Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Adjust torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

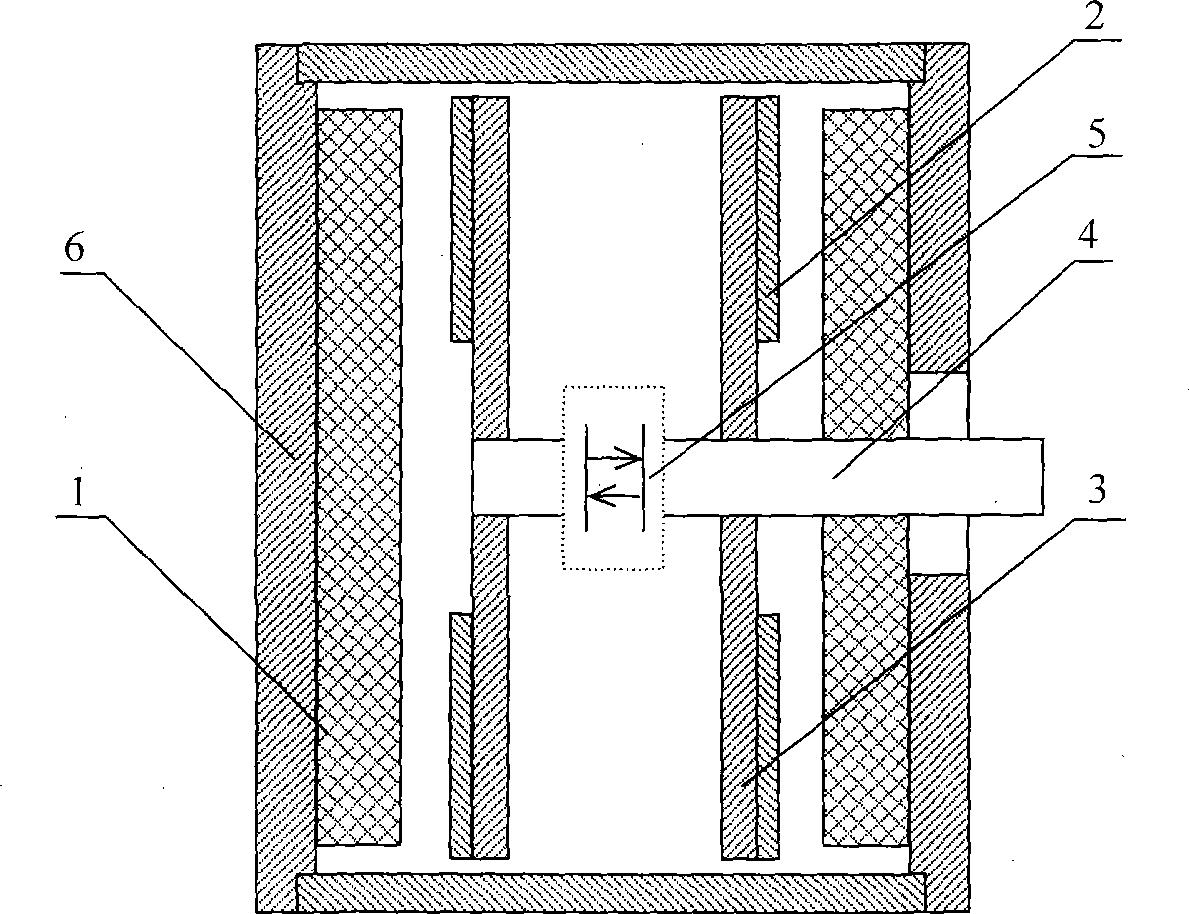

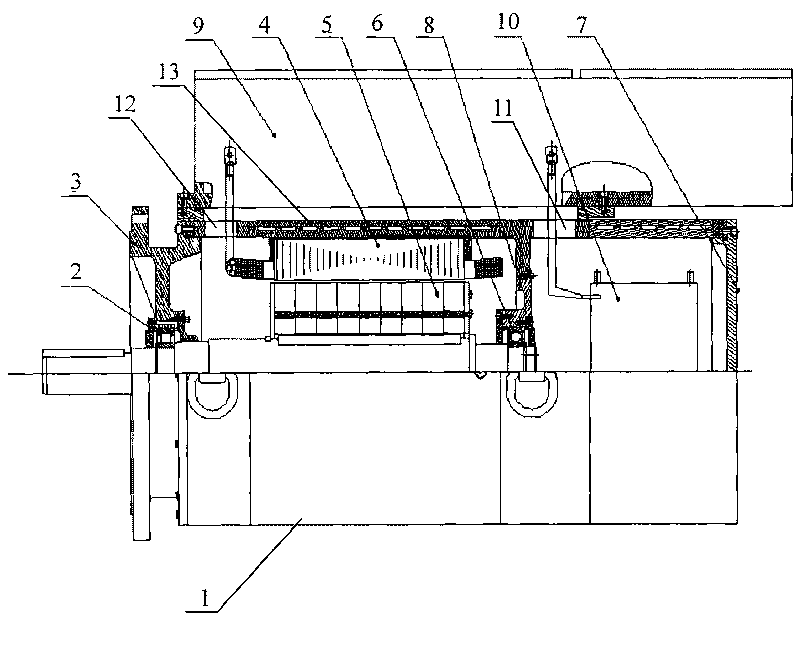

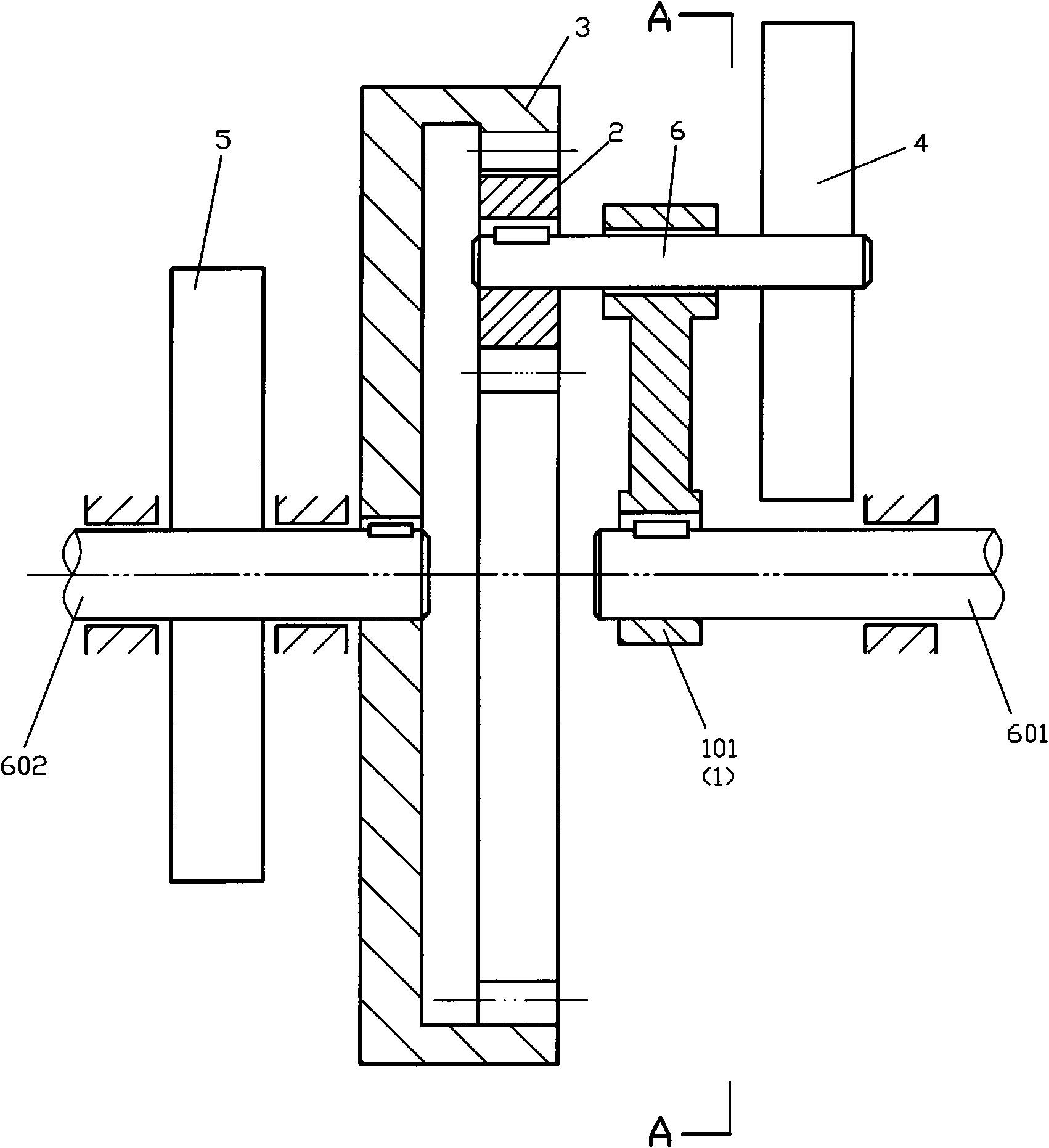

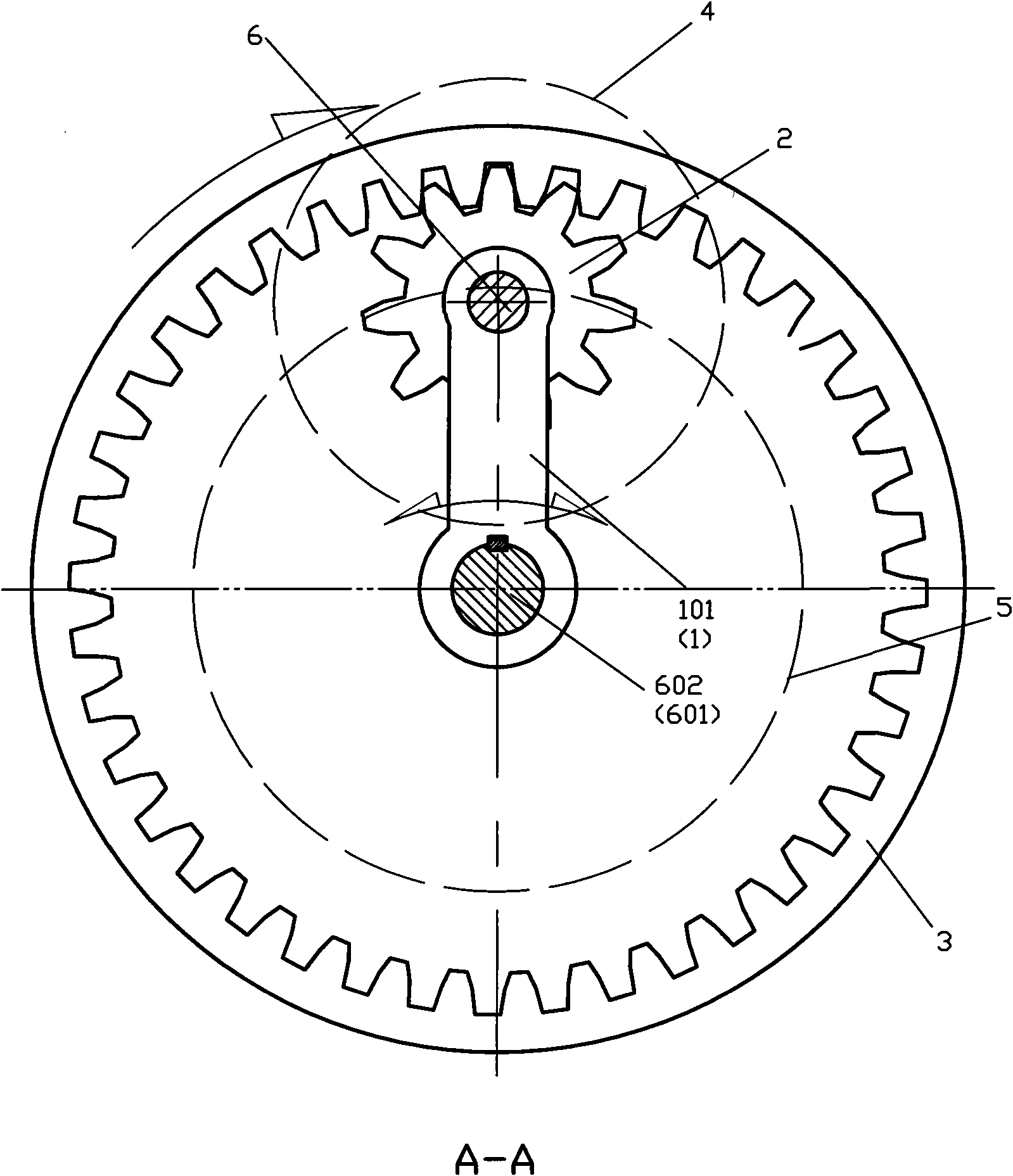

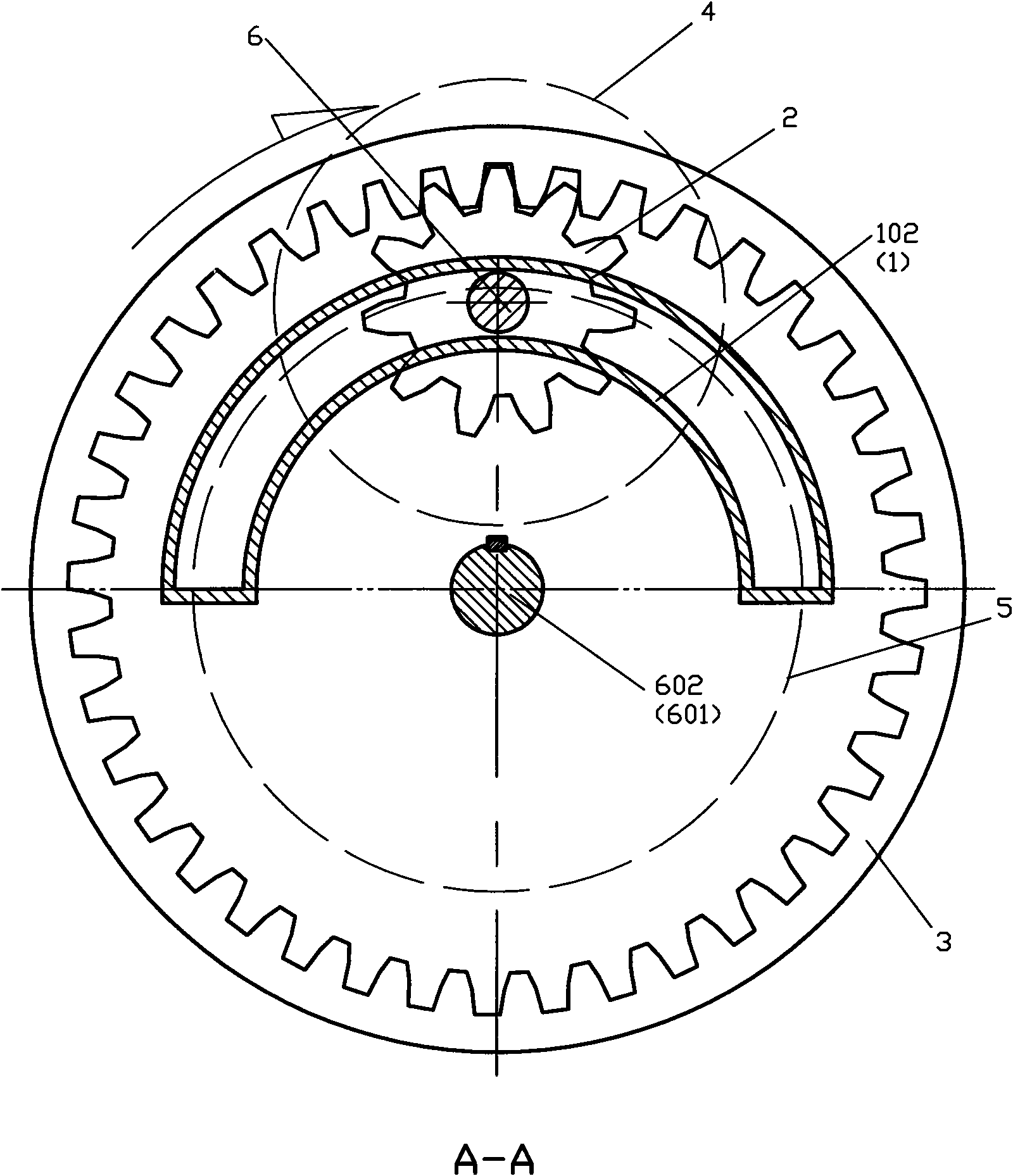

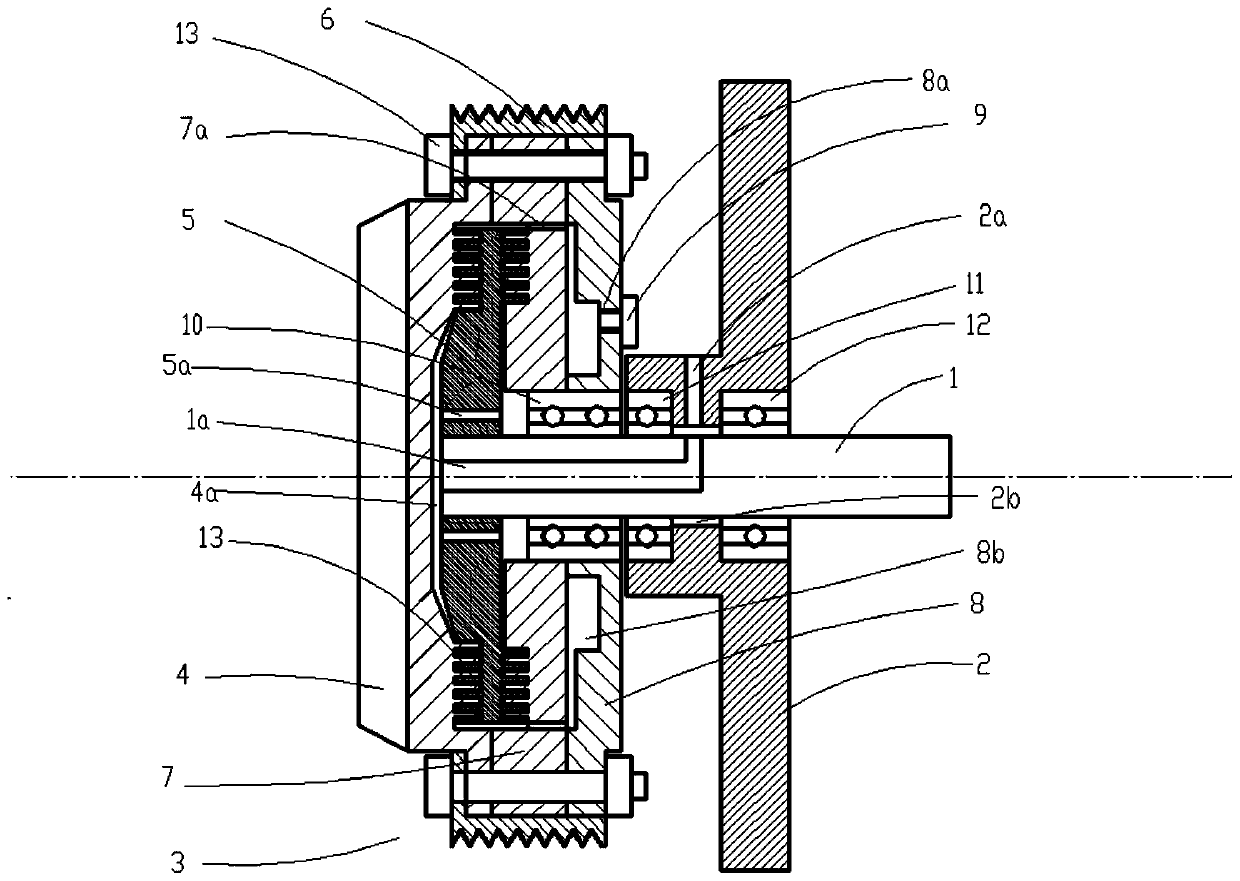

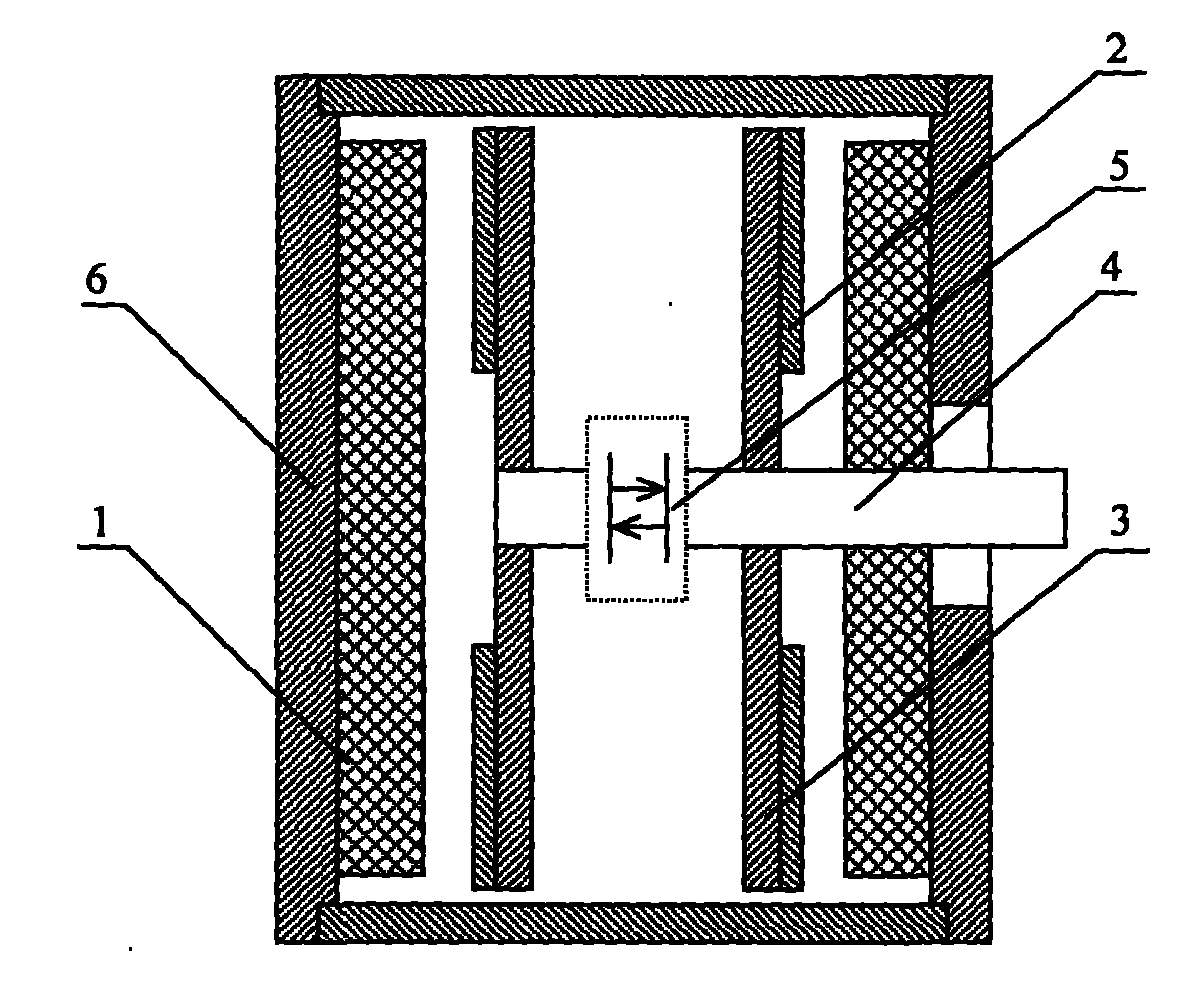

Air gap variant eddy speed regulating induction motor and working mode

InactiveCN101488691AWith soft startWith overload protectionMechanical energy handlingMagnetic circuit shape/form/constructionElectrical conductorElectric machine

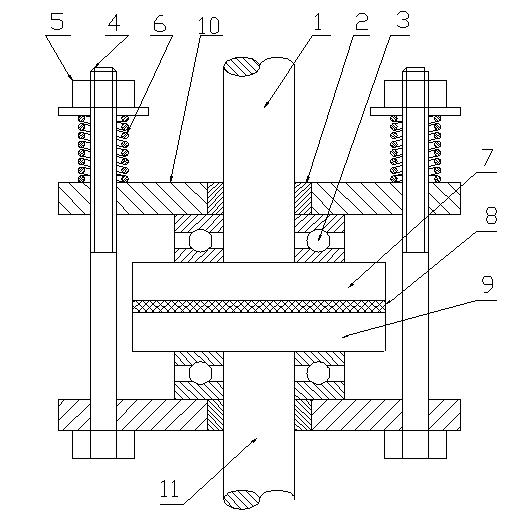

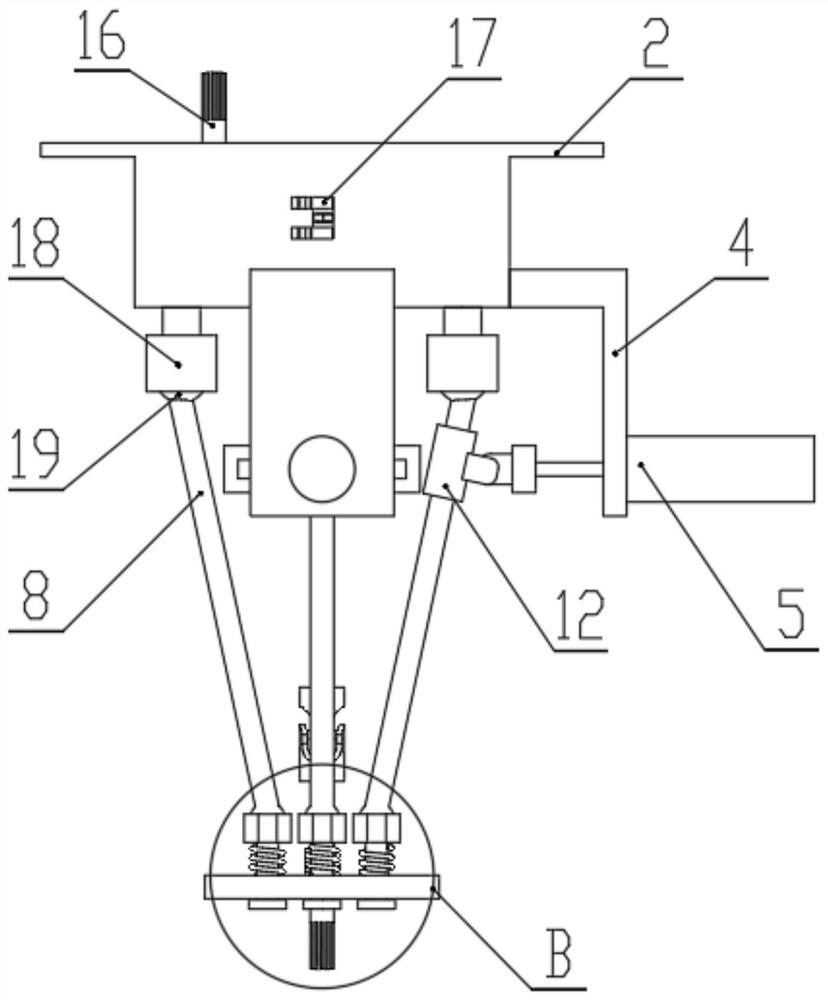

A variable air gap vortex flow speed regulating induction motor can achieve the aim of transmitting torque from an electric motor to a load by the interaction of air gap field between an electrical conductor and a winding. The variable air gap vortex flow speed regulating induction motor comprises a stator, a rotor, an air gap regulating component and the like, and is characterized in that the stator (1) comprises an iron core and the winding, wherein, the iron core is fixed on an end cover (6); the rotor includes a copper disc (2) and a back yoke (3), and is fixed on an output rotating shaft (4) which can change the air gap distance between the stator (1) and the copper disc (2) by the air gap regulating component (5); the motor adopts a disc structure, and the intensity of the air gap field can be conveniently regulated by regulating the air gap regulating component on the output rotating shaft, thus achieving the aim of regulating the rotating speed and the torque of the motor and leading the motor to start at underload and operate at full load.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

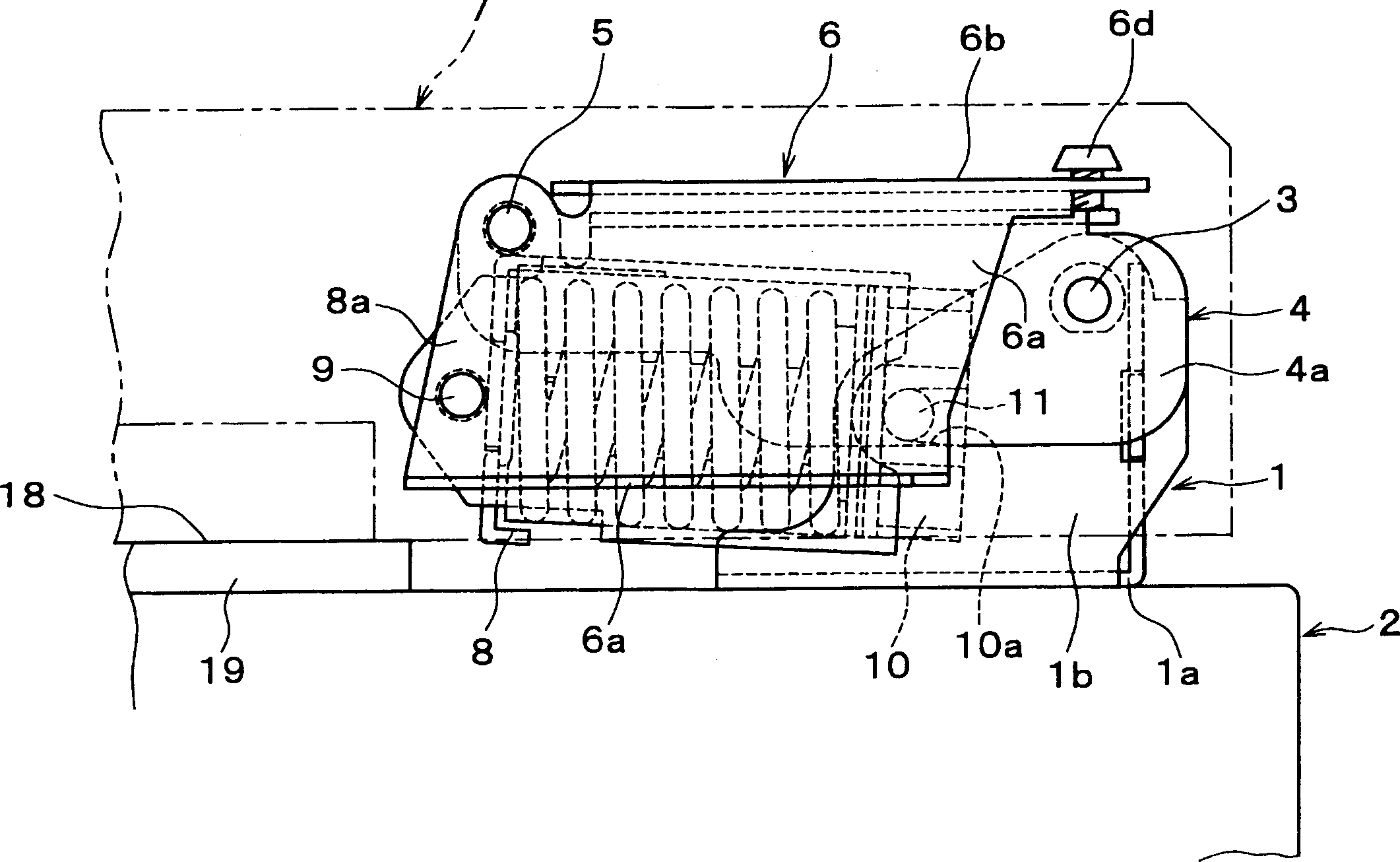

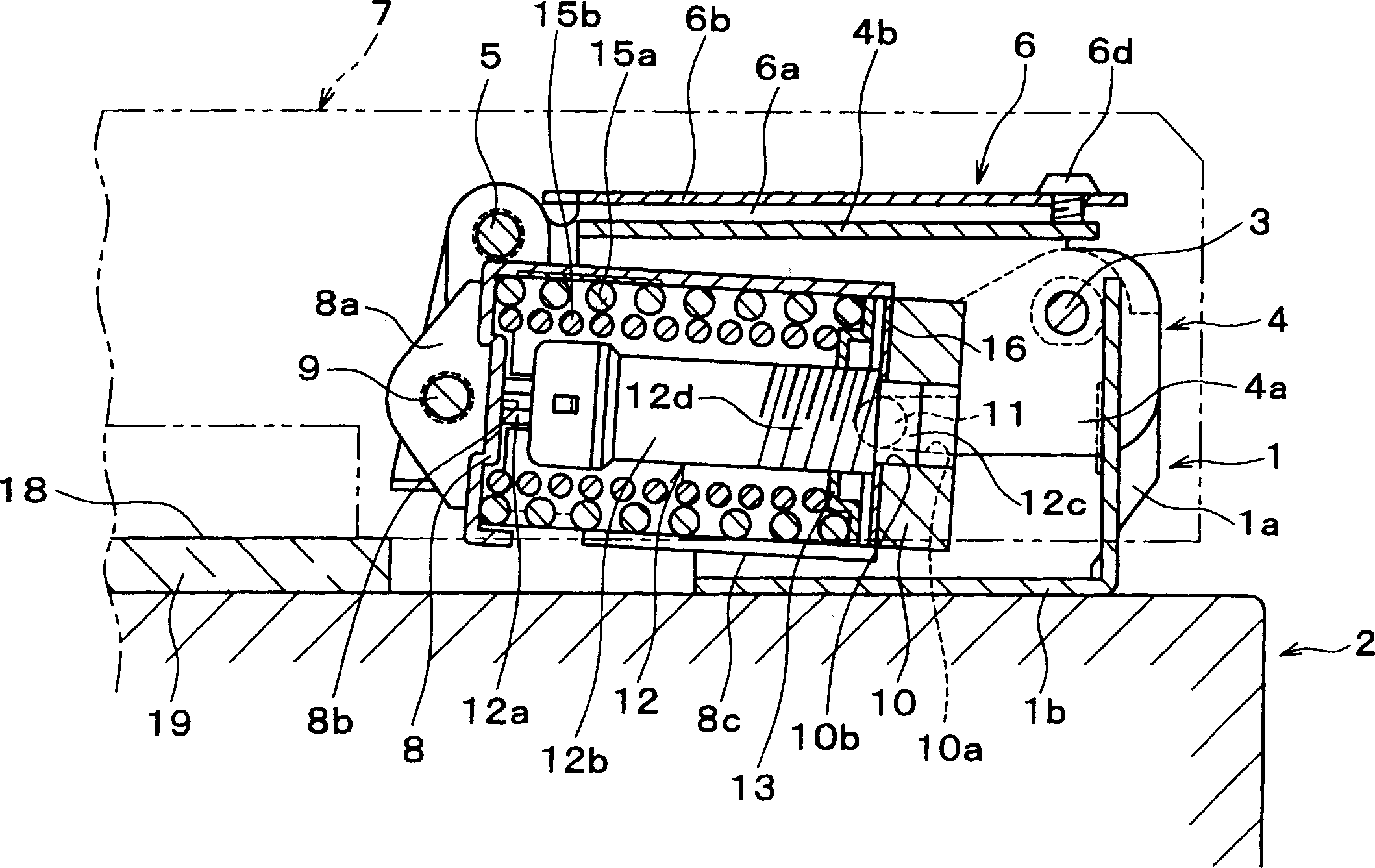

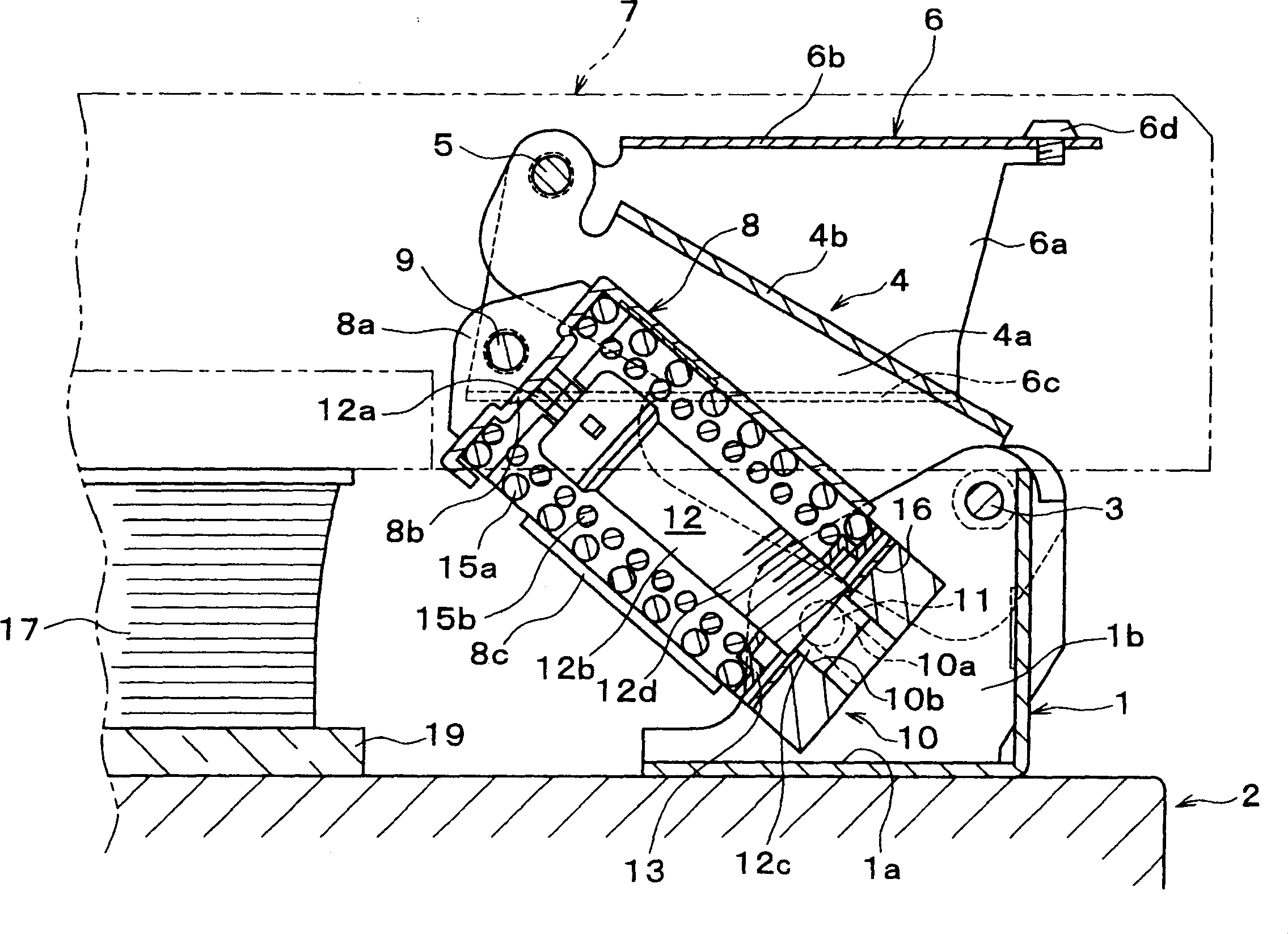

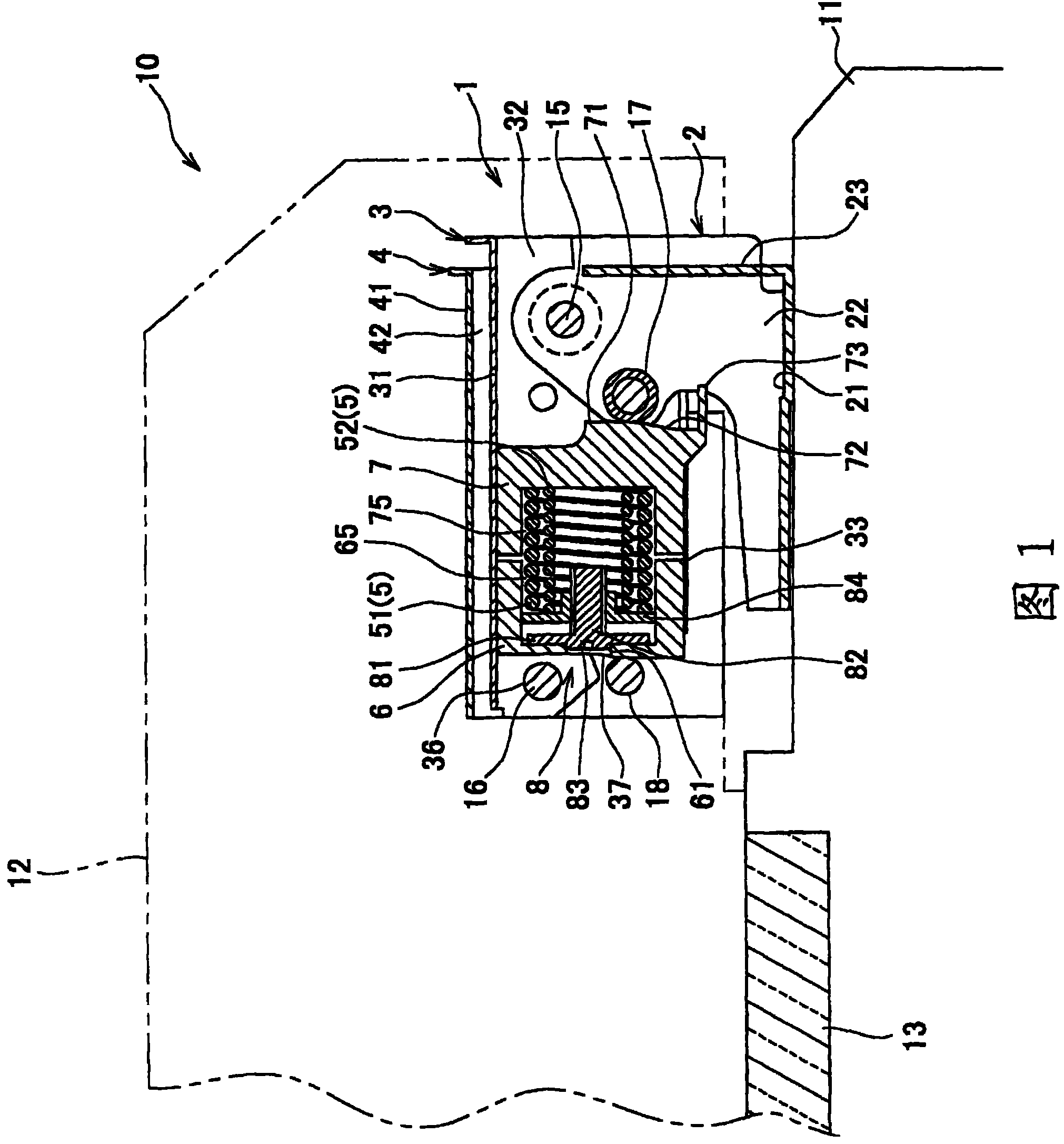

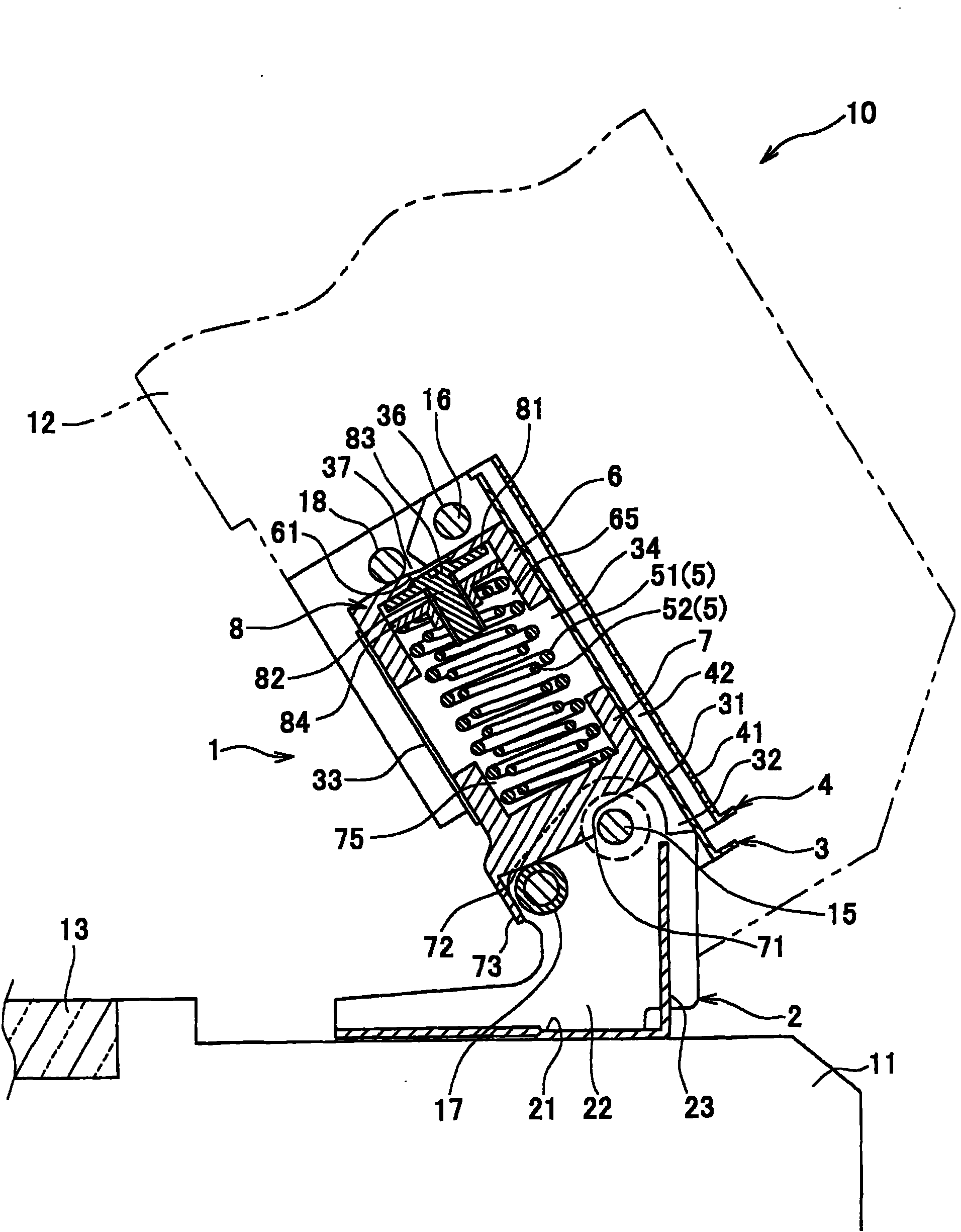

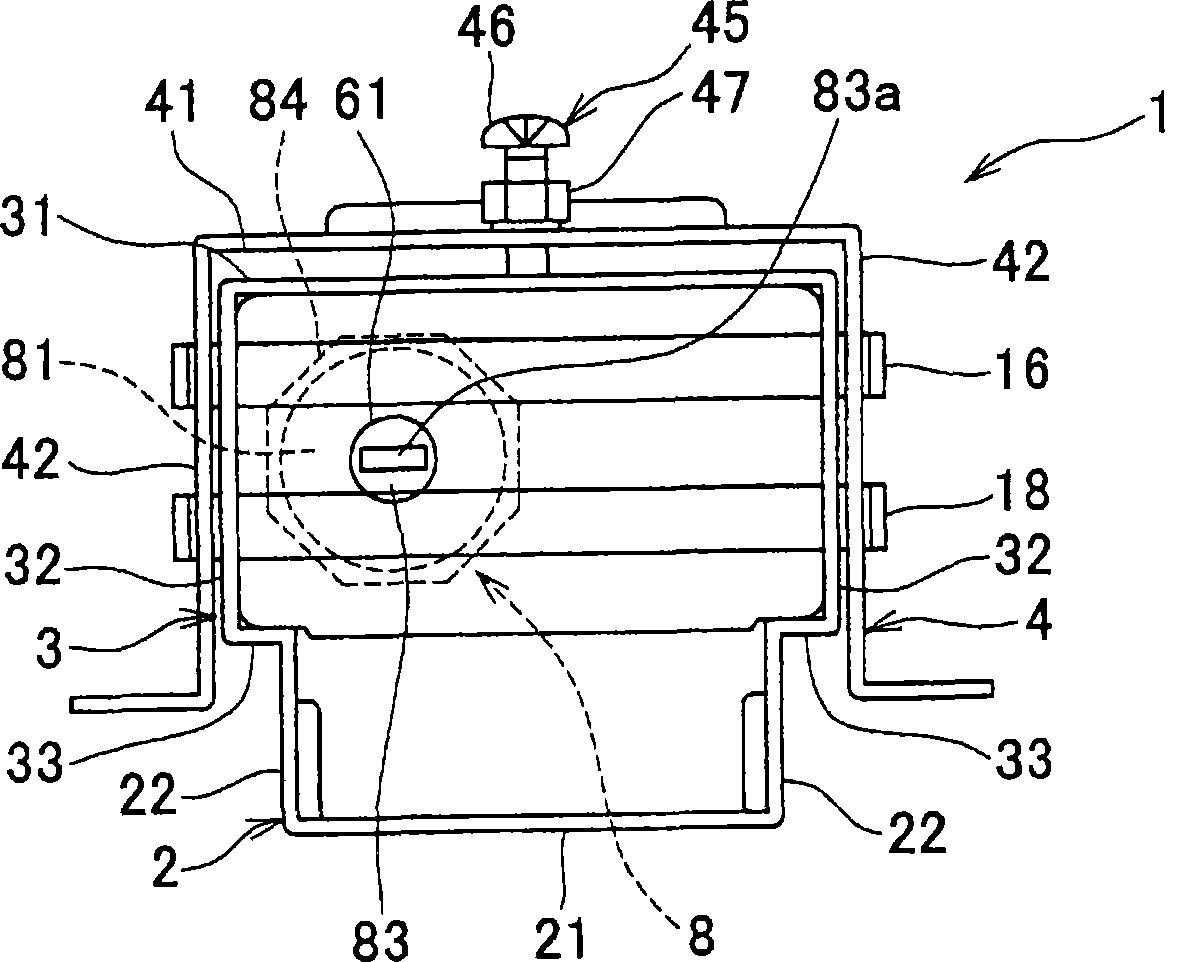

Hinge apparatus

InactiveCN1487209AAdjust torqueBuilding braking devicesWing accessoriesEngineeringMechanical engineering

Provided is a hinge device for adjusting torque without changing the closing angle of an original cover plate on which a damper acts. The hinge device is constituted of an attaching member attached to a device main body side, a supporting member for supporting the original cover plate turnably attached to the attaching member through a hinge pin, a compression spring elastically provided between the supporting member side and the attaching member, and the damper which is provided to be housed inside the compression spring and whose base part is attached to either or both of the attaching member side and the free end side of the supporting member so as to rock. In the hinge device, an adjusting plate is attached to the damper so as to move in a shaft direction and the compression spring is elastically provided between the adjusting plate and the supporting member side or the attaching member side.

Owner:KEM HONGKONG

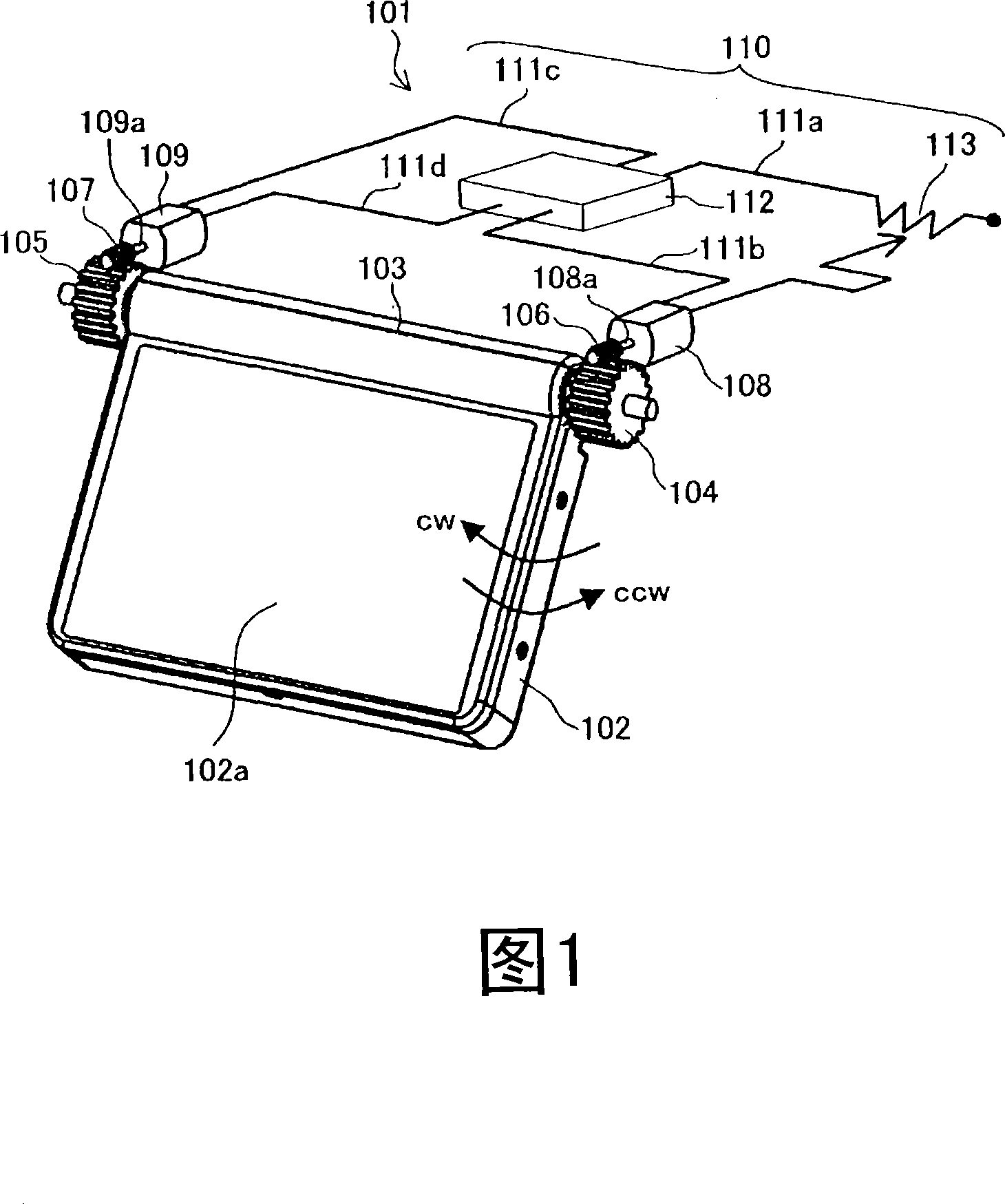

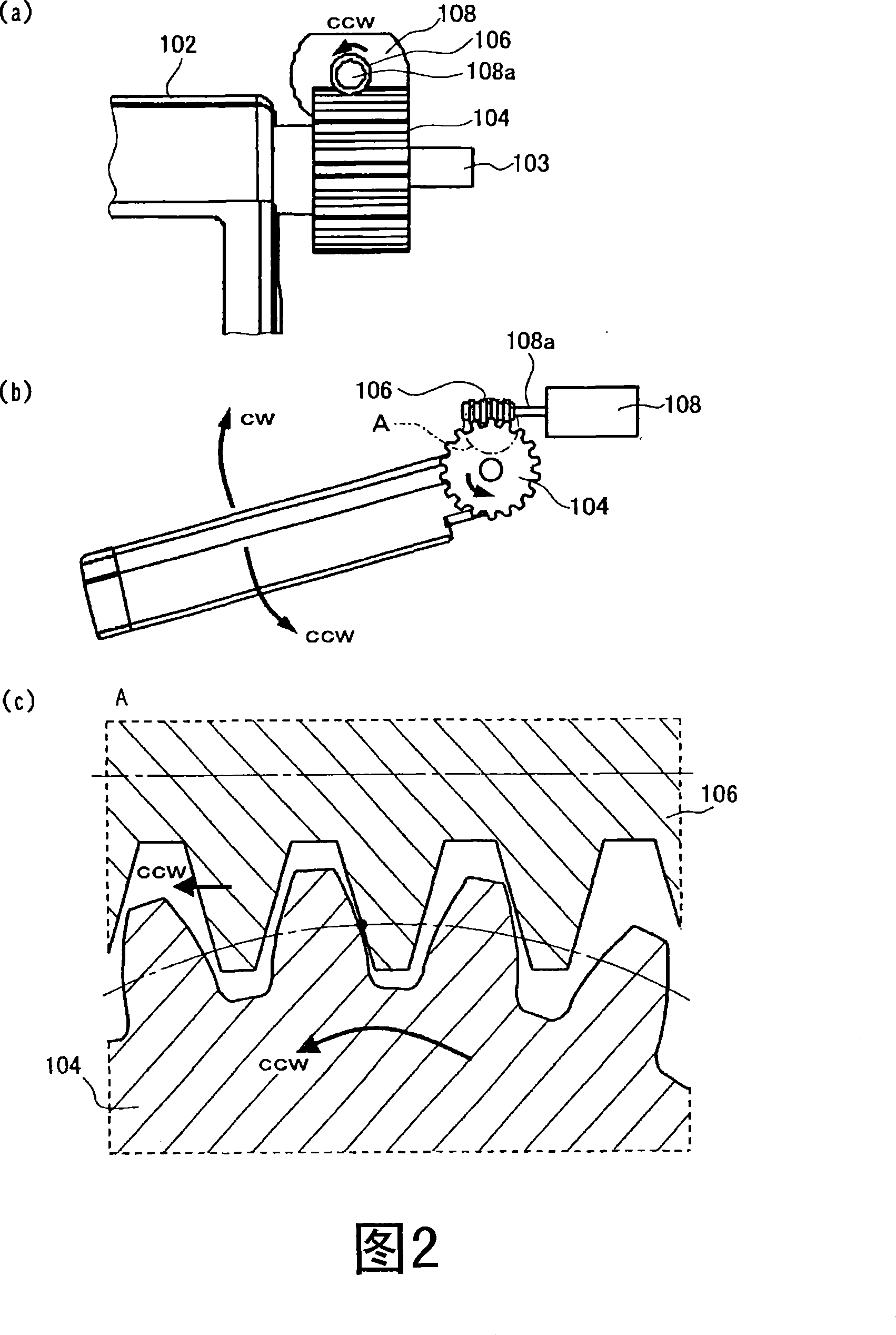

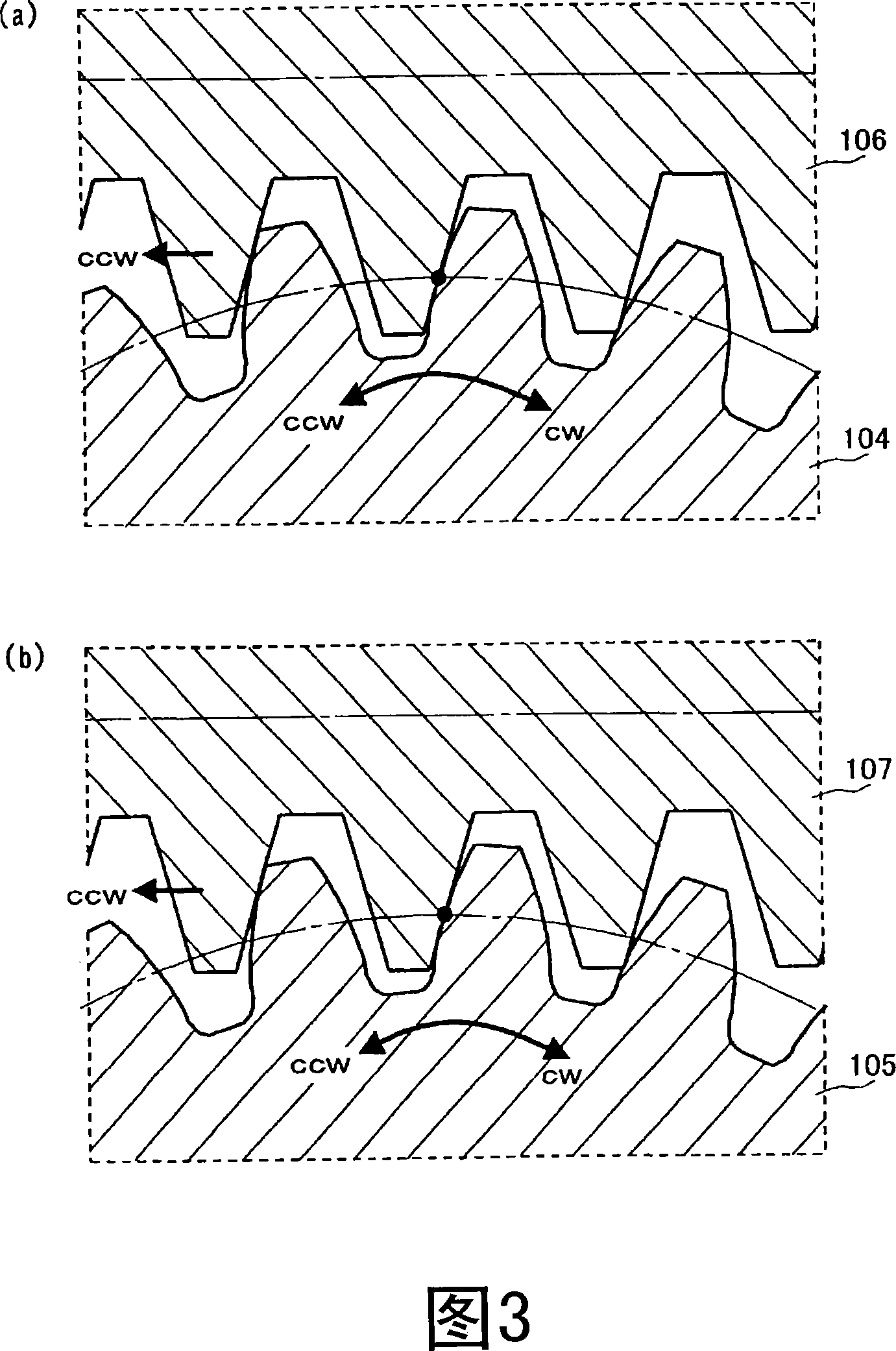

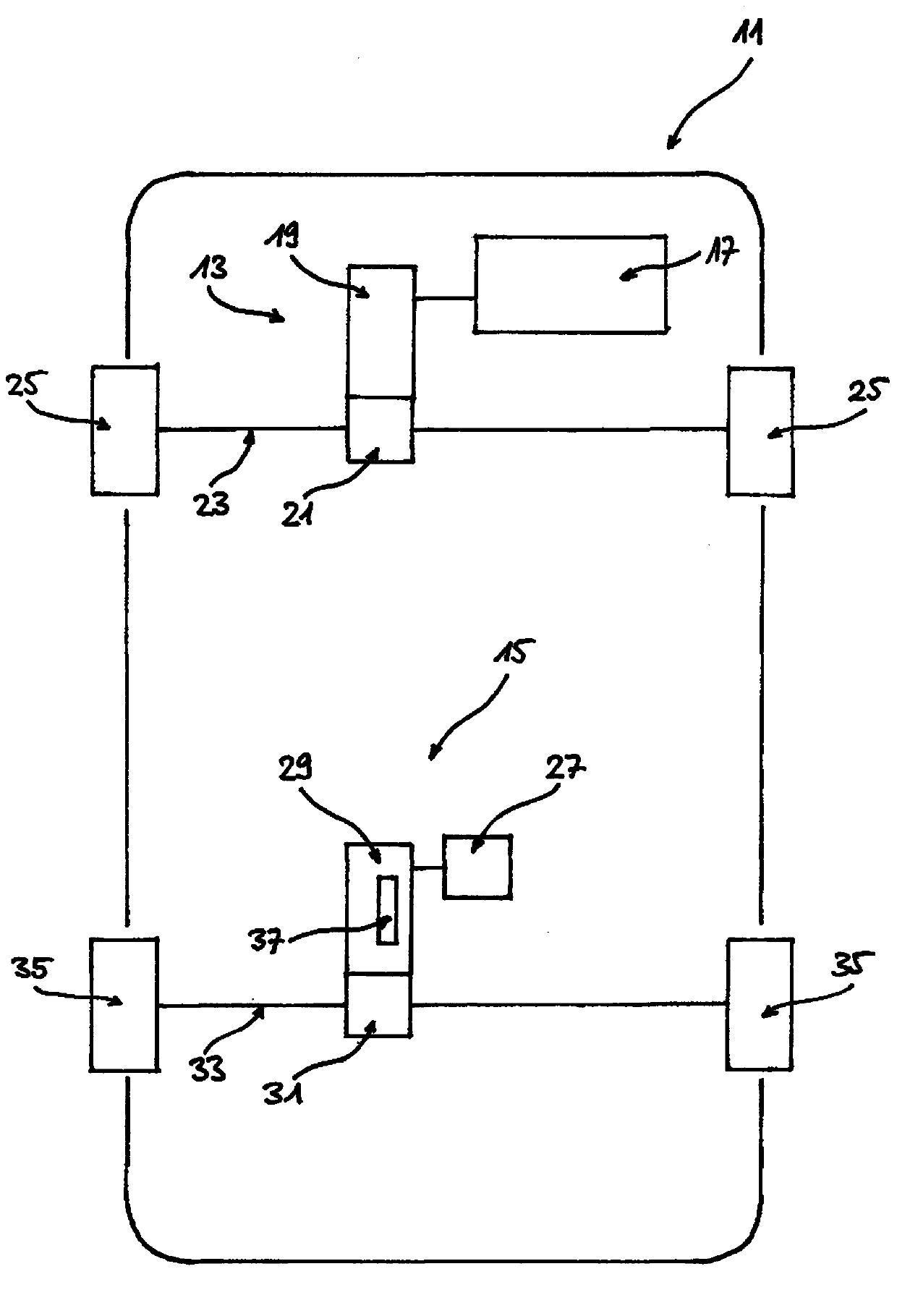

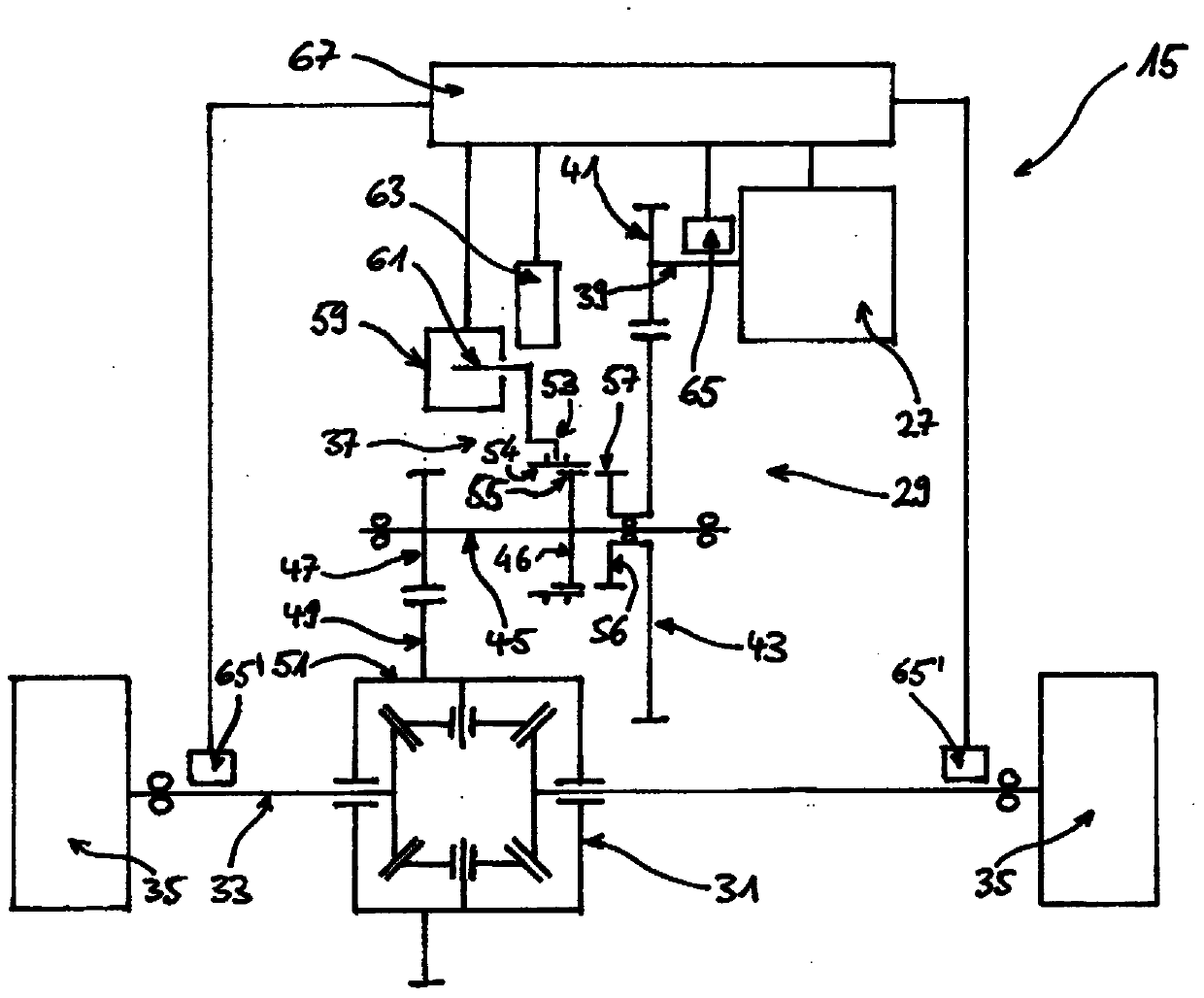

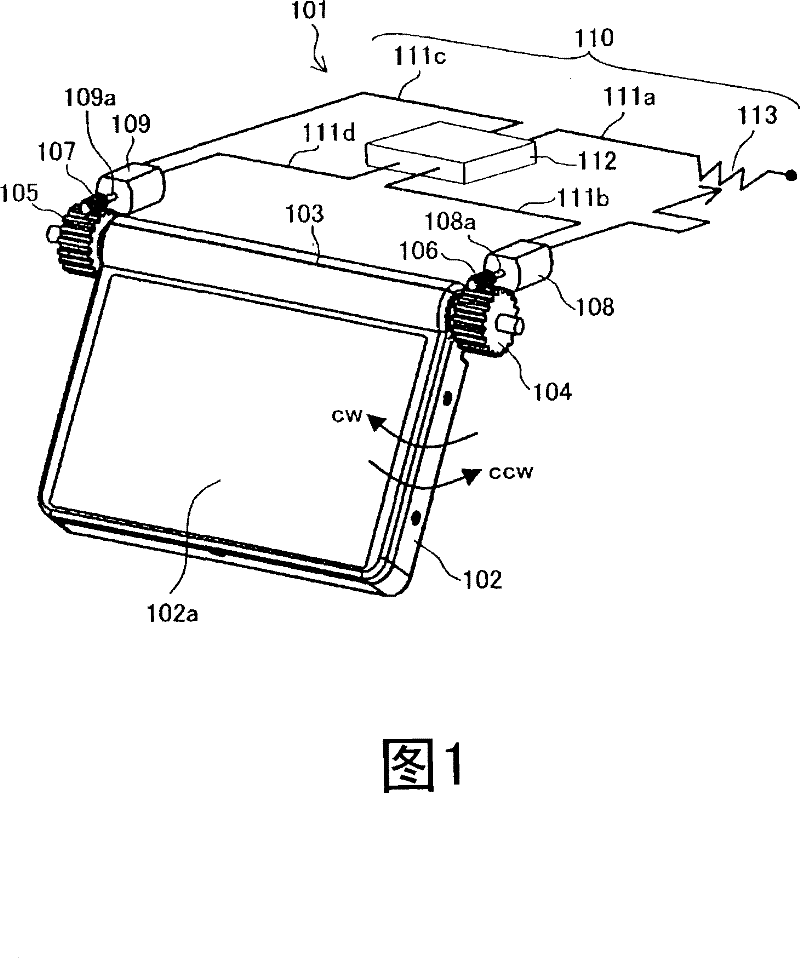

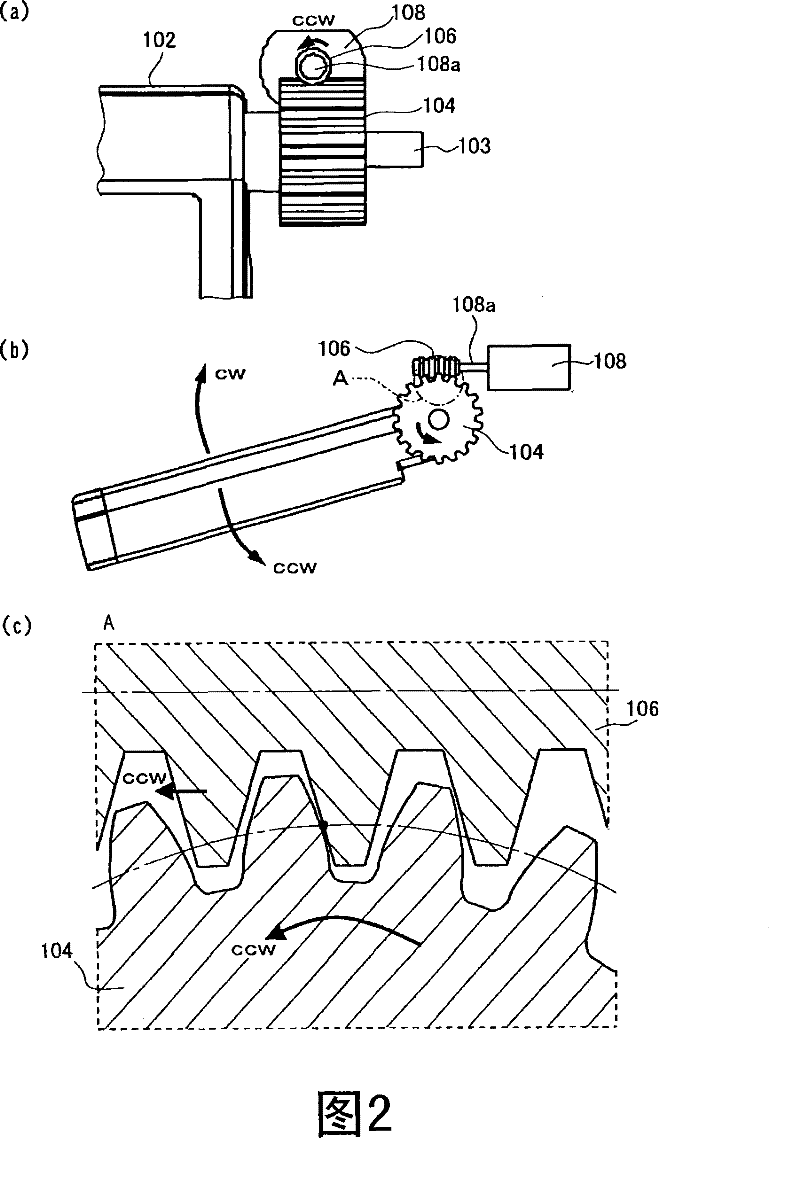

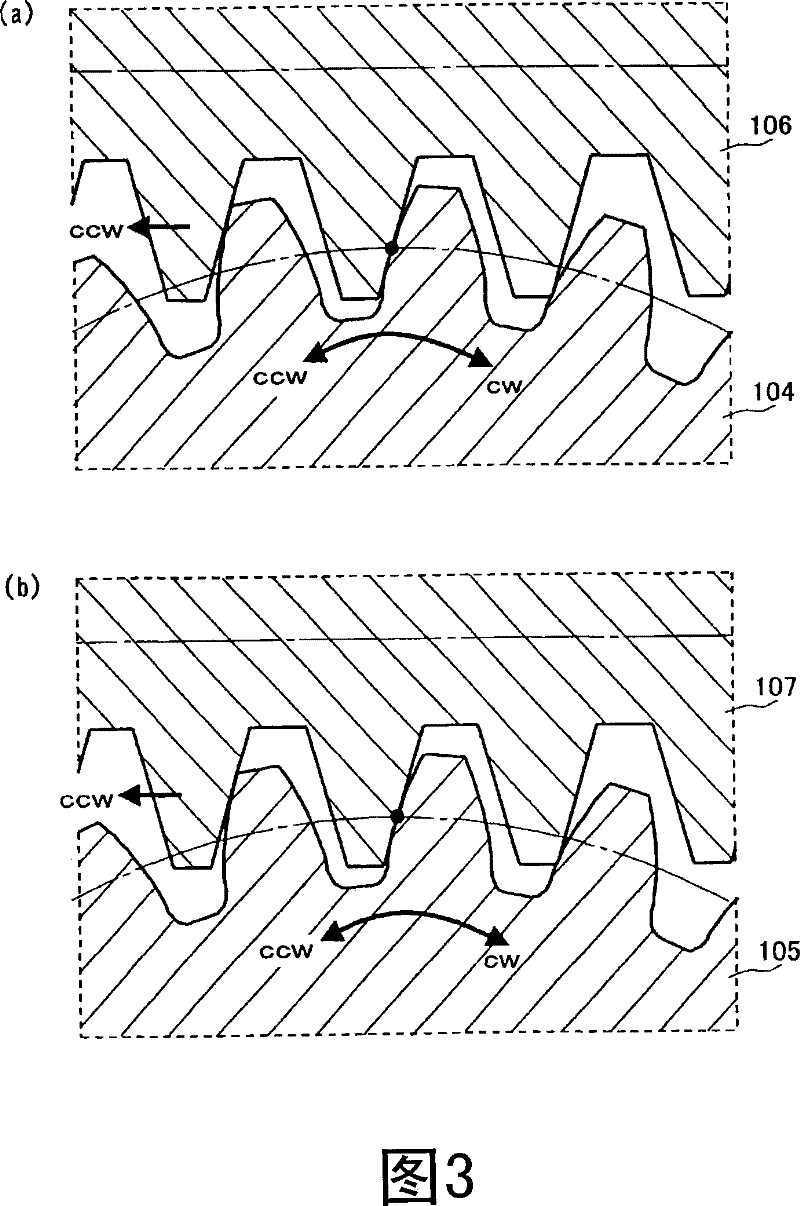

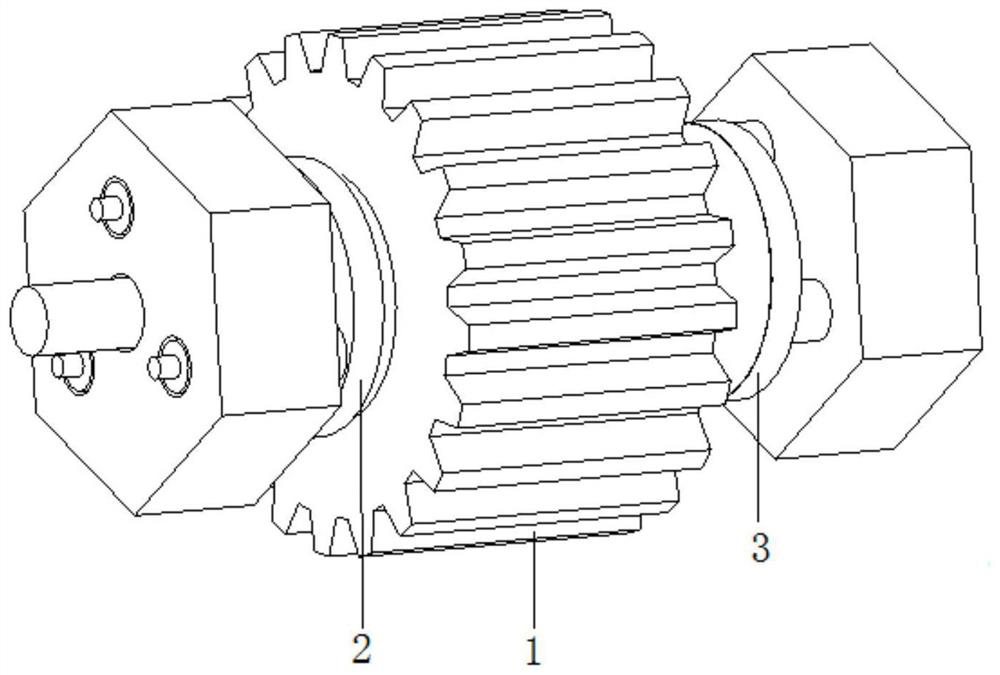

Power transmission device, and display device and display panel pedestal that have the power transmission device

InactiveCN101184939AEliminate backlashAdjust torqueToothed gearingsVehicle componentsDisplay deviceDrive motor

A power transmission device capable of adjusting a torque to be applied to an output shaft easily and removing a backlash between gears exactly, and a display device and a display panel pedestal that have the power transmission device. A power transmission device 101 includes a display panel 102, an output shaft 103 to which the display panel is connected, output gears 104 and 105 rotating integrally with the output shaft, transmission gears 106 and 107 engaged with the respective output gears, motors 108 and 109 providing driving forces to the respective transmission gears, and a control circuit 110 controlling the motors. The control circuit 110 causes the motors 108 and 109 to rotate the transmission gears 106 and 107 at different rotation numbers, and to transmit different driving forces to the respective output gears 104 and 105. The output shaft 103 receives not only a torque on a rotation direction side, but also a torque on a side opposite to the rotation direction, whereby the occurrence of play due to the direction change of a weight torque of the display panel 102 is suppressed.

Owner:PANASONIC CORP

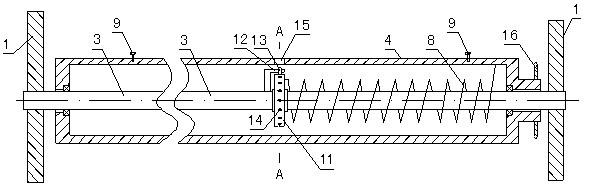

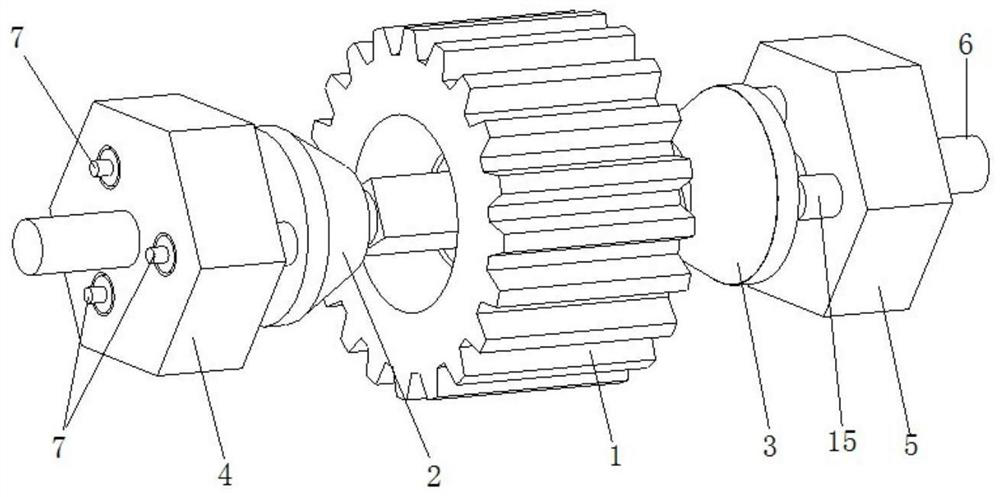

Torsion overload safety protection device

InactiveCN103122948ARegulating pressureAdjust friction torqueSlip couplingDrive shaftTorque regulation

The invention discloses a torsion overload safety protection device which is provided with a framework fixed by corresponding annular press plates and tension bars. Nuts and springs are arranged on the lower portions of the two upper ends of the tension bars. The annular press plates are provided with sliding bearings. A driving shaft penetrates through the upper end of a position between the annular press plates in a transverse mode, and a driven shaft penetrates through the lower end a position between the annular press plates in a transverse mode. A friction plate is fixed between the driving shaft and the driven shaft, and is composed of a driving friction plate and a driven friction plate. A friction piece is fixed between the driving friction plate and the driven friction plate. Surface bearings are arranged at two ends of the driving shaft and the driven shaft. The torsion overload safety protection device not only has the function of adjusting torsion, but also has the advantages of adjusting the torsion conveniently at the same time.

Owner:JIANGSU RENAN HI TECH

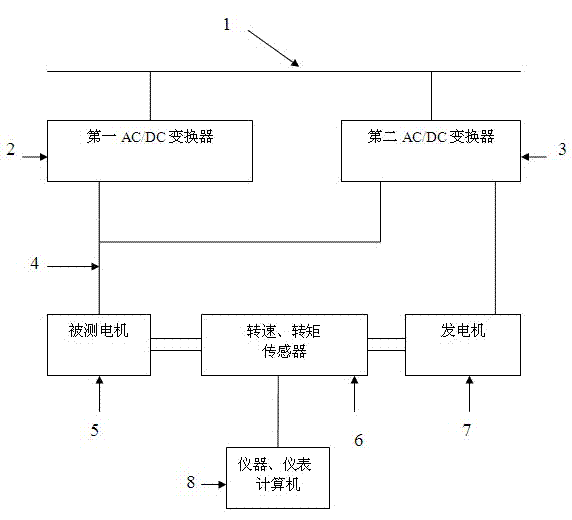

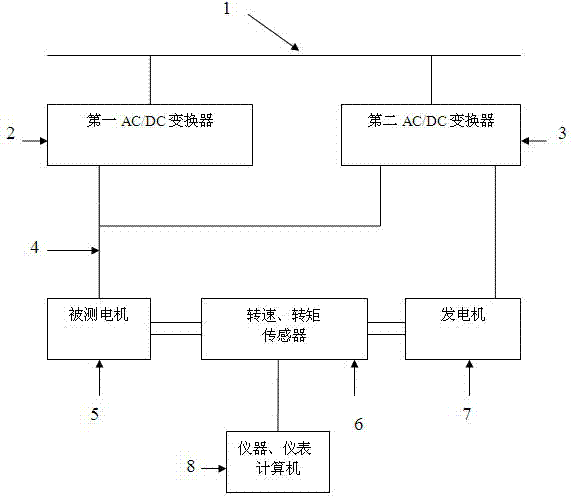

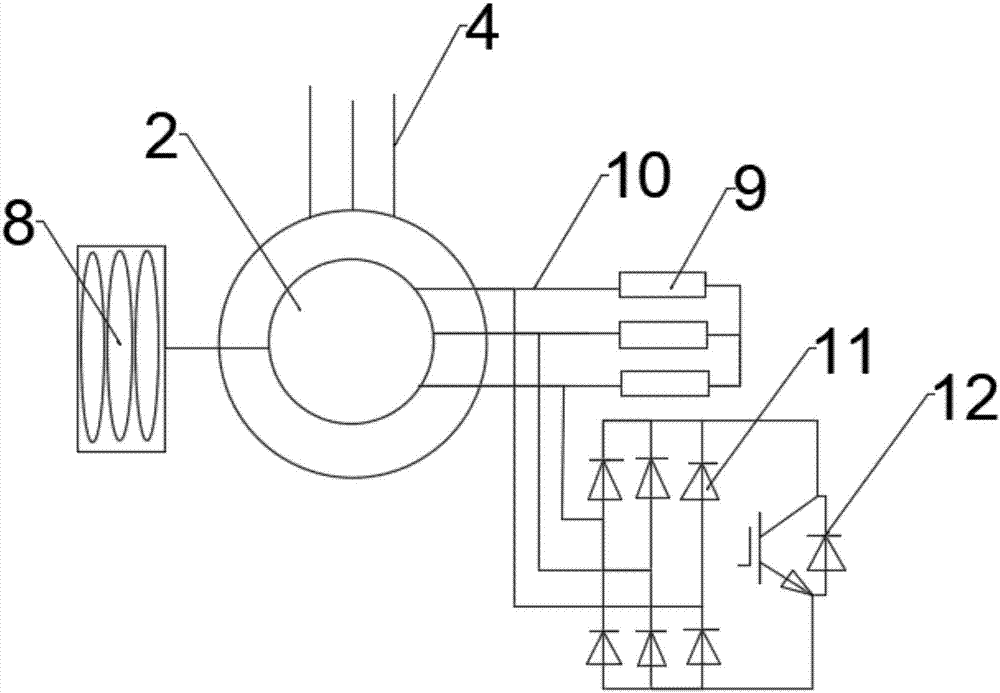

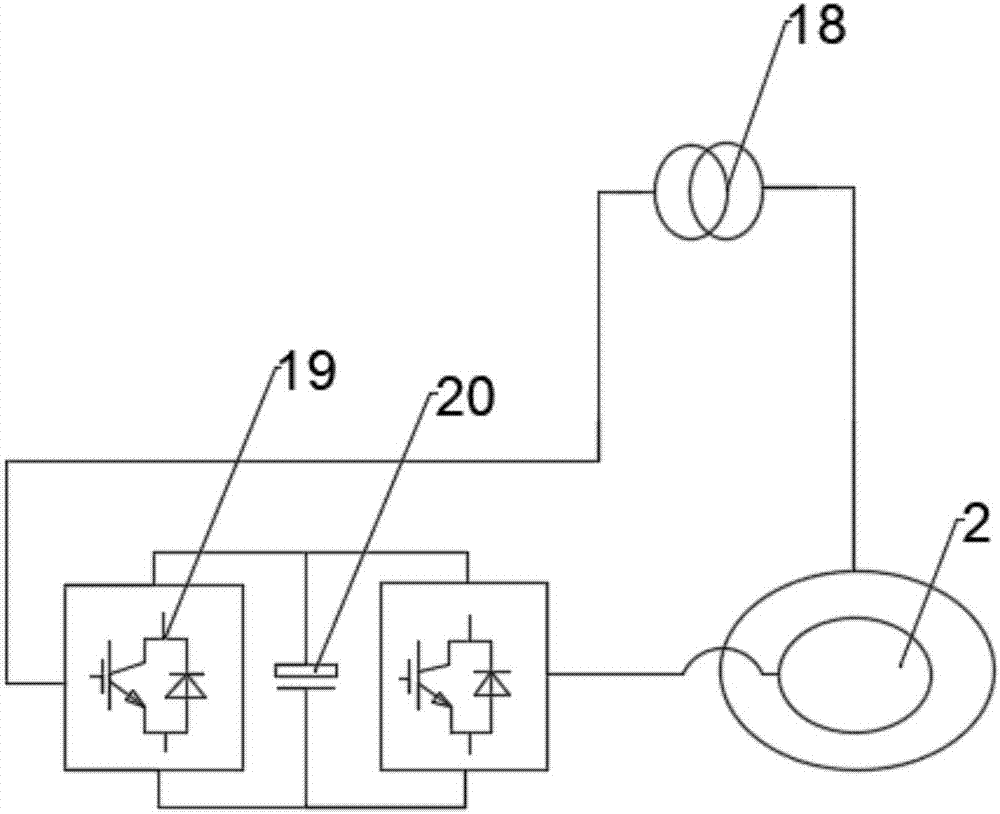

Direct current feed type motor testing system

InactiveCN102435947AAdjust torqueReduce power supply capacityDynamo-electric machine testingMotor testingBusbar

The invention relates to a direct current feed type motor testing system, belongs to the technical field of testing of motors and is used for measuring rotational speed, rotational moment, power, efficiency and other parameters of the tested motor. The direct current feed type motor testing system comprises at least two independent AC / DC (alternating current / direct current) converters, a direct current power generator and a rotational speed and rotational moment sensor. The inputs of the two independent AC / DC converters are respectively connected with an alternating current input busbar of a power grid, wherein the direct current side of one AC / DC converter is connected to a direct current busbar of the tested motor; and the direct current side of the other AC / DC converter is connected with the output of the direct current power generator in series and then connected to the direct current busbar of the tested motor, the output of the AC / DC converter is regulated to realize feedback of electric energy and regulation of the rotational moment of the tested motor, the overall power supply capacity of the system is reduced by utilizing the feedback energy and the efficiency of the system is improved.

Owner:扬州华泰电子有限公司

Electronic power converter

InactiveCN107332484ASimple structureMature control methodSingle network parallel feeding arrangementsWind energy generationWinding machineConstant frequency

The invention discloses an electronic power converter. The converter comprises a transmission mechanism and a double-fed motor, the left end of the transmission mechanism is connected with a wind machine through rotating shafts, the output end of the transmission mechanism is connected with the double-fed motor through control wires, and the signal end of the double-fed motor is connected to power grids through power windings, wherein the output end of the double-fed motor is connected with PWM rectifiers through control windings, and the PWM rectifiers are connected with the power grids in a series-parallel connection structure; the double-fed motor adopts a wound-rotor asynchronous generator and is provided with stator windings on the left end, the right end of the double-fed motor is connected with resistors and stabilivolts through the stator windings separately, and the control ends of the stabilivolts are in parallel connection with the rectifiers, so that the volume of a relative total-power converter is greatly reduced, the reliability of system operation is improved, and the technical scheme of the electronic power converter can serve as an optimum proposal for variable-speed constant-frequency power generation in wind power generation.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Multi-way reversing valve

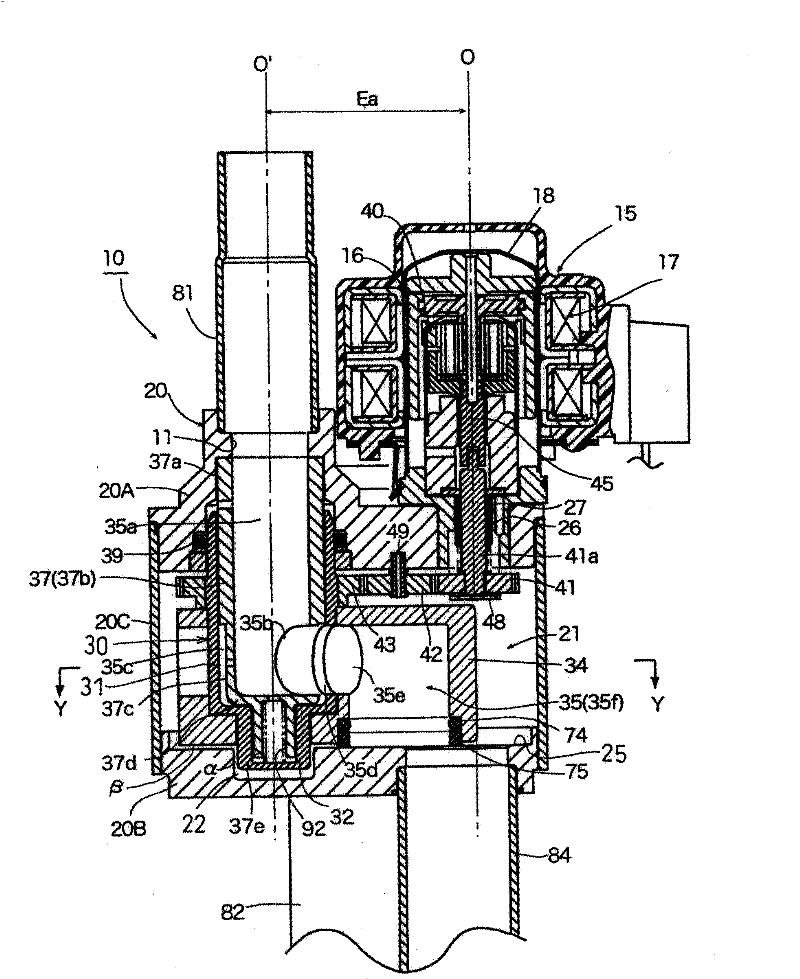

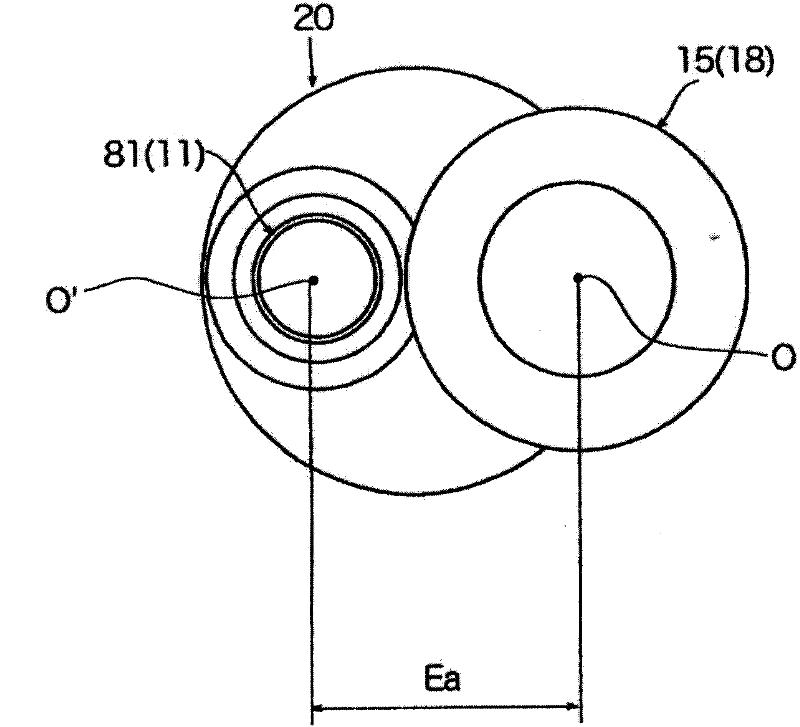

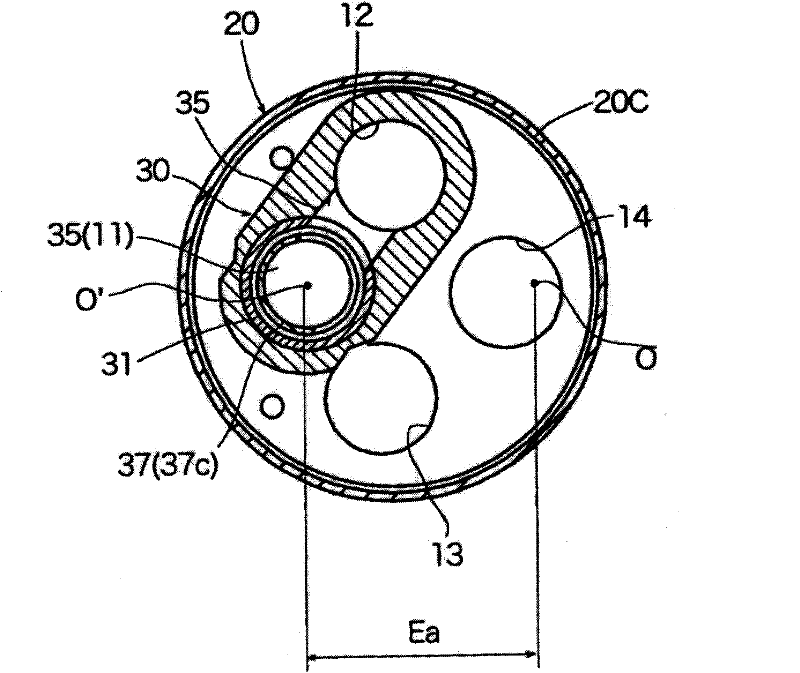

ActiveCN102213331AAchieve configuration freedomLower assembly and processing costsOperating means/releasing devices for valvesMultiple way valvesRotational axisEngineering

The present invention provides a multi-way reversing valve that allows for a reduction in size, an improvement in layout freedom, a reduction in assembly processing costs, etc. The multi-way reversing valve includes a valve housing having a valve seat part in which a plurality of fluid in / out ports are formed; a valve member adapted to be rotated; and an actuator adapted to rotationally actuate the valve member. A fluid inlet port and / or a fluid outlet port is / are formed in the valve housing. A passage adapted to selectively place the fluid inlet port or the fluid outlet port in communication with the plurality of fluid in / out ports is formed within the valve member. Flow paths are reversed by rotating the valve member to selectively place the fluid inlet port or the fluid outlet port in communication with one of the plurality of in / out ports via the passage. The rotational axis line O' of the valve member is laterally eccentric relative to the rotational axis line O of an output shaft of the actuator by a predetermined distance Ea.

Owner:FUJIKOKI MFG CO LTD

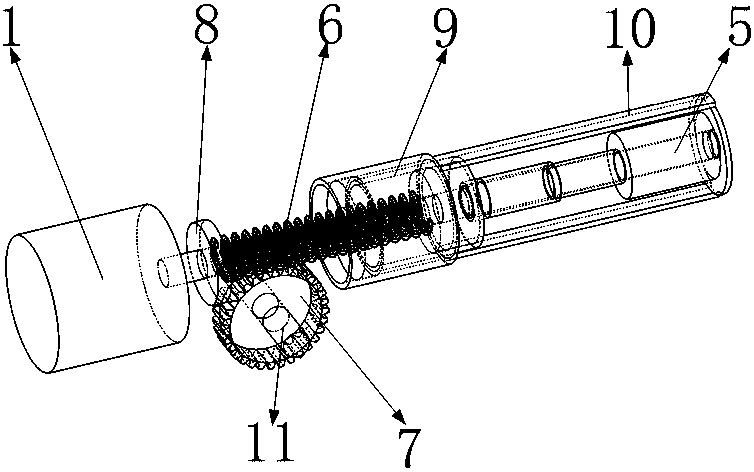

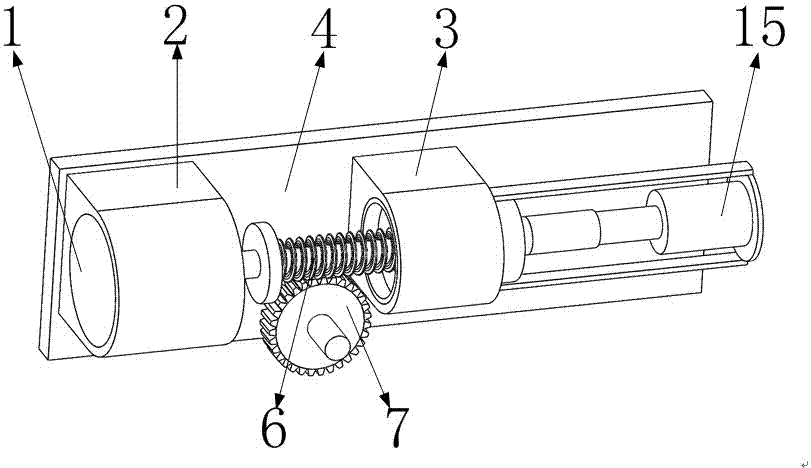

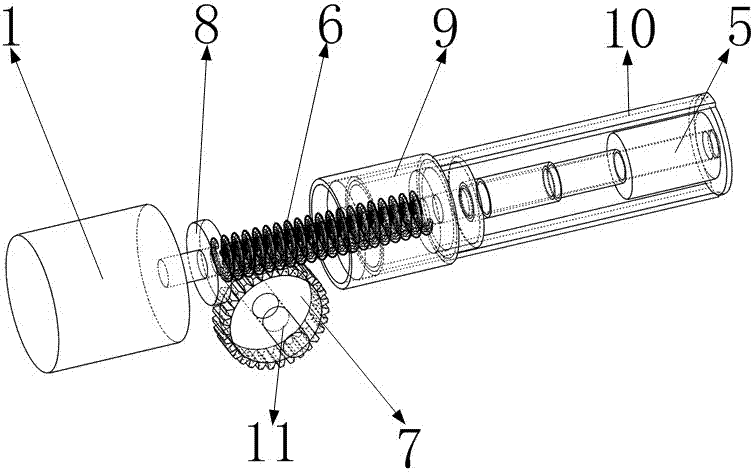

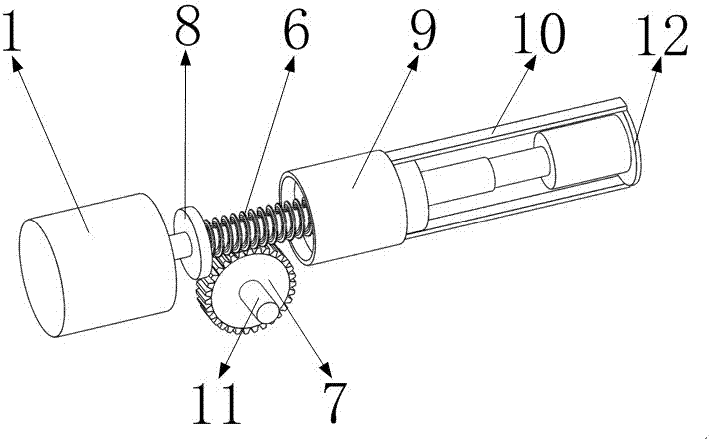

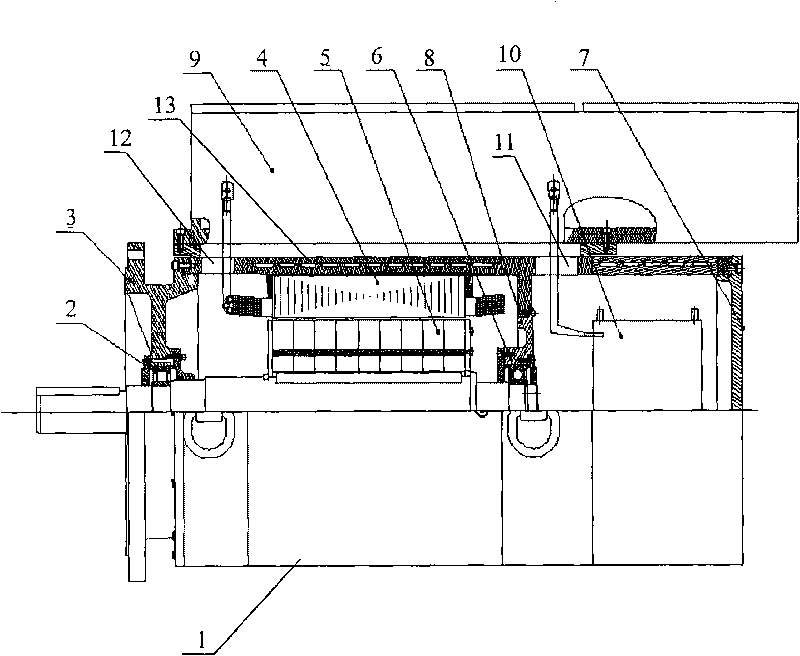

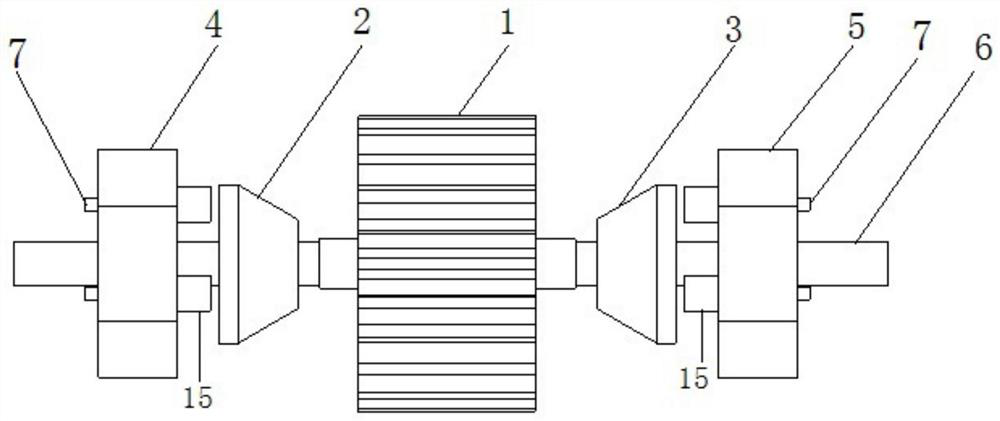

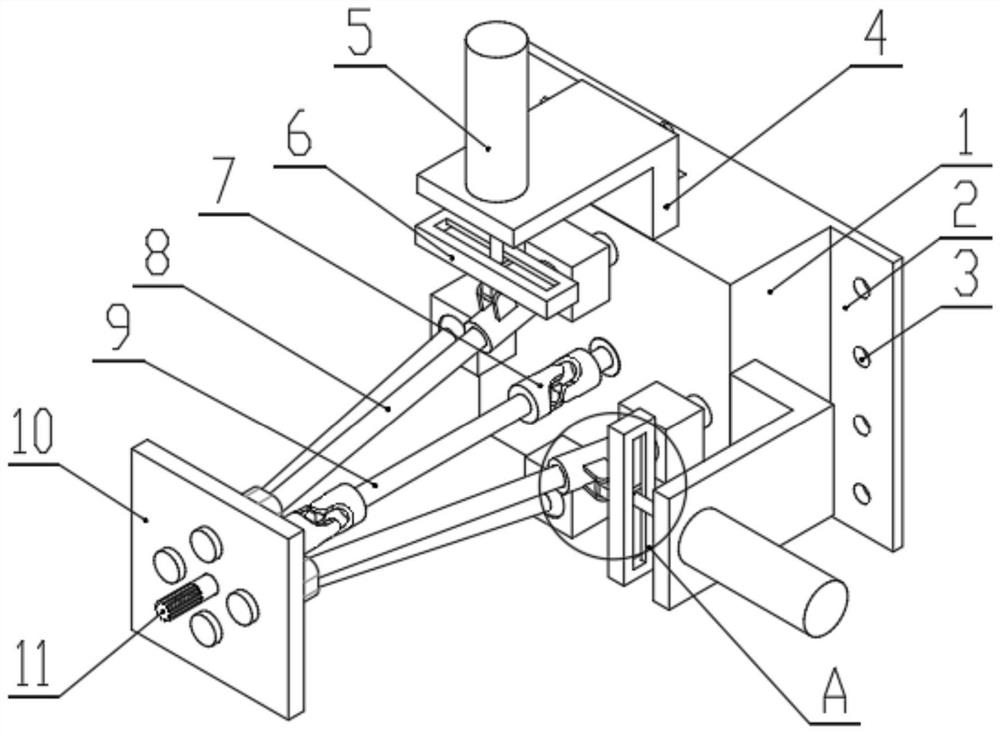

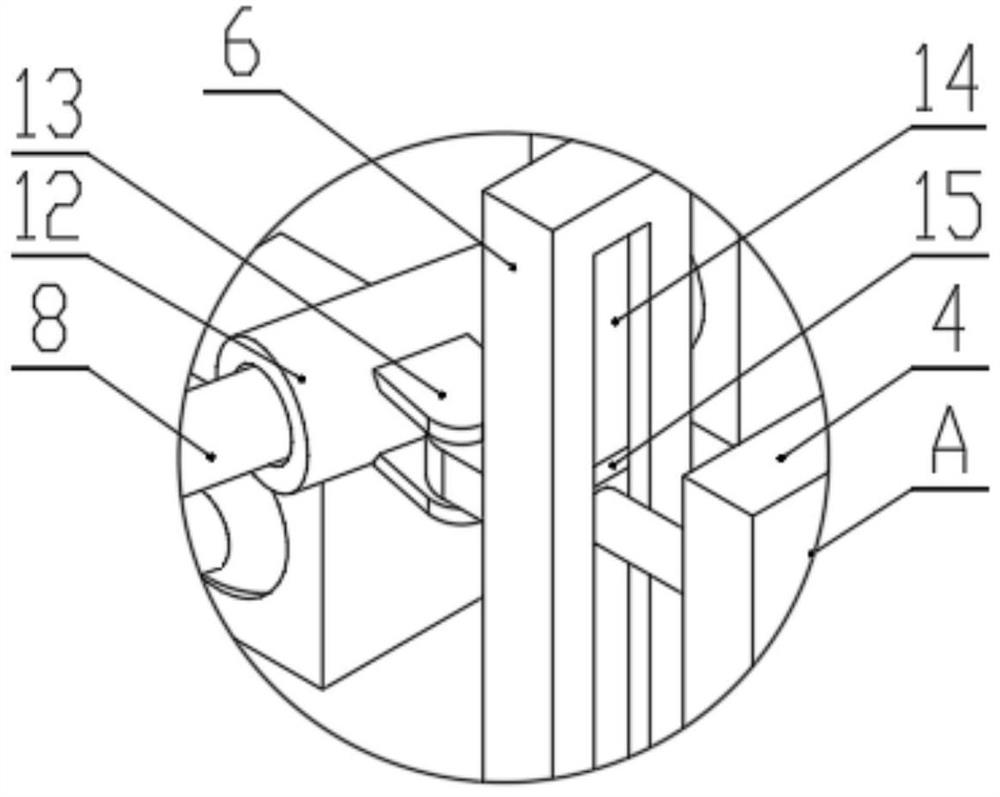

Adjustable and controllable worm transmission mechanism used for wheelchair

InactiveCN107654580AControl initial elastic propertiesControl torqueWheelchairs/patient conveyanceToothed gearingsMaximum torqueWheelchair

The invention belongs to the technical field of wheelchair driving, and particularly relates to an adjustable and controllable worm transmission mechanism used for a wheelchair. The adjustable and controllable worm transmission mechanism comprises a driving motor, a driving spring and a transmission gear. When people use the wheelchair, an adjusting motor is controlled by people before using; an adjusting U-shaped ring is driven to rotate by the adjusting motor, an adjusting threaded wheel is driven to rotate by the adjusting U-shaped ring, and when the adjusting threaded wheel rotates, the adjusting threaded wheel can move along an axis of the adjusting threaded wheel, namely, initial elastic performance of the driving spring can be controlled through the adjusting motor, and maximum torque which can be transmitted by the driving spring is controlled accordingly; and when initial elastic performance of a thread is well adjusted by people, the driving motor is controlled to start to work, a transmission shaft is driven to rotate by the driving motor, two spring fixed discs are driven to rotate by the transmission shaft, the driving spring is driven to rotate by the two spring fixeddiscs, the transmission gear is driven to rotate by rotating of the driving spring, a gear shaft is driven to rotate by the transmission gear, and the wheelchair is driven to work by rotating of thegear shaft.

Owner:CHANGSHU PINGFANG WHEELCHAIR CO LTD

Adjustable worm transmission mechanism for wheelchair

PendingCN107496089AControl initial elastic propertiesControl torqueWheelchairs/patient conveyanceMechanical energy handlingMaximum torqueGear drive

The invention belongs to the technical field of wheelchair driving, and especially relates to an adjustable worm transmission mechanism for a wheelchair. The adjustable worm transmission mechanism comprises a driving motor, a driving spring and a transmission gear. When the wheelchair is used, an adjusting motor is controlled before the wheelchair is used; an adjusting U-shaped ring is driven by the adjusting motor to rotate; an adjusting thread wheel is driven by the adjusting U-shaped ring to rotate; and the adjusting thread wheel rotates so that the adjusting thread wheel can move along an adjusting thread wheel axis, namely initial elastic property of the driving spring can be controlled by the adjusting motor. Then the maximum torque which can be transmitted by the driving spring is controlled. When the initial elastic property of the thread is adjusted, the driving motor is controlled to start to work; the driving motor drives a transmission shaft to rotate; the transmission shaft drives two spring fixing discs to rotate; the two spring fixing discs drive the driving spring to rotate; the driving spring rotates and drives the transmission gear to rotate; the transmission gear drives a gear shaft to rotate; and the gear shaft rotates and drives the wheelchair to work.

Owner:CHANGSHU PINGFANG WHEELCHAIR CO LTD

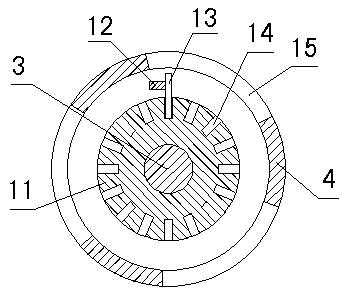

Frequency conversion motor and engineering machine with same

InactiveCN101710761AReduce in quantityCompact structureAssociation with control/drive circuitsCooling/ventillation arrangementFrequency changerFrequency conversion

The invention relates to a frequency conversion motor comprising a motor unit (1) and a frequency converter unit, wherein the motor unit (1) is provided with a drive end bearing (2), a drive end cover (3), a stator (4), a rotor (5), a non-drive end bearing (6) and a non-drive end cover (7); the frequency converter unit is integrated with the motor unit (1) into a whole, wherein a frequency conversion control cabinet (9) of the frequency converter unit is arranged on a bed designed into a part of the motor unit (1), and an incoming line reactor (10) of the frequency converter unit is arranged in the bed. Besides, the invention also relates to a coal planer with the frequency conversion motor.

Owner:三一集团有限公司北京分公司

Angular momentum mechanism

The invention discloses an angular momentum mechanism which comprises an orbital structural body, a planetary gear, a central gear and a planet rotating inertia body. The orbital structural body is provided with an orbital pivoting arm. The planetary gear is meshed with the central gear and the inertia thereof is connected to the planet rotating inertia body in a transferring manner. The planetary gear is provided with a planetary shaft which is fixedly connected with the planetary gear and is connected with the orbital pivoting arm in a rotating manner. When the planet rotating inertia body is arranged on the planetary shaft, the angular momentum mechanism is provided with or without a central rotating inertia body; and when the angular momentum is provided with the central rotating inertia body or the planet rotating inertia body is not arranged on the planetary shaft, the central rotating inertia body is connected with the central gear in a transferring manner. The angular momentum mechanism transforms the reciprocating or oscillating movement into rotary movement and has the advantages of high efficiency and simple structure.

Owner:靳北彪

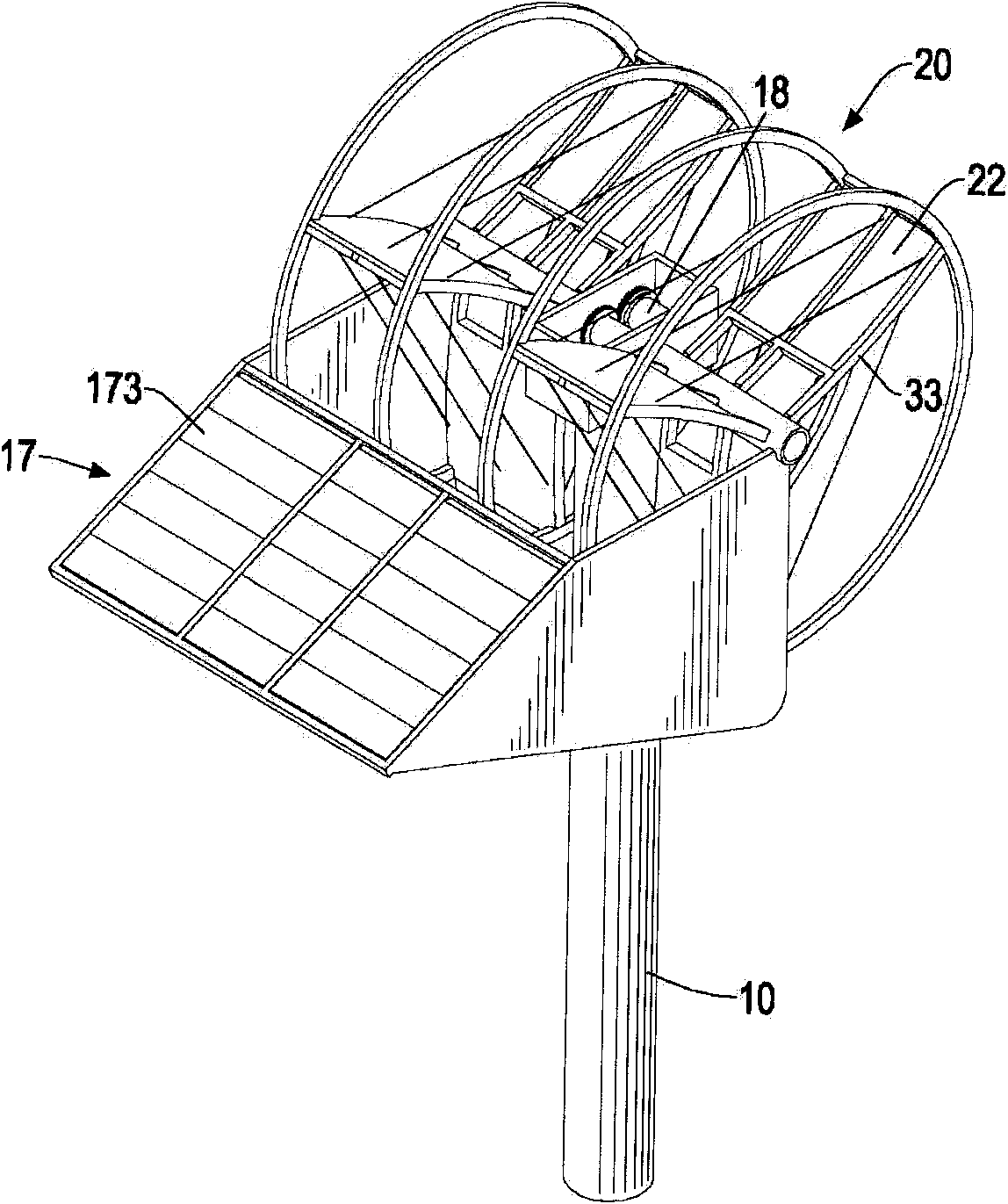

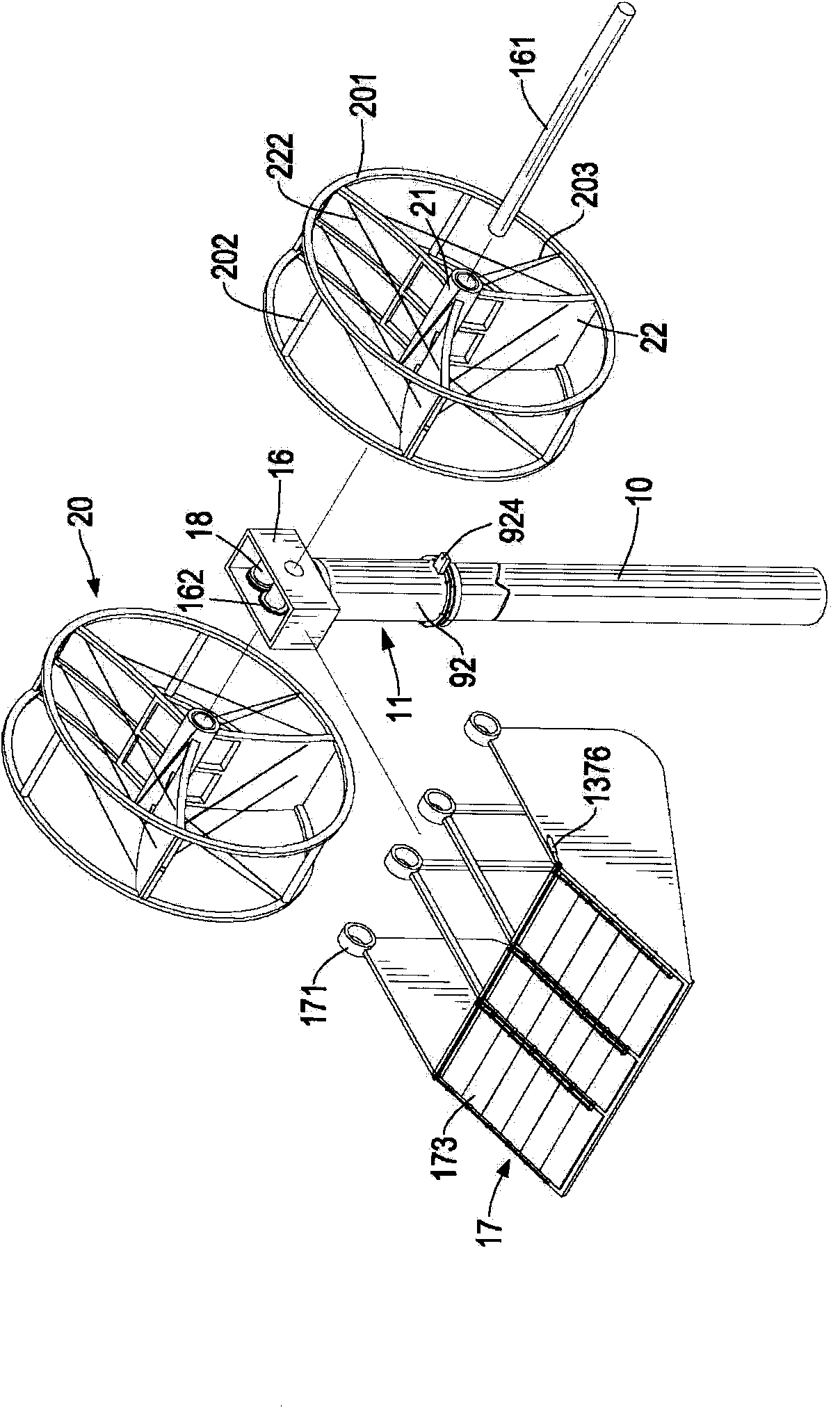

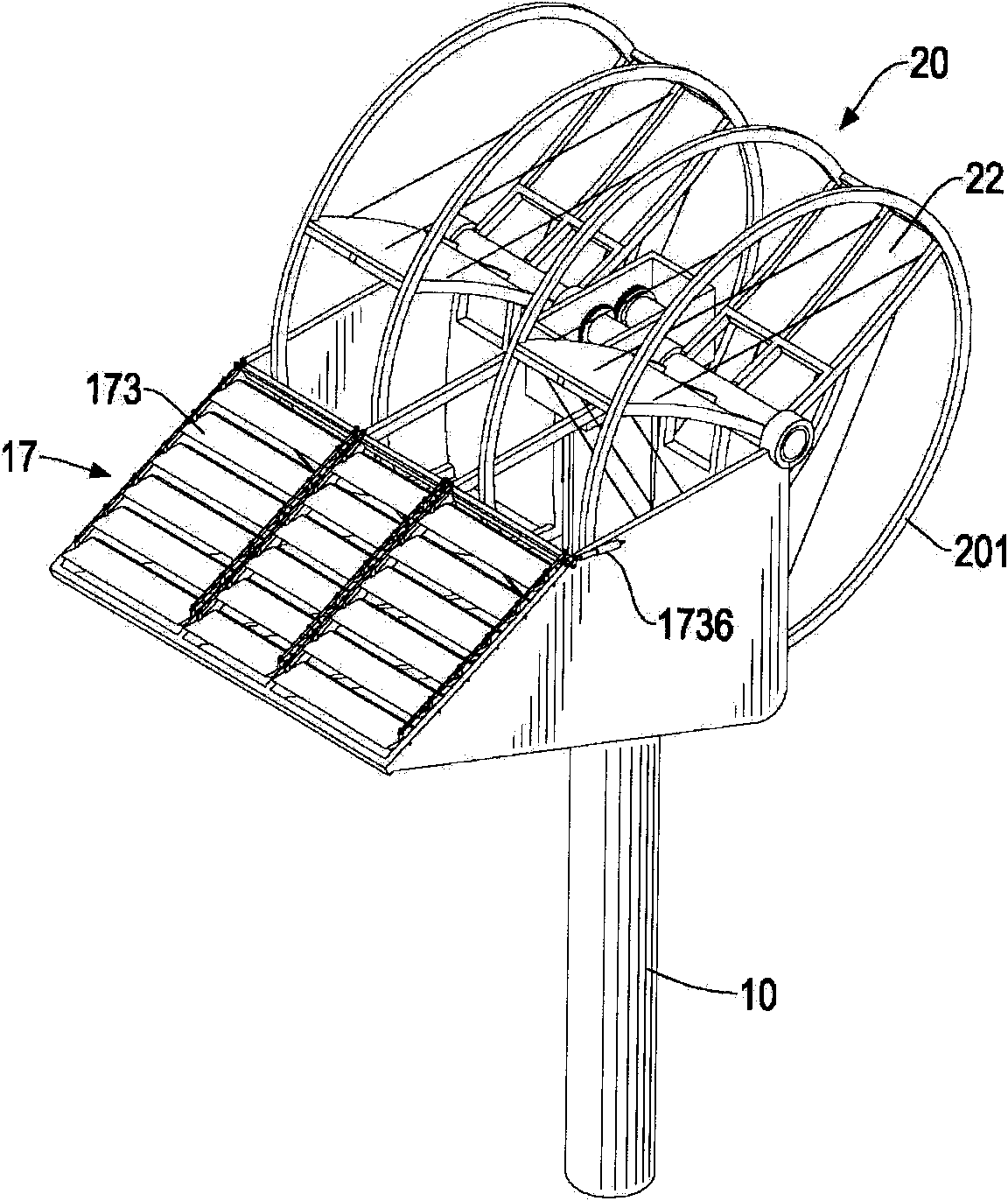

Wind generator set

InactiveCN101825065AAdjust torqueWind motor supports/mountsMachines/enginesElectricityMechanical energy

The invention relates to a wind generator set, comprising a bracket, a rotary device, a frame, two blade bodies and an air deflector. The rotary device is arranged on a top end of the bracket, the frame is rotatably linked to the rotary device, and provided with a main shaft and a power generator laterally, all blade bodies are pivoted on the main shafts at the two sides of the frame symmetrically so as to form a plurality of blades around a central axis rod. The air deflector and the frame are combined and located on the radial outer sides of the two blade bodies, face the windward position when the wind force acts, so that the two blade bodies can be connect with and drive the generator of the frame and the mechanical energy generated as the wind force acts to drive the two blade bodies can be converted into electric energy, wherein, a torque that the natural wind pushes the blade bodies can be adjusted; and therefore, a wind generator set capable of safely and efficiently generating electricity is provided.

Owner:廖福彰

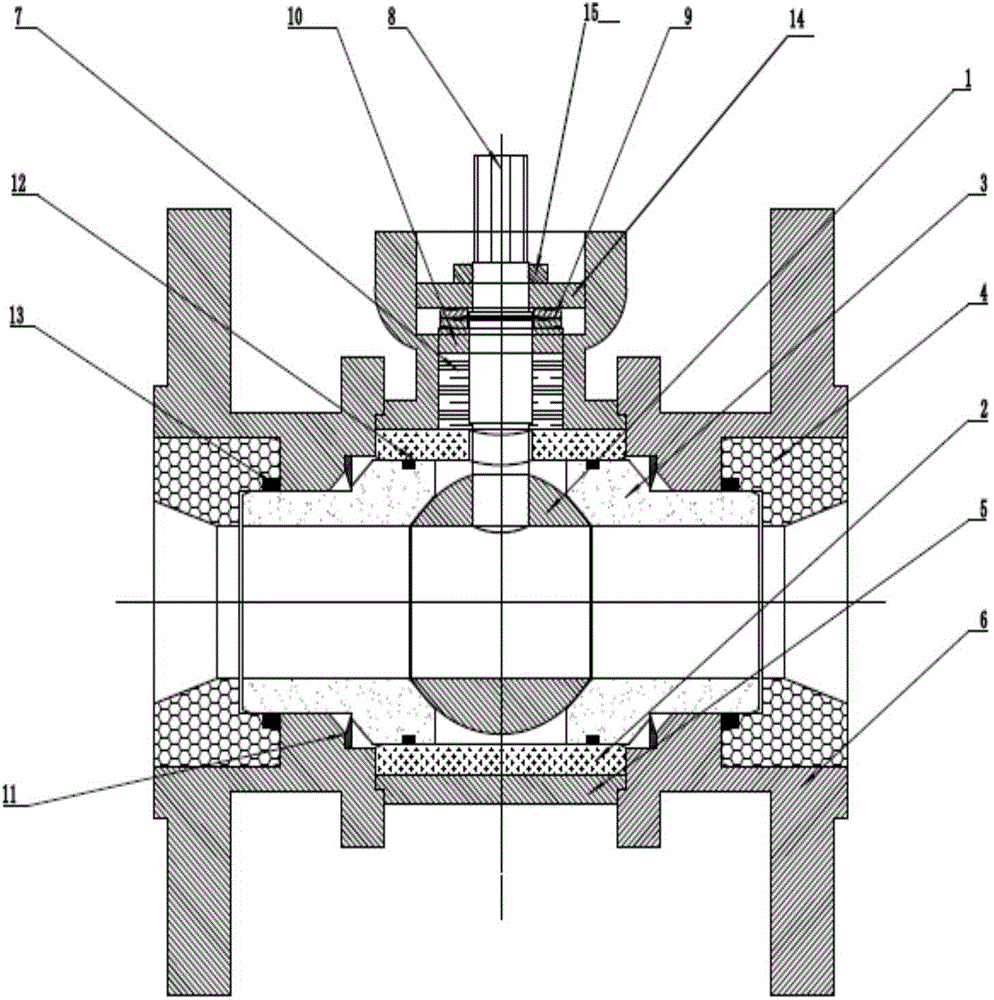

Ceramic ball valve

InactiveCN104948766AAutomatic torque adjustmentAdjust torqueSpindle sealingsPlug valvesEngineeringVALVE PORT

The invention discloses a ceramic ball valve. The ceramic ball valve comprises a valve seat mounted in a midbody; a runner allowing a fluid to pass is arranged in the valve seat; a valve core is mounted in the valve seat; a flange is mounted on each of two sides of the midbody outside the valve seat; a valve rod is connected with the valve core through a hole in the midbody and mounted in a housing; a flange inner lining is embedded into each of the flange on the outer side of the valve seat; bevel steps are arranged on the valve seat, close to the two outer sides of the midbody, and the valve seat, at the inner-side junctions of the flanges; cushioning springs are mounted between the valve seat at the bevel steps and the flanges; steps are formed at the contact parts of the flanges and the inner end parts of the flange inner linings; the inner end parts of the flange inner linings and the flanges are in compressed contact at the steps of the flanges; between the valve rod and the housing, a sealing filler, a compression ring, a disc spring, a pressure plate and a limiting ring are sequentially arranged from the outer side of the midbody to the outside; and the pressure plate is fixed on a platform in the housing through a bolt. By adoption of the structure, the valve seat can be automatically repaired under the action of the disc spring after being abraded.

Owner:王林振

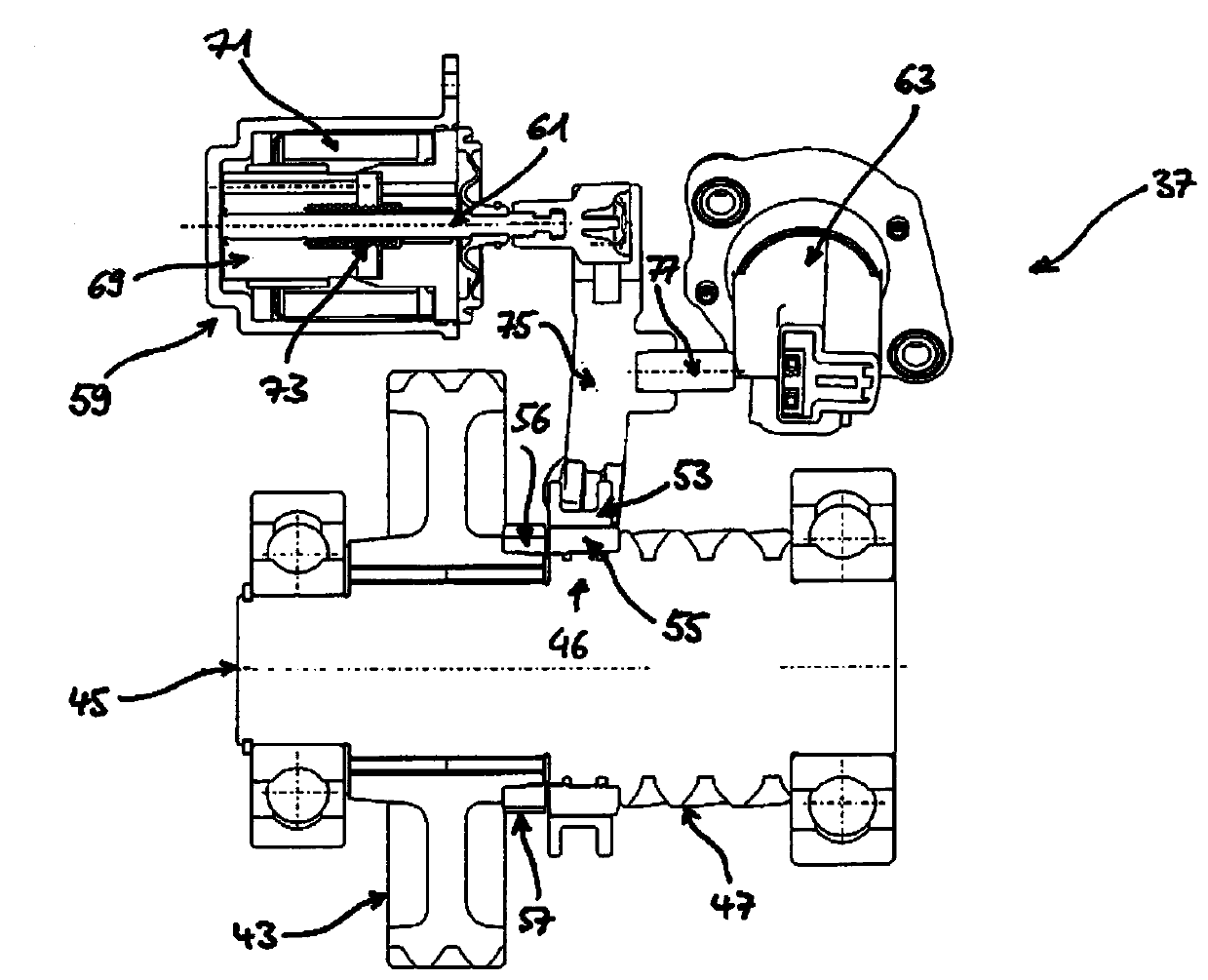

Positive-locking clutch

ActiveCN104011420AEasy to closeEasy to openMagnetically actuated clutchesEngine controllersCouplingEngineering

A positive-locking clutch (37) for a motor vehicle (11) comprises a coupling element (53) with toothing (54), a rotatable counterpart element (56) with counterpart toothing (57) and an electromagnetic actuator (59). The coupling element (53) can be moved by means of the electromagnetic actuator (59) between a disengaged position and an engaged position, wherein the toothing (54) of the coupling element (53) is meshed with the counterpart toothing (57) of the counterpart element (56) in the engaged position. A circumferential backlash is provided between the toothing (54) of the coupling element (53) and the counterpart toothing (57) of the counterpart element (56), even after the engaged position of the coupling element (53) has been fully reached.

Owner:MAGNA POWERTRAIN AG & CO KG

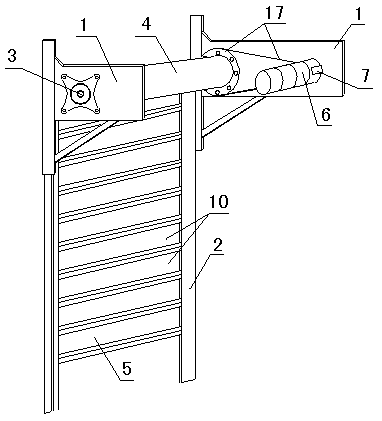

Energy-saving electric rolling shutter door capable of adjusting pre-torsion of torsional spring

PendingCN108397118AAdjust torqueGuaranteed torqueShutters/ movable grillesElectricityRolling shutter

The invention relates to an energy-saving electric rolling shutter door capable of adjusting pre-torsion of a torsional spring. The energy-saving electric rolling shutter door comprises a bracket plate, a guide rail, a reel, a winding drum, a roller shutter, a rolling door machine, a stopper, the torsional spring and an adjusting rod. The winding drum is internally provided with an adjusting wheel, an anti-motion rod and anti-motion pins, the adjusting wheel and the reel are rotatably connected, and a plurality of countersinks are formed in the outer circumference of the adjusting wheel and the reel. The anti-motion rod is arranged on the radial outer side of the adjusting wheel, and is fixedly connected with the reel. The anti-motion pins are matched with the countersinks, after each anti-motion pin is inserted into each countersink, one end of each anti-motion pin outside the countersink can lean against the anti-motion rod, the winding drum at the corresponding position of the adjusting wheel is provided with a plurality of slots, one end of the torsional spring is fixedly connected with the inner wall of the winding drum, and the adjusting wheel is fixedly connected with the other end of the torsional spring . A driven chain wheel which is in transmission connection with a door rolling machine is arranged at one end of the winding drum, the adjusting rod can be inserted into each countersink through each slot, the diameter of the adjusting rod matches the diameter of each countersink. Torsion force of the torsional spring is convenient to adjust, the structure is simple, and energy and electricity are saved.

Owner:漳州市龙文区仁信工业设计有限公司

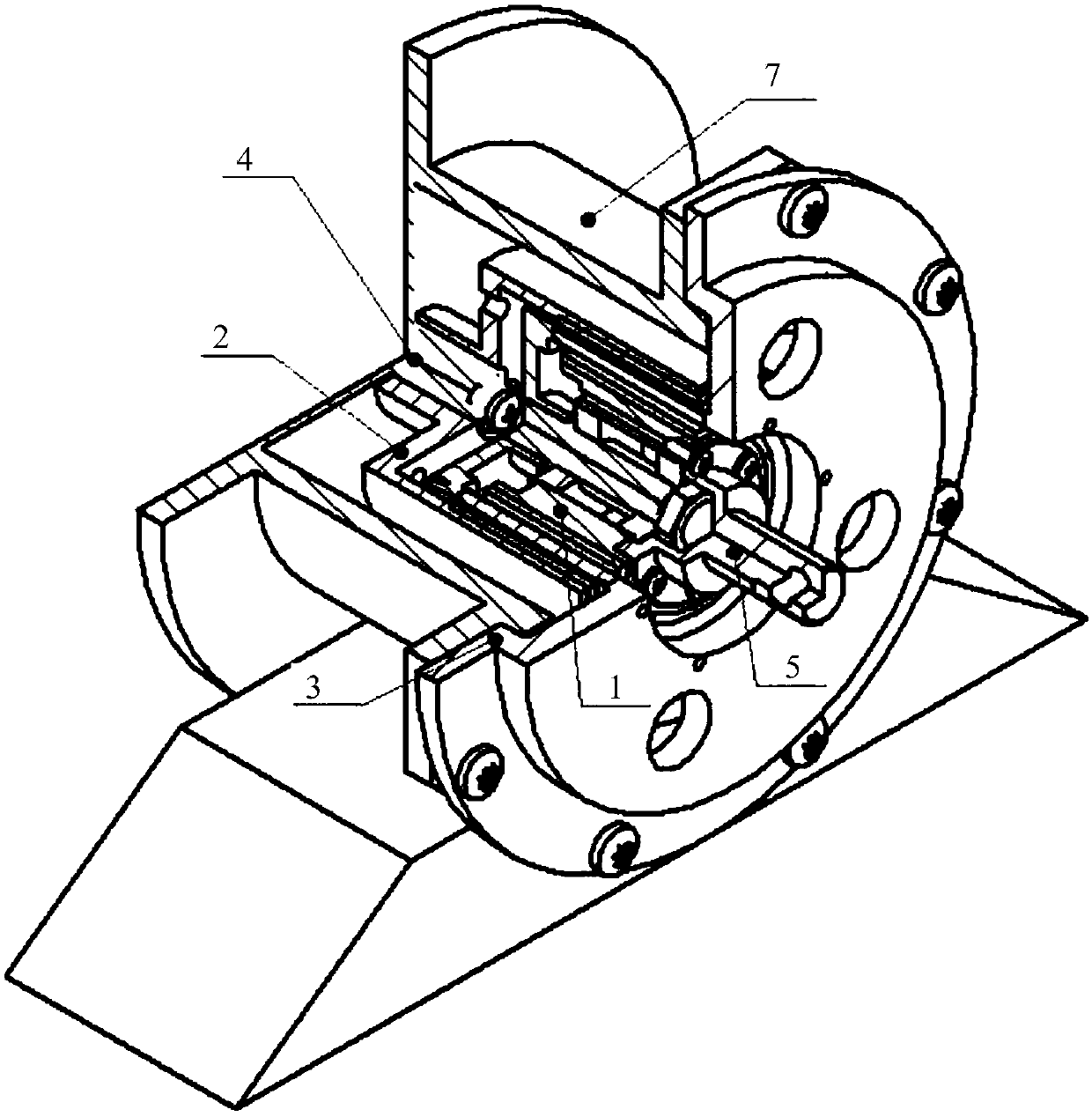

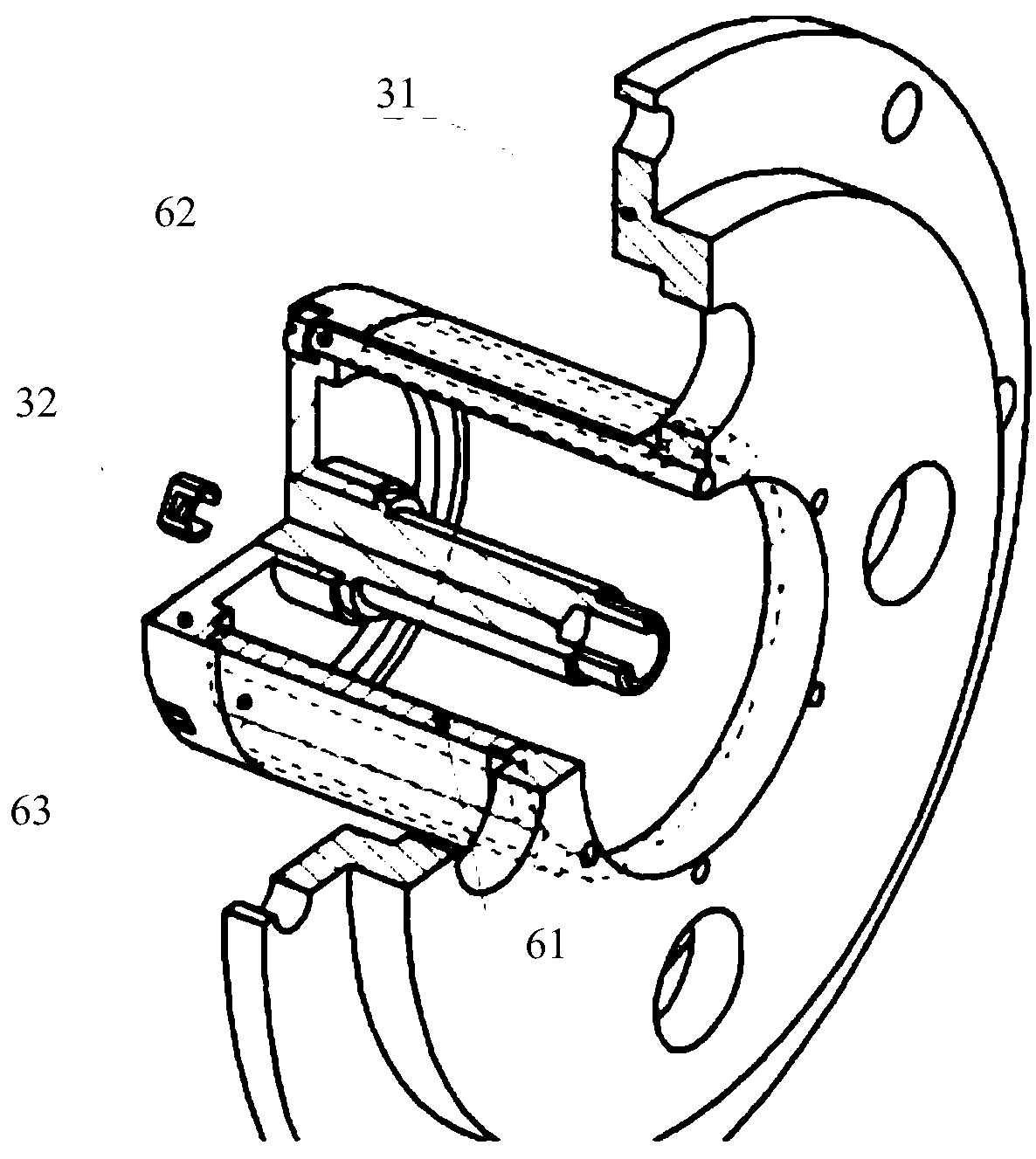

Speed regulation magnetic gear for pump

PendingCN107666232AAdjust rated speedAdjust torquePermanent-magnet clutches/brakesImpellerCircular disc

The invention discloses a speed regulation magnetic gear for a pump. The gear comprises an inner rotor, an outer rotor, an isolation sleeve, an input shaft, an output shaft and a magnetism adjusting ring. The isolation sleeve comprises a first end cover and a second end cover. The cross section of the isolation sleeve is of a T-type structure and the transverse end of the isolation sleeve is the disc-shaped first end cover. The vertical end is in a shape of a hollow cylinder. The second end cover is clamped to the end part of the vertical end. The magnetism adjusting ring is encapsulated to the vertical end of the isolation sleeve through encapsulation glue. Two ends of the magnetism adjusting ring are inserted into the first end cover and the second end cover. The input shaft and the output shaft are connected to one end of the outer rotor and one end of the inner rotor. The other end of the inner rotor, the T-type vertical end of the isolation sleeve and the other end of the outer rotor are successively nested from the interior to the exterior. According to the invention, through optimized design, the invention provides the magnetic gear with adjustable speed under the conditionof not changing the structure of a pump body; under the premise that the reliability and the continuous working time are not reduced, the rotation speed range of impellers is effectively expanded; thelife and the flows of the pump are changed and the application prospects of the pump are extended.

Owner:深圳市泉胜新技术开发有限公司

Controllable driving device for engine

ActiveCN110332253AReduce in quantityExtended service lifePump componentsPumpsViscous liquidIntake pressure

The invention relates to a controllable driving device for an engine. The controllable driving device for the engine is applied to a water pump of an automotive engine. The controllable driving devicefor the engine comprises a main shaft. A driven portion and a driving portion are installed on the main shaft, and at least one coupled region exists between the driving portion and the driven portion and transmits the force moment between the driving portion and the driven portion. The coupled regions are filled with adhesive liquid, and the filling amount of the adhesive liquid in the coupled regions is controlled in the mode that at least one pneumatic actuator changes the intake pressure. The controllable driving device for the engine adopts the pneumatic actuators, is low in driving power and saves more energy; an electromagnetic valve which is directly installed on the water pump is omitted, and the structure is more compact; the number of parts is reduced, the reliability is higher; and the adhesive liquid inside an adhesive clutch can be replaced and maintained, and the service life of the clutch is prolonged.

Owner:FAW JIEFANG AUTOMOTIVE CO

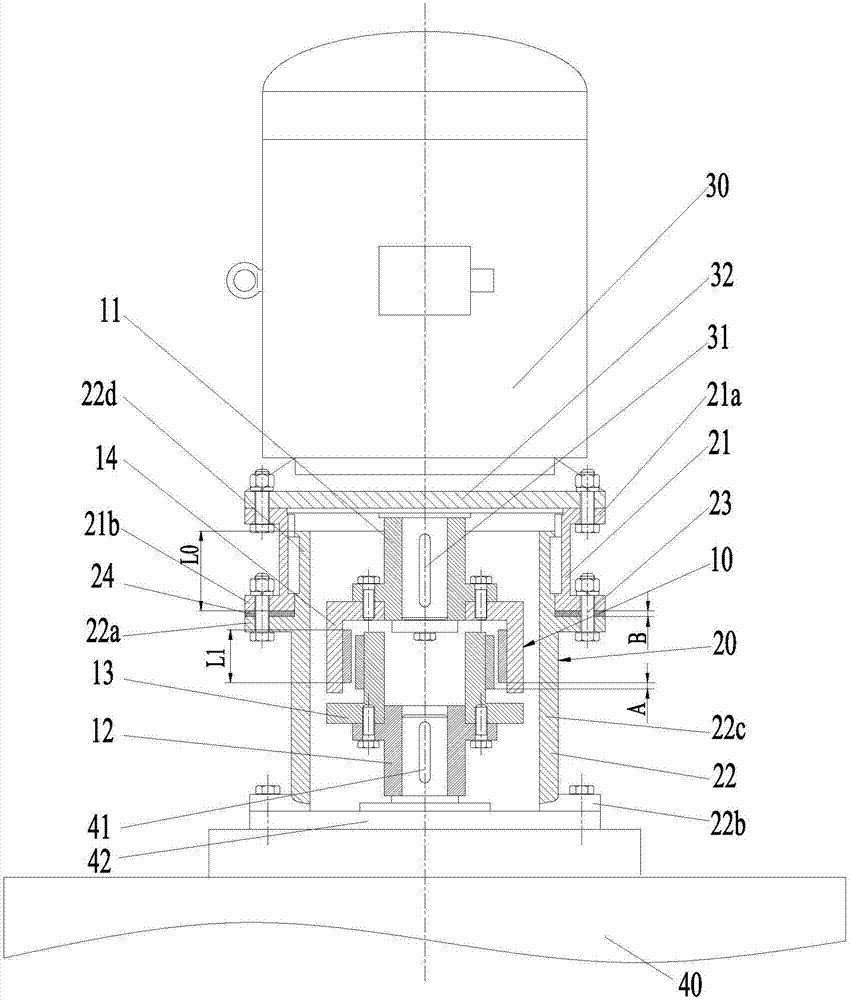

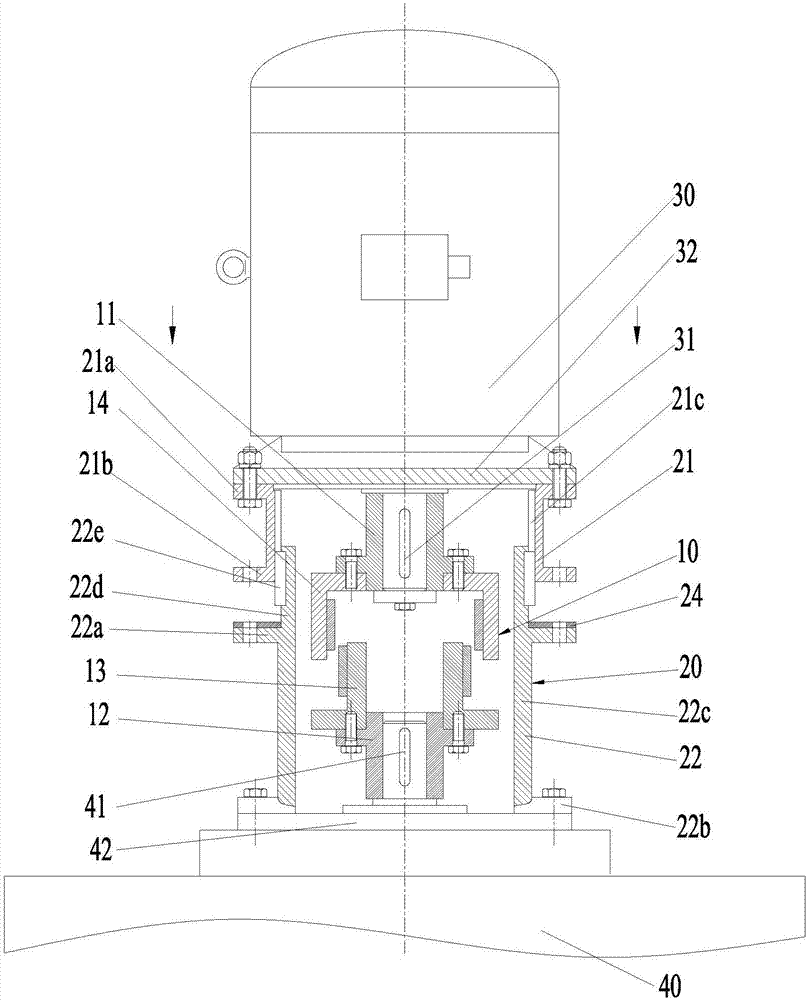

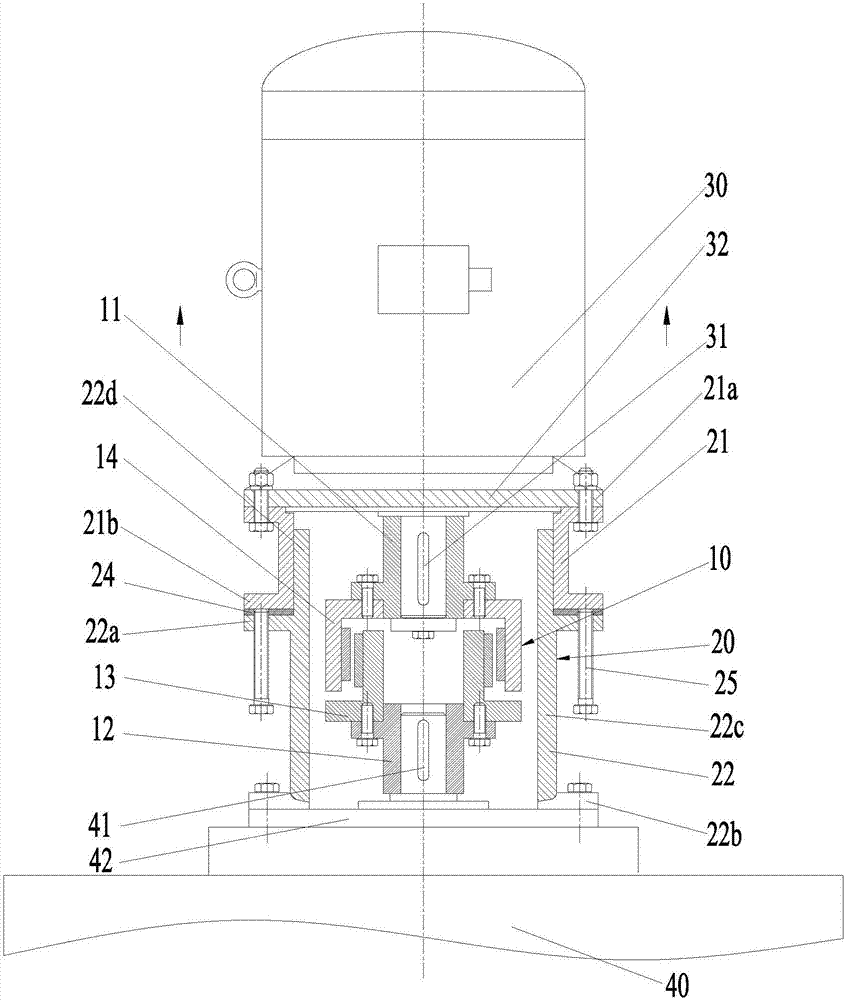

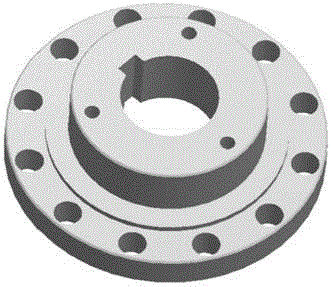

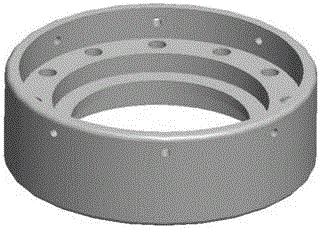

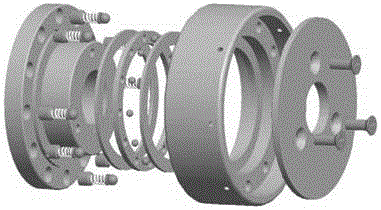

Vertical mounting structure and vertical mounting method of permanent magnetic coupling, online separating and resetting method

PendingCN107370337AReduce installation errorsUniform air gapManufacturing dynamo-electric machinesPermanent-magnet clutches/brakesElectrical and Electronics engineeringMechanical engineering

The invention relates to a vertical mounting structure and a vertical mounting method of a permanent magnetic coupling, and an online separating and resetting method. The vertical mounting structure comprises a permanent magnetic coupling and a supporting sleeve which are coaxially arranged. One end of the supporting sleeve is connected with a vertical motor, and the other end is connected with a load end. The permanent magnetic coupling is arranged in the supporting sleeve. The permanent magnetic coupling comprises a first shaft sleeve, a second shaft sleeve, a driven rotor and an active rotor. The first shaft sleeve sleeves the output shaft of a vertical motor and is connected with the active rotor. The second shaft sleeve sleeves an input shaft at the load end and is connected with the driven rotor, wherein the supporting sleeve comprises a first sleeve and a second sleeve which are separately arranged and are detachably connected. The first sleeve is connected with the vertical motor, and the second sleeve is connected with the load end. The vertical mounting structure and the vertical mounting method have advantages of settling a problem of vertical mounting of the permanent magnetic coupling, realizing easy connection and separation, and realizing online separated maintenance and resetting of a faulted motor in a motor-motor linked system.

Owner:JIANGSU MAGNET VALLEY TECH

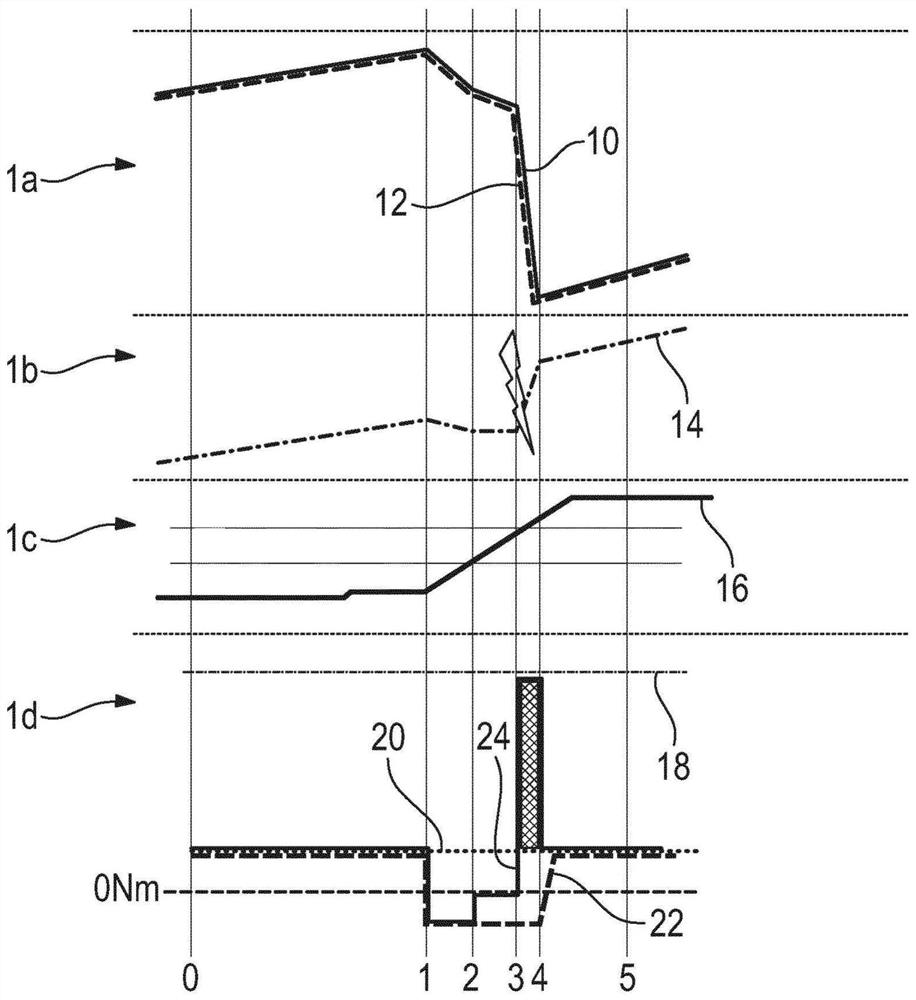

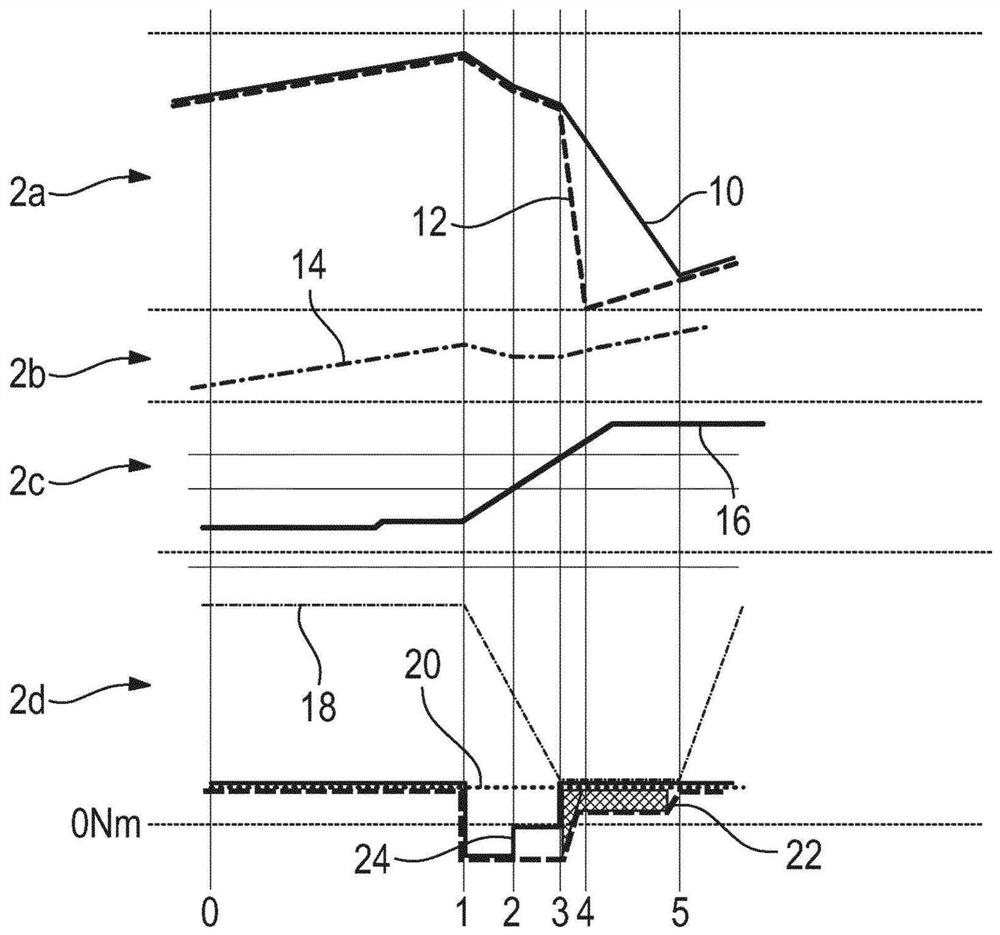

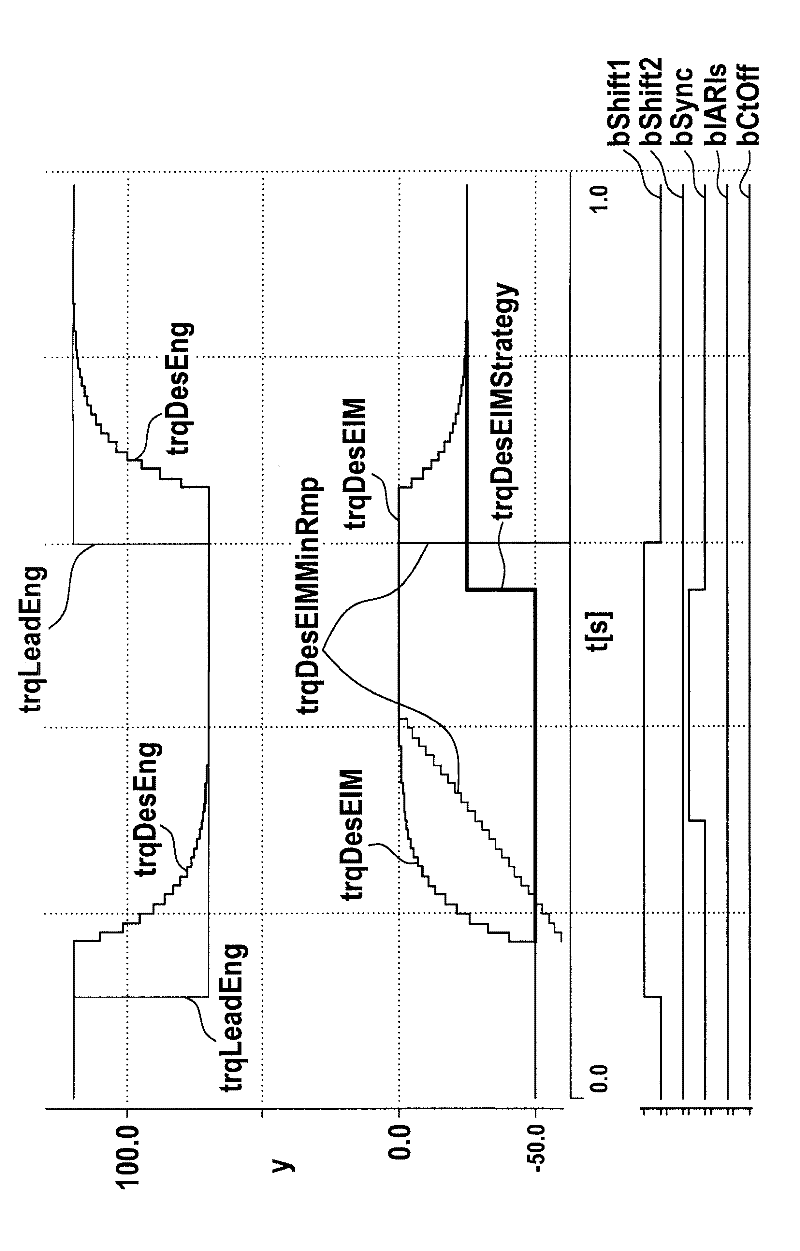

Method for carrying out a shifting operation in a sequential manual transmission

The invention relates to a method for carrying out a shifting operation in a sequential manual transmission, in particular a shifting claw transmission. During the shifting operation, a maximum clutch torque (24) that can be transmitted by a clutch arranged between an engine and a transmission input shaft is automatically reduced without completely disengaging the clutch.

Owner:BAYERISCHE MOTOREN WERKE AG

Handwheel mechanism with adjustable torque

ActiveCN105048187AChange spring forceAdjust torqueCoupling device engaging/disengagingCoupling device detailsSpring forceSteel ball

The invention discloses a handwheel mechanism with an adjustable torque. A way of compressing elastic elements by a first bolt is used; and different groups of elastic elements are installed (based on a second bolt-spring-bush-steel ball structure) and the screwing depth of the second bolt is adjusted, so that spring forces of the elastic elements can be changed and thus the handwheel torque can be adjusted. Therefore, different using demands can be satisfied and the product application range is enlarged. According to the ahndwheel provided by the invention, the structure containing steel balls, steel ball support plates, and steel ball holding plates is used for replacing the traditional rim rolling structure. During assembling, a handwheel body, the structure containing steel balls, steel ball support plates, and steel ball holding plates, a handwheel ring, a cover plate and a first bolt are successively installed at the forward direction; and when the second bolt-spring-bush-steel ball structure is installed in an inverted mode. The installation becomes convenient and rapid; repeated dismounting and parts replacement of the handwheel assemblies can be realized; and the product maintainability is enhanced.

Owner:杭州航天电子技术有限公司

Weightlifting device

The invention relates to a weightlifting device, which comprises a base, a supporting device, a first connecting shaft, a second connecting shaft, a first incomplete gear, a first bevel gear, a firsttorsion device, a second incomplete gear, a second bevel gear, a lifting structure and a holding rod, wherein the base comprises a base plate;the supporting device comprises two supporting rods and aplurality of transmission pieces; the first torsion device comprises an upper torsion cover, an outer torsion cylinder and a torsional spring; the lifting structure comprises a shell body, a verticalplate, racks and a supporting rod hole, the shell body is driven to move upwards when the holding rod is lifted by a hand; the first incomplete gear and the second incomplete gear are made to rotate reversely by means of the two racks; and then the first bevel gear and the second bevel gear are driven to rotate reversely, and the torsional spring generates torque. According to the weightlifting device, the torsional spring is used for increasing the weight, namely, the weightlifting force acts on the torsional spring, so that a balancing weight is omitted, the occupied area of the weightlifting device is reduced, the space is saved, the condition that the balancing weight slips off is avoided, and the use safety is improved.

Owner:HENAN VOCATIONAL COLLEGE OF APPLIED TECH

Power transmission device, and display device and display panel pedestal that have the power transmission device

InactiveCN101184939BEliminate backlashAdjust torqueToothed gearingsVehicle componentsDisplay deviceDrive motor

Provided are a power transmission device where torque to be applied to an output shaft can be easily adjusted and a backlash between gears can be reliably removed, and a display device and a display panel pedestal that are provided with the power transmission device. The power transmission device (101) has a display panel (102), an output shaft (103) to which the display panel is connected, output gears (104, 105) rotated integrally with the output shaft, transmission gears (106, 107) meshing with the output gears, motors (108, 109) for applying driving force to the transmission gears, and a control circuit (110) for controlling the motors. The control circuit (110) causes the motors (108, 109) to drive the transmission gears (106, 107) at different rotation speeds to transmit different magnitudes of driving force to the output gears (104, 105). The output shaft (103) receives, besides torque in the direction of rotation of the shaft, torque in the opposite direction to the rotation direction of the shaft, and this suppresses occurrence of play caused by a change in the direction of torque produced by the weight of the display panel (102) it self.

Owner:PANASONIC CORP

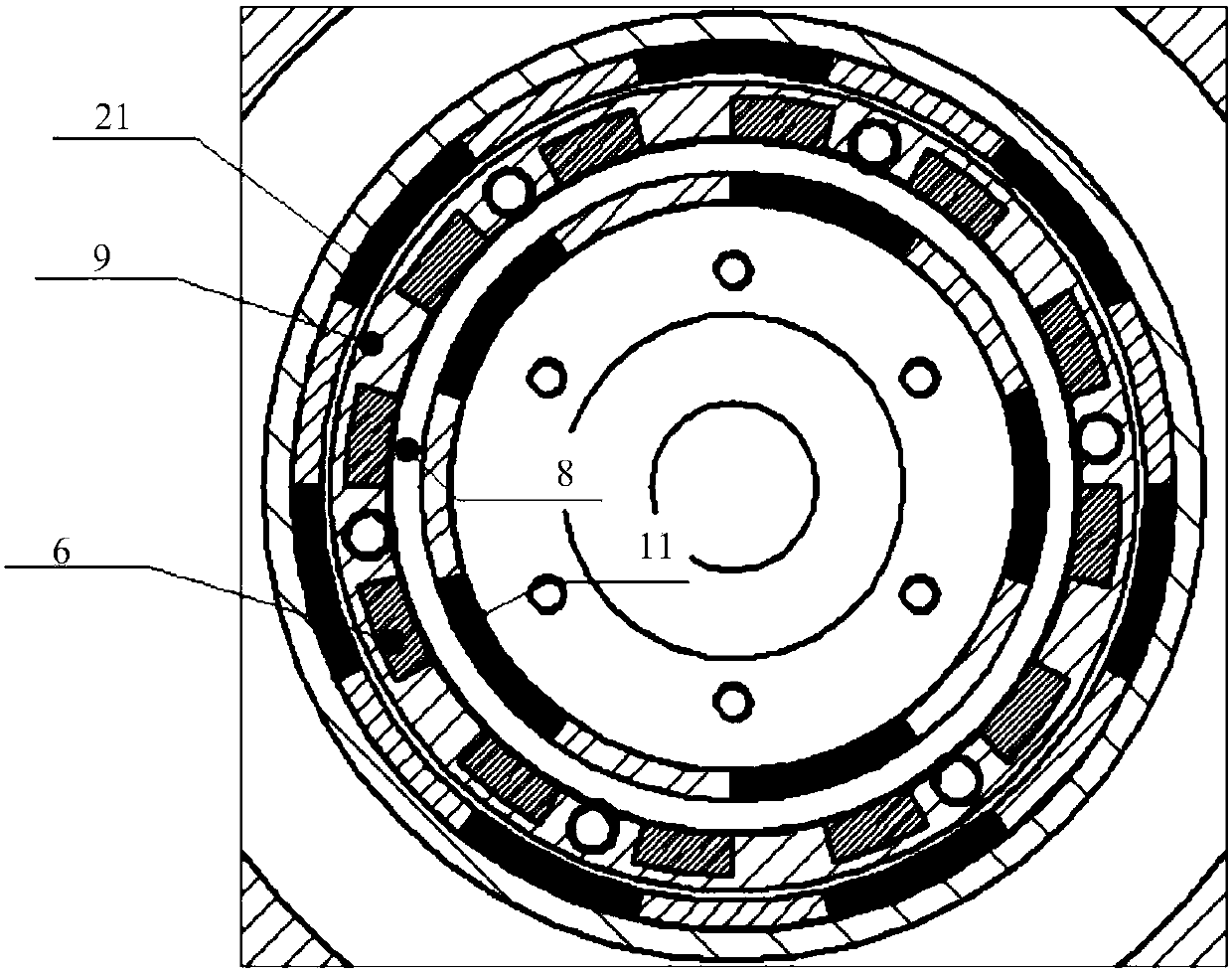

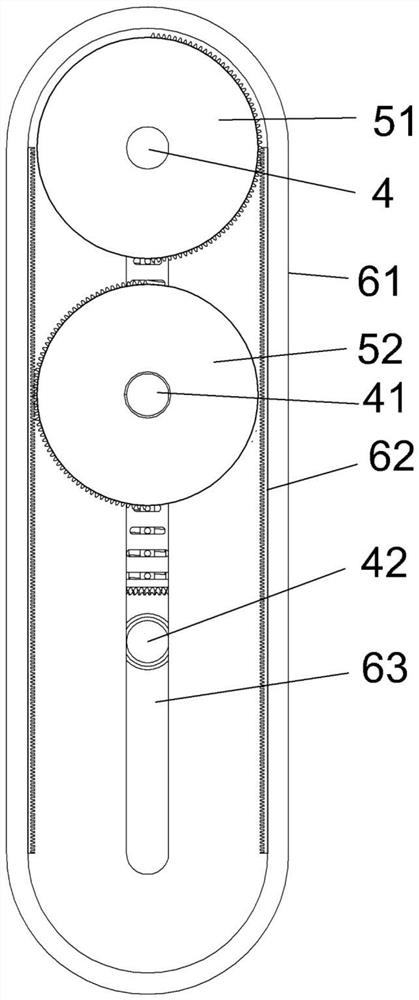

Hydraulic loading type internal friction overload protection synchronous pulley device

InactiveCN111878520AReduce the maximum loadAdjust torqueAutomatic clutchesHydraulic cylinderDrive shaft

The invention discloses a hydraulic loading type internal friction overload protection synchronous pulley device, and belongs to the technical field of synchronous pulleys. The technical scheme that asynchronous pulley, a left circular truncated cone friction sleeve, a right circular truncated cone friction sleeve, a left loading hydraulic body and a right loading hydraulic body are arranged on atransmission shaft, loading hydraulic cylinder holes are formed in the left loading hydraulic body and the right loading hydraulic body, and hydraulic pistons are machined at one end of a loading hydraulic shaft and inserted into the loading hydraulic cylinder holes is adopted, and after the loading hydraulic cylinder holes are filled with high-pressure oil liquid with the pressure being P, the loading hydraulic shaft tightly abuts against the left circular truncated cone friction sleeve and the right circular truncated cone friction sleeve under the pressure of the high-pressure oil liquid;friction force between the left circular truncated cone friction sleeve and the synchronous pulley and friction force between the right circular truncated cone friction sleeve and the synchronous pulley are increased, transmission of the synchronous pulley is achieved through the friction force, when the transmission load torque on the transmission shaft is larger than the torque generated by thefriction force, the synchronous pulley and the transmission shaft slip, the overload protection effect is achieved, and the phenomena of tooth skipping, slipping and synchronous belt abrasion are prevented.

Owner:李涛涛

Manuscript pressure plate switching device and office device having the same

ActiveCN101377633BWon't distortAdjust torqueHingesElectrographic process apparatusEngineeringMechanical engineering

Owner:KEM HONGKONG

A drive shaft device for swing arm type agricultural machinery

ActiveCN112243697BImprove applicabilityImprove structural stabilityAgricultural machinesHarvestersDrive shaftAgricultural engineering

Owner:山东智汇新谷科技企业孵化器有限公司

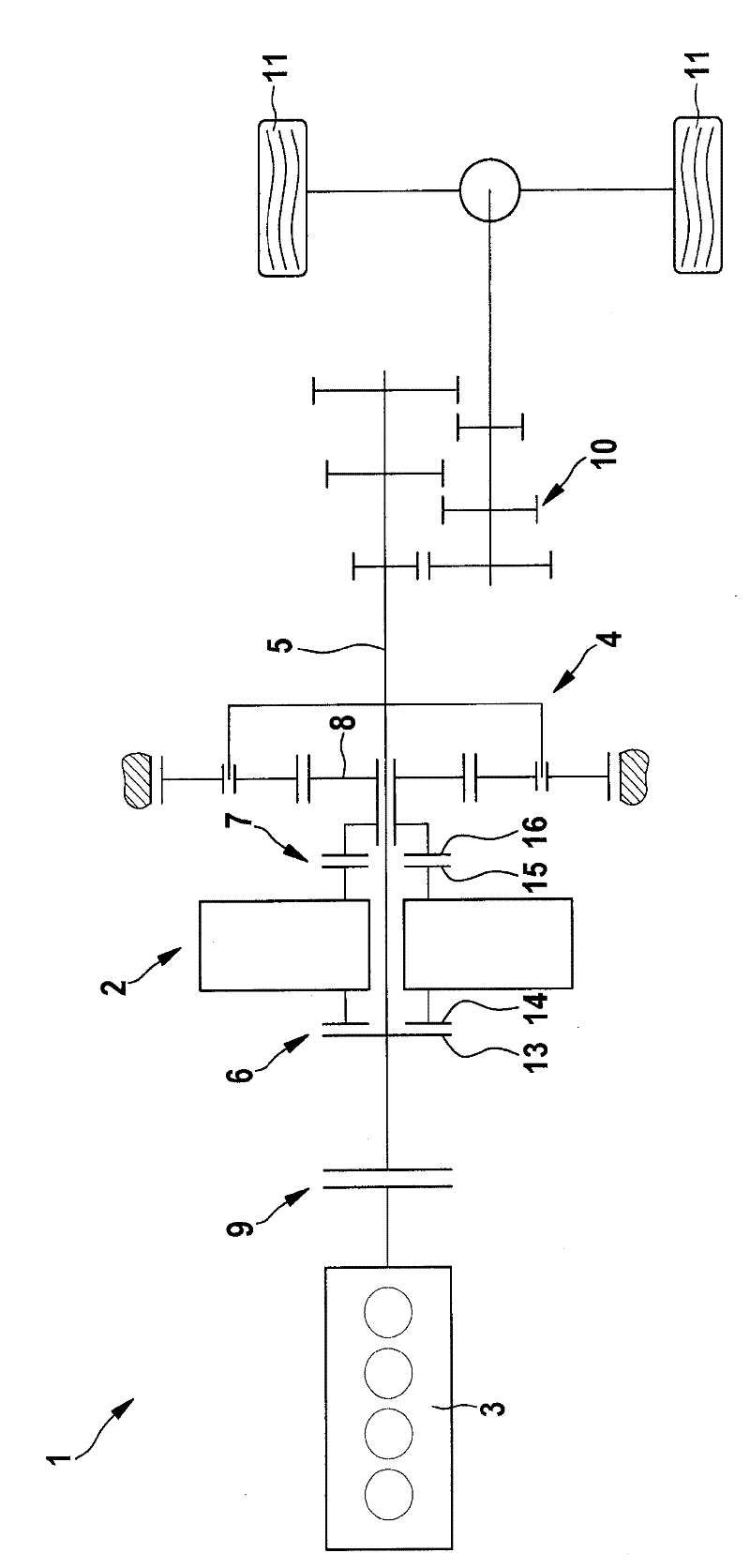

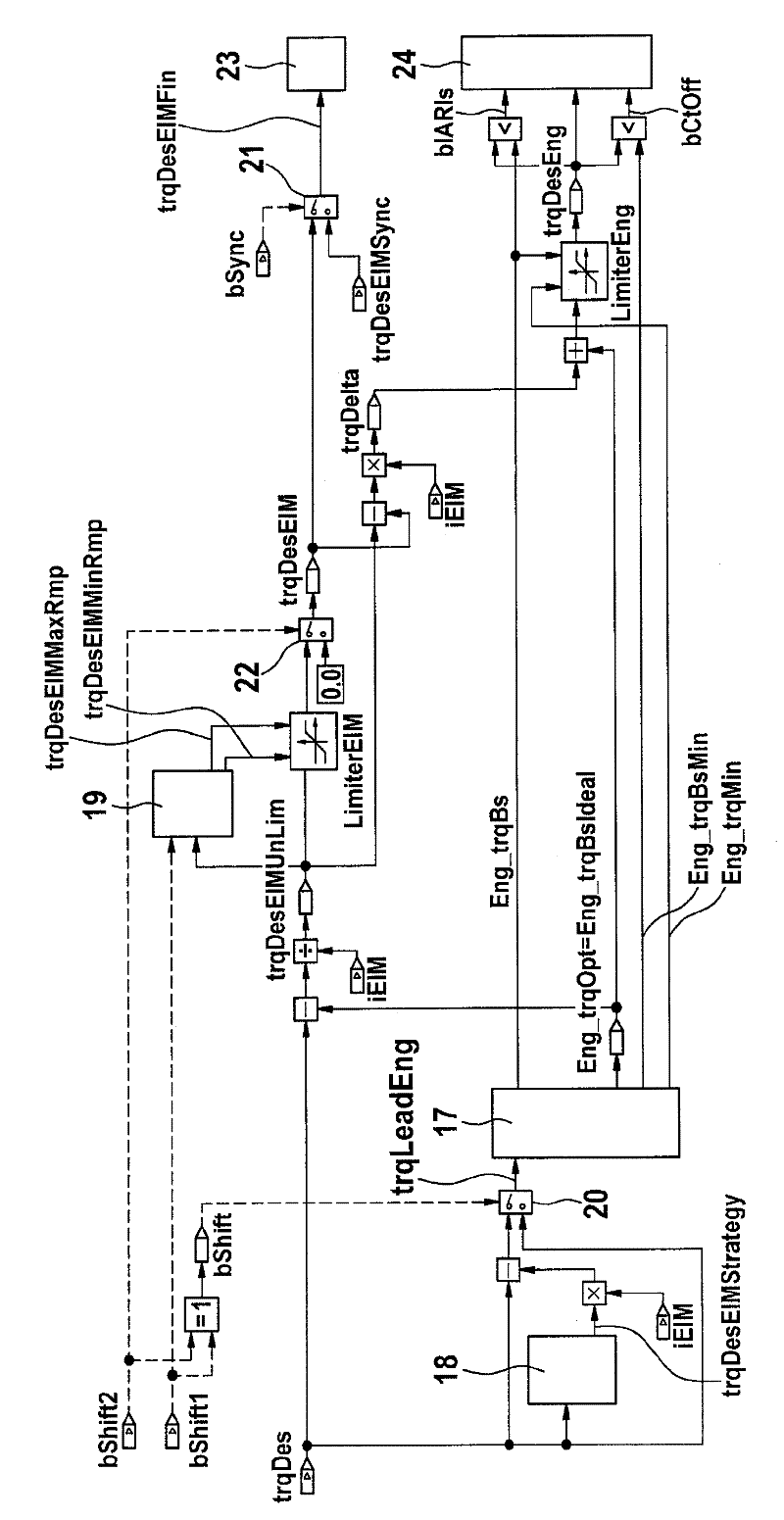

Method for changing a drive unit's mechanical coupling to a motor vehicle power train

ActiveCN102556052AReduce or expand torqueRaise or lower limit valueMechanical apparatusPlural diverse prime-mover propulsion mountingOperating pointCoupling

A method for changing a drive unit's mechanical coupling to a motor vehicle power train which has at least two drive units, wherein at least one first drive unit (2) of the two drive units (2, 3) is coupled via various mechanical couplings, especially mechanical transmission ratios (iEIM), during the travel of the motor vehicle, a power or torque influence of the two drive units (2, 3) occurring if there is a change of the mechanical coupling. To ensure a change of the mechanical coupling without the vehicle occupants perceiving it, the change of the mechanical coupling of the first drive unit (2) of the two drive units occurs (2, 3) in at least two operating modes, a first operating mode causing a slower operating point change with respect to time of the two drive units(2, 3), while a more rapid operating point change as to time of the two drive units(2, 3) is provided in a second operating mode.

Owner:ROBERT BOSCH GMBH

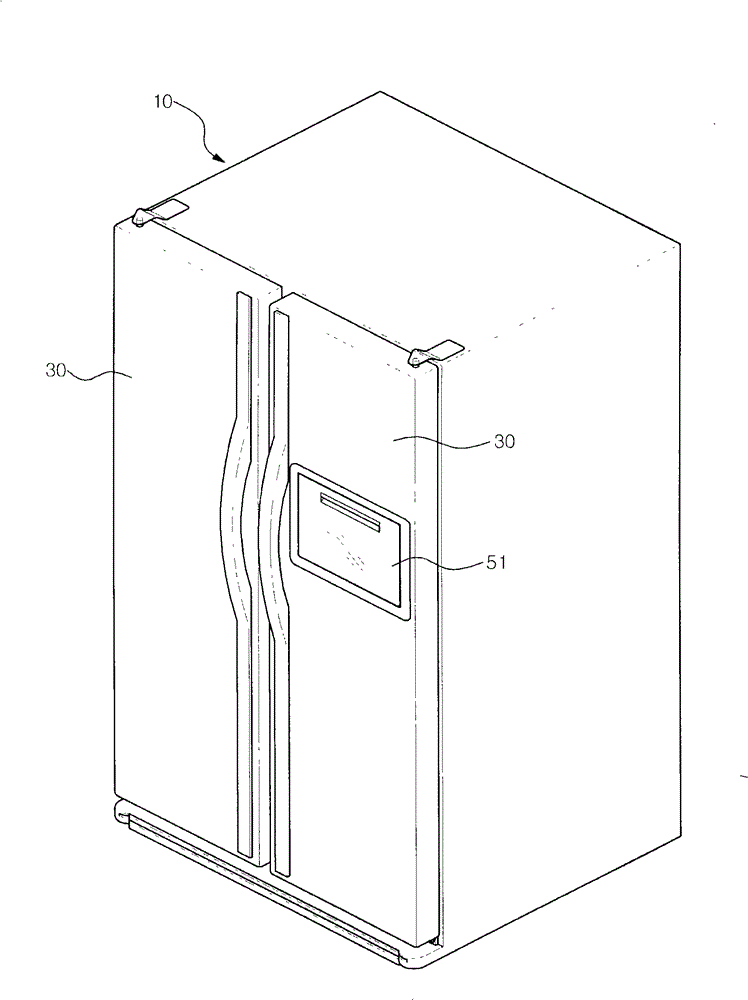

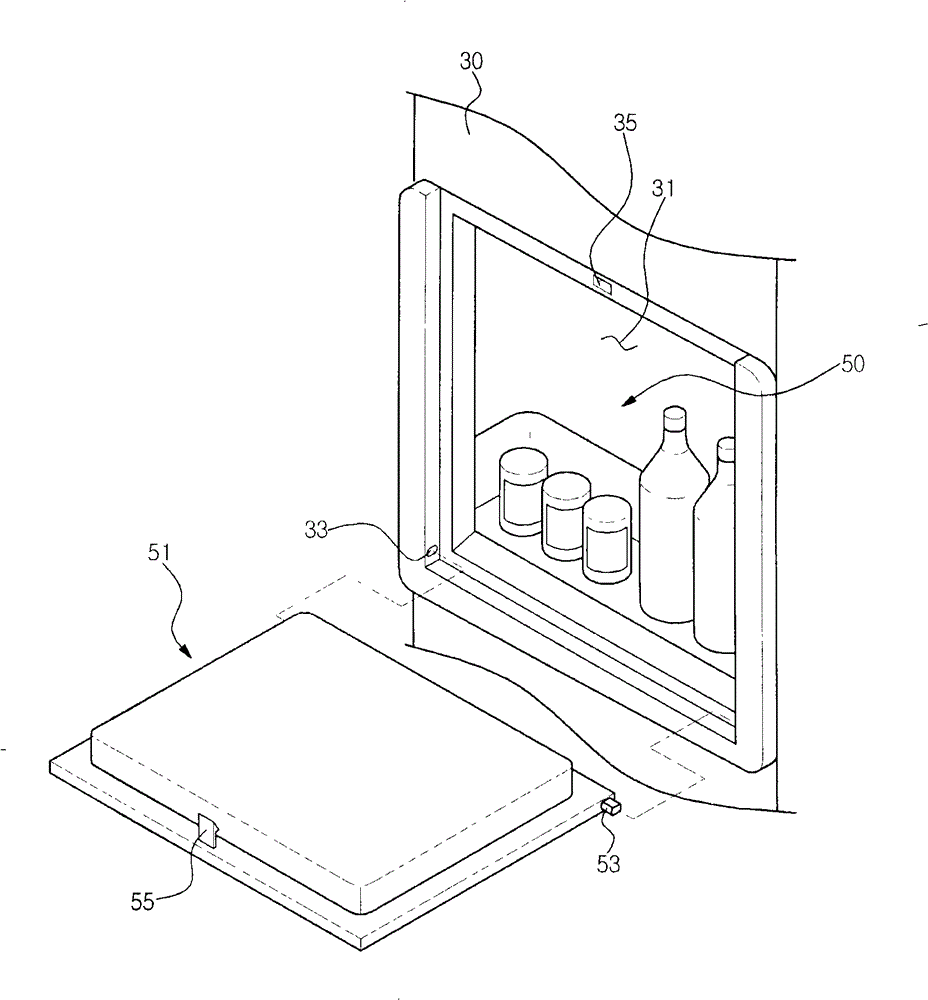

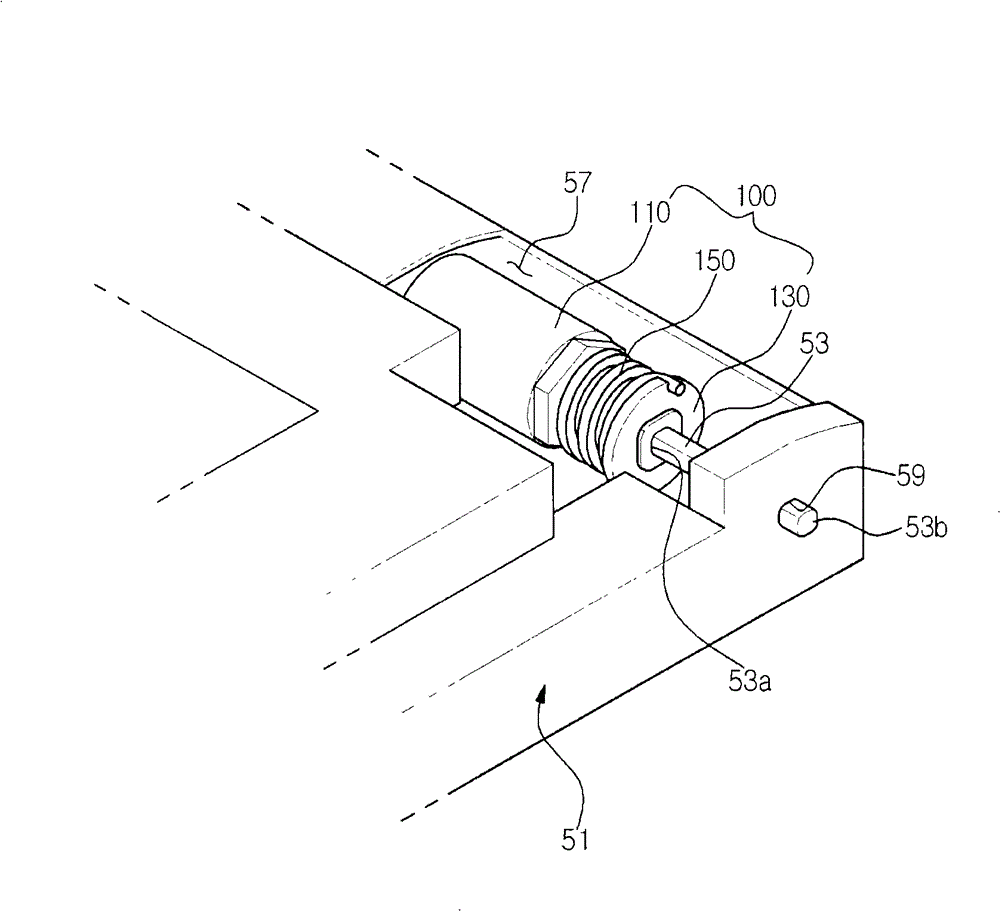

Damping unit and refrigerator with the same

InactiveCN101566414BImprove aestheticsImprove space utilizationLighting and heating apparatusBuilding braking devicesEngineeringMechanical engineering

Owner:SAMSUNG ELECTRONICS CO LTD

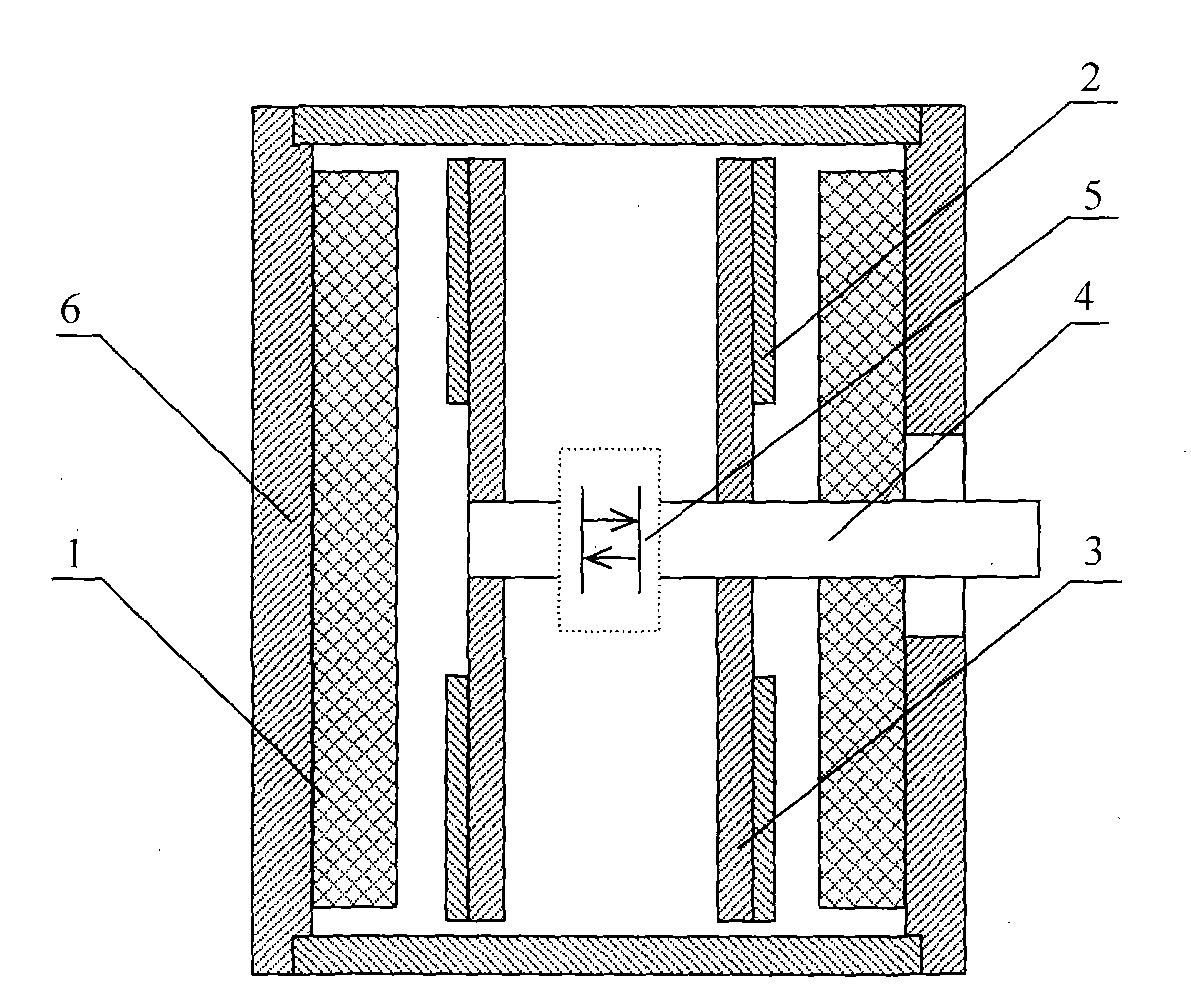

Air gap variant eddy speed regulating induction motor and working mode

InactiveCN101488691BWith soft startWith overload protectionDynamo-electric machinesElectrical conductorElectric machine

A variable air gap vortex flow speed regulating induction motor can achieve the aim of transmitting torque from an electric motor to a load by the interaction of air gap field between an electrical conductor and a winding. The variable air gap vortex flow speed regulating induction motor comprises a stator, a rotor, an air gap regulating component and the like, and is characterized in that the stator (1) comprises an iron core and the winding, wherein, the iron core is fixed on an end cover (6); the rotor includes a copper disc (2) and a back yoke (3), and is fixed on an output rotating shaft(4) which can change the air gap distance between the stator (1) and the copper disc (2) by the air gap regulating component (5); the motor adopts a disc structure, and the intensity of the air gap field can be conveniently regulated by regulating the air gap regulating component on the output rotating shaft, thus achieving the aim of regulating the rotating speed and the torque of the motor and leading the motor to start at underload and operate at full load.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

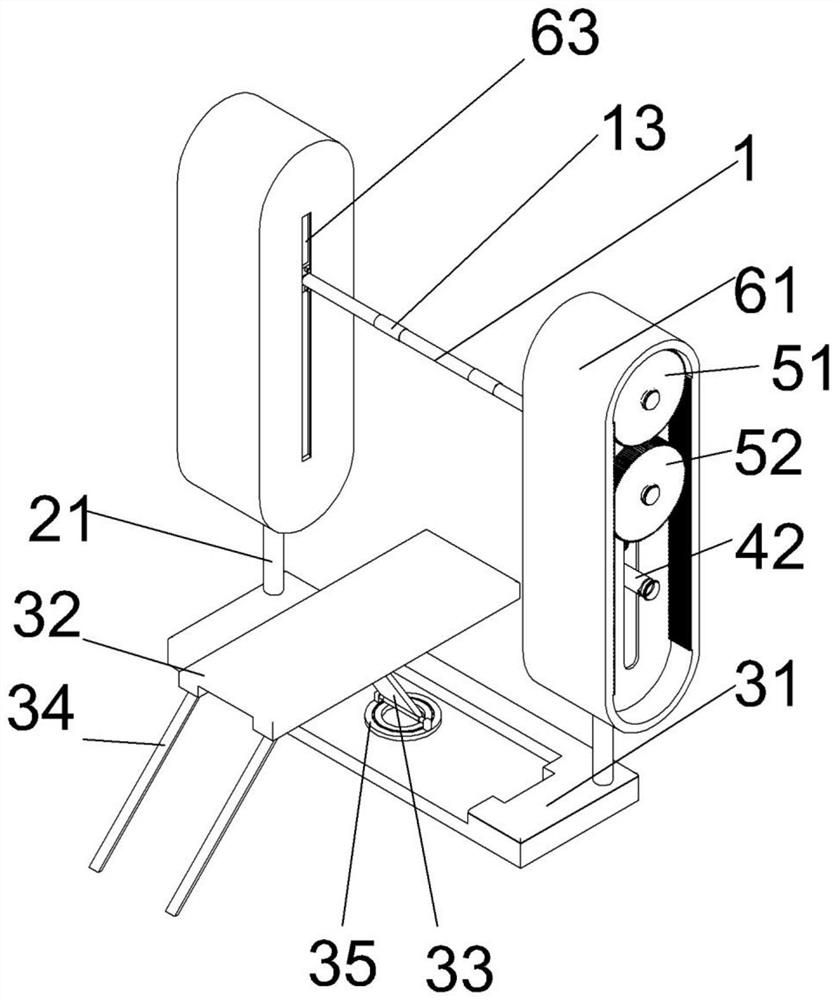

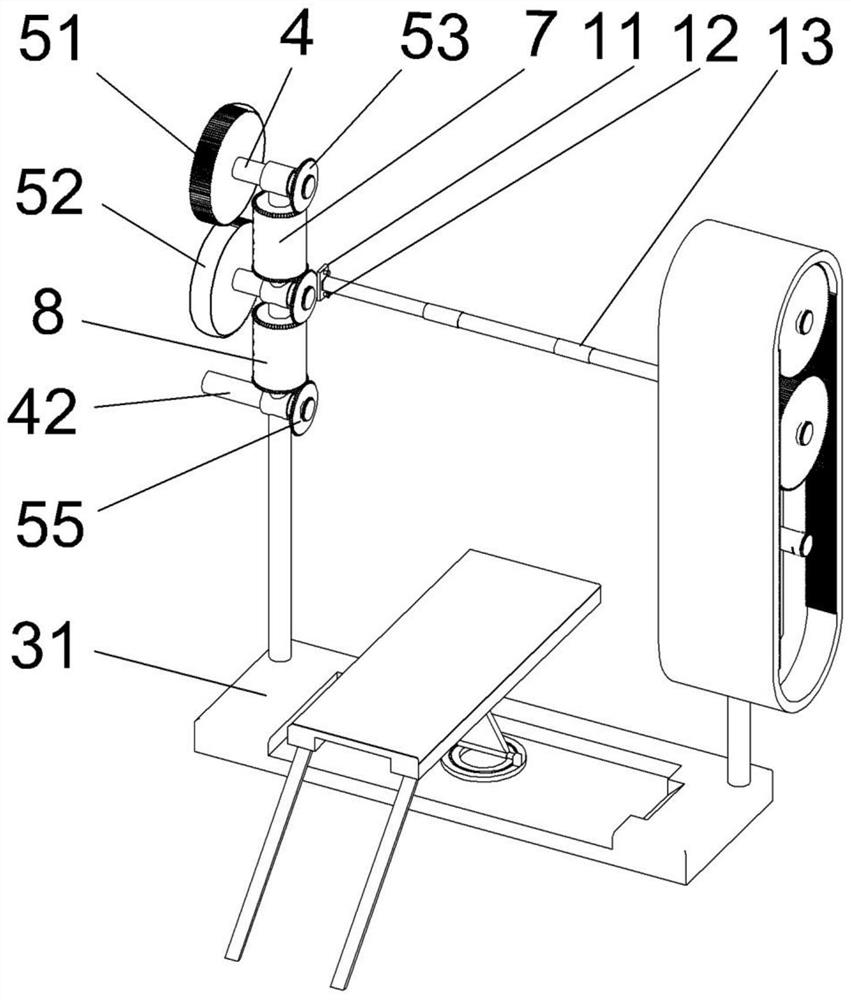

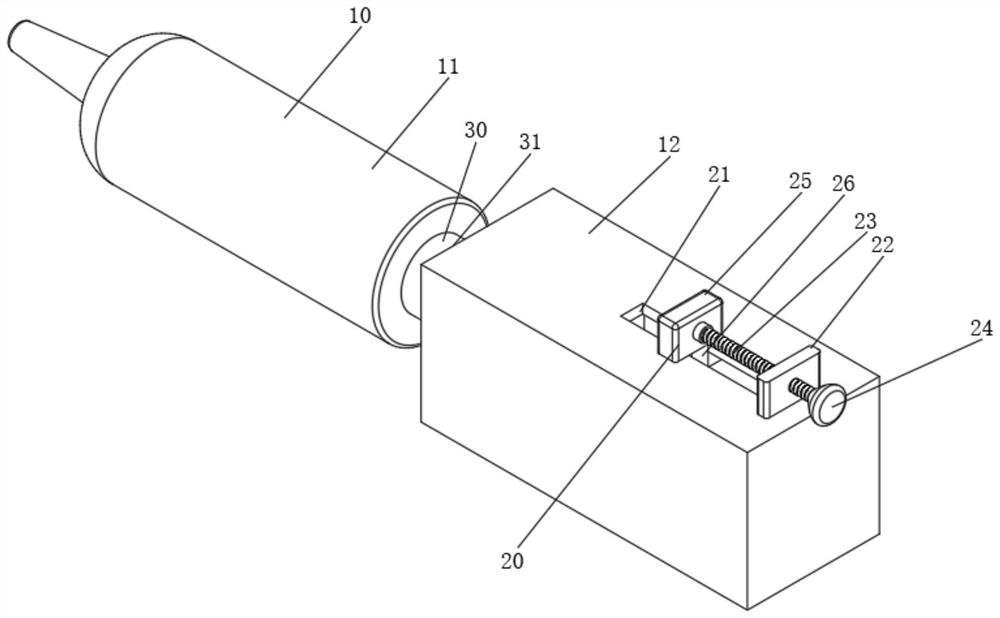

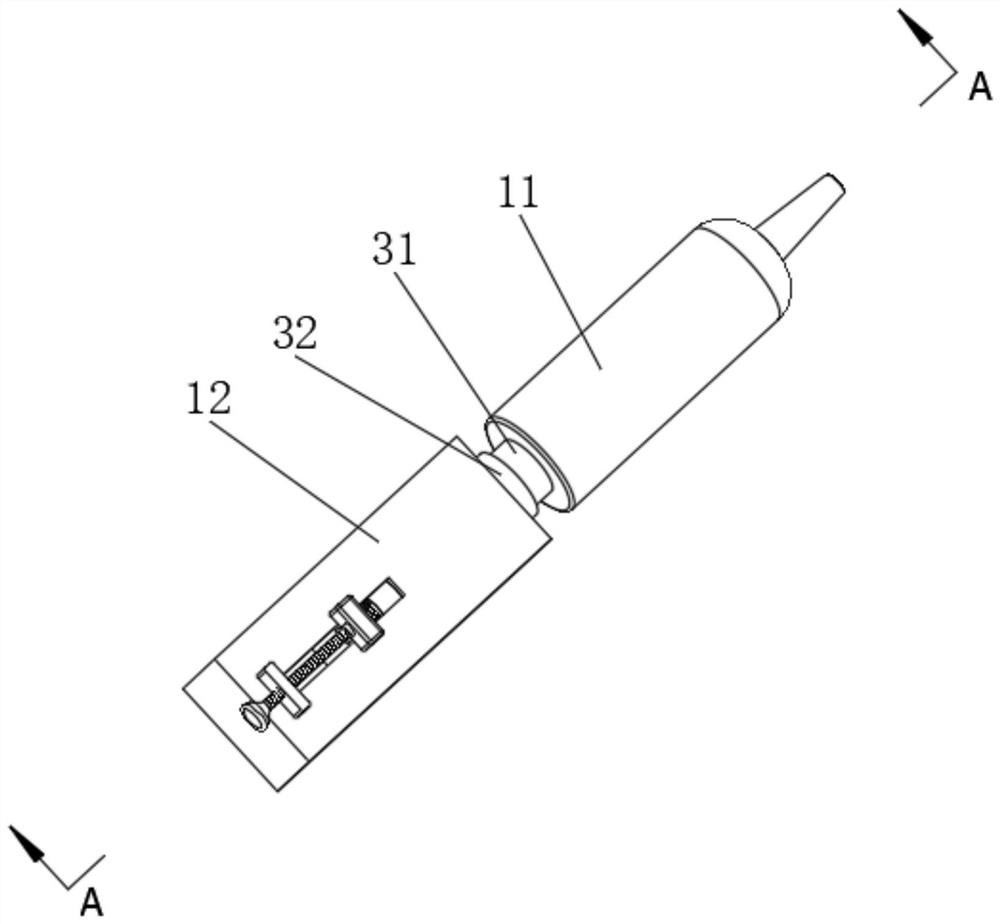

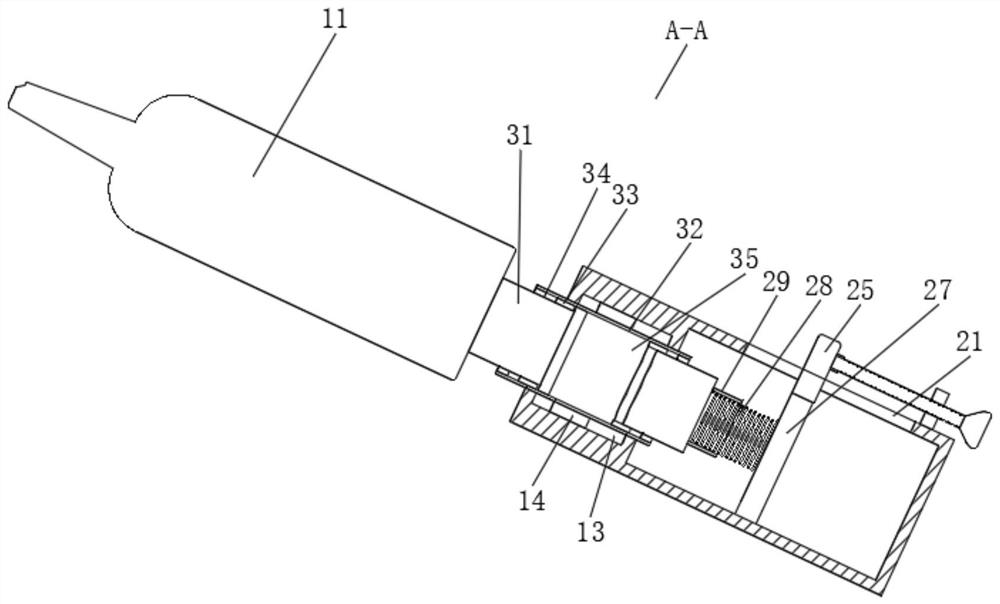

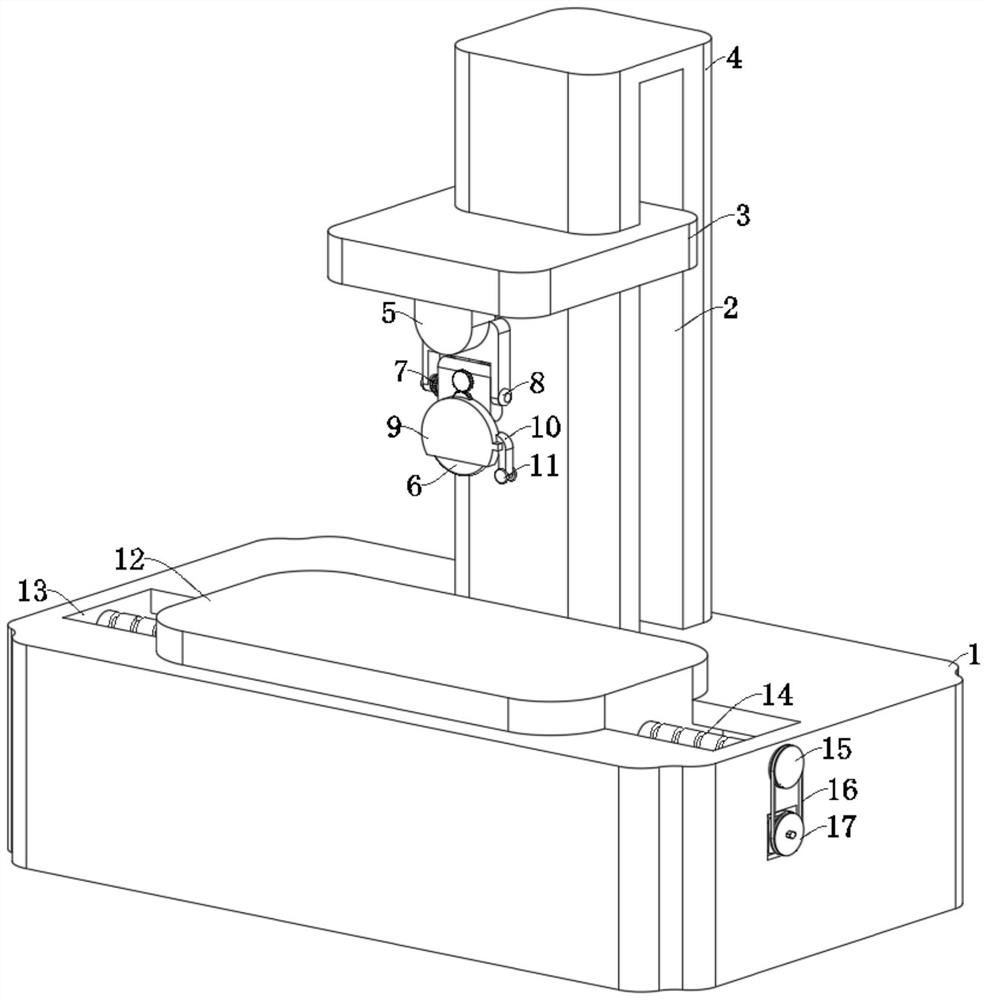

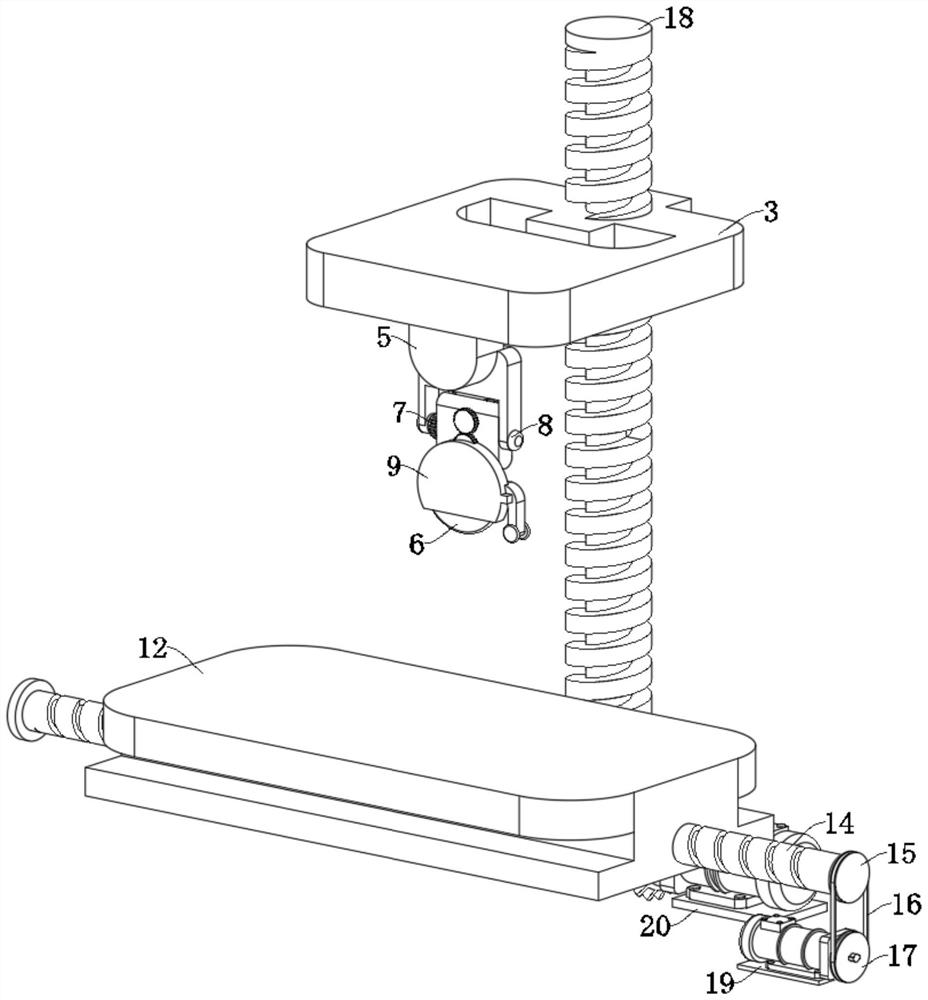

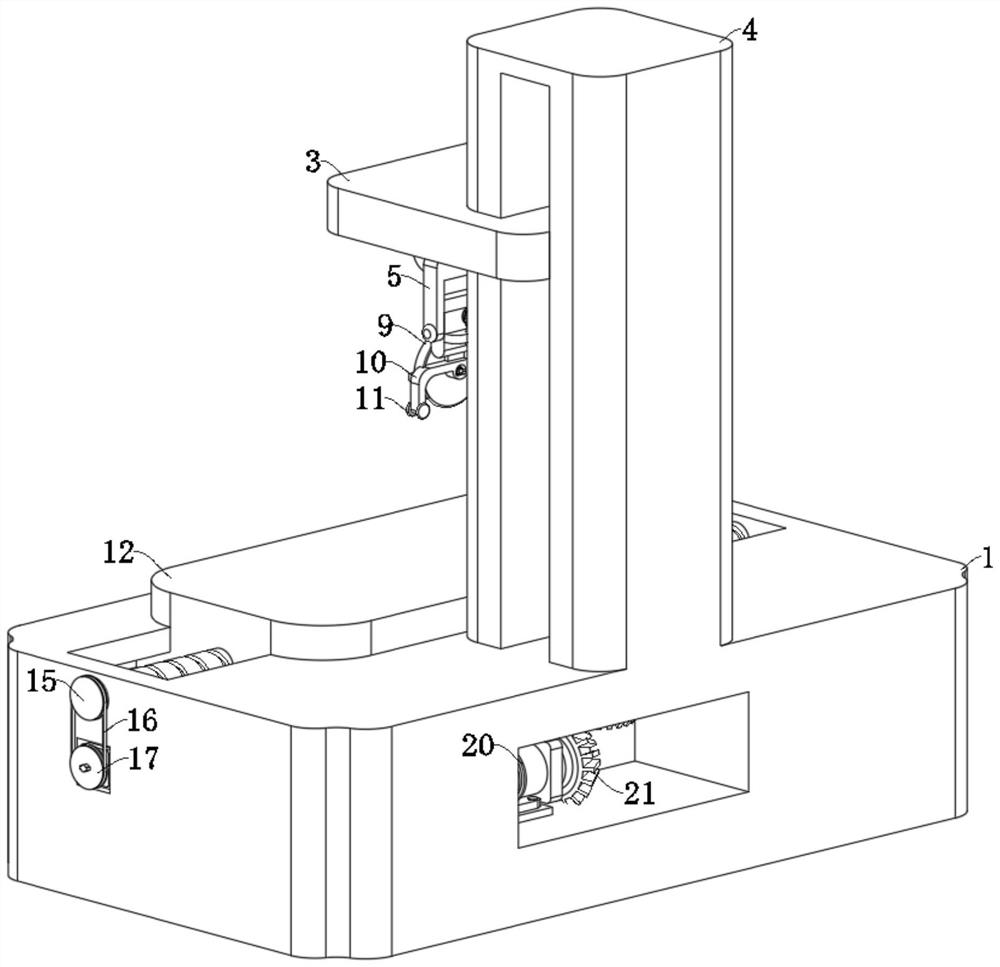

Power transmission device for aluminum wire cut electrical discharge machining of elastic center

PendingCN113814503AImprove cutting accuracyDoes not affect power deliveryElectrical-based auxillary apparatusWire cuttingStructural engineering

The invention provides a power transmission device for aluminum wire cut electrical discharge machining of an elastic center. The power transmission device comprises a main body assembly, a torque force adjusting assembly and a rotary power transmission assembly, and the main body assembly comprises the elastic center, a shell, a sliding chute and a sliding block; the torque force adjusting assembly is installed on the upper surface and the interior of the shell; and the rotary power transmission assembly comprises a first conductive rod, a pipe body, a first bearing, a first insulation pad, a conductive block, a second bearing, a second conductive rod and a second insulation pad. According to the power transmission device, during power transmission, through arrangement of the first conductive rod, the second conductive rod and the conductive block, after a power source is fed into the second conductive rod, electric power is transmitted to the first conductive rod through the conductive block, and finally transmitted to the elastic center; in the power transmission process, through arrangement of the first bearing and the second bearing, both the first conductive rod and the second conductive rod can be rotated; normal power transmission is not affected, the power transmission effect is guaranteed; and the aluminum wire cutting precision is improved.

Owner:CHENGDU ENGINE GROUP

High-flexibility numerical control cylindrical grinding machine

PendingCN114770244ASurfaceImprove machining accuracyGrinding wheel securing apparatusRevolution surface grinding machinesNumerical controlEngineering

The invention discloses a high-flexibility numerical control cylindrical grinding machine, and relates to the technical field of article processing and grinding equipment, the high-flexibility numerical control cylindrical grinding machine comprises a machine tool with a support column at the top, a lifting mechanism arranged on the support column, and a direction adjusting mechanism arranged on the lifting mechanism, the direction adjusting mechanism comprises a driving part, a fixed base plate, a rotating shaft, a rotating plate and a driven toothed bar, the fixed base plate is arranged on the lifting mechanism, and the rotating shaft is rotationally connected to the fixed base plate. According to the high-flexibility numerical control cylindrical grinding machine, the direction of the grinding wheel can be adjusted through the use of the direction adjusting mechanism, and the grinding wheel can be adjusted when positions such as an arc surface and a corner of a ground object appear, so that the grinding wheel is more attached to the surface of the object, and the machining precision is greatly improved; the position of the grinding wheel can be sensed in the advancing direction, so that the overall use is more flexible, the structure is stable and reliable, meanwhile, the structure is simple, manufacturing is easy, the grinding advantage is highlighted, and the grinding efficiency is improved.

Owner:厦门创云精智机械设备股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com