Soft coal seam controllable jet punching pressure relief antireflective device and method thereof

A soft coal seam and punching technology, which is applied in the field of soft coal seam controllable jet punching pressure relief and anti-reflection device, can solve the problems of gas exceeding the limit, soft coal seam, poor air permeability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

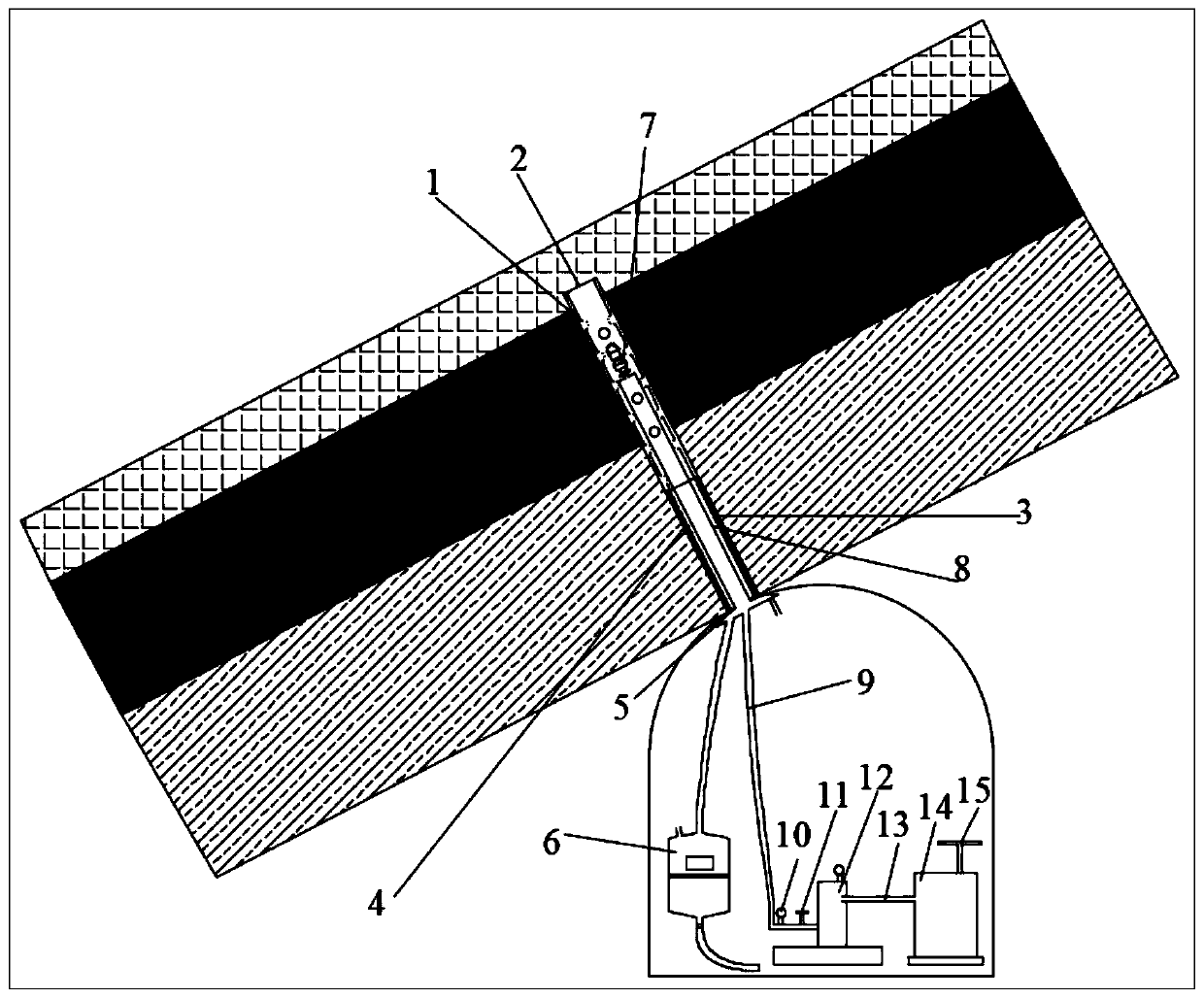

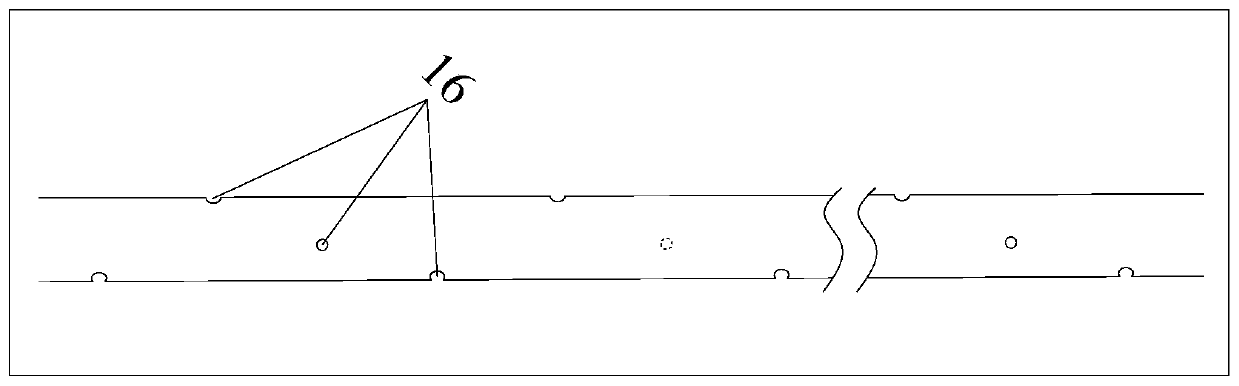

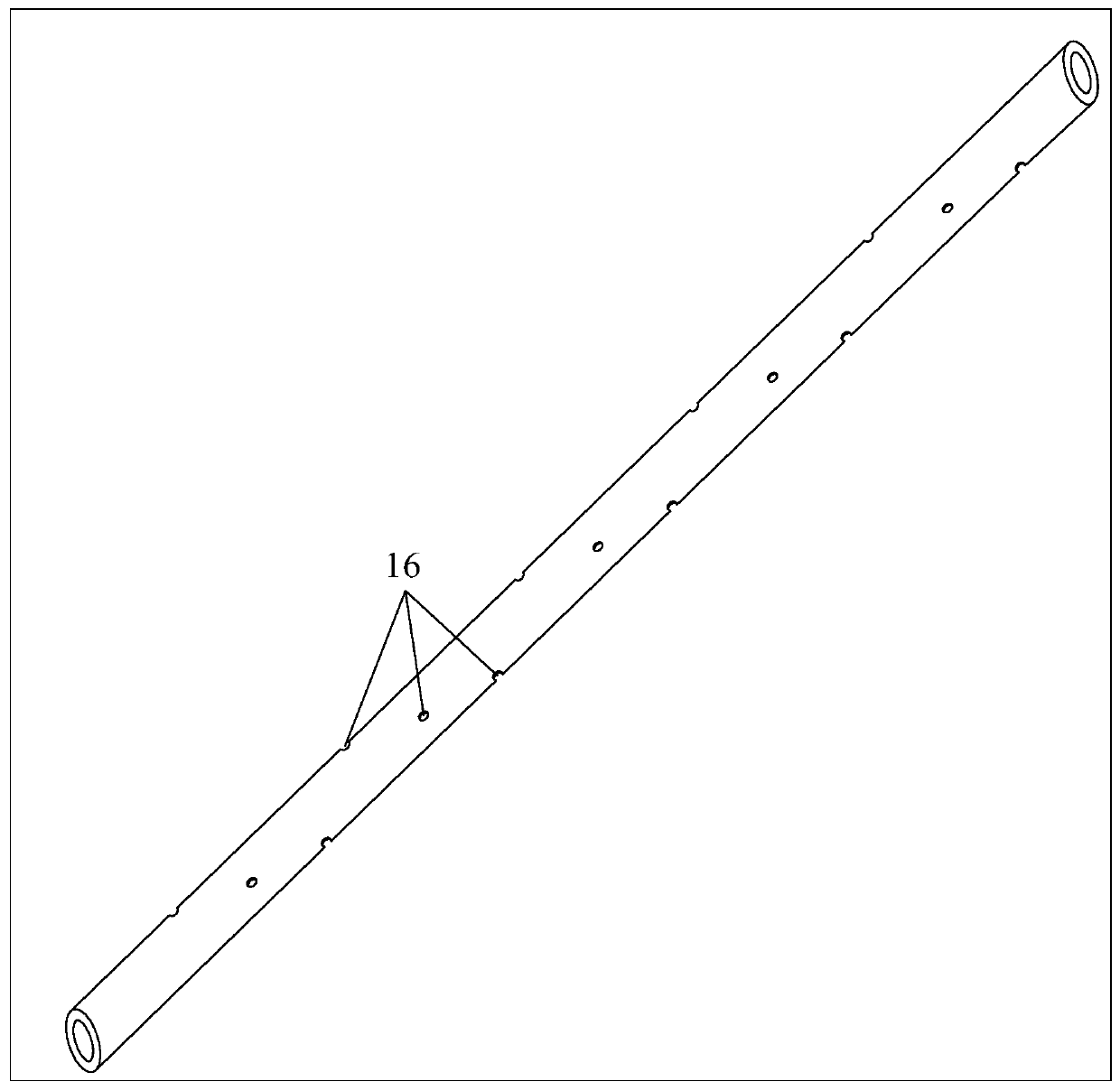

[0033] see Figure 1 to Figure 5 , shows the soft coal seam controllable jet punching pressure relief anti-reflection device of the present invention.

[0034] The controllable jet punching pressure relief and anti-reflection device for the soft coal seam may include a blowout protection hole screen pipe 1, a terminal cover 2, a sealing pipe 3, an orifice flange 5, an air slag water separator 6, The high-pressure self-rotating nozzle 7, the high-pressure pipe 8 and the high-pressure supply assembly, the orifice flange 5 is arranged on the orifice, the sealing pipe 3 and the blowout protection hole screen 1 are arranged on the hole wall, and the end protection The cover 2 is arranged at the bottom of the hole, the high-pressure pipe 8 extends into the hole from the orifice flange 5 and the end is provided with a high-pressure rotation nozzle 7, the rear end of the high-pressure pipe 8 is connected to the high-pressure supply assembly, and the orifice is provided Air slag water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com