Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Simple set" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

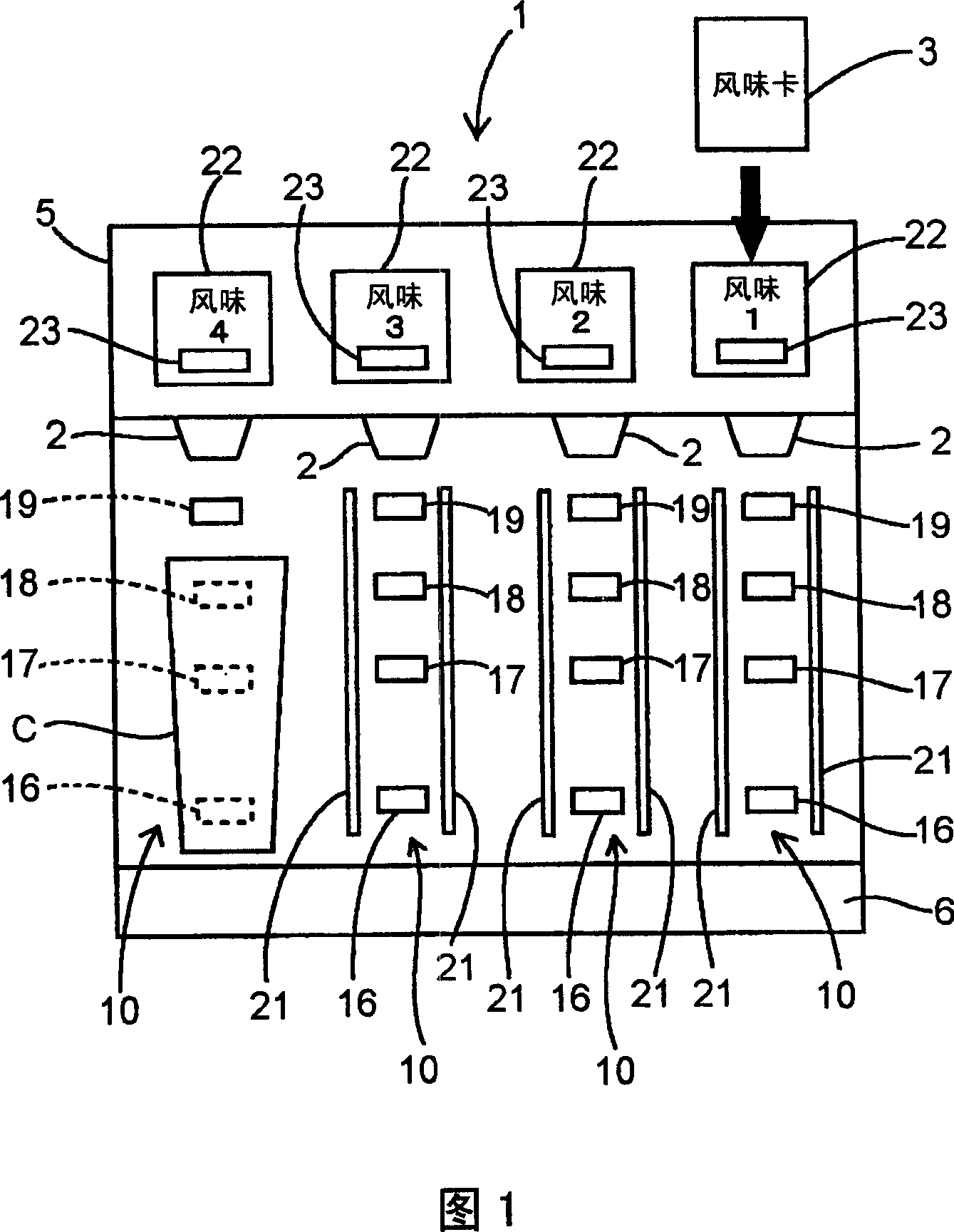

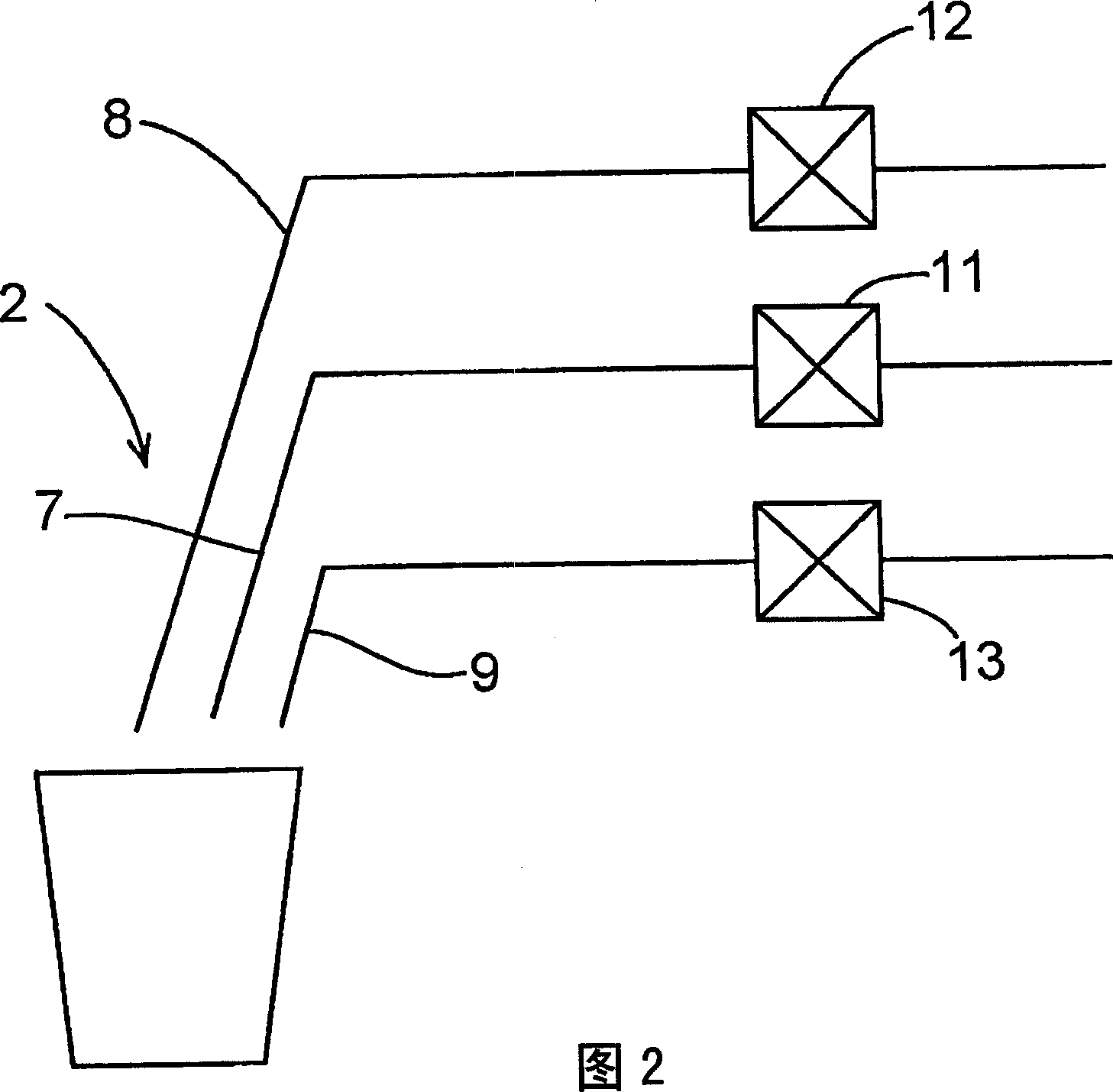

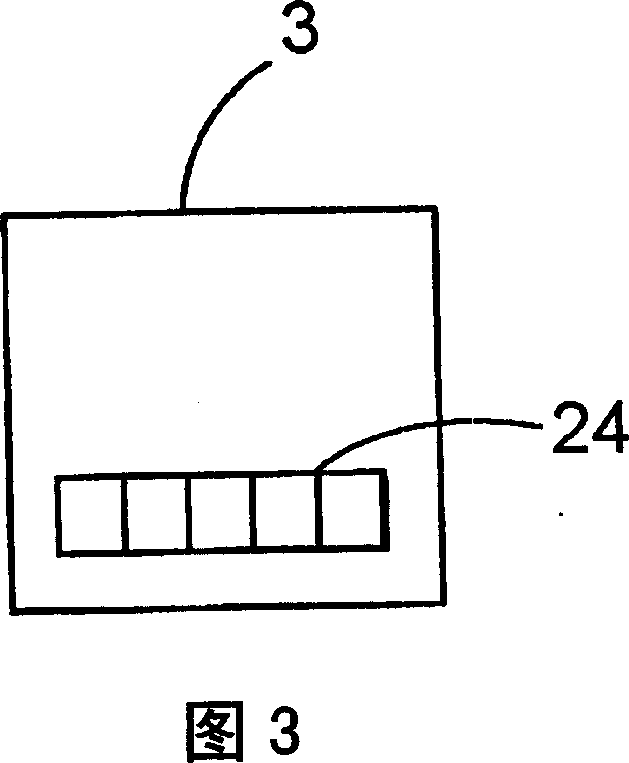

Beverage supply device

InactiveCN101044956ASimple setTake precautions to avoid undesired situations of incorrect settingsBeverage vesselsLiquid dispensingFlavorEngineering

An object of the present invention is to provide a beverage supply device (1) in which a setting operation for each beverage is simplified and in which supply of a wrong beverage can be avoided in advance, the beverage supply device executes a beverage supply operation of discharging a beverage material (syrup) and a diluting liquid into a cup to mix the beverage material and the diluting liquid, and the device includes: an information output section (24) of a flavor card (3) which retains inherent information such as a dilution ratio of a beverage; an information detecting section (23) which reads out the inherent information of the beverage retained by this information output section; and a control unit (26) which executes the beverage supply operation based on the inherent information read out by this information detecting section.

Owner:SANYO ELECTRIC CO LTD

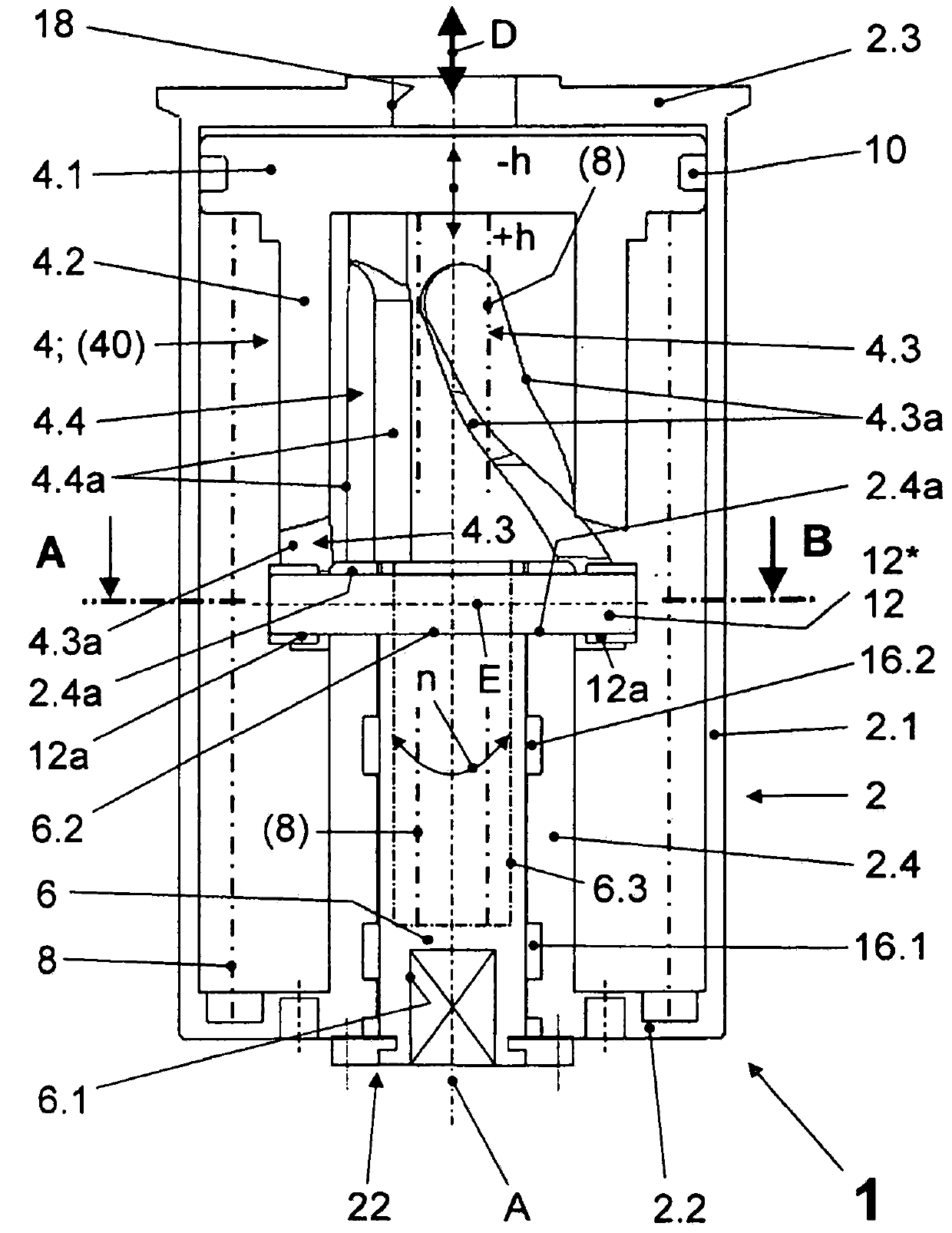

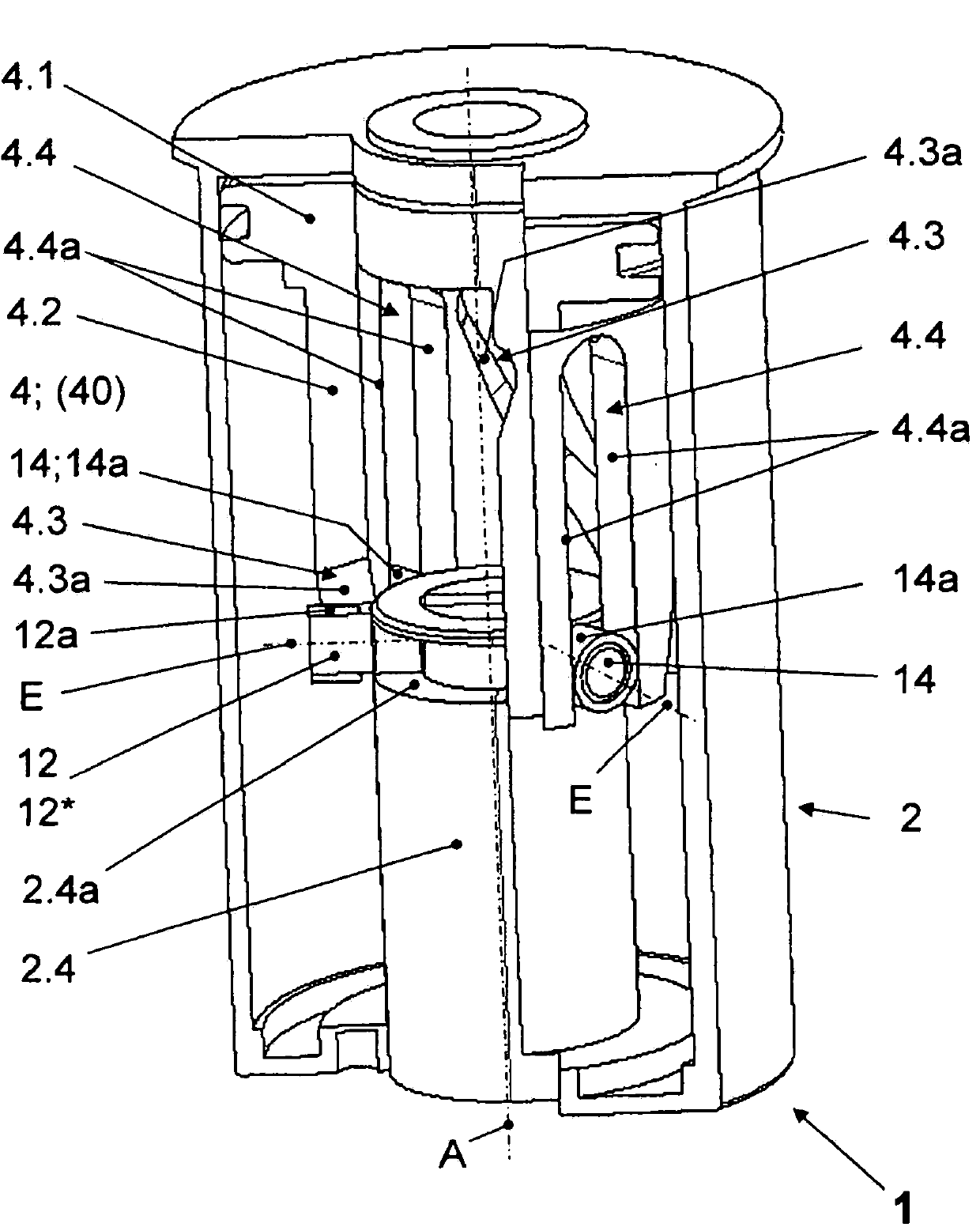

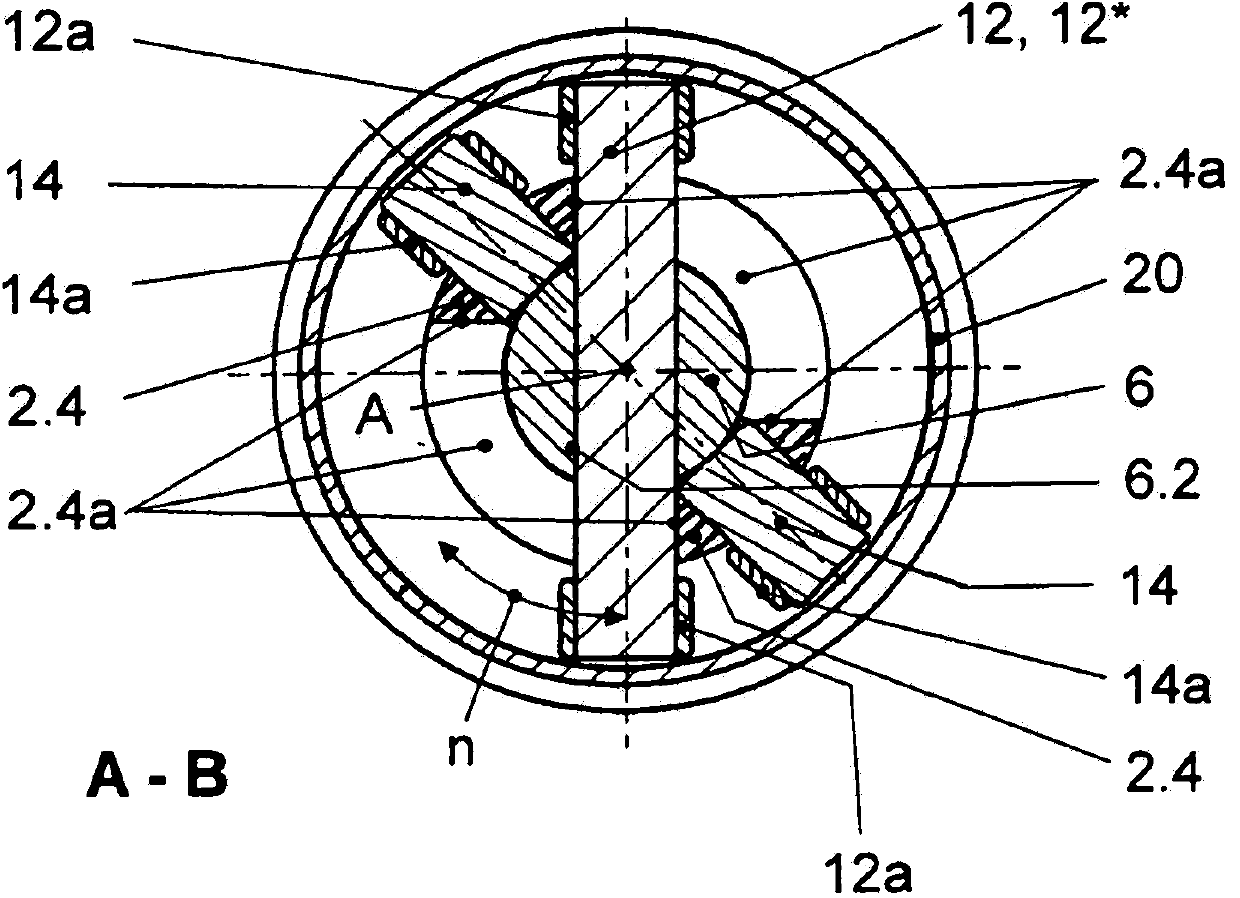

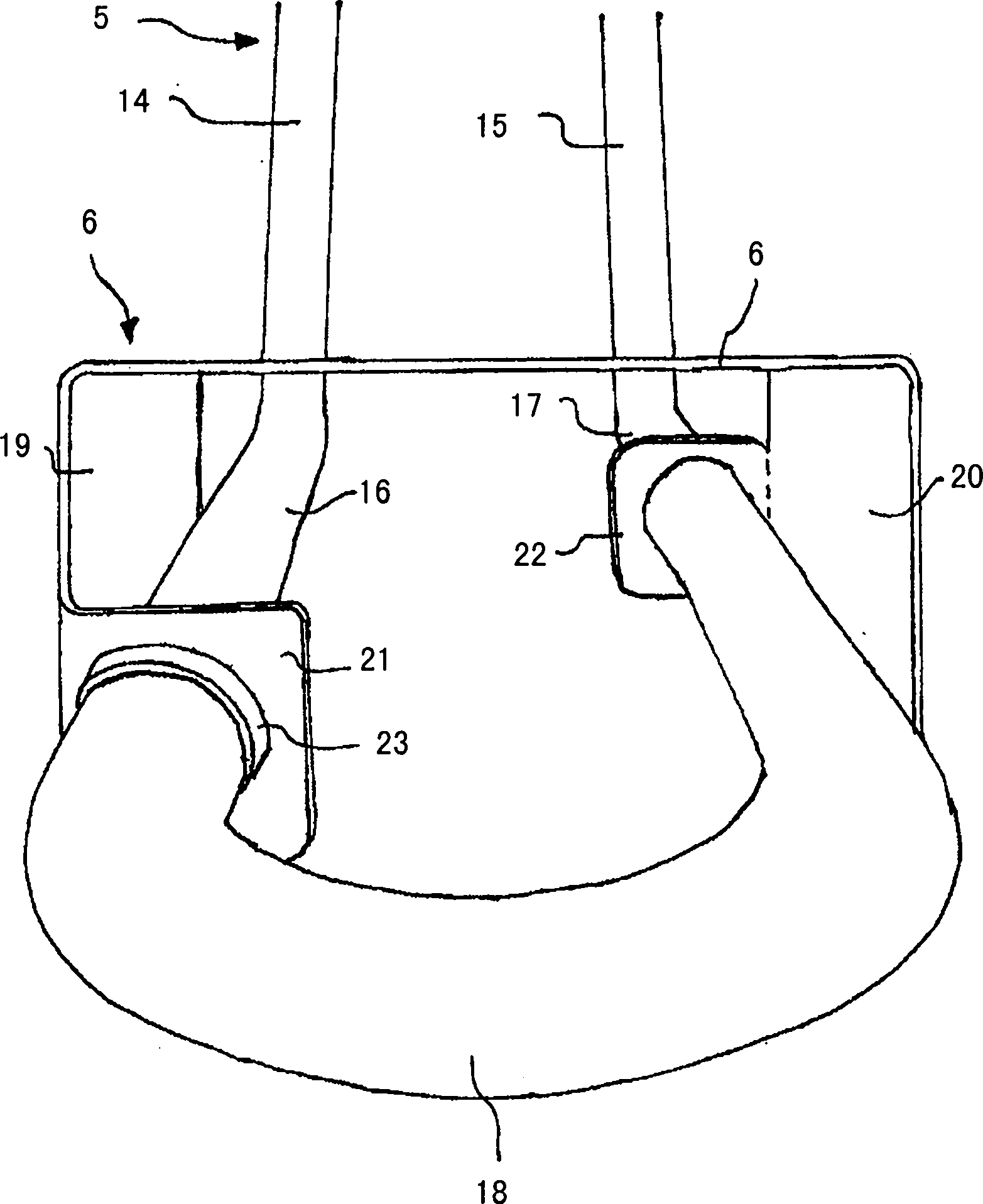

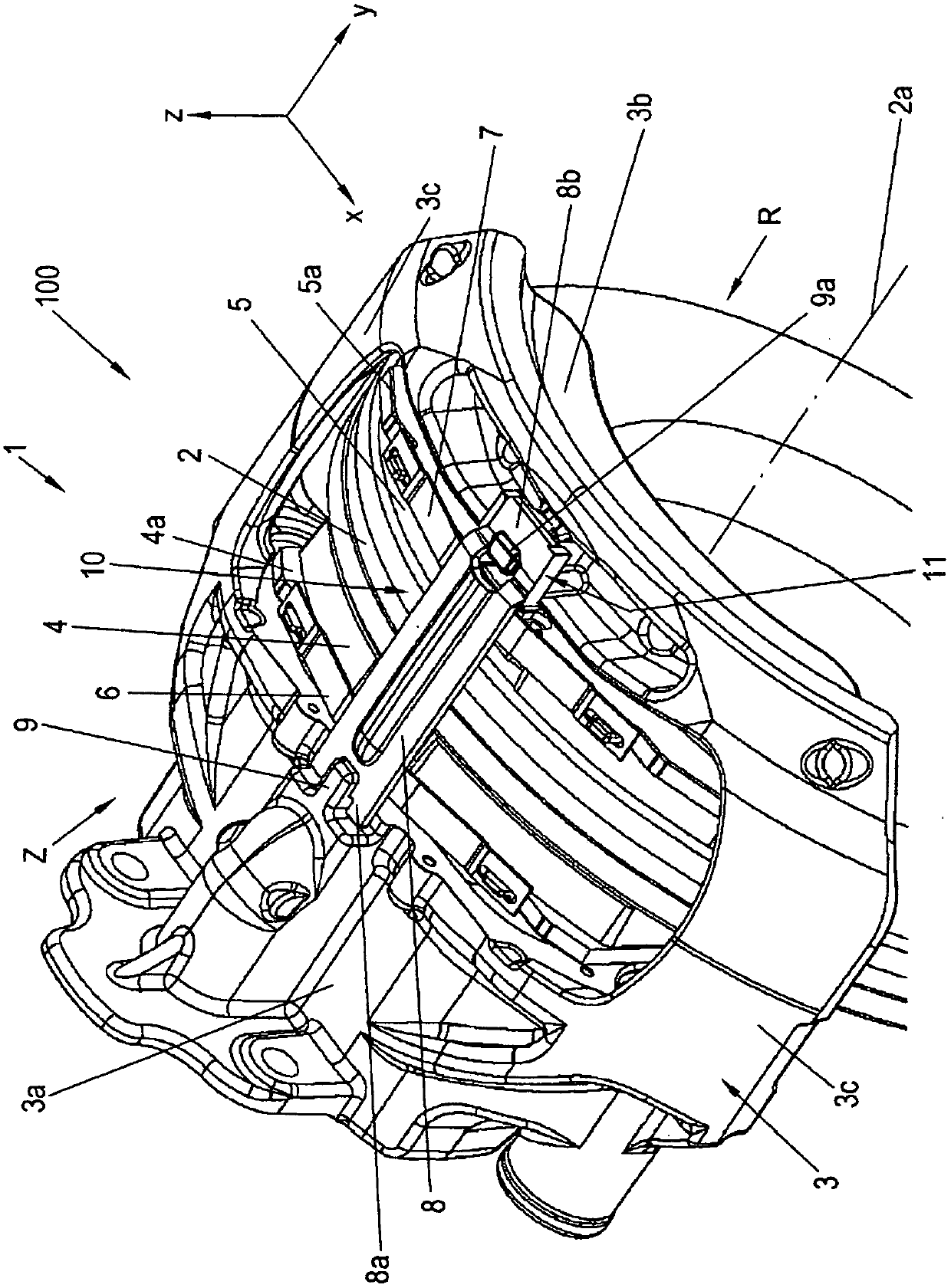

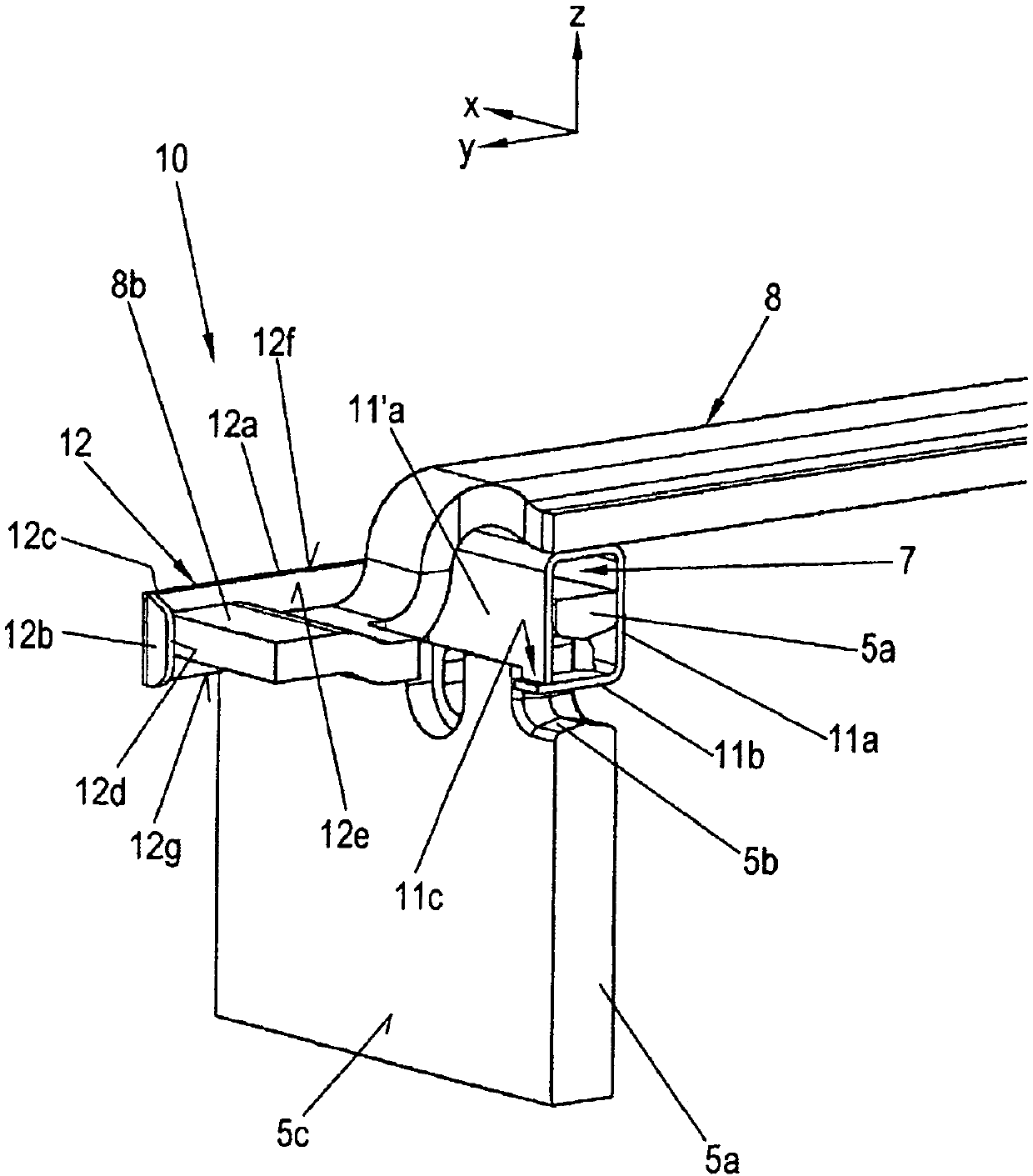

Actuating device for a rotatable closure part of a valve

ActiveCN104024710AEasy to guideImprove stabilityOperating means/releasing devices for valvesFluid-pressure actuatorsRotational axisDrive shaft

The invention relates to an actuating device 1 for a rotatable closure part of a valve, in particular a pneumatically or hydraulically actuable rotary drive for a disc valve or throttle valve, according to the preamble of claim 1. The invention is based on the problem of providing an actuating device of the generic type which is of simple construction, has high stability in the region of the mounting of the drive shaft and in the region of the rectilinear and curved guide which is arranged in the driving piston, and has a stroke-independent, direct rotary-angle limiting means with accuracy which is as great as possible. This is achieved by virtue of the fact that the drive shaft (6) is mounted radially on two sides in a bearing sleeve (2.4) which engages into the housing (2), is connected fixedly to the latter and ends in the latter, that the piston skirt (4.2; 40b.2) is mounted axially displaceably and radially on the outer circumferential surface of the bearing sleeve (2.4), and that the at least one drive pin (12) experiences a stroke-independent, direct limiting of the rotational movement thereof about the rotational axis (A) by way of stop means (2.4a) which are provided in the bearing sleeve (2.4).

Owner:GEA TUCHENHAGEN GMBH

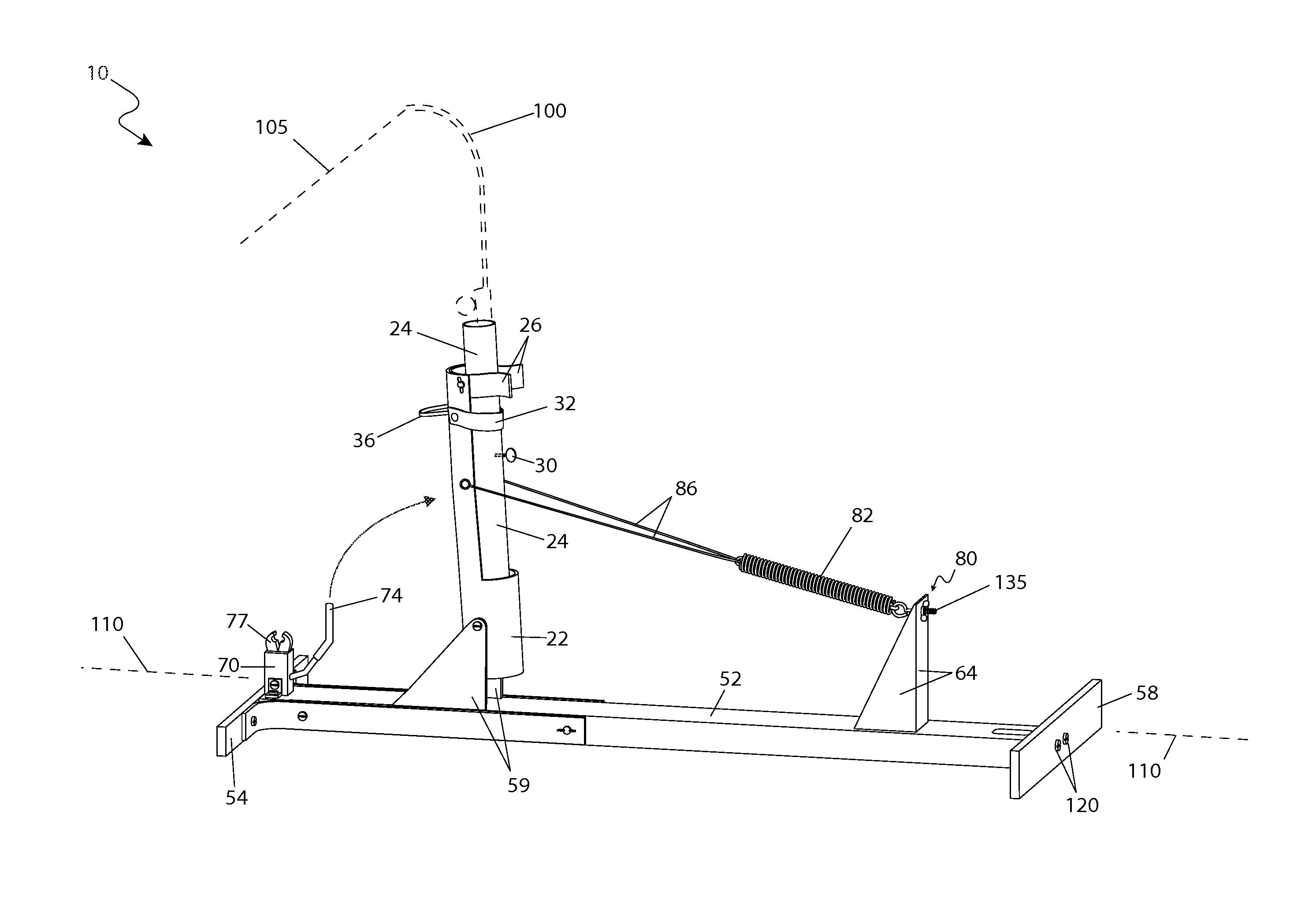

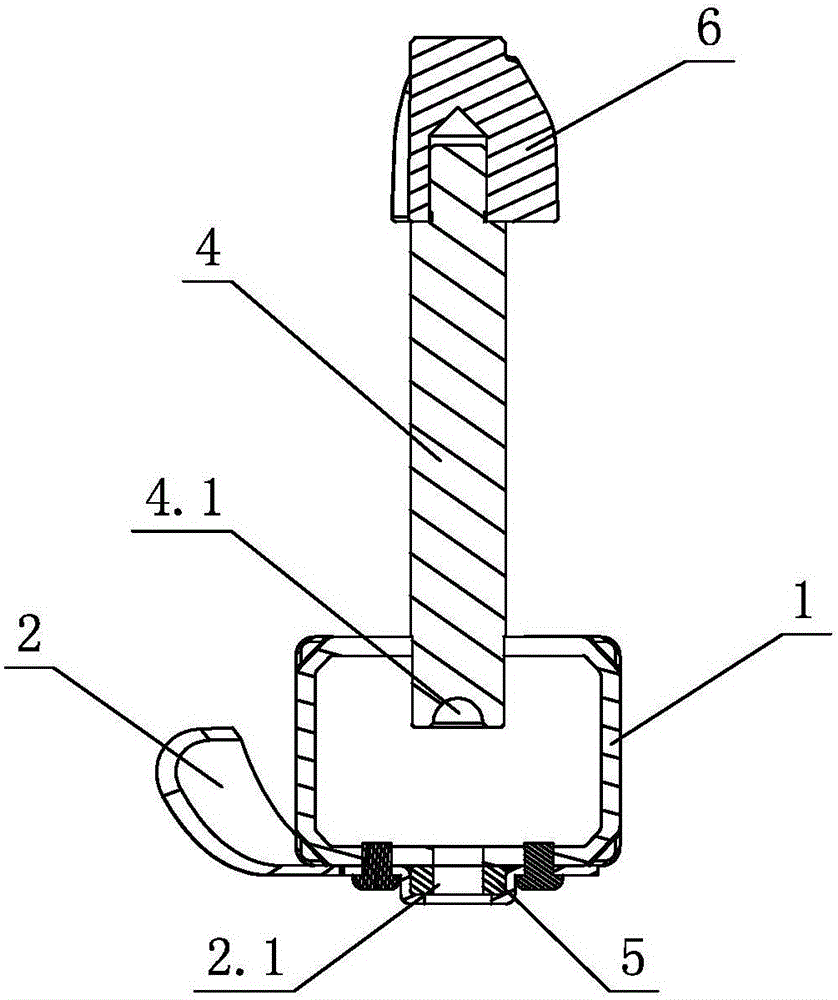

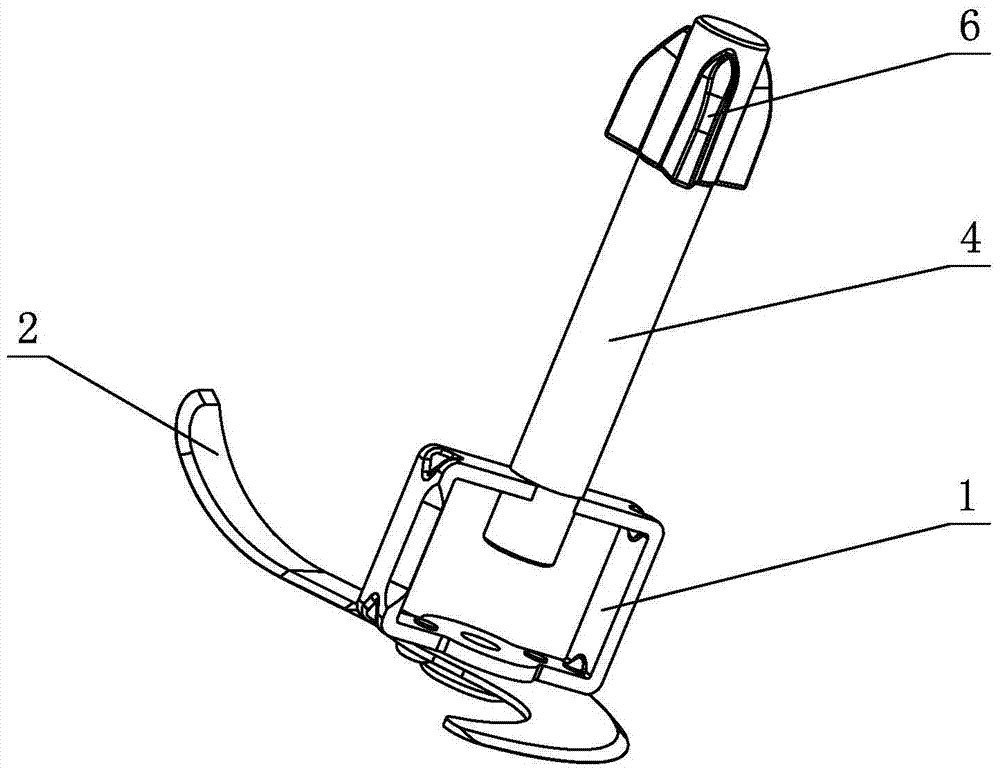

Fishing rod holder with hook setting capability

A device for automatic setting of a hook for use with an existing fishing rod comprises a base, a holder, and a trigger mechanism. The base comprises a weighted bottom portion and adjustable leg portions which provide stability to an existing fishing rod. The fishing rod is held at an angled position on the base via insertion of a handle portion into a tubular receiver. The holder mechanism comprises an adjustable-force coil spring for setting the hook. Furthermore, the trigger mechanism allows a user to place a rod in the holder and selectively adjust the tension required to release the trigger, such that a force applied by a hooked fish will cause the trigger to release, thereby allowing the coil spring to pull the rod upright to set the hook in the fish's mouth.

Owner:BABBS RONALD J +1

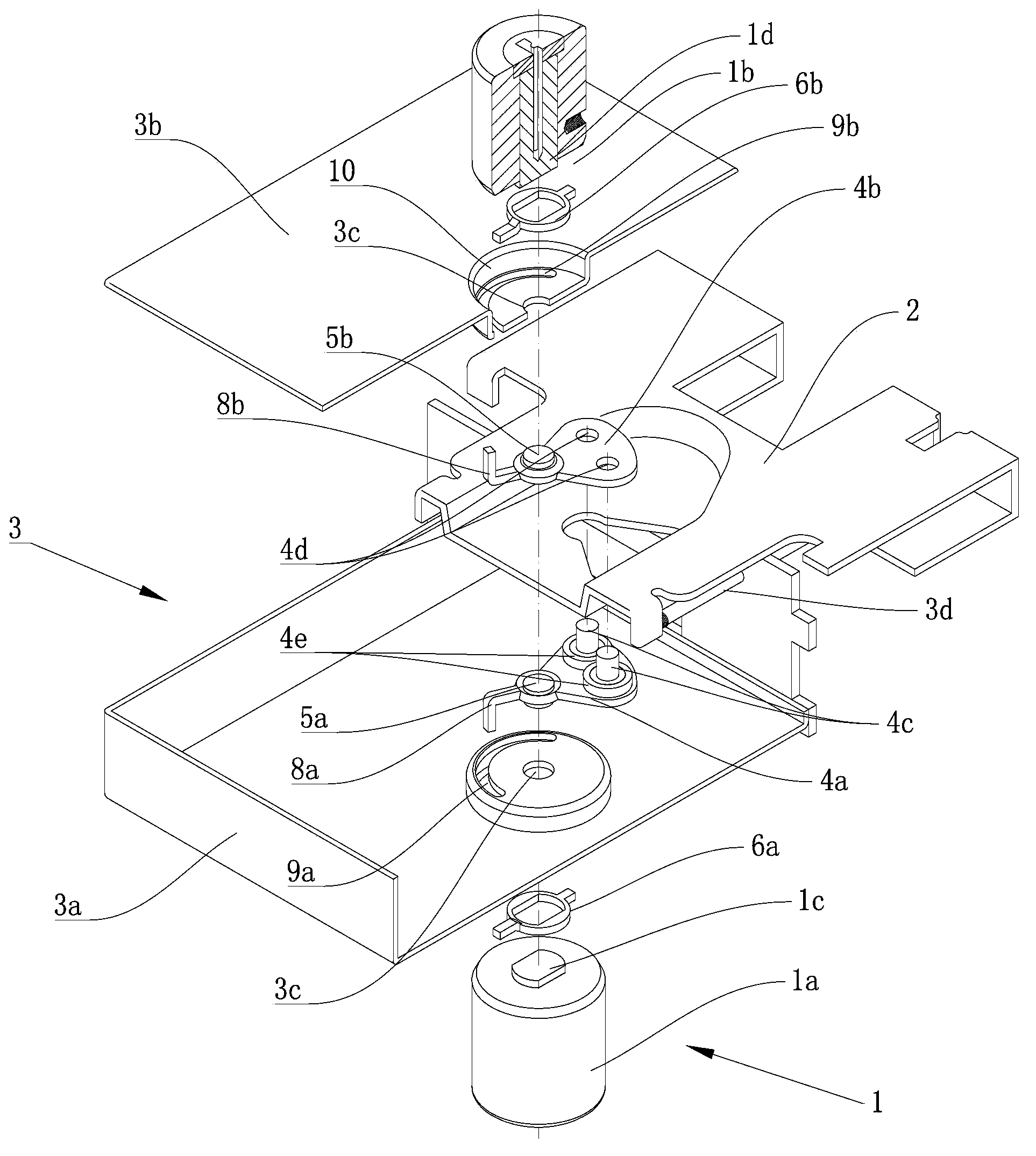

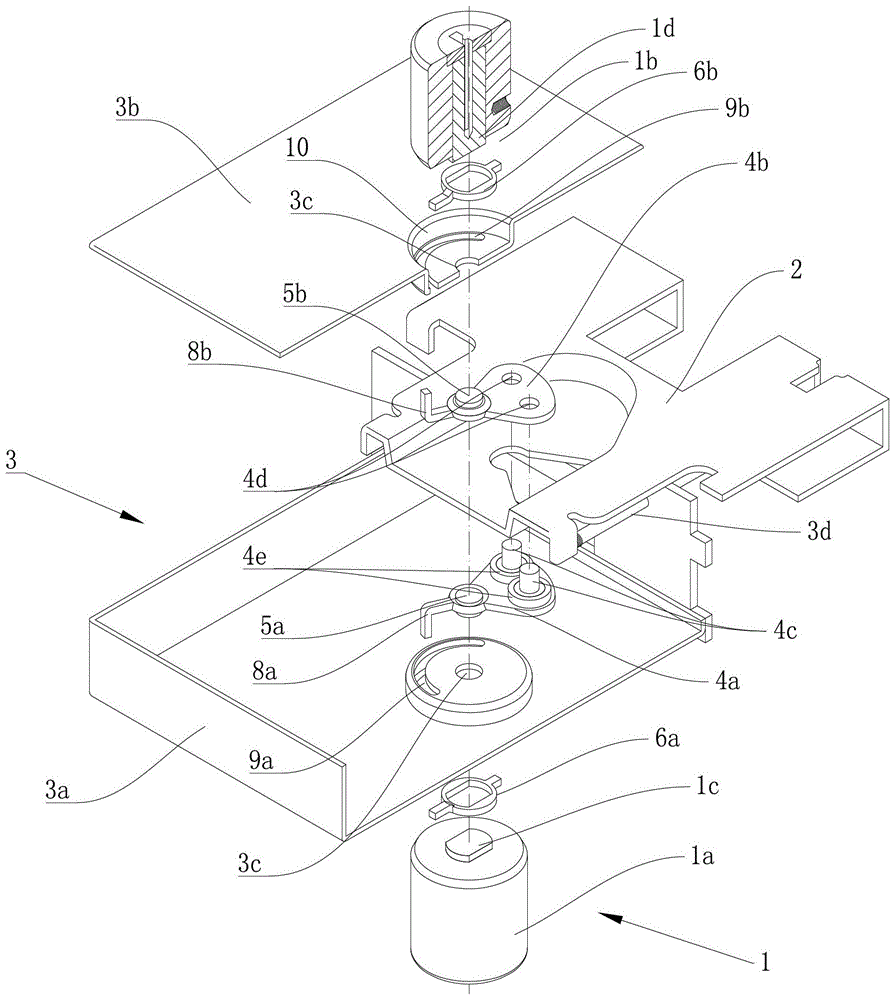

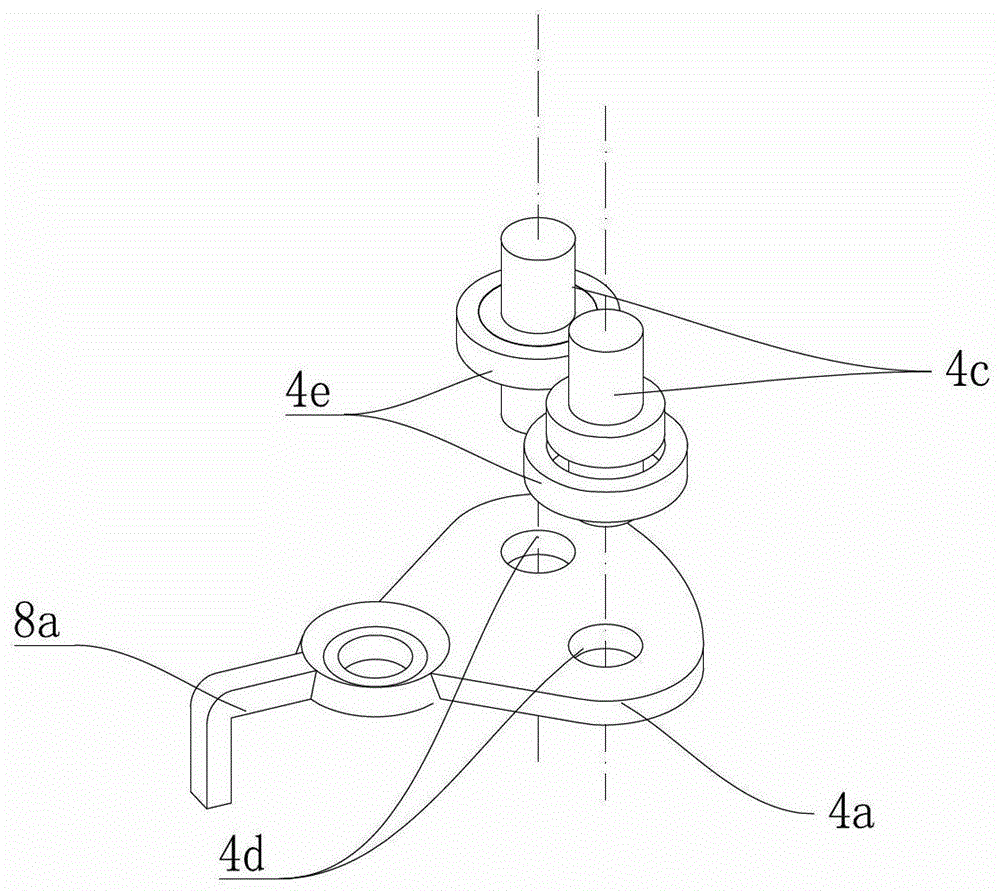

Control mechanism of dual-opening lock

ActiveCN104100146AMovement does not blockThere will be no co-rotationBuilding locksMechanical engineeringEngineering

The invention discloses a control mechanism of a dual-opening lock. The control mechanism comprises a lock assembly, a lock-in and lock-out mechanism, a swinging piece and two switching pieces, wherein the lock-in and lock-out mechanism comprises an installing shaft, the installing shaft is located between lock cores of an indoor lock and an outdoor lock, the position of the installing shaft is fixed relative to lock core shafts, and the installing shaft is independent of the lock core shafts; the swinging piece is rotationally arranged on the installing shaft and is provided with sliding pins which are used for pushing a bolt plate to move along the lock-in and lock-out direction; the two switching pieces are used for respectively driving the swinging piece to rotate around the installing shaft under the driving of the corresponding lock core shafts; one switching piece does not rotate synchronously when the swinging piece is driven to rotate by the other switching piece; a gap which is used for a bolt plate to move along the lock-in and lock-out direction is reserved between the lock core of the indoor lock and the lock core of the outdoor lock.

Owner:WONLY SECURITY & PROTECTION TECH CO LTD

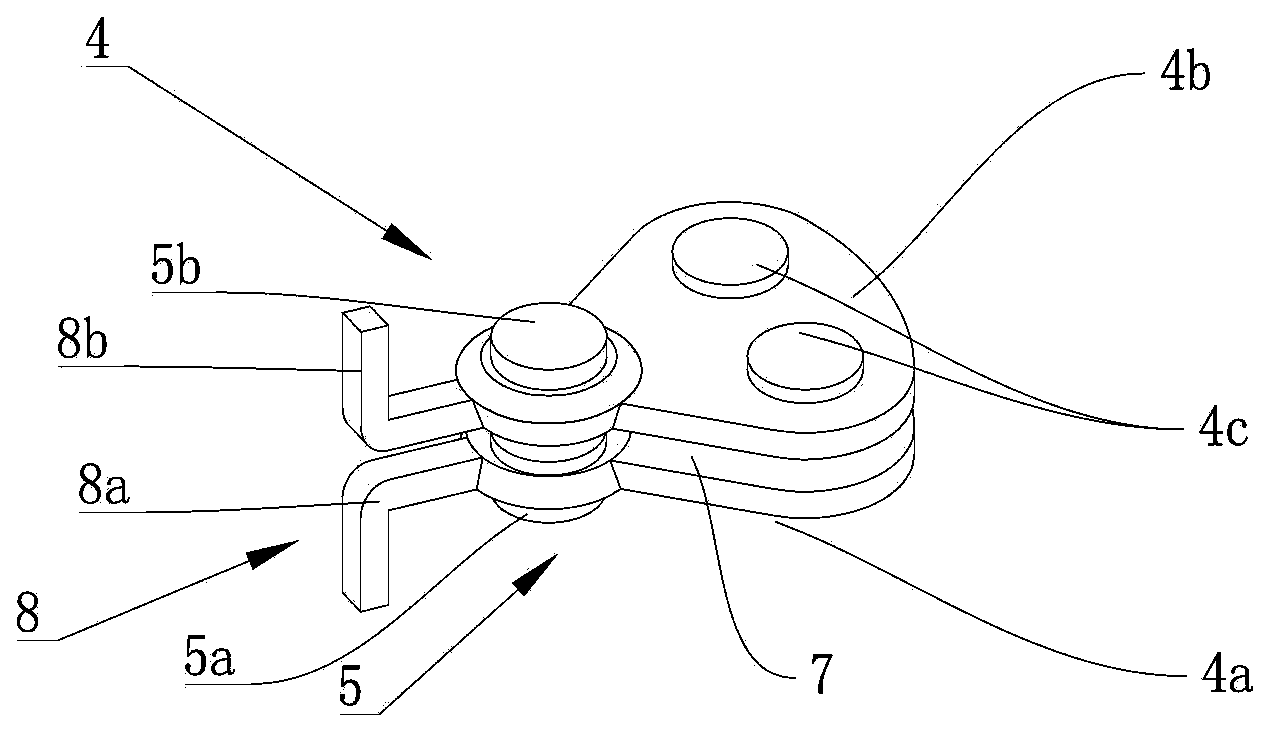

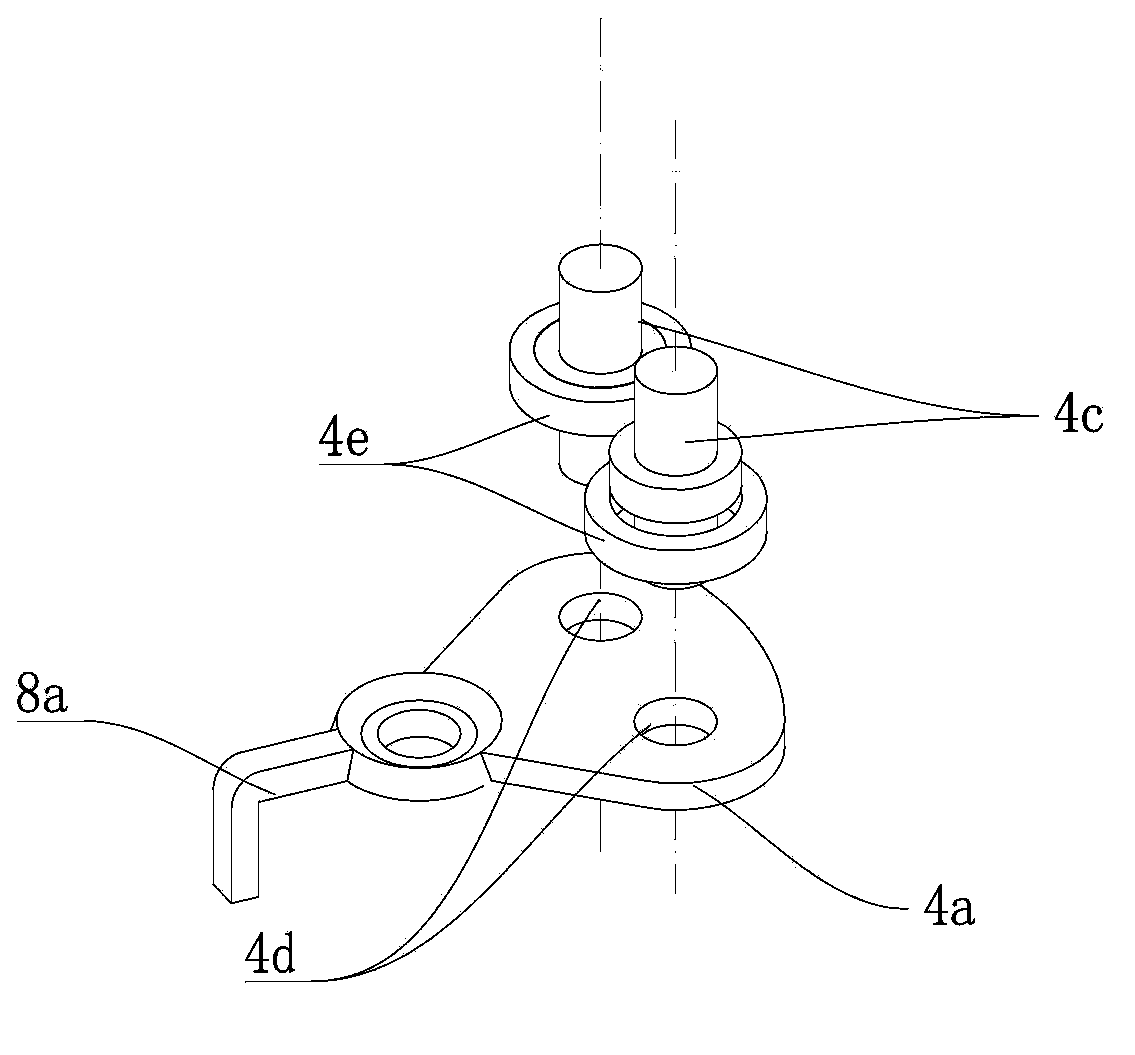

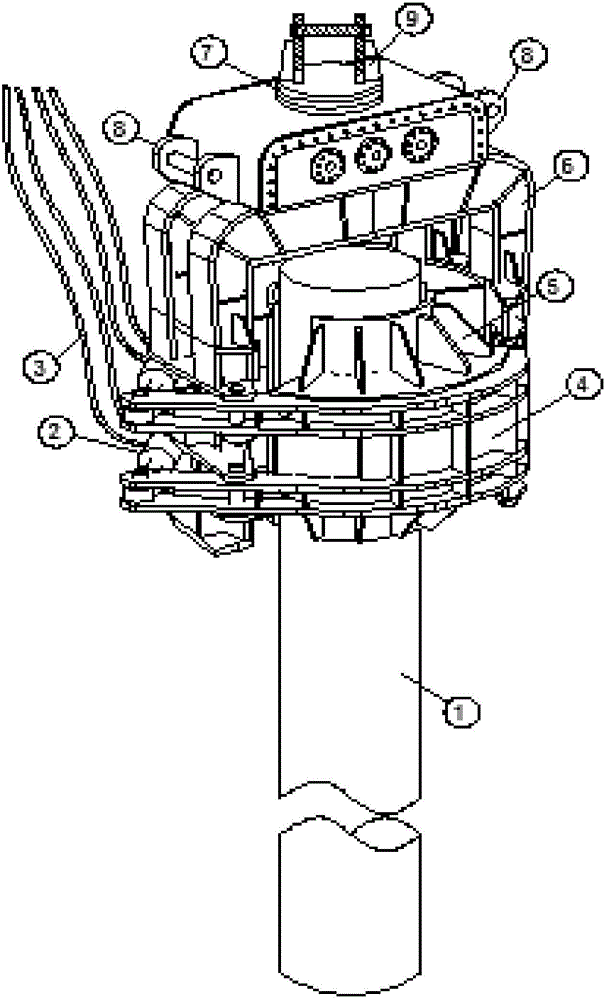

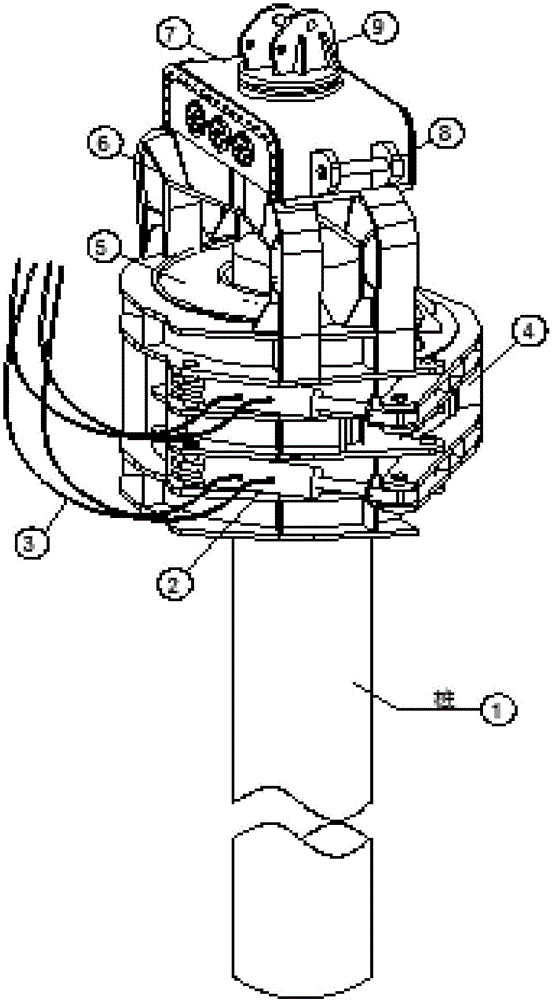

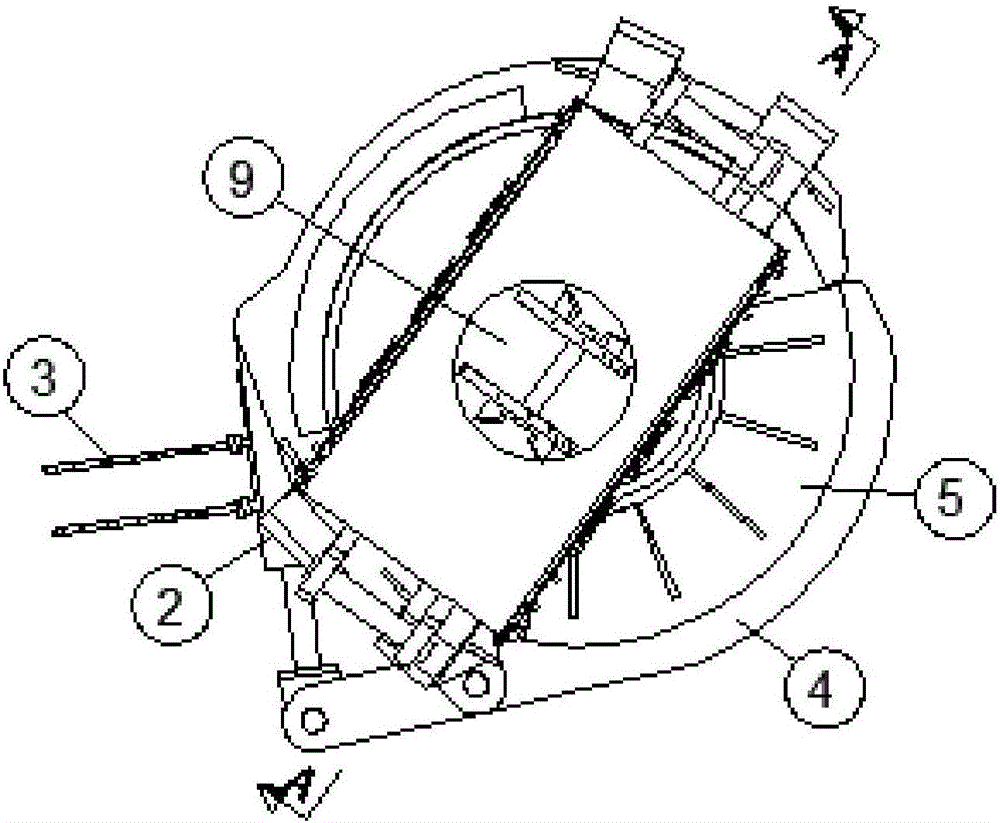

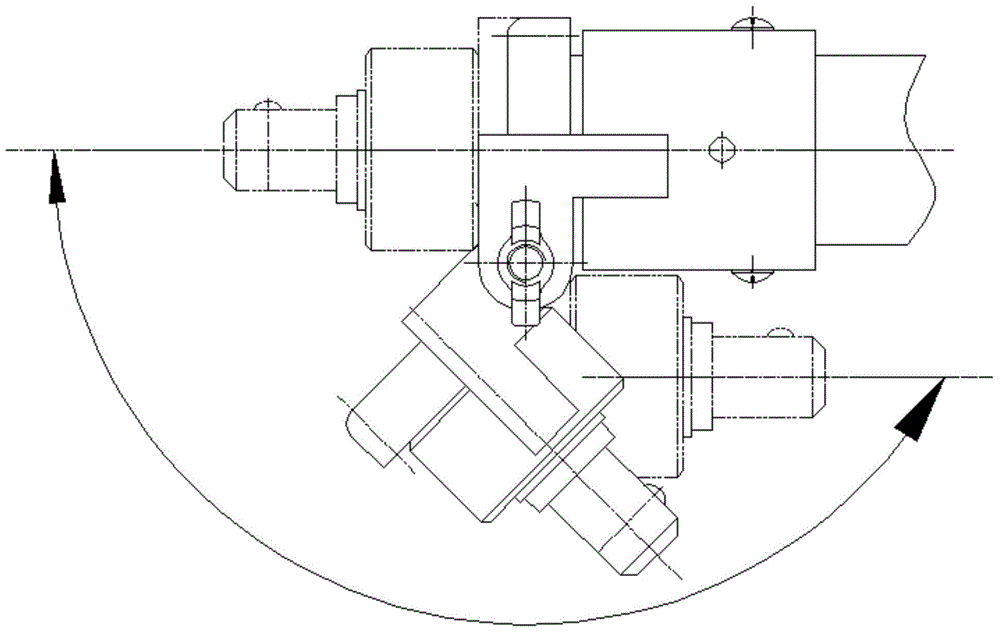

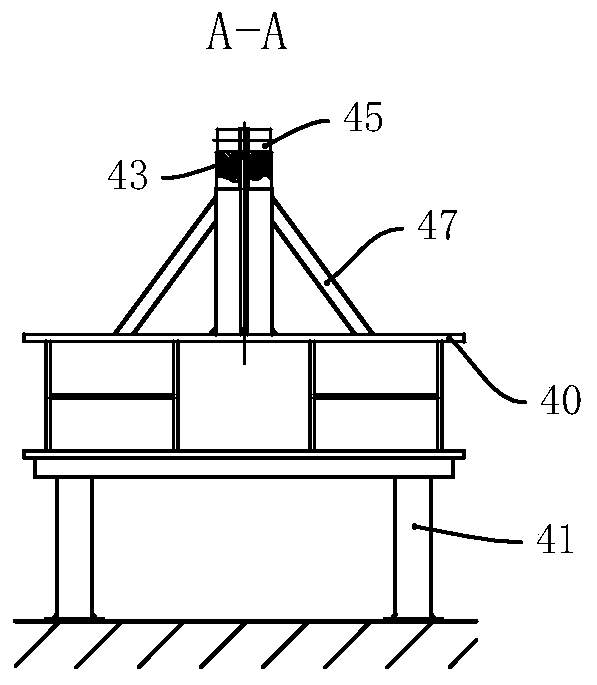

Hydraulic tong type pile pulling machine and pile pulling method

ActiveCN106759341ASo as not to damageIncrease frictionBulkheads/pilesControl theoryBuilding construction

The invention discloses a hydraulic tong type pile pulling machine and a pile pulling method. The hydraulic tong type pile pulling machine comprises a hydraulic tong type clamping device and a vibration machine. The vibration machine is arranged on the hydraulic tong type clamping device and provided with lifting lugs. The hydraulic tong type clamping device comprises an inner movable clamp and an outer clamp. The inner movable clamp comprises multiple movable blocks, and the multiple movable blocks form a clamp ring. The outer clamp comprises two tong arms. One end of one of the tong arms is connected with one end of the other tong arm through bolts, and electric hydraulic jacks are connected between the other ends of the tong arms. The outer clamp is arranged on the outer circle of the inner movable clamp in a sleeving manner, and the inner movable clamp is arranged on the outer circle of a to-be-pulled pile in a sleeving manner. The outer clamp locks the inner movable clamp through the electric hydraulic jacks, so that the inner movable clamp is closely attached to the to-be-pulled pile for clamping. The hydraulic tong type pile pulling machine is simple in sleeving assembly, large in clamping force, safe and reliable and attached to the pile more; the slipping-off situation generated in the pile pulling process is avoided; the pile can be pulled out more easily; efficiency is improved; a pile body is prevented from being damaged; and the hydraulic tong type pile pulling machine is simple in structure, easy to operate, small in size and free of limitation of geographic positions and facilitates construction.

Owner:CHINA FIRST METALLURGICAL GROUP

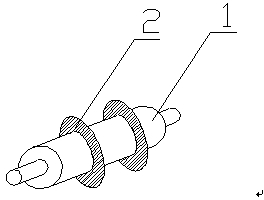

Guide roller with rubber rings

Owner:WUXI DAAFU INFORMATION TECH

Water feeder for livestock breeding

InactiveCN108668935APrevent drinkingAvoid illnessAnimal watering devicesAvicultureLivestock breedingEngineering

The invention discloses a water feeder for livestock breeding. The water feeder comprises a water supply tank and a mounting baseplate, a control panel is fixedly installed on the outer wall of the left side of the water supply tank, and the top of the water supply tank is provided with a storage battery and a water inlet; an electric heating device, a high water level sensor and a sensor device are fixedly installed in the water supply tank, a waterproof motor is fixedly installed at the bottom of the water supply tank, and water outlets are formed in the bottom of the waterproof tank; supporting columns are fixedly connected to the bottom of the water supply tank, water conveying pipes are arranged in the supporting columns of a hollow structure, and the water outlets are connected to water conveying pipes; the mounting baseplate is fixedly connected to the lower end faces of the supporting columns, fixing bolts are arranged on the mounting baseplate, and fixed columns are fixedly installed on the mounting baseplate; a sliding column is slidingly connected to the fixed columns, drinking bowls are fixedly connected to the upper end face of the sliding column, first supporting columns are fixedly connected to the lower end face of the mounting baseplate, and universal wheels are arranged at the lower ends of the first supporting columns. The water feeder for livestock breedingis simple in structure and reasonable in design and can be conveniently moved and fixed, and livestock drink water conveniently.

Owner:LIUZHOU HUANSHU ECOLOGICAL CULTURE PARK

Cap for writing tool

InactiveCN101049782AImprove buffering effectPrevent pen cocoonsWriting connectorsNon-propelling pencilsEngineering

Owner:TOMBOW PENCIL CO LTD

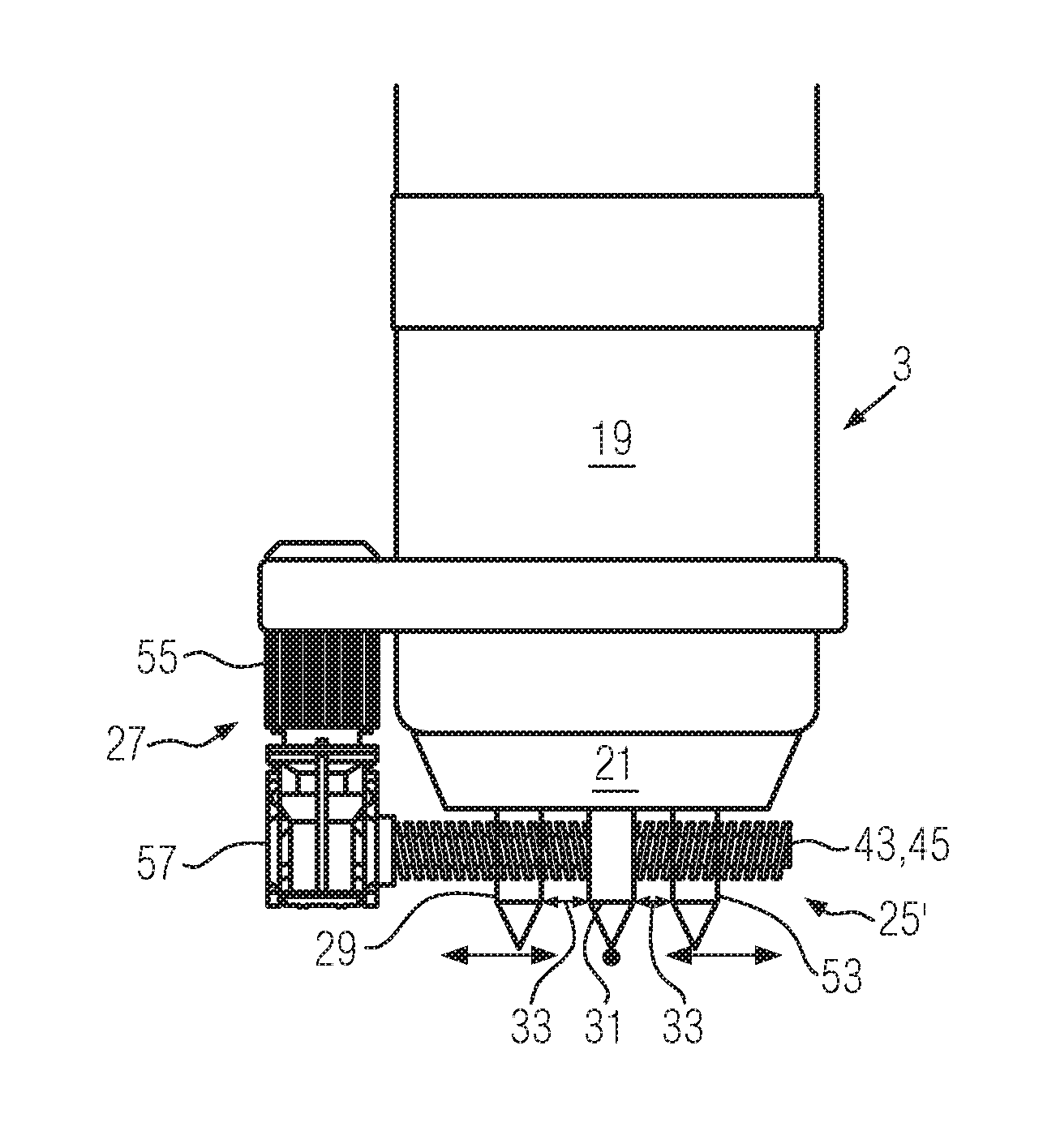

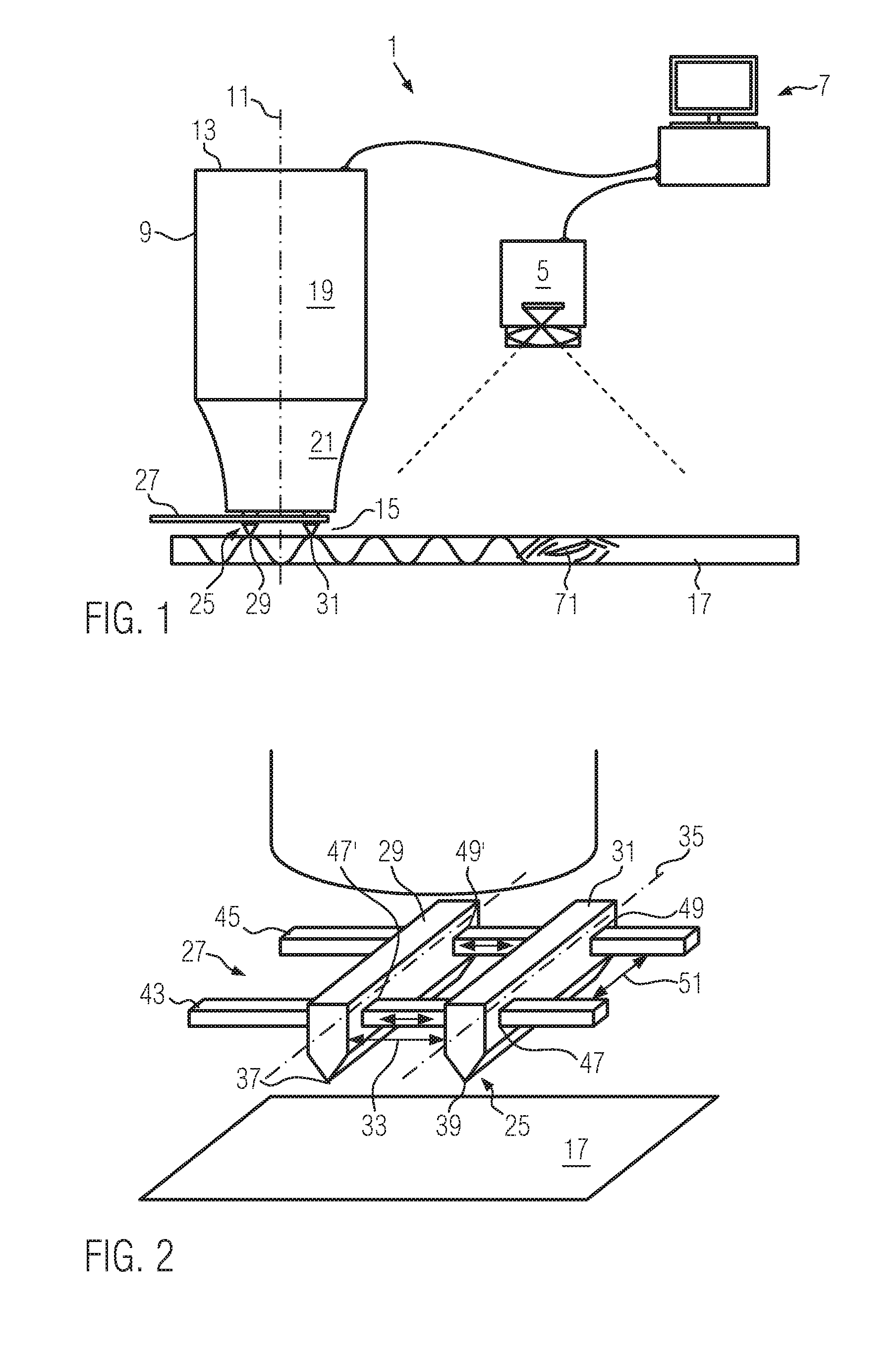

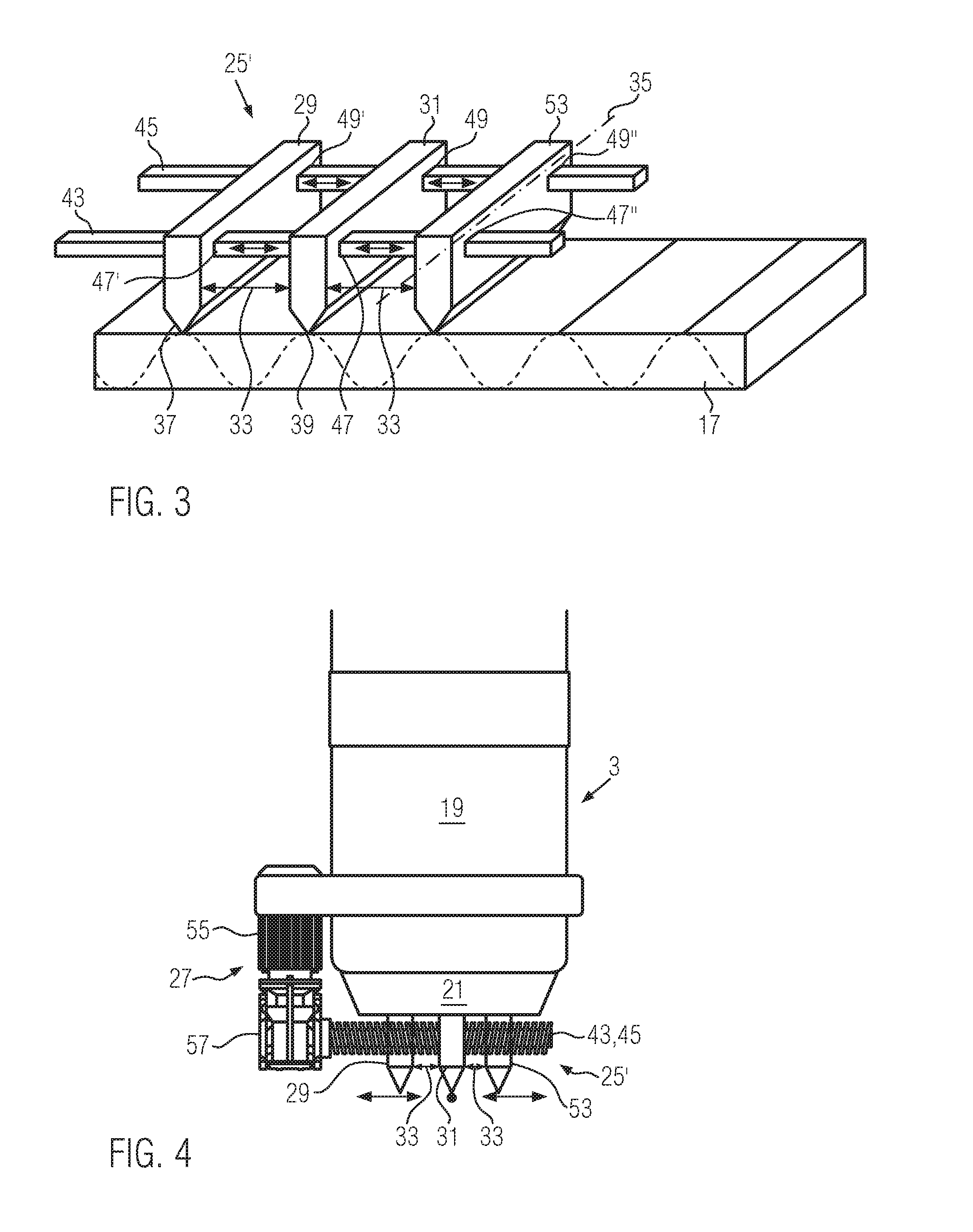

System for non-destructive inspection of structural components

ActiveUS20160299108A1Simple setStructural defectMaterial analysis using sonic/ultrasonic/infrasonic wavesRadiation pyrometryEngineeringUltrasound probe

A system for non-destructive inspection of structural components comprising an ultrasonic probe having a contact face for contacting a surface of a structural component to be inspected and being adapted to emit ultrasonic energy into the structural component when the contact face abuts on a surface of the structural component, a thermal imaging camera adapted to inspect a portion of a surface of the structural component to detect region of the surface of the structural component where an increase of the temperature occurs, and a control unit connected to the ultrasonic probe and the thermal imaging camera. The contact face extends in a plane and is provided with at least two bars which are arranged in parallel and have a common separation distance from each other.

Owner:AIRBUS OPERATIONS GMBH

Hip abduction orthosis

ActiveUS8118764B2Simple setStrong attachmentRestraining devicesNon-surgical orthopedic devicesSet distanceKnee orthosis

A hip abduction orthosis for stabilizing the hip joints of a user, provided with a trunk engaging part, first and second thigh engaging parts and first and second coupling parts, wherein the first coupling part connects the first thigh engaging part with the trunk engaging part and the second coupling part connects the second thigh engaging part with the trunk engaging part. A distance between the first and / or the second thigh engaging part and the trunk engaging part is settable. An abduction angle of that thigh engaging part is settable. The distance and the abduction angle are coupled such that a first set distance between that thigh engaging part and the trunk engaging part is coupled with a first set abduction angle and a second set distance different from the first set distance is coupled with a second set abduction angle different from the first set abduction angle.

Owner:OSSUR EURO

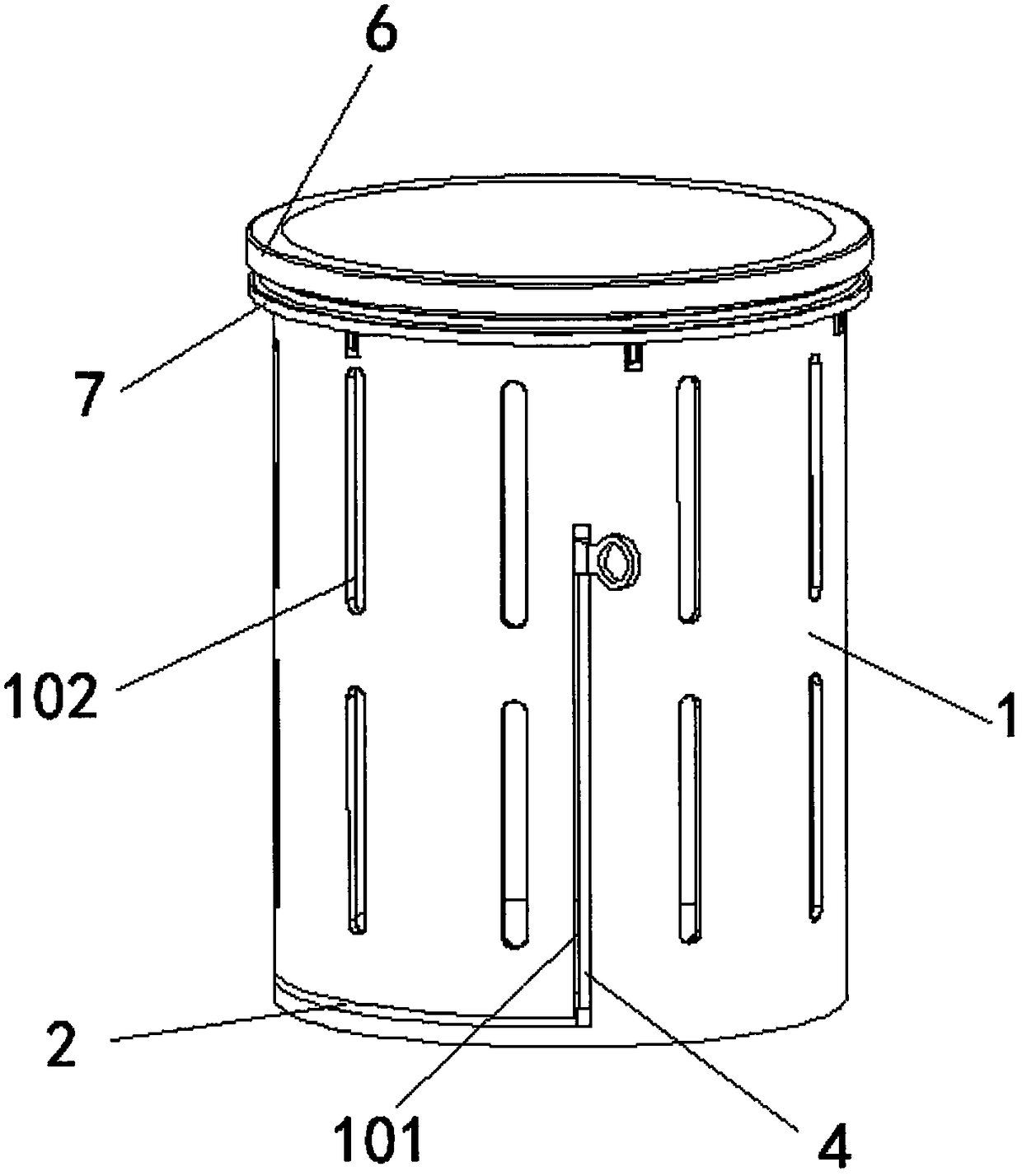

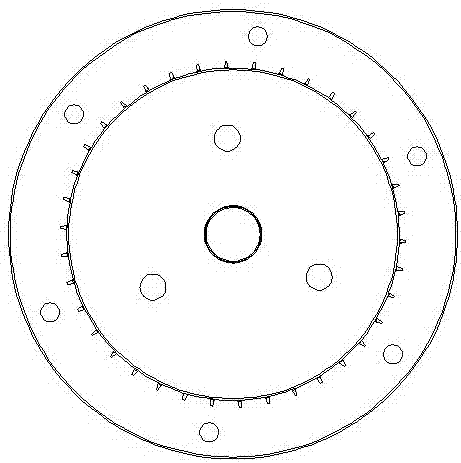

Garbage bin with garbage bag being conveniently mounted in sleeved mode

The invention relates to the technical field of garbage bins, in particular to a garbage bin with a garbage bag being conveniently mounted in a sleeved mode. The garbage bin comprises a garbage bin body which is a cylindrical bin body, and further comprises a clamping mechanism, the outer wall of the lower end of the garbage bin body is provided with a storing groove, an elastic clamping ring is stored in the storing groove in a matched mode, a vertical rod is fixed to the end of the elastic clamping ring, and the top of the vertical rod is rotatably connected with a handle; and the clamping mechanism comprises a first clamping ring and a second clamping ring, the first clamping ring is coaxially fixed to the top edge of the garbage bin body, strip-shaped rods are evenly fixed on the circumference of the outer wall of the garbage bin body, and sliding grooves are formed in the outer end faces of the strip-shaped rods in a clamped mode. The garbage bin can effectively solve the problemthat in the prior art, as for a garbage bin, a garbage bag is inconveniently mounted in a sleeved mode, and simultaneously solves the problem that the garbage bin is prone to being contaminated by garbage.

Owner:邓芝英

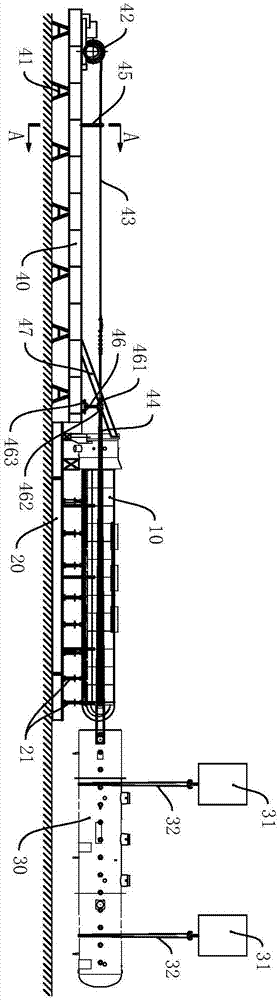

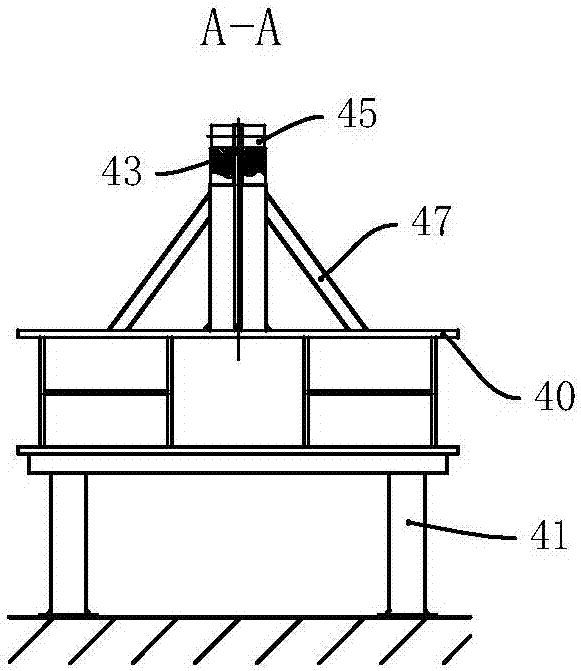

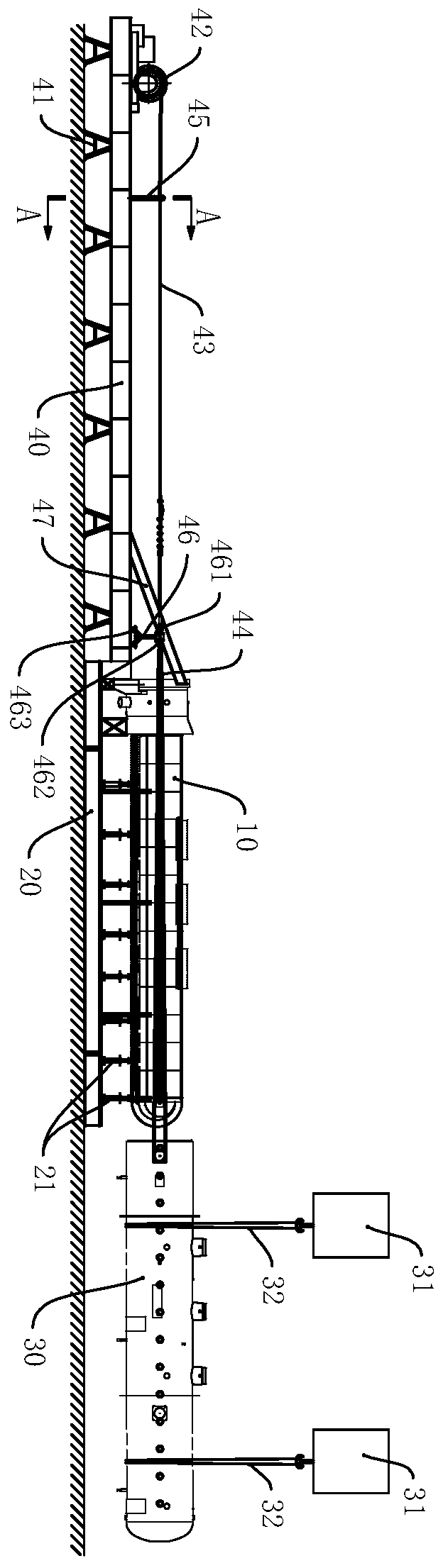

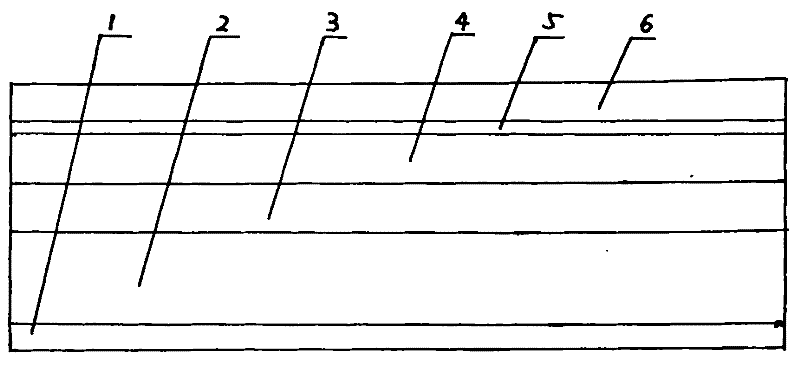

Sleeving device and sleeving method for pipe system without guide rollers and shell

The invention discloses a sleeving device and a sleeving method for a pipe system without guide rollers and a shell. The device comprises the pipe system, the shell, and a support platform positioned below the pipe system; the support platform is provided with multiple bracket units connected with the bottom of the pipe system in a support manner and independent from each other; a working platform is arranged on one side of the head end of the pipe system; the shell is arranged on one side of the tail end of the pipe system; a walking crane for naturally hanging the shell is arranged above the shell; a windlass and a rope limiting device are fixedly arranged on the working platform; a first traction rope extending from a rope outlet of the windlass penetrates through the rope limiting device, and the tail end of the first traction rope is connected with a rope separation device; the first traction rope is connected with a first joint of the rope separation device; and a second traction rope extending from a second joint of the rope separation device is respectively connected to two sides of the shell. The method realizes sleeving between the pipe system and the shell, and achieves the effects of low deformation of the pipe system, precise matching between the pipe system and the shell and completion of once stable sleeving.

Owner:DONGFANG (GUANGZHOU) HEAVY MASCH CO LTD

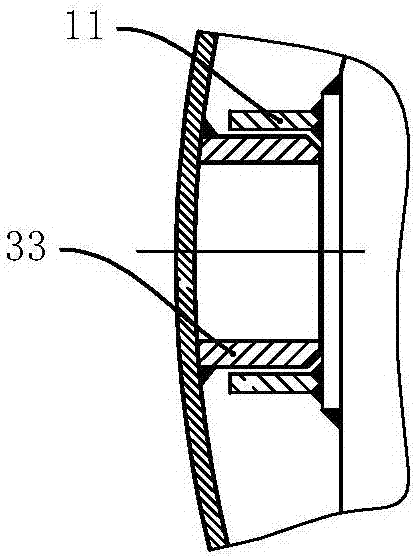

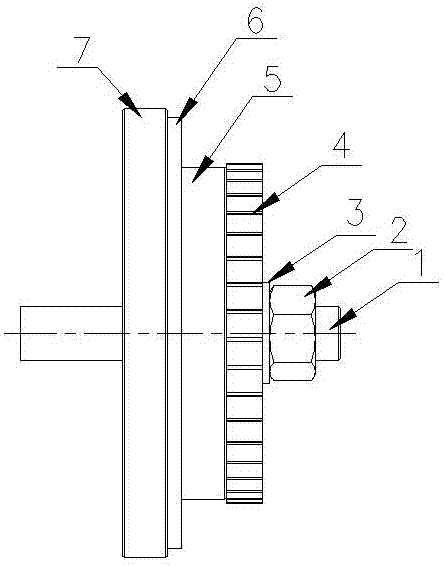

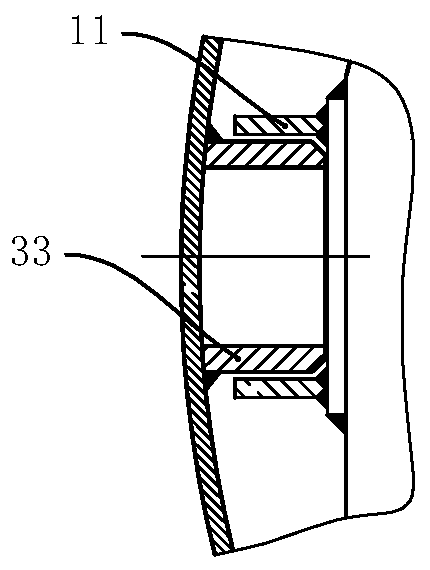

Voltage-regulating middle insulation structure of 330kV on-load voltage-regulating transformer

PendingCN108630414AHigh dielectric strengthReduce the chance of partial dischargeTransformers/inductances coils/windings/connectionsVariable inductancesTransformerVoltage regulation

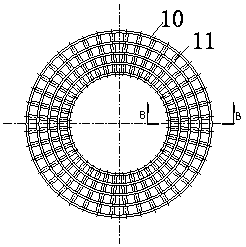

The invention relates to a voltage-regulating middle insulation structure of a 330kV on-load voltage-regulating transformer, and belongs to the technical field of the transformer equipment. The technical scheme is as follows: the structure comprises a voltage-regulating coil one (1), a 330kV lead outgoing device (4), a voltage-regulation coil two (5), a composite insulation cylinder (6) and an insulation paper ring (7); the 330kV lead outgoing device (4) is arranged between the voltage-regulating coil one (1) and the voltage-regulating coil two (5); the composite insulation cylinder (6) and the insulation paper ring (7) are filled among the voltage-regulating coil one (1), the 330kV lead outgoing device (4) and the voltage-regulating coil two (5); the insulation paper ring (7) is arrangedat the middle location beside the 330kV lead outgoing device (4), the composite insulation cylinder (6) is arranged at two ends of the insulation paper coil (7); and the composite insulation cylinder(6) is formed by sleeving an insulation cylinder (10) and a stay (11). The voltage-regulating middle insulation structure disclosed by the invention improves the insulation intensity at the middle ofthe 330kV on-load voltage-regulating transformer, reduces the local discharge possibility, and simple in manufacturing and sleeving.

Owner:BAODING TIANWEI BAOBIAN ELECTRICAL

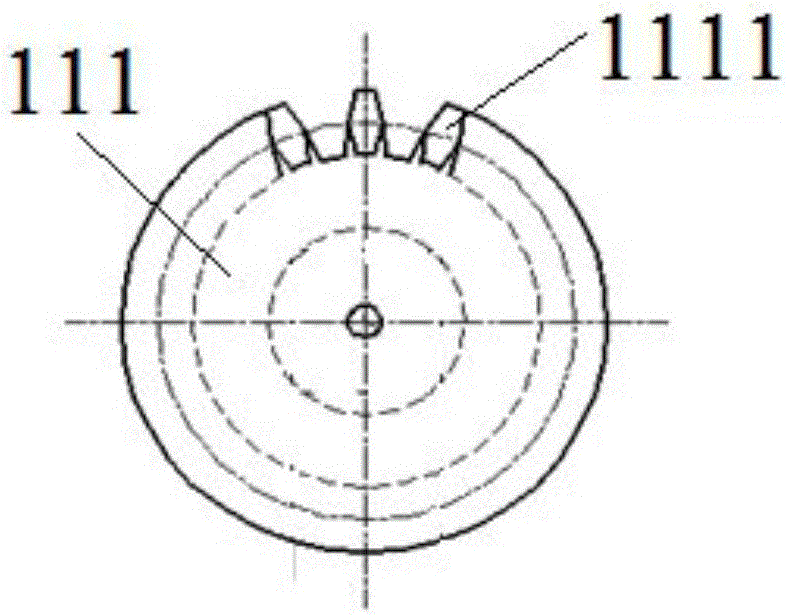

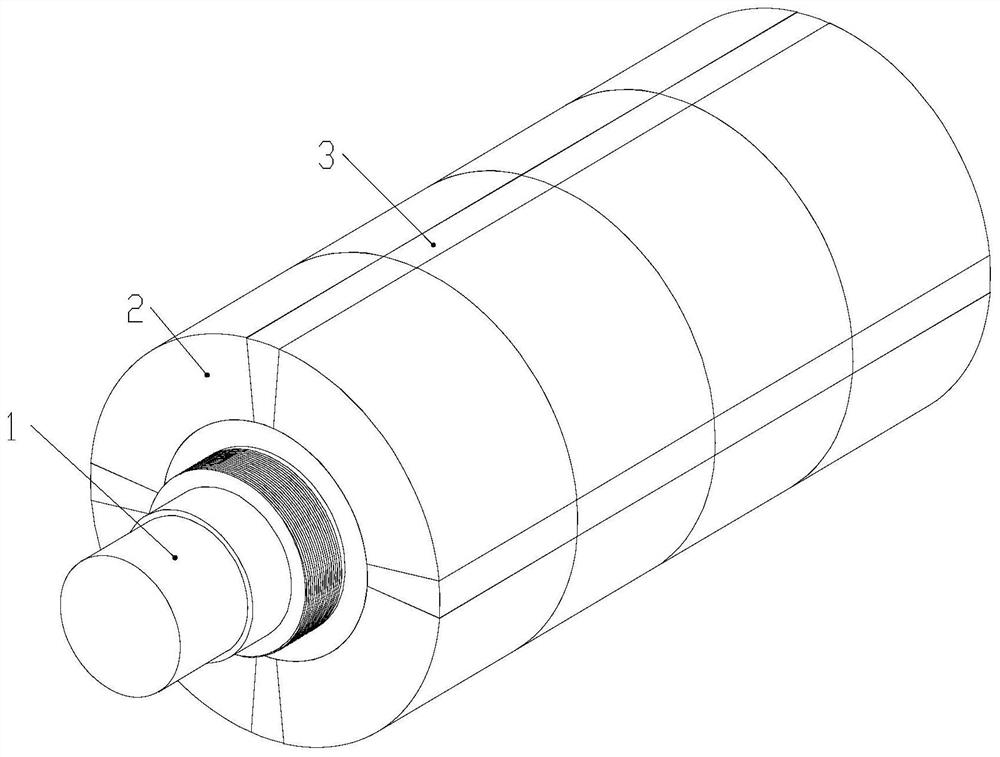

High-speed high-power permanent magnet synchronous motor rotor

ActiveCN110571959ASimple structureImprove reliabilityMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsSynchronous motorPermanent magnet synchronous motor

The invention provides a high-speed high-power permanent magnet synchronous motor rotor, which belongs to the technical field of motors. The problems that the existing high-speed high-power permanentmagnet synchronous motor has difficulty in sheathing the sheath of the rotor and the prestress cannot be adjusted according to requirements are solved. The motor rotor mainly comprises a rotation shaft, a main permanent magnet, an auxiliary permanent magnet, a positioning key, a pre-tightened wedge, a pre-tightened nut and a sheath. The pre-tightened nut is used to axially squeeze a tapered or wedge-shaped device. According to the rotor diameter and the rotation speed, the prestress acting on the permanent magnets is radially flexibly adjusted. The rotor provided by the invention is mainly applied in the field of motors.

Owner:HARBIN INST OF TECH

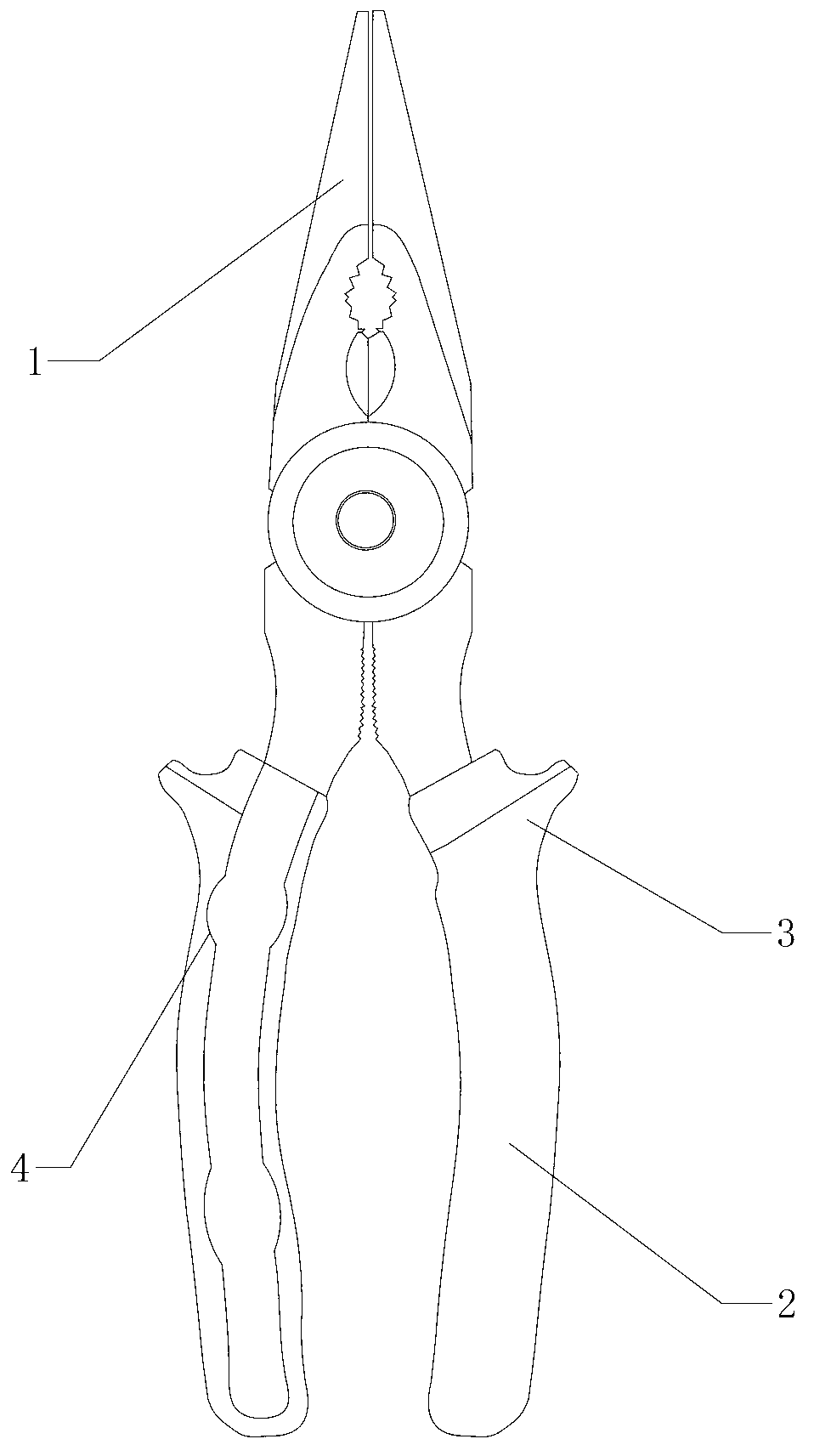

Pincers

The invention discloses a pair of pincers, which comprises a pincer mouth and handles, wherein the handles are sleeved by handle sleeves; and anti-dropping structures for preventing the handle sleeves from dropping are arranged between the handles and the handle sleeves. The friction between the handles and the handle sleeves is increased by adopting the anti-dropping structures, so that the probability of dropping of the handle sleeves is greatly reduced, and the pair of pincers is used to the greatest extent.

Owner:张家港市新谊五金工具有限公司

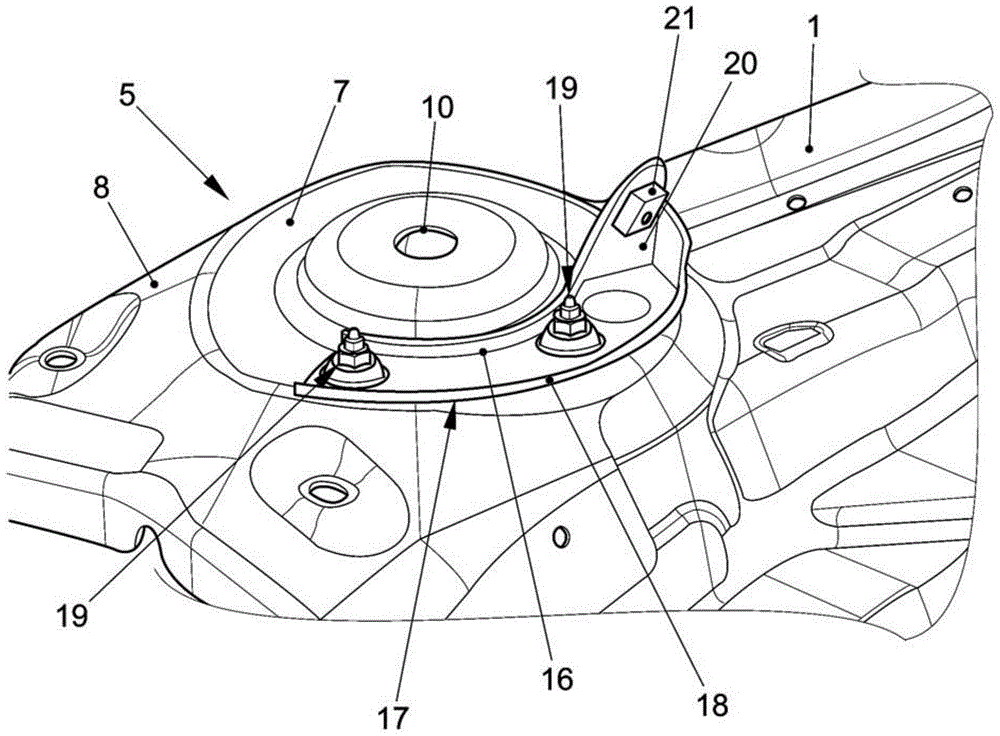

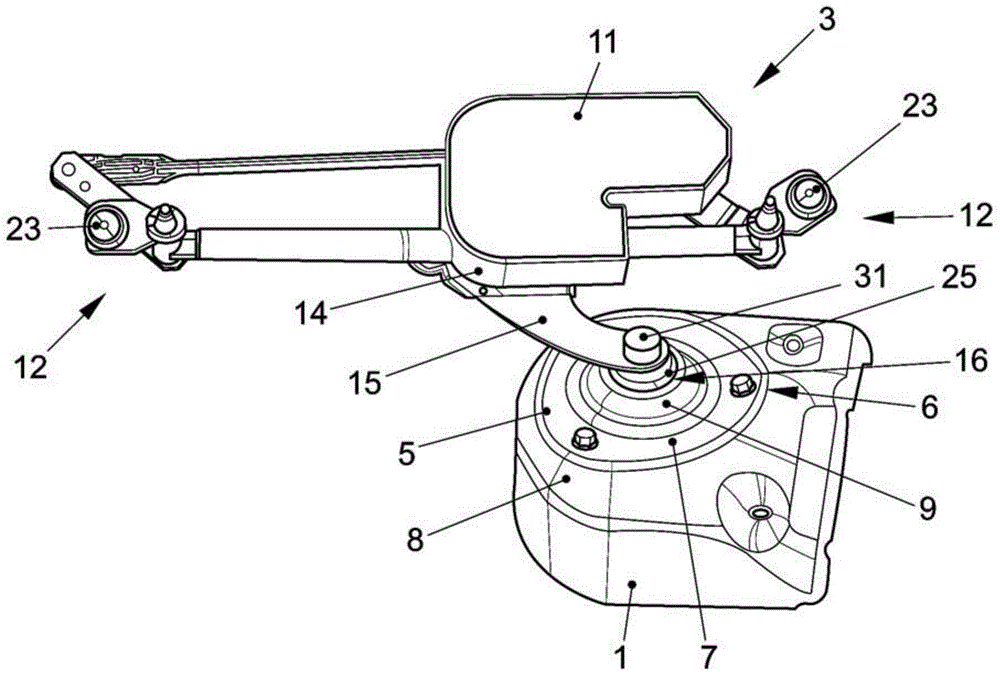

Device for securing wipers

ActiveCN104029656BReduce vibrationAvoid noiseSuperstructure subunitsVehicle cleaningCouplingEngineering

Owner:VOLKSWAGEN AG

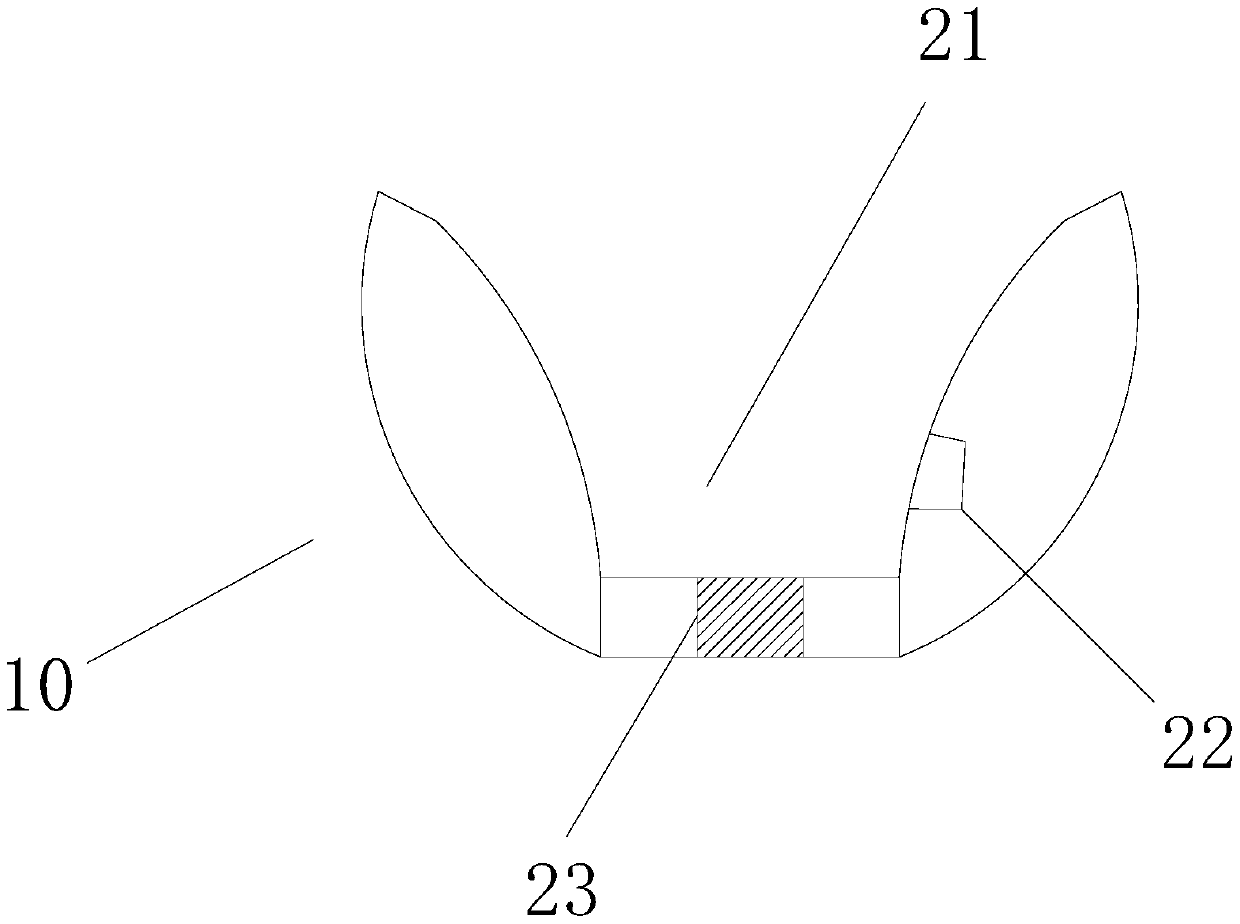

A mixing knife assembly

A stirring knife assembly at least comprises a knife bracket and a stirring shaft; the knife bracket is of a framework structure and is fixedly provided with at least one blade; the stirring shaft is fixedly connected with the knife bracket. The lower part of the knife bracket is provided with a first blade, and the upper part of the knife bracket can be provided with a second blade or can be not provided with the blade; the stirring shaft is not provided with a blade or is provided with at least one blade; the mode of blade arrangement on the knife bracket can be combined randomly with the mod of blade arrangement on the stirring shaft. Because the blade is connected with the stirring shaft through a non-injection molding mode, the defects brought by the injection molding process are avoided, the shape and the number of the blades have no limitation, and the blade arranged positions are relatively flexible; and moreover, the blade bracket adopts the framework structure, the braking structure is simplified, at the same time, a deep hole structure, which is matched with a positioning shaft of a stirrer, of a stirring shaft of a traditional stirring knife assembly is avoided, moreover, enough space is left for food to pass through, food is avoided from remaining in the deep hole structure, no cleaning dead angle exist, cleaning becomes easy, and the practicability is high.

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

Double lock head control mechanism

ActiveCN104100146BThere will be no co-rotationExtended service lifeBuilding locksEngineeringMechanical engineering

The invention discloses a control mechanism of a dual-opening lock. The control mechanism comprises a lock assembly, a lock-in and lock-out mechanism, a swinging piece and two switching pieces, wherein the lock-in and lock-out mechanism comprises an installing shaft, the installing shaft is located between lock cores of an indoor lock and an outdoor lock, the position of the installing shaft is fixed relative to lock core shafts, and the installing shaft is independent of the lock core shafts; the swinging piece is rotationally arranged on the installing shaft and is provided with sliding pins which are used for pushing a bolt plate to move along the lock-in and lock-out direction; the two switching pieces are used for respectively driving the swinging piece to rotate around the installing shaft under the driving of the corresponding lock core shafts; one switching piece does not rotate synchronously when the swinging piece is driven to rotate by the other switching piece; a gap which is used for a bolt plate to move along the lock-in and lock-out direction is reserved between the lock core of the indoor lock and the lock core of the outdoor lock.

Owner:WONLY SECURITY & PROTECTION TECH CO LTD

Water filter tube welding mould

PendingCN107363464AAchieve normalizationUniform gapWelding/cutting auxillary devicesAuxillary welding devicesWater filterWater pipe

The invention discloses a water filter tube welding mould. The water filter tube welding mould consists of a central shaft, a fixed-size ring, a steel wire fixed ring, a guide slot ring and an insulating gasket, wherein a plurality of axial V-shaped slot openings are processed in the inner wall of the steel wire fixed ring; the V-shaped slot openings are consistent with a V-shaped wire used for processing a water filter tube in shape, and are matched with the V-shaped wire in size; the steel wire fixed ring is connected and fixed onto a connecting plate of a water filter tube welding machine through a bolt; the central shaft gets out from a central hole of the connecting plate of the water filter tube welding machine; the fixed-size ring is arranged on the central shaft in a penetrating mode and is inserted into the steel wire fixed ring; the insulating gasket is connected onto the steel wire fixed ring through a bolt; the guide slot ring corresponds to the V-shaped slot in the steel wire fixed ring; the shaft end of the central shaft is equipped with outer threads; and a nut is rotatably arranged on outer threads at the shaft end of the central shaft. Compared with the prior art, the water filter tube welding mould realizes normalization of the water filter tube welding mould, so that the processed water filter tube is uniform in gap and is consistent in internal diameter, and easily sleeves a steel tube with processed hole shape; and moreover, the water filter tube welding mould is high in outer surface smoothness, and is attractive and beautiful.

Owner:河北伟业地热新能源科技有限公司

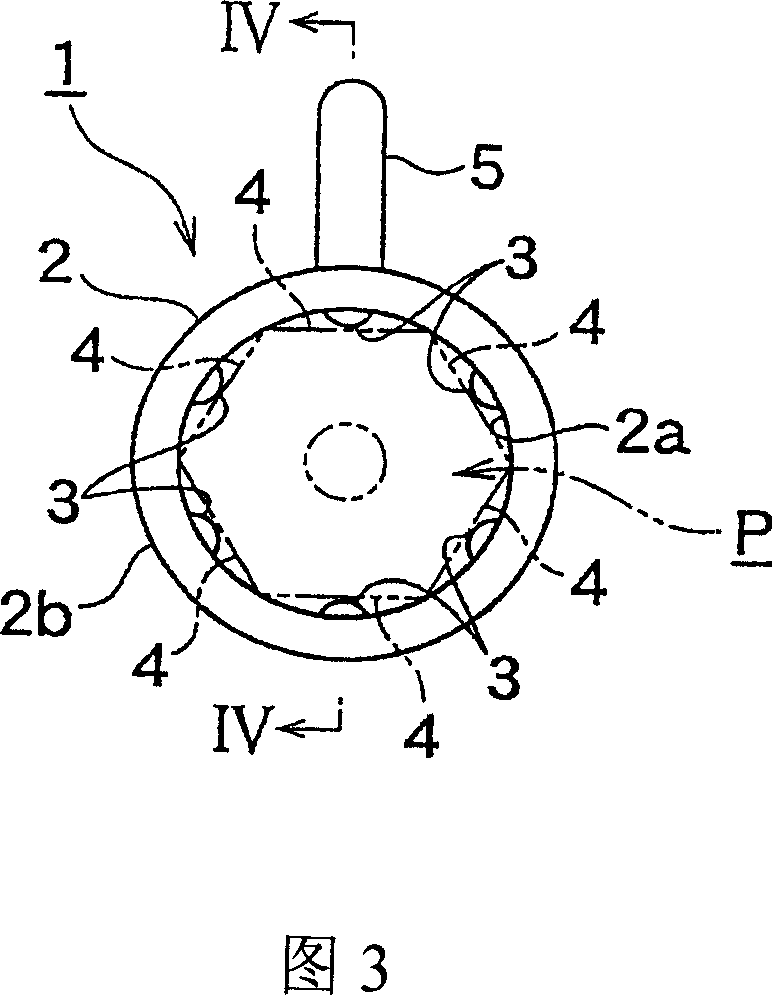

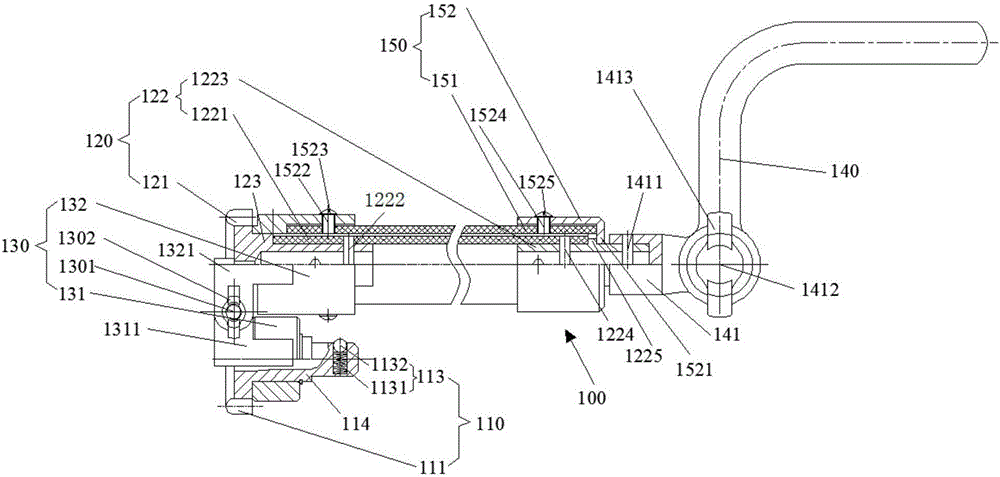

Special 360° steering sleeve device and method of use for overhead cable live peeling

The invention provides a special 360-degree turning sleeve device for aerial cable electrified peeling and an application method. The sleeve device (100) comprises a sleeve head, a sleeve head drive mechanism (110) used for fixing the sleeve head and driving the sleeve head to rotate, and a transmission mechanism (120) which is installed on the sleeve head drive mechanism (110) in an overturning mode and used for driving the sleeve head drive mechanism (110) to rotate so as to drive the sleeve head to rotate. According to the special 360-degree turning sleeve device for aerial cable electrified peeling and the application method, a feed screw can be rotationally unscrewed so as to adjust the depth of the feed screw of an electrified peeler, and the sleeve head can be easily arranged on the head of the feed screw in any installing position in a sleeving mode by adjusting the relative position of a drive gear and a driven gear. The sleeve device is convenient to use, easy to operate, safe and reliable.

Owner:YUNNAN POWER GRID CO LTD LINCANG POWER SUPPLY BUREAU

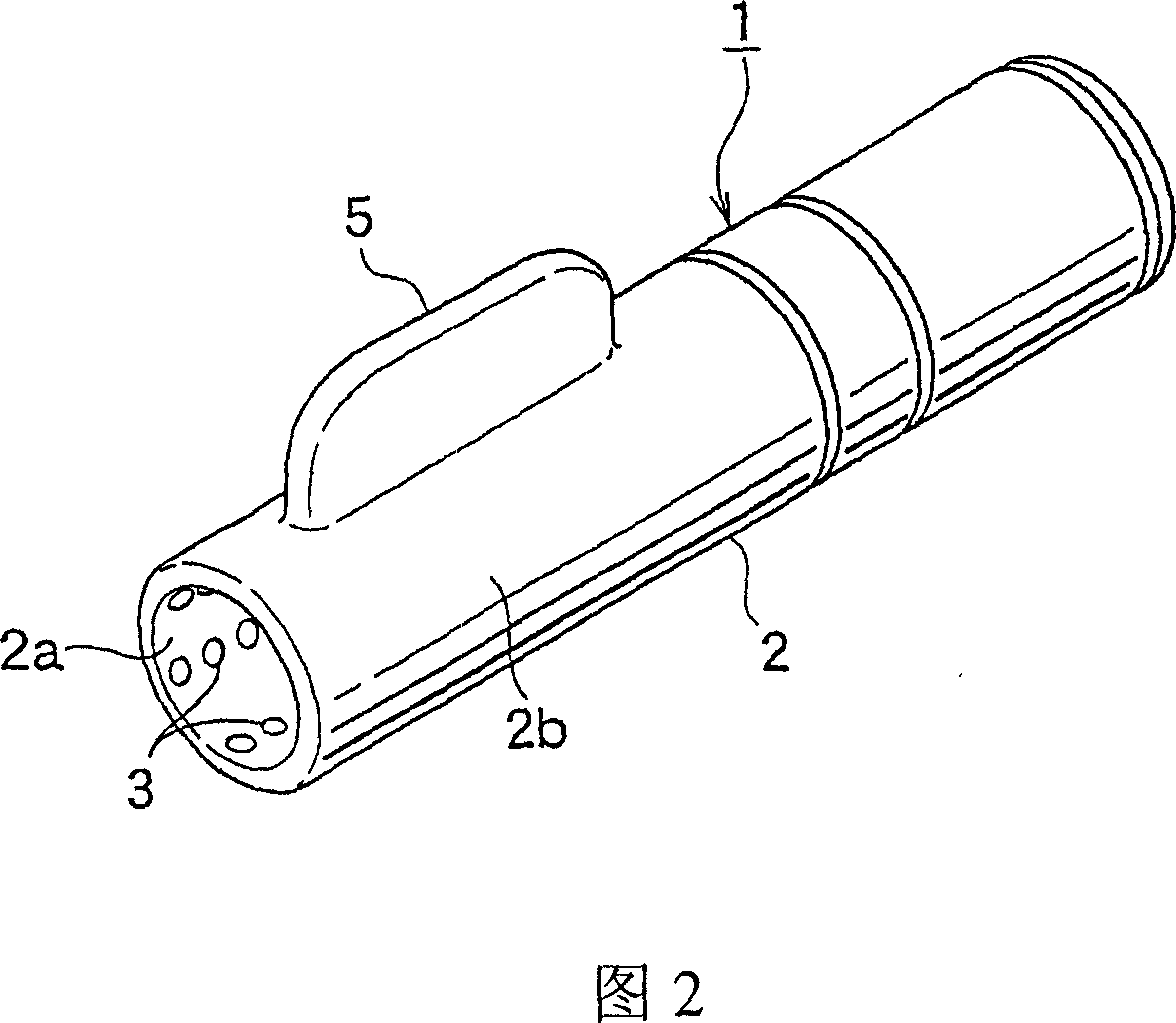

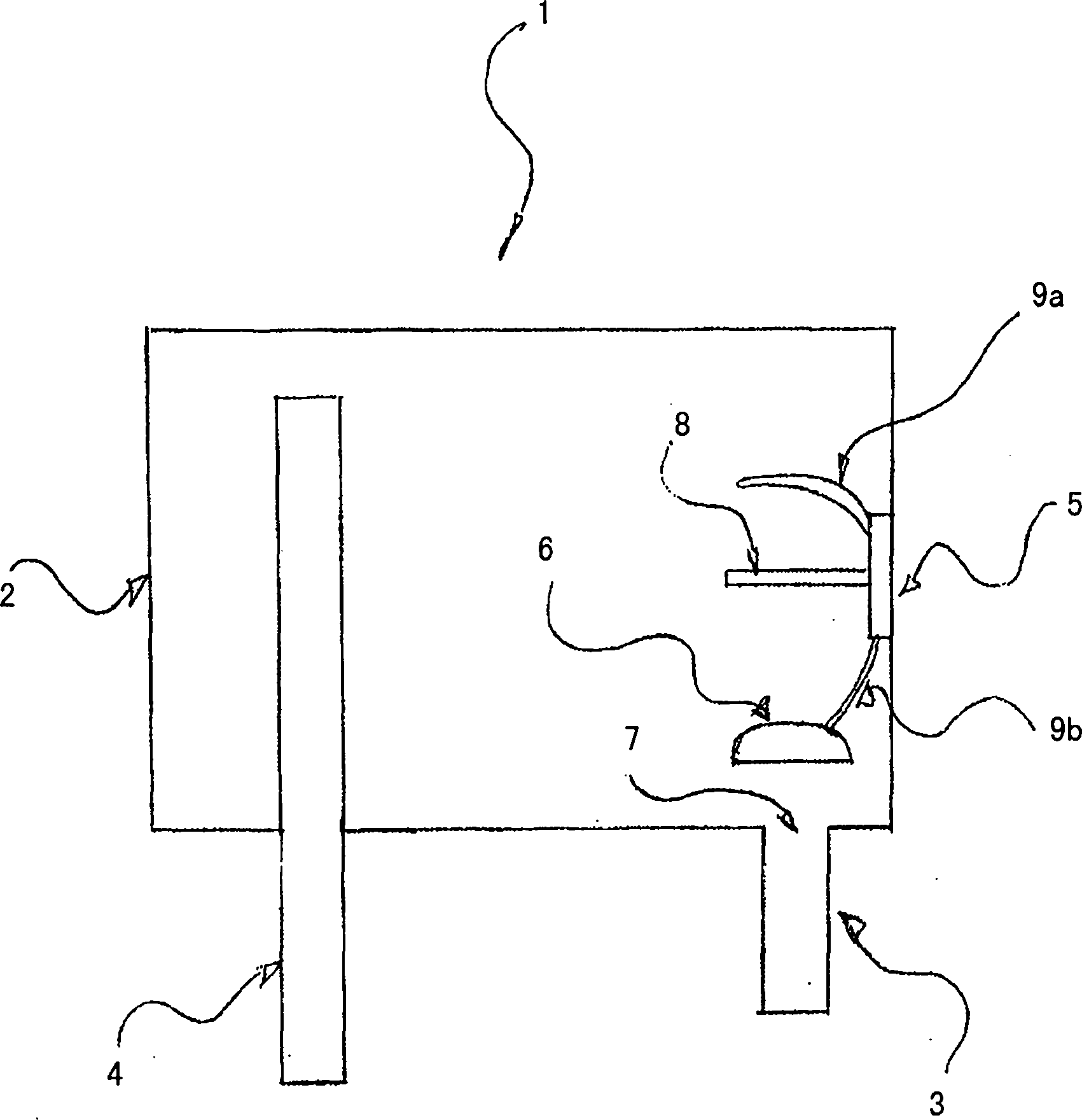

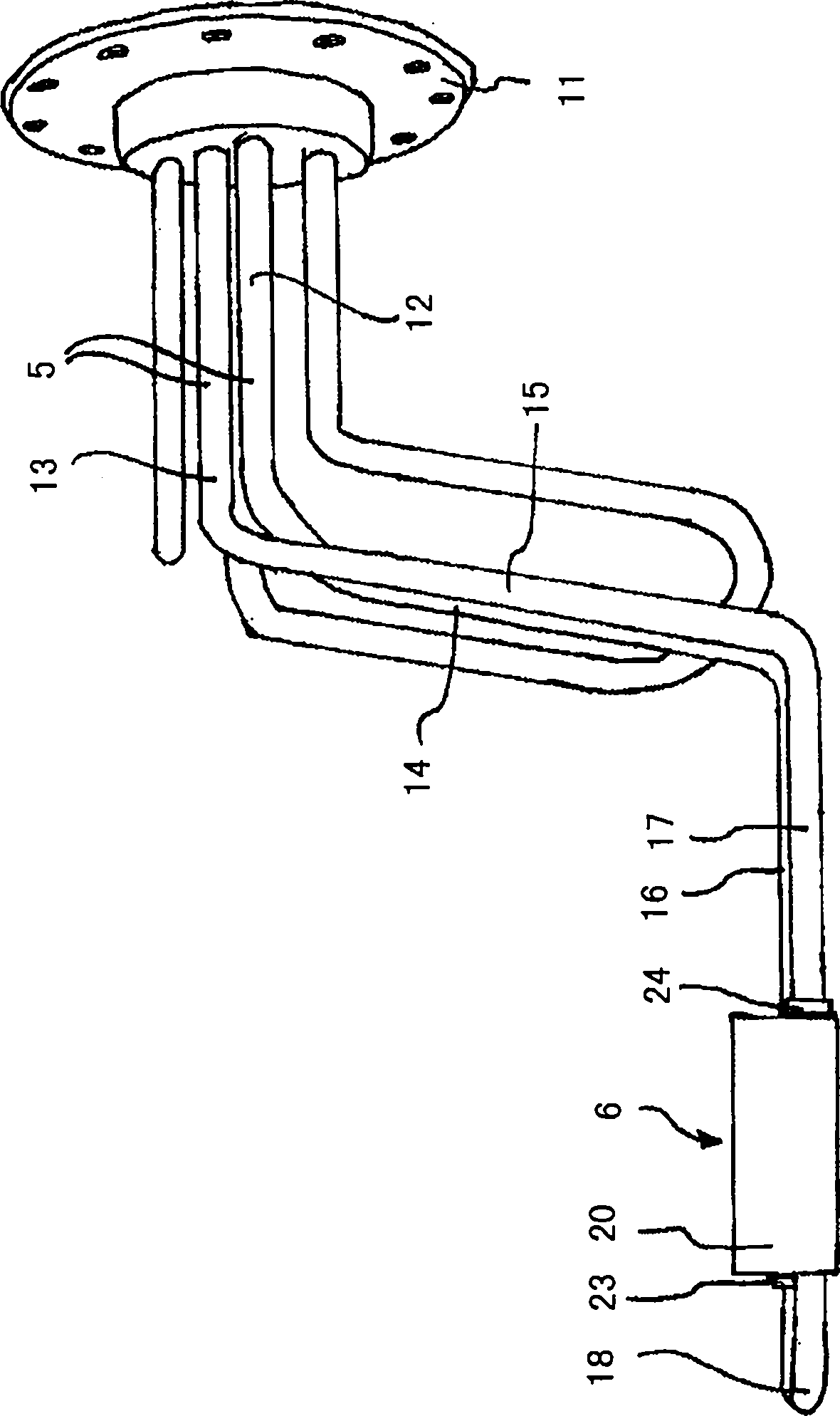

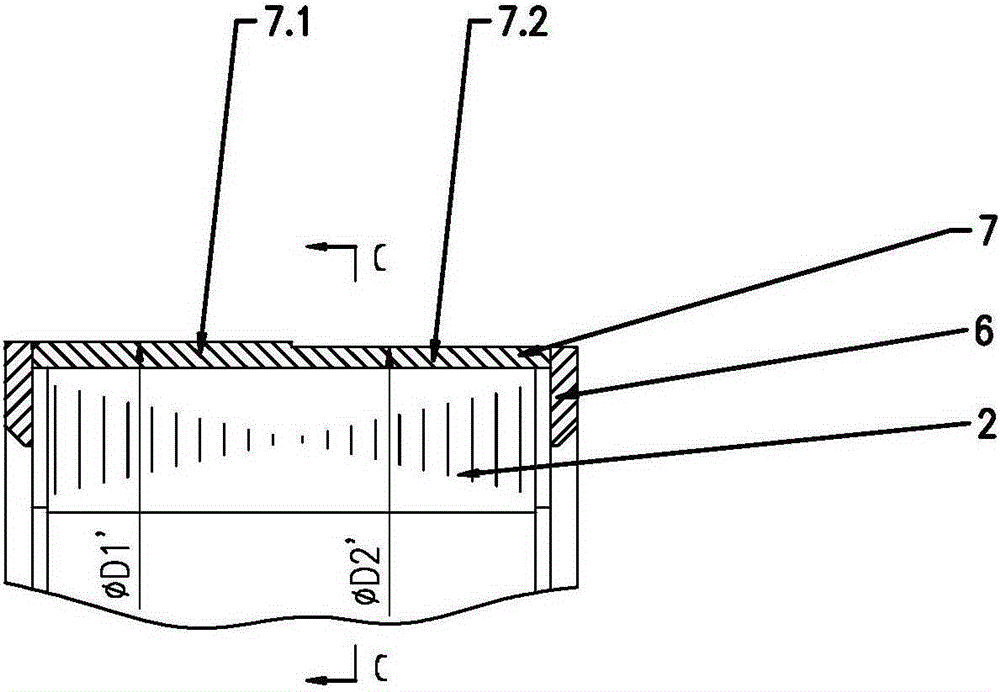

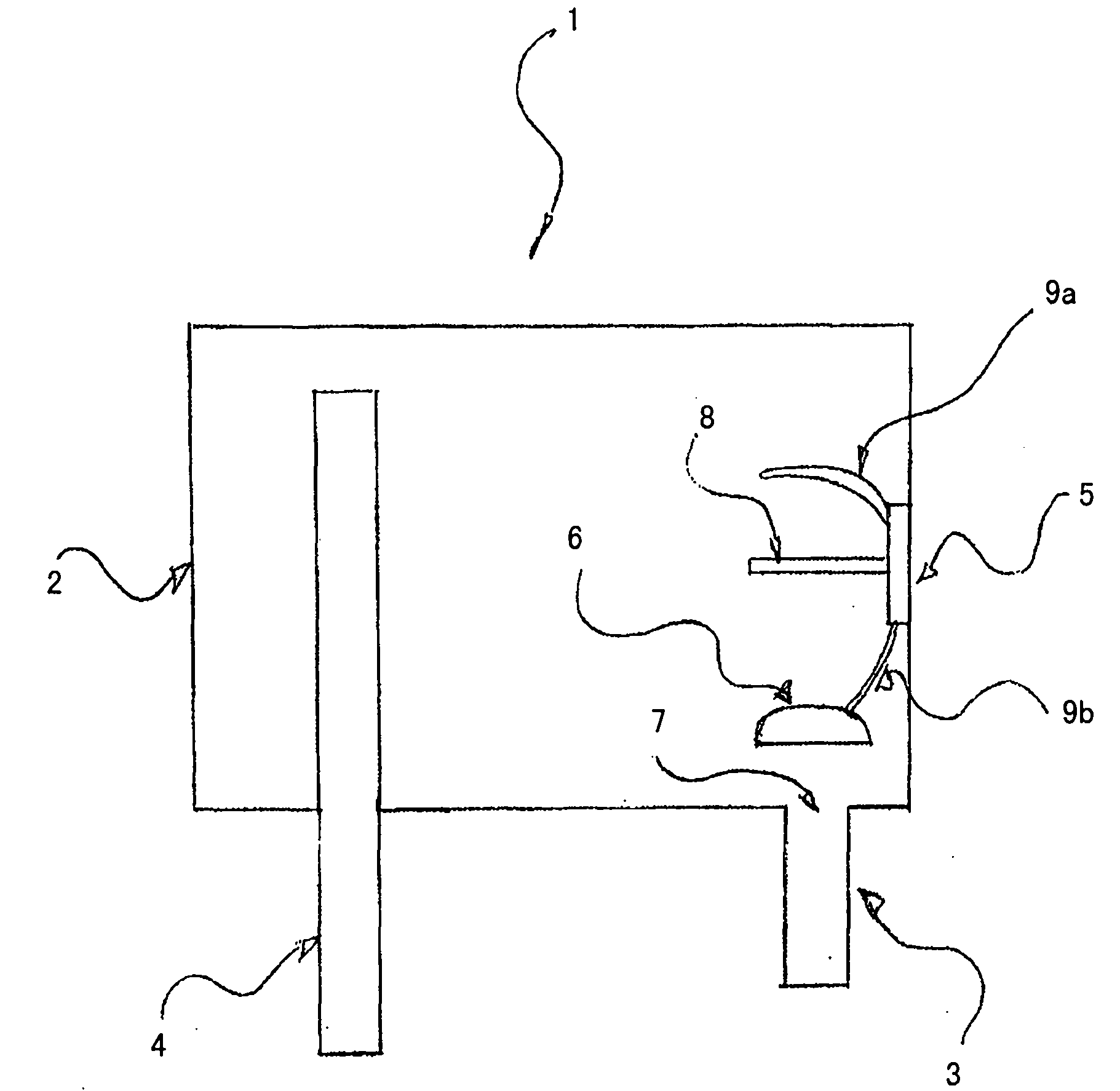

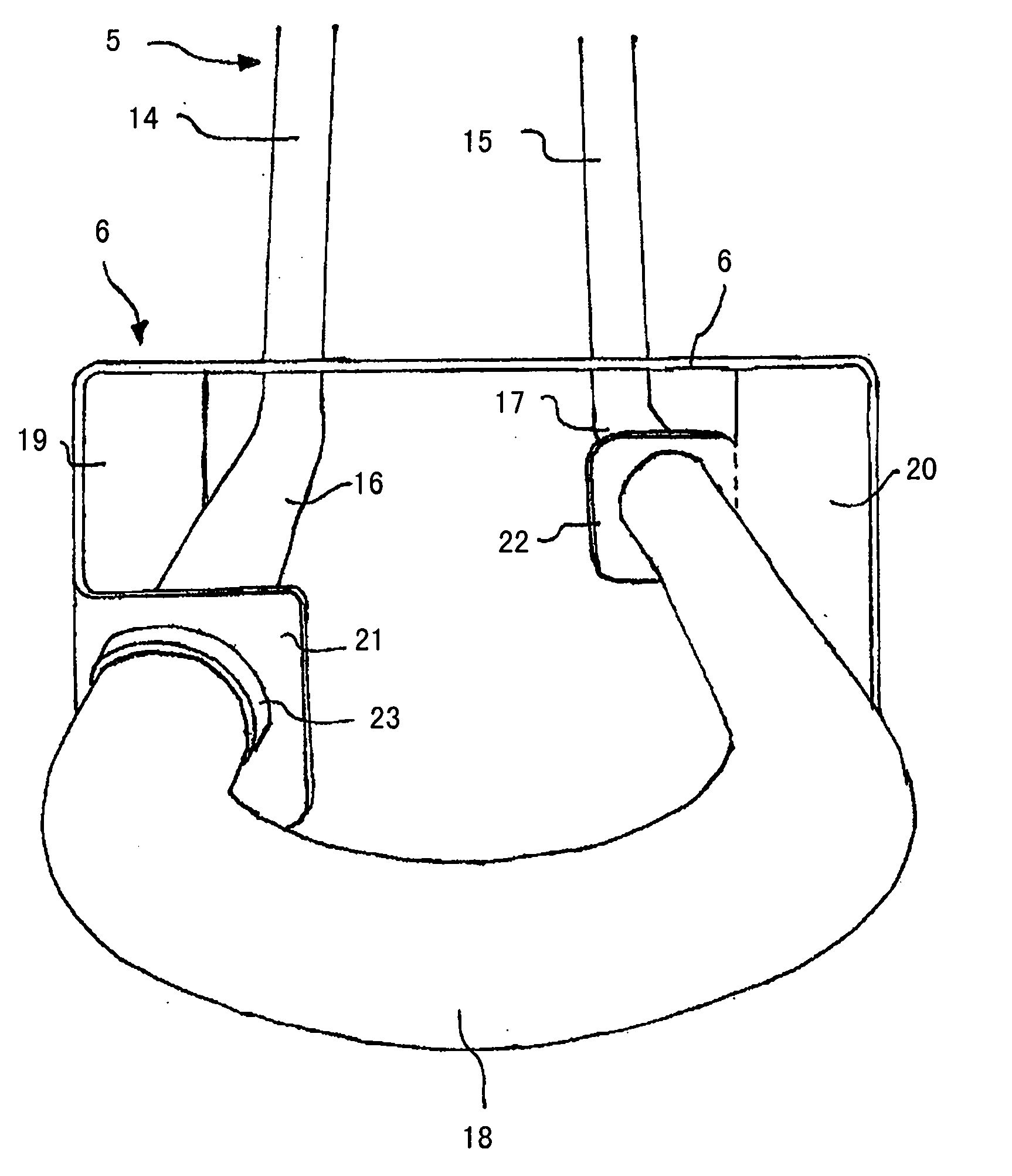

Hot water appliance

InactiveCN102216694BWith maximum temperatureEnsure maximum temperatureWater heatersThermal waterHeating element

The invention relates to a hot water appliance (1) at least comprising a water tank (2), a water supply pipe (3), a water discharge pipe (4), a heating element (5), and a means (6) for at least partly covering an inlet point (7) of the water supply pipe (3). The invention is characterized in that the heating element (5) is connected to the means (6) for at least partly covering the inlet point (7) of the water supply pipe (3), said means (6) for at least partly covering the inlet point (7) of the water supply pipe (3) deflecting at least some of the water to the bottom of the water tank (2).

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

Special 360-degree turning sleeve device for aerial cable electrified peeling and application method

The invention provides a special 360-degree turning sleeve device for aerial cable electrified peeling and an application method. The sleeve device (100) comprises a sleeve head, a sleeve head drive mechanism (110) used for fixing the sleeve head and driving the sleeve head to rotate, and a transmission mechanism (120) which is installed on the sleeve head drive mechanism (110) in an overturning mode and used for driving the sleeve head drive mechanism (110) to rotate so as to drive the sleeve head to rotate. According to the special 360-degree turning sleeve device for aerial cable electrified peeling and the application method, a feed screw can be rotationally unscrewed so as to adjust the depth of the feed screw of an electrified peeler, and the sleeve head can be easily arranged on the head of the feed screw in any installing position in a sleeving mode by adjusting the relative position of a drive gear and a driven gear. The sleeve device is convenient to use, easy to operate, safe and reliable.

Owner:YUNNAN POWER GRID CO LTD LINCANG POWER SUPPLY BUREAU

A set-up device and set-up method for a pipe system and a shell without guide rollers

The invention discloses a sleeving device and a sleeving method for a pipe system without guide rollers and a shell. The device comprises the pipe system, the shell, and a support platform positioned below the pipe system; the support platform is provided with multiple bracket units connected with the bottom of the pipe system in a support manner and independent from each other; a working platform is arranged on one side of the head end of the pipe system; the shell is arranged on one side of the tail end of the pipe system; a walking crane for naturally hanging the shell is arranged above the shell; a windlass and a rope limiting device are fixedly arranged on the working platform; a first traction rope extending from a rope outlet of the windlass penetrates through the rope limiting device, and the tail end of the first traction rope is connected with a rope separation device; the first traction rope is connected with a first joint of the rope separation device; and a second traction rope extending from a second joint of the rope separation device is respectively connected to two sides of the shell. The method realizes sleeving between the pipe system and the shell, and achieves the effects of low deformation of the pipe system, precise matching between the pipe system and the shell and completion of once stable sleeving.

Owner:DONGFANG (GUANGZHOU) HEAVY MASCH CO LTD

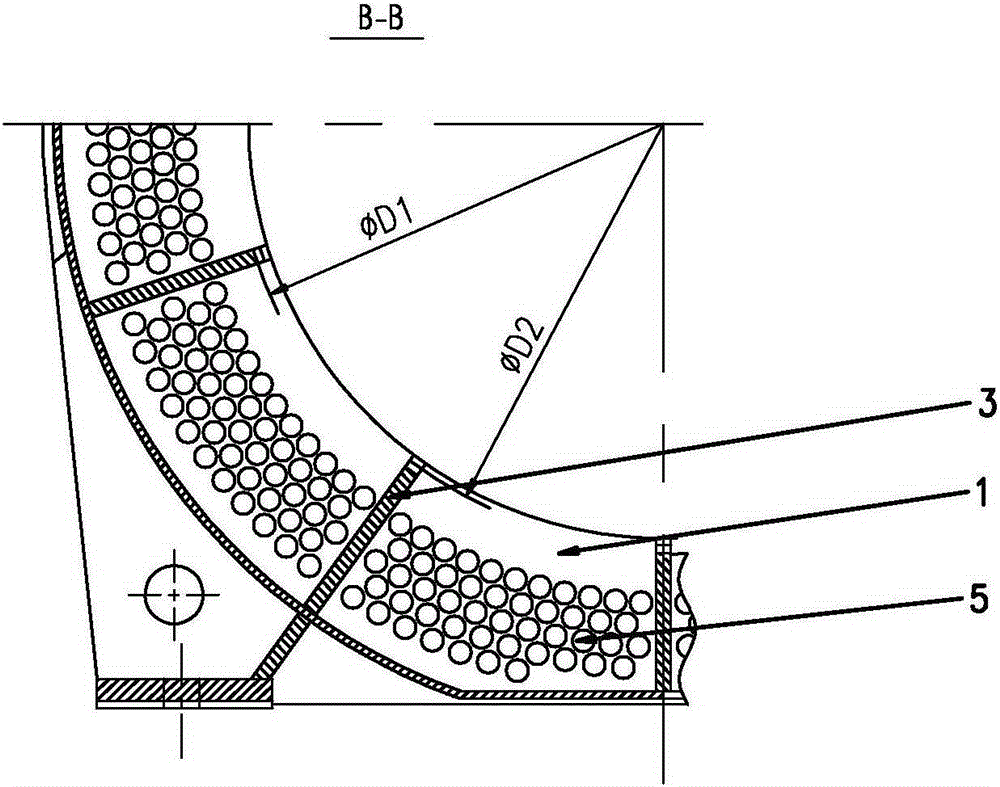

Surrounding pipe layout motor stator core outer press-fit structure

ActiveCN103580394BSimple structureCompact structureManufacturing dynamo-electric machinesInterference fitEngineering

The invention relates to a motor stator iron core outer press fitting structure with pipes distributed on the periphery, in particular to a hot press fitting structure of a motor stator iron core hot sleeve machine base with pipes distributed on the periphery and belongs to the technical field of motors. The motor stator iron core outer press fitting structure with the pipes distributed on the periphery comprises a machine base and an iron core. The stator iron core is arranged in the machine base in a sleeved mode. The machine base is in interference fit with the stator iron core. The machine base is of a cage-shaped supporting rib structure and comprises an upper machine base bottom plate and a lower machine base bottom plate which are parallel to each other. Multiple machine base supporting ribs are used for connecting the upper machine base bottom plate and the lower machine base bottom plate. The stator iron core is of the cage-shaped supporting rib structure and comprises an upper stator iron core bottom plate and a lower stator iron core bottom plate which are parallel to each other. The upper stator iron core bottom plate is connected with the lower stator iron core bottom plate through stator iron core supporting ribs. The motor stator iron core outer press fitting structure is simple, compact and reasonable, the iron core is arranged in the heating machine base in a sleeved mode, the iron core supporting ribs are in interference fit with the machine base supporting ribs, key grooves do not need to be machined in the machine base and the iron core, the motor stator iron core outer press fitting structure is convenient to machine and arrangement in a sleeved mode is easy to achieve.

Owner:SEC ELECTRIC MACHINERY

Hot water appliance

The invention relates to a hot water appliance (1) at least comprising a water tank (2), a water supply pipe (3), a water discharge pipe (4), a heating element (5), and a means (6) for at least partly covering an inlet point (7) of the water supply pipe (3). The invention is characterized in that the heating element (5) is connected to the means (6) for at least partly covering the inlet point (7) of the water supply pipe (3), said means (6) for at least partly covering the inlet point (7) of the water supply pipe (3) deflecting at least some of the water to the bottom of the water tank (2).

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

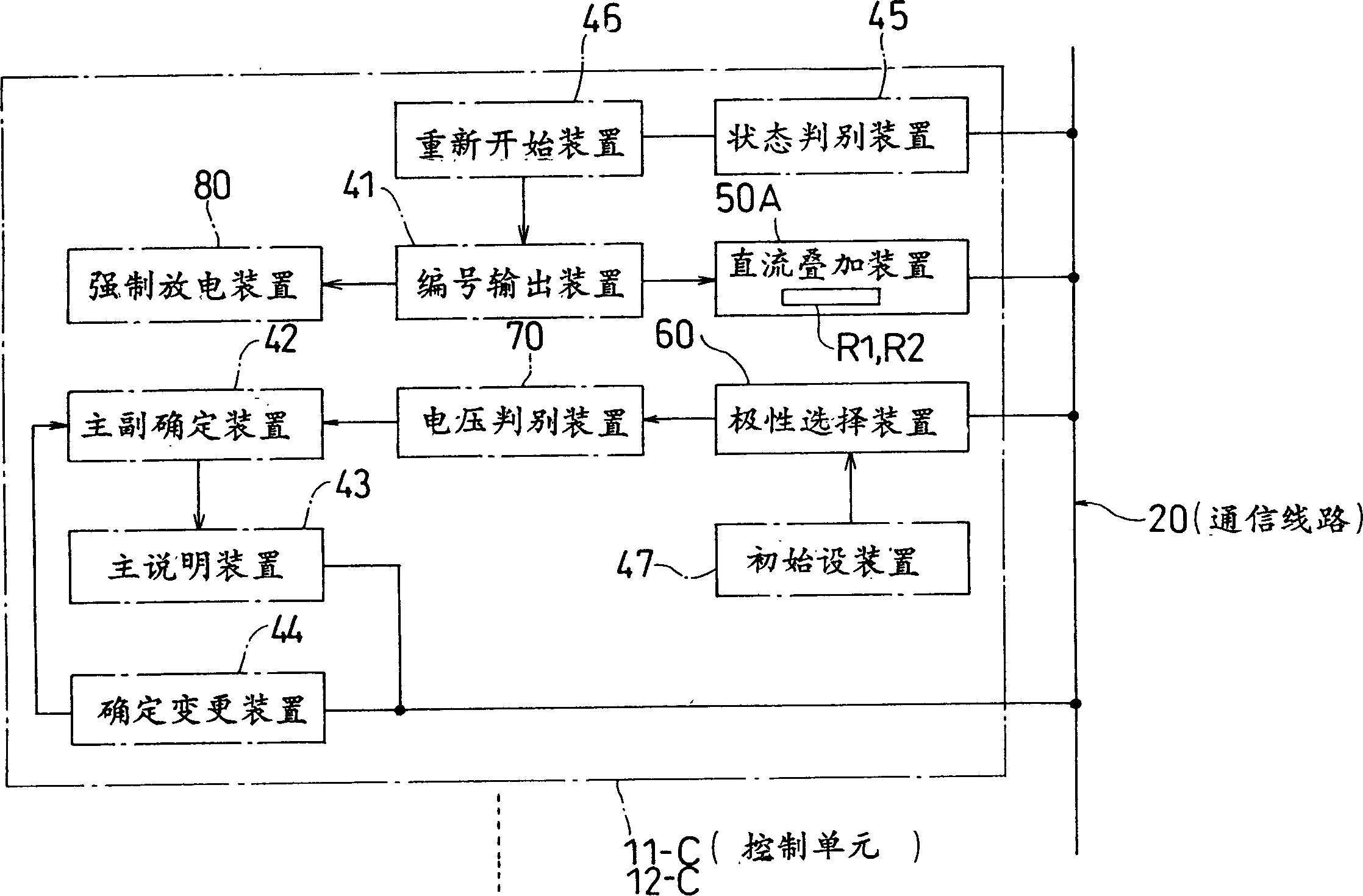

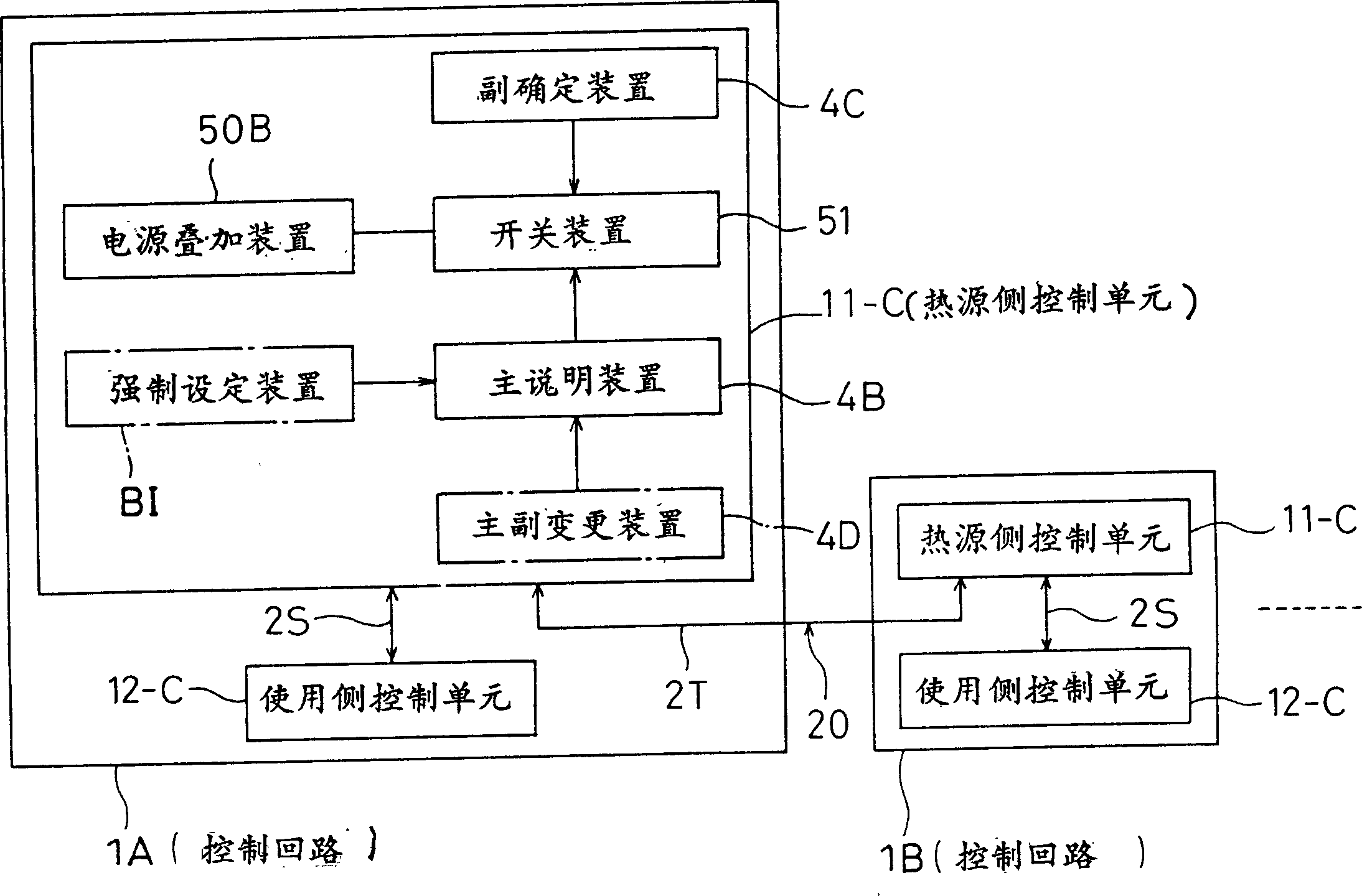

Transmitter

InactiveCN1137600CSimple setPrevent wrong settingsElectric signal transmission systemsCircuit arrangementsTerminal voltageElectrical polarity

Control units are connected to each other through a communication line. Discharging resistors for releasing the residual charge on the line are provided. Each control unit is provided with a DC superimposing circuit which applies a DC voltage and outputs a specific number signal to the line from the circuit. The control unit is also provided with a polarity selecting circuit having a negative resistance characteristic that the electric current flowing through the circuit increases as the voltage applied drops, and a voltage discriminating circuit which detects the terminal voltage of the circuit. The control unit detects the voltage of communication line and determines whether its own control unit is a master unit or a slave unit utilizing output signals from the voltage discriminating circuit and a polarity discriminating circuit.

Owner:DAIKIN IND LTD

Stirring knife assembly

A stirring knife assembly at least comprises a knife bracket and a stirring shaft; the knife bracket is of a framework structure and is fixedly provided with at least one blade; the stirring shaft is fixedly connected with the knife bracket. The lower part of the knife bracket is provided with a first blade, and the upper part of the knife bracket can be provided with a second blade or can be not provided with the blade; the stirring shaft is not provided with a blade or is provided with at least one blade; the mode of blade arrangement on the knife bracket can be combined randomly with the mod of blade arrangement on the stirring shaft. Because the blade is connected with the stirring shaft through a non-injection molding mode, the defects brought by the injection molding process are avoided, the shape and the number of the blades have no limitation, and the blade arranged positions are relatively flexible; and moreover, the blade bracket adopts the framework structure, the braking structure is simplified, at the same time, a deep hole structure, which is matched with a positioning shaft of a stirrer, of a stirring shaft of a traditional stirring knife assembly is avoided, moreover, enough space is left for food to pass through, food is avoided from remaining in the deep hole structure, no cleaning dead angle exist, cleaning becomes easy, and the practicability is high.

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

Fitting tool for a brake retaining clip with a securing arrangement of a disk brake, disk brake, and brake pad set

InactiveCN107850142AAchieve the correct orientationCompact structureAxially engaging brakesBraking elementsEngineeringMechanical engineering

The invention relates to a fitting tool (13) for fitting a brake retaining clip to and / or removing said brake retaining clip from a securing arrangement of a disk brake, wherein the securing arrangement has a securing element (11), which is fixedly connected to a rear-side backing plate (5a) of a rear-side brake pad of the associated disk brake and has at least two spring arms (12), characterizedin that the fitting tool (13) has a base, a spreading device, and a guiding device.

Owner:KNORR BREMSE SYST FUER NUTZFAHRZEUGE GMBH

Method for making flower art wall

InactiveCN101496480BRapid establishmentQuick and easy flower arrangementReceptacle cultivationFloriculturePlant soil

The invention relates to a preparation method for a floriculture wall. The preparation method comprises the following operation steps: preparing a shelf having a wire mesh on the bottom according to the dimensional requirements of an exhibition wall body; filling the iron shelf with flower earth which is as high as the shelf; watering the flower earth thoroughly at one pass; spraying 1 to 2cm planting soil on the flower earth to form a grass seed planting layer; sowing grass seeds on the planting soil and carrying out the elaborate management and culture for 20+ / -3 days to form a continuous grass carpet; covering the grass seeds with a wire mesh to ensure the fixed and safe use of material; and unreeling wires according to a preset pattern to outline the general shape, and inserting flower according to the shape so as to form the floriculture wall. The preparation method can achieve rapid establishment, convenient and rapid flower inserting, simple decoration, and various modes. The floriculture wall is suitable for the exhibitions at public points such as parks, botanical gardens, exhibition halls, and the like.

Owner:WUHAN BOTANICAL GARDEN CHINESE ACAD OF SCI

High speed and high power permanent magnet synchronous motor rotor

ActiveCN110571959BSimple structureImprove reliabilityMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsElectric machinePermanent magnet synchronous motor

A high-speed and high-power permanent magnet synchronous motor rotor belongs to the technical field of motors. The invention solves the problems that the existing high-speed and high-power permanent magnet synchronous motors have difficulty in fitting the rotor sheath and that the prestress cannot be adjusted as required. It mainly includes the rotating shaft, main permanent magnet, auxiliary permanent magnet, positioning key, pre-tightening wedge, pre-tightening nut and sheath; the pre-tightening nut is used to axially squeeze the conical or wedge-shaped device, so that according to the rotor diameter and speed The small diameter flexibly adjusts the prestress acting on the permanent magnet. The invention is mainly applied in the field of motors.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com