Safety valve emergency blow-down system in coking production process

A venting system and production process technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve problems such as environmental hazards, environmental protection problems, difficulties in long-distance transmission, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

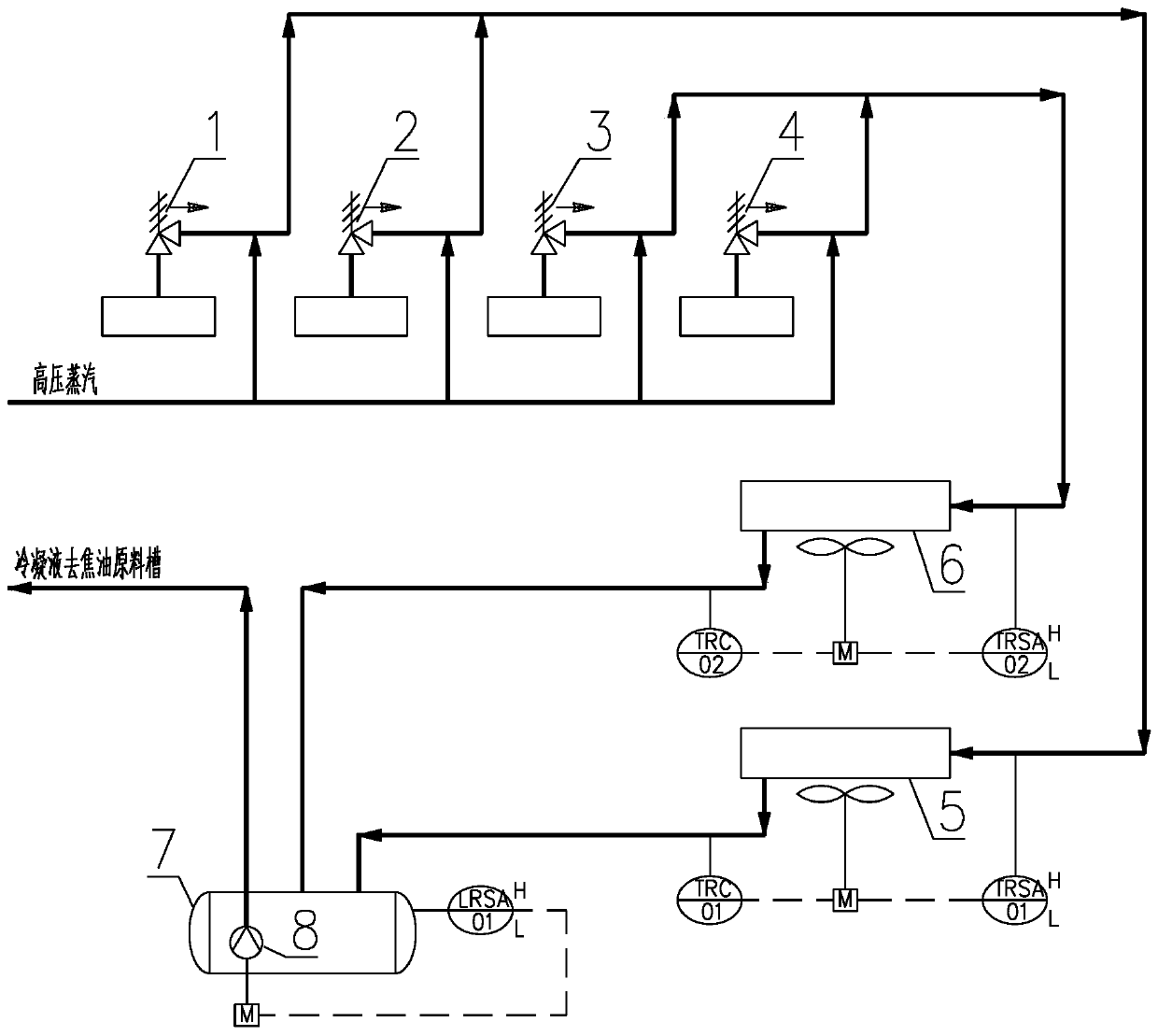

[0024] like figure 1 As shown, an emergency venting system for a safety valve in a coking production process according to the present invention includes an exhaust gas collection pipeline, air coolers 5, 6 and an emergency discharge tank 7; the exhaust gas collection pipeline is a plurality of, each One end of the exhaust gas collection pipeline is connected to the emergency relief ports of the safety valves / safety valve groups 1, 2, 3, and 4 of different towers / kettles in the coking system, and the other end is connected to the gas phase inlets of the air coolers 5 and 6. The liquid-phase outlets of the devices 5 and 6 are connected to the emergency relief tank 7 through the first condensate conveying pipeline.

[0025] The air coolers 5 and 6 are provided with cooling fans, the temperature record interlock alarm instrument TRSA01 / TRSA02 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com