Pneumatic fiber nesting device

A fiber and collector technology, used in textiles and papermaking, drafting equipment, spinning machines, etc., can solve the problems of inconvenient operation of adding and unloading pressure, and achieve the effect of eliminating negative effects and strengthening agglomeration and compaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

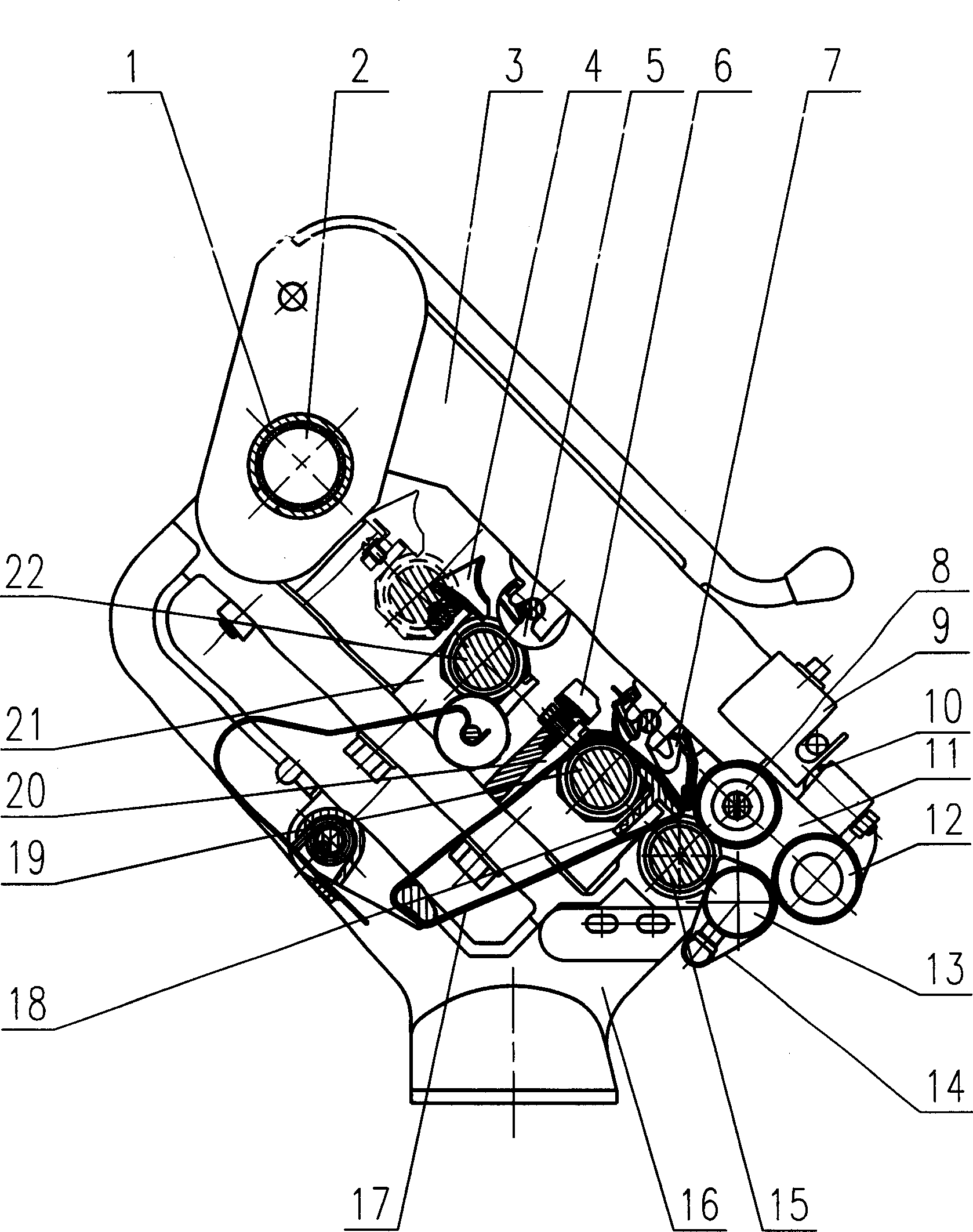

[0017] exist figure 1 In the shown pneumatic fiber gathering device, the front roller 15 is rotatably supported by the roller bearing at the front end of the roller seat 16; Cradle 3, each cradle 3 corresponds to each spindle. The cradle support 1 is a circular tubular support, which is positioned by positioning pins. The cradle support 1 can also be a polygonal support such as a regular hexagonal tubular support. An air bag 2 is installed in the tubular support lumen of the cradle support 1 to pass The lever makes the weighting arm obtain the pressurized force. On the roller seat 16, the middle roller 19 and the rear roller 22 are rotatably supported by the middle roller slide seat 20 and the rear roller seat 21 respectively. On the positions of the cradle 3 corresponding to the front roller 15, the middle roller 19 and the rear roller 22, the front top roller 8, the apron iron roller assembly 7 and the rear top roller 5 are clamped.

[0018] The front side of front roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com