Calibration device for large weighing apparatus

A technology for calibrating devices and weighing instruments, applied in the direction of weighing equipment testing/calibration, etc., can solve problems such as insufficient accuracy and easy environmental influence, and achieve the effects of high accuracy, reduced weight handling, and simple and reliable force traceability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

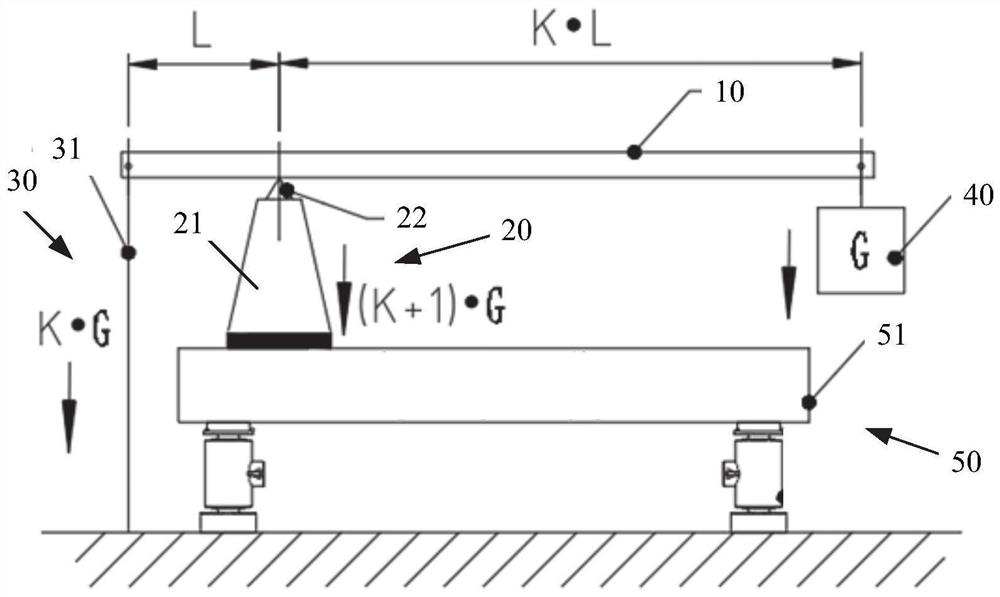

[0053] figure 1 It is a schematic structural diagram of the first embodiment of the forehead calibration device for a large scale of the present invention.

[0054] like figure 1 As shown, the present invention discloses a calibration device for a large weighing instrument, which includes a lever 10, a bracket assembly 20, a pull rod assembly 30 and a weight group 40, the weight group 40 is installed at one end of the lever 10, and the pull rod assembly 30 is installed At the other end of the lever 10, the bracket assembly 20 is mounted on the upper end face of the weighing instrument 50 to be calibrated, and supports the lever 10 upward. A downward force is applied to the scale 50 through the bracket assembly 20 by adjusting the lever assembly 30 or the bracket assembly 20 so that the lever 10 is held horizontal.

[0055] Preferably, the bracket assembly 20 in this embodiment includes a bracket 21 and a lever fulcrum 22 , the bracket 21 is placed on the weighing platform 51...

Embodiment 2

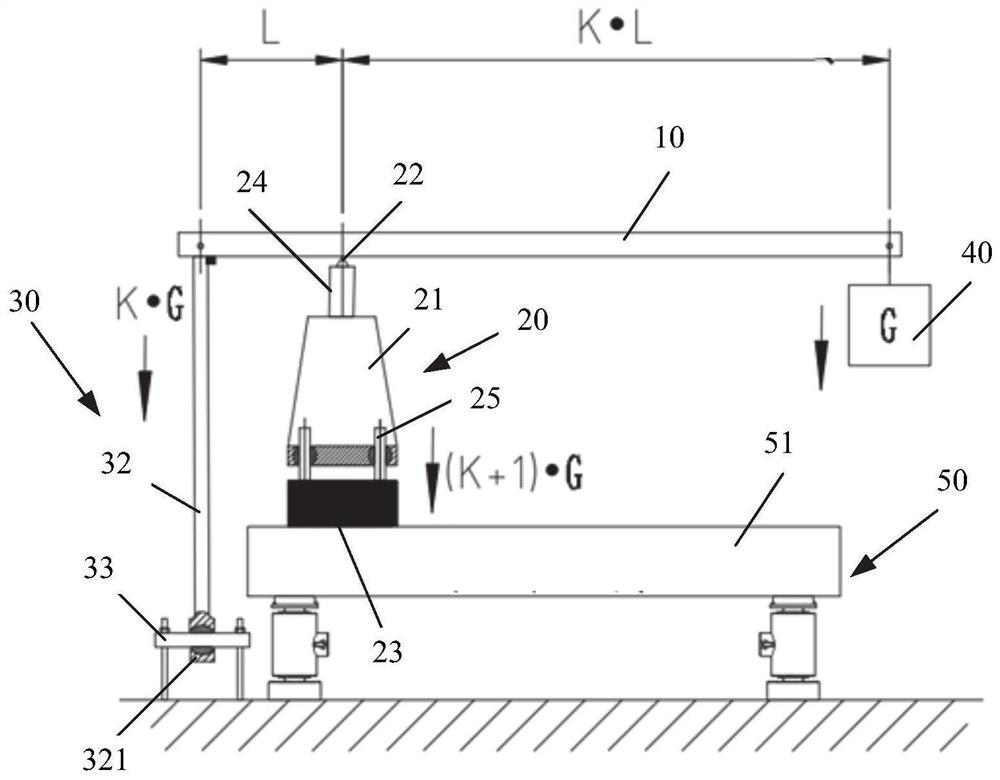

[0061] figure 2 It is a schematic structural diagram of Embodiment 2 of the forehead calibration device for large scales of the present invention.

[0062] like figure 2As shown, the present invention discloses a calibration device for a large weighing instrument, which includes a lever 10, a bracket assembly 20, a pull rod assembly 30 and a weight group 40, the weight group 40 is installed at one end of the lever 10, and the pull rod assembly 30 is installed At the other end of the lever 10, the bracket assembly 20 is mounted on the upper end face of the weighing instrument 50 to be calibrated, and supports the lever 10 upward. A downward force is applied to the scale 50 through the bracket assembly 20 by adjusting the lever assembly 30 or the bracket assembly 20 so that the lever 10 is held horizontal.

[0063] Preferably, in this embodiment, the bracket assembly 20 includes a base 23 , a bracket 21 , a first lifting mechanism 24 and a lever fulcrum 22 , the base 23 is p...

Embodiment 3

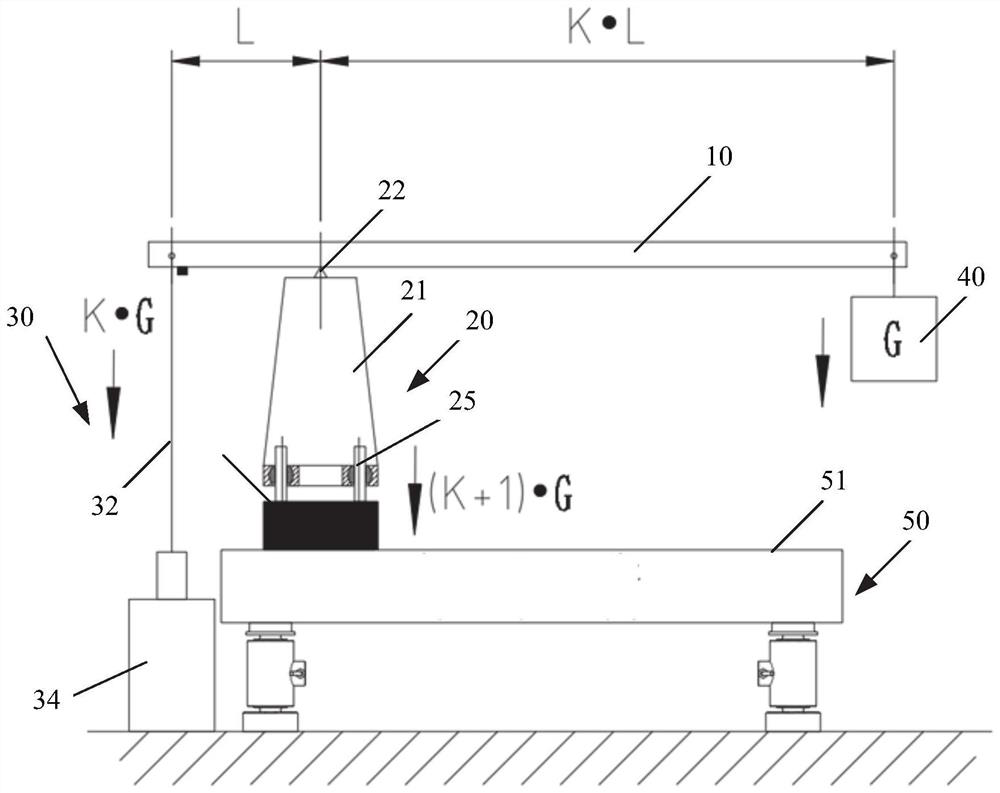

[0071] image 3 It is a schematic structural diagram of Embodiment 3 of the forehead calibration device for large scales of the present invention.

[0072] like image 3 As shown, the present invention discloses a calibration device for a large weighing instrument, which includes a lever 10, a bracket assembly 20, a pull rod assembly 30 and a weight group 40, the weight group 40 is installed at one end of the lever 10, and the pull rod assembly 30 is installed At the other end of the lever 10, the bracket assembly 20 is mounted on the upper end face of the weighing instrument 50 to be calibrated, and supports the lever 10 upward. A downward force is applied to the scale 50 through the bracket assembly 20 by adjusting the lever assembly 30 or the bracket assembly 20 so that the lever 10 is held horizontal.

[0073] Preferably, in this embodiment, the bracket assembly 20 includes a base 23 , a bracket 21 and a lever fulcrum 22 , the base 23 is placed on the weighing platform 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com