Device for machining compact siro covering yarns

A processing device and technology of core-spun yarn, which is applied in the direction of yarn, spinning machine, textile and paper making, etc., can solve the problems of large core-spun yarn hairiness and low yarn strength, increase cohesion force, reduce yarn hairiness, The effect of stable draft ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solution of the present invention is further illustrated below through specific examples.

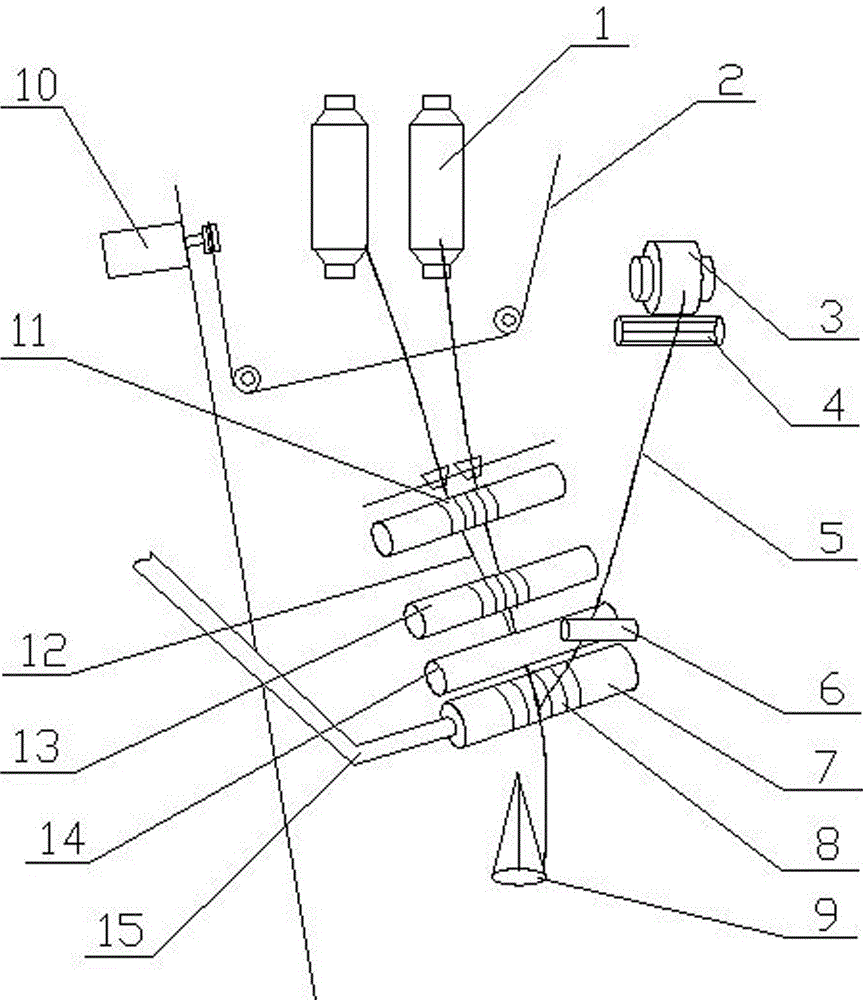

[0012] Such as figure 1 Shown: a processing device for compact Siro core-spun yarn, comprising rear roller 11, middle roller 13, front roller 14, yarn pulling device 9, roving yarn bobbin 1 and spandex yarn bobbin 3, the yarn The line traction device 9 is fixed on the lower end of the frame, and connects the front roller 14, the middle roller 13, the back roller 11 and the roving bobbin tube 1 in sequence upwards through the yarn 12, and the roving bobbin tube 1 is provided with two. The distance between two adjacent roving yarn shaft tubes 1 is between 10-15cm; a suction pipe 7 is also set between the front roller 14 and the yarn pulling device 9, and a grid ring 8 is sleeved on the suction pipe 7, Two suction grooves are provided on the position corresponding to the grid ring 8 on the suction pipe 7, and the two suction grooves are arranged in an inverted "eight"...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com