Automatic screw matching concrete stirring conveyer

An automatic proportioning and concrete technology, which is applied in the direction of clay preparation device, mixing operation control, mixing operation control device, etc., can solve the problems of inability to achieve continuous and stable preparation of concrete, batching ratio stability and low precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

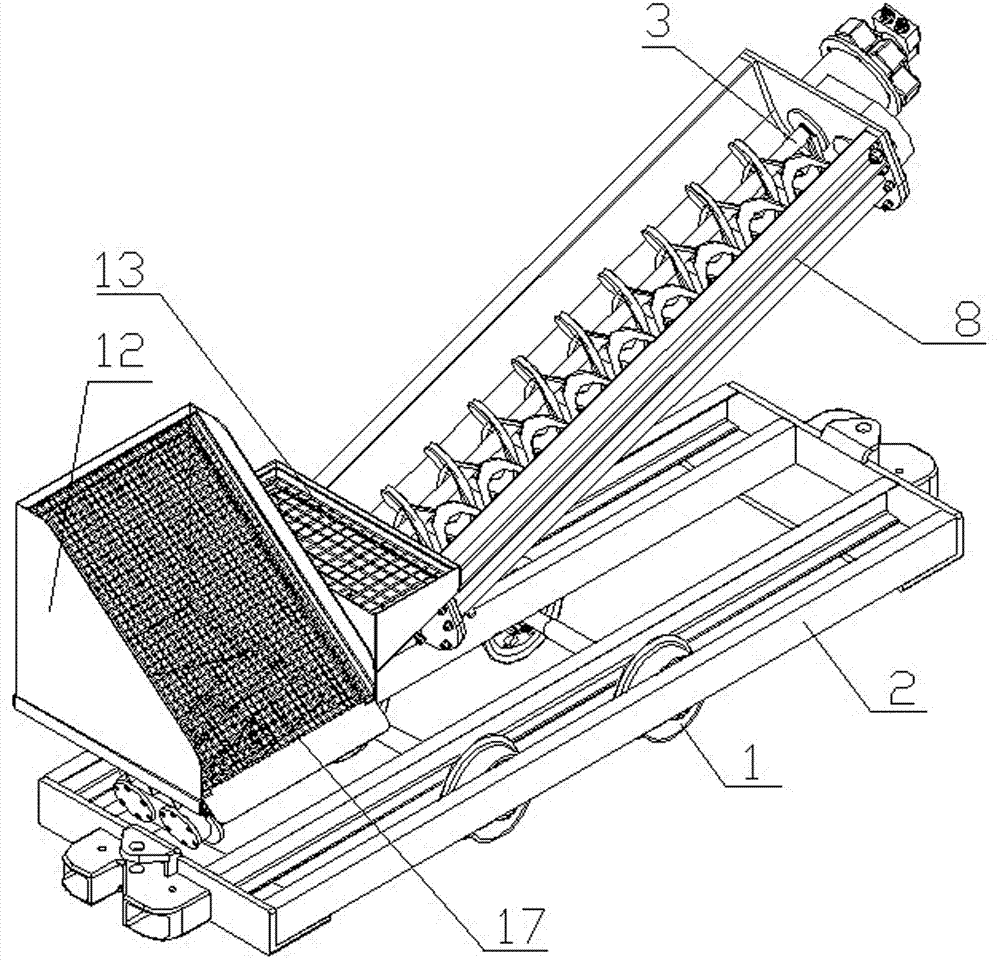

[0019] Examples of the present invention Figures 1 to 3 As shown, the spiral automatic proportioning concrete mixing conveyor is a double-shaft structure, including a mine car chassis 2 with a road wheel 1 and a conveying and mixing system. The mine car chassis is a special or general chassis that can adapt to underground rails. There are two parallel conveying stirring shafts 3 arrayed along the horizontal direction. The two ends of the conveying stirring shafts 3 are supported on the two ends of the conveying channel through bearings. One end of the two conveying stirring shafts 3 is connected by a synchronous gear, and one of the conveying stirring shafts 3. It is connected with a power source. The power source can be an electric motor or a hydraulic motor. The two conveying stirring shafts 3 rotate in opposite directions. The conveying channel is connected to the chassis 2 of the mine car. Adjust the height and elevation angle of the conveying channel, the conveying stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com