Vehicle hybrid power system and control method thereof

A technology of hybrid power system and hybrid power module, which is applied in hybrid power vehicle, transmission control, power plant, etc., can solve the problems of large diameter, large volume, prone to jitter, easy to cause jitter, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

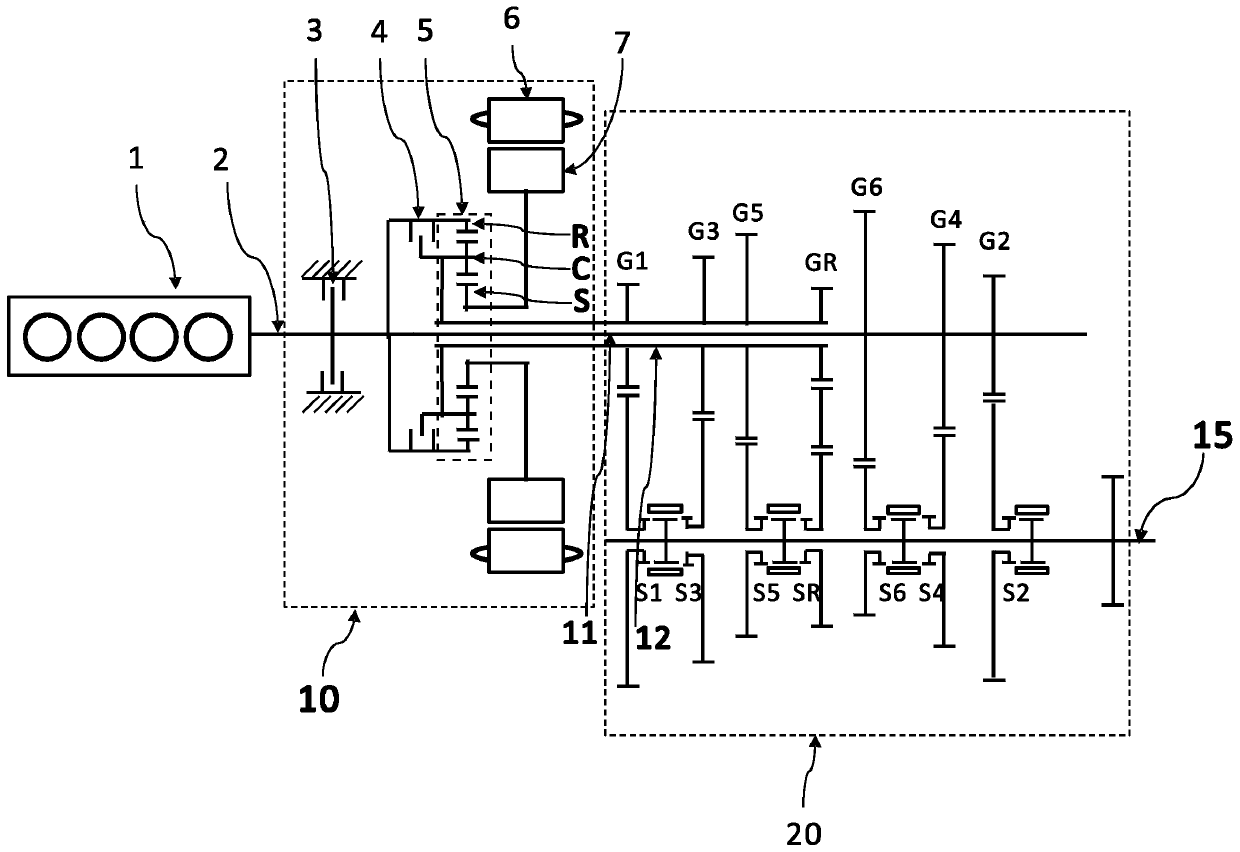

[0066] Such as figure 1 As shown, the hybrid power system for a vehicle includes an engine 1, a hybrid power module 10 and a double input shaft transmission mechanism 20, and the hybrid power module 20 is composed of a motor 6, a planetary gear train 5, a first clutch 4 and a brake Composed of 3, the planetary gear system 5 has at least 3 rotating shafts, the axis lines of the 3 rotating shafts are on a straight line, and the 3 rotating shafts are the rotating shaft of the sun gear S, the rotating shaft of the planetary gear carrier C, and the rotating shaft of the ring gear R. The power output shaft 2 of 1 is connected with the rotating shaft of the ring gear R, and is connected with the second input shaft 12 of the double input shaft transmission mechanism 20, the rotor 7 of the motor 6 is connected with the rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com