Novel method and device for processing vortex ring spun yarn

A processing method and technology of vortex rings, which are applied to spinning machines, open-end spinning machines, continuous winding spinning machines, etc., can solve the problems of easy hair curling, fiber damage, and limited improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In traditional ring spinning, the bobbin (15) rotates through the rotation of the spindle, driving the traveler (13) to rotate along the raceway of the steel ring (14), thereby transferring the twist to the front roller (12) and the front rubber roller (11) ) at the beard of the holding part, and at the same time, the friction force between the traveler (13) and the steel ring (14) causes a speed difference, thereby winding the yarn (7) onto the bobbin (15).

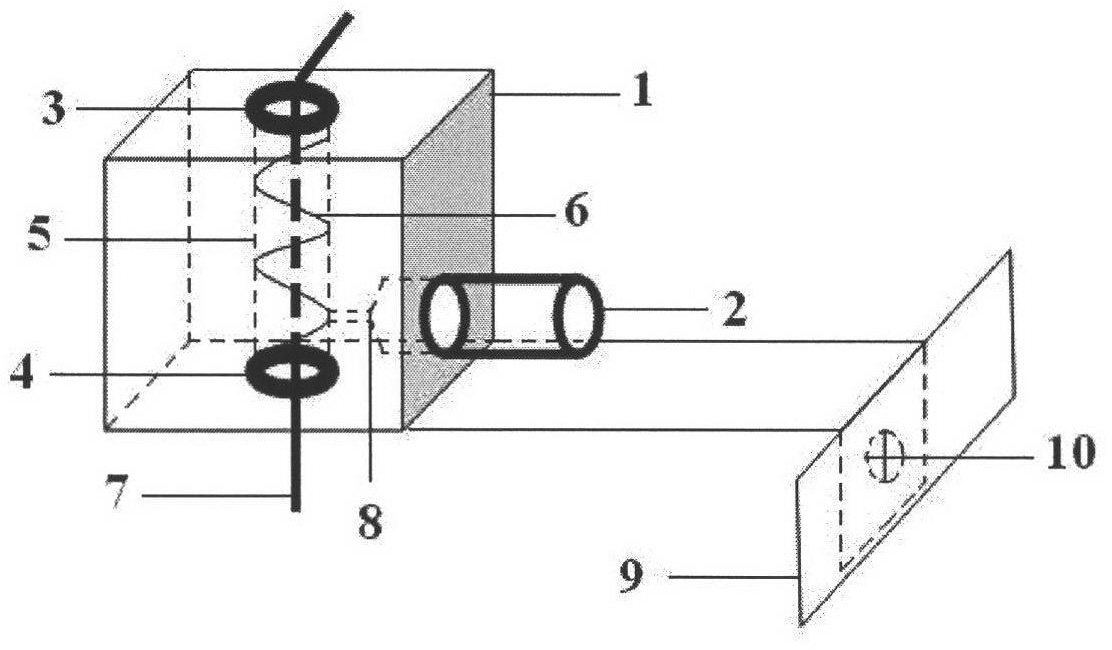

[0010] Depend on figure 1 As shown, the eddy current yarn guide device is mainly composed of the eddy current yarn guide device (1) and the compressed airflow input interface (2), replacing the original yarn guide hook, and the eddy current yarn guide device is installed and fixed on the yarn guide by screws (10). on the board (9). The eddy current guide (1) has a cylindrical yarn guide channel (5) in the vertical direction, and the inner wall of the cylindrical yarn guide channel (5) is processed into a left-han...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com