Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

78results about How to "Reduce the amount of drilling work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-pressure water burst and CO2 fracturing combined coal bed gas displacement extraction technology

InactiveCN105332684AAccurately determine the scope of influenceWide variety of sourcesFluid removalGas removalHigh pressure waterHigh pressure

The invention discloses a high-pressure water burst and CO2 fracturing combined coal bed gas displacement extraction technology. The high-pressure water burst and CO2 fracturing combined coal bed gas displacement extraction technology comprises the following steps: ground stress state determination, hole sealing section drilling and sealing, hole drilling and slitting, charging, water injection hole sealing, high-pressure water burst crack starting, supercritical or liquid CO2 fracturing and gas extraction. A ceramsite proppant is mixed in the supercritical or liquid CO2, in a continuous fracturing process of the liquid CO2, extension conditions of burst cracks can be monitored in real time by a microseism monitoring instrument, and fracturing is stopped after an expected effect of extension in a set range is achieved. During guided slitting, slitting can be carried out step by step after holes are drilled according to the number of slits and a set distance between each two adjacent slits, and a mode of drilling holes and slitting alternately can also be adopted. The high-pressure water burst and CO2 fracturing combined coal bed gas displacement extraction technology has the advantages that the permeability of a low-permeability coal bed gas reservoir can be increased effectively, construction amount is reduced, and coal bed gas extraction efficiency is high.

Owner:CHONGQING UNIV

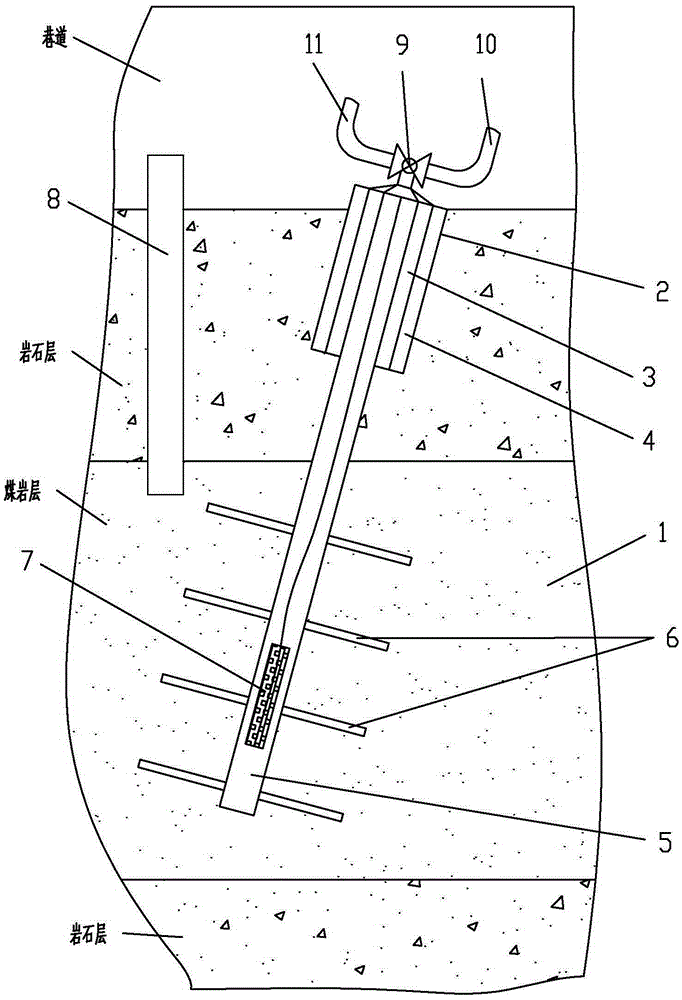

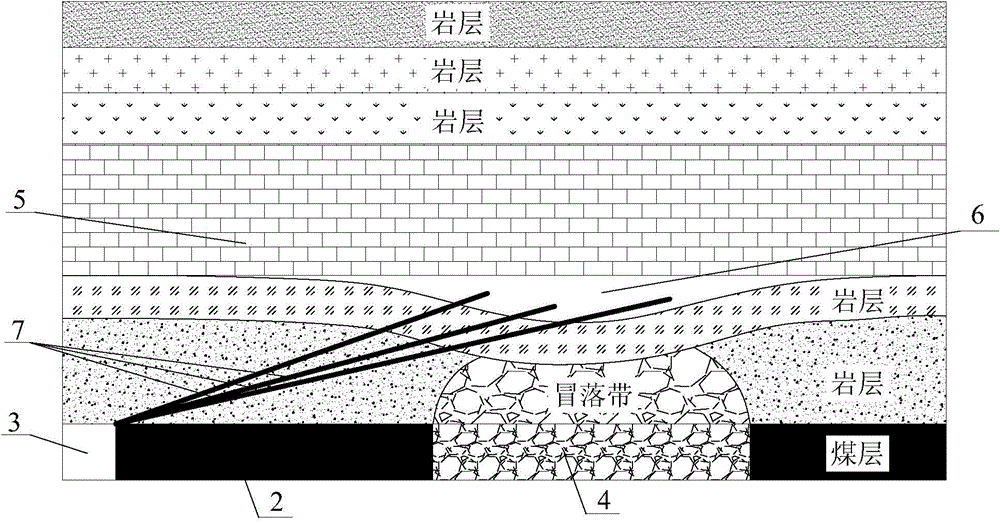

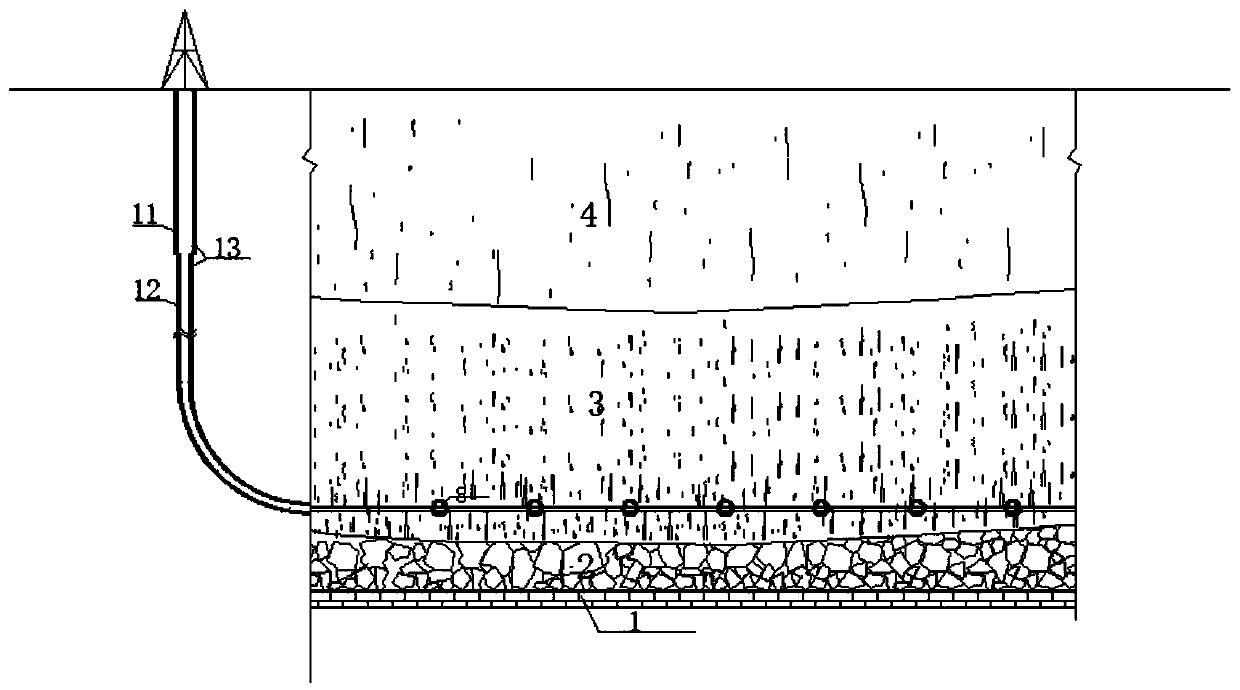

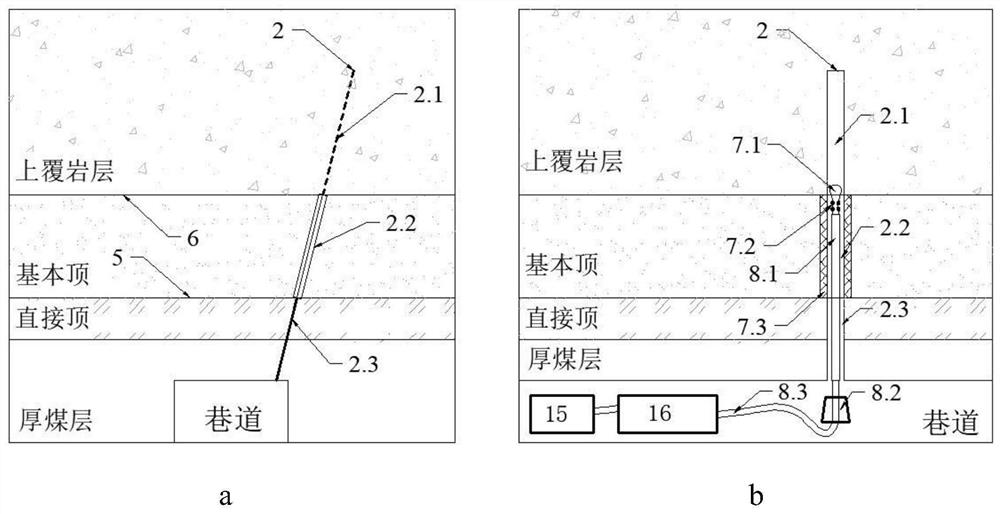

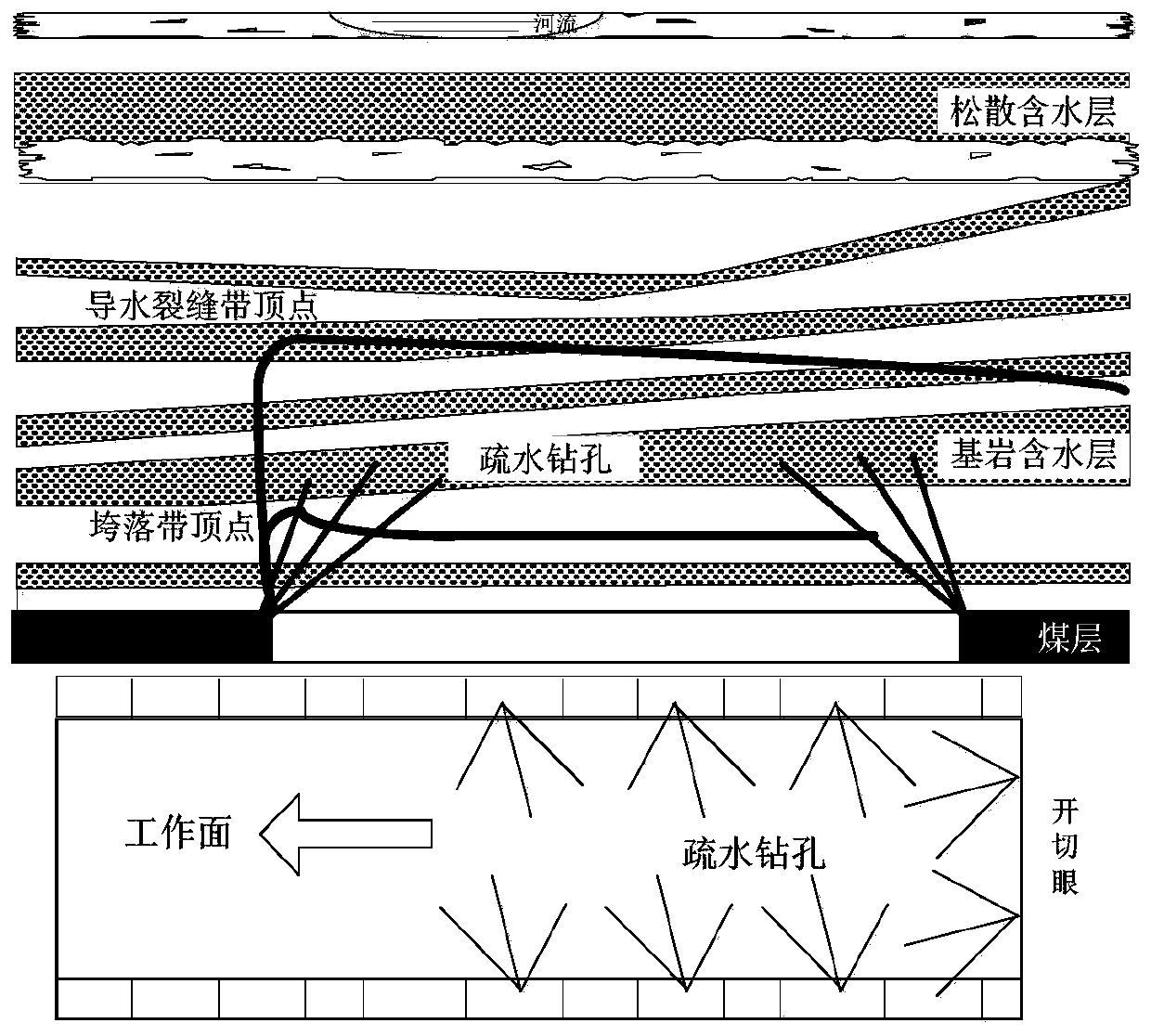

Method for extracting gas from separation layer below overlying strata, draining water and grouting through combined drill hole

ActiveCN104863629AHigh extraction rateImprove grouting effectMaterial fill-upDrainageDrill siteCement paste

The invention discloses a method for extracting gas from a separation layer below an overlying strata, draining water and grouting through a combined drill hole and belongs to a mine disaster prevention method. The method for extracting gas from the separation layer below the overlying strata, draining water and grouting through the combined drill hole includes that installing a drill site at a transportation roadway of a preparatory work face adjacent to a coalface, constructing the combined drill hole in the part about to generate the separation layer below the overlying strata above the gob of the coalface in a mode of keeping away from a caving zone, wherein the combined drill hole is composed of an inside gas extraction pipe and a water draining-grouting pipe; after the separation layer is generated, preventing the mine disaster according to the stages that firstly, draining water from the separation layer through the combined drill hole; secondly, after the gas is gathered in the separation layer after the water in the separation layer is emptied, using the primary combined drill hole to extract the gas from the separation layer; finally, after the water and gas are completely drained and extracted from the separation layer, filling cement paste to the separation layer through the primary combined drill hole. The method for extracting gas from the separation layer below the overlying strata, draining water and grouting through the combined drill hole is capable of solving the mine disasters of water bursting in mine, gas outburst (gas emission), rock burst, surface subsidence and the like through the combined drill hole, the separation layer water and gas extraction rate is high, and the grouting effect is good.

Owner:CHINA UNIV OF MINING & TECH

Coal road stripe region burst-preventing method

InactiveCN104314610AImprove breathabilityReduce the amount of drilling workGas removalCoalBuilding construction

The invention discloses a coal road stripe region burst-preventing method which comprises the following steps: enabling a to-be-dug coal road to be directly positioned in a pressure relieving region of a pre-digging bottom plate rock gangway and performing stripe-drilling on drawing-out coal bed gas, namely, pre-digging the bottom plate rock gangway along a trend just below the to-be-dug coal road coal bed, performing pressure relief on the to-be-dug coal road on the bottom rock gangway, and performing gas drawing-out on the upper edge and the lower edge of the to-be-dug coal road by adopting stripe-drilling. According to the coal road stripe region burst-preventing method, the purposes of relieving pressure of the to-be-dug coal road stripe coal bed, increasing the breathability, and improving the gas extraction effect can be realized. The coal road stripe region burst-preventing method has the characteristics of improving the safety and reliability of stripe-drilling construction, reducing the burst-preventing project, shortening the construction time, and improving the burst-preventing effect of the coal road stripe region.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD +1

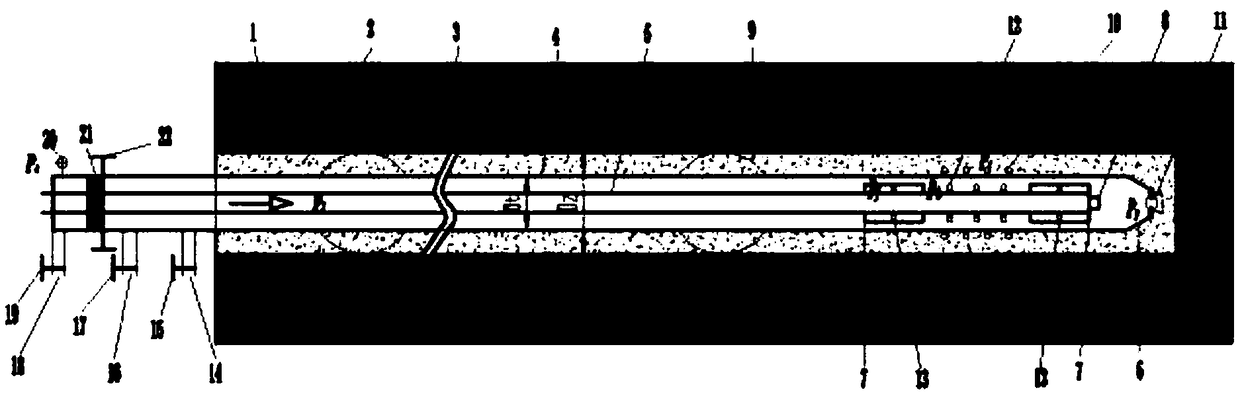

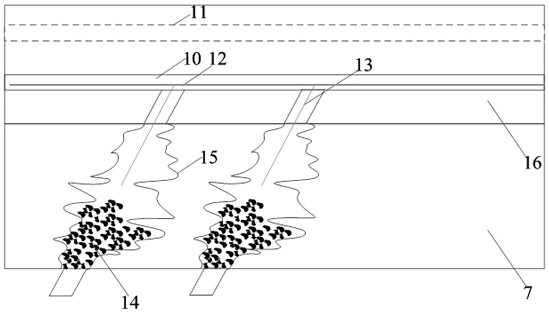

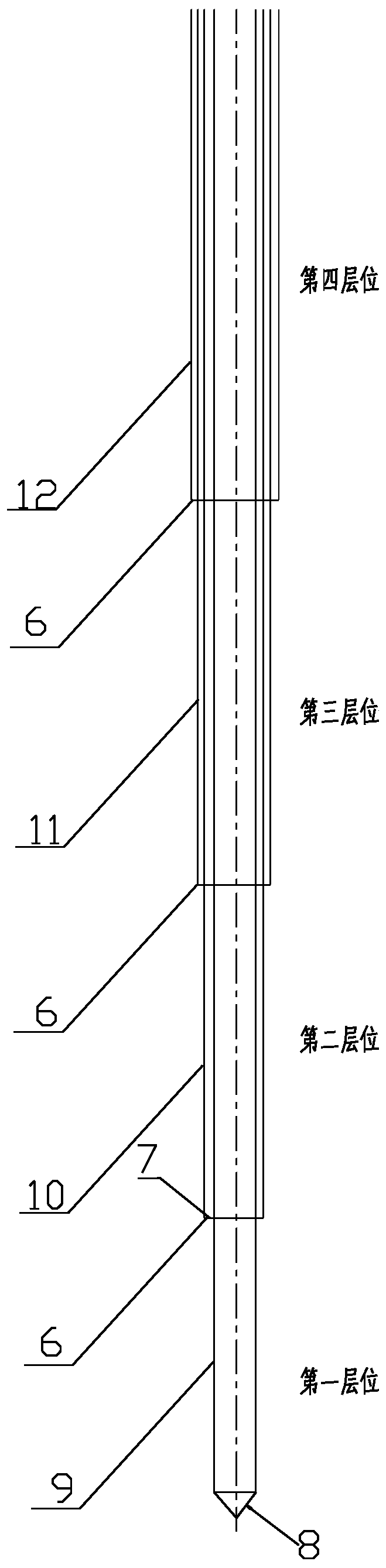

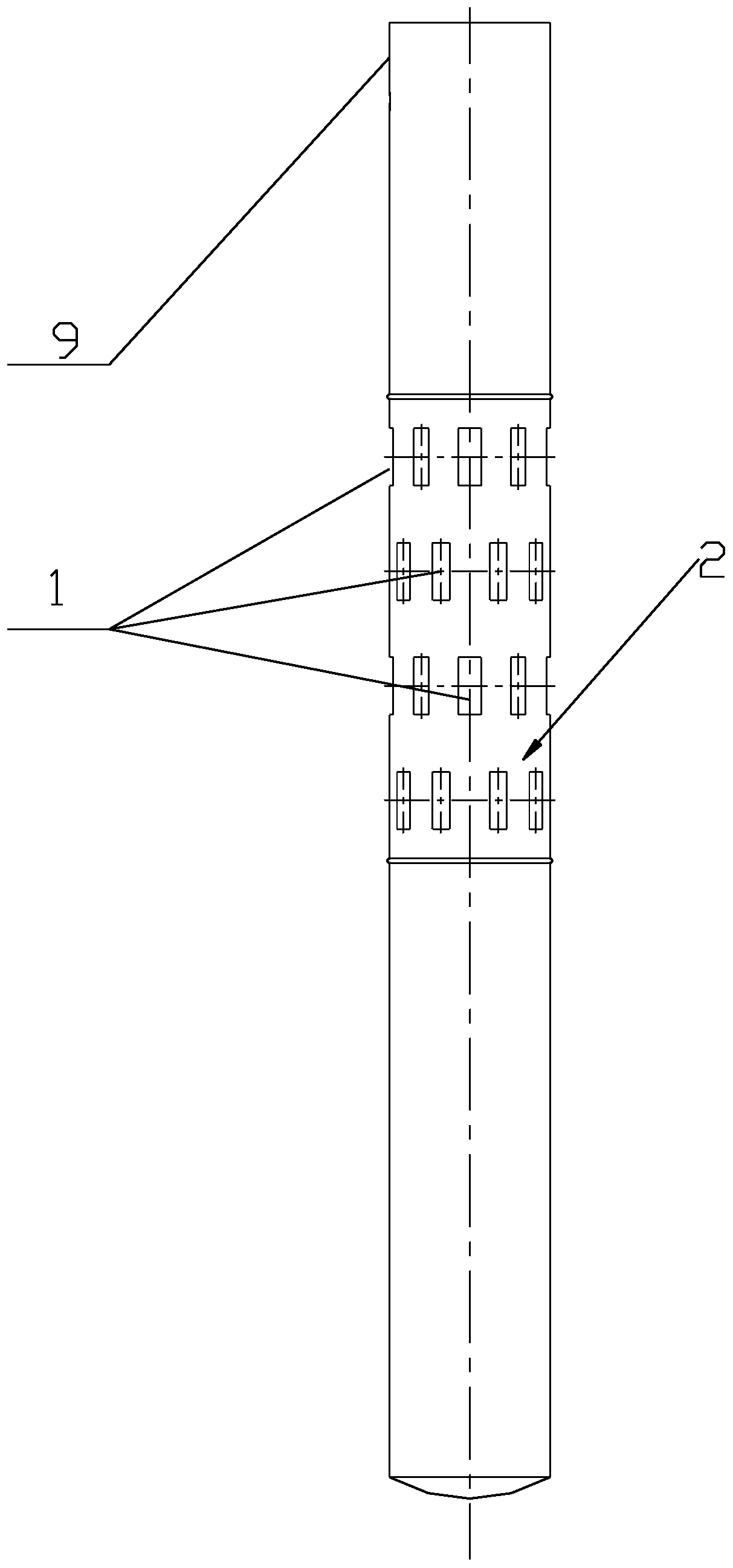

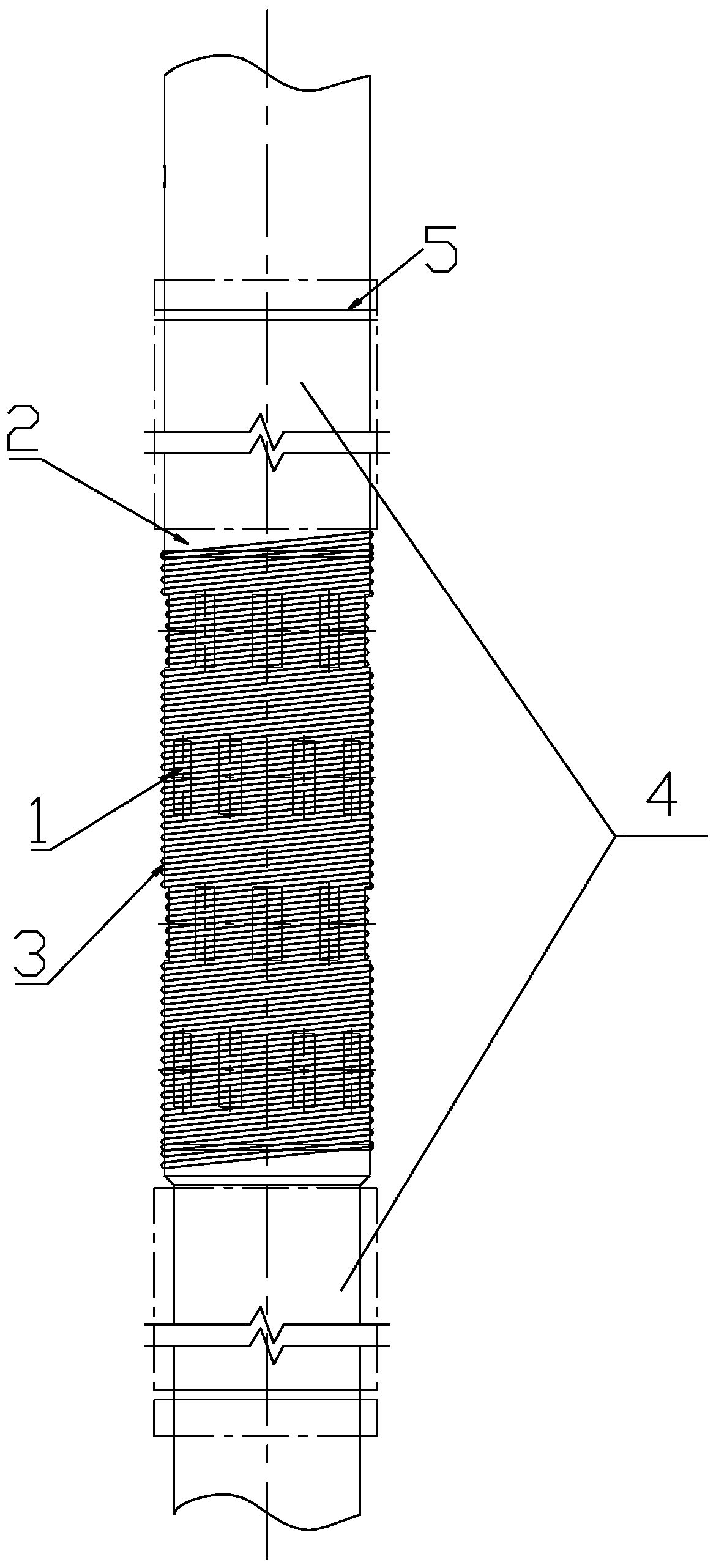

Coal mine underground coal seam long drill hole staged fracturing permeability increase and gas extraction method

ActiveCN108643877AIncrease the scope of fracturing anti-reflectionEfficient extractionFluid removalGas removalUnderground tunnelCement paste

The invention discloses a coal mine underground coal seam long drill hole staged fracturing permeability increase and gas extraction method. The coal mine underground coal seam long drill hole stagedfracturing permeability increase and gas extraction method comprises the steps that a long drill hole with the length more than 100m are drilled into a coal seam using a underground tunnel drilling machine for a coal mine or a kilometer drilling machine; a rigid casing with an one-way valve is lowered into to protect the hole directly using the underground tunnel drilling machine or the kilometerdrilling machine, and casing centralizers are installed at regular intervals; after the casing is lowered, preset volumetric cement paste is injected into an annular space between the outer wall of the casing and a drill hole wall to carry out blocking and sealing; a rigid fracturing pipe with two or multiple packers is lowered into the casing to carry out coal seam staged fracturing step by stepor multistage staged fracturing; and the fracturing pipe and the packers are removed after staged fracturing permeability increase, the casing of coal seam long drill hole opening is accessed with a gas extraction pipeline after drainage finishes to carry out efficient extraction of gas. The engineering amount of a tunnel and hole-drilling can be greatly reduced, the coal seam gas extraction efficiency is improved, and the coal mine underground gas treatment cost is reduced.

Owner:CHINA UNIV OF MINING & TECH

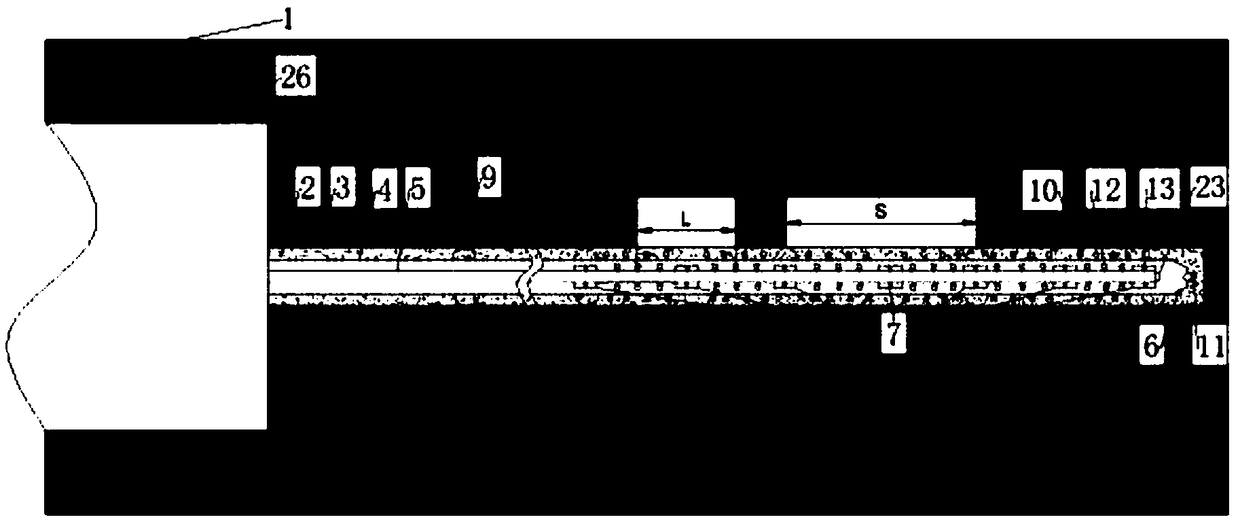

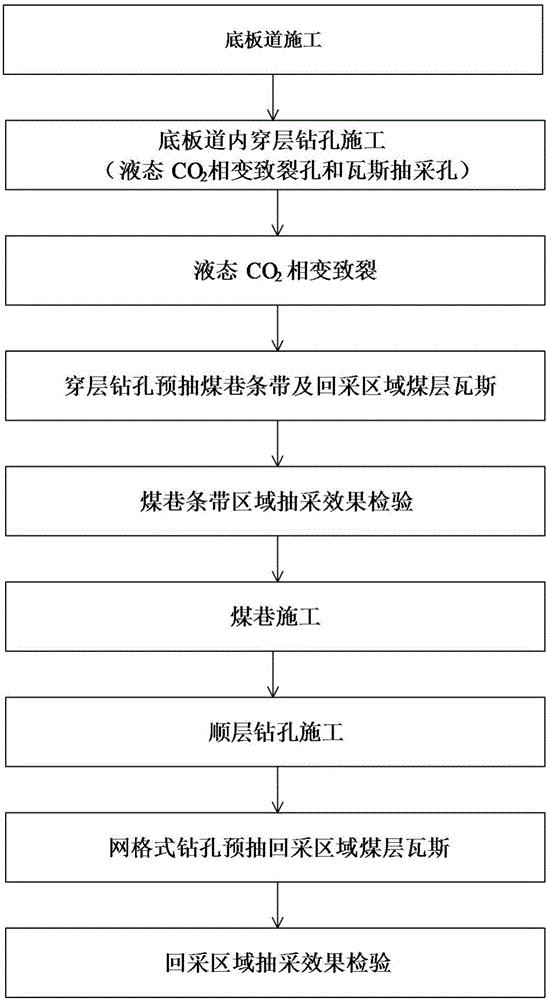

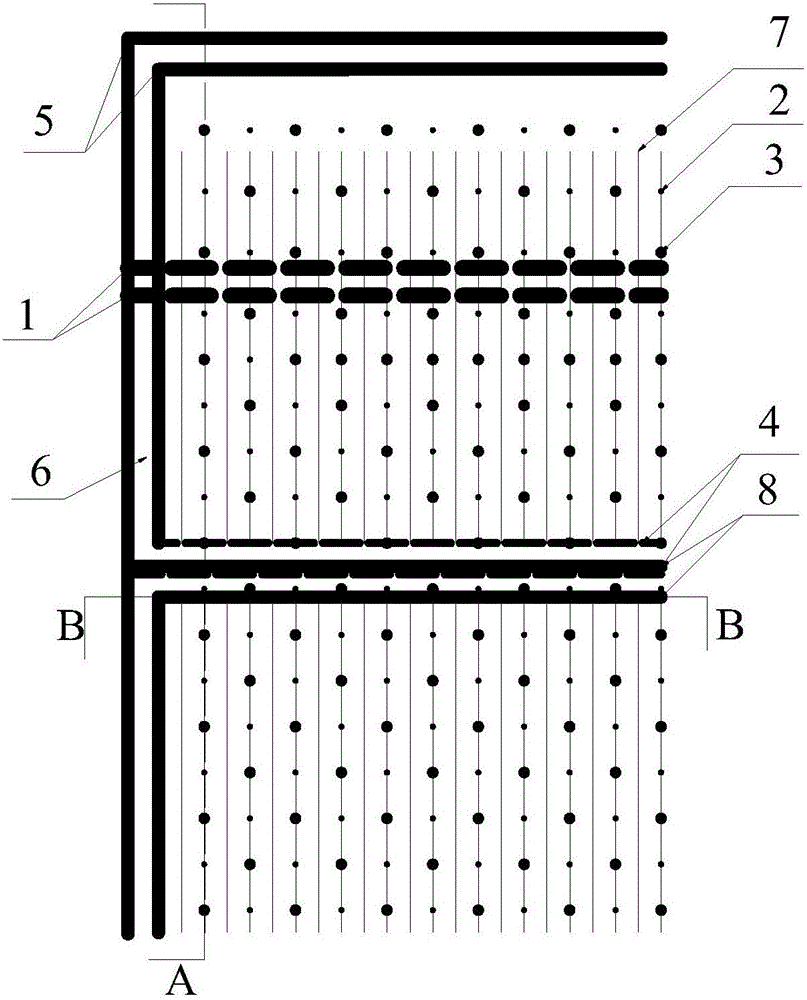

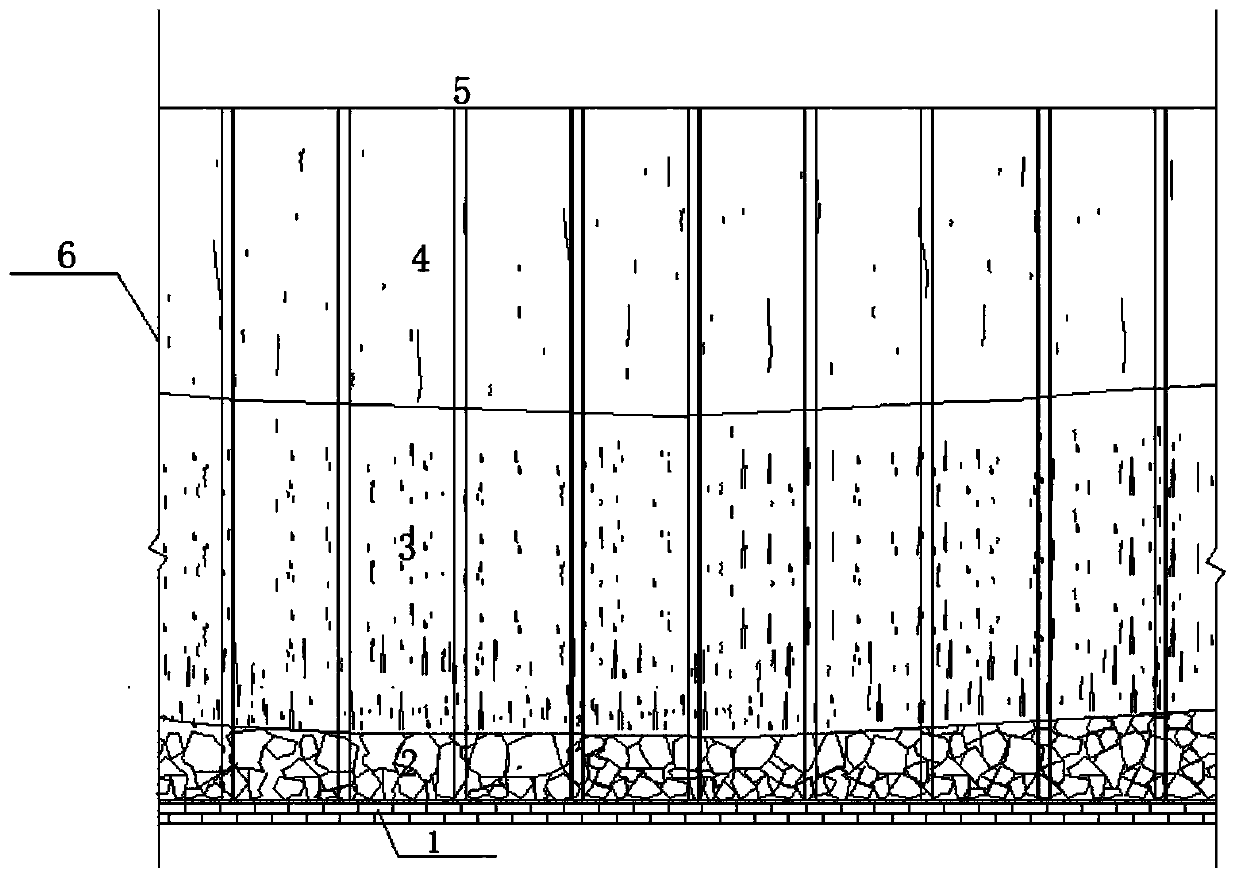

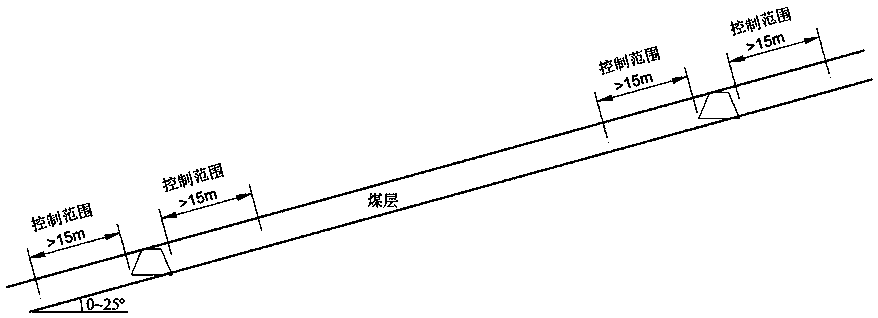

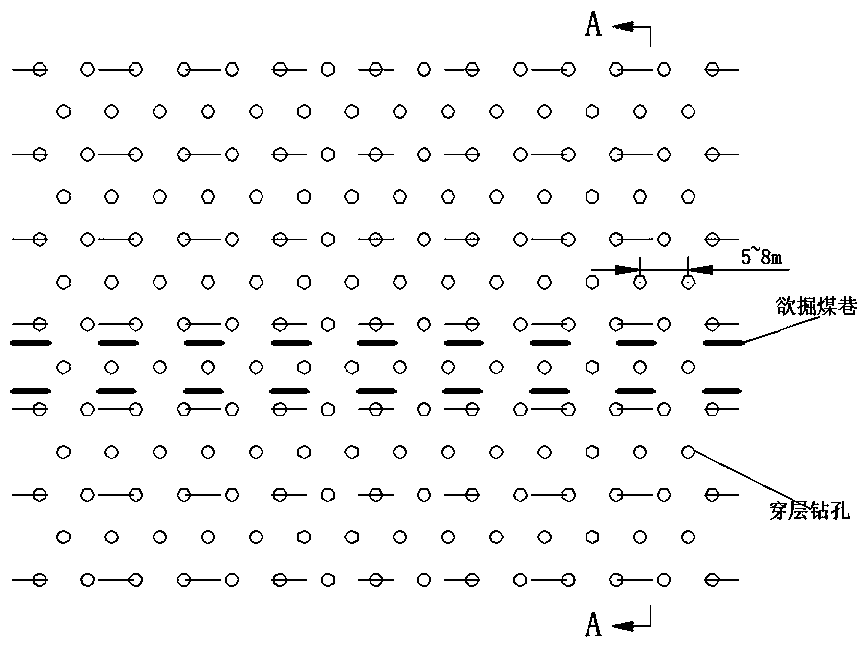

Liquid-phase CO2 phase change cracking permeability-increasing grid type gas extraction method for low-permeable coal seam

ActiveCN106194244AIncrease gas extractionEliminate outstanding hazardsFluid removalGas removalDrill holeProcess engineering

The invention discloses a liquid-phase CO2 phase change cracking permeability-increasing grid type gas extraction method for a low-permeable coal seam. The method comprises the following steps that (1) a bottom board passage is constructed; (2) crossing drilling construction is carried out in the bottom board passage; (3) liquid CO2 phase change cracking is carried out; (4) gas of coal seams of a coal roadway strip and a recovery area is pre-drained with crossing drill holes; (5) the extraction effect of the coal roadway strip area is detected; (6) coal roadway construction is carried out; (7) hole drilling down the seam is carried out; (8) gas of the coal seam in the recovery area is pre-drained with grid type drill holes; and (9) the extraction effect of the recovery area is detected. The method can improve the quantity of drainage of gas of underground coal mine, achieve the purpose of rapidly eliminating danger of outburst for high-gas low-permeable outburst coal seams, prevent coal and gas outburst accidents and guarantee safety production of the underground coal mine.

Owner:CHONGQING UNIV

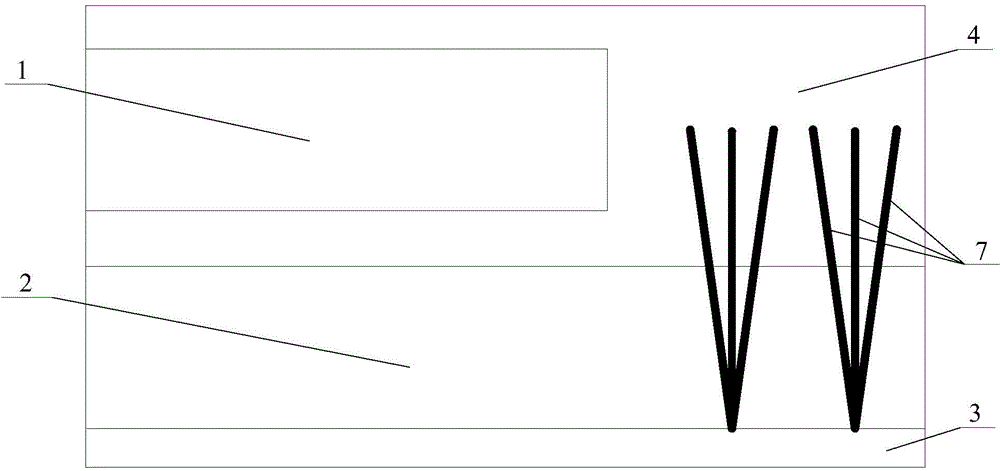

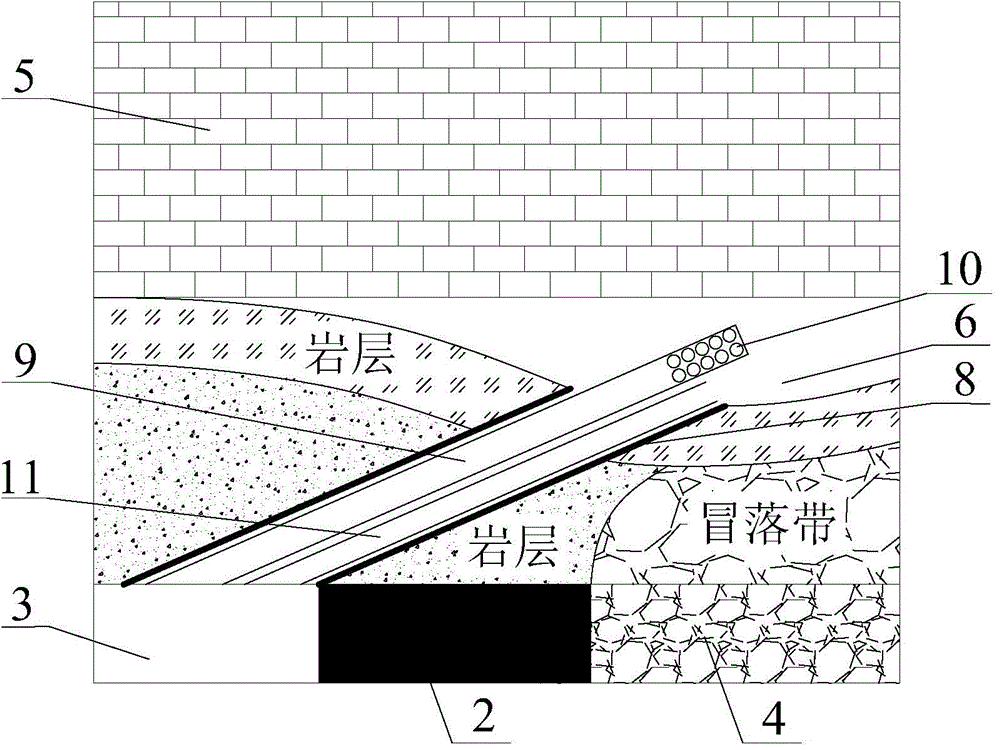

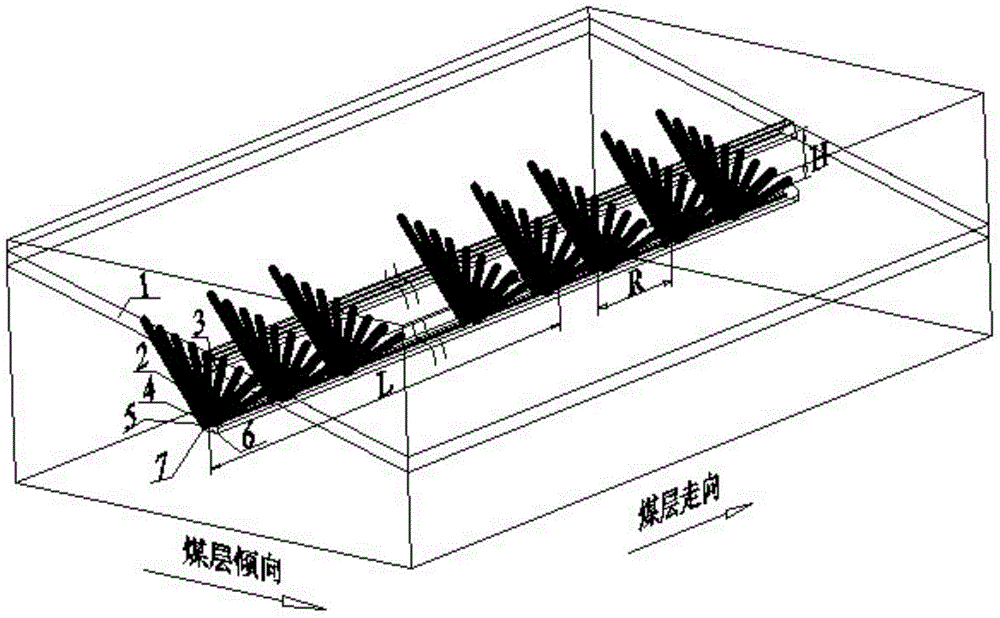

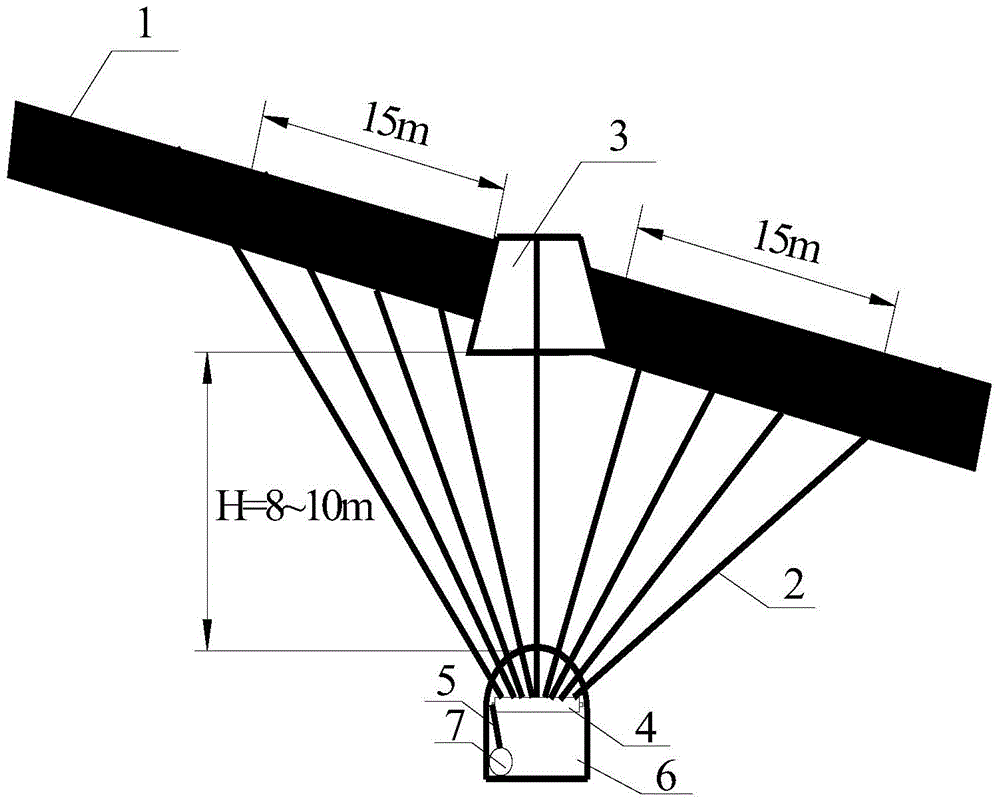

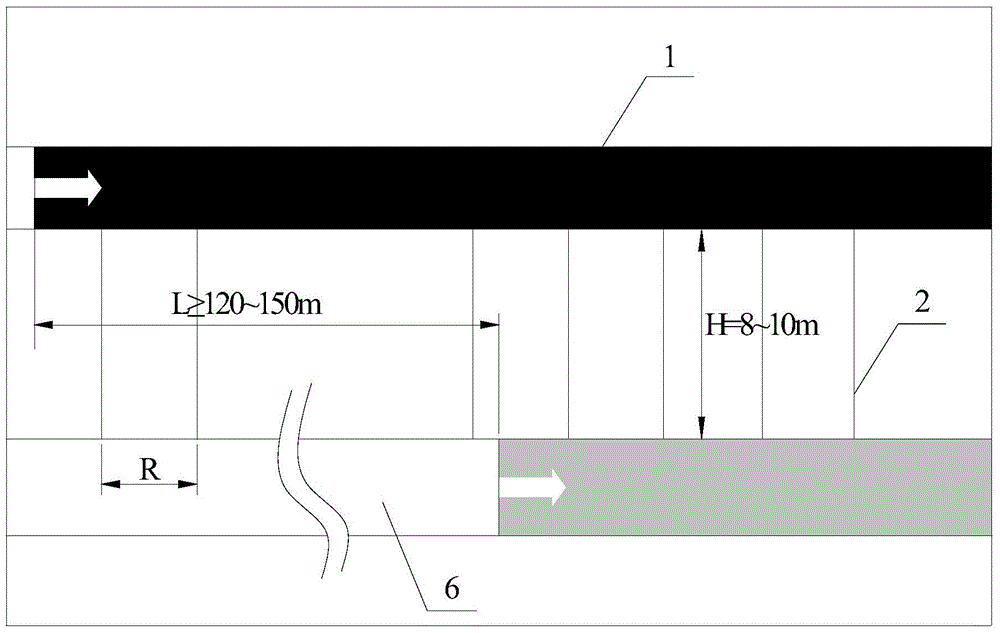

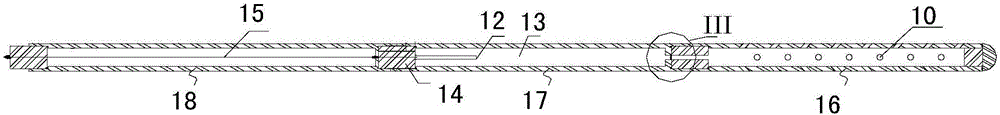

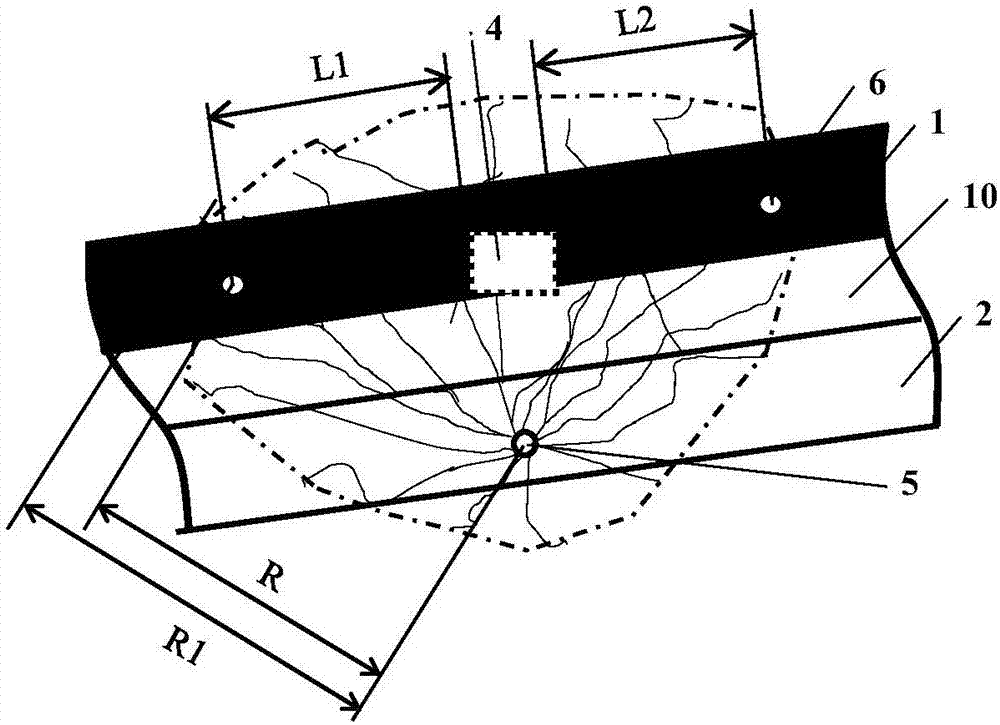

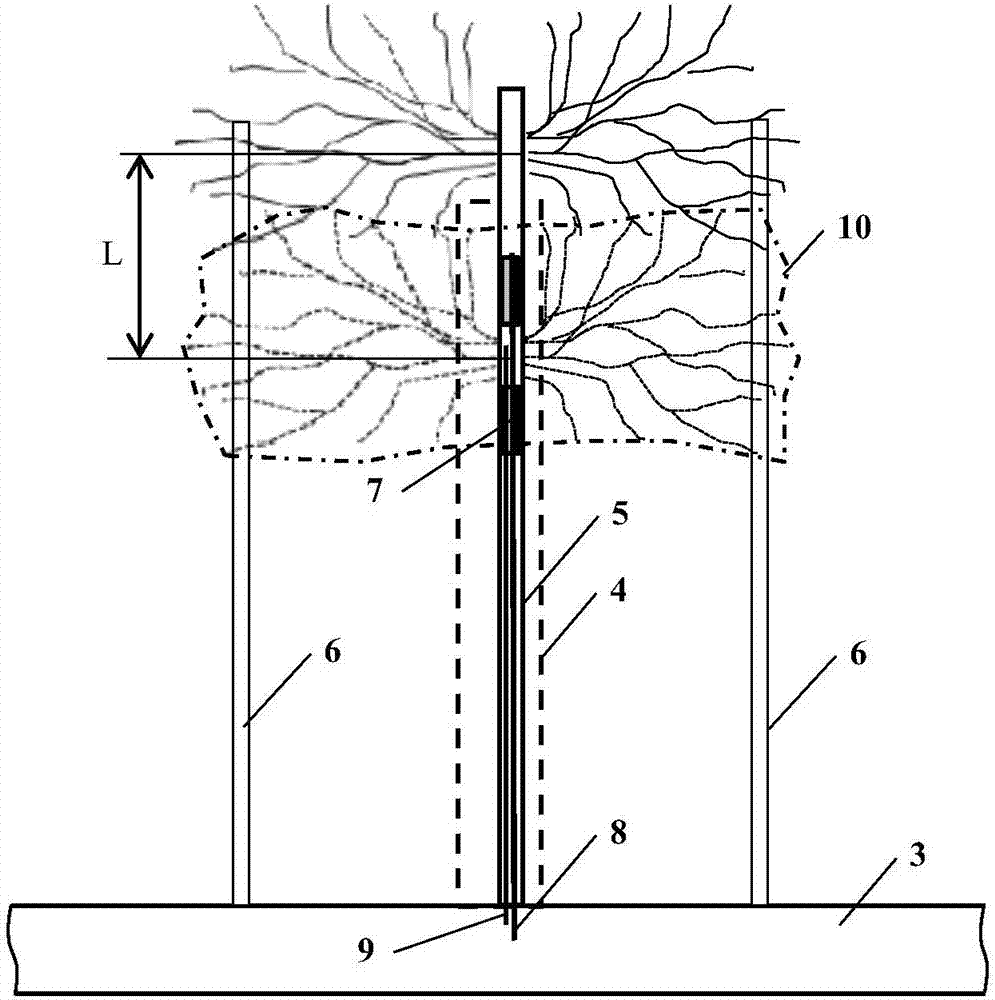

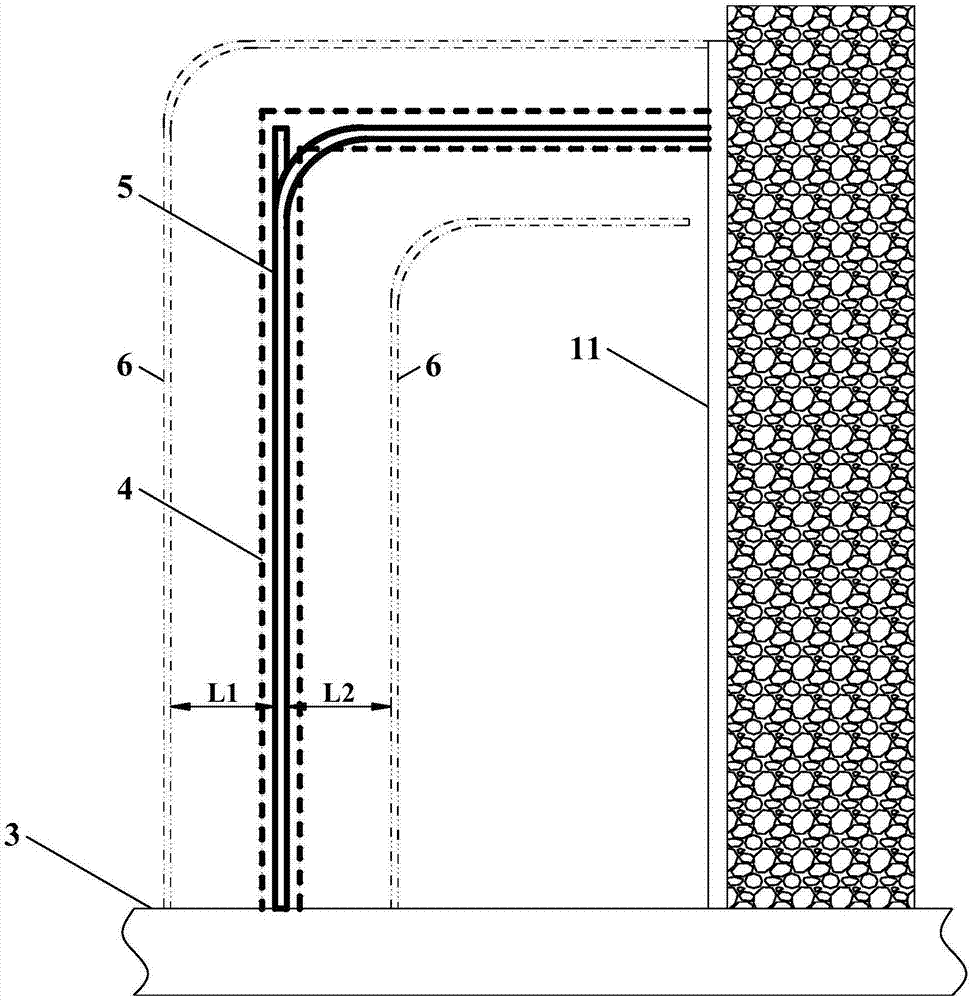

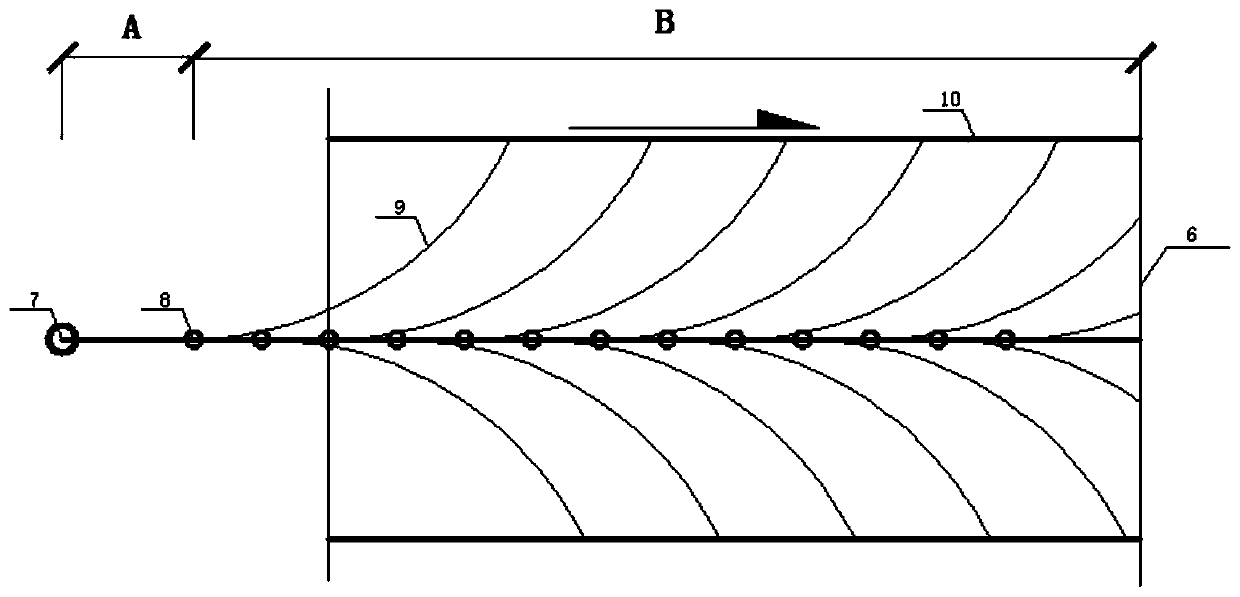

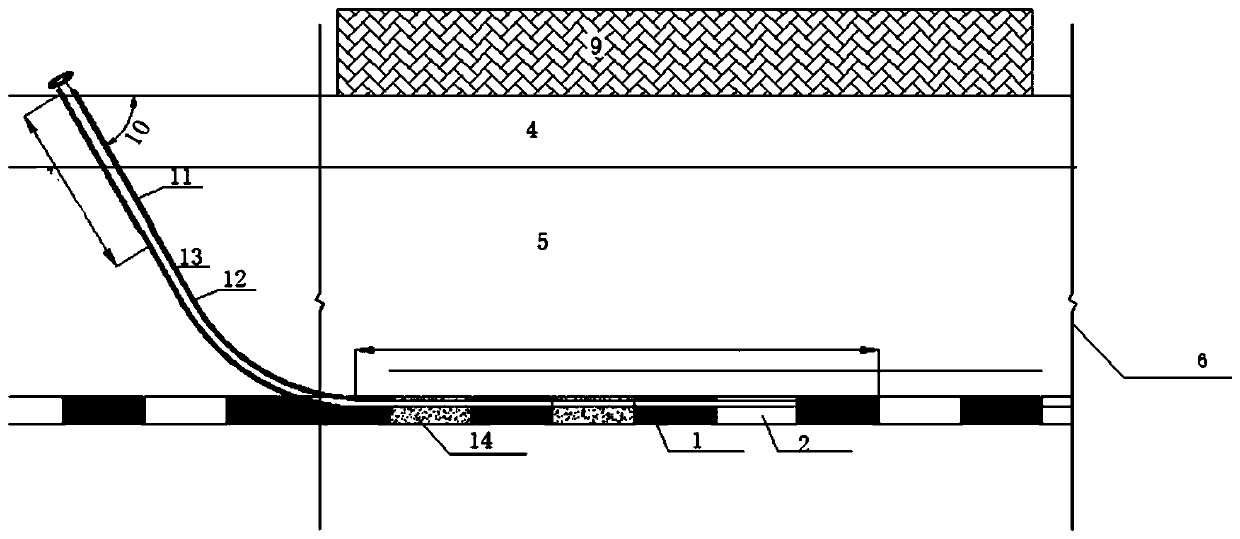

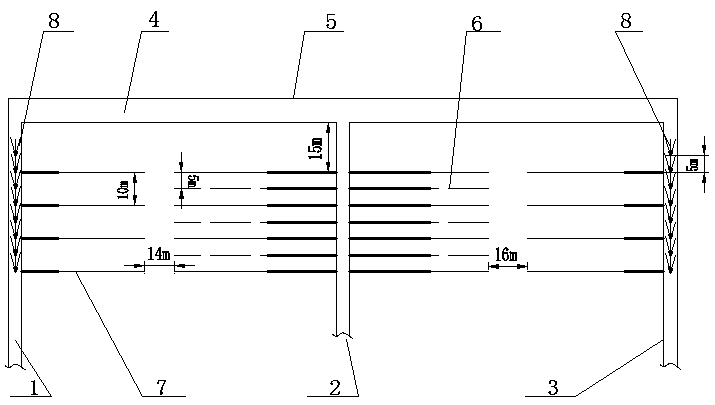

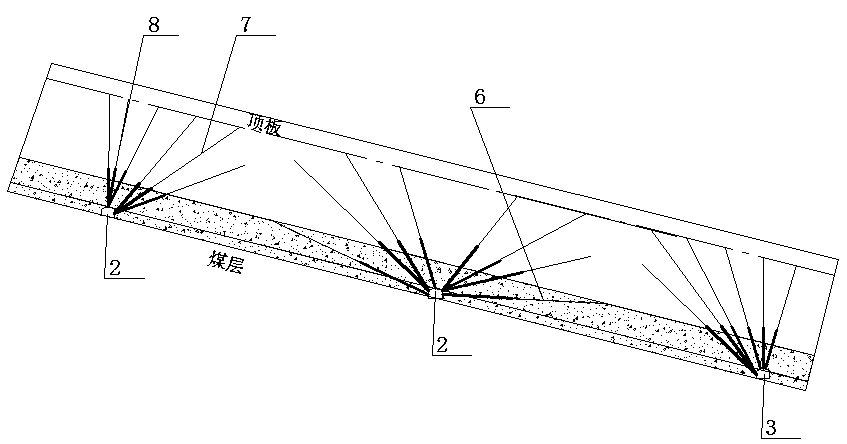

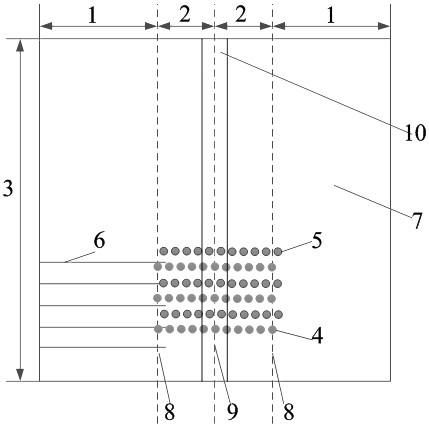

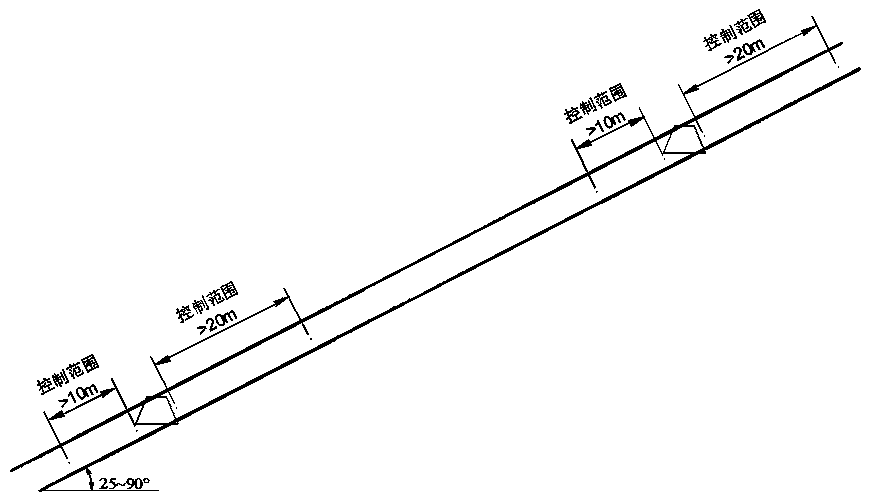

Method for gas drainage and regional outburst elimination of coal roadway strips by staged fracturing and along seam long borehole drilling in floor strata

ActiveCN106907175ANo increase in roadway engineering volumeReduce the amount of drilling workFluid removalGas removalCoalStandard time

The invention provides a method for gas drainage and regional outburst elimination of coal roadway strips by staged step-by-step fracturing and along seam long borehole drilling in a floor strata. The method is suitable for being applied to coal roadway excavating region outburst elimination, backstoping region outburst elimination and other projects. Along seam long boreholes are drilled in the hard floor strata with outburst-hazard coal seams in an existing roadway along the to-be-excavated coal roadway direction, staged step-by-step fracturing is conducted, fracturing holes are used for segmental drainage or the whole drainage, and outburst elimination is conducted on the coal roadway strips; according to the drainage amount, exhausting and mining standard evaluation is conducted, after exhausting and mining reach the standard, boreholes are drilled in the coal seams at the boundaries, in the range of regions adopting effective outburst prevention measures, on the two sides of the coal roadway, regional outburst prevention measure effect checking is conducted, drainage is then conducted, and coal roadway excavating is conducted when regional checking measures and local four-in-one measures are implemented. The method has the advantages that boreholes replace the roadway, drilling project amount is less, the fracturing range is large, the fracturing region surrounding coal stress concentration degree is low, stress relieving and permeability improving effects are good, exhausting and mining up-to-standard time is short, the coal parameter adaptability is high and the application range is wide.

Owner:CHINA UNIV OF MINING & TECH

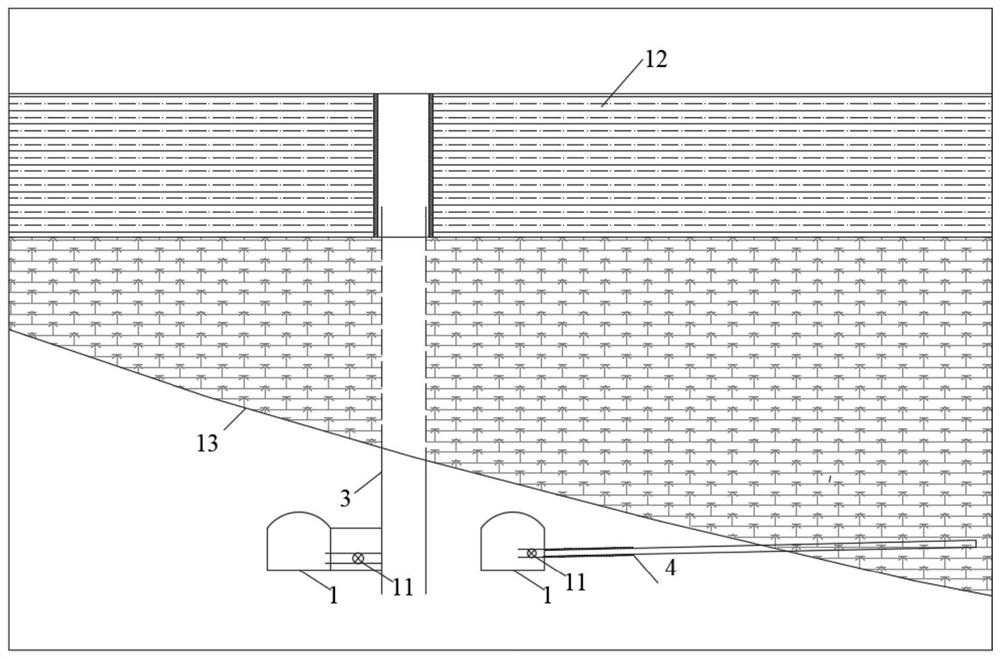

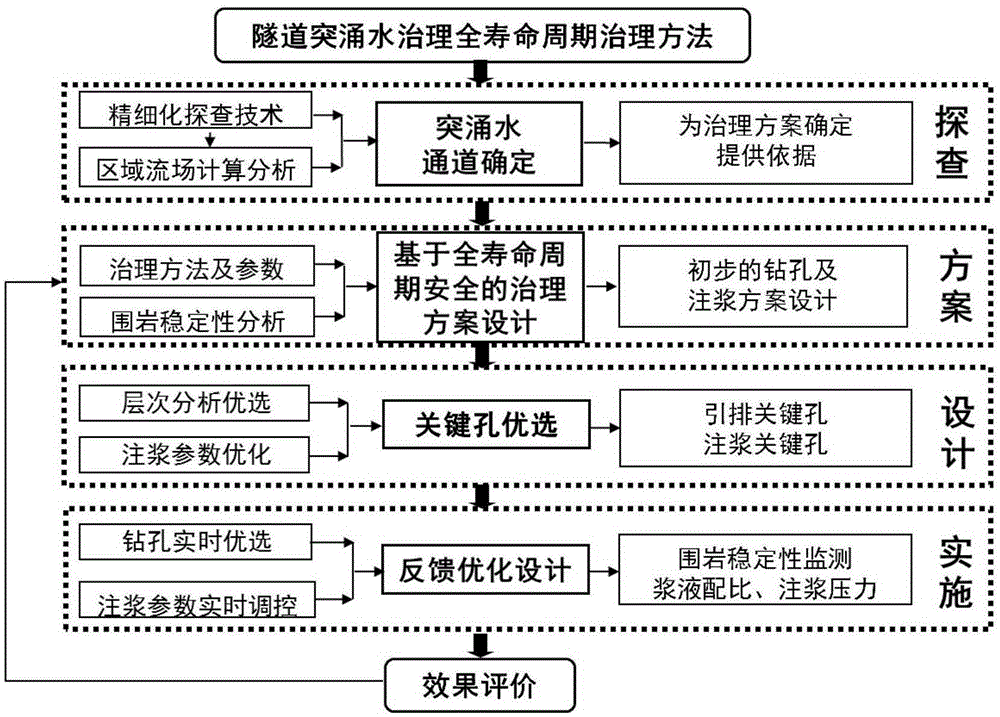

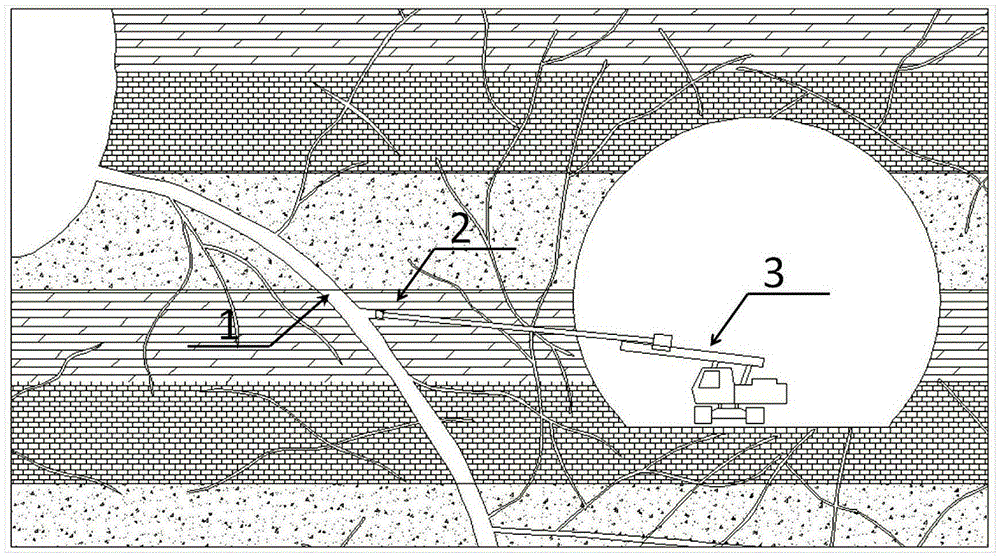

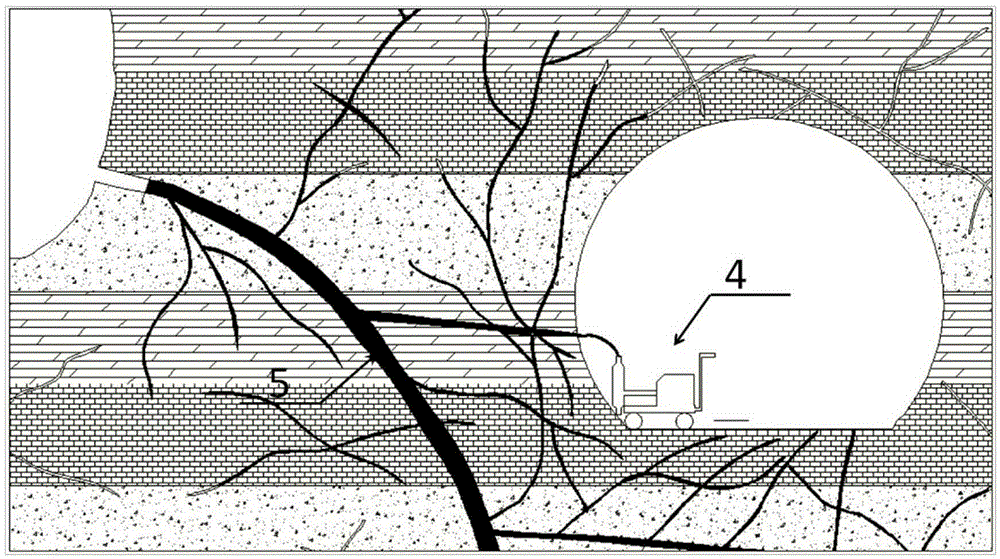

Life-cycle treatment method of water inrush in tunnel

ActiveCN105041345AImprove targetingImprove effectivenessUnderground chambersTunnel liningWall rockTunnel construction

The invention discloses a life-cycle treatment method of water inrush in a tunnel. The method comprises the steps that three-dimensional morphologic features of a water conductive structure of a water inrush zone in the tunnel are obtained by combining geological data, excavation data, detection results of comprehensive geophysical detection and numerical calculation results; grouting sealing water inrush is taken into account, surrounding rock physical mechanical parameters are improved simultaneously, design of a treatment scheme is conducted on the water inrush zone in the tunnel, and design of a keyhole and a drainage keyhole is conducted according to a water inrush main controlling structure; the stability of the tunnel in the construction period and the safety in the operation period are guaranteed by conducting numerical simulation on the tunnel section which is reinforced according to the design scheme; grouting construction is conducted according to the design scheme, a monitoring device is buried during the construction process, and feedback optimal design is implemented; inspection is conducted on the treatment effect of the grouting reinforcement section in the tunnel, and the excavation time is determined. According to the life-cycle treatment method of the water inrush in the tunnel, it is guaranteed that the surrounding rock in the tunnel construction period is stale and water inrush of the tunnel does not occur in the operation period, the chronic problem that nine of the ten tunnels leak is completely eradicated, and the effective treatment of the water inrush in the tunnel and the environmental protection are achieved.

Owner:SHANDONG UNIV

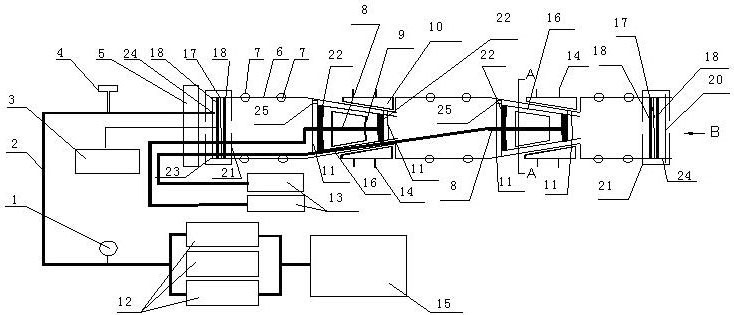

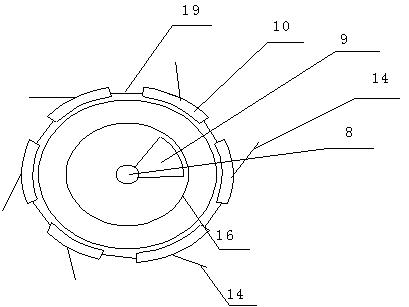

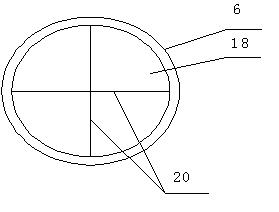

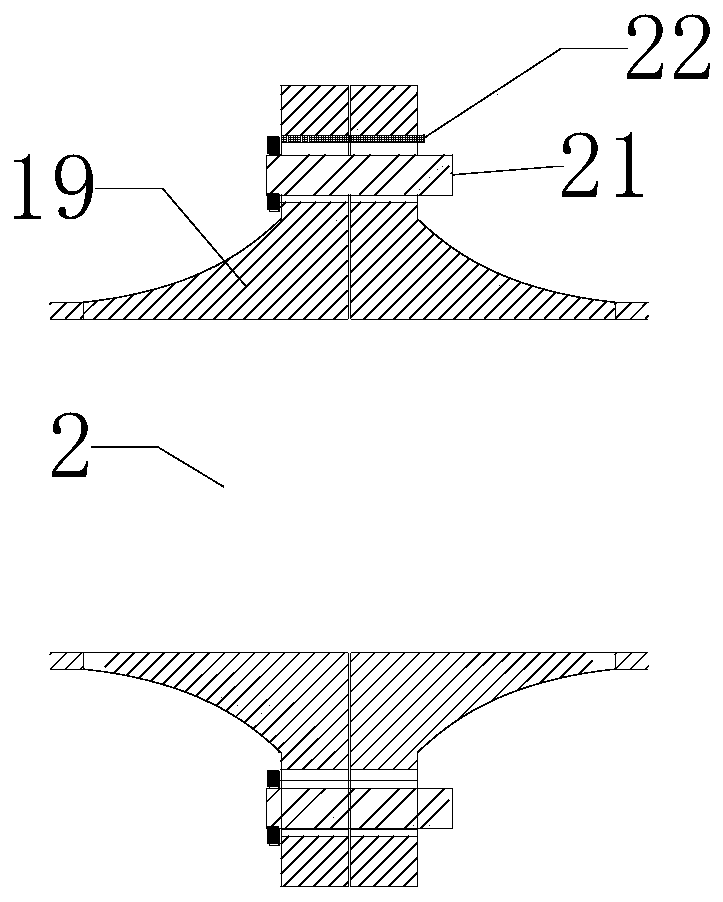

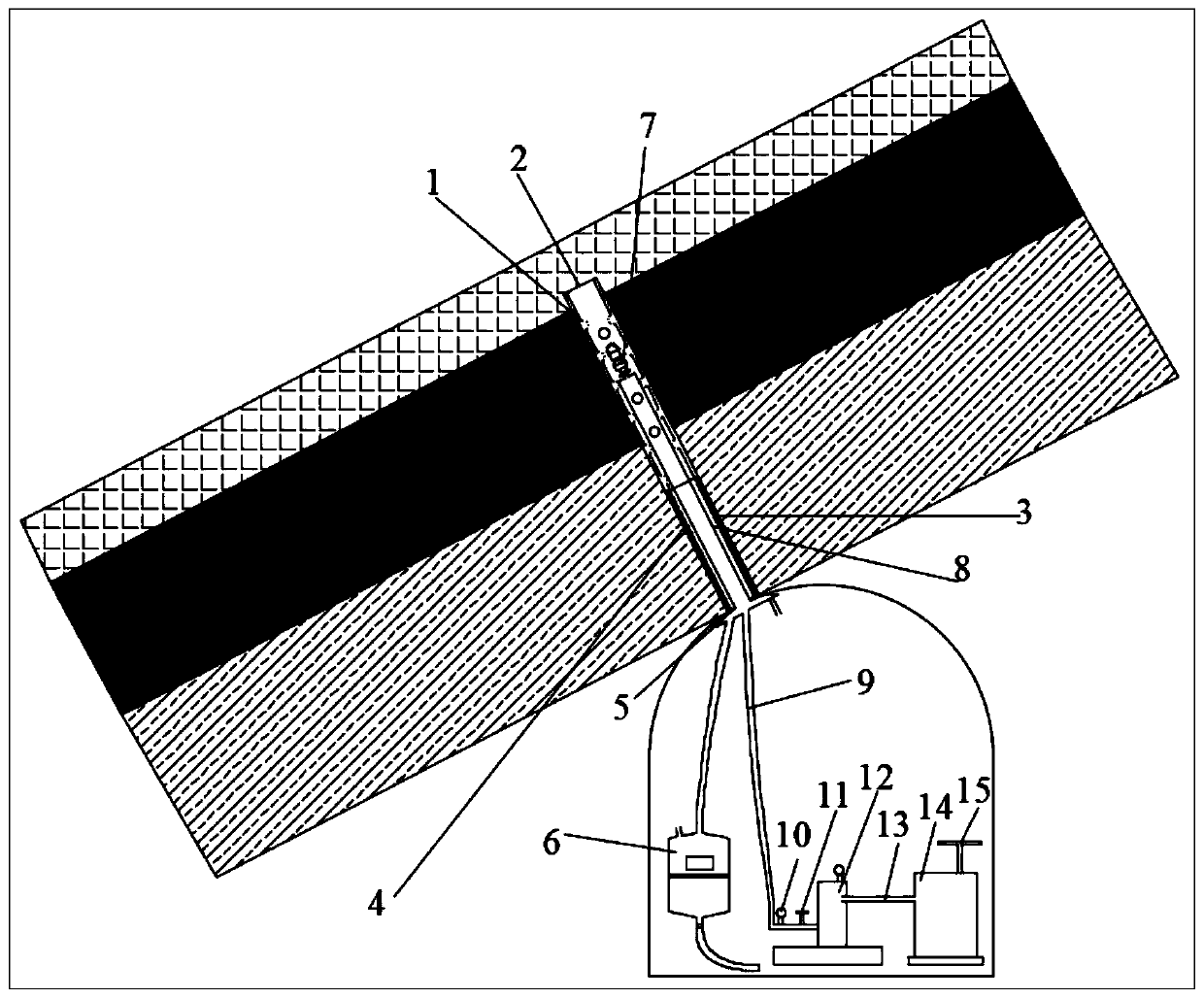

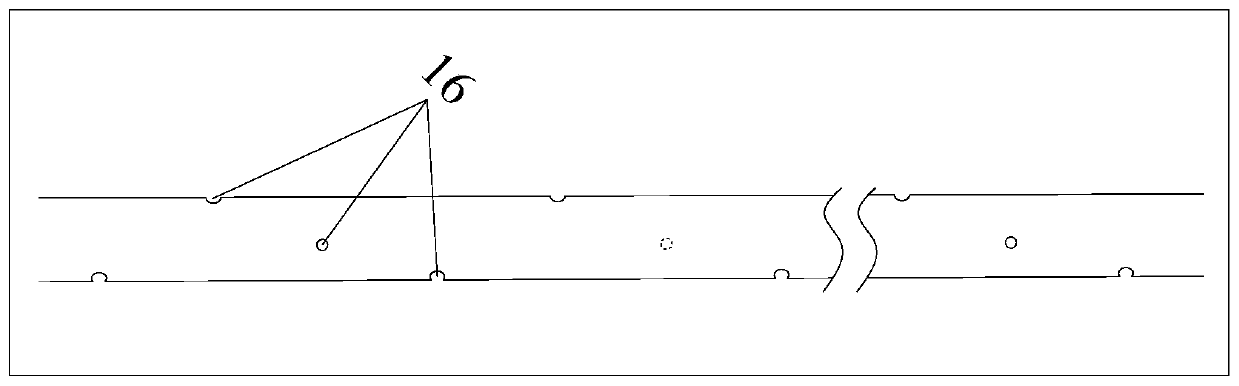

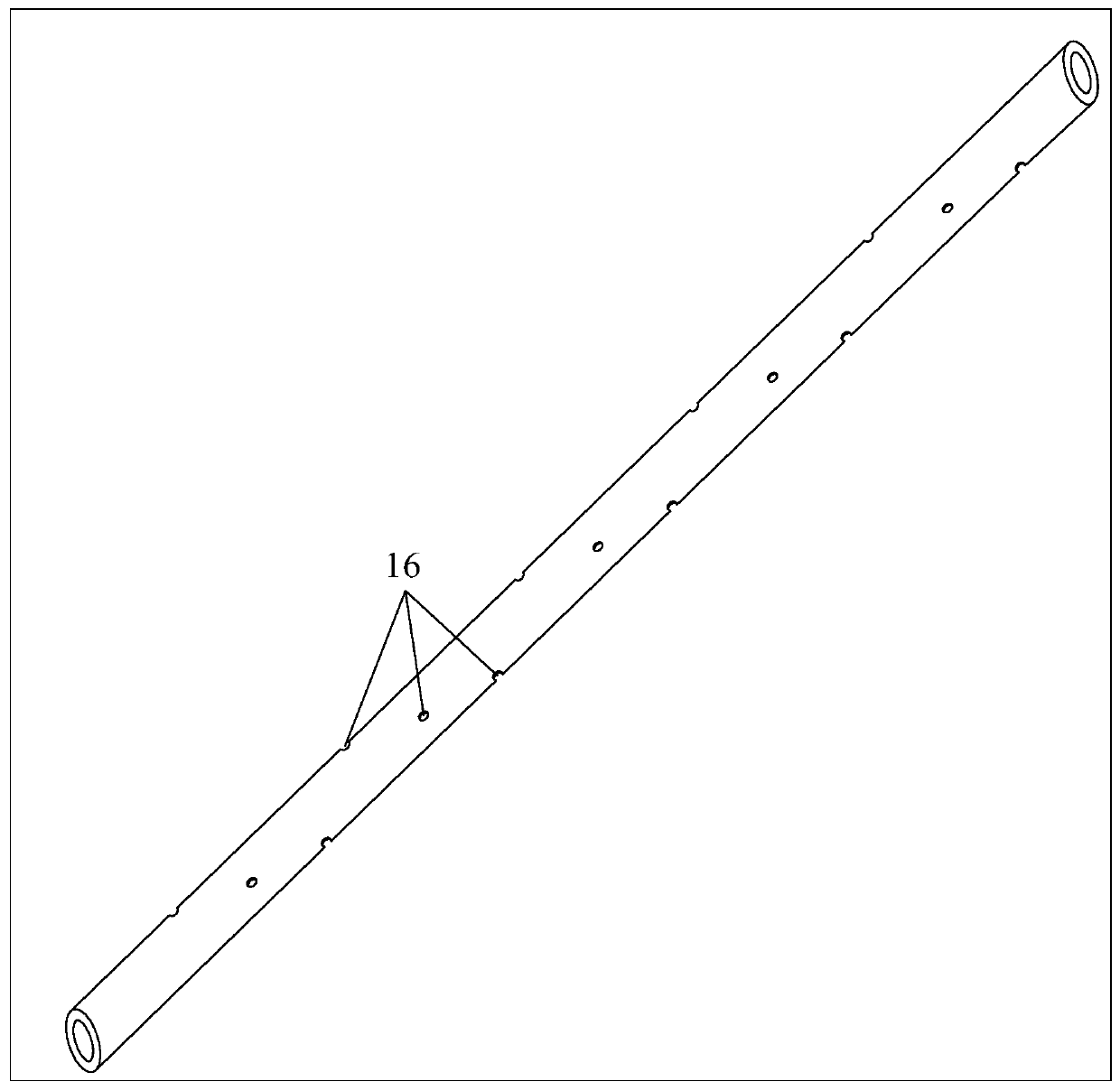

Gas extraction equipment and method for low coal penetration layer

InactiveCN102071920AImprove the extraction effectIncreased pumping distanceFluid removalGas removalSpray nozzleHigh pressure water

The invention discloses gas extraction equipment and a gas extraction method for a low coal penetration layer. The gas extraction equipment for the low coal penetration layer comprises a hollow drill rod, wherein the tail end of the drill rod is connected with a high-pressure water pump through a pipeline; the high-pressure pump is communicated with a water tank; nozzles are arranged at intervalson the rod body of the drill rod; and a vibrator is arranged in the drill rod. The gas extraction method for the low coal penetration layer comprises the following steps of: arranging the gas extraction equipment for the low coal penetration layer, inserting the drill rod into a drill hole, determining whether to start the vibrator or not according to the structure of a coal body, starting the vibrator for vibrating a coal layer if the coal body is a soft coal layer, feeding high-pressure water to the drill rod by using the high-pressure water pump and spraying the high-pressure water to the coal layer through the nozzles; and if the coal body is a hard coal layer, starting the high-pressure water pump for feeding water into the drill rod and spraying the water onto the coal layer throughthe nozzles of the drill rod or vibrating during water jetting. Specific to the problems of poor air permeability and the like of a coal reservoir in a gas pre-extraction process, in the gas extraction equipment and the gas extraction method for the low coal penetration layer, the stress of the coal reservoir is released effectively.

Owner:HENAN POLYTECHNIC UNIV

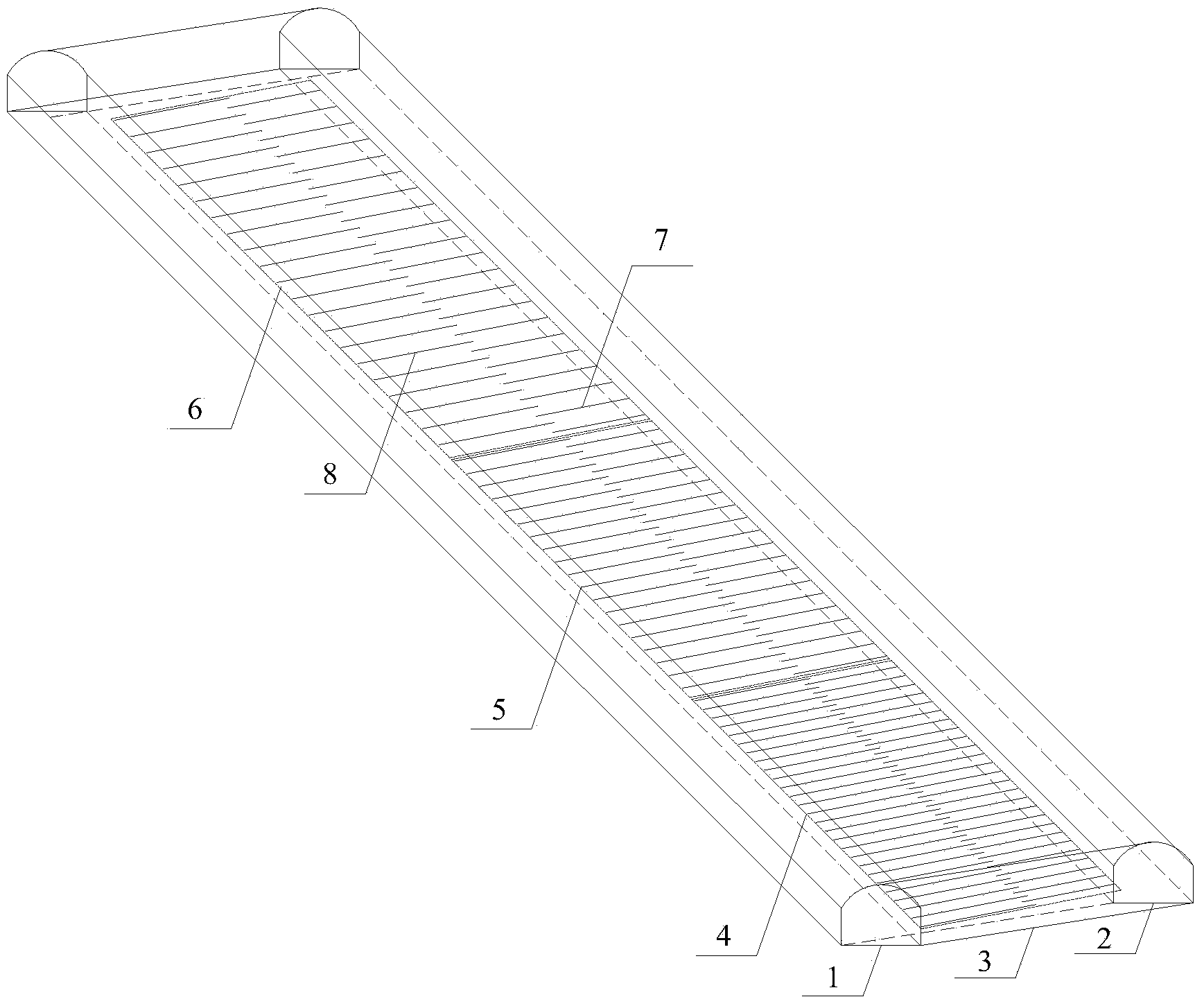

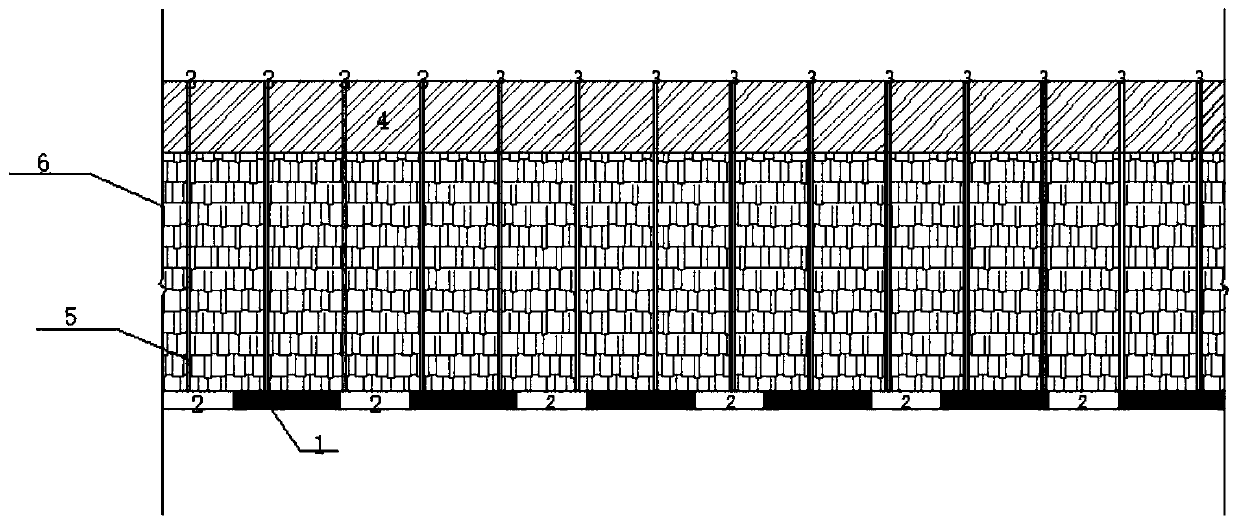

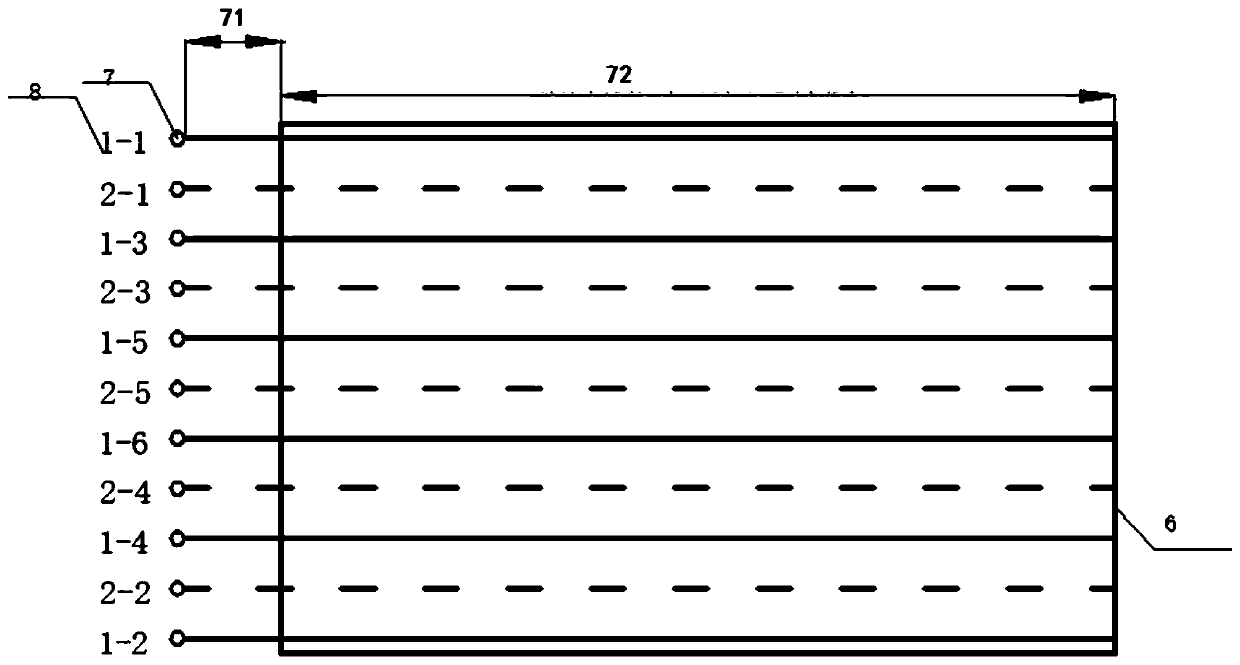

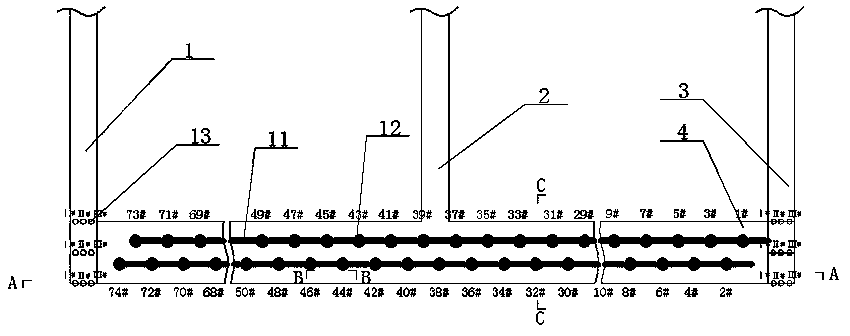

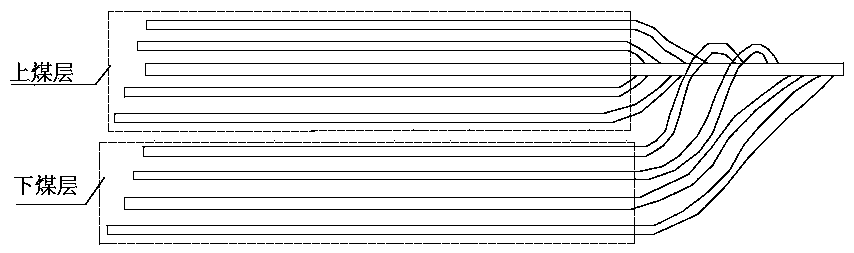

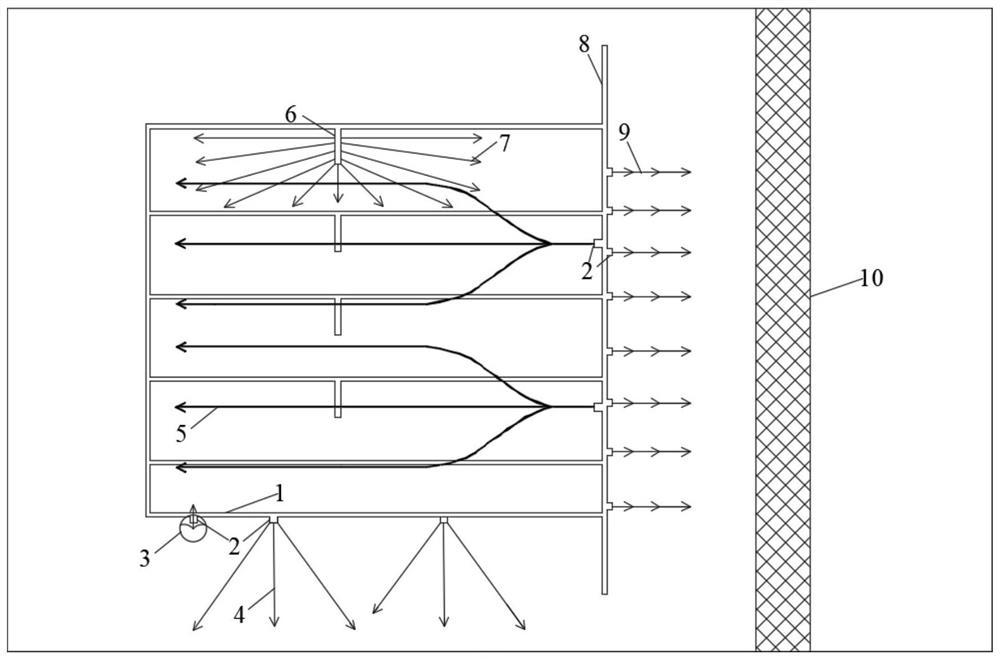

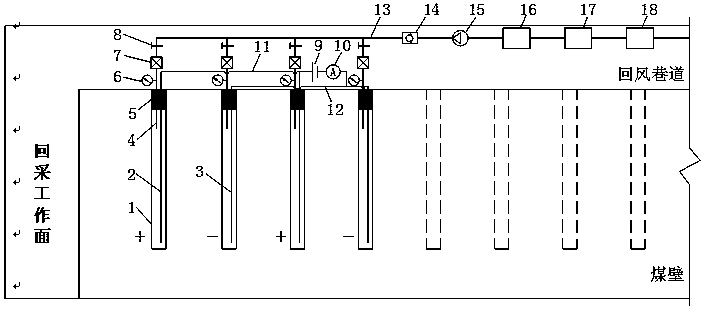

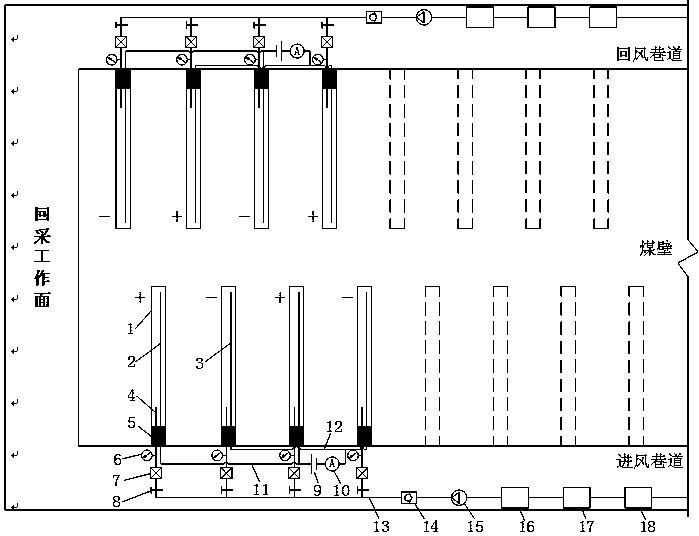

Method for bedding drilling and working surface gas pre-extraction

InactiveCN104018874AShorten production timeImprove the extraction effectGas removalSealing/packingProcess engineeringEngineering

The invention discloses a method for bedding drilling and working surface gas pre-extraction. According to the extraction time difference and the difference in distances to the cut openings, downward bedding drilled holes with different hole distances are parallelly constructed along the tendency of a coal seam respectively in working surface air returning following grooves, upward bedding drilled holes with different hole distances are parallelly constructed along the tendency of the coal seam in working surface conveying following grooves, gas extraction pipelines are respectively arranged on the sides of the conveying following grooves and the air returning following grooves close to a working surface coal wall, the downward bedding drilled holes and the upward bedding drilled holes of the conveying following grooves and the air returning following grooves enter a mine gas extraction system through the gas extraction pipelines, and after grouting and hole sealing, the extraction system is in combination to perform gas extraction. According to the technical scheme, by adjusting a drilling arrangement mode, the bedding drilled holes with different hole bottom distances are constructed according to the extraction time difference and the difference in distances to the cut openings, the drilling engineering quantity is reduced, production time of the working surface is shortened to the largest extent, the gas extraction effect is improved, and coal and gas simultaneous extraction is achieved.

Owner:CHINA COAL TECH ENG GRP CHONGQING RES INST +1

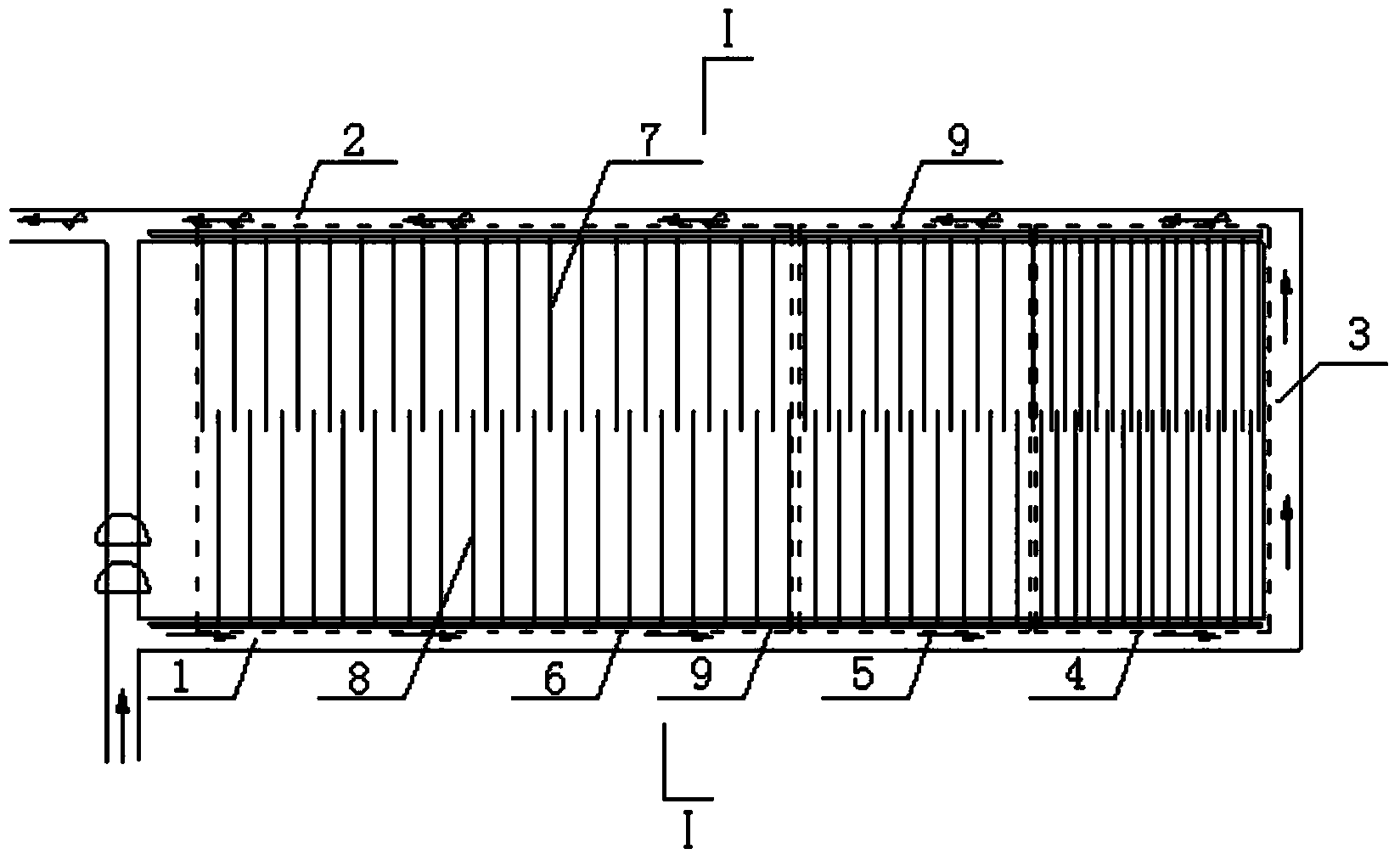

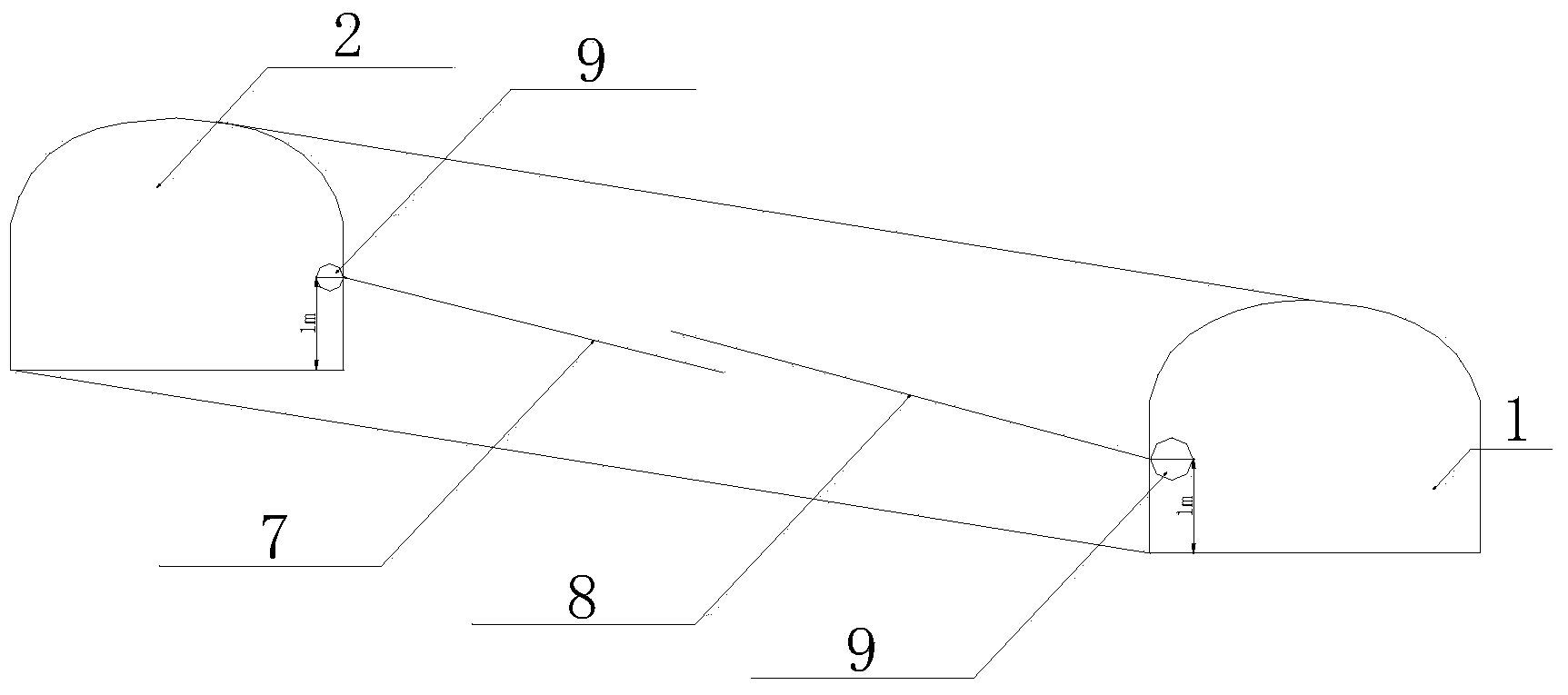

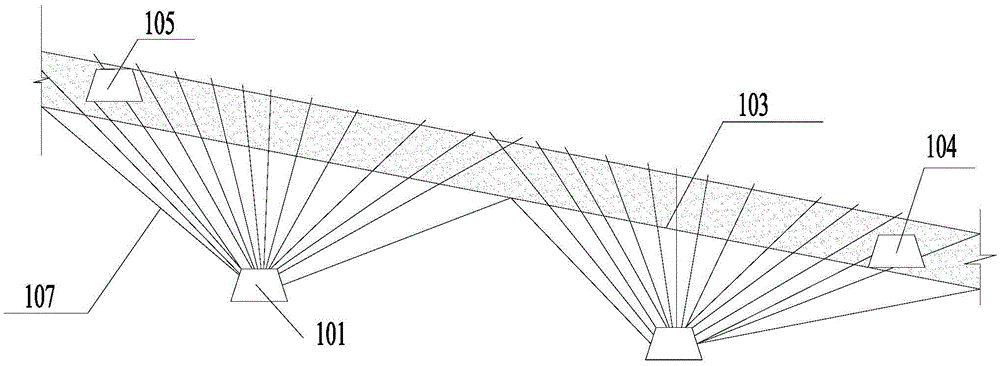

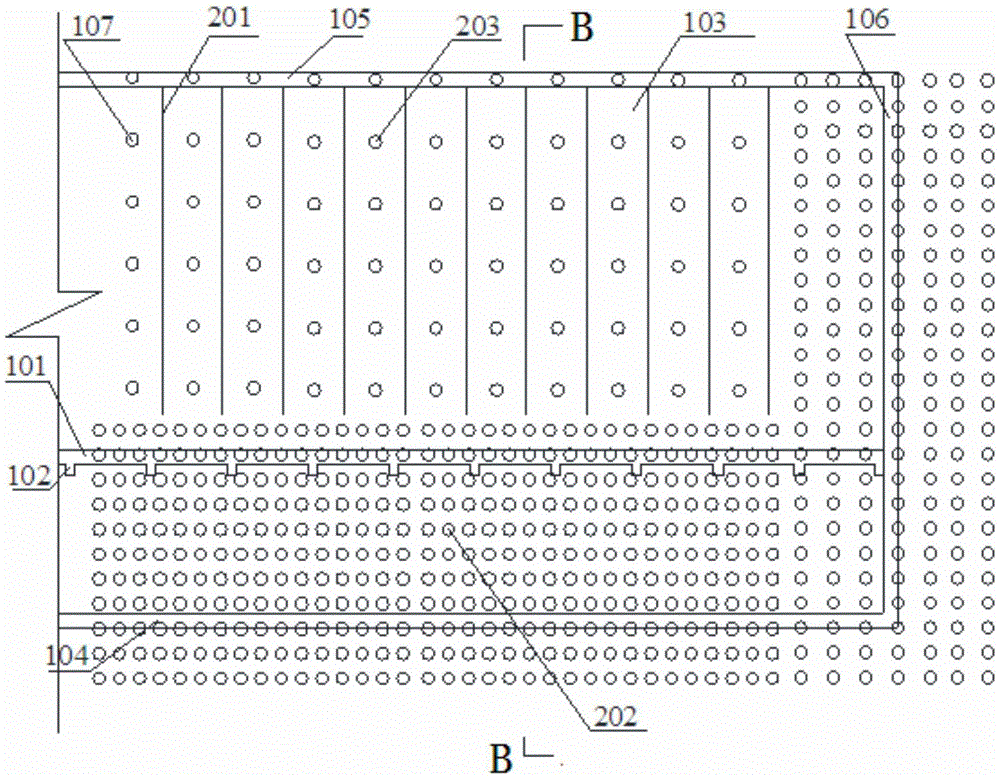

Goaf grouting method based on pinnate horizontal branch directional drilling technology

InactiveCN109899089AReduce the amount of drilling workReduced rig handlingUnderground chambersTunnel liningGeomorphologyGrout

The invention discloses agoaf grouting method based on pinnate horizontal branch directional drilling technology. The goaf grouting method based on pinnate horizontal branch directional drilling technology comprises the following steps thatstep 1, drilling is arranged, specifically,pinnate horizontal branch directional drilling is designed in a treatment area of a fully mechanized goaf, a verticalsection, a deflecting section, and afissure zone horizontal extension section; step 2, a grouting material is determined, and the grouting material consists of cement, flyash or clay, and an accelerator; step 3, drilling and grouting operations of each directional drilling are conducted, a drill tool is first lowered and drills into the vertical section and the deflecting section, and a forward drilling grouting ishorizontally conducted.Thus, according to the goaf grouting method based on pinnate horizontal branch directional drilling technology,disadvantages of vertical drilling technology in fully mechanized working face goaf grouting technology are overcome, the pinnate horizontal branch directional drilling is constructed from the earth surface to the lower middle layer of the fissurezone, grout is filled and strengthening is conducted on goaf caving zone rock mass, underground residual cavities, and fissures, activation space of an old goafis thoroughly eliminated, and thegoaf treatment is more effective.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Freezing-thawing cycle anti-reflection promoting extraction safe and efficient rock cross-cut coal uncovering method

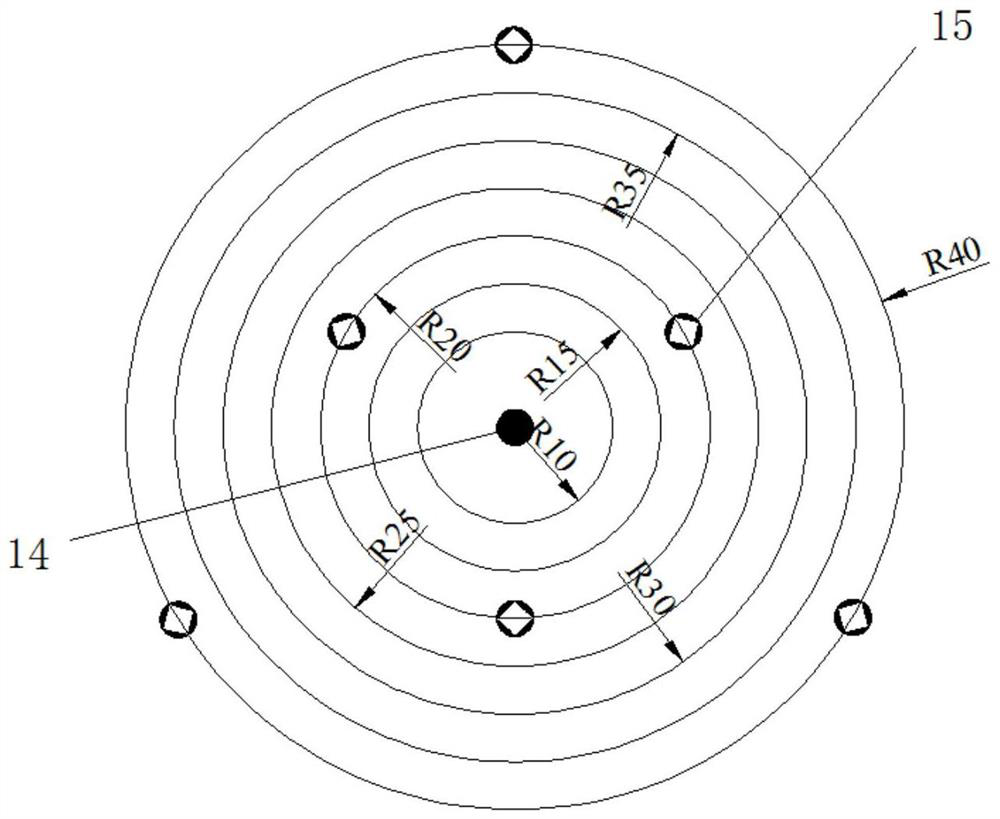

ActiveCN110056355AImprove breathabilityEliminate outstanding hazardsUnderground miningFluid removalFreeze thawingCross cut

The invention provides a freezing-thawing cycle anti-reflection promoting extraction safe and efficient rock cross-cut coal uncovering method. The freezing-thawing cycle anti-reflection promoting extraction safe and efficient rock cross-cut coal uncovering method comprises the following steps that (1) the influence radius Phi of a coal seam high-pressure water injection is measured; (2) drilling holes are constructed in a drilling field to a coal seam top plate or a bottom plate; (3) the drilling holes are divided into water injection hole bodies and freezing hole bodies, and the water injection hole bodies and the freezing hole bodies are arranged alternately; (4) hole sealing is carried out on the water injection hole bodies and the freezing hole bodies; (5) water injection is carried out on the water injection hole bodies, liquid nitrogen is injected into the freezing hole bodies to enable coal bodies on the periphery of the water injection hole bodies to be frozen, after a period of time, hot nitrogen is injected into the freezing hole bodies to enable the frozen coal bodies on the periphery of the water injection hole bodies to be unfrozen and thawed, and the liquid nitrogen is gasified; (6) gas discharged from the water injection hole bodies is extracted; (7) after gas extraction is carried out for 48 hours, the step (5) is repeated; and (8) rock cross-cut coal uncoveringoperation is carried out. According to the freezing-thawing cycle anti-reflection promoting extraction safe and efficient rock cross-cut coal uncovering method, through a coal body freezing-heat injection technology, the coal seam air permeability is effectively increased, the coal seam gas extraction effect can be greatly increased, the coal seam gas pressure is reduced, and the coal seam outburst risk is eliminated.

Owner:HENAN POLYTECHNIC UNIV

Small coal mine goaf grouting method based on directional drilling technology

ActiveCN109854297AReduce the amount of drilling workReduced rig handlingDirectional drillingMaterial fill-upDirectional boringStraight segment

The invention provides a small coal mine goaf grouting method based on a directional drilling technology. The advantages of controllable drilling tracks, high goaf disclosing efficiency, high ground adaptability, small drilling work amount, less solid pipe material consumption, low labor strength and the like of the directional drilling technology are fully used for opening up a creatively new path for geological disaster control in a coal mine goaf. The small coal mine goaf grouting method based on the directional drilling technology comprises the steps that a coal seam is horizontally entered through an obliquely straight segment and a deflecting segment, continuous drilling is carried out when coal pillars are encountered in the horizontal drilling process, when the goaf is encountered,a drill rod is recycled, grouting is carried out, after filling grout solidification reaches an another pore-forming condition, hole sweeping is carried out to a previous forming position along an original drilling track, continuous drilling is carried out in solidified man-made geological body, and grouting filling is carried out when entering the goaf again in the forming process. Therefore, the work amount is greatly reduced and the project cost is reduced on the premise of ensuring the grouting control effect of the small coal mine goaf, the innovativeness is greatly achieved, the application range is wide, and market prospects are better.

Owner:中煤科工生态环境科技有限公司

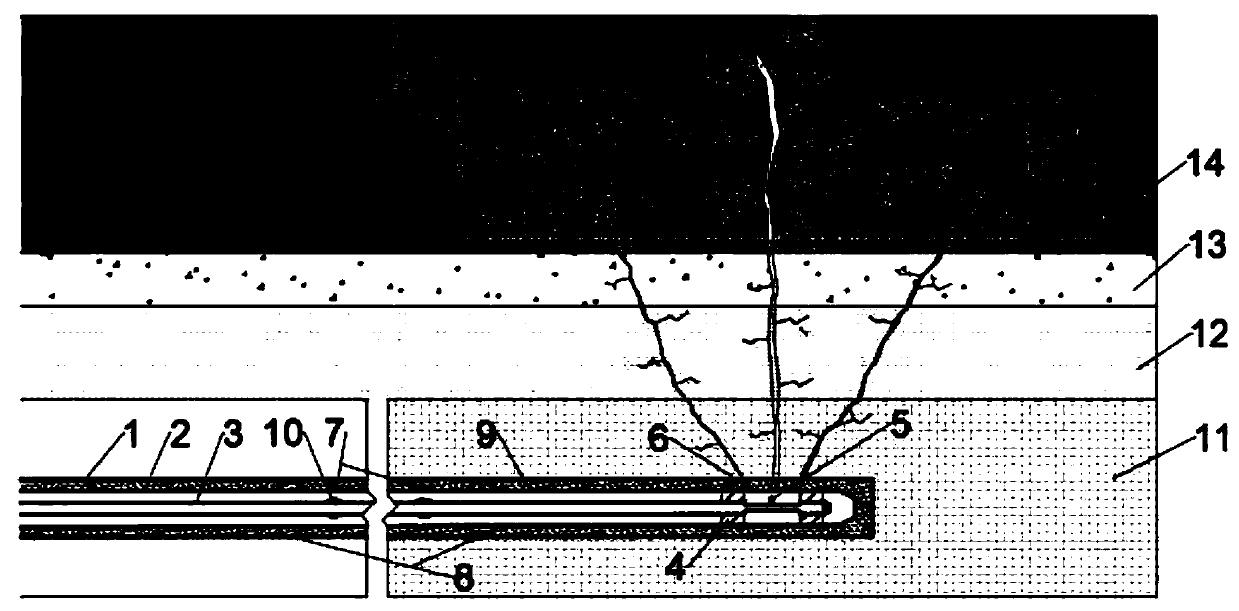

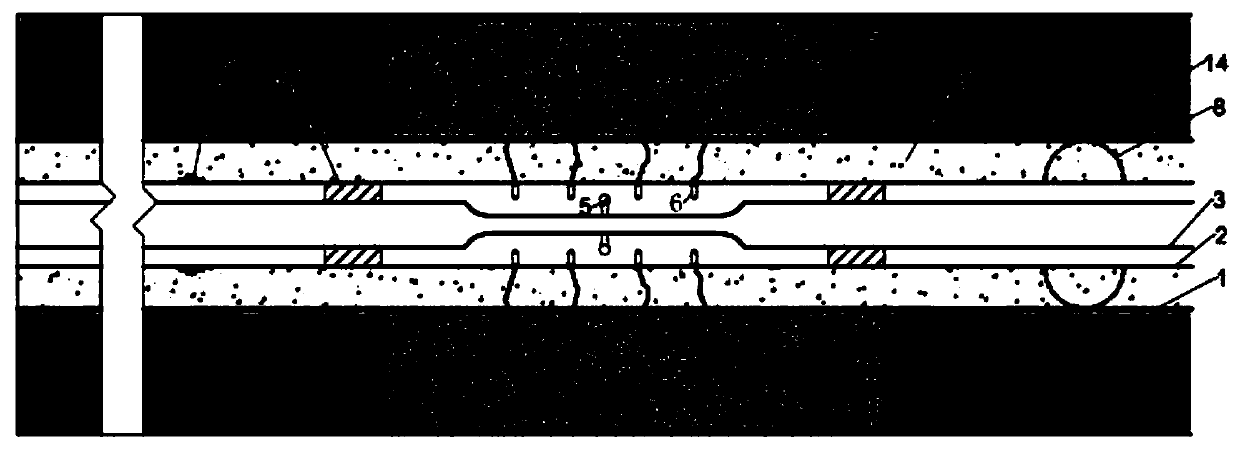

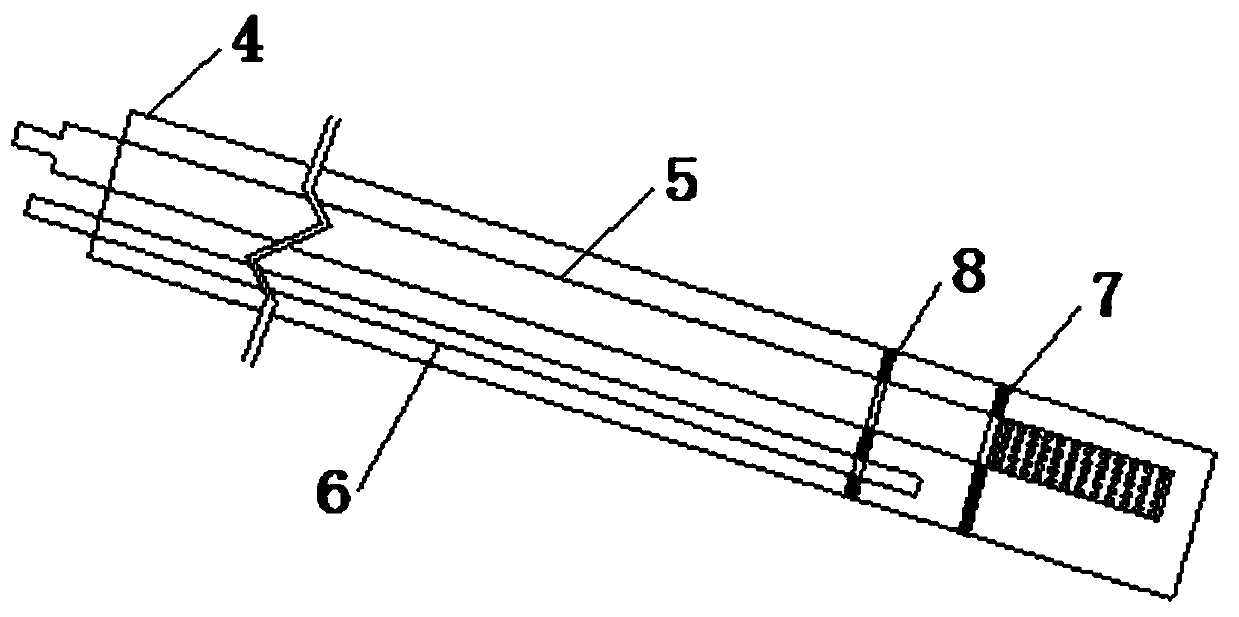

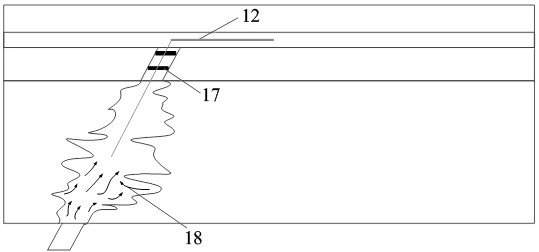

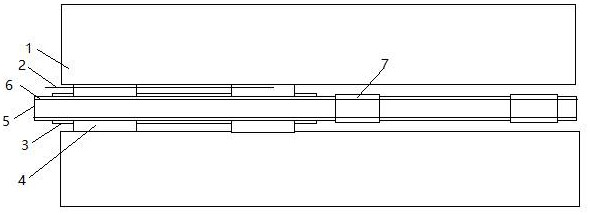

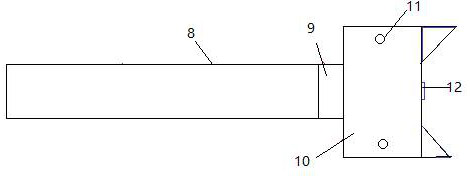

Directional fracturing device and method for underground drilling

ActiveCN110344805AAvoid mindless fracturingImprove fracturing precisionFluid removalGas removalEngineeringFracture control

The invention discloses a directional fracturing device and method for underground drilling. The device comprises a plurality of sections of casing pipes and fracturing pipes which are connected end to end, wherein the casing pipes are provided with directional fracturing control devices, and each directional fracturing control device comprises a screw hole with an adjustable angle and a one-way destructive conical screw matched with the screw hole; and the casing pipes are connected through stroke-controllable threaded connection assemblies or flange connection assemblies, and alignment scribed lines corresponding to the positions of the directional fracturing control devices in the circumferential direction are arranged on the casing pipes, so that the alignment scribed lines and the directional fracturing devices are always aligned. The method is mainly characterized in that after a hole is drilled in a roadway, the casing pipes are sent into the drilled hole, and the annular spacebetween the casing pipes and the drilled hole is sealed by grouting; and fracturing pipes provided with front packers and rear packers are sent into the casing pipes, and after entering the casing pipes from the fracturing pipes, the pressurized fluid flushes the casing pipes to fracture the coal rock mass when the pressure reaches the maximum bearing pressure of the directional fracturing controldevices. According to the directional fracturing device and method for underground drilling, provided by the invention, the fracturing direction is controllable, and various directional expansion forms can be realized.

Owner:CHINA UNIV OF MINING & TECH

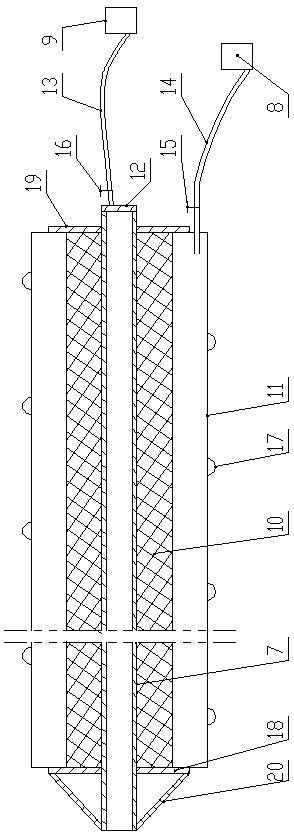

Soft coal seam controllable jet punching pressure relief antireflective device and method thereof

ActiveCN110953013AImprove breathabilityImprove extraction efficiencyLiquid/gas jet drillingFluid removalPunchingJet flow

The invention discloses a soft coal seam controllable jet punching pressure relief antireflective device and a method thereof. The device comprises a blowout prevention hole protective screen pipe, anend head protective cover, a hole sealing solid pipe, an orifice flange plate, a gas-slag-water separator, a high-pressure reverse rotation spray head, a high-pressure pipe and a high-pressure supplyassembly, wherein the orifice flange plate is arranged on an orifice, the hole sealing solid pipe and the blowout prevention hole protective screen pipe are arranged on the hole wall, the end head protective cover is arranged on the hole bottom, the high-pressure pipe extends into the hole from the orifice flange plate, the high-pressure reverse rotation spray head is arranged at the tail end ofthe high-pressure pipe, the rear end of the high-pressure pipe is connected to the high-pressure supply assembly, and the orifice is provided with the gas-slag water separator. According to the device, raw materials are convenient to obtain, the operation is simple, the implementation process is safe and controllable, the drilling gas extraction efficiency can be improved, the drilling engineeringquantity is reduced, and the coal outlet quantity and the gas emission amount in the hydraulic punching process can be effectively controlled while the gas extraction effect of the soft and strong outburst coal seam is improved.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Method for optimizing outburst-prevention technical measures for coal and gas outburst mine

InactiveCN105569724AReduce the amount of drilling workEasy extractionGas removalWeight coefficientWorkload

The invention discloses a method for optimizing outburst-prevention technical measures for a coal and gas outburst mine. The method comprises the following specific steps: 1), various outburst-prevention technical measures are made according to the on-site condition of a coal mine; 2), a value of a cluster evaluation index under each outburst-prevention technical measure is determined; and a cluster evaluation index matrix is established; 3), the outburst-prevention technical measures made in the step 1) are divided into multiple grades, and white functions of each cluster evaluation index in different grades in the technical schemes are determined; 4), the weight coefficient of each cluster evaluation index is determined; 5), index fixed weight cluster coefficients are solved, and a fixed weight cluster coefficient matrix is established; 6), the largest coefficient in the fixed weight cluster coefficient matrix is found, and the corresponding outburst-prevention technical measure is the optimal technical scheme. With the adoption of the method, the optimal outburst-prevention technical measure for the coal mine can be acquired, the gas treatment cost is reduced, the drilling workload is reduced, drilling construction time is shortened, and a basis is laid for increase of gas suction capacity on a coal seam and comprehensive treatment of gas in the mine.

Owner:HUNAN UNIV OF SCI & TECH

Hydraulic fracturing roof cutting gob-side entry retaining method for thick coal seam

ActiveCN112901166AReduce disturbanceMitigate overrunDisloding machinesStructural engineeringHydraulic fracturing

The invention discloses a hydraulic fracturing roof cutting gob-side entry retaining method for a thick coal seam. The method comprises the specific steps of calculating the roof cutting height of the thick coal seam, constructing fracturing drill holes, cutting hole walls through high-pressure jet flow, conducting single-hole multi-time hydraulic fracturing, sequentially fracturing multiple sets of fracturing drill holes, conducting roof cutting entry retaining and taking auxiliary measures. According to the method, the disturbance effect of the hydraulic fracturing technology on a roadway is small, the problems of gas accumulation and harmful gas overrun are relieved, fracturing construction mainly consumes underground industrial water and has little influence on the environment, hydraulic fracturing can be conducted on the multiple sets of fracturing drill holes simultaneously or alternately, the time cost is saved, the excavation and replacement efficiency is improved, and the method can replace the energy gathering blasting technology to achieve safe, efficient and rapid roof cutting entry retaining of thick coal seam mining.

Owner:CHINA UNIV OF MINING & TECH

Method for preventing and controlling rock burst and gas emission of high-length short-distance drilling linkage

InactiveCN111237006ASimple ventilation systemReliable ventilation systemTunnel/mines ventillationGas removalMining engineeringStructural engineering

The invention relates to a method for preventing and controlling rock burst and gas emission of high-length short-distance drilling linkage. The method comprises the steps that in the tunneling process of a roadway of a recovery work surface of an underground coal mine, a process roadway is formed in the middle of the work surface, so that the process roadway and upper and lower through grooves ofthe work surface form a ventilation system in U and L shapes, and the ventilation system is easier and more stable and reliable. Top plate super-front deep hole presplitting blast holes are constructed in the process roadway, super-front presplitting holes of upper and lower ends of the construction work surface, close to the upper edge of the upper through groove and close to the lower edge of the lower through groove are used for performing presplitting blasting on a coal bed and a top plate of the coal bed, and the disaster of rock burst of the work surface is prevented and controlled. Through presplitting blast, the top plate of the coal bed generates a large quantity of secondary interstices, so that a good channel is provided for long-distance and short-distance high-position boringexploitation of pressure relief gas when construction is performed in the process roadway and the upper through groove in the recovery period of the work surface, the gas emission intensity of air return corners of the work surface in the recovery period can be greatly lowered, and the safe and efficient exploitation of the work surface are practically guaranteed.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

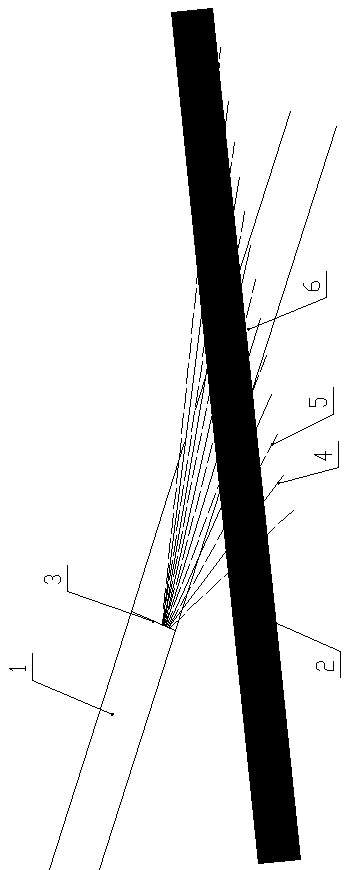

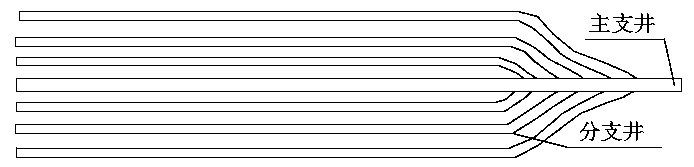

Ground area stripe coal mine gas outburst elimination technique

InactiveCN108643960AReduce the amount of drilling workShorten construction timeFluid removalGas removalCoalCoal mine methane

The invention provides a ground area stripe coal mine gas outburst elimination technique. The ground area stripe coal mine gas outburst elimination technique comprises the following steps that a branch arrangement mode is optimized; a well location of a vertical well is optimized; a deflection point is optimized; a branch parameter is optimized; a reservoir modification technology is optimized; well drilling and deflecting are carried out; drilling of a main branch section is completed, and a coal rock core is observed; drilling of branches is completed; main branch hydraulic jetting fracturing is completed; and drainage and mining is started according to a drainage and mining design. The ground area stripe coal mine gas outburst elimination technique has the beneficial effects that the development cost of ground coal bed gas can be reduced, a gas extraction period can be shortened, the aim that coal seam gas-bearing capacity is quickly reduced is realized, and a great promoting function of improving coal mine production and accelerating rapid development of the coal industry is achieved.

Owner:HENAN INST OF ENG

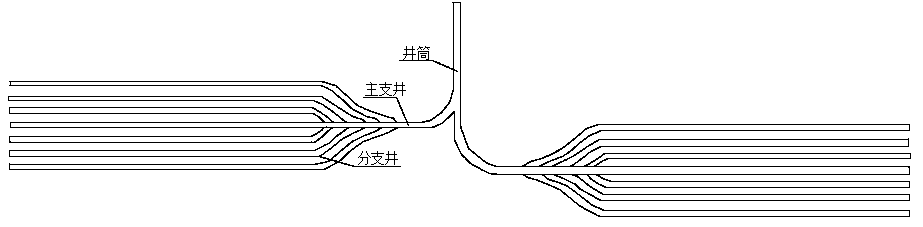

Poly-generation shaftless coal underground gasification method

ActiveCN110145293AAchieve reuseSolve the reuse problemDrilling rodsConstructionsCombustionProcess engineering

The invention discloses a poly-generation shaftless coal underground gasification method. The method comprises the steps of drilling work, well cementation work, gas extraction work, coal undergroundgasification work, combustion area treatment work, CO2 sealing work and the like. According to the poly-generation shaftless coal underground gasification method, the drilling work amount can be greatly reduced, based on the single-time drilling construction process, a drawing-injection integrated multi-purpose pipe assembly can be used for sequentially completing gas extraction work, coal underground gasification work, combustion area treatment work, gas sealing work and hole sealing work, the drilling utilization rate is greatly improved, and production cost is reduced while poly-generationcoal underground gasification work is achieved; and reutilization of underground waste space can be achieved, the defects that in the prior art, the drilling utilization rate is low and production cost are high can be effectively overcome, and the method is especially suitable for coal underground gasification work.

Owner:CHINA UNIV OF MINING & TECH

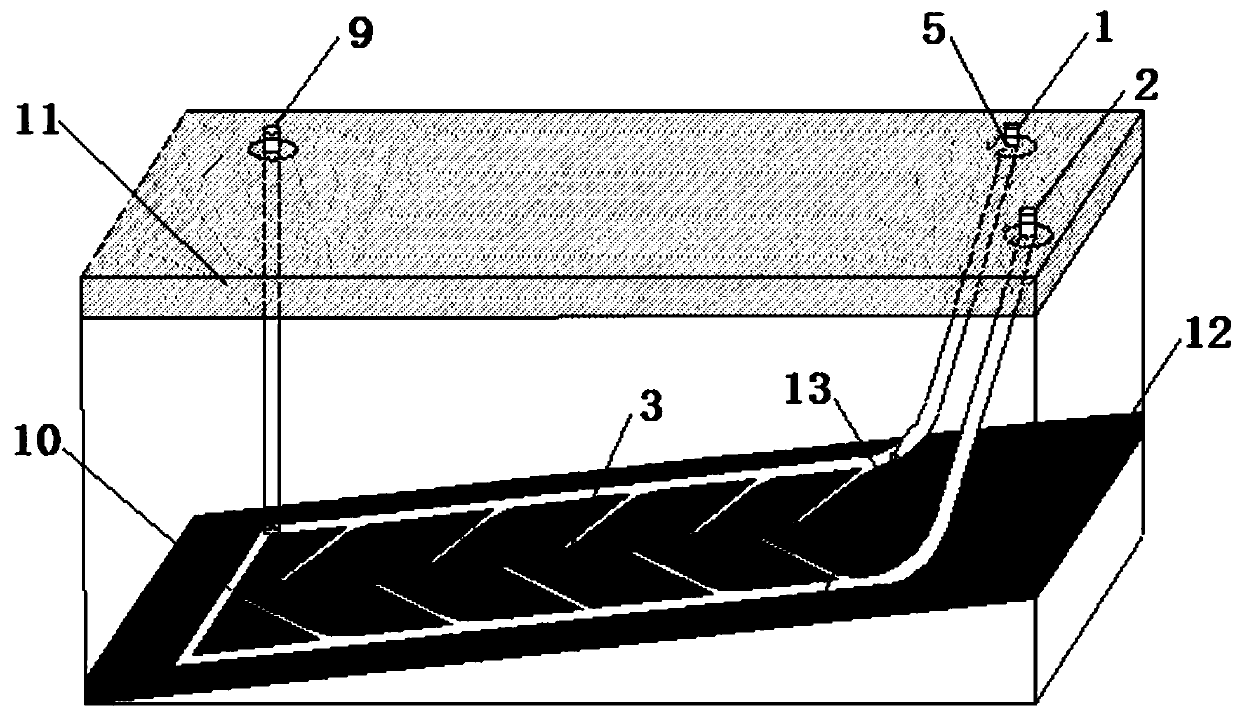

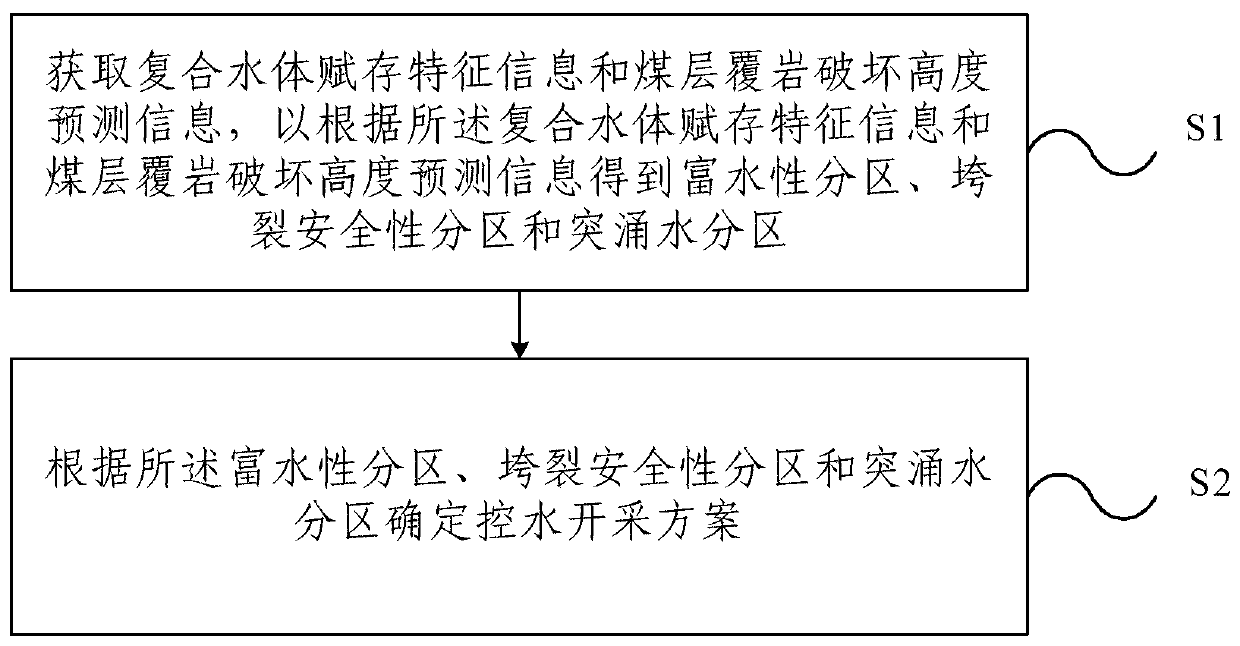

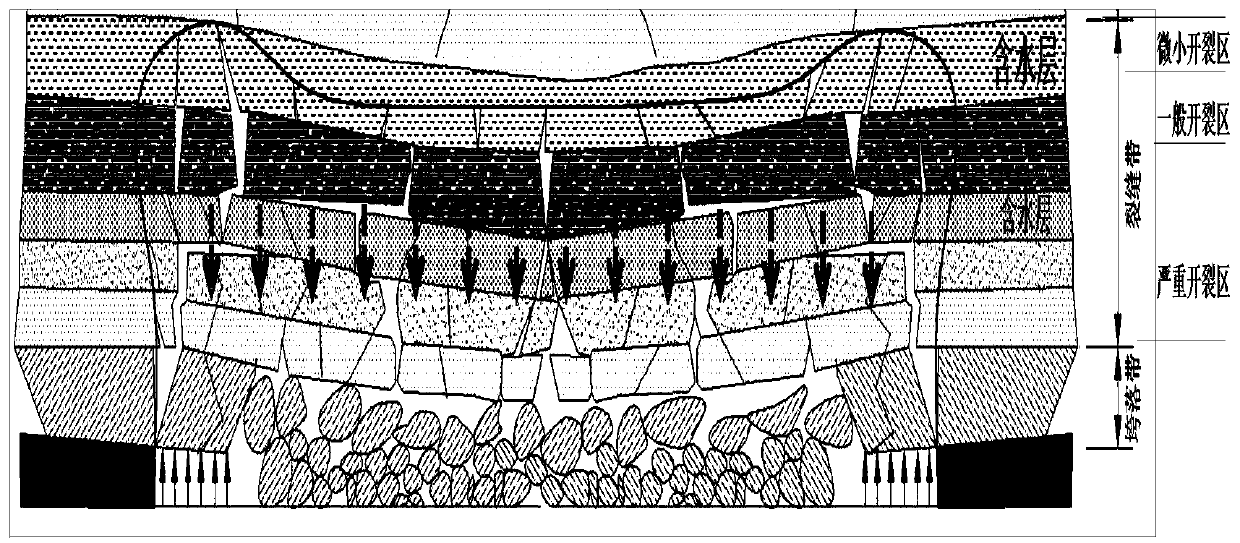

Water control coal mining method and device below compound water body

ActiveCN111379562AReduce hidden dangersMining is efficient and greenUnderground miningMineral miningMining engineeringDischarge

The embodiment of the invention provides a water control coal mining method and device below a compound water body. The method includes the steps that compound water body occurrence characteristic information and coal seam mining overburden failure height predictive information are obtained so that a watery zone, a collapse and fracture safety zone and a sudden water gushing zone can be obtained according to the compound water body occurrence characteristic information and the coal seam mining overburden failure height predictive information; and a water control mining scheme is determined according to the watery zone, the collapse and fracture safety zone and the sudden water gushing zone. Through detection of water body and rock mass detection and the technology combining underwater mining with unwatering or drainage mining, combining hole drilling mining after drainage with mining while drainage, combining hole drilling unwatering or drainage with stoping unwatering or drainage andcombining overburden control with the aquifer drainage degree, the water gushing amount and the water gushing form of a working face are controlled, the man-made water guide passageway hidden danger caused by excessive water drainage and discharge is reduced, the hole drilling work amount and the water drainage expense are reduced, and safe, efficient and green mining of coal resources pressed below the compound water body is achieved.

Owner:CCTEG COAL MINING RES INST

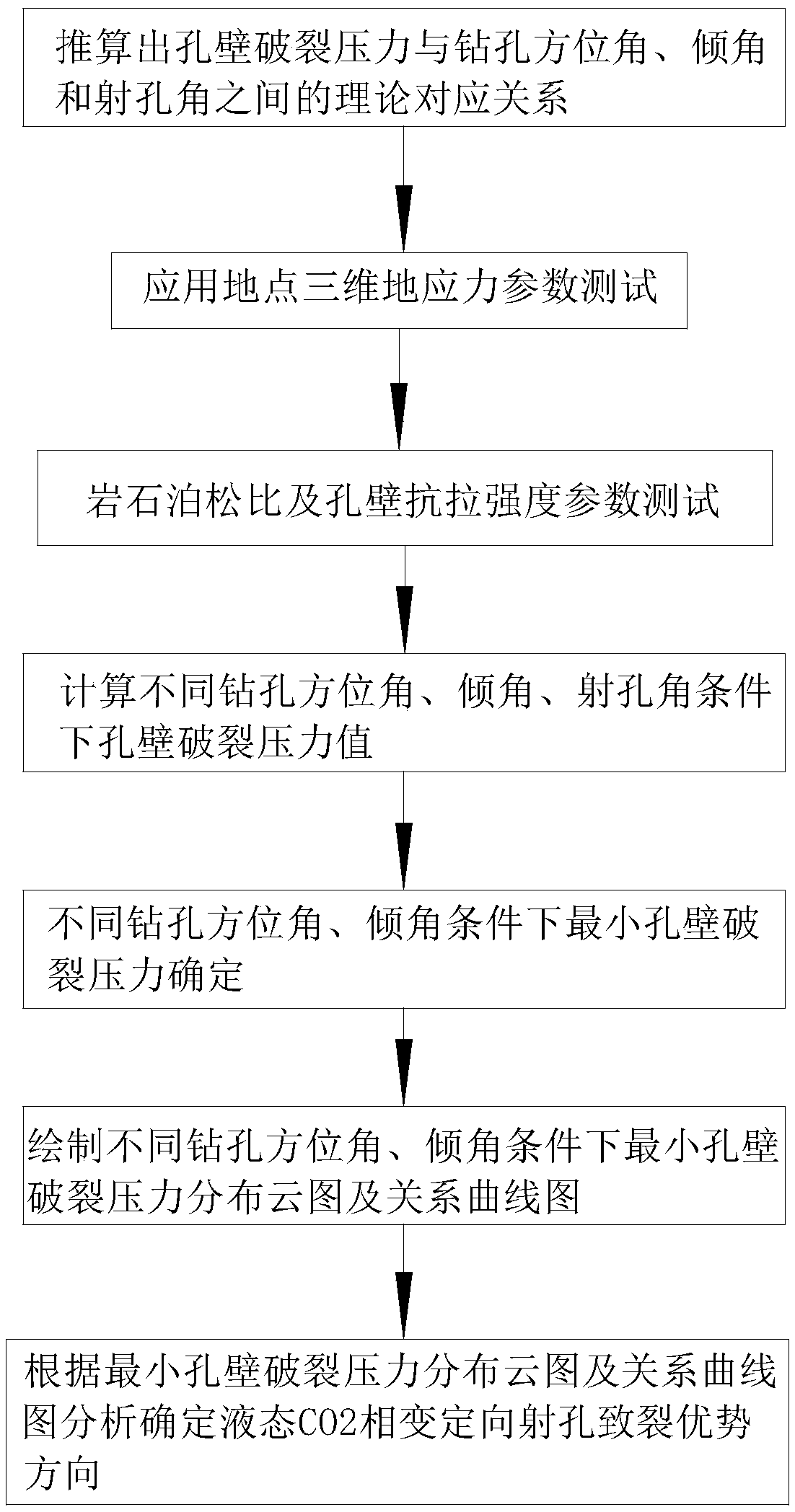

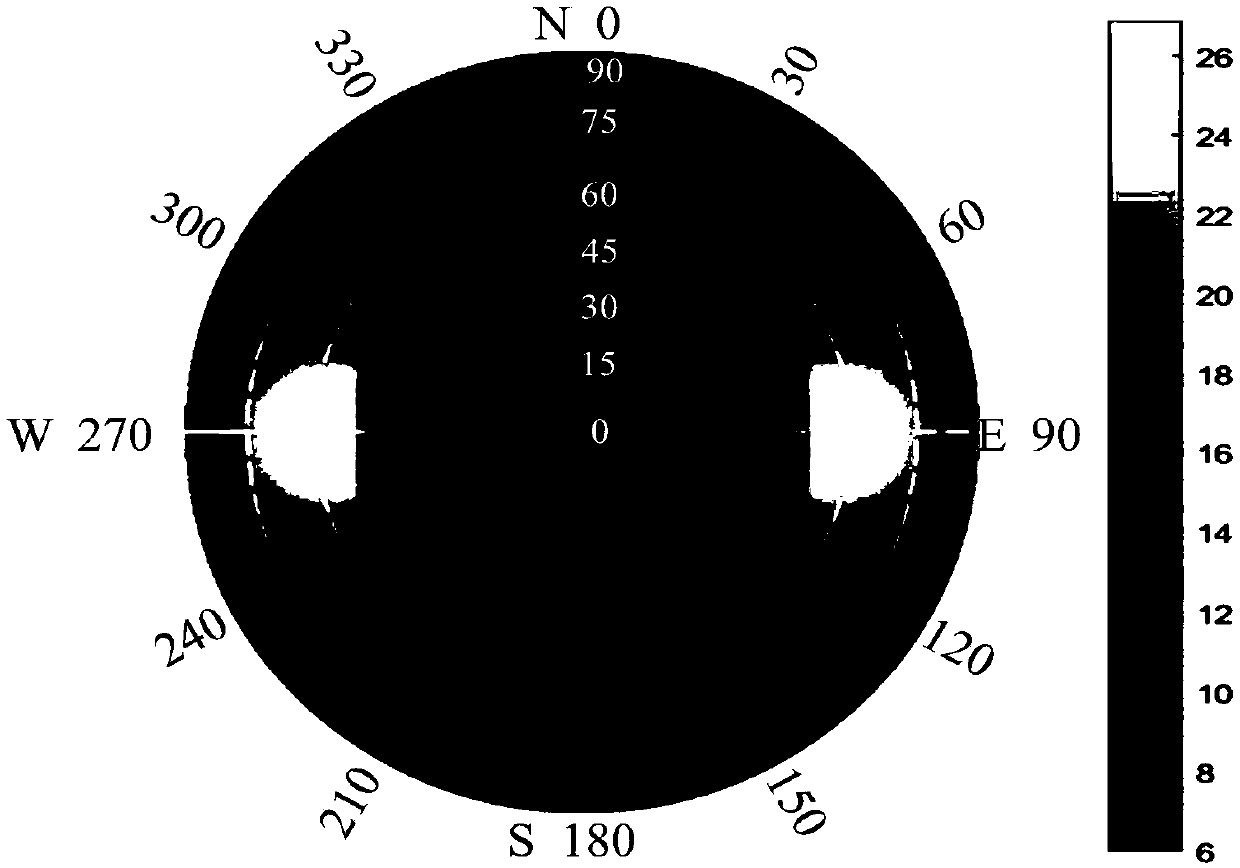

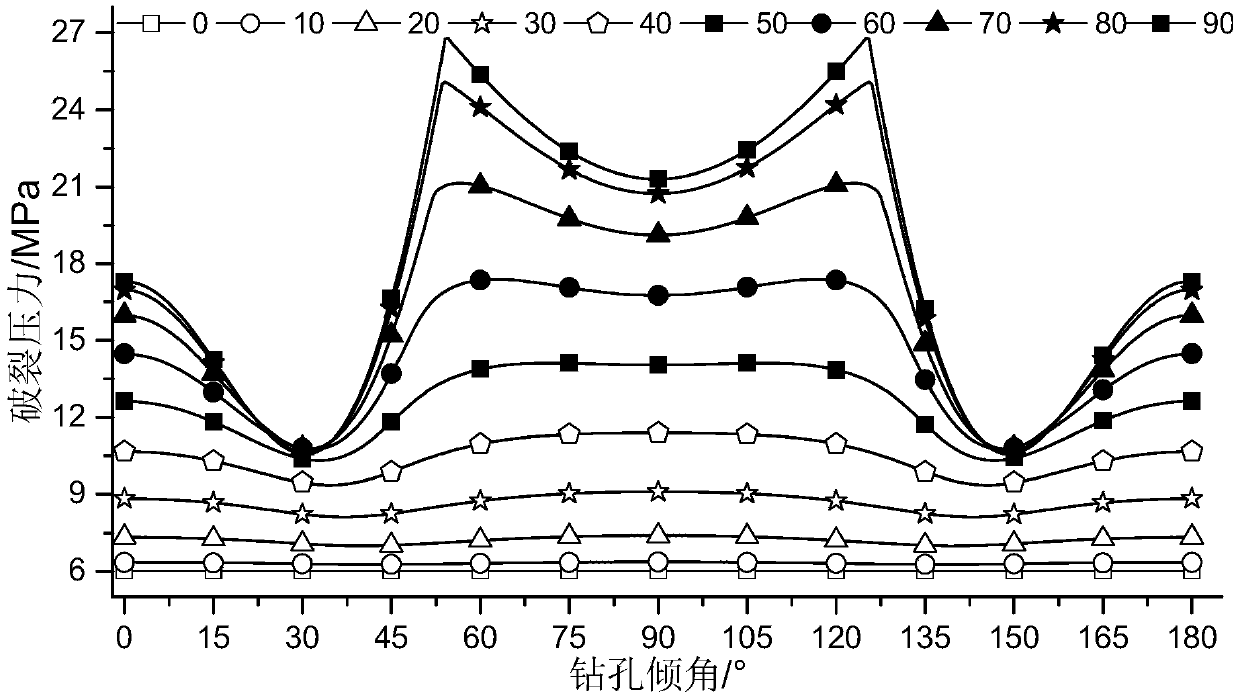

Coal seam liquid CO2 phase change oriented perforation fracturing dominant direction judgment method

ActiveCN108710762AIncrease radius of influenceReduce the amount of drilling workFluid removalDesign optimisation/simulationPhase changeMaterial Perforation

The invention discloses a coal seam liquid CO2 phase change oriented perforation fracturing dominant direction judgment method. The method comprises the steps that first, the theoretical correspondingrelation among hole wall fracture pressure P, a drilling azimuth alpha, a dip angle beta and a perforation angle theta is inferred; second, a three-dimensional ground stress test is performed; third,a rock Poisson's ratio and hole wall tensile strength parameter test is performed; fourth, hole wall fracture pressure values under different drilling azimuths, dip angles and perforation angles arecalculated; fifth, minimum hole wall fracture pressure under different drilling azimuths and dip angles is determined; sixth, a distribution cloud chart and a relation curve graph of the minimum holewall fracture pressure under different drilling azimuths and dip angles are drawn; and seventh, the liquid CO2 phase change oriented perforation fracturing dominant direction is determined through analysis. Through the method, theoretical support can be provided for optimizing a drilling layout in the application process of the liquid CO2 phase change fracturing permeability increase technology, the influence radius of coal seam liquid CO2 phase change oriented perforation fracturing is effectively increased, the drilling work amount is reduced, and construction efficiency is improved.

Owner:CHONGQING UNIV

Extraction method combining roof extraction roadway cross-layer drilling presplitting blasting with multi-branch directional holes

ActiveCN112377241ARealize anti-reflection sampling in advanceThe principle is simpleFluid removalFlushingMining engineeringCoal

The invention discloses an extraction method combining roof extraction roadway cross-layer drilling presplitting blasting with multi-branch directional holes, belongs to the field of coal mine underground gas extraction. The extraction method aims to be applied in a high-gas mine or a coal and gas outburst mine which is soft in coal quality, large in coal seam gas endowment amount and poor in coalseam fluidity. The extraction method is a gas control method which is characterized in that gas extraction needs to be conducted on a coal seam before coal seam extraction, gas in the coal seam is extracted in advance and the outburst risk of the coal seam is eliminated.

Owner:HENAN UNIVERSITY

CO2 mineralization grouting method for old goaf

PendingCN114673551AReduce the amount of drilling workLow cost of grouting fillingMining devicesMaterial fill-upExhaust fumesSlurry

The invention discloses a CO2 mineralization grouting method for an old goaf, and belongs to the technical field of goaf treatment. Comprising the following steps that firstly, the goaf grouting range is divided into a straddling zone and a fissure zone, the grout diffusion radius of a caving zone and the grout diffusion radius of the fissure zone under the isobaric grouting condition are determined through experimental area grouting, the caving zone and the fissure zone share the same drill hole for grouting, the grout diffusion radius of the caving zone serves as an index to design the drill hole distance for grouting filling work, and the grouting filling work is completed; filling a caving zone and a fissure zone; then, a mineralizing material and industrial waste gas are injected into the goaf, injected mineralizing material slurry can react with the industrial waste gas, and the goaf is supported while the industrial waste gas is fixed. The industrial waste gas is injected into the goaf to react with the slurry to be sealed underground, the environmental pollution is effectively reduced, a product generated after the reaction with the slurry plays a role in supporting and protecting the goaf, and a positive role is played in environmental protection and treatment.

Owner:ANHUI UNIV OF SCI & TECH

Method for extracting coal tunnel stripe coal bed gas based on controllable shock waves

PendingCN110656972AImprove breathabilityReduce the amount of drilling workFluid removalGas removalSlagEngineering

The invention provides a method for extracting coal tunnel stripe coal bed gas based on controllable shock waves. The method for extracting coal tunnel stripe coal bed gas based on the controllable shock waves comprises the steps that antireflective technological parameters of the controllable shock waves are determined in a geological unit where controllable shock wave anti-reflection is to be implemented; shock wave anti-reflection hole drilling is conducted on a coal bed or the coal bed bottom plate and top plate in the range of coal tunnel stripe in the bottom plate or the top plate extraction tunnel corresponding to the to-be-dug coal tunnel; coal slag or rock slag in drilled holes are discharged; casing pipes are lowered, and holes are solidified; a controllable shock wave generationdevice is lowered into a drilled hole to a target shock position through a drilling machine; and the shock wave anti-reflection drilled holes are sealed, the shock wave anti-reflection drilled holesare constructed by utilizing a controller of the controllable shock wave generation device outside the drilled holes, after the shock wave anti-reflection operation is completed, connected hole extraction is conducted on extraction drilled holes in the influence range of shock wave anti-reflection operation, and the gas extraction effect is improved. According to the method, the coal bed top plateand bottom plate are transformed into virtual storage layers with fracture development so that coal bed gas which is farther away from the extraction holes can be transported to the extraction holesthrough fractures in the top plate or the bottom plate and extracted out; the gas extraction time is shortened; and the extraction effect is improved.

Owner:郑州慧矿智能科技有限公司 +1

Gas prevention and control method for gob-side entry self-pressure-relief outburst-elimination rapid tunneling

ActiveCN112343647AReduced number of extraction boreholesIncrease extraction concentrationSurveyGas removalMining engineeringEngineering

The invention provides a gas prevention and control method for gob-side entry self-pressure-relief outburst-elimination rapid tunneling, and relates to the technical field of mine gas prevention and control. According to the gas prevention and control method, a pressure relief zone area, which is close to a coal body, of a upper section stope face is accurately determined, so that roadway tunneling in the pressure relief zone area is guaranteed; additionally, the outburst of gas of a coal seam on the inner side of a roadway is eliminated, the number of gas extraction drill holes is reduced, the work amount of the drill holes is reduced, the tunneling speed of the outburst coal seam is obviously increased, and the outburst risk in a tunneling process is greatly reduced; in the roadway tunneling process, the range of the pressure relief zone area is further enlarged, the gas extraction concentration and the extraction amount of the gas extraction drill holes are increased to a certain degree, the gas extraction time is shortened, and the gas pressure and content of the coal seam are rapidly reduced; and plugging materials are used for guniting and plugging the coal wall of the outerside of the roadway, and a damaged fracture gas seepage channel is effectively plugged, so that the inrush of goaf gas is reduced, and the concentration of return current gas is prevented from exceeding the limit.

Owner:CCTEG CHINA COAL RES INST

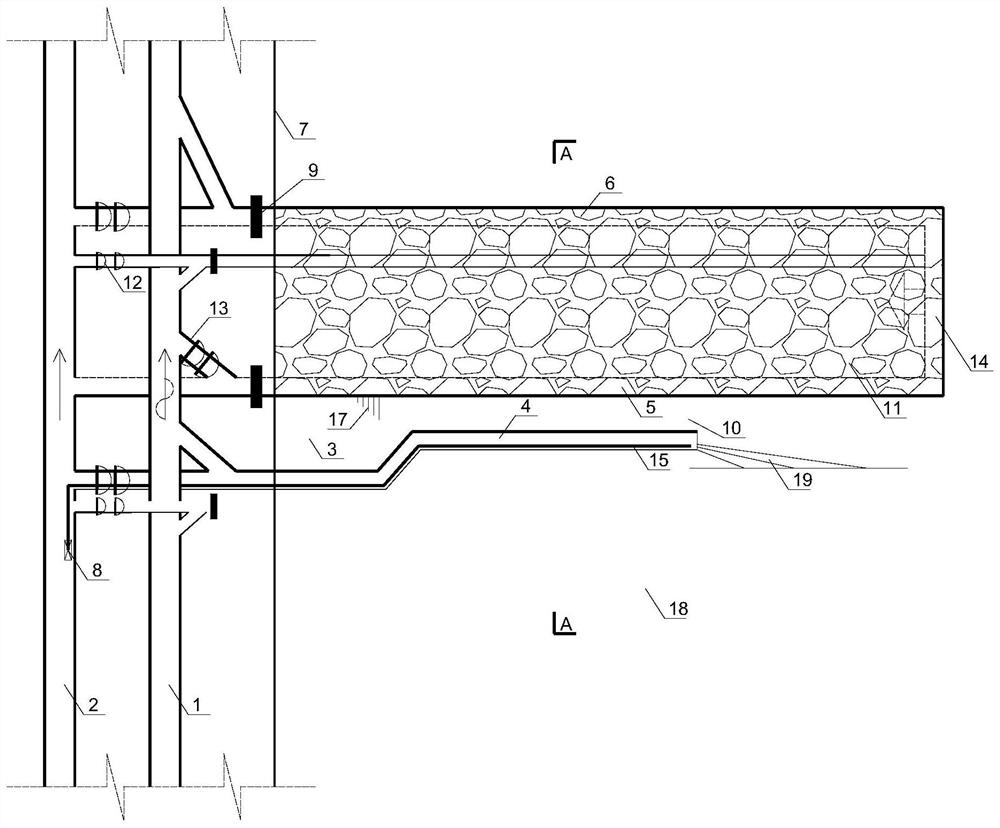

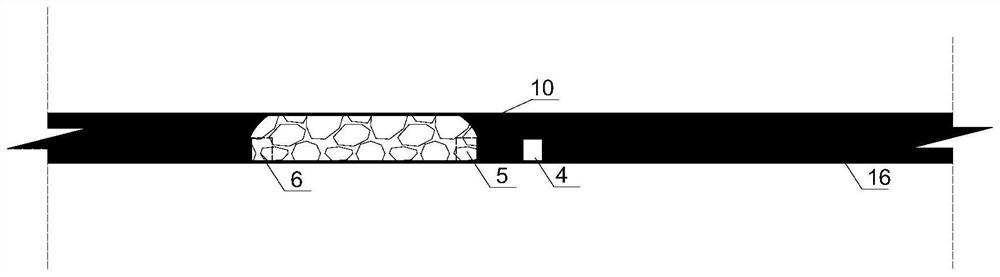

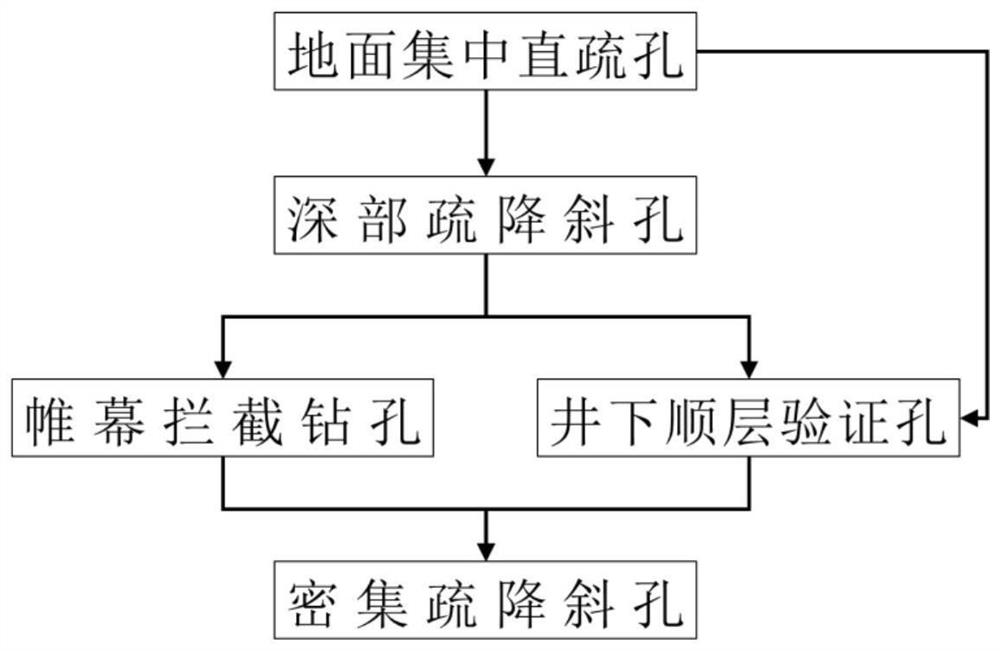

Full-area rapid dredging and descending method after underground curtain closure

The invention discloses a full-area rapid dredging and descending method after underground curtain closure. The method comprises the steps that centralized dredging and descending are conducted on a water-bearing stratum through ground straight dredging holes, and if the dredging and descending requirement cannot be met, the deep portion of the water-bearing stratum is dredged and descended through underground deep dredging and descending inclined holes; then, before mining area tunneling, the dredging and descending effect of a mining area is subjected to area inspection through underground bedding verification holes; and finally, before working face stoping, the water-bearing stratum of a working face top plate is accurately inspected through dense dredging and descending inclined holes, and curtain seepage water passing is intercepted and dredged through curtain intercepting drill holes. According to the method, according to the occurrence condition, hydrogeological characteristics, coal seam excavation design and the like of the water-bearing stratum, multiple dredging and descending modes and means are utilized for different areas and assist and combine with one another, and full-area rapid dredging and descending of the water-bearing stratum after curtain closure are achieved.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP +1

A whole life cycle treatment method for tunnel water inrush

ActiveCN105041345BImprove targetingImprove effectivenessUnderground chambersTunnel liningTherapeutic effectEffective treatment

The invention discloses a life-cycle treatment method of water inrush in a tunnel. The method comprises the steps that three-dimensional morphologic features of a water conductive structure of a water inrush zone in the tunnel are obtained by combining geological data, excavation data, detection results of comprehensive geophysical detection and numerical calculation results; grouting sealing water inrush is taken into account, surrounding rock physical mechanical parameters are improved simultaneously, design of a treatment scheme is conducted on the water inrush zone in the tunnel, and design of a keyhole and a drainage keyhole is conducted according to a water inrush main controlling structure; the stability of the tunnel in the construction period and the safety in the operation period are guaranteed by conducting numerical simulation on the tunnel section which is reinforced according to the design scheme; grouting construction is conducted according to the design scheme, a monitoring device is buried during the construction process, and feedback optimal design is implemented; inspection is conducted on the treatment effect of the grouting reinforcement section in the tunnel, and the excavation time is determined. According to the life-cycle treatment method of the water inrush in the tunnel, it is guaranteed that the surrounding rock in the tunnel construction period is stale and water inrush of the tunnel does not occur in the operation period, the chronic problem that nine of the ten tunnels leak is completely eradicated, and the effective treatment of the water inrush in the tunnel and the environmental protection are achieved.

Owner:SHANDONG UNIV

Water level observation pipe capable of realizing layered report of frozen wall intersection conditions

ActiveCN111103027AReduce the amount of drilling workReduce the cost of hole making constructionMachines/enginesLevel indicatorsHorizonEnvironmental engineering

The invention discloses a water level observation pipe capable of realizing layered report of frozen wall intersection conditions. The water level observation pipe comprises N horizon observation pipes, wherein N is a positive integer and is greater than or equal to 2; the N horizon observation pipes are coaxially sleeved together, the upper ends of the N horizon observation pipes extend out of the ground, and the lower ends of the N horizon observation pipes are located at different observation horizon positions. A water return hole communicated with the fluid at the horizon to be observed isformed in the wall of the water return pipe at the position, corresponding to the horizon to be observed, of each horizon observation pipe, and the water return holes of the horizon observation pipesare not communicated with one another. According to the water level observation pipe, only one water level observation hole is constructed in each shaft, water level conditions of multiple layers canbe reported, reporting tasks of different layers are completed, the number of construction water level observation holes is reduced, the construction cost is reduced, the construction time is saved,well completion speed is increased, the possibility of water mixing of the water level observation holes is reduced, the risk that frozen walls are difficult to intersect due to water mixing of the water level observation holes is reduced, and safety and reliability of the frozen wall intersection process are guaranteed.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

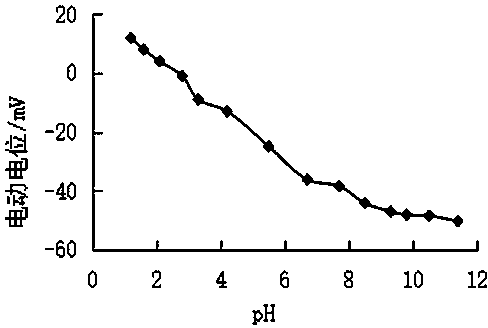

Method for intensifying coal seam water injection through pressing dynamic-electrodynamic coupling effect

The invention discloses a method for intensifying coal seam water injection through the pressing dynamic-electrodynamic coupling effect. A row of drilling holes are drilled in the positions, perpendicular to the coal wall, in an air inlet / return roadway, and a high-pressure water injection pipe and an electrode bar are arranged in each drilling hole; the water injection pipes in all the drilling holes are connected together through a high-pressure rubber hose; anode electrodes and cathode electrodes in the drilling holes are connected in series through insulated wires correspondingly; a directcurrent power supply is connected while water is injected into the drilling hole through the dynamic pressure; and coal seam water injection is intensified through the pressing dynamic-electrodynamiccoupling effect. According to the method, through the water injection pressure, electric osmosis acting force and capillary acting force, water is quickly driven from large cracks to micro hole cracks, efficient full wetting of coal bodies is achieved, after a coal reservoir is acted, the single hole wetting range is expanded, the water injection speed rate and the water content are increased, meanwhile, the drilling engineering quantity is further reduced greatly, economical, practical, simple, convenient and reliable effects are achieved, the effect is remarkable, and high application and popularization value is achieved.

Owner:TAIYUAN UNIV OF TECH

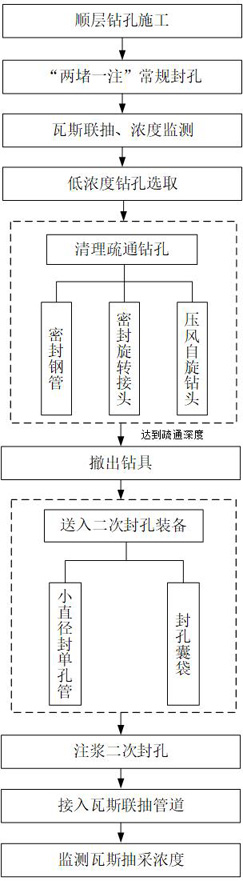

Secondary hole sealing method for underground coal mine gas drainage drill hole

ActiveCN113756742AIncrease extraction concentrationImprove extraction efficiencyMining devicesGas removalSlagCoal

The invention discloses a secondary hole sealing method for an underground coal mine gas drainage drill hole. The secondary hole sealing method comprises the following steps that (1) a bag type grouting hole sealing device and a two-blocking one-injecting hole sealing process are adopted for implementing first-time hole sealing and continuous drainage; (2) during gas drainage, a low-concentration gas drainage drill hole is selected, and a connected gas drainage pipeline is disconnected; (3) a sealing steel pipe is connected with a compressed air self-rotating drill bit and then inserted into a first-time hole sealing pipe, a high-pressure air supply pipeline is connected, and coal slag in the hole sealing pipe and the drill hole is cleaned through the compressed air self-rotating drill bit and high-pressure air blowing; (4) the sealing steel pipe is withdrawn, and a second-time hole sealing device is plugged into the first-time hole sealing pipe to a designed position; (5) grouting is conducted on the second-time hole sealing device for implementing secondary hole sealing; and (6) a hole sealing pipe of the second-time hole sealing device is connected into the gas drainage pipeline for gas drainage. According to the secondary hole sealing method for the underground coal mine gas drainage drill hole, the application engineering cost is low, the process is relatively simple, the drainage efficiency is fully improved, the drainage time is shortened, and gas disasters are eliminated to the maximum extent.

Owner:山西兰花科创玉溪煤矿有限责任公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com