High-flexibility numerical control cylindrical grinding machine

A cylindrical grinding machine, a high-flexibility technology, used in grinding machines, grinding machine parts, machine tools designed for grinding the rotating surface of workpieces, etc. , the time of grinding and shaping becomes longer, etc., to achieve the effect of highlighting the advantages of grinding, simple structure and flexible use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

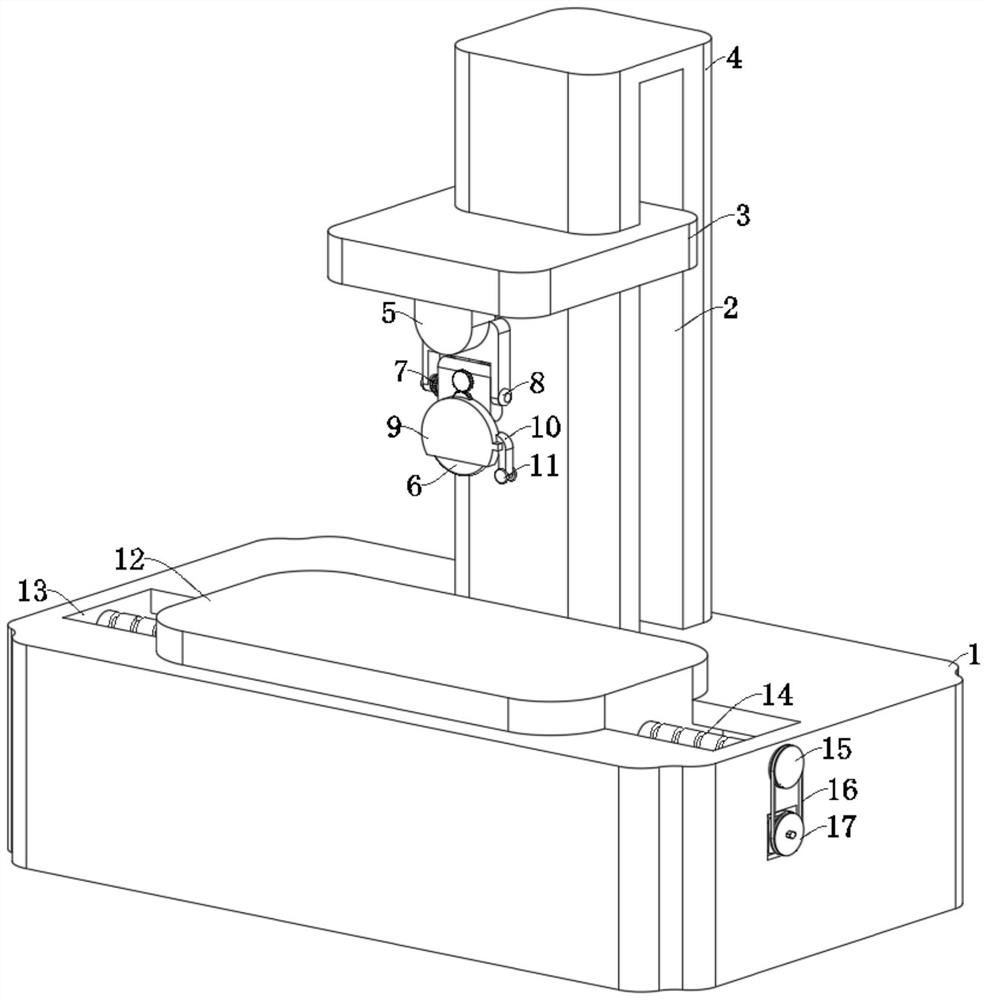

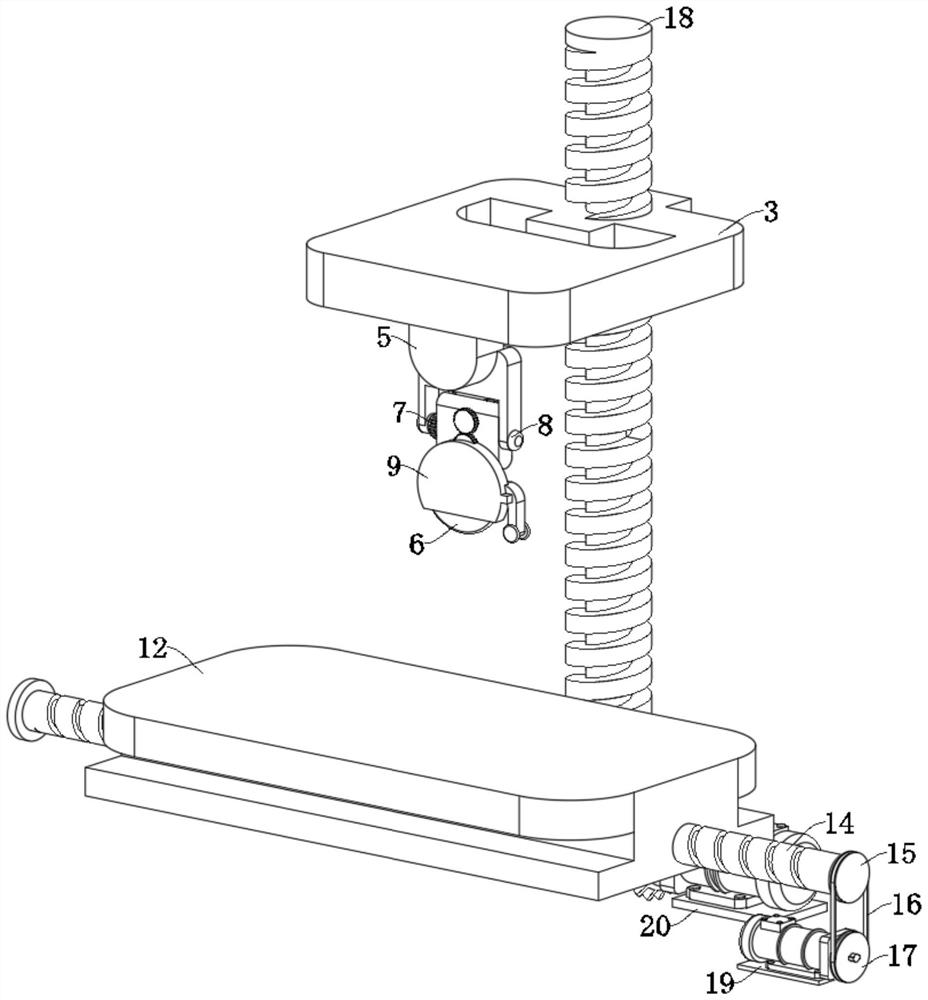

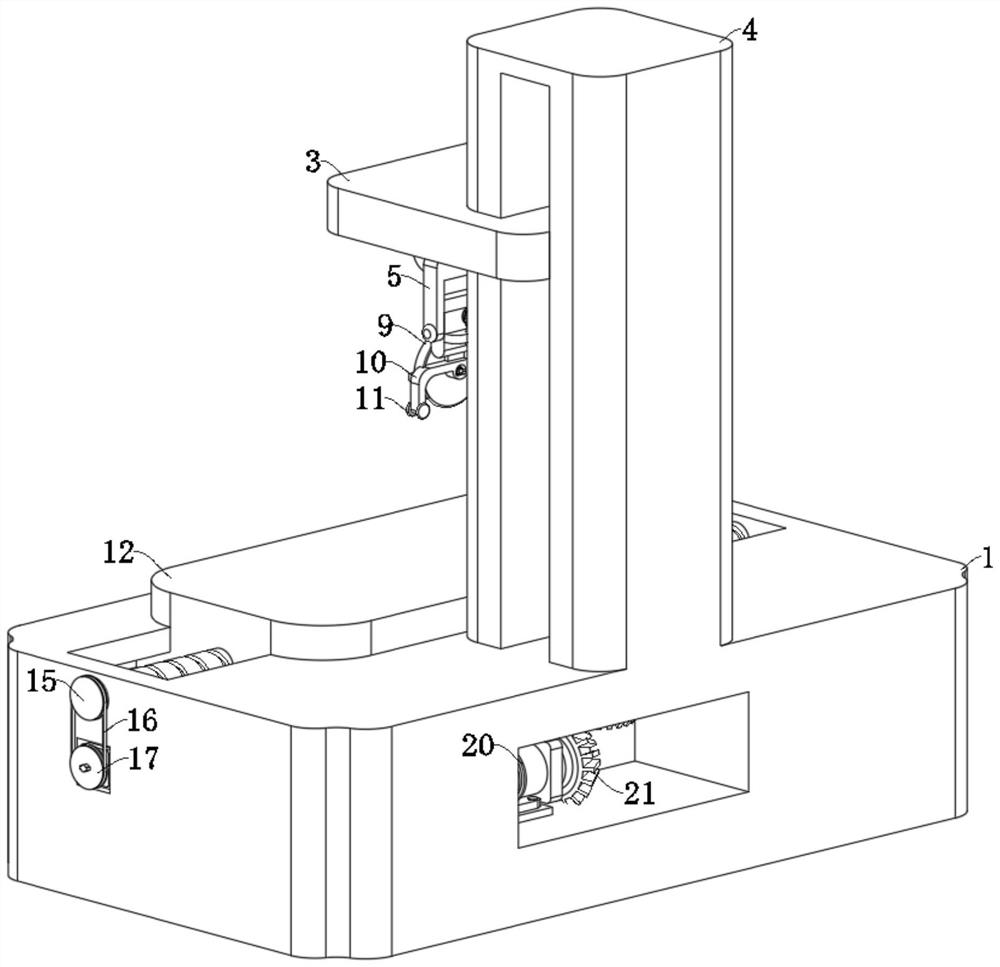

[0043] Embodiment 1, refer to Figure 1-12 : A highly flexible CNC cylindrical grinding machine, including:

[0044] A machine tool 1 with a pillar 4 on the top;

[0045] The lifting mechanism is arranged on the pillar 4;

[0046] The direction adjustment mechanism is set on the lifting mechanism, wherein: the direction adjustment mechanism includes a driving component, a fixed base plate 5, a rotating shaft 8, a rotating plate 30 and a driven gear rod 29, the fixed base plate 5 is set on the lifting mechanism, and the rotating shaft 8 rotates is connected to the fixed base plate 5, the rotating plate 30 is fixedly connected to the rotating shaft 8, and the driven rack 29 is rotatably connected to the outer surface of the rotating plate 30 near the center; and

[0047] The guide mechanism is arranged on the driven driven gear rod 29, wherein: the guide mechanism includes a guide rod 10 and an induction guide wheel 11, the guide rod 10 is fixedly connected to the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com