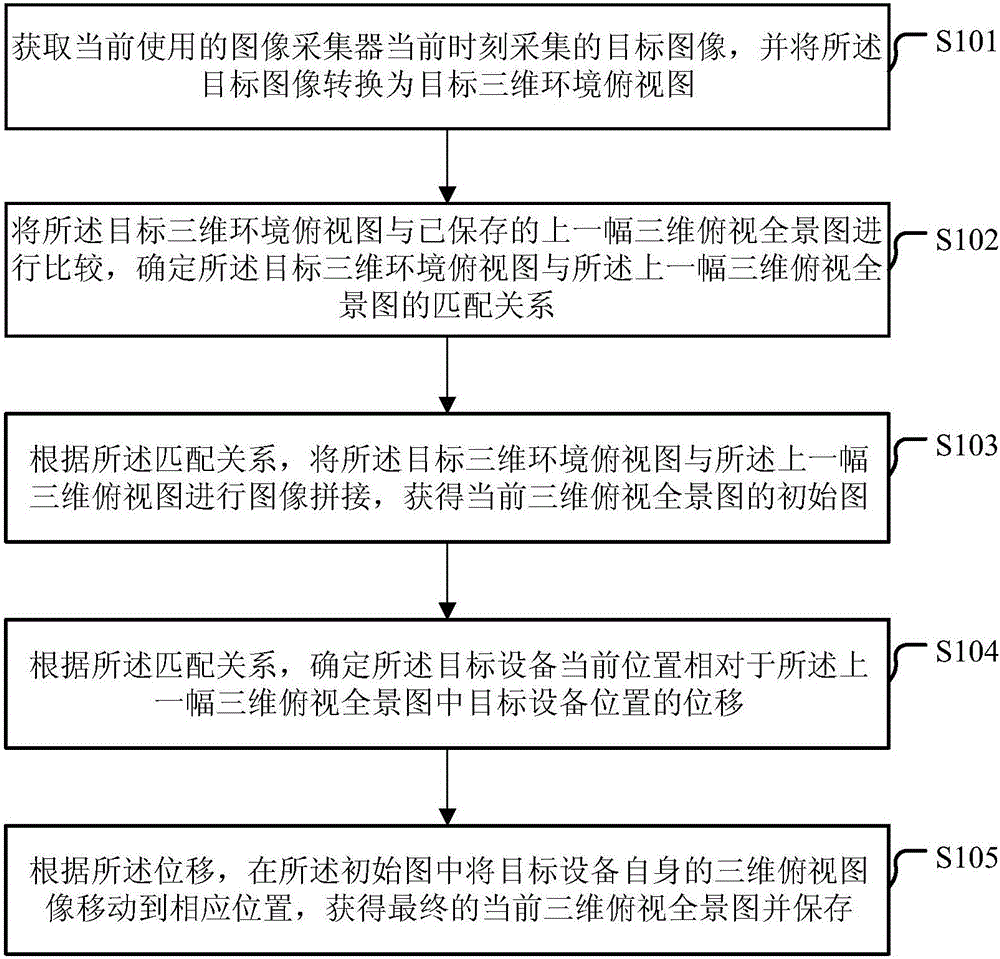

Method and apparatus for obtaining three-dimensional top-view panoramic image in device moving process

InactiveCN106846243ASimplify calibration workReduce installation costsGeometric image transformation3D modellingComputer visionPerformed Imaging

Embodiments of the invention disclose a method and an apparatus for obtaining a three-dimensional top-view panoramic image in a device moving process. The method comprises the steps of obtaining a target image collected at a current moment by a currently used image collector, and converting the target image into a target three-dimensional environment top-view image; comparing the target three-dimensional environment top-view image with a stored previous three-dimensional top-view panoramic image, and determining a matching relationship between the target three-dimensional environment top-view image with the stored previous three-dimensional top-view panoramic image; according to the matching relationship, performing image splicing on the target three-dimensional environment top-view image with the previous three-dimensional top-view image to obtain an initial image of the current three-dimensional top-view panoramic image; determining a displacement of a current position of a target device relative to the position of the target device in the previous three-dimensional top-view panoramic image; and according to the displacement, moving the three-dimensional top-view image of the target device to the corresponding position, obtaining a final current three-dimensional top-view panoramic image and performing storage. Only one image collector is required to collect the target image, so that the calibration work is simple and the installation cost is greatly reduced.

Owner:深圳中科龙智汽车科技有限公司

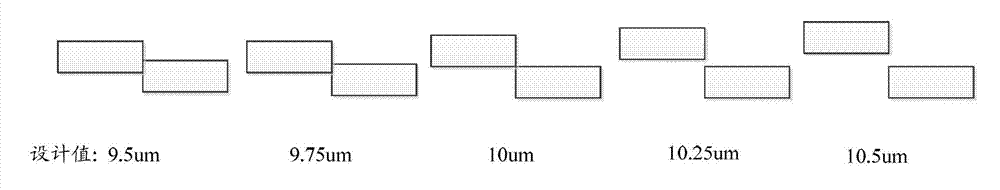

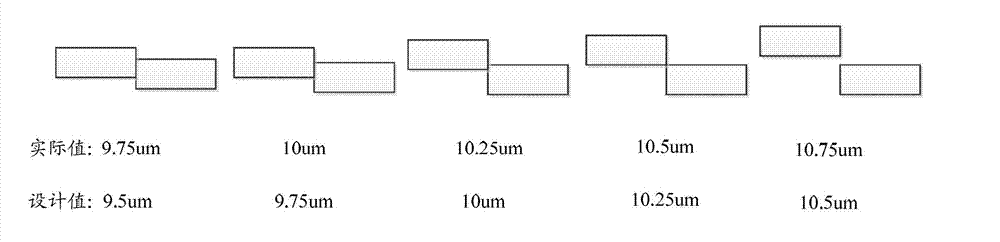

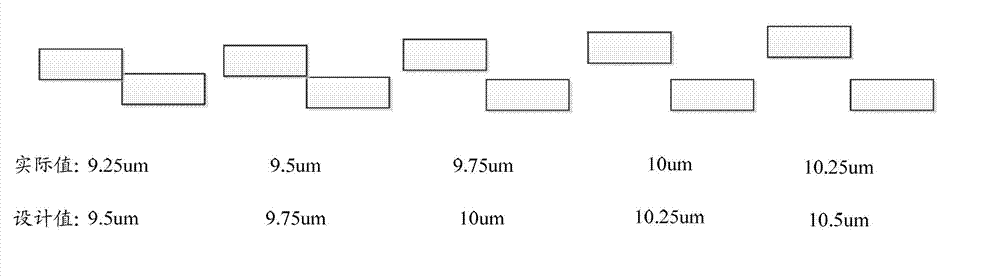

Calibration unit and method for critical dimension testing

InactiveCN103713471ASimplify calibration workGuaranteed Calibration AccuracyPhotomechanical exposure apparatusMicrolithography exposure apparatusCritical dimensionComputer science

The invention discloses a calibration unit and a method for critical dimension testing. At least a group of Marks are arranged on a Mask. The actual value of DICD is obtained by figures formed on a substrate after an etching process is performed by utilization of the Mask, accordingly, the CD testing results are calibrated. The unit and the method simplify calibration of the DICD testing value and guarantee the calibration precision.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

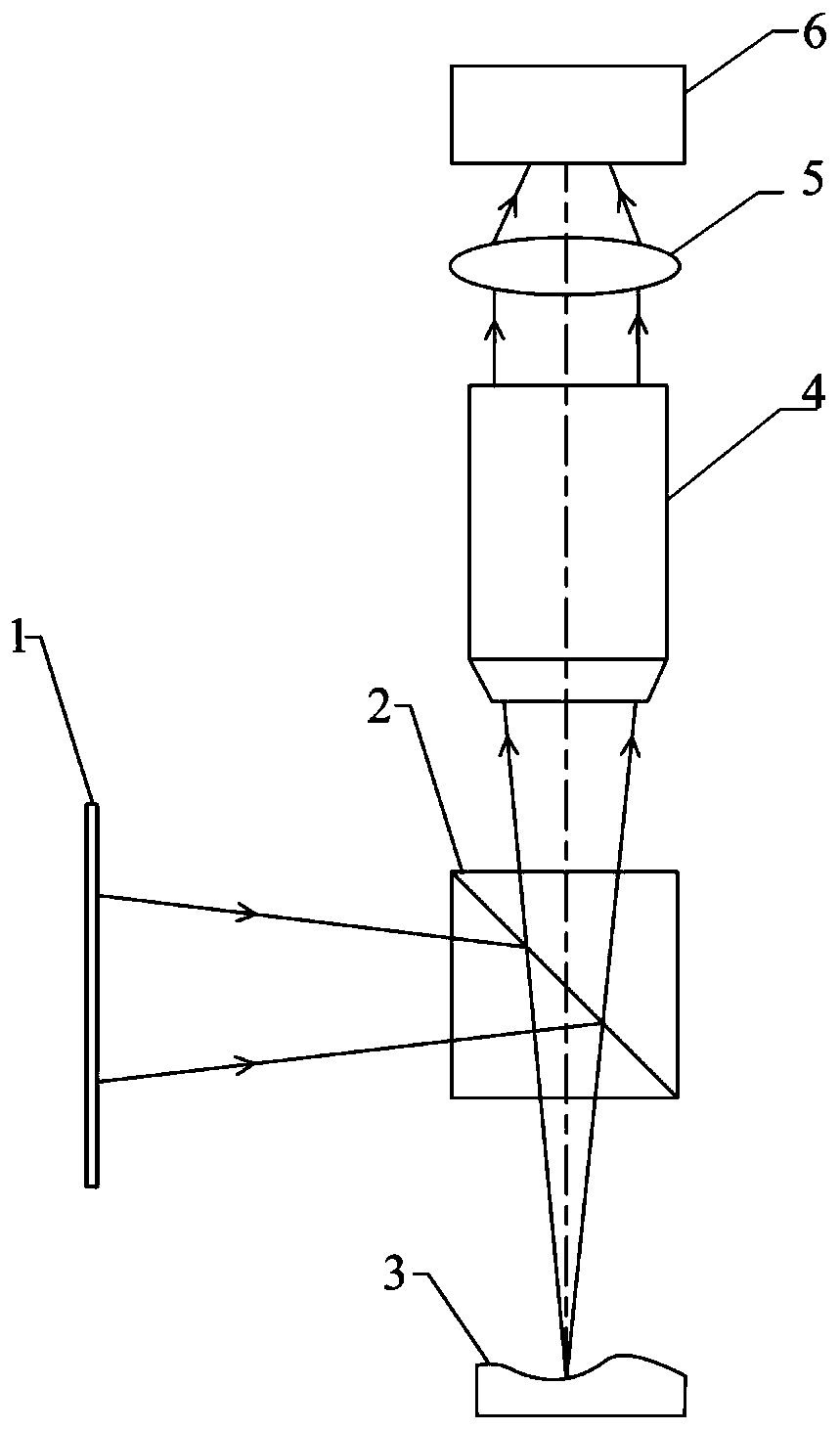

Optical deflection microscopic surface measuring device and method

ActiveCN110763159AImprove the problem of low spatial resolutionSimplify calibration workUsing optical meansHigh spatial resolutionLight spot

The invention discloses an optical deflection microscopic surface measuring method. The method comprises the following steps that a structural position parameter S of the optical deflection microscopic surface measuring device is measured and calibrated by adopting three-coordinate measuring equipment; phase distribution of a deformed fringe light signal is calculated according to the measured andcalibrated structural position parameter S, wherein the deformed fringe light signal comprises microscopic surface profile characteristic information of a to-be-measured element; actual light spot distribution corresponding to the microscopic surface of the to-be-measured element is acquired according to the phase distribution; and the actual light spot distribution is compared with preset ideallight spot distribution to obtain a microscopic surface profile of the to-be-measured element. Correspondingly, the invention further discloses an optical deflection microscopic surface measuring device. By means of the method and the device, the microscopic measurement technical scheme with the high precision, the low cost, the high spatial resolution and the high measurement speed is realized.

Owner:CHINA JILIANG UNIV

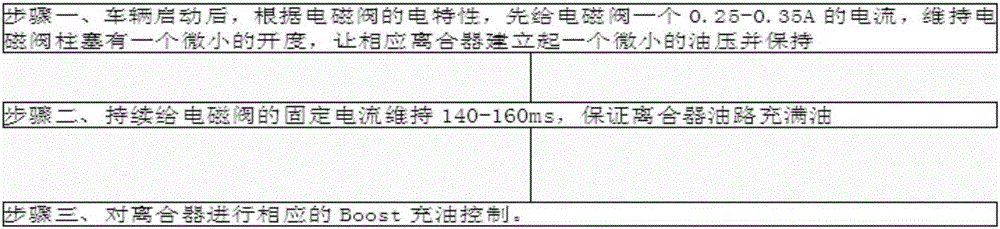

Oil charge control method for clutch in automatic transmission

InactiveCN105179680AGuaranteed accuracySimplify the control problemGearing controlAutomatic transmissionSolenoid valve

The invention discloses an oil charge control method for a clutch in automatic transmission, and relates to the technical field of control of automatic transmission. In order to solve the problems that an oil charge control method for a clutch in a current automatic transmission is not precise in control and great in working task load. The oil charge control method for the clutch in the automatic transmission comprises the following steps: step I, after a vehicle is started, applying current of 0.25-0.35A, according to electrical characteristics of a solenoid valve, to the solenoid valve, keeping a small aperture of a solenoid valve plunger piston, enabling the corresponding clutch to establish small oil pressure and keeping the small oil pressure; step II, continuously keeping fixed current of the solenoid valve for 140-160 seconds, and guaranteeing that a clutch oil path is filled up with oil; and step III, carrying out corresponding Boost oil charge control on the clutch. According to the oil charge control method, software control and calibration work is simplified, and oil charge control accuracy of the clutch is also guaranteed.

Owner:HARBIN DONGAN AUTOMOTIVE ENGINE MFG CO LTD

Gas analyzer calibration device

ActiveCN104267154BAvoid wastingSimplify calibration workMaterial analysisGas analysisProcess engineering

The invention relates to a gas analyzer calibration device, comprising a standard gas source, the standard gas source is connected to the air inlet of a gas distribution device through a pipeline, the gas outlet of the gas distribution device is connected to the gas box inlet through a pipeline, and the gas distribution device is a gas analysis device. The instrument calibration provides different concentrations and different types of standard gases. The gas box outlet is connected to the pump inlet through a pipeline, the pump outlet is connected to the gas analyzer to be calibrated, and the gas analyzer outlet is connected to the residual gas recovery device. breath. The invention can automatically configure multiple standard gases of different types and concentrations, and the metering department does not need to purchase a large number of standard gases of different concentrations and types, so that the calibration of the gas analyzer becomes easy, the calibration speed is fast, and the accuracy rate is improved. The operation is simple, and the residual gas recovery device is installed to avoid leakage, thereby avoiding gas waste, cost saving, no pollution to the environment, and no threat to the health of calibration personnel.

Owner:HENAN PROVINCE INST OF METROLOGY

A new energy vehicle battery management system

ActiveCN109606200BAccurate SOC stateSimplify calibration workElectric powerElectric vehicle charging technologyAutomotive batteryNew energy

Owner:江苏科达车业有限公司

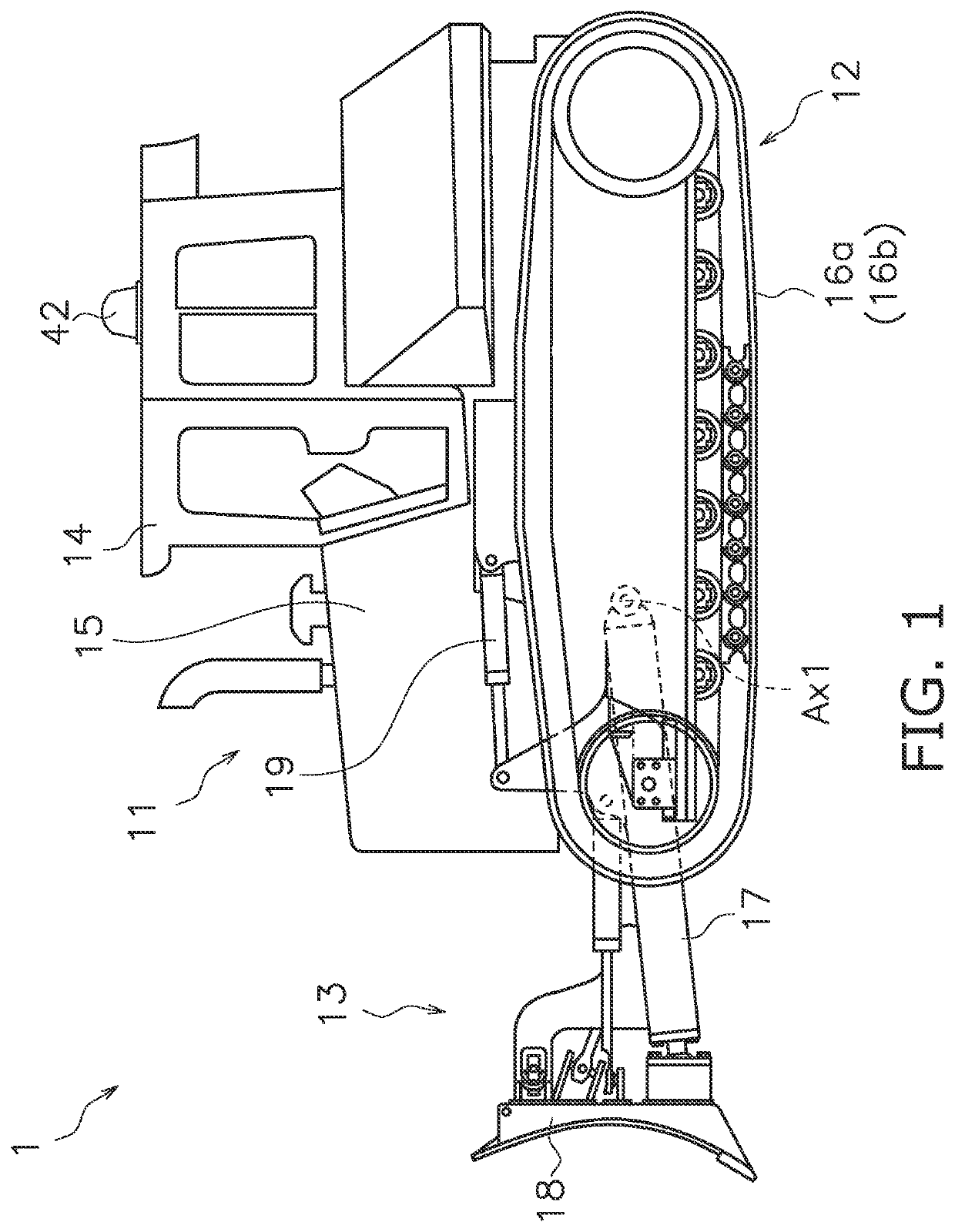

System, method and device for calibrating work machine

PendingUS20220081879A1Reduce in quantitySimplify calibration workSoil-shifting machines/dredgersControl engineeringData calibration

A work machine includes a vehicle body and a work implement attached to the vehicle body. A system calibrates the work machine by using an external measurement apparatus. The system includes an attitude sensor, a positional sensor attached to the vehicle body, a storage device, an input device and a processor. The attitude sensor outputs attitude data indicative of an attitude of the vehicle body. The storage device stores machine data indicative of a position of the positional sensor in a vehicle body coordinate system. The input device receives an input of calibration data including a position of a predetermined measurement point on the work machine measured by the external measurement apparatus, and a position of the positional sensor measured by the external measurement apparatus. The processor calibrates the machine data based on the calibration data and the attitude data.

Owner:KOMATSU LTD

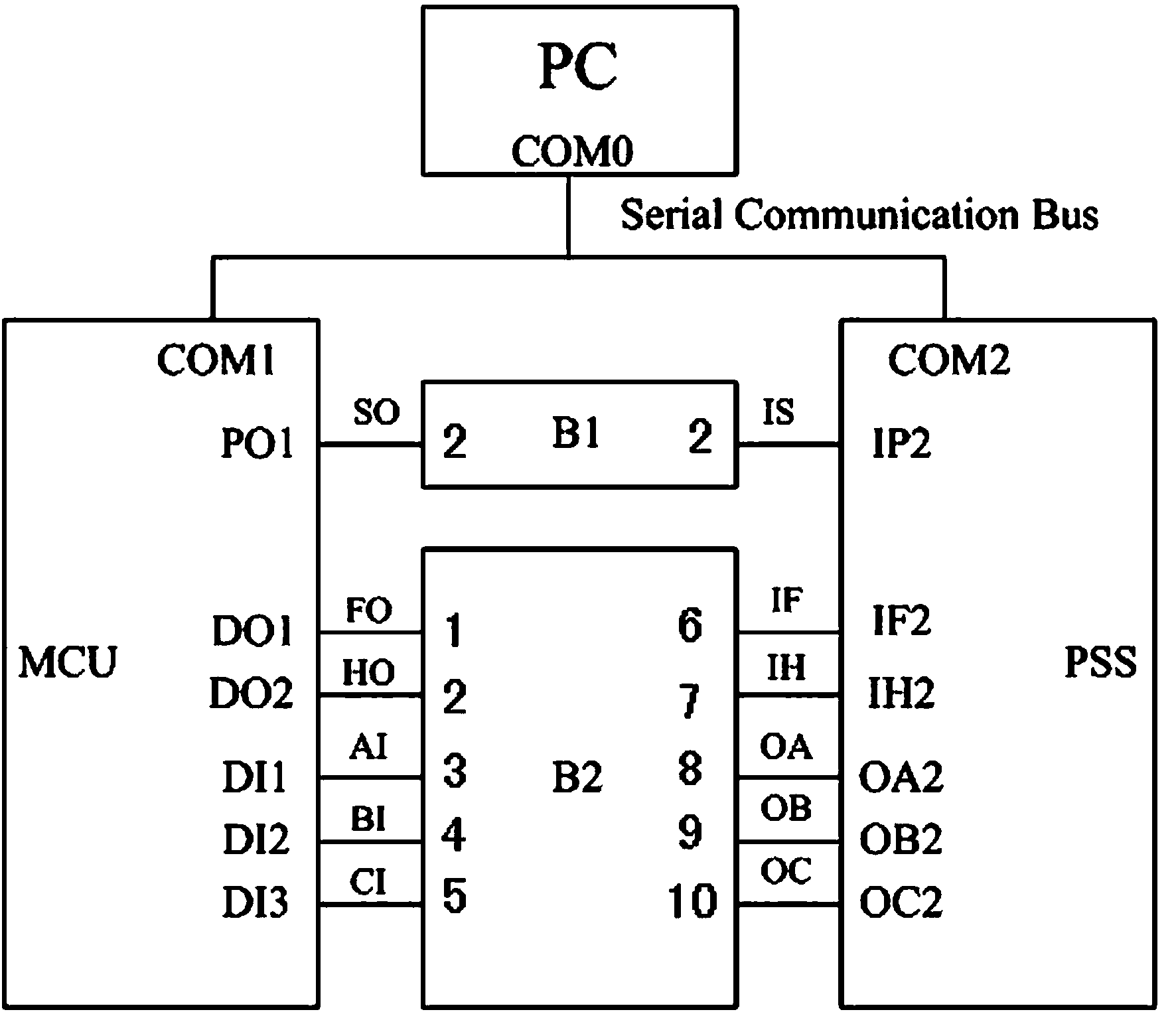

Phase selection switch verifying device and phase selection switch verifying method

ActiveCN103424689ASimplify calibration workNo need for manual cumbersome operationsCircuit interrupters testingMicrocomputerMicrocontroller

The invention discloses a phase selection switch verifying device and a phase selection switch verifying method. The phase selection switch verifying device comprises a single chip microcomputer MCU, a smoothing and isolating changing circuit B1, an isolating circuit B2, an upper computer PC, a three-phase selection switch PSS, a serial communication interface of the single chip microcomputer MCU is connected with a serial communication interface of the three-phase selection switch PSS and a serial communication interface of the upper computer PC. A PO1 interface of the single chip microcomputer MCU is connected with an SO signal input interface of the smoothing and isolating changing circuit B1, an IS signal output interface of the smoothing and isolating changing circuit B1 is connected with an IP2 interface of the three-phase selection switch PSS, and D01, D02, D11, D12 and D13 interfaces of the single chip microcomputer MCU are respectively connected with corresponding interfaces of the isolating circuit B2. The method is used for manufacturing the special device for automatic verification, complex manual operation is not needed, therefore, man-made mistakes are avoided, and the verifying efficiency is improved.

Owner:江苏绿谊静风机设备有限公司

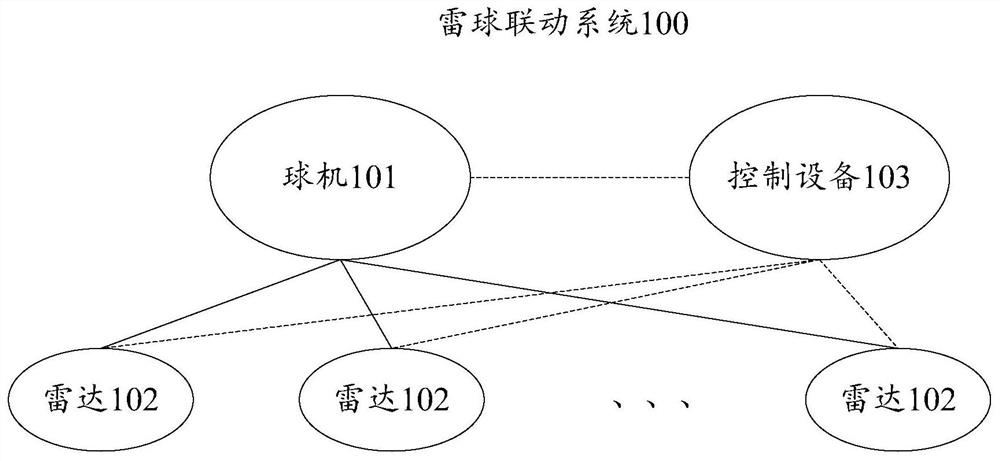

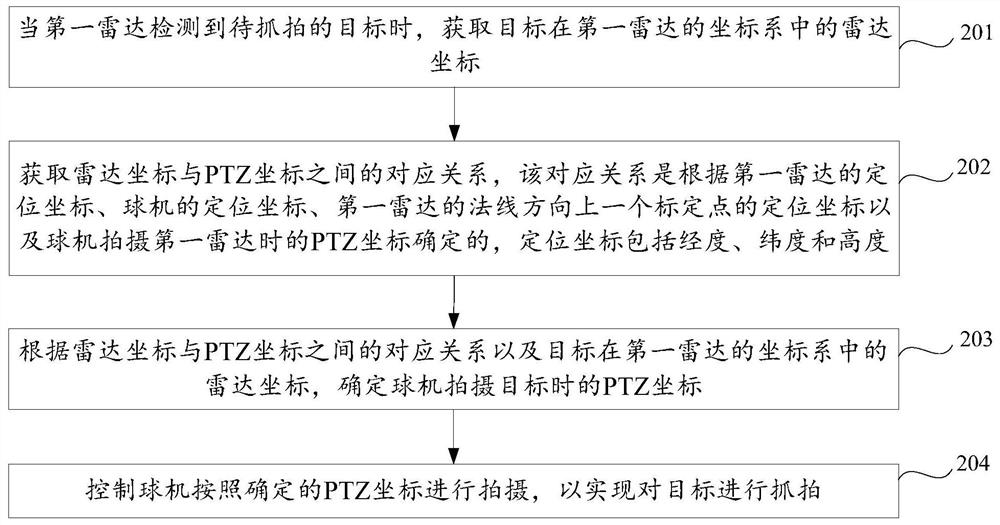

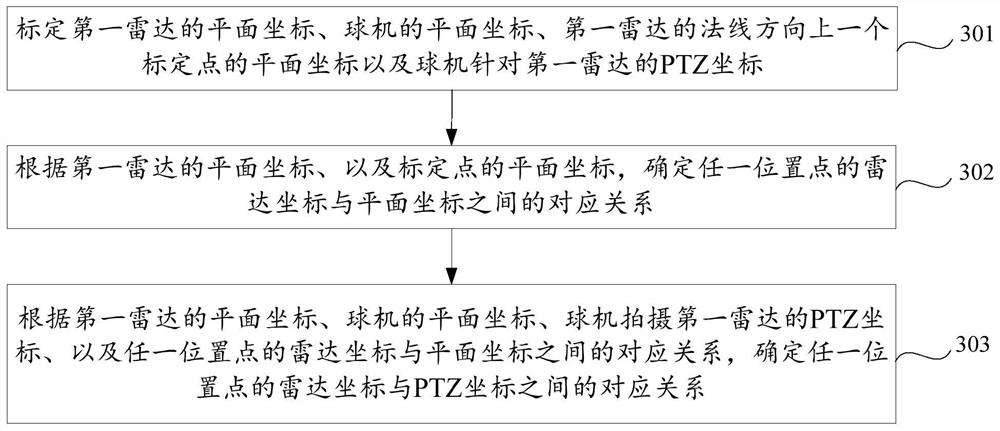

Snapshot method and device and computer storage medium

ActiveCN112243083ASimplify calibration workTelevision system detailsColor television detailsComputer visionSnapshot (computer storage)

The invention discloses a snapshot method and device and a computer storage medium, and belongs to the field of intelligent security and protection. In the method disclosed in the invention, the corresponding relationship between the radar coordinates and the PTZ coordinates is determined according to the positioning coordinates of the first radar, the positioning coordinates of the dome camera, the positioning coordinates of one calibration point in the normal direction of the first radar and the PTZ coordinates when the dome camera shoots the first radar. Thus, before snapshot, only the plane coordinate of the first radar, the plane coordinate of the dome camera, the plane coordinate of one calibration point in the normal direction of the first radar and the PTZ coordinate of the first radar shot by the dome camera need to be acquired; there is no need to configure four calibration points in advance and determine the calibration radar coordinate and the calibration PTZ coordinate ofeach calibration point; calibration work before snapshot is simplified, and popularization of the snapshot method provided by the invention is facilitated.

Owner:HANGZHOU HIKVISION DIGITAL TECH

Automatic calibrating device of digital display type vibration measurer and calibrating method thereof

ActiveCN102288278BSimplify calibration workCalibration Work IntelligenceSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansFrequency ratioSignal generator

The invention discloses an automatic calibrating device of a digital display type vibration measurer, which comprises a signal generator, a power amplifier, a standard vibration table, a camera, a laser vibration measurer, a frequency ratio counter and a processor. A digital display type vibration measurer to be calibrated is mounted on the standard vibration table. The automatic calibrating method comprises the following steps of: adjusting the gain of the power amplifier to a predetermined position; increasing the amplitude Ui of an output signal of the signal generator to an initial value to measure the real-time vibration level of the standard variation table; measuring the real-time vibration level of the vibration table; adjusting the deviation of the vibration level to be smaller than the control precision of the vibration level; reading the vibration level of the standard vibration table measured by the digital display type vibration measurer by adopting an image recognizing method; judging whether a test is completed or not; and generating a test report form. The calibrating device and the calibrating method have the advantages that the calibration work of the digital display type vibration measure becomes simple and intelligent; the calibration time is shortened greatly; and the labor intensity is also lightened greatly.

Owner:ZHEJIANG UNIV

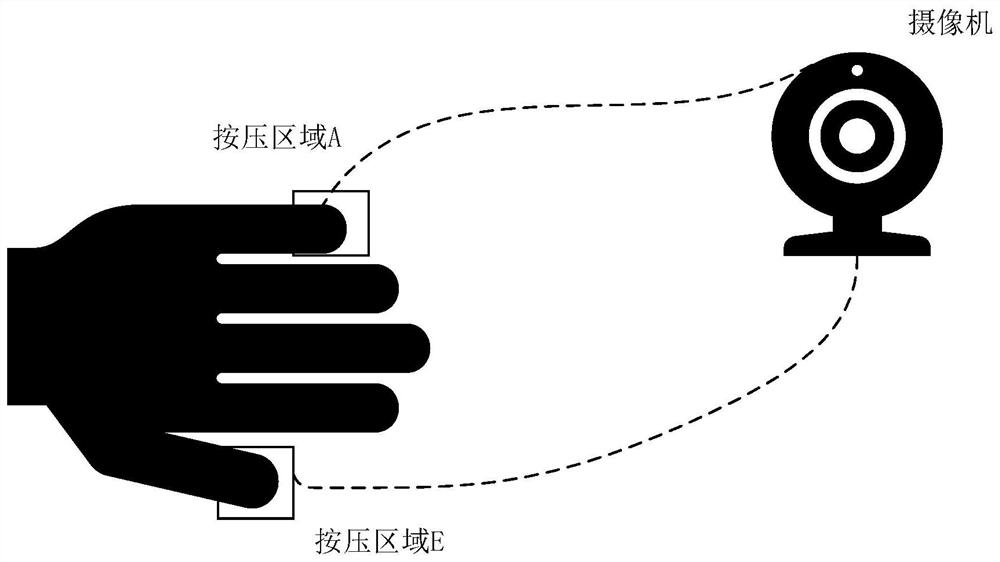

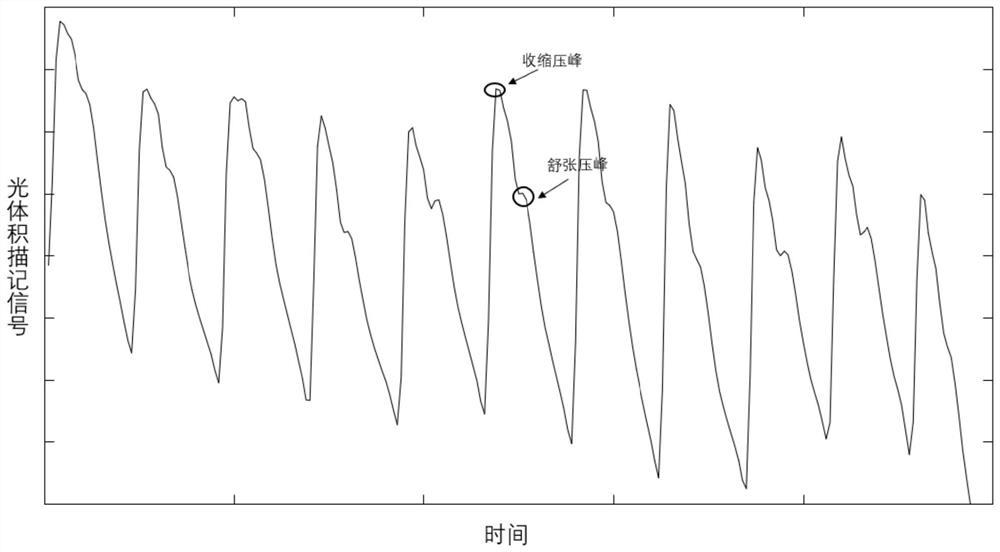

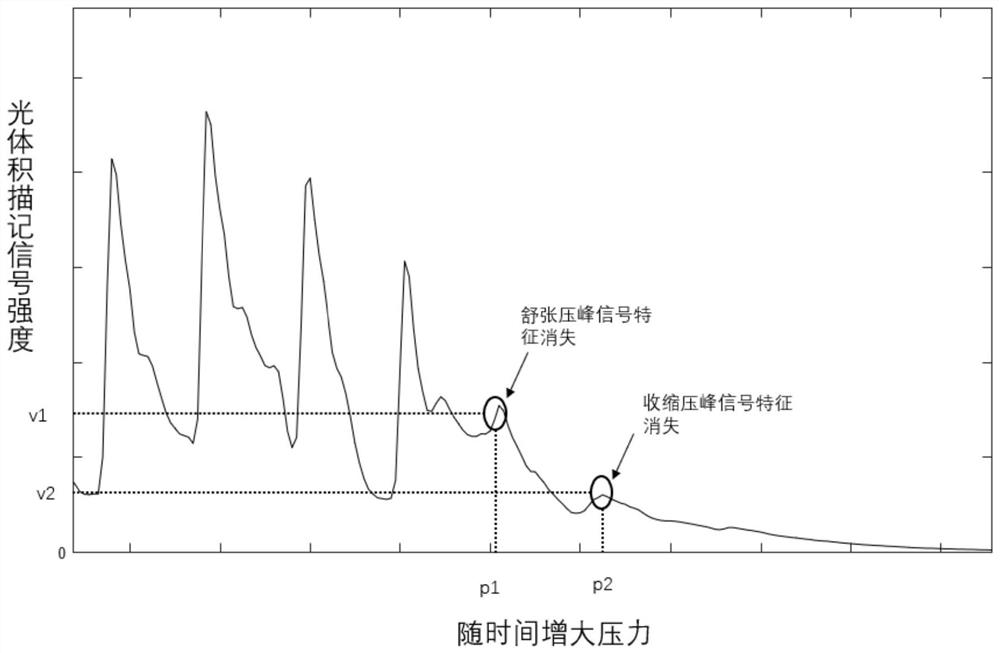

Pressing position positioning and pressure measuring method based on light volume change tracing imaging

PendingCN113670516AEasy and flexible measurementSimple methodEvaluation of blood vesselsAngiographyEngineeringPressure measurement

The invention discloses a pressing position positioning and pressure measuring method based on light volume change tracing imaging, and the method does not need a pressure sensor, only needs a camera, and can carry out the positioning of a pressing area and the measurement of a pressure value. Before measurement is started, only one-time simple calibration work is needed, light volume signal characteristics corresponding to diastolic pressure and systolic pressure disappear one by one along with gradual increase of pressing force, two groups of pressure values and corresponding light volume signal intensity values are recorded, and a relation curve of pressure and blood light volume change can be fitted. Through the relation curve, pressure values corresponding to different blood light volume signal intensities can be obtained. Different from a traditional technical route, the invention provides a non-contact measurement method for determining the pressing position and measuring the pressure through a camera. The method is simple, a pressure sensor does not need to be installed, and a plurality of pressing areas can be flexibly and conveniently measured on the surface of any object.

Owner:ZHEJIANG LAB

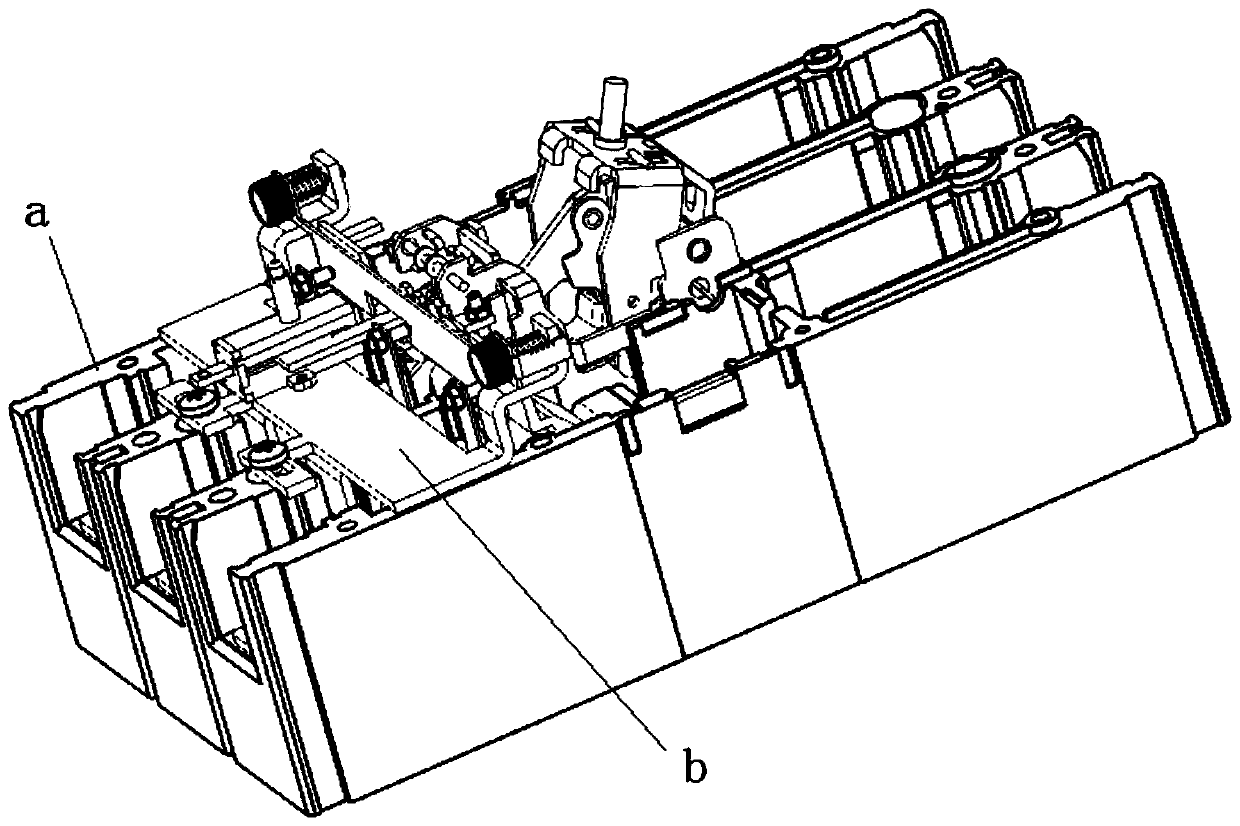

Thermal overload release adjusting device for molded case circuit breaker

ActiveCN111048362AVersatileSimple structureElectric switchesProtective switch operating/release mechanismsStructural engineeringCircuit breaker

The invention discloses a thermal overload release adjusting device for a molded case circuit breaker. The device comprises a mounting assembly, a release stroke tester and a thermal overload releaseadjusting assembly; the mounting assembly comprises a mounting plate, fixing screws and positioning pieces; the thermal overload release adjusting assembly comprises a thermal overload release adjusting reference plate, reference plate springs and hand screws; the fixing screws penetrate through first mounting clamping grooves to mount and fix the positioning pieces on the mounting plate; the positioning pieces enable the thermal overload release adjusting device to be installed and positioned on a circuit breaker needing to be detected; the release stroke tester is installed at the second mounting clamping groove of the mounting plate through screws; and the thermal overload release adjusting reference plate and the reference plate springs are fixed at the mounting hole positions of the mounting plate through the hand screws. The thermal overload release adjusting device for the molded case circuit breaker has rich functions, is simple in structure and convenient to disassemble, repair and maintain; and the production and verification work of the circuit breaker can be simplified, so that the production and verification of the circuit breaker are quantified.

Owner:CHANGSHU TONGRUN SWITCHGEAR FACTORY CO LTD

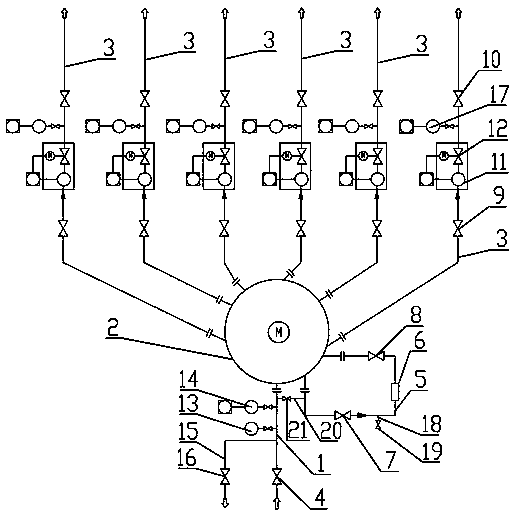

Integrated automatic well-selecting on-line calibration water-distribution device

PendingCN108331564AReduce configurationGuaranteed water injection timingFluid removalRemote controlEngineering

The invention relates to the technical field of oilfield single well water-injection calibration, in particular to an integrated automatic well-selecting on-line calibration water-distribution device.The integrated automatic well-selecting on-line calibration water-distribution device comprises a PLC, a water inlet pipeline, a multi-ported valve well-selecting device and at least one water outletpipeline; a first stop valve is fixedly mounted on the water inlet pipeline, the multi-ported valve well-selecting device is connected with an empty head and a calibration joint, the empty head is connected with a calibration pipeline, a calibration flowmeter is fixedly mounted on the calibration pipeline, and a second stop valve is mounted on the calibration pipeline; a third stop valve is mounted on the position, on the water outlet side of the calibration flowmeter, of the calibration pipeline; and a water outlet of the calibration pipeline communicates with a water inlet of the calibration joint, and a water outlet of the calibration joint communicates with water inlets of the water outlet pipelines. According to the integrated automatic well-selecting on-line calibration water-distribution device, the structure is reasonable and compact, controlling of single well injection allocation starting and stopping, single well injection allocation amount and injection allocation pressurecan be realized through remote control of the PLC, attended operation and refining water injection management are achieved, the phenomenon of insufficient injection is reduced, and the benefits of water injection development are increased.

Owner:XINJIANG PETROLEUM ENG DESIGN CO LTD

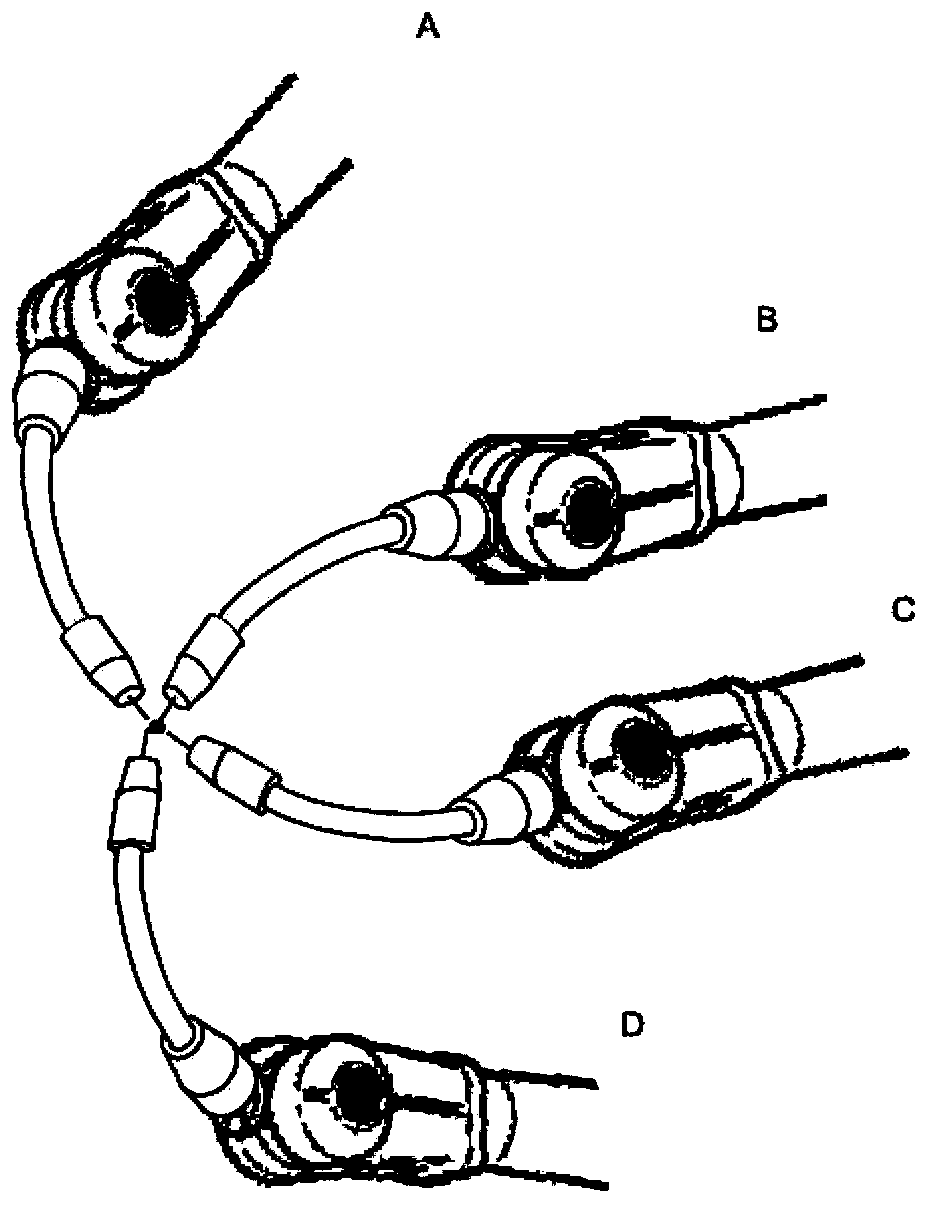

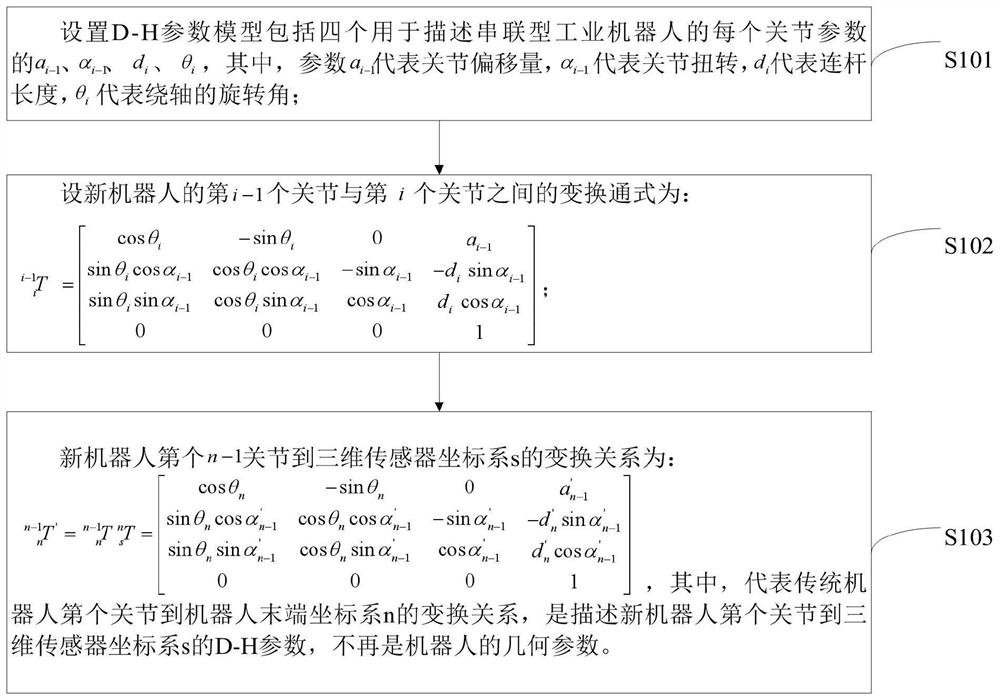

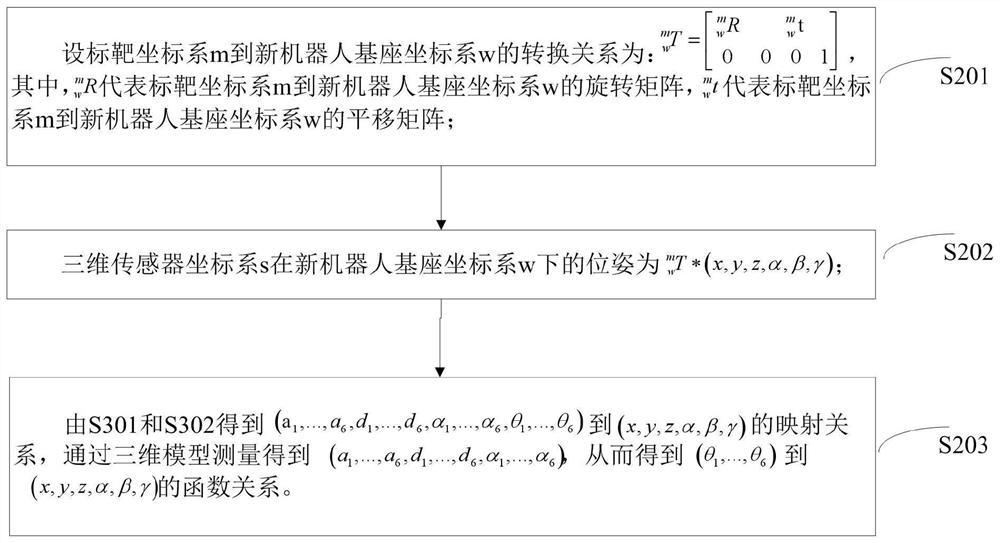

A Unified Calibration Model of Robot Structural Parameters and Hand-eye Relationship

ActiveCN109895098BHigh precisionSimplify calibration workProgramme-controlled manipulatorRobotic systemsEngineering

The invention provides a unified calibration model for robot structure parameters and hand-eye relations. A three-dimensional sensor is used for replacing optical tracking equipment which needs to beused in robot parameter calibration; a robot-three-dimensional sensor system is taken as a new robot system; a three-dimensional sensor coordinate system is regarded as a new robot tail end coordinatesystem; and the hand-eye relations in the original robot-three-dimensional sensor system are simultaneously calibrated in the process of calibrating D-H parameters of a new robot, namely, the calibration work of the robot structure parameters and the hand-eye relations are completed through one-time calibration according to an existing method, and the calibration precision is improved. The coordinate system conversion relation of a traditional method is as follows: a laser tracker coordinate system l - a robot base coordinate system w - a robot tail end coordinate system n - a three-dimensional sensor coordinate system s; and the coordinate system conversion relation of the unified calibration model is as follows: a target coordinate system m - a robot base coordinate system w - a three-dimensional sensor coordinate system s. By means of the unified calibration model, the calibration work is simplified, the calculation work is reduced, and the calibration precision is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

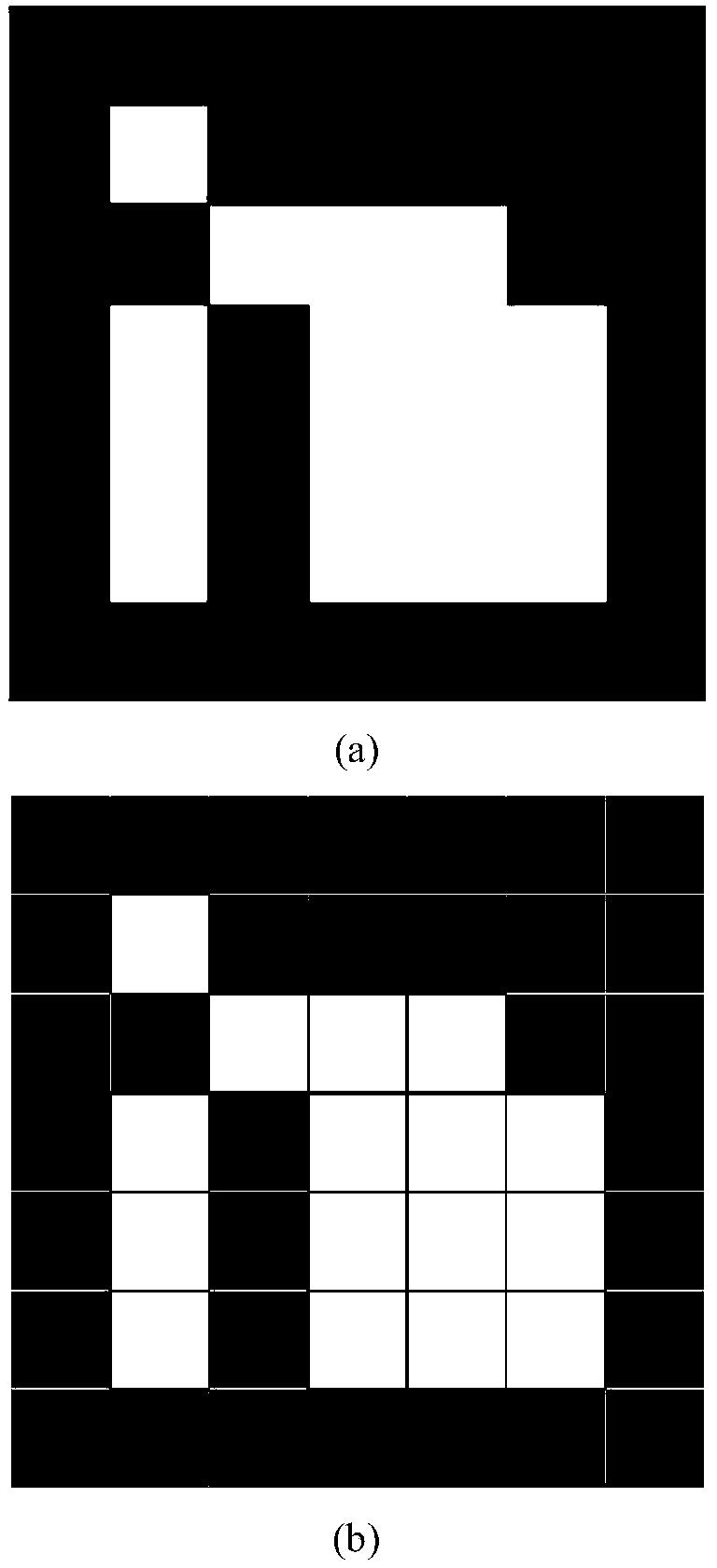

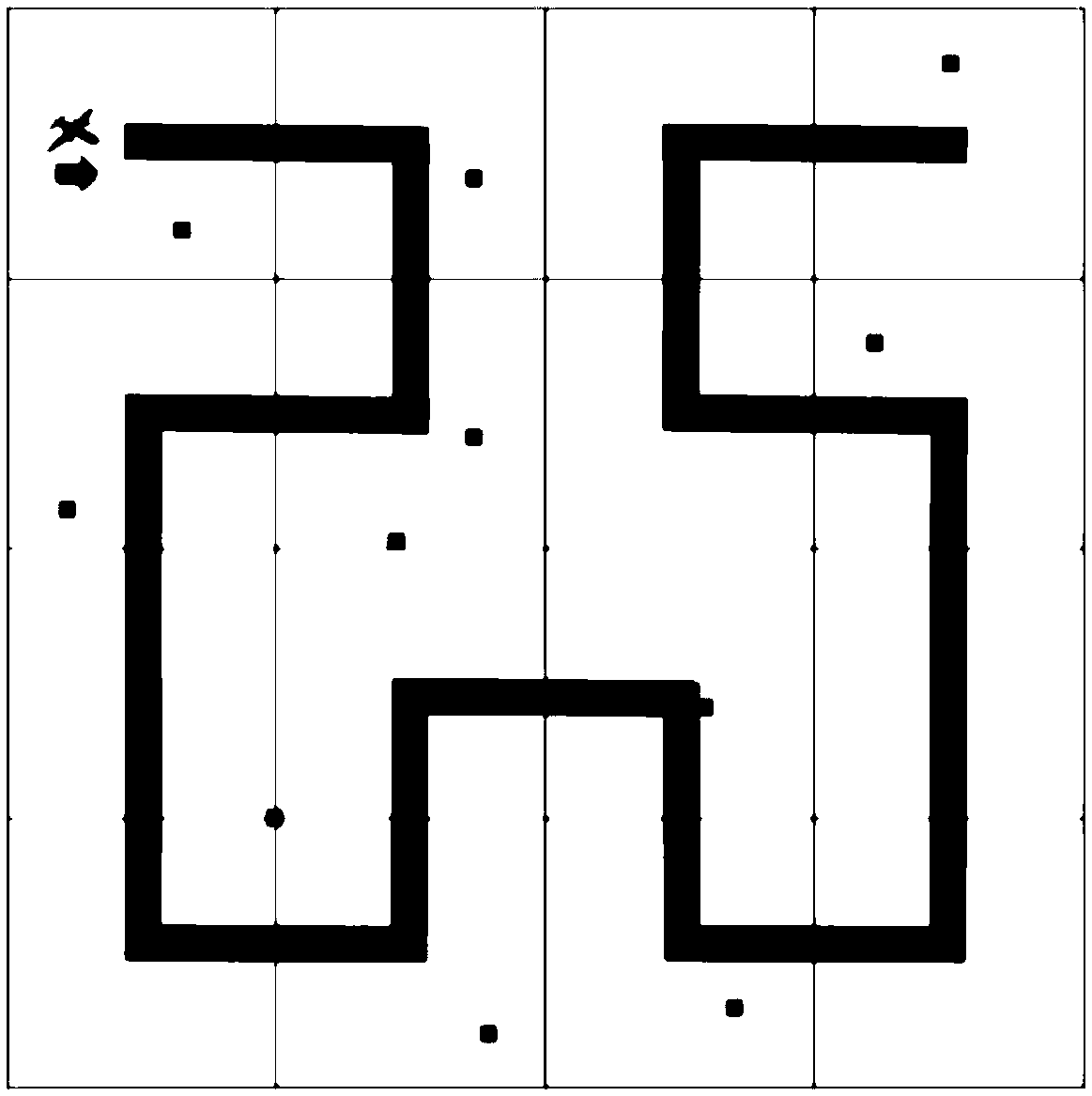

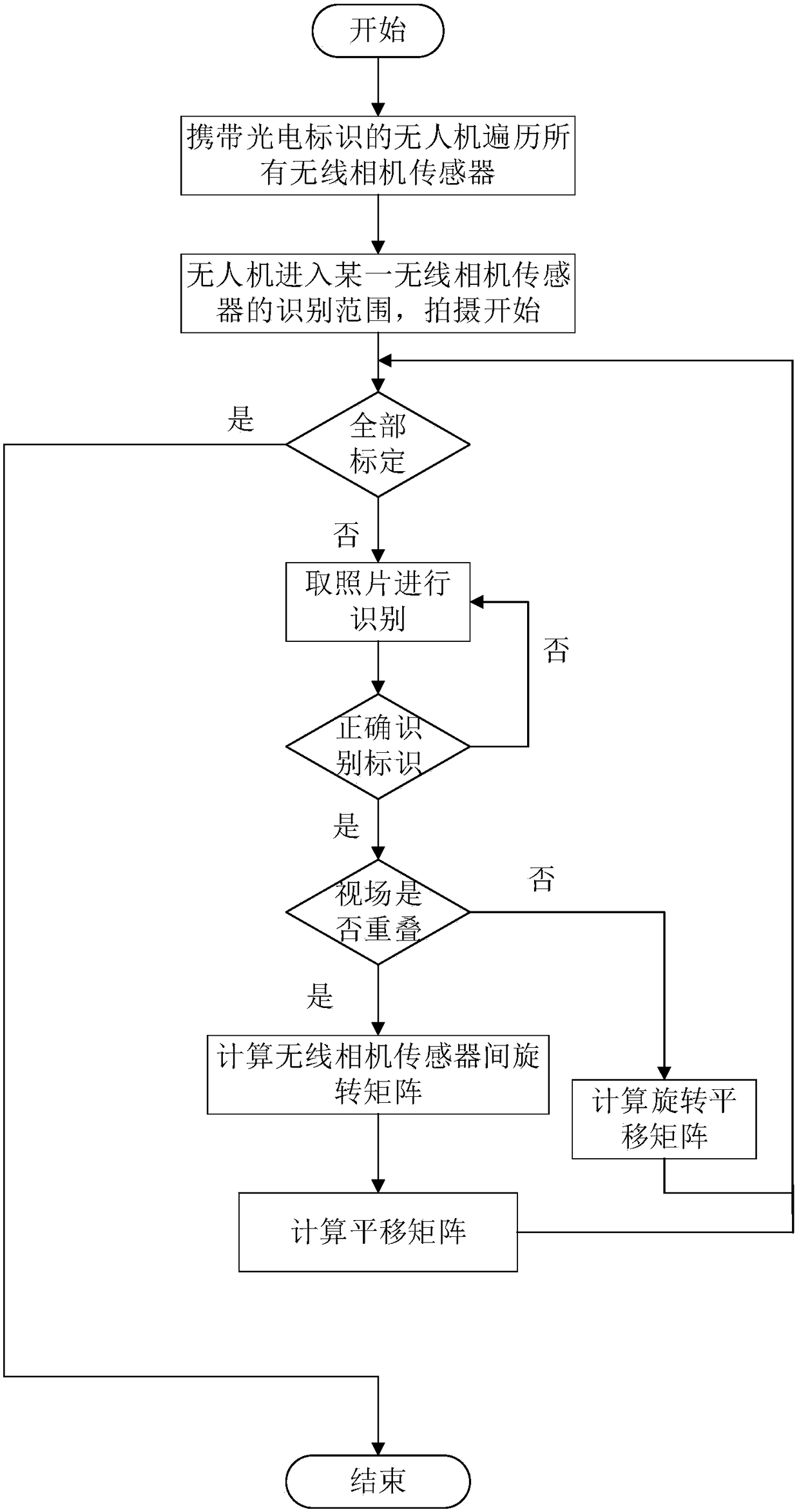

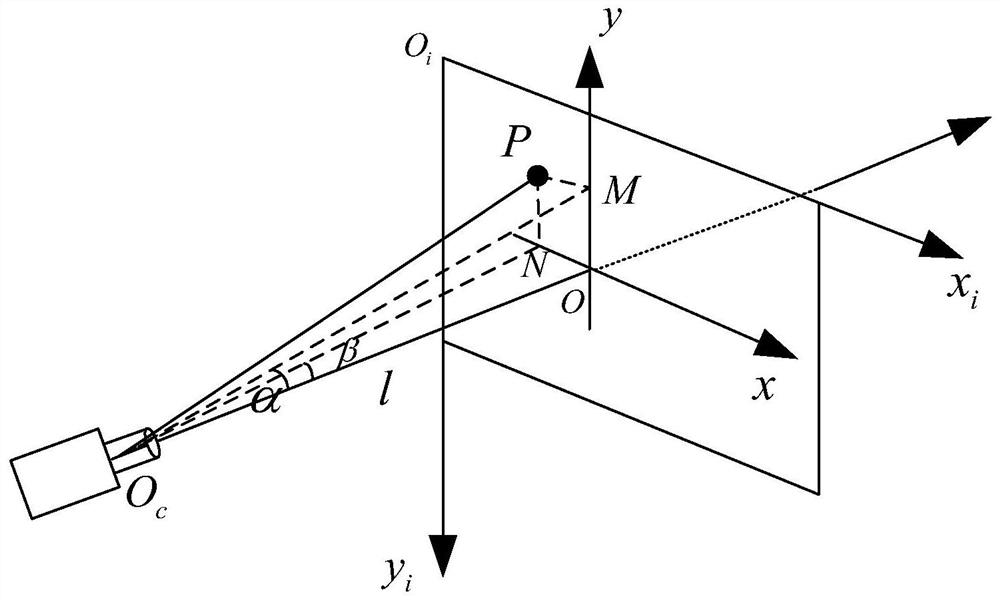

A wireless camera sensor pose calibration method for wireless camera sensor networks

ActiveCN105931229BQuick calibrationCalibration IntroductionImage enhancementImage analysisFeature point matchingWireless camera

Owner:NORTHEASTERN UNIV LIAONING

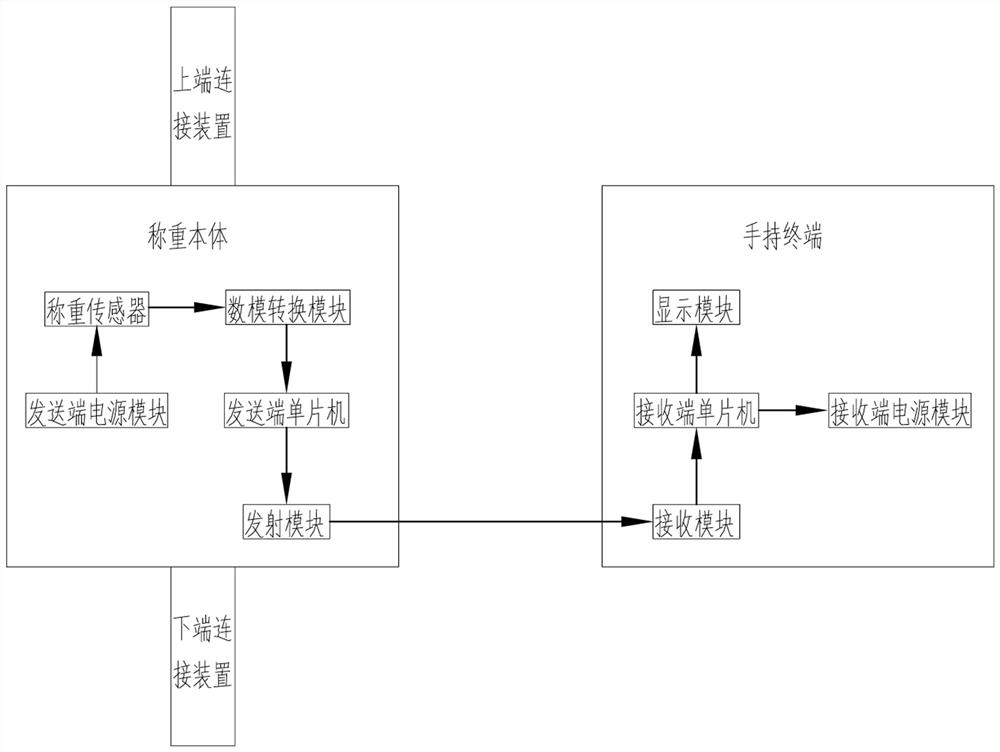

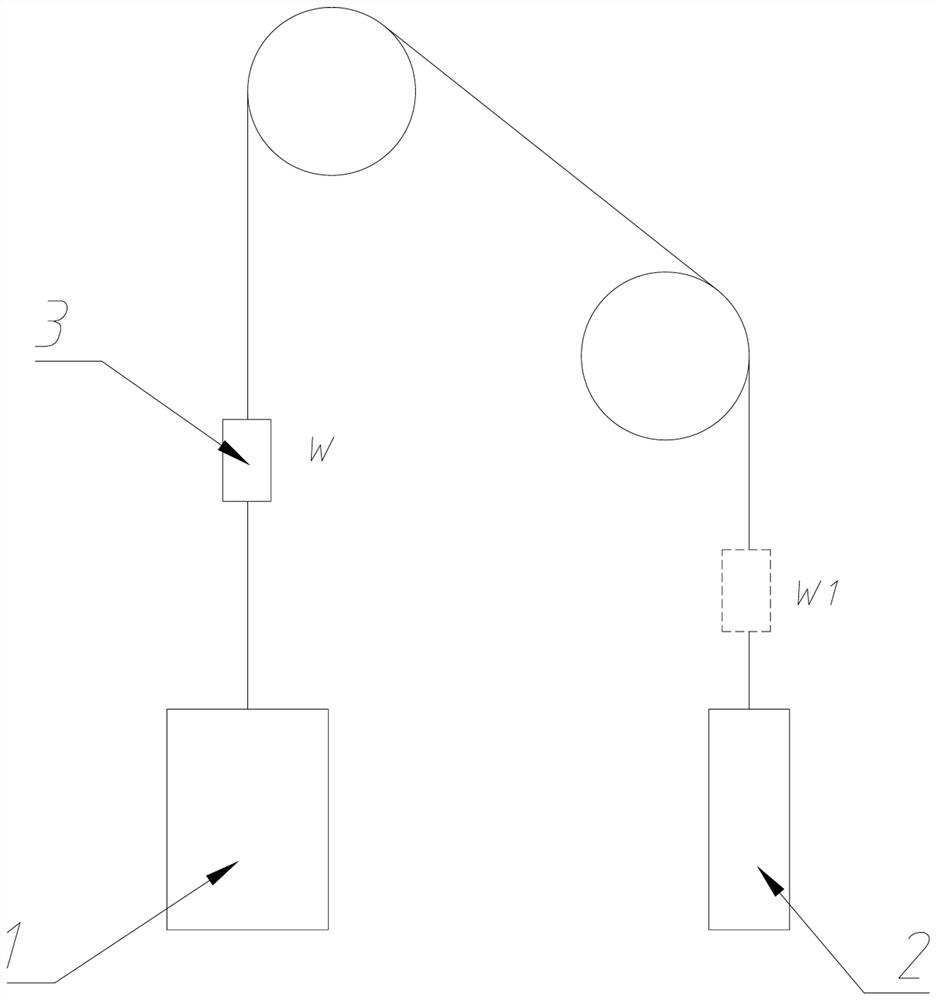

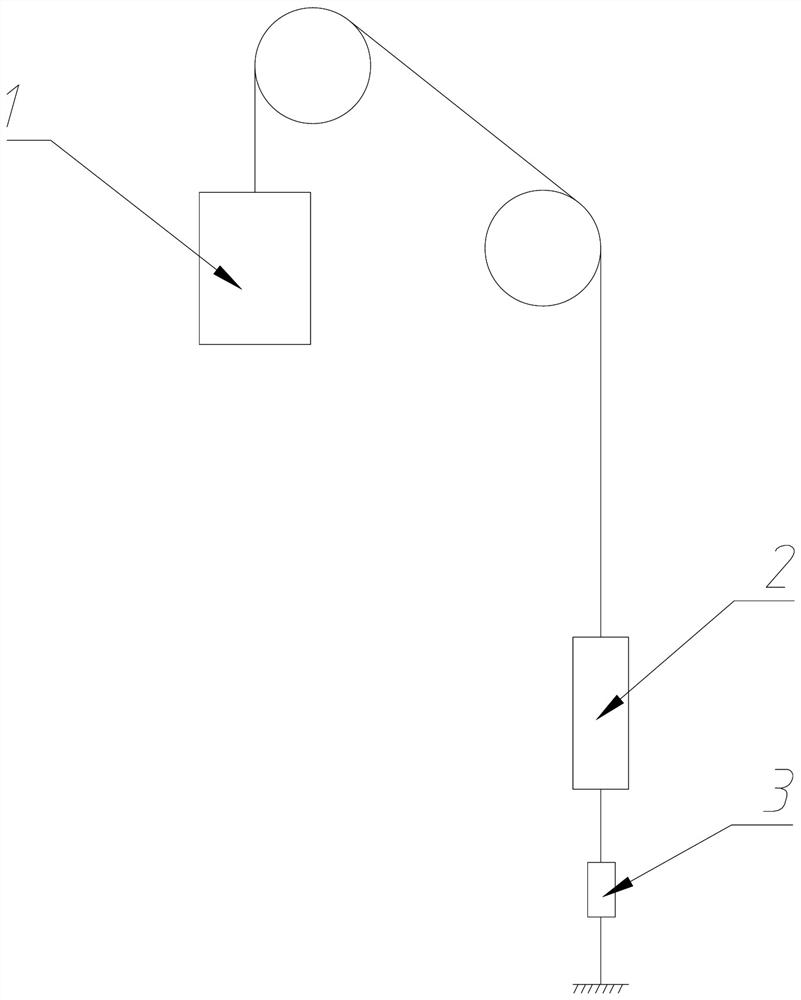

Elevator safety performance parameter measuring device and method and application

The invention relates to the field of elevator safety performance parameter measurement, in particular to an elevator safety performance parameter measurement device and method and application. The elevator safety performance parameter measurement device comprises a weighing body and a handheld terminal, the weighing body is provided with a weighing sensor, a transmitting end power supply module is connected with an analog-to-digital conversion module through the weighing sensor, and the analog-to-digital conversion module is connected with a wireless transmitting module through a transmitting end single-chip microcomputer. The handheld terminal comprises a receiving module, the receiving module is connected with a display module through a receiving end single-chip microcomputer, and a receiving end power supply module is connected with the receiving end single-chip microcomputer. The transmitting module is connected with the receiving module in a wireless transmission mode. The device is convenient to carry, a load does not need to be carried in the whole testing process, the measuring process is simple and fast, two persons can complete the testing process, the testing instrument is easy to operate, the device is divided into a measuring end and the handheld terminal which are in transmission connection through wireless signals, testing results are all numerical values and are directly displayed, data are accurate, and traceability is achieved.

Owner:李宏

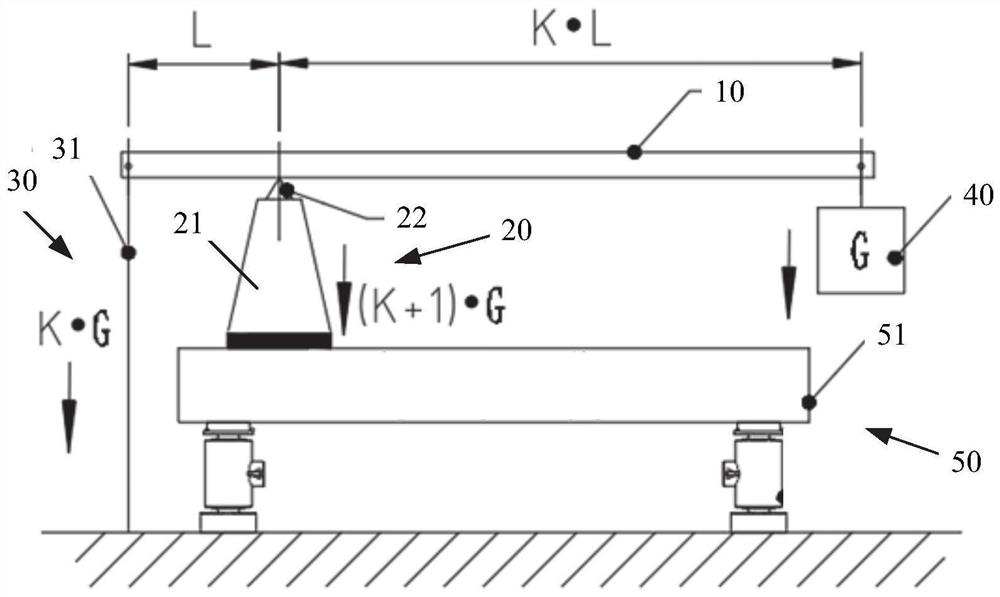

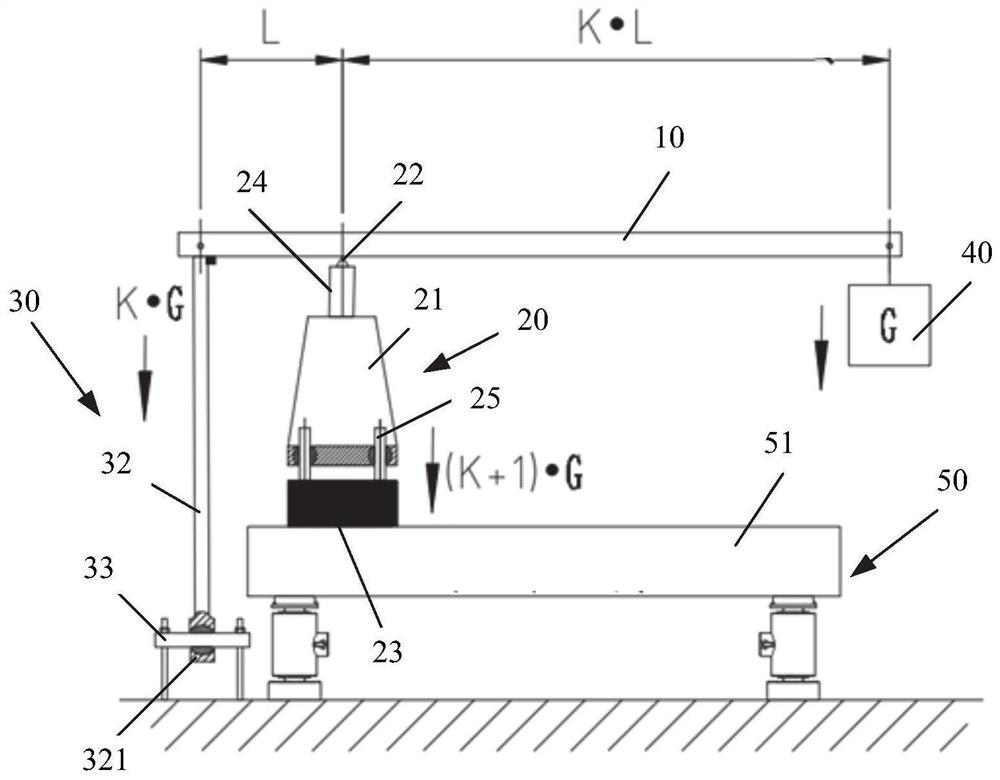

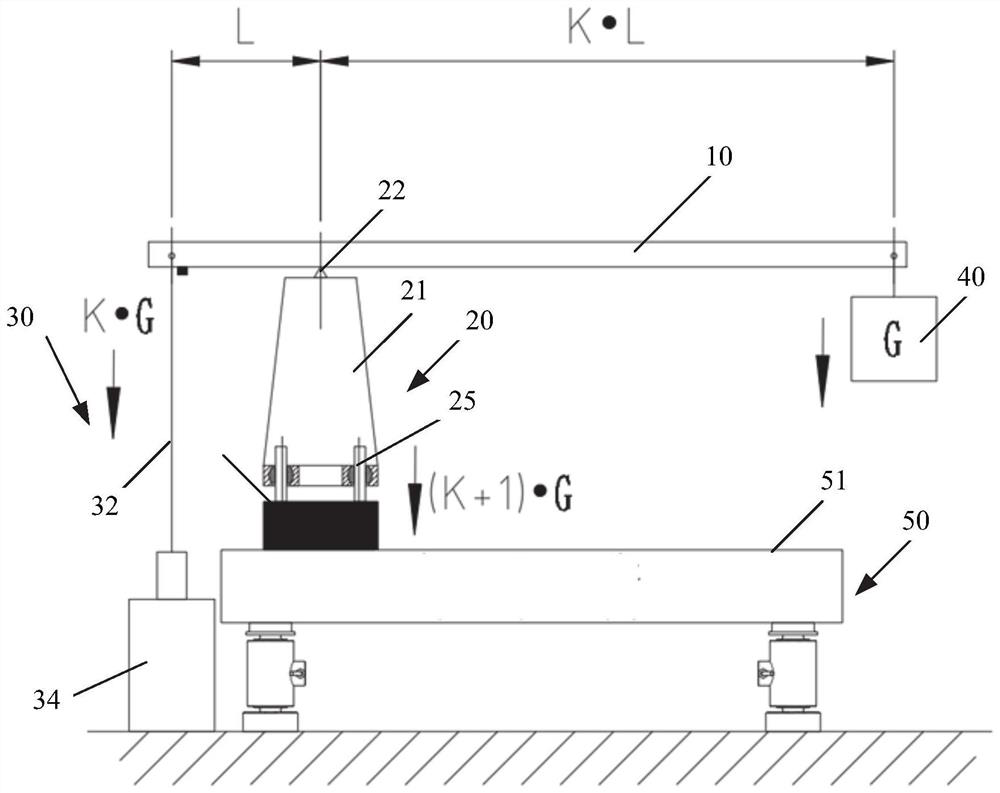

Calibration device for large weighing apparatus

PendingCN114543963AReduce workloadImprove calibration productivityWeighing apparatus testing/calibrationControl engineeringField calibration

The invention provides a calibration device for a large weighing apparatus, the calibration device comprises a lever, a support assembly, a pull rod assembly and a weight set, the weight set is installed at one end of the lever, the pull rod assembly is installed at the other end of the lever, and the support assembly is installed on the upper end face of the weighing apparatus to be calibrated and supports the lever upwards; the lever is kept horizontal by adjusting the pull rod assembly or the support assembly, so that downward force is applied to the weighing apparatus through the support assembly. According to the calibration device for the large weighing apparatus, on the premise that the calibration precision is guaranteed, the workload of field calibration is reduced, and the calibration efficiency is improved. The weight carrying is reduced, and the time and the cost can be greatly saved. The calibration device can realize calibration automation. Compared with other weight calibration substitution methods, the calibration device is higher in precision and simpler and more reliable in force value traceability.

Owner:METTLER TOLEDO (CHANGZHOU) MEASUREMENT TECH CO LTD +2

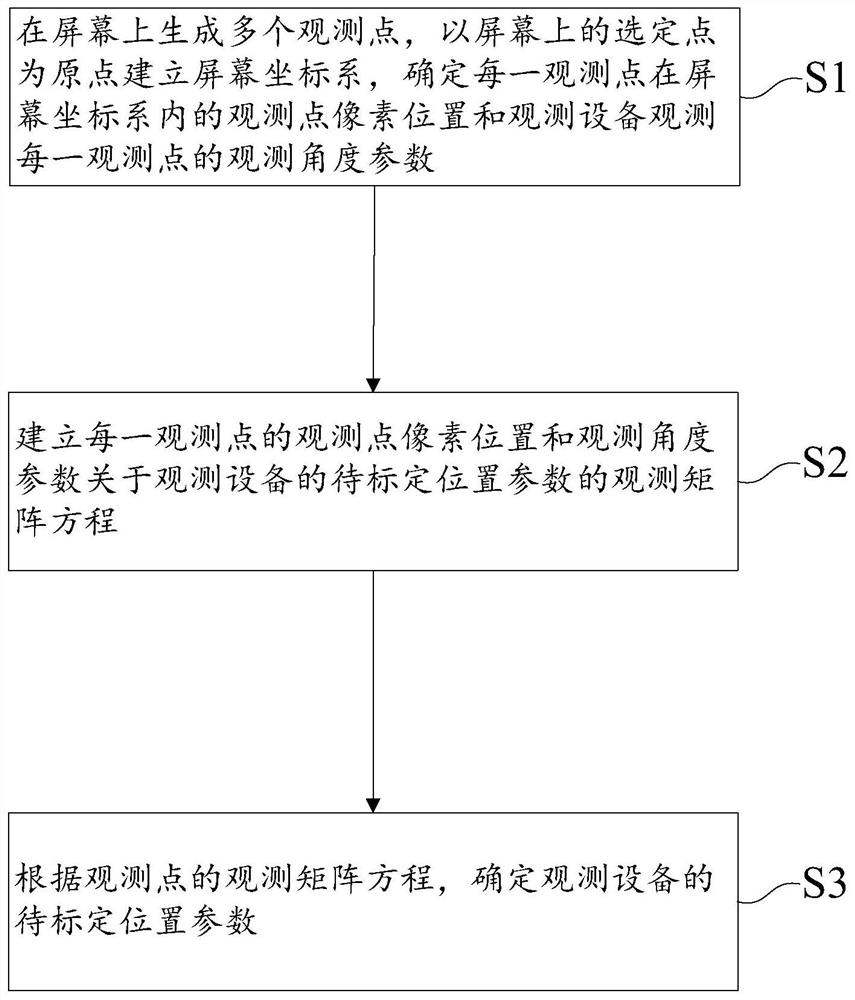

Method and system for camera position calibration of screen observation equipment

The invention relates to the technical field of TV tracking system simulation, in particular to a method and system for calibrating zero position of screen observation equipment. The method includes the following steps: generating a plurality of observation points on a screen, and establishing a screen with a selected point on the screen as the origin Coordinate system, determine the pixel position of the observation point of each observation point in the screen coordinate system and the observation angle parameters of each observation point observed by the observation equipment; establish the pixel position of the observation point and the observation angle parameters of each observation point. The observation matrix equation for calibrating the position parameter; according to the observation matrix equation of the observation point, the position parameter to be calibrated of the observation equipment is determined. This solution can solve the problems in the prior art that the center point of the screen observation device is manually adjusted to coincide with the center point of the screen, and the operation process is very complicated and the precision is low.

Owner:THE GENERAL DESIGNING INST OF HUBEI SPACE TECH ACAD

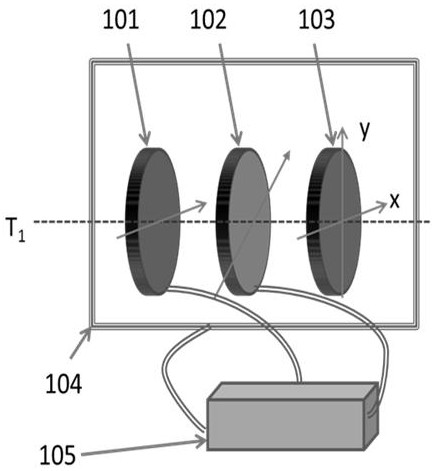

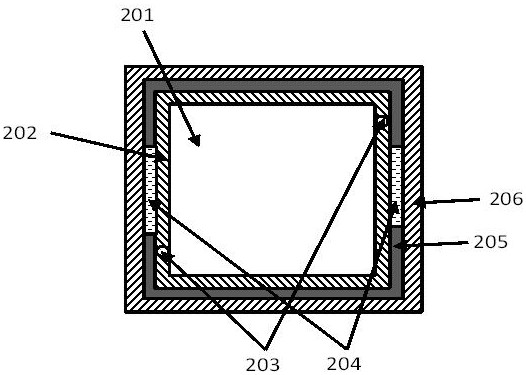

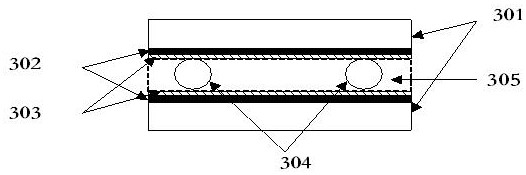

A Novel Liquid Crystal Polarization Modulator and Its Detection Method

ActiveCN112432904BReduce mistakesReduce the difficulty of analysisMethod using image detector and image signal processingStatic indicating devicesCrystallographyPolarizer

The invention discloses a novel liquid crystal polarization modulator and a detection method thereof. The novel liquid crystal polarization modulator includes a liquid crystal polarization modulation component, and the liquid crystal polarization modulation component includes a twisted nematic liquid crystal wave plate, an antiparallel nematic liquid crystal wave plate and A linear polarizer, the antiparallel nematic liquid crystal wave plate is arranged between the twisted nematic liquid crystal wave plate and the linear polarizer, the twisted nematic liquid crystal wave plate is located at the front end; the twisted nematic liquid crystal wave plate The alignment directions of the front-end alignment film and the rear-end alignment film of the antiparallel nematic liquid crystal wave plate are all located in the vertical plane of the detection light incident direction; flat. The invention solves the problems of many error sources and low modulation precision in the existing liquid crystal polarization modulation module composed of two nematic liquid crystal adjustable phase retarders and one linear polarizer.

Owner:INST OF FLUID PHYSICS CHINA ACAD OF ENG PHYSICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com