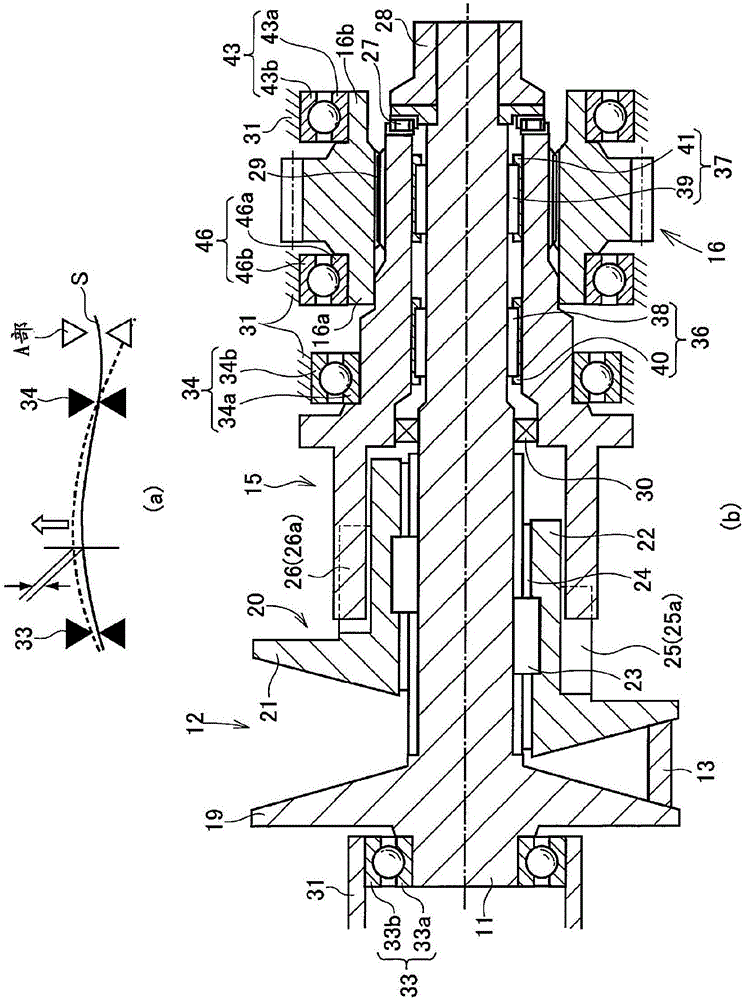

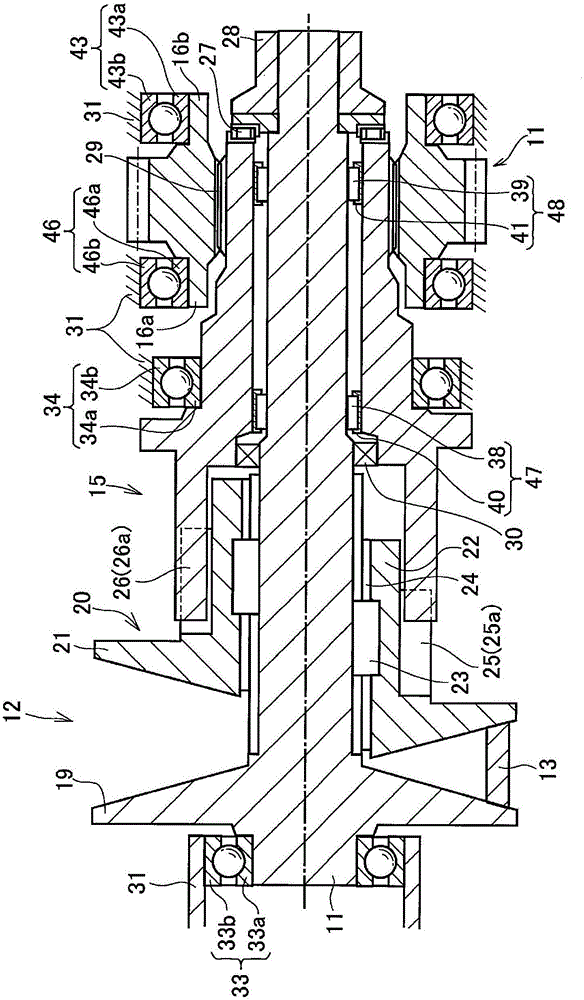

Shaft support structure for belt-type stepless transmission

A technology of continuously variable transmissions and bearings, which is applied to components with teeth, belts/chains/gears, transmissions, etc., which can solve the problems of increased displacement and length, and achieve the effect of improving rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Next, the configuration of a power transmission device including a belt-type continuously variable transmission targeted by the present invention will be described. Figure 6 It is a frame diagram for explaining an example of the structure of this power transmission device. Figure 6 The illustrated power transmission device has a power source 1 such as an engine or a motor. In addition, a hybrid drive device including an engine and a motor may be used as the power source 1 . In addition, in the example described below, the engine 1 is used as a power source.

[0028] A torque converter 3 is connected to an output shaft 2 of the engine 1 . The torque converter 3 is configured to transmit power through a fluid flow and to amplify and output torque in a converter region where the rotational speed on the input side is higher than the rotational speed on the output side, similarly to conventionally known torque converters. In addition, the torque converter 3 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com