False twist texturing machine for special filament processing

A false twist texturing machine, a special technology, applied in textiles and paper making, etc., can solve the problems of additive oxidation failure, difficult additives, easy loss of additive performance, etc., to achieve stable performance, prevention of additive oxidation, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

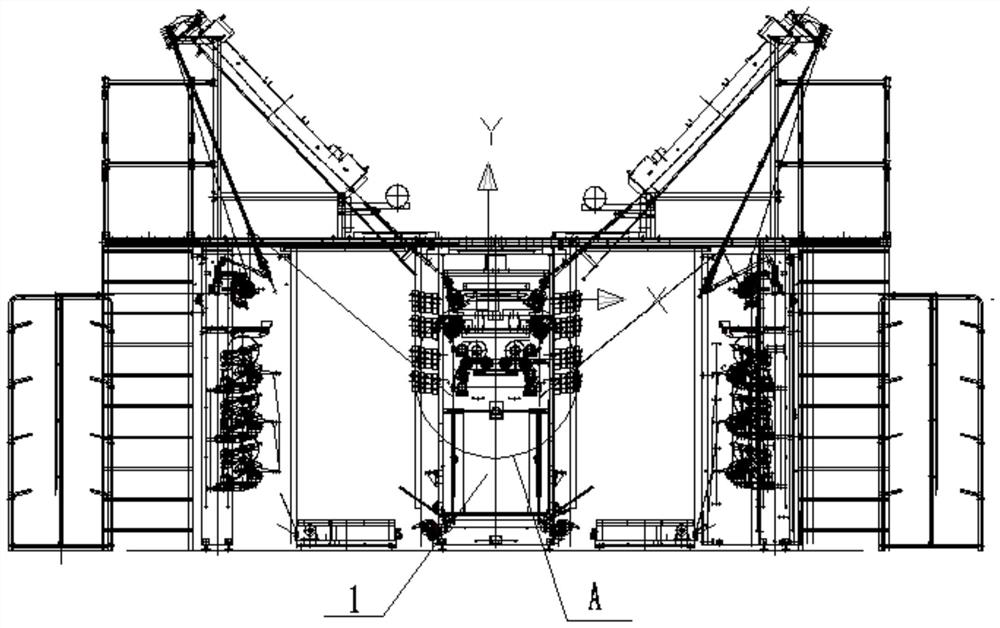

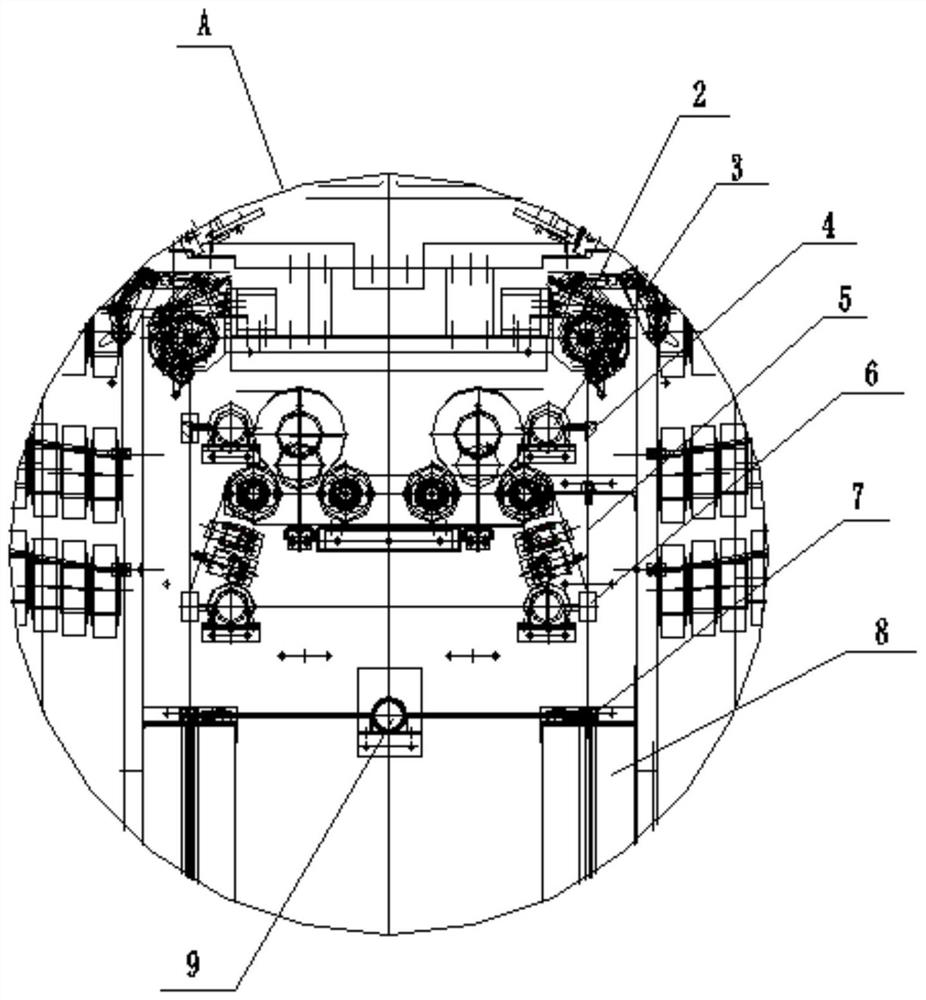

[0031] refer to Figure 1 to Figure 8 The embodiment of a false twist texturing machine for special yarn processing of the present invention will be further described.

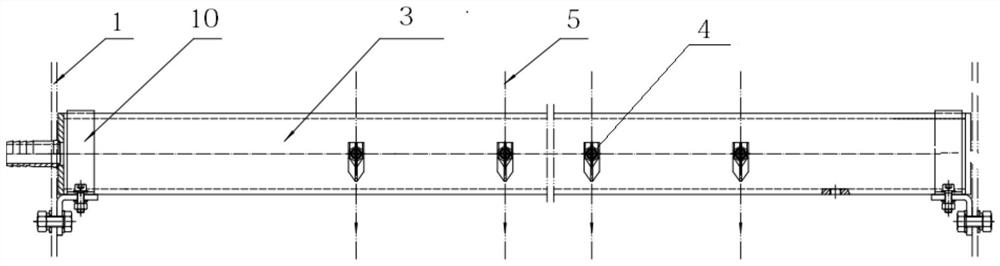

[0032] A false-twist texturing machine for special yarn processing, comprising a main frame 1, a false-twister 2 is arranged on the main frame 1, and a closed additive pipe 3 is arranged on the main frame 1 after the false-twister 2, so the The additive pipeline 3 is provided with one or more oil holes, the oil holes are connected with a first connector, the first connector is connected with an oil nozzle 4, and the main frame 1 is provided with steam after the additive pipeline 3 Pipe 9, the steam pipe 9 is provided with one or more air holes, the air holes are connected with a second connecting piece, the second connecting piece is connected with a core body seat 7, and the core body seat 7 is provided with a core body body 17, an annular cavity 23 is formed between the core body 17 and the inner cavity of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com