Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59results about How to "Shorten shaft length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

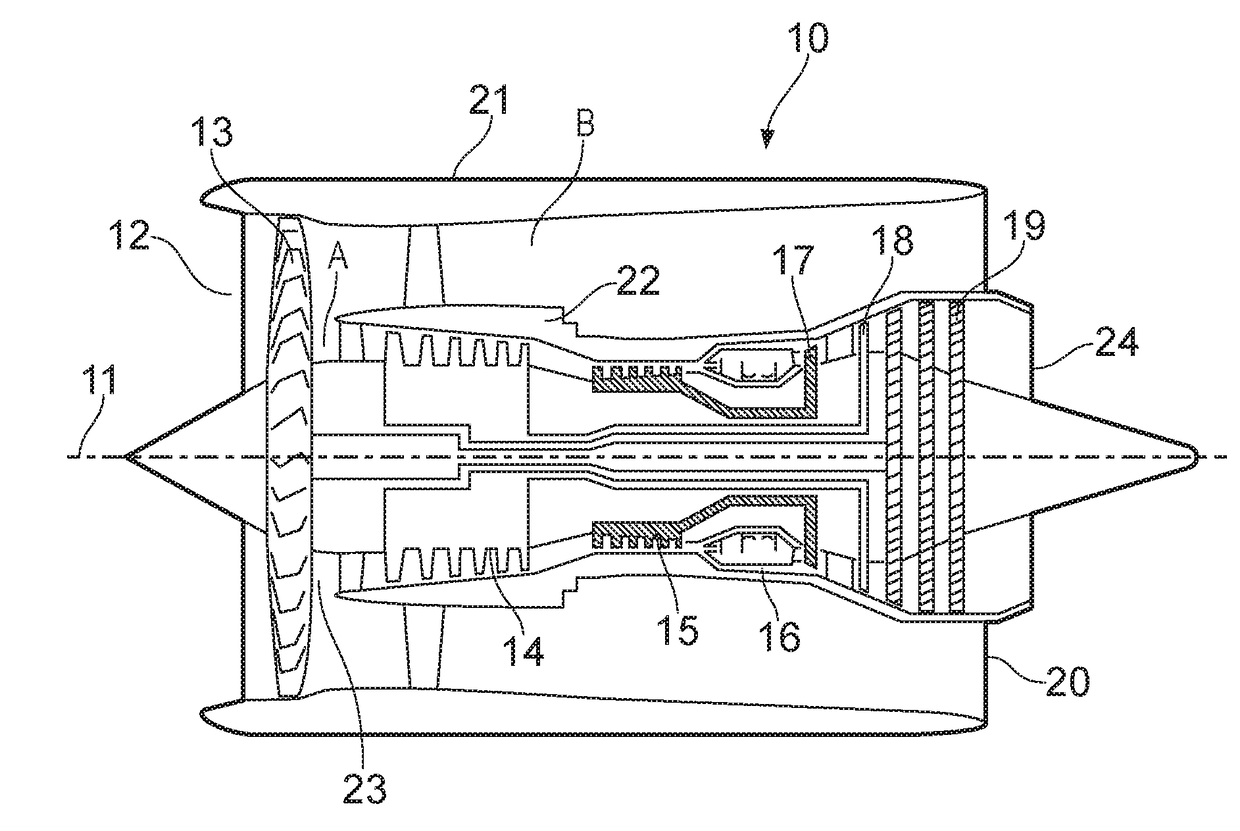

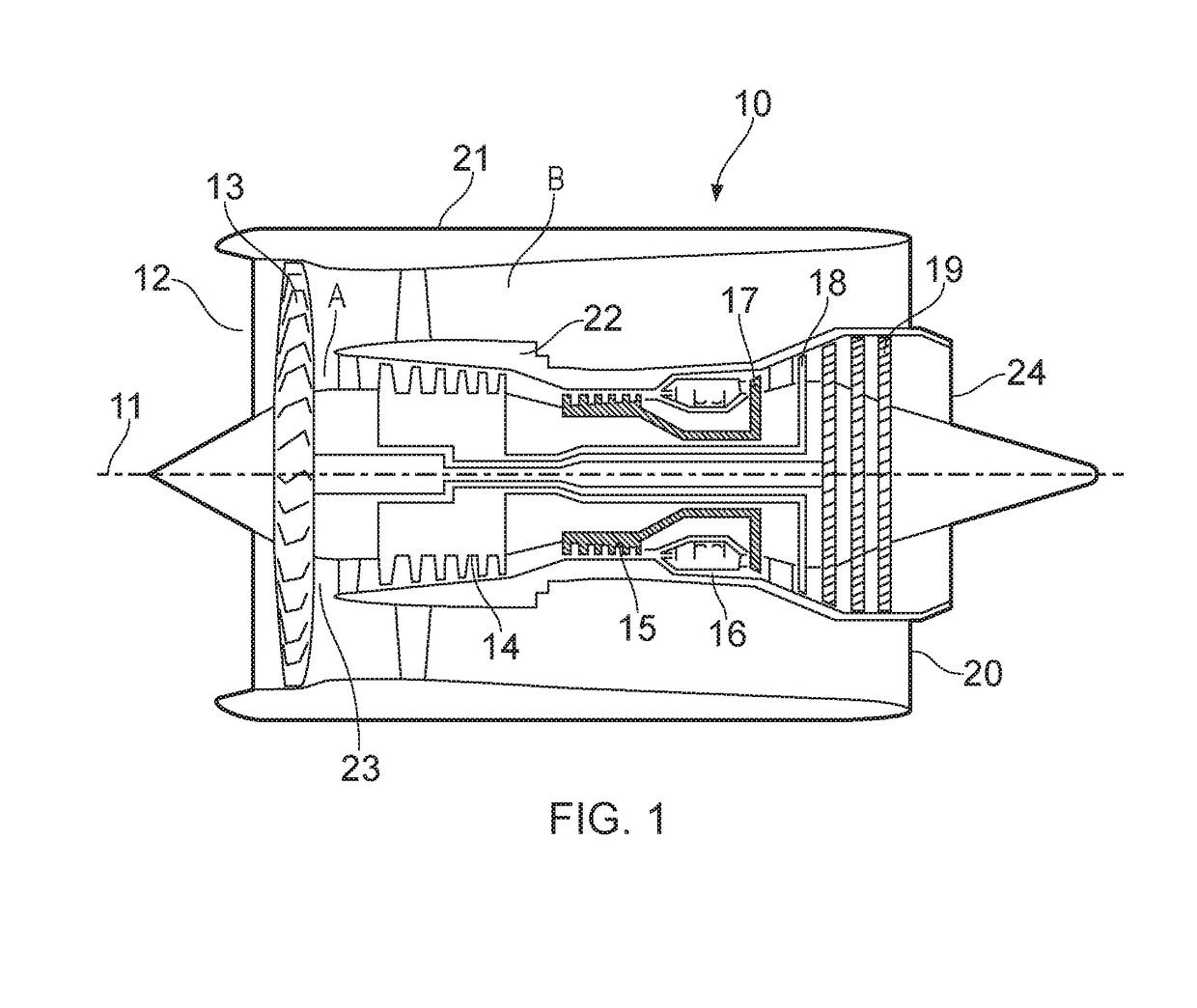

Gas turbine engine

InactiveUS20170369179A1Improve turbine efficiencyReduce in quantityElectric power distributionGas turbine type power plantsTurbineGas turbines

An aircraft gas turbine engine (110) comprises first and second non-coaxial propulsors (113a, 113b), each propulsor (113a, 113b) being driven by a common gas turbine engine core (176) comprising a propulsor drive turbine (143) arranged to drive the first and second propulsors (113a, 113b) via a propulsor drive coupling (127). The core (176) further comprises a first core module (190) comprising a first compressor (129) and a first turbine (131) interconnected by a first shaft (177), and a second core module (191) comprising a second compressor (128) and the propulsor drive turbine (143) interconnected by a second shaft (127), the first and second core modules (190, 191) being axially spaced.

Owner:ROLLS ROYCE PLC

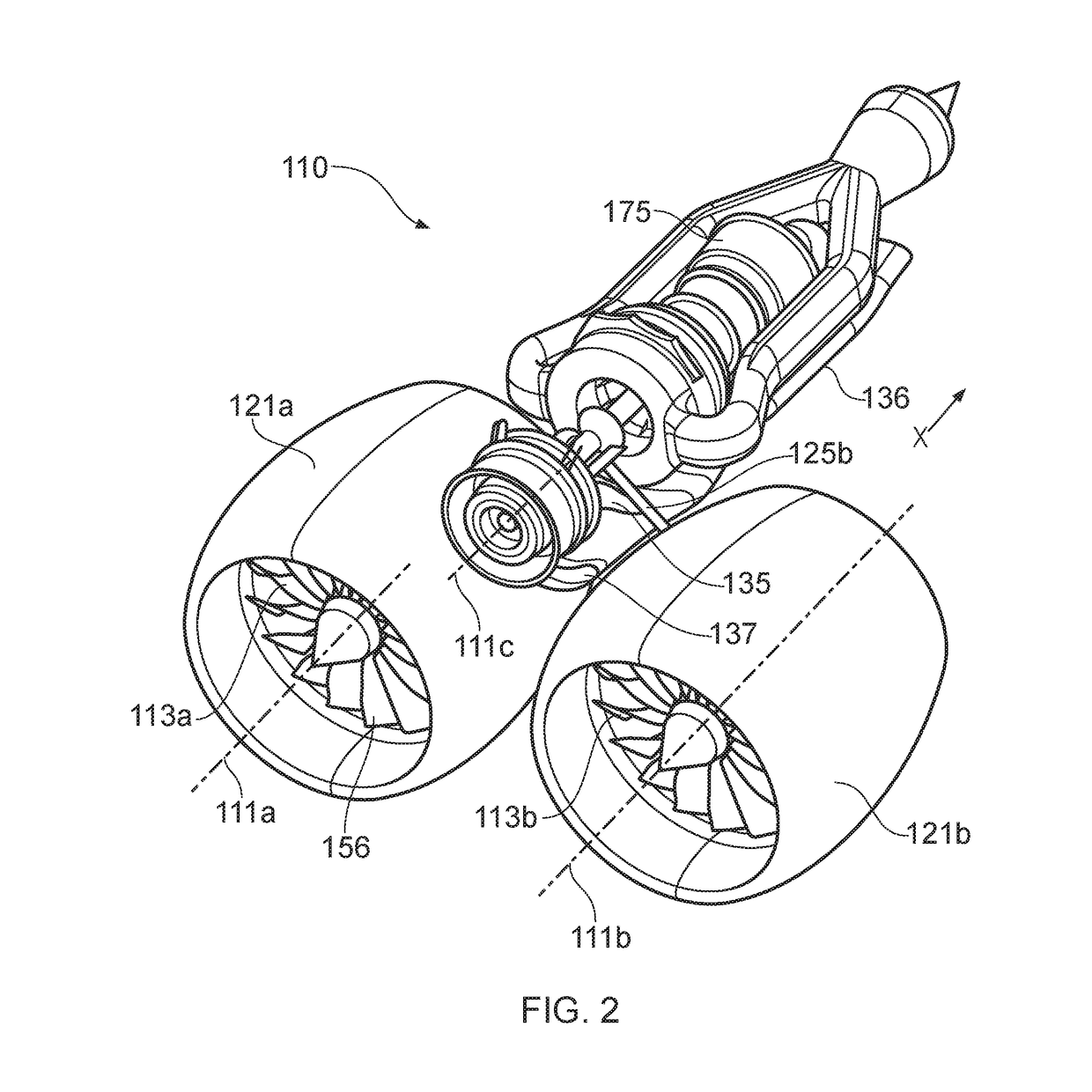

Utility iron

InactiveUS20150057097A1Extended driving distanceLess attentionGolf clubsRacket sportsEngineeringGolf Ball

The present invention relates to a utility iron which is characterized in that it has a lie angle of 58 to 64°, a loft angle of 20 to 28°, a head weight of 270 to 300g, and a shaft length of 35 to 38 inches. Thus, the loft angle is relatively reduced so as to prevent a golf ball from being hit high and increasing flight distance. Also, because the lie angle is relatively increased, the possibility of a hook or a slice occurring is reduced. Because the weight of the head is increased, repulsive force is augmented by the striking of the golf ball, which relatively increases the flight distance of the golf ball. Because the length of the shaft is relatively shortened, swing trajectory is reduced, and accurate striking is made easier so as to also increase flight distance.

Owner:CHO HEE JIN

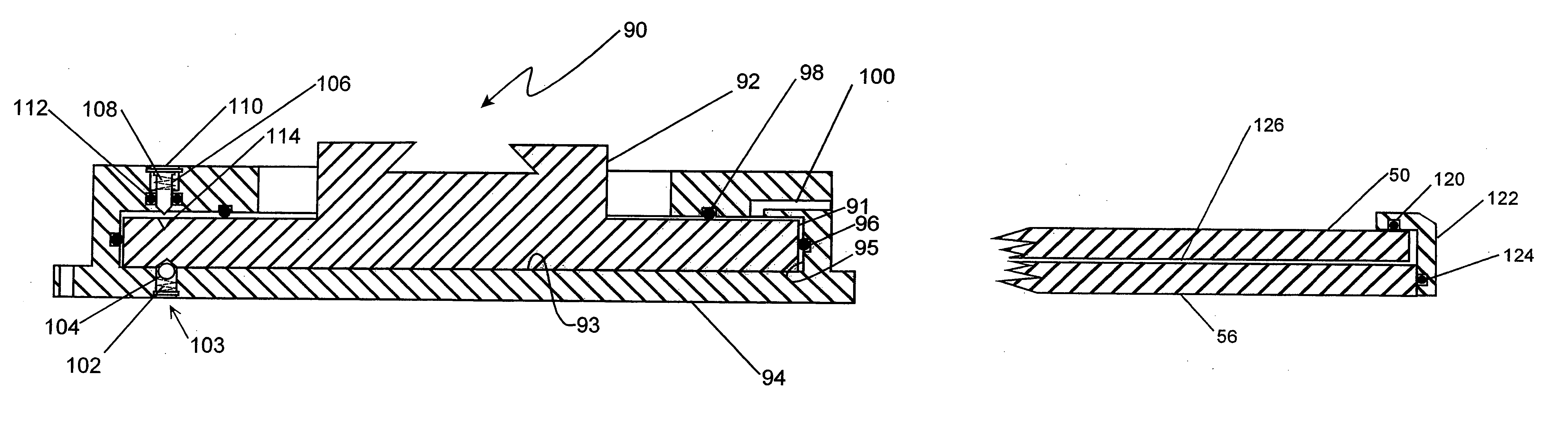

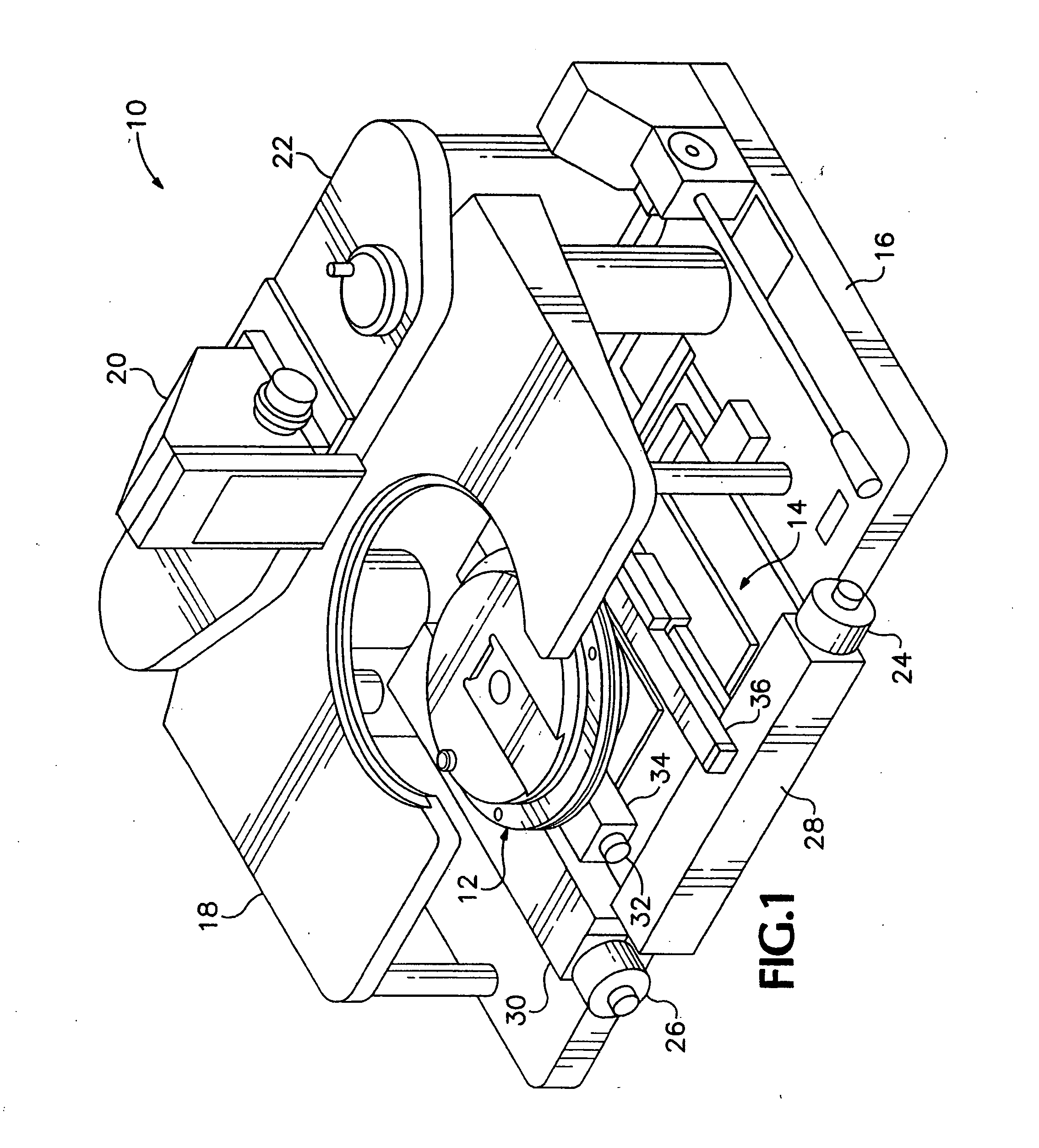

Indexing rotatable chuck for a probe station

InactiveUS20050127927A1Shorten shaft lengthGood planaritySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingProduction rateRapid rotation

A rotary chuck with indexed rotation promotes rapid rotation of a device under test and increases the productivity of a probe station on which the device is being tested. A device mounting member of a rotatable chuck is supported for rotation on a first surface of a base until a vacuum is applied drawing the device mounting member into contact with a second surface of the base and constraining the device mounting member against rotation.

Owner:CASCADE MICROTECH

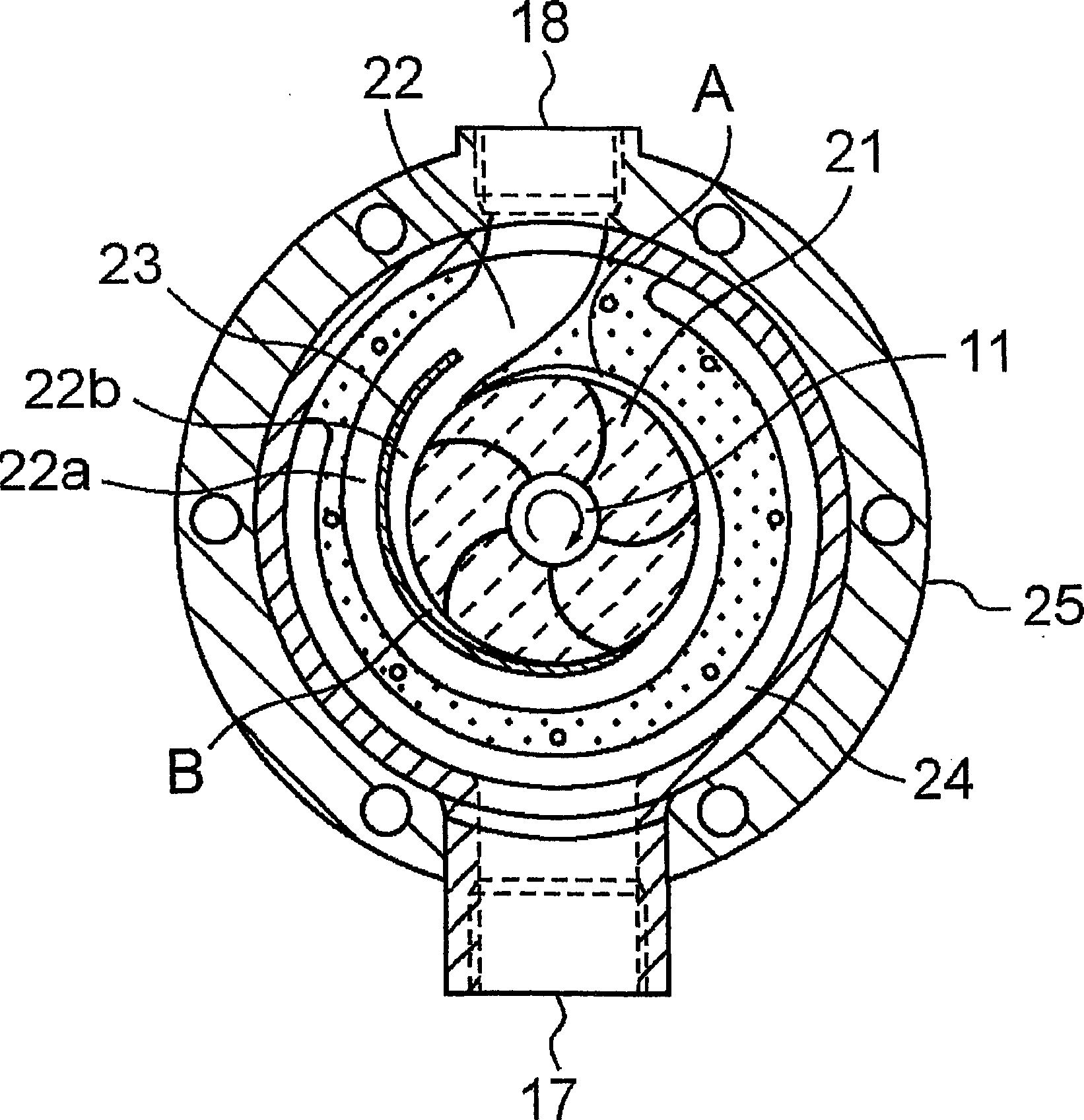

Axial force balancing structure of centrifugal closed impeller

ActiveCN104343747ANo effect on efficiencyShorten shaft lengthPump componentsPumpsImpellerEngineering

An axial force balancing structure of a centrifugal closed impeller comprises a sealing ring which is arranged between an impeller cover and a housing and near the outlet of the centrifugal closed impeller, an impeller inlet seal arranged near the inlet of the centrifugal closed impeller, and a housing inlet formed in the housing, wherein the impeller cover, the housing, the sealing ring and the impeller inlet seal form a cavity; a high pressure medium is introduced into the cavity from the outside through the housing inlet; the pressure of the high pressure medium is higher than the medium pressure at the outlet of the centrifugal closed impeller. The axial force balancing structure can balance an existing axial force from an impeller disc to the impeller cover of the centrifugal closed impeller; the axial force balancing structure does not affect flowing of the medium inside the centrifugal closed impeller, so that the efficiency of an impeller is not affected; the axial force balancing structure does not increase the axial length; the high pressure medium can be from the medium at an outlet of a pressure expander behind the centrifugal closed impeller, so that a risk of medium leakage is avoided; the axial force balancing structure is simple in structure and easy to implement.

Owner:TSINGHUA UNIV

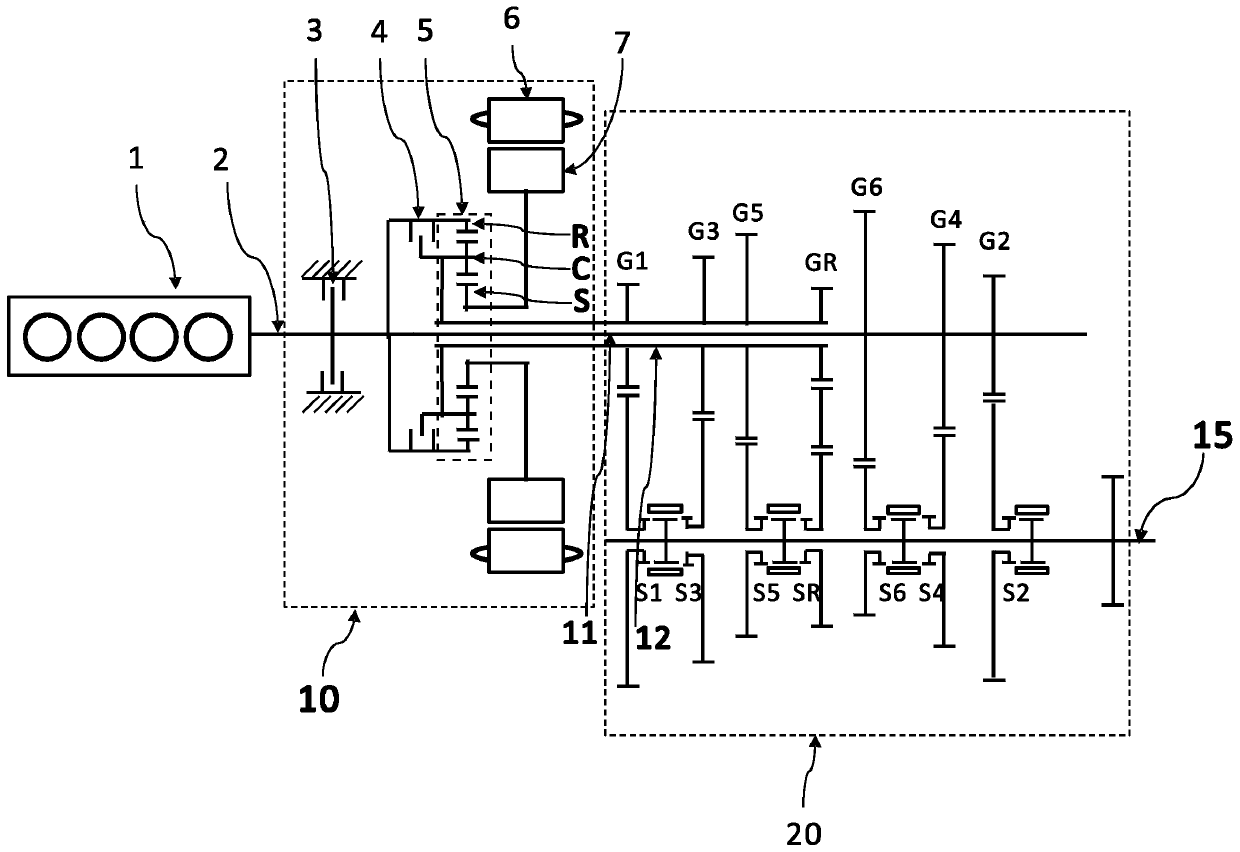

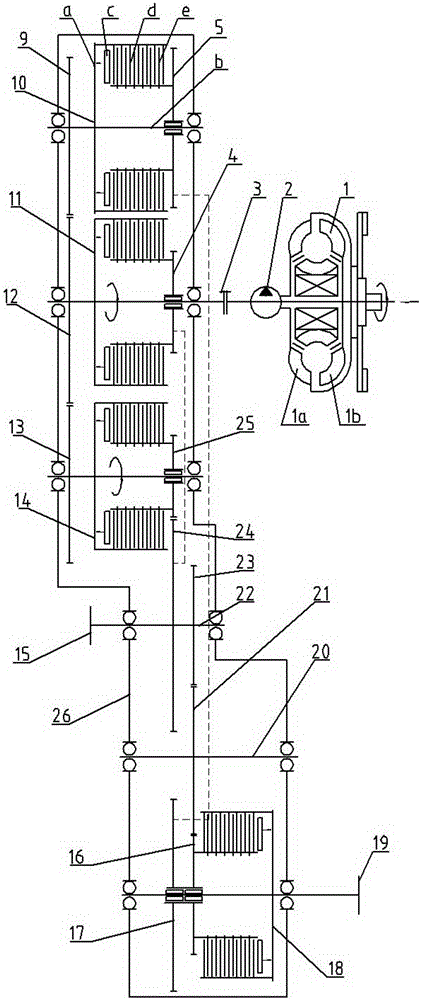

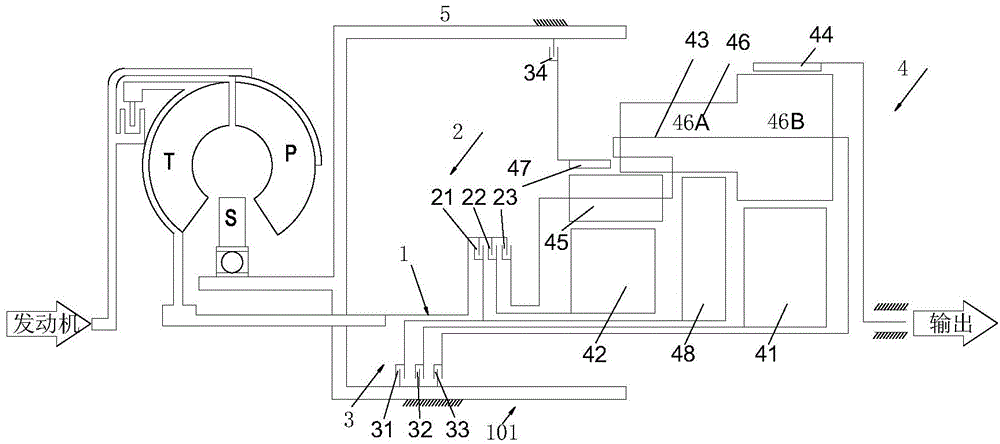

Vehicle hybrid power system and control method thereof

ActiveCN110525191AAdjust torqueTorque balanceHybrid vehiclesGas pressure propulsion mountingElectric machineGear wheel

The invention discloses a vehicle hybrid power system and a control method thereof. The system involves an engine, a hybrid power module and a double-input-shaft speed change mechanism, wherein the hybrid power module is composed of a motor, a planetary gear train and a first clutch, the planetary gear train is provided with at least three rotating shafts, the three rotating shafts comprise a rotating shaft X1, a rotating shaft X2 and a rotating shaft X3, axes of the three rotating shafts are on one straight line, the rotating speed of the rotating shaft X2 is between the rotating speed of therotating shaft X1 and the rotating speed of the rotating shaft X3, a first clutch is arranged between any two of the three rotating shafts, a power output shaft of the engine is connected with the rotating shaft X3 or the rotating shaft X1 of the planetary gear train and a second input shaft of the double-input-shaft speed change mechanism, a rotor of the motor is connected with the rotating shaft X1 or the rotating shaft X3, and the rotating shaft X2 is connected with a first input shaft of a double-input-shaft gearbox. According to the system and the method, the transmission efficiency is high, multiple gears are provided, the three-axis double-freedom-degree planetary gear train is introduced, a vehicle is driven to start by the differential between the engine and the motor, starting of the vehicle is stable, the smoothness of gear shifting is good, and the impact of gear shifting is small.

Owner:段志辉

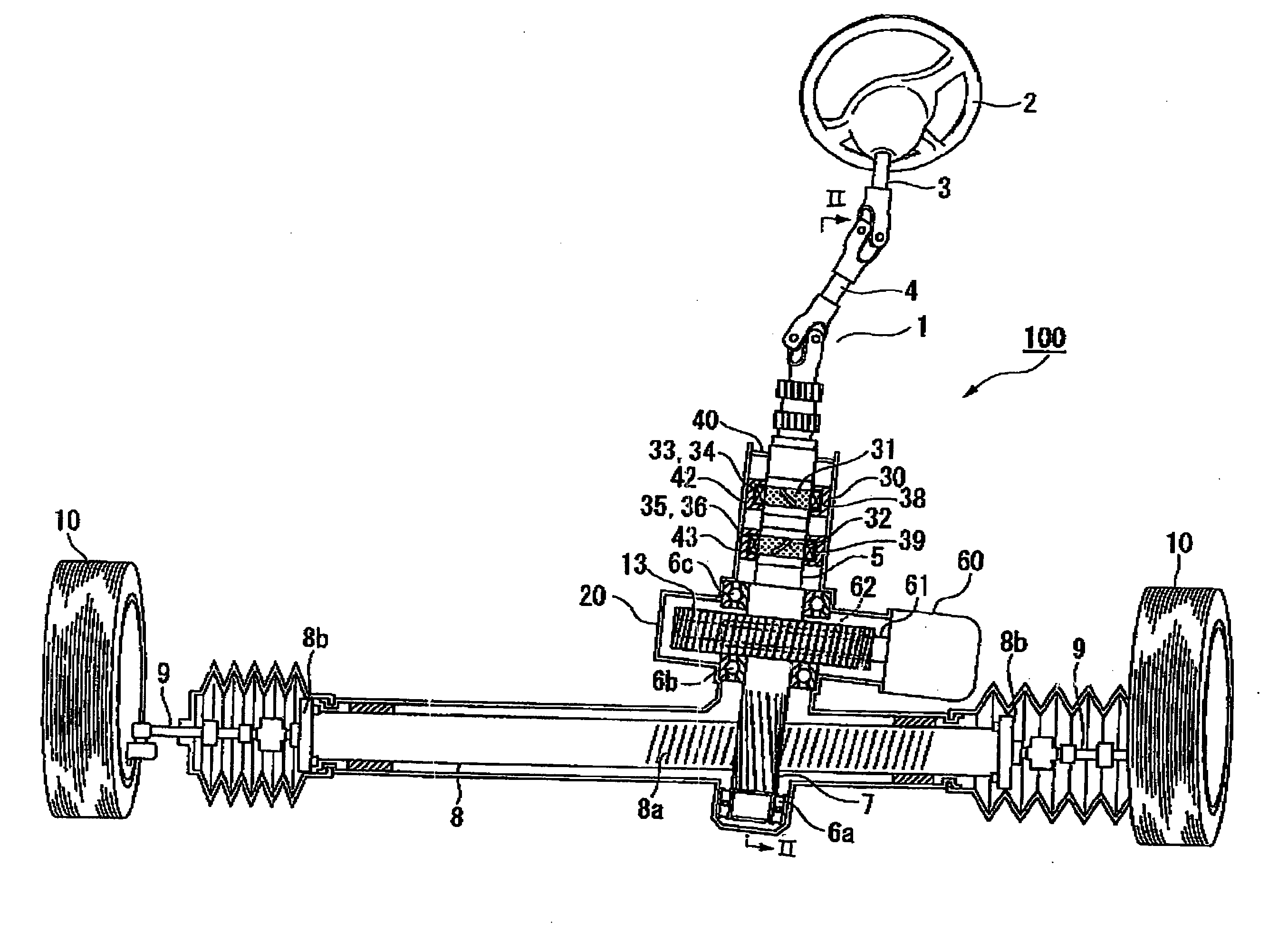

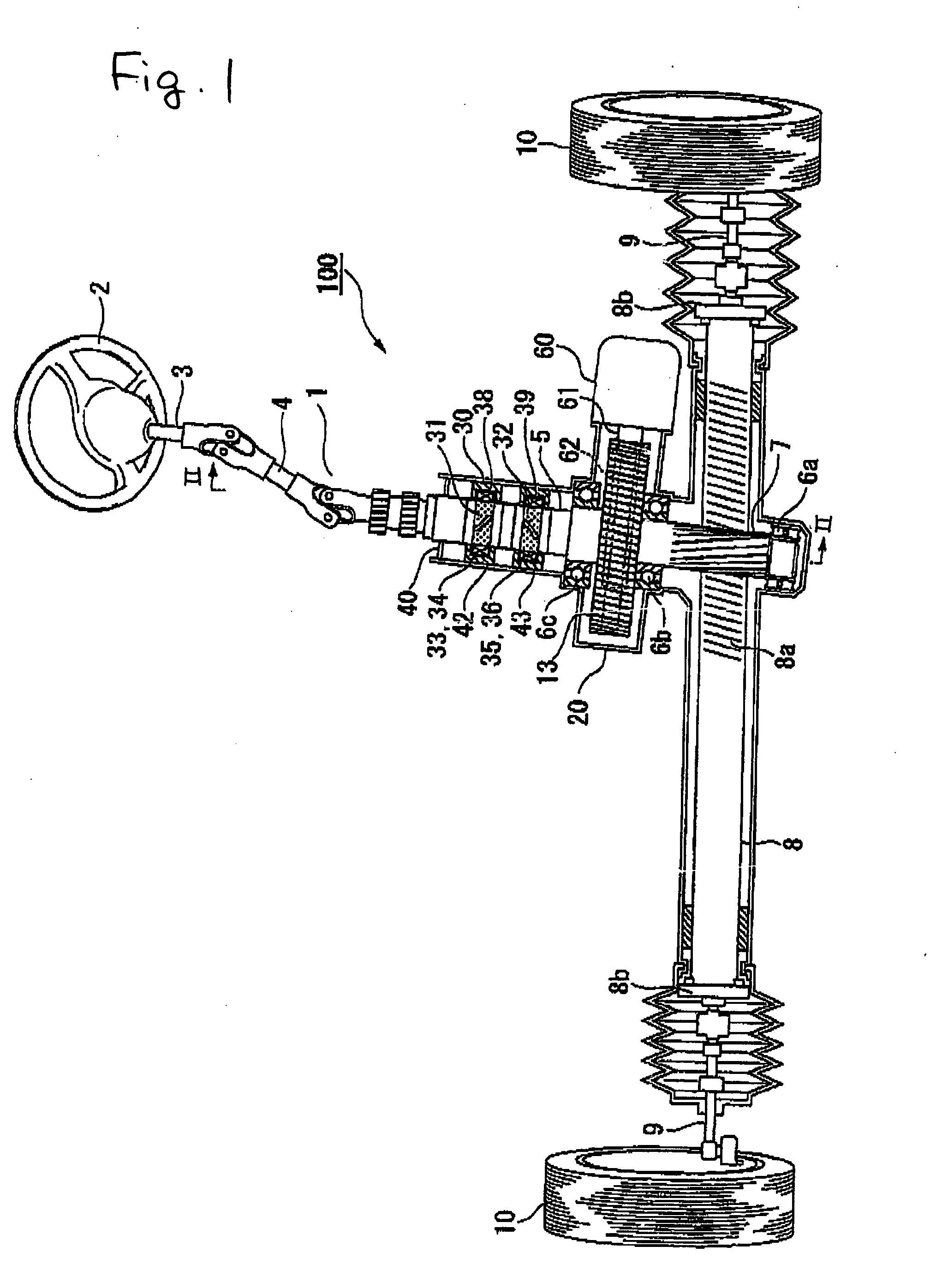

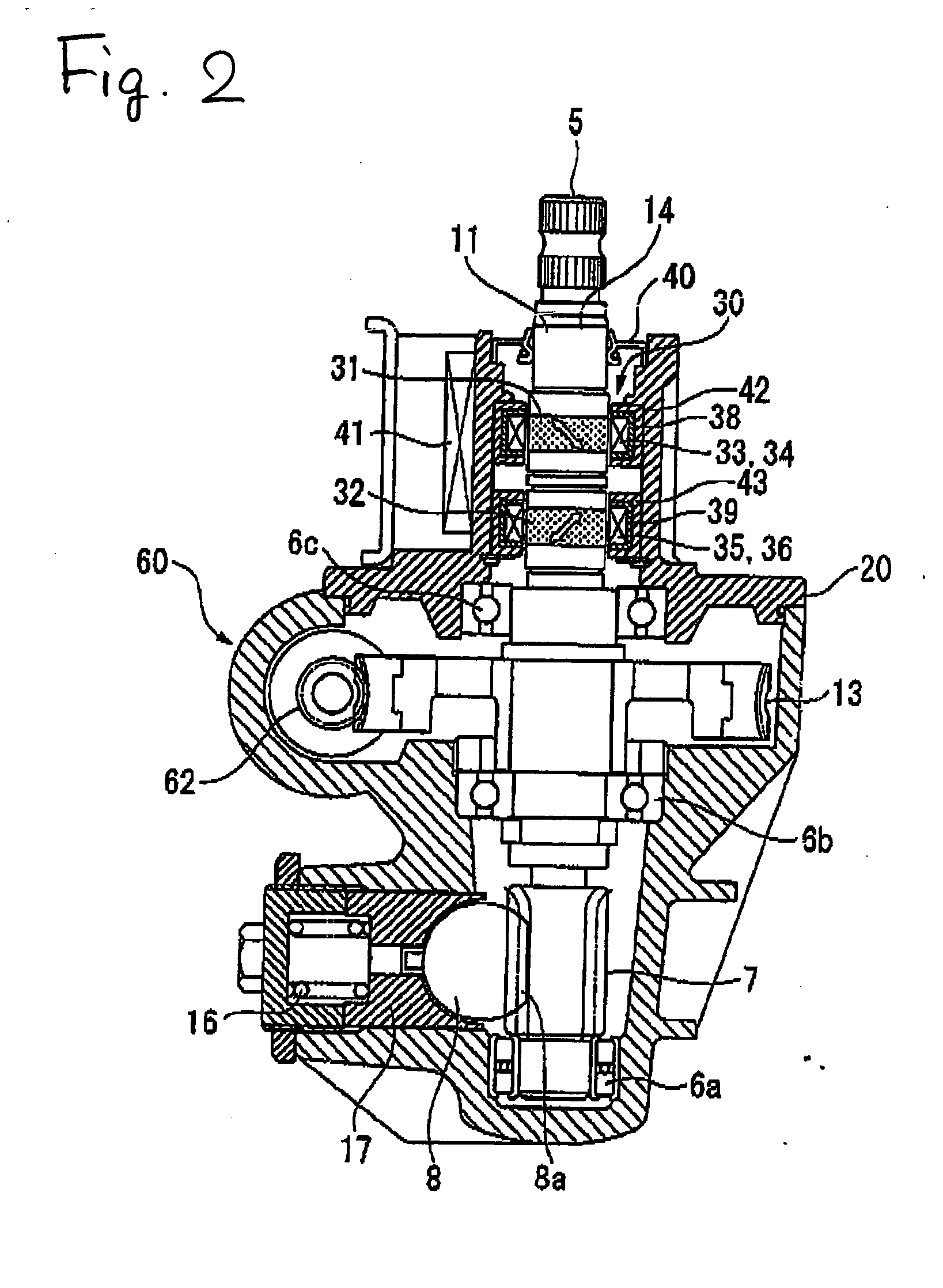

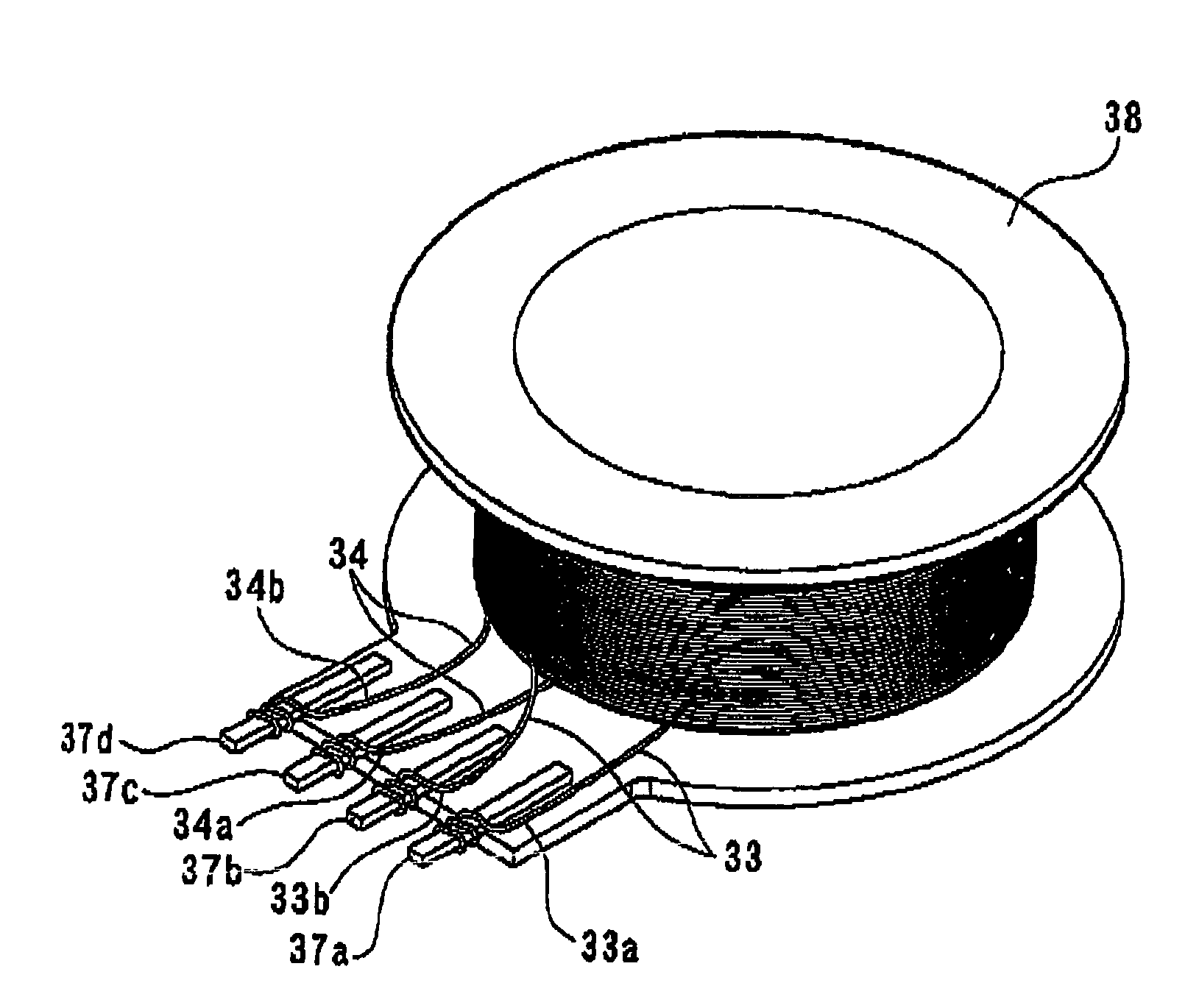

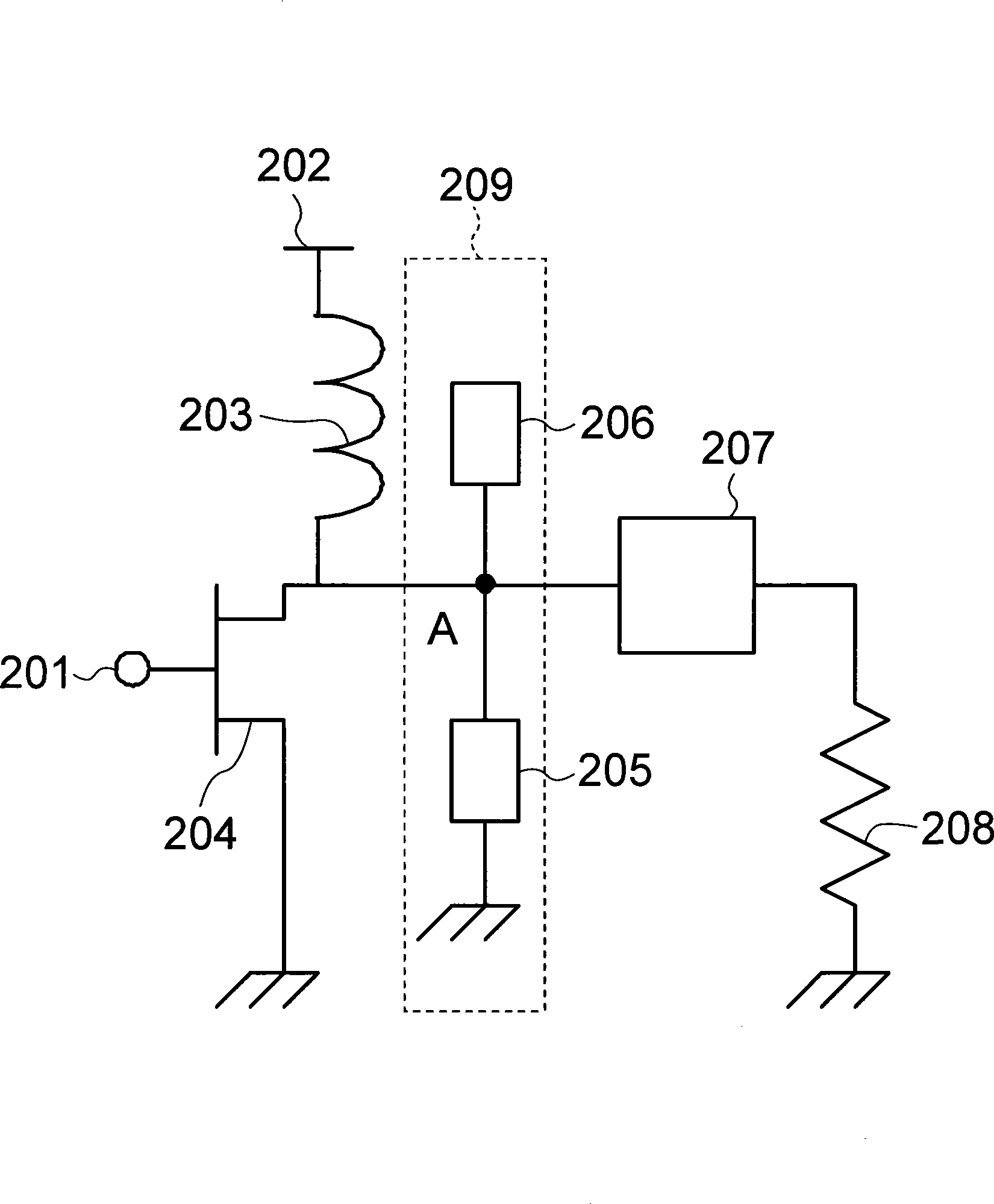

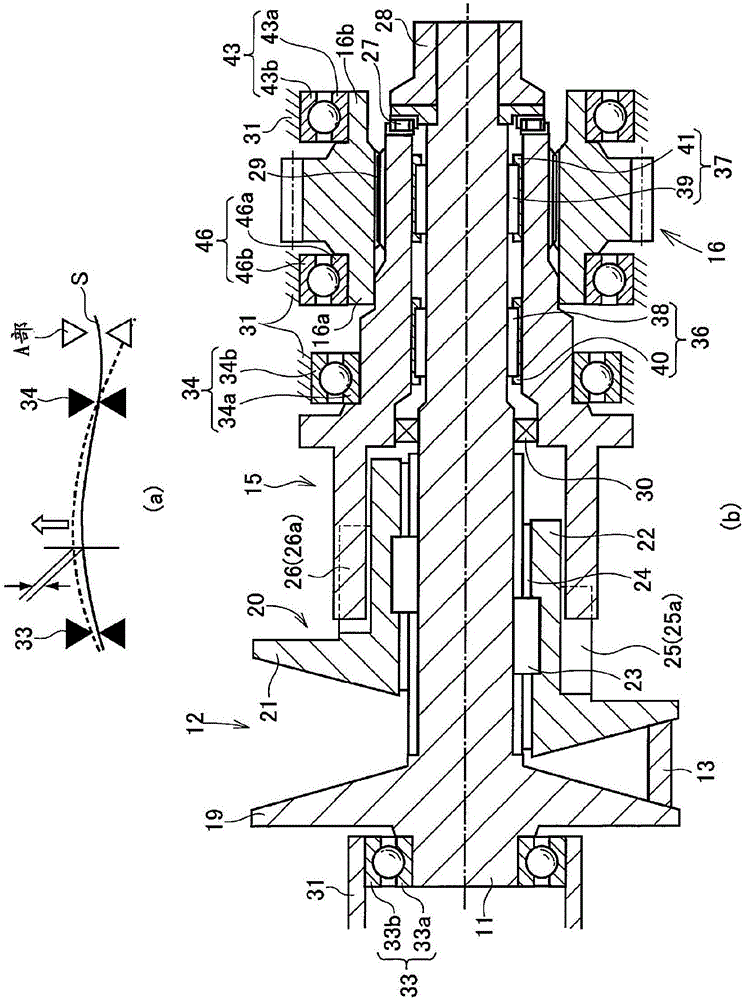

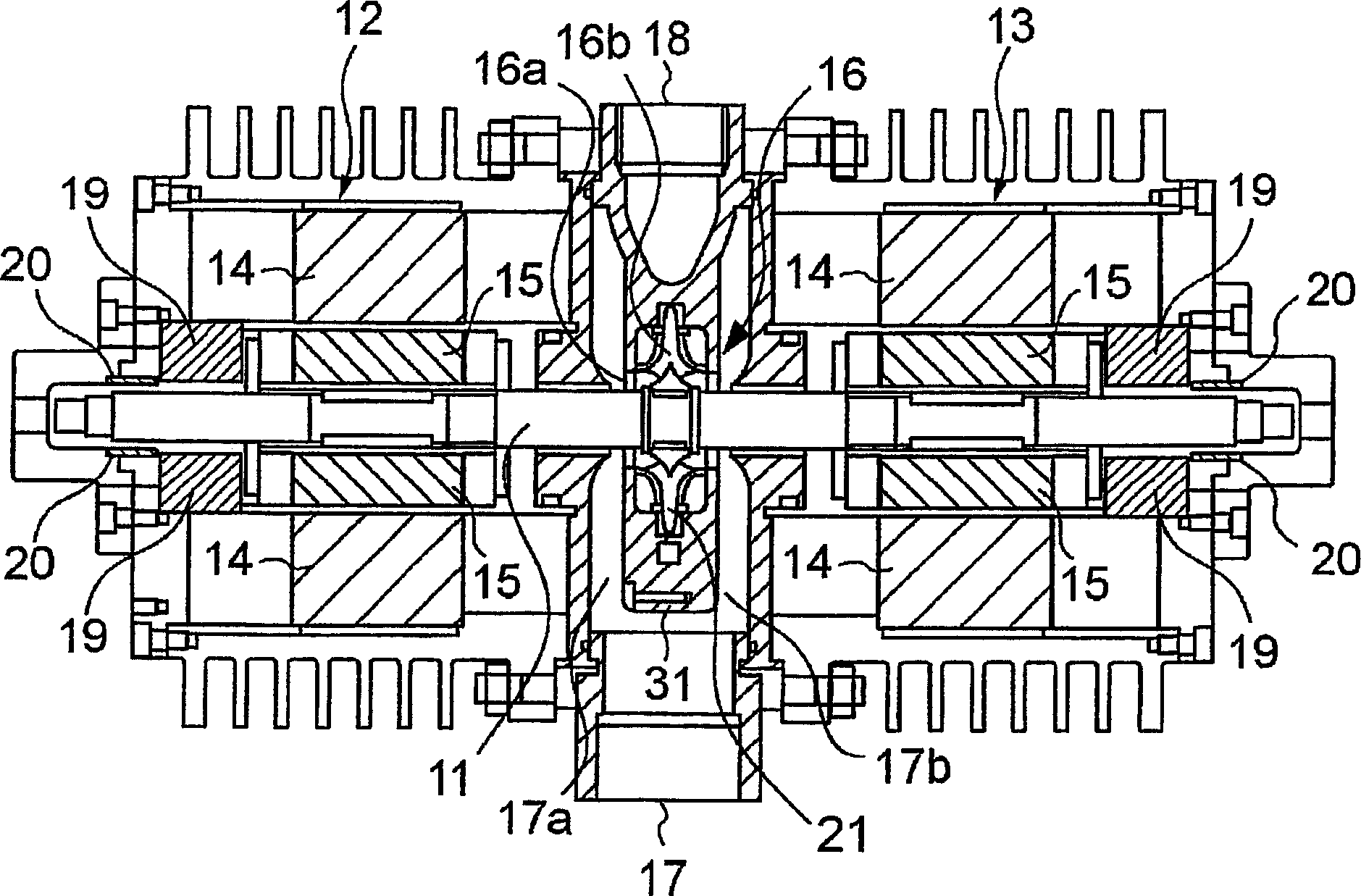

Magnetostrictive torque sensor and electric power steering apparatus

ActiveUS20070295111A1Reduce the differenceElectrical size reductionWork measurementAutomatic steering controlElectric power steeringMagnetic anisotropy

A magnetostrictive torque sensor having a first magnetostrictive film and a second magnetostrictive film, which are both provided on a shaft and have different magnetic anisotropies. A first detection coil and a second detection coil are arranged to face the first magnetostrictive film, and a third detection coil and a fourth detection coil are arranged to face the second magnetostrictive film. The first and second detection coils are wound around the same coil bobbin, while the third and fourth detection coils are wound around another common coil bobbin.

Owner:HONDA MOTOR CO LTD

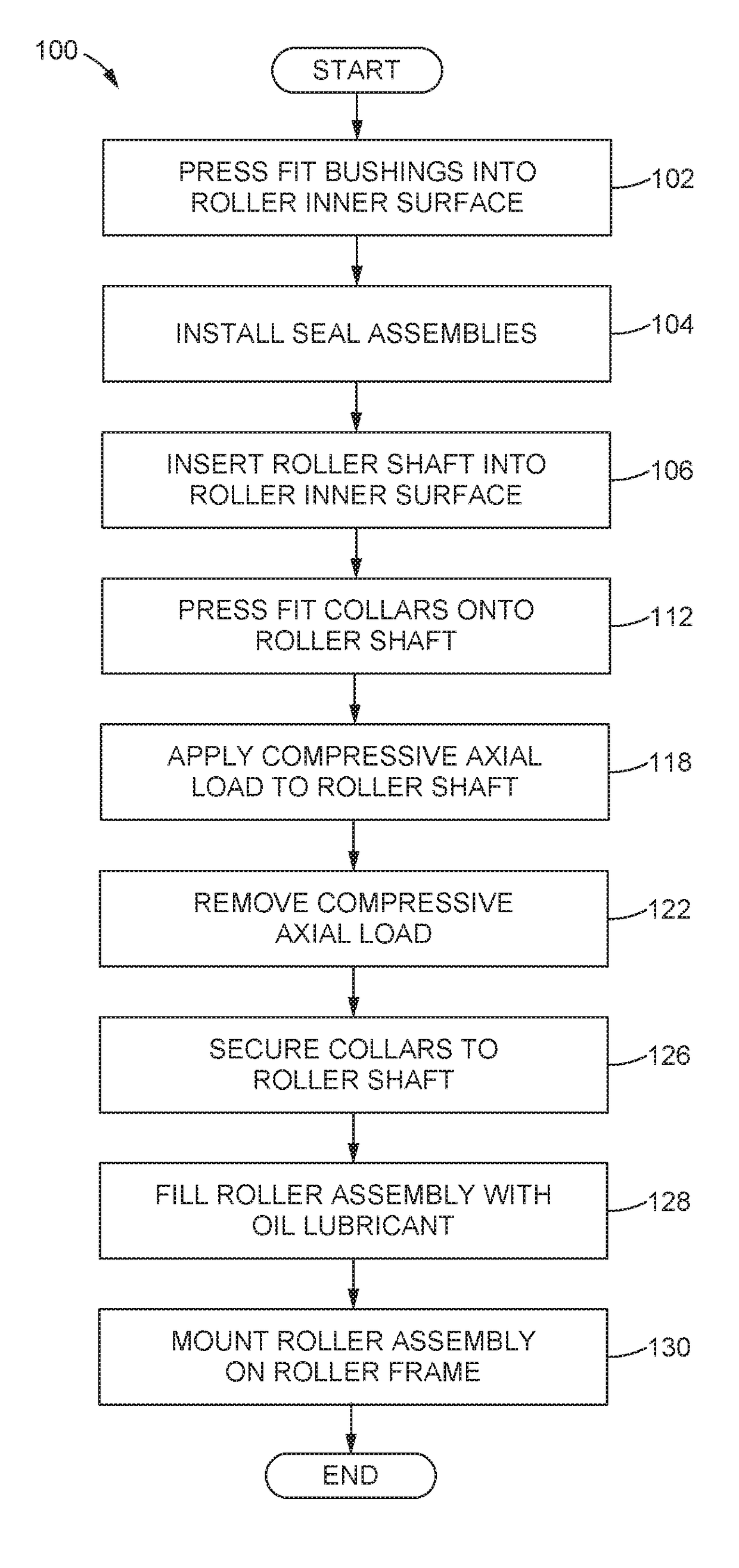

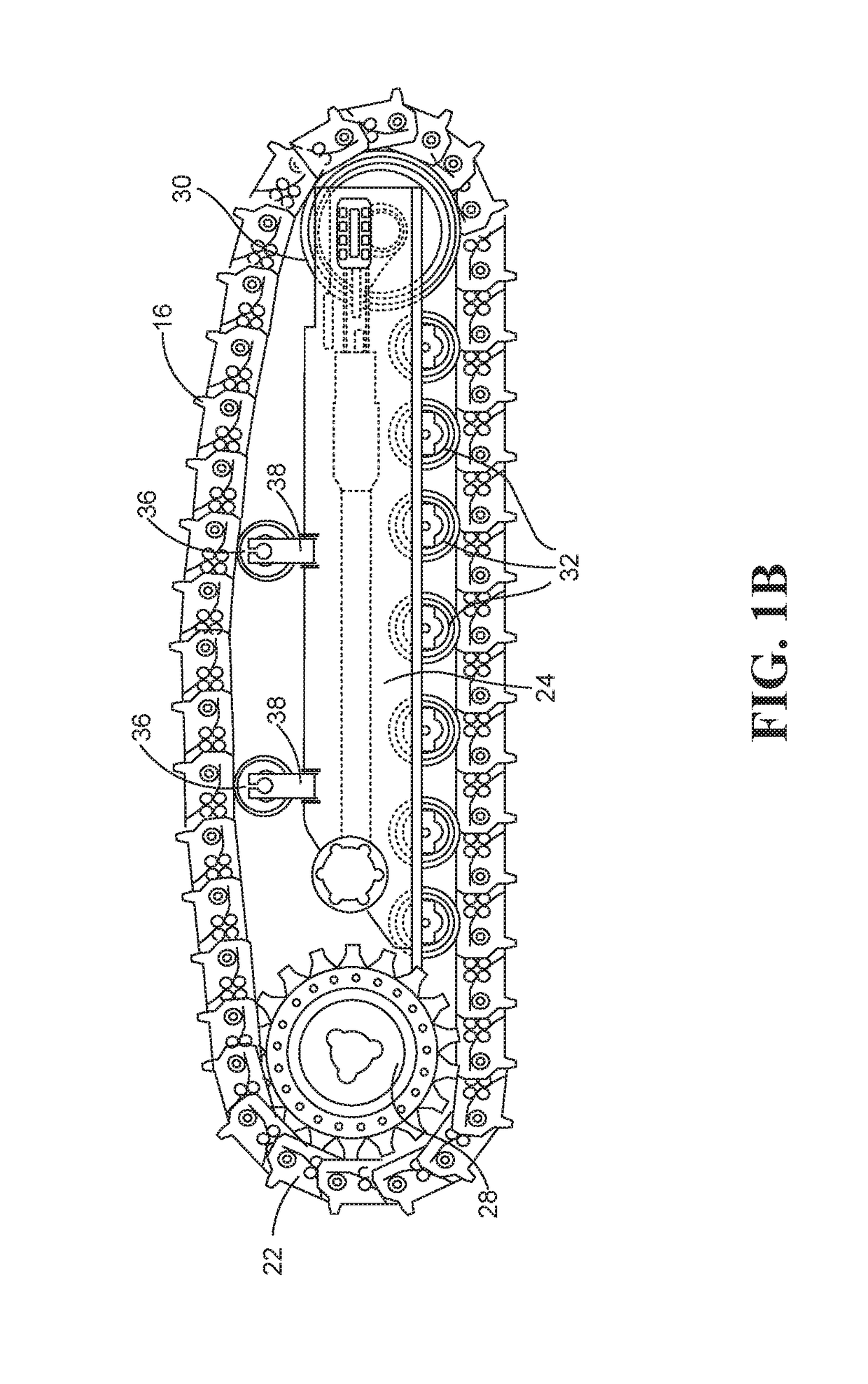

Track Roller Assembly and Method

ActiveUS20170369111A1Shorten shaft lengthPrevent inward movementMechanical machines/dredgersEndless track vehiclesEngineeringMechanical engineering

A track roller assembly may have a track roller, a roller shaft and collars press fit onto either end of the roller shaft to retain the track roller on the roller shaft with an axial clearance between the collars and the track roller. During assembly, the collars may be press fit onto the shaft ends and forced axially inwardly until further axial movement of the collars is prevented by engagement shoulders of the track roller. A compressive axial load may be applied to the roller shaft to reduce a shaft length of the roller shaft and to cause the roller shaft to slide inwardly relative to the collars. The compressive axial load is removed from the roller shaft so that the roller shaft extends back to the normal shaft length and the collars move axially farther apart as the roller shaft extends back to the normal shaft length.

Owner:CATERPILLAR INC

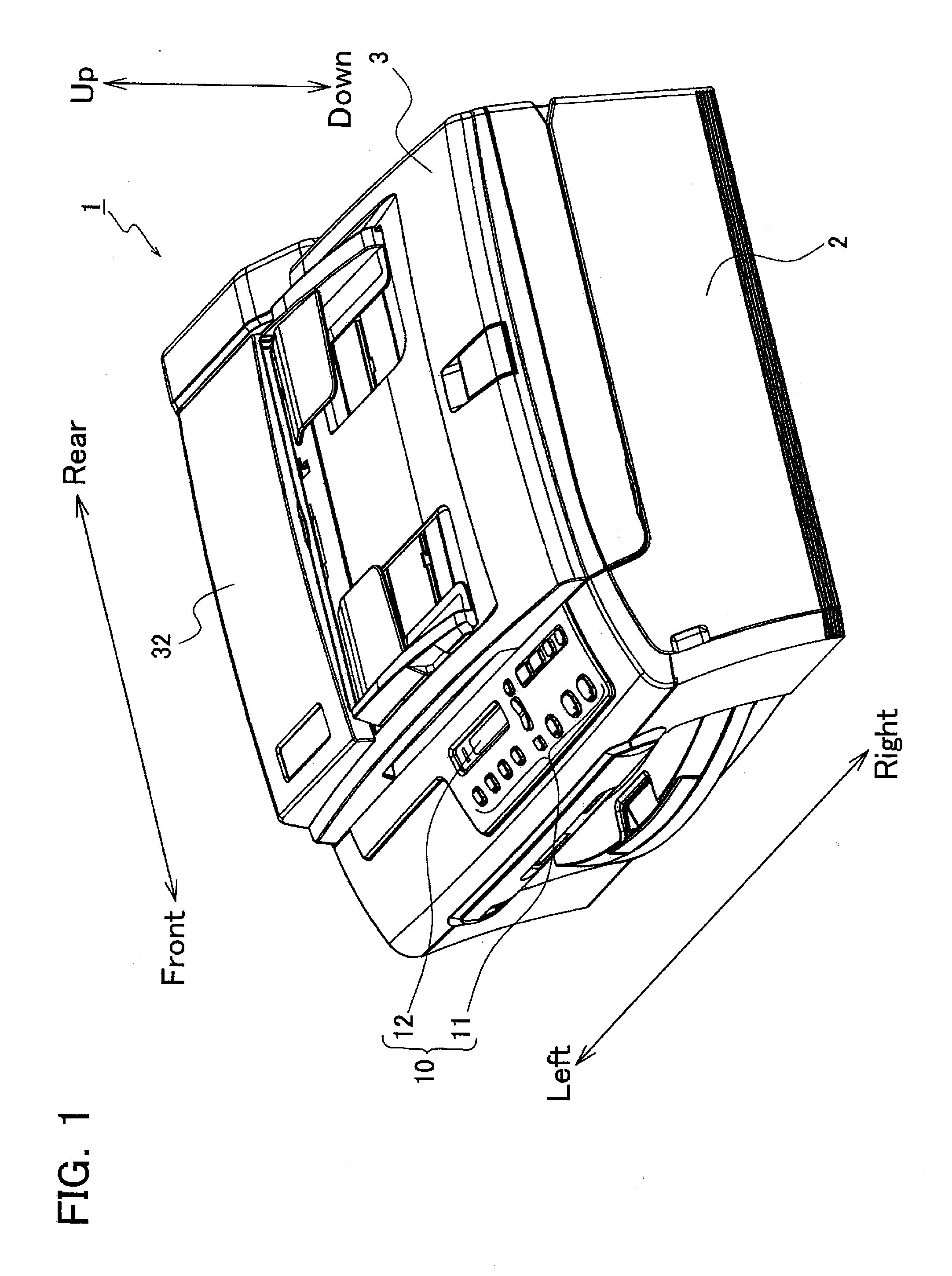

Driving device and scanner

ActiveUS20070287566A1Shorten shaft lengthMove preciselyToothed gearingsPictoral communicationMotor shaftEngineering

The driving device is provided with a motor, a pinion, a first gear, a second gear, and a frame. The frame has a motor side surface and a gear side surface, and includes a first portion and a second portion. A motor housing of the motor is fixed to and supported at the motor side surface of the first portion. A motor shaft extends from the motor housing, penetrating the first portion from the motor side surface to the gear side surface. The pinion is fixed to the distal end of the motor shaft at the gear side surface. The first gear and the second gear are coaxially disposed and rotatably supported at the gear side surface of the second portion. The driving force of the motor is transmitted to the first gear and the second gear through the pinion. The gear side surface of the second portion is offset toward the motor side than the motor side surface of the first portion.

Owner:BROTHER KOGYO KK

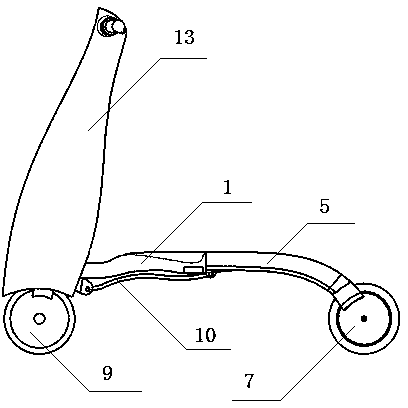

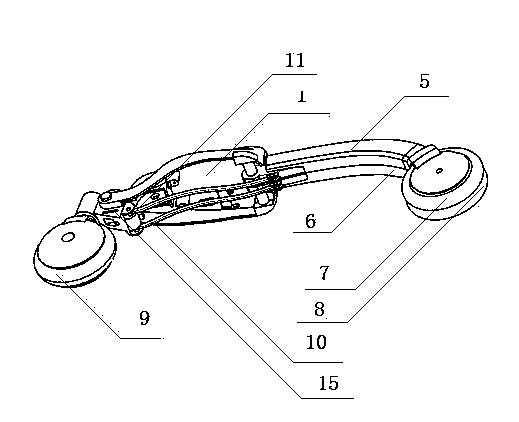

Pedal of electric folding vehicle

Owner:路海燕

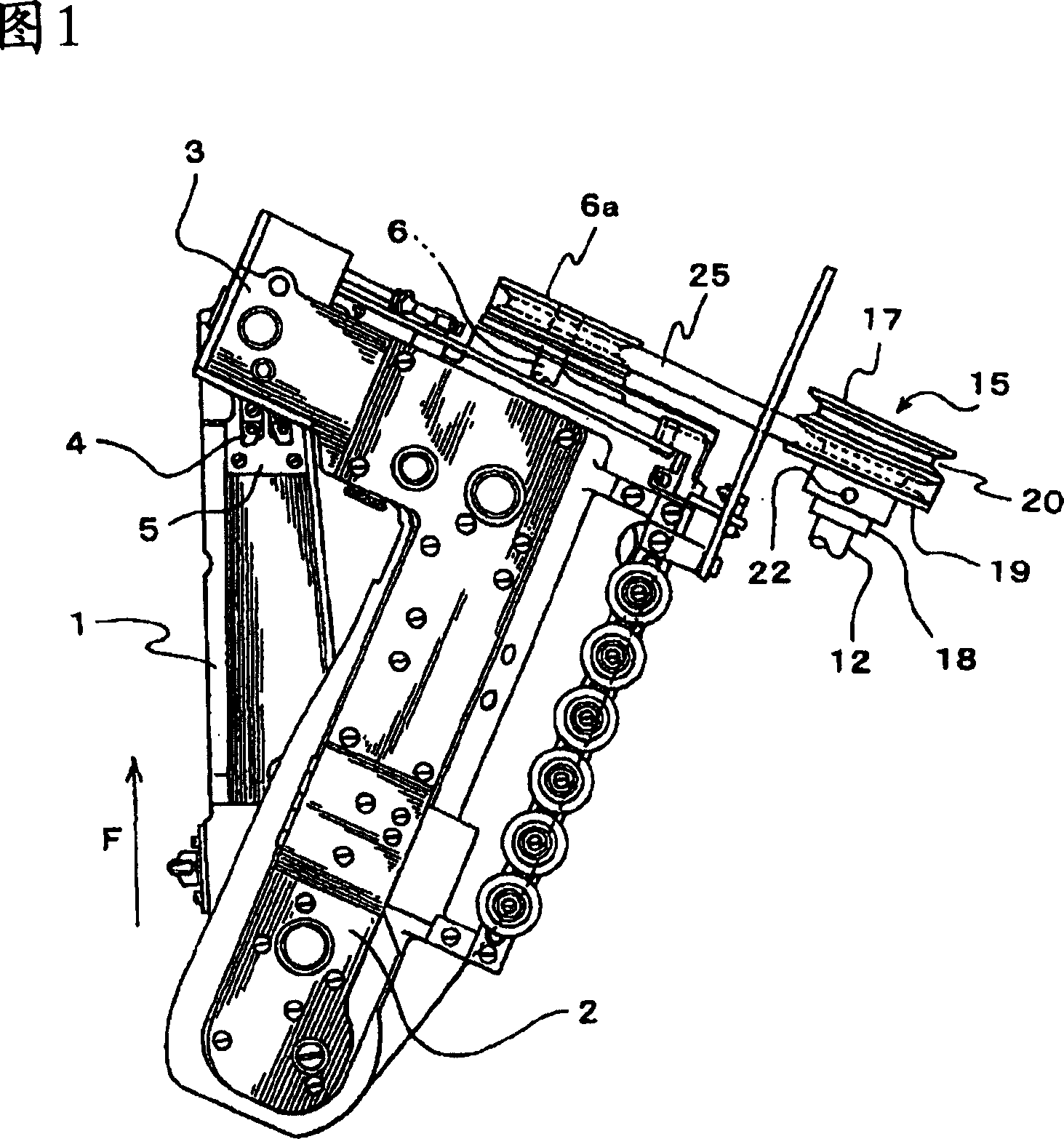

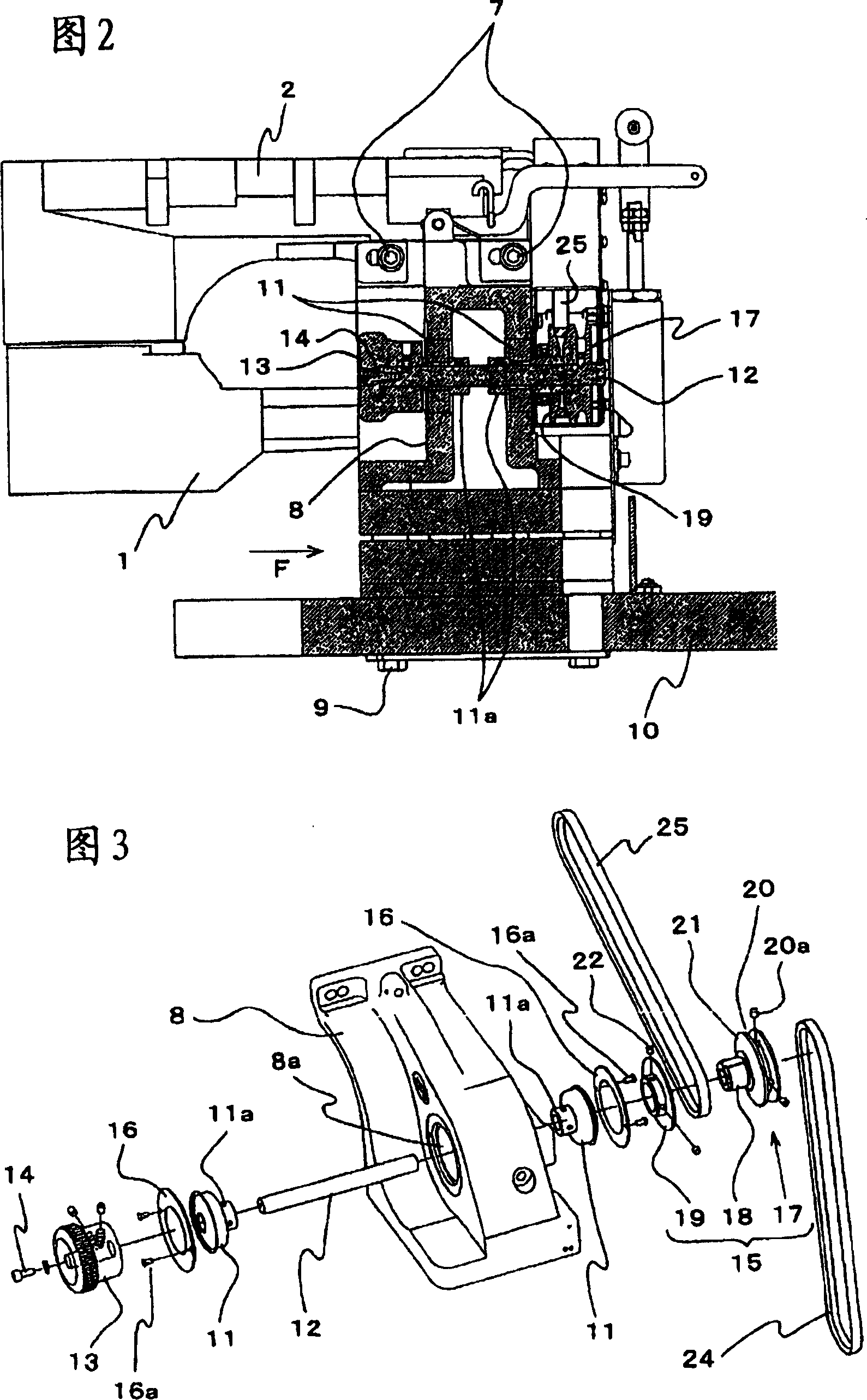

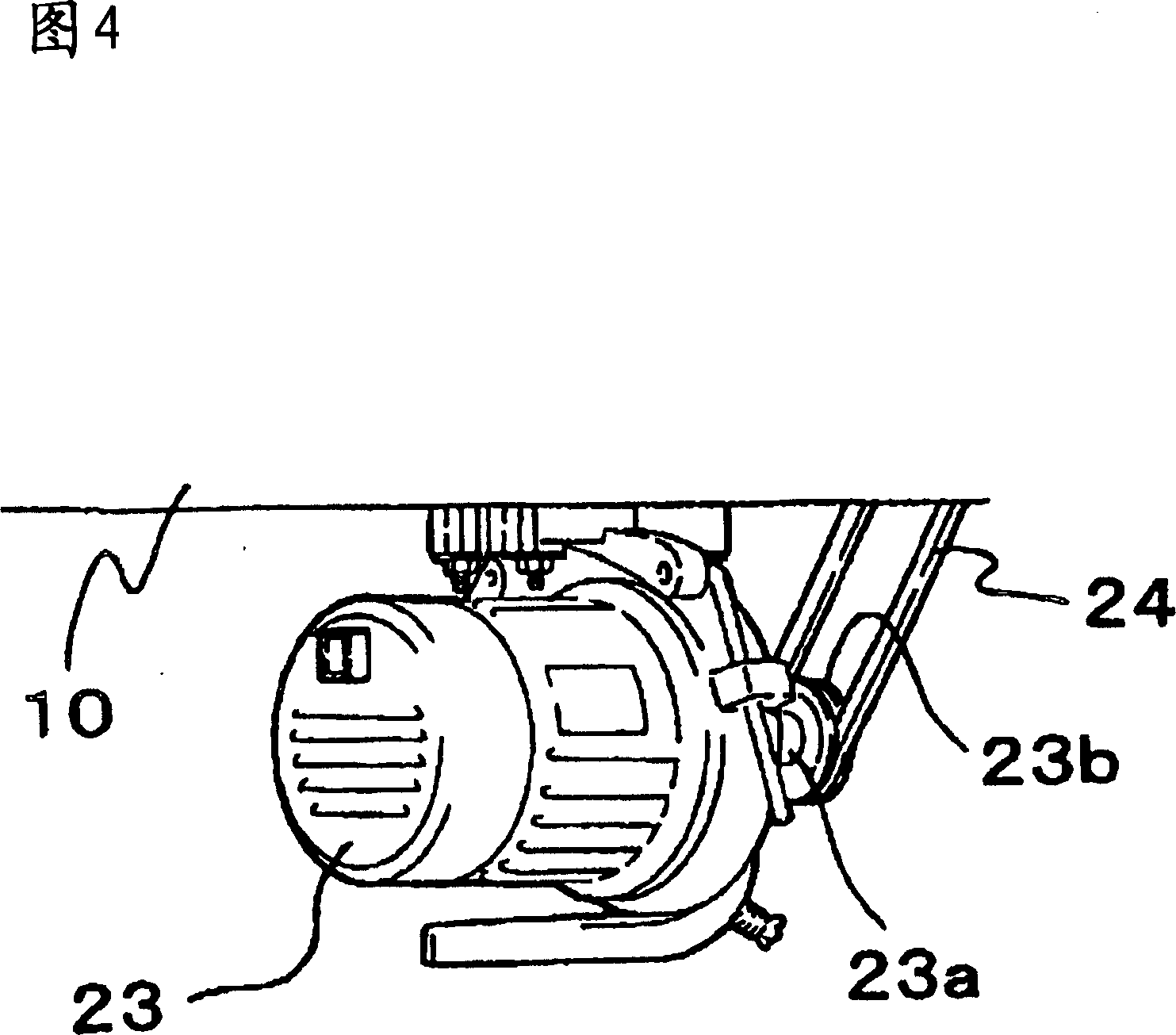

Driving device for crank arm type sewing mechine

ActiveCN101016679AShorten shaft lengthClosely linkedSewing-machine control devicesDrive shaftEngineering

A driven device of crankweb feeding sewing machine, wherein main shaft is supported by axises on level arm extending along the skew direction; transmission shaft is supported by axises on bracket fixing the level arm on the working table, and has manual turn knob on ends; driven motor is located near the working table; cyclic belt combines with the fixed pulley on the transmission shaft to transfer rotation of motor shaft to main shaft, the pulley comprises flange main part, support guide apparatus, and second inclined tablet, wherein, the flange main part comprises first groove and first inclined tablet connecting to the groove and and forming axes. The support guide apparatus and the flange main part are formed together. The second inclined tablet is located opposited to the first inclined tablet, and movably fixed on the support guide apparatus. First groove and second groove which forms by the two inclined tablets combines with different cyclic belts, wherein, one of the cyclic belts is located on the main shaft, and the other cyclic belt is located on the motor shaft.

Owner:株式会社飞马

Vehicle ac generator

InactiveUS20120025657A1Easily set attachment direction of battery terminalShorten shaft lengthDynamo-electric brakes/clutchesSynchronous machinesShaft lengthBattery terminal

In order to provide a vehicle AC generator capable of easily setting an attachment direction of a battery terminal and reducing the total shaft length of the generator, in the vehicle AC generator including a case composed of a front bracket and a rear bracket, and a rotor and a stator which are arranged in the case, the vehicle AC generator includes a battery terminal arranged on an outer circumferential portion of the rear bracket, an engaging body provided on the battery terminal, and a plurality of fitting portions to which the engaging body is fitted.

Owner:MITSUBISHI ELECTRIC CORP

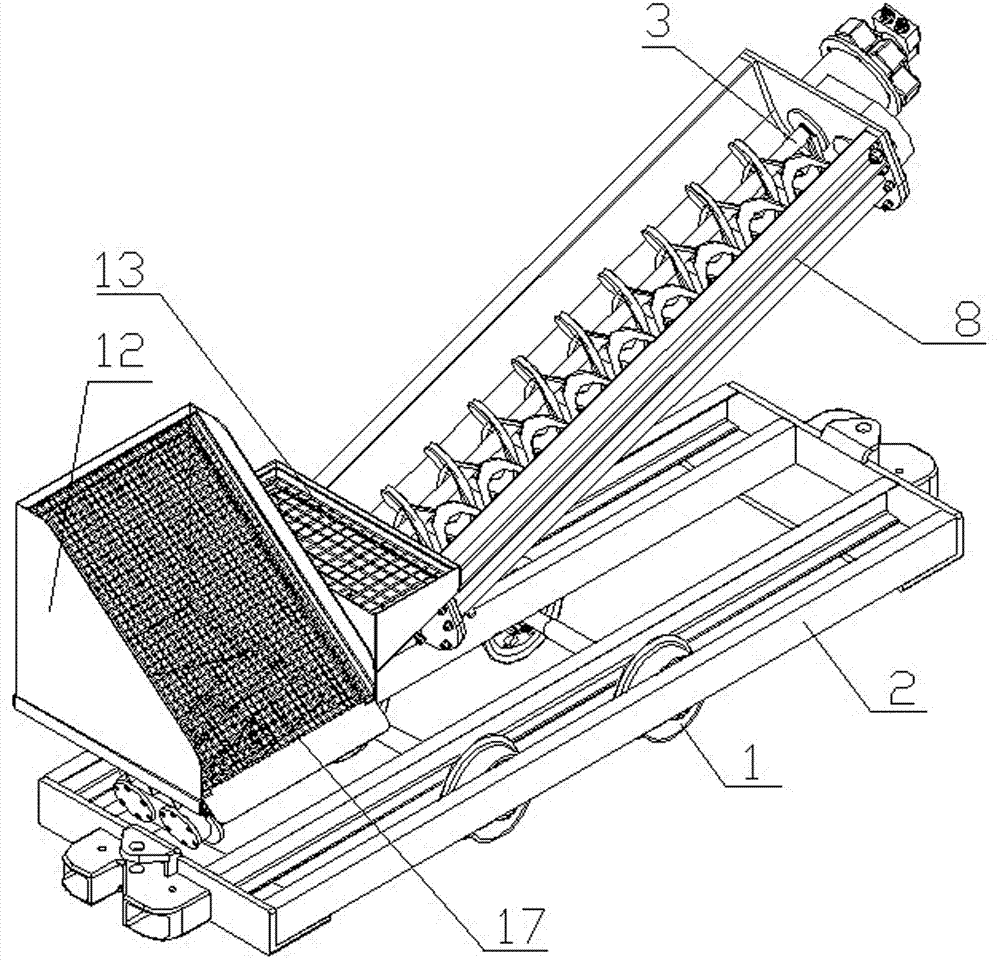

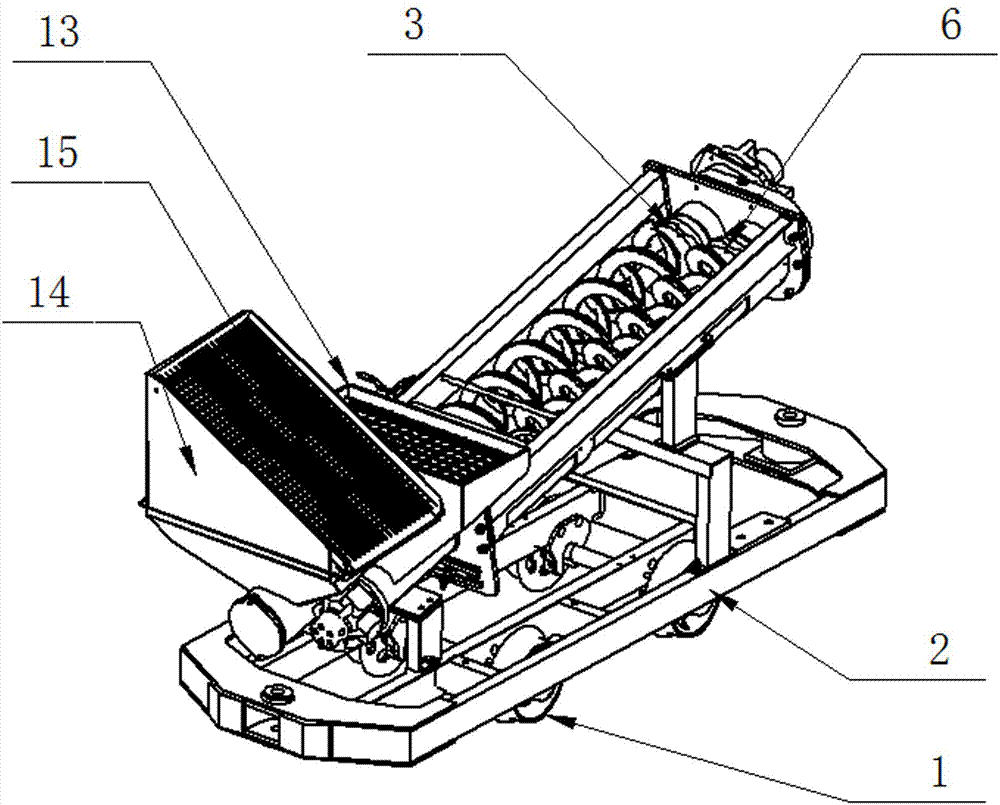

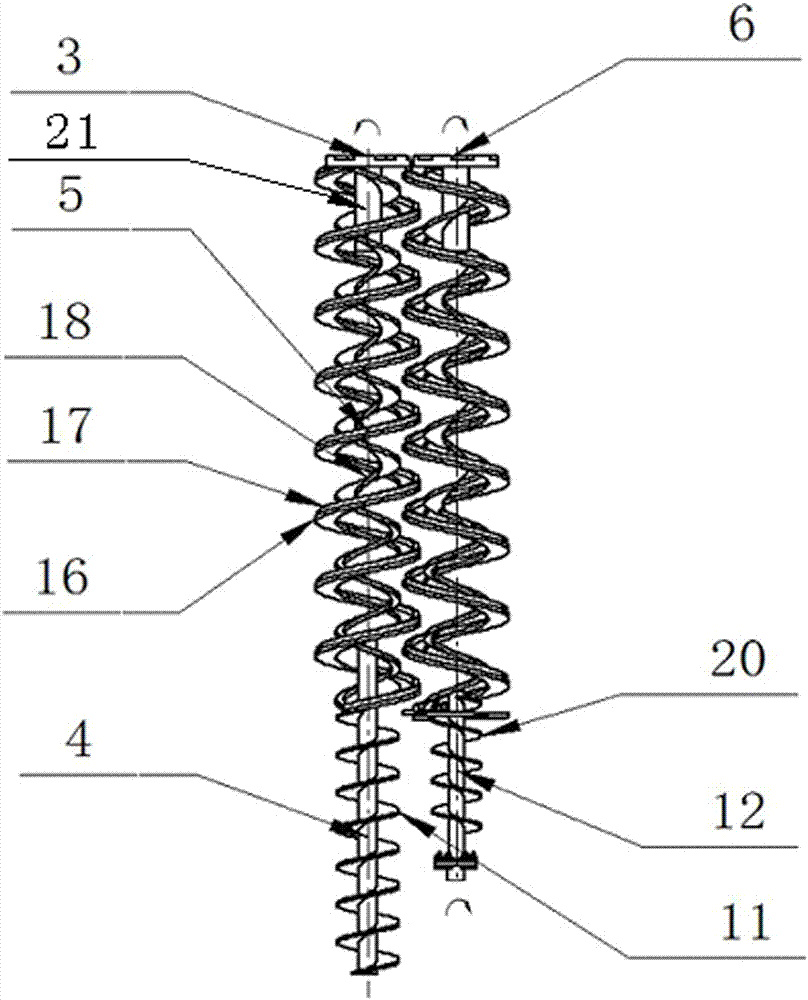

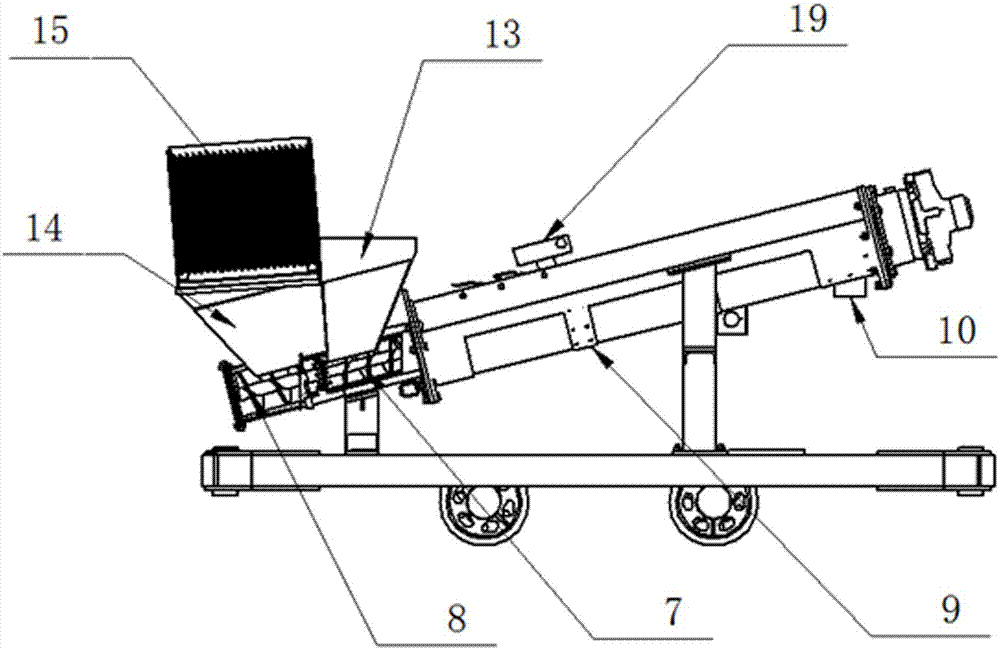

Automatic screw matching concrete stirring conveyer

The invention discloses an automatic screw matching concrete stirring conveyer. The automatic screw matching concrete stirring conveyer is provided with two conveying and stirring shafts in parallel; each conveying and stirring shaft is sequentially provided with a primary feeding section, a secondary feeding section and a stirring and mixing section from the head end to the tail end according to the conveying direction; the shaft body of each conveying and stirring shaft at the first feeding section part and the second feeding section part is respectively provided with feeding screw sheets at the same screw direction, namely a primary feeding screw sheet and a secondary feeding screw sheet respectively; the feeding screw sheets of the two conveying and stirring shafts are opposite in direction; the volume of screw sheets in a screw pitch of the primary feeding screw sheets is less than the volume of screw sheets in a screw pitch of the secondary feeding screw sheets; the shaft bodies of the stirring and mixing sections of the two conveying and stirring shafts are connected with large hollow stirring screw sheets through support plates; spaces between the large stirring screw sheets and the shaft bodies are internally provided with small stirring screw sheets. The automatic screw matching concrete stirring conveyer can match stably and accurately, can stir slurry repeatedly and fully, is high in efficiency, and is suitable for being popularized and applied.

Owner:SHANGYASHAN JINQUAN MACHINERY MFG CO LTD

Magnetostrictive torque sensor and electric power steering apparatus

ActiveUS7762148B2Reduce the differenceElectrical size reductionWork measurementAutomatic steering controlElectric power steeringMagnetic anisotropy

A magnetostrictive torque sensor having a first magnetostrictive film and a second magnetostrictive film, which are both provided on a shaft and have different magnetic anisotropies. A first detection coil and a second detection coil are arranged to face the first magnetostrictive film, and a third detection coil and a fourth detection coil are arranged to face the second magnetostrictive film. The first and second detection coils are wound around the same coil bobbin, while the third and fourth detection coils are wound around another common coil bobbin.

Owner:HONDA MOTOR CO LTD

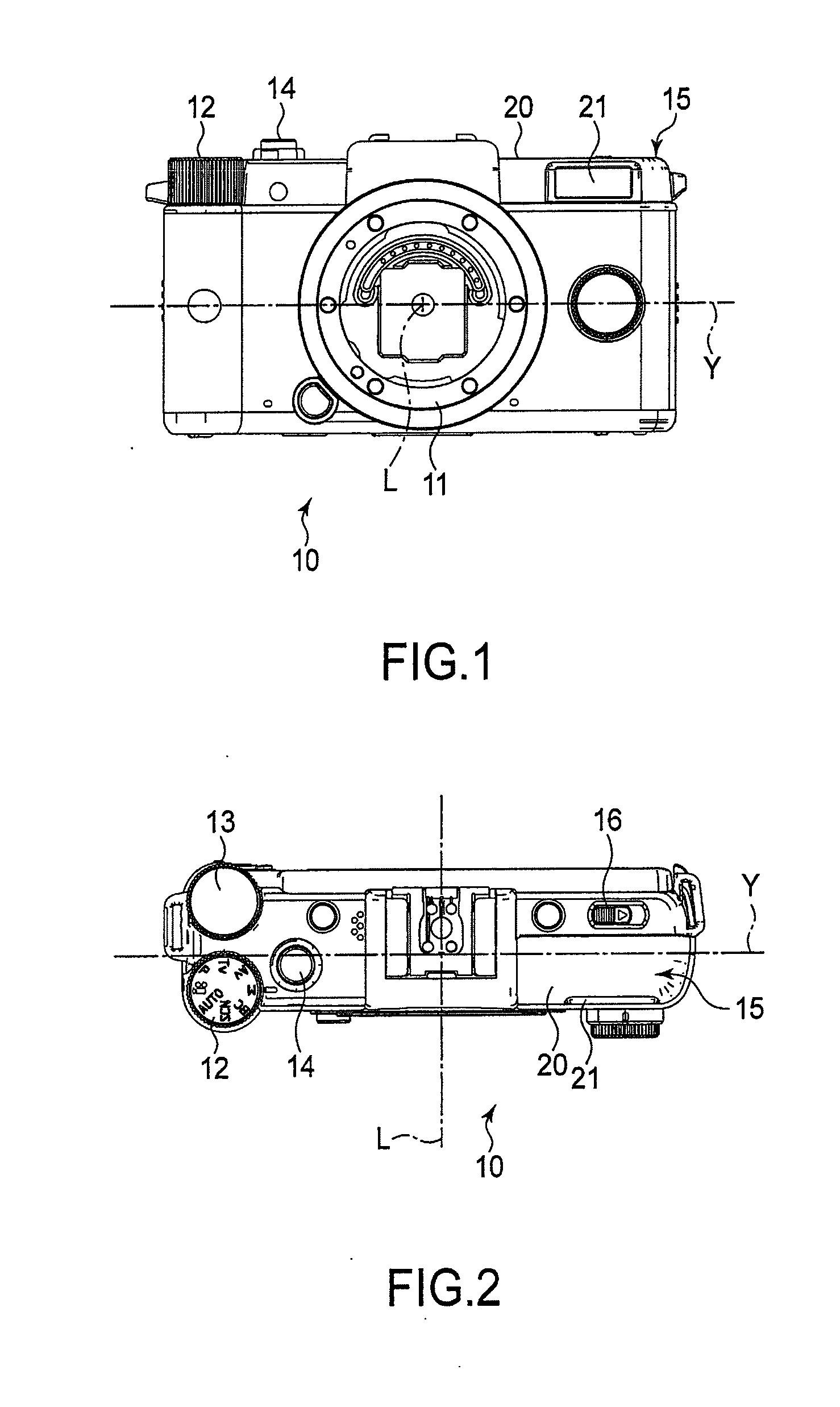

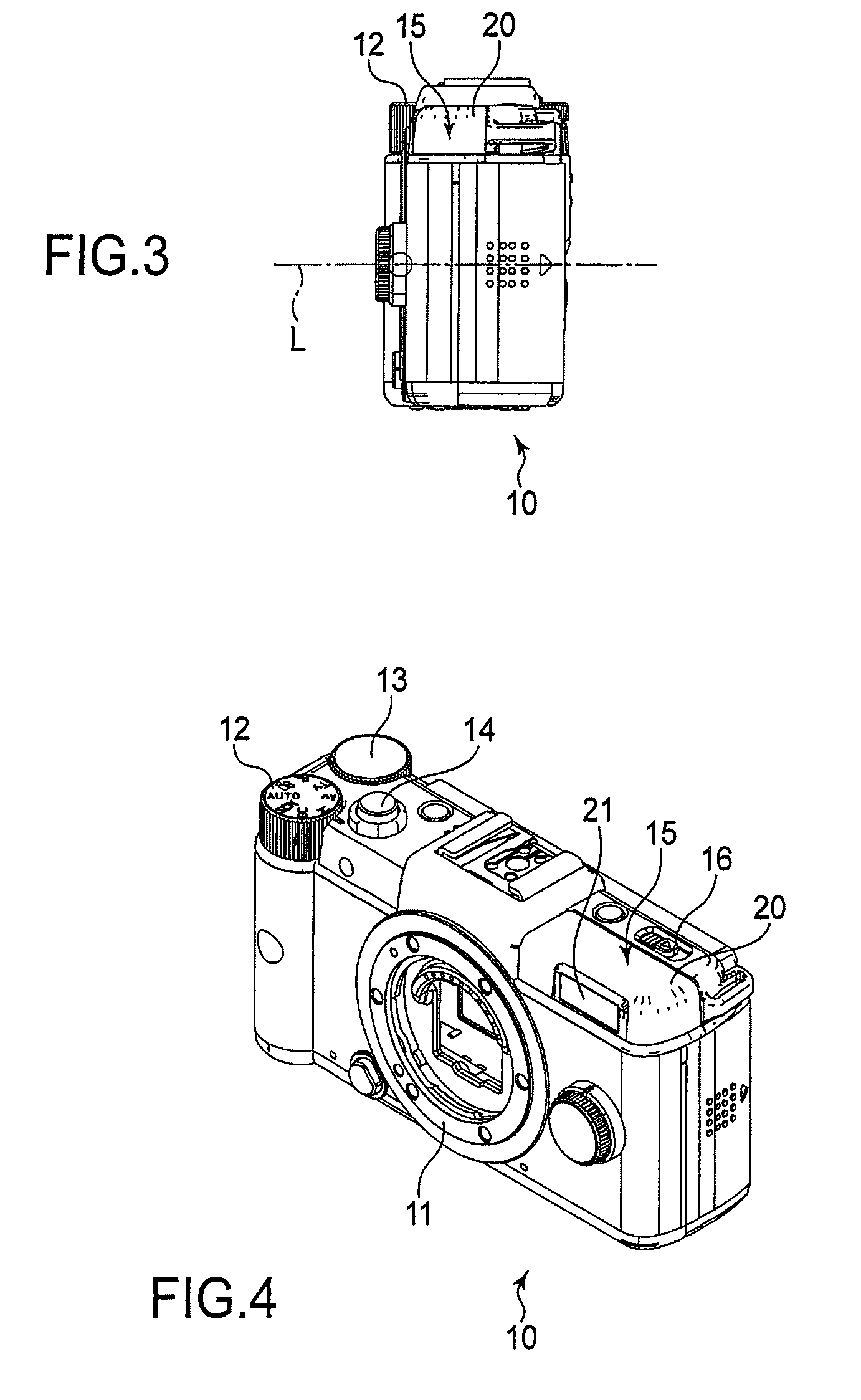

Built-in flash pop-out mechanism

InactiveUS20120294601A1Small sizeGood effectLighting support devicesLight fasteningsOptical axisFuselage

A built-in flash pop-out mechanism comprises a shaft member movable along a first axis; an arm member where one end is pivotally fixed at an end of the shaft member about a second axis; a flash-support member pivotally fixed at the other end of the arm member about a third axis; a first biasing member biasing the shaft member along the first axis; a second biasing member biasing the arm member about the second axis; a third biasing member biasing the flash-support member about the third axis. The built-in flash is extended from a camera body with coplanar motions that pop out the built-in flash to increase its distance from an optical axis. The motions include a translation of the shaft member along the first axis and rotations of the arm member and flash-support member about the second and third axes.

Owner:RICOH IMAGING COMPANY

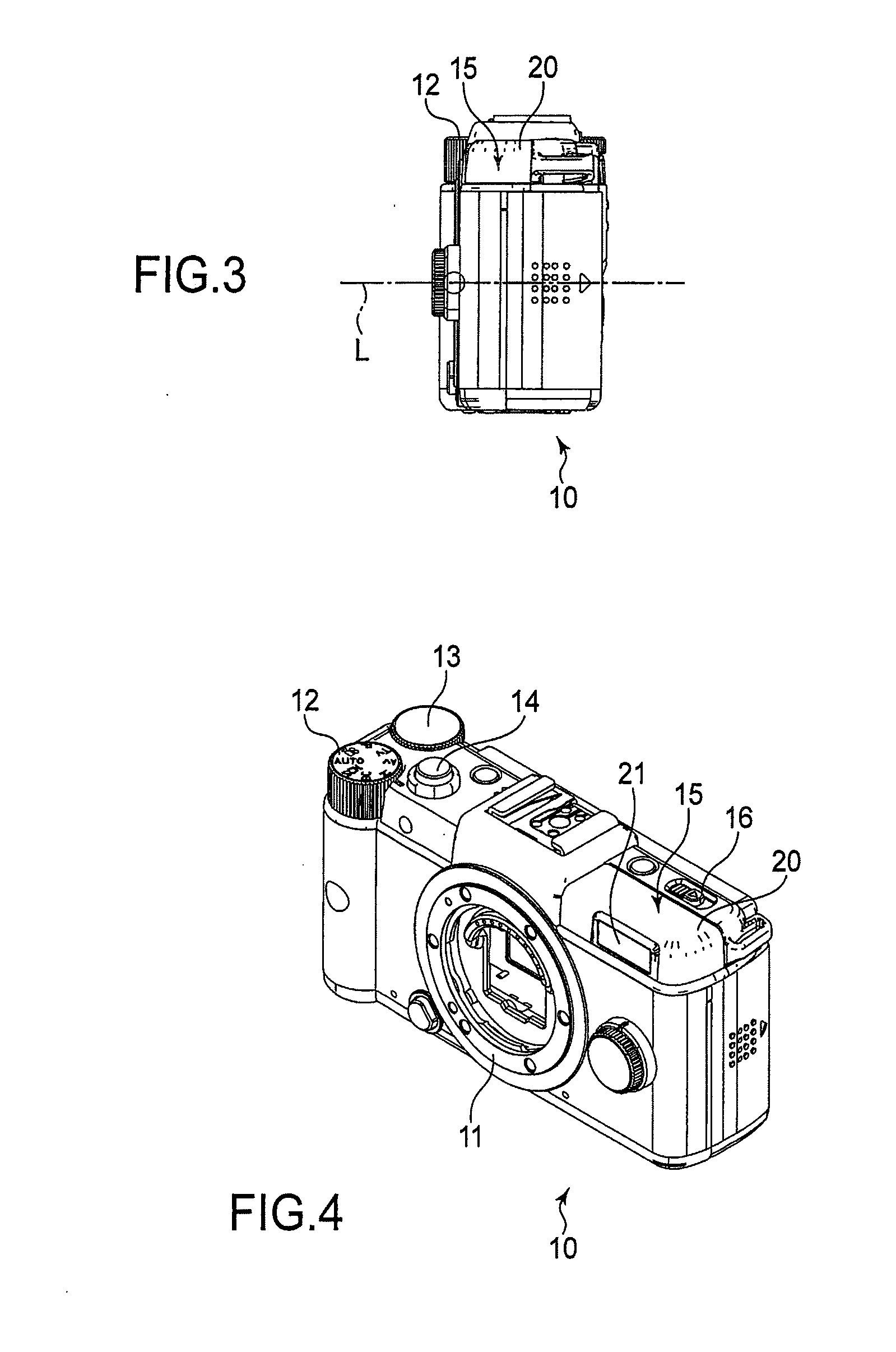

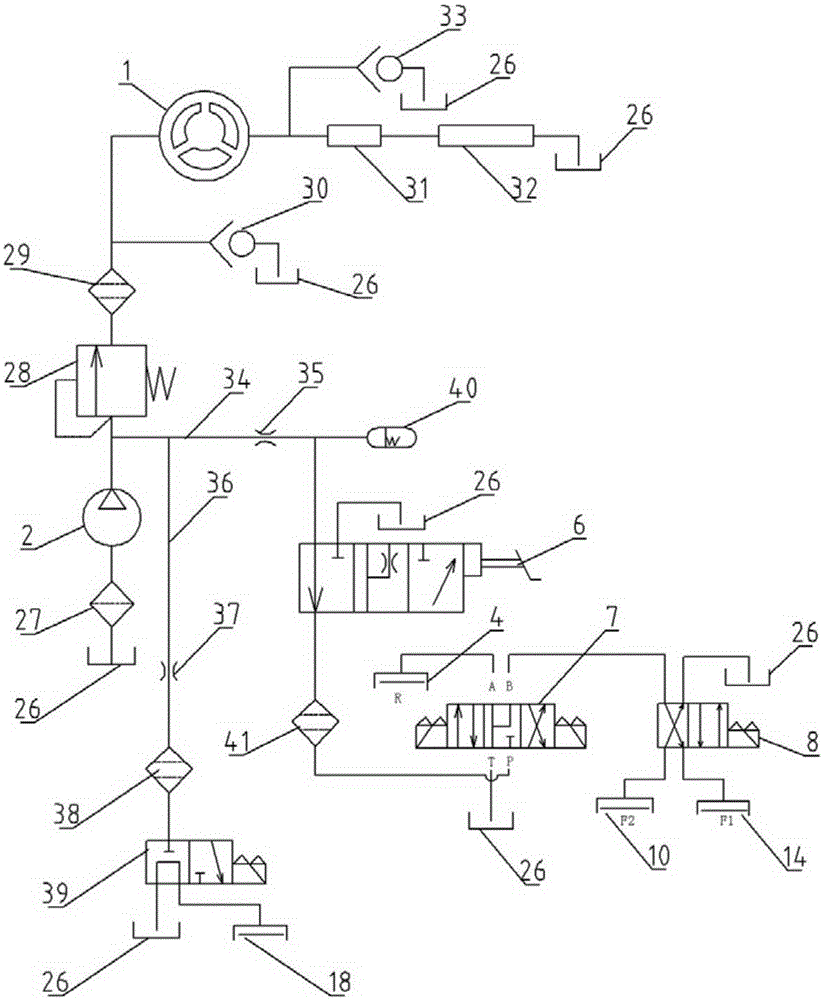

Hydraulic transmission system driven by four wheels

The invention discloses a hydraulic transmission system driven by four wheels. The hydraulic transmission system comprises a torque converter, a fuel feed pump and a gearbox. A pump wheel on the torque converter is connected with the fuel feed pump. A turbine on the torque converter is connected with a connecting shaft on a reversing clutch drum through a spline. A first transmission gear is fixedly connected to the connecting shaft of the reversing clutch drum and is meshed with a second transmission gear and a third transmission gear. The second transmission gear and the third transmission gear are fixed to a connecting shaft of a high-speed advancing clutch drum and a connecting shaft of a low-speed advancing clutch drum respectively. A reversing gear, a high-speed advancing-gear gear and a low-speed advancing-gear gear are arranged on an internal friction piece of the reversing clutch drum, an internal friction piece of the high-speed advancing clutch drum and an internal friction piece of the low-speed advancing clutch drum respectively. According to the hydraulic transmission system driven by the four wheels, combining and disengaging of a bridge disengaging device are achieved through a hydraulic clutch, electronic control is convenient, and therefore conversion between four-wheel driving and two-wheel driving can be achieved without shutdowns, and operation is more convenient and more rapid.

Owner:ZHEJIANG ZHONGCHAI MACHINERY

Eight-gear automobile automatic transmission

ActiveCN104964006AFew mechanical partsEasy to controlToothed gearingsTransmission elementsClutch controlAutomatic transmission

The invention belongs to the technical field of automatic transmissions and particularly relates to an eight-gear automobile automatic transmission. The transmission solves the technical problems that in the prior art, adjacent planetary gears interfere with one other, an obtained transmission ratio depends on a presumed transmission ratio, and the limitation of the transmission ratio of a system is large. The transmission comprises a box, a power input shaft, three clutches, four brakes and a planetary gear system. The planetary gear system comprises a first sun gear, a second sun gear, a third sun gear, a first gear ring, a second gear ring, a first planetary gear with a step, a first planetary gear without a step and a planetary frame. The second sun gear, the third sun gear and the planetary frame are controlled by the first clutch, the second clutch and the third clutch respectively. The second sun gear, the first sun gear, the planetary frame and the second gear ring are controlled by the first brake, the second brake, the third brake and the fourth brake respectively. The transmission is easy to control, transmission efficiency of all gears is high, and the adjacent planetary gears do not interfere with one other.

Owner:朗道科教设备(肇庆)有限公司

High frequency power amplifier and high frequency heating device

InactiveCN101364795AShorten shaft lengthReduce transmission lossDielectric heatingAmplifiers wit coupling networksHigh frequency powerHarmonic

The invention provides a harmonic control circuit with a small size and low transmission loss for improving the power utilization efficiency of the high frequency power amplifier. A high frequency power amplifier includes an amplification element, a harmonic control circuit, an output matching circuit, and a load resistor. A high frequency signal input from an input end is amplified in the amplification element, passes through the harmonic control circuit and the output matching circuit, and is then supplied to the load resistor. The harmonic control circuit includes a first dielectric resonator and a second dielectric resonator.

Owner:PANASONIC CORP

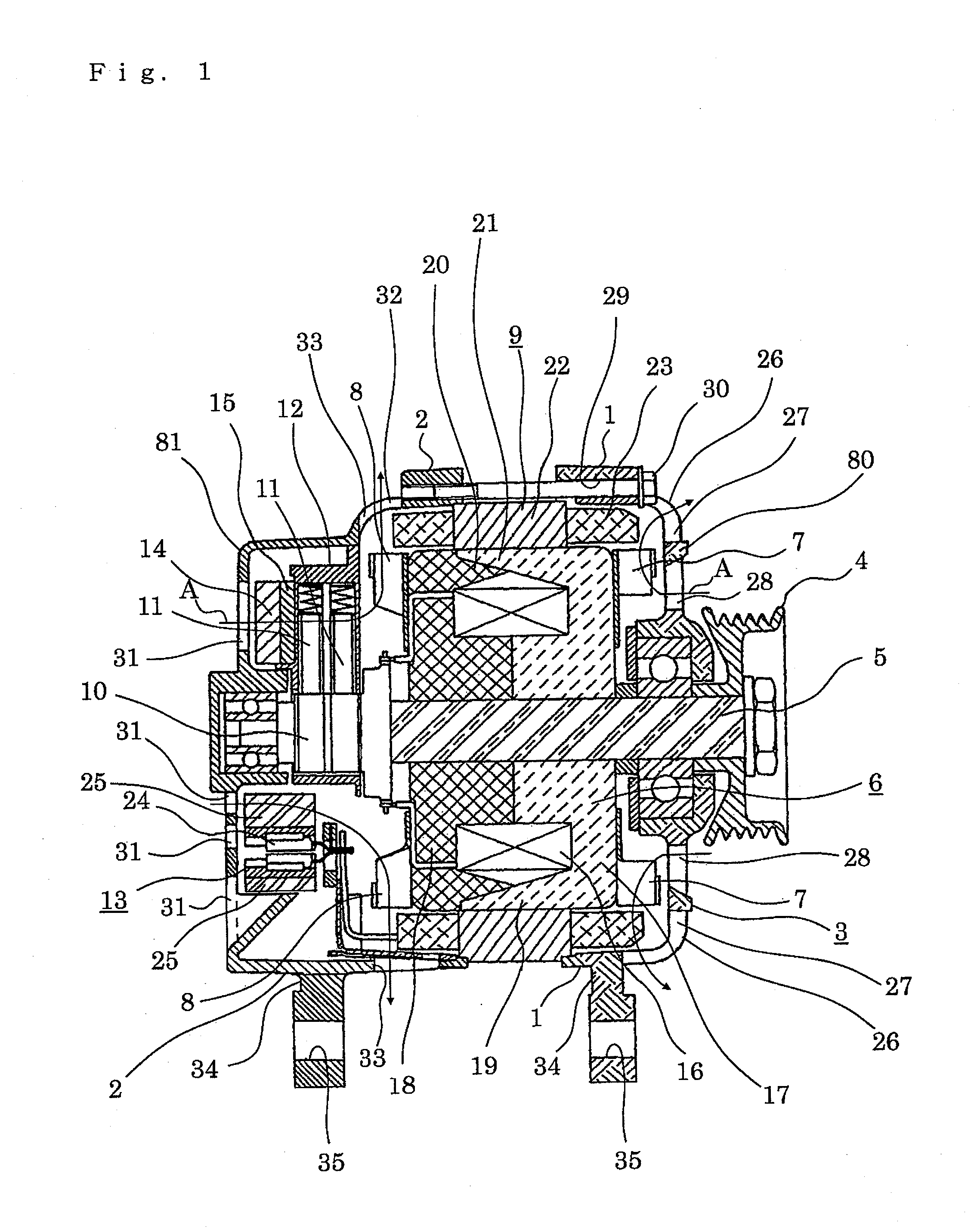

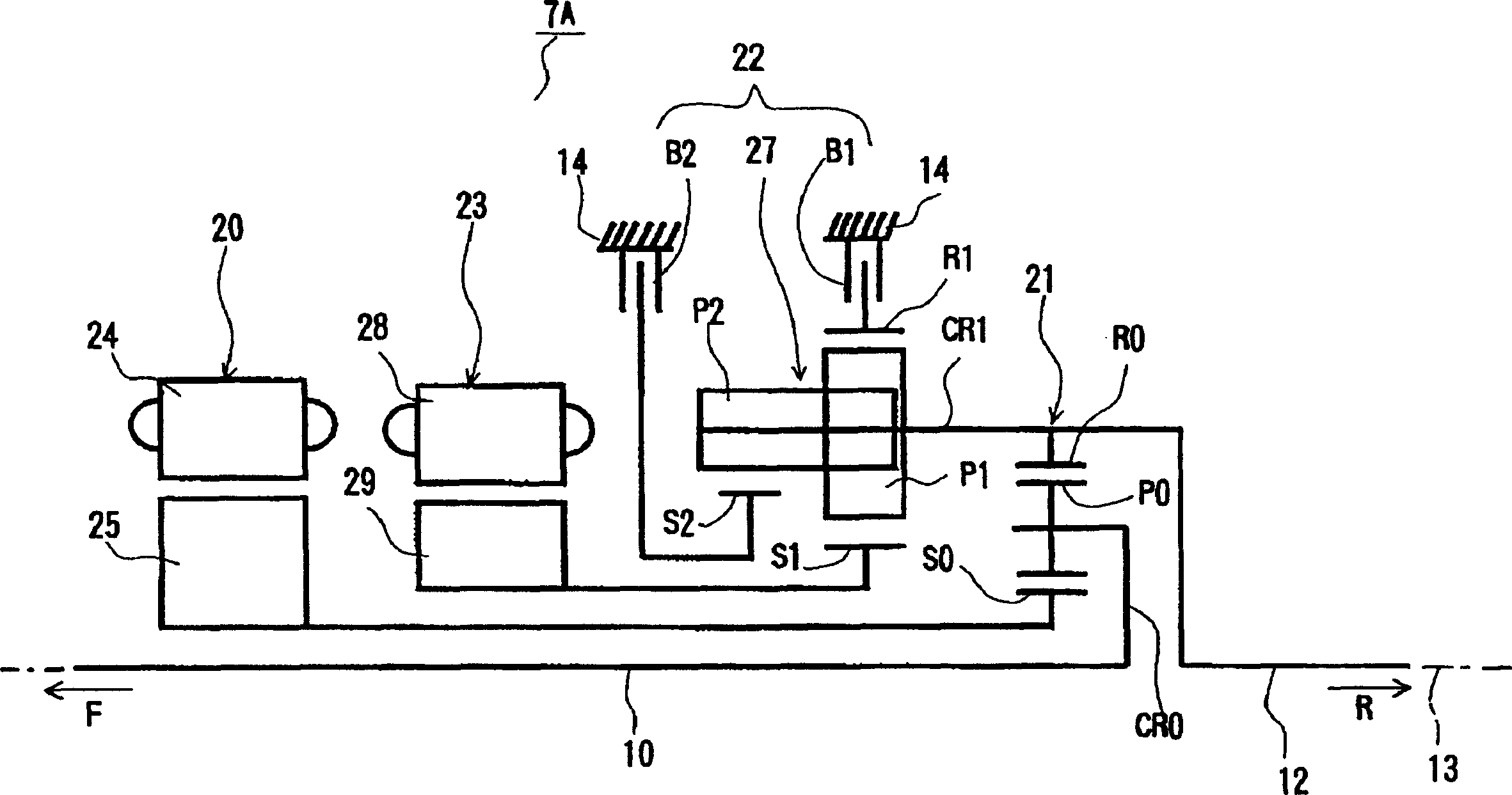

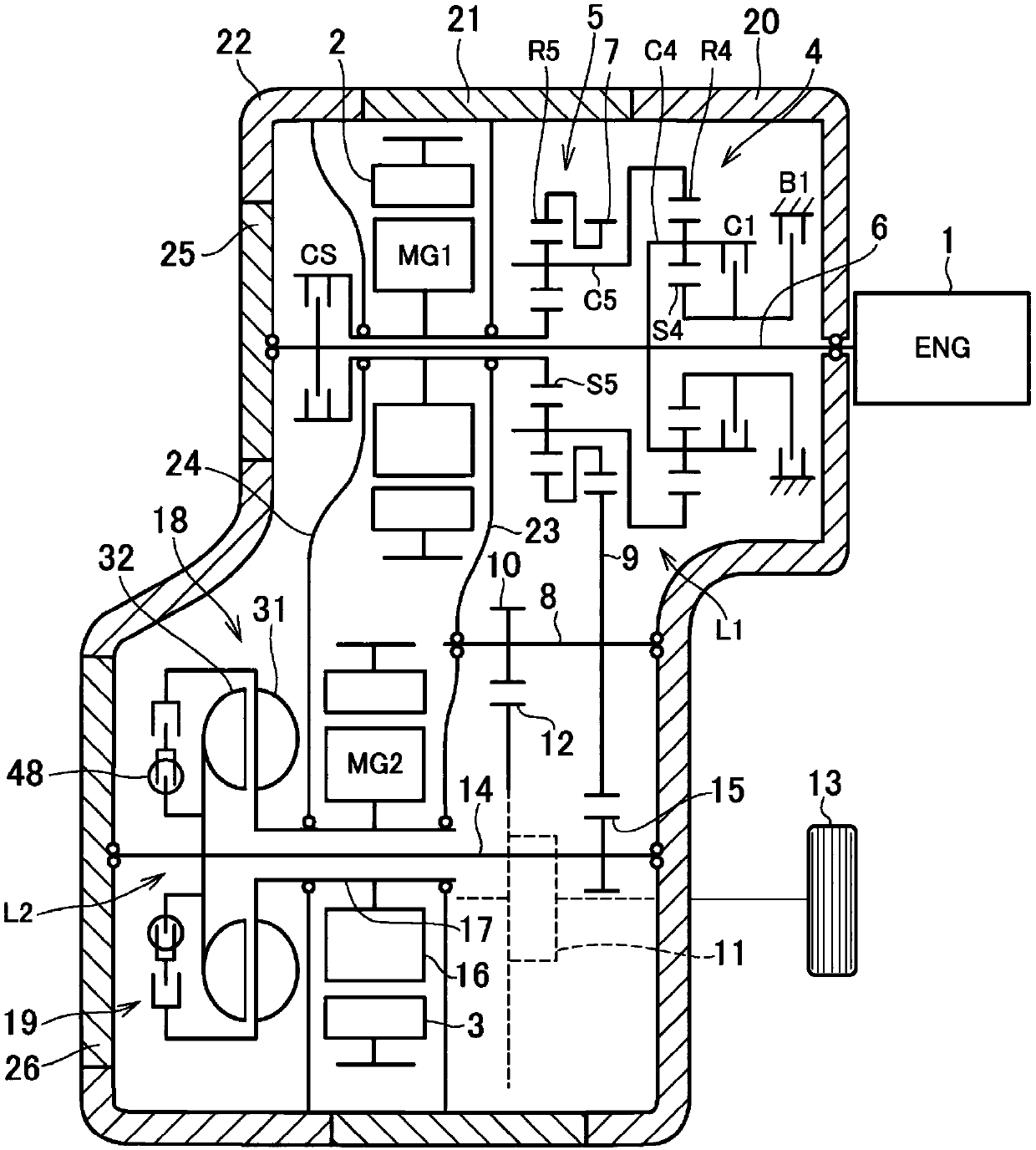

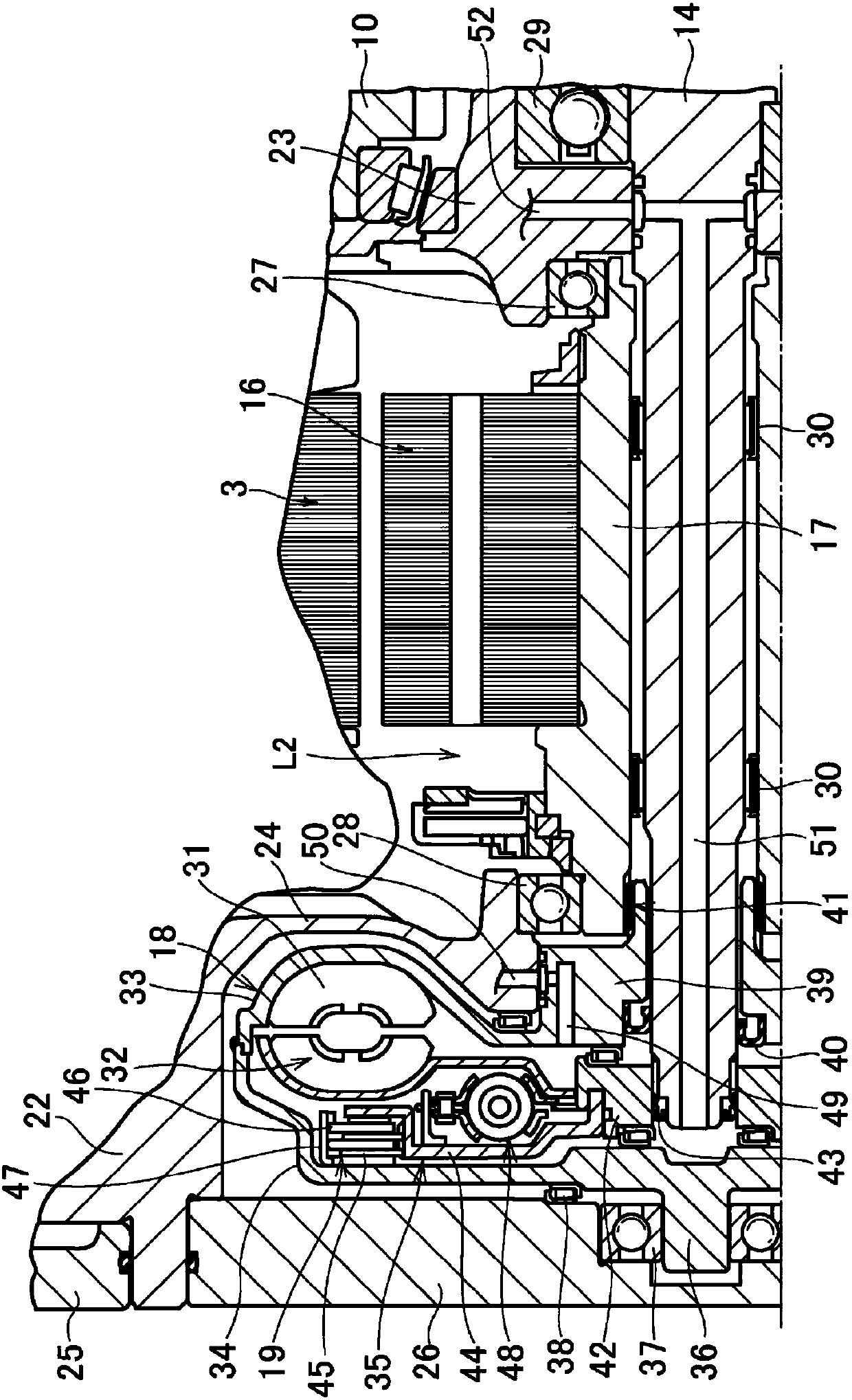

Hybrid drive device and automobile with device mounted thereon

InactiveCN1701000AEasy to assembleIncrease carrying capacityHybrid vehiclesElectrodynamic brake systemsPower splitHybrid drive

Owner:TOYOTA JIDOSHA KK

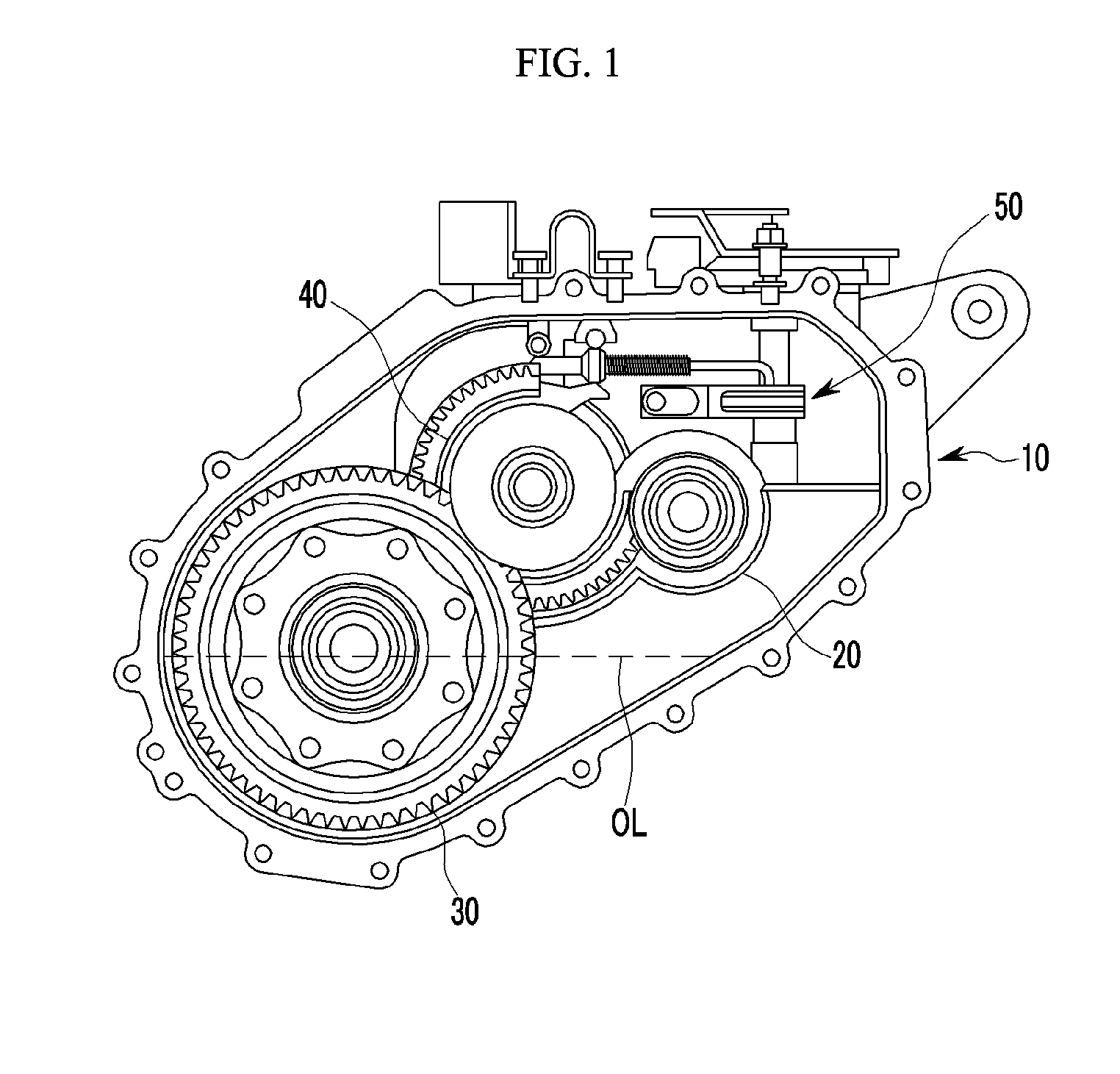

Layout for parking system of decelerator for electric motor vehicle

InactiveUS20120138419A1Small sizeImproving layout of a parking unit and gearsGearing controlGear wheelReduction drive

A layout for parking system of decelerator for an electric motor vehicle is provided herein. More specifically, the layout includes a decelerator housing, an input gear disposed within the decelerator housing, an output gear disposed within the decelerator housing, an intermediating gear connecting the input gear and the output gear and a parking unit disposed above the input gear and selectively trammeling the intermediating gear. Further, in the present layout the parking unit is disposed above an oil line in the decelerator housing.

Owner:HYUNDAI MOTOR CO LTD +1

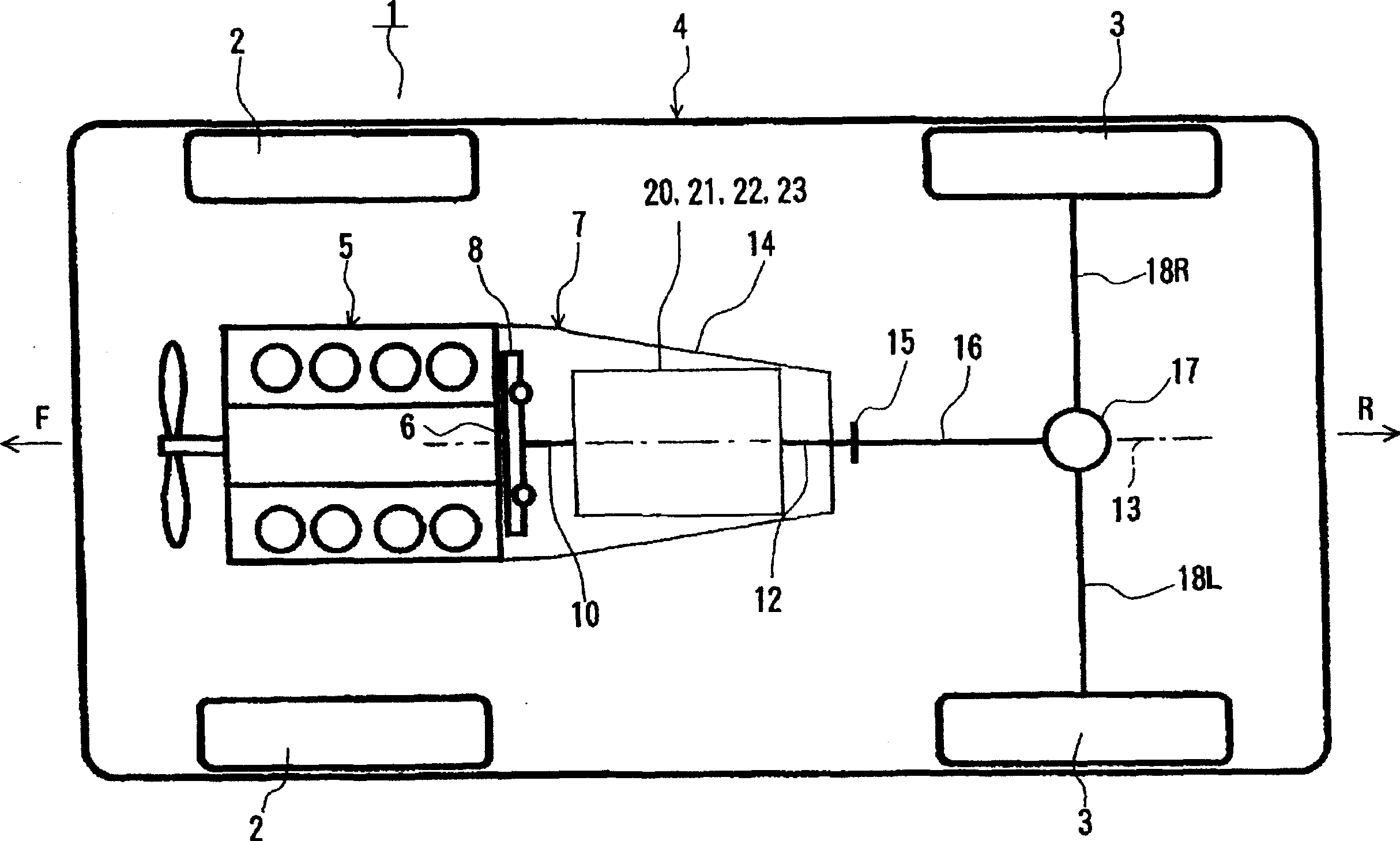

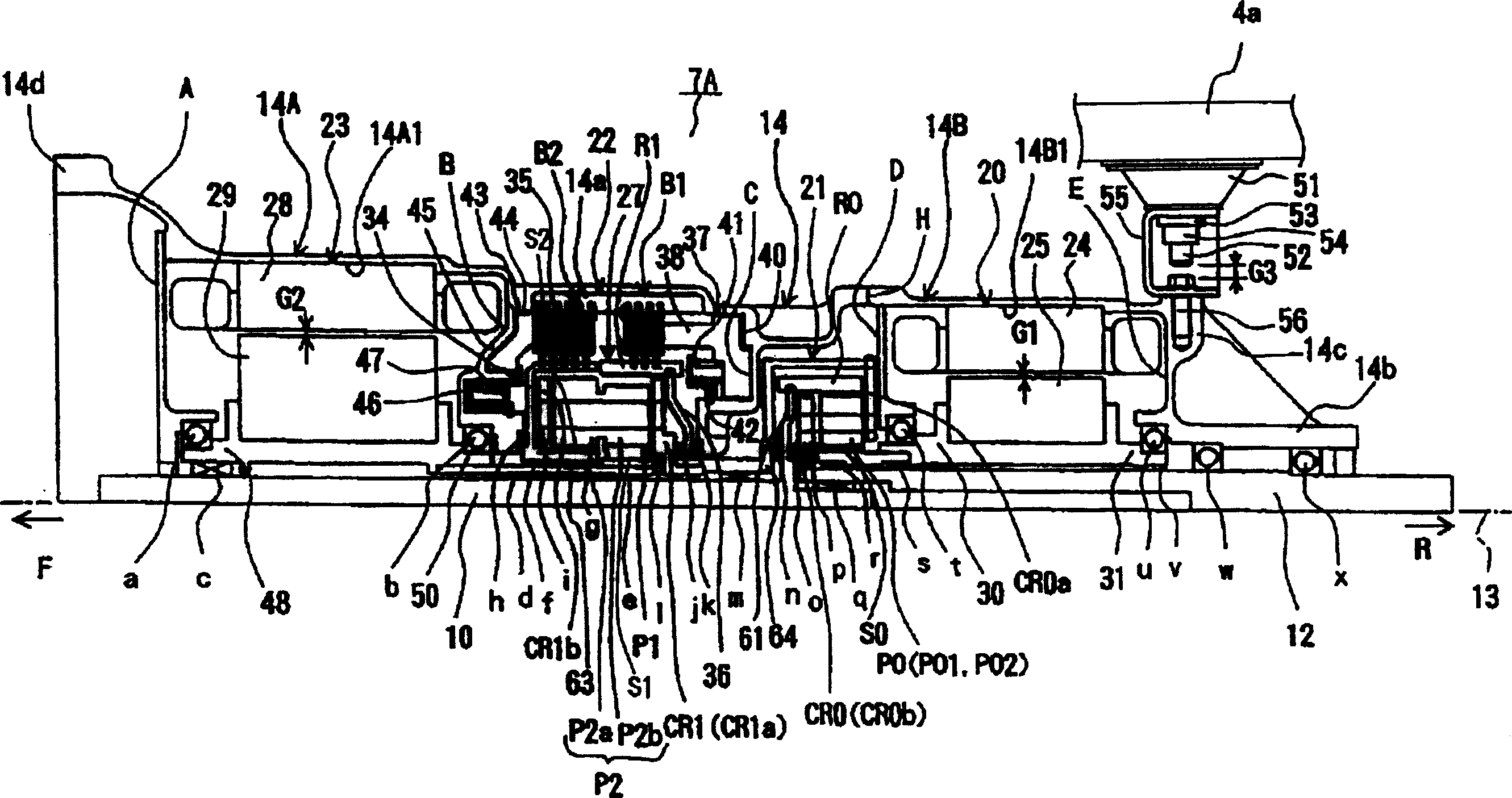

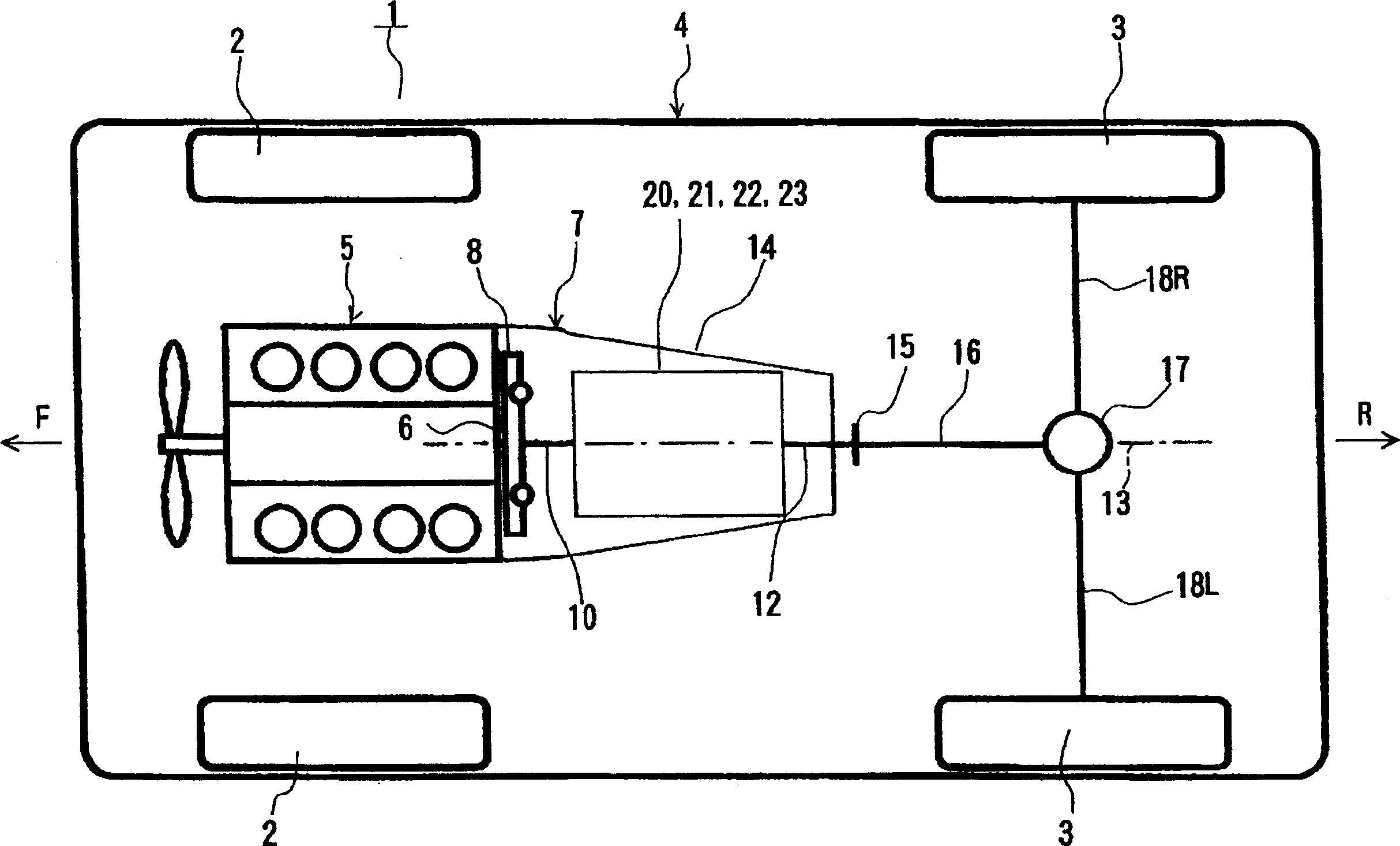

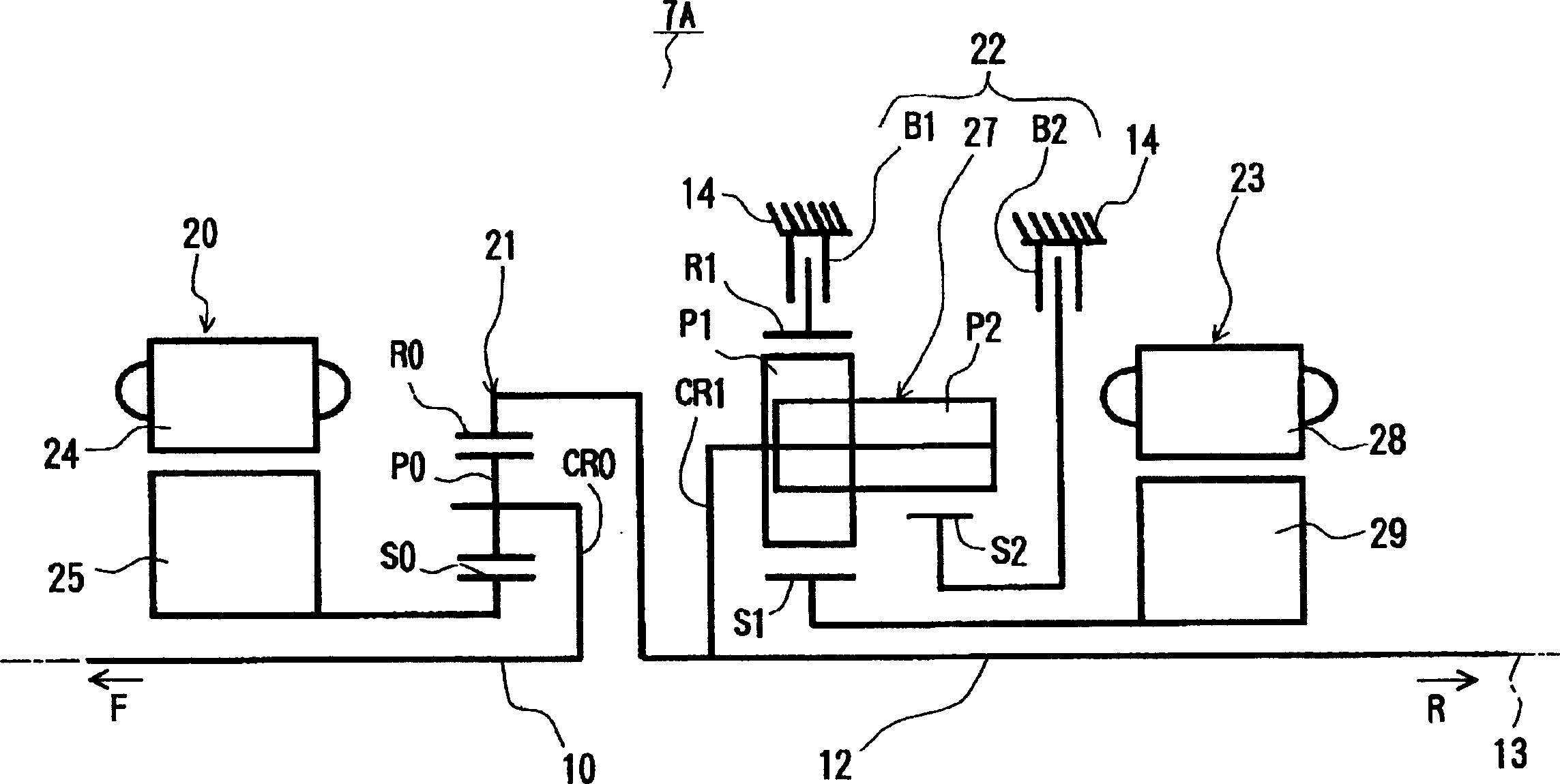

Hybrid drive device and automobile with device mounted thereon

InactiveCN1700998ASuppression lengthShorten the lengthHybrid vehiclesElectric propulsion mountingEngineeringHybrid drive

A hybrid driving unit (7) in which a second electric motor (23) is disposed on the side closer to the front (the side closer to an internal combustion engine (5)) than a first electric motor (20). A casing member (14) is formed such that an inner diameter of a part thereof in which a stator (28) of the second electric motor (23) is fixed is larger than that of a part in which a stator of the first electric motor (20) is fixed. It allows the second electric motor (23) to be constructed so as to have a large radial dimension and to that extent, allows the length thereof in the longitudinal direction to be suppressed. Accordingly, it allows the length of the whole hybrid driving unit (7) to be shortened.

Owner:TOYOTA JIDOSHA KK

Track roller assembly and method

ActiveUS10023251B2Shorten shaft lengthPrevent inward movementMechanical machines/dredgersEndless track vehiclesEngineeringShaft collar

A track roller assembly may have a track roller, a roller shaft and collars press fit onto either end of the roller shaft to retain the track roller on the roller shaft with an axial clearance between the collars and the track roller. During assembly, the collars may be press fit onto the shaft ends and forced axially inwardly until further axial movement of the collars is prevented by engagement shoulders of the track roller. A compressive axial load may be applied to the roller shaft to reduce a shaft length of the roller shaft and to cause the roller shaft to slide inwardly relative to the collars. The compressive axial load is removed from the roller shaft so that the roller shaft extends back to the normal shaft length and the collars move axially farther apart as the roller shaft extends back to the normal shaft length.

Owner:CATERPILLAR INC

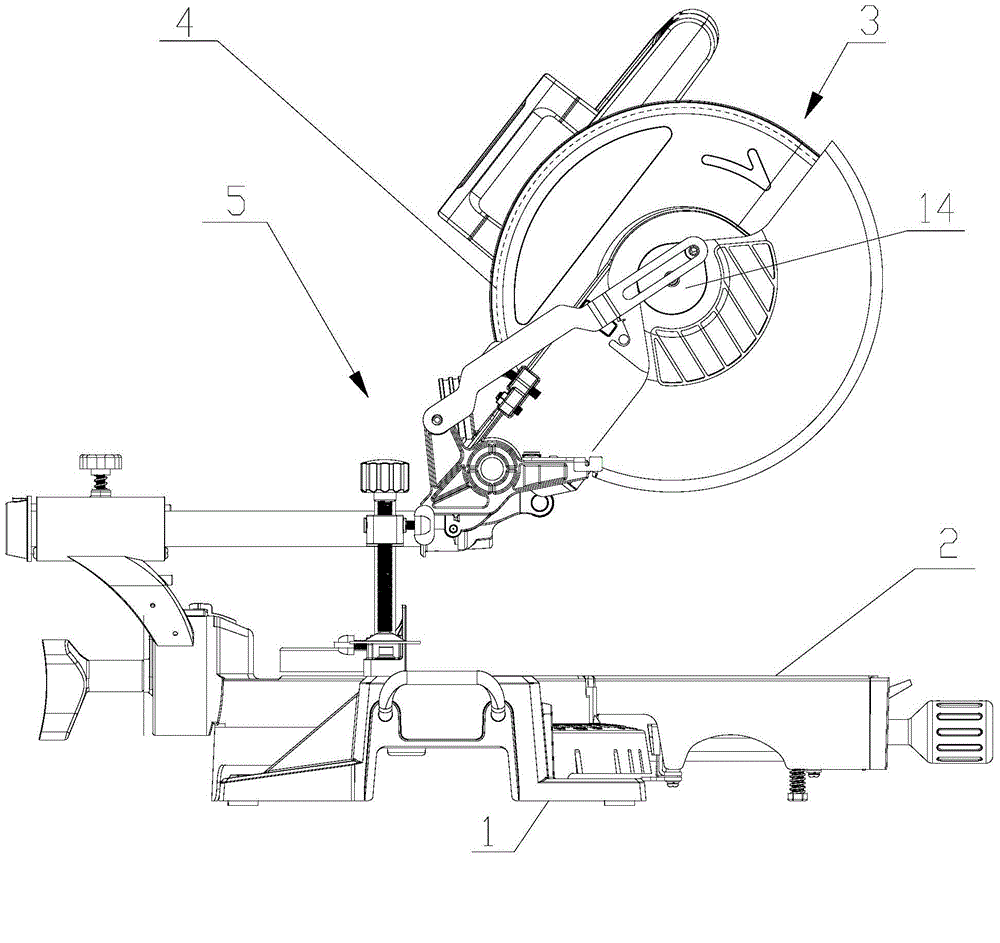

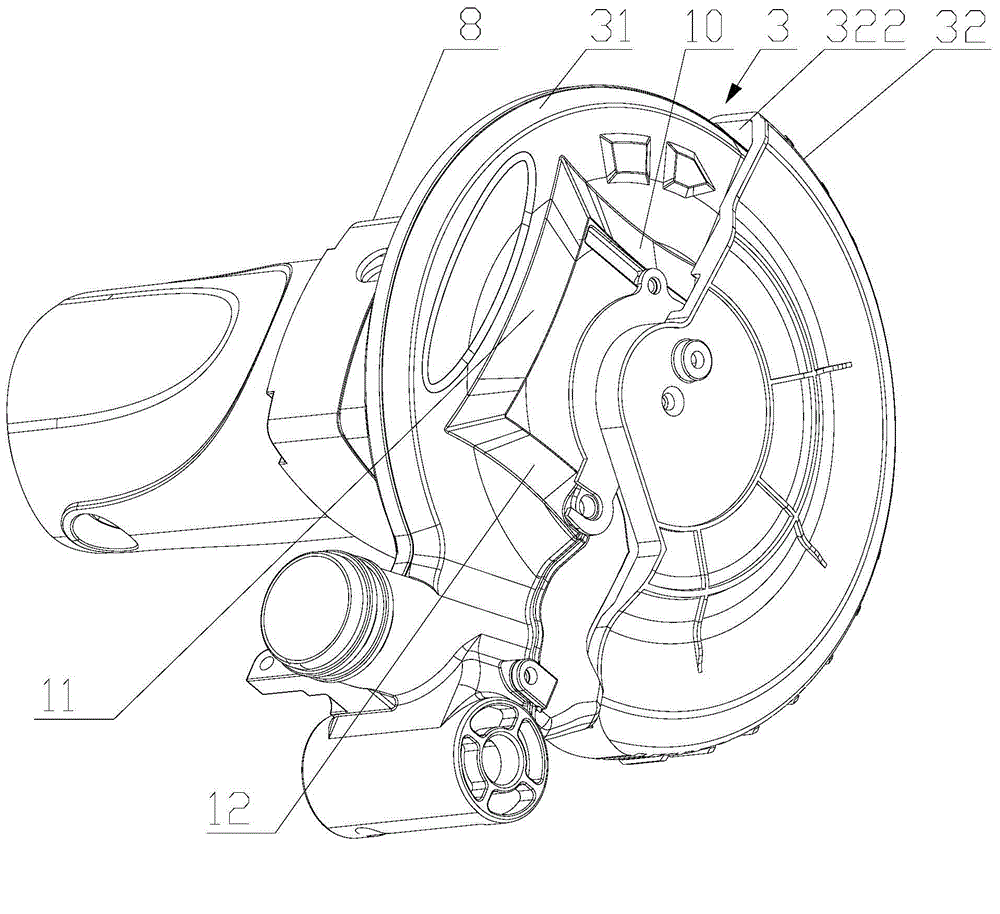

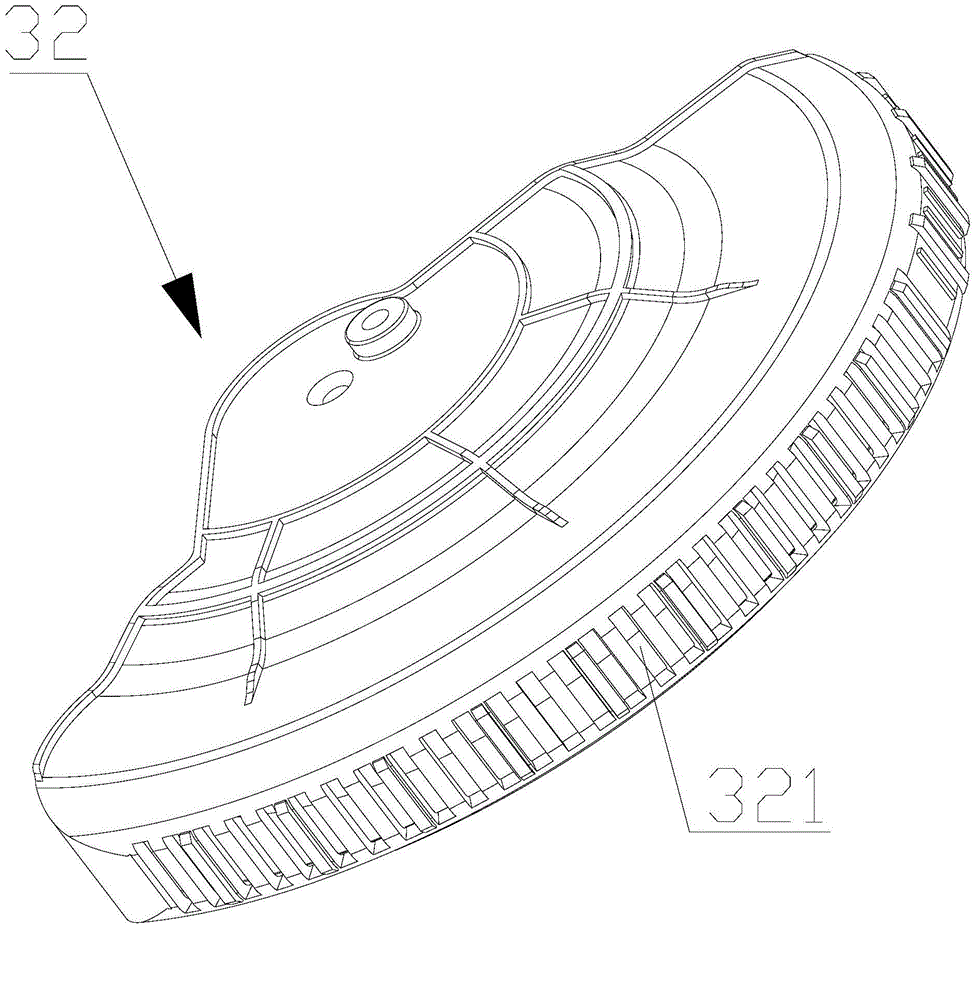

Cutting machine with double oblique draw bars

ActiveCN104668655ALess consumablesReduce weightMetal sawing devicesMetal sawing accessoriesInternal pressureMaterial consumption

The invention relates to a cutting machine, and discloses a cutting machine with double oblique draw bars. The cutting machine comprises a base, a worktable, a rotary mechanism and a saw blade. A semicircular movable protective cover is arranged on the outside of the saw blade, an inner pressure plate and an outer pressure plate are arranged on two sides of the saw blade, the saw blade is sandwiched between the inner pressure plate and the outer pressure plate and is connected with a plastic gear box by a belt pulley transmission gear, the belt pulley transmission gear comprises a four-groove belt, and the inner pressure plate is clamped and embedded on the outer pressure plate. The cutting machine has the advantages that the saw blade can be positioned and clamped by a clamping and embedding type positioning and clamping device, accordingly, minor-axis sections can be shortened to the greatest extent, and a protective device can be narrowed to the greatest extent; the semicircular movable protective cover which is coaxially arranged is hinged onto a fixed protective cover, can move along with a cutting device and has a movable protective function; a front tank and a rear tank can be closed, and the rear tank is integrally connected with a motor shell, so that the gear box can be formed; the gear box and the motor shell are made of plastics, and accordingly the cutting machine is low in material consumption and cost and is light.

Owner:ZHEJIANG JINGSHEN IND

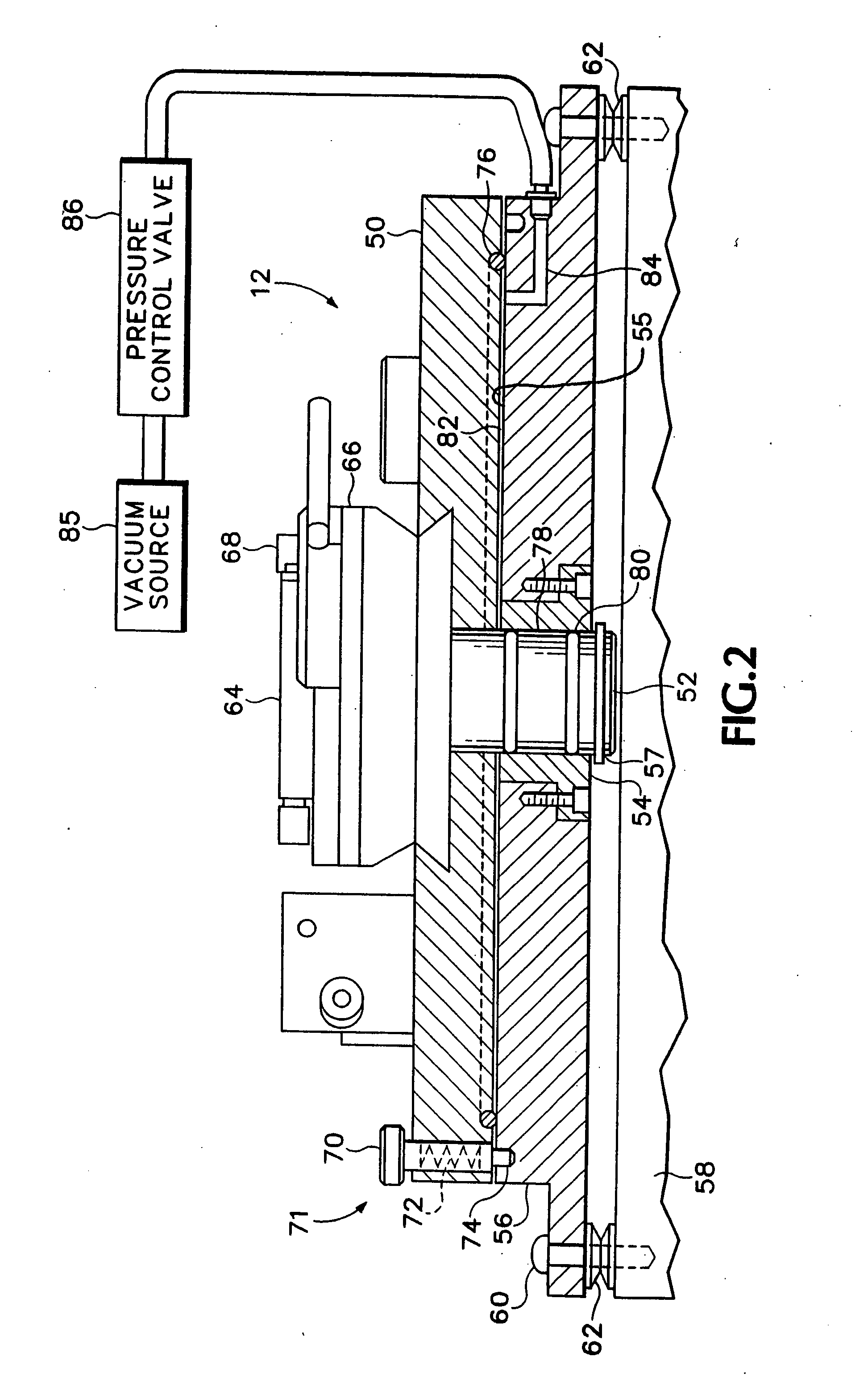

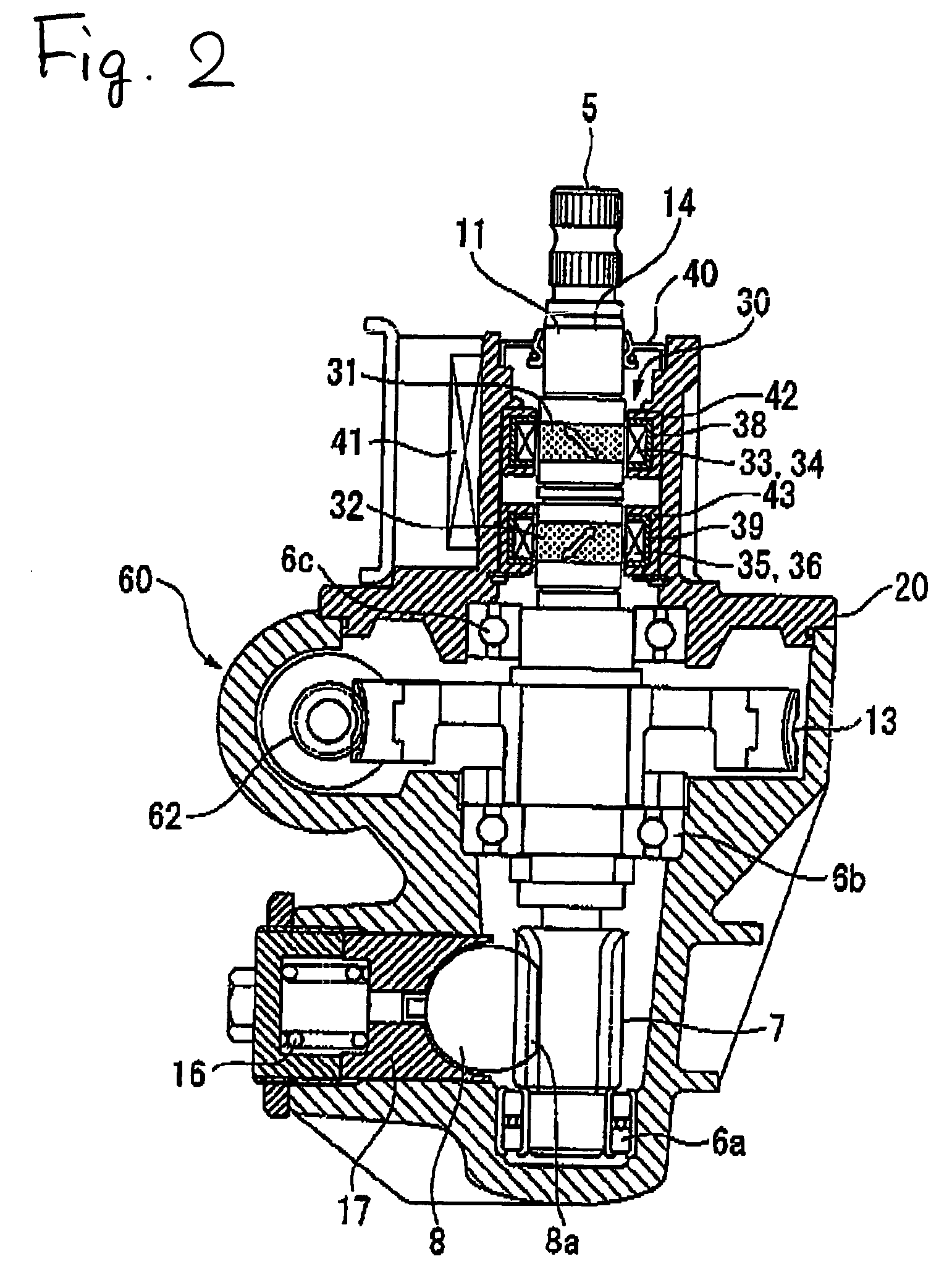

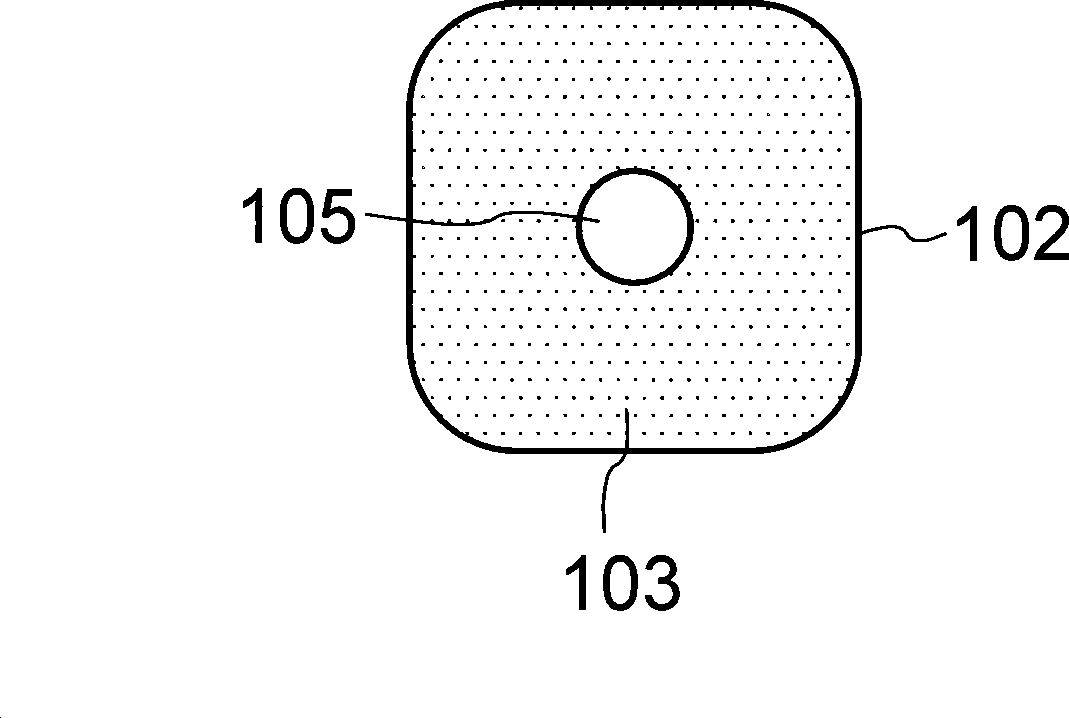

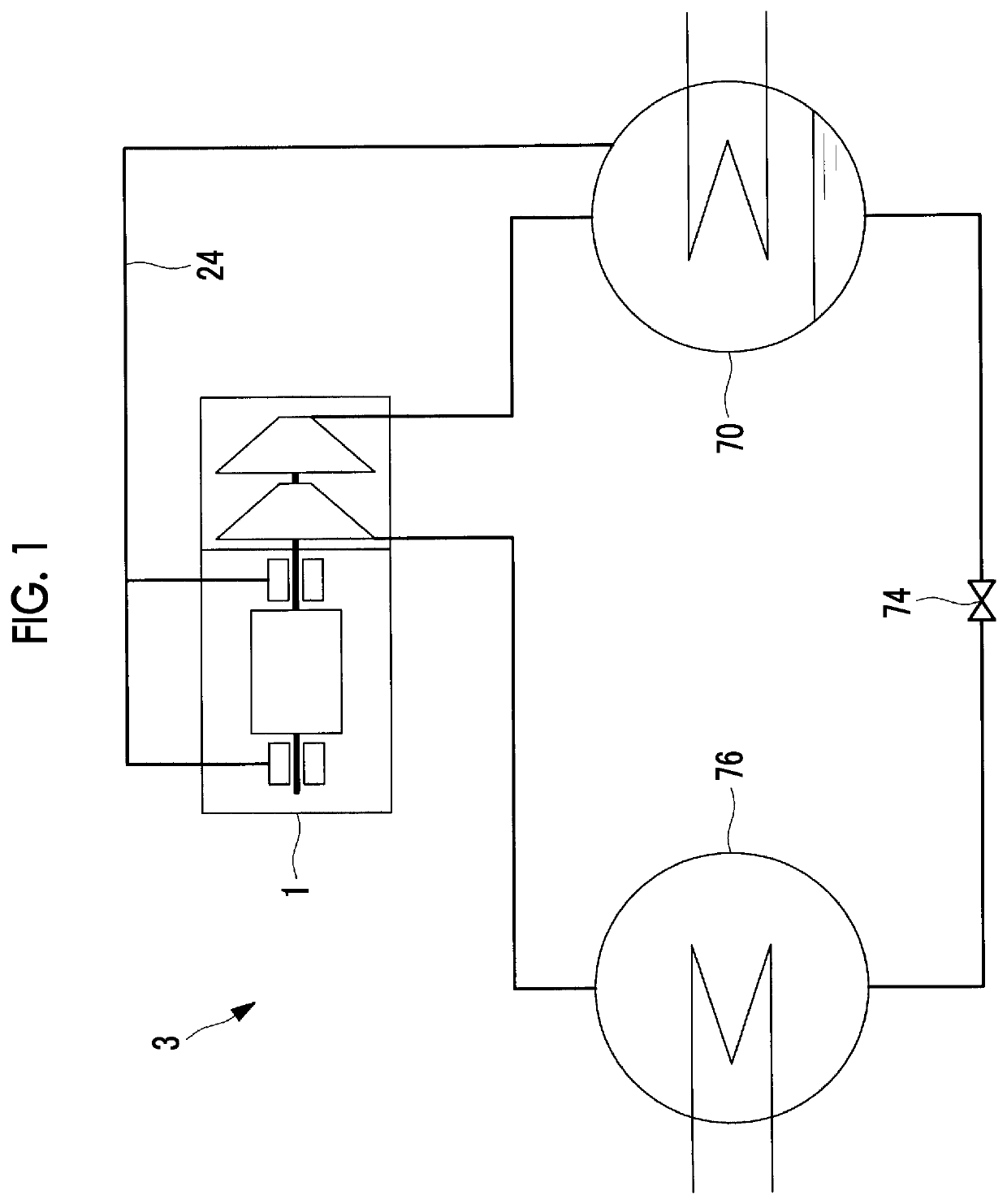

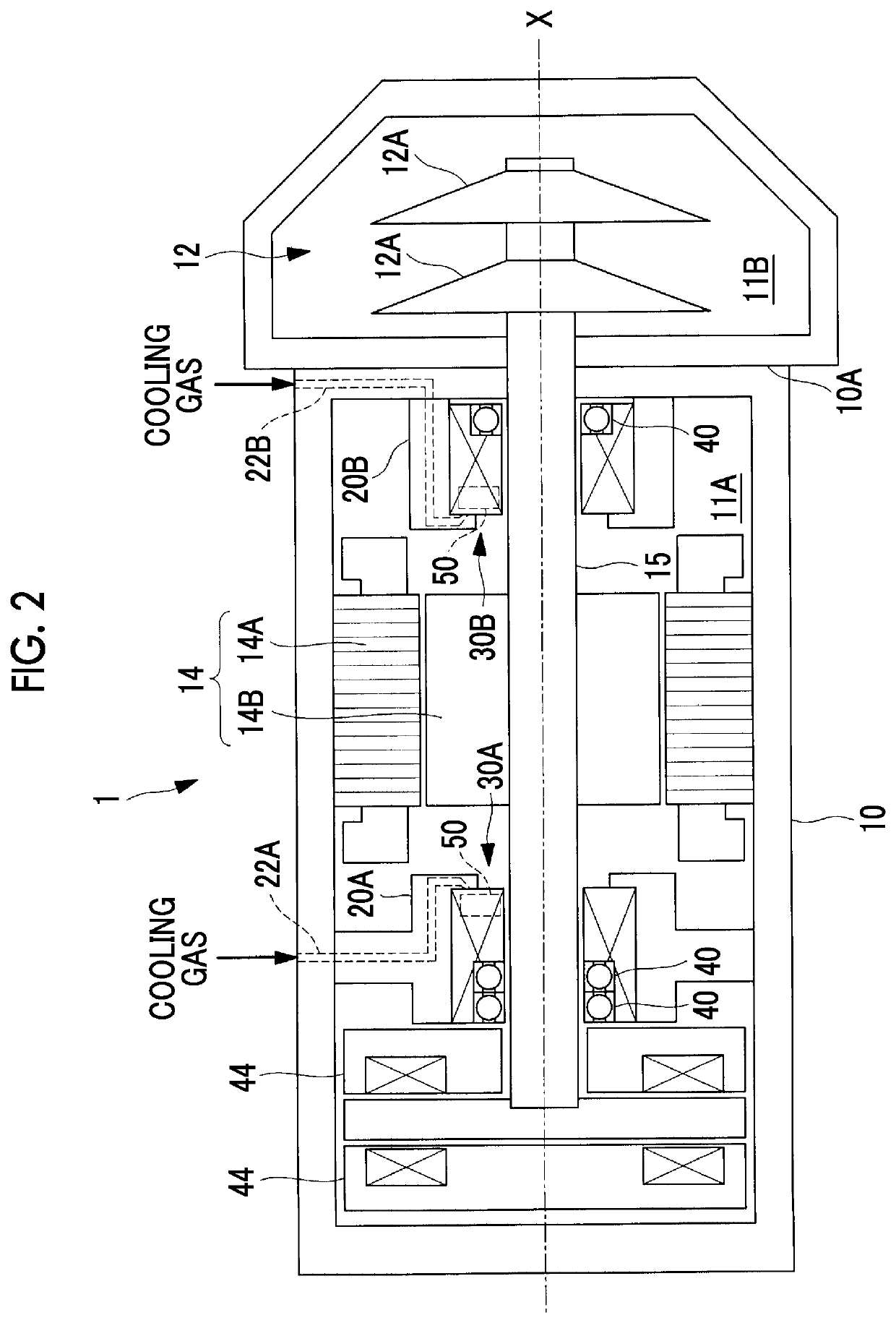

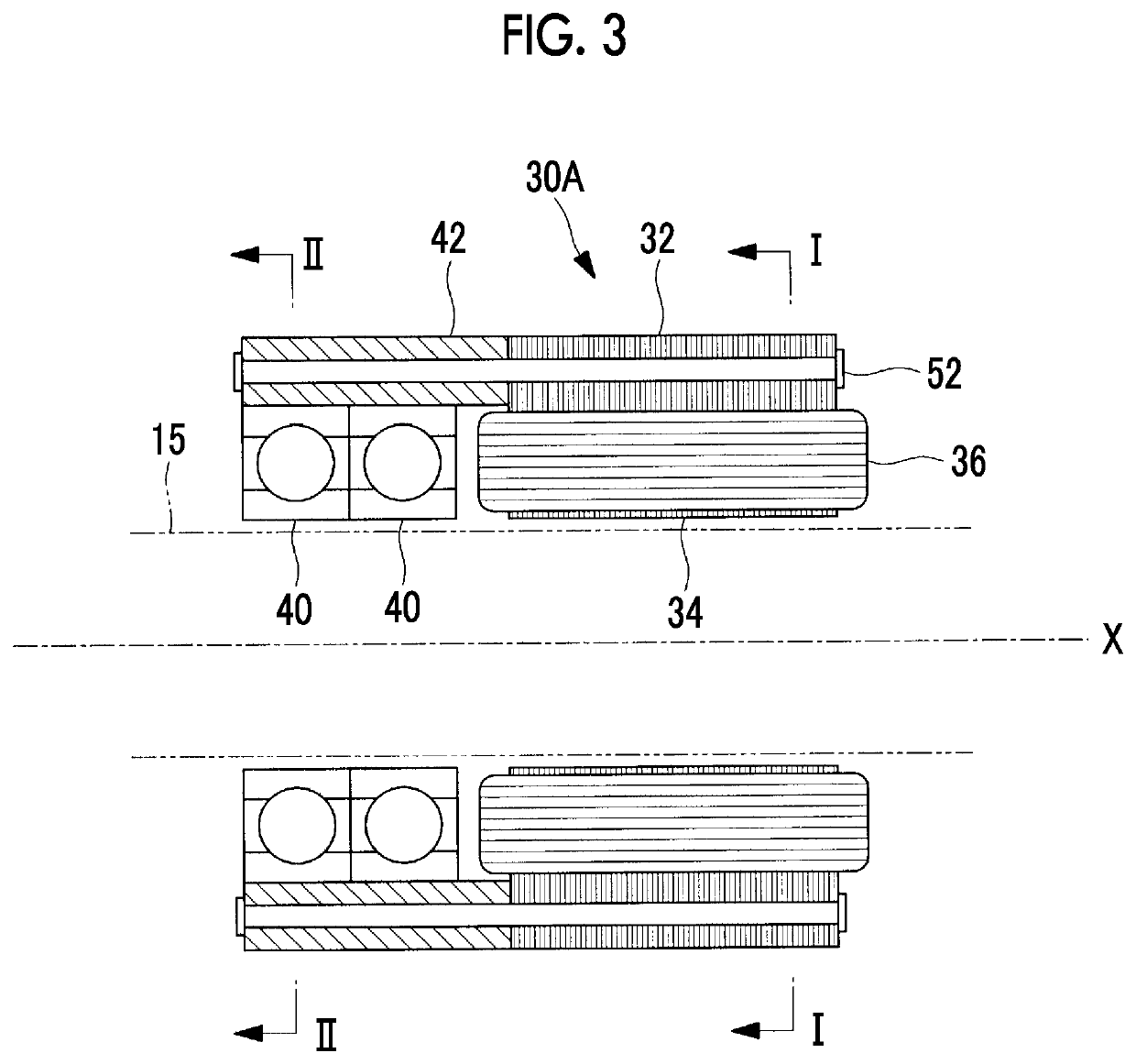

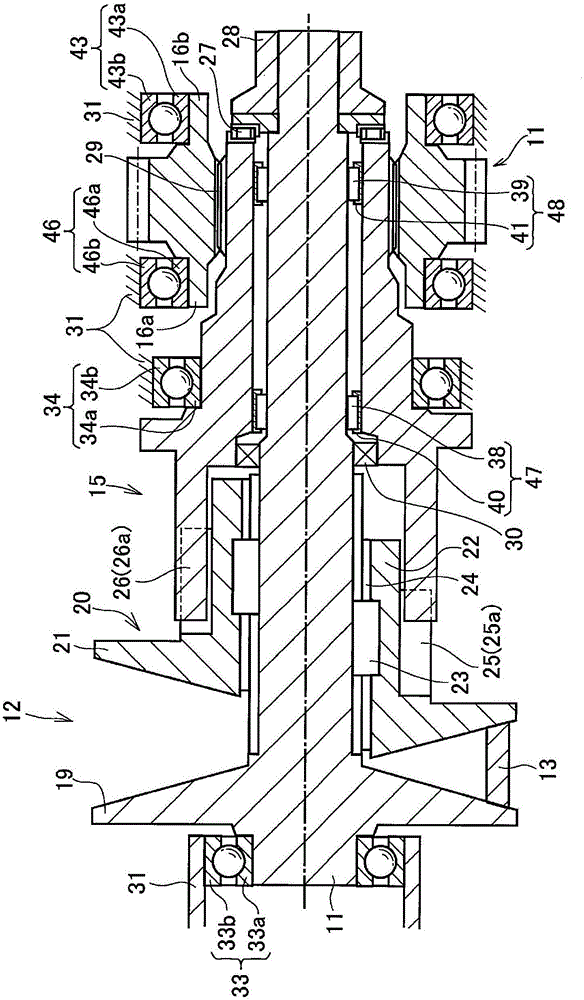

Turbo compressor and centrifugal chiller comprising same

PendingUS20210010719A1Shorten shaft lengthShorten lengthPump componentsCompression machines with non-reversible cyclePhysicsRotational axis

Provided are a turbo compressor and a centrifugal chiller comprising the same with which the length of a shaft in an axial direction can be shortened, rotational shake accompanying rotation of the shaft is suppressed, and a device can be made small. A turbo compressor comprising: a compressor part which compresses refrigerant; a shaft (15) which drives the compressor part around an axis of rotation X; a magnetic bearing (30A) which has provided thereto an iron core part (32) comprising a plurality of teeth parts (34) formed at equiangular intervals around the axis of rotation X, and, a plurality of coils (36) respectively wound around the plurality of teeth parts (34), and said magnetic bearing (30A) allows the shaft (15) to pass through and supports said shaft (15) without contacting the same; an auxiliary bearing which allows the shaft (15) to pass through; and a displacement sensor (50) which detects displacement of the shaft (15), wherein the displacement sensor (50) is provided between neighboring coils (36).

Owner:MITSUBISHI HEAVY IND THERMAL SYST

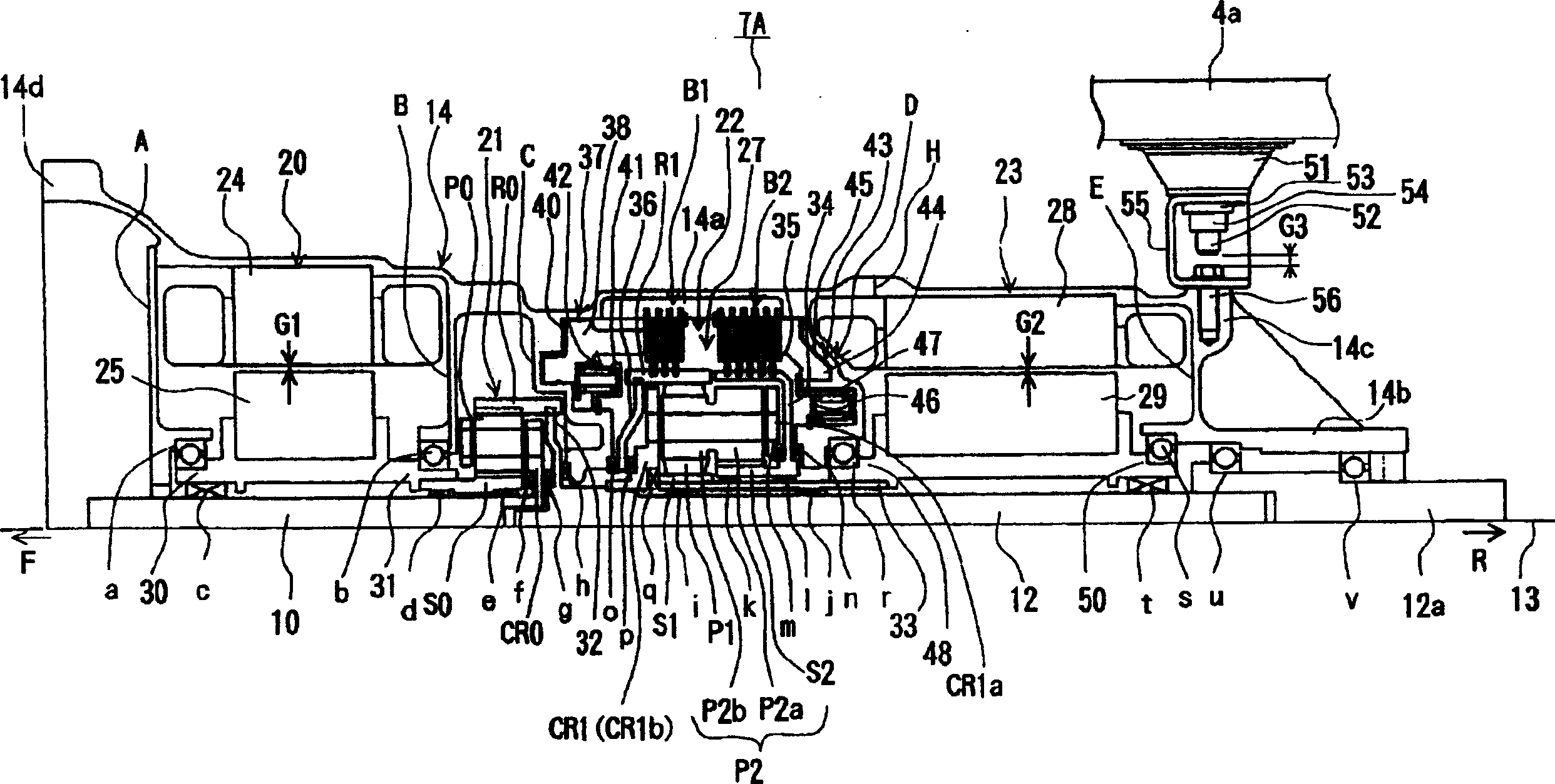

Hybrid drive device and automobile mounted with device

ActiveCN1700999AStable supportInhibition of oversizingElectric propulsion mountingPropulsion using engine-driven generatorsHybrid driveElectric motor

A connection portion (14d) at a front end portion of a case member (14) is connected to an internal combustion engine, and the case member is mounted on a portion (4a) of a vehicle body using a mount portion (installation portion) (14c) at a rear end portion of the case member (14). Further, a second electric motor (23), a heavy object, is disposed at the rearmost end portion of a line where a first electric motor (20), a planetary gear (21) for power distribution, a second electric motor (23), and a speed changer (22) are arranged on one shaft (13) of the case member (14). This suppresses vibration occurring in the case member (14).

Owner:TOYOTA JIDOSHA KK

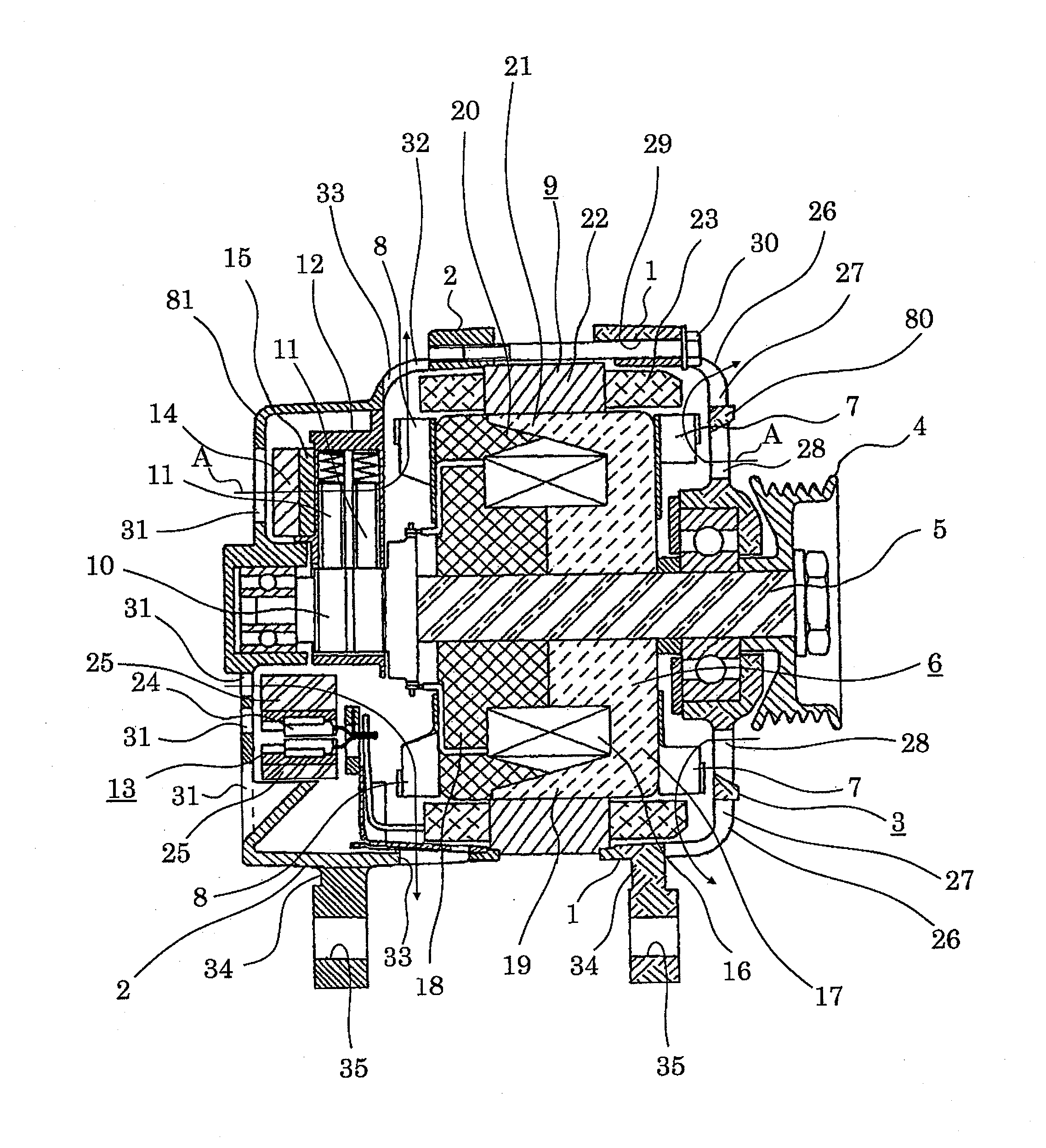

A three-phase electric asynchronous motor

ActiveCN102969855BShorten shaft lengthShorten the axial widthAsynchronous induction motorsSupports/enclosures/casingsThree phase asynchronous motorEngineering

The invention discloses a three-phase electric asynchronous motor. The three-phase electric asynchronous motor comprises a motor installation base plate and a motor casing, wherein the motor installation base plate is installed at an axial non-power output end of the motor casing, the motor installation base plate is round, the diameter of the motor installation base plate is larger than that of the motor casing, the motor casing is in a step shape, a corresponding stator inside the motor casing is also in the step shape, a rotor is located inside the stator, no rotating shaft exists in the rotor, and a disc-shaped output end is arranged on the end portion of the rotor. A clutch type component can be installed at the disc-shaped output end. The diameter of the rotor is more than twice the width of the rotor. According to the three-phase electric asynchronous motor, the problem of large sizes of three-phase asynchronous motors can be solved, the axial length of the motor can be greatly shortened, the axial width of the motor can be shortened, and the occupied space of the motor can be saved.

Owner:WUXI NEW GREAT POWER ELECTRICAL MACHINE

Shaft support structure for belt-type stepless transmission

Provided is a shaft support structure for a belt-type stepless transmission, the shaft support structure being configured so that the length of a shaft on which a torque cam is provided can be reduced. A first bearing (36), which supports both a rotating shaft (11) and a torque cam (15) so that the rotating shaft (11) and the torque cam (15) can rotate relative to each other, is provided between the outer peripheral surface of the rotating shaft (11) and the inner peripheral surface of the torque cam (15). A second bearing (42), which rotatably supports one axial end of an output member (16) on a case (31), is provided on the outer peripheral side of the first bearing (36) in the radial direction. A space is formed at a position on the inner peripheral side of the second bearing (42) and on the outer peripheral side of the torque cam (15). A seal member (32) which is fitted to the outer peripheral surface of the torque cam (15) is installed in the space.

Owner:TOYOTA JIDOSHA KK

Shaftless spiral automatic proportioning concrete mixing conveyor

ActiveCN105856425BImprove the ratio accuracyImprove efficiencyMixing operation control apparatusCement mixing apparatusDrive shaftSlurry

The invention provides a shaftless, spiral and automatically-mixing concrete stirring and conveying machine and relates to the technical field of concrete stirring and conveying equipment. The shaftless, spiral and automatically-mixing concrete stirring and conveying machine comprises a conveying and stirring main drive shaft and a conveying and stirring driven shaft which are parallel to each other, and the conveying and stirring shafts are each provided with a feeding segment and a stirring and mixing segment from the head end to the tail end in the conveying direction; a shaft body, at the position of the feeding segment, of the conveying and stirring main shaft is provided with a spiral sand feeding spiral piece, the heal end of the conveying and stirring driven shaft is provided with the corresponding feeding segment in the conveying direction, a shaft body, at the position of the feeding segment, of the conveying and stirring driven shaft is provided with a cement feeding spiral piece, and the two feeding spiral pieces are contrary to each other in the turning direction as well as the rotation direction; shaft bodies, at the stirring and mixing segments, of the two conveying and stirring shafts are provided with hollow and shaftless big spiral pieces, and inner diameter spaces of the stirring big spiral pieces are provided with stirring small spiral pieces contrary in turning direction. By means of the shaftless, spiral and automatically-mixing concrete stirring and conveying machine, stable and precise mixing and reciprocating slurry stirring can be achieved, stirring can be more sufficient, efficiency is higher, and the shaftless, spiral and automatically-mixing concrete stirring and conveying machine is suitable for application and popularization.

Owner:SHANGYASHAN JINQUAN MACHINERY MFG CO LTD

Built-in flash pop-out mechanism

InactiveUS8521018B2Small sizeGood effectLighting support devicesLight fasteningsOptical axisEngineering

A built-in flash pop-out mechanism comprises a shaft member movable along a first axis; an arm member where one end is pivotally fixed at an end of the shaft member about a second axis; a flash-support member pivotally fixed at the other end of the arm member about a third axis; a first biasing member biasing the shaft member along the first axis; a second biasing member biasing the arm member about the second axis; a third biasing member biasing the flash-support member about the third axis. The built-in flash is extended from a camera body with coplanar motions that pop out the built-in flash to increase its distance from an optical axis. The motions include a translation of the shaft member along the first axis and rotations of the arm member and flash-support member about the second and third axes.

Owner:RICOH IMAGING COMPANY

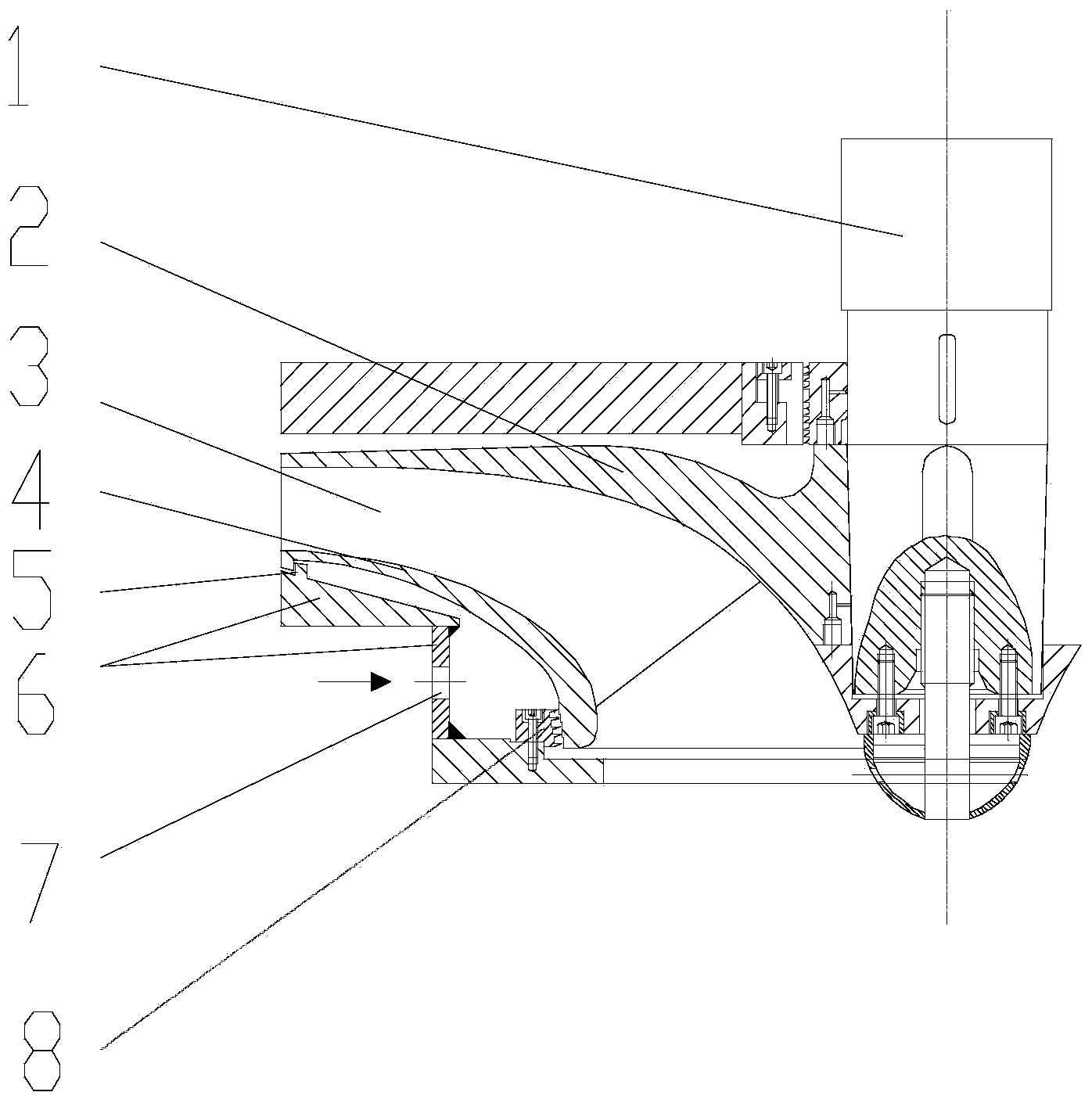

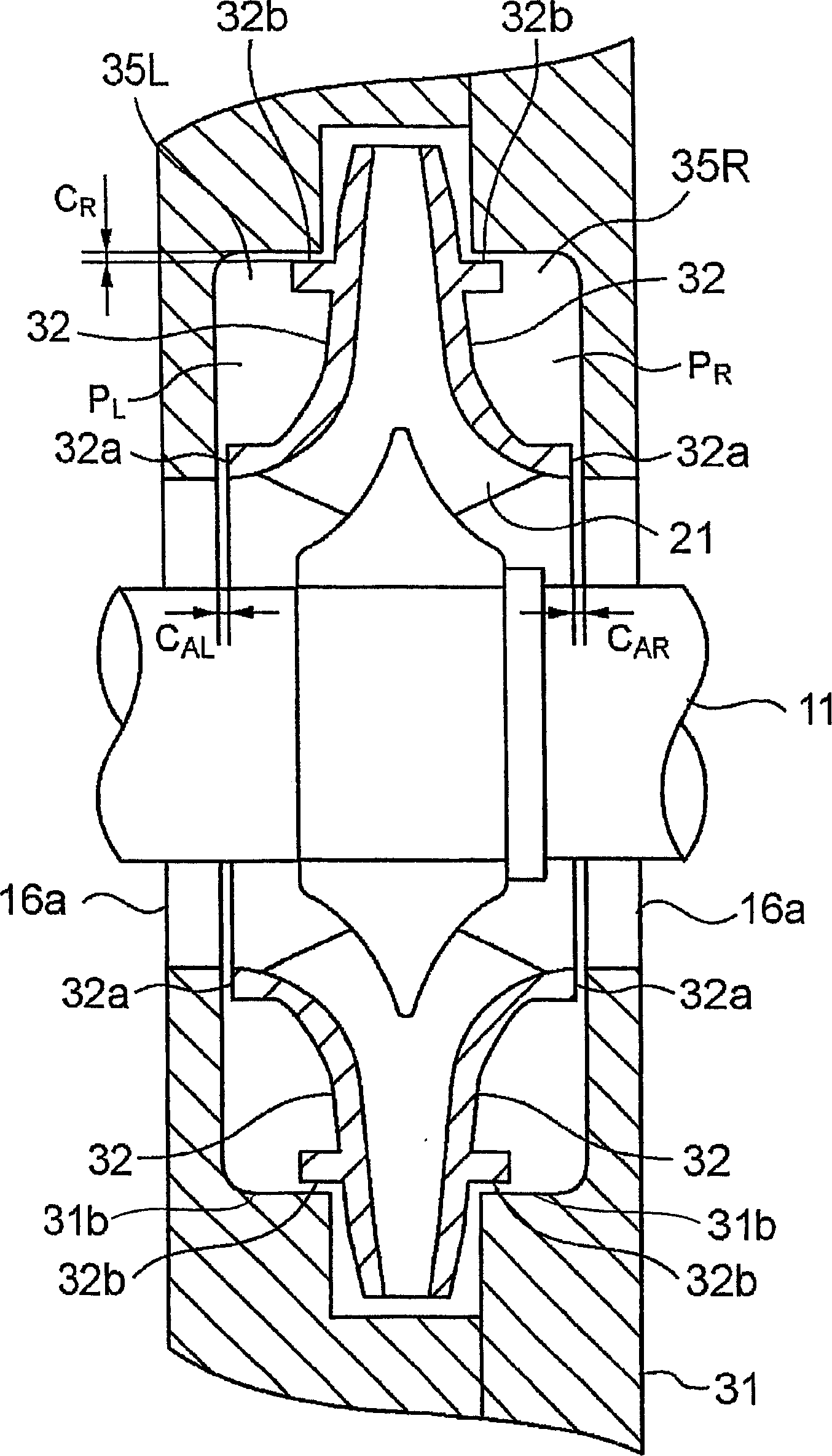

Fluid transportation machine

InactiveCN1890469AShorten shaft lengthNo frictionPump componentsPump installationsImpellerMagnetic bearing

A fluid transportation machine has a rotating shaft (11), a double suction-type pump (16), and magnetic levitation motors (12, 13) having functions as radial magnetic bearings for supporting the rotating shaft (11) without contact and as motors for rotatingly driving the rotating shaft (11). The double suction-type pump (16) has a double suction-type blade wheel (21) attached to the rotating shaft (11), a pump casing (31) provided so as to surround the blade wheel (21), and a pressure balance mechanism for axially positioning the rotating shaft (11). The pump (16) is positioned at substantially the center of the rotating shaft (11), and the two magnetic levitation motors (12, 13) are arranged on both sides of the pump (16).

Owner:EBARA CORP

Vehicle drive device

InactiveCN107848391AIncreased durabilityAvoid or suppress the condition of becoming a single-phase locked stateHybrid vehiclesElectric devicesDrive wheelControl theory

The purpose of the present invention is to provide a vehicle drive device that prevents, without loss of durability, a motor from entering a single-phase lock state, the motor serving as a drive powersource. Provided is a vehicle drive device comprising a first power transmission path (L1) for transmitting drive force output by an engine (1) to a drive wheel (13) and a second power transmission path (L2) for transmitting drive force output by a motor (3) to the drive wheel (13), wherein: the second power transmission path (L2) includes an intermediate shaft (14) for transmitting drive force output by the motor (3) to the first transmission path (L1); a fluid joint (18) is provided between the motor (3) and the intermediate shaft (14); and a clutch mechanism (19) is provided between the motor (3) and the intermediate shaft (14) in parallel with the fluid joint (18).

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com