Yarn guide for lubricating yarns

A yarn guide hook and yarn technology, applied in textiles and papermaking, etc., can solve the problems of high yarn breakage rate, increased fabric cost, and low production efficiency, and achieve the effects of reducing yarn hairiness, easy maintenance, and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

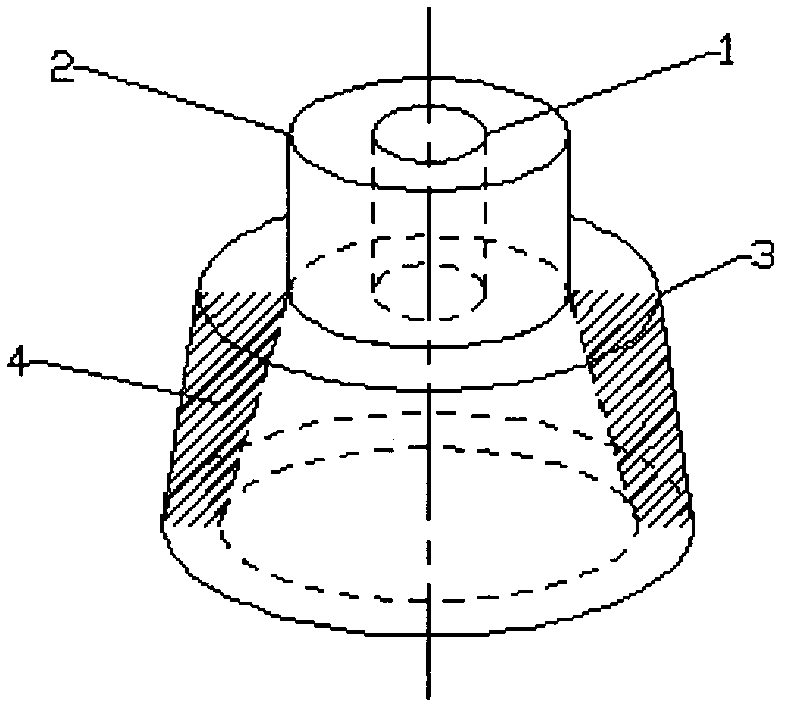

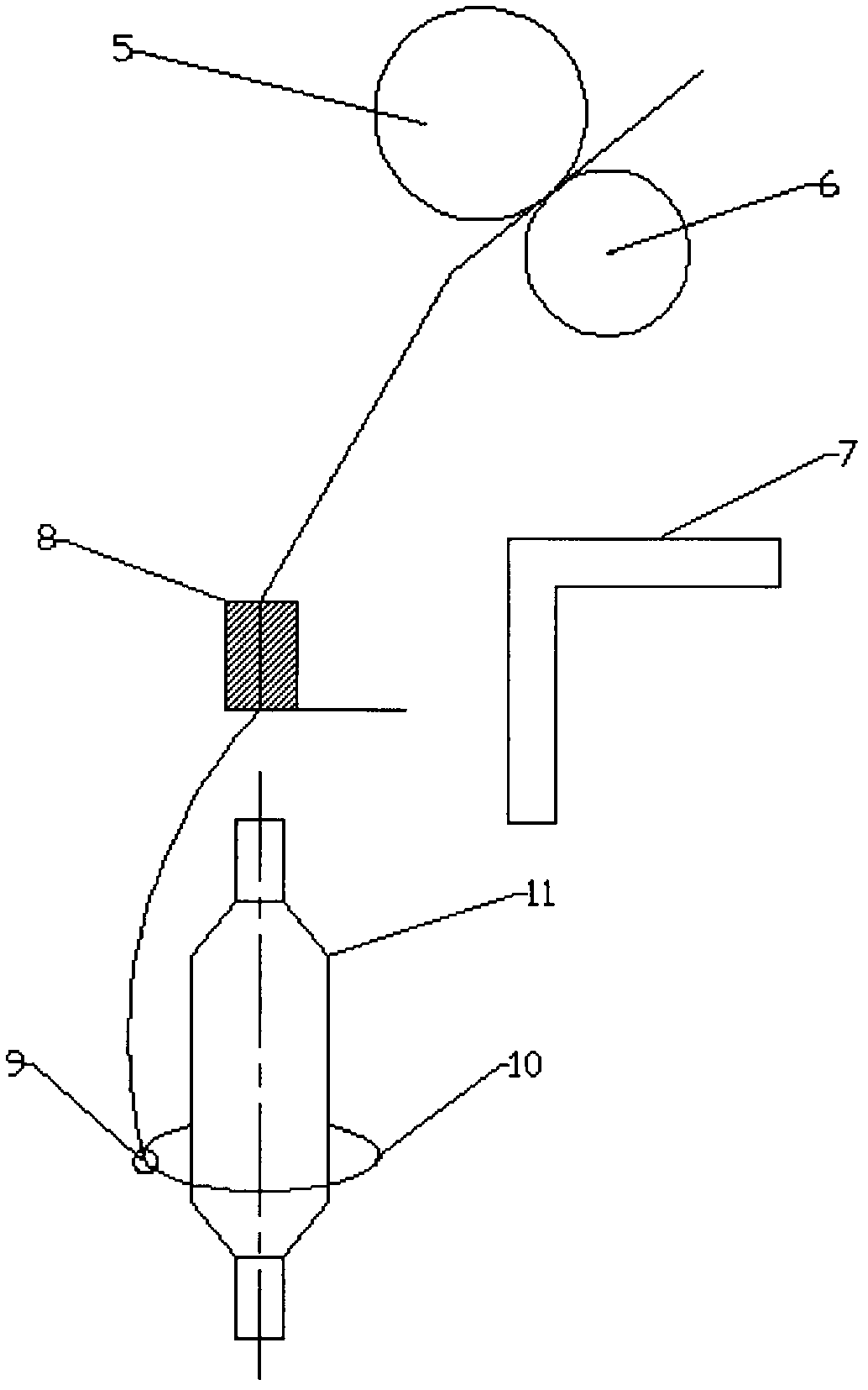

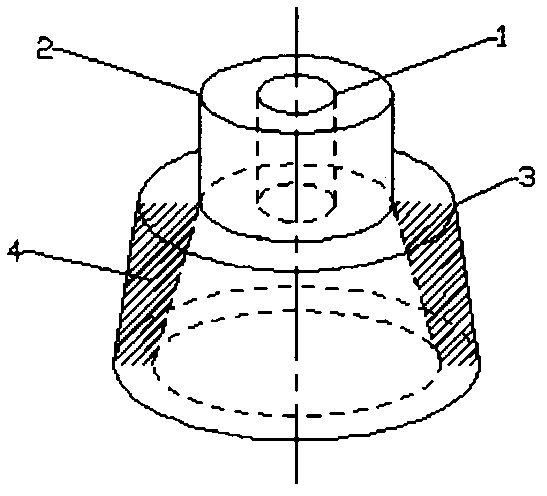

[0008] by figure 1 versus figure 2 As shown, after the fiber strands are gripped and output from the front roller (6) and the front rubber roller (5), they pass through the car table (7) to the yarn guide hook (8), so that the yarn passes through the porcelain eye (1), and then The surface of the paraffin wax (4) rotates, and the traveler (9) is driven to rotate along the racetrack of the ring (10) through the rotation of the spindle, and the yarn is twisted and wound onto the bobbin (11). The yarn guide hook (8) is composed of a porcelain eye (1), a lu block (2), a protective cover (3) and a paraffin wax (4). The porcelain eye (1) is protected by a lu block (2) and inserted into the top center hole of the paraffin wax (4), and the paraffin wax (4) is protected by a protective cover (3) to avoid contact with the outside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com