Small coal mine goaf grouting method based on directional drilling technology

A goaf and directional drilling technology, which is applied in directional drilling, earthwork drilling, mining equipment, etc., can solve the problems of large proportion of invalid drilling, large consumption of steel pipe materials, and waste of drilling costs, etc., to expand coverage and accuracy, avoiding difficult-to-drill areas, and reducing the amount of drilling work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

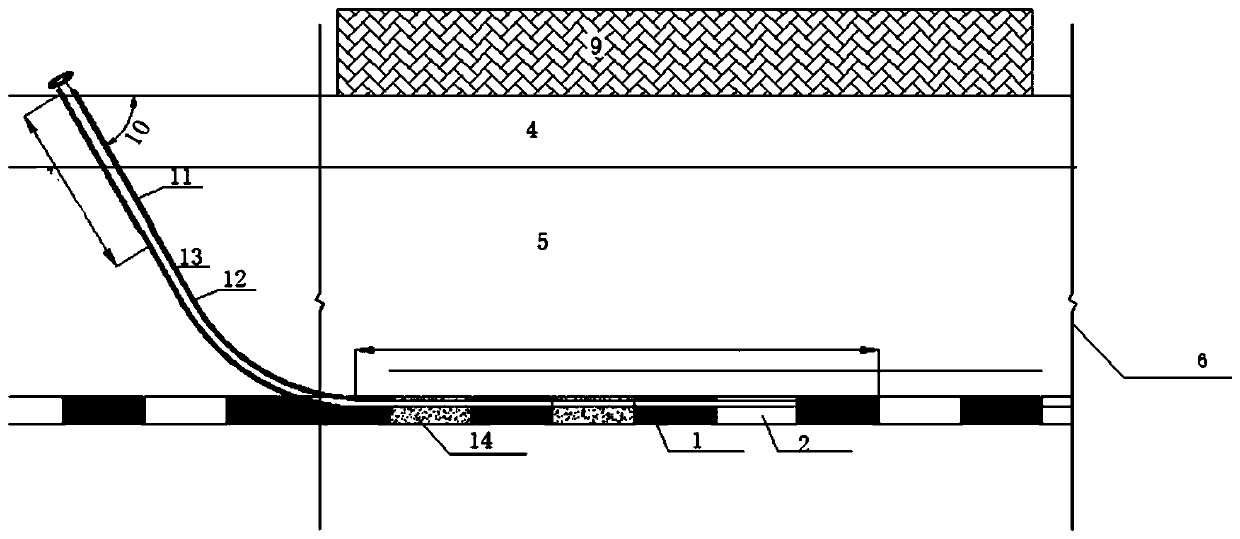

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

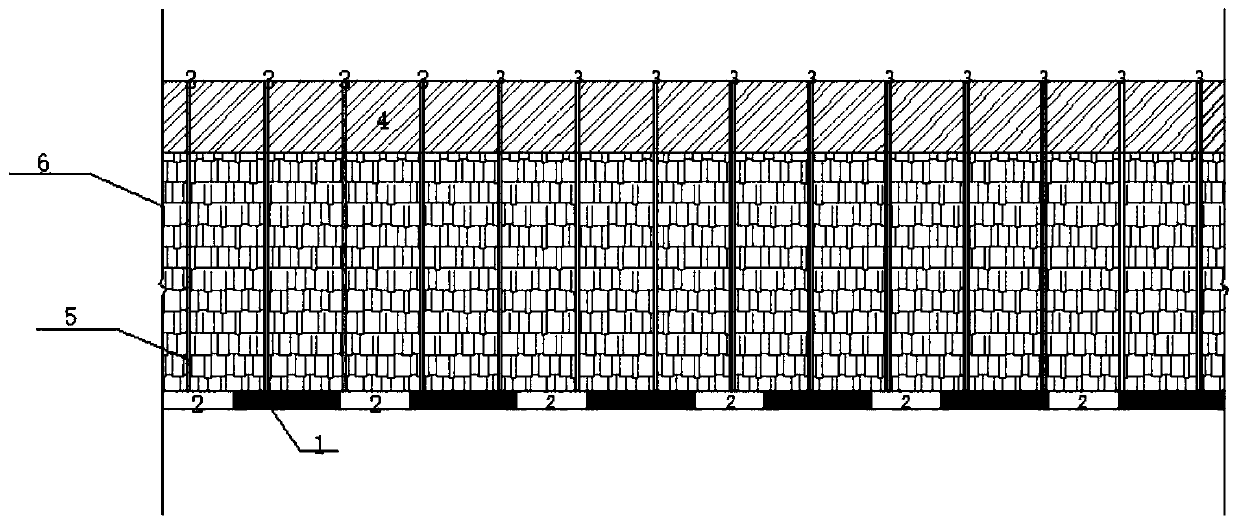

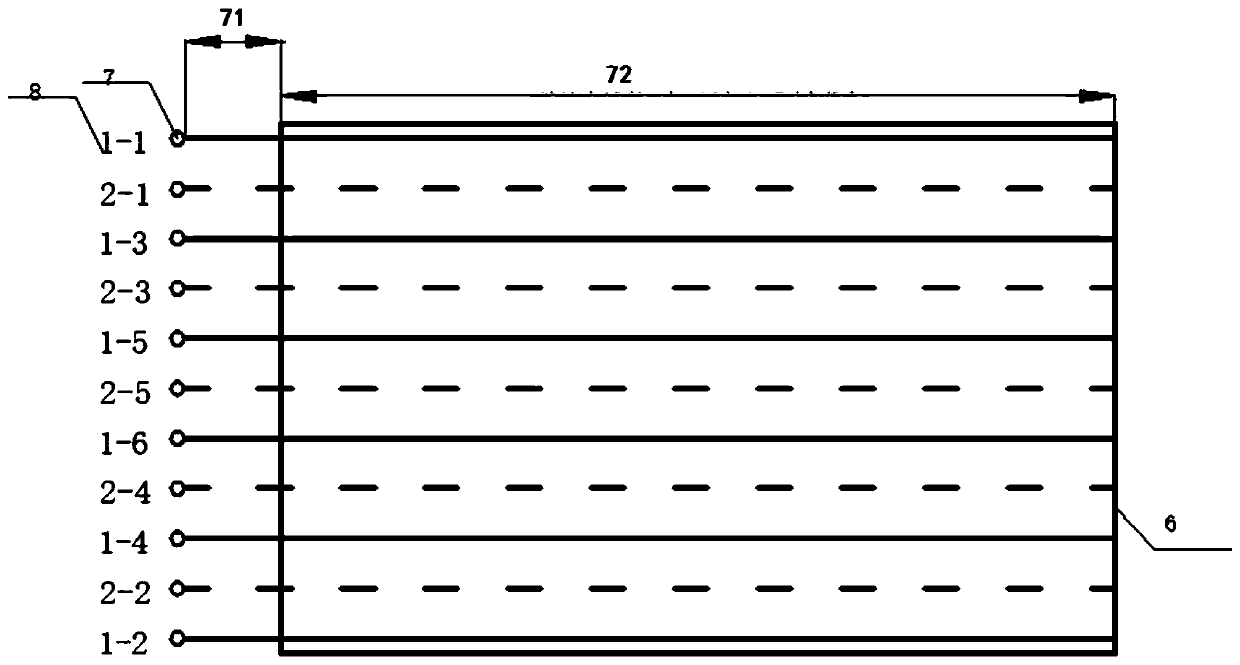

[0034] see figure 2 with image 3 , has shown the small coal kiln goaf grouting method based on directional drilling technology of the present invention, and it specifically implements according to the following steps:

[0035]Step 1, drilling layout, design the layout and quantity of directional drilling in the goaf control area of small coal mines, and determine the parameter design of directional drilling. The layout of directional drilling is carried out according to the transformation of the goaf control area of small coal mines. Among them, for linear projects such as roads, bridges, railways, and high-speed rails that need to be implemented on the goafs of small coal mines, the direction of directional drilling is set as Lay out perpendicular to the direction of the line. For those that need to implement site projects such as da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com