Water filter tube welding mould

A technology for welding molds and water filter pipes, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., to achieve the effect of saving manpower, uniform gap, and consistent inner diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

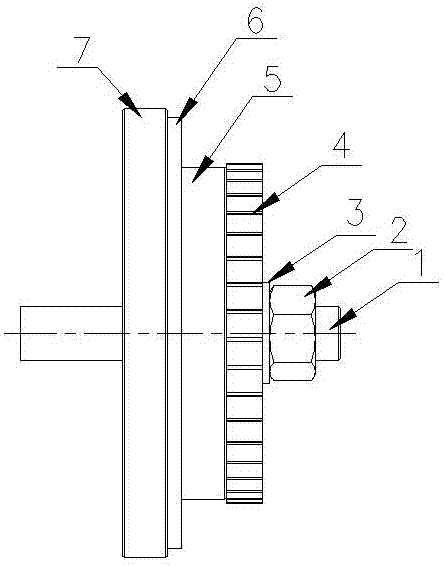

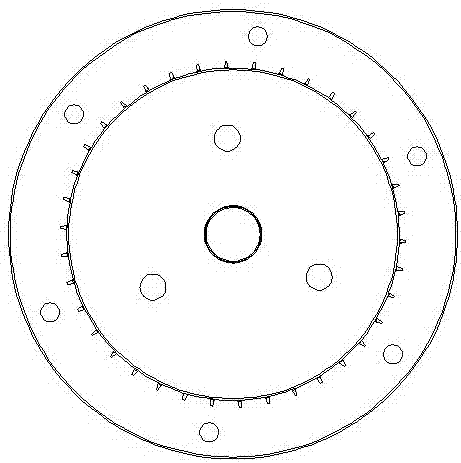

[0012] As shown in the figure, this mold has a total of five parts combinations. The innermost steel wire fixing ring 7 is N "V" notches formed by wire cutting according to the number of inner support ribs required for processing the diameter of the water filter pipe. , which is consistent with the shape of the V-shaped wire used in the processing of the water filter pipe, which can fix the phenomenon that the inner support ribs of the steel wire are not crooked or biased, and make the outer surface of the processed water filter pipe smooth. Fix the steel wire fixing ring 7 to the connection plate of the filter pipe welder through bolt connection, pass the central axis 1 through the center hole of the connection plate of the filter pipe welder, and pass the dimension ring 5 of the processed size from the outside The central axis 1 is inserted into the inside of the steel wire fixing ring 7 and is parallel to the connecting plate of the filter pipe. It plays the role of fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com