Fiber collecting device for condensed ring spinner

A technology of tight ring and tensioning device, applied in spinning machine, textile and paper making, spinning machine with continuous winding, etc., can solve the problem of stuttering, the complex transmission of the gathering top roller and the front top top roller, and the influence of spun yarn into yarn. Power indicators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

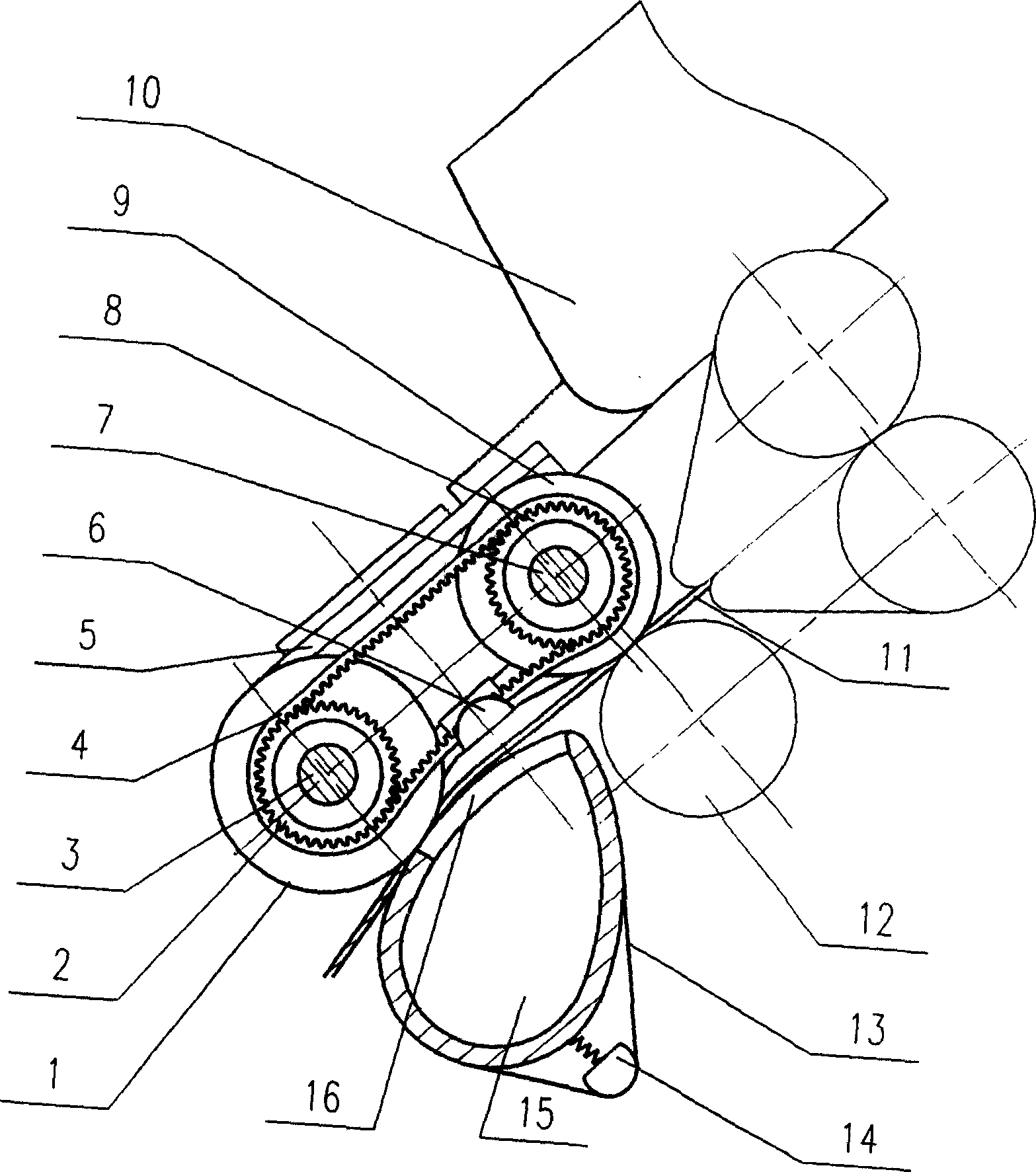

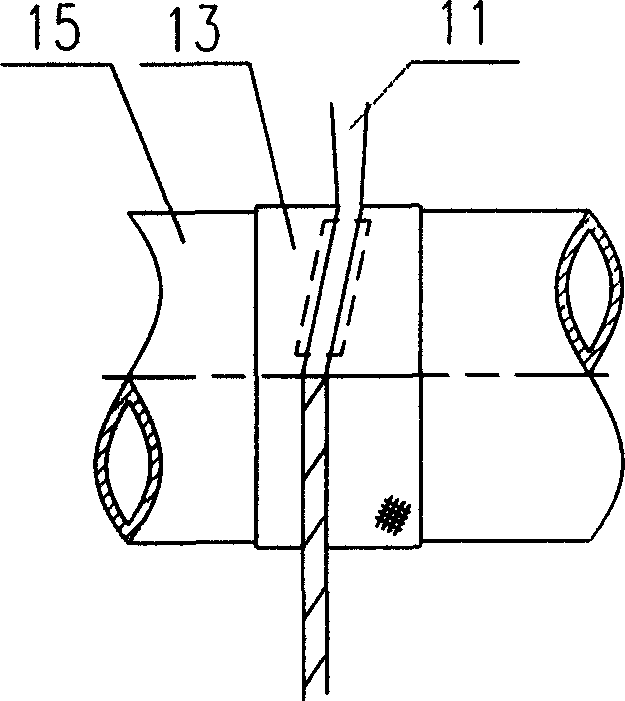

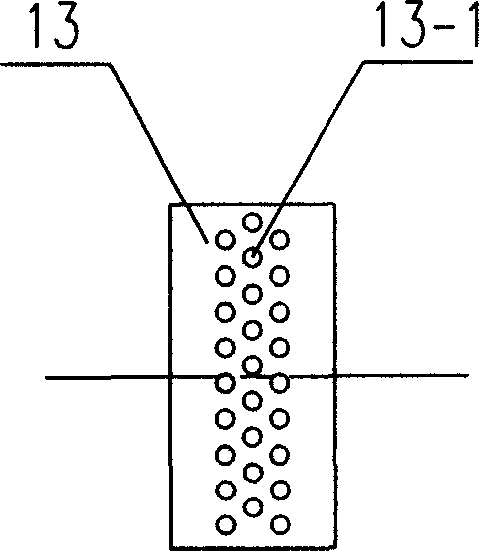

[0011] figure 1 In the compact ring spinning fiber gathering device shown, a front top roller shaft 7 and a gathering top roller shaft 3 are respectively installed on the bracket 5, and the front top roller shaft 7 and the gathering top roller shaft 3 are respectively rotatably installed with the front The top roller 9 and the gathering roller 1. The front roller 12 is located below the front top roller 9, and the front roller 12 and the front top roller 9 form a fiber bundle output nip; below the gathering top roller 1, a suction pipe 15 is arranged, and the suction pipe 15 is connected to the fiber bundle There is a suction groove 16 at the corresponding position of the path. The front top roller 9 and the gathering roller 1 are respectively fixedly connected with the front top roller synchronous belt wheel 8 and the gathering roller synchronous belt wheel 2, and the front top roller synchronous belt wheel 8 and the gathering synchronous roller The pulley 2 is driven by meshin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com