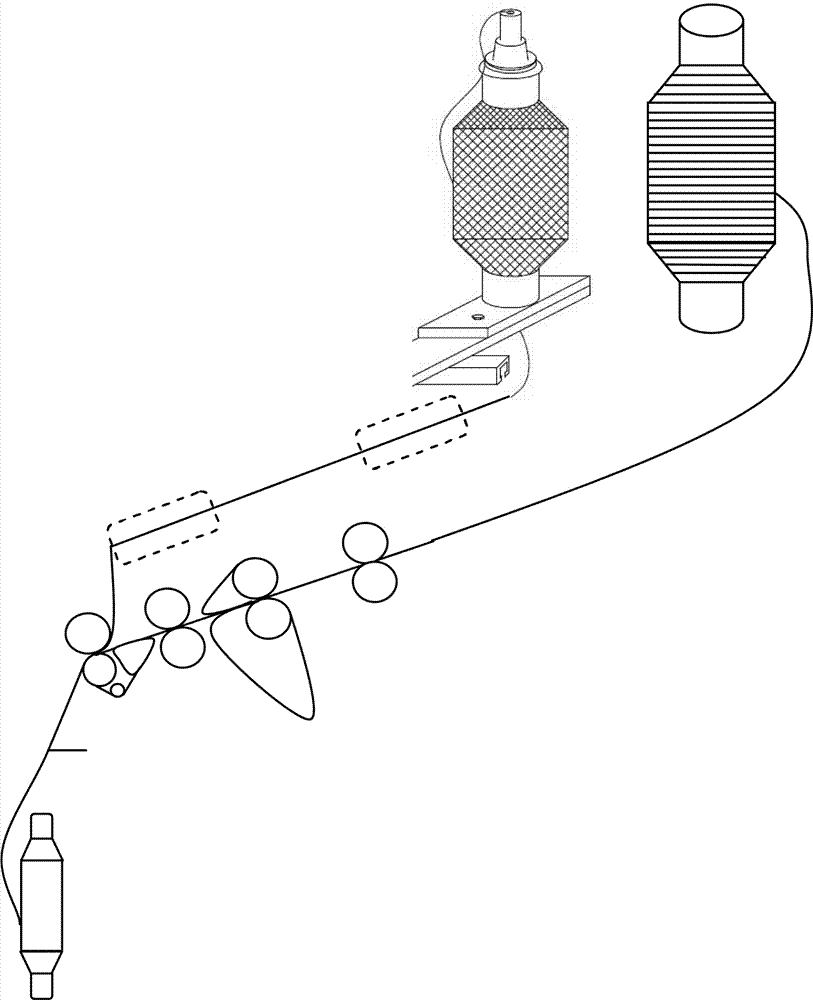

Clustered sirofil-spun SOLOTEX composite yarn and spinning method of composite yarn

A technology of sirofil spinning and composite yarn, applied in spinning machine, yarn, filament/thread forming, etc., can solve the limitation of sirofil spinning yarn application, many broken ends, high yarn hairiness, etc. problems, to achieve the effect of enriching sirofil spinning products, soft and elastic fabrics, and reduced yarn hairiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

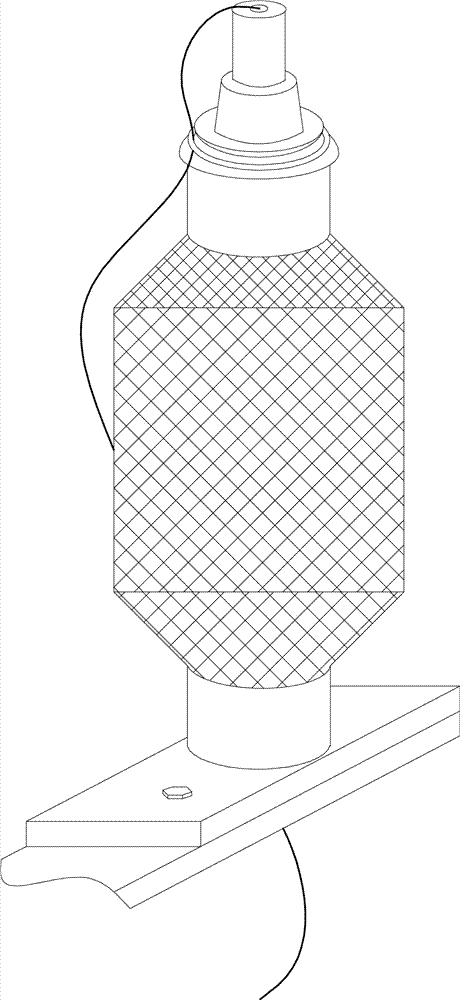

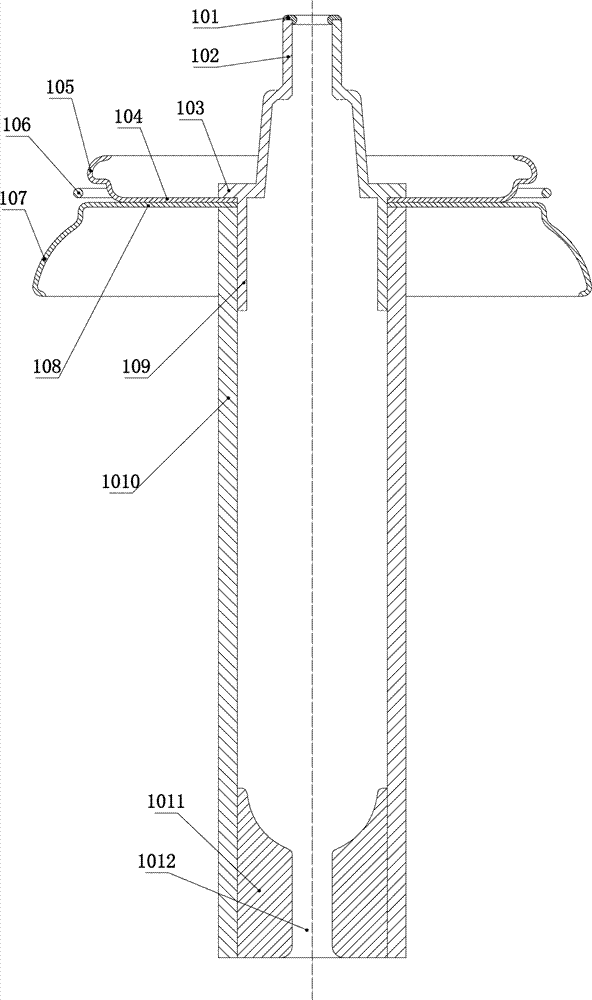

Method used

Image

Examples

Embodiment 1

[0039] fiber

[0040] The spinning method is as follows:

[0041] Step 1 Pretreatment of silkworm silk: Prepare a health-preserving solution according to the dry weight ratio of silkworm silk raw materials. The ingredients of the health-preserving solution are 0.8% of crude oil, 0.5% of antistatic agent, and 11% of water. Spray the mixed solution evenly on the surface of silk raw material, and seal it for 24 hours.

[0042] Step 2 Cleaning and mixing: Tencel A100, Coolmax moisture-wicking polyester, and silkworm silk are mixed according to the following process: FA002A disc grabbing machine → FA022-6 multi-bin cotton blending machine → baler → FA002A disc Cotton grabbing machine → FA022-6 multi-compartment blending machine → ZF1102A card needle opener → FA046A vibrating cotton box feeder → FA141A single hand lapping machine to make mixed cotton laps. Feed 3 to 5 tencel rovings synchronously during lap forming to prevent laps from sticking.

[0043] Step 3 Carding, ...

Embodiment 2

50D(36f) DTY

[0050] Spinning method step 1, step 2, step 5 are the same as embodiment one, step 3, step 4 main process parameters are listed in the table below, and all the other process parameters are the same as embodiment one.

[0051]

[0052] Breaking strengthcN / tex

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com