Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Reduce yarn hairiness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

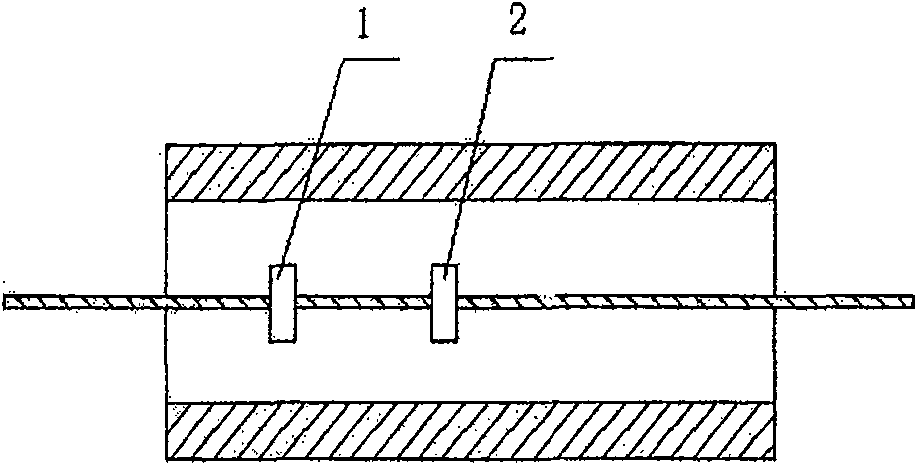

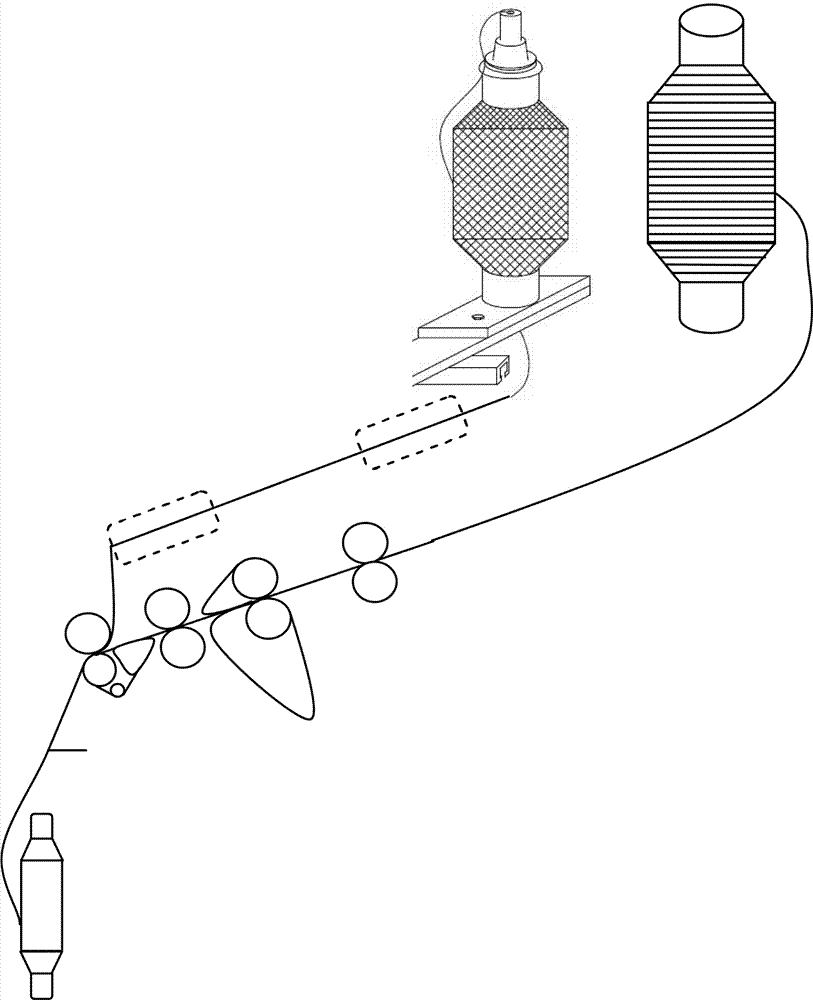

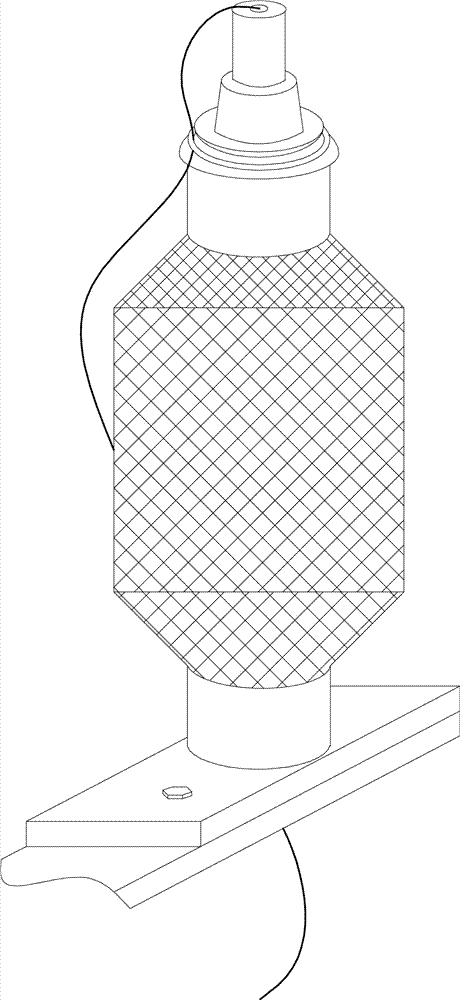

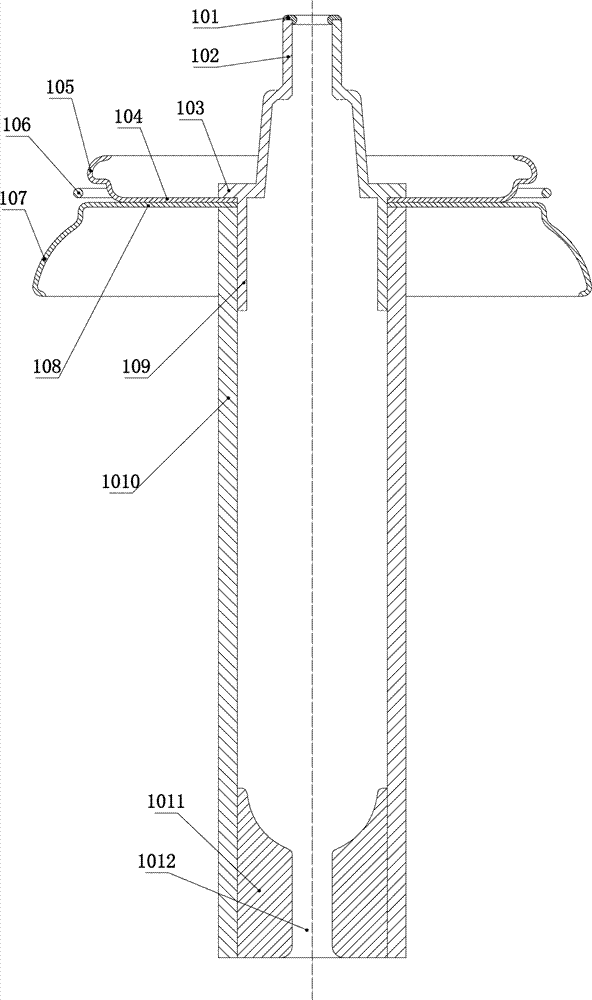

Method for reducing resultant yarn filoplume

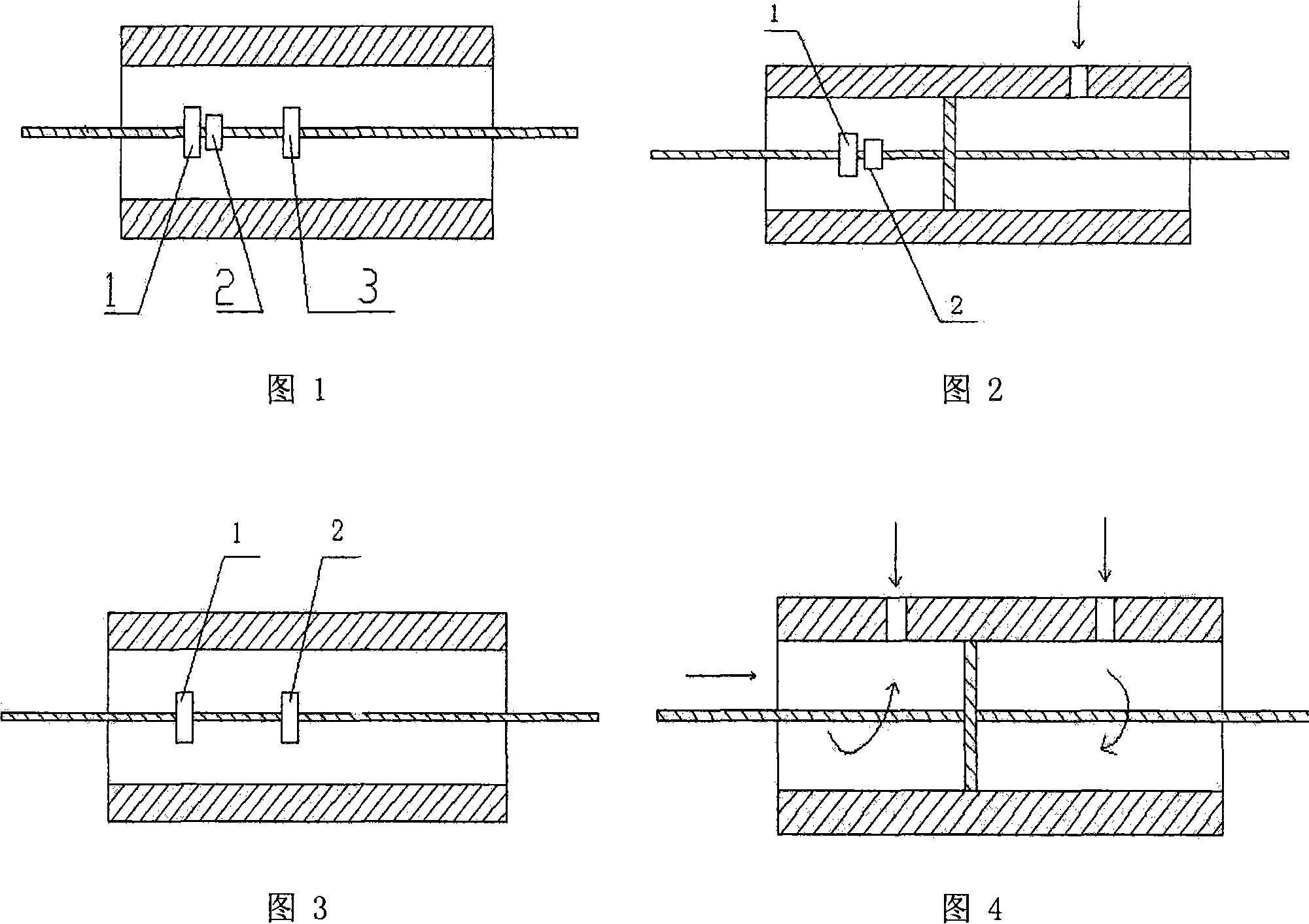

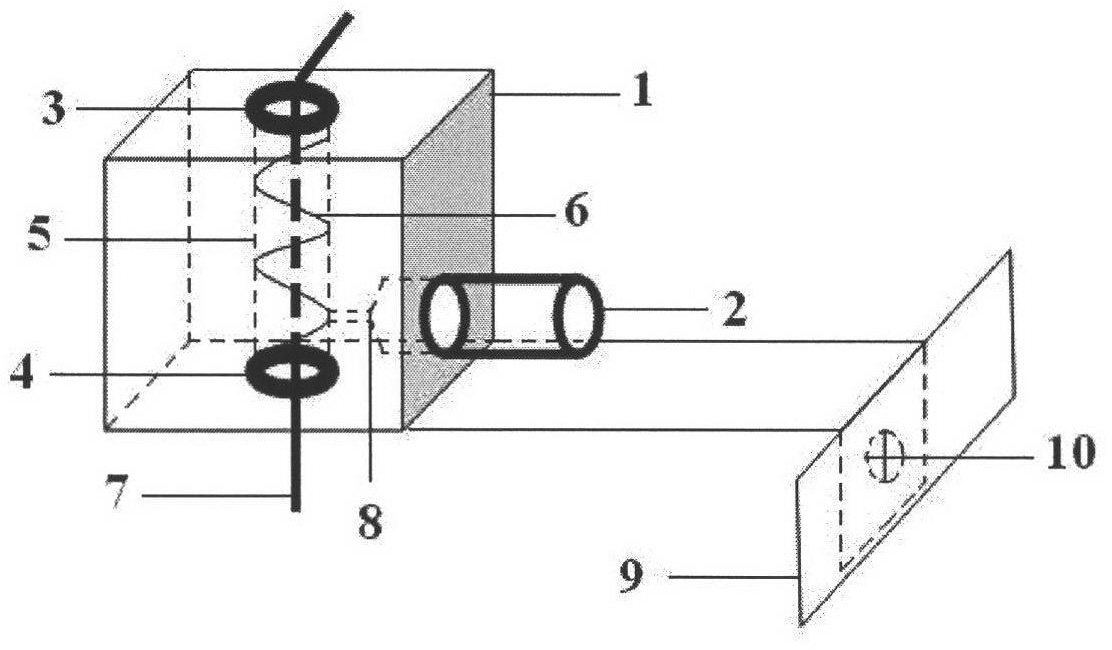

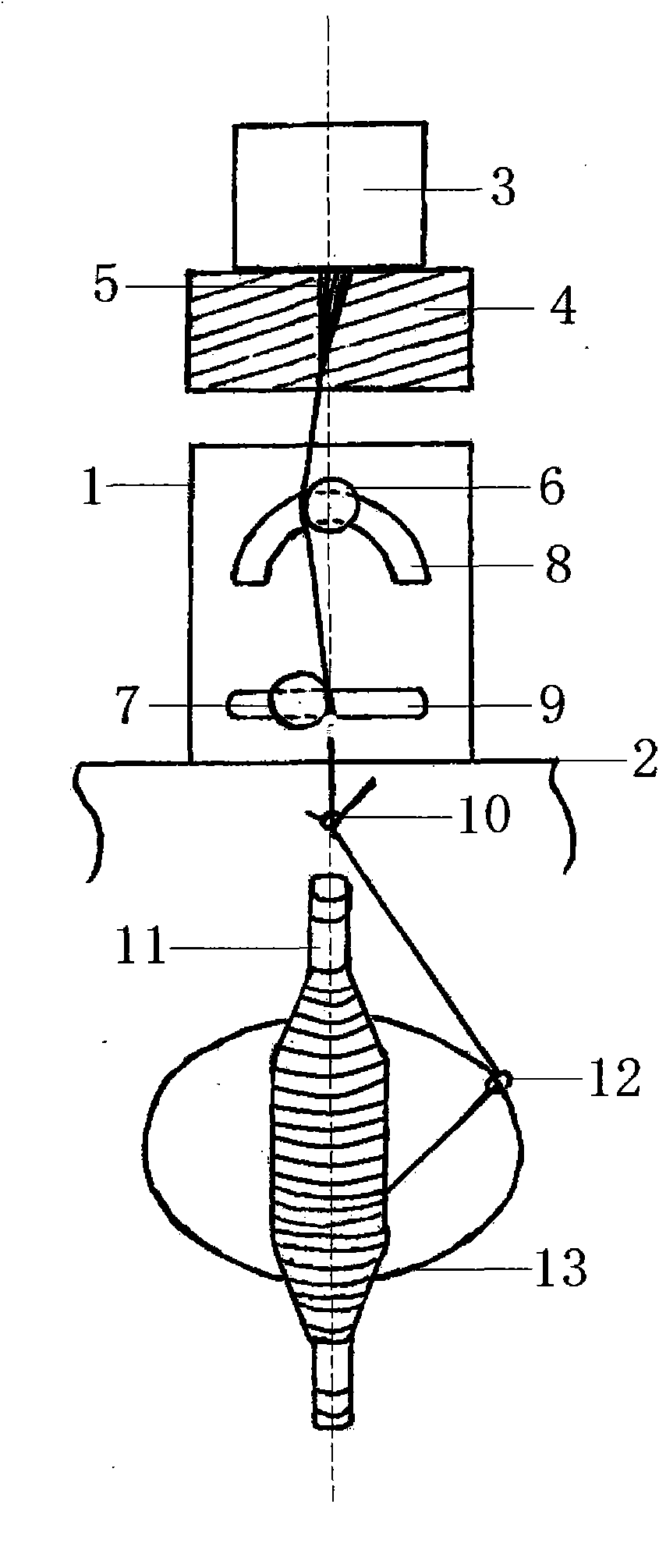

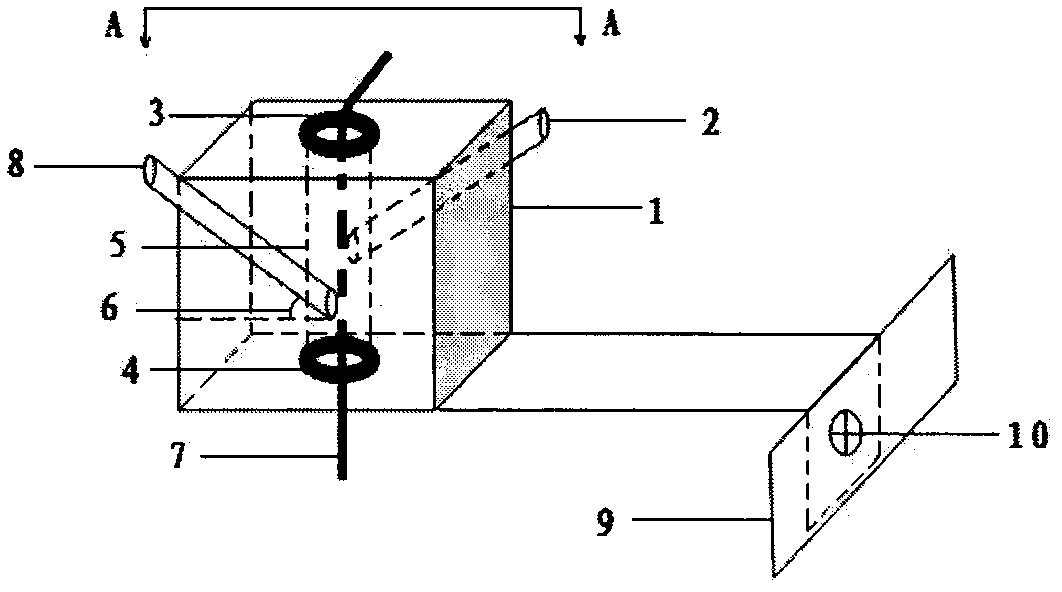

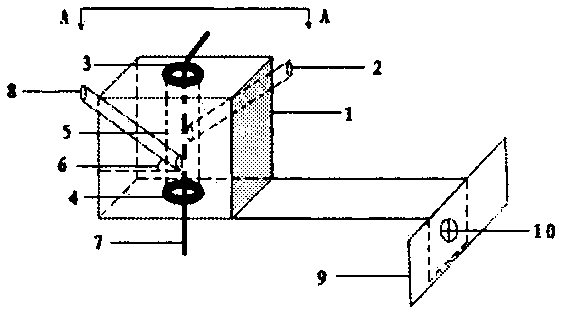

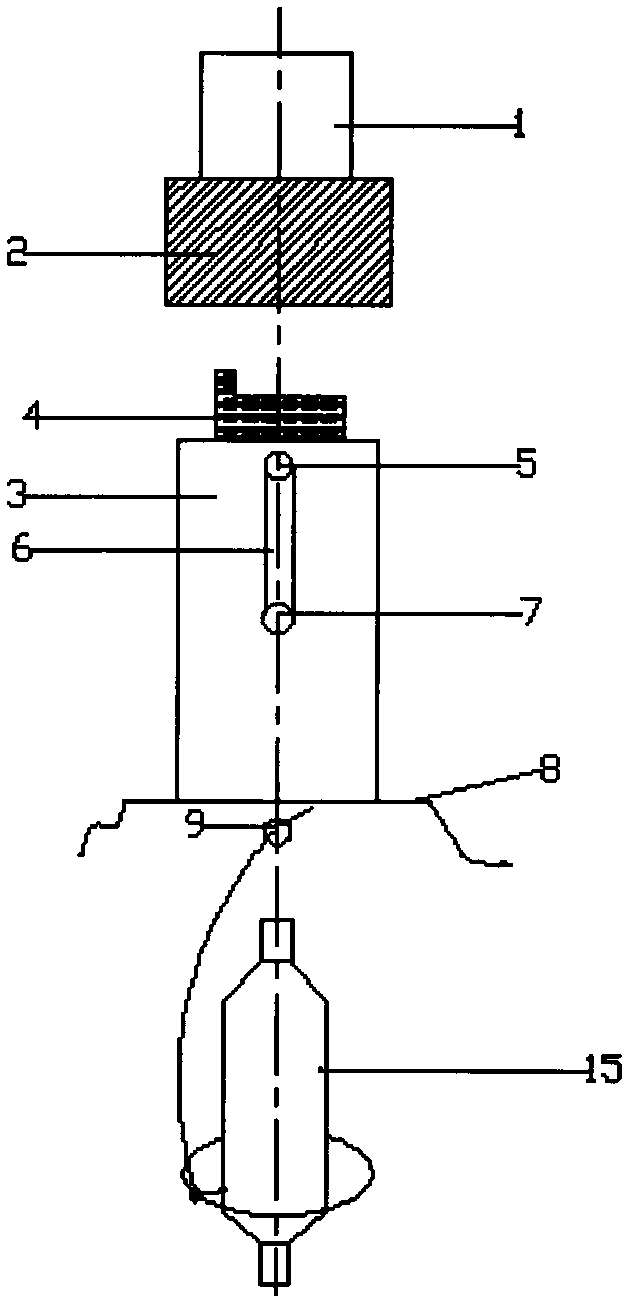

The invention relates to a textile processing technology concerning operations after the spinning that can reduce hairiness in finished yarn, and pertains to the technical field of textile processing. The invention provides a hairiness reducer for finished yarn that de-twists and heats on the advancing channel of the yarns, which reduces hairiness of finished yarns by de-twisting, heating, softening and twisting again yarns. The hairiness reducer for finished yarn that de-twists and heats can outstandingly reduce hairiness in finished yarns, and make yarn structure more tight, efficiently avoid the forming of hairiness because the fiber in the yarn stretches out from the yarn surface in subsequent operation. In addition, the hairiness reducer for finished yarn that de-twists and heats can be used on spooling, warping even knitting machines, the reducer consumes low energy, is easy to install and use, and is good for spreading and application widely.

Owner:WUHAN TEXTILE UNIV

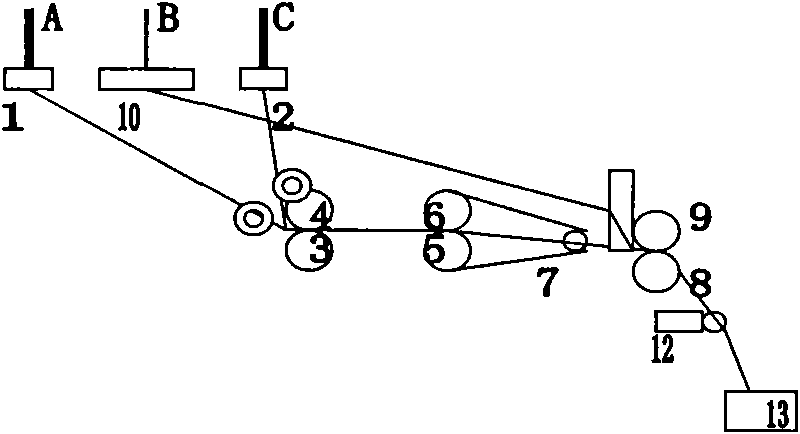

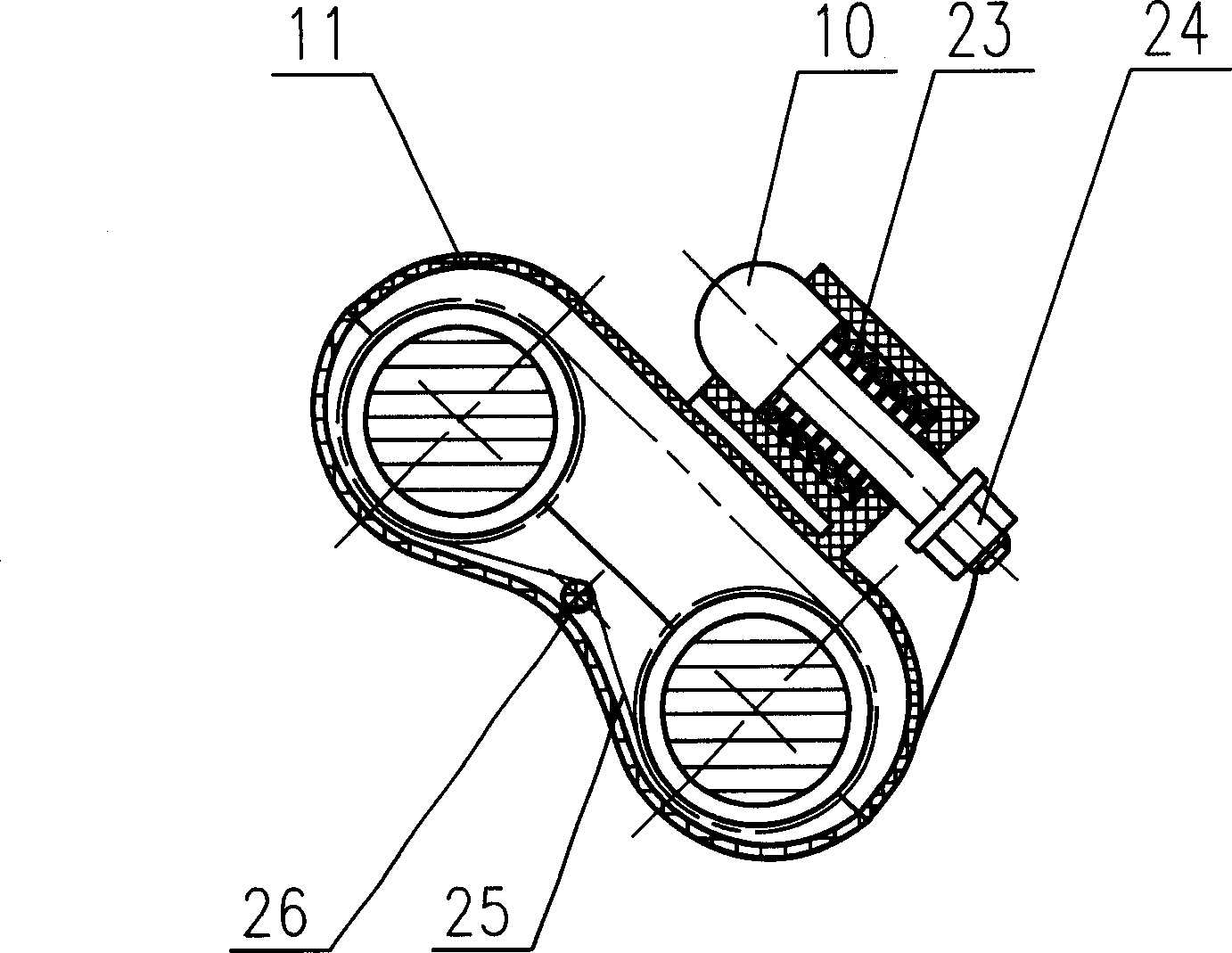

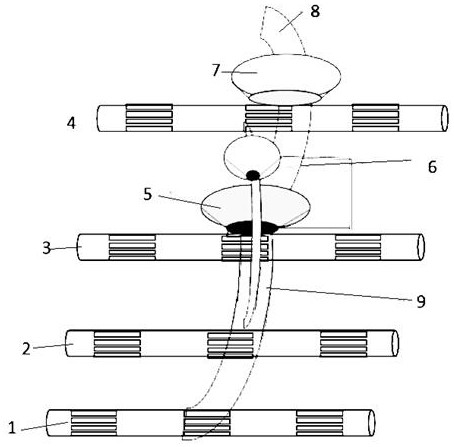

Spinning method and device of high-elastic core-spun combined yarn

InactiveCN101935898AOvercoming Yi Ruth's FlawsSolve Ruth PhenomenonDrafting machinesContinuous wound-up machinesYarnEngineering

The invention relates to the spinning field, in particular to a novel spinning method of the high-elastic core-spun combined yarn. The method is characterized in that the method comprises the following steps: two rough yarns are added and the rough yarns are combined with the stretch yarn to spin in a spinning area. The method overcomes the defect of the original core-spun technology that yarns are easy to expose; the original core-spun technology is that one rough yarn is added and combined with the stretch yarn to spin in a trigonal spinning area, yarns are easy to expose when the stretch yarn wheel is not centered; the spinning technology of the high-elastic core-spun combined yarn is that two rough yarns are added and combined with the stretch yarn in the spinning area to spin; and as the sliver discharged by the front roller is wide, the yarn-exposing phenomenon is well solved. The method of the invention has the advantages that the raw material adaptability is better, the grade of raw cotton can be lowered, the raw material cost is reduced, the spinning benefit can be maximized,etc. The invention also relates to a combined yarn spinning device used in the method.

Owner:湖北维新纺织股份有限公司

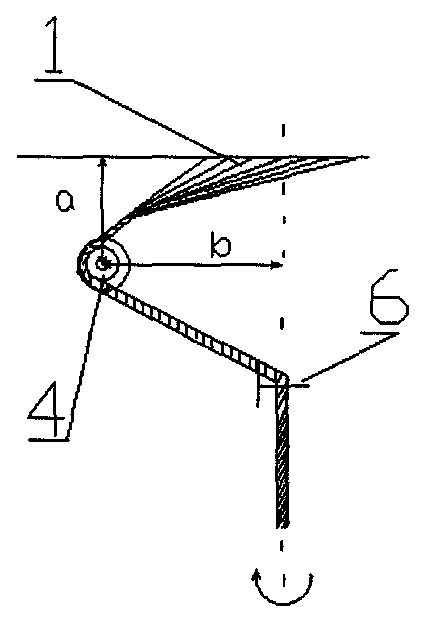

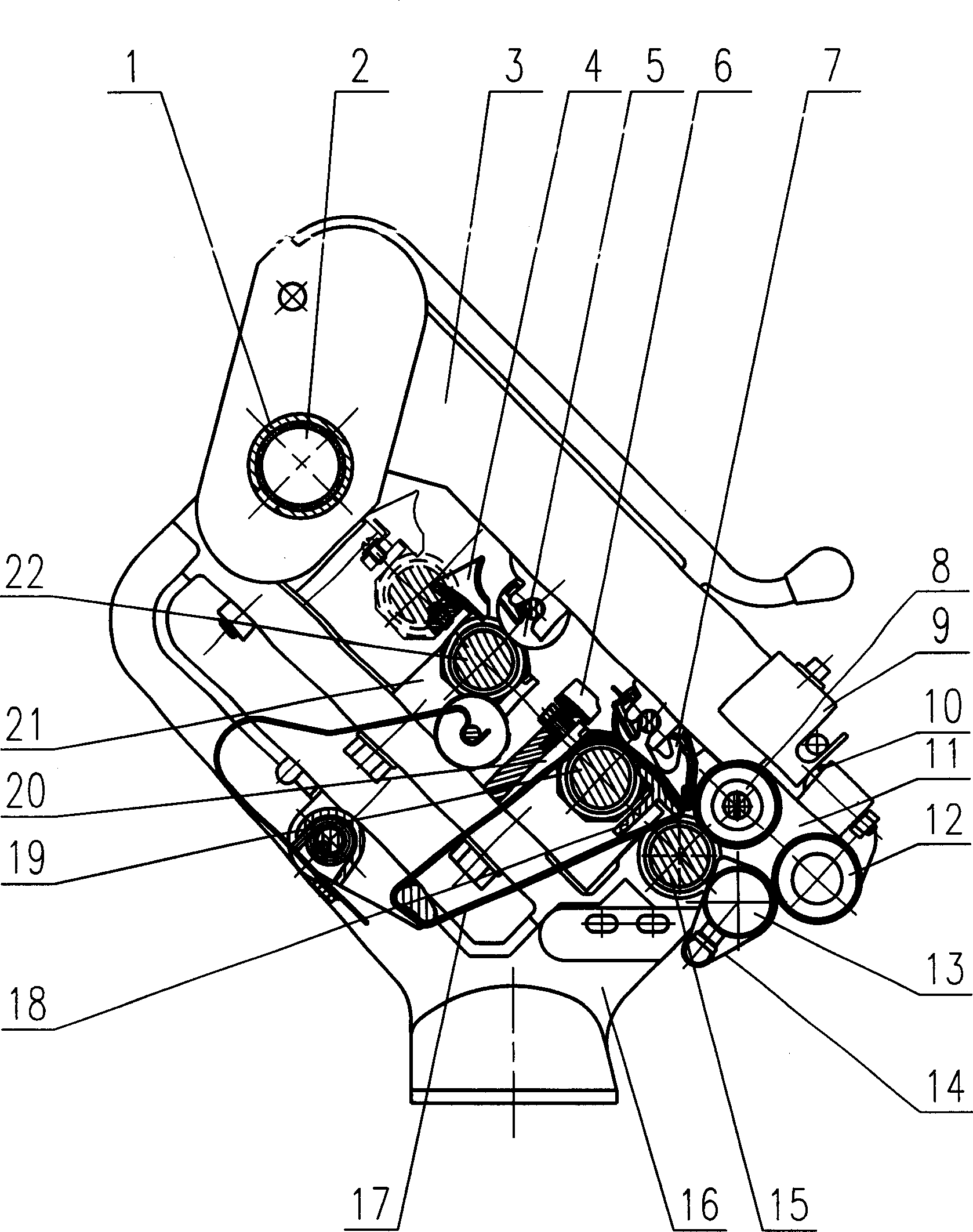

Novel method and device for processing vortex ring spun yarn

InactiveCN102433619AHigh strengthWeaken the twisting effectContinuous wound-up machinesOpen-end spinning machinesPrice ratioAtmospheric pressure

The invention relates to a novel method and device for processing vortex ring spun yarn. The technical transformation of a winding and twisting section which is configured at a drawing part in a spinning machine and used for finally sending yarn out of a downstream part of a roller in a paired manner can be directly applied to the technical transformation of the spinning machine. By adopting the method and the device for processing the vortex ring spun yarn to replace original guide wires, the twist fault effect of the original guide wires is weakened, vortex generated by compressed air is effectively utilized for changing twist transmission and yarn formation during the yarn formation process, the flow rate of compressed airflow can be changed in a range from 0-0.5MPa through an air pressure valve according to different yarn counts and process demands, thereby being conductive to the reduction of yarn-forming hair feather and increase of the strength of the yarn. Compared with other technologies, the device is simple and convenient to mount and high in performance-price ratio.

Owner:JIANGNAN UNIV

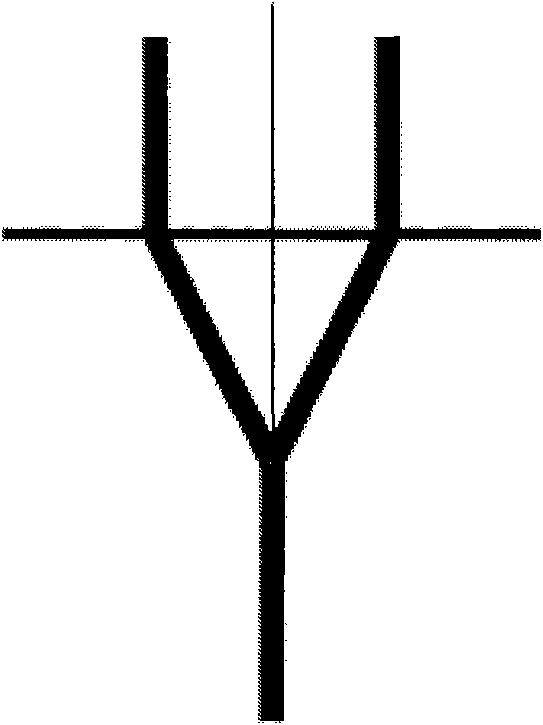

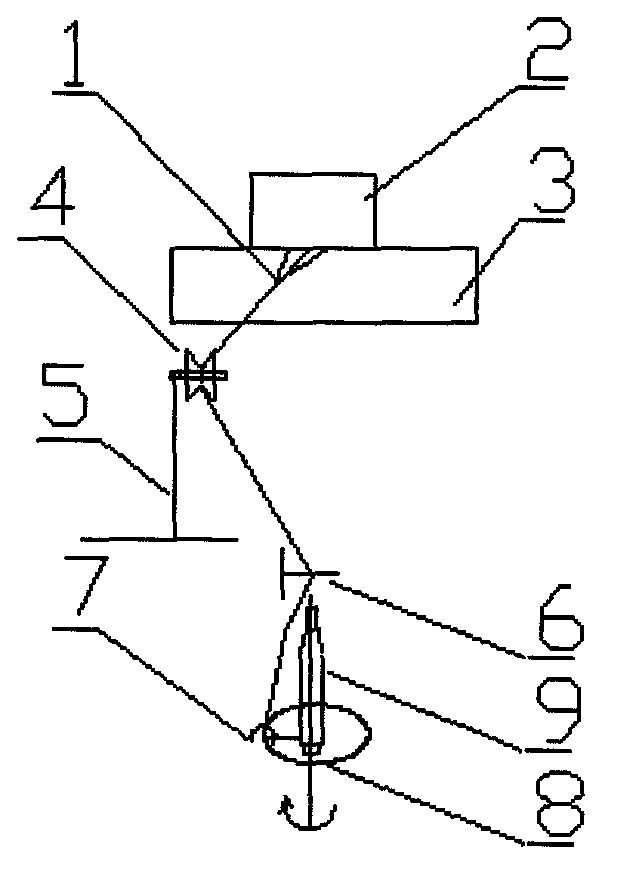

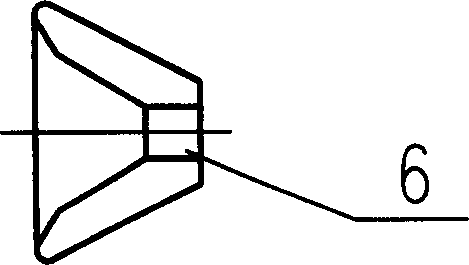

Guide wheel system positioning spinning method

The invention relates to a guide wheel system positioning spinning method and belongs to the technical field of textile processing. Guide wheels are additionally mounted on a front roll of a ring throstle and in front of a front roller. A groove of the guide wheel is V-shaped. A V-shaped bottom of the guide wheel groove is located in one side of a common tangent face of the front roll and the front roller. A shaft of the guide wheel is perpendicular to the common tangent face, yarn is output from a jaw formed by the front roll and the front roller, guided by the guide wheel, and wound on a ring bobbin through a yarn guide hook, a steel collar and a steel wire ring. A non-twist section of the yarn output from a front jaw is eliminated, and spinning efficiency is improved. Yarn texture is more compact, yarn hair is strong, and evenness of yarn is more excellent. The method is suitable for all technical ring throstle spinning systems, simple to modify and convenient to operate and use.

Owner:WUHAN TEXTILE UNIV

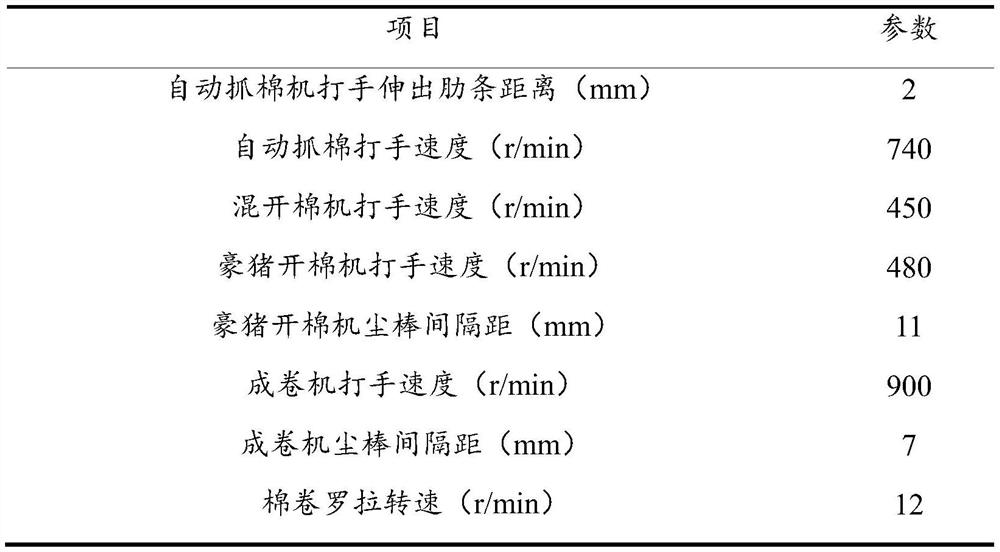

Hemp and long-staple cotton blended 80-count yarn and production method

ActiveCN106048801AGood moisture absorption and perspirationNatural antibacterial healthCarding machinesYarnYarnCombing

The invention belongs to the weaving field, and particular relates to a hemp and long-staple cotton blended 80-count yarn and a production method. <{EN2}>The blended 80-count yarn is produced by blending the hemp and the long-staple cotton in a weight proportion of 40-50:60. <{EN3}>The production method comprises the steps of cotton blending, blooming, combing, fine combing, drawing, roving, spinning and winding. <{EN4}>The 80-count yarn blended by the hemp and the long-staple cotton belongs to high count yarns and the content of the hemp is 40% and more, and realizing the purpose of producing a high count yarn when the content of the hemp is high. <{EN5}>The blended 80-count yarn can be used to produce clothes, and the fabrics obtained has the clean feeling of hemp and the soft feeling of cotton fabrics, no scratchiness and has bacteriostasis and antibacterial function; the yarn has the advantages of moisture absorption, ventilation, cool and comfort feeling; the yarn is safe and has excellent ultraviolet resistance function, antistatic performance, heatproof performance, lightfastness and no pollution; and the yarn is the first choice for producing a high-grade shirt.

Owner:JIHUA 3509 TEXTILE

Production method of flax blended knitting yarns

The invention discloses a production method of flax blended knitting yarns. In the method, flax and modal fibers are blended according to a ratio of 15:85 to 85:15. The method comprises a spinning process and a rotor spinning process. The modal fibers selected in the invention are the most ideal material for light and thin knitted fabrics for their sweat-absorbing, thermal-insulation and cooling properties and integration of the comfortableness of cotton, the drapability of adhesive, the strength of terylene and the handfeel of real silk. The flax-modal blended knitting yarns exploit development space for high-quality flax light and thin knitted fabrics. Although the flax and modal fibers are susceptible to generating hairiness, the rotor spinning used in the invention is one-step bobbin forming and therefore reduces the hairiness of finished fibers and ensures the knitted fabrics are clear and full in appearance. The rotor spun yarns also have the advantages of few yarn faults, high elasticity, pilling resistance, wear resistance and the like. The method has the advantages that: the process flow is short; the cost is low; high grade flax knitting yarns with high balance of various performance indexes such as high fineness, little hairiness, yarn levelness and soft handfeel; and the application value in textile processing field is high.

Owner:QIQIHAR UNIVERSITY

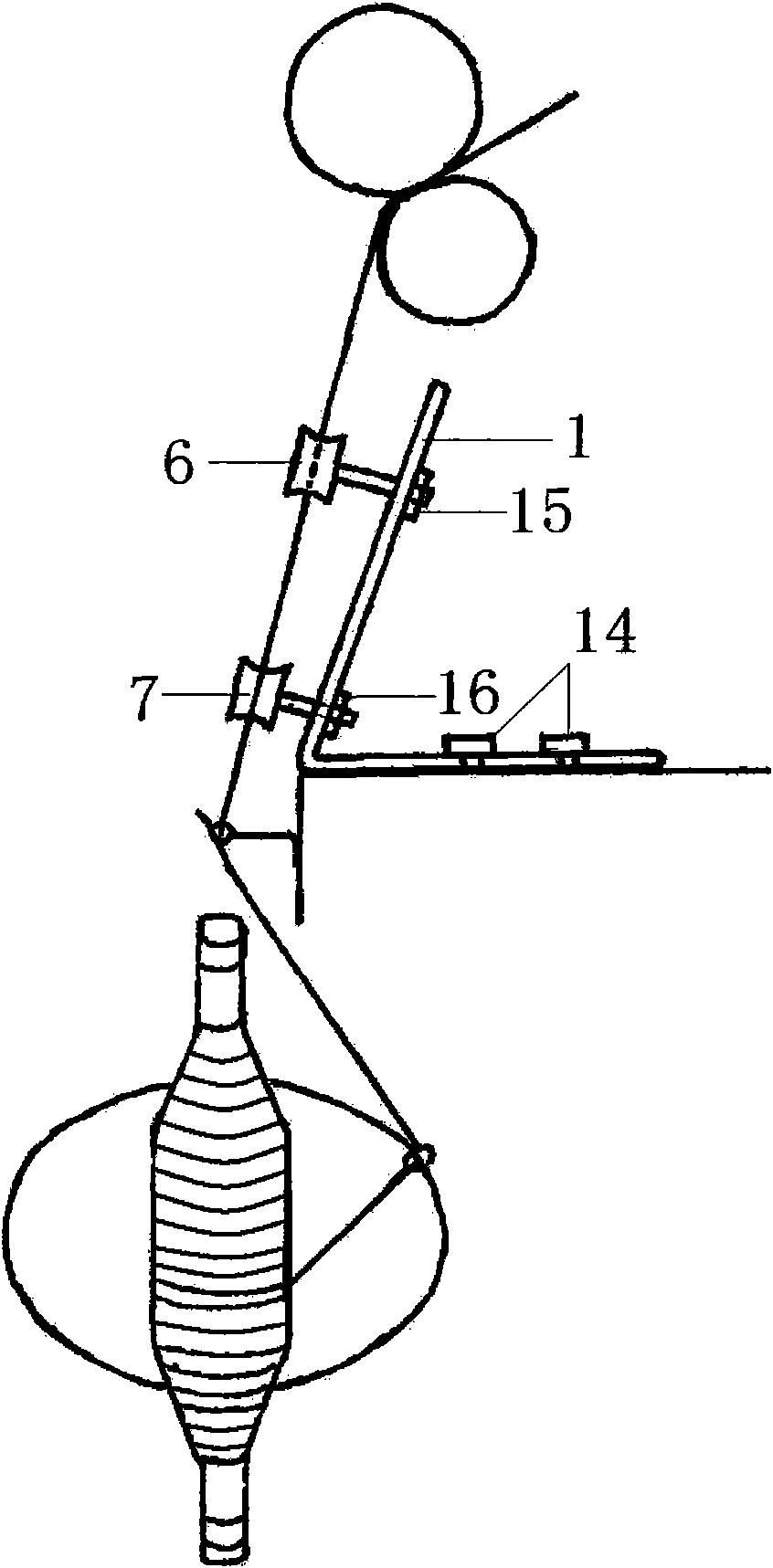

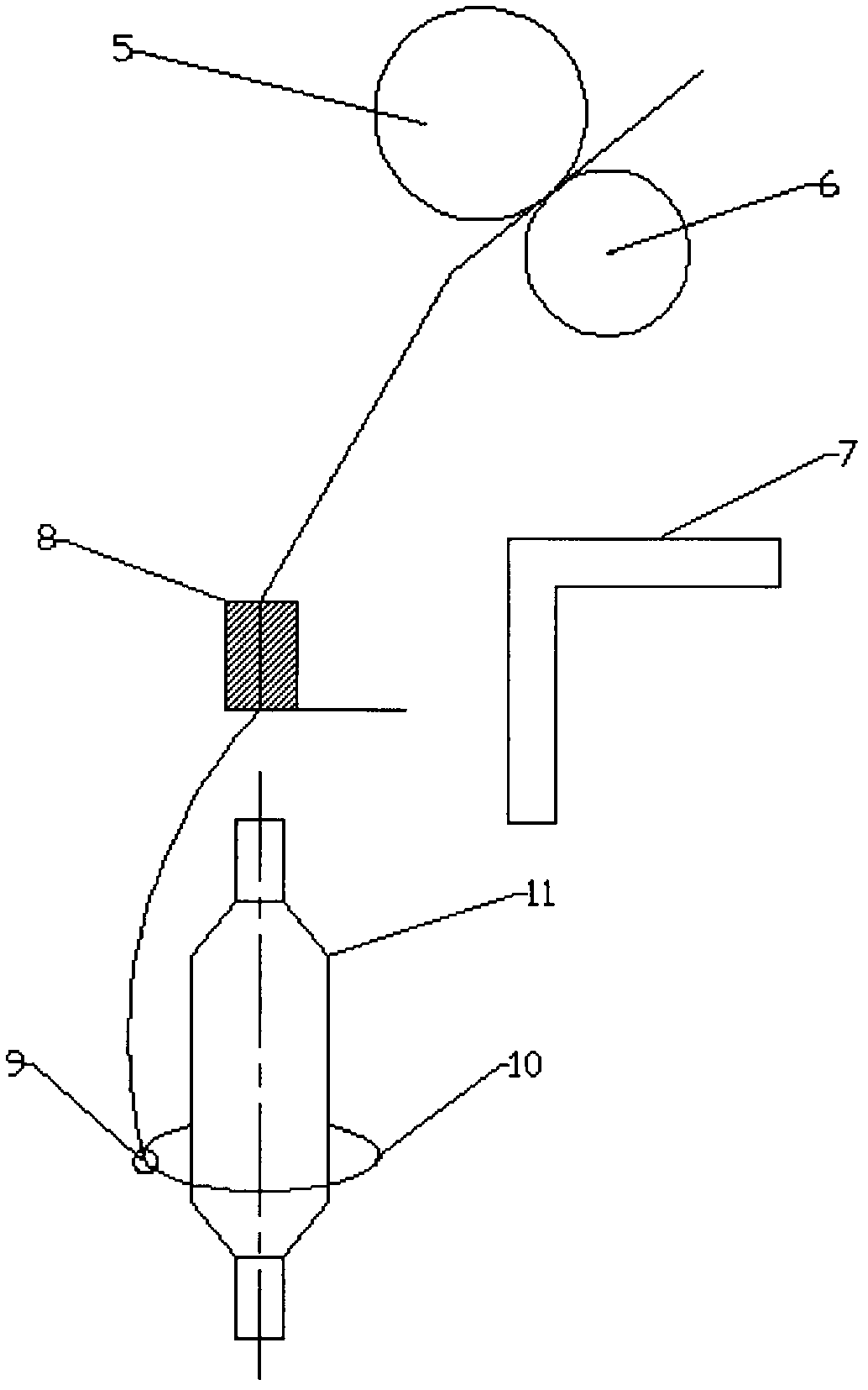

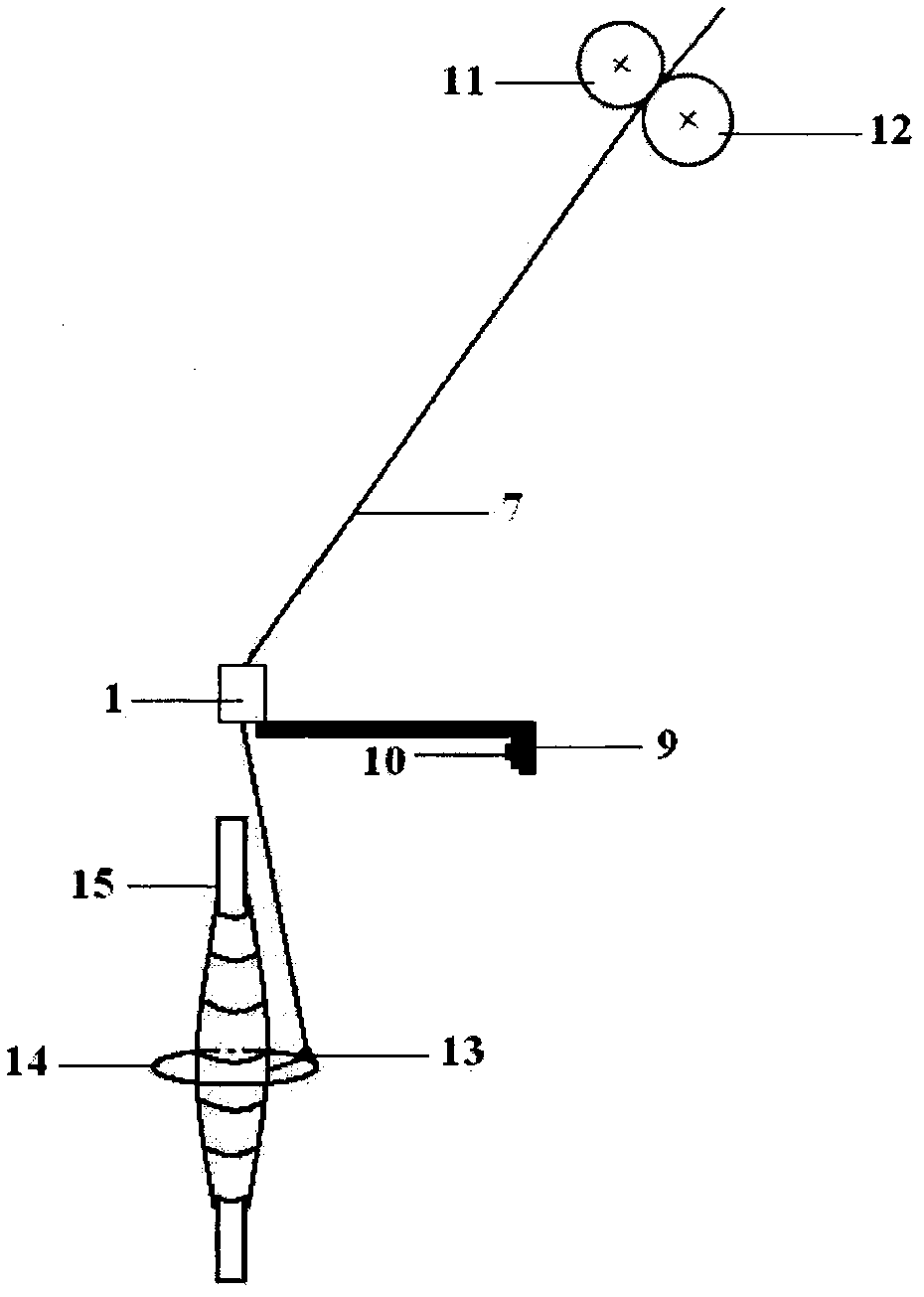

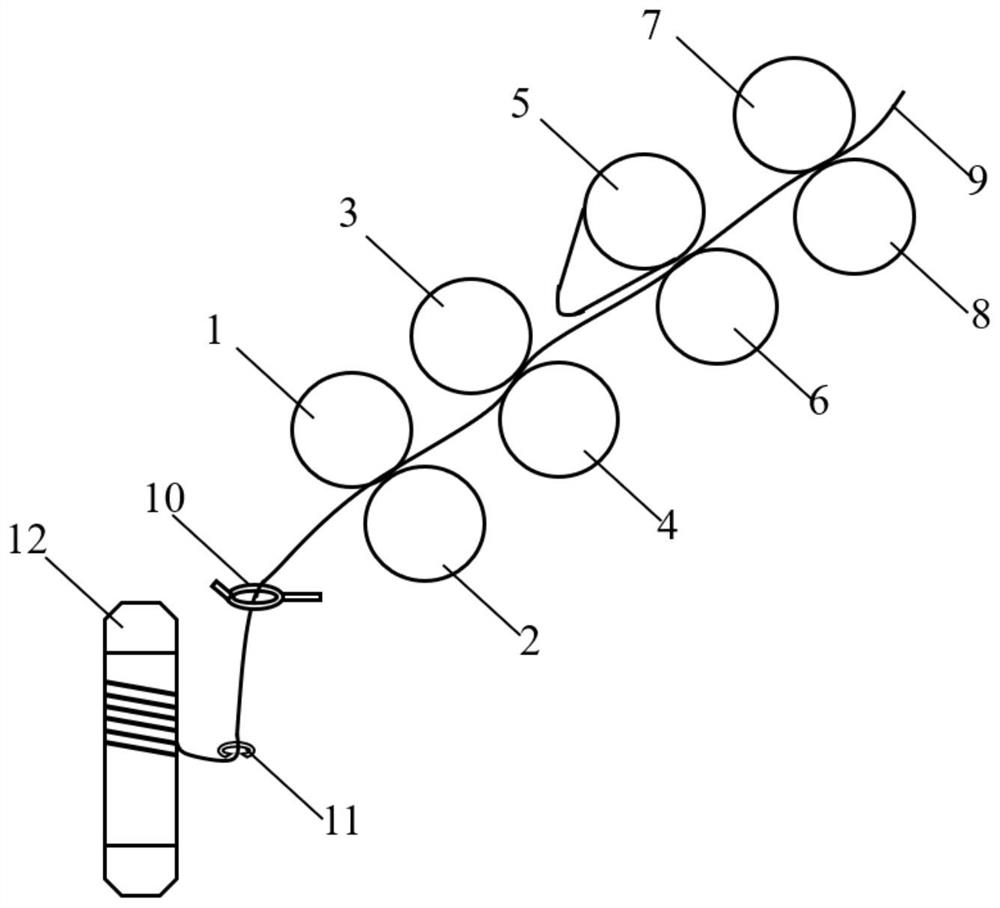

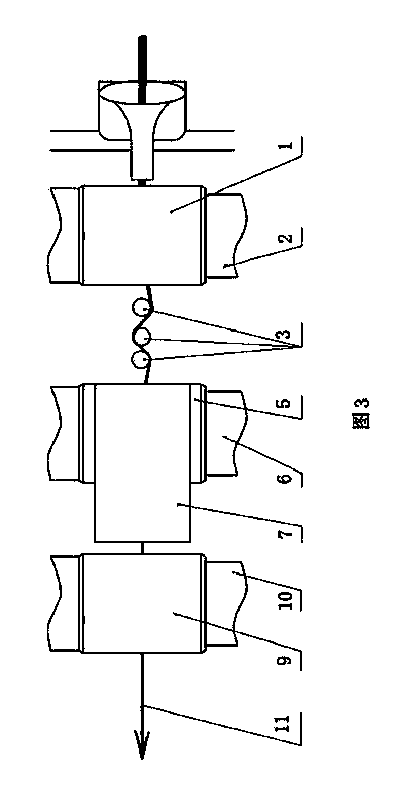

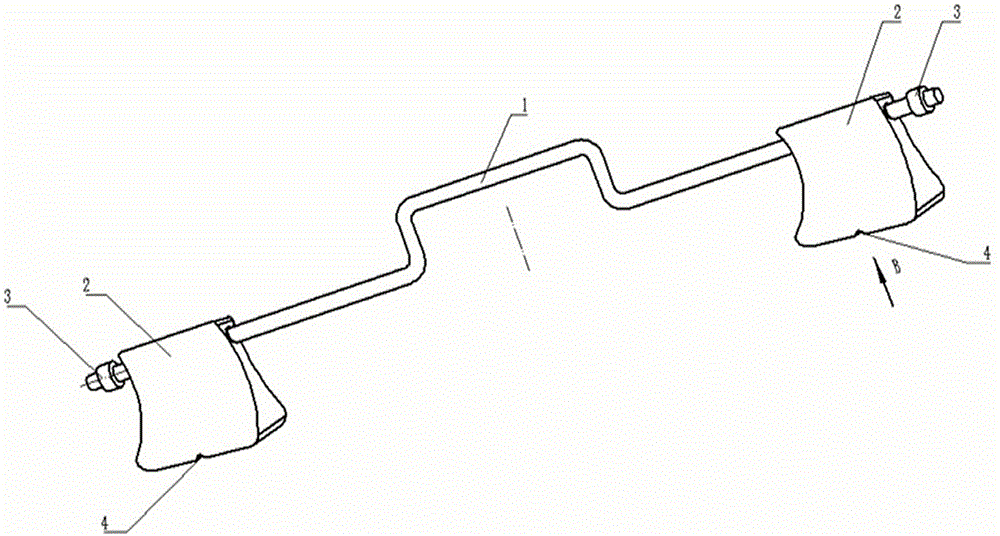

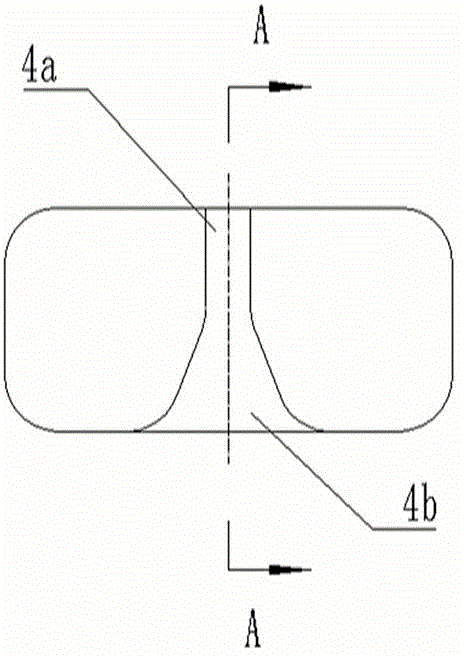

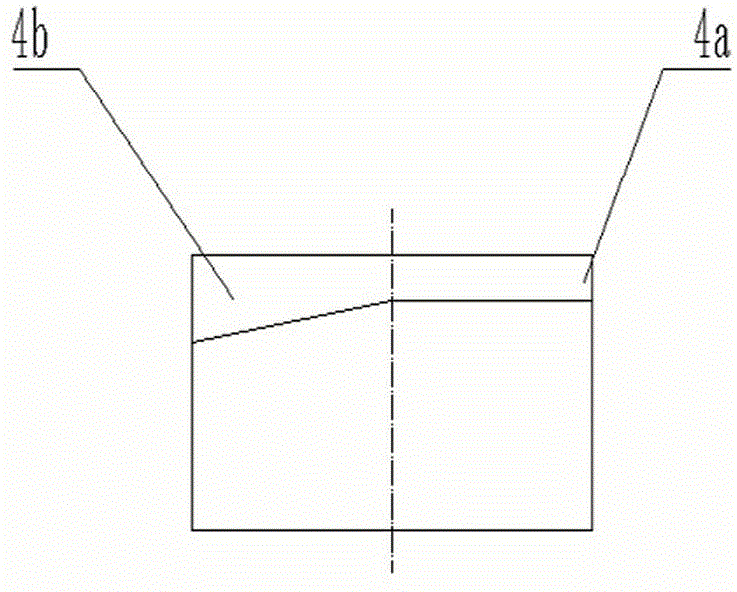

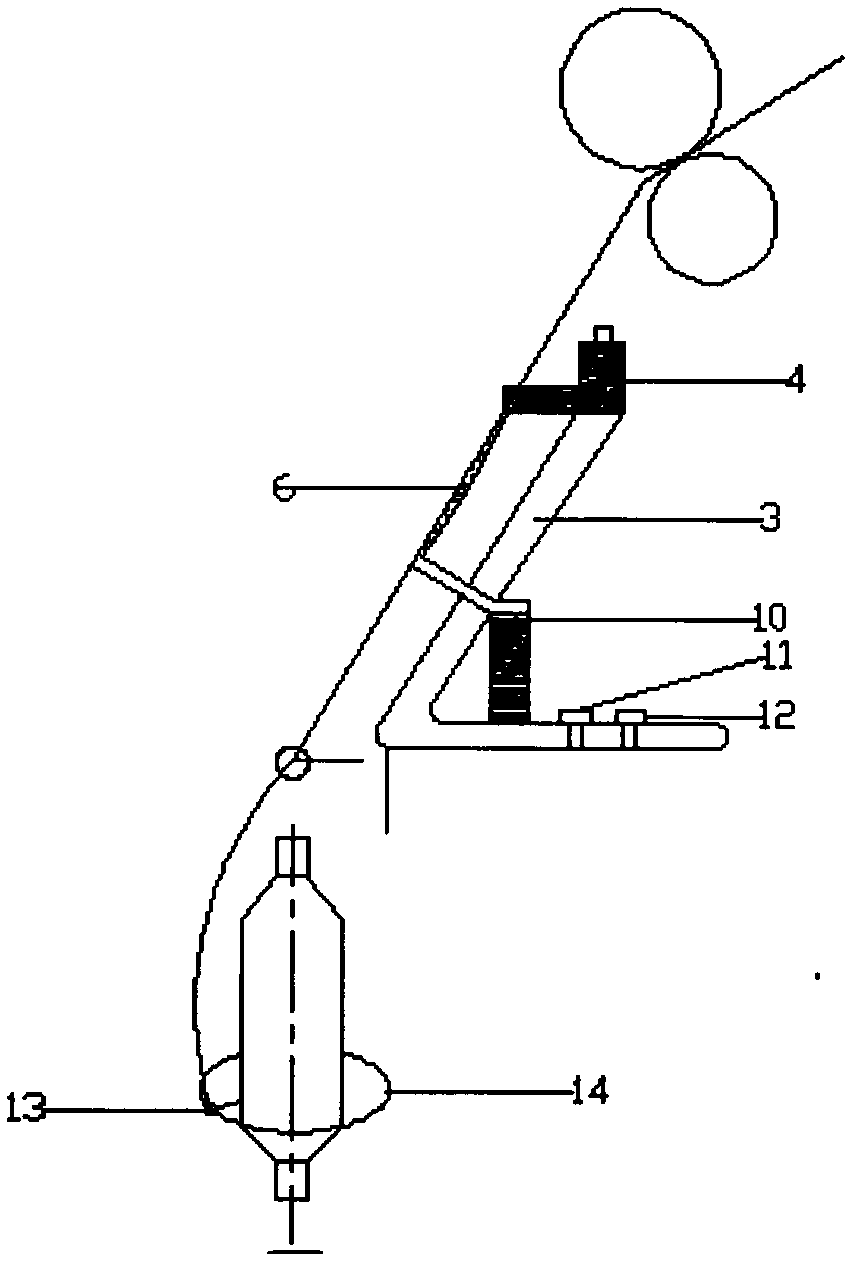

Device for changing form of ring spinning twisting triangular space

InactiveCN102011219AReduced degree of internal and external transferReduce areaContinuous wound-up machinesYarnEngineering

The invention discloses a device for changing the form of a ring spinning twisting triangular space, which is arranged downstream final pairwise output rollers of a drafting part in a spinning frame. The device mainly comprises a bracket and a pair of yarn guide wheels which can be positioned. The device can be applied to the technical improvement of the spinning frame, changes the form of the twisting triangular space by the pair of positioned yarn guide wheels arranged on the vehicle top bracket so as to be favorable for reducing spinning hairiness and improving the evenness of yarns, and compared with the prior art, is simple and convenient to arrange and high in cost performance.

Owner:JIANGNAN UNIV

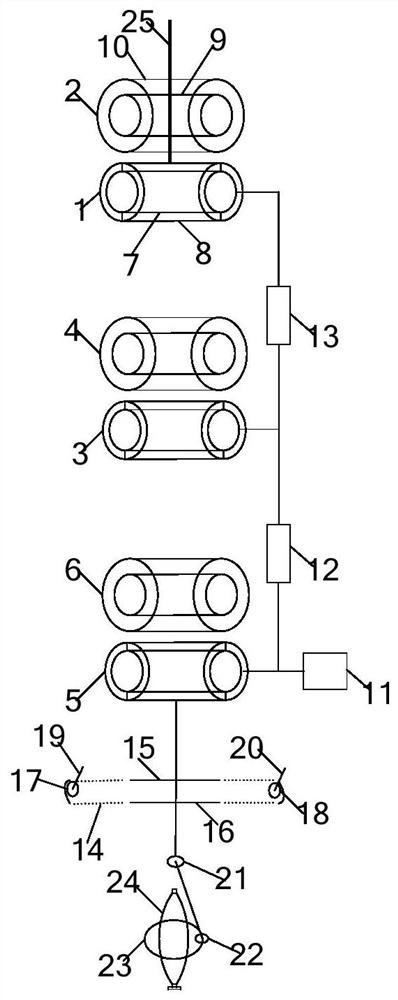

Vortex spinning process

InactiveCN102719938ALow costQuality improvementContinuous wound-up machinesOpen-end spinning machinesYarnRecovery period

The invention relates to a vortex spinning process, belonging to the technical field of cotton spinning. The spinning process specifically comprises the process flows: raw cotton beating and impurity removal, combing treatment, pre-drawing treatment, lap forming and doubling treatment, fine combing, final drawing treatment, and vortex spinning to obtain purified cotton vortex yarn. Compared with the traditional ring spinning method, the method has the advantages of high yield, low energy consumption, short working time, little yarn filoplume, small occupied area, rapid starting and short investment recovery period, and is a first choice to replace ring spinning.

Owner:南昌凤凰纱业有限公司

Method for reducing resultant yarn filoplume

The invention relates to a textile processing technology concerning operations after the spinning that can reduce hairiness in finished yarn, and pertains to the technical field of textile processing. The invention provides a hairiness reducer for finished yarn that de-twists and heats on the advancing channel of the yarns, which reduces hairiness of finished yarns by de-twisting, heating, softening and twisting again yarns. The hairiness reducer for finished yarn that de-twists and heats can outstandingly reduce hairiness in finished yarns, and make yarn structure more tight, efficiently avoid the forming of hairiness because the fiber in the yarn stretches out from the yarn surface in subsequent operation. In addition, the hairiness reducer for finished yarn that de-twists and heats can be used on spooling, warping even knitting machines, the reducer consumes low energy, is easy to install and use, and is good for spreading and application widely.

Owner:WUHAN TEXTILE UNIV

Yarn guide for lubricating yarns

A yarn guide for lubricating yarns mainly comprises an aluminum block, a ceramic eyelet, solid paraffin and a dust cover. The yarn guide is applicable to technical modification of a spinning frame. The yarn guide can be placed at a position of the yarn guide, a yarn can be circled to slide on the surface of the solid paraffin, and accordingly, the fibers can be shaped, yarn hairs are reduced, and friction coefficient is reduced. Compared with the prior art, the yarn guide is simple in mounting and high in cost performance.

Owner:JIANGNAN UNIV

Method for producing jade silkworm fiber pure 60s compact spinning yarn

The invention relates to a method for producing jade silkworm fiber pure 60s compact spinning yarn. Needed cheese yarn can be produced by jade silkworm fiber through processes of roving, spinning and spooling after the processes of blowing, carding and three-passage drawing. According to the method disclosed by the invention, the blowing and carding processes have the advantages that scutching is replaced by carding, the shifting is quick, the winding is prevented, and the fiber damage is reduced; the drawing process adopts the three-passage drawing, thus the weight irregularity of a silver is reduced, and the evenness of a drawn silver is improved; the roller gauge of the roving process and the tension of a cradle are appropriately enlarged, thus the roving tension is controlled, and the additional draft is reduced; a spinning machine is additionally provided with a four-roller grid ring-shaped compact spinning device; and the electric cleaning technology is optimized by the spooling process. According to the method disclosed by the invention, the quality of the compact spinning yarn which is produced through the method is better, the silver evenness, the hairness and the force index of the compact spinning yarn are all better than those of a common ring spinning yarn, and the compact spinning yarn is the qualitative material of textiles, contacting the skin of a human body, such as high-grade underwear, shirts, pillow and quilt cases, bedclothes, scarfs and socks; and weaving dresses and casual clothes made by of the jade silkworm fiber are fresh in color, smooth and gentle in silky brightness and flexible in overhanging elegant innervation.

Owner:JIHUA 3509 TEXTILE

Production method for bright, clean and soft yarn

InactiveCN102433623AReduce yarn hairinessEasy to installTextiles and paperEngineeringAtmospheric pressure

The invention discloses a production method for bright, clean and soft yarn, which is applied to technological improvement on twist rolling parts which are arranged at a drafting part of a spinning frame and are finally sent out from the downstream of a roller in a pair manner, and can be directly applied to technological improvement on the spinning frame, an original yarn guide hook is replaced by a cyclone generator, a twist falling effect of the original yarn guide hook is reduced, rotational flow generated by compressed air is effectively utilized to change twist transfer and yarn forming during forming of the yarn, the flow quantity of the compressed air can be changed through an air pressure valve according to different yarn counts and process requirements and ranges from 0 to 0.6MPa, so that the reduction of yarn hairiness is facilitated, and the purposes of reducing the yarn hairiness, making the yarn softer and more fluffy and improving the yarn performance are achieved.

Owner:JIANGNAN UNIV

Device for machining compact siro covering yarns

ActiveCN105780235AStable draft ratioEnsure consistencyDrafting machinesYarnYarnPulp and paper industry

The invention discloses a device for machining compact siro covering yarns. The device comprises a rear roller, a middle roller, a front roller, a yarn traction device, thick yarn shaft tubes and a spandex yarn shaft tube, wherein the yarn traction device is fixed at the lower end of a rack and is connected with the front roller, the middle roller, the rear roller and the thick yarn shaft tubes upwards in sequence through yarns. The device is characterized in that an air sucking tube is further arranged between the front roller and the yarn traction device; the air sucking tube is sleeved by a grid loop; two air sucking grooves are formed in positions corresponding to the grid loop, on the air sucking tube; a buffer shaft is further arranged between a yarn guide roller and the air sucking tube; and under the traction of the yarn traction device, spandex yarns are led downwards to be twisted with yarns on the grid loop through the yarn guide roller and the buffer shaft. By adopting the device, resultant yarn hairiness can be greatly reduced, the strength of the yarns can be improved, an effect of tightening the yarns can be achieved, and a high-quality product can be provided for the high-end denim market.

Owner:SHANDONG TEXHONG TEXTILE CO LTD

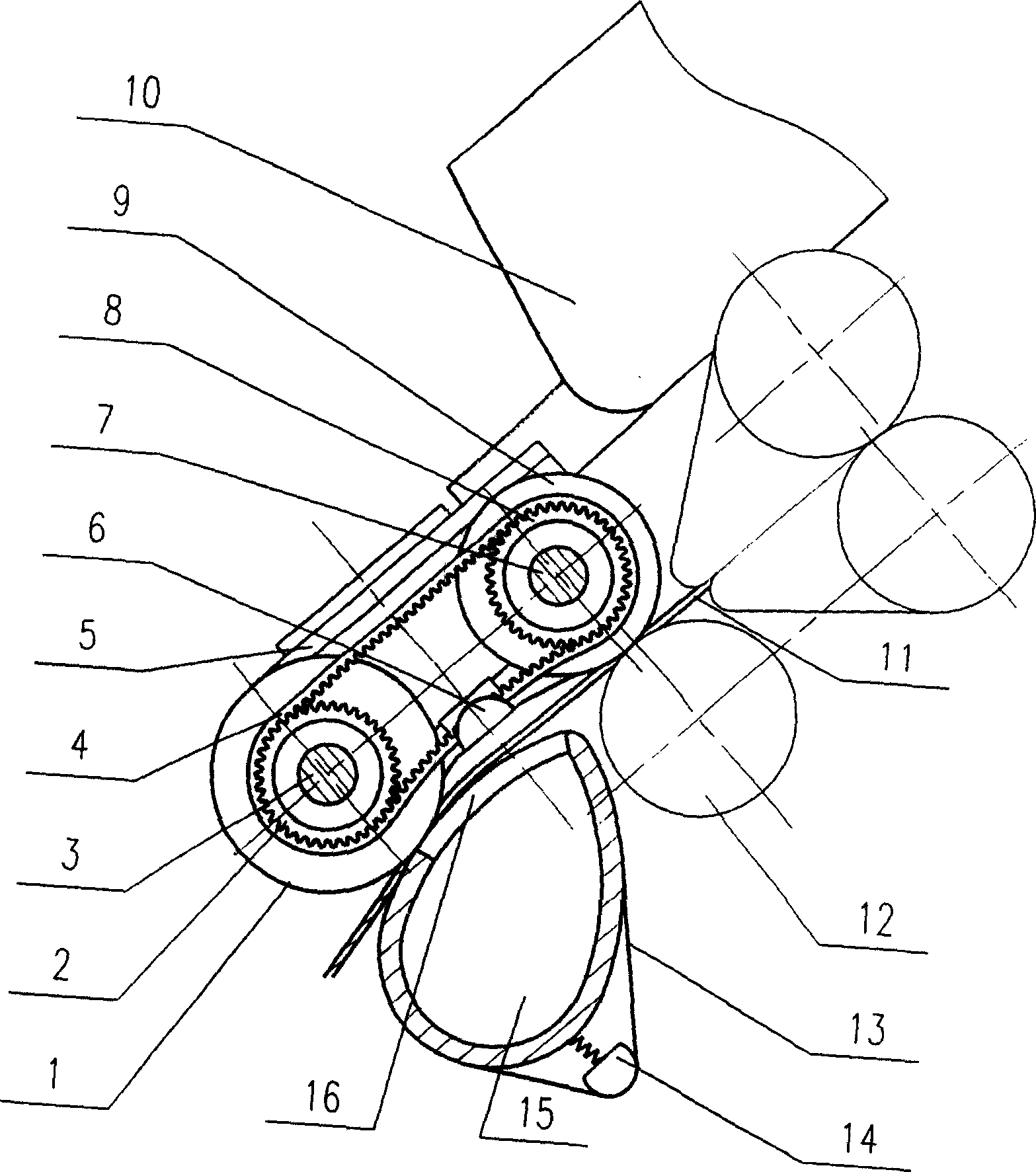

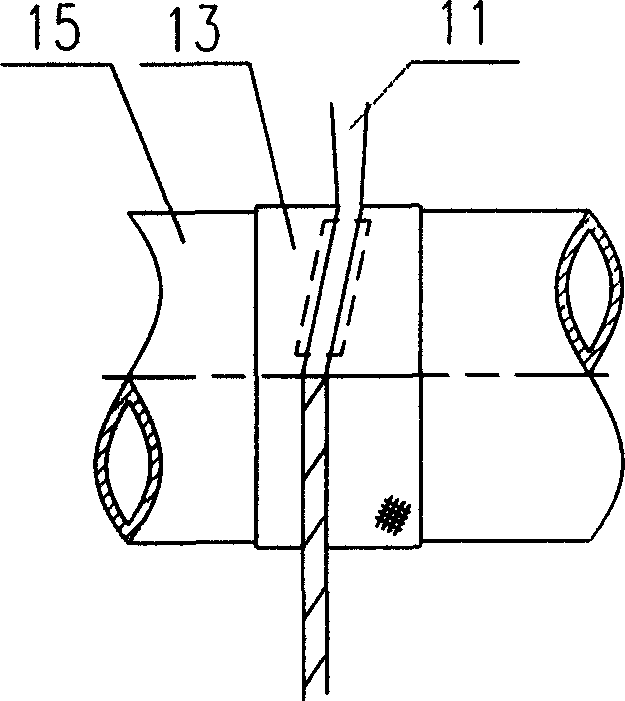

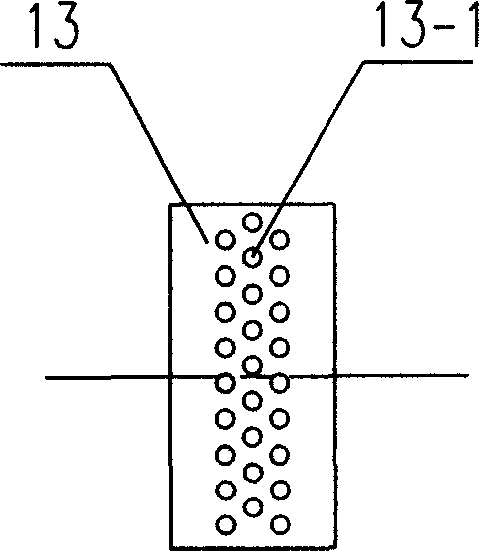

Fiber collecting device for condensed ring spinner

InactiveCN1566424AReduce yarn hairinessImprove yarn qualityDrafting machinesContinuous wound-up machinesYarnFiber bundle

The invention provides a compact frame spinning fiber nesting device, which comprises a support, a front leather roller, a nesting leather roller, and an indraft tube arranged under the nesting leather roller. An indraft groove is arranged in the position of said indraft tube, which corresponds to the fiber path, the indraft tube has holed leather ring, and synchronous pulleys, which are driven in gear by serrated belt are fixedly connected with said front leather roller and said nesting leather roller. The invention effectively controls the fiber bundle in spinning course and eliminates twisting triangular space, as a result, produces yarn with less hairiness, has simple, compact structure, stable drive, better resultant yarn, and is convenient for maintenance and use.

Owner:DONGTAI TEXTILE MASCH CO LTD

Production technology of soy protein spandex covering yarn

The invention discloses a production technology of a soy protein spandex covering yarn, which is characterized in that: soy fiber can be pre-processed, and the moisture regain of the raw material is 8-12%; a scotching machine is used for scotching; a carding machine is used for carding, the relative humidity of the raw material is 65-75%, and the temperature is 18-26 DEG C; a drawing frame is used for drawing from three ways, the quantity of the drawing silver evenness is 7-12g / 5m, the moisture regain is 7-8%, and the silver evenness CV is 2.5-3.5%; roving and yarn fining are carried out; and spooling is carried out, and the relative humidity of the yarn is 72-83%. The soy protein spandex covering yarn produced by the technology has better leading indicators such as strength, hairiness and the like than the traditional ring spinning; in addition, the yarn has good cladding effect, so as to meet the using requirement.

Owner:蔡晔

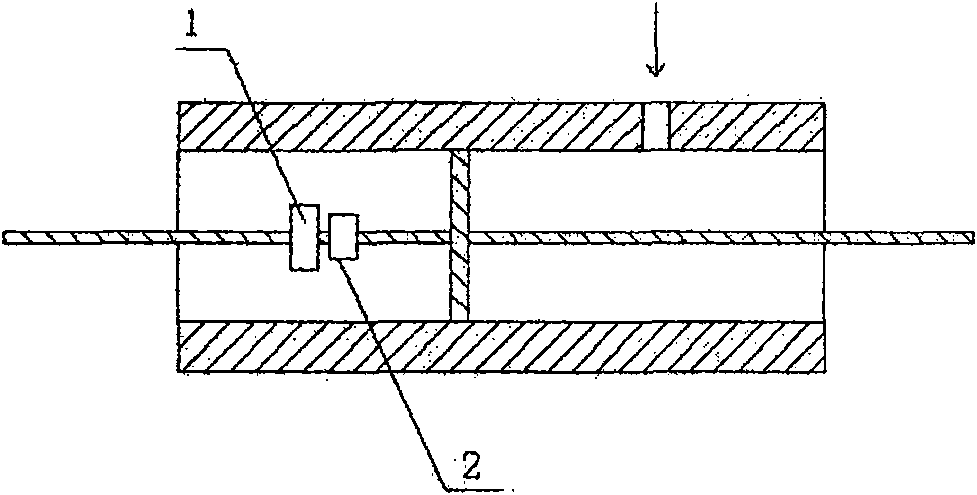

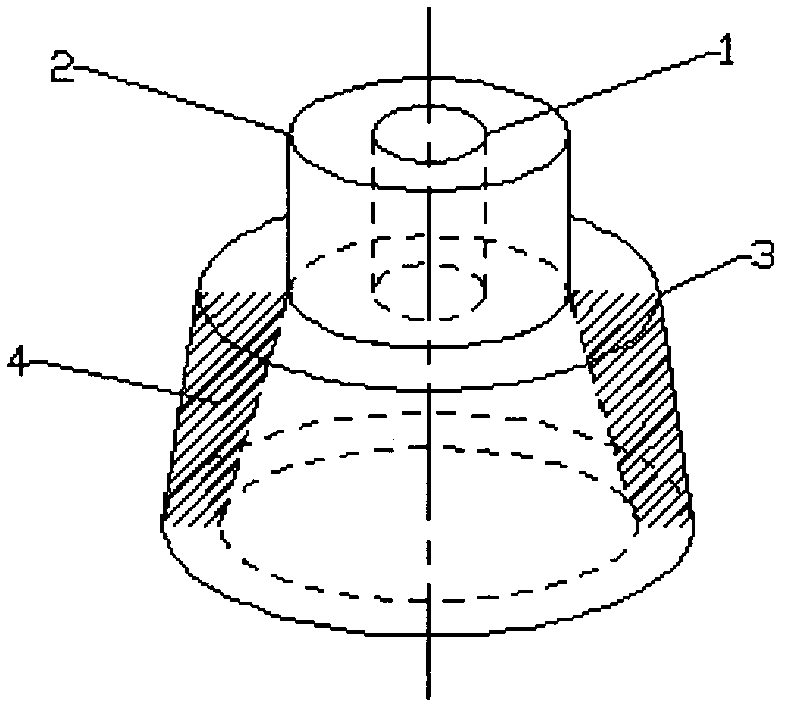

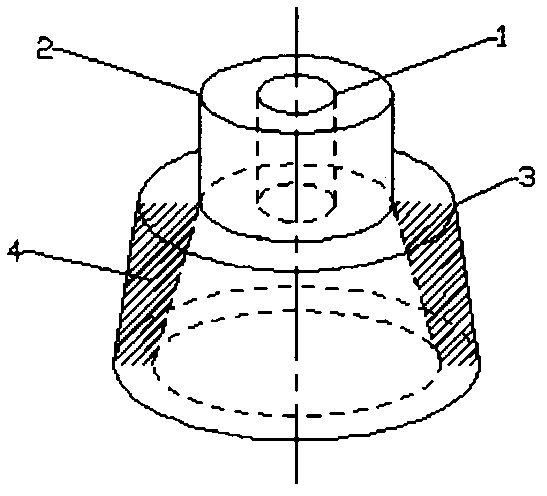

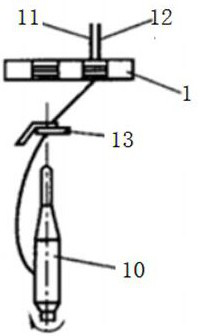

Three-roller superlarge-drafting ironed yarn production method

The invention relates to a three-roller superlarge-drafting ironed yarn production method. A device is arranged at the position of a carriage table top and mainly composed of a baseplate, an electric heating element, a thermolator, a press plate and a shell. The three-roller superlarge-drafting ironed yarn production method can be applied to a three-roller superlarge-drafting spinning machine for simple technical transformation, and the device is mounted on the carriage table top. Fiber roving is output from a front jaw for temperature-adjusting ironing, and yarn is fully shaped, so that hairiness of resultant yarn is reduced, and fibers in the yarn are uniform stressed. Compared with the prior art, the device has the advantages of simplicity and convenience in mounting and high performance-cost ratio.

Owner:JIANGNAN UNIV

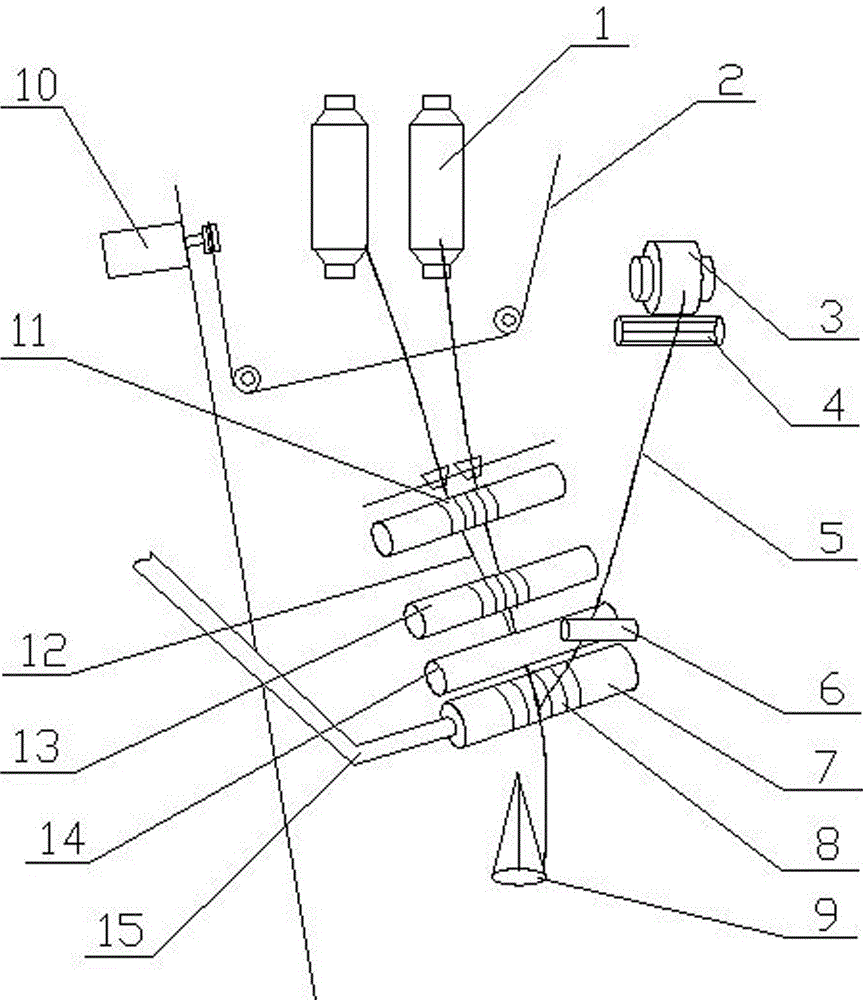

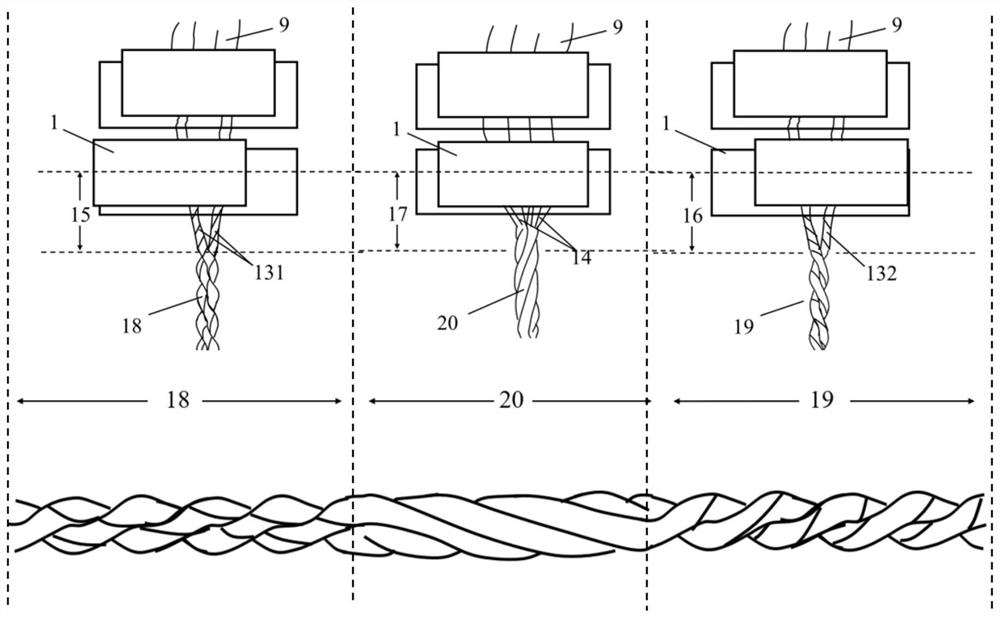

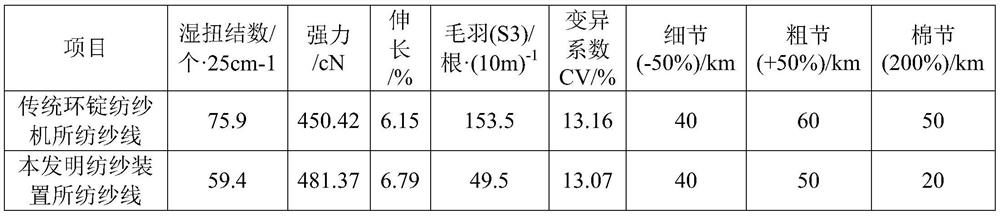

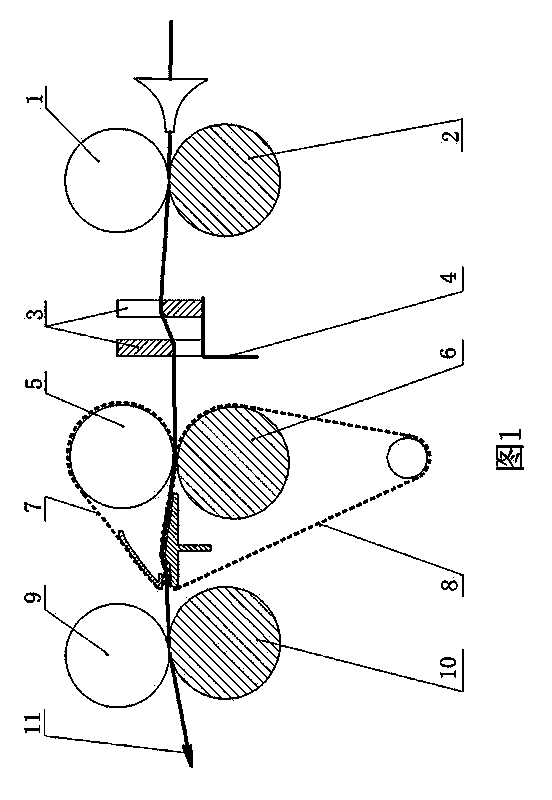

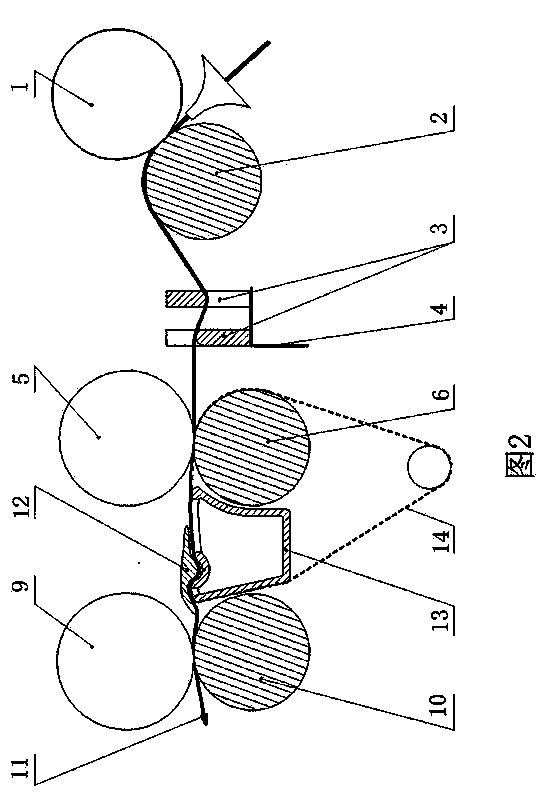

Processing method and device for spinning single yarns of plied yarn structures on ring spinning frame and yarns

The invention relates to a processing method for spinning single yarns of plied yarn structures on a ring spinning frame. A twisting mechanism arranged at the front ends of a front leather roller and a front roller is adopted; the twisting mechanism consists of the twisting leather roller and the twisting roller which do rotary motion and reciprocating motion; fibers arranged in parallel in fiber strands are twisted under the friction action of the twisting mechanism to form pre-added twisting orientation; two bundles of pre-twisted ring spun staple fiber yarns subjected to twisting treatment are output through a twisting jaw composed of the twisting roller and the twisting leather roller; and the two bundles of pre-twisted ring spun staple fiber yarns are converged and plied in a triangular twisting area under the action of twisting force of cohesive twisting and internal torque force of slivers subjected to twisting finishing, so that the single yarns of the plied yarn structures integrating main body double-strand spiral type and local twisting cohesive type are formed, the strength, abrasion resistance and flexibility of the yarns are improved, the technological process of doubling and plying of the single yarns are reduced, the application range is wide, the operation is convenient, and the large-area popularization and application are facilitated.

Owner:WUHAN TEXTILE UNIV

Method for producing Coolvisions fiber yarn

The invention discloses a method for producing Coolvisions fiber yarn, which relates to the technical field of spinning engineering. A Coolvisions fiber is blown and carded to form a raw sliver; the raw silver is subjected to two processes of combination mixture pure spinning or three processes of mixture spinning with other fiber raw silvers to be made into a drawn sliver; the drawn sliver is subjected to rough spinning, fine spinning and spooling, and the formed spool yarn can be made into fabrics, such as thermal underwear, outdoor sports wear, polar fleece, T-shirt, military special clothes, and the like. The Coolvisions fiber yarn can be printed and dyed at normal temperature and normal pressure, has high dyeing rate, good color fastness, rapid moisture guide, ventilation, deodorization, flexible hand feeling, good elasticity, difficult deformation, good abrasive resistance, cool feeling, body attachment and bright and rich fabric color, and meets the application requirements of high-grade cloth fabrics, fashionable dress fabrics, and the like.

Owner:NANTONG DOUBLE GREAT TEXTILE

Curve drafting device

InactiveCN103451786APrecise positioningIncrease frictionDrafting machinesFiber bundleThree-dimensional space

The invention discloses a curve drifting device applicable to the field of spinning. The curve drafting device structurally comprises a back jaw, a middle jaw, a front jaw and positioning bodies, the back jaw is composed of a back roller and a back-upper roller, the middle jaw is composed of a middle roller and a middle-upper roller, and the front jaw is composed of a front roller and a front-upper roller. Two or more than two positioning bodies are arranged between the jaws of a same spin. A connected line from fiber bundles into a back drafting zone till out of the same shows that the positioning bodies can control fiber bundles to move forward in the form of three-dimensional space curves. By the curve drafting device, friction boundary on the middle-back portions of the drafting zone can be enhanced, fibers are benefited in speed-change point leading forward, collecting and stabilizing, edge fibers of the fiber bundles can be collected, yarn hairiness is reduced, and a three-dimensional space can be accurately positioning during a drafting process of the fiber bundles.

Owner:程登木

Production method of flax blended knitting yarns

The invention discloses a production method of flax blended knitting yarns. In the method, flax and modal fibers are blended according to a ratio of 15:85 to 85:15. The method comprises a spinning process and a rotor spinning process. The modal fibers selected in the invention are the most ideal material for light and thin knitted fabrics for their sweat-absorbing, thermal-insulation and cooling properties and integration of the comfortableness of cotton, the drapability of adhesive, the strength of terylene and the handfeel of real silk. The flax-modal blended knitting yarns exploit development space for high-quality flax light and thin knitted fabrics. Although the flax and modal fibers are susceptible to generating hairiness, the rotor spinning used in the invention is one-step bobbin forming and therefore reduces the hairiness of finished fibers and ensures the knitted fabrics are clear and full in appearance. The rotor spun yarns also have the advantages of few yarn faults, high elasticity, pilling resistance, wear resistance and the like. The method has the advantages that: the process flow is short; the cost is low; high grade flax knitting yarns with high balance of various performance indexes such as high fineness, little hairiness, yarn levelness and soft handfeel; and the application value in textile processing field is high.

Owner:QIQIHAR UNIVERSITY

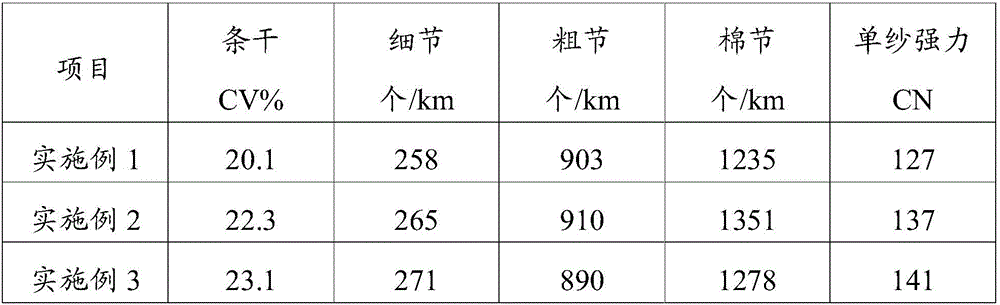

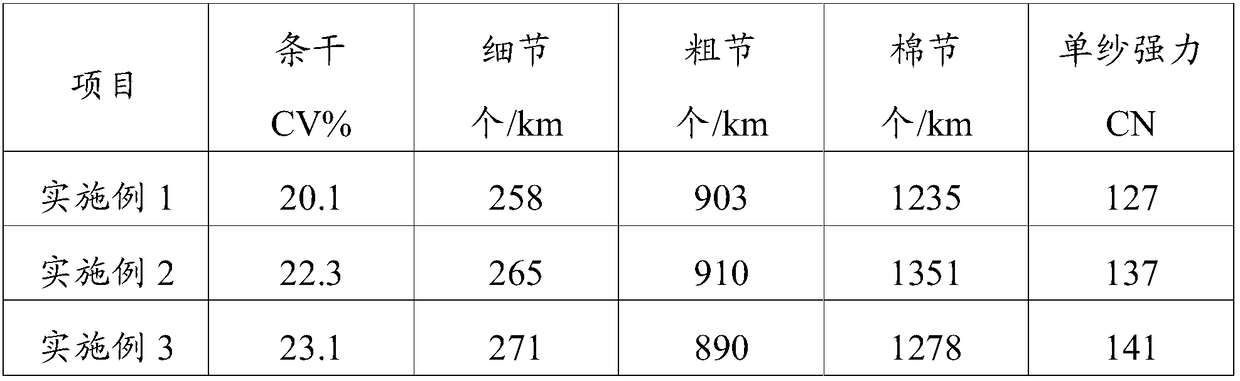

Clustered sirofil-spun SOLOTEX composite yarn and spinning method of composite yarn

ActiveCN107151845AIncrease the concentration areaReduce yarn hairinessDrafting machinesFilament/thread formingAdditive ingredientMoisture absorption

The invention relates to a clustered sirofil-spun SOLOTEX composite yarn. An English count of the yarn is 20S-60S; the yarn comprises the following ingredients by percentage of weight of a fiber at a conventional moisture regain: 30-40% of tencel, 30-40% of cross-shaped section moisture absorption and sweat releasing polyester, 5-10% of spun silk yarn and 20-40% of SOLOTEX. A SOLOTEX filament is a 50D / 36F FDY (fully drawn yarn) or DTY (draw texturing yarn). A spinning method of the clustered sirofil-spun SOLOTEX composite yarn comprises the following steps: 1) preparing a health preservation solution, uniformly spraying the mixed solution onto the surface of a spun silk raw material for sealing and health preservation for 24-48h, 2) opening and mixing the tencel, the cross-shaped section moisture absorption and sweat releasing polyester and the spun silk yarn according to a procedure, 3) performing heckling, drawing and roving: allowing a cotton roll to pass through a hackling machine, 3 drawing frames and a roving frame to prepare a rough yarn, 4) spinning a spun yarn, and 5) performing winding: winding the composite yarn with an automatic winder into a cone yarn.

Owner:山东联润新材料科技有限公司

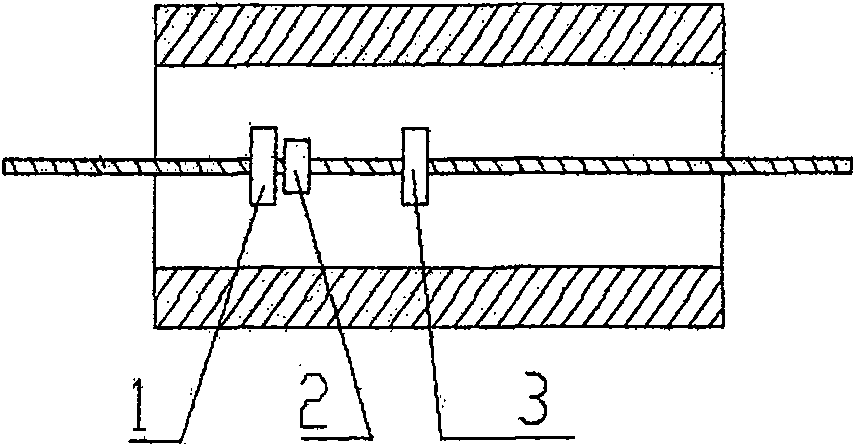

Cotton collector for reinforcing three-dimensional control of fiber strand

The invention relates to a cotton collector for reinforcing three-dimensional control of a fiber strand. The cotton collector comprises a Pi-shaped supporting rod, wherein solid cotton collector blocks are arranged on two ends of the Pi-shaped supporting rod in a mirroring manner, and a guide groove is respectively formed in the bottom of each solid cotton collector block; the Pi-shaped supporting rod outside each solid cotton collector block is provided with a positioning clamp. The cotton collector is simple in structure, the efficiency for removing burrs of the fiber strand can be greatly improved, and the quality of a finished product yarn is greatly improved.

Owner:ANHUI HUAMAO TEXTILE

Pneumatic fiber nesting device

InactiveCN1699649AGuaranteed periodic traverseEliminate negative effectsDrafting machinesFiberEngineering

The present invention discloses a kind of assembly device for pneumatic fiber out of ring frame, comprising a forward drawing roller pair with front roller and a front leather roller clamping the front end of a rocking frame, and an assembly twist retarding pair with a suction hose and an assembly leather roller. The said assembly twist retarding pair is located in the front side of the front drawing roller pair; the said suction hose has a suction rift where there is a permeable conveyer belt operating through a sliding socket joint. The said rocking frame is a pneumatic device for increasing pressure, which bears the supporting stand of the rocking frame. The inflatable bag is placed in the pipe cavity of the supporting stand for the rocking frame. The pneumatic fiber assembly device has not only avoided 'the plus-twisting delta area' and enabled the fiber ribbon to become close and tight, but also kept a stable plus-pressure through the rocking frame and a little difference in pressure among different spindles, thus bringing about the best composite spinning capacity.

Owner:DONGTAI TEXTILE MASCH CO LTD

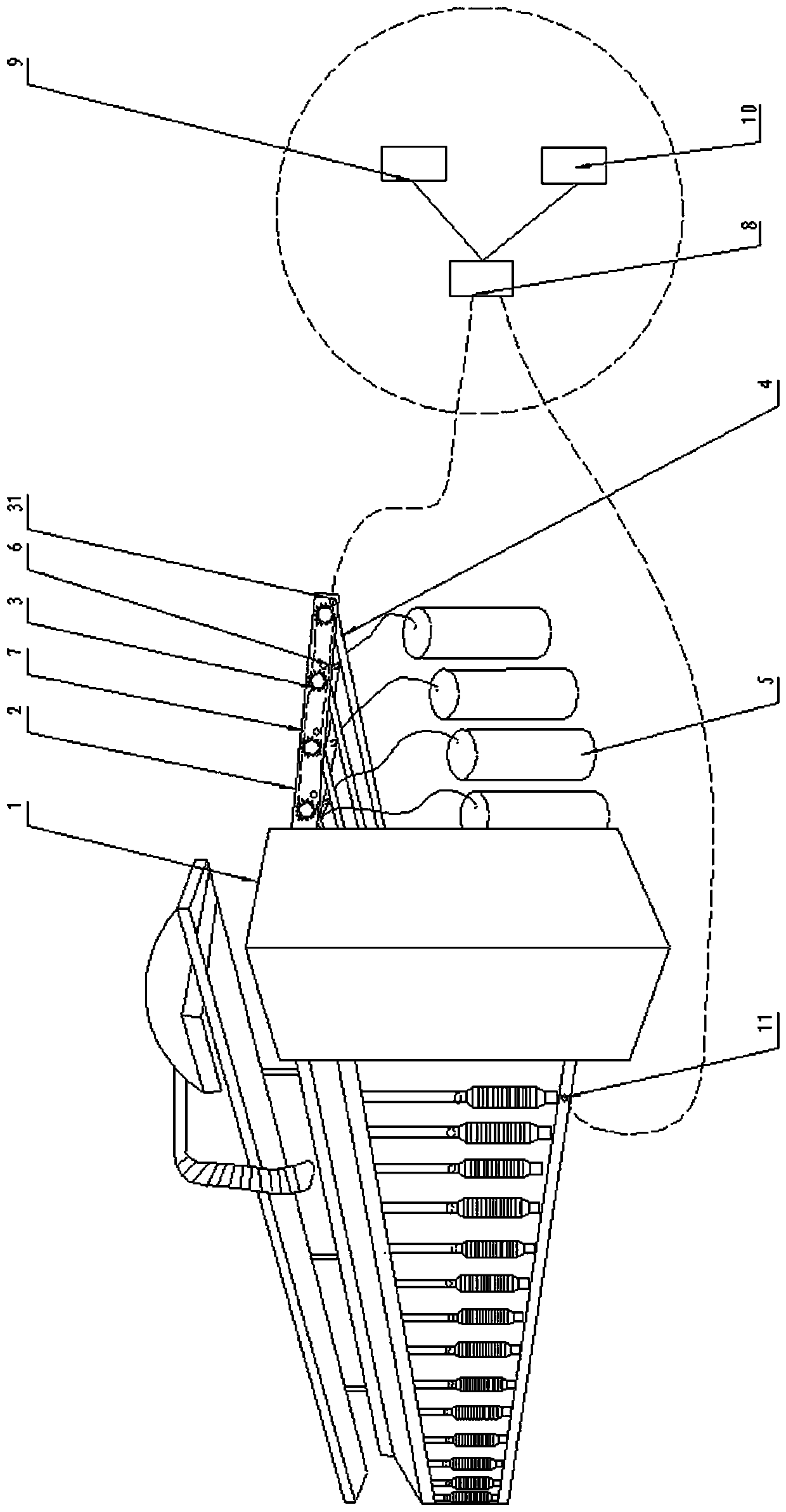

Viscose imitation silk yarn production device and spinning method thereof

ActiveCN109594154BAchieve productionRealize the imitation silk effectDrafting machinesContinuous wound-up machinesYarnPolymer science

Owner:JIANGNAN UNIV

Device for reducing hairiness of ring-spun segmented colored yarn

A device for reducing hairiness of ring-spun segmented colored yarn is configured between a front-roller jaw and a yarn guiding hook of a spinning frame, and mainly comprises a dry glue plate, a hydraulic press and a recycling bottle. The device can be applied to technical transformation of the spinning frame; and the yarn is shaped with dry glue by means of the dry glue plate mounted on a support of a table board of the device, so that hairiness of resultant yarn is reduced, and a layer of a protection film is formed outside the yarn. Compared with the prior art, the device is easy and convenient to install and high in performance cost ratio.

Owner:JIANGNAN UNIV

Method for producing jade silkworm fiber pure 60s compact spinning yarn

Owner:JIHUA 3509 TEXTILE

A kind of multi-component hygroscopic fiber compact siro spinning and its production method and application

The invention belongs to the technical field of textile, and specifically relates to a multi-component hydroscopic fiber compact sirospun single yarn, and a production method and application thereof. According to the production method, three hydroscopic fibers such as hygroscopic and sweat releasing dacron, China hemp and fine staple cotton are adopted as materials, and the multi-component hydroscopic fiber compact sirospun yarn of 36 counts is obtained through a picking process, a cotton carding process, a combing process, a drawing process, a roving process, a spinning process and a winding process. The multi-component hydroscopic fiber compact sirospun yarn is advantaged by moisture absorption, permeability, comfortableness, heat dissipation, mildew resistance, bacteriostasis and ultraviolet prevention, and can be used for civil use to produce casual clothes and sports clothes and can also be used for military use to produce military clothes such as flight suits according to the specific easy-washing, quick-drying, stiff and smooth and antibacterial wearability.

Owner:湖北名仁纺织科技有限公司

Device for Preventing Accidental Elongation of Cooked Sliver on Roving Frame

ActiveCN105483881BReduce accidental draftReduce frictionTextiles and paperBobbinProgrammable logic controller

Owner:ANHUI HUAMAO TEXTILE

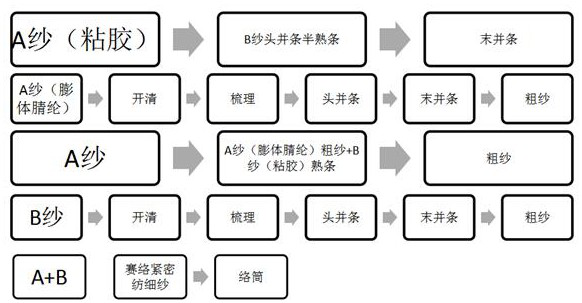

Spinning method for siro compact spinning large-difference-proportion short fiber skin-core wrapped yarn

ActiveCN114808224AHigh strengthWide application applicabilityDrafting machinesYarnEngineeringYarn strength

The invention discloses a spinning method of a siro compact spinning large-difference-proportion short fiber skin-core fasciated yarn, which specifically comprises the following steps: two raw materials A and B with different properties are respectively and independently subjected to opening and cleaning, carding, drawing and roving procedures according to processing requirements to be independently prepared into roving, the roving A contains small-proportion fibers and needs to be independently and repeatedly subjected to opening and cleaning, carding, drawing and roving procedures once, and the roving B contains small-proportion fibers; after roving is made, the roving A and large-proportion fibers are fed at the drawn sliver feeding position at the same time to produce roving A, then the roving A is fed into a drafting area through a double-eye horn mouth on a siro compact spinning frame and output after drafting and gathering, fiber strands are output, the principle that the fiber strands on the right side wrap the fiber strands on the left side is utilized, and twisting is conducted in a staggered spinning mode to form yarn; according to the method, the technological process of spinning the core filament staple fiber yarn in advance is reduced, the problem of cloth cover crosspiece caused by core filament fiber leakage is solved, yarn hairiness can be greatly reduced, the yarn strength is improved, and the yarn quality is improved.

Owner:山东联润新材料科技有限公司

A kind of 80-count yarn blended with hemp and long-staple cotton and its production method

The invention belongs to the weaving field, and particular relates to a hemp and long-staple cotton blended 80-count yarn and a production method. <{EN2}>The blended 80-count yarn is produced by blending the hemp and the long-staple cotton in a weight proportion of 40-50:60. <{EN3}>The production method comprises the steps of cotton blending, blooming, combing, fine combing, drawing, roving, spinning and winding. <{EN4}>The 80-count yarn blended by the hemp and the long-staple cotton belongs to high count yarns and the content of the hemp is 40% and more, and realizing the purpose of producing a high count yarn when the content of the hemp is high. <{EN5}>The blended 80-count yarn can be used to produce clothes, and the fabrics obtained has the clean feeling of hemp and the soft feeling of cotton fabrics, no scratchiness and has bacteriostasis and antibacterial function; the yarn has the advantages of moisture absorption, ventilation, cool and comfort feeling; the yarn is safe and has excellent ultraviolet resistance function, antistatic performance, heatproof performance, lightfastness and no pollution; and the yarn is the first choice for producing a high-grade shirt.

Owner:JIHUA 3509 TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com