Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

107results about How to "Safe and smooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

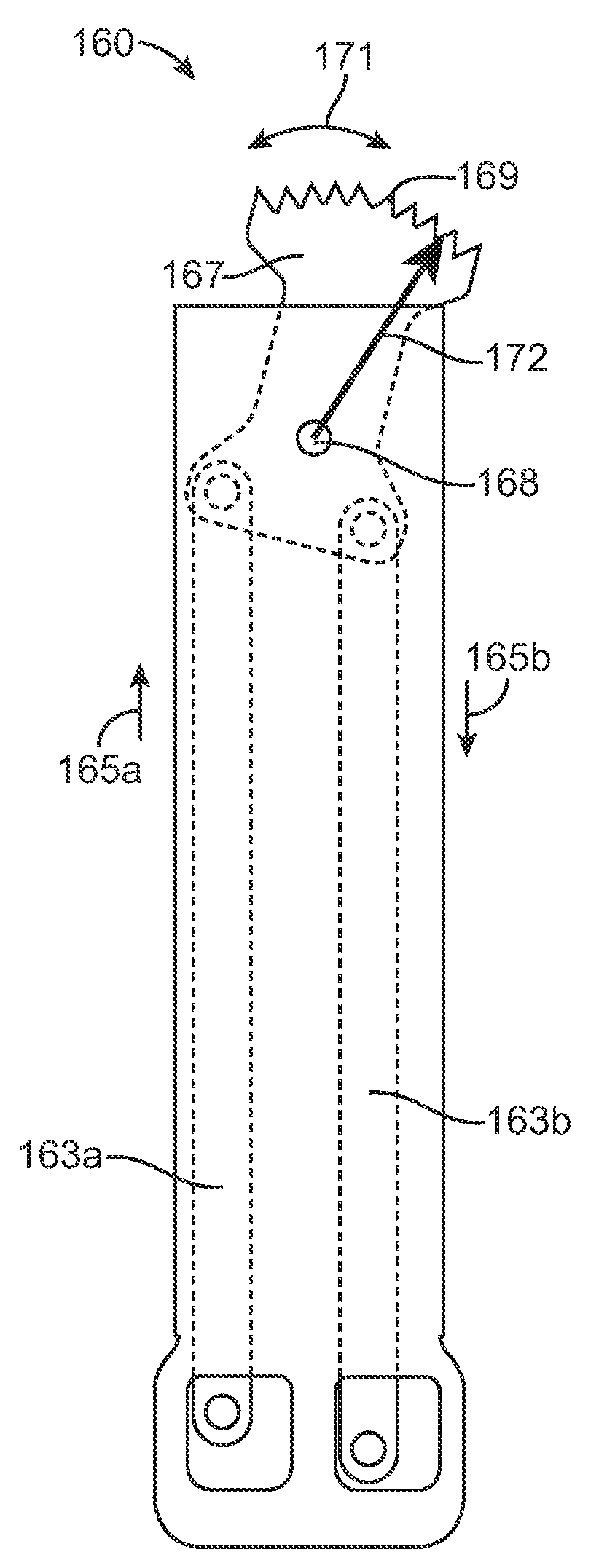

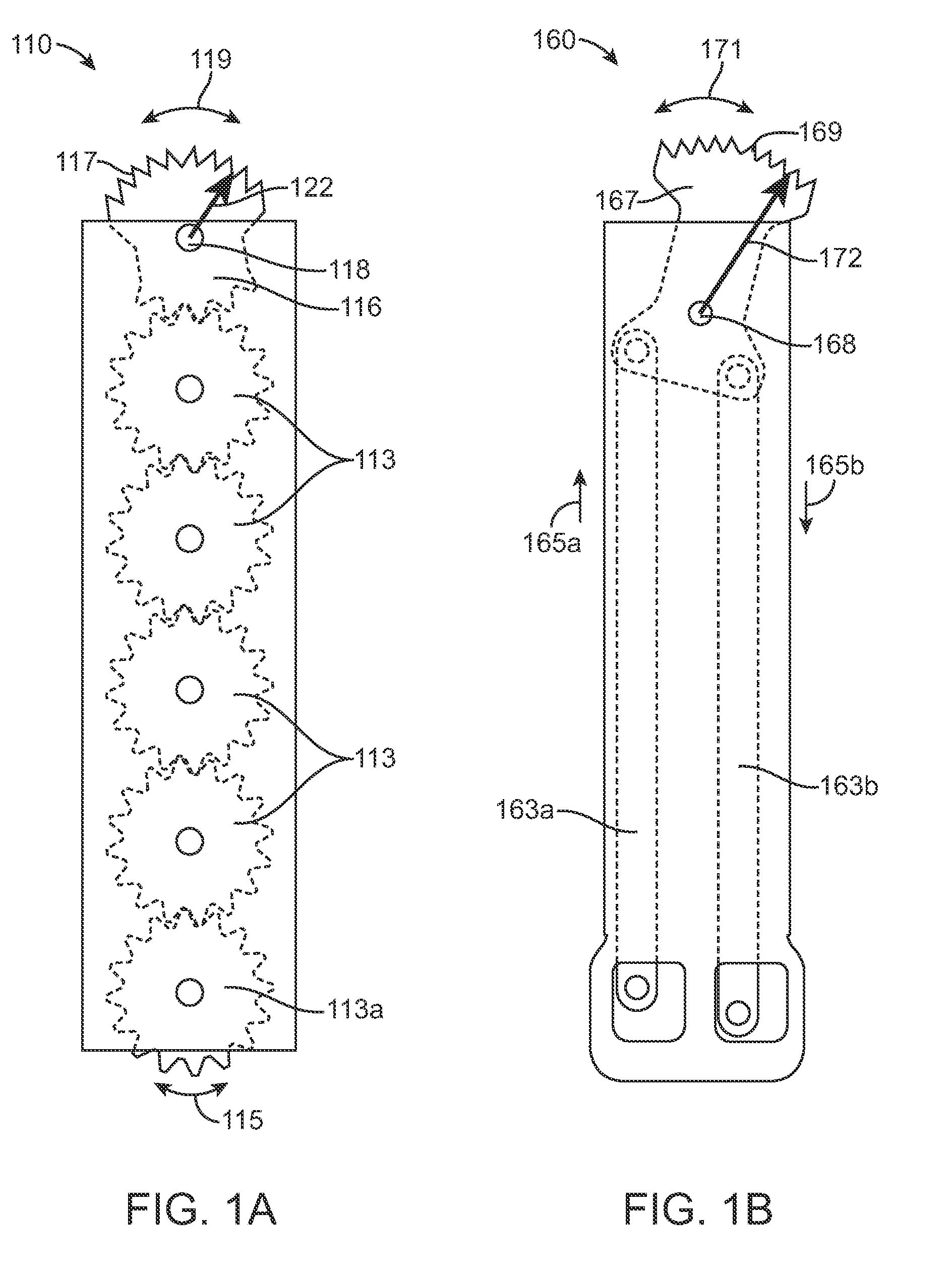

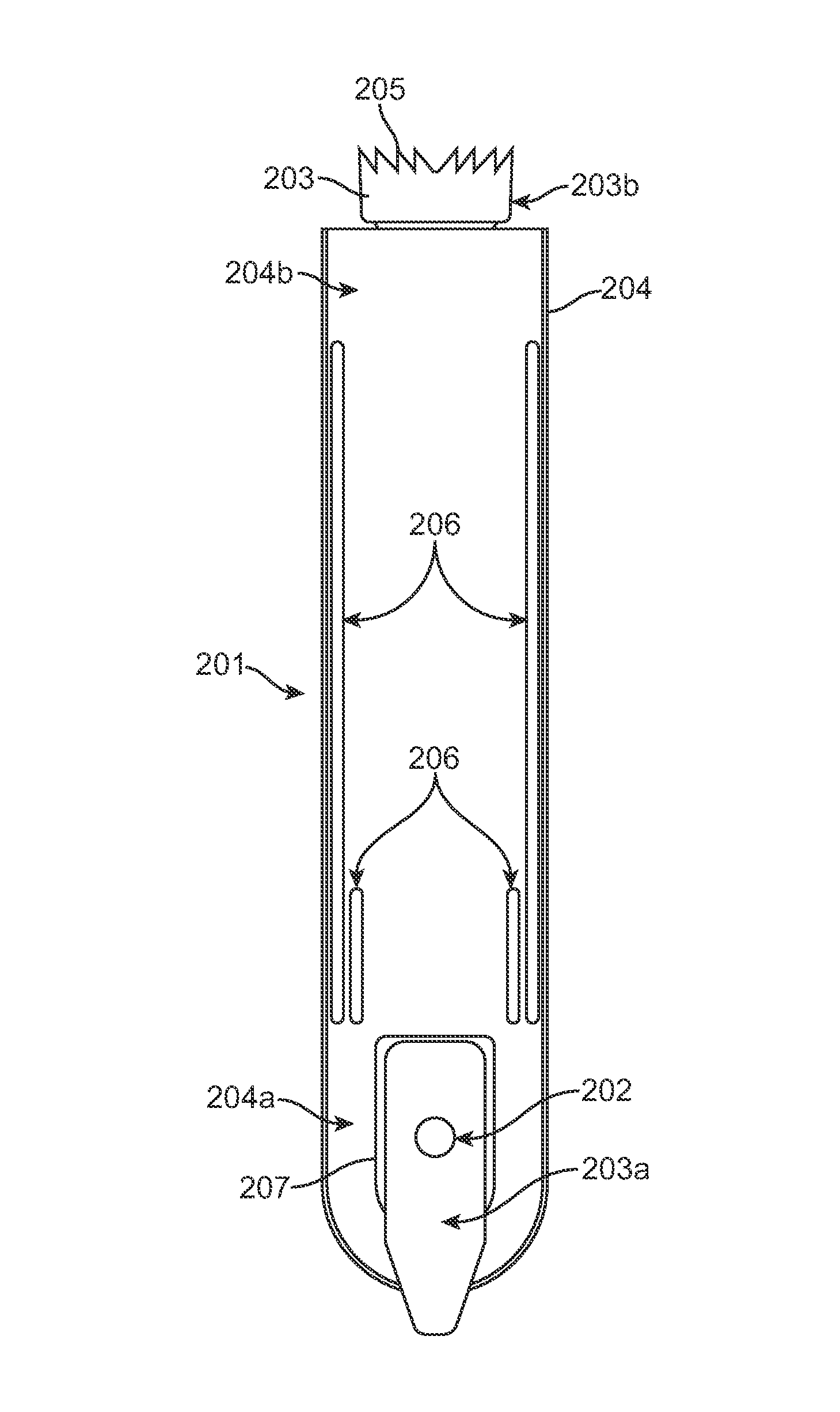

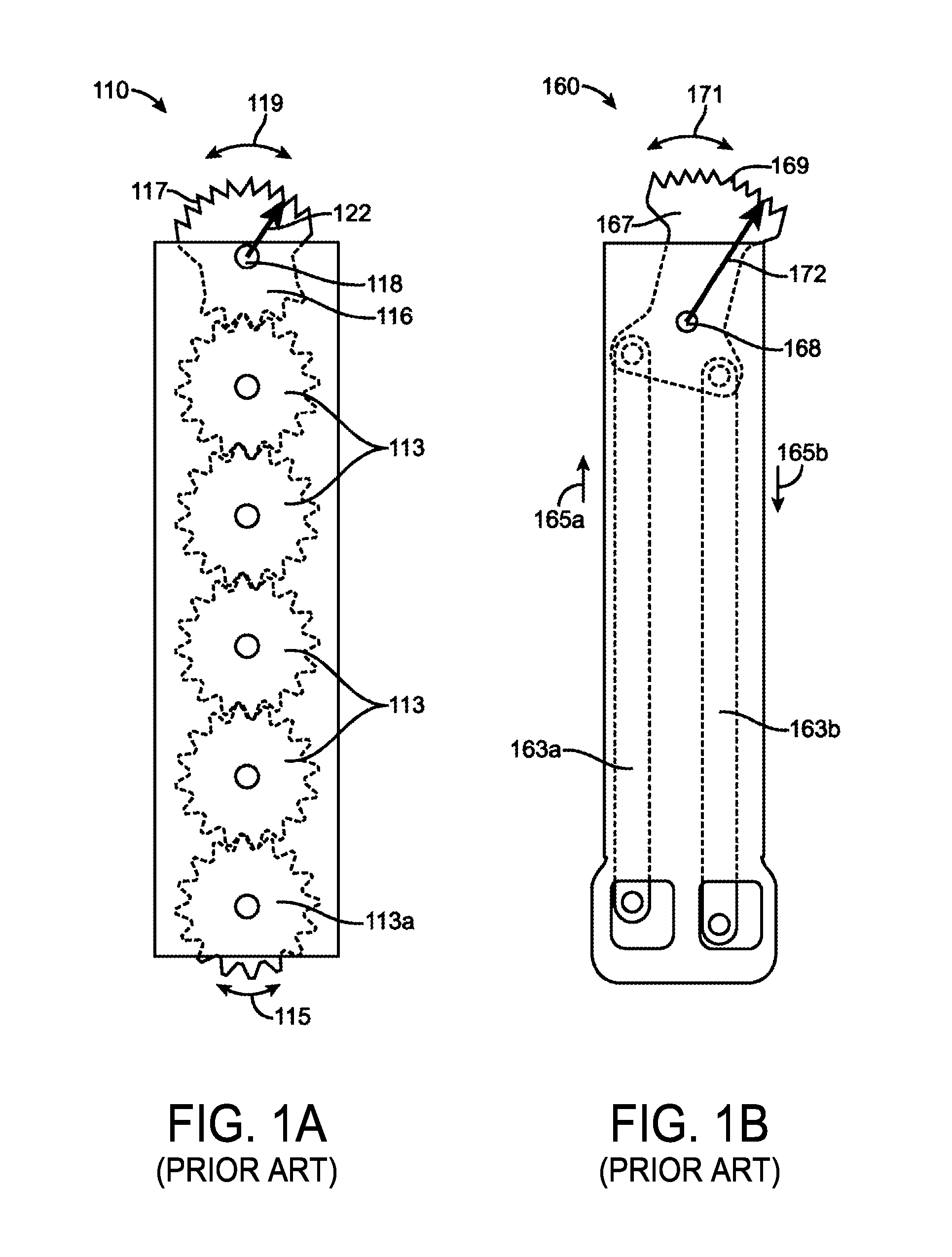

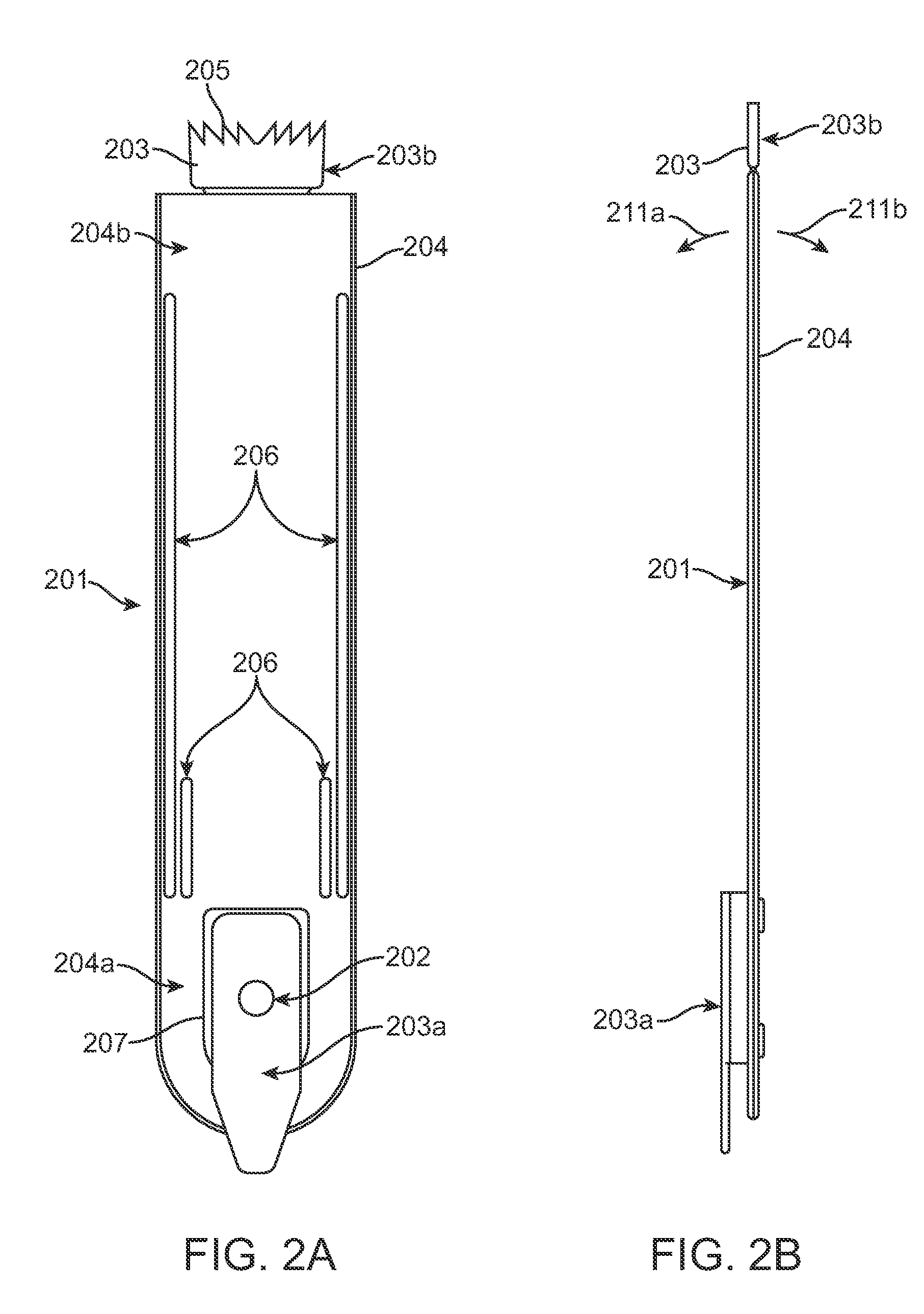

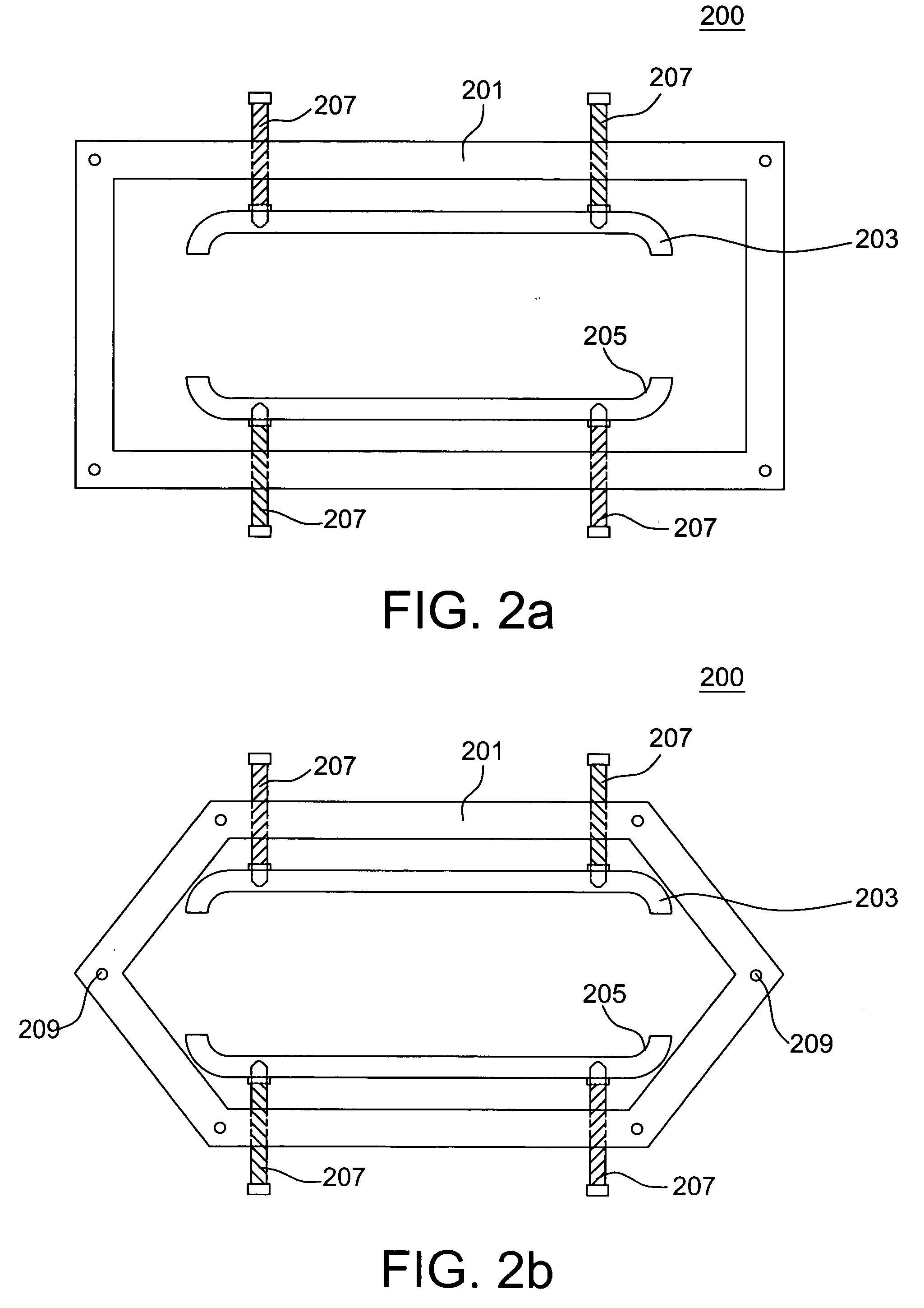

Surgical saw blade device and system

A saw blade assembly for use with a driver having an oscillatory drive member comprises an elongate sheath and an elongate monolithic blade. The sheath's proximal end is removably mountable on the driver. The sheath has an open interior which receives the blade. The blade's proximal end is pivotably mounted to the sheath's proximal end. The blade's distal cutting end extends out of the sheath's distal end and is transverse to the blade's central longitudinal axis. When cutting bone, the drive member pivots the blade's cutting end back and forth in an arc about a pivot point at the blade's proximal end while the driver holds the sheath stationary to protect surrounding tissues from the motions of the remainder of the blade. The long pivot radius between the proximal pivot point and the distal cutting end contributes to minimizing the angle of engagement of the cutting end to the bone.

Owner:SYNVASIVE TECH

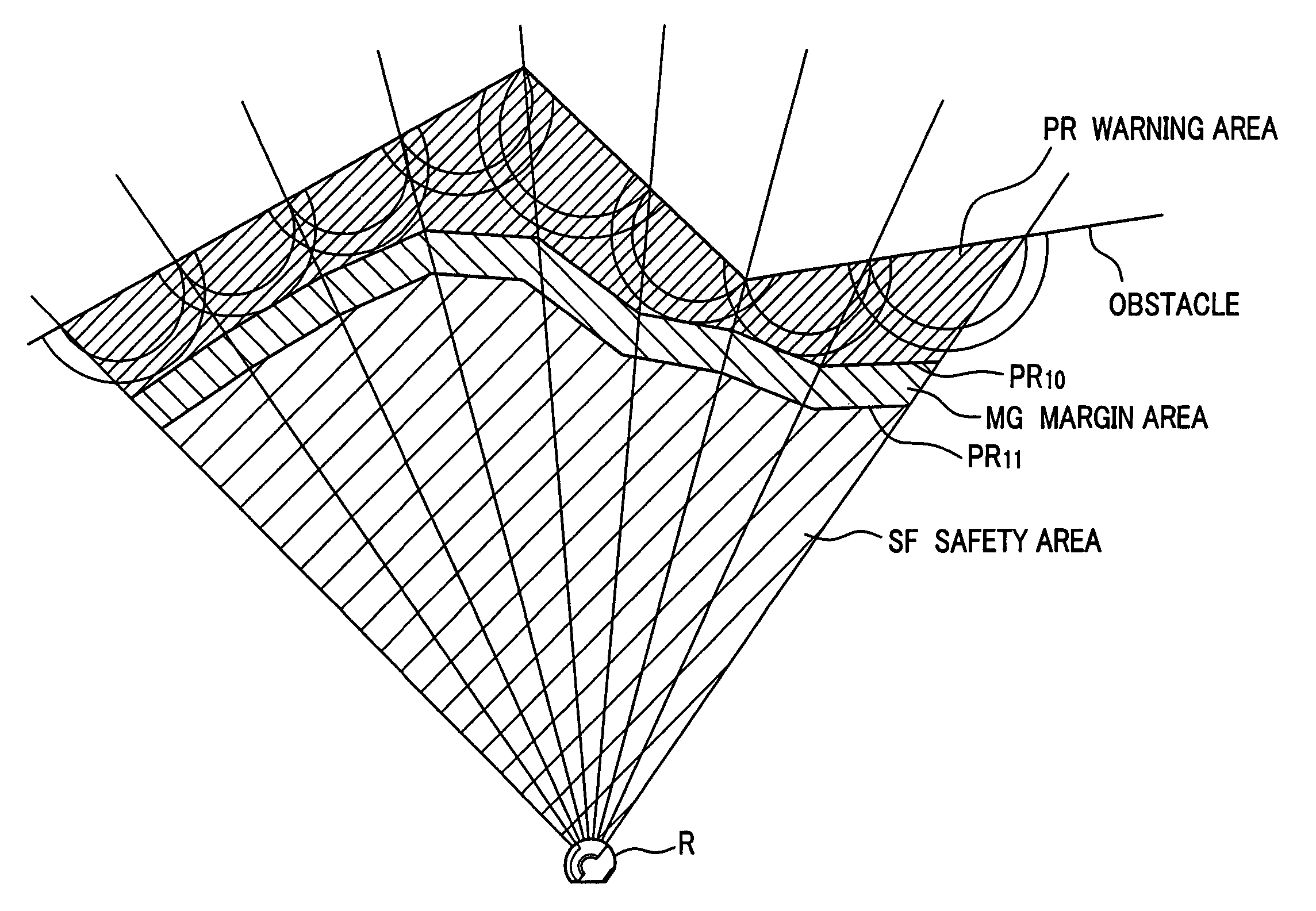

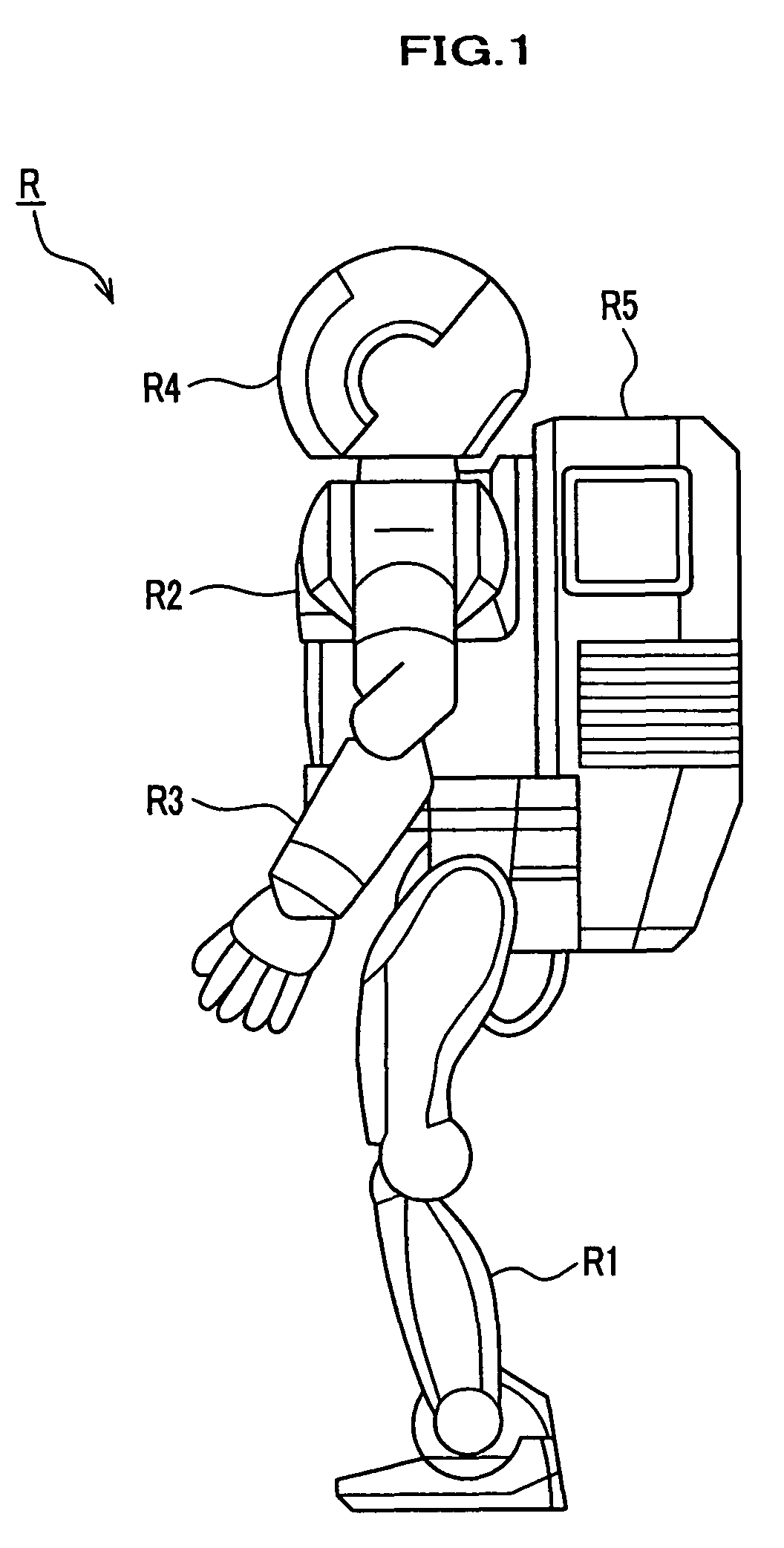

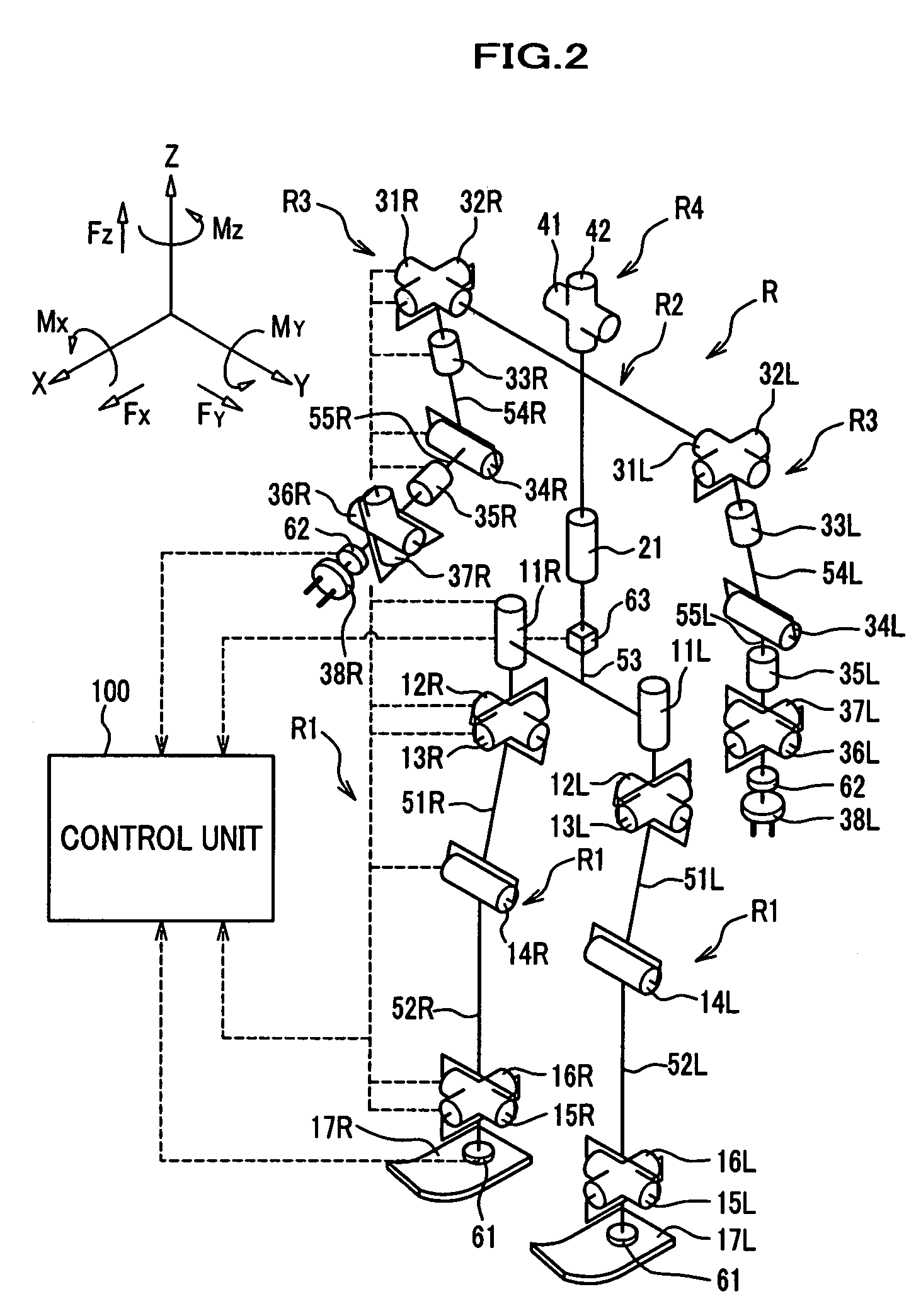

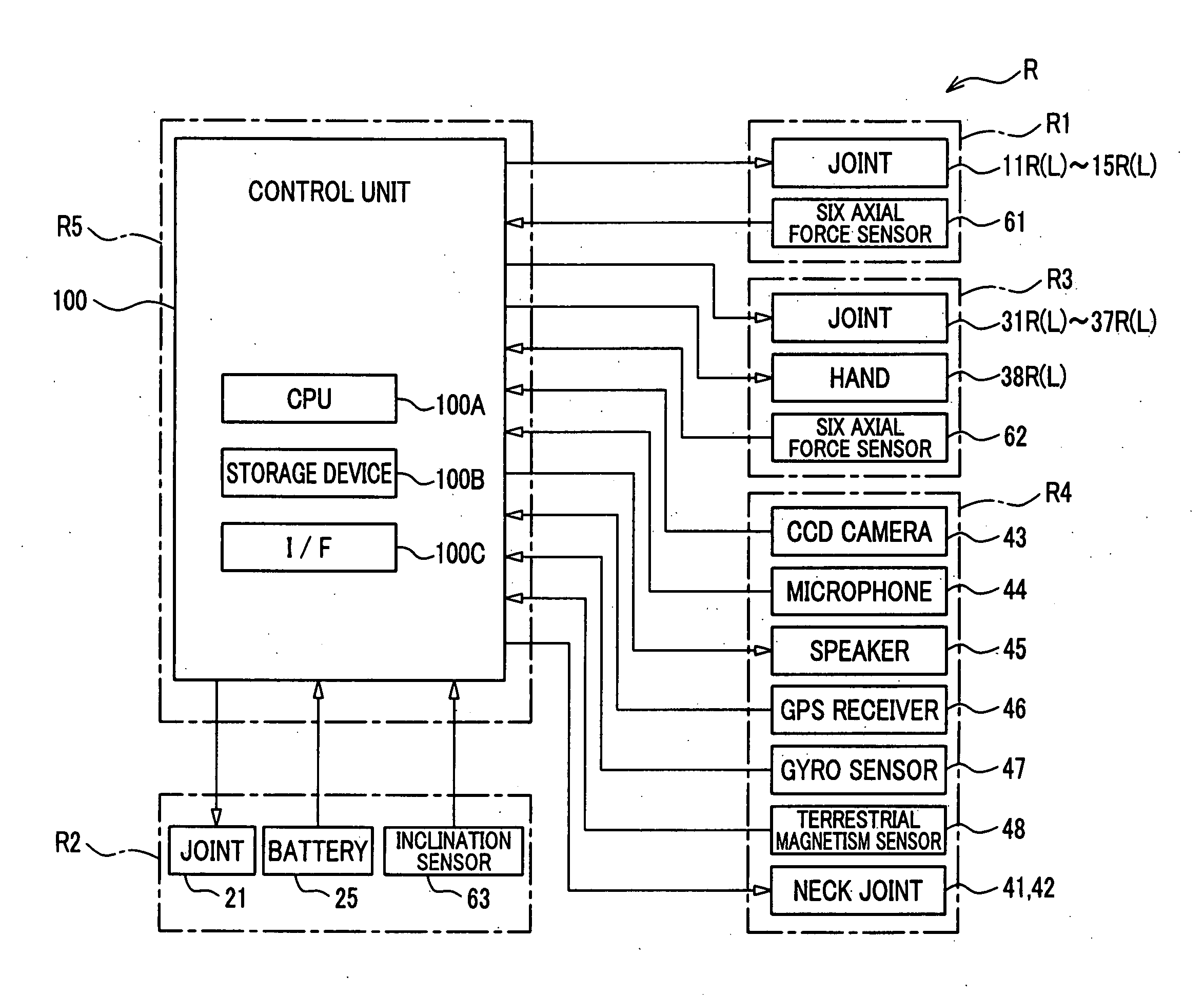

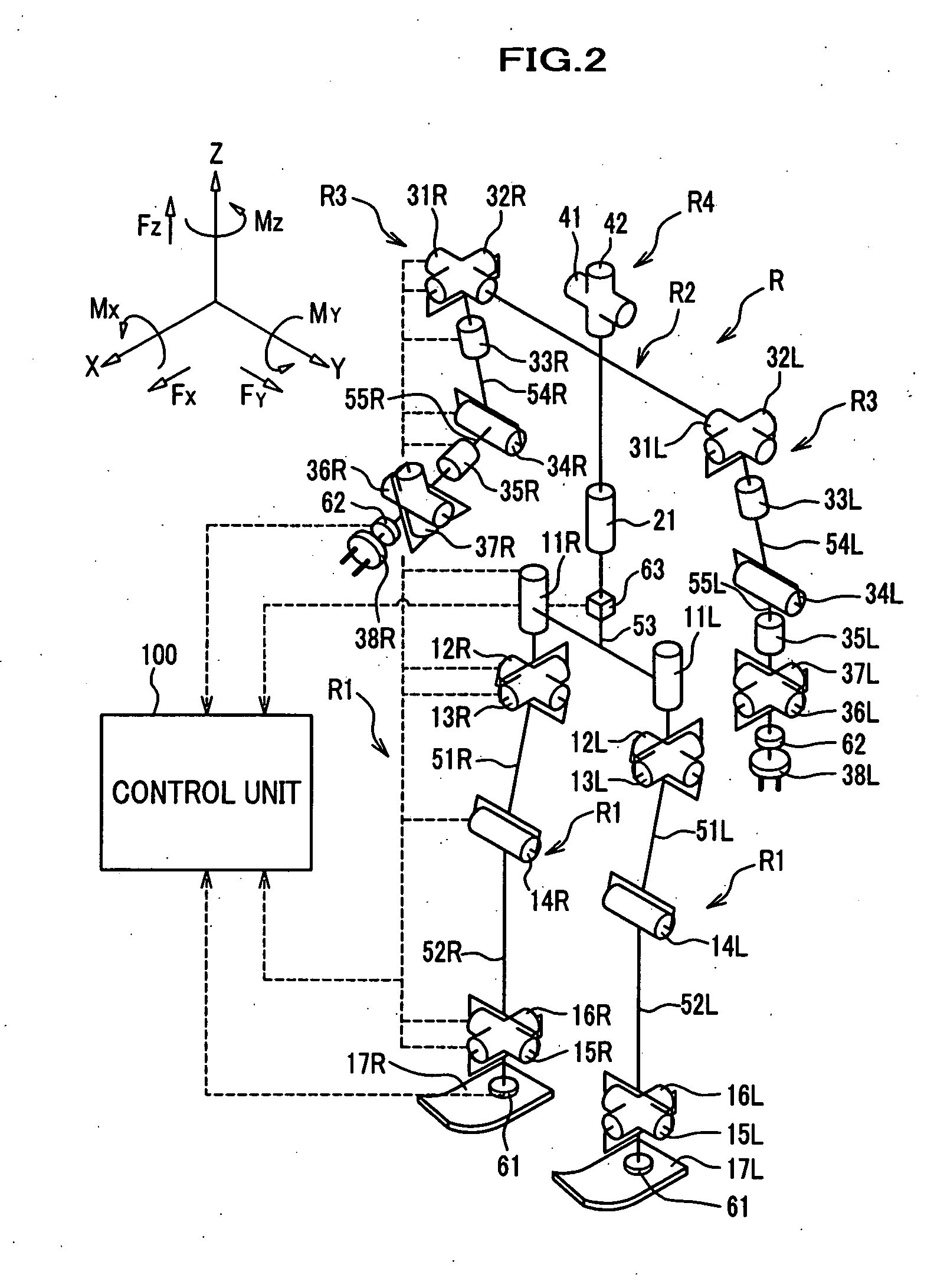

Robot navigation system avoiding obstacles and setting areas as movable according to circular distance from points on surface of obstacles

InactiveUS7873448B2Safe and smoothSmooth mobile operationImage analysisComputer controlNavigation systemSpeech sound

The content of the voice designation of a designator is recognized by a voice recognition part 130 at the time of controlling a robot, and the content of the indication of gesture or the like is recognized by an image recognition part 120. A movement destination and a map around the specific position designated are referred from a map data base 150 registering the position of an obstacle and the current position estimated by a self-position estimation part 140. After movement ease is decided by a movement ease decision part 112, the behavior is decided. When movement designation is given to the robot, correspondence according to a situation can be performed.

Owner:HONDA MOTOR CO LTD

Robot control device, robot control method, and robot control program

InactiveUS20060173577A1OptimizationPromote circulationImage analysisComputer controlRobot controlSpeech sound

The content of the voice designation of a designator is recognized by a voice recognition part 130 at the time of controlling a robot, and the content of the indication of gesture or the like is recognized by an image recognition part 120. A movement destination and a map around the specific position designated are referred from a map data base 150 registering the position of an obstacle and the current position estimated by a self-position estimation part 140. After movement ease is decided by a movement ease decision part 112, the behavior is decided. When movement designation is given to the robot, correspondence according to a situation can be performed.

Owner:HONDA MOTOR CO LTD

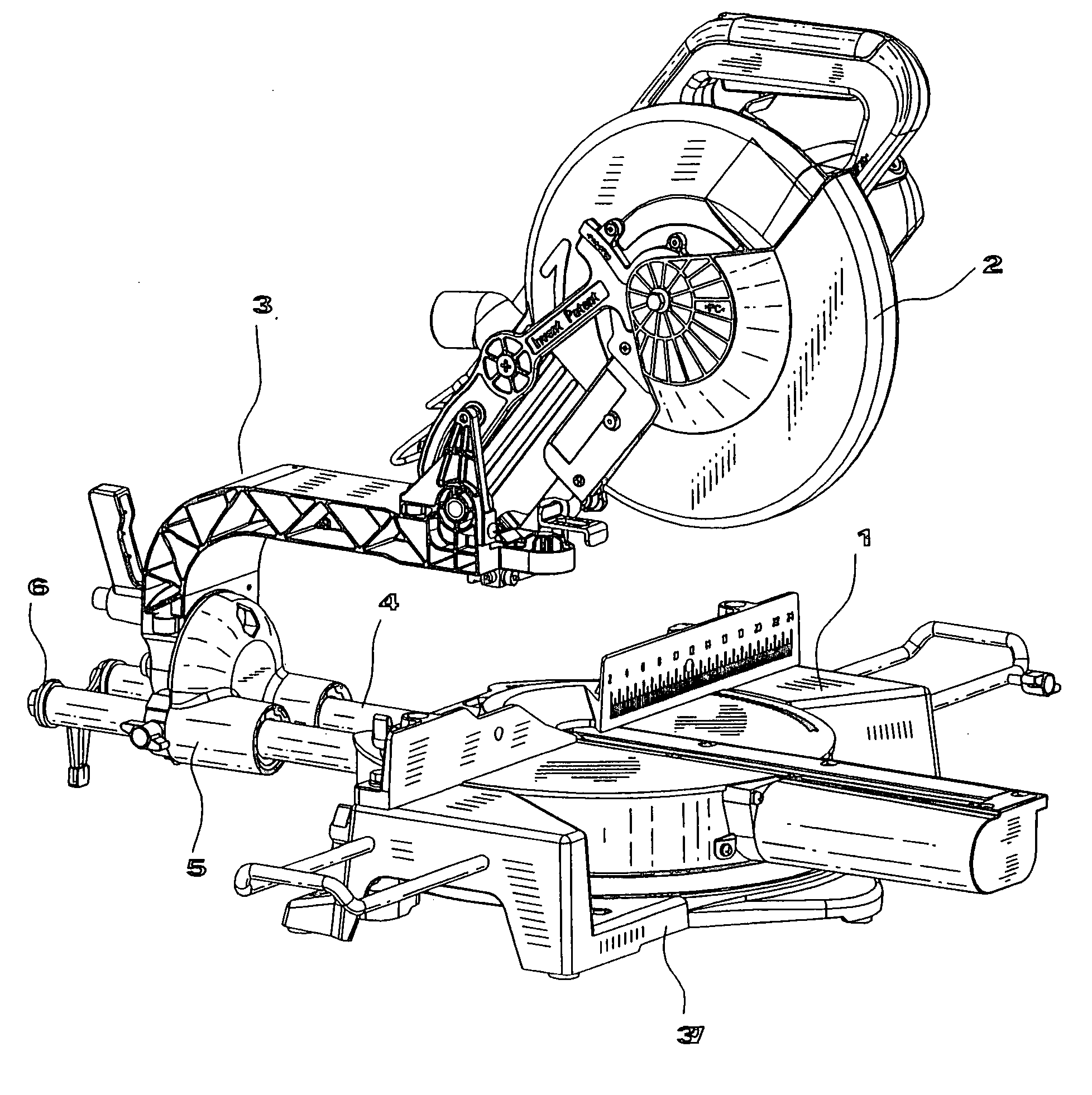

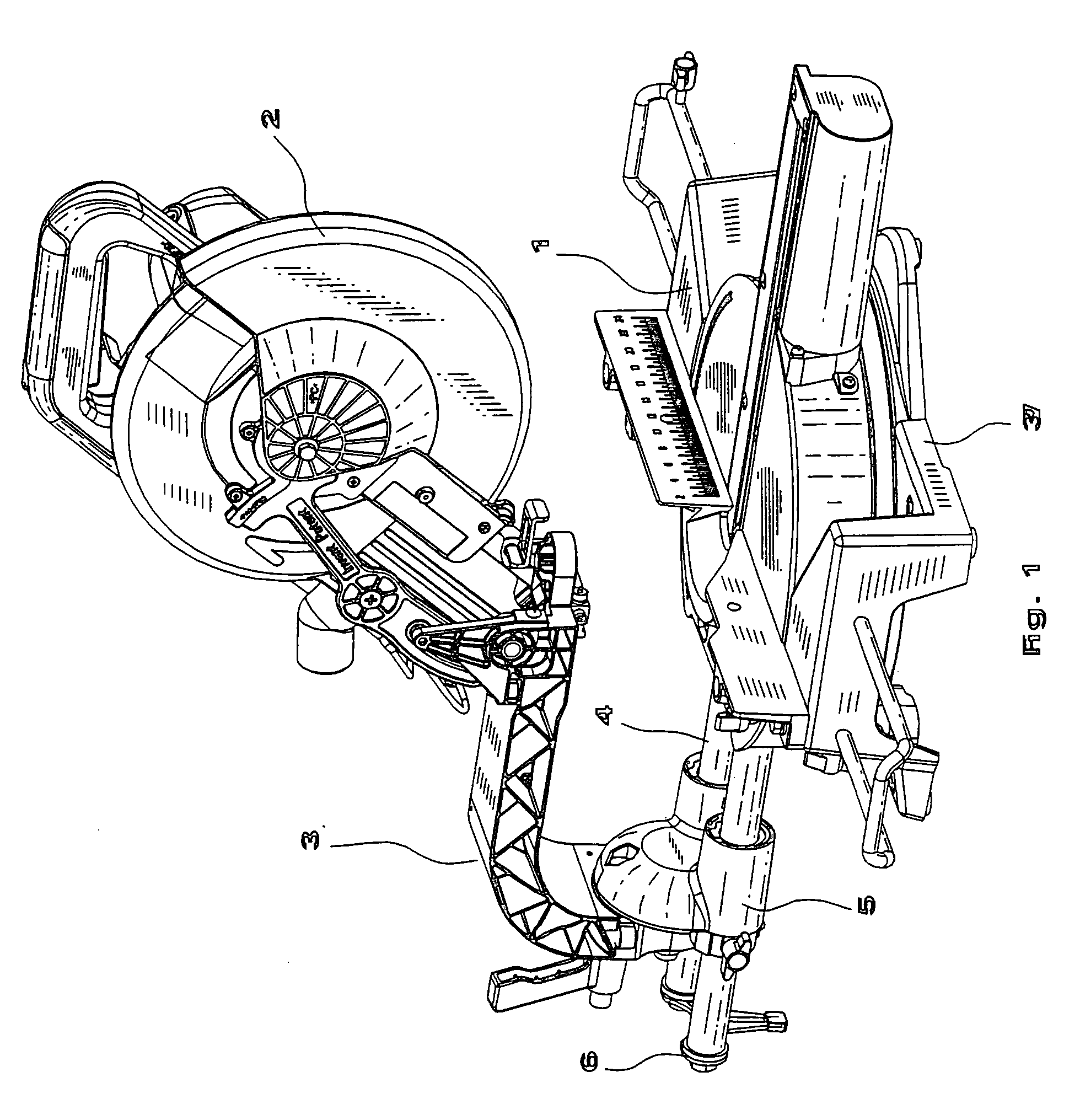

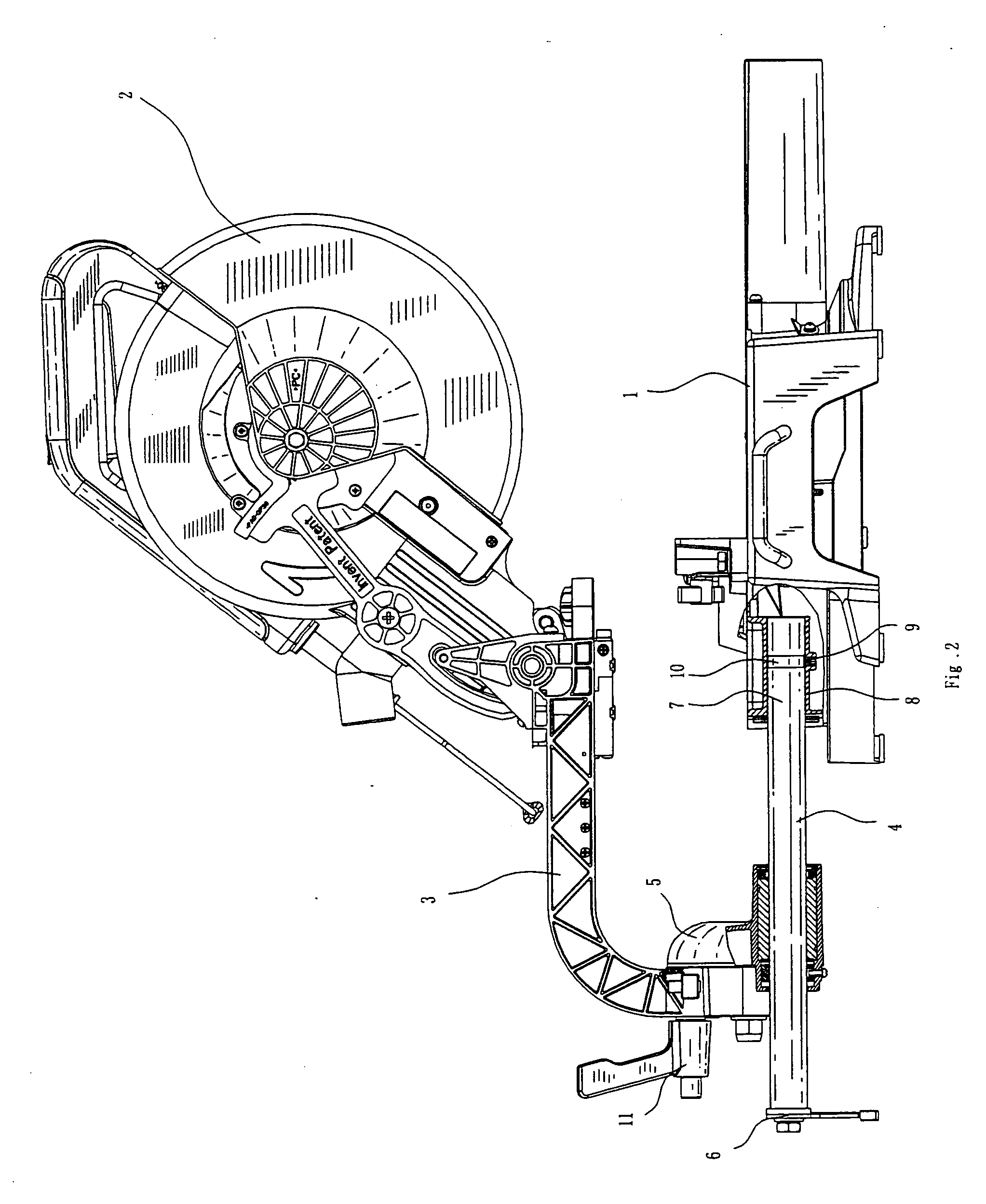

Electric miter saw

InactiveUS20070074611A1Efficient use ofExpand the cutting rangeMetal sawing devicesGuide fencesBall bearingEngineering

An electric miter saw includes a base, a cutting table, a cutting member and a link arm. The cutting table is mounted on the base. The upper portion of the link arm is connected to a cutting member with the cutting saw blade driven by a motor. The lower portion of the link arm is connected to the upper portion of a supporting member and secured by a threaded central bolt. The linear ball bearing is mounted in the inner aperture of the supporting member, which is slidably connected to the slide rod by a linear ball bearing. At the outer end of the slide rod is mounted a position limit socket. The inner end of the slide rod is connected and secured beneath the cutting table via a releasable securing configuration mentioned above. A flexible blade guard is also provided.

Owner:NIG BO YANG MING ELECTRIC TOOLS

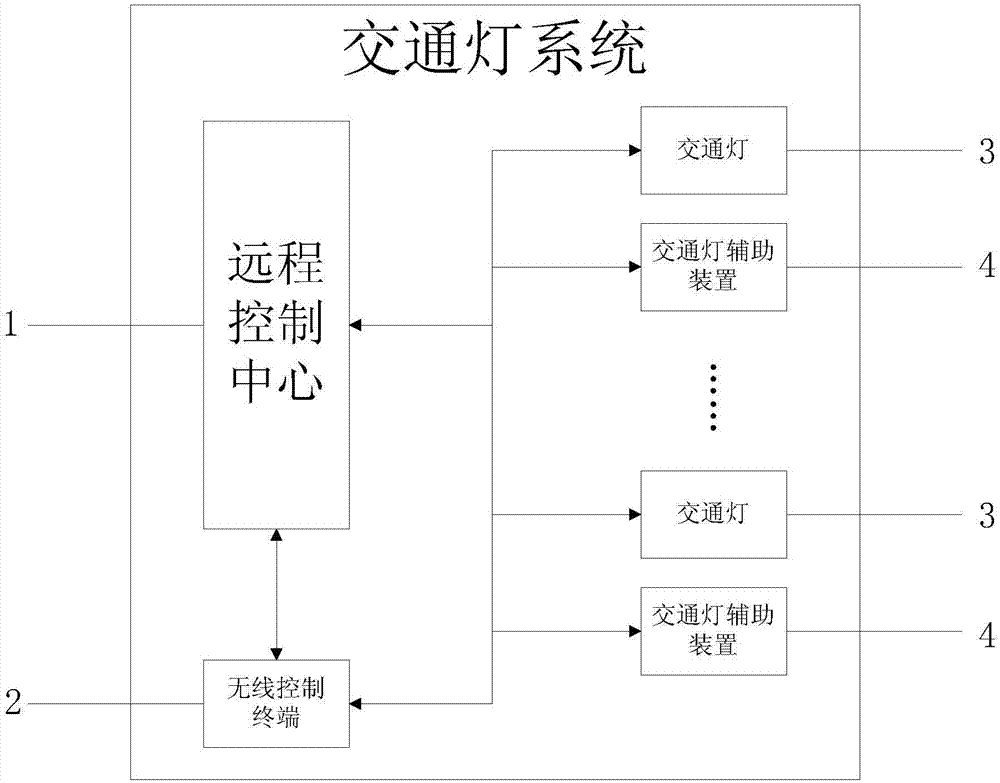

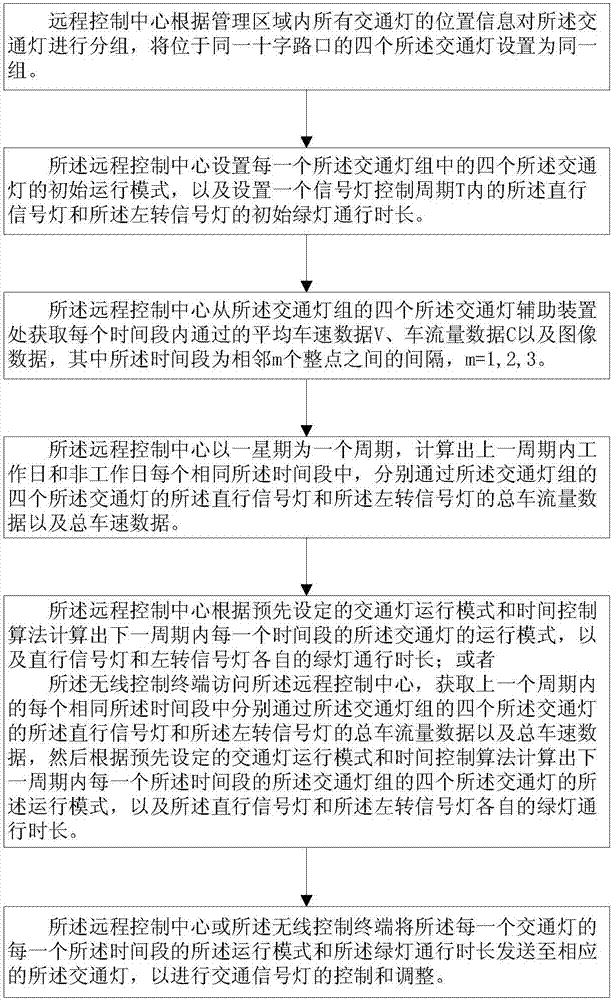

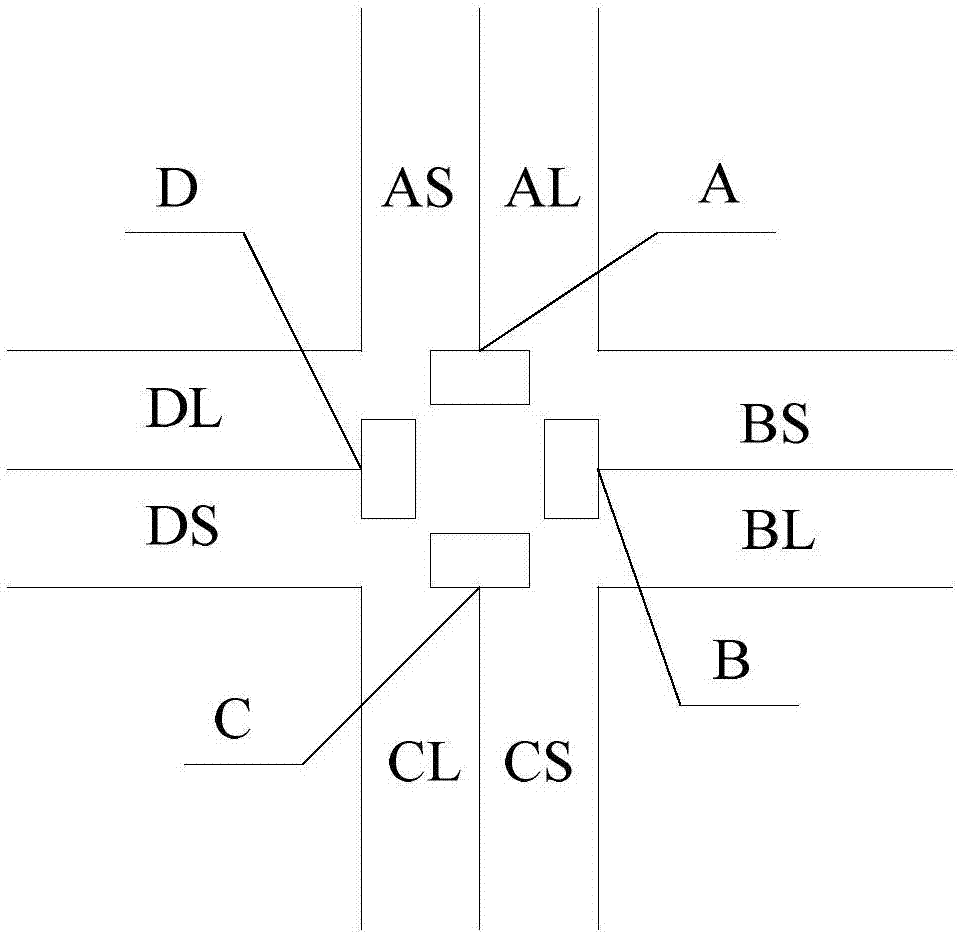

Crossroad traffic light control method based on Internet of Things

InactiveCN106875702ARealize intelligent controlSafe and smoothControlling traffic signalsWireless controlOperation mode

The invention provides a crossroad traffic light control method based on Internet of Things. The method is applied to a traffic light system comprising a remote control center, a wireless control terminal, traffic lights and a traffic light auxiliary device. The remote control center calculates total vehicle flow data and total vehicle speed data passing a straight going signal lamp and a left turning signal lamp of four traffic lights in a traffic light group in the same time period of working days and non working days in the previous period; and carrying out data calculation according to a traffic light operation mode and a time control algorithm to obtain an operation mode of the four traffic lights, and the green light passing duration of each straight passing signal light and each left turning signal light in the each time period in the next period. According to the invention, the operation mode and green light passing time are dynamically adjusted according to flows and speed of vehicles in each direction of the crossroad, so intelligent control of traffic is achieved and the safe and unblocked crossroad is ensured.

Owner:冀嘉澍

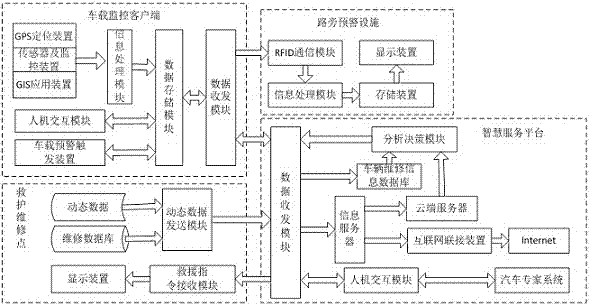

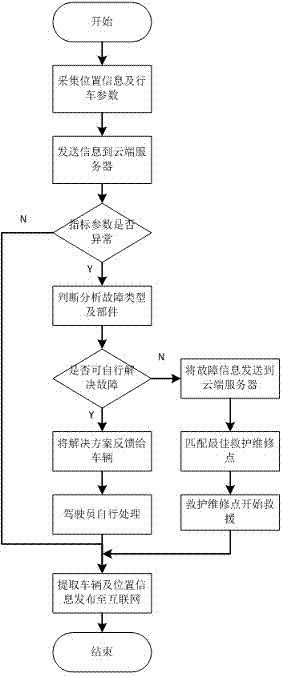

System and method for intelligent vehicle break-down service on basis of vehicle internet

ActiveCN103209220AGood matchImprove rescue level and service qualityTransmissionService systemVehicle networks

The invention discloses a system and method for vehicle break-down intelligence service on the basis of a vehicle internet. The vehicle network technology is used as a carrier, and the intelligent vehicle break-down service system composed of a vehicle-mounted monitoring client, a roadside communication facility, a rescue maintenance station and an intelligent vehicle service platform is built. A vehicle-mounted device acquires that vehicle running information and the intelligent service platform are interacted, and the intelligent service platform performs remote monitoring diagnosis control so as to master vehicle running state in real time and give specialized instruction. Once a vehicle runs abnormally, a vehicle-mounted terminal can automatically upload information to the intelligent service platform to request rescue, the intelligent service platform is interacted with information of the rescue maintenance station to feed back an optical rescue maintenance scheme to the broken-down vehicle so as to achieve efficient docking with emergency rescue, and simultaneously the broken-down vehicle enables warning content to be published on the roadside communication facility so as to perform early warning on subsequent vehicles in time.

Owner:JIANGSU UNIV

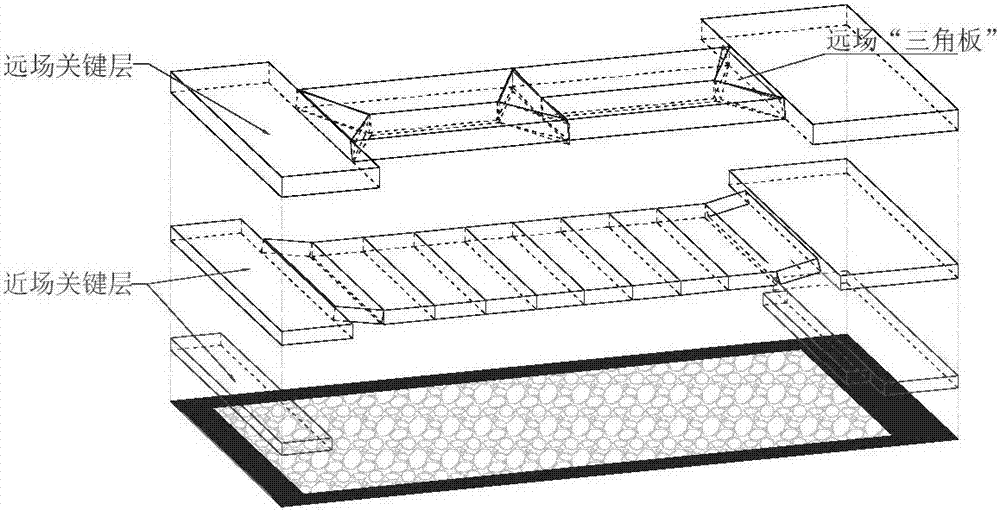

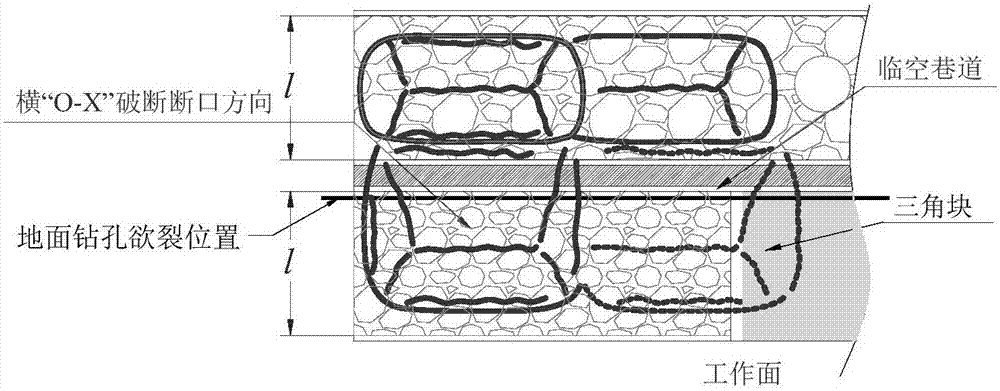

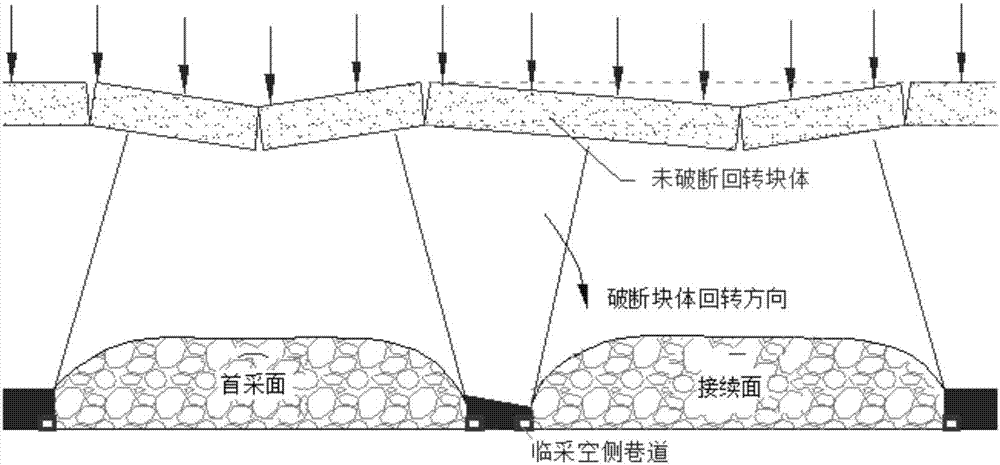

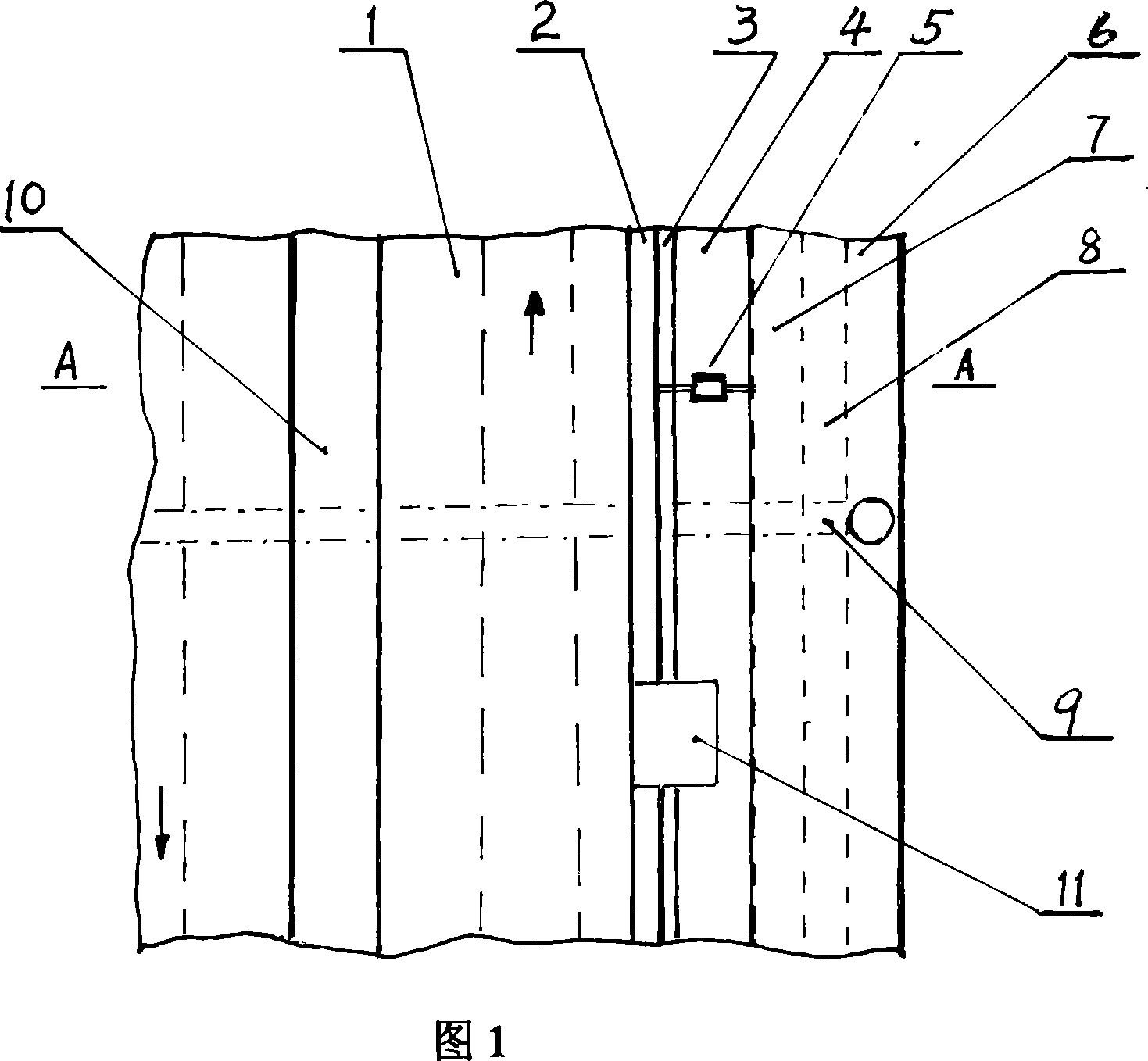

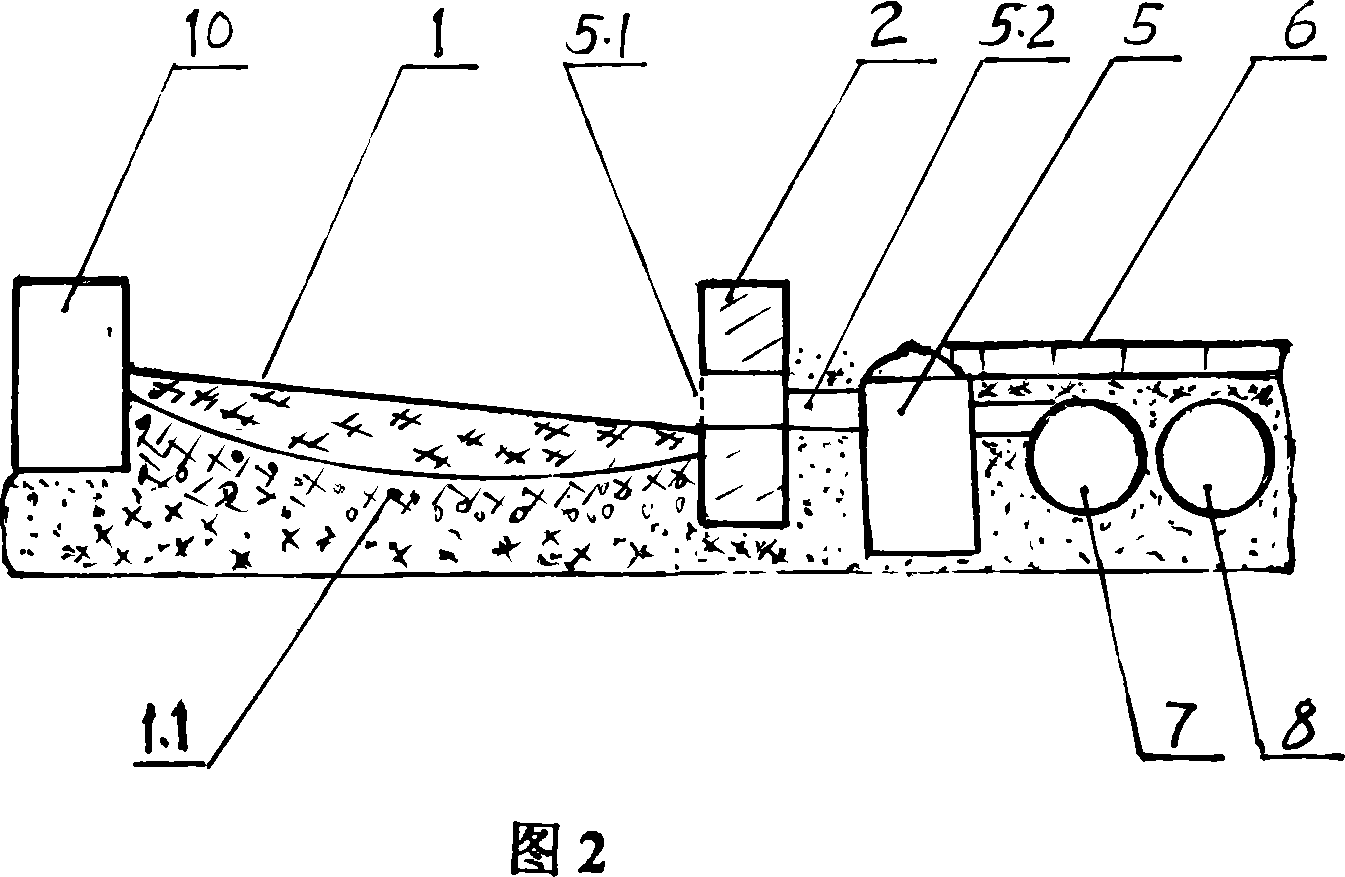

Far field key stratum roof cutting and pressure releasing roadway protection method based on triangular plate structure model

InactiveCN106894816AAlleviate the appearance of strong mine pressureSafe and smoothUnderground miningSurface miningEconomic benefitsEngineering

The invention discloses a far field key stratum roof cutting and pressure releasing roadway protection method based on a triangular plate structure model and belongs to the field of coal mining. The method comprises the steps that the stratum position of a far field key stratum influencing working face free roadway mine pressure behavior is determined; the arranged position coordinate of ground drilling is determined, and drilling construction is conducted; and a complete cutting fracture plane parallel to a coal pillar is formed on the far field key stratum through the ground drilling fracturing technology. Presplitting of the far field key stratum above a free roadway in advance is facilitated, and the cutting plane parallel to the coal pillar is formed on the far field key stratum, so that stress transferring is obstructed, mine pressure is released, the length of a lateral rotation block body of a fractured side original roof rock stratum of the free roadway is reduced, the strong mine pressure behavior of the free roadway can be relieved essentially, the supporting requirement of a roof is reduced, accordingly the reserved width of the coal pillar is reduced greatly, the coal recovery rate is increased effectively, and economic benefits are increased.

Owner:CHINA UNIV OF MINING & TECH

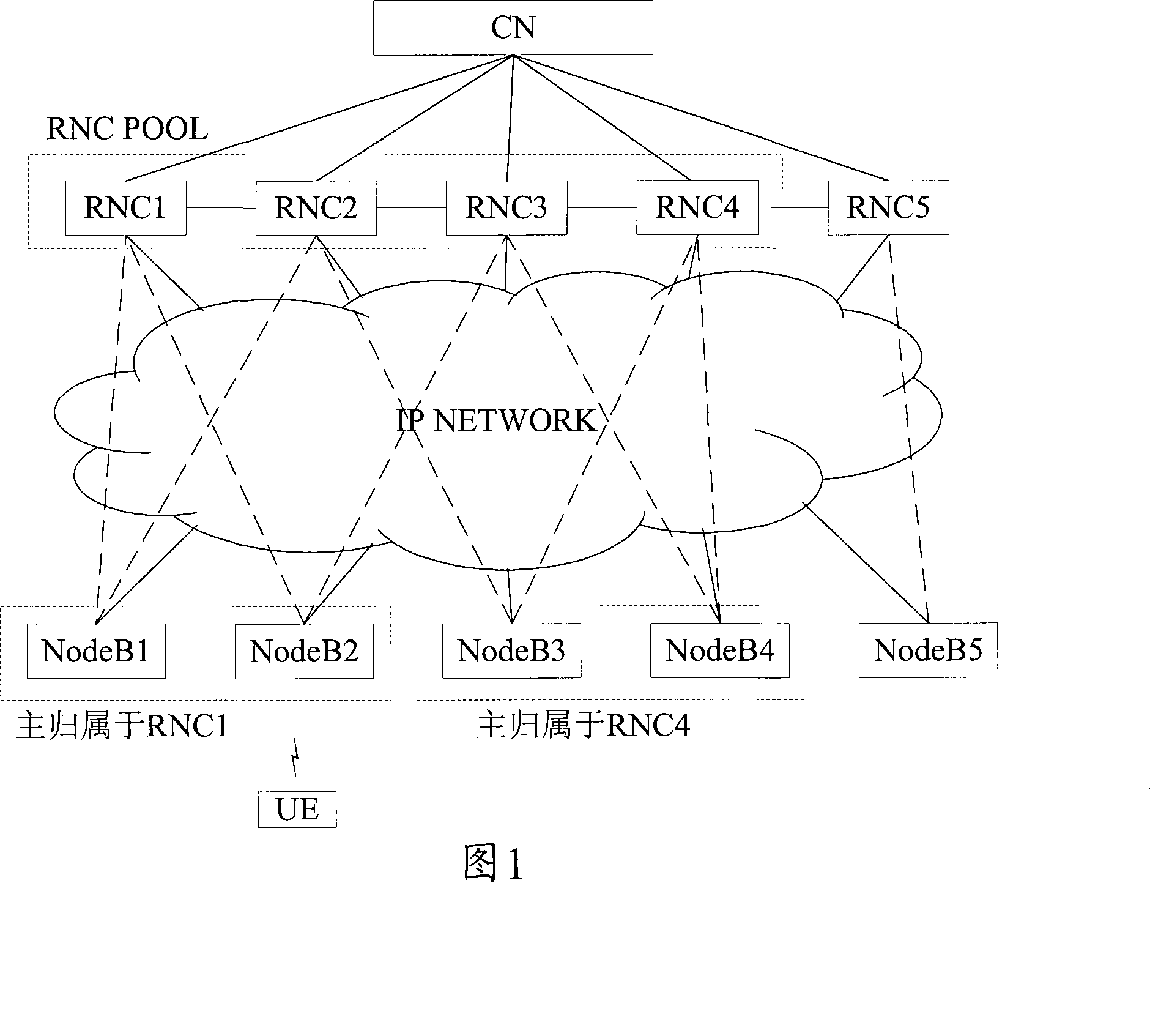

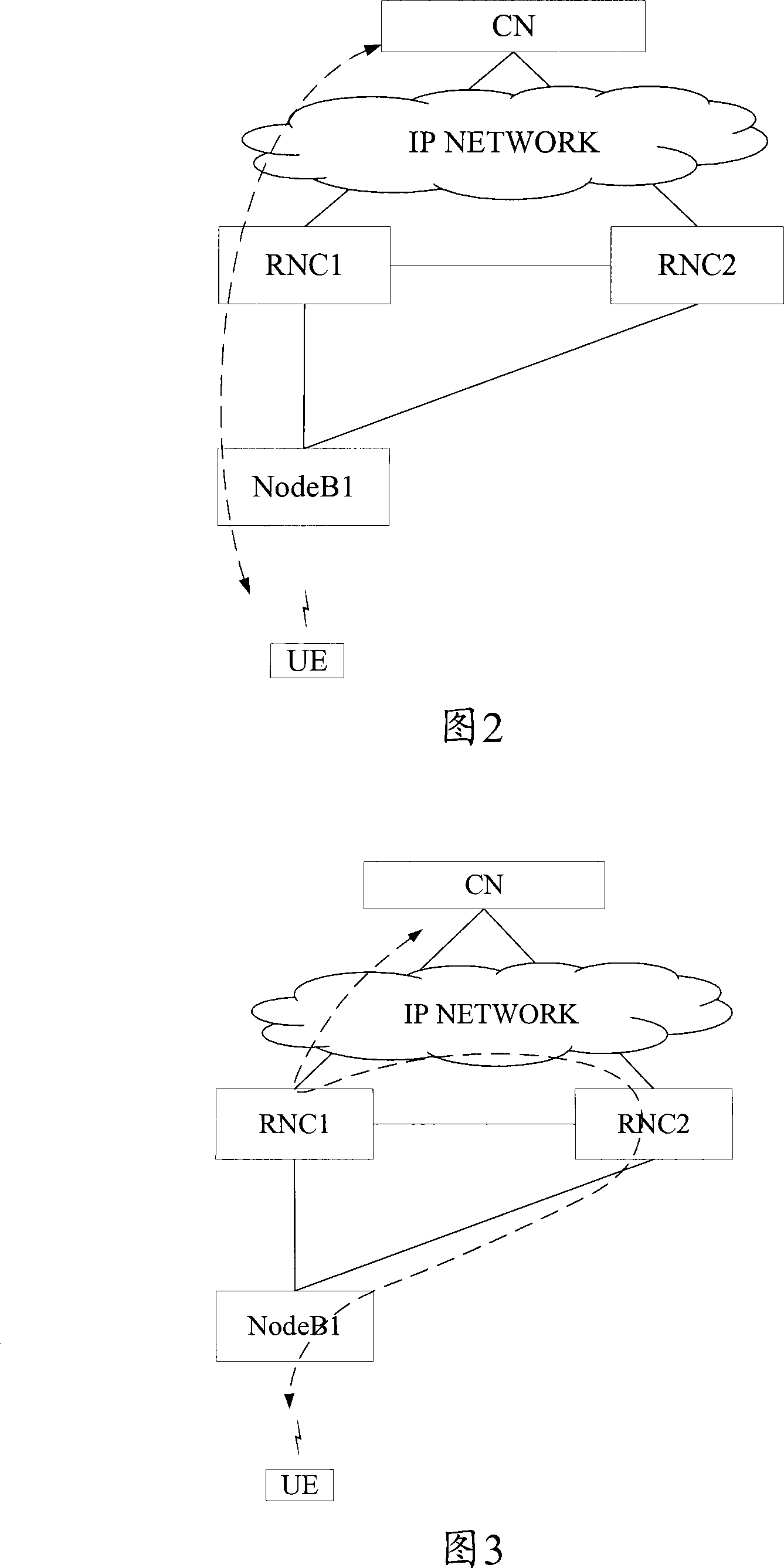

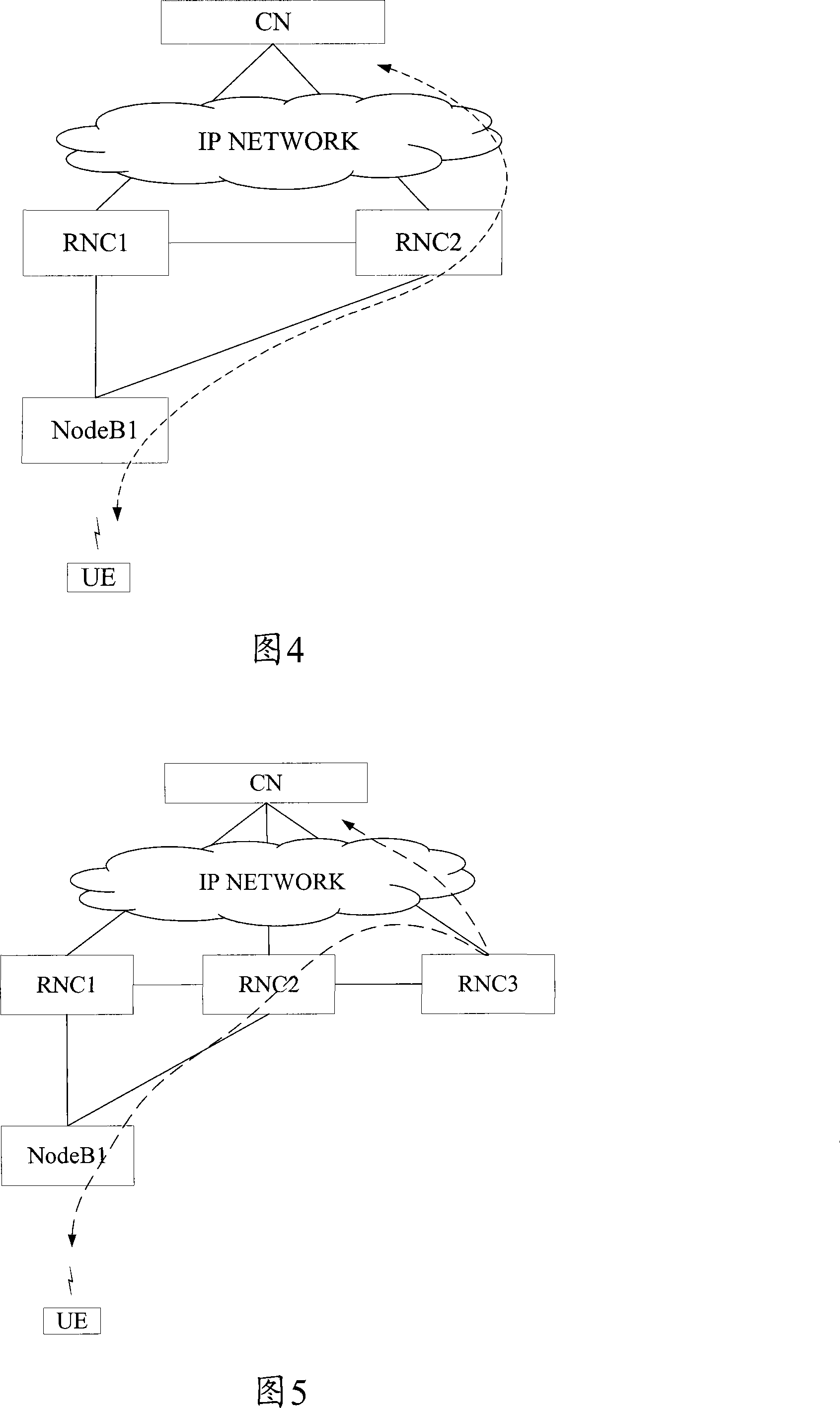

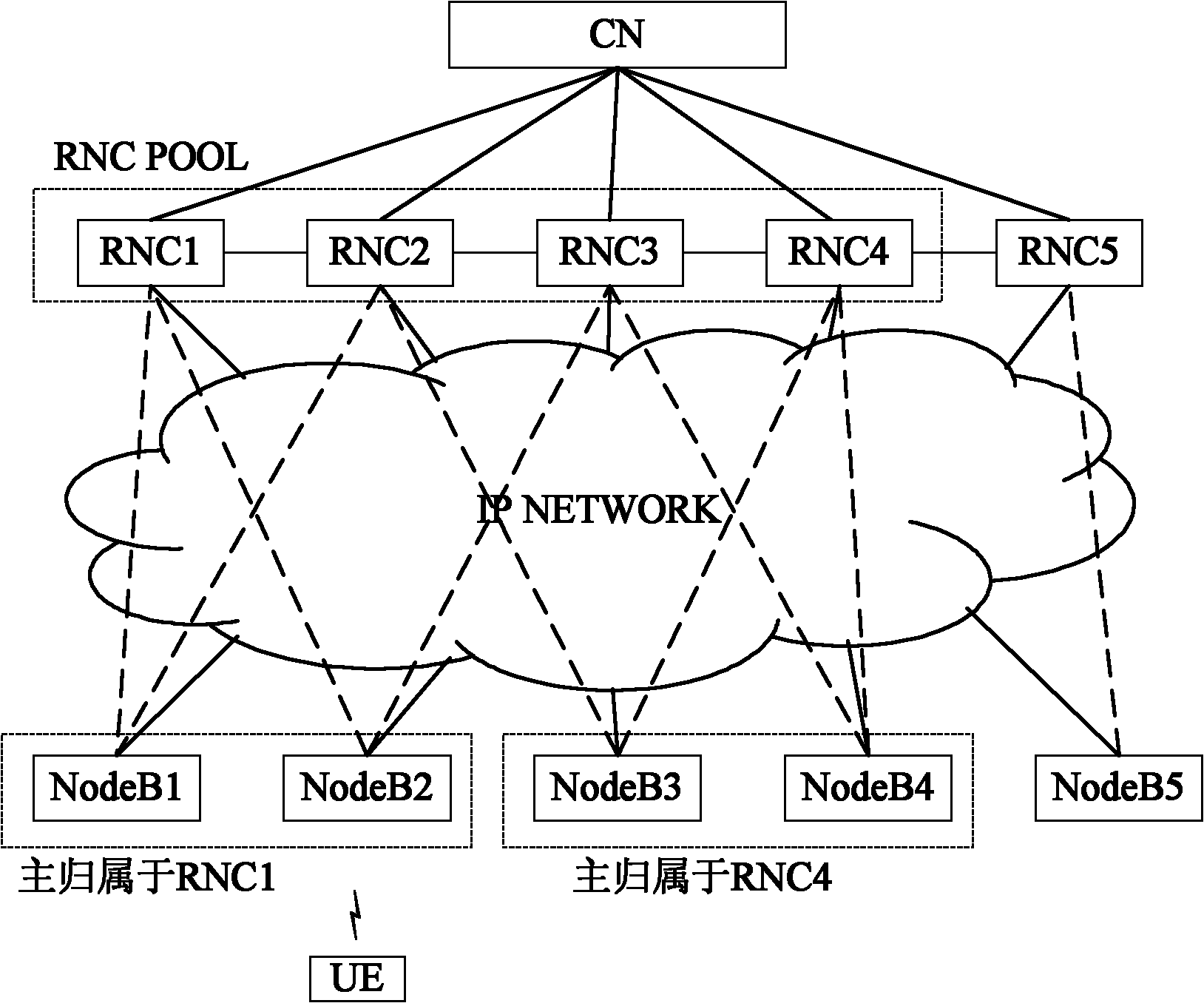

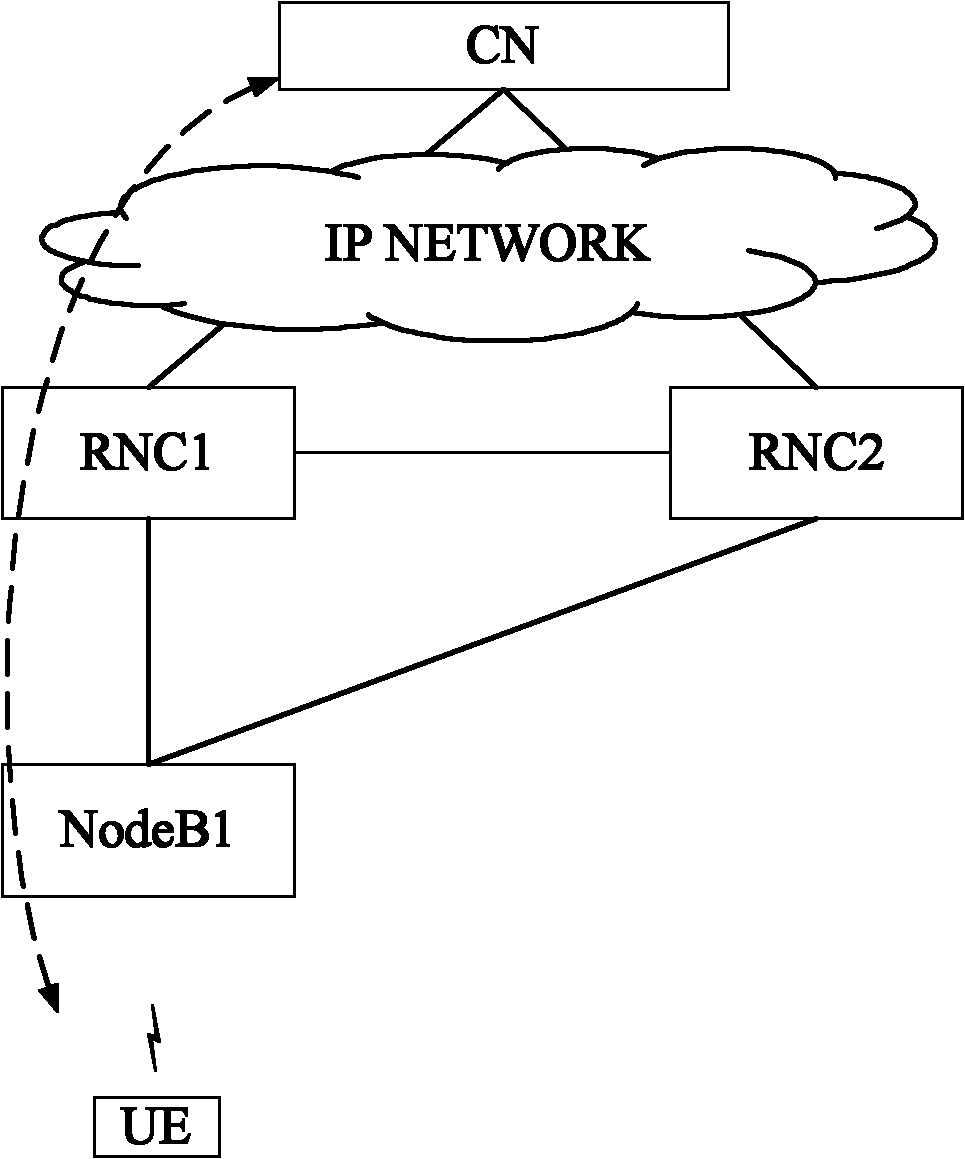

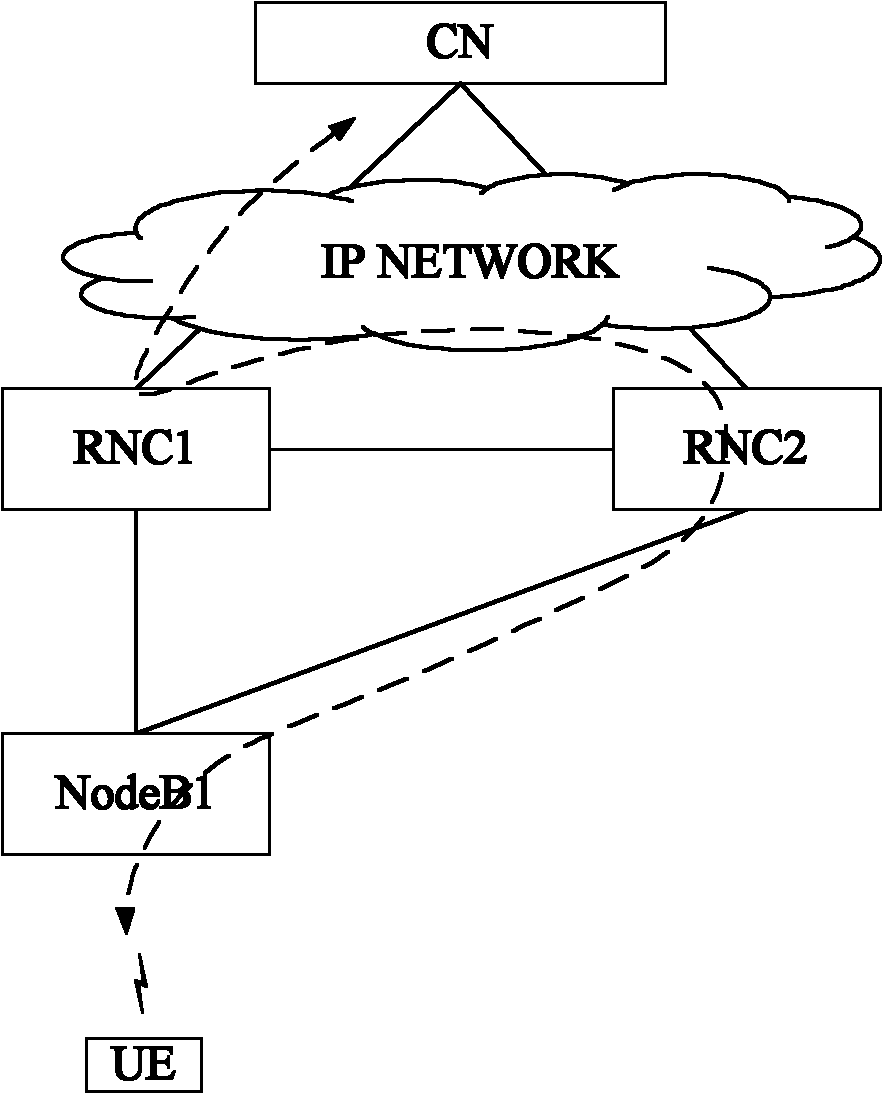

Wireless network system and communication method thereof

InactiveCN101232402AImprove reliabilitySafe and smoothError preventionData switching networksResource poolDependability

The embodiment of the invention discloses a wireless network system, which comprises a controller resource cell including all or some controllers in a wireless network. The controller resource cell includes a first controller and a second controller. The first controller is used for establishing a master attribution link with a base station, and the second controller is used for establishing a slave attribution link with the base station. When the master attribution link fails, the second controller is used for establishing a new master attribution link with the base station. The embodiment of the invention further discloses a communication method of the wireless network system, a controller and a base station. The scheme provided by the embodiment of the invention improves the reliability of network, increases utilization ratio of device resources and resistance to burst flow, reduces cost, shortens time for disaster-tolerant switching / interrupting service, and can satisfy high reliability requirement of a network operator.

Owner:HUAWEI TECH CO LTD

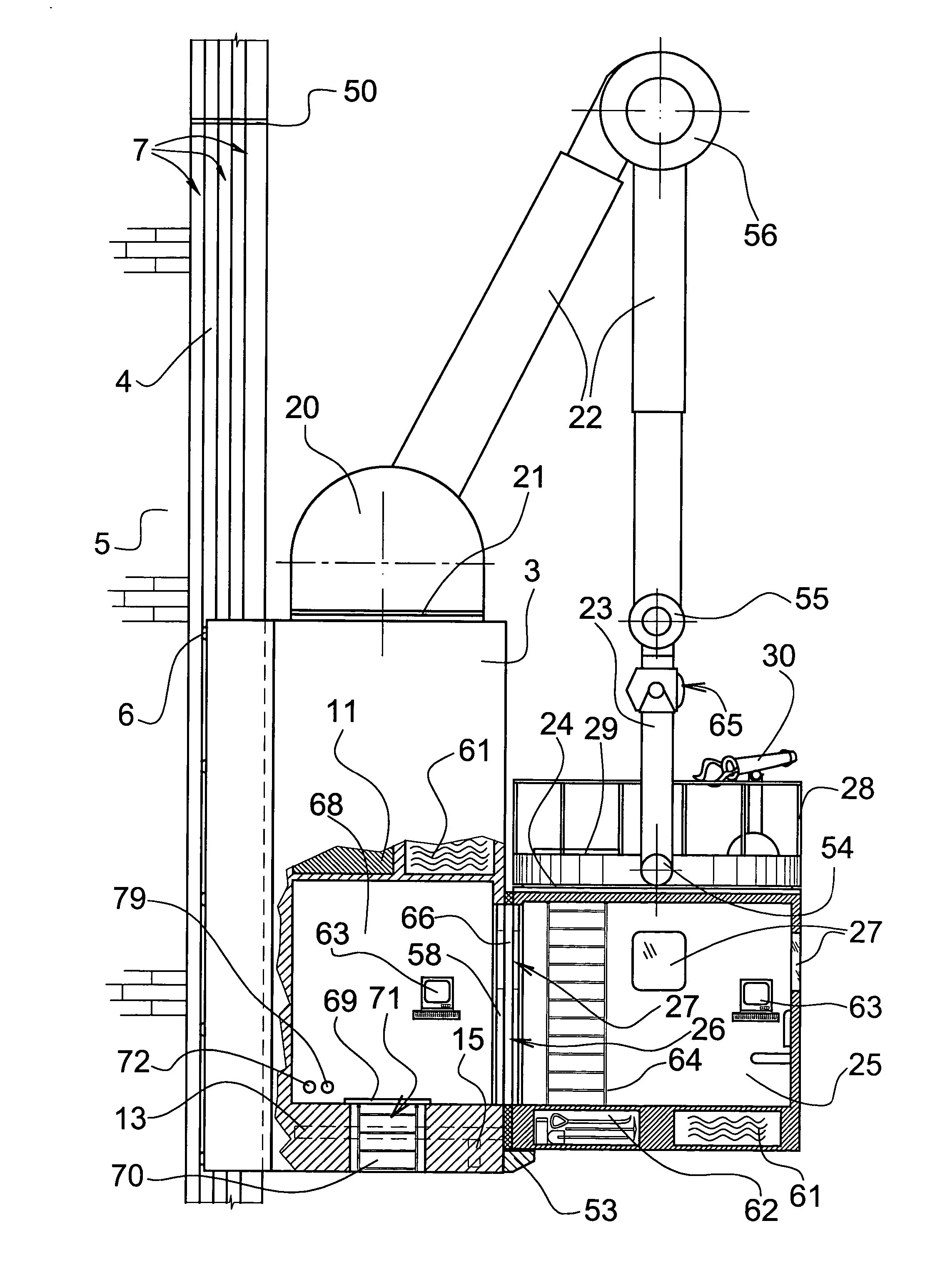

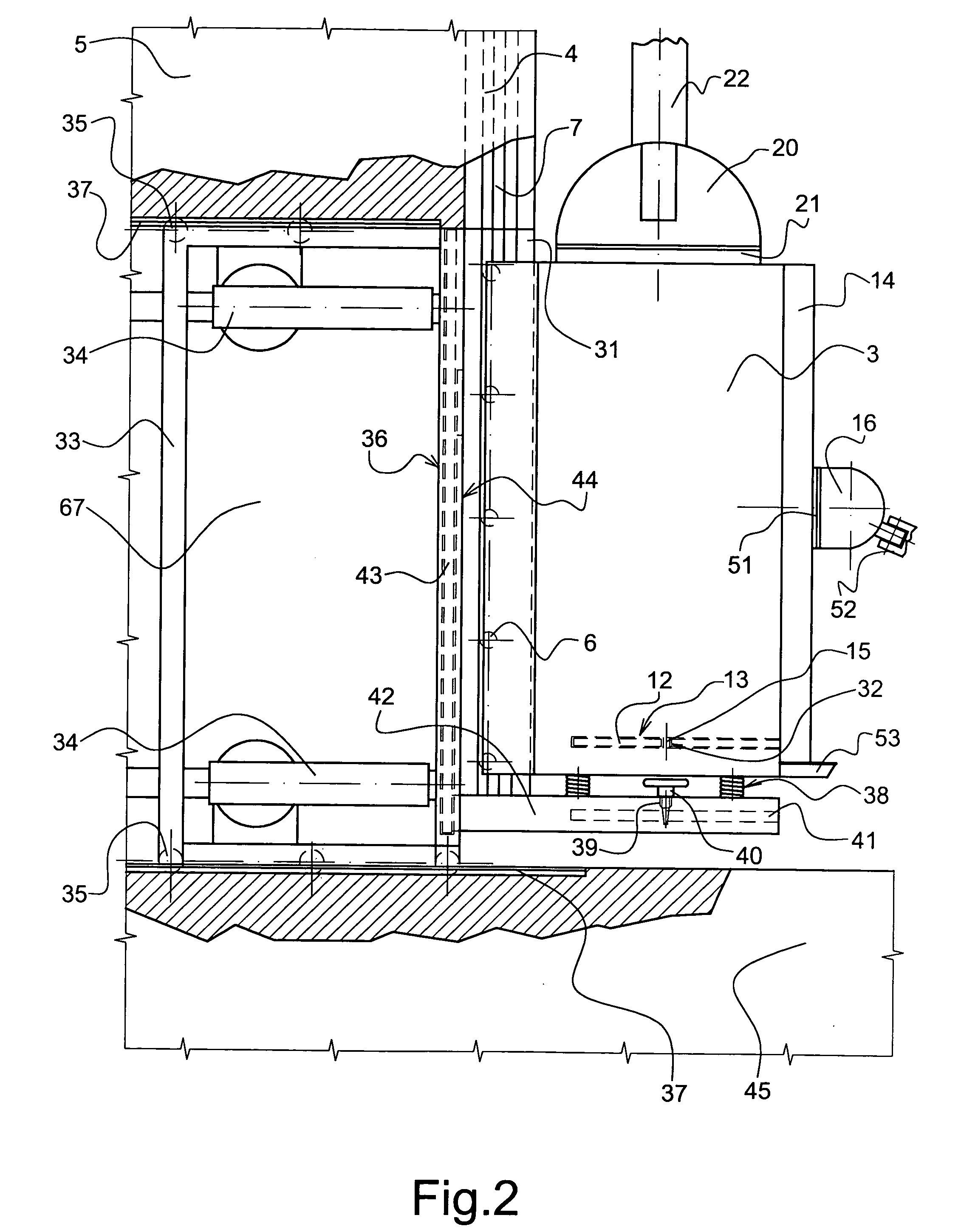

High-rise, fire-fighting, rescue and construction equipment

InactiveUS20050006178A1Transportation safetySafe and smoothBuilding roofsBuilding rescueNacelleElevator system

An elevator system for traveling on a rail attached to the outside of a high-rise building. One elevator has a telescopic arm attached for reaching any position on or above the building. The telescopic arm consists of two parts, which are interconnected with a pivoting mechanism. The crane portion has a rotating mechanism and a pivoting mechanism for supporting one end of the arm. A functional compartment is provided in a building, a sliding frame is mounted in this compartment, connected with jack mechanisms; with the help of these mechanisms the sliding frame can slide beyond the outer limits of the building and back. Smooth and safe sliding of the frame is ensured by its supporting wheels sliding in guiding rails mounted in the surfaces of the functional compartment. The sliding frame is equipped in its front part, with a receiving panel with the right and left “pocket” guiders on it. The attachable section of the H-shaped rail is equipped with a mounting panel, wit the similar square structure as of the receiving panel. The thickness of the mounting panel is less than a clearance between the “pocket” guiders and the outer surface of the receiving panel. The receiving panel is supplied with beveled guiding sides, and the mounting panel—with lower rounded corners. The lower part of the functional compartment has a concrete basis. The auxiliary portion has a movable ladder. The back surface of the cabin is equipped with an attachable frame supplied with round mechanical brushes and a profile with holes for fluid sprayers and air routes. The frame is also equipped with fixing handles for mounting-demounting operations of the attachable frame.

Owner:KORCHAGIN PAVEL V +4

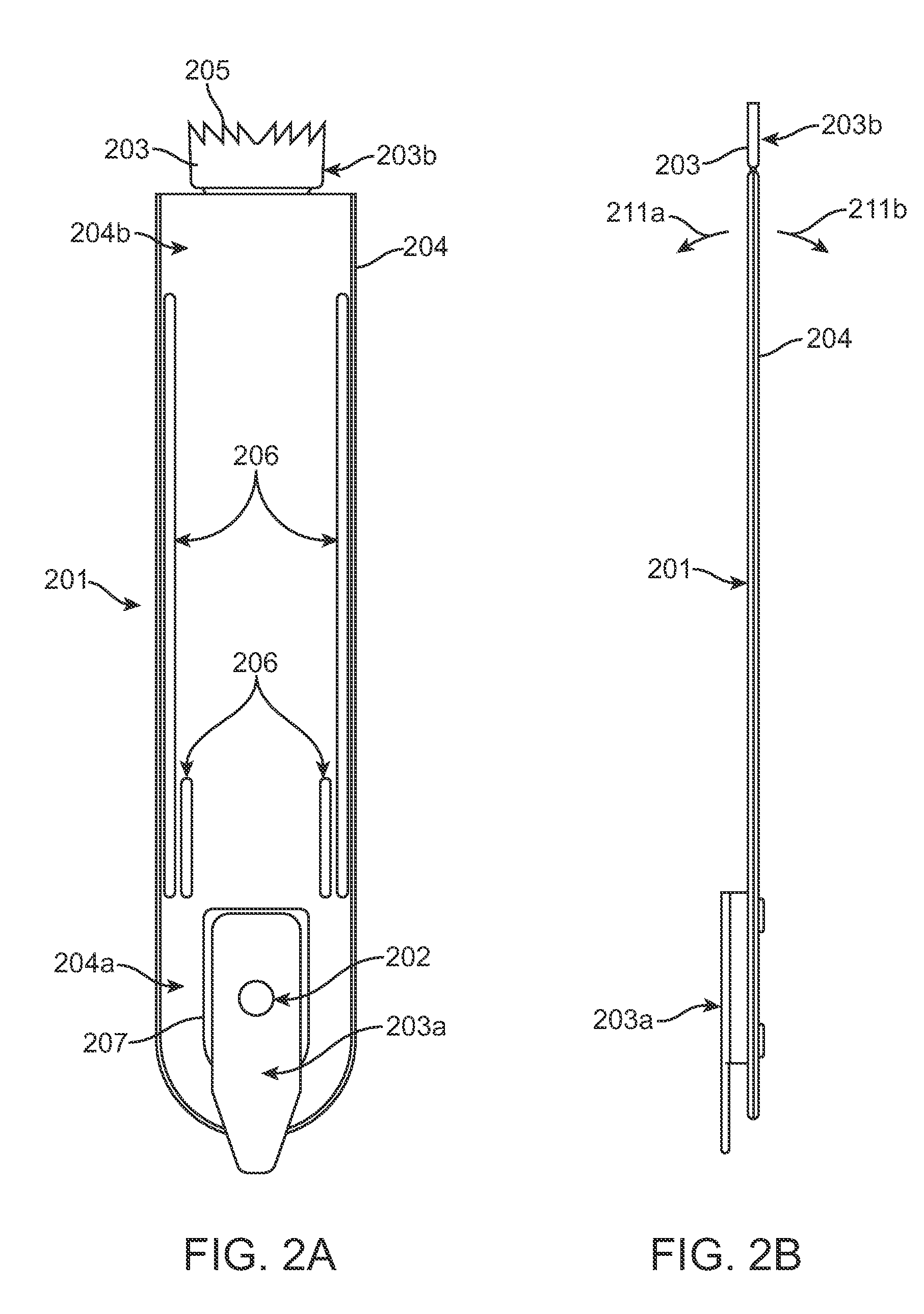

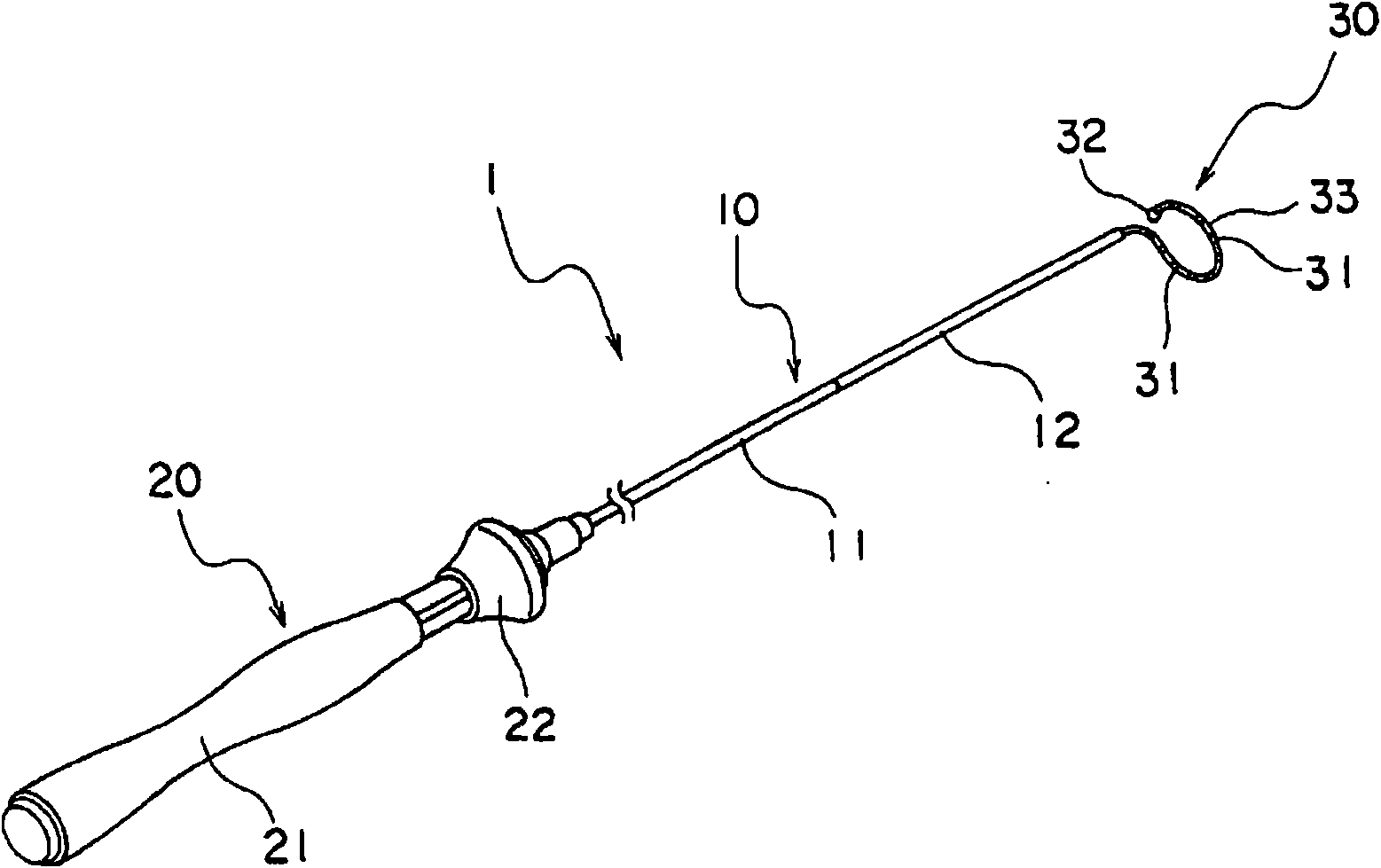

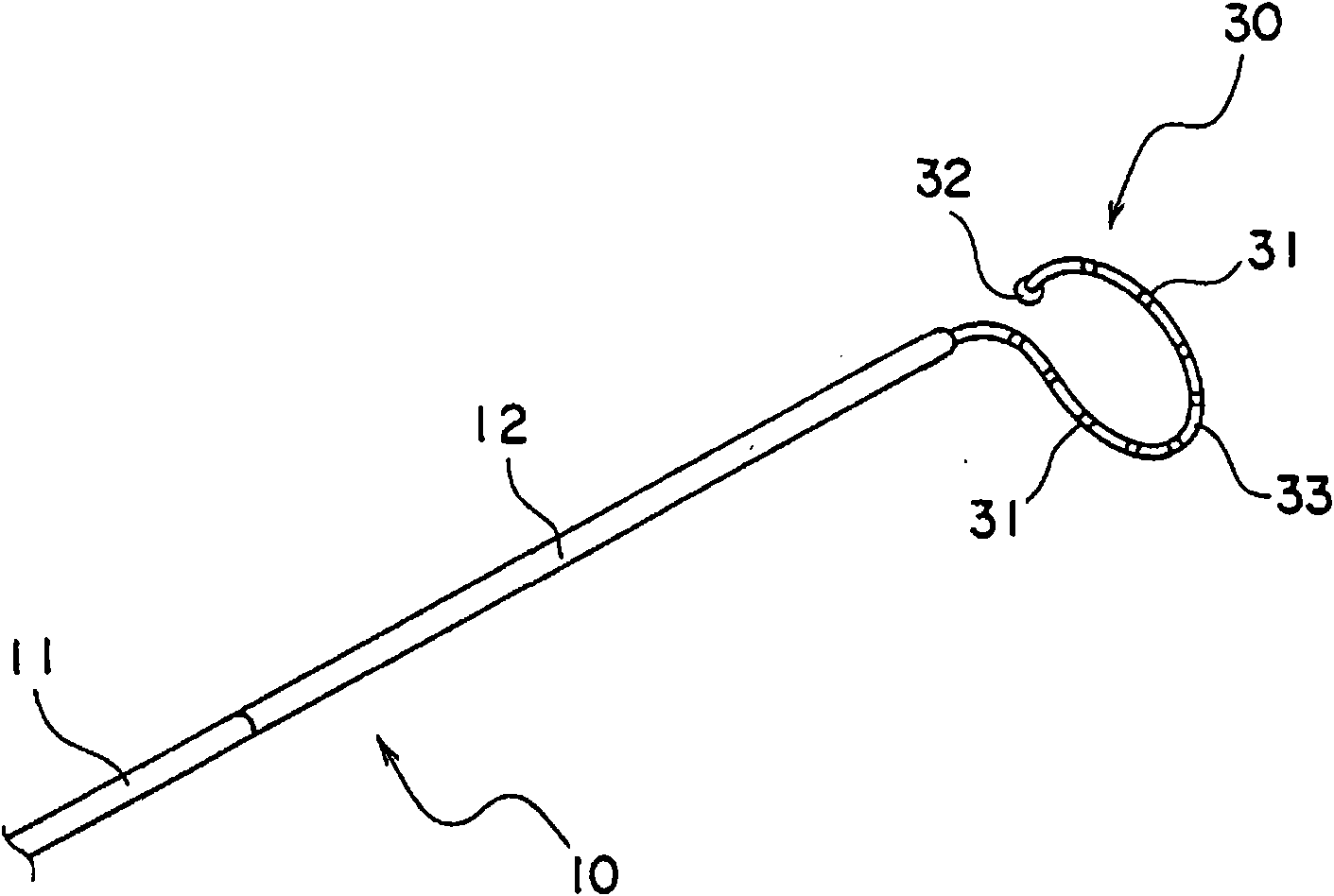

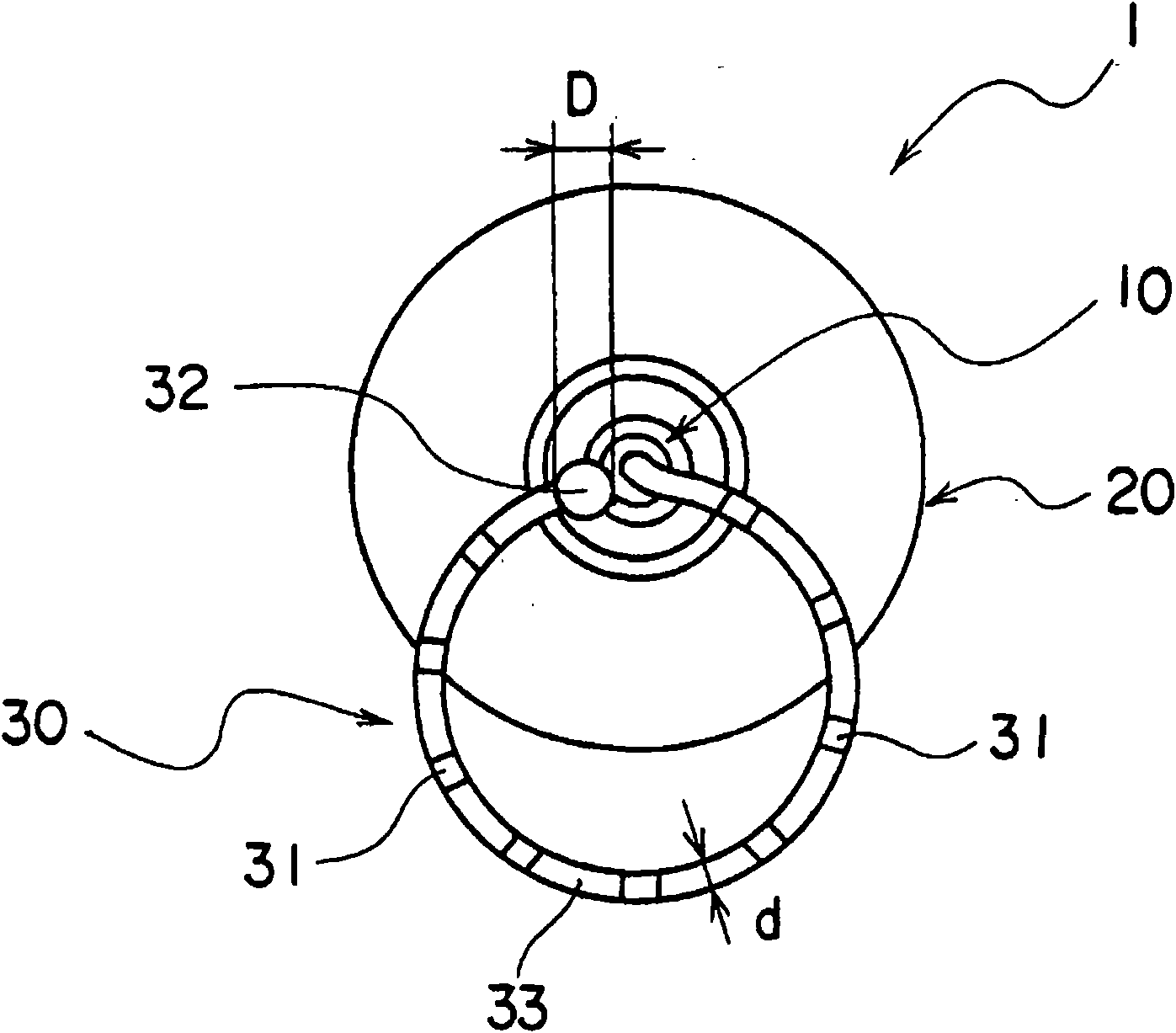

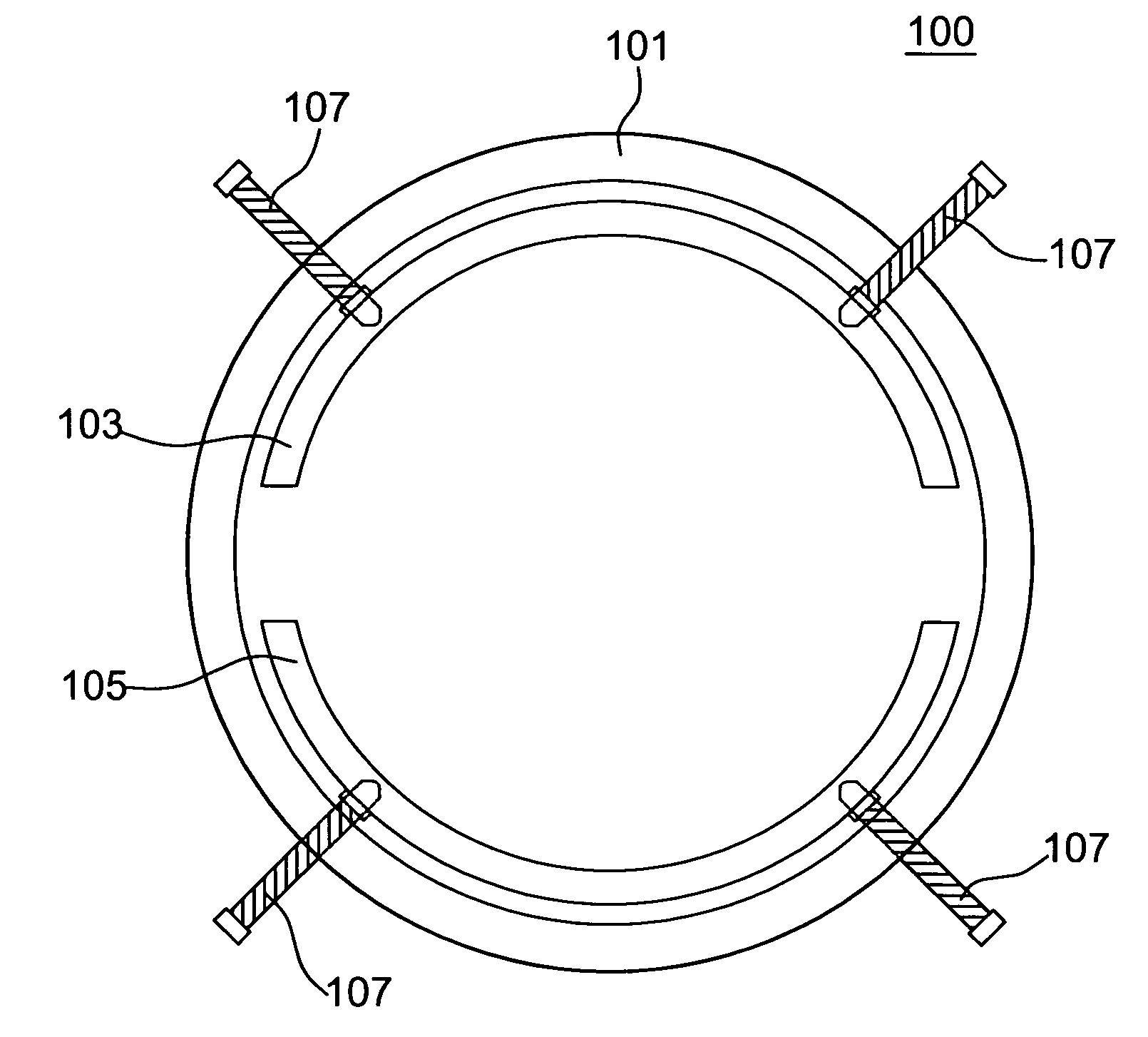

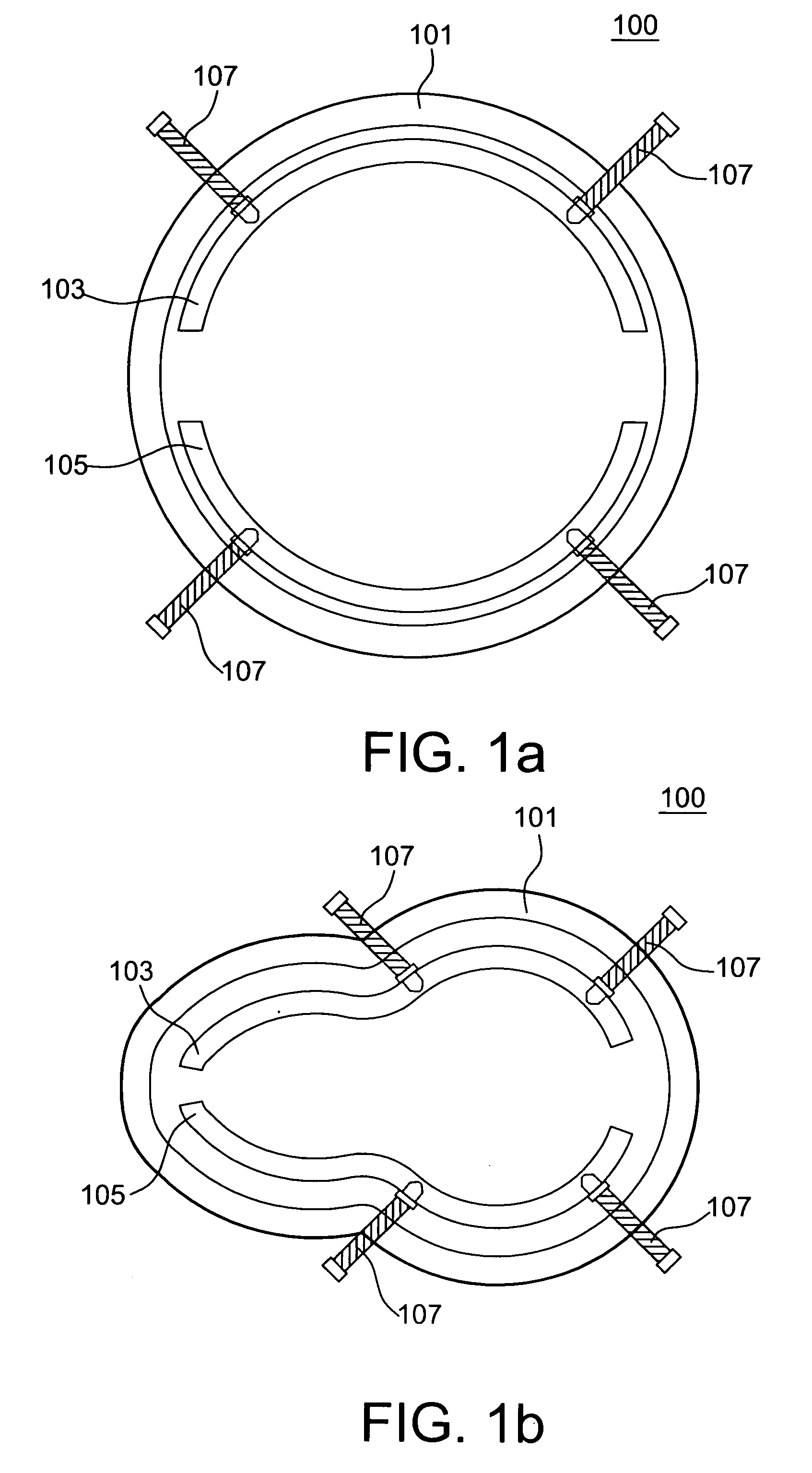

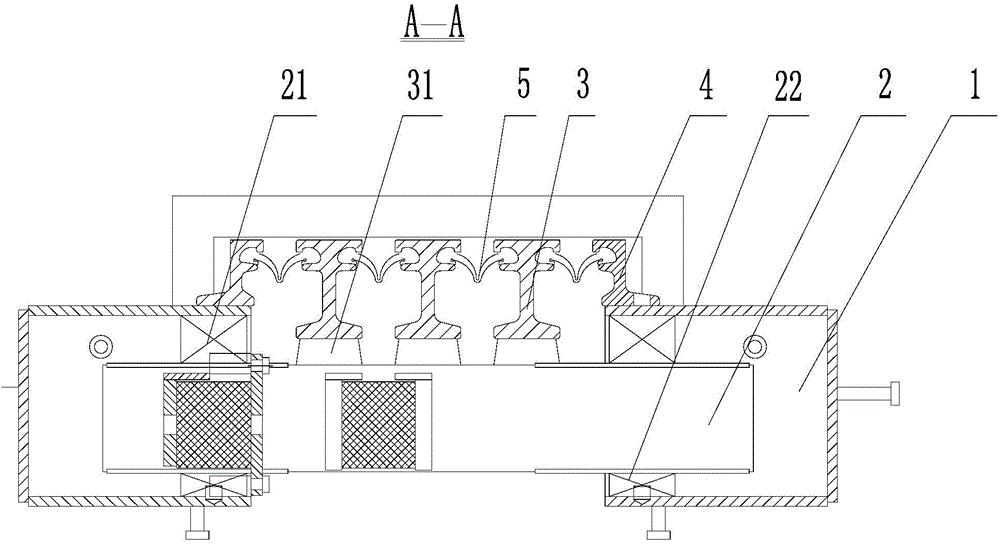

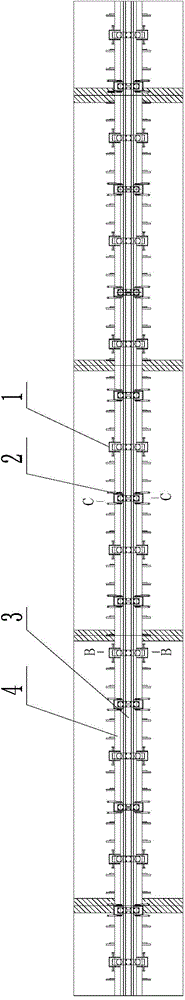

Electrode catheter

InactiveCN101626723ASafe and smoothReduce the risk of injuryElectrocardiographyCatheterBlood vesselCatheter device

An electrode catheter comprising: a catheter body (10) having one or more inner pores; a control handle (20) connected to the base end of the catheter body (10); and a catheter tip (30) which is connected to the top end of the catheter body (10), which has an inner pore communicatively connected to at least one of the inner pores of the catheter body (10), and which is formed in a circular, loop-like shape, wherein the catheter tip (30) has two or more ring-shaped electrodes (31) attached around the rim thereof and also has a spherical chip electrode (32) attached to the end part thereof. The electrode catheter can measure a potential almost on the whole area of the catheter tip and hardly damages the inner wall of a blood vessel with the end part of the catheter tip.

Owner:JAPAN LIFELINE CO LTD

Surgical saw blade device and system

A saw blade assembly for use with a driver having an oscillatory drive member comprises an elongate sheath and an elongate monolithic blade. The sheath's proximal end is removably mountable on the driver. The sheath has an open interior which receives the blade. The blade's proximal end is pivotably mounted to the sheath's proximal end. The blade's distal cutting end extends out of the sheath's distal end and is transverse to the blade's central longitudinal axis. When cutting bone, the drive member pivots the blade's cutting end back and forth in an arc about a pivot point at the blade's proximal end while the driver holds the sheath stationary to protect surrounding tissues from the motions of the remainder of the blade. The long pivot radius between the proximal pivot point and the distal cutting end contributes to minimizing the angle of engagement of the cutting end to the bone.

Owner:SYNVASIVE TECH

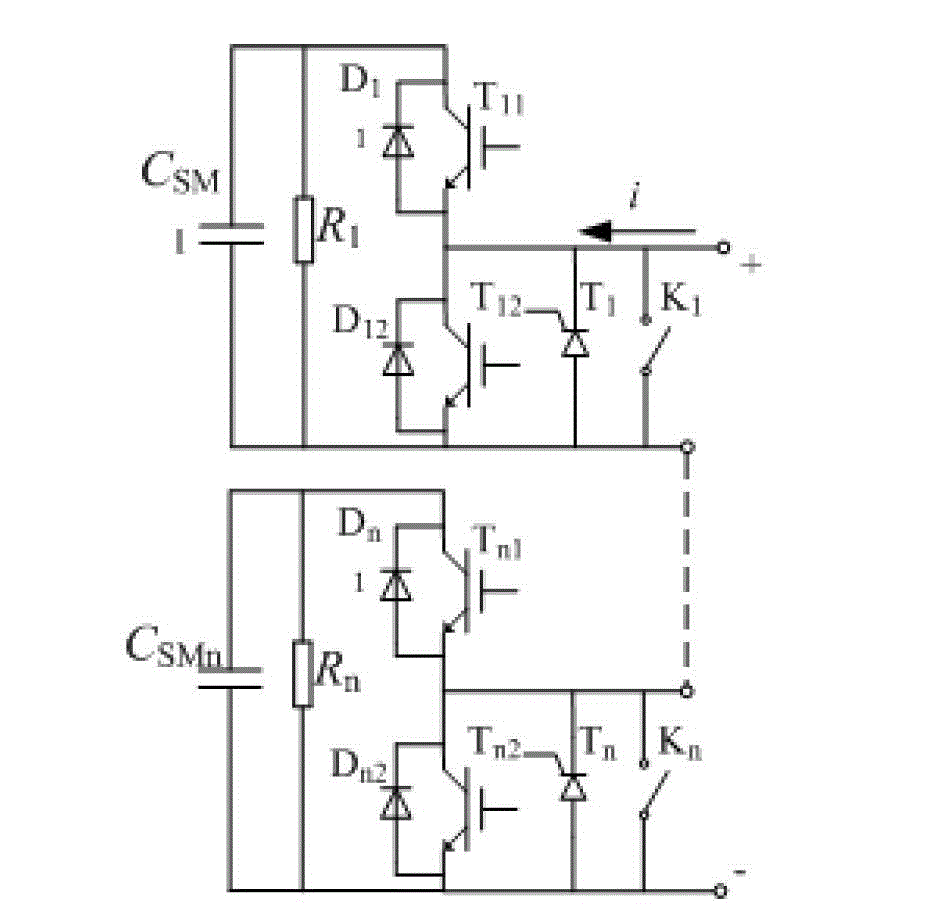

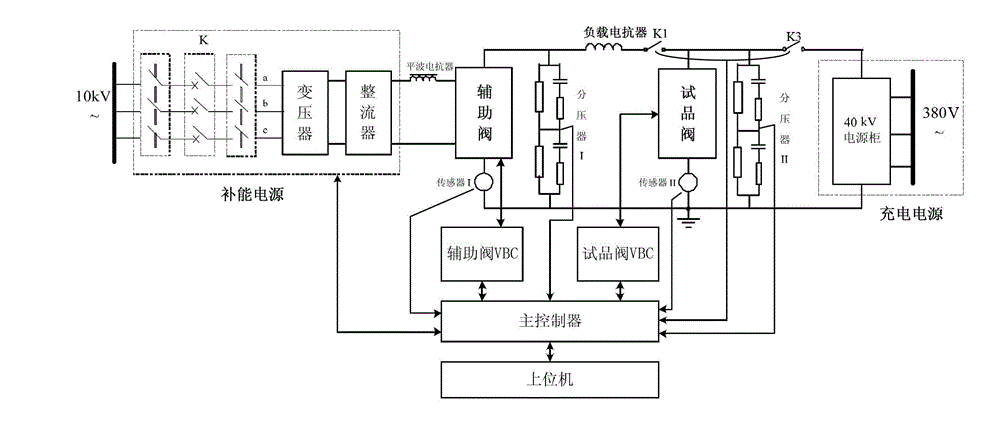

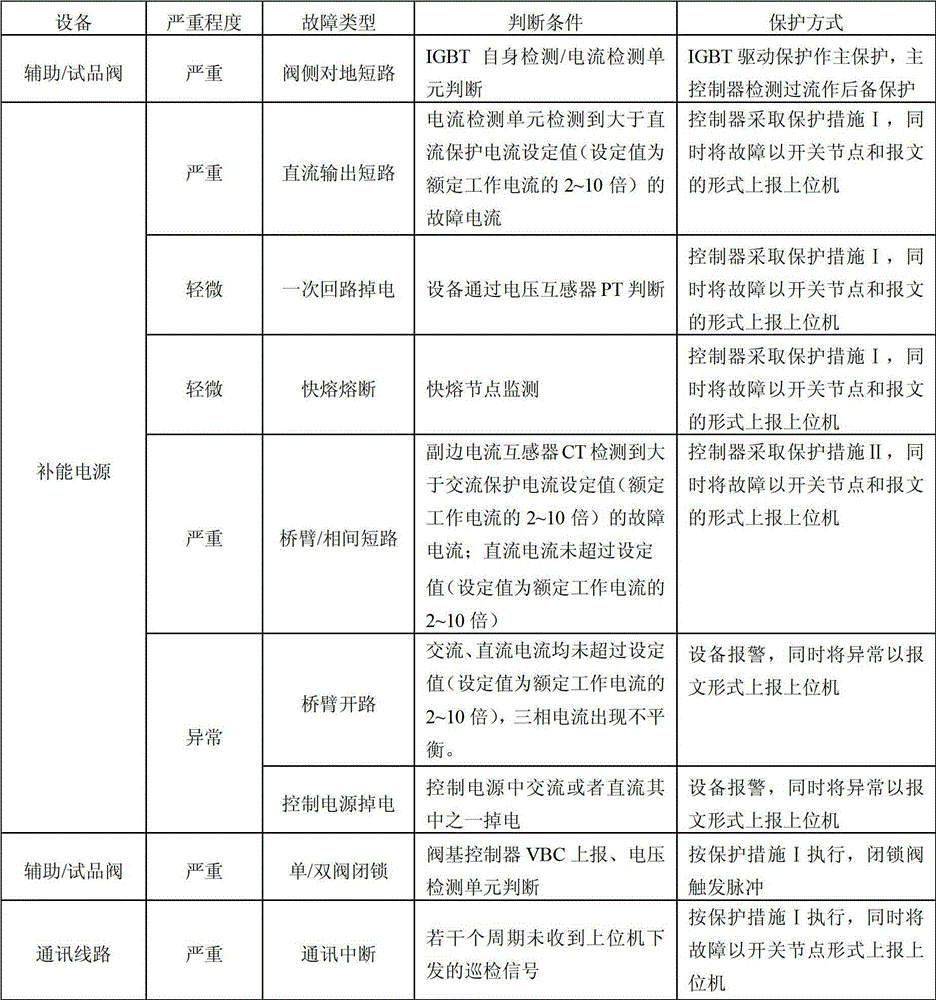

Fault protection method for steady-state operation testing apparatus of modular multilevel converter (MMC) valve

ActiveCN103064016AGuaranteed speedGuaranteed sensitivity and reliabilityAc-dc conversionCircuit interrupters testingRapidityReliability engineering

The invention relates to a fault protection method for steady-state operation testing apparatus of a modular multilevel converter (MMC) valve. The fault protection method selects one protection mode according to fault types. The fault types include earth fault, energy complementing power fault, valve fault and communication fault. When the earth fault occurs, insulated gate bipolar translator (IGBT) driving protection of an MMC auxiliary valve or an MMC sample valve is used as main protection and over-current detection of a main controller is used as backup protection. When the energy complementing power fault occurs, a protective measure I or a protective measure II is carried out, the energy complementing power gives an alarm and reports the fault or abnormality to an upper computer. When the valve fault occurs, the protective measure I is carried out, trigger pulse of the MMC auxiliary valve or the MMC sample valve is shut. When the communication fault occurs, the protective measure I is carried out and fault is reported to the upper computer. By means of the fault protection method, fault types are recognized and all the faults are graded, all kinds of protection are arranged in different levels and are matched with one another, and thus rapidity of protecting actions is ensured and fault removal of the testing device is benefited.

Owner:STATE GRID CORP OF CHINA +2

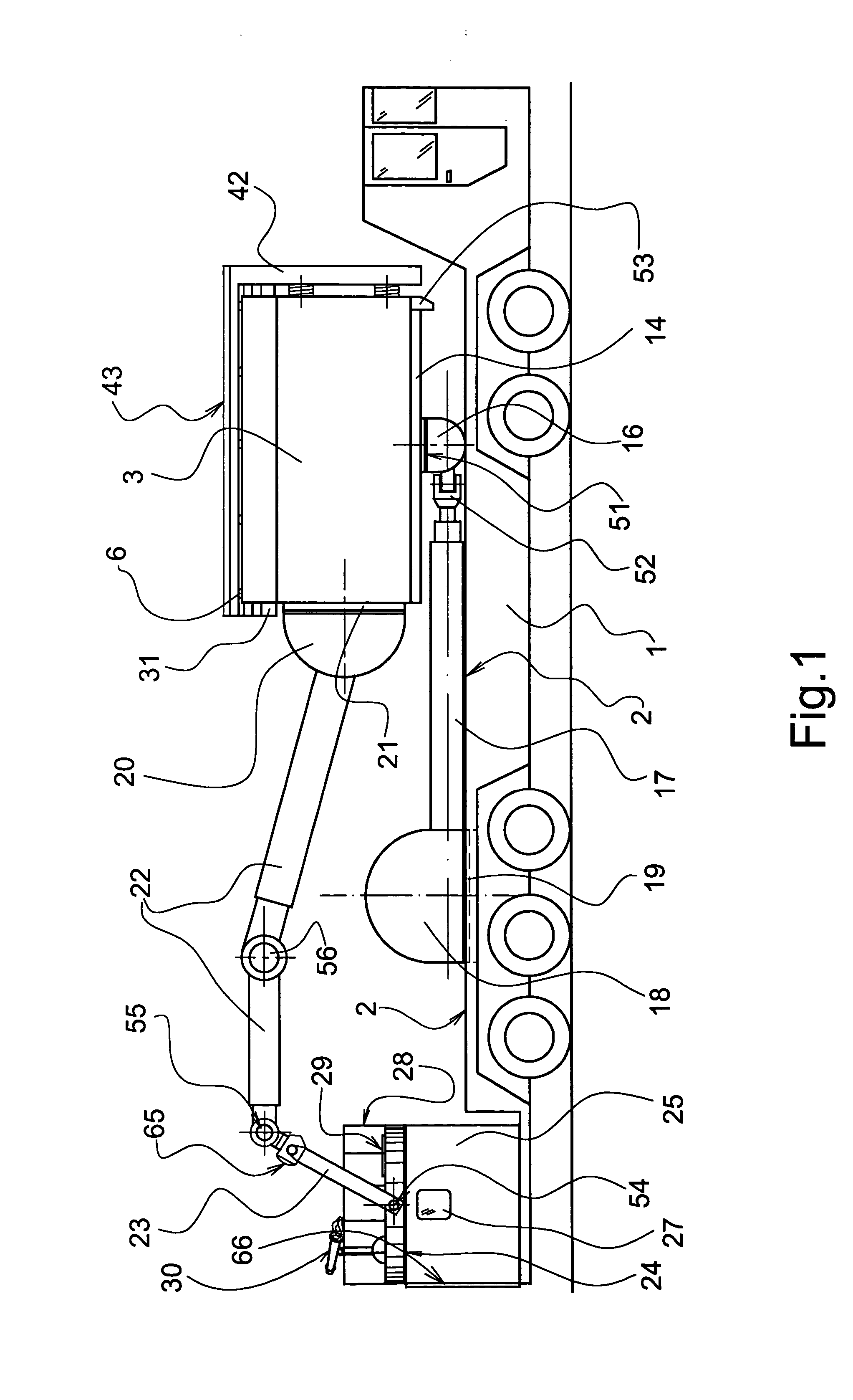

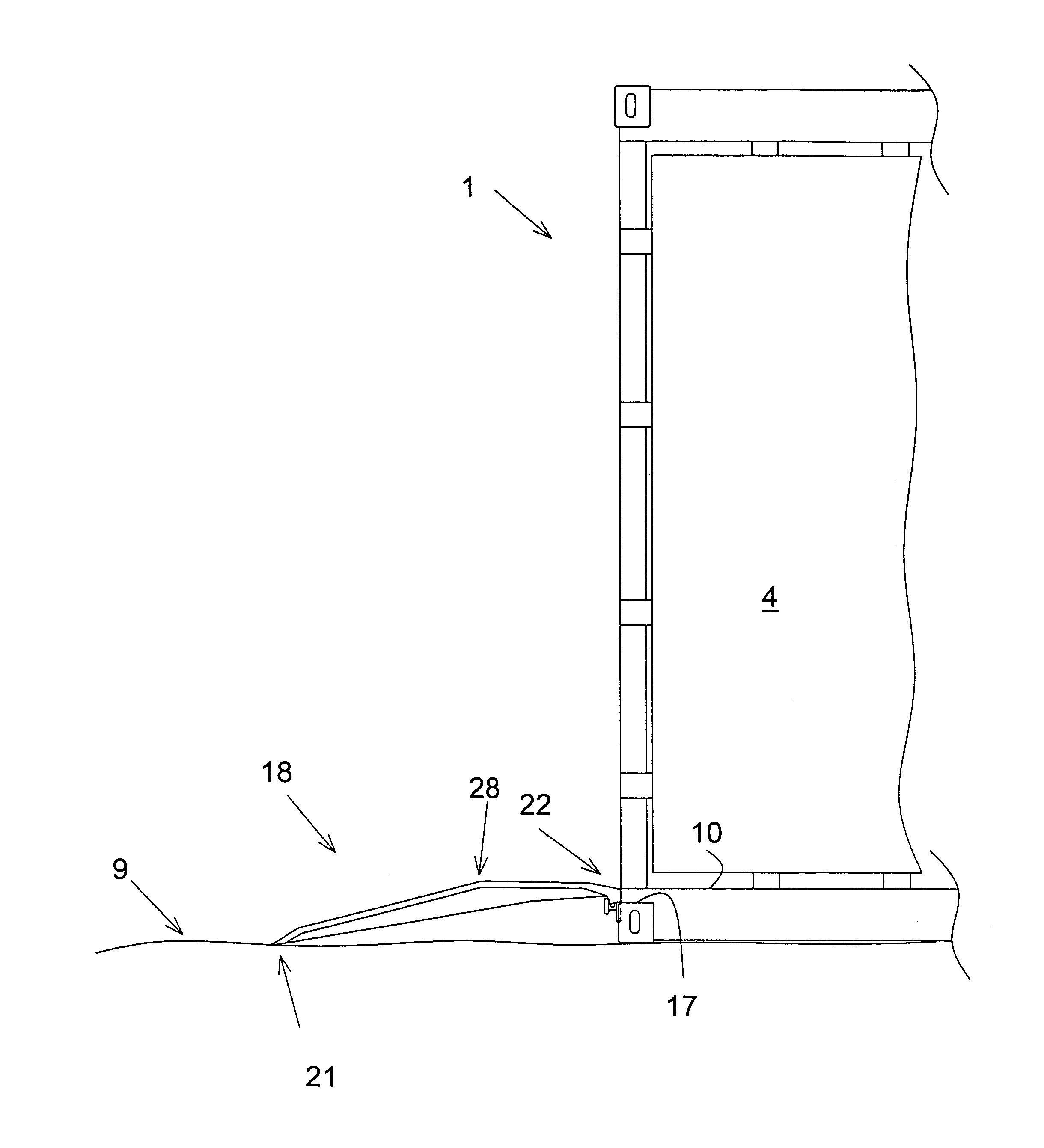

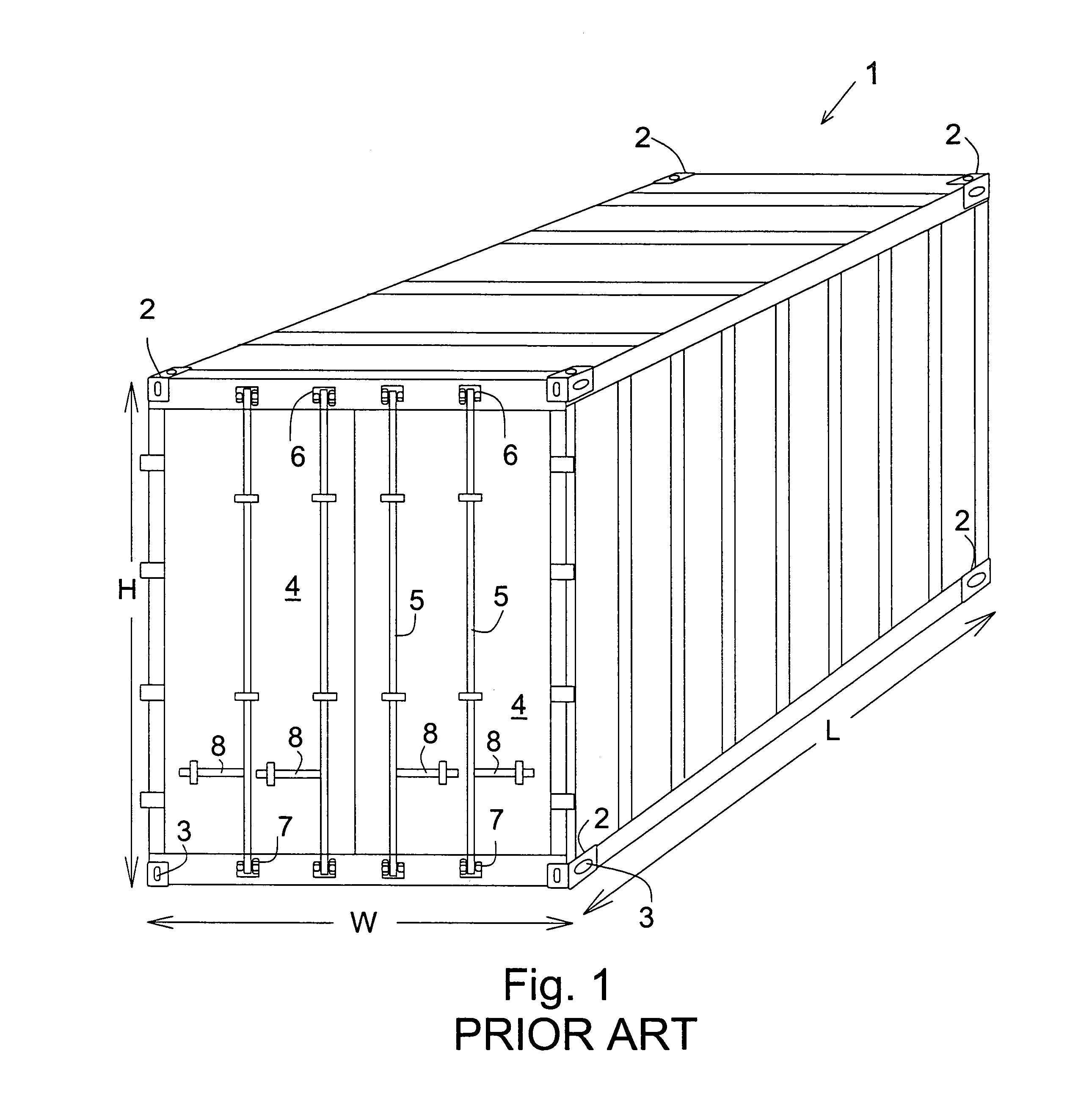

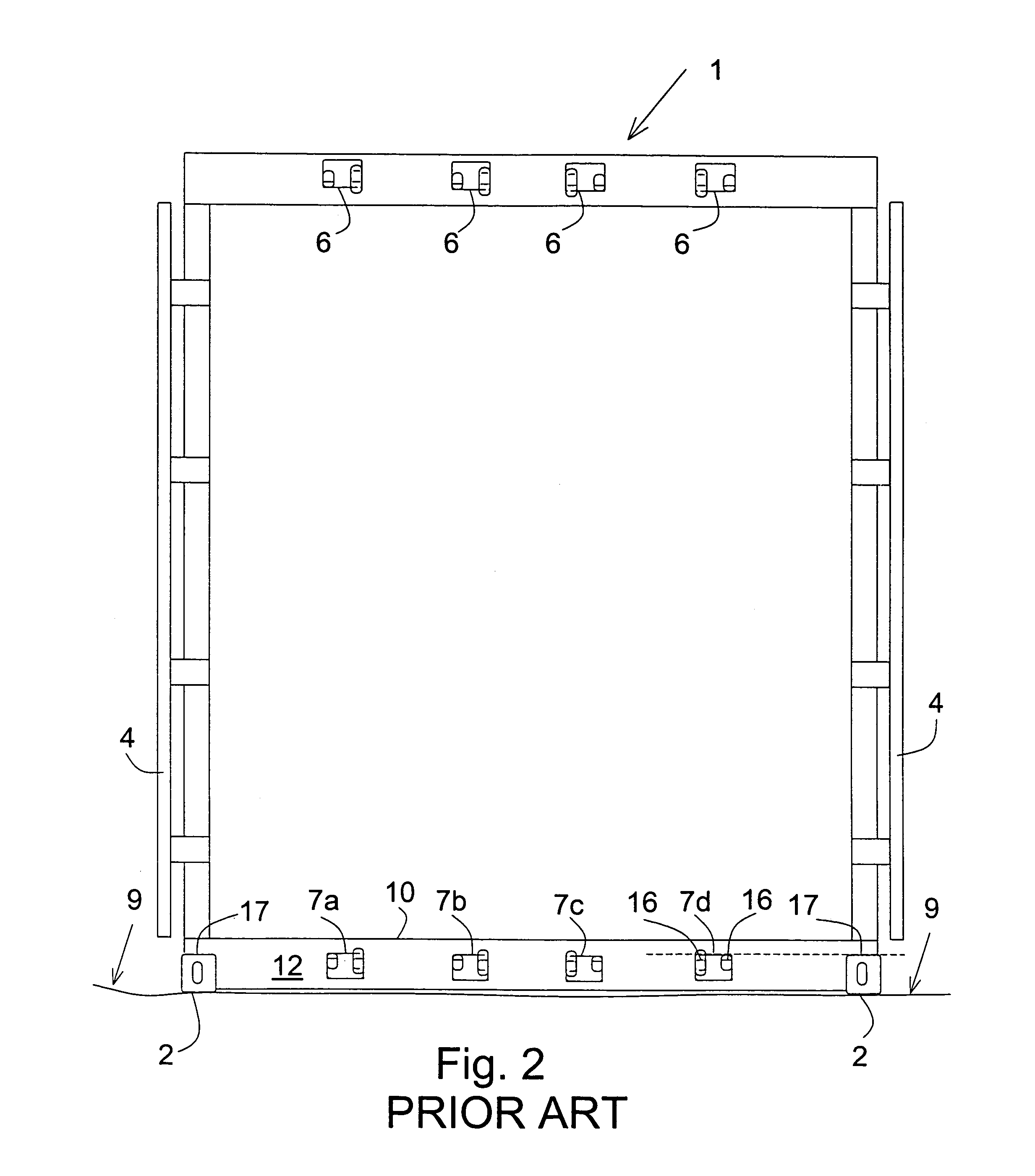

Loading ramp for standardized intermodal freight containers

A ramp for use in bridging from a floor of an ISO standardized intermodal freight container to a placement pad on which the container is placed. An upper lip of the ramp is configured to engage with lower locking lugs of the container, which, although they are not covered by the standard, are found on most containers to be of similar design and located at substantially the same location on each container. The engaged upper lip of the ramp prevents movement of the ramp away from the container and in sideward directions to provide a safe surface for use by workers and equipment when loading or unloading the container.

Owner:EAGLE MFG

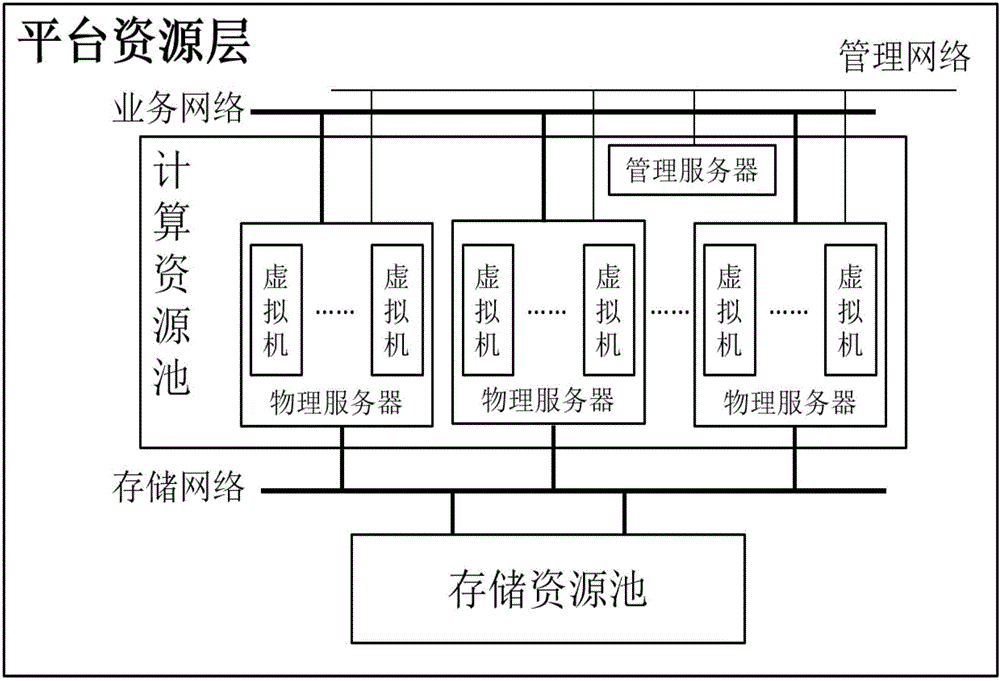

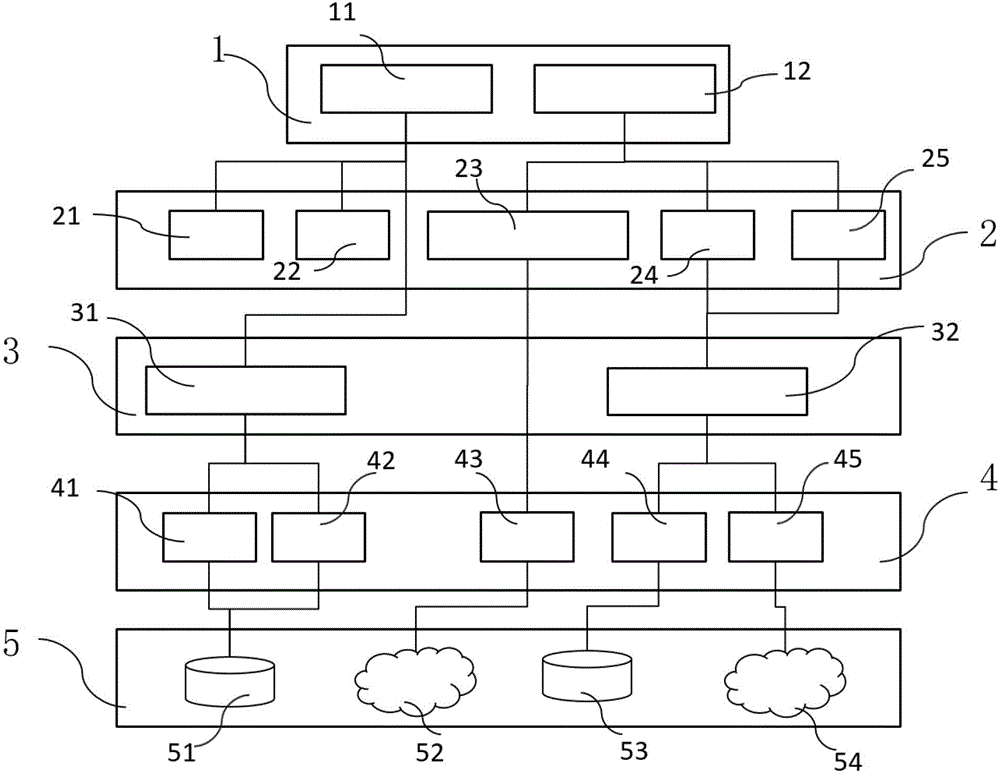

Multi-store e-commerce cloud system based on cloud computing and mobile Internet technology and ordering shopping realization method thereof

InactiveCN106372995AGuaranteed unitySafe and smoothBuying/selling/leasing transactionsTechnical designMobile internet

The invention relates to the computer application technology field and particularly relates to a multi-store e-commerce cloud system based on cloud computing and the mobile Internet technology and an ordering shopping realization method thereof. The system comprises a presentation layer, a business layer, a service layer, a basic application layer and a platform resource layer, wherein the presentation layer is a user experience end, including a Web end mall, APP, or a micro mall of a WeChat public number, and the business layer is a business flow layer and is used for realizing main business flows of the e-commerce cloud system. According to the system, a data processing speed and information exchange timeliness are improved through advanced configuration, and better merchant and client experience effects are realized. The system further has advantages of safety, advancement, normalization, investment protection, high availability, reliability, applicability, easy operation, scalability and compatibility.

Owner:陈建强 +2

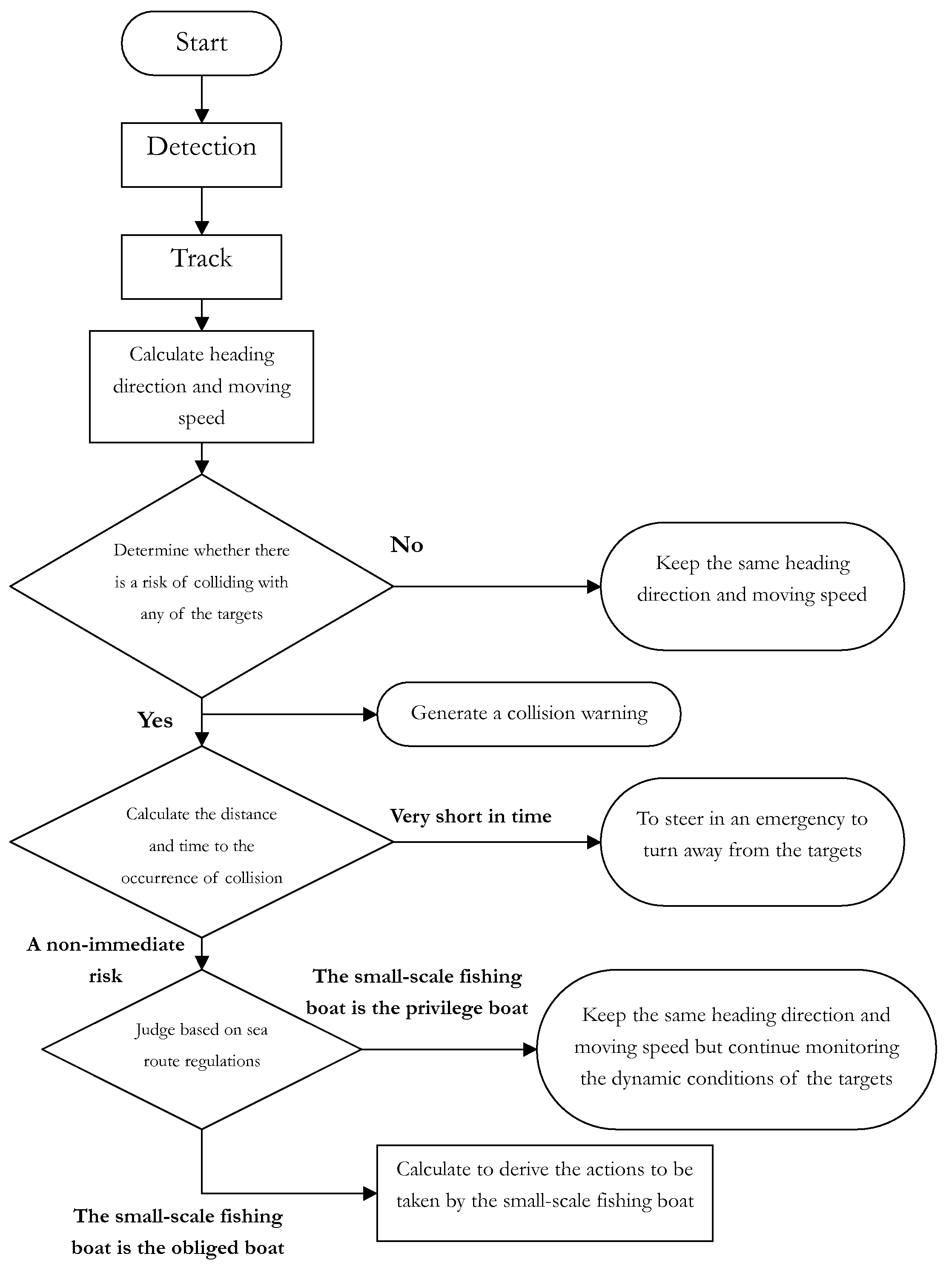

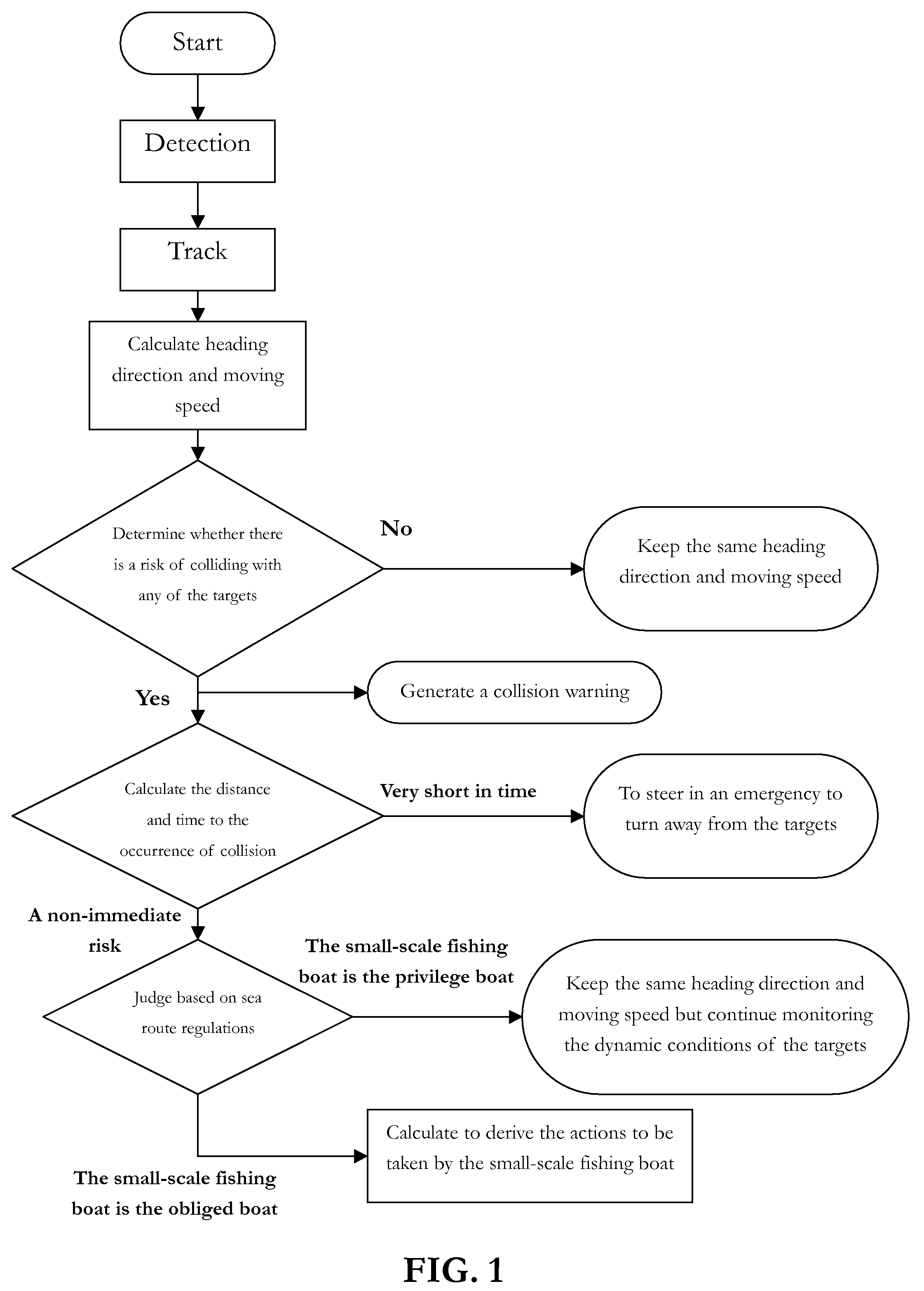

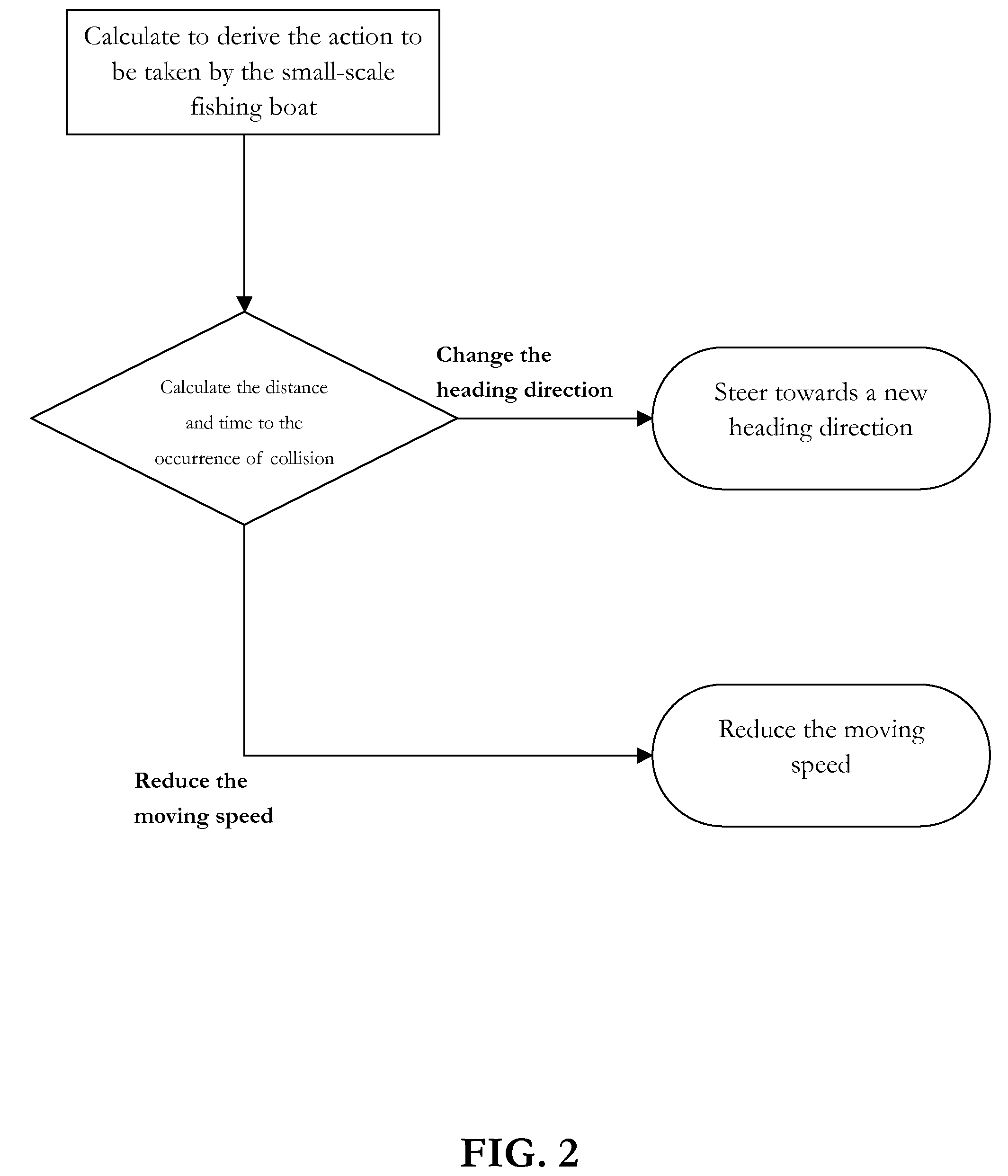

Method for small-scale fishing boat equipped with radar receiver to avoid ship collision and the radar receiver therefor

InactiveUS7710309B2Reduce collisionSafe and smoothAnti-collision systemsMarine craft traffic controlTime informationFishing

A method for small-scale fishing boat to avoid ship collision includes the steps of: (1) equipping the small-scale fishing boat with a radar signal receiver for scanning and receiving radar signals transmitted by other ships within the receiving range of the radar signal receiver; (2) using a monitoring computer having a Marine Geographic Information System (Marine GIS) installed thereon to obtain at real time information about the distance, bearings, and etc. of other approaching ships in order to monitor the dynamic conditions of the approaching ships within the fishing boat's operating water area; and (3) actuating a collision warning mechanism based on the intensities of received radar signals when there is more than one approaching ship, so that the small-scale fishing boat can timely receive a collision warning to reduce the risk of collision and maintain safe and smooth voyage on the sea.

Owner:NATIONAL TAIWAN OCEAN UNIVERSITY

Road soil-slope willow stake protection technology

InactiveCN101008180AEnsure safetyQuick resultsClimate change adaptationExcavationsDirect effectsEngineering

A road soil slope willow post protection technique comprises a slope protection and a bridge protection. The invention is characterized in that the slope protection comprises seed selection, ground furnish and mechanical posting; the bridge protection comprises seed selection, ground furnishing, drawing line and positioning, digging concaves, and planting the seed. The invention can be used to protect two side slopes of road.

Owner:杨玉林

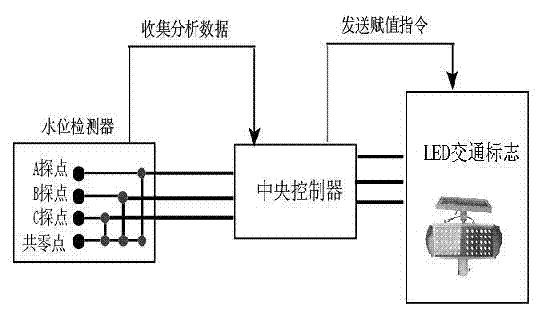

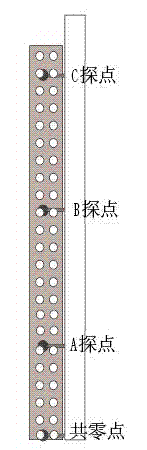

Auto-induction warning sign for ponding road segments

ActiveCN102817331AAchieve timelinessAchieve effectivenessTraffic signalsRoad signsElectricityEngineering

The invention discloses an auto-induction warning sign for ponding road segments. The warning sign is characterized by comprising a water level detector, a light-emitting diode (LED) traffic sign and a central control unit. The central control unit is connected with the water level detector and the LED traffic sign to achieve the central control function of the ponding road auto-induction warning sign, and converts monitoring data of the water level detector into various warning display states of the LED traffic sign; and a solar storage battery arranged on the LED traffic sign supplies power for the warning sign. The auto-induction warning sign for ponding road segments warns passers-by to notice the front water level situations in advance and drive cautiously, hence, the promptness and the effectiveness of traffic management and control are achieved, accidents are prevented, and the smooth traffic safety of wading roads is guaranteed; the solar storage battery is used for supplying power, external power supplies are not needed, so that external limits that electricity is unavailable in remote sections are avoided.

Owner:NANJING SKY TRAFFIC IND

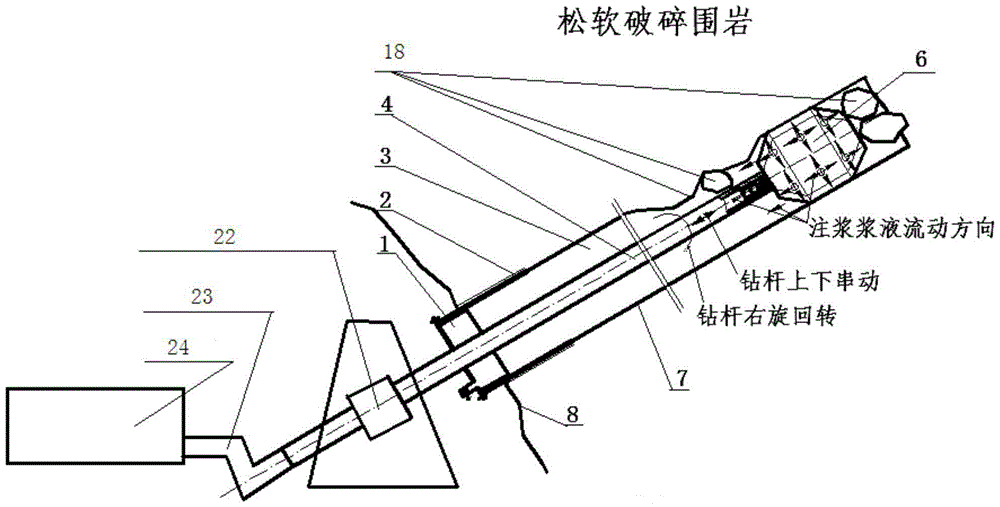

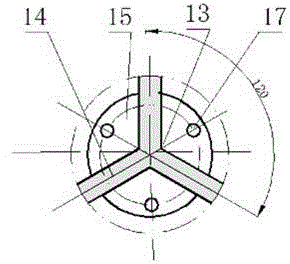

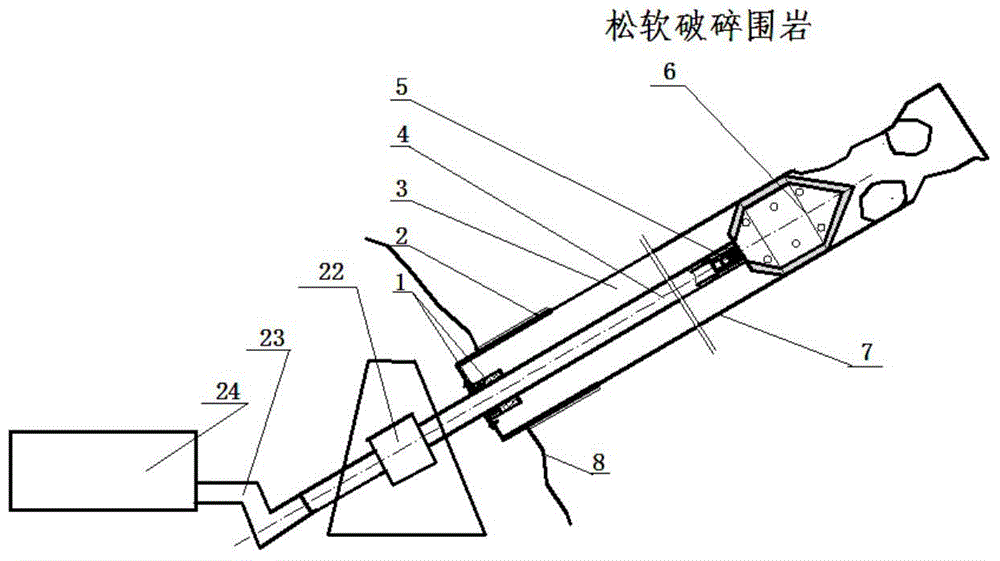

Collapse-prevention two-way rib wing jetting grouting drill bit and using method thereof

The invention discloses a collapse-prevention two-way rib wing jetting grouting drill bit and a using method thereof. The collapse-prevention two-way rib wing jetting grouting drill bit comprises a drill bit body connected with an outer flat drill rod. A rib wing is arranged on the side face of the drill bit body in the longitudinal direction of the drill bit. The rib wing comprises a forward wing piece, a reverse wing piece and a lateral wing piece, wherein the forward wing piece is arranged at the front end of the drill bit, the reverse wing piece is arranged at the rear end of the drill bit, and the lateral wing piece is connected with the forward wing piece and the reverse wing piece. The included angle formed between the forward wing piece and the lateral wing piece and the included angle formed between the reverse wing piece and the lateral wing piece are obtuse angles. An inner through hole communicated with a through hole in the outer flat drill rod is formed inside the drill bit body. A jetting hole communicated with the inner through hole is formed in the surface of the drill bit body. When the drill bit rotates, vertical movement is achieved through rotation of the forward wing piece and the reverse wing piece, drop pieces of the wall of the hole can be eliminated through cutting of the rib wing or the drop pieces can be extruded into the wall of the hole again, and grouting reinforcement and repairing of the wall of the hole are achieved.

Owner:SHANDONG UNIV

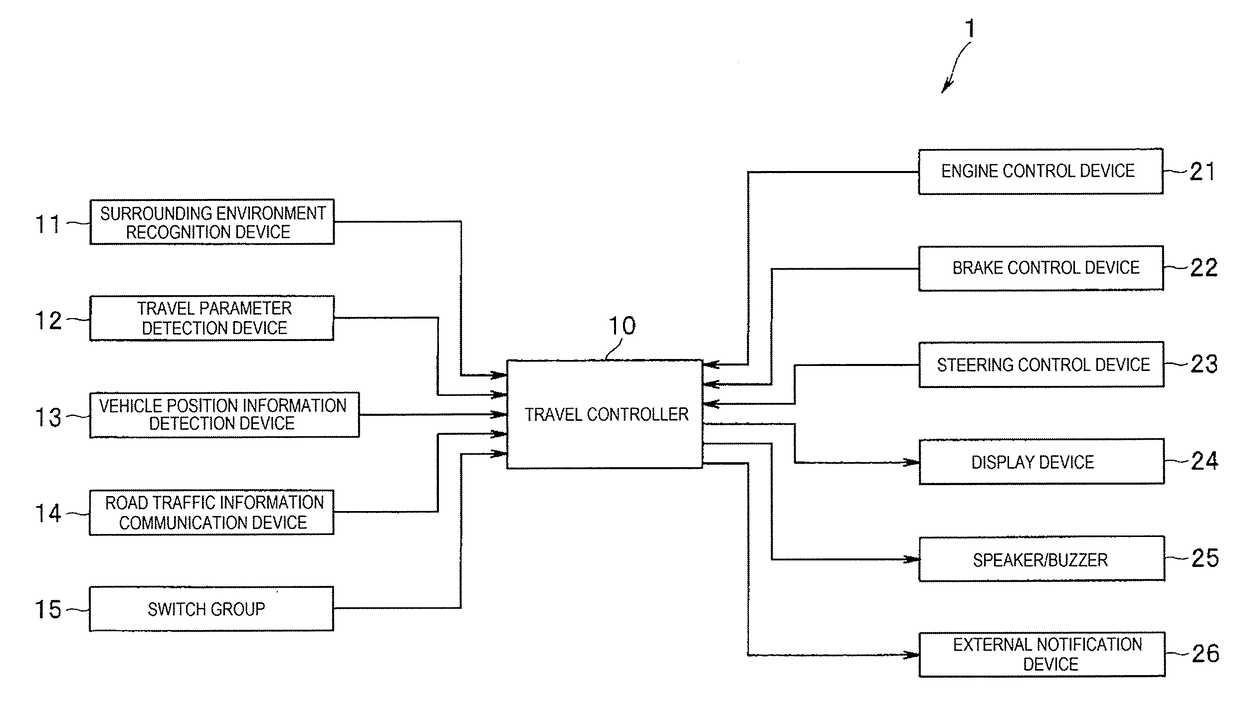

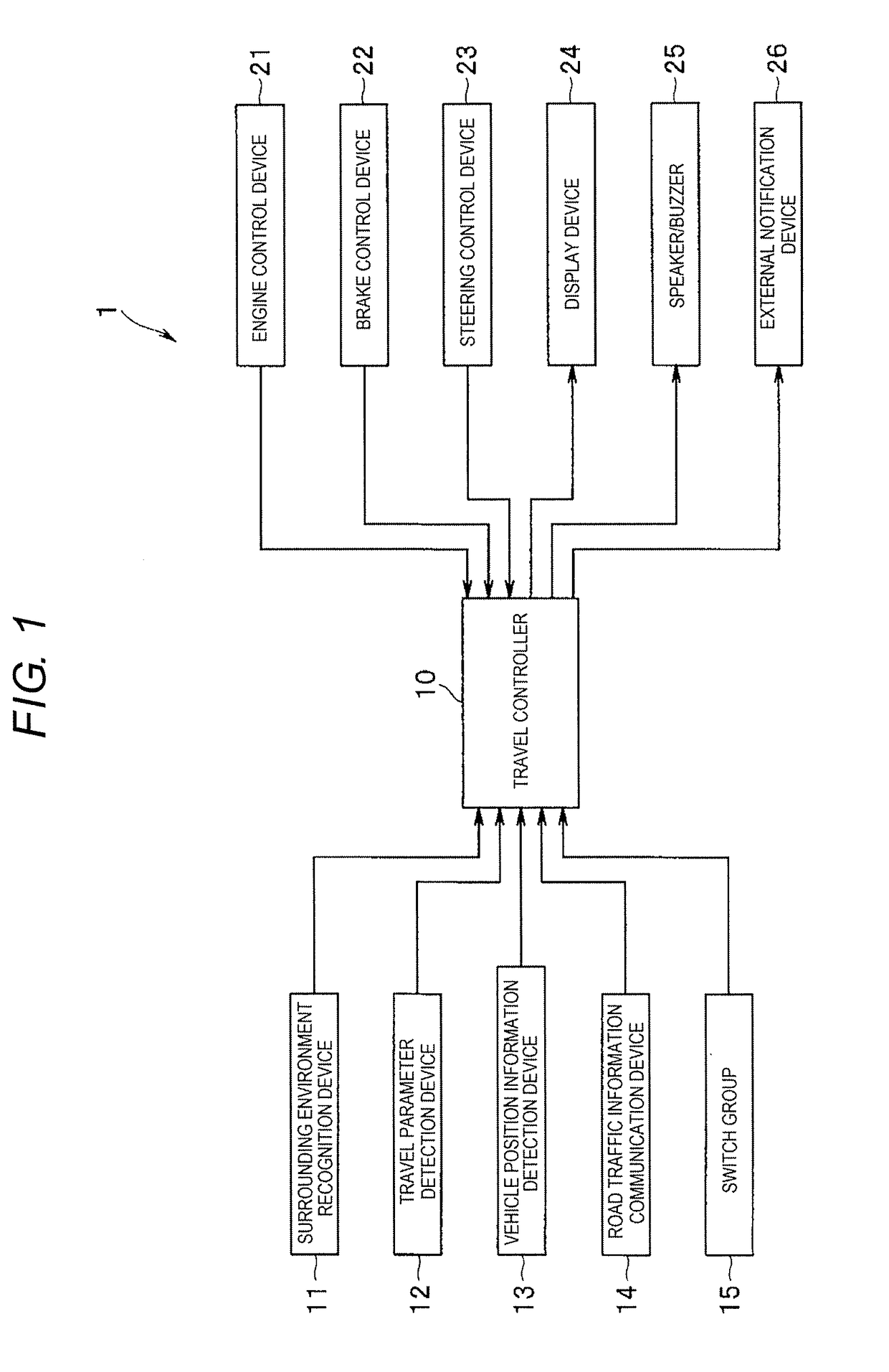

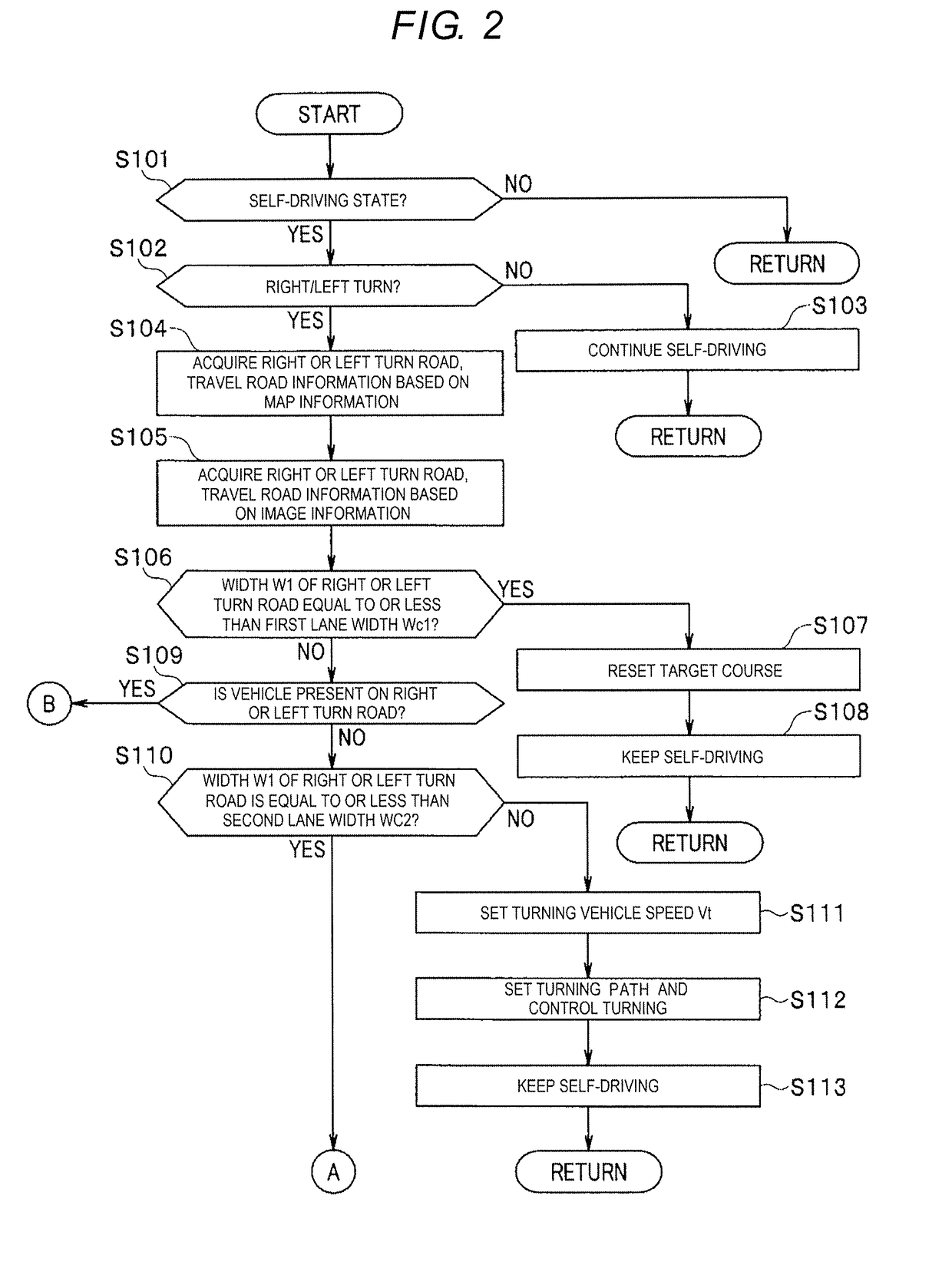

Travel control device for vehicle

ActiveUS20170351926A1Ensure correct executionSafe and smoothControl safety arrangementsScene recognitionEngineeringSelf driven

Owner:SUBARU CORP

Pipe-jacking construction method for large section of complicated formation

ActiveCN109594990ANo water seepageGuarantee the quality of the projectUnderground chambersTunnel liningSewageEngineering

The invention discloses a pipe-jacking construction method for a large section of a complicated formation. The pipe-jacking construction method for the large section of the complicated formation comprises the steps of control of settlement of existing structures in a pipe-jacking construction process, control of construction parameters during jacking in different geological formations, control ofjacking in a formation which is soft in top and hard in bottom, control of jacking in a hard rock stratum and line-type control in curve pipe-jacking and process. A seam at a curve pipe-jacking jointmeets the requirement, it ensures that water does not leak from a seam between pipes, the engineering quality is ensured, a jacking pipe can successively downwards penetrate through a high-speed waterguiding pipe and a sewage pipe, the safety of various structures is ensured, it can be ensured that settlement of a pipe-jacking line is in a controlled state, potential safety hazards are reduced, settlement can be controlled effectively, the jacking pipe can safely and smoothly penetrate through the formation, the safety of opening a bin for changing a knife can be ensured, and smooth jacking of a pipe-jacking machine under the condition of hard rocks is ensured.

Owner:CHINA RAILWAY ERJU CHENGDU NEW-TECH BLASTING ENG CO LTD

Arrangement method for town road

The invention provides a town road layout method for the road field, and utilizes the method to improve part establishment of the road, characterized in that, the rain is deposited in the rain underground tube arranged on the sideway or between the roadside trees, while the rain grate is changed on the kerbstone wall, and the kerbstone is provided with a channel wall. Under the road stratum is presupposed with a underground line skid bar, and the rain sedimentation basin is laid using the double face water seepage brick. The roadbed lay of the roadway is in a concave shape to enhance the durability and the security of the roadway, enlarge the effective through capacity, and use the rain water to irrigate the crop and the flower, which has the marked advantages of small invest, high efficiency etc, and is applicable in the generalization for the urban-rural road.

Owner:张仁学

Breast and subcutaneous surgery hemostasis apparatus

A hemostasis device for controlling bleeding during a surgery is provided. The hemostasis device includes a first portion, which has a close structure, an adjusting device connected with the first portion, and a second portion connected with the adjusting device. The first portion is affixed to the patient to surround the surgical area, and a user adjusts the adjusting device to move the second portion to stress the patient to control bleeding during the surgery.

Owner:CHIU KWOK WAI +1

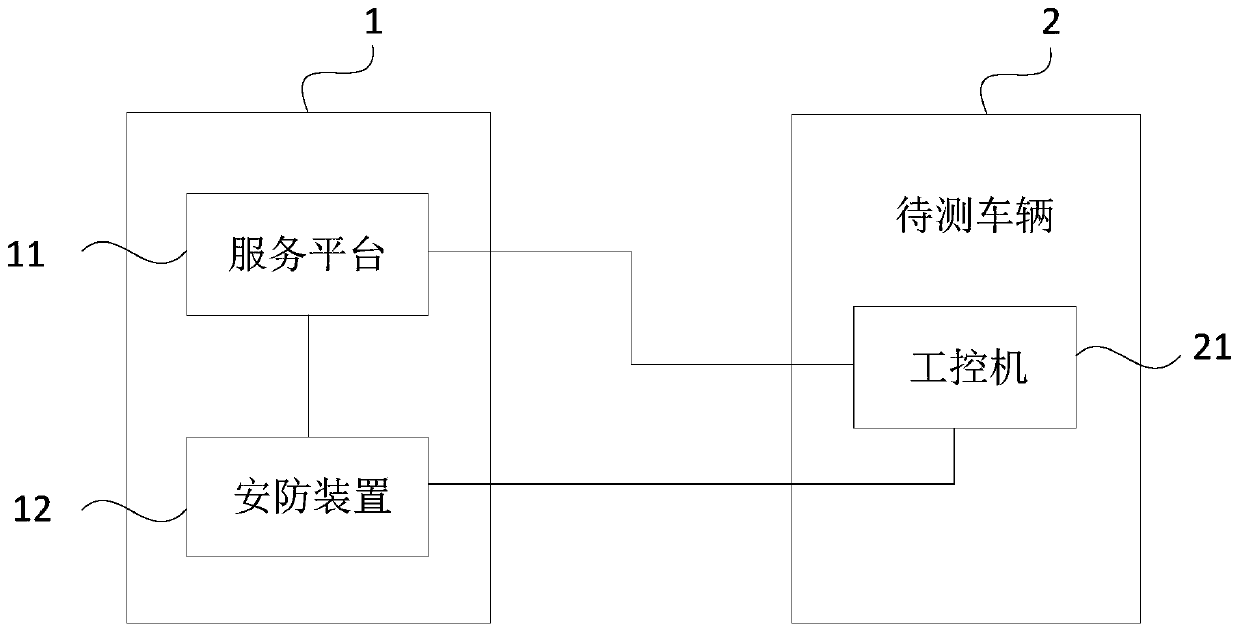

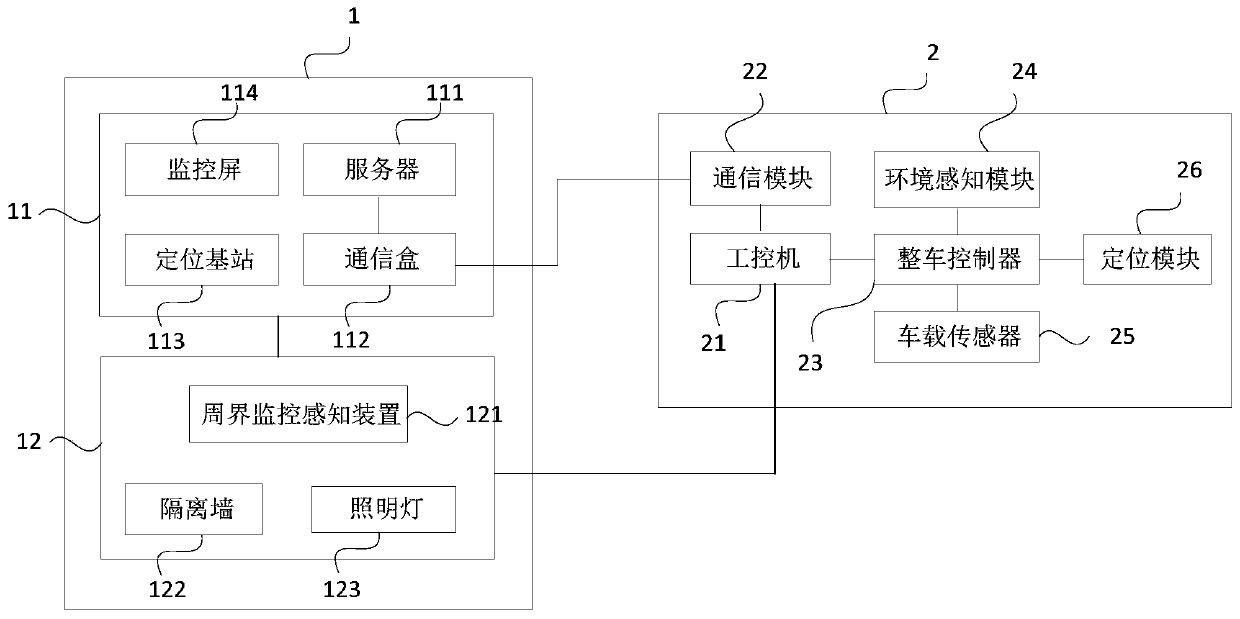

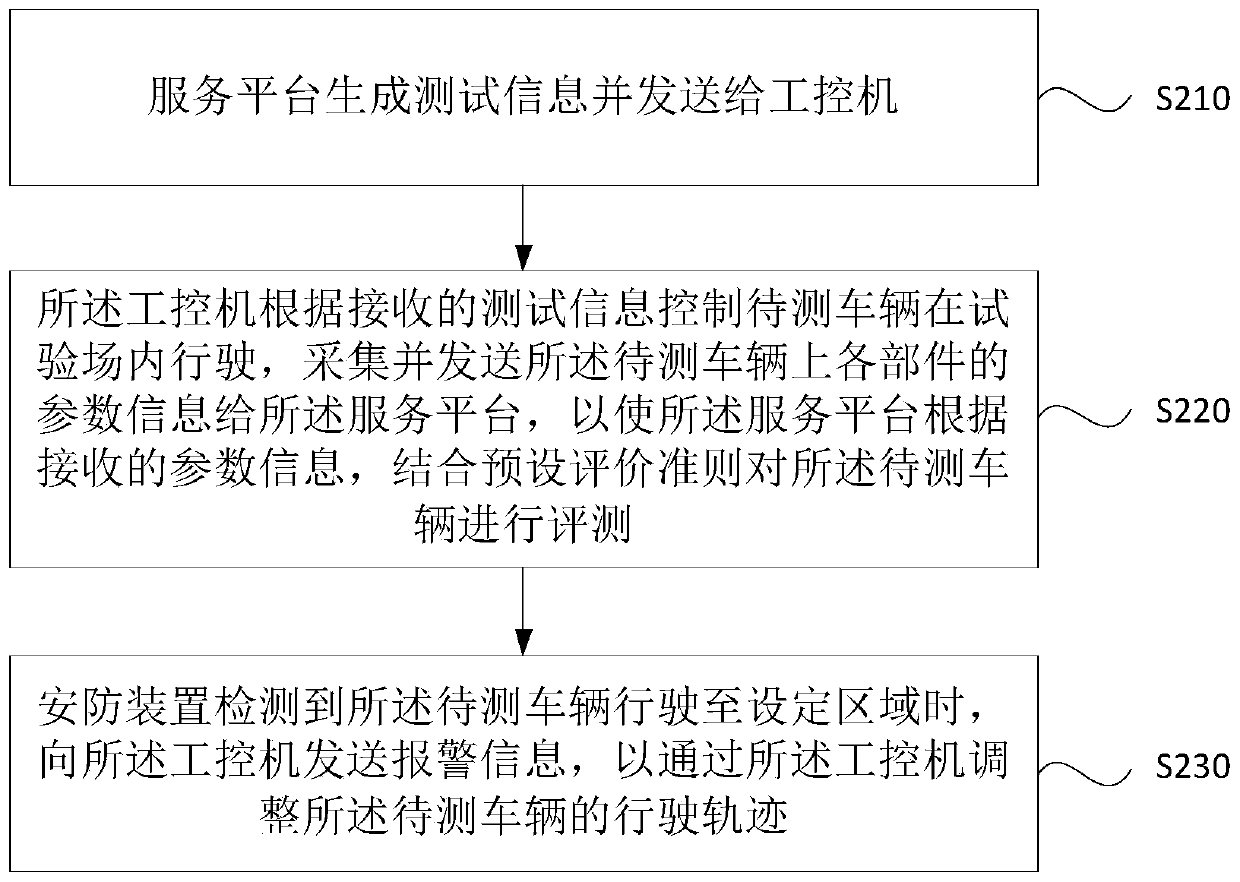

Automated testing system and method

InactiveCN110823592AImplement automated testingSafe and smoothVehicle testingAutomatic testingReliability engineering

Owner:CHINA FIRST AUTOMOBILE

Wireless network system and communication method thereof

InactiveCN102131221AImprove reliabilitySafe and smoothWireless communicationTraffic volumeResource pool

The embodiment of the invention discloses a wireless network system. The wireless network system comprises a controller resource pool which is formed by all or part of controllers in a wireless network; the controller resource pool comprises a first controller and a second controller, wherein the first controller is used for establishing a primary affiliation connection with a base station, and the second controller is used for establishing a secondary affiliation connection with the base station and establishing a new primary affiliation connection with the base station when a fault occurs in the primary affiliation connection. The embodiment of the invention also discloses a communication method of the wireless network system, the controllers and the base station. By the scheme provided by the embodiment of the invention, the reliability of the network is improved, the utilization ratio of equipment resources is increased, the capability of burst flow resistance is improved, the cost is reduced, the service interrupting time by fault-tolerant switching is shortened, and the requirement for high reliability of an operator is met.

Owner:陈明明

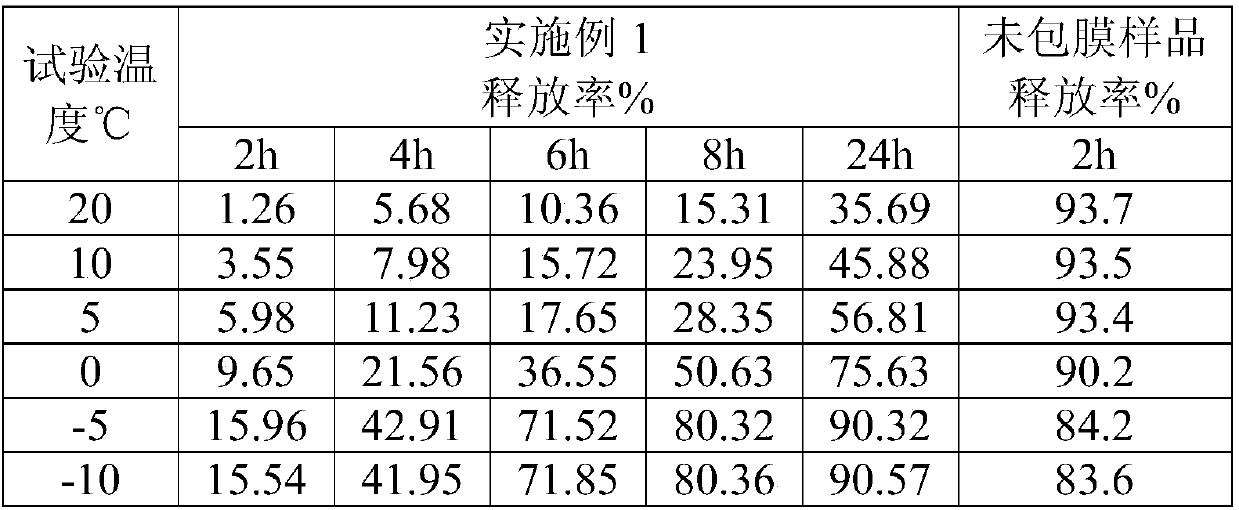

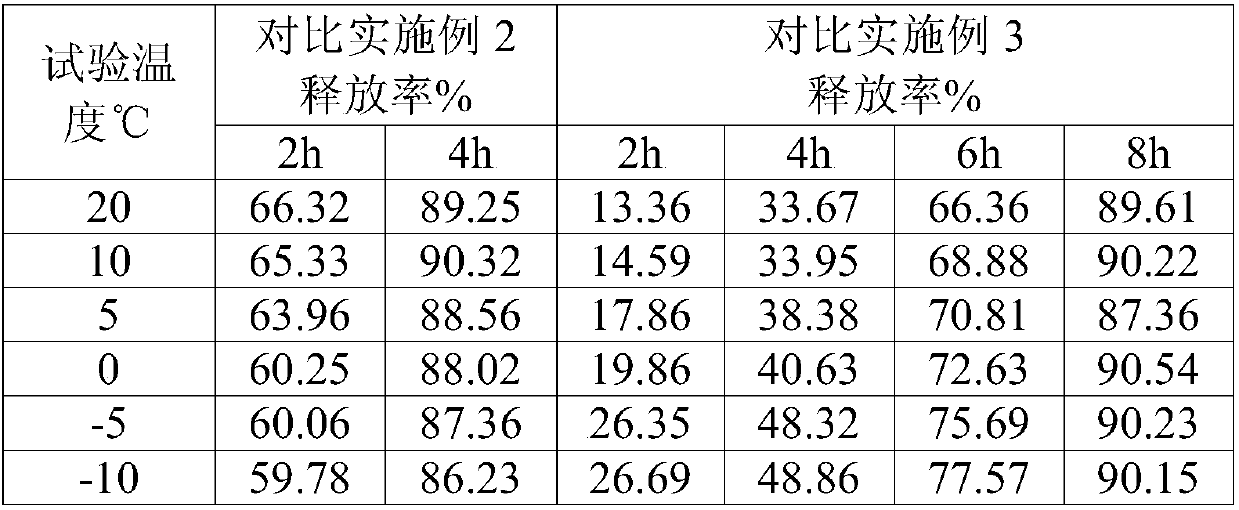

Temperature-control-based anti-freezing material and preparation method and application thereof

The invention relates to a temperature-control-based anti-freezing material and a preparation method thereof. Hydrophobic treatment is performed on anti-freezing agent core material at first, then theanti-freezing agent core material is thrown into a hydrogel reaction liquid, and the temperature-control-based anti-freezing material is manufactured after a hydrogel is formed on the surface of thecore material. The temperature-control-based anti-freezing material is hydrophobic due to hydrogel shrinkage under the high-temperature condition, and is hydrophilic due to hydrogel swelling at low temperature, and release of the saline content in the anti-freezing material can be controlled in real time according to the external temperature, so that an anti-freezing agent can work normally in winter. Invalid release of the saline content can be prevented for reduced in a high-temperature rainy season, so that the function time limit of the saline content in bituminous pavements is effectivelyincreased, and the service life of the anti-freezing material is prolonged.

Owner:CHINASALT JINTAN

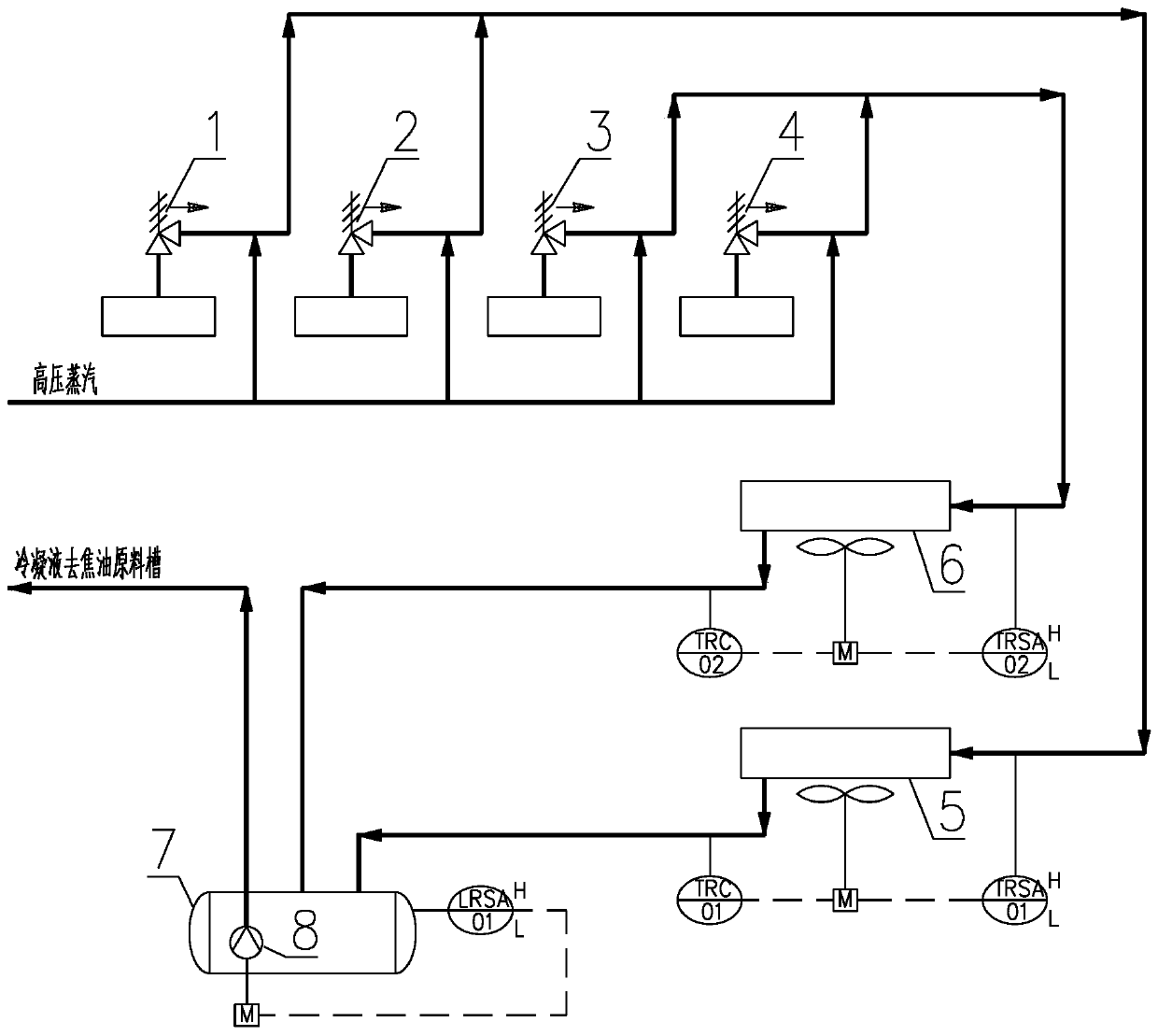

Safety valve emergency blow-down system in coking production process

The invention relates to a safety valve emergency blow-down system in the coking production process. The safety valve emergency blow-down system in the coking production process comprises a pluralityof exhaust collection pipelines, an air cooler and an emergency relief groove; one ends of the exhaust collection pipelines are separately connected with emergency relief openings of safety valves / safety valve assemblies of different towers / kettles in a coking system, the other ends of the exhaust collection pipelines are connected with a gas phase inlet of the air cooler, and a liquid phase outlet of the air cooler is connected with the emergency relief groove through a first condensed liquid conveying pipeline. According to the safety valve emergency blow-down system in the coking productionprocess, the gas phase emergently relieved by the different tower and kettle safety valves can be recycled through the air cooler, the environment is protected, products are recycled, the technologyis simple, the arrangement is convenient, and an optimal path for solving the types of problems is achieved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

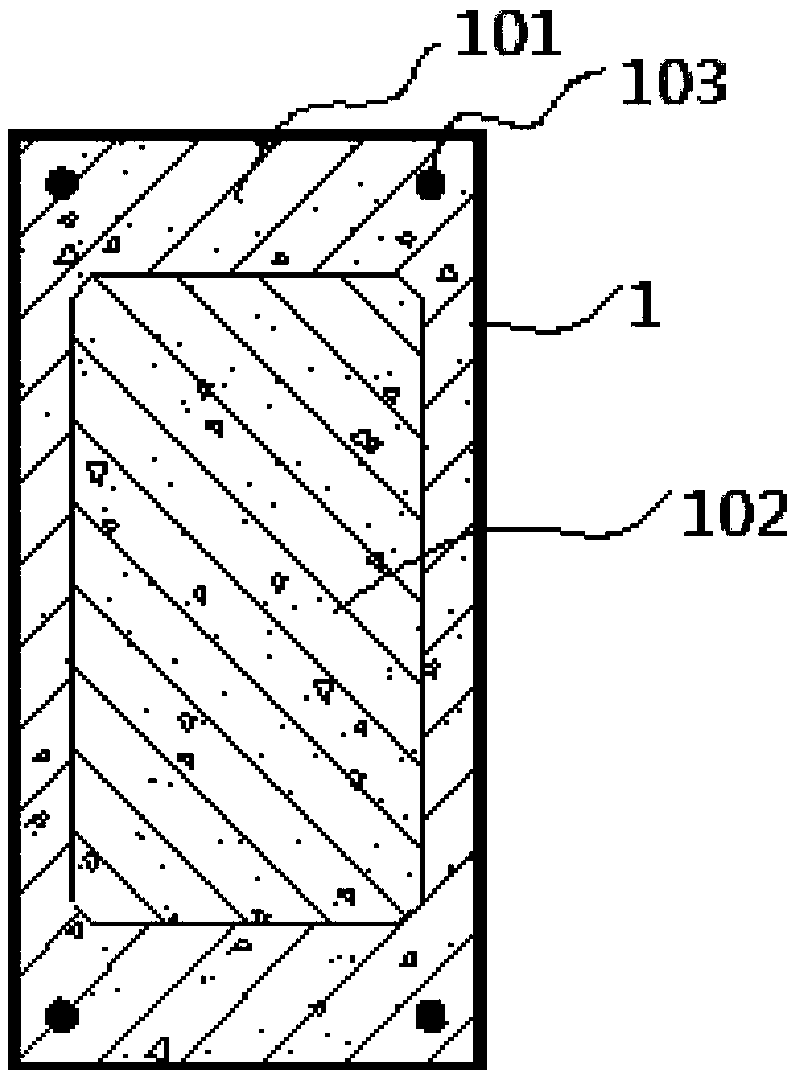

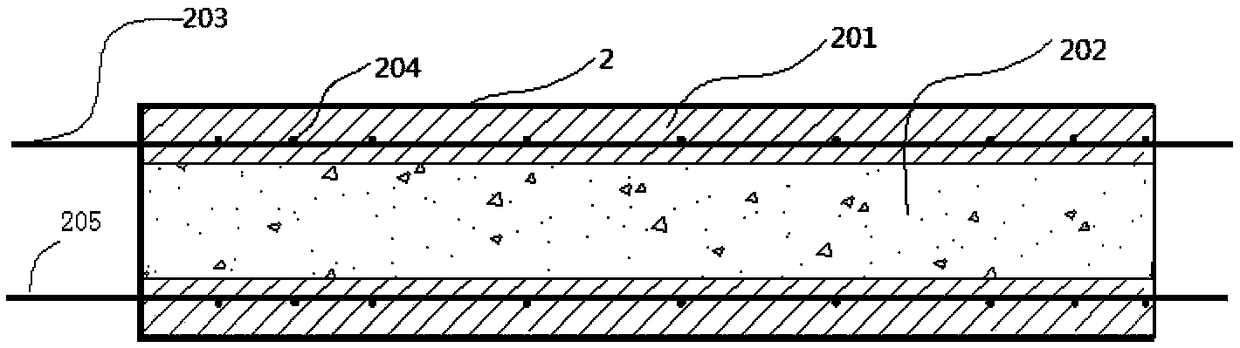

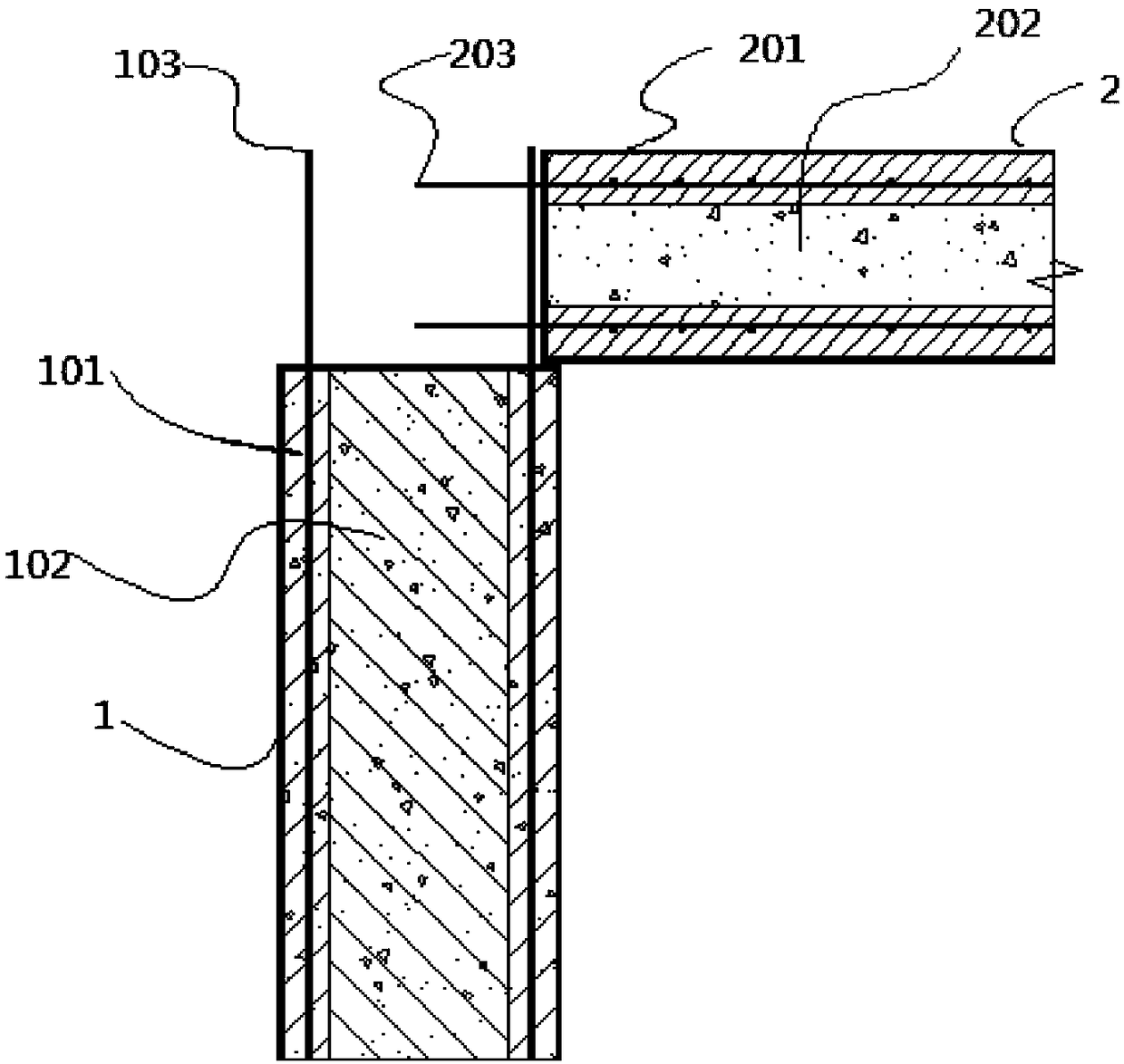

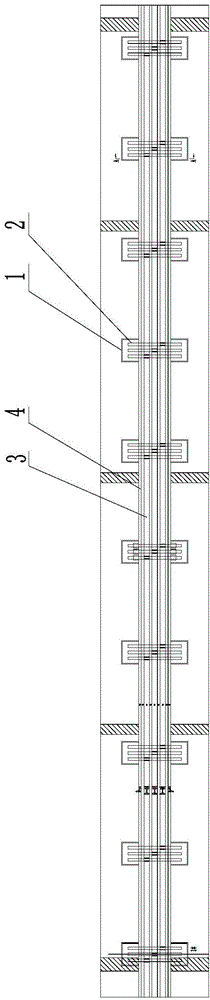

Frame structure system and construction method thereof

ActiveCN108343148AHigh strengthImprove stress resistanceProtective buildings/sheltersShock proofingConcrete beamsLap joint

The invention provides a frame structure system and a construction method thereof. The frame structure system comprises a plurality of composite columns and composite beams. Each composite column comprises a prefabricated column mold shell and a cast-in-situ concrete column inner core. Each composite beam comprises a prefabricated beam mold shell and a cast-in-situ concrete beam inner core. The top side of each prefabricated beam mold shell is provided with a grouting hole and an exhaust hole. 1-20cm of the end head of each composite beam is in lap joint with the edge of the top side of the corresponding composite column. The composite beams and the composite columns are connected through cast-in-situ concrete to form beam-column joints. The end heads of beam rebars of the composite beamsextend out of the ends of prefabricated beam mold shells and are anchored in the cast-in-situ concrete of the beam-column joints. The construction method comprises the following steps that prefabricated column mold shells are hoisted to the predetermined positions; the cast-in-situ concrete beam inner cores of the composite columns are formed through grouting; the prefabricated beam mold shells are hoisted, and 1-20cm of the end heads of the prefabricated beam mold shells are in lap joint with the edges of the top sides of the prefabricated column mold shells; templates at the beam-column joints are erected; the cast-in-situ concrete beam inner cores of the composite beams are formed through grouting; the concrete at the beam-column joints is grouted; and the steps are repeated until construction of the building frame is completed.

Owner:江苏千禧杭萧装配式建筑科技有限公司

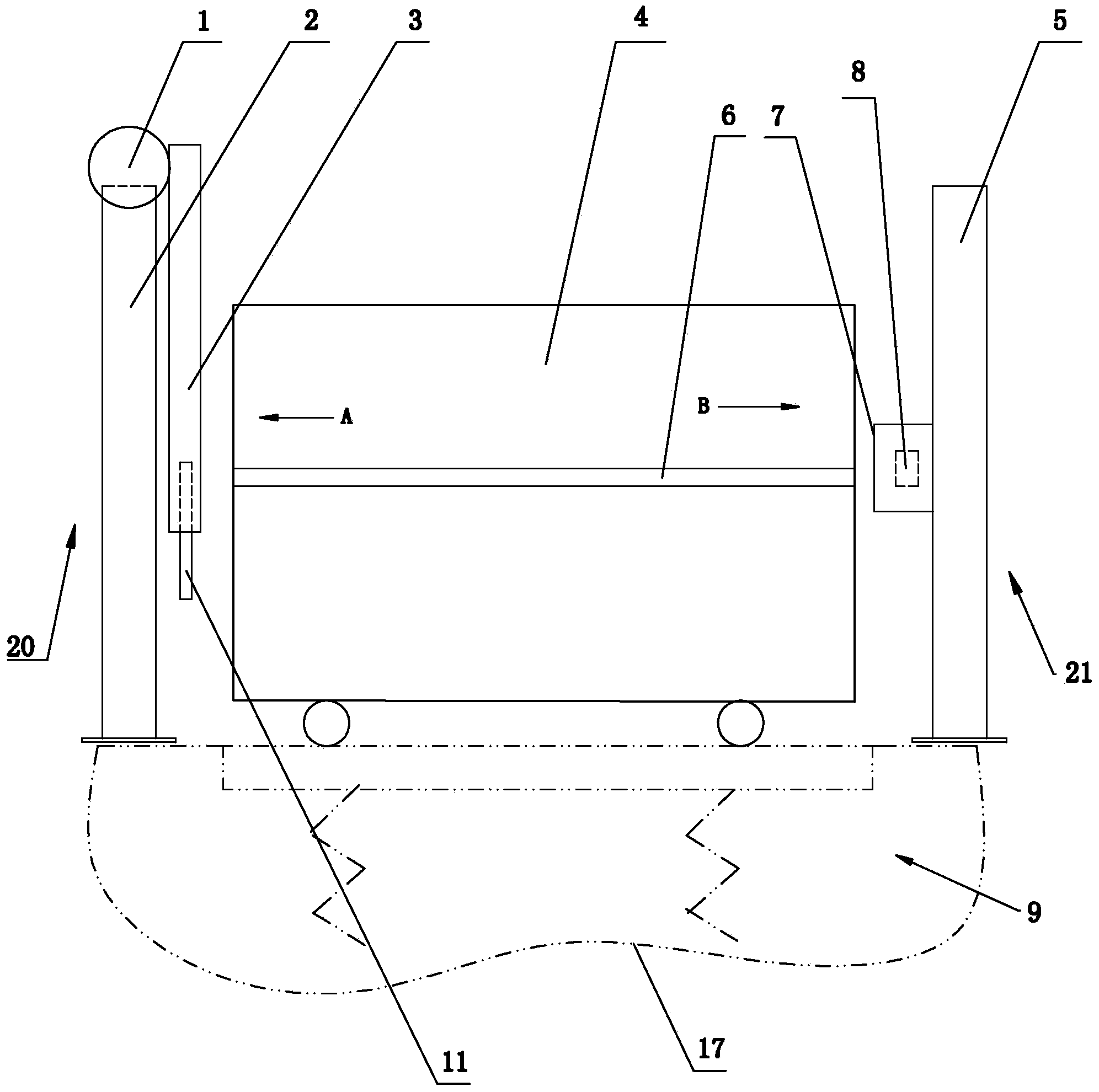

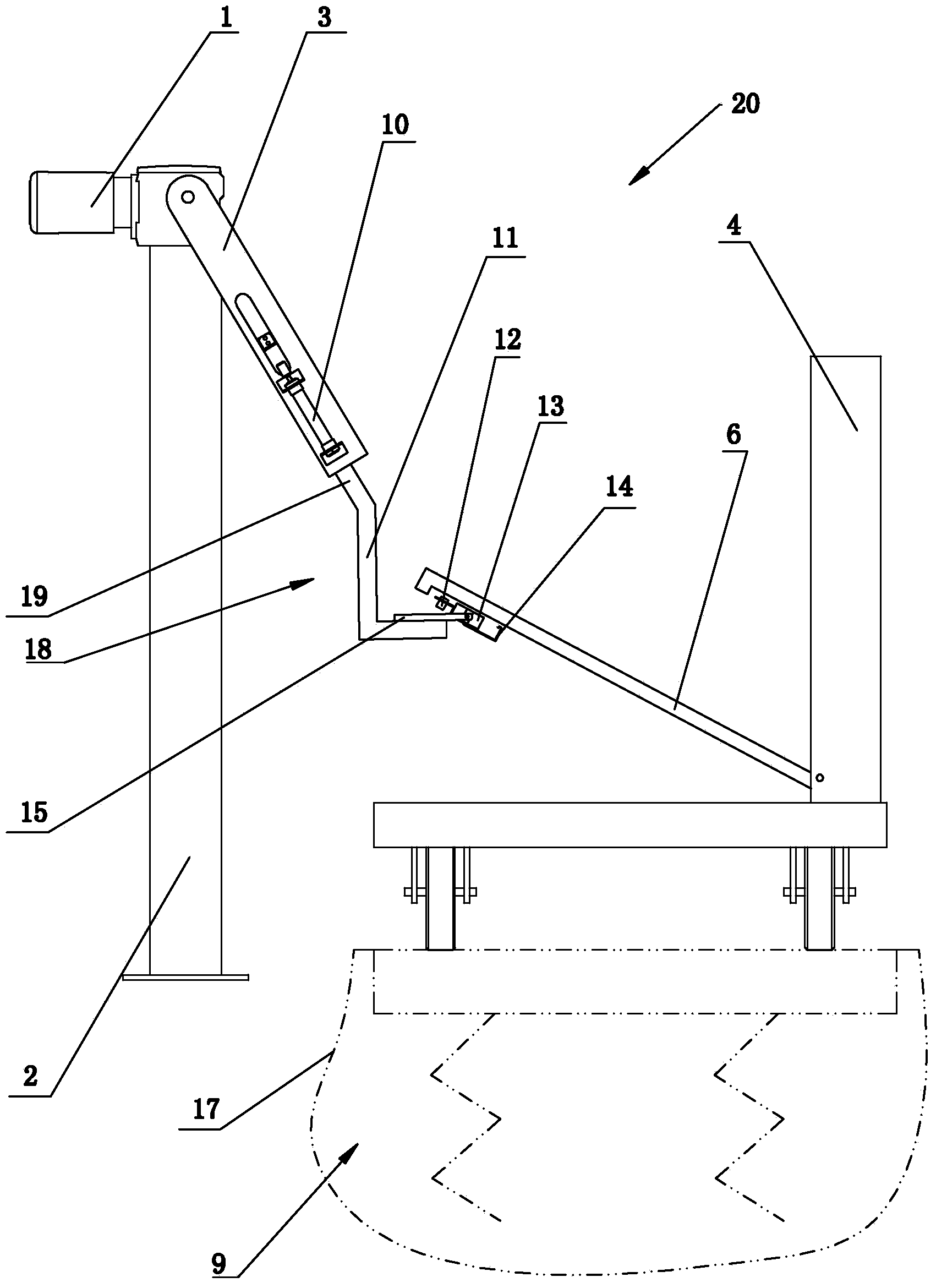

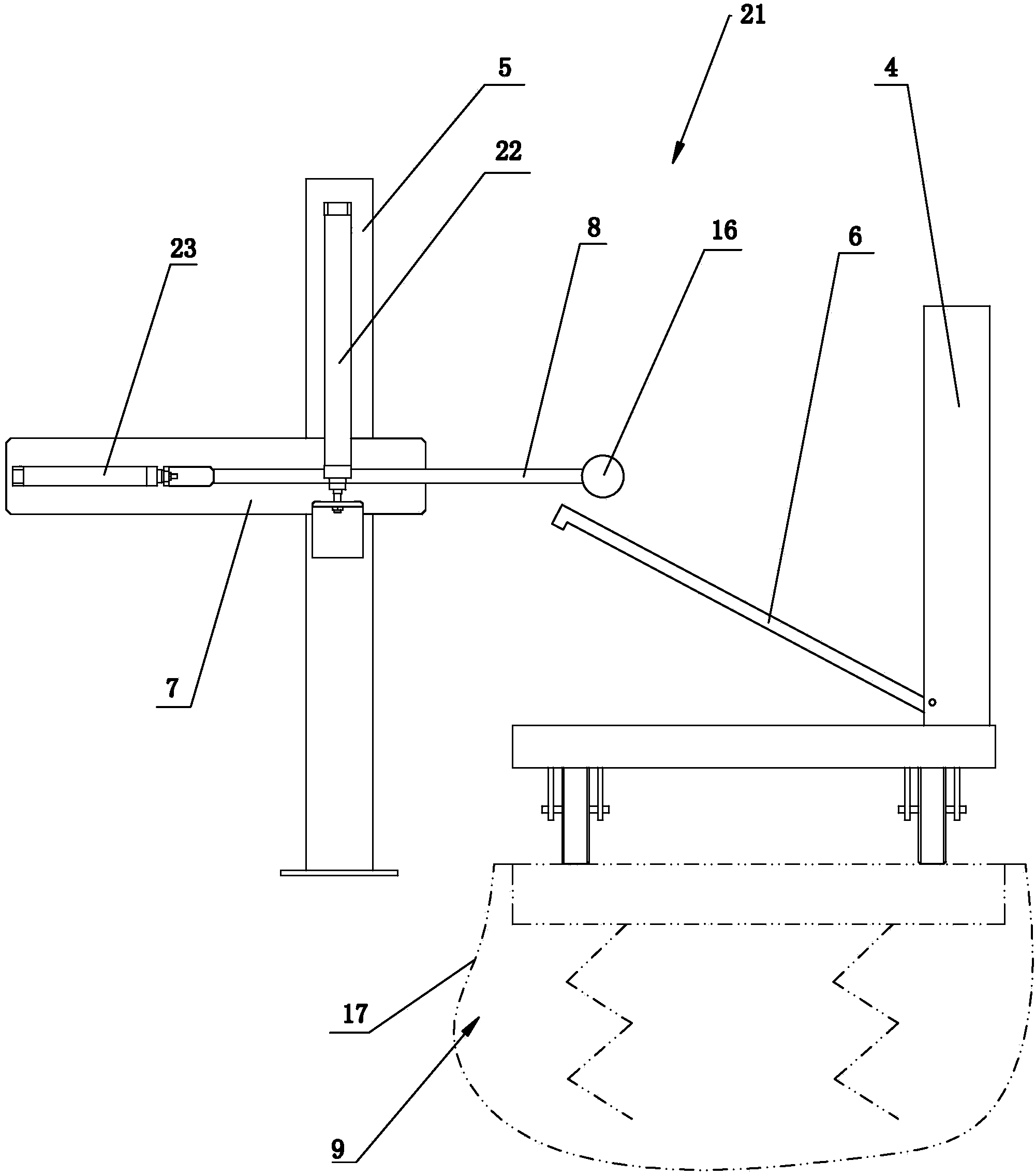

Turning device for tread storage book truck

The invention discloses a turning device for a tread storage book truck, and belongs to the technical field of tire manufacturing equipment. The turning device for the tread storage book truck comprises a first vertical column and a second vertical column, wherein the first vertical column and the second vertical column are oppositely arranged on two sides of the book truck; the first vertical column is provided with a sucking mechanism which is used for turning louver plates at a vertical position of the book truck at an angle; and the second vertical column is provided with a pressing mechanism which is used for pressing the louver plates turned at an angle to a horizontal position. The louver plates can be turned into a horizontal state from a vertical state by matching operation of the sucking mechanism and the pressing mechanism, a whole work procedure can be automatic without any manual operation, the labor intensity of an operator is greatly reduced, the production efficiency is effectively improved, and the danger accidents which are easily caused during manual operation are avoided.

Owner:山东三江智能装备有限公司

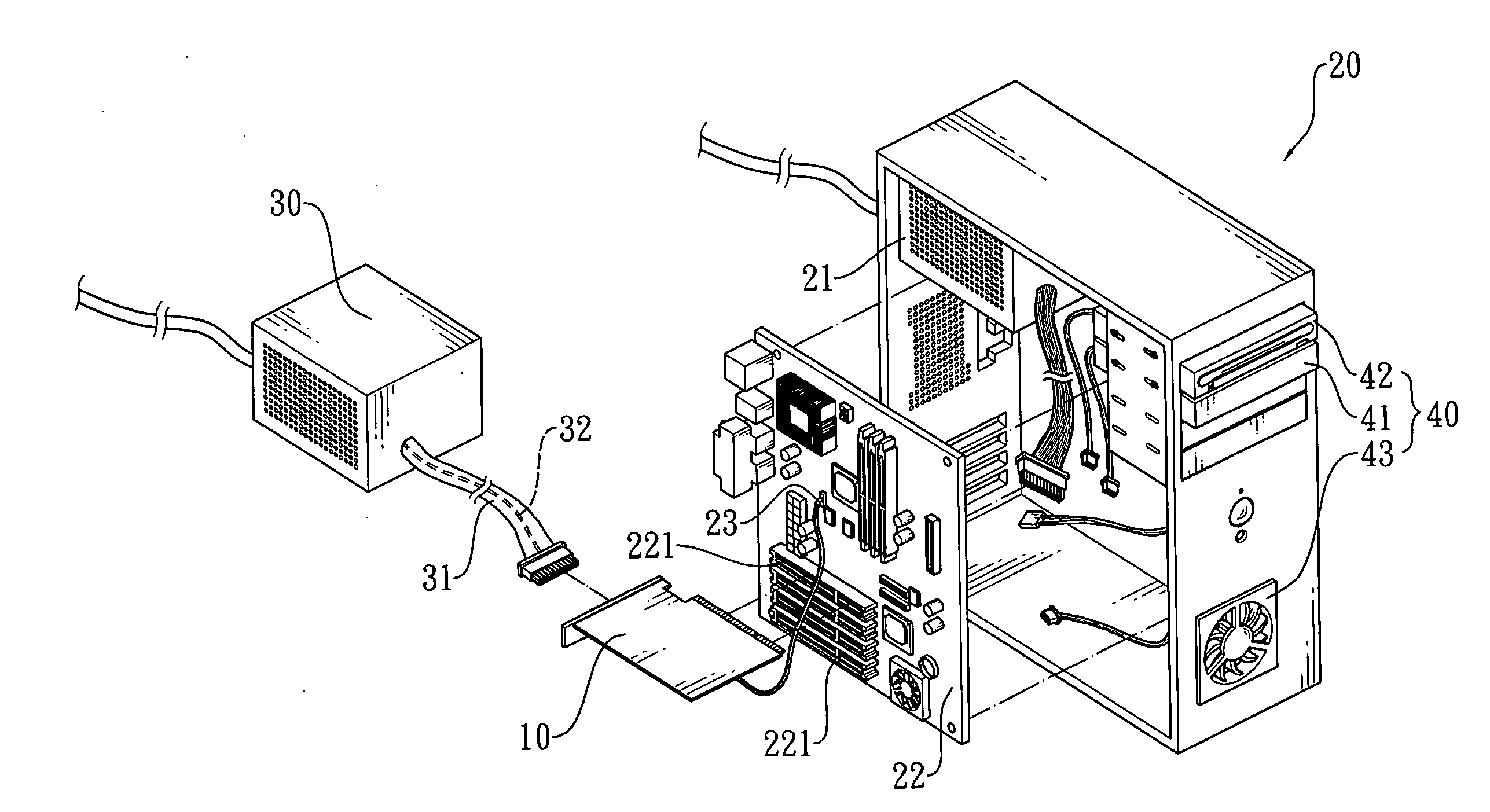

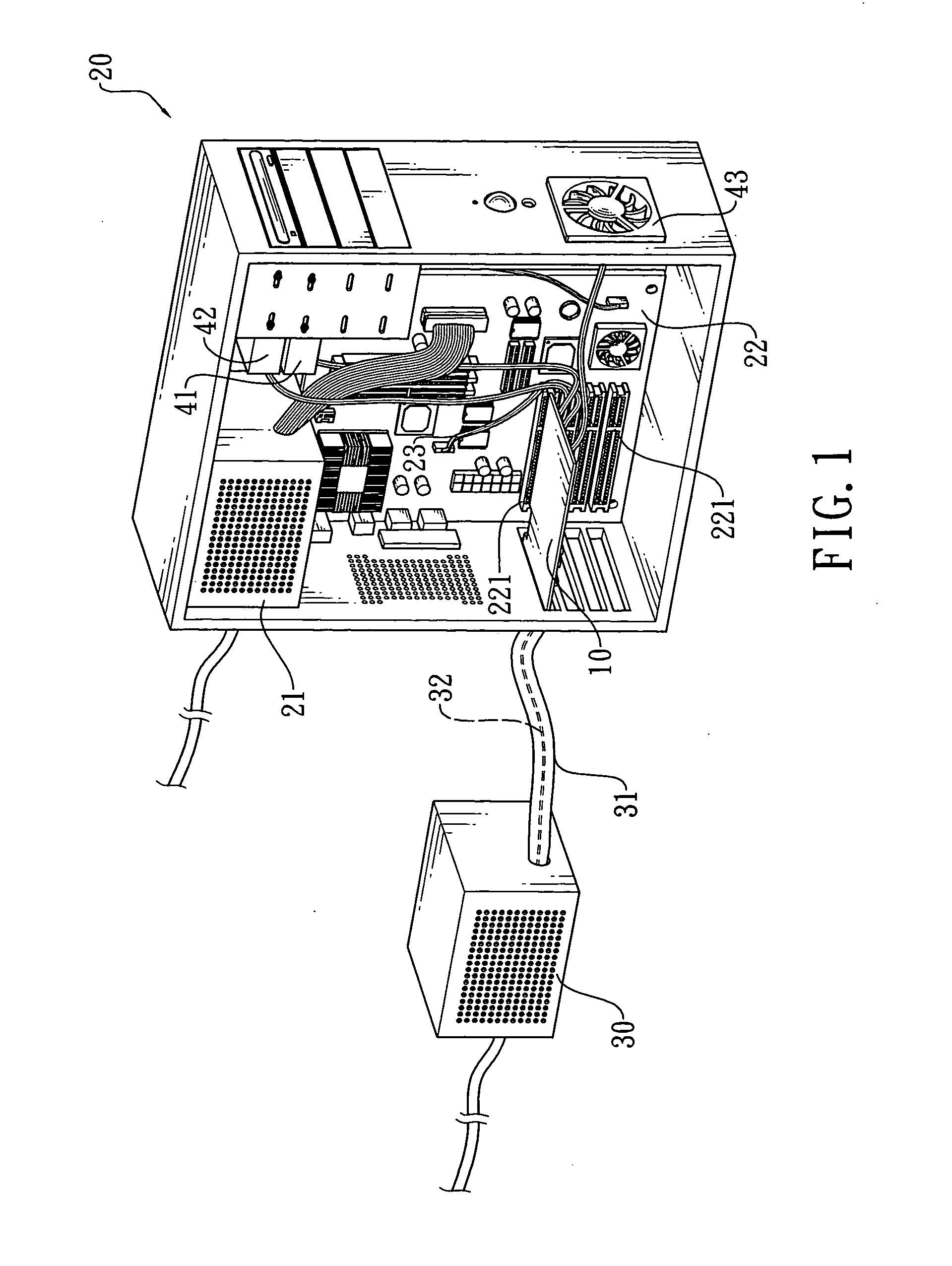

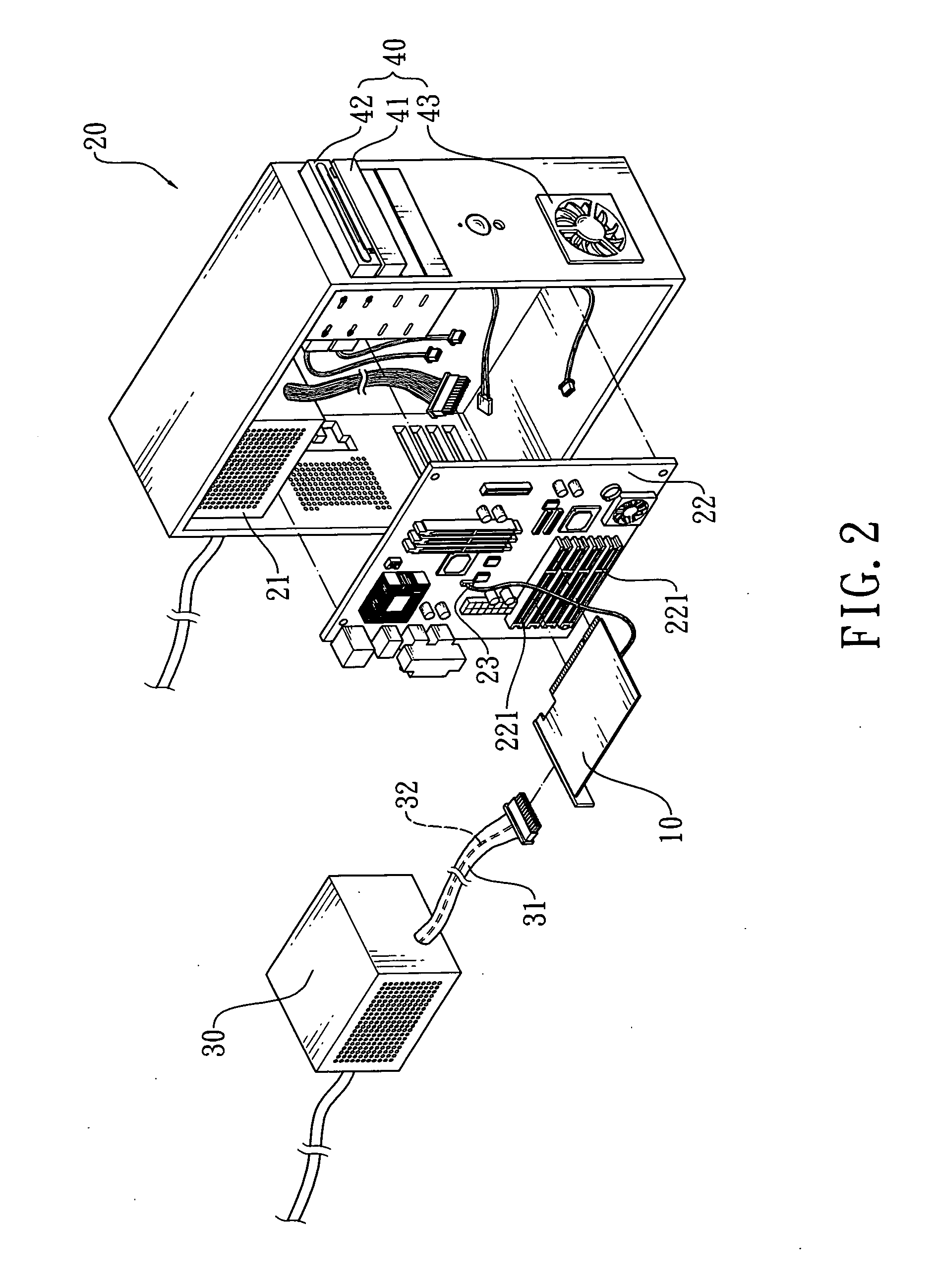

Delayed shutdown system for auxiliary power supply device of personal computer

InactiveUS20100115294A1Improve securityClose smoothlyDigital data processing detailsSufficient timeTime segment

Disclosed is a delayed shutdown system applicable to a computer system including two power supply devices and a slave power supply interface card. A secondary power supply device of the delayed shutdown system serves as an auxiliary power supply to the computer system. The slave power supply interface card includes a delayed shutdown circuit, which delays the shutdown of the auxiliary power supply when the computer system is shut down, so that after the computer system is shut down, the secondary power supply device is maintained in operation for a given period of time. Thus, even the peripheral devices connected to the slave power supply interface card are set in a signal silent condition after the computer is shut down, they can maintain in operation with the electrical power supplied from the auxiliary power supply during the given period of time and thus they are provided with sufficient time complete a smooth shutdown operation by returning to a home position / an original condition and sufficiently dissipating heat therefrom.

Owner:HSIEH CHEN KUAN WEI

Treatment method for expansion joint of bridge

ActiveCN104404871AReduce maintenance costsSafe and smoothBridge structural detailsBridge erection/assemblyEngineeringExpansion joint

The invention relates to the technical field of bridge repair, in particular to a treatment method for an expansion joint of a bridge. The method comprises the following steps of inspecting the expansion joint of the bridge at a preset time period; positioning a damaged part in an expansion structure; lifting a support beam, and replacing the damaged part. According to the treatment method for the expansion joint of the bridge, the expansion joint of the bridge is periodically inspected, and whether a part in the expansion structure in the expansion joint of the bridge is damaged or not is timely discovered; a complete set of expansion joint is not required to be integrally dug out to cause damage to a concrete structure at the expansion joint of the bridge, so that the expansion joint is not required to be integrally replaced, the bridge of which the complete set of expansion joint is to be replaced is not required to be controlled for 30 to 45 days, the maintenance cost is reduced, the bridge can be maintained within a short time (about 2 to 3 days), and the traffic safety and smoothness of the bridge are ensured.

Owner:刘金顶

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com