Spinning method and device of high-elastic core-spun combined yarn

A core-spun, high-elasticity technology, applied in the field of high-elasticity core-spun aggregate yarn spinning method and its device, can solve problems such as the uniformity of yarn formation in special fields, stretch yarn wheel dew, uneven yarn weight, etc. , to achieve the effect of giving full play to the spinning efficiency, improving the quality of the cloth surface, and reducing the unevenness of the yarn weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

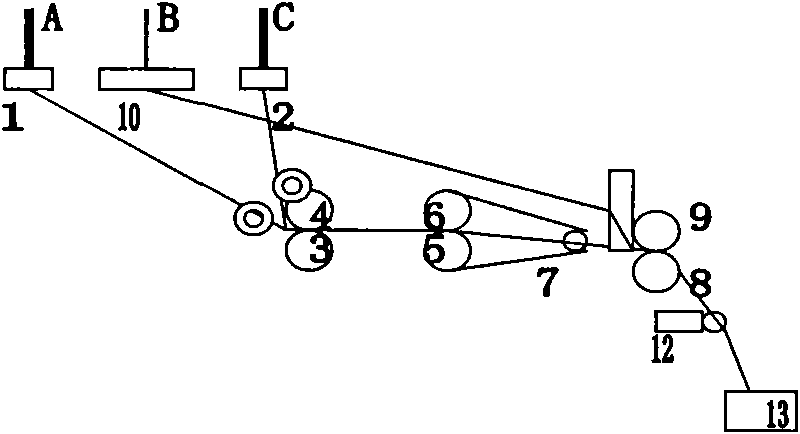

[0018] The device used in this example is image 3 As shown, it includes two yarn guide horns 1, 2, a drafting zone composed of rear roller 3, rear top roller 4, middle roller 5, middle top roller 6, apron 7, front roller 8, and front top roller 9, Automatic unwinding system 10, system guide wheel 11, yarn guide hook 12, spinning bobbin 13. Its spinning line is as image 3 As shown, on the ring spinning frame, the two rovings A and C unwound from the roving bobbins respectively pass through the bell mouths of the guide horns 1 and 2 and enter in parallel with the rear roller 3, rear top roller 4, middle roller 5, The drafting area composed of middle top roller 6, apron 7, front roller 8, and front top roller 9 is used for drafting; the filament B is under the control of the automatic unwinding system 10, and the speed is adjusted according to the feeding ratio, and the filament B passes through the tension control system. The guide wheel 11, the filament is fed from the rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com