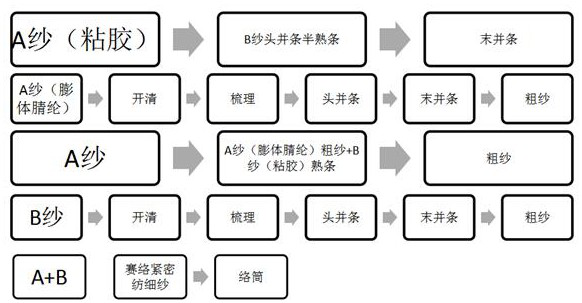

Spinning method for siro compact spinning large-difference-proportion short fiber skin-core wrapped yarn

A technology of siro tight and wrapping yarn, applied in spinning machine, yarn, textile and paper making, etc., can solve the problems of outer leaky core fiber, limited application scope of fiber, discontinuous and horizontal fabric surface, etc. The effect of yarn hairiness, yarn quality improvement and yarn strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

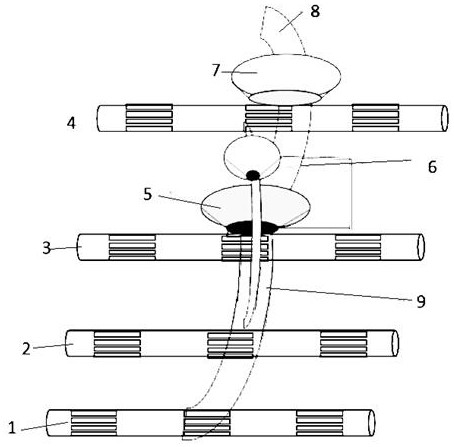

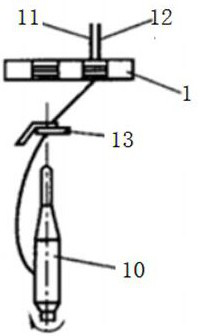

Method used

Image

Examples

Embodiment 2

[0032] Embodiment 2, each process technology:

[0033] Opening and cleaning: The carding process is designed according to the different fiber characteristics of viscose and expanded acrylic. Among them, viscose fiber is processed by blowing and carding, and the equipment configuration is FA002A cotton grabbing machine → FA028C-6 multi-silo cotton mixing machine → JWF1124 cotton opener → ZF9104 frequency conversion cotton feeding fan; the main process parameters are: the thickness of cotton grabbing is 5mm / time , The walking speed of the cotton catching trolley is 10m / min, and the speed of the cotton opener beater is 750rpm. Bulk acrylic fiber is processed in rolls, and the equipment is configured as FA002A disc grabbing machine → FA022-6 multi-silo cotton blending machine → ZF1102A carding needle opener → FA046A vibrating cotton box feeding machine → FA141A single-hand roll machine; The main process parameters are: ZFA1102A needle beater speed 600rpm, roller and card beater g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com